Patents

Literature

6675 results about "Thin sheet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

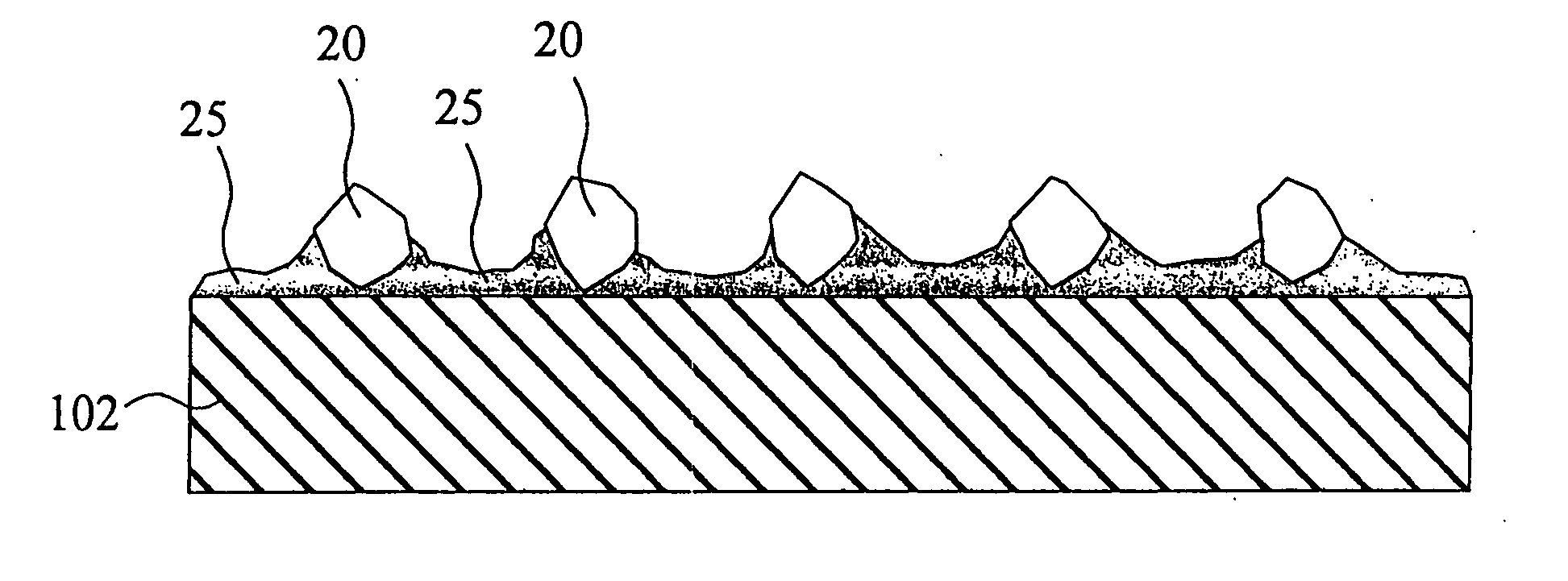

Graphene film as transparent and electrically conducting material

ActiveUS20070284557A1Material nanotechnologyConductive materialGraphene flakeTransparent conducting film

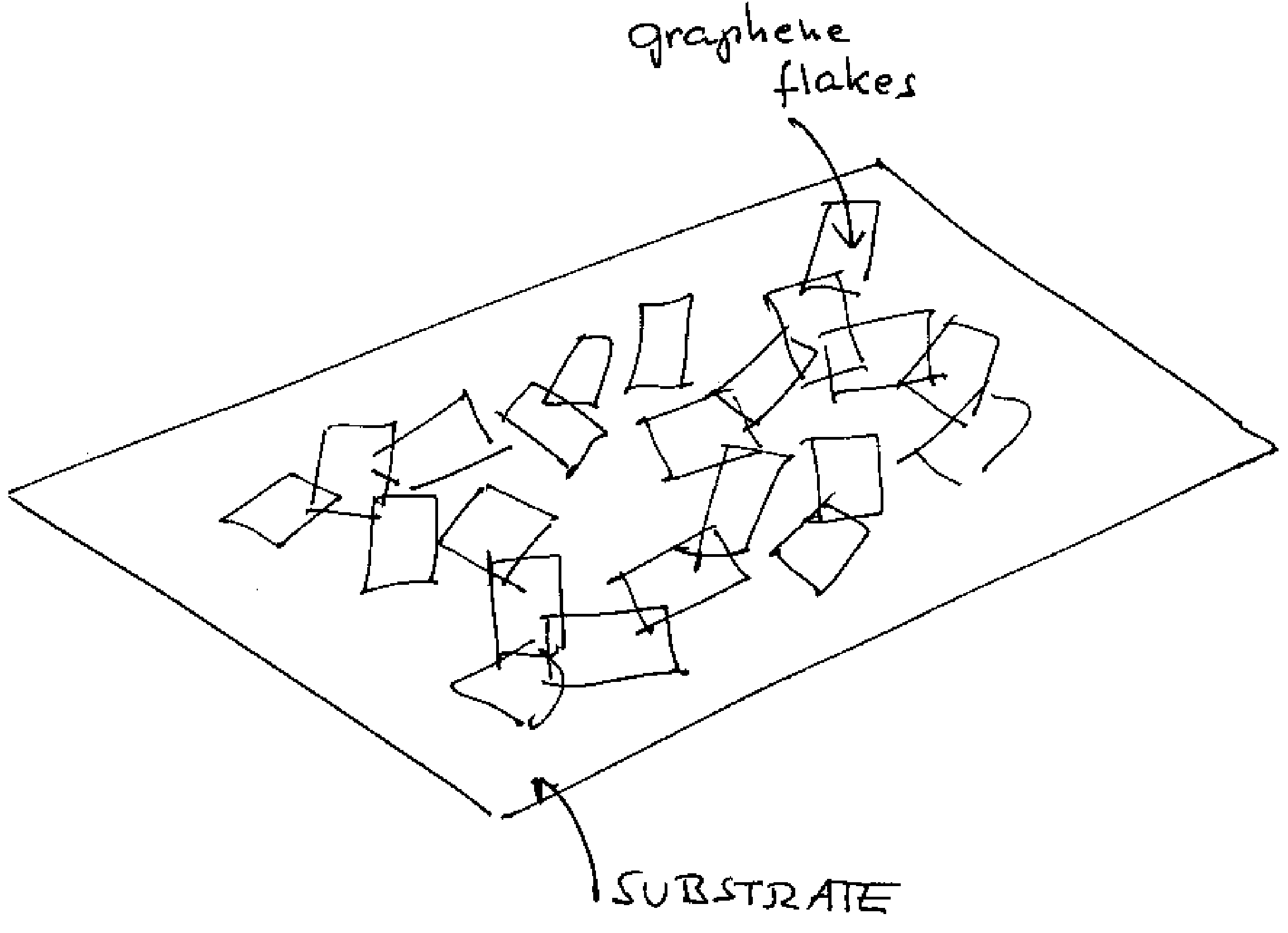

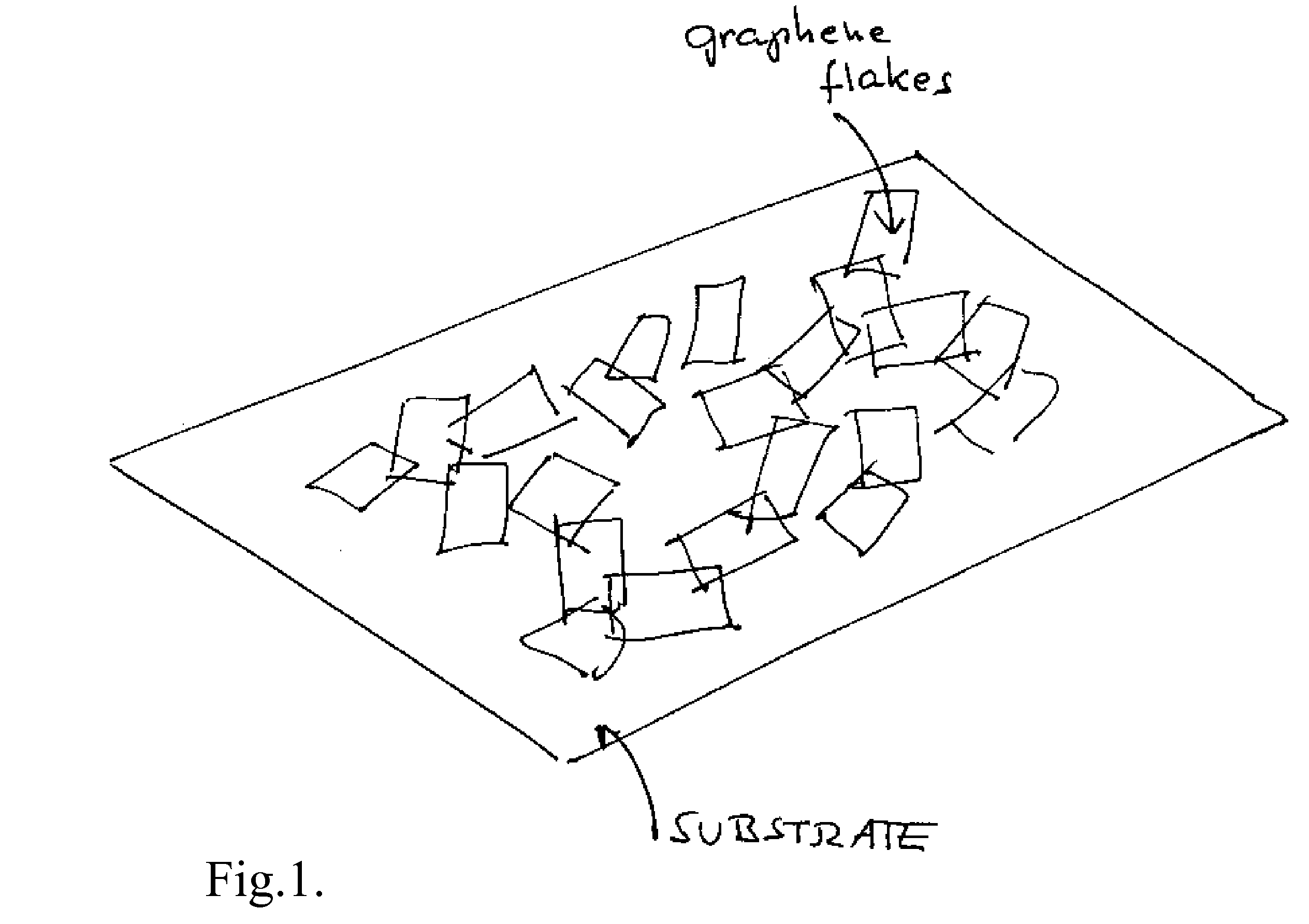

A transparent and conductive film comprising at least one network of graphene flakes is described herein. This film may further comprise an interpenetrating network of other nanostructures, a polymer and / or a functionalization agent(s). A method of fabricating the above device is also described, and may comprise depositing graphene flakes in solution and evaporating solvent therefrom.

Owner:SAMSUNG ELECTRONICS CO LTD

Nano-scaled graphene plate nanocomposites for supercapacitor electrodes

ActiveUS7623340B1Increase specific surface area and electrical conductivityMaterial nanotechnologyElectrolytic capacitorsCapacitancePolymer science

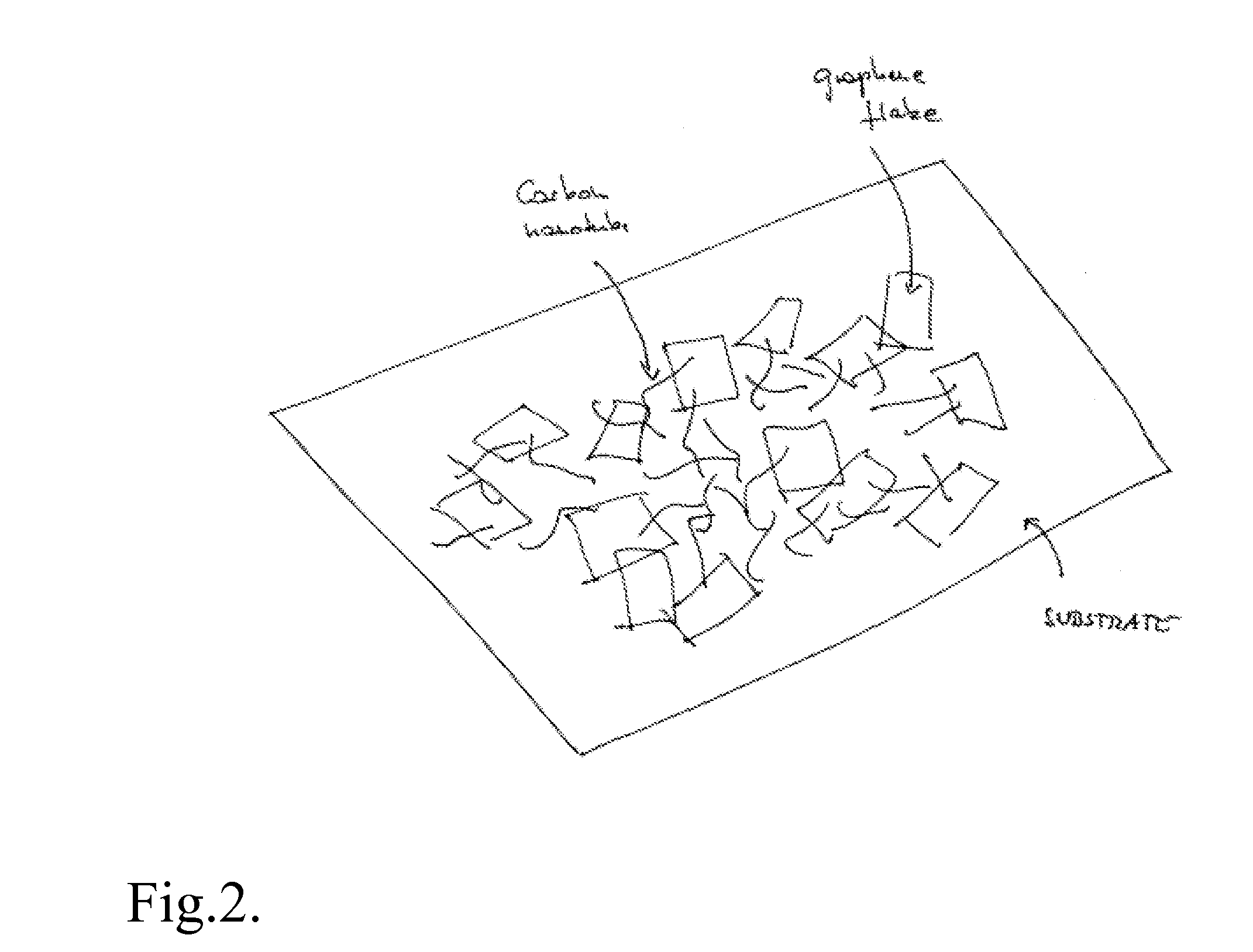

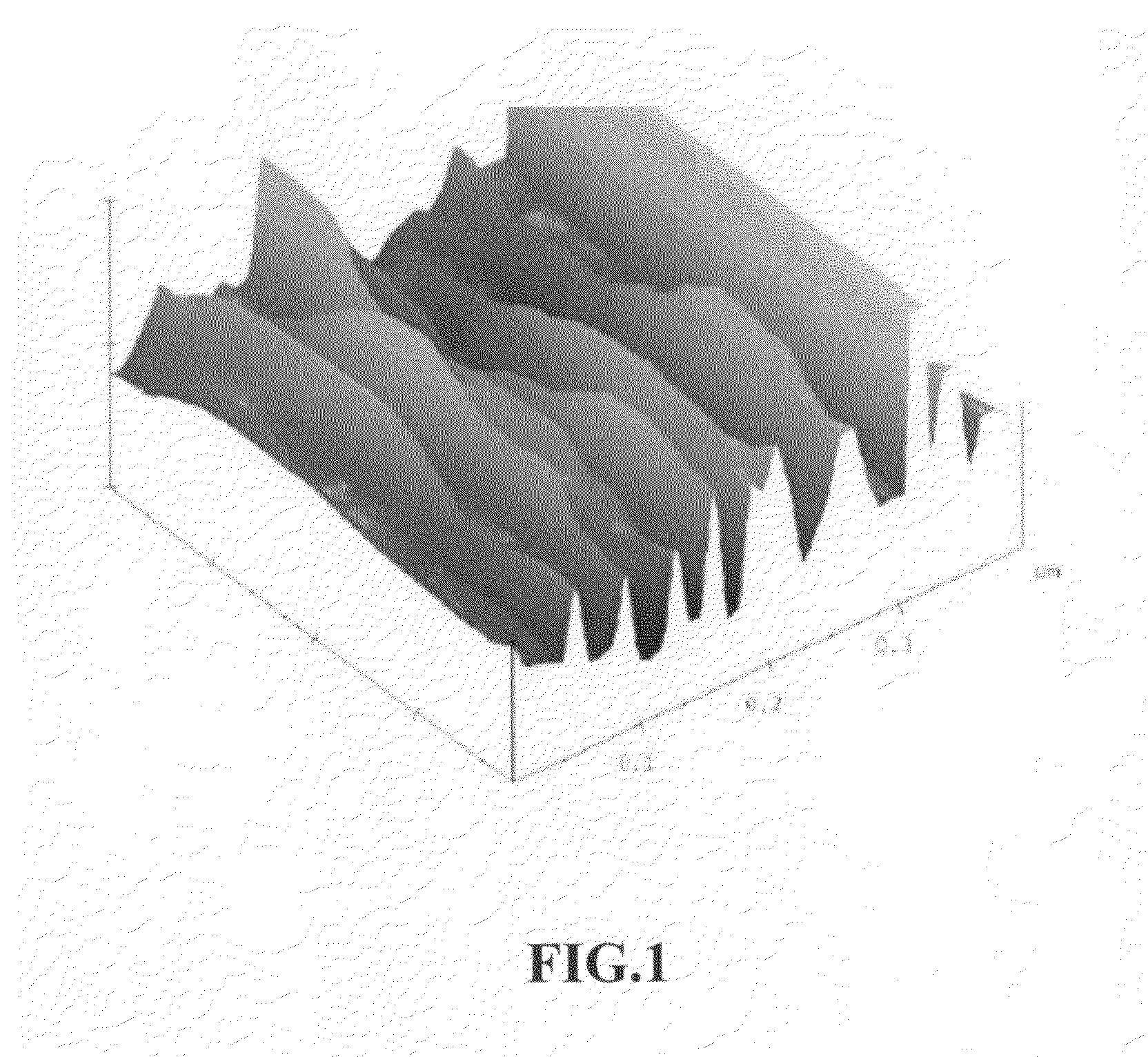

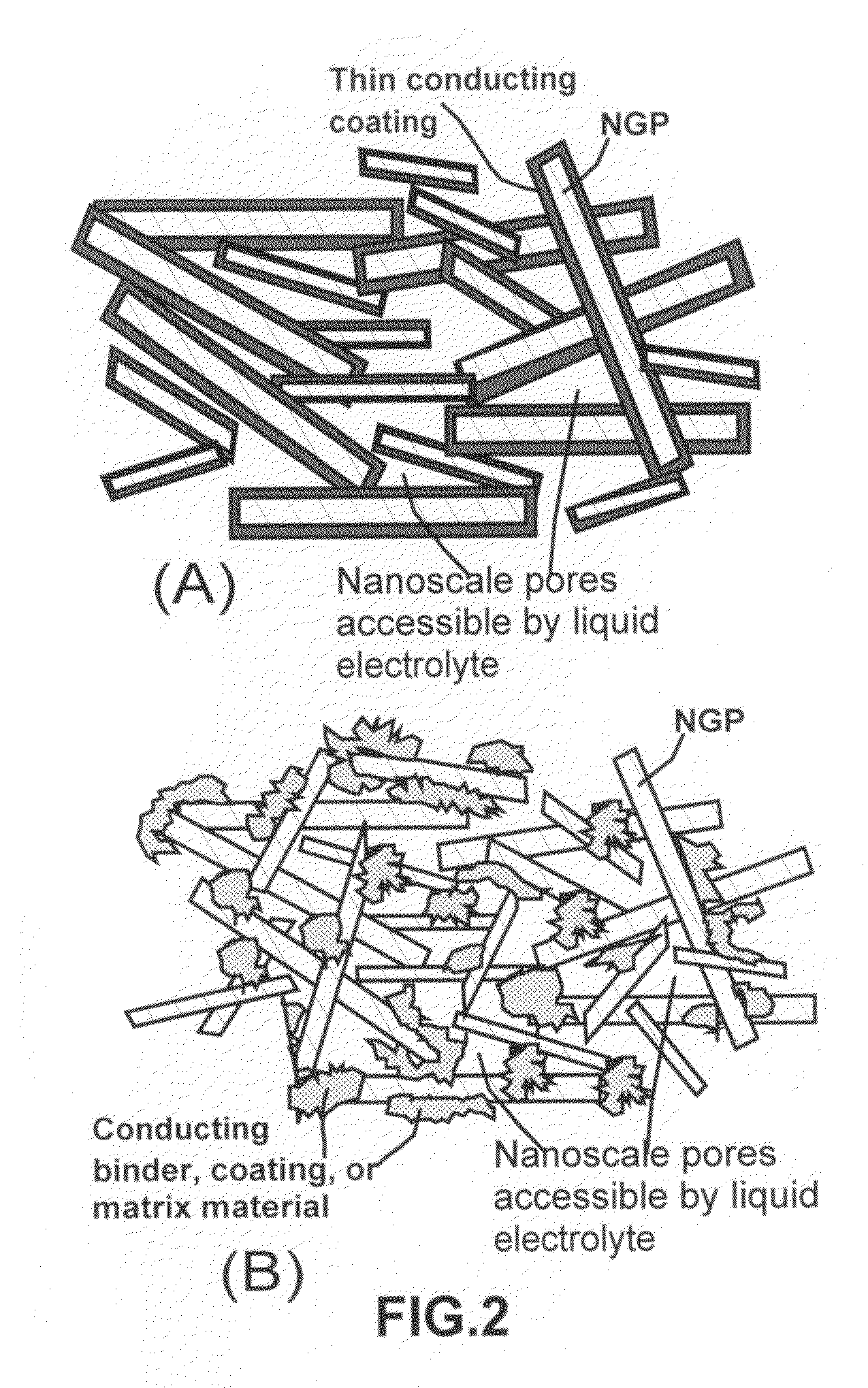

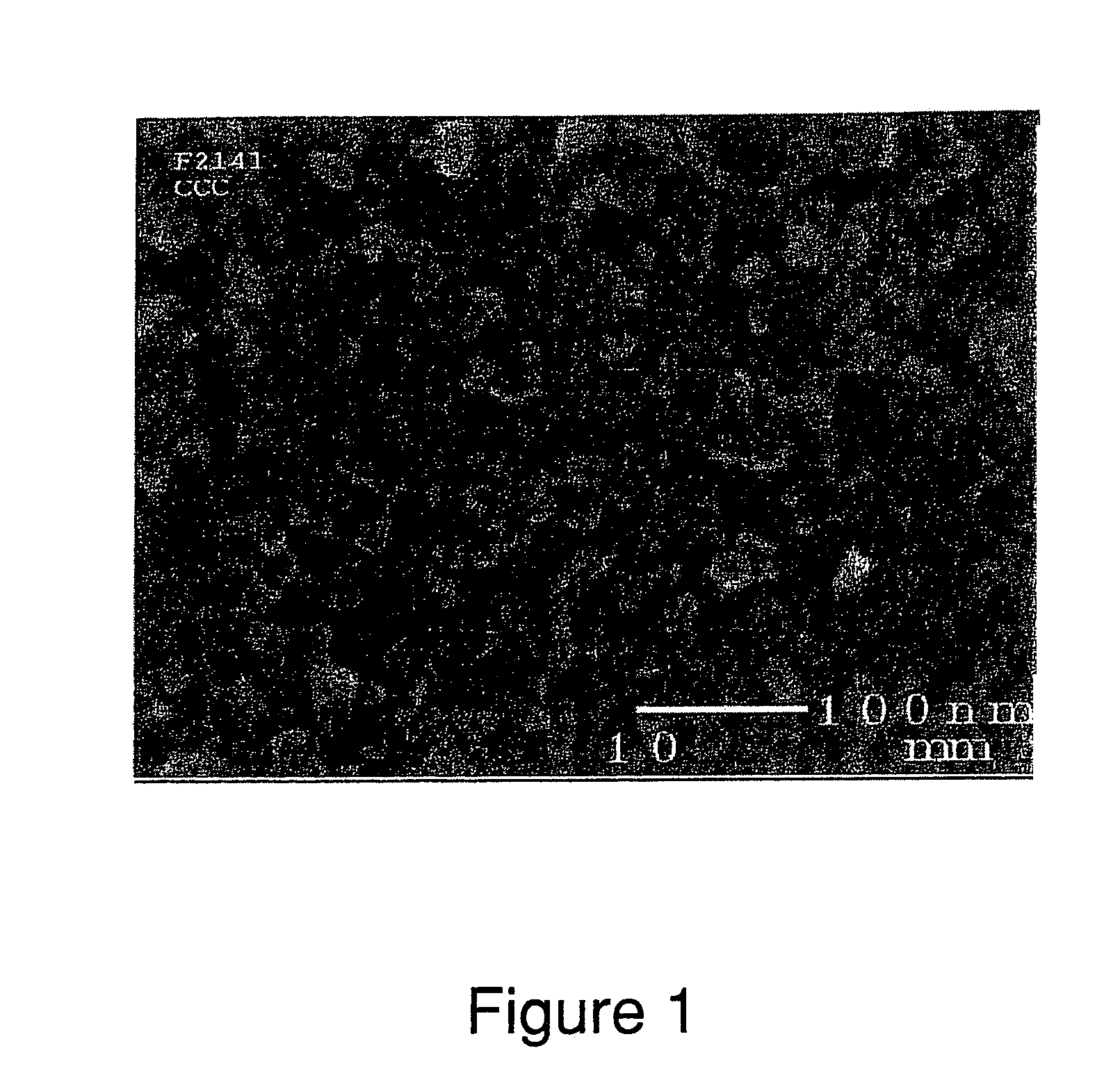

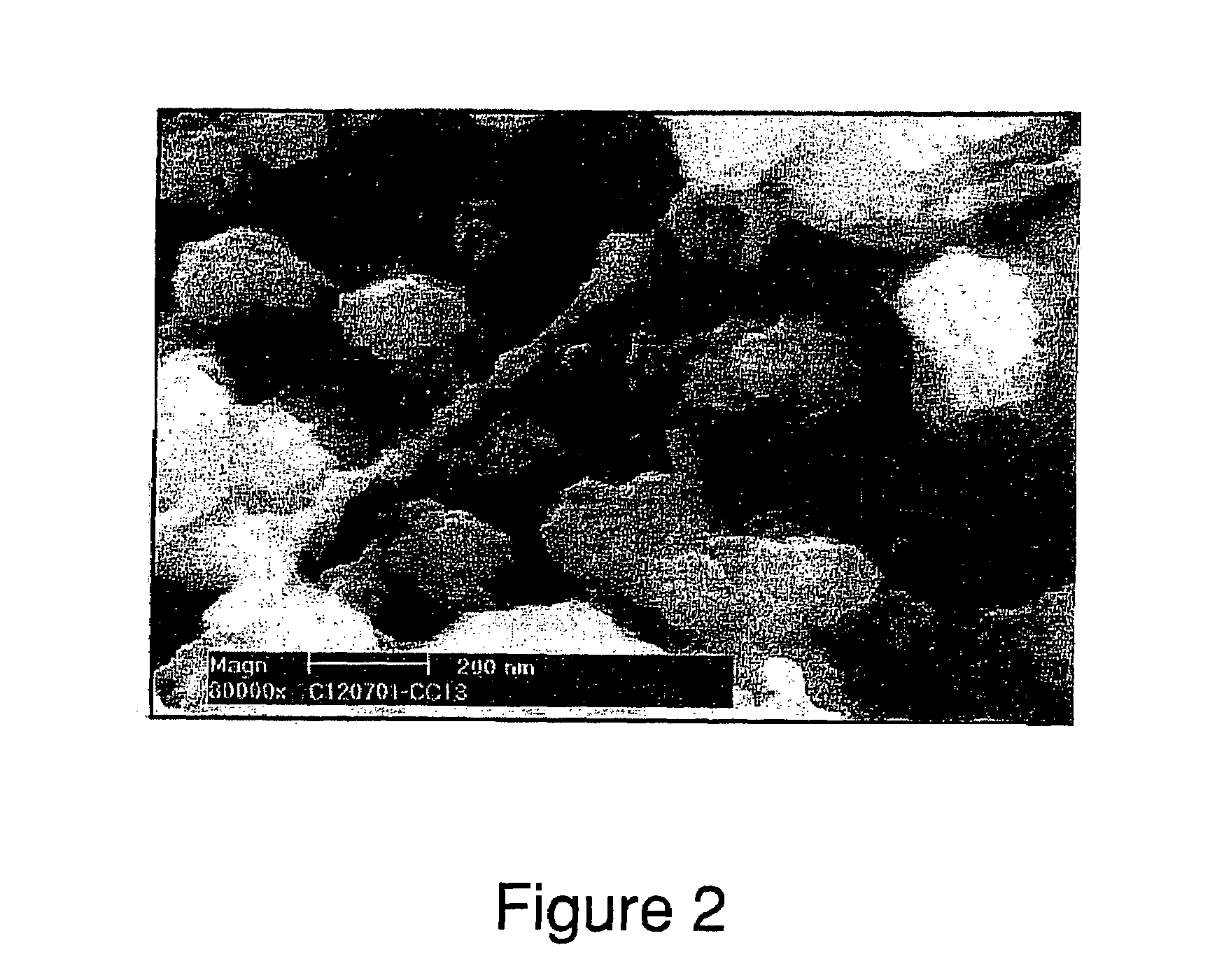

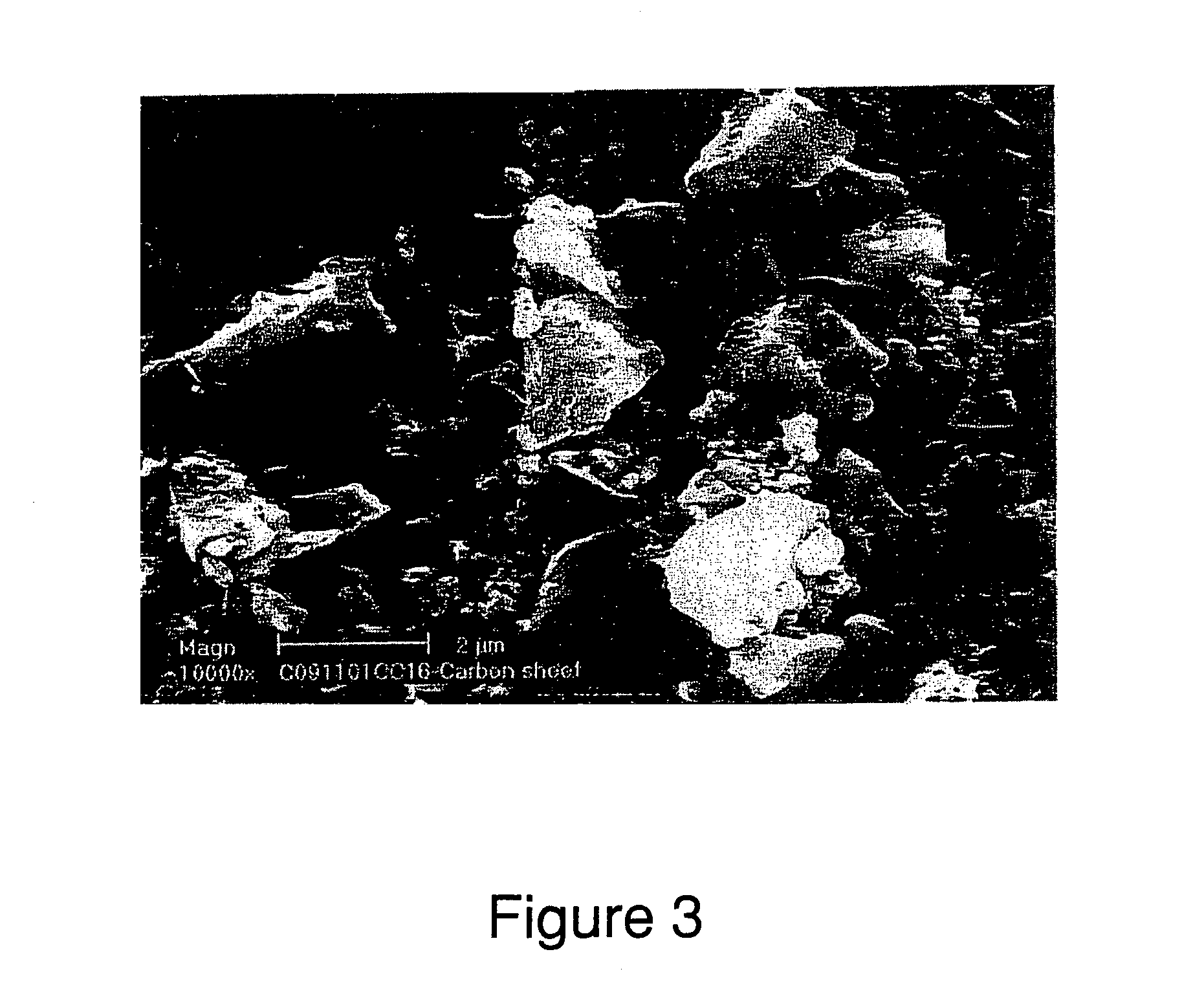

A preferred embodiment of the present invention is a meso-porous nanocomposite material comprising: (A) nano-scaled graphene platelets, wherein each of the platelets comprises a sheet of graphite plane or multiple sheets of graphite plane, and the platelets have a thickness no greater than 100 nm (preferably smaller than 10 nm) and an average length, width, or diameter no greater than 10 μm (preferably smaller than 500 nm); and (B) an electrically conducting binder or matrix material attached or bonded to the platelets to form the nanocomposite material having liquid accessible pores, which provide a surface area greater than about 100 m2 / gm, preferably greater than 500 m2 / gm, and most preferably greater than 1000 m2 / gm. Also disclosed is a capacitor that includes at least an electrode comprising such a meso-porous nanocomposite material. A supercapacitor featuring such a nanocomposite exhibits an exceptionally high capacitance value.

Owner:SAMSUNG ELECTRONICS CO LTD +1

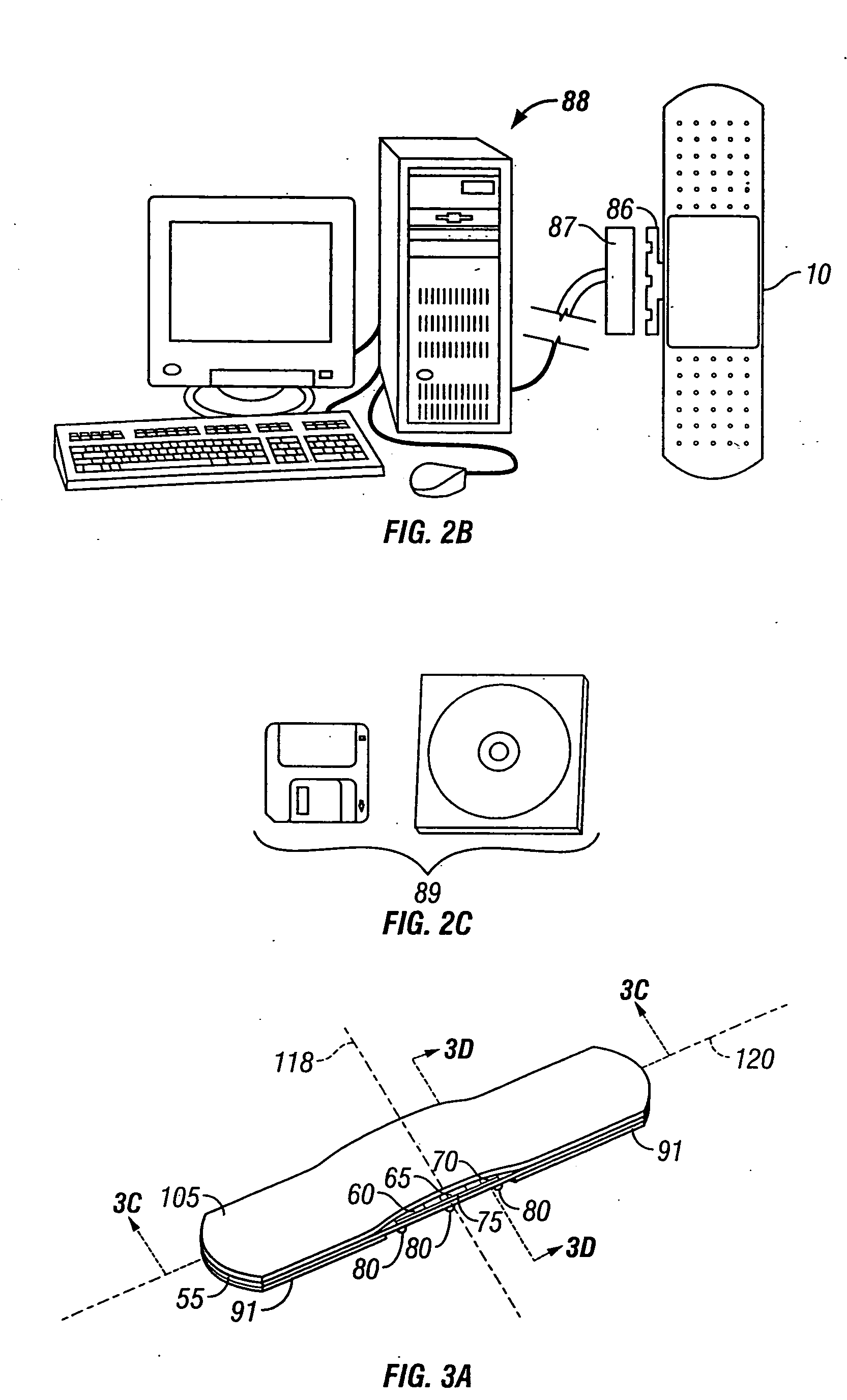

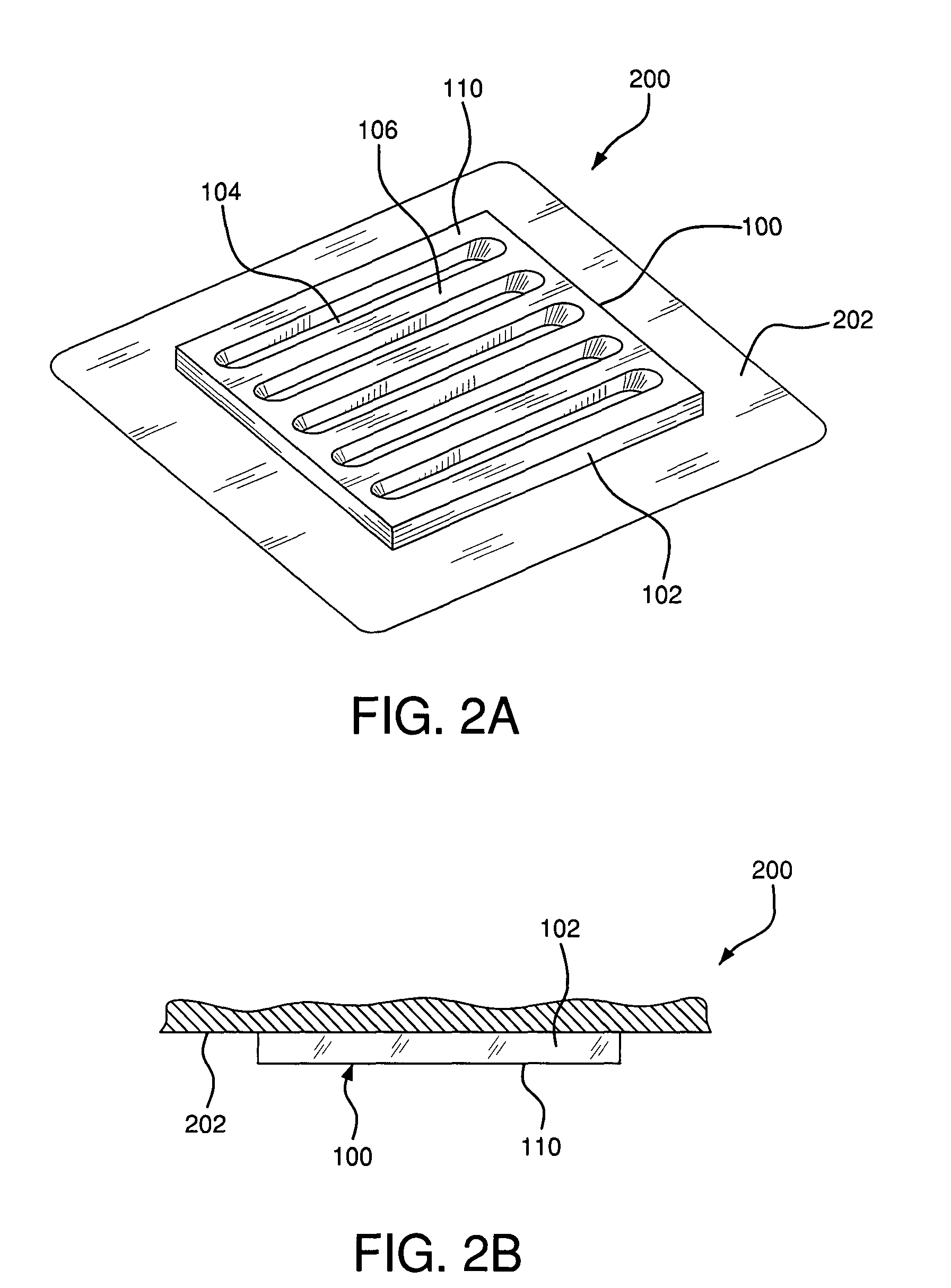

Wearable biomonitor with flexible thinned integrated circuit

InactiveUS20050096513A1Accurately reflectLow profileSolid-state devicesForce measurementWireless dataEngineering

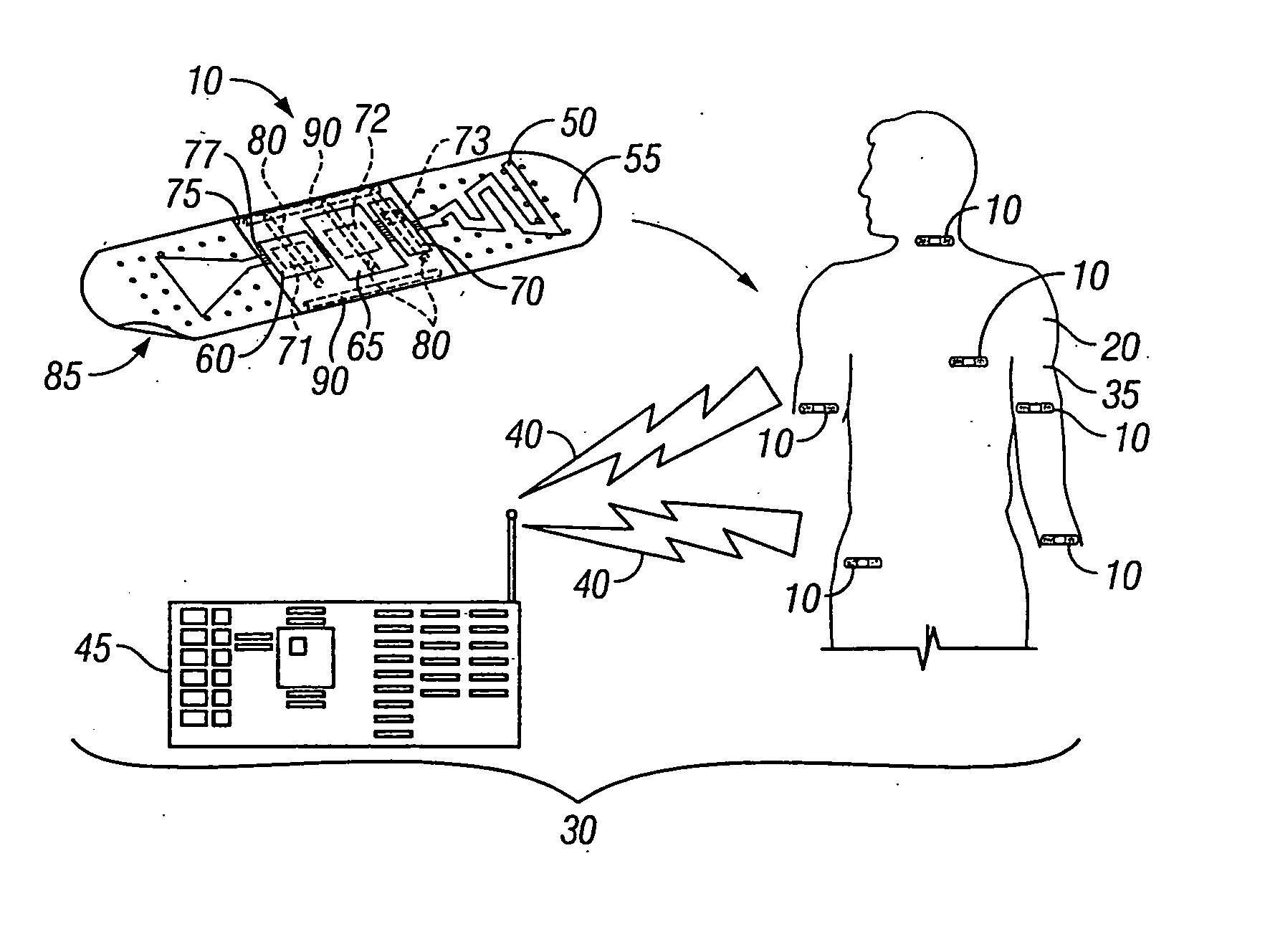

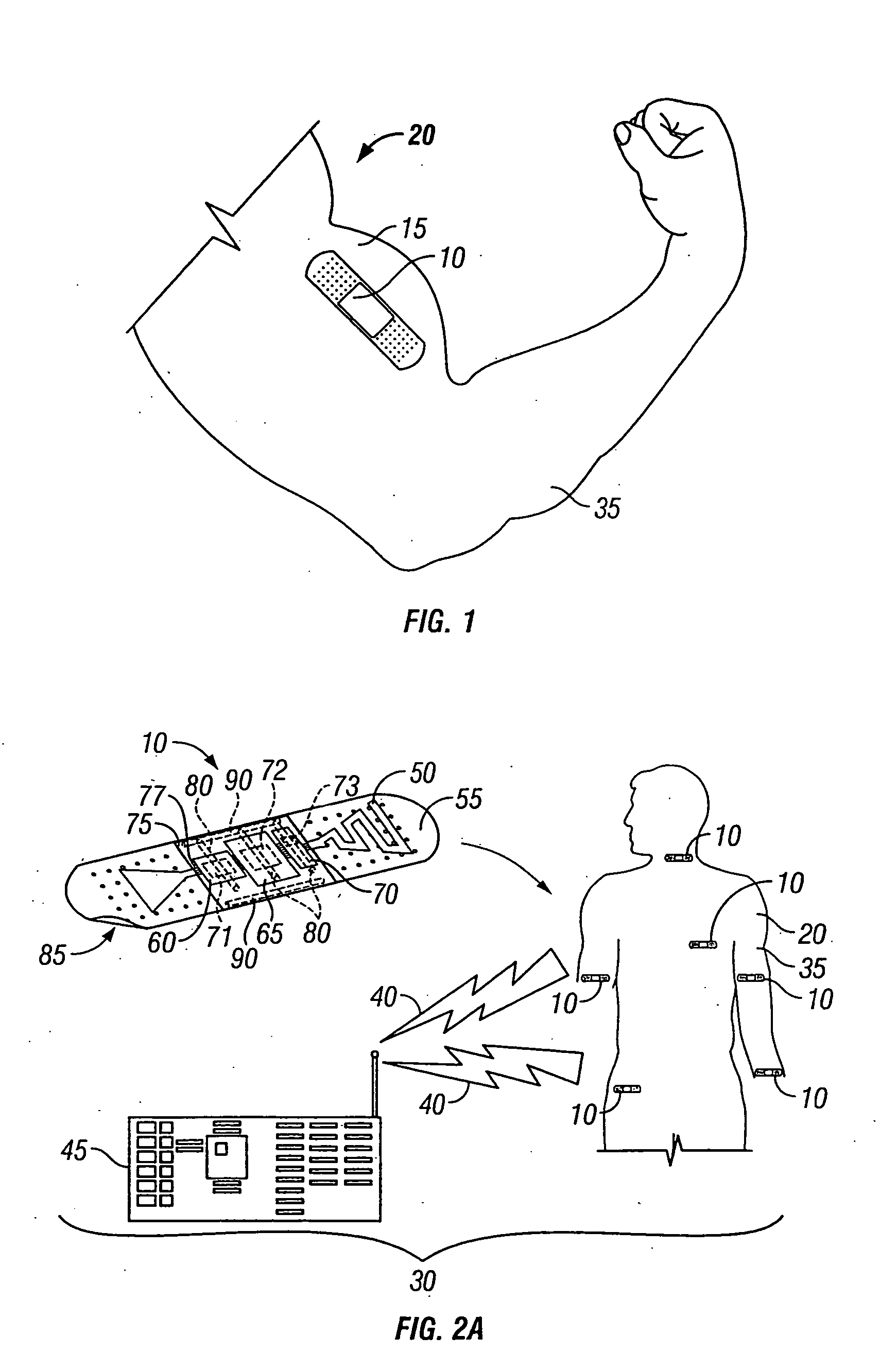

A sensor system (30) has a sensor module (10) and a receiver module (45). The sensor module (10) functions as a wireless data collection device and has a flexible thin sheet of silicon (60, 65, 70) comprising circuitry (71, 72, 73), a flexible power source (105), and a flexible support substrate (55). The silicon, power source, and flexible support substrate are integrated as layers of the sensor module (10). The layers are placed together in the form of an adhesive bandage (10). A plurality of electrodes (80) are connected to the sensor module (10) and protrude from the flexible substrate (55) for contacting the skin of a subject body (20). The receiver module (45) includes one of an RF receiver with a wireless port for continuously receiving data (40), or a physical I / O port (87) to which the sensor module (10) can be physically connected for downloading stored data from the sensor module (10).

Owner:IRVINE SENSORS

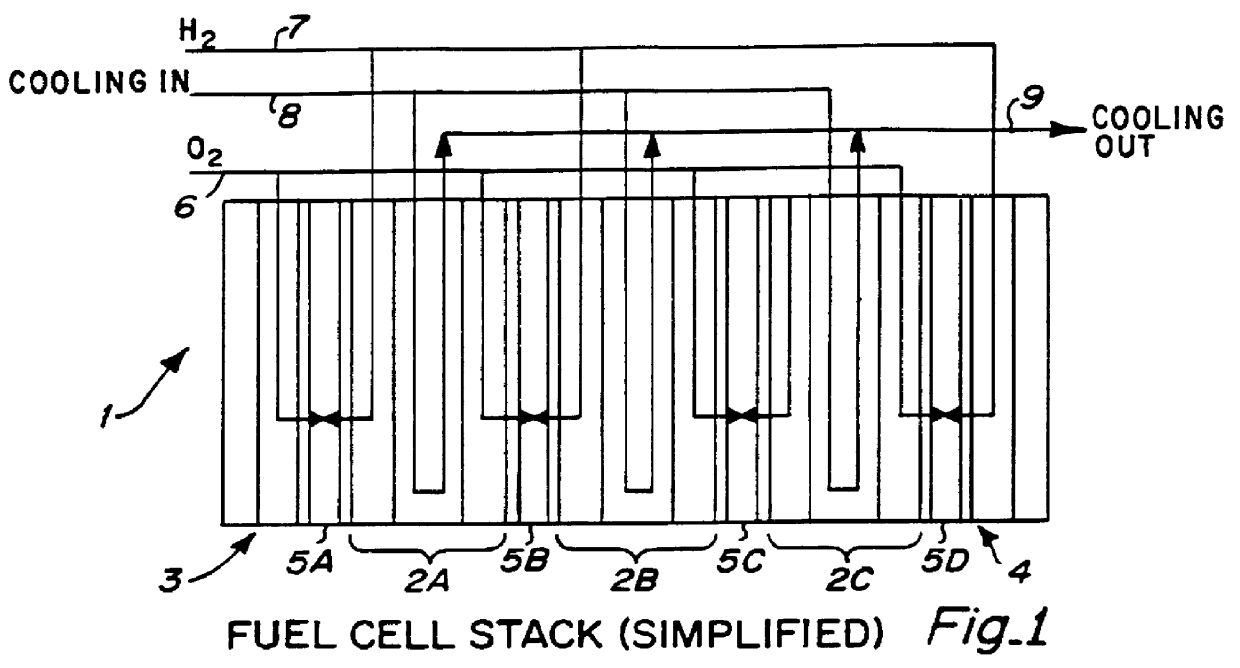

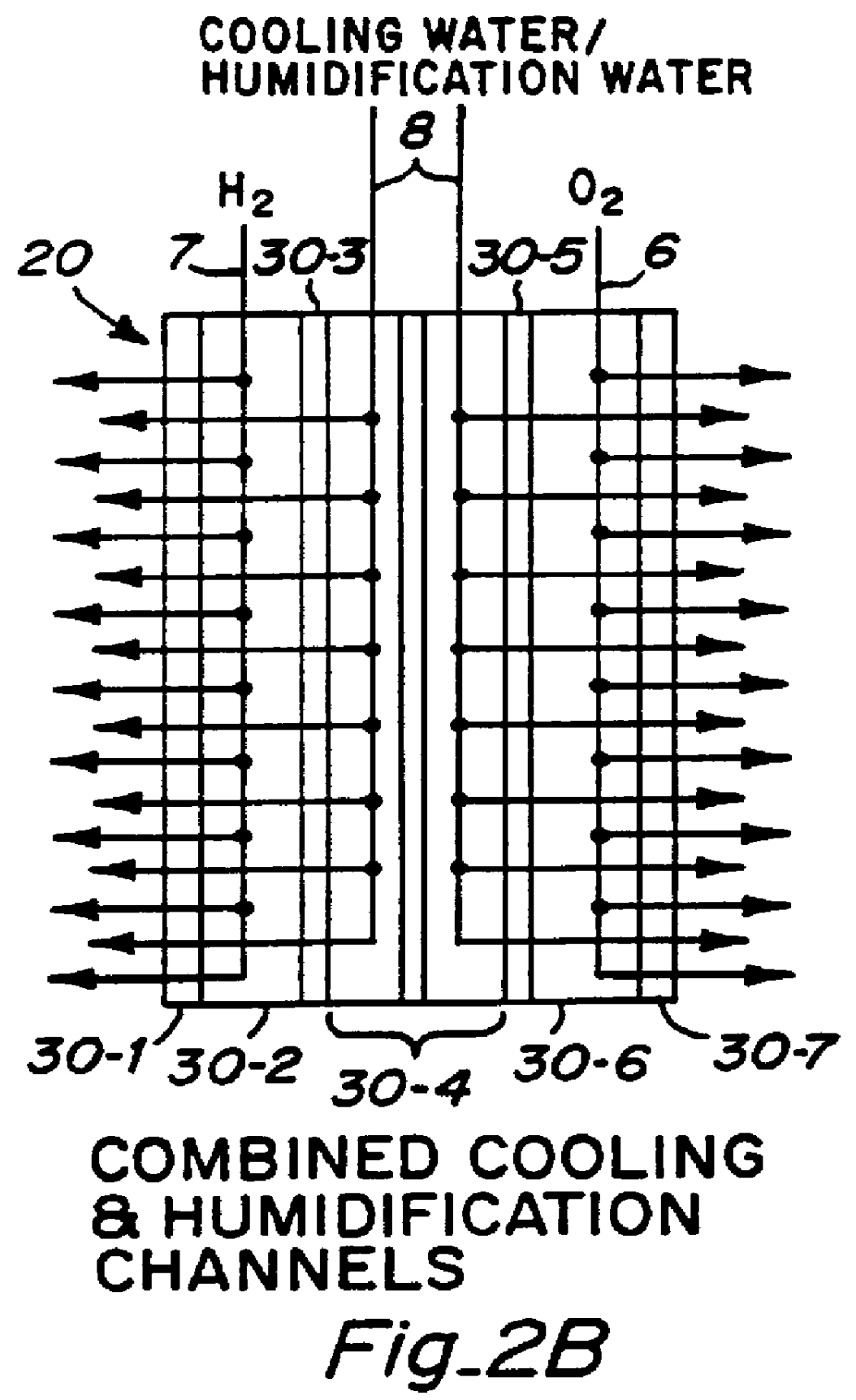

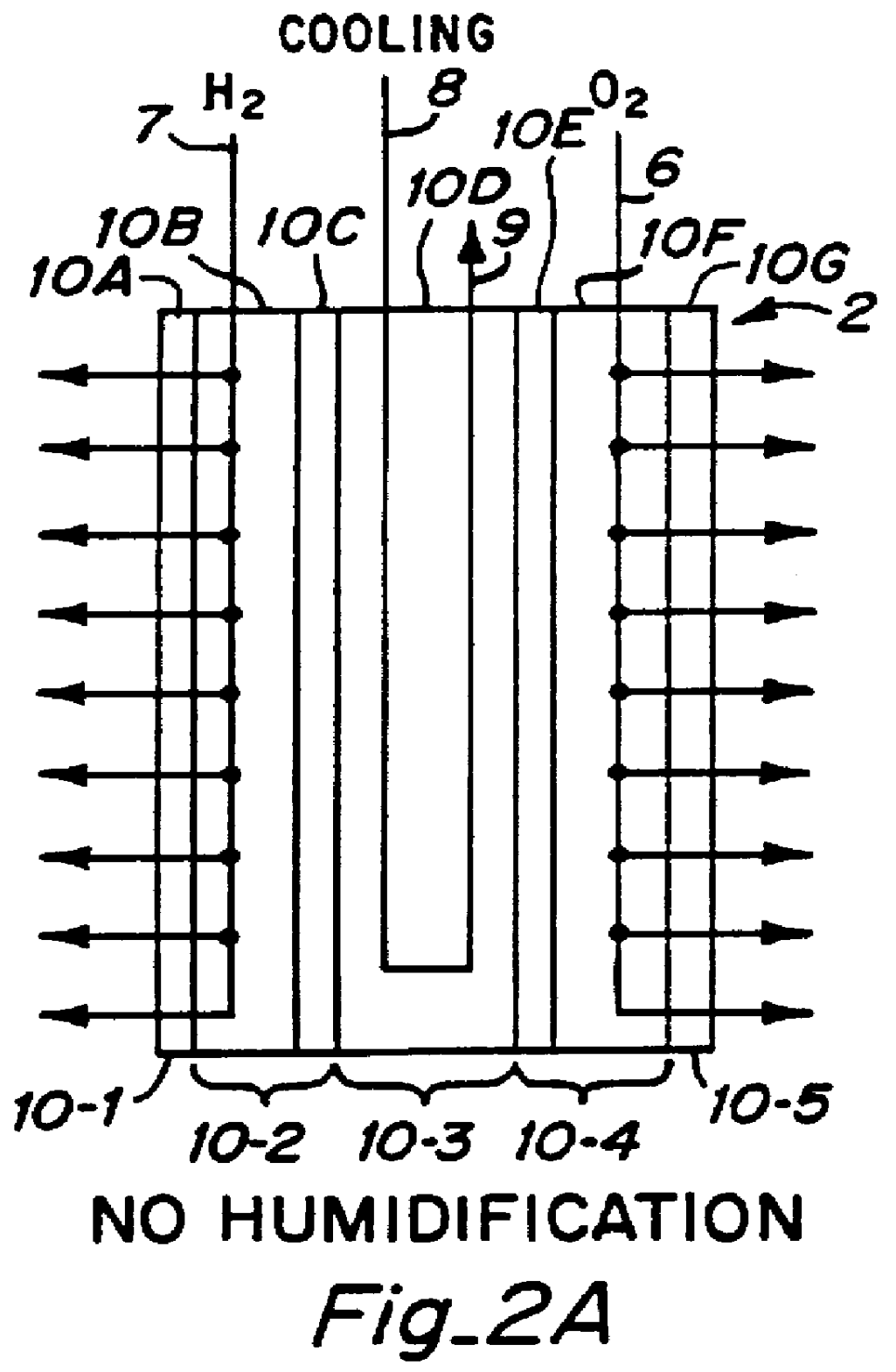

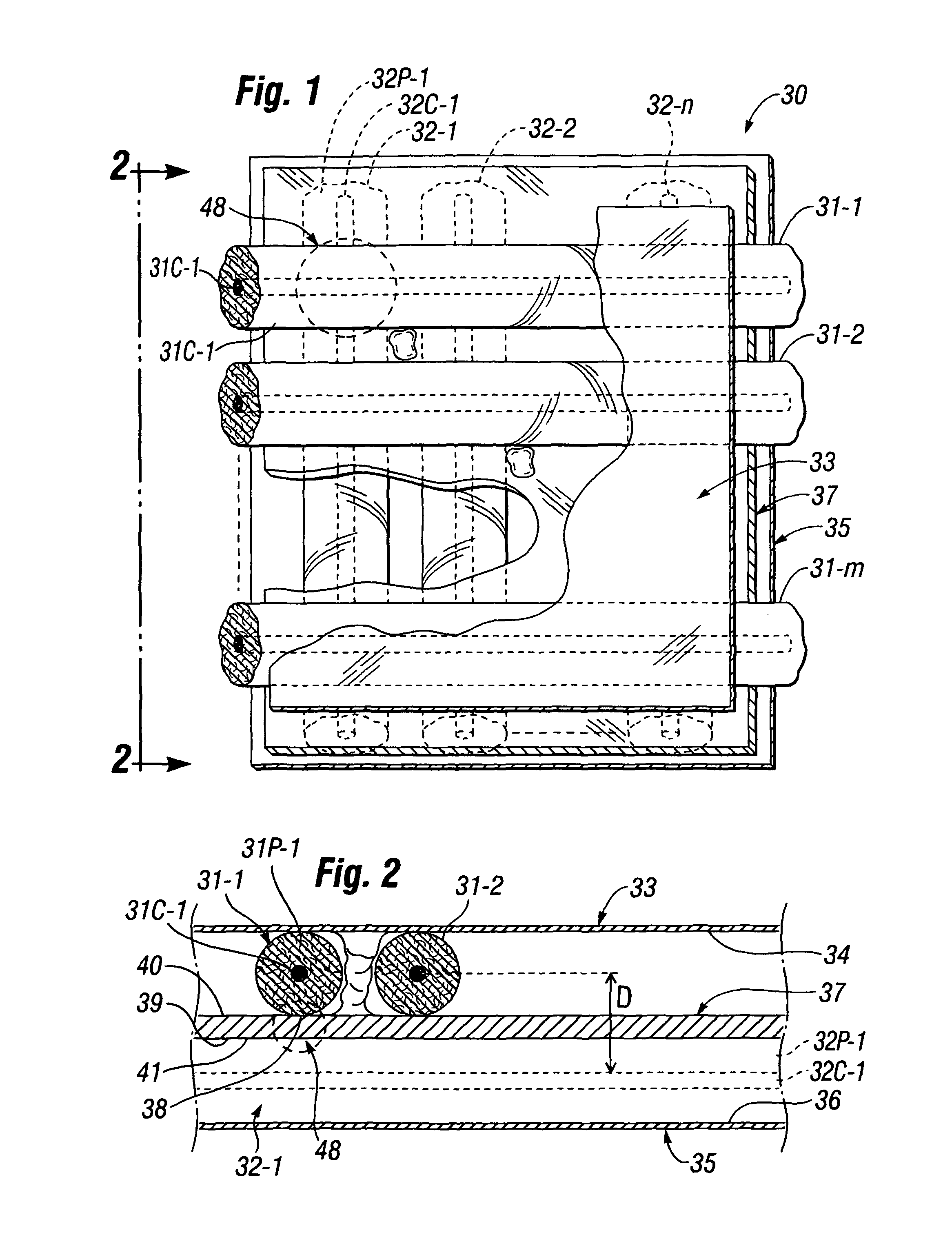

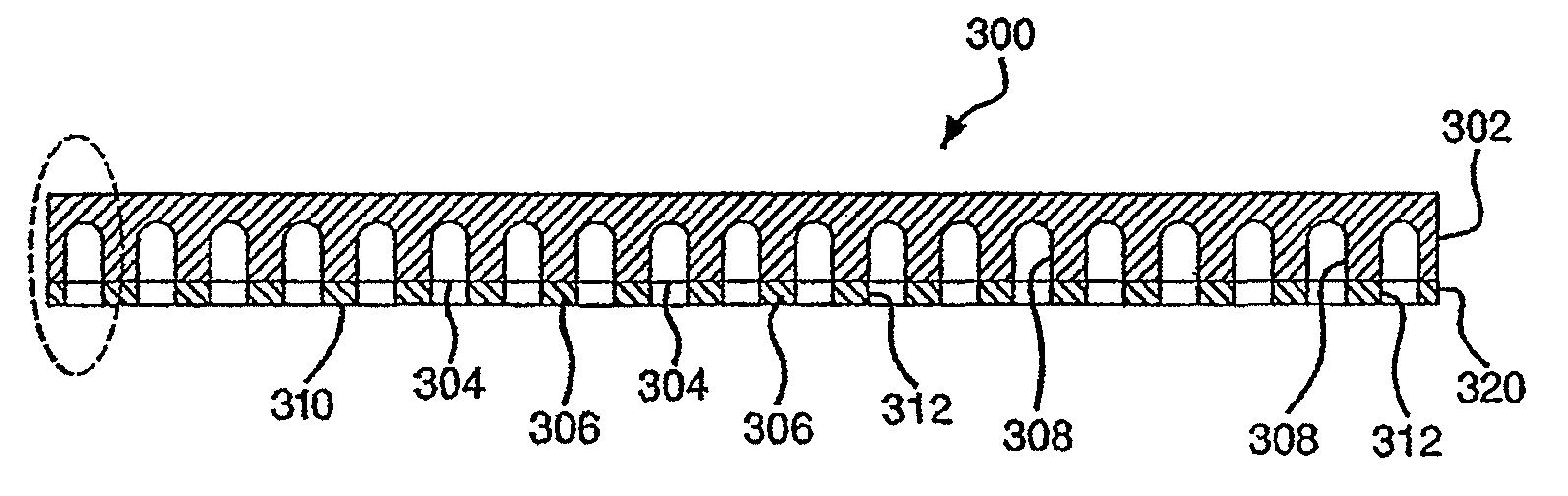

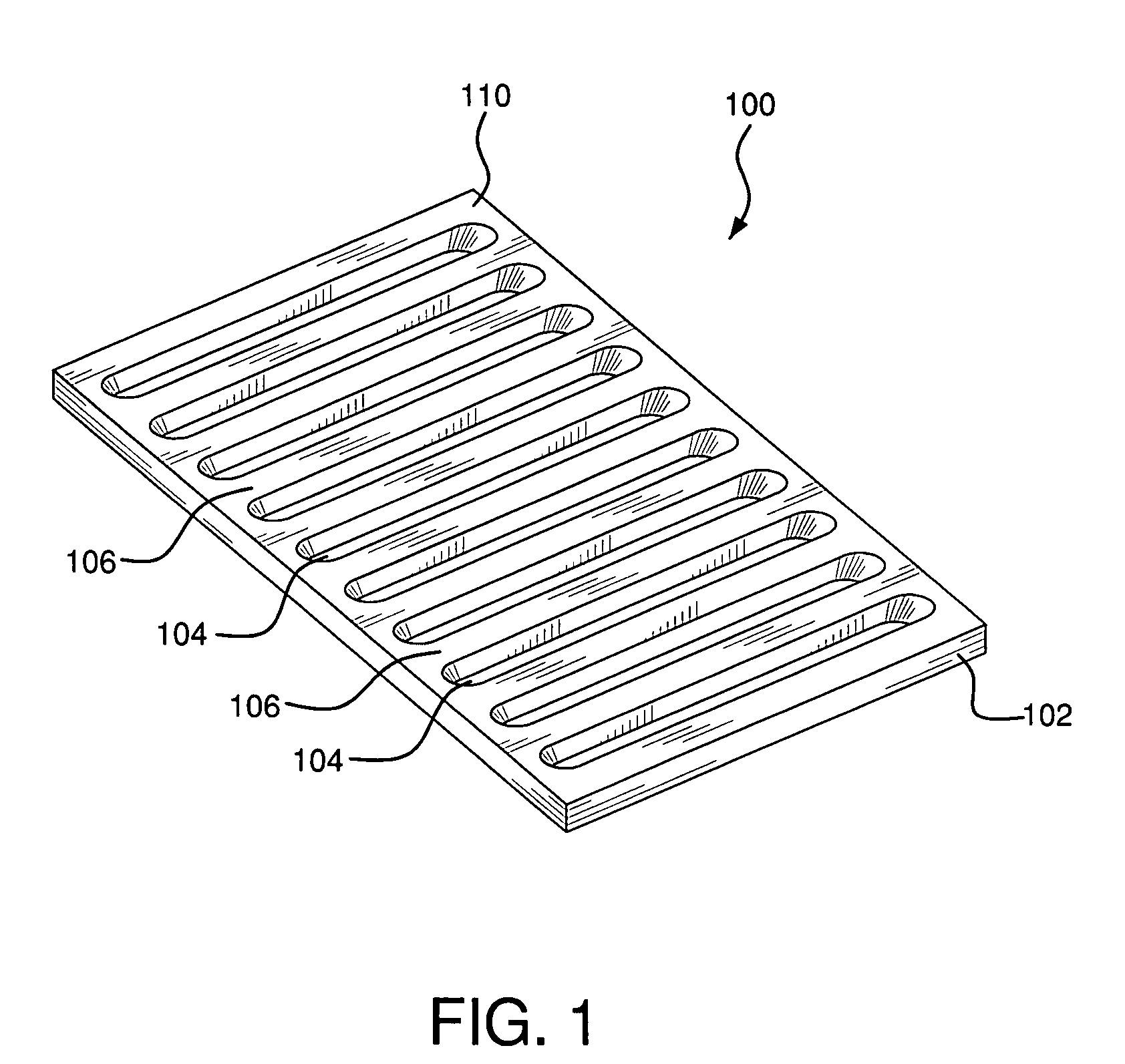

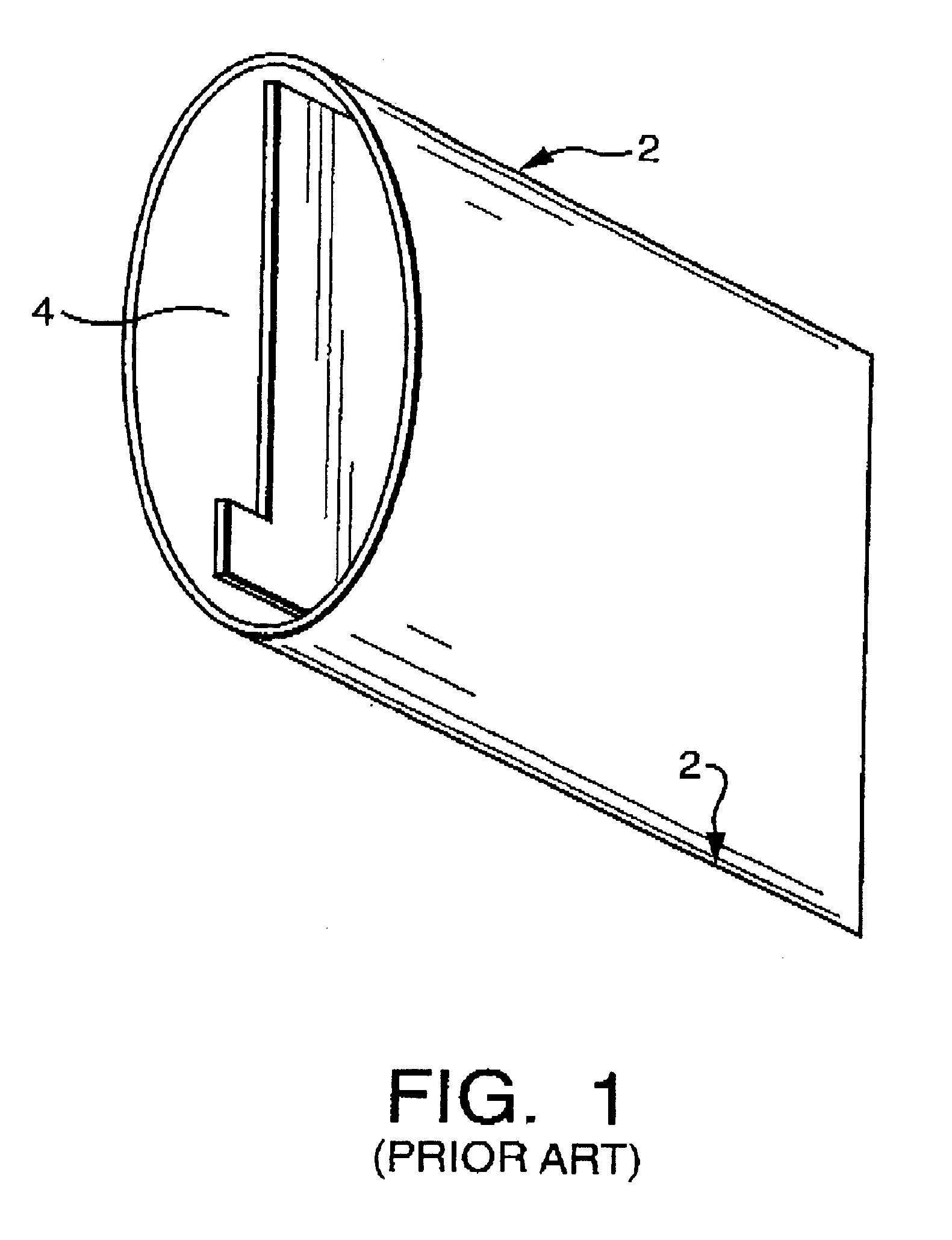

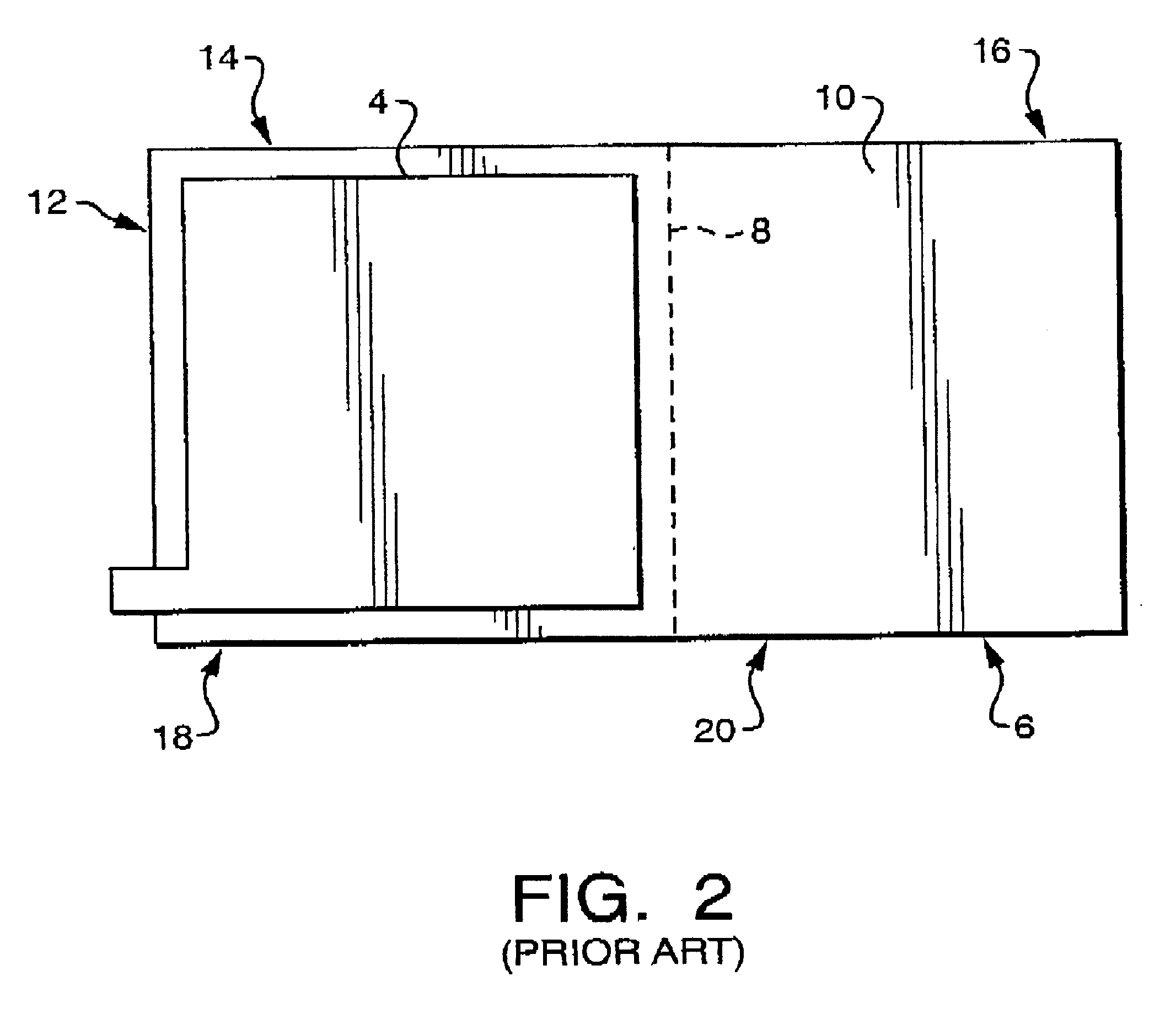

Fuel cell platelet separators having coordinate features

InactiveUS6051331ASimple designEvenly distributedSolid electrolytesFuel cells groupingLaser etchingFuel cells

PCT No. PCT / US95 / 13325 Sec. 371 Date Sep. 28, 1997 Sec. 102(e) Date Sep. 28, 1997 PCT Filed Oct. 10, 1995 PCT Pub. No. WO96 / 12316 PCT Pub. Date Apr. 25, 1996Fuel cell stacks comprising stacked separator / membrane electrode assembly fuel cells in which the separators comprise a series of thin sheet platelets, having individually configured serpentine micro-channel reactant gas humidification active areas and cooling fields therein. The individual platelets are stacked with coordinate features aligned in contact with adjacent platelets and bonded to form a monolithic separator. Post-bonding processing includes passivation, such as nitriding. Preferred platelet material is 4-25 mil Ti, in which the features, serpentine channels, tabs, lands, vias, manifolds and holes, are formed by chemical and laser etching, cutting, pressing or embossing, with combinations of depth and through etching preferred. The platelet manufacturing process is continuous and fast. By employing CAD based platelet design and photolithography, rapid change in feature design can accommodate a wide range of thermal management and humidification techniques. One hundred H2-O2 / PEM fuel cell stacks of this IFMT platelet design will exhibit outputs on the order of 0.75 kW / kg, some 3-6 times greater than the current graphite plate PEM stacks.

Owner:H POWER

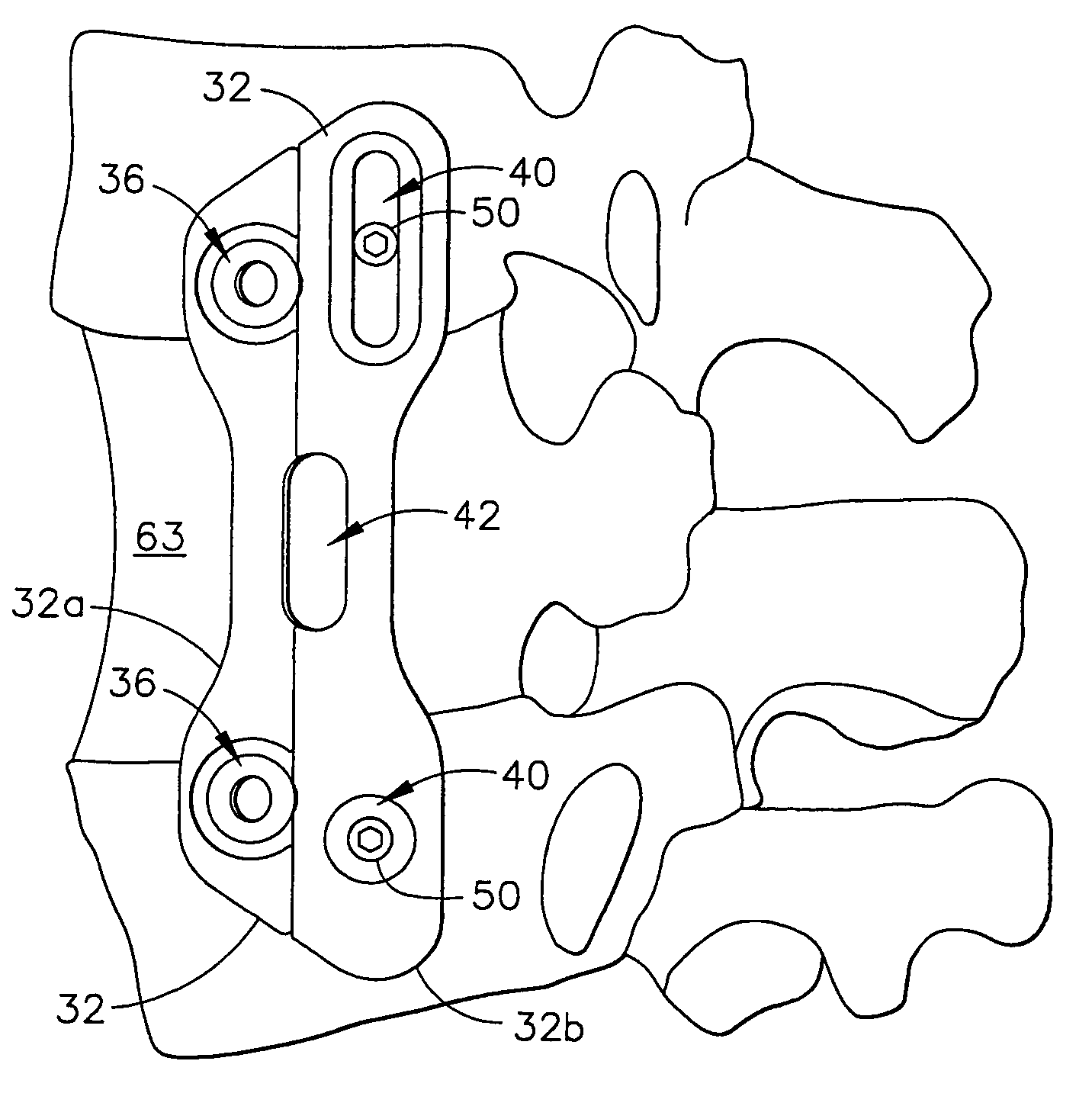

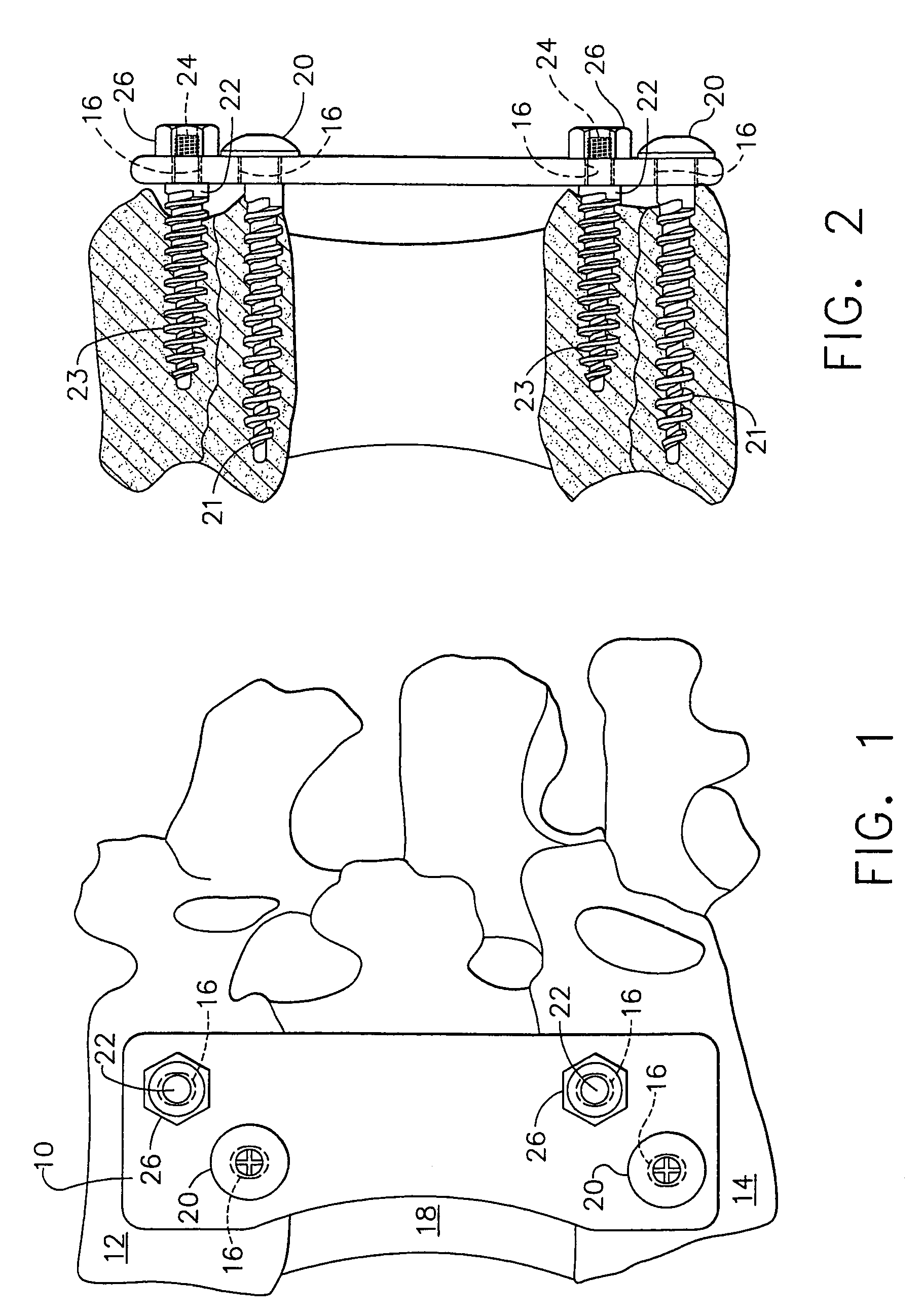

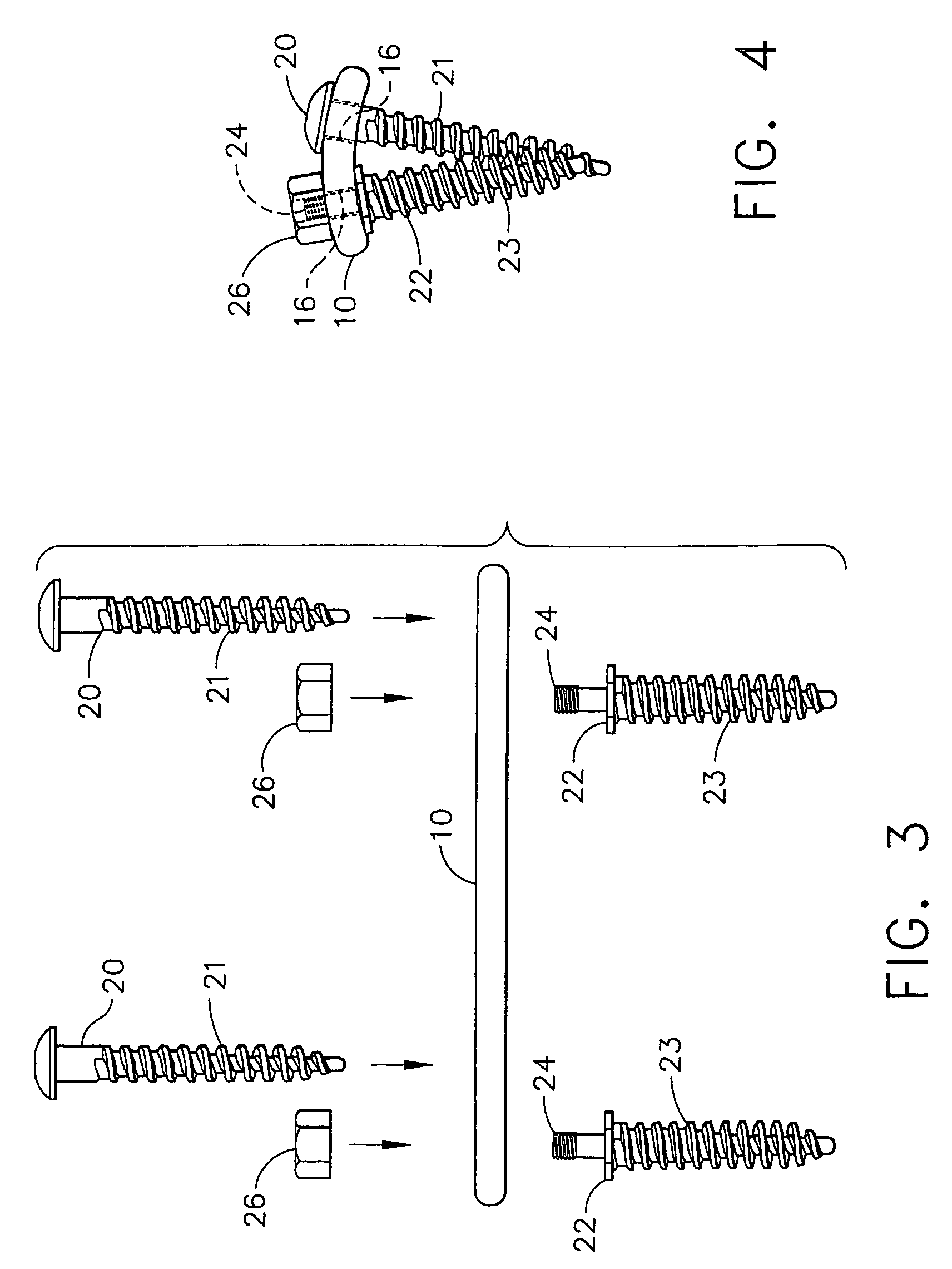

Hinged anterior thoracic/lumbar plate

InactiveUS7341590B2Low profileComfortably fits patient 's anatomyInternal osteosythesisDiagnosticsAnterior chestEngineering

An anterior thoracic / lumbar system comprising a thin plate and fasteners for securing the plate to vertebrae or other osseous material. The plate may be hinged along the central axis, with a pair of collinear holes on each portion of the plate. Each of the holes accommodates a bolt which is screwed into the vertebrae and secured to the plate using a nut.

Owner:NUVASIVE

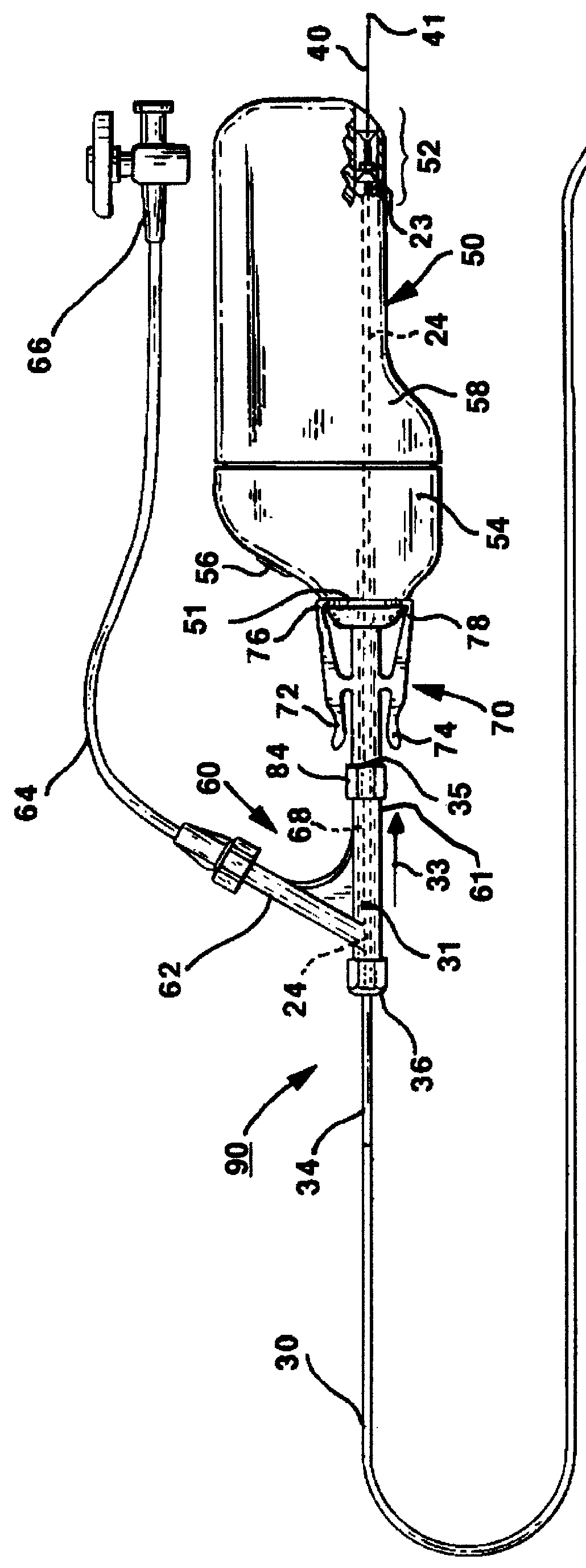

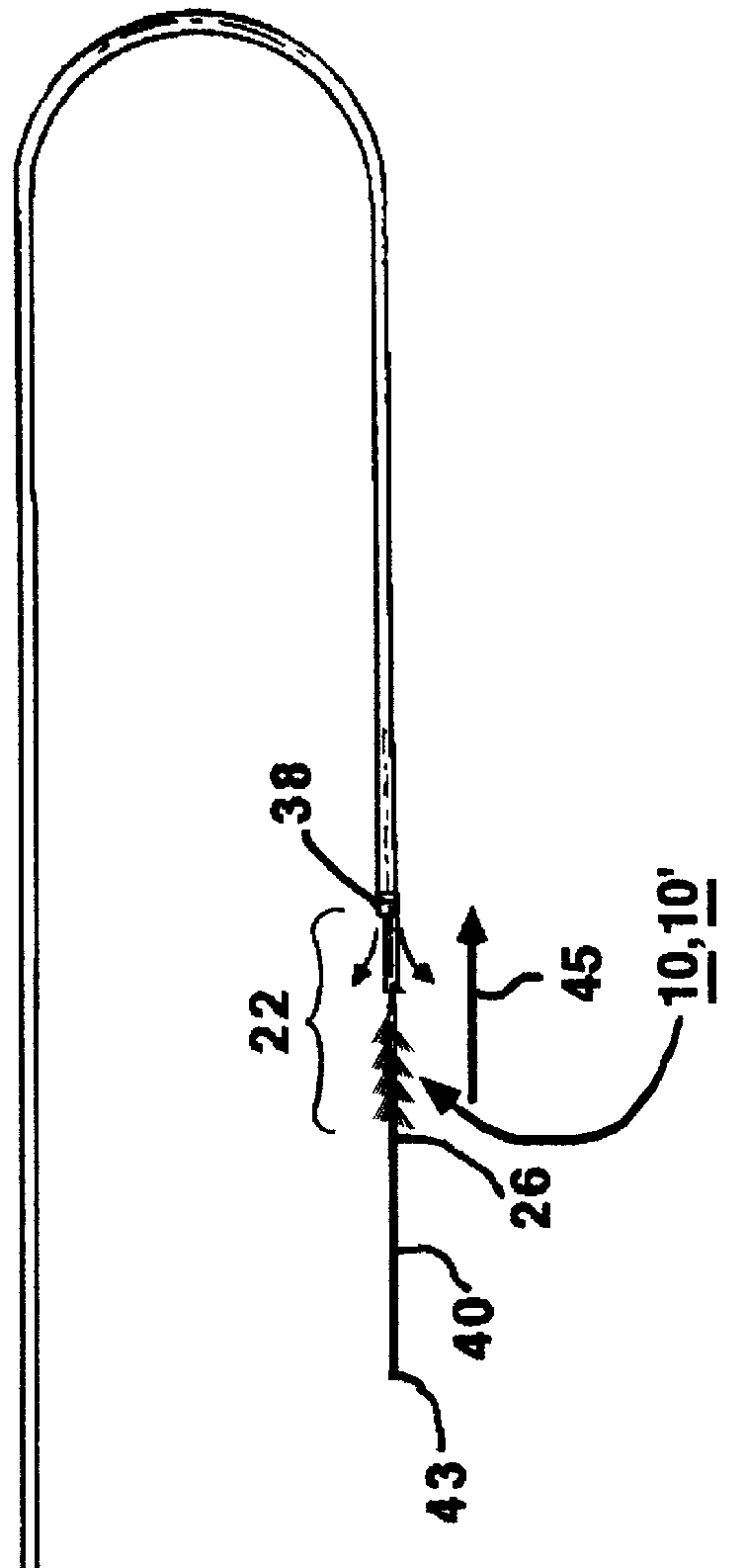

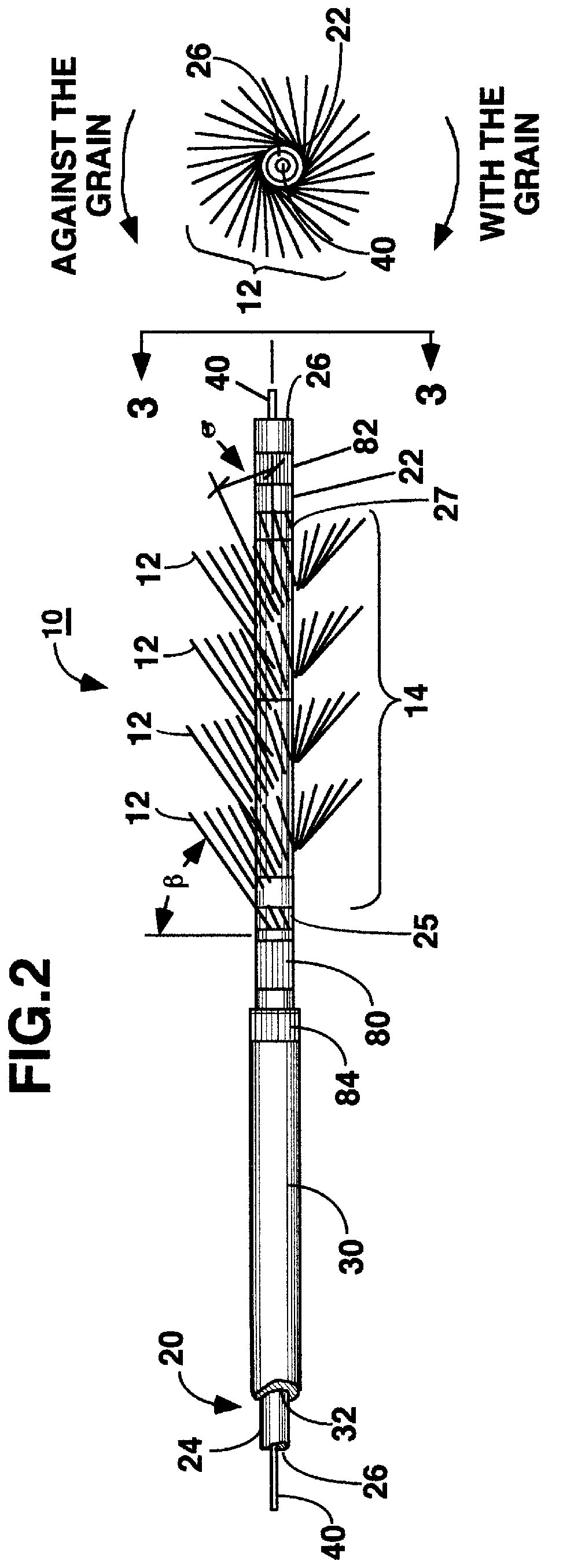

Miniaturized medical brush

A miniaturized brush particularly adapted for medical use formed at the distal end of an elongated brush drive shaft having a hollow lumen formed therein for introduction over a guidewire. The brush drive shaft is enclosed in the lumen of a brush delivery catheter and other components of a brush sub-assembly adapted to deliver infusate through the catheter lumen and to be coupled to a drive motor unit for rotating the brush drive shaft and brush. The brush bristles of the distal brush are adapted to be garaged in a distal end section of the brush delivery catheter lumen during introduction through a body lumen. The brush bristles are formed of a thin sheet of rigid plastic material that is shaped to have a plurality of fringe elements extending in parallel from a mounting web. The mounting web is wound about and attached to a distal end section of the drive shaft outer circumference so that the fringe elements extend outward from the drive shaft surface and obliquely of the drive shaft axis. Preferably, proximal and distal spiral brush sections are formed in this manner so that fluids are impelled distally and proximally, respectively, between the proximal and distal brush sections as infusate is delivered.

Owner:TYCO HEALTHCARE GRP LP

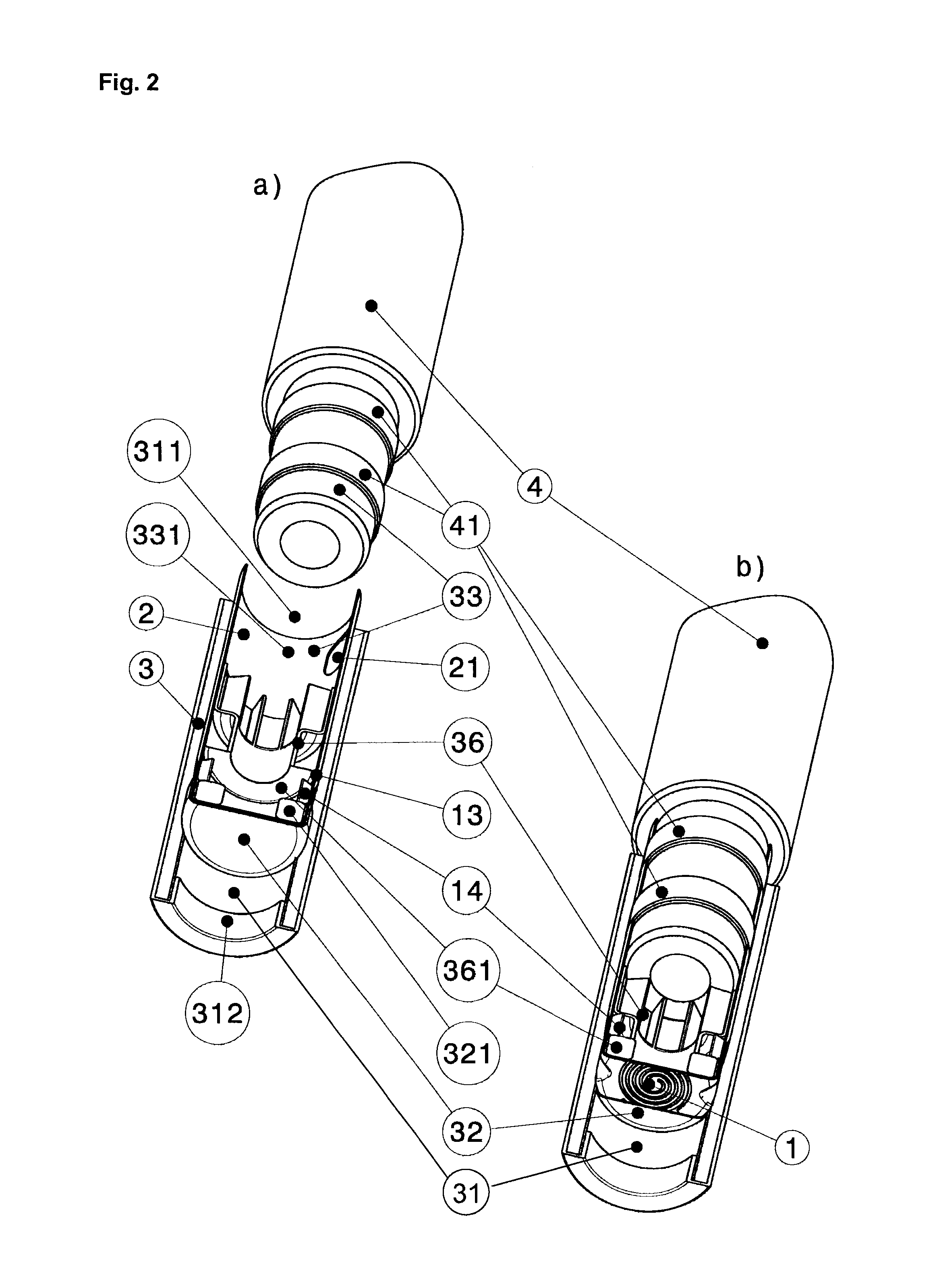

Permeable electric thermal resistor foil for vaporizing fluids from single-use mouthpieces with vaporizer membranes

ActiveUS20140305454A1Low costReduce material usageTobacco pipesTobacco devicesMetallic foilDual coil

A vaporizer device for vaporizing substances is provided, containing active and / or aroma materials, including a mouthpiece with a fluid inlet and a fluid outlet, and including: a heating device with a thermal resistor being a metallic foil or a thin sheet configured as a dual coil and / or sinuous line with two ends and dimensions of the cross-section of a cigarette or a small cigar, wherein the interspaces of the dual coil and / or sinuous line allow fluid flow therethrough, contact tabs are connected to respective opposed ends of the dual coil and / or sinuous line and are not in direct contact with one another, and at least one permeable and wettable vaporizer membrane in large-area contact with the thermal resistor, wherein the thermal resistor and the at least one vaporizer membrane are arranged orthogonally or at an angle to the direction of the fluids passing through the mouthpiece.

Owner:PHILIP MORRIS PROD SA

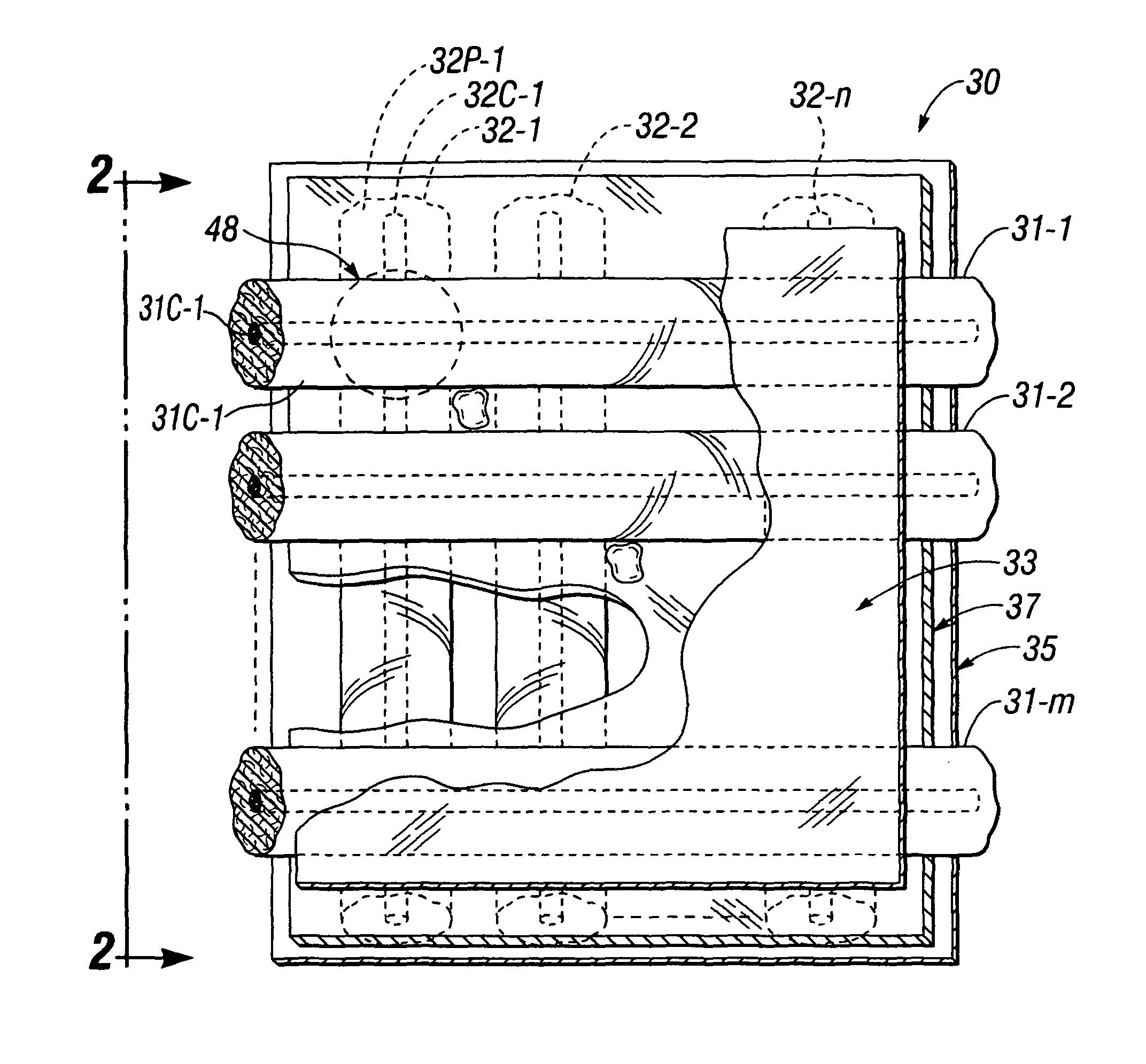

Elastically stretchable fabric force sensor arrays and methods of making

ActiveUS8161826B1Facilitate measuring and mapping forcesWork measurementMaterial strength using tensile/compressive forcesSensor arrayConductive polymer

Force or pressure transducer arrays have elastically stretchable electrically conductive polymer threads disposed in parallel rows and columns that contact at intersections thereof a piezoresistive material which has an electrical resistivity which varies inversely with pressure or force exerted thereon to form a matrix array of force or pressure sensor elements. The threads are fixed to a single one or pair of flexible elastically stretchable substrate sheets made of thin sheets of an insulating polymer such as PVC, or for greater elasticity and conformability to irregularly-shaped objects such as human body parts, an elastically stretchable fabric such as LYCRA or SPANDEX. Elastic stretchability of the sensor arrays is optionally enhanced by disposing either or both row and column conductive threads in sinuously curved, serpentine paths rather than straight lines.

Owner:PATIENTECH LLC

Method for producing 700Mpa V-N microalloyed high-strength air corrosion-resistant steel based on sheet bar continuous casting tandem rolling process

InactiveCN1884608AHigh strengthGood formabilityTemperature control deviceMetal rolling arrangementsSheet steelChemical composition

This invention exposed the producing method of V-N microalloyed high strength weathering steel which produced with near net shape con-casting technology. It is smelted in electric furnace or converter, refined, con-casted, casted, then directly sent into roller hearth furnace or soaking pit, hot-rolled, laminar cooled, coiled. The liquid steel's chemical elements are (Wt.%): C: <=0.08%, Si: 0.25- 0.75%, Mn: 0.8-2.0%, P: 0.070-0.150%, S: <=0.040%, Cu: 0.25-0.60 %, Cr: 0.30-1.25 wt%, Ni: <=0.65%, V: 0.05-0.20%, N: 0.015-0.030%. This invention can get the high intensity, formation, weathering, joining character stably. The alloying cost is relatively low. So it can be used to produce container, carriage, and other industry facility.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

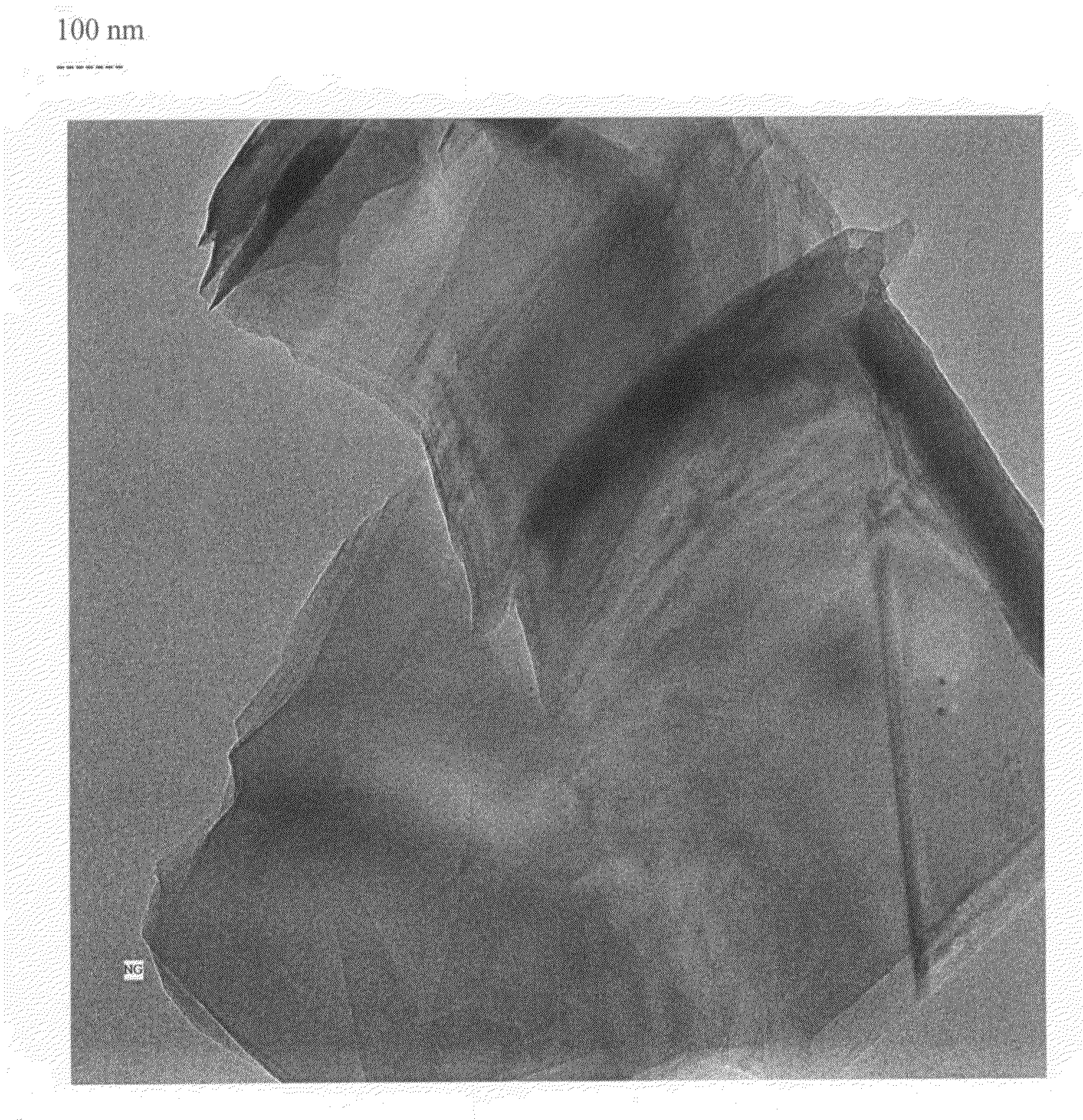

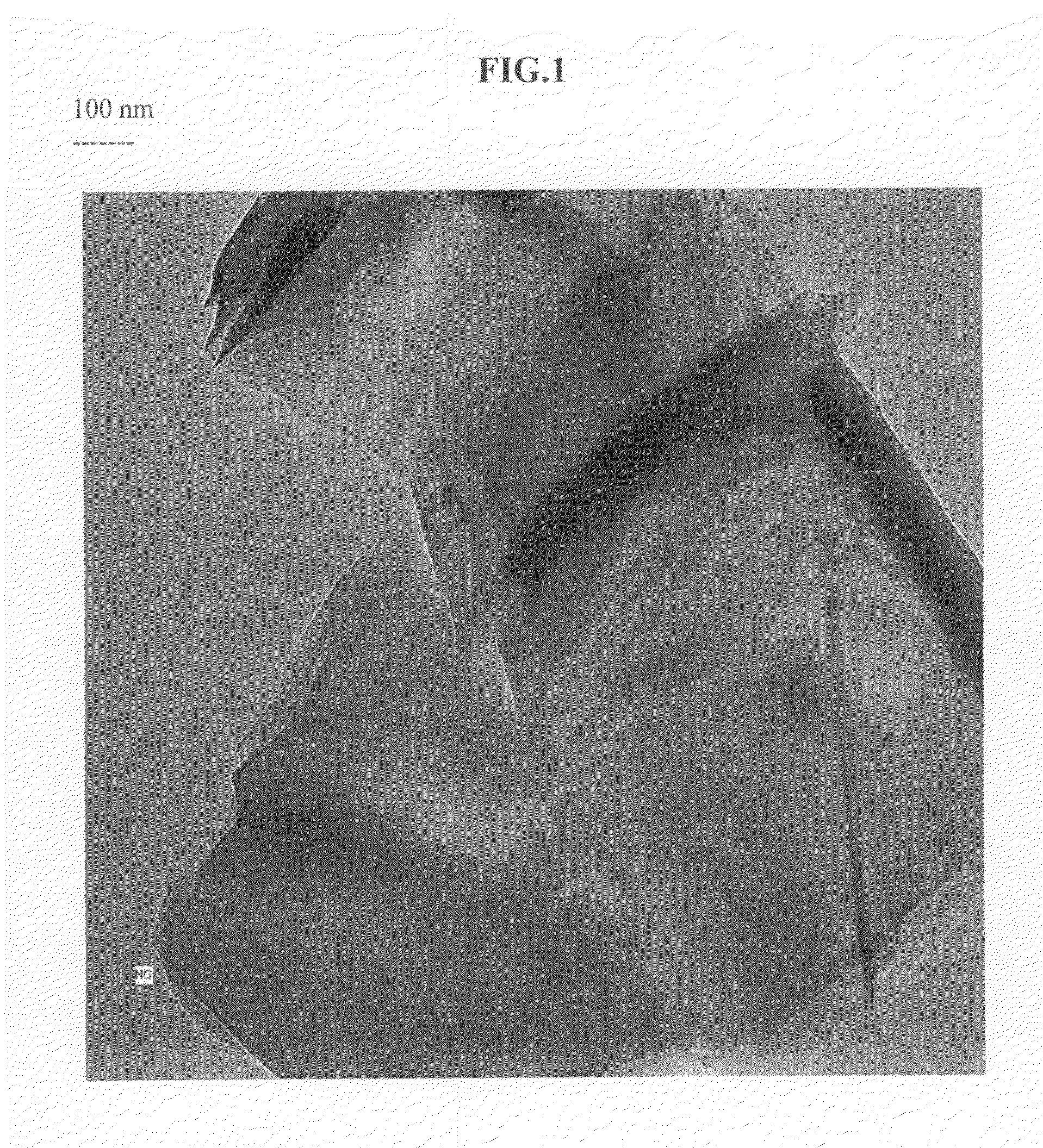

Method of producing exfoliated graphite, flexible graphite, and nano-scaled graphene platelets

The present invention provides a method of exfoliating a layered material (e.g., graphite and graphite oxide) to produce nano-scaled platelets having a thickness smaller than 100 nm, typically smaller than 10 nm. The method comprises (a) dispersing particles of graphite, graphite oxide, or a non-graphite laminar compound in a liquid medium containing therein a surfactant or dispersing agent to obtain a stable suspension or slurry; and (b) exposing the suspension or slurry to ultrasonic waves at an energy level for a sufficient length of time to produce separated nano-scaled platelets. The nano-scaled platelets are candidate reinforcement fillers for polymer nanocomposites. Nano-scaled graphene platelets are much lower-cost alternatives to carbon nano-tubes or carbon nano-fibers.

Owner:GLOBAL GRAPHENE GRP INC

Brazed diamond tools and methods for making the same

Owner:SUNG CHIEN MIN

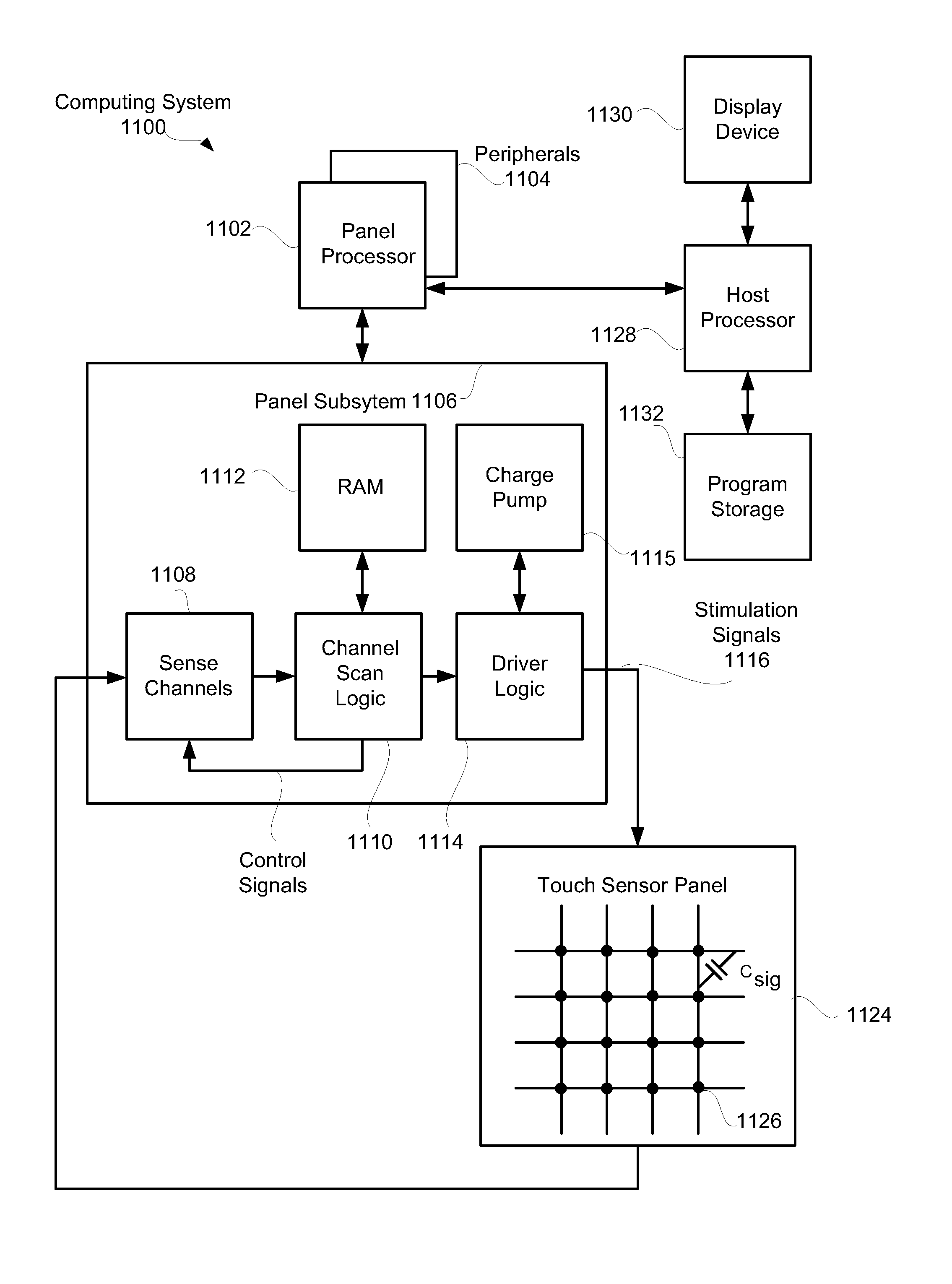

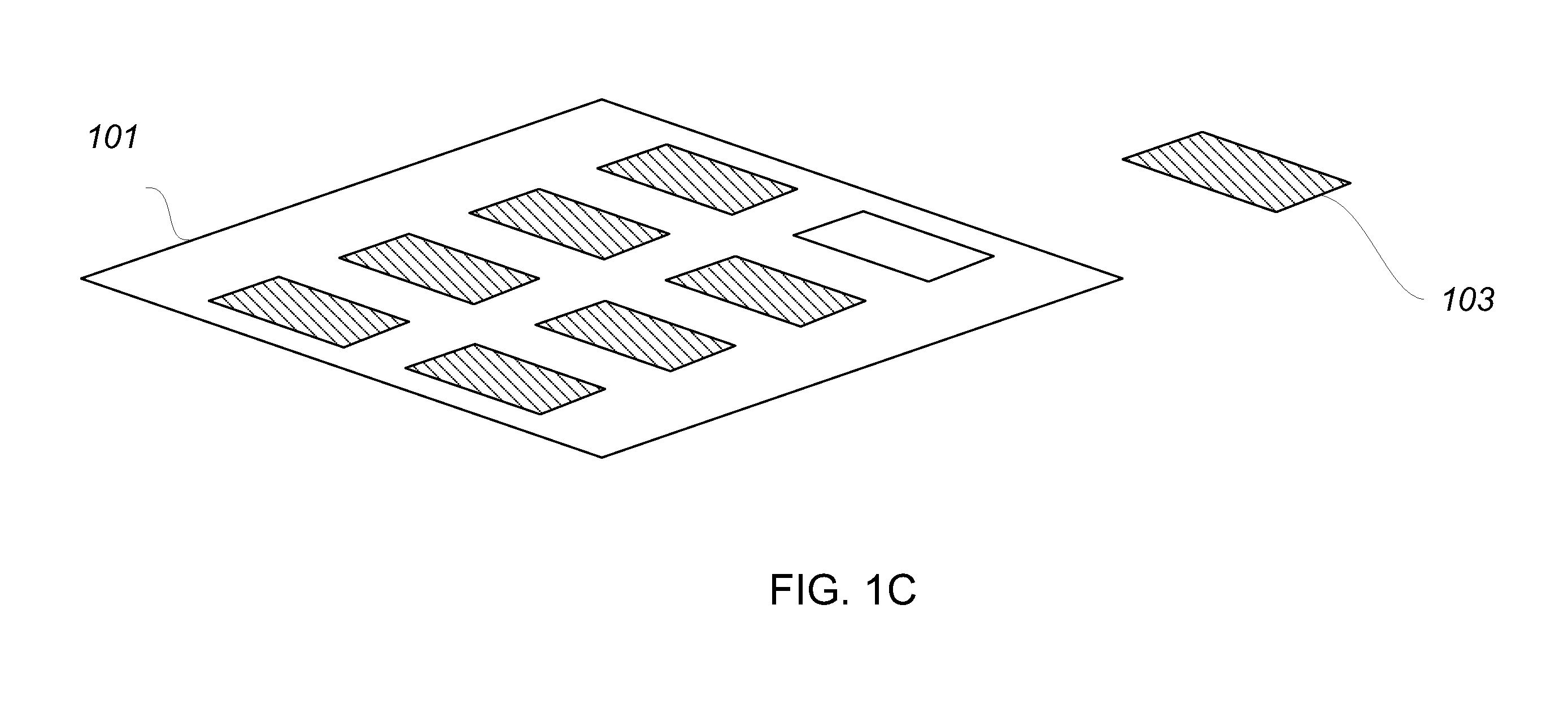

Thin Glass for Touch Panel Sensors and Methods Therefor

Improved techniques are disclosed for fabrication of touch panels using thin sheet glass, coupling external circuitry, and securely holding the touch panel within a portable electronic device. The thin sheet glass may be chemically strengthened and laser scribed.

Owner:APPLE INC

Decorative packaging with special effects

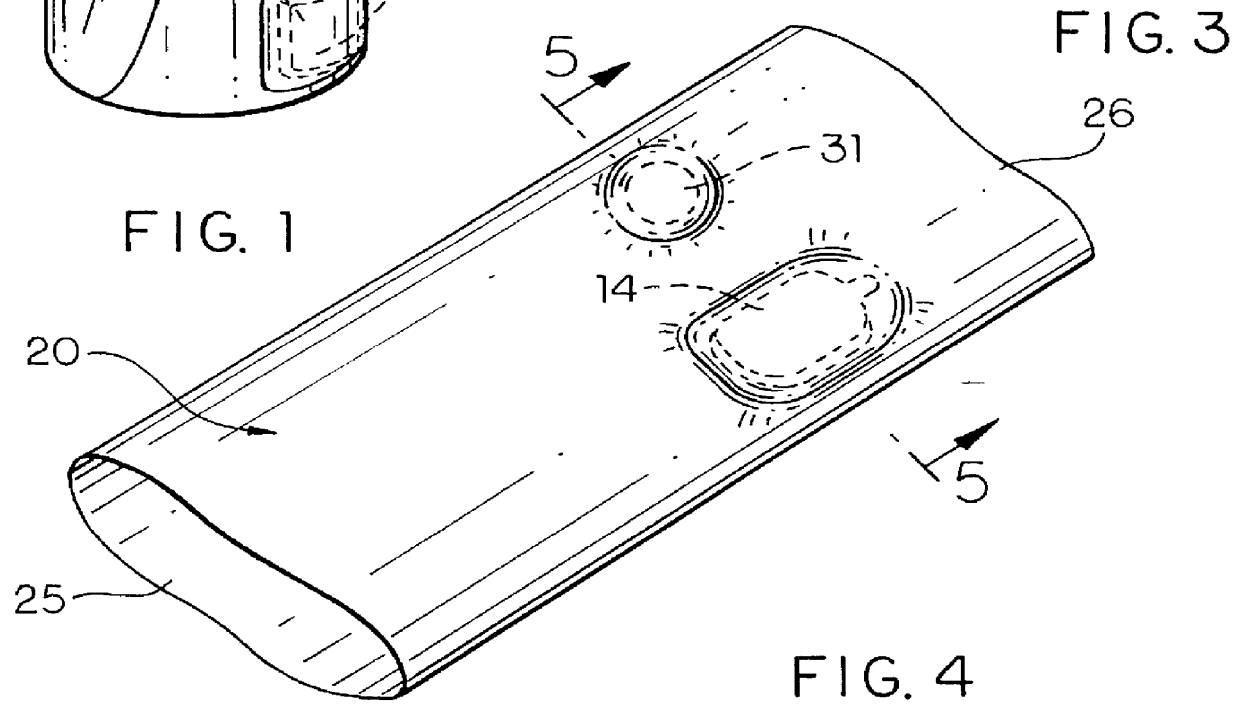

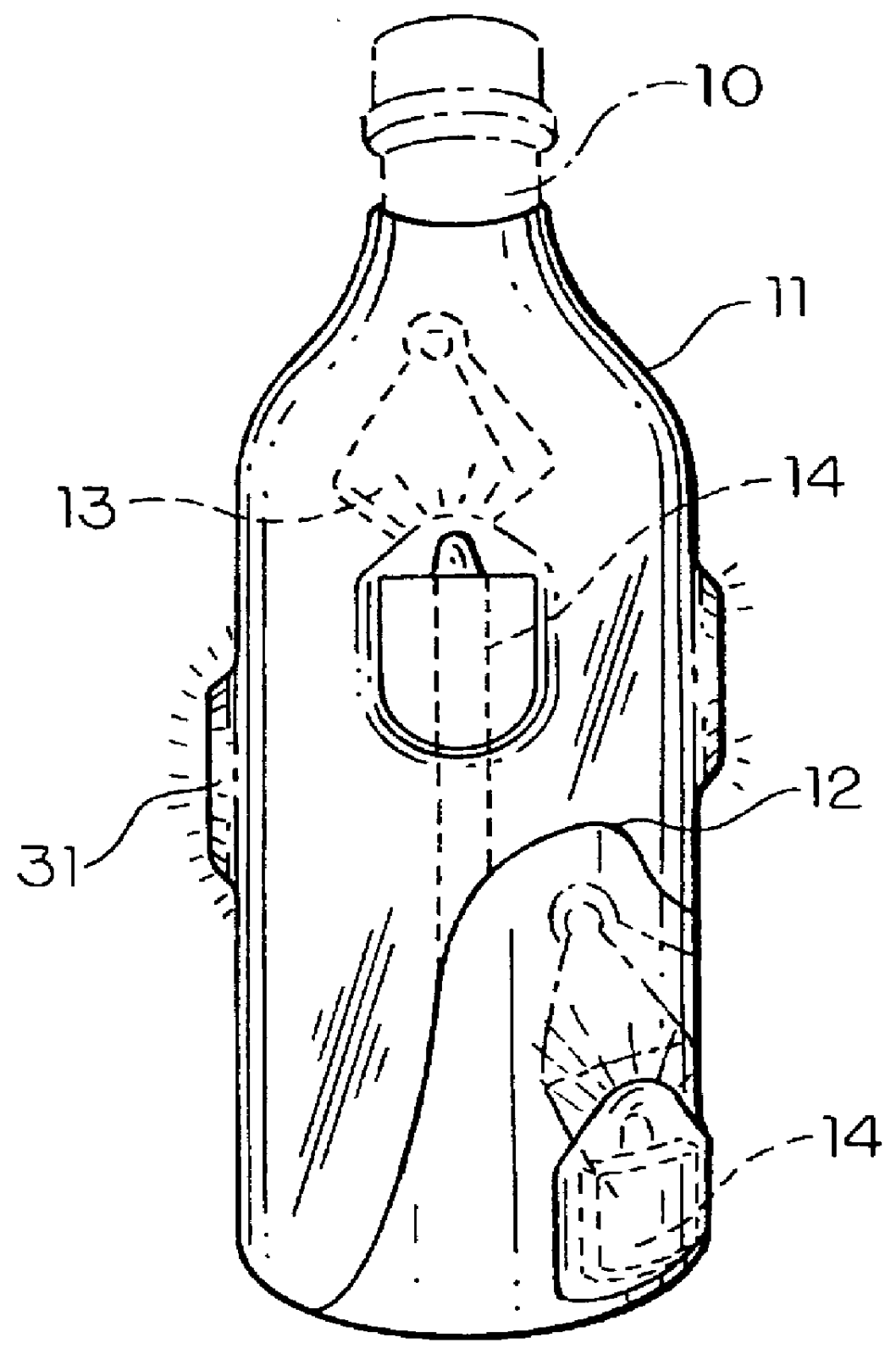

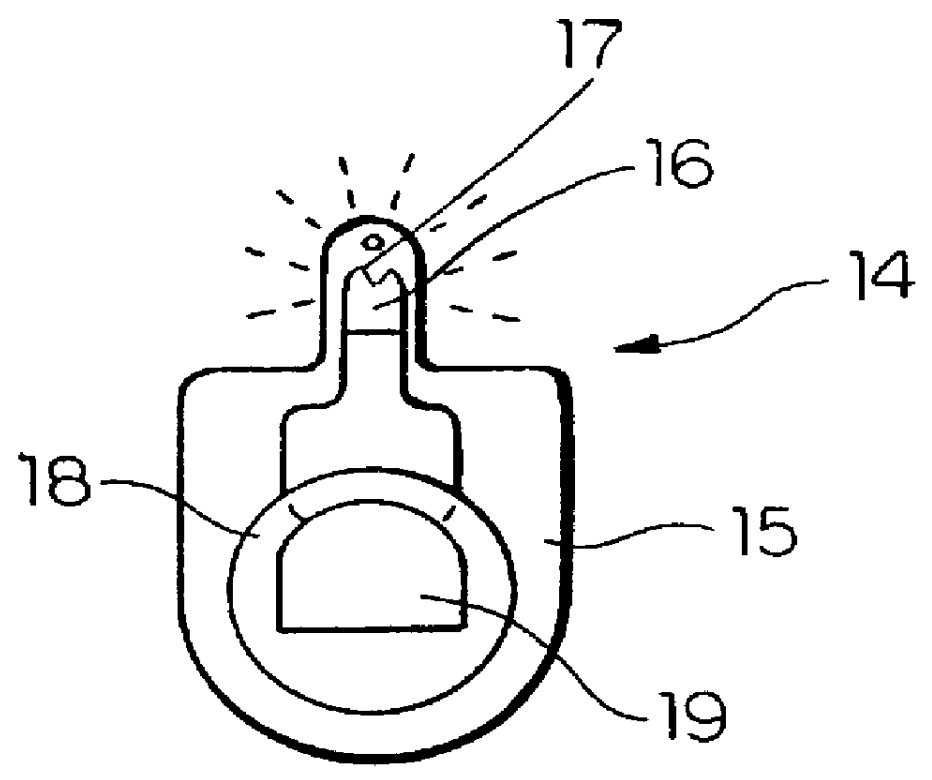

A package wrap for decoratively covering a container having side walls defining an interior space for carrying a product therein, includes a flexible thin sheet of polymeric material adapted to be shrink-wrapped onto the exterior of the container. An illuminating or a sound producing device is positioned between the flexible thin sheet of polymeric material and the exterior of the container so that when the flexible sheet of polymeric material is shrink-wrapped onto the container, the illuminating device or the sound device will be held securely in place. The illuminating device is adapted to be illuminated upon activation by a pressure, motion, or acoustically sensitive switch. The sound device is adapted to produce an audible signal upon activation by a pressure or motion sensitive switch. When the illuminating device is activated, illumination therefrom will be visible through the flexible thin sheet of polymeric material to enhance and highlight a printed pattern on the exterior of the package wrap.

Owner:DECICCO RICHARD J

Adsorbent sheet material for parallel passage contactors

ActiveUS7077891B2Maximize capacityImprove efficiencyMaterial nanotechnologyOther chemical processesParticulatesSorbent

An adsorbent material fabricated into a reinforcement-free, self-supported coherent thin sheet and configured for use as a parallel passage contactor element in adsorption / separation applications with gases and liquids is disclosed. The adsorbent sheet material is obtained by enmeshing fine adsorbent particulates in a polymer binder. Particulates include but are not limited to carbon particles, inorganic oxides particles, or ceramic particles, or synthetic polymer resin particles. The adsorbent sheet advantageously contains a large volume percentage of active adsorbent particles. The parallel passage contactor device fabricated from the adsorbent sheet material is characterized by minimal mass transfer resistance and better separation efficiency expressed as height equivalent to a theoretical plate, while it maintains most of the adsorptive properties of the starting particulates, and can be used in gas separation applications with short adsorption cycles, such as rapid pressure swing adsorption, rotary concentrators, rapid electric swing adsorption.

Owner:AIR PROD & CHEM INC

Growth stimulating wound dressing with improved contact surfaces

A wound contact device comprising a permeable material and a wound contact layer having voids extending through the contact layer to a depth in the permeable material. The wound contact layer can comprise a thin sheet or film forming a generally flat and smooth wound contact surface having essentially no discontinuities or gaps. The wound contact layer can comprise a thin sheet of highly calendered fabric forming a wound contact surface having a mean surface roughness in the range of about 0 microns to about 200 microns. In progressive wound healing, an embodiment of the wound contact device having the fabric contact surface is used in earlier healing stages and an embodiment of the wound contact device with film contact surface is used in later healing stages. The wound contact device is particularly useful in wound dressings for use in suction-assisted wound therapy.

Owner:BOEHRINGER TECH

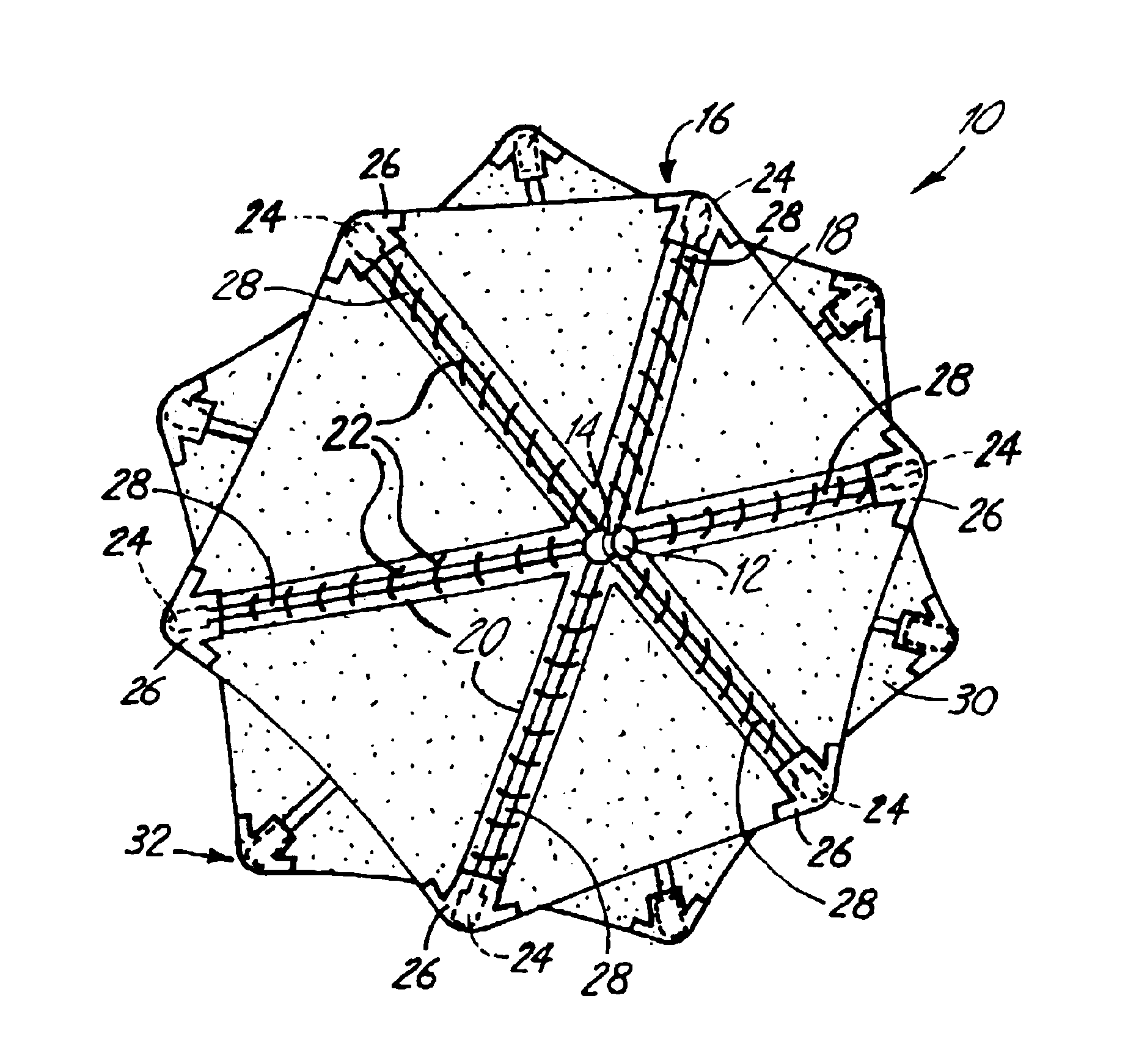

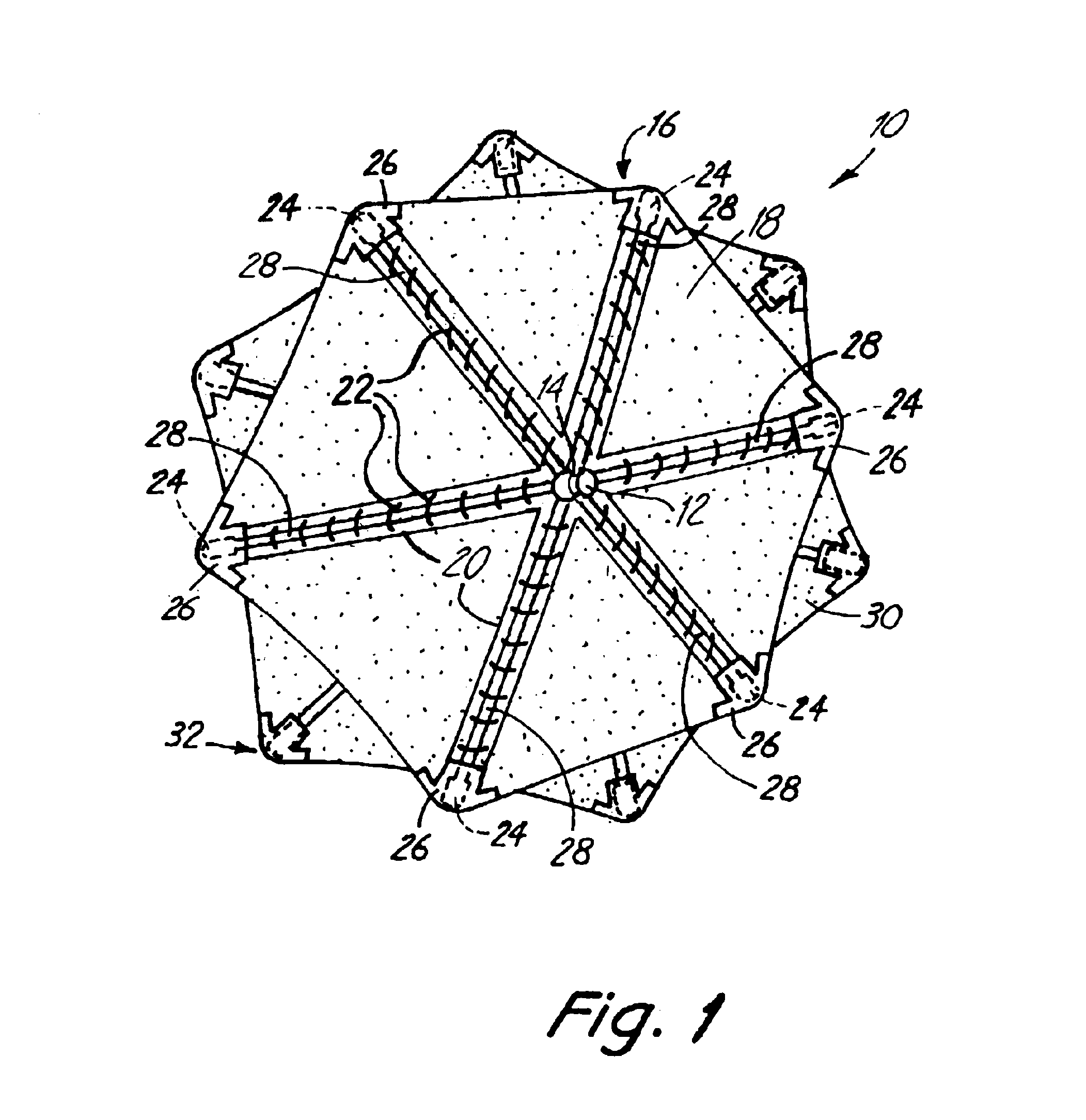

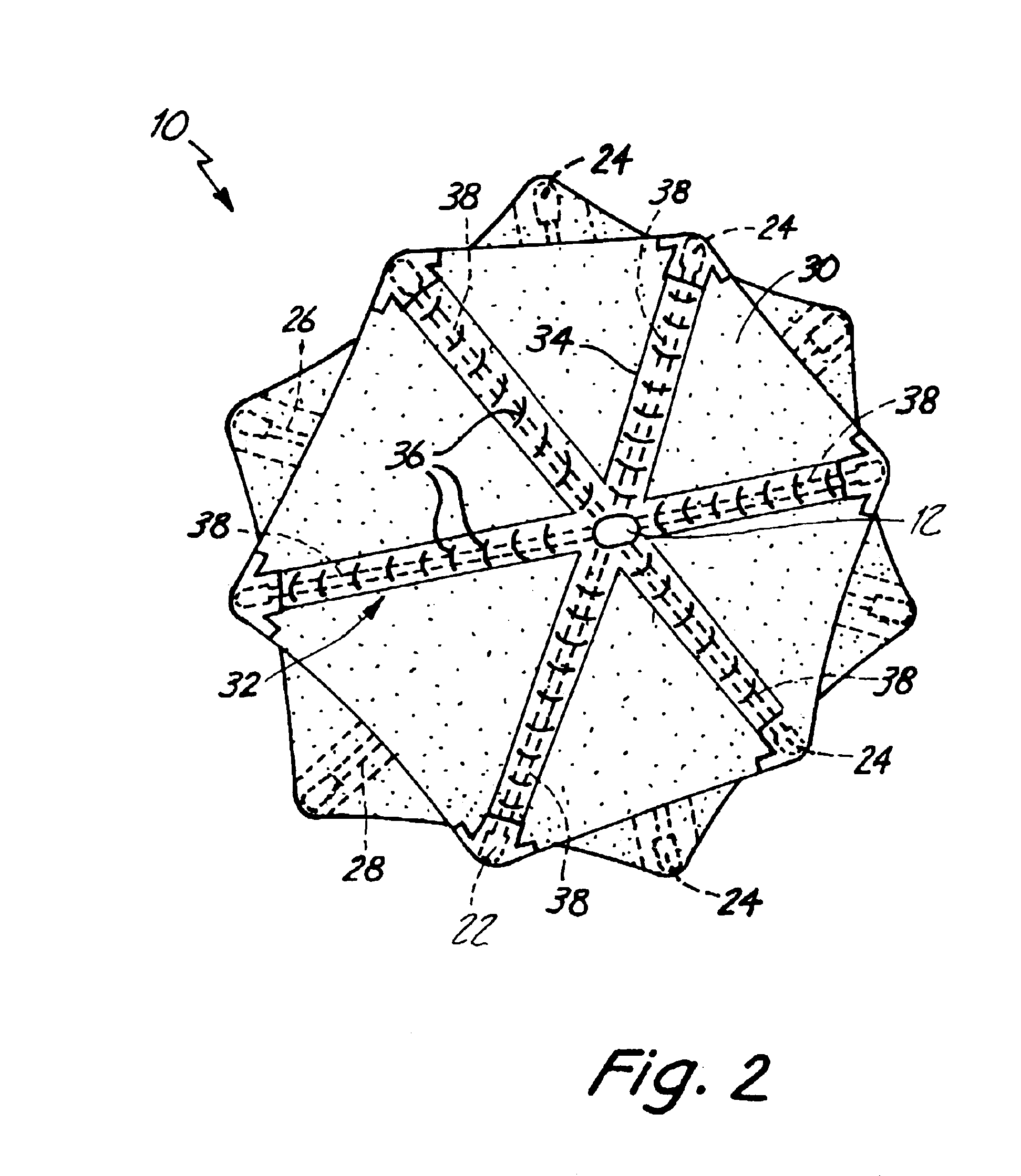

Laminated sheets for use in a fully retrievable occlusion device

An occlusion device having laminated polyvinyl alcohol sheets for occluding a defect. The laminated polyvinyl alcohol sheets provide an increased tear strength to the sheets that allows the device to be fully retrievable through the same catheter used to deploy it. The laminated sheets are created by obtaining thin sheets of polyvinyl alcohol foam, arranging the sheets on one another, and applying heat and pressure to laminate the sheets together.

Owner:CARDIA INC

System and method for biomass fractioning

ActiveUS20100180805A1Easy inputIncrease productionDrying solid materials with heatBiofuelsSyngasThin sheet

A biomass fractionator and method are described for inputting ground biomass and outputting several vapor streams of bio-intermediate compounds along with syngas and biochar. In one embodiment, a method for biomass fractioning, comprises dispensing biomass into thin sheets of ground biomass; subjecting the thin sheets to ramps of temperature; and selectively collecting various groups of compounds as they are released from the thin sheets.

Owner:COOL PLANET ENERGY SYST

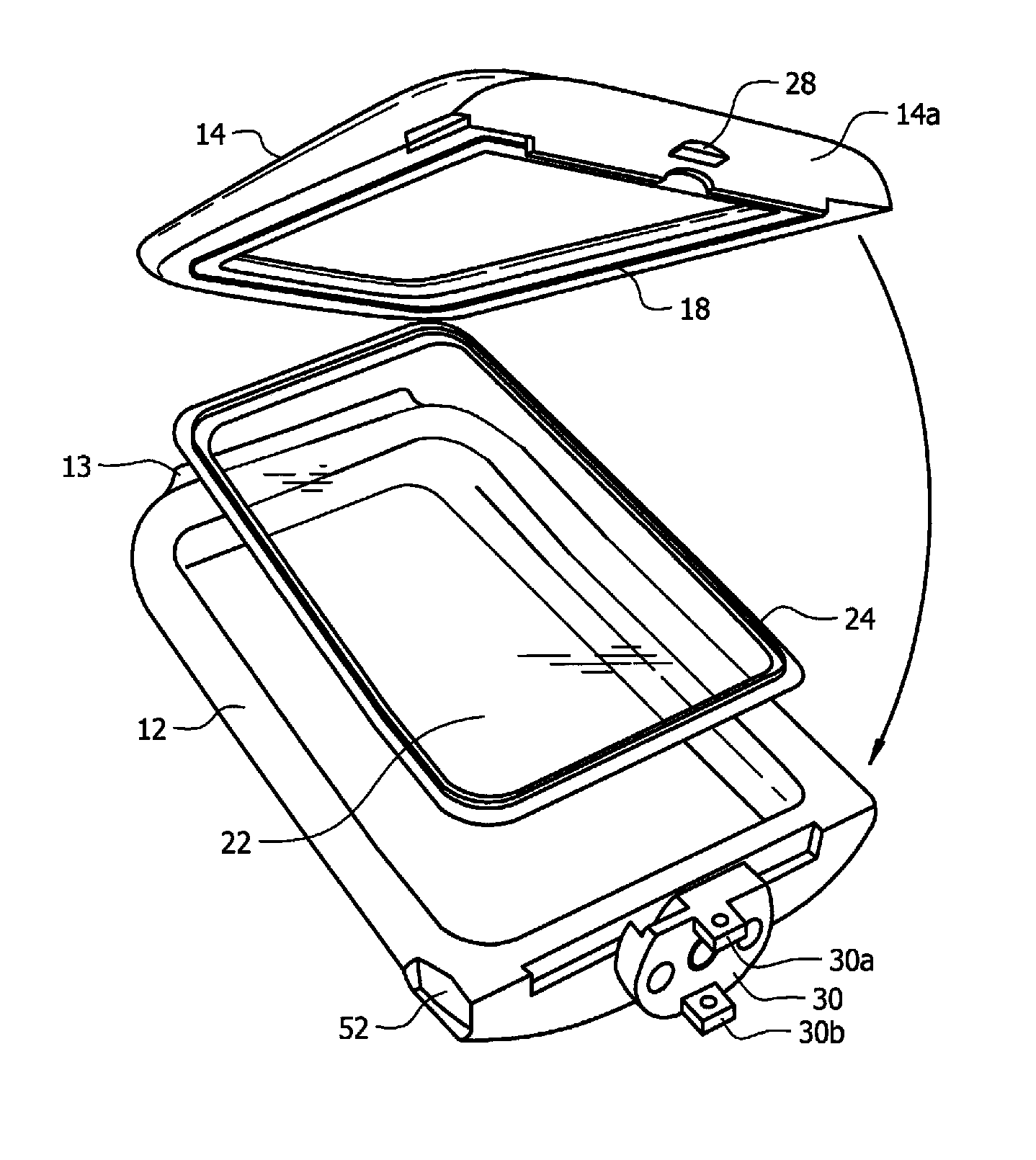

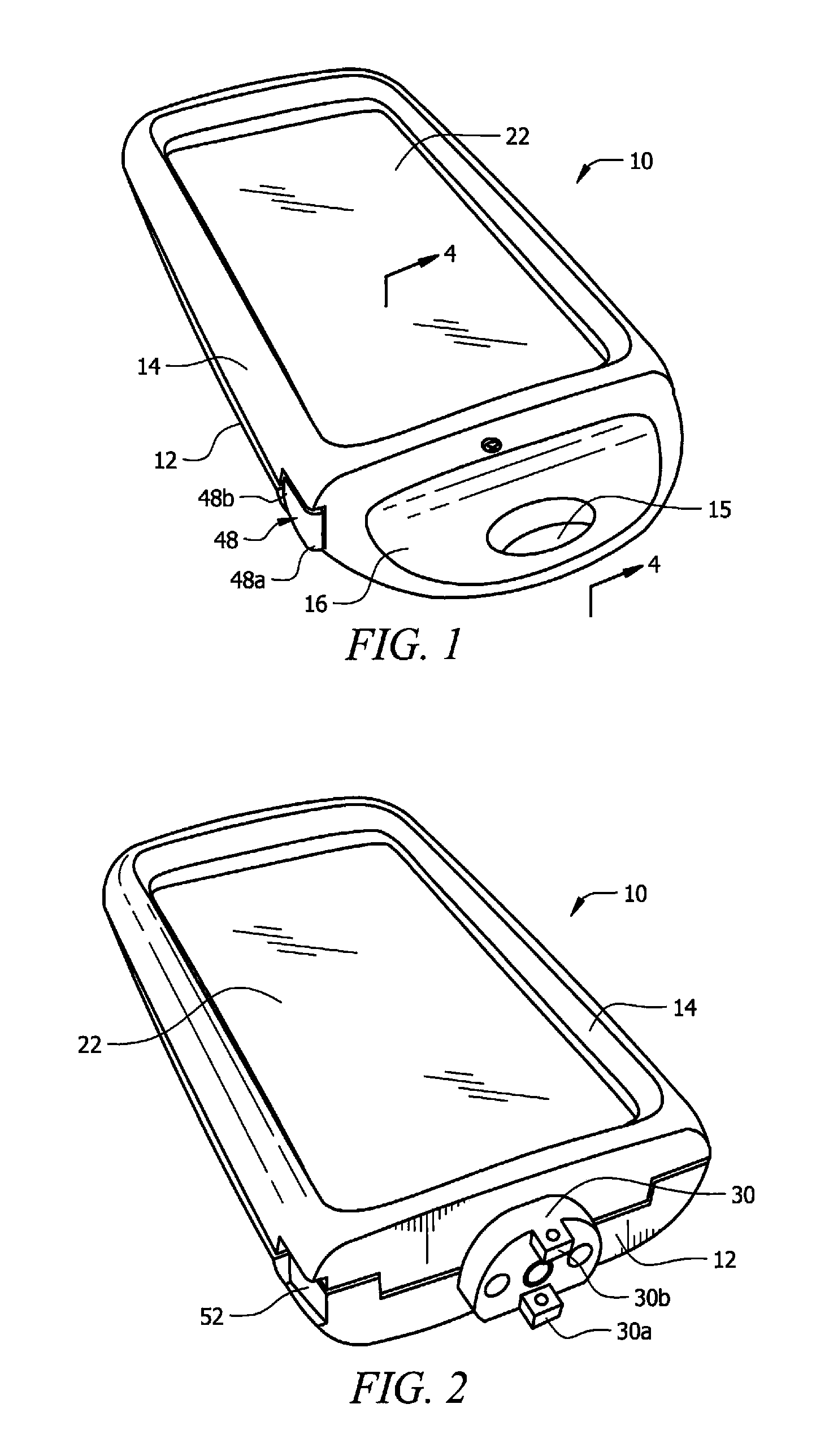

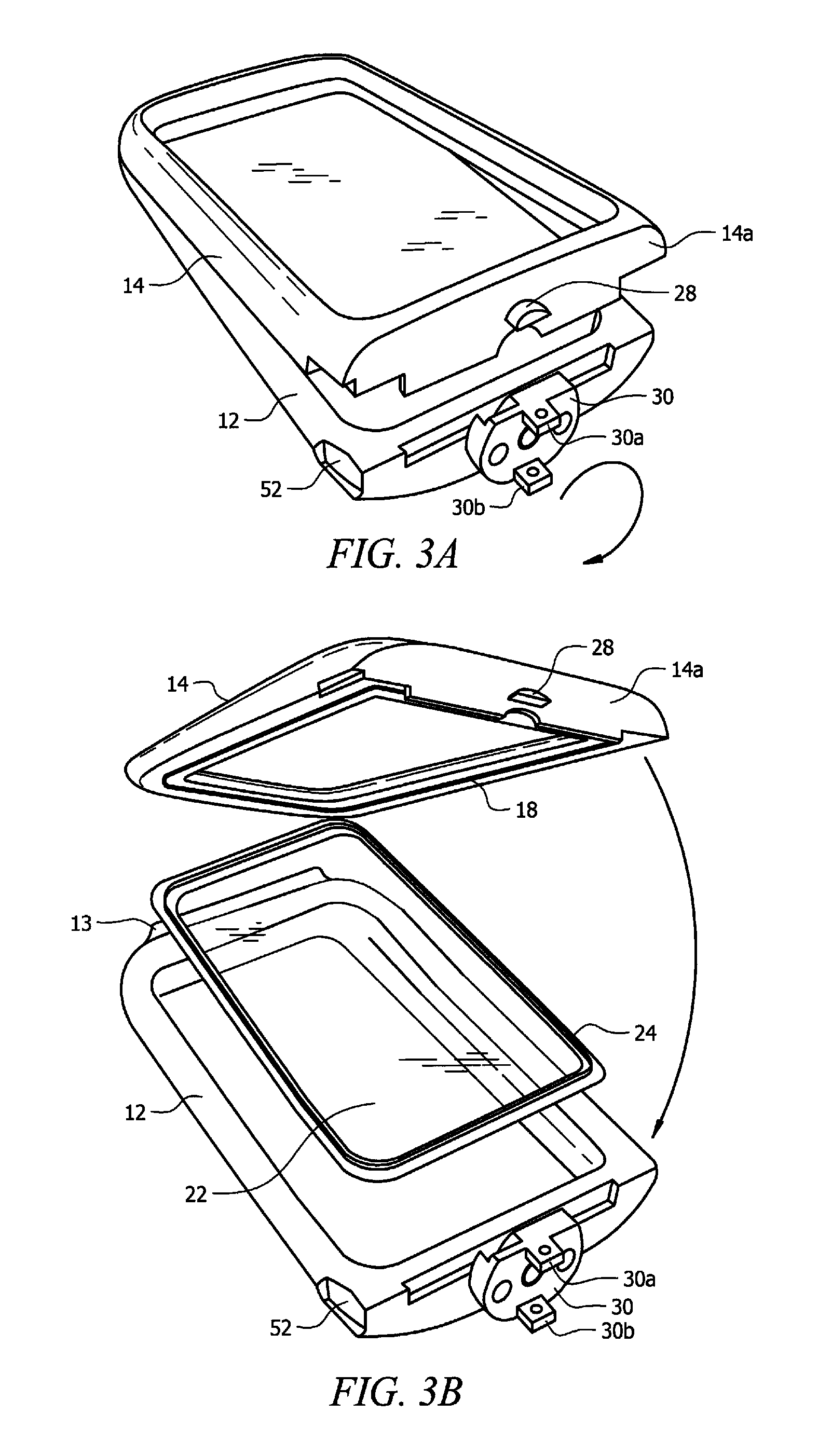

Protective cover for communication device

A water-proof container for holding a mobile device includes a base adapted to support a mobile device, a cover, a hinge for interconnecting the base and cover to one another, and a locking mechanism for locking the cover to the base. A groove is formed in an interior wall of the cover in circumscribing relation to the cover. A thin, transparent sheet of plastic has a bead formed in its peripheral edge and the bead is press fit into the groove so that the thin sheet of plastic closely overlies the operative face of the mobile device when the cover is latched to the base. A hollow lock housing is pivotally mounted about a pivot pin. A one hundred eighty degree (180°) rotation of the lock housing positions the opening on an opposite side of the container 10, capturing the latch.

Owner:MORE CHARM

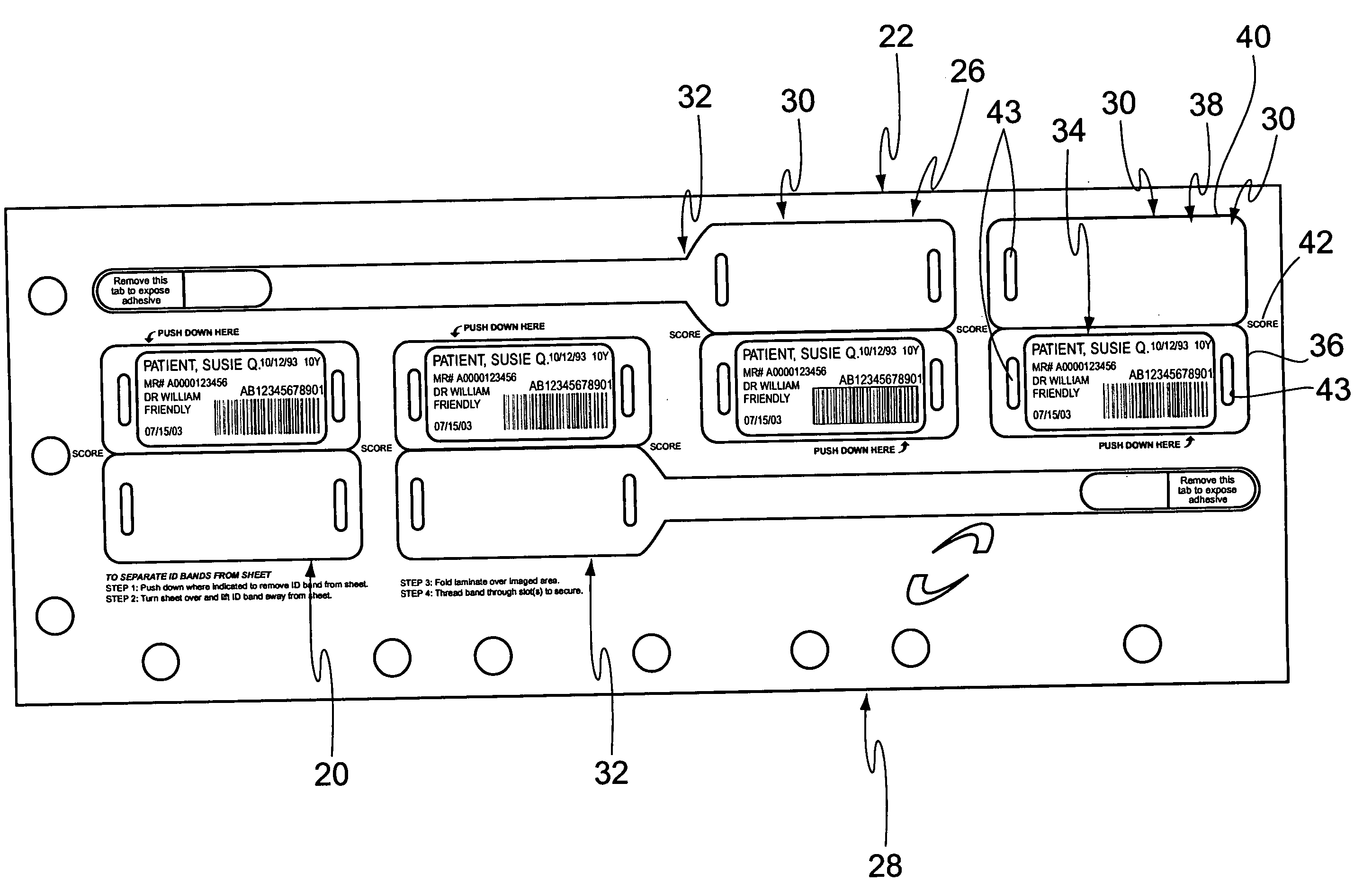

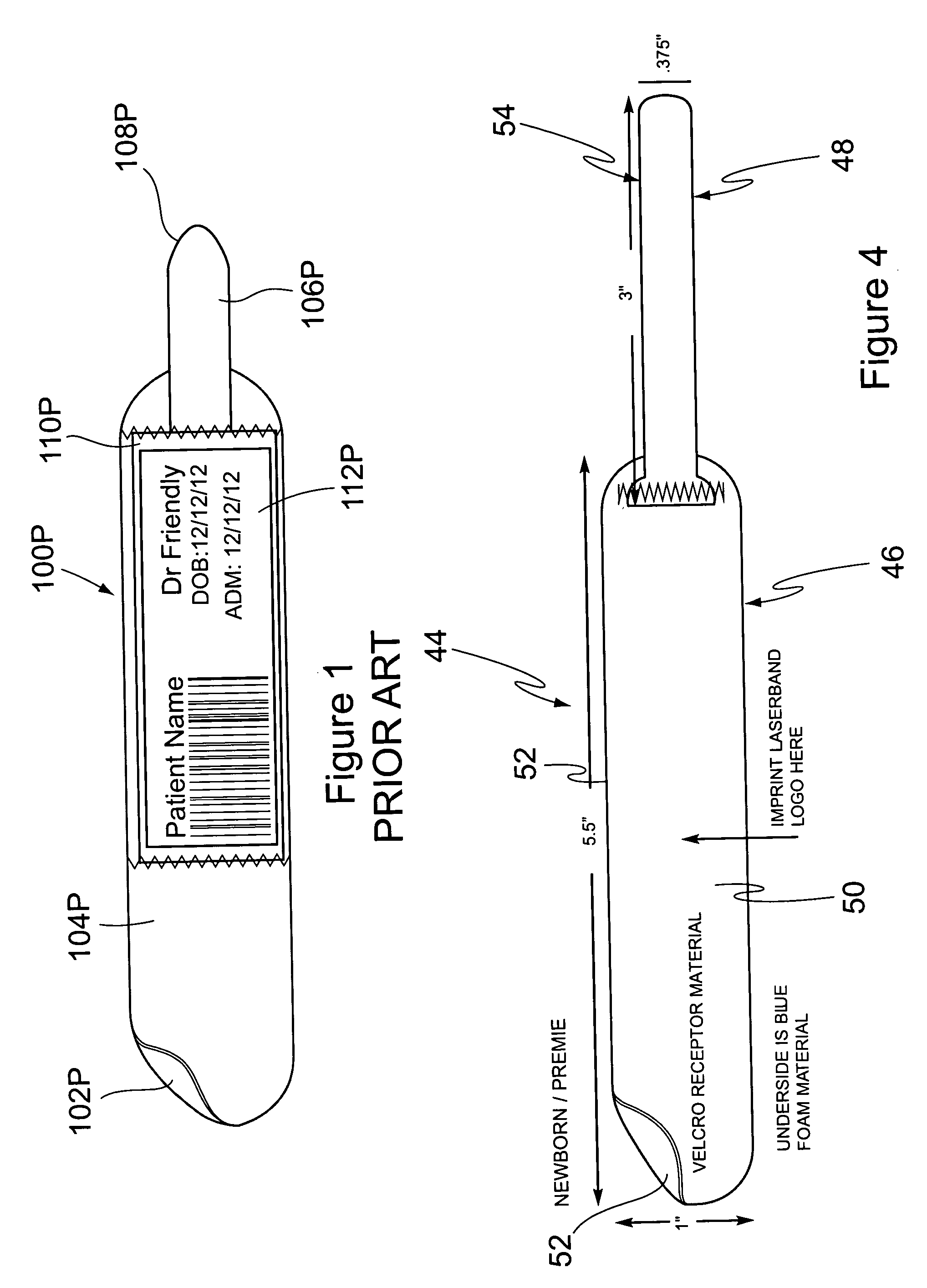

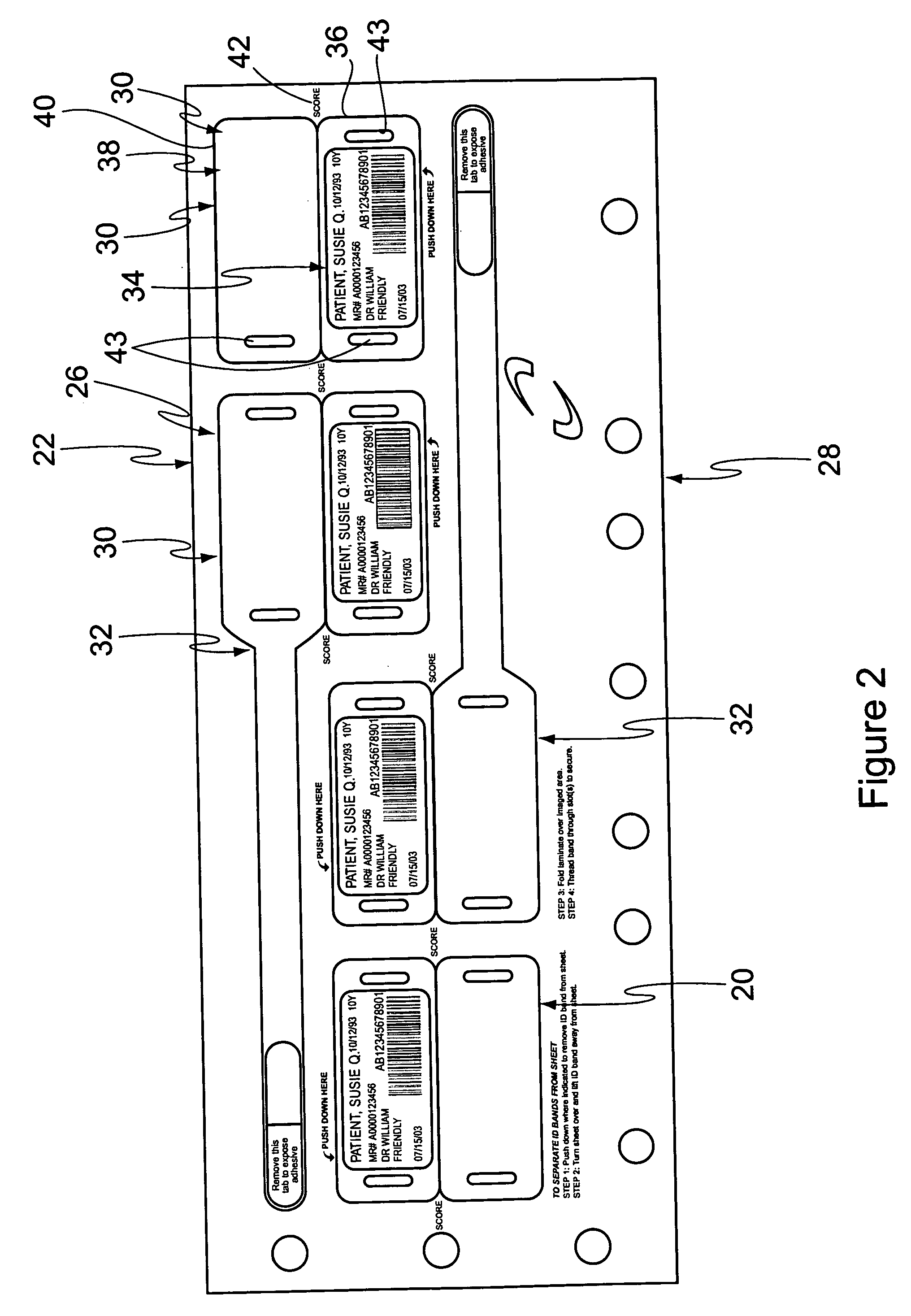

Cushioned wristband with self-laminating identity tag

ActiveUS20050279001A1Reliable identificationWithout any discomfortStampsOther printing matterEngineeringAppendage

A cushioned wristband includes a carrier having a multi-layered band portion and a strap sewn to the back of the band portion of the carrier. The band has a surface with loop material and the strap has a surface of hook material, the hook and loop surfaces being intended to secure the band in place as it is wrapped about a patient's appendage. The strap is appropriately sized to insert through one or both of two cinch slots of a self-laminating hang tag which may be printed with patient information and separated from a sheetlet or page sized business form processed through a printer for imaging of patient information thereon. The band portion of the carrier includes a cushioned layer of soft foamy or spongy material for contacting a patient's skin to thereby substantially eliminate any possibility for abrasion, rash, or other irritation or injury to the patient through wearing of the wristband.

Owner:ZEBRA TECH CORP

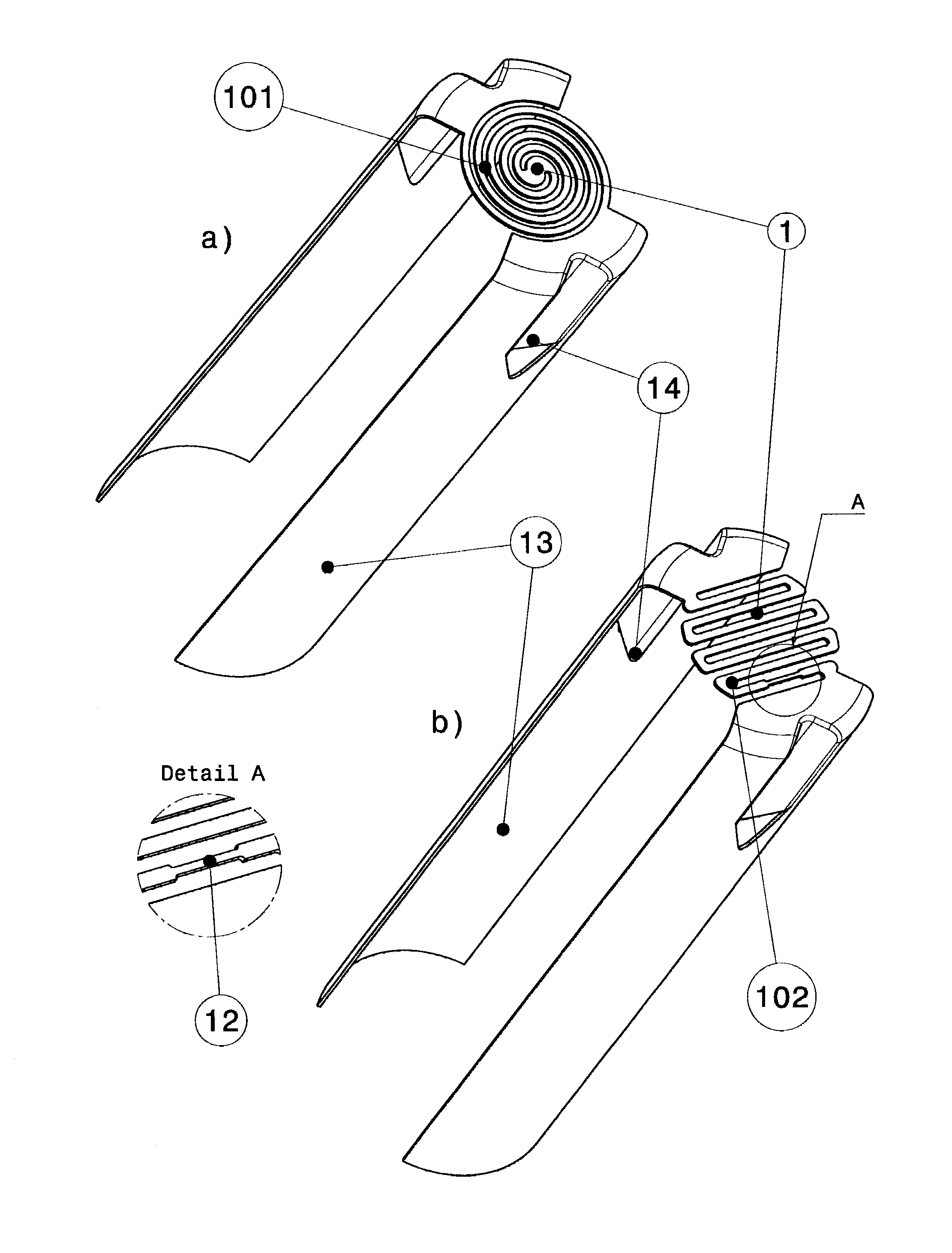

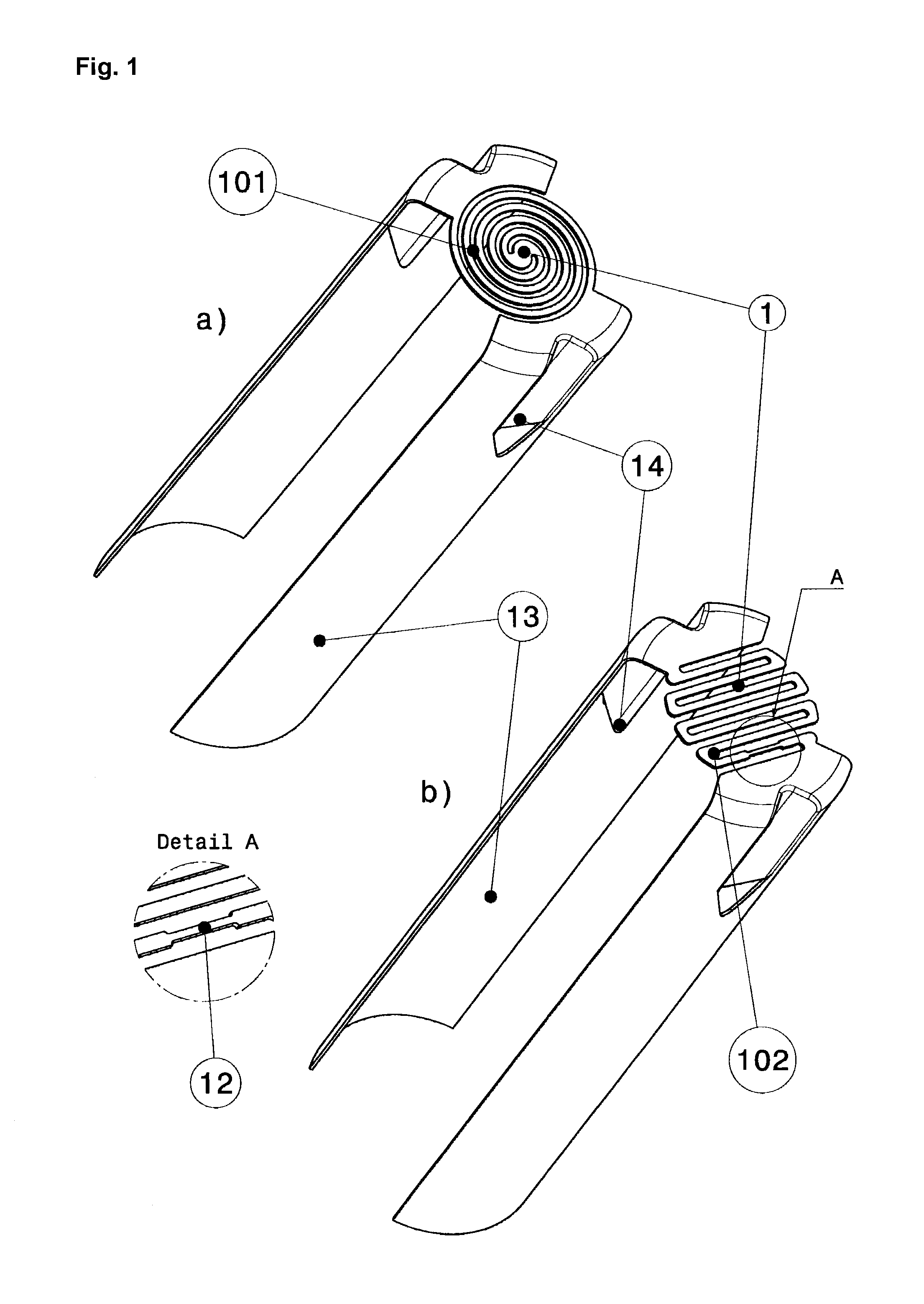

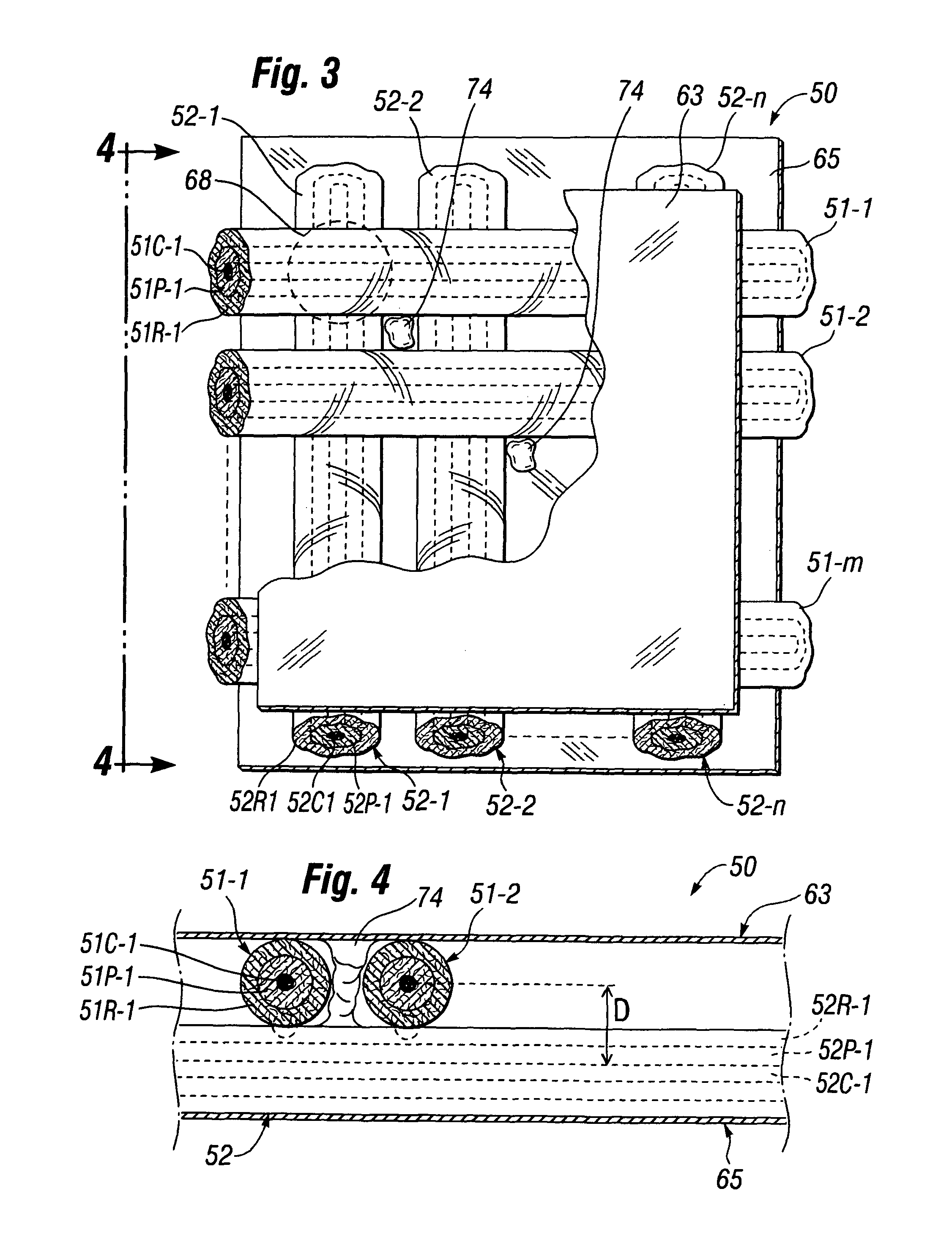

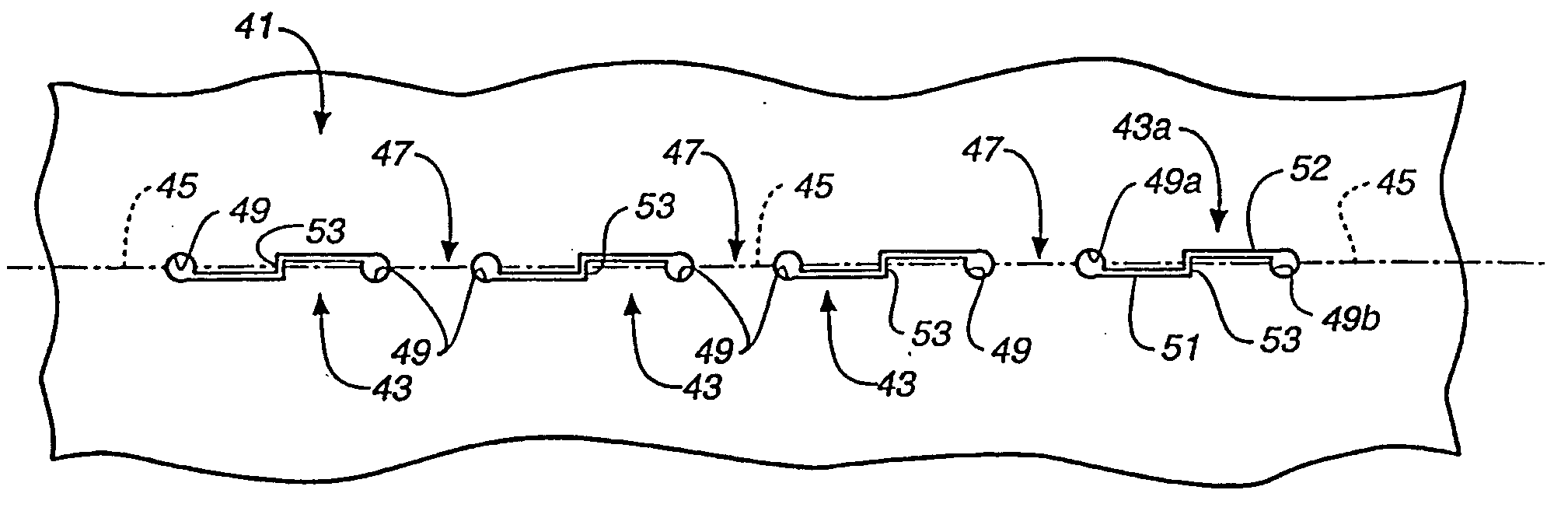

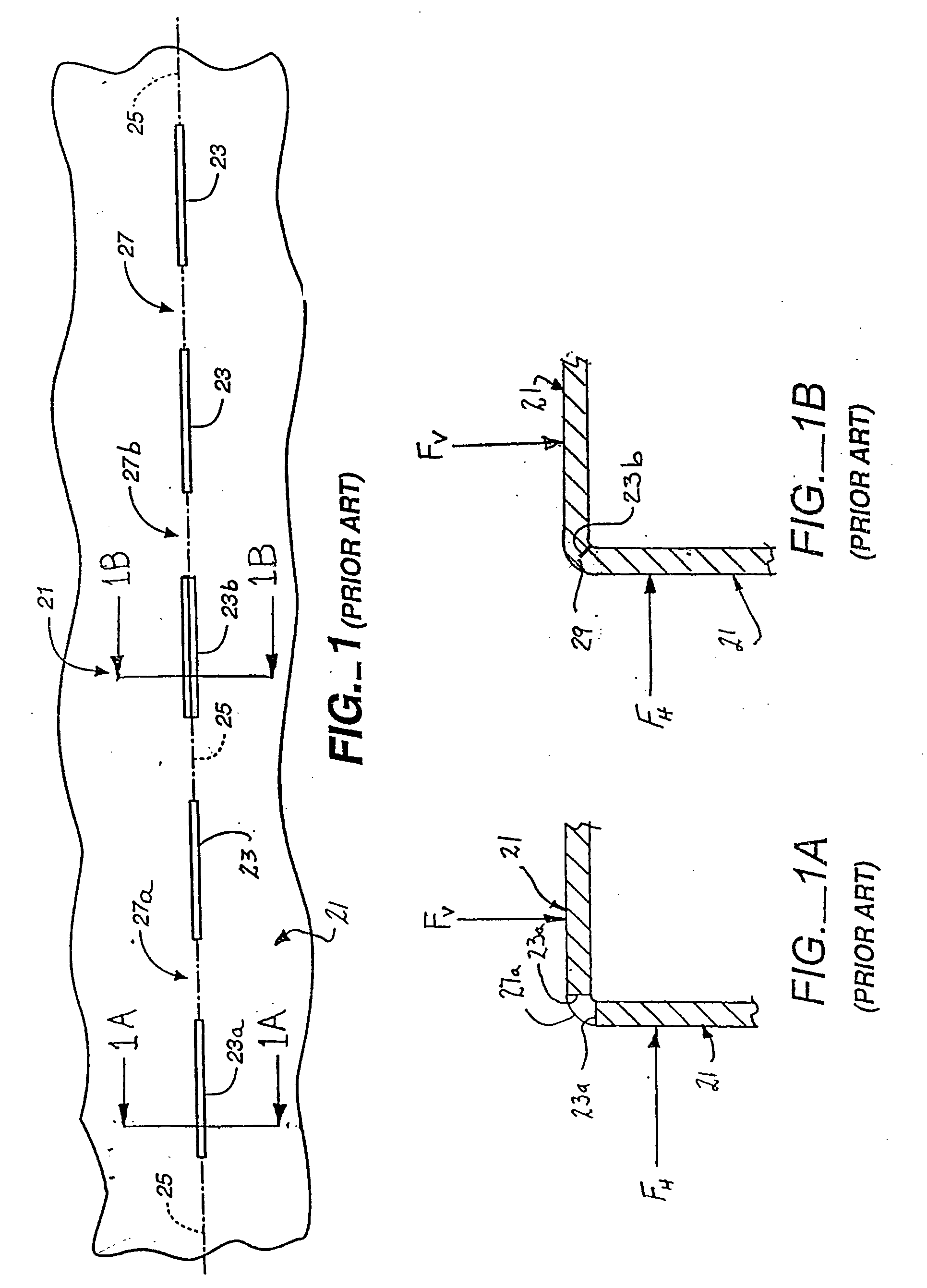

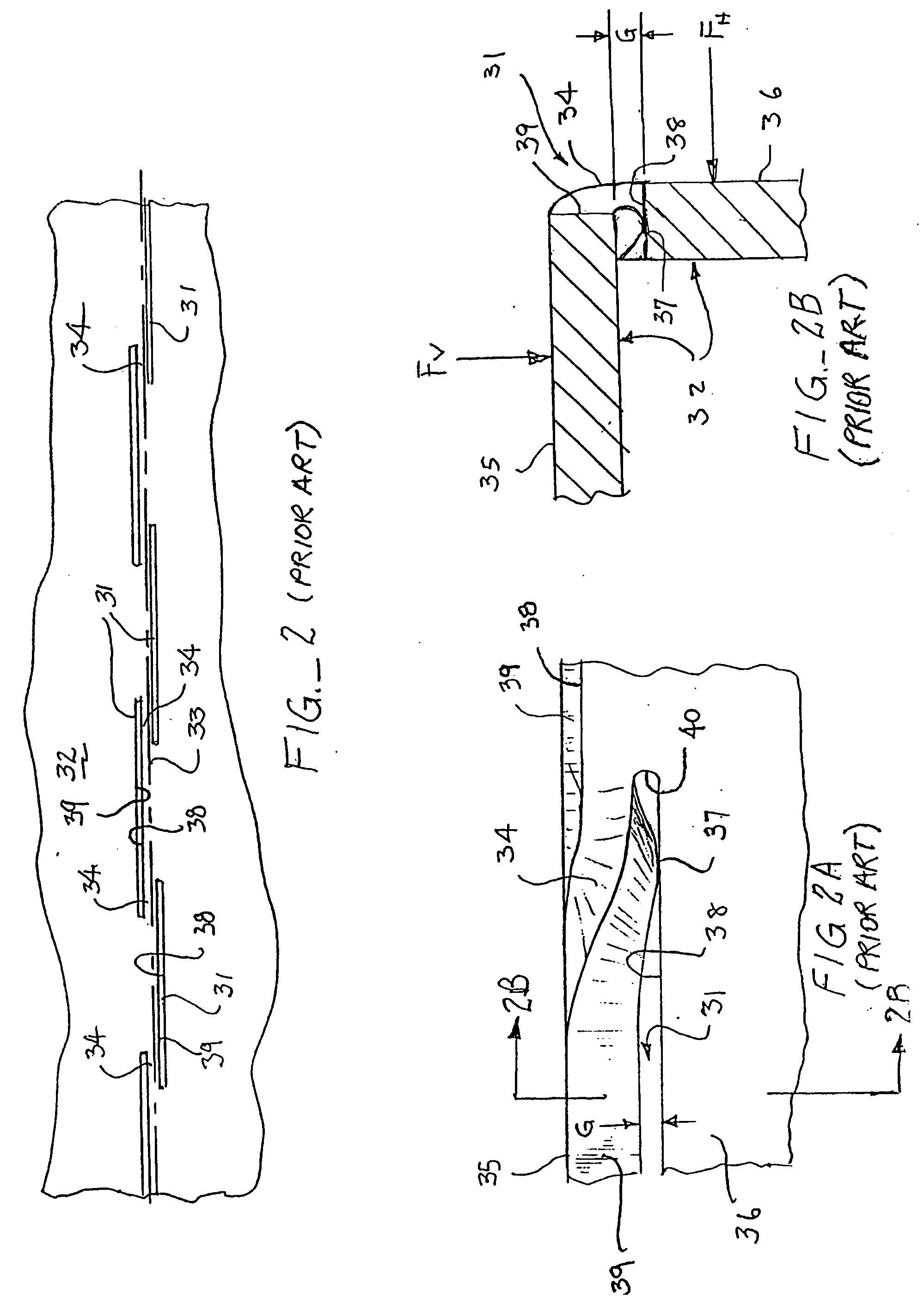

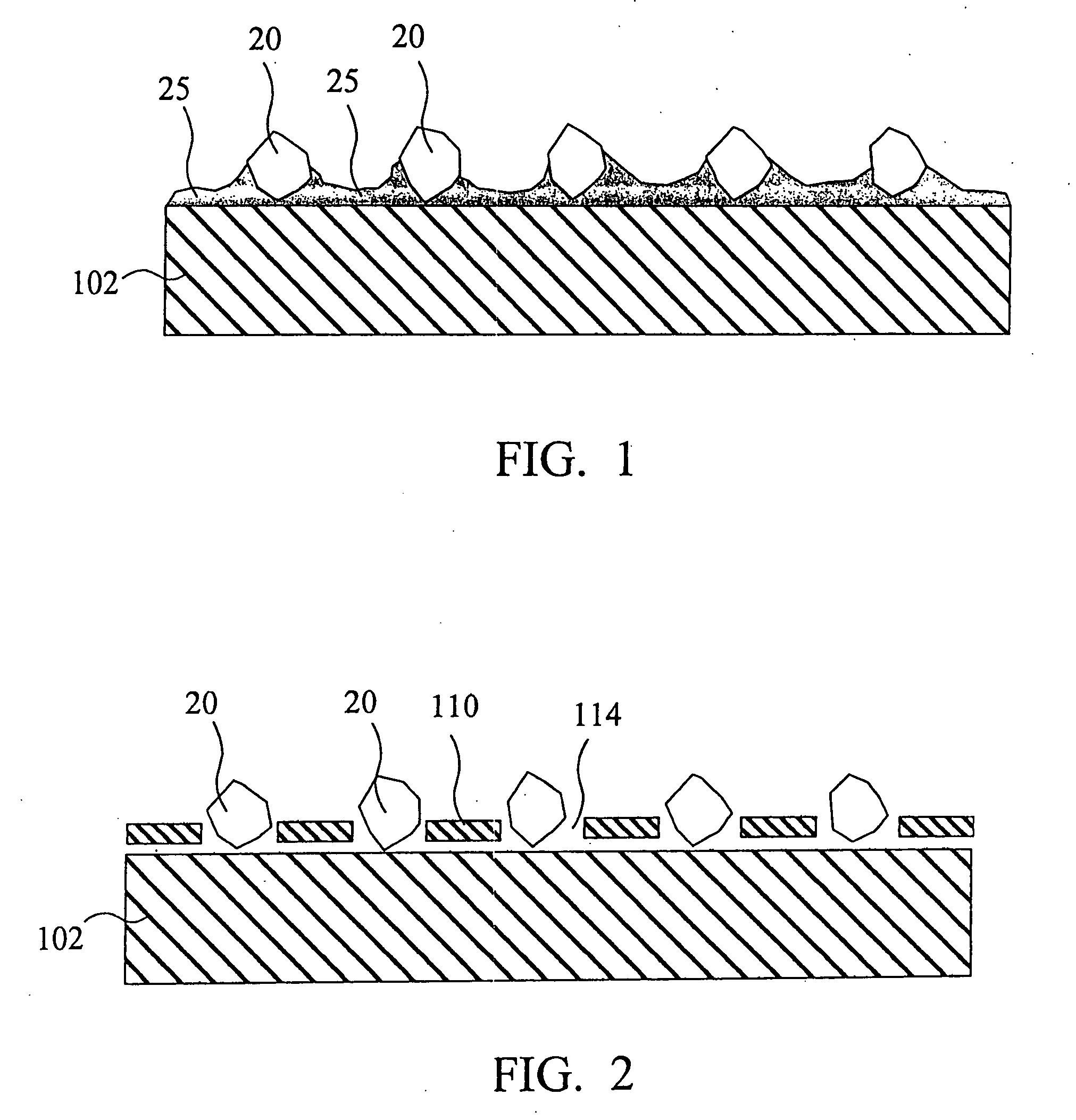

Techniques for designing and manufacturing precision-folded, high strength, fatigue-resistant structures and sheet therefor

InactiveUS20040134250A1High precisionImprove bending strengthAdditive manufacturing apparatusConstruction materialManufacturing technologyEngineering

A process for designing and manufacturing precision-folded, high strength, fatigue-resistant structures and a sheet therefore. The techniques include methods for precision bending of a sheet of material (41, 241, 341, 441, 541) along a bend line (45, 245, 345, 445,543) and a sheet of material formed with bending strap-defining structures, such as slits or grooves (43, 243, 343, 443, 542), are disclosed. Methods include steps of designing and then separately forming longitudinally extending slits or grooves (43, 243, 343, 443, 542) through the sheet of material in axially spaced relation to produce precise bending of the sheet (41, 241, 341, 441,541) when bent along the bend line (45, 245, 345, 445, 543). The bending straps have a configuration and orientation which increases their strength and fatigue resistance, and most preferably slits or arcs are used which causes edges (257, 457) to be engaged and supported on faces (255, 455) of the sheet material on opposite sides of the slits or arcs. The edge-to-face contact produces bending along a virtual fulcrum position in superimposed relation to the bend line (45, 245, 345, 445, 543). Several slit embodiments (43, 243, 343, 443, 542) suitable for producing edge-to-face engagement support and precise bending are disclosed, as is the use of the slit sheets to produce various three-dimensional structures and to enhance various design and fabrication techniques.

Owner:IND ORIGAMI INC CA US

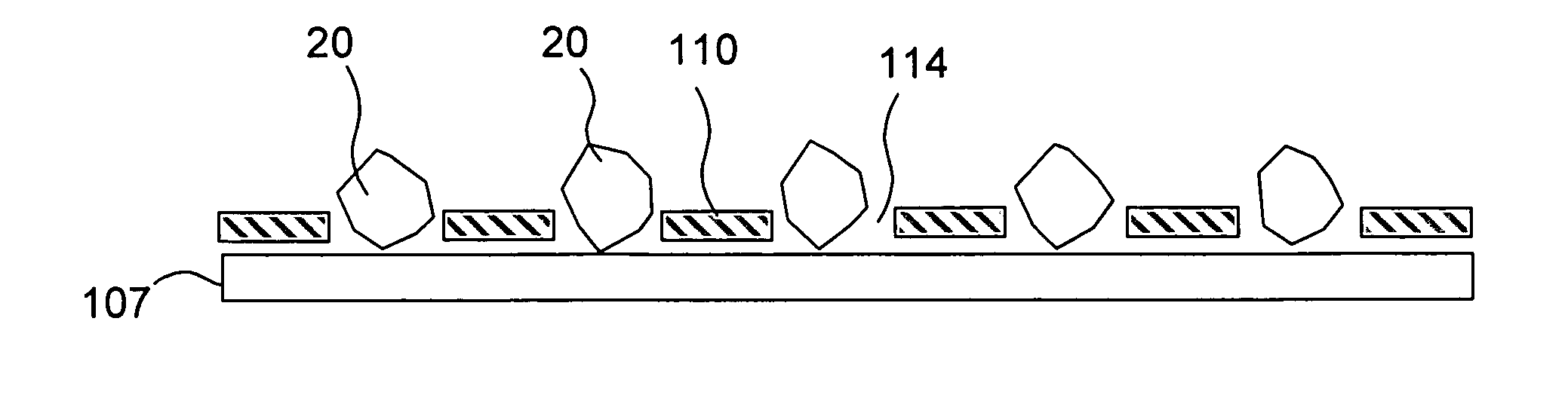

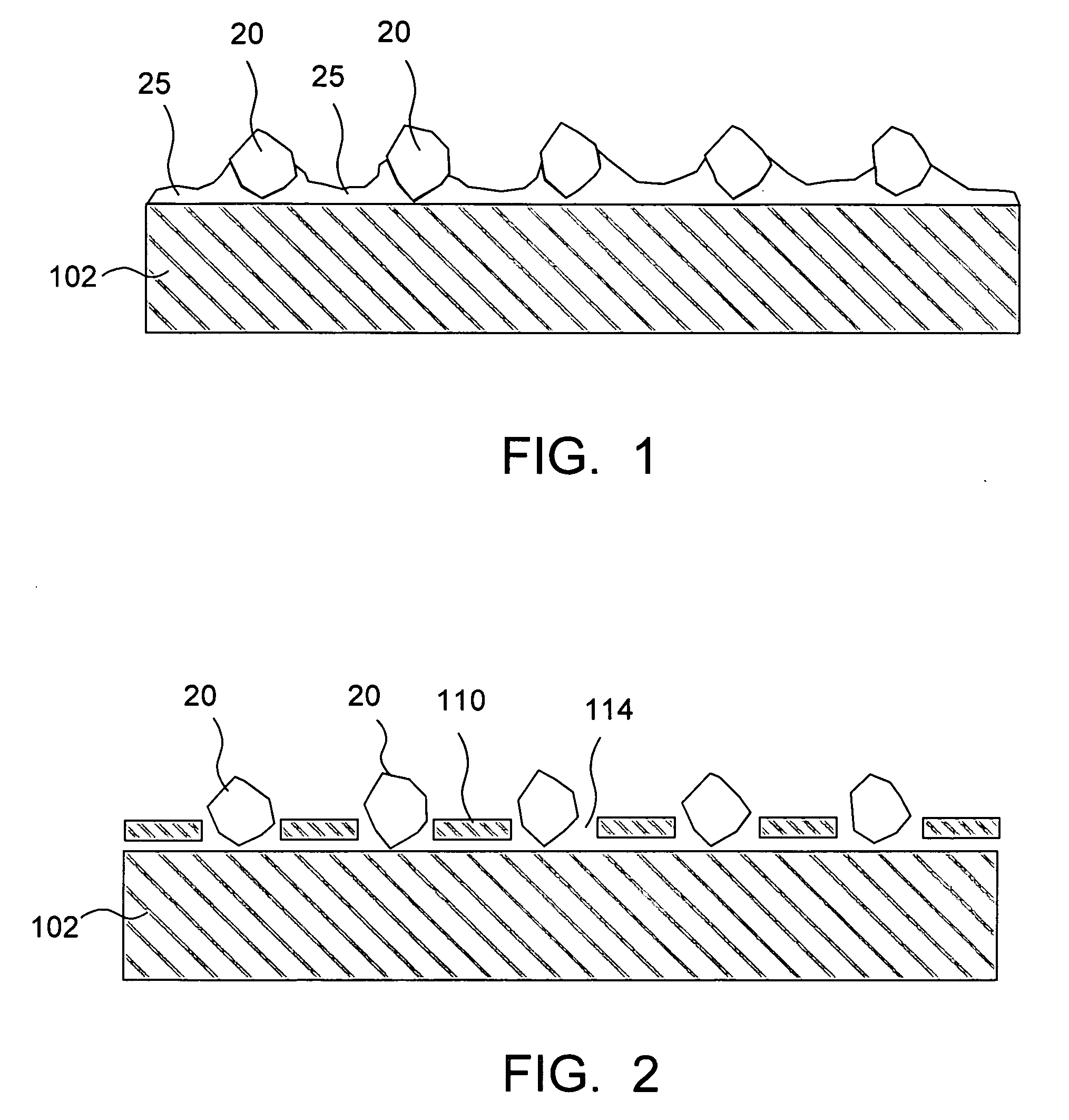

Dispersible and conductive Nano Graphene Platelets

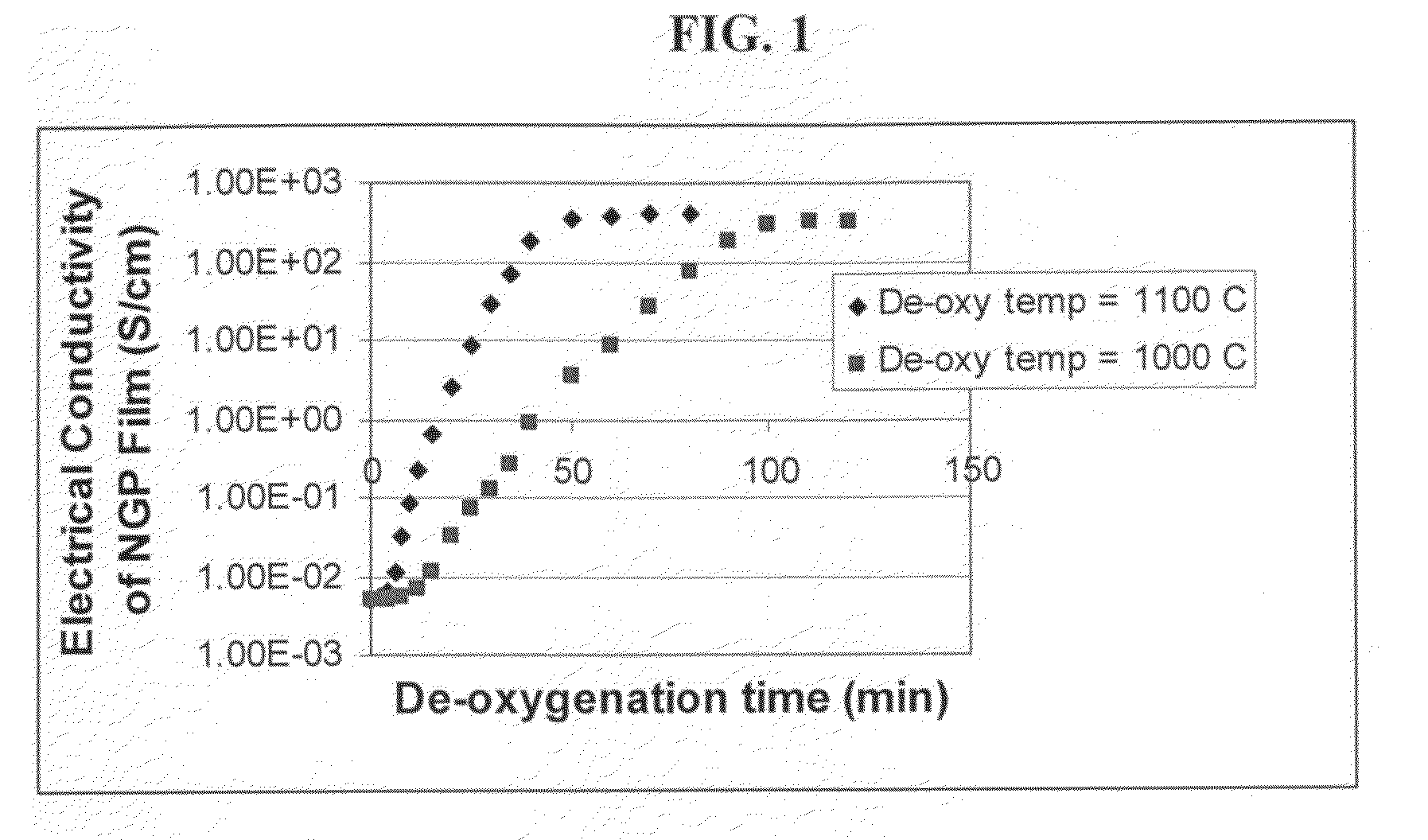

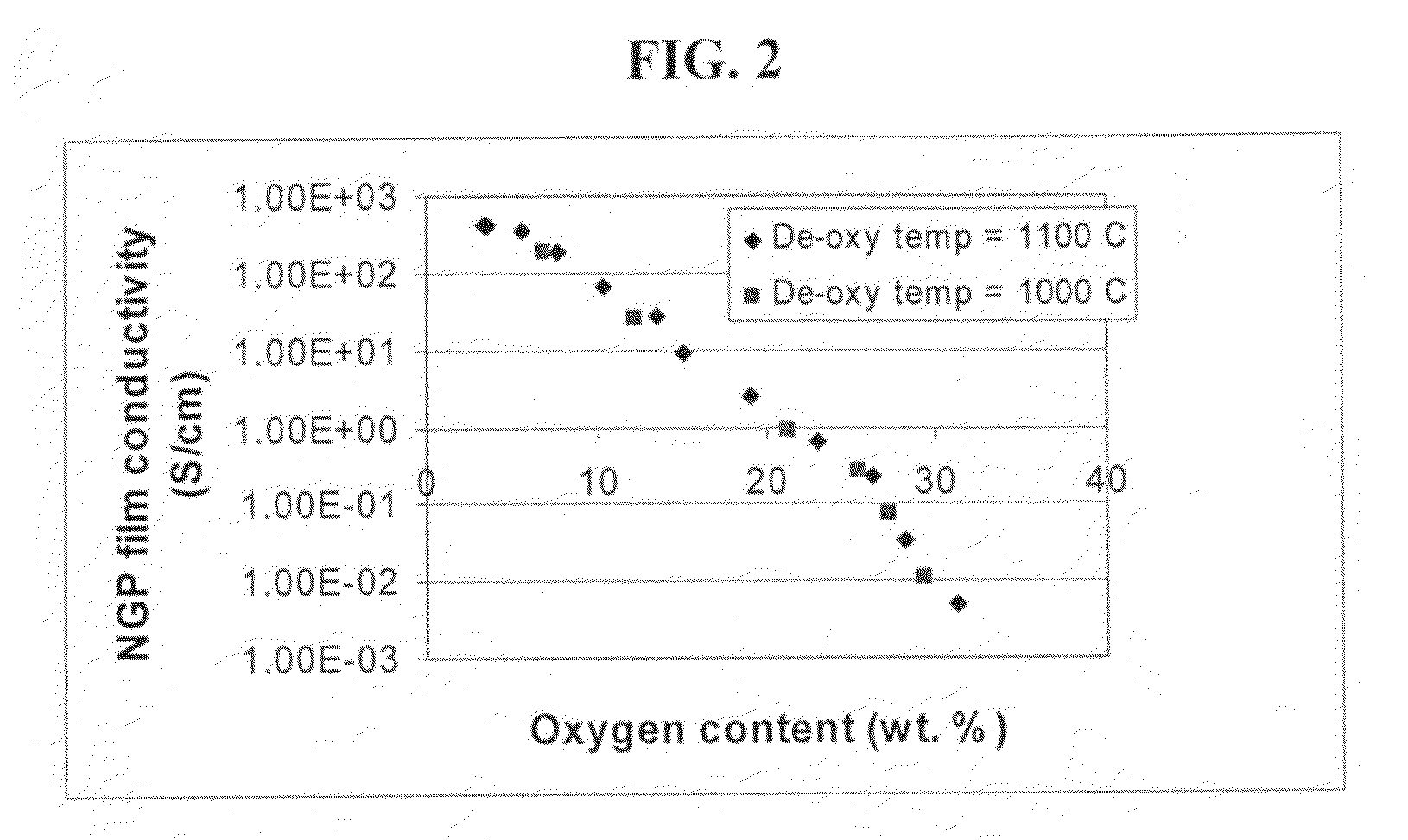

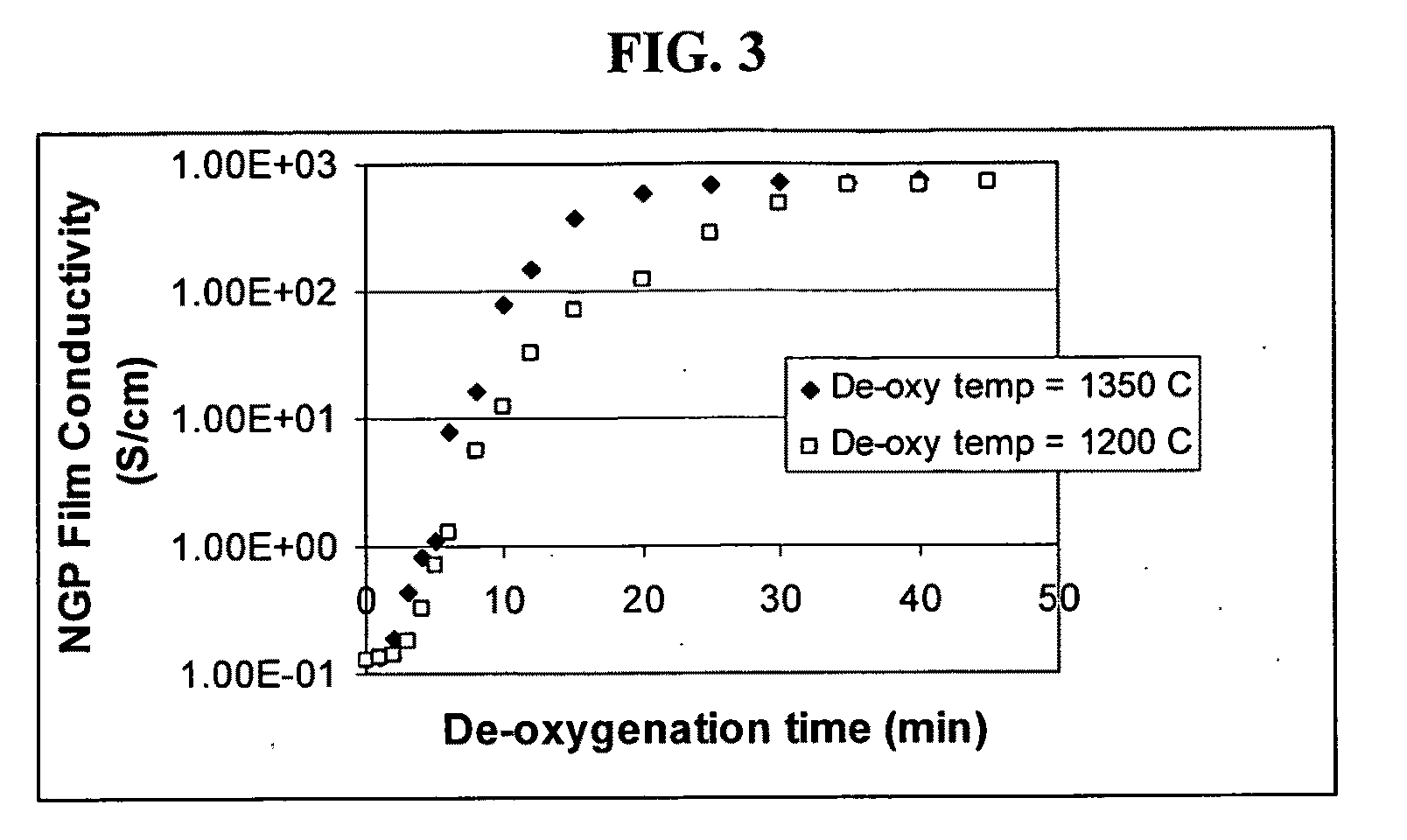

ActiveUS20100055458A1Impart dispersibilityImpart solubilityMaterial nanotechnologySynthetic resin layered productsDisplay deviceSolar cell

The present invention provides a dispersible and electrically conductive nano graphene platelet (NGP) material comprising at least a single-layer or multiple-layer graphene sheet, wherein the NGP material has an oxygen content no greater than 25% by weight and no less than 5% by weight. This NGP material can be produced by: (a) preparing a pristine NGP material from a graphitic material; and (b) subjecting the pristine NGP material to an oxidation treatment. Alternatively, the production process may comprise: (A) preparing a graphite oxide (GO) from a laminar graphite material; (b) exposing the GO to a first temperature for a first period of time to obtain exfoliated graphite; and (c) exposing the exfoliated graphite to a second temperature in a protective atmosphere for a second period of time. Conductive NGPs can find applications in transparent electrodes for solar cells or flat panel displays, additives for battery and supercapacitor electrodes, conductive nanocomposite for electromagnetic wave interference (EMI) shielding and static charge dissipation, etc.

Owner:GLOBAL GRAPHENE GRP INC

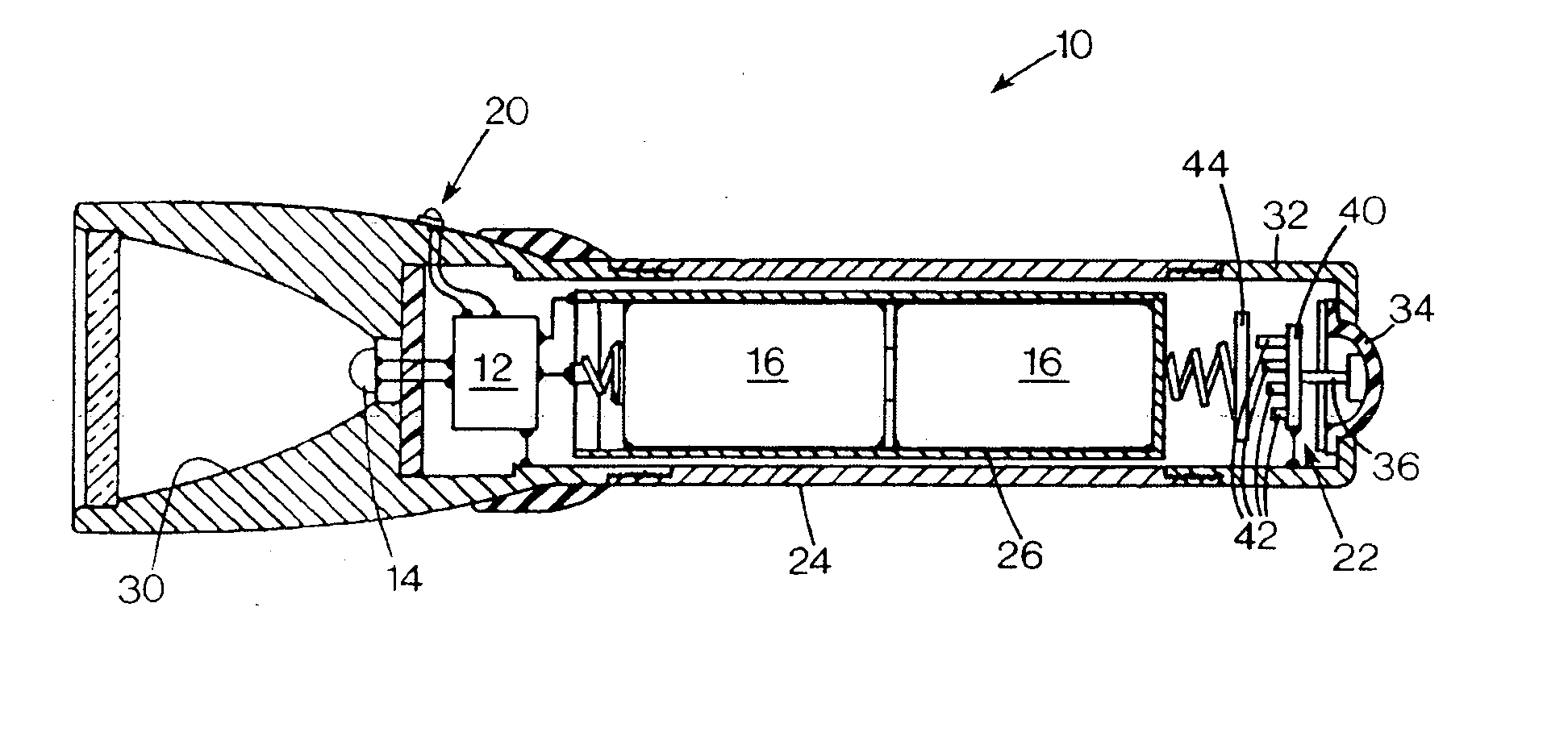

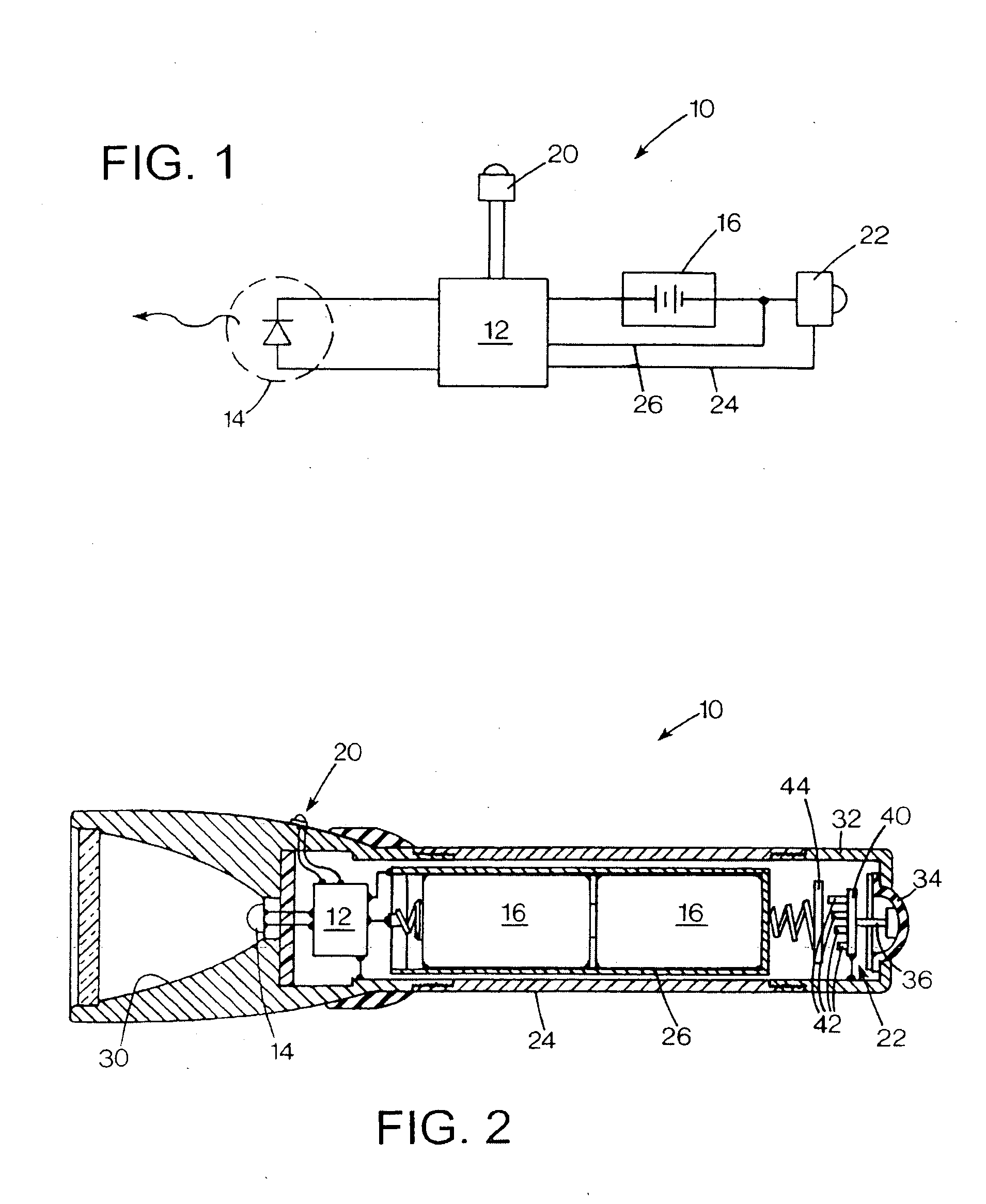

Flashlight with detented rotary control

ActiveUS20050237737A1Low profileOvercome limitationsLight source combinationsPoint-like light sourceEngineeringThin sheet

A flashlight has a lamp assembly with a number of different output states. The flashlight has an elongated housing defining a housing axis, and a control ring encompasses the housing and rotates on the housing axis. The control ring operates to change the output state in response to rotation of the element. A detent mechanism operably connects the control ring to the housing. The detent mechanism provides a number of different stable positions of the control ring with respect to the housing, and may provide a low profile by employing a thin sheet or wire spring compressing in an axial direction.

Owner:SUREFIRE LLC

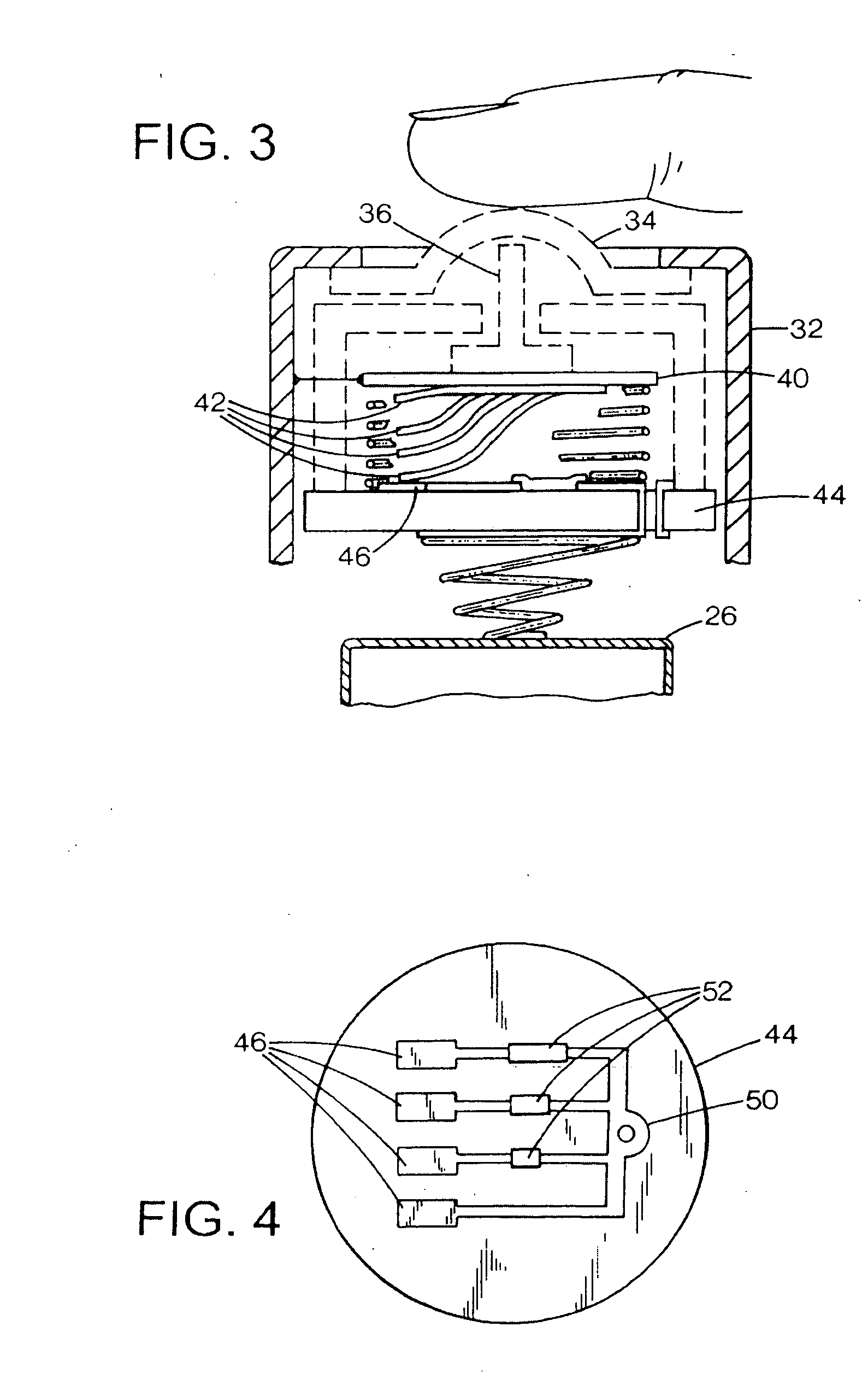

Brazed diamond tools and methods for making the same

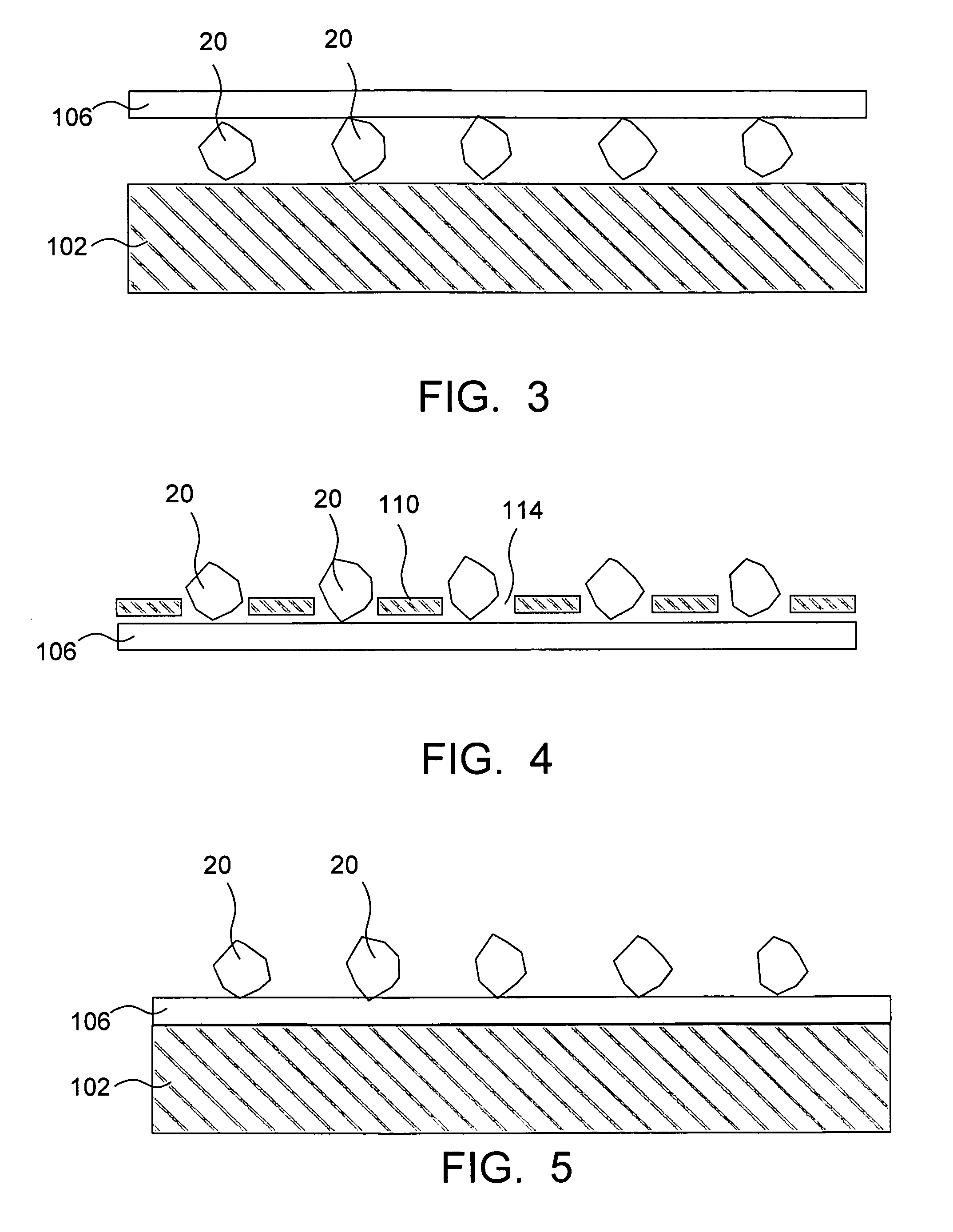

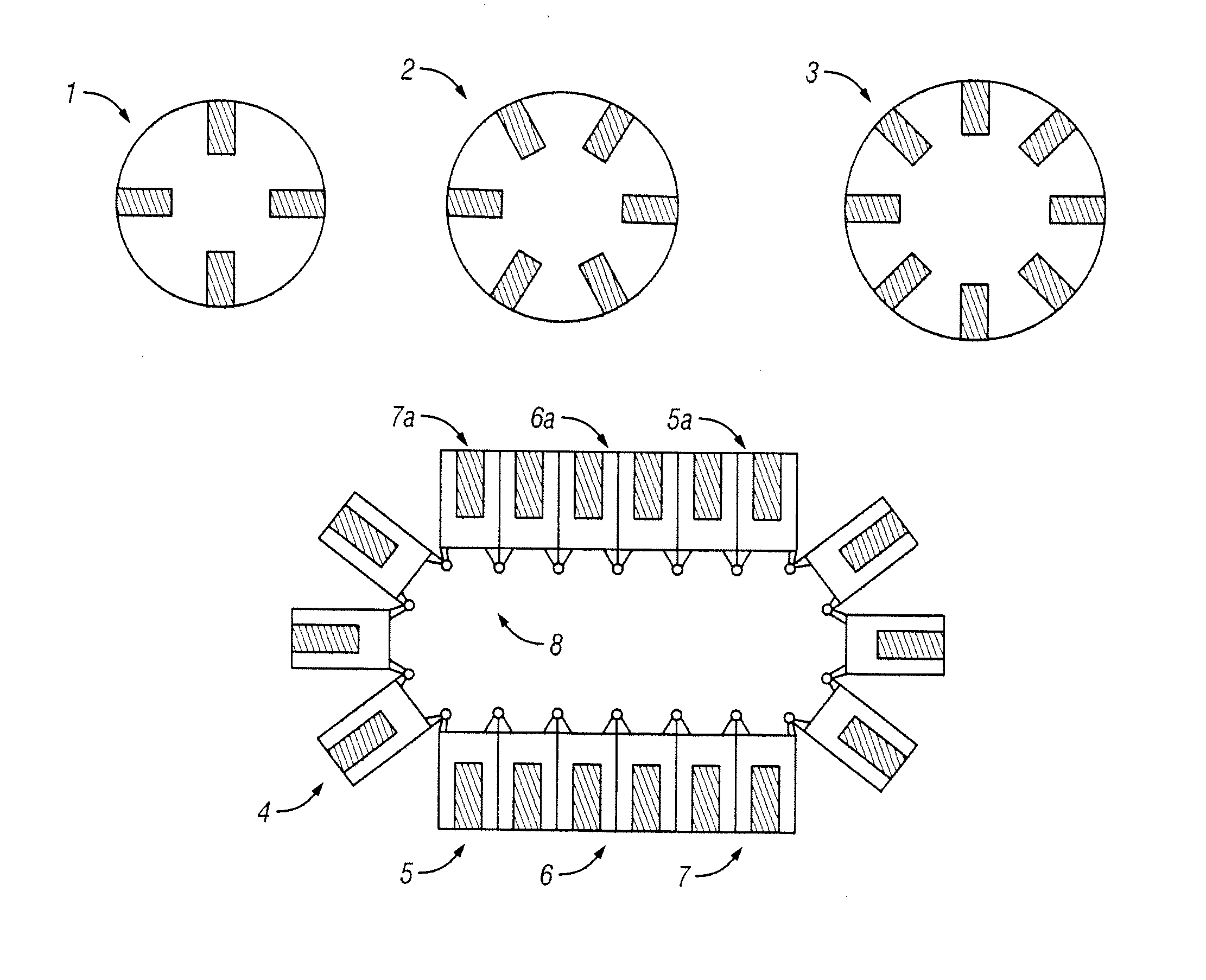

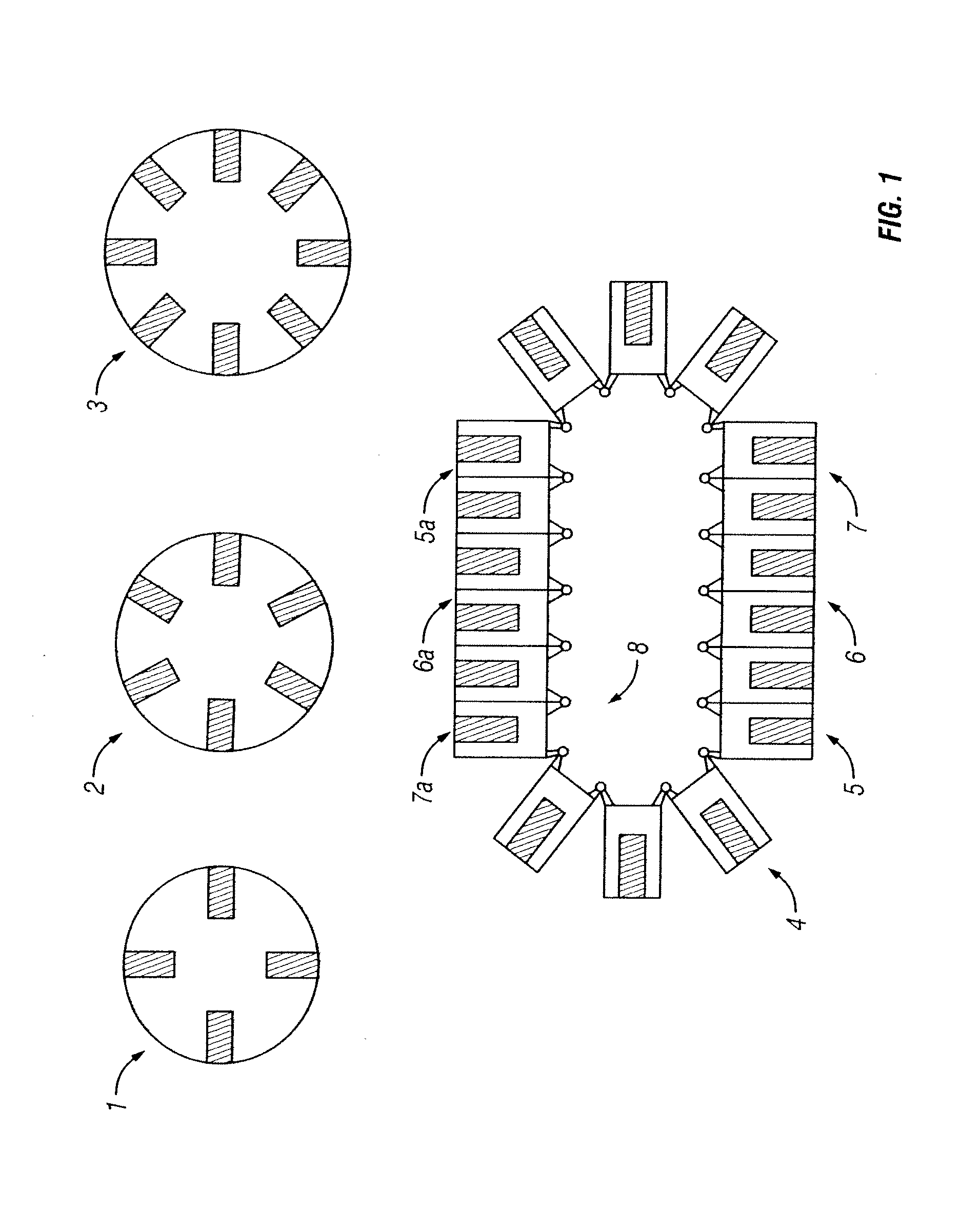

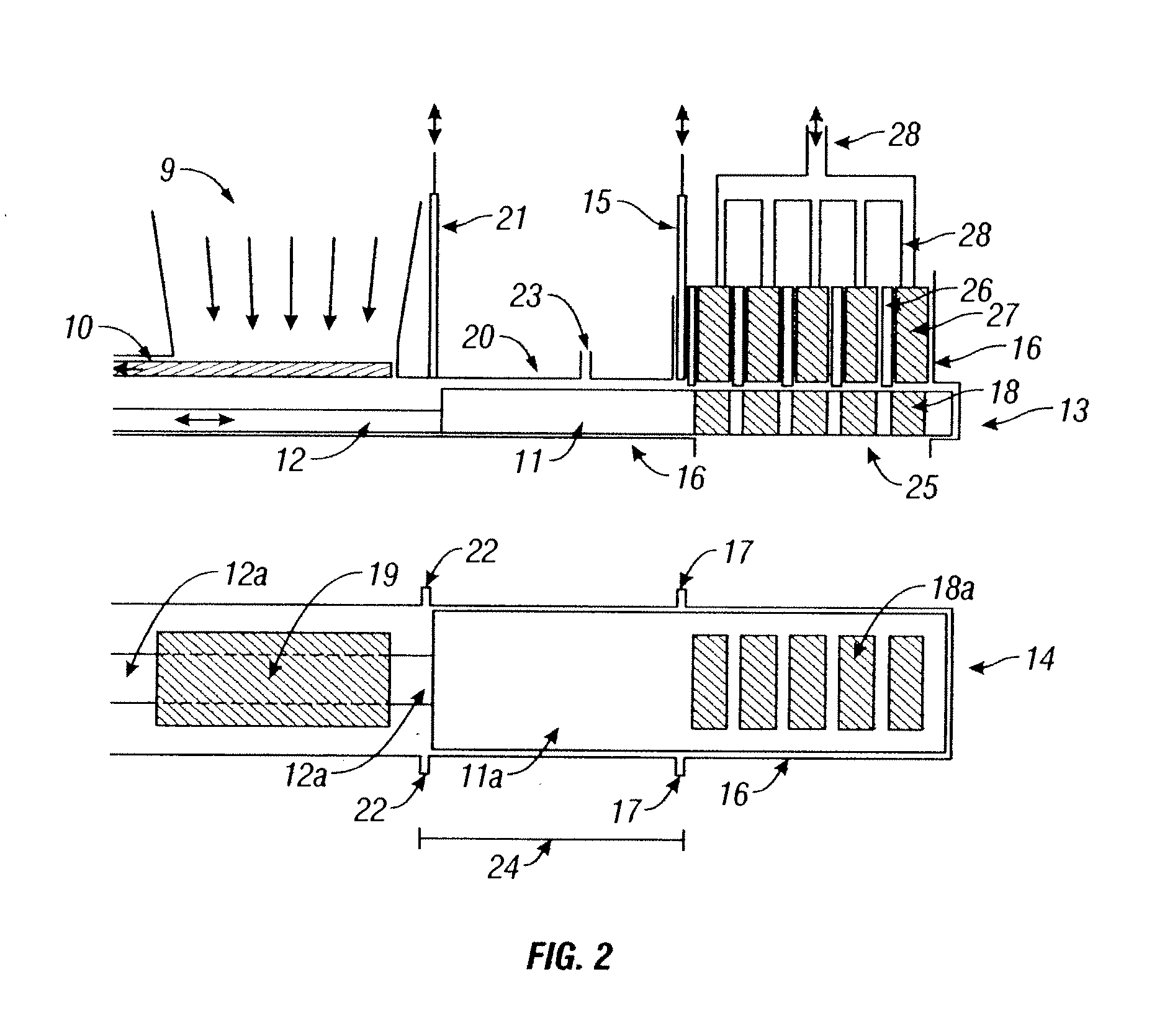

InactiveUS20040112359A1Avoid large movementsImprove cutting efficiencyDrill bitsConstructionsChemical LinkageBraze alloy

Superabrasive tools and methods for the making thereof are disclosed and described. In one aspect, superabrasive particles are chemically bonded to a matrix support material according to a predetermined pattern by a braze alloy. The brazing alloy may be provided as a powder, thin sheet, or sheet of amorphous alloy. A template having a plurality of apertures arranged in a predetermined pattern may be used to place the superabrasive particles on a given substrate or matrix support material.

Owner:SUNG CHIEN MIN

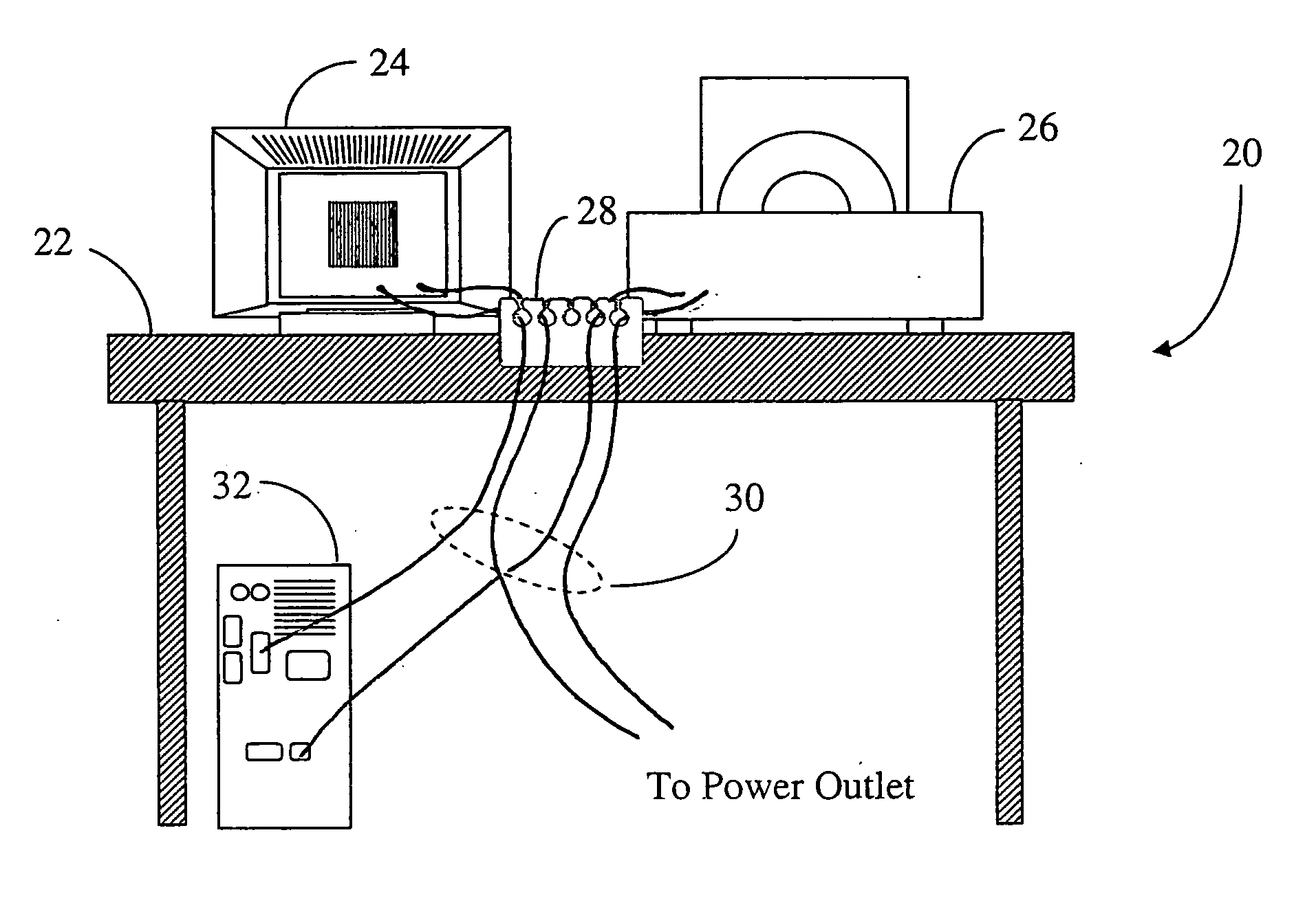

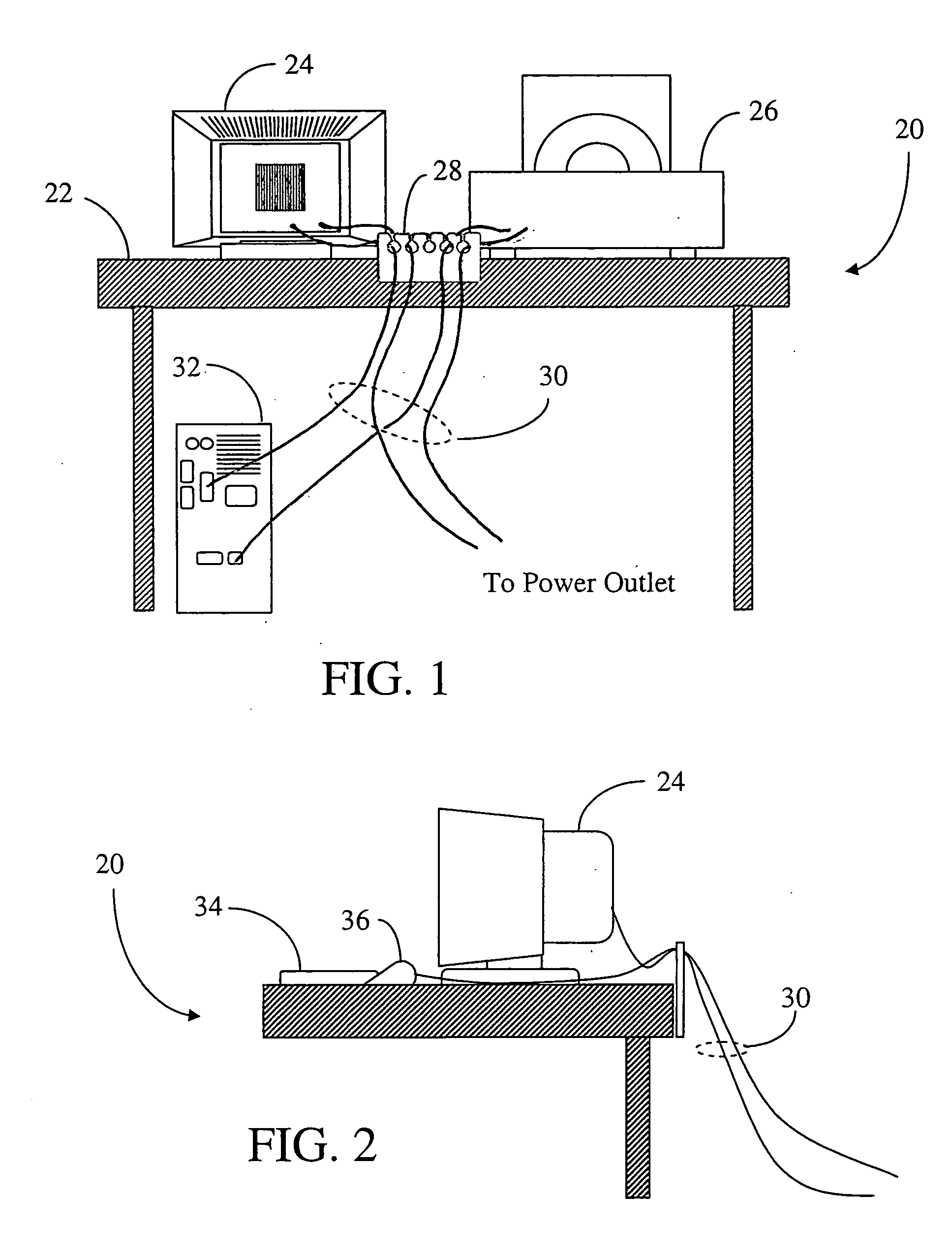

Cable organizer

InactiveUS20050189453A1Improve fastnessConvenient lengthPipe supportsElectrical apparatusMechanical engineeringThin sheet

Disclosed is a cable organizer for organizing and retaining cables including a thin sheet of flexible material having at least one opening adjacent an edge of the material. The cable organizer is further comprised of openings arranged along an edge of the cable organizer and in communication with the edge to allow the passage of a cable into the opening. The openings are sized to to prevent the passage of a cable connector such that a cable connector located on the end of the cable is unable to pass through the opening. Thus, the cable end may be retained by the cable organizer in a convenient position for future re-connection. The cable organizer may also provided with an adhesive strip for adhering the cable organizer to an object.

Owner:DEGUEVARA ORLANDO

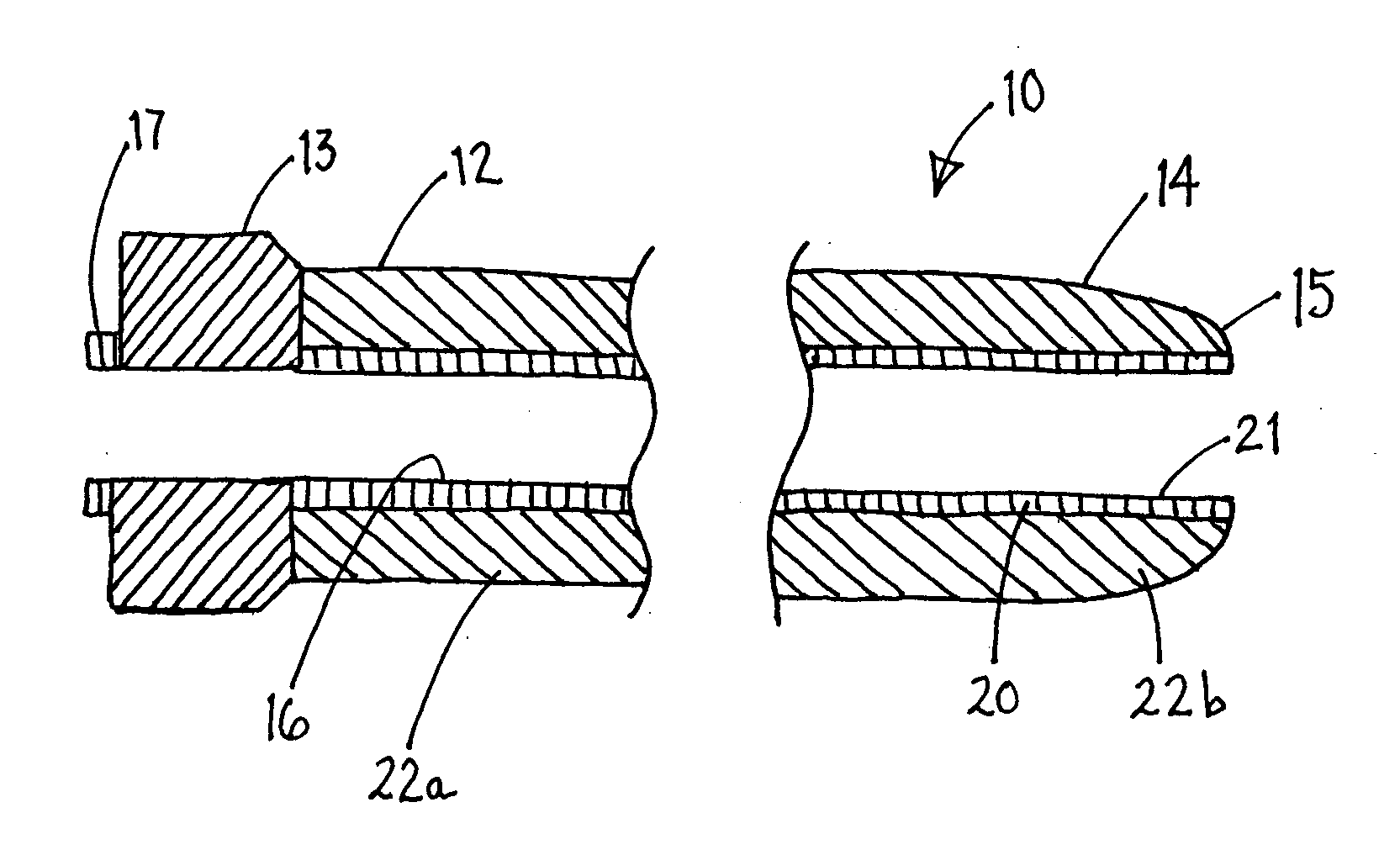

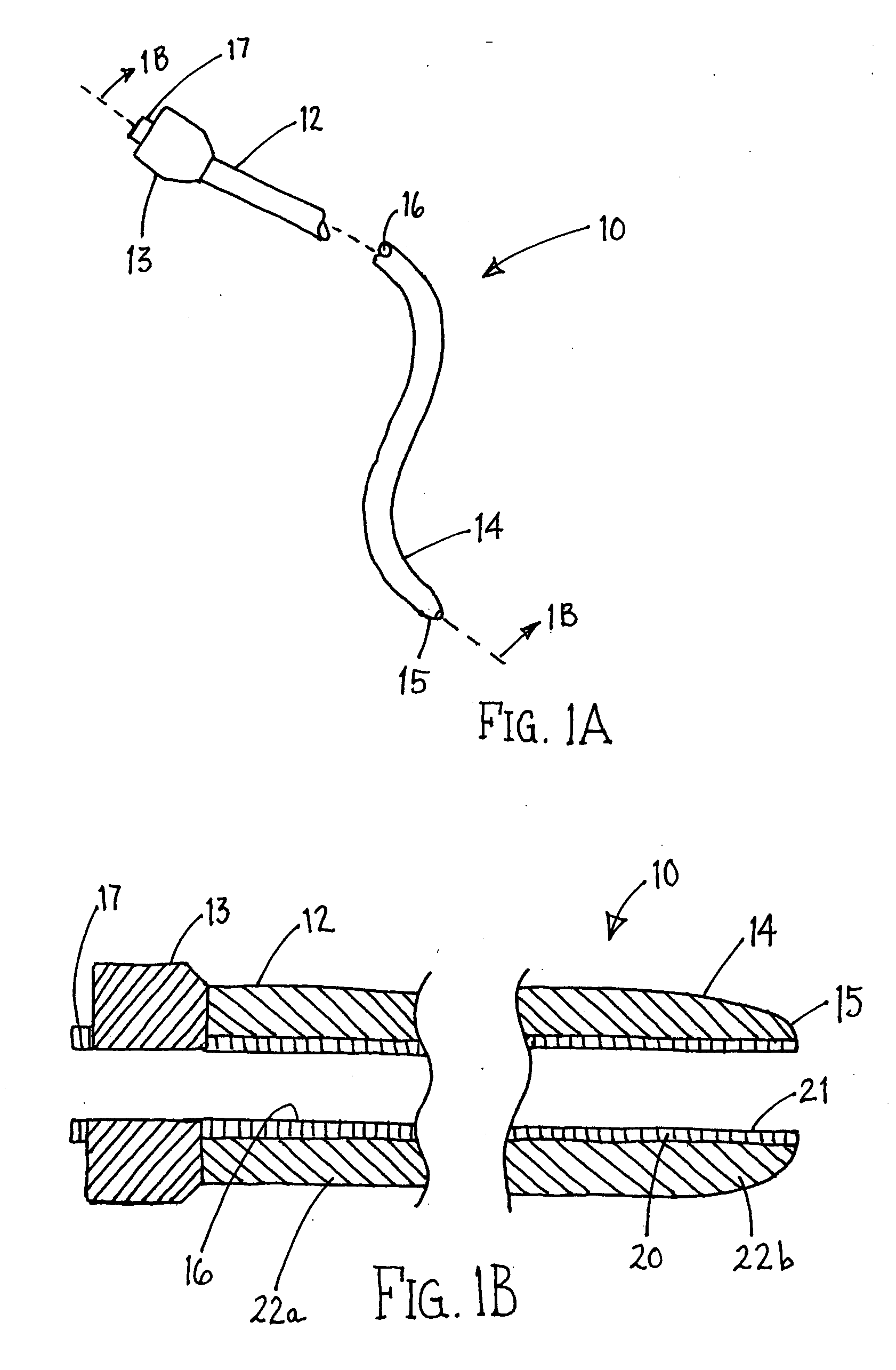

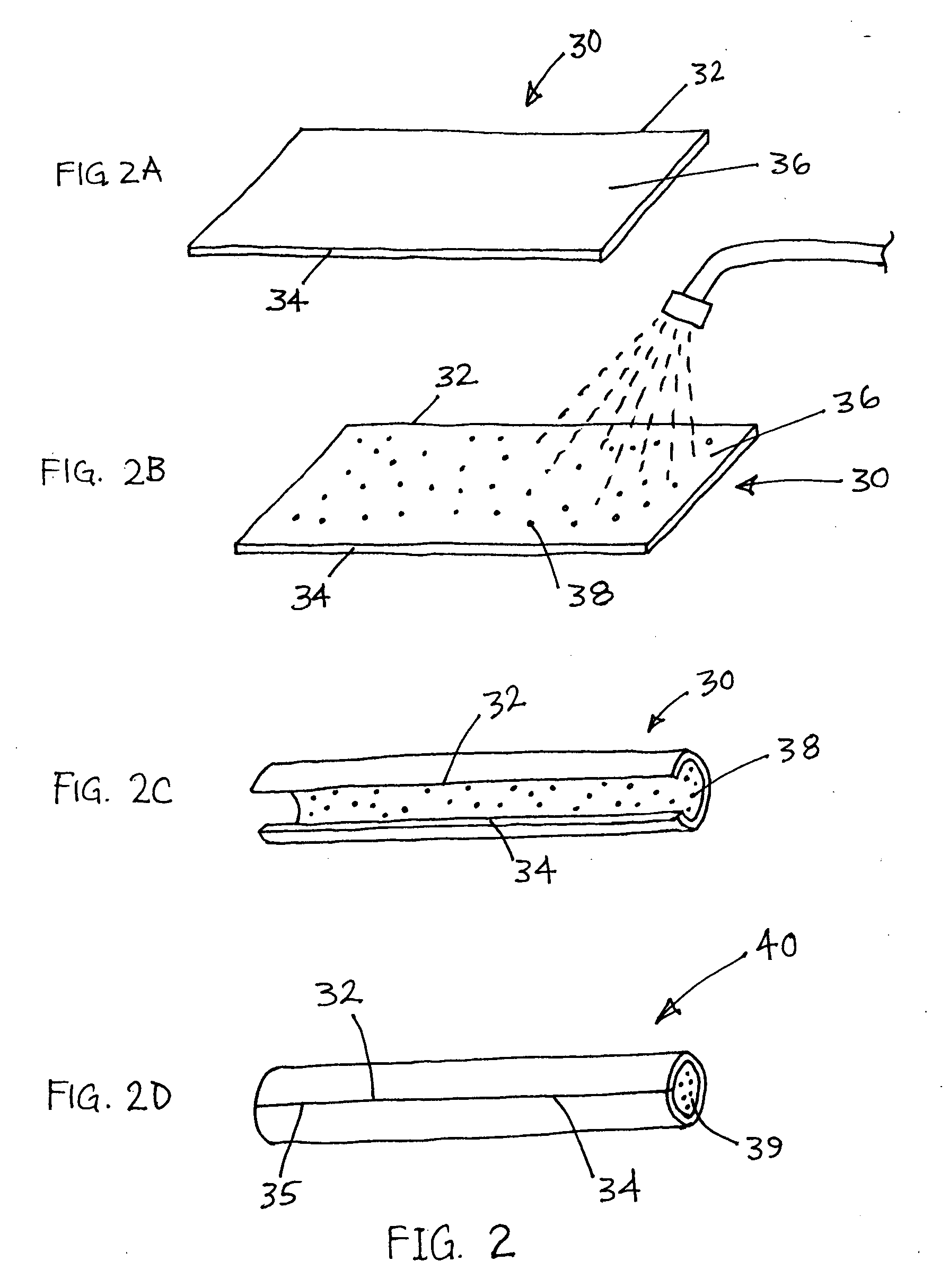

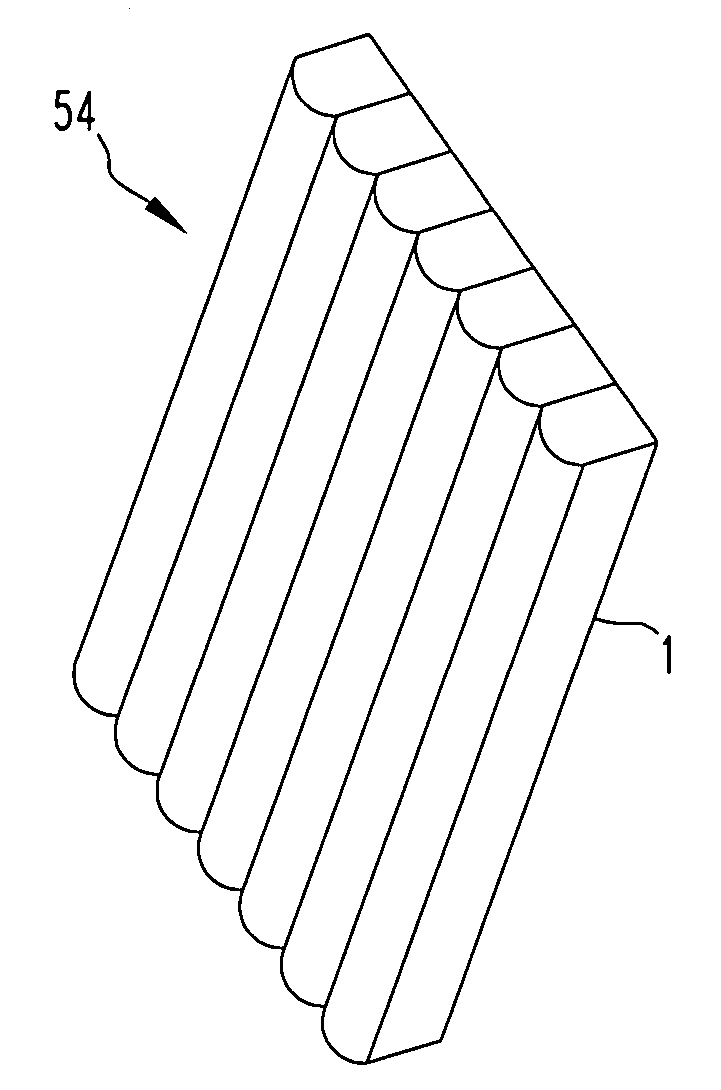

Catheters with lubricious linings and methods for making and using them

ActiveUS20070074805A1Simple methodImprove cross linking and adhesionPaper/cardboard wound articlesMedical devicesEngineeringMechanical engineering

A method for making a tubular device includes coating a first surface of a thin sheet, rolling the sheet such that side edges of the sheet are disposed adjacent one another with the coating disposed inwardly, creating a longitudinal seam along the side edges to create a sleeve, and attaching a tubular structure around the sleeve. In another embodiment, the method includes coating a first surface of a thin sheet, wrapping the sheet partially around a mandrel with the coating disposed inwardly, positioning a slotted tube around the sheet and mandrel, attaching the tube to the thin, and trimming any excess material of the sheet. In another embodiment, the method includes coating an outer surface of a thin sleeve, inverting the sleeve, and attaching a tubular structure around the inverted sleeve, thereby providing a tubular device including a lubricious, hydrophilic, and / or otherwise coated inner surface.

Owner:CLPH

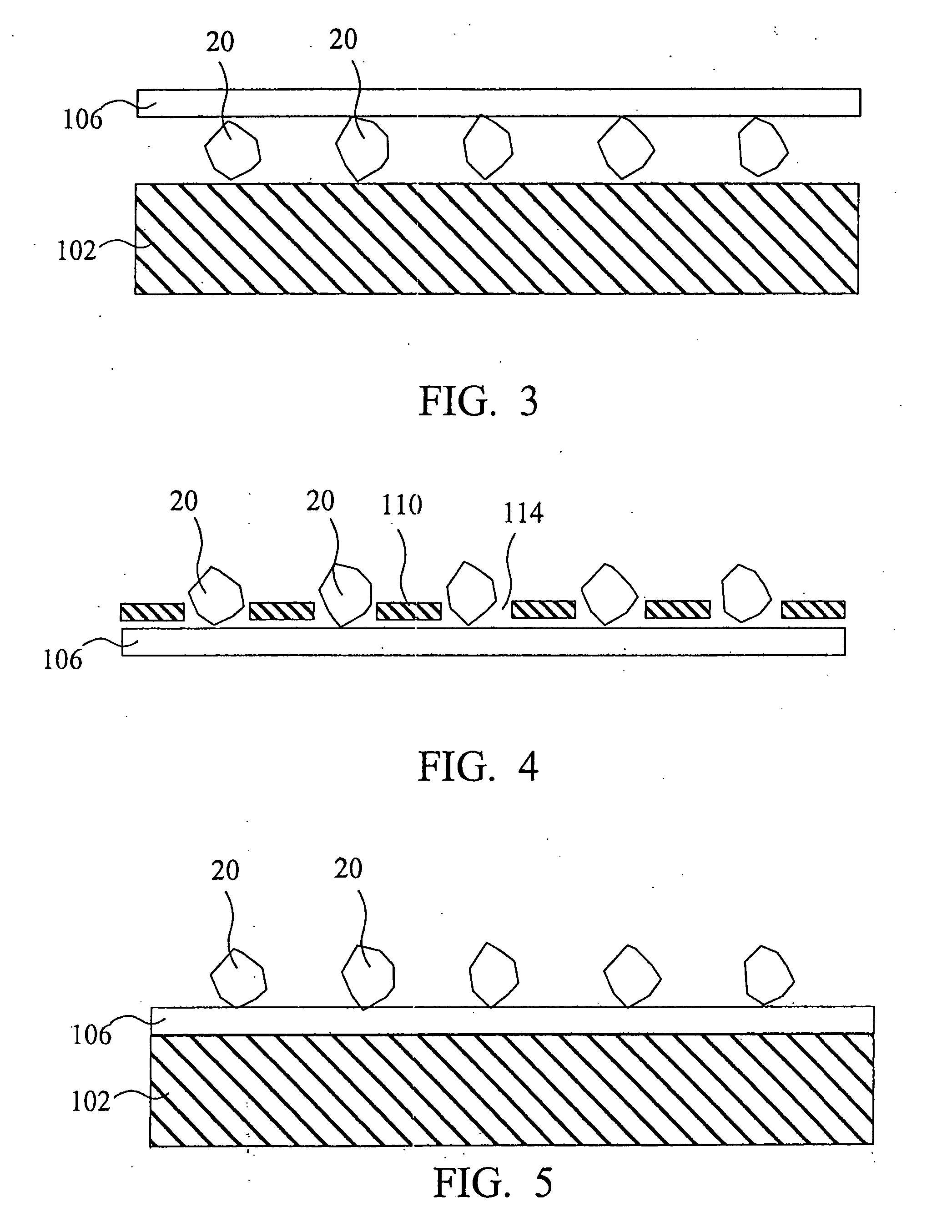

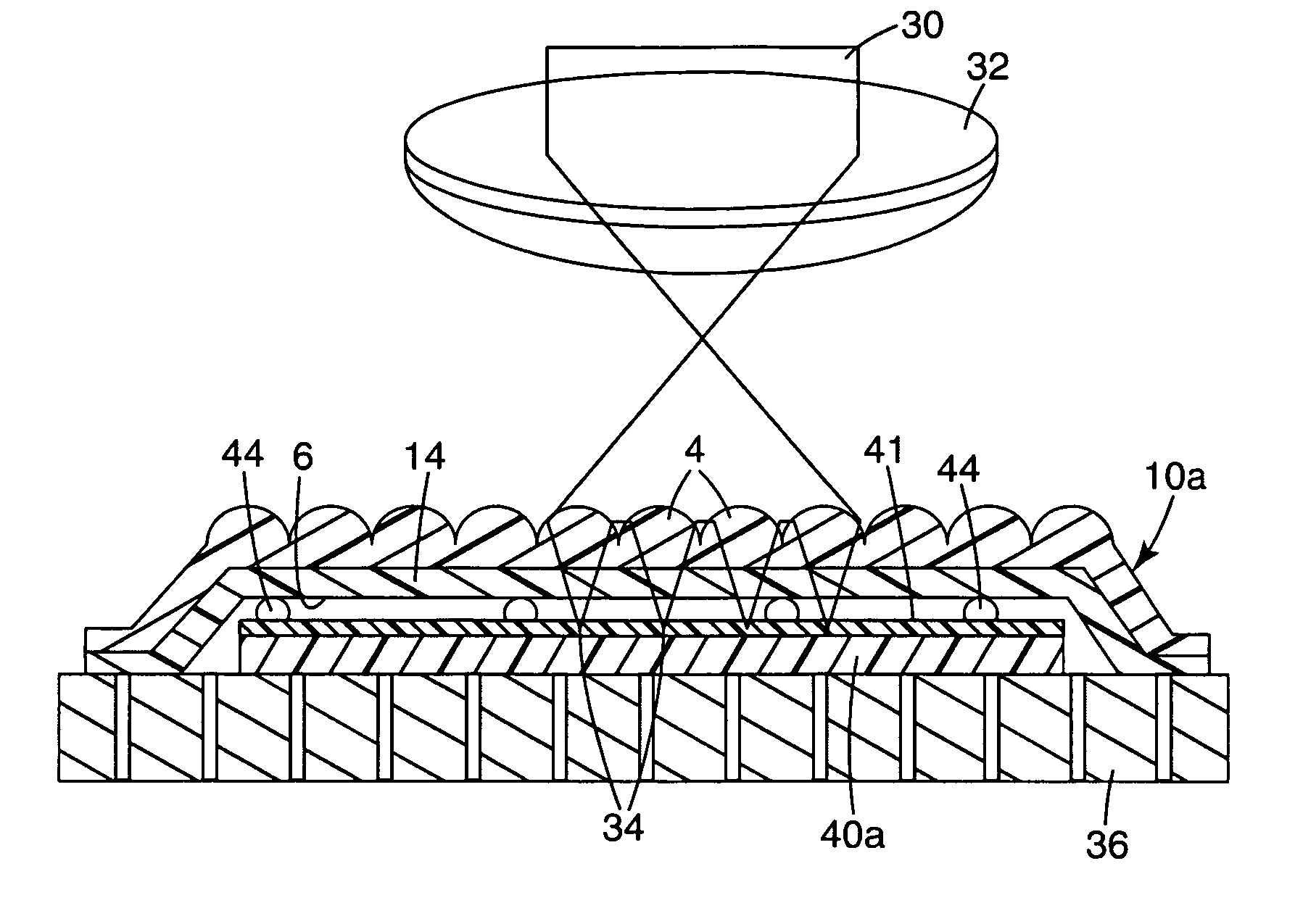

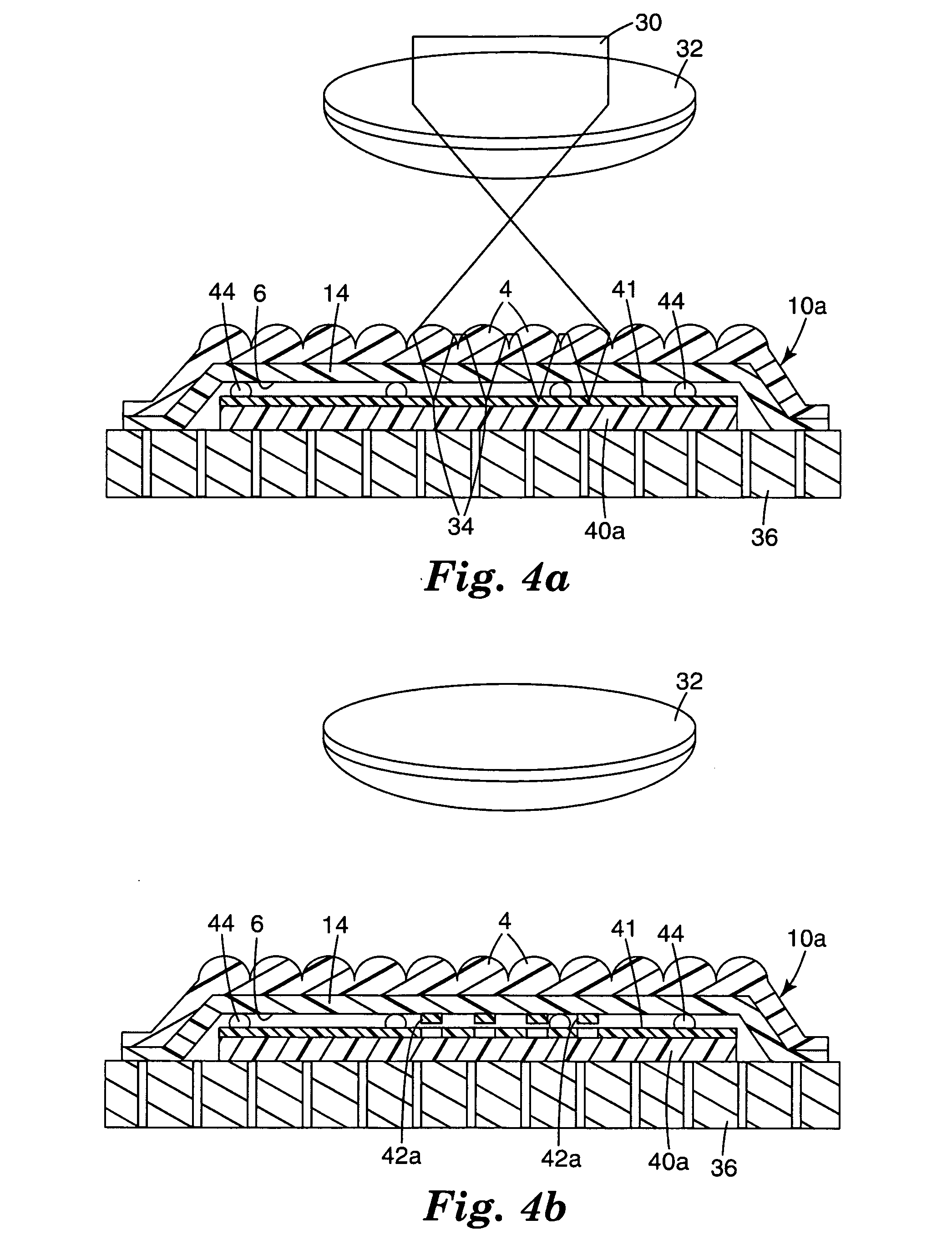

Retroreflection based multitouch sensor

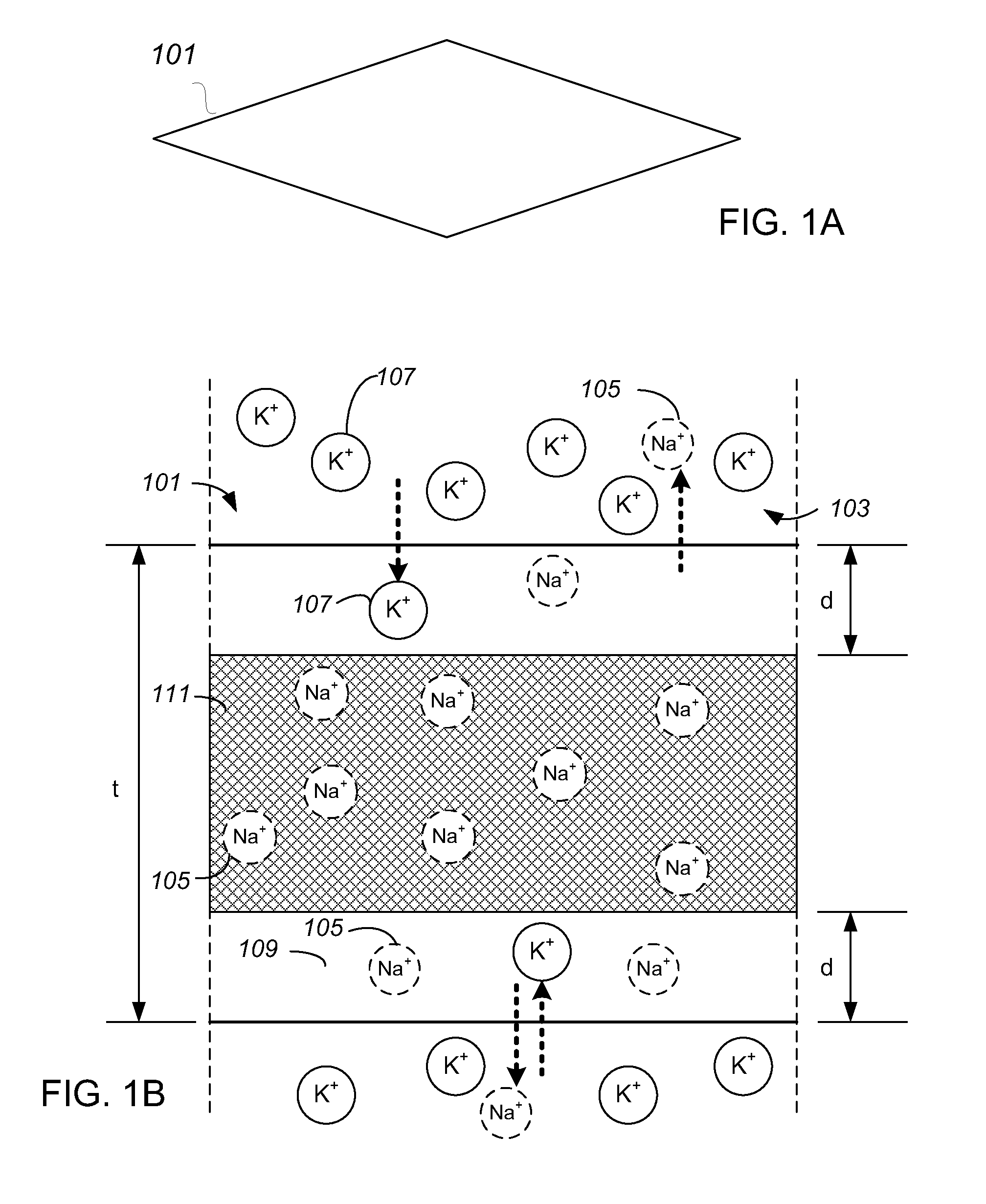

A detection apparatus includes a multilocation sensor. The apparatus includes a sheet in communication with the sensor, which when a plurality of locations of the sheet are simultaneously activated, the sensor senses these locations, simultaneously. Alternatively, the apparatus includes a surface. The apparatus includes a sensor in communication with the surface that detects variable pressure regarding a touch on the surface. Alternatively, the apparatus includes a sensor in communication with the surface that is capable of detecting a touch on a surface and also a presence of an object near the surface but not touching the surface. Alternatively, the apparatus includes a lenslet array where the lenslets are diffractive. The apparatus includes a sensor for determining where the array is being touched. The sensor includes a first light source producing light at a first frequency, a second light source producing light at a second frequency, a camera which records images from the frequencies of light from the array, and a computer which determines where the surface is being touched from the images. Alternatively, the apparatus includes a sensor for determining where the surface is being touched, including a plurality of cameras that take images of the surface, a first array of lights positioned such that light from the first array is on a vertical line with one or more of the cameras, a second array of lights that are positioned such that light from the second array is on a horizontal line with one or more of the cameras and a computer connected to the cameras which determines where the surface is being touched from the images. Alternatively, the apparatus includes a sheet containing a plurality of elements which are at least one of refractive, diffractive, retroreflective, reflective, or focusing. The apparatus includes a sensor which determines where the sheet is touched based on light being one of refracted, diffracted, retroreflected, reflected or focused by the sheet to the sensor. Alternatively, the apparatus includes a sheet having no active components in, on, or adjoining the sheet. The apparatus includes active components separate and apart from the sheet which determine where the sheet is touched. The apparatus can include an autostereo display including a multitouch retroreflective surface and a projector. A method for detection. A software program stored on a computer 5 readable medium.

Owner:NEW YORK UNIV

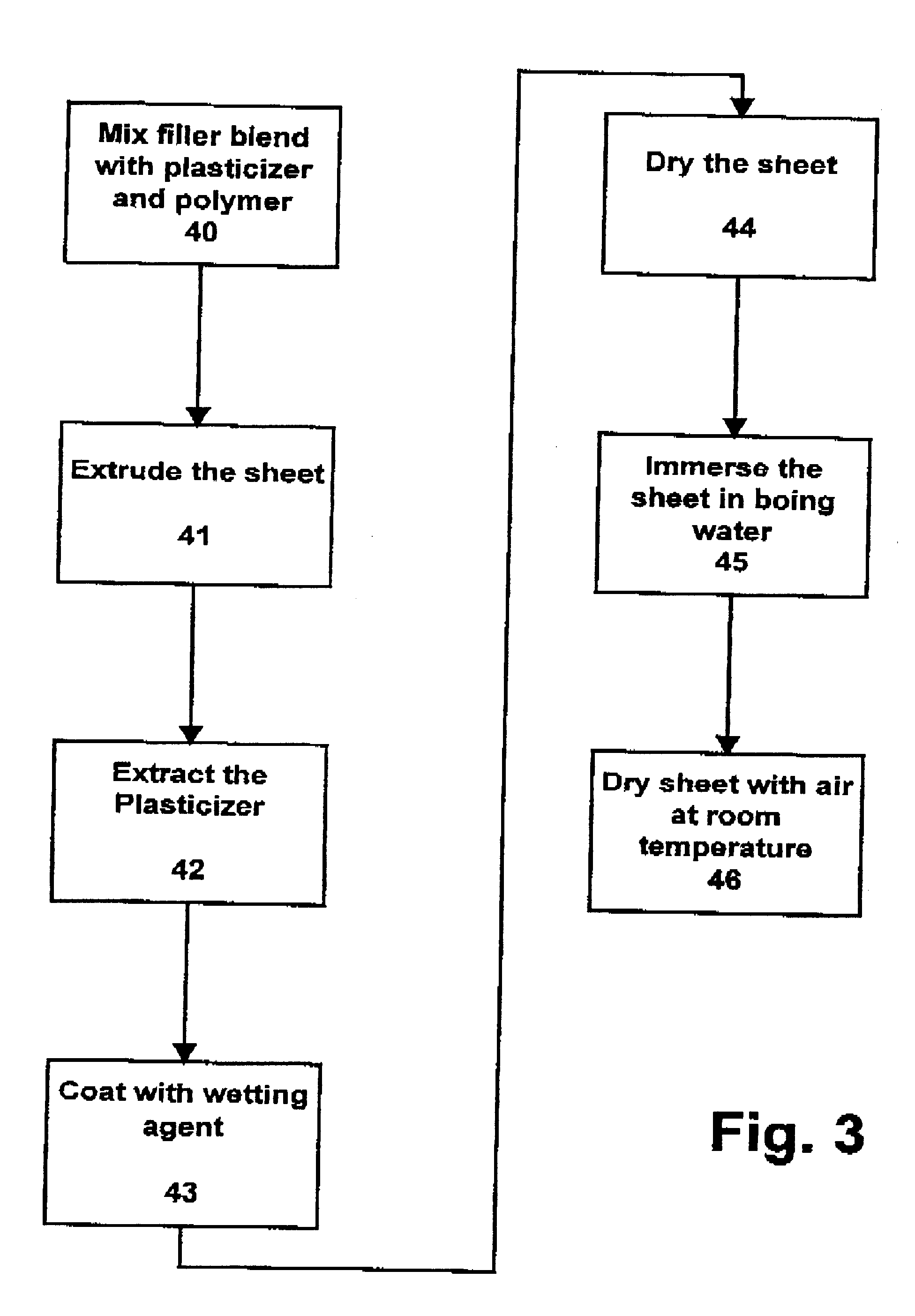

Microporous membrane battery separator for silver zinc batteries

InactiveUS6372379B1Improve cycle lifeExtended calendar lifeSilver accumulatorsCell component detailsPolyolefinFuel oil

A separator membrane for use in silver-zinc batteries is produced by extruding a blend of two fillers with the same chemical formula but different particle size. A polyolefine polymer and a plasticizer are blended and extruded to form a thin sheet of 1 to 10 mil thickness. The plasticizer is then extracted to leave submicron voids in the membrane. Plasticizers are added as processing aids, and can be either soluble or insoluble in water, and include petroleum oils, lubricating oils, fuel oils, and natural oils such as tall oils and linseed oils. The oil are then extracted from the membrane by conventional procedures such as single stage extraction using a suitable solvent. Commercially available wetting agents known to the art such as dodecylphenoxy polyethoxy ethanol and isooctyl phenyl polyethoxy ethanol are coated onto the sheet to improve wettability. The sheet is then dried, and boiled in distilled water for one minute or more, before being finally dried.

Owner:ZPOWER LLC

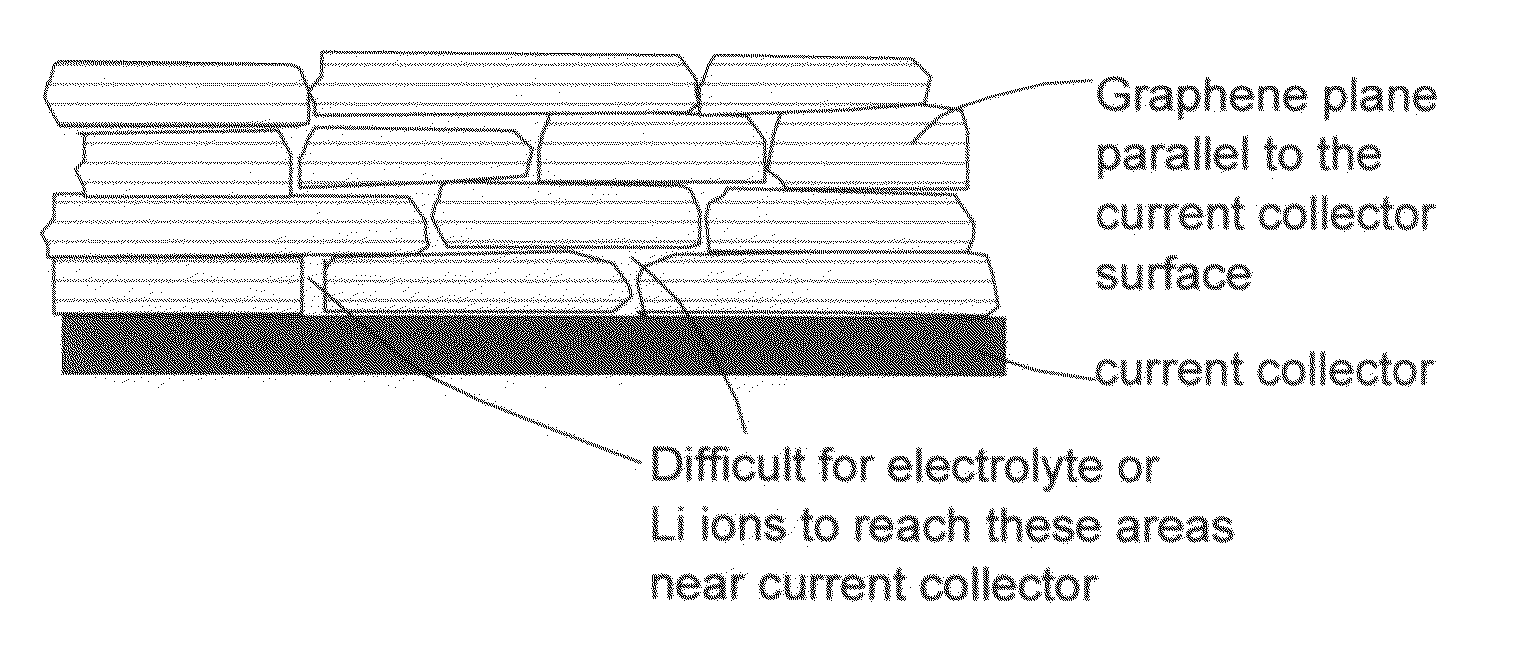

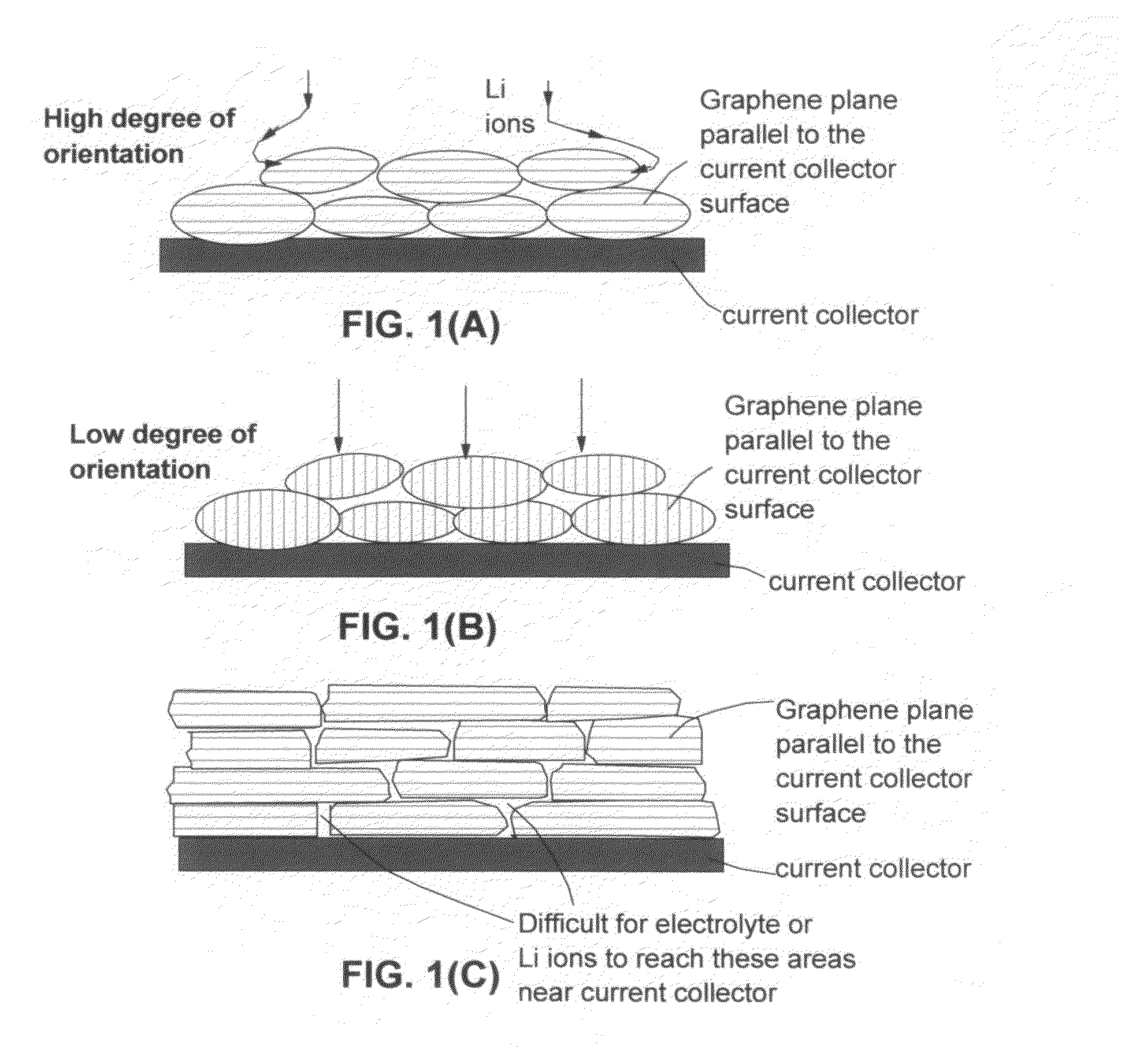

Graphite or carbon particulates for the lithium ion battery anode

This invention provides a graphite or graphite-carbon particulate for use as a lithium secondary battery anode material having a high-rate capability. The particulate is formed of a core carbon or graphite particle and a plurality of satellite carbon or graphite particles that are each separately bonded to the core particle wherein the core particle is spherical in shape, slightly elongate in shape with a major axis-to-minor axis ratio less than 2, or fibril in shape, and wherein the satellite particles are disc-, platelet-, or flake-like particles each containing a graphite crystallite with a crystallographic c-axis dimension Lc and a lateral dimension. Preferably, Lc is less than 100 nm and the flake / platelet lateral dimension is less than 1 μm. The core particle may be selected from natural graphite, artificial graphite, spherical graphite, graphitic coke, meso-carbon micro-bead, soft carbon, hard carbon, graphitic fibril, carbon nano-fiber, carbon fiber, or graphite fiber. Preferably, the flat-shaped particles are randomly oriented with respect to one another.

Owner:GLOBAL GRAPHENE GRP INC

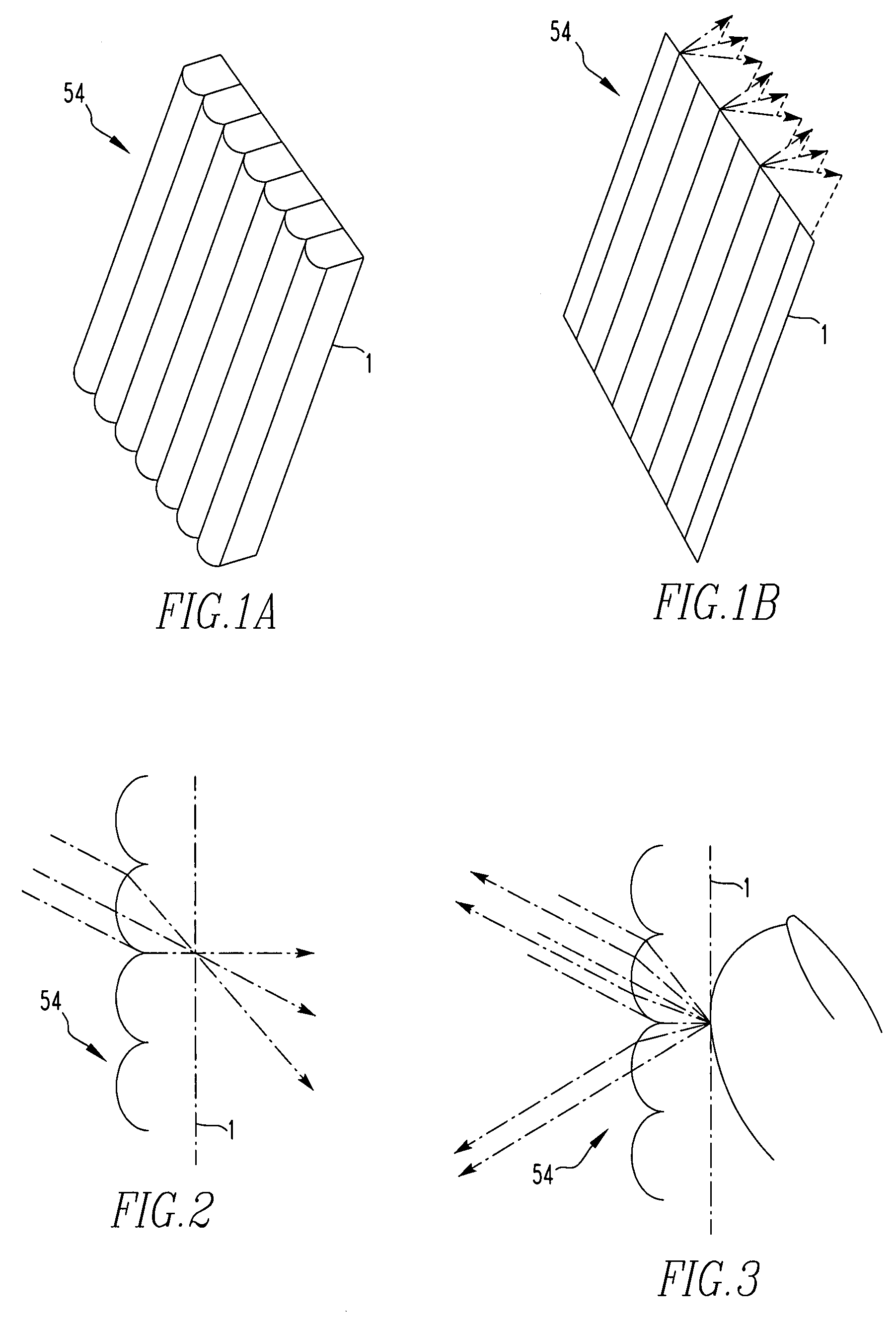

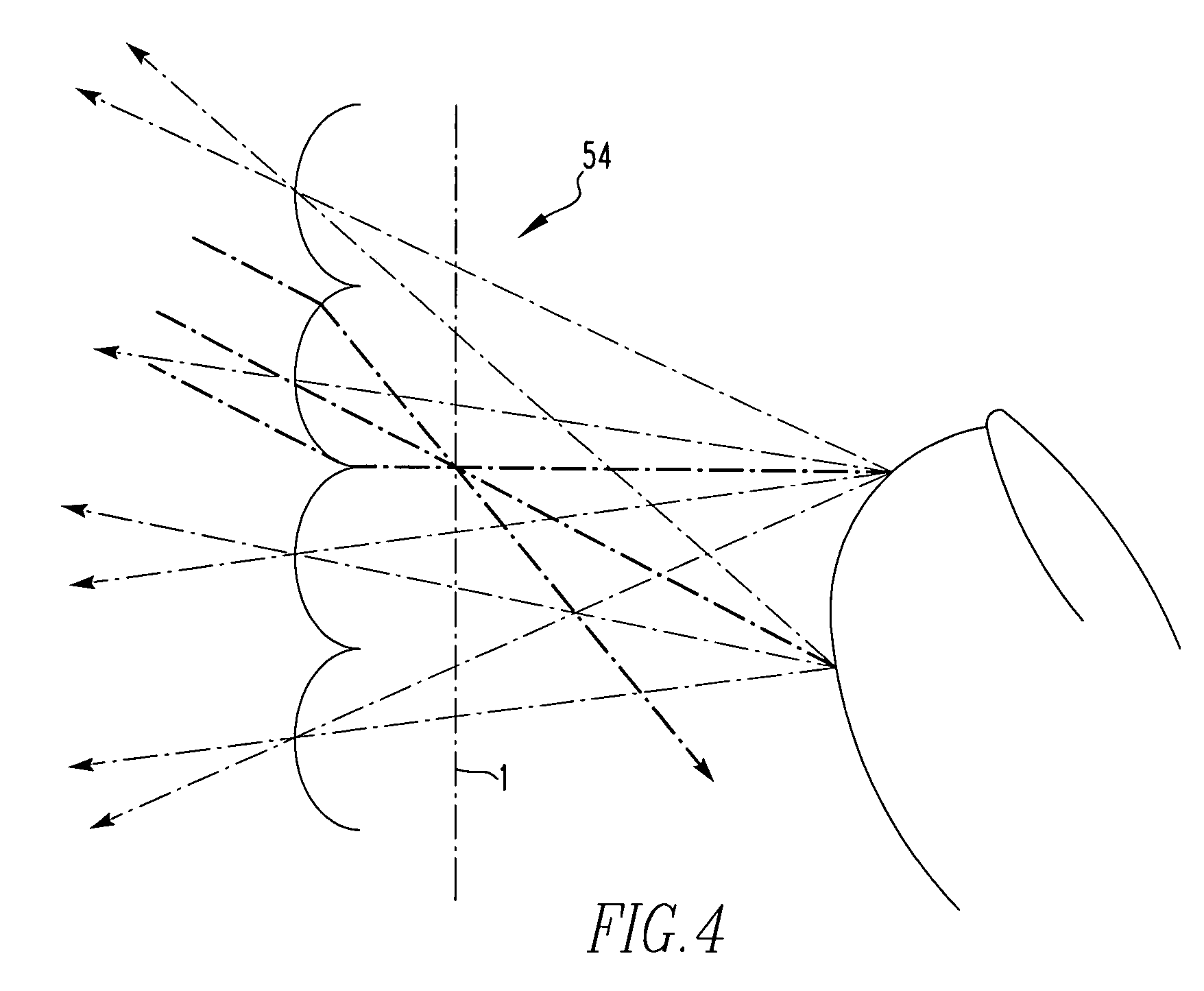

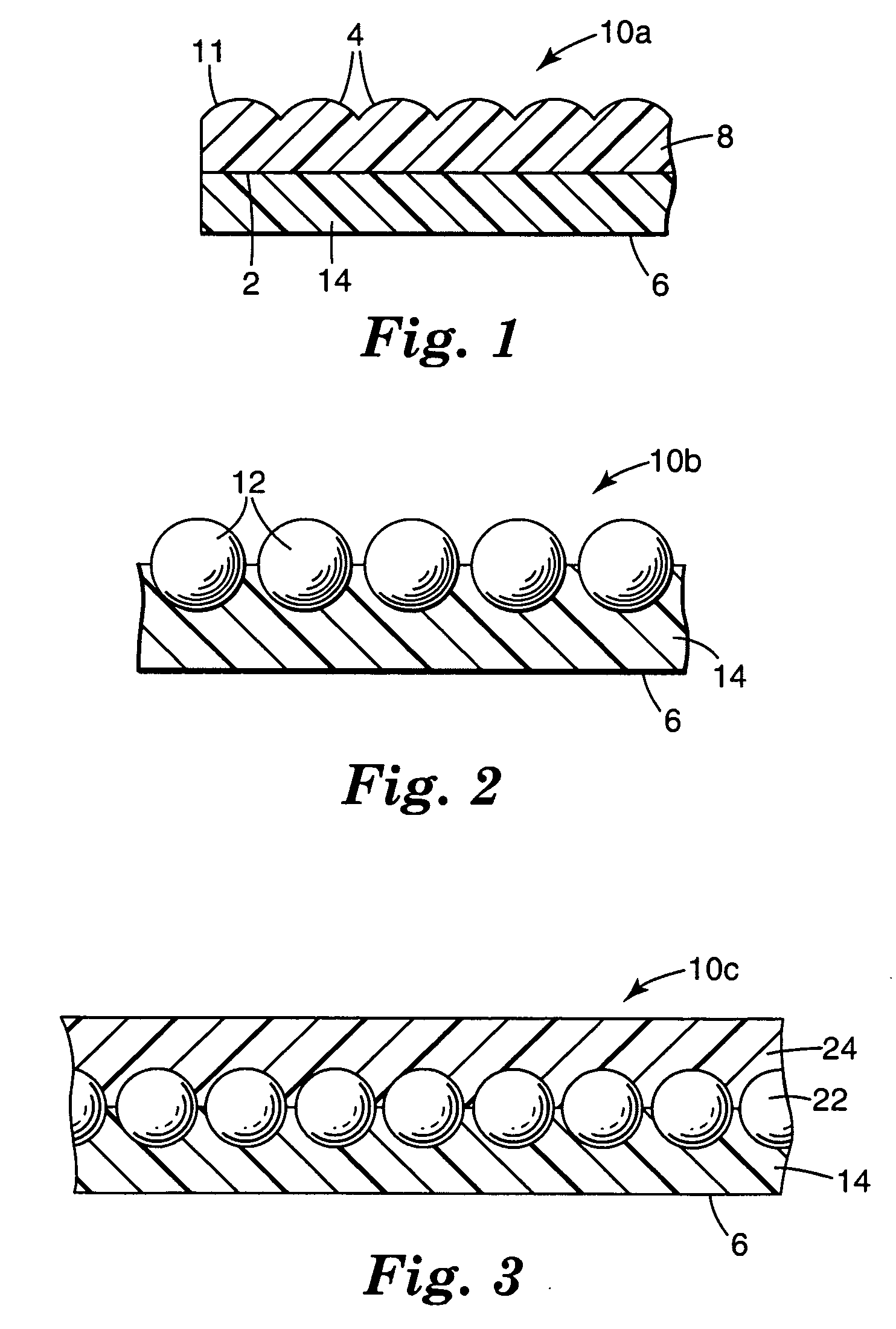

Methods of forming sheeting with a composite image that floats and sheeting with a composite image that floats

Microlens sheetings with composite images are disclosed, in which the composite image floats above or below the sheeting, or both. The composite image may be two-dimensional or three-dimensional. Methods for providing such an imaged sheeting are also disclosed.

Owner:3M INNOVATIVE PROPERTIES CO

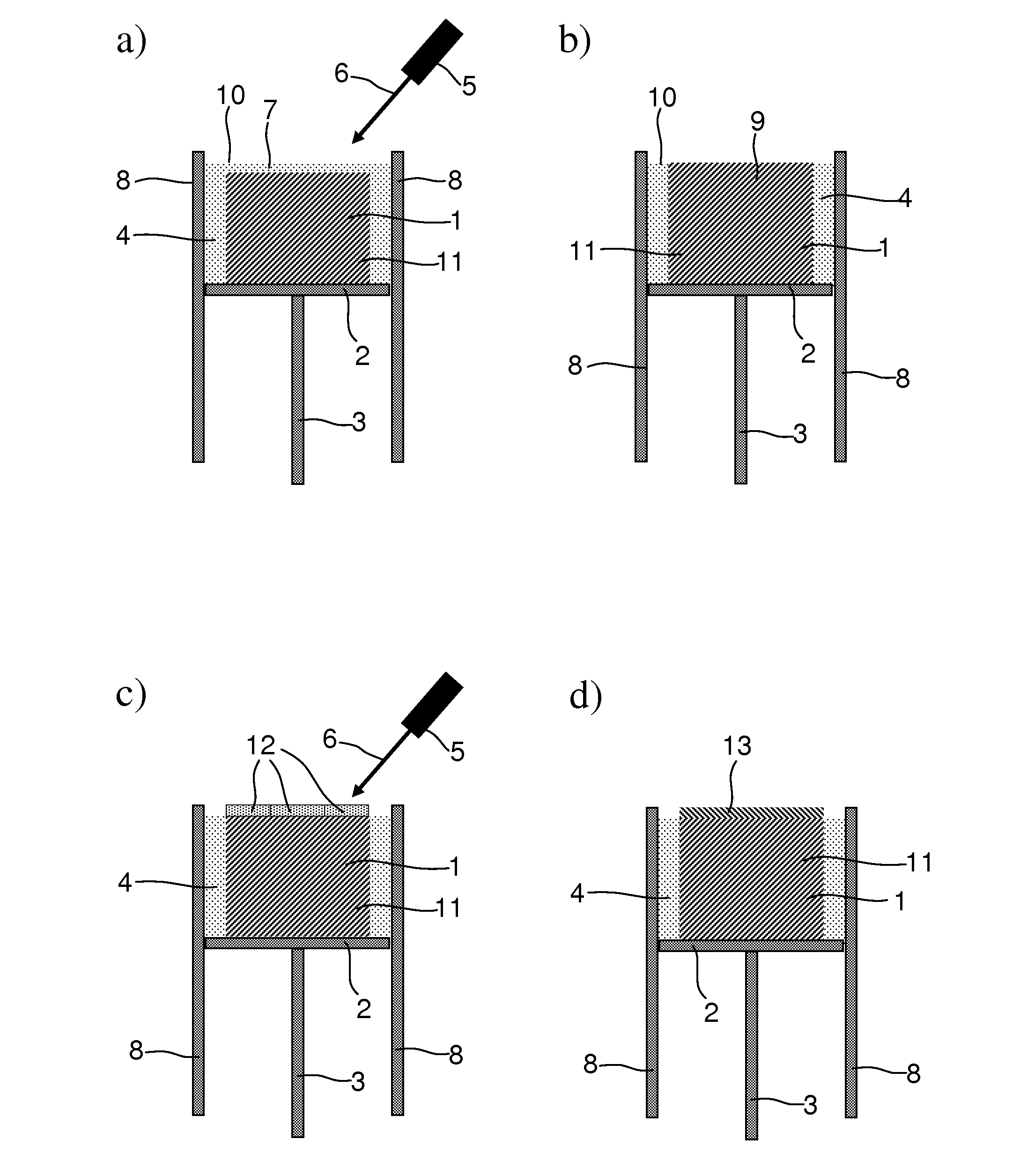

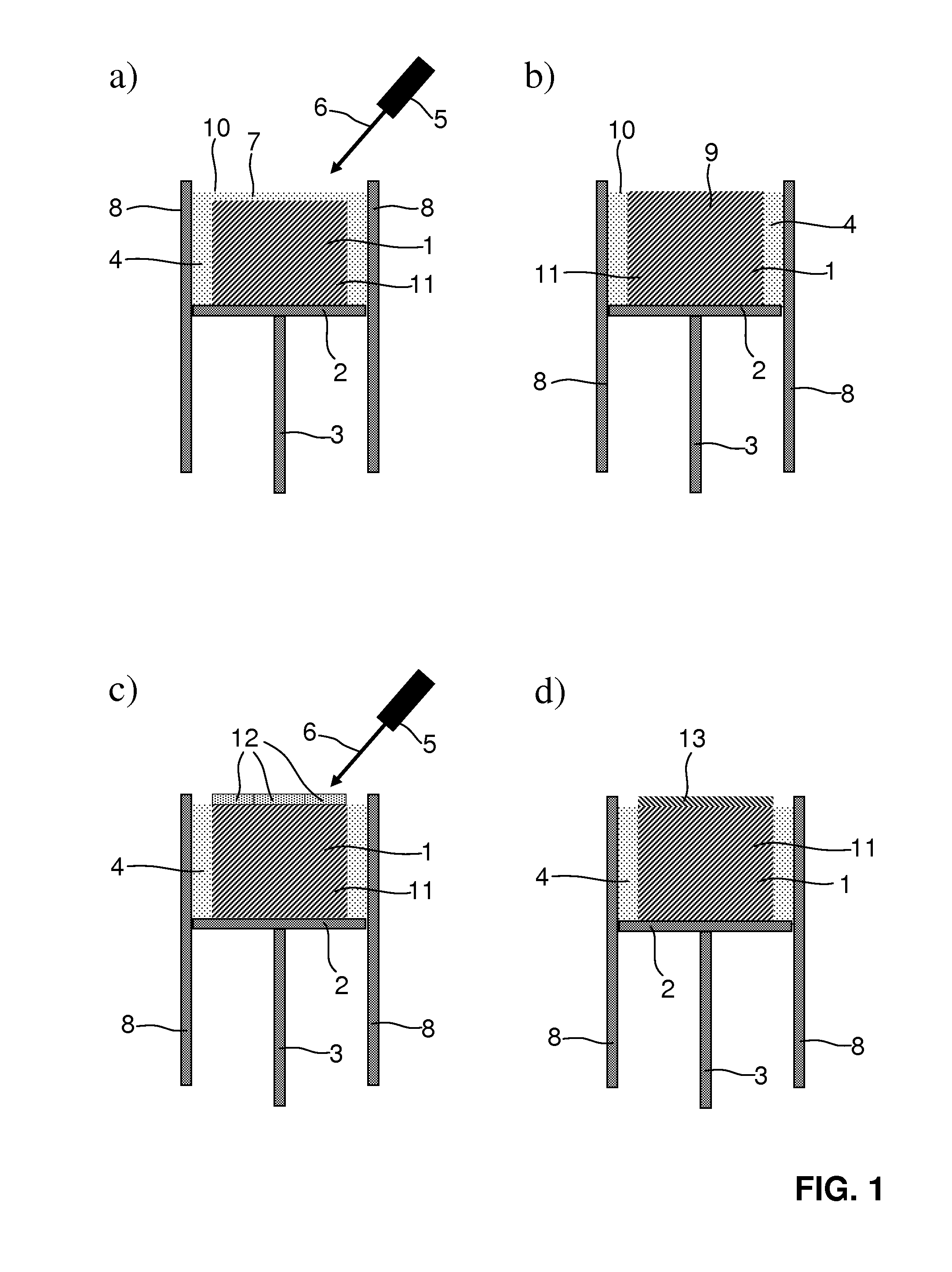

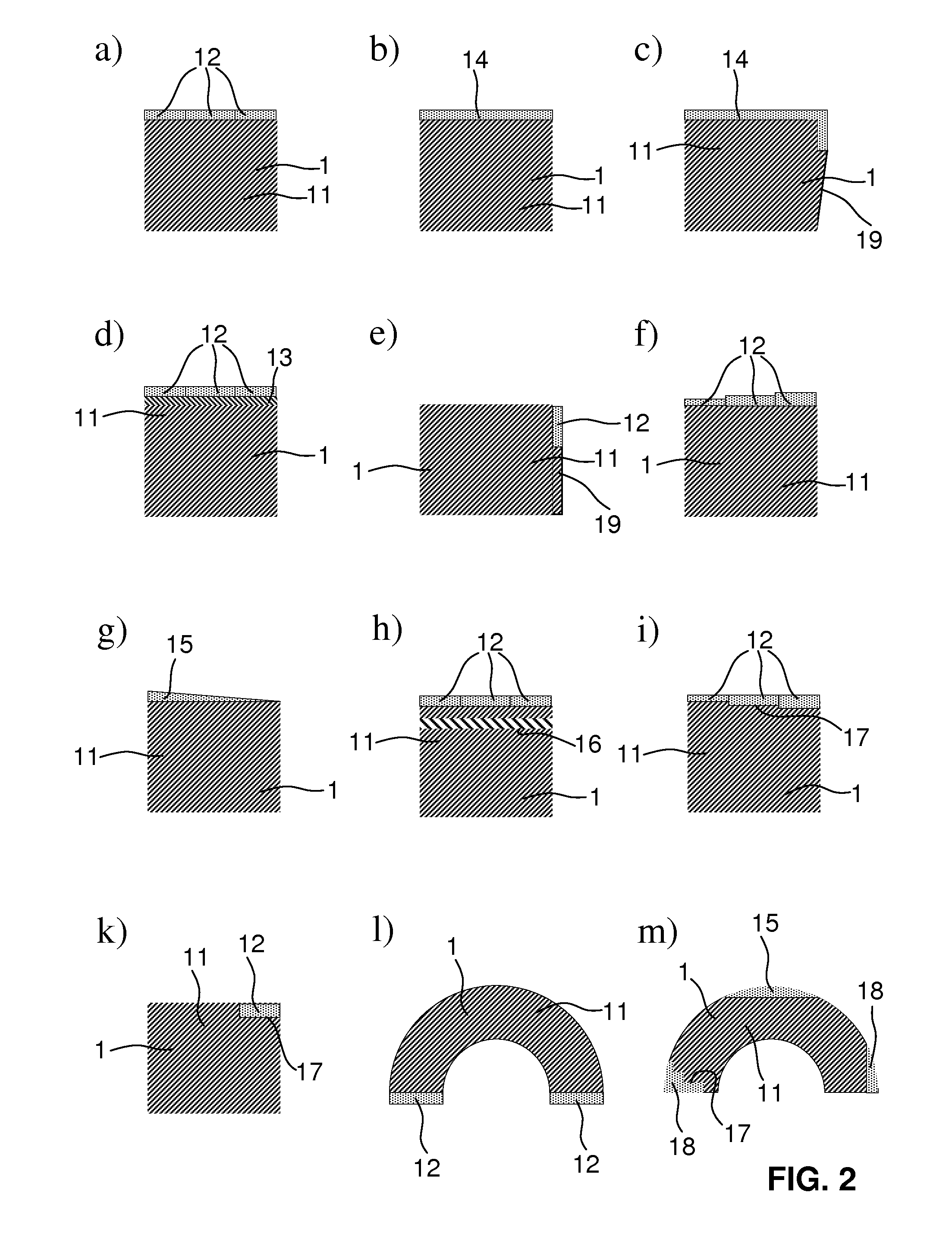

Method of applying multiple materials with selective laser melting on a 3D article

InactiveUS20110106290A1Increase weld ability/brazeabilityEasy to optimizeTurbinesAdditive manufacturingMulti materialSelective laser melting

In a method for manufacturing an article (1), particularly a prototype of a product or component, a tool prototype or spare part, by using selected laser melting, for the application onto the article (1) of a layer (13) or portion of a second metallic material, which is different from the material of the first metallic powder (4), a tape (12), sheet (14), foil or three-dimensional pre-form (18) of a second material is applied to the article (1) and is heated by a focused laser or electron beam (6) to a specified temperature such that the tape (12), sheet (14), foil or pre-form, respectively, are made molten by the electron laser beam (6), wherein the focused beam (6) is applied to a given area corresponding to a selected cross-sectional area of the model of the article (1) under formation of a new layer or part made of second material integral with the article (1).

Owner:ANSALDO ENERGIA IP UK LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com