Preparation method of graphene

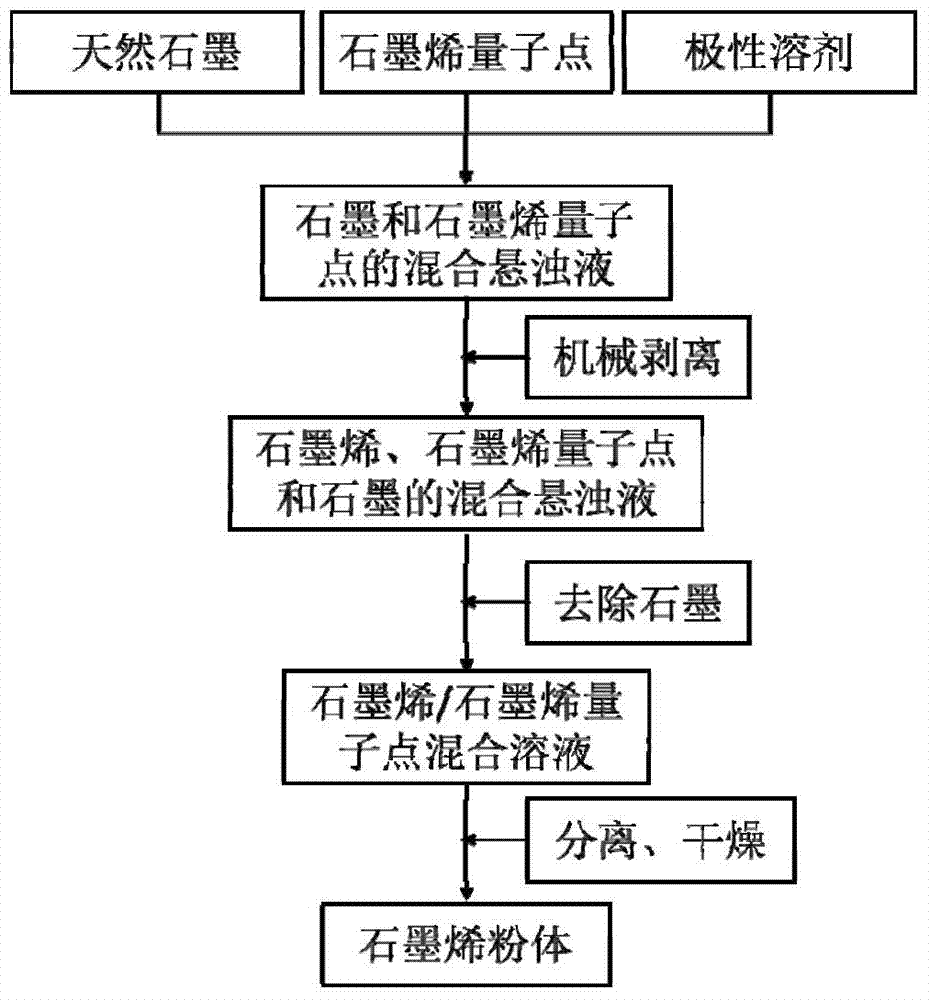

A technology of graphene and graphene quantum dots, applied in the direction of graphene, nano-carbon, etc., can solve the problems of impurity removal, low peeling yield, difficult to remove residual solvents, etc., and achieve the effect of simple process and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

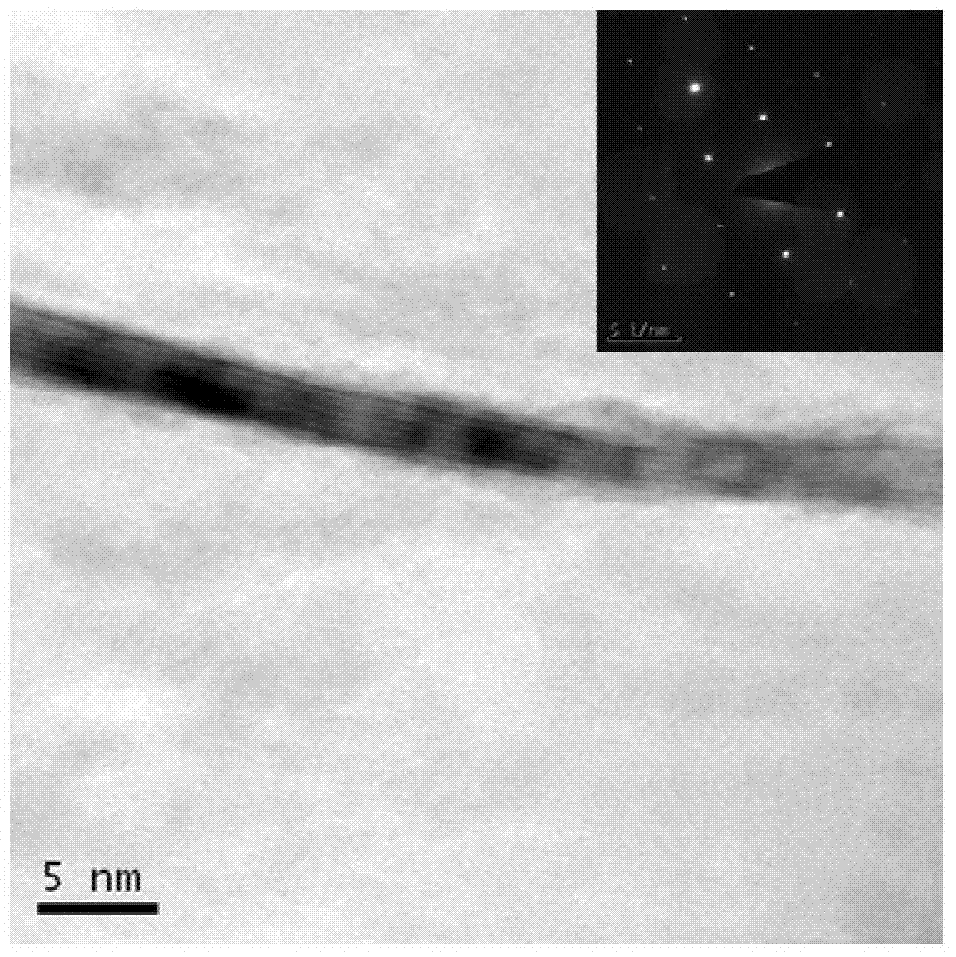

[0015] Example 1: Weigh 100mg of natural graphite, 10mg of graphene oxidized by concentrated sulfuric acid, concentrated nitric acid or their mixed acid to obtain graphene quantum dot powder, wherein the carbon and oxygen atomic content ratio is 20:1, and the average lateral dimension About 10nm. The above two powders were added to 50 mL of deionized water to prepare a mixed suspension of graphite and graphene quantum dots. Ultrasonic treatment of the suspension with a probe to obtain a suspension of graphene, graphene quantum dots and graphite. Centrifuge the above suspension, take the graphene / graphene quantum dot mixed solution stably dispersed in the upper layer, filter and separate the graphene quantum dot and graphene, and dry the filter cake to obtain 12.5 mg of graphene powder. figure 2 It is a high-resolution transmission electron microscope picture of the obtained graphene, as can be seen from the figure, the number of atomic layers of the graphene is less than 10 ...

Embodiment 2

[0016] Example 2: Weigh 100 mg of natural graphite, 20 mg of graphene oxidized by concentrated sulfuric acid, concentrated nitric acid or their mixed acid to obtain graphene quantum dot powder, wherein the carbon and oxygen atomic content ratio is 11:1, and the average lateral dimension About 20nm. The above two powders were added into 100mL ethanol to prepare a mixed suspension of graphite and graphene quantum dots. Ultrasonic treatment of the suspension with a probe to obtain a suspension of graphene, graphene quantum dots and graphite. Centrifuge the above suspension, take the graphene / graphene quantum dot mixed solution stably dispersed in the upper layer, filter and separate the graphene quantum dot and graphene, and dry the filter cake to obtain 21 mg of graphene powder.

Embodiment 3

[0017] Example 3: Weigh 300mg of natural graphite, 30mg of graphene is oxidized and cut by concentrated sulfuric acid and concentrated nitric acid mixed acid to obtain graphene quantum dot powder, wherein the carbon and oxygen atomic content ratio is 4:1, and the average lateral size is about 20nm . The above two powders were added to 50mL of N-2-methylpyrrolidone (NMP) to prepare a mixed suspension of graphite and graphene quantum dots. The above-mentioned suspension is added to a ball mill jar for high-speed ball milling to obtain a suspension of graphene, graphene quantum dots and graphite. Put the suspension above still, take the graphene / graphene quantum dot mixed solution stably dispersed in the upper layer, filter and separate the graphene quantum dot and graphene, and dry the filter cake to obtain 162 mg of graphene powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com