Patents

Literature

98results about How to "Reduce unit power consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

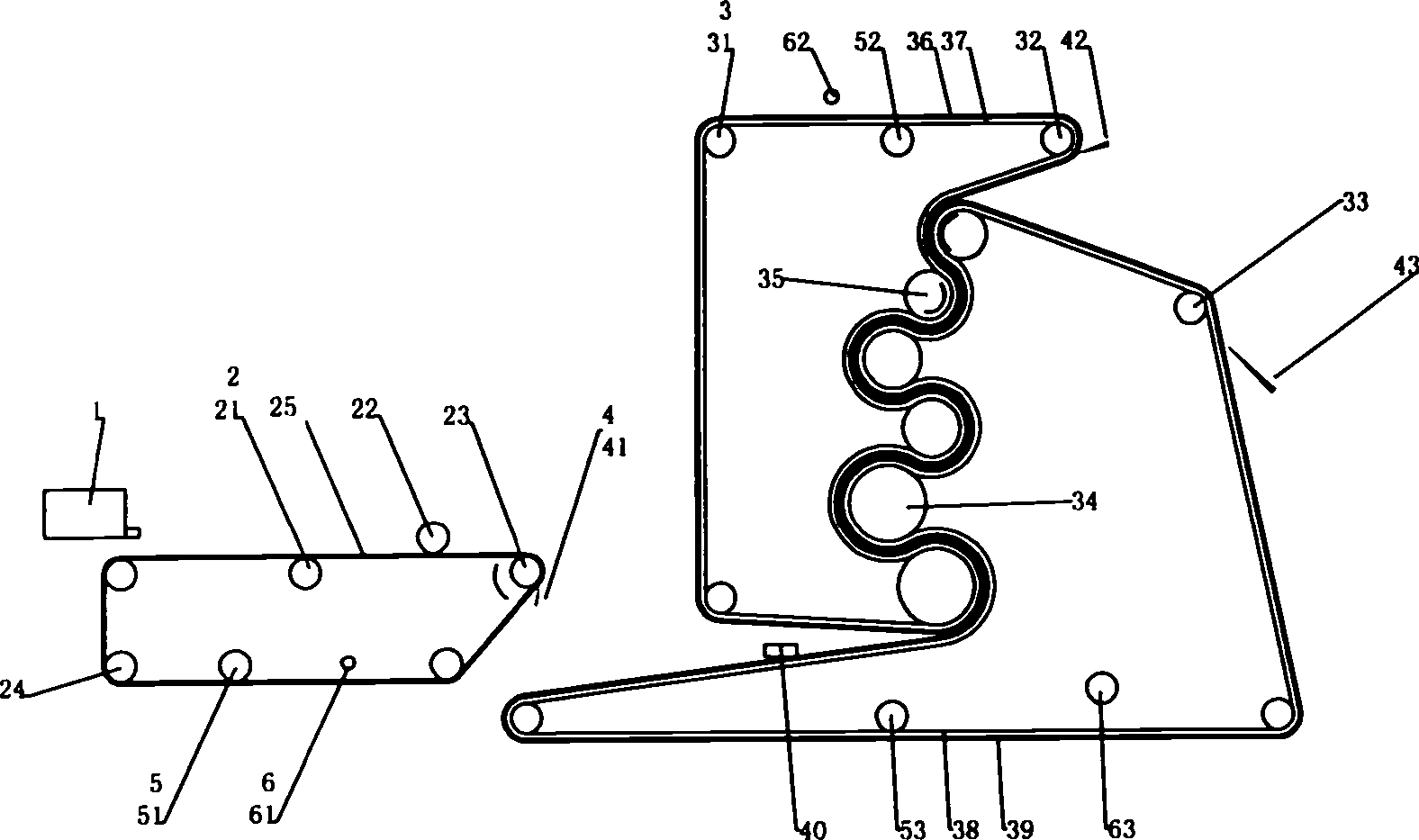

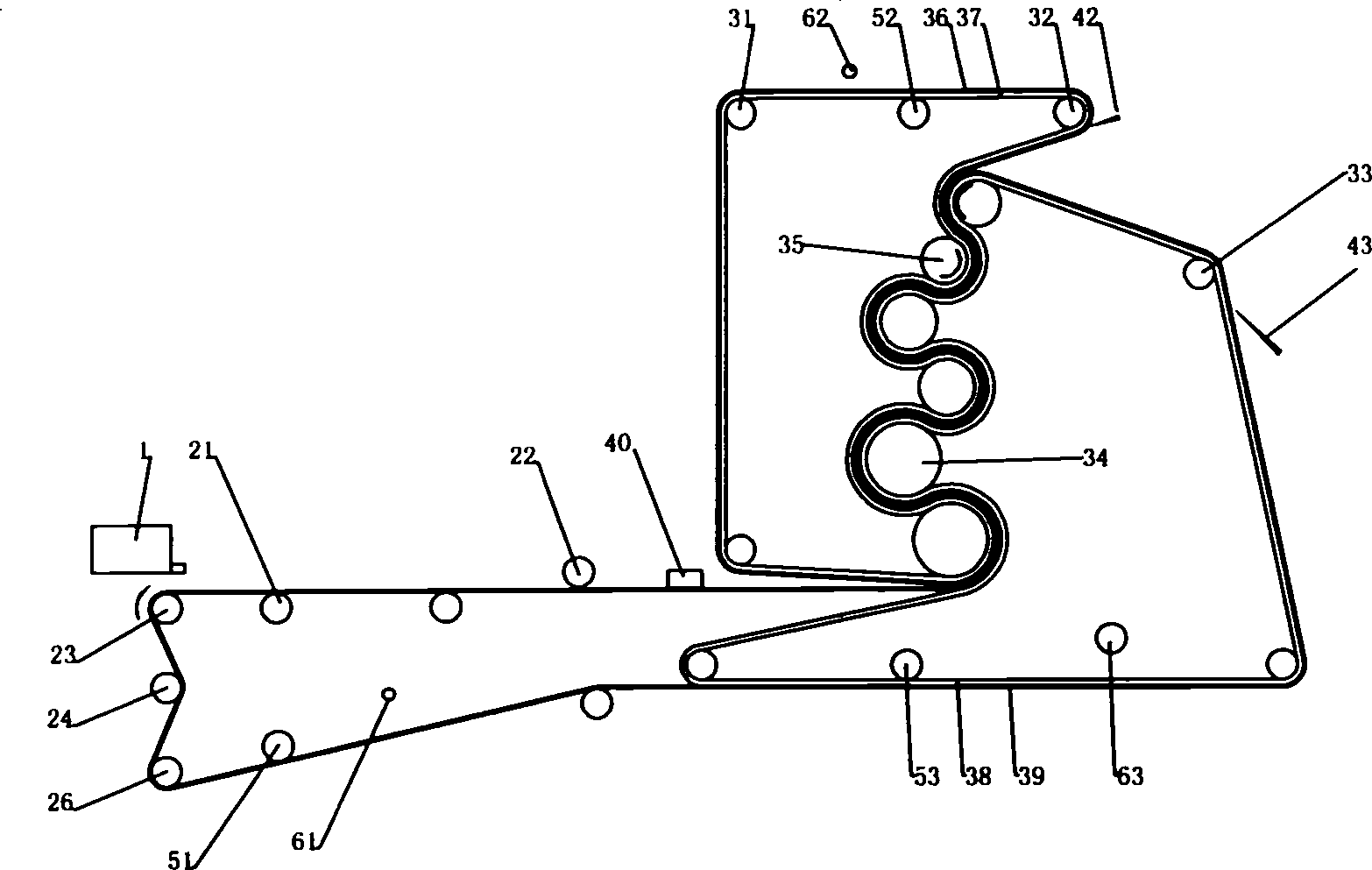

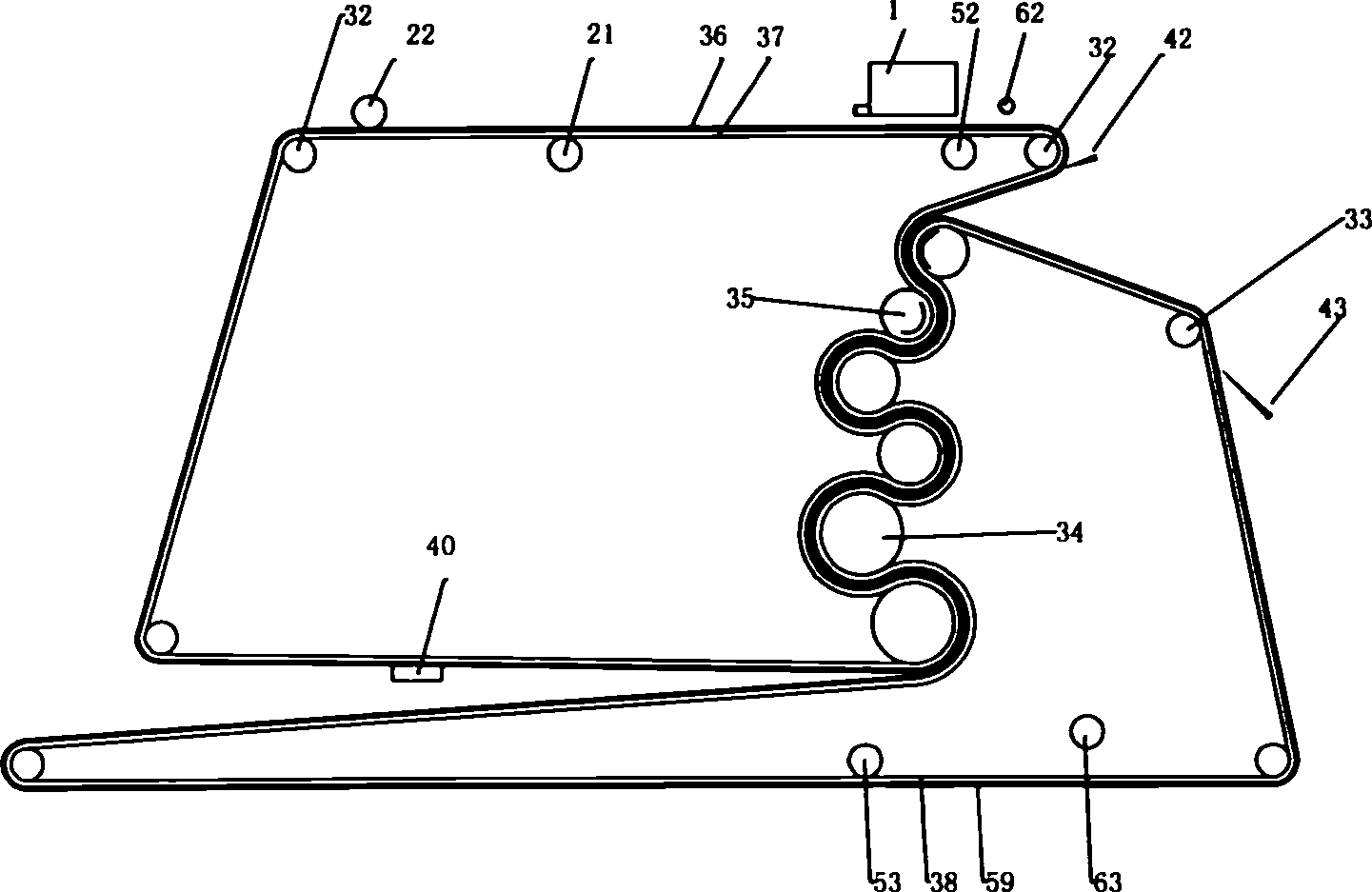

Belt type filter press

ActiveCN1879932AHigh filtration pressureHigh filter pressureMoving filtering element filtersEngineeringFilter press

The invention relates to a belt compress filter for dewatering the micro grains, wherein it is formed by a frame, a driver, a feeding device, a compress area and an auxiliary device; said compress area comprises a compress filtering roller and a filtering belt; the driver comprises a motor and a gear box; the auxiliary device comprises a tension roller, a scrape device, a water collector, a corrector, and a filter belt washer. The invention is characterized in that: the back of filter belt is lined with steel compress belt; the compress filtering rollers are compacted arranged. The invention can improve the filter pressure of compress filter to improve the balance point between the filter pressure and the filter resistance, to overcome the defects of present technique, while it can improve the dewatering efficiency and the yield.

Owner:ZHEJIANG HUAZHANG TECH

Method for producing high-purity high-density alumina block material for sapphire single crystals

ActiveCN101913636AReduce unit power consumptionEase of mass productionPolycrystalline material growthAluminates/aluminium-oxide/aluminium-hydroxide purificationCrystal clusterHeating power

The invention discloses a method for producing a high-purity high-density alumina block material for sapphire single crystals. A high-frequency induction power supply is utilized as a heating power supply, an alumina micropowder raw material in a cold crucible is melted to form a molten bath, and a Bruceton-process single crystal growing process making the cold crucible slowly reduced is combined, so that alumina in the molten bath generates multi-nucleus directional crystallization, and fine columnar or needle-like alumina smallcrystal clusters are obtained finally. The method is used for producing the high-purity high-density alumina block raw material, has low unit electricity consumption and is easy for mass production; and the obtained alumina smallcrystals have the purity of over 99.997 percent, the volume density of not less than 3.7g / cm<3> and the bulk density of not less than 2.0g / cm<3>.

Owner:李振亚 +1

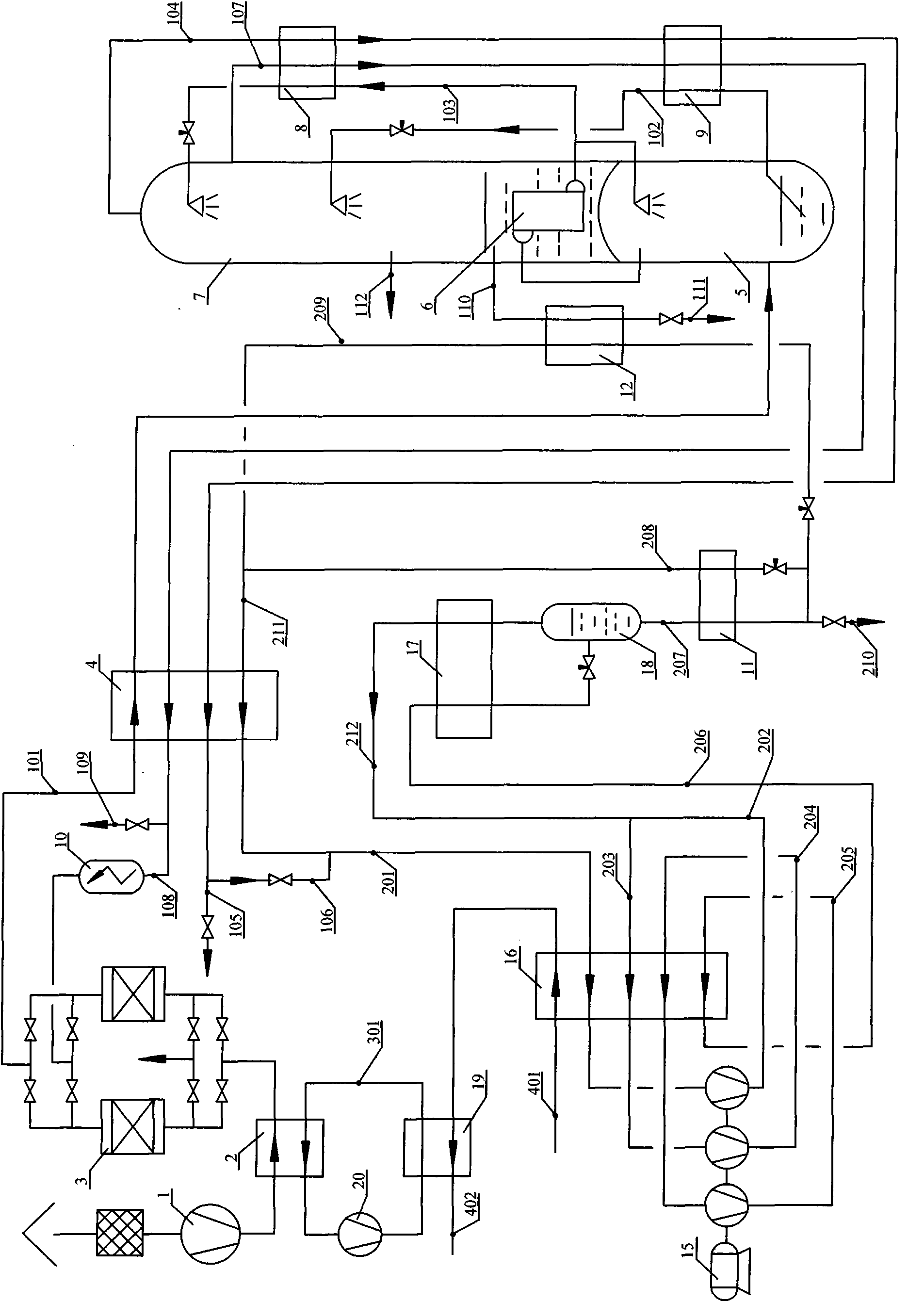

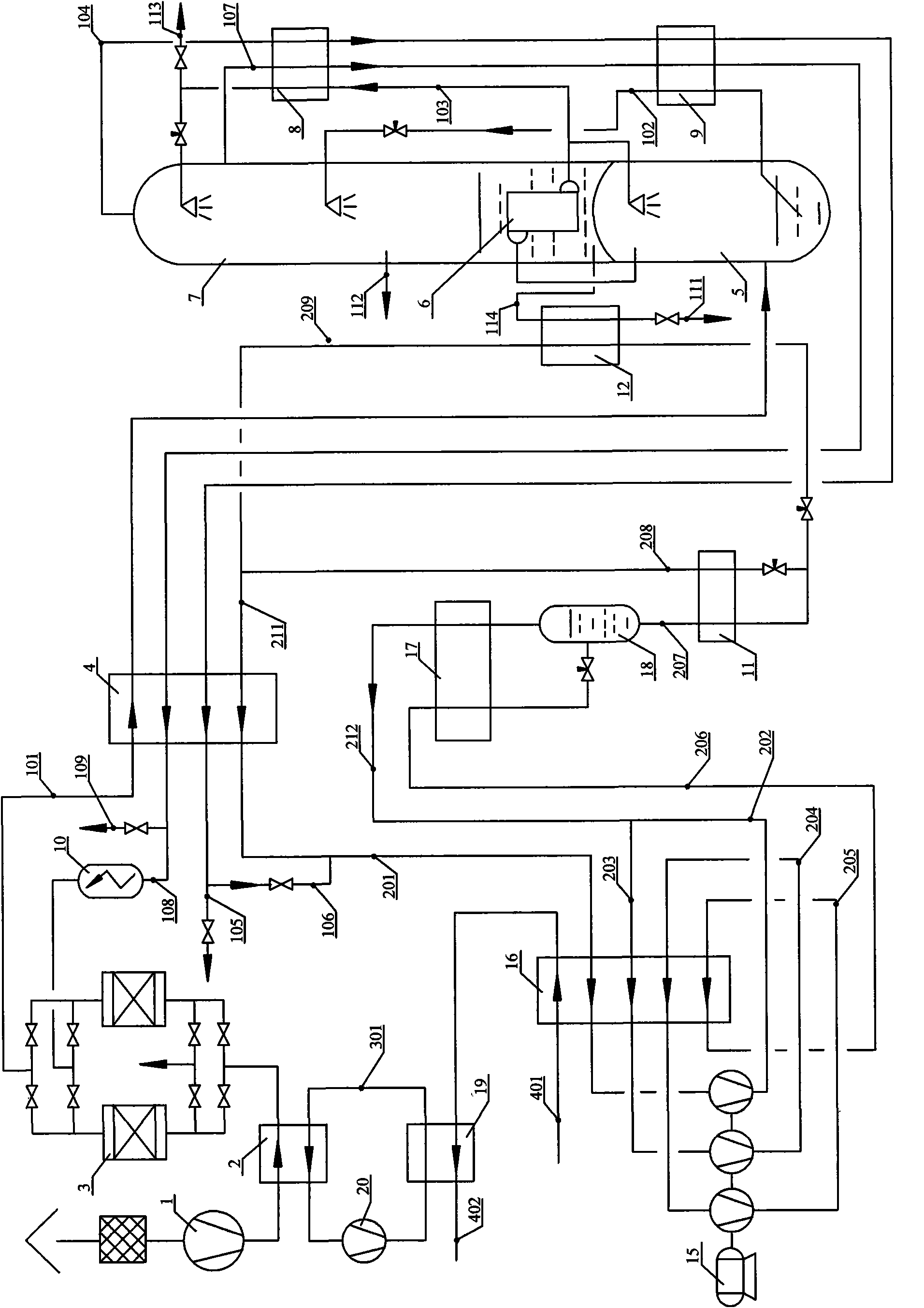

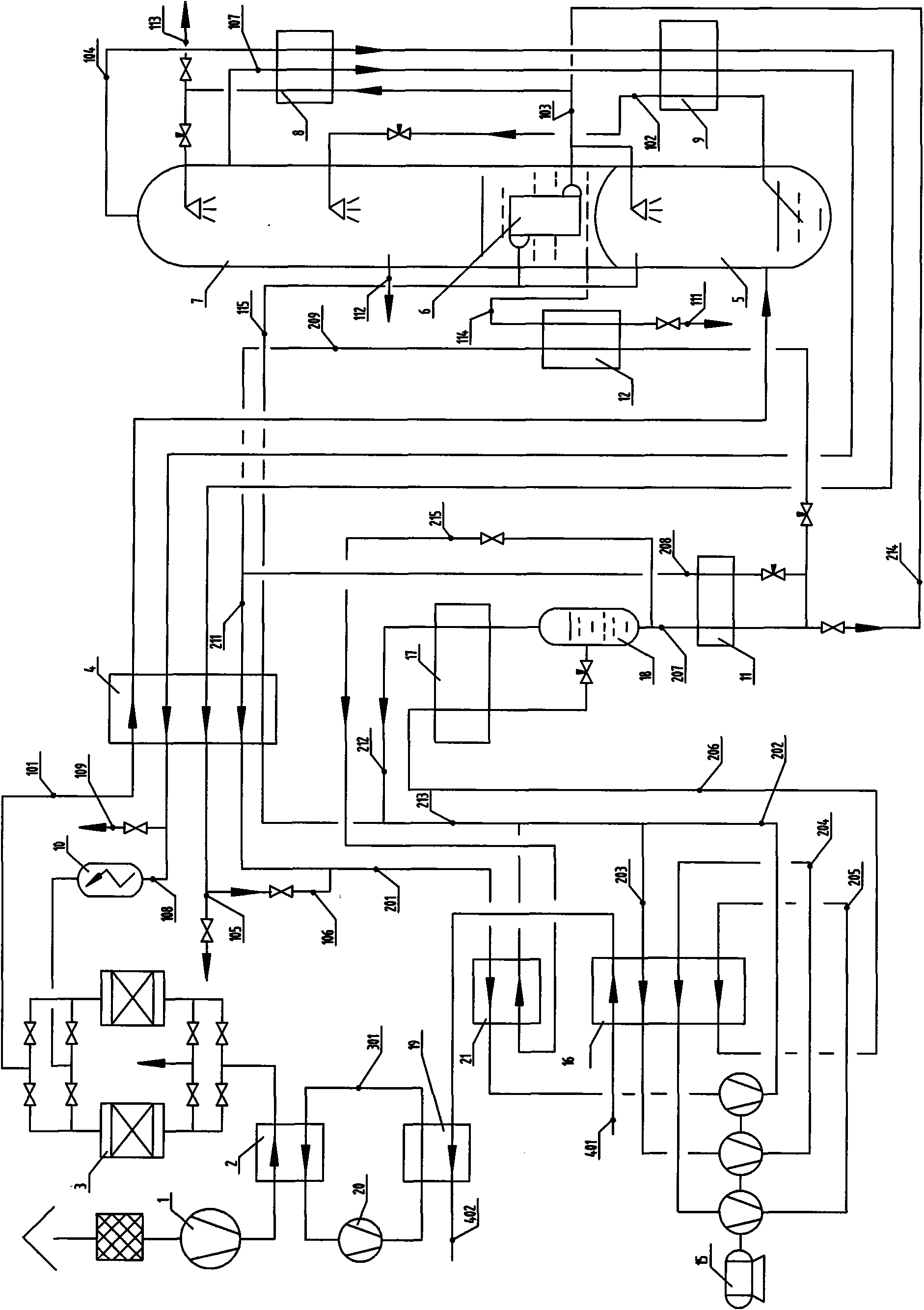

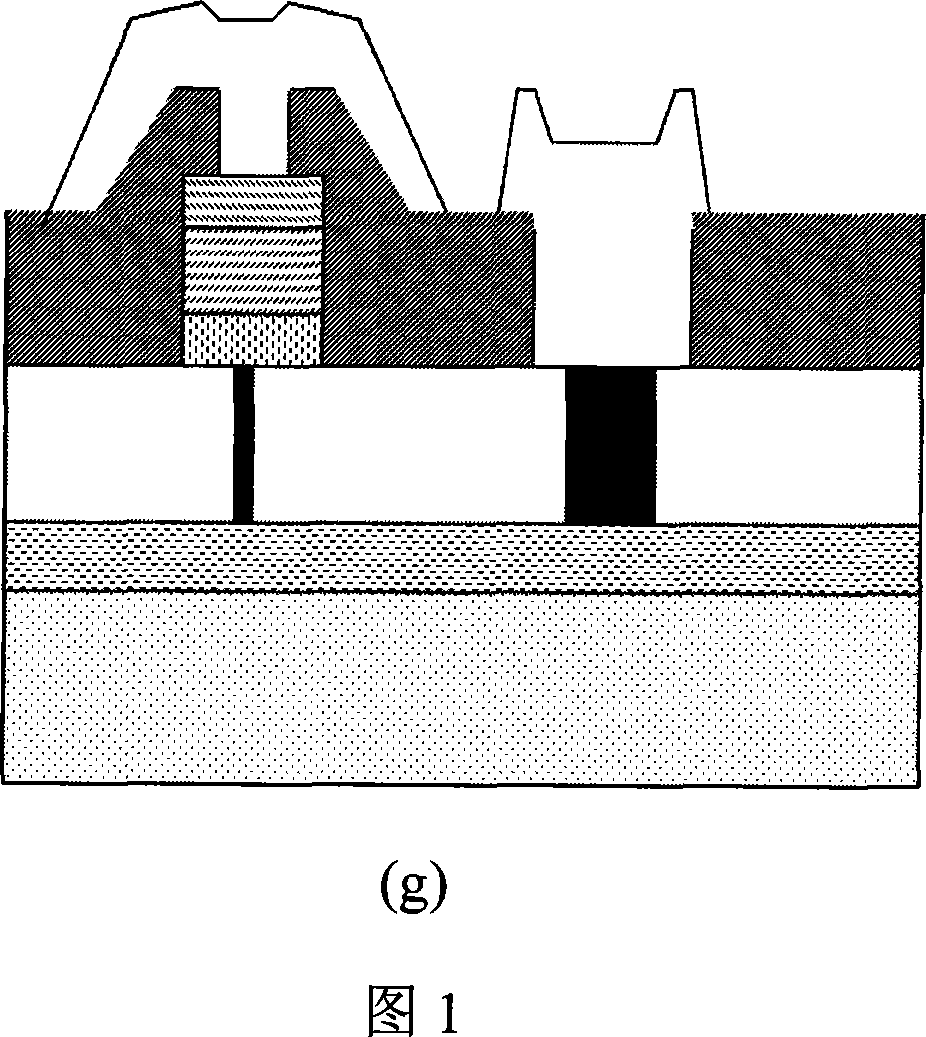

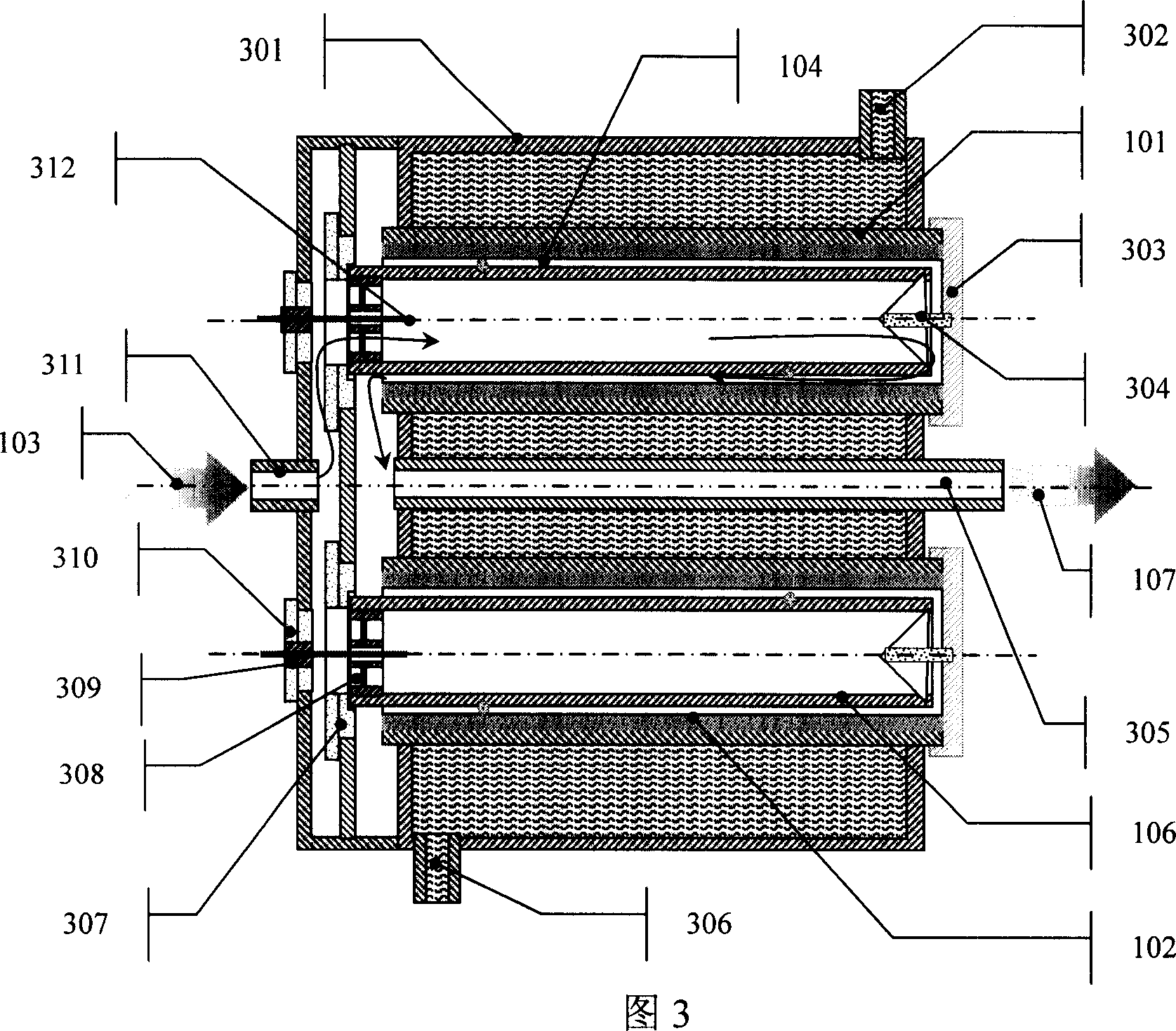

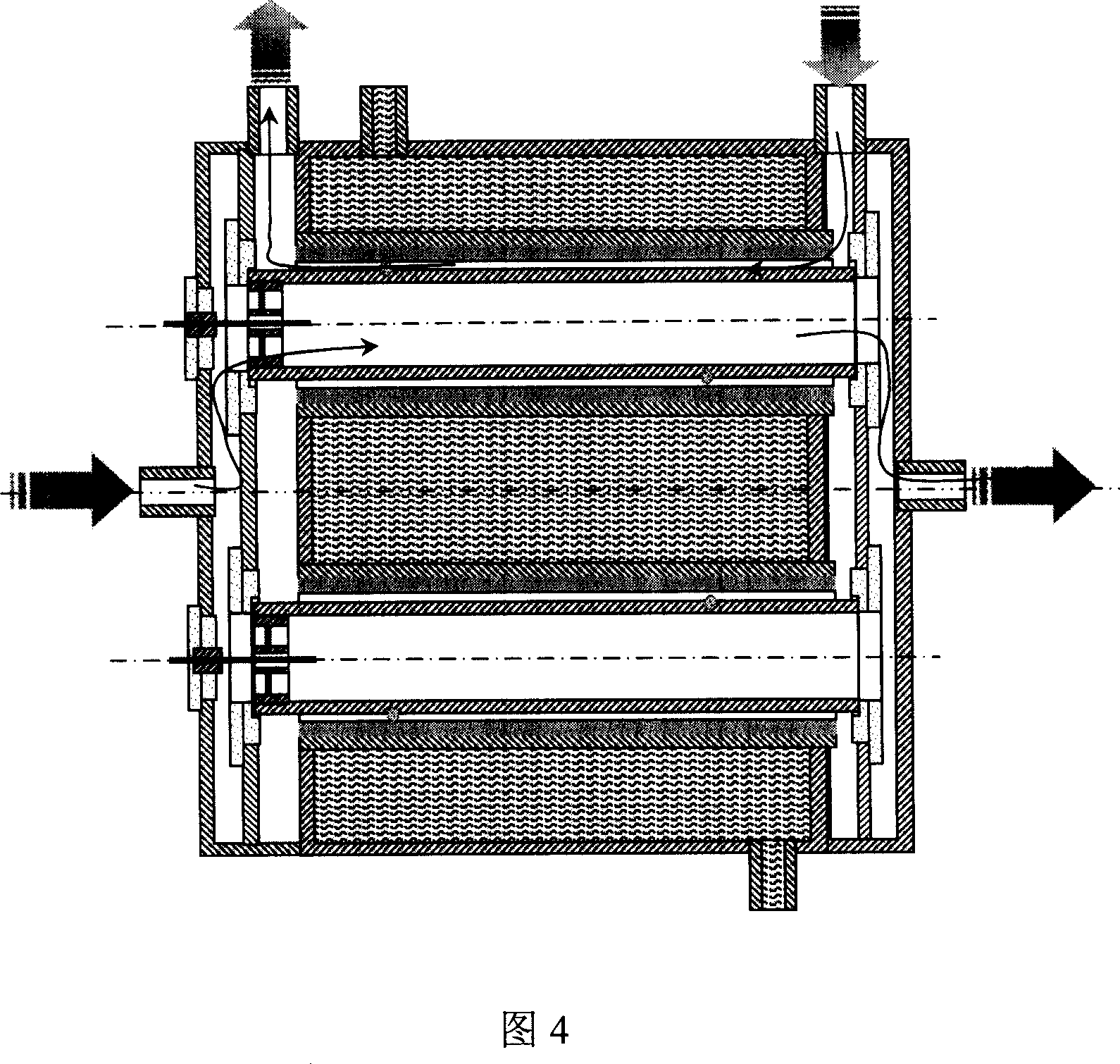

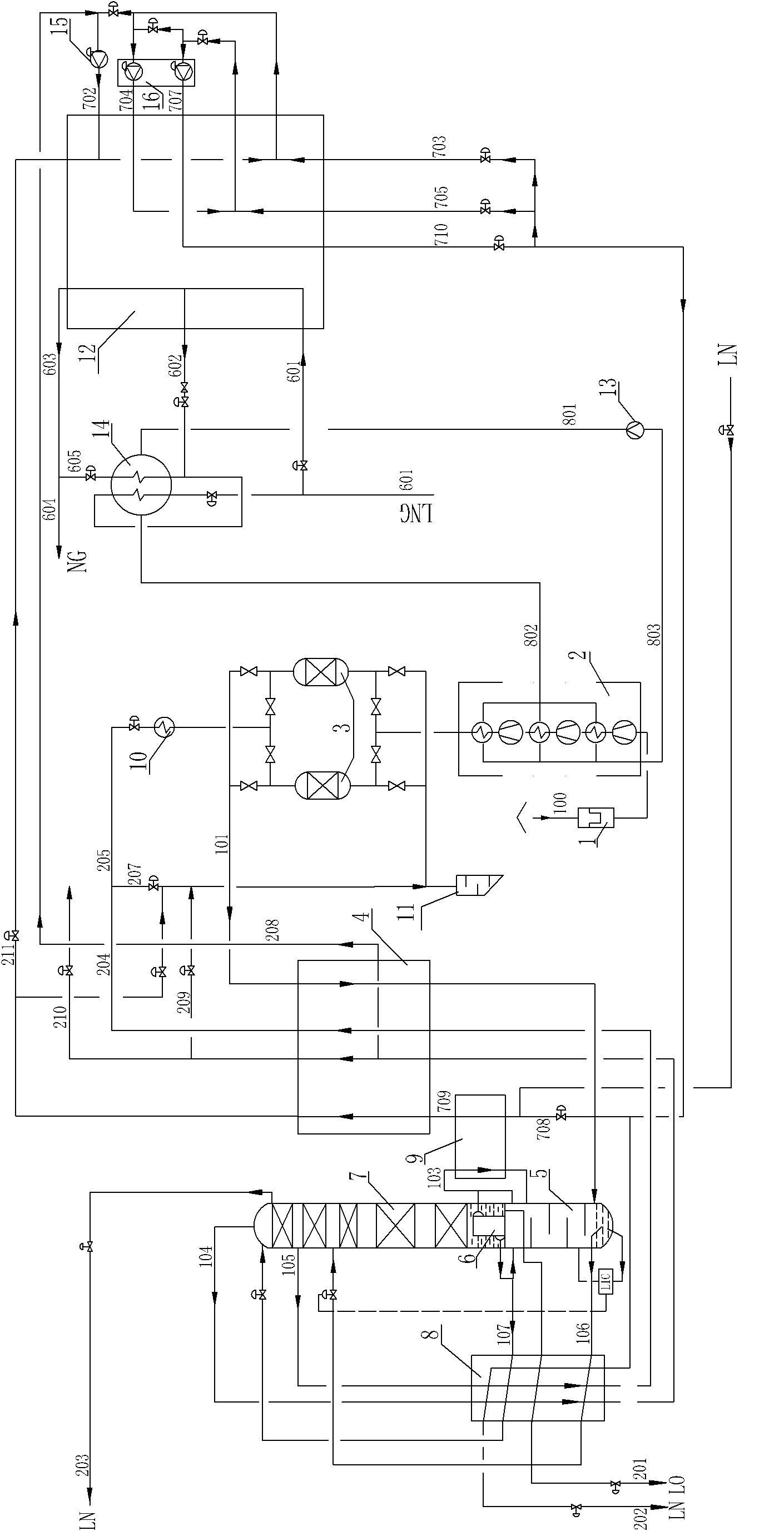

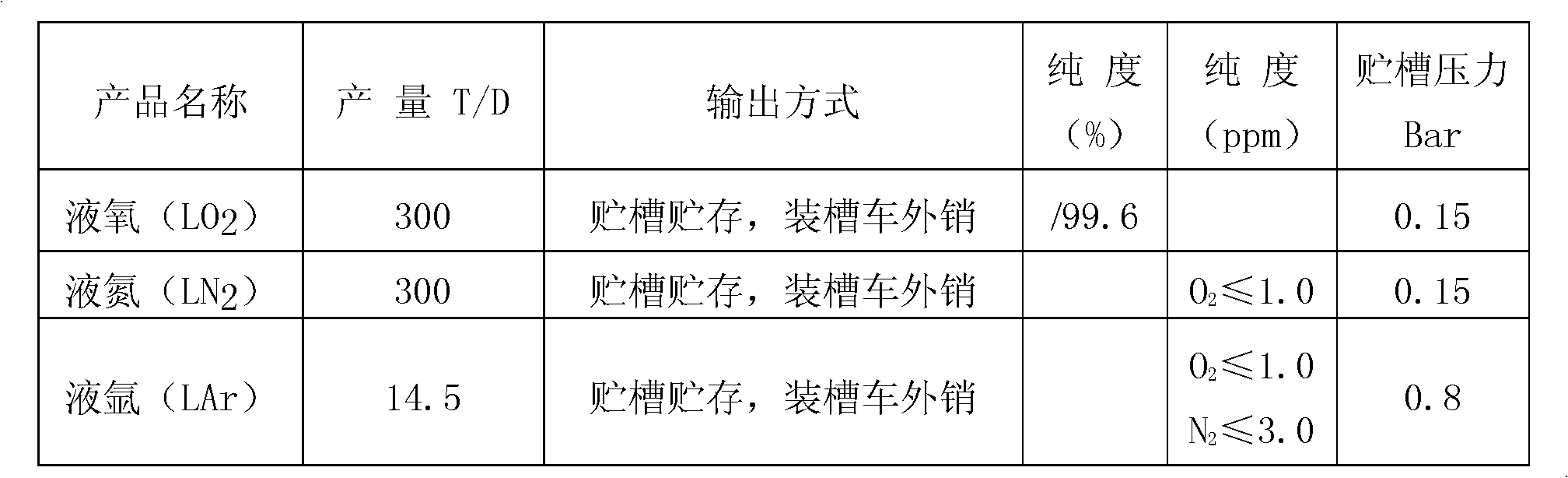

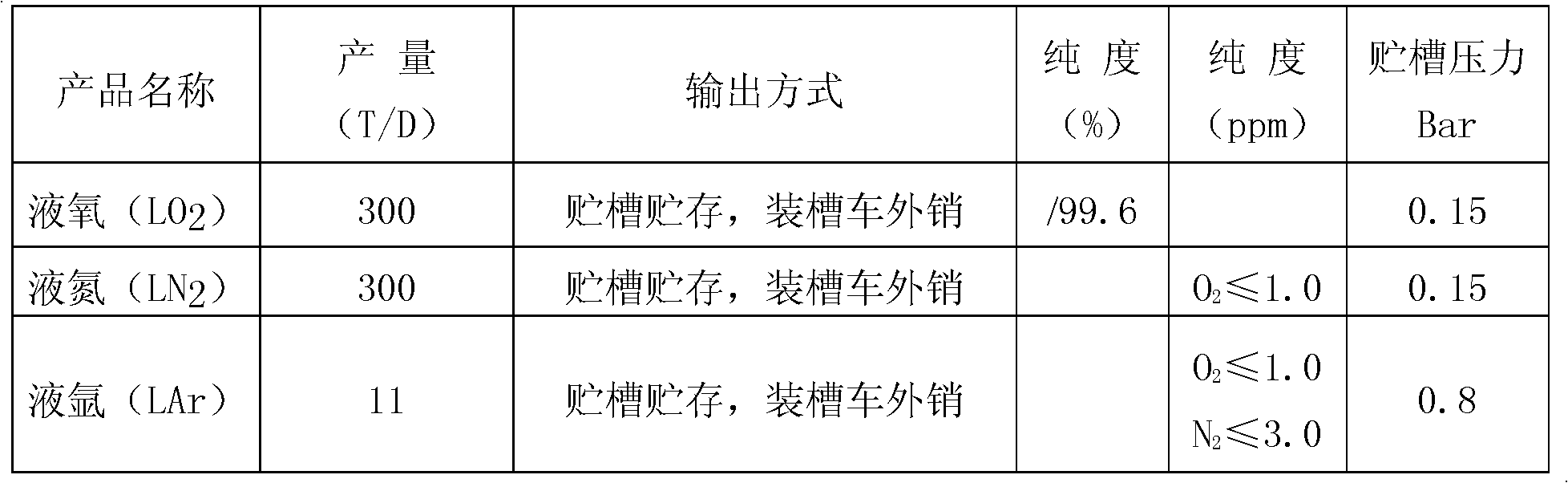

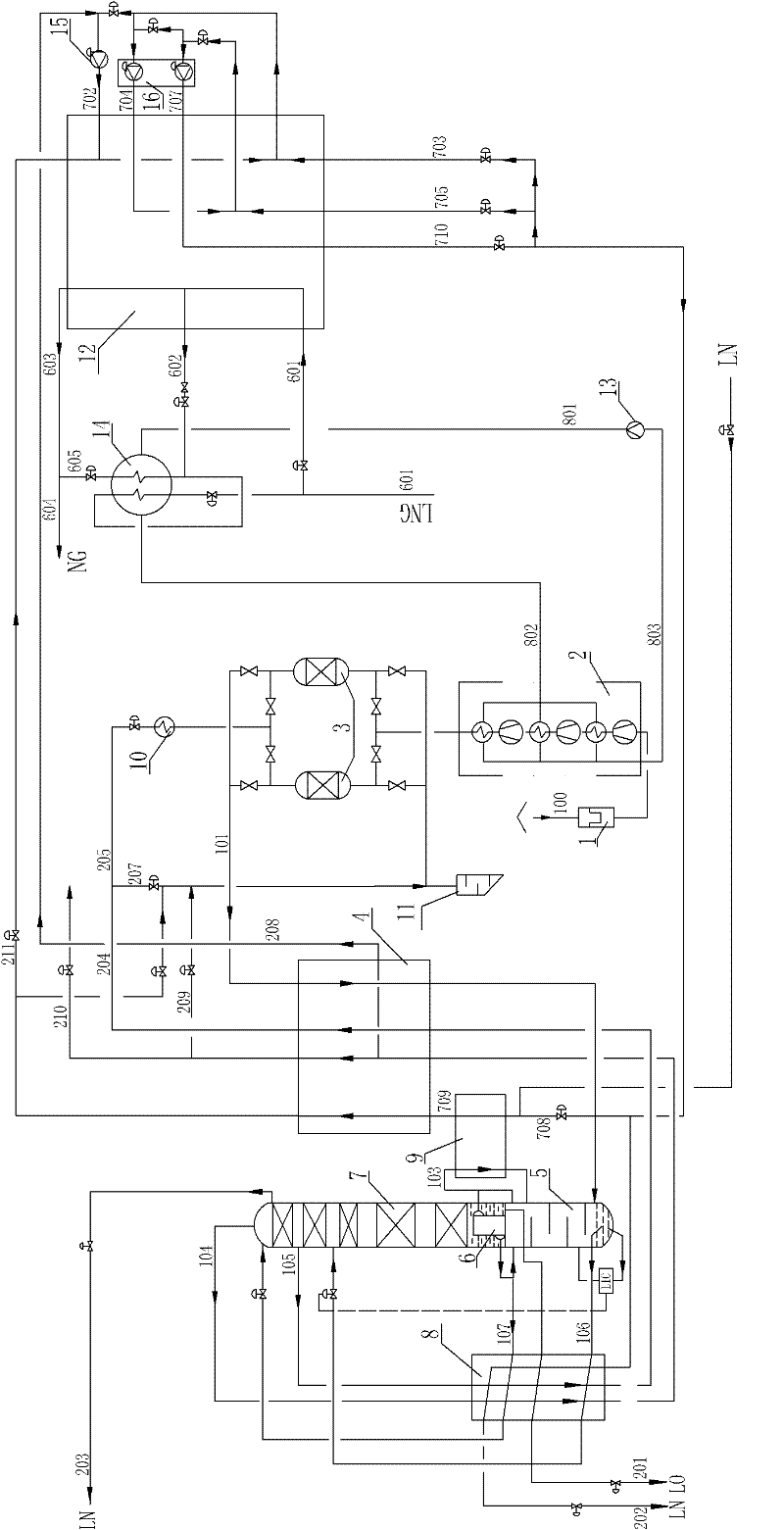

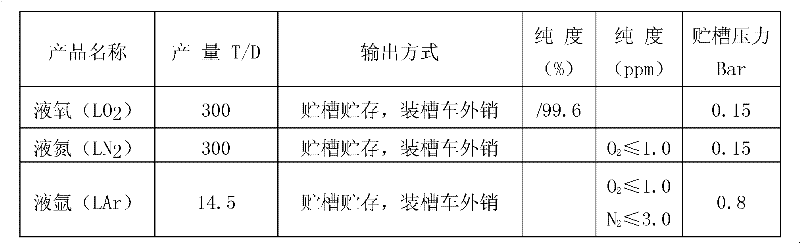

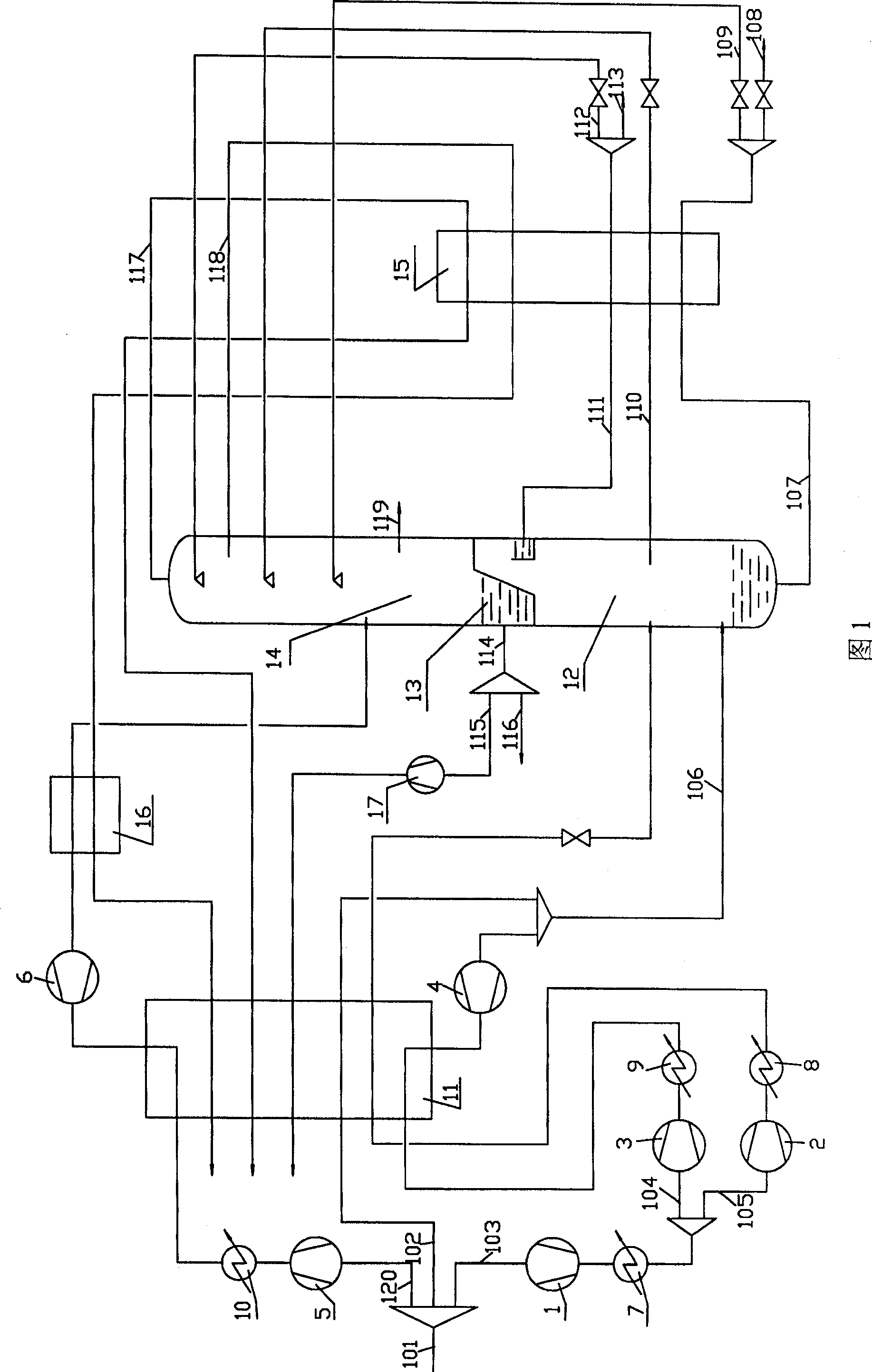

Air separation method utilizing liquefied natural gas cold energy

ActiveCN101571340AReduce unit power consumptionConform to energy savingSolidificationLiquefactionLiquefied natural gasSocial benefits

The invention discloses an air separation method utilizing liquefied natural gas cold energy, comprising an air separation unit, an LNG cold energy utilization unit providing refrigeration energy for the LNG cold energy utilization unit and a glycol water solution circulation unit utilizing NG high temperature cold energy. In the invention, low temperature cold energy of the LNG is applied to the air separation system, thus unit power consumption of a liquid air separation product can be reduced to about 0.30kwh / m, which is one third of the unit power consumption of a liquid air separation product in conventional process production; and unit power consumption of the internal compressed gas product also can be greatly reduced, and meanwhile a large number of cooling water can be saved, thus being in accordance with the trend of energy saving, consumption reduction and circular economy developing and having obvious social benefit and economic benefit.

Owner:CHINA NAT OFFSHORE OIL CORP +3

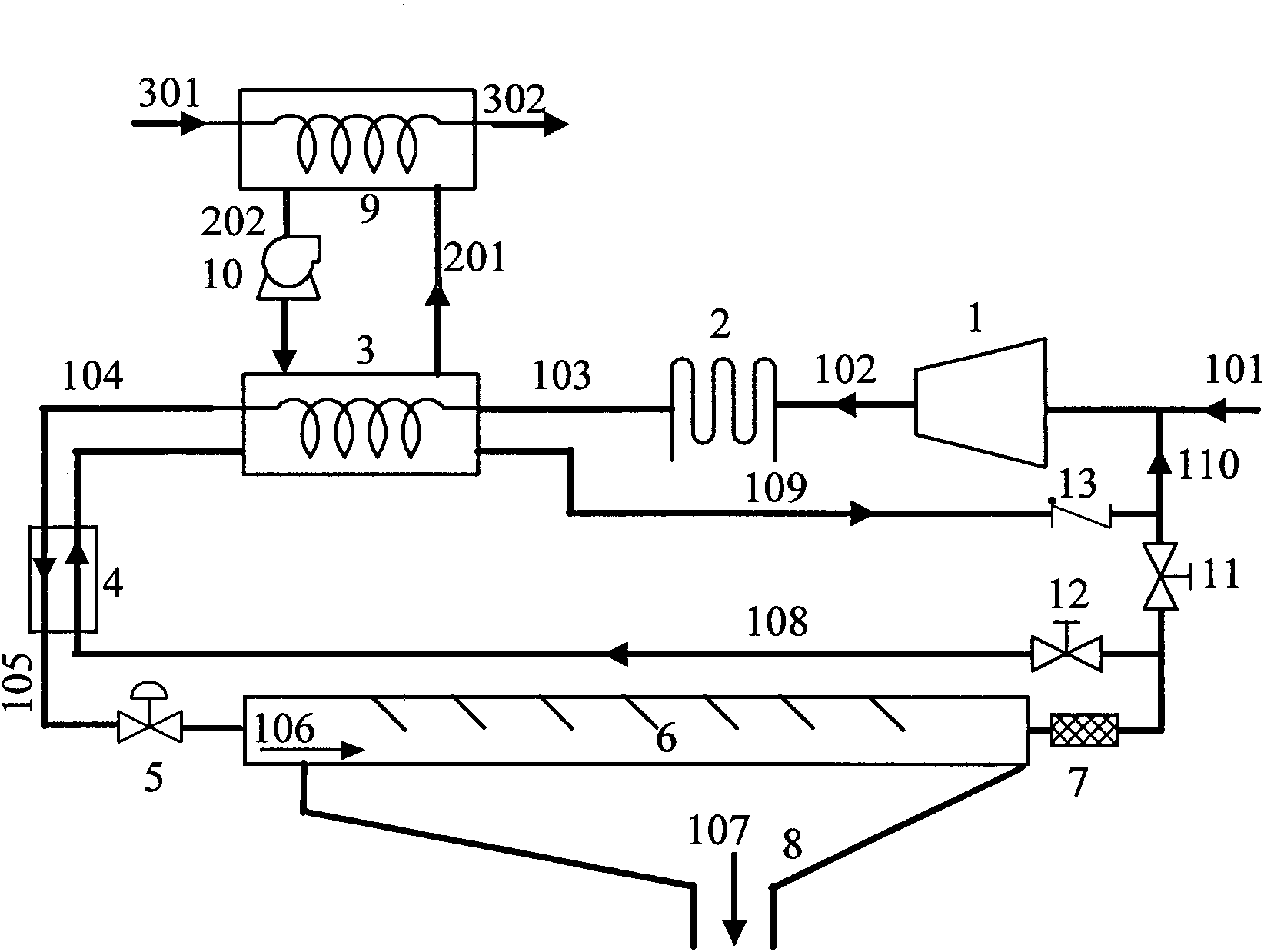

Device and method for manufacturing dry ice by using liquefied natural gas cold energy

InactiveCN101913604AEasy to transportEasy to handleCarbon compoundsChemical industryGas compressorHigh pressure

The invention discloses a device and a method for manufacturing dry ice by using liquefied natural gas (LNG) cold energy. An outlet of a CO2 gas compressor is sequentially connected with a water cooler, a high-temperature passage of a propane heat exchanger, a high-pressure coiled tube of a low-temperature heat exchanger, a throttle valve, a dry ice collector, a filter screen, a stop valve, a low-pressure coiled tube of the low-temperature heat exchanger, a low-temperature passage of the propane heat exchanger, a check valve and an inlet of the CO2 gas compressor; a bypass valve is arranged between the stop valve and the check valve; a funnel is arranged below the dry ice collector; the outlet of a low-temperature pump is connected with the inlet of a low-temperature pump through the low-temperature passage of the propane heat exchanger and a shell pass of a natural gas heat exchanger; and liquefied natural gas is introduced into a tube pass of the natural gas heat exchanger. The LNG cold energy is applied to the production of the dry ice, the pressure at the outlet of the CO2 compressor can be reduced from 2MPa when the LNG cold energy is not used to below 1MPa, so that the power consumption of the compressor can be reduced by over 1 / 3. The method accords with the general trend of saving energy, reducing consumption and developing circular economy and has obvious environmental benefit and economic benefit.

Owner:ZHEJIANG UNIV

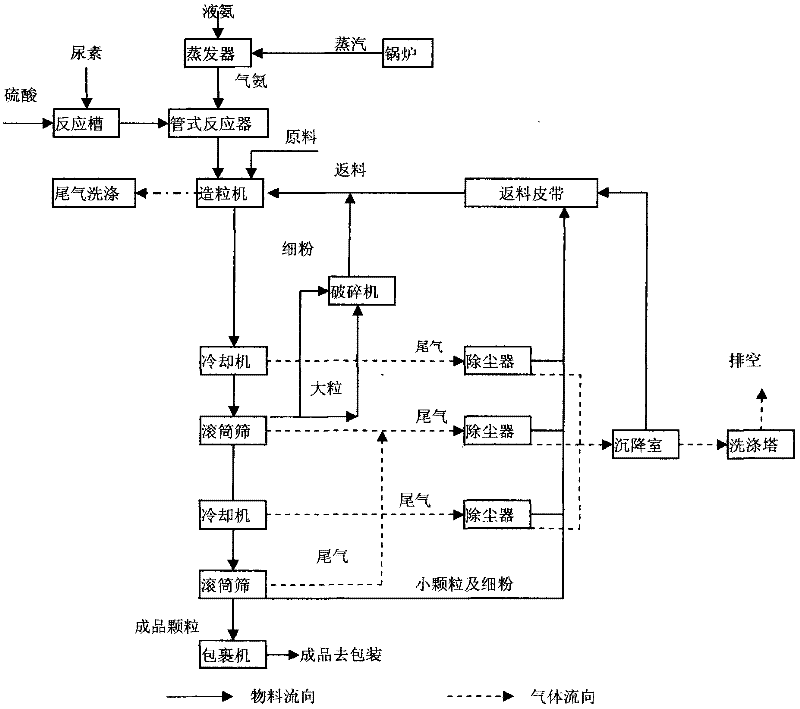

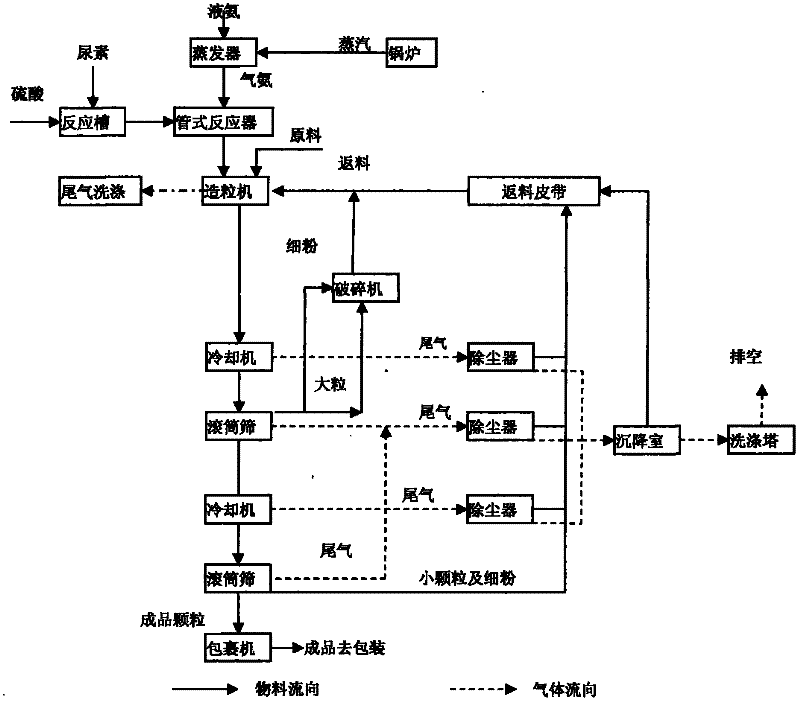

Process for producing urea sulfate ammoniated compound fertilizer

InactiveCN102503622AReduce steam consumptionReduce moisture contentFertiliser formsFertilizer mixturesAmmonium sulfateCooking & baking

The invention discloses a process for producing a urea sulfate ammoniated compound fertilizer. The process comprises the following steps of: (1) putting sulfuric acid and urea which are in a mixture ratio into a reaction vessel for producing urea sulfate; (2) preparing a 75% urea sulfate solution from the urea sulfate by using a tail gas washing solution of a pelleting machine; (3) reacting the urea sulfate solution with gas ammonia and steam in a tubular reactor so as to generate a large number of high-temperature high-pressure superheated steam and produce ammonia sulfate and urea molten slurry; (4) loading a fertilizer containing nitrogen, phosphorus and potassium and fillers in the pelleting machine, meanwhile, carrying out atomized spray pelleting on the various materials at a feed port of the pelleting machine by using the ammonia sulfate and the urea molten slurry; (5) feeding a compound fertilizer material obtained after carrying out atomized spray pelleting into the pelleting machine for flowing bonding pelleting; and (6) carrying out twice cooling and twice screening on the compound fertilizer discharged from the pelleting machine to obtain the urea sulfate ammoniated compound fertilizer. According to the invention, the drying and baking procedures are omitted, so that raw materials and energy can be saved, and a product is high in pelletization rate and good in quality.

Owner:山东金山化肥有限公司

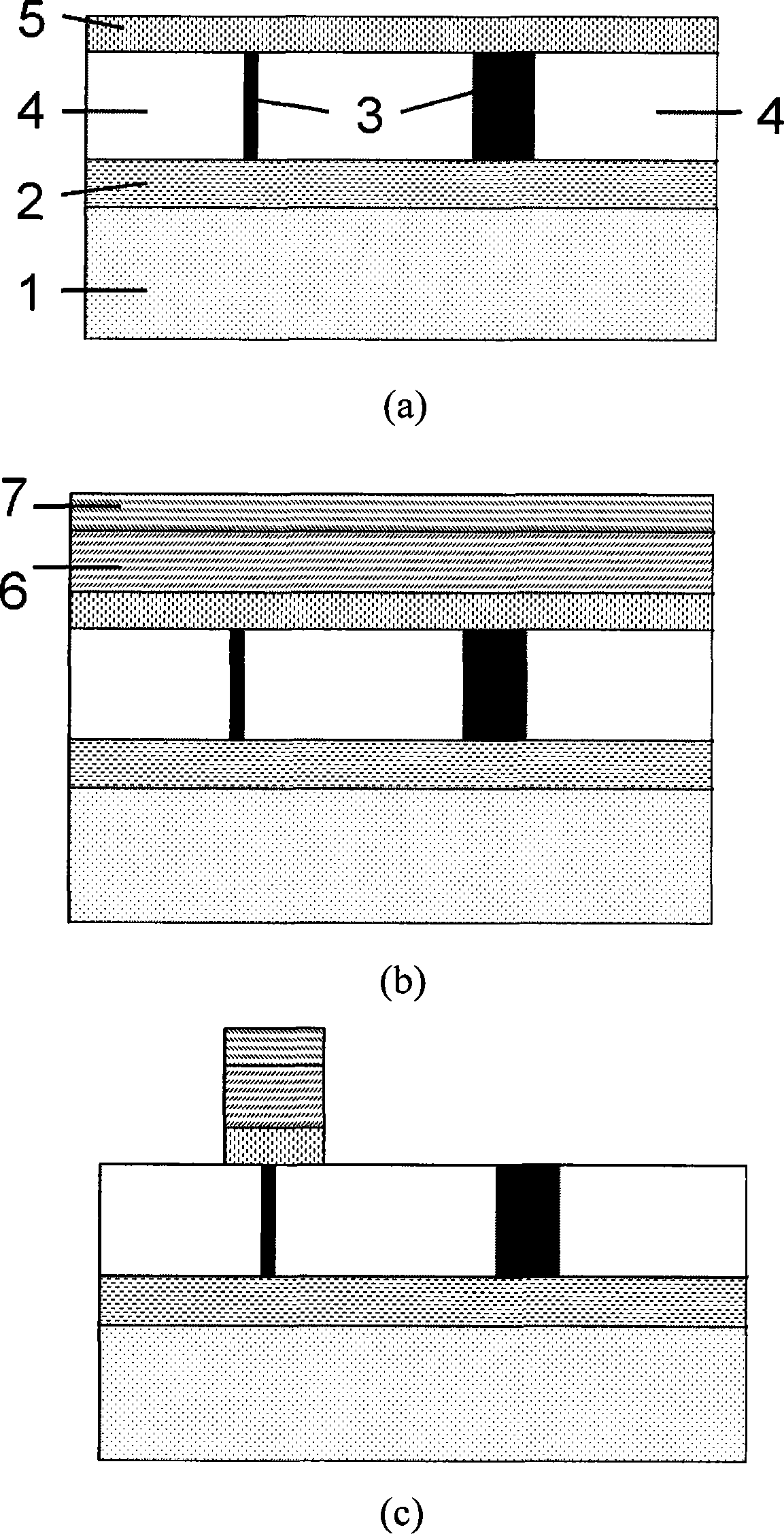

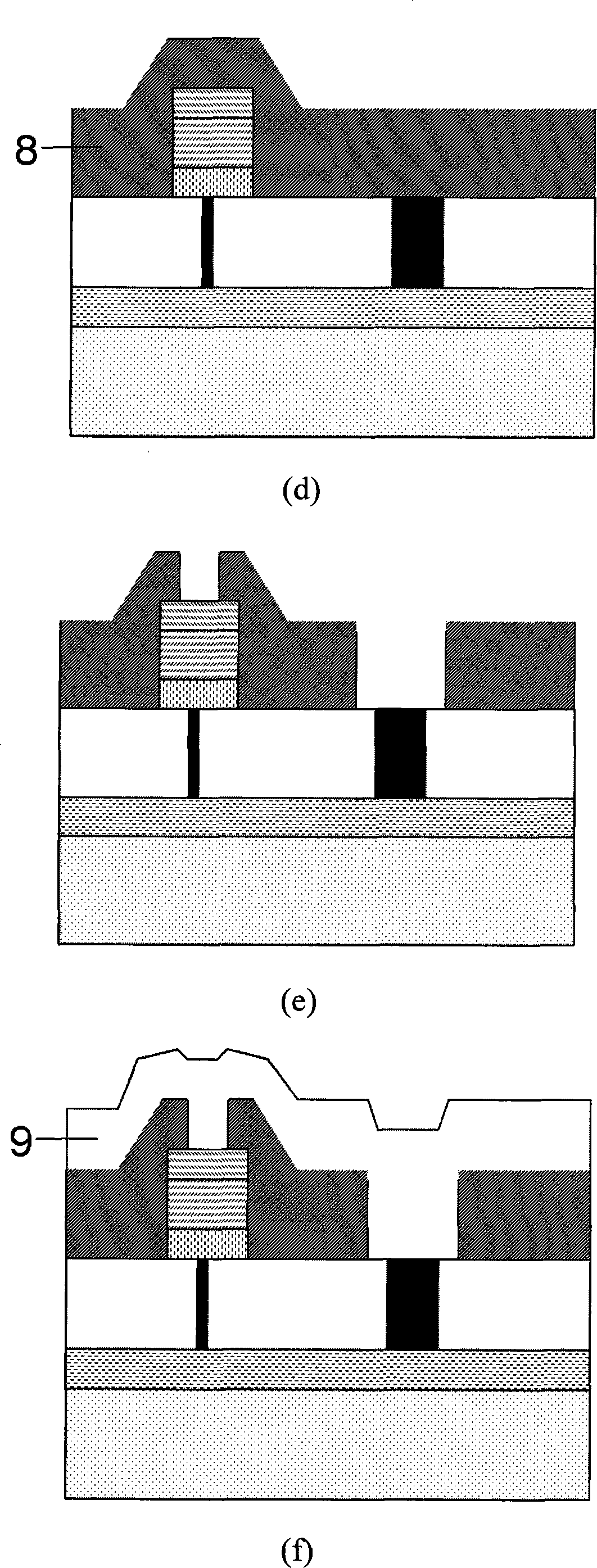

Oxide heat insulation layer for reducing phase-change memory cell power consumption and implementation method thereof

InactiveCN101226990AImprove thermal stabilityImprove thermal effectSolid-state devicesRead-only memoriesMarked effectMicro nano

The invention relates to an oxide insulating layer which is capable of being used to discover a material which reduces the power of a phase change memory and an improvement on the structure of an unit device and an implementation method, and belongs to the field of microelectronics. The invention is characterized in that the oxide insulating layer is added between a bottom heating W electrode and a chalcogenide compound thin film layer, and the thickness of the insulating layer is controlled below 10nm. The optional materials of the oxide insulating layer comprise TiO2 and the like. The improvement of the unit device is achieved through that after various needed thin films are deposited on a substrate, a phase change operation unit in micron is obtained through a micro-nano processing technology, and an upper electrode and a lower electrode which are capable of being used to test the performance are led. Because the oxide insulating layer has excellent thermal stability and thermal conduction which is far lower than a bottom heating W electrode, is compatible with a CMOS standard manufacturing technology, increases marked effect of the unit thermal effect of the device, and the purpose of effectively reducing the power of the unit is achieved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

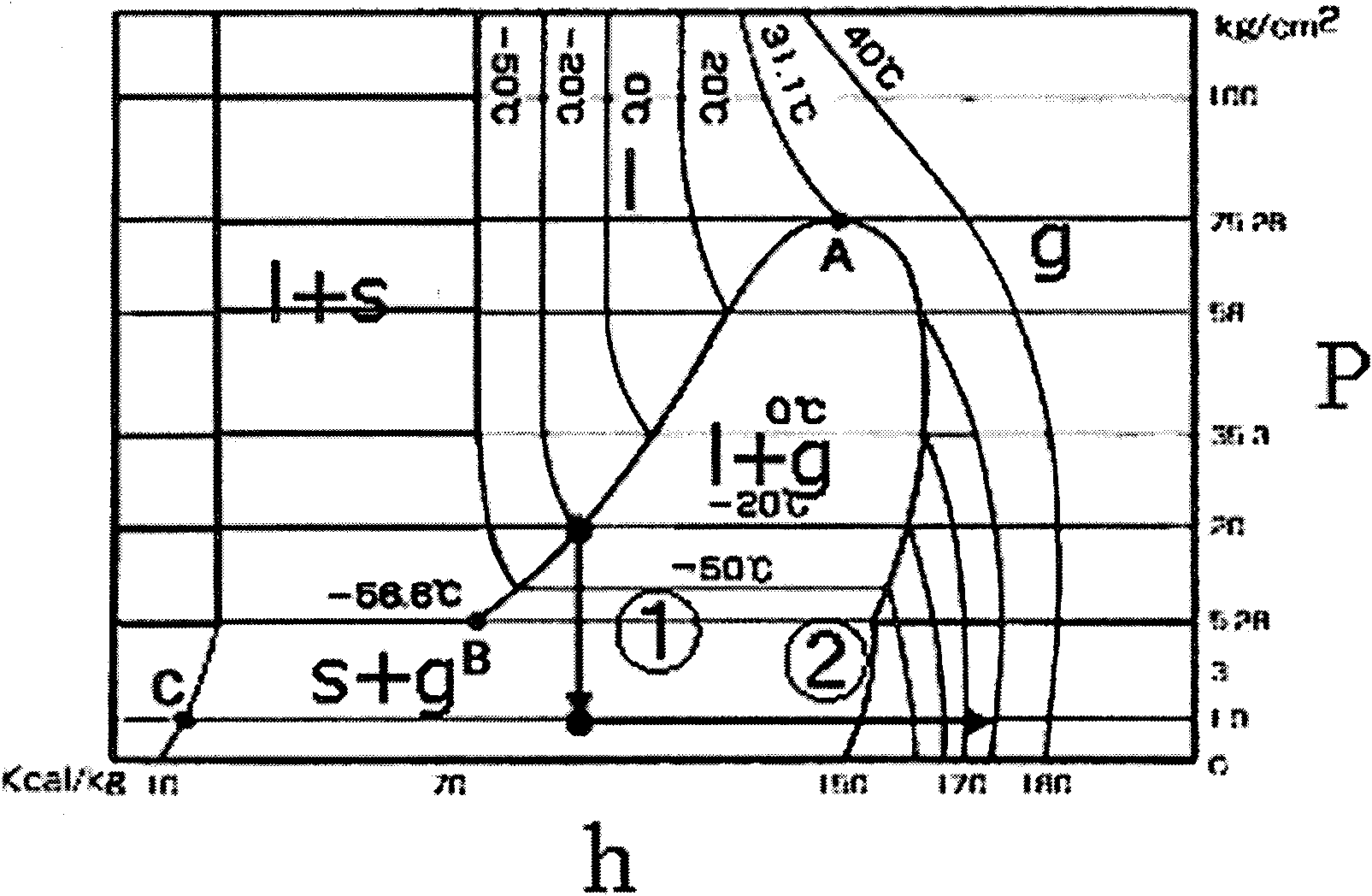

Air separating device and method therefor

ActiveCN1865822AReduce unit power consumptionImprove energy savingSolidificationLiquefactionElectricityAir separation

The invention relates to a method for using rectification at low temperature to separate air, and relative device. Wherein, said device comprises a booster (5), an expander (6), and a cooler (10) to form one low-temperature boost turbine expander, which will boost and cool another air to be reduced temperature, expanded and cooled in the main heat exchanger to be fed into the upper tower (14) of rectification tower for rectification. In the separation process, it uses different expanders as middle pressure and low pressure, which expand in different pressures and temperatures to supply cold energy to the separation process; the expanded air is fed into the upper and lower towers for rectification. The invention has lower unit electricity consumption as 2.5% reduced.

Owner:唐山瑞鑫液化气体有限公司

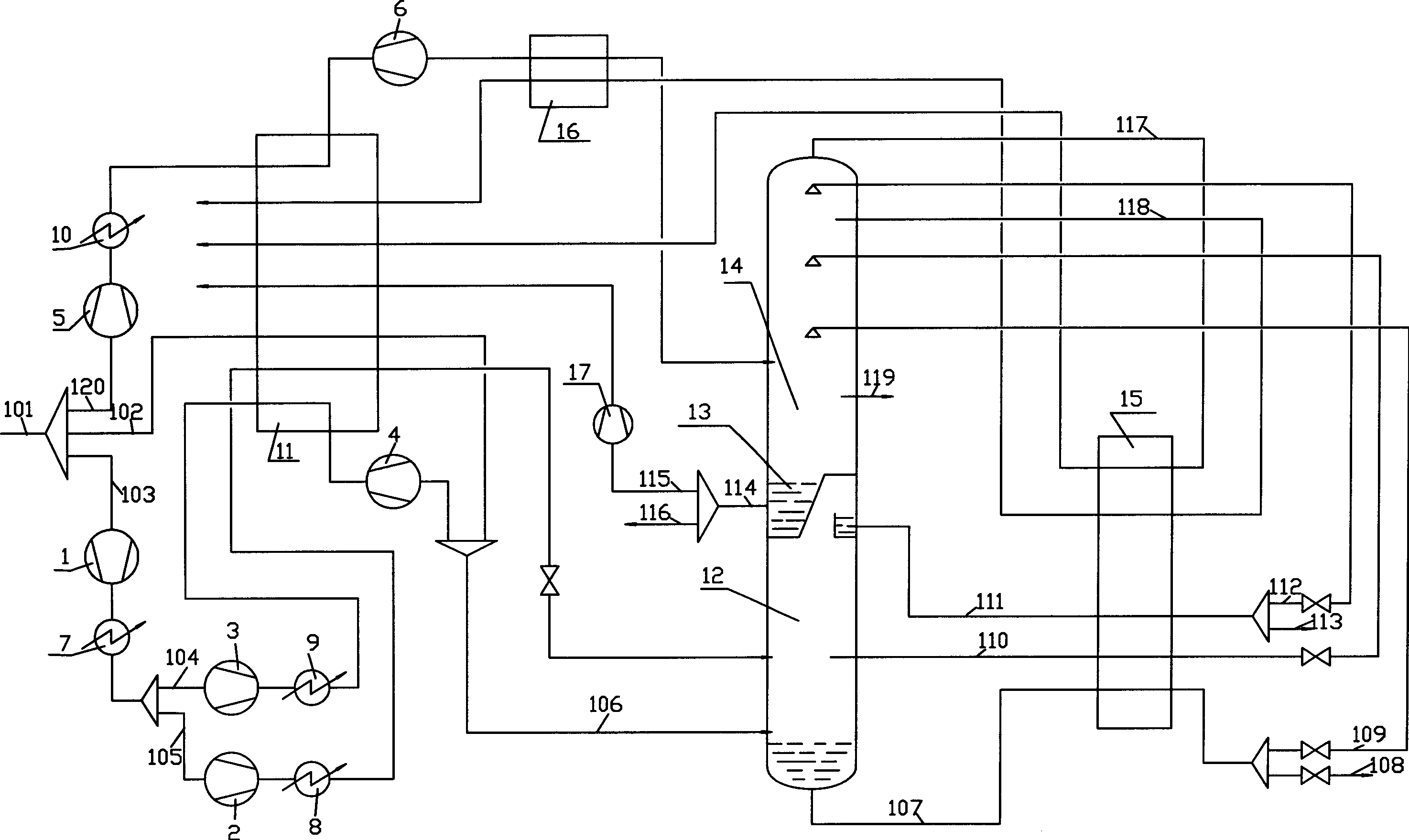

Double cooled ozone discharging tube

InactiveCN101003363AUniform and dense materialIncreased ozone yieldOzone preparationOzone generatorTitanium

This invention discloses a double-cooling ozone discharge tube for producing ozone. The discharge tube comprises a high-voltage electrode made of metal tube, and a ground electrode. A titanium layer is coated on the high-voltage electrode and the ground electrode. A dielectric layer is used as the inner lining of the ground electrode. A discharge tube assembly is placed at the outer wall of the high-voltage electrode, which forms a sliding concentric circle with the gap convex block supported by the dielectric layer, and has a discharge chamber air gap. The material for the dielectric layer is ceramic, enamel, glaze, glass, or their composite. Compared with the present technique, the discharge tube in this invention has such advantages as simple structure, high ozone generation efficiency, rapid assembly / disassembly, and easy cleaning. The discharge tube can be integrated into large power ozone generator.

Owner:TSINGHUA TONGFANG CO LTD

Air separation method utilizing cold energy of liquefied natural gas

ActiveCN101943512AHigh extraction rateReduce unit power consumptionSolidificationLiquefactionEngineeringEnergy conservation

The invention discloses an air separation method utilizing cold energy of liquefied natural gas (LNG), which comprises three parts of an air separation unit, an LNG cold energy utilization unit for providing the cold energy for the air separation unit and a circulating coolant circulation unit utilizing NG high-temperature cold energy. The air separation method can greatly reduce the unit power consumption of a liquid air separation product or an internal compressed gas product after utilizing low-temperature cold energy of the LNG for the air separation unit, obtain a large number of liquid nitrogen products, lead the extraction rate of argon to be high, simultaneously save a large amount of cooling water, be in line with the big trend of energy conservation, consumption reduction and development of cyclic economy and have obvious social benefits and economic benefits.

Owner:CNOOC ENERGY TECH & SERVICES +1

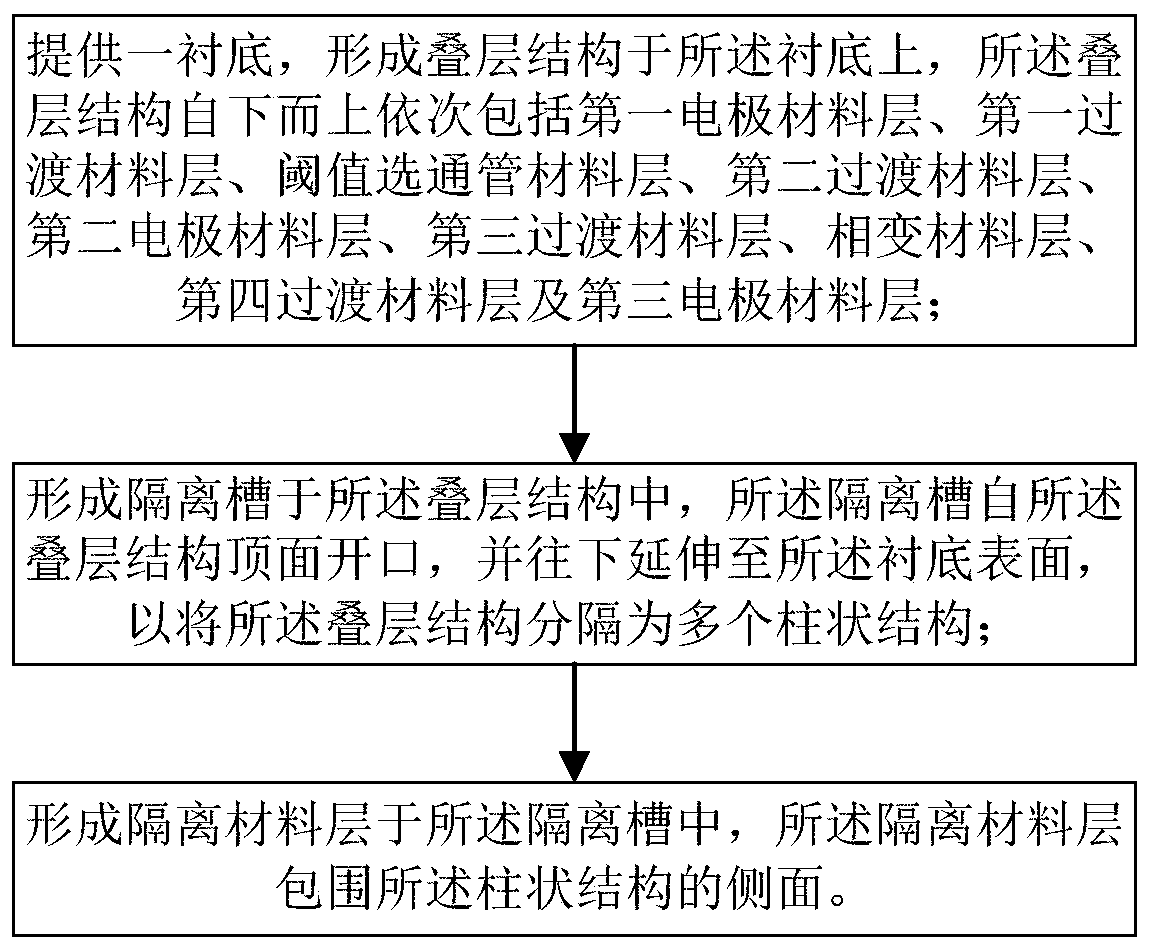

Phase change memory and manufacturing method thereof

InactiveCN110335942ALow thermal conductivityHigh thermal efficiencySolid-state devicesSemiconductor devicesPhase-change memoryHigh density

The invention provides a phase change memory and a manufacturing method thereof. The phase change memory comprises a substrate, a plurality of phase change memory units and isolation material layers.The phase change memory units are discretely arranged on the substrate. Each phase change memory unit comprises a first electrode material layer, a first transition material layer, a threshold gate tube material layer, a second transition material layer, a second electrode material layer, a third transition material layer, a phase change material layer, a fourth transition material layer and a third electrode material layer in turn from bottom to top. The isolation material layers are located on the substrate and surround the sides of the phase change memory units, and the phase change memoryunits are isolated from one another through the isolation material layers. In the phase change memory of the invention, the phase change material and the OTS material are limited in the same space bythe isolation material, and the transition material layers are located between the phase change material and the electrode material, between the phase change material and the OTS material and betweenthe OTS material and the electrode material, so that the phase change memory has the characteristics of high density, high speed, low power consumption and long life.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

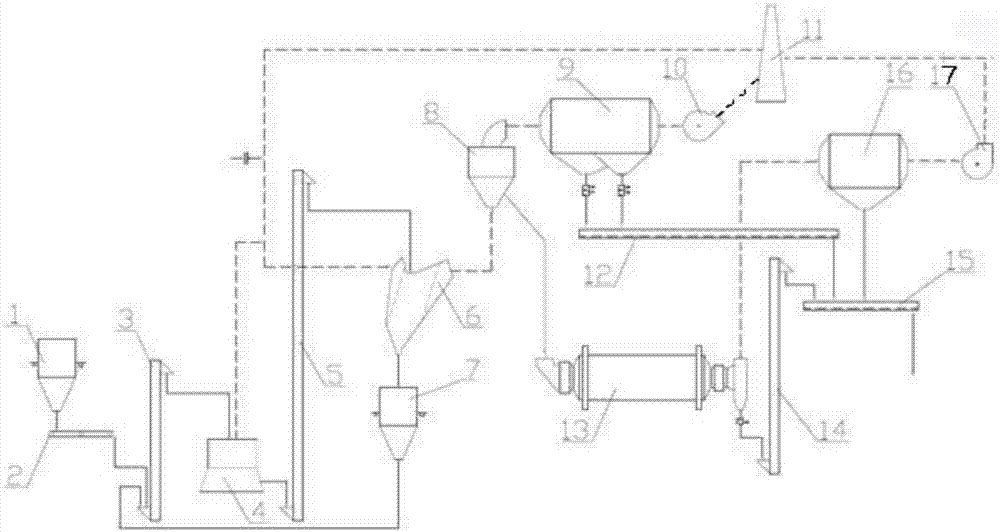

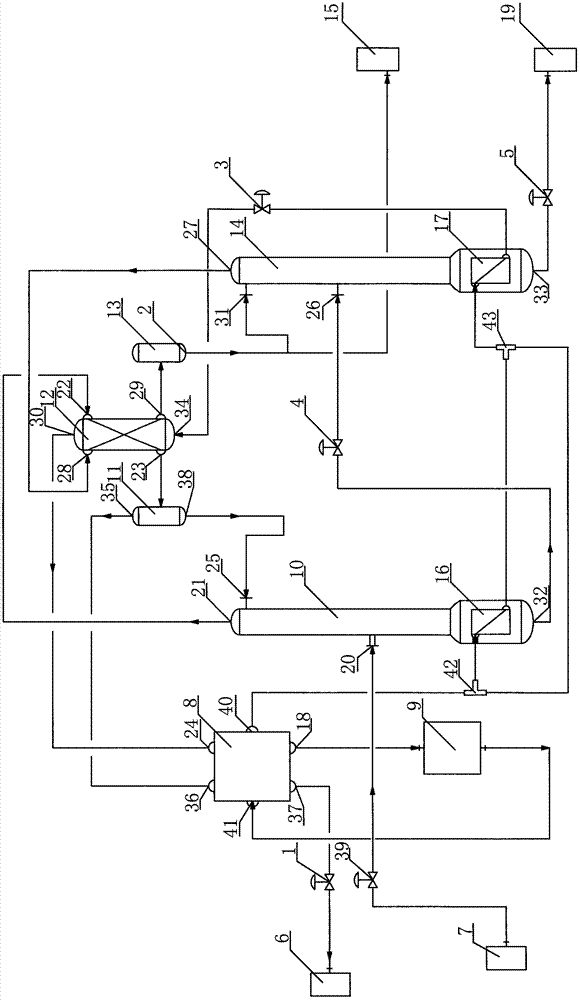

Built-out powder concentrator type vertical mill combined grinding system adopting non-metal grinding medium

PendingCN107350062AReduce adsorptionImprove grinding efficiencyCement productionGrain treatmentsBall millMetal

The invention relates to a built-out powder concentrator type vertical mill combined grinding system adopting a non-metal grinding medium. The built-out powder concentrator type vertical mill combined grinding system adopting the non-metal grinding medium is characterized by comprising a material distribution bin, a weighing scale, a feeding lifting machine, a vertical mill, a V-shaped powder concentrator feeding lifting machine, a V-shaped powder concentrator, a buffering bin, an efficient powder concentrator, a system dust collector, a system draught fan, a chimney, a first finished-product conveying chute, a ball mill, a mill tail lifting machine, a second finished-product conveying chute, a mill tail dust collector and a mill tail dust collection draught fan, wherein the material distribution bin, the weighing scale, the feeding lifting machine, the vertical mill, the V-shaped powder concentrator feeding lifting machine, the V-shaped powder concentrator, the buffering bin, the efficient powder concentrator, the system dust collector, the system draught fan, the chimney, the first finished-product conveying chute, the ball mill, the mill tail lifting machine, the second finished-product conveying chute, the mill tail dust collector and the mill tail dust collection draught fan are sequentially connected. The built-out powder concentrator type vertical mill combined grinding system adopting the non-metal grinding medium can stabilize operation of the vertical mill, adjust the cement grain size grading, relieve the ball coating phenomenon in the mill, improve the grinding efficiency in the mill, lower the noise of the ball mill in the operation process, reduce the pollution to finished products, reduce the unit power consumption and improve the performance of finished cement.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

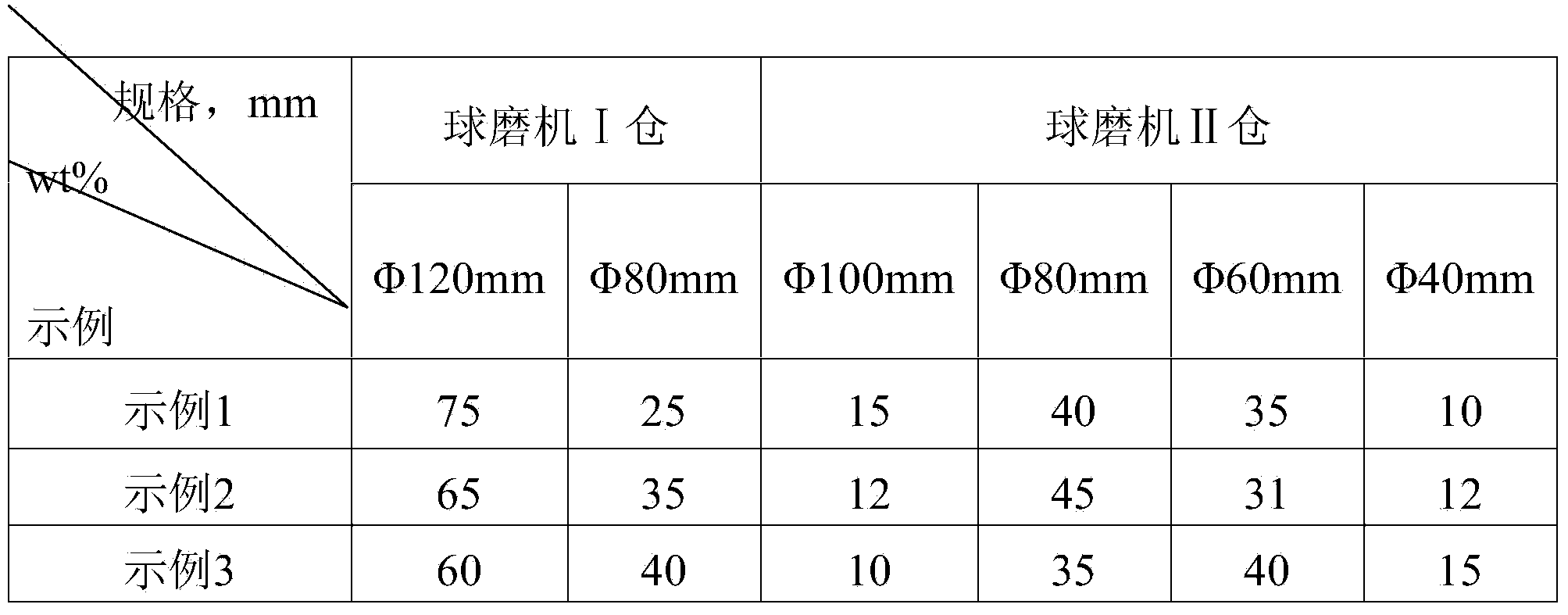

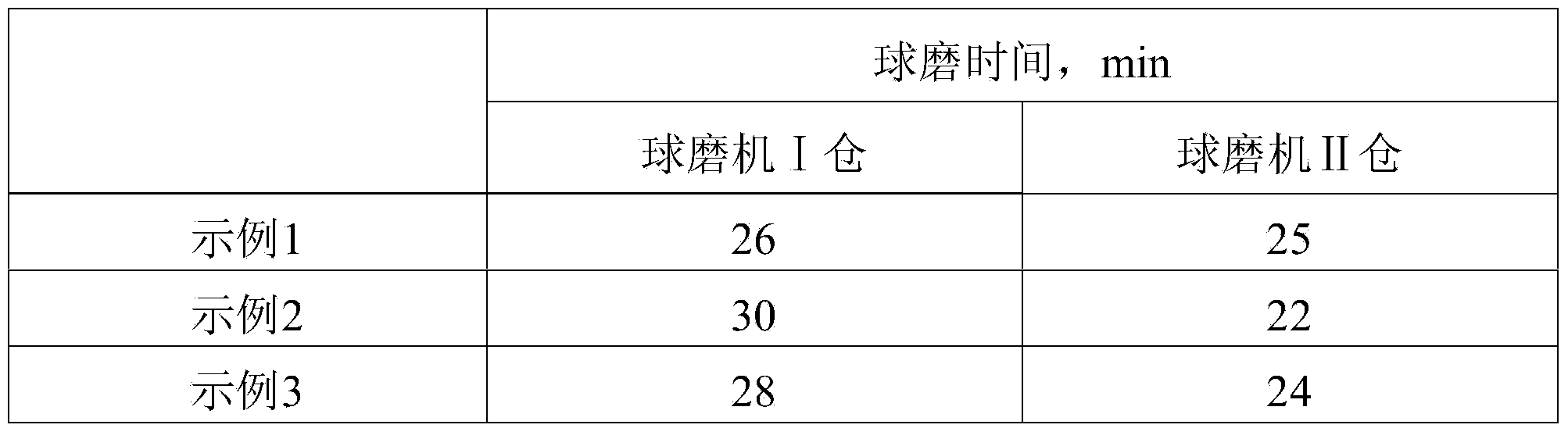

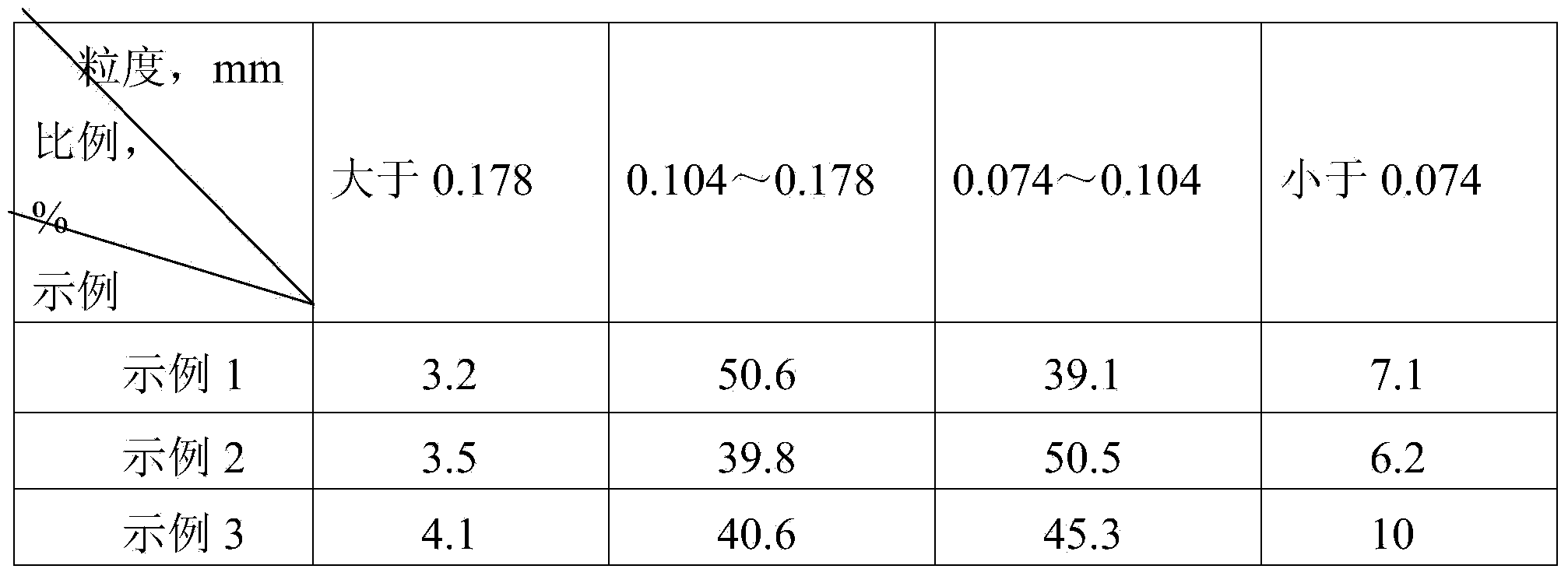

Carbide slag grinding method and low temperature chlorination method for preparing TiCl4

InactiveCN103816963AReduce unit power consumptionReduce usageTitanium halidesGrain treatmentsSlagCarbide

The invention provided a carbide slag grinding method and a low temperature chlorination method for preparing TiCl4. The grinding method comprises the following steps: adding the carbide slag raw material in a first cabin of a ball grinding mill for crushing; then feeding the crushed carbide slag into a second cabin for grinding to obtain carbide slag powder, wherein first cabin grinding bodies in the first cabin comprise 60-75 weight percent of steel balls with the diameter of 120 mm, 25-40 weight percent of steel balls with the diameter of 80 mm; second cabin grinding bodies in a second cabin comprise 10-15 weight percent of steel balls with the diameter of 100 mm, 25-45 weight percent of steel balls with the diameter of 80 mm, 25-40 weight percent of steel balls with the diameter of 60mm and 10-15 weight percent of steel balls with the diameter of 40 mm. According to the carbide slag grinding method and the low temperature chlorination method for preparing TiCl4, most of the carbide slag can be grinded to 0.074mm-0.178mm through the reasonable steel ball graduation of the ball grinding mill; the smooth progress of follow-up technology of low temperature fluidizing chlorination of the carbide slag for the production of titanium tetrachloride is guaranteed.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Air separation method utilizing cold energy of liquefied natural gas

ActiveCN101943512BHigh extraction rateReduce unit power consumptionSolidificationLiquefactionEngineeringEnergy conservation

The invention discloses an air separation method utilizing cold energy of liquefied natural gas (LNG), which comprises three parts of an air separation unit, an LNG cold energy utilization unit for providing the cold energy for the air separation unit and a circulating coolant circulation unit utilizing NG high-temperature cold energy. The air separation method can greatly reduce the unit power consumption of a liquid air separation product or an internal compressed gas product after utilizing low-temperature cold energy of the LNG for the air separation unit, obtain a large number of liquid nitrogen products, lead the extraction rate of argon to be high, simultaneously save a large amount of cooling water, be in line with the big trend of energy conservation, consumption reduction and development of cyclic economy and have obvious social benefits and economic benefits.

Owner:CNOOC ENERGY TECH & SERVICES +1

Evaporation crystallization method for treating salt-containing wastewater and device for implementing method

PendingCN106957122AReduce heat transfer temperature differenceReduce evaporationWater/sewage treatment by irradiationMultistage water/sewage treatmentHigh concentrationVapor–liquid separator

The invention discloses an evaporation crystallization method for treating salt-containing wastewater. The method comprises the following steps: allowing the salt-containing wastewater to sequentially pass through an electromagnetic wave emitting device and a primary preheater, and then feeding the wastewater into a two-effect falling film evaporator for evaporation; feeding the primary concentrated liquid after evaporation in the two-effect falling film evaporator into a gas-liquid separator for separation, and then feeding the primary concentrated liquid after the separation of the gas-liquid separator into a one-effect falling film evaporator for evaporation crystallization, thus obtaining a secondary concentrated liquid in a supersaturated state; feeding the secondary concentrated liquid into a crystallization separator for crystallization, and then feeding the liquid obtained in the crystallization separator into the one-effect falling film evaporator for circulating evaporation, and discharging crystals obtained in the crystallization separator through a solid discharging device. According to the invention, the evaporation crystallization process of high-concentration brine is divided into an unsaturated evaporation process and a supersaturated crystallization process, thereby ensuring that a part of water is evaporated out firstly from the material at a relatively low concentration and reducing the influences of reduced heat transfer temperature difference in the evaporator, reduction of evaporation effect and accordingly energy consumption increase due to the elevation of boiling point of the supersaturated brine.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

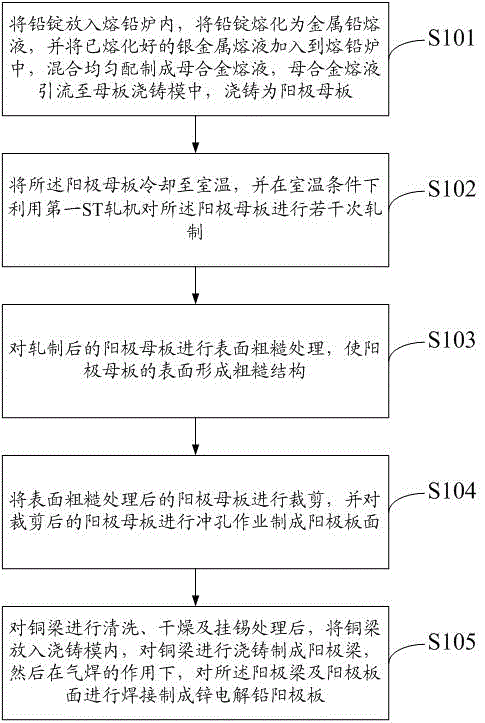

Zinc electrolytic lead anode plate and manufacturing method thereof

ActiveCN102912376AExtended service lifeQuality improvementPhotography auxillary processesElectrodesRough surfaceIngot

The invention discloses a zinc electrolytic lead anode plate and a manufacturing method thereof. The zinc electrolytic lead anode plate is formed by welding an anode plate surface and an anode beam, wherein the surface of the anode plate surface is of a rough surface structure. As the step of rerolling the anode plate surface by a second ST rolling mill is adopted, the rough surface structure is formed on the anode plate surface. The produced lead anode plate can be directly used without other processes when being used by manufacturers, so that the service life of the lead anode plate is prolonged. Moreover, the time of forming a stable protection layer by the lead anode plate in the electrolysis process is greatly shortened, the lead content in the separated zinc sheet is remarkably reduced, the zinc ingot quality is improved, and the electric energy unit consumption is reduced at the same time.

Owner:云南云铜锌业股份有限公司

Pulse electrochemical process for removing ammonia-nitrogen in landfill leachate

ActiveCN102086077AApparently reducing propertiesGood repeatabilityMultistage water/sewage treatmentElectrolysisEmission standard

The invention relates to a variable-frequency pulse electrochemical process for removing ammonia-nitrogen in landfill leachate. Variable-frequency pulse electrochemical pretreatment is carried out before anaerobic biological treatment and aerobic biological treatment or variable-frequency pulse electrochemical deep treatment is carried out after the anaerobic biological treatment and the aerobic biological treatment; the variable-frequency pulse electrochemical treatment adopts a variable-frequency pulse electrochemical device which comprises an electrobath and a variable-frequency pulse power supply connected with an electrode plate of the electrobath, wherein the variable-frequency pulse power supply is arranged in a power cabinet, the input end of the variable-frequency pulse power supply is externally connected with a three-phase power of 380V / 50Hz, the output ends are used for guiding out anode and cathode which are respectively connected with the positive pole and the negative pole of the electrode plate of the electrobath, and a control panel of the power cabinet is provided with frequency, voltage and current adjusting buttons. Due to the adoption of the variable-frequencypulse electrochemical process, the ammonia-nitrogen removal rate can reach 70-100 percent, and the effluent of the landfill leachate with the unit electricity consumption of 4-8 kwh / m<3>, which is treated by the full process line, has the NH3-N content less than 6 mg / L and reaches the emission standard of national municipal solid waste landfill pollution control standard of GB16889-2008.

Owner:中钢集团武汉安全环保研究院有限公司 +2

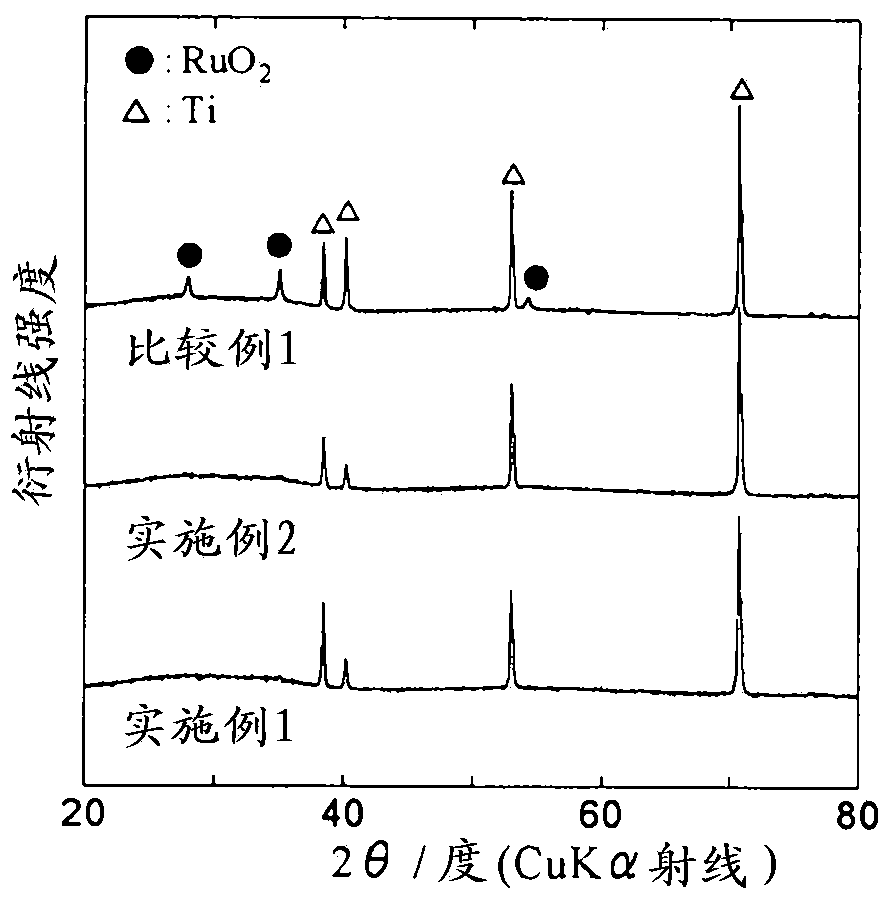

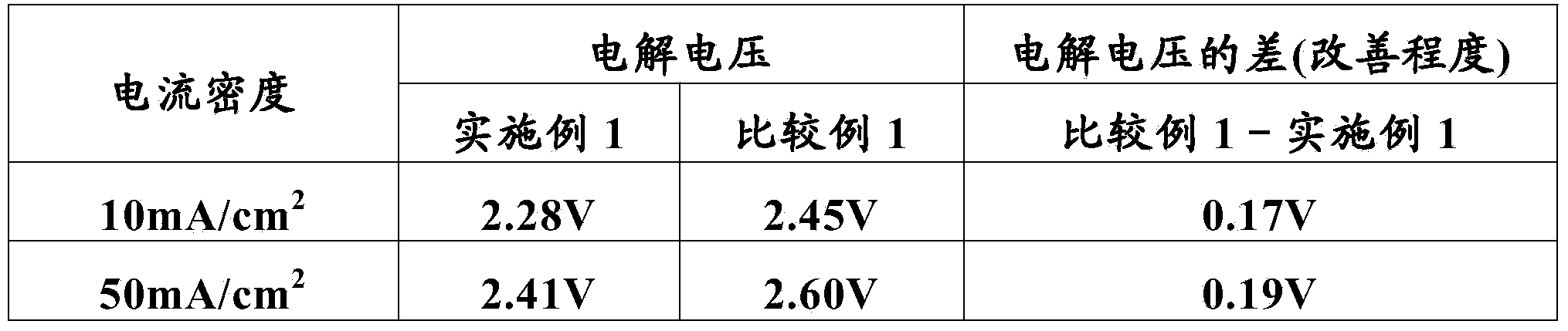

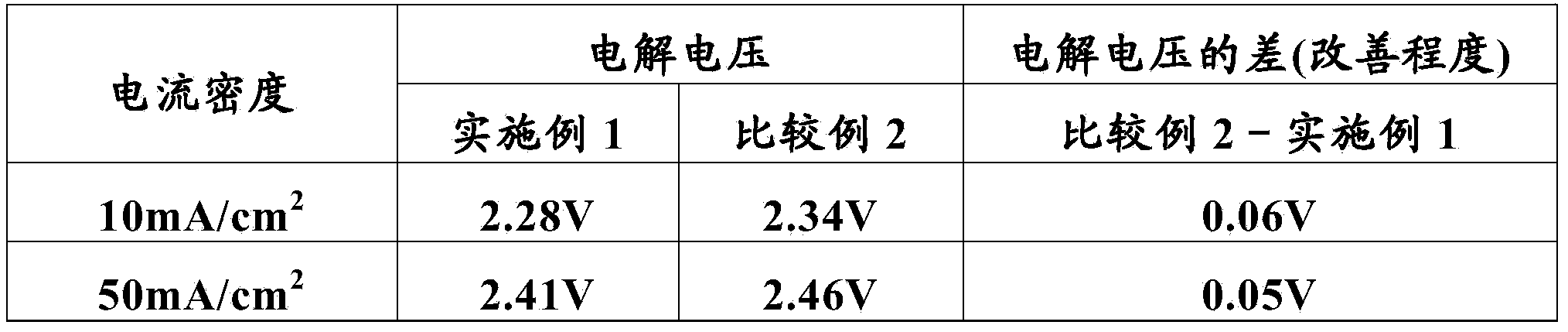

Anode for electrowinning and electrowinning method using same

ActiveCN103476970ALower potentialReduce the electrolysis voltageElectrodesTitanium electrodeElectrolysis

Provided is an anode for electrowinning such that, in electrowinning using a sulfuric acid-based electrolyte solution, the electric potential for oxygen generation is lower than for a lead electrode, lead alloy electrode, and coated titanium electrode, the electrolysis voltage for electrowinning can be reduced, and the basic units for electric energy can be reduced for a desired metal. This anode can be used as the anode for electrowinning of various types of metal and has superior mass productability. The anode for electrowinning is used in the electrowinning that uses a sulfuric acid-based electrolyte solution, and a catalyst layer that includes noncrystalline ruthenium oxide and noncrystalline tantalum oxide is formed on a conductive base substance.

Owner:DOSHISHA CO LTD

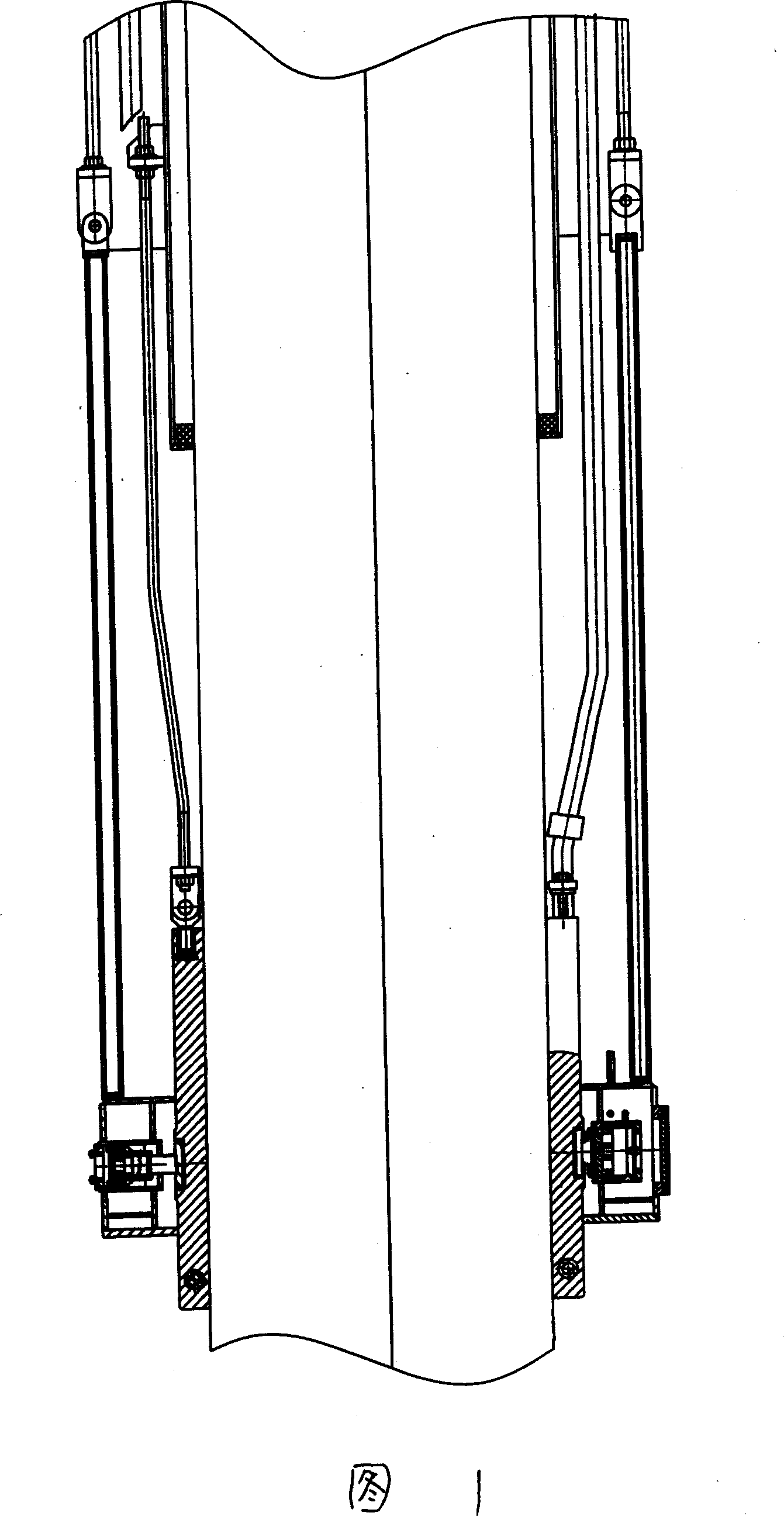

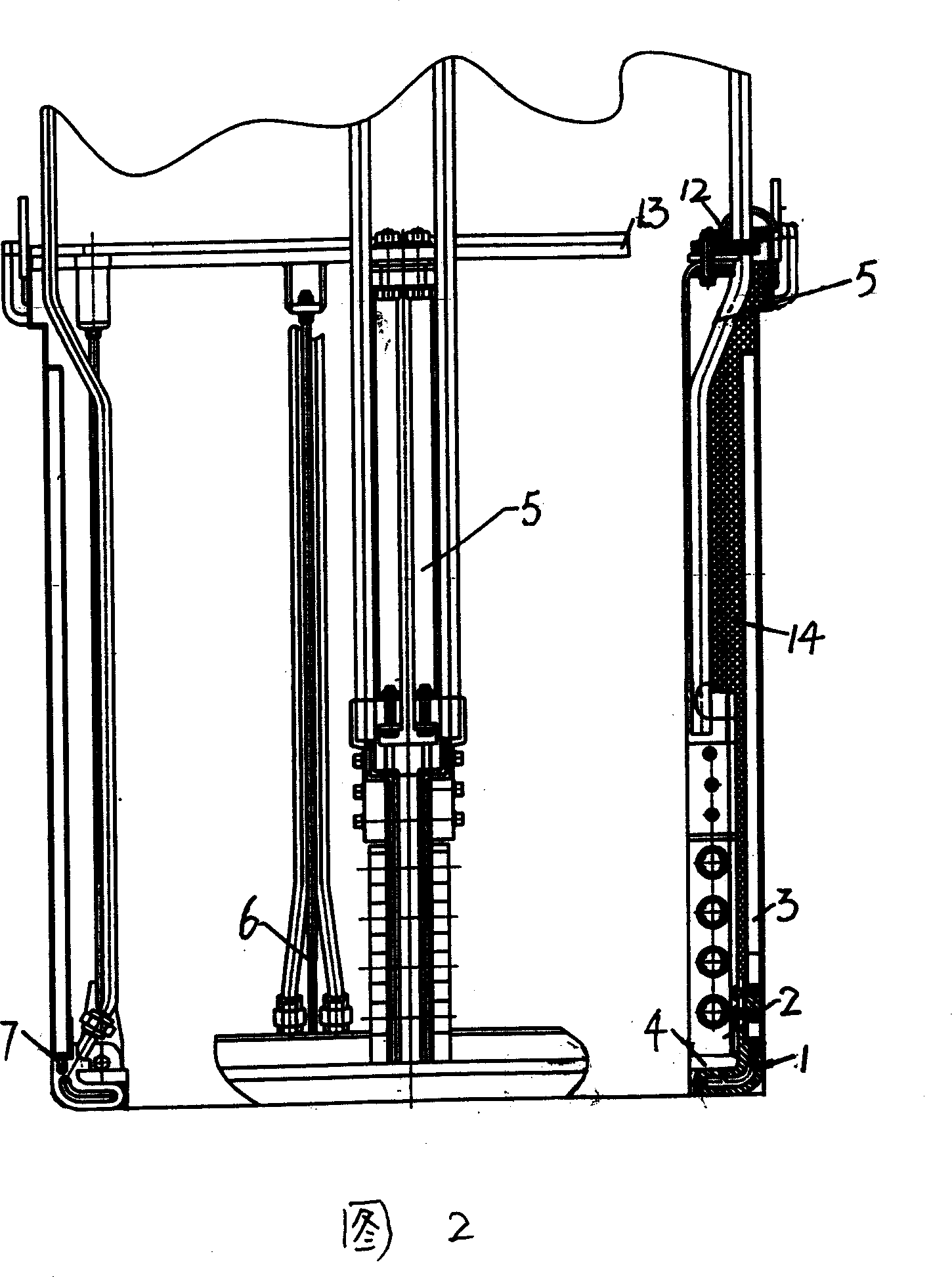

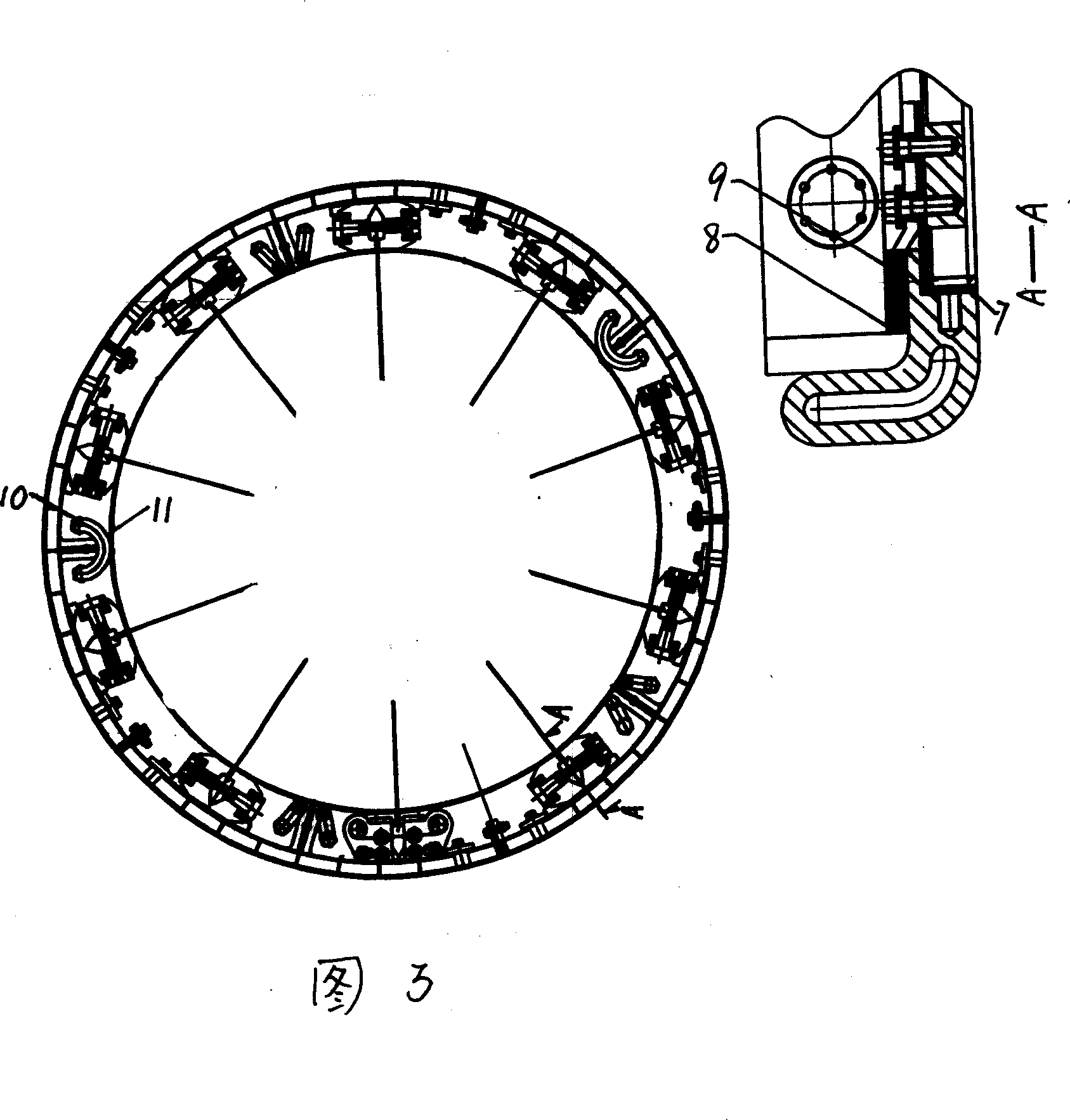

Combined holder for ore furnace

A combined holder for ore-smelting furnace relates to an electrode holder for ore-smelting furnace, comprises a holding cylinder, an electrode shell which is welded by a plurality of arc plates and rib plates, two sides of the electrode shell external rib plate are provided with a conductive element group which is connected by adjusting bolts and butterfly-springs, the top of the conductive element group is fixed on a holding cylinder flange by a stainless steel bent plate, the bottom thereof is arranged on a bottom ring which is fixed on the holding cylinder flange by a suspender, a stainless steel protecting cover is arranged outside of the conductive element group, the conductivity of the device and stability of current delivery are improved greatly, thereby the service life of the conductive element group is improved greatly, and unit current drain of products can be reduced.

Owner:江苏德诚冶金电炉设备有限公司

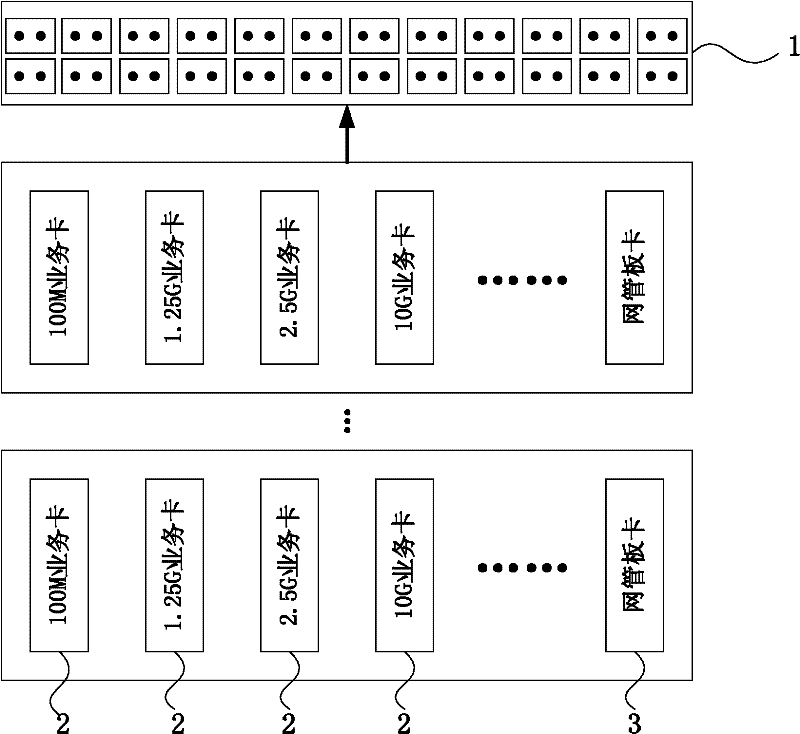

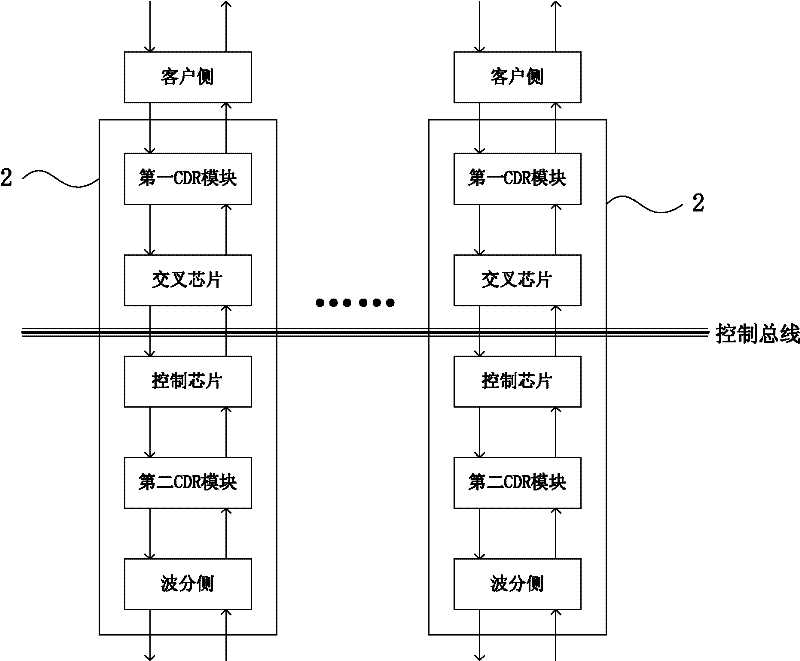

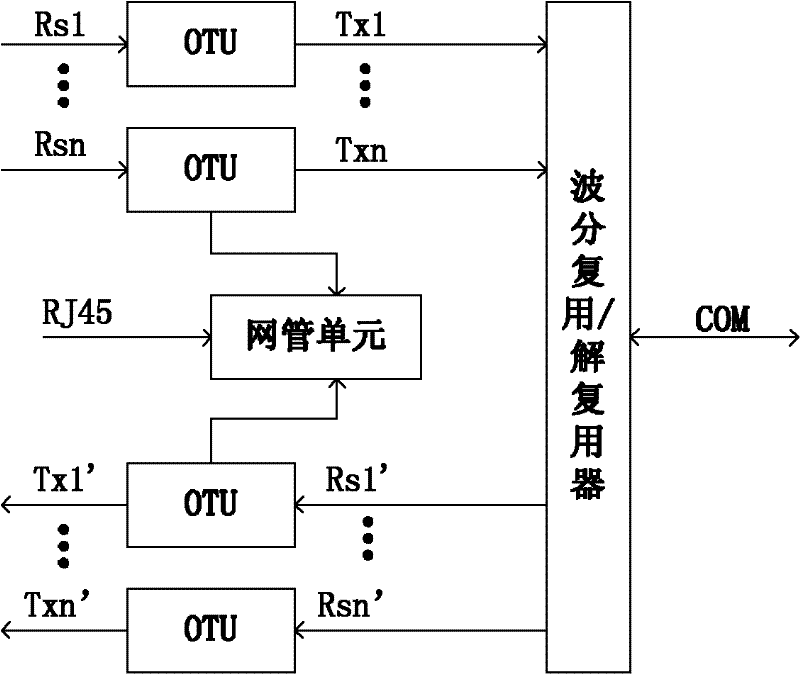

Transmission method of optical fiber transmission subsystem

InactiveCN102546022AHighly integratedReduce unit power consumptionFibre transmissionEmbedded systemVIT signals

The invention discloses a transmission method of an optical fiber transmission subsystem. The optical fiber transmission subsystem comprises an equipment machine frame, a plurality of service cards and a webmaster board. The service cards with different rates are managed by the webmaster board. The equipment machine frame is provided with N board slots, wherein one of slot positions is occupied by the webmaster board, and any one of the 1-N slot positions is selected by each service card. The transmission method comprises the following steps of: step 1, respectively receiving signals with different rates from different clients by the service cards with the different rates; step 2, realizing communication control of the service cards with the different rates with the clients with the corresponding rate under the condition that the service cards with the different rates are connected with a control bus. According to the transmission method disclosed by the invention, services with the different rates of 100 M, 1.25 G and 2.5 G are compatible with the subsystem simultaneously, and the service with a rate of 10 G can be further expanded. Therefore, the conventional equipment is used to the greatest extent, the entire cost is lower, the smooth transfer between a novel system and a traditional system is realized, and the transmission method has the advantages of flexible system configuration capability and logic control function.

Owner:上海鼎频通信技术有限公司

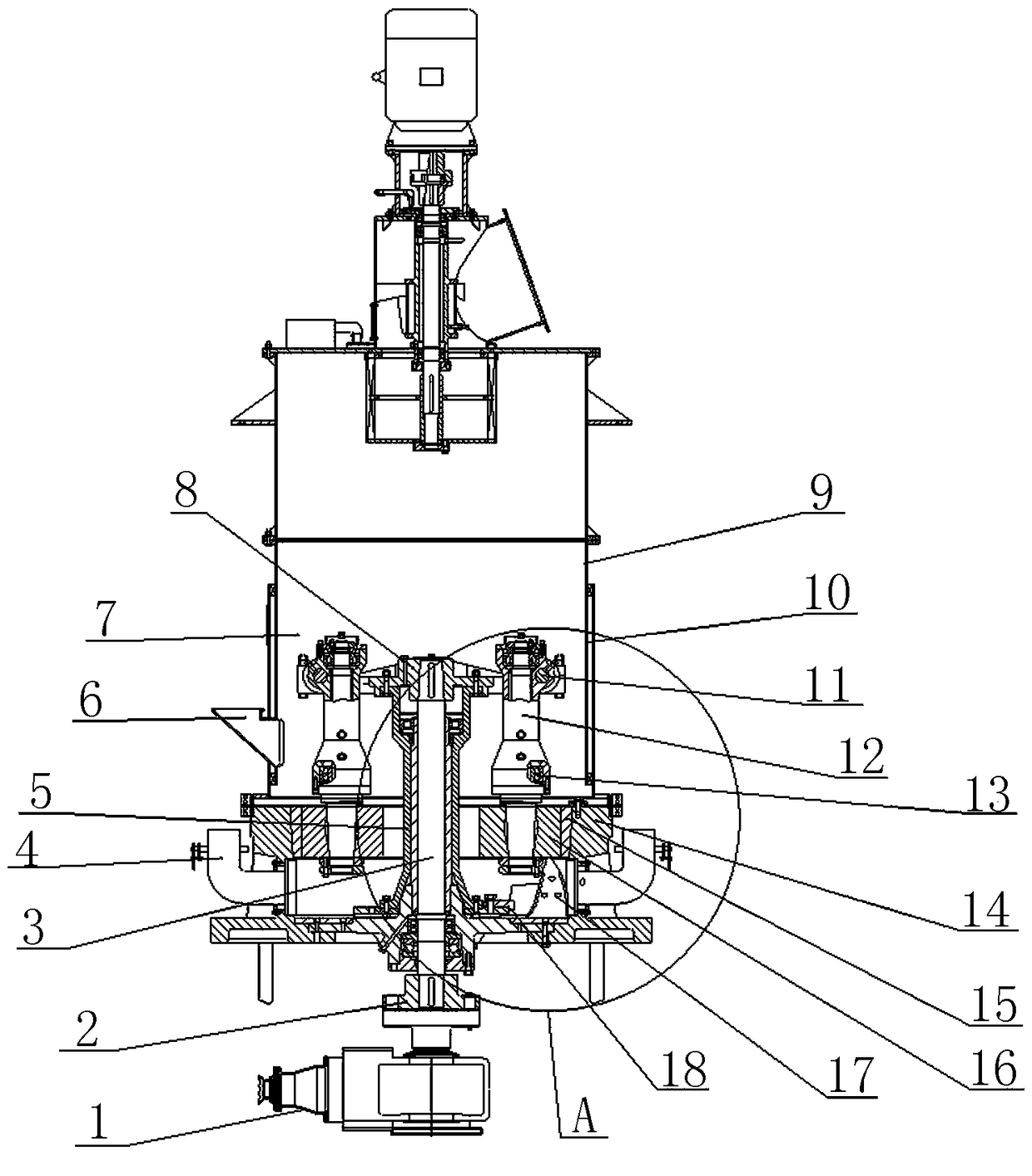

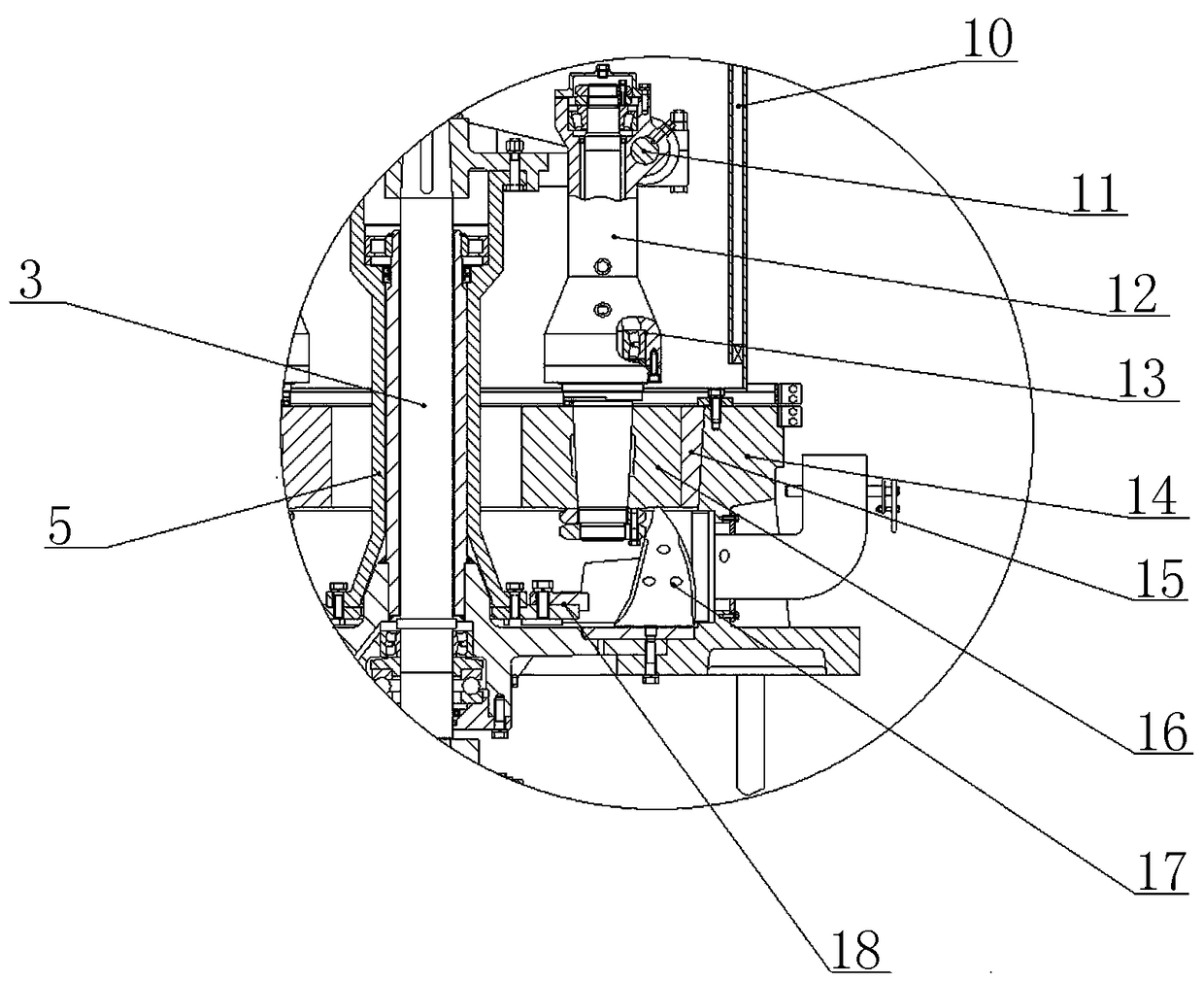

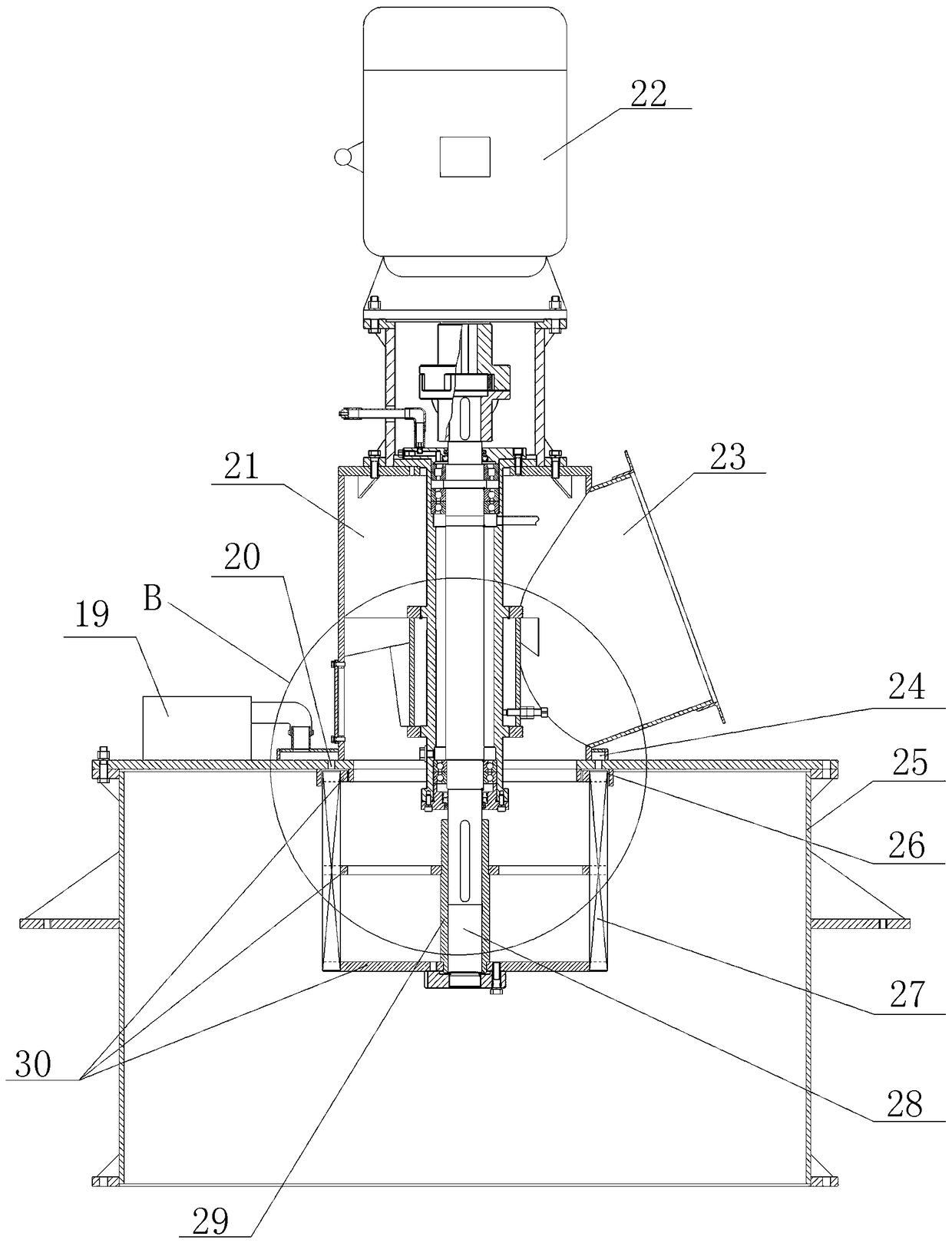

Pendulum type all-purpose flour mill

InactiveCN108435337AHigh strengthImprove rigidityGas current separationGrain treatmentsEngineeringEnergy consumption

The invention discloses a pendulum type all-purpose flour mill. The pendulum type all-purpose flour mill comprises a flour mill host machine and a grader. The grader is mounted on the upper portion ofthe flour mill host machine. The flour mill host machine comprises a barrel, a central rotary spindle and a grinding roller device. The barrel is mounted on a base and is internally provided with a flour milling chamber. The central rotary spindle is arranged in the center of the flour milling chamber and the base in a penetrating mode. The lower end of the central rotary spindle extends out of the base and is connected with a power mechanism. A plum-blossom-shaped rack is mounted at the upper end of the central rotary spindle. A shovel blade rack is mounted at the lower middle end of the central rotary spindle. Two or more cross arm shafts are uniformly distributed on the plum-blossom-shaped rack. A shovel blade rack lower seat is mounted on the shovel blade rack. A shovel blade is mounted on the shovel blade rack lower seat. The upper end of the grinding roller device is mounted on the plum-blossom-shaped rack through the cross arm shafts. The barrel is of a double-layer structure.An air duct is formed between an inner barrel body and an outer barrel body. The pendulum type all-purpose flour mill is high in milling efficiency, low in unit energy consumption, stable in whole machine performance, long in service life and wide in processing particle size range.

Owner:桂林欣新机械有限公司

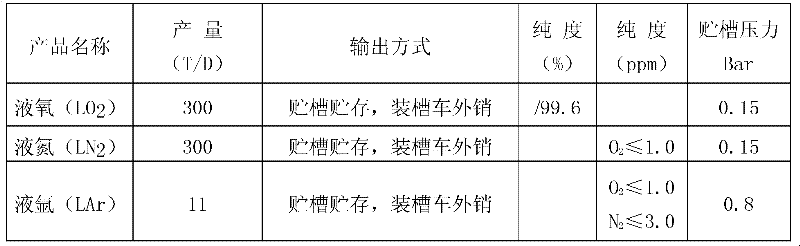

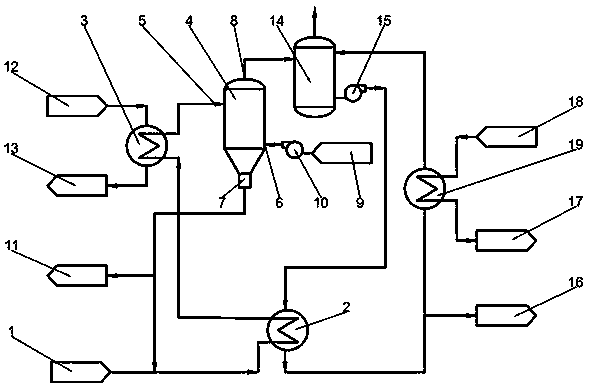

Device for rectifying and producing high-purity ethylene using ethylene heat pump, and high-purity ethylene production technology

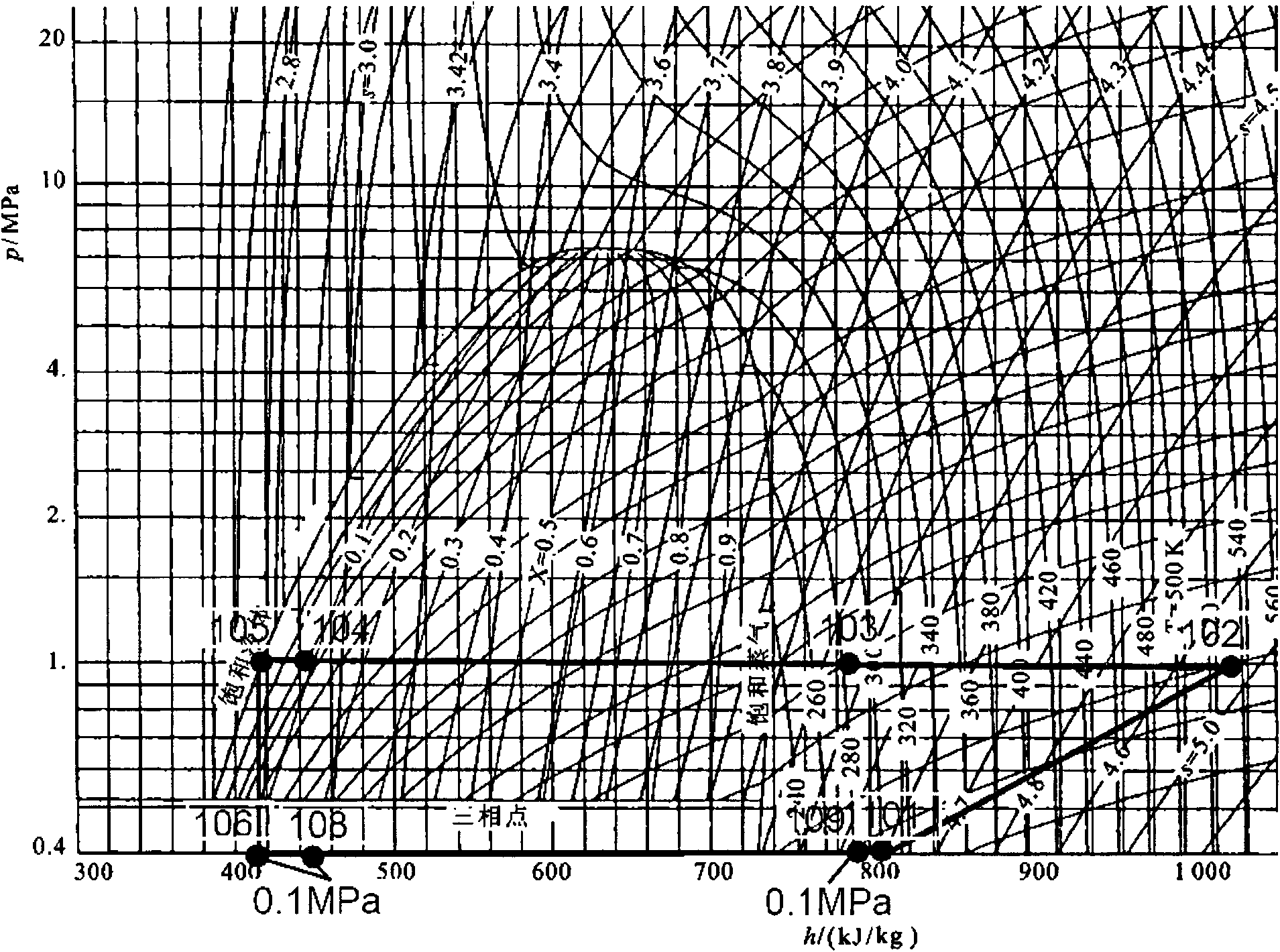

ActiveCN107144092AImprove energy utilizationIncrease diversitySolidificationLiquefactionVapor–liquid separatorGas phase

The invention relates to a device for rectifying and producing high-purity ethylene using an ethylene heat pump, and a high-purity ethylene production technology. The device comprises a feed solution tank and a product tank. The feed solution tank is connected to a second gas-liquid separator through a first feed solution inlet of a first rectifying tower, a gas phase outlet of the first rectifying tower, a first feed gas inlet of a first heat exchanger, a first feed gas outlet of the first heat exchanger, an inlet of a first gas-liquid separator, a liquid phase outlet of the first gas-liquid separator, a second feed solution inlet of the first rectifying tower, a liquid phase outlet of the first rectifying tower, a first feed solution inlet of a second rectifying tower, a gas phase outlet of the second rectifying tower, a second feed gas inlet of the first heat exchanger, and a second feed gas outlet of the first heat exchanger, and the liquid phase outlet of the second gas-liquid separator is connected to the second feed solution inlet of the second rectifying tower and the product tank. The device has the advantages of simple technological process, stable operation, low energy consumption, safe and reliable operation, low unit power consumption, low production cost and high product purity.

Owner:HENAN XINLIANXIN SHENLENG ENERGY

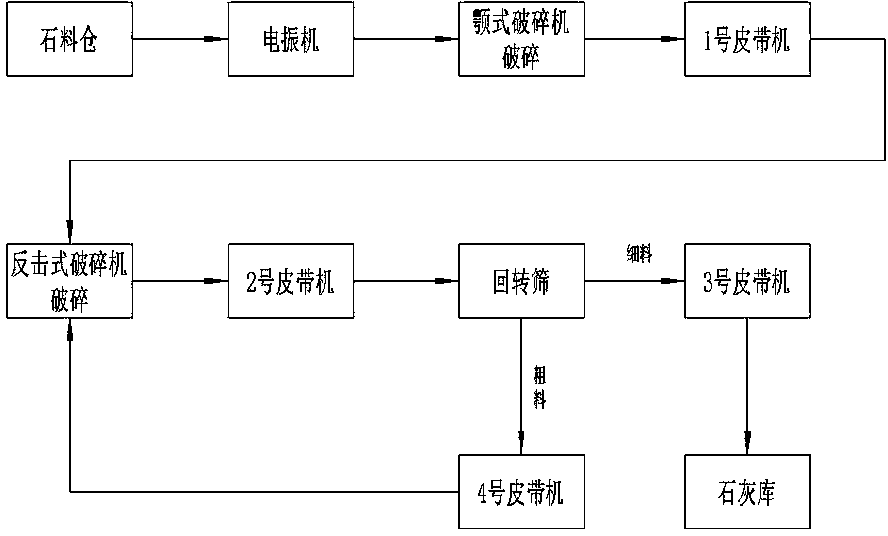

Stone recrushing process

The invention discloses a stone recrushing process. The stone recrushing process comprises the following process flows: performing treatment by a stone cabin, an electric vibrator, crushing of a jaw type crusher, a belt conveyor 1, crushing of an impact crusher, a belt conveyor 2, and a gyratory screen on a raw material in sequence, conveying a fine material to a limestone warehouse through a belt conveyer 3; conveying a rough material screened by the gyratory screen to the impact crusher through a belt conveyer 4 for recrushing, and then conveying the recrushed material to the limestone warehouse through the belt conveyor 2, the gyratory screen and the belt conveyors so as to complete the stone treatment; machine-hour yield of a grinder is increased by 20% to 30%, the production cost is reduced, and the economic benefit is increased.

Owner:洛阳宝诺重型机械有限公司

Air separation method capable of being matched with cold energy supply in receiving station

ActiveCN104019629AReduce unit power consumptionEfficient use ofSolidificationLiquefactionEngineeringAir separation

The invention discloses an air separation method capable of being matched with cold energy supply in a receiving station. The method includes the following steps that when LNG supply is sufficient, nitrogen from an air separation system is compressed many times and then exchanges heat with LNG, high-pressure supercooling liquid nitrogen can be obtained, and cooling capacity is provided for the air separation system; a stream of liquid nitrogen is extracted from the high-pressure supercooling liquid nitrogen and throttled and then exchanges heat with second stream of raw material air, the temperature of the liquid nitrogen rises so that low pressure nitrogen can be generated, the low pressure nitrogen is added into the nitrogen exchanging heat with the LNG, the temperature of the second stream of raw material air is lowered so that liquid air can be generated through liquidation, and the liquid air forms stock liquid air; when LNG supply is not sufficient, the stock liquid air is fed into an upper tower of the air separation system, cooling capacity and part of separation air are provided for the air separation system, no heat exchange happens between the LNG and the nitrogen from the air separation system at the moment, the LNG exchanges heat with cooling liquid of a raw material air compressor, and the LNG is fed into a natural gas pipeline after the temperature of the LNG rises to reach the pipeline conveying temperature. With the air separation method, the requirement of the air separation method for LNG cold energy can be well matched with supply of LNG cold energy.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Production method for smelting ferrosilicon by utilizing crystalline silicon cutting waste powder

The invention discloses a production method for smelting ferrosilicon by utilizing crystalline silicon cutting waste powder. The production method is characterized in that the crystalline silicon cutting waste powder can be directly molten into a ferrosilicon component under a high-temperature melting state by utilizing the matter characteristic that the high-purity simple substance silicon in the crystalline silicon cutting waste powder is a silicon component in ferrosilicon; unit power consumption and coke consumption of smelting the ferrosilicon can be greatly reduced by reducing silicon dioxide in silica raw materials through strong reduction characteristic of silicon carbide and releasing a great deal of reaction heat; equipment investment is not required to be increased, so that in case of current equipment, crystalline silicon cutting waste powder (namely powder tailings) can be recycled on a large scale for being added into furnace burden for smelting production of a ferrosilicon product, and therefore, a silicon resource raw material treasury with high energy storage property and strong reducing property is developed for producing and smelting the ferrosilicon product in the metallurgical industry, the environmental pollution problem caused by stocking and stacking the cutting waste powder for a long time in the crystalline silicon slicing industry can be effectively solved, and remarkable social environment-friendly effect and great economic benefits are achieved.

Owner:四川川投峨眉铁合金(集团)有限责任公司

Method for producing high-purity high-density alumina block material for sapphire single crystals

ActiveCN101913636BReduce unit power consumptionMeet needsPolycrystalline material growthAluminates/aluminium-oxide/aluminium-hydroxide purificationSingle crystalHeating power

The invention discloses a method for producing a high-purity high-density alumina block material for sapphire single crystals. A high-frequency induction power supply is utilized as a heating power supply, an alumina micropowder raw material in a cold crucible is melted to form a molten bath, and a Bruceton-process single crystal growing process making the cold crucible slowly reduced is combined, so that alumina in the molten bath generates multi-nucleus directional crystallization, and fine columnar or needle-like alumina smallcrystal clusters are obtained finally. The method is used for producing the high-purity high-density alumina block raw material, has low unit electricity consumption and is easy for mass production; and the obtained alumina smallcrystals have the purity of over 99.997 percent, the volume density of not less than 3.7g / cm<3> and the bulk density of not less than 2.0g / cm<3>.

Owner:李振亚 +1

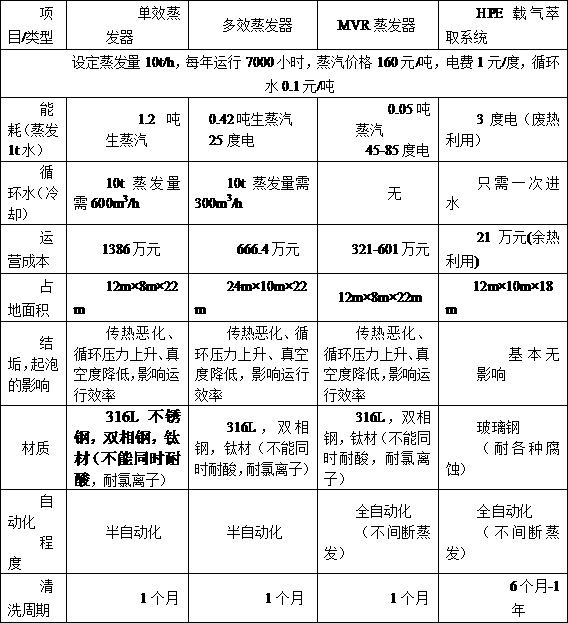

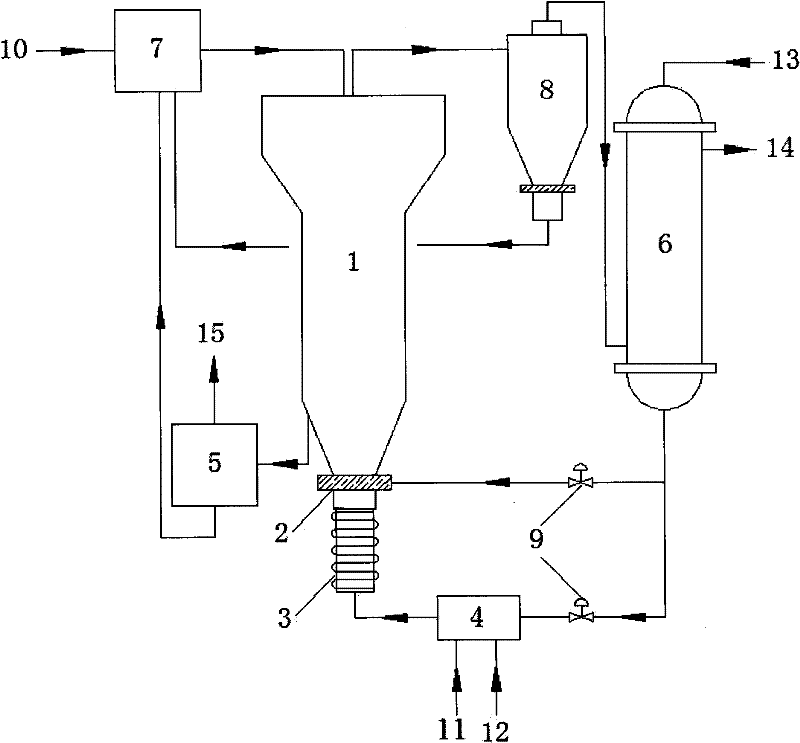

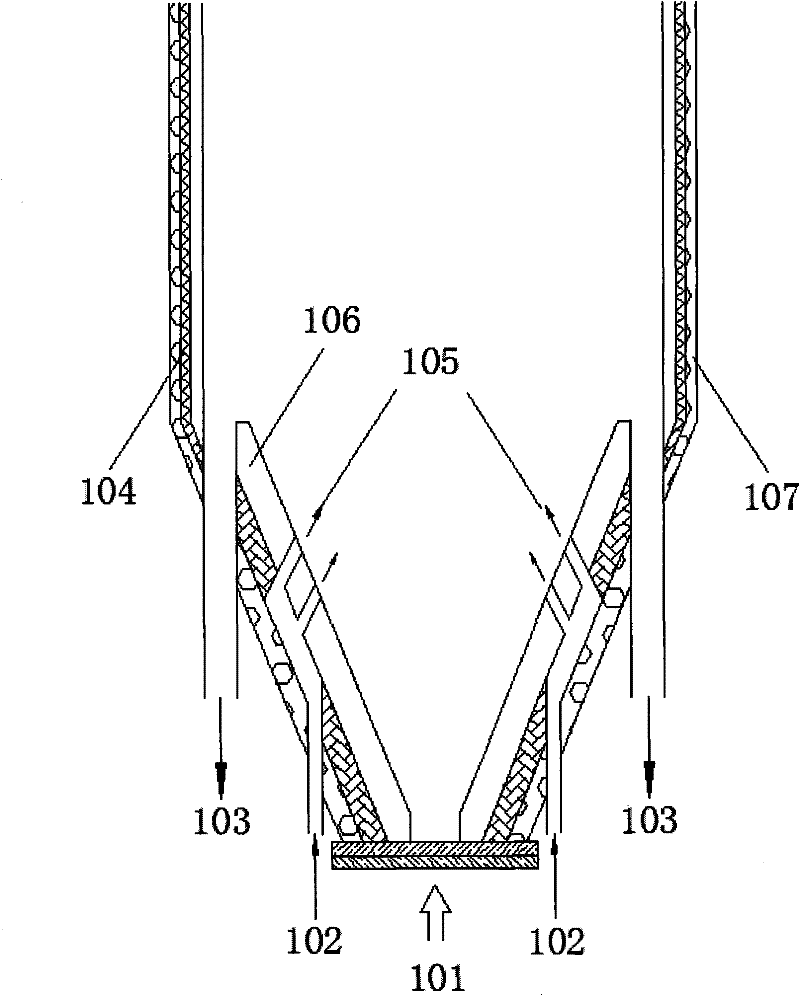

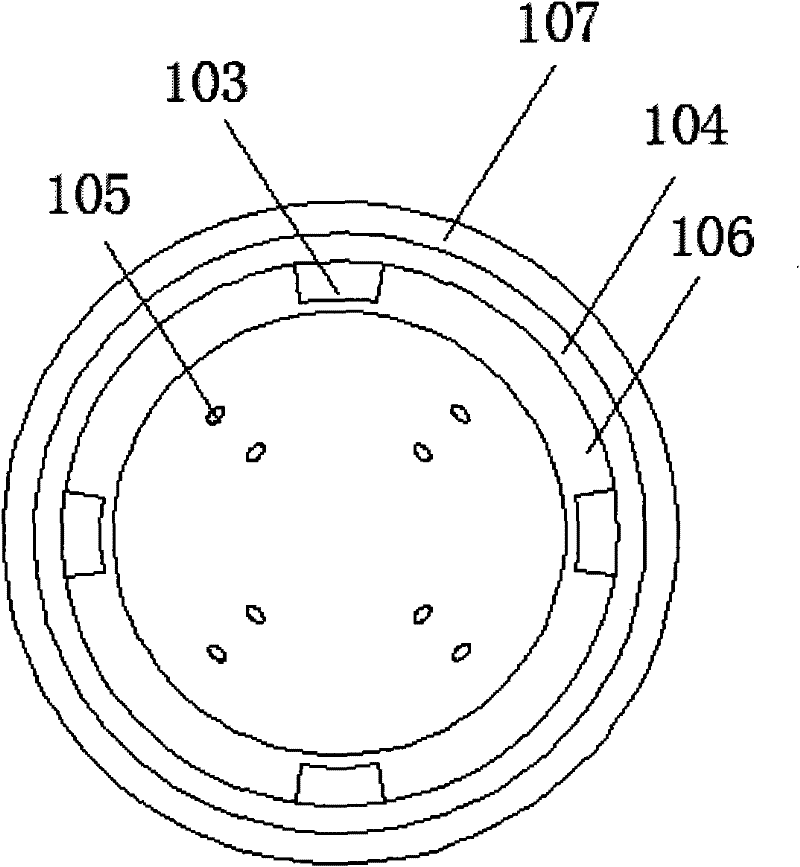

HPE evaporation system for carrier gas extraction

PendingCN110451596AImprove thermal efficiencySave energyWaste water treatment from quariesWater/sewage treatment by heatingVapor–liquid separatorIndustrial effluent

The invention relates to an HPE evaporation system for carrier gas extraction. The system comprises an air blower, a heat exchanger, an evaporator, a vapor-liquid separator, a process pump and a condensing water tank; the components of the HPE evaporation system for carrier gas extraction are connected with one another through a pipeline and are controlled through a PLC system; an inlet of the evaporator is connected with the air blower and the heat exchanger, and the outlet is connected with the vapor-liquid separator and a high-salt wastewater discharge outlet; and gas carrier air is continuously introduced into the evaporator by utilizing the air blower, water vapor is extracted from industrial wastewater through carrier gas in the closed system, and at the same time, brine is concentrated to 25% salinity for recycling. The system provided by the invention can effectively concentrate the industrial salt-containing wastewater, and fully utilize useful substances generated by recoveryof the wastewater, a high-efficiency extraction rate of the evaporation system for carrier gas extraction is utilized, so that the energy loss is reduced, and the investment costs are reduced.

Owner:黑珀(上海)工业技术有限公司

Method and device for producing polysilicon by using plasma assisting fluidized bed process

The invention discloses a method and a device for producing polysilicon by using a plasma assisting fluidized bed process. One or more of silane or halogenated silanes are adopted as raw gases, nitrogen is adopted as a reducing gas, all or partial raw gases are converted into plasma through a plasma generation device after mixed with the nitrogen, mixed gases after being carried out plasma react to be deposited for manufacturing the granular polysilicon; or the raw gases directly enter into a fluidized bed reactor and are mixed with the converted nitrogen subjected to plasma in the fluidized bed reactor, and the mixed gases subjected to plasma react to be deposited for manufacturing the granular polysilicon. The invention realizes normal pressure continuous operation, lower reaction temperature, high deposition rate and high once through yield of the polysilicon, can directly utilize side products in the traditional polysilicon production process by lower unit electricity consumption and operation cost and produce the granular polysilicon with high purity.

Owner:JIANGSU ZHONGNENG POLYSILICON TECH DEV

Air separating device and method therefor

ActiveCN100472159CReduce unit power consumptionImprove energy savingSolidificationLiquefactionElectricityAir separation

The invention relates to a method for using rectification at low temperature to separate air, and relative device. Wherein, said device comprises a booster (5), an expander (6), and a cooler (10) to form one low-temperature boost turbine expander, which will boost and cool another air to be reduced temperature, expanded and cooled in the main heat exchanger to be fed into the upper tower (14) of rectification tower for rectification. In the separation process, it uses different expanders as middle pressure and low pressure, which expand in different pressures and temperatures to supply cold energy to the separation process; the expanded air is fed into the upper and lower towers for rectification. The invention has lower unit electricity consumption as 2.5% reduced.

Owner:唐山瑞鑫液化气体有限公司

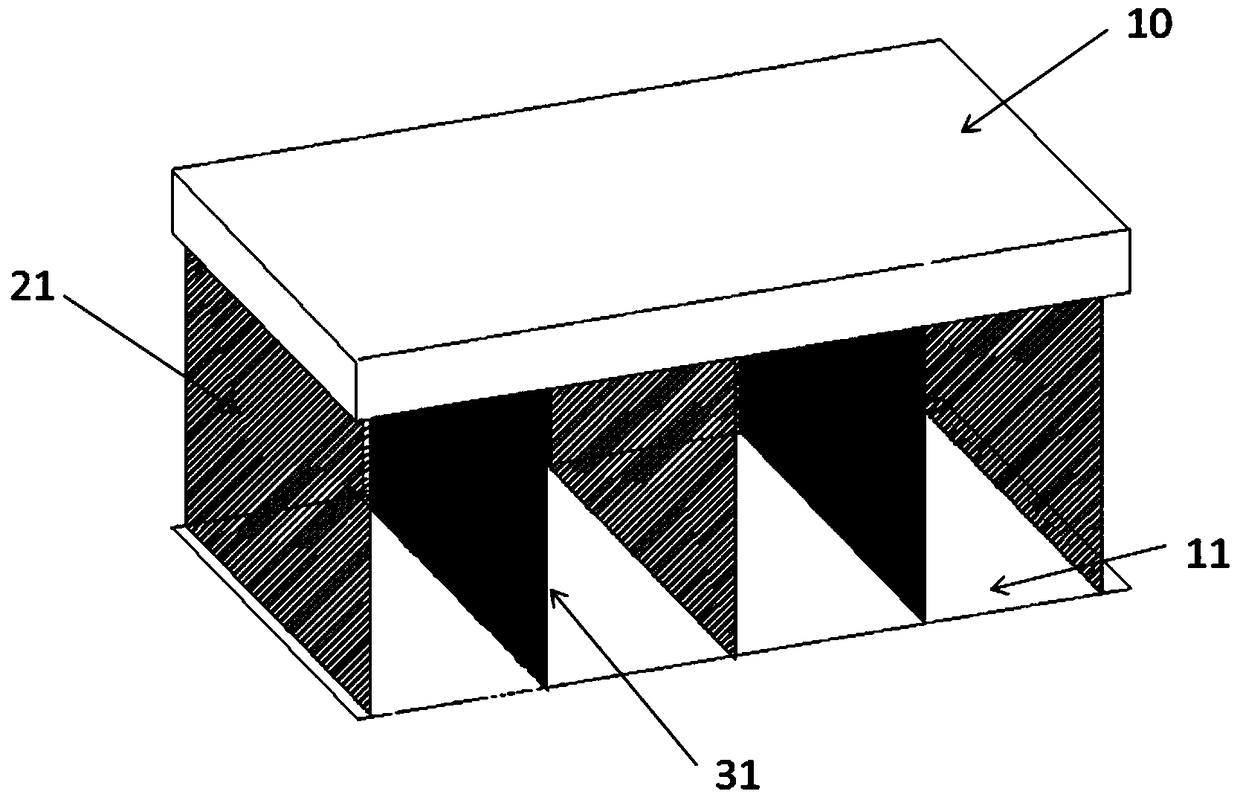

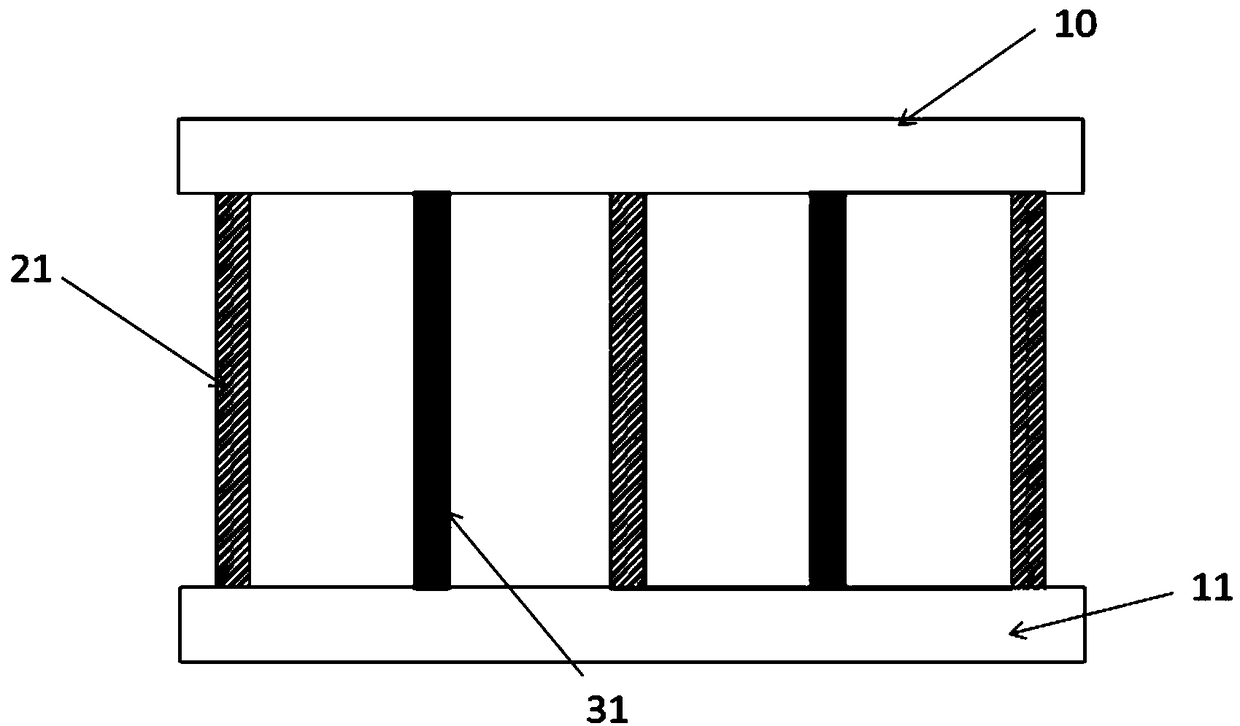

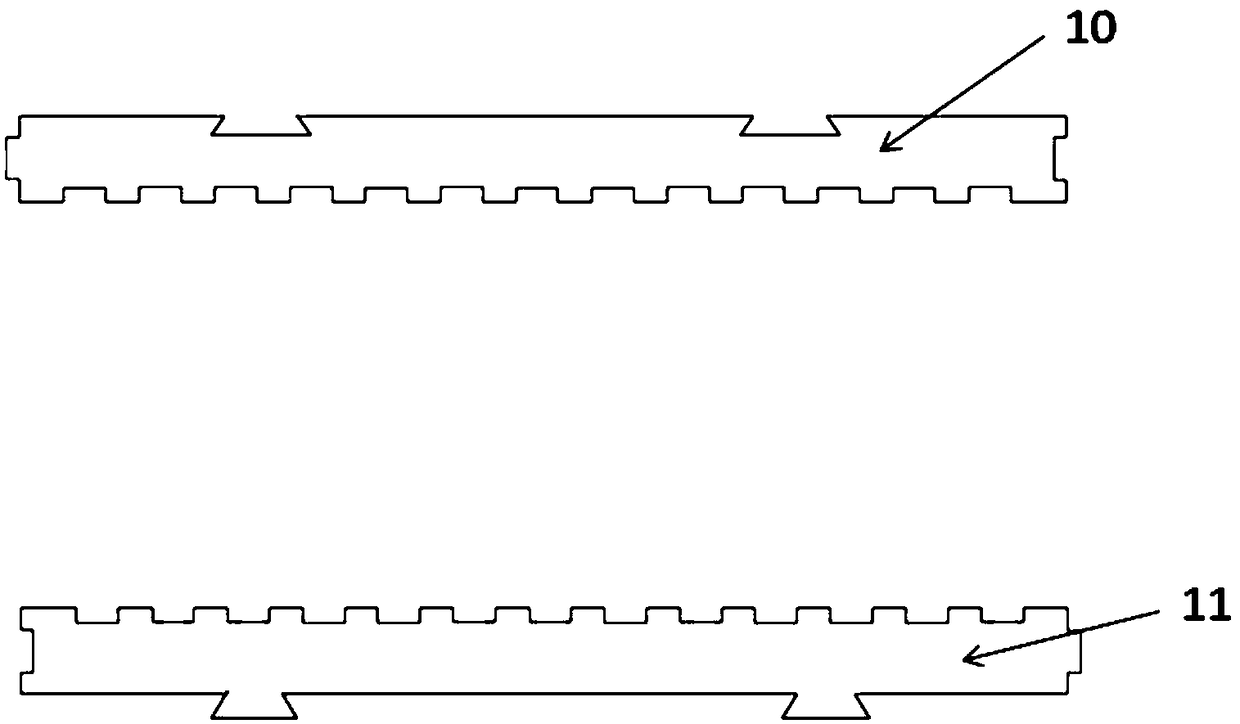

Arrangement type filth and rust adsorbing electrode device with adjustable electrode spacing

ActiveCN109052576AMeet the needs of sizeHigh treatment efficiencySpecific water treatment objectivesWater/sewage treatmentEngineeringRust

The invention discloses an arrangement type filth and rust adsorbing electrode device with an adjustable electrode spacing. The electrode device comprises an electrode holder, external electrodes andinternal electrodes, wherein the electrode holder is U-shaped and is used for fixing the external electrodes and the internal electrodes; the external electrodes and the internal electrodes are arranged at interval and are arrayed in the electrode holder in parallel; the spacing between each external electrode and the corresponding internal electrode is adjustable; grooves and protrusions are respectively formed in and arranged on the side faces of two ends of upper and lower electrode fixing plates; the upper side face of the upper electrode fixing plate is provided with dovetail grooves; thelower side face of the lower electrode fixing plate is provided with dovetail bumps matched with the dovetail grooves and is used for expansion link of the electrode device. The arrangement type filth and rust adsorbing electrode device with the adjustable electrode spacing, disclosed by the invention, realizes convenient adjustment of the spacing between the electrode plates, and has the advantages of remarkable improvement of scale absorbing efficiency, convenience in assembly and cleaning, easiness in expansion, no need of disassembly and capability of realizing online cleaning.

Owner:林科(广东)环保工程有限公司

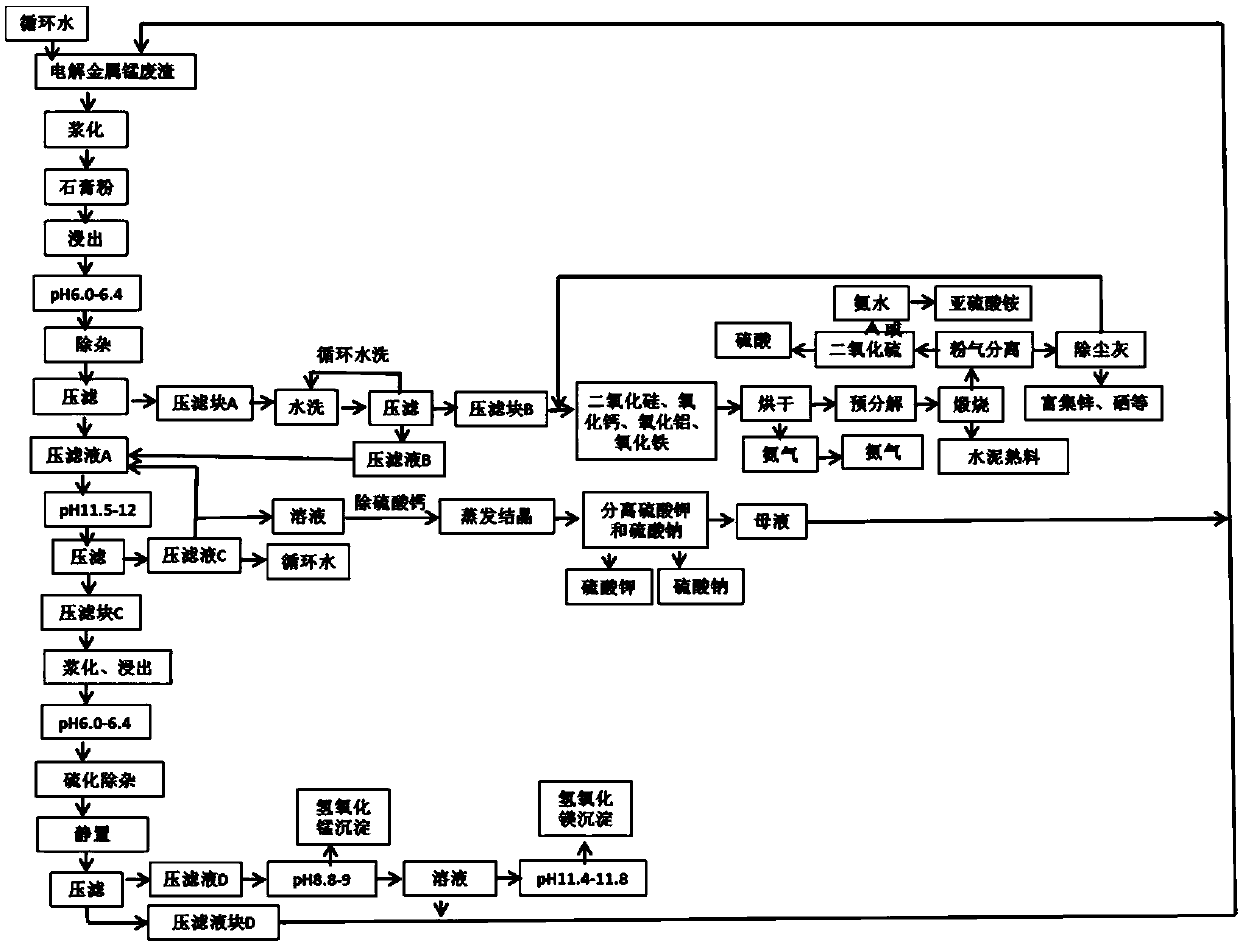

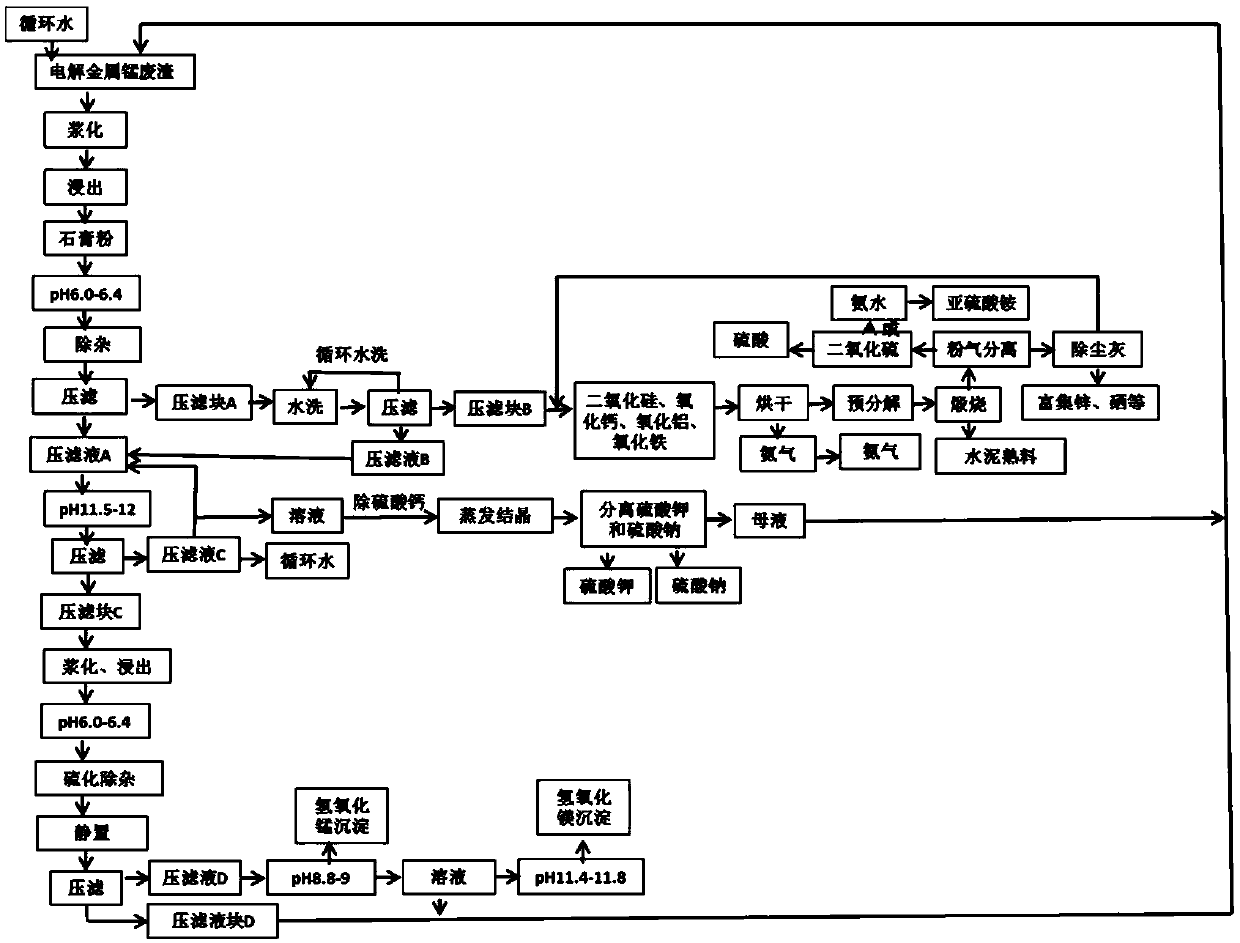

Method for combining electrolytic manganese metal waste residues and gypsum to produce cement clinker and ammonium hydroxide

ActiveCN110732543AImprove recycling ratesEnable recyclingSolid waste disposalElectrolysisClinker (waste)

The invention relates to a treatment method of electrolytic manganese metal waste residues. The treatment method comprises the following steps: A, grinding gypsum or drying calcined gypsum and then grinding to obtain gypsum powder; B, slurrying the electrolytic manganese metal waste residues, leaching, and adding the gypsum powder; adjusting the pH of a solution to 6.0-6.4, removing iron, carryingout filter pressing to obtain a filter pressing block A and a filter pressing solution A, washing the filter pressing block A with water, and then carrying out filter pressing to obtain a filter pressing block B and a filter pressing solution B; adjusting the pH of the filter pressing solution A to 11.5-12, and carrying out filter pressing to obtain a filter pressing block C and a filter pressingsolution C; C, adding silicon dioxide, calcium oxide, aluminum oxide and iron oxide into the filter pressing block B, drying, pre-decomposing, and calcining to obtain cement clinker; D, slurrying thefilter pressing block C, leaching, adjusting the pH to 6.0-6.4, removing impurities, standing, and carrying out filter pressing to obtain a filter pressing block D and a filter pressing solution D, adding ammonia water into the filter pressing solution D to adjust the pH to 8.8-9, and continuously adding an ammonia water solution to adjust the pH to 11.4-11.8. The method realizes recycling of resources.

Owner:庞炼红

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com