All-vanadium redox flow battery electrode and preparation method thereof, and all-vanadium redox flow battery

An all-vanadium redox flow battery and electrode technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of high cost and time consumption, complicated and cumbersome preparation process, etc., and achieve reduced capacity decay rate, reduced penetration, and improved The effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

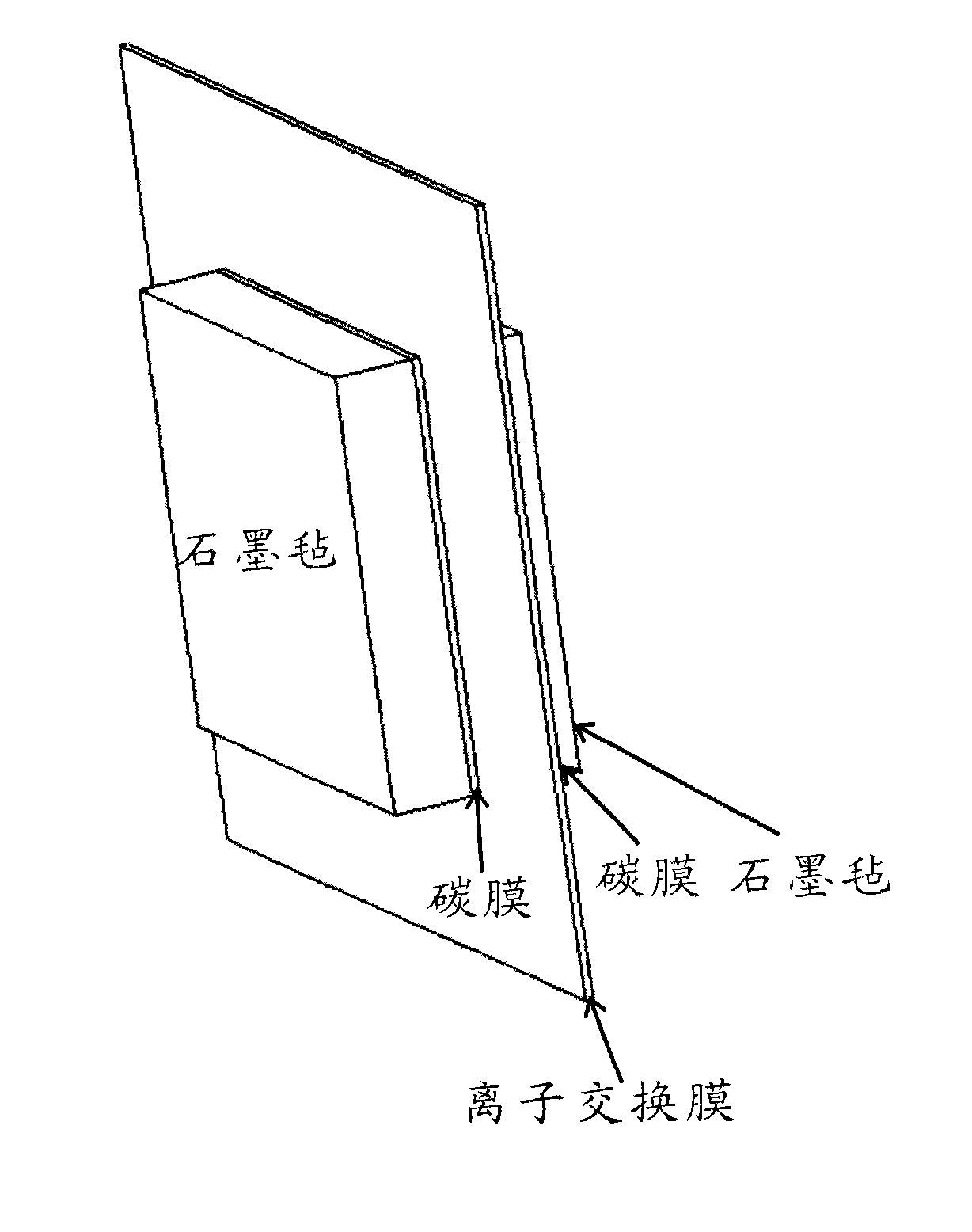

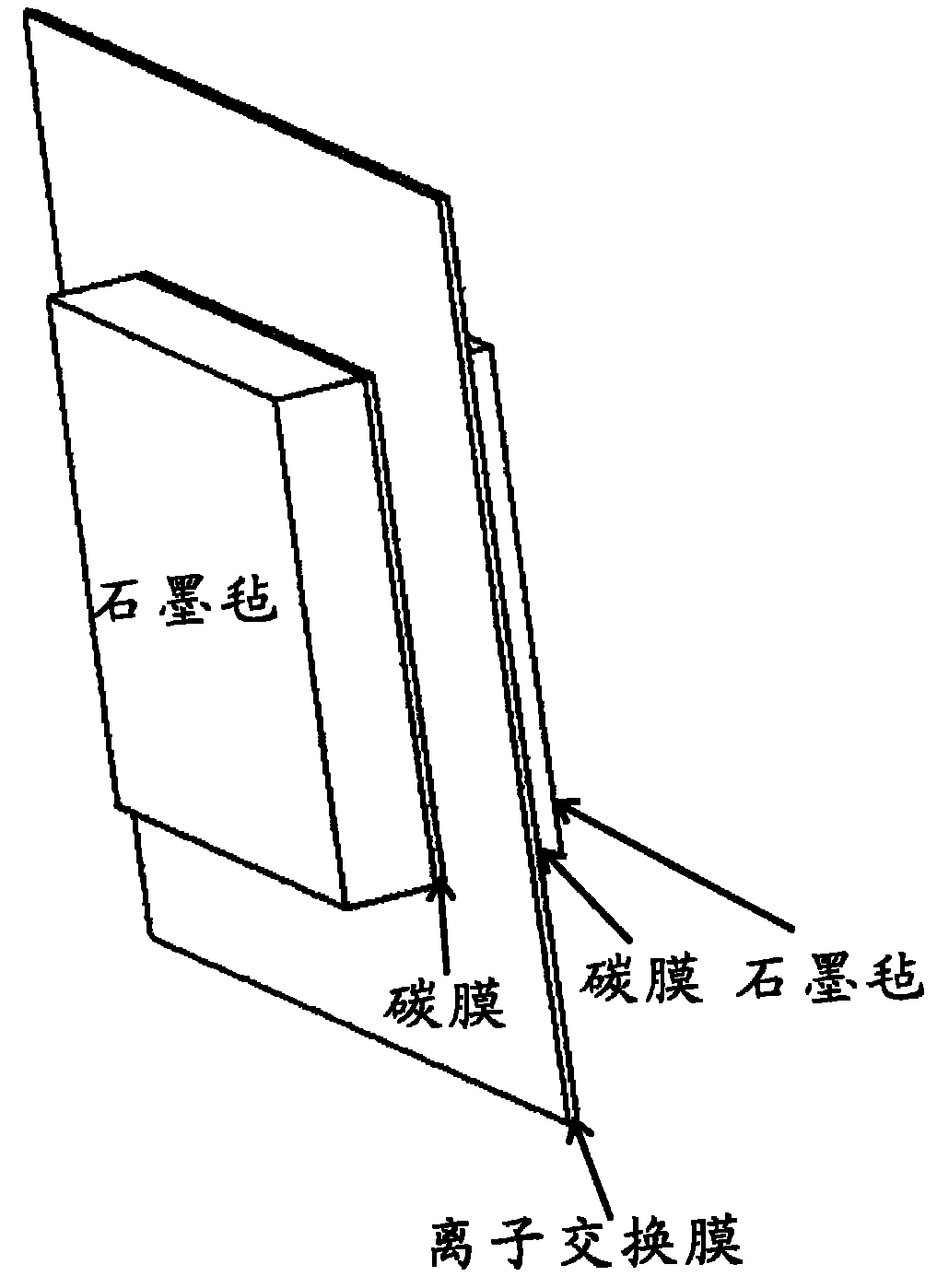

[0040] Therefore, the second aspect of the present invention is to provide a method for preparing the electrode of the all-vanadium redox flow battery. The preparation method includes the following steps: the first step is to apply a suitable high molecular polymer paste slurry on one side of the base electrode material such as graphite felt, and then heat the high molecular polymer to melt to form a film; In the second step, at a temperature suitable for carbonizing the high molecular polymer, carbonize the obtained base electrode material coated with the high molecular polymer film to form a microporous carbon film; in the third step, activate the first carbon film with an acid The base electrode material with a microporous carbon film on one side obtained in the second step; the fourth step, bonding the activated base electrode material and the ion exchange membrane together to form the all-vanadium redox flow battery electrode of the present invention .

[0041] The high ...

Embodiment 1

[0055] (1) Firstly, phenolic resin (produced by Wuhan Tegus Technology Development Co., Ltd.) was dissolved in ethanol, and a paste slurry with a concentration of 40% by mass was prepared. Then spin coating on one side of graphite felt (produced by Hunan Jiuhua Carbon Hi-Tech Co., Ltd.) with a thickness of 5 mm to form a layer of polymer film with a film thickness of 2 μm, and then place the graphite felt at a temperature of 150 ° C in air Heating for 2 hours allowed it to melt, resulting in a dense polymer film.

[0056] (2) Carbonize the graphite felt obtained above at 700° C. for 2 hours in an inert gas to obtain a microporous carbon film with a pore diameter of 4.2 angstroms.

[0057] (3) Immerse the carbonized graphite felt in concentrated sulfuric acid with a concentration of 98% by mass, activate it at 60° C. for 5 hours, then wash it with pure water until neutral, and finally dry it in air at 60° C.

[0058] (4) On the side that graphite felt is attached to film, spra...

Embodiment 2

[0063] (1) Firstly, phenolic resin (manufactured by Wuhan Tegus Science and Technology Development Co., Ltd.) was dissolved in ethanol to form a paste slurry with a concentration of 30% by mass. Then spin-coat on one side of graphite felt (produced by Hunan Jiuhua Carbon Hi-Tech Co., Ltd.) with a thickness of 5 mm to form a layer of polymer film with a film thickness of 5 μm, and then heat the graphite felt in air at 100 ° C for 0.5 Hours, it is melted to obtain a dense polymer film.

[0064] (2) Carbonize the graphite felt obtained above at 1000° C. in an inert gas for 0.5 hour to obtain a microporous carbon film with a pore diameter of 5 angstroms.

[0065] (3) Immerse the carbonized graphite felt in concentrated sulfuric acid with a concentration of 98% by mass, activate it at 30° C. for 8 hours, then wash it with pure water until neutral, and finally dry it in air at 60° C.

[0066] (4) On the side of the graphite felt with the microporous carbon membrane, spray 15% by ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Capacity decay rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com