Preparation method of supported iron-molybdate catalyst and application of catalyst to degradation of dye wastewater

An acid catalyst, iron molybdate technology, applied in molecular sieve catalyst, physical/chemical process catalyst, textile industry wastewater treatment and other directions, can solve the problems of difficult separation and recovery of suspension system, high operating cost, poor reproducibility, etc. Large surface, high catalytic efficiency, small particle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

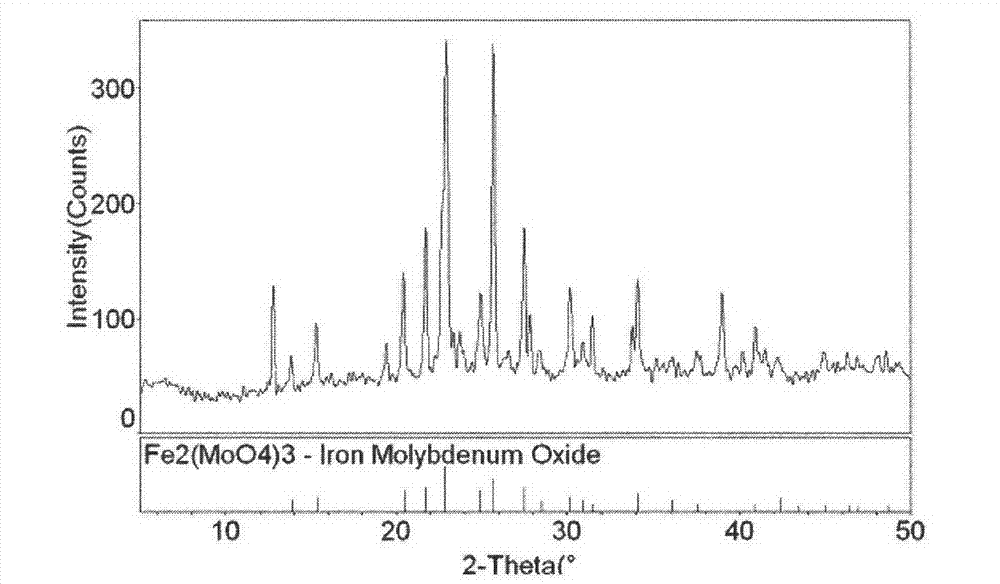

[0031] Embodiment 1: the preparation of unsupported iron molybdate catalyst

[0032] According to the ratio of the amount of substance n Mo : n Fe = 2:1, respectively weigh ammonium molybdate and ferric nitrate solids, and prepare a certain concentration of ammonium molybdate and ferric nitrate solutions.

[0033] Add 8-12mL of 2mol / L ammonia water to 100mL of ammonium molybdate aqueous solution, and adjust the pH until the solution is weakly alkaline. Add 100mL ferric nitrate aqueous solution dropwise to the mixture, stir vigorously at room temperature for 2h to obtain a precipitate, filter, wash with distilled water, dry at 105°C, and calcinate in a muffle furnace at 550°C for 2h.

Embodiment 2

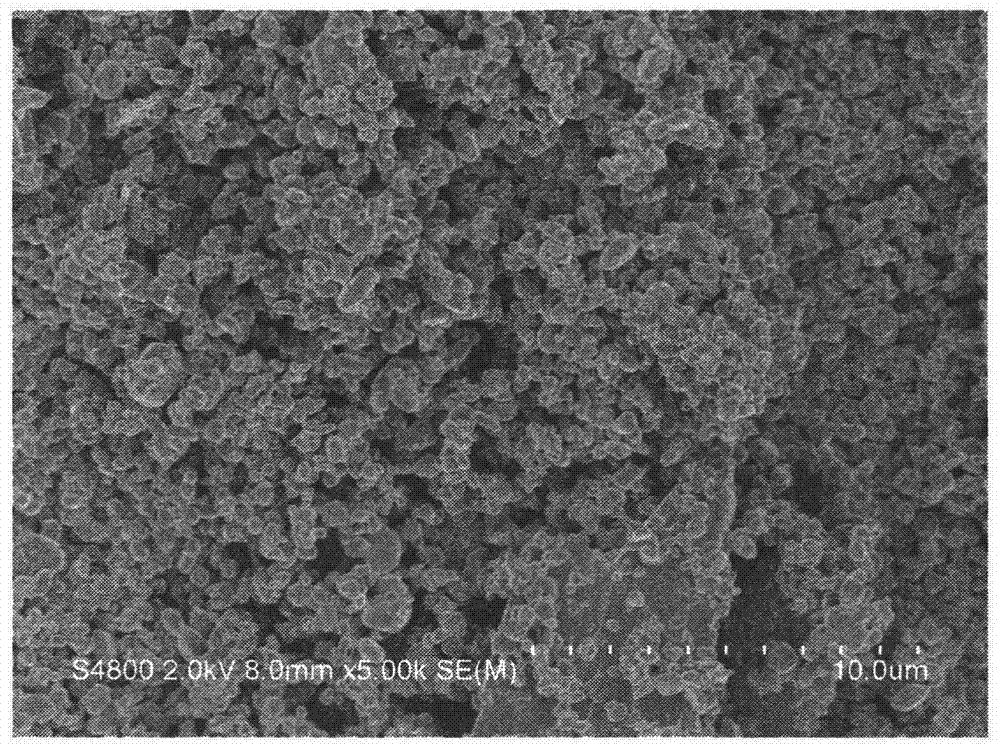

[0034] Embodiment 2: the preparation of diatomite supported iron molybdate catalyst

[0035] Wash 30g of diatomaceous earth for 3 times and then dry at 130°C for 1h. According to m 载体 :m 催化剂 =4:1 relationship, get 12g of diatomaceous earth for subsequent use.

[0036] According to the ratio of the amount of substance n Mo : n Fe = 2:1, respectively weigh ammonium molybdate and ferric nitrate solids, and prepare a certain concentration of ammonium molybdate and ferric nitrate solutions.

[0037] Add 8-12mL of 2mol / L ammonia water to the suspension of 100mL of ammonium molybdate and 12g of diatomaceous earth, and stir evenly. Add 100mLmol / L ferric nitrate solution dropwise to the above mixture, stir vigorously at room temperature for 2h to obtain a precipitate, which is aged for 3 hours, filtered, washed with distilled water, dried at 105°C for 12h, and calcined in a muffle furnace at 550°C 2h.

Embodiment 3

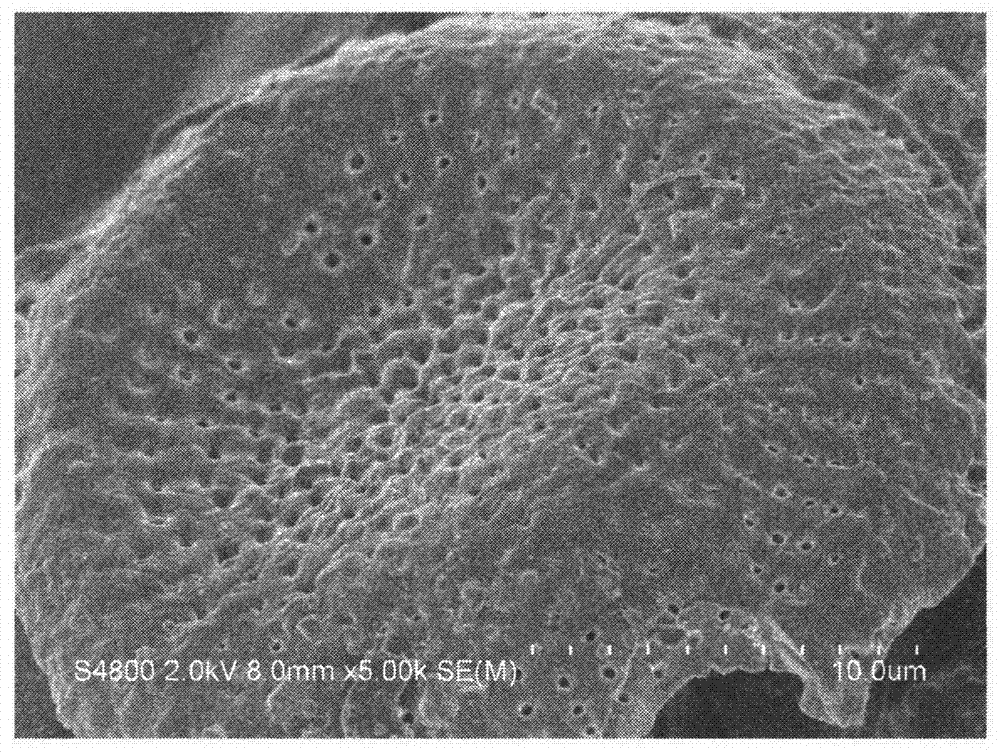

[0038] Embodiment 3: Preparation of zeolite-supported iron molybdate catalyst

[0039] Zeolite with different specifications (80 mesh, 100 mesh, 120 mesh) was washed, dried, and set aside.

[0040] According to the ratio of the amount of substance n Mo : n Fe = 2:1, respectively weigh ammonium molybdate and ferric nitrate solids, and prepare a certain concentration of ammonium molybdate and ferric nitrate solutions.

[0041] Add 8-12mL 2mol / L ammonia water to the suspension of 100mL ammonium molybdate and 12g zeolite, and stir evenly. Add 100mL of ferric nitrate solution dropwise to the mixture, stir vigorously at room temperature for 2h to obtain a precipitate, which is aged for 3 hours, filtered, washed with distilled water, dried at 105°C for 12h, and calcined in a muffle furnace at 550°C for 2h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com