HPE evaporation system for carrier gas extraction

An evaporation system and extraction technology, which is applied in the field of industrial wastewater desalination devices, can solve the problems of easy corrosion of equipment materials, high cost of wastewater desalination, and endangering the ecological environment, and achieve energy saving, significant energy saving effect, and high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

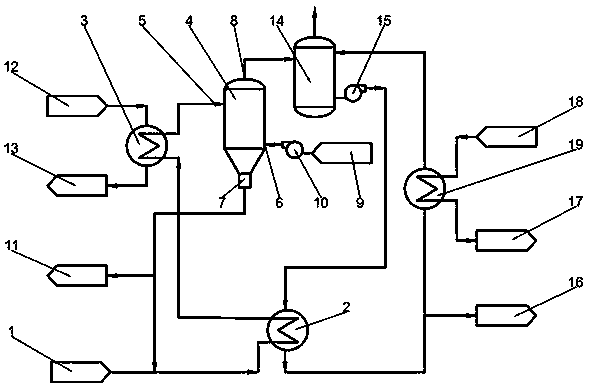

[0022] The present invention will now be described in further detail with reference to the drawings and preferred embodiments. These drawings are simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the constitution related to the present invention.

[0023] Such as figure 1 As shown, the present invention proposes a carrier gas extraction HPE evaporation system. The inlet 5 of the evaporator 4 is arranged between the outlet end 3 of the second heat exchanger and the inlet end 8 of the high-salt wastewater and is connected in sequence in order, and The inlet 6 of the evaporator continuously passes the ambient air 9 into the evaporator 4 through the blower 10; the outlet 7 of the evaporator is respectively connected to the high-salt wastewater tank 12 and the wastewater inlet 1 for brine recovery. The outlet two 8 is connected with the gas-liquid separator 14 to enter the condensation system.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com