Carbon-sulphur composite used for cathode material of lithium sulphur battery as well as preparation method and application thereof

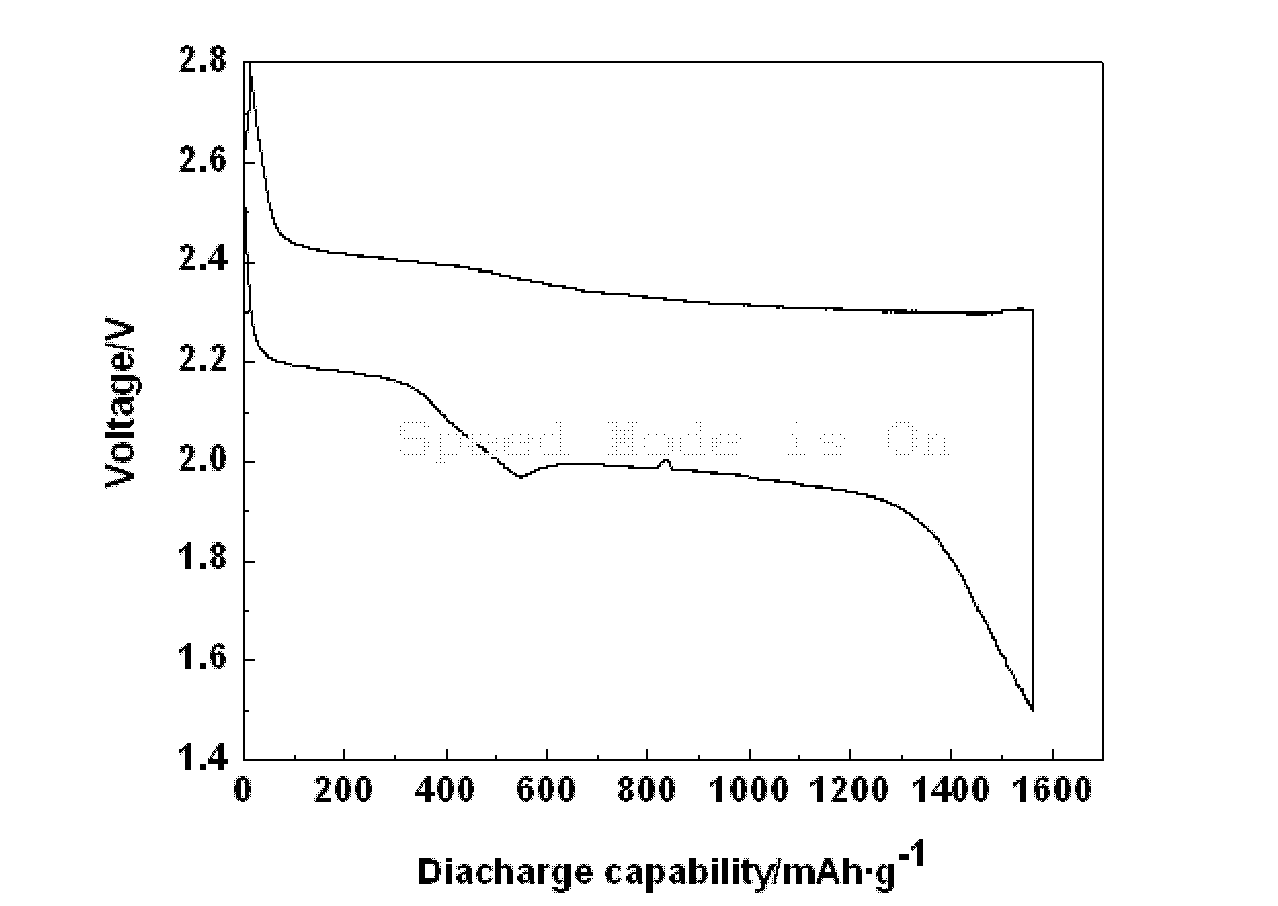

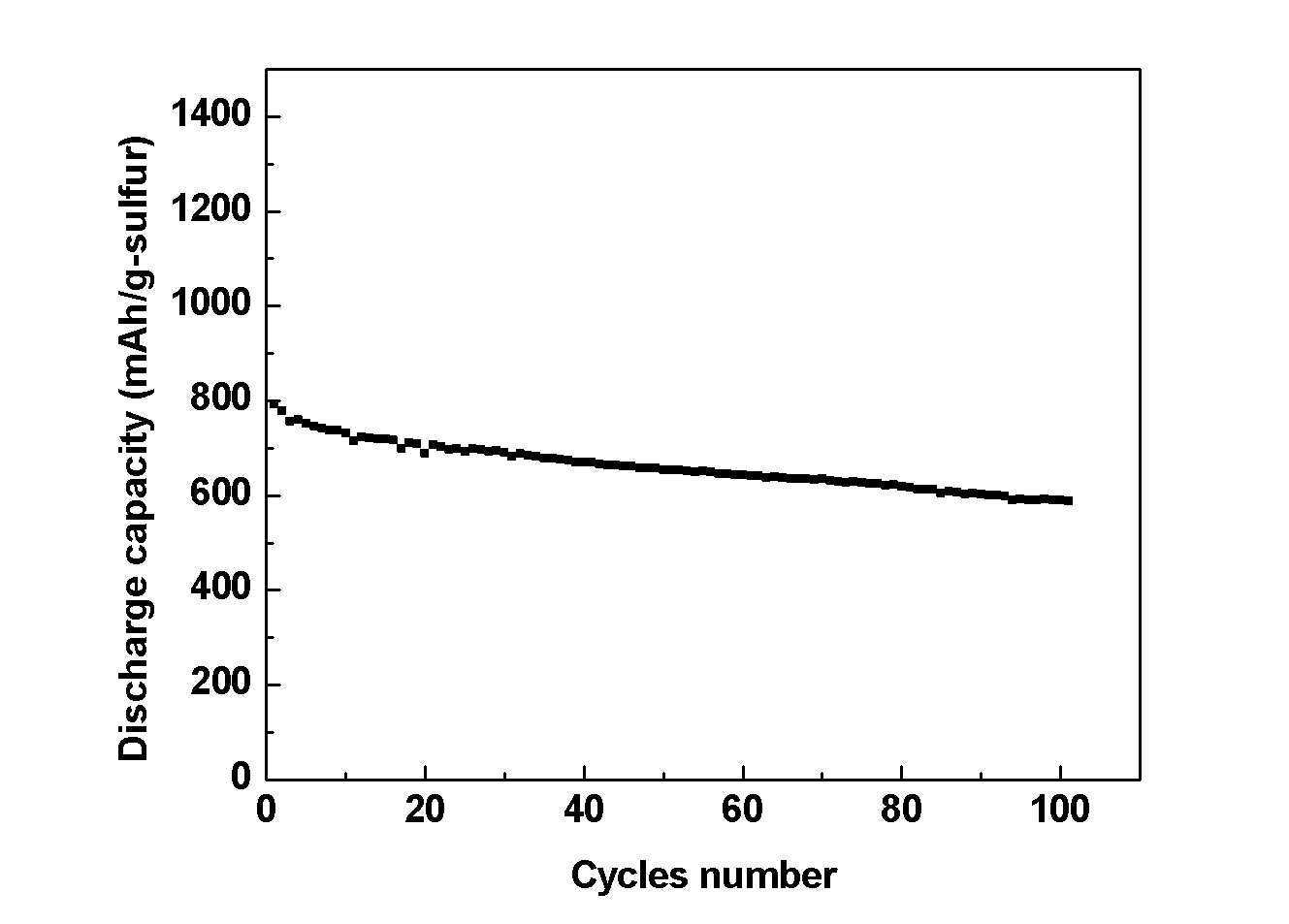

A lithium-sulfur battery and cathode material technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve the problems of low utilization rate of active material sulfur, restrictions on industrialized large-scale production, unsafe and environmentally friendly thiophene, etc., and achieve raw material prices Inexpensive, conducive to diffusion and transport, and the effect of improving electrochemical capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

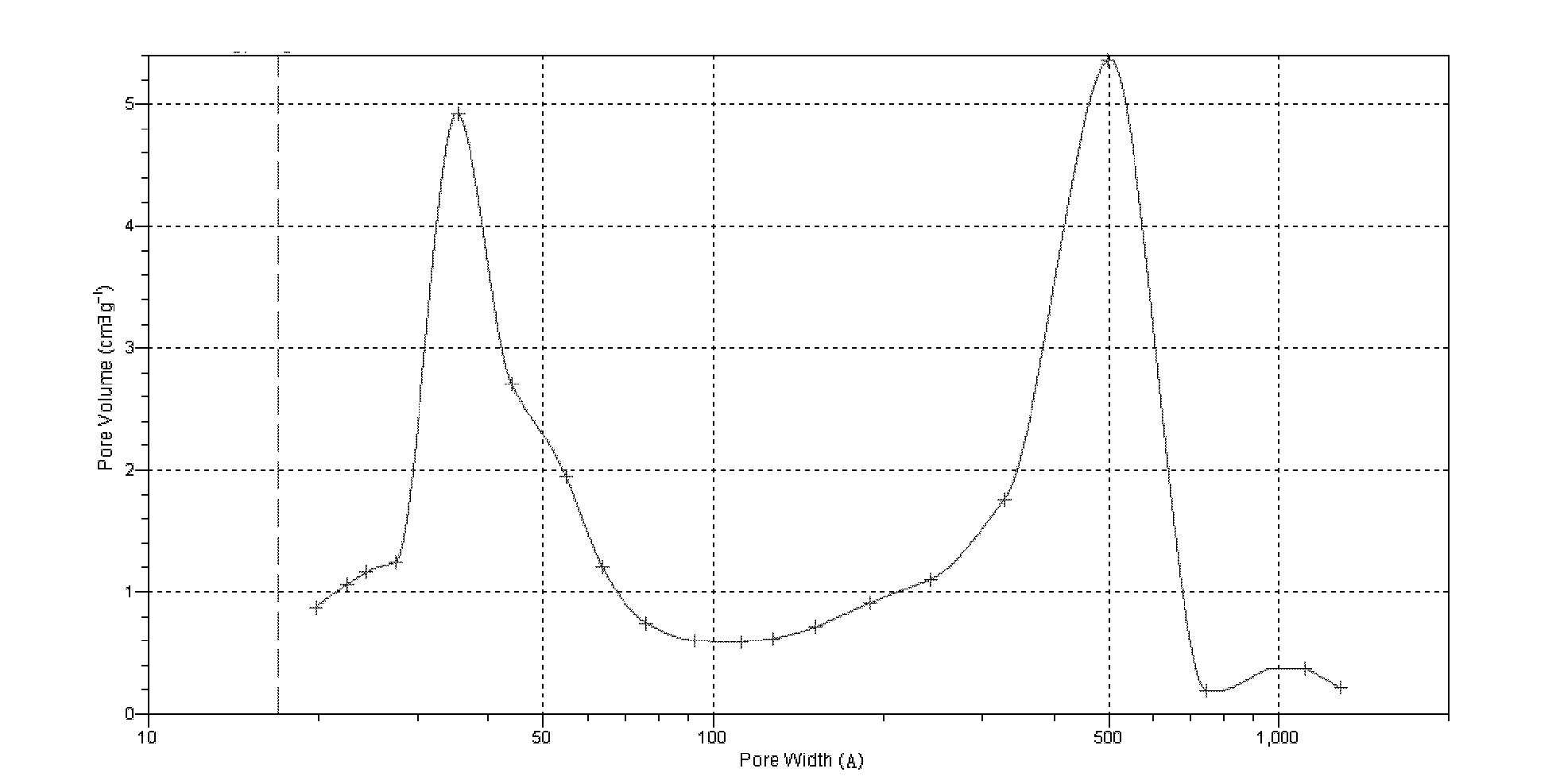

[0037] Mix 1g of tri-block copolymer (P123), 7.5ml of water, 30g of 2.0mol / L HCl, and dissolve with magnetic stirring at 38°C for 4 hours, then add 2.08g of tetraethyl orthosilicate (TEOS) dropwise to the solution. Continue to stir After 20 hours, it was crystallized in a high-pressure hydrothermal reactor at 100°C for 72 hours, cooled, filtered, washed, and dried. The dried product was calcined at 550° C. for 5 hours to remove the high-molecular substances in the silica to obtain the mesoporous silica material SBA-15.

[0038] In addition, SBA-15 is used as a template and sucrose as a carbon source to prepare mesoporous carbon materials. The steps are: dissolve 1.25g of sucrose in 5g of water, add 1g of mesoporous silica template, and slowly add 0.14g of 98% concentrated Sulfuric acid. Ultrasound mixed evenly, carbonized at 100°C for 6 hours, and carbonized at 160°C for 6 hours; another 0.75g of sucrose was dissolved in 5g of distilled water, added to the above product, and 0...

Embodiment 2

[0044] Mix 1g of P123, 7.5ml of water and 30g of 2.0mol / L HCl, stir and dissolve at 38°C for 4 hours, then add 4g of TEOS dropwise to the solution. After stirring for 10 minutes, crystallize in a high-pressure hydrothermal reactor at 100°C 24h, cooling, filtering, washing and drying. The dried product was calcined at 550° C. for 5 hours to remove the high-molecular substances in the silica to obtain the mesoporous silica material SBA-15.

[0045] In addition, SBA-15 was used as a template, and sucrose was used as a carbon source to prepare mesoporous carbon materials. The steps were: dissolve 1.25g sucrose in 5g water, add 1g mesoporous silica template, and slowly add 0.14g concentrated sulfuric acid. Ultrasound Mix evenly, carbonize at 100°C for 8 hours, and carbonize at 160°C for 8 hours; add 0.75g of sucrose to 5g of distilled water and add to the above product, slowly add 0.08g of concentrated sulfuric acid. Carbonize for 8 hours, and then continue to carbonize at 160°C f...

Embodiment 3

[0050] Mix 1 g of P123, 7.5 ml of water, 30 g of 2.0 mol / L HCl, and dissolve with magnetic stirring at 40°C for 4 hours, then add 1.0 g of TEOS dropwise to the solution. After continuing to stir for 20h, crystallize in a high-pressure hydrothermal reactor at 100°C for 48h, cool, filter, wash, and dry. The dried product was calcined at 550° C. for 5 hours to remove the high-molecular substances in the silica to obtain the mesoporous silica material SBA-15.

[0051] In addition, SBA-15 is used as a template and hot phenolic resin is used as a carbon source to prepare mesoporous carbon materials. The steps are: dissolve 1.25g of hot phenolic resin in 5g of water, add 1g of mesoporous silica template, and slowly drop 0.14g Concentrated sulfuric acid. Ultrasonic mixing, carbonization at 100°C for 6 hours, and carbonization at 160°C for 6 hours; another 0.75g of hot phenolic resin dissolved in 5g of distilled water, added to the above product, slowly added dropwise 0.08g of concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com