Patents

Literature

1555 results about "Non noble metal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Two stage process for hydrodesulfurizing distillates using bulk multimetallic catalyst

InactiveUS6929738B1Preparation by oxo-reaction and reductionOrganic compound preparationLiquid productHydrogen

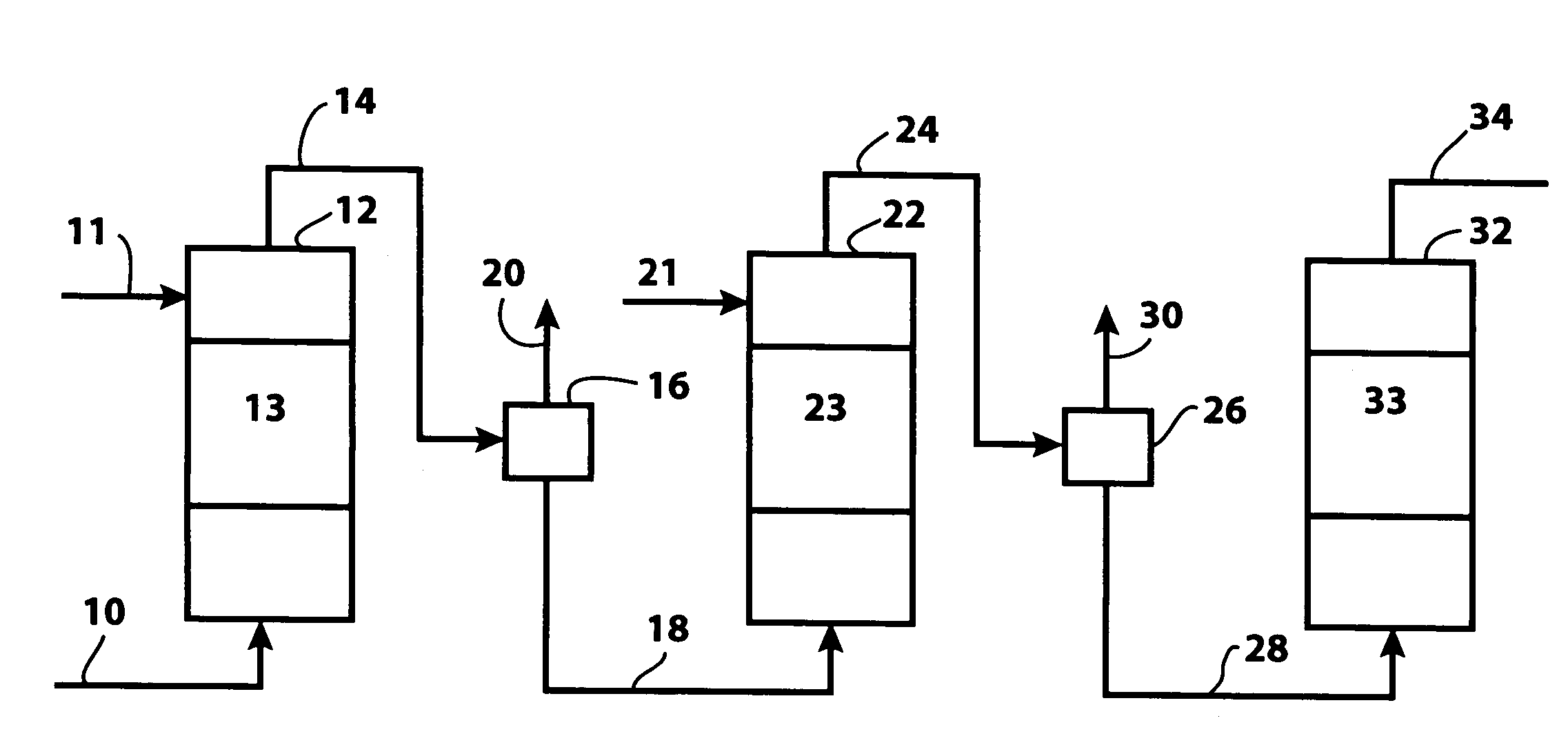

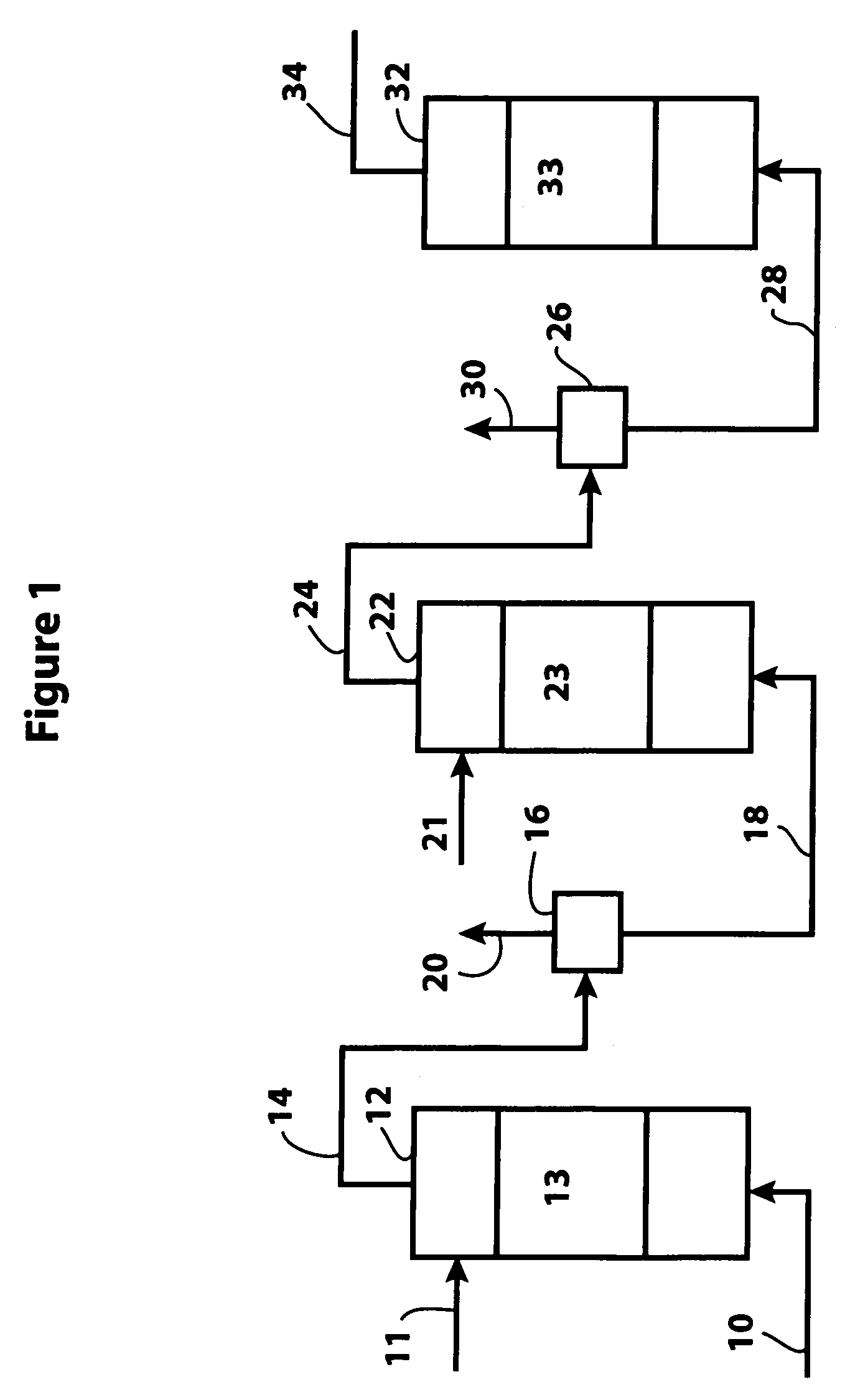

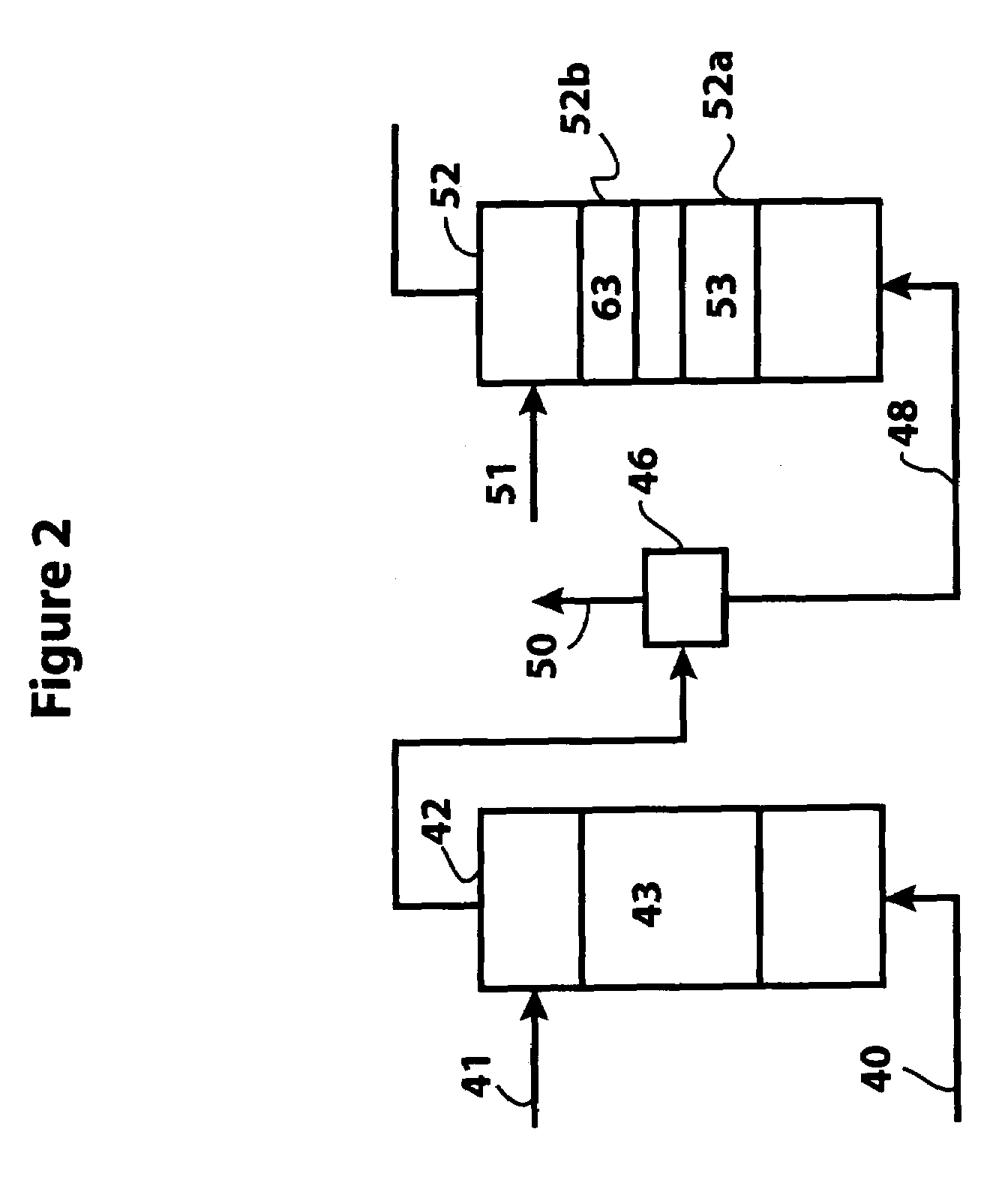

A two stage hydrodesulfurizing process for producing low sulfur distillates. A distillate boiling range feedstock containing in excess of about 3,000 wppm sulfur is hydrodesulfurized in a first hydrodesulfurizing stage containing one or more reaction zones in the presence of hydrogen and a hydrodesulfurizing catalyst. The liquid product stream thereof is passed to a first separation stage wherein a vapor phase product stream and a liquid product stream are produced. The liquid product stream, which has a substantially lower sulfur and nitrogen content then the original feedstream is passed to a second hydrodesulfurizing stage also containing one or more reaction zones where it is reacted in the presence of hydrogen and a second hydrodesulfurizing catalyst at hydrodesulfurizing conditions. The catalyst in any one or more reaction zones is a bulk multimetallic catalyst comprised of at least one Group VIII non-noble metal and at least two Group VIB metals.

Owner:EXXON RES & ENG CO

Process for upgrading naphtha

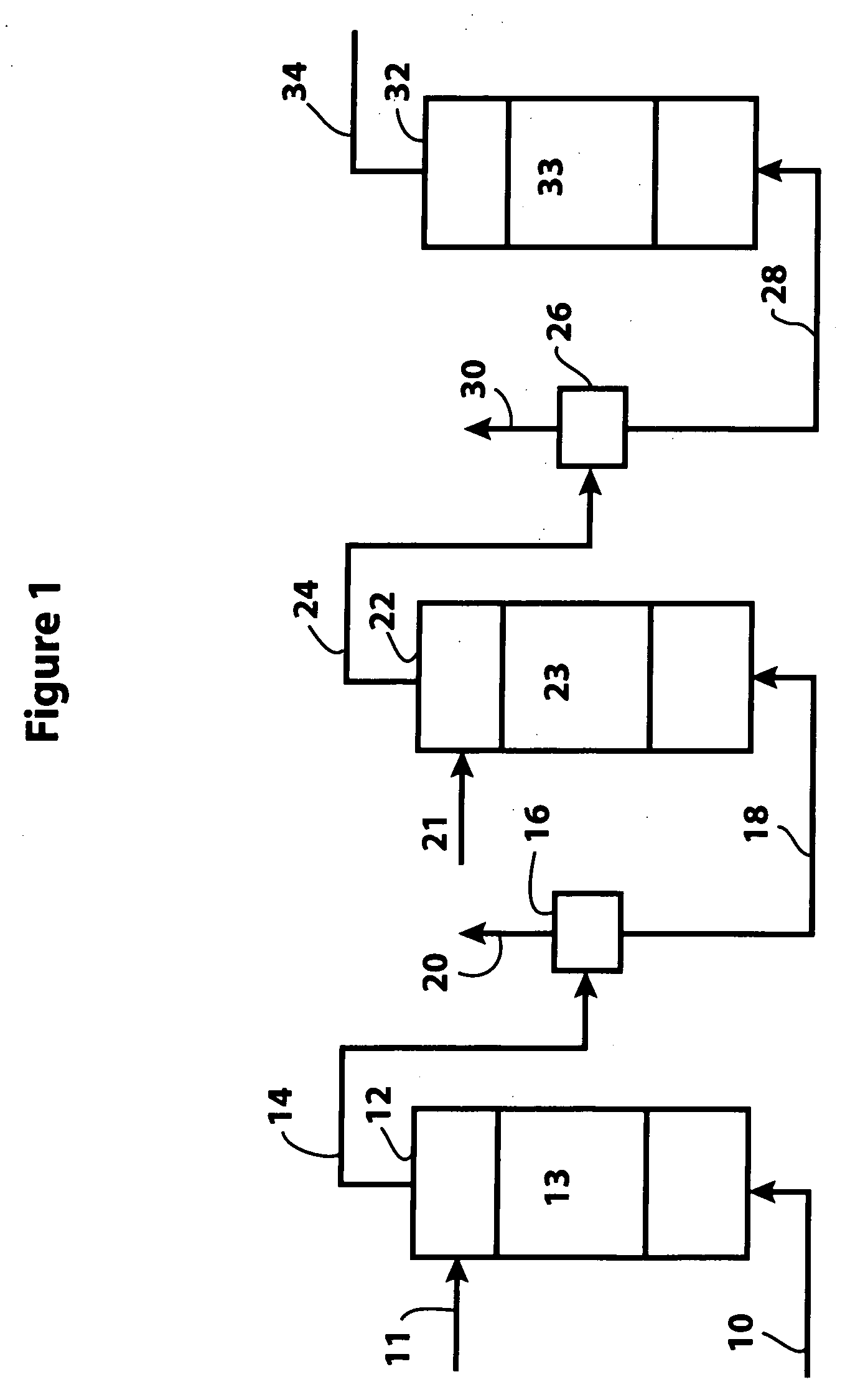

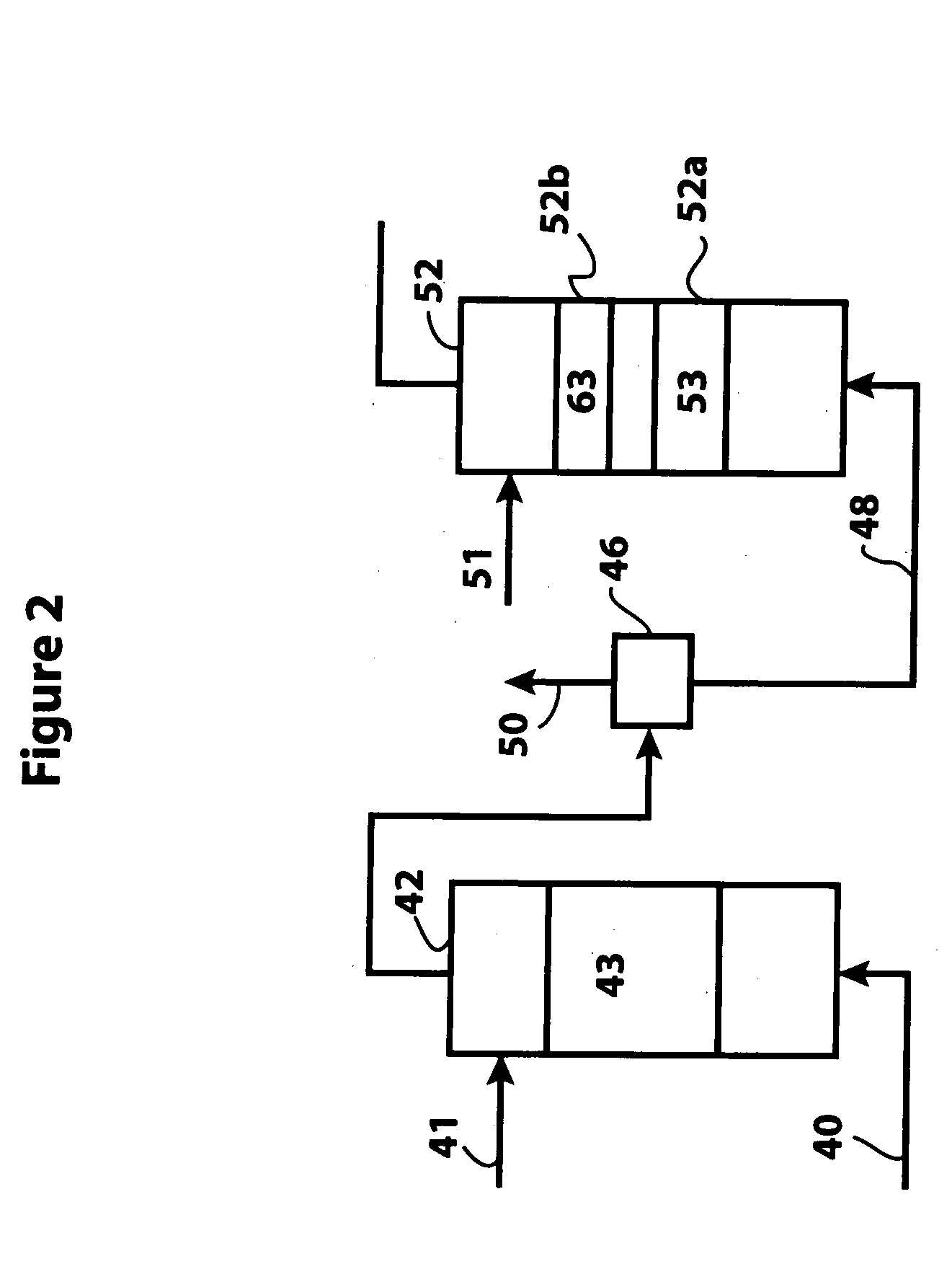

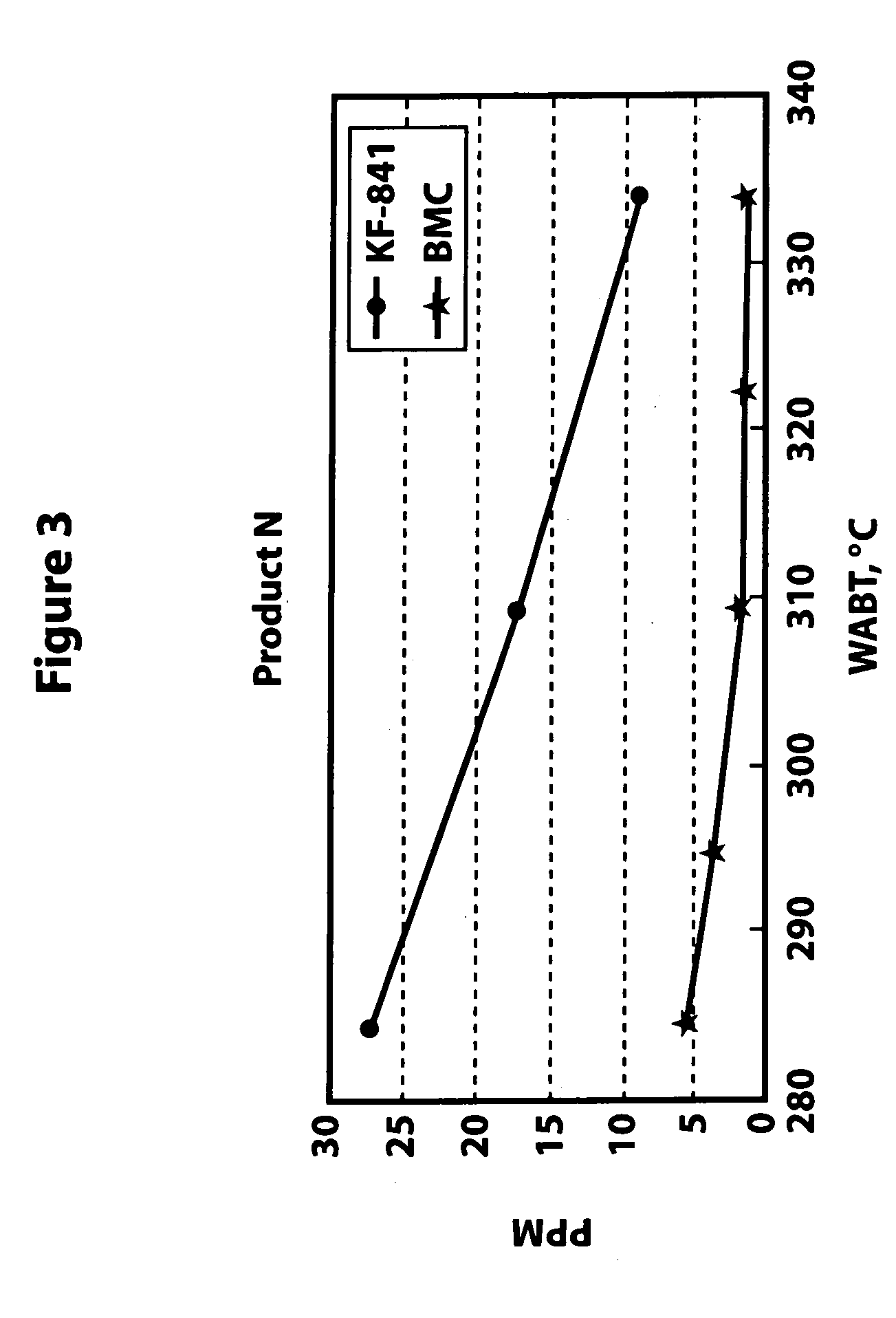

A method for upgrading a naphtha feed to a naphtha product containing less than about 10 wppm of nitrogen and less than about 15 wppm sulfur, the method comprising contacting said naphtha feed with hydrogen in the presence of a bulk multimetallic catalyst under effective reactor conditions to hydrodesulfurize and hydrodenitrogenize said naphtha feed to produce said naphtha product, wherein said bulk multimetallic catalyst comprises at least one Group VIII non-noble metal and at least two Group VIB metals.

Owner:EXXON RES & ENG CO

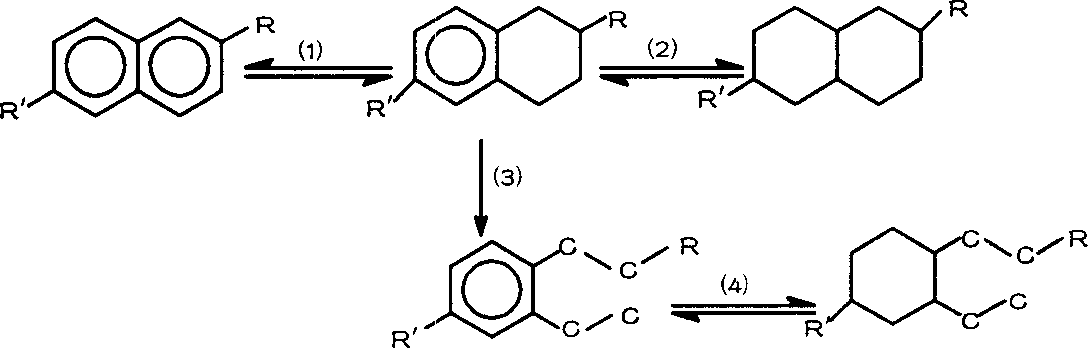

Hydrogenation process for hydrocarbon resins

InactiveUS20030150778A1Improve productivityIncrease volumePreparation by oxo-reaction and reductionCatalyst activation/preparationProduction rateHalogen

This invention provides a process for hydrotreating hydrocarbon resins, which process comprises contacting a feedstock comprising a hydrocarbon resin or rosin, under suitable hydrotreating conditions, with a bulk multimetallic catalyst comprised of at least one Group VIII non-noble metal and at least two Group VIB metals and wherein the ratio of Group VIB metal to Group VIII non-noble metal is from about 10:1 to about 1:10. The process accord invention can achieve increased hydrocarbon resin productivity through increase in throughput volumes and effective catalyst lifetimes. The process of the invention is desirably practiced with a bulk catalyst consisting of only the combination of the metal species with the active metal components. The absence of carrier substrates largely removes the possibility of halogen accumulation on substrate surfaces that, in turn, can acidify metal catalysts such that additional, progressive cracking of the hydrocarbon resin molecules occurs.

Owner:EXXONMOBIL CHEM PAT INC

Process for upgrading naphtha

A method for upgrading a naphtha feed to a naphtha product containing less than about 10 wppm of nitrogen and less than about 15 wppm sulfur, the method comprising contacting said naphtha feed with hydrogen in the presence of a bulk multimetallic catalyst under effective reactor conditions to hydrodesulfurize and hydrodenitrogenize said naphtha feed to produce said naphtha product, wherein said bulk multimetallic catalyst comprises at least one Group VIII non-noble metal and at least two Group VIB metals.

Owner:EXXON RES & ENG CO

Catalytic process for converting renewable resources into paraffins for use as diesel blending stocks

A process for converting renewable resources such as vegetable oil and animal fat into paraffins in a single step which comprises contacting a feed which is a renewable resources with hydrogen and a catalyst which comprises a non-precious metal and an oxide to produce a hydrocarbon product having a ratio of odd-numbered hydrocarbons to even-numbered hydrocarbons of at least 2:1.

Owner:REFINING TECH SOLUTIONS LLC

Molecular sieve-containing catalyst for cracking hydrocarbons and a method for preparing the same

ActiveUS20040266608A1Reduced activityEasy to crackCatalytic crackingMolecular sieve catalystsReduction ActivityMolecular sieve

A molecular sieve-containing catalyst for cracking hydrocarbons, comprising molecular sieve, refractory inorganic oxide, clay and a metal component, wherein the amount of said molecular sieve is from 1 to 90% by weight, the refractory inorganic oxide is from 2 to 80% by weight, the clay is from 2 to 80% by weight, and the metal component is from 0.1 to 30% by weight, calculated as the oxide of said metal having its maximum valence state, based on the total amount of the catalyst, wherein said metal component exists essentially in a reduction state and is one or more metals selected from the group consisting of metals of Group III A(other than aluminum), and metals of Group IVA, VA, IB, IIB, VB, VIB and VIIB, and non-noble metals of Group VIII of the periodic table. The catalyst has higher cracking activity and higher sulfur reduction activity.

Owner:CHINA PETROCHEMICAL CORP +1

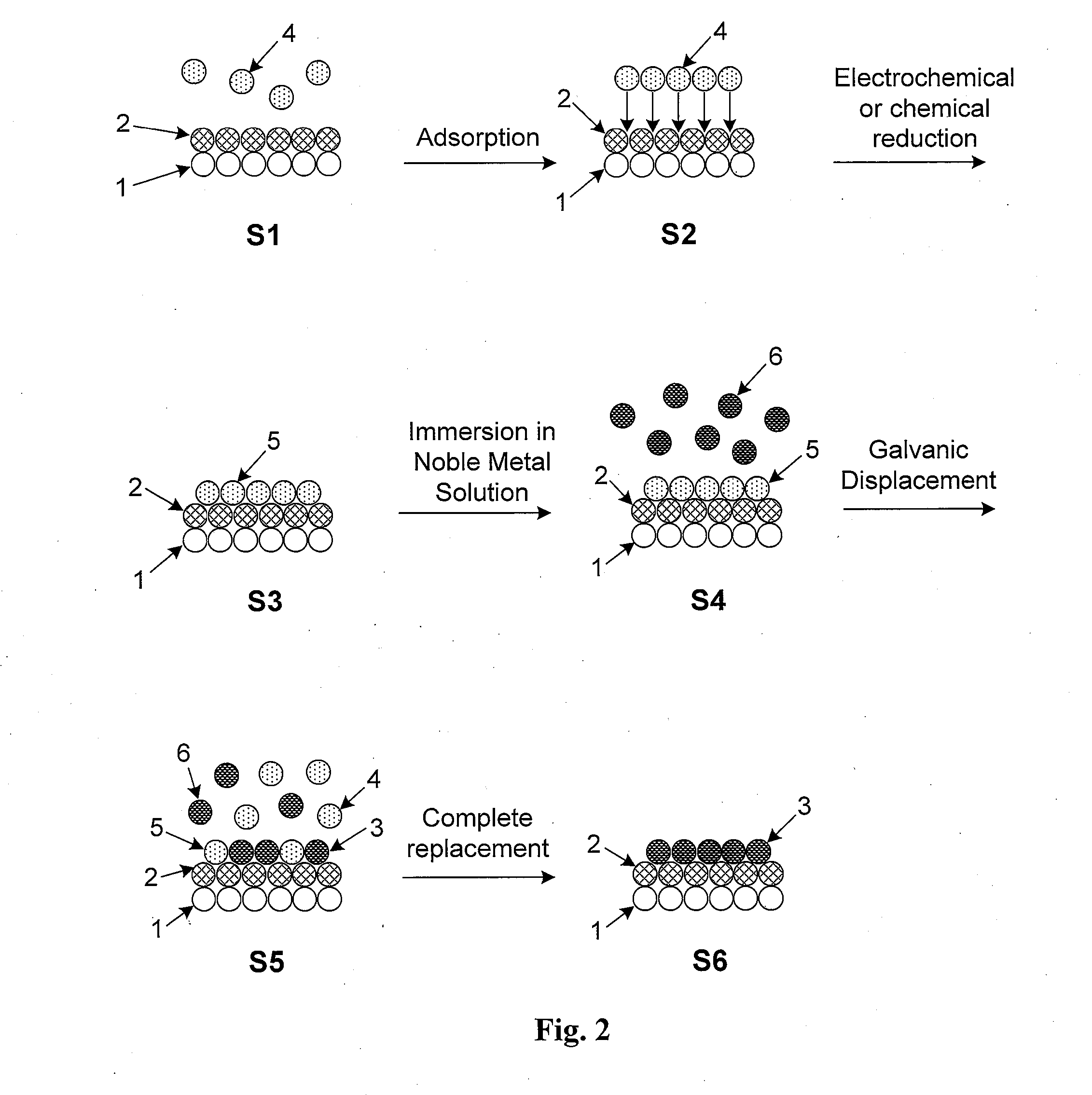

Platinum-Based Electrocatalysts Synthesized by Depositing Contiguous Adlayers on Carbon Nanostructures

InactiveUS20100177462A1High catalytic activityImprove stabilityMaterial nanotechnologyCarbon compoundsNanostructurePt element

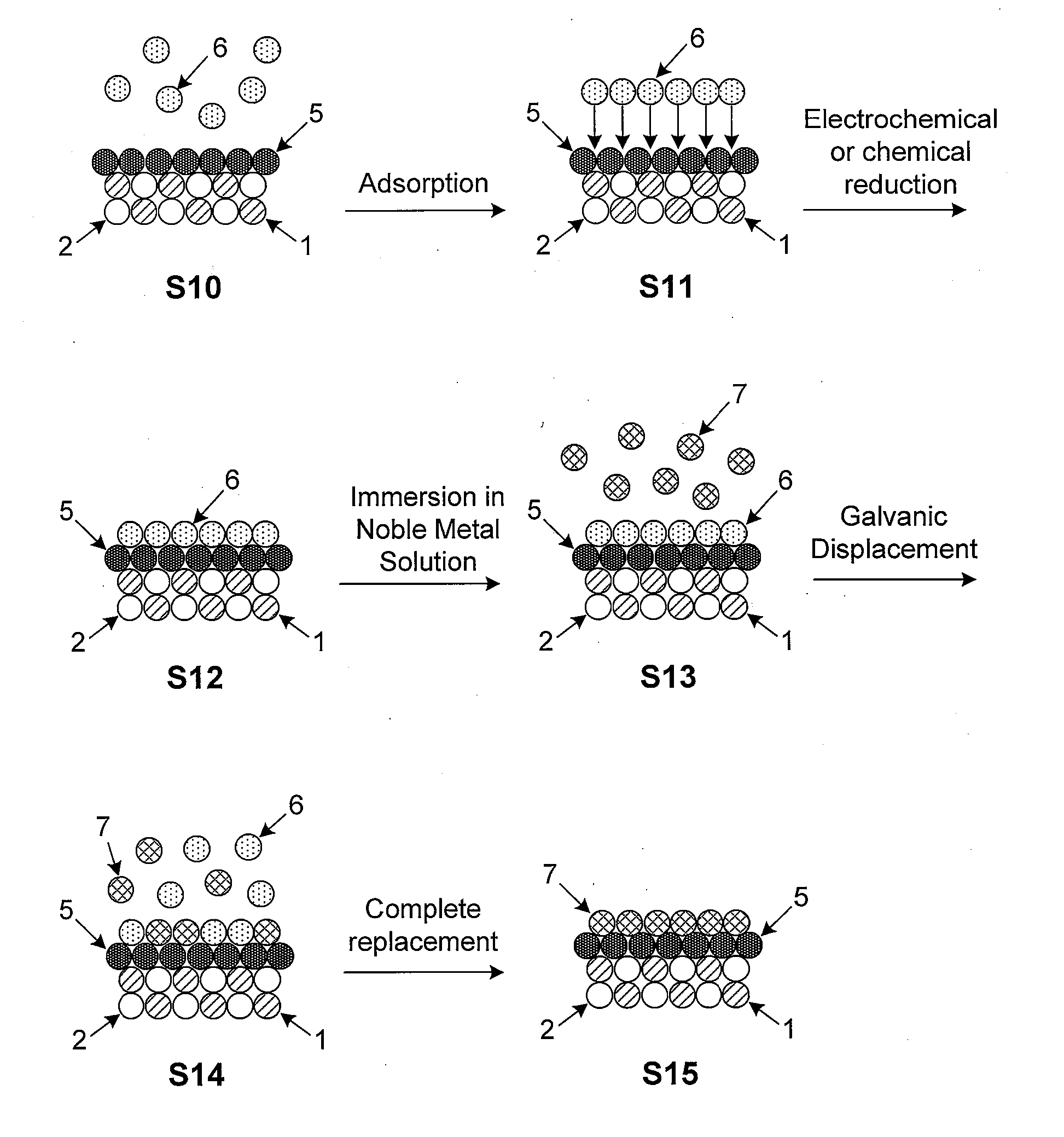

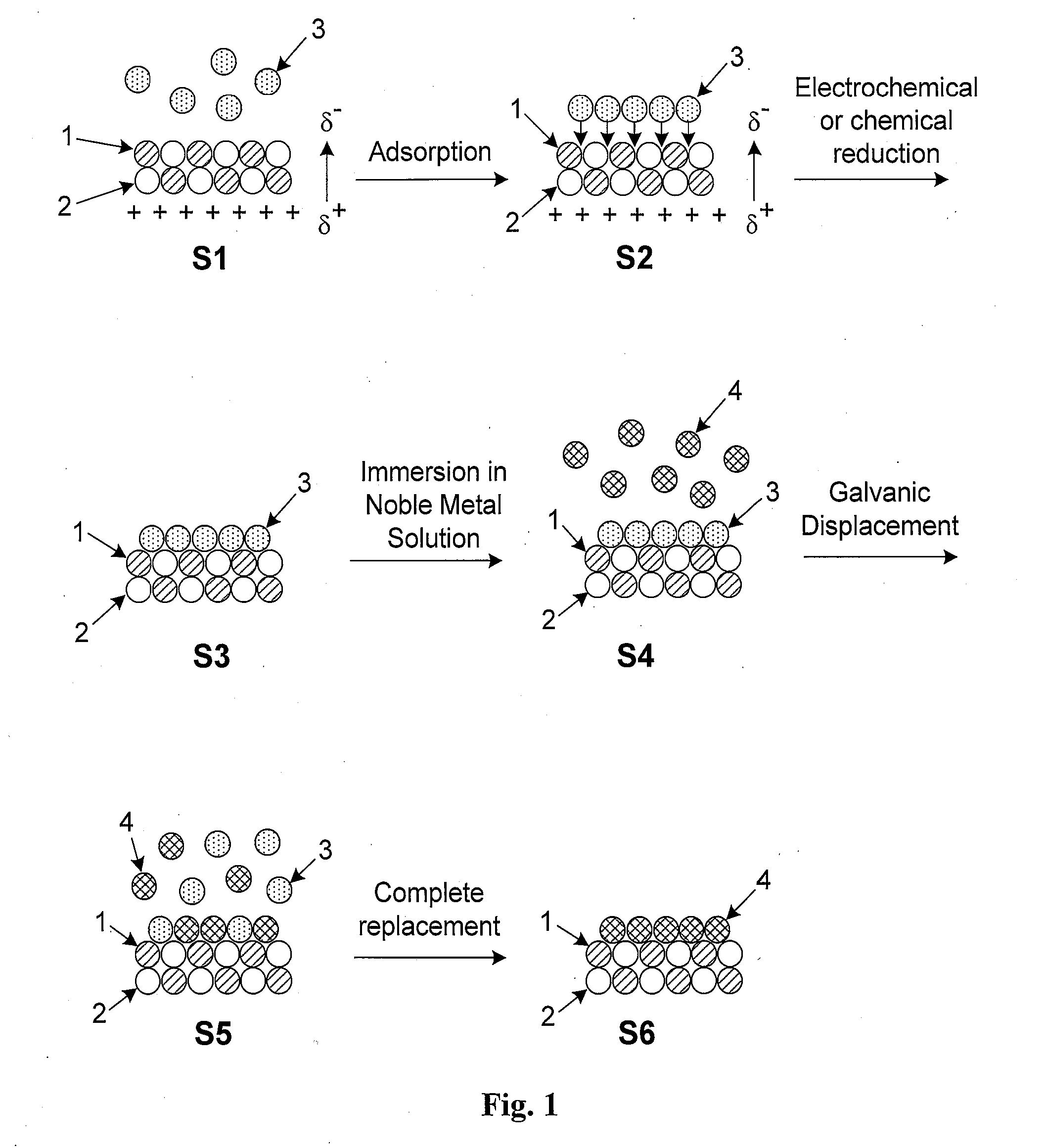

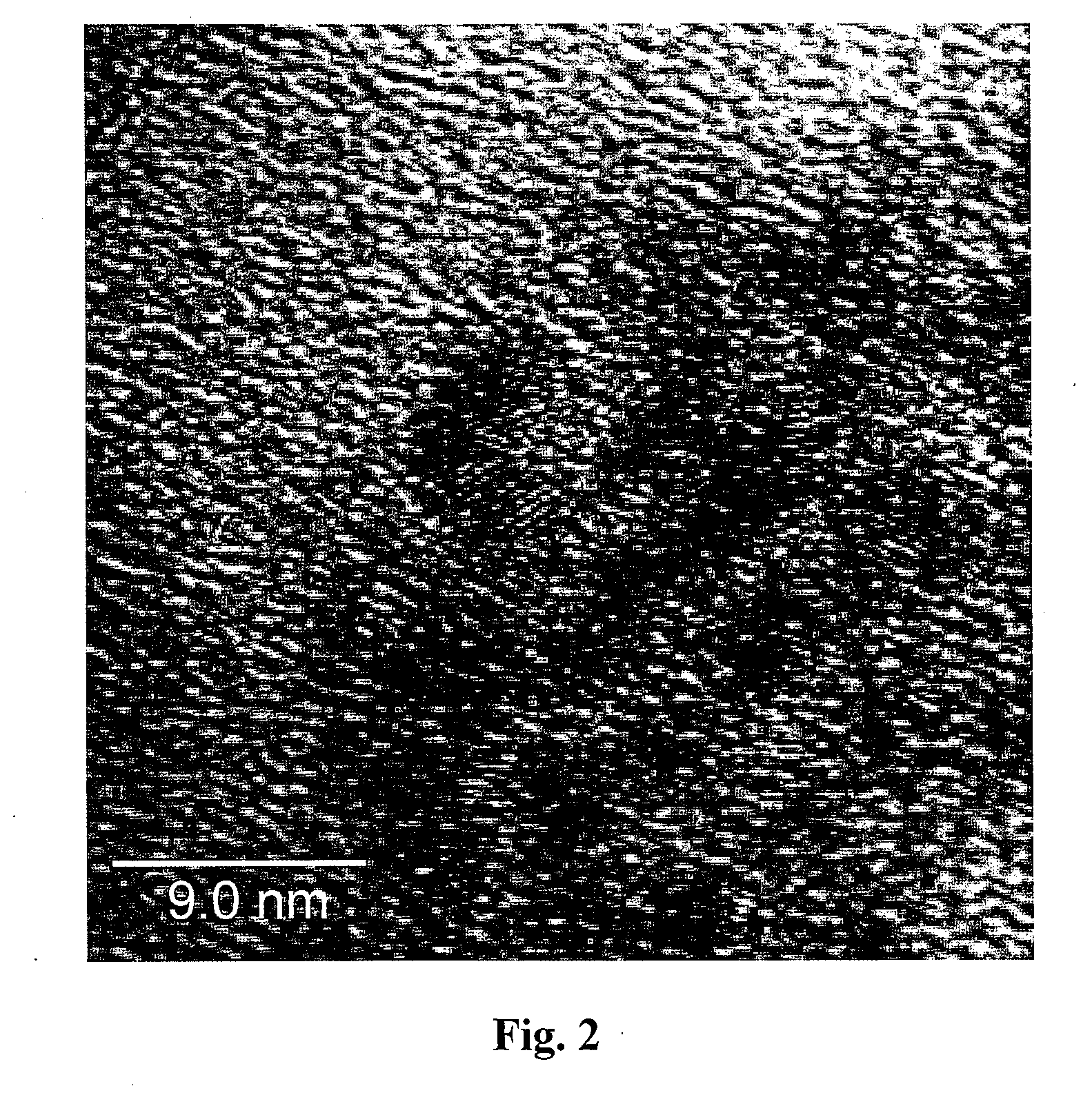

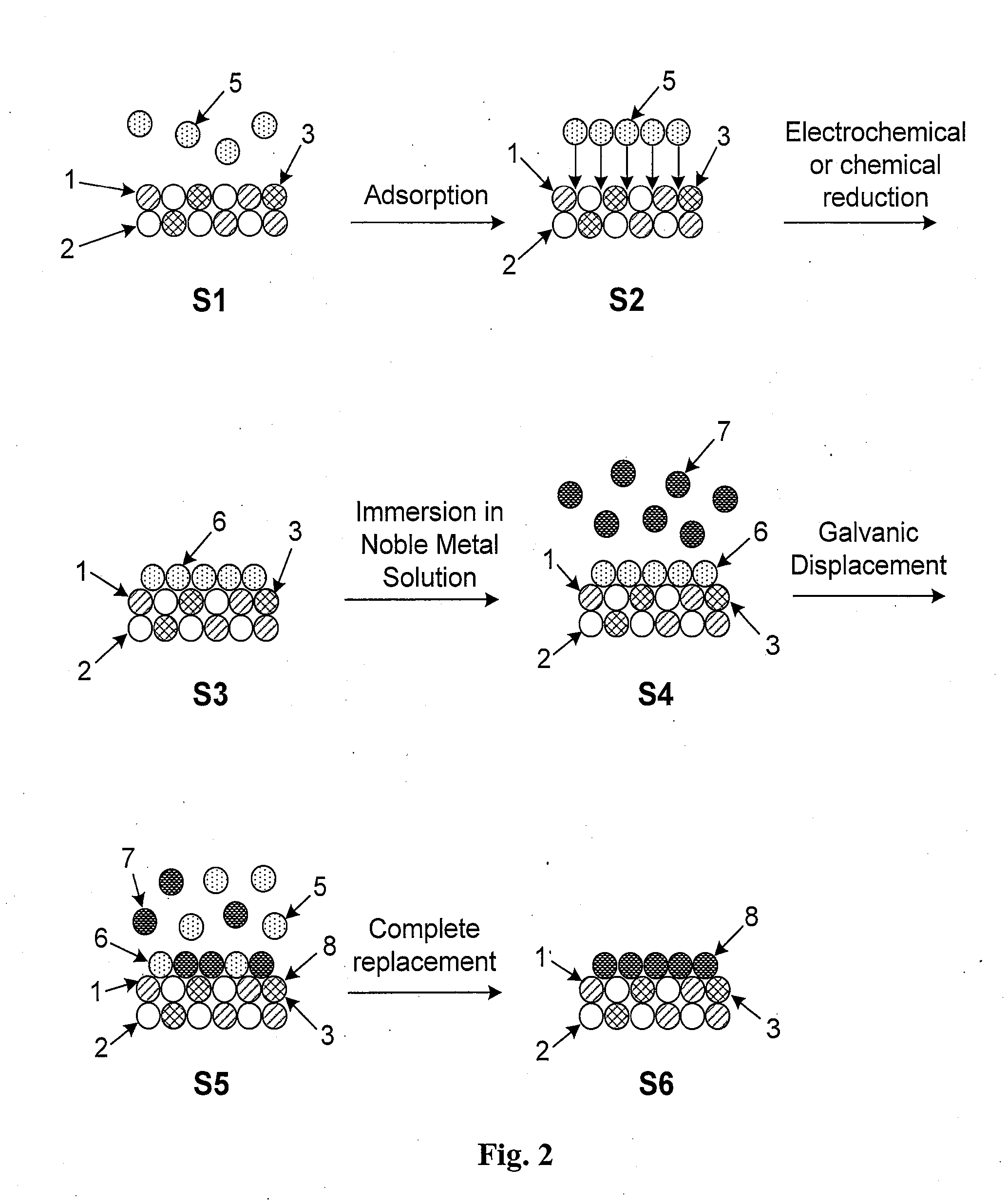

High-surface-area carbon nanostructures coated with a smooth and conformal submonolayer-to-multilayer thin metal films and their method of manufacture are described. The preferred manufacturing process involves the initial oxidation of the carbon nanostructures followed by immersion in a solution with the desired pH to create negative surface dipoles. The nanostructures are subsequently immersed in an alkaline solution containing non-noble metal ions which adsorb at surface reaction sites. The metal ions are then reduced via chemical or electrical means and the nanostructures are exposed to a solution containing a salt of one or more noble metals which replace adsorbed non-noble surface metal atoms by galvanic displacement. Subsequent film growth may be performed via the initial quasi-underpotential deposition of a non-noble metal followed by immersion in a solution comprising a more noble metal. The resulting coated nanostructures may be used, for example, as high-performance electrodes in supercapacitors, batteries, or other electric storage devices.

Owner:BROOKHAVEN SCI ASSOCS

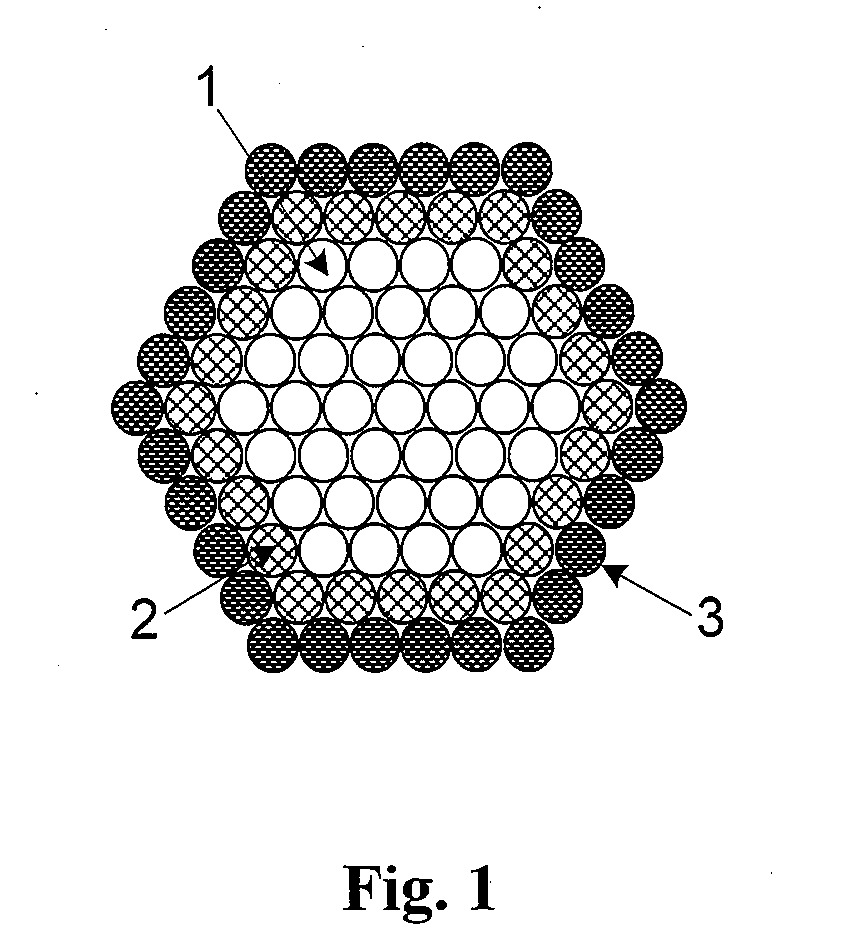

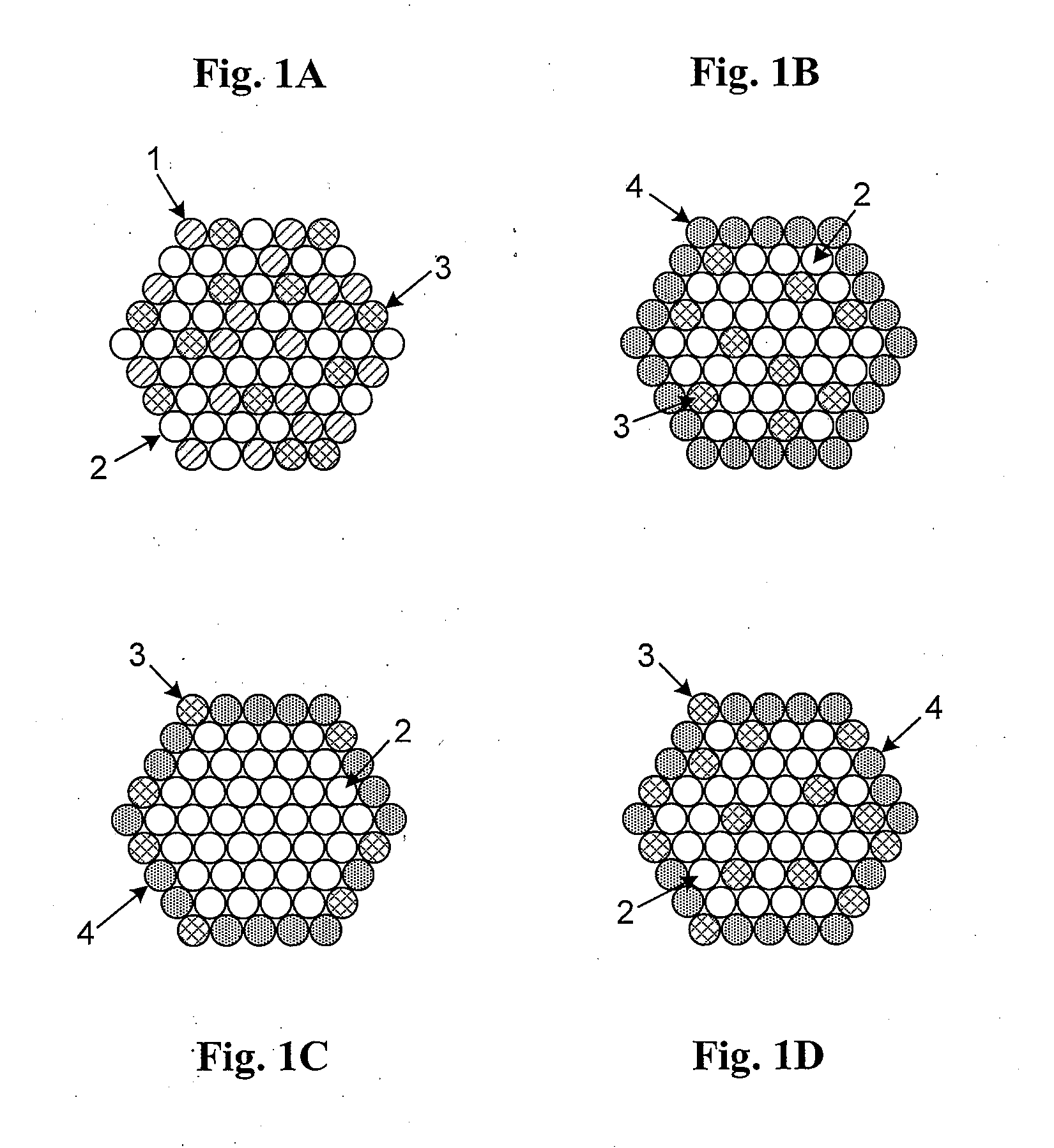

Platinum-Coated Non-Noble Metal-Noble Metal Core-Shell Electrocatalysts

InactiveUS20100197490A1Minimal loadingEfficiently formedMaterial nanotechnologyCell electrodesAlloyPt element

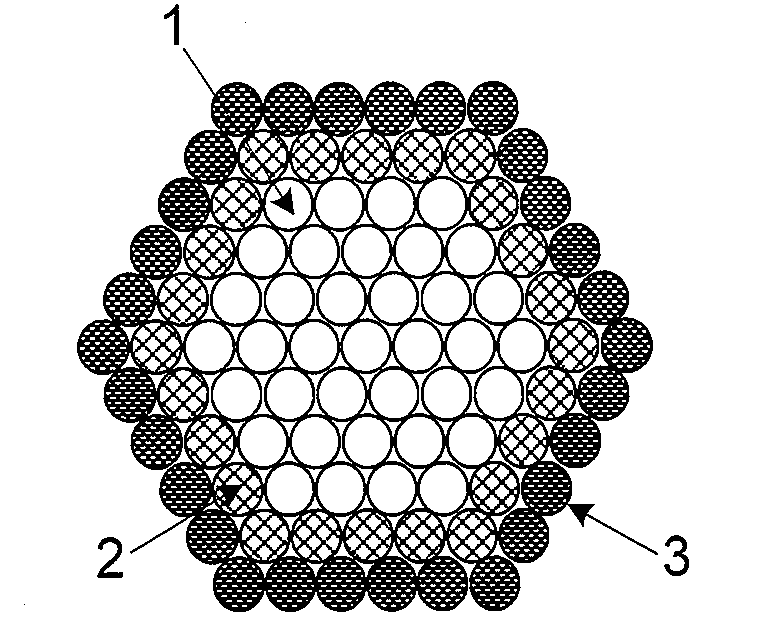

Core-shell particles encapsulated by a thin film of a catalytically active metal are described. The particles are preferably nanoparticles comprising a non-noble core with a noble metal shell which preferably do not include Pt. The non-noble metal-noble metal core-shell nanoparticles are encapsulated by a catalytically active metal which is preferably Pt. The core-shell nanoparticles are preferably formed by prolonged elevated-temperature annealing of nanoparticle alloys in an inert environment. This causes the noble metal component to surface segregate and form an atomically thin shell. The Pt overlayer is formed by a process involving the underpotential deposition of a monolayer of a non-noble metal followed by immersion in a solution comprising a Pt salt. A thin Pt layer forms via the galvanic displacement of non-noble surface atoms by more noble Pt atoms in the salt. The overall process is a robust and cost-efficient method for forming Pt-coated non-noble metal-noble metal core-shell nanoparticles.

Owner:BROOKHAVEN SCI ASSOCS

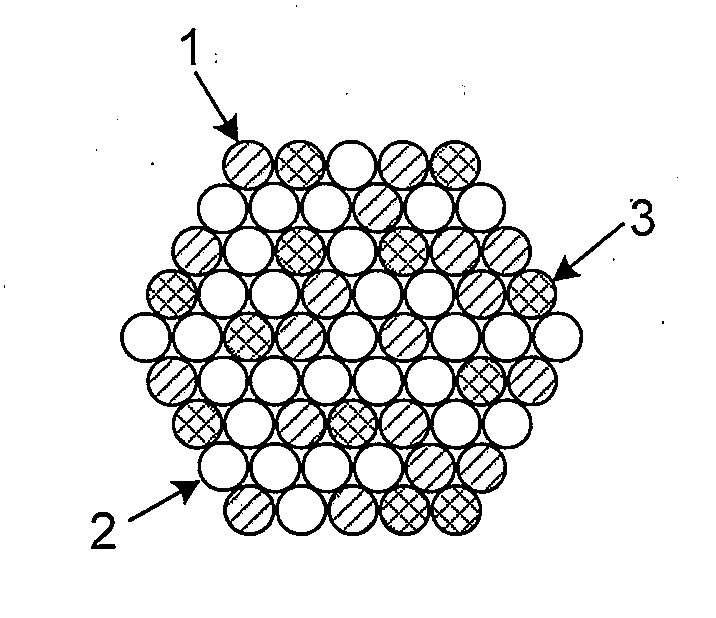

High Stability, Self-Protecting Electrocatalyst Particles

InactiveUS20100216632A1Avoid corrosionCell electrodesMetal/metal-oxides/metal-hydroxide catalystsCore shell nanoparticlesAlloy

High-stability, self-protecting particles encapsulated by a thin film of a catalytically active noble metal are described. The particles are preferably nanoparticles comprising a passivating element having at least one metal selected from the group consisting of columns IVB, VB, VIB, and VIIB of the periodic table. The nanoparticle is preferably encapsulated by a Pt shell and may be either a nanoparticle alloy or a core-shell nanoparticle. The nanoparticle alloys preferably have a core comprised of a passivating component alloyed with at least one other transition metal. The core-shell nanoparticles comprise a core of a non-noble metal surrounded by a shell of a noble metal. The material constituting the core, shell, or both the core and shell may be alloyed with one or more passivating elements. The self-protecting particles are ideal for use in corrosive environments where they exhibit improved stability compared to conventional electrocatalyst particles.

Owner:BROOKHAVEN SCI ASSOCS

Hydroisomerization catalyst, preparation method and application thereof, and hydroisomerization method for hydrocracked tail oil

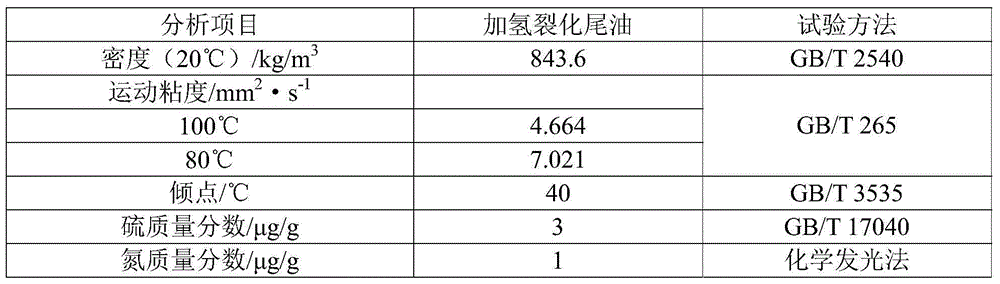

ActiveCN105582992AHigh catalytic activityHigh isomerization reaction selectivityMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveHalogen

The invention discloses a hydroisomerization catalyst, a preparation method and an application thereof. The preparation method comprises the following steps: a) providing a catalyst precursor containing a carrier, and a compound containing noble metals in the VIII group and a compound containing a second metal which are both supported on the carrier, wherein the two compounds hereinabove are both non-oxides, the second metal is one or more than two selected from the metal in the VB group, the metal in the VIB group, non-noble metal in the VIII group and lanthanum-series metals, the carrier containing mesoporous molecular sieve; and b) roasting the catalyst precursor in an atmosphere formed by a gas containing an oxidizing gas and a halogen-containing compound. The invention also discloses a hydroisomerization method for hydrocracked tail oil with the hydroisomerization catalyst. The hydroisomerization catalyst, when being used in the hydroisomerization for the hydrocracked tail oil, can be used for producing an isomerized product having high viscosity index and low pour point, which is suitable for being used as lubricant basic oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic process for converting renewable resources into paraffins for use as diesel blending stocks

ActiveUS20080308458A1Fatty acid chemical modificationMolecular sieve catalystsParaffin waxVegetable oil

A process for converting renewable resources such as vegetable oil and animal fat into paraffins in a single step which comprises contacting a feed which is a renewable resources with hydrogen and a catalyst which comprises a non-precious metal a first oxide and optionally a second oxide wherein at least one of the first oxide or second oxide comprises a zeolite, through hydrodeoxygenation and one or both of hydroisomerization and hydrocracking.

Owner:REFINING TECH SOLUTIONS LLC

Membrane-electrode assembly and fuel battery using the same

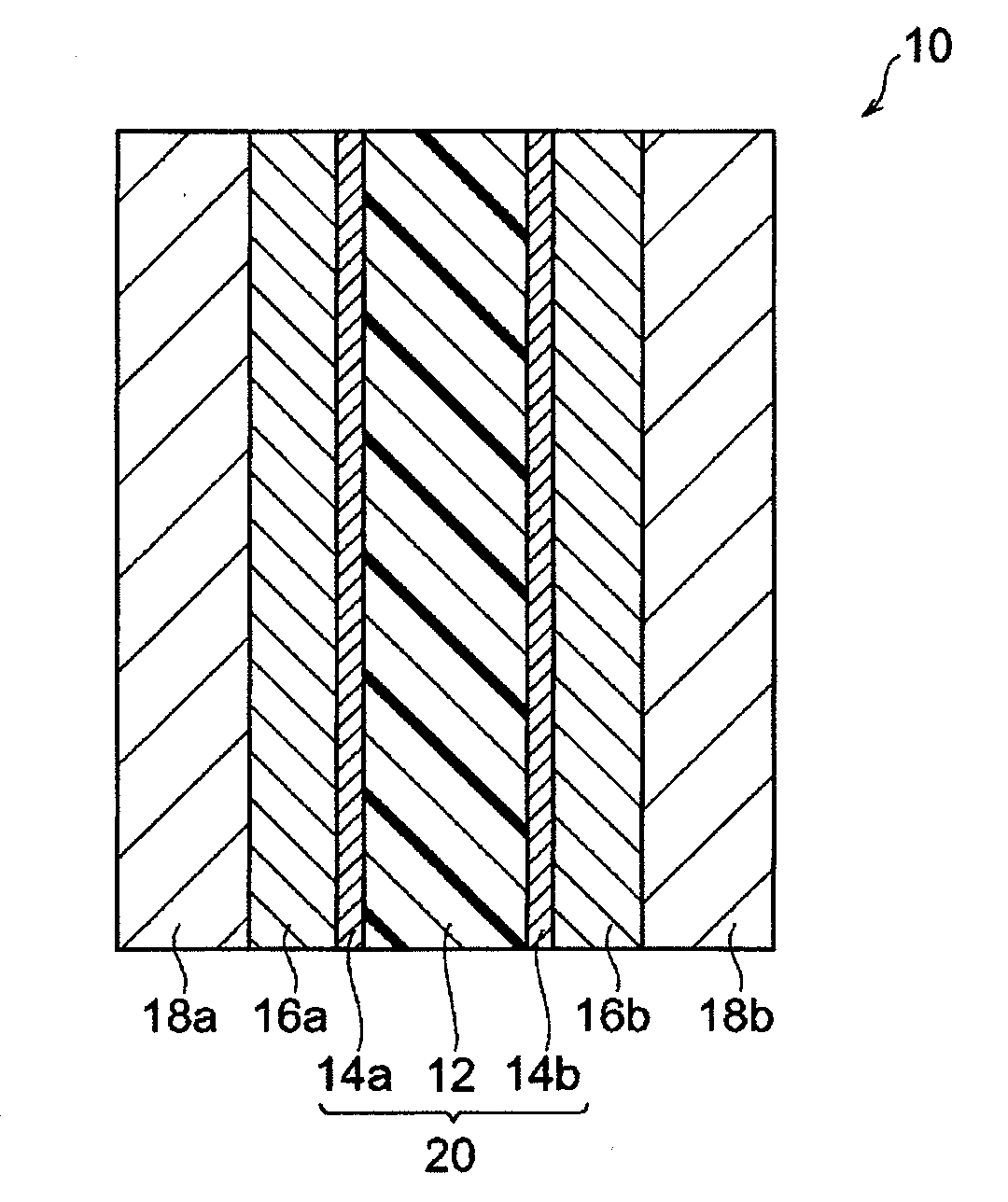

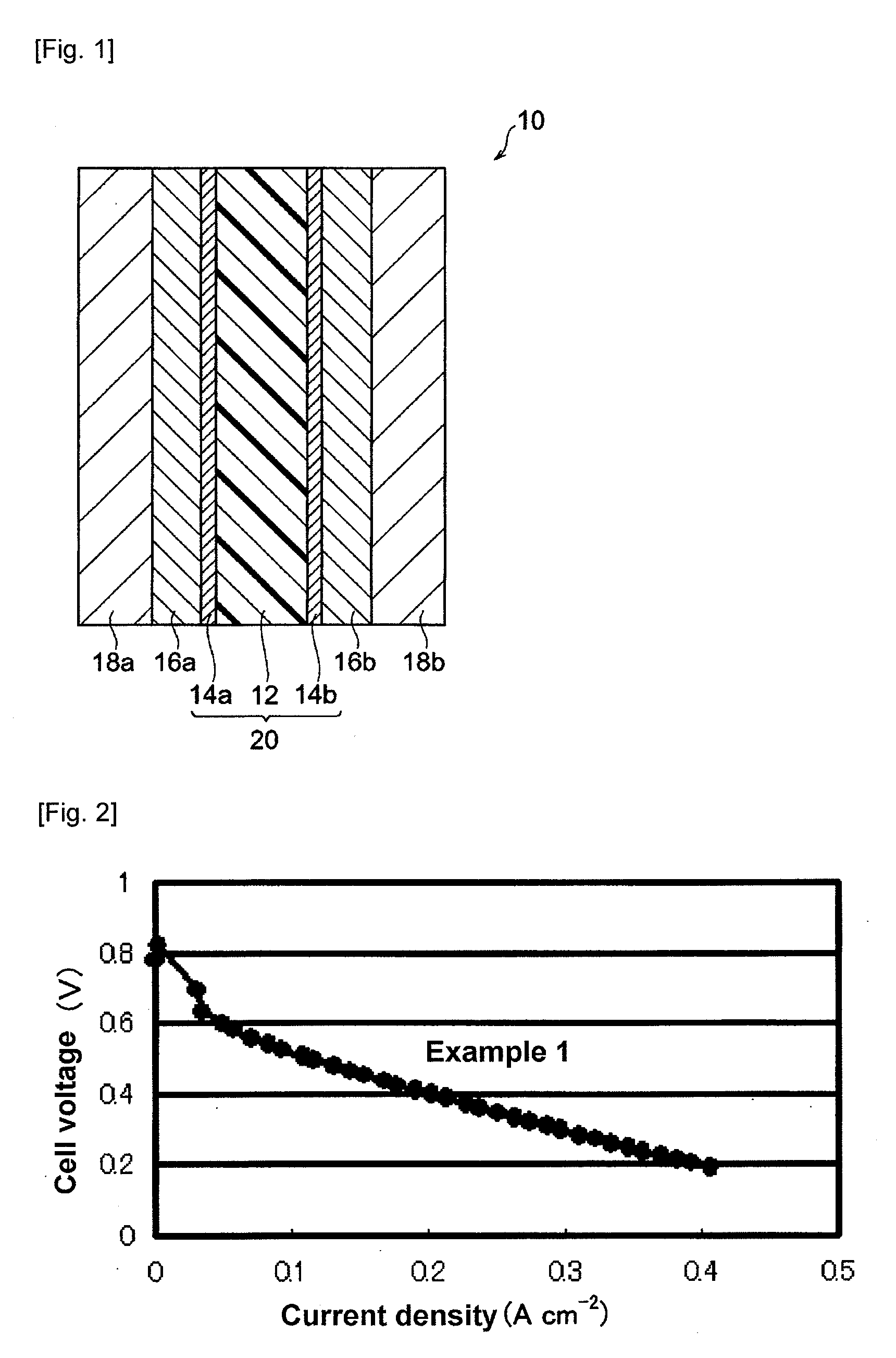

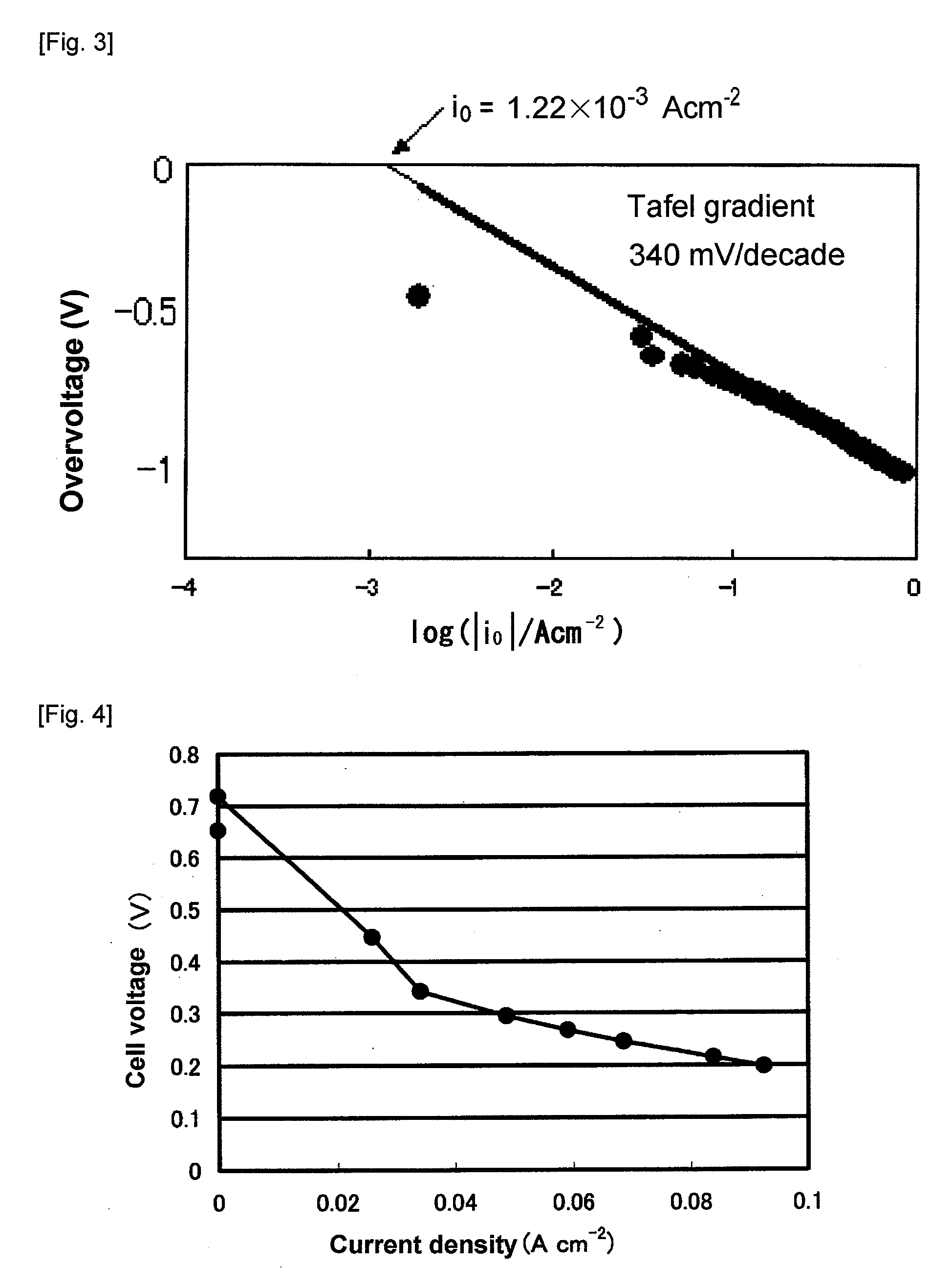

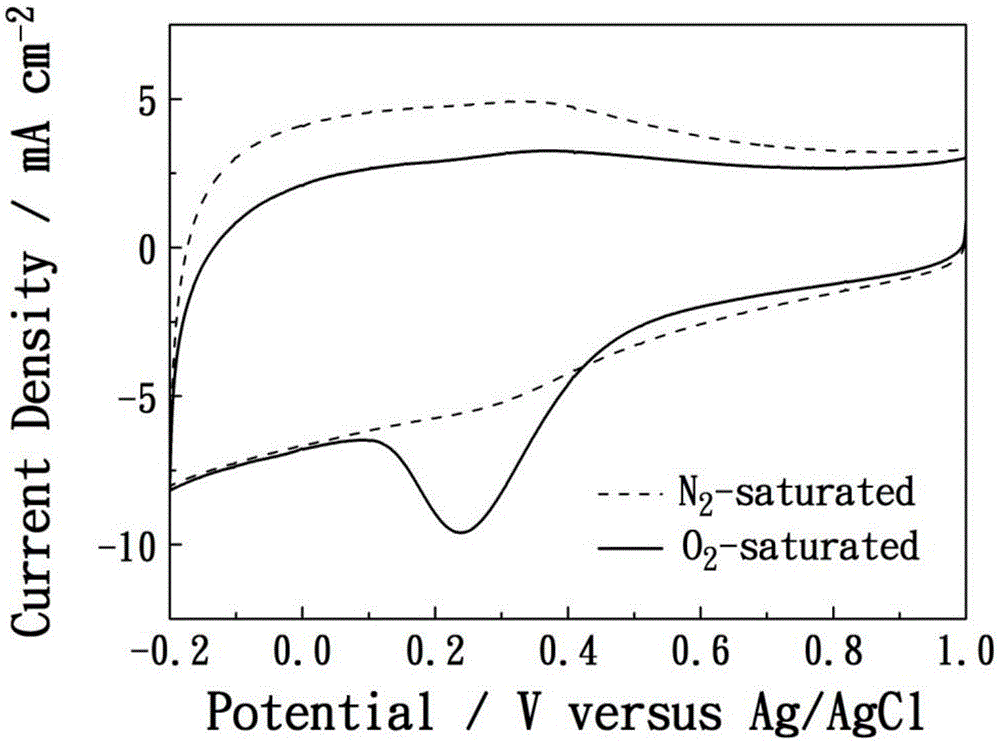

InactiveUS20100086823A1Improve stabilityFuel cells groupingCell electrodesFuel cellsExchange current density

A membrane-electrode assembly, containing an electrode catalyst containing a base metal complex, in which exchange current density i0 obtained from a Tafel plot, which is related to current density and voltage, is 5.0×10−4 Acm−2 or more, and in which a Tafel slope obtained from the Tafel plot is 450 mV / decade or less; anda membrane-electrode assembly, containing catalyst layers each containing an electrode catalyst on both sides of an electrolyte membrane, in which at least one of the catalyst layers comprises a non-noble metal-based electrode catalyst, and in which the electrolyte membrane is a hydrocarbon-based electrolyte membrane.

Owner:SUMITOMO CHEM CO LTD

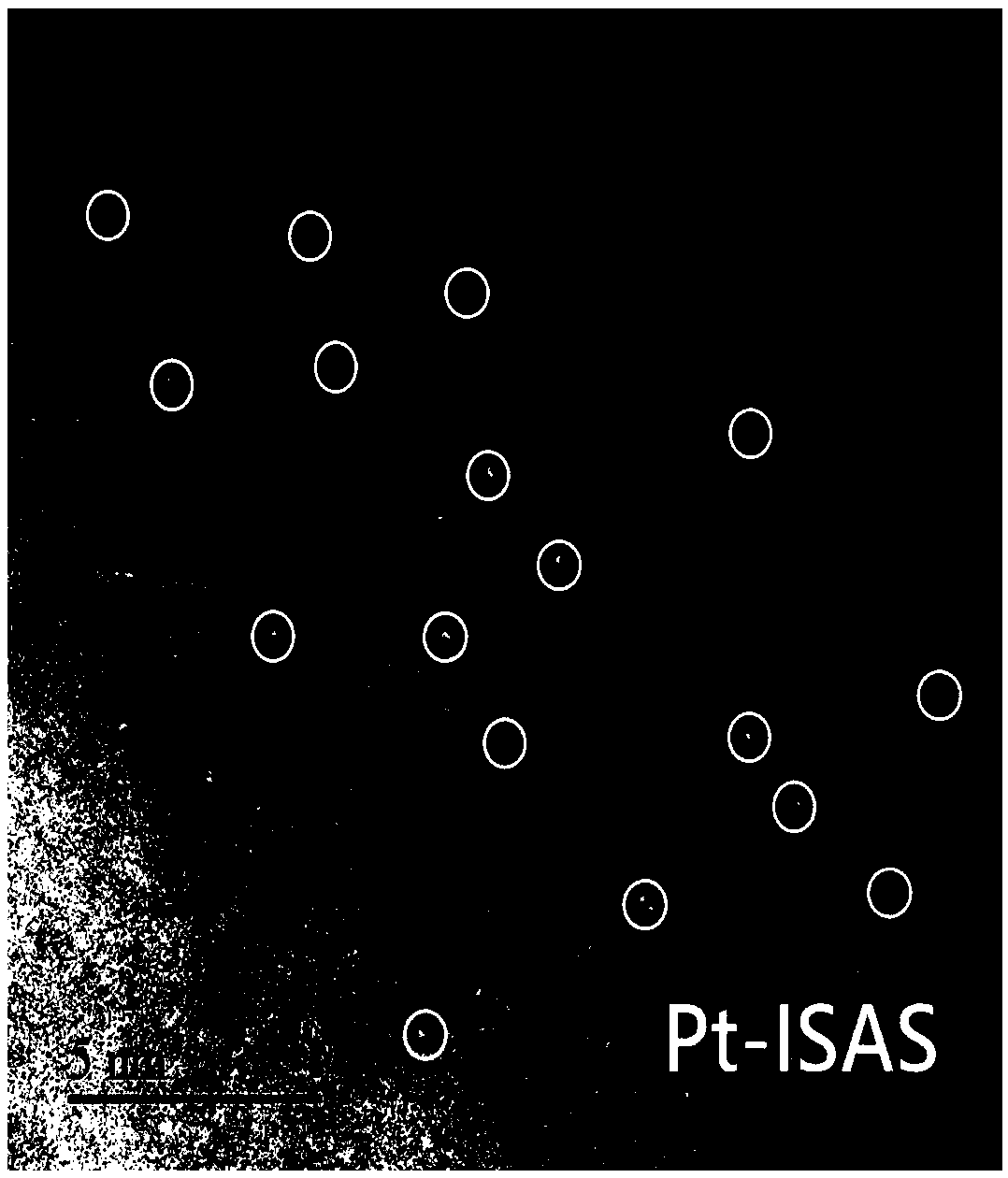

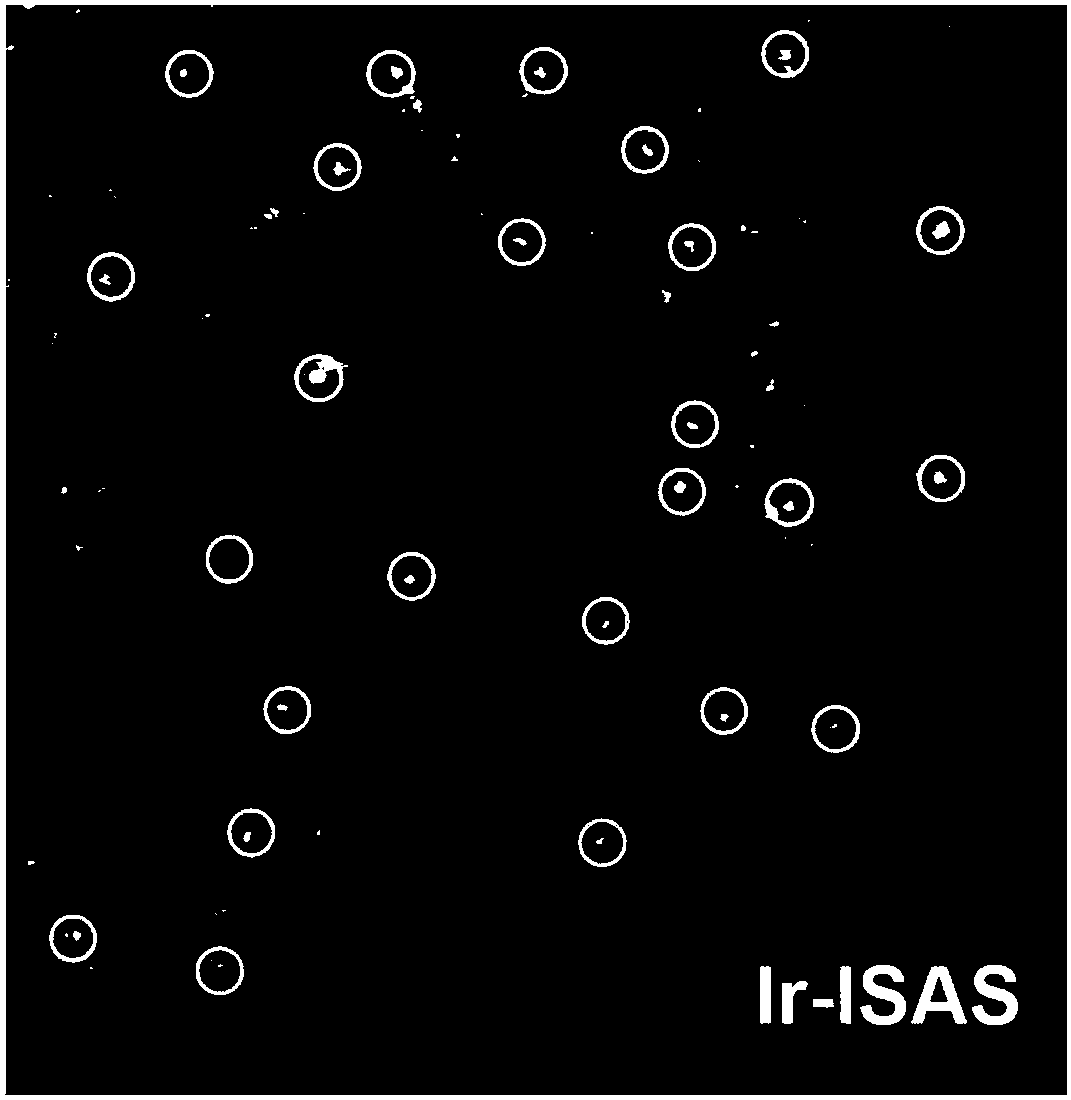

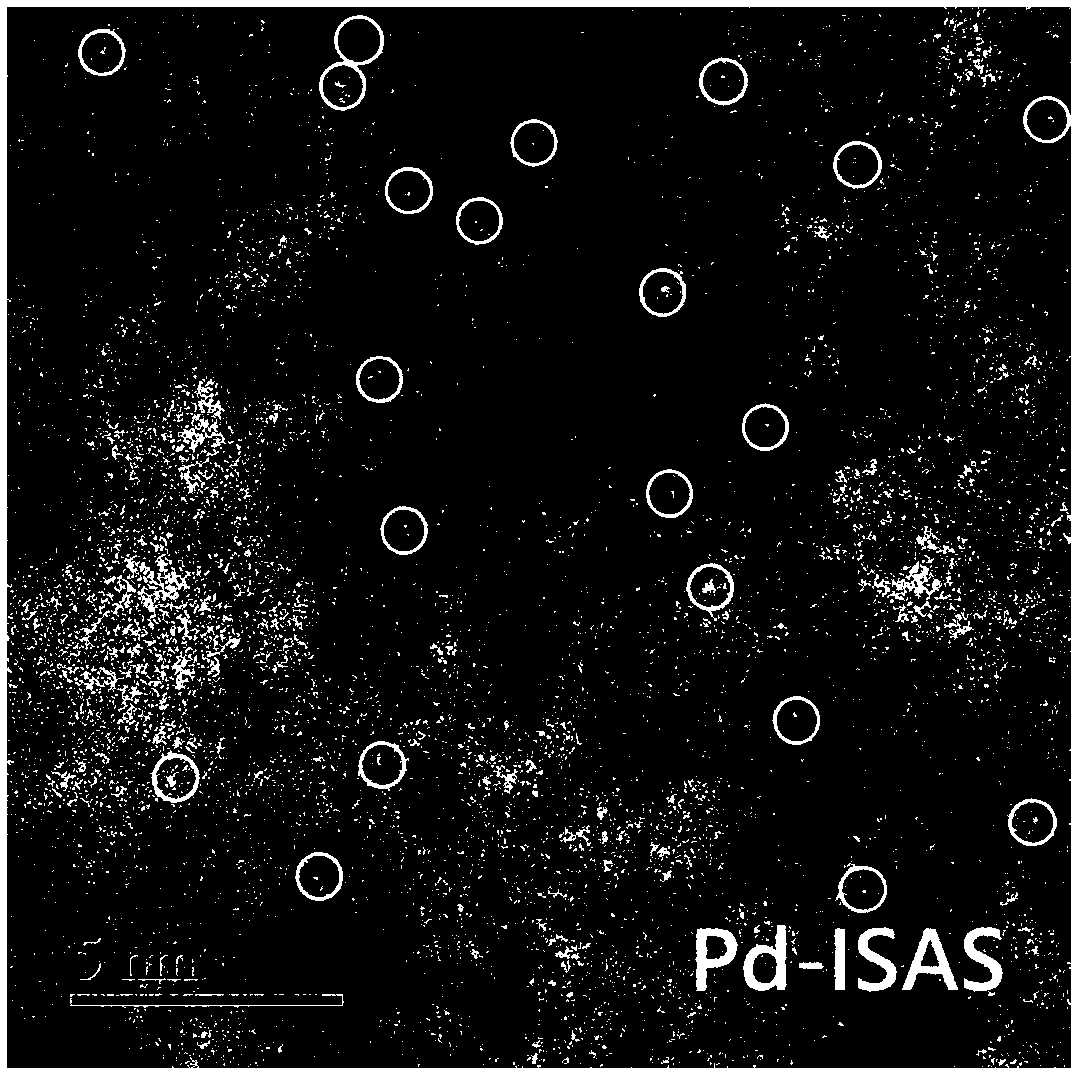

Preparation method of metal monatomic site catalyst

ActiveCN107626294ASmall particlesUniform particle size distributionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsZinc compoundsPorous carbon

The invention provides a preparation method of a metal monatomic site catalyst. According to the synthetic strategy, a porous complex composite material coated with an acetylacetone metal salt is formed from a zinc compound and an imidazole organic ligand through coordination in a methanol solution of the acetylacetone metal salt, and then a porous carbon support doped with nonmetal heteroatomic nitrogen is formed from the imidazole organic ligand through a high-temperature pyrolytic reaction in an inert gas atmosphere, wherein metal atoms interact with surrounding nonmetal heteroatomic nitrogen and exist in the form of single atoms. The method is simple, safe, low in cost and applicable to synthesis of various noble metal and non-noble metal monatomic site catalysts, and the obtained metal monatomic site catalyst is high in metal concentration and good in heat stability, can be applied to the fields of energy, catalysis, medicine, biology and the like and has quite broad market prospect.

Owner:TSINGHUA UNIV

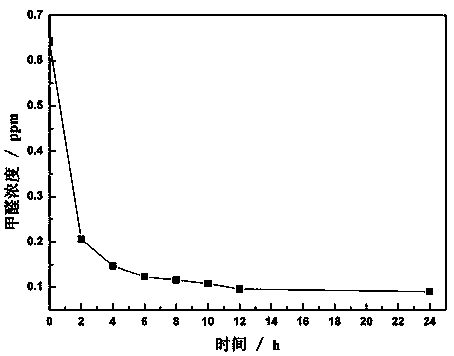

Preparation of room temperature formaldehyde catalyst

Belonging to the technical field of adsorption catalysis and air pollution control, the invention relates to preparation of a room temperature formaldehyde catalyst. The invention is characterized in that: zeolite, sepiolite, a porous activated carbon material, cordierite or a self-made carrier is adopted as the catalyst carrier, one or more non-noble metal oxides, like magnesium oxide, aluminum oxide, silicon oxide, manganese oxide, iron oxide, cobalt oxide, nickel oxide, copper oxide, zinc oxide, zirconium oxide, lanthanum oxide or cerium oxide are taken as active components, and an impregnation technique is employed to prepare the catalyst, which can be powdery, strip, blocky, spherical or honeycomb. The loading amount of the non-noble metal oxides is 2-15wt%, and the content of the catalyst carrier is 85-98%. Under normal temperature and ambient humidity conditions, the catalyst has the capacity of catalytic oxidation of formaldehyde into non-toxic and harmless CO2 and H2O up to over 95%, no intermediate product is generated, and the catalyst has the characteristics of high catalytic oxidation activity, strong moisture resistant ability, stable operation, long service life and the like, thus being suitable for formaldehyde purification treatment in offices, office buildings, living rooms, shopping malls, hospitals, hotels and other places.

Owner:江苏瑞丰科技实业有限公司

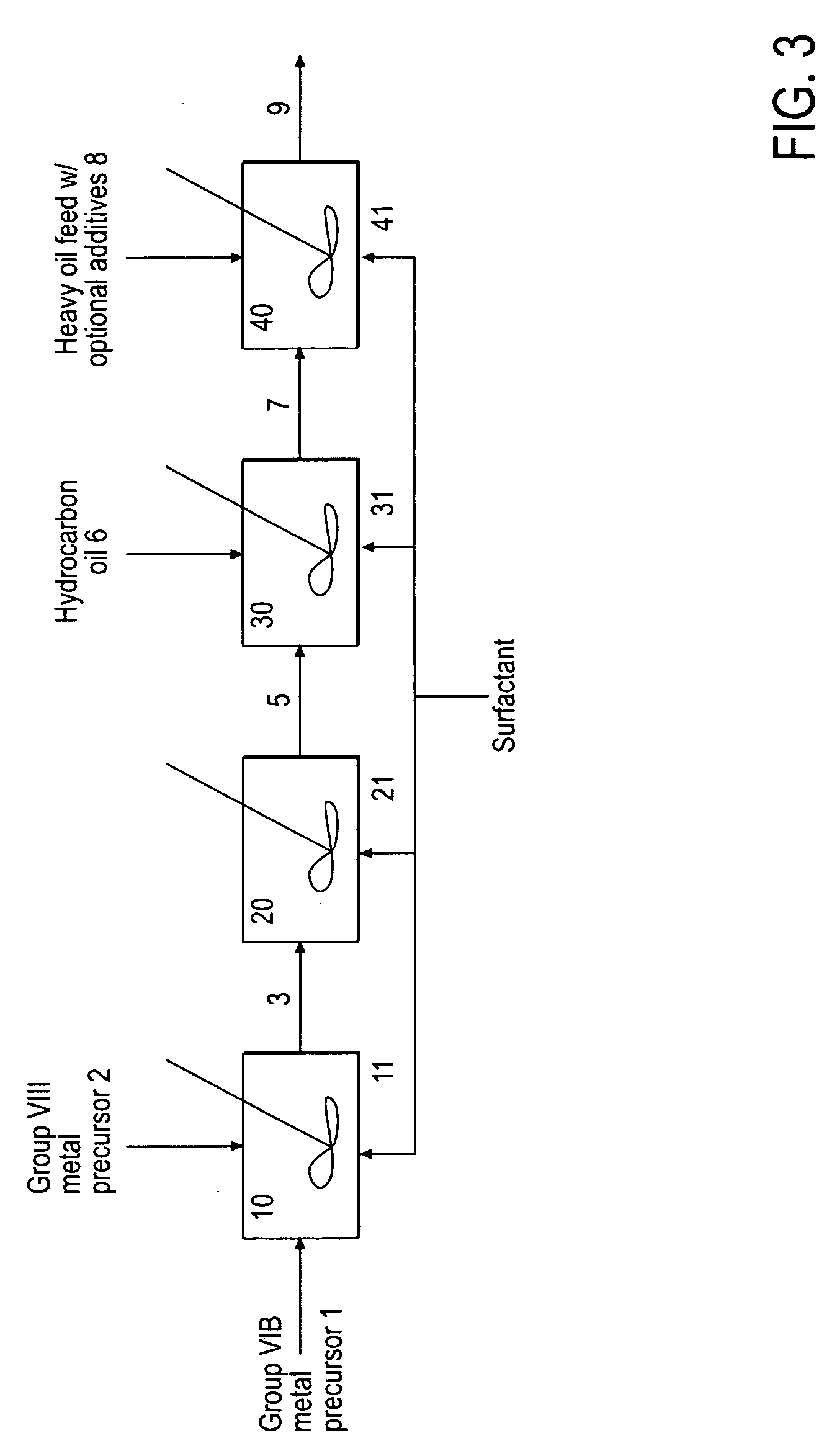

Ultradispersed catalyst compositions and methods of preparation

InactiveUS20070161505A1Catalyst activation/preparationHydrocarbon oil crackingNon noble metalInorganic chemistry

The present invention relates generally to ultradispersed catalyst compositions and methods for preparing such catalysts. In particular, the invention provides catalyst composition of the general formula: BxMyS[(1.1 to 4.6)y+(0.5 to 4)x]where B is a group VIIIB non-noble metal and M is a group VI B metal and 0.05≦y / x≦15.

Owner:INTREVEP SA

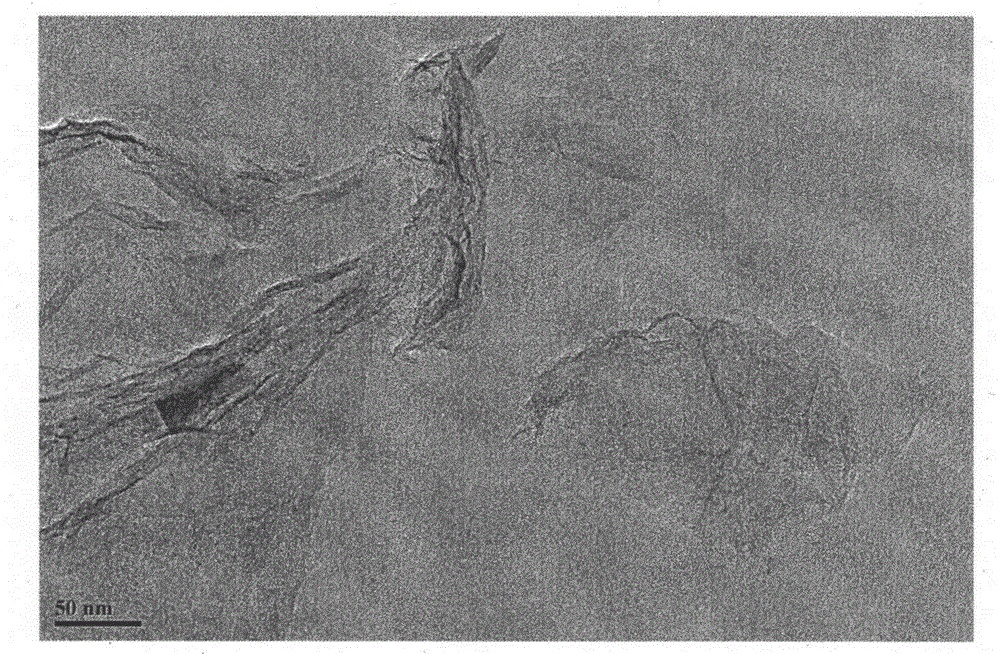

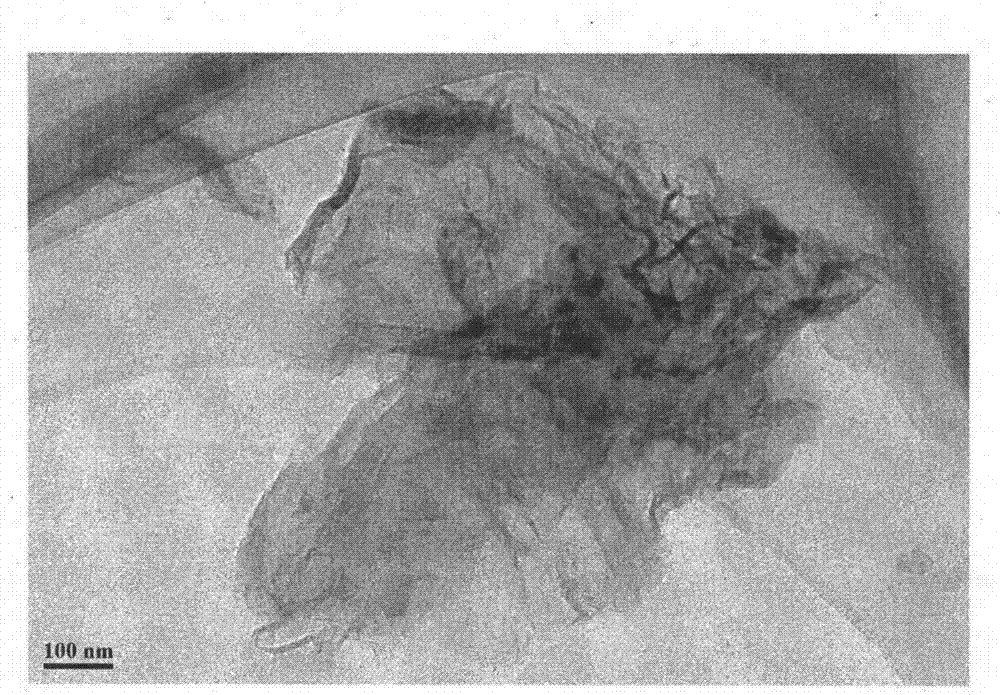

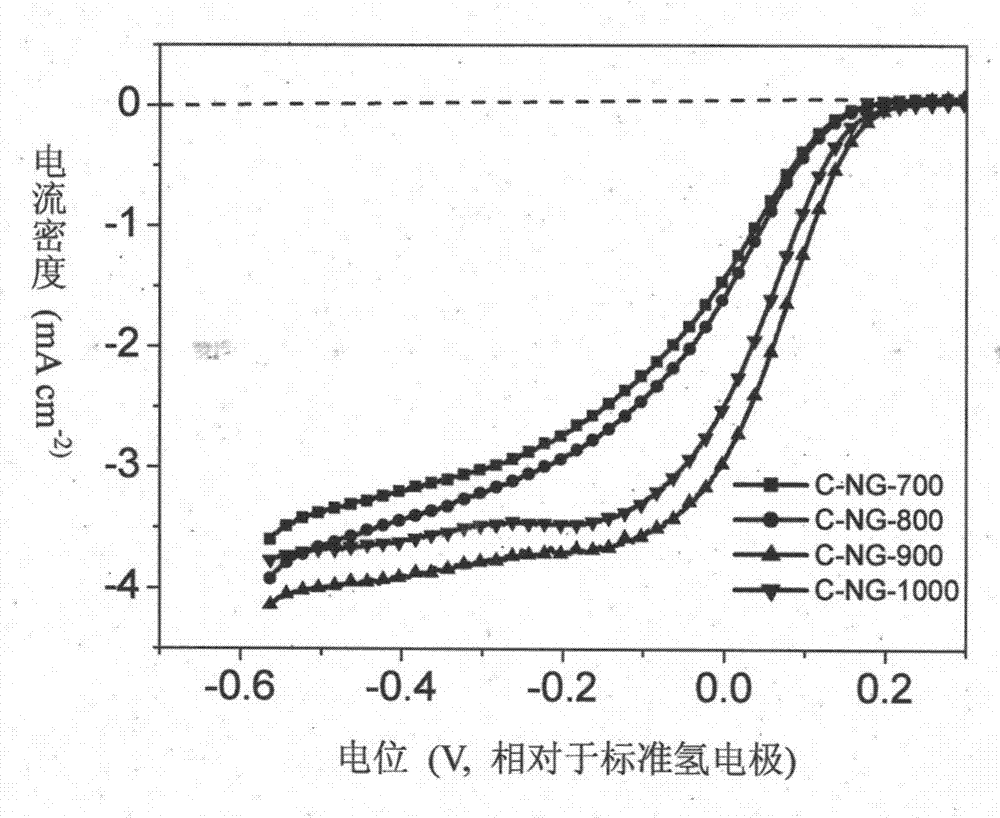

Preparation and application of nitrogen doped graphene fuel cell catalyst

InactiveCN103599805AReduce manufacturing costSimple preparation processPhysical/chemical process catalystsCell electrodesDoped grapheneAir cell

The invention provides preparation and application of a nitrogen doped graphene fuel cell catalyst, wherein a preparation method of the nitrogen doped graphene fuel cell catalyst is characterized by comprising the following steps: dispersing graphene oxide into a solvent, and carrying out ultrasonic treatment, thereby obtaining a graphene solution; dispersing at least one of non-noble metal salt as well as hydrate thereof and nitrogenous small organic molecules into the solvent, thereby obtaining a mixed solution; dropping the graphene oxide solution into the mixed solution, drying the solvent by distillation, thereby obtaining a nitrogen doped graphene precursor, warming to 600-1000 DEG C under the protection by inert gases, keeping the temperature for 1-4 hours, and cooling naturally, thereby obtaining the doped graphene catalyst. The nitrogen doped graphene preparation process provided by the invention is simple; required raw materials are low in cost, high in yield, can achieve industrial production easily, have very high oxygen reduction catalytic activity, can be applied to the fields of fuel cells, metal-air cells as well as microorganism fuel cells and the like.

Owner:DONGHUA UNIV

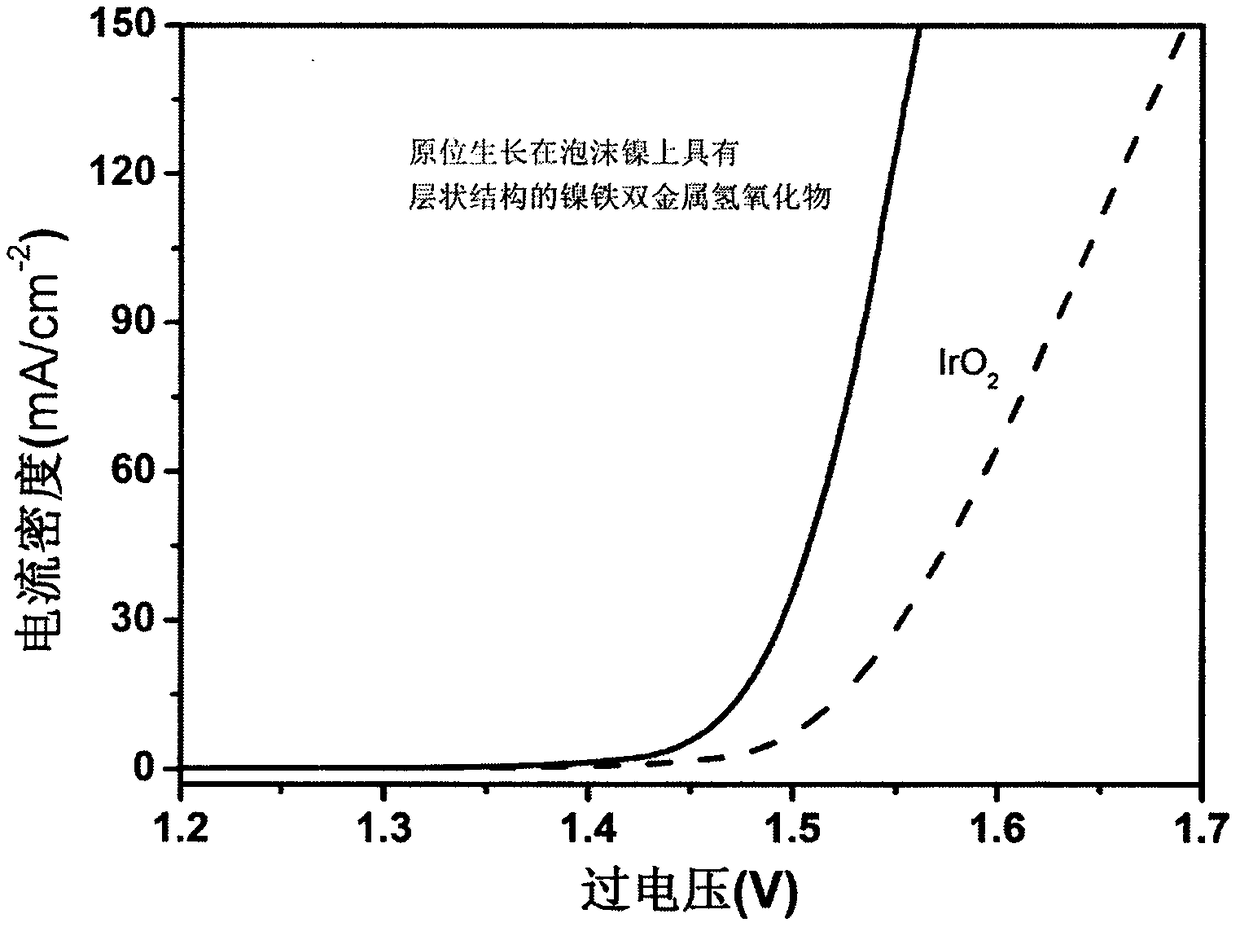

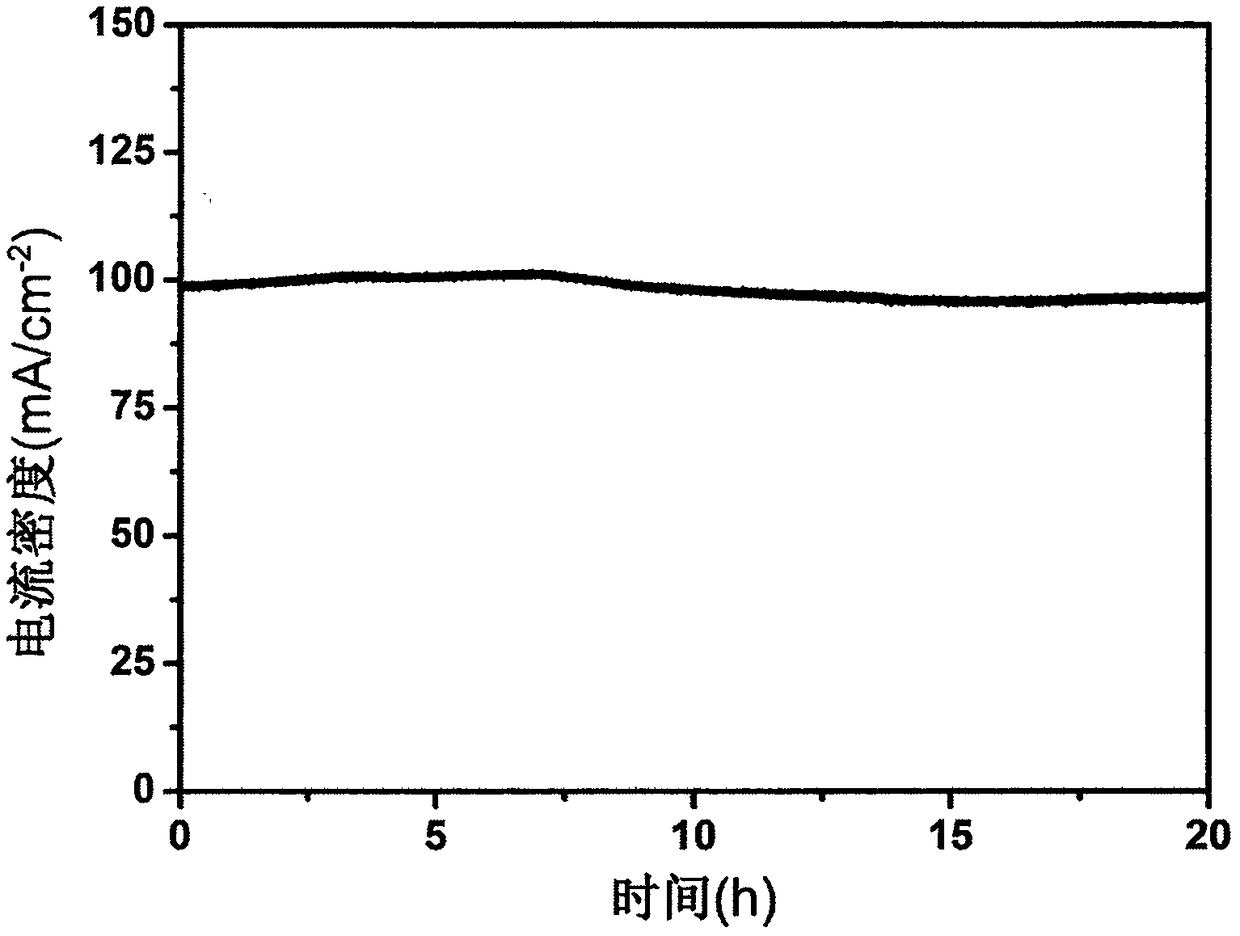

Preparation method of ferro-nickel bi-metal hydroxide of sheet structure on foamed nickel through in-situ growth

InactiveCN108283926AImprove performanceHigh catalytic activityMetal/metal-oxides/metal-hydroxide catalystsElectrodesElectrolysisOxygen

The invention discloses a preparation method of a ferro-nickel bi-metal hydroxide of a sheet structure on foamed nickel through in-situ growth, and belongs to the field of electrochemistry. Nickel nitrate hexahydrate, iron nitrate nonahydrate, urea, ammonium fluoride and foamed nickel are adopted as main raw materials, and an electrocatalyst through water electrolysis oxygen production is successfully prepared. The sheet structure of the catalyst supplies abundant active sites, due to existence of substrate foamed nickel, the electrical conductivity is enhanced, and when the hydroxide is adopted as the electro-catalysis oxygen production catalyst, the excellent catalysis activity is shown. The activity of a traditional non-noble metal material under an oxygen evolution reaction (OER) in analkaline electrolyte is not ideal. Accordingly, the OER catalysis performance of the non-noble metal material under the alkaline condition is improved, and the method is of great significance in solving the fossil fuel energy crisis. Nickel and iron earth reserve volumes are quite abundant, the OER catalytic performance of the ferro-nickel bi-metal hydroxide of the sheet structure under the alkaline condition is excellent, and the hydroxide is a catalytic material with the wide prospect.

Owner:QINGDAO UNIV

Non-noble metal supported selective hydrogenation catalyst and preparation method and application thereof

ActiveCN101664682AEvenly distributedNarrow particle size distributionHydrocarbon purification/separationHydrocarbonsDispersityEmulsion

The invention relates to a non-noble metal supported selective hydrogenation catalyst and a preparation method and application thereof. The catalyst comprises a carrier, and a main active component and an auxiliary active component which are loaded on the carrier, wherein the main active component is nickel, and the auxiliary active component is at least one of Mo, La, Ag, Bi, Cu, Nd, Cs, Ce, Zn and Zr; and the active components exist in amorphous forms, the average grain diameter is less than 10 nanometers, and the catalyst is prepared by a micro-emulsion method. The catalyst has evenly distributed active components and high dispersity, and can resist the erosion of poisonous materials of arsenium, sulfur and the like. The catalyst has good hydrogenation performance which is higher than that of the prior level of the conventional non-noble metal catalyst and is close to the level of a noble metal Pd catalyst in the reaction for removing acetylene hydrocarbon through C2 selective hydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

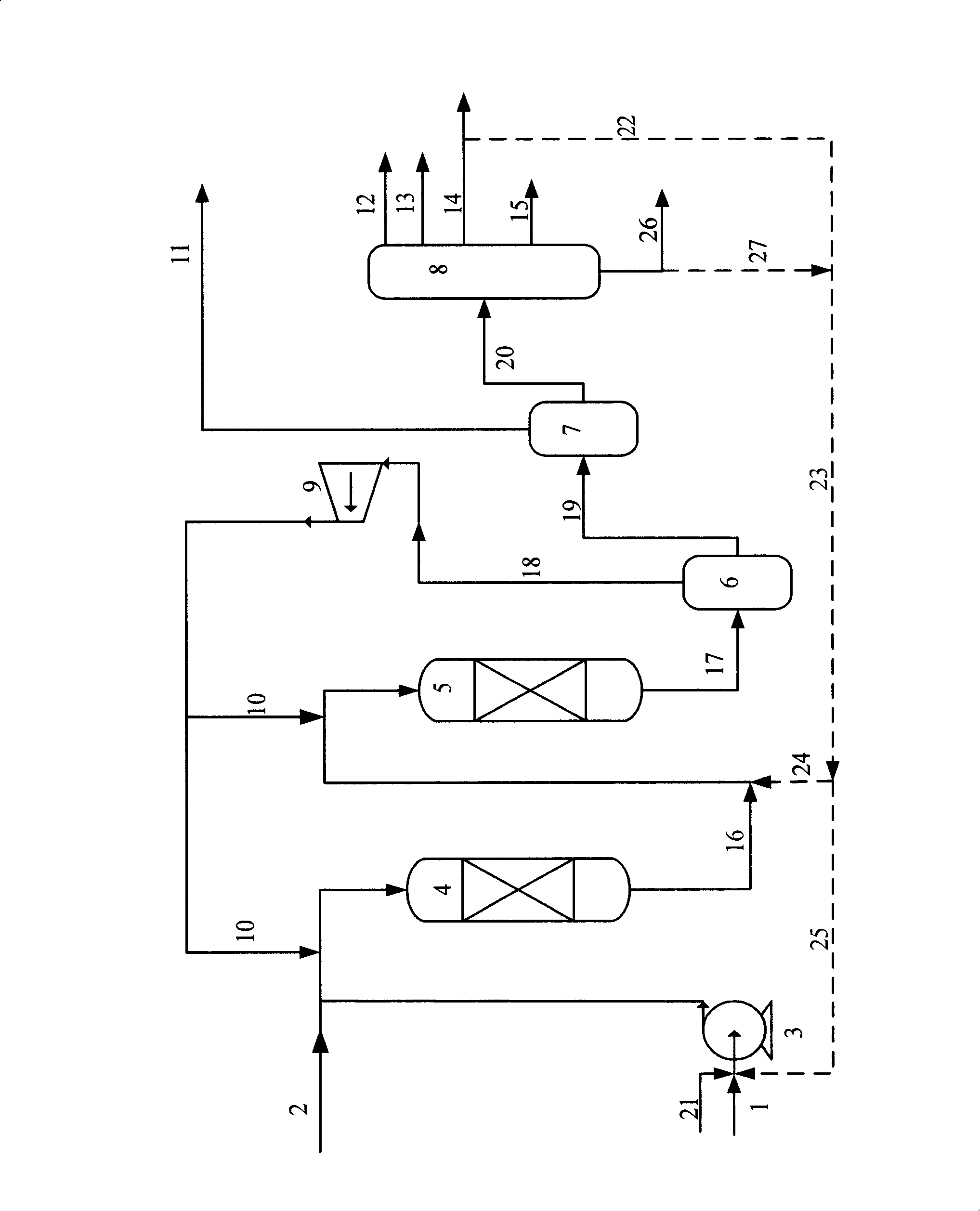

Hydrogenation method for producing high grade diesel oil and high grade reforming raw material

ActiveCN101210198AHigh saturation activityImprove hydrodesulfurization activityHydrocarbon oil crackingTreatment with hydrotreatment processesWaxHydrogen

A hydrogenation method for producing high-quality diesel oil and high-quality reforming materials comprises the following steps of: mixing diesel oil and / or a light wax oil material with hydrogen gas, and sequentially contact-reacting with a hydrorefining catalyst and a hydrocracking catalyst without middle separation, cooling the reaction result, and separating to obtain a light naphtha fraction, a heavy naphtha fraction, a kerosene fraction, a diesel oil fraction and a tail oil fraction, wherein the kerosene fraction and / or the tail oil fraction can be directly extracted or partially or completely recycled back to the reaction system. By adopting single-stage once-through process and a non-noble metal catalyst, the invention can produce the reforming materials with high aromatic content and the diesel oil fraction with high cetane number, wherein the yield of the reforming material is larger than 20wt%, and the cetane number of the diesel oil fraction can be improved by more than 15 units. The method provided by the invention has high operation flexibility and can flexibly adjust the technical scheme according to different raw materials and different product scheme requirements.

Owner:CHINA PETROLEUM & CHEM CORP +1

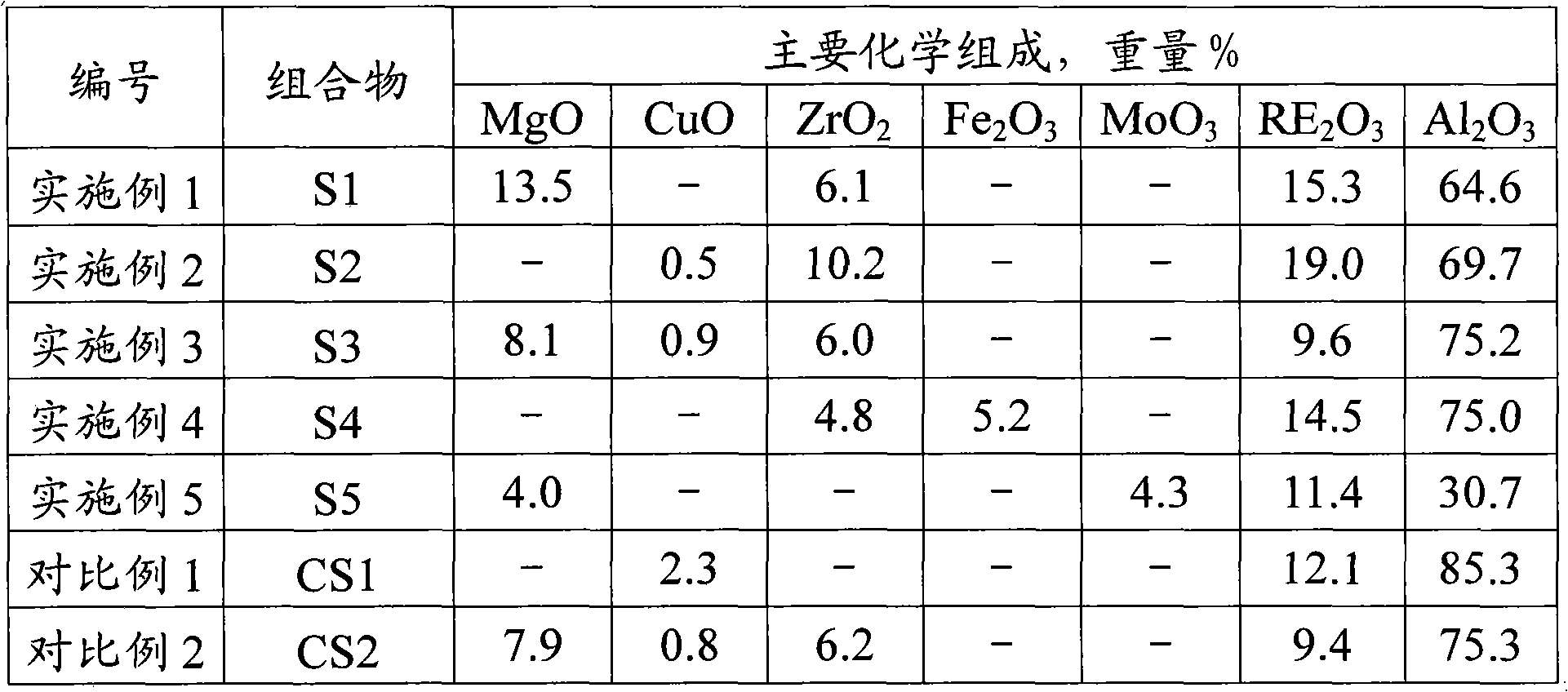

Composition for reducing discharge of NOx in regeneration flue gas of fluid catalytic cracking (FCC)

ActiveCN102371150AReduced activityReduce yieldCatalytic crackingMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementFlue gas

The invention provides a non-noble metal composition for reducing discharge of NOx in regeneration flue gas of catalytic cracking. The bulk density of the composition is no more than 0.65 g / ml, and the composition comprises, based on the weight of the composition, in terms of oxides, (1) 50 to 99 wt % of an inorganic oxide carrier, (2) 0.5 to 40 wt % of one non-noble metal or more non-noble metals selected from the group consisting of Group IIA, Group IIB, Group IVB and Group VIB, and (3) 0.5 to 30 wt % of a rare earth element. When the composition prepared in the invention is utilized in FCC, the discharge of NOx in regeneration flue gas can be substantially reduced, low yield of dry gas and coke is obtained, and distribution of FCC products is better.

Owner:CHINA PETROLEUM & CHEM CORP +1

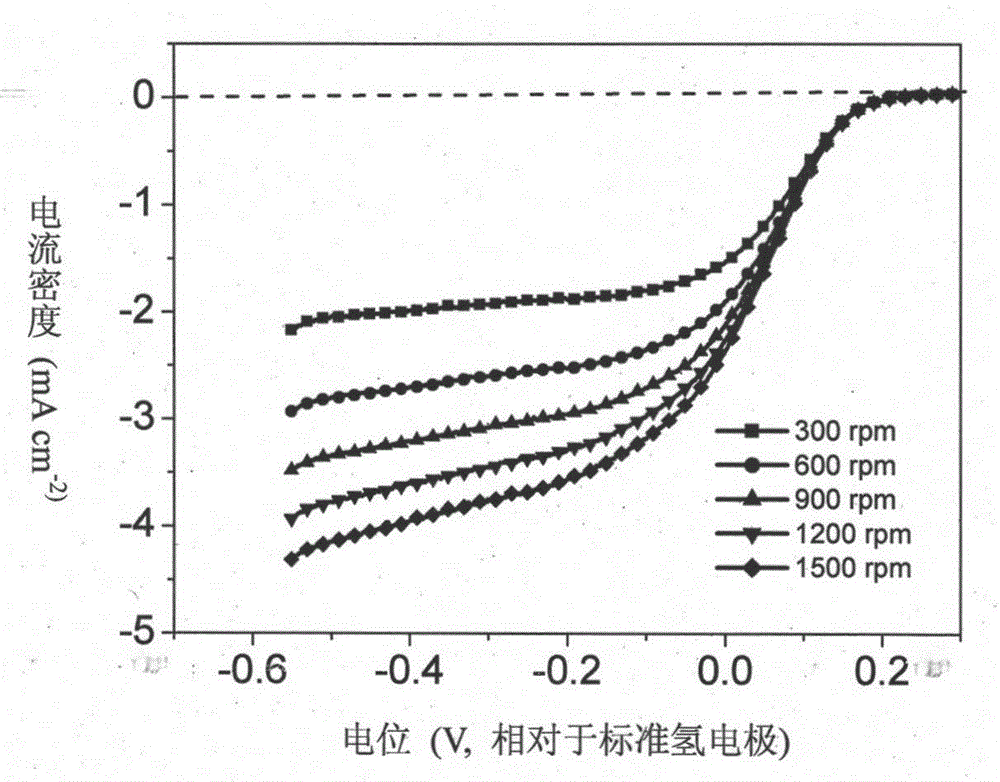

Nitrogen and phosphorus co-doped porous carbon catalyst and preparation method thereof

InactiveCN105457666AAperture controllableImprove adsorption capacityPhysical/chemical process catalystsCell electrodesPorous carbonAniline

The invention provides a preparation method and an application of a nitrogen and phosphorus co-doped porous carbon catalyst and belongs to the field of oxygen reduction catalysts for a fuel cell cathode. Nitrogen and phosphorus are introduced with an in-situ doping method, and the nitrogen and phosphorus doping amount is changed by adjusting the content of a nitrogen and phosphorus precursor. Besides, nitrogen and phosphorus co-doped porous carbon is prepared with a hard template method, and controllability of pore diameters of the porous carbon is realized by adjusting a hard template. The method comprises steps as follows: an earlier polymer of aniline monomers, a phosphorus precursor, a silica-based hard template and non-precious metal salt is prepared; the earlier polymer is calcined, and solids are obtained; the solids are etched, cleaned and dried, and the carbon material is obtained. More importantly, the prepared nitrogen and phosphorus co-doped porous carbon material has an excellent oxygen reduction electro-catalytic property under the acid condition and has huge application potential.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Catalyst precursors, catalysts and methods of producing same

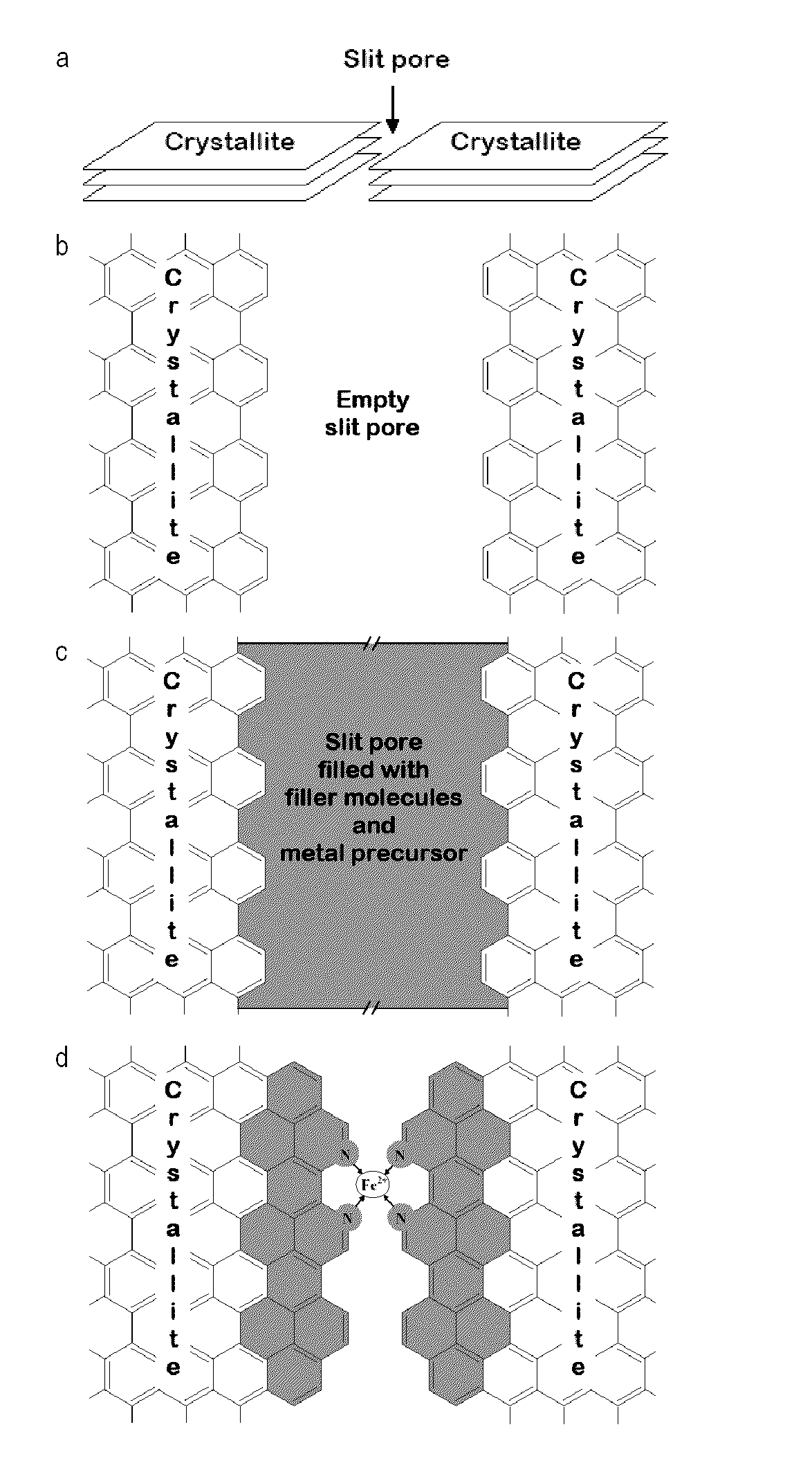

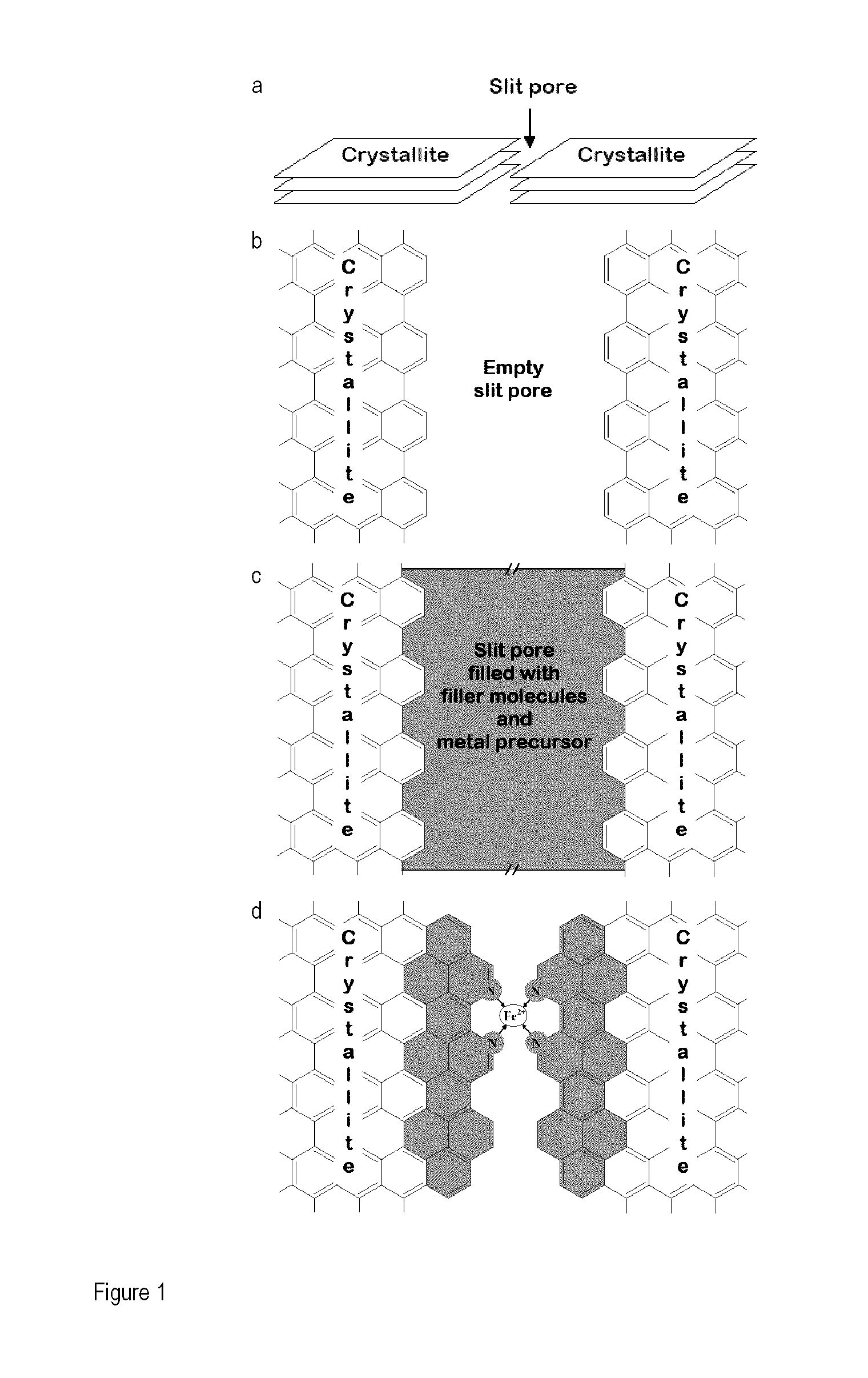

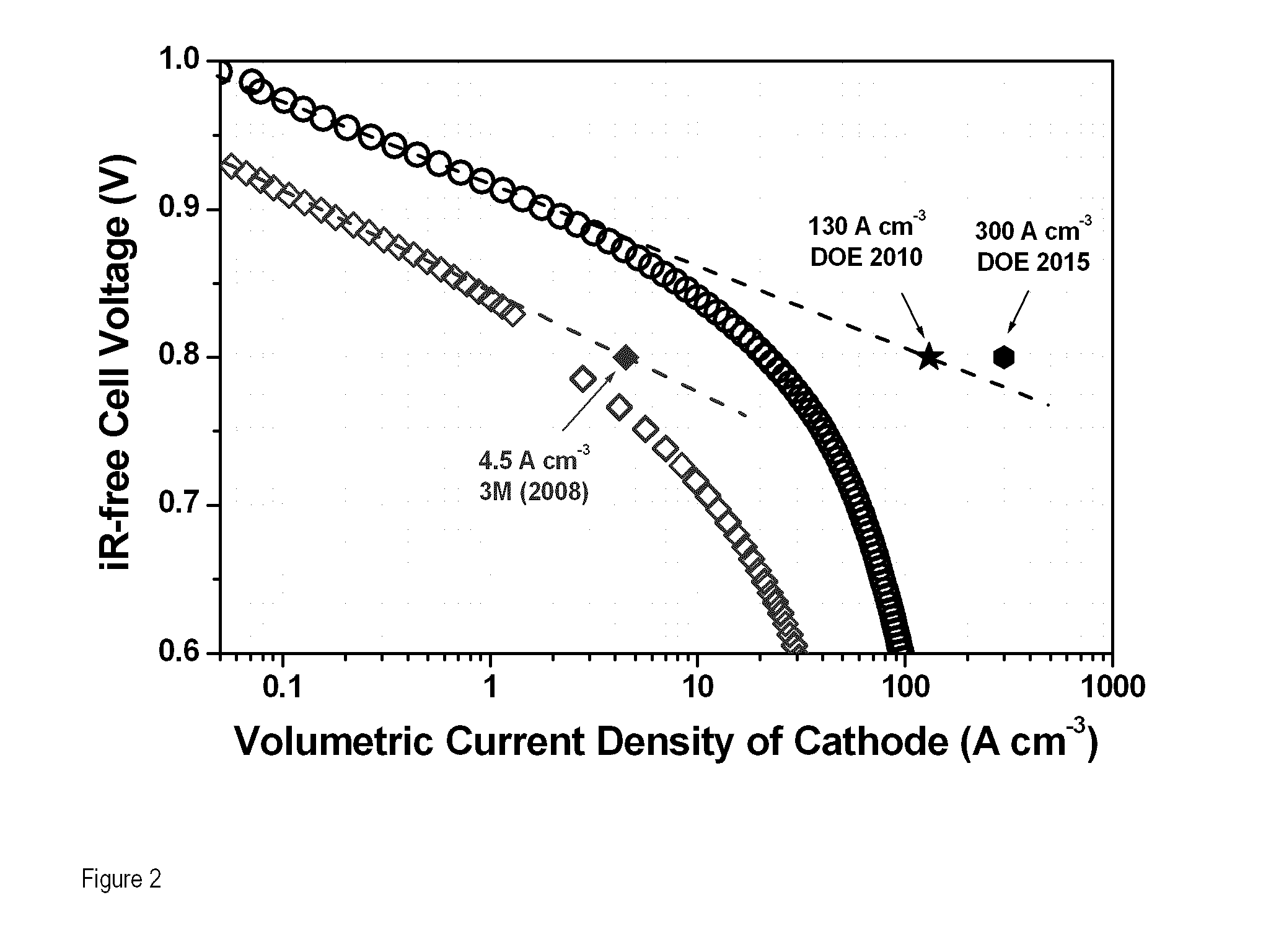

ActiveUS20110294658A1Increase the number ofEasily construct active siteCell electrodesCatalyst activation/preparationNitrogenNon noble metal

A catalyst precursor comprising (A) a microporous support, (B) a non-noble metal precursor, and (C) a pore-filler, wherein the micropores of the microporous support are filled with the pore-filler and the non-noble metal precursor so that the micropore surface area of the catalyst precursor is substantially smaller than the micropore surface area of the support when the pore-filler and the non-noble metal precursor are absent is provided. Also, a catalyst comprising the above catalyst precursor, wherein the catalyst precursor has been pyrolysed so that the micropore surface area of the catalyst is substantially larger than the micropore surface area of catalyst precursor, with the proviso that the pyrolysis is performed in the presence of a gas that is a nitrogen precursor when the microporous support, the non-noble metal precursor and the pore-filler are not nitrogen precursors is also provided. Methods of producing the catalyst precursor and the catalyst are provided.

Owner:MCGILL UNIV +1

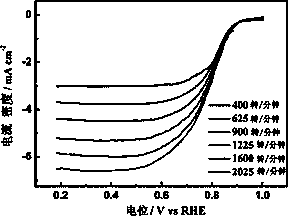

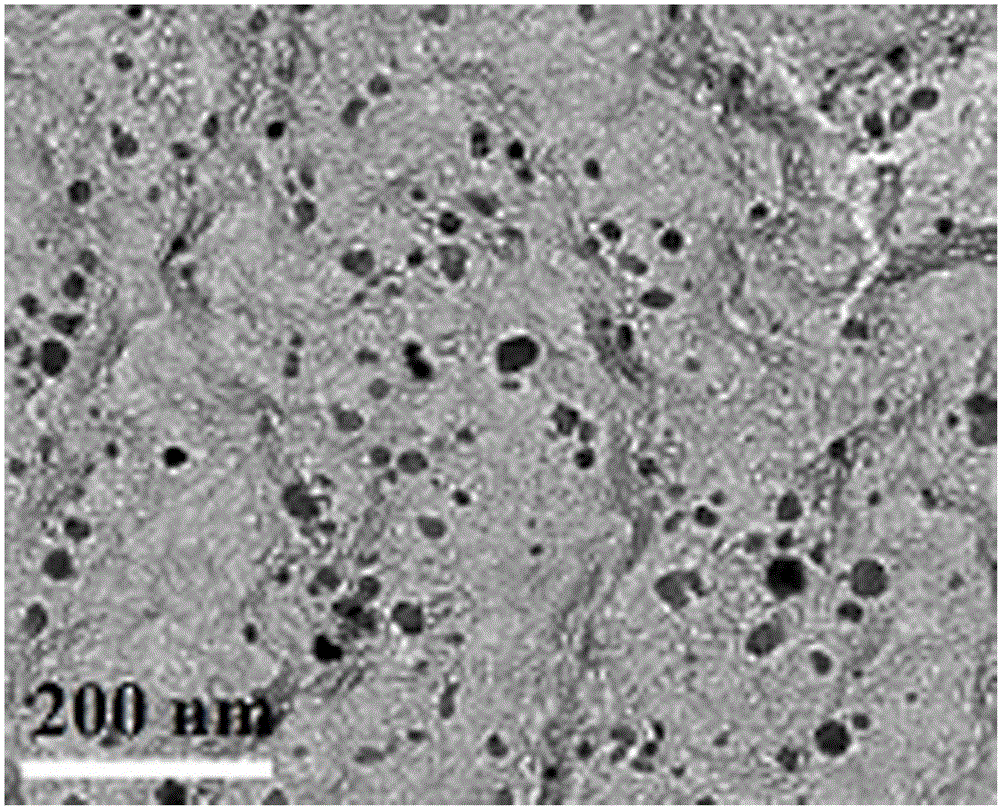

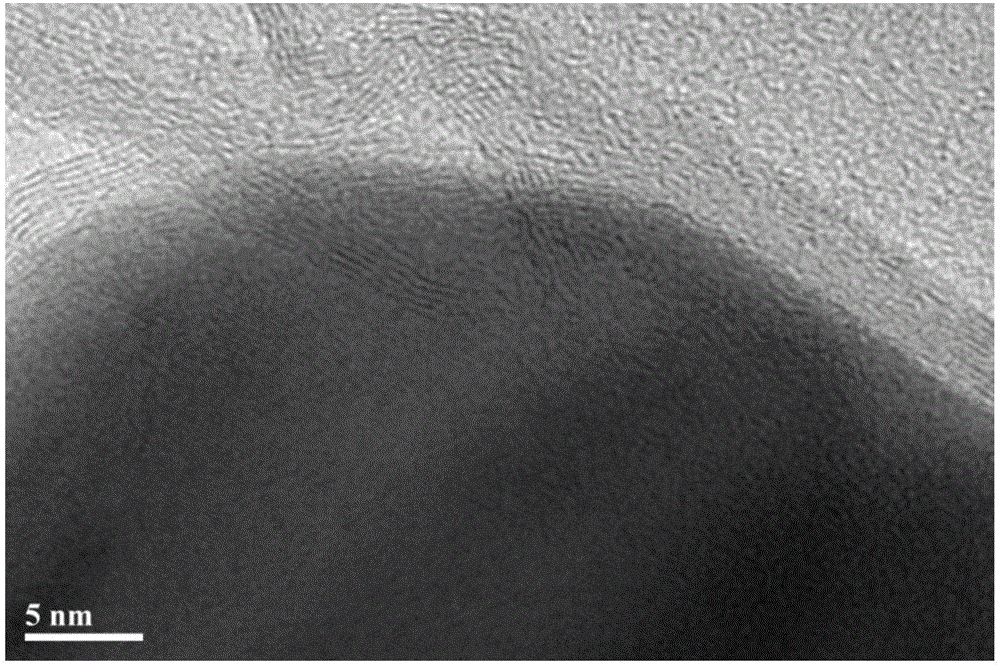

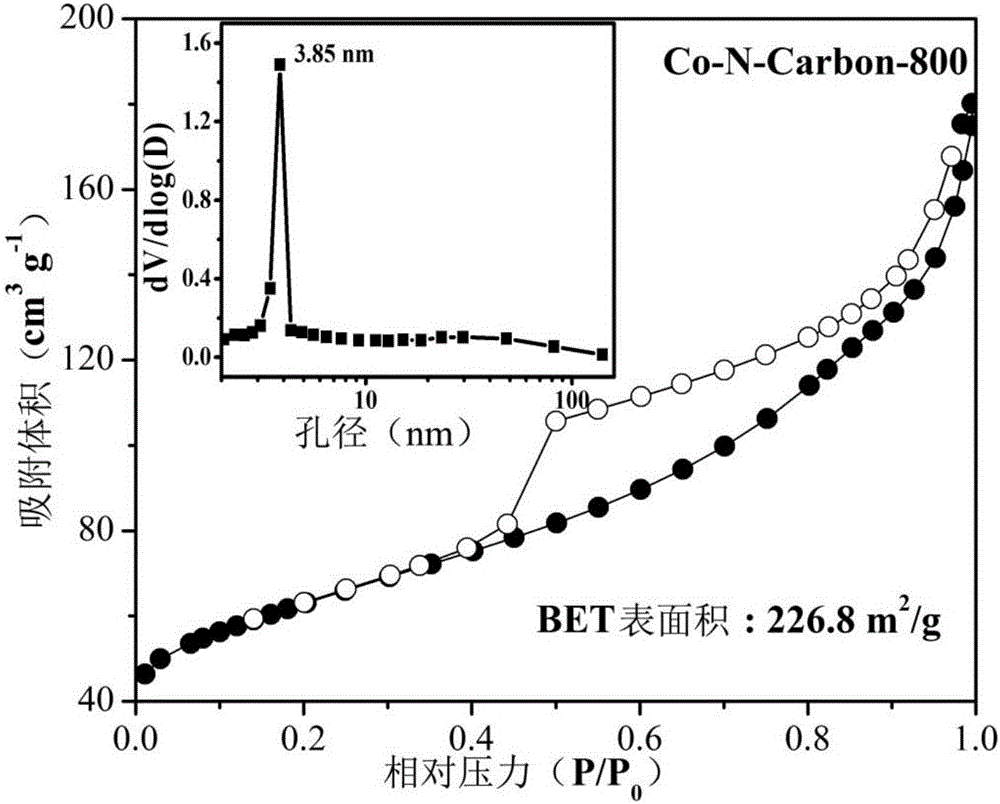

Porous nano composite material for fuel cell oxygen reduction catalyst

InactiveCN103811775AImprove cycle stabilityEasy to operateMaterial nanotechnologyPhysical/chemical process catalystsPorous carbonOxygen

The invention discloses a porous nano composite material for a fuel cell oxygen reduction catalyst, and is an M-N-C porous nano composite material, wherein M in M-N-C refers to base metal ferrum, cobalt or nickel, N refers to nitrogen, and C refers to carbon; small-particle-size metal nano particles are uniformly dispersed and embedded in a nitrogen-doped porous carbon carrier material; the base metal nano particles have the particle size range being 5-100nm; the mass percentage of nitrogen contained in the porous carbon carrier is 3-7%. The porous nano composite material for the fuel cell oxygen reduction catalyst, which is provided by the invention, has the advantages that because of the in-situ nitrogen doping of a carbon substrate, the implant of base metal nano particles in uniform distribution and the formation of the porous structure with high specific area, the catalytic oxygen reduction capability of the porous nano composite material is improved obviously, and the cycle stability of the material is improved; a precursor prepared by the composite material is low in cost, is easy to prepare, is controlled easily in the preparation process, is simple to operate, and facilitates industrial large-scale production.

Owner:NANKAI UNIV

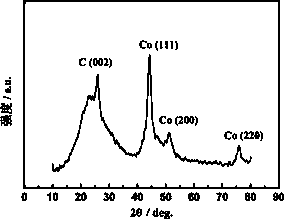

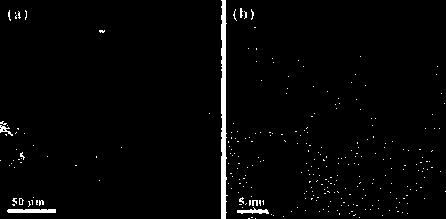

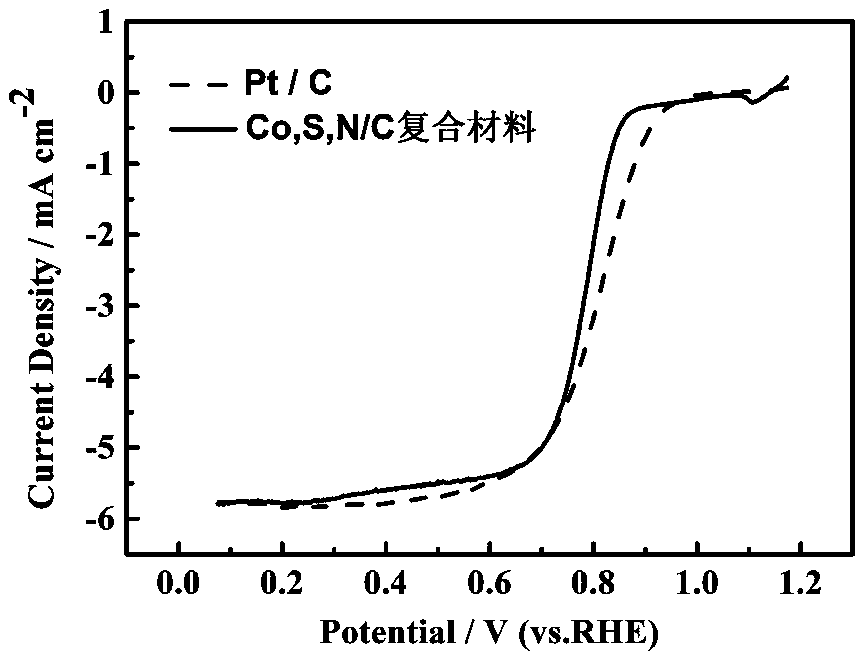

Dual-function oxygen electrode catalyst containing non-noble-metal nanoparticles coated with nitrogen-doped porous carbon layer and preparation method of dual-function oxygen electrode catalyst

InactiveCN106669758AHigh degree of graphitizationLarge void structurePhysical/chemical process catalystsCarbon layerPorous carbon

The invention relates to the field of catalysts for energy-producing devices such as fuel cells, metal-air cells, electrolysed water and the like, in particular to a dual-function non-noble-metal catalyst and a preparation method thereof. The structure of the dual-function catalyst with activity of realizing oxygen reduction and oxygen release simultaneously is that non-noble-metal nanoparticles are dispersedly coated with a two-dimensional nitrogen-doped porous carbon layer, and the active center of the catalyst is the non-noble-metal nanoparticles coated with nitrogen-carbon, non-noble-metal-nitrogen-carbon and the carbon layer. The non-noble-metal oxygen electrode catalyst has the advantages that raw materials are cheap, a preparation process is simple and template removal and other complicated operating steps are avoided, thereby being suitable for commercial production and capable of substantially reducing cost under the premise that catalytic performance is guaranteed.

Owner:EAST CHINA UNIV OF SCI & TECH

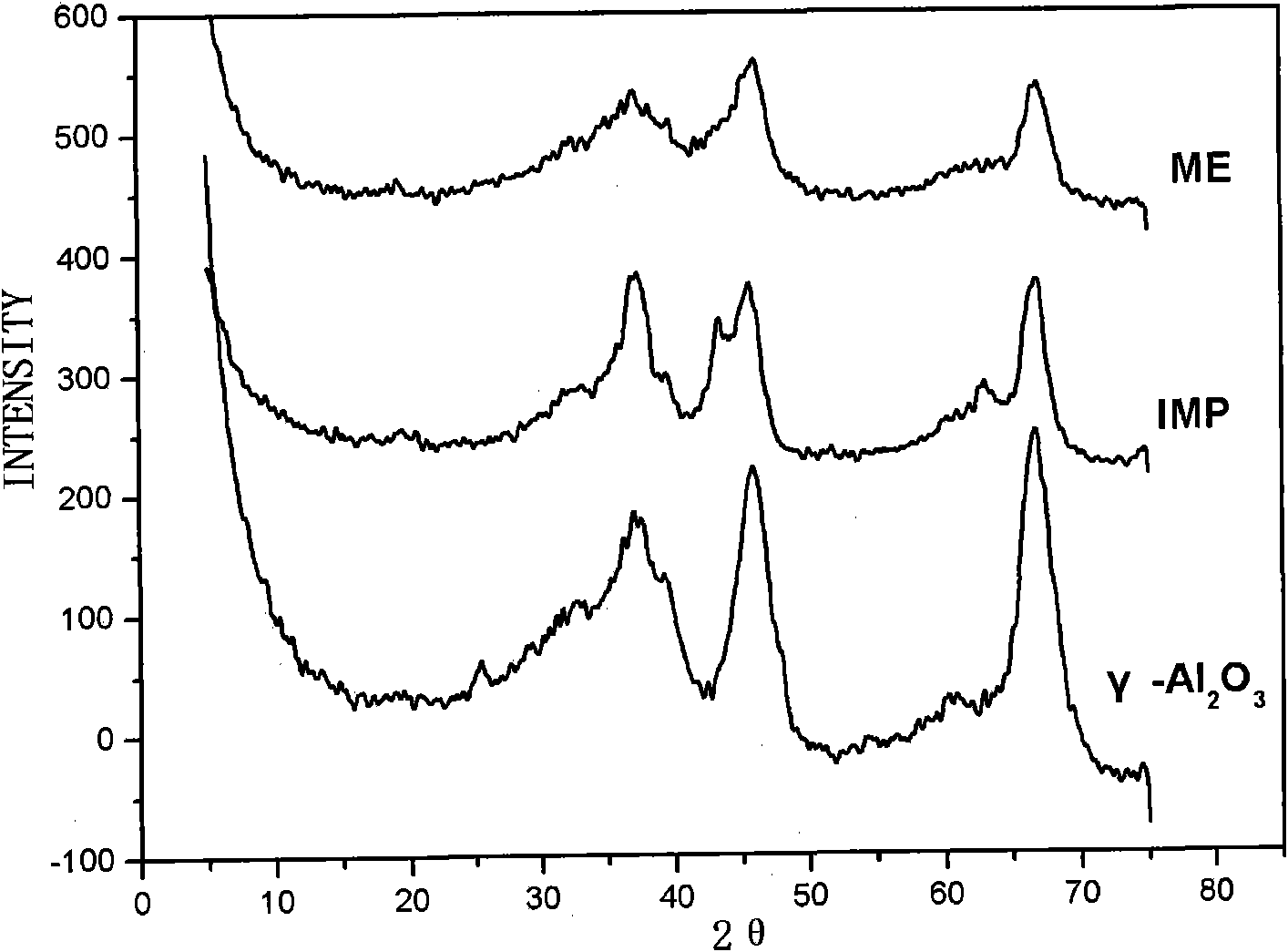

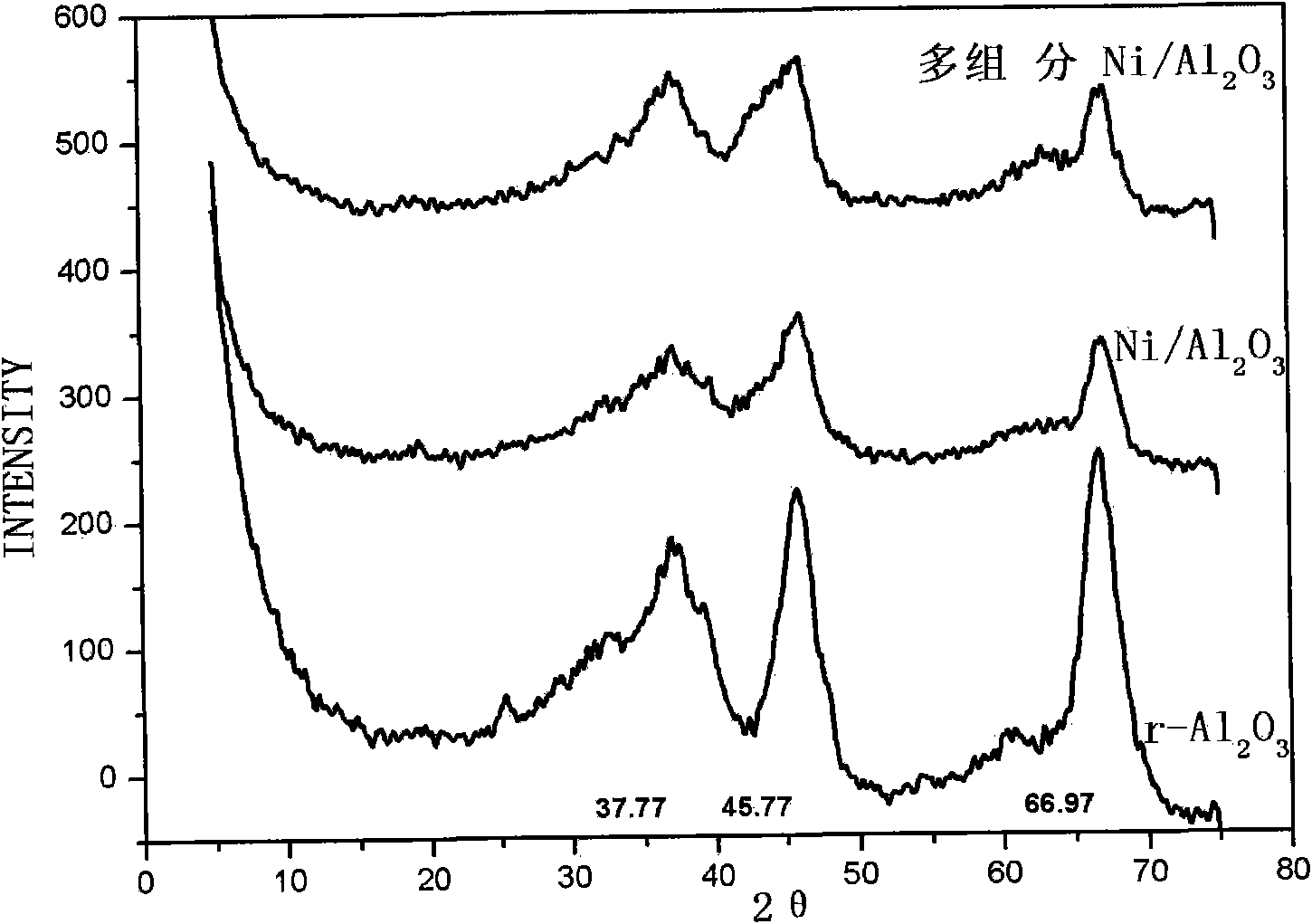

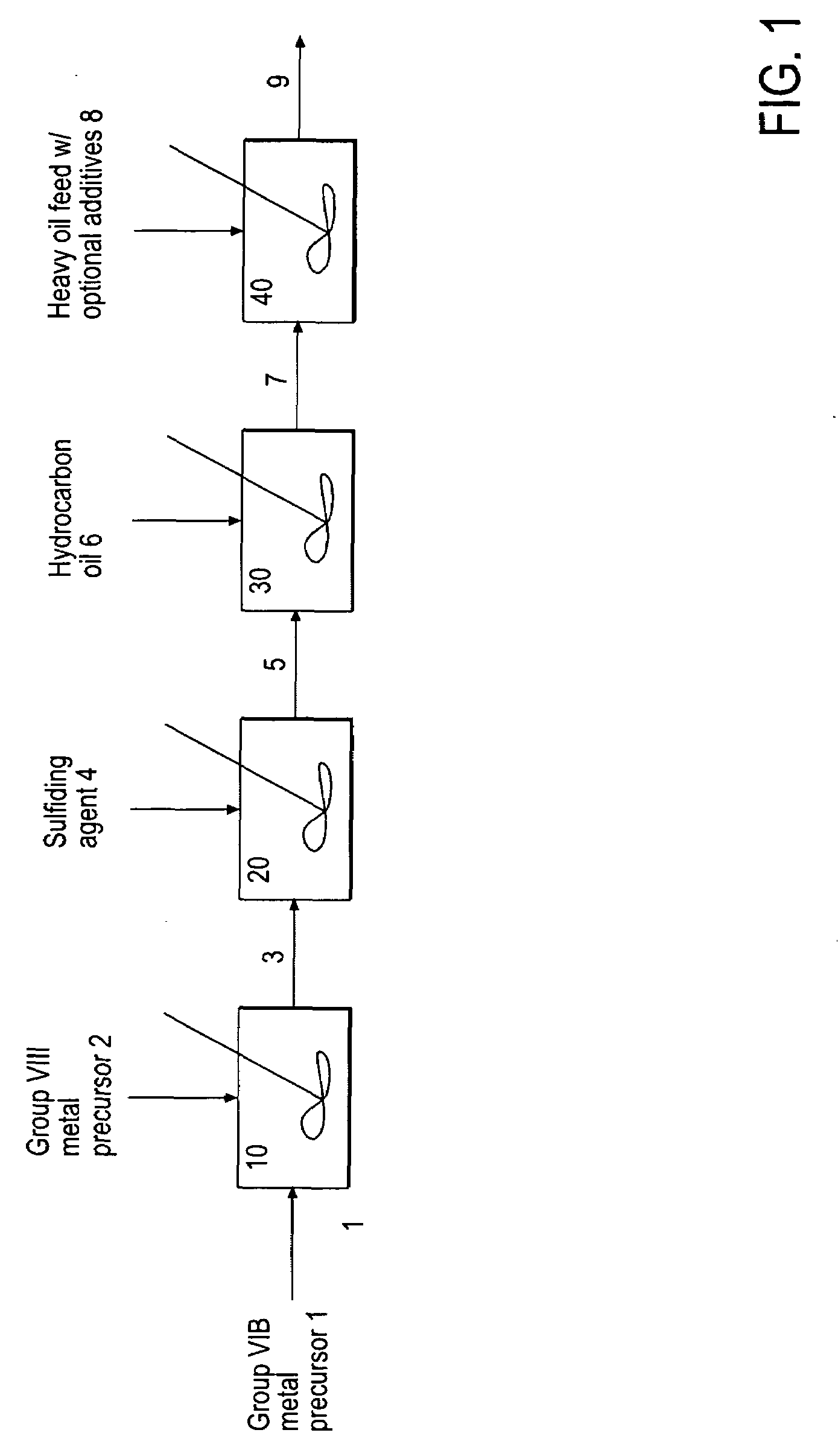

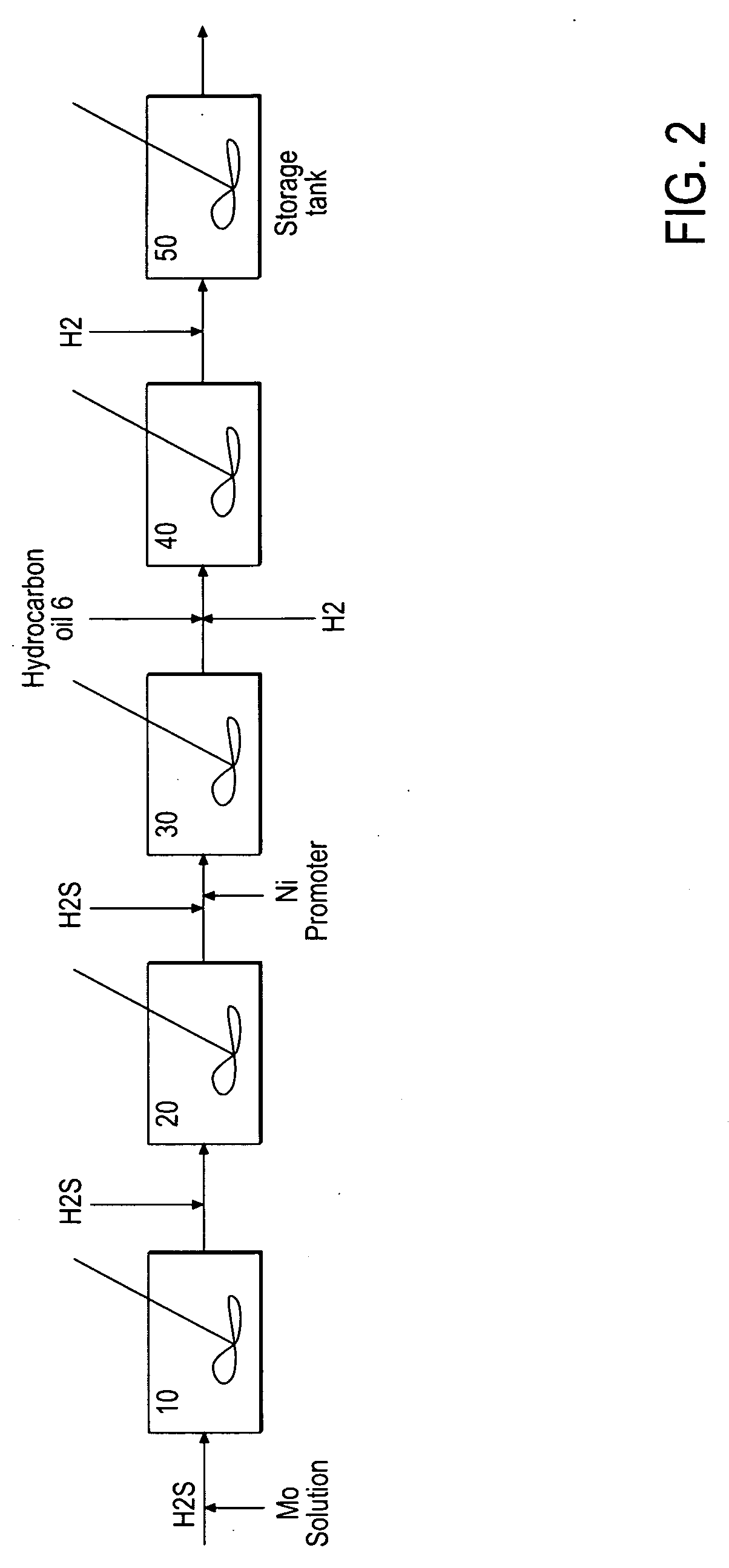

Hydroprocessing bulk catalyst and uses thereof

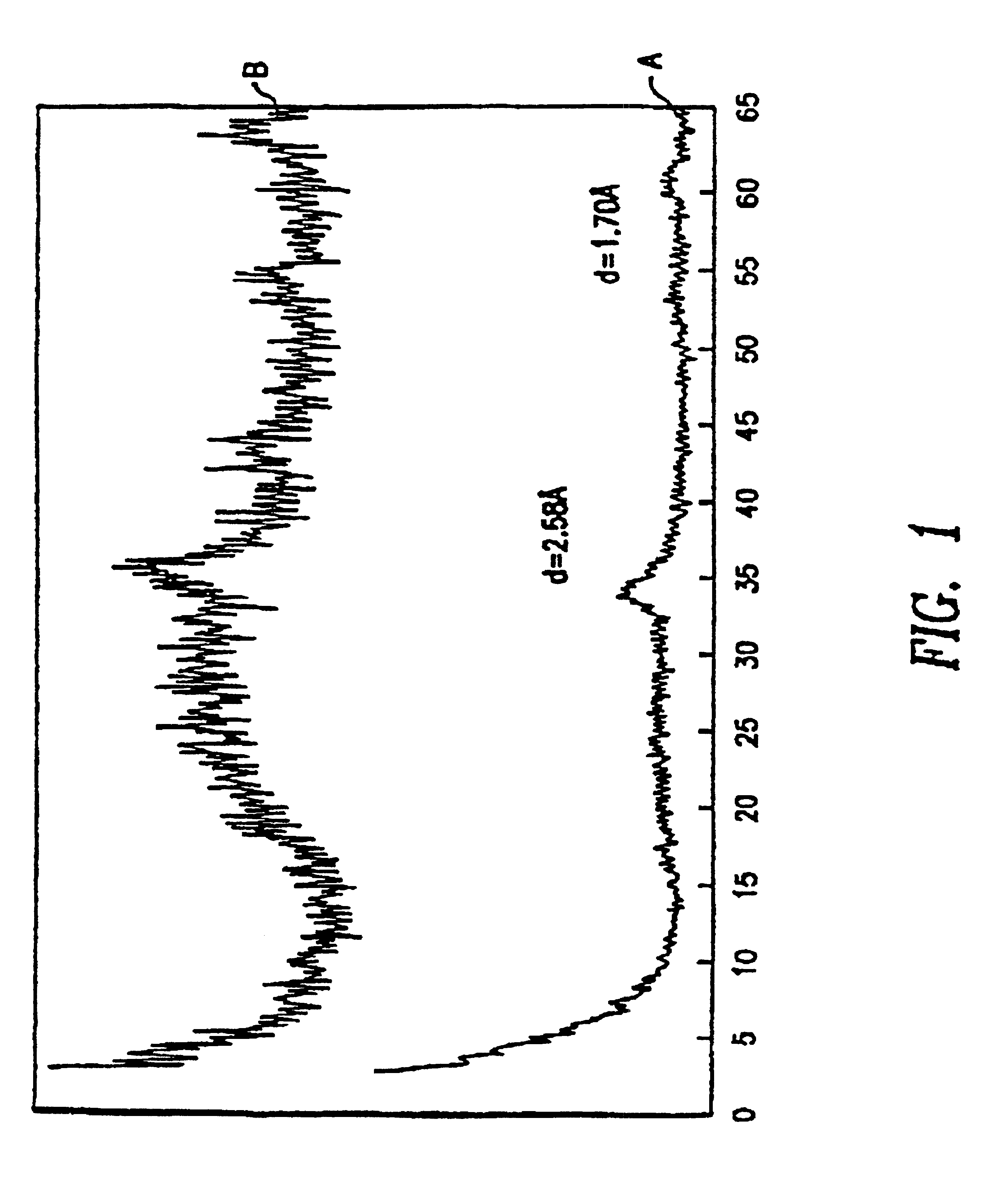

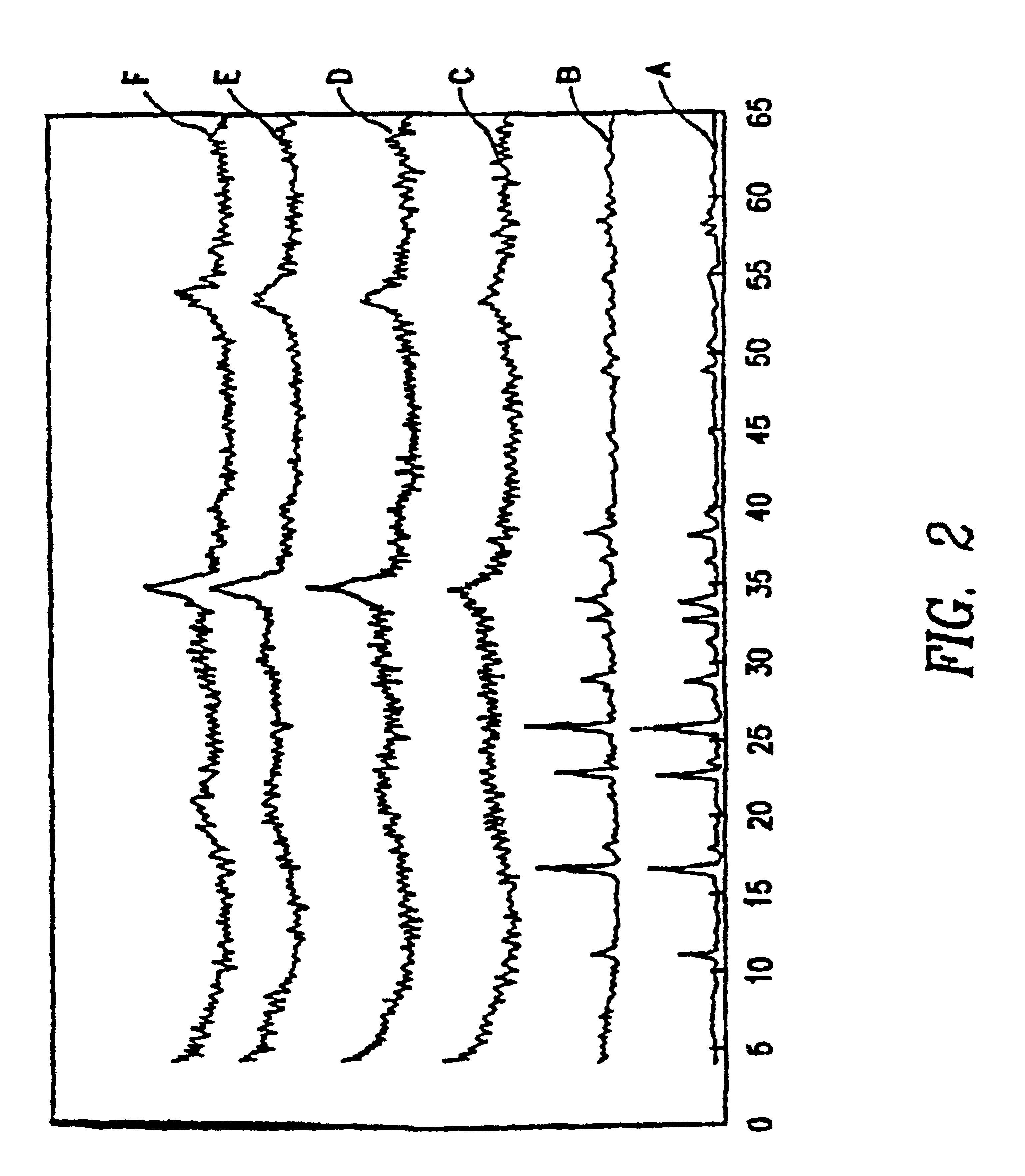

ActiveUS20090057201A1Inorganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsNon noble metalPowder diffraction

A hydroprocessing bulk catalyst is provided. A process to prepare hydroprocessing bulk catalysts is also provided. The hydroprocessing catalyst has the formula (Mt)d(Lu)b(Sv)d(Cw)e(Hx)f(Oy)g(Nz)h, wherein M is at least one group VIB metal; promoter metal L is optional and if present, L is at least one Group VIII non-noble metal; t, u, v, w, x, y, z representing the total charge for each of the components (M, L, S, C, H, O and N, respectively); ta+ub+vd+we+xf+yg+zh=0; 0 =<b; and 0=<b / a=<5, (a+0.5b)<=d<=(5a+2b), 0<=e<=11(a+b), 0<=f<=7(a+b), 0<=g<=5(a+b), 0<=h<=0.5(a+b). The catalyst has an X-ray powder diffraction pattern with at least one broad diffraction peak at any of Bragg angles: 8 to 18°, 32 to 40°, and 55 to 65° (from 0 to 70° 2-θ scale). In one embodiment, the catalyst is prepared by sulfiding at least one Group VIB metal compound and optionally at least one group VIII metal compound with a sulfiding agent forming a catalyst precursor; and mixing the catalyst precursor with a hydrocarbon compound to form the hydroprocessing catalyst composition.

Owner:CHEVROU USA INC

Selective hydrogenation desulfurization method for gasoline

ActiveCN101314734AReduce lossesIncrease flexibilityHydrocarbon oils refiningHydrogenHydrodesulfurization

A gasoline selective hydrodesulfurization method comprises the following steps: mixing full-range gasoline and / or heave gasoline distillate with hydrogen, carrying out selective hydrodesulfurization reaction in the presence of hydrodesulfurization catalyst I and hydrodesulfurization catalyst II, and cooling and separating the resultants to obtain hydrogenated gasoline distillate, wherein the heavy gasoline distillate is obtained by cutting full-range gasoline at a cutting temperature of 50 to 75 DEG C, and the hydrodesulfurization catalyst I and hydrodesulfurization catalyst II are VIB-group metal and / or VIII-group non-noble metal catalysts loaded on aluminum and / or silica-alumina carrier. The method can be used for processing catalytic cracking gasoline to obtain gasoline product with sulfur content meeting EuroIV emission standard or even meeting EuroV emission standard, and the gasoline product has less octane number loss and RON loss less than 2.0.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nitrogen-doped graphene catalyst and preparation method and application thereof

InactiveCN103611555AReduce manufacturing costEasy to makePhysical/chemical process catalystsCell electrodesMicrobial fuel cellFuel cells

The invention provides a nitrogen-doped graphene catalyst and a preparation method and application thereof. The nitrogen-doped graphene catalyst is characterized by being prepared by roasting a nitrogen-doped graphene precursor; the nitrogen-doped graphene precursor is prepared from the raw materials including at least one of non-precious metal salt and hydrate thereof, graphite oxide and nitrogen-containing small organic molecules; in the raw materials, the mass percent of the graphite oxide is 10-89wt%, the mass percent of the nitrogen-containing small organic molecules is 10-89wt%, and the mass percent of at least one of non-precious metal salt and hydrate thereof is 1-10wt%. The preparation process of the nitrogen-doped graphene provided by the invention is simple, the process is easy to operate, the activity is high, the cost is low, and industrial production is easy to implement; the nitrogen-doped graphene can be applied to the fields of fuel cells, metal-air cells, microbial fuel cells and the like.

Owner:DONGHUA UNIV

Preparation of non-noble metal/carbon composites based on metal-organic framework, non-noble metal/carbon composites and their applications

ActiveCN109216712AEfficient reductionReduce consumptionCell electrodesCarbon compositesMetal-organic framework

The invention discloses a preparation method of a non-noble metal / carbon composite material based on a metal-organic framework, comprising the following steps: (1) preparing a metal-organic frameworkcomplex; (2) placing the metal-organic frame complex obtained in the step (1), the non-noble metal compound and / or the heteroatom compound in an open container respectively, and placing the open container in a closed container for heat treatment to obtain a metal-organic frame complex composite material; (3) carbonizing the metal-organic framework complex composite material obtained in the step (2) in an inert atmosphere to obtain a non-noble metal / carbon composite material. The invention also correspondingly provides a non-noble metal / carbon composite material obtained by the preparation method and the application thereof. The preparation method of the invention can ensure the high dispersibility of the metal or the metal compound, greatly improves the utilization rate of the metal and has high catalytic activity.

Owner:CENT SOUTH UNIV

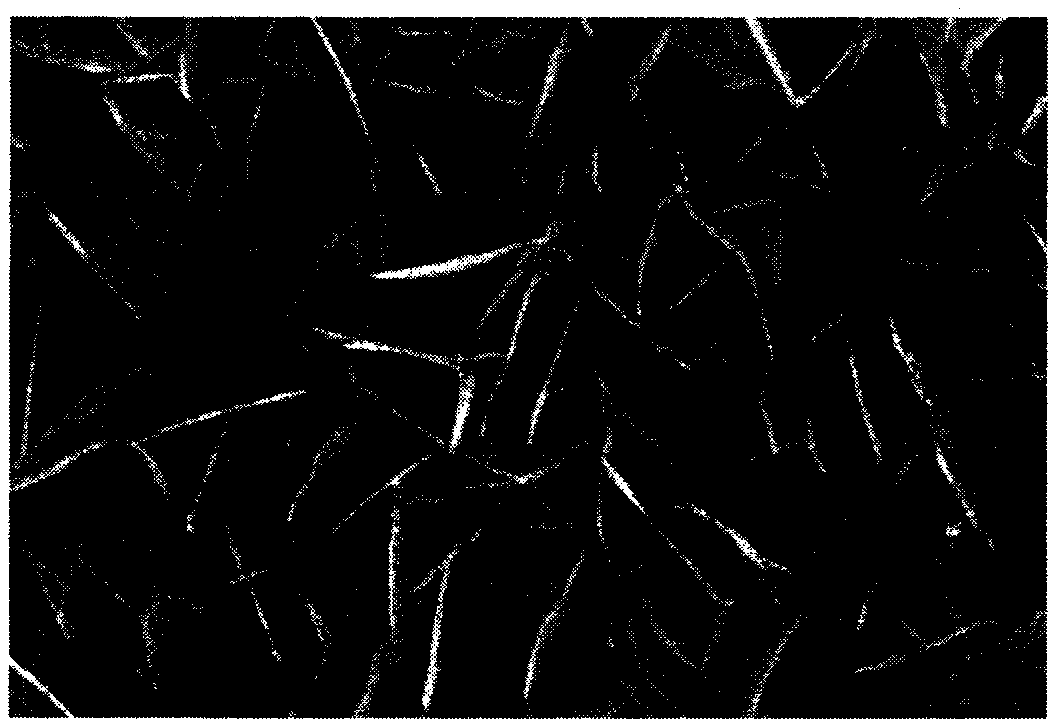

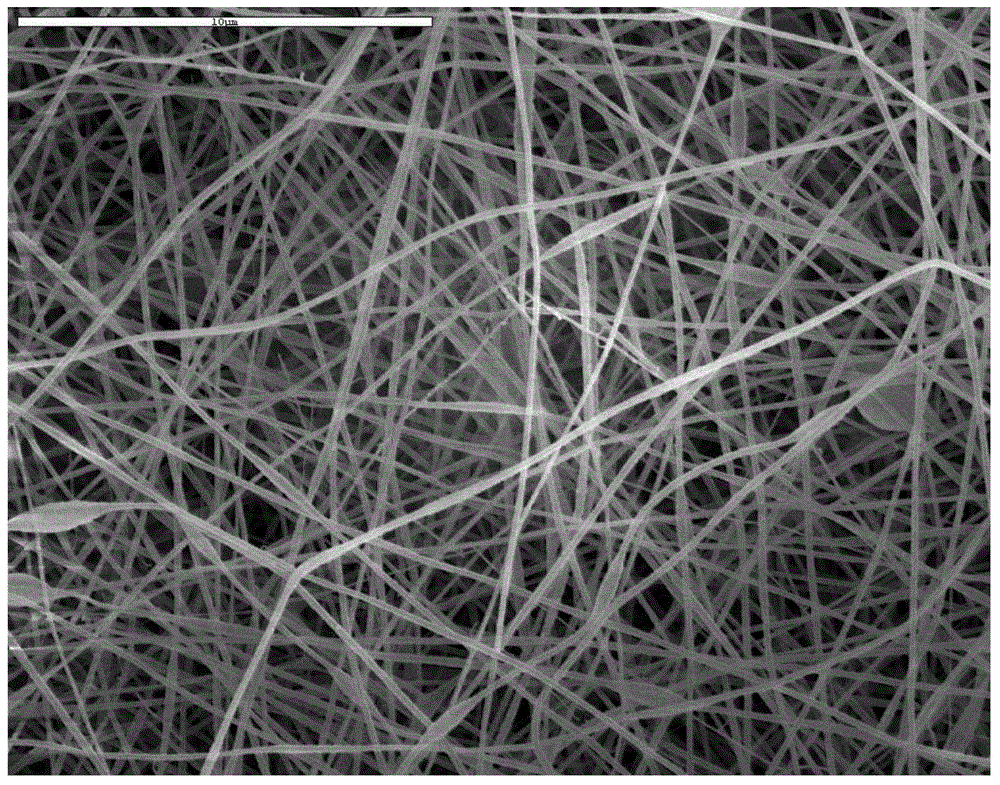

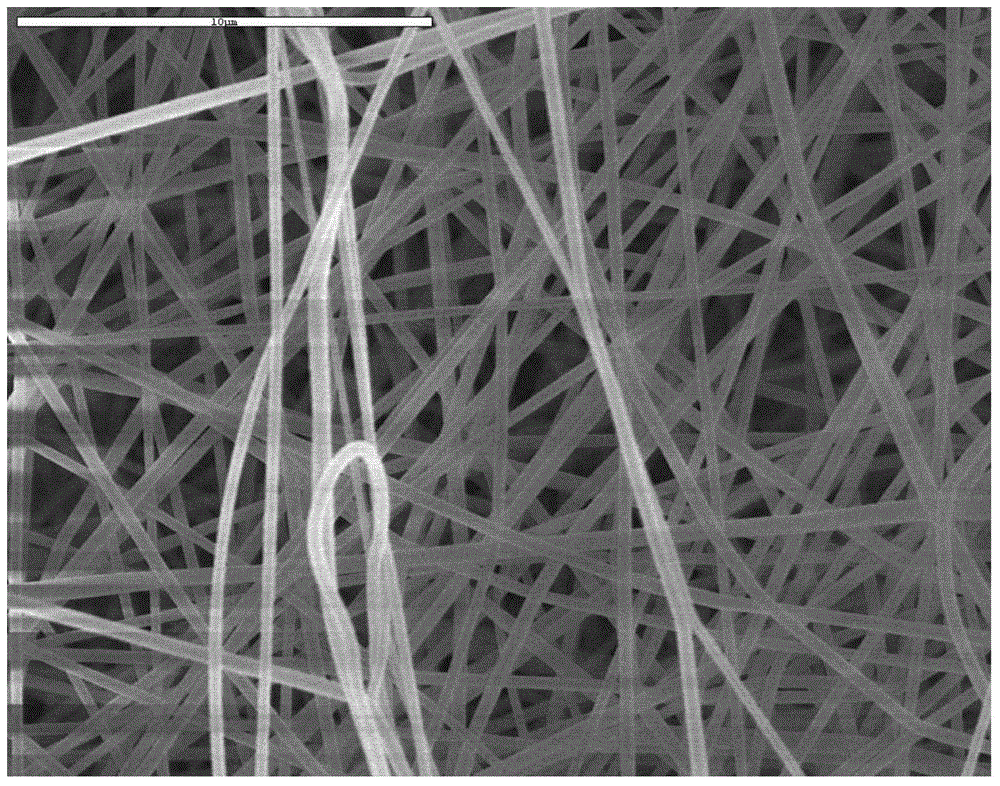

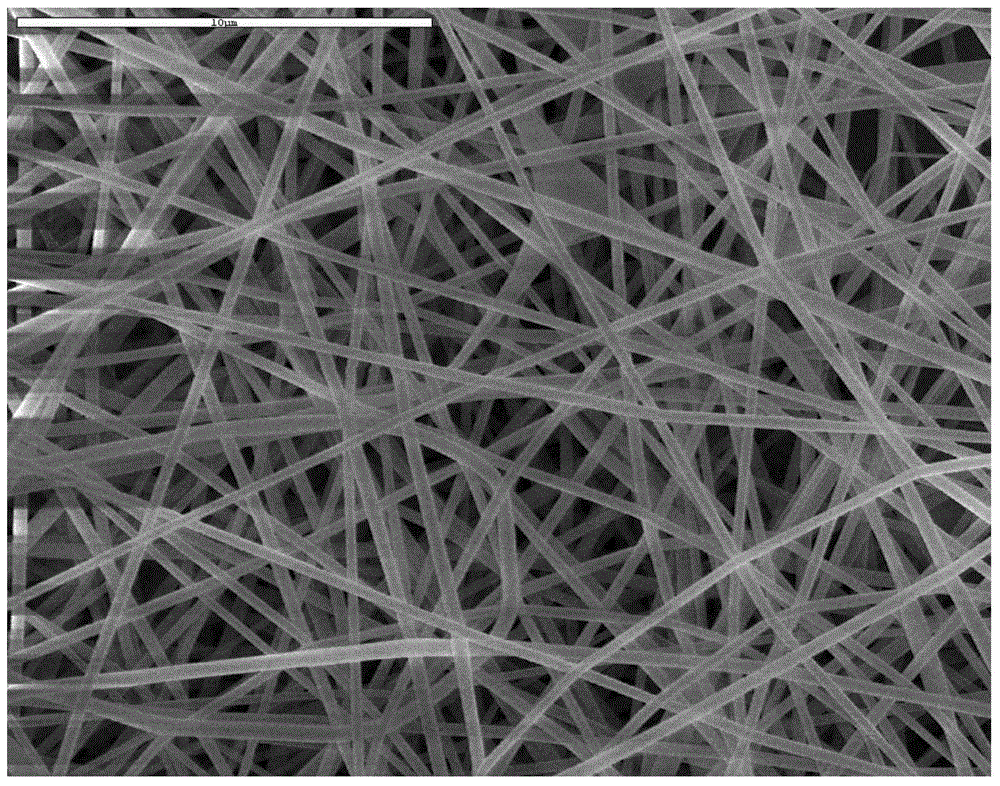

Method for preparing carbon nanofiber based non-noble-metal catalyst through oxidation improved electrostatic spinning

InactiveCN103606689ALow priceEasy to operate and controllableCell electrodesCarbon fibersCarbon nanofiber

The invention discloses a method for preparing a carbon nanofiber-based non-noble-metal catalyst through oxidation improved electrostatic spinning in the technical field of carbon nanofibers and fuel cell catalysts. The method disclosed by the invention comprises the following steps: dissolving at least one transition metal salt and polyacrylonitrile in a solvent to form a precursor solution; carrying out electrostatic spinning on the precursor solution under certain parameter conditions to obtain iron-containing polyacrylonitrile nanofibers; and heat treating the iron-containing polyacrylonitrile nanofibers in an atmosphere containing a small amount of oxidizing gas to obtain carbon nanofibers containing transition metal and nitrogen element and improved by the small amount of oxidizing gas. According to the method, the cost of the raw materials is low, the operation is convenient and controllable, the operation is easy, the surface structure of the catalyst can be regulated and controlled, and the prepared oxidation improved carbon nanofiber based non-noble-metal catalyst has good catalytic activity on oxygen reduction reaction. The whole preparation process can be combined with a traditional carbon fiber technique, and the method has a prospect that large scale and industrialization of the non-noble metal catalyst can be realized.

Owner:TSINGHUA UNIV

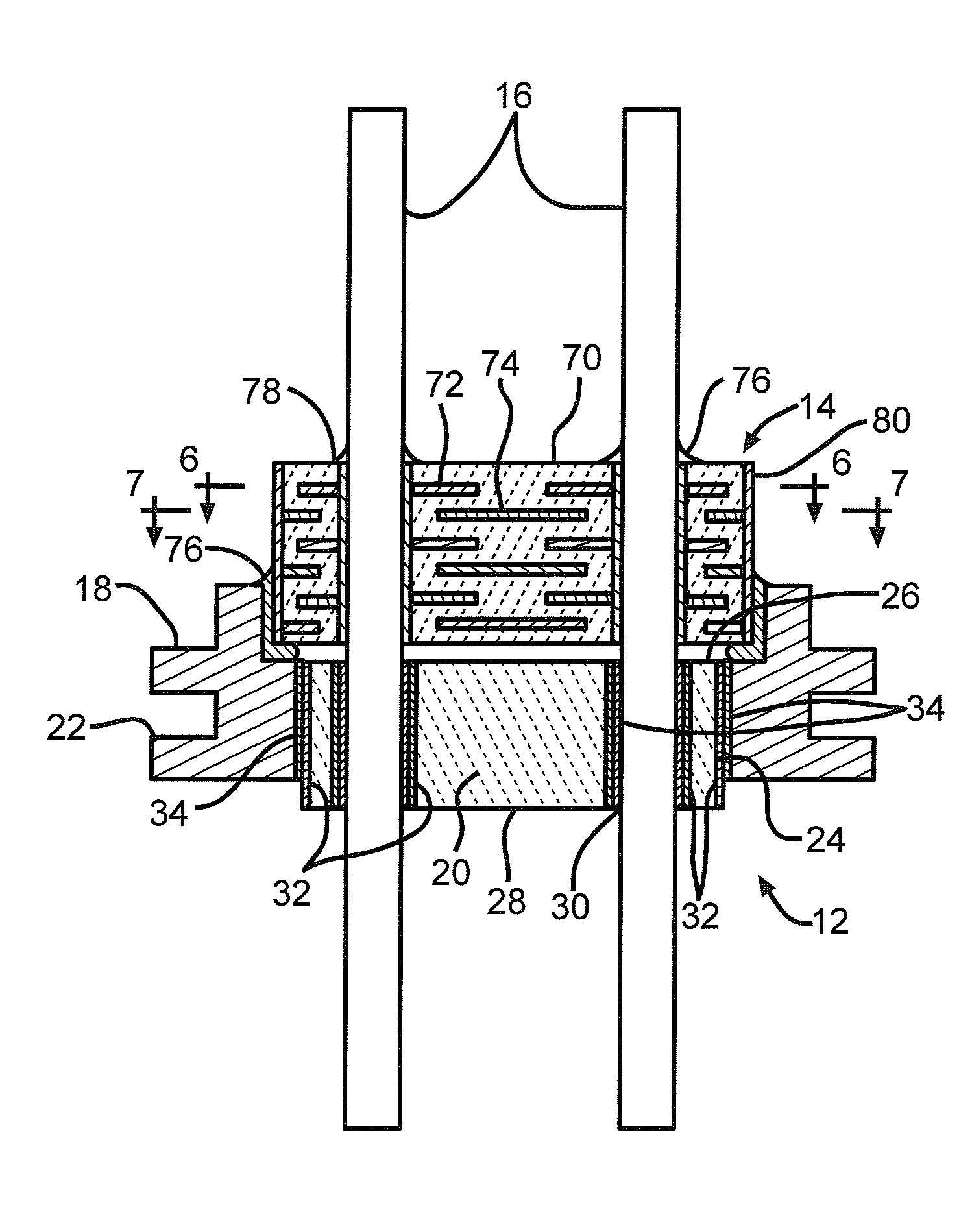

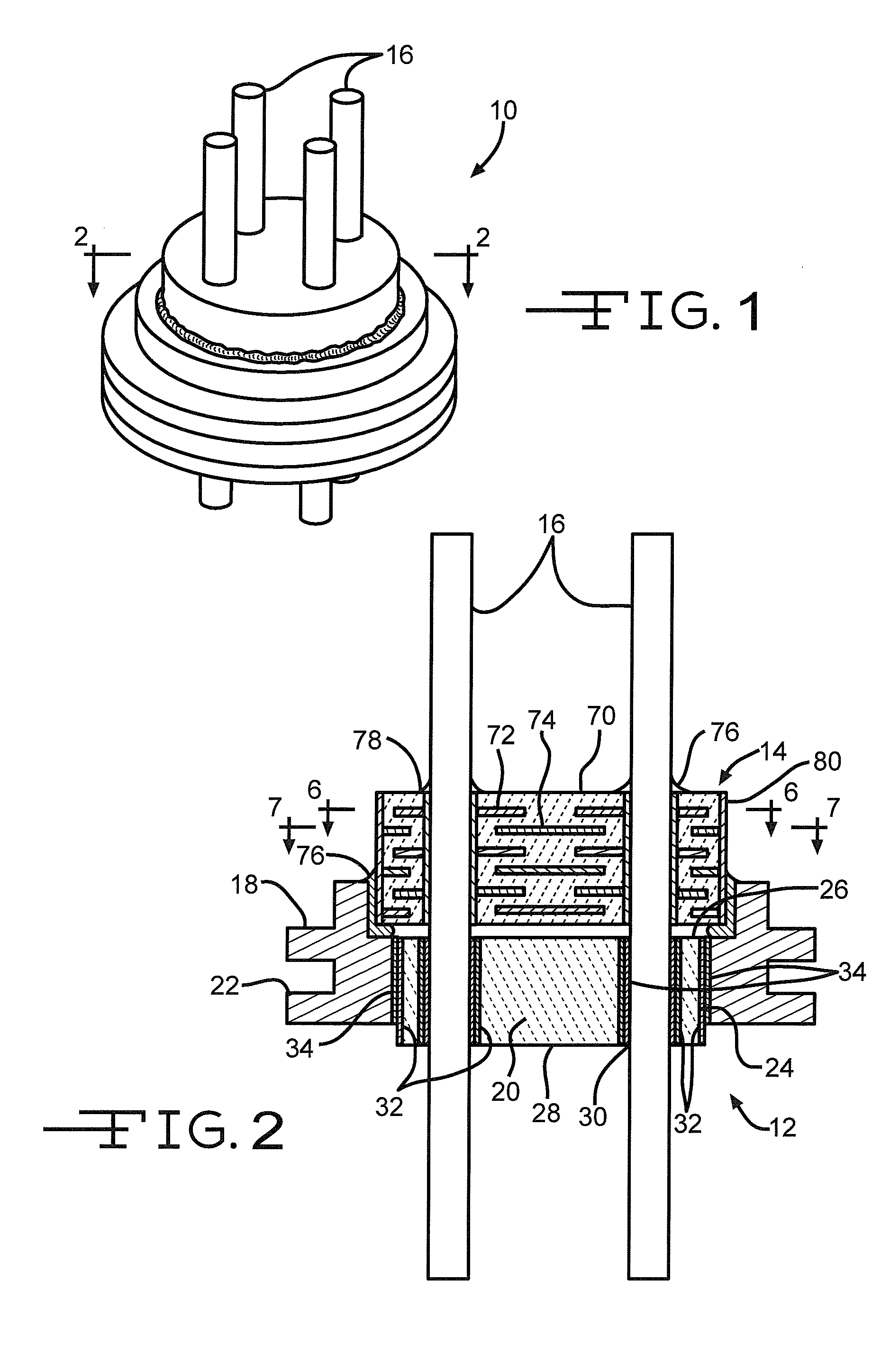

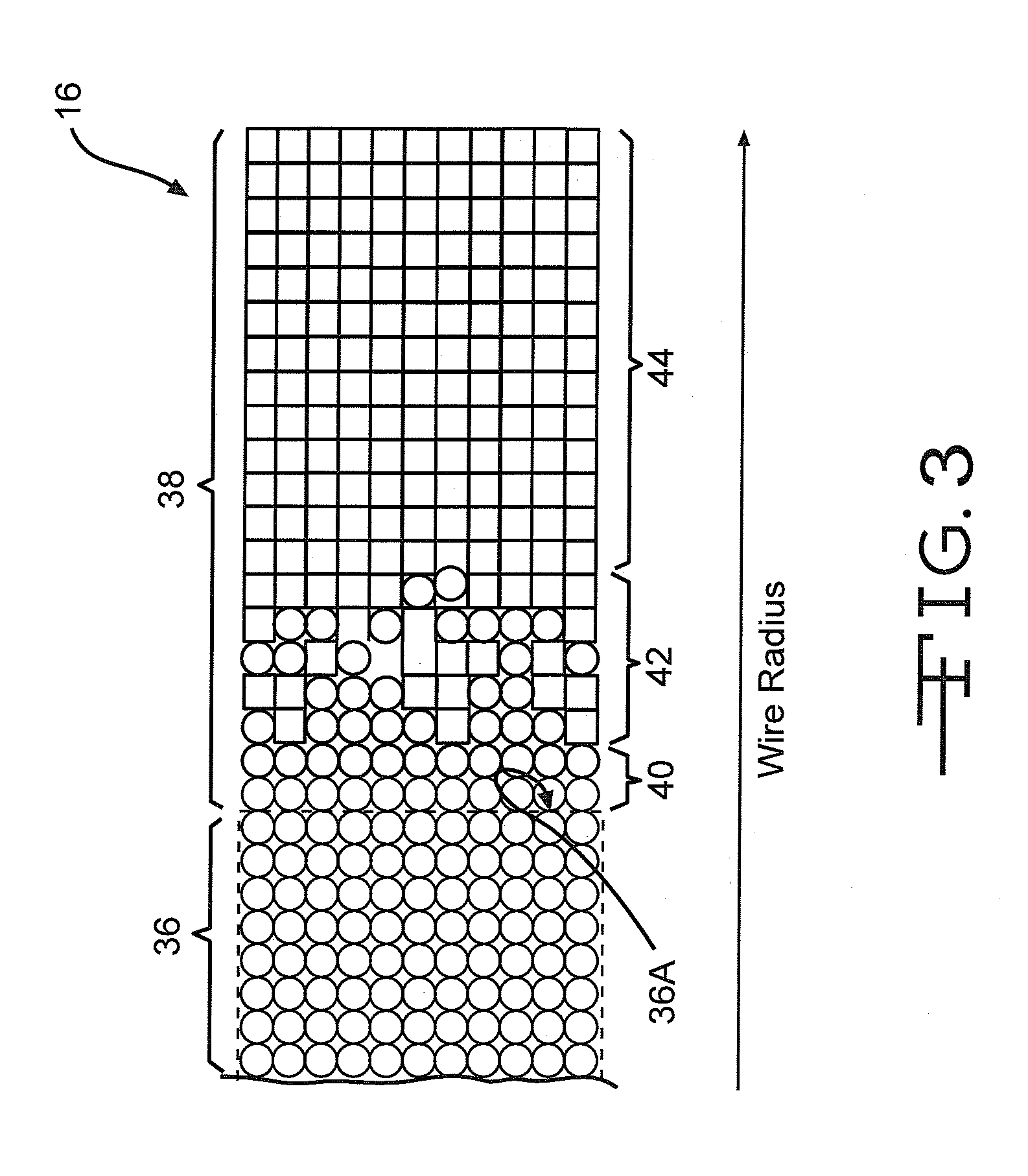

Functionally graded coatings for lead wires in medical implantable hermetic feedthrough assemblies

A feedthrough filter capacitor assembly is described. The feedthrough filter capacitor assembly comprises an outer ferrule hermetically sealed to an insulator of a dielectric material seated within the ferrule. The insulative material is also hermetically sealed to at least one lead wire. Instead of being made of platinum or platinum / iridium, the lead wire comprises a core of a non-noble metal supporting a functionally graded coating. The metal core has an inner layer of the same the non-noble metal of the core and an outer layer of a noble metal. A gradient transition zone exists between the non-noble metal and the outer noble metal. Consequently, lead wires having all the beneficial attributes of platinum and platinum / iridium wire can be built into hermetic feedthroughs, but at a significantly reduced cost. In a preferred form, a filter capacitor is mounted on the insulator and electrically connected to the lead wires and to the ferrule to prevent unwanted EMI signals from traveling along the wires and entering the interior of the medical device.

Owner:WILSON GREATBATCH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com