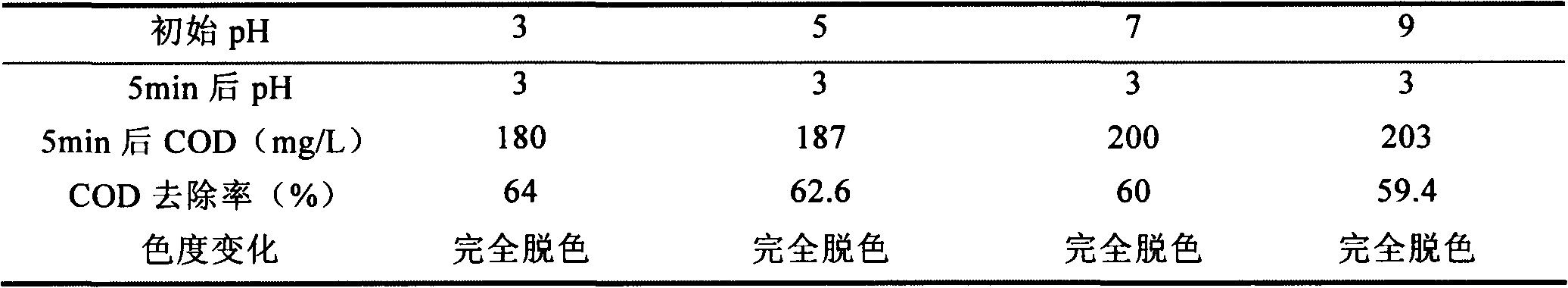

Patents

Literature

86 results about "Turquoise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Turquoise is an opaque, blue-to-green mineral that is a hydrated phosphate of copper and aluminium, with the chemical formula CuAl₆(PO₄)₄(OH)₈·4H₂O. It is rare and valuable in finer grades and has been prized as a gemstone and ornamental stone for thousands of years owing to its unique hue. In recent times, turquoise has been devalued, like most other opaque gems, by the introduction onto the market of treatments, imitations and synthetics.

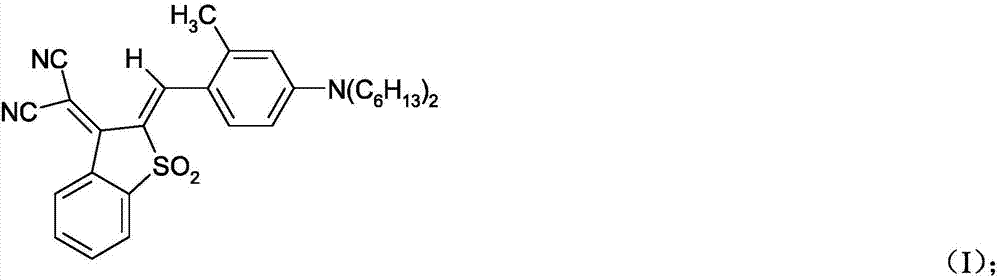

High-fastness turquoise blue disperse dye composition

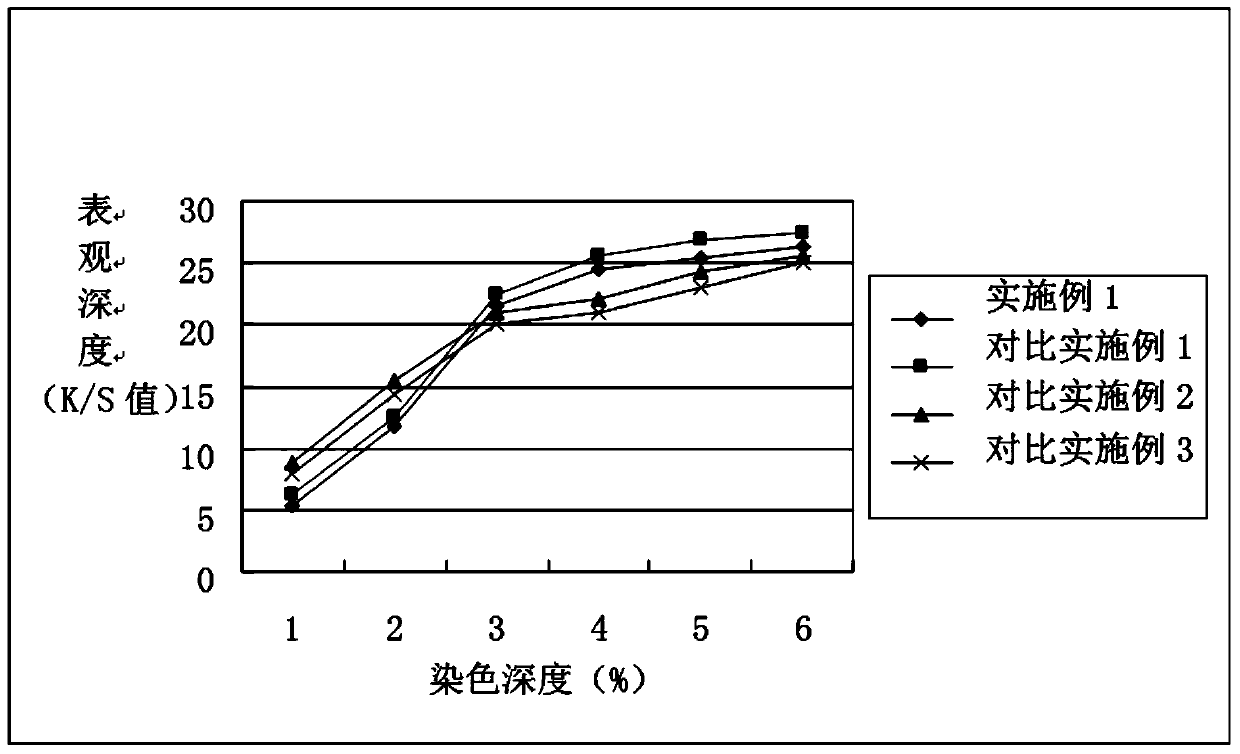

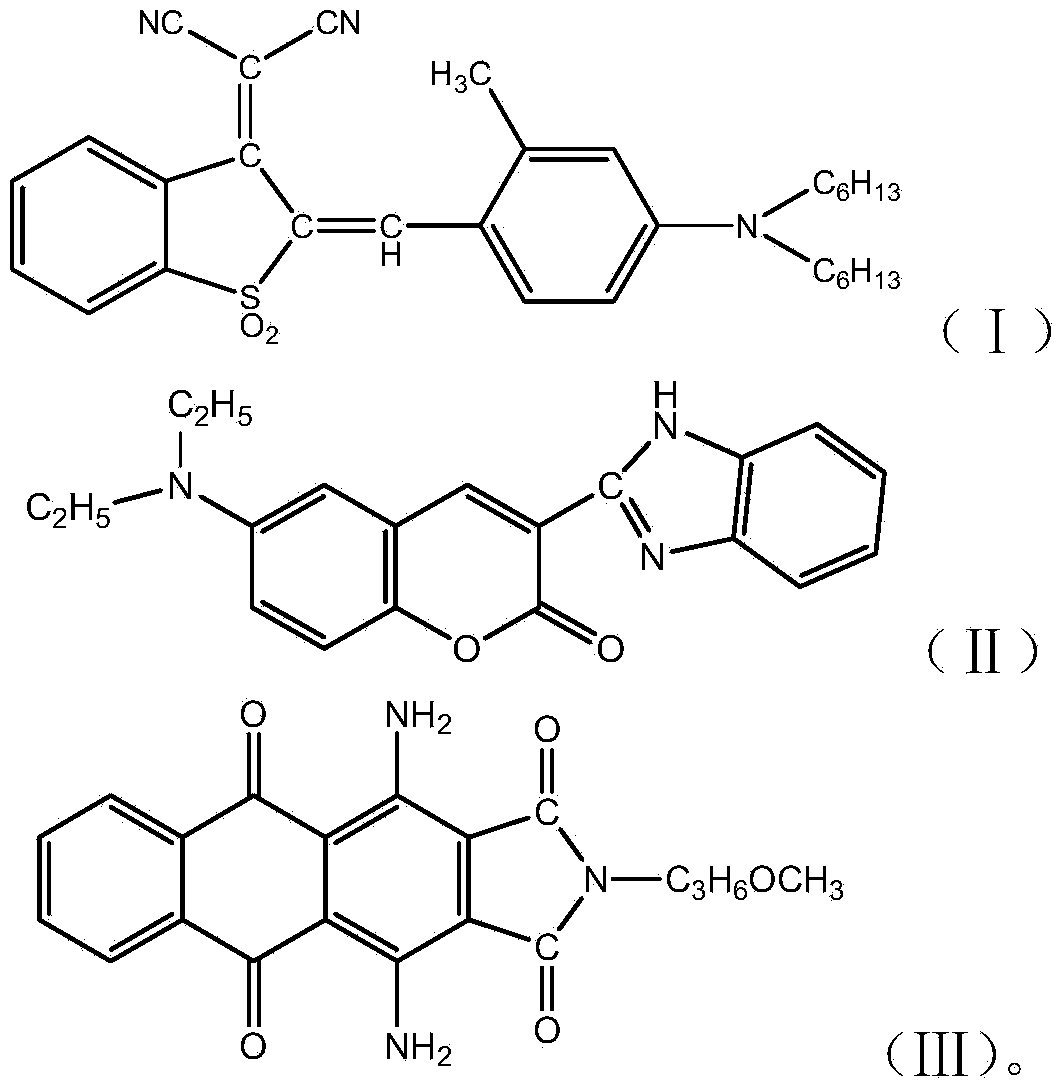

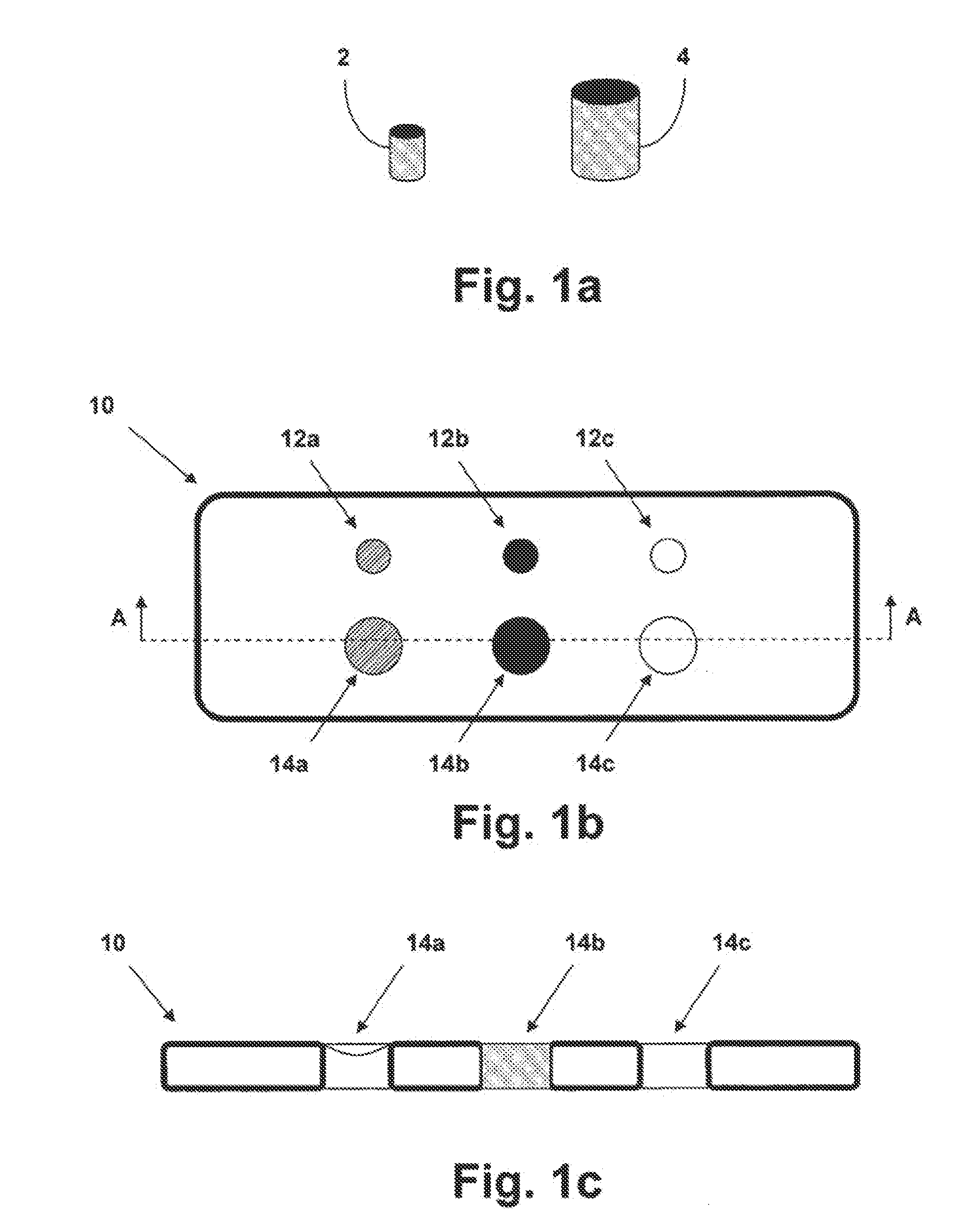

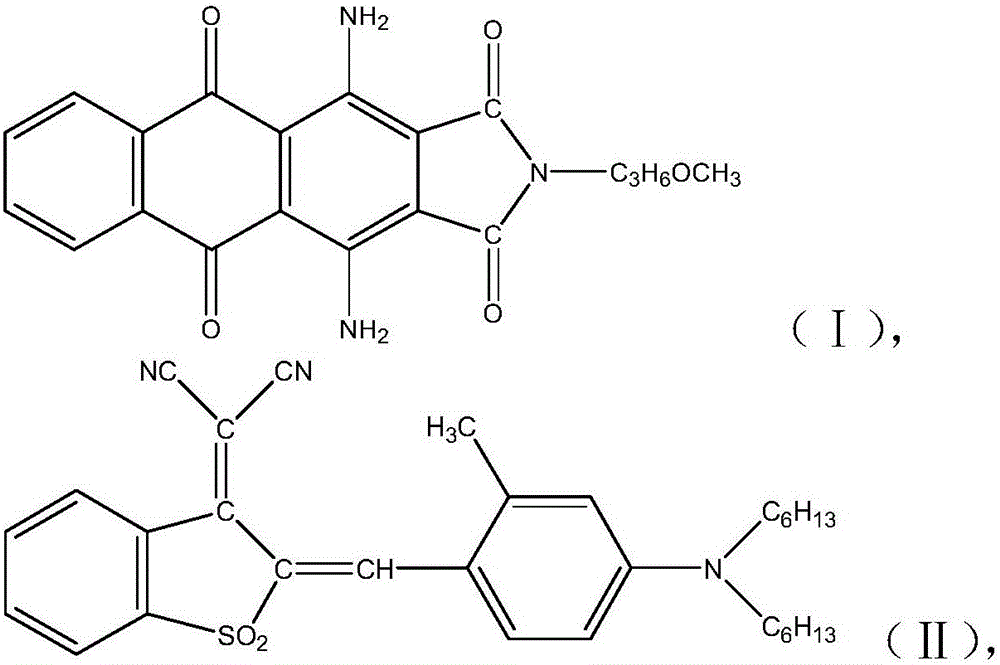

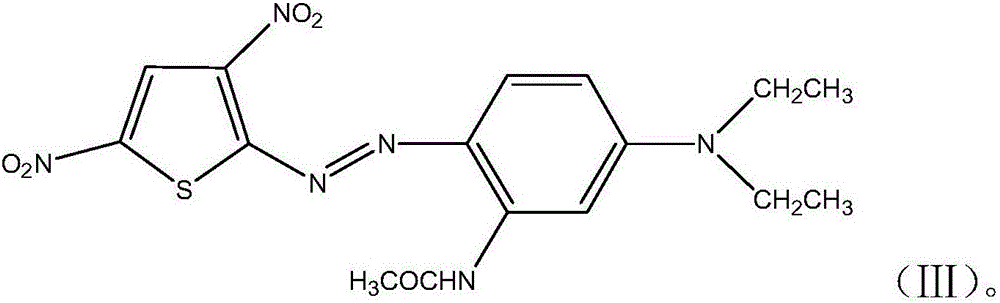

The invention provides an environment-friendly and economical high-fastness turquoise blue disperse dye composition with bright colored light, good leveling property, good elevating power and excellent washing fastness and sublimation fastness. The high-fastness turquoise blue disperse dye composition mainly comprises the following components in parts by weight: 50-90 parts of a component A shown by a formula (I), 0.1-10 parts of a component B shown by a formula (II) and 0.1-45 parts of a component C shown by a formula (III). After being commercialized, the turquoise blue disperse dye composition provided by the invention can be ground to be in a liquid state by a sand mill or a grinder, and can be in the shape of powder or particle after being subjected to spray drying, so that the turquoise blue disperse dye composition is suitable for dyeing of polyester and a blended fabric thereof, and particularly suitable for dyeing of a spandex blended fabric, and has the characteristics of good elevating power, small contamination to spandex, excellent washing fastness, excellent color fastness to sublimation and the like.

Owner:ZHEJIANG LONGSHENG GROUP

Processing method of tujia salt-preserved egg

The invention discloses a processing method of a tujia salt-preserved egg, belonging to the technical field of processing of poultry and eggs. A plurality of Chinese herbal medicines such as cinnamon, artemisinin, clove and the like are added into early flavoring liquid, and cooked together with salt; then quick lime is brewed; the flavored flavoring liquid not only has tujia characteristics, but also can be rapidly immersed into yolk; the egg is coated by seasoning mud after being carefully preserved and maintained while the seasoning mud is prepared by adding yellow mud, soda and quick lime after being cooked by quality spices with tujia characteristics, such as radix curcumae longae, rhizoma acori graminei, and elecampane; the egg white has preserved eggs taste after being carefully maintained; the salt-preserved egg is obtained by cleaning and steaming; the yolk of the prepared salt-preserved egg is a golden sand core, and is sandy, crisp, fragrant and sticky to eat; the egg white is turquoise preserved egg gel, is glittering and translucent, transparent, and elastic, has strong mellow, and leads a person to feel endless aftertastes; and one salt-preserved egg has two tastes. Compared with the existing salt-preserved egg, the processing method has the advantages that the quality guarantee period is greatly prolonged; and the salt-preserved egg can be stored for 6 months at normal temperature, and does not deteriorate.

Owner:CHONGQING DONGRUN TOURISM DEV

Preparation method of supported iron-molybdate catalyst and application of catalyst to degradation of dye wastewater

InactiveCN103357416AEasy to synthesizeNo pollution in the processMolecular sieve catalystsWaste water treatment from textile industrySludgeSynthesis methods

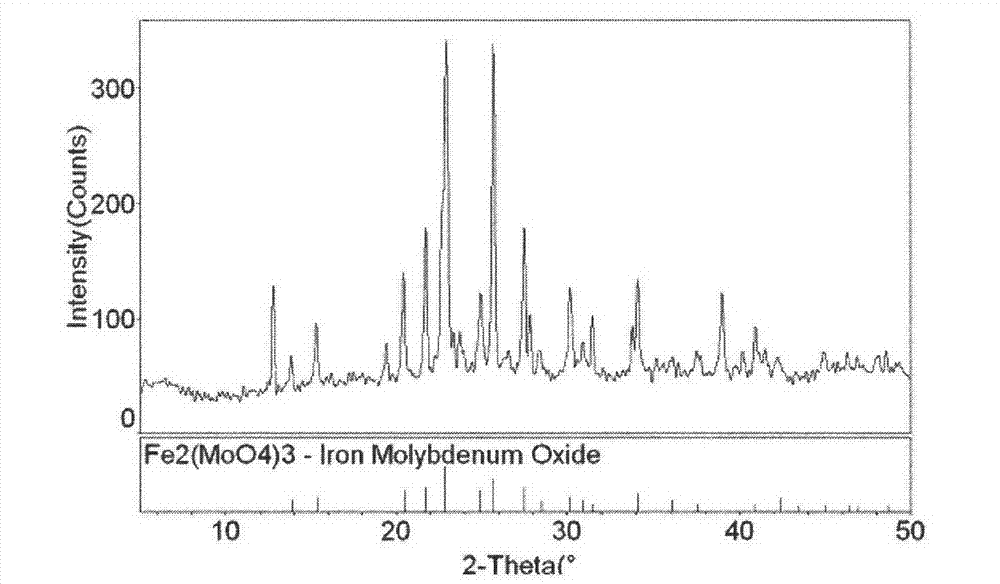

The invention relates to a preparation method of a supported iron-molybdate catalyst and an application of the supported iron molybdate catalyst to the degradation of dye wastewater. The supported iron-molybdate solid acid catalyst is synthesized from such raw materials as ammonium molybdate, ferric nitrate, diatomaceous earth, zeolite and a molecular sieve by adopting an aqueous precipitation method. The synthesis method of the supported iron-molybdate solid acid catalyst comprises the following steps of mixing a carrier with a solution of ammonium molybdate fully, adjusting the pH value of a medium by using aqueous ammonia until the medium is weakly alkaline; and dropwise adding a solution of ferric nitrate into the solution of ammonium molybdate, stirring the two solutions fully, ageing, filtering, washing, drying, and calcining in a muffle furnace for 2 hours at the temperature of 550 DEG C. The supported iron-molybdate solid acid catalyst can be used for degrading the methylene-blue simulated wastewater and the turquoise blue real wastewater quickly and effectively without adjusting the pH value of the dye and generating iron sludge, thus reagents are saved, and the separation becomes easy. The supported iron-molybdate solid acid catalyst can be recycled.

Owner:JIANGNAN UNIV

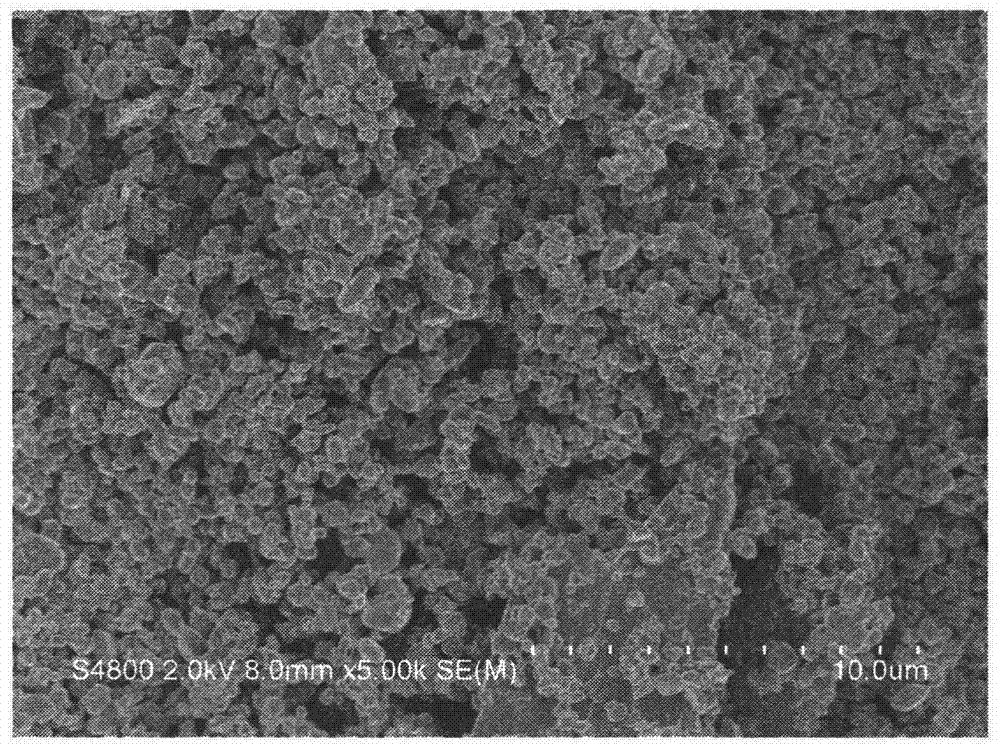

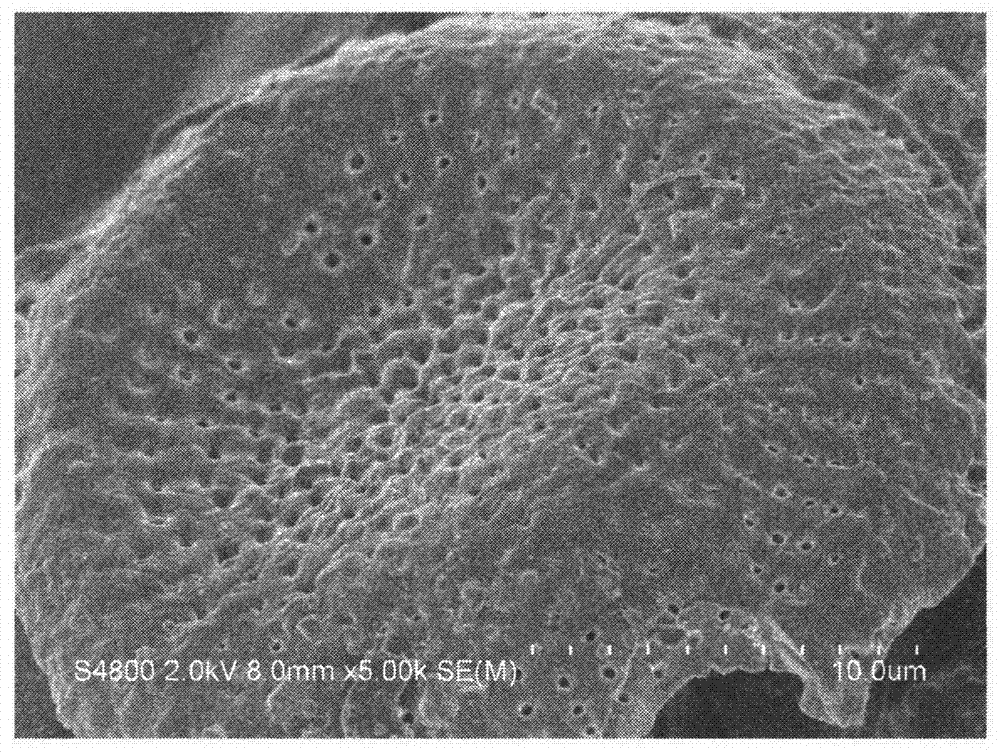

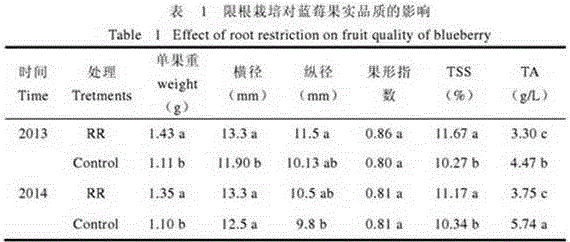

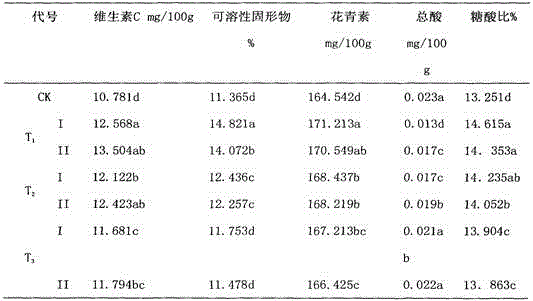

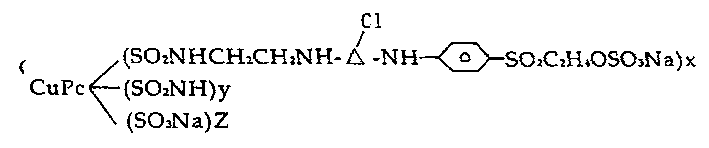

Cultivation method for increasing blueberry anthocyanin content and fruit internal quality

InactiveCN106358944AGuaranteed soil conditionsGuarantee green healthCultivating equipmentsColor changesInflorescence

The invention relates to a cultivation method for increasing the blueberry anthocyanin content and the fruit internal quality. The cultivation method comprises the following steps of (1) establishing an orchard, and preparing soil; (2) preparing a mixed matrix which is prepared from the following components in mass percent: 35 to 45% of saw dust, 25 to 30% of leaf mold, 15 to 20% of straws, 4 to 10% of pig manure organic fertilizer, 6 to 9% of river sand and 1 to 4% of perlite, wherein the sum of the mass percent is 100%; (3) field-planting; (4) reshaping and pruning; (5) managing fertilizer and water: laying silver reflector films on both sides of crowns along the lines of trees at the earlier stage of color change of blueberry fruits, wherein the outer edges of the reflector films are aligned with the outer edges of the crowns, the films are not pierced during pressing, and the films are not removed until fertilizer is applied after harvesting; (6) harvesting: harvesting in batches because the blooming sequence of the blueberry fruits in inflorescence is one after the other and the mature stages of the fruits are different, wherein the fruits are mature when the surfaces of the fruits change from turquoise to red to bluish violet to purple black, and generally, harvesting is performed once every two to three days at a full fruit stage and is performed once every four to six days at a primary fruit stage and an end fruit stage.

Owner:周翠华

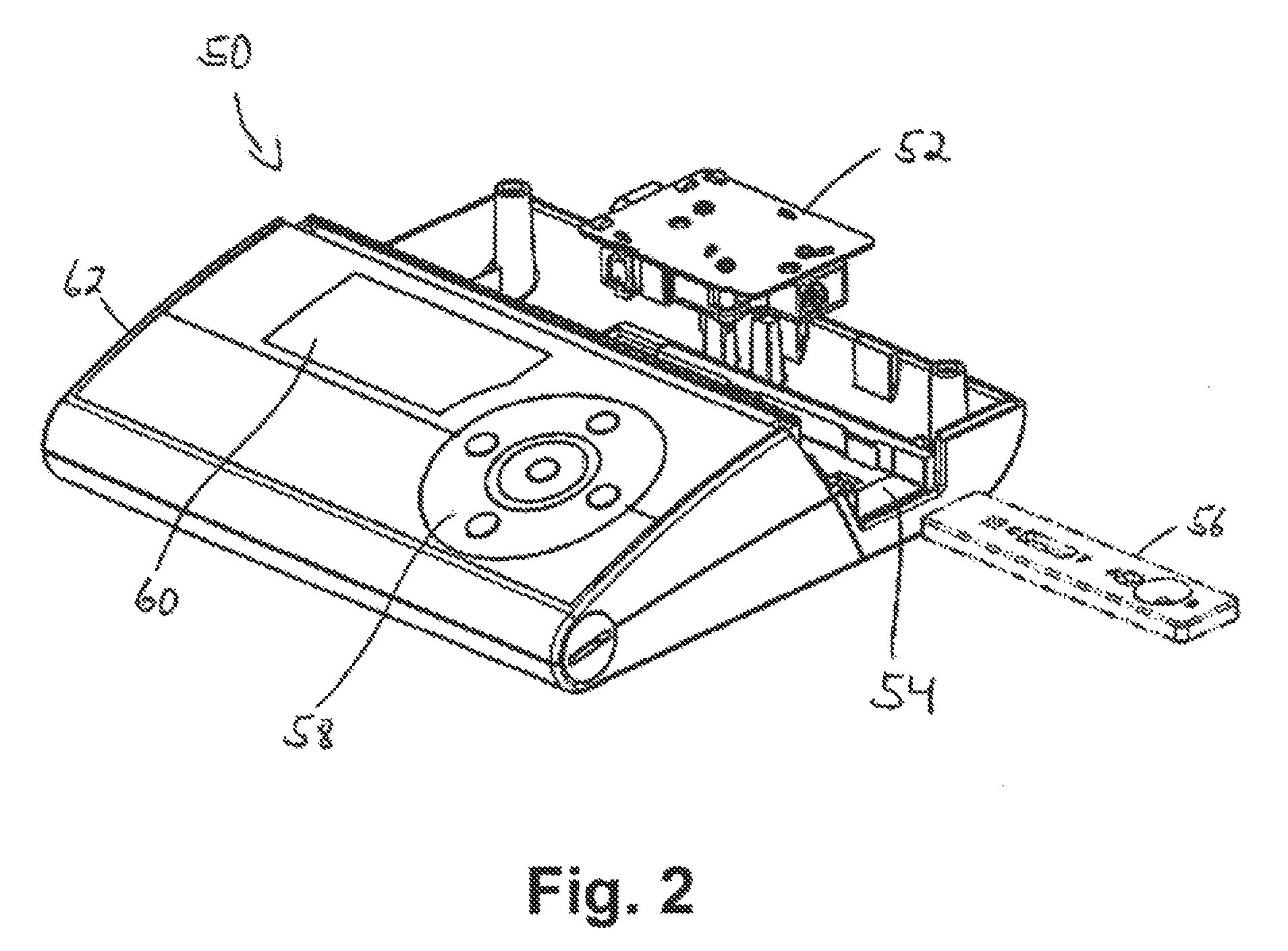

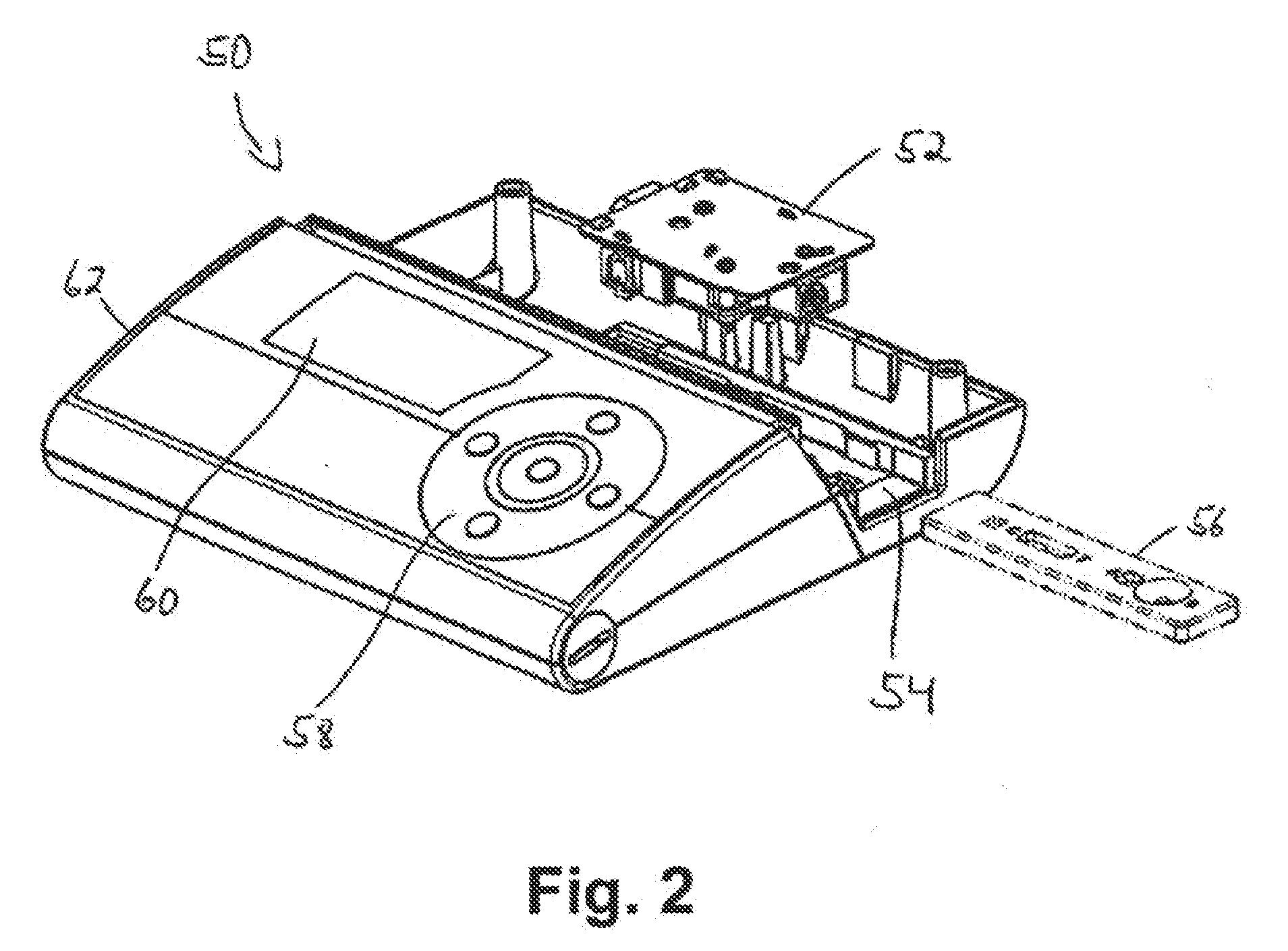

Fluorescence standard, and the use thereof

InactiveUS8704158B2Improve homogeneityOptical radiation measurementBioreactor/fermenter combinationsFluorescenceApatite

Owner:QIAGEN LAKE CONSTANCE GMBH

Fluorescence standard, and the use thereof

InactiveUS20110076687A1Improve homogeneityBioreactor/fermenter combinationsPhotometry using reference valueFluorescenceApatite

The invention concerns fluorescence standards, and in particular fluorescence standards for calibrating optical detectors. According to the invention, a fluorescent mineral or mixtures of minerals are employed for use as a fluorescence standard. The fluorescent mineral can be a naturally occurring mineral or a synthetically produced mineral. Preferred fluorescent minerals for use as fluorescence standards are corundum, fluorite, turquoise, amber, zircon, zoisite, iolite or cordierite, spinel, topaz, calcium fluorite, sphalerite or zincblende, calcite or calcspar, apatite, scheelite or calcium tungstate, willemite, feldspars, sodalite, a uranium mineral, a mineral containing Al3+, and in particular ruby and sapphire.

Owner:QIAGEN LAKE CONSTANCE GMBH

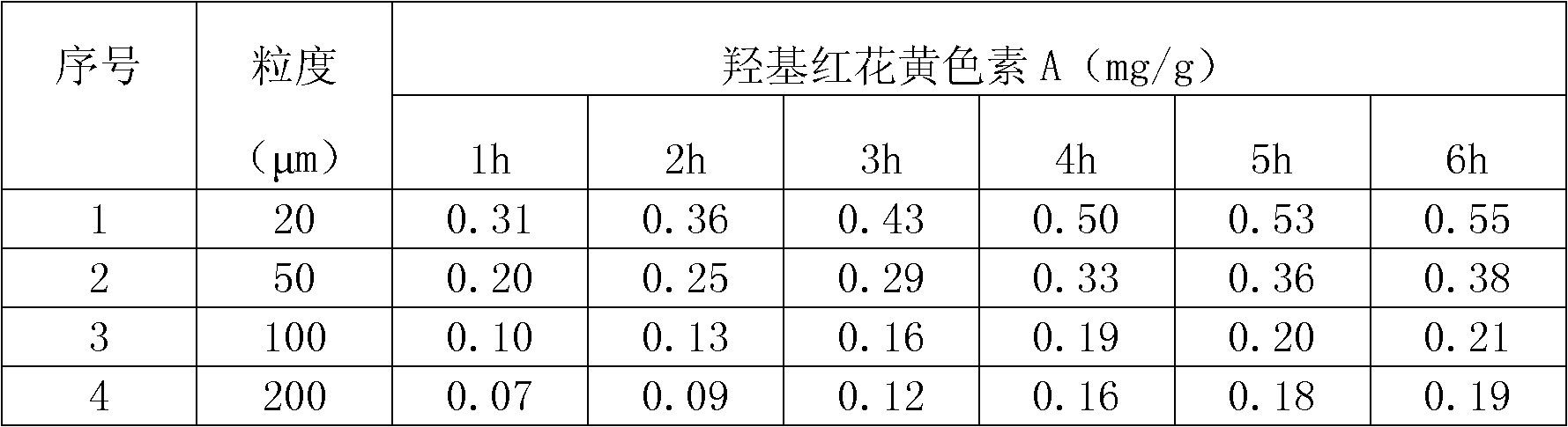

Method for producing electric-melting zirconia used for turquoise pigment and glaze

ActiveCN101703958ANarrow particle size distributionThe particle size distribution range is reasonableGrain treatmentsZirconium oxidesCalorescenceAtmospheric pressure

The invention relates to a method for producing electric-melting zirconia used for turquoise pigment and glaze, which is characterized in that: in a process of fine crushing, a feed particle size D50 is controlled between 20 and 25mu m, the working air pressure of a nozzle of a jet mill is 0.8MPa, a cyclonecluster is adjusted to 45Hz, a grader is adjusted to 18Hz, and the size distribution after the crushing meets the conditions that: D10 is not less than 3mu m, D50 is kept between 14 and 15mu m, and the difference between D90 and D10 is not more than 30mu m. The method has the advantages that: the narrow size distribution range of zirconia powder is realized, and reasonable grain size distribution is realized; and the electric-melting zirconia is favorable for color development of the turquoise pigment and glaze compared with the traditional electric-melting zirconia, comprehensively improves the blue degree of corresponding pigment and glaze, reduces a brightness value, makes the pigment develop more bright and vivid color in the glaze, and improves the beautifulness of corresponding ceramic products. The electric-melting zirconia after reasonable particle size control and adjustment can improve the high temperature resistance of the turquoise pigment and glaze more obviously than the electric-melting zirconia which is not controlled, and still can keep bright tone at the temperature higher than 1,200DEG C so as to promote the application to high temperature pigments.

Owner:BENGBU ZHONGHENG NEW MATERIALS SCI & TECH CO LTD

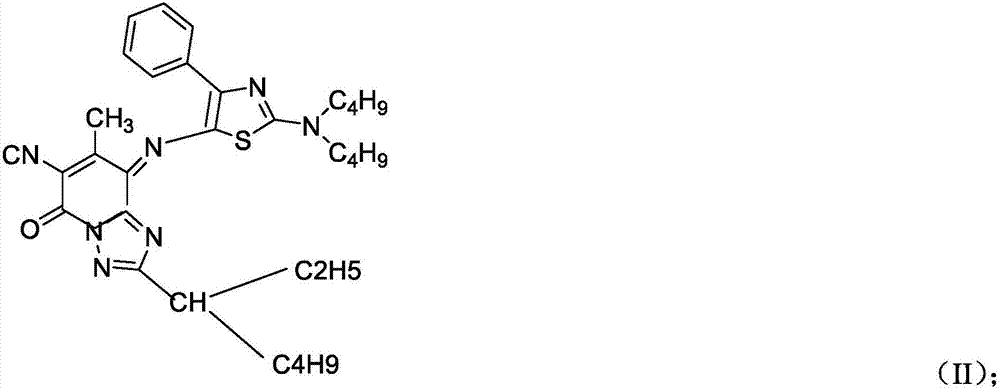

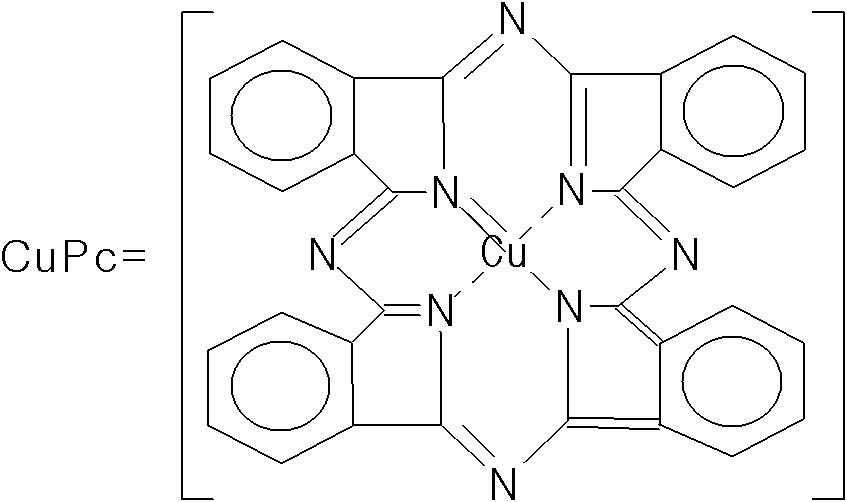

Disperse turquoise blue dye composition and disperse turquoise blue dye

The invention relates to a disperse turquoise blue dye composition and a disperse turquoise blue dye. The disperse turquoise blue dye mainly comprises a component A, a component B, a component C, a component D and an accessory ingredient, wherein the mass fraction of the component A is 10 to 60 percent, the mass fraction of the component B is 5 to 30 percent, the mass fraction of the component C is 0 to 10 percent, the mass fraction of the component D is 0 to 5 percent, and the mass fraction of the accessory ingredient is 35 to 80 percent. Polyester fiber and blended fabrics thereof are dyed by using the mixed component of the disperse turquoise blue dye provided by the invention so as to be bright-colored and beautiful in fabric, good in lifting property, and excellent in laundering durability, rub resistance and color fastness to sublimation.

Owner:菲诺染料化工(无锡)有限公司

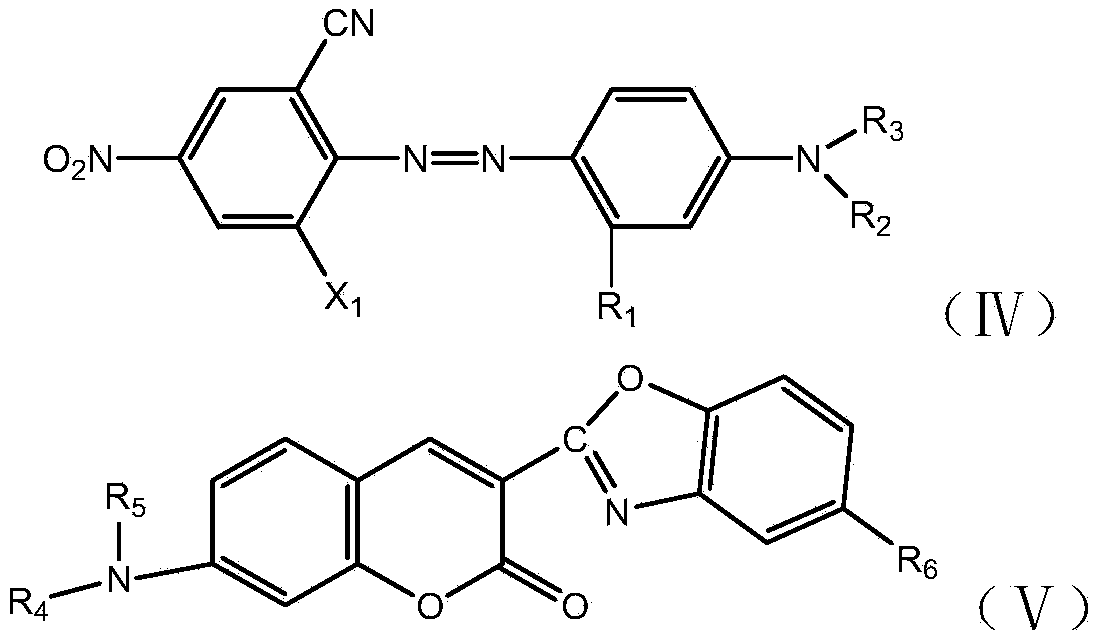

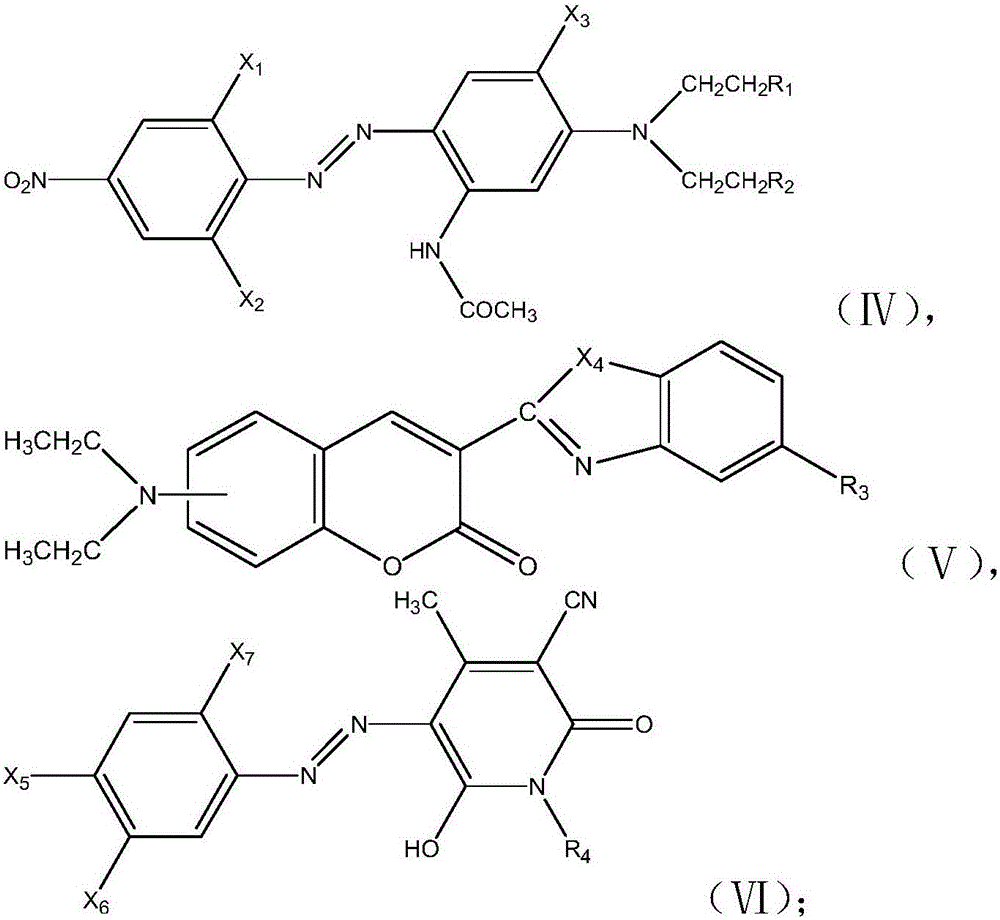

Economic complex dispersive turquoise blue dye

The invention discloses an economic complex dispersive turquoise blue dye and relates to an azo, pyridine thiazole and coumarin dye compound. The economic complex dispersive turquoise blue dye comprises the following components in percentage by weight: 0.5-75% of monomeric dye A, 0.1-50% of monomeric dye B, 0.1-5% of monomeric dye C and 0.1-50% of monomeric dye D. Compared with the prior art, the dispersive turquoise blue dye disclosed by the invention is used for dyeing polyester materials, dyeing yarns and printing, has excellent high-temperature thermosol dyeing performance, excellent fastness performance, and excellent color fastness to sunlight, color fastness to sublimation and washing fastness and can be on a par with the commercial finished C.I. dispersive turquoise blue 60 dye.

Owner:ZHEJIANG BOAO DYESTUFF IND

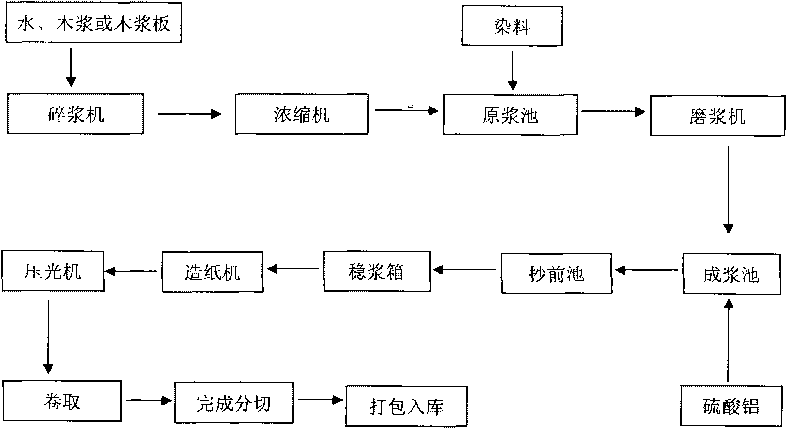

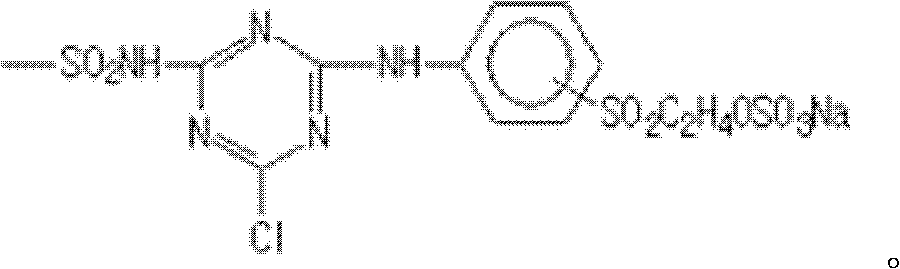

Process for dyeing viscose yarns on bobbins

ActiveCN105908534AUniform dyeingSolve in, inDry-cleaning apparatus for textilesDyeing processYarnBobbin

A process for dyeing viscose yarns on bobbins belongs to the technical field of dyeing viscose yarns on bobbins. The process comprises the steps of 1) adding auxiliaries, 2) adding a dye, 3) adding an accelerating agent, 4) pre-adding alkali, 5) adding alkali while heating, 6) dyeing, 7) washing with cold water for the first time, 8) washing with an acid, 9) soaping, 10) washing with hot water, 11) washing with cold water for the second time, 12) adding a softening agent, and 13) dewatering and drying. In the step 1), while a liquor in a dye vat is kept at a temperature in the range of 40-50 DEG C, 1-2 g / L of anionic surfactant, 1-2 g / L of polymer dispersant and 0.5-2 g / L of leveling agent are added into the vat and circulated for 10-15 minutes. The process for dyeing viscose yarns on bobbins belongs provided by the present invention is capable of solving the problem of not easy uniform dyeing of viscose yarns on bobbins, and in particular the tough problem of dyeing of brilliant blue and turquoise blue products as well as products with the two colors in the industry. The obtained viscose yarns on bobbins have high color fastness and are dyed uniformly; the viscose yarns on bobbins are allowed to have consistent inside, central and outside color yield when dyed with the brilliant blue and the turquoise blue.

Owner:ZIBO DARANFANG SILK GRP

Dyeing process of olive-green insulating paperboard

InactiveCN101713157AUniform colorHigh process retentionPlastic/resin/waxes insulatorsPaper/cardboardAluminium sulfatePaperboard

The invention relates to a dyeing process of an olive-green insulating paperboard. The dyeing process adopts the following raw material prescriptions: (a) raw material: 1,000kg of 100 percent softwood pulp board accounted by dry pulp; (b) dye: 0.50+ / -0.01 percent: 1.2kg / 1,000kg pulp+ / -0.0025 percent of direct turquoise blue and 3.8kg / 1,000kg pulp+ / -0.0075 percent of alkaline bright yellow; and (c) a fixing agent: 20kg / 1,000kg pulp of aluminum sulfate.

Owner:XINSHAO GUANGXIN ELECTRICAL INSULATING MATERIALS

Dyeing technology for carrying out one-bath scouring and dyeing on lycra-containing cotton knitted fabric by active turquoise blue

ActiveCN104179041AReduce process stepsReduce water consumptionBiochemical fibre treatmentBleaching apparatusElectricityEngineering

The invention discloses a dyeing technology for carrying out one-bath scouring and dyeing on a lycra-containing cotton knitted fabric by active turquoise blue, mainly aims at solving the problems that a traditional technology is relatively large in water consumption and coal consumption, long in technology duration and high in power consumption. The dyeing technology comprises the working procedures of preshaping, stitching the edge, carrying out one-bath scouring and dyeing, and carrying out aftertreatment and afterfinish in sequence, wherein in the working procedure of the preshaping, a chelating agent, a deoiling agent, tea saponin, a tea saponin dispersion dispersion liquid and a scouring agent are fed; in the working procedure of the one-bath scouring and dyeing, the deoiling agent, a defoaming agent and refined enzyme are fed into a dye vat after being diluted by clear water, a leveling agent, anhydrous sodium sulphate and sodium carbonate are fed into the dye vat in a way of circulating material injection, the active turquoise blue and urea are fed in a way of dissolving the materials by the clear water, and the heat preservation is carried out at the temperature of 80 DEG C. After the dyeing technology is adopted, the lycra-containing cotton knitted fabric can be bleached, dyed and scoured by the working procedure of the one-bath scouring and dyeing, so that a plurality of tasks can be completed in one working procedure, the technological process is shortened, the processing steps are reduced, and the water consumption, the electricity consumption and the coal consumption in the processing steps can be omitted.

Owner:JIHUA 3543 KNITTING CLOTHING

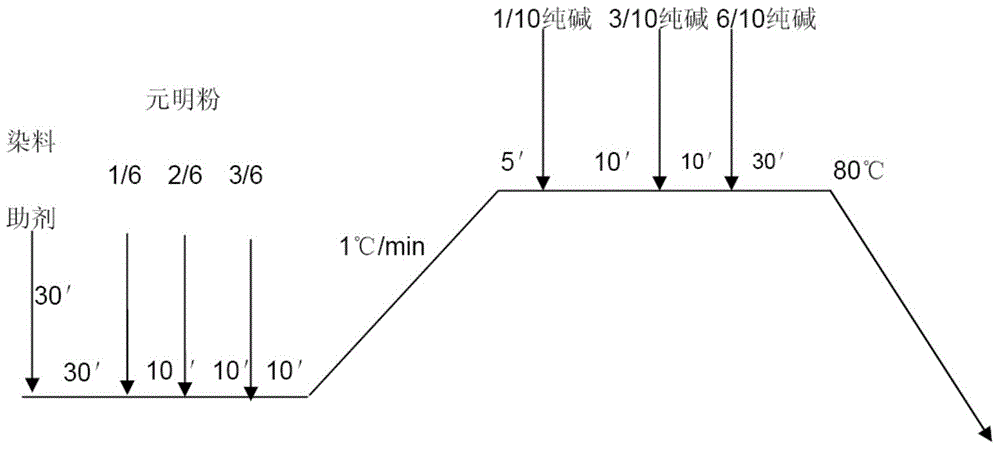

Turquoise blue dyeing process of cellulose fiber

The invention discloses a turquoise blue dyeing process of cellulose fiber. The dyeing process comprises pretreatment of cellulose fiber, wherein during the pretreatment, a foamless pretreatment aid or a low-foam pretreatment aid is used instead of a silicon-containing defoaming agent. During dyeing, all anhydrous sodium sulfate and a special turquoise blue leveling agent are completely added at normal temperature, and then a dye is added, so as to avoid salting-out caused by the significant reduction in the solubility of the dye in the case that electrolyte concentration is too high. In addition, a color matching component is firstly melted and uniformly stirred with 21# turquoise blue hot water, the mixture is cooled to 50 DEG C and then another color matching dye is uniformly stirred and added into a jar, so as to fully guarantee the sufficient dissolution of turquoise blue and to avoid the hydrolysis of a reactive dye caused by excessively high temperature. The mixture is heated up to 85 DEG C, is subjected to heat preservation for 20min, and is cooled to 80 DEG C. By virtue of dyeing at 85 DEG C, the solubility and leveling property of the reactive dye as well as the migration property of the turquoise blue dye can be greatly improved, and the dyeing property of the turquoise blue dye can be greatly enhanced.

Owner:ZHEJIANG JINGGUANG IND

Artificial high-yield blueberry planting method

InactiveCN106212191AGuaranteed soil conditionsGuarantee green healthCultivating equipmentsSoil-working methodsOrganic fertilizerInflorescence

An artificial high-yield blueberry planting method includes the following steps of orchard establishing and soil preparing; matrix preparing, wherein a mixed matrix is prepared from, by mass, 35-45% of saw dust, 25-30% of leaf mold, 15-20% of straw, 4-10% of pig manure organic fertilizer, 6-9% of river sand and 1-4% of perlite, and the sum total is 100%; planting; shaping and pruning; fertilizer and water management; harvesting, wherein blooming of inflorescence of blueberry fruits is in sequence, maturing stages of the fruits are inconsonant, the fruits need to be harvested in batches, the fruit surfaces gradually become red from original turquoise and then become bluish violet and black purple so that the fruits are matured, generally, the fruits are harvested once at the interval of 2-3 days in the full bearing stage and once at the interval of 4-6 days in the primary fruit stage and the tail fruit stage.

Owner:周翠华

Feed for rabbit and producing method thereof

InactiveCN101258901ALong-lasting flavorKeep natural turquoise for a long timeFood processingAnimal feeding stuffFiberDisease

The invention discloses a rabbit feed and a preparation method thereof. The rabbit feed is characterized in that the rabbit feed is made by the following components by weight percentage: 25-40 percent of grass meal, 60-70 percent of grain and grain outgrowth, 2-4 percent of additive premix and 0.05-0.2 percent of ethoxyquin. The rabbit feed of the invention keeps not only the grass flavor and the natural turquoise, but also leads crude protein, crude fiber, vitamin, amino acid, calcium, phosphorus, etc., which are not to be easily oxidized, thus fulfilling well the nutritional requirement and nutritive equilibrium for the rabbit; since rabbit food tastes good, the rabbit likes eating the rabbit food rather than anorexia, which improves the feed intake, enhances the immunity of the rabbit, reduces occurrences of diseases, such as flatulence, diarrhea, etc., and promotes production capability; compared with the prior art, average daily gain of commercial rabbit which taking the rabbit feed of the invention is increase by 10-20 percent.

Owner:SICHUAN TONGWANG AGRI & LIVESTOCK GROUP

Complex reactive turquoise blue dye

A composite reactive kingfisher blue dye is prepared from the reactive kingfisher blue dye B-BGFN (60-94 wt.%), dust-proofing agent (1-10) and solubilizer (5-30). Its advantages are gay color, high color fastness and no pollution.

Owner:孙德锁

Turquoise glaze for colored pottery products

The invention provides a turquoise glaze for colored pottery products. The turquoise glaze is characterized by being prepared from the following components in parts by weight: 50-70 parts of electronic-grade red lead, 10-30 parts of silicon dioxide, 4-6 parts of Soochow clay, 4-6 parts of copper oxide, 4-6 parts of modified sea mud, 0.1-0.3 part of graphite, 0.1-0.3 part of barium stearate, 0.1-0.3 part of cordierite powder, 1-3 parts of borax, 0.4-0.6 part of morganite, 2-4 parts of aluminum silicate, 0.4-0.6 part of selenium powder, 1-2 parts of cyanite, 0.4-0.6 part of zirconium silicate, 0.2-0.4 part of zinc oxide, 0.1-0.3 part of cobalt powder and 0.2-0.4 part of shell powder. The prepared and fired turquoise glaze is glittering and translucent, bright and smooth in glaze color, and is as shine as the turquoise, and therefore, when the turquoise glaze is applied to colored pottery artworks, an excellent decoration effect can be achieved; the modified sea mud is added so that the finished product can be protected from peeling permanently and can be preserved permanently.

Owner:界首市王京胜彩陶艺术有限公司

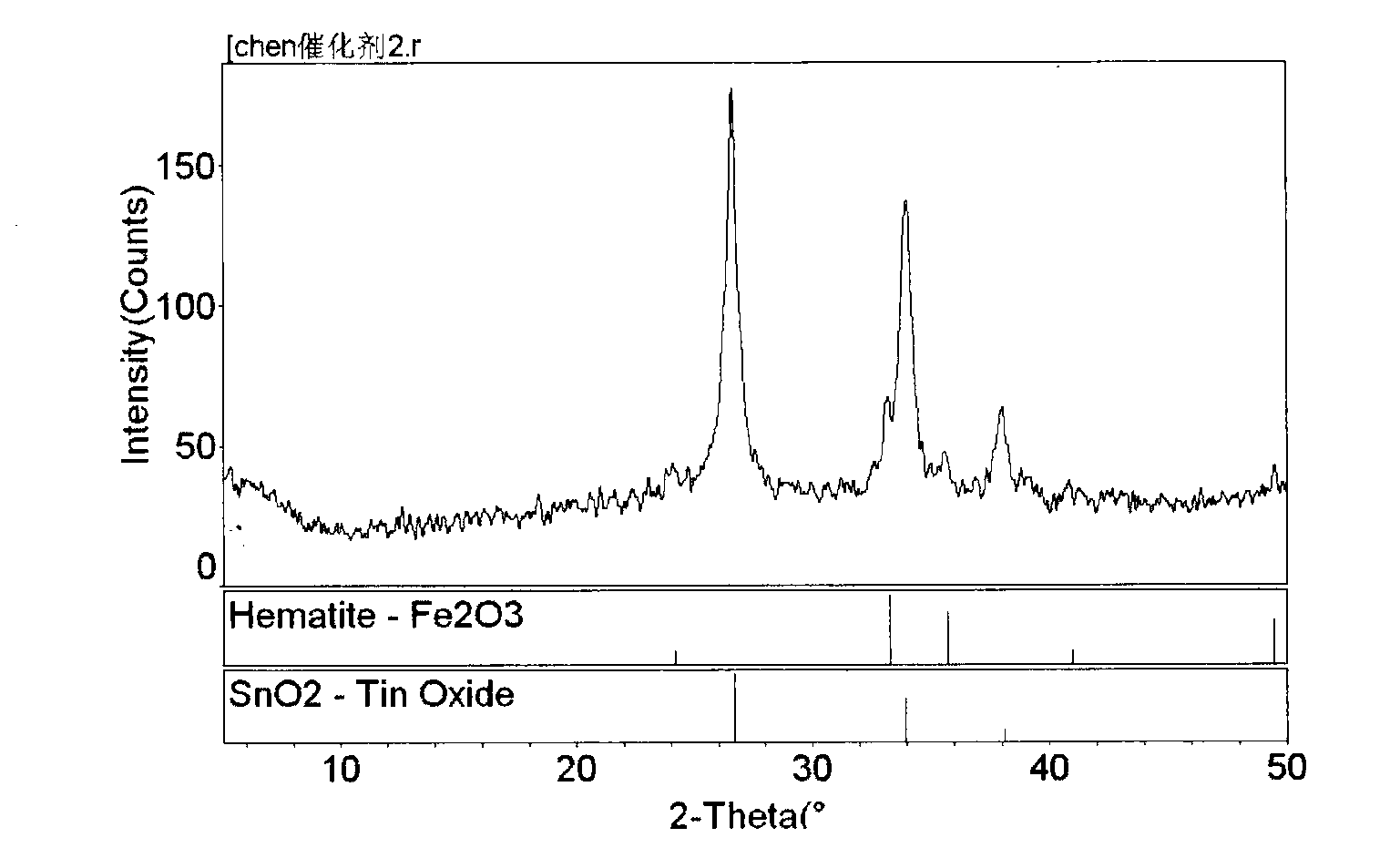

Novel mesoporous Fe2O3-SnO2-ZSM-5 solid acid prepared by impregnation method, and application study for catalyzing degradation of organic pollutants

InactiveCN103157504AApplicable to a wide range of pHImprove responseMolecular sieve catalystsCatalyst activation/preparationZSM-5Sulfate radical

The invention relates to a multi-component composite solid acid formed by using a mesoporous molecular sieve as a carrier of a solid acid catalyst and introducing other metal oxides by an impregnation method, with stannum oxide and ferric oxide as accelerators. During synthesis, firstly, a SnCl4.5H2O water solution and the mesoporous molecular sieve are mixed with stirring; then, a certain ratio of Fe2(SO4)3 is added to the above mixture; and concentrated ammonia water is used to adjust pH, so as to obtain a precipitate; a product is impregnated, sedimentated through centrifugation, dried, grinded and screened to obtain a mixed oxide precursor; the precursor is impregnated by sulfuric acids with different concentrations, filtered, dried and calcined in a muffle furnace at a high temperature to obtain a stannum-ferrum-silicon solid acid (abbreviated SFZ1) with sulfate radicals as an accelerator; and a heterogeneous Fenton-like system is formed by using the obtained SFZ1 catalyst and hydrogen peroxide and catalyzes the hydrogen peroxide to produce hydroxyl radicals (?OH) with extremely strong oxidizability to perform efficient and rapid degradation on the pollutants. The catalyst can rapidly and effectively degrade imitated wastewater of methylene blue, methyl orange and nitrobenzene wastewater and real wastewater of turquoise blue, glyphosate and pharmaceutical intermediates, is in no need of adjusting the pH value of the wastewater, is very few in reagent usage amount, does not produce ferrum sludge, has extremely strong sedimentation performance and can be recycled for reuse.

Owner:JIANGNAN UNIV

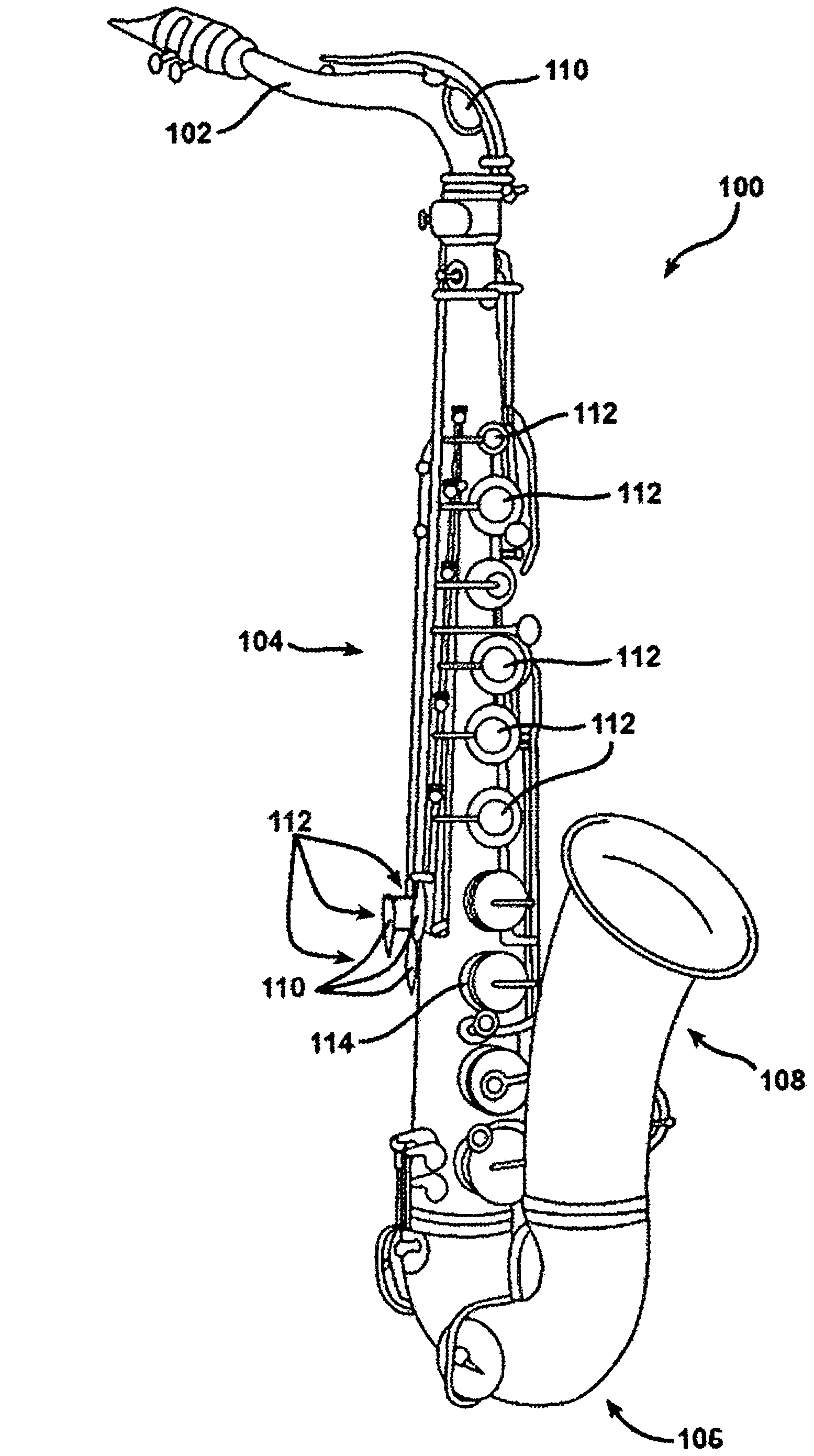

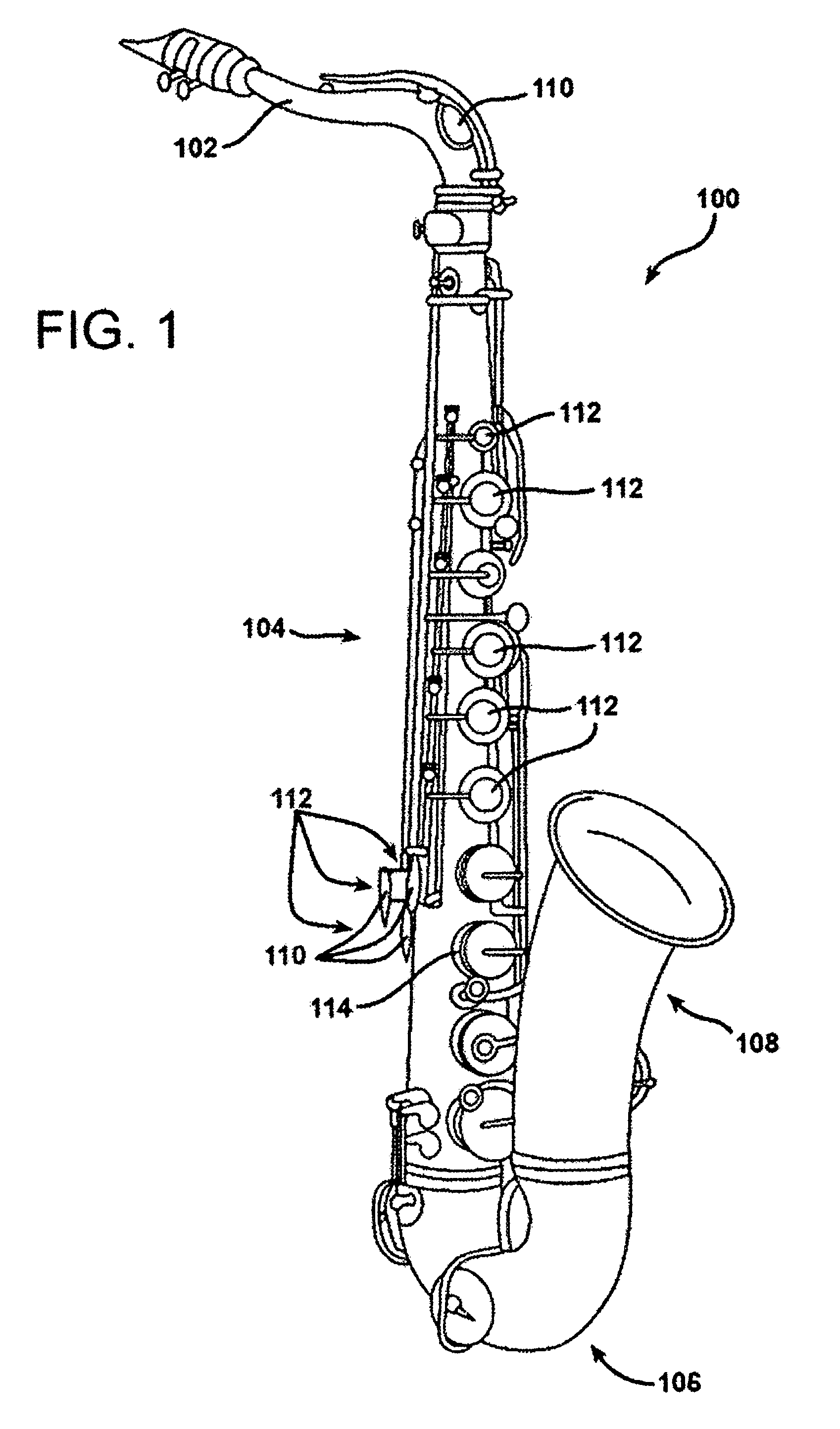

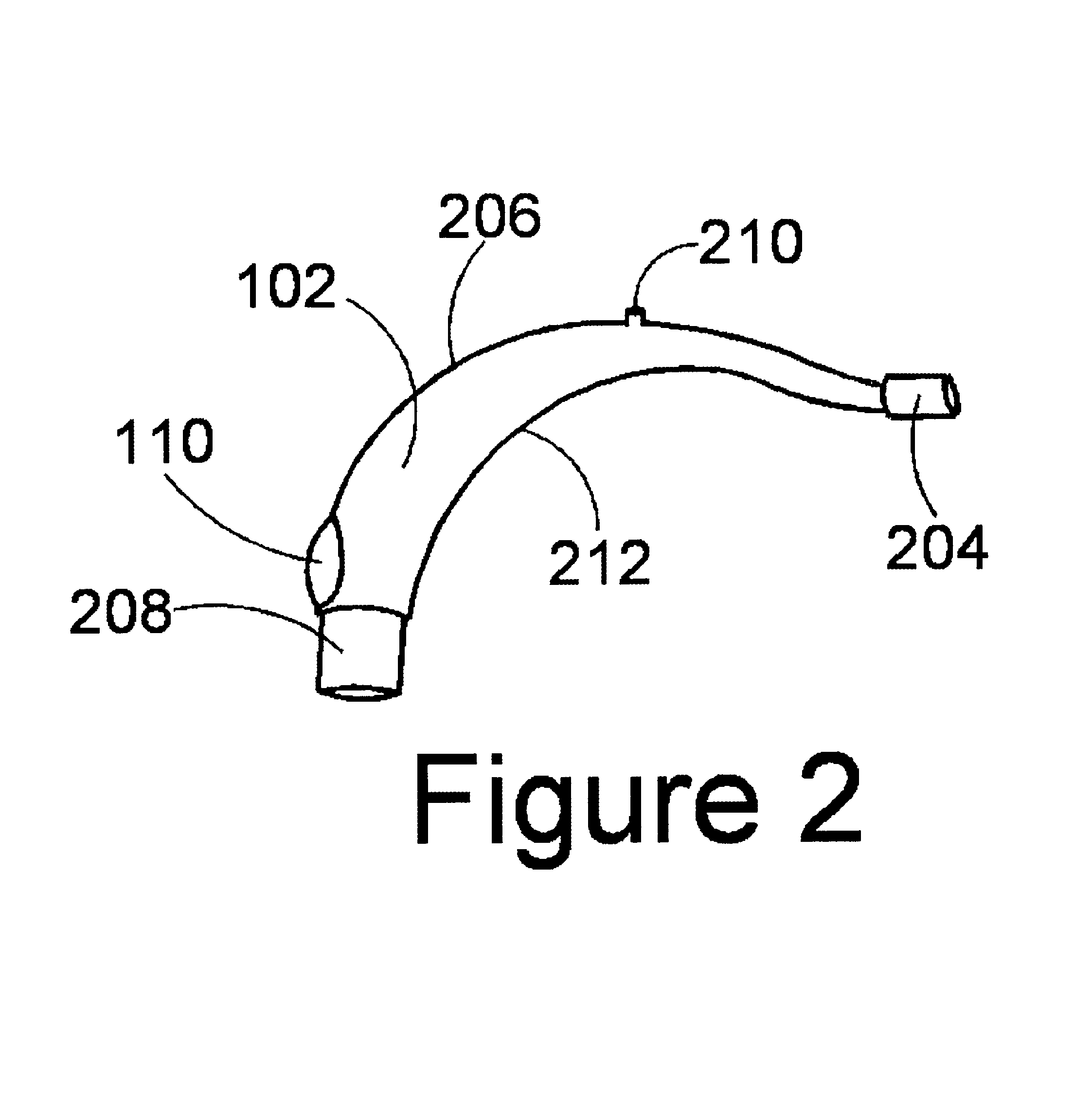

Woodwind instrument

A method of improving the tonal characteristics of a woodwind instrument. The method includes identifying a position on the woodwind instrument, wherein placement of a tonal material thereto causes a lowering of overtone amplitude during play, by observing overtone characteristics during play; positioning the tonal material to the woodwind instrument; measuring the overtone amplitude; playing the woodwind instrument; and repositioning the tonal material to optimal overtone amplitude position; and attaching the tonal material to the woodwind instrument, at the optimal overtone amplitude position. The tonal material comprises one of the group consisting of: garnet, jasper, agate, aventurine, carnelian, citrine, fluorite, hematite, malachite, obsidian, onyx, tiger's eye, turquoise, unakite, moonstone, peridot, jade, alexandrite, amethyst, chalcedony, quartz, aquamarine, lolite, rhodolite, opal, topaz, tourmaline, tanzanite, diamond, emerald, sapphire, ceylon sapphire, ruby, woodwind, other metals, and combinations thereof.

Owner:CANNONBALL MUSICAL INSTRUMENTS

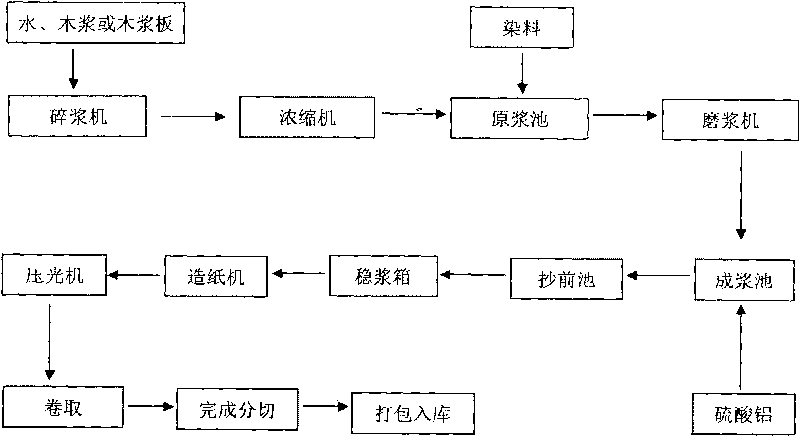

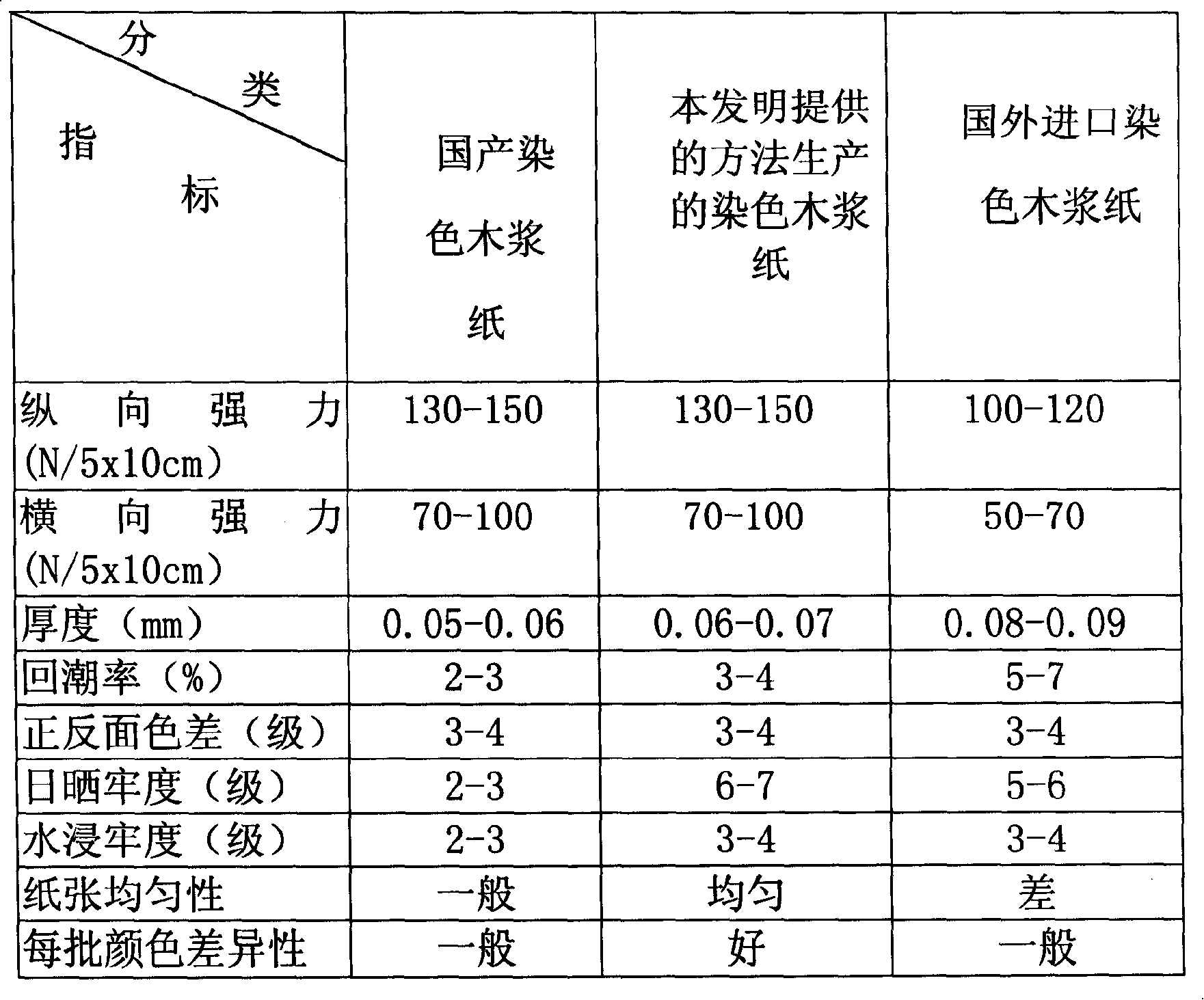

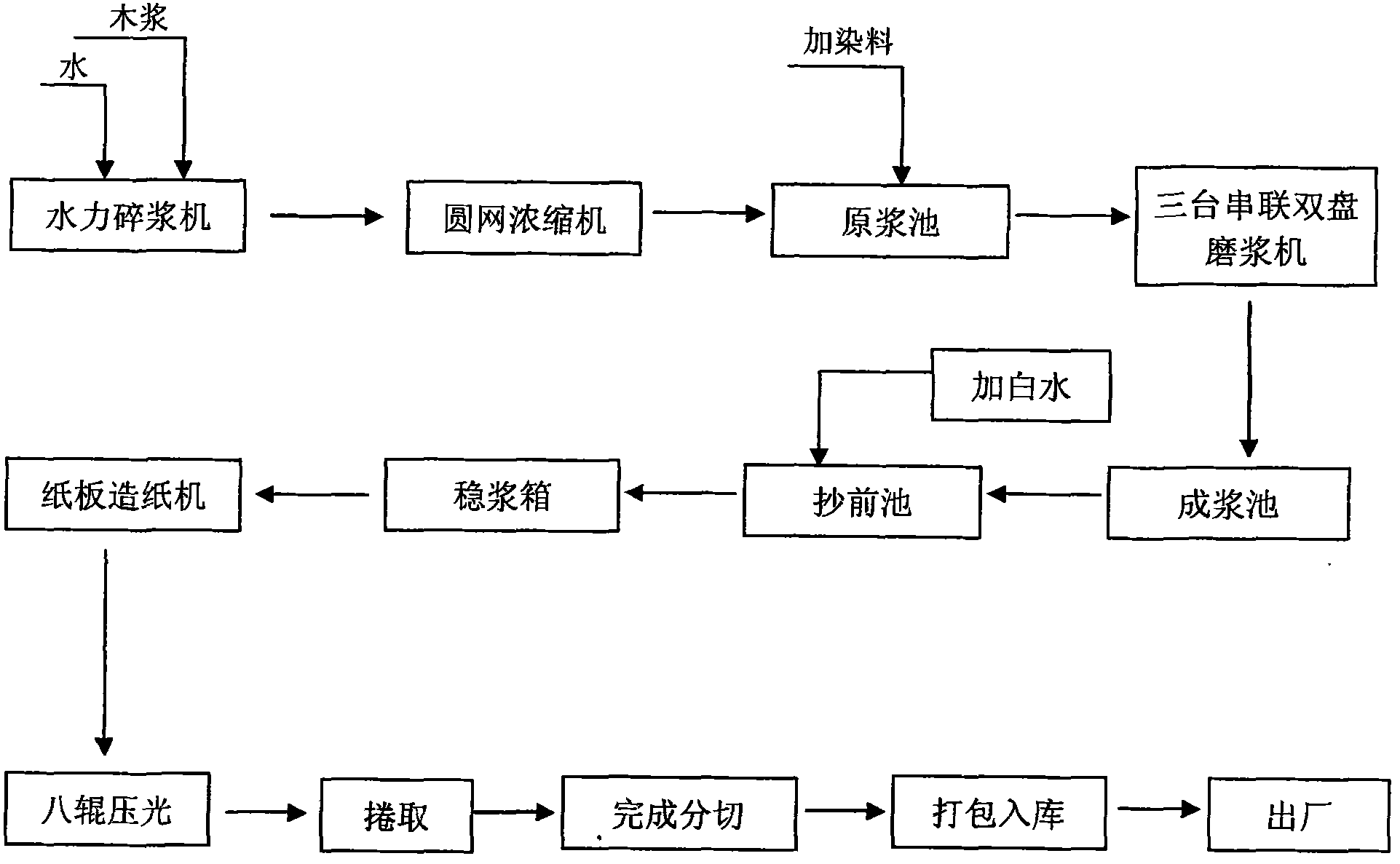

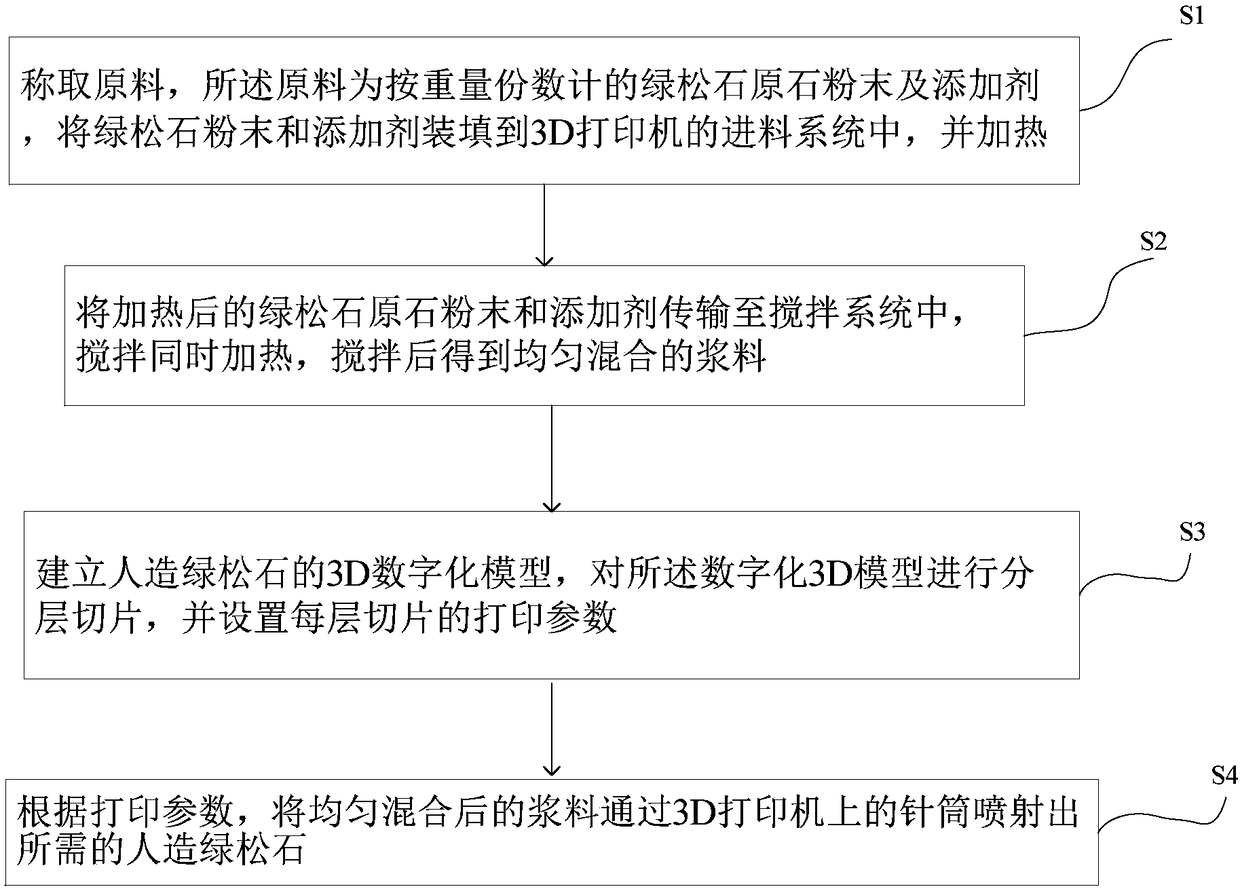

Dyeing technique of coloring wood-pulp paper used for non-woven material

InactiveCN101148845AImprovement of front and back chromatic aberrationGood light fastnessSpecial paperPaper/cardboardPaperboardPulp and paper industry

The present invention belongs to the field of paper making technology, and is especially technological process of dyeing wood pulp paper for making non-woven material. The technological process includes the steps of pulping, dyeing, fixing color, feeding, squeezing, stoving, etc. The dyeing step adopts the dye of DF turquoise blue, GDFN blue, RF bright blue, 3GSFN yellow or their mixture; and the color fixing agent is TF232 color fixing agent. The dyed product has homogeneous color, high color fastness, stable quality, low cost and other advantages.

Owner:XINLONG HLDG GROUP

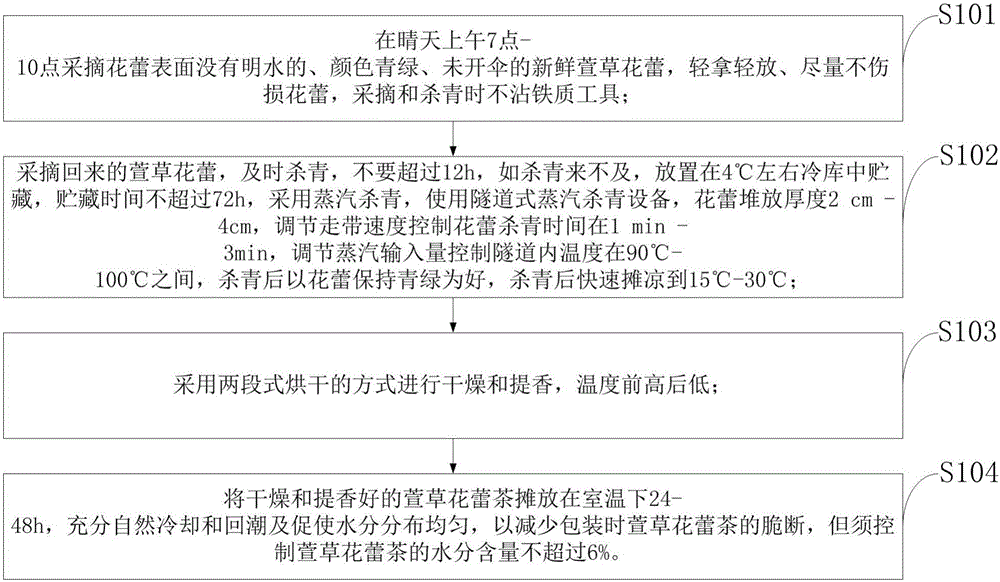

Preparing method of day lily bud tea

The invention discloses a preparing method of day lily bud tea. The preparing method comprises the steps that fresh day lily buds are picked; the picked day lily buds are subjected to fixation with steam, the bud fixation time is 1-3 min, the temperature in a tunnel is 90-100 DEG C, and the buds are rapidly spread and aired to the room temperature after fixation; drying and fragrance extraction are performed with a two-section type drying method, and the temperature is high before and low after; the dried and fragrance-extracted day lily bud tea is spread under the room temperature for 24-48 h, full cooling, moisture regain and moisture uniform distribution are performed, and the moisture content of day lily bud tea is controlled not to be higher than 6%; according to the day lily bud tea prepared with the method, the bar shapes are perfect and regular, the color quality is superior, the fragrance is delicate, and the day lily bud tea can be brewed for drinking and can also be used and eaten like dry day lily; the turquoise of the day lily bud tea can be maintained by steam fixation, and no black spot occurs to bud tips; the two-section tunnel type drying method is adopted, the temperature is high before and low after, the luster is well kept, and the fragrance is the best.

Owner:NANJING LONGZHUANG BIOTECH

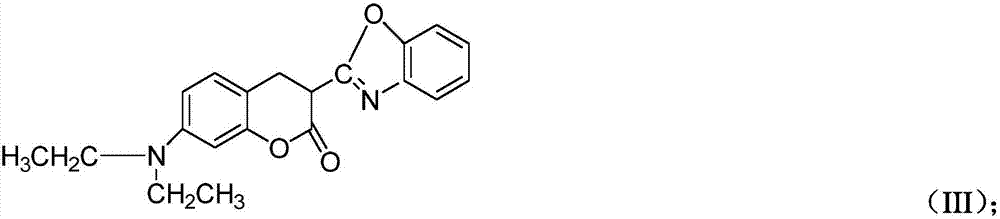

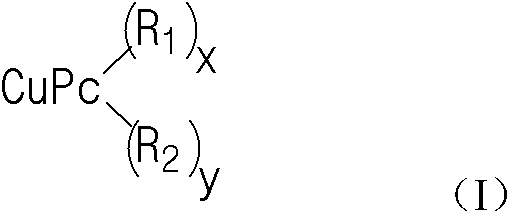

Turquoise blue dye and preparation method and application thereof

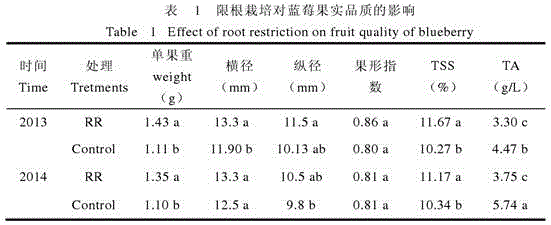

ActiveCN102504589ASmall average particle sizeReduce salt contentReactive dyesInksSalt contentTurquoise

Disclosed are a turquoise blue dye and a preparation method and application thereof. The dye has the structure as the formula, wherein x+y=3.5. The turquoise blue dye is small in average particle diameter and low in salt content, is gorgeous in luster, high in dyeing degree, stale and fine in repeatability during dyeing and is particularly applicable to ink jet printing and dyeing, excellent in application performance and convenient in use. Meanwhile, pollution to the environment can be reduced and required raw materials are low in cost by the aid of the preparation method and application of the turquoise blue dye.

Owner:TIANJIN DEK CHEM

Preparation method of accurate pH test paper

ActiveCN103033511AHigh sensitivityGuaranteed accuracyMaterial analysis by observing effect on chemical indicatorMalachite greenBromocresol green

The invention relates to a preparation method of accurate pH test paper. An indicator is prepared by dissolving Metanil yellow, malachite green, acid turquoise blue, bromphenol blue, cresol red, m-cresol purple and bromocresol green in a 30% ethanol water solution. The preparation method comprises the following steps: previously impregnating base paper of pH test paper in the prepared indicator solution, and drying with heating steam of 95-105 DEG C at normal pressure. The preparation method of accurate pH test paper is simple in process, stable in product quality and higher in sensitivity and accuracy in comparison with the common accurate test paper, and the accuracy can be up to 0.2 level. Thus, the preparation method can be widely used in the fields of scientific research, industry, agriculture, environmental protection, medicine and food.

Owner:杭州特种纸业有限公司

Olive wine and method for preparing same

InactiveCN101182451AFull of nutritionGood for clearing heat and detoxifyingAlcoholic beverage preparationAdditive ingredientGlycerol

The invention provides olive wine and contains ingredients at following proportion: 30 percent to 50 percent of olive, 40 percent to 50 percent of pure grain liquor of 20 degrees to 60 degrees, 2 percent to 10 percent of crystal sugar, 3 percent to 8 percent of citric acid, 3 percent to 10 percent of glycerin, and 2 percent to 5 percent of glycerol. The product is prepared according to the following steps: 1. processing of raw materials; 2. extraction of olive juice; 3. preparing; 4. filtering; 5. aging; and 6. sterilization. The invention has pure ingredients, and pure taste; the invention makes full use of nutritional and health-care functions of olive. The color is turquoise and a little brown, or is ruby color; the product is clear and transparent; the taste has the faint scent of olive fruit, and is sweet and delicious with taste of olive. The product has rich vitamins, rich nutrition, and helps to clear away the heat-evil and expel superficial evils, to calm liver and stimulate the appetite, to moist lung and nourish yin, to eliminate sputum and regulate vital energy, to procreate bodyfluid and prevent thirstiness; after being drunken for a long time, the product can build the body, and extend the lifespan.

Owner:张凤寿

Method for the treatment of turquoise by using aluminum phosphate salts

The invention relates to a method for the filling treatment of turquoise by using aluminum phosphate salts. A method for the treatment of turquoise by using aluminum phosphate salts is characterized in that the method comprises the following steps of: 1) pretreatment: wall rock and dirty surface are worn off on the surface of the turquoise with loose texture and are then put in a constant-temperature drying box for being dried for 3-4 hours at 80-110 DEG C after being cleaned, so as to obtain the pretreated turquoise; 2) preparation of an adhesive: KH2PO4, NaH2PO4 and MgO are respectively ground to 200 meshes and are then selected based on the proportion of Al(H2PO4)3 solution KH2PO4:NaH2PO4:MgO = 800mL:2-10g:1-20:1-20g to be mixed and stirred evenly, thus resulting in the adhesive; 3) the pretreated turquoise is vacuumized and then soaked in the adhesive for 1-30 days at 15-30 DEG C under normal pressure of 40Mpa; the turquoise is taken out and put into the constant-temperature drying box for heating and curing, upon the ending of the heating, the turquoise is naturally cooled to room temperature and is subsequently polished to a finished product. The method has simple process, low cost and good simulation.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Process for dyeing dark green industrial paperboard

InactiveCN101781864AUniform colorLong lastingOrganic dyesPulp material addition processesFiberAluminum sulphate

The invention relates to a process for dyeing a dark green industrial paperboard, which comprises the following steps: firstly, adding water into a paper pulp raw material until the paper pulp raw material is disintegrated by a hydrabrusher; dehydrating the disintegrated paper pulp with a decker and conveying the product into a primary pulp pool for uniform stirring and mixing with a sizing agent; feeding the mixture into a pulping machine with a stock pump for pulping; and introducing the pulped mixture into a machine chest for the use of a paper machine in the next procedure. The formula of a dye in the process comprises that: a, the paper pulp raw material is wood fiber; b, the using amount of the dye is 0.007+ / -0.00032 percent, wherein direct turquoise is 0.00630+ / -0.00030 percent and auramine is 0.00070+ / -0.00002 percent; and c, a fixing agent made from 0.2+ / 0.003 percent of aluminum sulphate. The product produced by the process is uniform in color and fadeless for long time.

Owner:XINSHAO GUANGXIN ELECTRICAL INSULATING MATERIALS

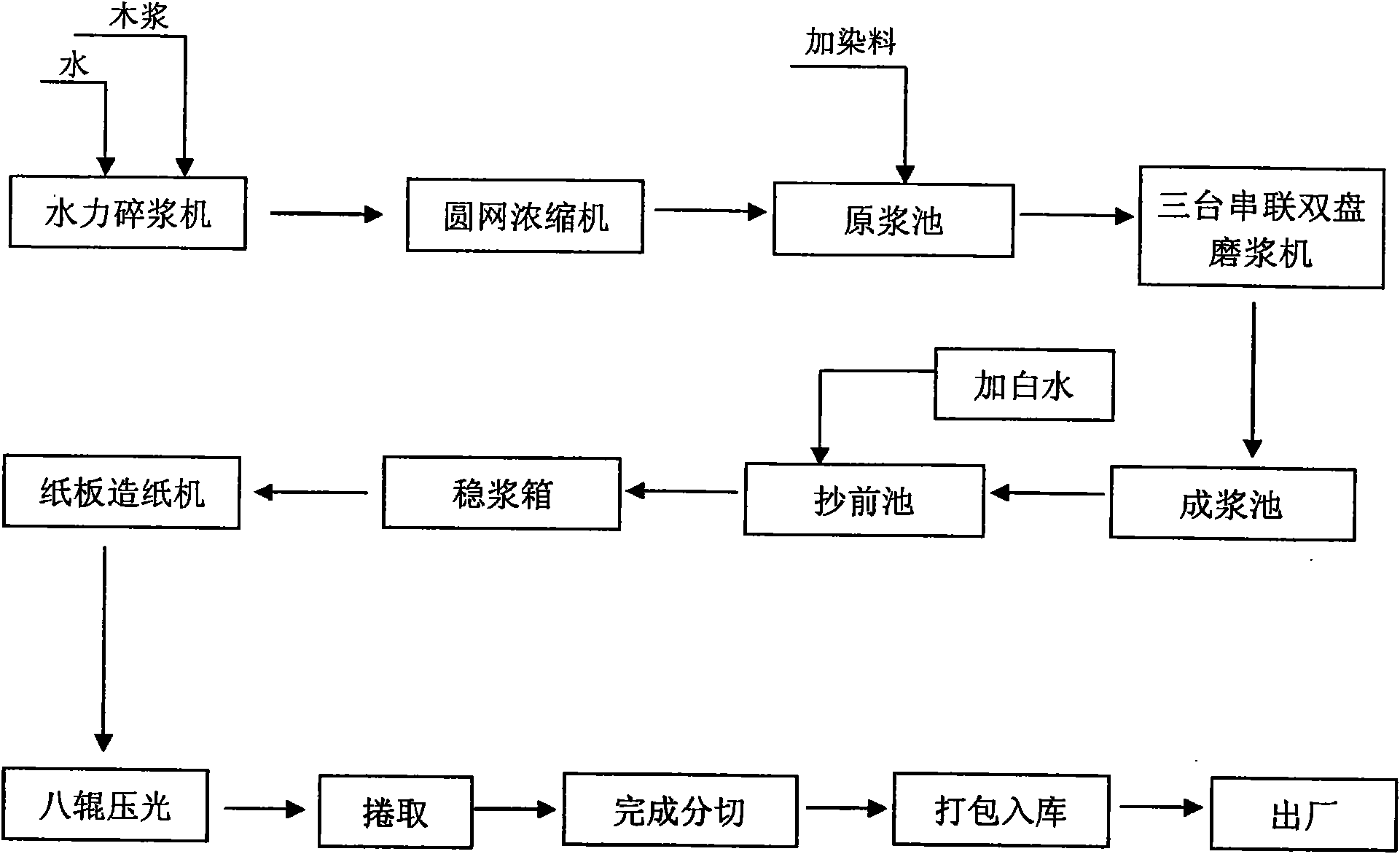

Formula and method for preparing artificial turquoise through 3D printing

InactiveCN108439942ASolve the problem of single engraving designReduce difficultyAdditive manufacturing apparatusCeramic shaping apparatusParaffin waxMacro level

The invention discloses a formula and a method for preparing artificial turquoise through 3D printing. According to the formula and the method, 60-85 parts by weight of raw turquoise powder with 15-40parts by weight of additives are mixed to obtain a raw material, wherein the particle size of the raw turquoise powder is not greater than 200 meshes; the additives are selected from two or more of paraffin, stearic acid, palm wax, liquid wax, mineral oil or plant oil; the raw turquoise powder with the added additives can meet the printing flowing requirement, and can be used for printing pre-designed shapes; the printed artificial turquoise can meet the requirements on gemological properties and is high in simulation degree; the used and recycled raw turquoise powder is low-cost and effectively utilizes the rare and precious resources; through a digital 3D model, the control on the structure can be achieved by jet molding; the accurate control on the gemstone at micro and macro levels can be ensured; the problems of simpleness and waste of the conventional turquoise carving are solved; the method is free of requirements on the technical proficiency and is capable of achieving different artificial turquoise designs.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Traditional Tibetan medicine composition and preparation for treating liver diseases, and preparation method thereof

InactiveCN102579870AEffective treatmentRetain medicinal ingredientsDigestive systemPlant ingredientsMedicinal herbsAdditive ingredient

The invention relates to a traditional Tibetan medicine composition for treating liver diseases and a preparation method thereof. The composition is prepared from 10-30 parts of turquoise, 10-30 parts of tabasheer, 20-60 parts of safflower, 4-10 parts of saffron, 25-75 parts of Meconopsis, 15-50 parts of Herba Dracocephali Tangutici, 15-50 parts of Corydalis impatiens, 15-50 parts of rock refine cream, 10-30 parts of clove, 2-5 parts of artificial ox gallstone, 10-30 parts of Indian false swertia herb, 5-15 parts of semen hertospermi, 2-5 parts of petrified bouquet and 1-3 parts of artificial musk. The preparation method comprises the following steps: evenly mixing the active pharmaceutical ingredients, micro-pulverizing into 0.01-100 mu m, adding conventional medicinal auxiliary materials, and preparing pills, micro-pills, dropping pills, tablets, capsules, granules, dispersible tablets and other clinically acceptable preparation formulations, or preparing bagged beverages or canned beverages. The composition can effectively treat liver diseases, and therefore, is very suitable for clinical popularization.

Owner:SHANDONG JINHE DRUG RES DEV

Production method for turquoise clear-mud inkstone

The invention discloses a production method for turquoise clear-mud inkstone, which solves problems that a production method for clear-mud inkstone is lost for years and colors of the inkstone cannot be manually controlled. The production method for turquoise clear-mud inkstone includes that ancient silt taken from the Hutuo river within the border of the Wutai county of Shanxi province is sun-dried, the dried ancient silt is placed in a water vat to be soaked for two hours, the soaked ancient silt is stirred to form mud, the mud is filtered, cattle bone powder with the weight of 5% of that of the mud is added into filtered mud, the mud is stirred again and filled in a cloth bag, water content in the mud is filtered out, the mud without the water content is beaten to form a mud pie, the mud pie is placed in a mold to make into a blank, the blank is placed in a fire-resistant box prior to being placed in a kiln, the temperature of the kiln is controlled to be in a range of 980 DEG C and 1050 DEG C, the blank is fired for 72 hours, and turquoise clear-mud inkstone is obtained. The production method has the advantages that the ancient technology is inherited while the production method is innovative, the production process, which is lost for a long time, for clear-mud inkstone is restored, and the produced clear-mud inkstone is excellent in quality and has advantages in terms of both the shape and the color.

Owner:WUTAI WENSHI CHENG MUD PROD

Active turquoise blue dye production wastewater reclamation process

ActiveCN104193045ACOD value is accurateAvoid depigmentation processing stepsMultistage water/sewage treatmentWaste water treatment from textile industryFilter pressDyeing wastewater

The invention discloses an active turquoise blue dye production wastewater reclamation process, which comprises the following steps: (1) directly transferring dye wastewater which is no more than 50 times in chromaticity to a wastewater collection tank, feeding dye wastewater which is more than 50 times in chromaticity to a decolorizing pool, physically decolorizing the dye wastewater in the decolorizing pool, and transferring the processed dye wastewater into the wastewater collection tank once again; (2) adding the dye wastewater in the wastewater collection tank of the step (1) into a neutralization kettle, and slowly adding lime milk while stirring uniformly; and stopping reaction when pH value is 7.0-8.5; (3) filter-pressing through a filter press to obtain filtrate I and a filter cake I; (4) adding the obtained filtrate I to a replacement kettle, and adding sodium carbonate for a replacement reaction; and (5) filter-pressing materials in the replacement kettle of the step (4) through the press filter to obtain filtrate II and a filter cake II. The wastewater processed by the process can be completely reclaimed for production of active turquoise blue dye, thus realizing a goal of clean production in a dye production process.

Owner:唐山明州科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com