Patents

Literature

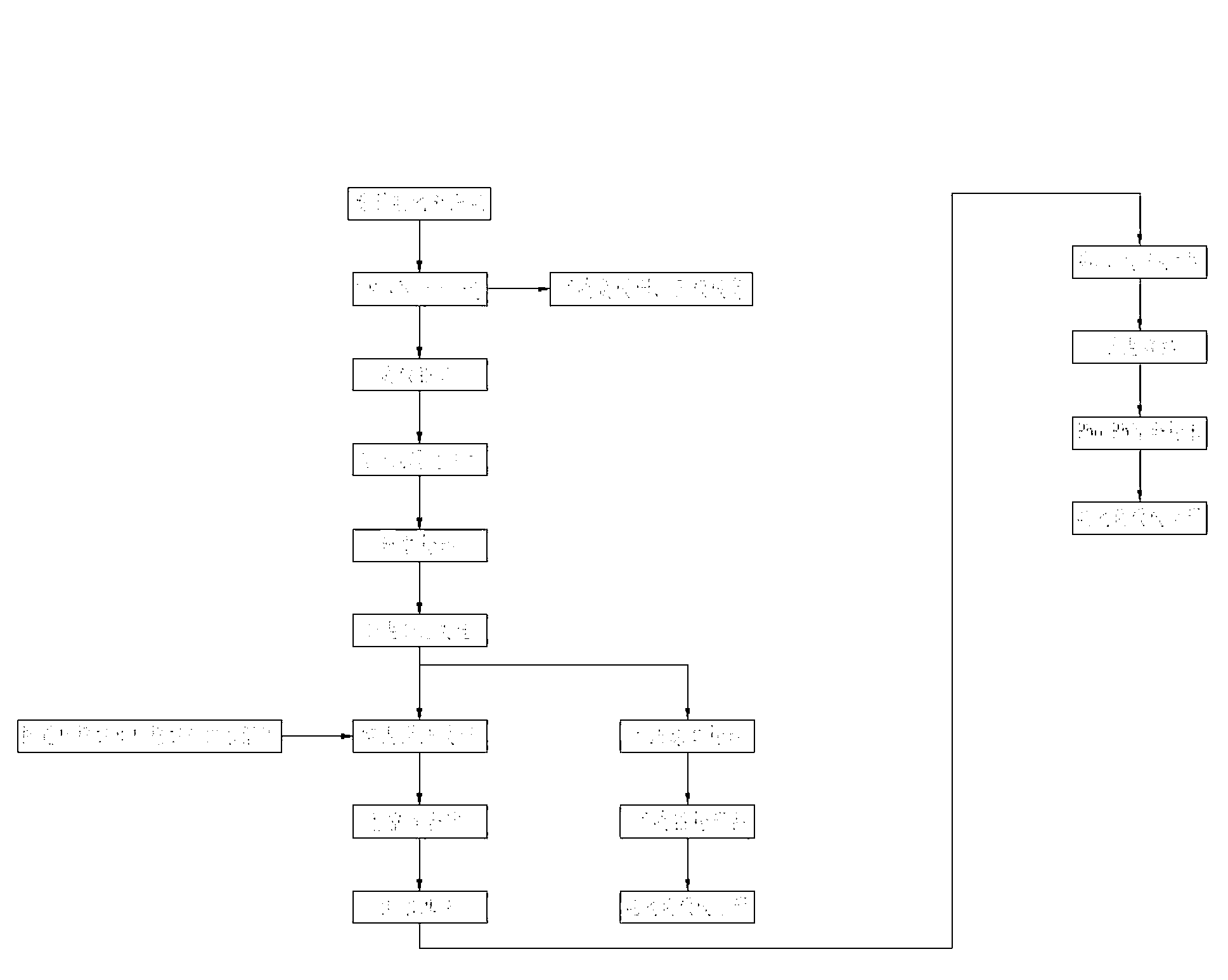

114results about How to "High electrochemical capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrode plate for lithium ion battery and manufacturing method thereof

InactiveCN101710619AChange the conductive contact interfaceImprove conductivityCell electrodesAdhesiveEngineering

The invention discloses an electrode plate for a lithium ion battery and a manufacturing method thereof, and particularly relates to the electrode plate for the lithium ion battery taking multi-layer graphene as a conductive agent and a manufacturing method thereof. The electrode plate of the invention consists of a positive electrode or negative electrode active substance, the conductive agent and an adhesive. The method comprises the steps of: using the positive electrode or negative electrode active substance, the conductive agent and the adhesive as raw materials to obtain electrode slurry through stirring and dispersing, and then obtaining the electrode plate through coating, drying and tabletting. The conductive agent adopted by the invention has the advantages of high dispersivity, high electric conductivity, good filling effect and the like; and the method has the advantages of simplicity, low production cost and convenient popularization and application. The method can remarkably improve the electric conductivity, electrochemical capacity and enhance charge-discharge capability of electrode materials by multiples, so the method can be widely applied to the preparation of electrode plates of lithium ion batteries.

Owner:CHONGQING UNIV

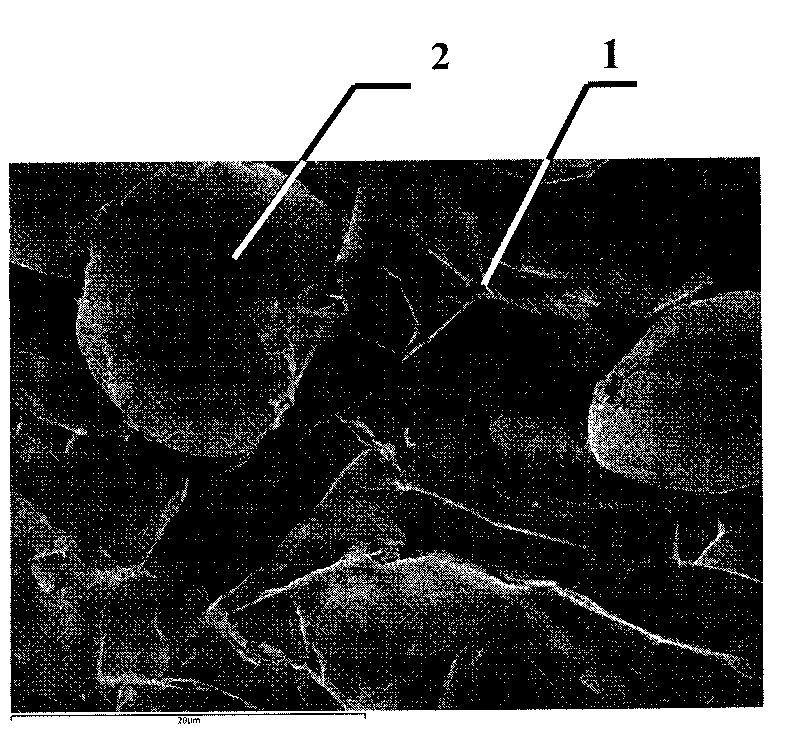

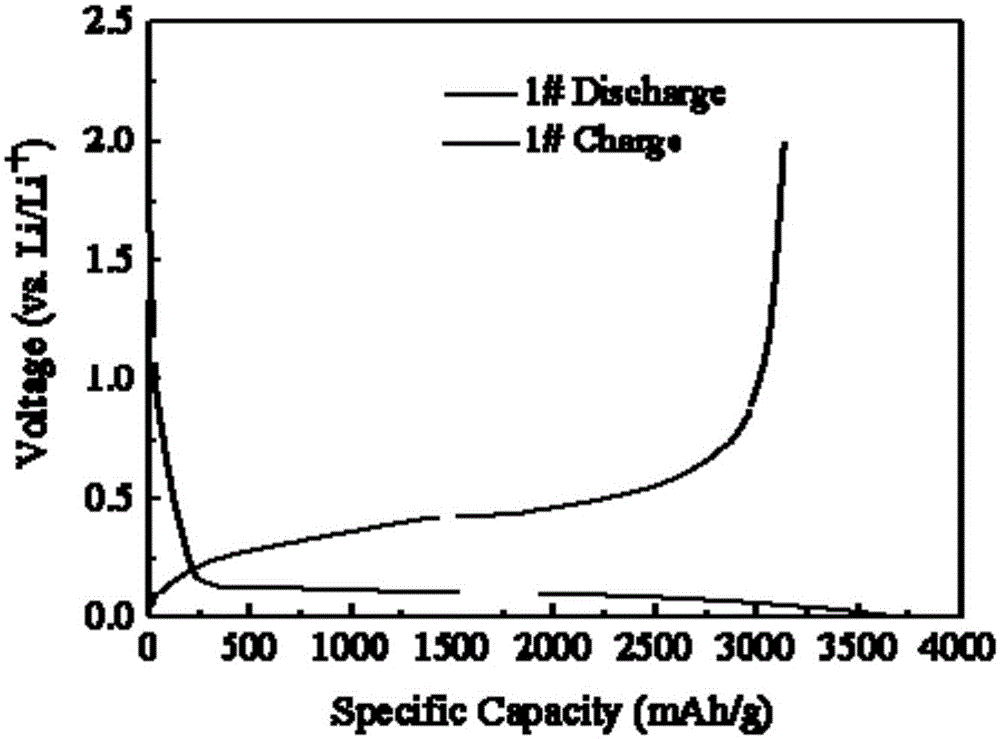

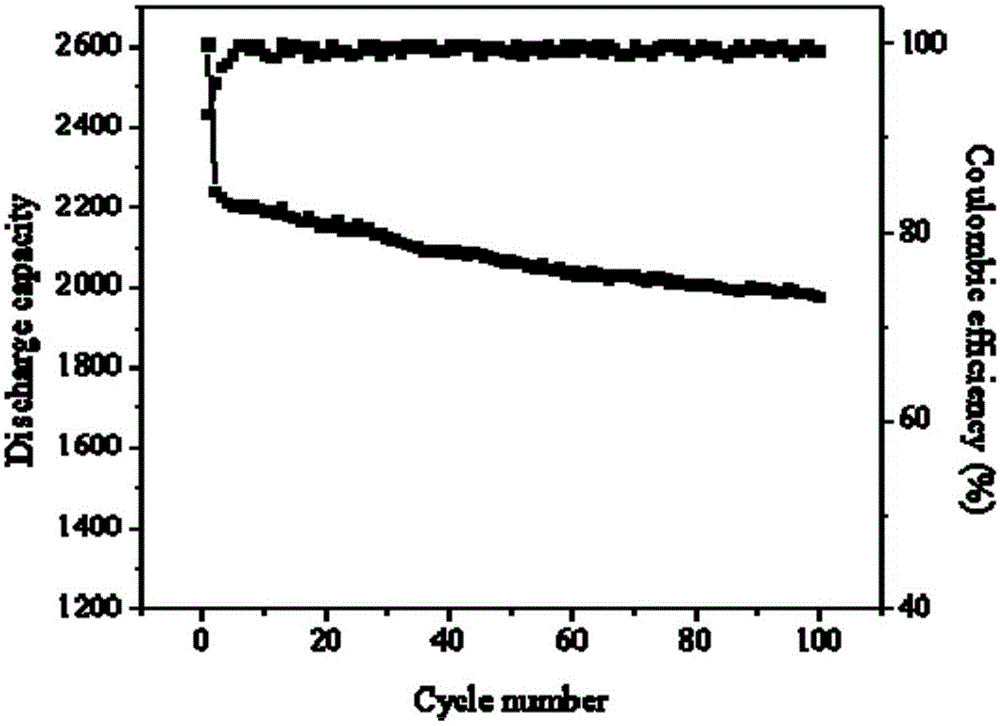

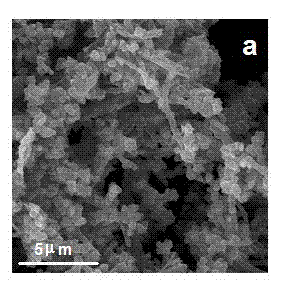

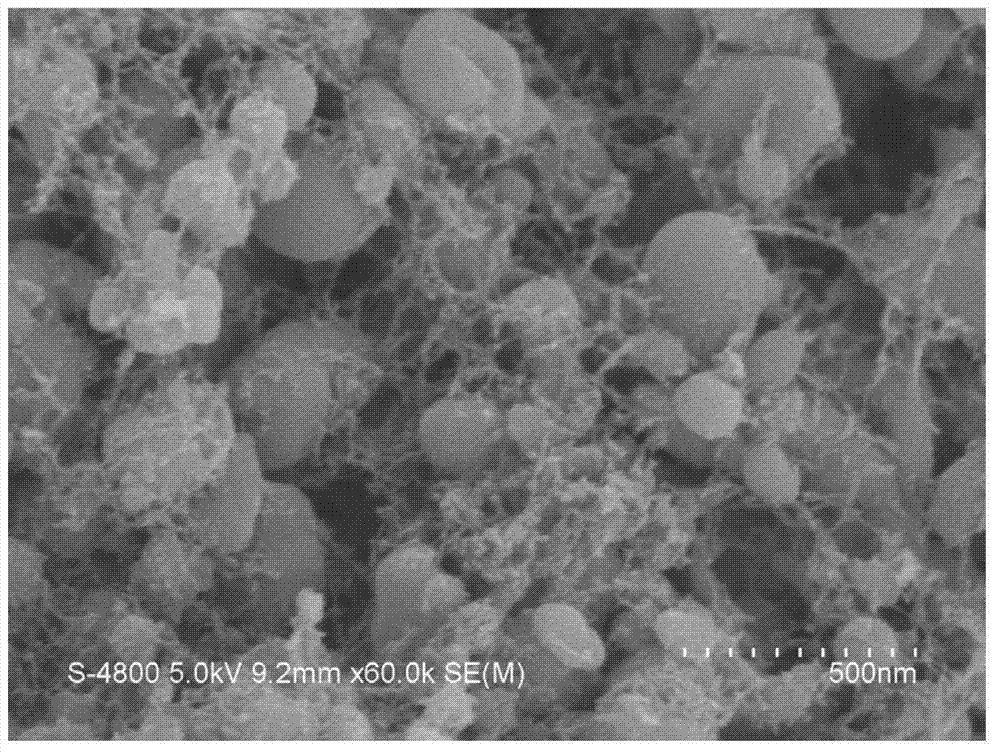

Graphene macroscopic body/tin oxide composite lithium ion battery anode material and process thereof

ActiveCN102244250AImprove conductivityLarge specific surface areaCell electrodesPorous grapheneElectrolytic agent

The invention relates to a graphene macroscopic body / a tin oxide composite lithium ion battery anode material and a process thereof. The anode material consists of a three-dimensional graphene macroscopic body and nano tin dioxide which grows in a pore of the three-dimensional graphene macroscopic body in an orientated way; and a volume is 500 to 2,000 mAh / g; the coulomb efficiency is 80 to 99.5 percent, wherein a mass ratio of the three-dimensional graphene macroscopic body to the tin dioxide is 1:(0.1-20). The characteristic of high electric conductivity of graphene is kept, the transfer and transport of charges are facilitated, and microscopic and macroscopic electric network structures are formed; meanwhile, the three-dimensional graphene macroscopic body has a big specific surface area and abundant pore spaces, so that the transfer of lithium ions is facilitated, and the contact area of the electrode material and electrolyte is enlarged; and the preparation process is environment-friendly, pollution-free and suitable for industrial production.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

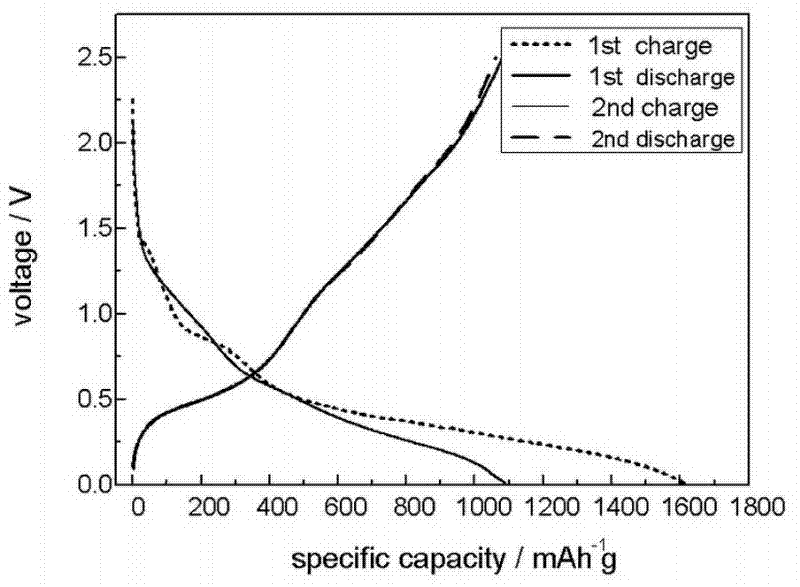

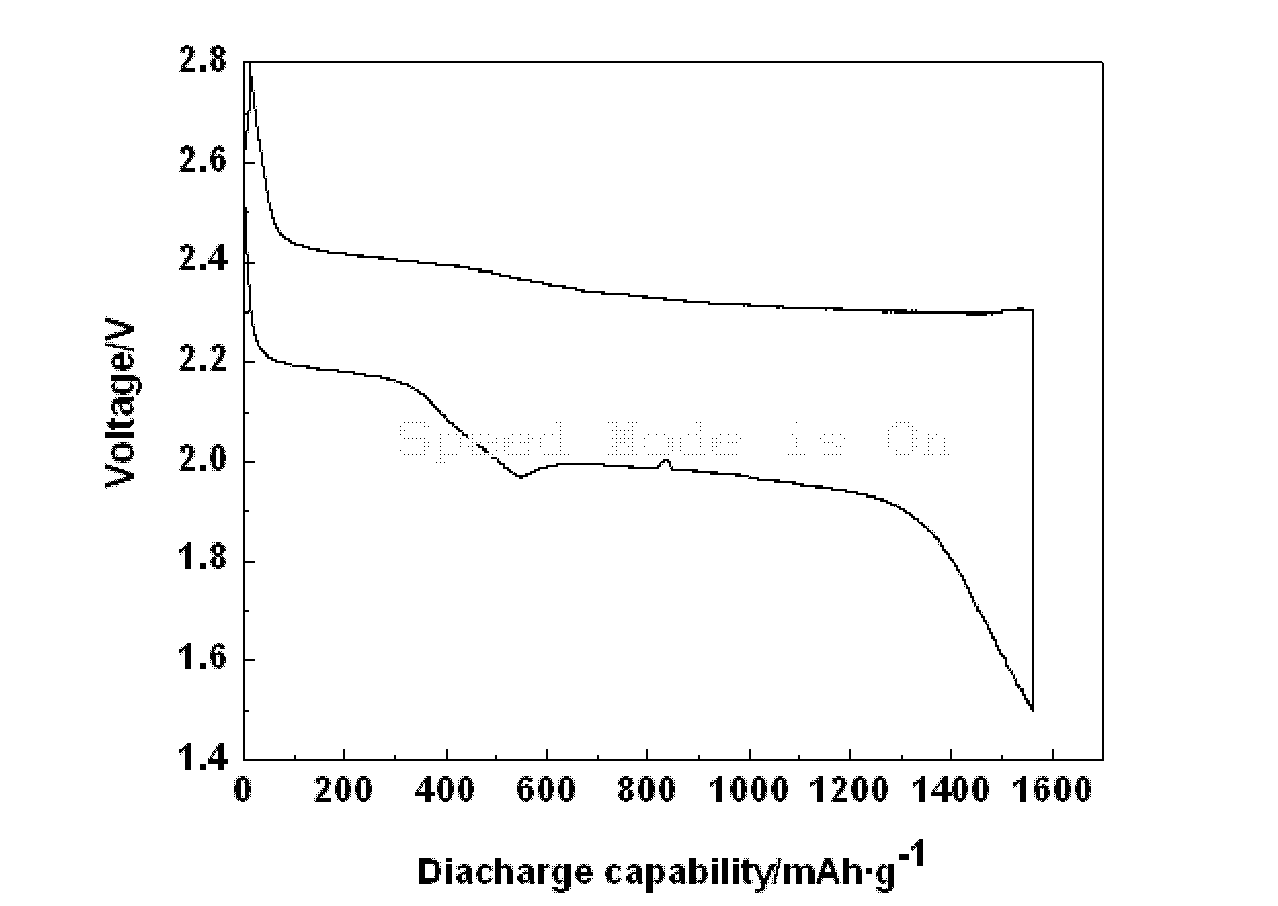

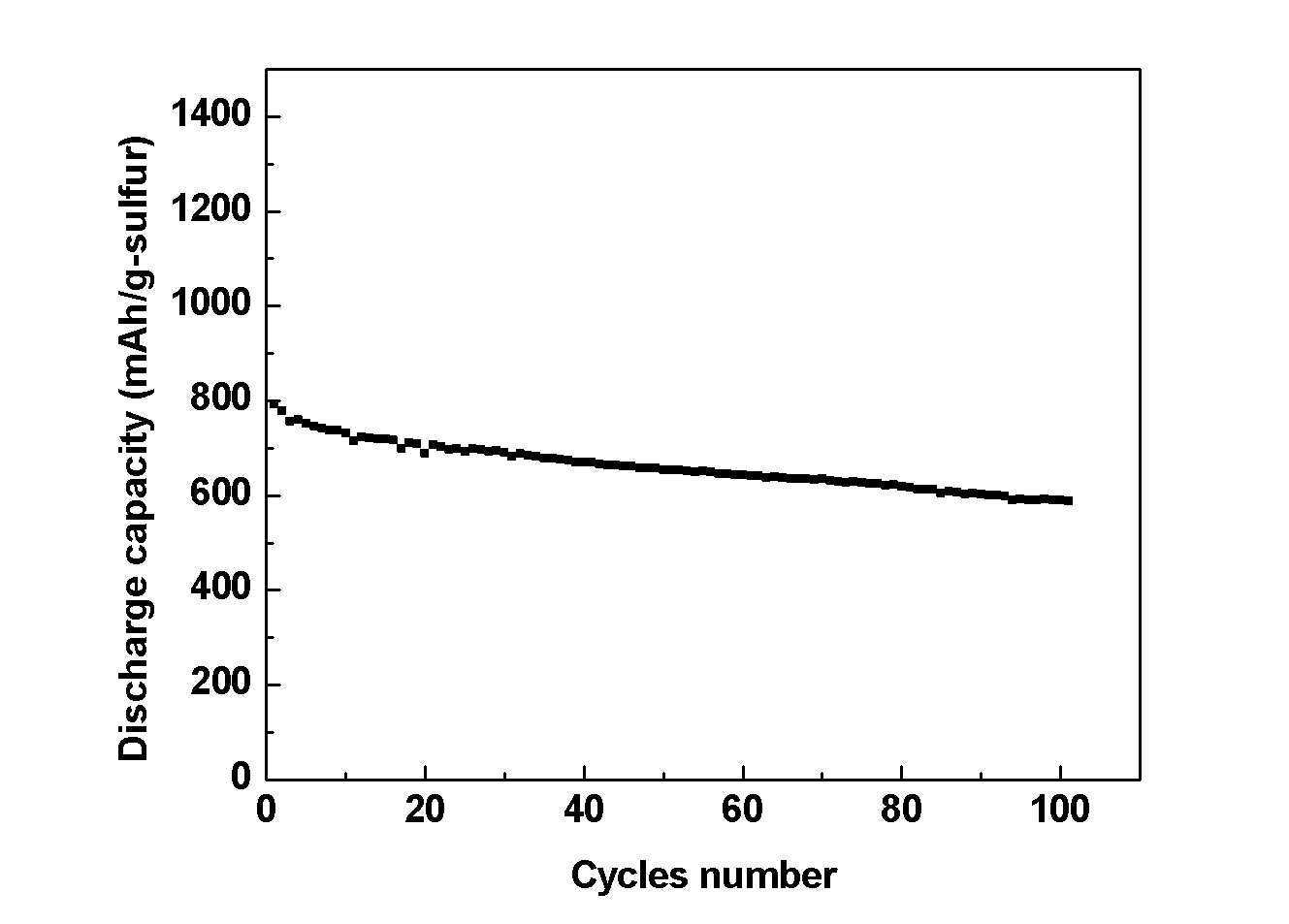

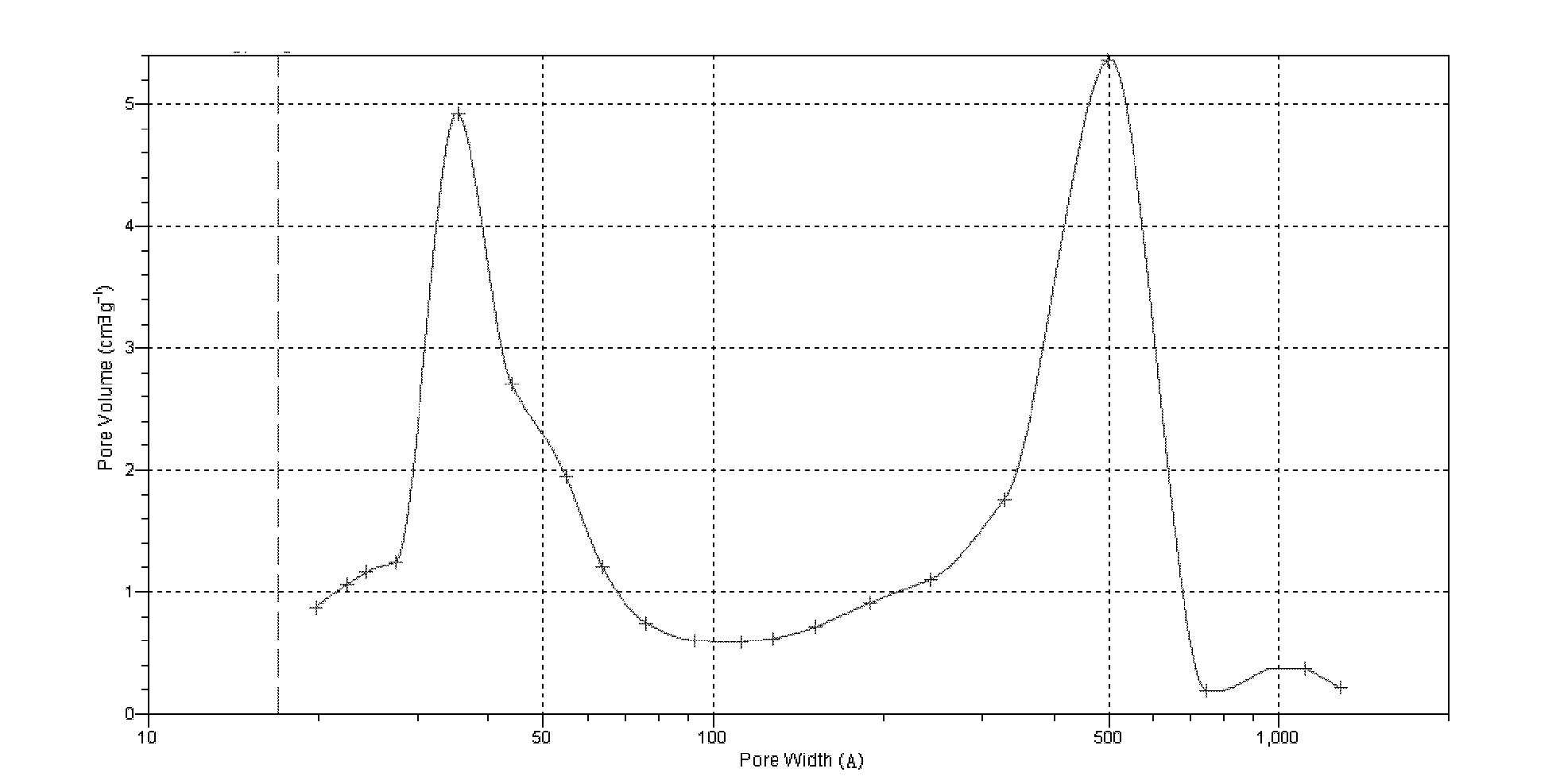

Carbon-sulphur composite used for cathode material of lithium sulphur battery as well as preparation method and application thereof

ActiveCN103050669AImprove discharge capacityLarger than surfaceNon-aqueous electrolyte accumulator electrodesLithium–sulfur batterySulfur electrode

The invention relates to a carbon-sulphur composite used for a cathode material of a lithium sulphur battery as well as a preparation method and application thereof. The carbon-sulphur composite comprises a carbon material and elemental sulphur, wherein the carbon material is formed by doping mesoporous carbon with the aperture of 2-5nm and electroconductive carbon with the aperture of 30-70nm, and the electroconductive carbon with the aperture of 30-70nm contains micropores with the aperture of 0.5-1.7nm; and the elemental sulphur accounts for 10-90wt% of the total quantity of the composite. Abundant micropores guarantee that the carbon material has larger specific surface, adsorption capacity to polysulphide is stronger, and dissolution of the polysulphide can be effectively limited, so that stability of a sulphur electrode is improved. Meso pores in porous distribution can load more sulphur active substances, electrochemical capacity of a composite material is improved, and diffusion and transmission of lithium ions and electrolyte solution can be facilitated, so that reduction polarization of the elemental sulphur is reduced and discharge plateau of the elemental sulphur is improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Silicon carbon composite material and preparation method thereof

InactiveCN105140477AHigh electrochemical capacityImprove conductivityMaterial nanotechnologyCell electrodesCvd grapheneSilicon particle

The invention discloses a silicon carbon composite material and a preparation method thereof. According to the preparation method, nano silicon powder particles are taken as a silicon substrate, a Si-C porous shell-core composite material is prepared, and the synergistic effect of silicon and carbon can be fully developed; the silicon material is high in electrochemical capacity, the carbon material is high in conductivity, and the flexible carbon material can be used for absorbing stress and buffering a volume effect of the silicon; meanwhile, the stable and firm shell-core structure can be used for maintaining the material stability; the porous structure can be used for increasing the contact structure of the silicon particles and an electrolyte and improving the compatibility of the silicon particles and the electrolyte; and the three-layer shell-core structure material is dispersed in a graphene material, the conductivity of the material can be further improved, and the capacity performance and the cycle life of an electrode material are improved.

Owner:HUBEI UNIV

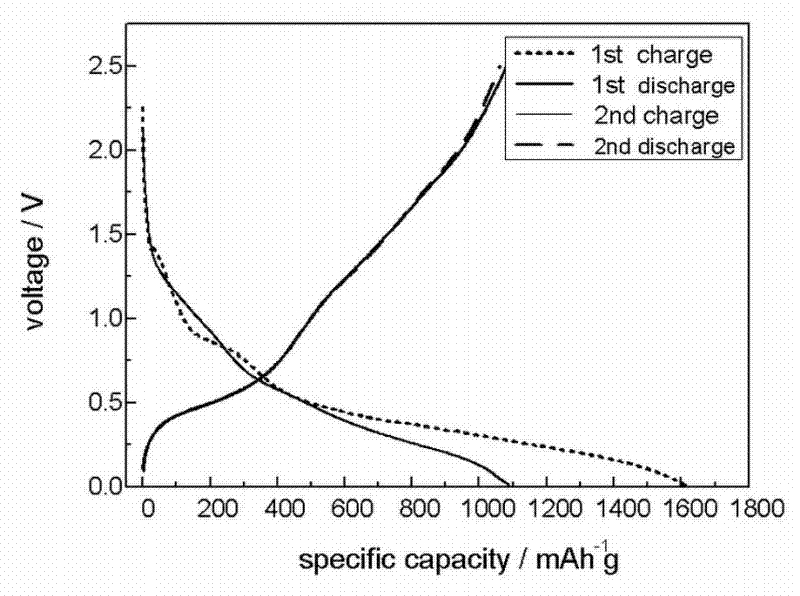

Sulfur/carbon composite material for lithium-sulfur secondary battery and preparation method thereof

InactiveCN102969481AHigh reactivityIncrease profitElectrode manufacturing processesNon-aqueous electrolyte accumulator electrodesCarbon compositesDischarge efficiency

The invention discloses a sulfur / carbon composite material for a lithium-sulfur secondary battery and a preparation method thereof. The composite material is formed by compositing a micro-pore carbon substrate with a lithium ion conduction property and elemental sulfur filled in the micro-pore structure. The carbon substrate is used as an electronic conductor in the composite material, and is further used as a lithium ion conductor, so that sulfur electrode reaction is directly carried out on a sulfur / carbon solid-solid interface in a conversion reaction manner without directly contacting with electrolyte. Therefore, the problem of circulation caused by that a polysulfide intermediate product is dissolved in the electrolyte can be solved. Compared with the other sulfur / carbon composite electrode, the composite material has the advantages of high electrochemical capacity, good circulation stability, high charging and discharging efficiency and the like; and meanwhile, the preparation method is simple and low in cost, and has a good application prospect.

Owner:WUHAN UNIV

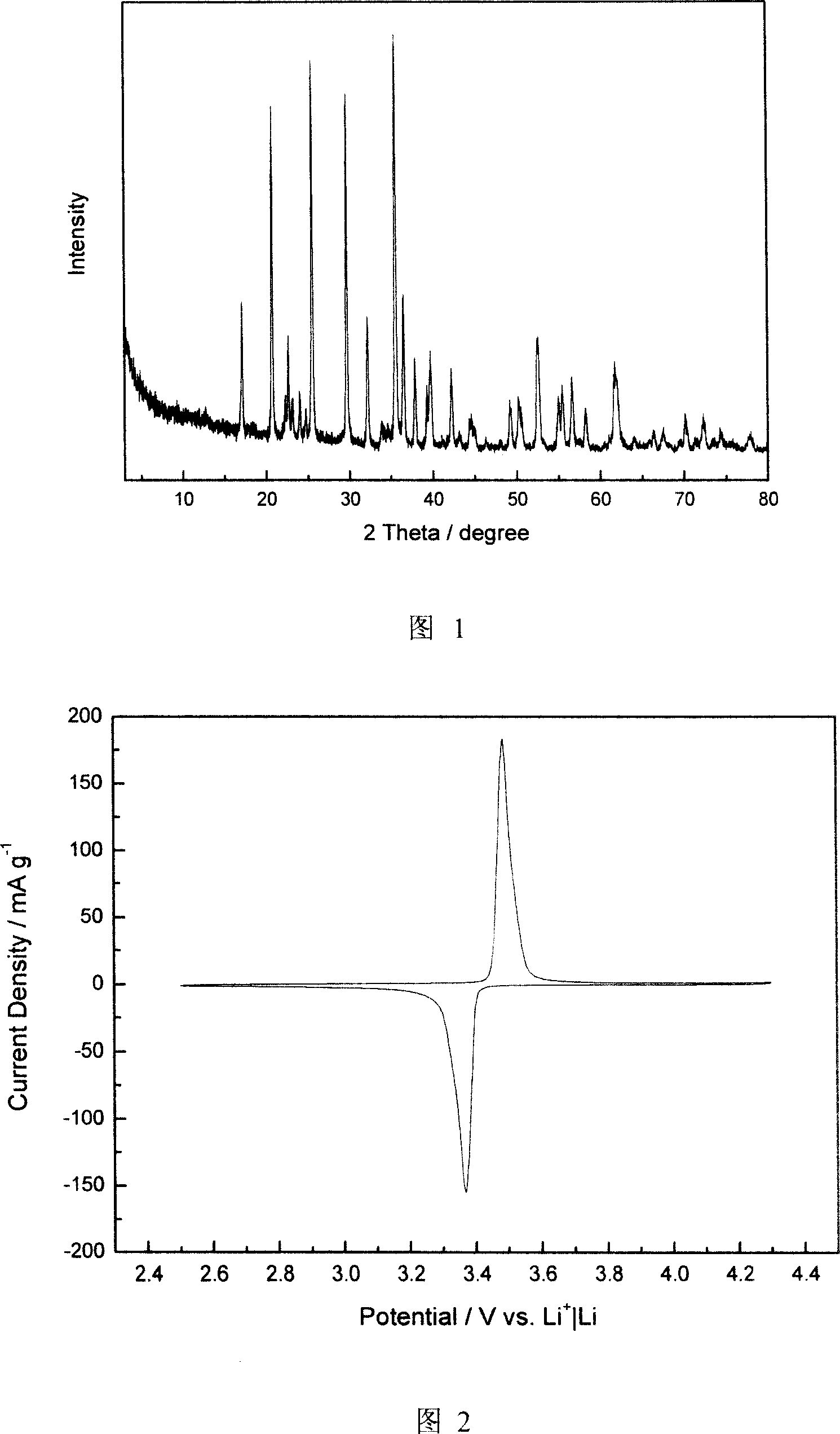

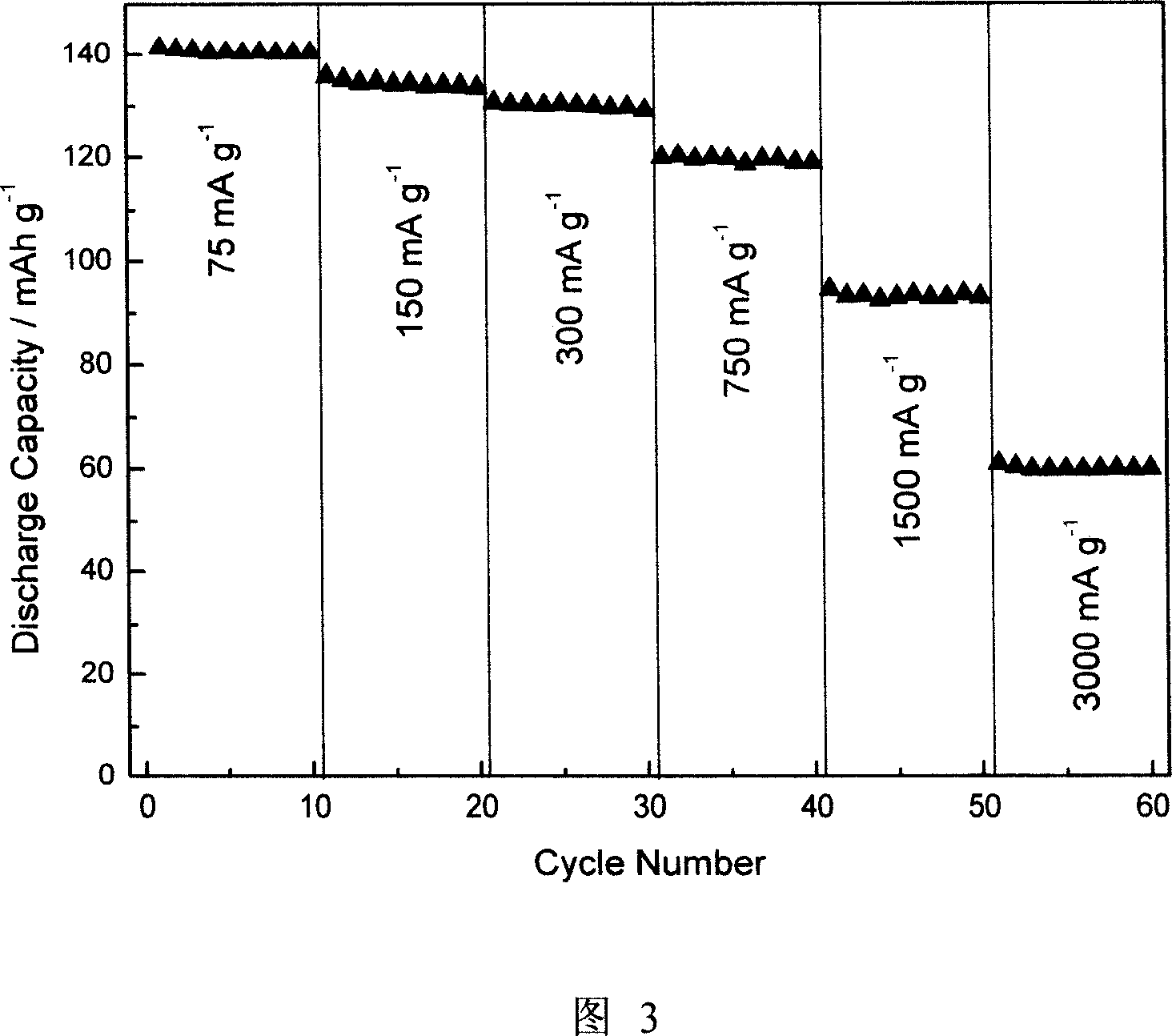

High charge-discharge magnification lithium iron phosphate material used for anode of lithium ion battery and its preparation method

InactiveCN1971981AHigh specific capacityImprove cycle stabilityElectrode manufacturing processesPhosphorus compoundsAluminium-ion batteryPhosphate

This invention relates to one lithium ion battery anode charging ferric phosphate lithium materials and its process method, which processes the front drive by gel-sol method under 30 to 90 degrees by materials of lithium compound, ferric compound and phosphate compound and conductive materials; then heating the front driver in inertia or weak educing atmosphere for analyzing under 100 to 450 degrees; in same atmosphere, heating by 1-30DEG C / min-1 and forging under 450 to 800 degrees for 2 to 24 hours and then culling naturally to get aim product.

Owner:NANKAI UNIV

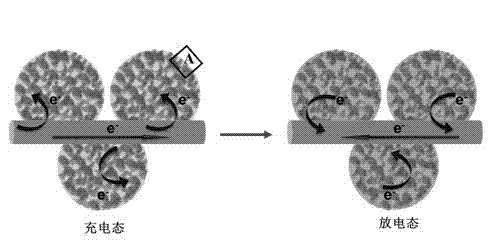

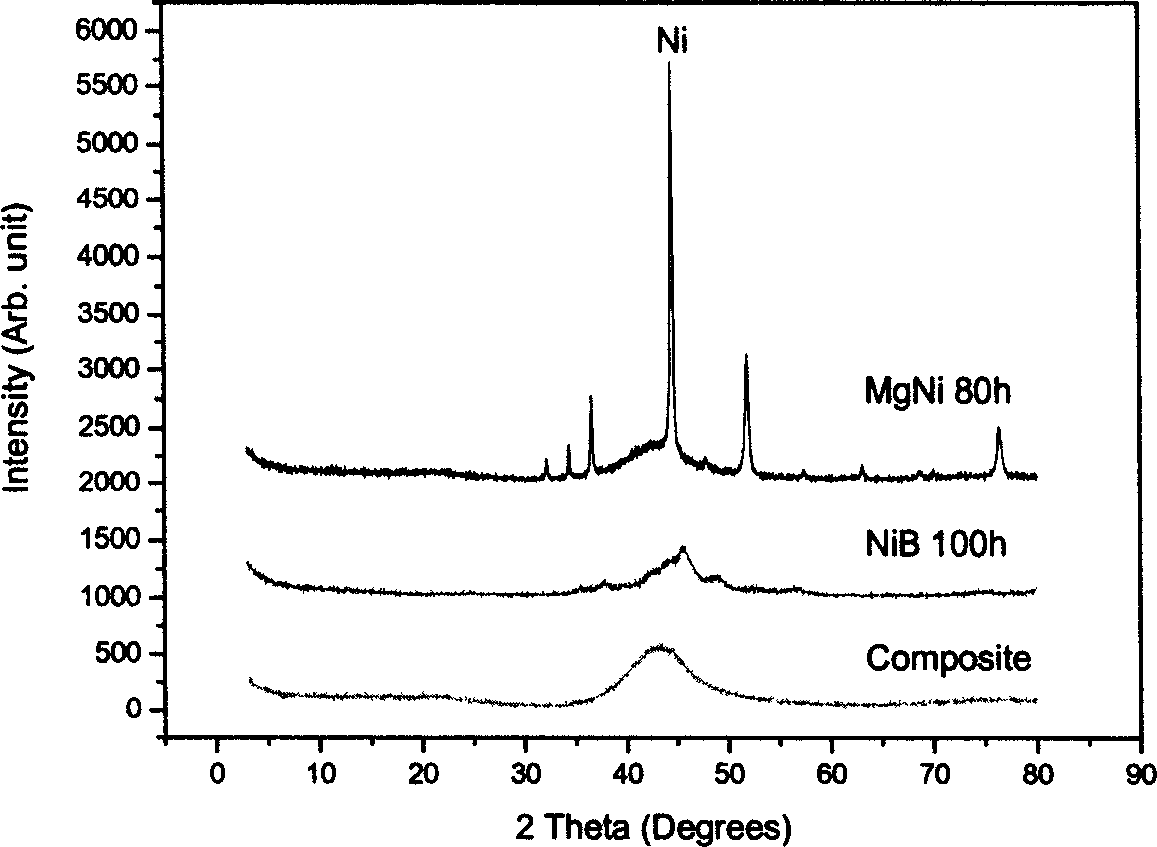

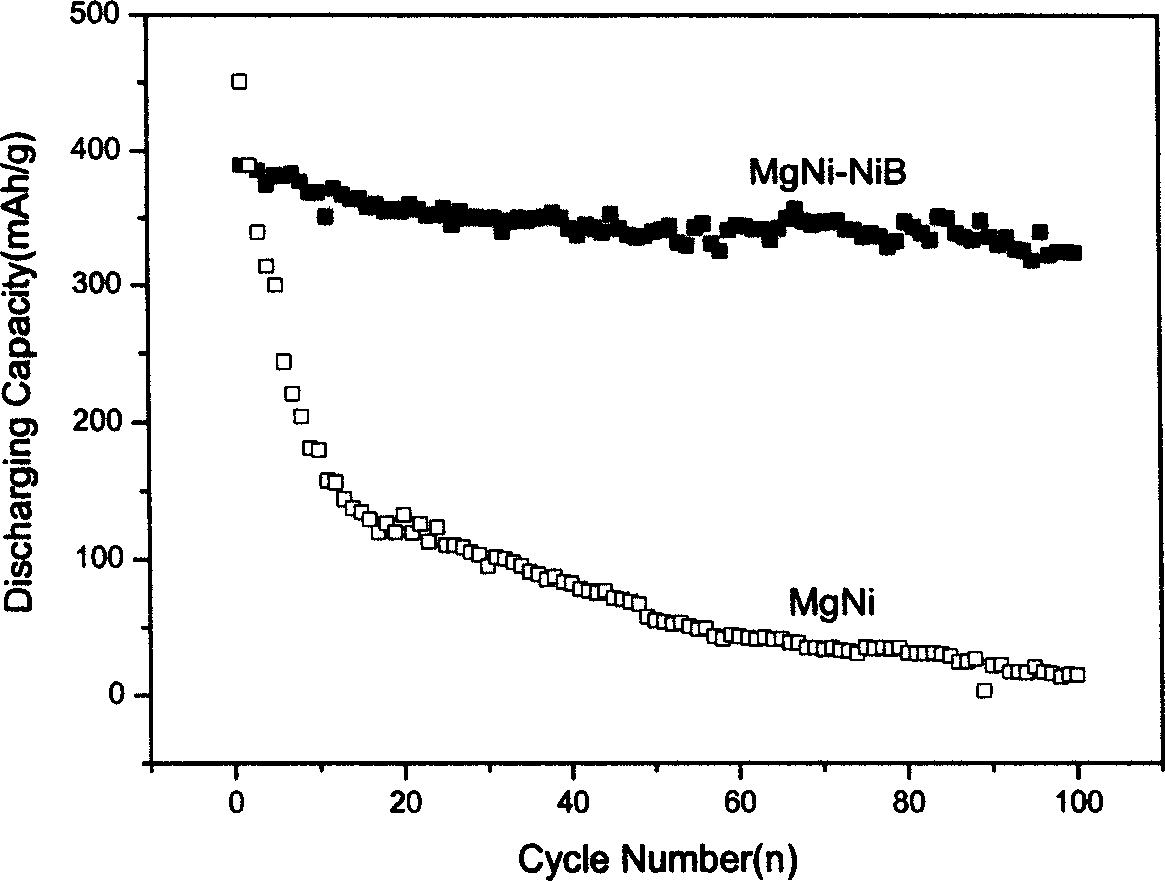

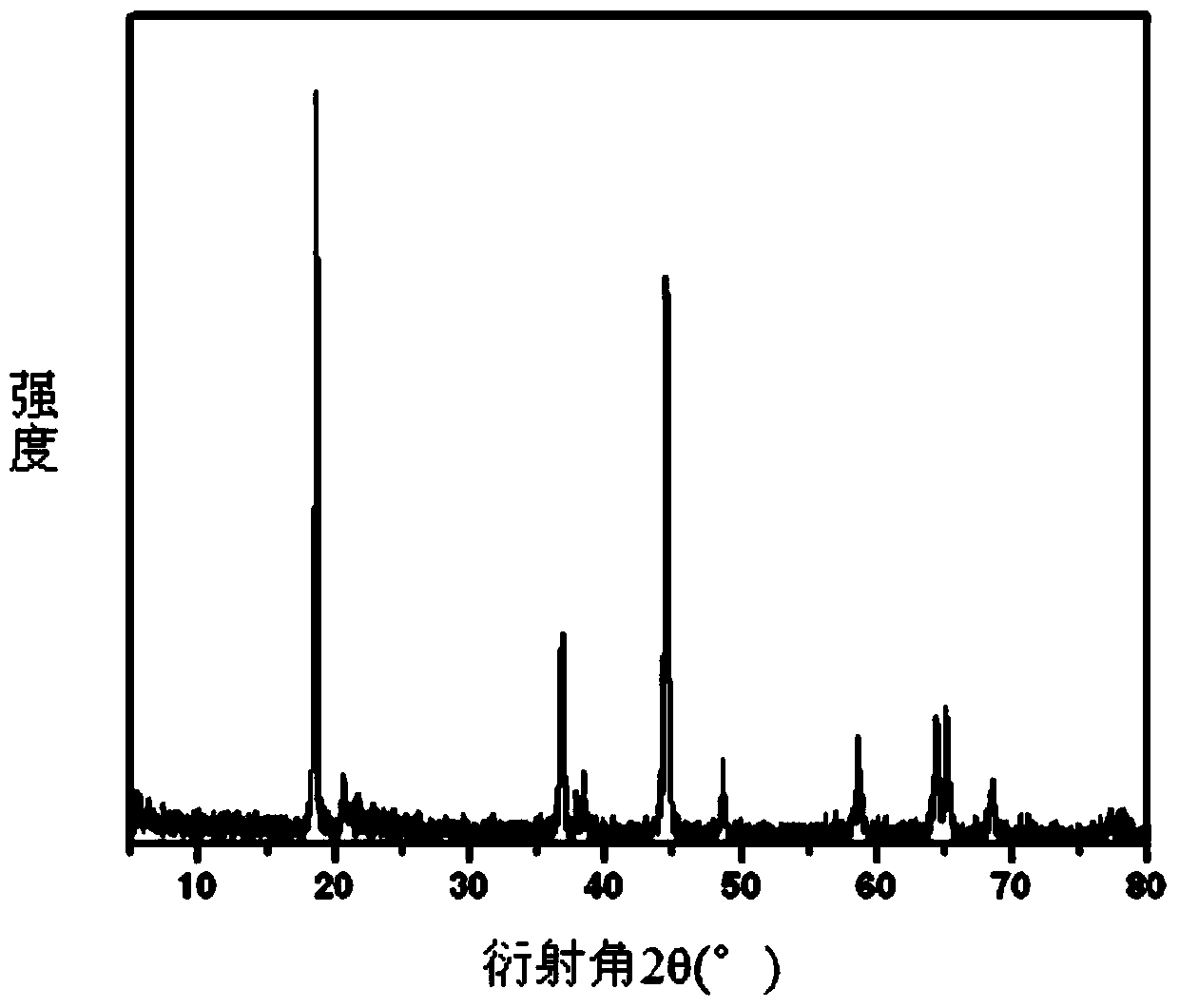

Magnesium based hydrogen storing alloy composite material and production thereof

The invention is about Mg-base hydrogen storage material and the method of the procedure. It has the chemical composition of Mgp-xMxNi-yNy-NieBf, M has the alternative of Al, Mn, Sn, Ca, Li, B, Na, B, Na, K, La, Ce, Nd, Pr, Y and misch metal. N has the alternative of V, Cu, Ti, Co, Fe, Ag, Cr, Zr, Se, Nb, Mo, W, Nb, C, Si and Sn, 1.0 <=p<=2.5, 0<=x<=1.0, 0<=y<=0.8, 1<=e<=3, 1<=f<=3. It has a good property under normal temperature and pressure, the electric pole that made by it has a high galvano-chemistry capability and cycle life. Its advantages include stable property; low price; extensive use of Ni-H battery, H accumulator, H power auto and fuel battery.

Owner:NANKAI UNIV

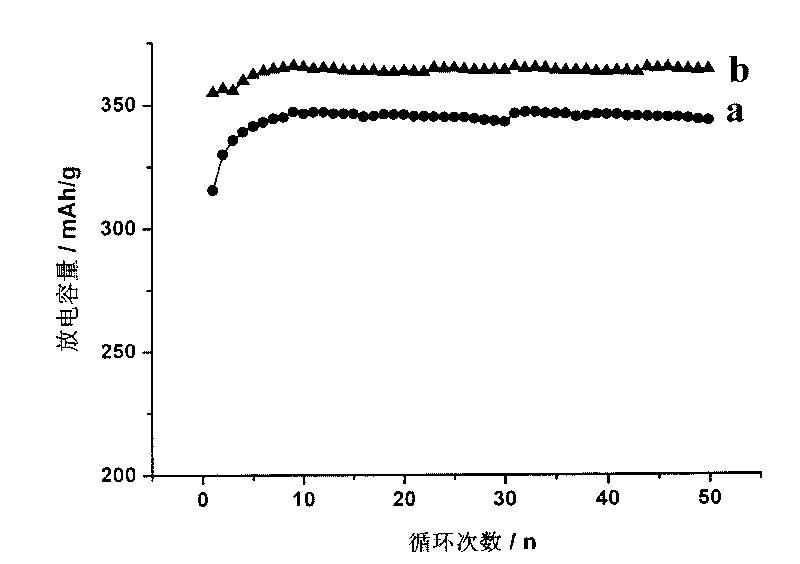

Negative pole made of silicon/graphite nanosheet composite material of lithium ion battery and preparation method thereof

InactiveCN101593827AComposite uniformAvoid the disadvantage of uneven mixingElectrode manufacturing processesActive material electrodesCopper foilElectrochemistry

The invention discloses a negative pole made of a silicon / graphite nanosheet composite material of a lithium ion battery, which comprises the following components in percentage by mass: 85 to 95 percent of nanometer silicon powder-graphite nanosheet composite material, and 5 to 15 percent of polyvinylidene fluoride, wherein the content of nanometer silicon powder is between 20 and 75 percent in the nanometer silicon powder-graphite nanosheet composite material. A preparation method thereof comprises the steps of: preparing graphite oxide, preparing a mixed dispersion system of the nanometer silicon powder and graphite oxide nanosheets; adding a reducing agent, namely hydrazine hydrate into the mixed dispersion system of the nanometer silicon powder and the graphite oxide nanosheets, and reducing the graphite oxide nanosheets into graphite nanosheets to obtain a composite material of the nanometer silicon powder and the graphite nanosheets; and fully mixing the composite material of the nanometer silicon powder and the graphite nanosheets with N-methylpyrrolidone sol of the polyvinylidene fluoride, blending the mixture into paste, evenly coating the paste onto a copper coil, and performing drying and roller compaction. The negative pole made of the silicon / graphite nanosheet composite material of the lithium ion battery has high electrochemical capacity and good cycling stability performance.

Owner:ZHEJIANG UNIV

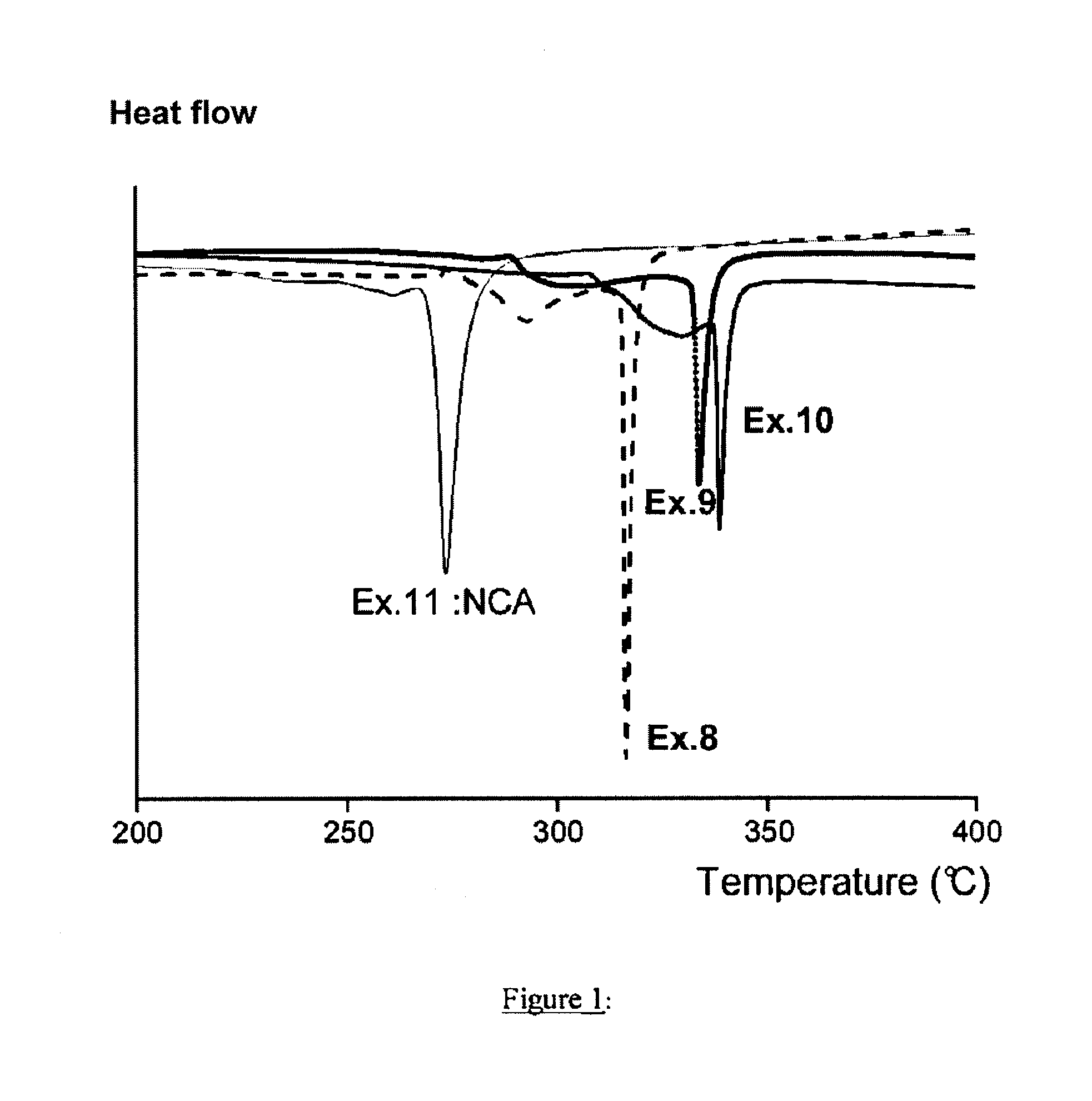

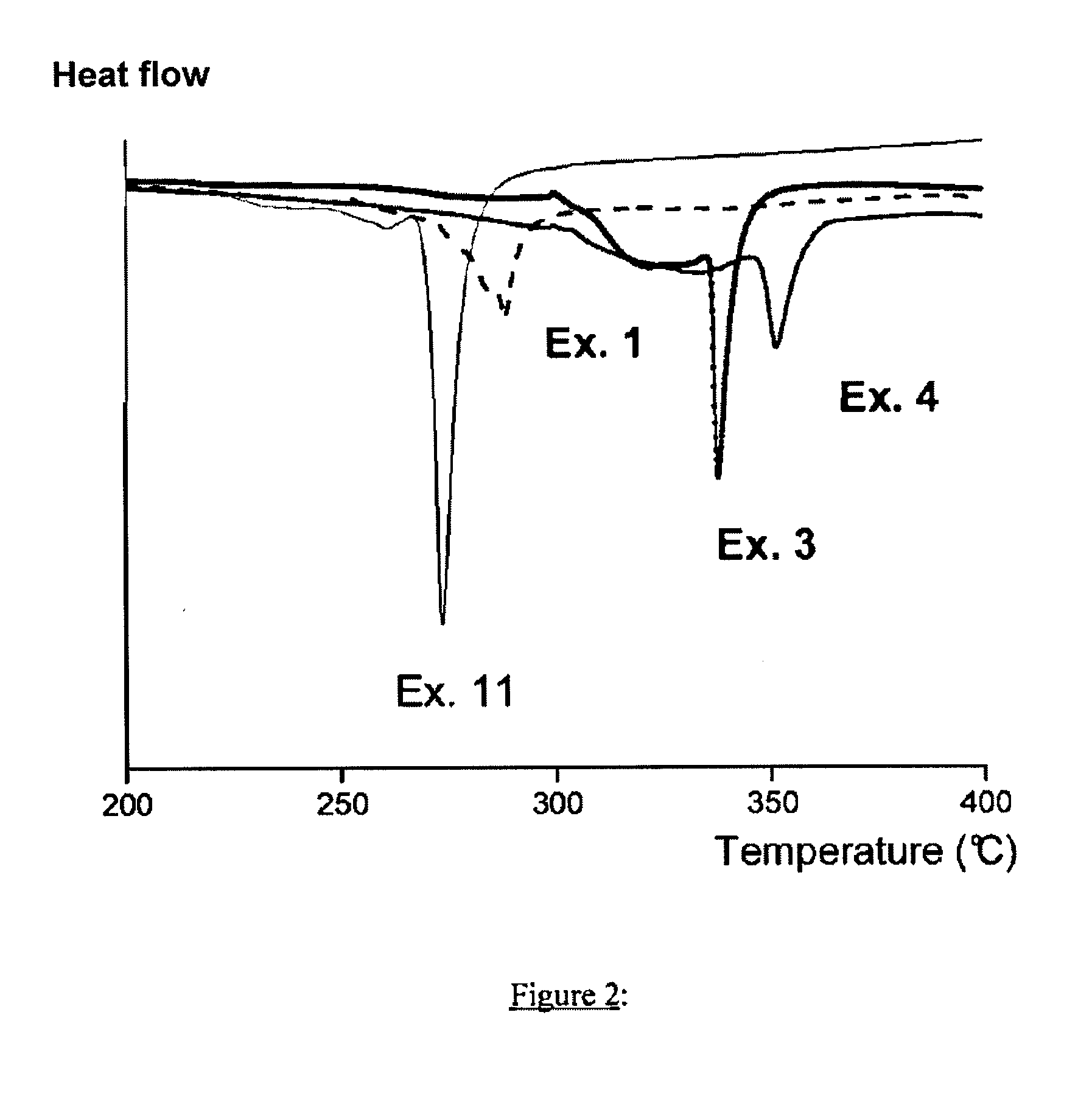

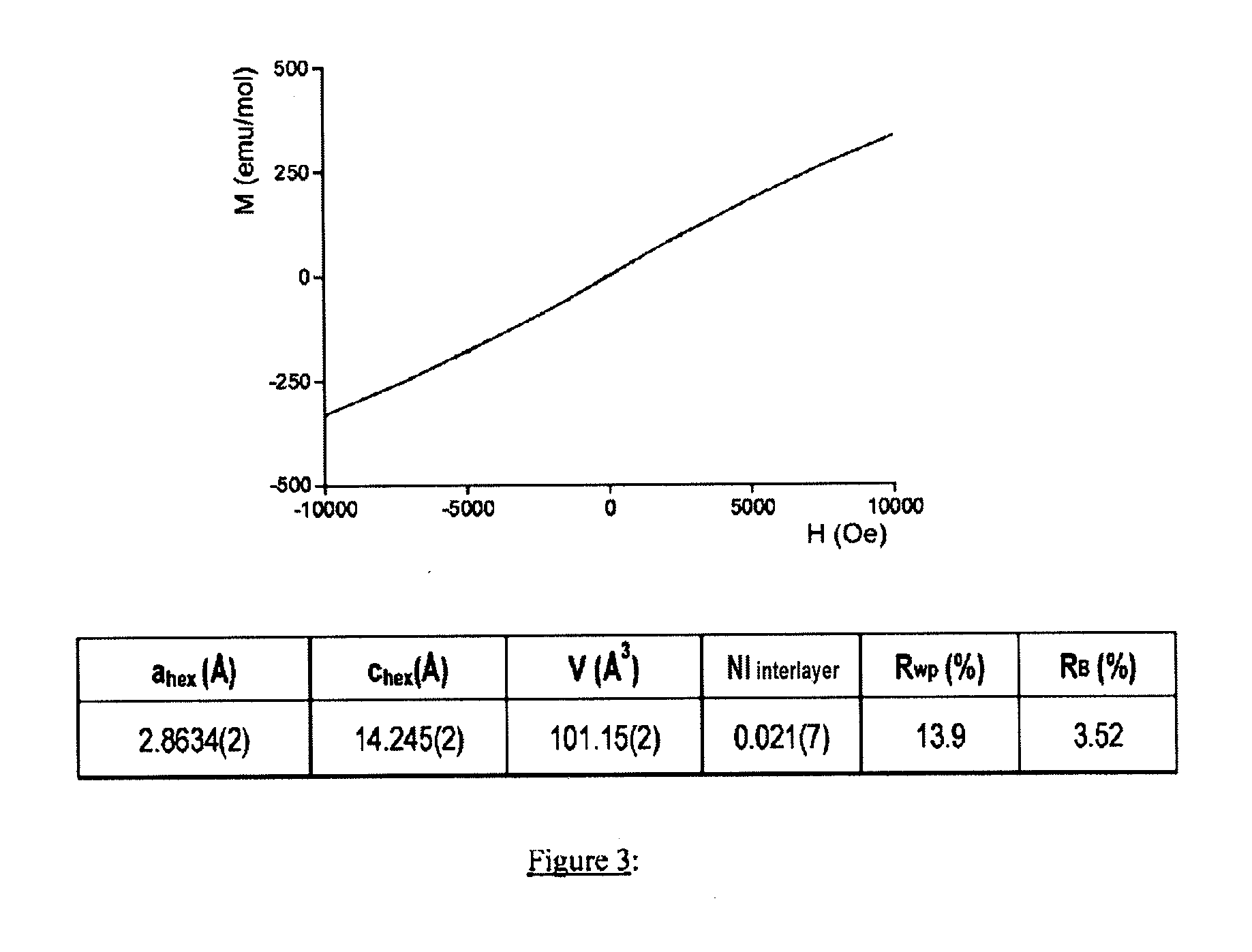

Positive electrode material for a lithium ion accumulator

ActiveUS20100108939A1High electrochemical capacityImprove thermal stabilityConductive materialSecondary cellsLithiumPhysical chemistry

Owner:SAFT GRP SA +2

Anode material of lithium battery and high temperature solid-phase sintering production method

InactiveCN101222046AHigh electrochemical capacityElectrode manufacturing processesLithium compoundsMicrometerRoom temperature

The invention relates to a lithium battery anode material provided with high electric capacity (more than 130 mAh / g) - LiBiSnO4 or LiBiTiO4 or LiBiPbO4 or LiInSnO4 or LiInTiO4 or LiInPbO4. The high-temperature solid state sintering preparation method for the lithium battery anode material comprises the following steps: Li2O or Bi2O3 or PbO2 and SnO2 or TiO2or PbO2 are taken as raw materials with a purity of 99.99 percent; the three raw materials are fully mixed according to the mole proportion of 1 to 1 to 2; mixture is grinded in a ball mill, and grain diameter of powder reaches 1 to 2 micrometers; the mixture is dried for 4+-2 hours under the temperature of 100+-20 DEG C; the powder is pressed into sheets and put into a high-temperature sintering furnace for burning; the sheets are crushed and pressed into sheets and then put into the high-temperature sintering furnace for the third time, and temperature is raised from room temperature to 900 to 1400 DEG C; after heat preservation for 25 to 36 hours, the sheets are cooled along with the furnace; the powder sheets are taken out and crushed, and grain diameter of the sheets after crushing is 0.5 to 1.2 micrometers; pure single-phase lithium battery anode material is prepared successfully.

Owner:NANJING UNIV

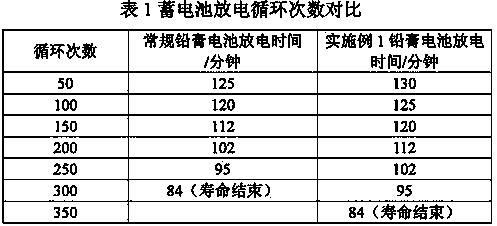

Method for recovering lead plaster of negative pole of disused lead acid storage battery and application of recovered lead plaster

ActiveCN103184340AReduce energy consumptionLarge specific surface areaWaste accumulators reclaimingProcess efficiency improvementElectrochemistryEnergy consumption

The invention discloses a method for recovering lead plaster of the negative pole of a disused lead acid storage battery and application of the recovered lead plaster. A preparation method of superfine lead powder comprises the following steps: firstly, a disused battery is fully charged; secondly, the lead plaster of the negative pole is separated from the lead acid storage battery; thirdly, the main substance of the lead plaster of the negative pole is changed into a lead raw material mainly composed of PbO and Pb via high temperature and humidity solidification; and lastly, dry grinding or crumbling of the lead raw material is carried out under the condition of oxygen, or wet treatment is carried out by using organic salt and organic acid to obtain superfine lead powder. The recovery method disclosed by the invention is low in cost, simple and convenient in process, high in recovery rate of lead, low in energy consumption and easy to achieve industrialization, and causes minor pollution to the environment during recovering the lead. The method directly prepares superfine lead powder which can be directly used to produce storage batteries. The superfine PbO powder prepared by the method has good performance, is high in technology added value, and can obtain a battery pole plate which has high electrochemistry capacity and a long charging / discharge service life.

Owner:SHENZHEN CENT POWER TECH

High-capacity lithium-enriched positive electrode material and preparation method thereof

ActiveCN104134797AHigh crystallinityUniform and controllable particle sizeCell electrodesSecondary cellsLithiumCalcination

The invention belongs to the field of electrochemistry and particularly relates to a high-capacity lithium-enriched positive electrode material and a reparation method thereof. The molecular formula of the high-capacity lithium-enriched positive electrode material is Li[Li<x-beta>Na<beta>Mn<1-y-z-alpha>Co<y>Ni<z>Y<alpha>]O2, wherein x is more than or equal to 0 and less than or equal to 0.6, y is more than 0 and less than or equal to 0.4, z is more than 0 and less than or equal to 0.4, alpha is more than or equal to 0 and less than or equal to 0.1 and beta is more than or equal to 0 and less than or equal to 0.2; the result of (1-y-z-alpha) is more than 0 and the result of (x-beta) is more than 0. The lithium-enriched positive electrode material containing Na and Y has the characteristics of low first-time irreversible capacity, large electrochemical capacity, high cycling stability, excellent rate performance and the like. The preparation method has the advantages that a preparation process is simple, raw materials are cheap and easily available, the cost is low, the high-temperature calcination time is very short, the repeatability is good and the industrialization is easy to realize.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

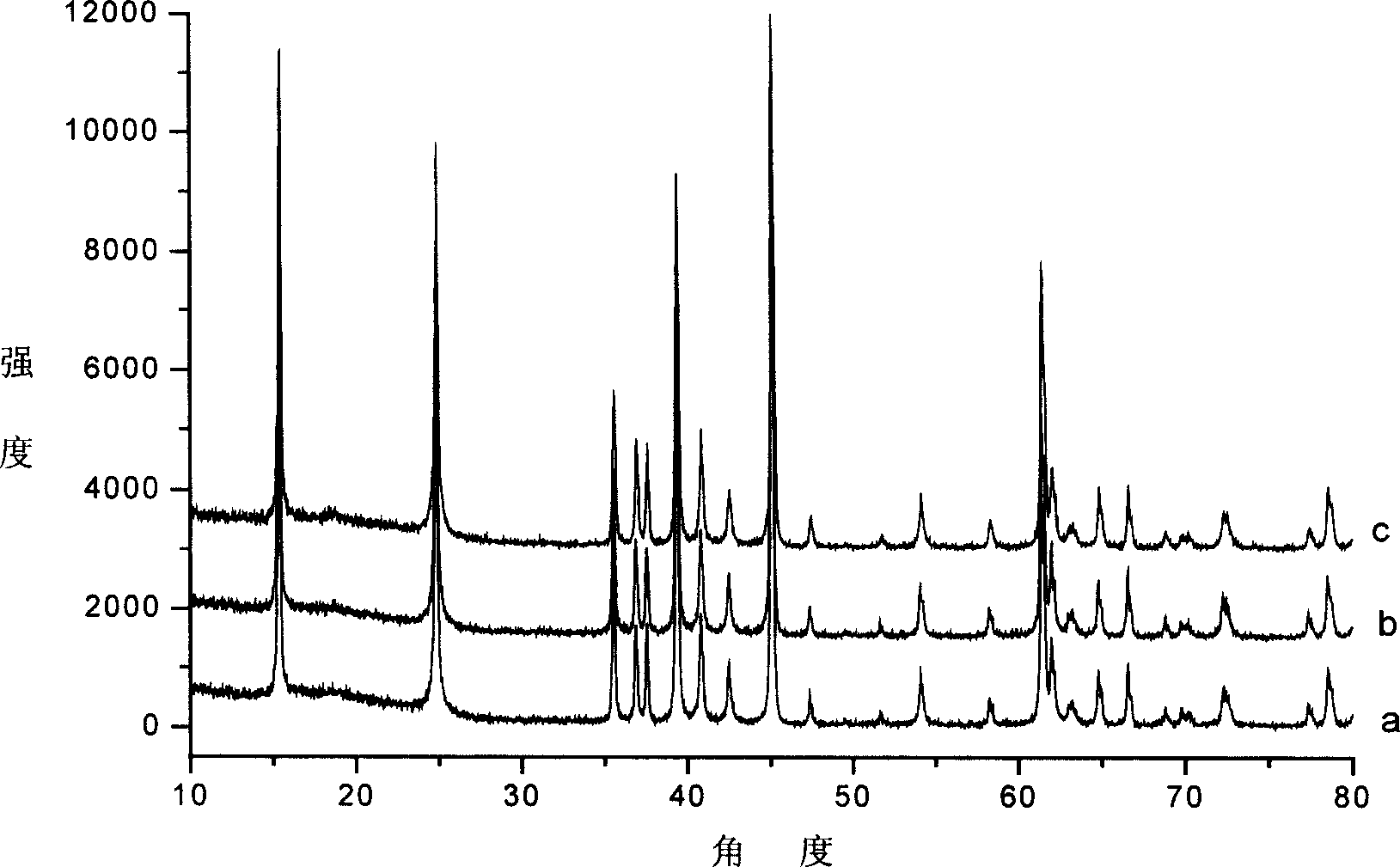

Titanium acid lithium battery cathode material containing rare metal elements

InactiveCN102054963AImprove fast charge and discharge performanceHigh electrochemical capacityCell electrodesIndustrial scaleRare-earth element

The invention relates to titanium acid lithium battery cathode material containing rare metal elements, which comprises a synthesized lithium titanate material. A or a plurality of rare metal elements are contained in the lithium titanate material; the rare metal elements adopt Zr, Al, La, Ce, Pr, Nd, Sm and Dy or Ho; the contents of the rare metal elements are 0.01-3 wt percent by oxidate; the lithium and titanium molar ratio in the lithium titanate material is 0.7-1.2; and the titanium acid lithium battery cathode material is produced by adopting the processes of material mixing, ball milling and sieving, high-temperature treatment, secondary ball milling, high-temperature heat preservation and the like. The titanium acid lithium battery cathode material containing the rare metal elements is doped with the rare metal elements, improves the quick charging and discharging properties, improves the electrochemical capacity and has excellent cycle performance, good repeatability and high consistency; and furthermore, the titanium acid lithium battery cathode material has the advantages of low raw material cost, short synthesis time, low temperature, low requirements for equipment and simple manufacturing process and is suitable for industrial scale production.

Owner:RISESUN MENGGULI NEW ENERGY SCIENCE & TECHNOLOGY CO LTD

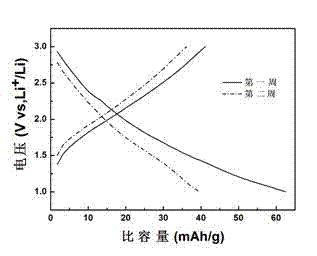

Lithium-rich manganese-based cathode material, its preparation method and lithium-ion battery

ActiveUS20170263931A1Excellent rate capability and cycle stabilityPoor rate capabilitySecondary cellsPositive electrodesLithium compoundSolvent

The present invention discloses a method for preparing lithium-rich manganese-based cathode material. The method comprises: dispersing α-MnO2 micron particles, a nickel salt and a lithium-containing compound in a solvent to obtain a mixture, then evaporating the mixture to remove the solvent, and calcining the solid product obtained from the evaporation; wherein the lithium-containing compound is a lithium salt and / or lithium hydroxide. The present invention also provides a lithium-rich manganese-based cathode material prepared by the above method. The present invention also provides a lithium-ion battery of which anode material contains the foregoing lithium-rich manganese-based anode material. The lithium-rich manganese-based cathode material provided by the present invention has high rate capability and prolonged cycle stability.

Owner:SUZHOU SUNMUN TECH CO LTD

Electrochemical insertion/deinsertion magnesium ion electrode with high capacity and stable circulation and preparation method

InactiveCN102142539AHigh electrochemical magnesium storage capacitySuper stable cycle performanceNon-aqueous electrolyte accumulator electrodesMaterials scienceMagnesium ion

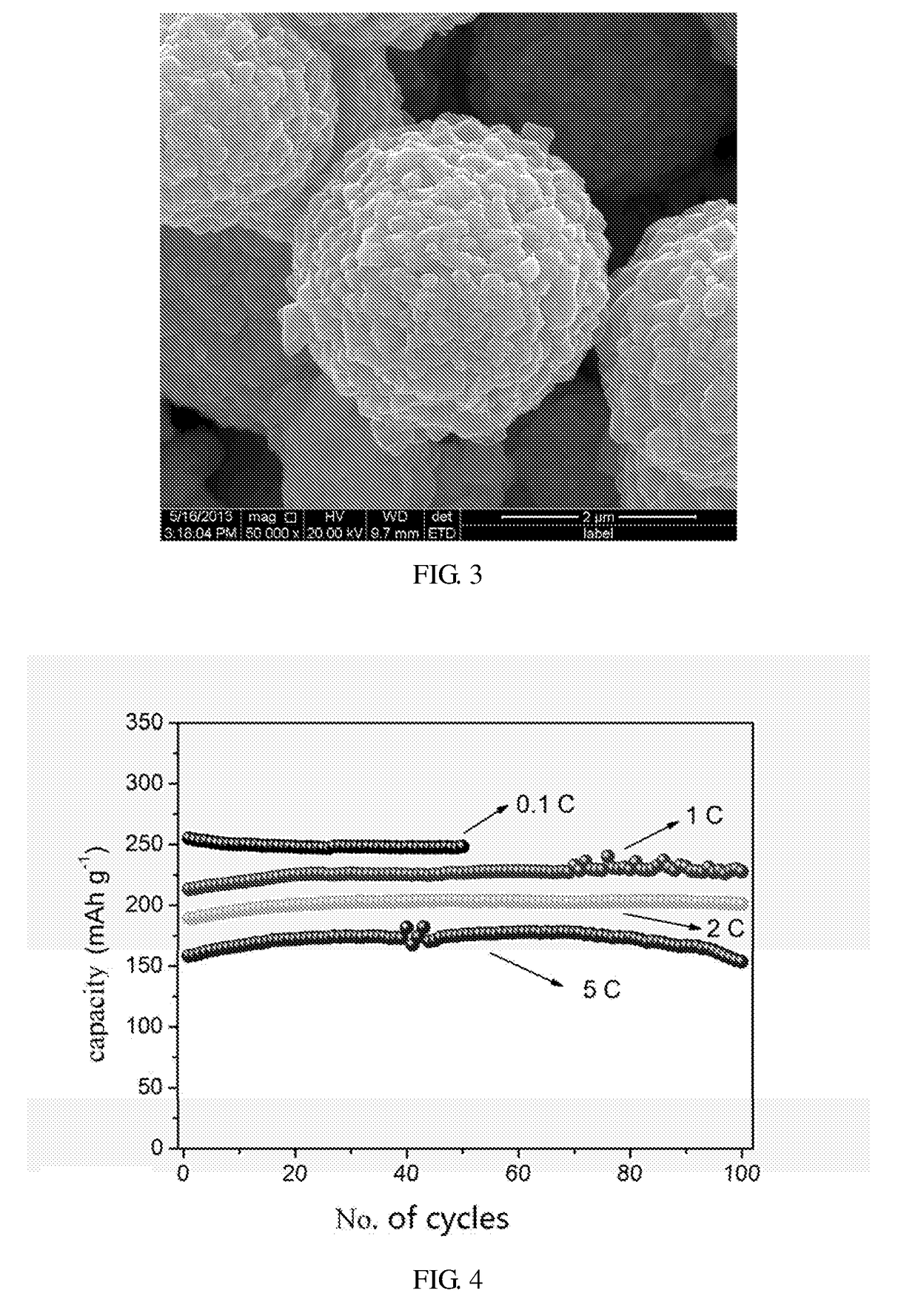

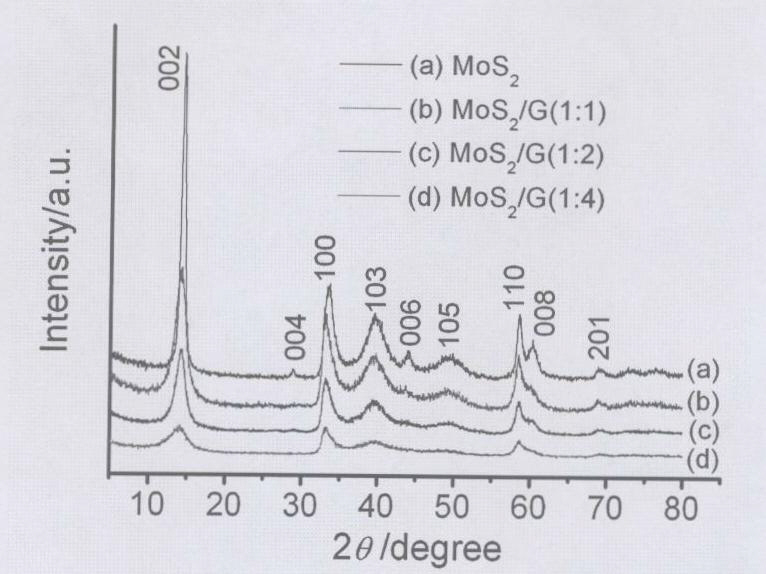

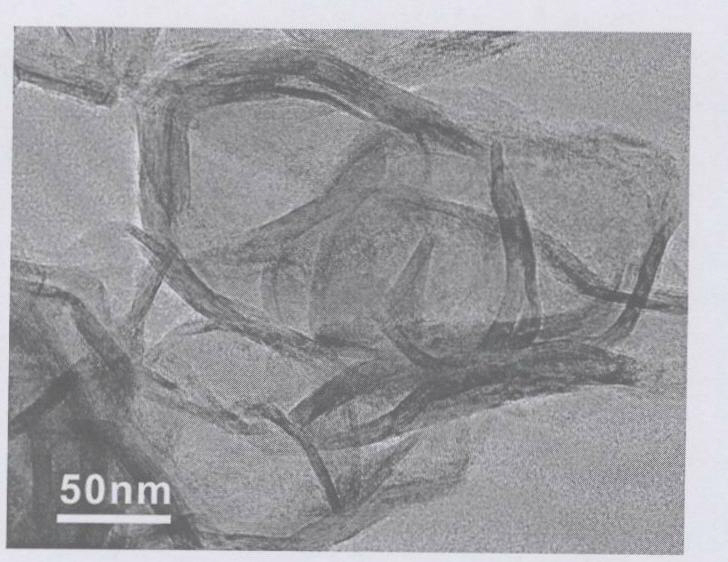

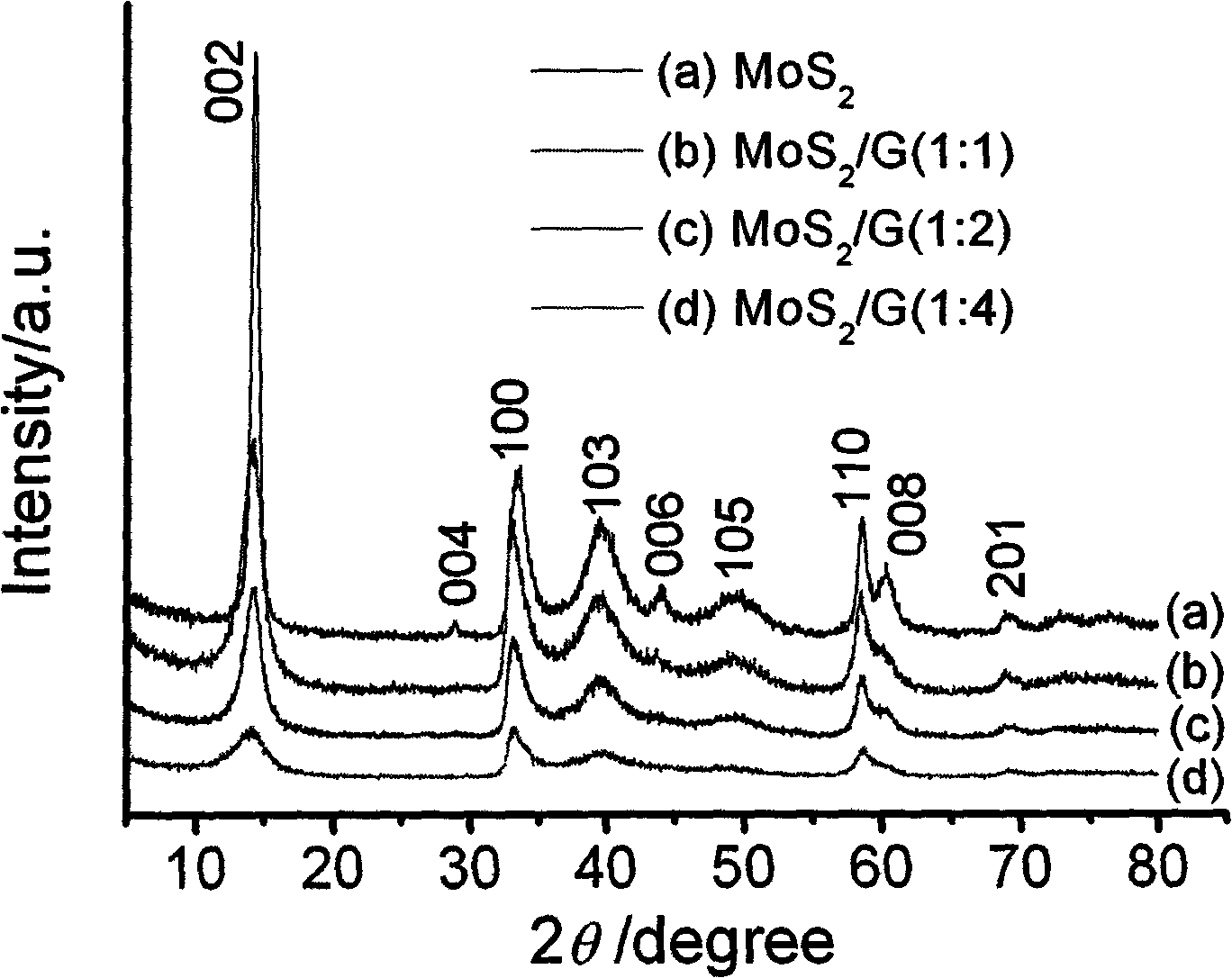

The invention discloses an electrochemical insertion / deinsertion magnesium ion electrode with high capacity and stable circulation and a preparation method. The active material of the electrode is a composite nano-material of graphene nano-sheets and MoS2, and the balance is acetylene black and polyvinylidene fluoride. The mass percentage of each component is: 75-85% of active material of composite nano-material, 5-10%of acetylene black and 10% of polyvinylidene fluoride, wherein the mass ratio of the graphene nano-sheets and the MoS2 nano-material in the active material of composite nano-material is 1 to 1-4 to 1. The preparation method of the electrode comprises the following steps of: using graphite as a raw material to prepare graphite oxide nano-sheets with a method of chemical oxidation; in the presence of the graphite oxide nano-sheets, compounding to obtain the composite nano-material of the graphene nano-sheets / MoS2 with a one-step hydrothermal in-situ reduction method; and finally using the composite nano-material of the graphene nano-sheets / MoS2 as the active material to prepare the electrode. The electrode has not only high electrochemical magnesium intercalating reversible capacity but also good stable circulation property and is widely applied to the new generation of magnesium ion batteries.

Owner:ZHEJIANG UNIV

Lithium battery electrode material Li2S/Co nanometer compound film and its preparation method

InactiveCN1794495AGood charge and discharge cycle performanceHigh specific capacityCell electrodesVacuum evaporation coatingSpecific volumePulsed laser deposition

This invention relates to an electrode active material used in Li ionic batteries and its preparation method, in which, the material is prepared by depositing a nm compound film made up of Li2S and a transition metal element Co with pulse laser and the size of the compound is smaller than 50nm, the specific volume is varied in the sphere of 400-650mAh / g along with the difference of Co and presents very good stability in the repeated charge / discharge process.

Owner:FUDAN UNIV

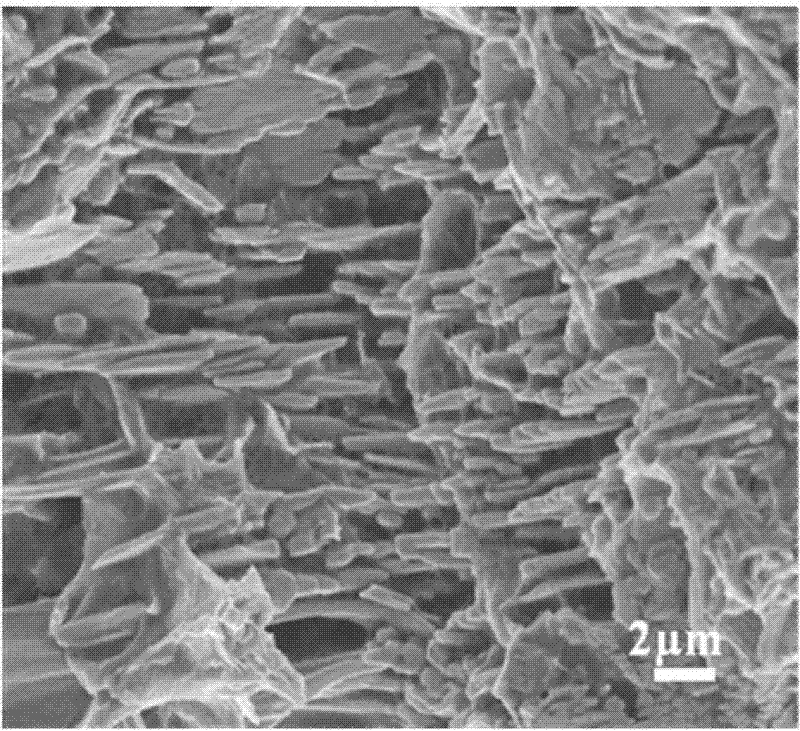

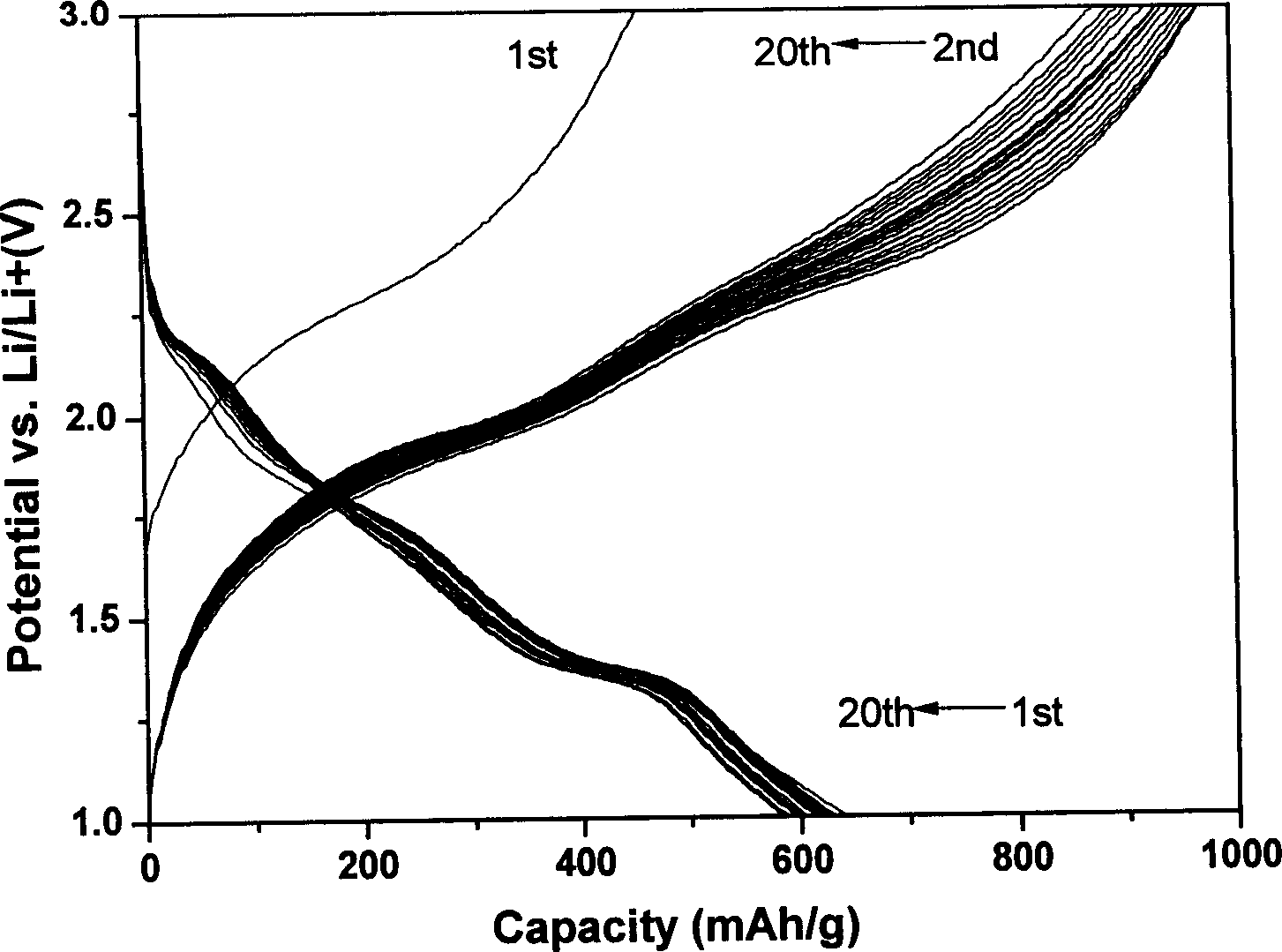

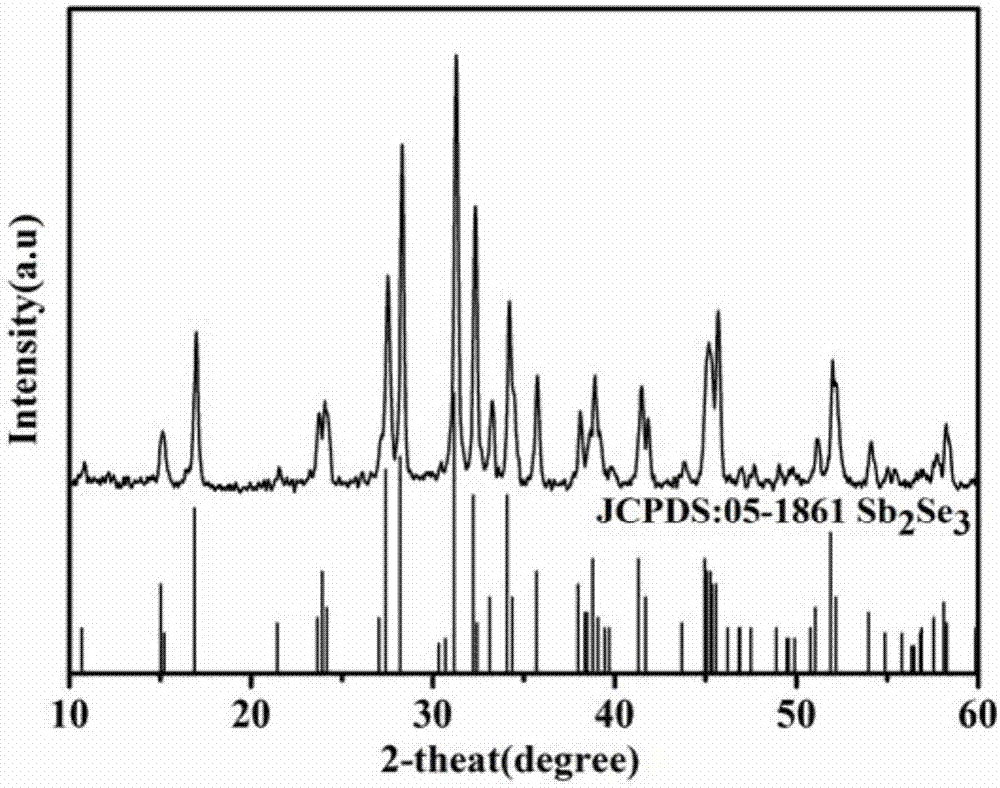

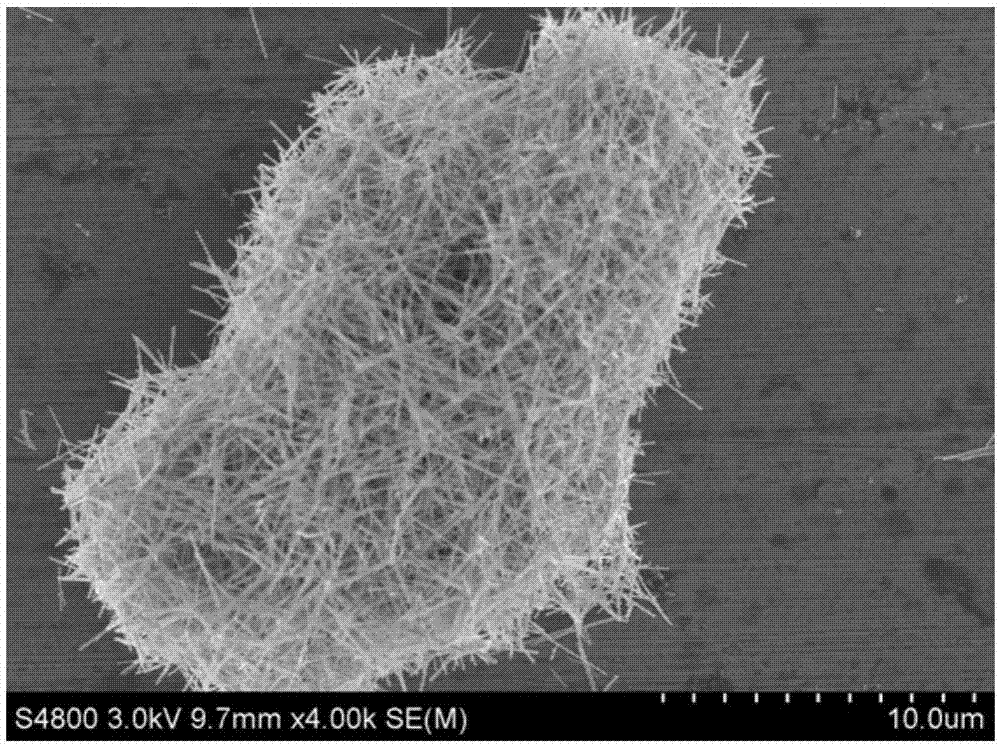

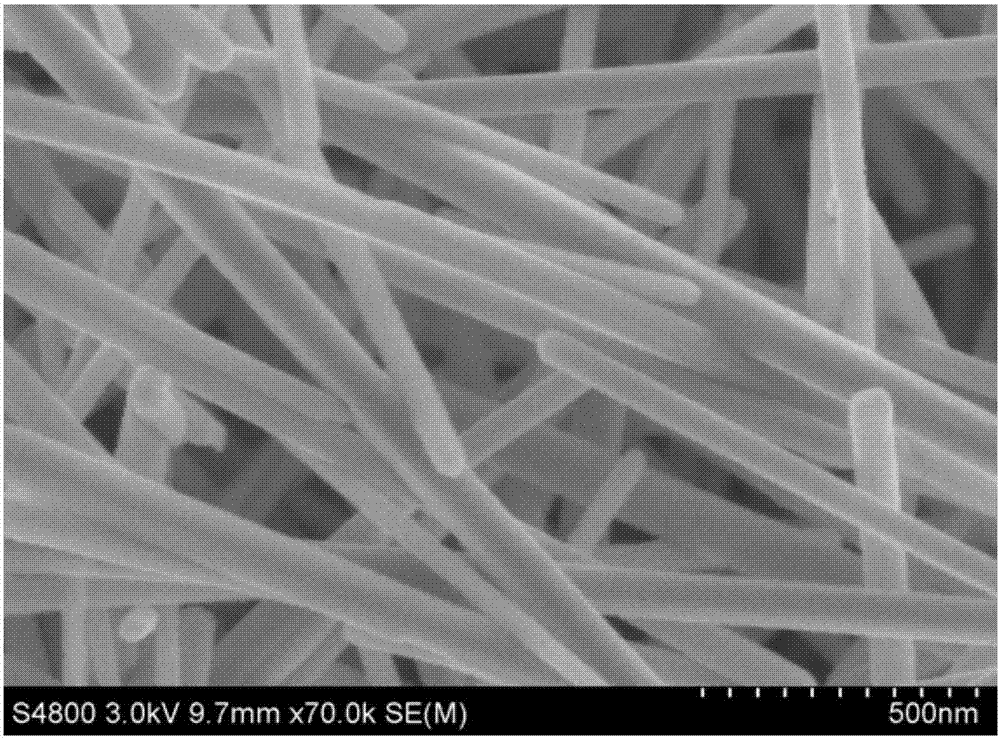

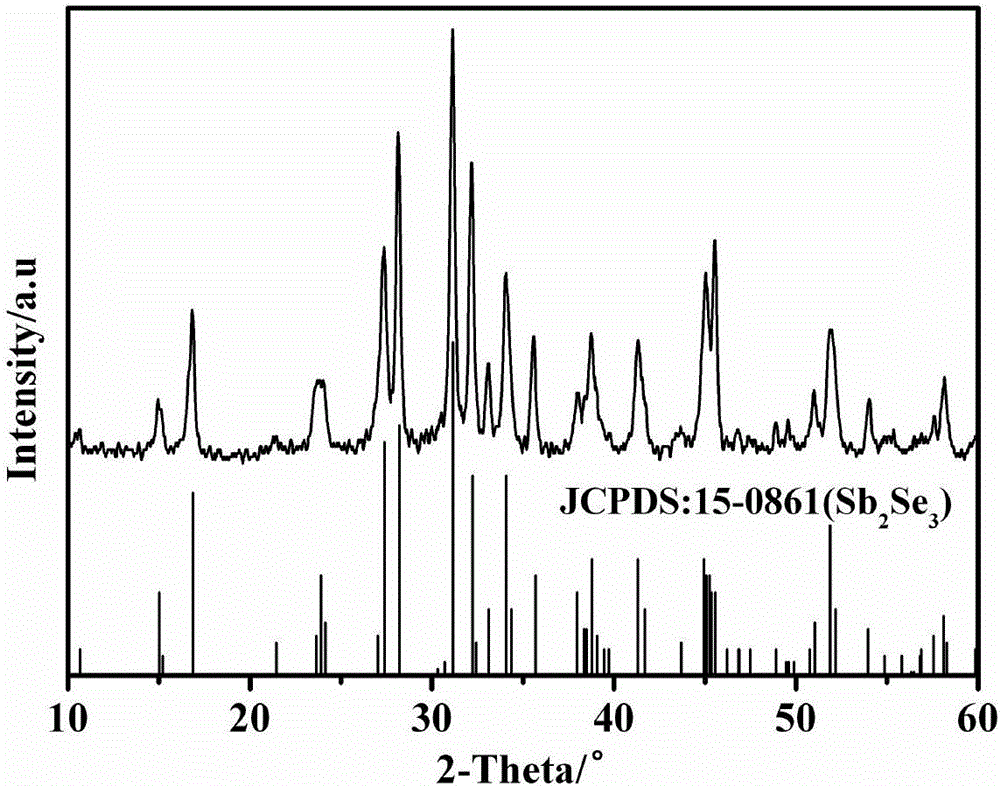

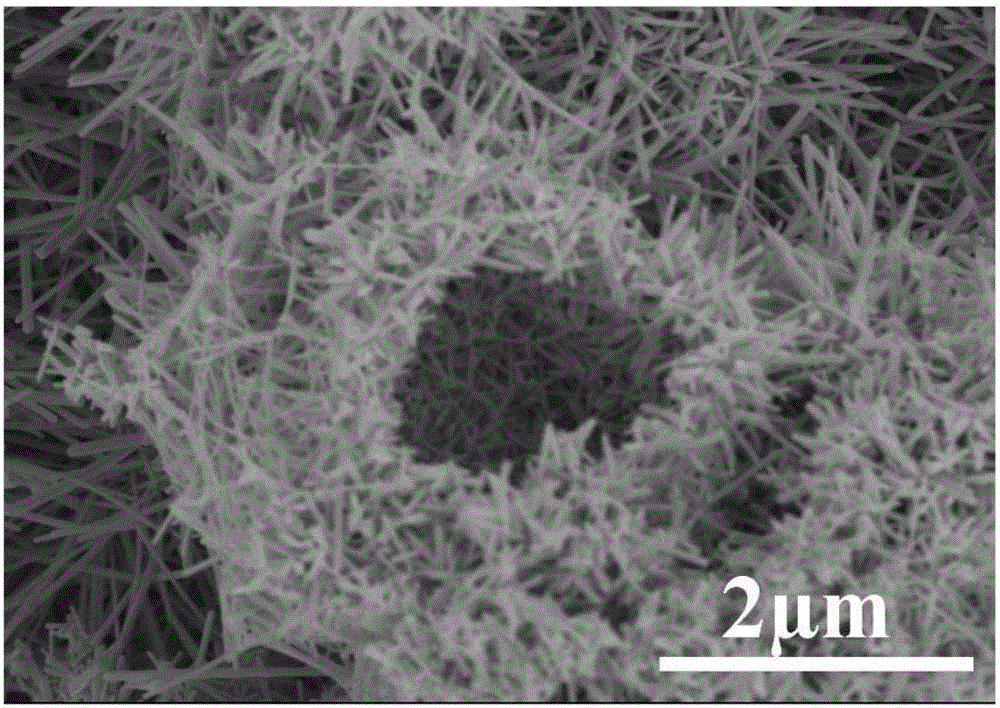

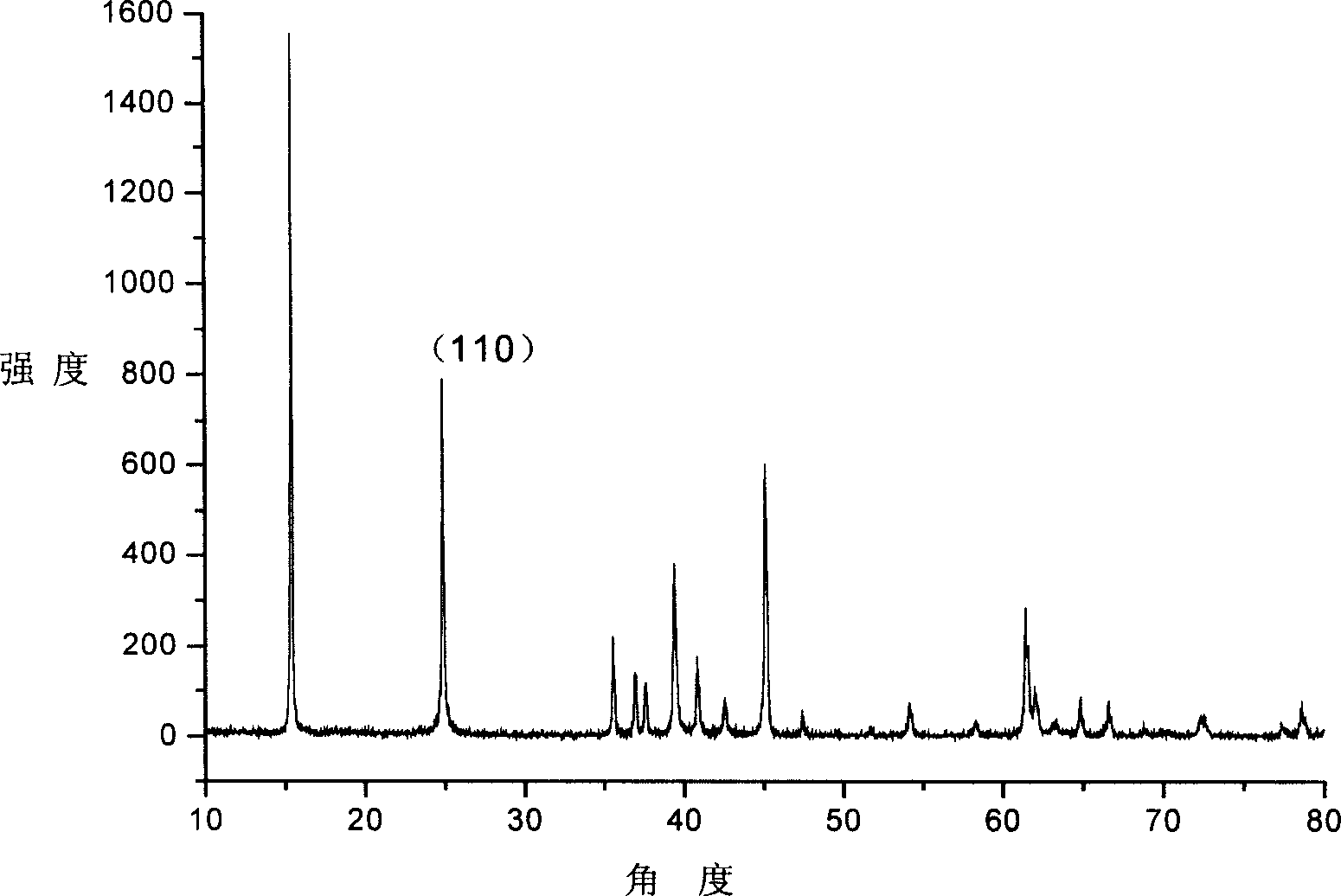

Method for preparing ultra-dispersed antimony selenide nanowires for sodium-ion battery negative electrodes with ultrasonic-assisted hydrothermal method

ActiveCN107140608AHigh purityIncrease profitMaterial nanotechnologyNegative electrodesNanowireAntimony potassium tartrate

The invention relates to a method for preparing ultra-dispersed antimony selenide nanowires for sodium-ion battery negative electrodes with an ultrasonic-assisted hydrothermal method. The method includes: adding beta-cyclodextrin into distilled water, and performing ultrasonic oscillation to obtain a solution A; adding tartaric acid and antimony potassium tartrate into distilled water with stirring to obtain a solution B; dispersing selenium powder into hydrazine hydrate, and performing ultrasonic oscillation to obtain a wine red solution C; adding the solution B into the solution A drop by drop with stirring to obtain a mixed solution D; adding the wine red solution C into the mixed solution D drop by drop, and stirring evenly prior to hydrothermal reaction at the temperature of 130-180 DEG C for 3-24h to obtain the ultra-dispersed antimony selenide nanowires for sodium-ion battery negative electrodes. The ultra-dispersed Sb2Se3 nanowires for sodium-ion battery negative electrodes are prepared by adopting the rational additives and surfactants to effectively and successfully control the reaction process under the assistance of ultrasonic waves, and the method has the advantages of good reproducibility, high raw material utilization rate and short cycle and is applicable to large-scale production of Sb2Se3 electrode materials.

Owner:SHAANXI UNIV OF SCI & TECH

Anode material of lithium cell and solid-phase sintering production method at high temperature

InactiveCN101219811AHigh electrochemical capacityConditions of temperature use are wideTin compoundsCell electrodesMicrometerRoom temperature

The invention relates to the anode material used by lithium battery with high capacity (bigger than 127mAh / g), which comprises LiSbSnO4, LiSbTiO4, LiSbPbO4, LiSbMnO4, LiBiMnO4, LiInMnO4, LiAlMnO4 LiAlSnO4 or LiAlTiO4. The preparation method comprises the steps: one in Sb2O3, Al2O3, Bi2O3 or In2O3, one in SnO2, MnO2, TiO2 or PbO2 and Li2O are taken as raw materials to be fully mixed with a molar ratio of 1:2:1 and then ball milled in a ball mill; particle diameter of the powder is 1-2 micrometers; the powder is parched for 4 hours under a temperature of 100 DEG C and is planished tablet to be sintered in a high-temperature sintering furnace. The temperature of the furnace is raised to 250-500 DEG C; the powder is put into the high-temperature sintering furnace for the third time and the temperature is raised to 900-1400 DEG C from the room temperature; then the pure anode material of the single-phase lithium battery is successfully prepared.

Owner:NANJING UNIV

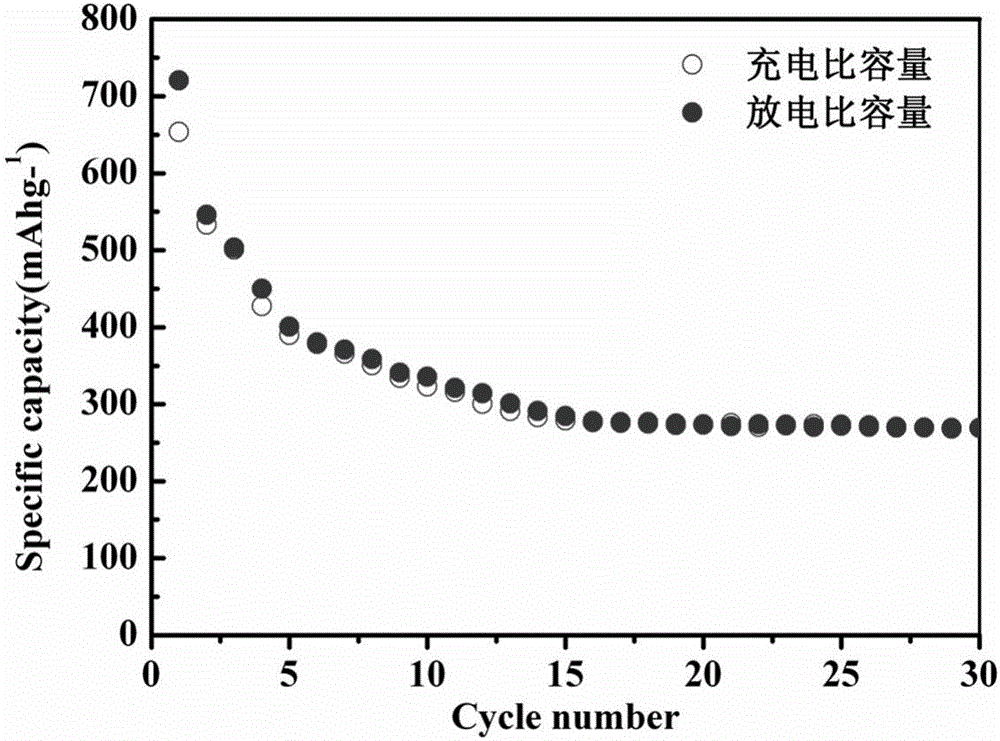

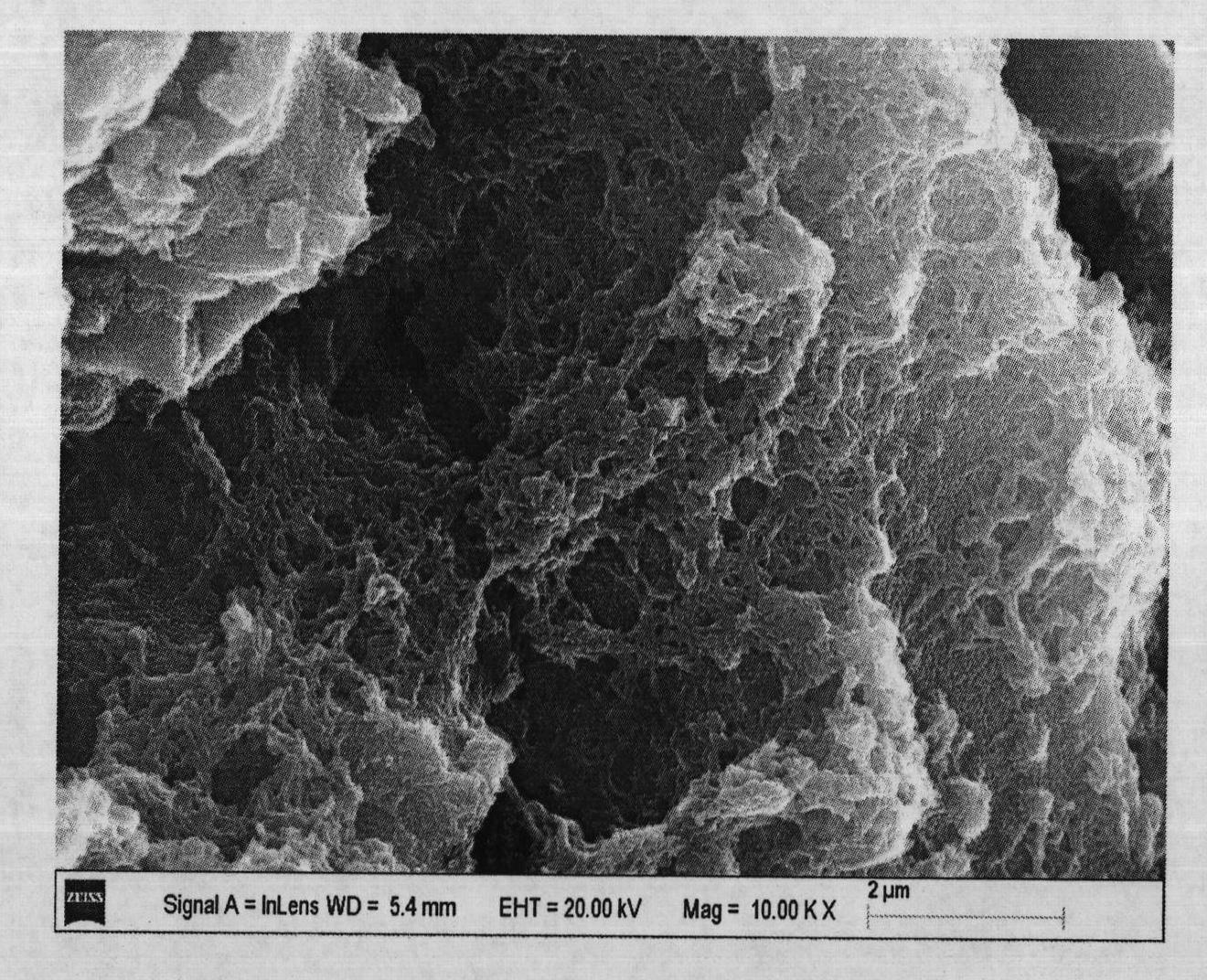

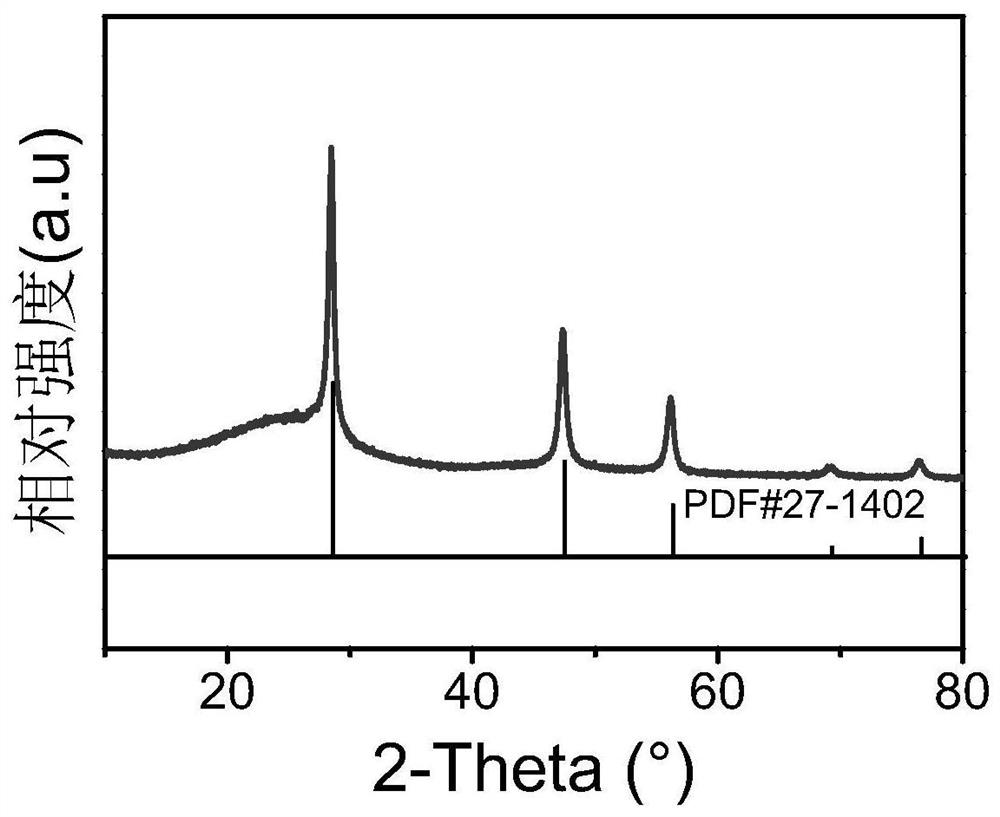

Preparation method of nest-like Sb2Se3 electrode material for sodium ion battery negative electrode

ActiveCN106848386AImprove dispersionHigh electrochemical capacityMaterial nanotechnologyCell electrodesIonSelenium

A preparation method of a nest-like Sb2Se3 electrode material for a sodium ion battery negative electrode comprises the following steps: 1) dissolving antimony potassium tartrate into deionized water, and completely stirring to completely dissolve the antimony potassium tartrate to obtain a mixed liquid A; 2) dispersing selenium powder into hydrazine hydrate with mass percentage being 50 percent, and stirring to obtain a mixed liquid B; 3) mixing the obtained mixed liquid B and the mixed liquid A to obtain a mixed liquid C, performing hydrothermal reaction at the temperature of 120 to 180 DEG C for 3 hours to 24 hours, naturally cooling to a room temperature after the reaction, washing and separating precipitate, and freeze-drying the precipitate obtained by separation under the vacuum condition to obtain the Sb2Se3 electrode material. The preparation method is simple in operation, easy in repletion, short in cycle, pollution-free and suitable for large-scale production of the Sb2Se3 electrode materials.

Owner:SHAANXI UNIV OF SCI & TECH

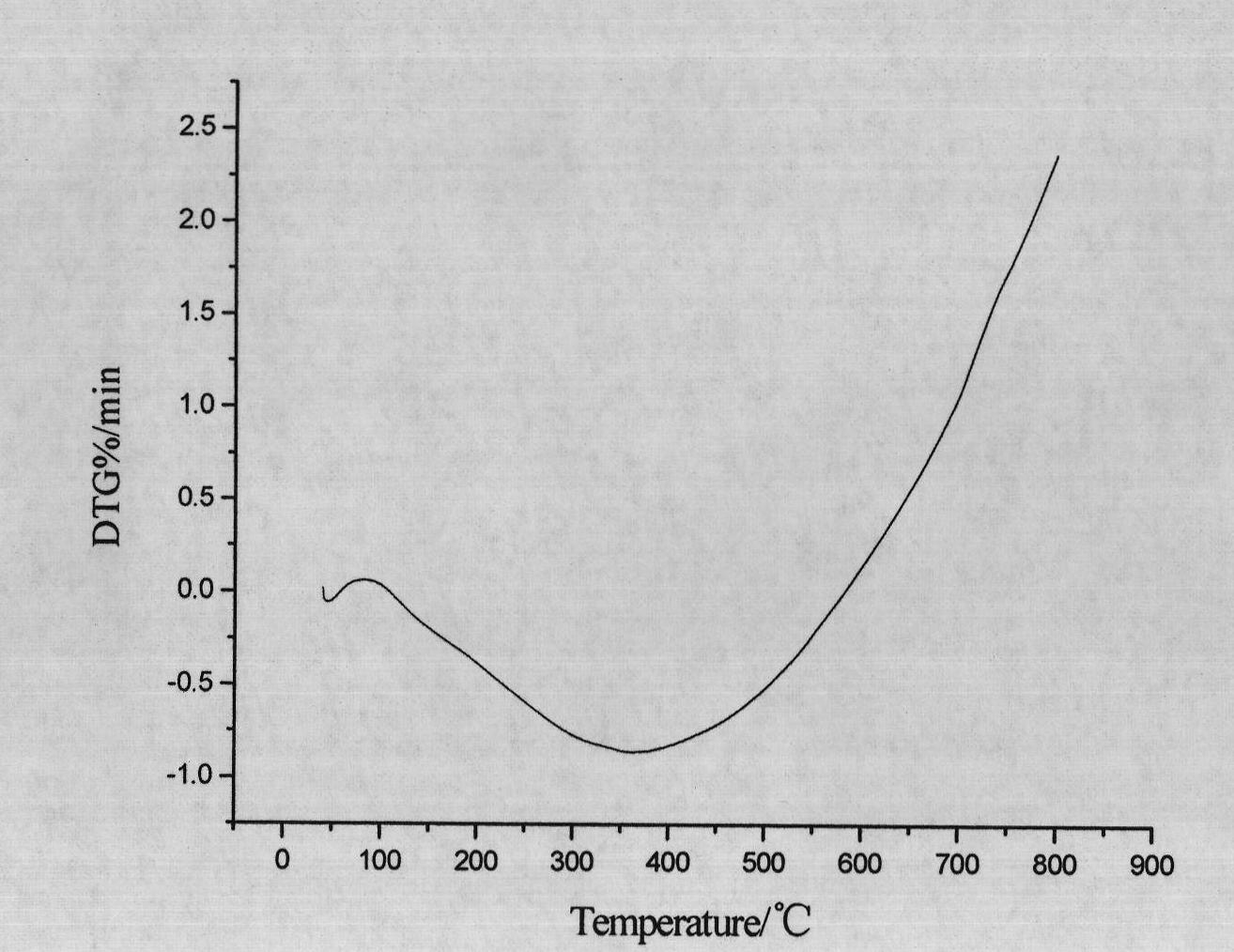

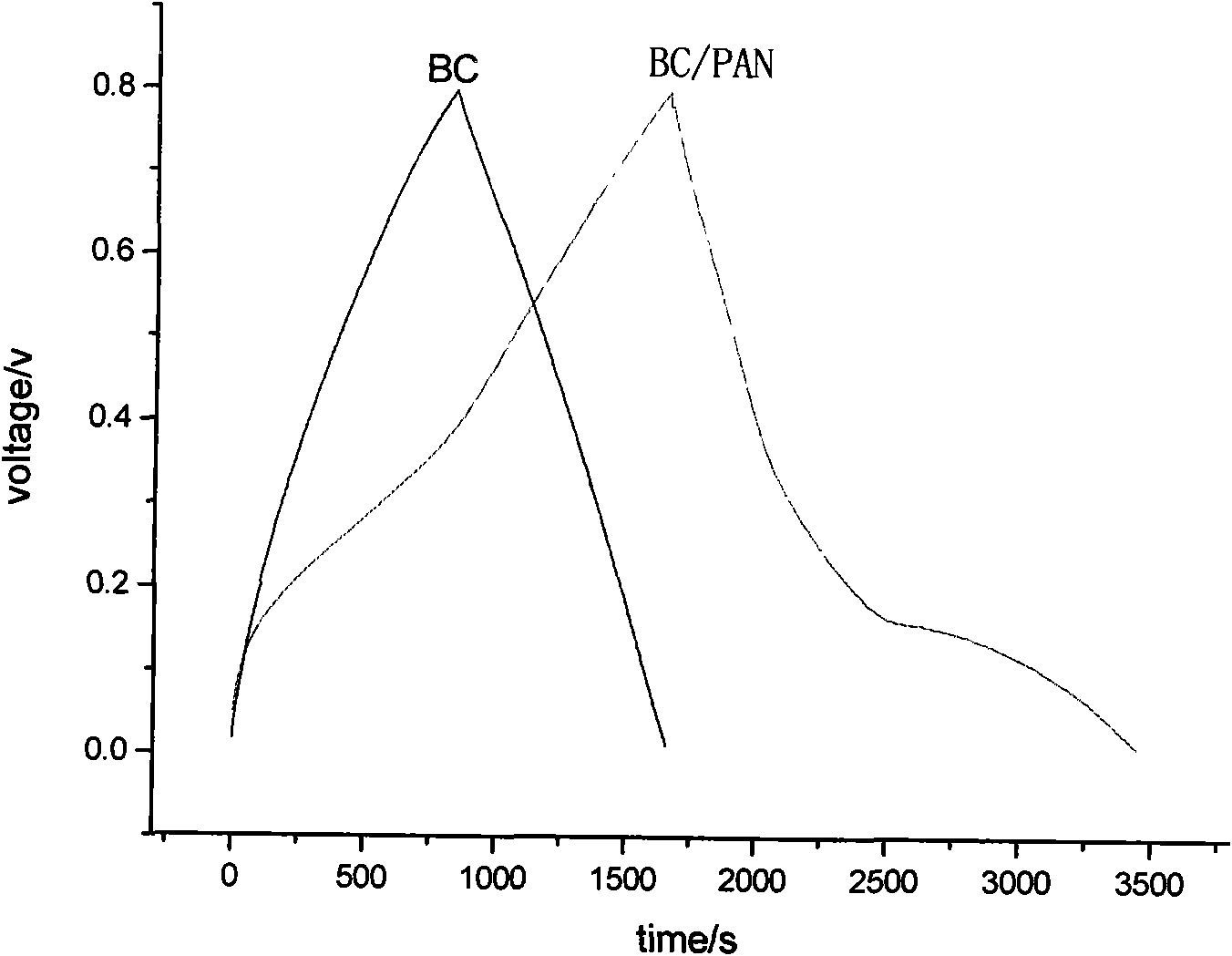

Method for preparing bamboo charcoal/polyaniline composite material by adopting bamboo charcoal

InactiveCN102134318ALow electrochemical capacityHigh electrochemical capacityHybrid capacitor electrodesCapacitor electrodesPolyaniline compositeAniline

The invention relates to a method for preparing a composite material by using biomass material and aniline, in particular to a method for preparing a composite material by adopting bamboo charcoal and aniline, belonging to the field of capacitor material. By compositing the polyaniline with a special feature on the surface and inside the bamboo charcoal, the electrochemistry performance of the composite material is superior to that of the raw material, and the thermal performance of the composite material is good.

Owner:陈晓红 +3

Method for preparing positive electrode material of Li-ion battery using impact-flow equipment

InactiveCN101510600AImprove reaction efficiencyImprove performanceElectrode manufacturing processesLithiumCooling down

The invention discloses a method which utilizes impinging stream equipment to prepare lithium ion battery anode materials. The method comprises the following steps: hydroxides or soluble salts of Li and soluble salts of transition metals are respectively dissolved into deionized water to form solutions, then the two solutions are impinged with each other in the impinging stream equipment at a speed of 2 m / s-30 m / s and react with each other, a sediment produced by the reaction is moved into a high temperature furnace after being washed and dried, calcined for 3h-15h at 300 DEG C-700 DEG C and then cooled down, finally a Li-ion battery anode material is obtained. The method provided by the invention has simple process, the reaction time can be effectively shortened and the production efficiency can be improved; the Li-ion battery anode material obtained by adopting the method has even grains, small grain size and high electrochemistry capacity.

Owner:广州鸿森材料有限公司

Preparation method of lithium-rich manganese-base anode material

InactiveCN103972491AHigh chemical uniformitySmall particle sizeCell electrodesSecondary cellsLithiumElectrochemistry

The invention discloses a preparation method of a lithium-rich manganese-base anode material. A chemical general formula of the lithium-rich manganese-base anode material is xLi2MnO3<-(1-x)> Limo2, wherein x is larger than or equal to 0 and smaller than or equal to 1, and M adopts transition metal elements of Ni, Co and Mn. The preparation method of the lithium-rich manganese-base anode material comprises the steps as follows: (1), a transition metal salt solution is prepared; (2), a precipitant solution is prepared; (3), the metal salt solution is subjected to ultrasonic atomization and then sprayed into the precipitant solution, and stirring is performed while spraying is performed; (4), the stirring is stopped, still standing is performed, and a precipitated product after reaction is washed to obtain a transition metal precursor; (5), the transition metal precursor and Li salt are mixed, subjected to ball milling in a dispersing agent and dried to obtain a precursor; and (6), the precursor is sintered at the high temperature and cooled to obtain the lithium-rich manganese-base anode material product. According to the invention, the transition metal precursor with higher chemical homogeneity and smaller particle size is prepared in a spraying manner, and the lithium-rich manganese-base anode material with higher electrochemistry capacity, lower capacity fading and better rate capability is obtained after sintering.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

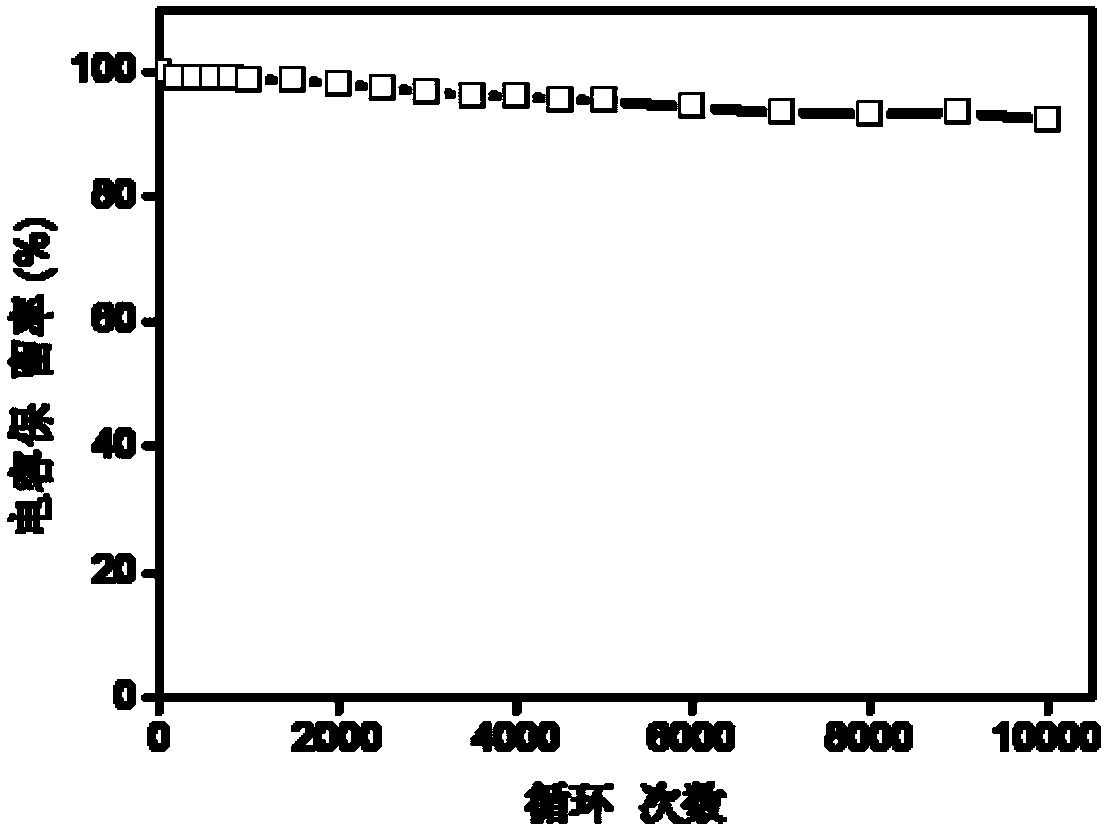

Enhanced super capacitor and preparation method thereof

ActiveCN107919234AIncrease powerHigh electrochemical capacityHybrid capacitor electrolytesHybrid capacitor electrodesSupporting electrolyteCapacitance

The invention discloses an enhanced super capacitor and a preparation method thereof, especially an electrolyte, a super capacitor based on the electrolyte and including an anthraquinone redox activesubstance, and a preparation method of the super capacitor. The electrolyte comprises a support electrolyte, the anthraquinone redox active substance and a solvent. The novel super capacitor has a higher specific capacitance compared with that of common carbon-based super capacitors, and obvious advantages in the capacitive performance compared with a super capacitor made of the same electrode material but does not include the anthraquinone redox active substance. A simple method is used, the circulation stability of the carbon-based super capacitor is improved, the capacitive performance of the carbon-based super capacitor is improved effectively, and the prepared super capacitor is characterized by high specific capacity, high energy density and high power density, and has huge application potentials.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Anode material of lithium cell and solid-phase sintering production method at high temperature

InactiveCN101219806AConditions of temperature use are wideHigh electrochemical capacityCell electrodesTantalum compoundsPhysical chemistryBall mill

The invention relates to the anode material of a lithium battery. The general formula is LiMNO4, wherein, the M is Mg or Ca; the N is Ta, Nb or V. A method of high-temperature solid state sintering of the invention comprises the following steps: Li2O, MO and N2O5 are taken as raw materials; the M is Mg or Ca; the N is Ta, Nb or V; Li2O, MO and N2O5 of which the purity is 99.99 percent are fully mixed by a molar ratio of 1:2:1 and then ball milled in a ball mill; particle diameter of the powder is 1-2 micrometers; the powder is parched for 4 plus or minus 2 hours under a temperature of 200 DEG C and is planished tablet to be sintered in a high-temperature sintering furnace. The temperature of the furnace is raised to 1000 plus or minus 50 DEG C from the room temperature and is preserved for 8-20 hours; furnace cooling is carried out and the powder tablet is taken out to be crashed until the particle diameter is 0.8-1.6 micrometers; after evenly grinded and planished tablet, the powder is put into the high-temperature sintering furnace for the third time and the temperature is raised to 1400 plus or minus 50 DEG C from the room temperature; the furnace cooling is carried out after heat preservation for 25-36 hours; then the powder tablet is taken out to be crashed until the particle diameter is 0.5-1.2 micrometers.

Owner:NANJING UNIV

Method for producing positive pole material-orthorhombic system LiMnO2 of lithium secondary battery

InactiveCN1674322AStable structureHigh crystallinityElectrode manufacturing processesLithium compoundsChemistryHigh pressure

A method for preparing orthogonal crystallization system LiMnO2 includes dissolving bivalent Mn compound, MnO2 and LiOH as mole raio of 1 : 1 : 7.5-30 in distilled water, agitating it for 4-6 hours in the air at room temperature, filling it into high pressure reactor to react for 5-7 days at constant temperature of 170-230 deg c, washing it by thin oxalic acid to make it be neutral in pH value after it is taken out from reactor, washing it by distilled water or deionized water and finally drying precipitant for obtaining LiMnO2 powder product.

Owner:JILIN UNIV

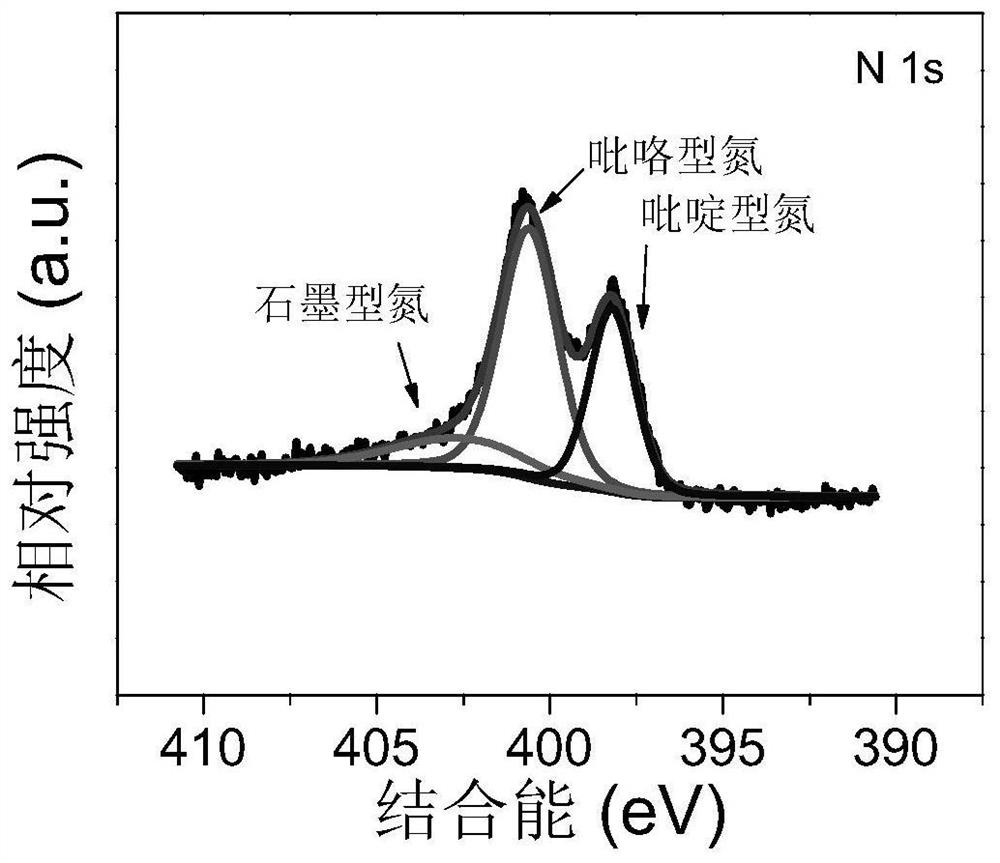

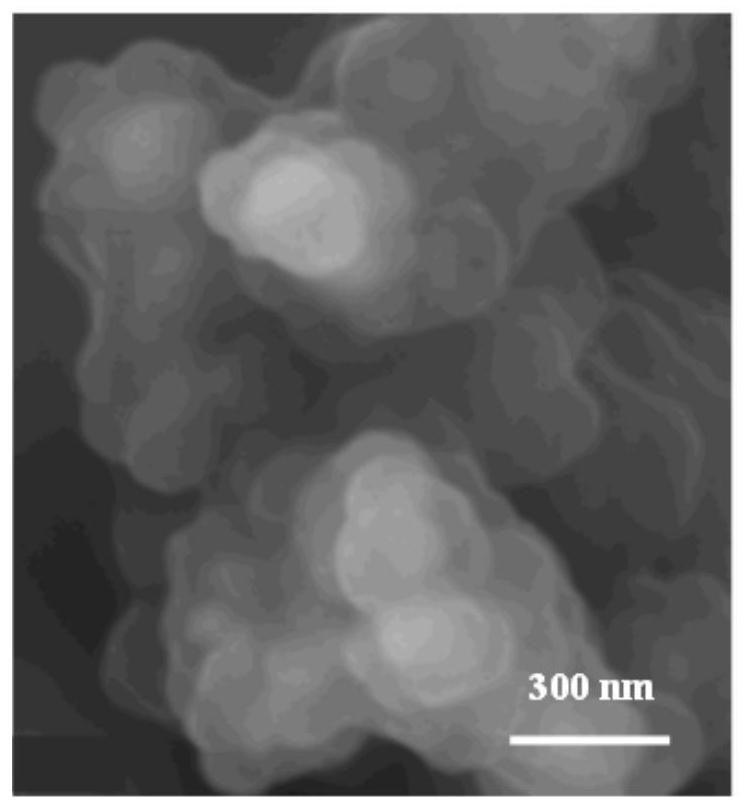

Nitrogen-doped carbon/nano-silicon composite negative electrode material and preparation method thereof

InactiveCN112110448AImprove the first charge and discharge efficiencyImprove electrochemical cycle stabilityMaterial nanotechnologySiliconElectrical batteryNew energy

The invention discloses a preparation method of a nitrogen-doped carbon / nano-silicon composite negative electrode material, belonging to the field of new energy materials and electrochemistry. The method comprises the following steps: (1) putting nano-silicon powder into a solvent, conducting ultrasonic dispersion, adding an initiator solution, and conducting sufficient stirring and mixing to obtain a dispersion liquid A, wherein the particle size of the nano-silicon powder is 30-80 nm; (2) adding a carbon source into the dispersion liquid A obtained in the step (1), conducting stirring and mixing, carrying out a polymerization reaction, performing filtering, and washing and drying the obtained solid to obtain a precursor B, wherein the carbon source comprises at least one selected from pyrrole, dopamine and aniline, and a ratio of the mass of the nano-silicon powder to the volume of the carbon source is 0.15-0.25 g: 400-800 [mu]L; and (3) heating and calcining the precursor B obtainedin the step (2) and then conducting cooling to obtain the nitrogen-doped carbon / nano-silicon composite negative electrode material. The invention also provides the nitrogen-doped carbon / nano-siliconcomposite negative electrode material prepared by using the method and a lithium ion battery containing the nitrogen-doped carbon / nano-silicon composite negative electrode material.

Owner:SUN YAT SEN UNIV

Lead plaster composition of positive electrode of internally formalized storage battery

ActiveCN103633320AAvoid generatingImproves deep cycle performanceCell electrodesO-Phosphoric AcidElectrical battery

The invention belongs to the technical field of storage batteries, and specifically relates to a lead plaster composition of a positive electrode of an internally formalized storage battery. The lead plaster composition of the positive electrode of the internally formalized storage battery is prepared from the following raw materials in parts by weight: 990-1010 parts of lead powder, 0.5-1.5 parts of fibers, 0.5-1.0 part of phosphoric acid, 1-2 parts of antimonous oxide, 0.7-1.2 parts of zinc oxide, 0.5-1.5 parts of aluminum oxide, 0.5-0.8 part of ammonium hydrogen carbonate, 0.3-0.5 part of cerium hydroxide, 0.7-1.5 parts of tin monoxide, 110-130 parts of water and 80-90 parts of dilute sulphuric acid. The lead plaster composition of the positive electrode is improved, so that capacity attenuation of the internally formalized battery in the early stage is inhibited, and the service life of deep circular discharge of the battery is prolonged.

Owner:HENAN CHAOWEI POWER SUPPLY

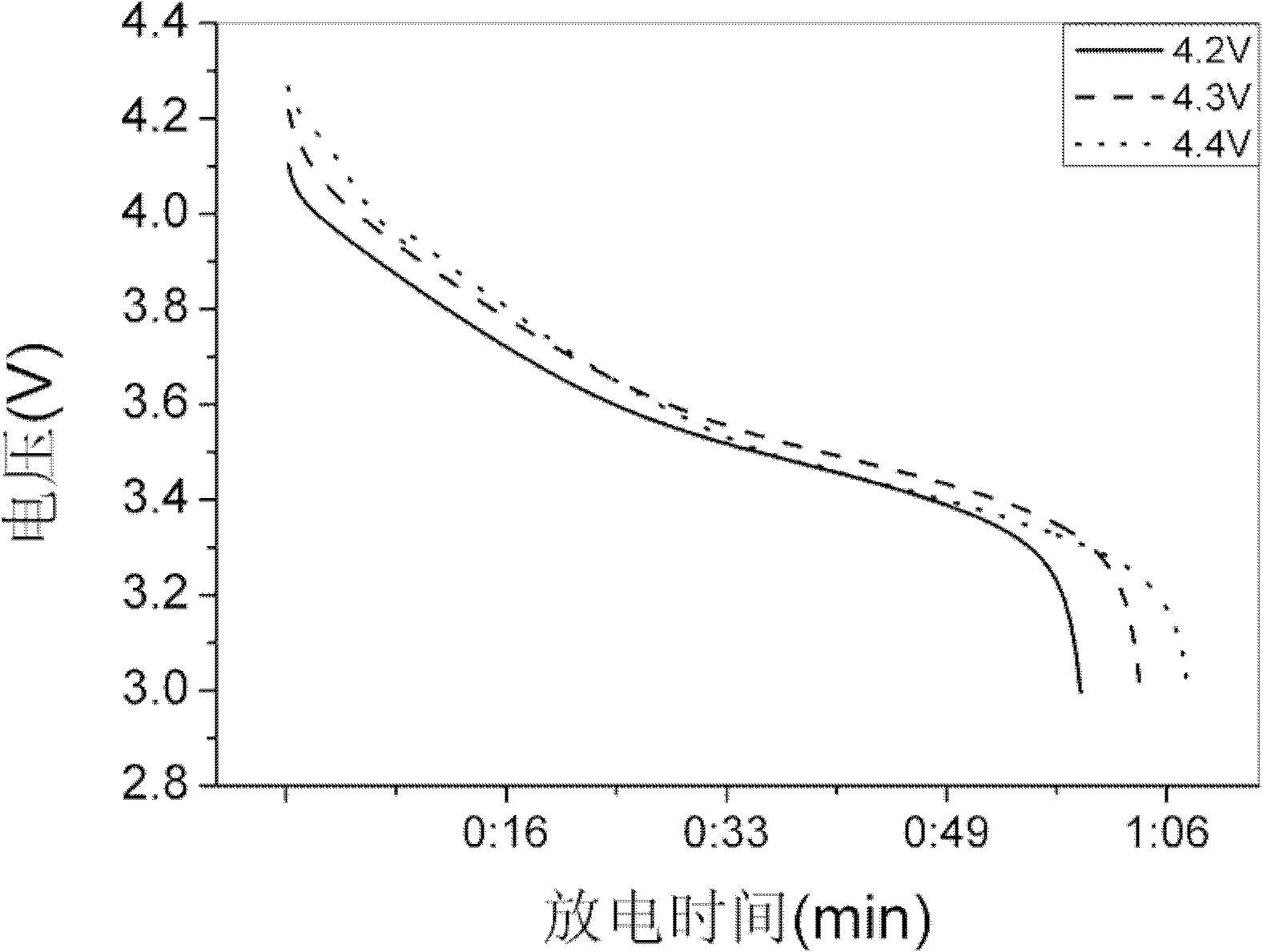

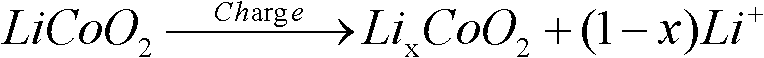

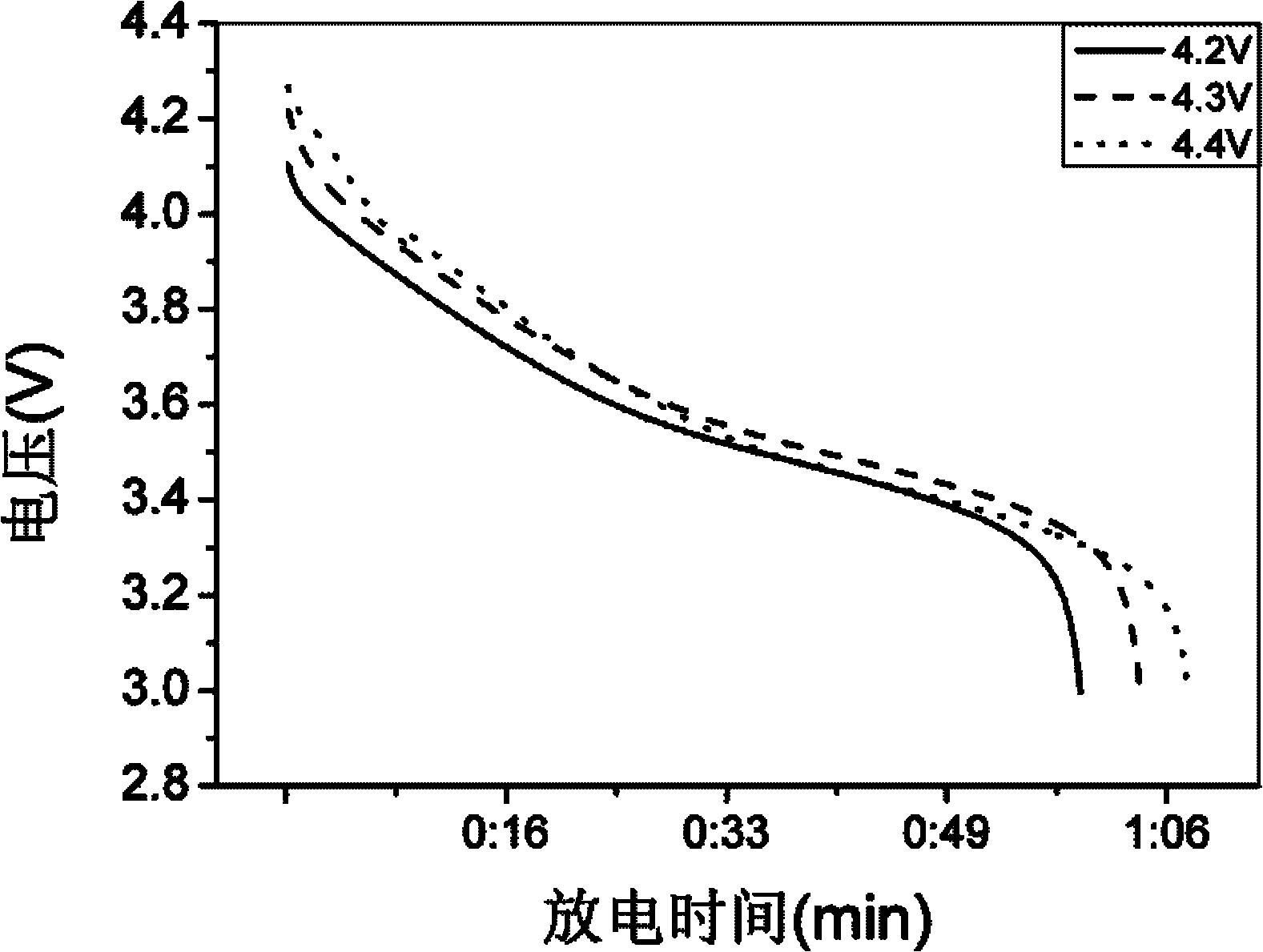

High energy density safe lithium-ion battery

InactiveCN102290597AImprove securityStable structureFinal product manufactureCell electrodesPolyolefinMass ratio

The invention discloses a high-energy-density safe lithium-ion battery, which includes a positive electrode sheet, a negative electrode sheet, a diaphragm and an electrolyte; the composition of the positive electrode sheet slurry is, by mass ratio: LiNixMnyCo1-x-yO2: oxygen absorber: carbon Black: PVDF=92-96%: 0.1-3%: 1-3.5%: 2-3.5%, wherein 1≤x≤9, 9≥y≥1; the slurry composition of the negative plate is, by mass ratio: Graphite: carbon black: CMC: SBR = 91-95%: 1-3.5%: 1.2-2.5%: 1-3%; the diaphragm of the battery is made of polyolefin porous membrane and aromatic polyamide fiber hot-pressed composite. In the lithium ion battery of the present invention, the positive electrode material combines the advantages of LiCoO2, LiMnO2 and LiNiO2, and has the characteristics of high electrochemical capacity and good cycle performance. When the charging upper limit voltage is greater than 4.3-4.5V, the material structure remains stable and can be used Higher gram capacity; the actual gram capacity of the negative electrode is close to the theoretical gram capacity by modifying artificial graphite and natural graphite; by using polyolefin-aromatic polyamide as the diaphragm material, the lithium-ion battery is effectively improved. safety performance.

Owner:GREAT POWER BATTRY ZHUHAI

Anode material-nanometer vanadium iron manganese lithium phosphate of lithium ion battery and preparation method of anode material

ActiveCN103094569AHigh electrochemical capacityImprove cycle stabilityCell electrodesSpecific energyLithium electrode

The invention discloses an anode material-nanometer vanadium iron manganese lithium phosphate of a lithium ion battery and a preparation method of the anode material. The anode material comprises carbon-coated nanometer vanadium iron manganese lithium phosphate, the primary particle size is 50-200 nm, and a chemical formula of nanometer vanadium iron manganese lithium phosphate is LiVxFeyMn(1-3 / 2x-y)PO4, wherein x is more than 0 and not more than 0.3 and y is more than 0 and not more than 0.5. The preparation method adopts an electrochemical-rheological phase method and comprises the steps of preparing a precursor, spray-drying and roasting. The anode material has the advantages of high specific energy and specific capacity and good safety; and the preparation method is easy for acquisition of raw materials, simple in process and low in production cost, and is suitable for large-scale industrial production.

Owner:WUHU HUAXINNUO ELECTROCHEM TECH

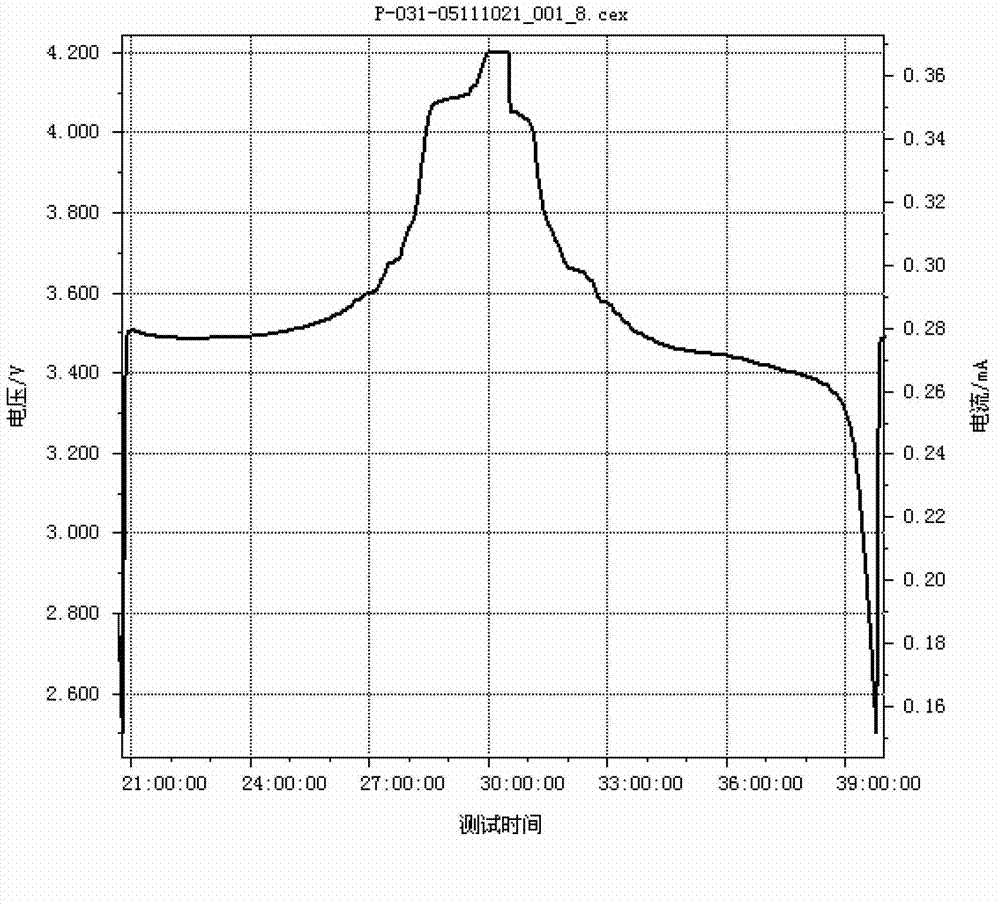

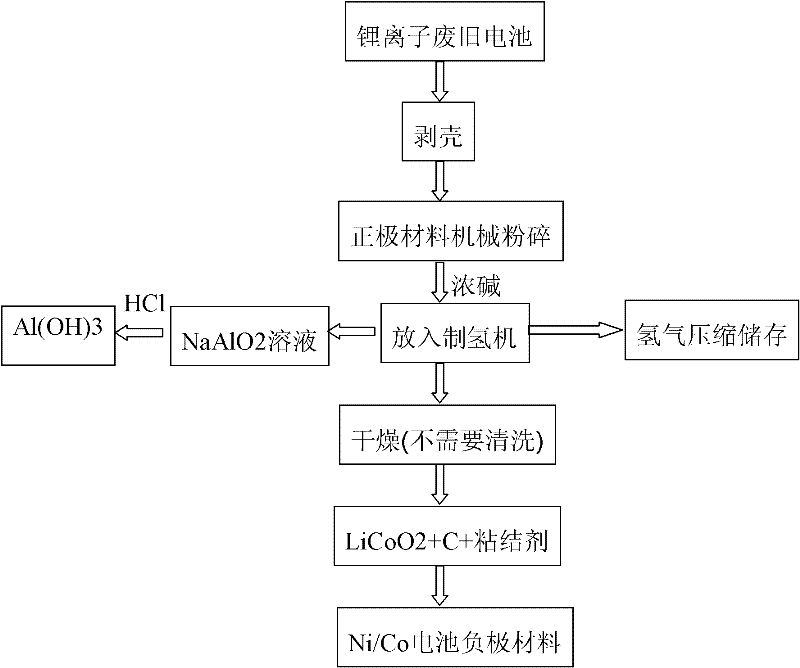

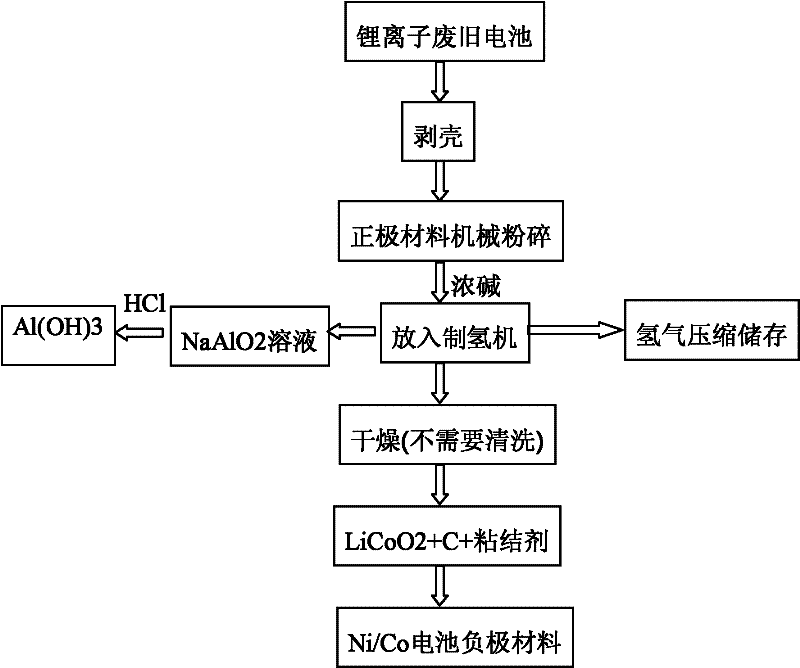

Method for applying waste lithium ion battery cathode material to nickel-cobalt battery anode material

InactiveCN102447149ALow costReduce pollutionAlkaline accumulator electrodesWaste accumulators reclaimingHydrogenRoom temperature

The invention relates to a new method for comprehensively recovering LiCoO2 from waste lithium cathode material industrially. The method comprises the following steps of: peeling the waste lithium ion battery material, separating out cathode material, and then mechanically crushing the separated cathode material; placing the crushed material into a hydrogen producing machine; adding excessive NaOH into the hydrogen producing machine for soaking the crushed cathode material at a room temperature; and after the reaction is finished, filtering the reactant, and obtaining the filter residue, i.e. a mixture containing LiCoO2, acetylene black and few conductive agent. After the mixture is dried, the mixture can be used as anode material of a Ni / Co battery, and a good electrochemical property can be shown. The method provided by the invention has the following advantages of simple manufacturing process, easily-obtained raw material, easiness for operation and environmental-friendliness, and provides a new environment-friendly and low-cost production technique for the anode material of the Ni / Co battery.

Owner:NANKAI UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com