Patents

Literature

304results about How to "Aperture controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

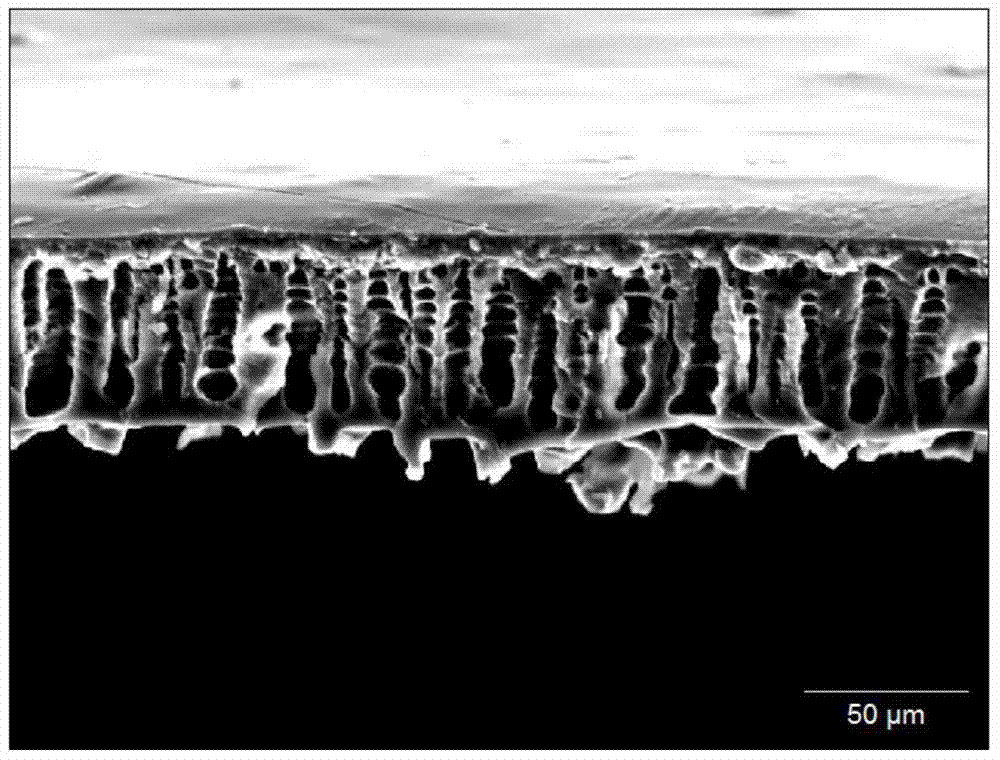

Porous polymer electrolyte supporting membrane material, preparation method thereof and application thereof

InactiveCN102199846AEasy to operateAperture controllableSecondary cellsFilament/thread formingSolventAbsorption rate

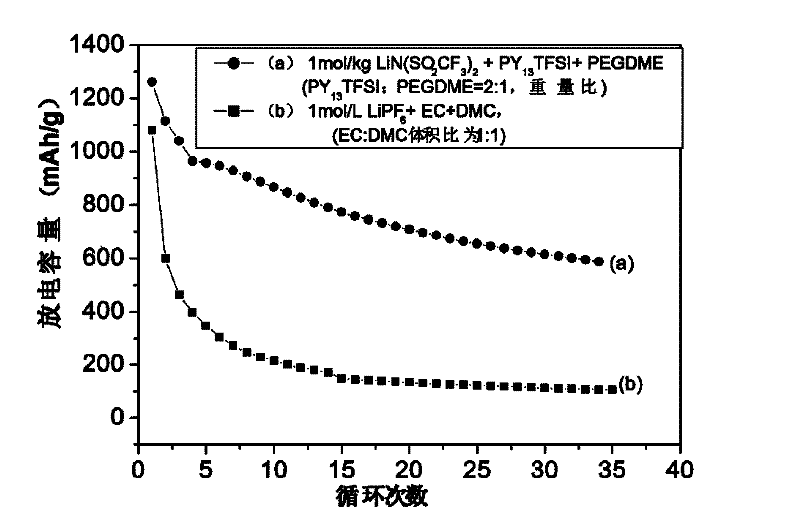

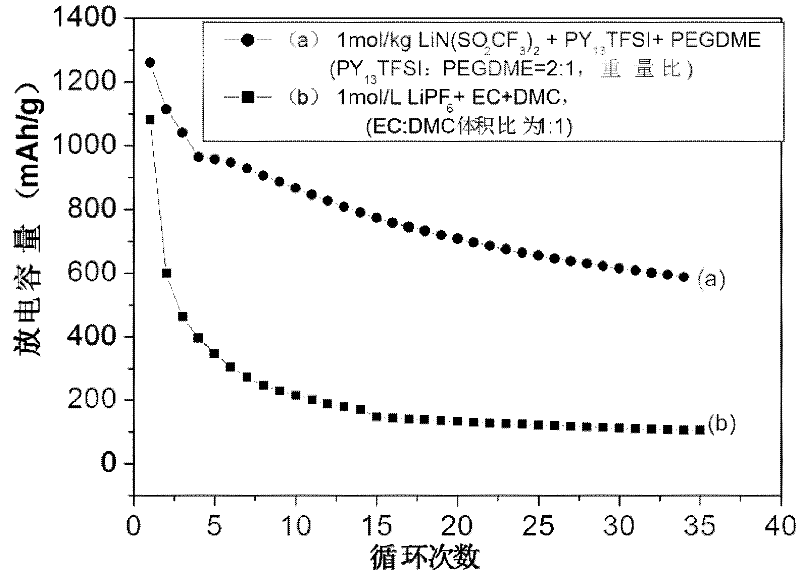

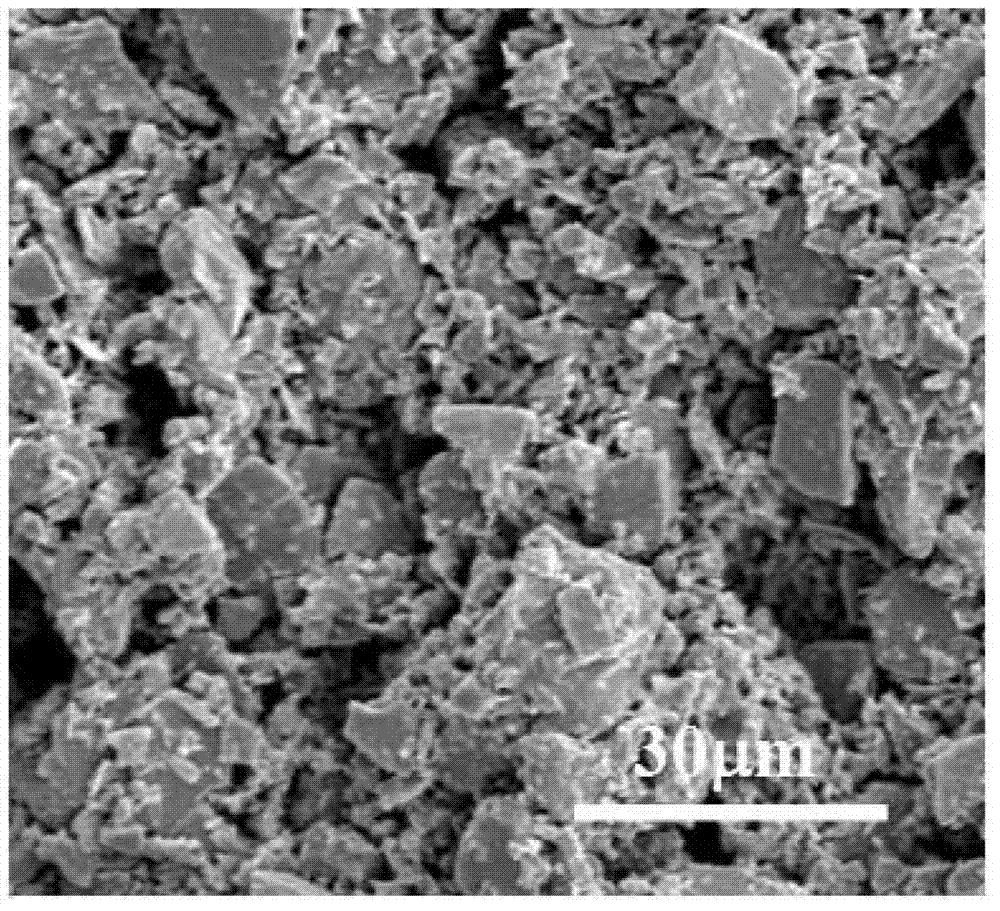

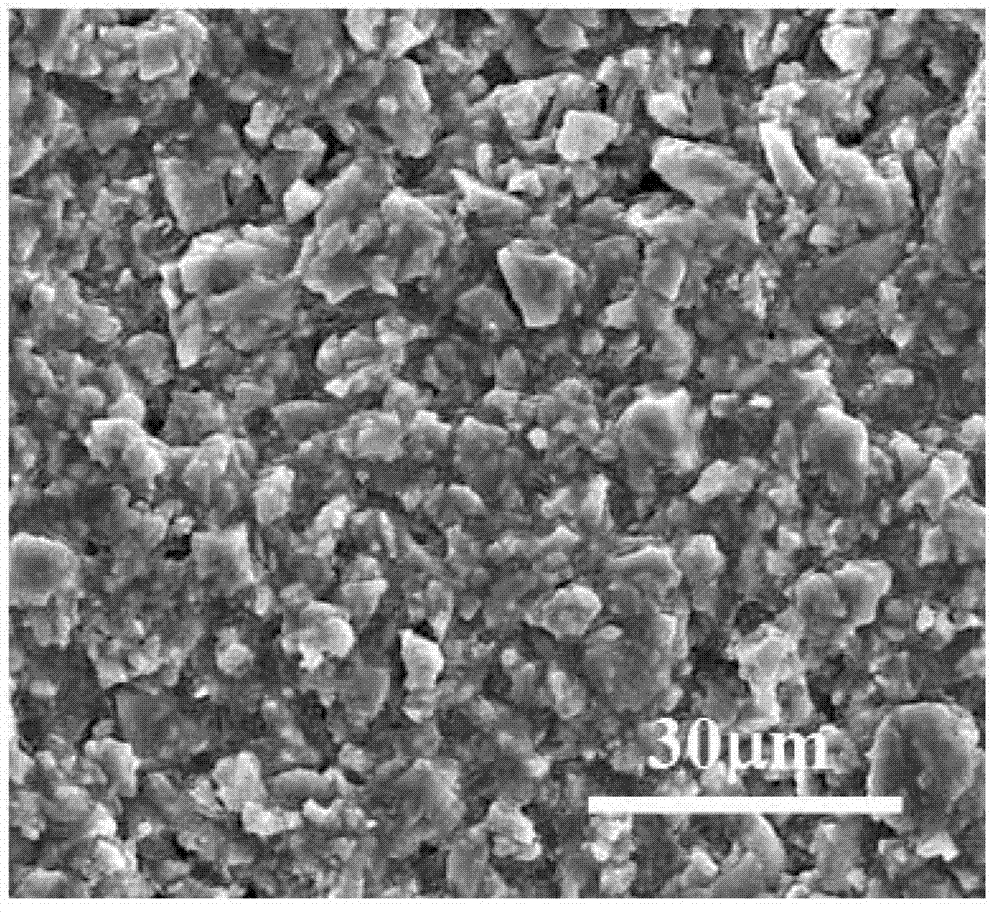

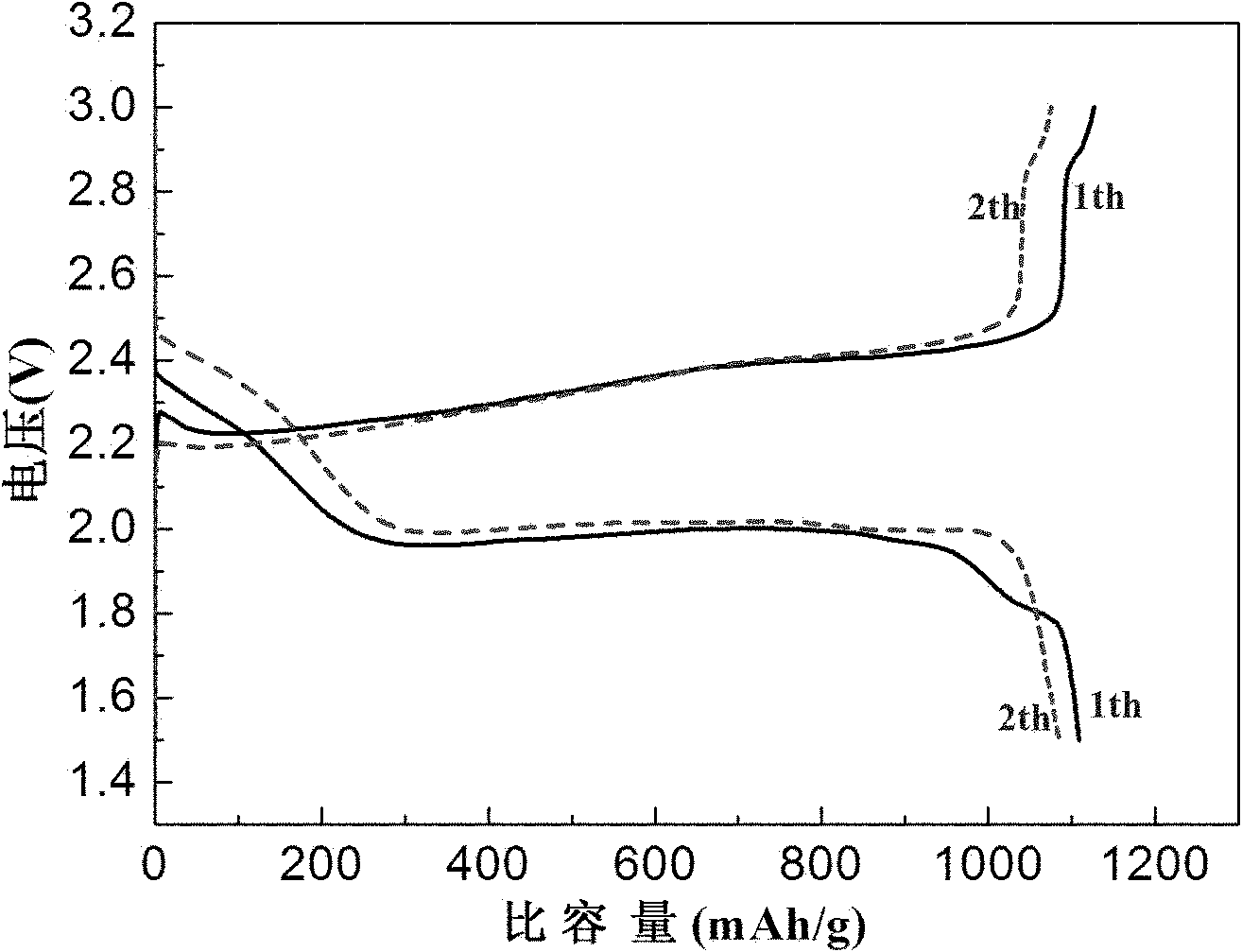

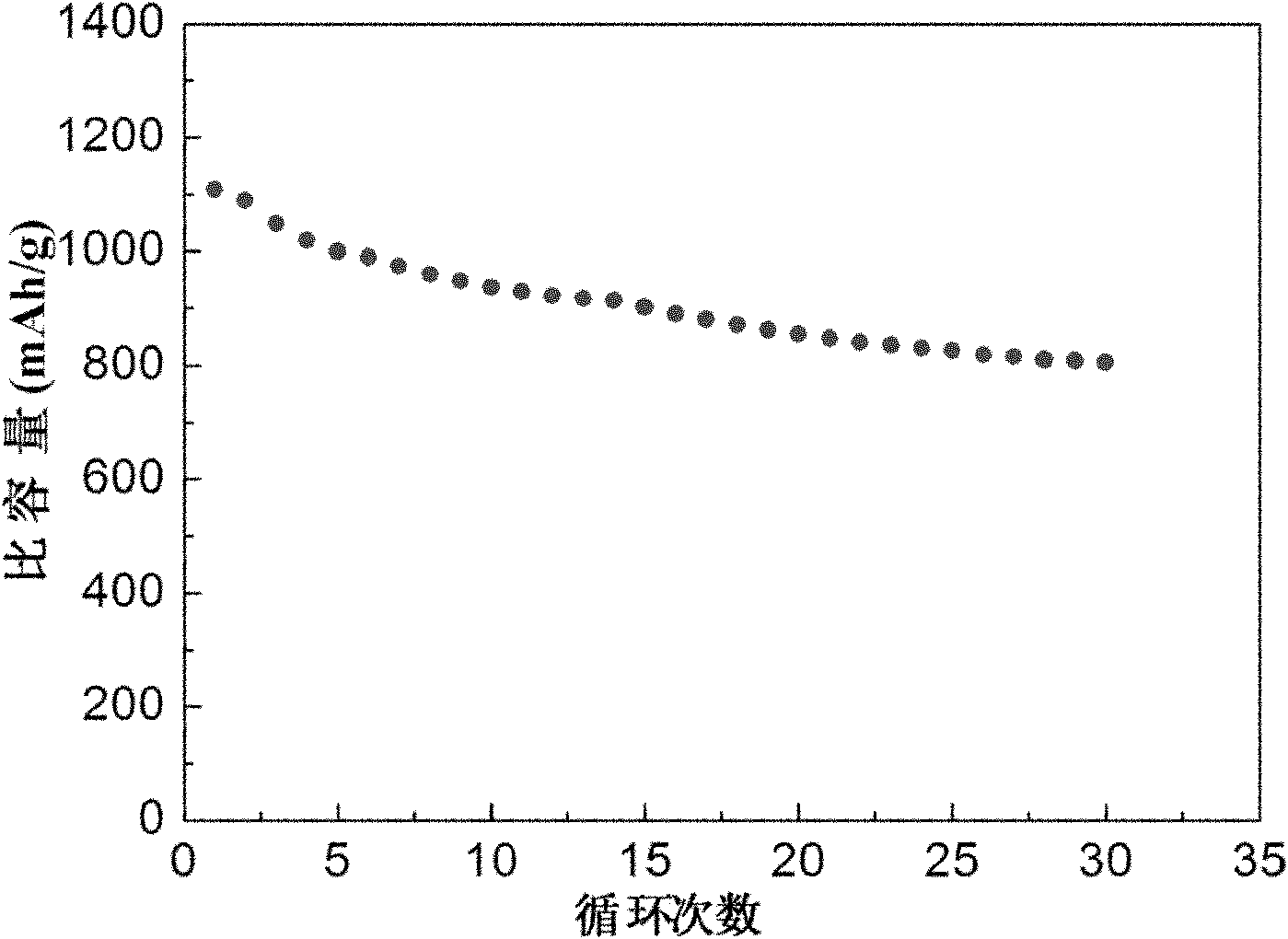

The invention discloses a porous polymer electrolyte supporting membrane material and a lithium sulphur battery gel polymer electrolyte made of the same. A preparation method for the gel polymer electrolyte comprises the following steps of: dissolving a polymer blend in a solvent so as to form a uniform polymer solution, carrying out electrical spinning on the polymer solution so as to obtain reticular fibers, drying the reticular fibers in vacuum so as to obtain the porous polymer electrolyte supporting membrane material, and immersing the supporting membrane material in an ionic liquid type electrolyte so as to obtain the gel polymer electrolyte. The porous polymer electrolyte supporting membrane material has the advantages of controlled and uniformly distributed pore size, higher porosity and liquid absorption rate; compared with the common electrolyte of the lithium sulphur battery, the prepared lithium sulphur battery gel polymer electrolyte has the advantage of greatly improving the utilization rate of anode active materials and the stability of battery circulation; and the technology is simple, has low requirements for operation and environments and provides a simple, convenient and practical condition for technology production.

Owner:SOUTH CHINA NORMAL UNIVERSITY

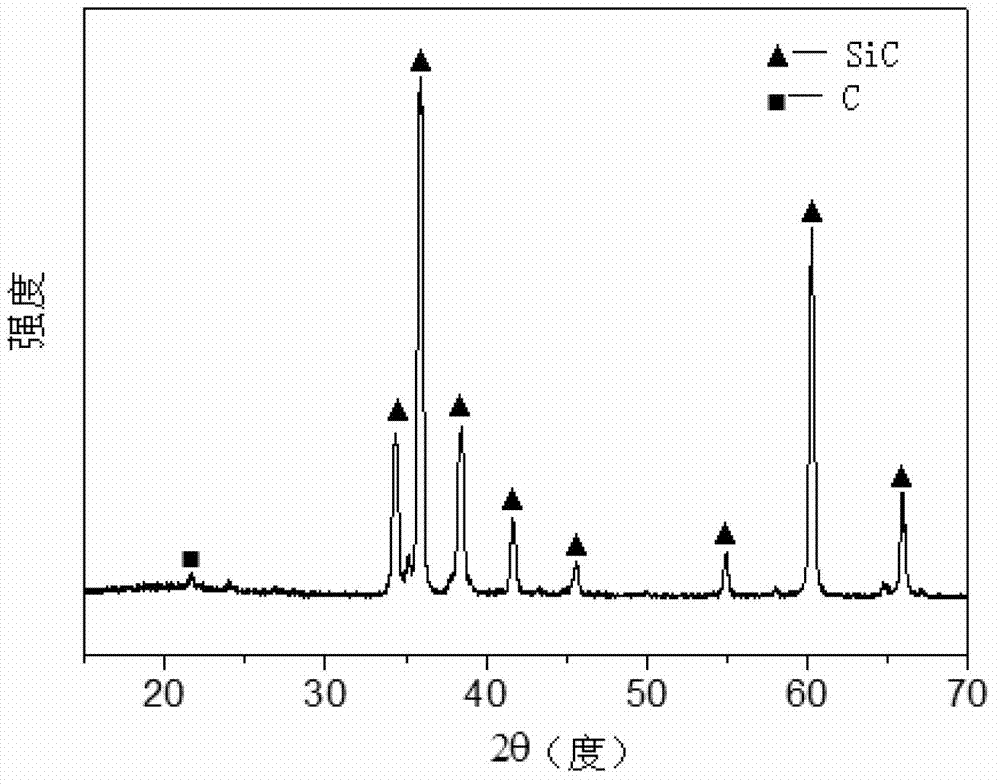

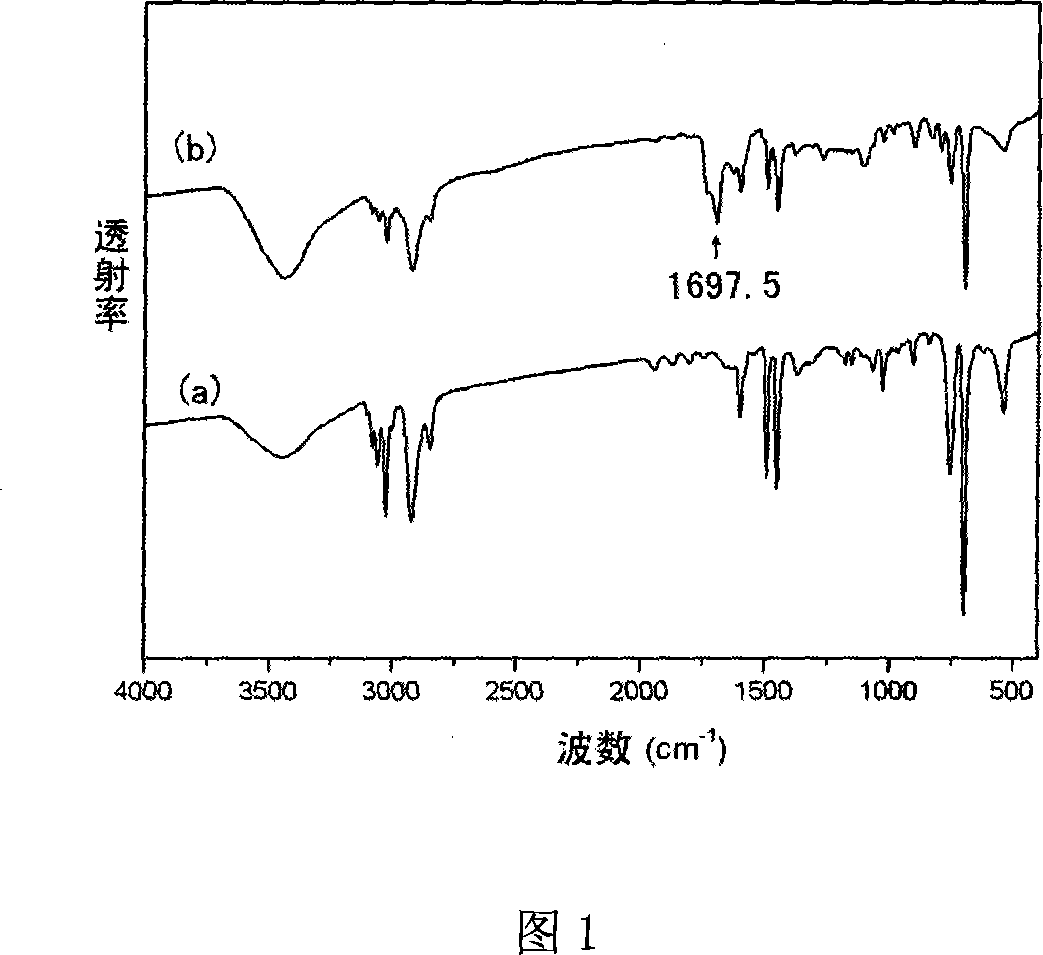

Method for preparing porous silicon carbide ceramic

ActiveCN102807391AImprove strength propertiesLow costCeramicwareSilica fumeMechanical properties of carbon nanotubes

The invention discloses a method for preparing porous silicon carbide ceramic, and relates to a method for preparing silicon carbide ceramic. The invention aims to solve the technical problems of low mechanical properties and low porosity of porous silicon carbide ceramic prepared through the existing method. The method comprises the following steps of 1, preparing pulp; 2, preparing a porous ceramic green body; 3, preparing a prefabricated body; 4, preparing carbon gel; 5, preparing a composite material of silicon carbide and the carbon gel; 6, preparing a composite material of porous silicon carbide and carbon aerogel; and 7, putting the composite material of the porous silicon carbide and the carbon aerogel and monatomic silicon powder into a sintering furnace to be sintered to obtain the porous silicon carbide ceramic. The porosity of the opening of the porous silicon carbide is 30-83 percent, the aperture size is 0.3-100m, and pore spaces can be uniformly distributed or directionally arranged. Through a three-point bending test, the bending strength of the finally prepared porous silicon carbide ceramic material with the porosity of 47.8 percent achieves 164.62 MPa.

Owner:HARBIN INST OF TECH

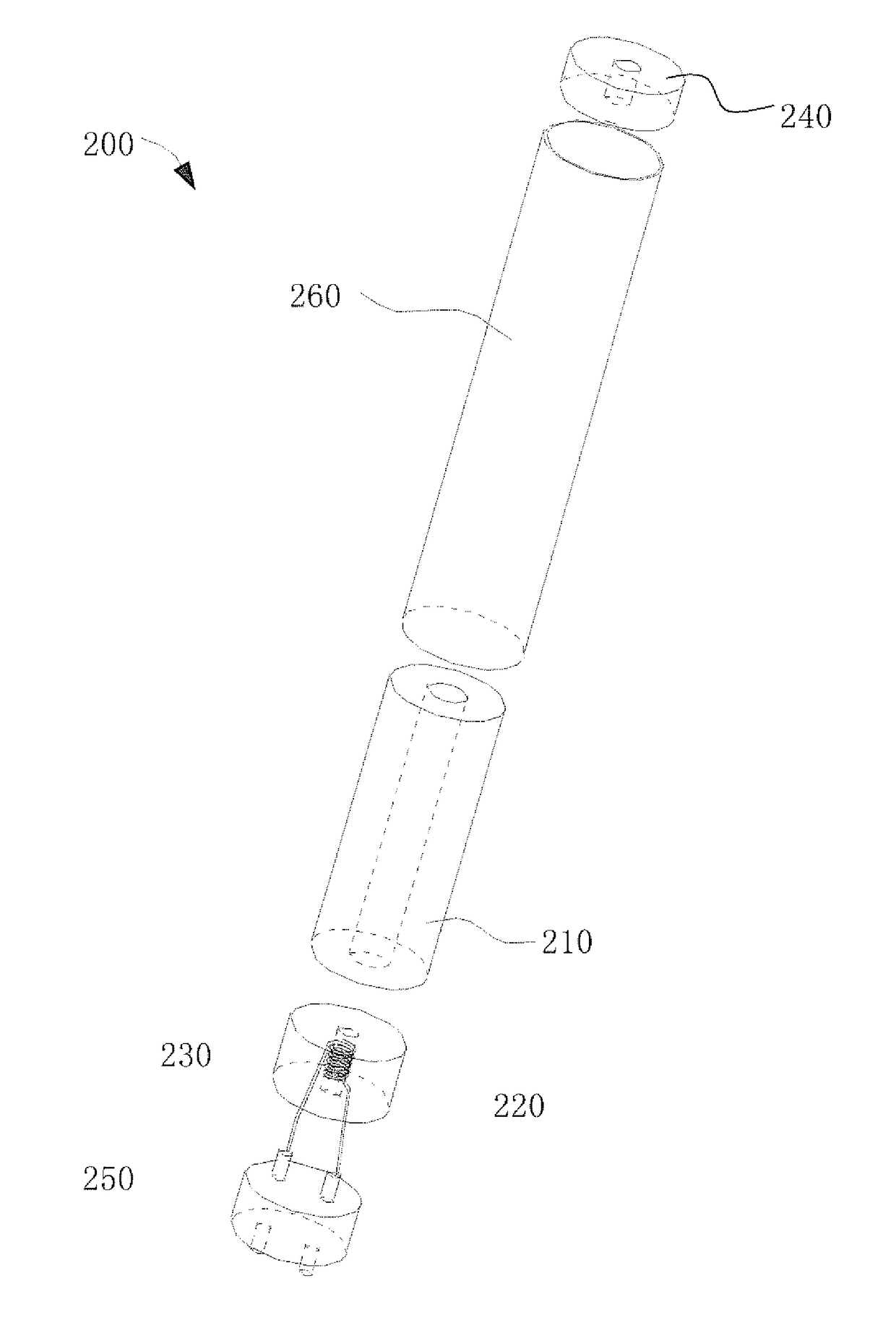

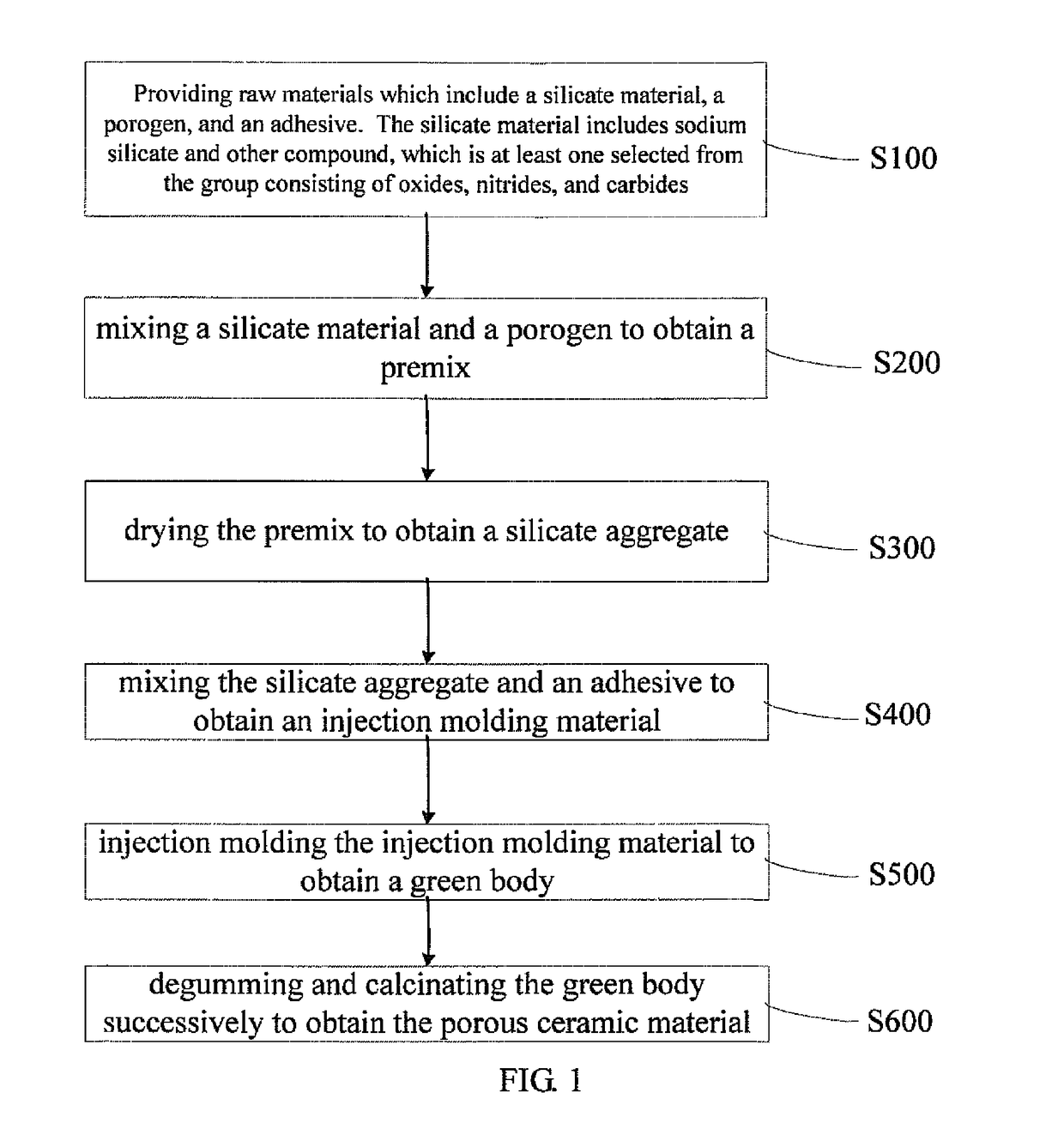

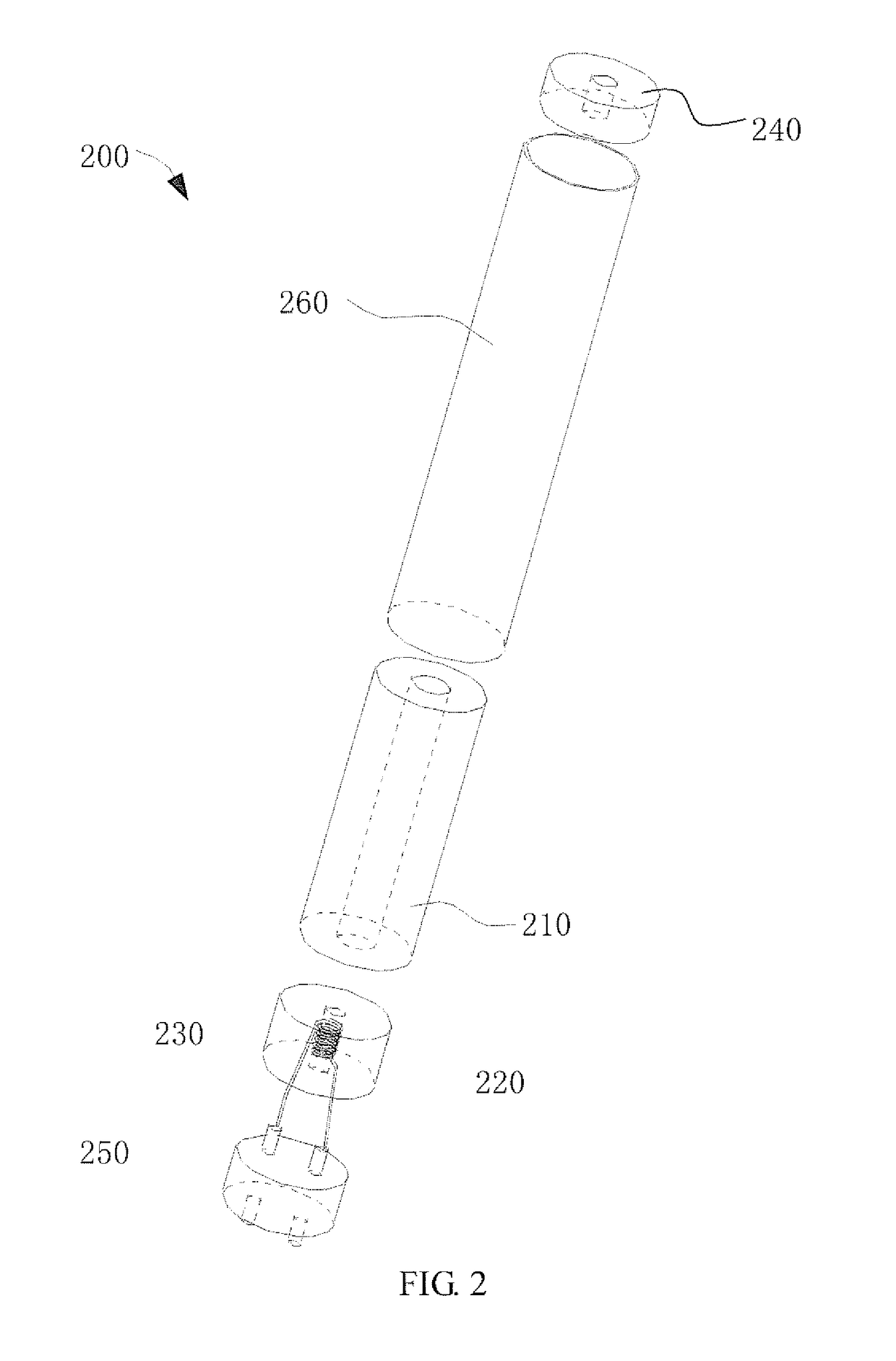

Porous ceramic material, manufacturing method and use thereof

ActiveUS9648909B2High porosityAperture controllableTobacco devicesCeramic shaping apparatusAdhesiveSpace Maintainers

Owner:SHENZHEN SMOORE TECH LTD +2

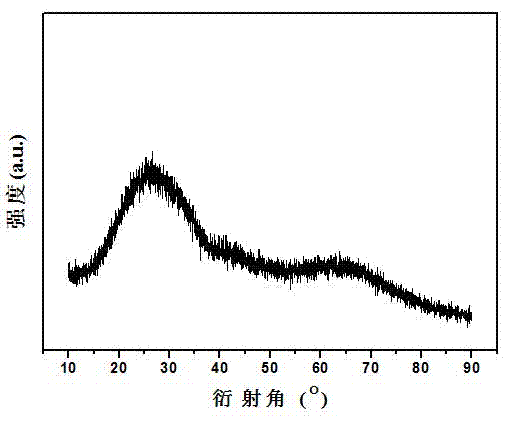

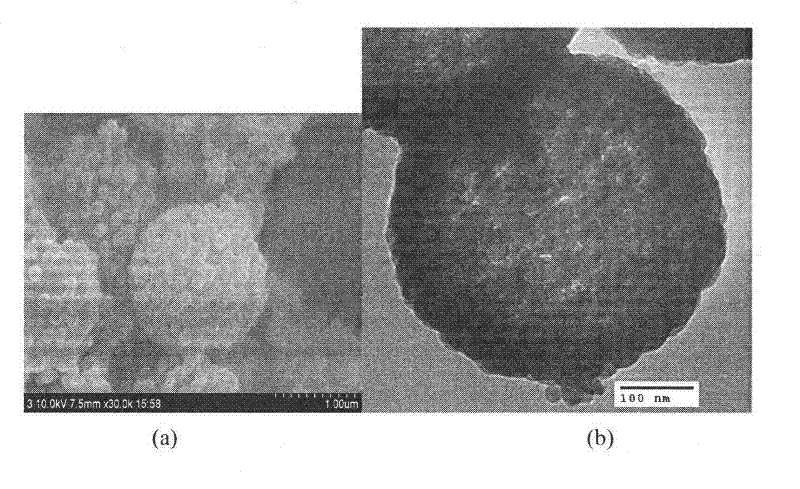

Porous nano carbon fiber material, lithium battery cathode material and cathode plate

ActiveCN102127828AEasy to operateAperture controllableFilament/thread formingSecondary cellsFiberCarbon fibers

The invention discloses a porous nano carbon fiber material, a lithium battery elemental sulfur / porous nano carbon fiber composite anode material and an anode plate which are prepared from the porous nano carbon fiber material. The lithium battery elemental sulfur / porous nano carbon fiber composite anode plate is prepared by using the method: (1) mixing lithium battery elemental sulfur / porous nano carbon fiber composite anode material shown by the right requirements 3 with acetylene black and an adhesive and uniformly stirring to obtain a mixture; and (2) adding an N-methyl pyrrolidone solution to the mixture obtained in the step (1), proportioning into paste and scraping the paste on a carbon-coated aluminum foil as a current collector and drying to obtain an elemental sulfur / porous nano carbon fiber composite anode plate. Lithium sulphur batteries made by utilizing the anode plate of the invention have greatly-improved cycle performance.

Owner:SOUTH CHINA NORMAL UNIVERSITY

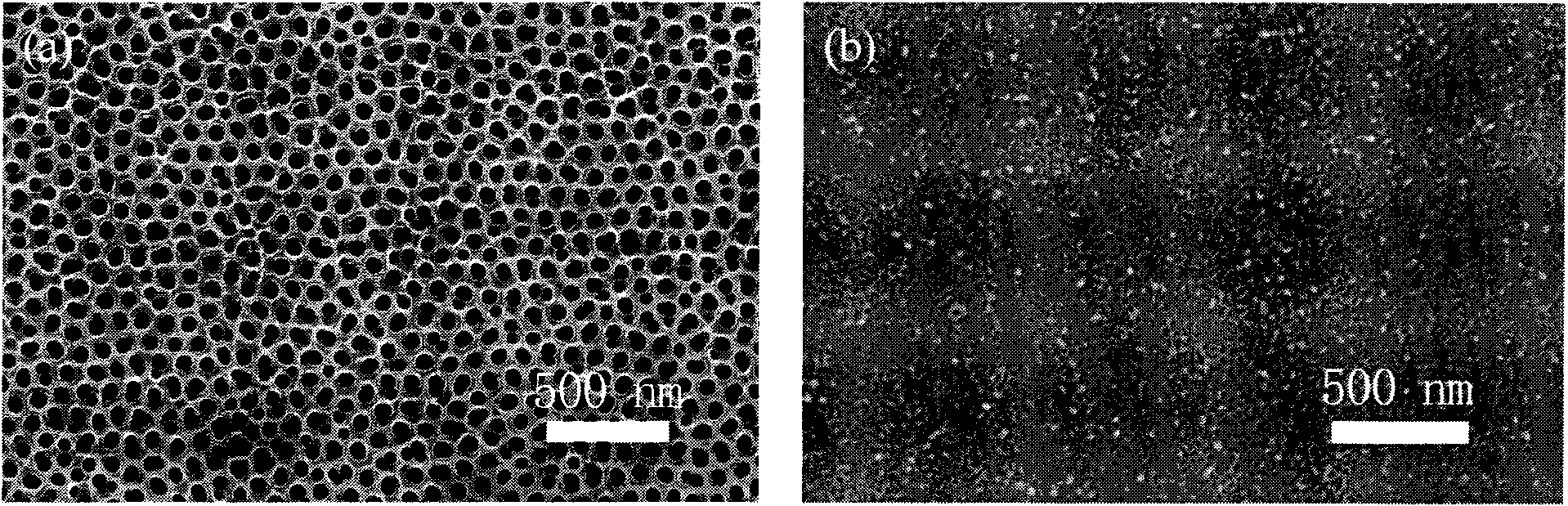

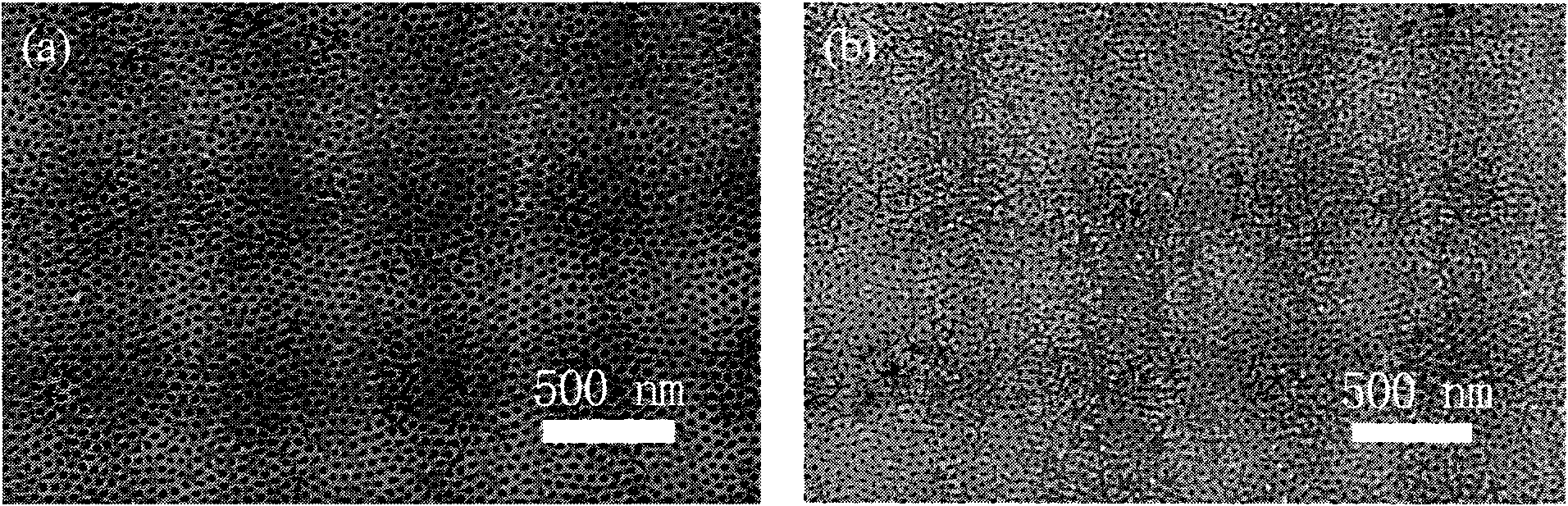

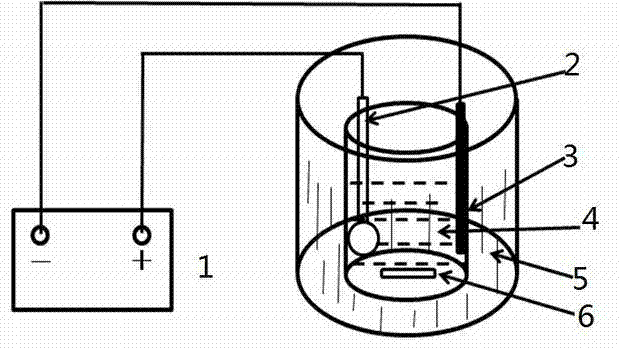

Method for preparing pore diameter controllable through hole anodized aluminum oxide film

The invention relates to technology for preparing an anodized aluminum oxide film, in particular to a method for preparing a pore diameter controllable through hole anodized aluminum oxide film. The method comprises the following steps of: performing anode electrolysis treatment on an anodized aluminum oxide film with an aluminum substrate in mixed solution of perchloric acid and acetone to obtain a pore diameter controllable anodized aluminum oxide film with two open ends in short time (2-300 seconds), wherein the pore diameters at the top end and the bottom end fo the anodized aluminum oxide film are accurately controllable in ranges of between 10 and 100nm and between 5 and 25nm; and putting the aluminum oxide film with the aluminum substrate subjected to stage depressurization-method oxidation into acetone solution of perchloric acid, and applying voltage 5-15V higher than film forming voltage for anode electrolysis treatment to obtain the pore diameter controllable through hole anodized aluminum oxide film. In the method, the pore diameters at the top end and the bottom end of the anodized aluminum oxide film can be respectively controlled, holing and removal of the aluminum substrate are completed by one step, and a plurality of problems of complicated process, time consumption, difficult control of pore diameters and the like in the conventional process for preparing the through hole anodized aluminum oxide film.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

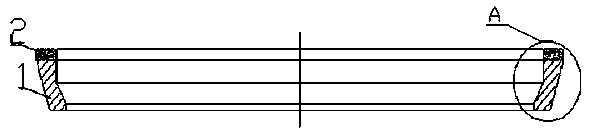

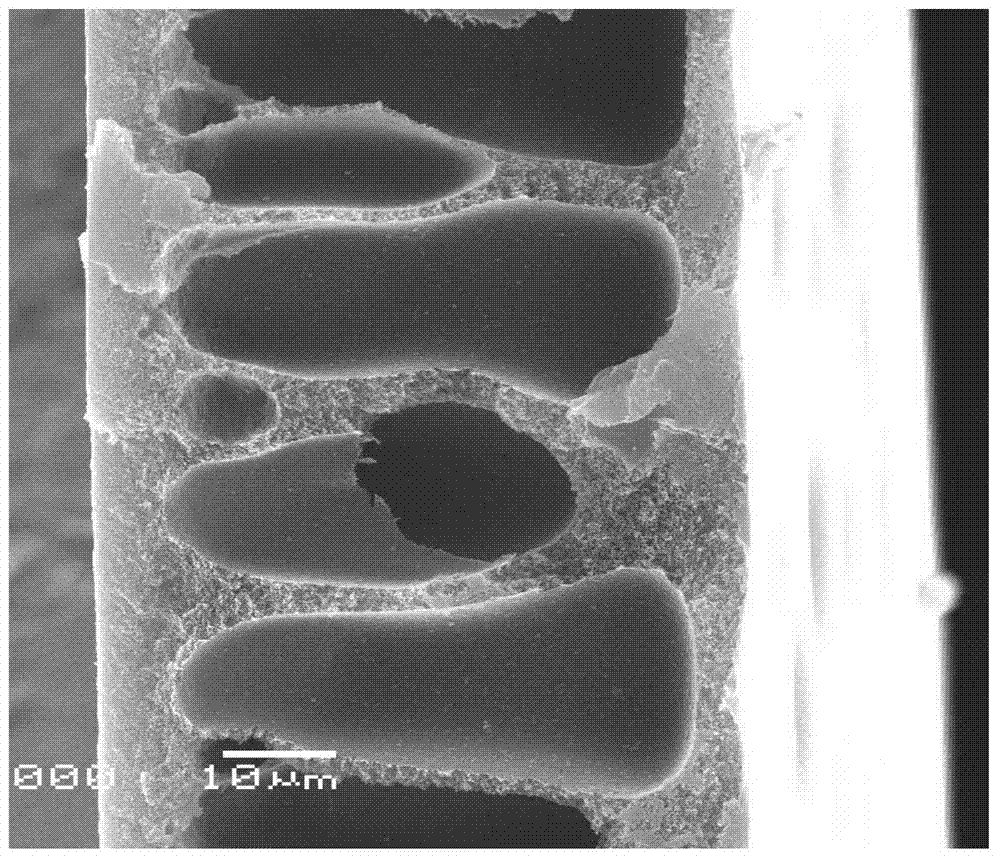

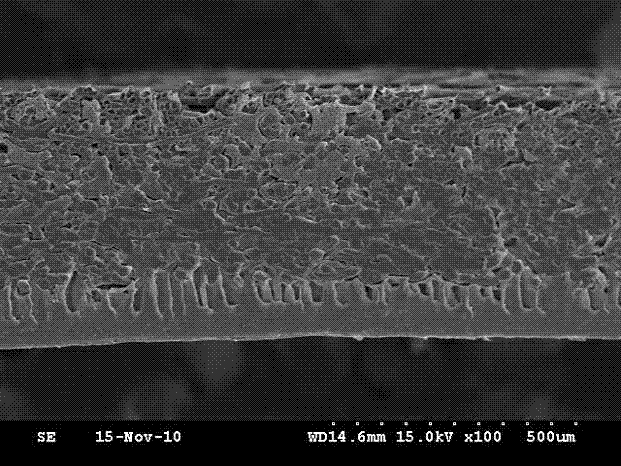

Hollow fiber porous membrane in perfluoro polymer and preparation method thereof

InactiveCN101884878ALower melt processing temperatureLow viscositySemi-permeable membranesTetrafluoroethyleneFiber

The invention discloses a hollow fiber porous membrane in a perfluoro polymer and a preparation method thereof. A membrane forming system of the membrane comprises the following components in percentage by weight: 40 to 60 percent of perfluoro polymer; 10 to 30 percent of polymer additive, 10 to 30 percent of composite pore-forming agent and 5 to 20 percent of organic low-molecular liquid; the perfluoro polymer is a copolymerized modified product of tetrafluoroethylene and a perfluoro second monomer; the polymer additive is fluor alkaline-containing polymers or a mixture thereof; the composite pore-forming agent comprises a soluble pore-forming agent and a non-soluble pore-forming agent; and the organic low-molecular liquid is a diluent of the polymer additive with a high boiling point. The preparation method comprises the following steps of: forcibly mixing the polymer additive, the composite pore-forming agent and the organic low-molecular liquid; uniformly mixing the mixture and the perfluoro polymer particles; and injecting the mixture into a double-screw machine, performing melt blended spinning at a temperature of between 300 and 360 DEG C and finally performing a conventional post-processing to obtain the hollow fiber porous membrane.

Owner:TIANJIN POLYTECHNIC UNIV

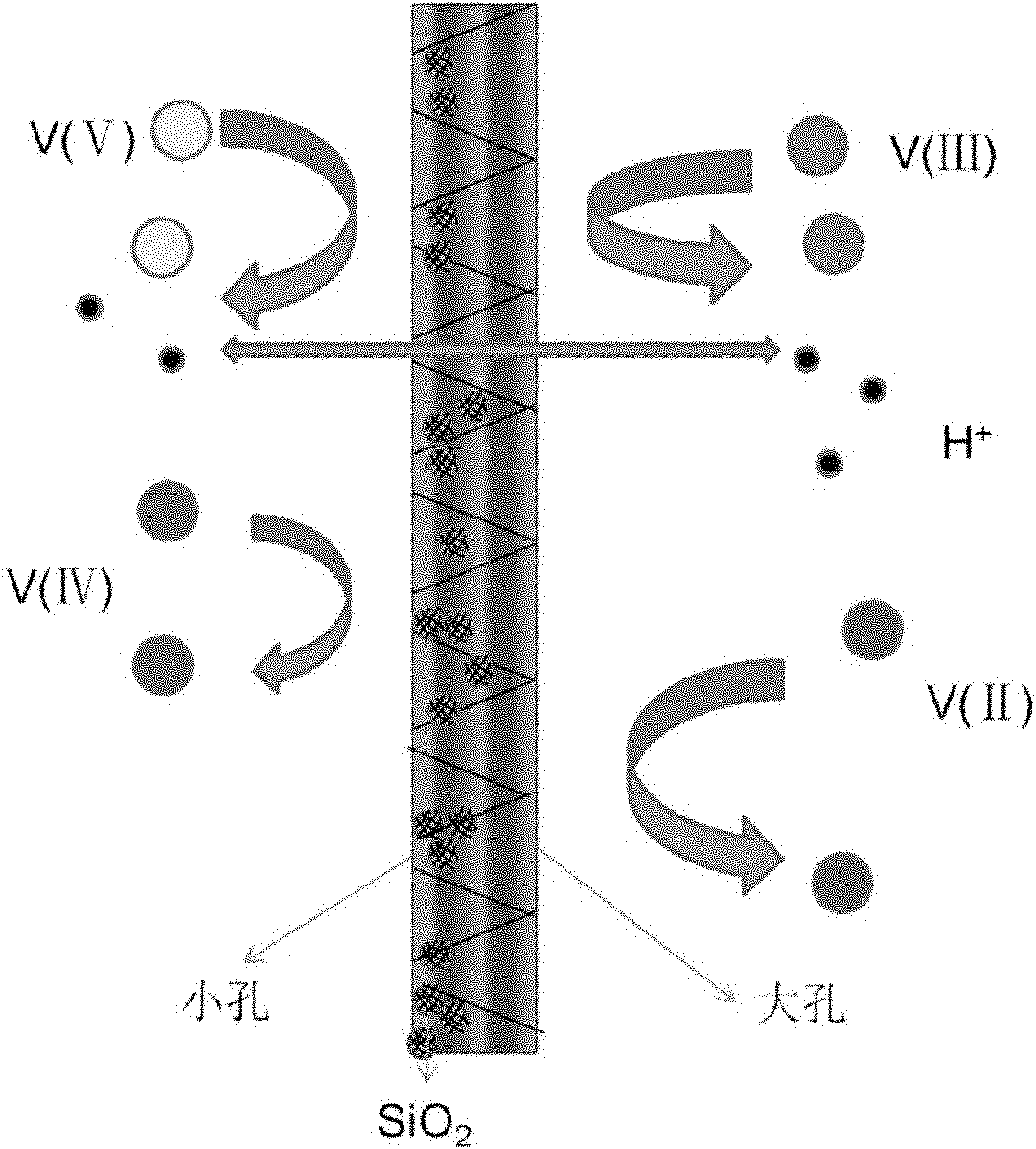

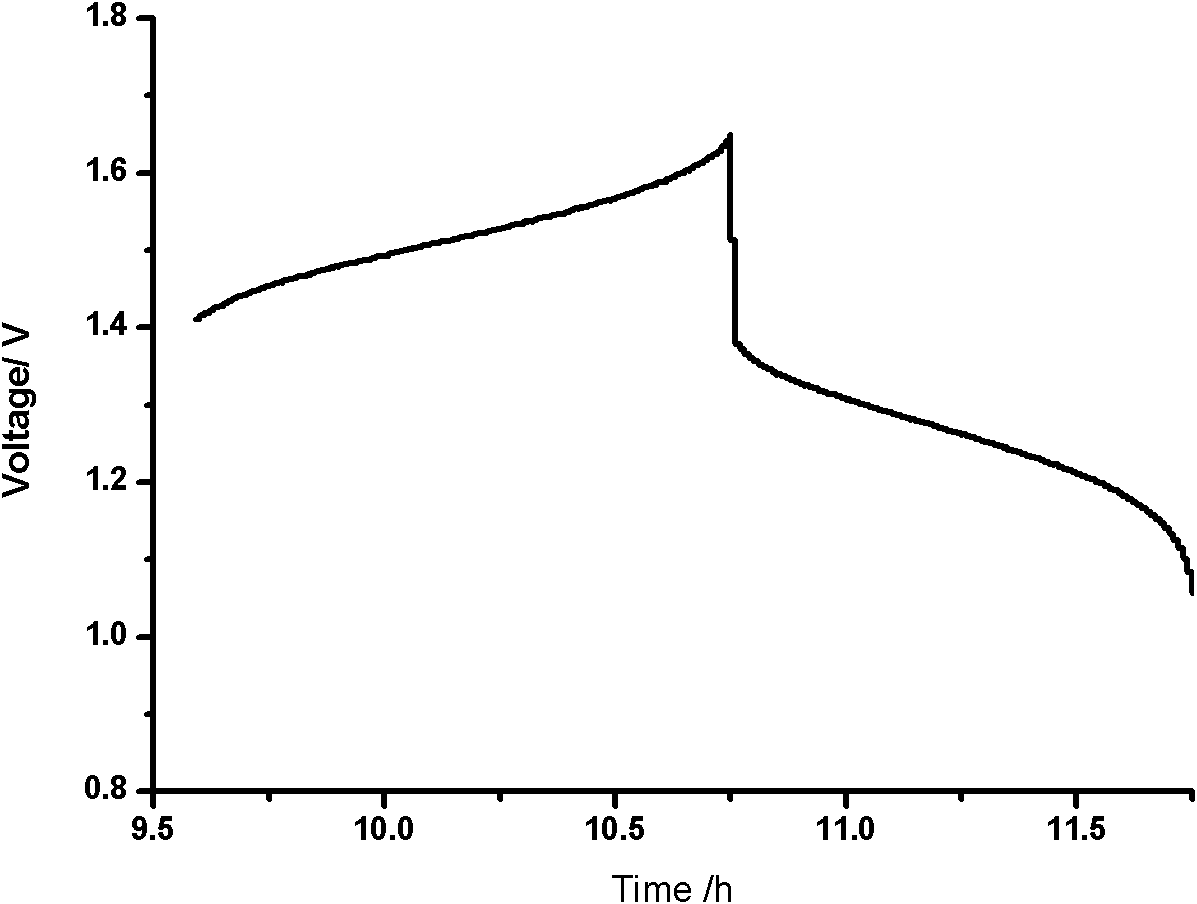

Inorganic matter-filled poriferous composite membrane for liquid flow energy-storage cell and use thereof

ActiveCN102569839ASelection throughEasy to prepareFinal product manufactureCell component detailsIon exchangeSilicon oxide

The invention discloses an inorganic matter-filled poriferous composite membrane for a liquid flow energy-storage cell and a use thereof. The inorganic matter-filled poriferous composite membrane for a liquid flow energy-storage cell is characterized in that one or more of organic polymer resins and sulfonated organic polymer resins are prepared into a poriferous diaphragm as a matrix; inorganic matter particles are filled into apertures of the matrix so that the inorganic matter-filled poriferous composite membrane is obtained; and the inorganic matter particles are prepared from one or more of silicon oxide, zirconia, titanium oxide, lead oxide, tungsten oxide and zirconium phosphate. The inorganic matter-filled poriferous composite membrane can be prepared by simple processes, has controllable apertures, is suitable for large-scale production, has high ion selectivity, hydrophily and ion conductivity, can realize ion transport without introduction of any ion exchange groups, and broadens a selection scope of liquid flow energy-storage cell membrane materials.

Owner:DALIAN RONGKE POWER

Peripheral edge grinding wheel for machining PCBN (polycrystalline cubic boron nitride) blades

InactiveCN103753413AEvenly distributedUniform pore sizeBonded abrasive wheelsGrinding devicesLithium hydroxideBoron nitride

The invention discloses a peripheral edge grinding wheel for machining PCBN (polycrystalline cubic boron nitride) blades. The peripheral edge grinding wheel comprises a grinding wheel matrix and a grinding material layer. The grinding material layer is positioned on the grinding wheel matrix and is made of raw materials including, by weight, 44-65% of diamond, 22.5-40.5% of ceramic bonding agents, 0.5-10% of pore forming agents and 5-10% of phenolic resin liquid; the ceramic bonding agents are made of raw materials including, by weight, 40-60.5% of silicon dioxide, 5.5-17% of alumina, 25-35% of boric acid, 2-7% of sodium carbonate, 8-11% of lithium hydroxide and 2-6% of calcium oxide; pore forming agents are alumina hollow balls. The peripheral edge grinding wheel has the advantages of good sharpness, high grinding quality and long service life.

Owner:江苏赛扬精工科技有限责任公司

Method for preparing recrystallized SIC high temperature gas filter element

InactiveCN1821180AAchieve functional optimizationAvoid erosionFiltration separationCeramicwareFiberPore distribution

The present invention relates to preparation process of porous ceramic filter element for high temperature corrosive condition use. The preparation process features the pore creating with organic pore creating agent, spray pelletizing and isostatic pressing formation, high temperature Ar protected sintering to prepare high strength and low filtering resistance recrystallized SiC filter element support, multiple spraying of ceramic slurry with pore creating agent of different granularity to the surface of the support, and sintering to form filtering mullite coating with gradient pore distribution, adding alumina fiber into the filtering layer to raise the strength of the filtering layer and the combination between the coating and the support. The filtering element of the present invention has high mechanical strength, high heat shock resistance, high corrosion resistance, high wear resistance, high filter precision, low pressure drop and high stability.

Owner:GUIZHOU NEW MATERIAL MINING DEV

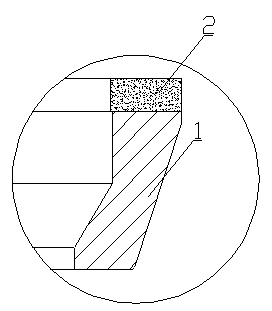

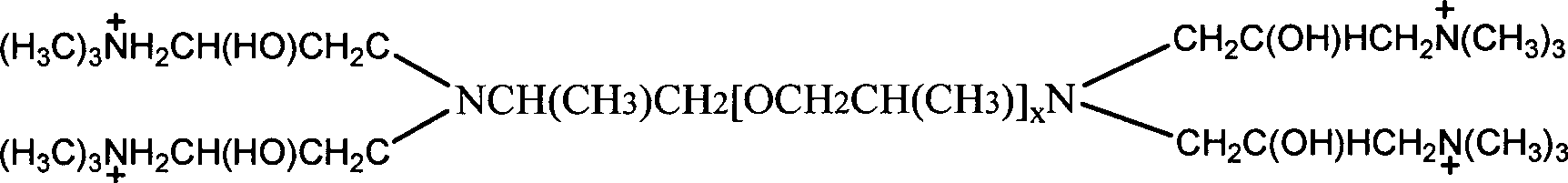

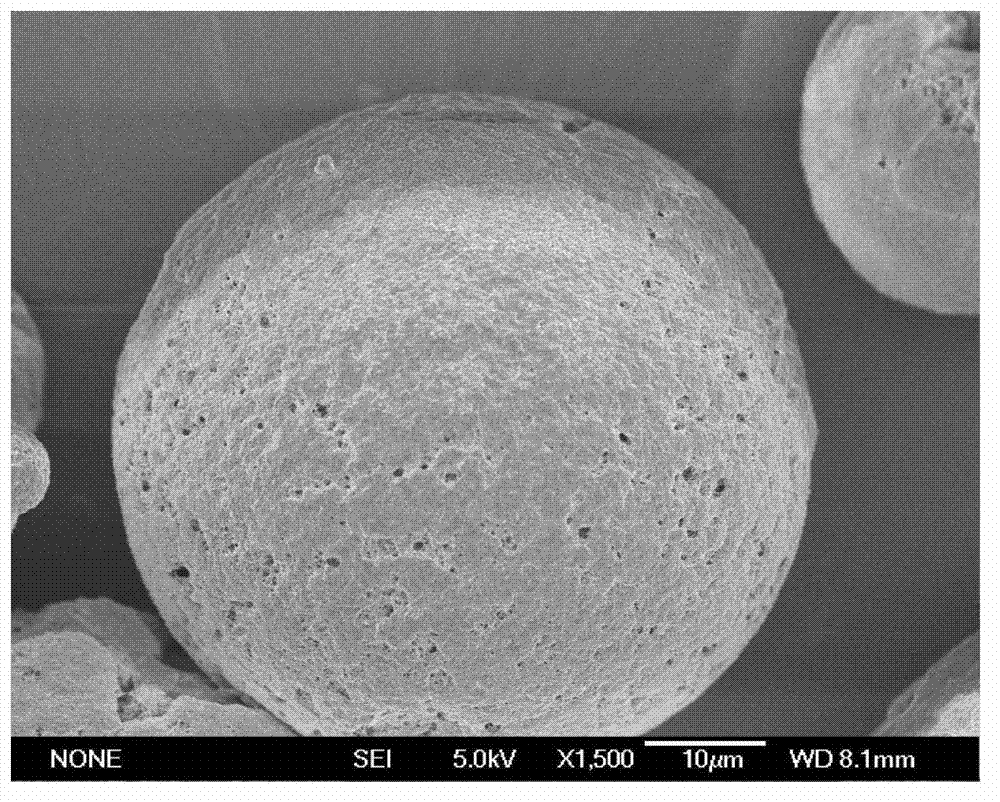

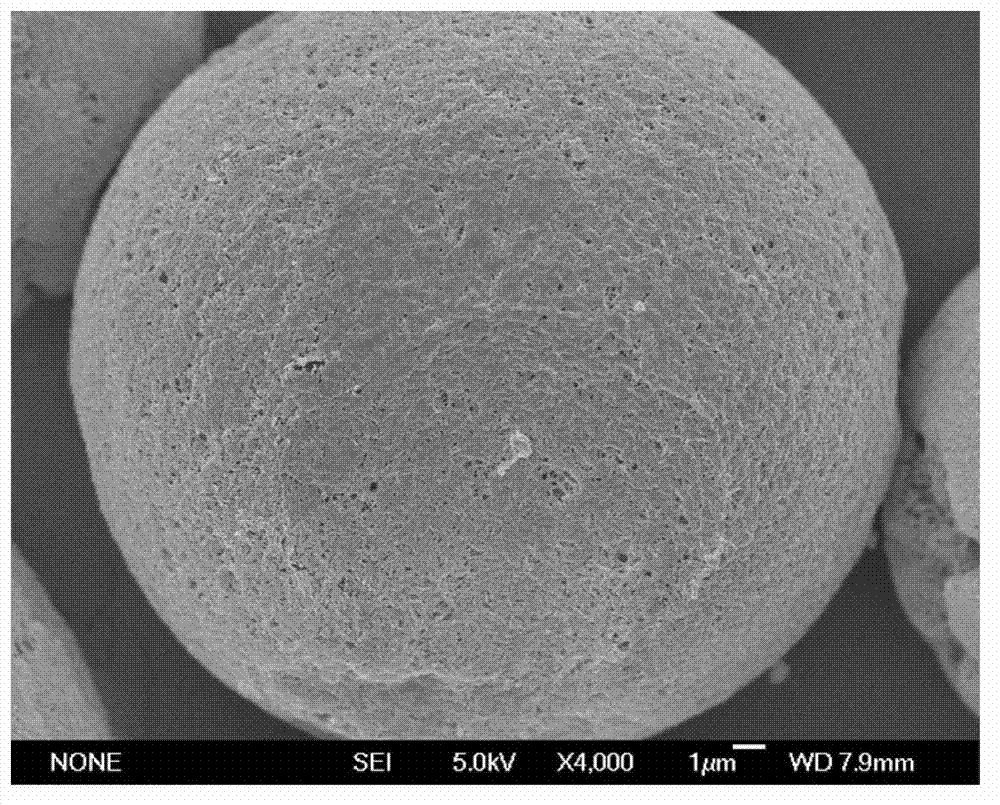

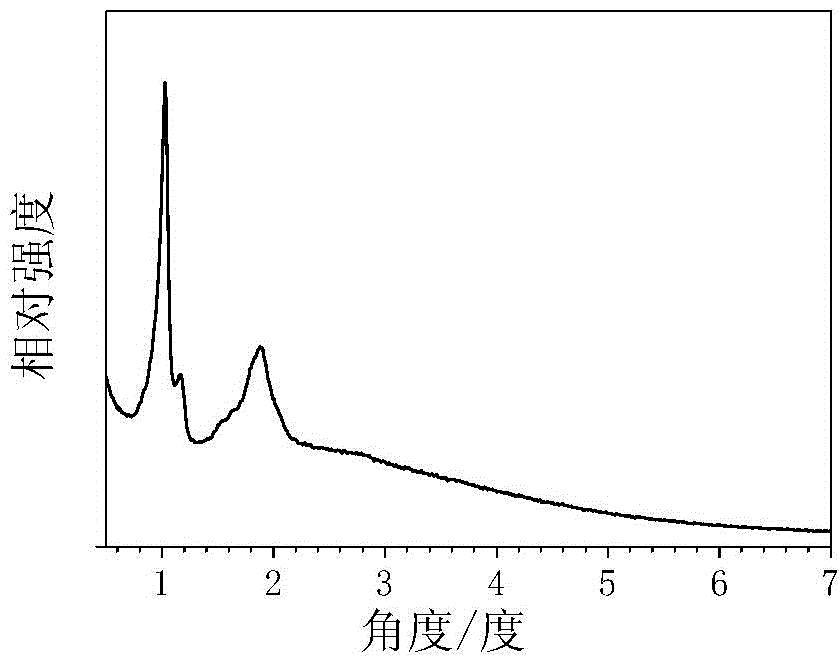

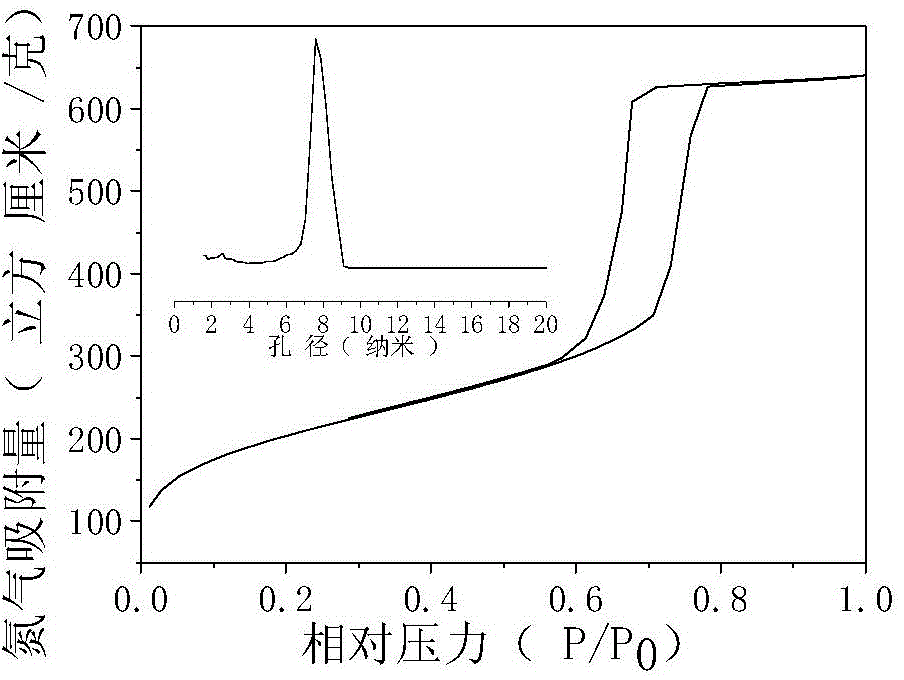

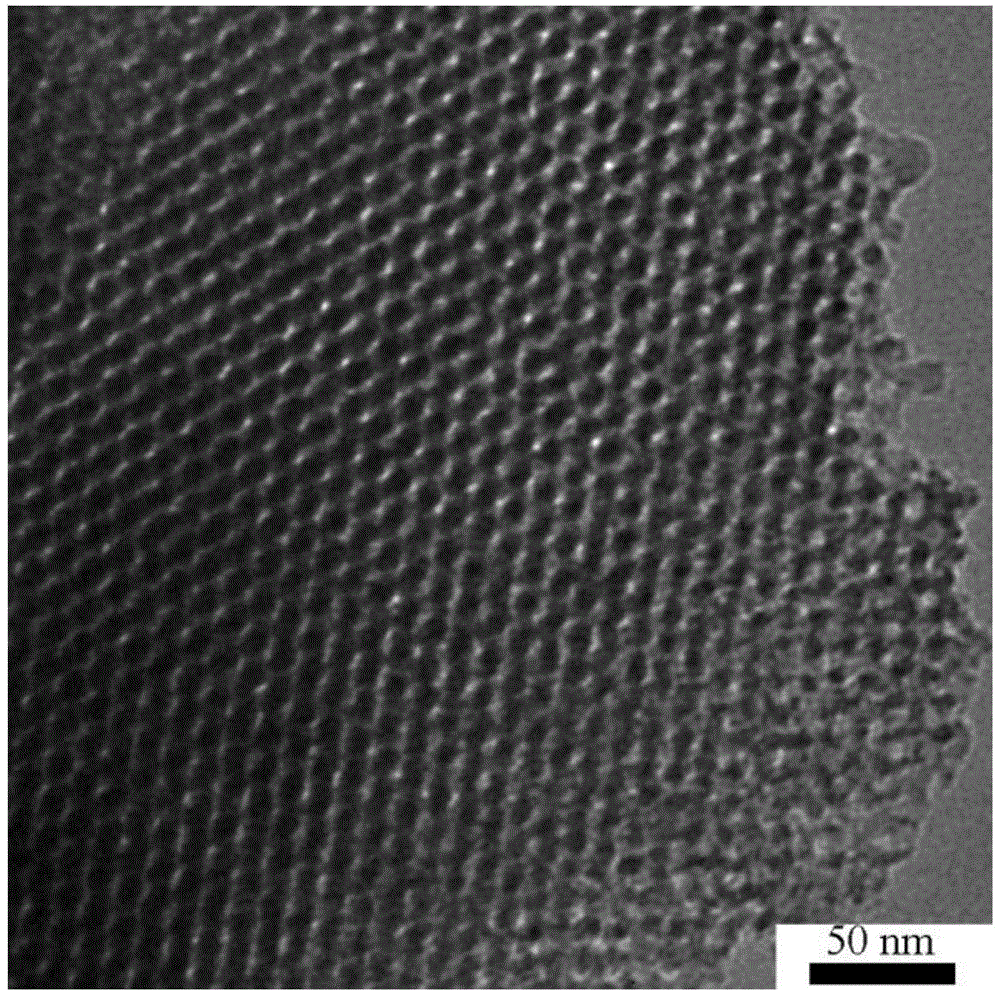

Preparation and use of pore diameter controllable mesoporous silicon dioxide microsphere

The invention discloses a method for preparing a mesoporous silicon dioxide microsphere with controllable aperture. The method takes a novel tetra-quaternary ammonium salt cation surface active agent as a structure-directing agent and synthesizes the mesoporous silicon dioxide microsphere in an ethanol water system under the alkaline condition by a sol-gel method. The method has the advantages that the prepared silicon dioxide is micron spherical particles and has good monodispersion and large specific surface area; the mesoporous microsphere with large aperture can be prepared without an expanding agent; and the silicon dioxide microsphere prepared by the method has stable performance and is suitable for high-efficiency liquid-phase chromatographic separation and analysis.

Owner:EAST CHINA UNIV OF SCI & TECH

Preparation method of anodized aluminum film of through hole

InactiveCN102776542ALow process pollutionLow priceSurface reaction electrolytic coatingElectrolytic agentOXALIC ACID DIHYDRATE

The invention discloses a preparation method of an anodized aluminum film of a through hole. The preparation method mainly comprises the following steps: after a high-purity aluminum sheet is subjected to annealing, oxide layer removing, degreasing and electrochemical polishing treatment, placing into an anodizing electrolytic cell to carry out primary anode oxidation by taking oxalic acid, sulfuric acid or phosphoric acid solution as electrolyte, after an oxide layer is removed through treatment of mixed aqueous solution of chromic acid and phosphoric acid once, the secondary oxidation is carried out under the same conditions, the residual aluminum-based substrate is removed in acid solution, and reaming is carried in the phosphoric acid, so that the anodized aluminum film of the through hole with small aperture, and the controlled aperture and thickness is obtained. According to the invention, the relatively cheap device is used, through the simpler process, a large amount of anodized aluminum films of through holes can be simply and uniformly prepared in a lossless manner, and heavy metals are not introduced in a process of removing the residual aluminum substrate, so that environmental pollution is reduced. The prepared anodized aluminum film has the advantages of good uniformity and repeatability, highly ordered nanometer pore passage, uniform period, and controlled thickness and aperture.

Owner:SOUTH CHINA UNIV OF TECH

Resistivity-controllable conductive silicon carbide foam ceramic material and its preparing process

The invention discloses a preparing method of conductive carbofrax foaming ceramic with controllable resistance rate, which adopts polygon patterned sealed ring as basic unit with each basic unit connecting to form three-dimensional communicating network, wherein the corresponding density of ceramic bar of polygon patterned sealed ring is not less than 99%; the component contains 80-96% carbofrax, 10-2% metal phase and 10-2% silicon phase; the changing scale of resistance rate is 5-0.01 omega .cm.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

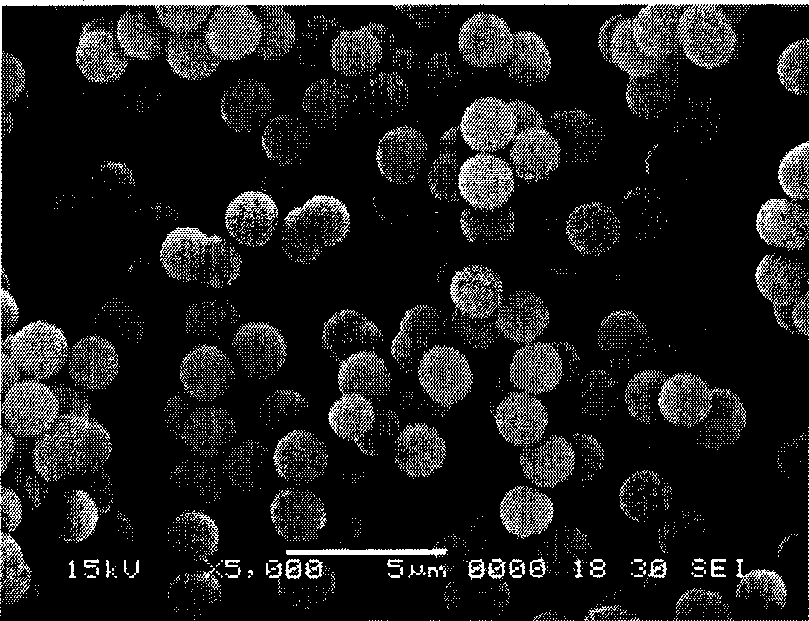

Preparation method of non-porous or porous polymer microsphere of surface function

InactiveCN101045755AAvoid defects that destroy the porous structure of the microspheresAvoid duplication of seed polymerization process stepsSolubilityPolymer science

This invention relates to a preparation method of surface functional, imperforation or multihole polymer microsphere, belongs to functional polymer material technosphere. The steps: remove polymerization inhibitor in alkene monomer; add mono-olefin monomer to continuous phase solvent, form reaction system, inlet nitrogen, takes reaction under homothermal condition to obtain seed polymer microsphere; mix seed polymer microsphere solution and activator, form first-order swelling reaction solution; then add mono-olefin monomer, monomer with functional group and cross-linking agent, and make them swell to seed microballoon sphere, form second grade swelling reaction solution; finally add water-solubility polymerization inhibitor, form blending reaction solution, isothermal reaction, ultimately separate to obtain imperforation polymer microsphere with functional surface; or use organic solvent to extract to obtain multihole polymer microsphere with functional surface.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing micropore ceramic separation film

InactiveCN101322919AUniform structureAperture controllableSemi-permeable membranesFiltration separationCross-linkMicroscopic observation

The invention relates to a preparation method for a millipore ceramic separation membrane which belongs to the technical fields of ceramics material preparing and processing. After ceramic powder with a grain diameter of 5 to 15Mu m is mixed with a dispersant, the mixture of organic monomer acrylamide and a cross-linking agent N,N'-methylene diacrylamide is added to manufacture suspended nitride with a solid volume fraction of 45 to 55 percent which is sintered into a porous ceramic supporter after drying and demoulding; then ceramic powder with a grain diameter of 2 to 6Mu m is manufactured into surface membrane suspended nitride with a solid volume fraction of 10 to 25 percent according to the method; the supporter is dipped into the surface membrane suspended nitride and is uniformly extracted to obtain the millipore ceramic separation membrane after being dried and sintered. Through microscopic observation, the supporter is firmly combined with the surface membrane; pores are uniformly distributed; the surface membrane is uniform without defects. The preparation method overcomes the problem that the normal ceramic separation membrane material is easy to form macropores and has asymmetric organizational structures, thus causing the surface membrane to be easy to have the defects of pinholes and cracks.

Owner:SUZHOU UNIV

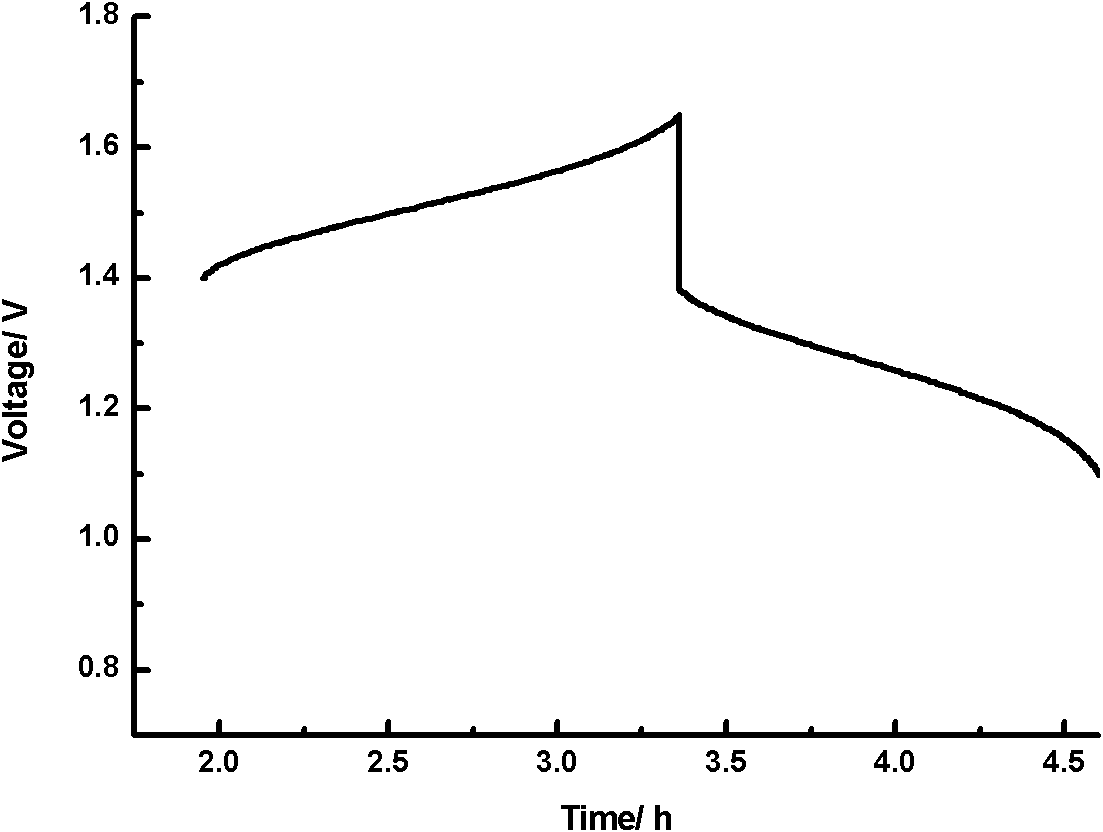

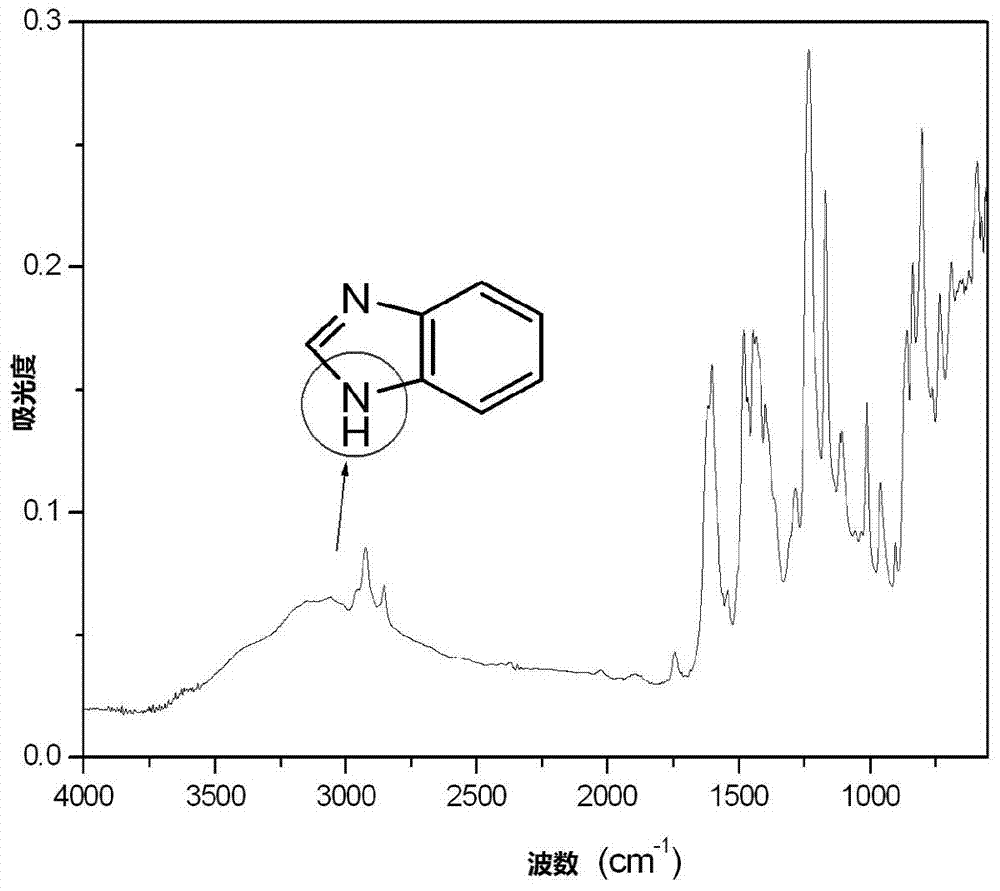

Use of crosslinking type polybenzimidazole porous separating membrane in liquid flow battery

InactiveCN104716352AImprove oxidation stabilityHigh selectivityCollectors/separatorsUltrasound attenuationPhysical chemistry

The invention relates to use of a crosslinking type polybenzimidazole porous separating membrane in a liquid flow battery, and the porous membrane material is a crosslinking type polybenzimidazole polymer material. The porous membrane prepared by the invention is used in the liquid flow battery, by use of a cross-linking method and controlling of the crosslinking reaction, the membrane material oxidation stability and ion selectivity can be improved, the function of an ion exchange membrane in the liquid flow battery can be realized, the problem of capacity attenuation of a porous diaphragm can be effectively solved, the aperture of the porous membrane can be further regulated by change of variety of the polymer and the crosslinking agent of the composite membrane, ion selectivity of the porous membrane can be effectively improved, and the membrane material has the advantages of simple preparation method, controllable pore size, low cost, and easy implementation of large batch production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

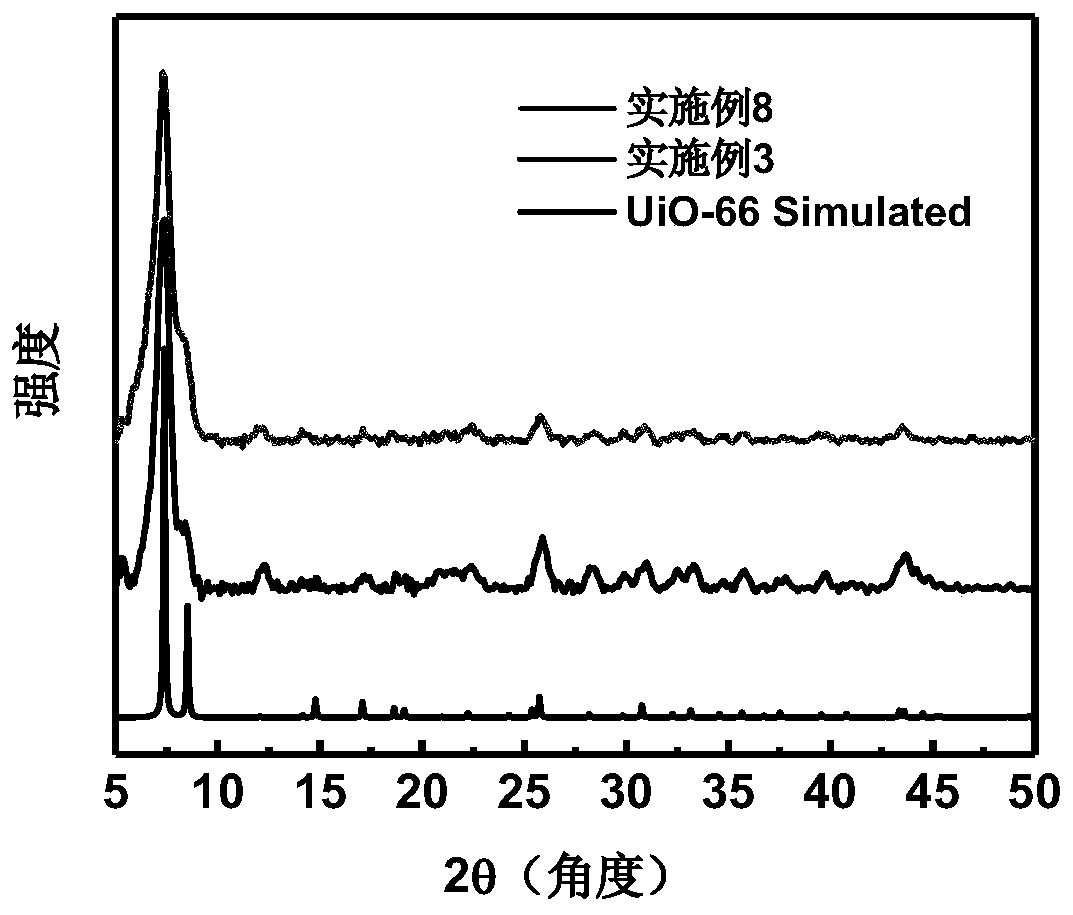

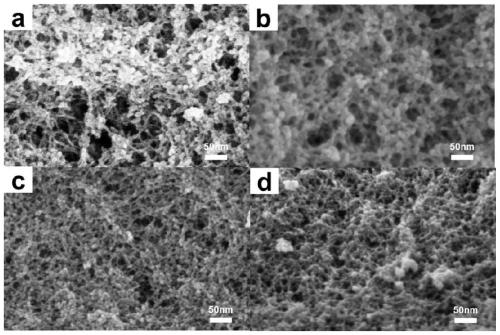

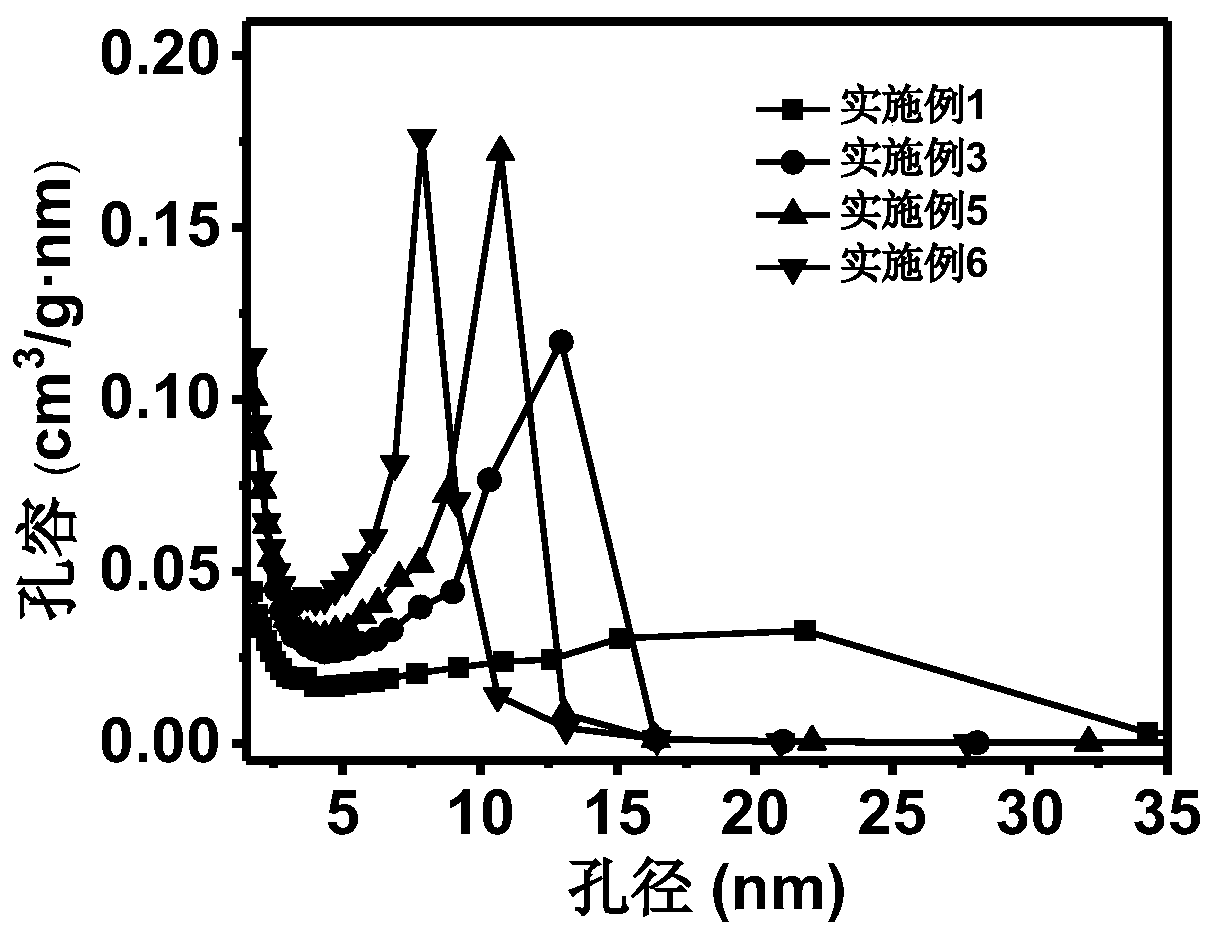

Preparation method and applications of multi-level pore structure metal organic framework material

ActiveCN110256683AAdvantages of preparation methodAperture controllableOrganic-compounds/hydrides/coordination-complexes catalystsEther preparation from oxiranesN dimethylformamideSynthesis methods

The invention provides a preparation method and applications of a multi-level pore structure metal organic framework material. The preparation method comprises: mixing a metal salt, an organic ligand, N,N-dimethylformamide, water and carboxylic acid, uniformly stirring, carrying out a hydrothermal reaction, cooling to a room temperature after completing the hydrothermal reaction, carrying out centrifugation, and purifying to prepare the multi-level pore structure metal organic framework material. According to the present invention, the prepared multi-level pore structure metal organic framework material has characteristics of stable performance and controlled and uniform pore size; and phosphotungstic acid is loaded in the mesoporous channel of the metal organic framework material through an in-situ synthesis method, the original framework structure can be remained after the loading, and the presence of the mesopores allows the contact between the large substrate molecule and the active site so as to extend the application range of the multi-level pore structure metal organic framework material.

Owner:WUHAN UNIV OF TECH

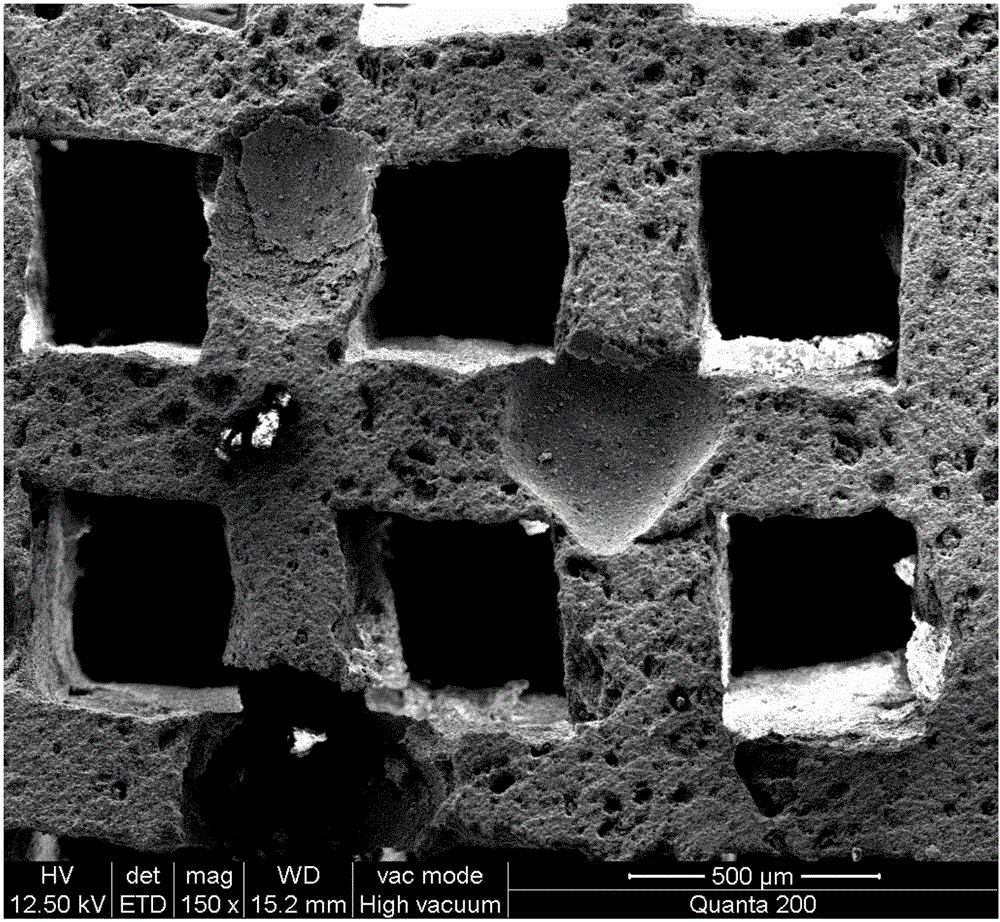

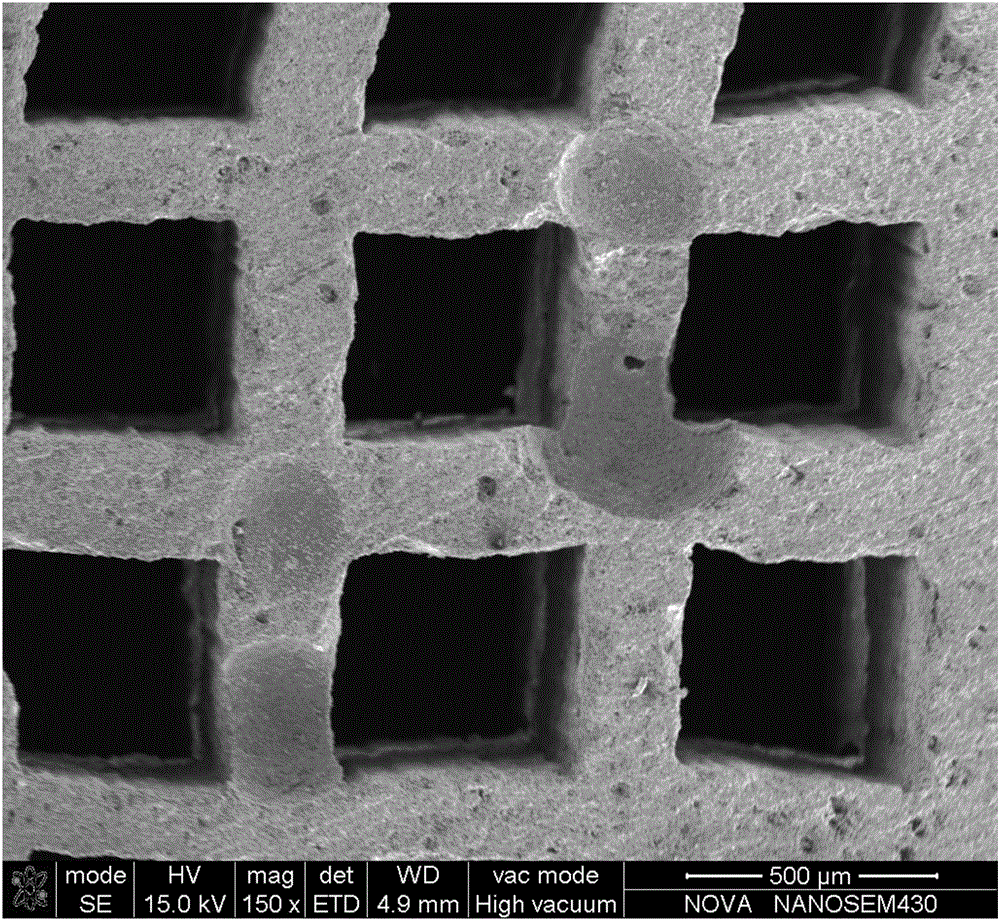

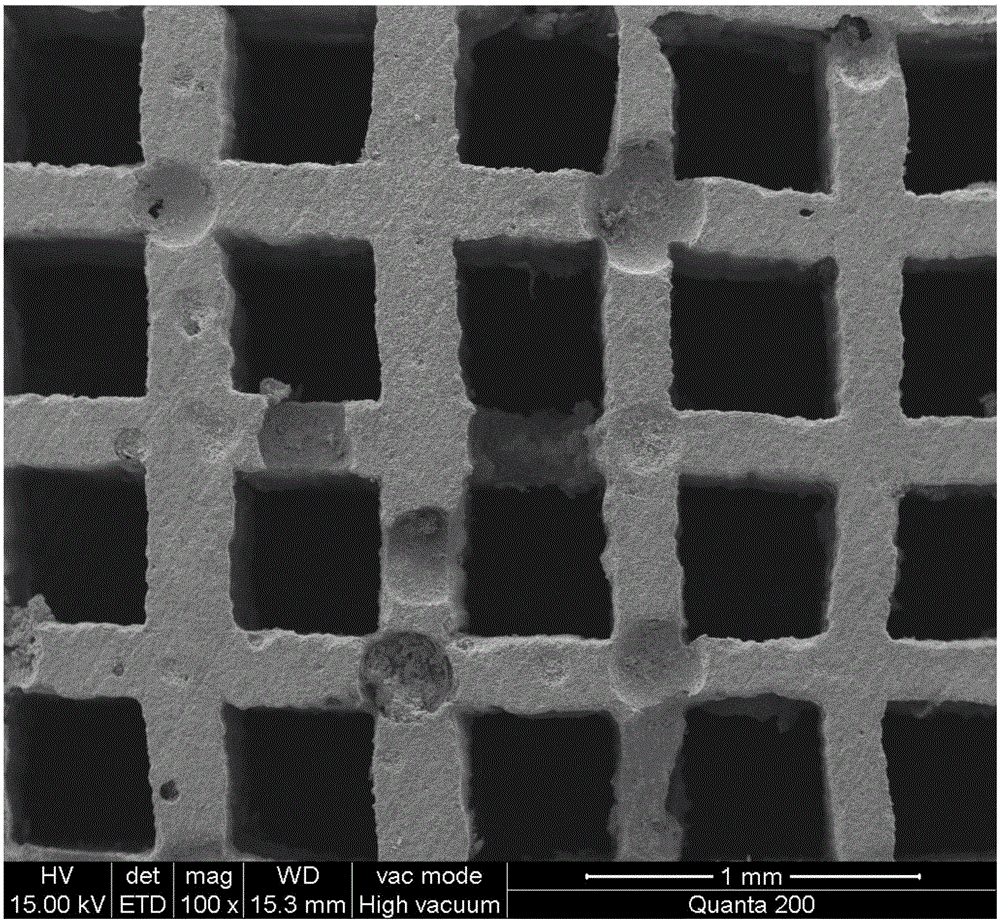

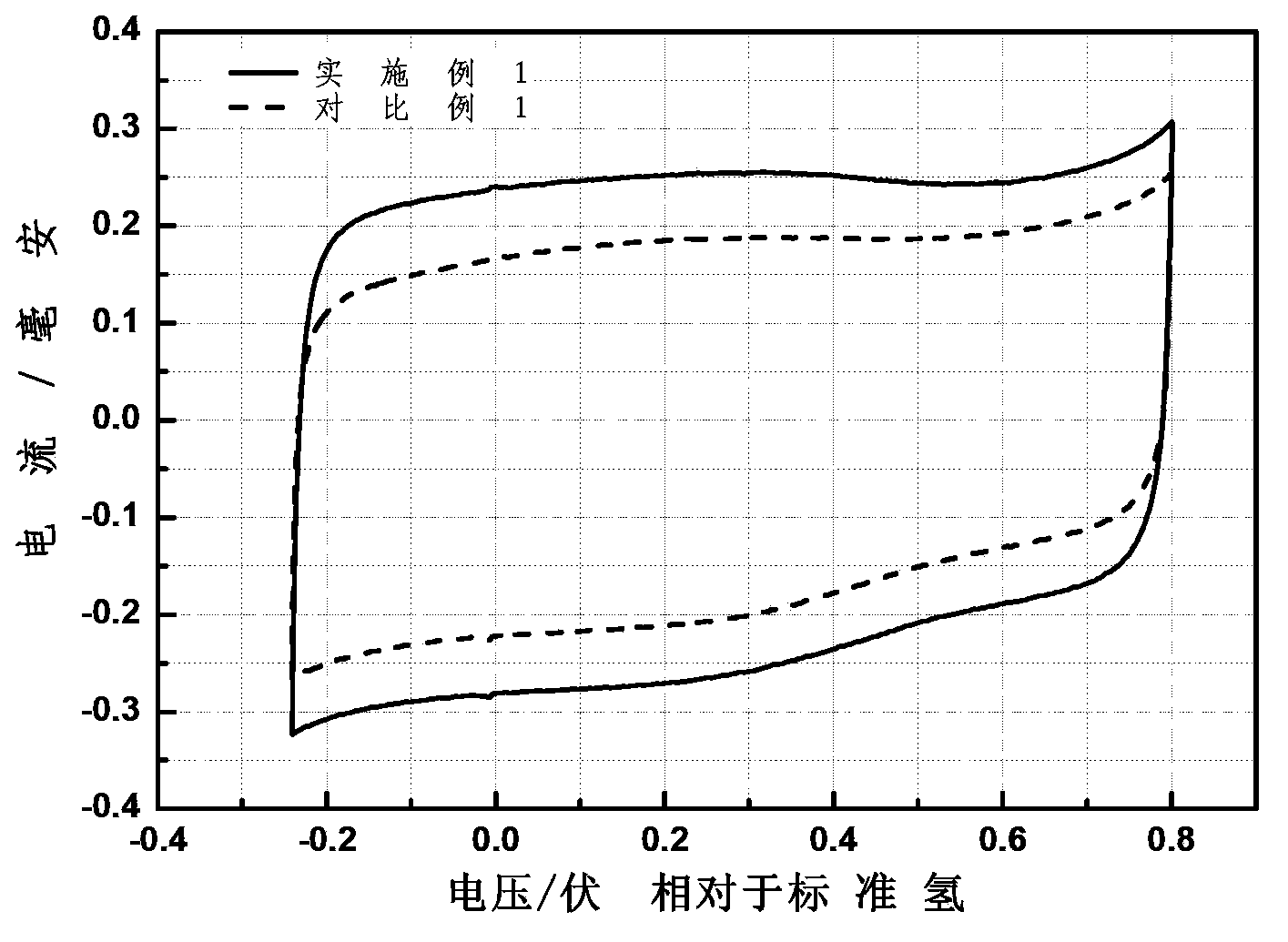

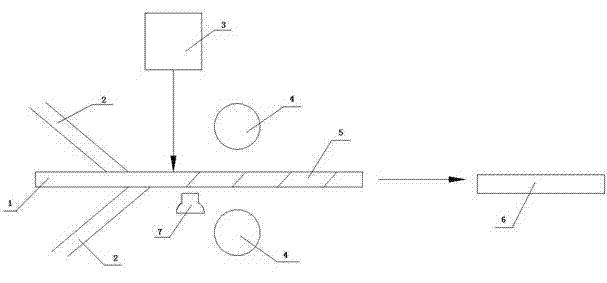

Aperture-controllable porous electrode and preparation method thereof

ActiveCN103274386AAperture controllableNo pollution in the processMaterial nanotechnologyCarbon preparation/purificationPorosityFuel cells

The invention discloses an aperture-controllable porous electrode and a preparation method thereof, and relates to a porous electrode. The aperture-controllable porous electrode consists of carbon materials and is a three-dimensional (3D) network framework thin film; the average aperture is concentrated between 0.1 micron and 5 microns; the thickness of the aperture-controllable porous electrode can be 50 to 0.1mm; and the porosity of the aperture-controllable porous electrode is more than 80 percent. The method comprises the following steps of: blending carbon material powder with an adhesive and a pore-forming agent; adding a dispersing agent, and stirring to be granular to obtain granular wet powder; and repeatedly rolling the obtained granular wet powder into a sheet thin film through a rolling shaft, folding and continuously rolling the sheet thin film until an electrode thin film is molded, and baking to obtain the aperture-controllable porous electrode. The aperture-controllable porous electrode is simple in preparation process, controllable in electrode aperture, low in cost and pollution-free, and can be widely applied to a high-charge-discharge magnification liquid-phase energy storage battery, a dual-electric-layer super capacitor, a fuel battery and other battery types containing the porous electrode as an assembly.

Owner:XIAMEN UNIV

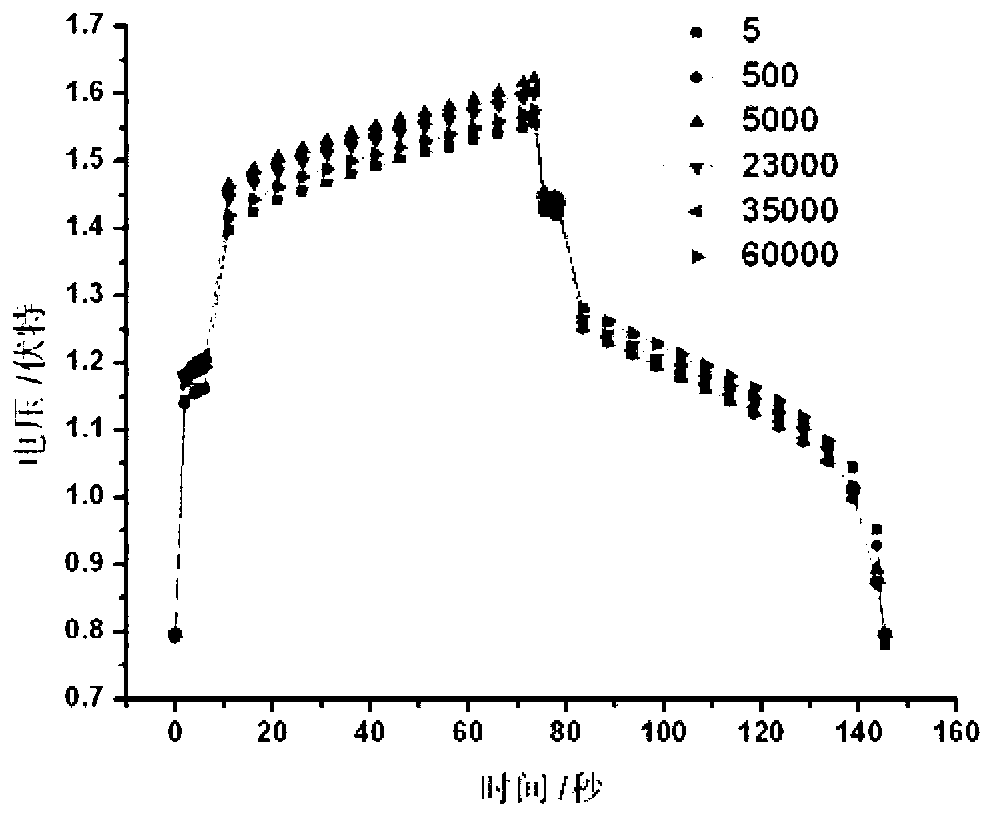

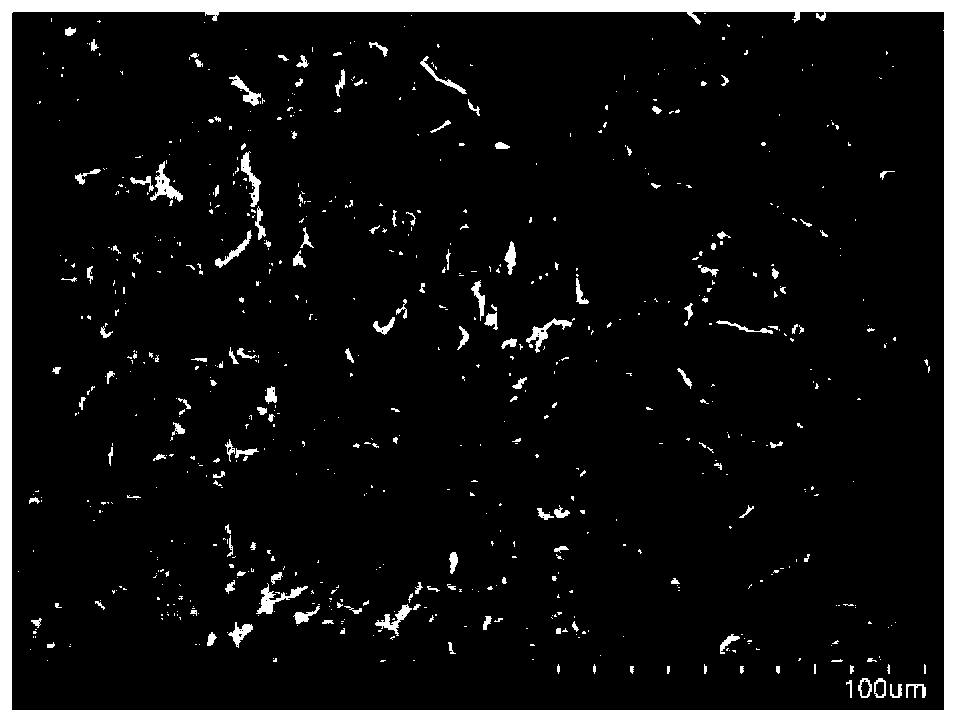

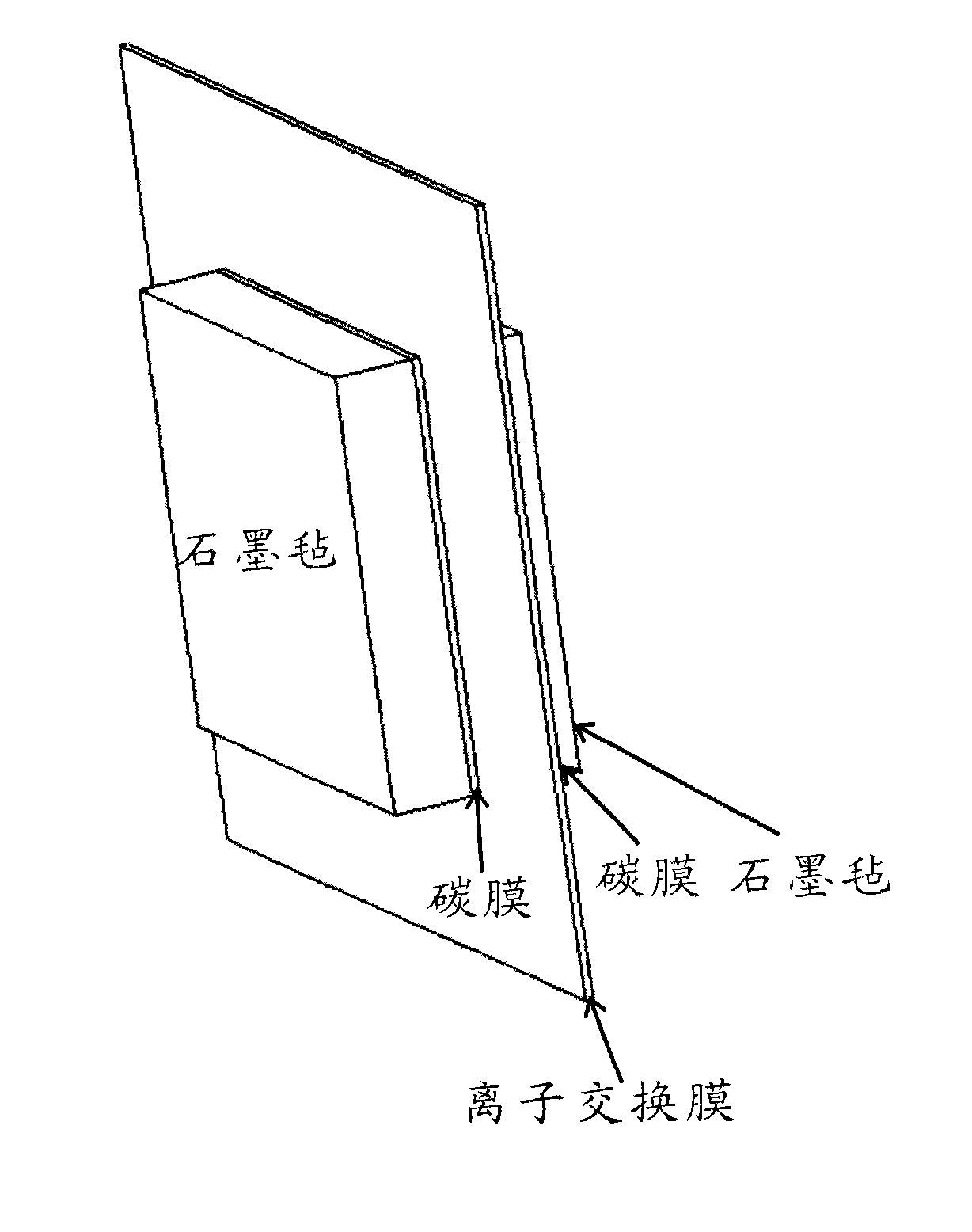

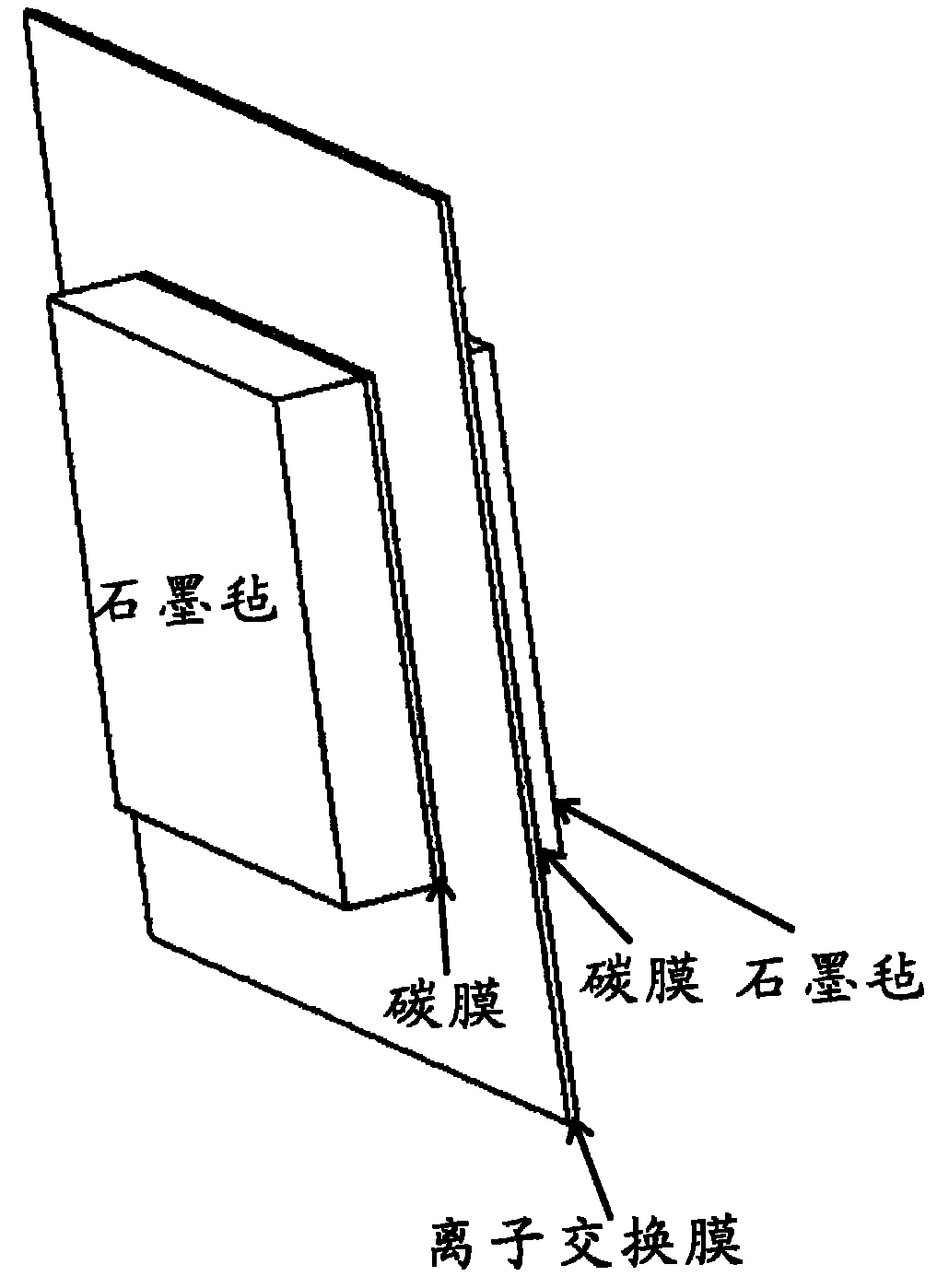

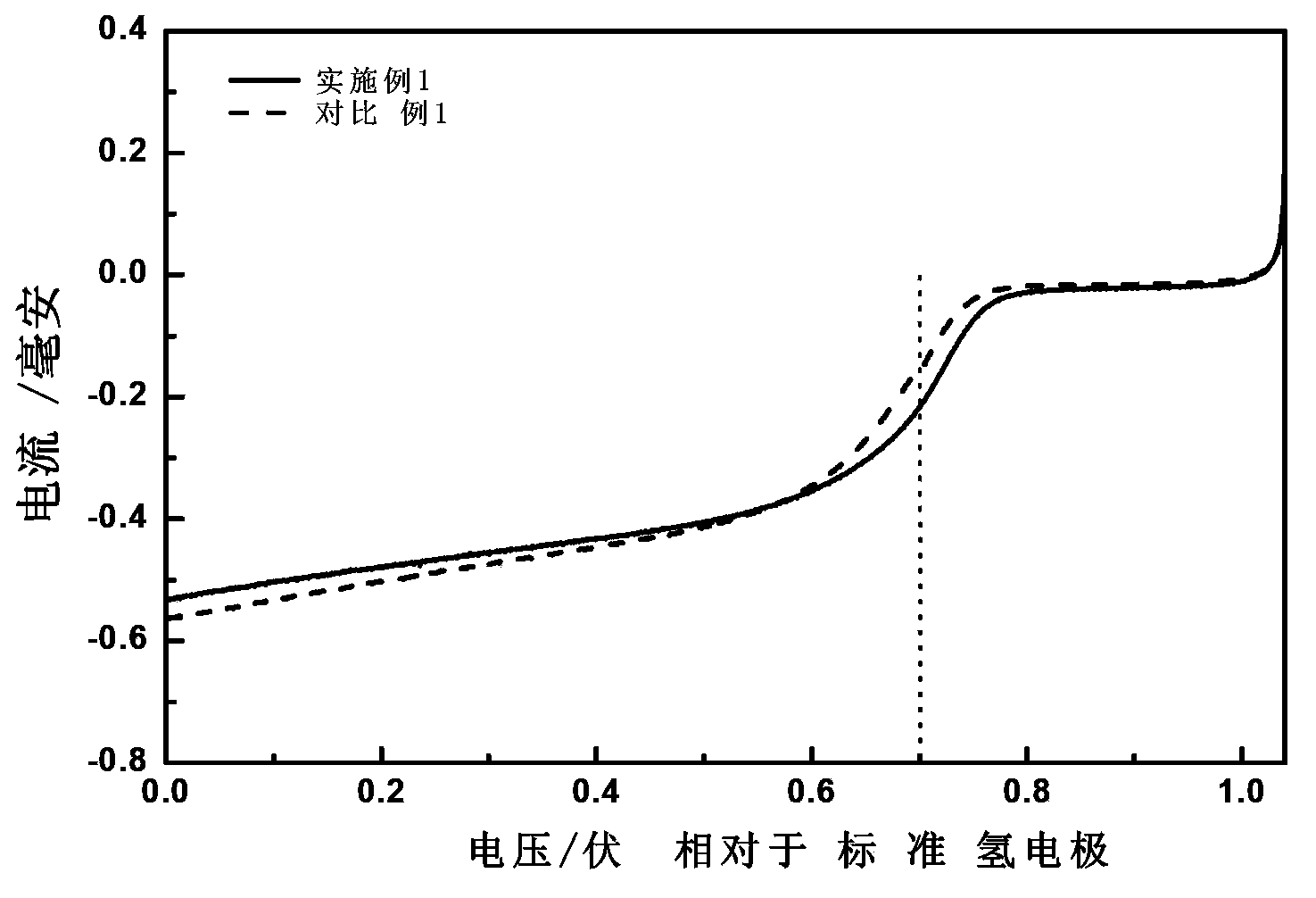

All-vanadium redox flow battery electrode and preparation method thereof, and all-vanadium redox flow battery

The invention discloses an all-vanadium redox flow battery electrode and a preparation method thereof, and an all-vanadium redox flow battery. The all-vanadium redox flow battery electrode comprises a substrate electrode material and an ion exchange membrane, wherein a side of the substrate electrode material is attached with a microporous carbon film, the ion exchange membrane is arranged on the microporous carbon film, only hydrogen ions can pass through the microporous carbon film, and vanadium ions can not pass through the microporous carbon film, such that the osmosis of the vanadium ions by the ion exchange membrane can be avoided or substantially reduced so as to substantially improve the durability and the corresponding charge and discharge efficiency of the vanadium battery, such that the capacity fading rate of the battery assembled by the all-vanadium redox flow battery electrode of the present invention is sufficiently reduced.

Owner:ENN SCI & TECH DEV

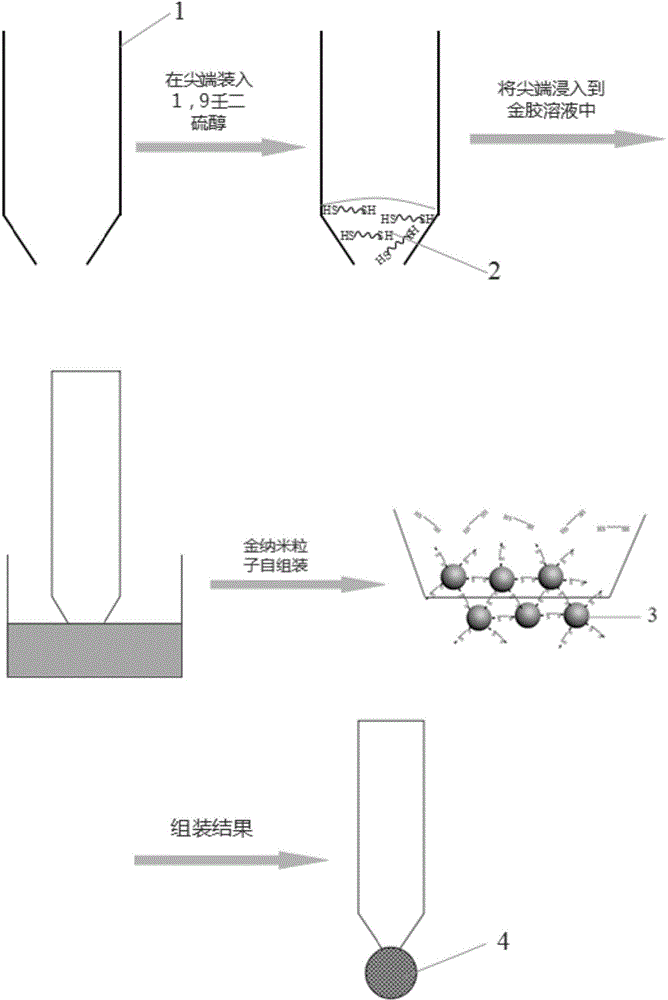

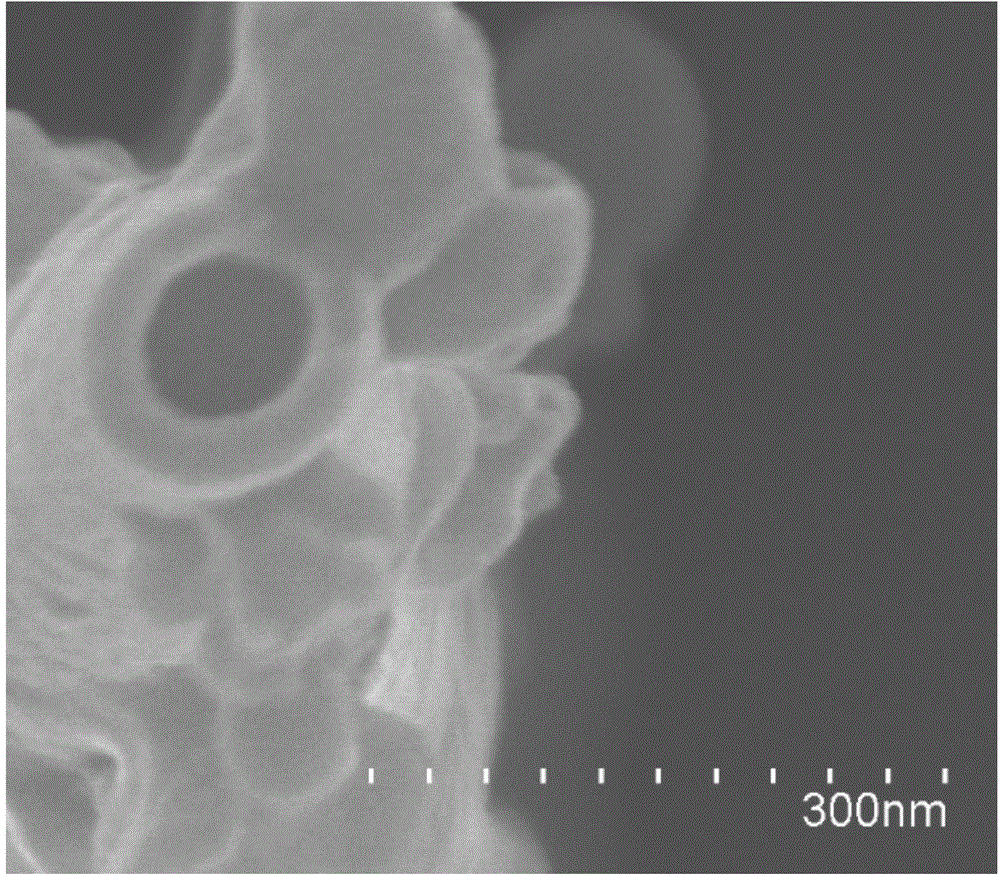

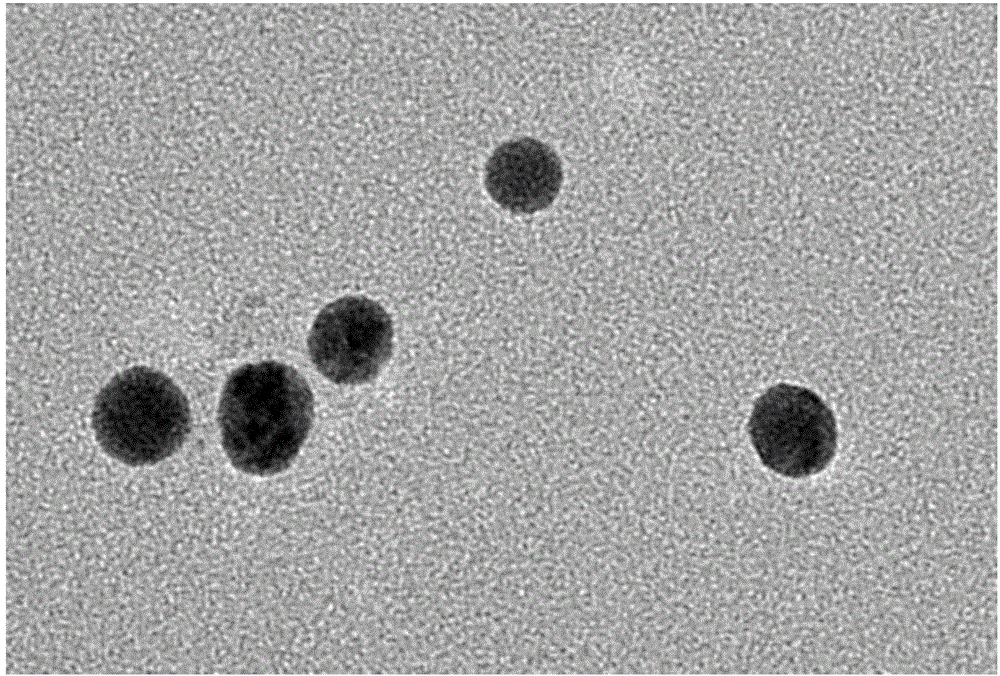

Method for preparing nano-porous structure based on nano-particle self-assembly and application thereof

ActiveCN104101630AMature processing technologyGood repeatabilityRaman scatteringNanosensorsNanoparticleCapillary Tubing

The invention relates to a method for preparing a nano-porous structure based on nano-particle self-assembly. Particularly, a capillary tube serves as a support body, and relying on the support body, nano-particles are self-assembled at the pointed end of the capillary tube through a cross-linking agent to form the nano-porous structure. The method for preparing the nano-porous structure is simple and low in cost, has the advantages that the nano aperture is adjustable in size, is convenient to move and position, and has an extensive application range.

Owner:NANJING UNIV

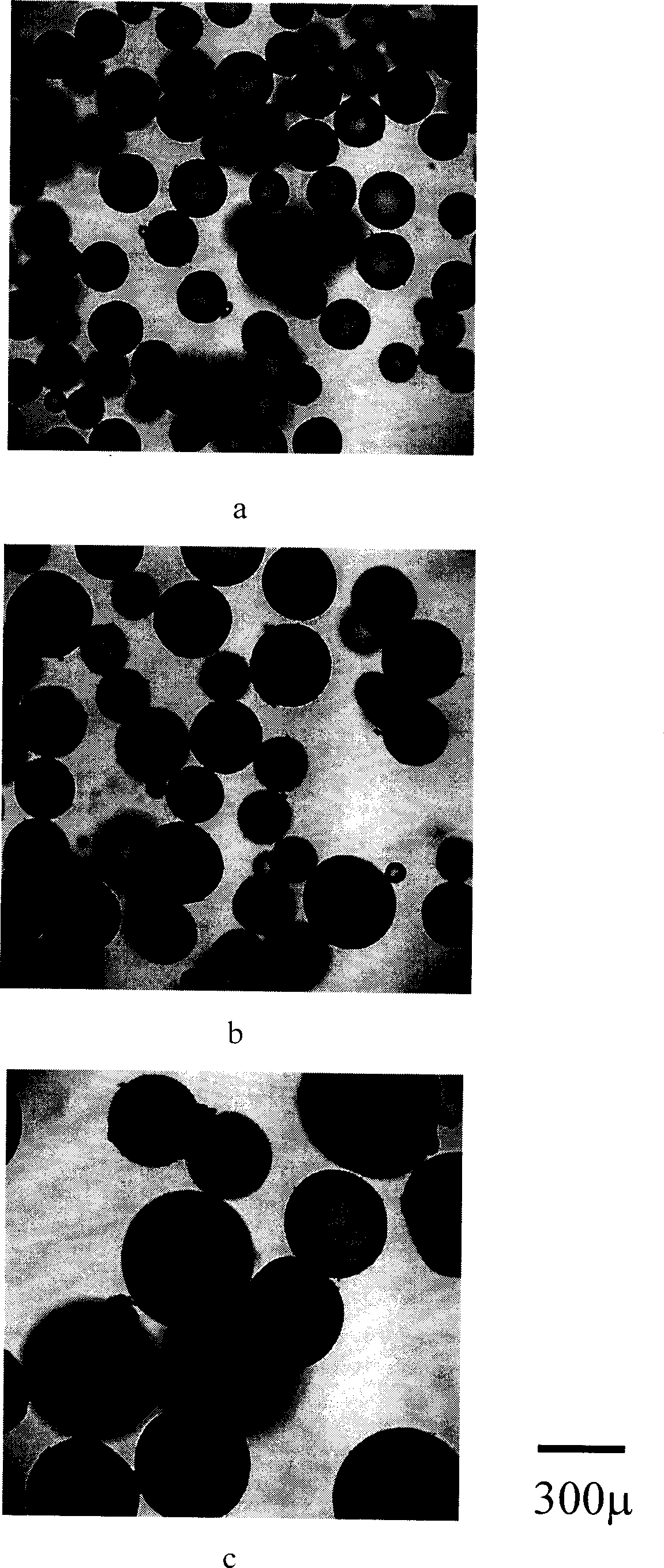

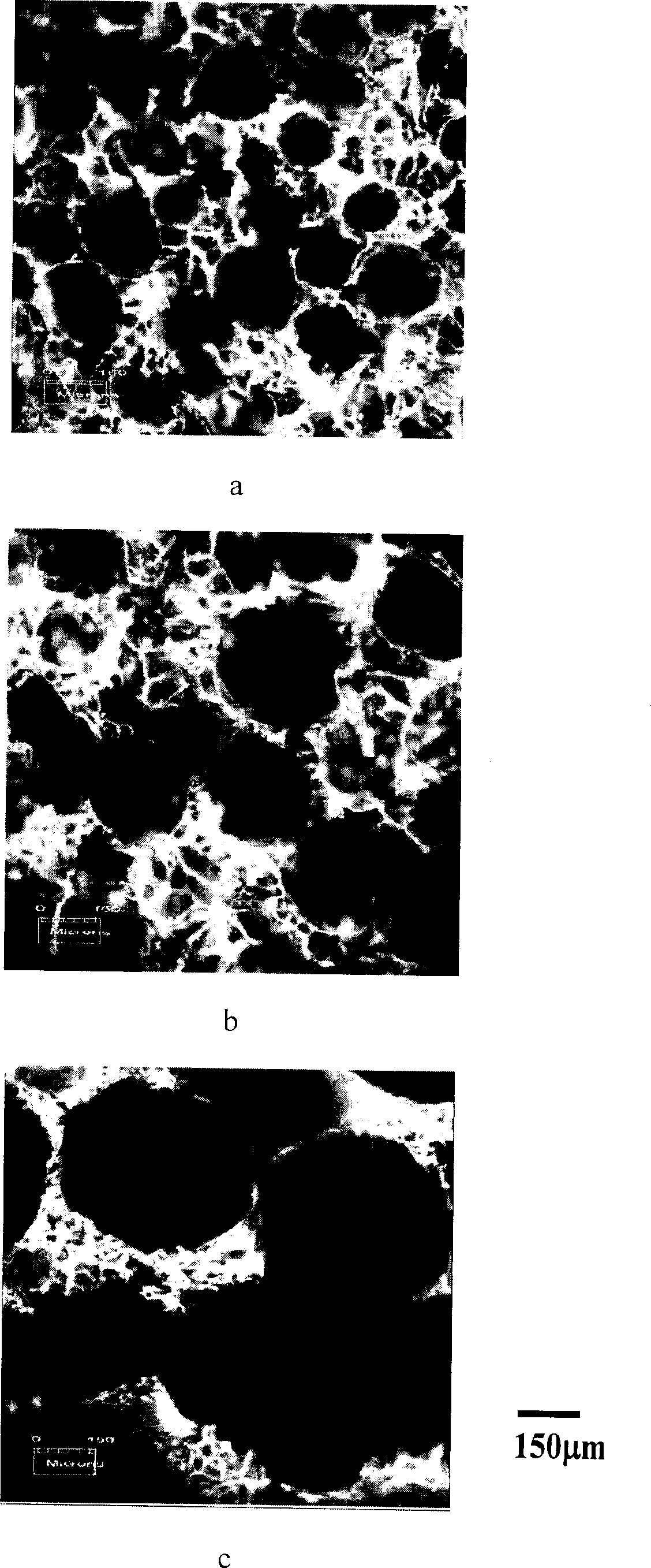

Process of preparing polymer porous leg by separation and combination of paraffin microballons porous making agent and thermotropic phase

The production process of porous polymer rack includes suspending dispersion to prepare paraffin microballoon, mixing paraffin microballoon and polymer solution, lowering temperature to make polymer solution produce phase separation, and freeze drying to eliminate solvent, boiled hexane washing or extracting to eliminate paraffin microballoon. The said process concentrates the advantages of bothpore creating process and thermal phase separation process and the produced porous polymer rack has macro pores with size determined by the paraffin microballoon as pore creating agent and micro pores produced in thermal phase separation and distributed on wall of the macro pores. The porous polymer rack has controllable pore size, good communication and high porosity.

Owner:ZHEJIANG UNIV

Three-dimensional connected honeycomb porous calcium phosphate ceramic artificial bone material and preparation method thereof

InactiveCN106518143AHigh porosityAperture controllableTissue regenerationProsthesisPorosityMetabolite

The invention discloses a three-dimensional connected honeycomb porous calcium phosphate ceramic artificial bone material. A plurality of longitudinal straight-through holes are distributed in the calcium phosphate ceramic artificial bone material in a honeycomb manner; and a plurality of transverse through holes are distributed in the hole walls of the straight-through holes to connect the adjacent straight-through holes. The invention also discloses a preparation method of the three-dimensional connected honeycomb porous calcium phosphate ceramic artificial bone material. The three-dimensional connected honeycomb porous calcium phosphate ceramic artificial bone material is prepared once through an extrusion molding technology and a pore forming agent adding technology. The straight-through holes are helpful for growing newborn bone tissues and forming blood vessels, and the three-dimensional connected holes are helpful for connecting cells into pieces and facilitate transportation of nutrient substances and discharging of metabolites. The preparation method is simple and can realize continuous production; and the prepared porous calcium phosphate ceramic has the advantages of high porosity, high connectivity and good mechanical performances.

Owner:SOUTH CHINA UNIV OF TECH

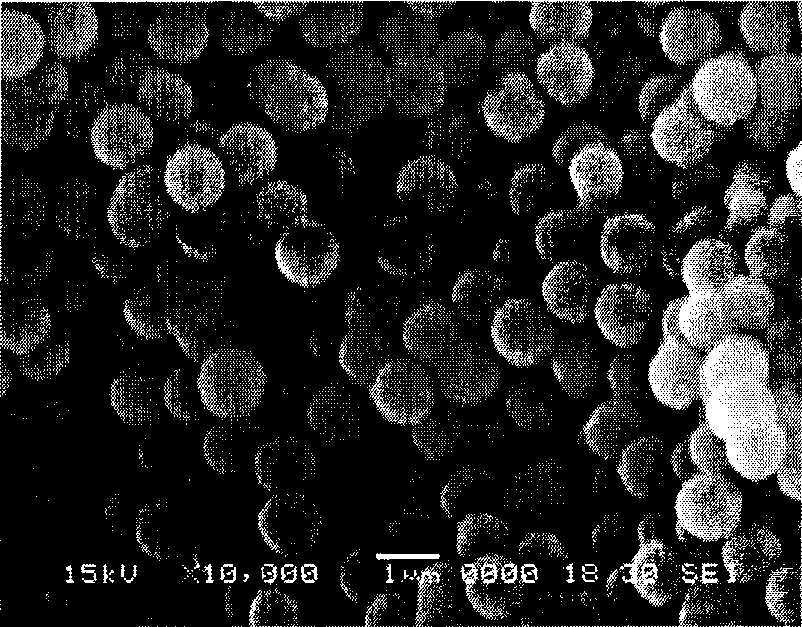

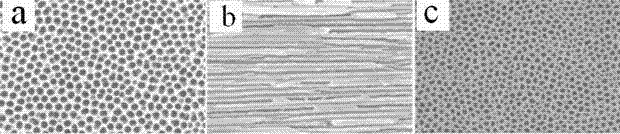

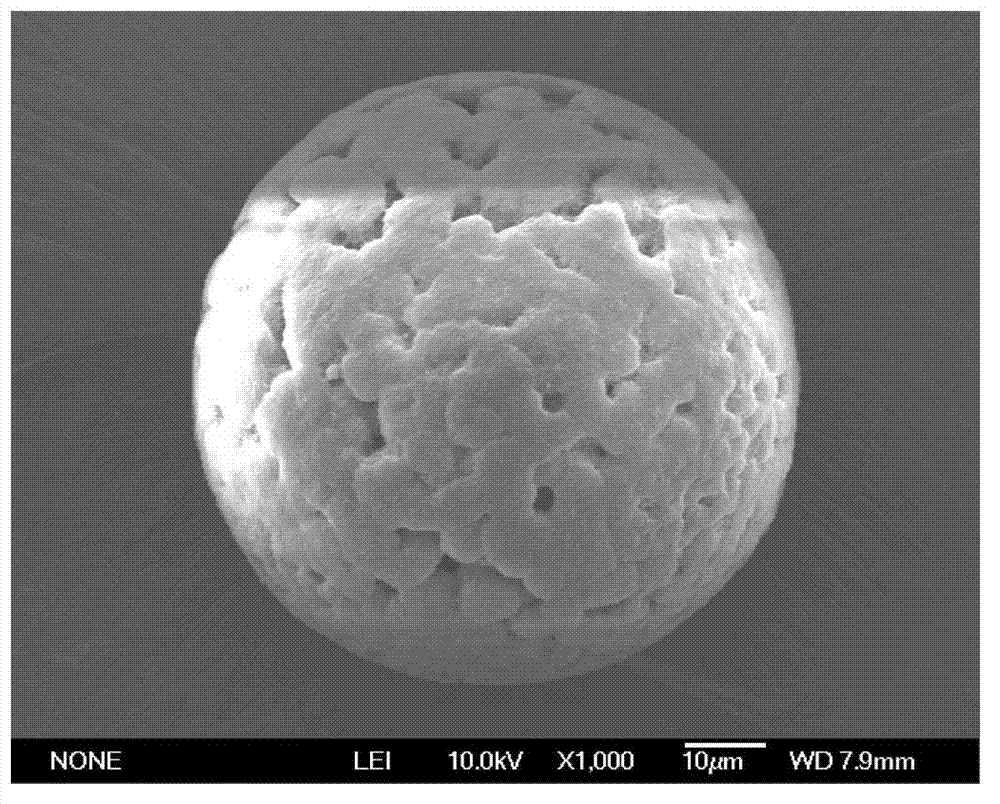

Macroporous/mesoporous hollow silica microballoon and its preparation method

The invention relates to a macroporous / mesoporous hollow silica microballoon and its preparation method. The macroporous / mesoporous hollow microballoon is prepared by the following steps of: carrying out self assembly on organic polymer microballoons with different particle sizes to obtain a template, generating a silica outer layer by in situ method, and calcining to remove the internal organic matter. The internal cavity of the microballon obtained is 500-2000nm controllable and the pore diameter of the microballoon surface is 10-100nm controllable, so as to form the macroporous / mesoporous hollow structure. The preparation method provided by the invention has characteristics of simple condition, convenient operation, easily obtained raw materials, pure product, environmental protection and the like. The silica hollow microballoon provided by the invention can be widely applied in a controllable transport and delivery system of medicament, dye, cosmetic and sensitive reagents such as enzyme and protein as a carrier material, can be used as a lightweight filling material, a high selectivity catalyst or a catalyst carrier, and has a very important value in the aspects of artificial cells, disease diagnosis and the like.

Owner:TIANJIN POLYTECHNIC UNIV

Metal-doped nitrogen-containing carbon-based catalyst of fuel cell and application thereof

ActiveCN103682379AStructurally effective regulationEffective control of morphologyCell electrodesFuel cellsReduction ActivitySurface-active agents

The invention relates to a metal-doped nitrogen-containing carbon-based catalyst of a fuel cell and application of the catalyst. The catalyst adopts organic surface active agents as a protection agent and a structural guide agent and adopts an aromatic compound and aldehyde as reaction monomers, metal elements are added in the reaction process to obtain a polymer-metal compound, and the polymer-metal compound is dried and then is subjected to high-temperature processing with inert gas or / and ammonia gas to finally obtain the metal-doped nitrogen-containing carbon-based catalyst. When the metal-doped nitrogen-containing carbon-based catalyst is used as a cathode catalyst of a proton exchange membrane fuel cell and a direct-methanol fuel cell, the oxide reduction activity, stability and toxicity resistance are excellent; moreover, the catalyst has an environment-friendly effect, is low in cost, controllable in aperture, high in specific surface area and rich in resource and can substitute for platinum to serve as an electric catalyst of the proton exchange membrane fuel cell.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of high-flux tubular microfiltration membrane

InactiveCN102806020AUniform pore size distributionIncrease membrane fluxSemi-permeable membranesFoaming agentMicrofiltration membrane

The invention relates to a preparation method of a high-flux tubular microfiltration membrane. The preparation method comprises preparing a membrane casting liquid and forming a membrane through phase inversion, and comprises the following specific steps of: mixing polyvinylidene fluoride, a pore-foaming agent, an additive and a solvent, heating to 30-80 DEG C, and stirring at the constant stirring speed of 100-1,000 revolutions per minute at a constant temperature for 10-48 hours to obtain a membrane casting liquid; standing the membrane casting liquid under the vacuum condition for defoaming for 10-48 hours, and winding a non-woven fabric into a non-woven fabric support pipe by using an integral tubular coating machine while completing membrane coating to obtain a tubular microfiltration basement membrane; and soaking the tubular microfiltration basement membrane into a coagulating bath, and performing phase inversion to obtain a finished tubular microfiltration membrane. The tubular microfiltration membrane has the characteristics of simple preparation process, high membrane flux, uniform pore diameter distribution, high mechanical strength, high chemical tolerance and the like.

Owner:JIANGSU KAIMI MEMBRANE TECH

Preparation and application of nerve tissue matrix derived tissue engineering scaffold material

InactiveCN102218160AKeep natural ingredientsGood biocompatibilityCatheterProsthesisFreeze-dryingDefect repair

The invention discloses preparation and application of a nerve tissue matrix derived tissue engineering scaffold material. A nerve tissue is taken as a raw material, matrix components (including nano-scale collagen microfilaments, fibronectin microfilaments and laminin microfilaments) favorable for nerve regeneration are extracted by means of medicine expansion, mechanical pulverization, enzymolysis treatment, dialysis collection and the like, and immunogenicity components (including Schwann cells, phospholipid and axons) not favorable for nerve regeneration are removed. The prepared nerve tissue matrix derived material can be further prepared into a three-dimensional porous oriented scaffold through oriented crystallization, freeze drying and crosslinking separately or by matching other polymer materials, or is prepared into a nano-scale film by an electrospinning technology, and the film is wound to form a nerve regeneration catheter. The tissue engineering scaffold or catheter prepared by the method is favorable for adhesion, proliferation and migration of seed cells, promotes nerve generation and can be used for never defect repair.

Owner:卢世璧

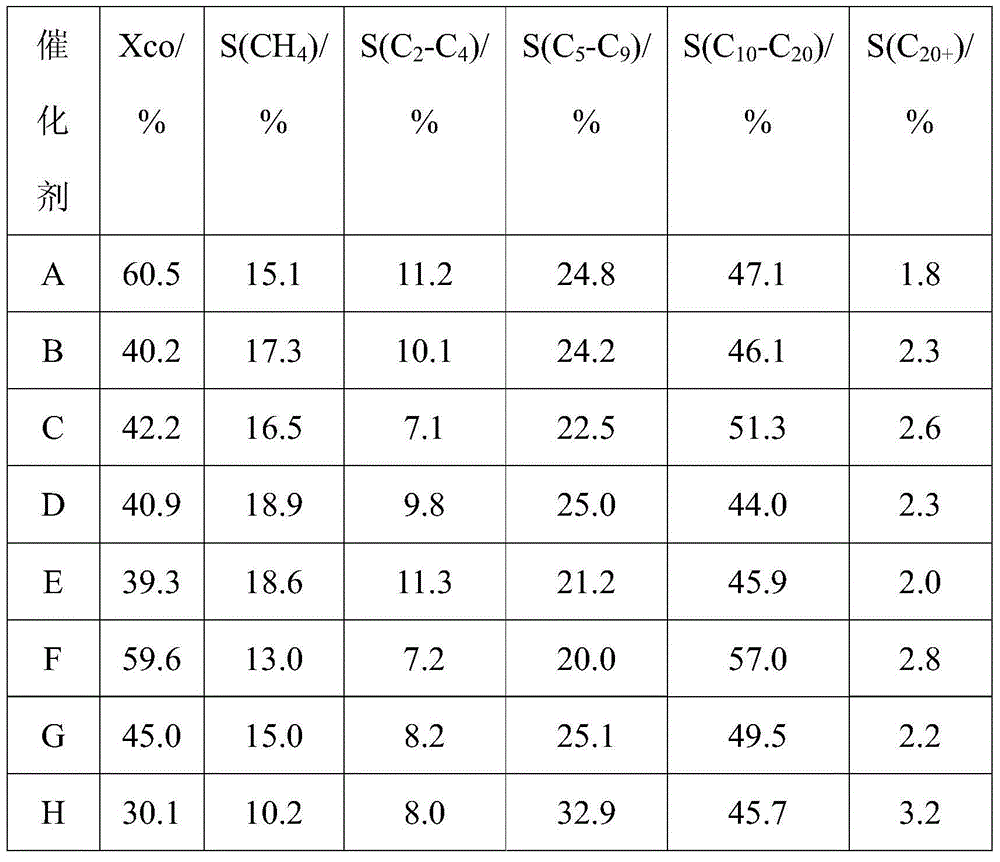

Cobalt-base Fischer-Tropsch synthesis catalyst and preparation method and application thereof

ActiveCN104368344AUniform size distributionFine particleLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsFischer–Tropsch processSol-gel

The invention discloses a cobalt-base Fischer-Tropsch synthesis catalyst and a preparation method and application thereof. The catalyst comprises a mesoporous carbon carrier and an active component cobalt, wherein the active component cobalt is confined in the mesoporous carbon carrier. The catalyst has specific surface area of 220-400 m<2> / g and particle diameter of 50-150 um. The preparation method employs phenolic resin solution as an organic precursor, and then a sol-gel method is employed to embed the active component Co into the mesoporous carbon carrier. The catalyst prepared by the invention before usage only requires introduction of inert gas into at a certain temperature without hydrogen reduction, so as to obtain the catalyst containing cobalt. The catalyst of the invention has the advantages of high reduction degree, high dispersity, good stability, uniform size of active component, controllable carrier aperture and high selectivity on diesel, and can meet the requirements of a slurry bed reactor on the wear resistance of the catalyst.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

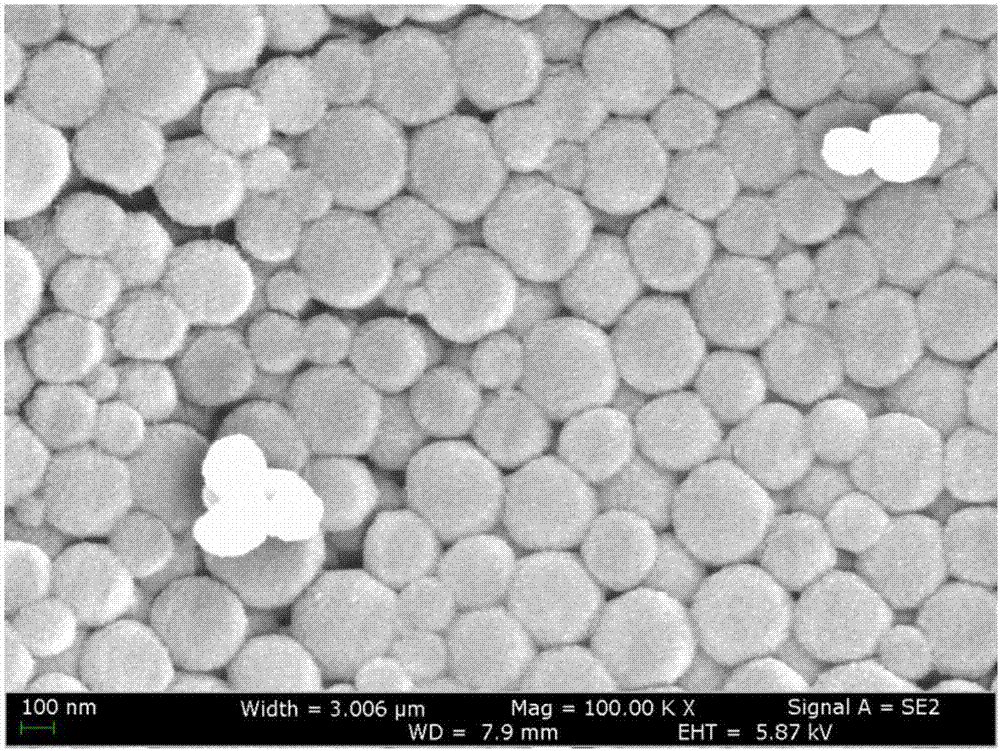

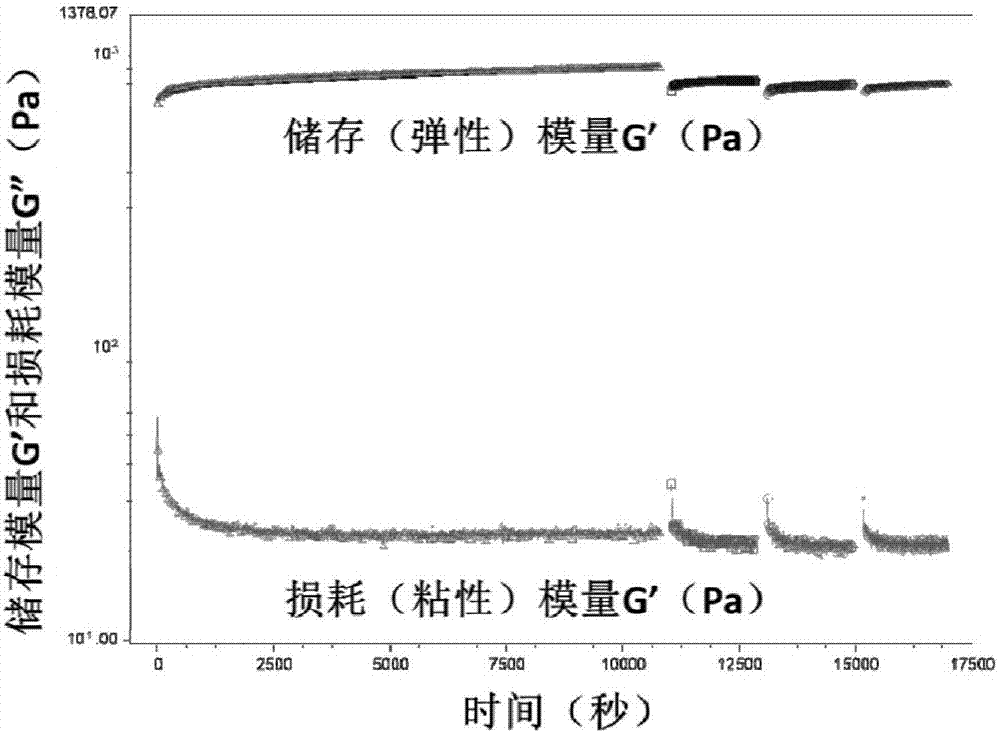

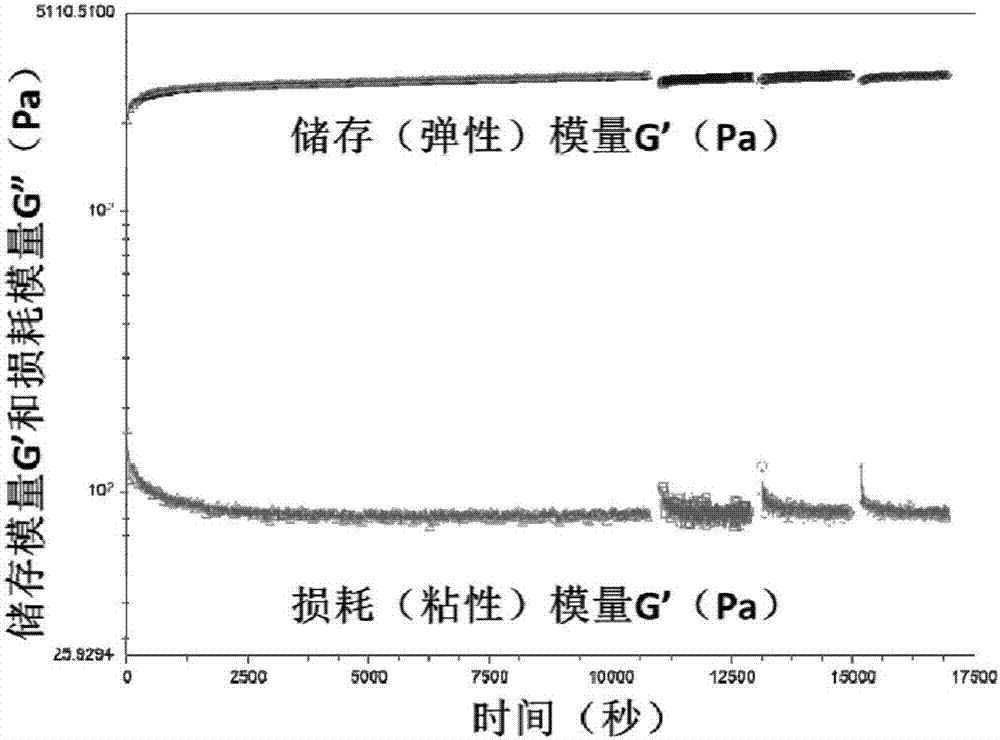

Injectable type self-healing hemostatic material as well as preparation method and application thereof

The invention discloses an injectable type self-healing hemostatic material as well as a preparation method and application thereof. The injectable type self-healing hemostatic material is obtained by self-assembling macromolecular microgel particles with surface charges through electrostatic interaction between the particles or the particles and macromolecules. The electrostatic action between the microgel particles or the particles and the macromolecules is physical crosslinking and has reversibility, so the hemostatic material prepared by the method has high injectability, self-healing capability and high mechanical strength, does not need to introduce chemical crosslinking reaction in the injection and solidification process, is different from chemical macromolecules, does not introduce a micromolecular crosslinking agent, has high biocompatibility, can be degraded and absorbed, does not have toxic or side effects, has high safety and makes wide application in the field of biomedicine possible.

Owner:SHENZHEN HUA NOVA BIOTECH LTD

Super-porous polysaccharide microsphere and preparation method thereof

The invention relates to a super-porous polysaccharide microsphere product and a preparation method thereof. The mean grain size of the microsphere is 1-500 microns and the mean bore diameter of the microsphere is controllable within a range of 90-800 nm. The preparation method of the super-porous polysaccharide microsphere comprises the following steps of: adding a high-content water-soluble surfactant to a water phase; dispersing the water-phase containing the surfactant to an oil phase to obtain large ports through oil-absorption swelling action of a micelle formed by the surfactant; and preparing the super-porous microsphere through crosslinking and curing of the larger pores. The product can be used as a separating and purifying medium, an immobilized enzyme carrier, a catalyst carrier or a high-efficiency adsorbent and is particularly suitable for being used as a separating medium for biological macromolecules.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparing method of metal chalcogenide nanomesh material

InactiveCN103910340AAperture controllableControllable hole arrangementMaterial nanotechnologyMolybdenum sulfidesMetal chalcogenidesMesoporous material

The invention discloses a preparing method of a metal chalcogenide nanomesh material. A mesoporous material is adopted as a template material. The metal chalcogenide nanomesh material is prepared by steps of: preparing a metal precursor into a solution, filling a pore channel space of the mesoporous template material with the solution so as to prepare a mesoporous material loading the metal precursor; mixing the mesoporous material loading the metal precursor with a chalcogenide precursor and putting the mixture into a heating space of a heating device, or putting the mesoporous material loading the metal precursor and the chalcogenide precursor side by side into the heating space of the heating device; raising the temperature rapidly to 300-900 DEG C under the protection of carrier gas and maintaining the temperature for 15-600 min; adding a template corroding agent into the obtained solid powder so that the mesoporous material is fully dissolved in the template corroding solution; and filtering and drying the filter cake. The metal chalcogenide nanomesh material is obtained by synthesis for the first time. The preparation method is free of use of precious metals, free of vacuum conditions, simple in synthetic process, and prone to large-scale production.

Owner:HANGZHOU NORMAL UNIVERSITY

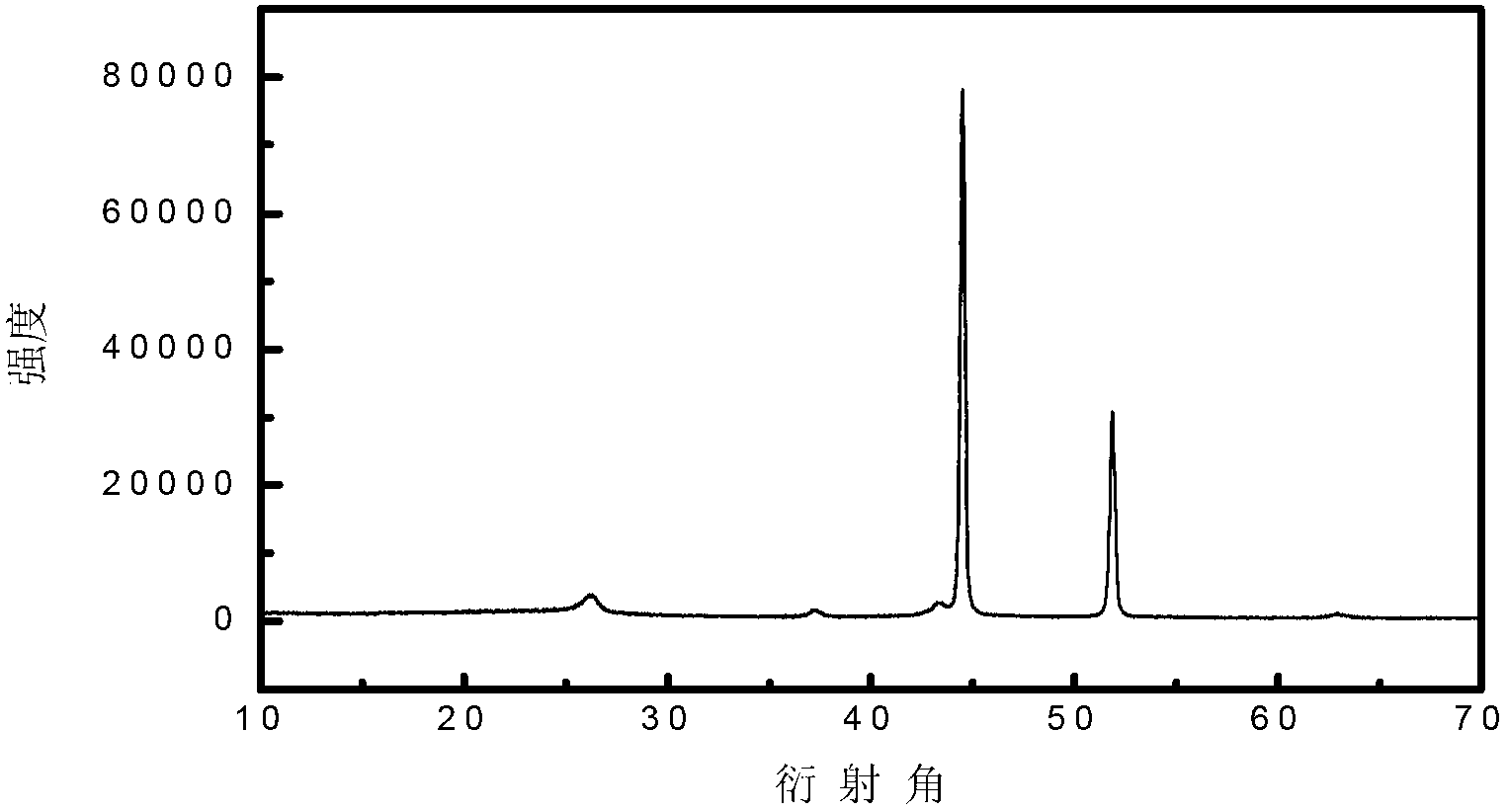

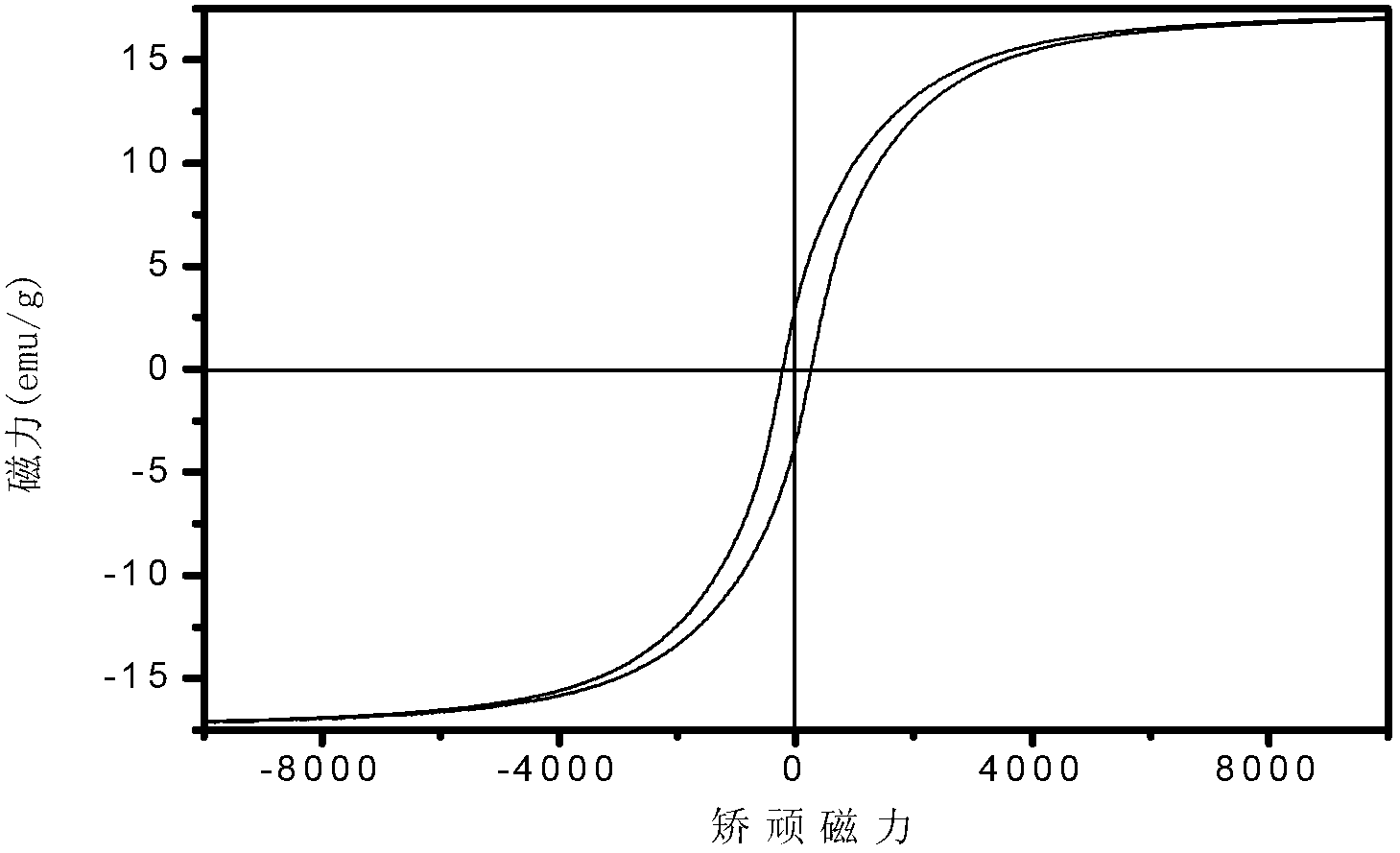

Preparation method of carbon-aerogel-based spherical anticorrosion magnetic material

InactiveCN102709017AReduce magnetismEasy to operateInorganic material magnetismCarbon preparation/purificationNickel saltReducing atmosphere

The invention relates to a preparation method of a carbon-aerogel-based spherical anticorrosion magnetic material, wherein nickel salts, aldehydes substances and aromatic amine phenols are taken as raw materials. The method comprises the process of preparing, drying and carbonizing nickel-containing gel, and is characterized in that the gel is prepared in a manner that the nickel salts are added into a solution prepared from the aldehydes substances and aromatic amine phenols substances according to proportion, a catalyst and a dispersant are added for gelation, vacuum drying is performed to form xerogel, and the nickel-containing gel is carbonized in a reducing atmosphere to prepare the carbon-aerogel-based spherical anticorrosion magnetic material. The method disclosed by the invention is easy to implement, short in preparation period and suitable for large-scale production.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com