Patents

Literature

61 results about "UREA SULFATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A process for the production of urea-ammonium sulfate granules from urea and ammonium sulfate by several granulation methods. The proportion of ammonium sulfate in the mixture was varied from 15 percent to 70 percent by weight resulting in products containing from 42 percent to 29 percent N and 3 percent to 17 percent S, respectively.

Urea sulfate and urea hydrochloride in paper and pulp processing

InactiveUS7029553B1Regulate securityLess process equipmentNon-fibrous pulp additionNatural cellulose pulp/paperFlocculationSulfate

The present invention relates to the use of urea sulfate or urea hydrochloride, or both, in process streams in the paper and pulping industries to control pH, to bring about flocculation or precipitation of various materials, and to replace all or part of the sulfuric acid, hydrochloric acid, and / or papermaking alum used in the paper and pulping industries.

Owner:PEACH STATE LABS +1

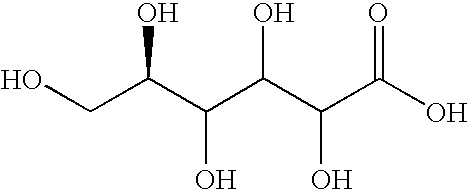

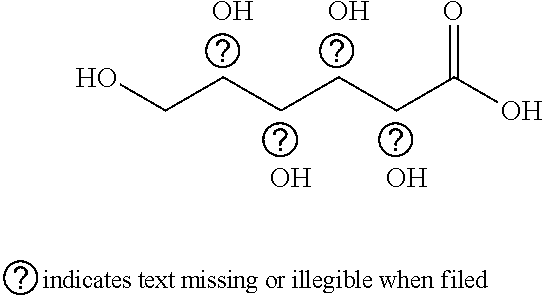

Acid cleaning and corrosion inhibiting compositions comprising gluconic acid

ActiveUS7828908B1Low corrosivityLow propertyOrganic detergent compounding agentsDetergent mixture composition preparationPhosphoric acidGluconic acid

Owner:ECOLAB USA INC

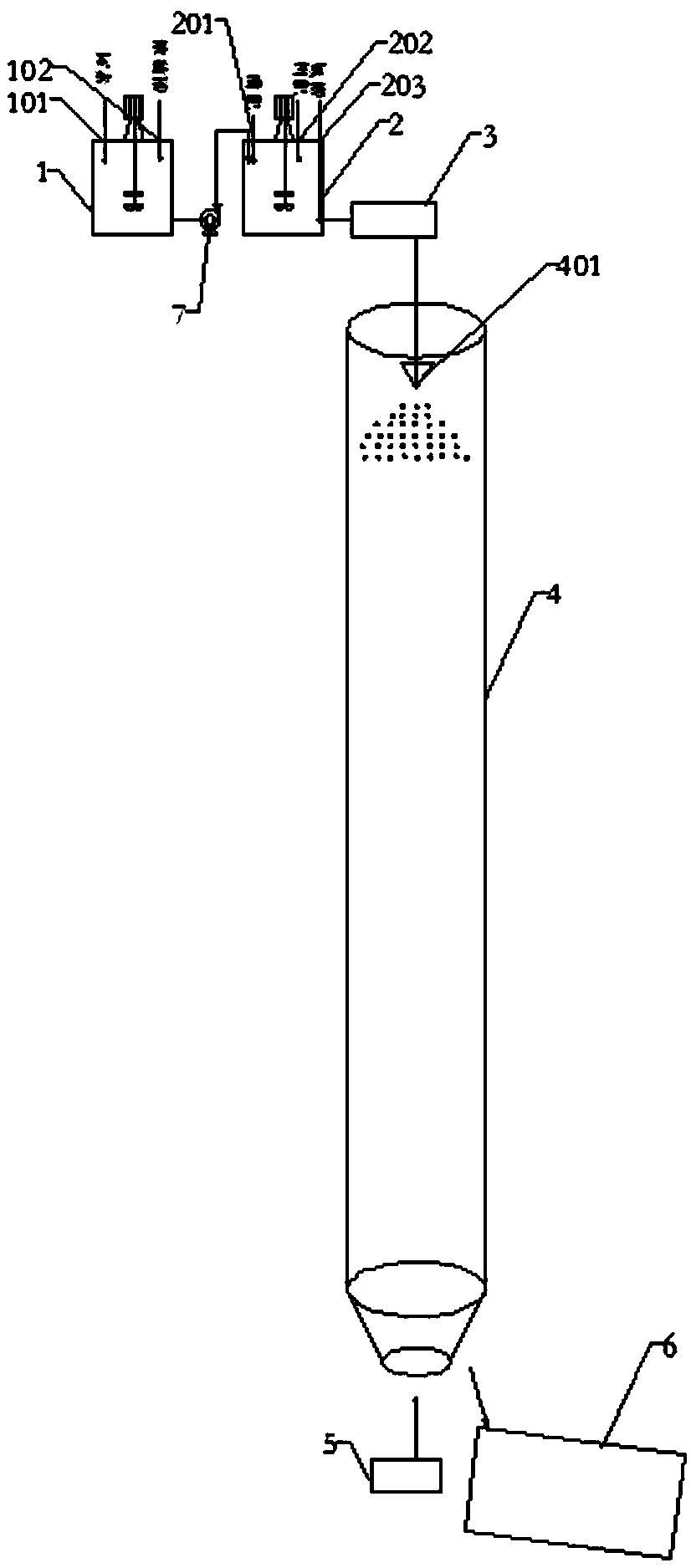

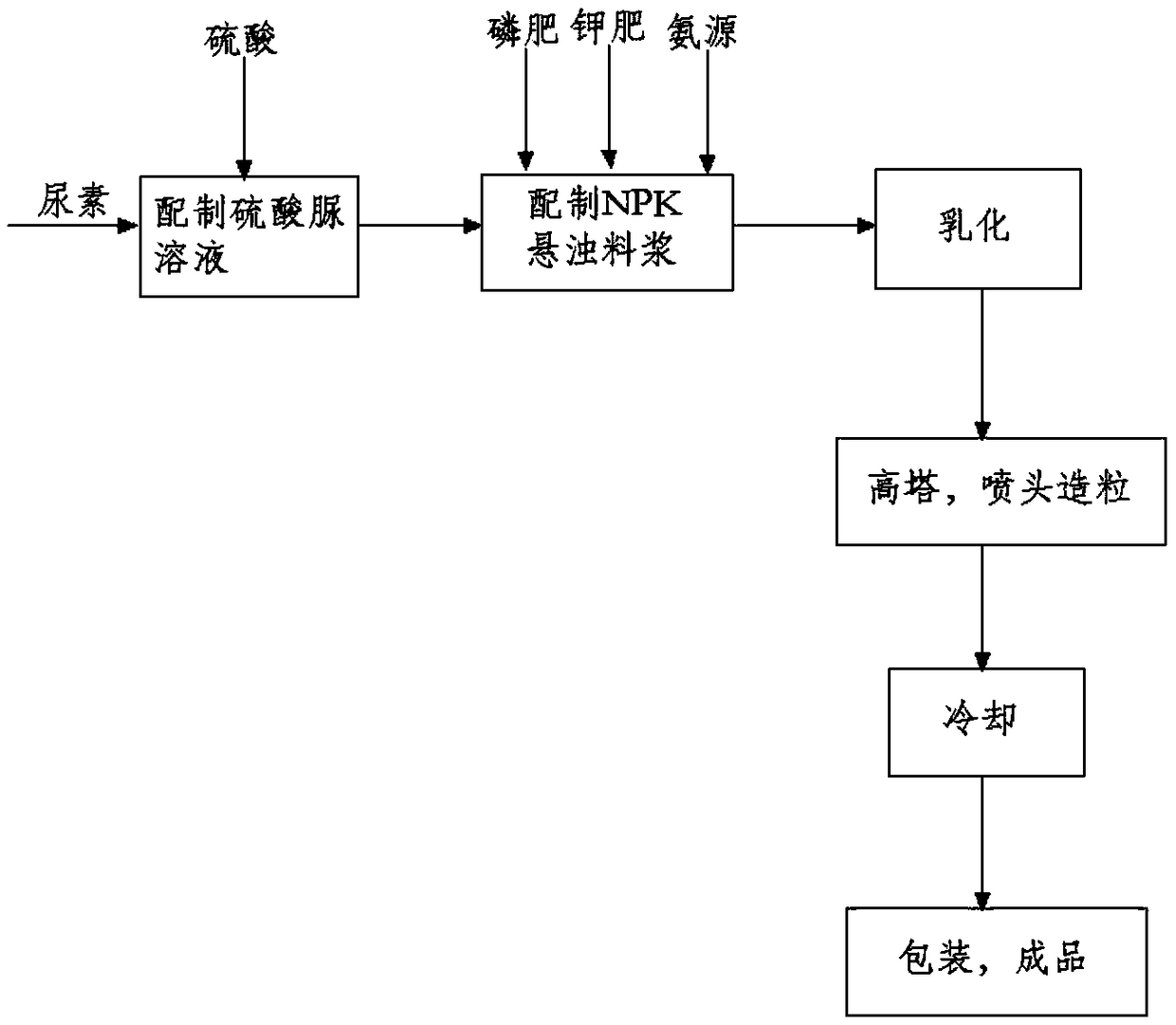

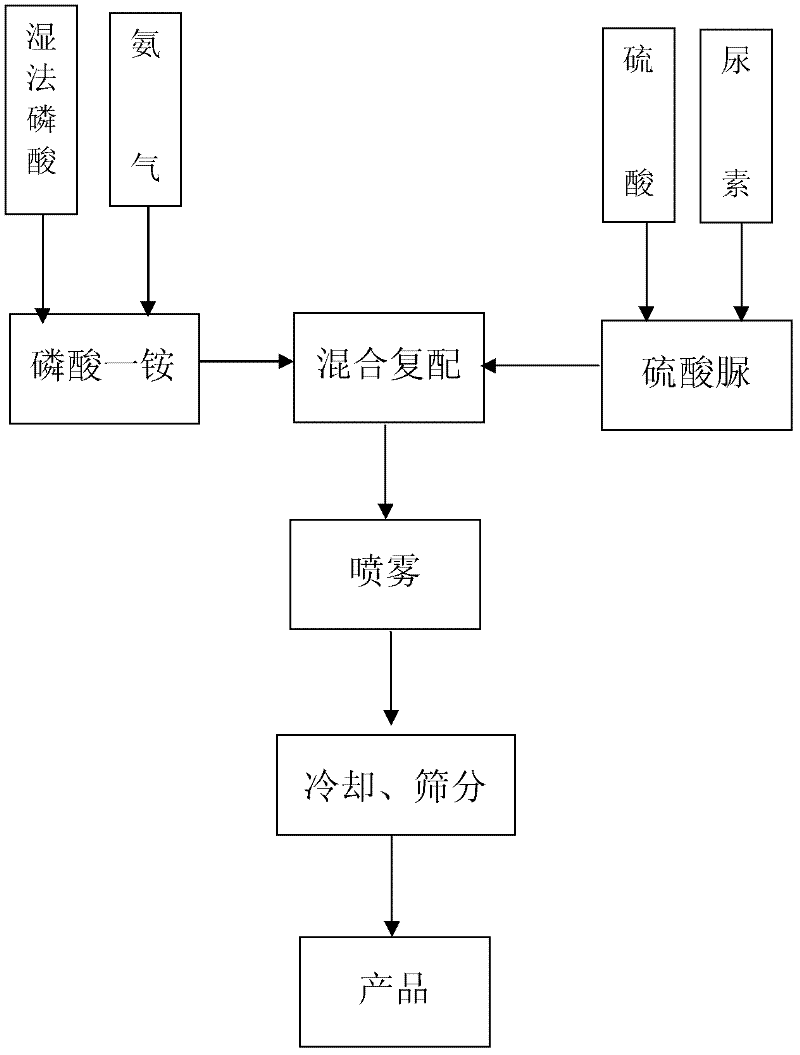

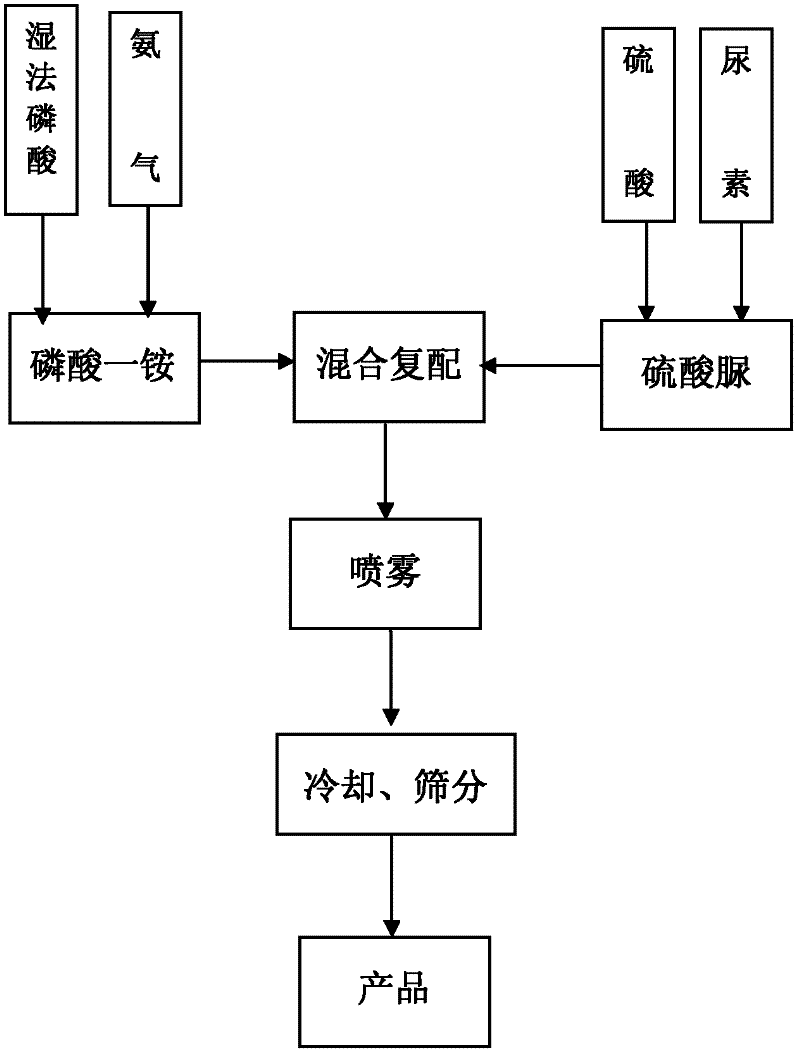

Method for producing compound fertilizer through high-tower granulating, system and compound fertilizer

PendingCN108707000AAvoid meltingAvoid heatingGranulation by liquid drop formationFertilizer mixturesSprayerPotassium

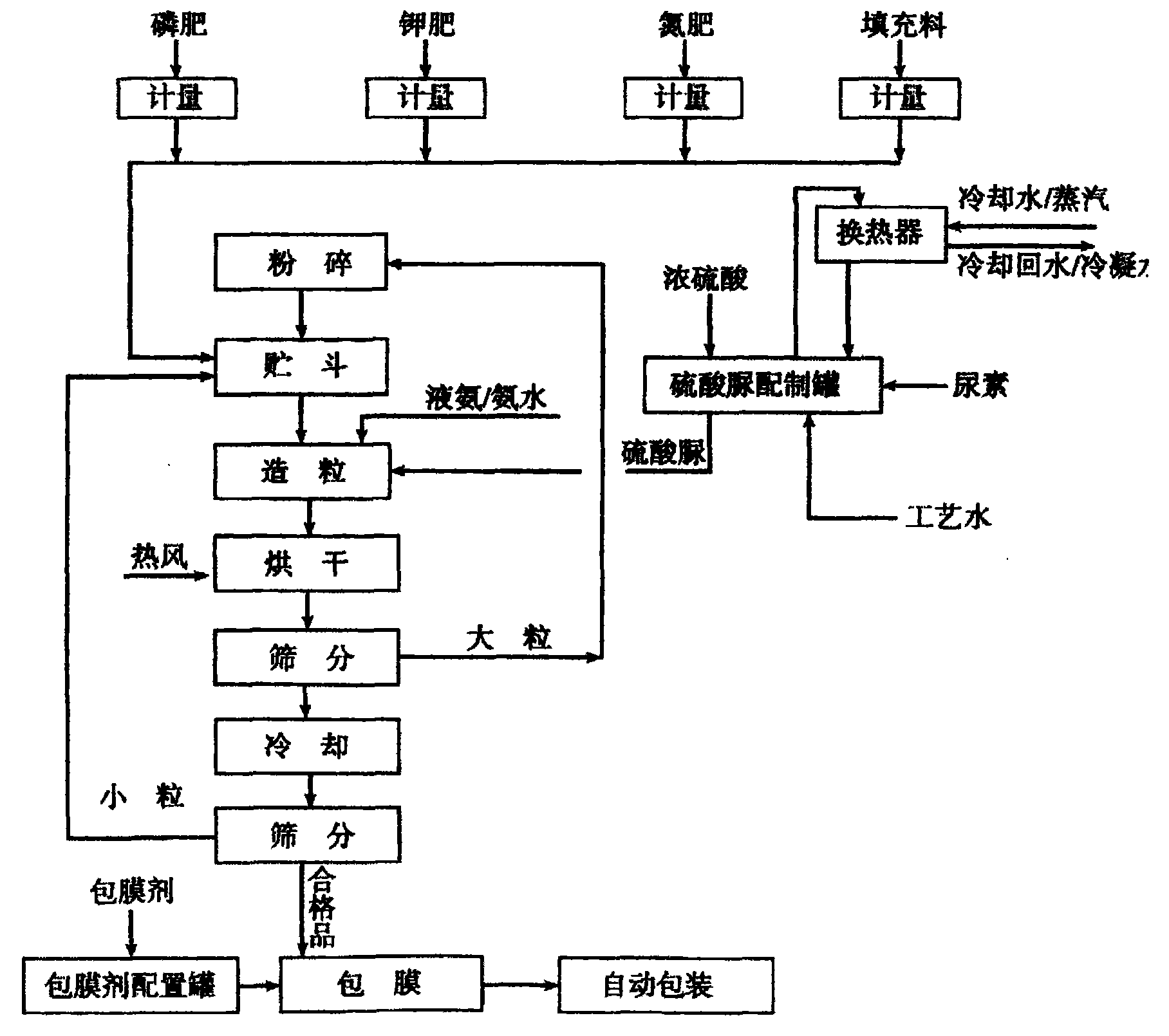

The invention belongs to the technical field of compound fertilizers and relates to a method for producing a compound fertilizer through high-tower granulating, a system and the compound fertilizer. The method for producing the compound fertilizer through high-tower granulating, provided by the invention, comprises the following steps: subjecting sulfuric acid and urea to a reaction so as to produce a urea sulfate solution; mixing the urea sulfate solution with an ammonia source, a phosphate fertilizer and a potassium fertilizer so as to form homogeneous-state NPK suspending slurry; spraying the NPK suspending slurry through a granulating sprayer in a high tower, thereby completing granulating in the tower. According to the method, the process is simple, the implementation is easy, the energy consumption and production cost can be greatly reduced, the method is a steam-free melt-free process, and the problems of the existing high-tower granulating processes that the steam consumption is high, the energy consumption is high, the cost is high and the like can be effectively solved.

Owner:秦皇岛农享田生物科技有限公司

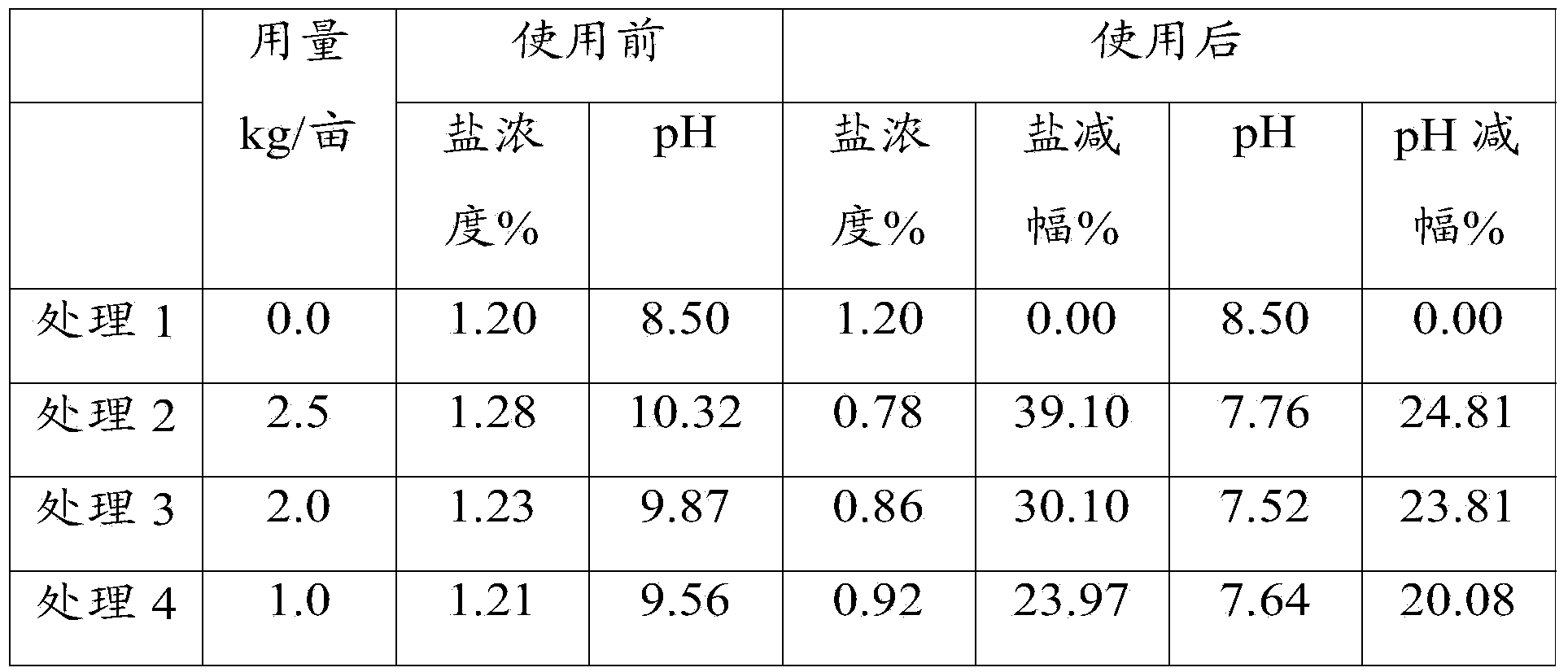

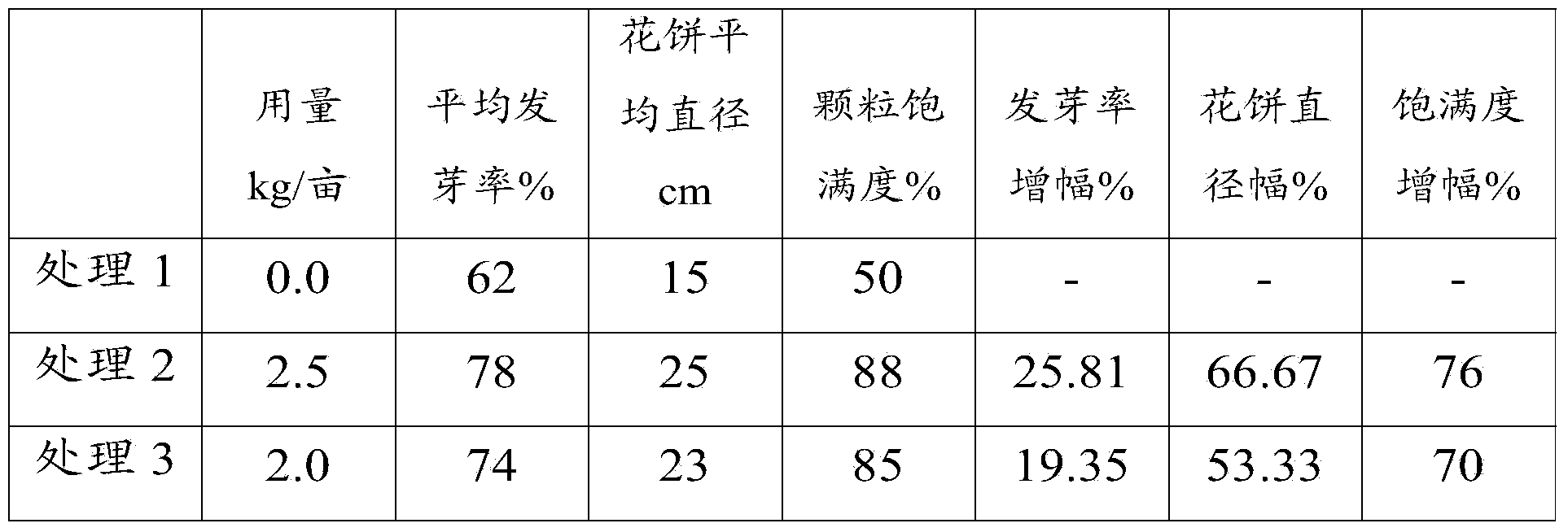

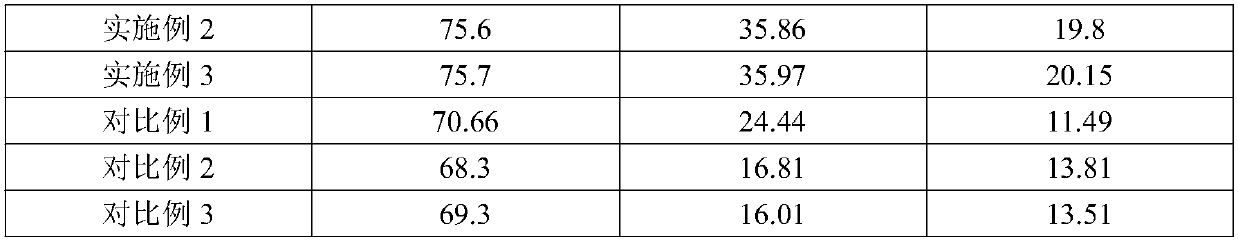

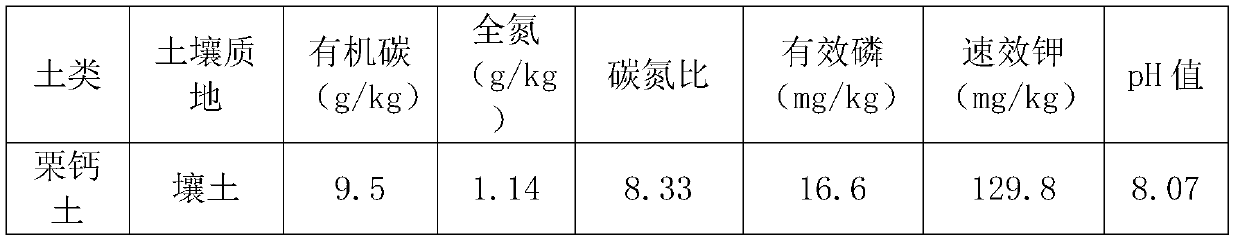

Saline-alkali soil conditioner and preparation method thereof

InactiveCN104371738AReduce pollutionReduce contentAgriculture tools and machinesOther chemical processesAlkali soilManganese

The invention provides a saline-alkali soil conditioner. The saline-alkali soil conditioner is prepared from the following water-soluble components as raw materials: 3-13% of urea sulfate, 8-18% of organic acids, 2-8% of calcium superphosphate, 3-12% of polyaspartic acid compound and the balance of water. The raw materials are water-soluble components and are convenient to prepare and apply. The saline-alkali soil conditioner is reasonable and scientific in preparation, various components coordinate together such that hydrogen ions are quickly released, the alkalinity in the saline-alkali soil can be rapidly neutralized and the purpose of 'alkalinity reduction' is achieved; since the saline-alkali soil conditioner comprises both organic components and inorganic components, each component coordinates together, the content of activated sodium ions in the soil is reduced and the purpose of 'salt removal' is achieved; by the saline-alkali soil conditioner, the osmotic pressure of the saline-alkali land can be improved, the activity of an enzyme system in a plant is increased, the saline-alkali soil conditioner can be complexed with heavy metal ions in the saline-alkali soil so as to form high-molecular metal complexes and thus the pollution of heavy metals to the soil is reduced, the content of nitrogen, phosphorus and sulfur in the soil can be increased and the absorption of the plant to trace elements such as iron, zinc and manganese can be promoted.

Owner:乌鲁木齐金昌隆农业科技有限公司

Urea sulfate and preparation method thereof

InactiveCN102358726AWide variety of sourcesMild process conditionsUrea derivatives preparationOrganic compound preparationUREA SULFATECost savings

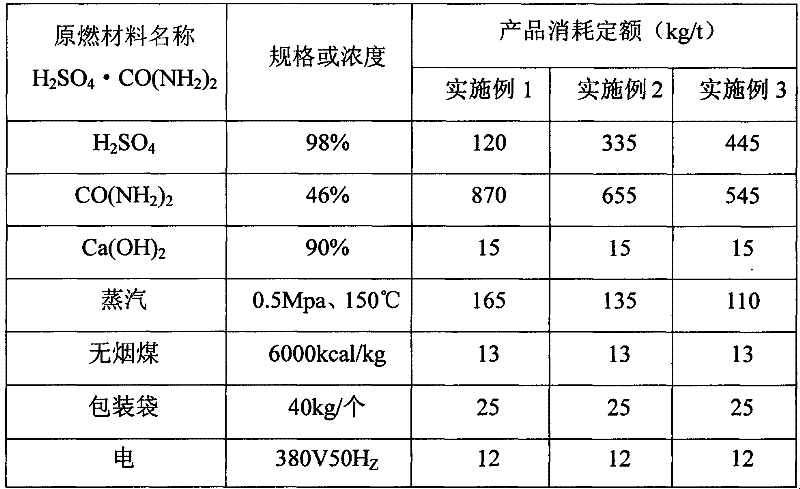

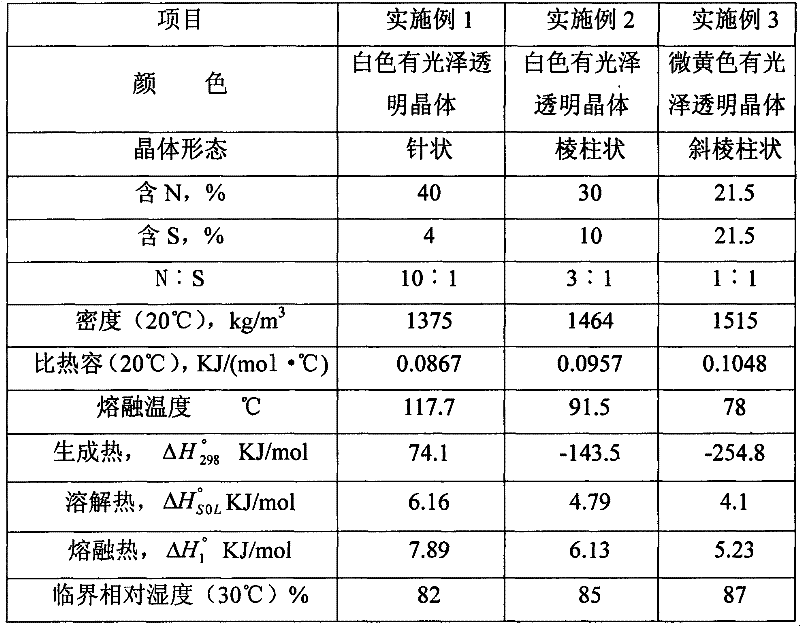

The invention relates to a fertilizer product and a preparation method thereof, and mainly to urea sulfate and a preparation method thereof. Under a melting temperature of 75-117 DEG C, a preheating temperature of 60-100 DEG C, and a mass ratio of a urea solution to a sulfuric acid solution of 11.83:1-2:1, the urea sulfate particles are prepared by a reaction, wherein a mass ratio of nitrogen to sulfur in the urea sulfate particles is 10:1-1:1. With the present invention, the defects of the traditional fertilizer are mainly overcome; the urea sulfate preparation method and the urea sulfate product are provided, with the method, the yield is increased, the product quality and the environment are not affected; the product has excellent advantages of energy-saving and cost-saving during the preparation.

Owner:熊建超

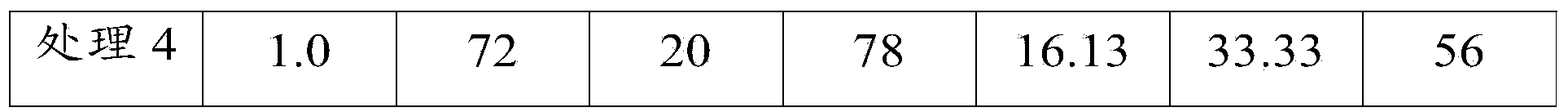

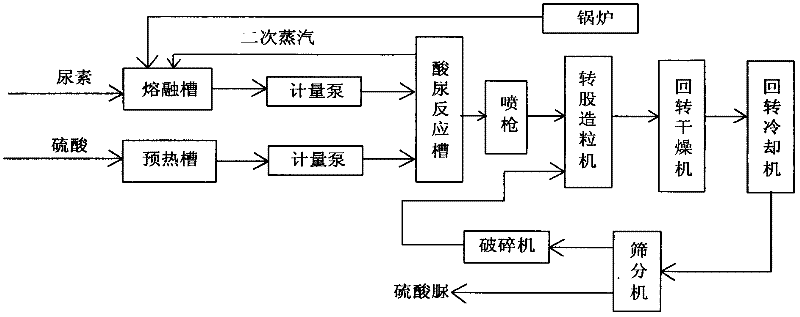

Production process for preparing compound fertilizer through urea sulfate ammoniation method

InactiveCN104108967ASpeed up the flowReduce manufacturing costFertilizer mixturesMaterials preparationSide reaction

The invention discloses a production process for preparing a compound fertilizer through a urea sulfate ammoniation method. The production process includes the steps of urea sulfate solution preparation, material preparation, granulation, drying, crushing, sieving, cooling, coating, packing and other steps. The production process has the advantages that urea can be dissolved without steam, side reactions generating biuret are reduced, the granulation granule-forming rate is high, drying energy consumption is low, the process adaptability is strong, and the product quality is good.

Owner:云中英

Water-soluble fertilizer special for alkaline soil and its preparation method

The invention relates to a water-soluble fertilizer special for alkaline soil and a preparation method of the water-soluble fertilizer special for alkaline soil, in particular to a strong acidic nitrogen phosphorus fertilizer suitable for spray drip irrigation, which belongs to the technical field of fertilizers. The inventive fertilizer has low cost, and convenient storage and transportation, provides a fertilizer source for saline-alkali arid areas in northwestern China such as Xinjiang, is adapted to spray drip irrigation systems in the saline-alkali arid areas, and can amend the alkaline soil. The preparation method comprises mixing monoammonium phosphate 50-95 weight parts, urea sulfate 5-50 weight parts and water to obtain slurry, and then performing spray drying, cooling, and sieving. The prepared fertilizer has low moisture absorption, and employs urea sulfate, which is a nitrogen and sulfur compound fertilizer with strong moisture absorption, in the fertilizer field. The method has simple process, low cost and convenient operation, and can realize large-scale industrial continuous production.

Owner:GUIZHOU CHANHEN CHEM CO LTD

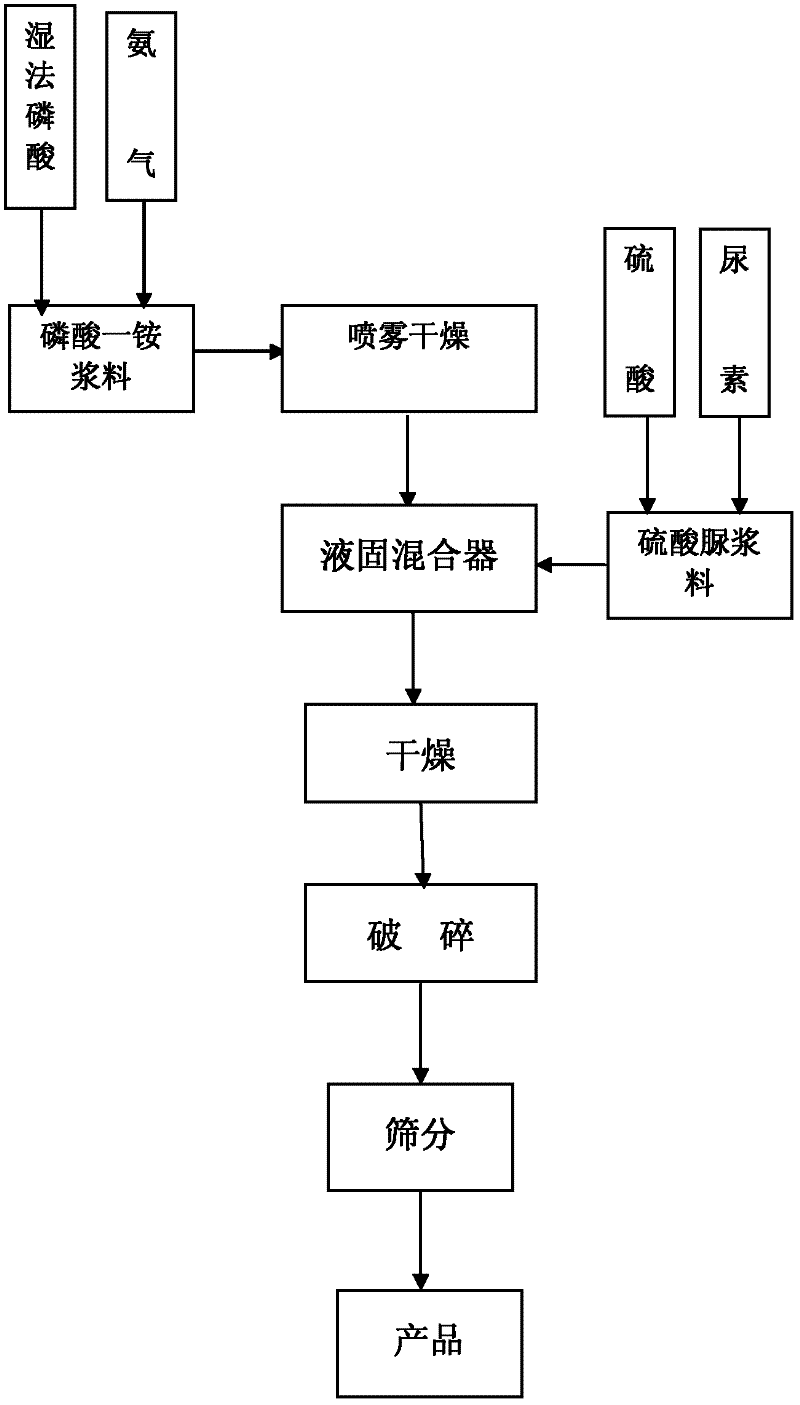

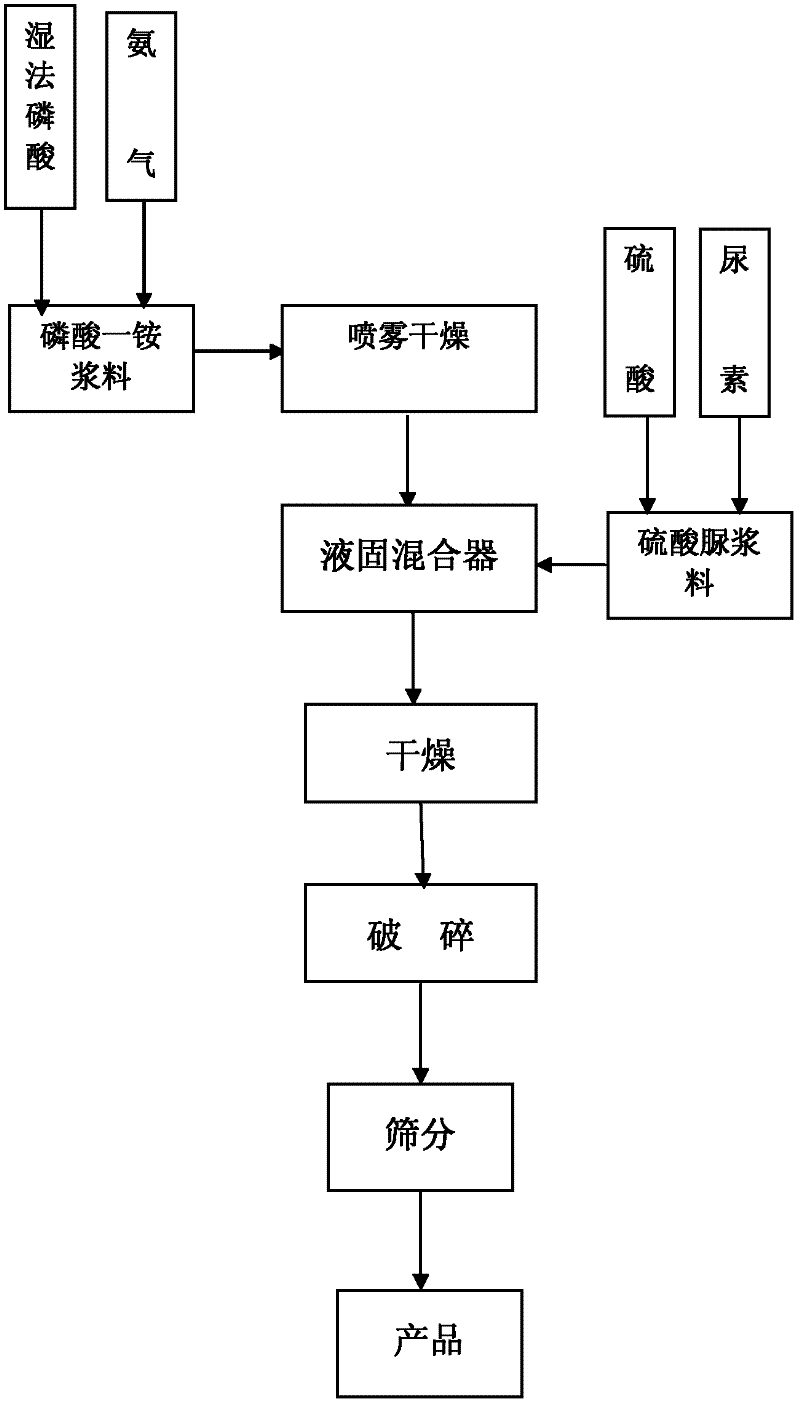

Preparation method of strong-acidic water-soluble fertilizer special for alkaline soil

The invention relates to a preparation method of a strong-acidic water-soluble fertilizer special for alkaline soil, which belongs to the technical field of fertilizers. The method comprises slowly adding urea into 93-98wt% sulfuric acid under stirring while controlling a temperature of slurry in a reactor at 85-90 DEG C, and stopping adding urea when a pH value of the slurry is 1.0-1.3 to obtainurea sulfate slurry; preparing powdered monoammonium phosphate; mixing the urea sulfate slurry 5-50 weight parts with the powdered monoammonium phosphate 50-95 weight parts via a liquid-solid mixer to obtain a semi-finished product; and drying, crushing, and sieving to obtain the strong-acidic water-soluble fertilizer special for alkaline soil. The inventive fertilizer has low production cost, and convenient storage and transportation.

Owner:GUIZHOU CHANHEN CHEM CO LTD

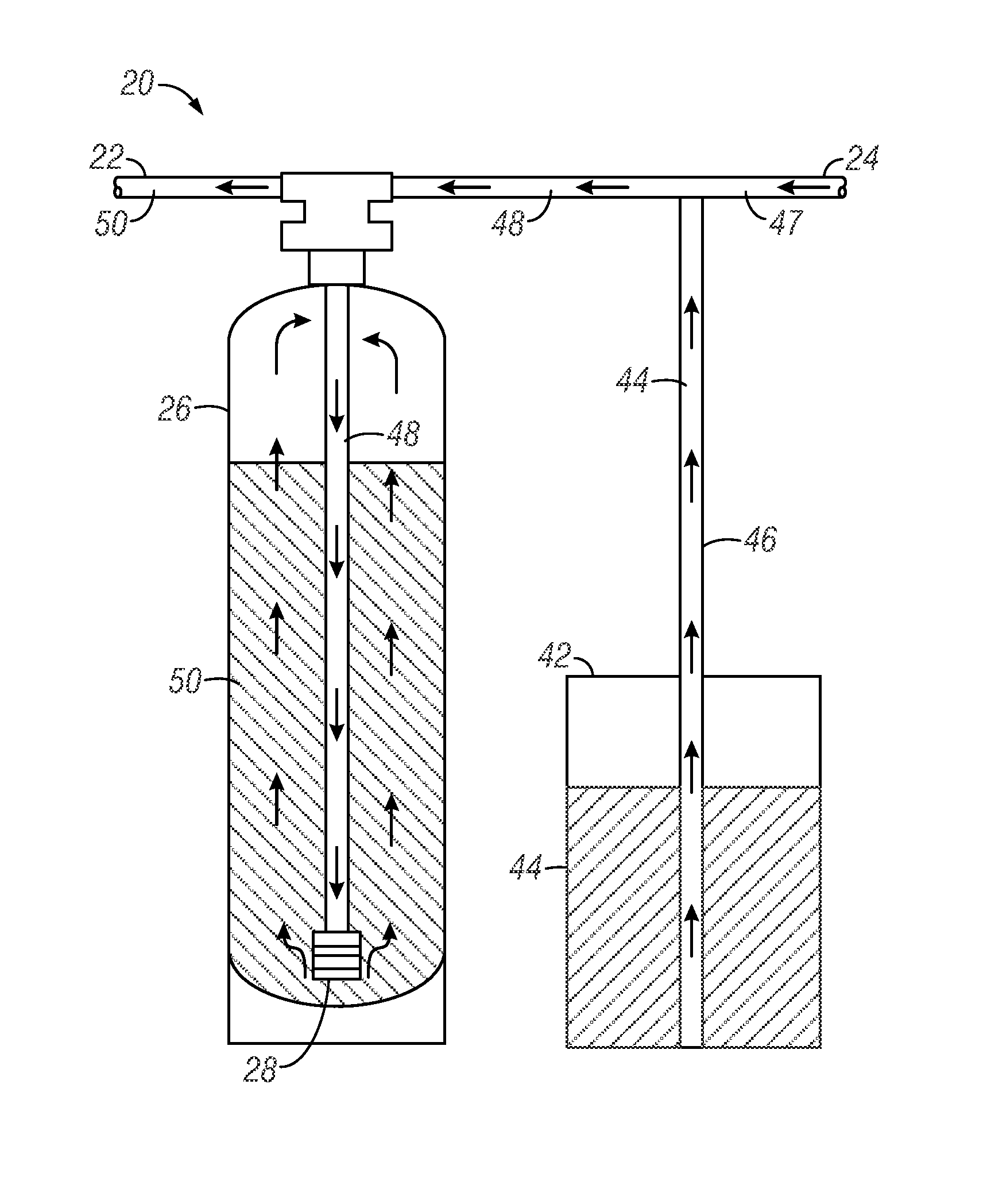

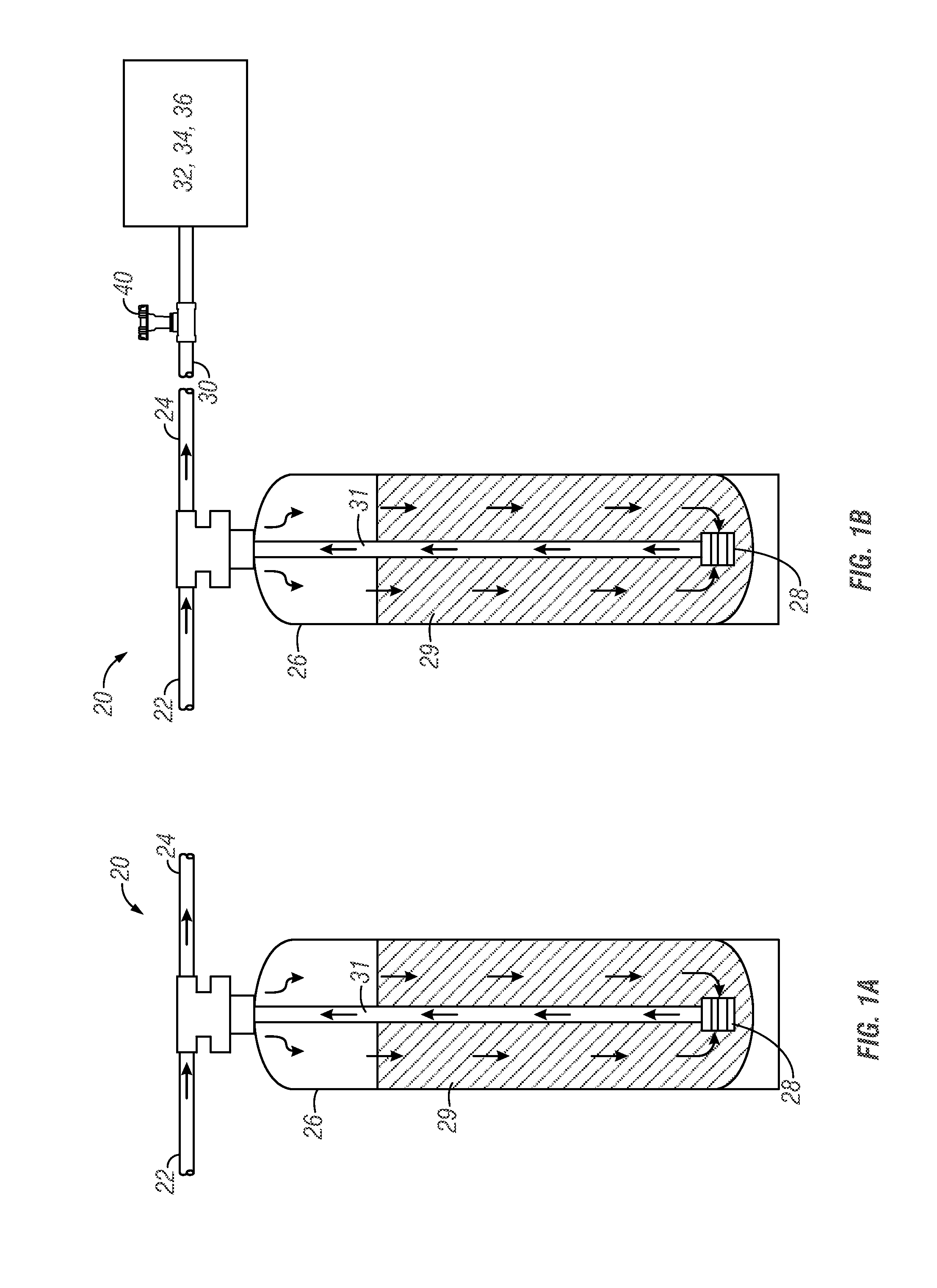

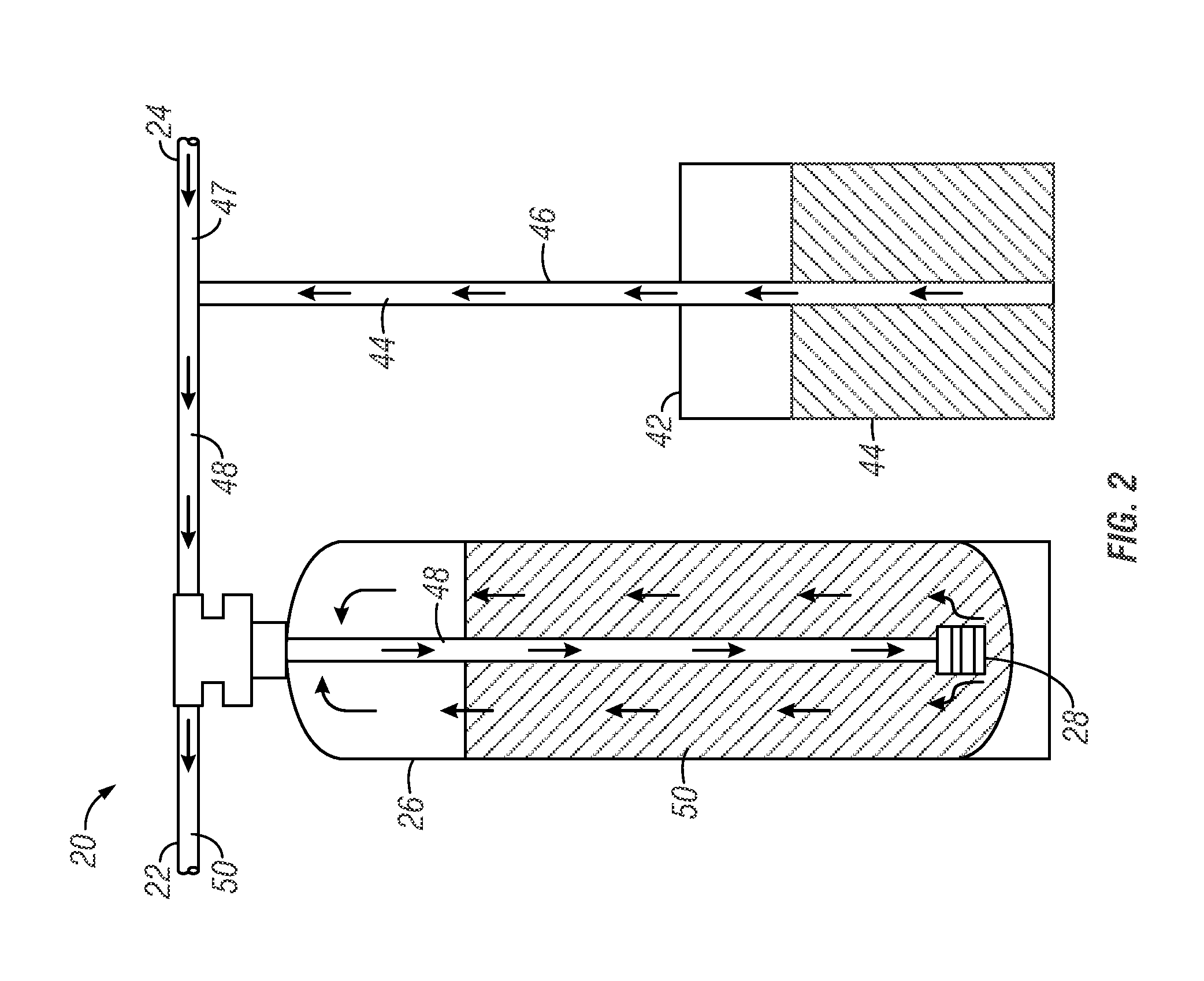

Urea sulfate and sodium chloride blend for regeneration of cation exchange resins

Methods and systems for acid regeneration of ion exchange resins are disclosed. Acid resins designed for use in a variety of cleaning application using a water source use a treated, softened, acidic water source according to the invention. Various methods of using the softened acidic water generated by acid regenerate-able ion exchange resins are disclosed to beneficially reduce spotting, filming and scale buildup on treated surfaces, reduce and / or eliminate the need for polymers, threshold reagents and / or rinse aids, and using protons generated in the acidic water effluent for triggering events useful in various cleaning applications.

Owner:ECOLAB USA INC

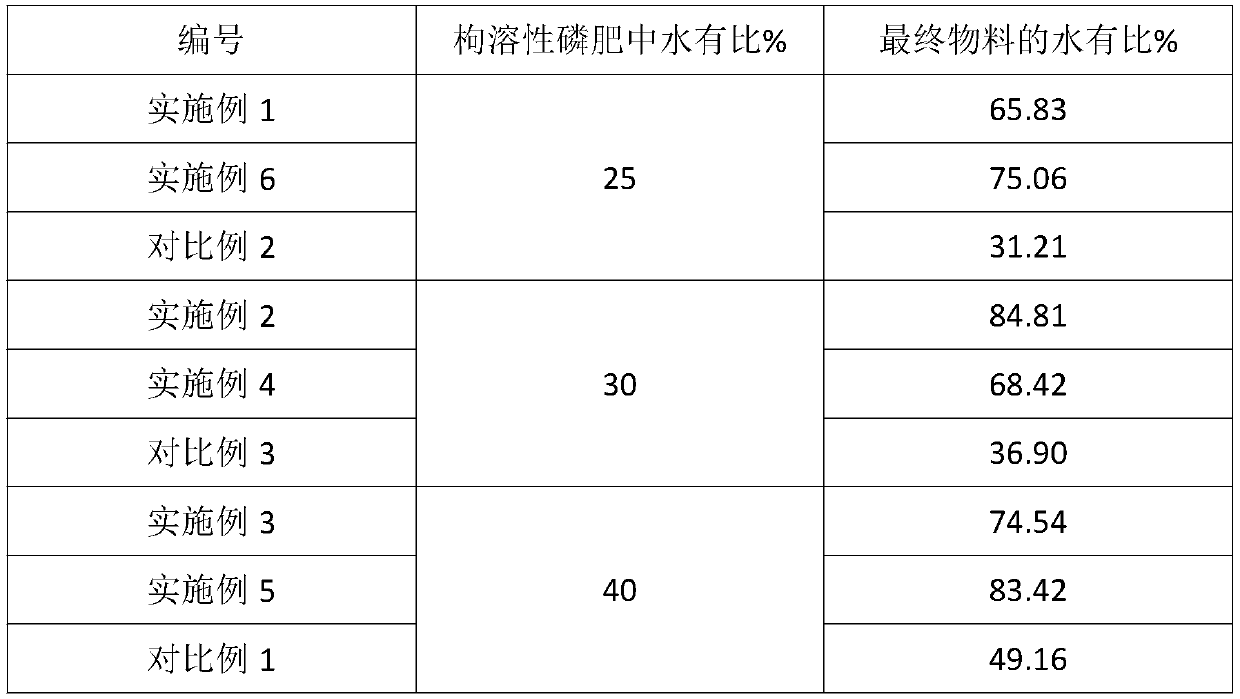

Production method of improving water soluble phosphorus content of phosphate fertilizer soluble in citric acid

PendingCN109593003AReduce lossesProcess stabilityUrea compound fertilisersFertilizer mixturesHydrogenReaction temperature

The invention provides a production method of improving water soluble phosphorus content of a phosphate fertilizer soluble in citric acid. The production method comprises the following steps: (1) mixing reaction: adding urea sulfate which accounts for 10-40% of the phosphate fertilizer soluble in citric acid into the phosphate fertilizer soluble in citric acid and mixing the urea sulfate and the phosphate fertilizer soluble in citric acid at a reaction temperature of 60-90 DEG C for 50-90 min to obtain a material a; (2) curing: curing a material A at 50-60 DEG C for 60-120 min to obtain a material B; and (3) curing: curing a material B at 45-55 DEG C for 1-3 days to obtain a compound fertilizer initial product. By mixing the urea sulfate with the phosphate fertilizer soluble in citric acid, the phosphorus soluble in citric acid is converted into water soluble phosphorus by means of hydrogen ions and acid radical ions after the urea sulfate is dissociated and urea is then complexed withwater soluble phosphorus to obtain the water soluble phosphorus in a complexed state. By treating the phosphate fertilizer soluble in citric acid by means of the method, the water soluble phosphoruscontent in the fertilizer is improved effectively. The method is simple in process and low in cost.

Owner:云南云天化以化磷业研究技术有限公司

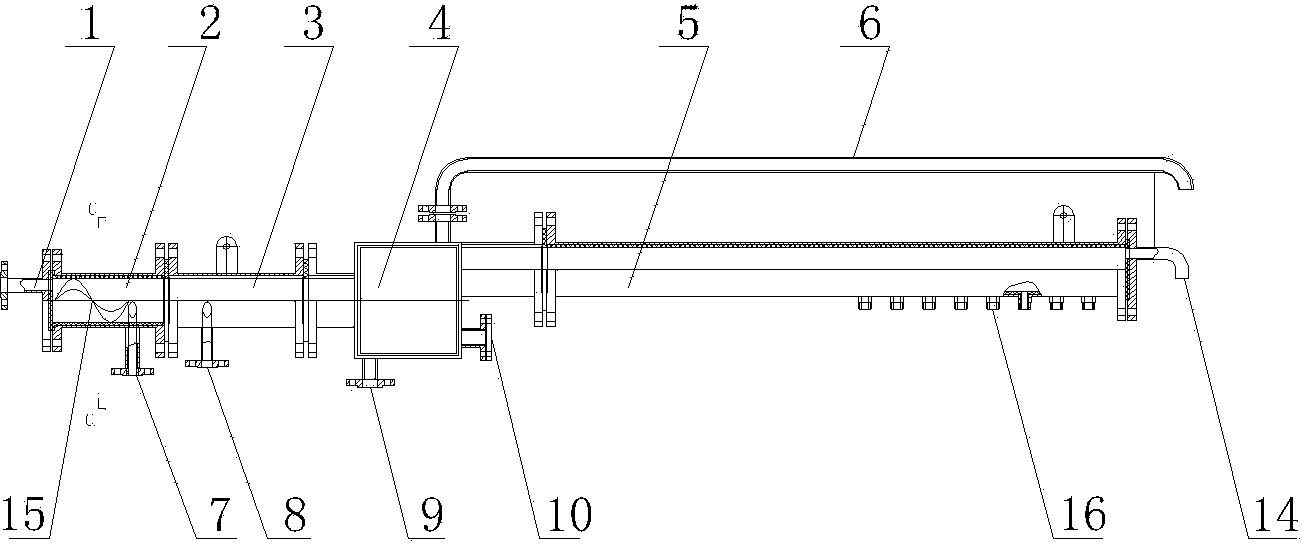

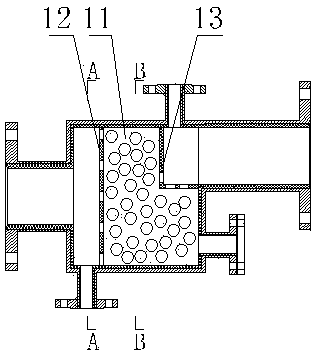

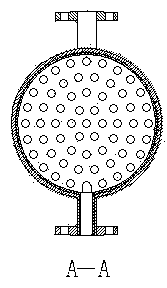

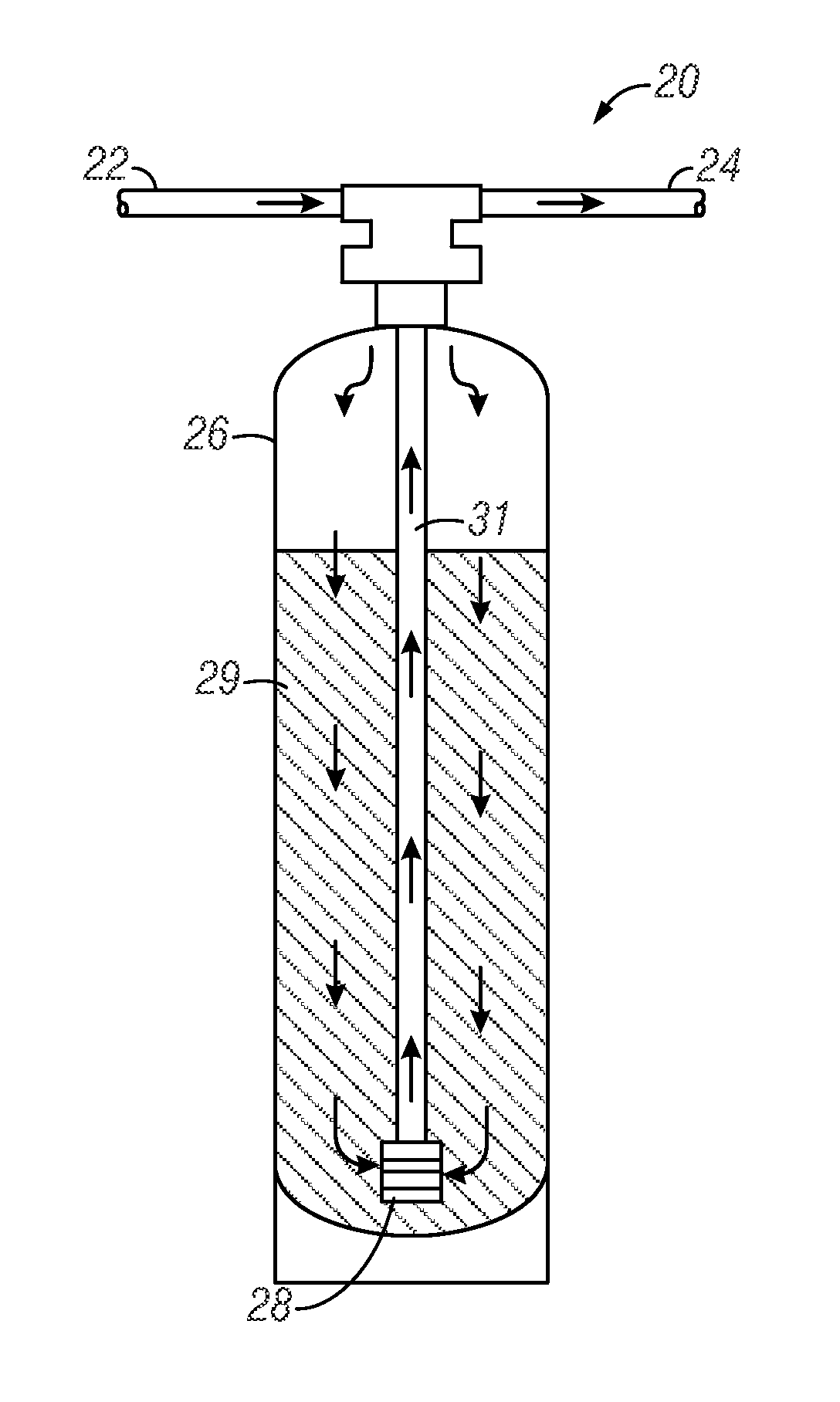

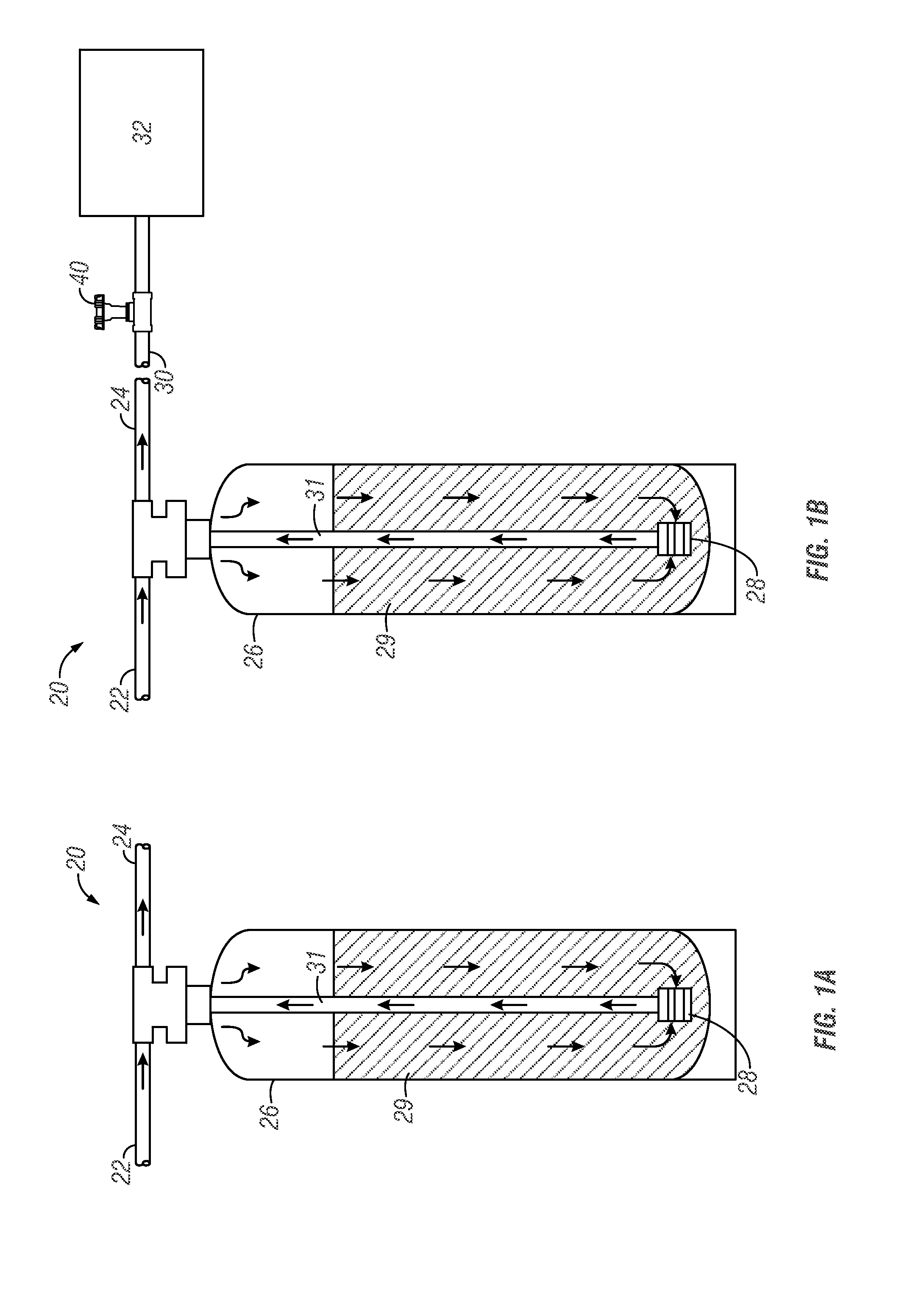

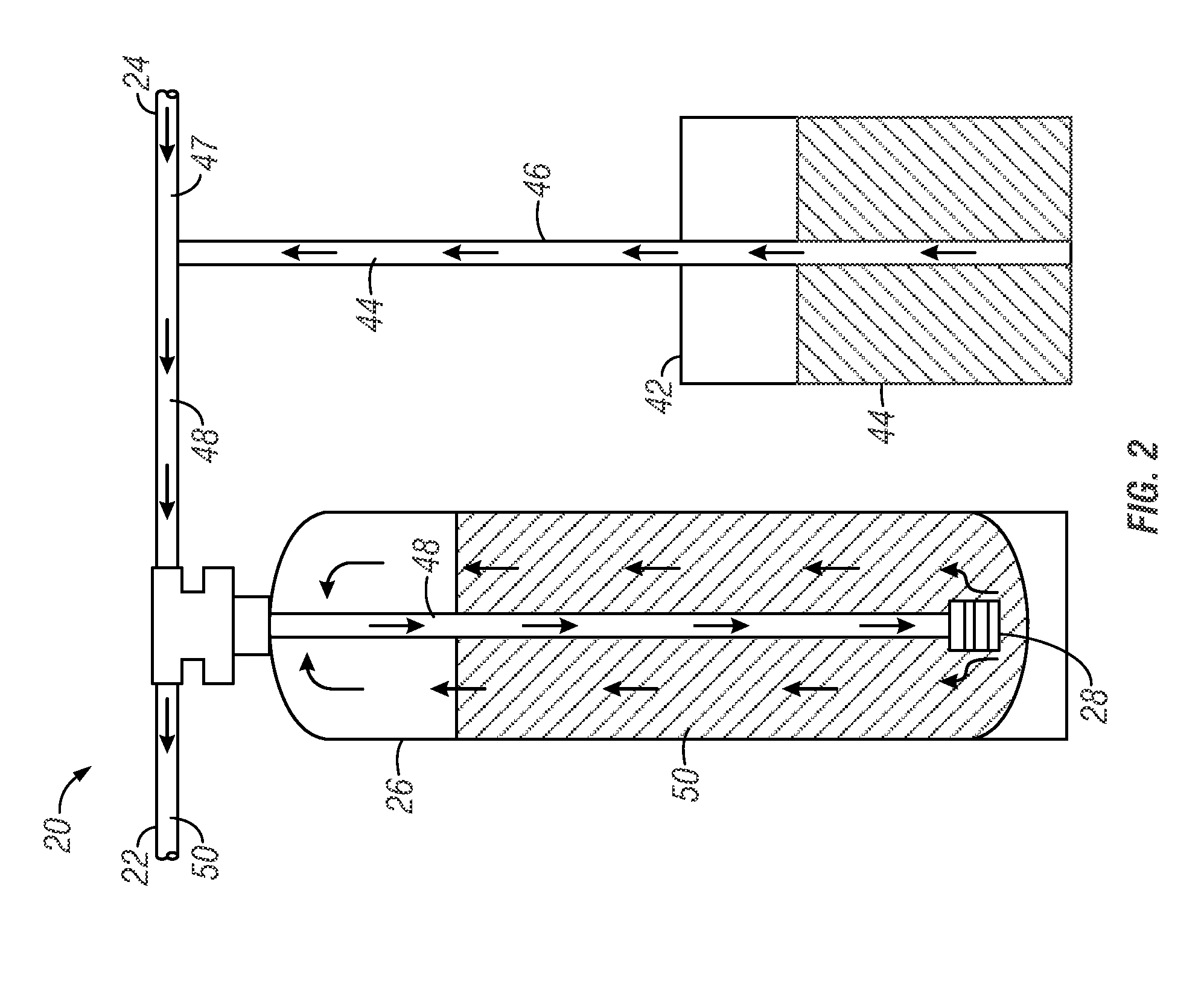

Urea sulfate reactor and application thereof

The invention provides a urea sulfate reactor and a compound fertilizer production process by using the same. While in use, concentrated sulfuric acid and a high-temperature urea solution are proportioned, then are added into the reactor, and are in full contact with each other in a short time; a large amount of reaction heat, a high-temperature viscous urea sulfate liquid, a high-temperature molten urea and high-temperature high-pressure steam are produced by undergoing a chemical reaction, and the high-temperature viscous urea sulfate liquid and the high-temperature molten urea are atomized and sprayed into a pelleting machine through a narrow and small atomizing spray nozzle under a certain pressure; because the atomized high-temperature materials are directly sprayed on the surface of a material bed of materials in the pelleting machine, the material temperature and the liquid phase amount in the pelleting machine can be increased through contact. The materials in the pelleting machine are pelletized into pellets when the pelleting machine rotates, at the same time, the materials sprayed out from the reactor contain sulfuric acid, sulfuric acid can undergo a chemical reaction with ammonium hydrogen carbonate added in the materials and releases water and a large amount of reaction heat, so the material temperature and the liquid phase amount in the pelleting machine are also allowed to be greatly increased, and thus the materials are more easily pelletized.

Owner:辽宁津大肥业有限公司

Disposable special fertilizer for sugar canes and fertilizer applying method

InactiveCN107226754AMeet nutrient needsEnsure nutrient needsAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersNitrification inhibitorsPlant growth

The invention relates to a disposable special fertilizer for sugar canes and a fertilizer applying method, and belongs to the technical field of fertilizer production and application. The special fertilizer comprises the following components as active components in percent by mass: 18-22% of nitrogen, 4-8% of phosphorus pentoxide, 13-18% of potassium oxide, 4-5.5% of urea sulfate, 2-3% of urea formaldehyde, 0.05-0.07% of a nitrification inhibitor, 0.01-0.03% of a urease inhibitor and 0.015-0.035% of a plant growth regulator. The disposable special fertilizer can meet nutrient needs in the whole growth period of the sugar canes, is safe and does not burn roots and seedlings in the earlier stage, does not lose fertilizer efficiency in the later stage, reduces fertilizer waste and increases economic benefits. After the disposable special fertilizer is matched with the fertilizer applying method provided by the invention, the nutrient needs in the whole growth period of the sugar canes can be guaranteed and earthing-up work can be eliminated, so that the labor input is greatly reduced, and more importantly, the labor for applying the fertilizer for many times can be reduced and the conflict between the management need for applying the fertilizer to the sugar canes for many times and the current rural situation can be effectively alleviated.

Owner:JIUHE

Compound fertilizer for greenhouse crops and preparation method thereof

The invention relates to the field of compound fertilizers in agricultural production, in particular to a compound fertilizer for greenhouse crops. The compound fertilizer consists of the following components in mole part: 1 mole of sulfuric acid, 0.01 to 1 mole of phosphate fertilizer, 1 to 10 moles of urea and 1 to 20 moles of water, and the sulfuric acid chemically reacts with the phosphate fertilizer, the urea and the water, so that the compound fertilizer with urea sulfate and urea phosphate as main components is synthesized. The invention can solve the problem of underdeveloped seedlings and underdeveloped fruits of vegetables and other crops in winter sunlight greenhouses.

Owner:NINGXIA UNIVERSITY

High-activity straw organic-inorganic fertilizer and preparation method thereof

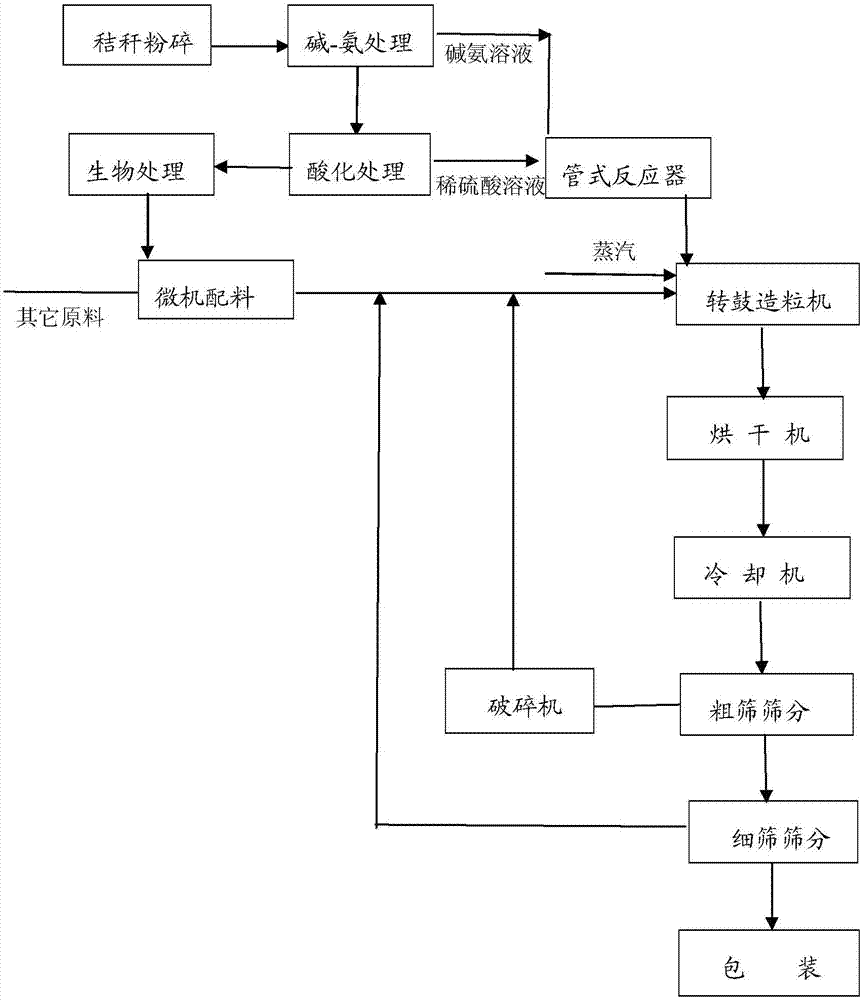

InactiveCN107459425AIncrease profitSolve difficult environmental problemsCalcareous fertilisersAlkali orthophosphate fertiliserChemical treatmentAdhesive

The invention discloses high-activity straw organic-inorganic fertilizer and a preparation method thereof. Straws, high-activity humic acid, inorganic fertilizer and kaolin are added into the materials. The preparation method comprises the following steps: treating the straws by various methods of alkali-ammonia composite treatment, acidification treatment and biological treatment; collecting and utilizing the residual solution; performing material pelleting by taking a calcium sulfate solution and a urea sulfate solution which are generated through the reaction of an alkali-ammonia solution and a dilute sulfuric acid solution as liquid phase required by material pelleting and taking urea sulfate and the kaolin with special viscosity as adhesive required by granulation; and preparing the granular products, wherein no waste water and no waste liquid are discharged in the production, so the environment-protecting problem that the solution is difficult to treat in the existing chemical treatment technology is solved. The product synthesizes the characteristics of organic fertilizer and inorganic fertilizer, and has the effects of improving and activating soil, improving reproduction activity of microorganism in the soil, improving the granular structure of the soil, improving the quality of crops and increasing the yield of the crops.

Owner:天津益农赢丰生态科技有限公司

Compound microorganism fertilizer with high nutrition content, and preparation method thereof

InactiveCN108276213ANo pollutionPromote growthAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersBacillus licheniformisChemical structure

The invention provides a compound microorganism fertilizer with a high nutrition content, and a preparation method thereof, and relates to the technical field of plant fertilizer. The compound microorganism fertilizer with the high nutrition content is prepared from the following raw materials: saccharomycetes, acetic bacteria, yield improvement bacteria, potassium humate, bacillus licheniformis,trichoderma koningii, bacillus megatherium, furfural residue, waste sugar solution, wheat bran, amino acid, microelement, nitramine phosphorus, urea sulfate, calcium magnesium phosphate, monopotassiumphosphate, potassium fulvic acid and magnesium citrate. According to the compound microorganism fertilizer with the high nutrition content, no environment pollution is caused, crop growth can be accelerated, crop quality is improved, the biological activity of soil can be improved, the substance circulation of a soil ecological system is accelerated, harmful cultures in soil can be effectively prevented from breeding, organic nutriments are provided, the physical and chemical structure of the soil is improved, and the contents of nutrition substances in the soil are improved.

Owner:WUHU OUBIAO AGRI DEV

Urea sulfate coated urea slow-release granular fertilizer and preparation method therefor

ActiveCN105001023ARealize double-membrane double-controlling effectLow costUrea compound fertilisersFertilizer mixturesCoated ureaMetasilicate

The invention discloses a urea sulfate coated urea slow-release granular fertilizer. The urea sulfate coated urea slow-release granular fertilizer is prepared through the following steps of: adding 100kg of urea granules of which the diameters are 2-4.5mm to a rotary drum type coating machine, preheating the urea granules to 40-45 DEG C, spraying 1-10kg of a binder namely urea sulfate, uniformly mixing the preheated urea granules and the urea sulfate so as to obtain a mixture, spraying 1-20kg of metasilicate powder, cooling the mixture and the metasilicate powder, spraying 1-10kg of mounting addition agents (a mixture of solid paraffin and liquid paraffin) of which the temperature is 50-60 DEG C, cooling the mixture, the metasilicate powder and the mounting addition agents to a room temperature, and repeating the coating operation 2-3 times. The binder namely the urea sulfate is prepared through the steps of slowly adding1-2kg of concentrated sulfuric acid of 90-98wt% to every 1-10kg of urea and performing a reaction in a reaction tank. The urea sulfate coated urea slow-release granular fertilizer disclosed by the invention adopts a urea sulfate metasilicate slow-release film, tests prove that the urea sulfate metasilicate slow release film has a favorable slow-release effect, and in the slow-release process, the slow-release film is not liable to collapse and is easy to degrade. The urea sulfate has subacidity, so that the application range of the urea sulfate is wider than that of sulfur coating urea. The urea sulfate coating film realizes double-film double-control effects, and has the advantages of high efficiency, environmental protection, low cost and the like.

Owner:JILIN YUNTIANHUA AGRI DEV CO LTD

Urea sulfate fertilizer additive and preparation method thereof

InactiveCN108218564APromote seedling growthImprove stress resistanceAnimal corpse fertilisersNitrogenous fertilisersAlcohol sugarsPotassium

The invention discloses a urea sulfate fertilizer additive, which is prepared from the following raw materials in parts by weight: 2 to 4 parts of amino acid, 2 to 4 parts of organic acid, 2 to 4 parts of low-molecular carbohydrate, 1 to 3 parts of potassium polyacrylate, 5 to 7 parts of fulvic acid, 13 to 15 parts of maltodextrin, 22 to 25 parts of water-soluble starch, 1 to 3 parts of nanometeriron oxide, 1 to 2 parts of nanosilicon dioxide powder, 1 part of zinc citrate, 1 part of sugar alcohol, 2 parts of polyacrylamide, 0.5 part of vitamin B, 2 to 4 parts of anti-blocking agent, 0.5 to 3parts of animal source raw material, 0.5 to 3 parts of plant source raw material, and 1 to 3 parts of pH regulator. The preparation method comprises the steps of mixing the effective components according to the matching ratio, adjusting the pH value, uniformly stirring, smashing, uniformly mixing, and obtaining the urea sulfate fertilizer additive. The urea sulfate fertilizer additive provided bythe invention can meet the requirement of crops on growth elements when being applied independently, and is good for improving a complexing capacity of trace elements when being added into a urea sulfate composite fertilizer, the fertilizer efficiency and the utilization ratio of the urea sulfate fertilizer are improved, and the yield and the quality of the crops is remarkably improved.

Owner:河南兴发昊利达肥业有限公司

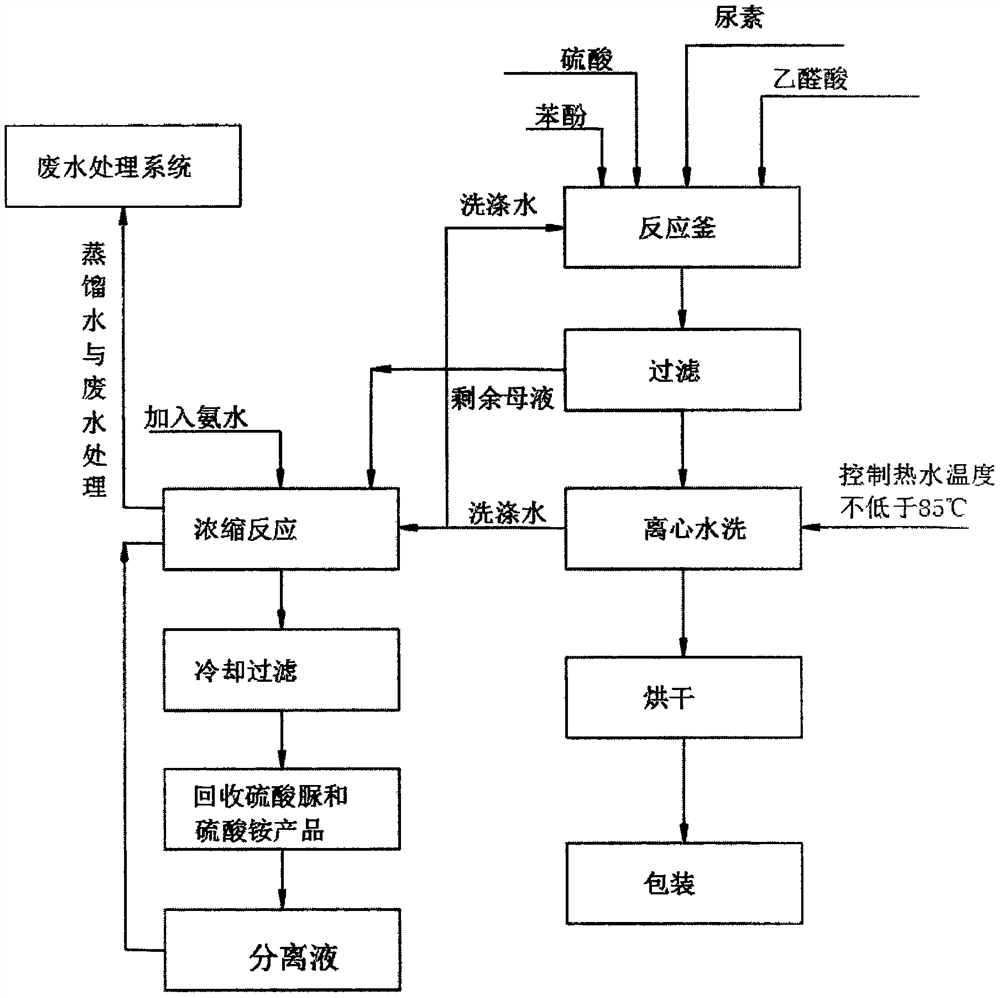

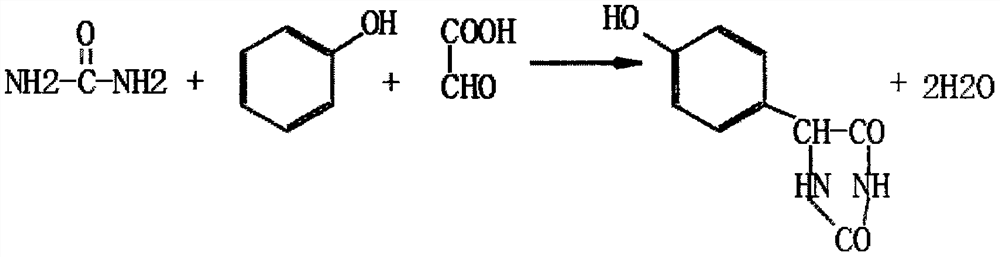

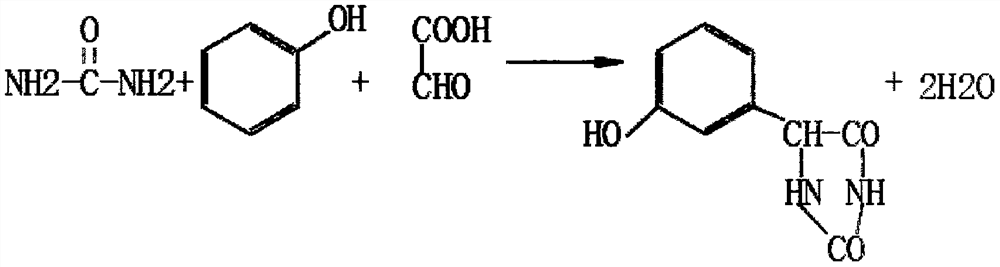

Production process of DL-p-hydroxybenzene hydantoin and urea sulfate/ammonium sulfate thereof

InactiveCN111807877AReduce processing costsQuality improvementUrea derivatives preparationOrganic compound preparationGlyoxylic acidBiochemical engineering

The invention discloses a production process of DL-p-hydroxybenzene hydantoin and urea sulfate / ammonium sulfate thereof. The production process comprises the following steps that 1, phenol, urea and sulfuric acid are added into a reaction kettle according to the molar ratio, the temperature is slowly increased, the reaction temperature is controlled to range from 70 DEG C to 95 DEG C, and heat preservation is conducted for 30 min; 2, glyoxylic acid is dropwise added into the reaction solution in step 1, and the dropwise adding time is controlled to be 2-8 h; and 3, after the drop-by-drop adding reaction is finished, the temperature in the reaction kettle is controlled to be not lower than 85 DEG C, the temperature is kept for 2-5 hours, and discharging is performed. Compared with a hydrochloric acid method for synthesizing the DL-p-hydroxybenzene hydantoin product, the process provided by the invention has the advantages that the product quality and yield are improved, and the problemsthat in the process of synthesizing the DL-p-hydroxybenzene hydantoin product by the hydrochloric acid method, a large amount of HCL gas is discharged from a production site, and other organic matters such as waste hydrochloric acid influence a production environment and production equipment are solved.

Owner:DINGTAO SANHUA PHARMA

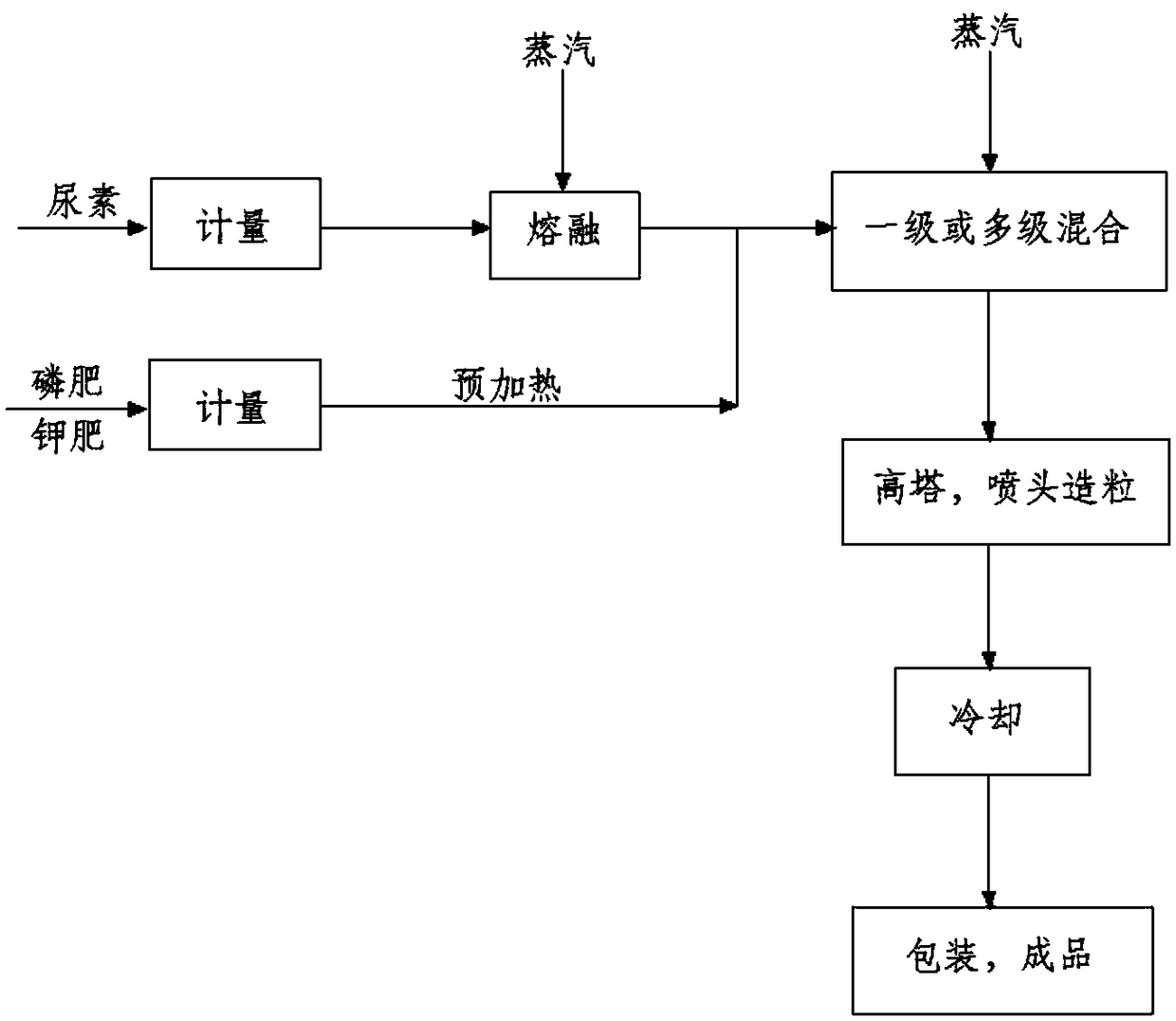

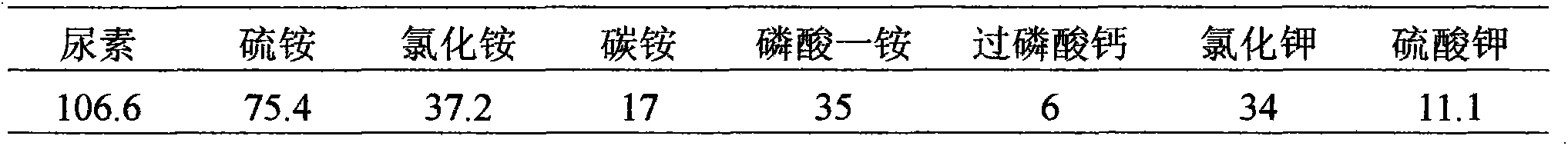

Production method of urea-based composite fertilizer

The invention relates to a production method of a urea-based nitrogen-phosphorus-potassium composite fertilizer. The production method comprises the following steps: carrying out a reaction among urea and sulfuric acid and water according to a certain ratio so as to generate a urea sulfate solution; sending the urea sulfate solution into a pelletizer, and carrying out a neutralization reaction between the urea sulfate solution and ammonia introduced into the pelletizer, pelletizing the reaction product and other basal fertilizers containing nitrogen, phosphorus and potassium in the pelletizer, drying, screening, cooling and packaging to obtain the final qualified product. By reasonable utilization of various kinds of reaction heat, energy consumption of production is greatly reduced. As the reaction for generation of urea sulfate is carried out at low temperature (60-80 DEG C), hydrolysis and condensation reaction of urea are less. Then, content of biuret of the final product is very low. Product quality can be fundamentally guaranteed. The technology is simple, and production cost is lower. The production method is easy to apply to existing composite fertilizer production equipment.

Owner:孙建和

Method for Lowering pH Using Urea Sulfate in the Presence of Corrosion Inhibitor

InactiveUS20130065971A1Corrosion minimizationWaste water treatment from quariesBiocideAqueous solutionMetal

A method for adjusting pH of an aqueous solution during a processing event that includes the addition of urea sulfate to the solution in the presence of a corrosion inhibitor. The processing event can be relating any number of applications, including but not limited to, textile, paper, agricultural, metals, and water applications.

Owner:JSK CAPITAL

Urea sulfate and sodium chloride blend for regeneration of cation exchange resins

ActiveUS20130192638A1Cation exchanger materialsTableware washing/rinsing machine detailsWater sourceIon exchange

Methods and systems for an integrated acid regeneration of ion exchange resins are disclosed for use in cleaning applications. Acid resins designed for use in a variety of cleaning application using a treated, softened, acidic water source are disclosed. Various methods of using the softened acidic water generated by acid regenerate-able ion exchange resins within a cleaning application, e.g. ware wash machine, are disclosed to beneficially reduce spotting, filming and scale buildup on treated surfaces, reduce and / or eliminate the need for polymers, threshold reagents and / or rinse aids, and using protons generated in the acidic water effluent for triggering events useful in various cleaning applications.

Owner:ECOLAB USA INC

Modified cotton straw adsorbent for removing pyrazinamide through adsorption

InactiveCN106975459AStrong selective adsorptionImprove adsorption capacityOther chemical processesWater contaminantsLithium chlorideSorbent

The invention discloses a modified cotton straw adsorbent for removing pyrazinamide through adsorption. The modified cotton straw adsorbent is prepared through the following steps of selecting cotton straws of which the particle size is 4-6mm, washing the cotton straws with deionized water, absolute ethyl alcohol and an NaOH solution and drying to obtain a substance Q; modifying the substance Q with a mixed liquid prepared from urea sulfate, guanidine nitrate, rhodium nitrate, cobalt sodium nitrate and iridous chloride, thus obtaining a substance R; modifying the substance R with a mixed liquid prepared from ceric ammonium nitrate, pyridine sulfur trioxide, duroquinol, pyridine sulfur trioxide, duroquinol, 1,5-naphthalene disulfonic acid, 2-amino-3-bromobenzoic acid and N-ethyl acetamide, thus obtaining a substance S; and modifying the substance S with a mixed liquid prepared from cupric nitrate, cadmium nitrate, lithium chloride, magnesium chloride and stannous chloride, thus obtaining a substance, namely the modified cotton straw adsorbent for removing the pyrazinamide through adsorption.

Owner:北京益净环保设备科技有限公司

Acid cleaning and corrosion inhibiting compositions comprising gluconic acid

InactiveUS20110245129A1Prohibits all corrosionBiodegradableDetergent mixture composition preparationInorganic non-surface-active detergent compositionsO-Phosphoric AcidGluconic acid

Owner:ECOLAB USA INC

Method for carrying out coupling and extraction separation treatment on waste sulfuric acid by reaction between urea and sulfuric acid

InactiveCN107089930AAchieving processing powerImplement resourcesUrea derivatives preparationOrganic compound preparationSolventImpurity

The invention discloses a method for carrying out coupling and extraction separation treatment on waste sulfuric acid by reaction between urea and sulfuric acid. In a technological process of the invention, reaction between urea and waste sulfuric acid is carried out to produce urea sulfate as an additive of a composite fertilizer; meanwhile, in an extraction separation process of a coupling solvent, organic impurities contained in the waste sulfuric acid are subjected to extraction separation, and the extracted solvent is distilled and recycled for repeated utilization. The invention provides a method for treating organic waste sulfuric acid with mild condition. Organic impurities in the waste sulfuric acid can be effectively separated, and sulfuric acid components in the waste sulfuric acid can be converted into a urea sulfate product. Compared with an existing industrial treatment method of the waste sulfuric acid, the method disclosed by the invention has the advantages of lower energy consumption, simplicity in operation, mild conditions and the like.

Owner:SICHUAN UNIV +1

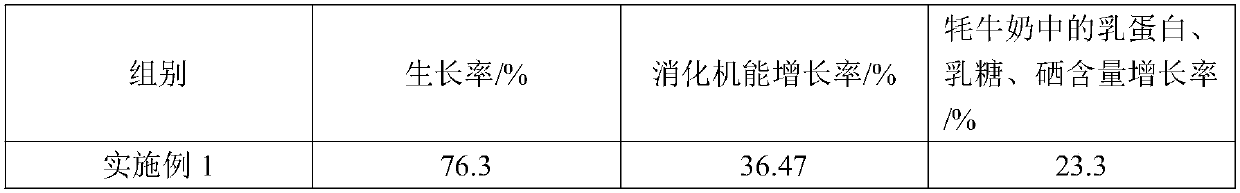

Yak breeding method

InactiveCN107667973APromote digestion and absorptionImprove the immunityFood processingAnimal feeding stuffAnimal scienceSelenium methionine

The invention discloses a yak breeding method. Yaks are bred by basic selenium-added daily ration, a healthcare additive, a nutrient additive and smashed forage grass through reasonable matching, theselenium-enriched feed is mixed with feed in the growth period of the yaks in combination with characteristics of yak growth and development, with the smallest feed consumption amount, the weight increase and selenium content can be guaranteed as high as possible, and the growth performance of the yaks is improved. The basic selenium-added daily ration is composed of mulberry leaf powder, urea phosphate, urea sulfate, green and dry oat grass, molasses, bran, edible salt, bone meal, selenium cysteine and selenium methionine.

Owner:孝感市鲁建农业开发有限公司

Denitration method of nitration waste acid

InactiveCN108033536AHigh operating costsLow running costWater contaminantsWater/sewage treatmentNitrationReaction temperature

The invention discloses a denitration method of nitration waste acid. The denitration method comprises the following steps: dropwise adding waste acid containing nitric acid and nitrous acid into a urea sulfate solution, wherein no yellow smoke is emitted during dropwise addition and the reaction temperature is 40-100 DEG C; after the dropwise addition, when no gas is emitted, cooling to room temperature, and detecting the nitrate content and the nitrite content of the waste acid, wherein the mass fractions of nitric acid and nitrous acid in the waste acid after denitration are lower than 0.1%and the denitration rate is 98% or above. By the denitration method, the nitric acid and the nitrous acid in the waste acid after a nitration reaction are reduced into clean nitrogen, carbon dioxideand water; the treatment condition is mild; the denitration rate is high; the denitration method has the advantages of low three-waste emission, low operating cost, high denitration rate, environmentfriendliness and the like, and can be applied to industrial production.

Owner:JIANGSU FENGSHAN GROUP

Urea sulfate microbial fertilizer for peanut and preparation method of urea sulfate microbial fertilizer

InactiveCN108129189AEmission reductionReduce pollutionCalcareous fertilisersAlkali orthophosphate fertiliserAnticaking agentPhosphate

The invention discloses a urea sulfate microbial fertilizer for peanut. The urea sulfate microbial fertilizer comprises the following raw materials: 100-140 parts of urea sulfate, 120-180 parts of urea, 110-140 parts of potassium sulphate, 100-150 parts of potassium nitrate, 280-335 parts of monoammonium phosphate, 70-90 parts of a compound microbial agent, 60-70 parts of a urea sulfate sustainedrelease function fortifier, 18-22 parts of a urea sulfate fertilizer microbial growth promoter, 0-10 parts of filler, and 10-12 parts of an anticaking agent; the urea sulfate sustained release function fortifier comprises 50 parts of humic acid, 7 parts of nanometer dolomite powder, 2 parts of borax, 2 parts of ferrochel, 2 parts of nanosilicon dioxide, 1 part of chelated zinc, and 1 part of a nitrification inhibitor; the urea sulfate fertilizer microbial growth promoter comprises 6 parts of soluble starch, 4 parts of soluble dextrin, 3 parts of citric acid, 2 parts of water retaining agent, 1part of malic acid, 1 part of yeast powder, 1 part of sugar alcohol, 1 part of polyacrylic acid, and 1 part of fertilizer synergist. The ammonia volatilization amount is reduced by 30-40%, and the growth of the peanut on the seedling stage is promoted by 20-35%.

Owner:河南兴发昊利达肥业有限公司

Special bio-organic fertilizer for beta vulgaris and preparation method of bio-organic fertilizer

PendingCN110229037AIncrease the sugar contentAvoid harmBio-organic fraction processingAlkali orthophosphate fertiliserDecompositionBiological activation

The invention discloses a special bio-organic fertilizer for beta vulgaris and a preparation method of the bio-organic fertilizer. The special bio-organic fertilizer for the beta vulgaris comprises the following components, in parts by mass: 25-30 parts of beta vulgaris tail roots, 25-35 parts of a sugar refinery residue mixture, 20-30 parts of cow and sheep dung, 3-5 parts of an activation biological fermentation liquid, 3-5 parts of a synergist, 8-10 parts of a yeast urea sulfate concentrate, and 0.2-0.5 part of concentrated bacterial powder. The preparation method comprises the following steps: (1) performing mixing under stirring; (2) performing fermentation culture; (3) performing aging decomposition; (4) performing drying; (5) performing granulation; and (6) performing coating. The method provided by the invention has the beneficial effects of realizing comprehensive utilization of the beta vulgaris tail roots, the sugar refinery residue and the yeast concentrate in a sugar refinery, solving the difficult problem of treatment of the three major waste, avoiding pollution to the environment by the three major waste, effectively utilizing multiple nutrient elements contained inthe three major waste, and forming the special bio-organic fertilizer capable of ameliorating soil, improving the sugar content of the beta vulgaris and increasing the yield of the beta vulgaris for the beta vulgaris.

Owner:内蒙古佰惠生新农业科技股份有限公司 +1

Method for preserving food and method for cleaning surfaces

InactiveUS20150148422A1Enhance and secure growth performanceDecrease pathogen loadBiocideAccessory food factorsMycotoxinPreserved Foods

A method for using urea sulfate as an anti-microbial agent, anti-mold agent, anti-fungal agent, and pH adjusting compound with the benefit of adding nitrogen and sulfur to the food supply. Urea sulfate provides a fundamental contribution to feed hygiene, as it suppresses the growth of mold and thus restricts the potential effect of mycotoxins. Consequently, feed safety is improved by adding this compound.

Owner:JSK CAPITAL

Compound detergent assistant as well as preparation method and application thereof

PendingCN110777020AEasy to operateSuitable for industrial productionSoap detergents with organic compounding agentsOrganic detergent compounding agentsFiberAcetic acid

The invention provides a compound detergent assistant as well as a preparation method and application thereof and belongs to the technical field of detergent assistants. The compound detergent assistant provided by the invention is prepared from the following components in parts by mass: 30-35 parts of 2-carboxyethylthiosuccinic acid, 5-8 parts of polyacrylic acid, 1-5 parts of glacial acetic acid, 3-5 parts of urea sulfate and 40-65 parts of water. The compound detergent assistant provided by the invention has very good chelating performance and dross dispersion performance upon ions of calcium, magnesium and iron, generation of precipitate in the printing and dyeing finishing processing process and re-contamination of metal salts upon various fibers. In addition, after the soaping of thecompound detergent assistant provided by the invention, a dyed cotton fabric is most approximately neutral; in terms of soaping performance, comparison experiment of the compound detergent assistantprovided by the invention and a dioscorea nipponica acidic soap detergent is implemented, tests show that the compound detergent assistant provided by the invention is good in color fastness and approximate in color change after soaping of black, red and turquoise blue textiles.

Owner:JIANGMEN POLYTECHNIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com