Carbide slag grinding method and low temperature chlorination method for preparing TiCl4

A carbonized slag and grinding technology, applied in titanium halide, grain processing, etc., can solve the problems of low yield, tail gas treatment system blockage, etc., and achieve unit power consumption reduction, production cost reduction, uniform and controllable carbide slag particle size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1-3

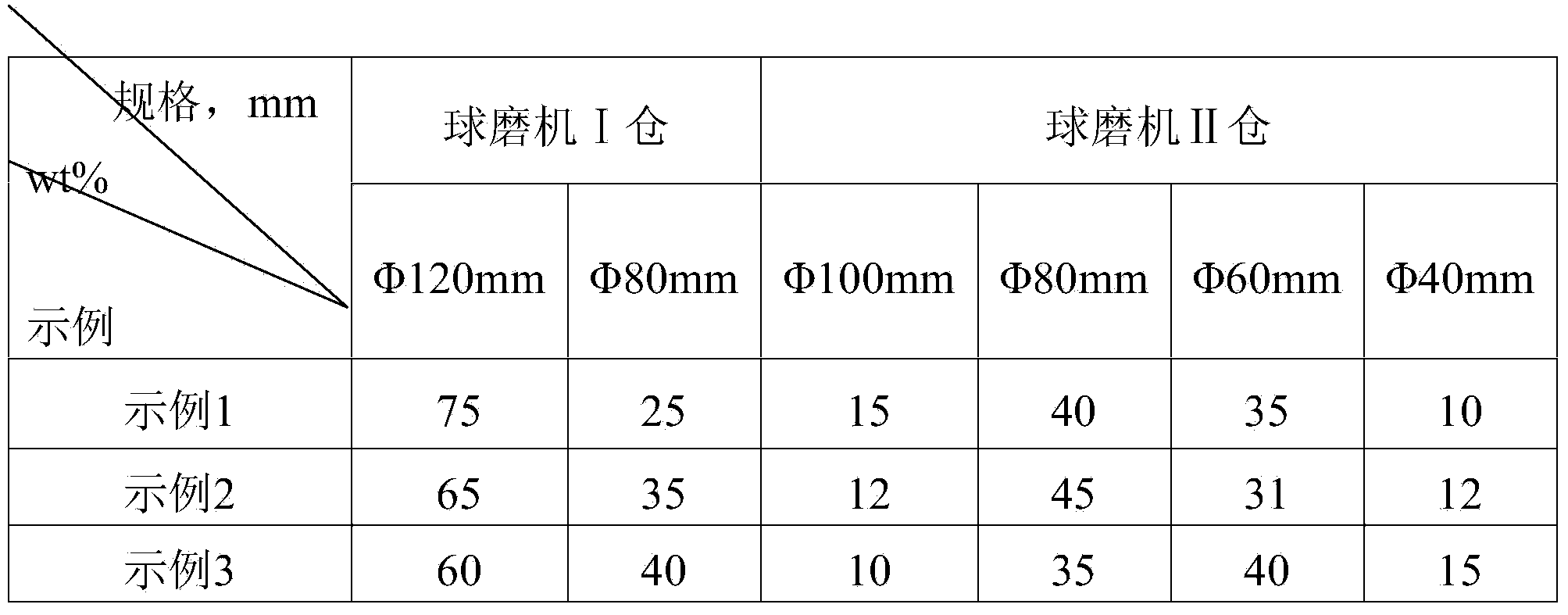

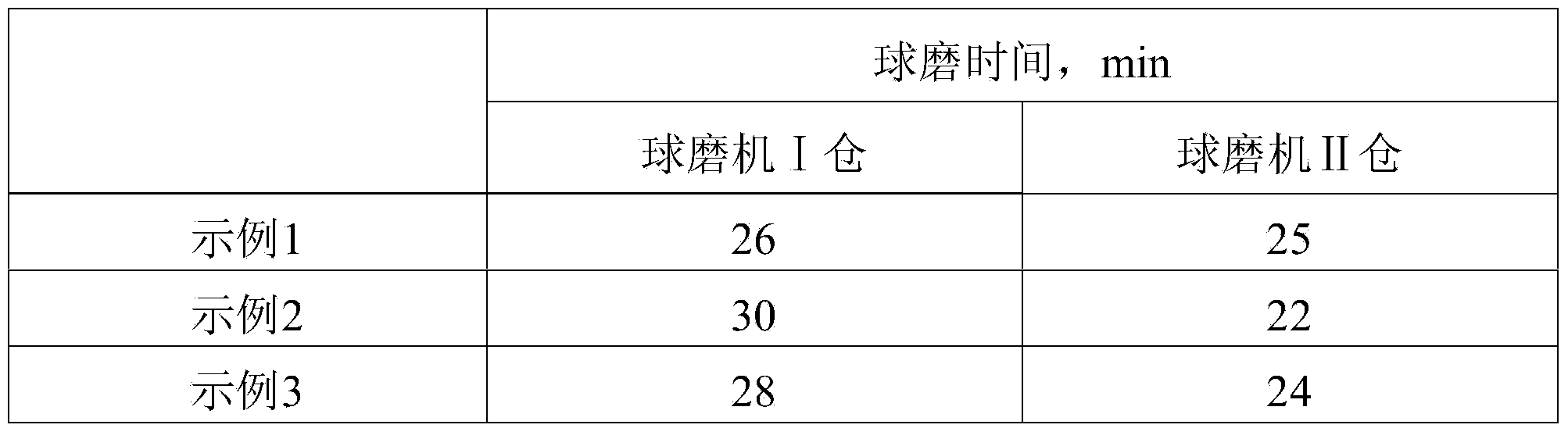

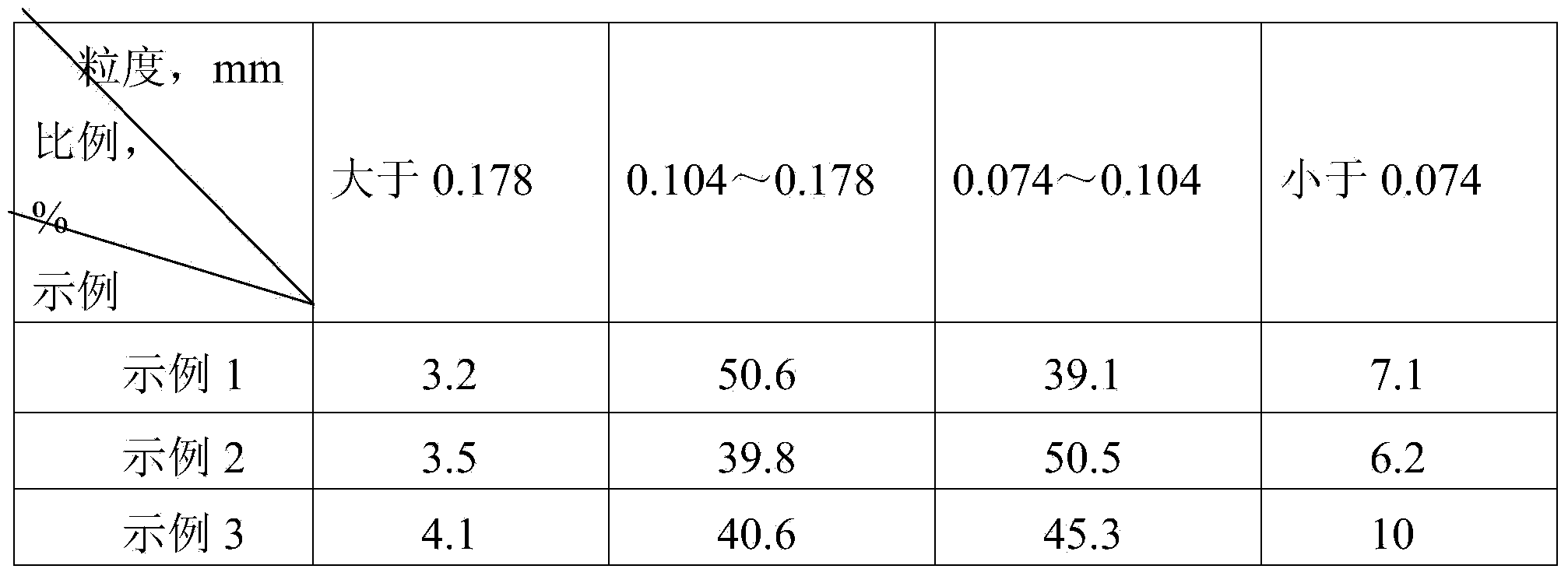

[0025] The main chemical composition of the carbide slag raw material processed in Example 1-3 is shown in Table 2 below; the model of the ball mill is MQGΦ1830×7000mm, and the main performance parameters of the ball mill are shown in Table 3; the steel ball grading scheme of Example 1-3 is as follows Table 4; the ball milling time of Examples 1-3 are shown in Table 5; the particle size distribution of the carbide slag powder obtained after the carbide slag raw material is ground by the ball mill is shown in Table 6.

[0026] Table 2 Main chemical composition of carbide slag used in Example 1-3 (wt%)

[0027] main ingredient

TiC

Al 2 o 3

CaO

MgO

MnO

SiO 2

TF

V 2 o 5

Example 1

13.95

17.50

28.40

6.85

0.35

24.95

0.50

0.10

Example 2

14.1

16.6

27.1

6.2

0.38

23.8

0.42

0.08

[0028] Example 3

13.5

17.8

26.5

7.1

0.4

25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com