Patents

Literature

246results about How to "Uniform and controllable particle size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microsphere type embolic agent and preparation technology thereof

The invention provides a microsphere embolic agent, which is an elastic microsphere formed by the crosslink polymer of the functionalized macromolecules with the biocompatibility, and the particle size of the microsphere ranges from 1 Mum to 1500 Mum. The preparing technology includes the steps as follows: in a covalent link, linking a crosslinkable micromolecules with an acrylic acid structure on the polyvinyl alcohol, polyethylene glycol or polysaccharide macromolecules, forming the functionalized macromolecules; after that, the functionalized macromolecules and the monomer of the 2- acrylamide-2-methyl propanesulfonic acid undertakes opposite suspension polymerization, obtaining the crosslink polymeric microsphere embolic agent. The embolic agent has comparatively large retractility and elasticity, whose particle size is controllable and has perfect dispersiveness; moreover, the raw material is non-toxic and at the same time has good biocompatibility and stability. The preparing technology is a real chemosynthesis technology, whose material and preparing process does not produce any virus pollution, according with various requirements of the international embolic agent, which can replace various import and domestic expensive embolic agent products and is extensively applicable to various surgeries in the interventional radiology field.

Owner:SUZHOU HENGRUI CALLISYN BIOLOGICAL MEDICINE TECH CO LTD

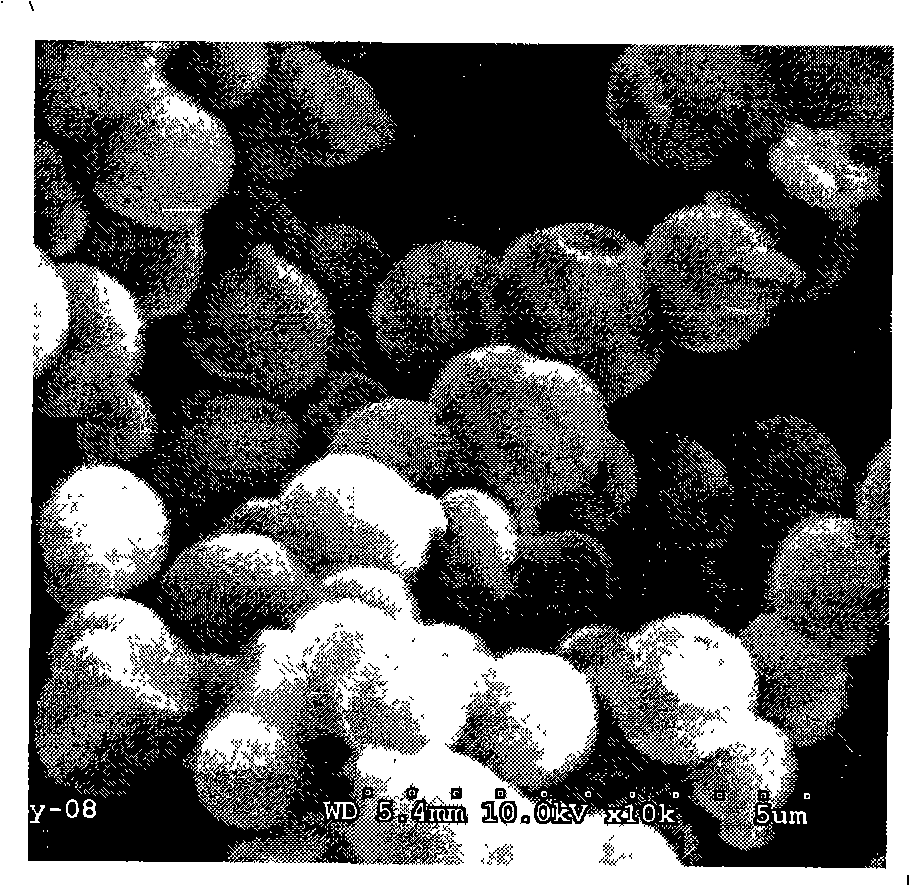

Magnetic fluorescent microspheres and preparation method thereof

InactiveCN101787163AEasy to manufactureSimplify separabilityOrganic/organic-metallic materials magnetismMicroballoon preparationGenotype AnalysisMicroparticle

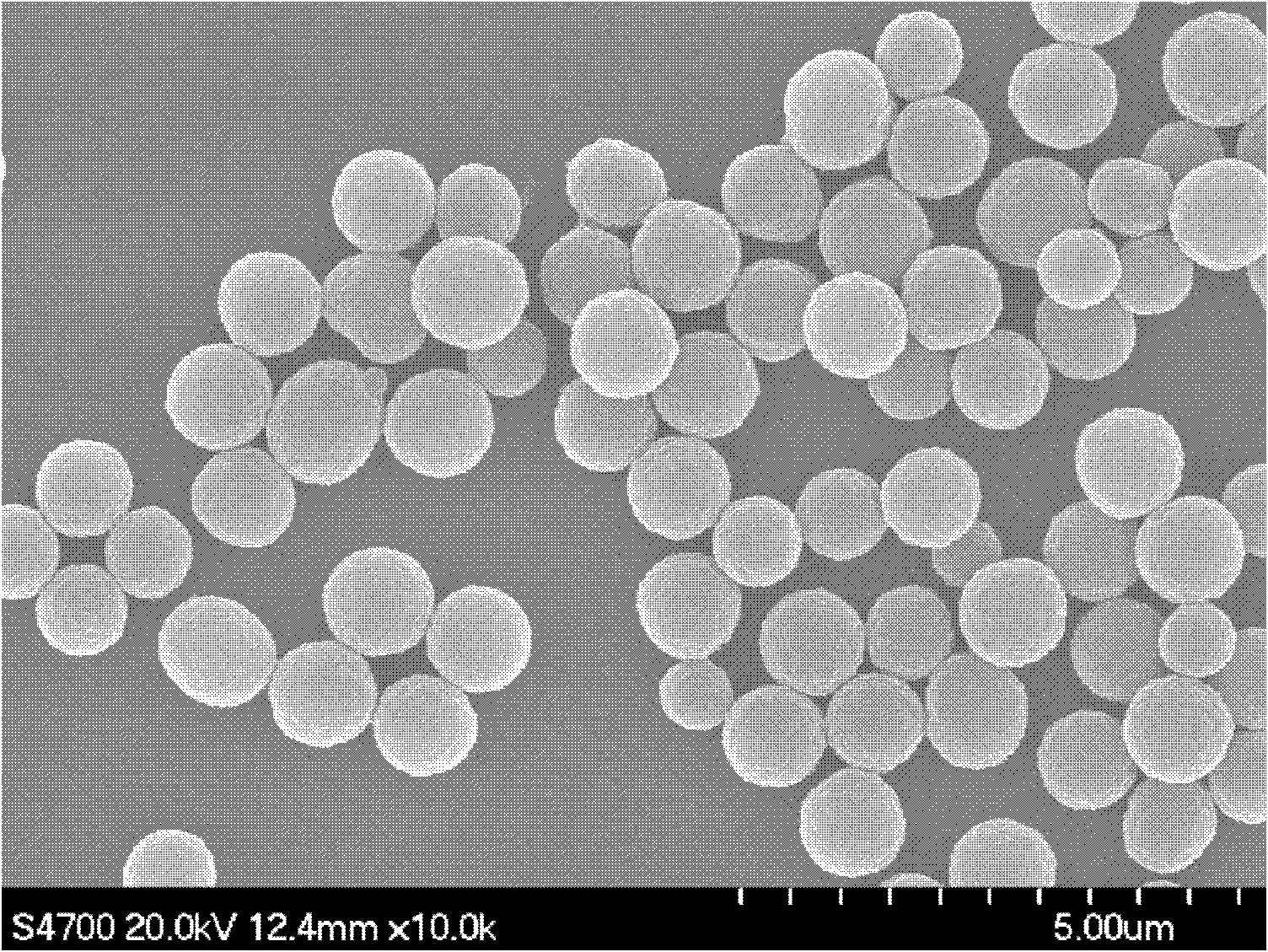

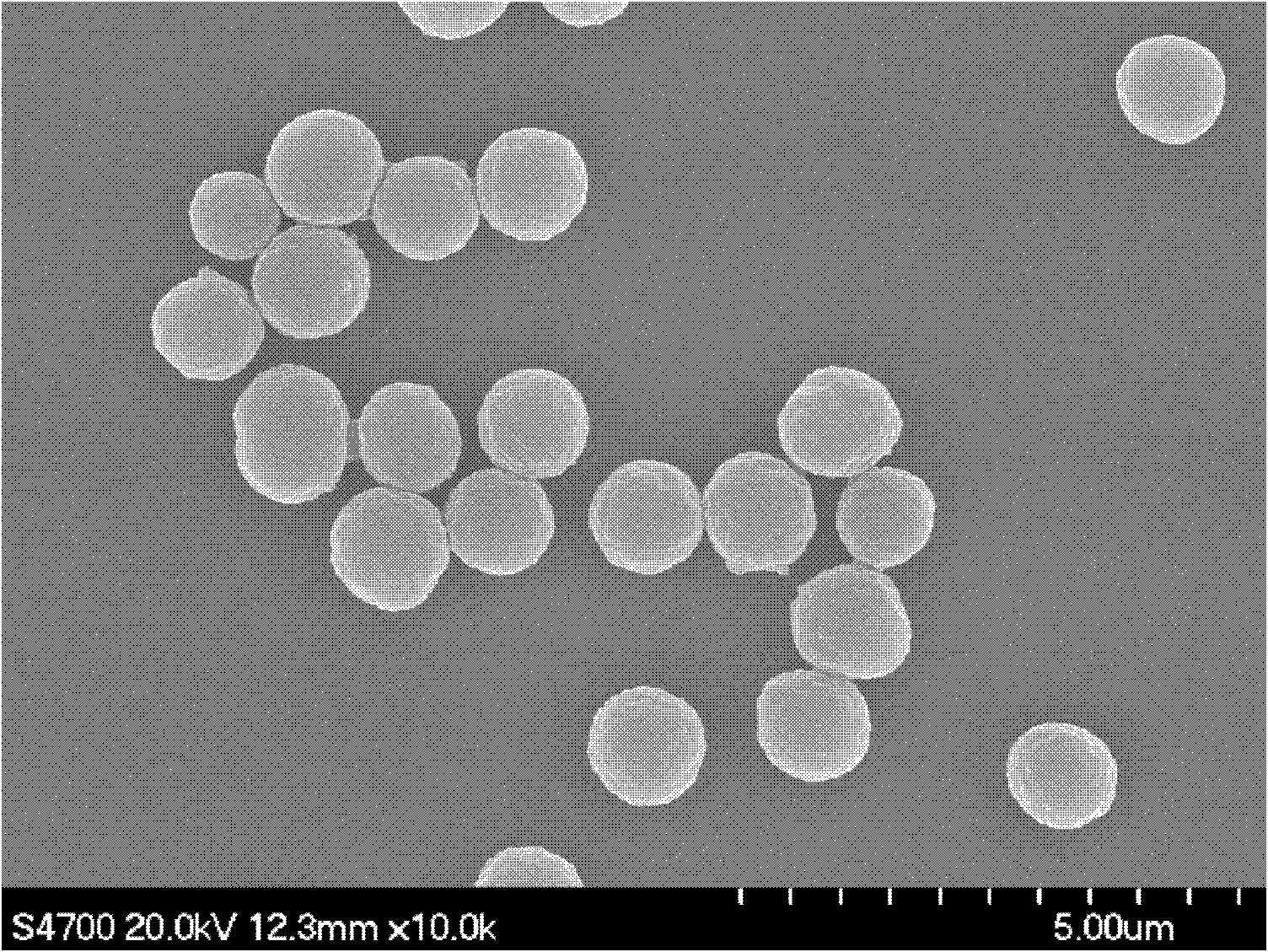

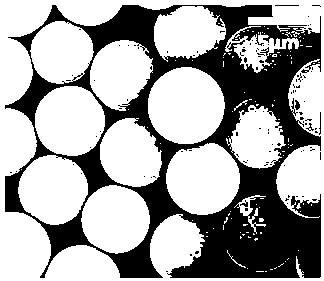

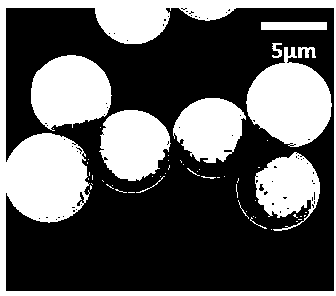

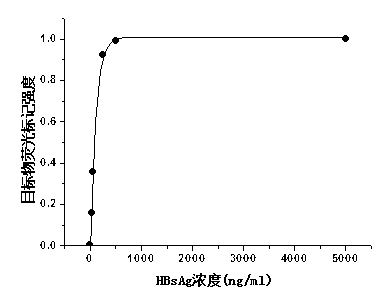

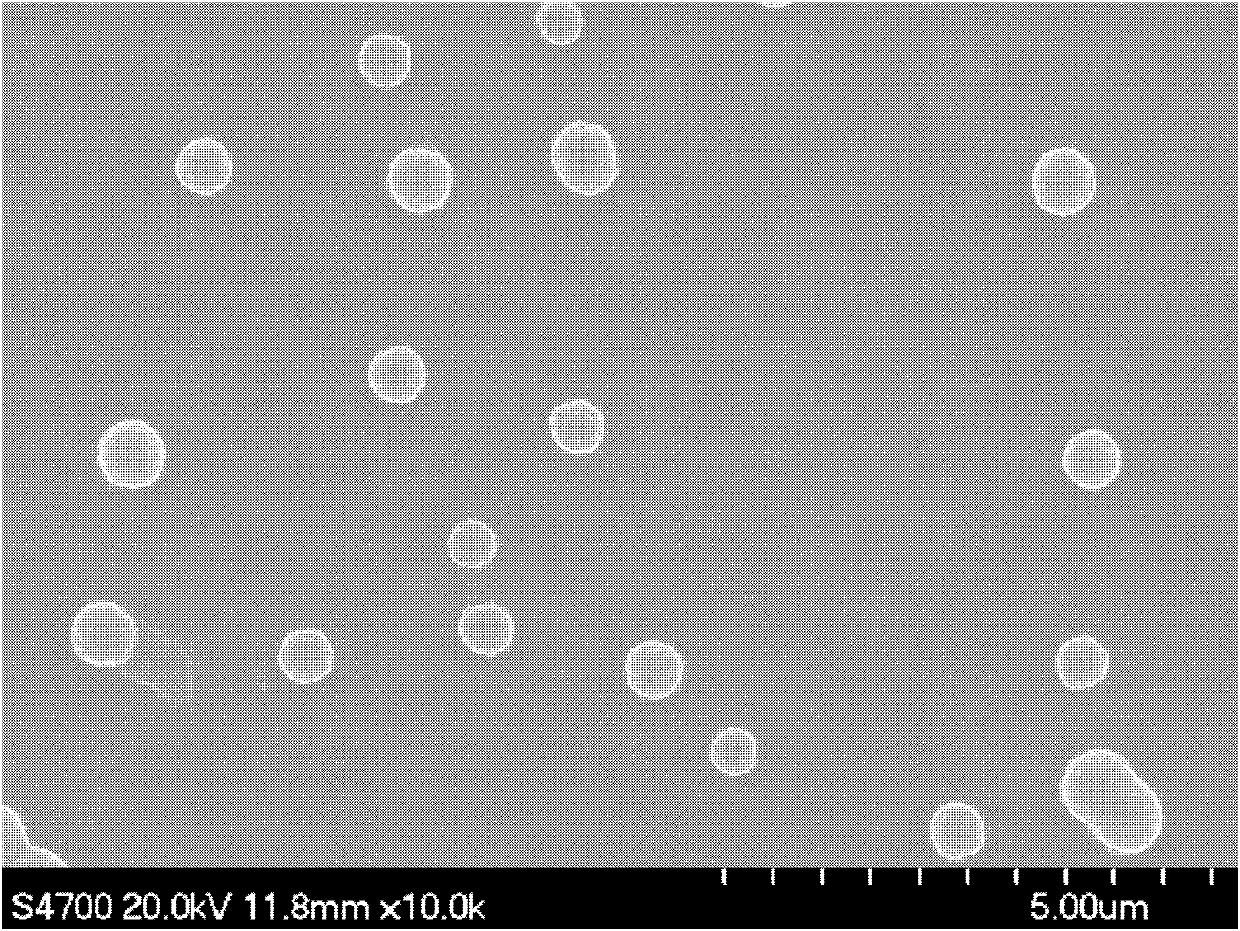

The invention relates to magnetic fluorescent microspheres and a preparation method thereof. The particle size of the magnetic fluorescent microspheres is 5-10 mu m, the fluorescence excitation wavelength range is 400-700nm, and the fluorescence intensity is not reduced within 24h. The prepration method comprises the following steps: adding a swelling agent into monodisperse carboxylated polystyrene microspheres, and adding magnetic nano microparticles into a swelling system; shaking on a decolorization shaker for 12-48h; using mixed solution of cyclohexane and ethanol for cleaning sediment, and sequentially carrying out ultrasonic dispersion and centrifugal separation till supernatant liquid is colorless under an ultraviolet lamp; and saving a final sediment product in 1ml of liquor. Compared with the existing magnetic fluorescent microspheres, the magnetic fluorescent microspheres have the advantages of uniform and controllable diameter, good fluorescence stability, simple preparation process, multiple types of fluorescence codes and the like, and can not only carry out fast separation and purification on reactants by being applied in the biological macromolecular detection, but also simultaneously detect a plurality of target molecules in a sample to be detected in a reaction tube and a hole, thereby being widely applied in the fields of immunoassay, nucleic acid hybridization, genotype analysis and the like.

Owner:TIANJIN UNIV

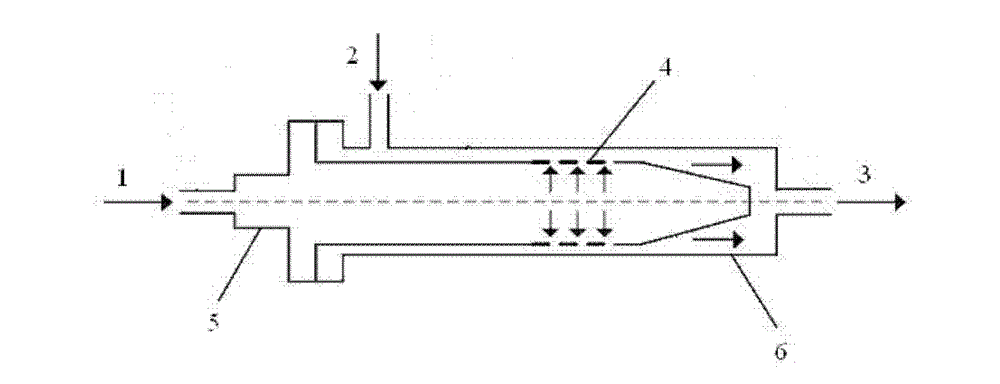

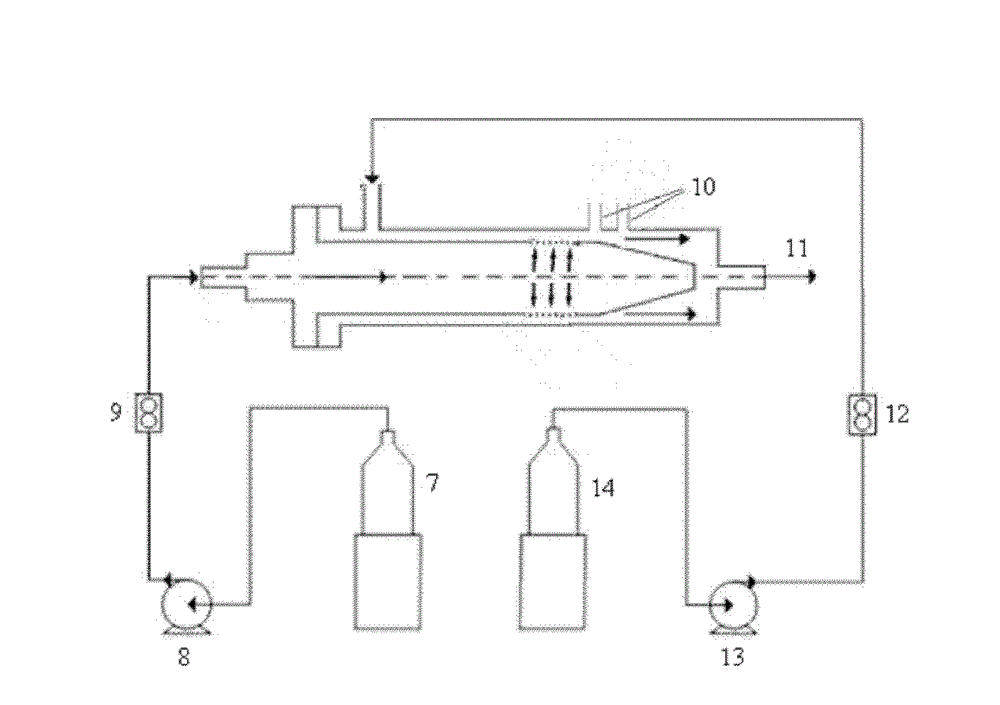

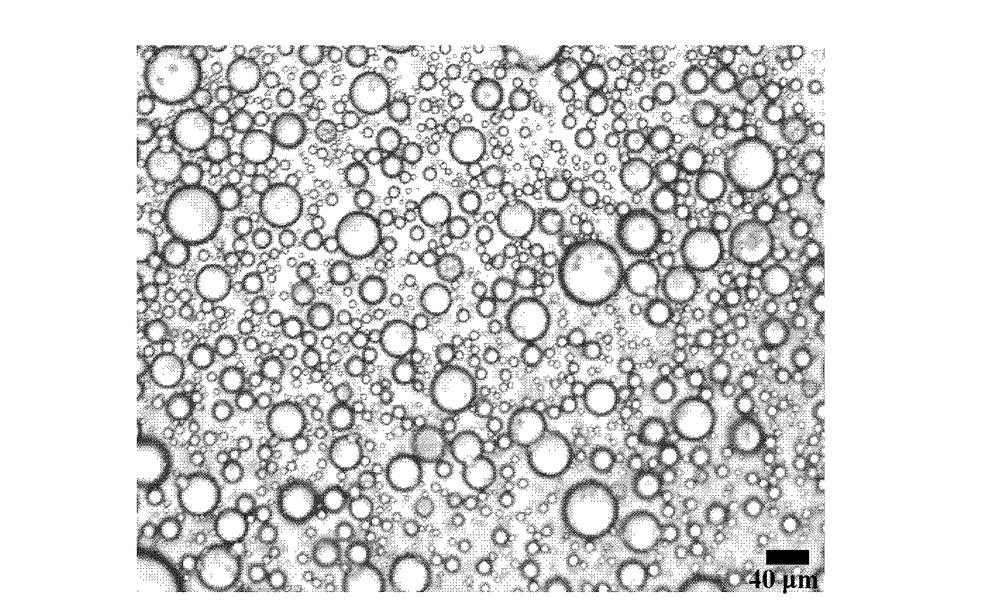

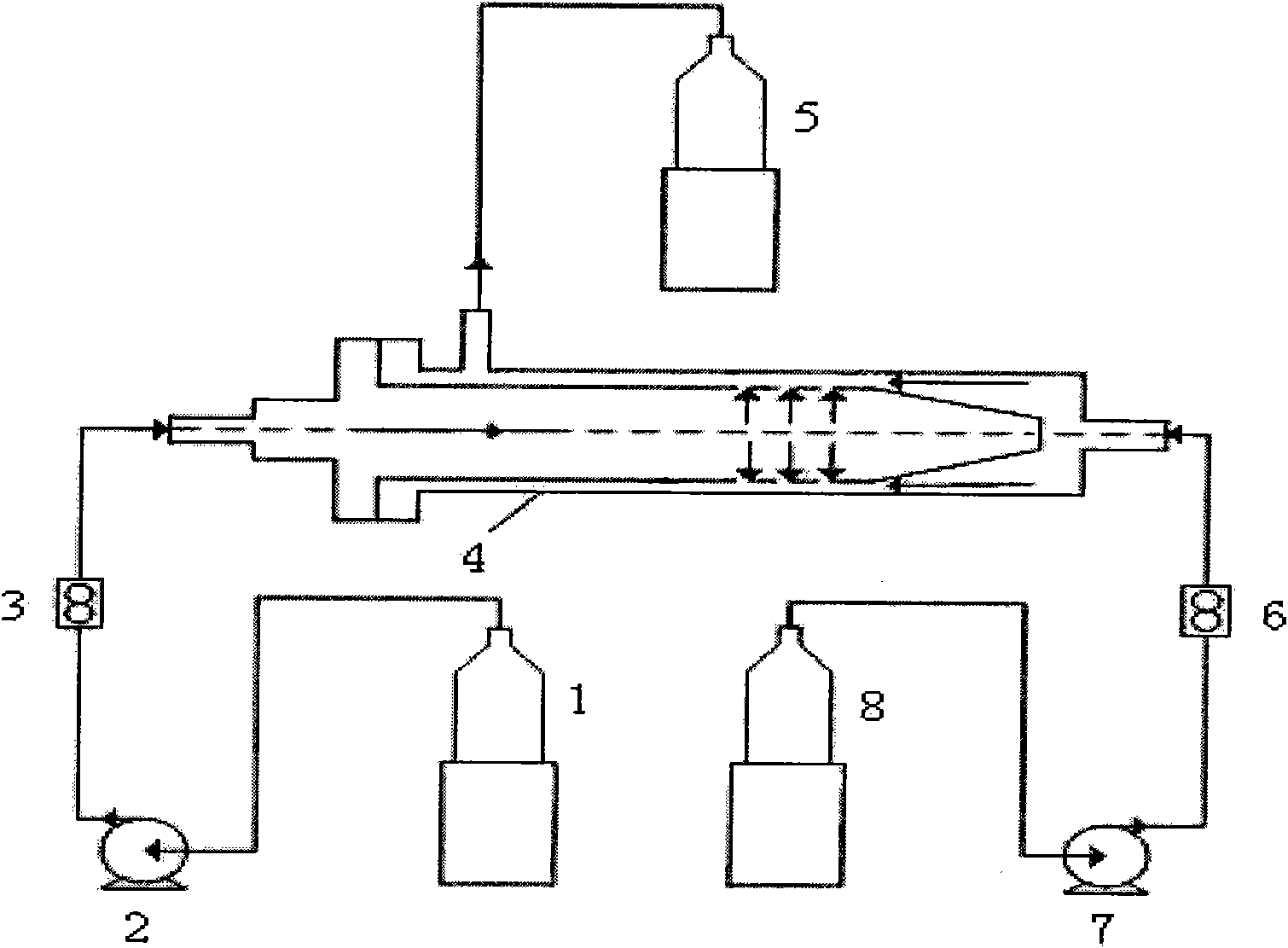

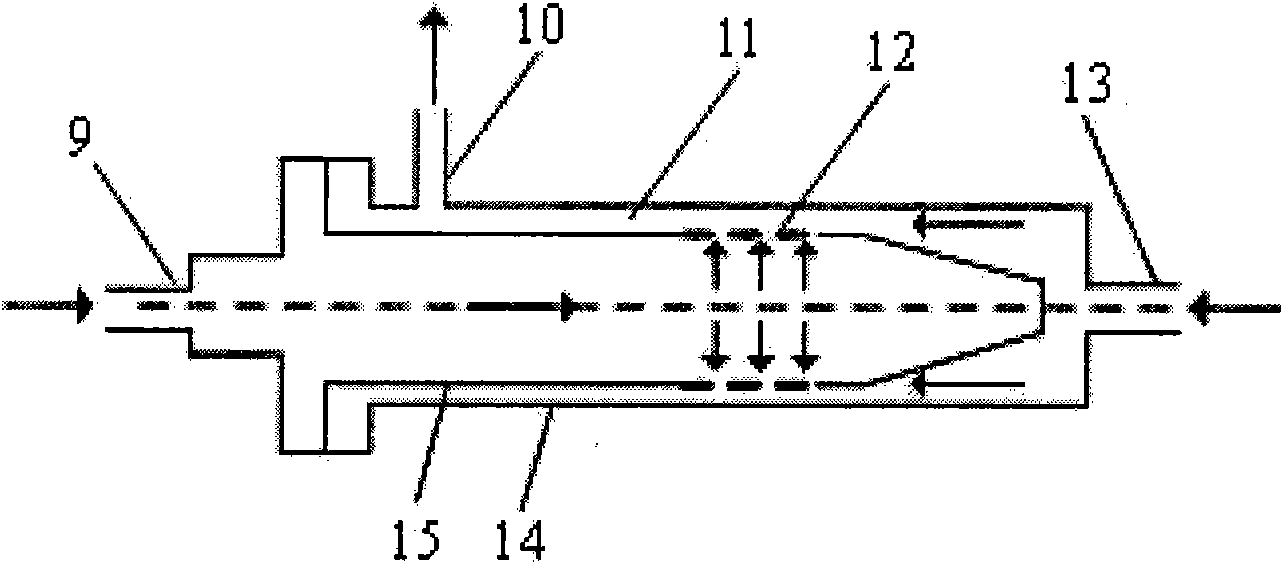

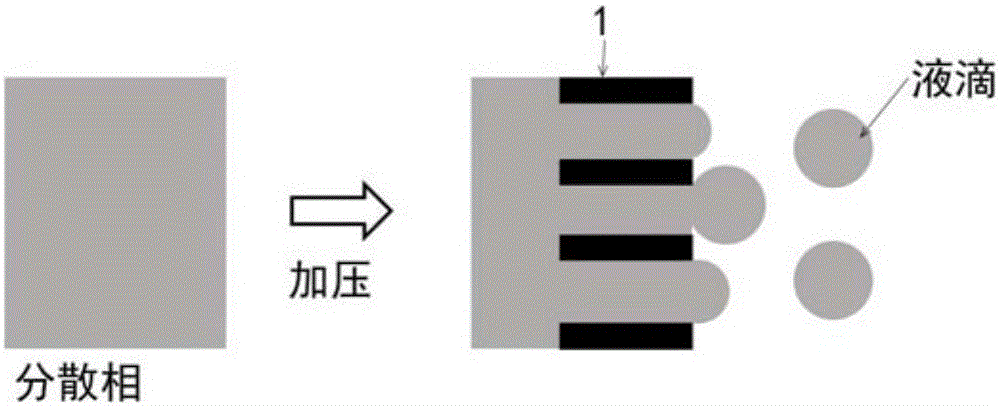

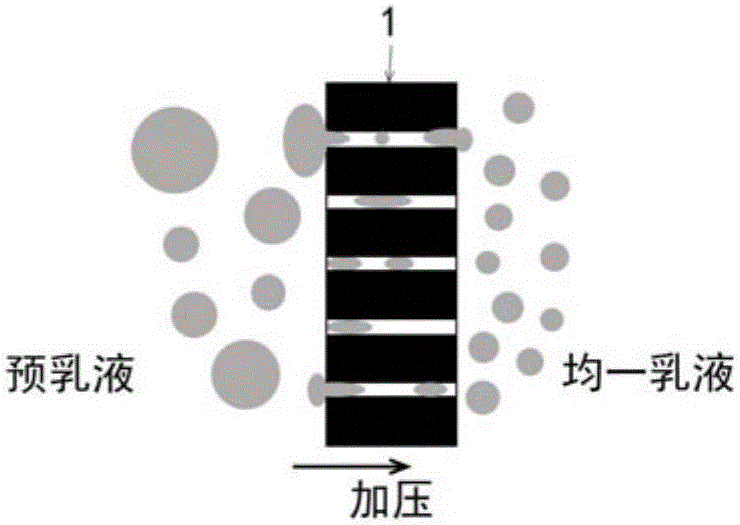

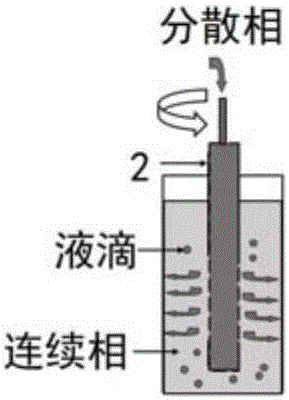

Method for preparing monodisperse emulsion

InactiveCN102794119AUniform particle sizeQuality improvementFlow mixersMixing methodsContact formationEmulsion droplet

The invention discloses a method for preparing monodisperse emulsion and belongs to the technical field of emulsion. The monodisperse emulsion is prepared by using a tube-in-tube annular channel reactor; a continuous phase is introduced into an outer tube of the tube-in-tube annular channel reactor, a disperse phase is introduced into an inner tube of the tube-in-tube annular channel reactor, and the continuous phase and the disperse phase fully contact on micropore parts to form the emulsion; and according to the method, equipment is simple, cost is low, flux is high, and continuous operation can be realized, so that the preparation cycle can be greatly shortened, and production efficiency is improved. The emulsion prepared by the method is high in quality, stable in performance, and high dispersibility; and emulsion droplets are uniform in particle size.

Owner:BEIJING UNIV OF CHEM TECH

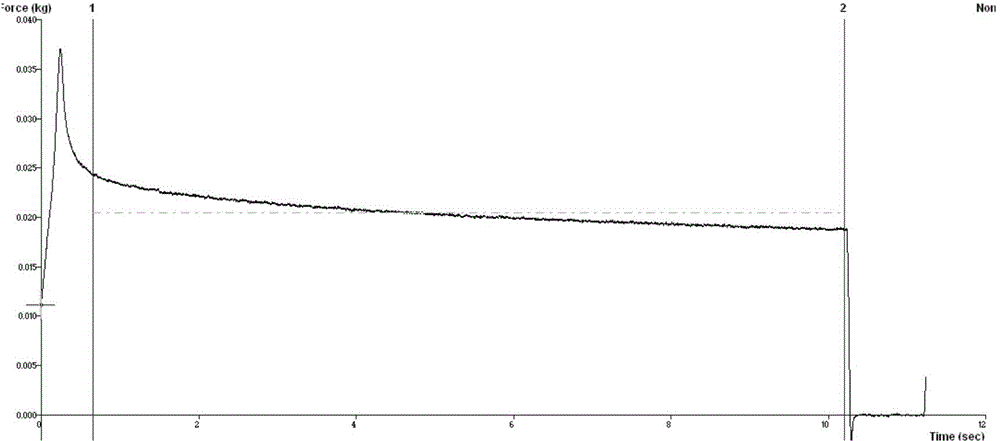

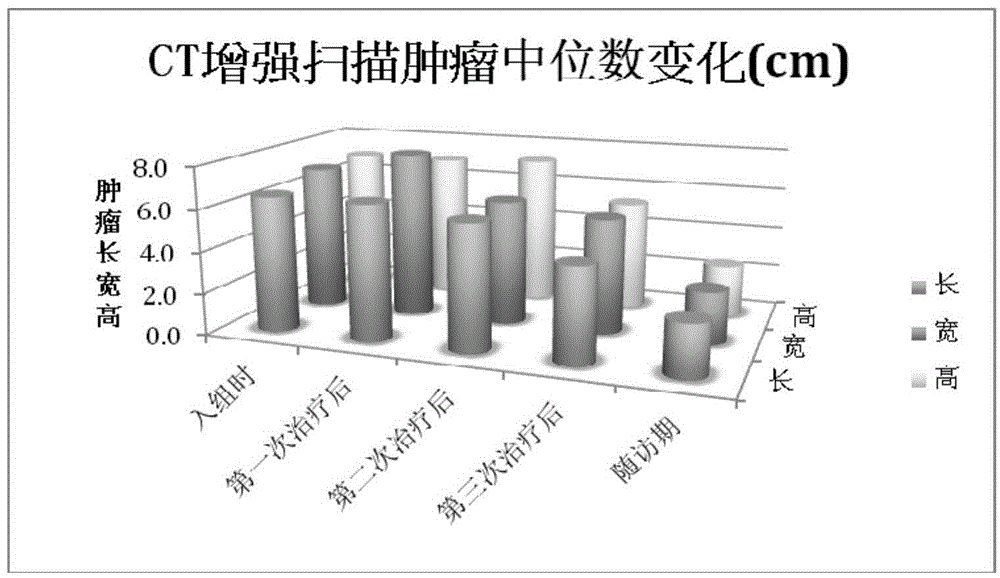

Polyhydroxyl polymer embolized microsphere and preparation process thereof

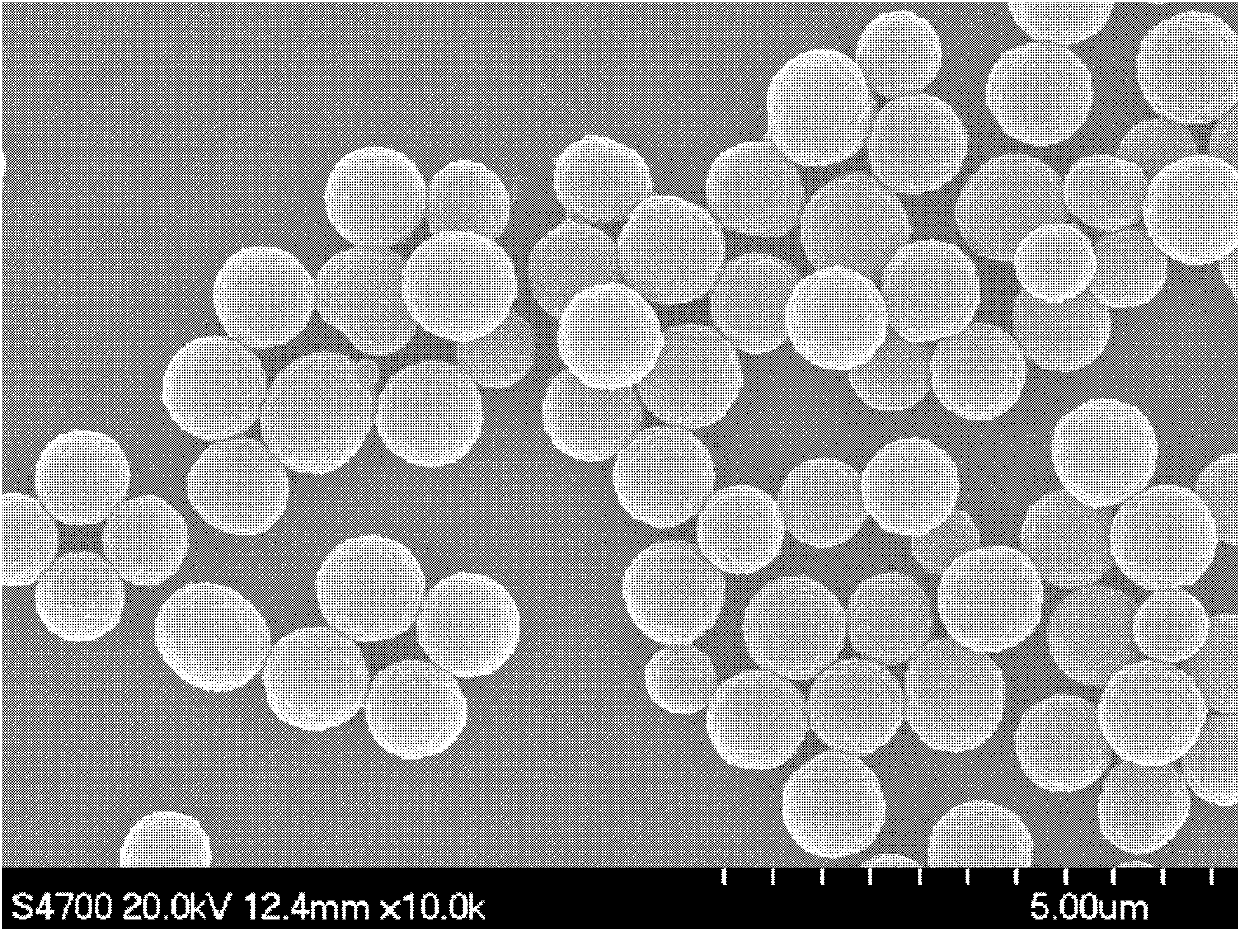

ActiveCN103977458AGood biocompatibilityGood biological stabilitySurgeryPharmaceutical non-active ingredientsCross-linkPolymer science

The invention relates to a polyhydroxyl polymer embolized microsphere, which is formed by cross-linking polymerization of biocompatible functional macromolecules. The embolized microsphere is characterized in that the functional macromolecule comprises a polymer, wherein at least two acetal structures containing acrylic acid or derivative radicals thereof connected on the main chain or at least two crosslinkable micro-molecules which are connected in a covalent bond mode and have acrylic acid or derivative structures thereof; the acetal structures or crosslinkable micro-molecules can form a hydrogel unsaturated functional group through free radical polymerization crosslinking; a functional group by using organic carboxylate as a negative charge carrier is contained inside the microsphere. The invention also provides a preparation process of the polyhydroxyl polymer embolized microsphere. The embolized microsphere has excellent biocompatibility and stability, large elastic stretching rate and recoverability, is uniform and controllable in granularity, excellent in dispersion, simple in use and operation and strong in targeting property, has excellent adsorption capability to bioactive substances, and can be used for various minimally invasive treatment.

Owner:SUZHOU HENGRUI CALLISYN BIOLOGICAL MEDICINE TECH CO LTD

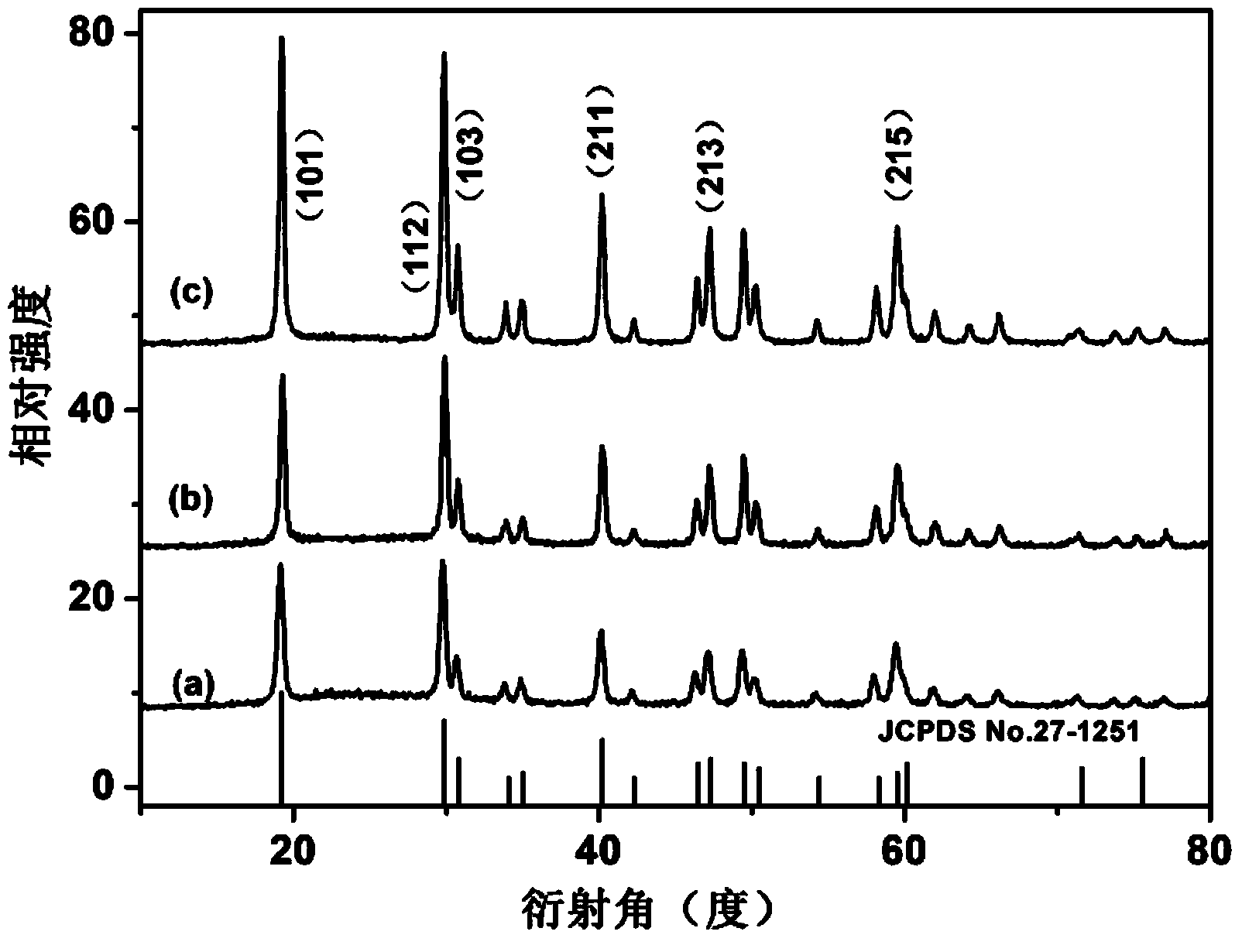

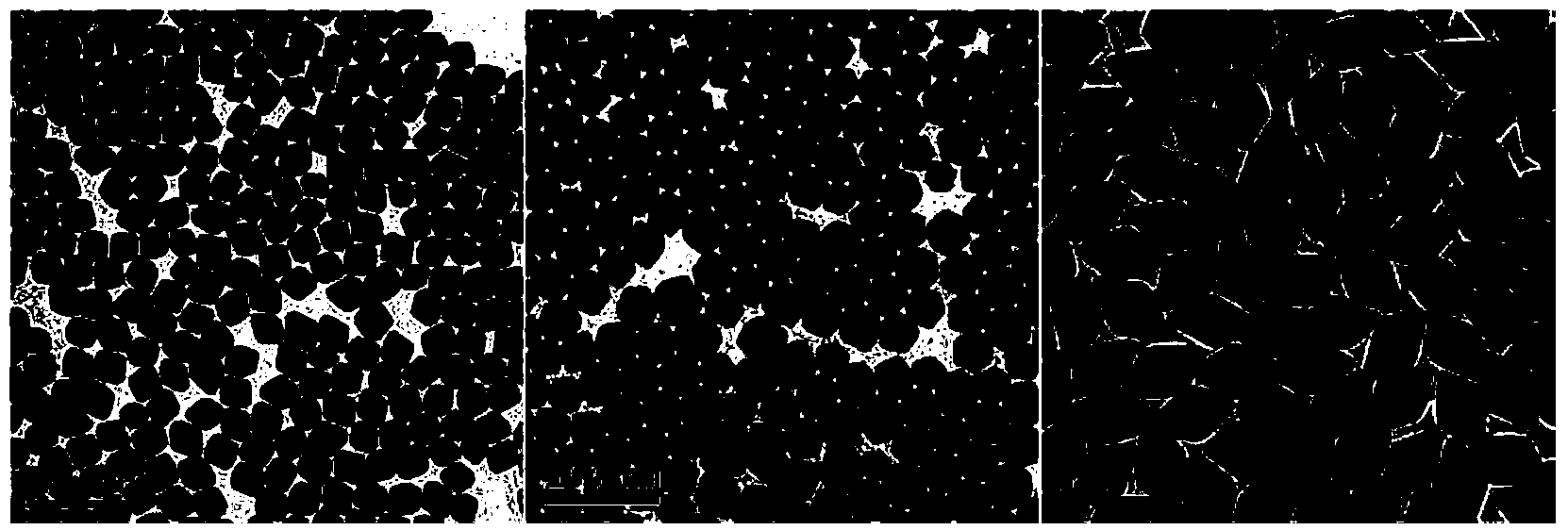

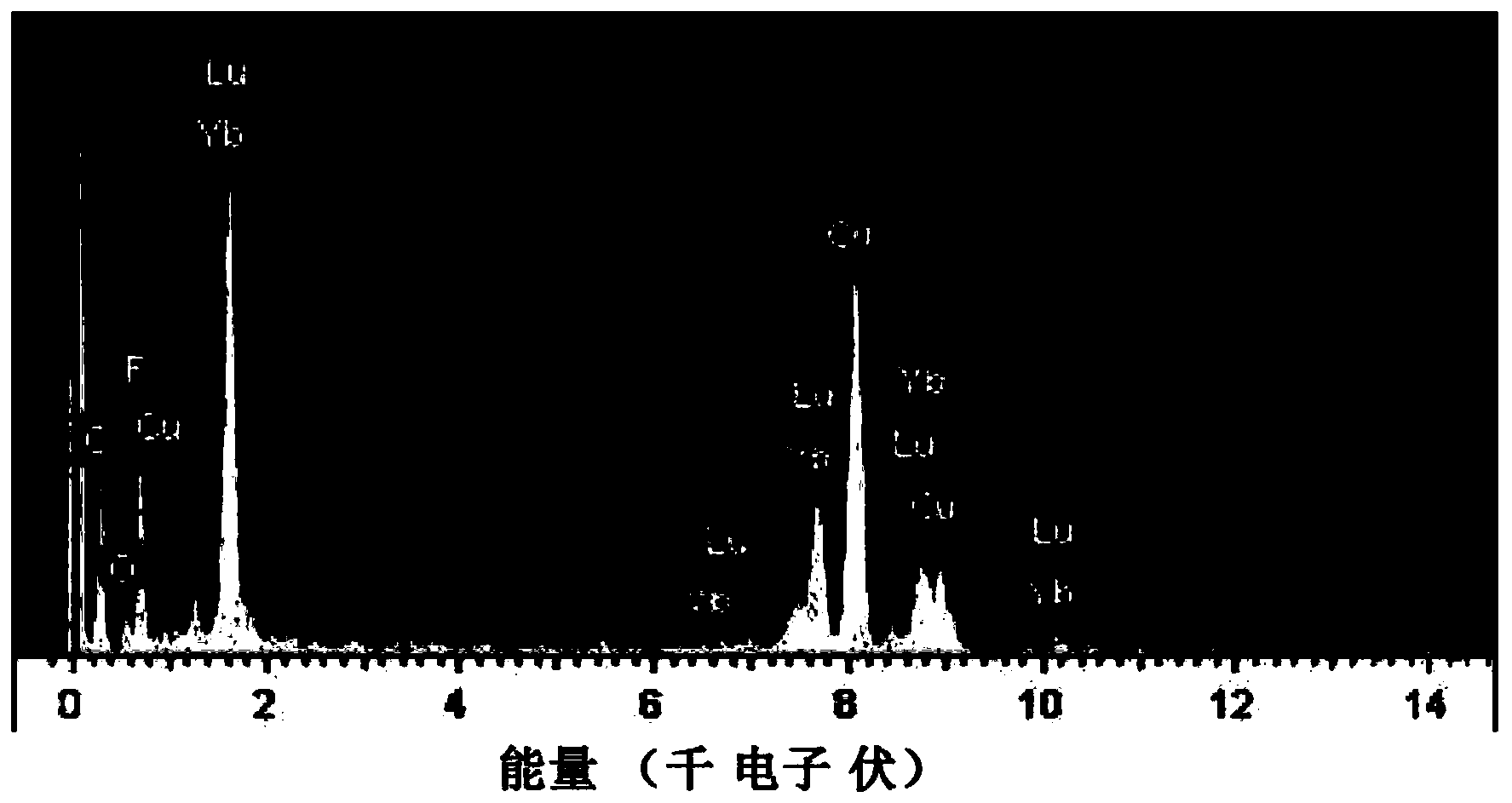

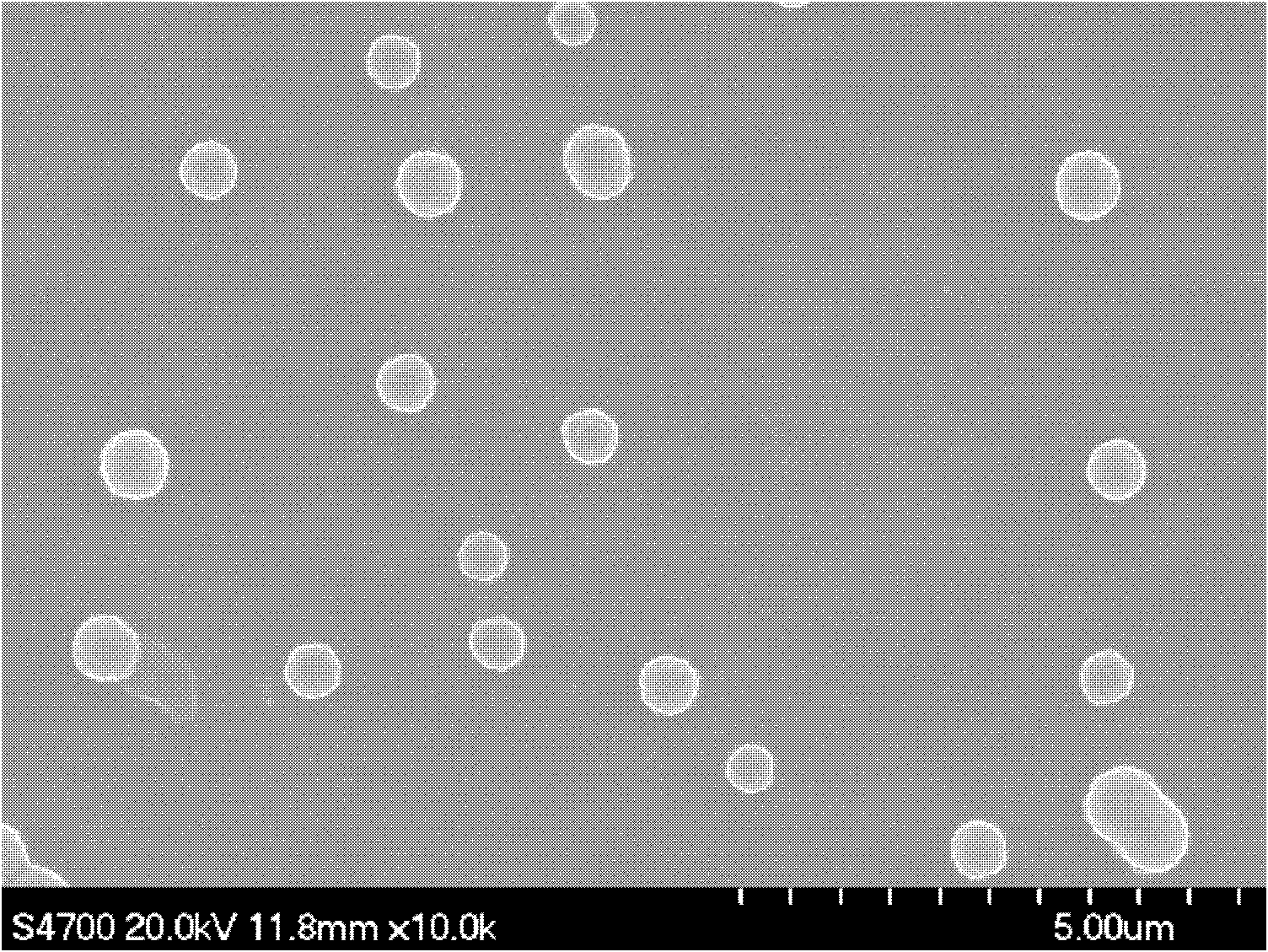

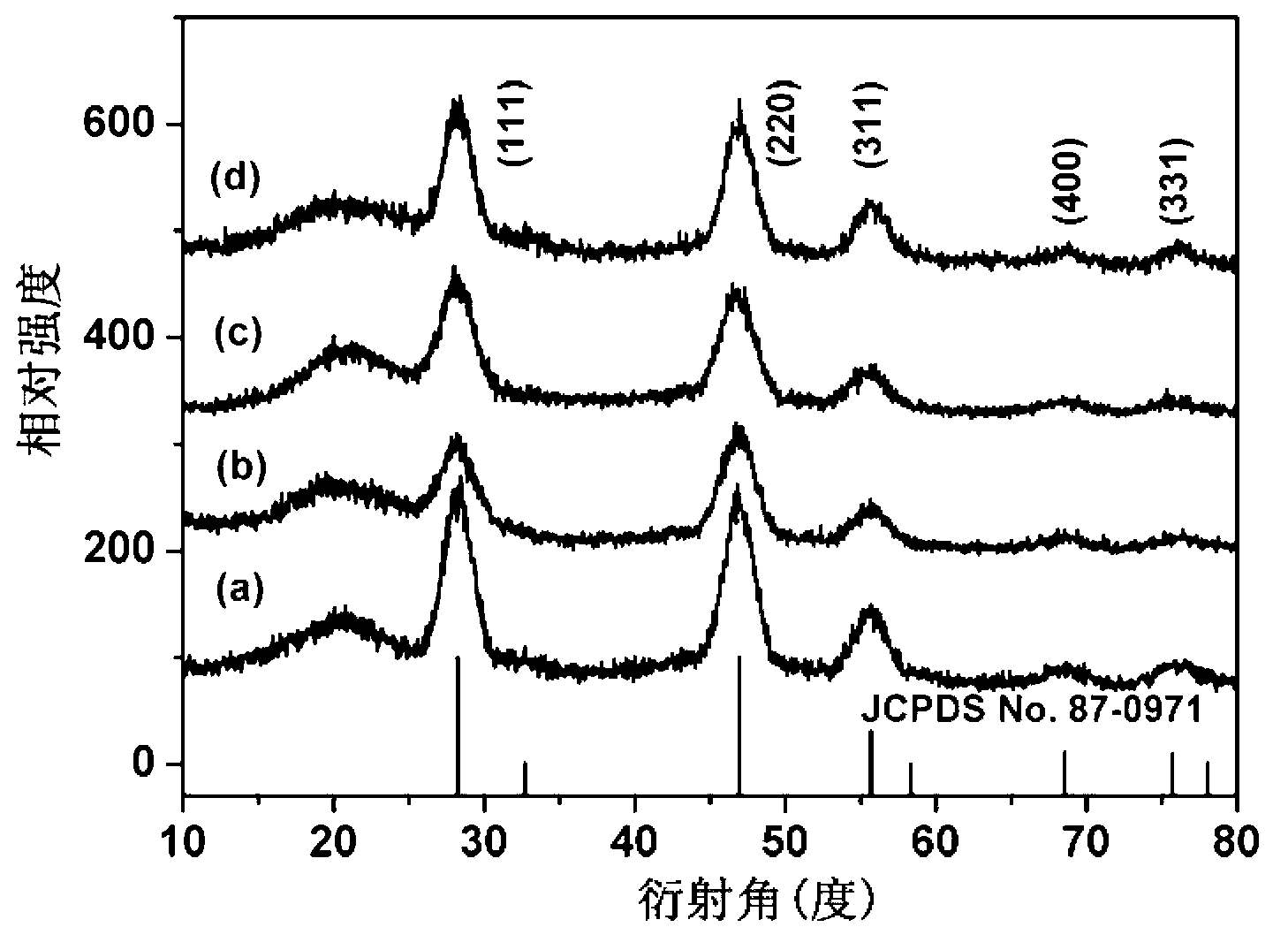

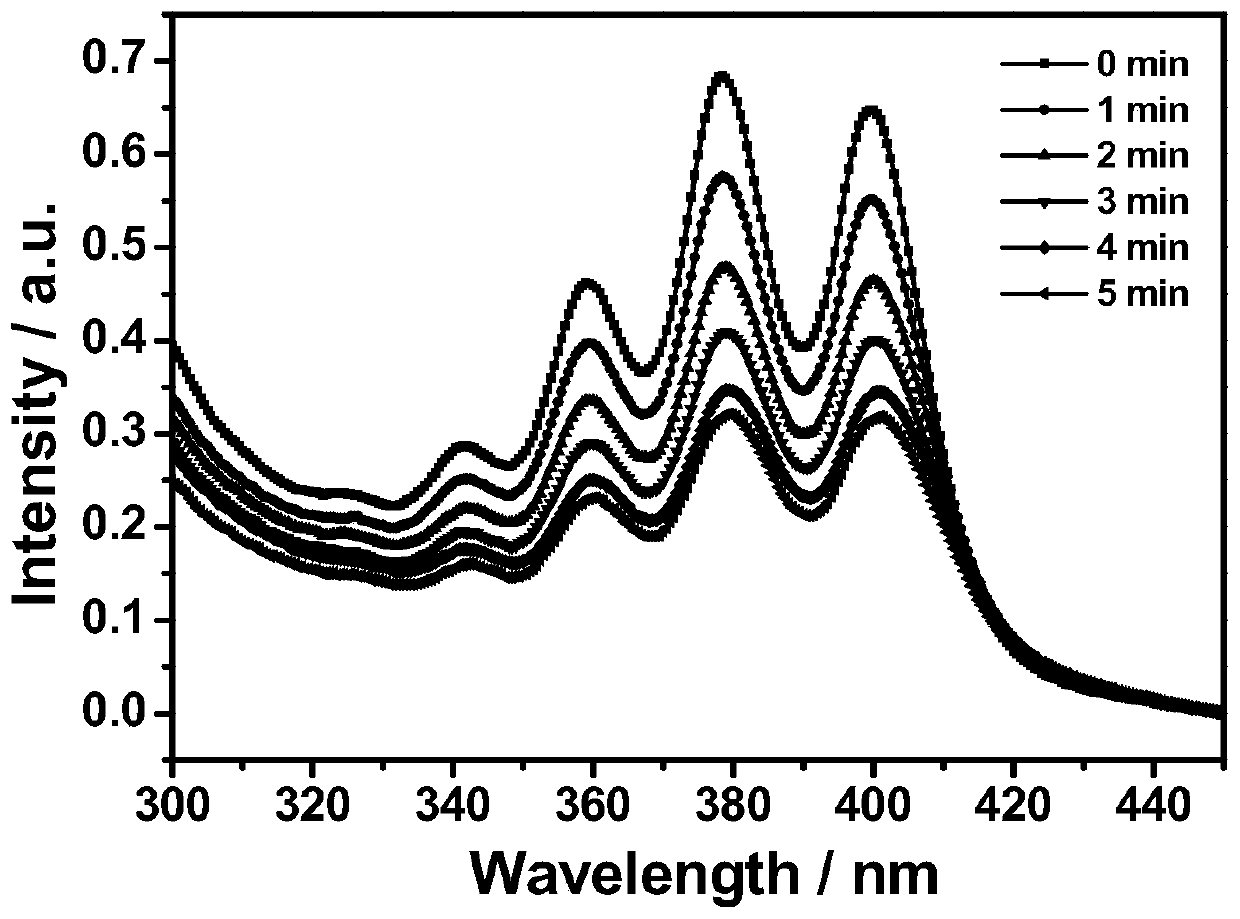

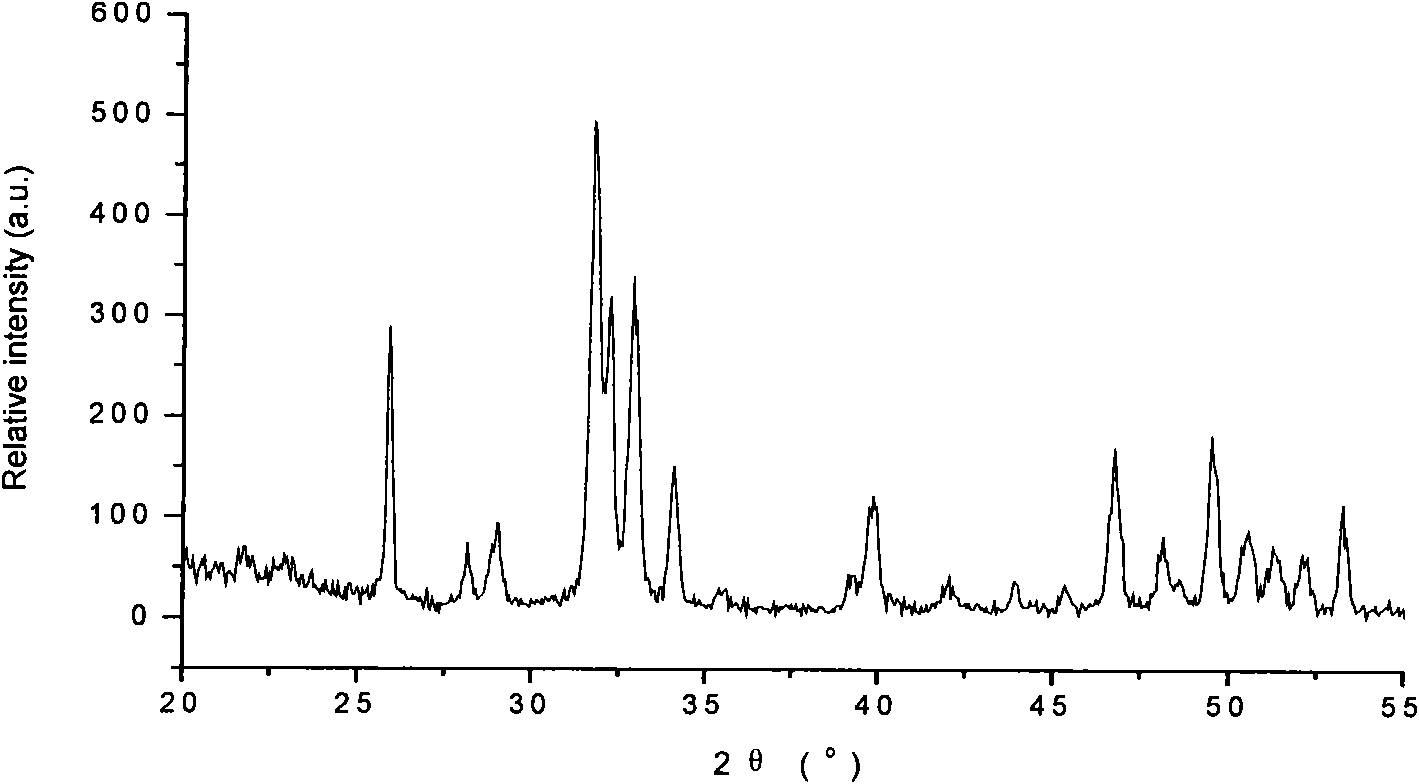

Rare earth-doped lithium lutetium fluoride nano-material, and preparation method and application thereof

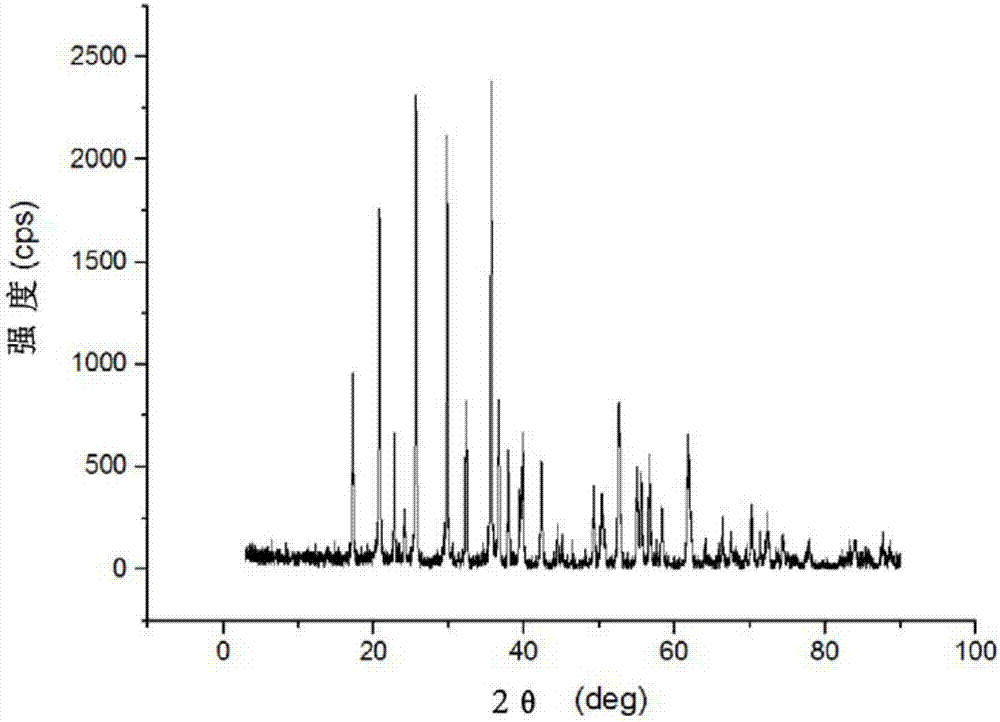

ActiveCN103589432AEasy to makeSynthesis conditions are easy to controlFluorescence/phosphorescenceLuminescent compositionsBio moleculesContrast medium

The invention discloses a rare earth-doped lithium lutetium fluoride nano-material, and a preparation method and an application thereof. The material is obtained by doping Yb / Er(20 / 1%) or Yb / Tm(20 / 0.5%) luminescent ions into a lithium lutetium fluoride matrix, can emit visible light under the excitation of 980nm infrared light, and can be used for the up-conversion heterogeneous detection and cell imaging through the connection with biological molecules. Additionally, heavy rare earth ions in the matrix also have a strong X-ray attenuation capability, and can be used as a computer tomography imaging contrast agent. The invention also provides the preparation method of the nano-material. The nano-material has a water solubility and excellent performances, so the nano-material can be applied in the fields of the biological detection, the biological imaging and the like.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Novel method for performing copolymerization reaction of dicyclopentadiene and maleic anhydride

The invention discloses a novel method for performing a copolymerization reaction of dicyclopentadiene and maleic anhydride, and belongs to the technical field of copolymers. The method comprises the following steps of: under the protection of nitrogen, adding monomers and an initiator into an organic medium and dissolving, reacting for 2 to 12h at the temperature of between 60 and 90 DEG C to obtain a self-stabilizing dispersion system of monodisperse microspheres of an alternating copolymer, and performing centrifugal separation, and drying to obtain a white solid of the dicyclopentadiene / maleic anhydride alternating copolymer, wherein the reaction monomers are the dicyclopentadiene and the maleic anhydride, and the molar ratio of the two monomers is 5:1-1:5; the medium is a mixed solvent of organic acid alkyl ester and organic alkane, and the organic acid alkyl ester accounts for 30 to 70 volume percent of the mixed solvent; and a chemical structure is that: R1 is a hydrogen atom, C1-C5 alkyl, phenyl or benzyl, and R2 is C1-C5 alkyl. A stabilizer and a costabilizer are not required to be added, the reaction system is simple, and a product is easy to separate; and polymer microspheres have smooth and clean surfaces, uniform particle sizes, controllable appearances, and high dispersibility.

Owner:BEIJING UNIV OF CHEM TECH

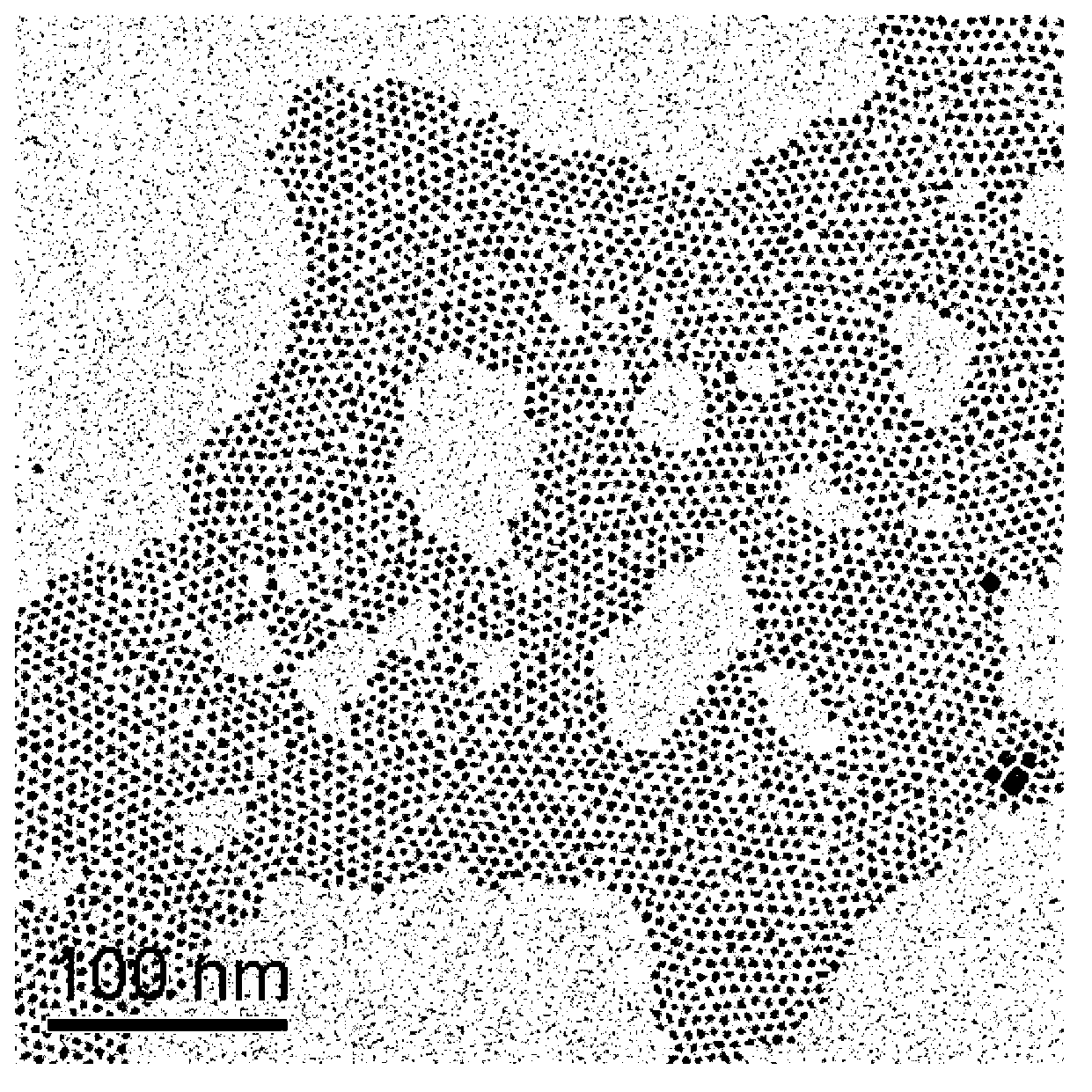

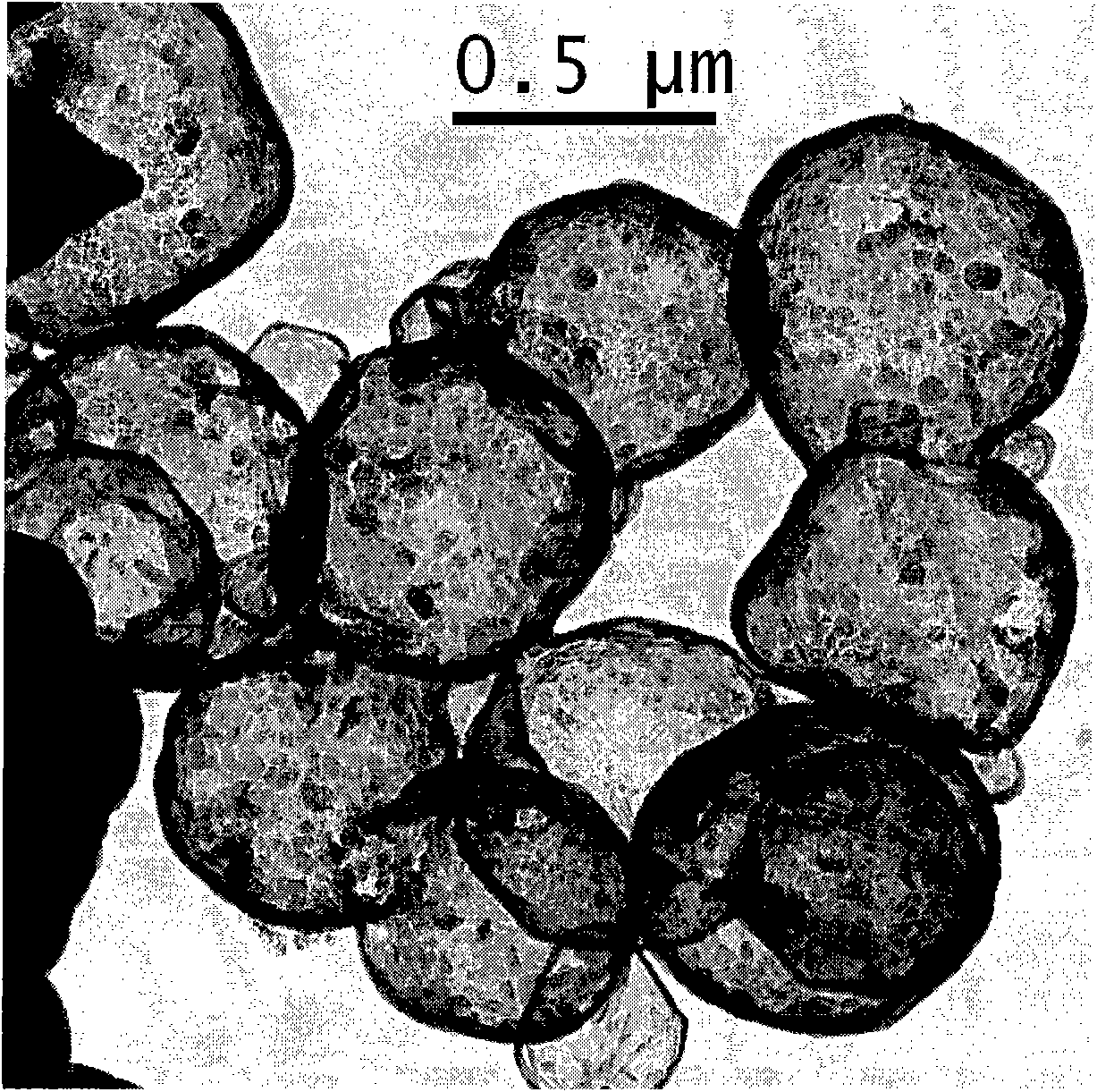

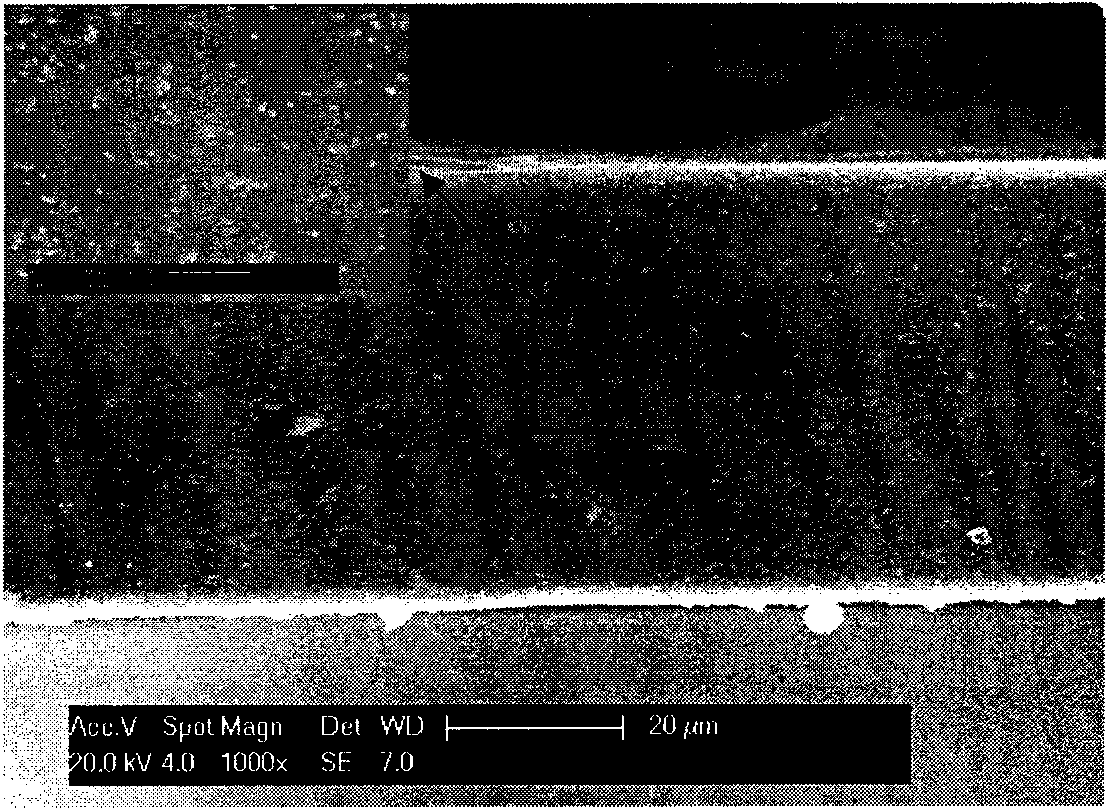

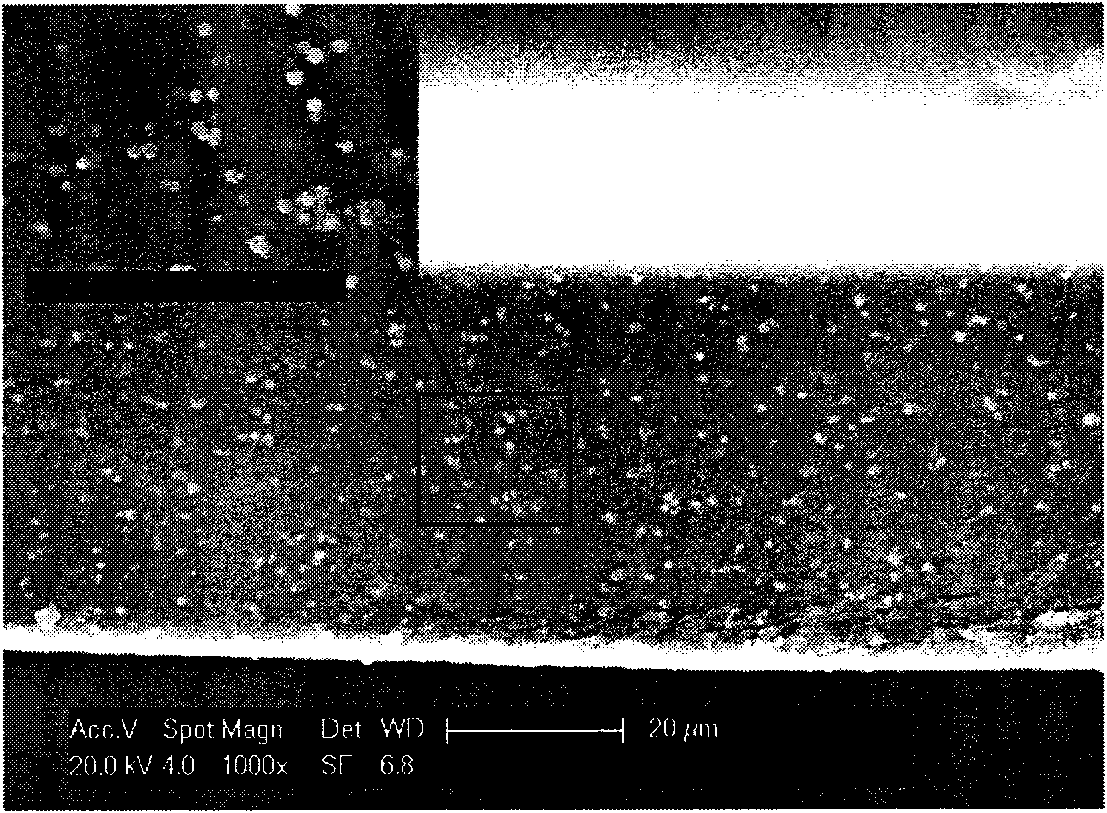

Functional nanometer particle composite non-crosslinking microspheres and preparation method and application thereof

InactiveCN102908961AIncrease productionUniform and controllable particle sizeFluorescence/phosphorescenceMacromolecular non-active ingredientsMembrane emulsificationMicrosphere

The invention relates to functional nanometer particle composite non-crosslinking microsphere powder, and a preparation method and application of the functional nanometer particle composite non-crosslinking microsphere powder. The functional nanometer particle composite non-crosslinking microsphere powder contains functional nanometer particle composite non-crosslinking microspheres; the functional nanometer particle composite non-crosslinking microspheres contain functional nanometer particles and polymers, average particle size is 0.1micron to 20micron, and particle size distribution variable coefficient is less than or equal to 9.1%. The preparation method is a combination of a membrane emulsification technique and a solvent volatilization method. The invention also relates to a biometric probe and application of the biometric probe based on the above composite non-crosslinking microsphere powder. The preparation method has the advantages that the functional nanometer composite non-crosslinking microsphere powder which is uniform in particle size can be prepared; the prepared functional nanometer composite non-crosslinking microspheres belong to micron order, the particle size variable coefficient is small, monodispersity is good, and performance is excellent; and the prepared functional nanometer composite non-crosslinking microspheres have broad application prospect in biometric and biomedical fields and the like.

Owner:XIN HUA HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

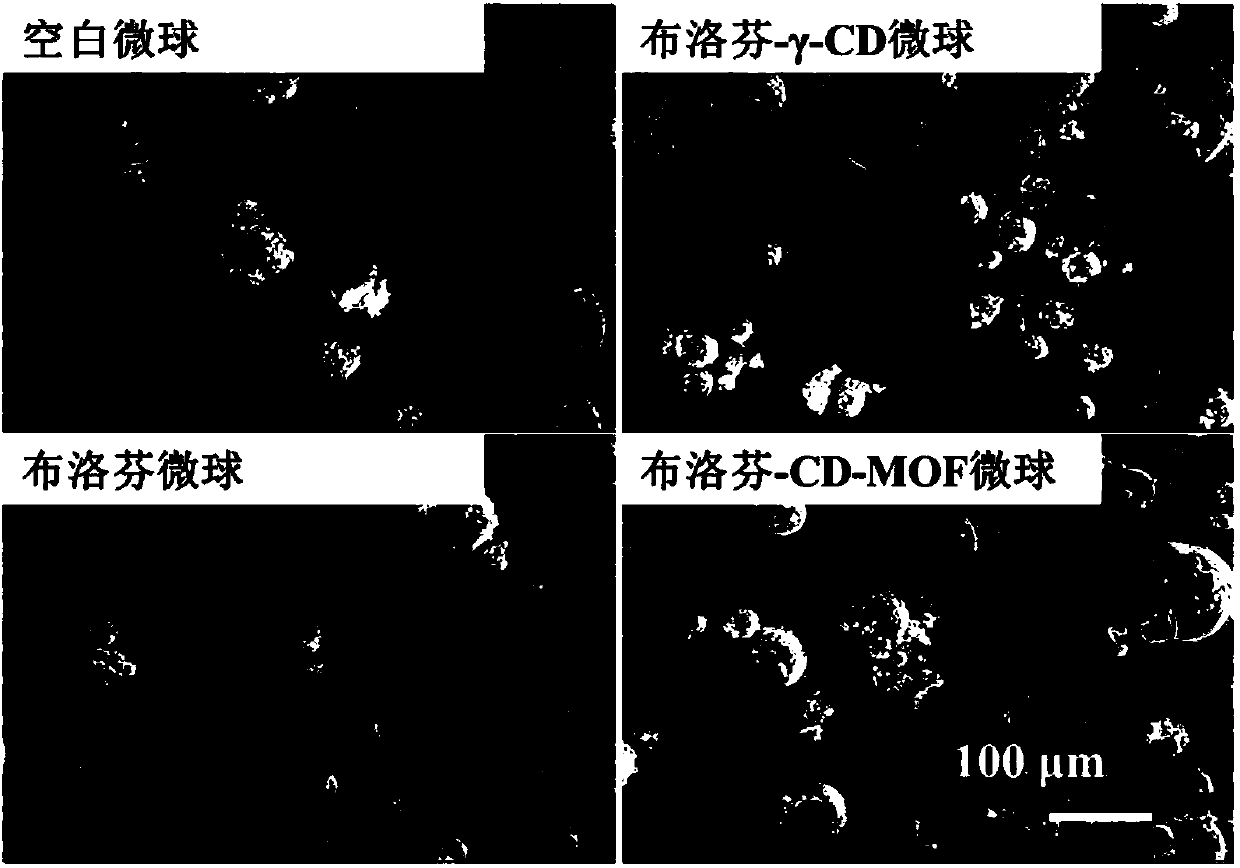

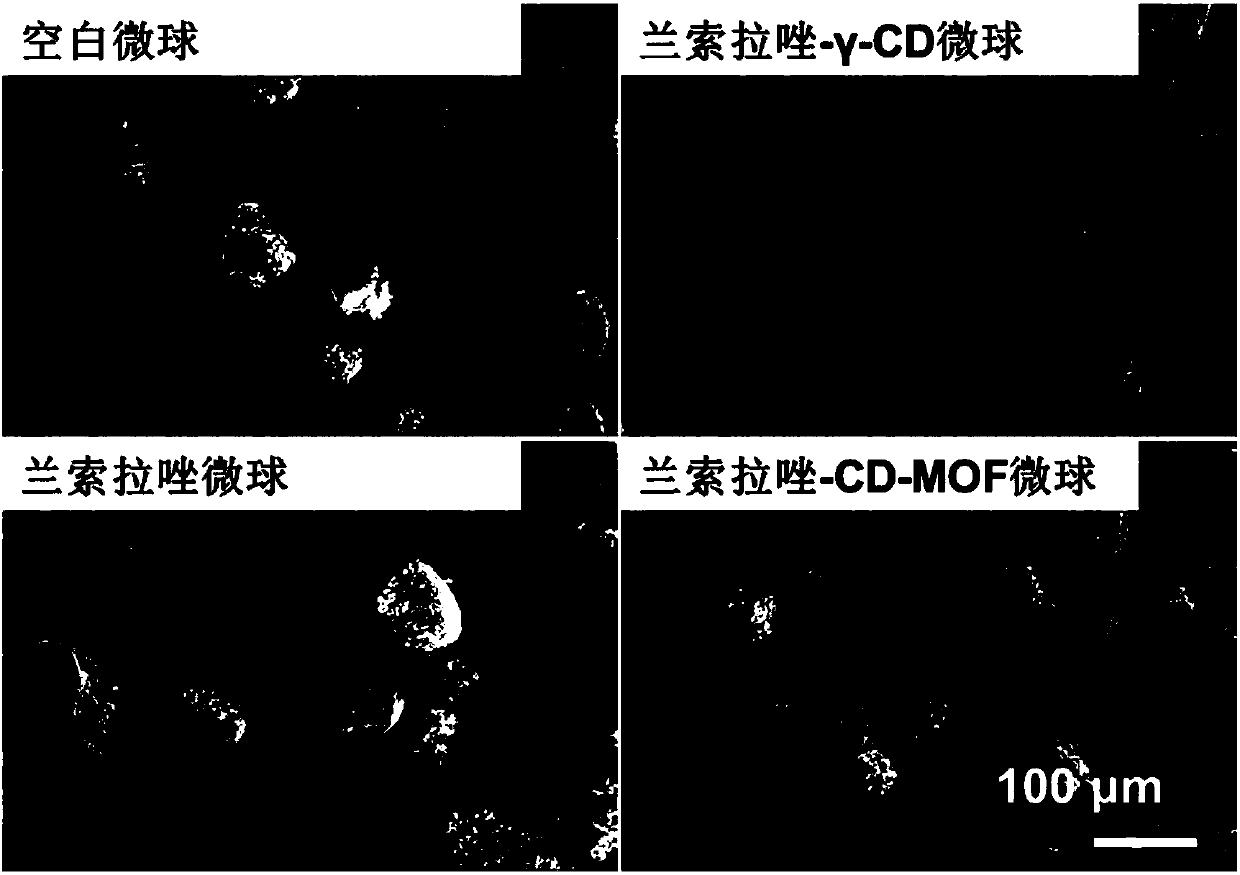

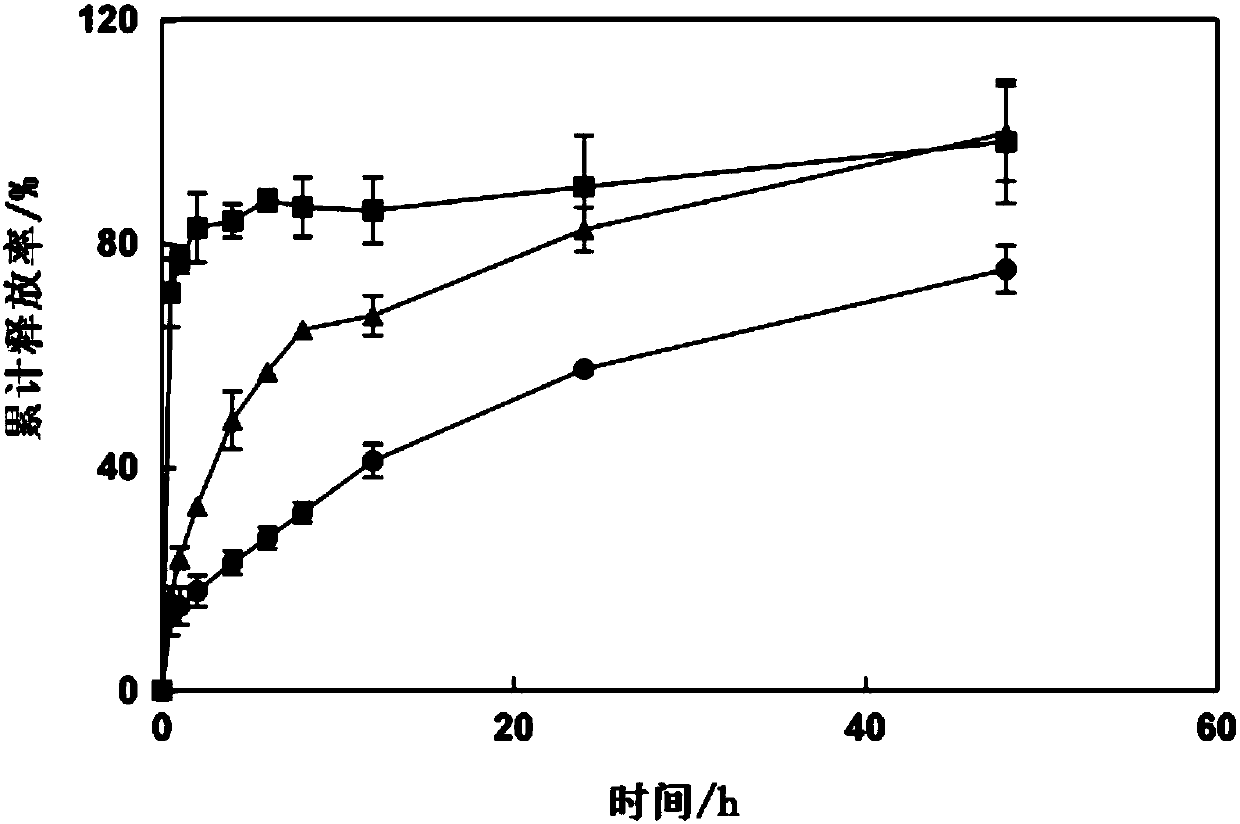

Cyclodextrin-metal organic framework (CD-MOF) composite microsphere and preparation method thereof

ActiveCN107837401AImprove protectionReduce releasePharmaceutical non-active ingredientsMicrocapsulesMicrosphereCyclodextrin

The invention provides a CD-MOF composite microsphere and a preparation method thereof. Specifically, the CD-MOF composite microsphere contains a drug-loaded CD-MOF component (a) of a cubic crystal structure and a component (b) wrapping the component (a). The composite microsphere provided by the invention can overcome the problem that CD-MOF used as a drug storage cavern disintegrates in the presence of water, protects the intactness of a CD-MOF porous skeleton structure, prevents burst release of drugs and realizes slow release of drugs.

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI

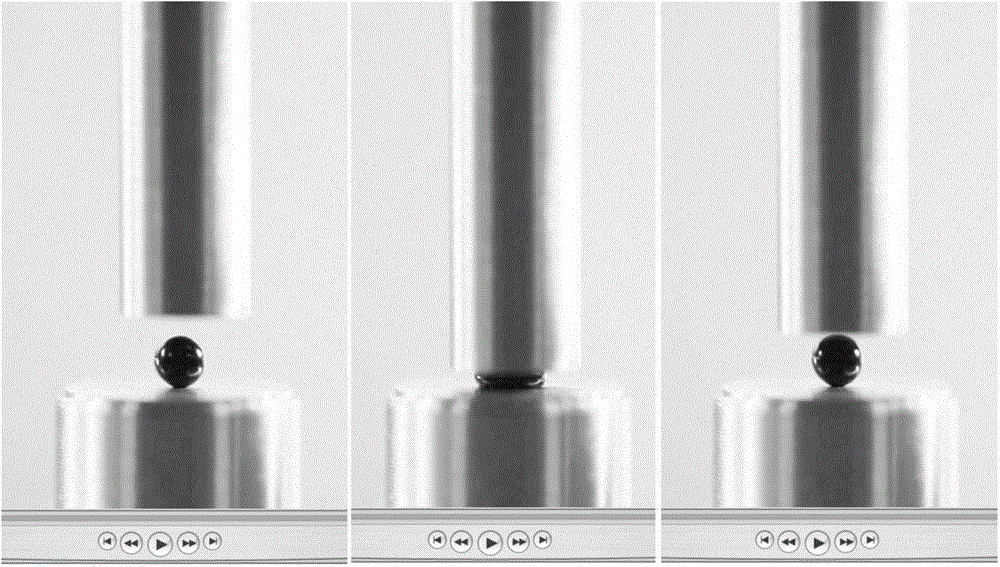

Preparation technology for microspheric embolization agent

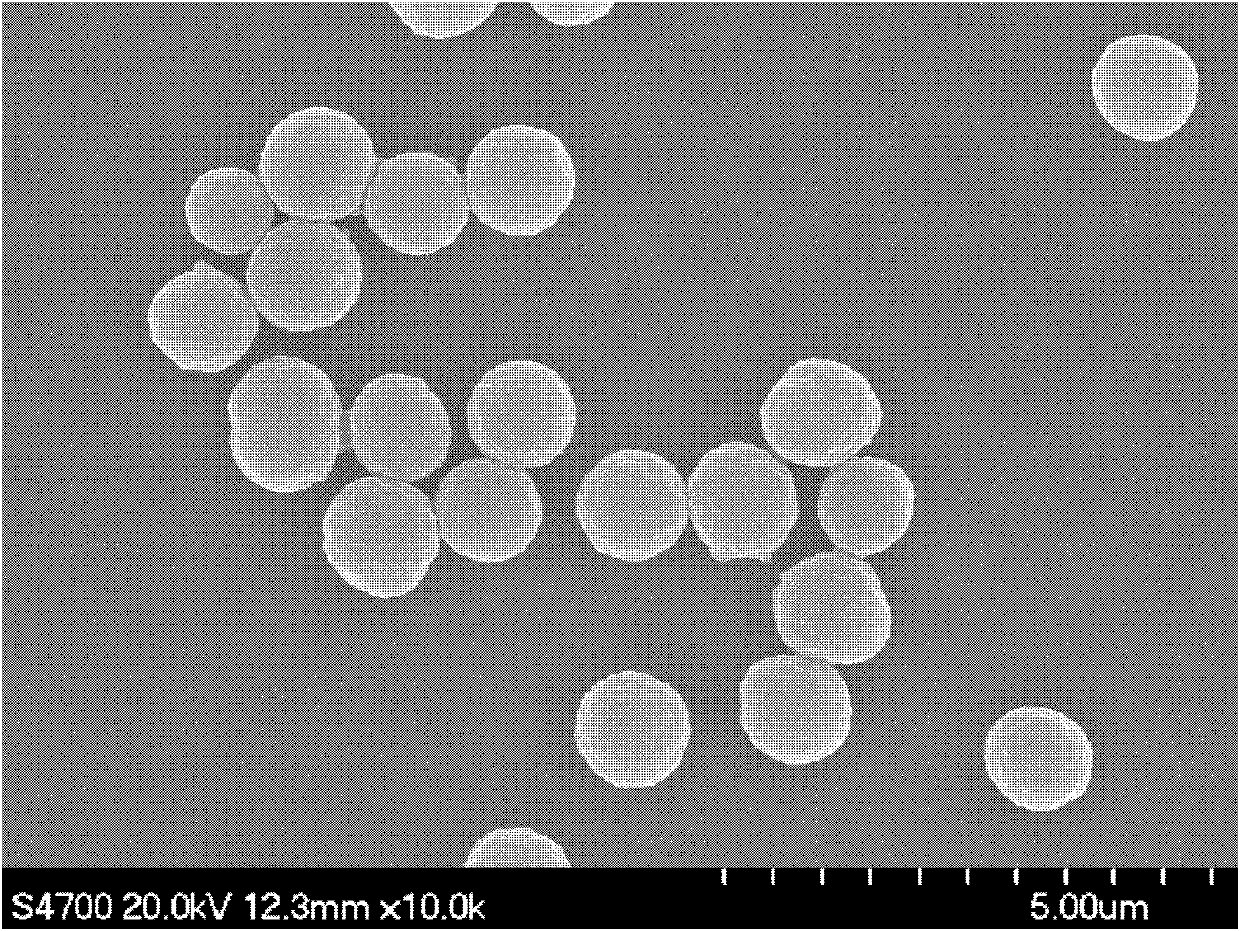

ActiveCN101810587AUniform particle sizeGood dispersionPharmaceutical non-active ingredientsGranular deliveryChemical synthesisCross-link

The invention relates to a preparation technology for a microspheric embolization agent. The preparation technology is used for preparing elastic microspheres cross-linked and polymerized by functionalized macromolecules with biocompatibility, wherein the grain range of the microspheres is 1-1500mu m. The preparation technology comprises the following steps that: a cross-linkable micromolecule with a crylic acid structure is connected on a polyvinyl alcohol, polyethylene glycol or polyose macromolecule in form of a covalent bond to form a functionalized macromolecule; and reversed phase suspension polymerization is conducted to the functionalized macromolecule and a 2-acrylamide-2-methylpropanesulfonic acid monomer to prepare cross-linked and polymerized microspheric embolization agent. The embolization agent has the advantages that the flexibility and the elasticity are high, the grain is even and is controllable, the dispersity is good, the raw materials are nontoxic and the biocompatibility and the stability are good. The preparation technology is a pure chemical synthesis technology, no virus pollution is caused to the raw materials and the preparation process, the requirements on international embolization agents are satisfied, and the embolization agent can substitute for all kinds of imported or domestic expensive embolization agent products and can be widely used in surgeries in the field of interventional therapy.

Owner:SUZHOU HENGRUI CALLISYN BIOLOGICAL MEDICINE TECH CO LTD

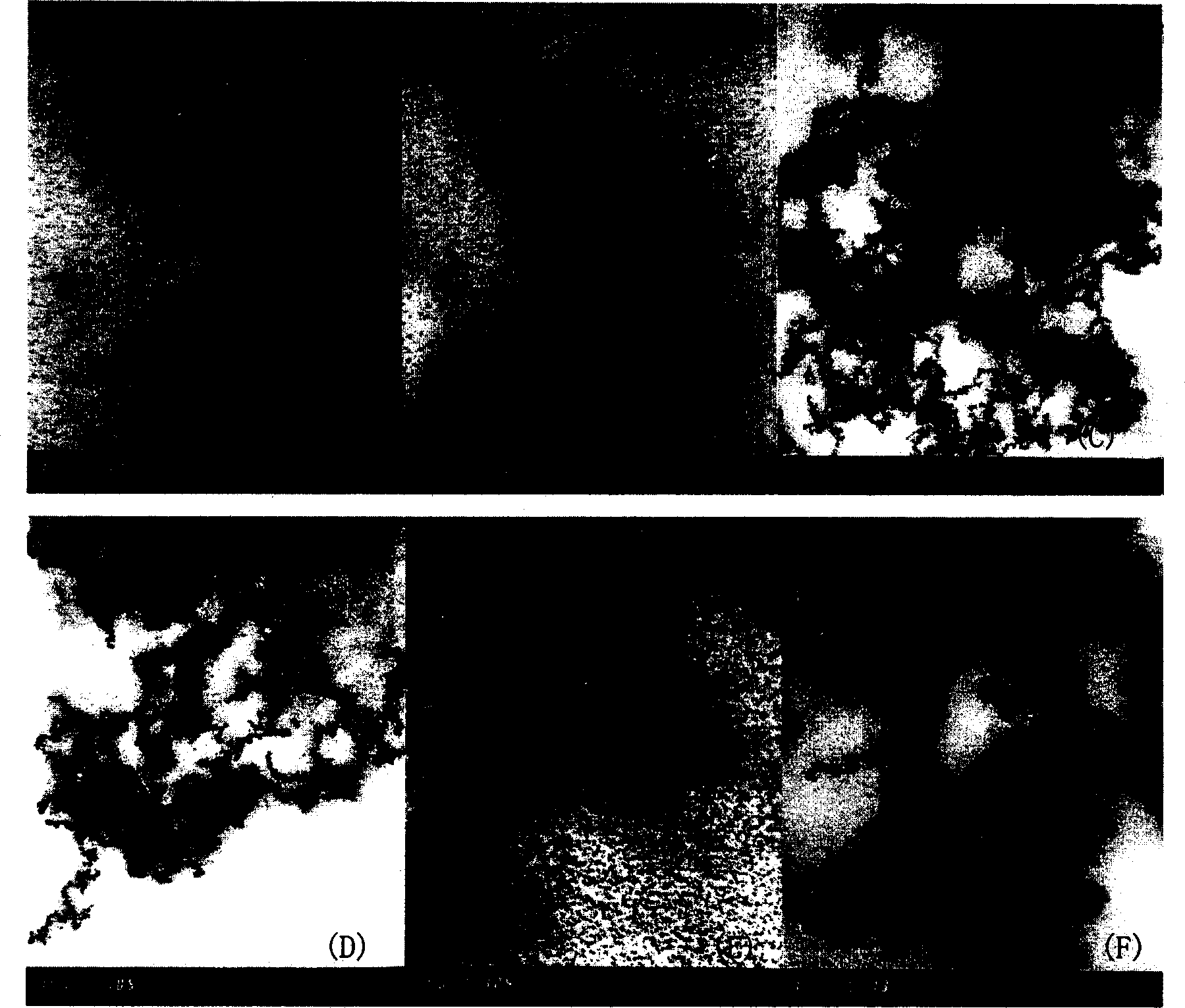

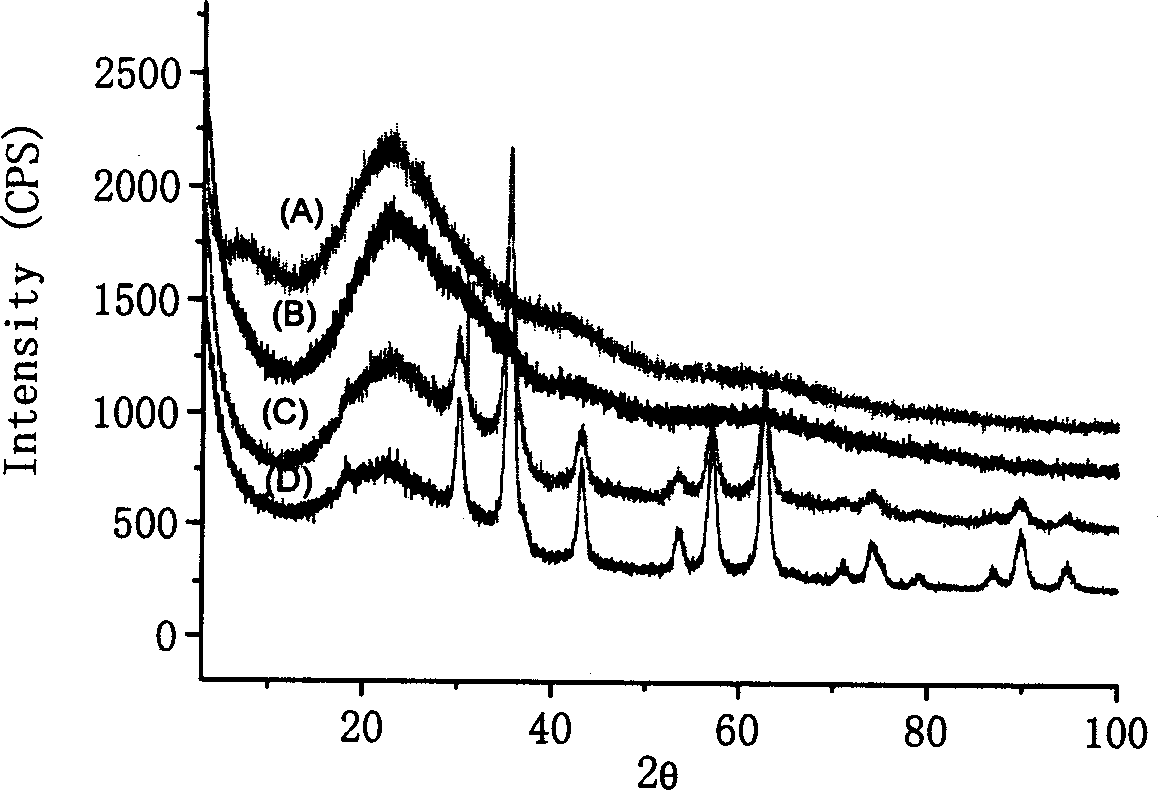

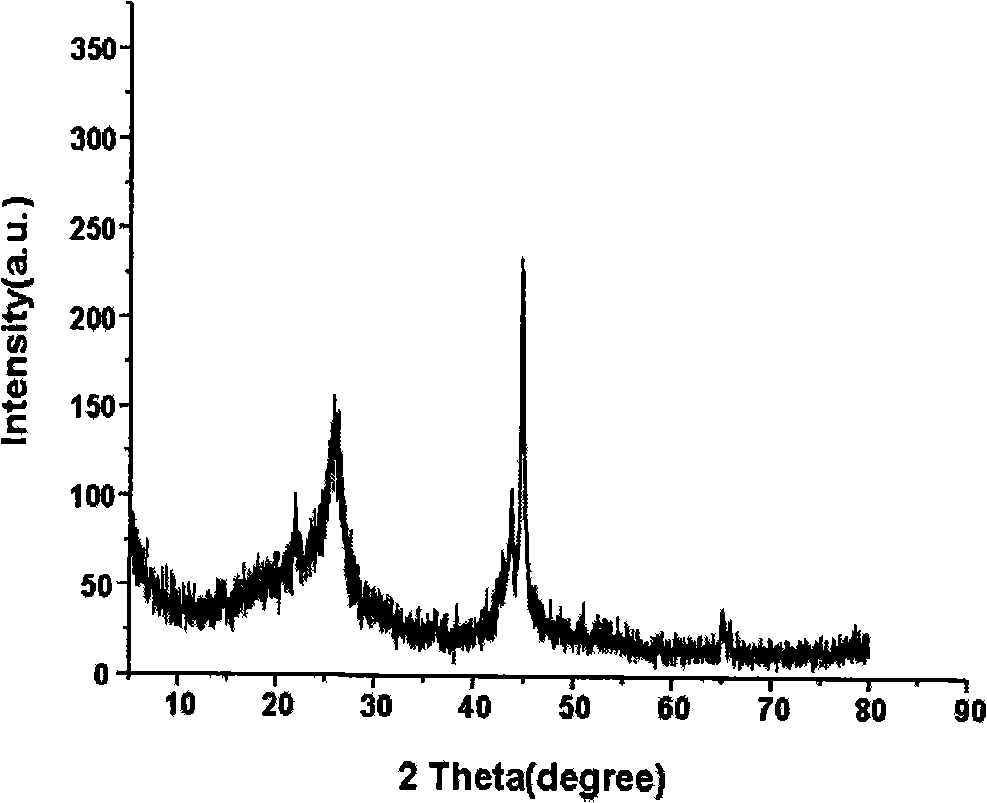

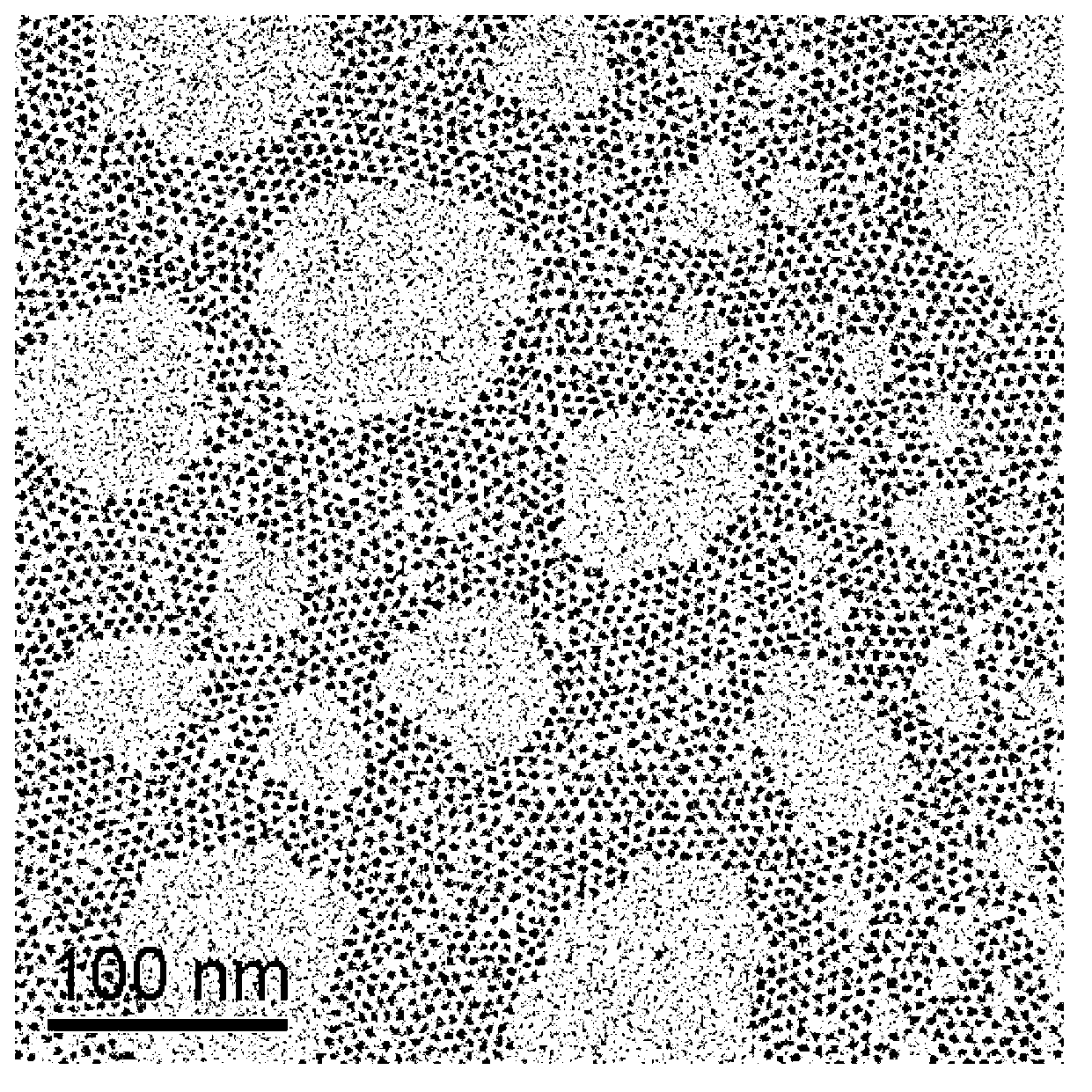

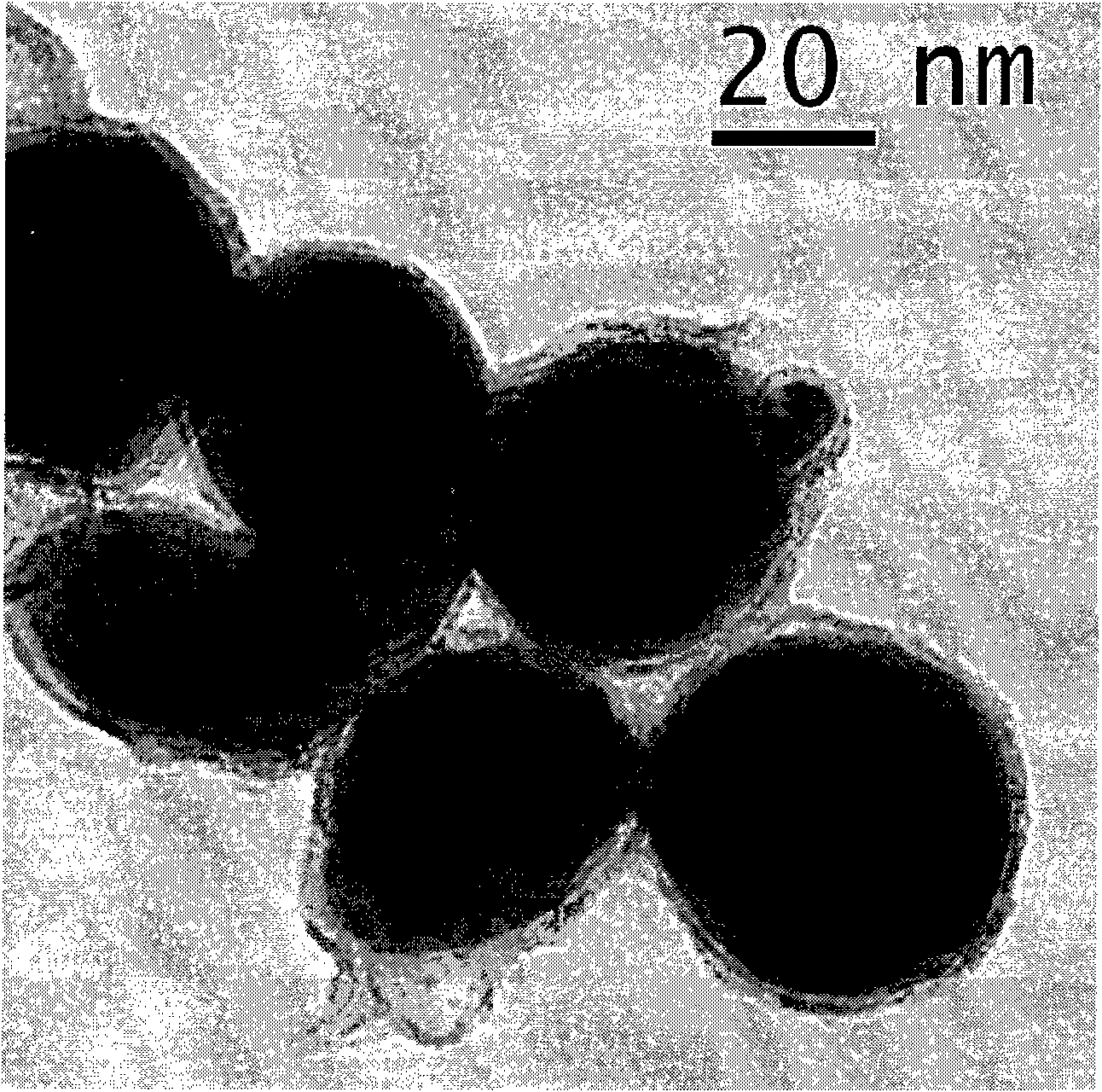

Method for preparing magnetic nano microparticles with biological compatibility

InactiveCN1461020AUniform and controllable particle sizeAdjustable crystallinityNanomagnetismNanostructure manufactureBoiling pointChemical compound

The preparation method of magnetic nano particle with bio-compatibility includes the following steps: heating and decomposing metal organic iron compound in high boiling point polar solvent in the presence of bio-compatibility molecule, precipitating and separating so as to obtain said magnetic nano particles with bio-compatibility. By adopting bio-compatibity molecules containing double-functional group (for example double-functional group polyglycol and its derivative, etc.) to make modification the magnetic nano particles whose surface has different functional groups can be obtained. By adopting different iron materials the nano particles with different types of Fe, gamma-Fe2O3 and Fe3O4 can be obtained.

Owner:苏州欣影生物医药技术有限公司

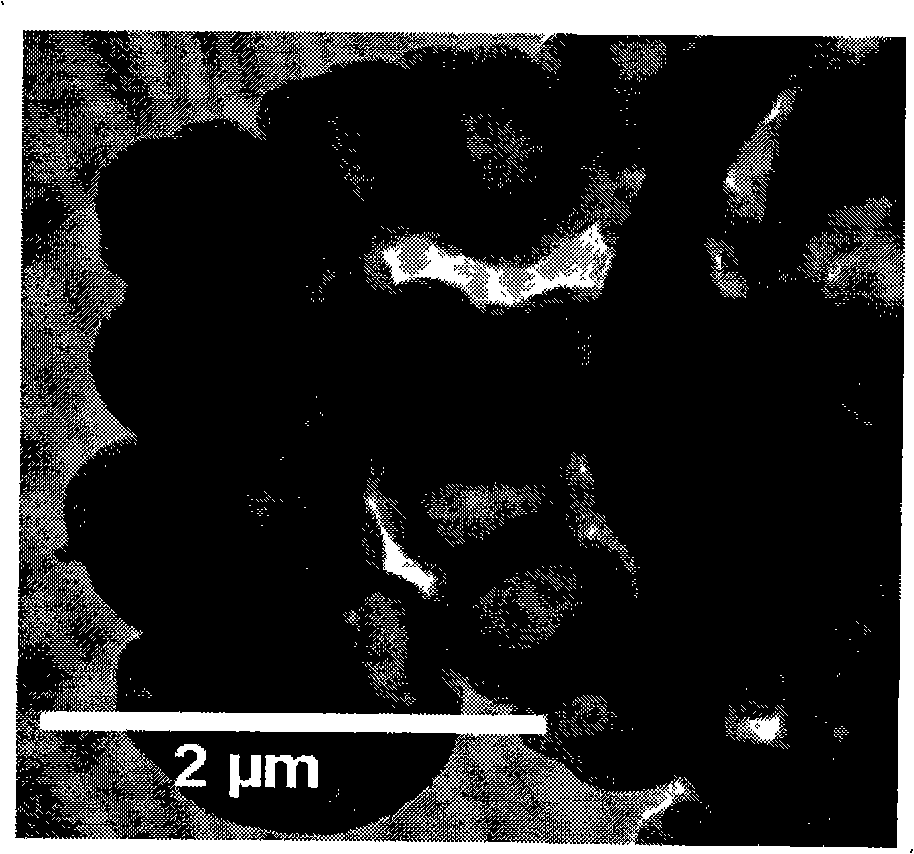

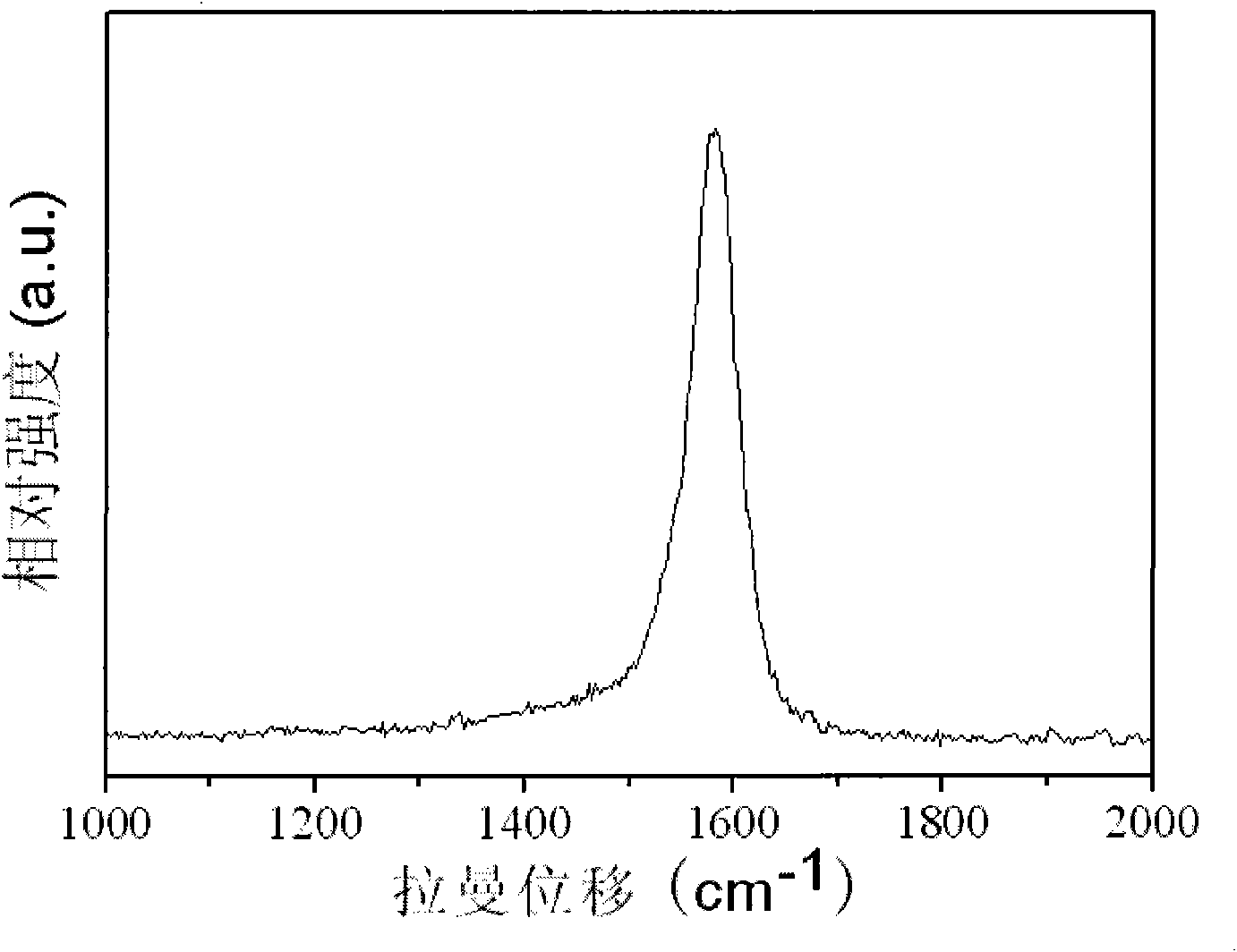

One-step synthesis method for hollow carbon case

The invention relates to a method for synthesizing a micro-nanometer level hollow polymer ball, a carbon ball and a graphitized ball by one step. The method comprises the following steps that: hydroxybenzene and aldehyde are used as raw materials; lysine is used as a catalyst; fatty alcohol is used as a solvent; a polymer hollow ball with an even dimension can be produced by polymerization at a temperature of 80 DEG C; and the polymer hollow ball is further charred to produce a hollow carbon ball. If Fe<3+> is introduced into the polymer hollow ball, the polymer hollow ball is charred to produce a graphitized hollow ball. Through changing a molar ratio of the hydroxybenzene and aldehyde, the catalyst amount and the type of the solvent, the hollow carbon ball with a grain diameter of between 0.6 and 2 mu m can be produced. The micro-nanometer level hollow carbon ball has an even and controllable grain diameter, high purity, smooth surface, stable performance and high technical added value, is suitable for a load type magnetic separation catalyst, an absorption separating agent of pigment and organic molecule and a separating agent of protein and salt and is used as an electrode material of a super capacitor with high power density and high energy density.

Owner:DALIAN UNIV OF TECH

Method for controlling roughness of silicon crystal substrate material surface

InactiveCN1864926ALow roughness controlImprove removal ratePolishing machinesSemiconductor/solid-state device manufacturingSurface roughnessSingle crystal

The invention relates to a method for controlling the surface roughness of silicon single-crystal liner material. According to the chemical property of silicon single-crystal liner material, the invention selects alkali medium; uses SiO2 hydrosol as abrasive; uses pH adjuster to adjust the pH value of solution 9-13.5; adds surface activator as FA / O to prepare the polish liquid. The invention uses two polishing steps as roughly polishing and finely polishing at different polishing conditions; roughly polishes for 10-20mins while the flux is 100-200ml / min, the temperature is 30-40Deg. C, the rotation speed is 40-120rpm and the pressure is 0.10-0.20MPa; finely polishing for 4-7mins while the flux is 800-1000ml / min, the temperature is 20-30Deg. C, the rotation speed is 30-60rpm, and the pressure is 0.05-0.10MPa. The invention can realize low roughness of single-crystal liner material.

Owner:HEBEI UNIV OF TECH

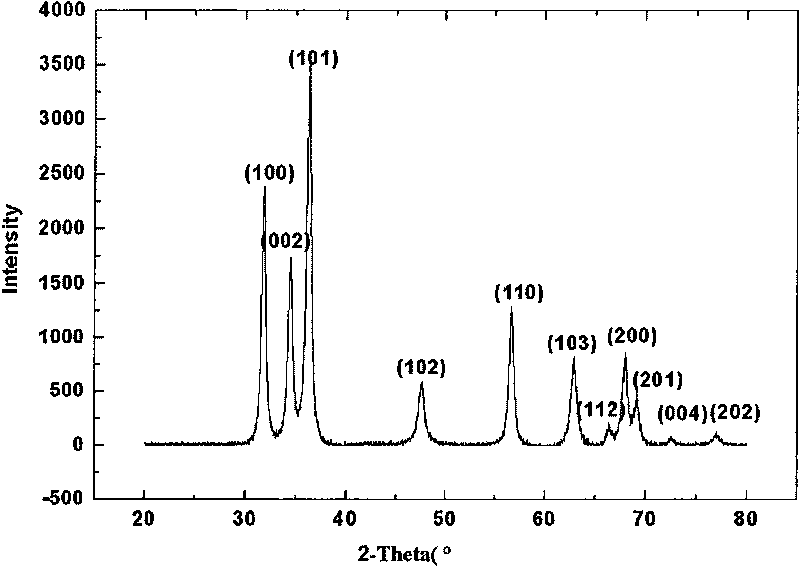

Controllable method for preparing nano zinc oxide powder

InactiveCN101734709AEasy to operate and produceEasy to implementZinc oxides/hydroxidesWater bathsPolyvinyl alcohol

The invention relates to a controllable method for preparing nano zinc oxide powder, which is characterized by adopting the salt of inorganic zinc nitrate and the chelating agent of citric acid which has the complexing function as the raw materials and the ethylene glycol, the polyethylene glycol, or the polyvinyl alcohol as the surfactant. The controllable method for preparing the nano zinc oxide powder specifically comprises the following steps: preparing solution from the zinc nitrate, the citric acid and the surfactant according to a certain molar ratio, reflowing the solution with water bath, aging, gelatinizing, drying and annealing to obtain the nano zinc oxide powder with single component and uniform distribution of the agglomeration-free particle of 20-100 nm. The nano zinc oxide powder has low cost, high quality and high yield, is prepared with simple equipment and can realize the industrial production easily.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Rare earth-doped alkaline earth metal fluoride nano material, and preparation method and application thereof

ActiveCN103224787AEasy to makeGood repeatabilityFluorescence/phosphorescenceIn-vivo testing preparationsSolubilityAlkaline earth metal

The invention discloses a water-soluble rare earth-doped alkaline earth metal fluoride nano material with the following components: xLn<3+>-yNa<+>-[1-(x+y)]MF2, wherein Ln<3+> is selected one or any number from Ce<3+>, Yb<3+>, Er<3+>, Tm<3+>, Ho<3+>, Eu<3+>, Gd<3+>, Tb<3+>, Dy<3+>, Sm<3+>, Nd<3+> or Pr<3+>; M is selected from Ca, Sr or Ba; x is larger than 0 mol% and smaller than or equal to 50 mol%; and y is larger than 0 mol%and smaller than or equal to 50 mol%. The material has relatively good water solubility and luminescent performance, and can be applied in the fields such as biological detection, biological imaging, etc.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

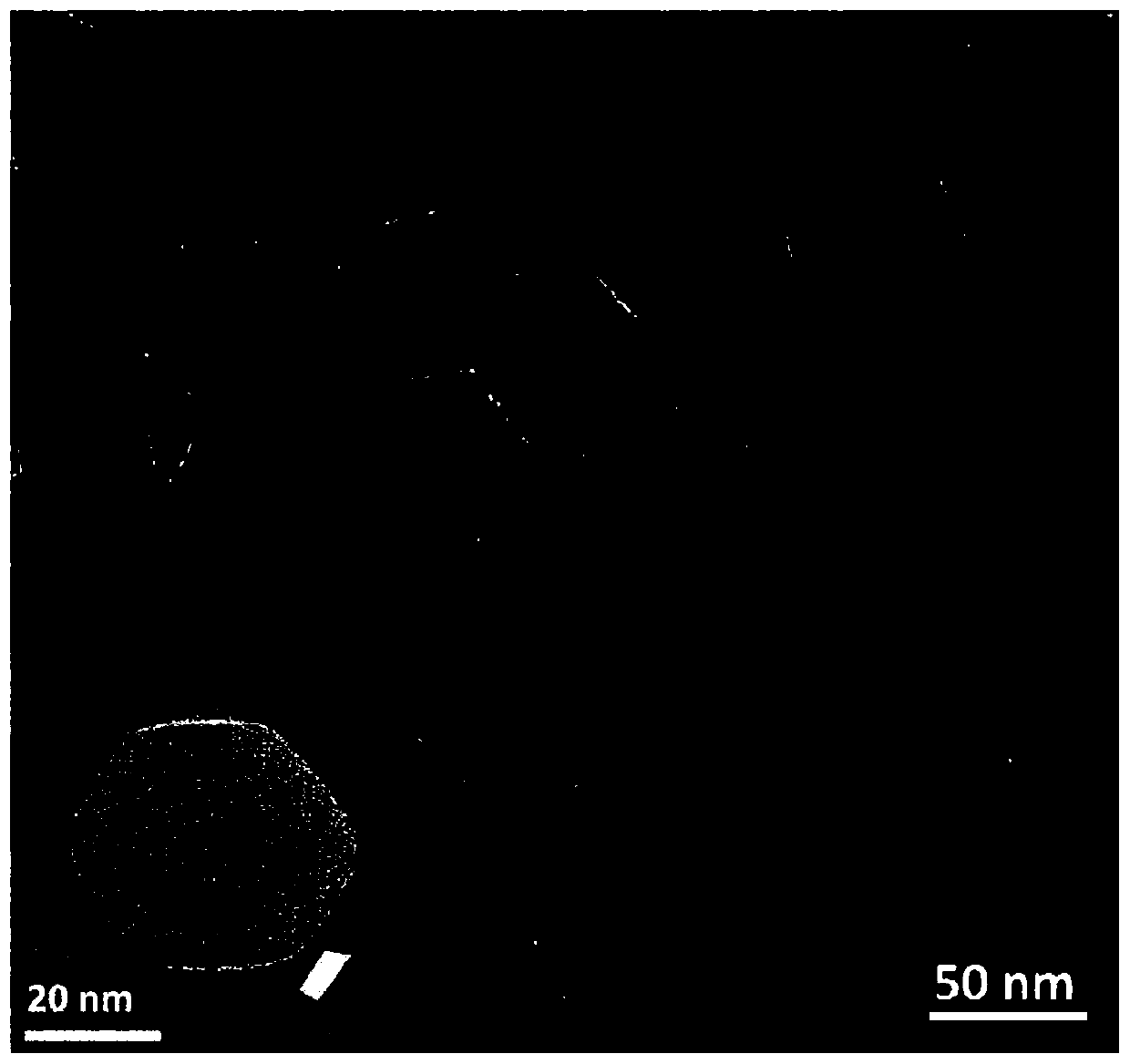

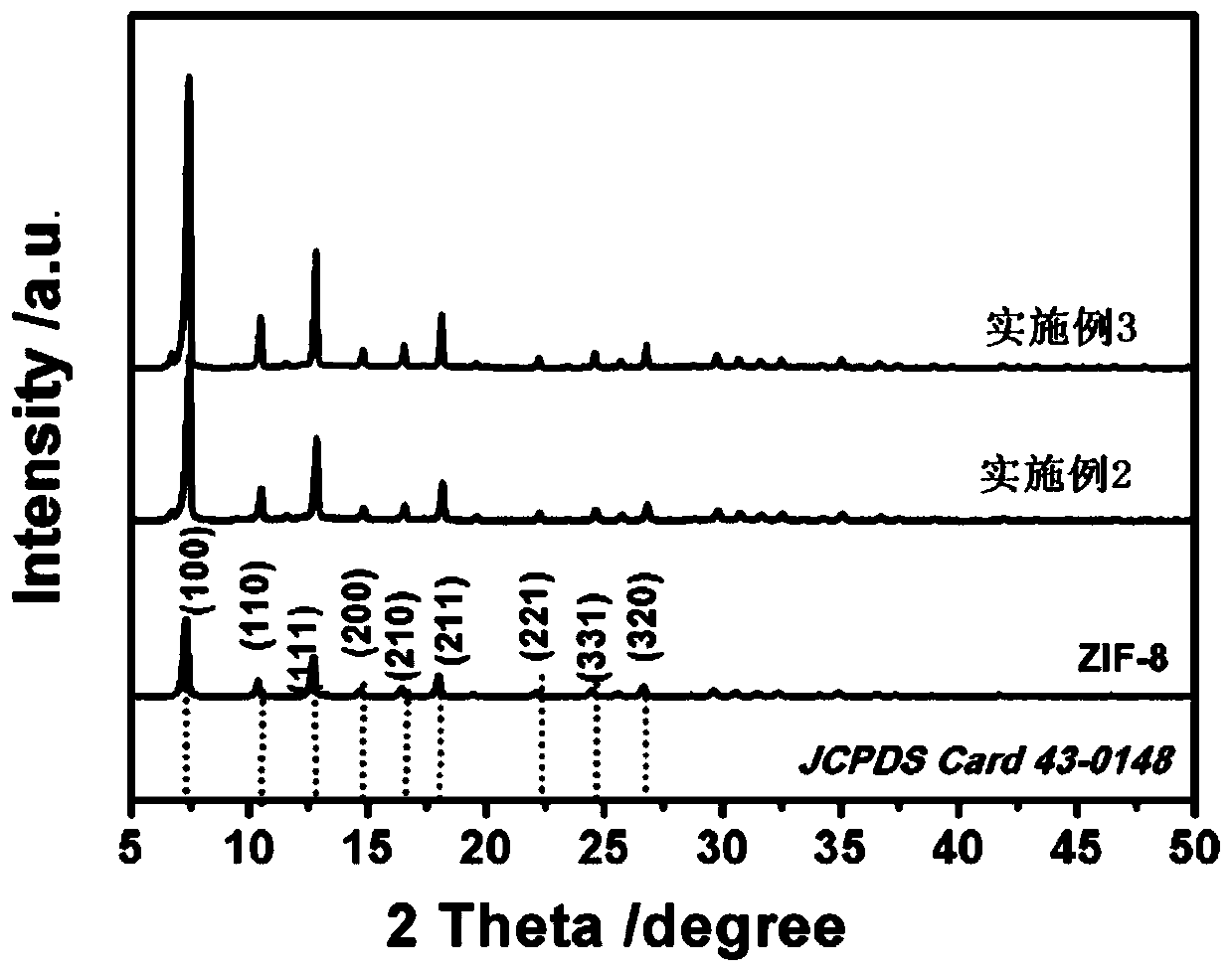

Method for preparing mixed-valent-state iron doped zeolite imidazate skeleton nano-material

InactiveCN110724272AUniform and controllable particle sizeHigh ROS Generation EfficiencyIron saltsMeth-

The invention relates to a method for preparing a mixed-valent-state iron doped zeolite imidazate skeleton nano-material. The method comprises the steps of simultaneously dispersing bivalent and trivalent iron salts and zinc nitrate into a methanol solvent to form an iron-zinc precursor solution, mixing a 2-methylimidazole methanol solution with the precursor solution, placing the mixture in an oil bath with the temperature of 40 DEG C to 100 DEG C, carrying out a sustained magnetic stirring reaction, and then, subjecting a product to centrifugation, washing and drying treatment, thereby obtaining the mixed-valent-state iron doped zeolite imidazate skeleton nano-material. The mixed-valent-state iron doped zeolite imidazate skeleton nano-material with relatively high yield and uniform and controllable particle size is obtained. According to the method disclosed by the invention, the total iron doped amount can reach 50% to the maximum through adjusting a ratio of bivalent iron salts totrivalent iron salts, and conversion ratios of zinc ions and iron ions can separately reach up to 78% and 60%. The method is simple and economical, and reacted mother liquor can be reused. The obtained nano-material has a relatively high active oxygen generating efficiency under ultrasonic induction, has a tremendous application value in degradation of environmental pollutants and sonodynamic therapy of tumors and can be applied to preparation of high-concentration monoatomic iron-carbon based catalysts.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of high-graphitized nanometer carbon material

InactiveCN101559938AHigh degree of graphitizationParticle size controllableNanostructure manufactureMicrowave ovenCarbon nanotube

The invention relates to a preparation method of a high-graphitized nanometer carbon material. The method comprises the following steps: (1), uniformly mixing magnetic metal or metal oxide particles with a solid organic carbon precursor material, wherein the magnetic metal or metal oxide particles in the mixture account for 10 to 80 percent of the total weight; and (2) putting the mixture in a microwave oven and processing in microwave for 3 seconds or longer under the microwave power of 300W to 3000W so as to obtain carbon-wrapped magnetic metal nanometer particles or a multi-wall carbon nanometer pipe material. The prepared carbon material has high graphitization degree, controllable grain diameter and thickness, simple technology, low preparation cost, high product purity, wide selective raw material range and easy mass preparation.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

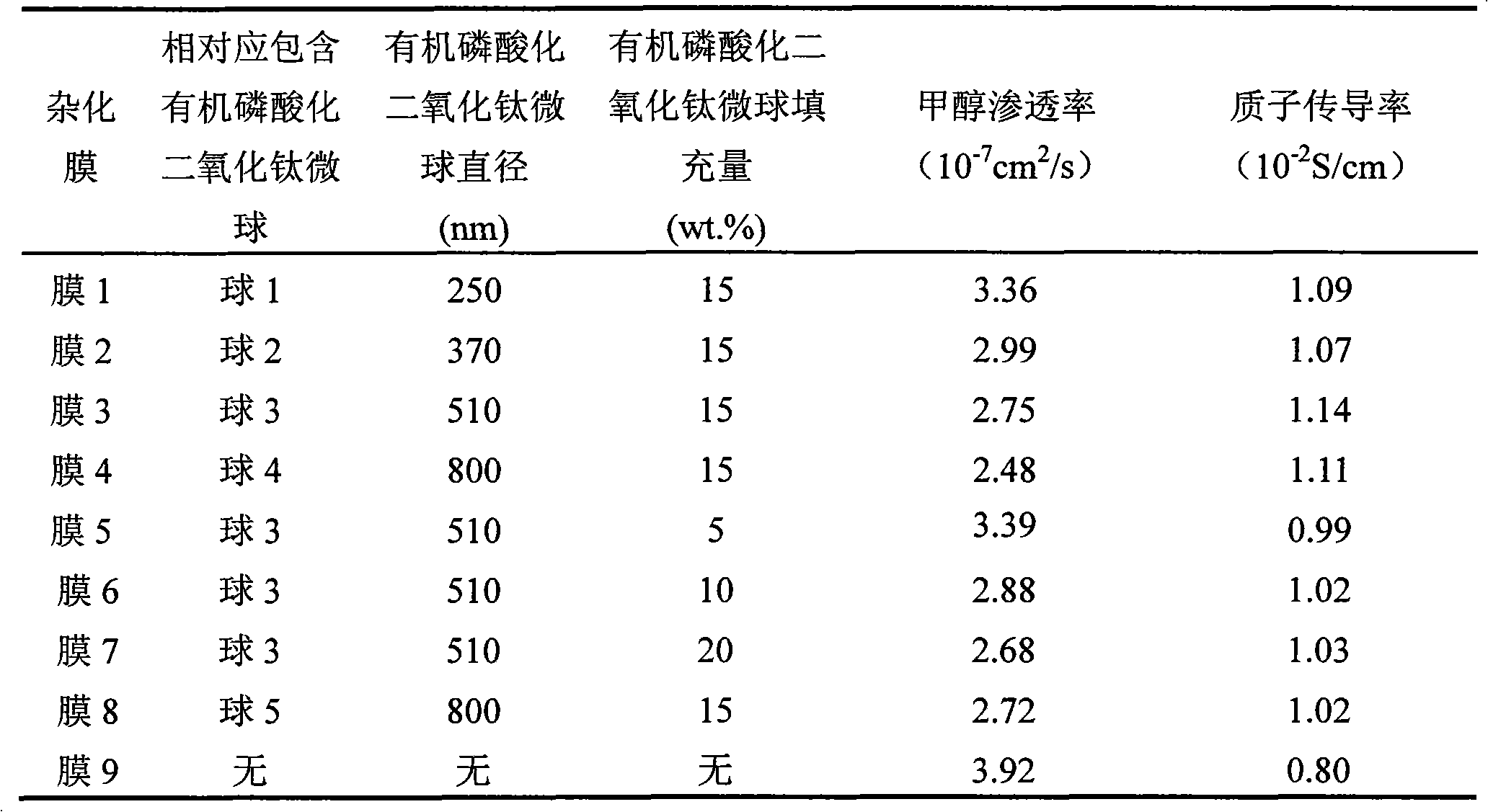

Organic phosphorylated titanium dioxide micrballon-filled chitosan hybrid membrane as well as preparation and application

InactiveCN101624449AEasy to makeUniform and controllable particle sizeCell component detailsSolid electrolyte fuel cellsO-Phosphoric AcidAqueous acetone

The invention relates to an organic phosphorylated titanium dioxide micrballon-filled chitosan hybrid membrane as well as a preparation and an application. The hybrid membrane is prepared by taking tetrabutyl titanate, glycol, organic phosphoric acid and chitosan as raw materials according to the following matching: the mole ratio of tetrabutyl titanate and glycol is 1:30-1:60 to prepare titanium dioxide micrballon, the mass volume ratio of titanium dioxide micrballon and organic phosphoric acid is 1:4-6, the mass ratio of titanium dioxide micrballon and chitosan is 0.05-0.2:1. The preparation method is as follows: the mixed solution of tetrabutyl titanate and glycol are precipitated in acetone water solution, washed and dried to obtain titanium dioxide micrballon which is put into organic phosphoric acid water solution for standing, the micrballon is put into glacial acetic acid water solution for ultrasound dispersion and is added with chitosan to obtain casting solution which subjects to casting on a substrate (glass plate) and is dried to form a membrane for crosslinking in sulphuric acid water solution, then washing and vacuum drying. The titanium dioxide micrballon and the membrane of the invention have rich source of raw materials, low cost and simple operation, and the prepared hybrid membrane has lower methanol permeability and higher proton conductivity, and can be used as direct methanol fuel cell membrane.

Owner:TIANJIN UNIV

Method for preparing hydroxylapatite ultrafine powder

The invention relates to a method for preparing hydroxylapatite ultrafine powder. The method comprises the following steps that: soluble calcium salt and soluble phosphate aqueous solution react in a sleeve-type annular microchannel reactor at normal temperature to prepare hydroxylapatite precursor; and the precursor is prepared into the hydroxylapatite ultrafine powder through hydro-thermal treatment, washing, drying and other simple subsequent processes. The method has simple equipment and low cost, and can realize continuous operation, thereby greatly shortening the preparation period, and improving the production efficiency; and the hydroxylapatite ultrafine powder product prepared by the method has excellent quality, stable performance and even grain diameter, and has grains which have short-clubbed appearances mainly and diameters of between 40 and 100nm generally.

Owner:BEIJING UNIV OF CHEM TECH

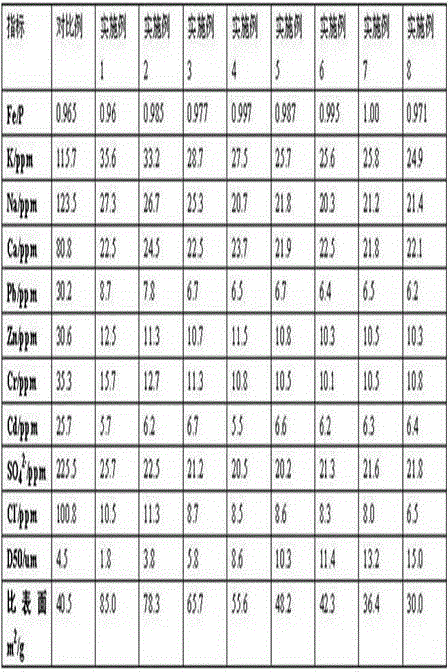

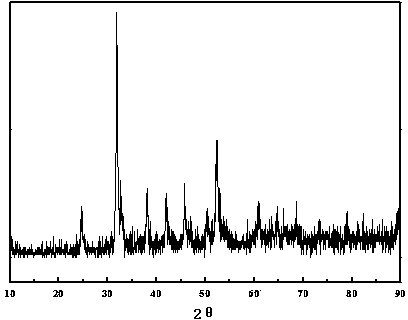

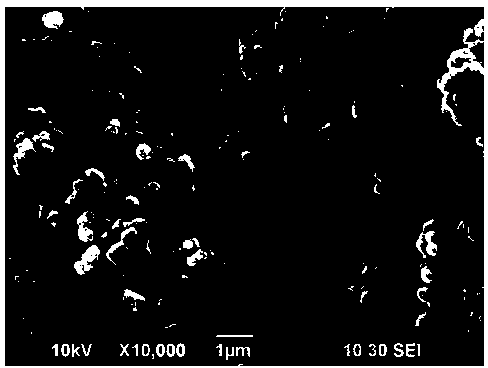

Production method of battery-grade iron phosphate

InactiveCN105118995AIncrease productionUniform and controllable particle sizeCell electrodesPhosphorus compoundsO-Phosphoric AcidElectrical battery

The invention relates to an ultrasonic production method of high-purity battery-grade iron phosphate. The production method comprises steps as follows: preparing a solution A with the concentration of 0.5-6 mol / L by mixing an iron source, an acid compound and a surfactant in a reaction kettle, preparing a solution B with the concentration of 0.5-6 mol / L by mixing phosphate and an oxidizing agent, adding the solution B to the reaction kettle, heating the solution B and the solution A, introducing the ultrasonic means, after a period of reaction, adding phosphoric acid or mixed acid of the phosphoric acid and other acids for transformation crystallization for several hours until the mixed solution turns milk white, and then filtering, washing, drying and crushing the mixed solution to obtain the battery-grade iron phosphate product. The ultrasonic synthesis method has the advantages that the product yield is high, the iron-to-phosphorus ratio is 0.96-1.00, the particle size is uniform and controllable (D50 is smaller than or equal to 15 mu m), the specific surface is 30.0-85.0 m<2> / g, the impurity content is low, the crystallinity is good, and the like, and the battery-grade iron phosphate is an ideal raw material for manufacturing lithium iron phosphate cathode materials of lithium-ion batteries.

Owner:HUNAN ZHENGYUAN ENERGY STORAGE MATERIALS & DEVICE INST

High-capacity lithium-enriched positive electrode material and preparation method thereof

ActiveCN104134797AHigh crystallinityUniform and controllable particle sizeCell electrodesSecondary cellsLithiumCalcination

The invention belongs to the field of electrochemistry and particularly relates to a high-capacity lithium-enriched positive electrode material and a reparation method thereof. The molecular formula of the high-capacity lithium-enriched positive electrode material is Li[Li<x-beta>Na<beta>Mn<1-y-z-alpha>Co<y>Ni<z>Y<alpha>]O2, wherein x is more than or equal to 0 and less than or equal to 0.6, y is more than 0 and less than or equal to 0.4, z is more than 0 and less than or equal to 0.4, alpha is more than or equal to 0 and less than or equal to 0.1 and beta is more than or equal to 0 and less than or equal to 0.2; the result of (1-y-z-alpha) is more than 0 and the result of (x-beta) is more than 0. The lithium-enriched positive electrode material containing Na and Y has the characteristics of low first-time irreversible capacity, large electrochemical capacity, high cycling stability, excellent rate performance and the like. The preparation method has the advantages that a preparation process is simple, raw materials are cheap and easily available, the cost is low, the high-temperature calcination time is very short, the repeatability is good and the industrialization is easy to realize.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

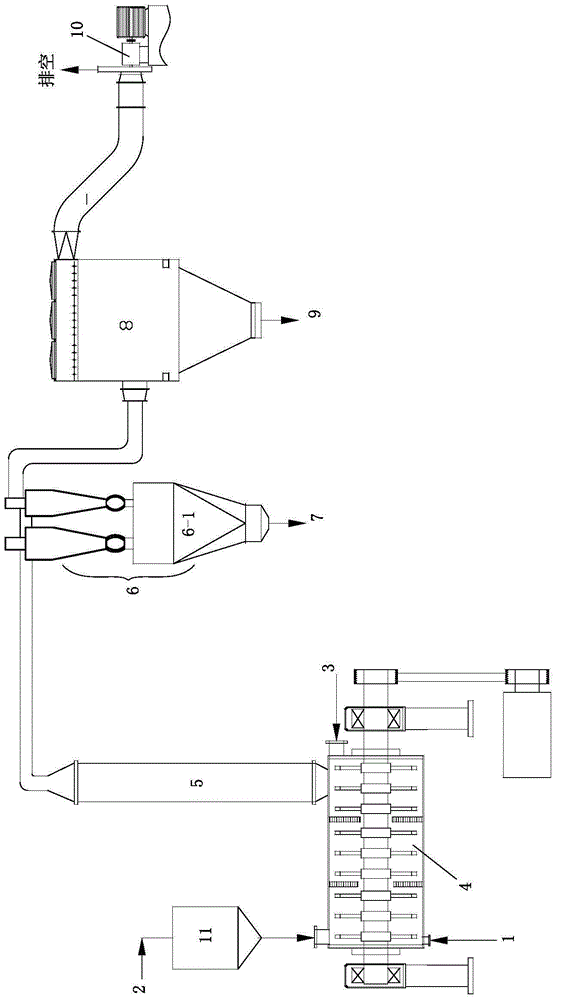

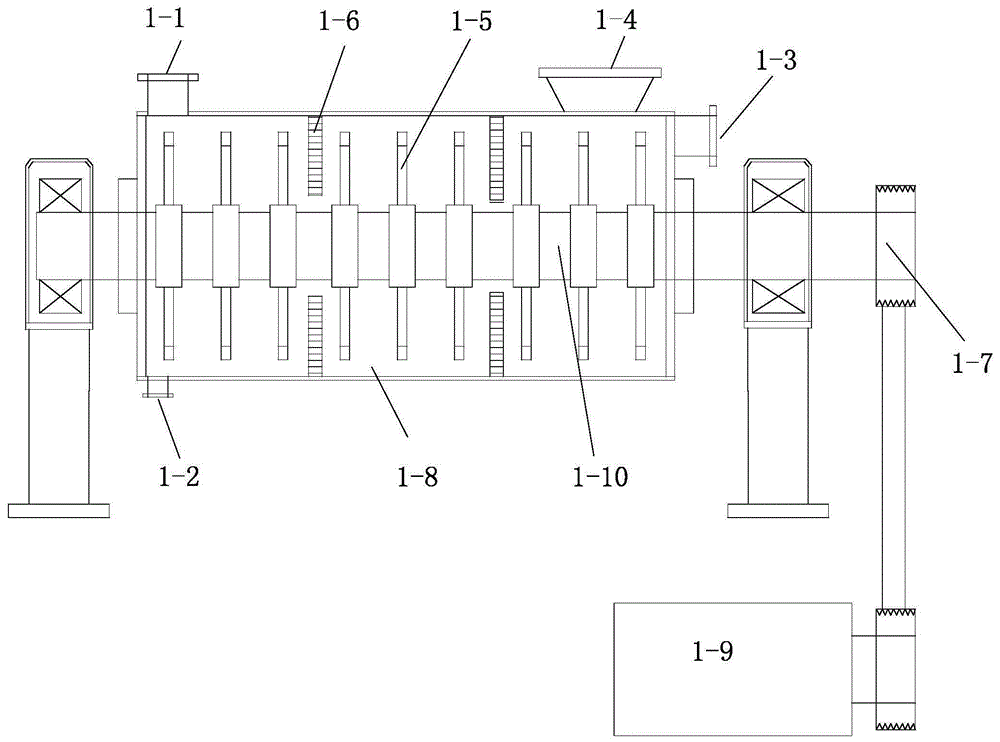

Process and device for continuously preparing powdery MES (fatty acid methyl ester sulfonate) particles

ActiveCN103820253AImprove low temperature solubilityImprove energy utilizationSurface-active detergent compositionsDetergent powders/flakes/sheetsChemistryAirflow

The invention relates to a process and a device for continuously preparing powdery MES (fatty acid methyl ester sulfonate) particles. A process flow is simple, and the provided preparation device is simple in structure. According to the technical scheme, the process for continuously preparing the powdery MES particles comprises the following steps of (1) causing a powdery mixture of a neutralizer, a wrapper and a stabilizer and fatty acid methyl ester acid ester to enter a high-shear reactor according to a certain proportion; (2) forming MES particles, and causing the MES particles to enter a flash dryer; (3) keeping the obtained MES particles at certain granularity; (4) causing mixed airflow discharged from an outlet of the flash dryer to enter a cyclone separator for separation; (5) obtaining a finished product. The device for continuously preparing the powdery MES particles comprises the high-shear reactor, the flash dryer, the cyclone separator, a bag-type dust collector and an induced draft fan, which are sequentially communicated, wherein the high-shear reactor is provided with an acid ester inlet, a powder inlet, an air inlet and a material outlet communicated with the flash dryer respectively.

Owner:ZANYU TECH GRP CO LTD +1

Non-spherical polymer particles uniform in particle size as well as preparation method and application of non-spherical polymer particles

ActiveCN105832704AUniform particle sizeParticle size controllableSsRNA viruses negative-sensePeptide/protein ingredientsPolymer scienceBiological drugs

The invention provides non-spherical polymer particles uniform in particle size as well as a preparation method and an application of the non-spherical polymer particles. The non-spherical polymer particles are in the form of ellipsoids, short rods or fibers, and the interiors of the non-spherical polymer particles are of solid, hollow or porous structures; the short diameter of the non-spherical polymer particles ranges from 100nm to 30[micron]m, the long diameter of the non-spherical polymer particles is 1-60[micron]m, the ratio of the long diameter to the short diameter is 2-40, and the particle size distribution coefficient of the particles is less than 20%. The non-spherical polymer particles disclosed by the invention, which are uniform and controllable in particle size, are prepared by taking disodium hydrogen phosphate and / or sodium dihydrogen phosphate as a deformation inducing agent and by taking the influence of such conditions as the concentration of the disodium hydrogen phosphate and / or sodium dihydrogen phosphate, self-properties of a polymer, mass concentration of the polymer in an oil phase, the size of emulsion drops and the like into comprehensive consideration; the non-spherical polymer particles can be applied to various fields such as biological drug delivery, vaccine adjuvants, enzymatic catalysis, bio-separation, human tissue engineering field and the like; and the preparation method is simple to operate, mild in condition and easy for industrial enlarged production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

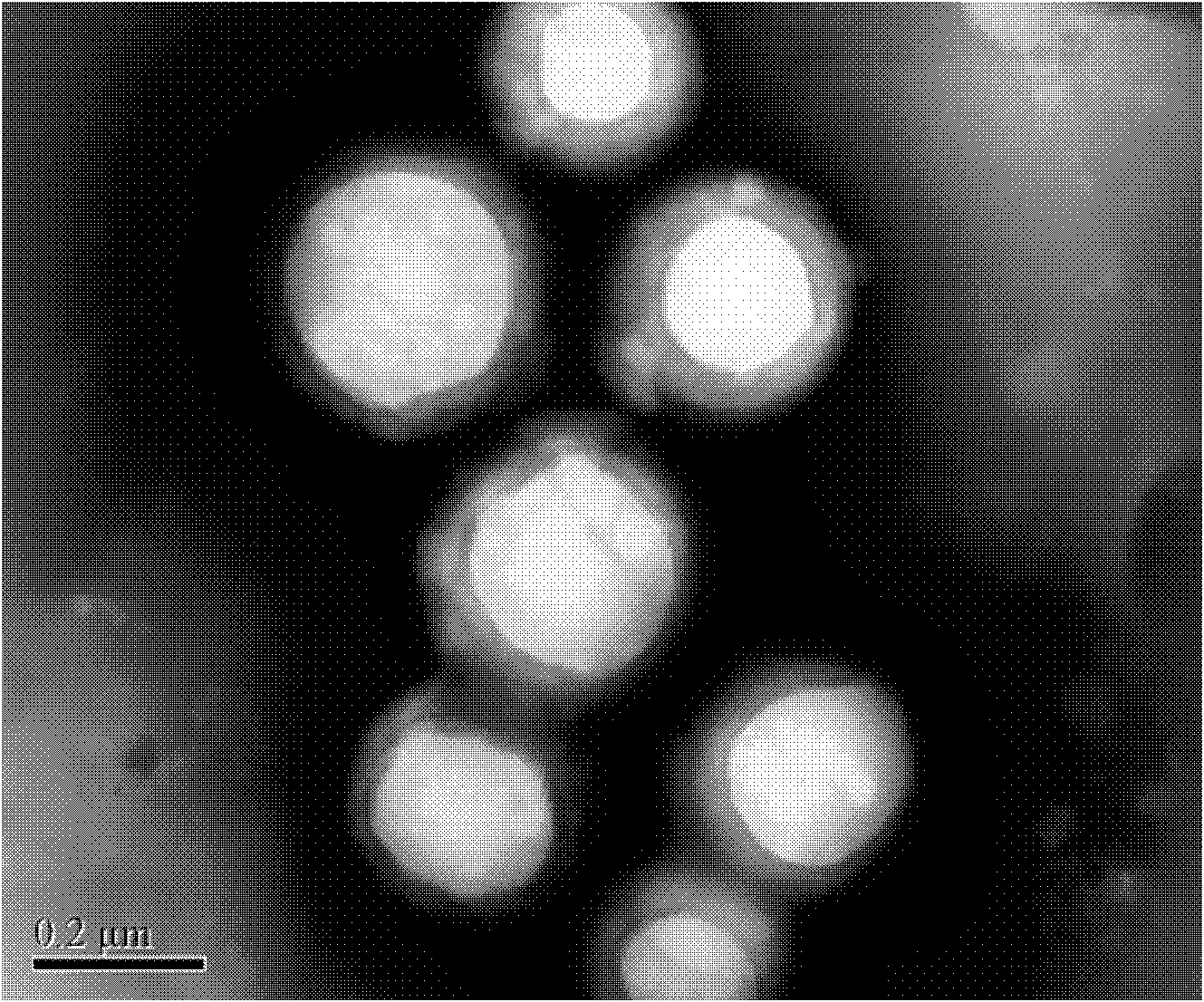

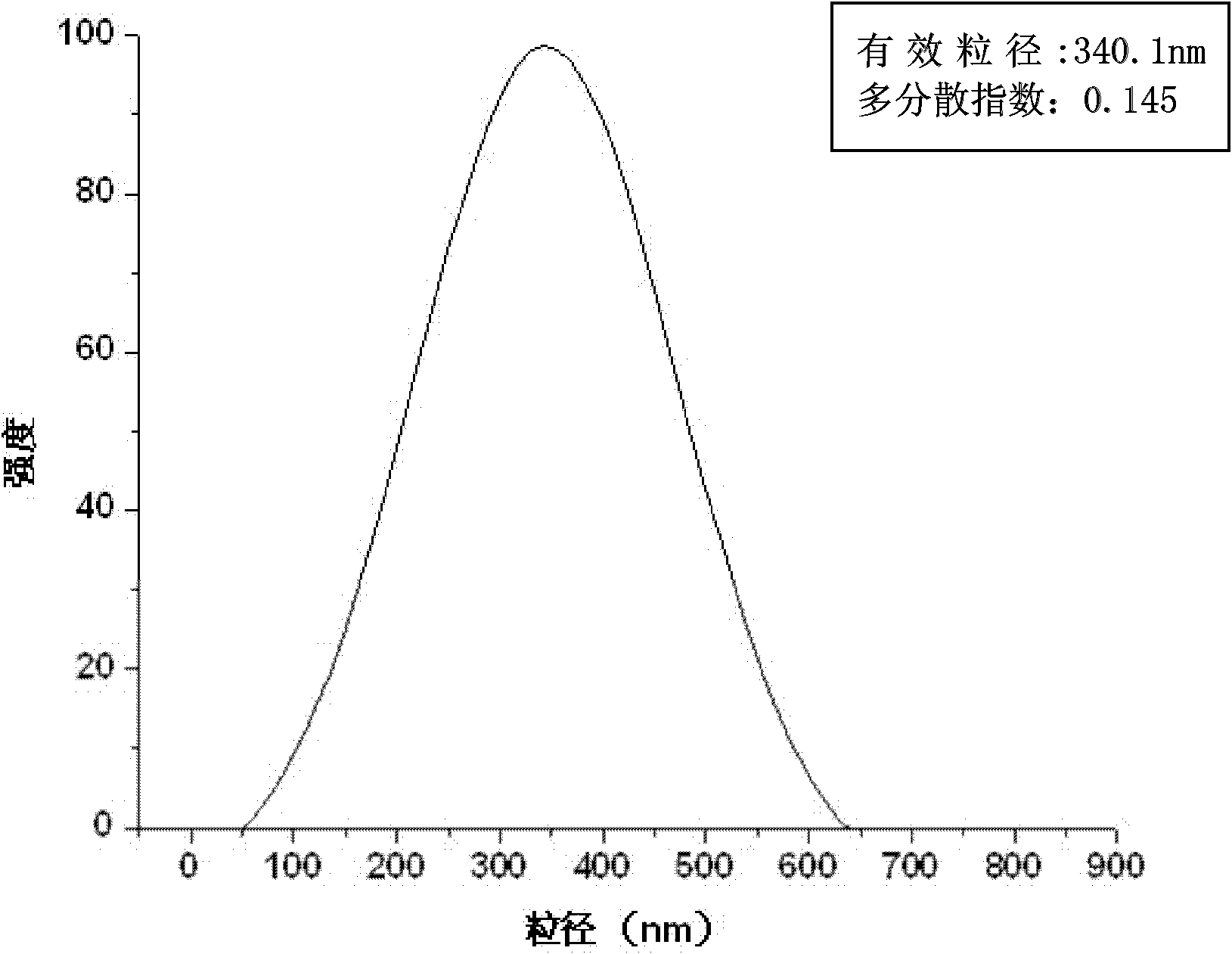

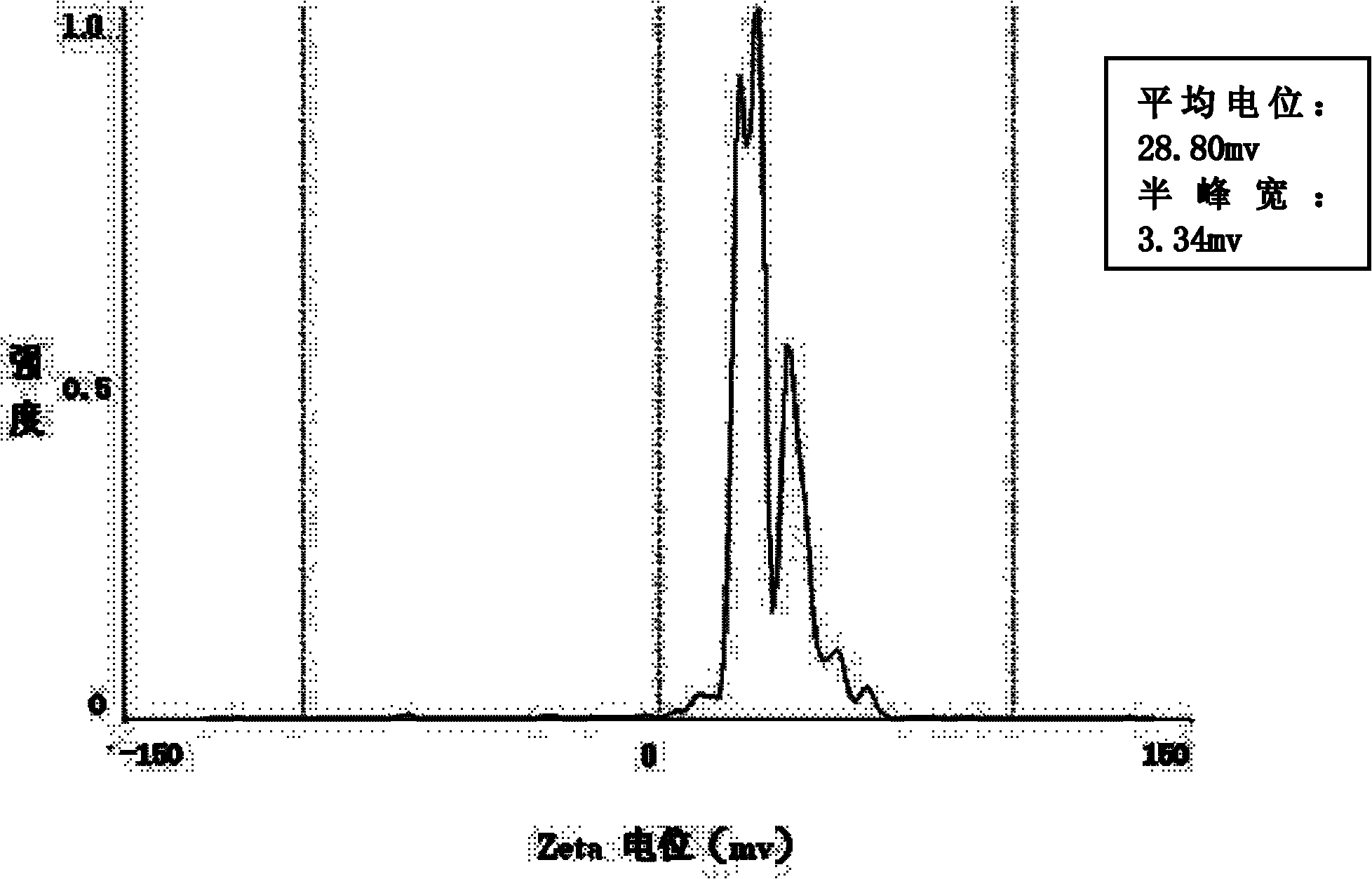

Composite drug carried microsphere, minocycline hydrochloride nano controlled-release composite drug carried microsphere system and preparation method thereof

InactiveCN101836961ALow toxicityGood slow releaseAntibacterial agentsTetracycline active ingredientsMicrosphereCholesterol

The invention relates to a composite drug carried microsphere, a minocycline hydrochloride nano controlled-release composite drug carried microsphere system and a preparation method thereof. A drug carried system with a nuclear shell structure is formed by embedding minocycline hydrochloride inside a poly D,L-lactide-co-glycolic acid polymer microsphere and covering a cationic polymeric liposome prepared from O-QACMC modified by polyethylene glycol, O-QACMC and cholesterol outside the poly D, L-lactide-co-glycolic acid polymer microsphere; and the composite drug carried microsphere system covered and carried with the minocycline hydrochloride has the grain diameter ranging from 340 nm to 400 nm and positive surface Zeta electric potential. The composite drug carried microsphere system can be remained in a water solution for at least 2 months, has high entrapment rate reaching larger than 90 percent on drugs and strong drug carrying capacity reaching 9 percent. The minocycline hydrochloride nano controlled-release composite drug carried microsphere system has the characteristics of uniform and controllable grain diameter, good preparation stability, simple preparation process, high drug carrying rate, favorable controlled release function, and the like, and is suitable for batch production.

Owner:TIANJIN UNIV

Method for preparing ceramic pigment titanium dioxide

ActiveCN106186054AOvercome hair color difference (grayOvercome the dark)Titanium dioxideHydrolysisImpurity

The invention discloses a method for preparing ceramic pigment titanium dioxide. An introduced purifying technology after ilmenite acidolysis comprises the following steps: 1) adding a certain amount of a polyacrylamide anionic surfactant in an acidolysis fluid suspension; 2) adding a certain amount of a polyacrylamide cationic surfactant and an inorganic salt flocculating agent; and 3) standing for 4-6 hours, extracting half part of clear liquid and conveying the half part of clear liquid to a filter press for solid-liquid separating, performing titanium liquid purification, and then introducing into a vacuum crystallization system for crystallization. A titanyl sulfate hydrolysis technology comprises the following steps: 1) adding seed crystal titanium liquid in liquid alkali to prepare seed crystal; 2) neutralizing the material and aging the material; and 3) adding preheated hydrolysis titanium liquid, heating the material to a boiling state for keeping for 3 hours, and stopping hydrolysis. The purifying technology after ilmenite acidolysis and titanyl sulfate hydrolysis technology are optimized and improved, impurity content in the product is low, product particle size is controlled in D50=2-2.5 [mu]m, and D90 is less than 5[mu]m.

Owner:GUANGXI JINMAO TITANIUM

Novel method for performing copolymerization reaction of dicyclopentadiene and maleic anhydride

InactiveCN102212166AEasy to separateSelf-stabilizing dispersion polymerization process system is simpleAlkaneChemical structure

The invention discloses a novel method for performing a copolymerization reaction of dicyclopentadiene and maleic anhydride, and belongs to the technical field of copolymers. The method comprises the following steps of: under the protection of nitrogen, adding monomers and an initiator into an organic medium and dissolving, reacting for 2 to 12h at the temperature of between 60 and 90 DEG C to obtain a self-stabilizing dispersion system of monodisperse microspheres of an alternating copolymer, and performing centrifugal separation, and drying to obtain a white solid of the dicyclopentadiene / maleic anhydride alternating copolymer, wherein the reaction monomers are the dicyclopentadiene and the maleic anhydride, and the molar ratio of the two monomers is 5:1-1:5; the medium is a mixed solvent of organic acid alkyl ester and organic alkane, and the organic acid alkyl ester accounts for 30 to 70 volume percent of the mixed solvent; and a chemical structure is that: R1 is a hydrogen atom, C1-C5 alkyl, phenyl or benzyl, and R2 is C1-C5 alkyl. A stabilizer and a costabilizer are not required to be added, the reaction system is simple, and a product is easy to separate; and polymer microspheres have smooth and clean surfaces, uniform particle sizes, controllable appearances, and high dispersibility.

Owner:BEIJING UNIV OF CHEM TECH

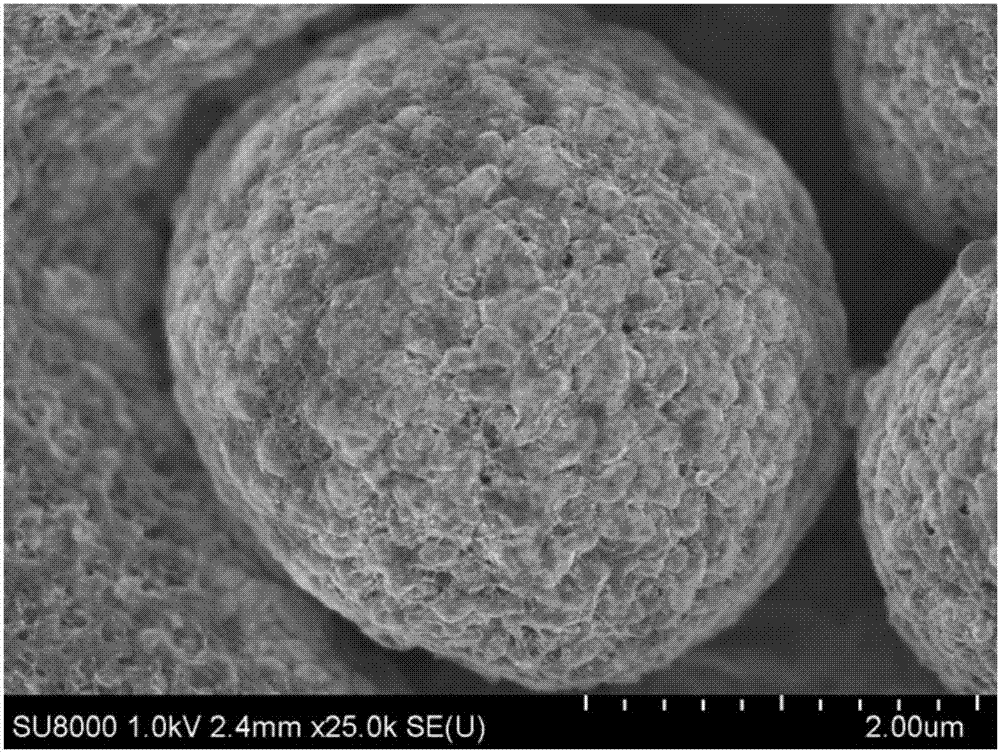

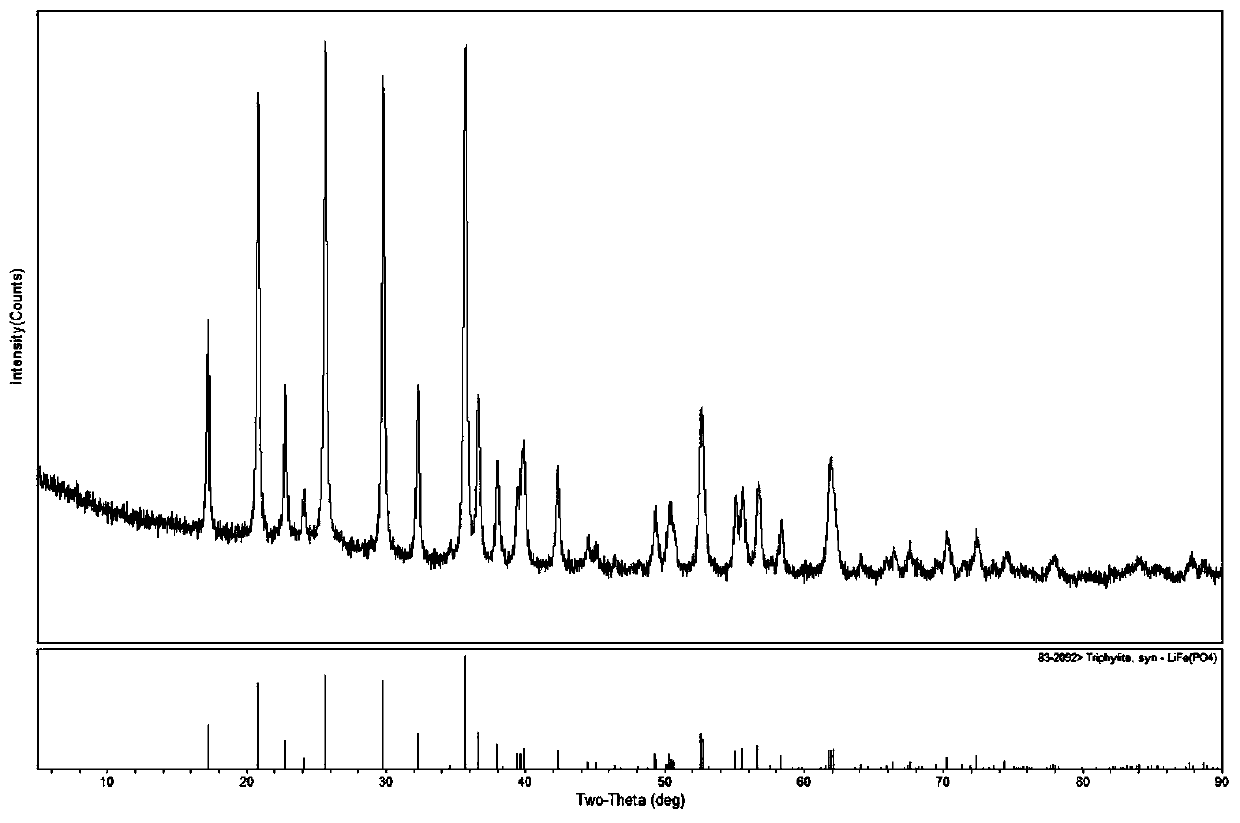

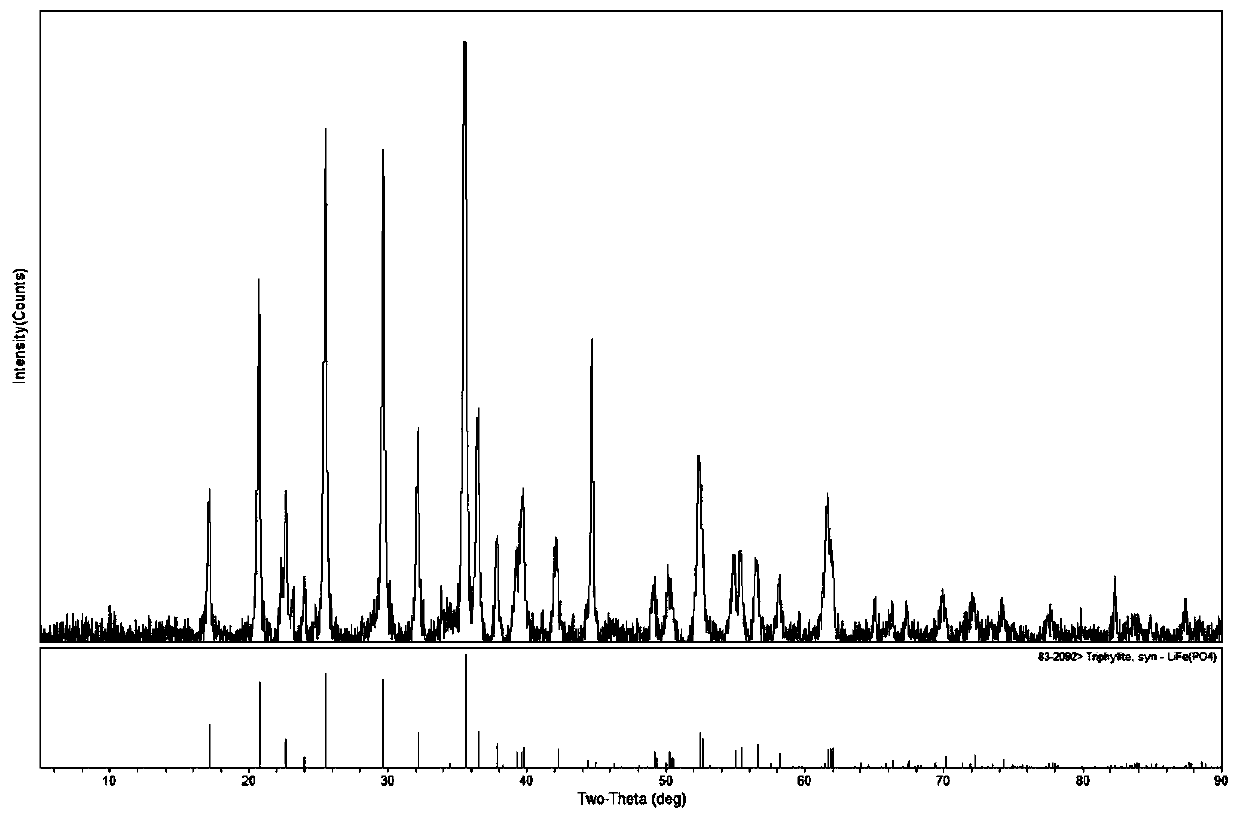

Preparation method of lithium iron phosphate, lithium iron phosphate and lithium ion battery

InactiveCN107359336AImprove conductivityImprove electrochemical performanceCell electrodesSecondary cellsLithium iron phosphateMicrometer

The invention provides a preparation method of lithium iron phosphate, lithium iron phosphate and a lithium ion battery, and relates to the technical field of lithium ion batteries. The preparation method comprises the following steps: mixing an iron source, a phosphorus source, a lithium source and a carbon source, calcinikng, grinding, drying, and then carrying out calcinations again so as to obtain lithium iron phosphate. By adopting the specific working procedures, the particles of prepared and obtained lithium iron phosphate are similarly spherical, the particle size is in a micrometer or nanometer level, the granularity is uniform and controllable, and a uniform and firm carbon cladding layer is formed on the surface of lithium iron phosphate more easily through the similarly spherical shape, so that a complete electric conduction network can be formed, the electric conductivity of lithium iron phosphate is obviously improved, and the electrochemical performance of lithium iron phosphate is improved. The invention also provides lithium iron phosphate obtained by adopting the preparation method, lithium iron phosphate is similarly spherical, the granularity is uniform and controllable, and the carbon cladding layer on the surface of lithium iron phosphate is uniform and firm, and the complete electric conduction network can be formed, so that lithium iron phosphate has good electrochemical performance.

Owner:NORTHERN ALTAIR NANOTECH CO LTD

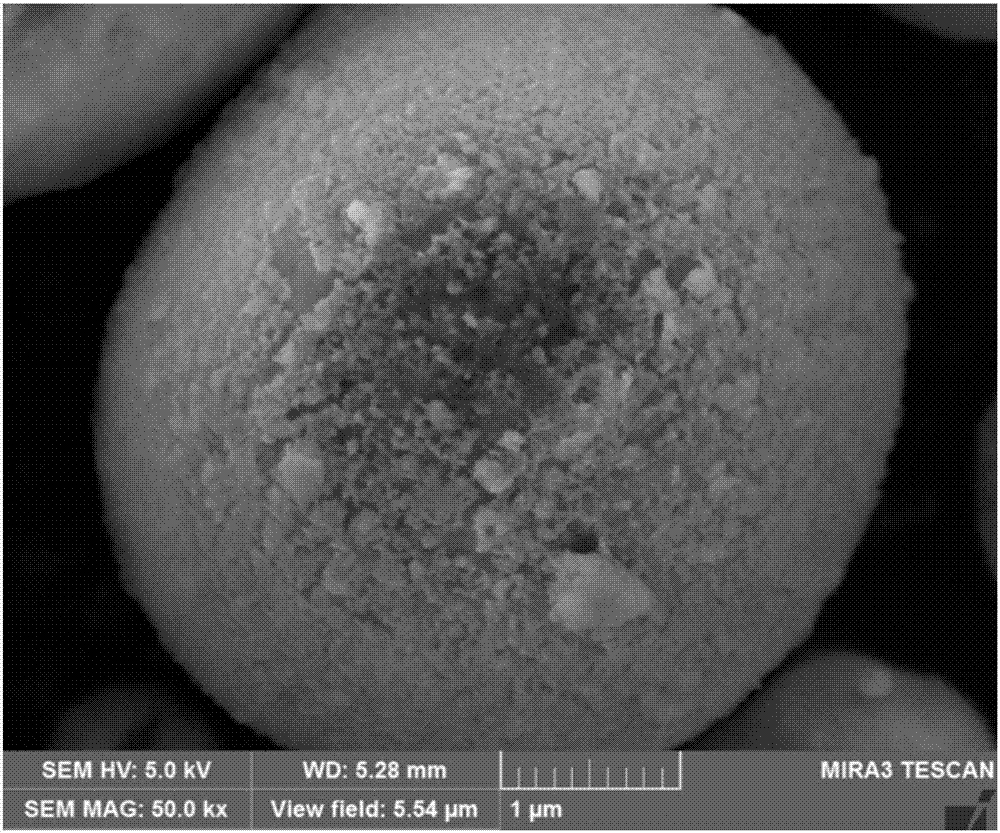

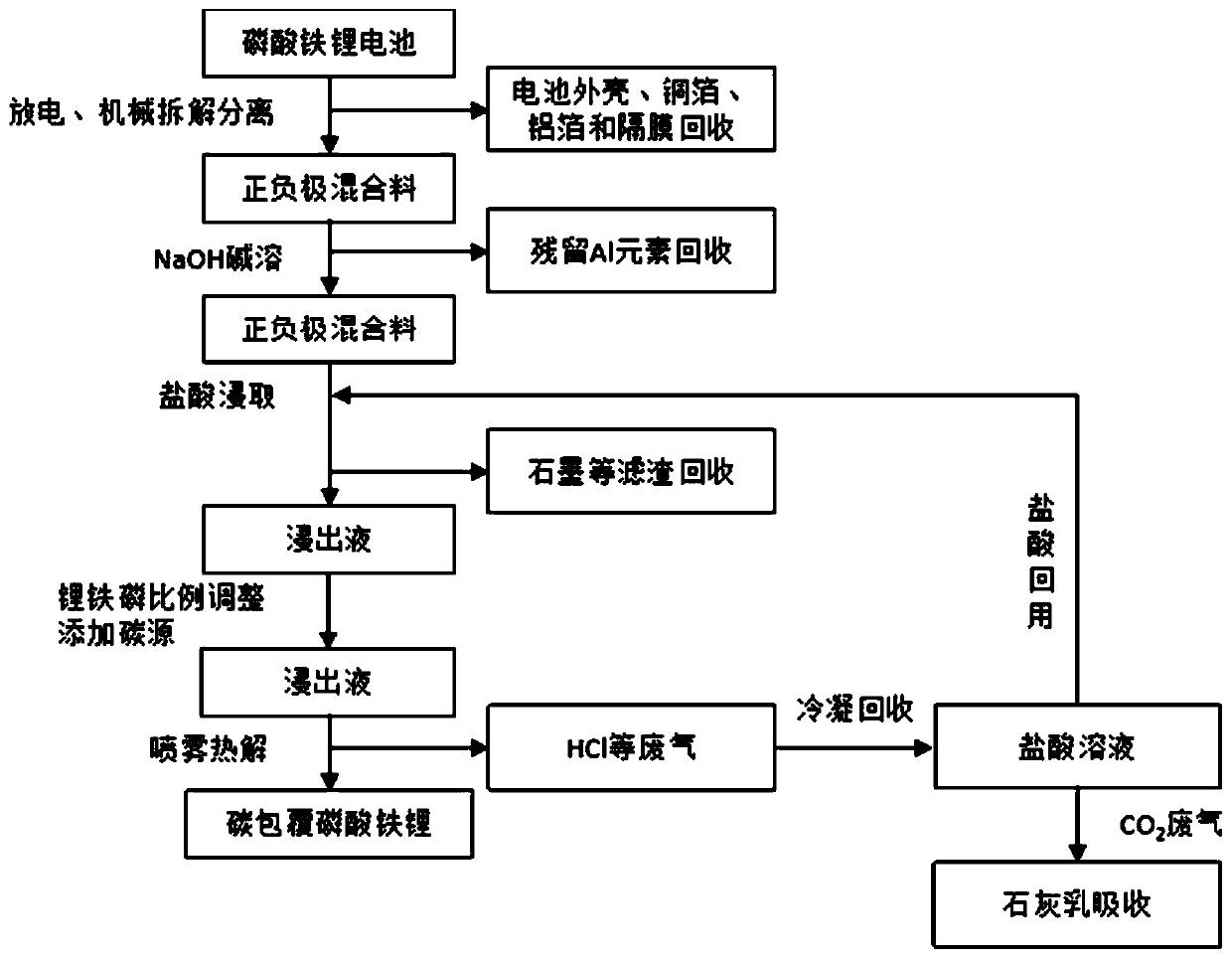

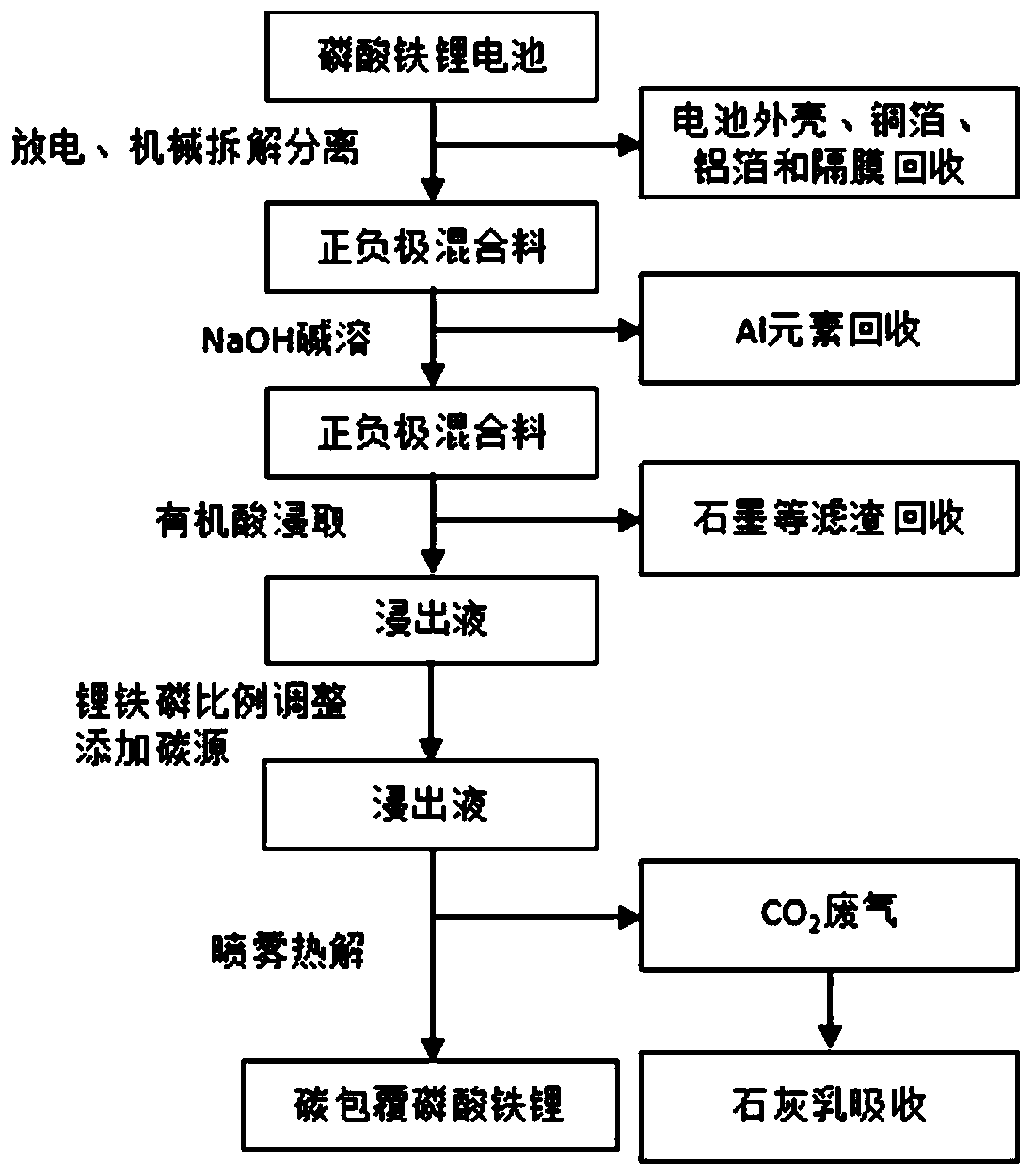

In-situ regeneration method of waste lithium iron phosphate battery positive electrode material

ActiveCN110581323ASimplified disassemblyAchieve mechanical disassemblyCarbon compoundsWaste accumulators reclaimingCopper foilCarbon source

The invention provides an in-situ regeneration method of a waste lithium iron phosphate battery positive electrode material. The in-situ regeneration method comprises the following steps: disassembling and separating out positive and negative electrode mixed powder, a battery shell, a copper foil, an aluminum foil and a diaphragm by a physical method after discharging the waste lithium ion battery; adding the positive and negative electrode mixed powder into a NaOH solution for dissolution and removing the residual Al element and then placing the mixture in a hydrochloric acid solution with acertain concentration to leach Li, Fe and PO431 , filtering and removing insoluble graphite to enable the positive electrode material to be separated from the negative electrode graphite material andrecovering and regenerating the negative electrode material after purification; then adding a lithium source, an iron source or a phosphorus source according to the determined element ratio of leaching solution to make the molar ratio of Li: Fe: PO43- to be 1-1.05: 1: 1 and adding a certain amount of carbon source; and obtaining the lithium iron phosphate coated with carbon after spray pyrolysis.The disassembling mode is simplified, the lithium iron phosphate positive electrode material can be synthesized in situ, the hydrochloric acid can be recycled, the disassembling cost of the waste battery can be reduced and industrial production can be realized.

Owner:SHENZHEN QINGYAN EQUIP TECH CO LTD

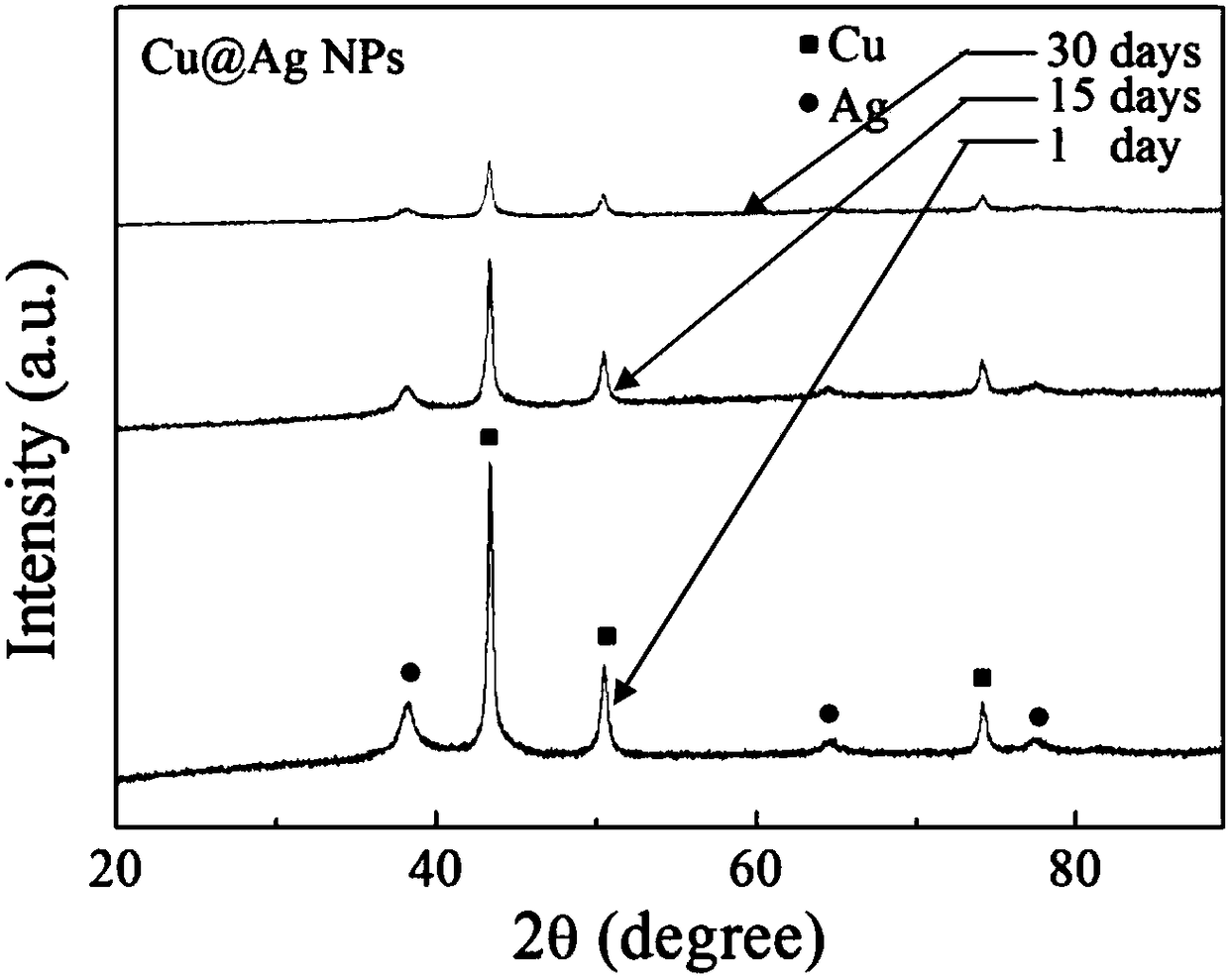

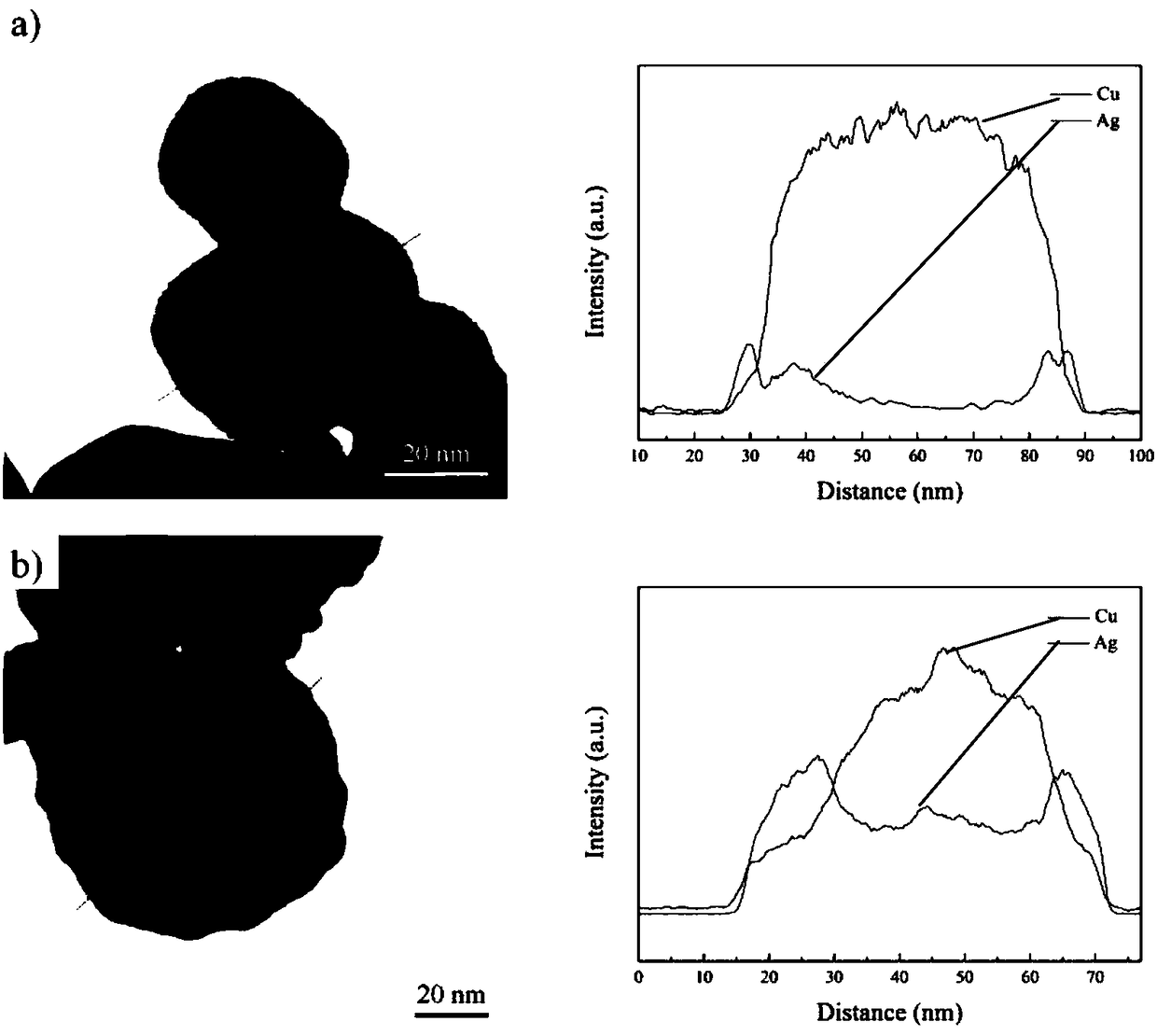

Material for RFID (Radio Frequency Identification) antenna conductive pattern

PendingCN108084799ARich in mineralsLower resistanceMaterial nanotechnologyTransportation and packagingStencil printingPrinting ink

The invention provides a material for an RFID (Radio Frequency Identification) antenna conductive pattern. The material for the RFID antenna conductive pattern has the following specific characteristics that the material is metal nano-particles which are of core-shell structures, wherein the inner cores are Cu particles of about 50 nm, and an Ag layer coats the surfaces of Cu through a composite method of displacement and chemical deposition; Cu@Ag nano-particles, absolute ethyl alcohol and deionized water are mixed to prepare conductive printing ink with the solid content of about 70 percent;the material is obtained through metal stencil printing and sintering. Antenna patterns with different thicknesses can be manufactured by the material by adopting metal stencil printing so as to meetdifferent impedance requirements of antennae of various frequency bands. The Cu@Ag nano-particles have the characteristics of low impedance, high conductivity, controllable Ag layer thickness and thelike; compared with Cu conductive printing ink, the Cu@Ag nano-particles have high oxidation resistance; compared with pure Ag or Au conductive printing ink, the cost is greatly reduced; optimal sintering performance can be realized by controlling the thickness of the Ag layer; moreover, a preparation process of the material is simple and convenient; a printing ink solvent is environment-friendlyand renewable, and has a very great application prospect in the field of conductive printing ink for the RFID antenna.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Method for recovering positive electrode material of waste lithium iron phosphate battery

ActiveCN110620278ARealize automatic mechanical dismantlingReduce dismantling costsPositive electrodesWaste accumulators reclaimingCopper foilLithium-ion battery

The invention provides a method for recovering a positive electrode material of a waste lithium iron phosphate battery. The method comprises steps: carrying out discharge treatment of the waste lithium ion battery, and separating positive and negative electrode mixed powder, a battery shell, a copper foil, an aluminum foil and a diaphragm through the physical method; adding the separated positiveand negative electrode mixed powder into NaOH solution for dissolving, removing residual Al elements, putting the residual Al elements into organic acid solution with a certain concentration, leachingLi, Fe and PO4<3->, filtering to remove insoluble graphite, separating a positive electrode material from a negative electrode graphite material, purifying the negative electrode material, and recycling the purified material; then adding a lithium source, an iron source or a phosphorus source according to the determined element ratio of the leachate, making a molar ratio of Li to Fe to PO4<3-> tobe (1-1.05): 1: 1; and carrying out spray pyrolysis under a certain temperature condition and inert gas atmosphere to obtain a carbon-coated lithium iron phosphate material. The method is advantagedin that the disassembling mode is simplified, leaching efficiency is high, impurity elements are not introduced, exhausted waste gas is mainly CO2, and industrial large-scale production is facilitated.

Owner:SHENZHEN QINGYAN EQUIP TECH CO LTD

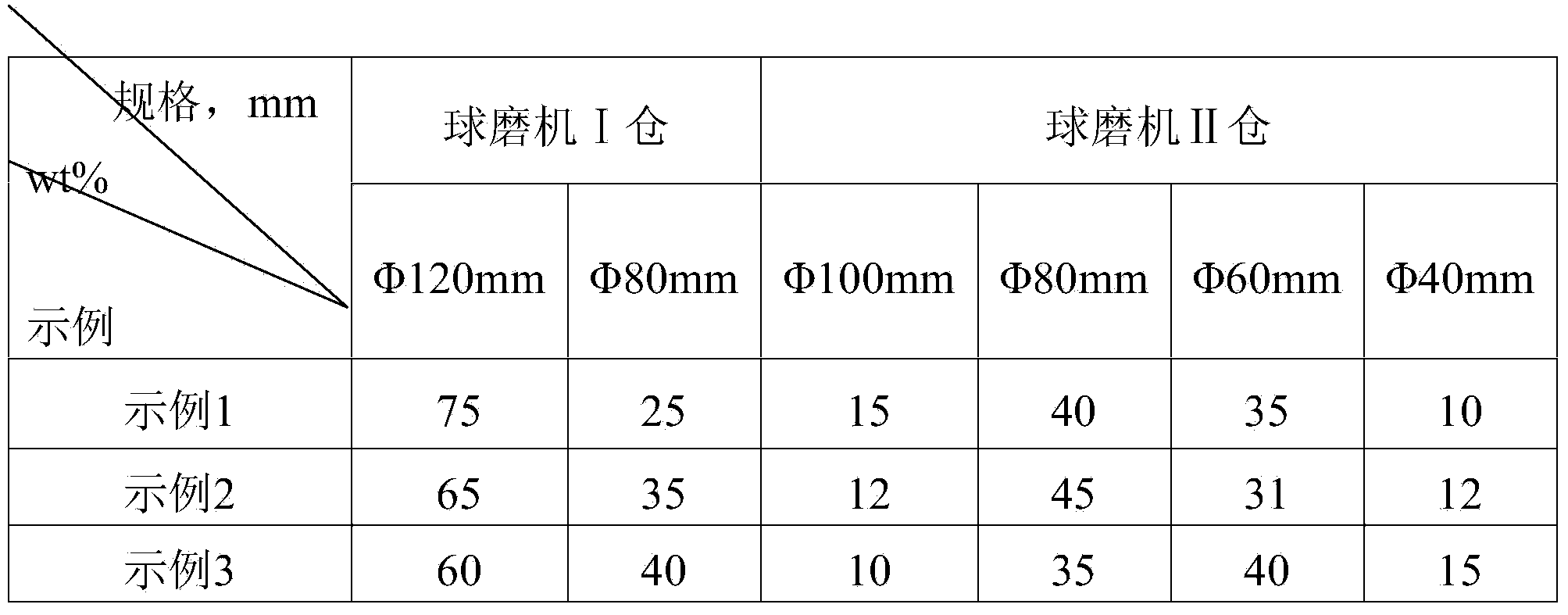

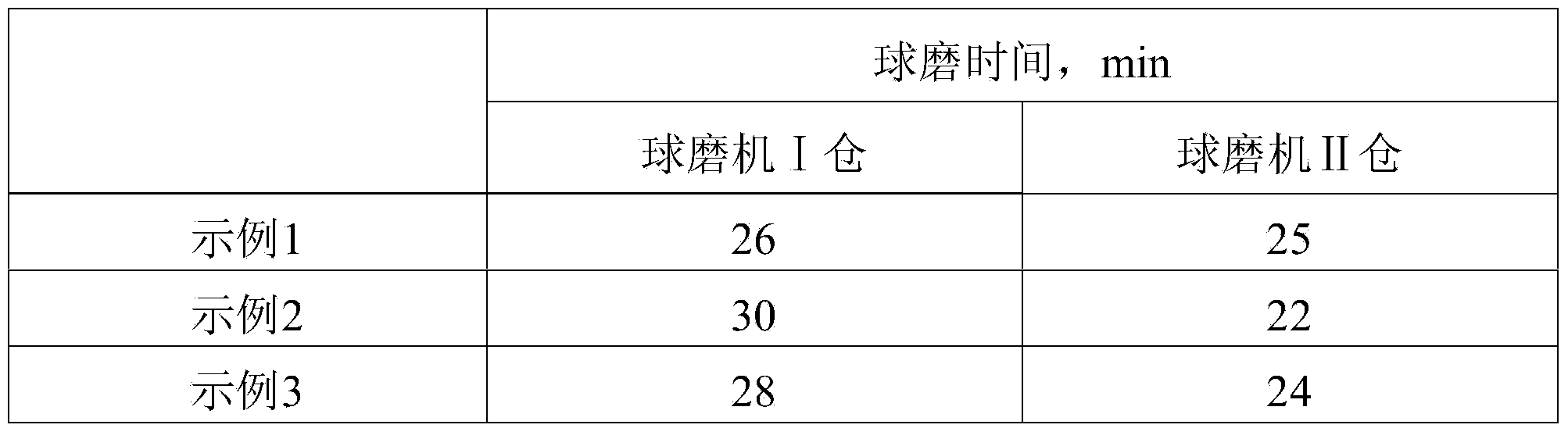

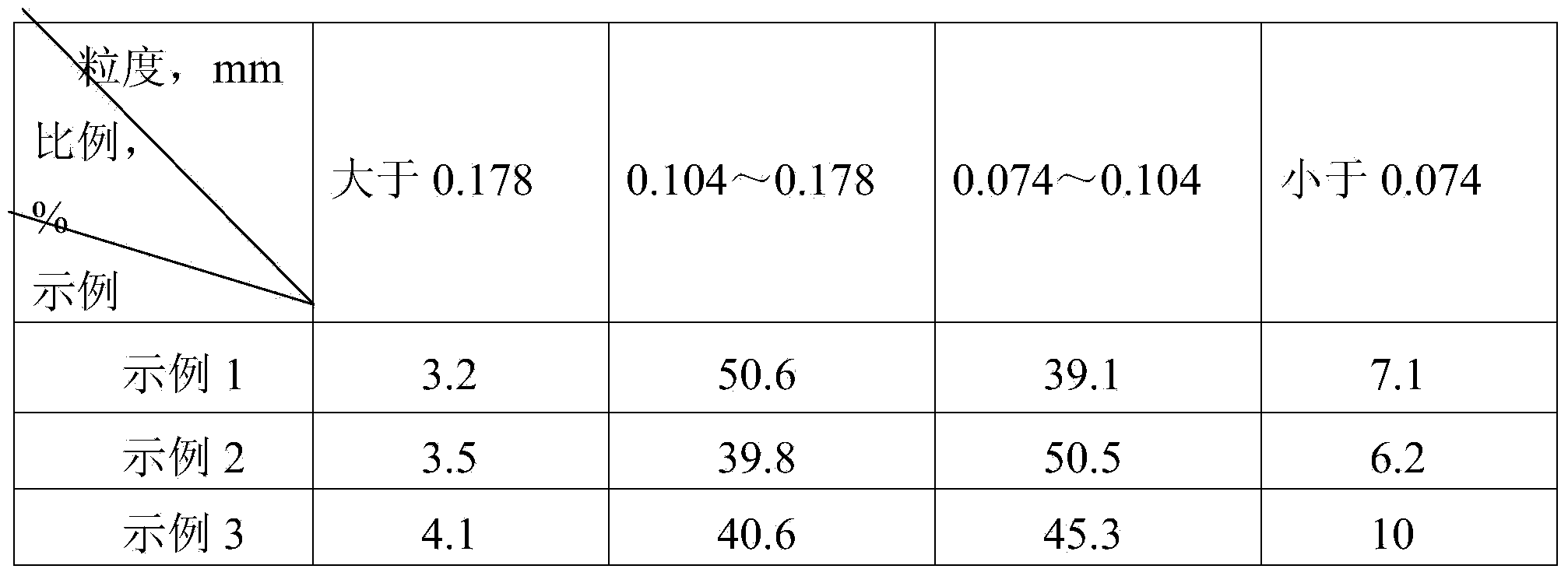

Carbide slag grinding method and low temperature chlorination method for preparing TiCl4

InactiveCN103816963AReduce unit power consumptionReduce usageTitanium halidesGrain treatmentsSlagCarbide

The invention provided a carbide slag grinding method and a low temperature chlorination method for preparing TiCl4. The grinding method comprises the following steps: adding the carbide slag raw material in a first cabin of a ball grinding mill for crushing; then feeding the crushed carbide slag into a second cabin for grinding to obtain carbide slag powder, wherein first cabin grinding bodies in the first cabin comprise 60-75 weight percent of steel balls with the diameter of 120 mm, 25-40 weight percent of steel balls with the diameter of 80 mm; second cabin grinding bodies in a second cabin comprise 10-15 weight percent of steel balls with the diameter of 100 mm, 25-45 weight percent of steel balls with the diameter of 80 mm, 25-40 weight percent of steel balls with the diameter of 60mm and 10-15 weight percent of steel balls with the diameter of 40 mm. According to the carbide slag grinding method and the low temperature chlorination method for preparing TiCl4, most of the carbide slag can be grinded to 0.074mm-0.178mm through the reasonable steel ball graduation of the ball grinding mill; the smooth progress of follow-up technology of low temperature fluidizing chlorination of the carbide slag for the production of titanium tetrachloride is guaranteed.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com