High-capacity graphite material and preparation method as well as application thereof

A graphite material, high-capacity technology, applied in the direction of graphite, electrical components, electrochemical generators, etc., can solve the problems of increasing the specific surface area of the particle surface, complex process, difficult to control, etc., to meet the requirements of large rate charge and discharge, Reduced manufacturing cost and high first-time efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

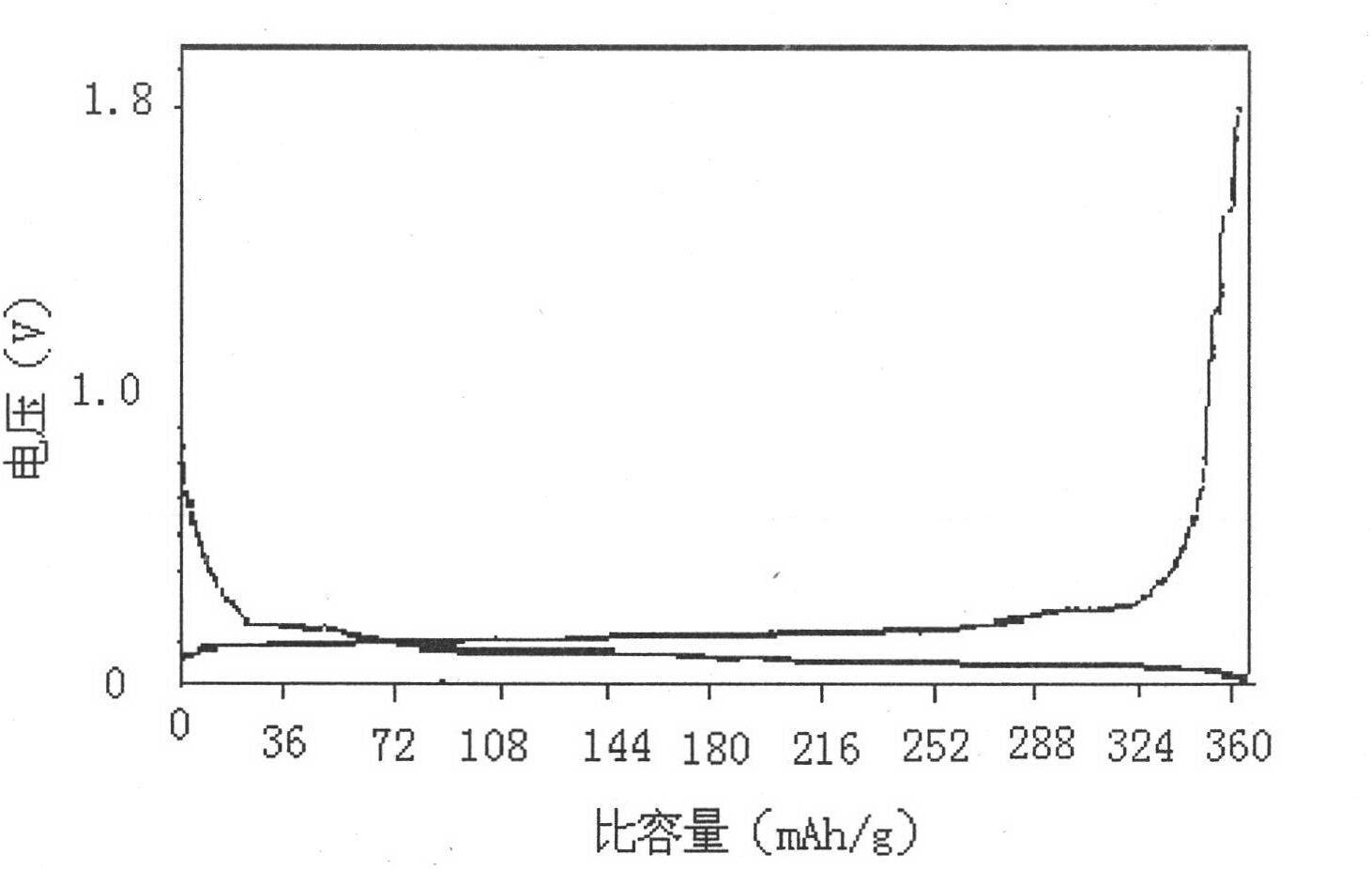

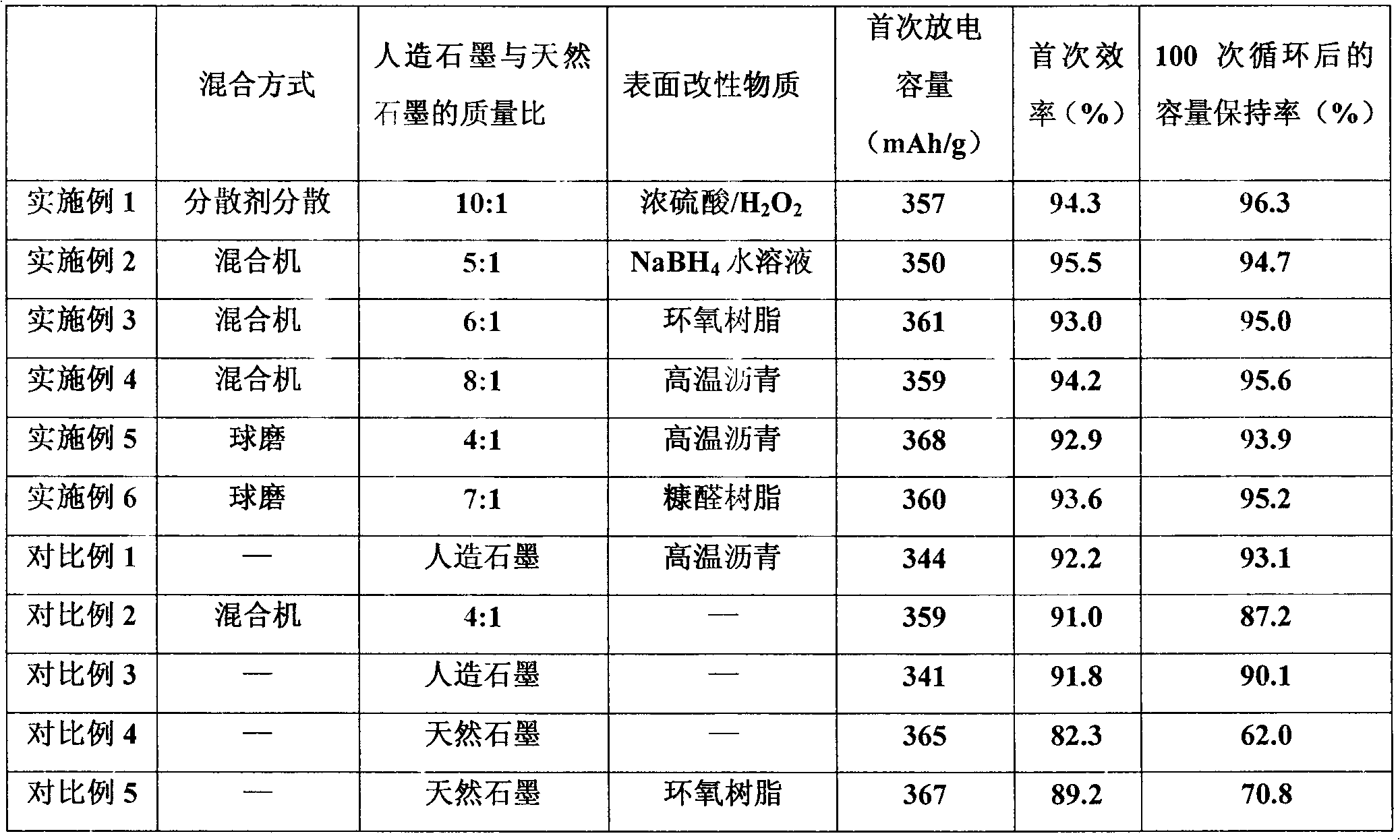

[0070] Example 1 Preparation and detection of graphite composite material of the present invention

[0071] The preparation method of graphite composite material of the present invention may further comprise the steps:

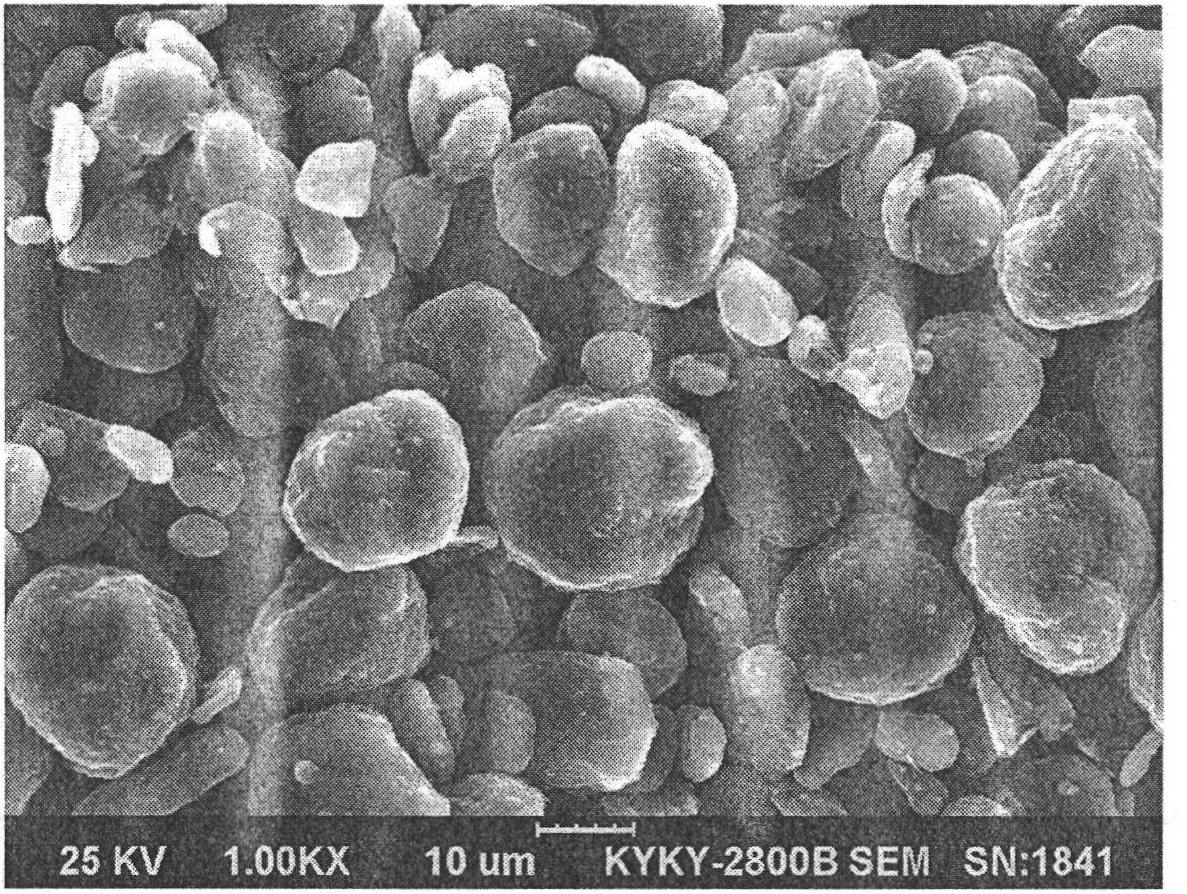

[0072] 1) will D 50 200 g of artificial graphite of 10 μm is placed in 500 ml of ethanol, mechanically stirred at a stirring rate of 150 r / min, and dispersed evenly to obtain an artificial graphite suspension;

[0073] 2) Under stirring conditions, the D 50 Add 20 g of natural graphite of 5 μm into the artificial graphite suspension prepared in step 1), stir at 350 r / min for 1 hour, filter, and dry in a vacuum oven at 50° C. for 8 hours to obtain a mixture of artificial graphite and natural graphite (also known as graphite). mixture);

[0074] 4) Under stirring conditions, add the graphite mixture prepared in step 3) into the mixed solution of sulfuric acid hydrogen peroxide, continue to stir for 2 hours, filter, wash with distilled water until the pH is ...

Embodiment 2

[0076] Example 2 Preparation and detection of graphite composite material of the present invention

[0077] The preparation method of graphite composite material of the present invention may further comprise the steps:

[0078] 1) will D 50 200g of 20μm artificial graphite with D 50 40g of natural graphite with a diameter of 5 μm was added to a three-dimensional motion mixer at the same time, and mixed for 20 minutes to obtain a graphite mixture;

[0079] 2) adding the graphite mixture prepared in step 1) to 2L of NaBH with a mass concentration of 60% 4 In aqueous solution, heated to 60°C, mechanically stirred for 2h, filtered, washed with distilled water until no sodium ions were detected, dried in a vacuum oven at 50°C for 8h, to obtain a surface-modified graphite mixture.

[0080] According to the detection method of the present invention, the surface-modified graphite mixture prepared in step 2) was assembled into a battery, and the electrochemical performance test was ...

Embodiment 3

[0081] Example 3 Preparation and detection of graphite composite material of the present invention

[0082] The preparation method of graphite composite material of the present invention may further comprise the steps:

[0083] 1) will D 50 20μm artificial graphite 180g and D 50 30 g of natural graphite with a diameter of 10 μm was added to a three-dimensional motion mixer at the same time, and mixed for 30 minutes to obtain a graphite mixture;

[0084] 2) 27g epoxy resin is dissolved in 500ml ethyl acetate, makes the ethyl acetate solution of epoxy resin;

[0085] 3) Add the graphite mixture prepared in step 1) into the ethyl acetate solution of epoxy resin prepared in step 2), wherein the mass ratio of epoxy resin to graphite mixture is 1:8, stir for 1h, and mix well , dried in a vacuum oven at 150°C for 8 hours, and the solvent was removed to obtain a graphite mixture precursor;

[0086] 4) Under the protection of argon, the graphite mixture precursor prepared in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com