Patents

Literature

1227 results about "Natural graphite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Natural graphite is graphite that is formed by Nature. Natural graphite is an important industrial mineral which finds applications in almost every facet of manufacturing including electronics, atomic energy, hot metal processing, friction, coatings, aerospace, powder metallurgy, etc.

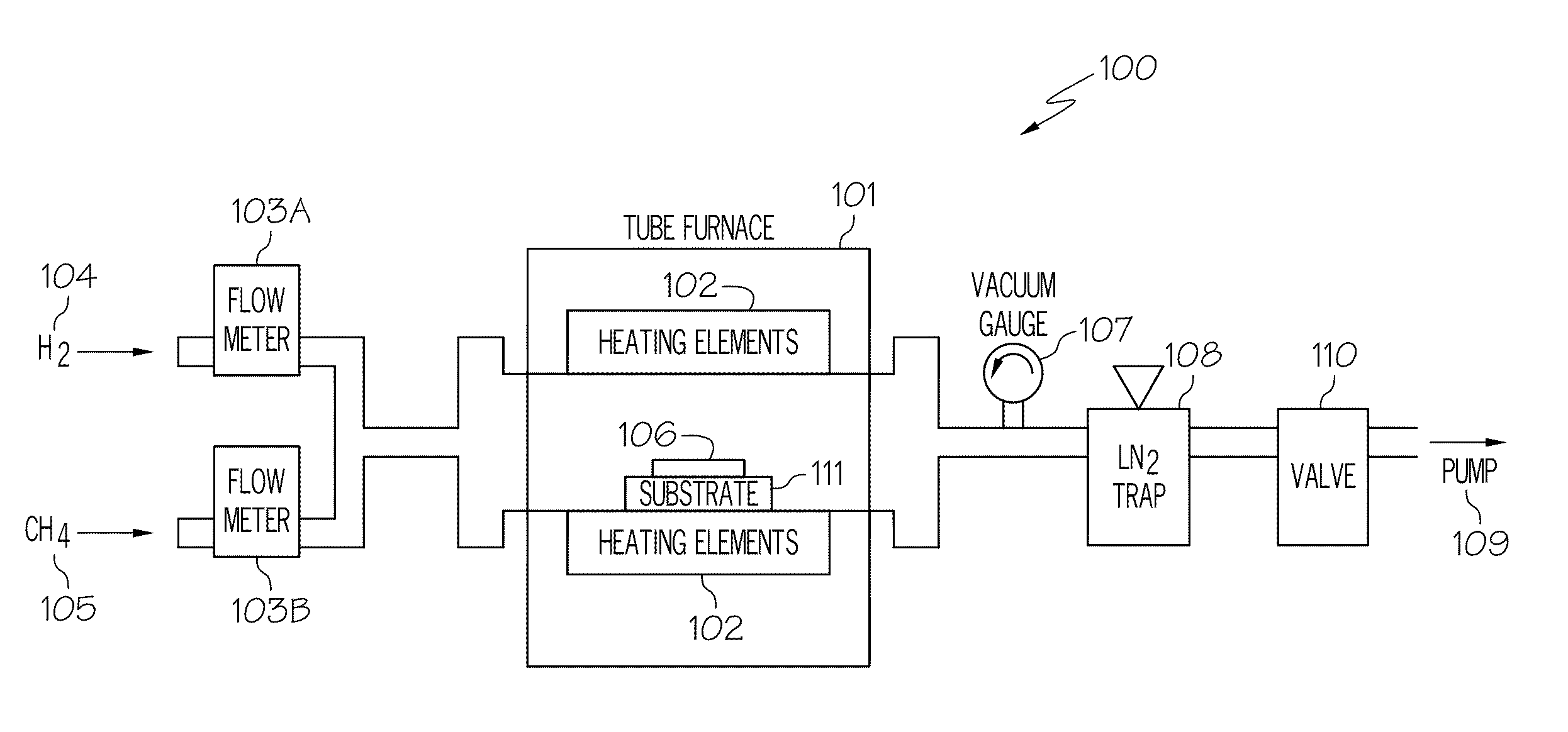

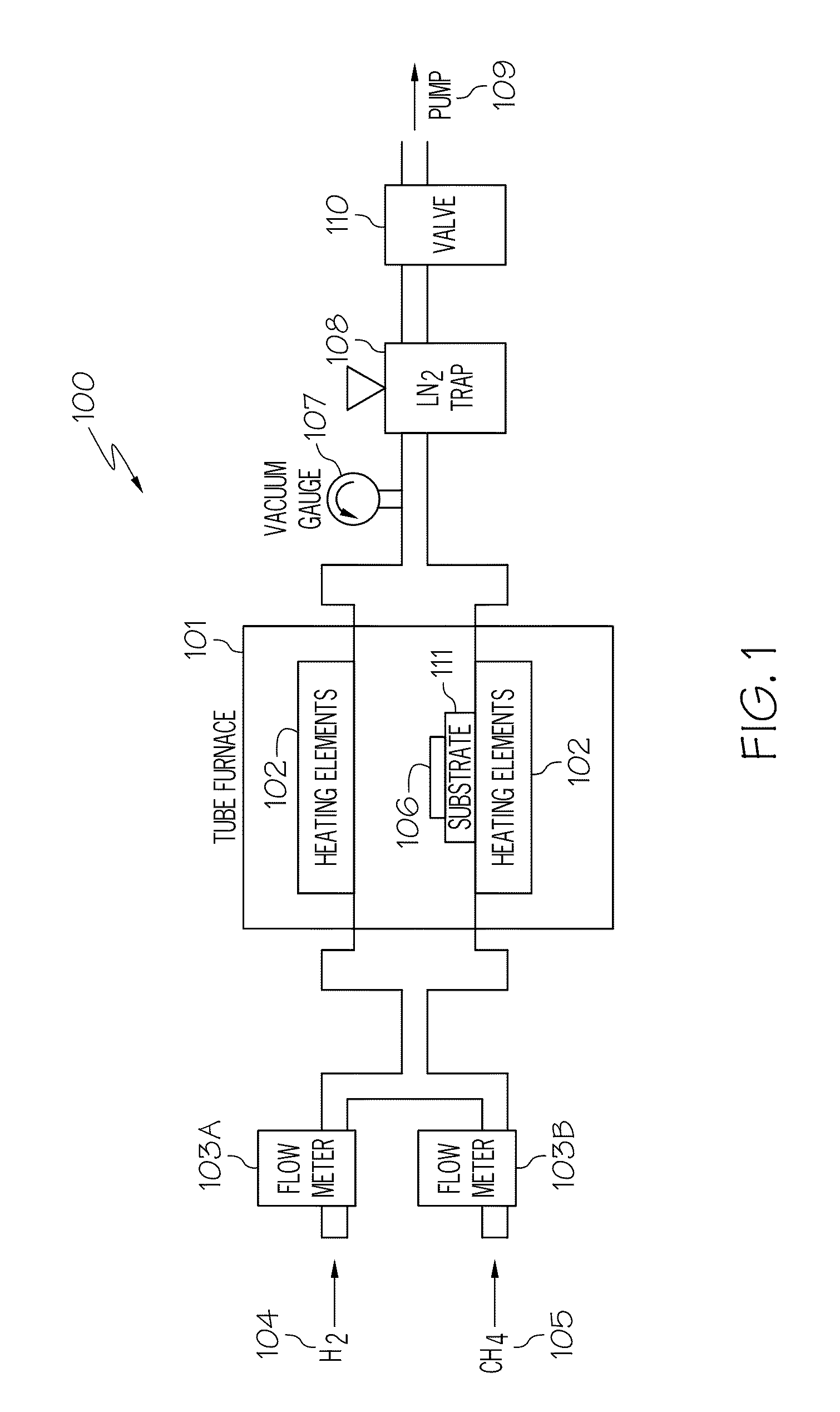

Graphene synthesis by chemical vapor deposition

Processes for synthesizing graphene films. Graphene films may be synthesized by heating a metal or a dielectric on a substrate to a temperature between 400° C. and 1,400° C. The metal or dielectric is exposed to an organic compound thereby growing graphene from the organic compound on the metal or dielectric. The metal or dielectric is later cooled to room temperature. As a result of the above process, standalone graphene films may be synthesized with properties equivalent to exfoliated graphene from natural graphite that is scalable to size far greater than that available on silicon carbide, single crystal silicon substrates or from natural graphite.

Owner:TEXAS INSTR INC +1

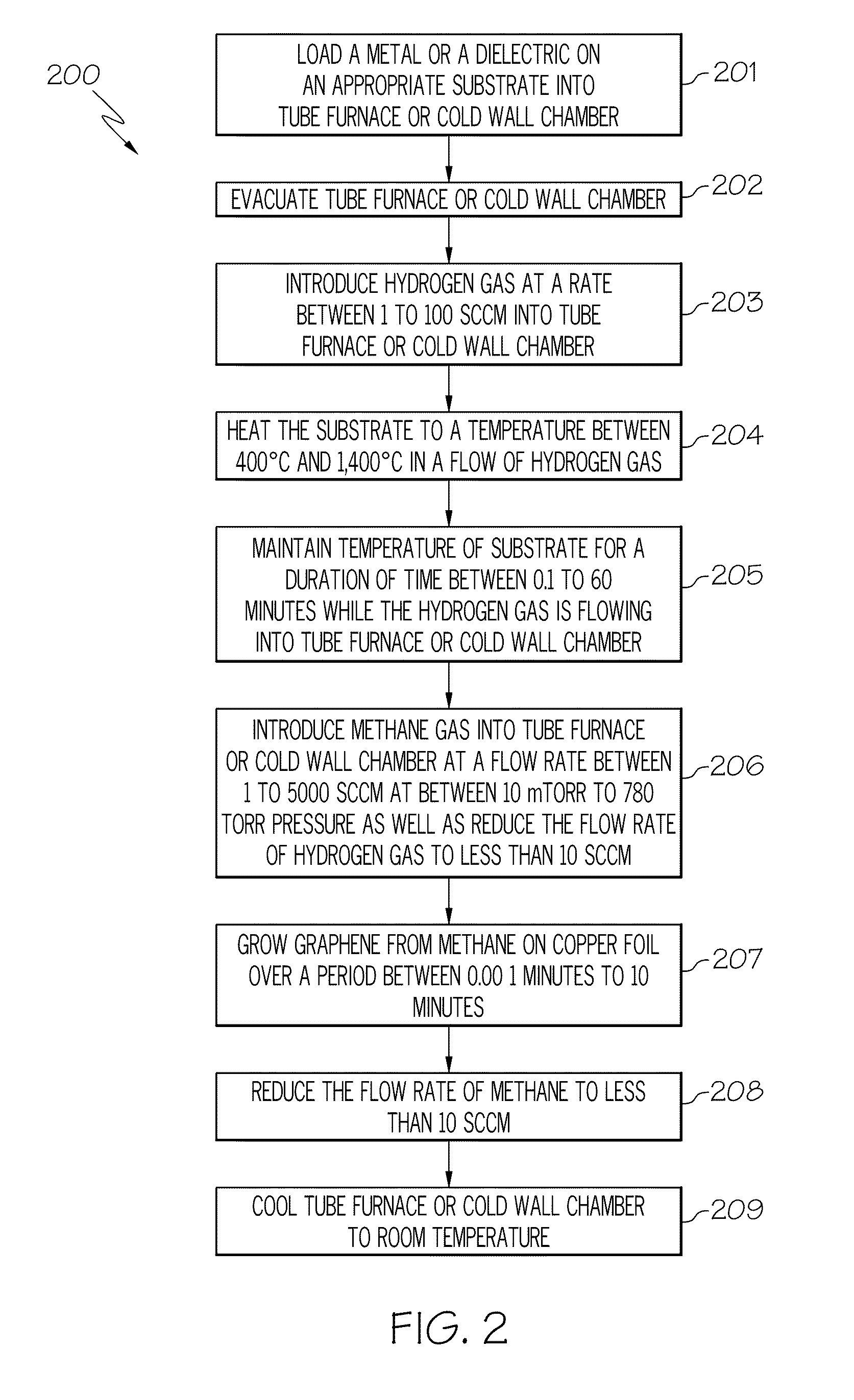

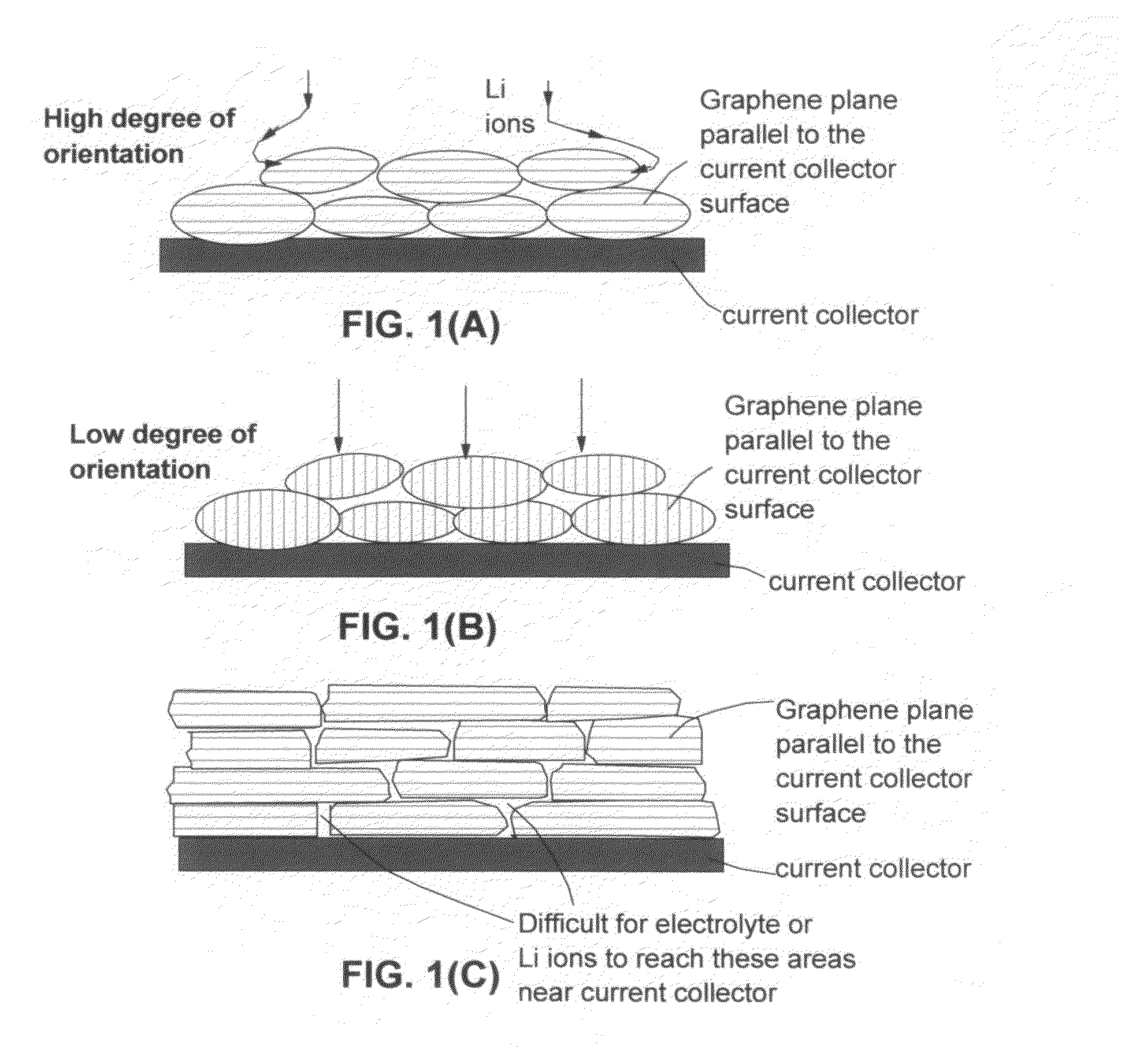

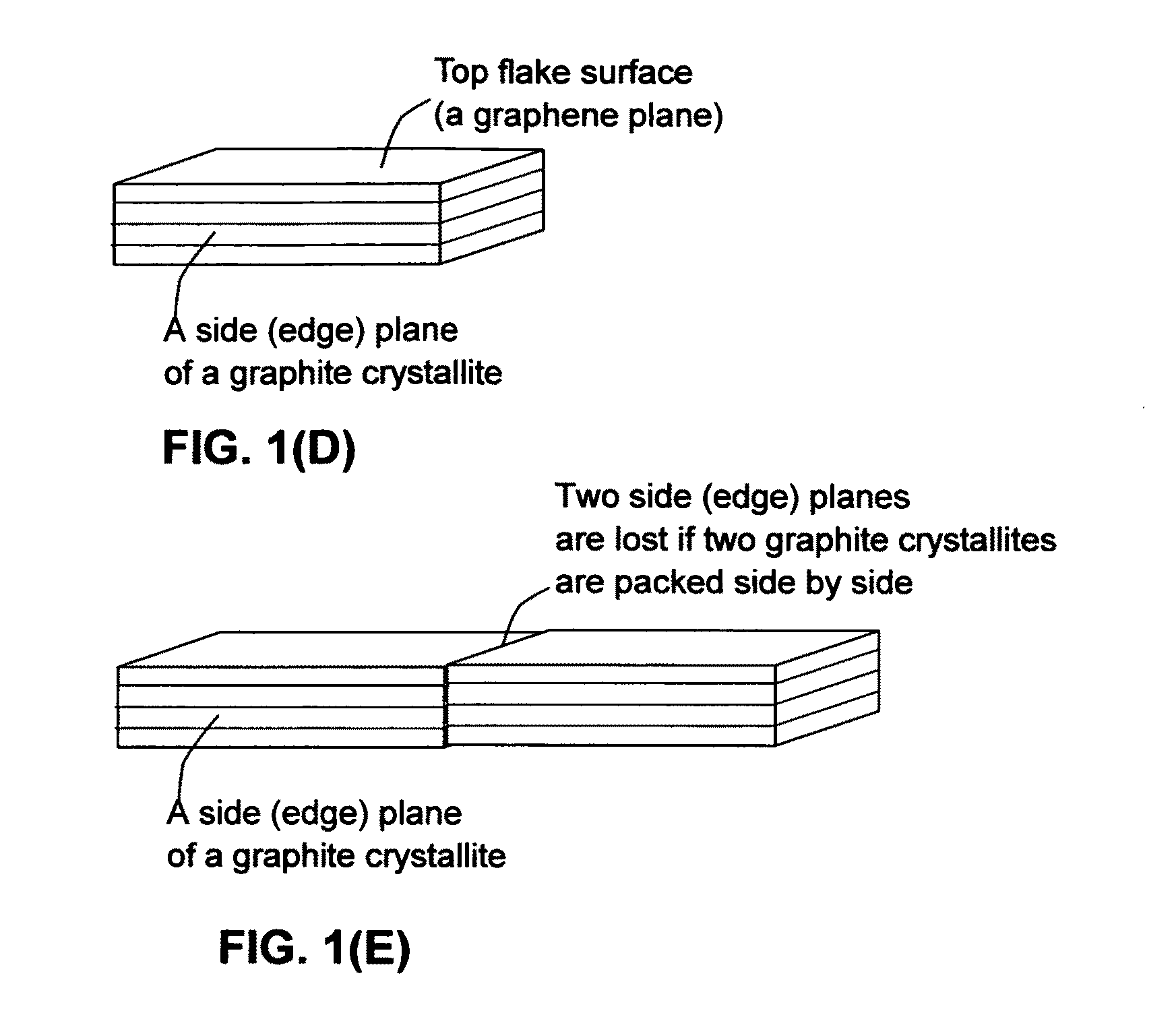

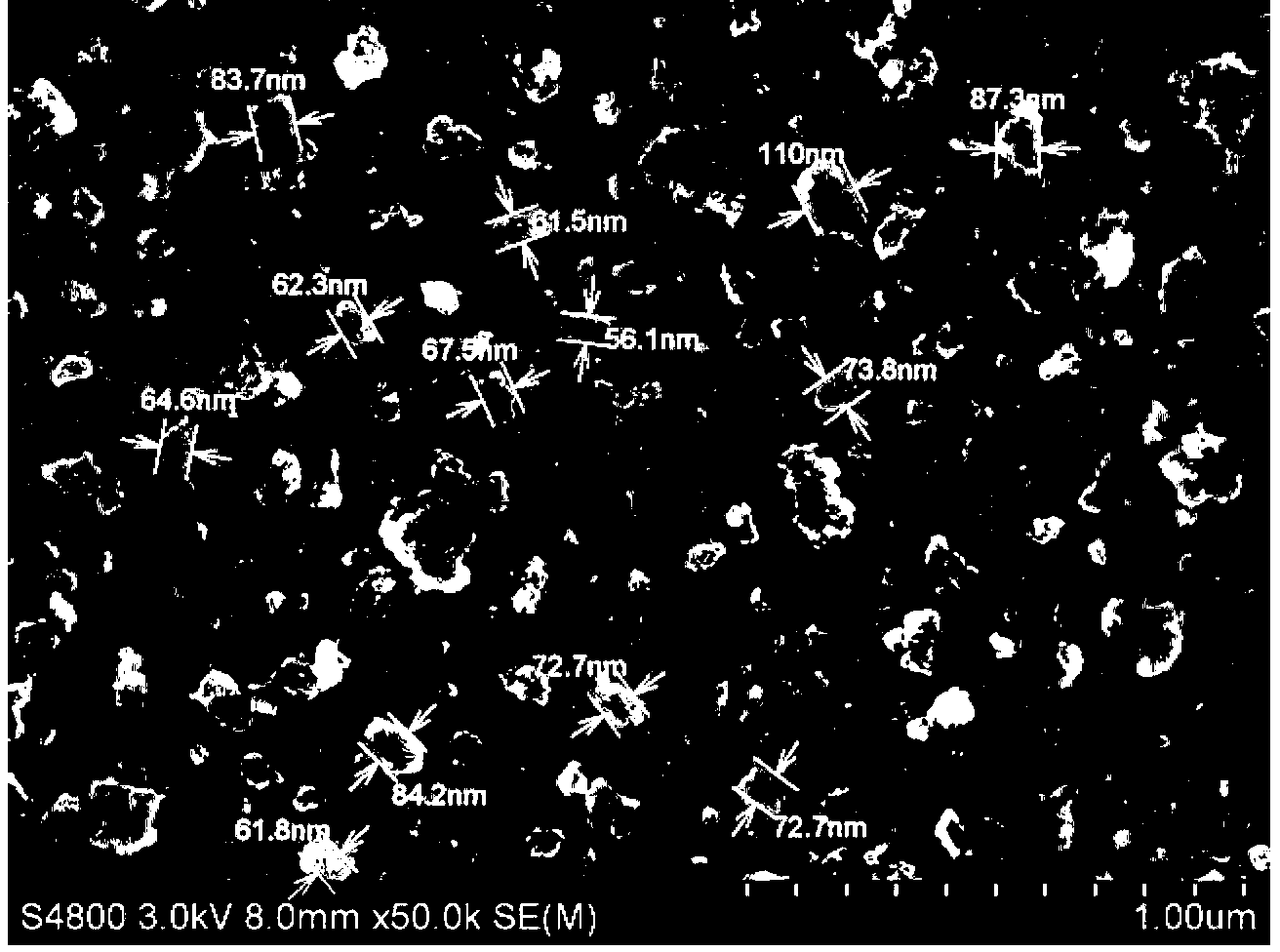

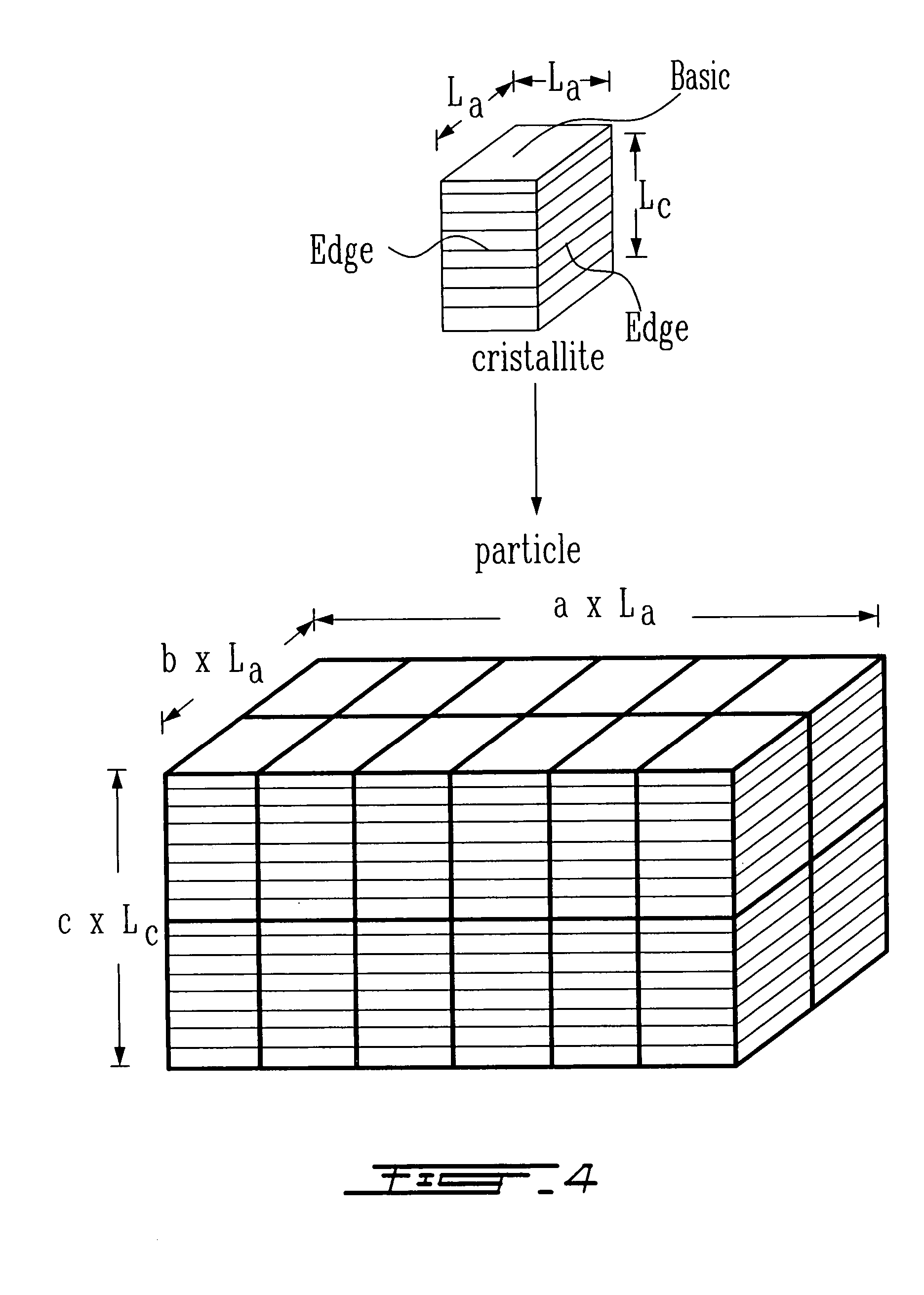

Graphite or carbon particulates for the lithium ion battery anode

This invention provides a graphite or graphite-carbon particulate for use as a lithium secondary battery anode material having a high-rate capability. The particulate is formed of a core carbon or graphite particle and a plurality of satellite carbon or graphite particles that are each separately bonded to the core particle wherein the core particle is spherical in shape, slightly elongate in shape with a major axis-to-minor axis ratio less than 2, or fibril in shape, and wherein the satellite particles are disc-, platelet-, or flake-like particles each containing a graphite crystallite with a crystallographic c-axis dimension Lc and a lateral dimension. Preferably, Lc is less than 100 nm and the flake / platelet lateral dimension is less than 1 μm. The core particle may be selected from natural graphite, artificial graphite, spherical graphite, graphitic coke, meso-carbon micro-bead, soft carbon, hard carbon, graphitic fibril, carbon nano-fiber, carbon fiber, or graphite fiber. Preferably, the flat-shaped particles are randomly oriented with respect to one another.

Owner:GLOBAL GRAPHENE GRP INC

Silicon-carbon negative electrode material of lithium ion battery and preparation method thereof

ActiveCN102394287AExcellent intercalation and delithiation abilityImprove cycle stabilityCell electrodesFiberCarbon composites

The invention discloses a silicon-carbon negative electrode material of a lithium ion battery and a preparation method thereof, and solves the technological problem of improving the charge and discharge cycling stability of the electrode material. The silicon-carbon negative electrode material is prepared by mixing a silicon-carbon composite material and a natural graphite material, wherein the weight of the silicon-carbon composite material is 7-20% and the silicon-carbon composite material is prepared by depositing carbon nanotube and / or carbon nanofiber on the surface of nanometer silica fume and / or embedding into the nanometer silica fume to form core, the surface of which is covered with 3-15wt% of a carbon layer. The preparation method provided by the invention comprises steps of: precursor silicon powder preparation; chemical vapor deposition; liquid-coating roasting; crushing; and mixing. In comparison with the prior art, the reversible specific capacity of the silicon-carbon composite negative electrode material is greater than 500mAh / g; the coulombic efficiency for a first cycle is greater than 80%; the capacity conservation rate of cycling for 50 weeks is greater than 95%. The preparation method is simple, is easy to operate, requires low cost and is suitable for a high-volume negative electrode material of lithium ion batteries used for various portable devices.

Owner:BTR NEW MATERIAL GRP CO LTD

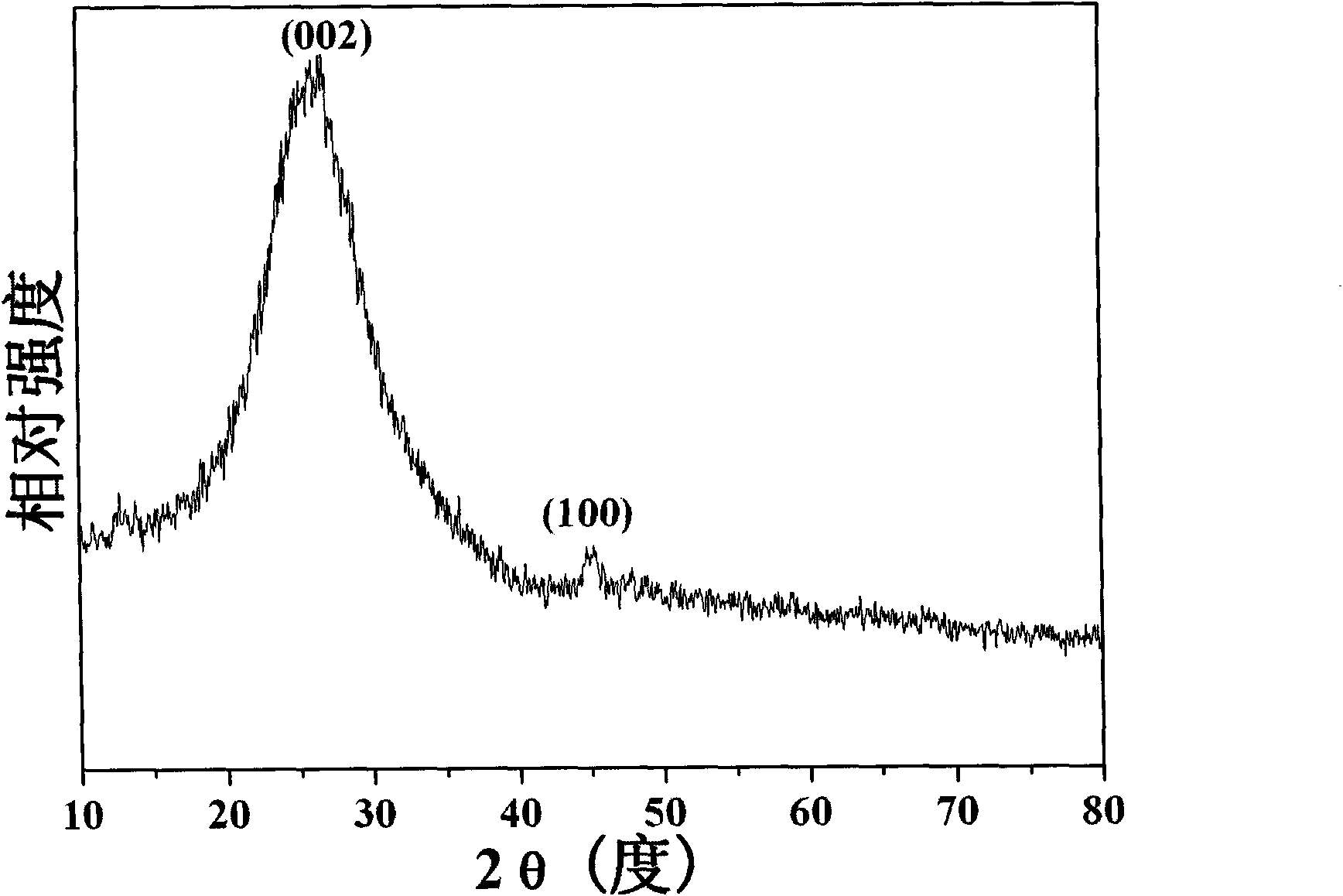

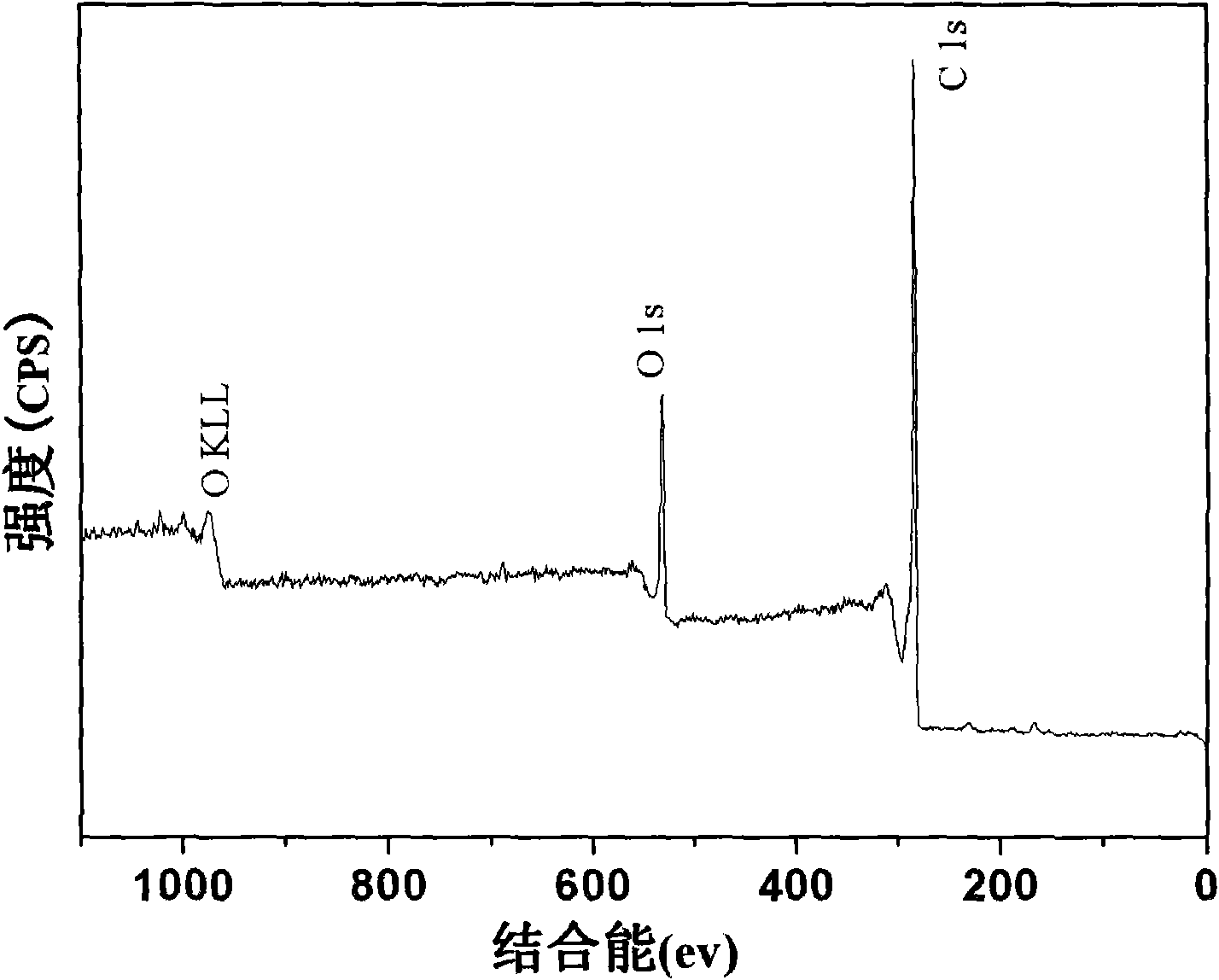

Method for simply and innoxiously preparing single-layer graphene

The invention relates to a method for simply and innoxiously preparing single-layer graphene, belonging to the chemical field of inorganic field. The technical processes of the invention are as follows: adopting a fixed amount of natural graphite powder; oxidizing the natural graphite powder in a strong oxidizing condition to obtain the graphite oxide; dispersing the obtained graphite oxide in the de-ionized water; then ultrasonically processing for a certain period in an ultrasonic machine to peel the graphite oxide off into single-layer graphite oxide sheet; then dispersing the graphite oxide sheet in the dimethylsulfoxide solution; transferring the mixture solution to a reaction kettle and reacting for 10 to 16 hours in 150 to 200 degrees centigrade; after filtered, obtaining the mass colour product, that is, single-layer grapheme. The invention adopts nontoxic reducing agent, dimethylsulfoxide, so it is good for environment protection. The invention has simple technique, operation convenience, and low manufacturing cost.

Owner:SHANGHAI UNIV

High-performance aqueous graphene paint and preparation method thereof

The invention discloses high-performance aqueous graphene paint and a preparation method thereof. The preparation method of the high-performance aqueous graphene paint comprises the following steps of: oxidizing natural graphite in an oxidant, adopting a two-step chemical reduction method to obtain organic molecule-modified graphene aqueous solution; and adding polyester, a neutralizing agent, a flatting agent, an antifoaming agent, a cross-linking agent and a catalyst by adopting a solution co-mixing method to obtain aqueous graphene paint. A conductive coating with high conductive performance and mechanical performance is obtained by carrying out spray-coating, ink-jet printing and printing on the obtained paint, the conductive coating can be applied to the field such as electromagnetic shielding, static electricity preventing, corrosion preventing, radiating, wear-resisting and electronic circuits, and therefore, the application value is extensive.

Owner:PEKING UNIV

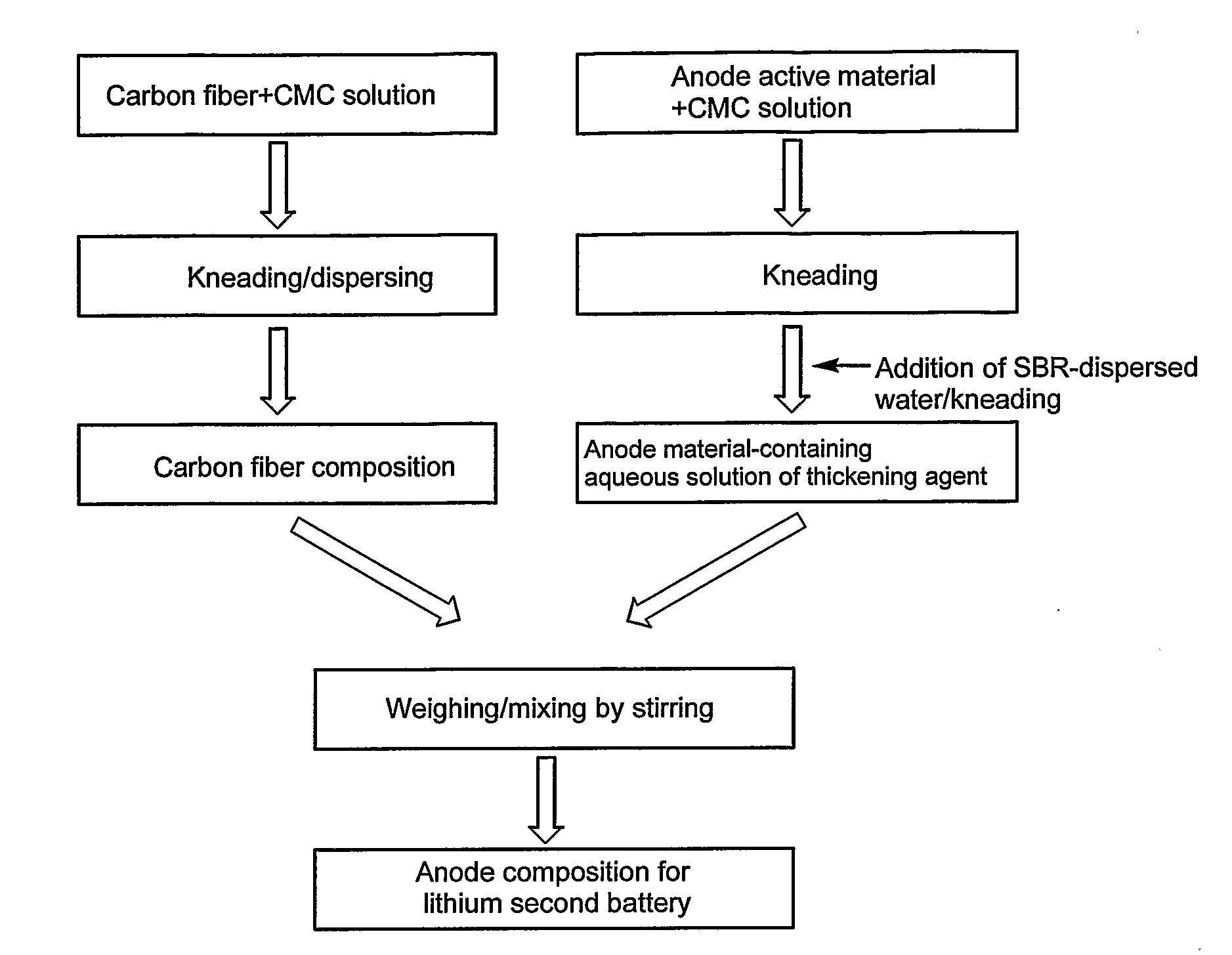

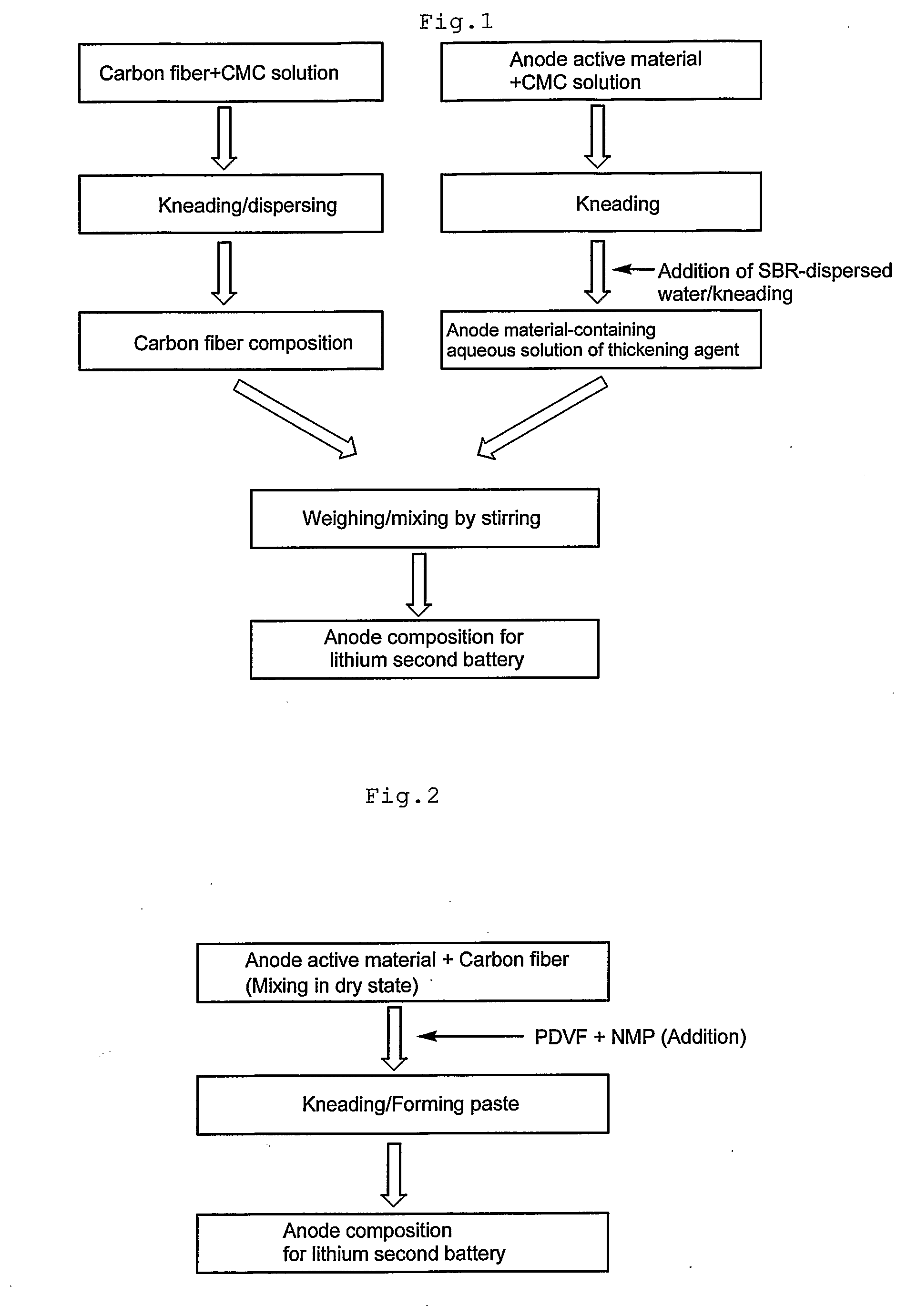

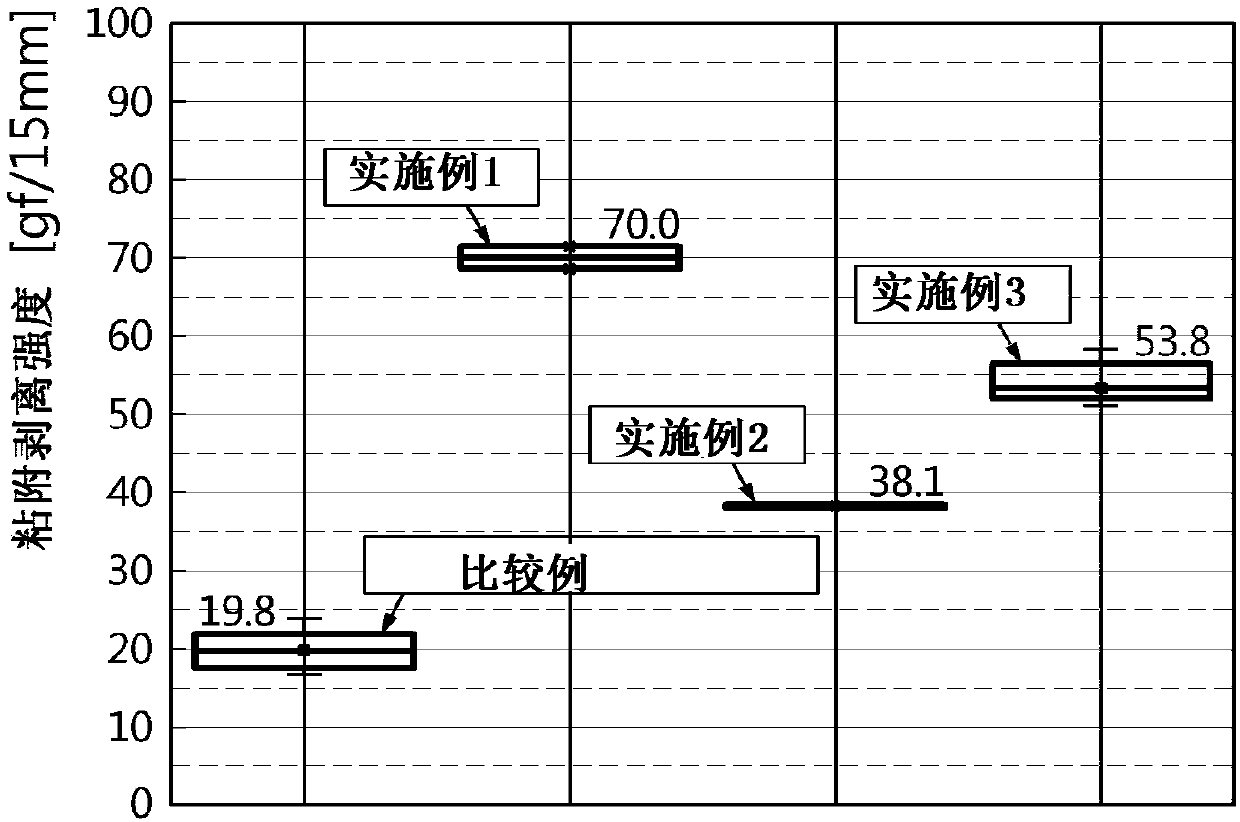

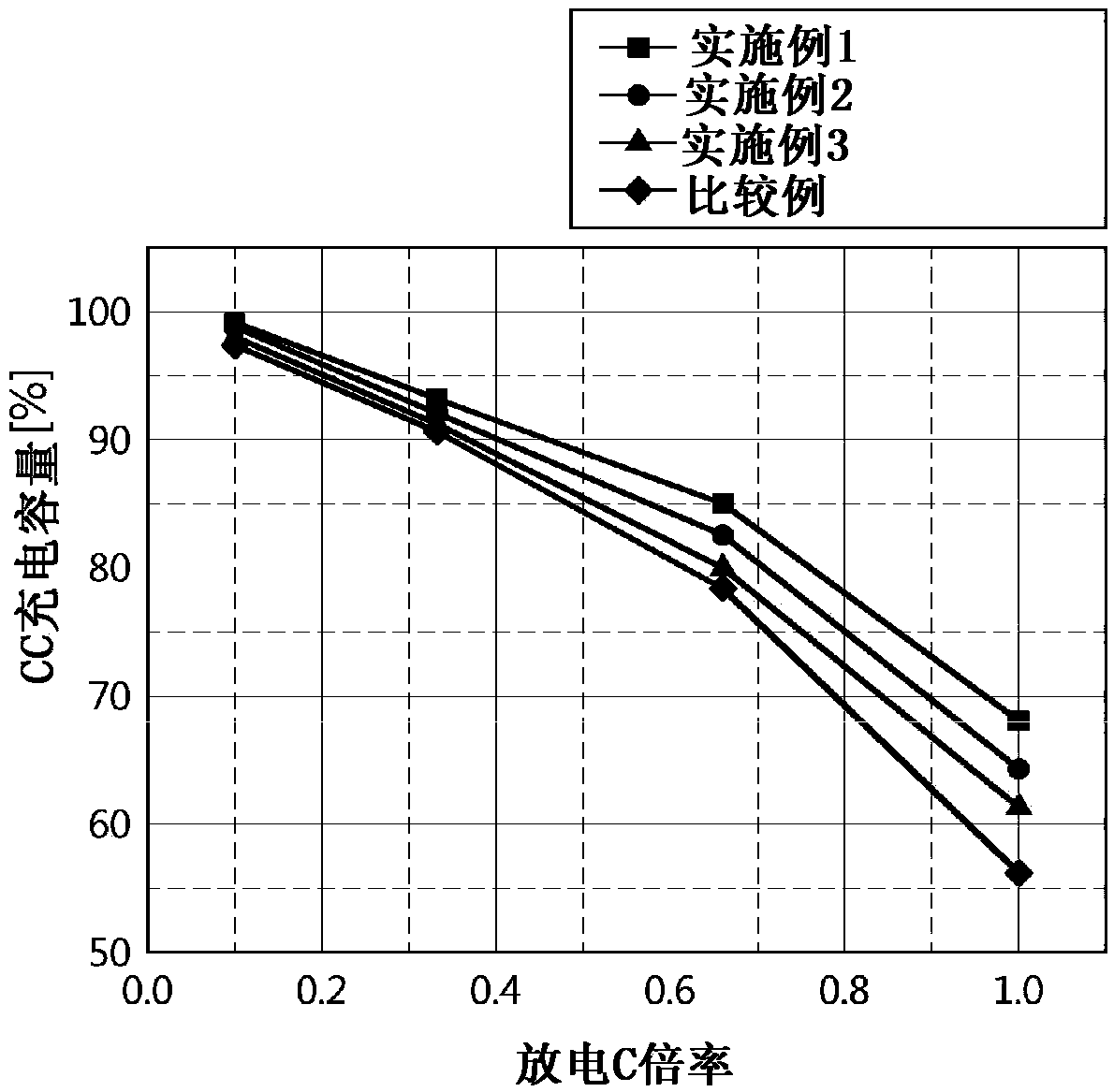

Method for producing anode for lithium secondary battery and anode composition, and lithium secondary battery

ActiveUS20090123850A1High capacity retentionImprove conductivityFinal product manufactureConductive materialFiberCarbon fibers

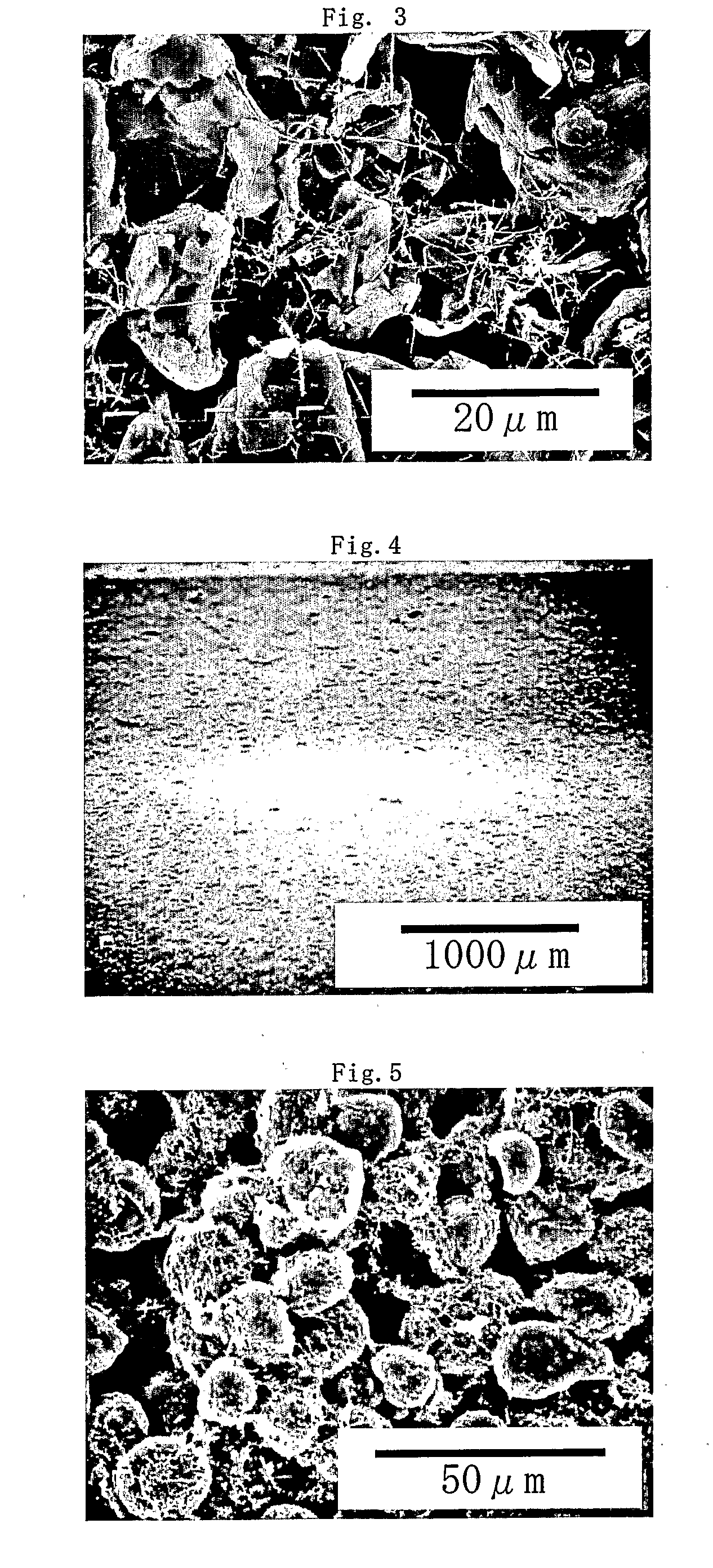

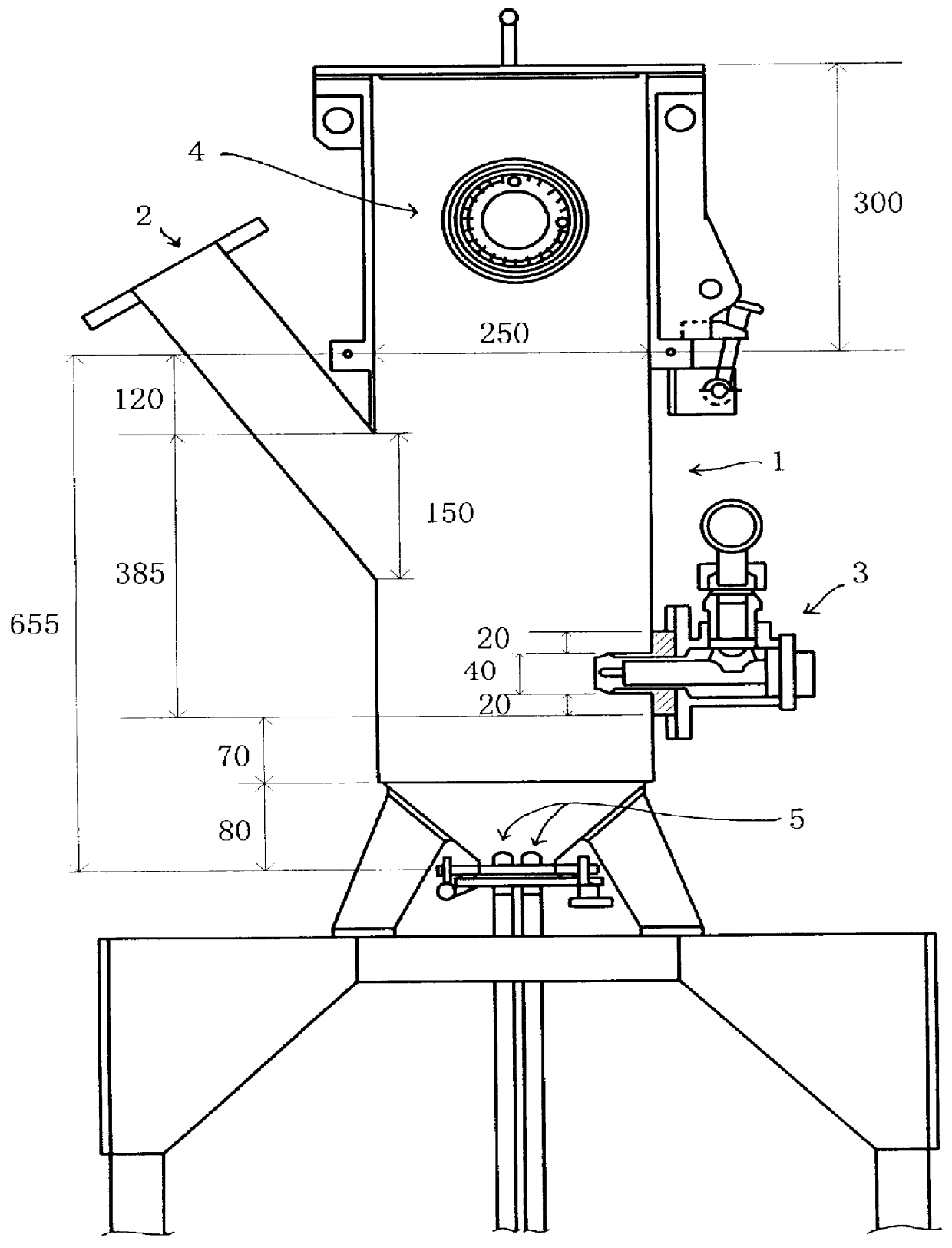

The invention relates to an anode for lithium secondary battery comprising vapor grown carbon fiber uniformly dispersed without forming an agglomerate of 10 μm or larger in an anode active material using natural graphite or artificial graphite, which anode is excellent in long cycle life and large current characteristics. Composition used for production for the anode can be produced, for example, by mixing a thickening agent solution containing an anode active material, a thickening agent aqueous solution and styrene butadiene rubber as binder with a composition containing carbon fiber dispersed in a thickening agent with a predetermined viscosity or by mixing an anode active material with vapor grown carbon fiber in dry state and then adding polyvinylidene difluoride thereto.

Owner:RESONAC CORP

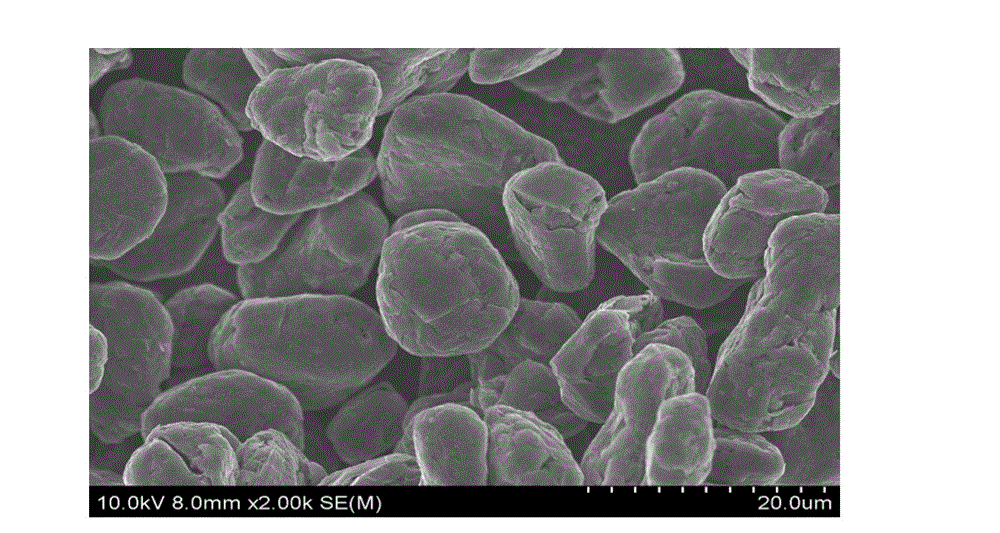

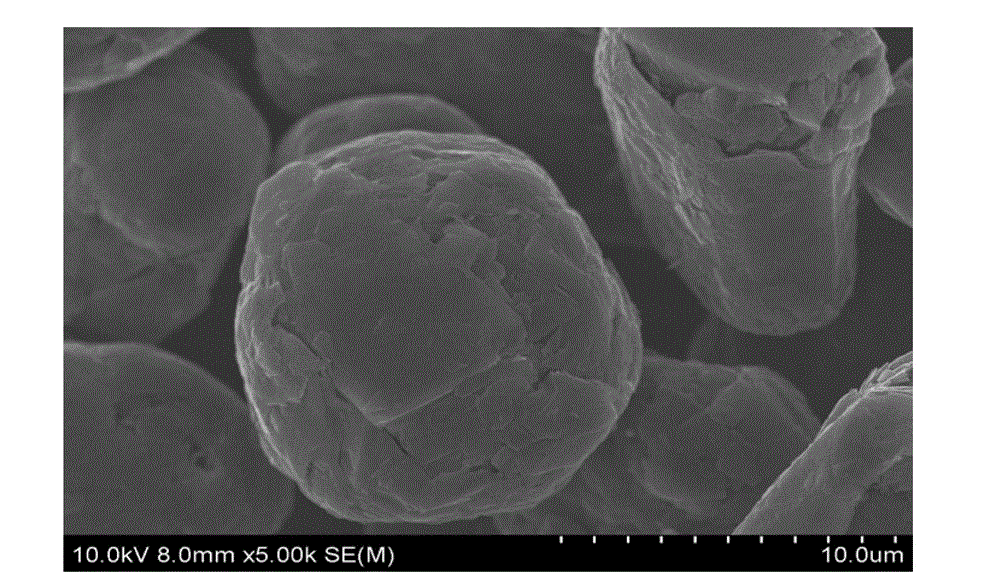

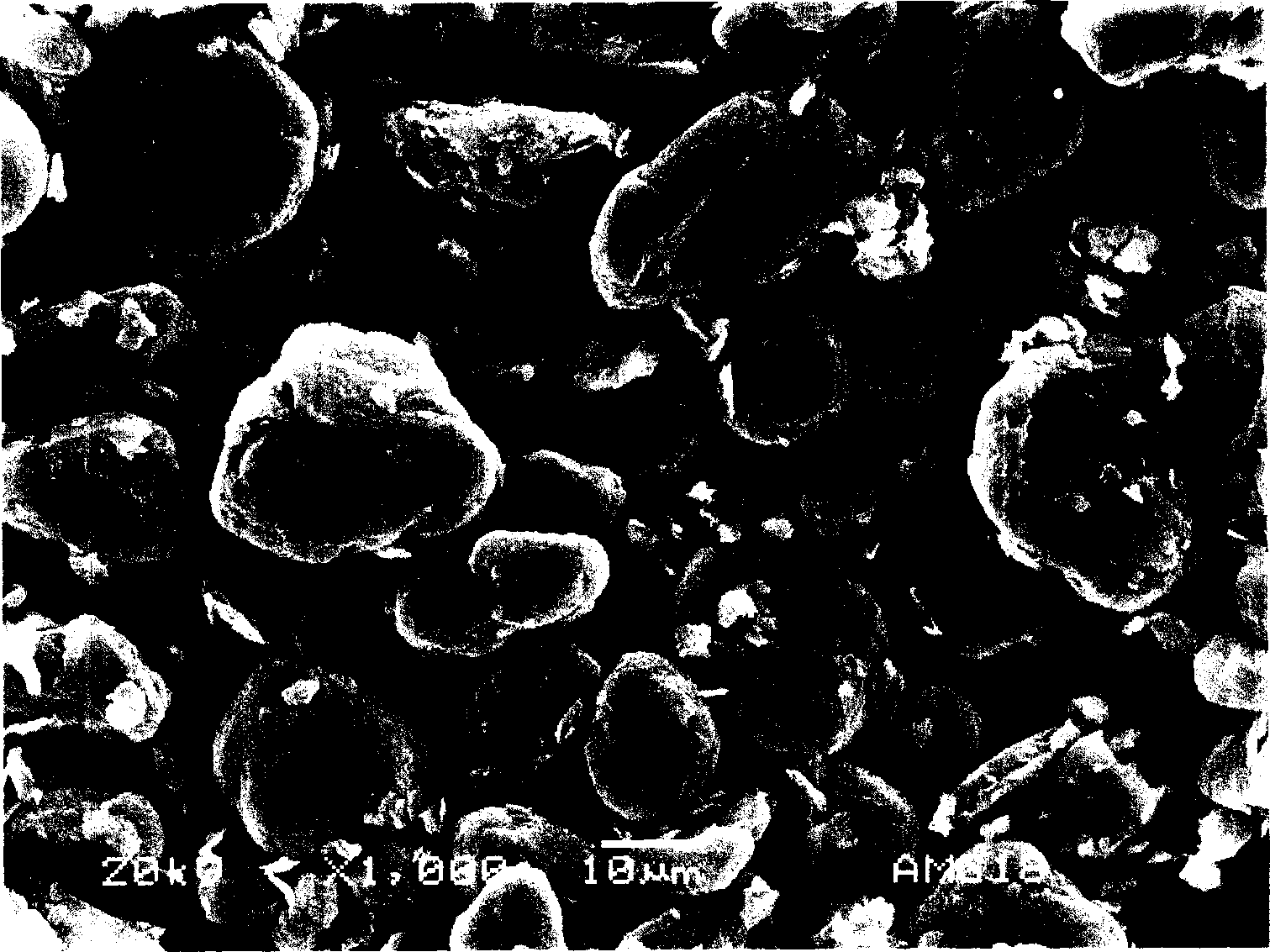

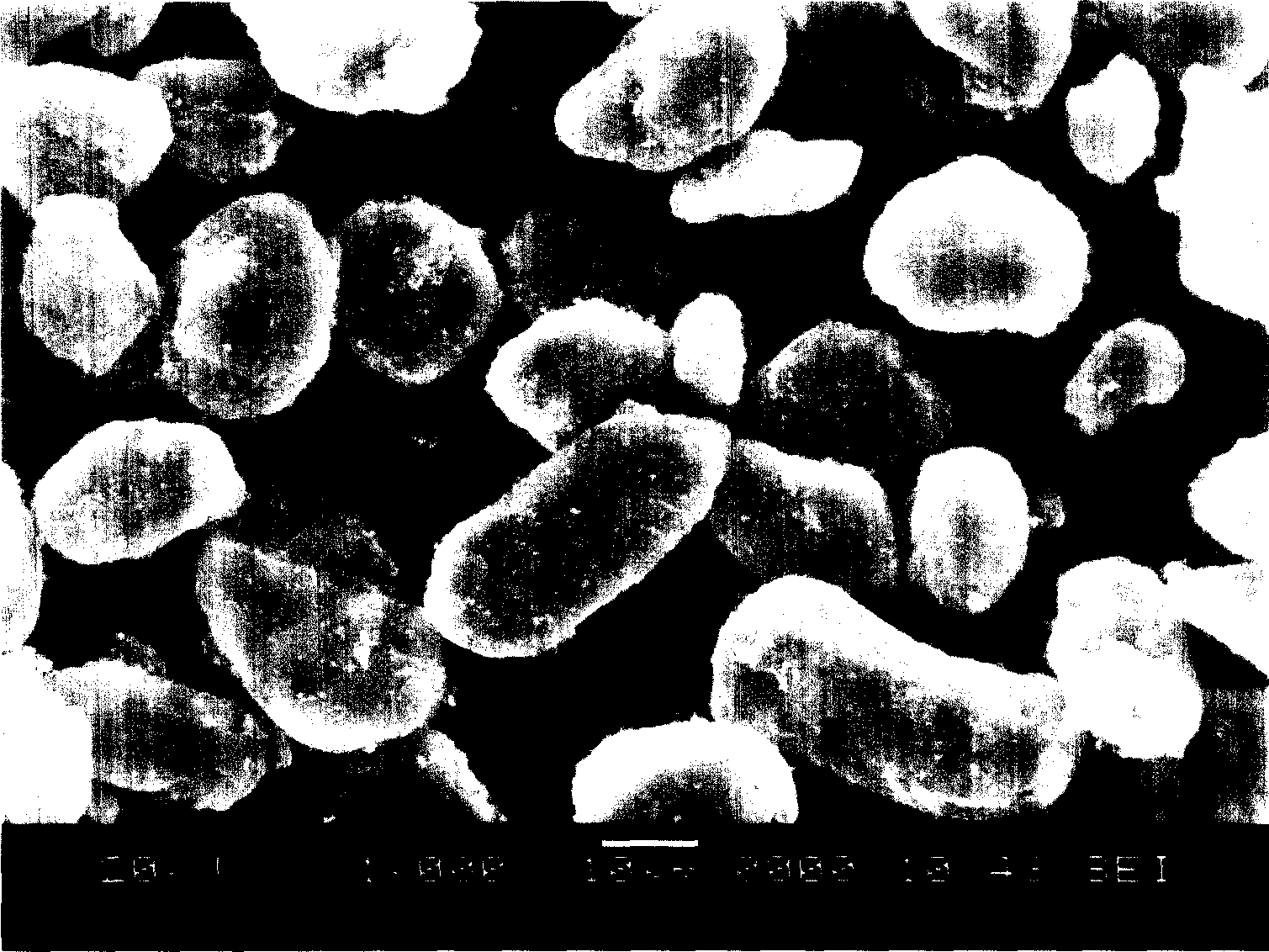

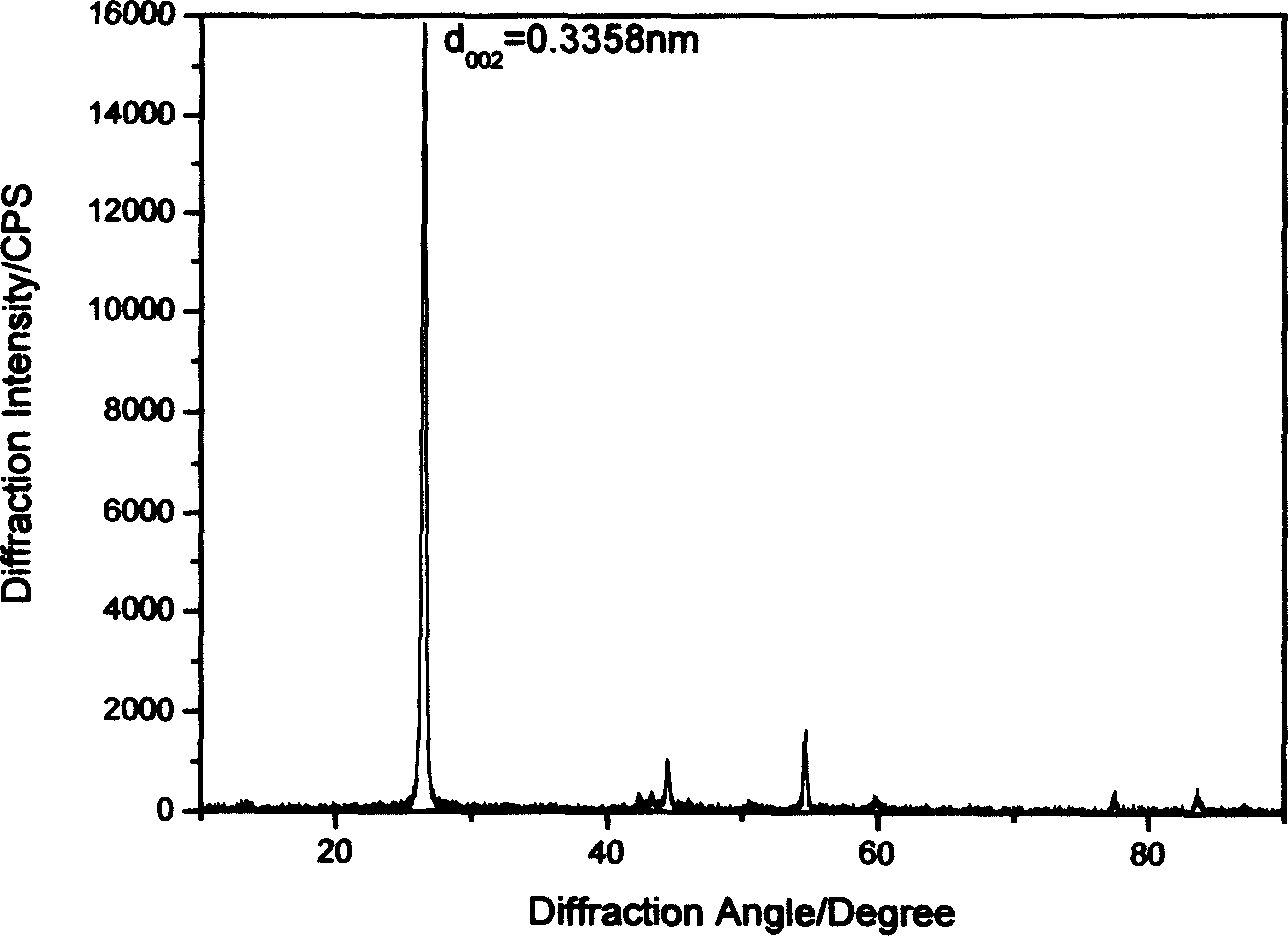

Modified graphite particles derived from scaly natural ones, production thereof and secondary battery

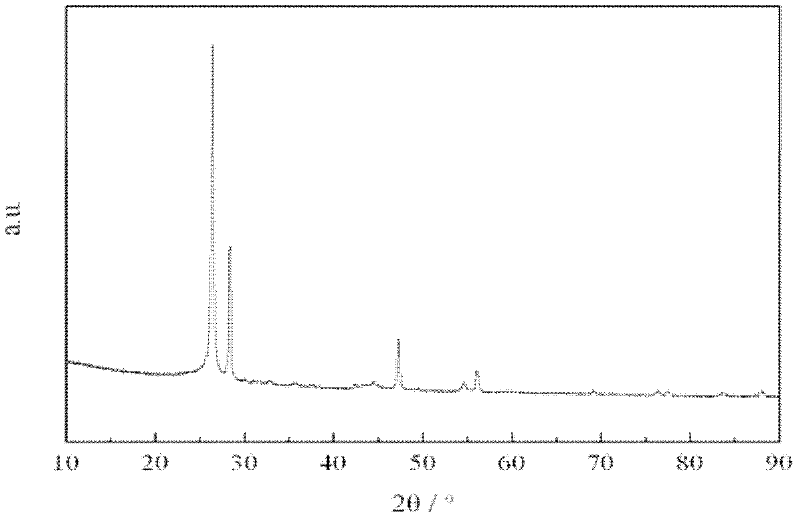

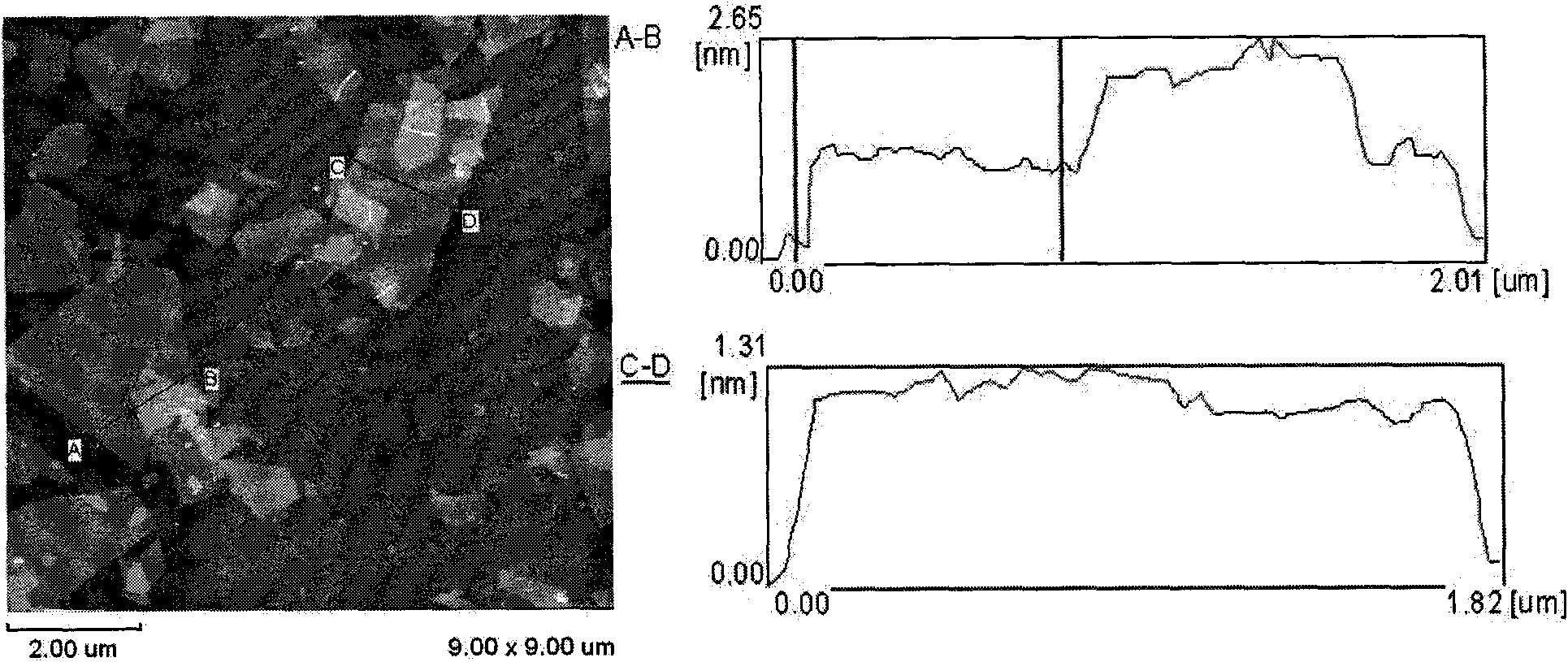

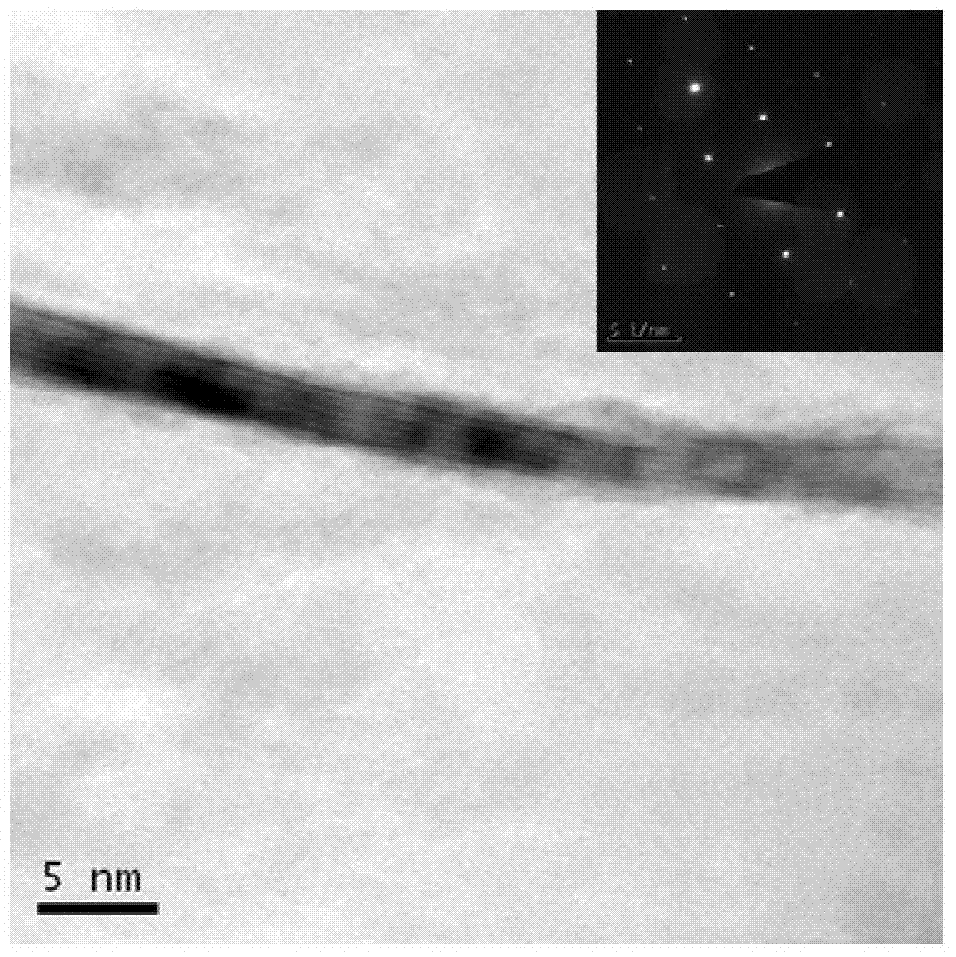

InactiveUS6139990APigmenting treatmentNon-aqueous electrolyte accumulatorsMicroscopic observationX-ray

Owner:MITSUBISHI CHEM CORP

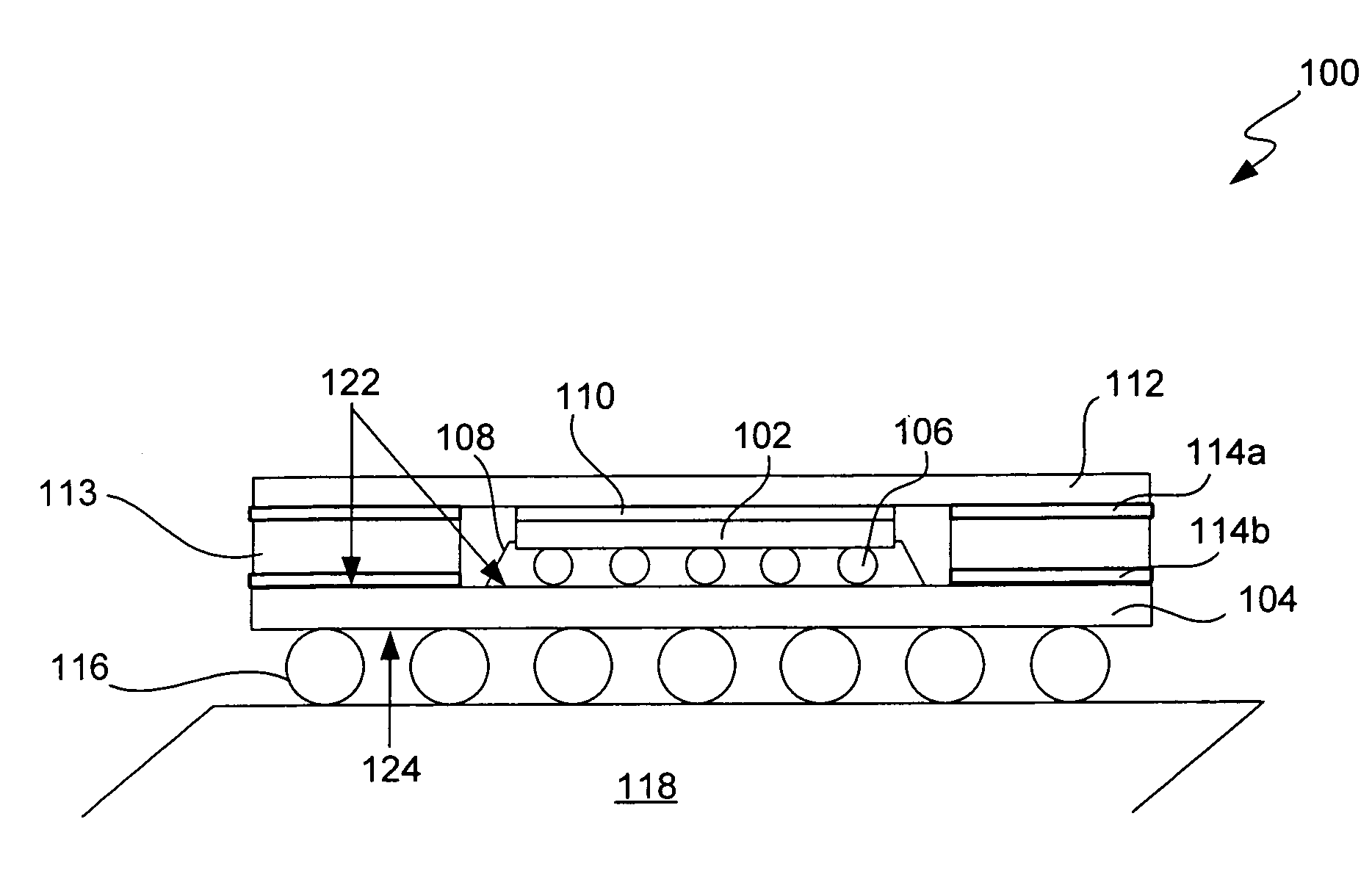

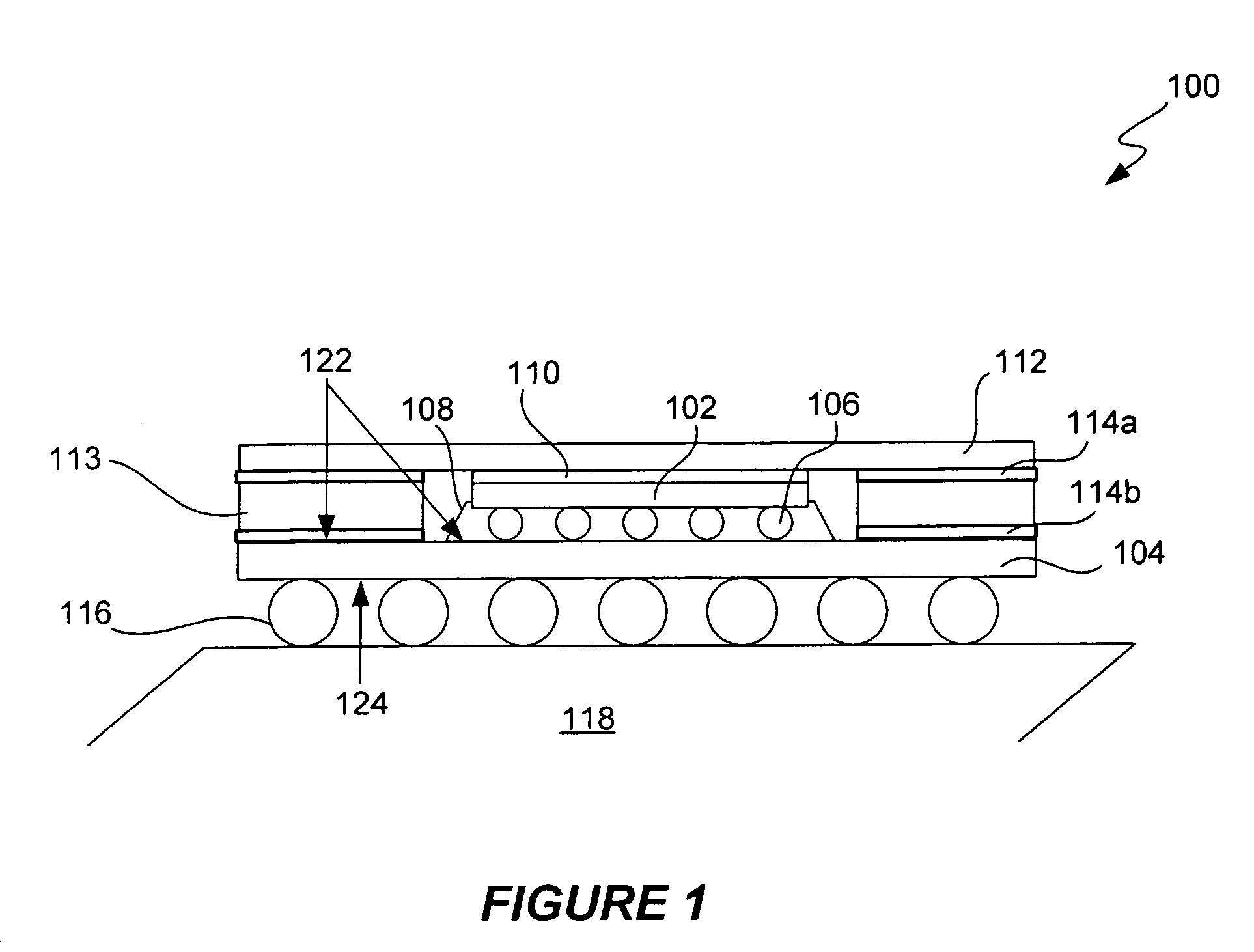

Stiffener for flip chip BGA package

ActiveUS7459782B1Improve package reliabilityLess bowingSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

Provided are semiconductor die flip chip packages with warpage control and fabrication methods for such packages. A package includes a heat spreader that is attached to a die and a stiffener, which are in turn attached to a package substrate. In general, the stiffener is made of a material that has a relatively low CTE value. For example, the stiffener material may have a CTE value less than 12 ppm / ° C. The material may also have a relatively low mass density value of less than 8.9 g / cm3. Such a material may include natural graphite or some composite form of it. The result is a package with less bowing and so improved co-planarity (e.g., in compliance with industry specifications) with the surface to which it is ultimately bound; thereby, improving the reliability of the package. Moreover, a package that is relatively lighter and more robust than conventional semiconductor die flip chip packages can be realized.

Owner:ALTERA CORP

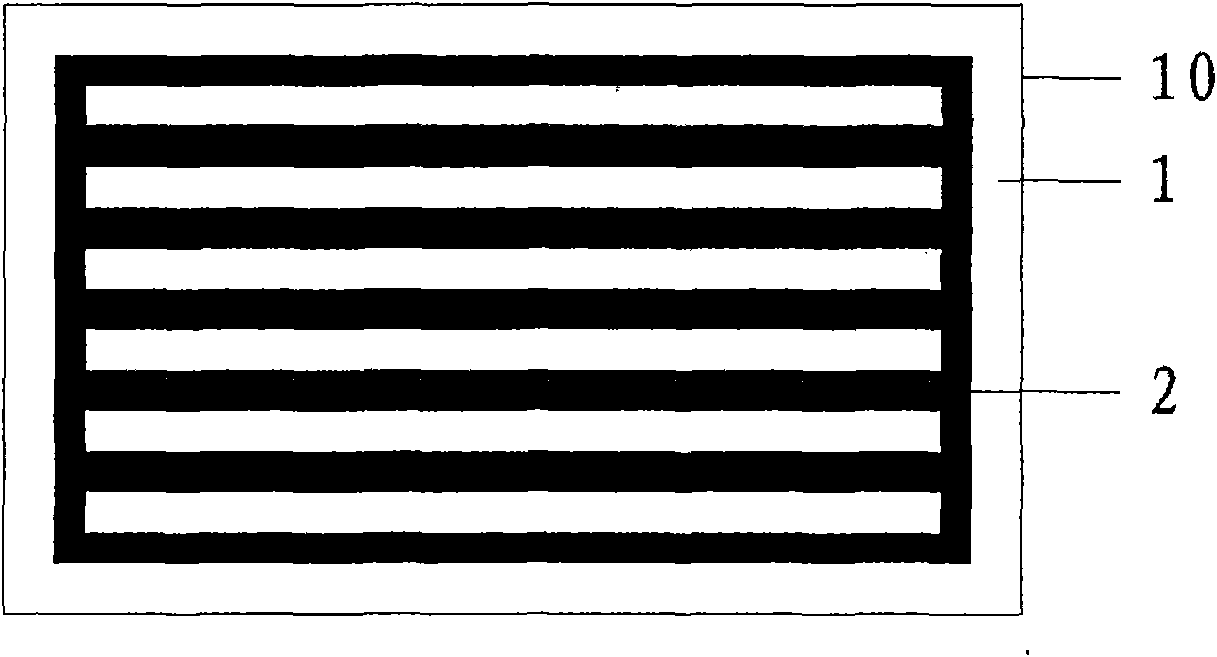

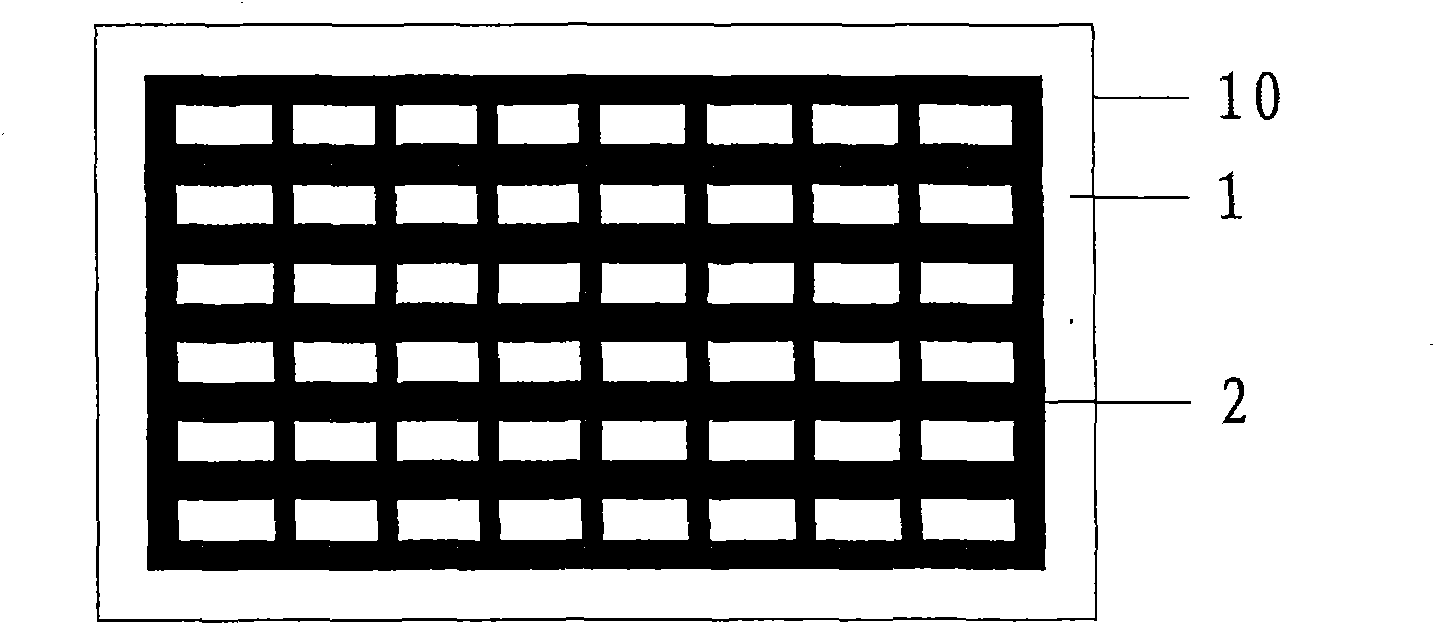

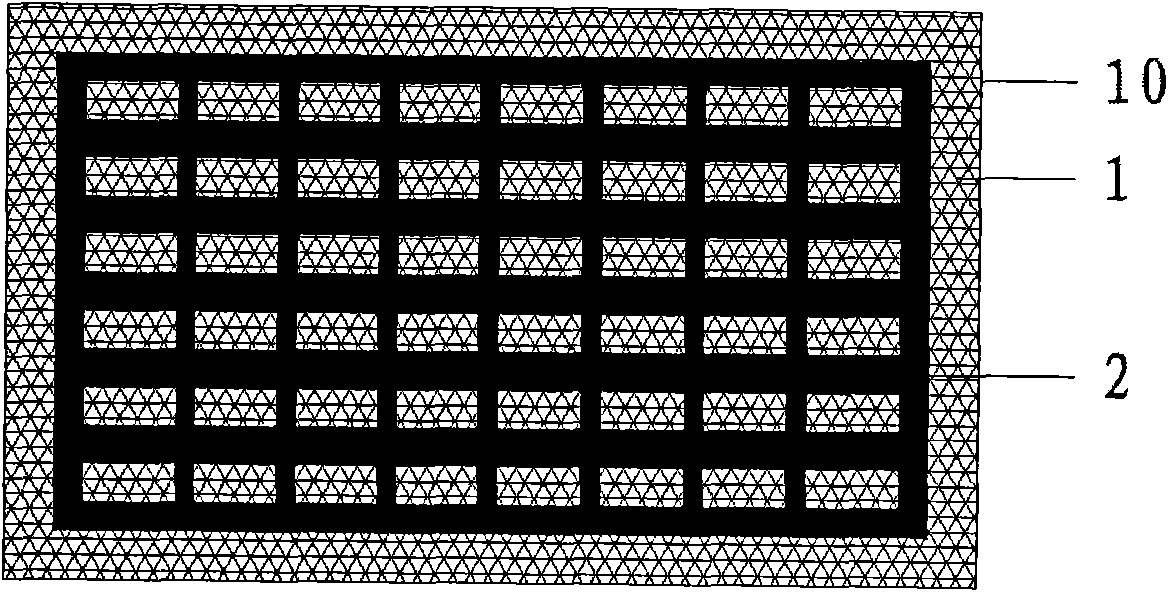

Conductive heating material, floor comprising same and manufacturing method

InactiveCN101600270AFacilitate industrialized mass productionLighting and heating apparatusElectric heating systemEpoxyCarboxymethyl cellulose

The invention relates to a conductive heating material. The material comprises a substrate and a conductive heating layer evenly adhered to the substrate, wherein the conductive heating layer is made from a conductive heating coating material; the conductive heating coating material comprises a conductive heating base material and a bonding agent; the conductive heating base material is selected from natural graphite, artificial graphite and conductive carbon black; the bonding agent is selected from acrylic resin, epoxy resin, polyurethane resin, glutin, carboxymethyl cellulose, polyvinyl alcohol, and the like; and the substrate can adopt paper in a plurality of practical implementation modes. The conductive heating material can be used to make the conductive heating floor; the surface temperature of the floor can reach 15 to 70 DEG C within 5 minutes after the floor is energized with 220V voltage; moreover, the floor can maintain stable temperature for a long time. Therefore, the conductive heating floor can be used to replace the prior ground heating system and has low cost, reliable operation, energy saving, environmental protection and convenient maintenance and replacement.

Owner:上海尚兰格暖芯科技有限公司

Carbon powder suitable as a negative electrode material for nonaqueous secondary batteries

InactiveUS20090196816A1Excellent charge and discharge characteristicsImprove discharge performanceFixed capacitor electrodesGraphiteDesorptionNitrogen

Carbon powder having low temperature calcined carbon derived from pitch adhered to a portion of the surface of natural graphite powder is obtained by solids mixing of natural graphite powder and pitch powder as a carbon precursor followed by heat treatment at 900-1500° C. to carbonize the pitch. The amount of pitch powder is such that the ratio V2 / V1 of the pore volume V2 of pores having a diameter of 50-200 nm to the pore volume V1 of pores having a diameter of 2-50 nm in a pore size distribution curve obtained by analysis of the nitrogen desorption isotherm of the resulting carbon powder by the BJH method is at least 1. This carbon powder can be used as a negative electrode material for a nonaqueous secondary battery able to operate at low temperatures.

Owner:NIPPON DENKO CO LTD

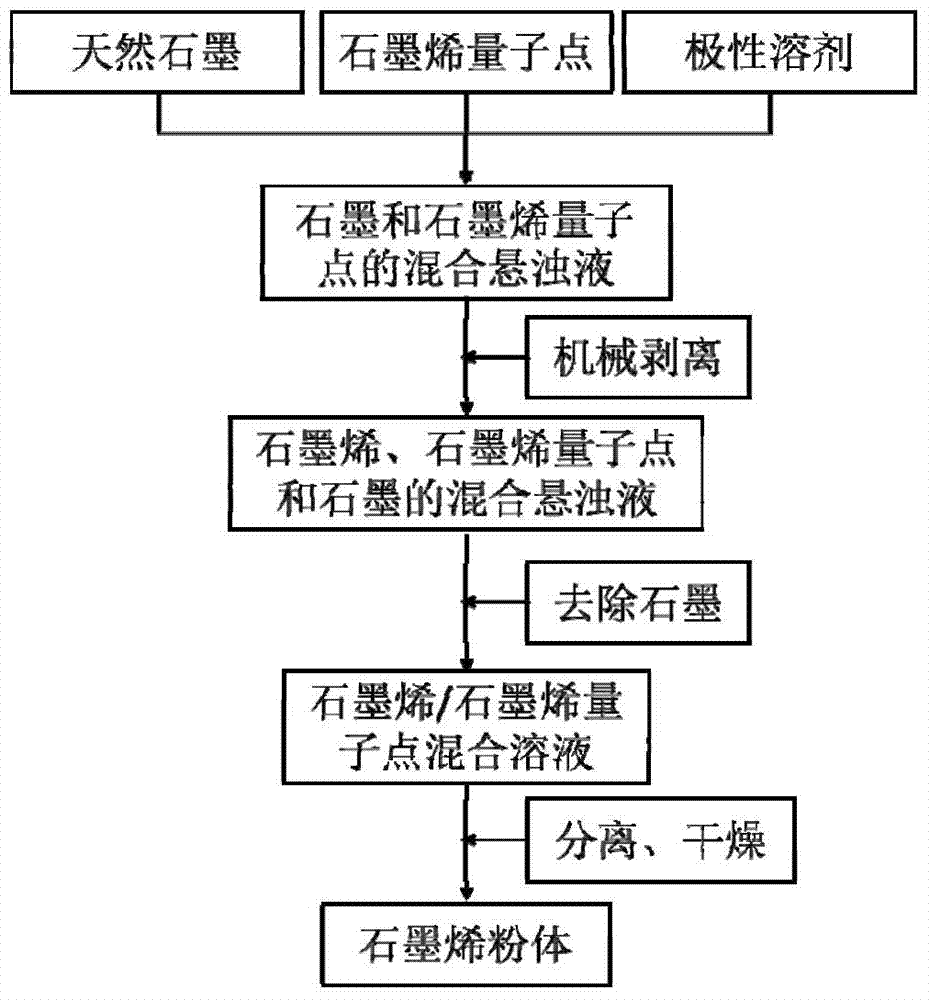

Preparation method of graphene

The invention discloses a preparation method of graphene, which is characterized in that natural graphite used as a raw material is subjected to mechanical stripping under the auxiliary action of graphene quantum dots by using a polar solvent as a dispersion medium to prepare the high-quality graphene. The stripping of the natural graphite and dispersion of the graphene nanosheets in the polar solvent are promoted by utilizing the favorable dispersivity of the graphene quantum dots in the polar solvent and the strong non-covalent bond combination between the graphene quantum dots and graphene / graphene laminae, thereby obtaining the high-quality graphene. According to the invention, the graphene powder is directly obtained from the natural graphite under the condition of not introducing any surfactant, inorganic salt, organic salt or any other impurity. Compared with the existing methods, the method is simple in technique, and can be perform in multiple polar solvents; the maximum yield of the obtained graphene can reach 50%, and the quality is good; the graphene quantum dots used for auxiliary stripping can be recycled; and thus, the method is very suitable for mass preparation of graphene.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

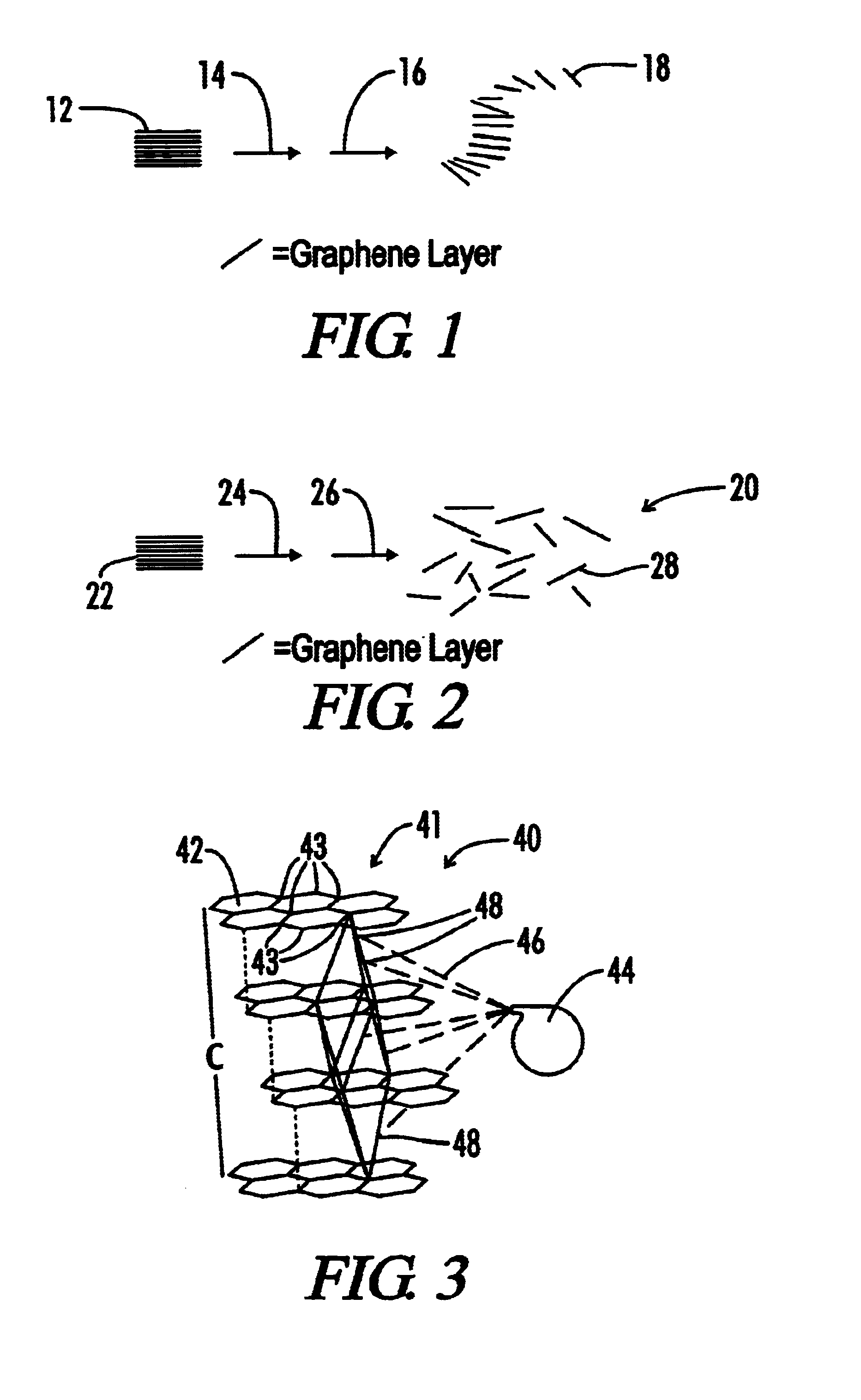

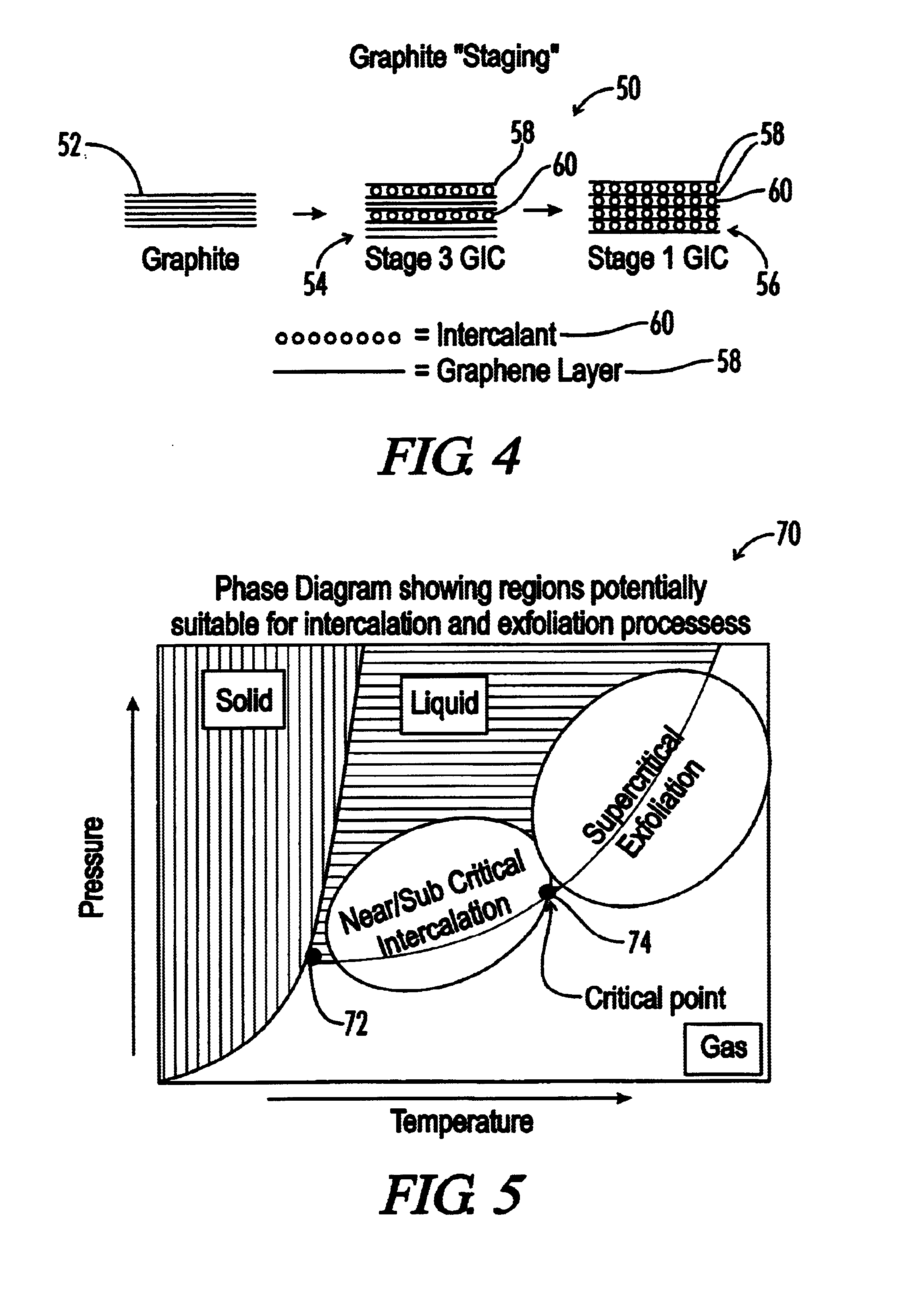

Graphite composites and methods of making such composites

InactiveUS6927250B2Improve volume expansionReduce needSpecial tyresBulk chemical productionConductive polymerPolymer composites

The invention may be practiced to make graphite composites. Preferred composites which may be made in accordance with the invention include conductive polymeric composites (thermally or electrically), paint composites, battery composites, capacitor composites, and pollution abatement catalyst support composites. One method of making the graphite aforementioned composites includes introducing an intercalant into at least one interstice of at least one flake of natural graphite. The method also includes introducing a fluid into the at least one interstices of the flake. Preferably, the fluid comprises at least one of a sub-critical fluid, near critical point fluid, or a supercritical fluid. Furthermore the method includes blending the flake with a polymer, thereby forming a graphite-polymeric composite.

Owner:GRAFTECH INT HLDG INC

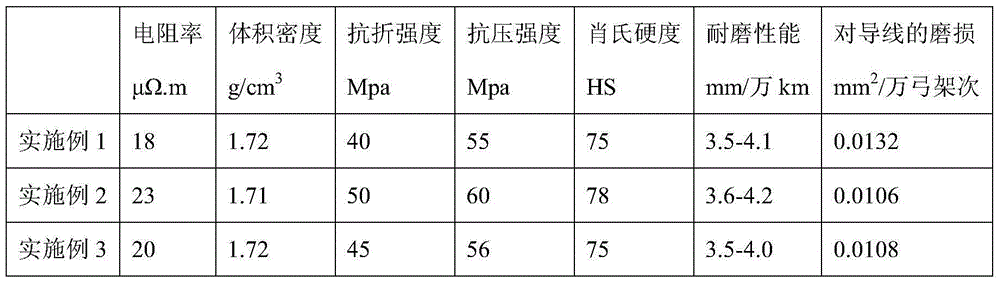

Carbon contact strip of pantograph and manufacturing method thereof

The invention discloses a carbon contact strip of a pantograph and a manufacturing method thereof. The carbon contact strip is prepared from following raw materials, by weight, 28-43 parts of petroleum coke powder, 25-28 parts of asphalt coke powder, 10-12 parts of sprayed carbon black, 2-5 parts of sulfur, 3-5 parts of boron nitride, 5-8 parts of carbon fiber, 4-6 parts of natural graphite, 5-7 parts of artificial graphite, 1-3 parts of calcium chloride powder and 30-35 parts of modified asphalt. The carbon contact strip is high in mechanical strength, is good in self-lubricating performance and electric arc resistance and is wear-resistant. The carbon contact strip can be not only used in various locomotives in railway main lines with speed per hour being 120-250 km / h, but also used in motor train units and high-speed trains with speed per hour being higher than 250 km / h. The carbon contact strip is free of limit of environment and climate conditions.

Owner:SUZHOU DONEKA NEW MATERIALS CORP LTD

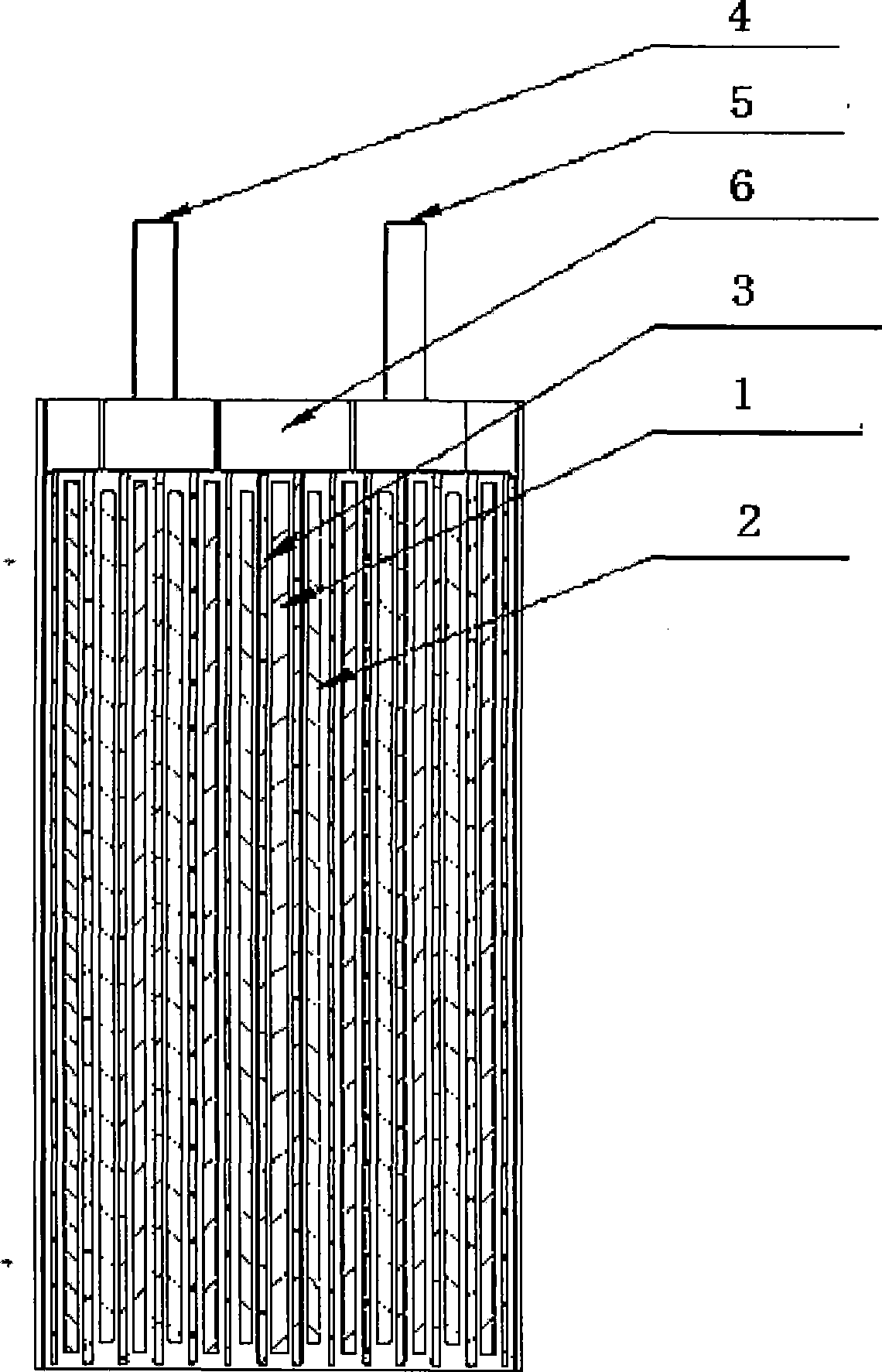

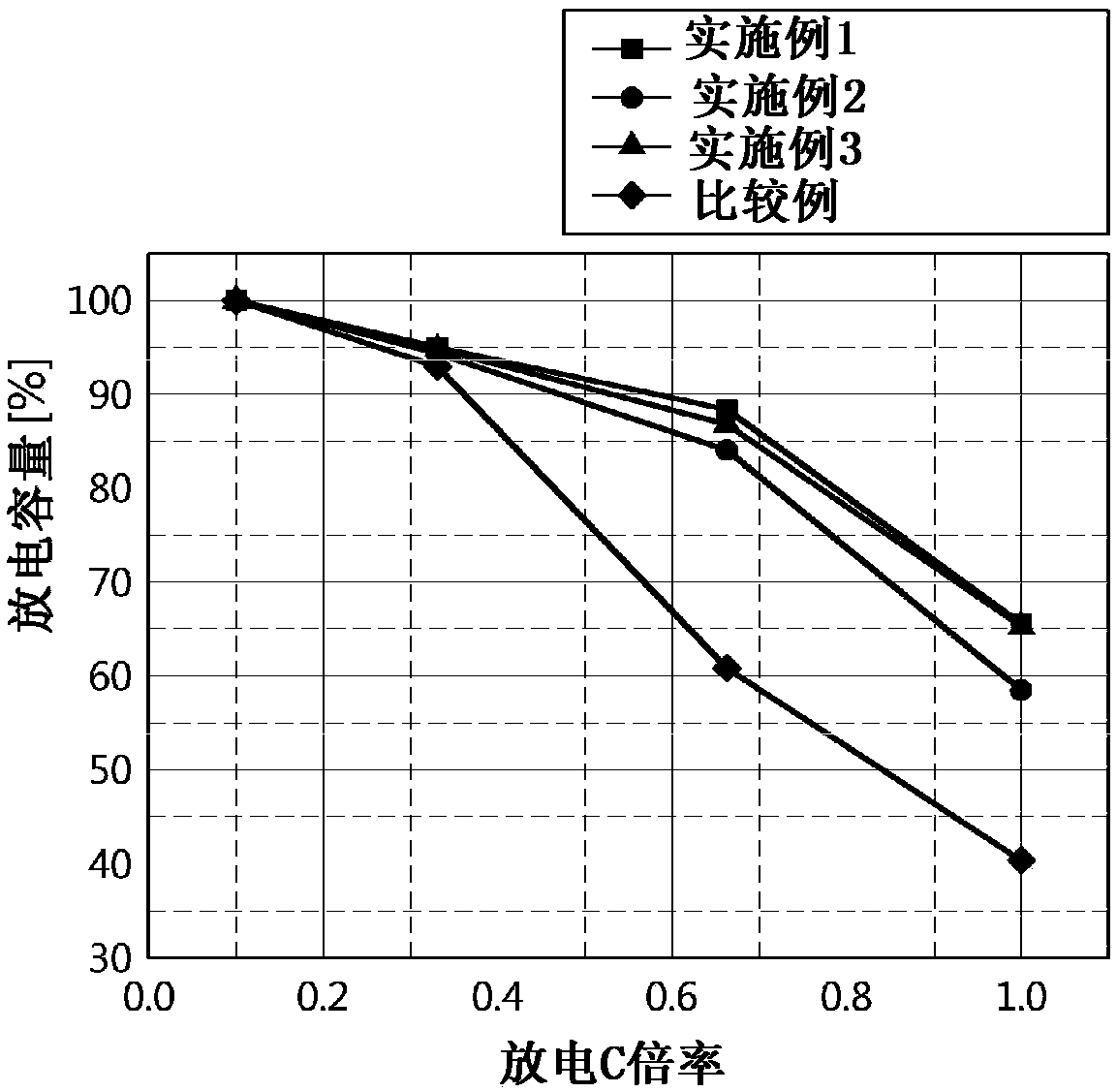

Multi-multiplying power charging-discharging lithium ion battery and method for producing the same

InactiveCN101499530AImprove high rate charge and discharge performanceImprove performanceElectrode manufacturing processesFinal product manufactureHigh rateMicrosphere

The invention provides a high-rate charge-discharge lithium-ion battery and a preparation method thereof. The anode active material of the lithium-ion battery is lithium manganate; the cathode active material is selected from one or more of mesocarbon microbeads, artificial graphite or natural graphite coated by mesophase pitch; a conductive agent is selected from one or more of conductive graphite, conductive carbon black, nano Ag, nano SiO2 or nano Al2O3. The preparation method of the lithium-ion battery comprises the preparation of the anode plate, the parathion of the cathode plate and the assembly of the battery. The lithium-ion battery has the advantages of high-rate charge-discharge performance, long cycle life, high capacity, safe use, environmental protection, low cost and the like. The preparation method has the advantage of simple and easy process operation, and is applicable to the mass production.

Owner:深圳市崧鼎实业有限公司

Battery cathode slurry, preparation and battery produced by the cathode slurry

InactiveCN101459237AHigh negative electrode volume specific capacityImprove negative electrode volume specific capacityElectrode manufacturing processesSecondary cellsSlurrySolvent

The invention discloses slurry for battery negative electrodes, which comprises a carbon negative active material, a conductive agent, a thickening agent, a binding agent and a solvent, the proportion by weight of the carbon negative active material, the conductive agent, the thickening agent, the binding agent and the solvent is 70-130: 1-10: 1-10: 1-10: 80-200, wherein the carbon negative active material is a mixture of native graphite and artificial graphite of the proportion of 0-3: 7-10. The invention further discloses a preparing method of the slurry for battery negative electrodes and a battery manufactured by utilizing the negative electrode slurry. Based on the artificial graphite, the invention creates a proper negative material aqueous formula, which can significantly increase volumetric capacity of the negative electrode based on the artificial graphite on the premise of excellent circulation performance, and thereby a lithium ion battery with high volumetric capacity and long cycle life can be manufactured.

Owner:ZHENGZHOU BAK BATTERY CO LTD

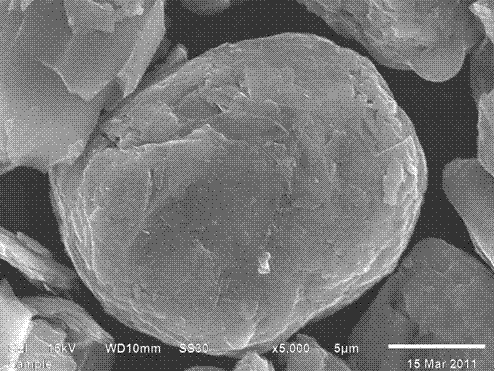

Modified natural graphite material used in lithium ion battery negative electrodes, and preparation method thereof

InactiveCN102231434AReduce crystallinityLarge interplanar distanceCell electrodesPower batteryCarbon layer

The invention discloses a modified natural graphite material used in lithium ion battery negative electrodes. With a core-shell structure, the material comprises an inner core and a shell coated on the inner-core. The inner-core is composed of natural graphite, and the shell coated on the core is composed of an inner shell and an outer shell. The inner shell is a boron-containing hard carbon layer, and the outer shell is a soft carbon layer. The boron-containing hard carbon layer is coated on natural graphite, and the soft carbon layer is coated on the boron-containing hard layer. The method has advantages of simple technology, suitability for mass production, low graphitization processing temperature, and low cost. With advantages of small specific surface area, high tap density, high first efficiency, high specific capacity, excellent cycling performance, and good rate performance, the modified natural graphite material can be applied in power batteries.

Owner:HENAN THINKER ENERGY MATERIALS

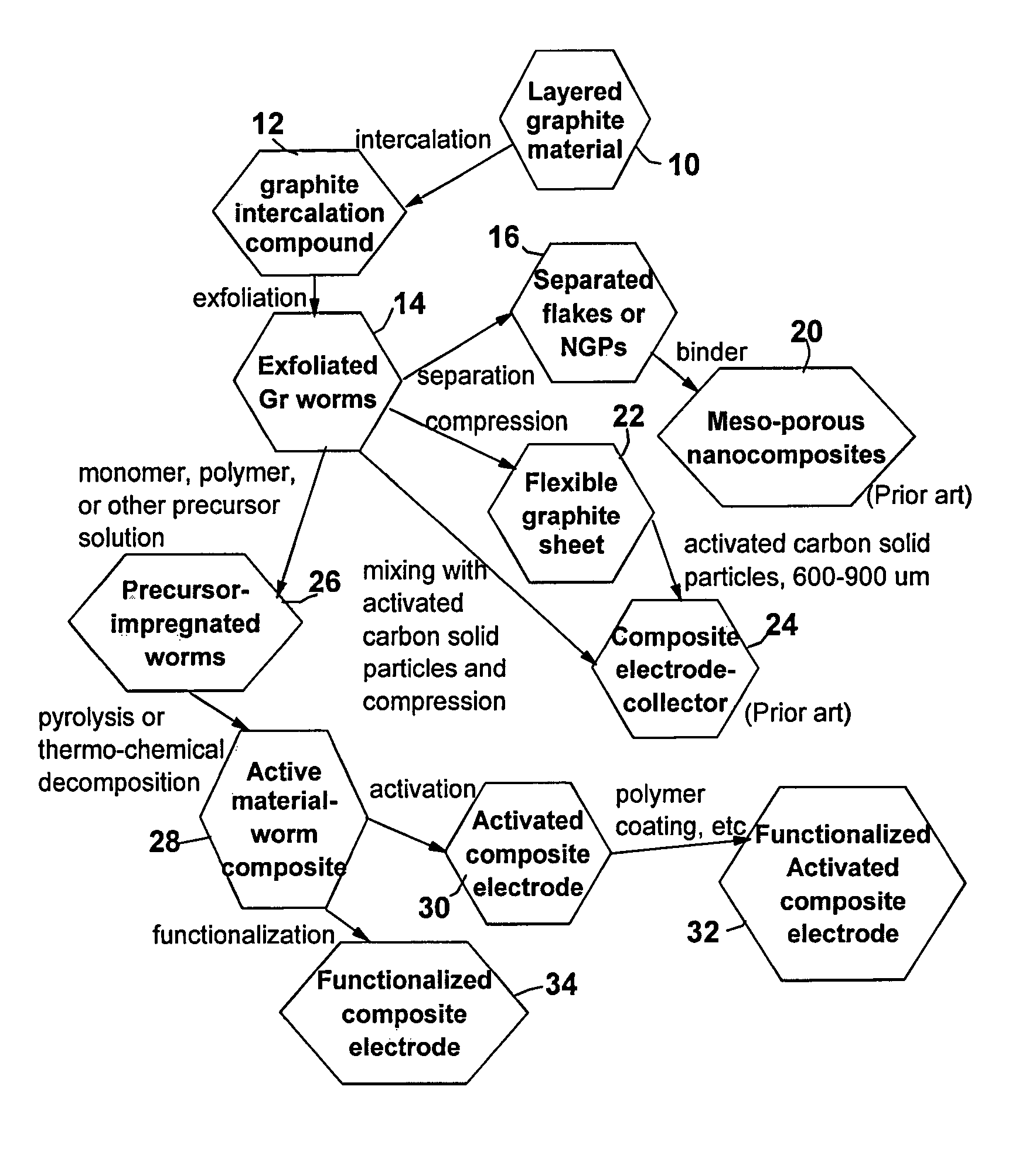

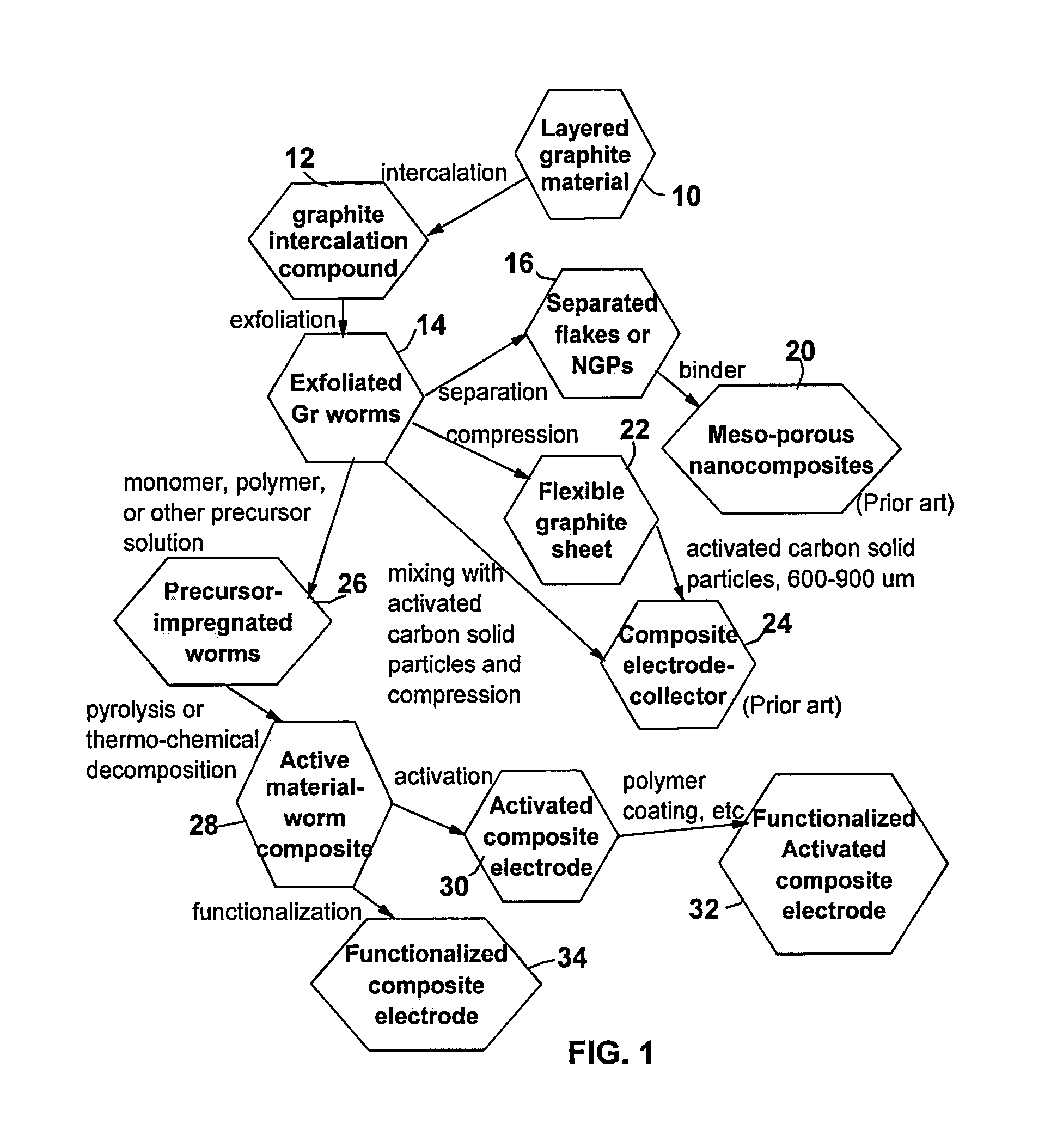

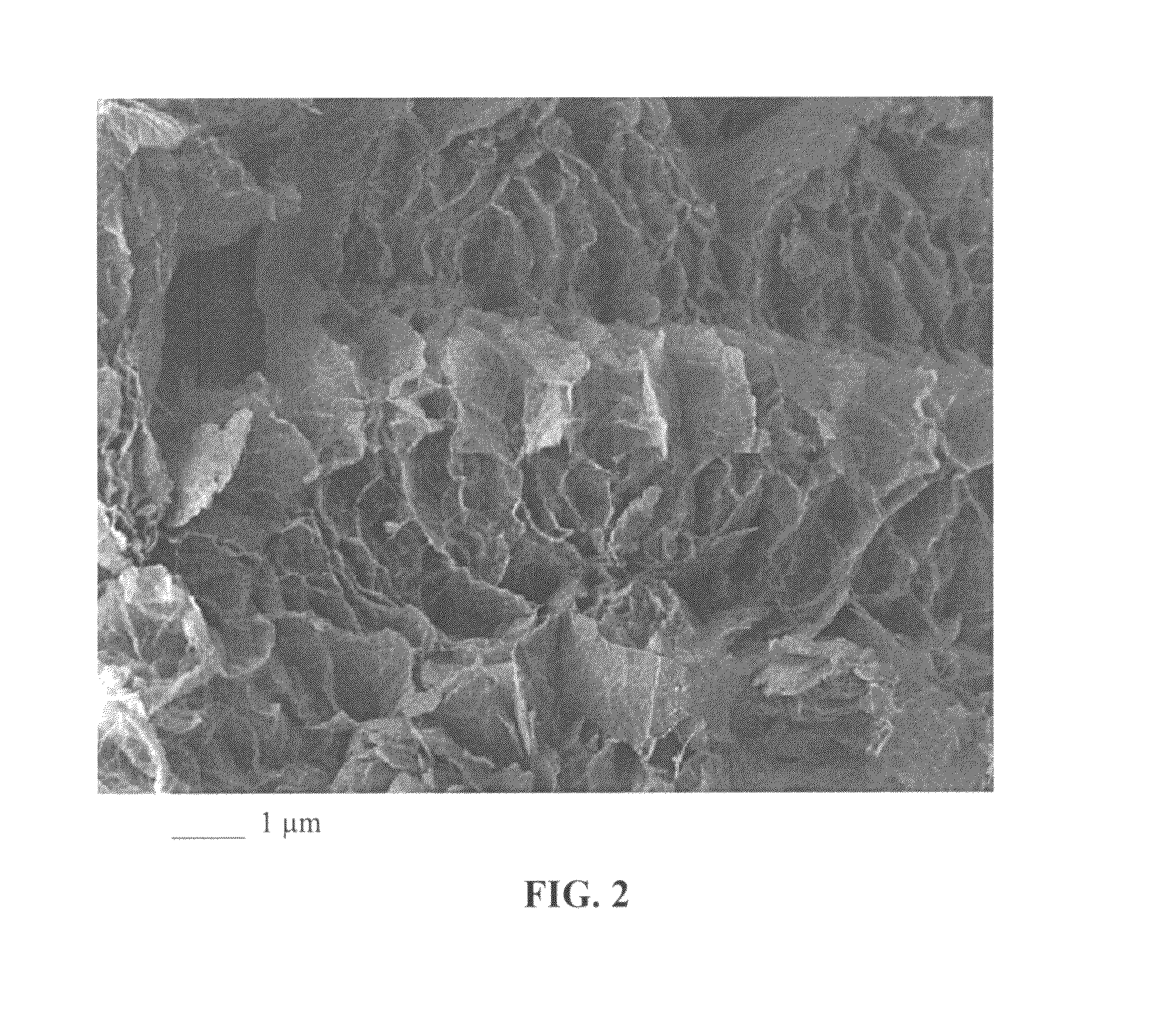

Method of producing graphite-carbon composite electrodes for supercapacitors

A method of producing a composite electrode having a specific surface area of at least 100 m2 / gm for use in an electrochemical capacitor. The method comprises (a) providing exfoliated graphite flakes that are substantially interconnected to form a porous, conductive graphite network comprising pores; and (b) incorporating an electrochemically active material into at least a pore of the graphite network to form the composite electrode. The exfoliated graphite flakes are preferably obtained from the intercalation and exfoliation of a laminar graphite material selected from natural graphite, spheroidal graphite, synthetic graphite, highly oriented pyrolytic graphite, meso-carbon micro-bead, carbon / graphite fiber, carbon / graphite whisker, carbon / graphite nano-fiber, carbon nano-tube, or a combination thereof. A supercapacitor featuring such a composite electrode exhibits an exceptionally high capacitance value and low equivalent series resistance.

Owner:NANOTEK INSTR GRP LLC

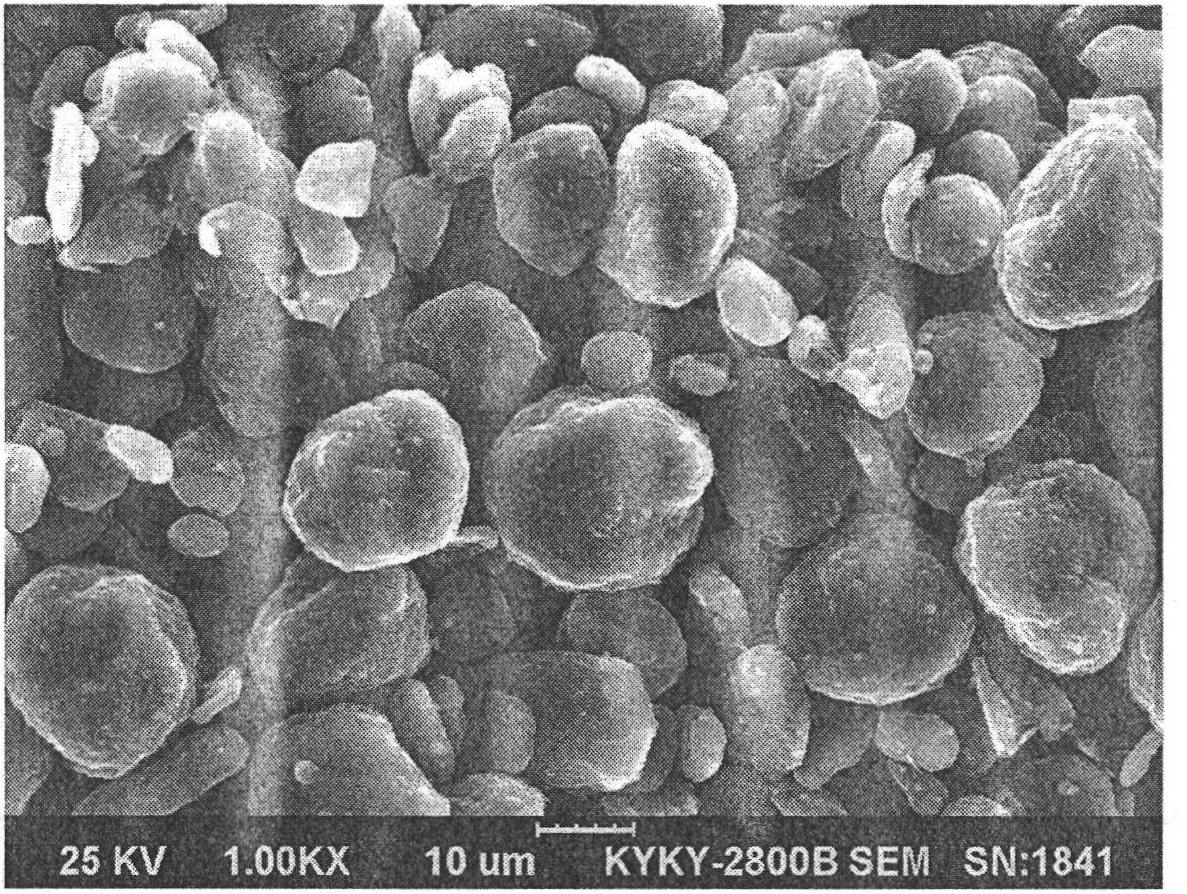

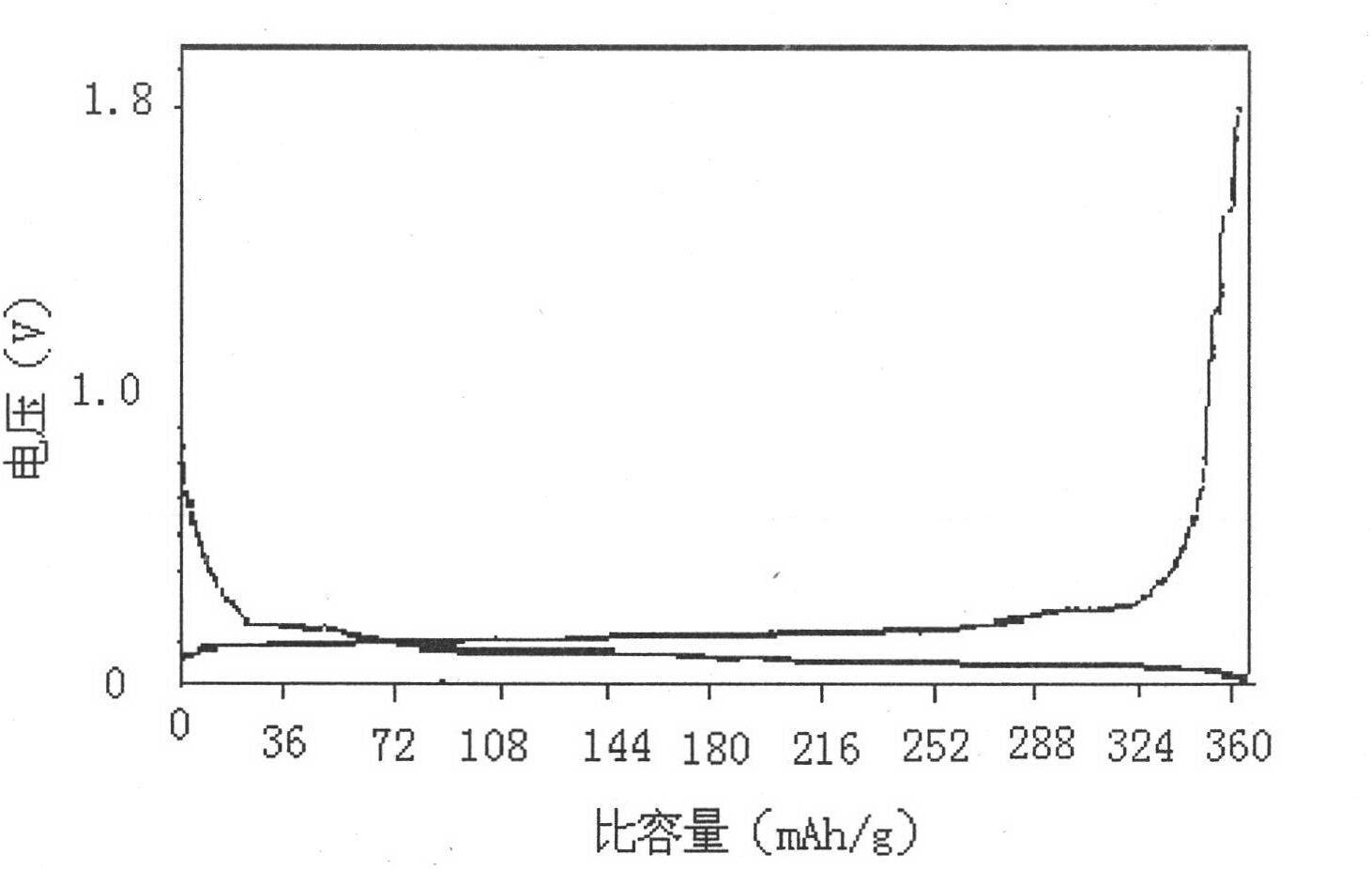

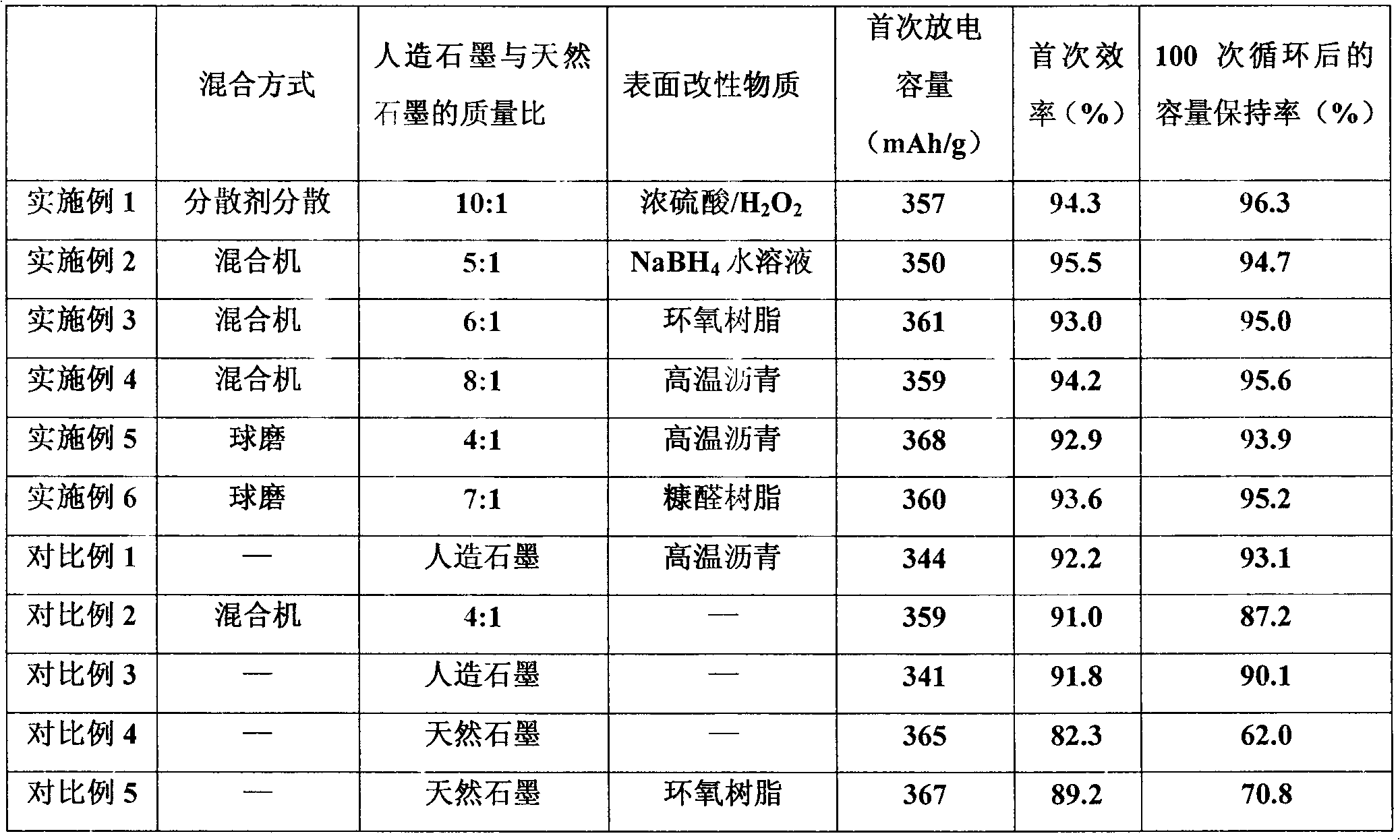

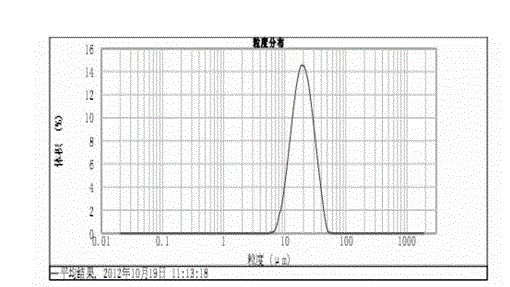

High-capacity graphite material and preparation method as well as application thereof

InactiveCN102659091AImprove discharge capacityImprove first-time efficiencyGraphiteCell electrodesMass ratioMetallurgy

The invention relates to a high-capacity graphite material and a preparation method as well as application thereof. The high-capacity graphite material comprises artificial graphite and natural graphite, wherein the mass ratio of artificial graphite to natural graphite is 20:1 to 1:1. According to the preparation method, the artificial graphite and the natural graphite are uniformly mixed according to a certain mass ratio, and then surface modification is carried out on the mixture. The prepared graphite material has the advantages of high discharge capacity, high first efficiency, long cycle life, low cost and the like; the discharge capacity of the high-capacity graphite material can reach up to more than 350mAh / g (even reach up to more than 368mAh / g); a half-cell of the high-capacity graphite material charges and discharges at the 1C multiple power; after the high-capacity graphite material cycles for 100 times, the capacity retention ratio of the high-capacity graphite material is still more than 90% (even reaches up to more than 96.3%); the first efficiency reaches up to more than 95.5%; and the manufacturing cost is reduced by about 1-10%. The high-capacity graphite material provided by the invention not only can meet the requirement of a lithium ion power battery for the high multiplying power charge-discharge of the material, but also reduces the manufacturing cost of the cathode material of the lithium ion battery.

Owner:天津市贝特瑞新能源科技有限公司

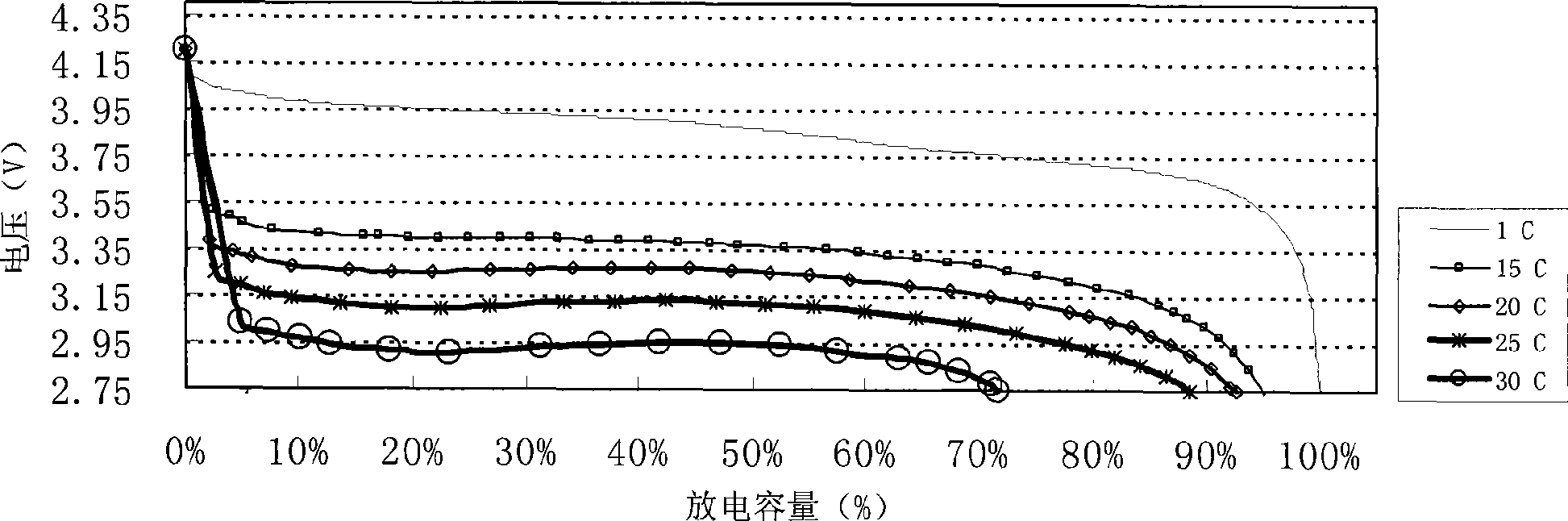

Preparation method of negative material for low-temperature lithium ion battery

ActiveCN103151497AWide variety of sourcesImprove the first charge and discharge efficiencyGraphiteCell electrodesHigh rateLithium-ion battery

The invented relates to a preparation method of a negative material for a low-temperature lithium ion battery. The preparation method comprises the steps of: carrying out ball-milling and refining treatment on natural graphite by adopting a ball mill, afterwards carrying out soft carbon coating for modification, then carrying out hard carbon coating, and finally curing and carbonizing the natural graphite modified by the soft-hard carbon double-layer coating to obtain final modified natural graphite. The preparation method provided by the invention is simple and convenient, low in cost, wide in raw material sources and easy to realize the industrial production; and the prepared negative material for the low-temperature lithium ion battery is high in first charging and discharging efficiency, and good in low-temperature performance and high-rate charging and discharging performance, and can satisfy the actual needs of people.

Owner:WUXI DONGHENGNEWENERGYTECHNOLOGYCO LTD

Aqueous anticorrosive modified graphene coating material, and preparation method and application thereof

ActiveCN105838183AImprove mechanical propertiesImprove water resistanceAnti-corrosive paintsPolymer modifiedWater dispersible

The invention relates to an aqueous anticorrosive modified graphene coating material, and a preparation method and an application thereof. The preparation method comprises the following steps: oxidizing natural graphite in an oxidant, modifying the surface of the obtained graphite oxide with an atom transfer radical polymerization (ATRP) initiator with different structures, adding a monomer, a high-valence catalyst, a ligand and a reducing agent to make the monomer undergo atom transfer radical polymerization (AGET ATRP) on the surface of graphene for electron transfer to generate an activator, and reducing graphene oxide (GO) by the reducing agent to obtain a water-dispersible polymer modified graphene material. The polymer modified graphene material can be used to prepare aqueous coatings, can be used to protect the surfaces of metal materials, can effectively isolate a corrosion medium from a substrate, and has excellent water, corrosion and weather resistance, and the preparation method has the advantages of simplicity, high efficiency, easy industrial production and wide application values.

Owner:CHANGZHOU HUAKE POLYMERS

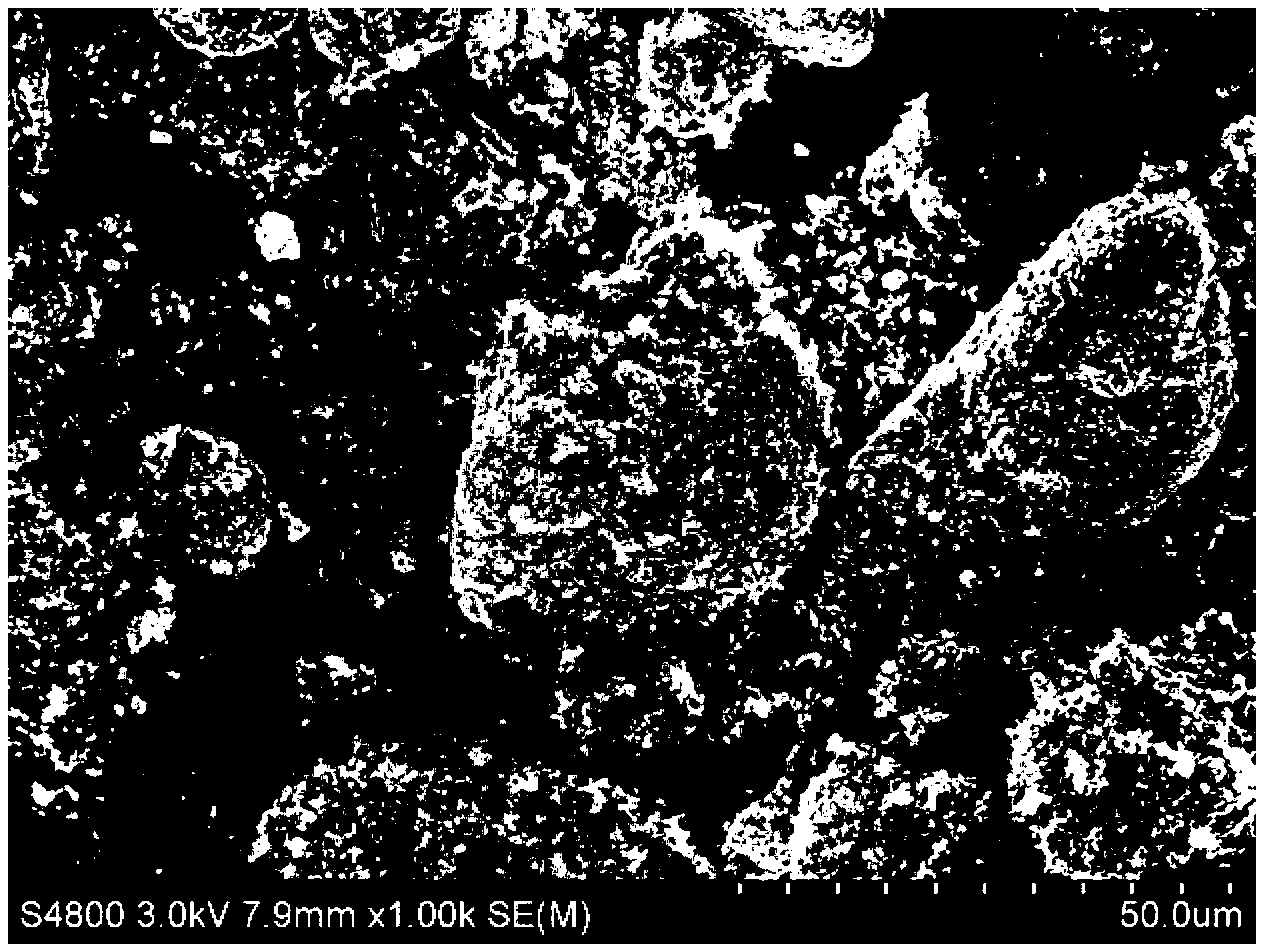

Silicon monoxide composite cathode material for lithium ion battery, and preparation method thereof

The invention discloses a silicon monoxide composite cathode material for a lithium ion battery, and a preparation method of the silicon monoxide composite cathode material, aiming at improving the cycle performance. The composite cathode material comprises the components by mass percent: 10-30% of composite particle material and 70-90% of natural graphite or artificial graphite, wherein the composite particle material is silicon monoxide covered by a carbon nano tube and an amorphous carbon coating layer. The method comprises the following steps of: forming the carbon nano tube and the amorphous carbon coating layer on the surface of silicon monoxide to obtain composite particles, and mixing the composite particles with the graphite. Compared with the prior art, the preparation method enables cracking carbon to be covered on the surfaces of silicon monoxide particles, so that the volume effect of the silicon monoxide particles can be effectively inhibited in the charge-discharge process of a battery, the cycle performance is good, the specific capacity is more than 500mAh / g, and the capacity retention ratio is more than 85% after the circulation is carried out for 100 times; and the preparation method is simple in preparation technology, low in raw material cost and suitable for the cathode material for the high-capacity lithium ion battery.

Owner:BTR NEW MATERIAL GRP CO LTD

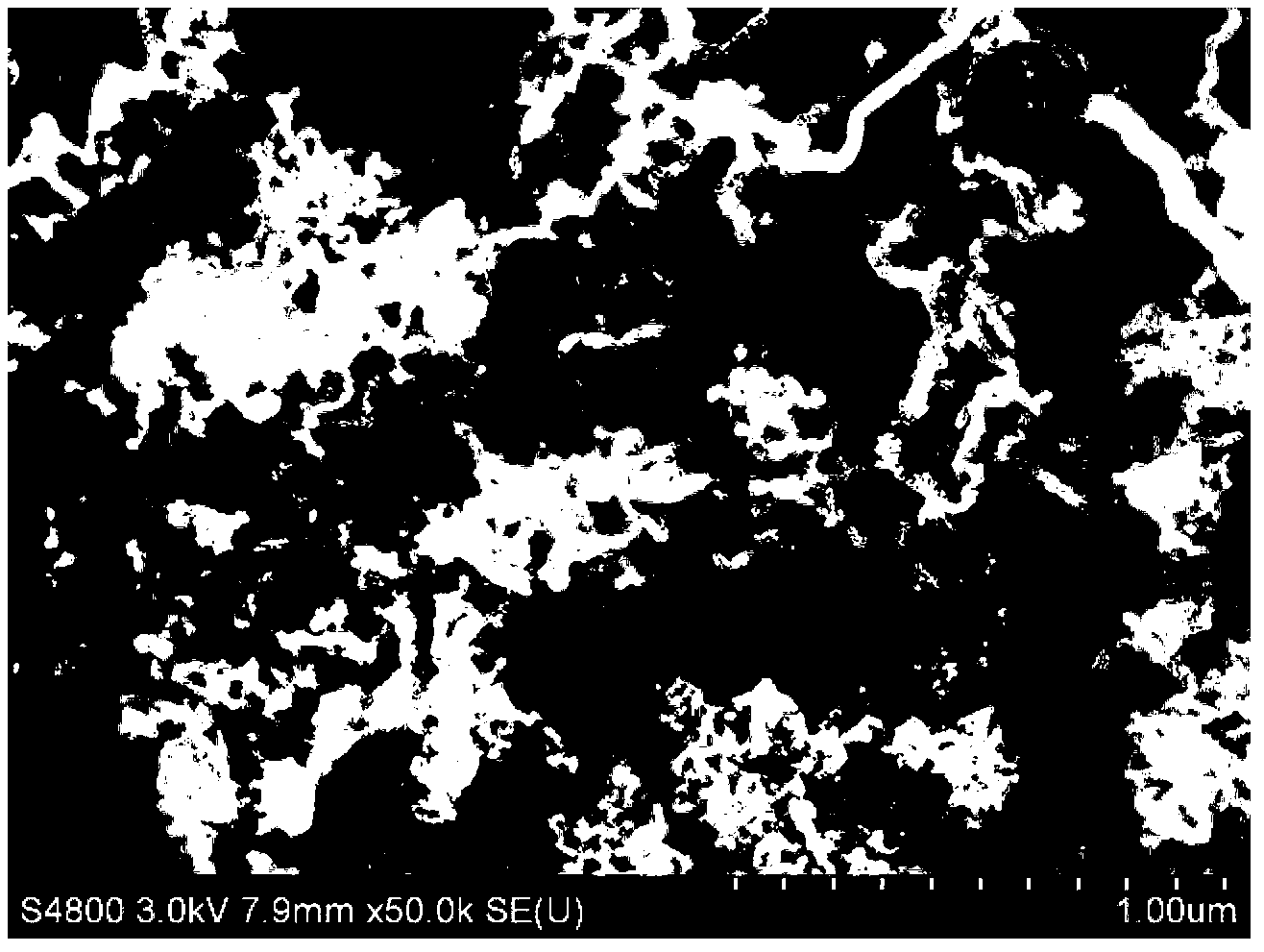

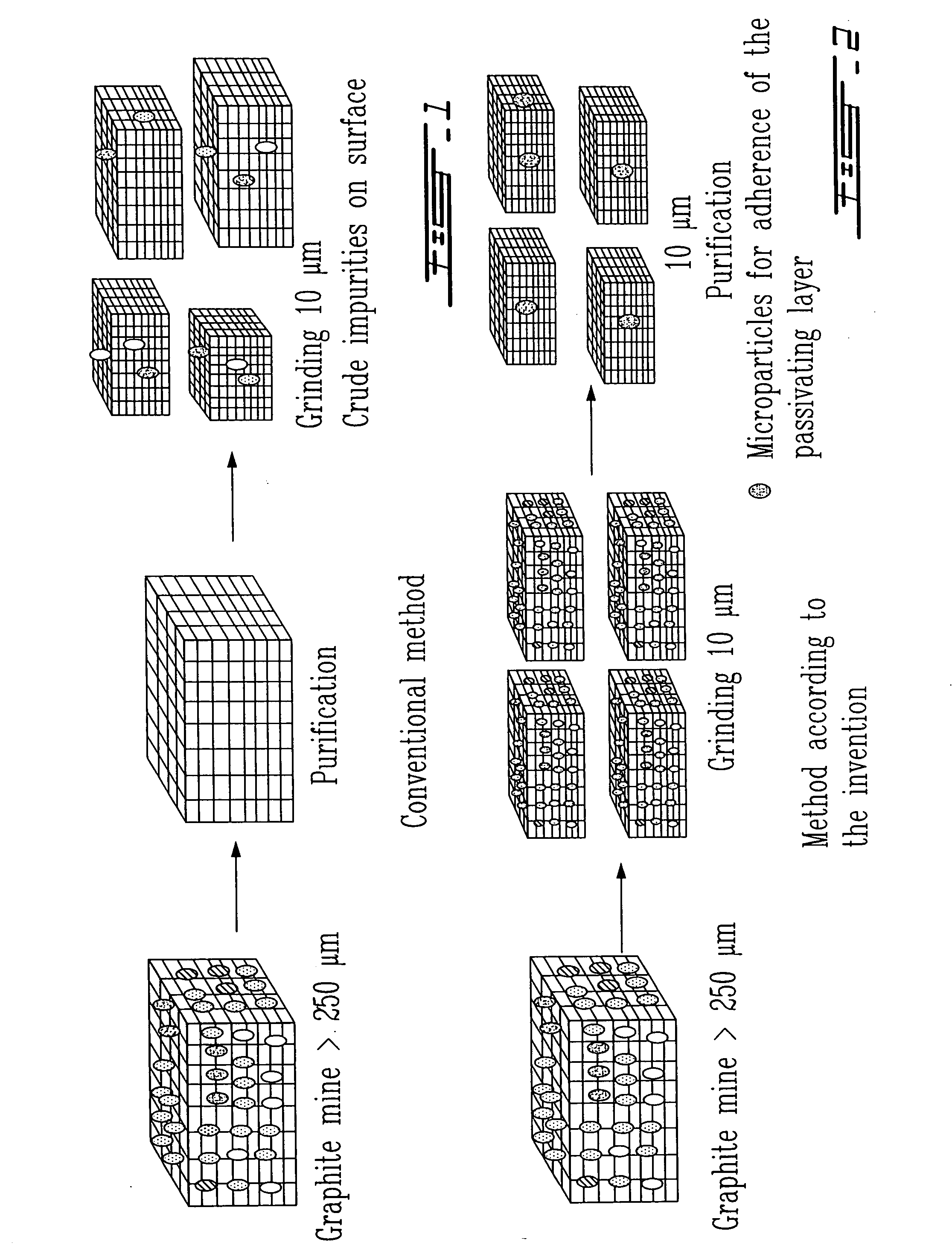

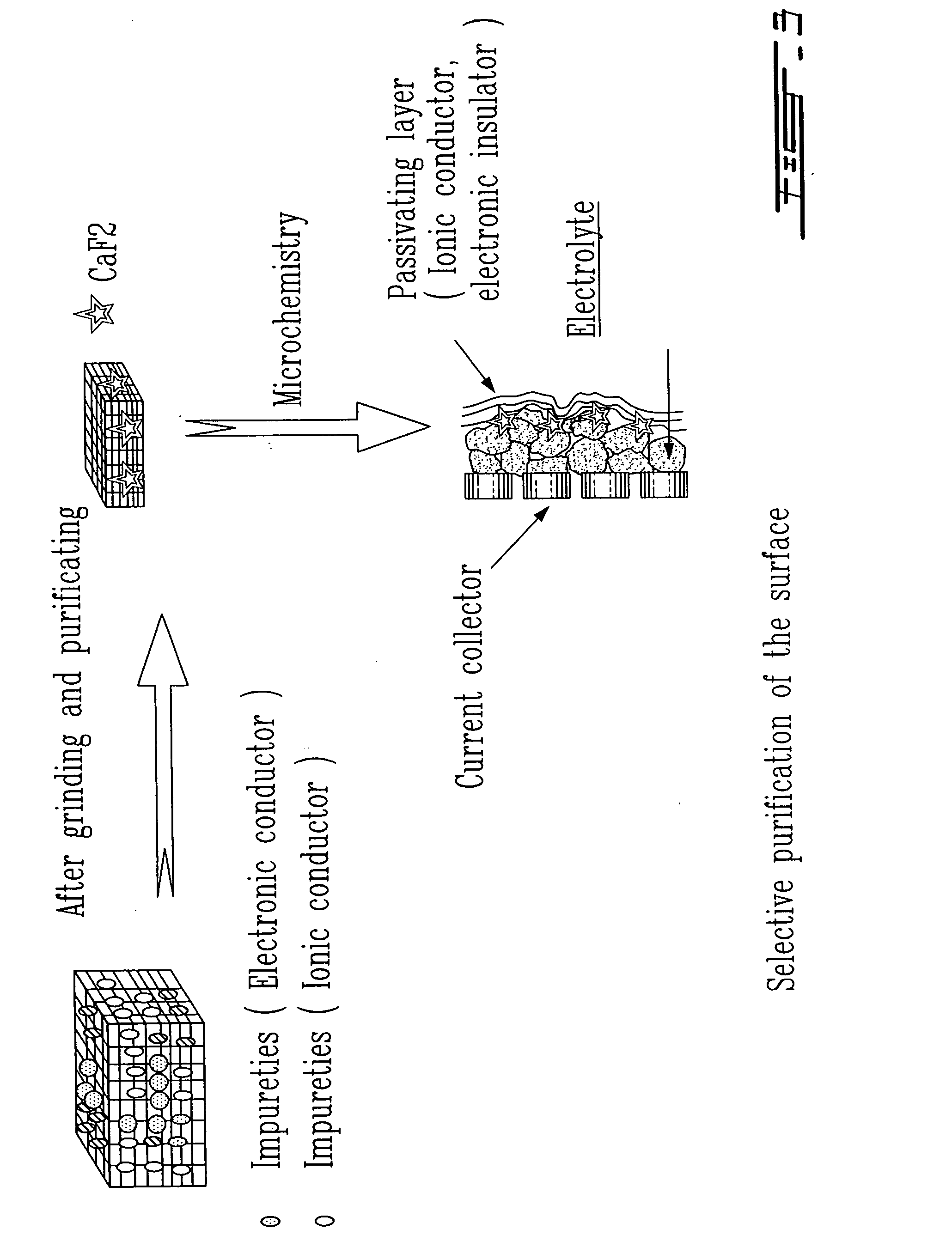

Surface preparation of natural graphite and the effect of impurities on grinding and the particle distribution

The present invention relates to the physical or chemical specific purification of natural mineral graphite. This purification is preferably applied to the surface of natural graphite in order to allow the formation of a passivation film during the first electrical discharge or the insertion of lithium in the graphite when the latter is used in a lithium-ion cell. The grinding to a small size before purification allows the optimization of the distribution of the particles, resulting in a more uniform electrode. This grinding is carried out in the presence of the natural impurities of the graphite that play the role of a micro-abrasive and result in a hardness of the graphite that increases its mechanical properties.

Owner:HYDRO QUEBEC CORP

High capacity lithium iron phosphate power cell and production technique thereof

InactiveCN101183729AFinal product manufactureElectrode carriers/collectorsCooking & bakingCopper foil

The invention relates to a high-capacity iron phosphate lithium power battery, which is characterized in that the anode material uses the iron phosphate lithium; an anode current collector uses the aluminum foil; a conductive agent uses the superconducting carbon black and the conductive graphite; the anode material binder uses the polyvinylidene fluorine; the cathode material uses the natural graphite or the artificial graphite; the cathode current collector uses copper foil; the conductive agent uses the superconducting carbon black and the conductive graphite; and the cathode material binder uses the polyvinylidene fluorine or the sodium carboxymethylcellulose and the styrene butadiene rubber. The invention also discloses a processing technology of the high capacity iron phosphate lithium power battery, comprising the following step: matching ingredients, coating, baking, rolling, processing slice, baking, staking, assembling upper cover , baking, liquid injection, formation and partial volume. The invention adopts a stacking type, and has simple processing technology, compact battery structure and stable performance; thus, the battery capacity is greatly improved. The invention has an advantage of providing the lithium ion secondary battery of a driving energy source to the small and medium sized electric tools, such as the household electric appliance, the electric bicycle, the electric motorcycle and the electric automobile.

Owner:山东海霸电池有限公司

Composite graphite negative electrode material for lithium ion secondary cell and its preparation method

ActiveCN1702892AImprove discharge capacityPromote circulationElectrode manufacturing processesSecondary cellsState of artLithium

This invention discloses one lithium ion second battery compound negative materials and its process method, wherein, the materials comprise modified natural graphite and artificial graphite with quality proportion of 30í†70í½80í†20 and the process method comprises the following steps: a, the natural graphite surface is covered with organism; b, making the thermal process in temperature range of 800íµí½1500íµ for one to six hours; c, mixing the natural graphite with the artificial graphite as proportion of 30í†70í½80í†20.

Owner:BTR NEW MATERIAL GRP CO LTD

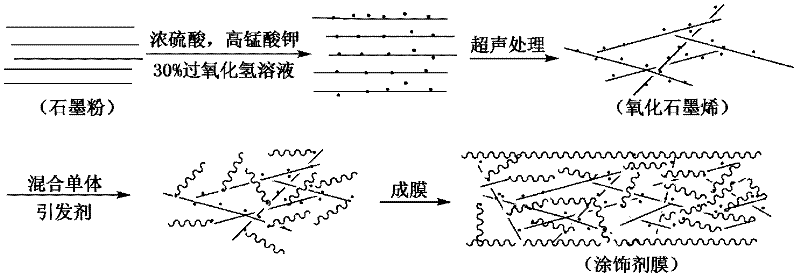

Preparation method of acrylic resin/graphene oxide nanometer composite leather finishing agent

The invention relates to a preparation method for an acrylic resin / graphene oxide nanometer composite leather finishing agent. In the preparation method, a nanometer graphene oxide suspension liquid is formed through peeling and dispersing; and then the acrylic resin / graphene oxide nanometer composite acrylic resin finishing agent is prepared through in-situ polymerization. The preparation methodcomprises the following specific steps: carrying out oxidization and ultrasonic stripping on natural graphite powder to prepare graphene oxide; adding graphene oxide to a mixed monomer of methyl acrylate, ethyl acrylate, butyl acrylate, acrylic acid and hydroxyethyl acrylate under the action of ultrasonic waves; and carrying out in-situ free radical copolymerization reaction under the action of an initiator ammonium persulfate to obtain the acrylic resin / graphene oxide nanometer composite leather finishing agent. The preparation method has the characteristics that the acrylic resin / graphene oxide nanometer composite leather finishing agent with excellent film-forming hand feel, strength and anti-static performances and no heat bonding and cold brittleness defects is prepared by using the specific laminated structure and performance of graphene oxide.

Owner:JIANGSU BESCON PHARMA

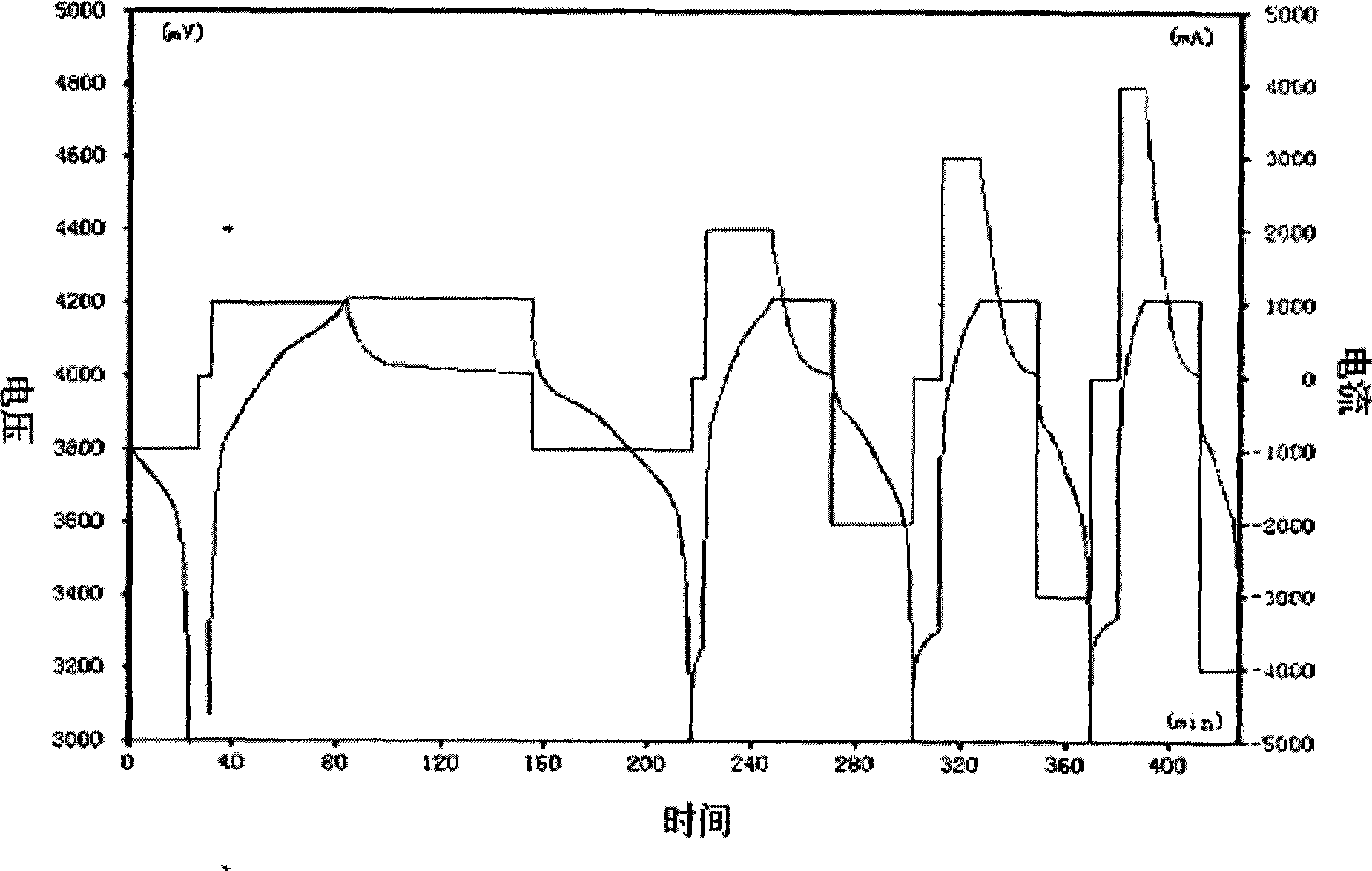

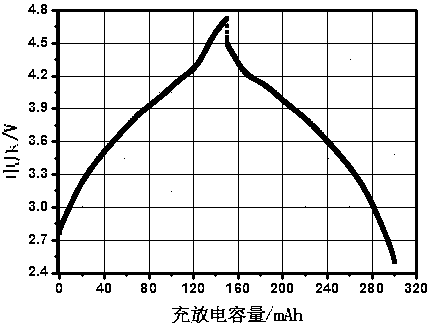

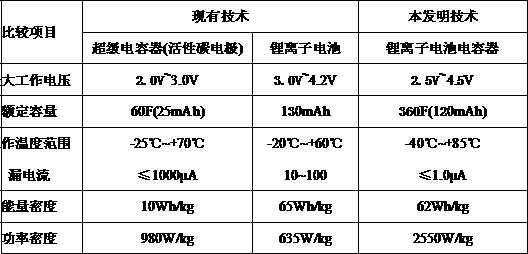

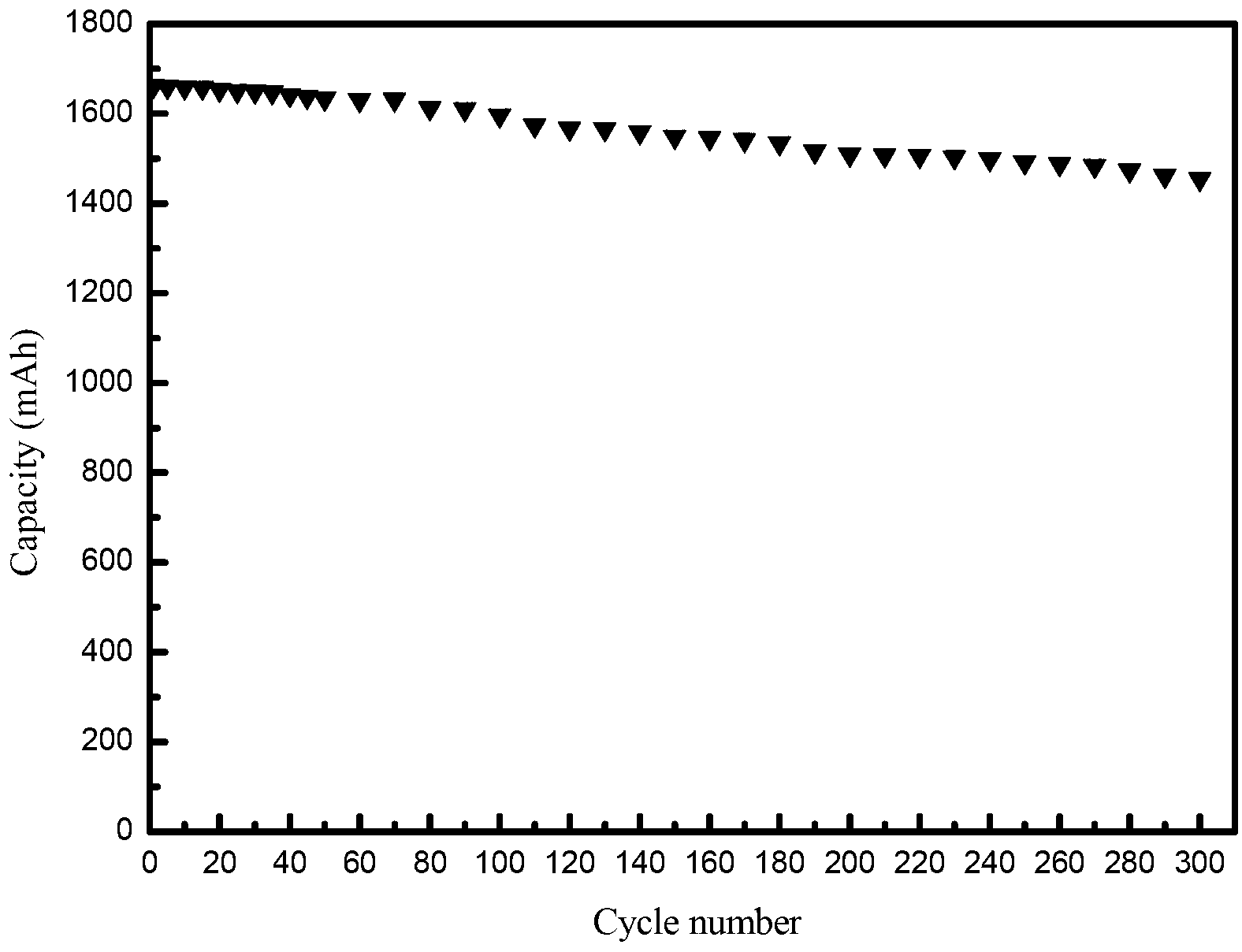

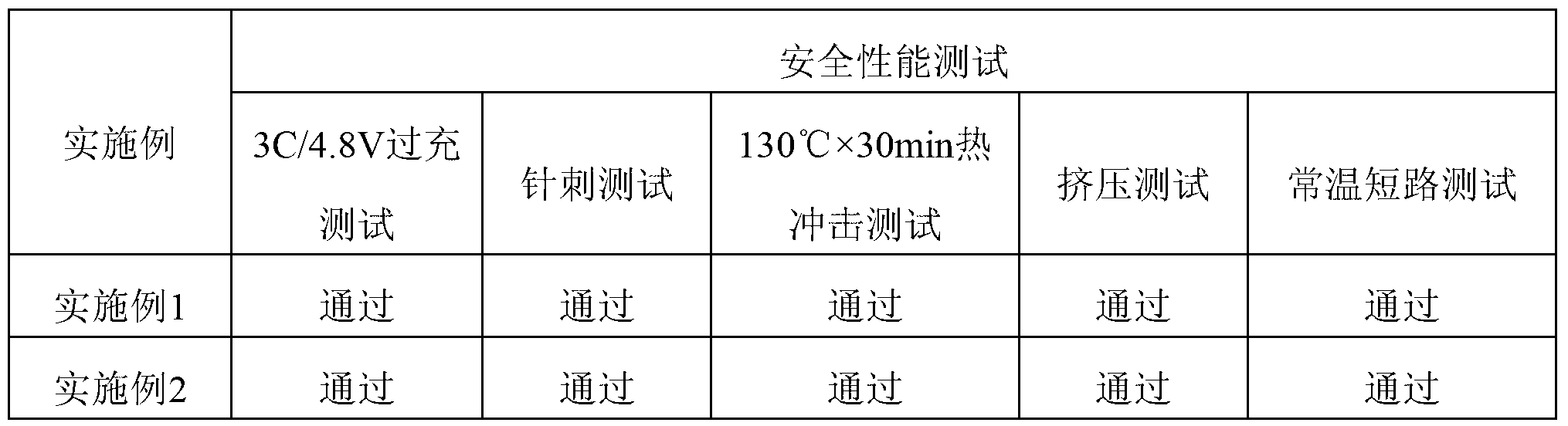

Capacitor of lithium ion battery

InactiveCN103021671ATypical charge and discharge characteristicsHigh energy density characteristicsHybrid capacitor electrolytesHybrid capacitor electrodesHigh energyPhysical chemistry

Owner:EVE ENERGY CO LTD

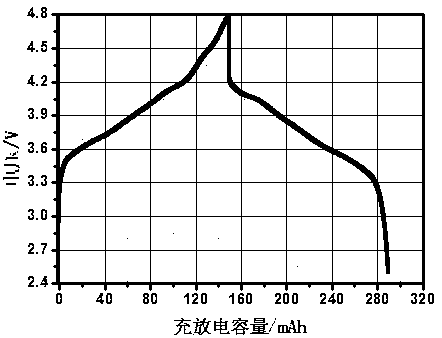

High-voltage high-energy-density lithium ion battery

InactiveCN103311539AIncrease energy densityHigh discharge platformFinal product manufactureElectrode carriers/collectorsElectrical batteryHigh energy

The invention discloses a high-voltage high-energy-density lithium ion battery which comprises a positive pole piece, a negative pole piece, a diaphragm, electrolyte and a shell, wherein the positive pole piece comprises a positive active material, a conducting agent, an adhesive and a current collector, and the weight percents of the positive active material, the conducting agent and the adhesion are 92 to 97%: 2 to 3.5%: 1 to 6%; the negative pole piece comprises a negative material, a conducting agent, an adhesive and a current collector, and the weight percents of the negative material, the conducting agent and the adhesive are respectively 90 to 96%, 1 to 5% and 4 to 10%; the lithium ion battery is prepared by adopting modified lithium cobalt oxides (LiCoO2) as the positive active material and the artificial graphite or natural graphite as the negative material and matching the corresponding ceramic diaphragm, high-voltage electrolyte, adhesive and conducting agent. The lithium ion battery not only has high energy density and high discharging platform, but also is good in chemical performance and safety performance and is applicable to the commercialized mass production.

Owner:SHENZHEN WISEWOD TECH +1

Method for preparing polyamide-amine in-situ intercalation graphene composite material

ActiveCN102390830AStructural damage is smallSolve the problem of not being conductivePolymer scienceOrganic solvent

The invention discloses a method for preparing a polyamide-amine in-situ intercalation graphene composite material. The method comprises the following steps of: (1) dispersing graphite in an imidazole-compound-containing organic solvent with ultrasonic, and centrifuging to obtain multi-layer graphene suspension; and (2) polymerizing to generate polyamide-amine in the multilayer graphene by adopting an in-situ polymerization method to prepare the polyamide-amine in-situ intercalation graphene composite material. According to the method, natural graphite is directly subjected to ultrasonic exfoliation in the organic solvent to obtain single-layer or multi-layer graphene suspension, the original sp2 structure of the graphene is slightly damaged because an oxidation step is not carried out, the polyamide-amine in-situ intercalation graphene composite material is prepared by using an in-situ polymerization method, so that graphene laminas are spread, interlamellar spacings are enlarged, the polyamide-amine on the surface of the graphene functionally prevents agglomeration of the graphene laminas, the graphene laminas are uniformly dispersed, and the product has good stability and is hardly precipitated.

Owner:SOUTH CHINA UNIV OF TECH

Composite carbon negative electrode material of lithium ion power battery and its preparation method

ActiveCN1885598AExcellent intercalation and delithiation abilityImprove cycle stabilityCell electrodesPower batteryGraphite particle

The disclosed composite carbon cathode material for Li ion electro-kinetic cell is prepared by bonding composite spherical or near-spherical graphite particle, wherein the material composes by: graphous or natural graphite powder or their mixture, 0.1-5wt% additive, and 1-50wt% bonding agent. The preparation method comprises: granulating, baking, dipping, impregnating, carbonizating, and graphitizing. Compared with prior art, this invention has reversible specific capacity more than 350mAh / g, first circulation coulomb efficiency more than 94%, capacity conservation rate more than 80% after 500 times of circulation, and other well performances.

Owner:BTR NEW MATERIAL GRP CO LTD

Negative electrode for lithium secondary battery and lithium secondary battery comprising the same

The invention relates to a negative electrode for a lithium secondary battery and a lithium secondary battery comprising the same. Disclosed is a negative electrode for a lithium secondary battery having excellent electric conductivity and adhesion even though a high-loading negative electrode is used, and the negative electrode includes a negative electrode current collector; a first negative electrode mixture layer containing a first negative electrode active material, a first polymer binder and a first conductive material and formed on at least one surface of the negative electrode currentcollector; and a second negative electrode mixture layer containing a second negative electrode active material, a second polymer binder and a second conductive material and formed on an upper surfaceof the first negative electrode mixture layer, wherein the first negative electrode active material contains natural graphite and silicon oxide, and the second negative electrode active material contains artificial graphite.

Owner:LG ENERGY SOLUTION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com