Patents

Literature

6048results about How to "High catalytic efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High activity olefin polymerization catalyst and process

ActiveUS6953764B2High catalytic efficiencyHigh monomer conversionGroup 4/14 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsOlefin polymerizationPolymerization catalysts

Group 4 metal complexes useful as addition polymerization catalysts of the formula: whereinG1 is a group containing from 1 to 40 atoms not counting hydrogen;T is a divalent bridging group of from 10 to 30 atoms not counting hydrogen, selected from mono- or di-aryl-substituted methylene or silylene groups or mono- or di-heteroaryl-substituted methylene or silylene groups, wherein at least one such aryl- or heteroaryl-substituent is substituted in one or both ortho-positions with a secondary or tertiary alkyl-group, a secondary or tertiary heteroalkyl group, a cycloalkyl group, or a heterocycloalkyl group,G2 is a C6-20 heteroaryl group containing Lewis base functionality,M is the Group 4 metal,X″″ is an anionic, neutral or dianionic ligand group,x″″ is a number from 0 to 5, andbonds, optional bonds and electron donative interactions are represented by lines, dotted lines and arrows respectively.

Owner:DOW GLOBAL TECH LLC

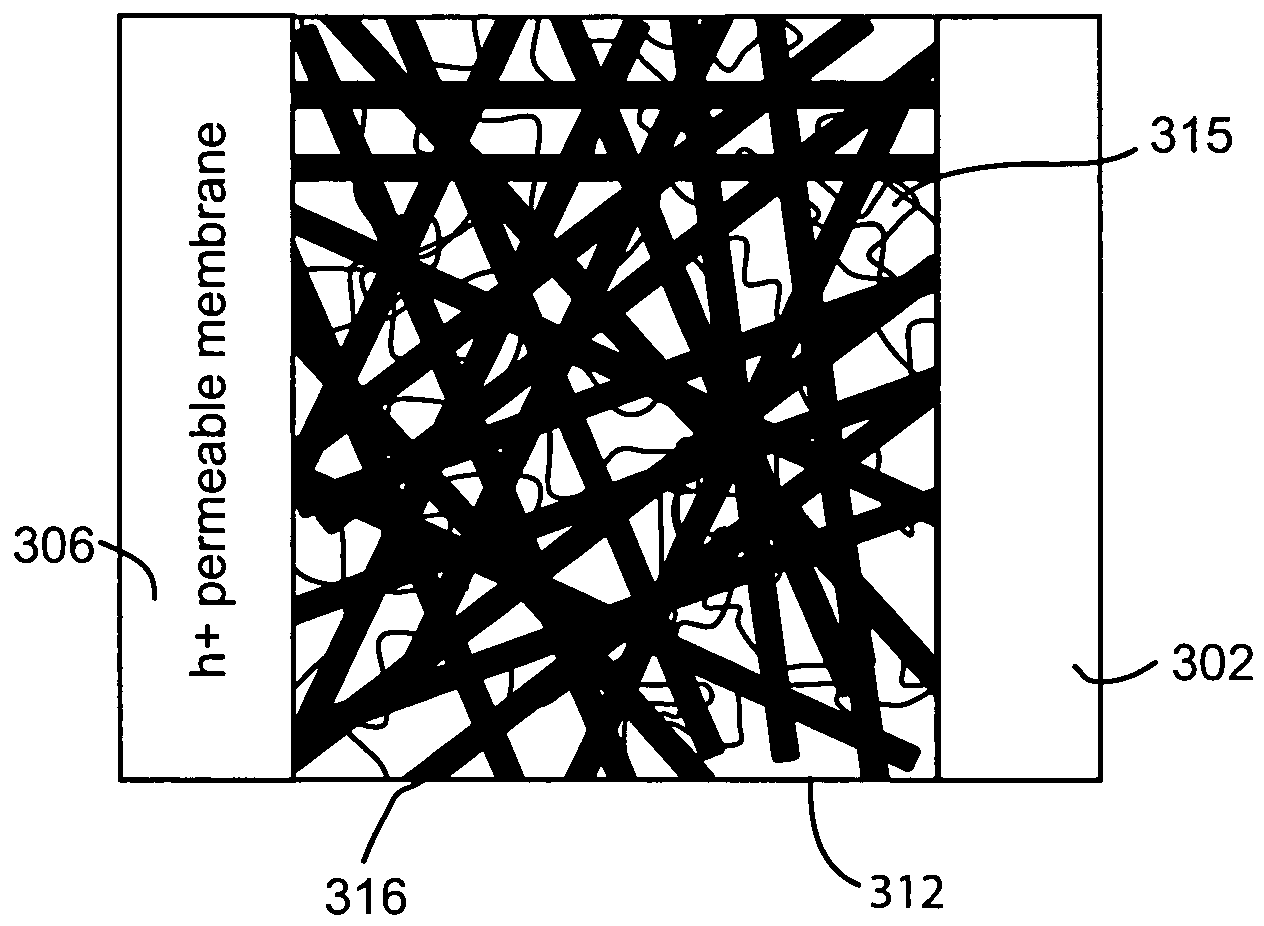

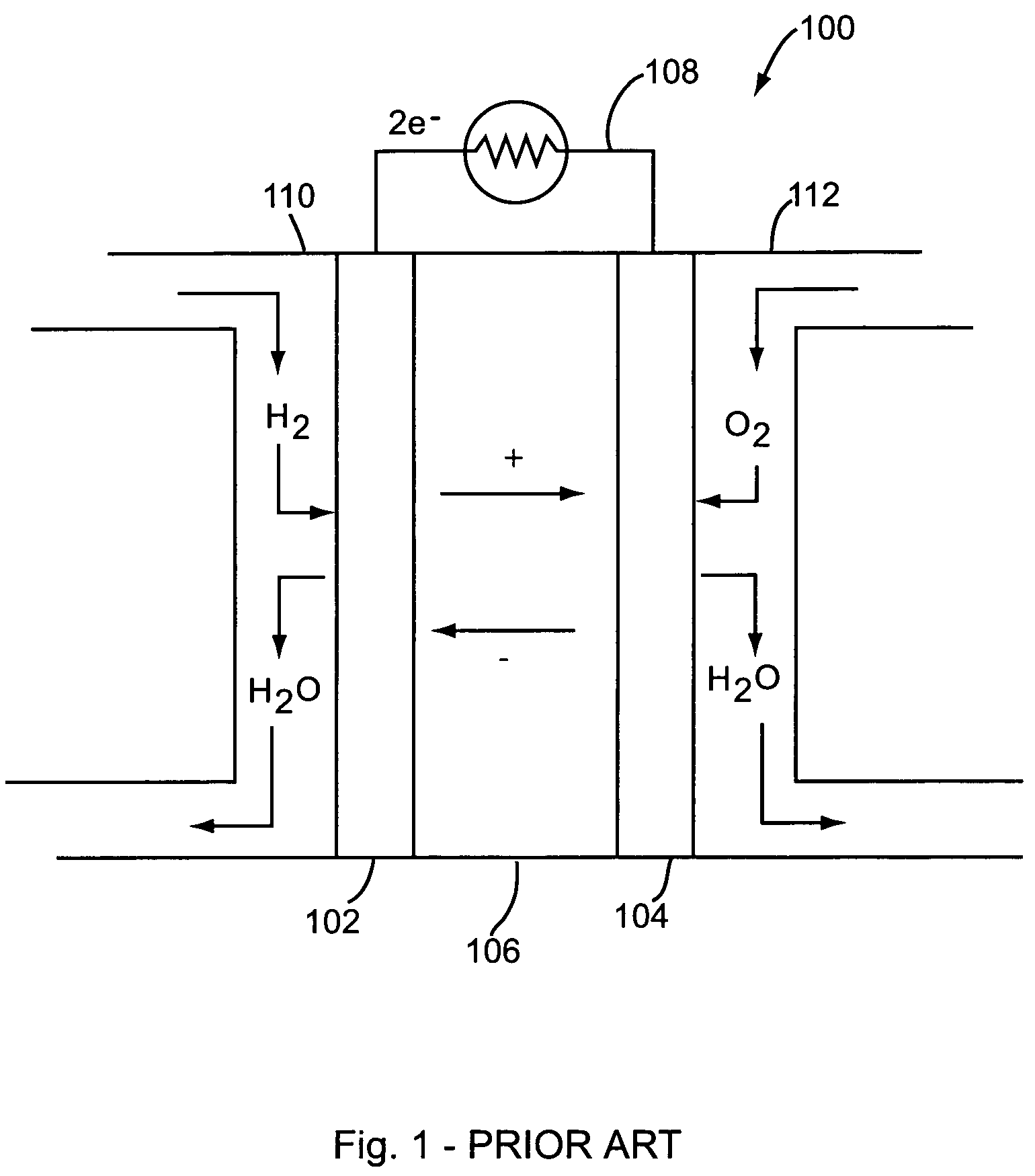

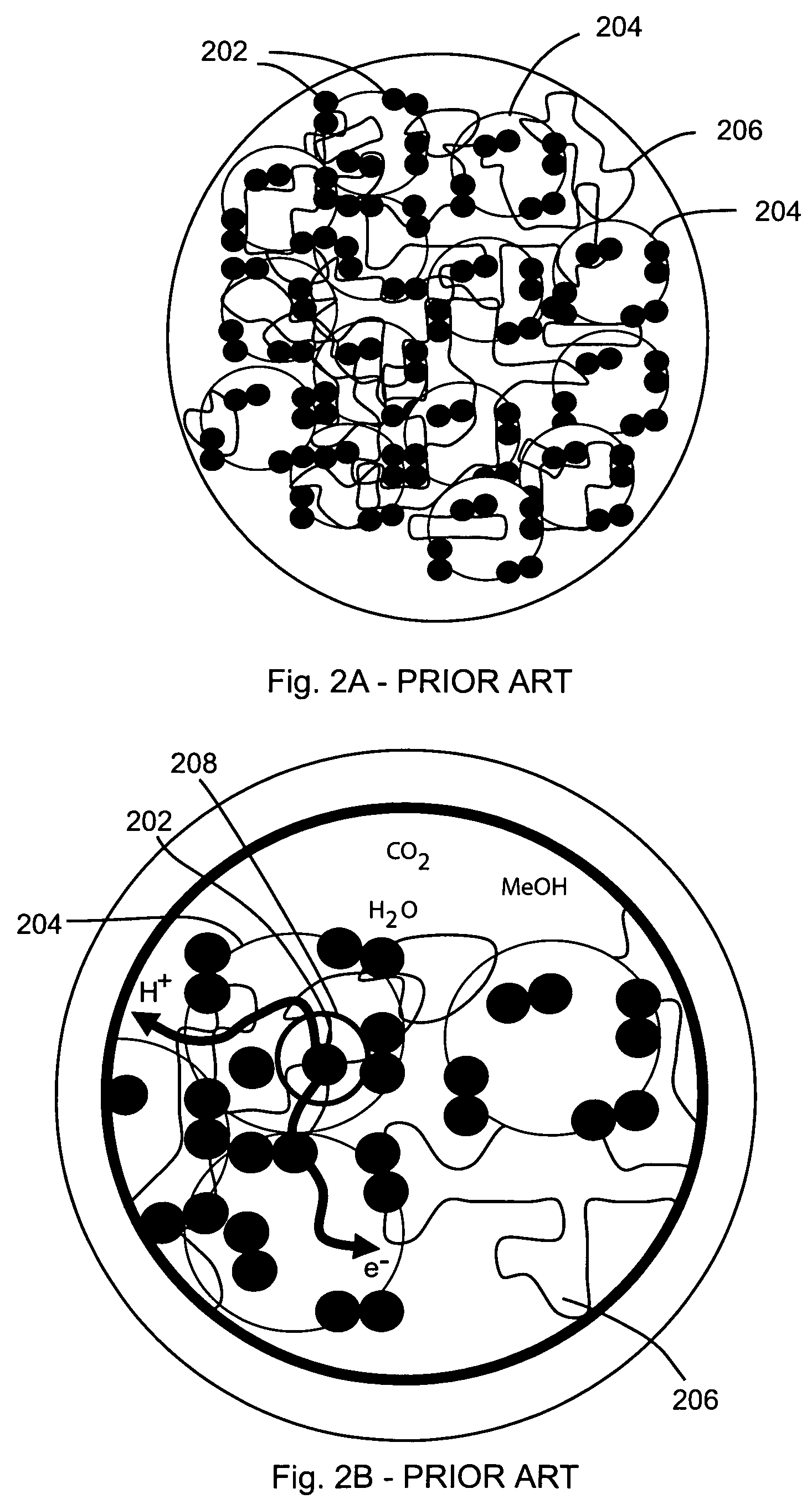

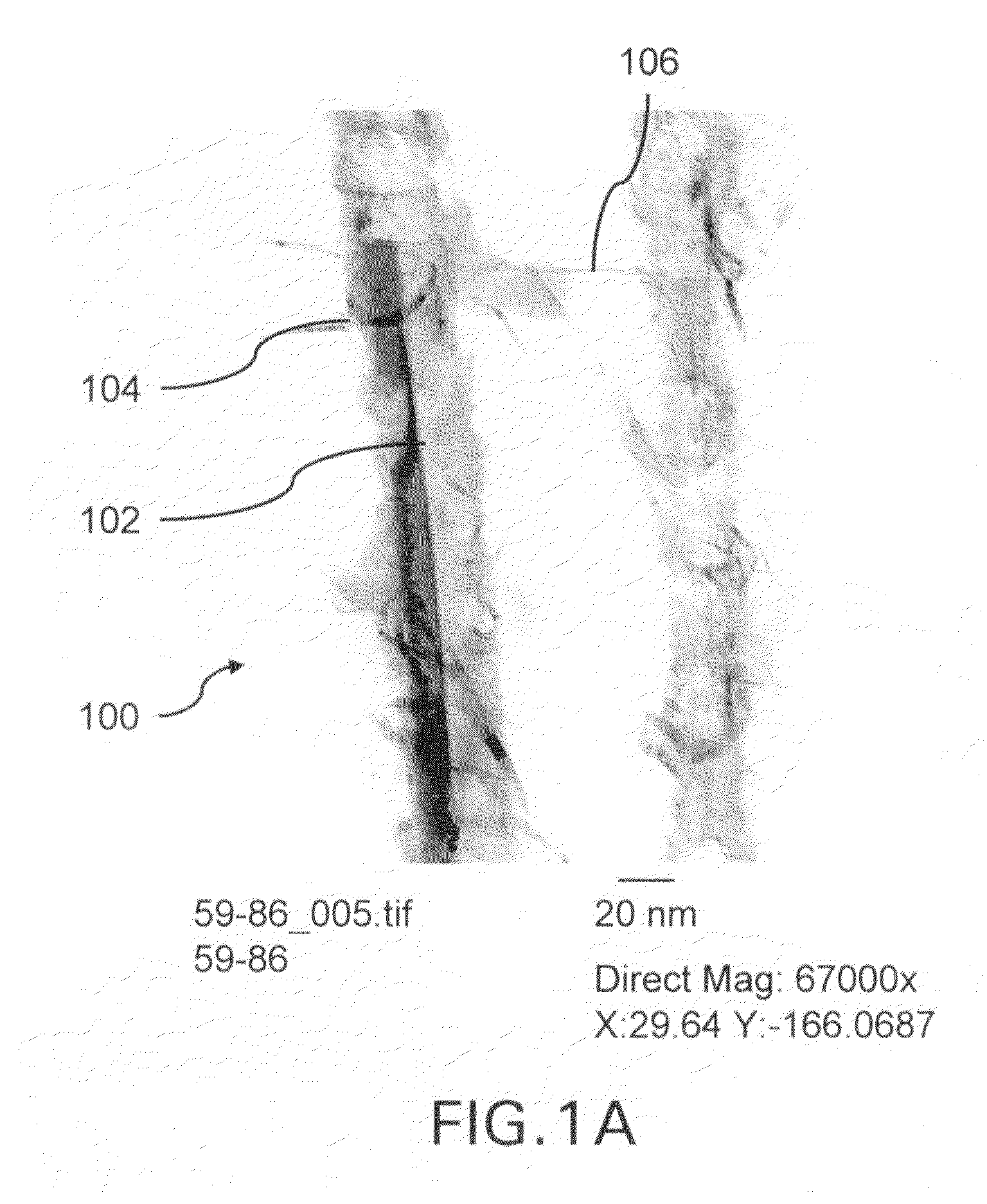

Nanowire-based membrane electrode assemblies for fuel cells

ActiveUS7179561B2High rateLow costMaterial nanotechnologyFinal product manufactureNanowirePtru catalyst

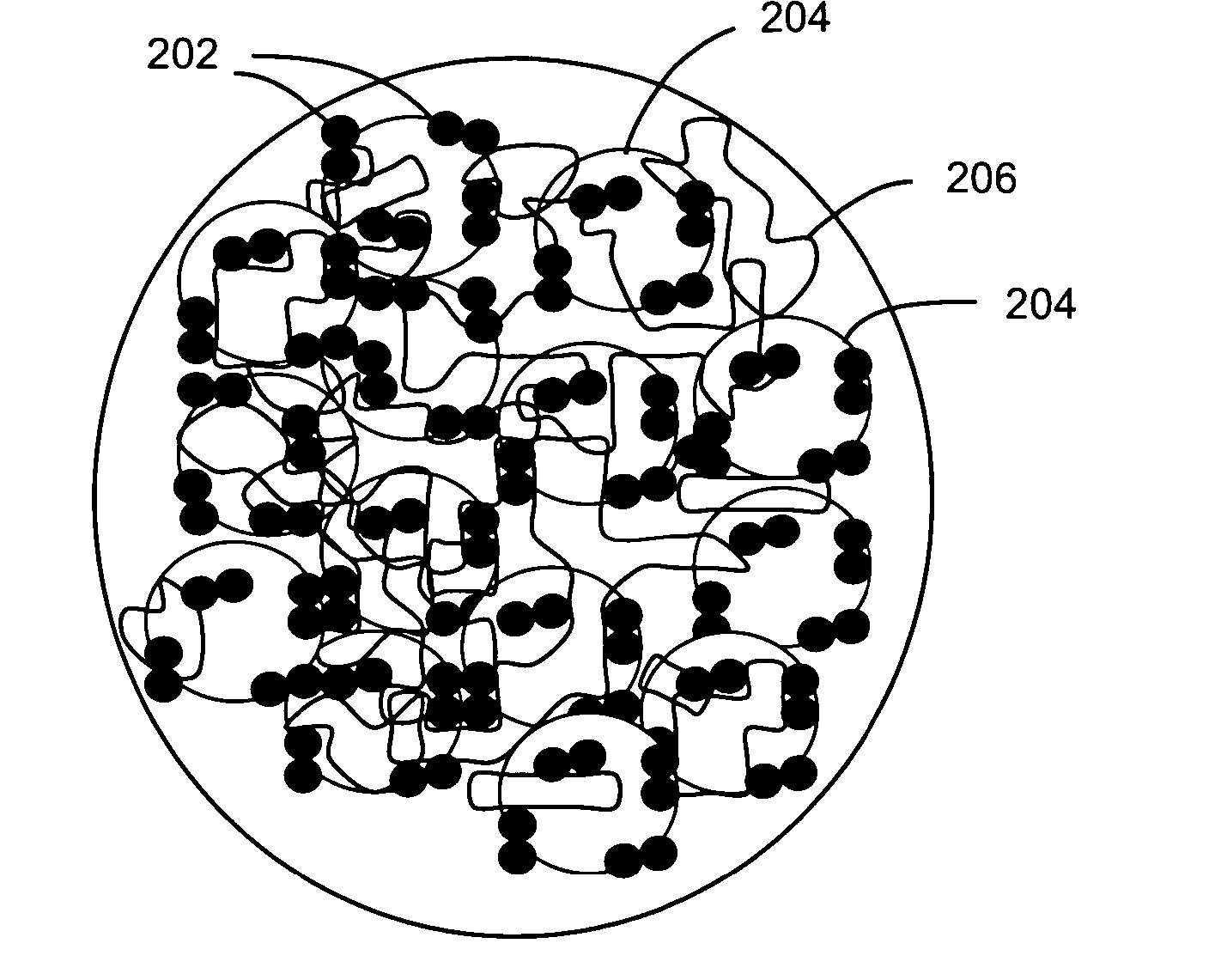

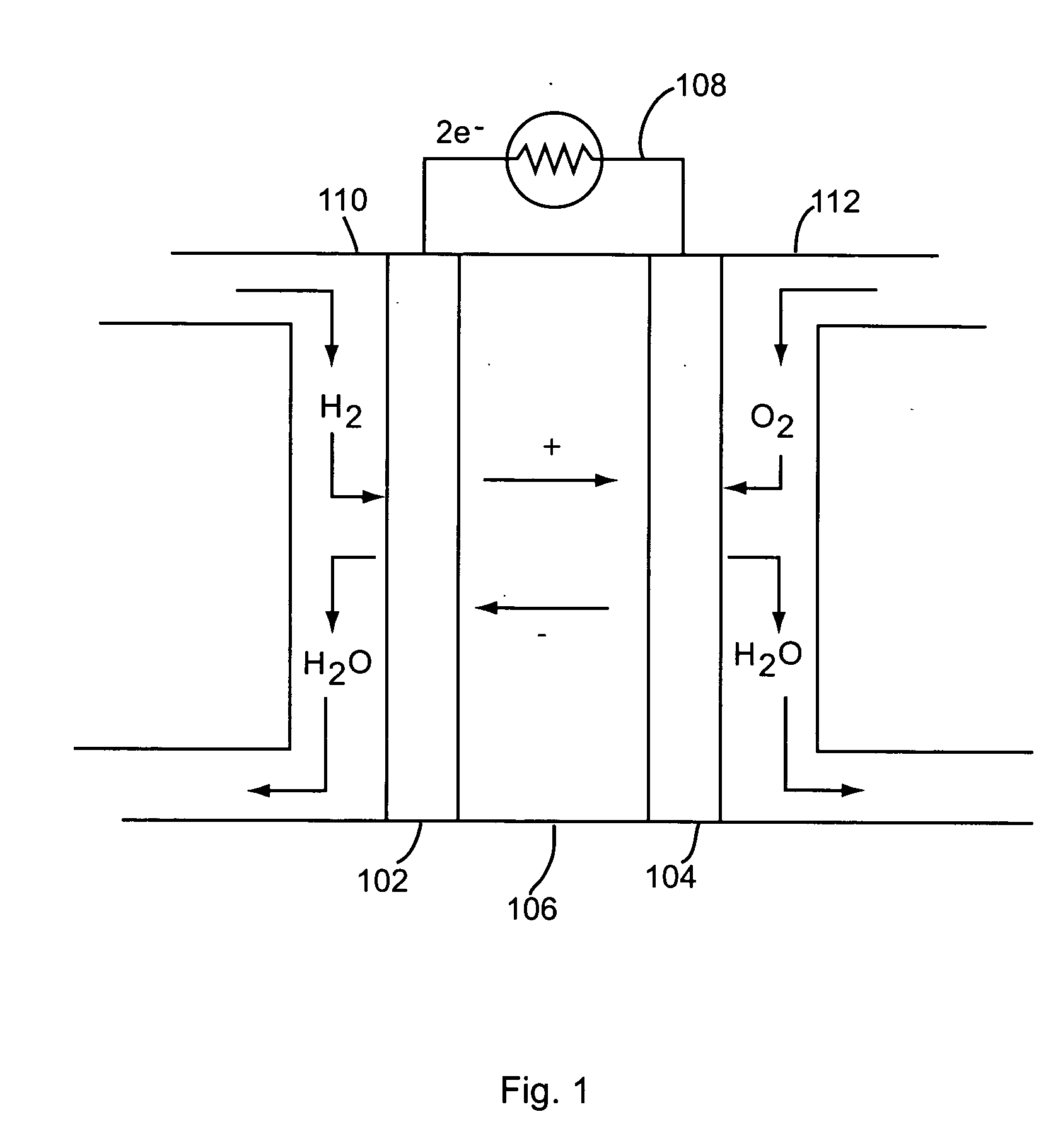

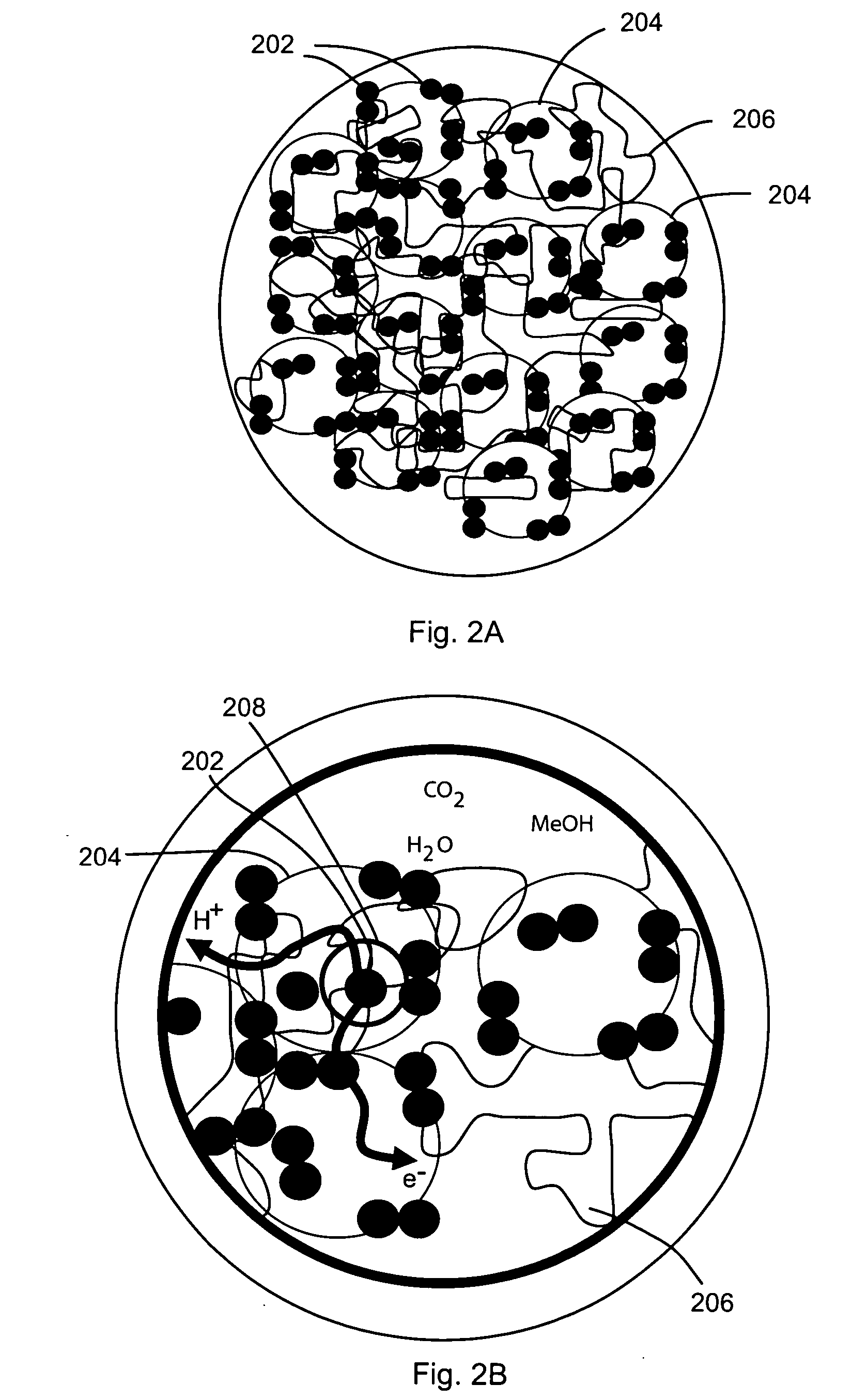

The present invention discloses nanowires for use in a fuel cell comprising a metal catalyst deposited on a surface of the nanowires. A membrane electrode assembly for a fuel cell is disclosed which generally comprises a proton exchange membrane, an anode electrode, and a cathode electrode, wherein at least one or more of the anode electrode and cathode electrode comprise an interconnected network of the catalyst supported nanowires. Methods are also disclosed for preparing a membrane electrode assembly and fuel cell based upon an interconnected network of nanowires.

Owner:ONED MATERIAL INC

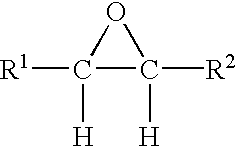

Alkylene oxide catalysts having enhanced activity and/or stability

InactiveUS6511938B1High catalytic activityEnhanced Efficiency StabilityOrganic chemistry methodsCatalyst activation/preparationChemistryOxide

Catalysts for the production of alkylene oxide by the epoxidation of alkene with oxygen comprise a silver-containing support, and a sufficient amount of cobalt component to enhance at least one of activity and / or efficiency and / or stability as compared to a similar catalyst which does not contain cobalt component.

Owner:DOW TECH INVESTMENTS

Nanowire-based membrane electrode assemblies for fuel cells

ActiveUS20060188774A1Higher catalytic metal utilization rateLow costMaterial nanotechnologyFinal product manufactureNanowirePtru catalyst

The present invention discloses nanowires for use in a fuel cell comprising a metal catalyst deposited on a surface of the nanowires. A membrane electrode assembly for a fuel cell is disclosed which generally comprises a proton exchange membrane, an anode electrode, and a cathode electrode, wherein at least one or more of the anode electrode and cathode electrode comprise an interconnected network of the catalyst supported nanowires. Methods are also disclosed for preparing a membrane electrode assembly and fuel cell based upon an interconnected network of nanowires.

Owner:ONED MATERIAL INC

Nanowire structures comprising carbon

ActiveUS20080280169A1Low overall diffusion resistanceLow costFinal product manufactureFuel cell auxillariesField emission deviceFuel cells

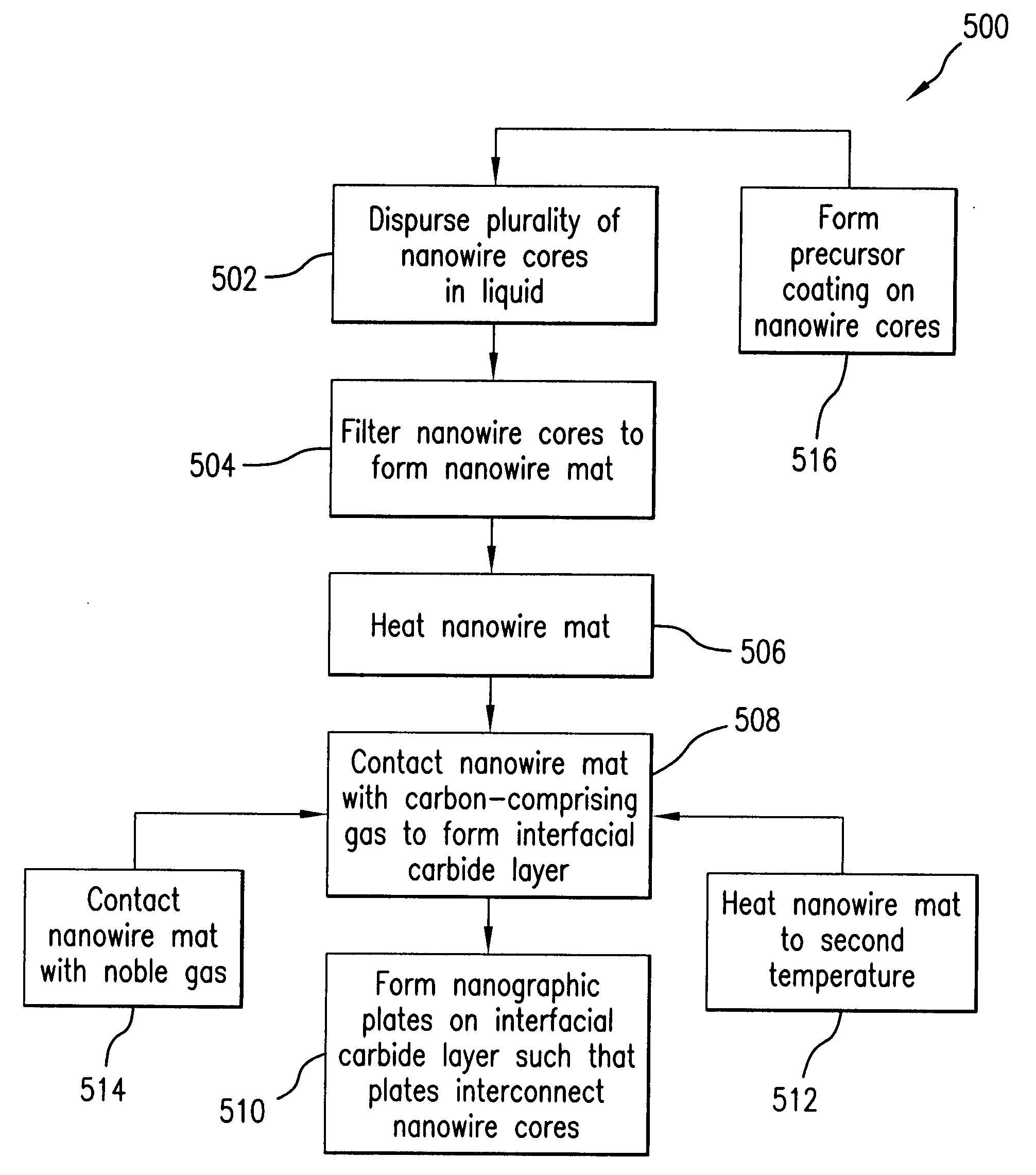

The present invention is directed to nanowire structures and interconnected nanowire networks comprising such structures, as well as methods for their production. The nanowire structures comprise a nanowire core, a carbon-based layer, and in additional embodiments, carbon-based structures such as nanographitic plates consisting of graphenes formed on the nanowire cores, interconnecting the nanowire structures in the networks. The networks are porous structures that can be formed into membranes or particles. The nanowire structures and the networks formed using them are useful in catalyst and electrode applications, including fuel cells, as well as field emission devices, support substrates and chromatographic applications.

Owner:ONED MATERIAL INC

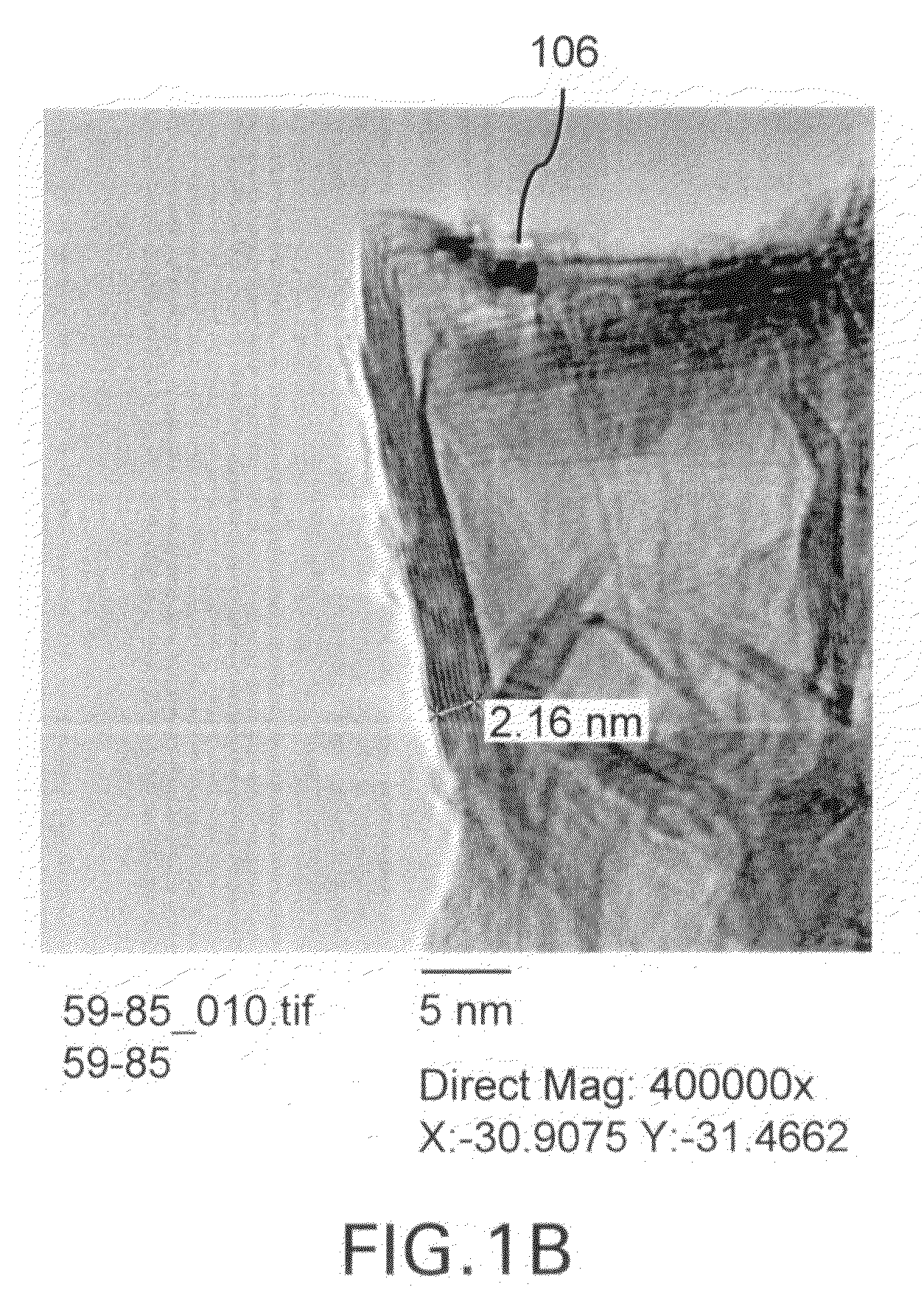

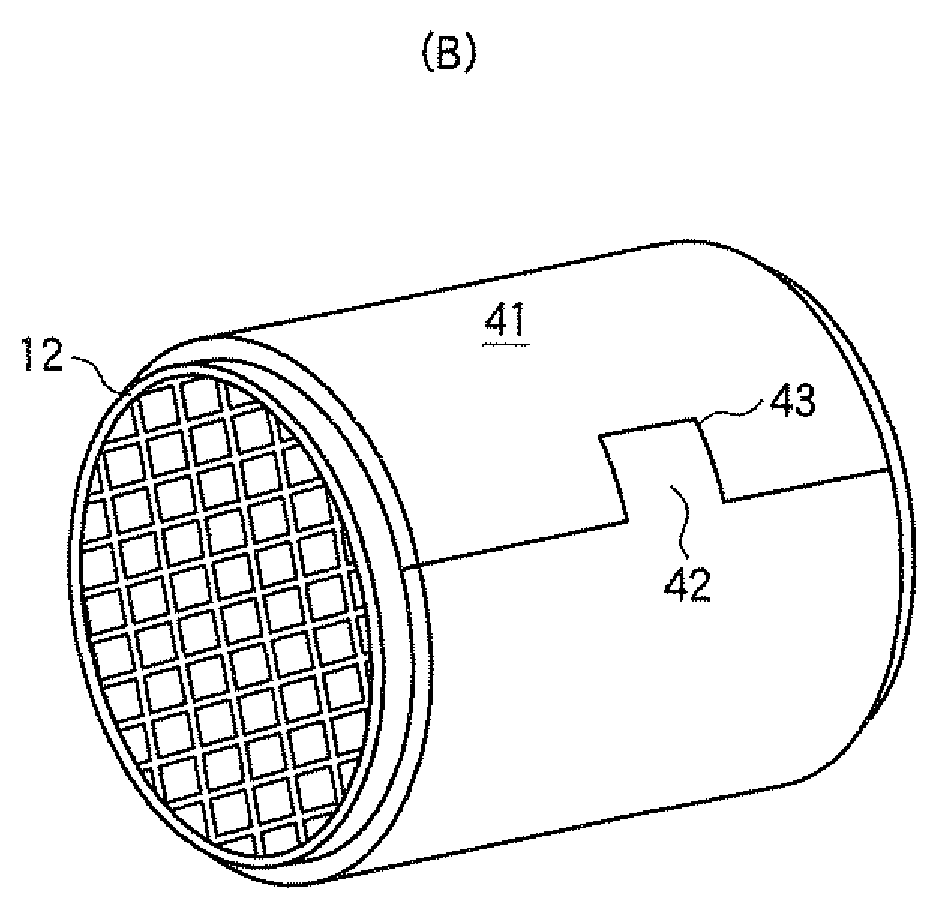

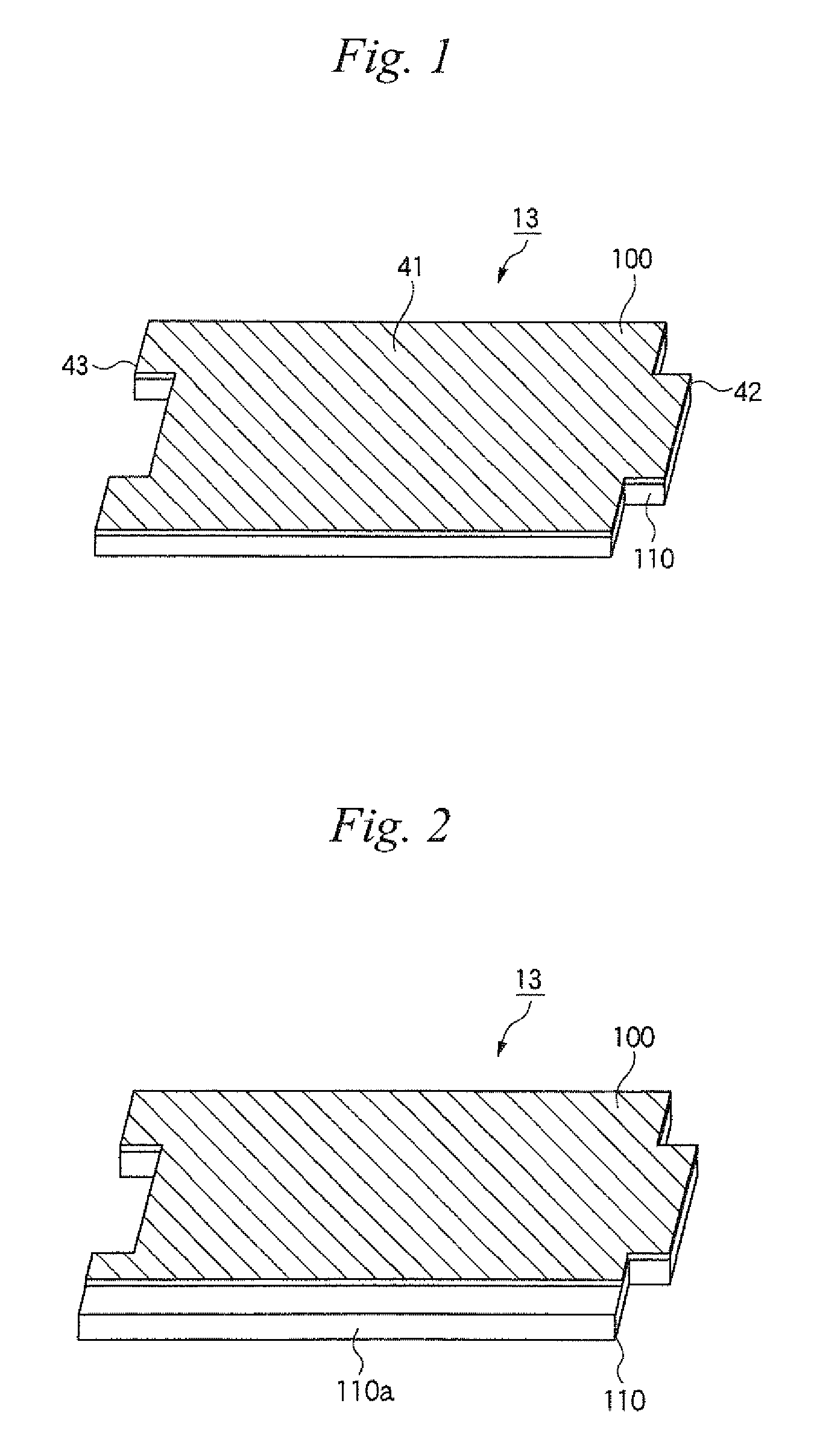

Catalytic converter, holding material for catalytic converter and production method thereof

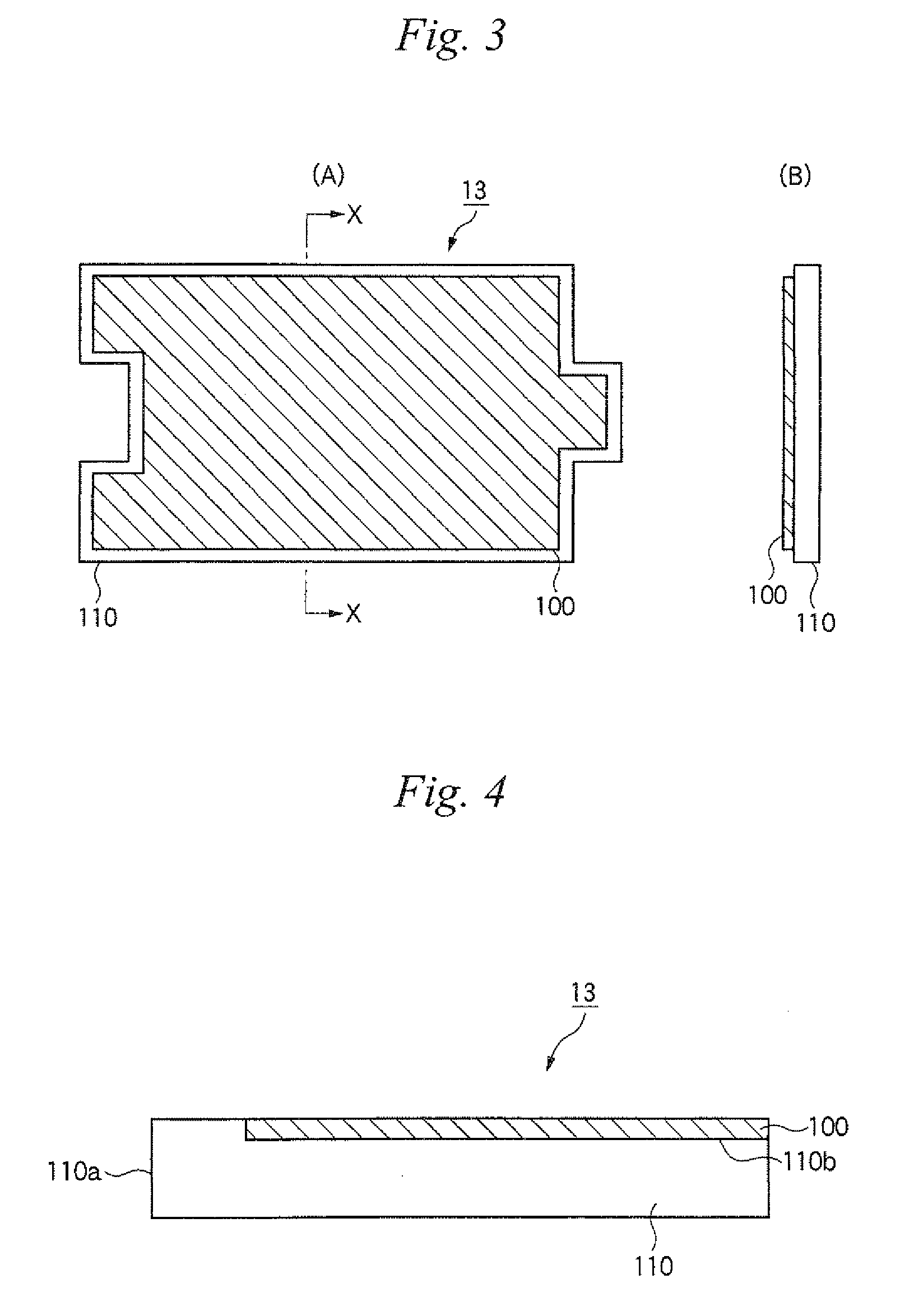

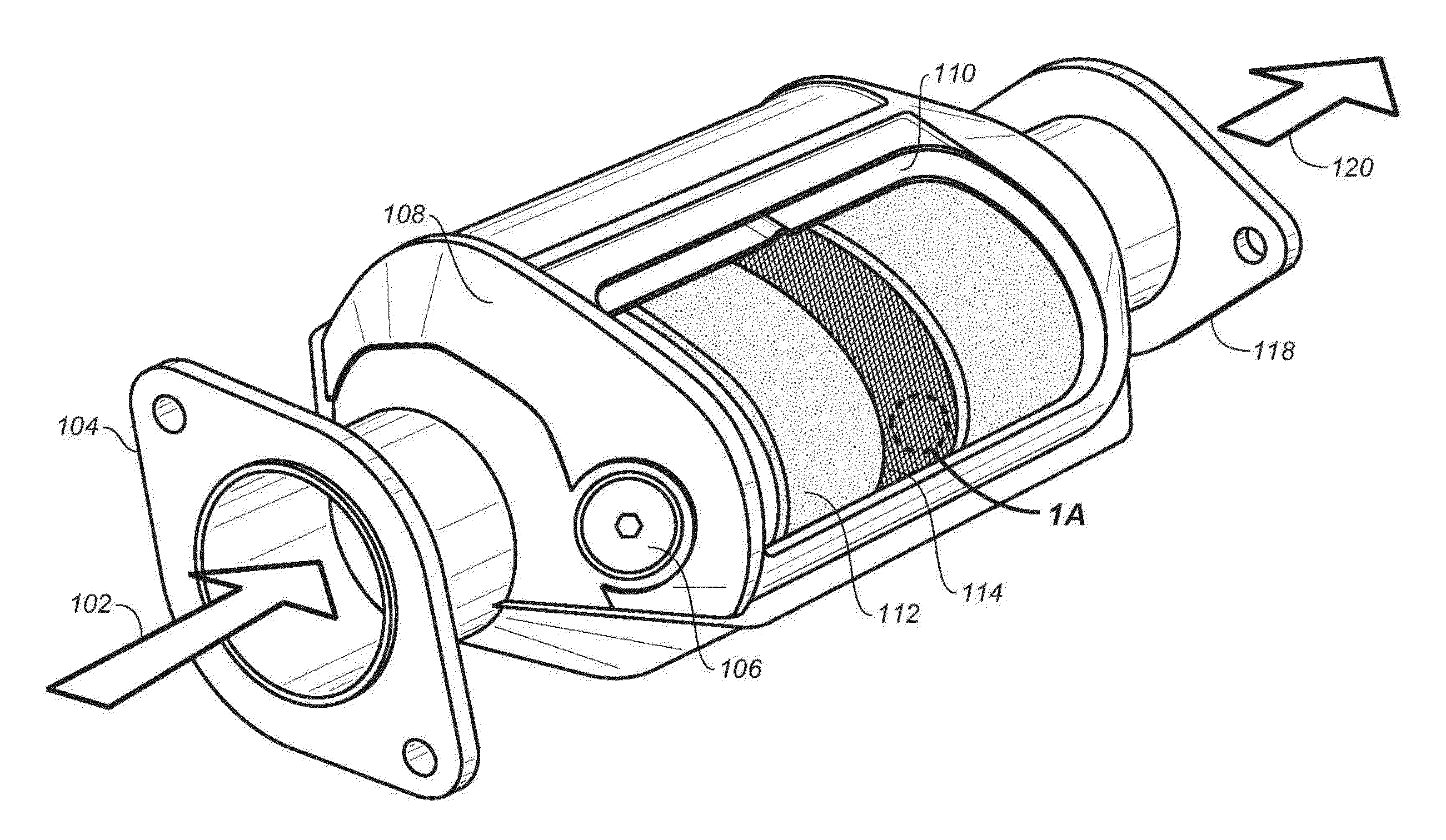

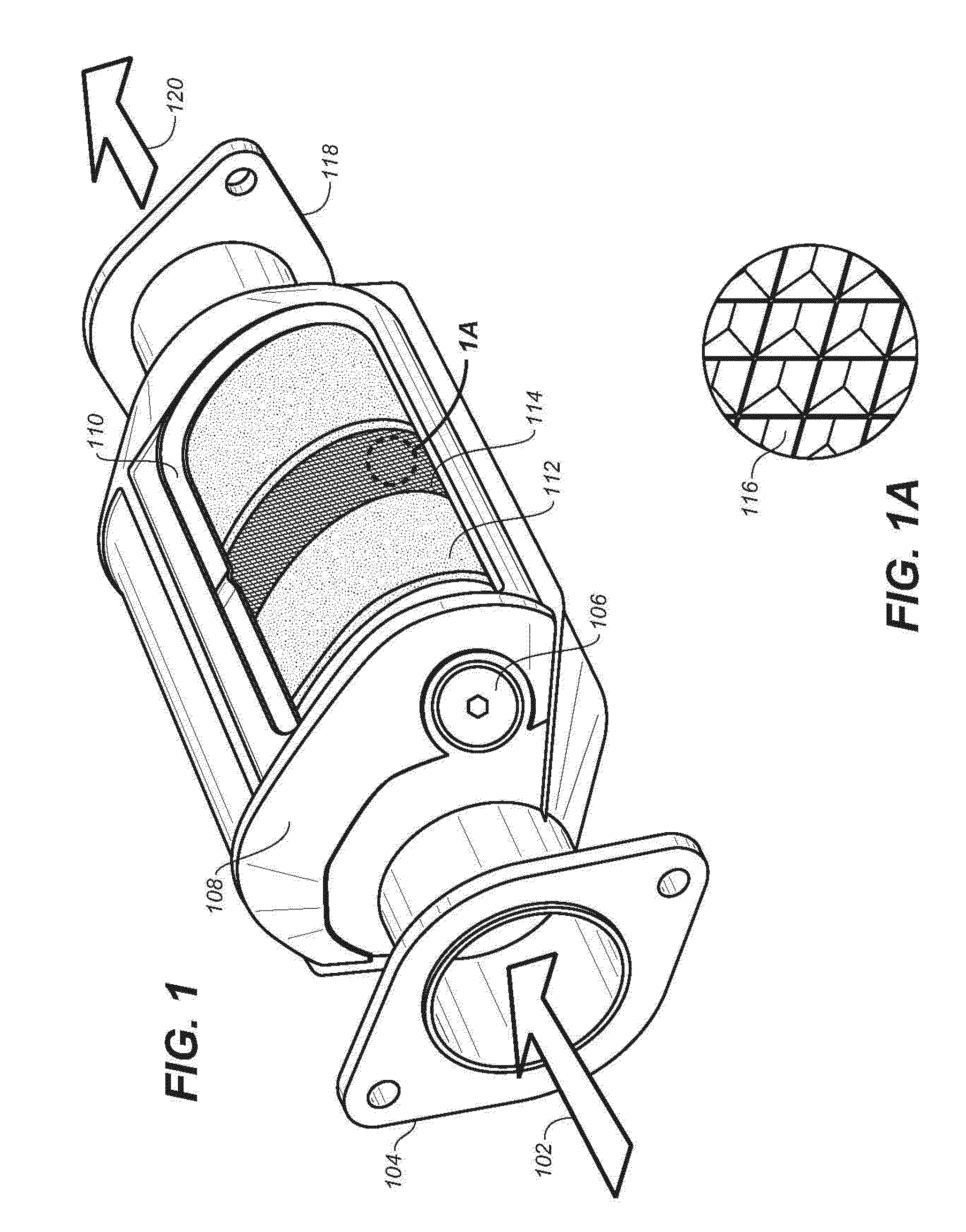

ActiveUS20090022633A1Improve insulation performanceImprove exhaust gas purification performanceCombination devicesLamination ancillary operationsPorous substrateCatalyst support

The present invention relates to a holding material for a catalytic converter including a catalyst carrier, a metal casing for receiving the catalyst carrier, and the holding material wound around the catalyst carrier and interposed in a gap between the catalyst carrier and the metal casing, the holding material including a low thermal conductivity layer, in which the low thermal conductivity layer includes: a molded material containing an inorganic powder; or a composite material of a porous substrate with an aerogel.

Owner:NICHIAS CORP

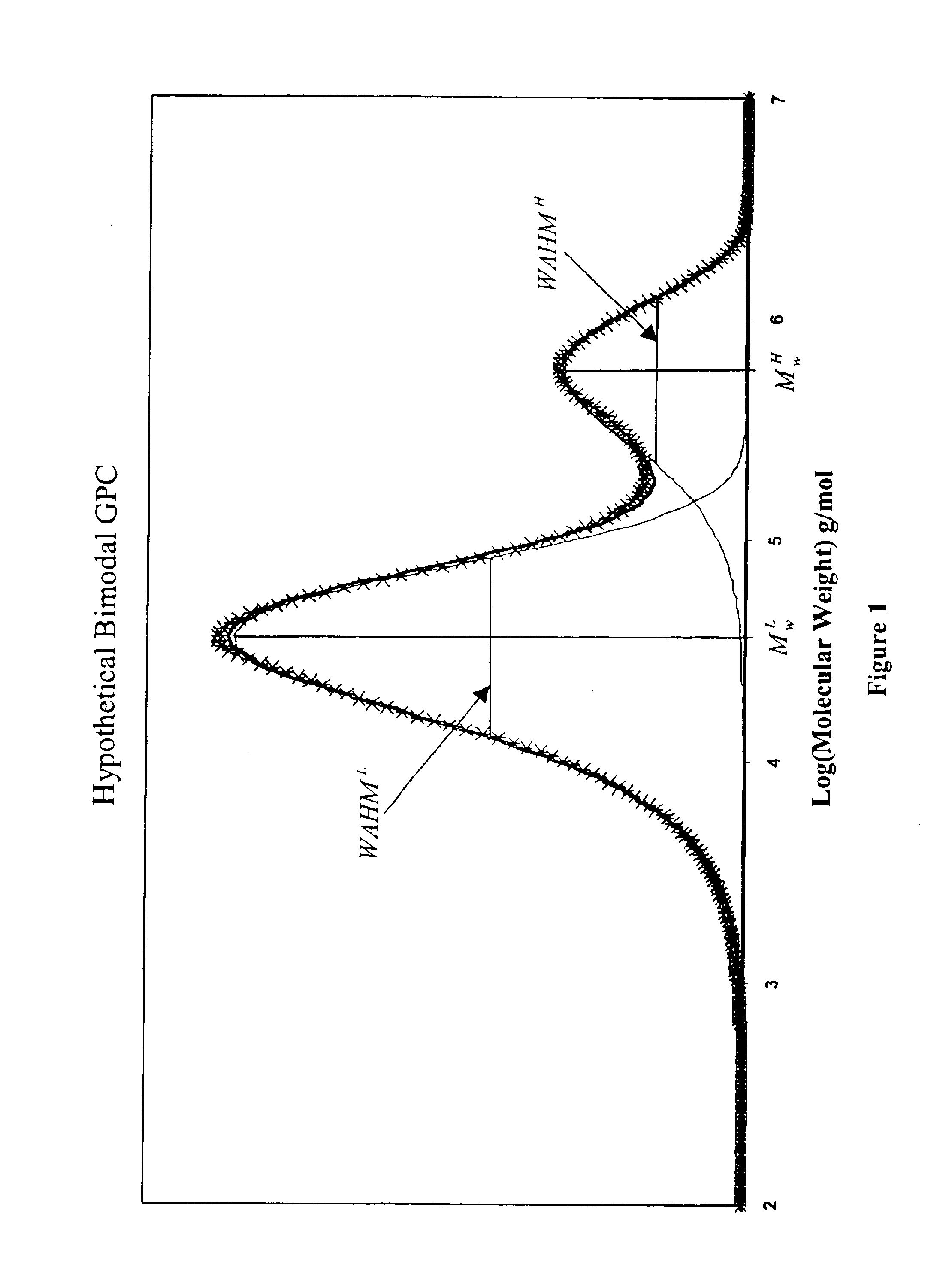

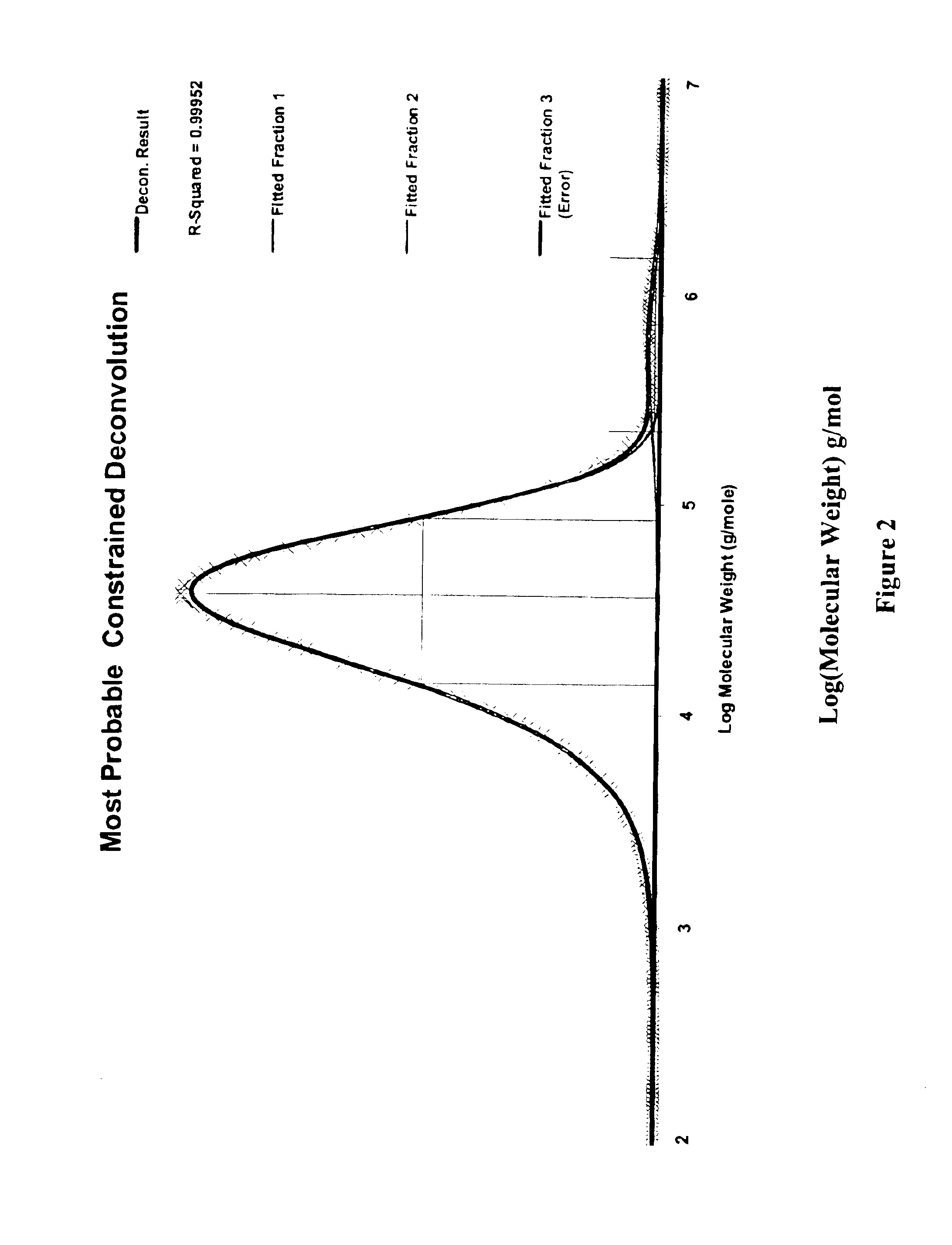

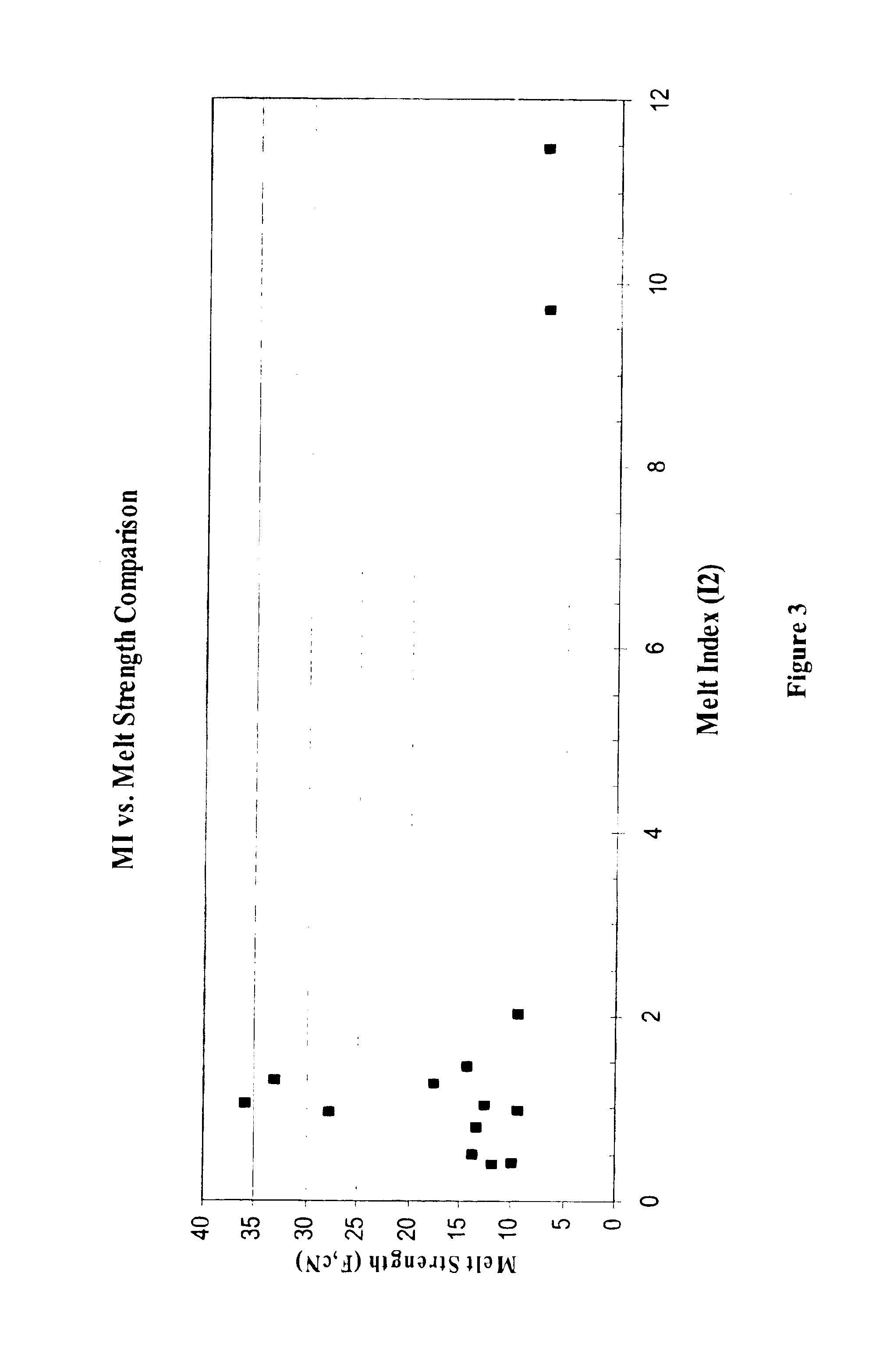

High melt strength polymers and method of making same

InactiveUS6875816B2Easy to processSacrificing efficiencyBulk chemical productionUltimate tensile strengthPolymer chemistry

A polymer composition comprises: (a) a high molecular weight, branched component; and (b) a low molecular weight, branched component. Some polymer compositions are characterized by a substantial absent of amyl or methyl branches and a melt strength (MS) that satisfies the following relationship: MS≥xI2+ywhere x is greater than or equal to about 12.5 and y is greater than or equal to about 3.Some polymers are characterized by a melt strength (MS) that satisfies the following relationship: MS≥xI2+ywhere x is greater than or equal to about 3 and y is greater than or equal to about 4.5 and a molecular weight distribution of greater than 3. A process for making polymers is also disclosed.

Owner:DOW GLOBAL TECH LLC

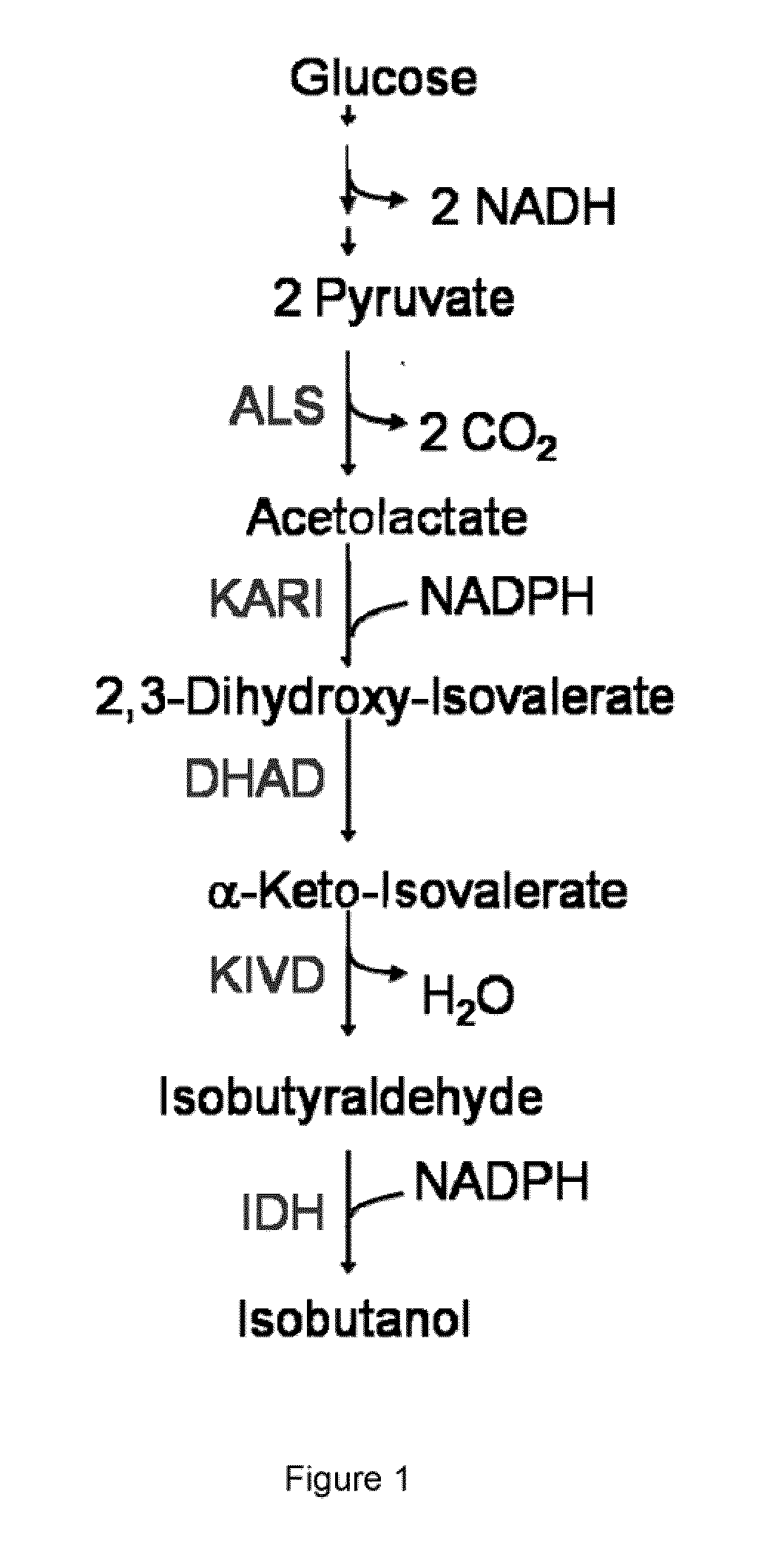

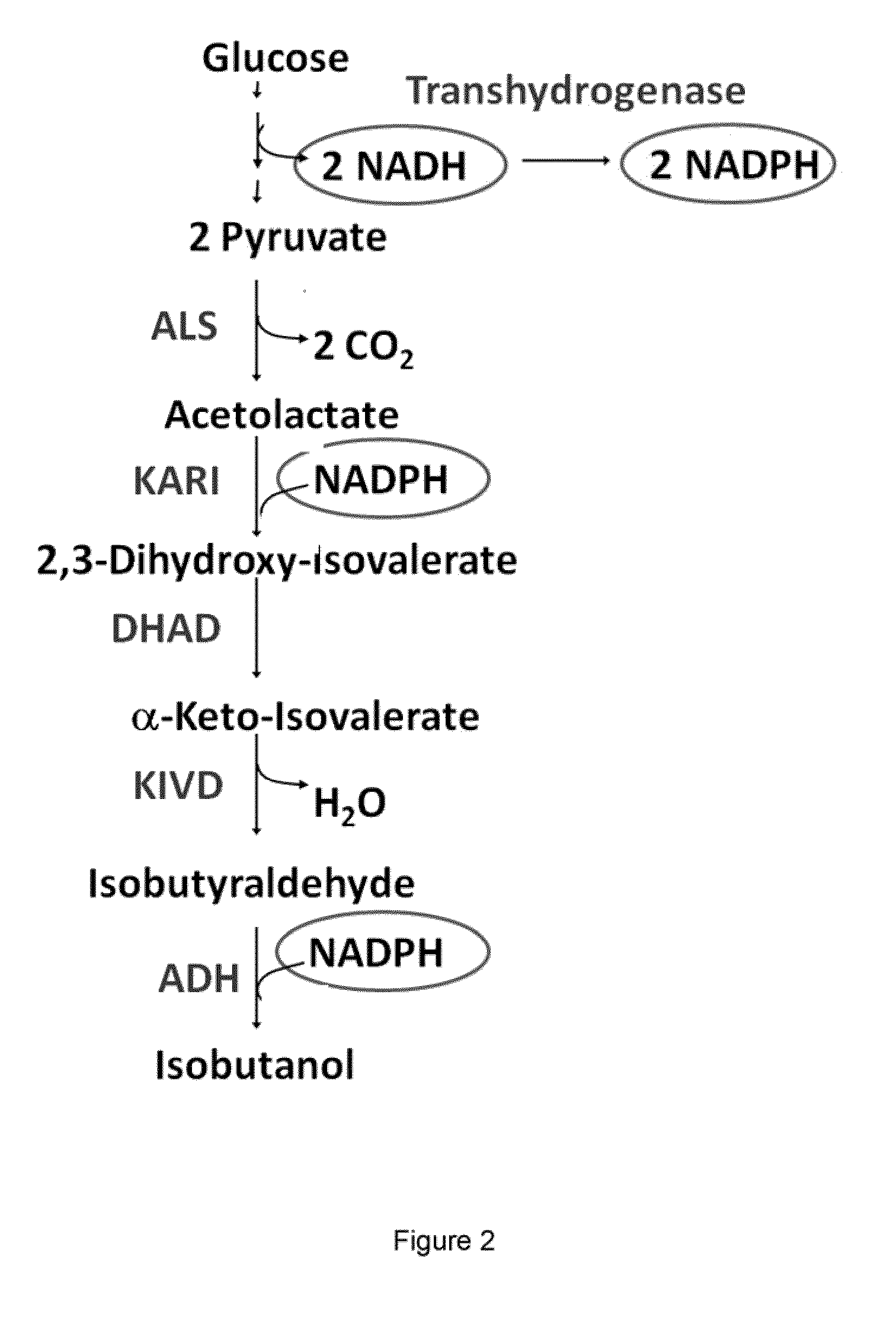

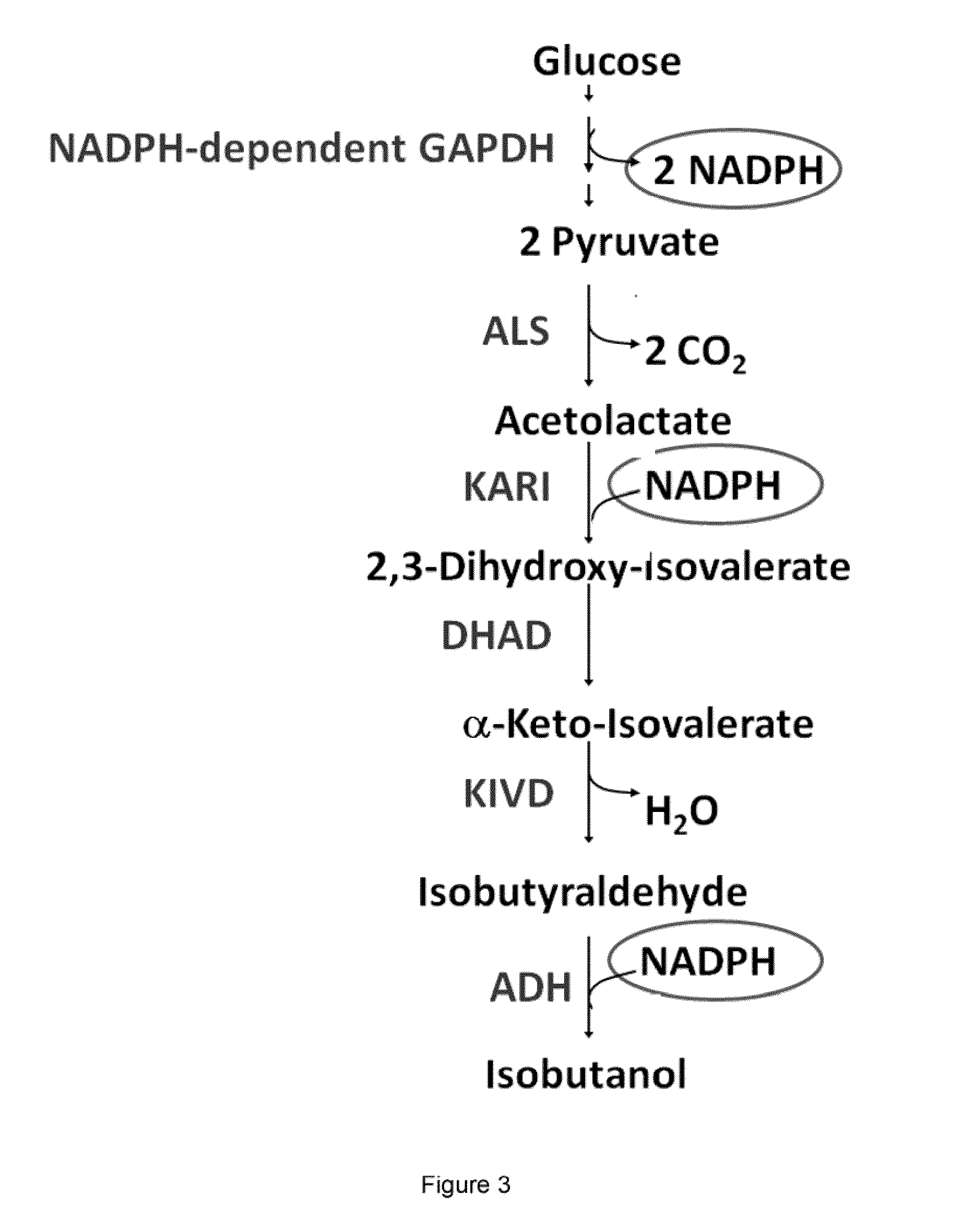

Engineered microorganisms capable of producing target compounds under anaerobic conditions

InactiveUS20100143997A1Improve abilitiesHigh catalytic efficiencyFungiBacteriaMicroorganismMetabolite

The present invention is generally provides recombinant microorganisms comprising engineered metabolic pathways capable of producing C3-C5 alcohols under aerobic and anaerobic conditions. The invention further provides ketol-acid reductoisomerase enzymes which have been mutated or modified to increase their NADH-dependent activity or to switch the cofactor preference from NADPH to NADH and are expressed in the modified microorganisms. In addition, the invention provides isobutyraldehyde dehydrogenase enzymes expressed in modified microorganisms. Also provided are methods of producing beneficial metabolites under aerobic and anaerobic conditions by contacting a suitable substrate with the modified microorganisms of the present invention.

Owner:GEVO INC

Hollow mesoporous carbon electrode-catalyst for direct methanol fuel cell and preparation thereof

ActiveUS20060166811A1Large average pore sizeDischarge is generatedCell electrodesInksMolecular sieveFuel cells

The present invention discloses a novel electrode-catalyst for direct methanol fuel cell prepared by introducing a carbon precursor into pores of a wormhole-like molecular sieve template, carbonizing the carbon precursor, removing the molecular sieve template to obtain a wormhole-like mesoporous carbon having a high specific surface of 800-1000 m2 / g and a pore size of 4-5 nm, and depositing catalyst metal such as Pt—Ru on the mesoporous carbon.

Owner:IND TECH RES INST

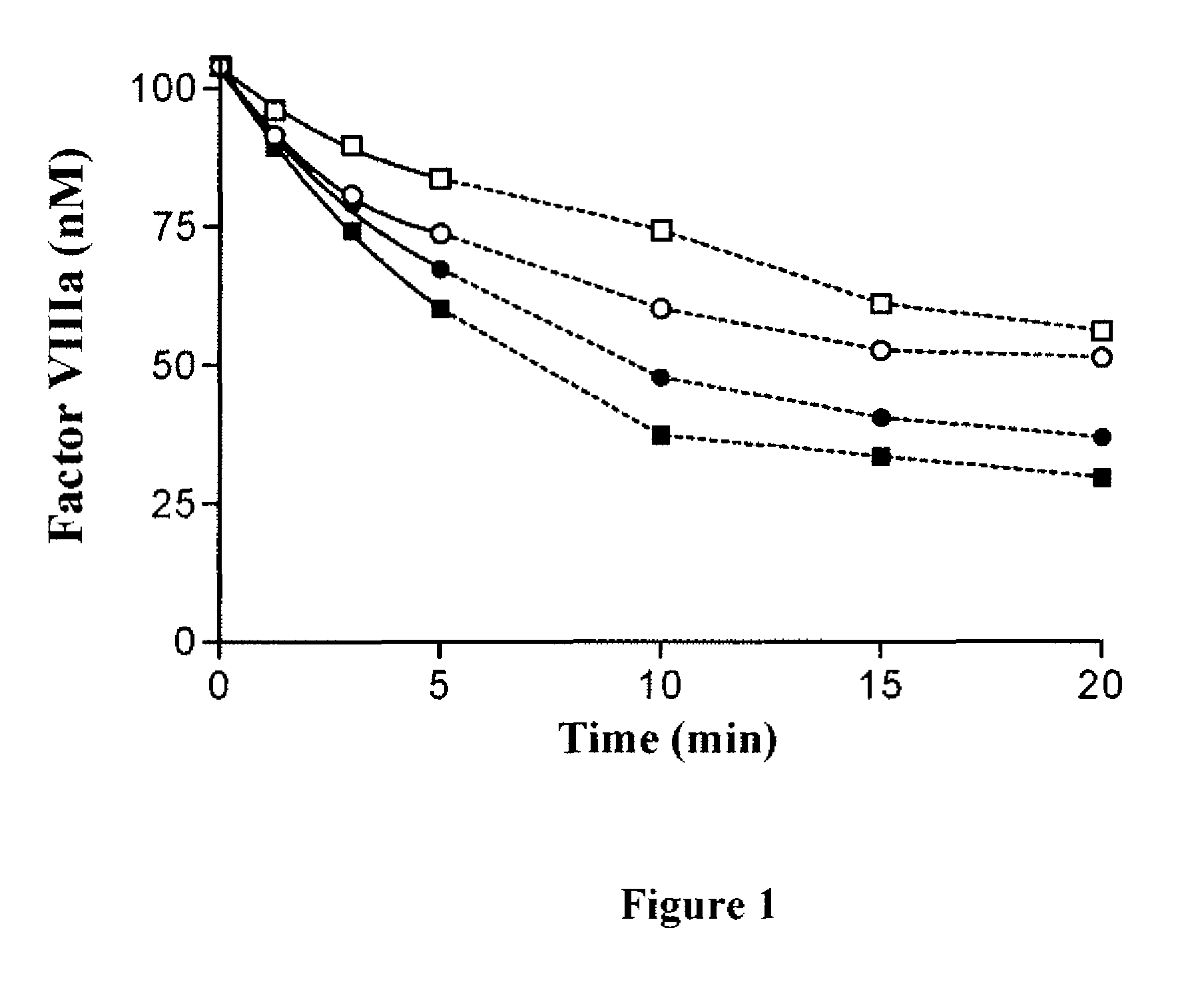

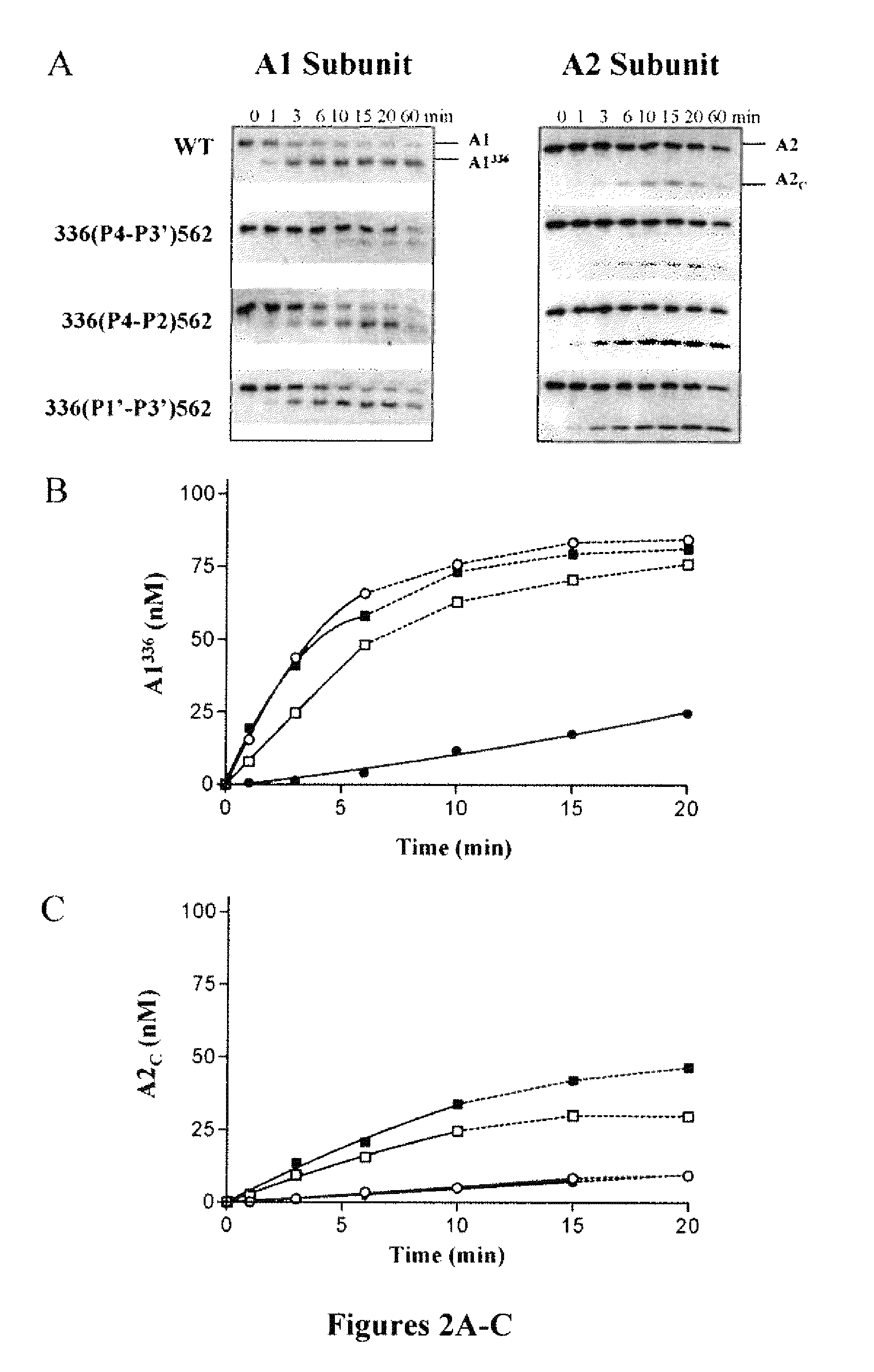

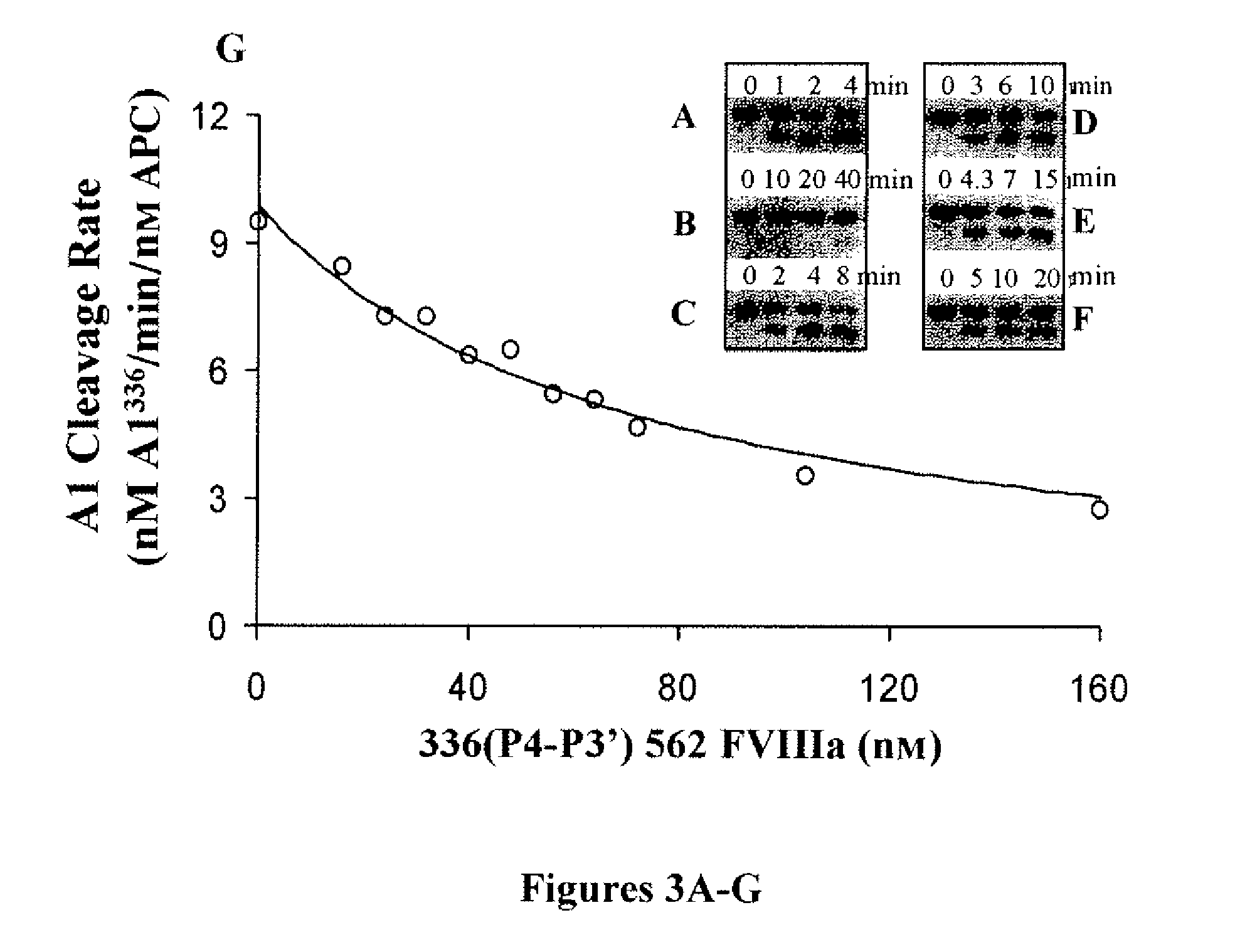

Recombinant factor VIII having reduced inactivation by activated protein C

ActiveUS8183345B2High catalytic efficiencyPromote localizationFactor VIIBacteriaProtein activationClotting disorders

The present invention relates to a recombinant factor VIII that is characterized by one or more mutations within a region surrounding an activated protein C cleavage site, which one or more mutations result in a reduced rate of inactivation by activated protein C. Isolated nucleic acid molecules, recombinant expression vectors, and host cells suitable for expression of the recombinant factor VIII are also disclosed. The recombinant factor VIII can be used for the treatment of clotting disorders, such as hemophilia A.

Owner:UNIVERSITY OF ROCHESTER

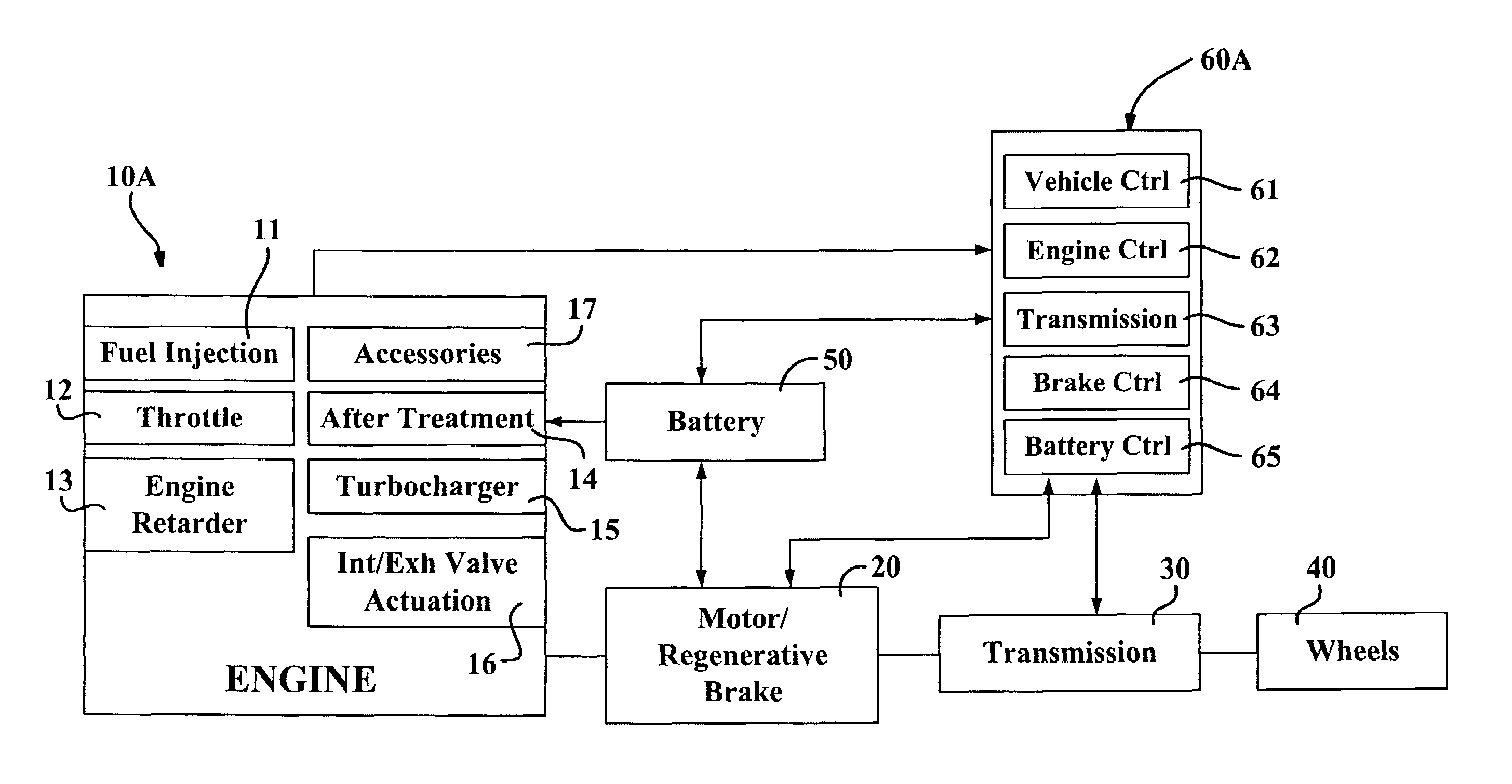

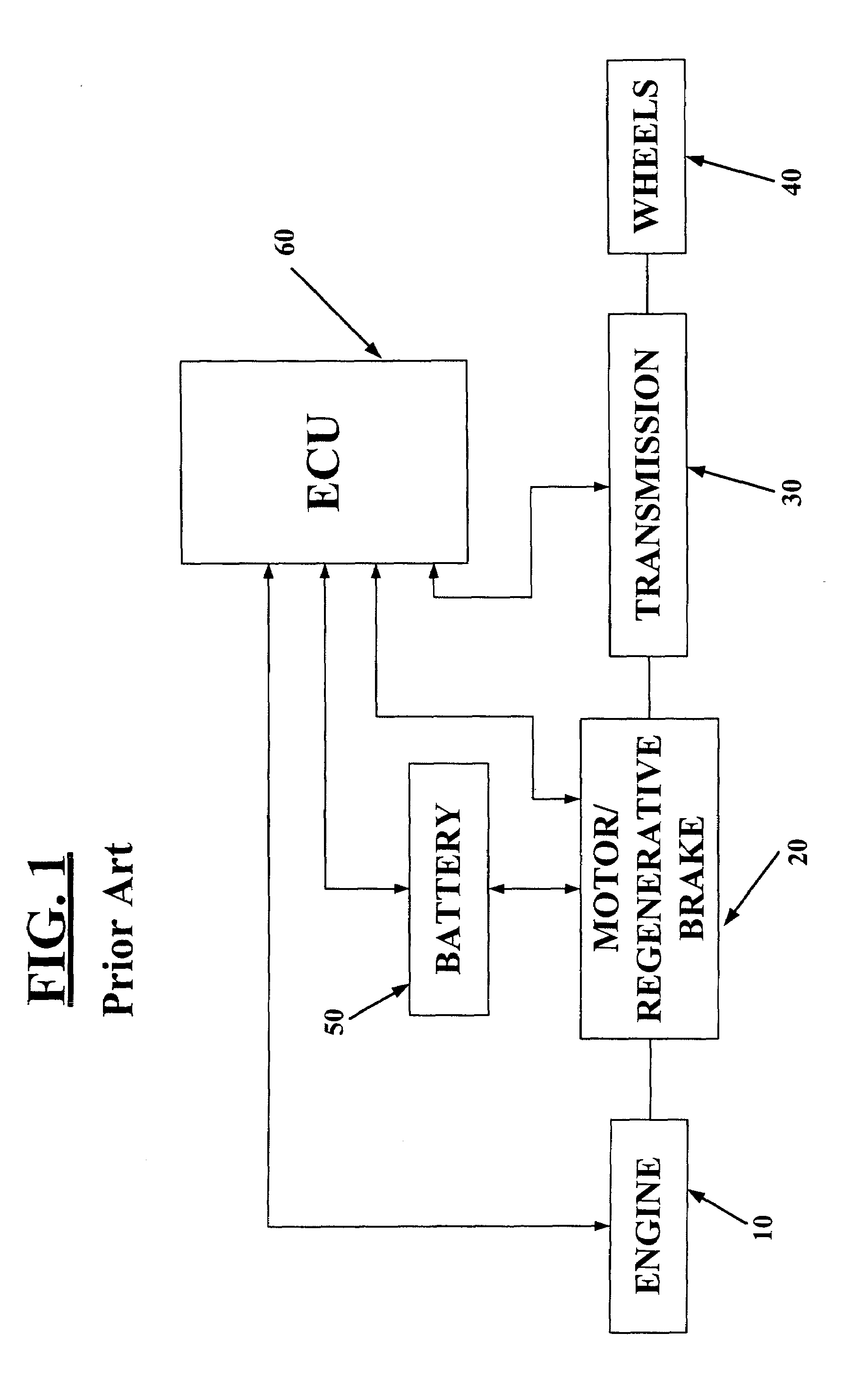

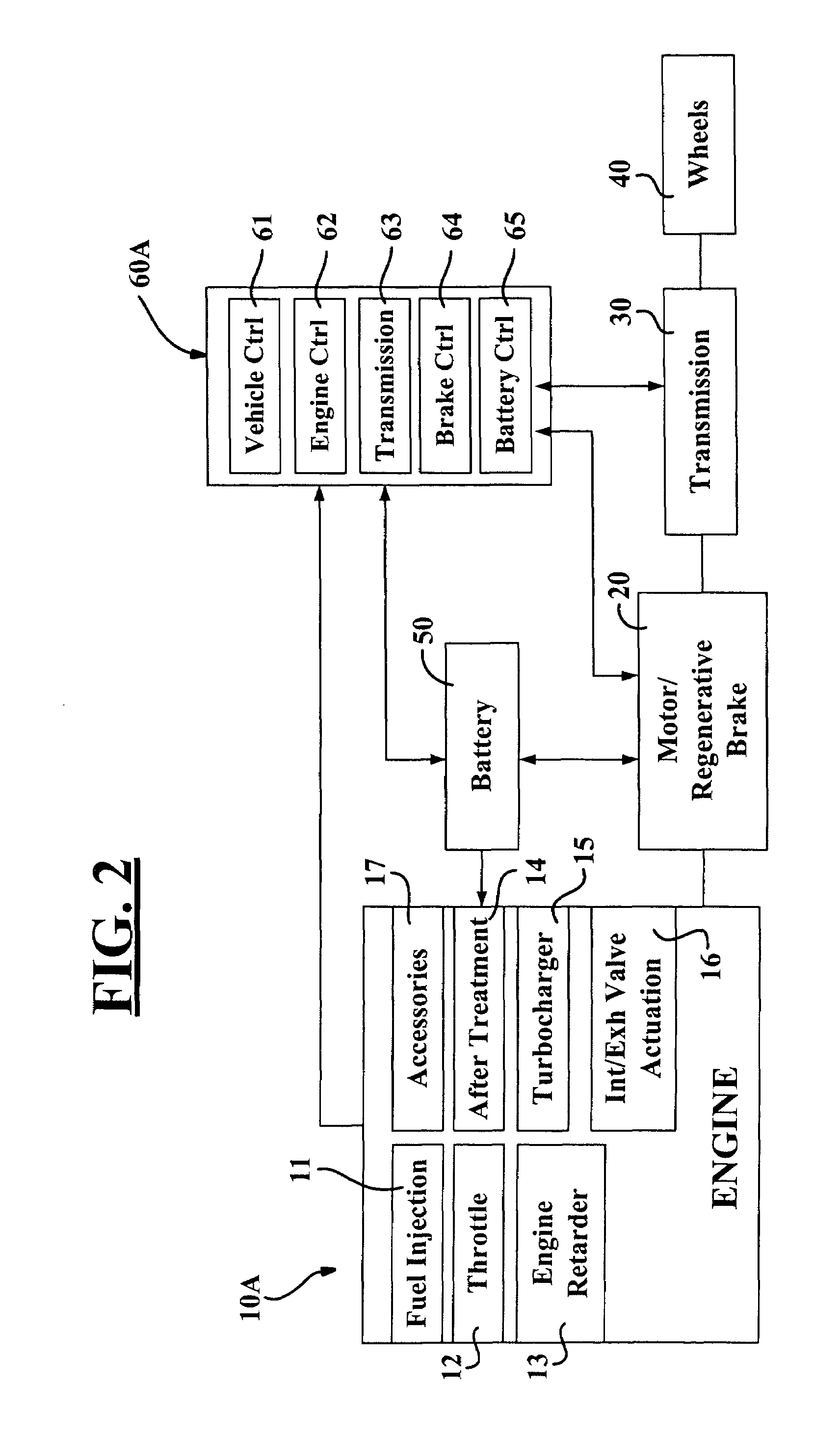

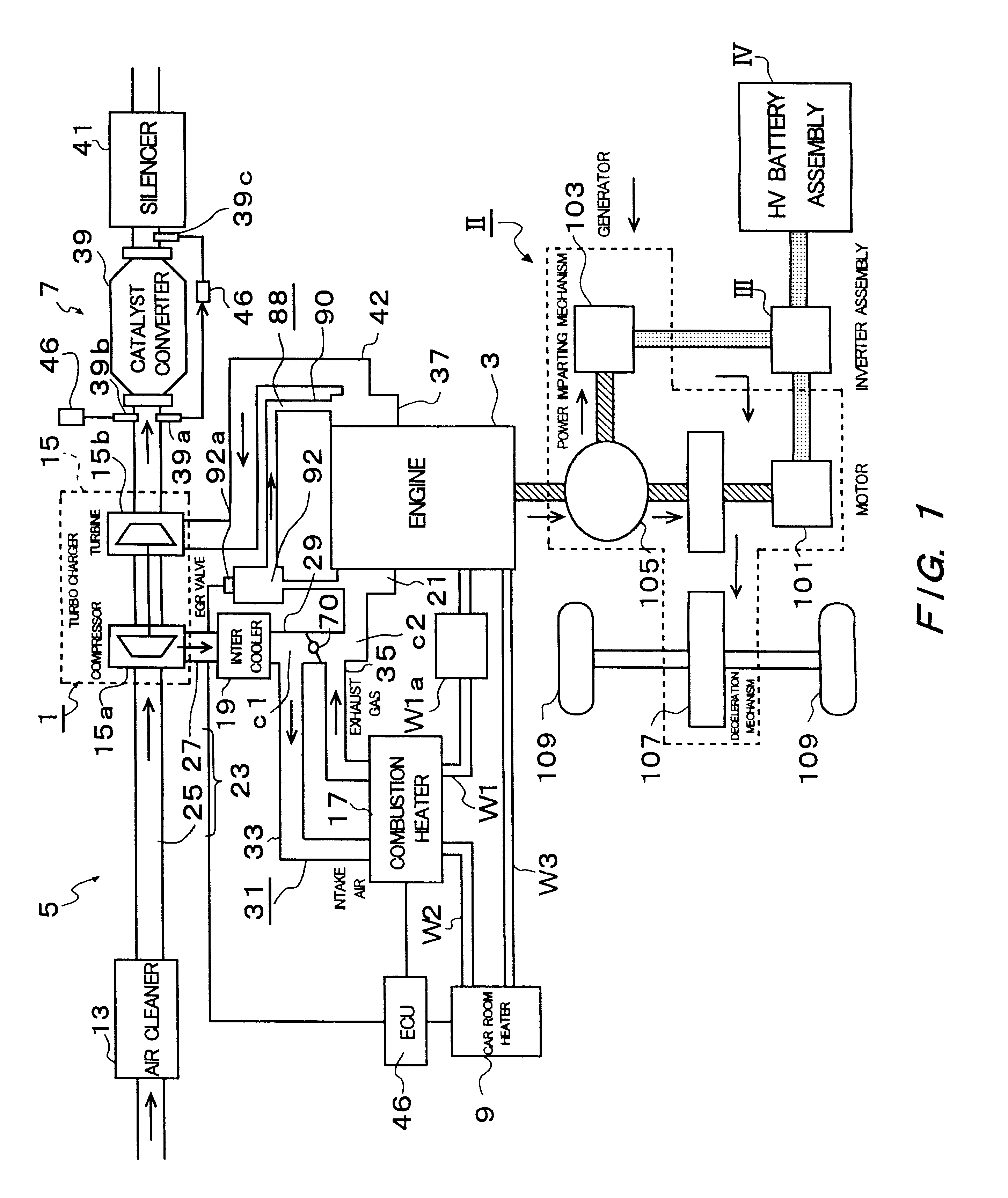

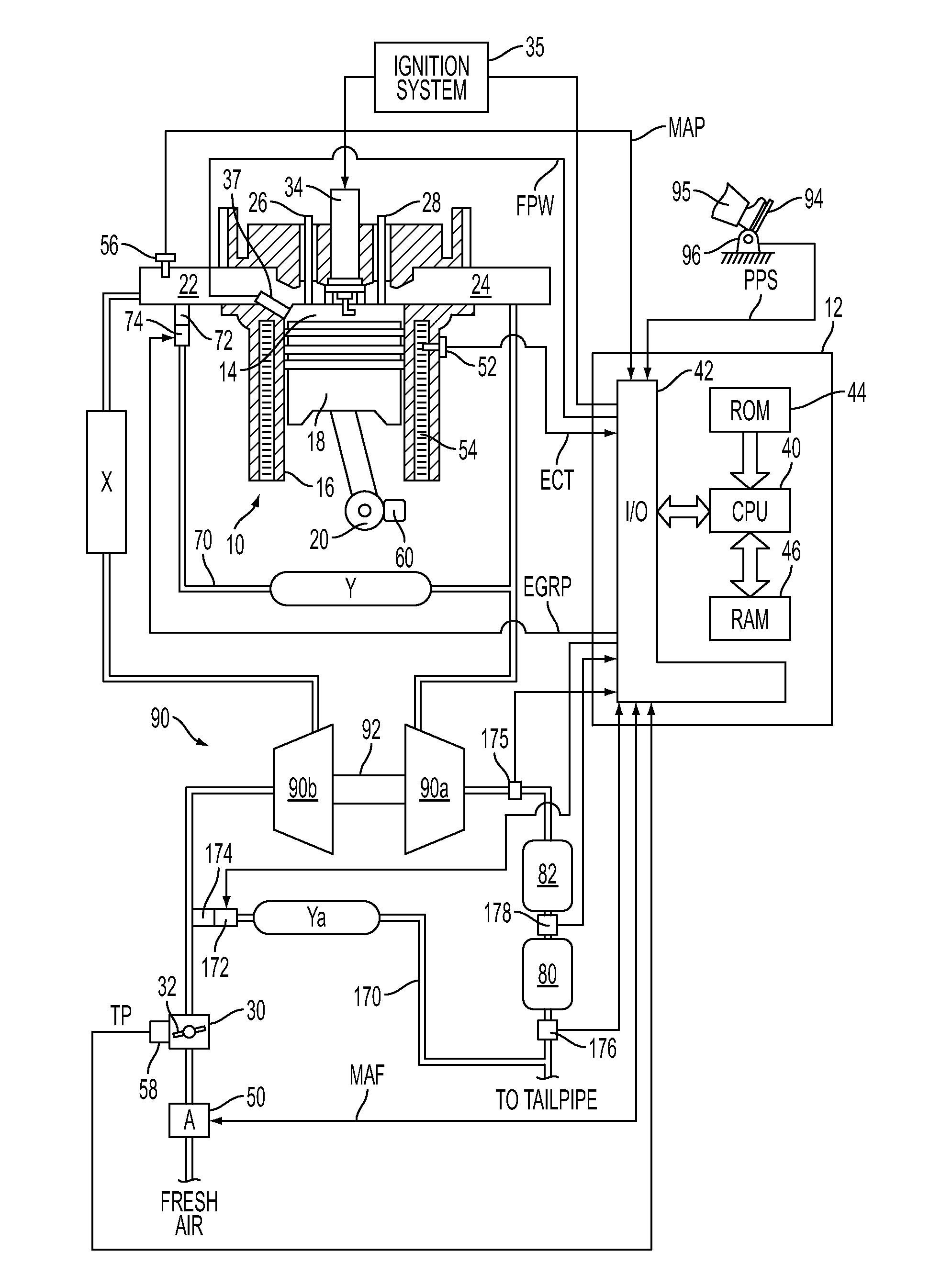

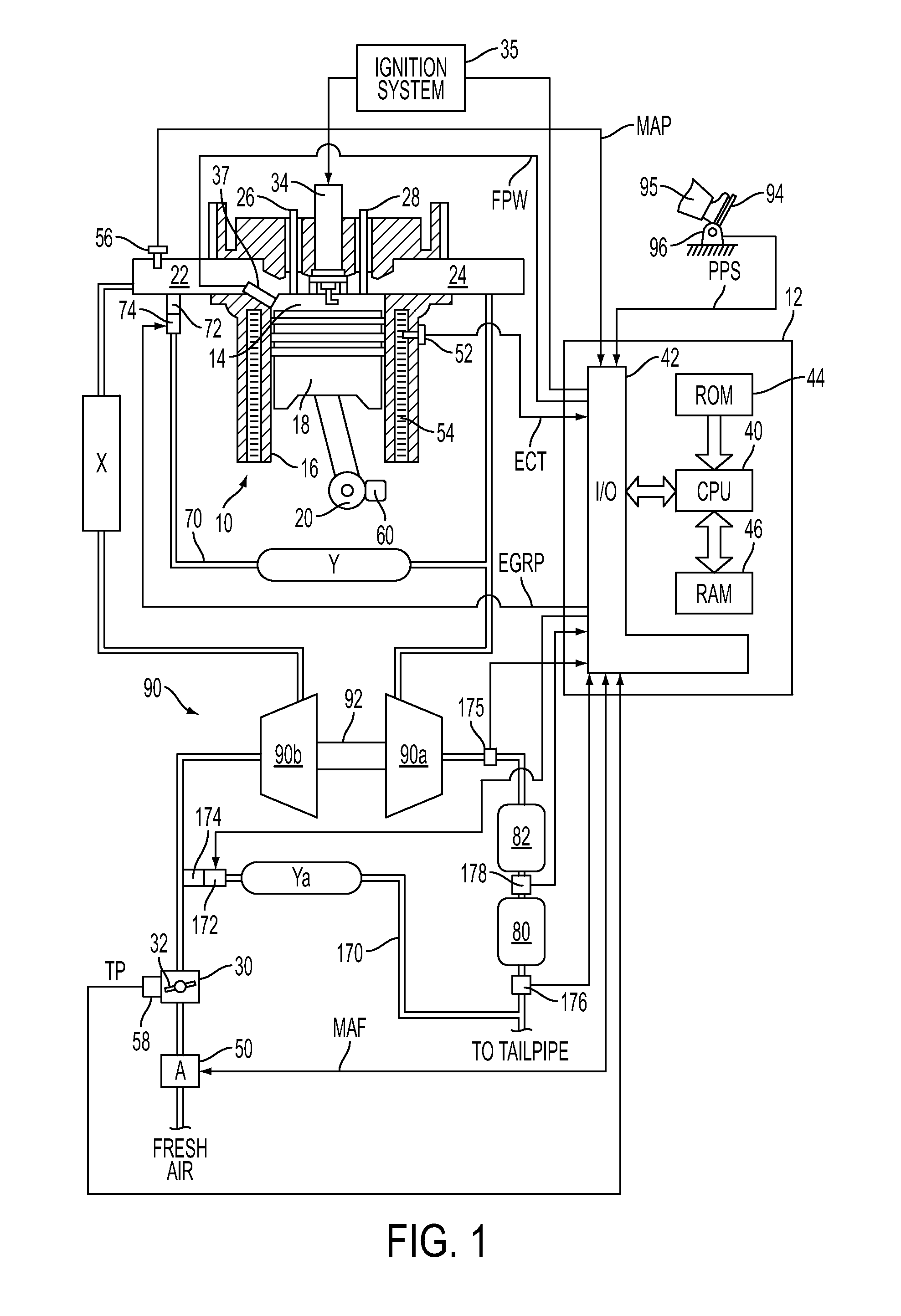

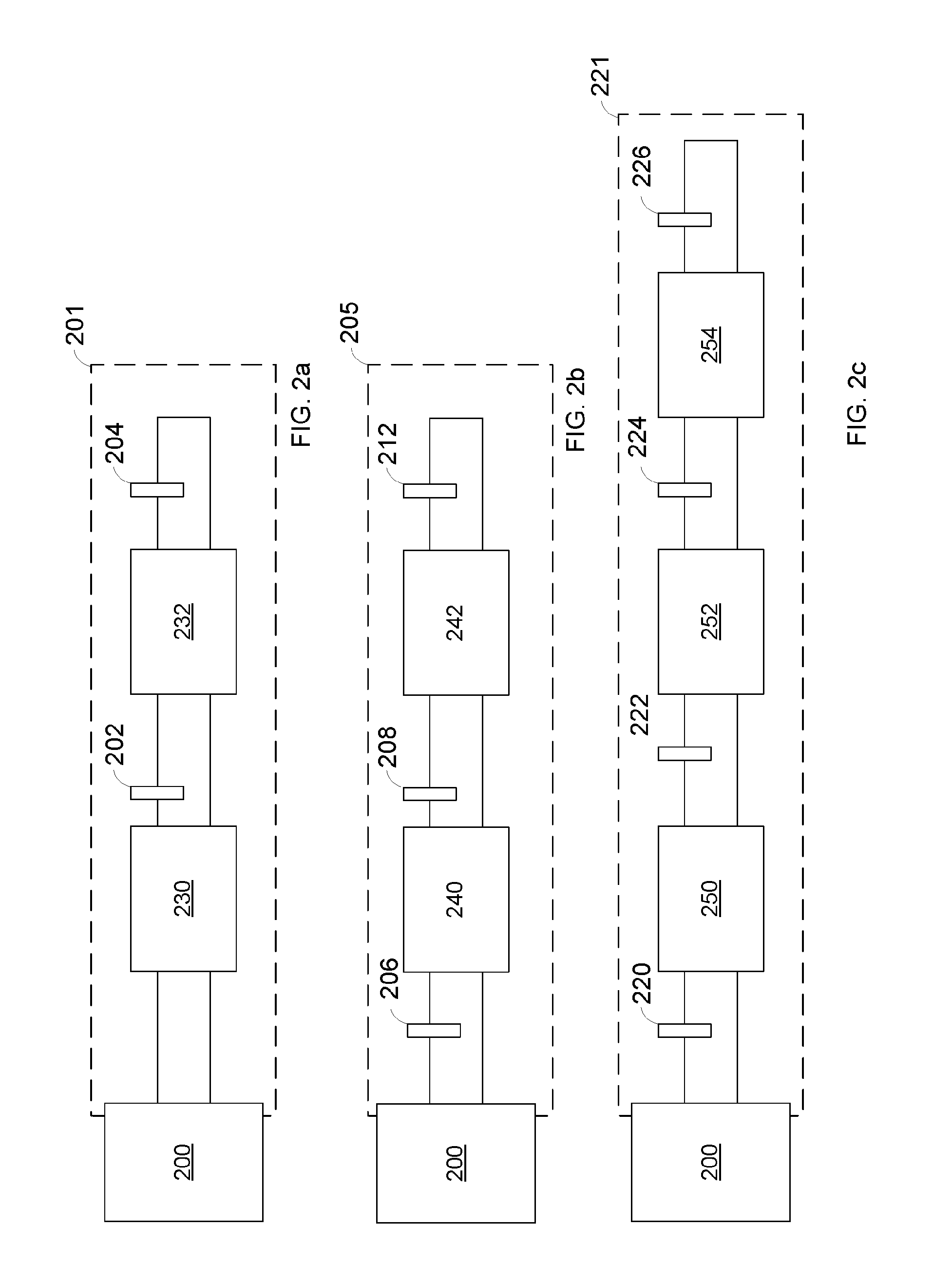

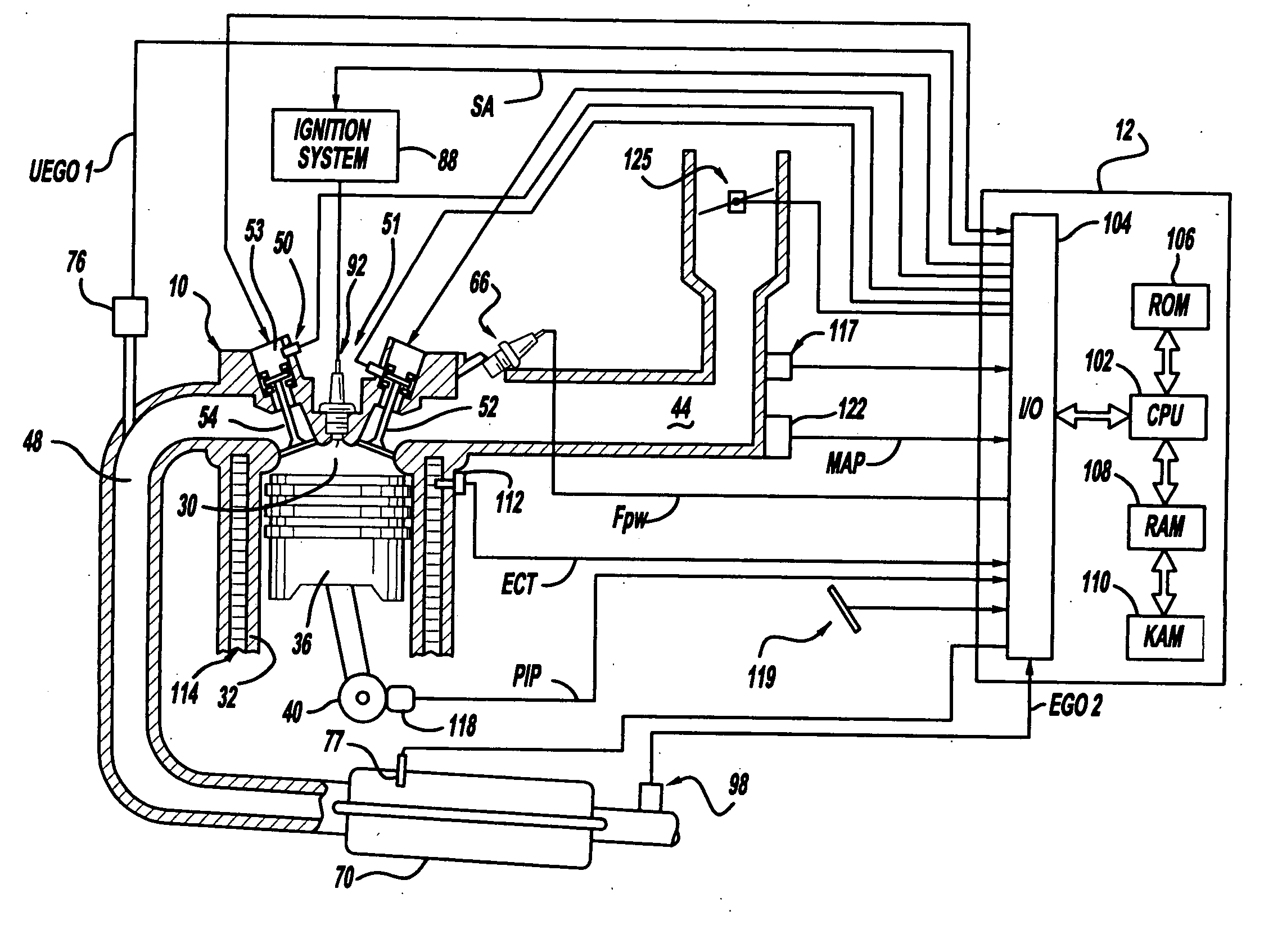

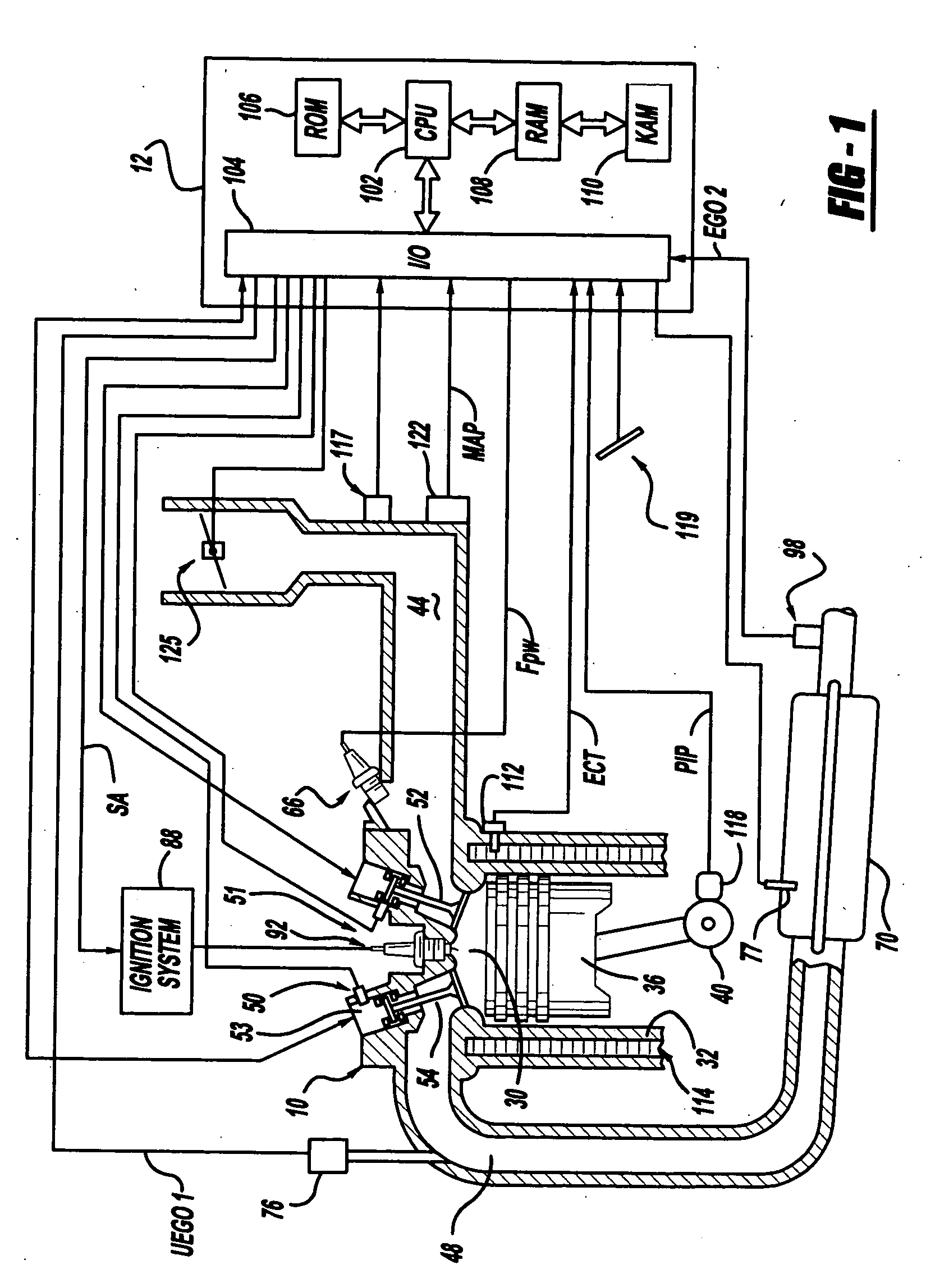

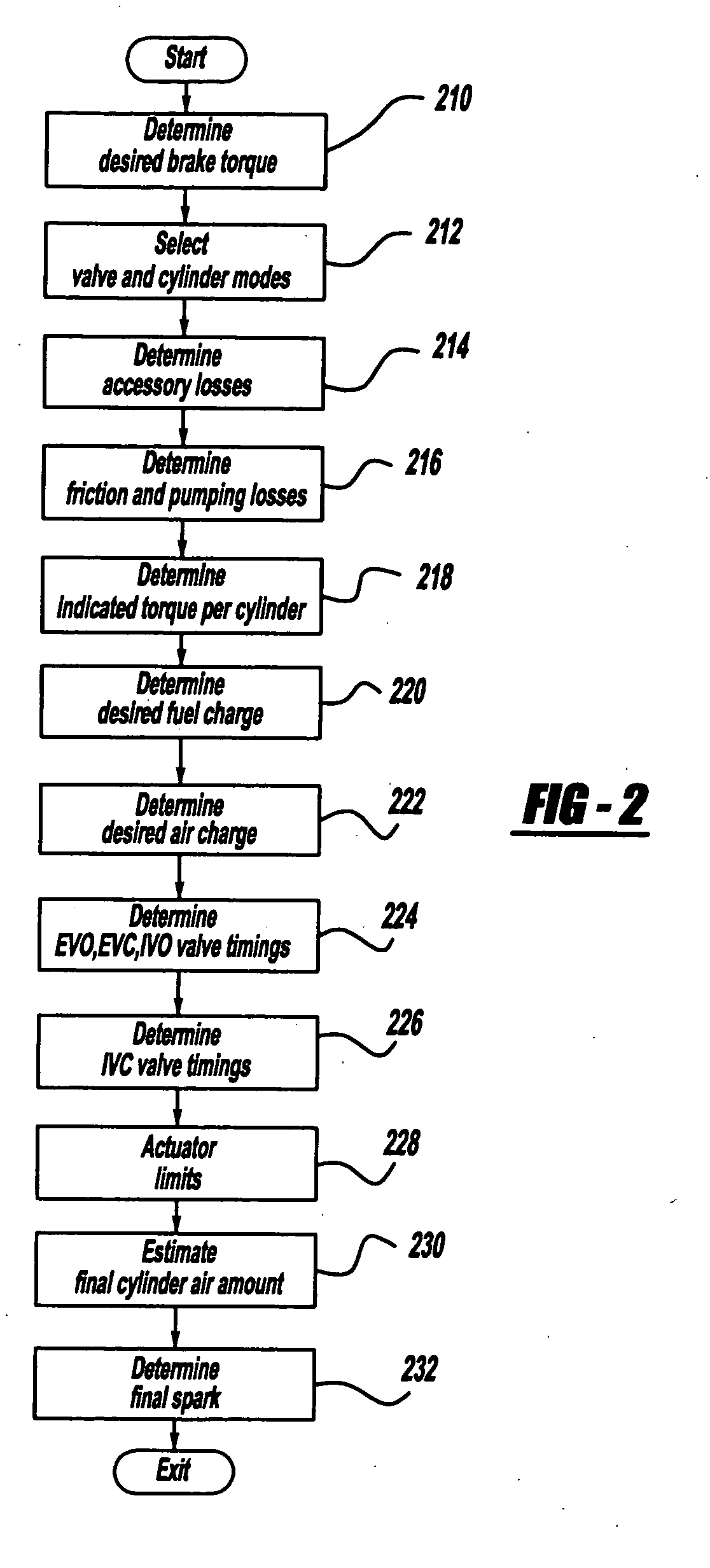

Internal combustion engines for hybrid powertrain

InactiveUS7028793B2Reduced fuel economyReduce power outputElectrical controlInternal combustion piston enginesCombustionRegenerative brake

A hybrid powertrain and method for operating same in which the operation of the engine is modified to effect an improvement in the fuel economy and / or emissions performance of the hybrid powertrain. In one embodiment, the battery of the powertrain is employed to provide auxiliary heat to an engine aftertreatment system to thereby improve the effectiveness of the aftertreatment system. In another embodiment, various components of the engine, such as a water pump, are wholly or partly operated by electric motors that receive power from the battery of the powertrain. In another embodiment, engine braking can be employed in situations where regenerative braking does not provide sufficient braking torque. In a further embodiment, the engine valves may be selectively opened to reduce pumping losses associated with the back-driving of the engine.

Owner:GREEN VISION TECH

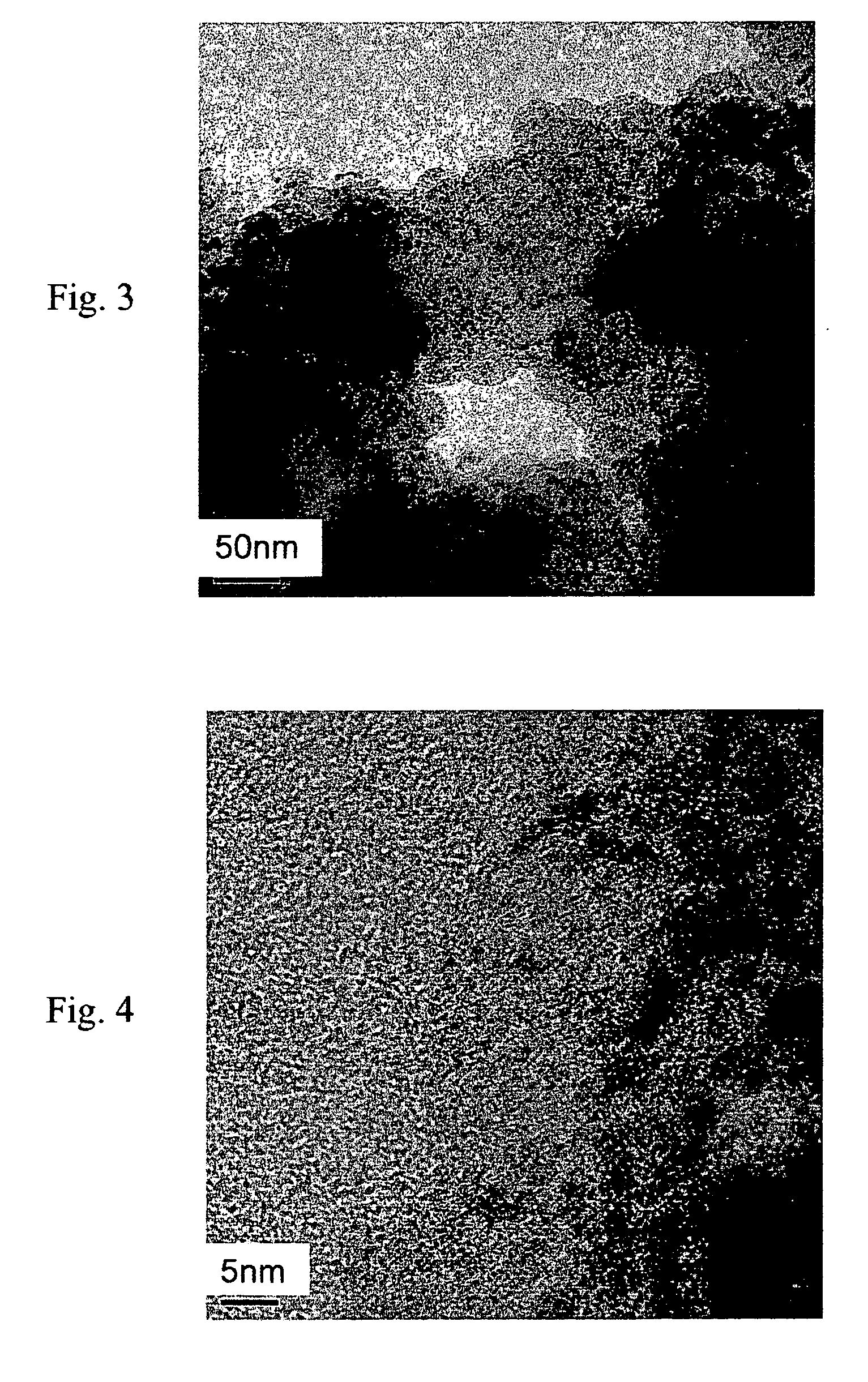

Ceria-based mixed-metal oxide structure, including method of making and use

InactiveUS20030186805A1Increase surface areaSimple structureRare earth metal oxides/hydroxidesMaterial nanotechnologyPtru catalystCerium(IV) oxide

A homogeneous ceria-based mixed-metal oxide, useful as a catalyst support, a co-catalyst and / or a getter, is described. The mixed-metal oxide has a relatively large surface area per weight, typically exceeding 150 m<2> / g, a structure of nanocrystallites having diameters of less than 4 nm, and including pores larger than the nanocrystallites and having diameters in the range of 4 to about 9 nm. The ratio of the pore volumes, VP, to skeletal structure volumes, VS, is typically less than about 2.5, and the surface area per unit volume of the oxide material is greater than 320 m<2> / cm<3>, such that the structural morphology supports both a relatively low internal mass transfer resistance and large effective surface area for reaction activity of interest. The mixed metal oxide is made by co-precipitating a dilute metal salt solution containing the respective metals, which may include Zr, Hf, and / or other metal constituents in addition to Ce, replacing water in the co-precipitate with a water-miscible low surface-tension solvent, and relatively quickly drying and calcining the co-precipitate at moderate temperatures. A highly dispersive catalyst metal, such as Pt, may be loaded on the mixed metal oxide support from a catalyst-containing solution following a selected acid surface treatment of the oxide support. The mixed metal oxide, as catalyst support, co-catalyst or getter, is applied in various reactions, and particularly water gas shift and / or preferential oxidation reactions as associated with fuel processing systems, as for fuel cells and the like.

Owner:INT FUEL CELLS

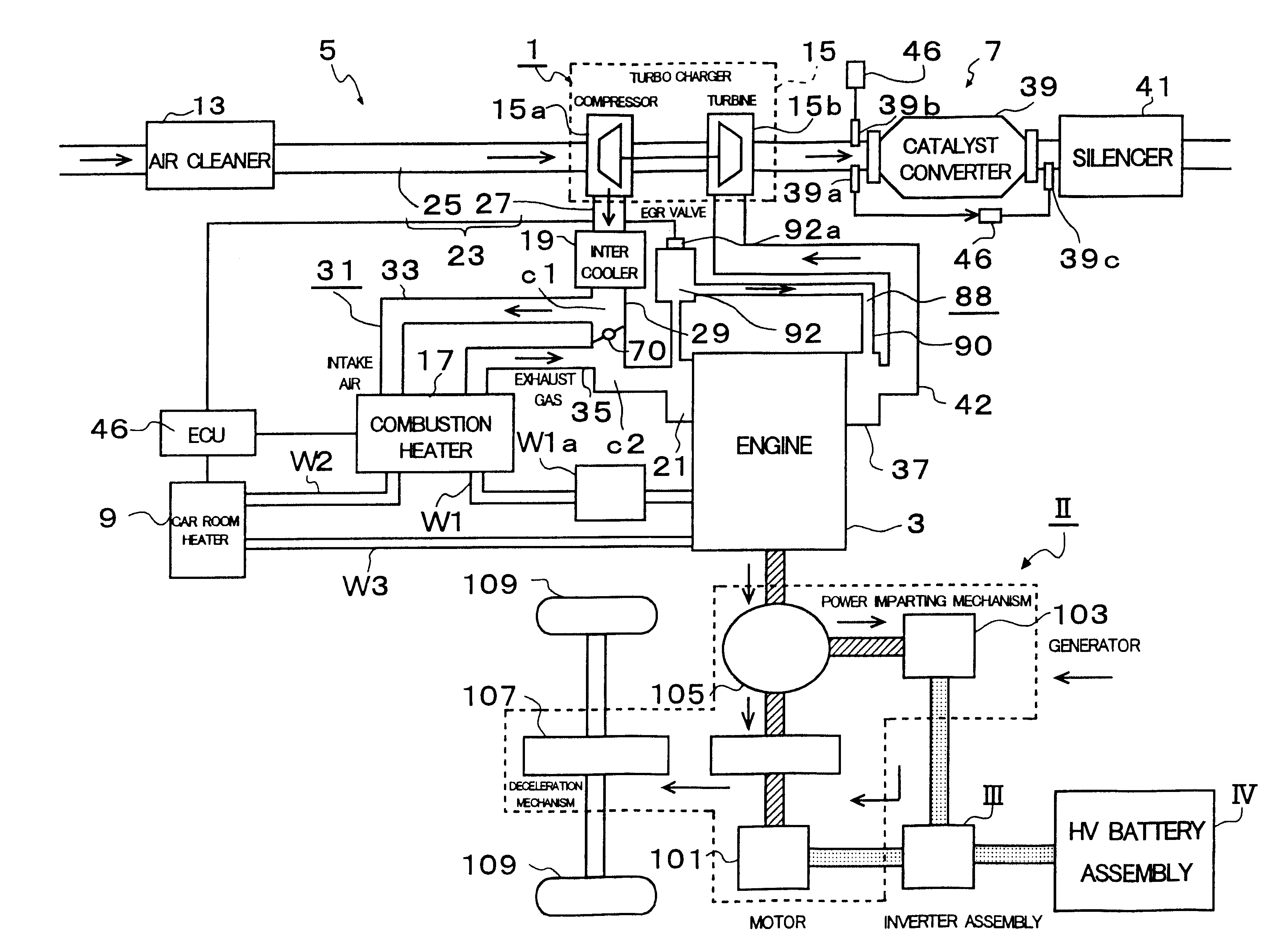

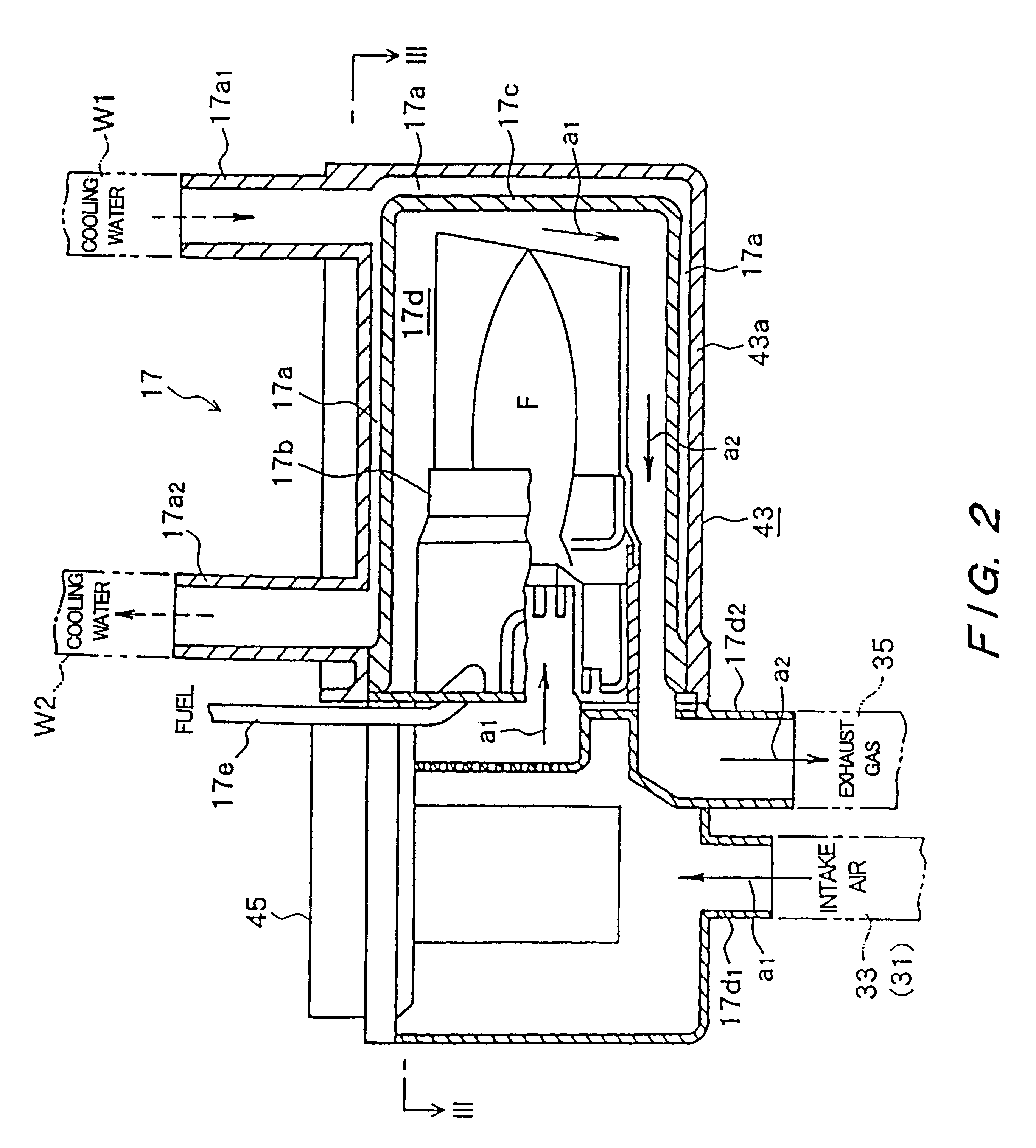

Exhaust emission control system of hybrid car

InactiveUS6266956B1Easy to produceHigh catalytic efficiencyHybrid vehiclesNon-fuel substance addition to fuelHybrid carCombustion

An exhaust emission control system of a hybrid car capable of relieving a load upon an engine fuel injection device by eliminating a use of sub-injection and recovering from S-poisoning as well as purifying an exhaust gas even by eliminating the use of sub-injection. The exhaust emission control system of an internal combustion engine, used for the hybrid car traveled by two types of power sources of a diesel engine and an electric motor, includes a combustion heater as separate body from the engine, a catalyst, provided in an exhaust passageway, for purifying an engine exhaust gas, a combustion gas passageway through which a combustion gas emitted from the combustion heater flows toward the catalyst, and a three-way valve for introducing the combustion gas to the catalyst via the combustion gas passageway or an EGR passageway when the diesel engine is in a stop state and when the electric motor is in a driving state.

Owner:TOYOTA JIDOSHA KK

Benzene selection noncrystalline catalyst with hydrogen added and containing ruthenium, boron as well as its preparing method

InactiveCN1446625AHigh catalytic efficiencyHydrocarbon by hydrogenationCatalyst activation/preparationBenzeneHydrogen

A non-crystal catalyst for preparing cyclodexene by selectively hydrogenating benzene is prepared from Ru, B meta or metal oxide modified M, and the oxide or metal hydroxide carrier L through reducing Ru ions and M in oxide form, and removing ions of impurities. Its advantage is high selectivity and hydrogenating activity.

Owner:FUDAN UNIV

Three-dimensional fiber-based aerogel catalyst carrier and preparation method thereof

ActiveCN103285920AGood flexibilitySufficient reactive sitesCatalyst carriersOrganic-compounds/hydrides/coordination-complexes catalystsFiberPliability

The invention relates to a preparation method of a three-dimensional fiber-based aerogel catalyst carrier and a product thereof. The preparation method comprises the following steps of: firstly dispersing fibers in solvents to form turbid liquid; secondly curing the turbid liquid to form cured pieces; thirdly removing cured solvents to form non-crosslinked fiber-based aerogel; finally carrying out crosslinking stabilization treatment and then carrying out activation treatment, thus obtaining the three-dimensional fiber-based aerogel catalyst carrier. The product is a three-dimensional network-shaped material formed through mutual penetration and stagger of fibers. The fiber crossing points are effectively interconnected through non-hydrogen-bond bonding. The three-dimensional fiber-based aerogel catalyst carrier has volume density of 0.1-500mg / cm<3>, average pore size of 0.01-2000mu m and specific surface area of 0.2-2000m<2> / g. The preparation method and the product have the advantages that the preparation process is simple; the raw material limitations are less; and the aerogel catalyst carrier product has good flexibility, connectivity and catalyst supporting capacity and has broad application prospects in the catalytic application field.

Owner:DONGHUA UNIV

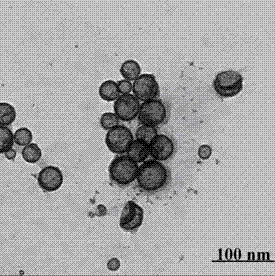

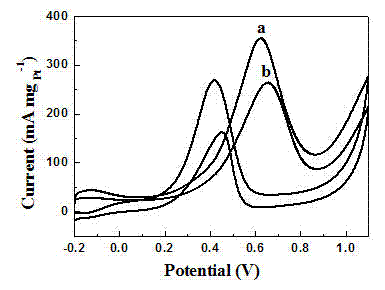

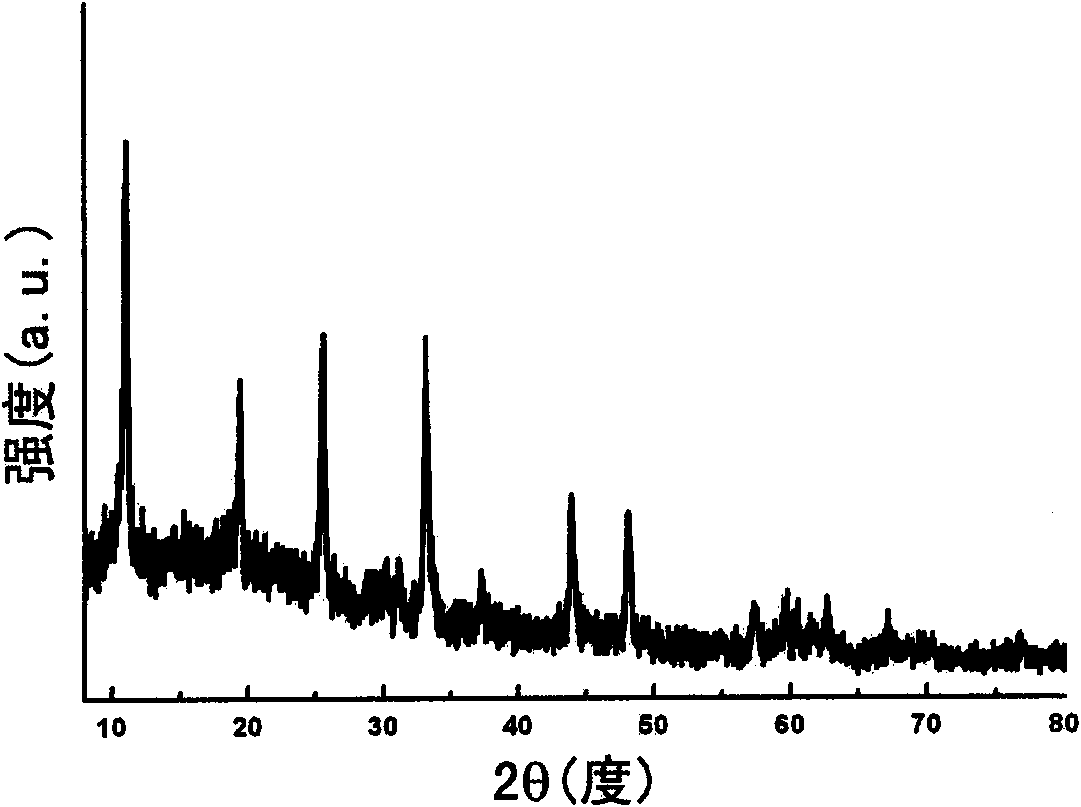

PtNi alloy/graphene combined nanometer catalyst with hollow structure and preparation method thereof

InactiveCN102430413AUnique hollow structureReduce dosageCell electrodesMetal/metal-oxides/metal-hydroxide catalystsNano catalystPlatinum salts

A PtNi alloy / graphene combined nanometer catalyst with a hollow structure adopts the graphene as a carrier and loads the PtNi alloy nanometer particles of which the grain diameter is 10-50 nm on the surface of the graphene, wherein the PtNi alloy nanometer particles are hollow spherical structures. The method for preparing the combined catalyst comprises the following steps: dispersing the graphene oxide in water liquor to which surfactant is added through ultrasound; uniformly mixing with soluble nickel salt (II); adding the reducing agent in inert gas atmosphere; adding soluble platinum salt (IV); stirring at 0-50 DEG C to execute the reduction reaction; centrifuging, washing and drying the reaction product to obtain the PtNi alloy / graphene combined nanometer catalyst with the hollow structure. The PtNi alloy / graphene combined nanometer catalyst with the hollow structure in the invention has good electro-catalytic property on electrochemical oxidation of methyl alcohol, and can be widely applied in methyl alcohol fuel cells.

Owner:NANJING NORMAL UNIVERSITY

Fuel control for spark ignited engine having a particulate filter system

ActiveUS20110072787A1Improve efficiencyLess tendencyElectrical controlNon-fuel substance addition to fuelGasoline direct injectionFilter system

A system for filtering and oxidizing particulate matter produced by a gasoline direct injection engine is disclosed. In one embodiment, engine cylinder air-fuel is adjusted to allow soot to oxidize at an upstream particulate filter while exhaust gases are efficiently processed in a downstream catalyst.

Owner:FORD GLOBAL TECH LLC

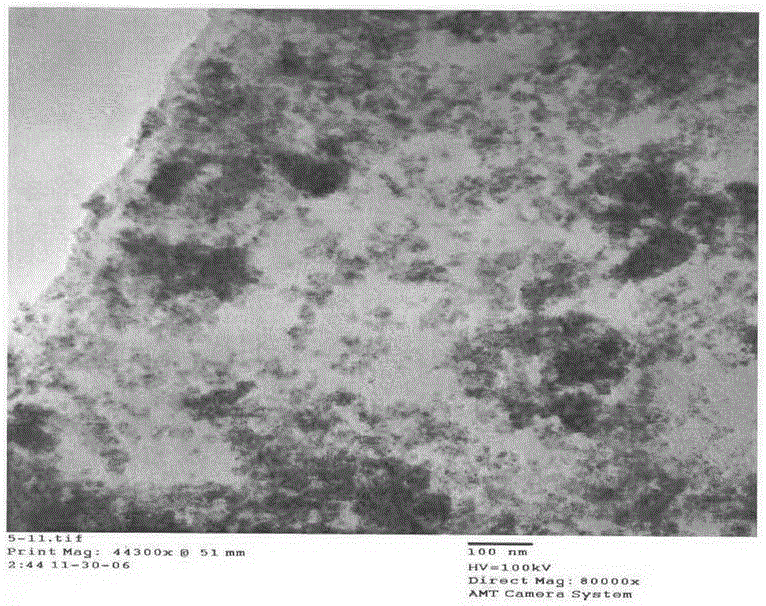

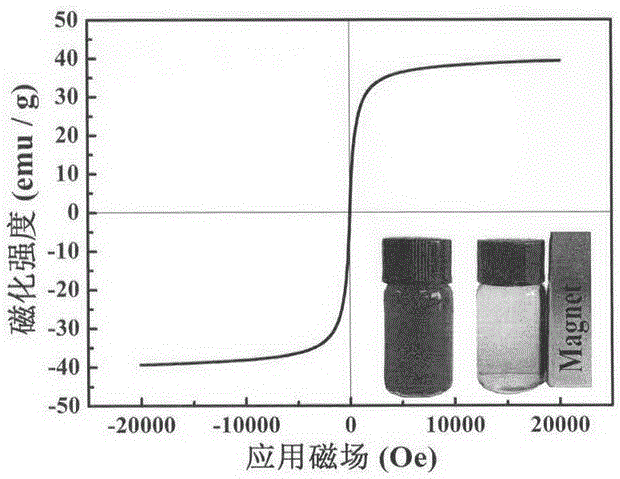

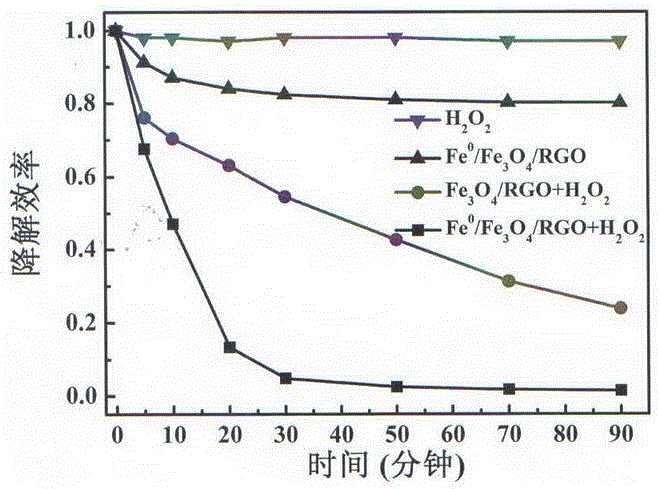

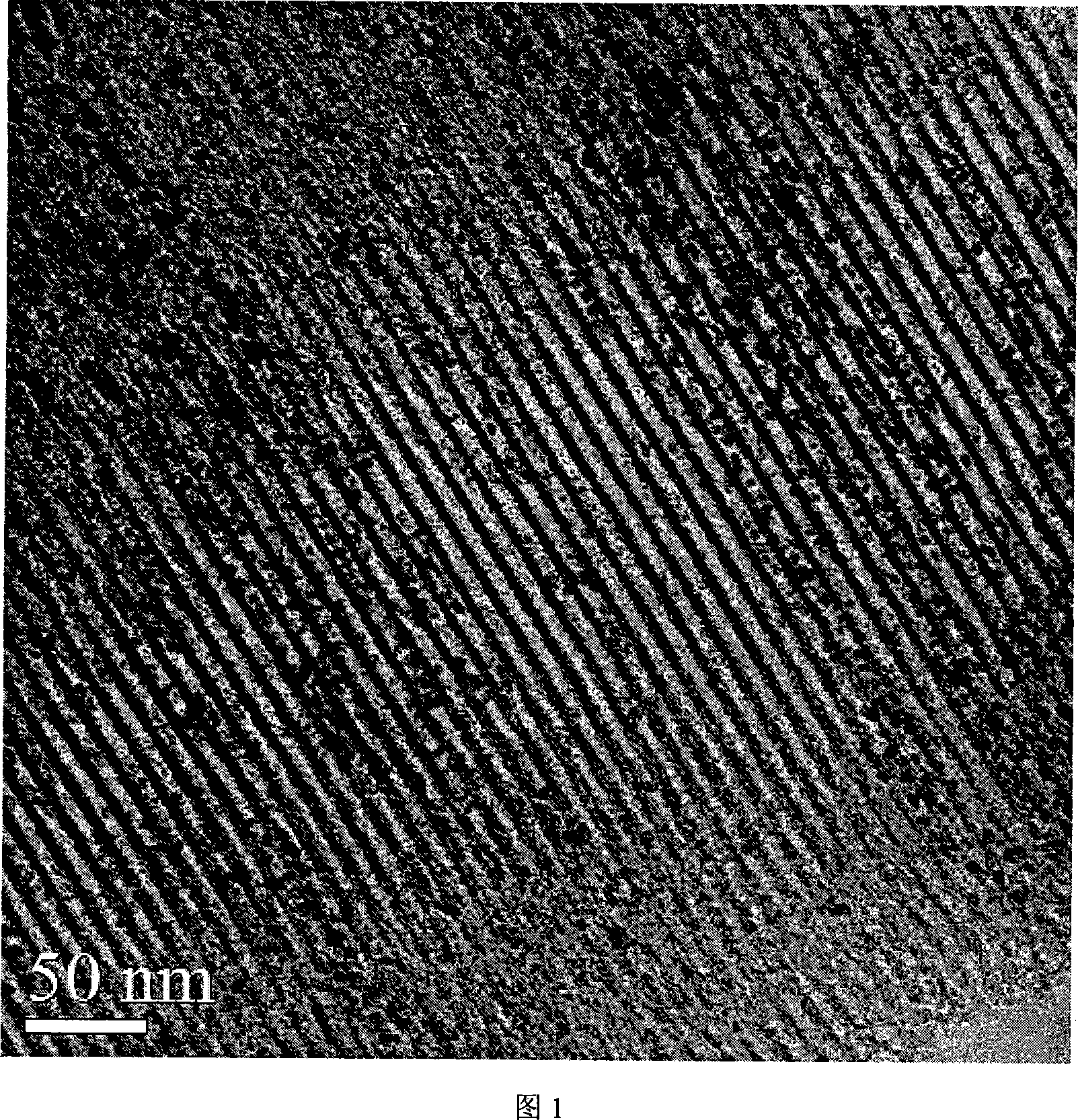

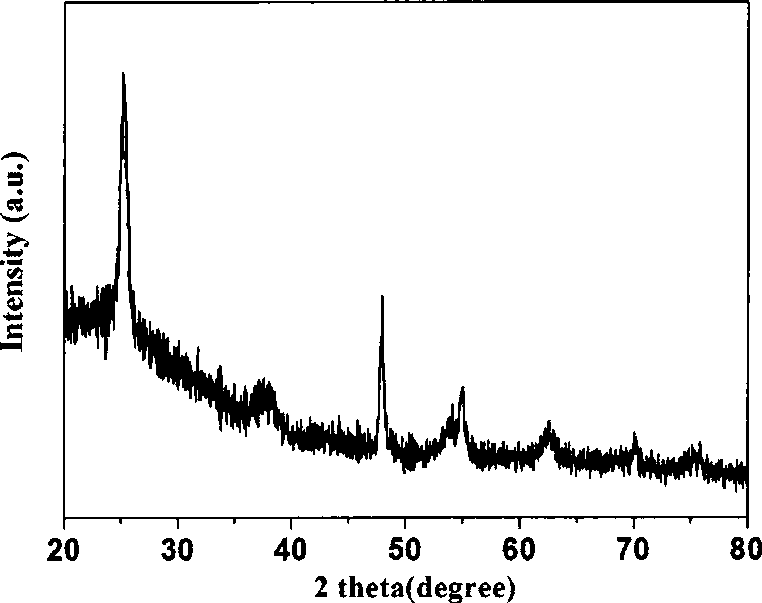

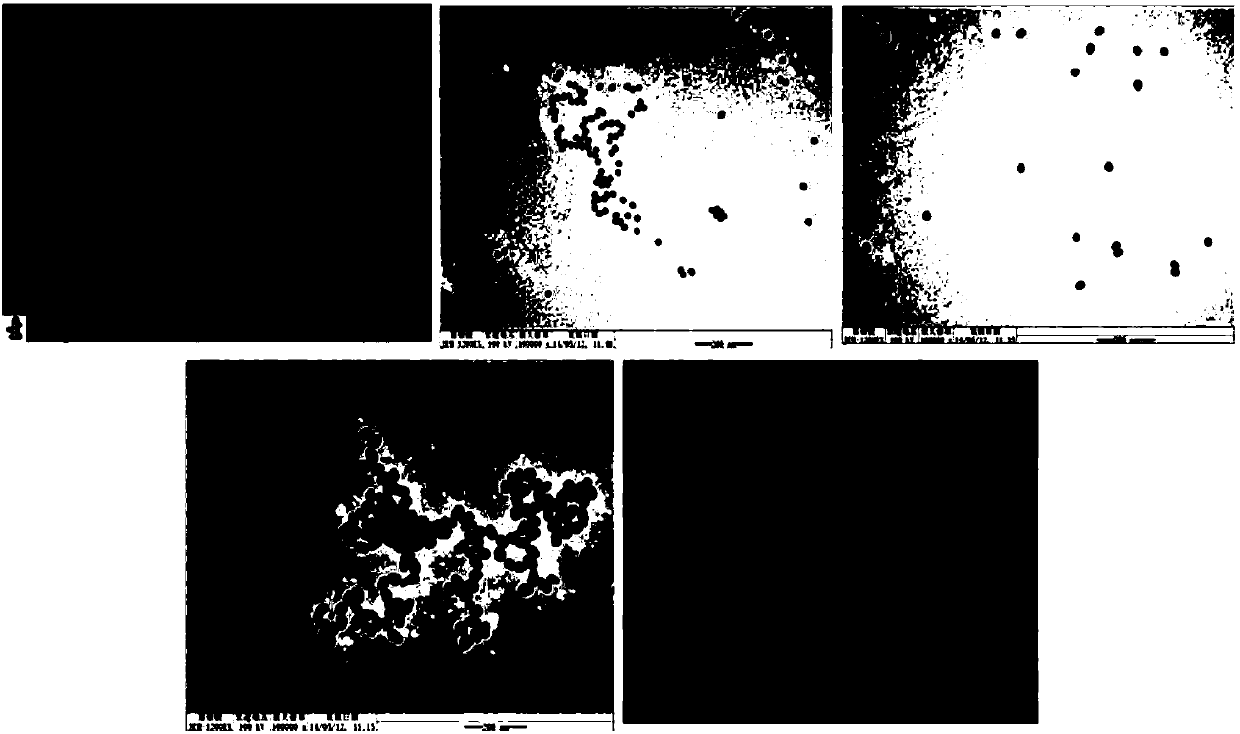

Preparation method of magnetic iron-based heterogeneous Fenton catalyst taking graphene as carrier and application

InactiveCN106669677APromote decompositionGood removal effectWater treatment compoundsWater contaminantsPtru catalystGraphene

The invention relates to a preparation method of a magnetic iron-based heterogeneous Fenton catalyst taking graphene as a carrier and an application. According to the method, the graphene serves as the carrier, magnetic nano-scale ferroferric oxide and nano-scale zero-valent iron (Fe0) are compounded to the surface of the graphene to serve as the heterogeneous Fenton catalyst in an in-situ growth mode, aggregation of catalytic active nano-particles can be effectively prevented by the graphene serving as the carrier, and more active sites are exposed. Besides, the graphene has high electron transfer capability, Fe0 easily transfers electrons to Fe3+ by taking the graphene as the carrier, Fe3+ is promoted to be transformed into Fe2+, so that catalytic activity of the catalyst is improved, the catalyst is easily recovered and reusable, pollutant removal efficiency is improved, phenol removal efficiency reaches 99% or more, and the used catalyst is recovered by an external magnetic field. The preparation method solves the problems that traditional Fenton catalysts are difficultly recycled and generate a lot of chemical sludge, and the preparation method has a certain economic value and practical value.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

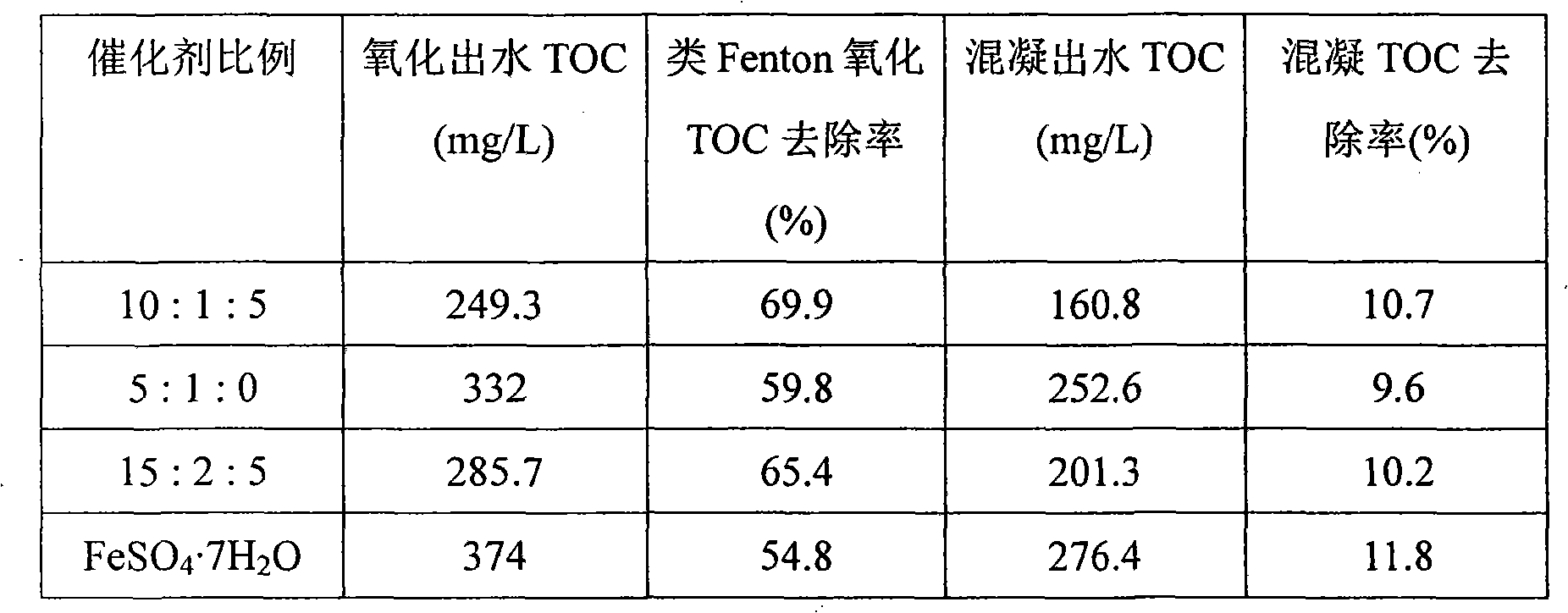

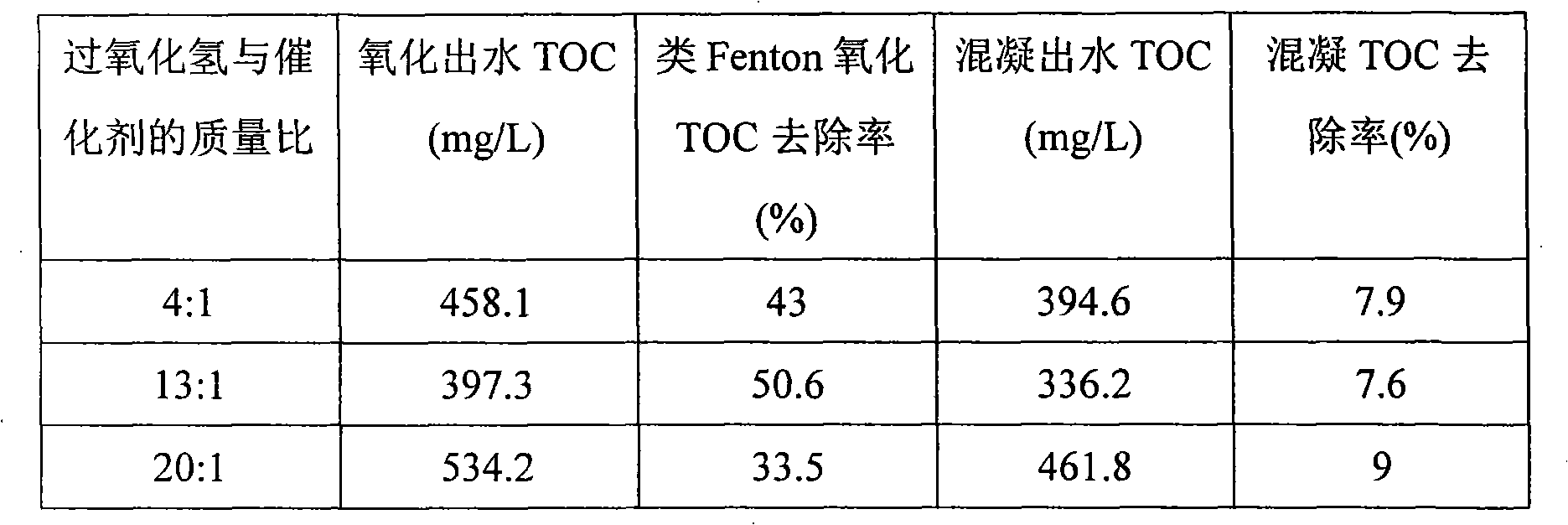

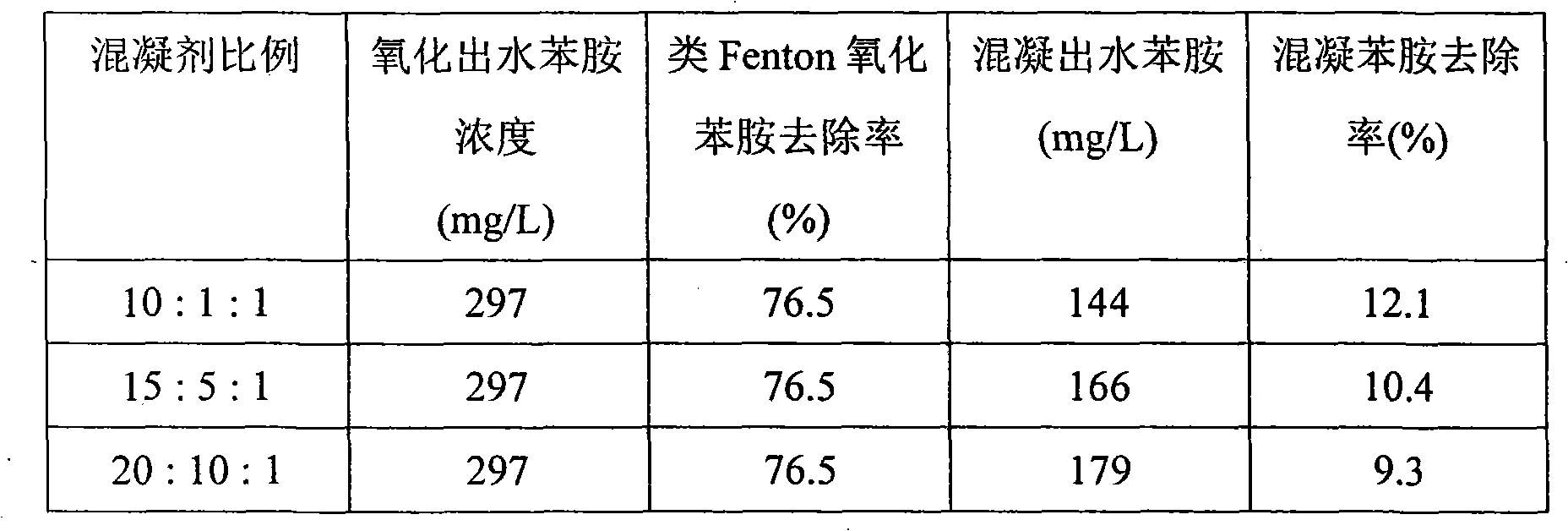

Method for treating organic amine industrial waste water by Fenton-like oxidation-flocculation

InactiveCN102399032AHigh catalytic efficiencyAdd lessMultistage water/sewage treatmentNature of treatment waterHigh concentrationIndustrial waste water

The invention relates to a method for treating organic amine industrial waste water by Fenton-like oxidation-flocculation. According to the method, the pH value of the waste water is adjusted to 3-5, and the temperature of the waste water is adjusted to 20-40 DEG C; a catalyst is added, wherein active ingredients of the catalyst comprise: ferrous sulfate, anhydrous cupric sulphate and manganese sulfate monohydrate, wherein the mass ratio of the ferrous sulfate to the anhydrous cupric sulphate to the manganese sulfate monohydrate is (5-10):1:(0-5); H2O2 (30%) is added, and the oxidation reaction time is 4 hours; after completing the oxidation reaction, sodium hydroxide is added to adjust the pH value of the waste water to 8-10; adding a chemical coagulant and an organic polymer flocculant, such that partial suspended solids, colloids and partial organic amines in the waste water are concurrently coagulated. According to the present invention, the Fenton-like oxidation-flocculation is adopted as the pretreatment for the organic amine waste water, such that the organic amines in the waste water can be effectively removed, the poison and the impact on microorganisms due to the high concentration organic amines in the wastewater can be reduced, the subsequent biological treatment is easily performed for the sewage.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for producing ruthenium base catalyst for producing cyclohexene with benzene selective hydrogenation

InactiveCN101219391AAvoid uneven loadHigh catalytic efficiencyMolecular sieve catalystsHydrocarbon by hydrogenationCyclohexeneMesoporous silica

The invention pertains to chemical engineering field, in particular to a preparation method of a Ru-based catalyst, the catalyst has uniform load and high catalytic efficiency and is used for preparing cyclohexene from benzene through selectively hydrogenation reaction. A precursor of the catalyst is prepared through a cyclohexene / water component solvent system, and then reduced by a mixing gas of H2 or Ar to prepare the catalyst, and the catalyst consists of ruthenium, a dressing agent and a mesoporous silicon dioxide carrier L, amongst which the active component is ruthenium metal, the dressing agent is a metal oxide, and the precursor is selected from the nitrate or chloride of metal elements in IIA main group, VIII group and IVA main group in the element periodic table; ruthenium and the dressing agent are uniformly carried on the carrier L through the preparation method of the invention. When being used in preparing cyclohexene from benzene through selectively hydrogenation reaction, and compared with the catalyst used for the selectively hydrogenation of industrial benzene, the catalyst has the advantages that: lower the ruthenium consumption, higher selectively hydrogenation activity and selectivity for benzene.

Owner:FUDAN UNIV

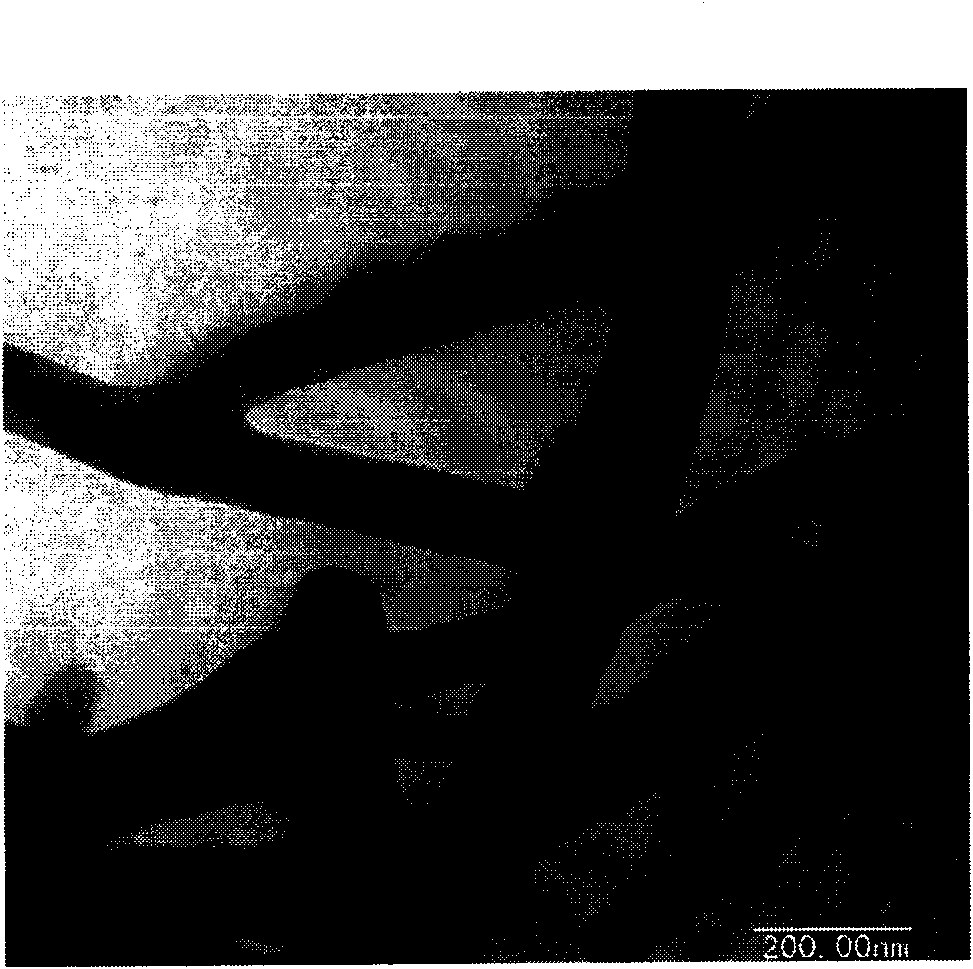

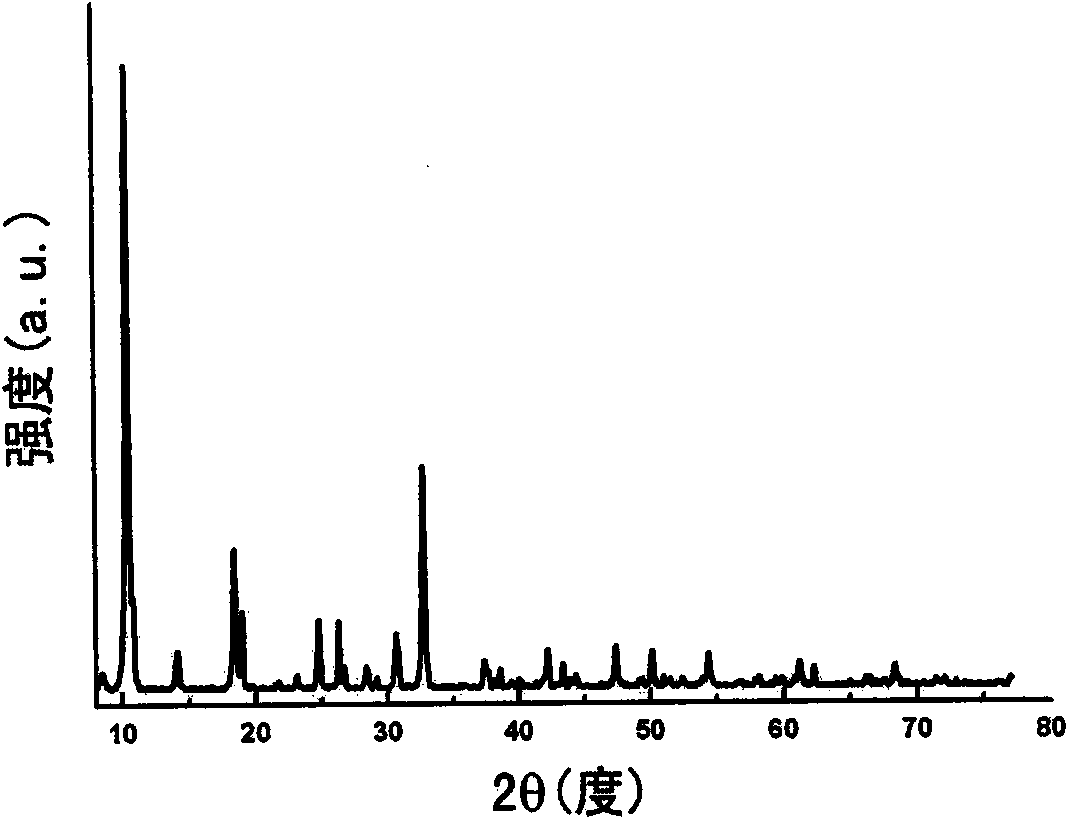

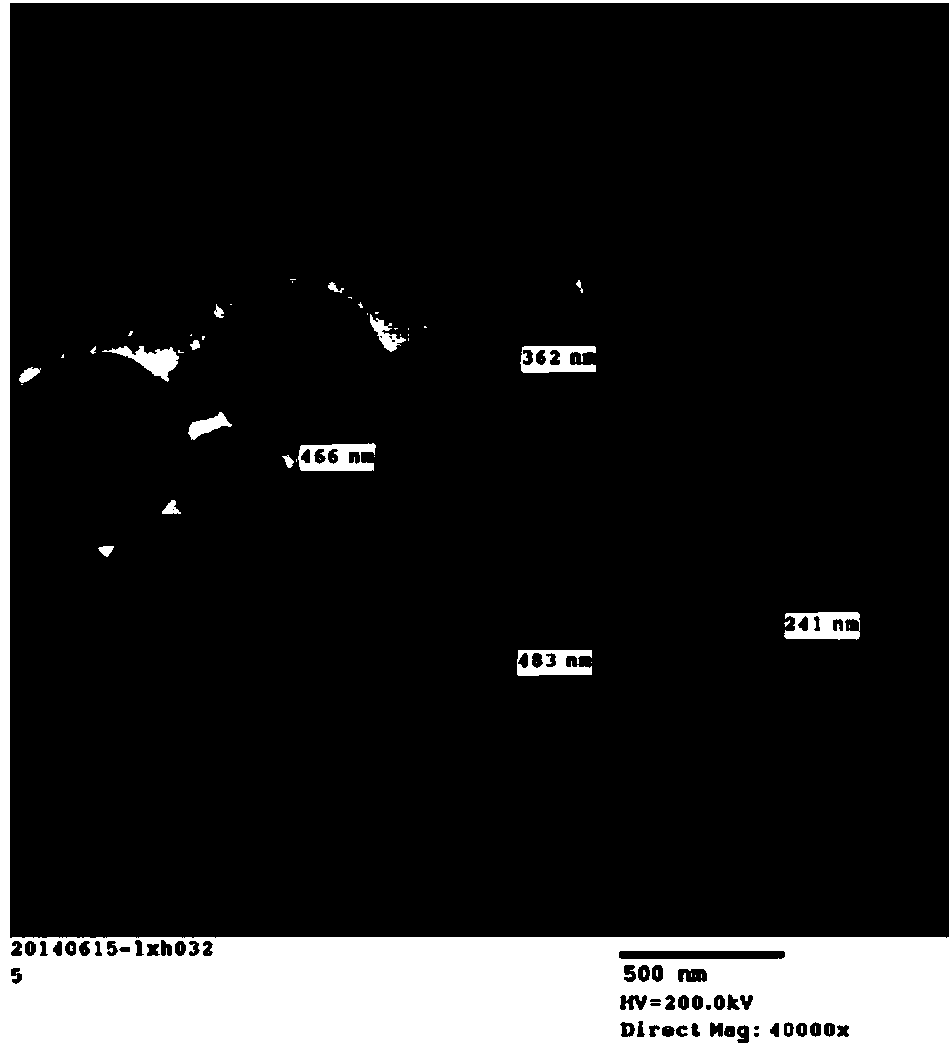

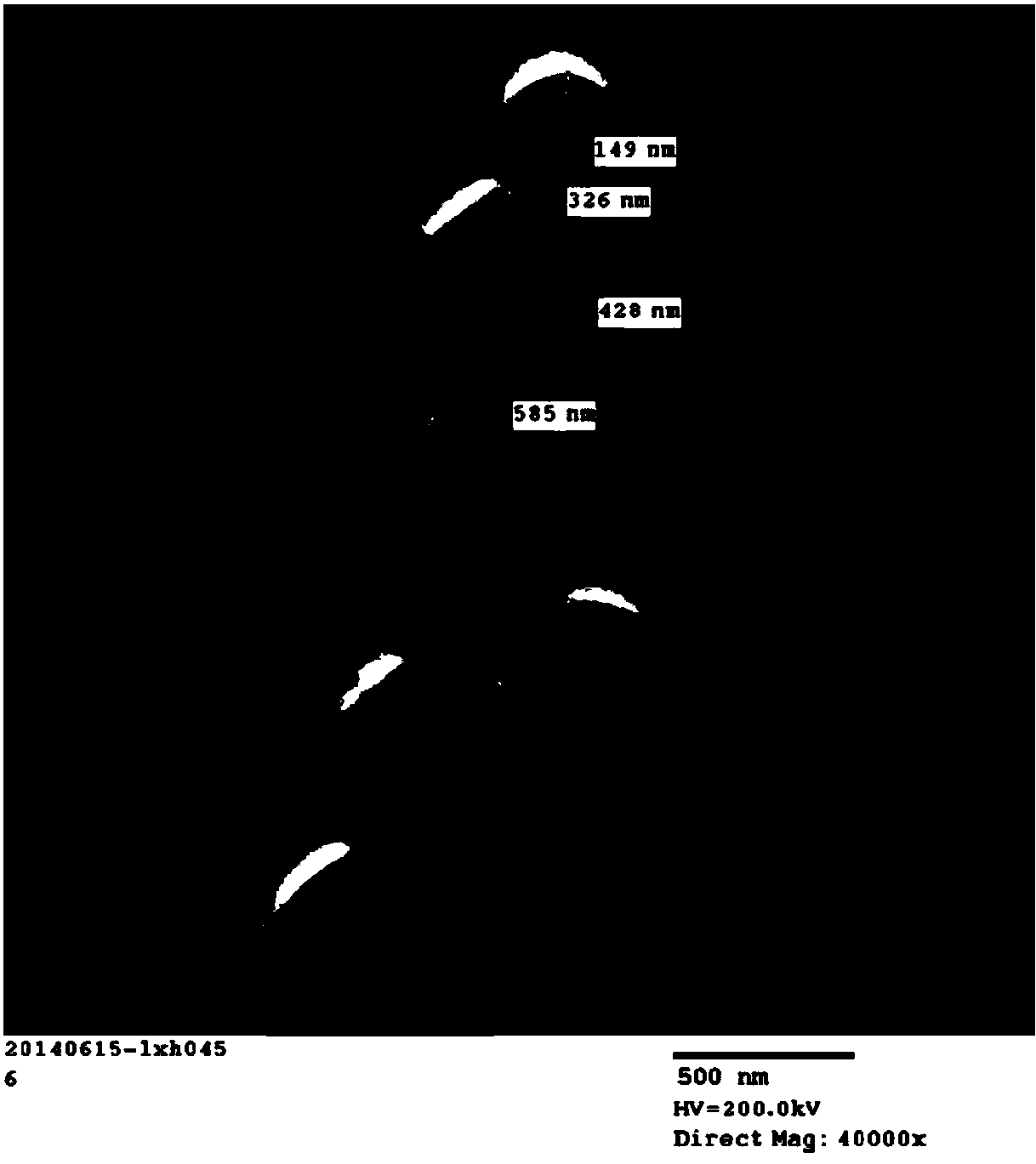

Titanium dioxide nanoplate and synthesizing method thereof

InactiveCN101462769AHigh catalytic efficiencyImprove cycle performanceTitanium dioxideHydrofluoric acidRoom temperature

The invention discloses titanium dioxide nano sheets and a method for synthesizing the same, and relates to a titanium dioxide nano material. The invention provides titanium dioxide nano sheets which are low in cost, high in catalytic activity and good in circularity and a method for synthesizing the same. The nano sheets are mainly in square rectangular shapes. The average thickness of the titanium dioxide nano sheets is 5 to 10nm. The average length of the titanium dioxide nano sheets is 30 to 150nm. The average width of the titanium dioxide nano sheets is 30 to 150nm. The top and bottom surfaces of the titanium dioxide nano sheets are high-activity surfaces (001) and exposed. The catalytic efficiency and the circularity of the titanium dioxide nano sheets are higher than those of commercial titanium dioxide (P25). The synthesis method comprises: placing tetrabutyl titanate and hydrofluoric acid into a reaction kettle and heating the mixture at 170 to 250 DEG C; keeping the temperature for 10 to 36 hours and cooling the mixture to room temperature; and taking out a sample, washing the sample with distilled water, ethanol, NaOH solution and water, and drying the sample to obtain the target product.

Owner:XIAMEN UNIV

Method of treating refractory pollutants through catalyzing H2O2 oxidation by pyrite cinder

ActiveCN101745197AApplicable to a wide range of pHImprove responseSolid waste disposalWater contaminantsCinderPollutant

A method of treating refractory pollutants utilizes the pyrite cinder as catalyst which forms a heterogeneous Fenton system with H2O2 to catalyze H2O2 to generate hydroxyl radical (.OH) with strong oxidability and degrade the organic pollutants efficiently and quickly. The method comprises the following steps: (1) after the waste water is added in a reactor, a given amount of pyrite cinder original sample or activated and pretreated cinder is added in the waste water; (2) H2O2 solution is added in a mixed liquid of the waste water and the pyrite cinder so as to form an analogous Fenton reagent with the pyrite cinder; (3) stirring is carried out so as to lead the pyrite cinder, the H2O2 solution and the waste water to be mixed for reaction, and the stirring is stopped at the set reaction time; and (4) standing is carried out, the pyrite cinder is quickly precipitated and the supernate is discharged, so that the pyrite cinder can be reused. The invention discovers a novel analogous Fenton oxidation catalyst, extends the resource utilization ways of the pyrite cinder, achieves the purpose of controlling waste by waste and realizes the comprehensive utilization of the waste.

Owner:TONGJI UNIV

Starting an engine with valves that may be deactivated

ActiveUS20050205037A1Reduce engine emissionsReduce vibrationHybrid vehiclesElectrical controlEngine valveInternal combustion engine

A system and method to control engine valve timing to during the start of an internal combustion engine. Valves that may be deactivated are controlled in a manner to reduce hydrocarbon emissions during the start of an internal combustion engine.

Owner:FORD GLOBAL TECH LLC

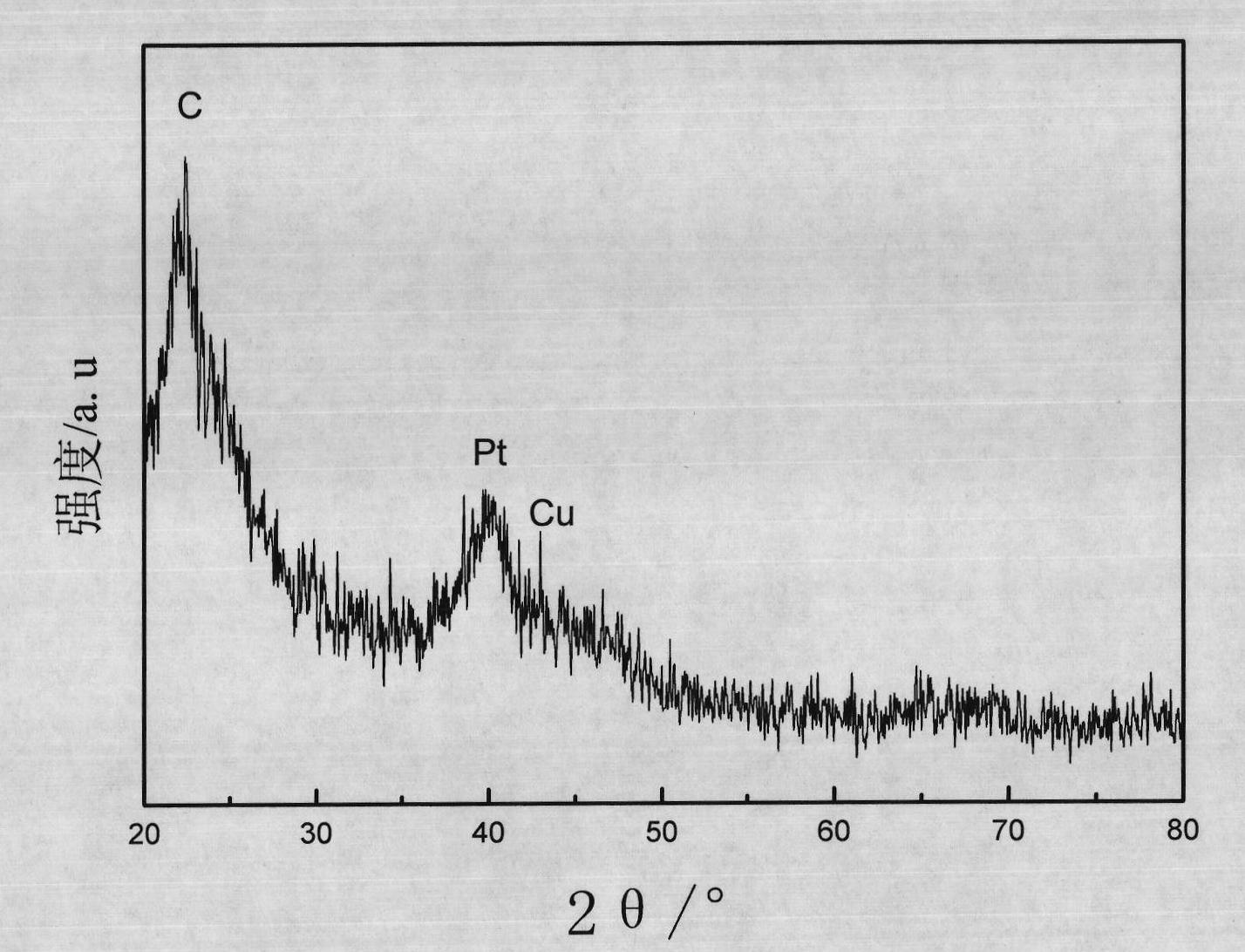

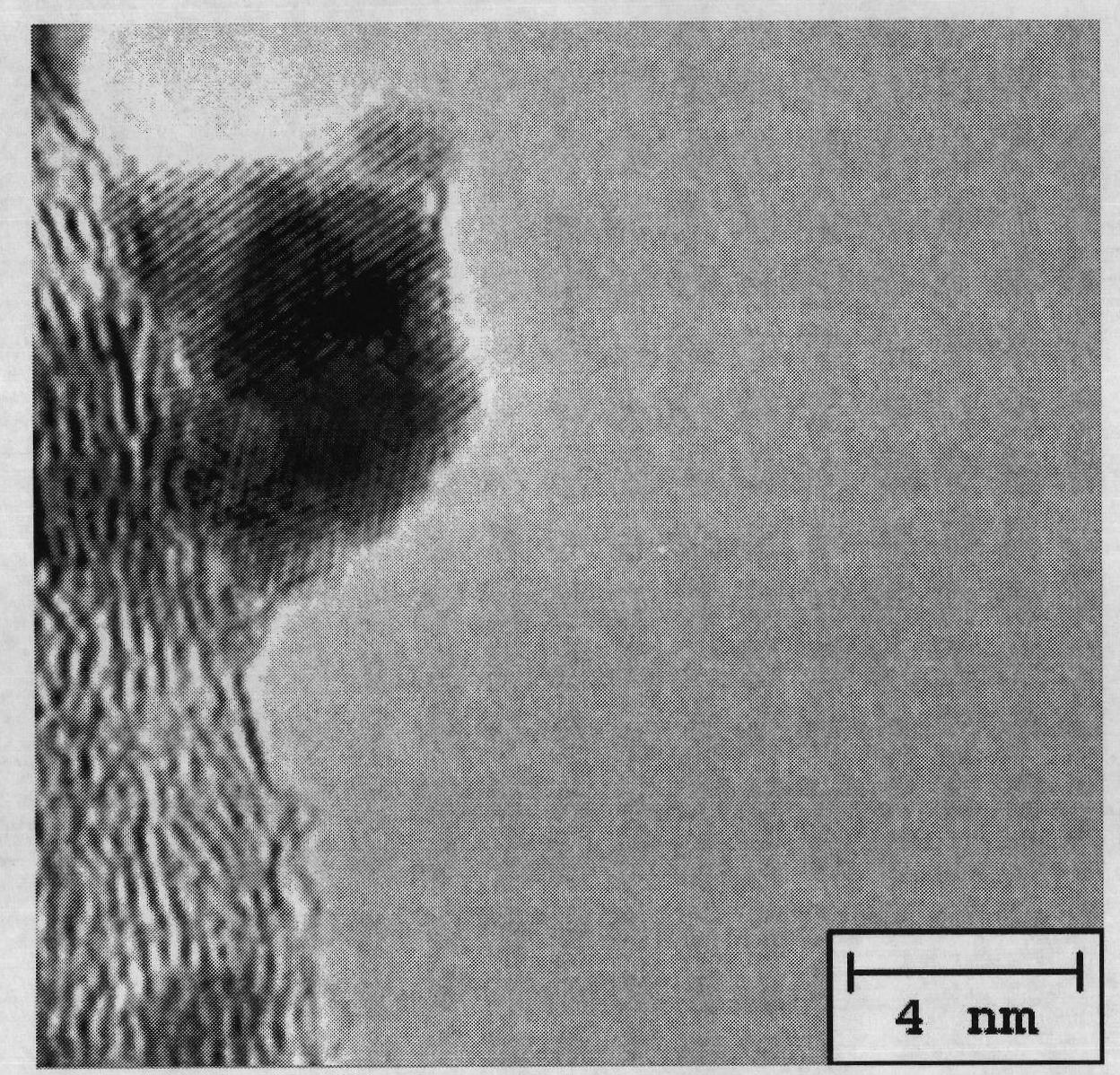

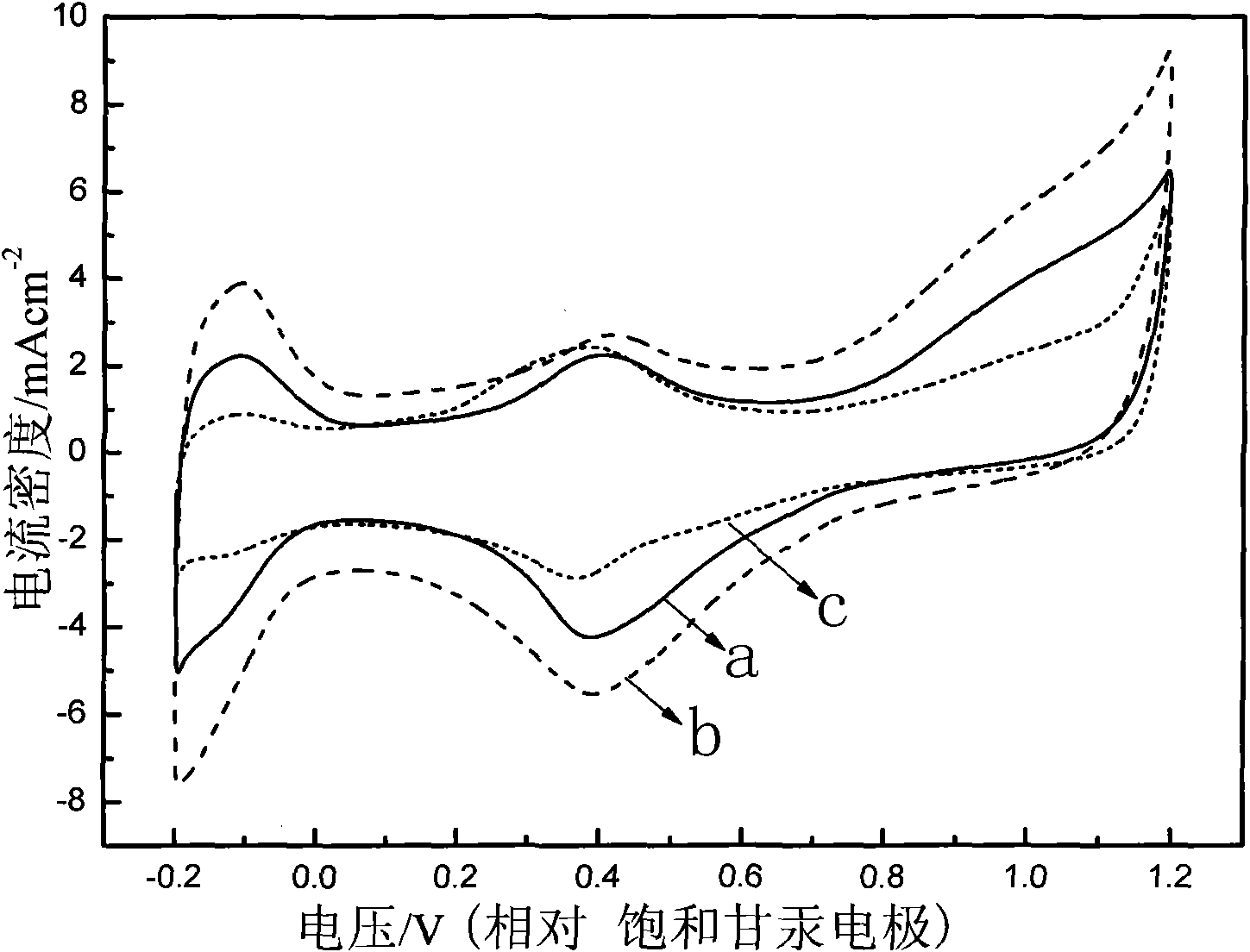

Carbon-carrying shell type copper-platinum catalyst for fuel cell and preparation method thereof

InactiveCN102088091ASmall particle sizeHigh catalytic efficiencyCell electrodesMetal/metal-oxides/metal-hydroxide catalystsMetal particleSolvent

The invention provides a carbon-carrying shell type copper-platinum catalyst (Cu@Pt / C) for a fuel cell and a preparation method thereof. In the method, glycol serves as a solvent and a reducing agent to prepare the Cu@Pt / C catalyst with the shell structure. In the method, a two-step reduction method is used to firstly reduce non noble metal and then reduce noble metal; and the temperature and the pH value of the reaction are controlled to cause the noble metal to deposit on the surface of the non noble metal so as to prepare the shell type catalyst. In addition, in the method, a carbon carrier is added in the preparation process, so that a nanometer metal particle directly grows on the carrier to enhance the combination of catalyst particles and the carbon carrier, and the catalyst is more stable so as to greatly improve the catalytic efficiency of the catalyst and the utilization ratio of the noble metal. Cu in the carbon-carrying shell type copper-platinum catalyst accounts for 2-30wt%, and Pt accounts for 5-30wt%.

Owner:BEIJING UNIV OF CHEM TECH

Nucleocapsid energizing agent for propelling agent and method for preparing same

InactiveCN101549289ASimple ingredientsLow priceCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsActive agentVacuum drying

The present invention discloses a nucleocapsid energizing agent for propelling agent and a method for preparing same, the energizing agent is a nucleocapsid structure energizing agent that carbon is encapsulated on a metallic oxide surfaced. The preparing method includes steps as follows: selecting one or some raw materials: address sugar, diose or soluble polysaccharide to mix according with random weight rate for confecting water solution 50-1500g / L, adding the surfactant or dispersant into the water solution, then adding the metallic oxide powder, the metallic oxide weight is 1-60% of the raw material total weight, the surfactants or dispersants weight is 0-4.5% of the metallic oxide weight, ultrasounding or stirring to distribute evenly, heating in 100-260 DEG C during 1-72 hours; reducing the product temperature to a room temperature, washing, centrifuging, removing the water-soluble impurity again and again, then vacuum drying for obtaining the nucleocapsid energizing agent. The nucleocapsid energizing agent has better compatibility with other component of the propelling agent, and has simple preparing technique, low cost, green process and is easy to mass production.

Owner:WUHAN UNIV

Preparation method and application of nano material monolithic column immobilized enzyme biological micro-reactor

InactiveCN104195042AFast catalytic efficiencyHigh catalytic efficiencyEnzyme production/based bioreactorsMicroorganism fixing/supporting apparatusMicroreactorFunctional monomer

The invention discloses a preparation method and an application of a nano material monolithic column immobilized enzyme biological micro-reactor. The preparation method comprises the following steps of firstly, preparing a porous organic polymer monolithic column by using a mixed solution of a functional monomer, a crosslinking agent, a pore forming agent and an initiating agent through in-situ thermal-initiated or light-initiated polymerization in the column, and then bonding a nano material after functional modification to obtain a nano material monolithic column; and secondly, realizing immobilization of the enzyme on the monolithic column by using the nano material as an intermediate ligand to obtain the nano material monolithic column immobilized enzyme biological micro-reactor. The biological micro-reactor is successfully applied to proteomic analysis, medicament chiral resolution and catalyzed ester exchange reactions. The biological micro-reactor disclosed by the invention has the following advantages that the preparation method is simple, the immobilization amount of the enzyme is large, the catalytic activity is high, the enzymolysis speed is high, the efficiency is high, the service life is long, and the biological micro-reactor can be reused.

Owner:BEIJING UNIV OF CHEM TECH

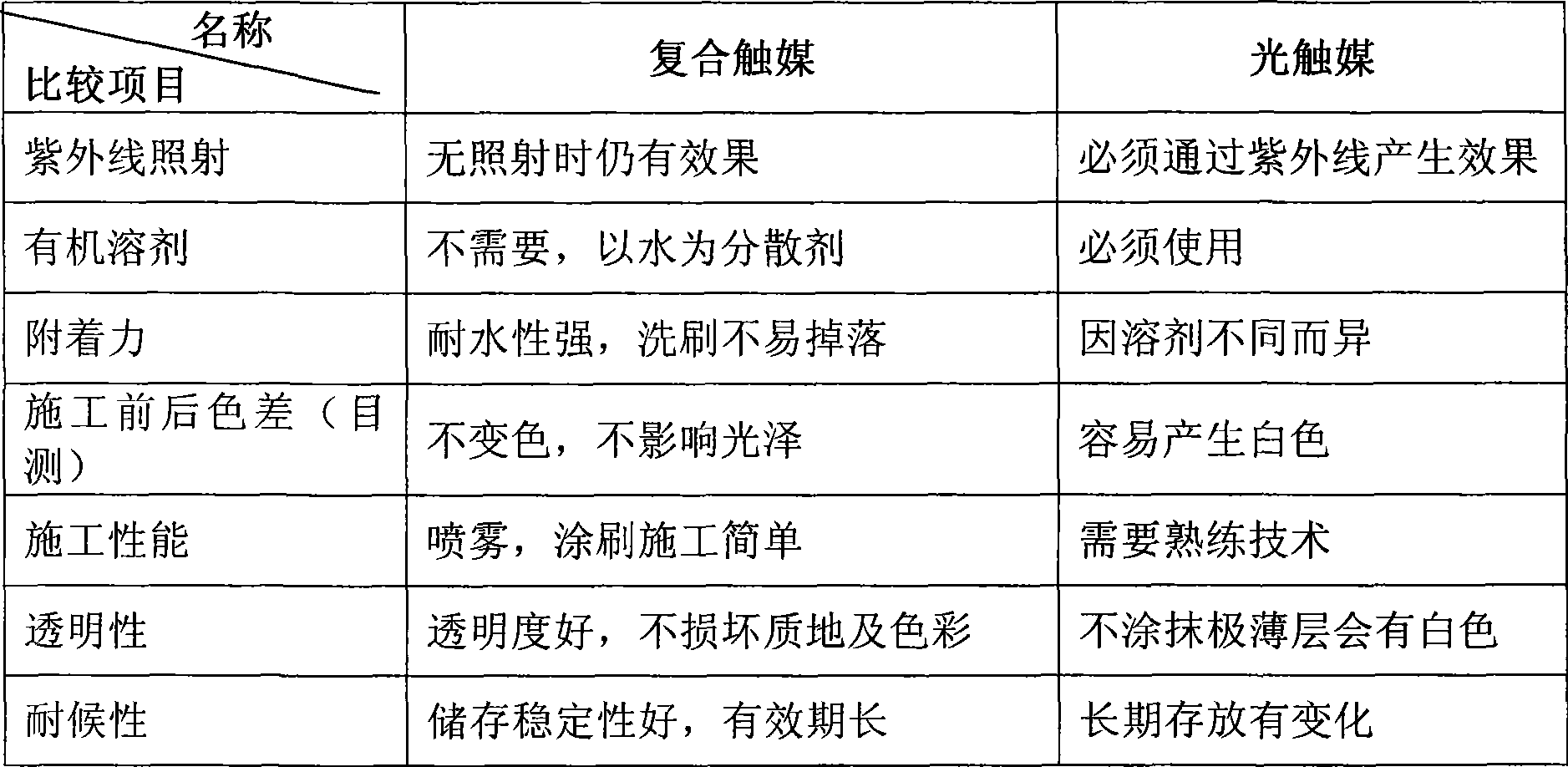

Compound catalytic material for purifying harmful gas

ActiveCN101474419ANo secondary pollutionNo light catalytic purification effectDeodrantsSide effectClearance rate

The invention relates to a compound catalytic material for purifying harmful gas. Deionized water is used as dispersant to compound nano-catalytic material, rare earth compound, p-type semiconductor, antimicrobial, plant extract and anion powder. The compound catalytic material can fast and thoroughly eliminate free formaldehyde, benzene homologue, ammonia and TVOC harmful gas. The compound catalytic material does not require ultraviolet light, has simple use and low cost and does not have toxic side effect and secondary pollution, and the purification effect can last for more than five years without rebound. At the same time, the compound catalytic material prevents bacteria, germina and mildew from invading human body, removes peculiar smell, odor, smoke, leather flavour, paint flavour and the like, increases anion and far infrared ray which are beneficial to human body and improves indoor air environmental quality comprehensively. The experiment detection shows that formaldehyde clearance rate within 24 hours is 91.6 percent; benzene clearance rate is 88.9 percent; ammonia clearance rate is 90.5 percent; TVOC clearance rate is 87.6 percent; sterilization and bacteriostasis rate is 99.99 percent; mould prevention is 0 grade; and acute oral toxicity is tested as actually nontoxic class.

Owner:HENAN MUBO INDAL

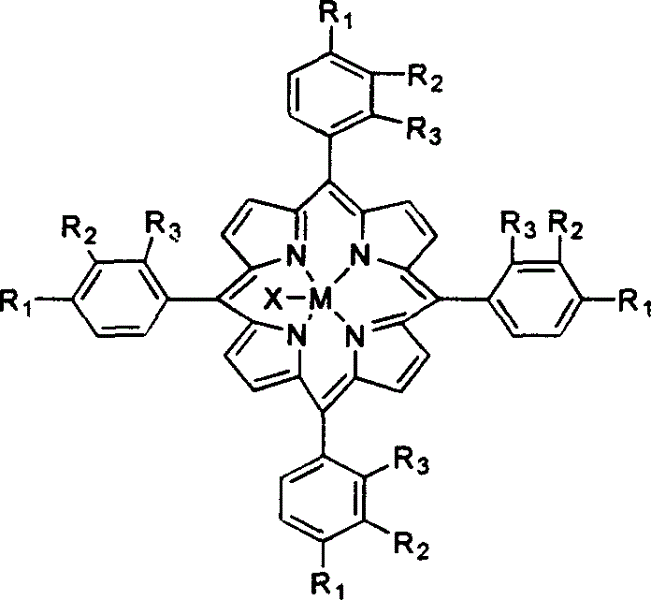

Method of preparing adipic acid by air-oxidating hexacarbocyclic compound

InactiveCN1535947AReduce dosageHigh catalytic efficiencyOrganic compound preparationCarboxylic compound preparationCyclohexanoneCyclohexene

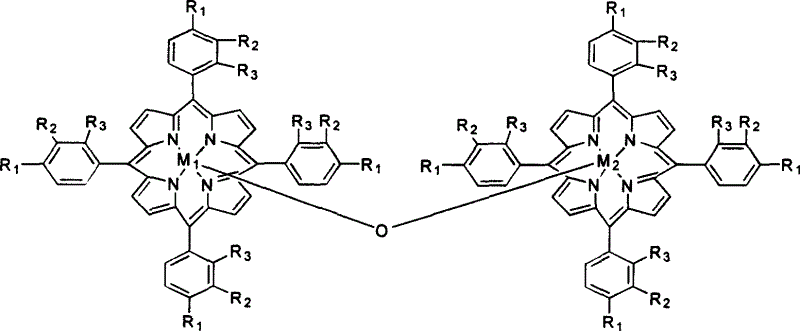

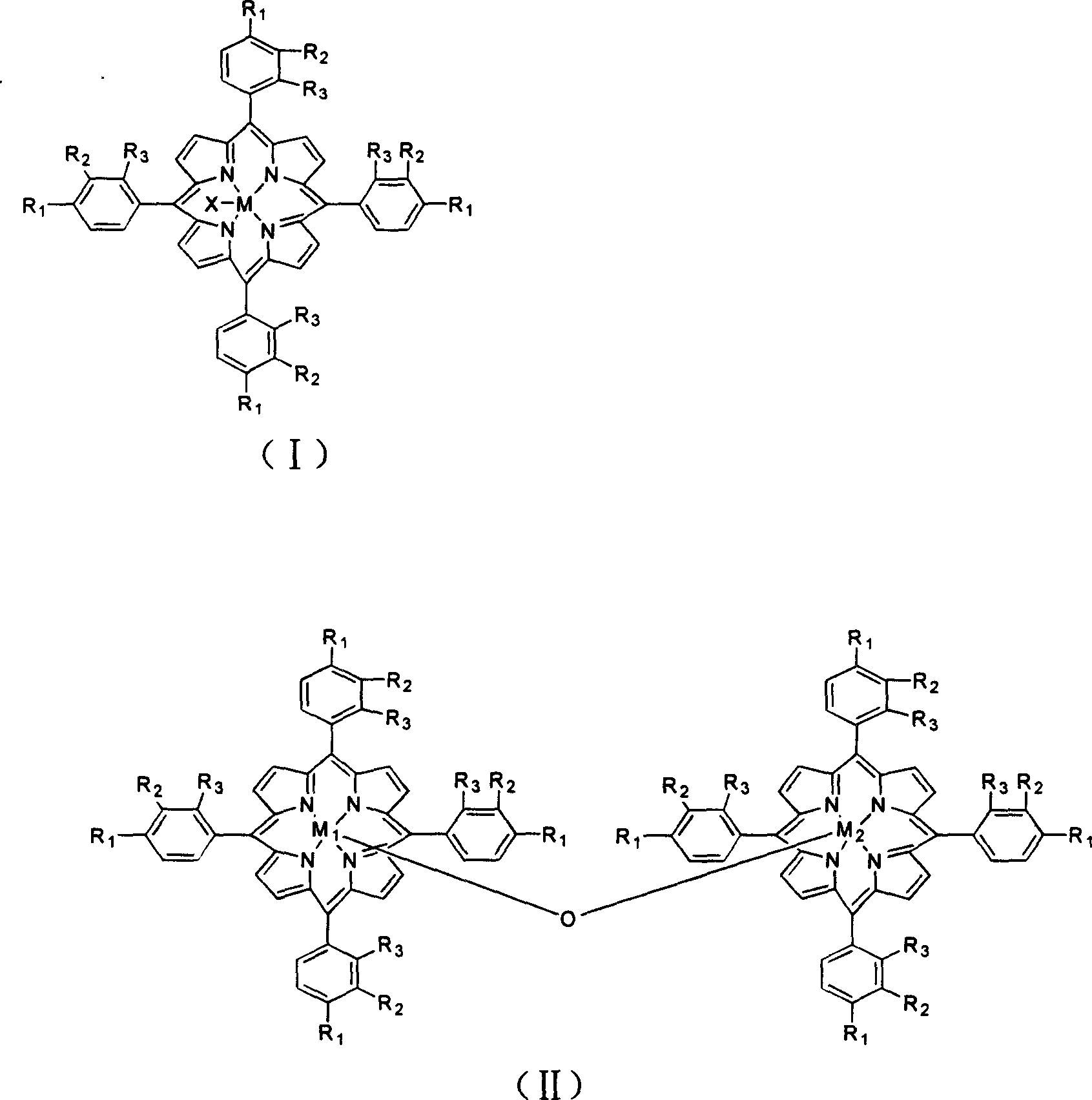

The present invention relates to a new process for preparing adipic acid by air oxidating cyclohexane, cyclohexanol, cyclohexanone and cyclohexene or mixture of cyclohexanol and cyclohexanone under the catalysis of metal porphyrin. Under the condition of 1-20 atm air and reaction temp. is 50-200 deg.C it can select and use mu-oxidized metal porphyrin and monometal porphyrin or their fixed carrier material as catalyst independently, also can select and use metal porphyrin or their fixed carrier material as main catalyst, and use transition metal salt or oxide as co-catalyst. The metal porphyrin like biological-enzyme can high-effectively and high-selectivity catalyze air under the biologicae concentration to directly oxidate the cyclohexane into adipic acid. Said invented dose of metal porphyrin is less, and its catalytic effect is good, it can make homogeneous catalysis, also can make heterogeneous catalysis after the carrier is fixed.

Owner:HUNAN UNIV

High surface area catalyst

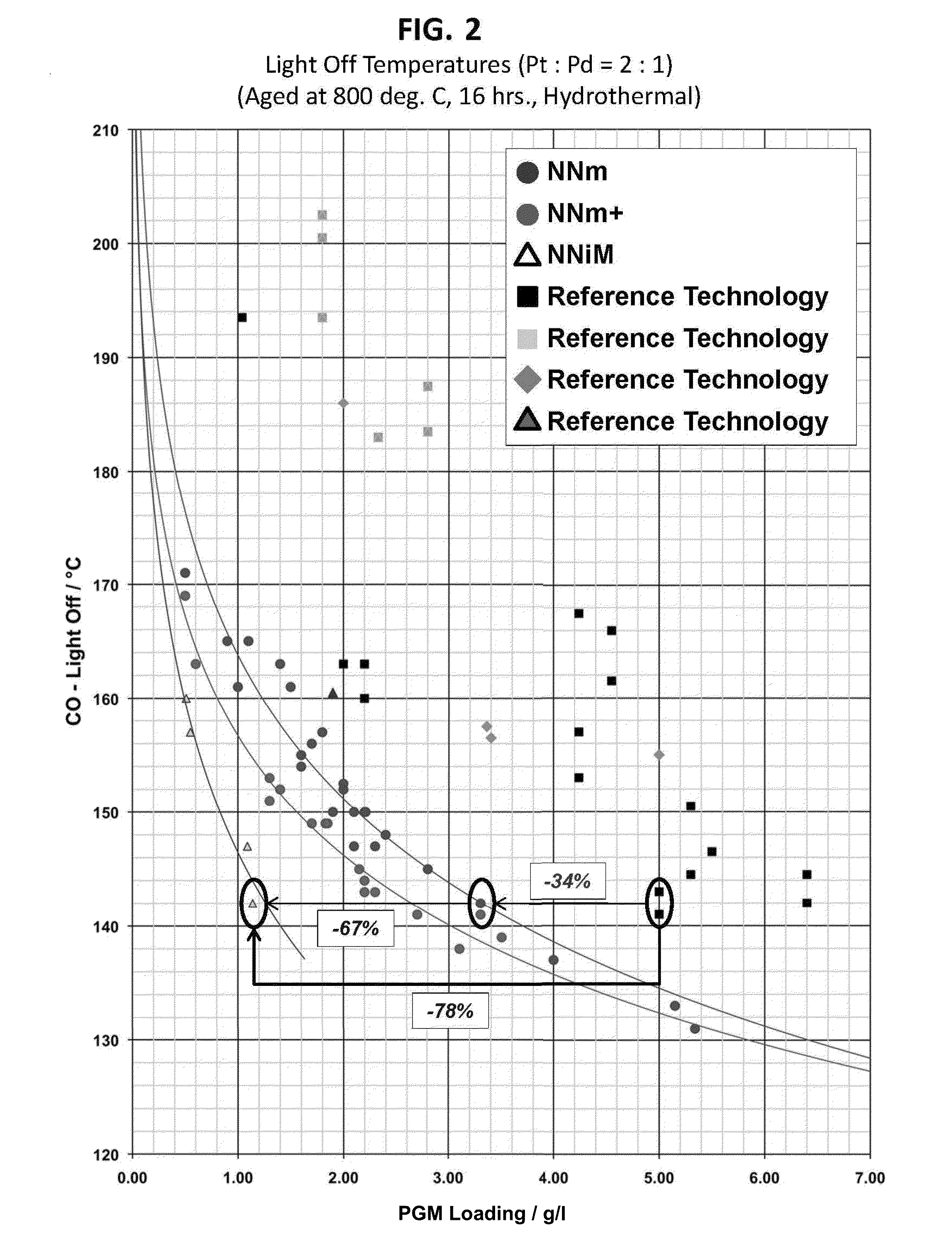

InactiveUS20150140317A1High catalytic efficiencyReduce impactMolecular sieve catalystsLayered productsPorosityNanoparticle

The present invention relates to the field of catalysts, and more specifically to nanoparticle catalysts. Materials with high porosity which contain nanoparticles can be created by various methods, such as sol-gel synthesis. The invention provides catalytic materials with very high catalytically active surface area, and methods of making and using the same. Applications include, but are not limited to, catalytic converters for treatment of automotive engine exhaust.

Owner:SDC MATERIALS

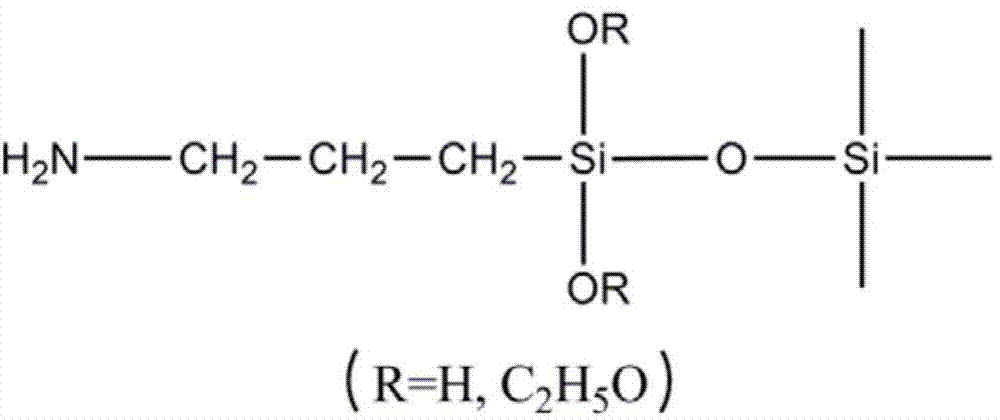

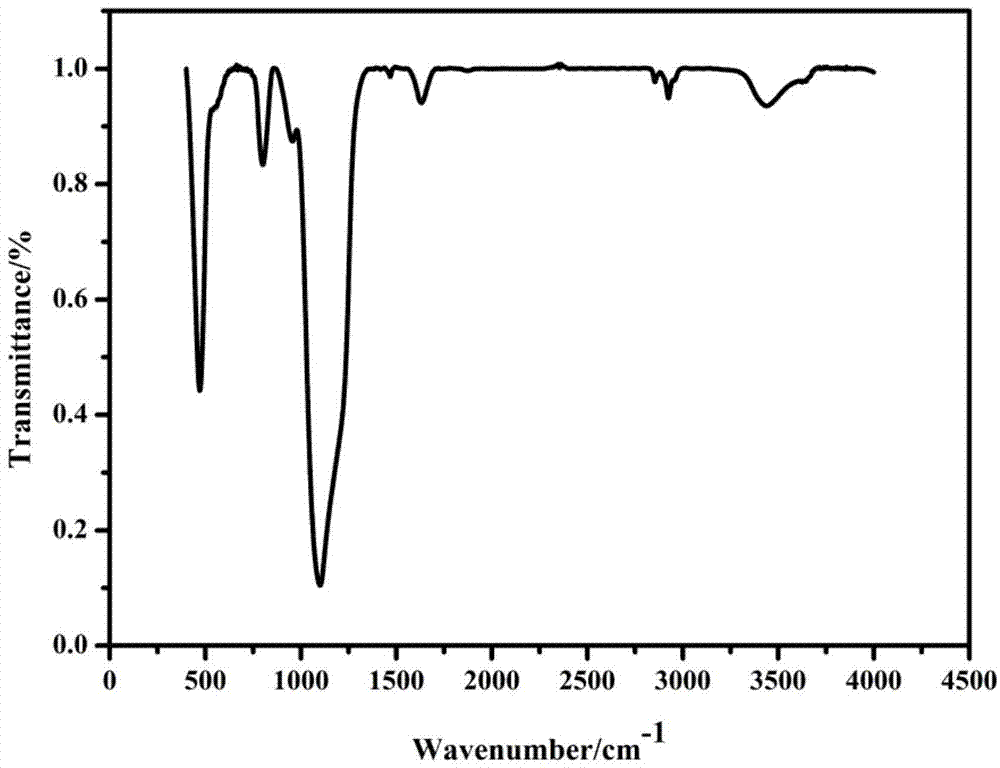

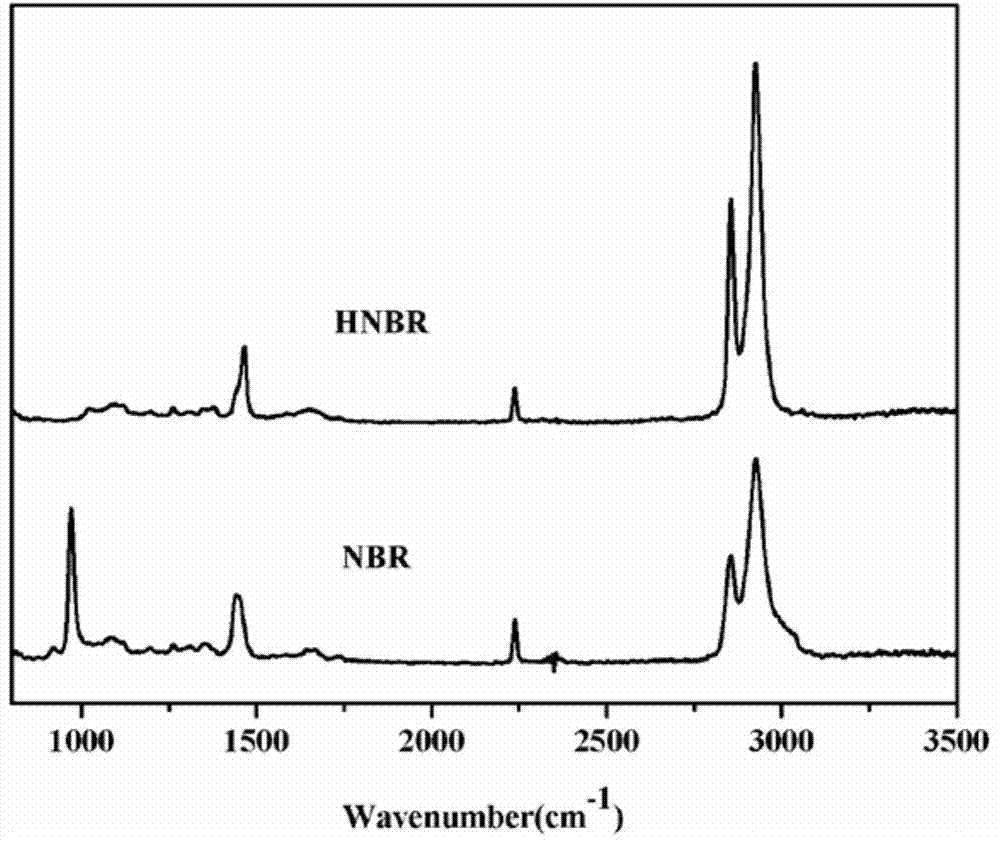

Preparation of silane coupling agent-modified SiO2 loaded rhodium catalyst and selective hydrogenation application of catalyst to butadiene-acrylonitrile rubber

ActiveCN103537304ASimple preparation processGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsChemical recyclingSilanesAcrylonitrile

The invention discloses preparation of a silane coupling agent-modified SiO2 loaded rhodium catalyst and a selective hydrogenation application of the catalyst to butadiene-acrylonitrile rubber. The method comprises the following steps: (1) carrier modification, namely, modifying SiO2 by utilizing a silane coupling agent with an amino group in an organic solution or water so as to obtain modified SiO2; and (2) loading catalyst preparation, namely, adding the modified SiO2 into a rhodium solution, standing, washing and drying so as to obtain the loaded catalyst APTS (aminopropyltriethoxysilane)-SiO2-Rh. The prepared catalyst is used for nitrile butadiene rubber (NBR) hydrogenation research, and the hydrogenated butadiene-acrylonitrile rubber with the hydrogenation strength being more than 98% can be obtained. The preparation process is simple, and the adopted reaction raw materials are wide in source scope and small in toxicity and are economic and practicable. The NBR hydrogenation research shows that the hydrogenation efficiency is greatly improved, the hydrogenation strength is improved to above 98% from the original 52% under the same condition, and moreover, the recycling performance of the catalyst is also greatly improved after the reaction is ended. The APTS-SiO2-Rh is a high activity recycled NBR hydrogenation heterogeneous catalyst and is beneficial to HNBR (hydrogenated butadiene-acrylonitrile rubber) large-scale production.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com