Patents

Literature

888results about How to "Improve charge and discharge efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-capacity lithium-ion electrolyte, battery and preparation method of battery

ActiveCN101771167AIncrease capacityLow costFinal product manufactureCell electrodesElectrolytic agentPhysical chemistry

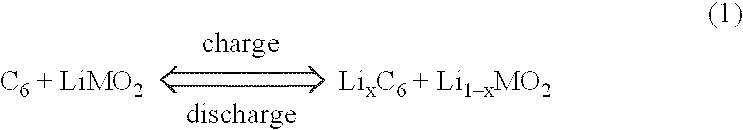

The invention relates to a high-capacity lithium-ion electrolyte, a battery and a preparation method of a battery, in particular to the high-capacity lithium-ion electrolyte and the battery using the high-capacity lithium-ion electrolyte and the preparation method of the battery. The electrolyte disclosed by the invention comprises lithium salt and non-aqueous organic solvent, and also consists of the following components in weight percent in terms of the total weight of the electrolyte: 0.5-7% of film-forming additive, 0-15% of flame-retardant additive, 2-10% of antiovefill additive, 0.01-2% of stabilizer and 0.01-1% of wetting agent; the electrolyte can enable the anode with high Ni content to work stably, and reduce the battery cost; the high-capacity lithium-ion battery can perform high ratio capacity and excellent safety and high temperature property and cyclic life fully due to the addition and synergetic functions of various functional additives.

Owner:JIUJIANG TINCI ADVANCED MATERIALS CO LTD

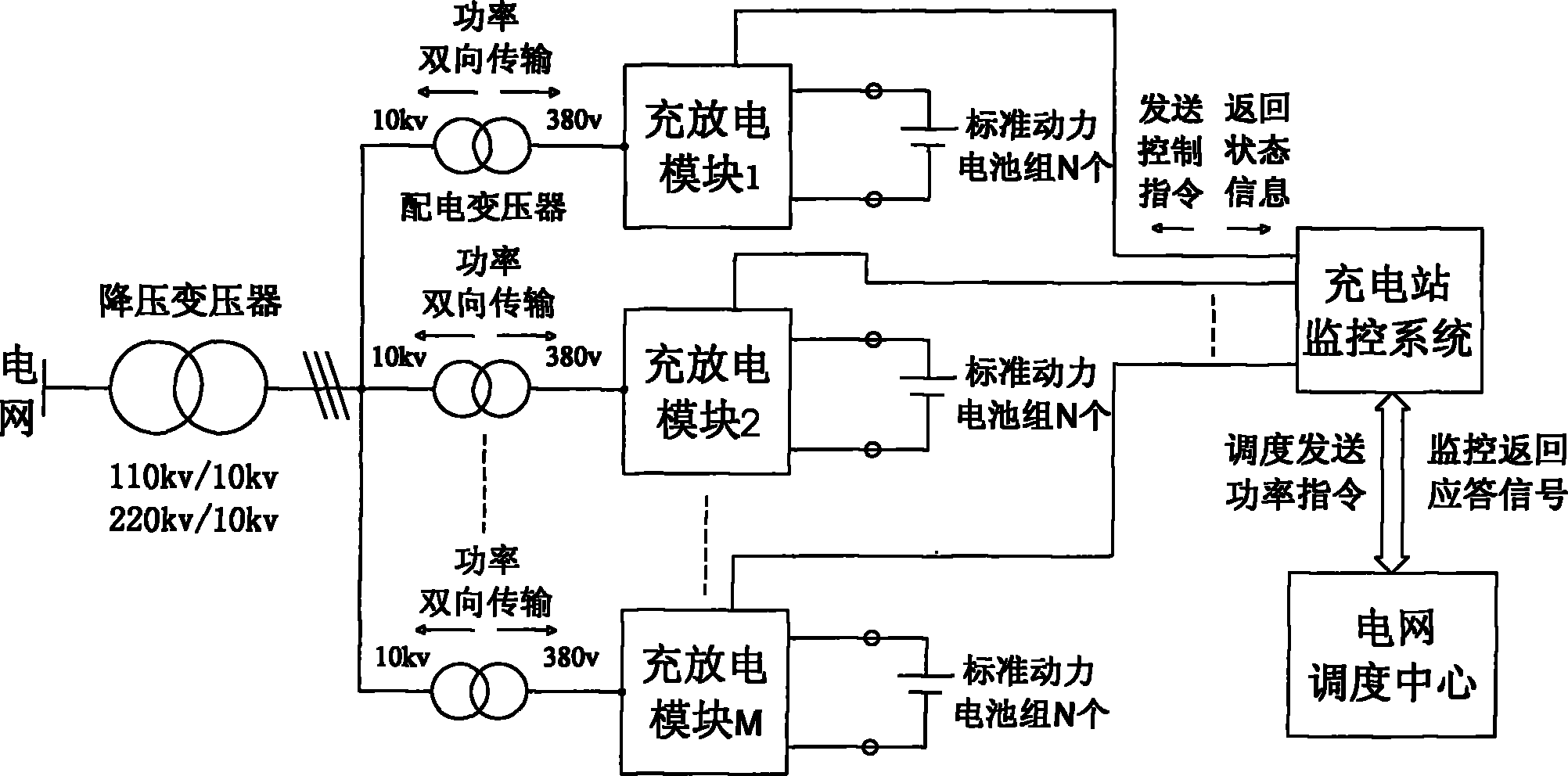

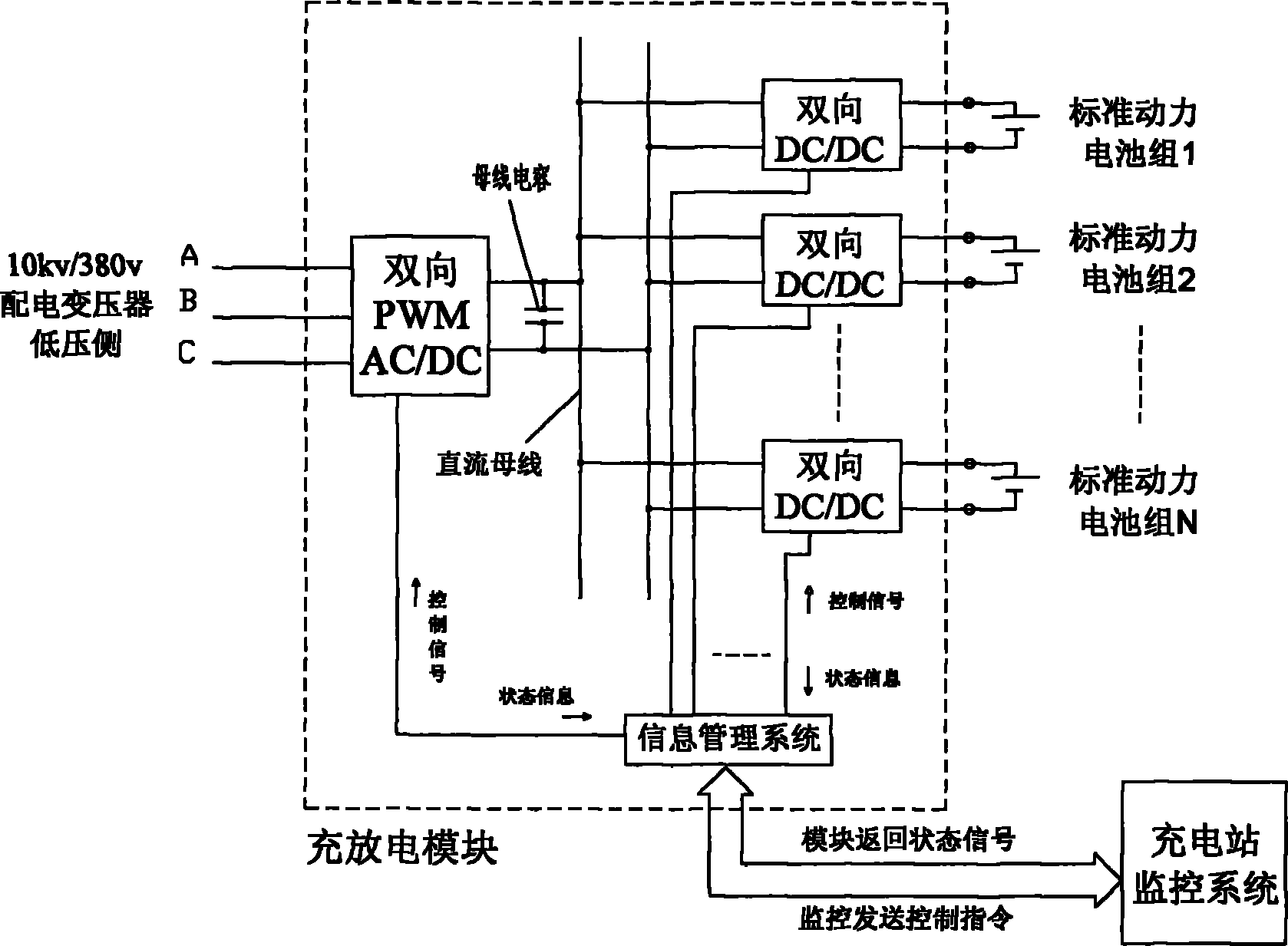

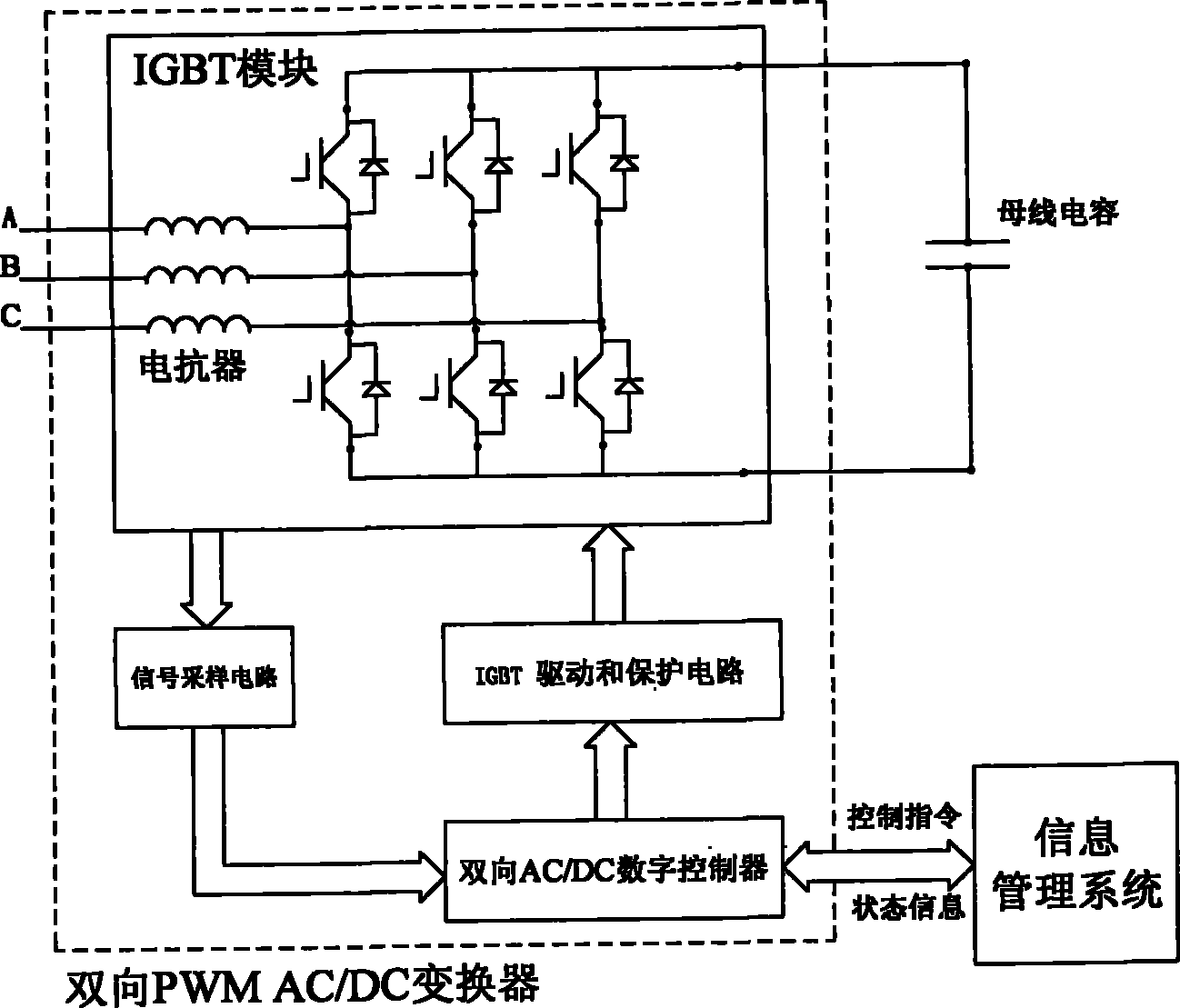

Modular charging/discharging system of power battery pack of multifunctional electromobile

InactiveCN102025182AExtend your lifeImprove charge and discharge efficiencyBatteries circuit arrangementsAc network load balancingElectric power transmissionLow voltage

The invention relates to a modular charging / discharging system of a power battery pack of a multifunctional electromobile, which aims to provide a system which can effectively meet the requirement for the bi-directional power transmission of a charging station and can exert the functions of peak clipping and valley filling as well as peak modulation and frequency modulation of a power grid. The technical scheme is as follows: the modular charging / discharging system of the power battery pack of the multifunctional electromobile comprises a charging-station monitoring system and an information management system, wherein the charging-station monitoring system is composed of a computer and a network communication system. The modular charging / discharging system is characterized by also comprising a three-phase step-down transformer, wherein the high voltage side of the three-phase step-down transformer is connected with a power grid, and the low voltage side of the three-phase step-down transformer is connected in parallel with a plurality of charging / discharging branches; each branch comprises a three-phase distribution transformer and a charging / discharging module, and the three-phase distribution transformer is connected in series with the charging / discharging module; and each charging / discharging module comprises a pulse-width modulation alternating current / direct current (PWM AC / DC) converter with the function of bi-directional power transmission, a plurality of electromagnetic isolation type DC / DC transform modules with the function of bi-directional power transmission and the information management system, and the electromagnetic isolation type DC / DC transform modules are connected in parallel.

Owner:梁一桥

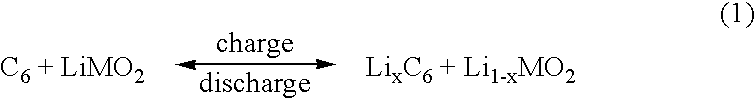

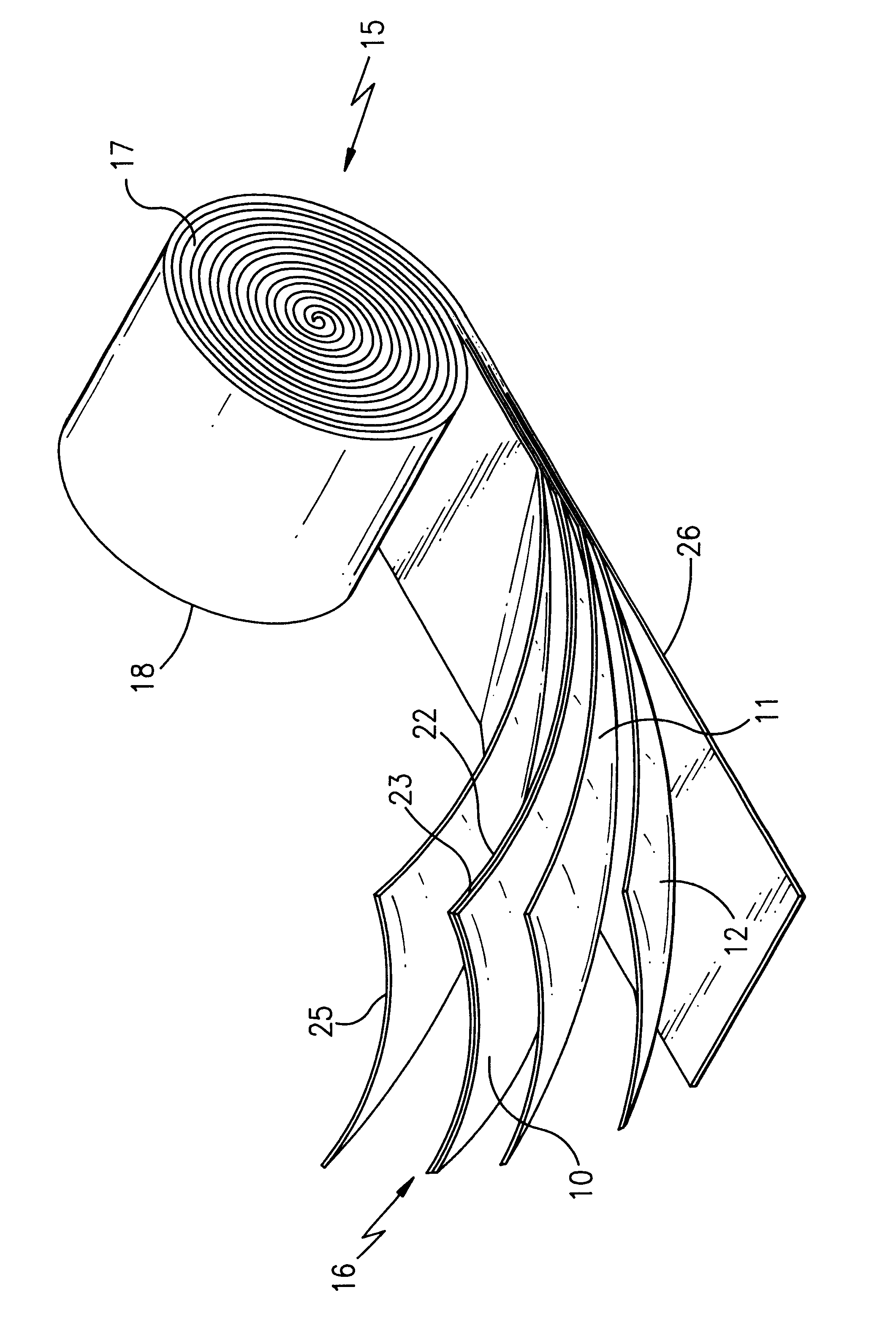

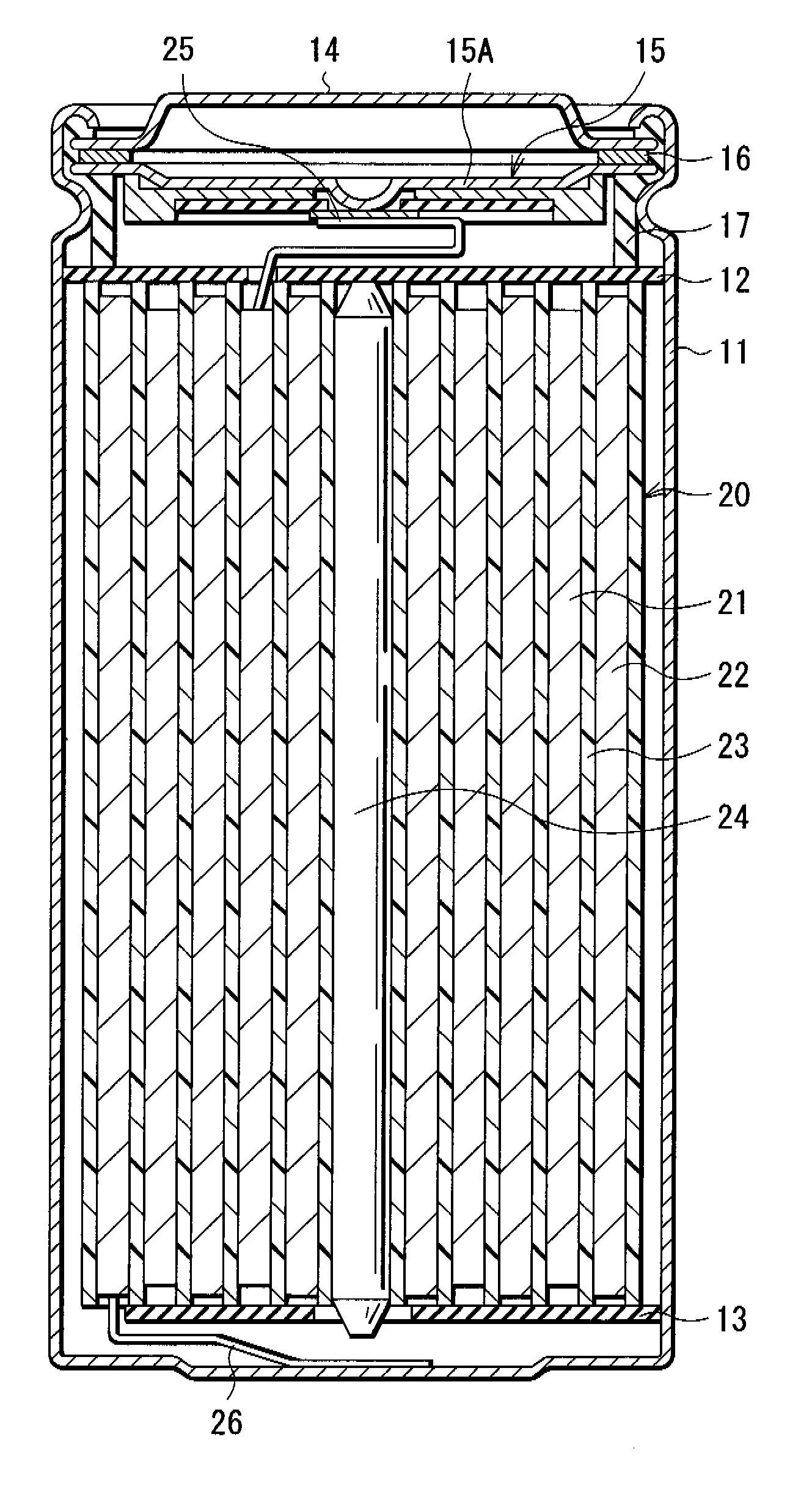

Lithium ion polymer electrolytes

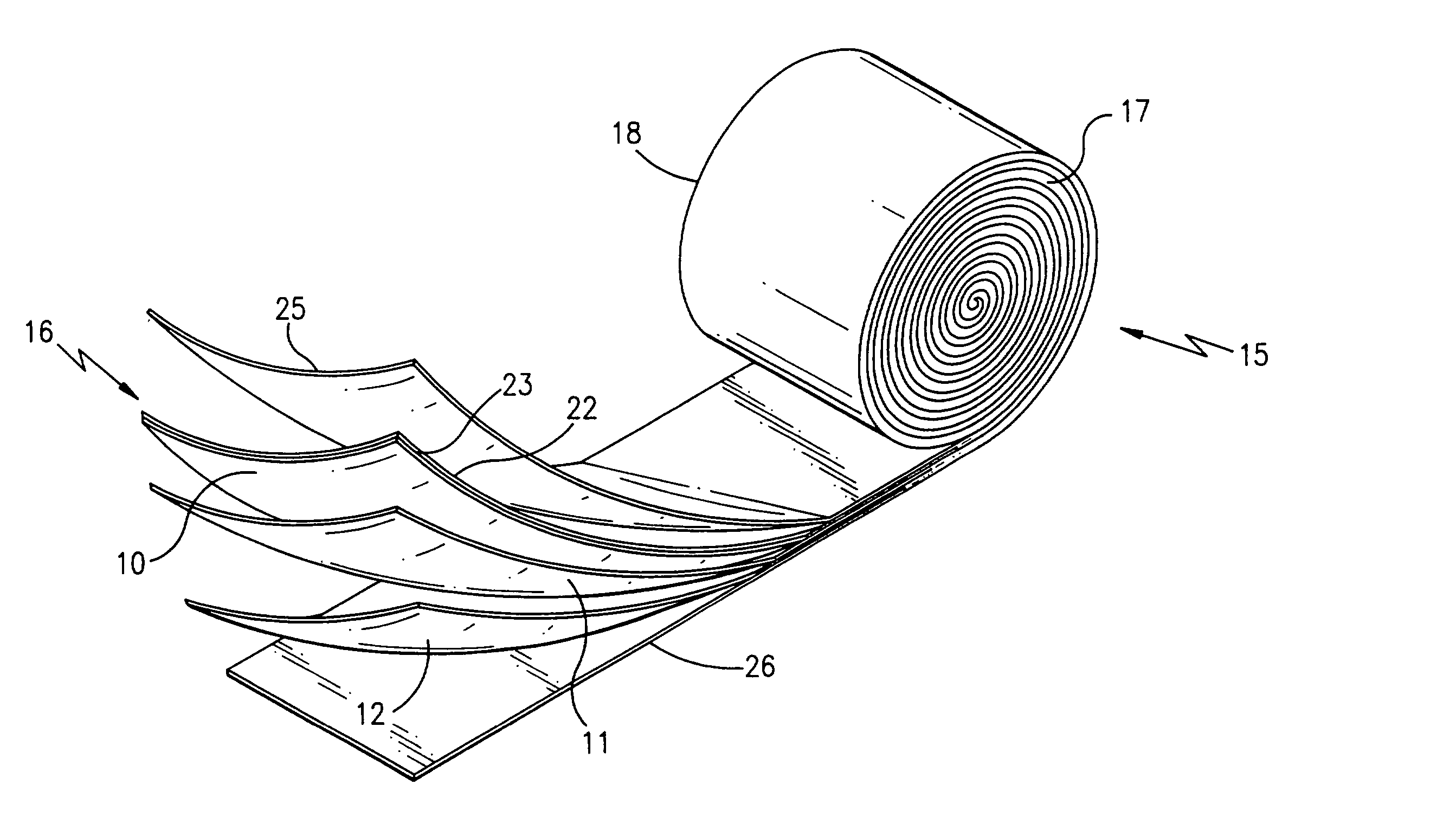

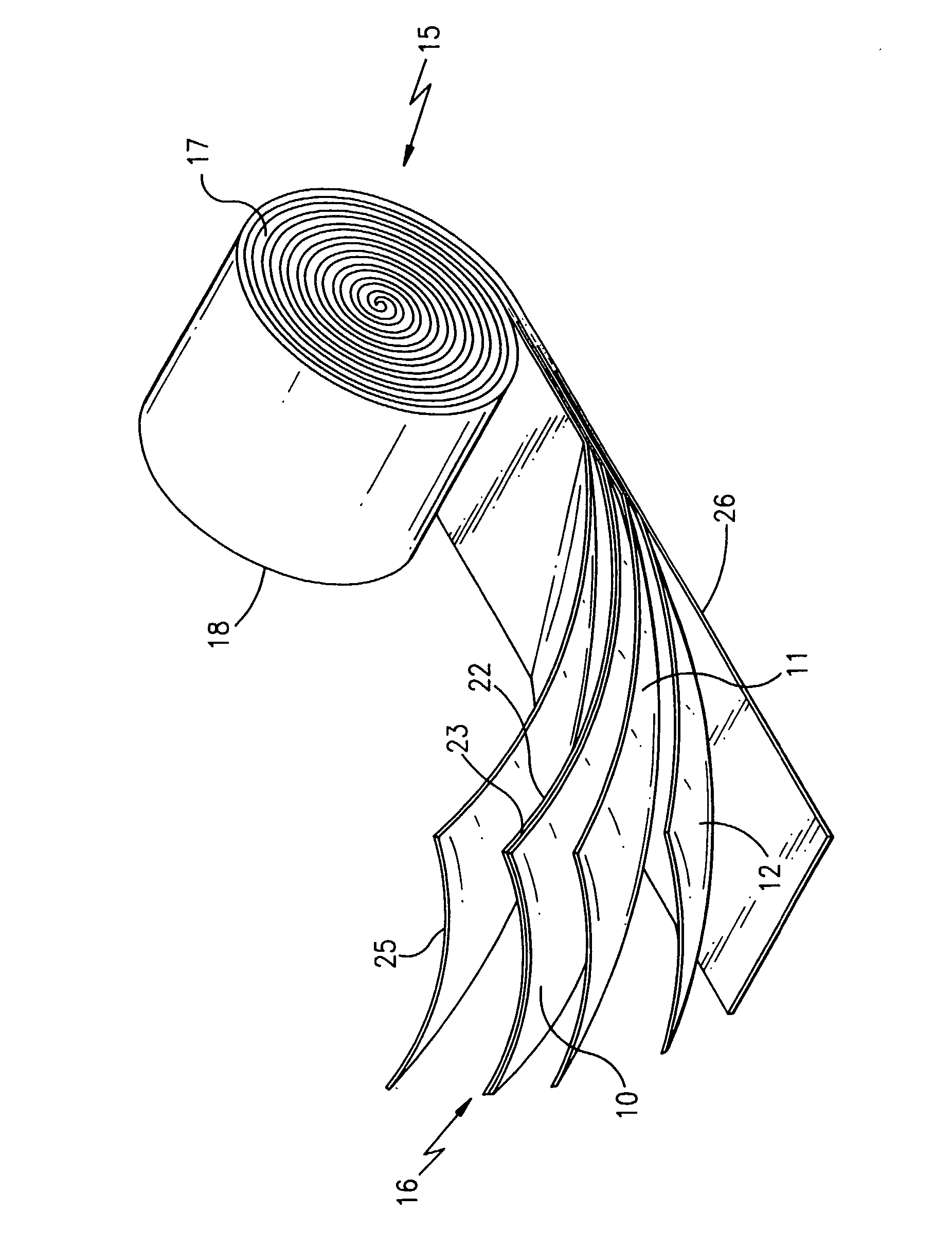

InactiveUS6413676B1Prevent kinkingAvoid deformationElectrode manufacturing processesFinal product manufacturePorosityCross-link

A dimensionally stable, highly resilient, hybrid copolymer solid-solution electrolyte-retention film for use in a lithium ion battery in one preferred embodiment has a predominantly amorphous structure and mechanical strength despite contact with liquid solvent electrolyte. The film is a thinned (stretched), cast film of a homogeneous blend of two or more polymers, one of which is selected for its pronounced solvent retention properties. A very high surface area inorganic filler dispersed in the blend during formation thereof serves to increase the porosity of the film and thereby enhance electrolyte retention. The film is soaked in a solution of liquid polymer with liquid organic solvent electrolyte and lithium salt, for absorption thereof. Use of a cross-linked liquid polymer enhances trapping of molecules of the electrolyte into pores of the film. The electrolyte film is sandwiched between flexible active anode and cathode layers to form the lithium ion battery. Novel methods are provided for forming the electrodes, the polymer substrate, and other elements of the battery.

Owner:LITHIUM POWER TECH

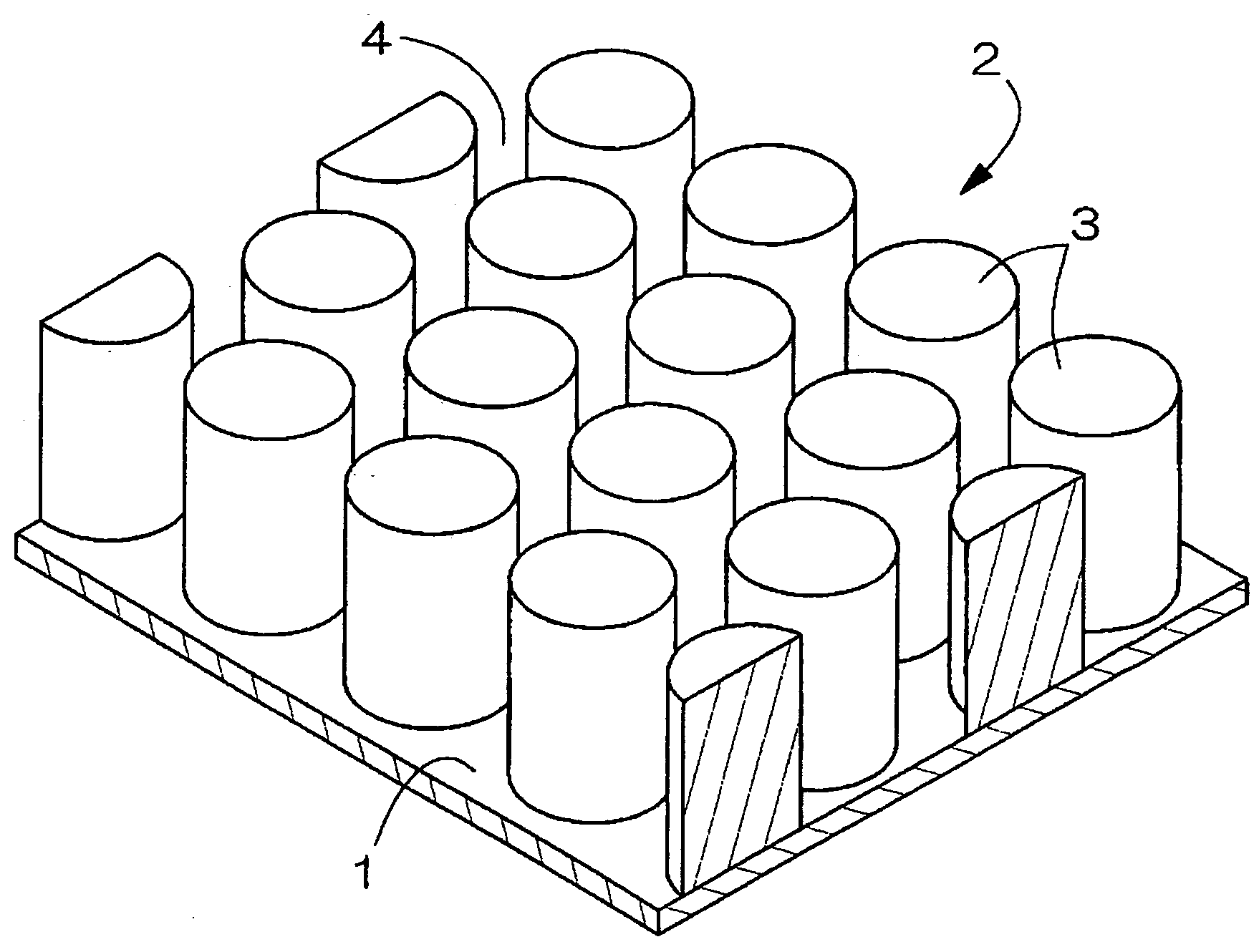

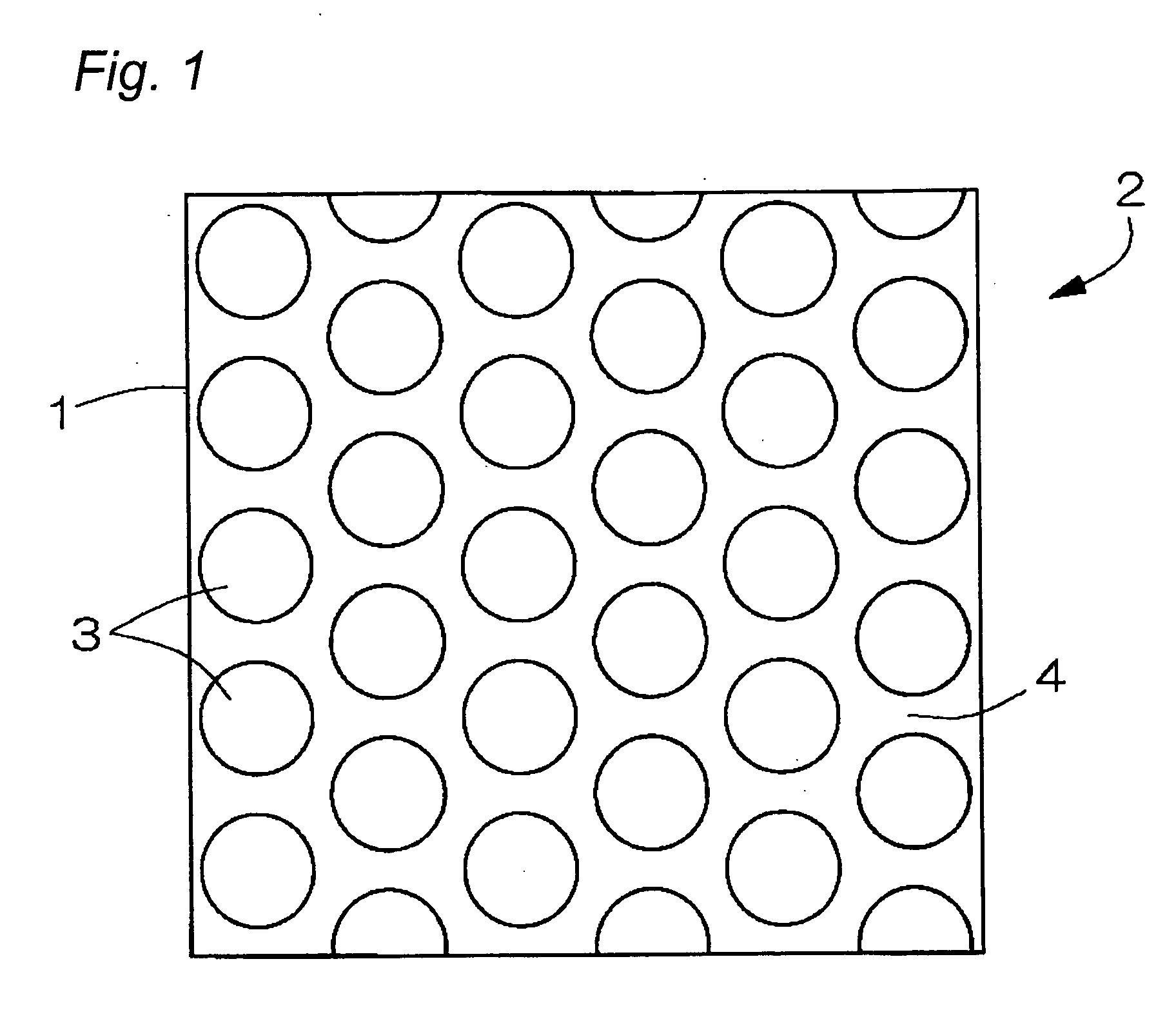

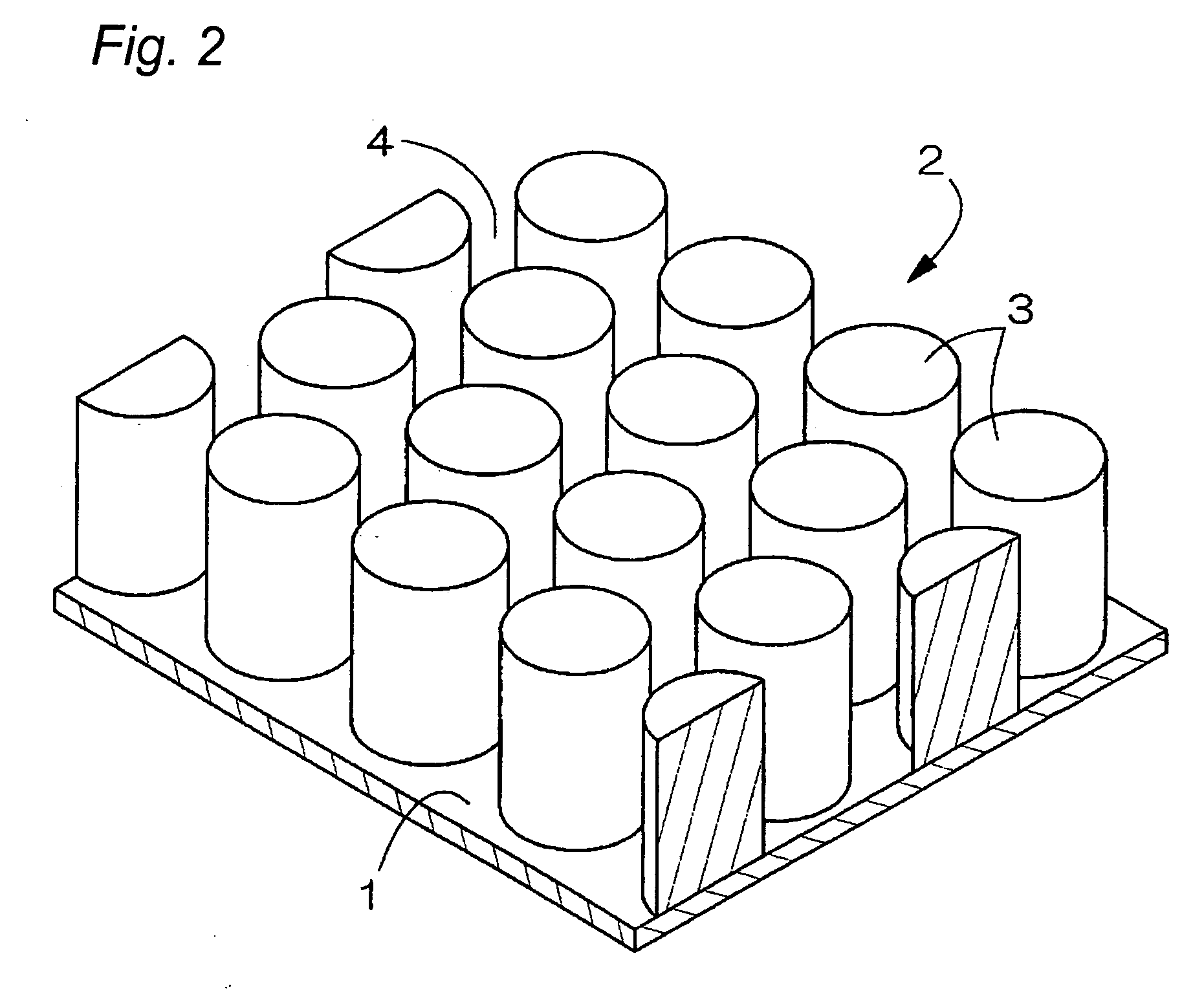

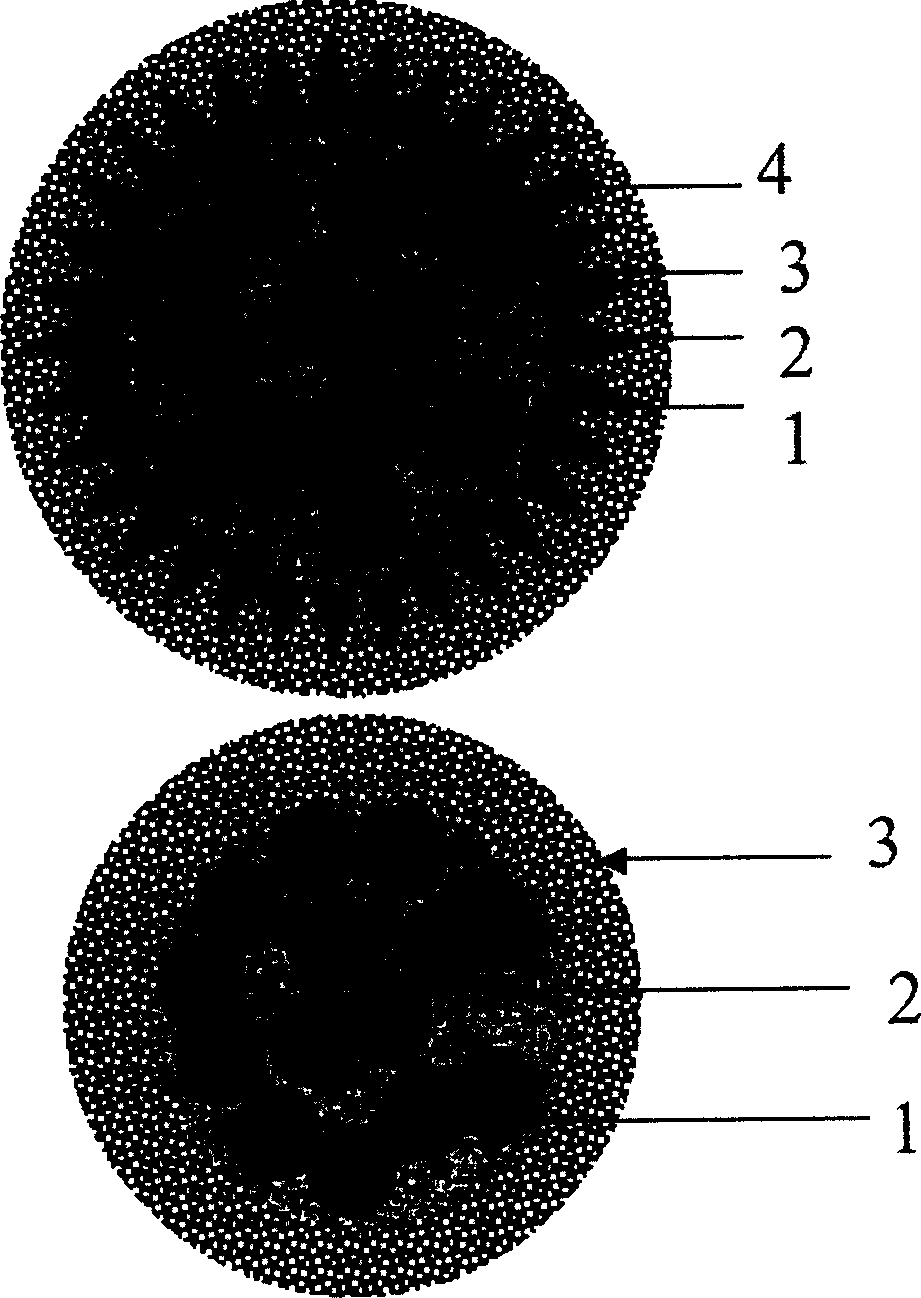

Electrode used for a non-aqueous electrolyte secondary battery and a non-aqueous electrolyte secondary battery using the same for a negative electrode

InactiveUS20050074671A1Increase capacityInsufficient releaseElectrode carriers/collectorsLi-accumulatorsPorosityMetallic materials

An electrode according to the invention can provide a non-aqueous electrolyte secondary battery having an ability to release a volume expansion at the time of charge and discharge as well as the time of a cycle. The electrode comprises a current collector made of a material which is not alloyed with Li, and a dot pattern 2 of a metallic material able to be alloyed with Li formed on the current collector. At the time of charge, since the volume expansion of each dot 3 is carried out so as to bury adjoining crevices 4 between the dots, a stress generated is released, thereby degradation of an electrode being avoided. Each dot may also be made into porosity.

Owner:HITACHI MAXELL ENERGY LTD

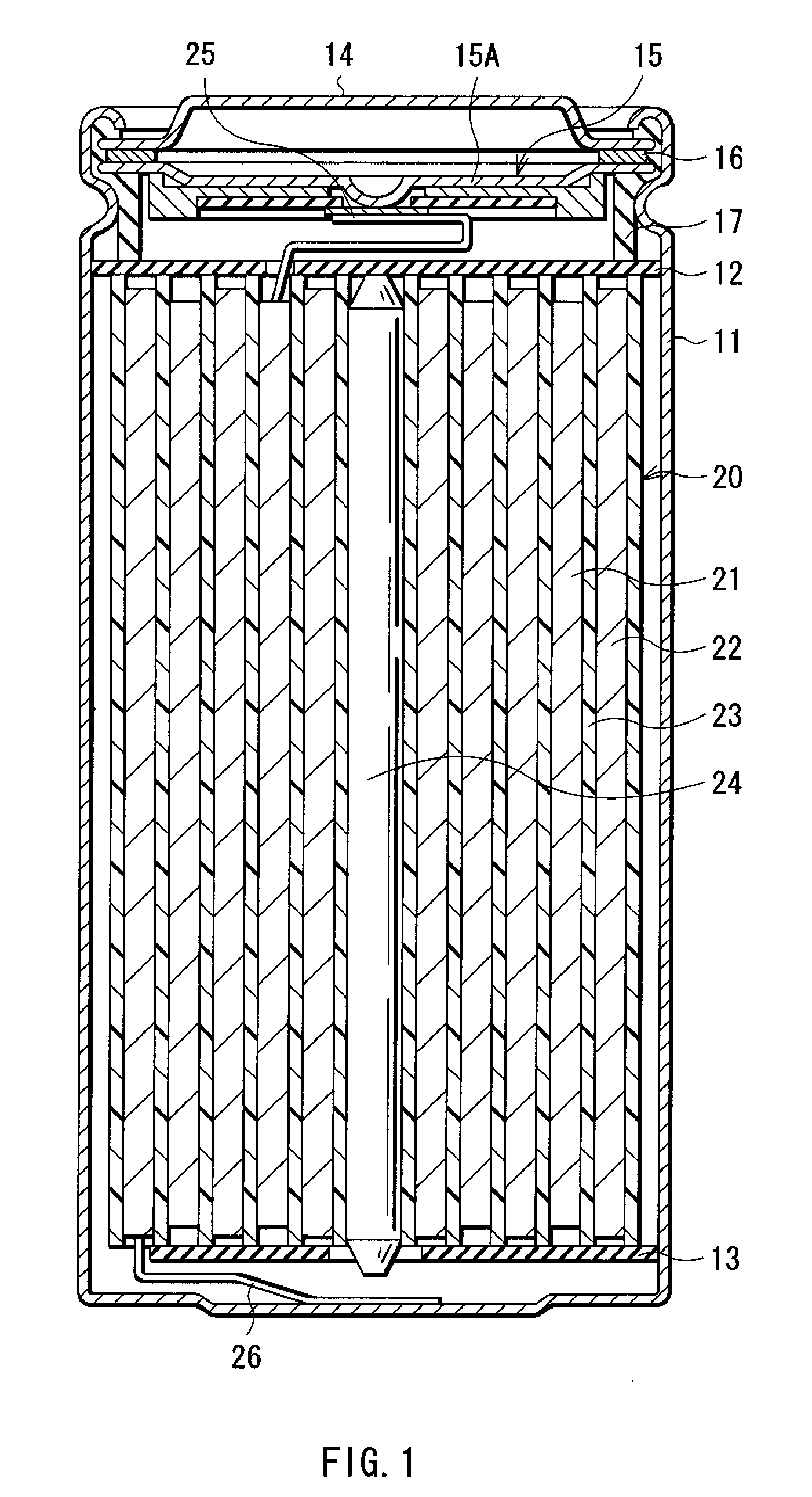

Anode material, anode and battery

ActiveUS20070122701A1High capacitySuperior charge-discharge efficiencyNon-aqueous electrolyte accumulatorsFinal product manufactureOxideAnode

An anode material capable of obtaining a high capacity and superior charge-discharge efficiency, and an anode and a battery using the anode material are provided. An anode includes an anode material including an active portion including at least one of silicon and tin as an element and a coating portion of a metal oxide arranged on a part of a surface of the active portion. The ratio of the coating portion to the active portion is within a range from 0.01 wt % to 10 wt % inclusive. Thereby, a high capacity and superior charge-discharge efficiency can be obtained.

Owner:MURATA MFG CO LTD

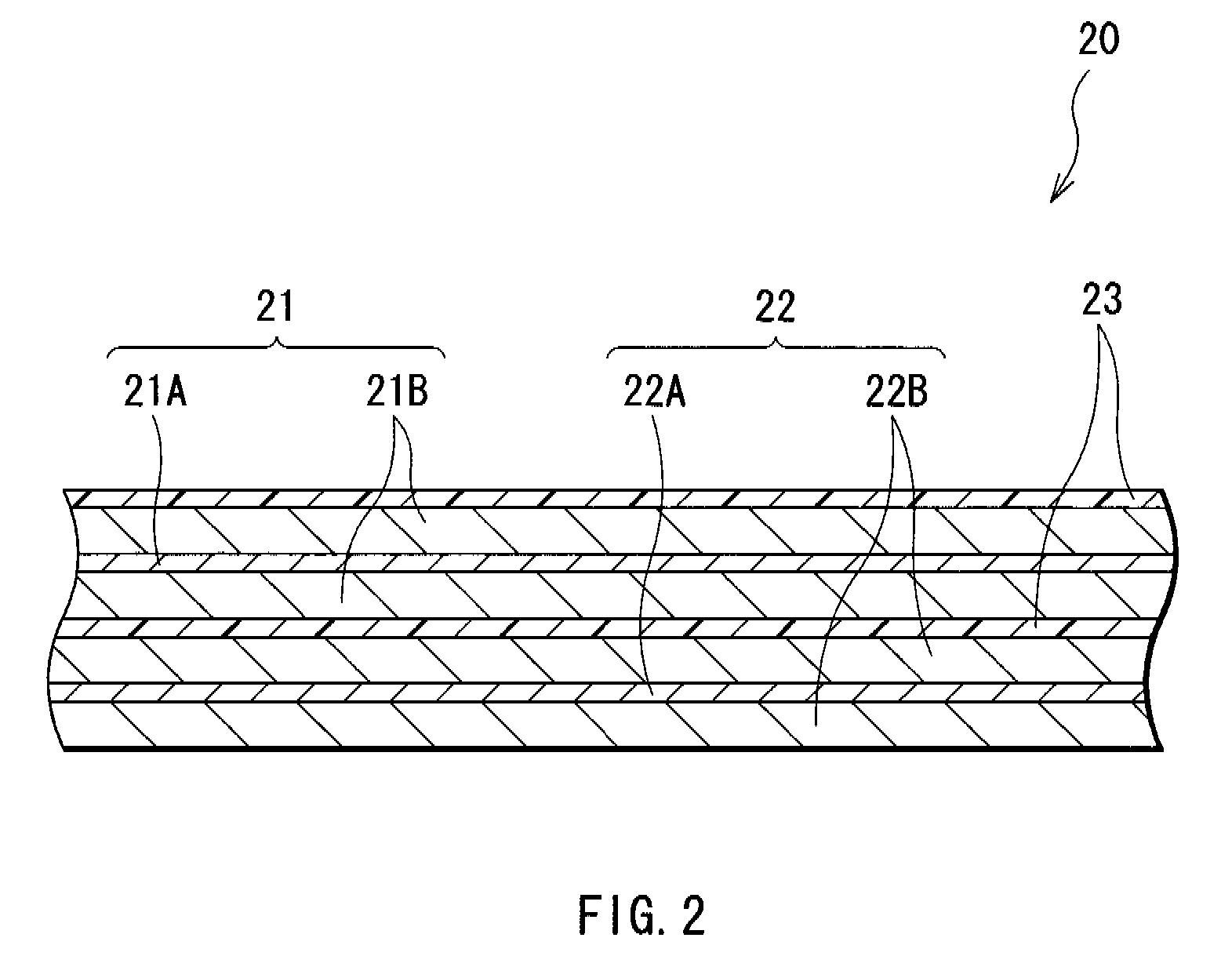

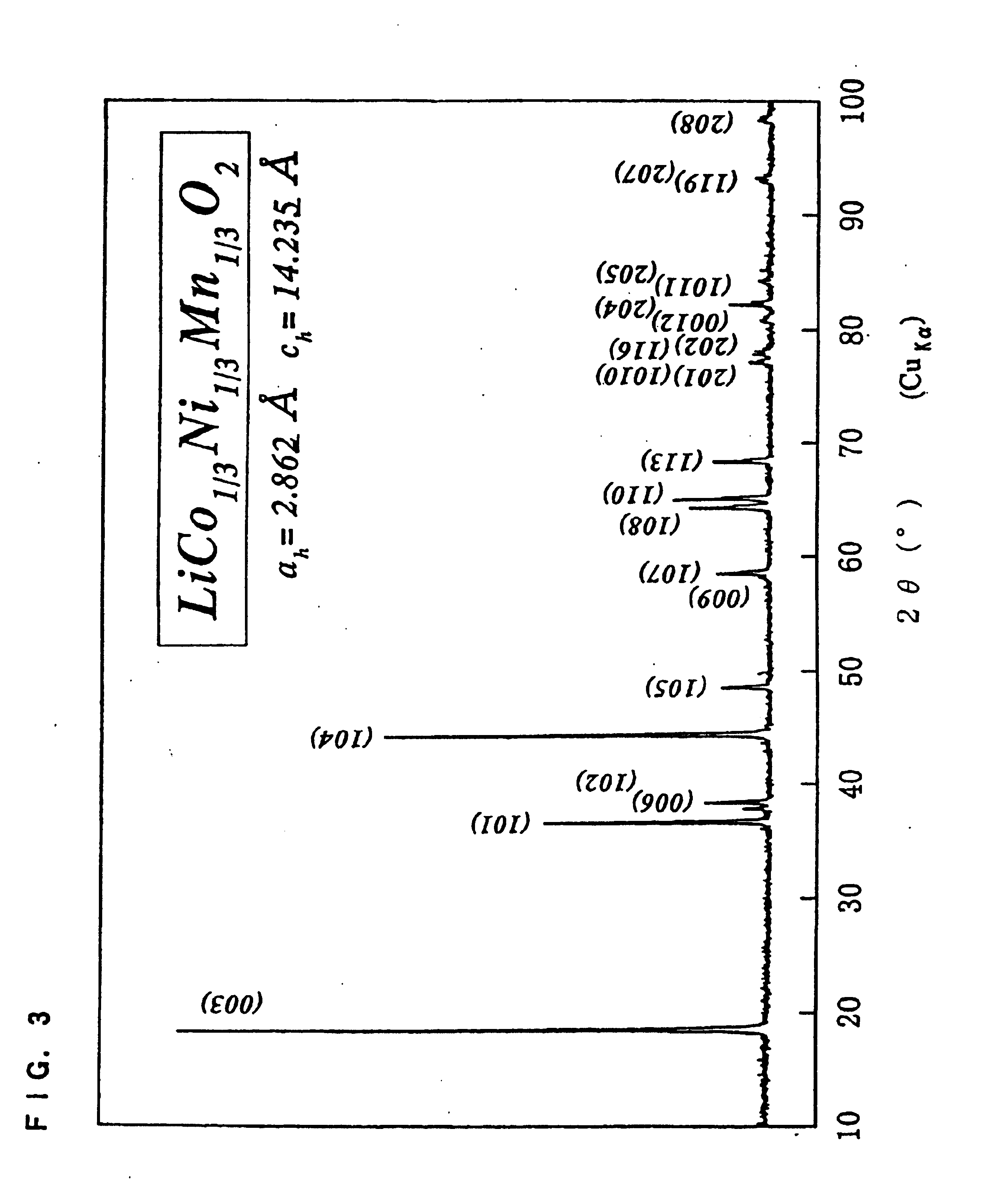

Positive electrode active material and nonaqueous electrolyte secondary cell including the same

InactiveUS20050079416A1Large capacityImprove charge and discharge efficiencyOxygen/ozone/oxide/hydroxideIron oxides/hydroxidesMetallic lithiumManganese

A nonaqueous electrolytic secondary cell produced at low cost and having a large capacity comprises a negative electrode having an active material mainly composed of a material that at least absorbs and releases lithium ions or metallic lithium, a positive electrode, and an electrolyte. The active material of the positive electrode is an oxide containing nickel, manganese, and cobalt, and the contents of the elements are substantial the same.

Owner:PANASONIC CORP +1

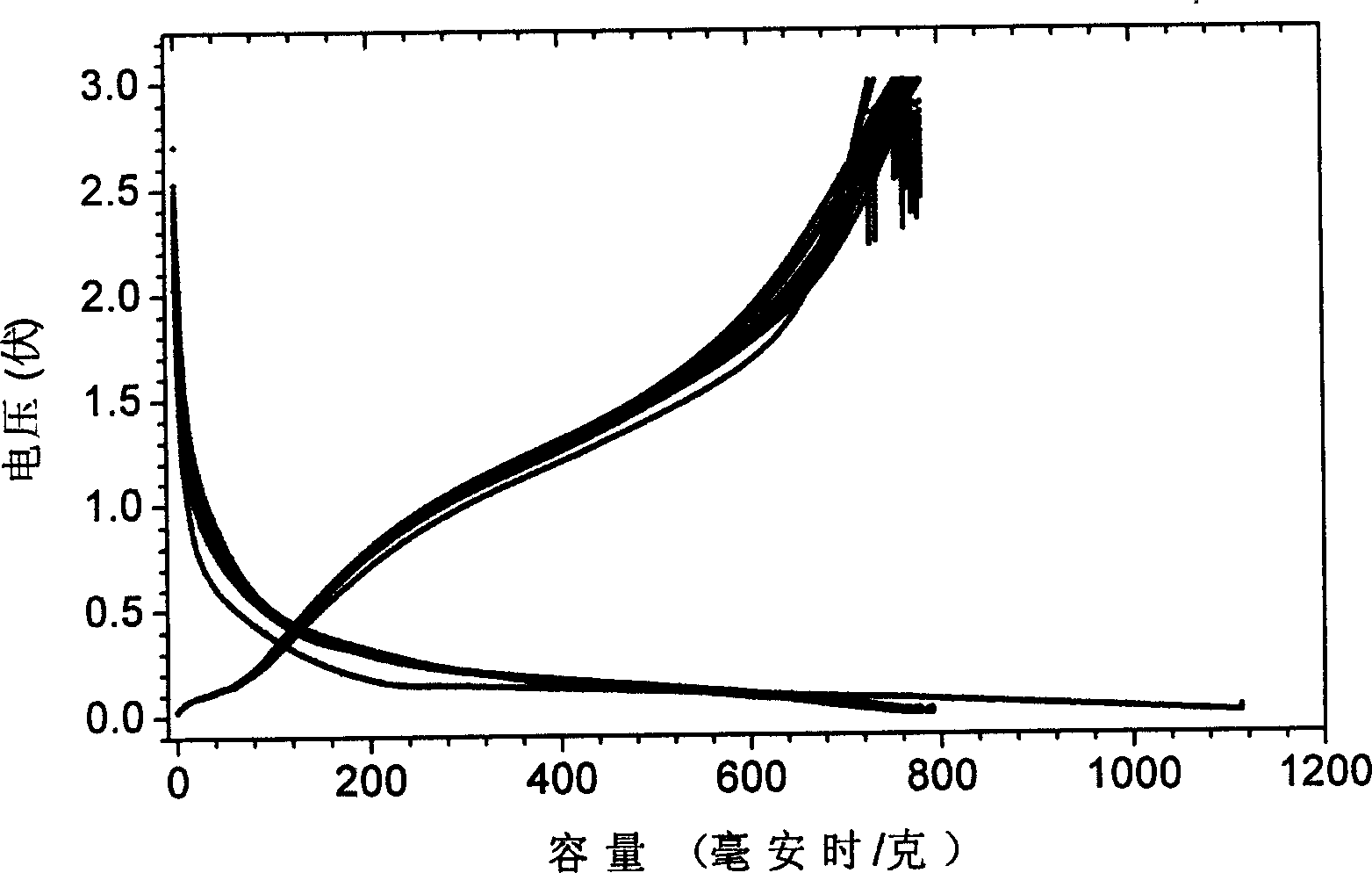

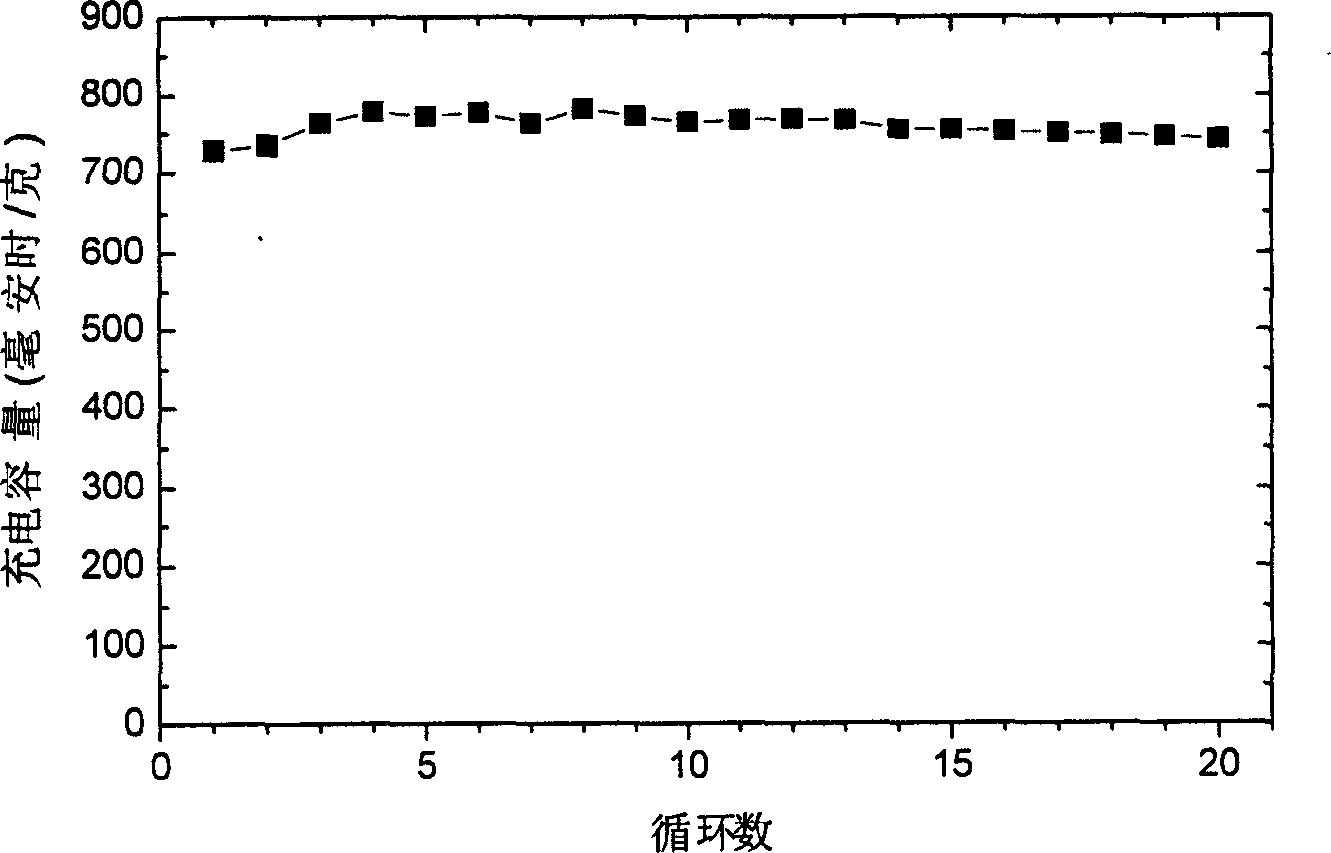

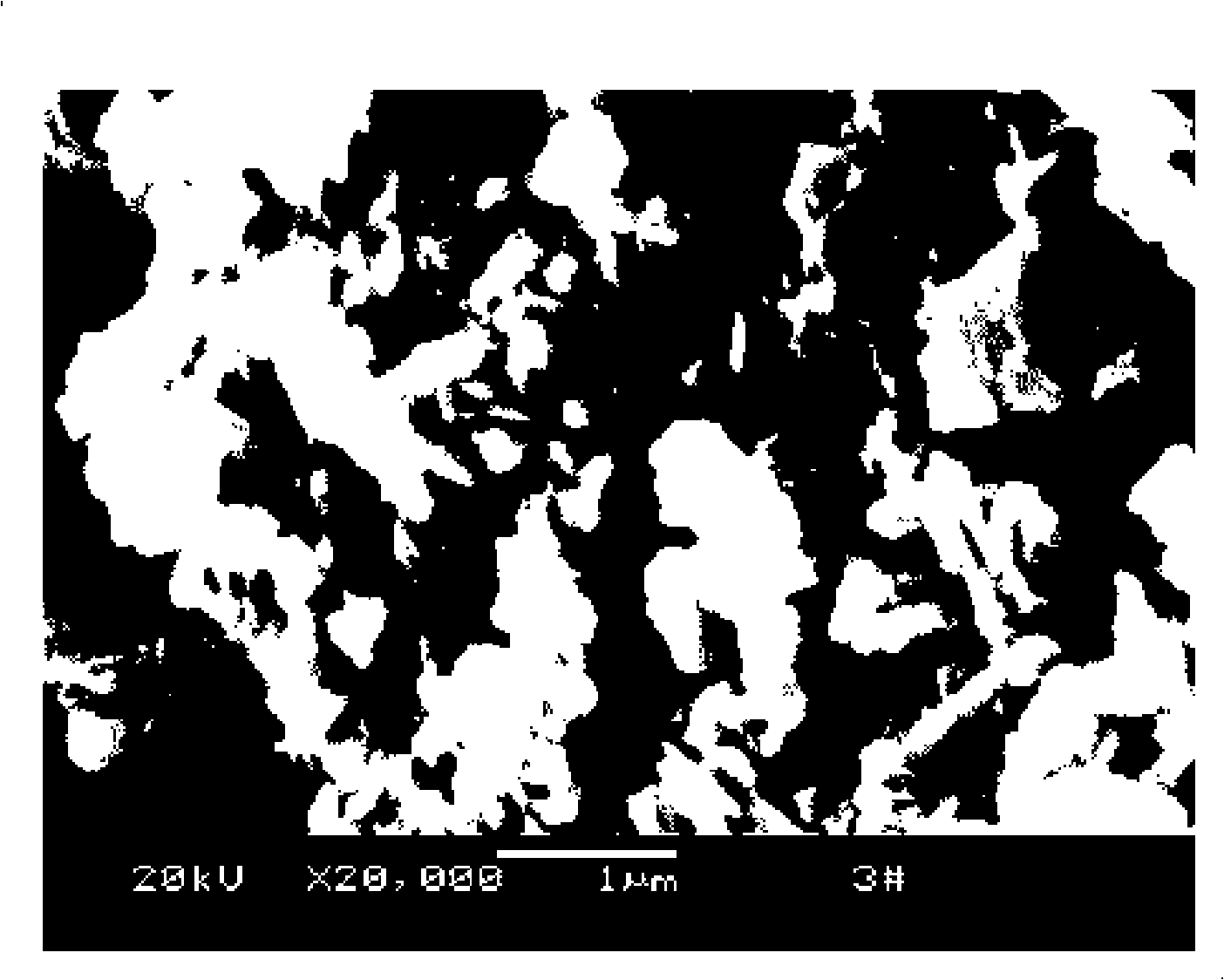

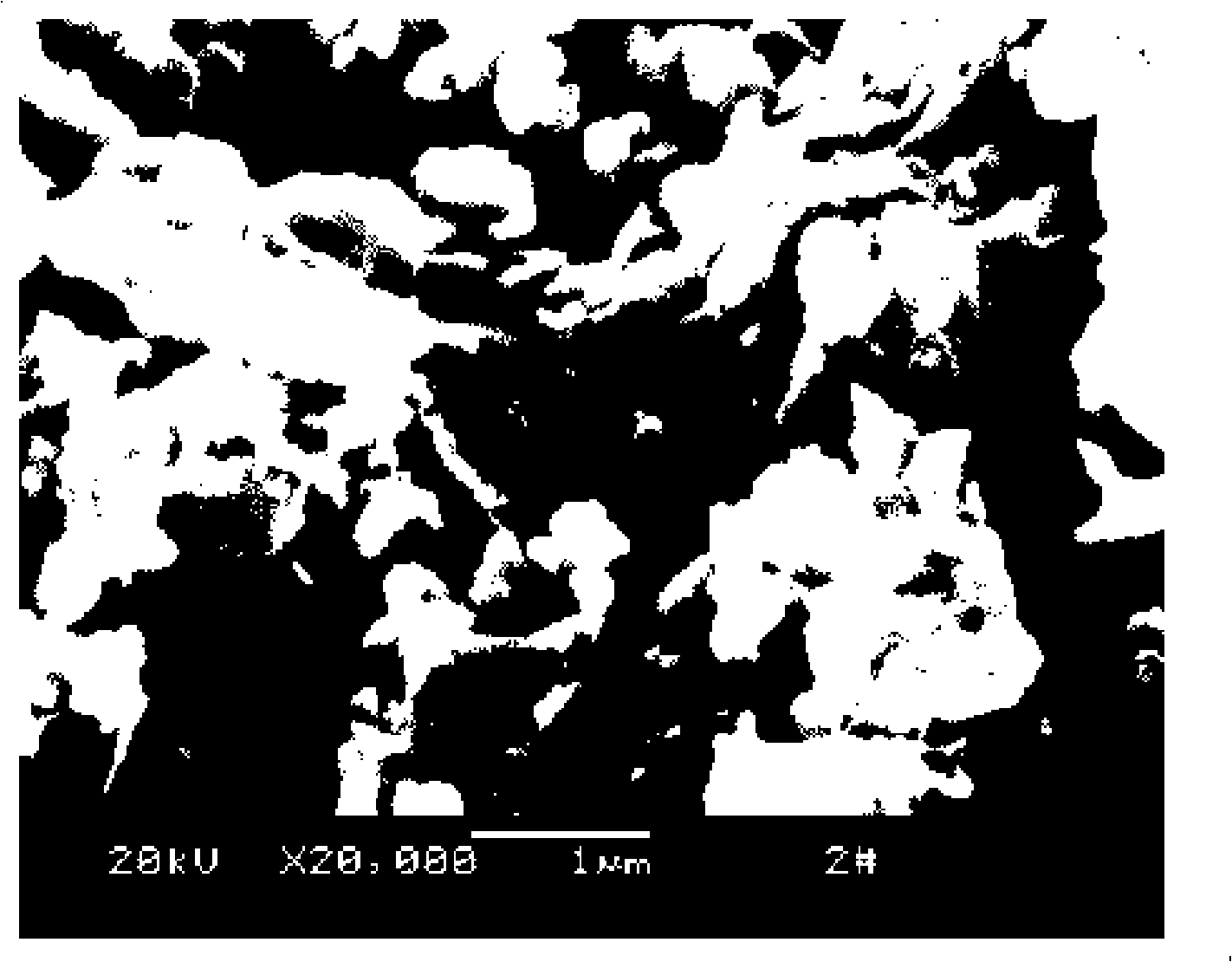

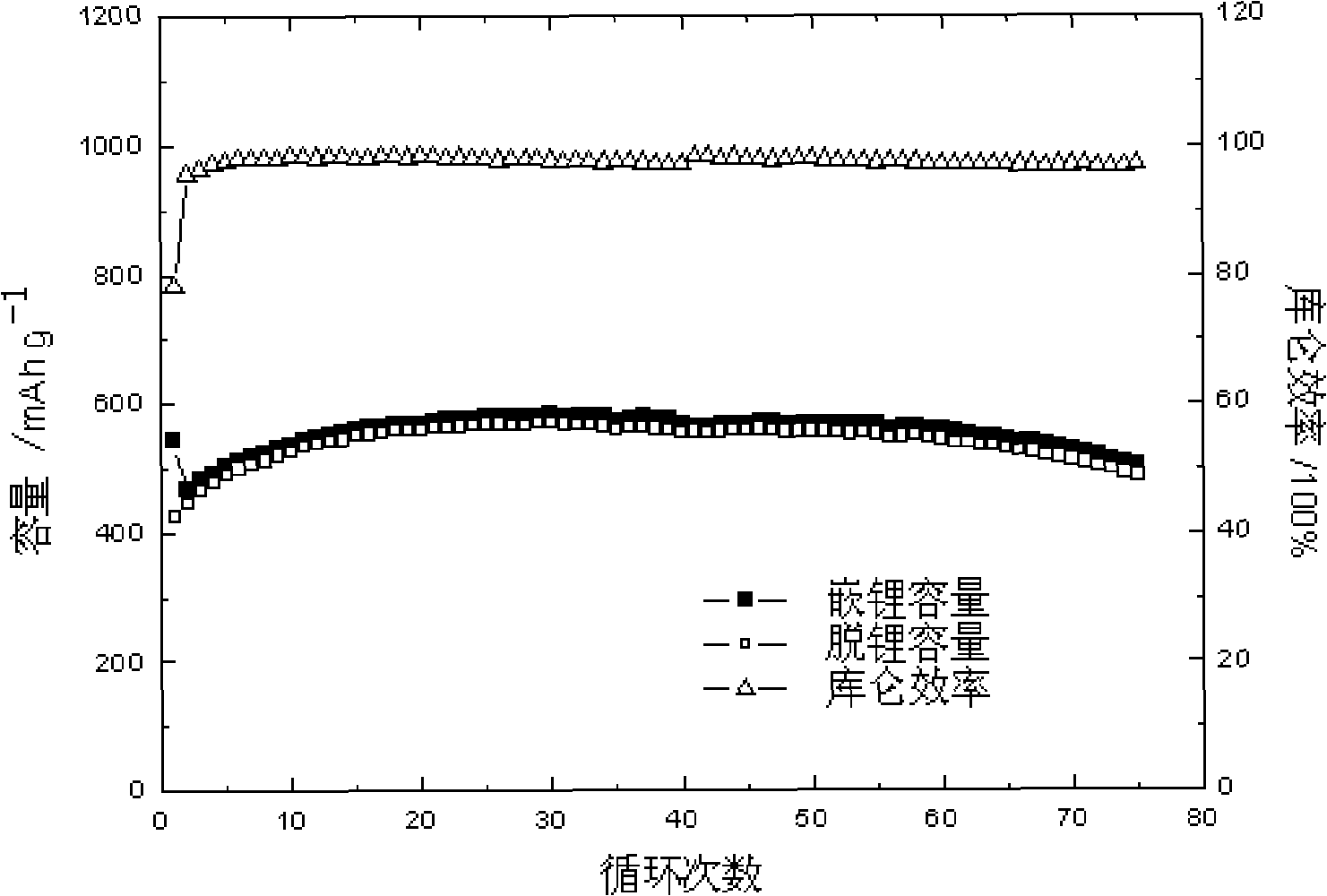

Negative electrode active material and use of secondary lithium battery

The invention has a grain structure with an outer shell and several inner cores. The grain size is from 100 nanometers to 100 microns. The inner cores are compound grain that includes active substance and conducting additive. The outer shell is a carbon layer. The active substance takes 20-95wt% of total cathode active material, and is mixture of one or several transition metallic compound selected from silicon and lithium storage whose thermodynamic equilibrium potential is less than 1.5v. The cathode material can be made by using mechanical process or thermal method, and can be directly used as cathode material or used with other existing cathode material.

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD

Ionically conductive polymer electrolytes

InactiveUS20030091904A1Good flexibilityLower resistanceElectrode manufacturing processesFinal product manufacturePorosityCross-link

A dimensionally stable, highly resilient, hybrid copolymer solid-solution electrolyte-retention film for use in a lithium ion battery in one preferred embodiment has a predominantly amorphous structure and mechanical strength despite contact with liquid solvent electrolyte. The film is a thinned (stretched), cast film of a homogeneous blend of two or more polymers, one of which is selected for its pronounced solvent retention properties. A very high surface area inorganic filler dispersed in the blend during formation thereof serves to increase the porosity of the film and thereby enhance electrolyte retention. The film is soaked in a solution of liquid polymer with liquid organic solvent electrolyte and lithium salt, for absorption thereof. Use of a cross-linked liquid polymer enhances trapping of molecules of the electrolyte into pores of the film. The electrolyte film is sandwiched between flexible active anode and cathode layers to form the lithium ion battery. Novel methods are provided for forming the electrodes, the polymer substrate, and other elements of the battery.

Owner:LITHIUM POWER TECH

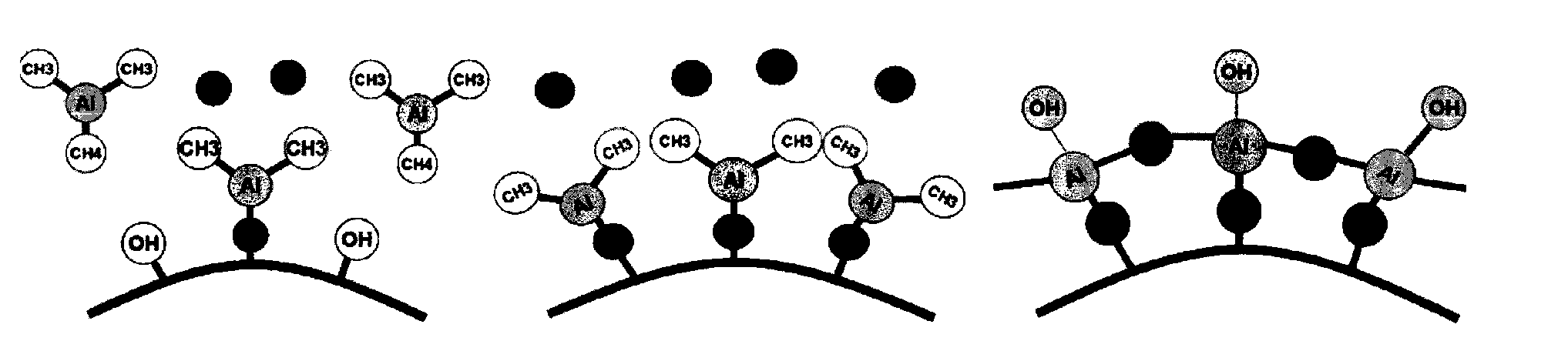

Modified positive electrode material of lithium ion battery and preparation method of modified positive electrode material

InactiveCN102738451AImprove performanceImproved performance characteristicsCell electrodesDischarge efficiencyElectrical conductor

The invention discloses a modified positive electrode material of a lithium ion battery and a preparation method of the modified positive electrode material. The modified positive electrode material is characterized in that the modified positive electrode material is made of a lithium fast ion conductor and a positive electrode material of lithium ion battery at a molar ratio of n:1, wherein n is larger than 0 and not larger than 0.15. The invention also discloses the preparation method of the modified positive electrode material of the lithium ion battery. The modified positive electrode material provided by the invention is improved in conductivity property performance and surface properties, thereby enhancing the specific volume of the lithium ion battery, and improving the charging-discharging efficiency, rate capacity, cycling performance and temperature adaptability of the lithium ion battery.

Owner:HENAN NORMAL UNIV

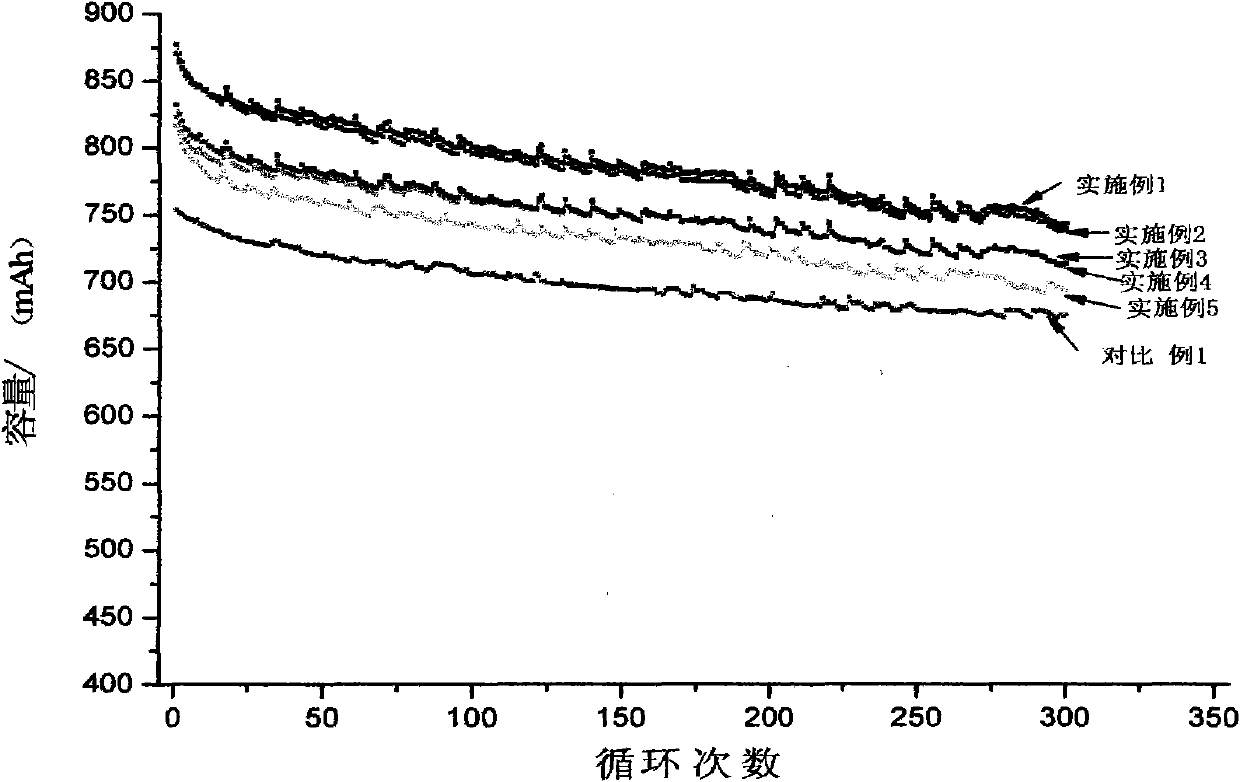

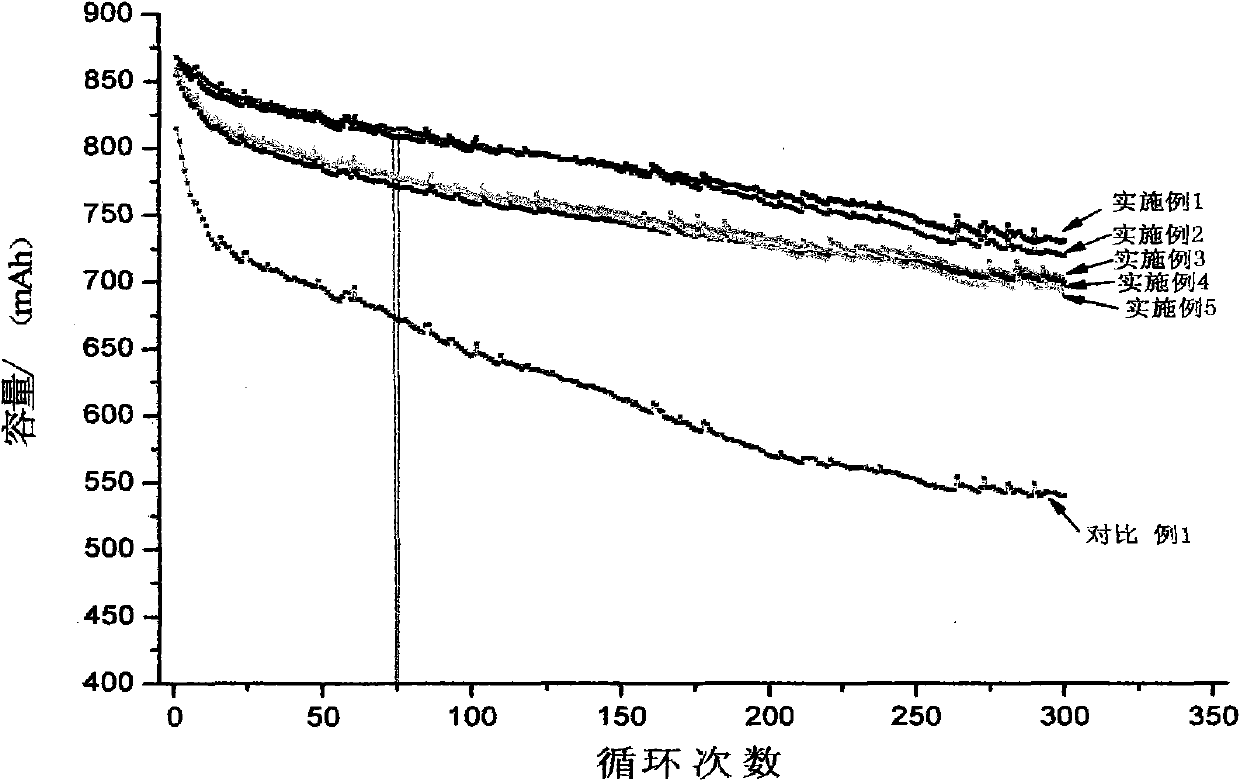

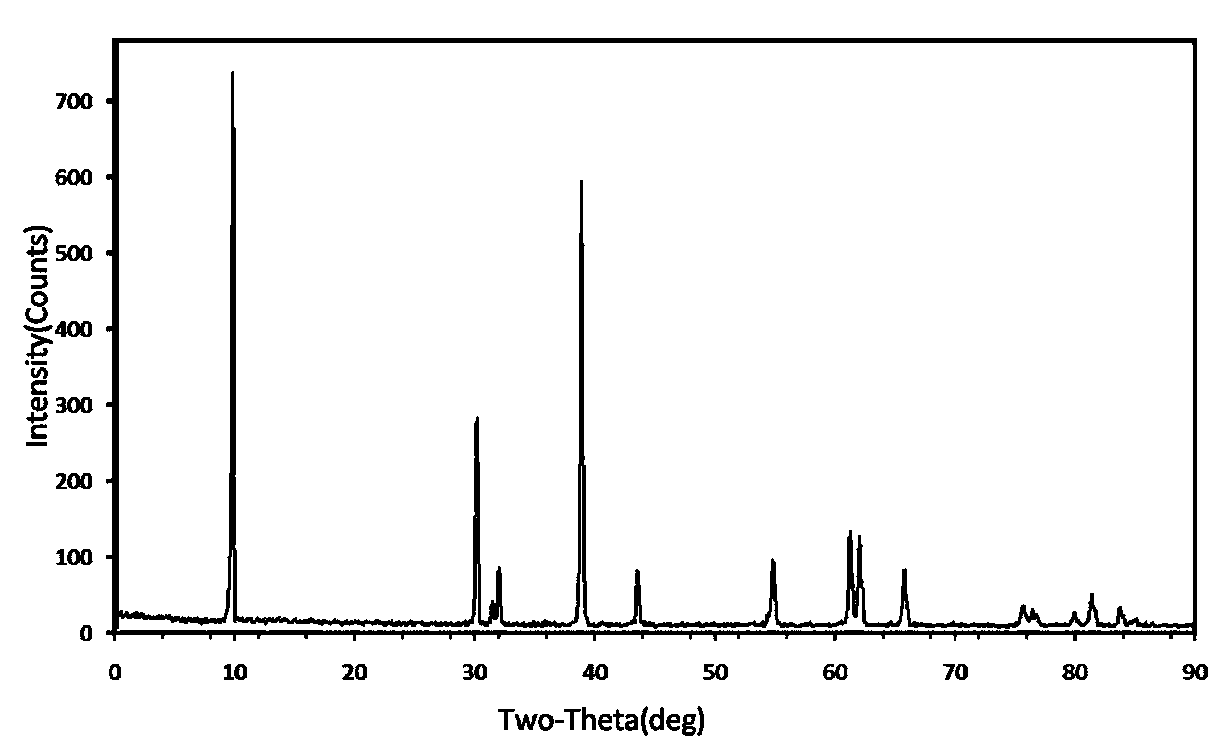

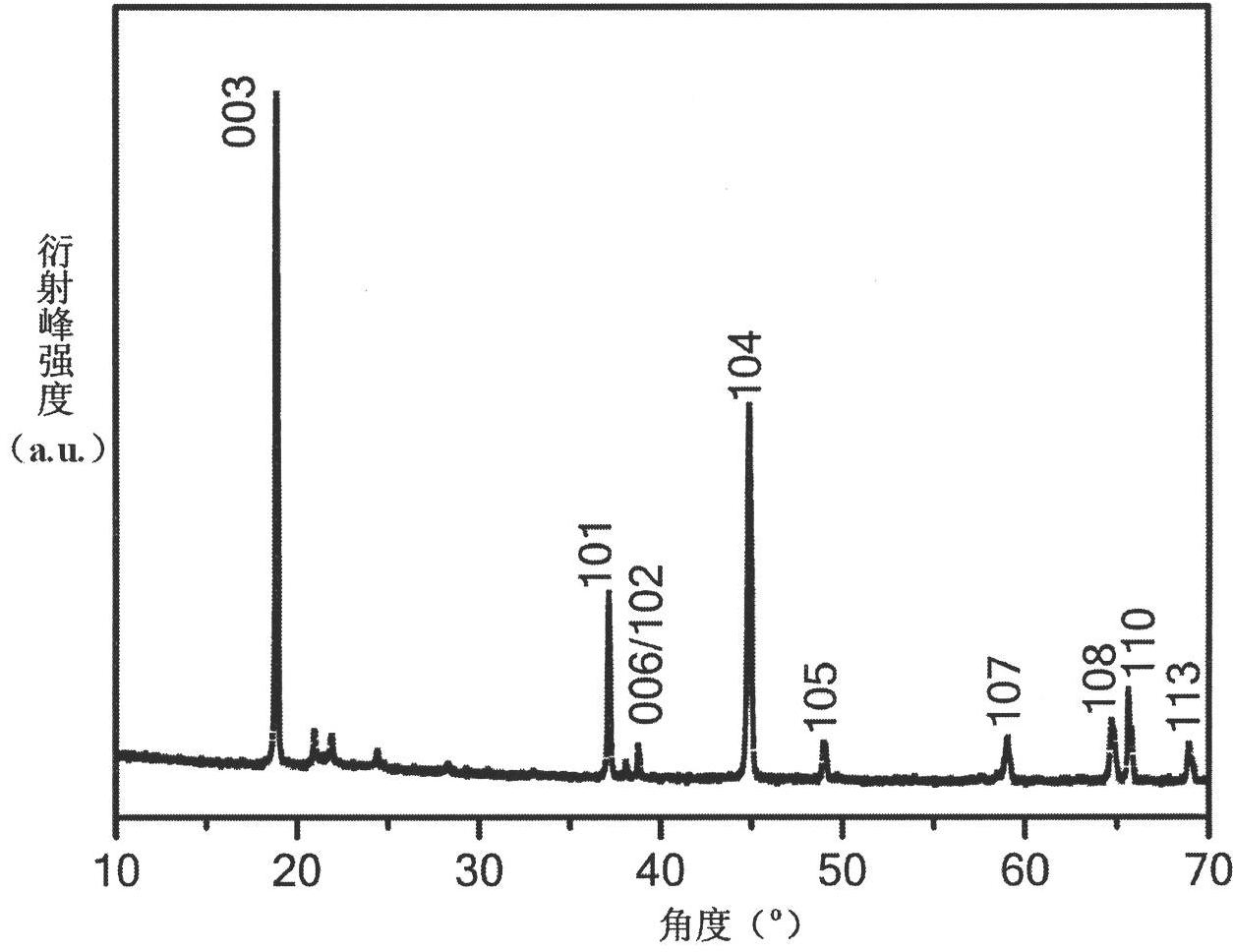

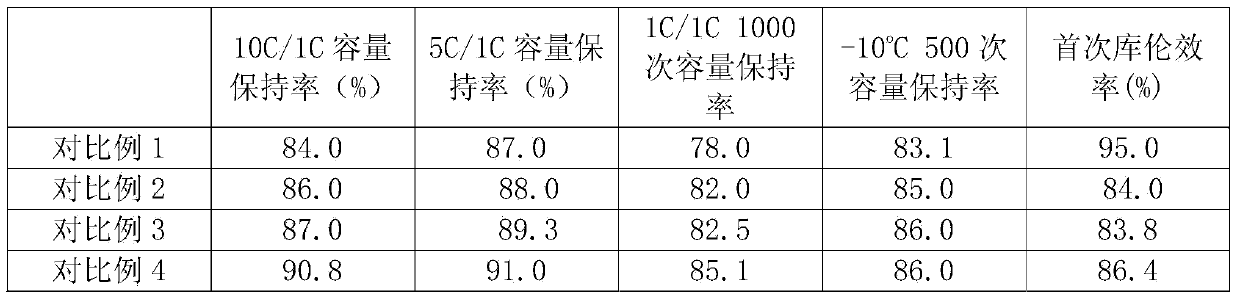

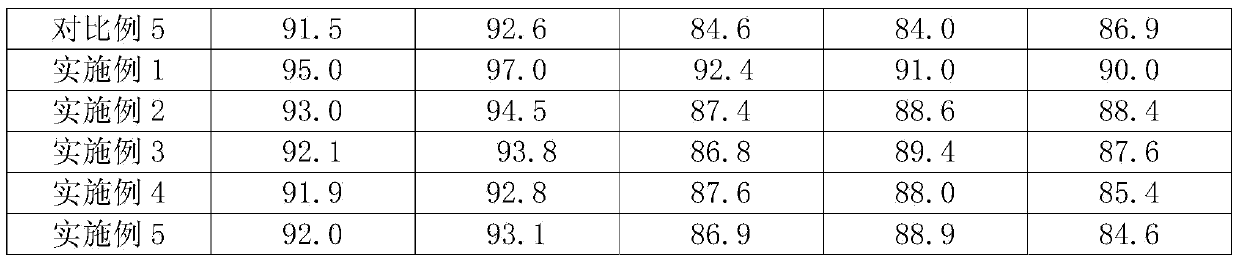

Rare-earth doping modified lithium ion battery ternary positive electrode material and preparation method thereof

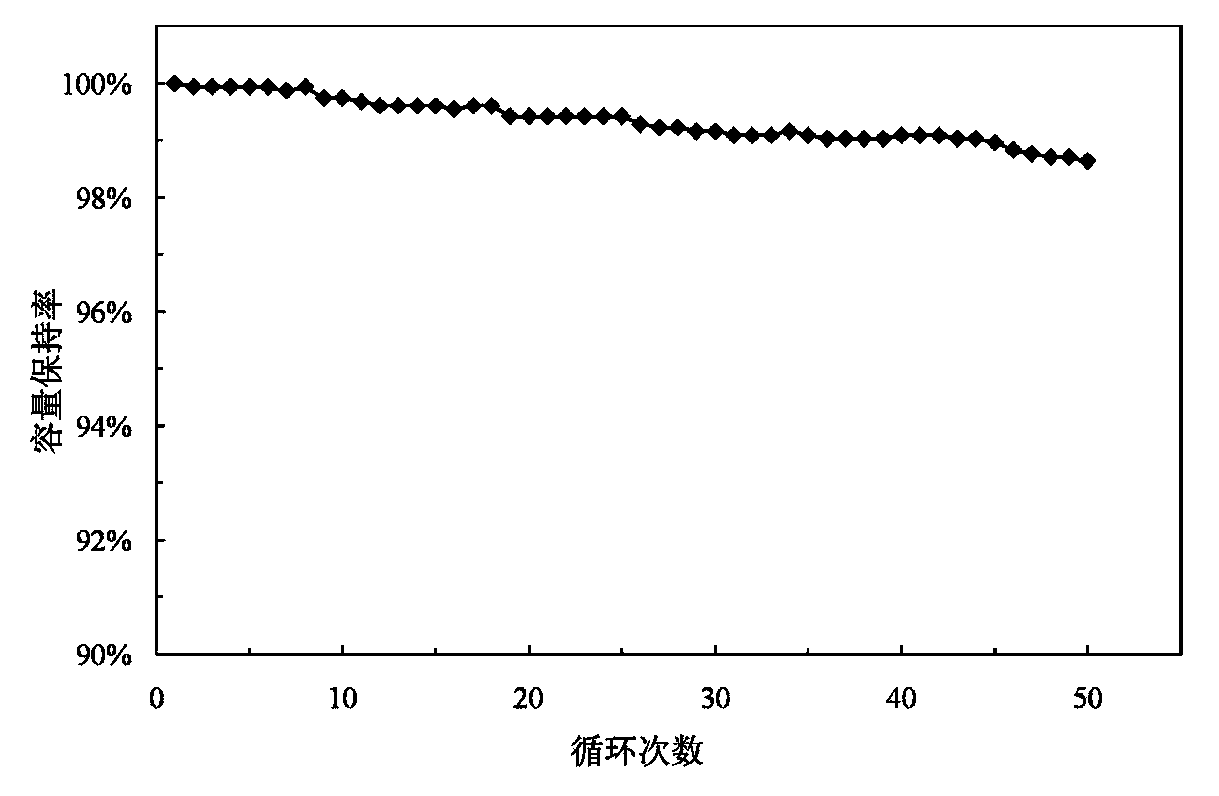

ActiveCN103855384AEase of industrial productionImprove charge and discharge efficiencyCell electrodesSecondary cellsCarbon compositesNickel salt

The invention relates to a rare-earth doping modified lithium ion battery ternary positive electrode material and a preparation method of the rare-earth doping modified lithium ion battery ternary positive electrode material. The chemical general formula of the material is as follows: LiNiaCo<1-a-b>MnbRxO2 / M, wherein a is more than 0 and less than 1, b is more than 0 and less than 1, (1-a-b) is more than 0 and less than 1, x is more than 0.005 and less than 0.1, R is one or more of rare-earth lanthanum, cerium, praseodymium and samarium, and M is a composite cladding layer of oxide of aluminum, titanium or magnesium and carbon. The soluble metal nickel salt, cobalt salt, manganese salt and rare-earth compound are mixed to prepare a mixed salt solution, the mixed salt solution is reacted with a mixed alkaline solution prepared by mixing NaOH and ammonium hydroxide, after the reaction solution is filtered, washed and dried, the obtained product is uniformly mixed with lithium salt powder to be ball milled, then the mixture is calcined at the high temperature and coated with the composite cladding layer of the aluminum, titanium or magnesium oxide and carbon, and finally the calcined mixture is calcined at a constant temperature to obtain the rare-earth doping modified lithium ion battery ternary positive electrode material. After doping the rare earth, the metal oxide and carbon composite cladding layer, which are cheap and easy to obtain, are adopted, so that the cycling performance and the rate performance can be improved, and the charging-discharging efficiency of the material also can be improved.

Owner:ZHEJIANG MEIDARUI NEW MATERIAL TECH CO LTD

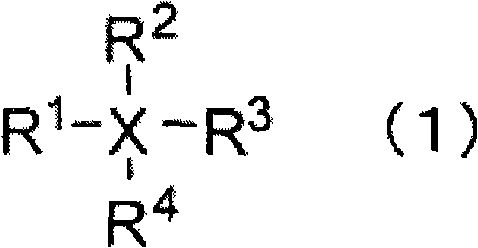

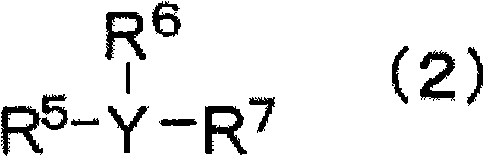

Electrolyte solution for secondary battery and secondary battery using same

ActiveUS20060292452A1Sufficient battery characteristicImprove efficiencyOrganic chemistryLight-sensitive devicesPhysical chemistrySolvent

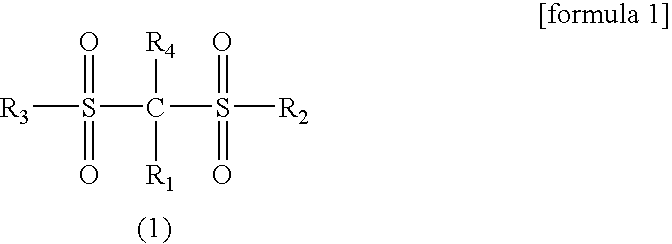

There is provided a lithium secondary battery which has excellent characteristics such as energy density and electromotive force and is excellent in cycle life and storage stability. An electrolyte solution for secondary battery comprising at least an aprotic solvent having an electrolyte dissolved therein and a compound represented by the general formula (1).

Owner:NEC CORP

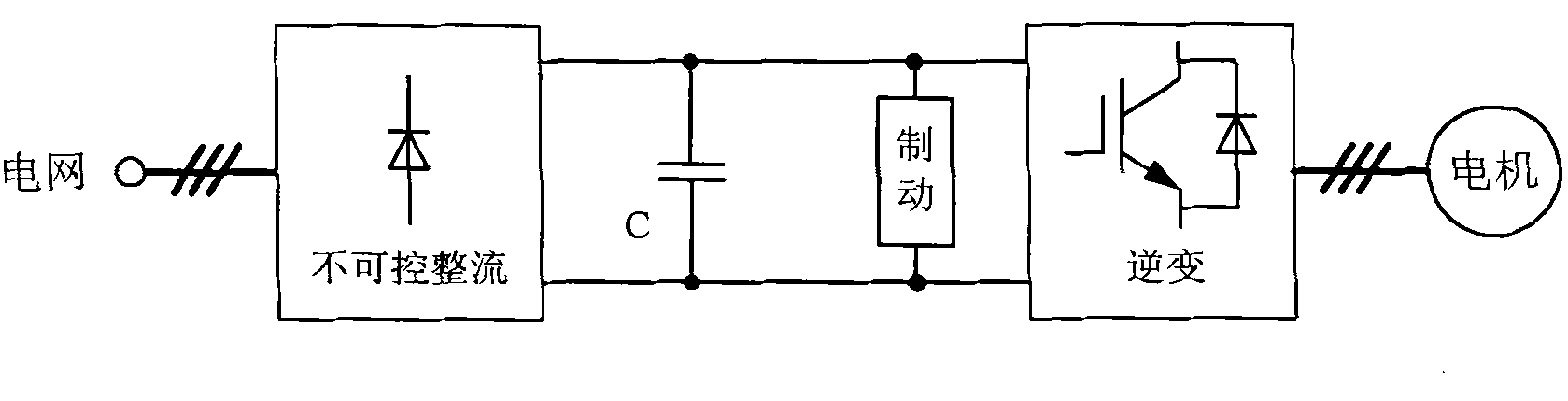

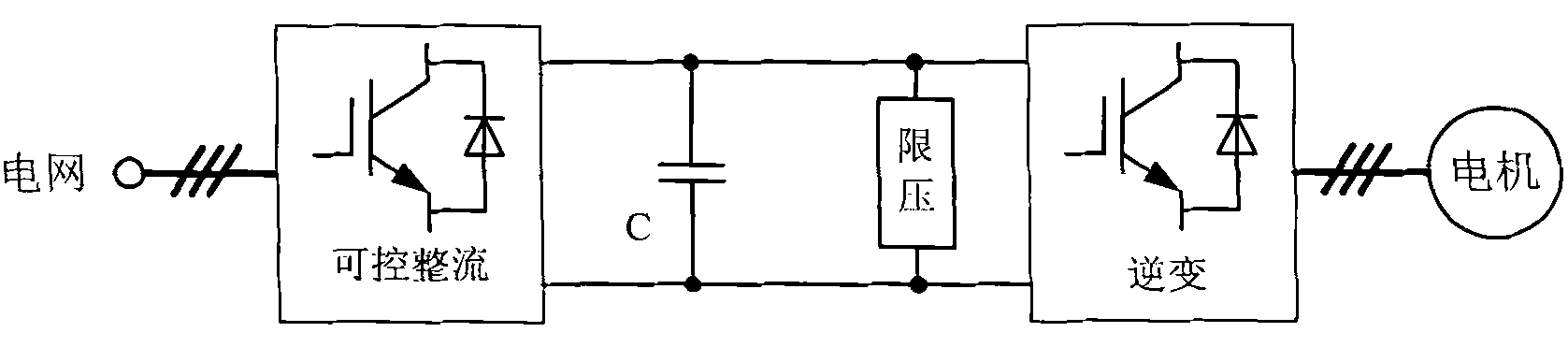

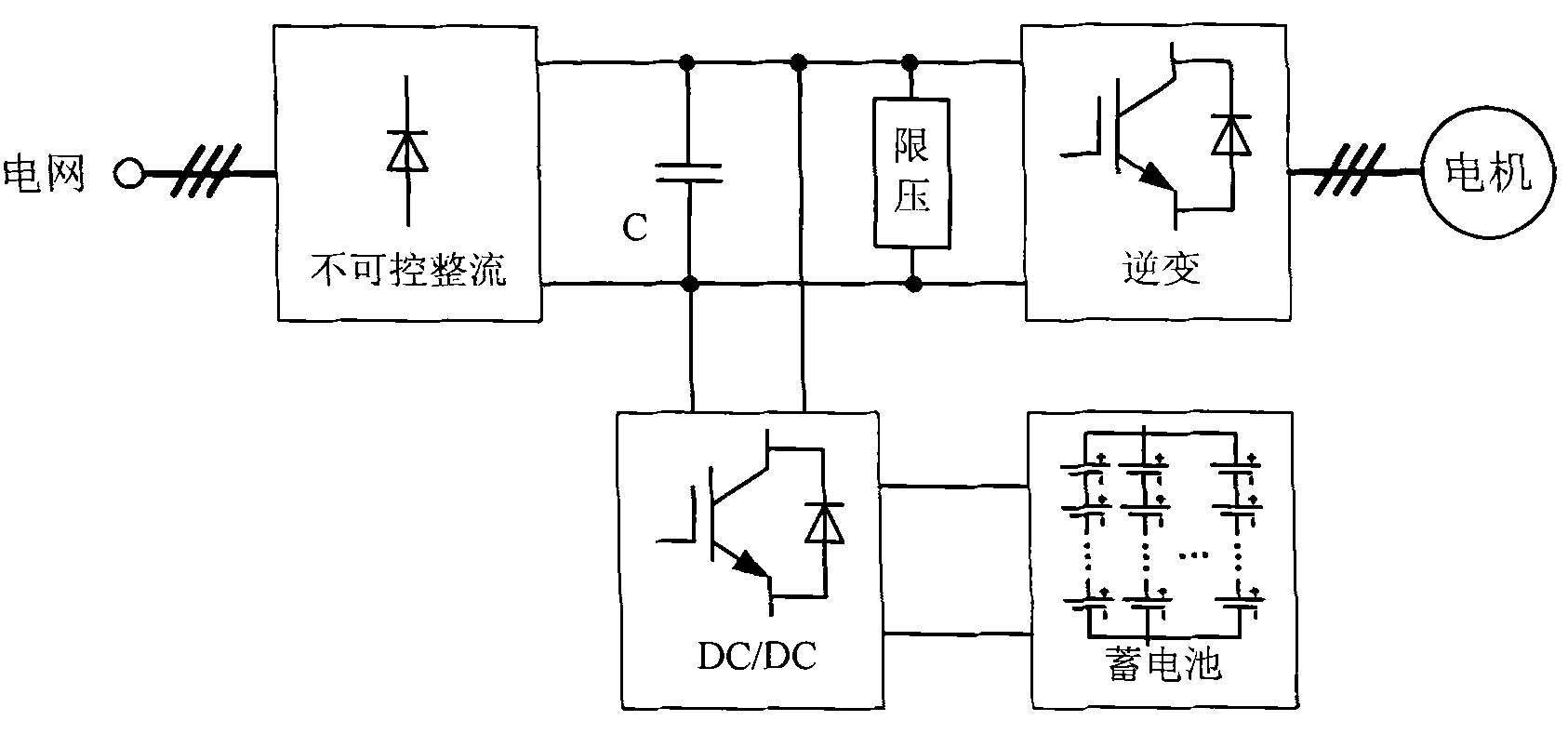

Super capacitor-based energy-saving drive circuit of motor and control method

InactiveCN101931366ARealize the power peak absorption functionReduce shockElectrical storage systemAC motor controlElectricityCapacitance

The invention relates to an energy-saving drive circuit of a motor, and aims to provide a super capacitor-based energy-saving drive circuit of a motor and a control method. The main circuit of the circuit consists of a super capacitor bank, a super capacitor charge / discharge management circuit, a controllable rectifying circuit, a controllable rectifying control circuit and the like. Impact to a power grid when an elevator runs is reduced by optimized control of the controllable rectifying circuit and the super capacitor charge / discharge circuit and absorption of running power peak of the elevator, the controllable rectifying circuit bears the smooth part of the electric and generating power of the motor and has emergency power supply function after the elevator is cut off electricity, and the super capacitor and a DC bus form through connection in a normal state to achieve high efficiency. The drive circuit has the advantages of compact line and high integral work efficiency, the service life of the super capacitor is prolonged, and the integral technical and economic performance of the energy feedback elevator is improved. The drive circuit is particularly suitable for driving the energy feedback energy-saving elevator, and is also suitable for motor energy-saving drive situations of a crane and the like.

Owner:ZHEJIANG UNIV

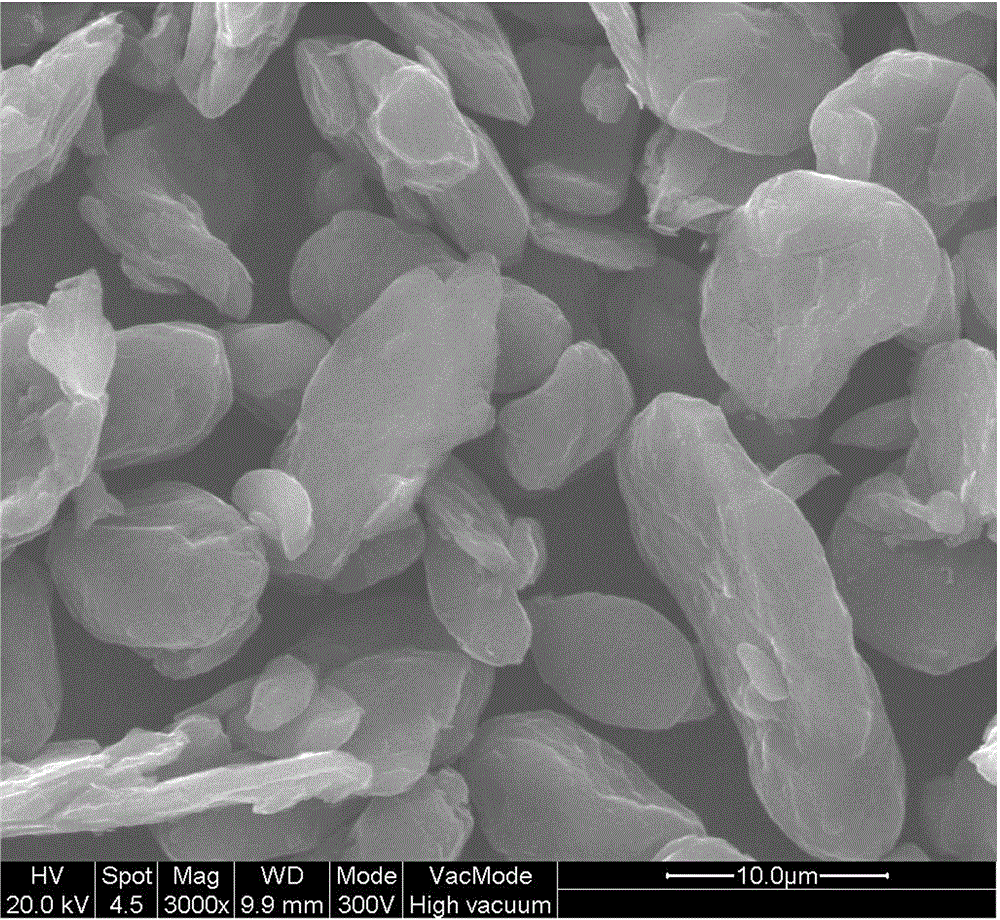

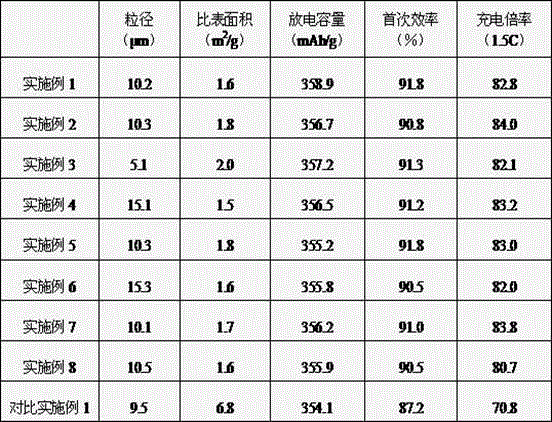

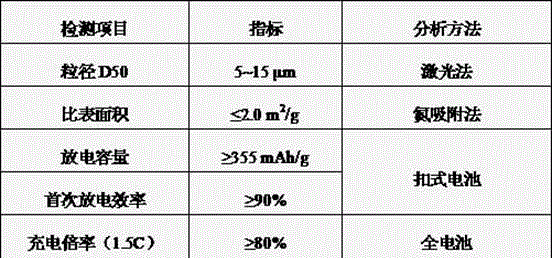

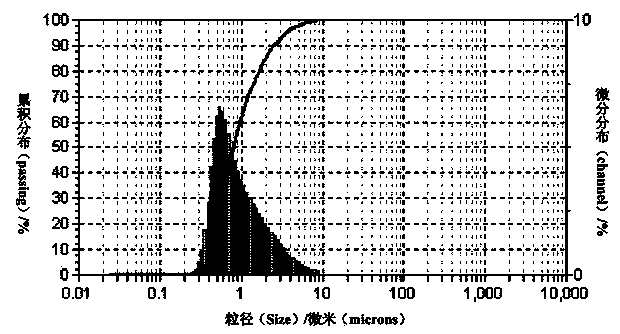

Negative electrode material for quickly rechargeable graphite lithium-ion battery and preparation method of negative electrode material

InactiveCN105024075ASmall specific surface areaIncrease charging rateCell electrodesSecondary cellsDischarge efficiencyElectrical battery

The invention discloses a negative electrode material for a quickly rechargeable graphite lithium-ion battery and a preparation method of the negative electrode material. The preparation method of the negative electrode material for the quickly rechargeable graphite lithium-ion battery comprises the following steps: (1) mixing a mixture containing a graphite precursor and bitumen and heating the mixture for kneading and crushing, wherein the mean grain size D50 of the graphite precursor ranges from 5 to 10 microns, and the mass ratio of the graphite precursor to the bitumen ranges from 50:50 to 90:10; (2) performing heat treatment at a temperature within the range of 300-700 DEG C under the protection of an inert gas; and (3) carrying out graphitizing. The mean grain size D50 of the negative electrode material prepared by use of the preparation method for the quickly rechargeable graphite lithium-ion battery is within the range of 5-15 microns and the specific surface area of the negative electrode material is below 2.0m2 / g; the first discharge capacity of a negative electrode, manufactured by use of the negative electrode material for the quickly rechargeable graphite lithium-ion battery, is more than 355mAh / g, and the initial charge-discharge efficiency of the battery is above 90%; if the battery is quickly charged (1.5C) for 45 minutes, the capacity of the battery can be above 80%; in short, the product is high in discharge capacity and charge / discharge efficiency, and good in rate capability. The invention also relates to a battery comprising the negative electrode material for the quickly rechargeable graphite lithium-ion battery.

Owner:SHANGHAI SHANSHAN TECH CO LTD

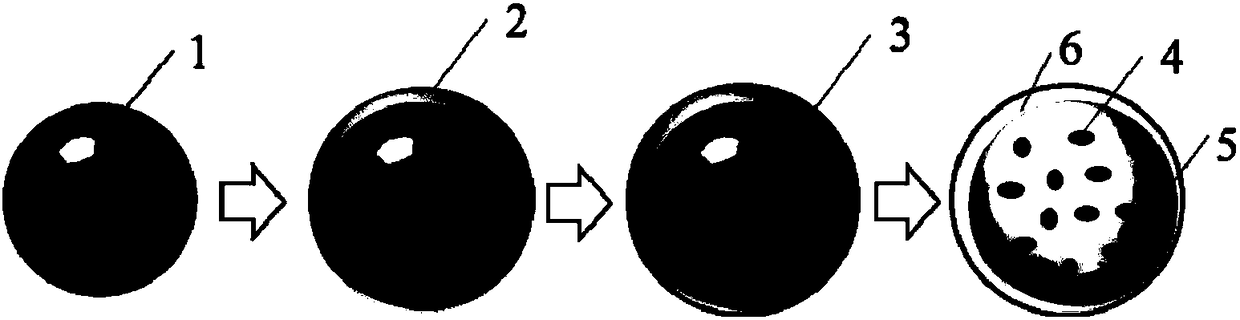

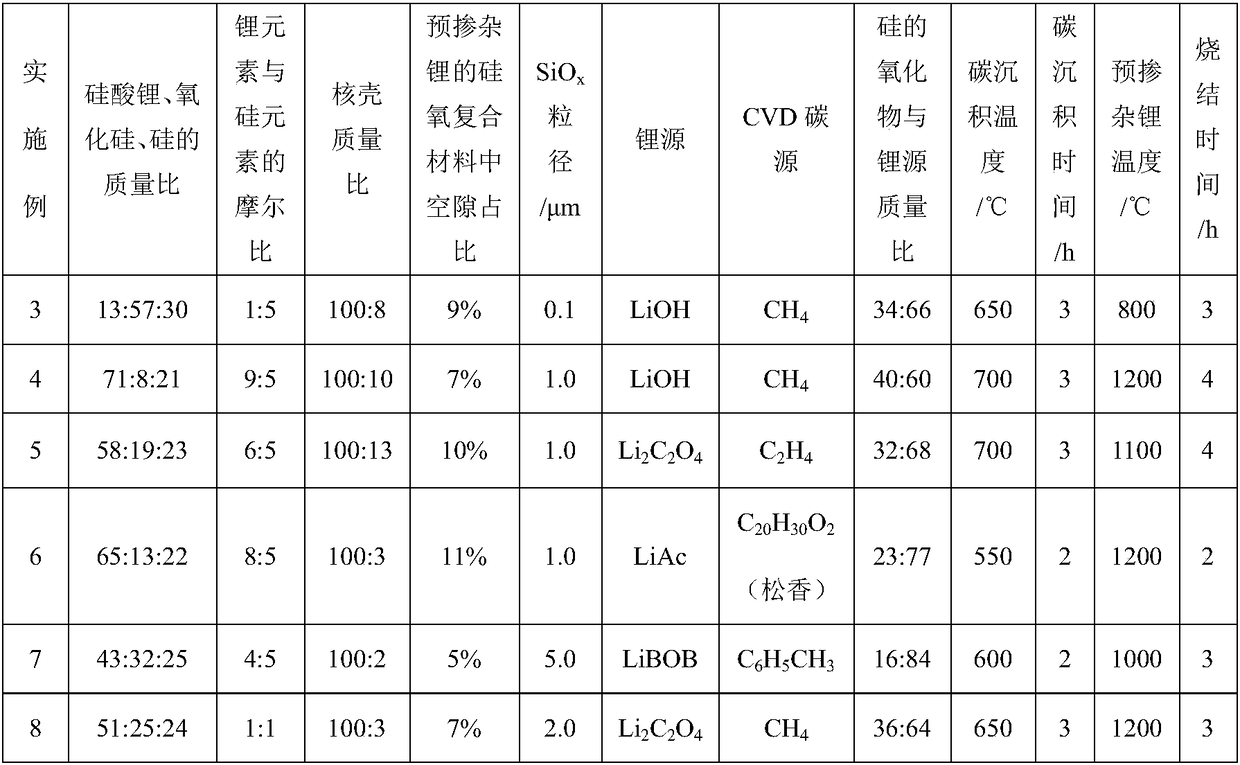

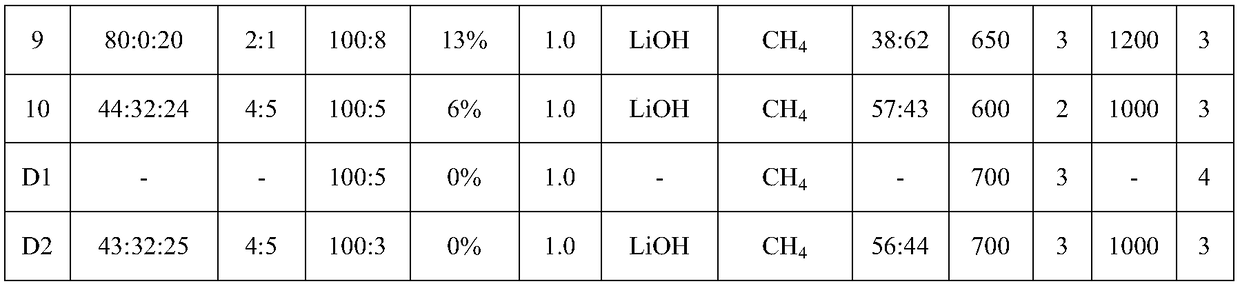

Space buffer lithium-doped silicon oxide composite material, preparation method of composite material and lithium ion battery

ActiveCN108232145AImprove charge and discharge efficiencyImproved cycle stability and rate characteristicsNegative electrodesSecondary cellsLithium electrodeSilicon oxide

The invention relates to a space buffer lithium-doped silicon oxide composite material, a preparation method of the composite material and a lithium ion battery, and belongs to the technical field ofthe lithium ion battery. The material is of a core shell structure; the core is a lithium predoped silicon oxide composite material; the shell is a coated with carbon layer. For the doped lithium, silicon oxide in the silicon oxide composite material is converted into lithium silicate through solid phase reaction in the preparation process. The preparation method of the space buffer lithium-dopedsilicon oxide composite material comprises the steps that after a lithium source is covered on the silicon oxide particle surface, a coating carbon layer is formed at the obtained particle surface through chemical vapor carbon deposition; the obtained coated material is sintered in vacuum or inert atmosphere; a surface coated lithium source reacts with silicon oxide; on one hand, the lithium doping of the silicon oxide material is realized; on the other hand, the building of a cavity structure is realized. The space buffer lithium-doped silicon oxide composite material has the characteristicsof high specific capacity, high first-time charging and discharging efficiency and long service life.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

Nonaqueous electrolyte, and rechargeable battery with the nonaqueous electrolyte

InactiveCN101663790AIncrease capacityExcellent cycle characteristicsSecondary cellsHigh current densityChemical structure

A subject is to provide a nonaqueous electrolyte excellent in cycle performances such as capacity retention after cycling, output after cycling, discharge capacity after cycling, and cycle discharge capacity ratio, output characteristics, high-temperature storability, low-temperature discharge characteristics, heavy-current discharge characteristics, high-temperature storability, safety, high capacity, high output, high-current-density cycle performances, compatibility of these performances, etc. Another subject is to provide a nonaqueous-electrolyte secondary battery employing the nonaqueouselectrolyte. The subjects have been accomplished with a nonaqueous electrolyte which contains a monofluorophosphate and / or a difluorophosphate and further contains a compound having a specific chemical structure or specific properties.

Owner:MITSUBISHI CHEM CORP

Combination electrode for all vanadium redox flow battery and preparation thereof

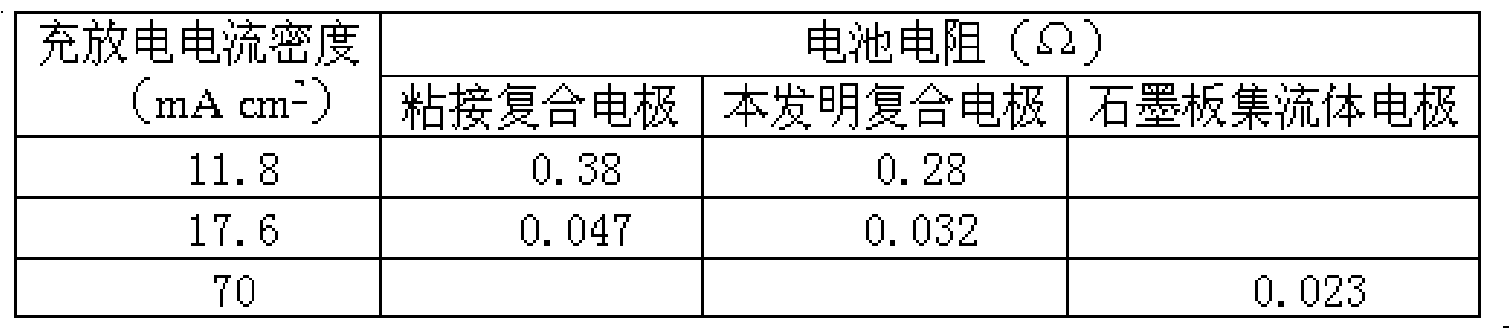

InactiveCN101335349AImprove mechanical propertiesImprove conductivityCell electrodesFiberVanadium redox battery

The invention relates to a composite electrode used in vanadium redox flow batteries and a preparation method thereof, pertaining to the vanadium battery manufacturing field. The composite electrode is prepared by adding three conductive fillers (conductive acetylene carbon black, conductive carbon fiber and graphite) into thermoplastic polymer to obtain a thermoplastic conductive plate which is compounded together with a graphite felt. Part of the conductive carbon fiber in the graphite felt is embedded into the surface of the conductive plate to form an interpenetrating conductive network and improve the conductivity of the whole product. Therefore, the composite electrode has excellent mechanical performance and conductivity (volume resistivity is less than or equal to 0.1omega question mark cm), integrates current collector and electrode into a whole, and effectively reduces surface resistance between the current collector and the electrode; meanwhile, during the process, no additional additive which can improve conductivity is used, thus ensuring relatively good conductivity and mechanical performance, and avoiding the falling of the additive which can improve conductivity into the electrolyte of a vanadium battery.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Negative electrode material used for lithium battery and preparation method and application thereof

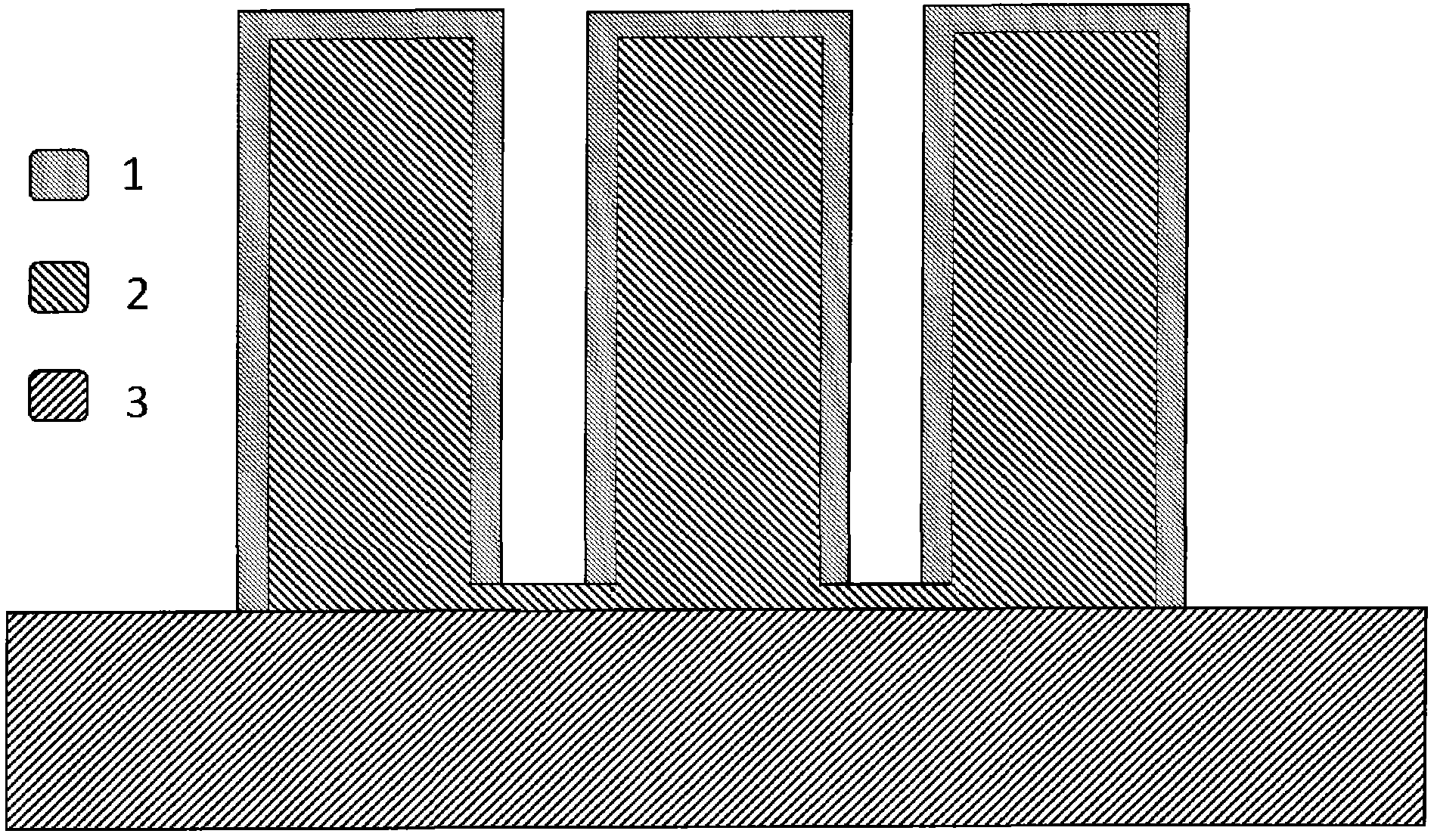

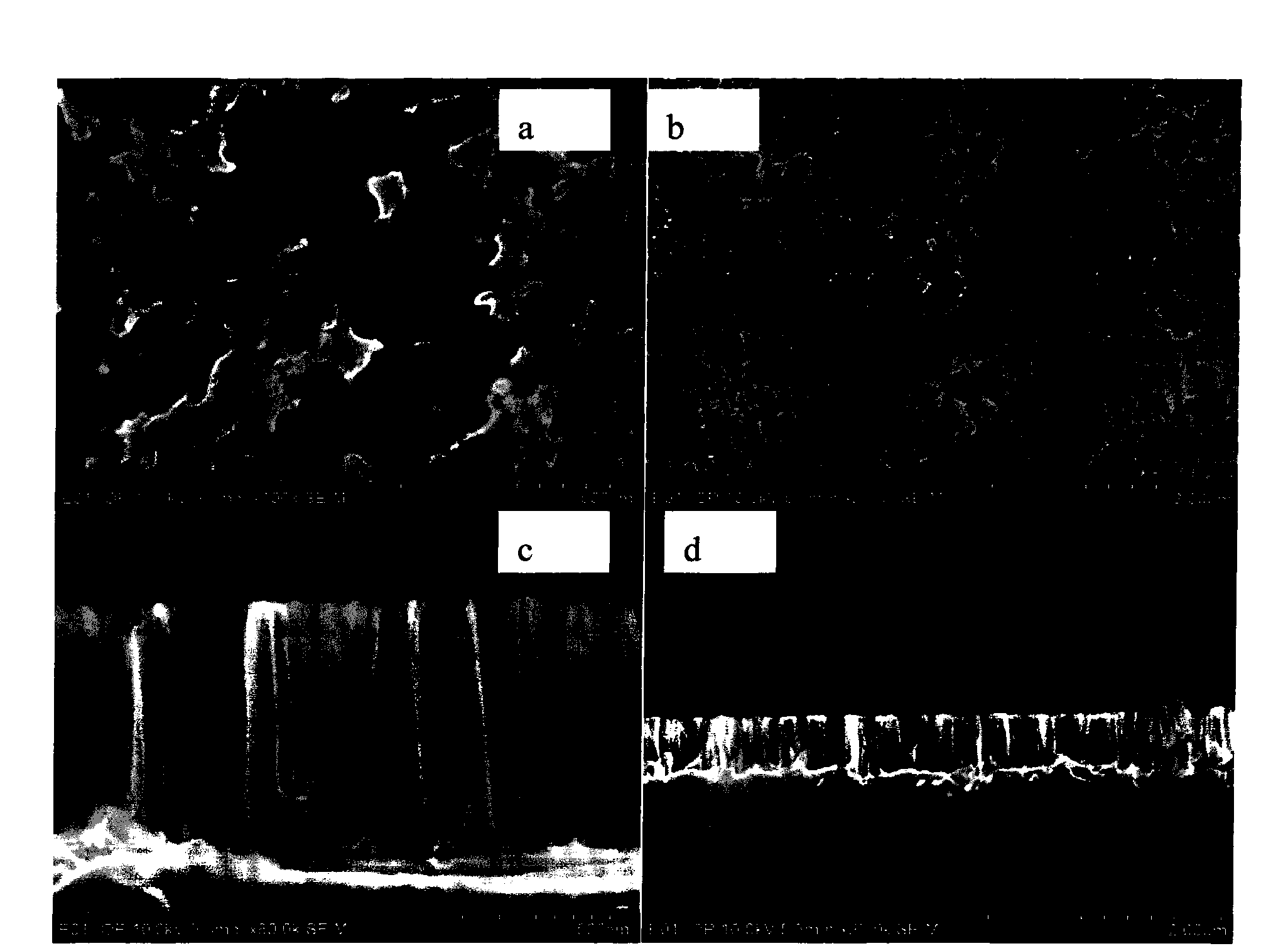

ActiveCN103474632AStable structureImprove performanceMaterial nanotechnologyCell electrodesPorosityMicro nano

The invention relates to a negative electrode material used for a lithium battery and a preparation method and application thereof, the negative electrode material includes a conductive substrate material layer and a silicon based thin film material layer, the silicon based thin film material layer contains one or more components selected from the group consisting of silicon element, SiOX and silicon alloy, wherein, 0 < X =< 2; in the silicon based thin film material layer, silicon accounts for 10-100% of the weight of the silicon based thin film material layer; the silicon based thin film material layer is a thin film formed by regular and / or irregular columnar and / or fibrous micro nano naps, wherein the micro nano naps are connected with each other by root parts, and the root parts of the micro nano naps are connected with the conductive substrate material layer; gaps are existed among the micro nano naps, and the porosity among the micro nano naps is 2%-98%; the diameter size of the micro nano naps is 1 nm to 10 mum, and the thickness of the silicon based thin film material layer is 50 nm-10 mum.

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD

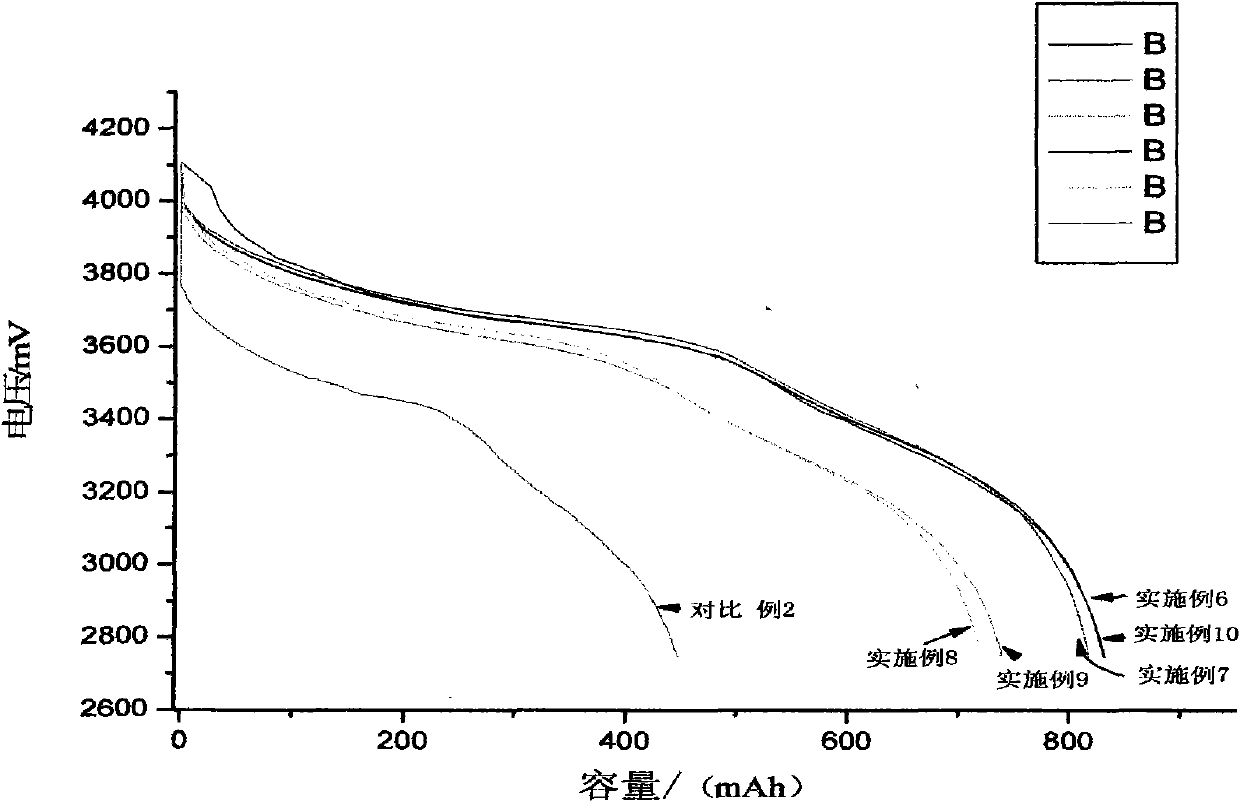

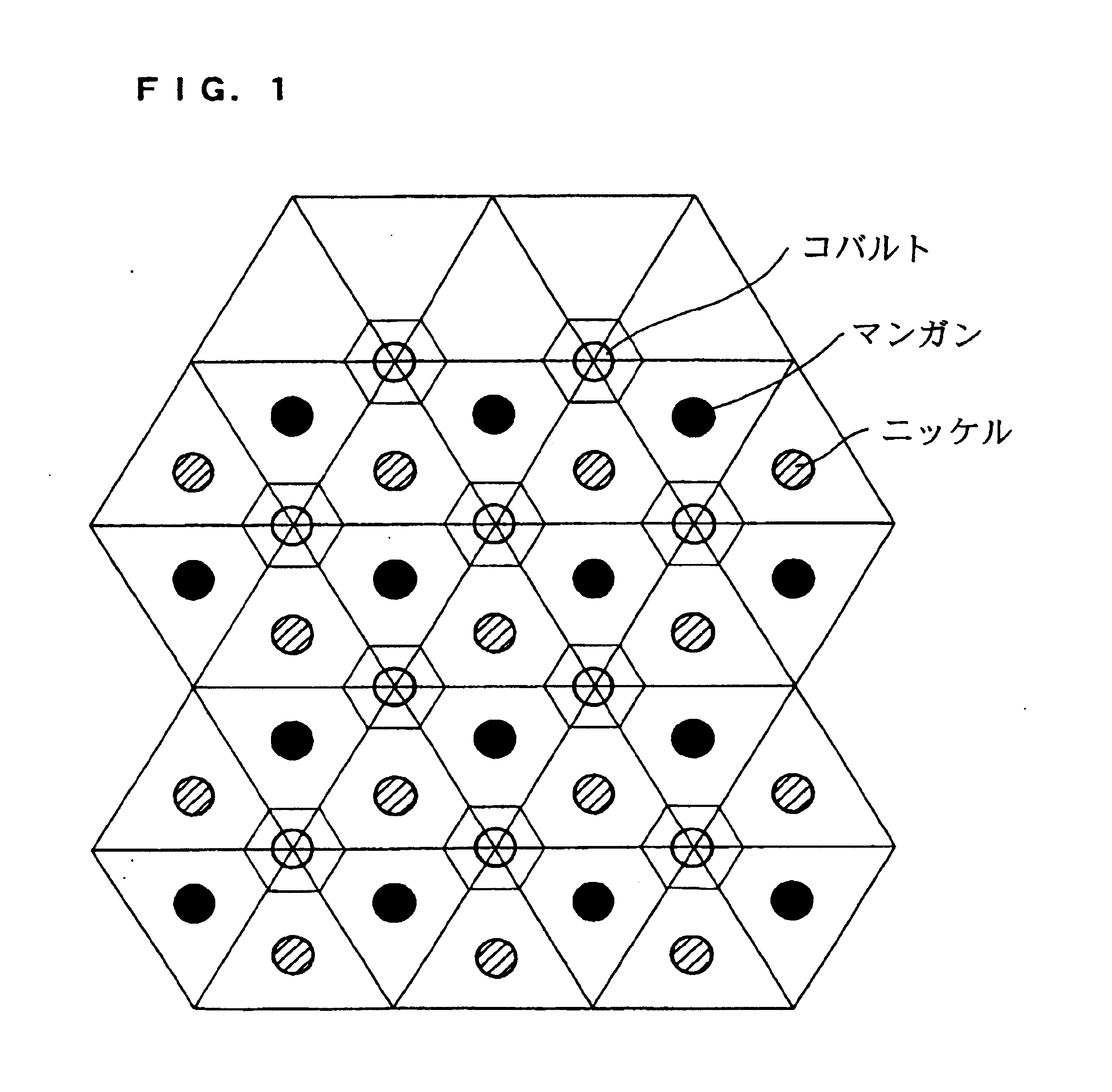

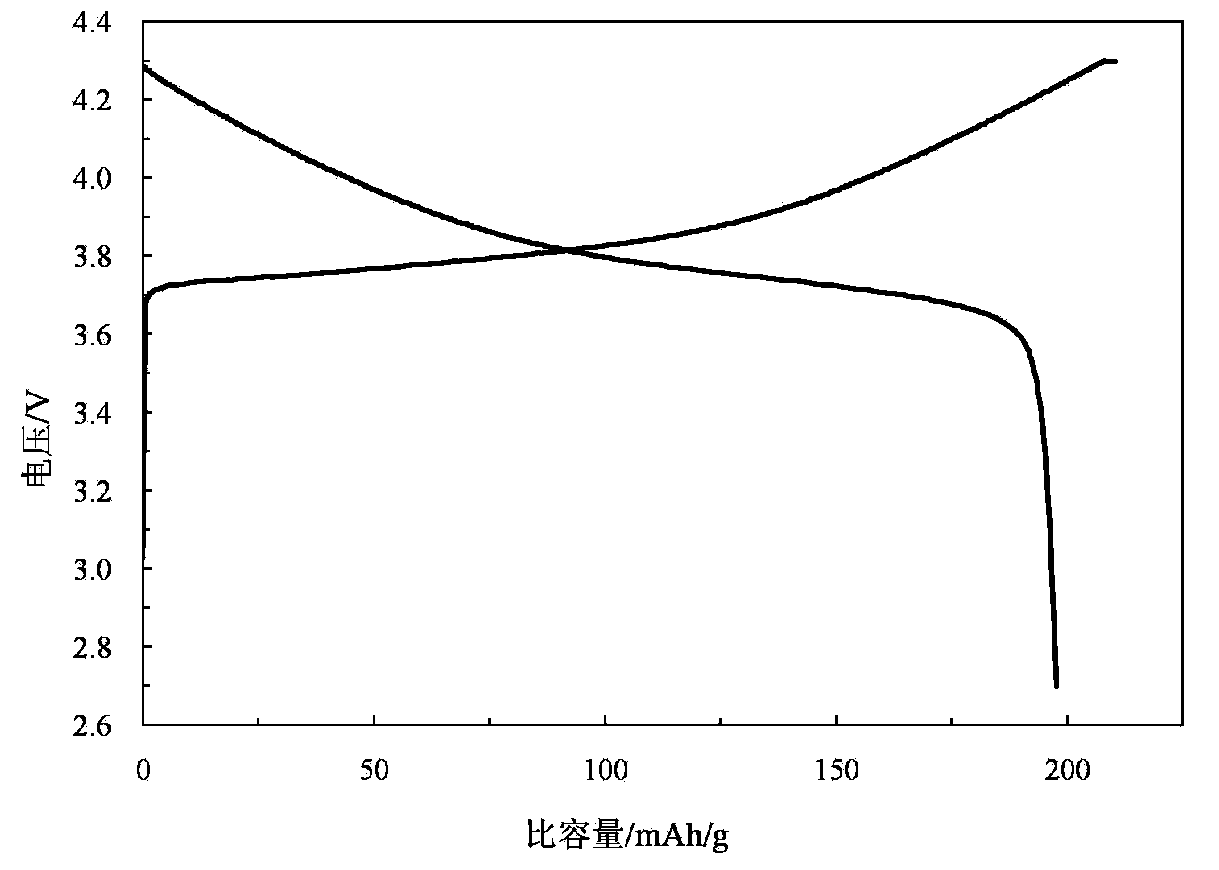

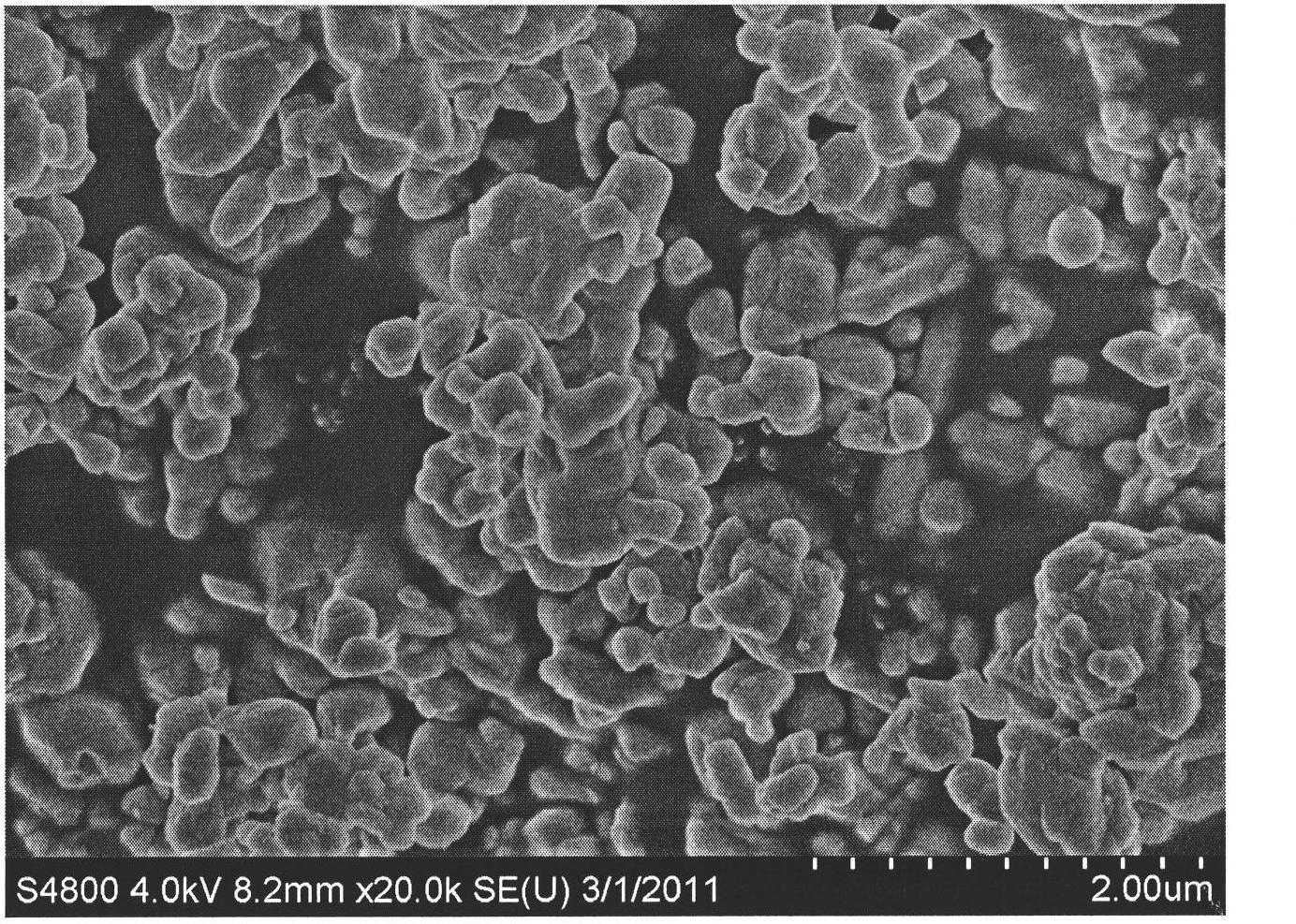

Preparation method of high-capacity layered lithium-rich manganese-based oxide

ActiveCN102354741AImprove charge and discharge efficiencyImprove cycle performanceCell electrodesManganeseNickel compounds

The invention relates to a preparation method of a high-capacity layered lithium-rich manganese-based oxide, and the method is characterized by comprising the following steps: a) fully mixing a nickel-containing compound, a manganese-containing compound I and a cobalt-containing compound with a solvent so as to get a solution or suspension; b) adding a precipitator into the solution or suspension obtained in the step a), and filtering to obtain a precipitate; c) drying the precipitate obtained in the step b) so as to get a precursor; d) uniformly mixing the precursor obtained in the step c), a manganese-containing compound II, a doping element M-containing compound and a lithium-containing compound in proportion so as to get mixed powder; and e) performing heat treatment on the mixed powder obtained in the step d) so as to get an ultrahigh-capacity manganese series lithium transition metal compound oxide with an expression of Li(Li0.2Mn0.8-delta-alpha-beta-Ni alpha Co beta M delta)O2. Compared with the prior art, the preparation method provided by the invention has the advantages of high utilization rate of raw materials and low production cost, and the prepared lithium-rich manganese-based oxide has the advantages of excellent charge-discharge performance and excellent cycle performance.

Owner:宁波富理电池材料科技有限公司

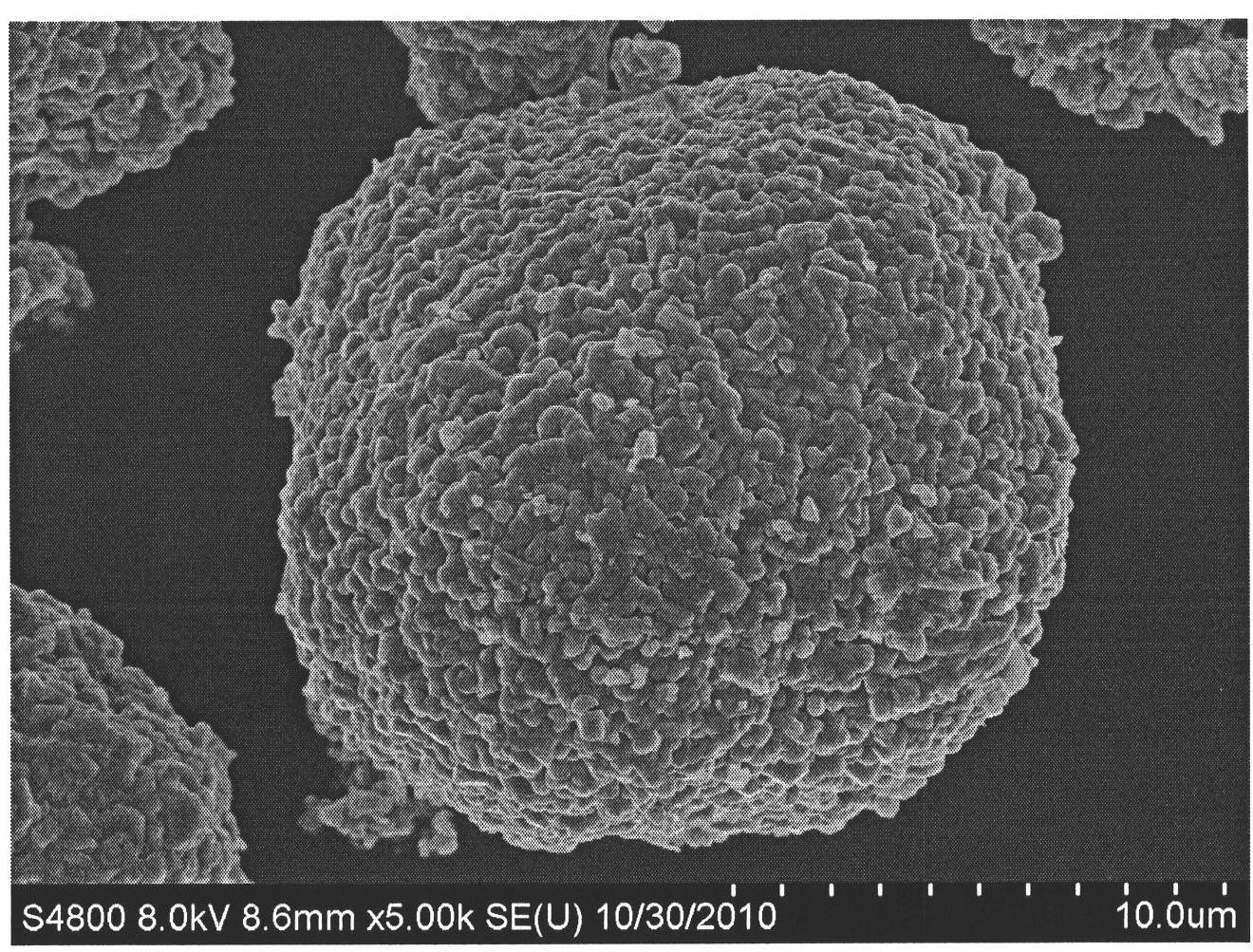

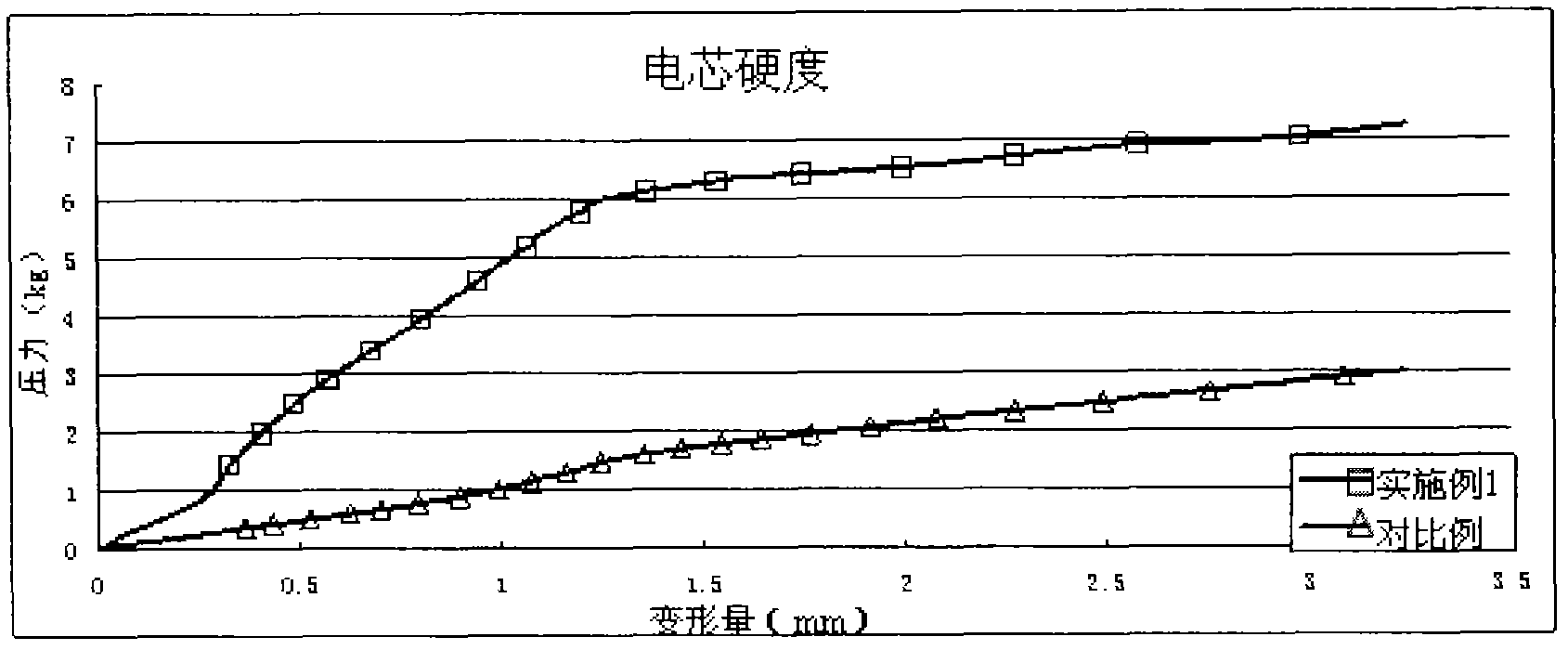

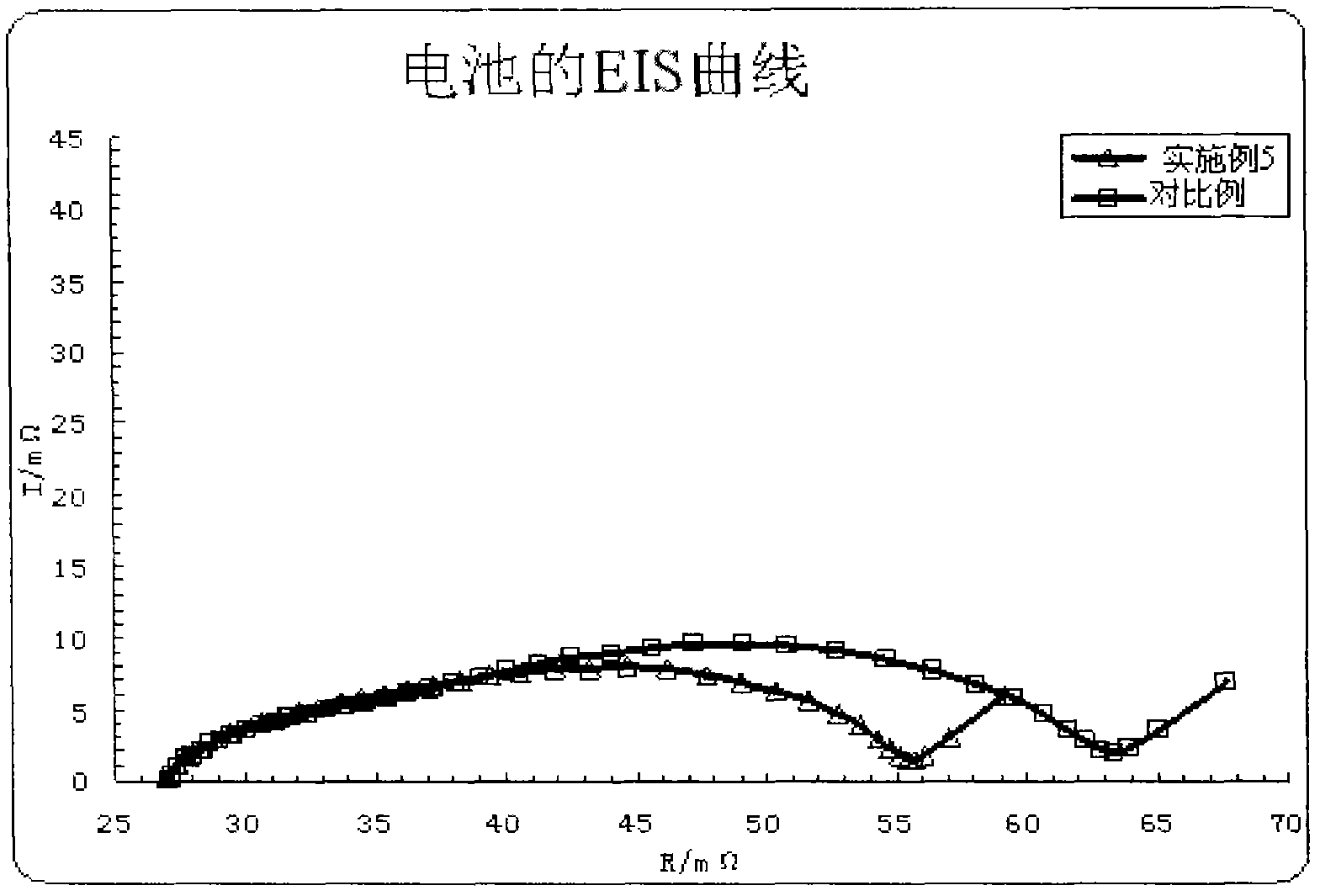

Method for improving hardness of lithium ion cell

ActiveCN102593520AFast charge and dischargeIncrease the speed of formationFinal product manufactureElectrolyte accumulators manufactureCooking & bakingLithium

The invention belonging to the technical field of lithium ion cells, and particularly relates to a method for improving hardness of a lithium ion cell by rapid formation. In the method, by adjusting the pre-baking time and temperature and the formation temperature of an electric core as well as the surface pressure on an electric core main body, the purpose of reducing the electric core polarization is achieved, high-current rapid formation is further realized, and finally the formation stopping potential is adjusted, so as to prepare the lithium ion cell with higher hardness. As compared with the prior art, the method has the following advantages: the high-temperature cramping and baking reshaping after formation is cancelled, so that the prepared electric core is higher in capacity; the electric core bears constant (or variable) pressure during the charge and discharge processes, thus the polarization in the charge and discharge processes is lower, and the capacity consistency of the prepared electric core is better; and because different temperatures and an SOC (state of charge) stopping manner are adopted for formation, the prepared electric core not only has excellent performance, but also has higher hardness.

Owner:NINGDE AMPEREX TECH +1

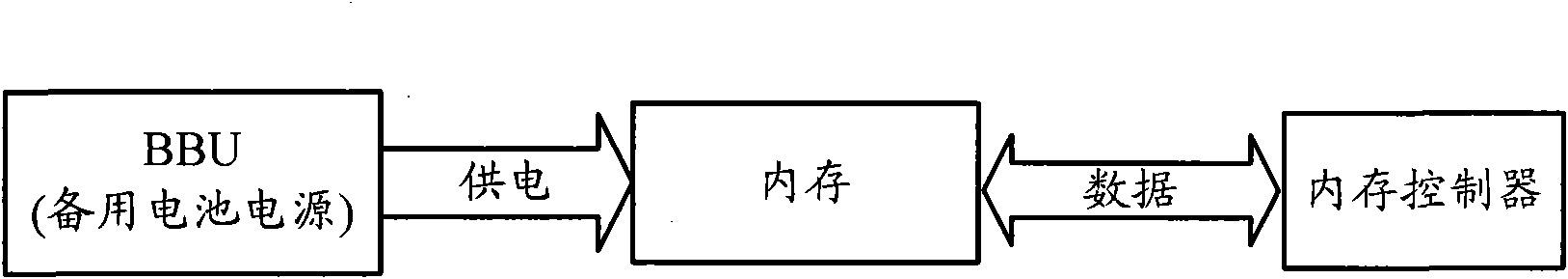

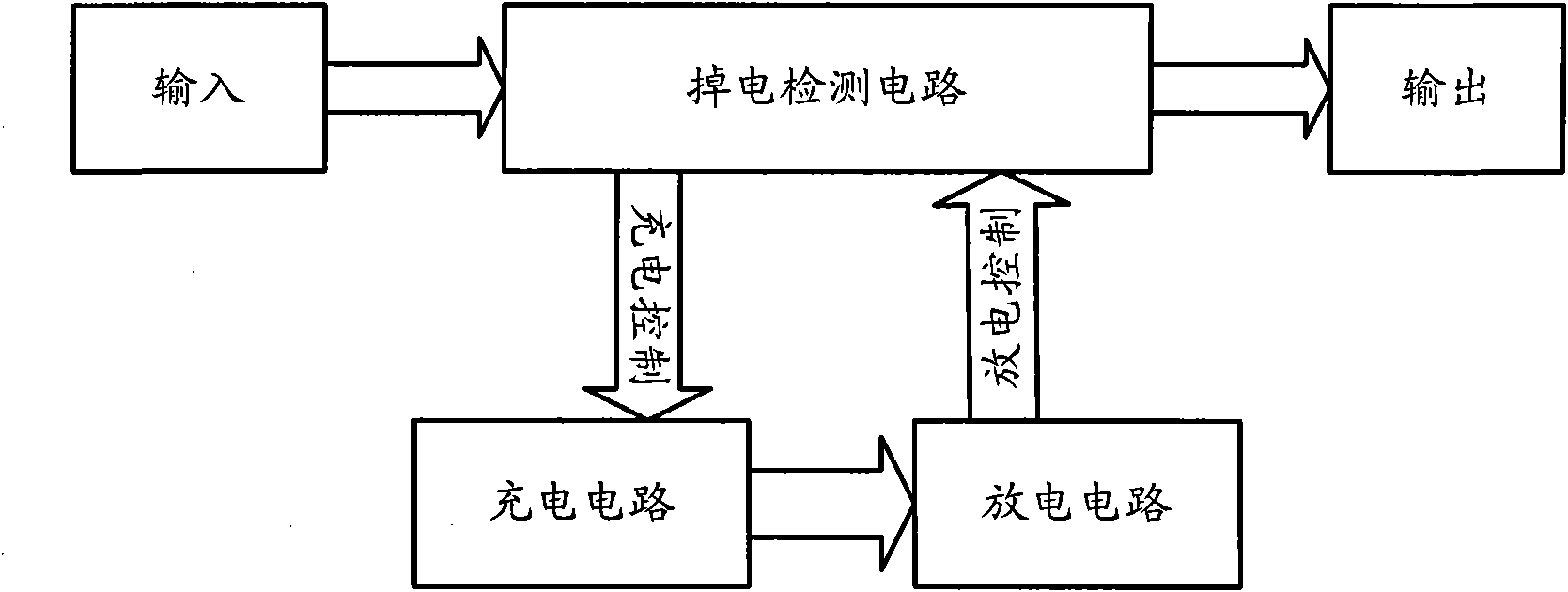

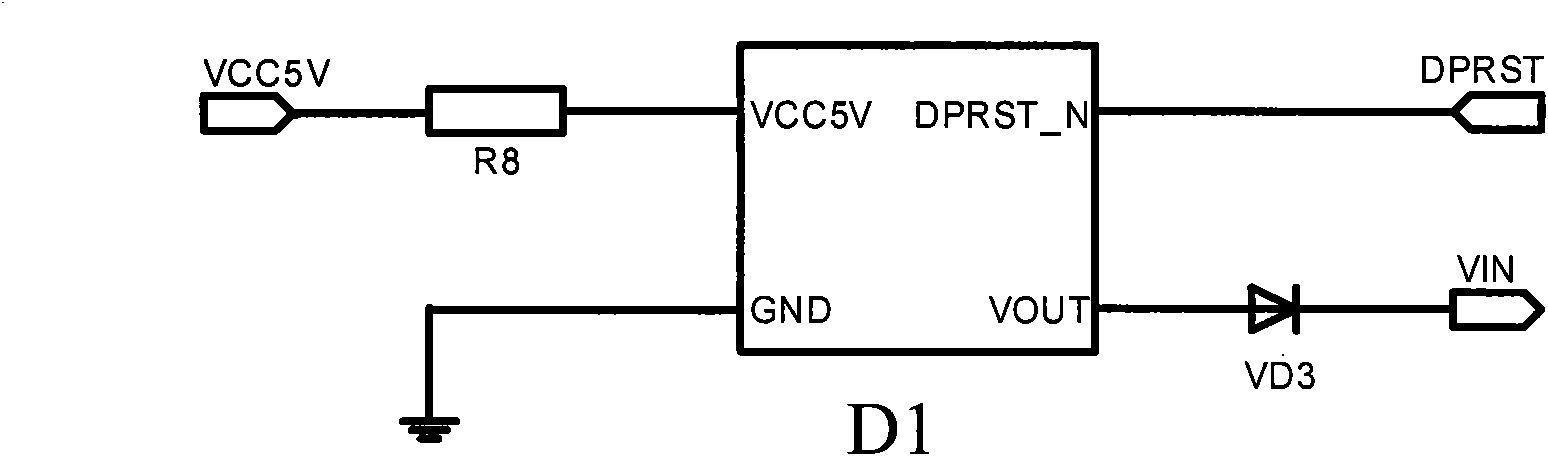

Circuit power fail safeguard device and protection method thereof

ActiveCN101667748ASolve the costSolve the problem of longevityBatteries circuit arrangementsCurrent/voltage measurementElectricityInternal memory

The invention discloses a circuit power fail safeguard device and a protection method thereof. The device comprises a power fail detection circuit, a charging circuit and a discharging circuit, wherein the power fail detection circuit is connected with a circuit to be detected and is used for detecting whether the circuit to be detected has the phenomenon of power failure; the charging circuit isconnected with the power fail detection circuit and is used for storing electrical energy; and the discharging circuit is respectively connected with the charging circuit and the circuit to be detected and is used for supplying power for the circuit to be detected when the circuit to be detected has the phenomenon of power failure. The invention overcomes the defects of high cost and short service life caused by using a stand-by battery, and simultaneously expands the protection range and increases the protection for cache data and register data of a memory controller, thus being capable of supplying power for an internal memory and an internal memory controller under the condition that equipment suddenly have power down phenomenon, and ensuring the equipment to completely store the processed data and the related status messages. In addition, the invention also has the advantages of simple circuit, low cost, short charging time, high efficiency, small volume and long service life.

Owner:ZTE CORP

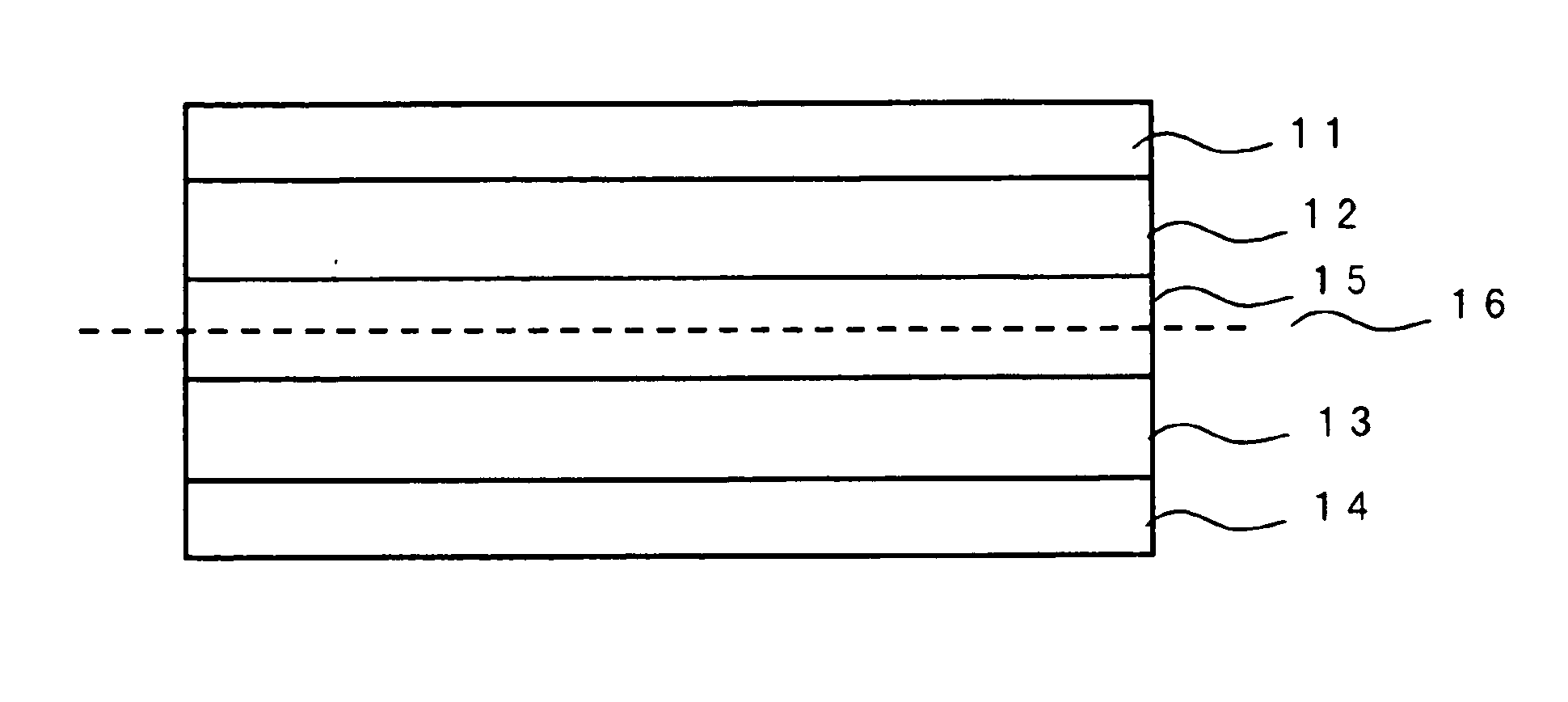

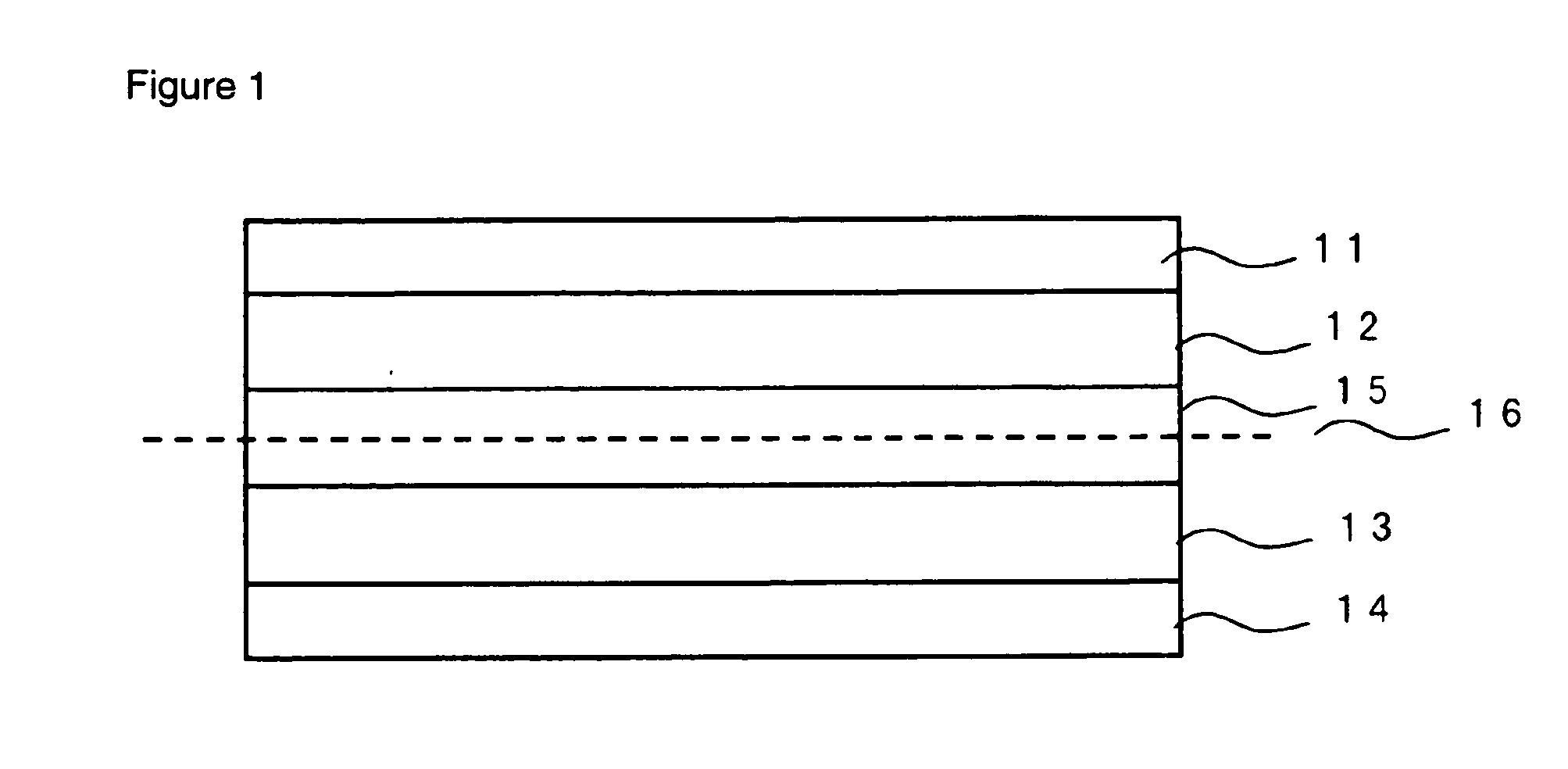

Lithium ion battery negative electrode piece using hard carbon and soft carbon as active materials and lithium ion battery

ActiveCN103633293AHigh peel strengthFacilitate strippingCell electrodesSecondary cellsMetal foilHigh rate

The invention relates to a manufacture technology of a lithium ion battery, and particularly relates to a lithium ion battery negative electrode piece using hard carbon and soft carbon as active materials and a lithium ion battery with the negative electrode piece. The lithium ion battery negative electrode piece using hard carbon and soft carbon as the active materials comprises a metal foil current collector, a first graphitic layer, a main body functional layer and a second graphitic layer, wherein the surface of the metal foil current collector is coated with the first graphitic layer, the surface of the first graphitic layer is coated with the main body functional layer, and the surface of the main body functional layer is coated with the second graphitic layer. According to the lithium ion battery negative electrode piece using hard carbon and soft carbon as the active materials, the characteristics of a graphite material and hard carbon and soft carbon materials are fully utilized, and thus the heavy-current rate performance can be effectively improved; the lithium ion battery negative electrode piece using hard carbon and soft carbon as the active materials has the advantages of good cycle performance, high safety, high-rate charge and discharge resistance, and the like, and meets the requirement of charge performance of the lithium ion battery at a low temperature; meanwhile, a manufacture method is simple, and the lithium ion battery negative electrode piece can be produced by using existing lithium ion battery production equipment.

Owner:鲍添增

Recovery method of positive active material in lithium ion battery waste material

InactiveCN103794832AHigh charge and discharge capacityImprove charge and discharge efficiencyWaste accumulators reclaimingBattery recyclingElectrochemistryLithium electrode

The invention provides a recovery method of a positive active material in a lithium ion battery waste material. The method includes the following steps: S1, heat treatment of the waste material is performed at 350-500DEG C in inert gas or reducing gas atmosphere; S2, powder product obtained in the step S1 is sintered at 600-800DEG C in the inert gas or reducing gas atmosphere; and the positive active material is obtained by recovery; the positive active material is one or multiple substance selected from lithium phosphate, lithium silicate or a vanadium material of lithium. The positive active material obtained by recovery is high in charge and discharge capacity, and high in charge and discharge efficiency, the obtained positive active material is even in particle size distribution, and complete in crystal structure, the technical process of the recovery method is simple, the requirement on equipment is low, the process is easy to control, at the same time, the recovery process may not cause a negative impact on the active material, physical and chemical properties and electrochemical activity of the active material may not be affected, the recovery and reuse of the positive active material raw material can be realized, the cost can be saved, and the recovery method has environmental-friendly benefits.

Owner:BYD CO LTD

Composite cathode material for lithium ion cell and preparing method thereof

ActiveCN101286560AEvenly dispersedWell mixedElectrode manufacturing processesChemical/physical/physico-chemical processesComposite cathodeGraphite

The invention relates to a lithium ion battery composite cathode material and a preparation method thereof, which belongs to the technical field of lithium ion battery. The invention aims at improving the cycle performance of silicon cathode material at the same time when keeping the high ratio volume of lithium ion battery silicon cathode material. The proposal of the invention is that silica-based material coated by disordered carbon is treated with surface modification processing by utilizing lithium salt, namely, the lithium salt is coated on the surface of Si / G / DC (silicon / graphite / disordered carbon) to be prepared into the composite cathode material, therefore, the lithium-embedding and removing depth of the silicon can be effectively controlled, and the material is the lithium ion battery composite cathode material which has high specific capacity and good cyclical stability; furthermore, the material is safe and pollution-free, and presents higher thermal stability in various lithium salt electrolytes and solvents.

Owner:CHENGDU ZHONGKE LAIFANG POWER SCI & TECH CO LTD

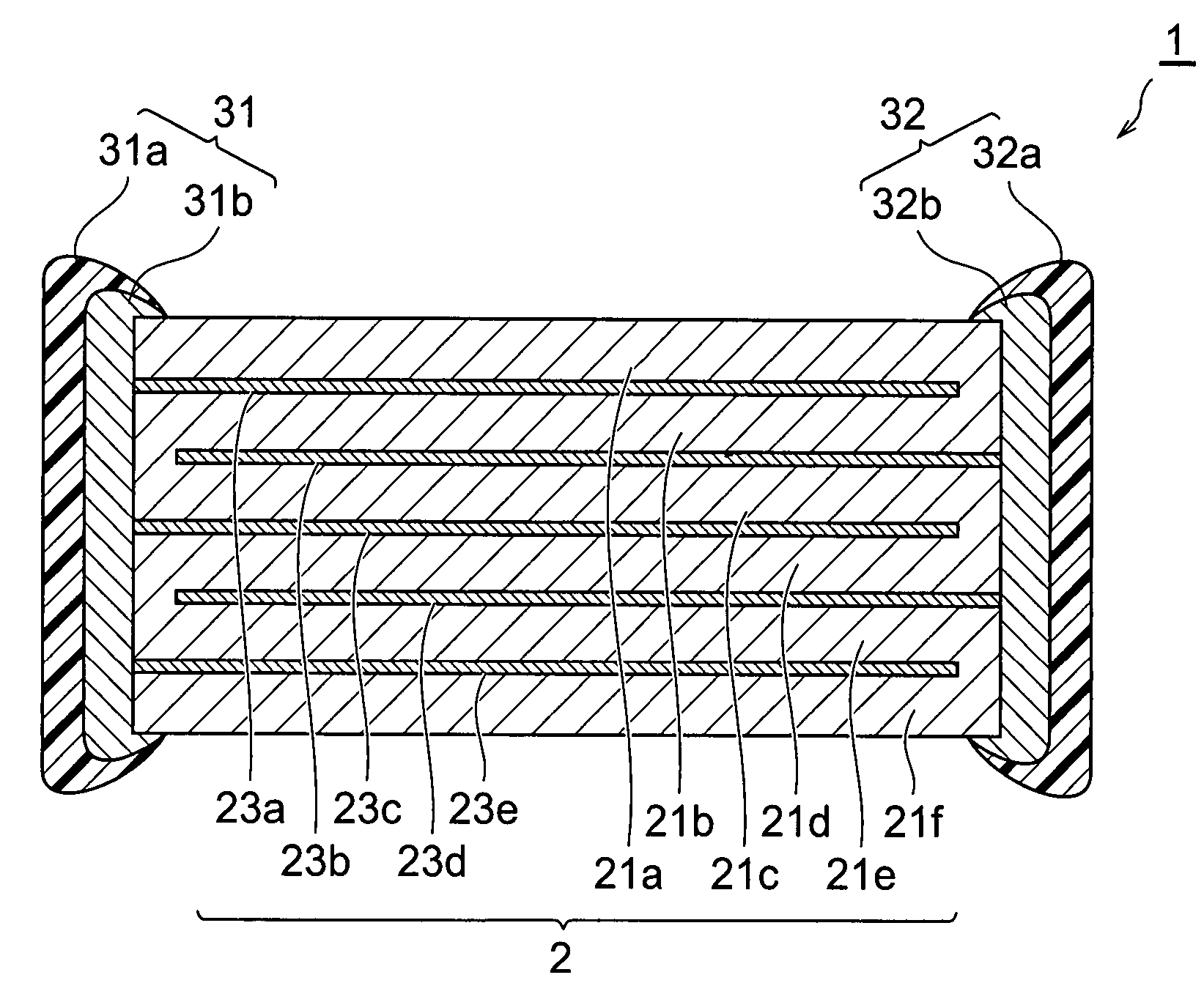

Laminate type electronic component

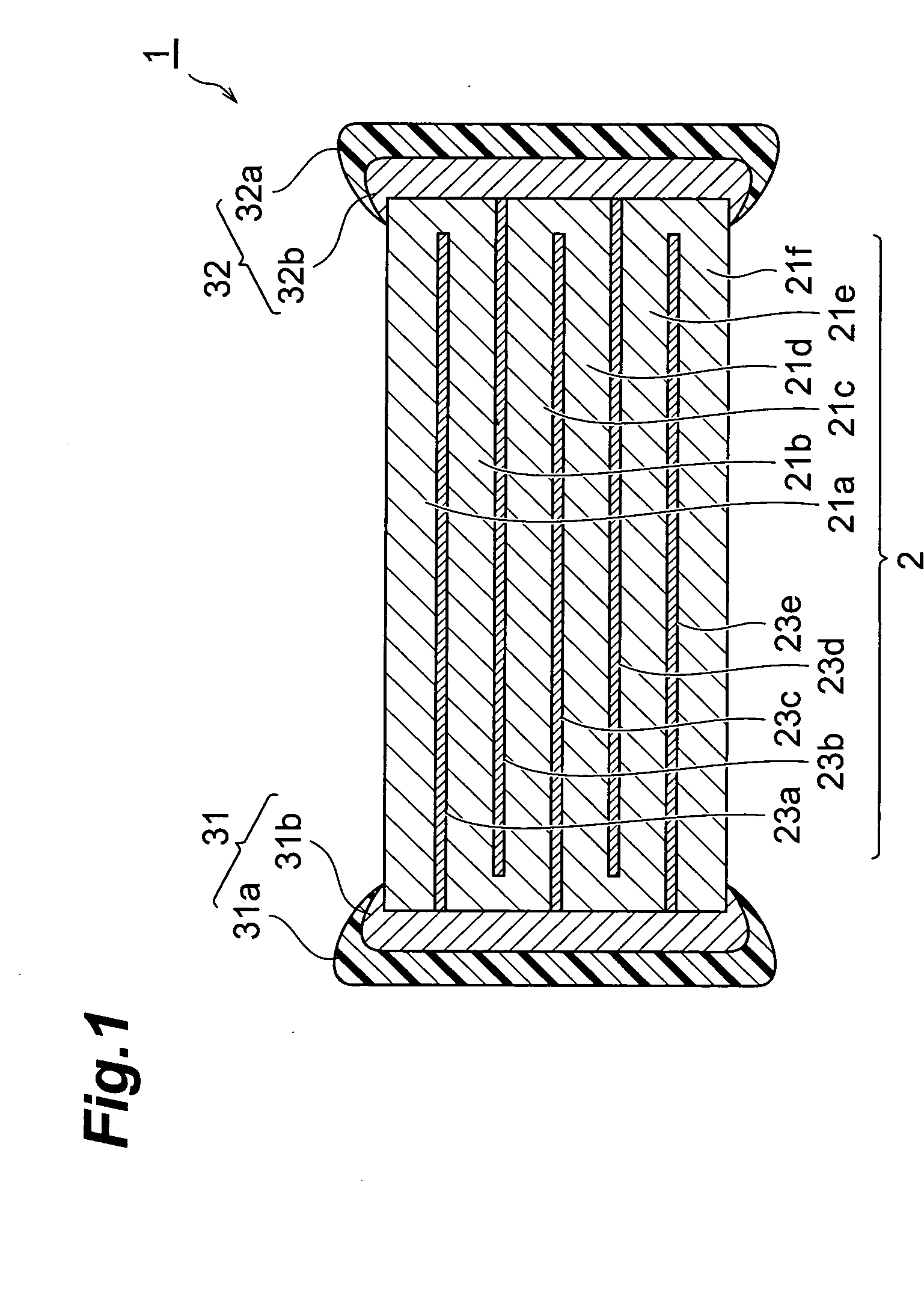

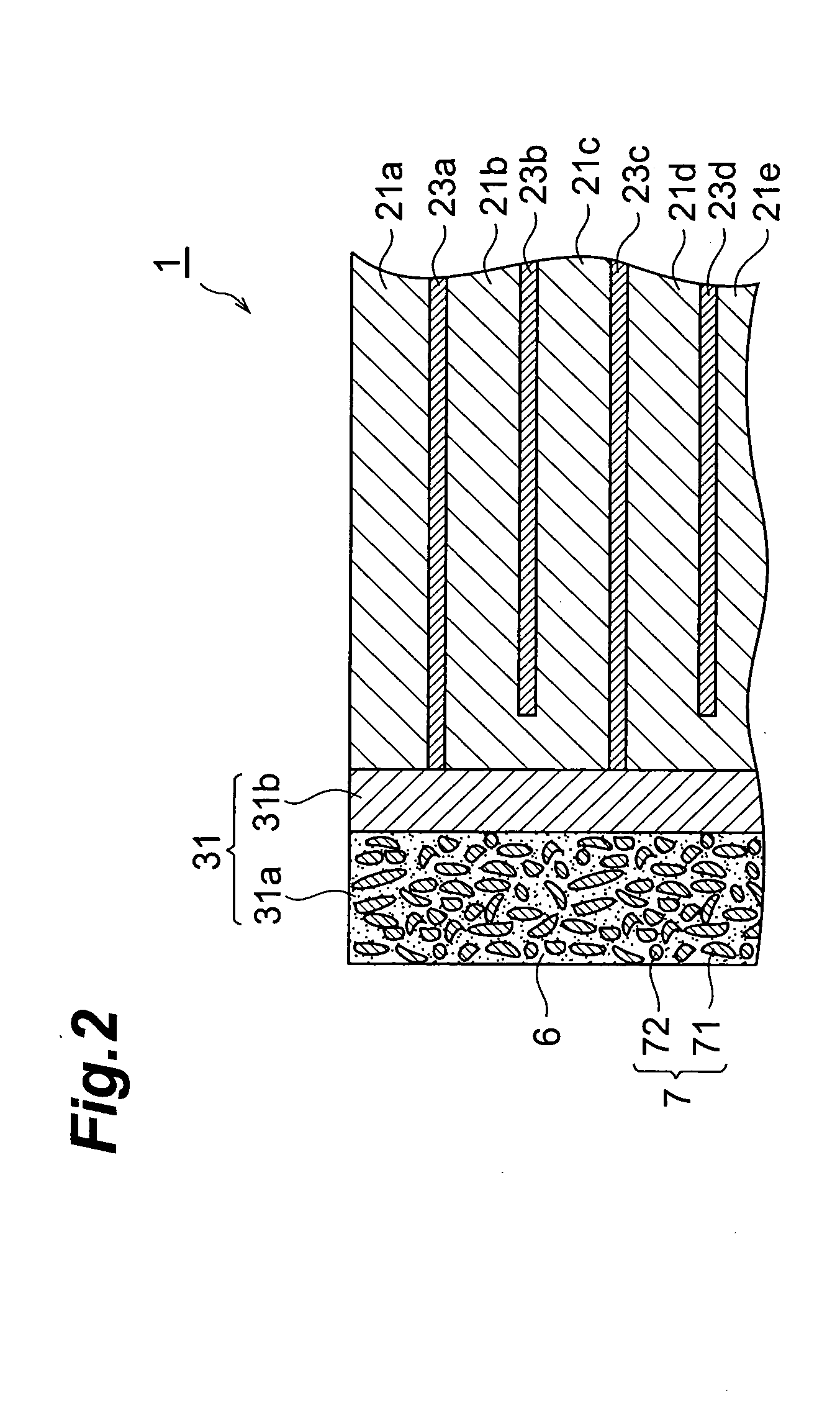

InactiveUS20050083637A1Sufficiently be lowEfficiently manufactureSubstation/switching arrangement detailsFixed capacitor dielectricAspect ratioDielectric

A laminate type electronic component 1 comprises, at least, a dielectric part 2 containing a dielectric as a constituent material, and a pair of a first external electrode 31 and a second external electrode 32, each disposed in close contact with the dielectric part 2, opposing each other by way of the dielectric part 2. The dielectric part 2 comprises laminated dielectric layers 21a to 21f; and at least two internal electrodes 23a to 23e disposed one by one between layers adjacent each other in the dielectric layers 21a to 21f, while each being electrically connected to one of the first external electrode 31 and second external electrode 32. At least one of the internal electrodes 23a to 23e is electrically connected to the first external electrode 31, and at least one of the internal electrodes 23a to 23e is electrically connected to the second external electrode 32. The first external electrode 31 and second external electrode 32 comprise resin electrode layers 31a and 32a, each made of a conductive resin mainly composed of a thermosetting resin and a conductive particle; a metal electrode layer 31b disposed between the resin electrode layer 31a and the dielectric part 2; and a metal electrode layer 32b disposed between the resin electrode layer 32a and the dielectric part 2. The conductive particle content in the conductive resin is 70 to 75 mass %, whereas the conductive particle contains, as a main ingredient, acicular particles 71 having an average longitudinal length of 30 to 70 μm and an aspect ratio of 1.5 to 3.3.

Owner:TDK CORPARATION

Preparation method of super capacitor

InactiveCN101661840AEasy to manufactureLower internal resistanceElectrolytic capacitorsHybrid/EDL manufactureGas phaseArgon atmosphere

The invention relates to a preparation method for a super capacitor, comprising the following steps: (1) placing a foam nickel substrate in a chemical gas phase deposition reacting furnace, introducing argon for 10-60 minutes, exhausting air in the furnace, then heating the furnace to 450-750 DEG C, introducing hydrocarbon gases in an argon atmosphere at a flow rate between 25ml / min and 40ml / min,reacting the mixture for 30 seconds to 50 minutes at a temperature of 450-750 DEG C, and obtaining foam nickel on which carbon nano tubes grow after finishing the reaction; (2) removing surface loosing layer products, directly using the foam nickel substrate on which the carbon nano tubes grow as electrodes of the super capacitor; and (3) drying the electrodes with same thickness and size, which are obtained from the step (2), fully soaking the electrode with electrolyte for 1-36 hours, separating a diaphragm soaked with the electrolyte and assembling the components to obtain the super capacitor; and the hydrocarbon gases are acetylene, methane, ethylene or propylene. The carbon nano tubes directly grow on the foam substrate without a binding agent; and the foam nickel is used as the substrate, the volume density of electrode substances is higher and holes are reasonably distributed.

Owner:JIANGSU CHUANGLAN SOLAR AIR CONDITIONER

Conducting-polymer dipped and coated lithium-ion battery composite-electrode material and preparation method thereof

InactiveCN102522563ADon't need protectionReduce energy consumptionHybrid capacitor electrodesLi-accumulatorsDischarge efficiencyConductive polymer

The invention provides a conducting-polymer dipped and coated lithium-ion battery composite-electrode material and a preparation method thereof. A high-polymer conducting polymer is coated on the lithium-ion battery electrode material of the composite electrode material, the conducting polymer is the conducting polymer which is easily dispersed into an aqueous solution, and the aqueous solution of dispersants, such as polystyrolsulfon acid and the like is used as a dispersing medium. The composite electrode material is prepared through the following steps of: dipping a lithium-ion anode material or cathode material into the aqueous solution of the high-polymer conducting polymer, and obtaining the surface-coated lithium-ion battery composite-electrode material through dipping and coating processing. The composite electrode material has cheap preparation raw materials, the surface of the novel composite electrode material is uniformly coated, and the composite electrode material has the advantages of high specific capacity, high charging and discharging efficiency and long cycling life. Compared with the prior art, the preparation method of the composite electrode material has the advantages of simple process, low cost, good effect and green and environment-friendly production process, is easy for industrial popularization and is convenient for large-scale industrialized production.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

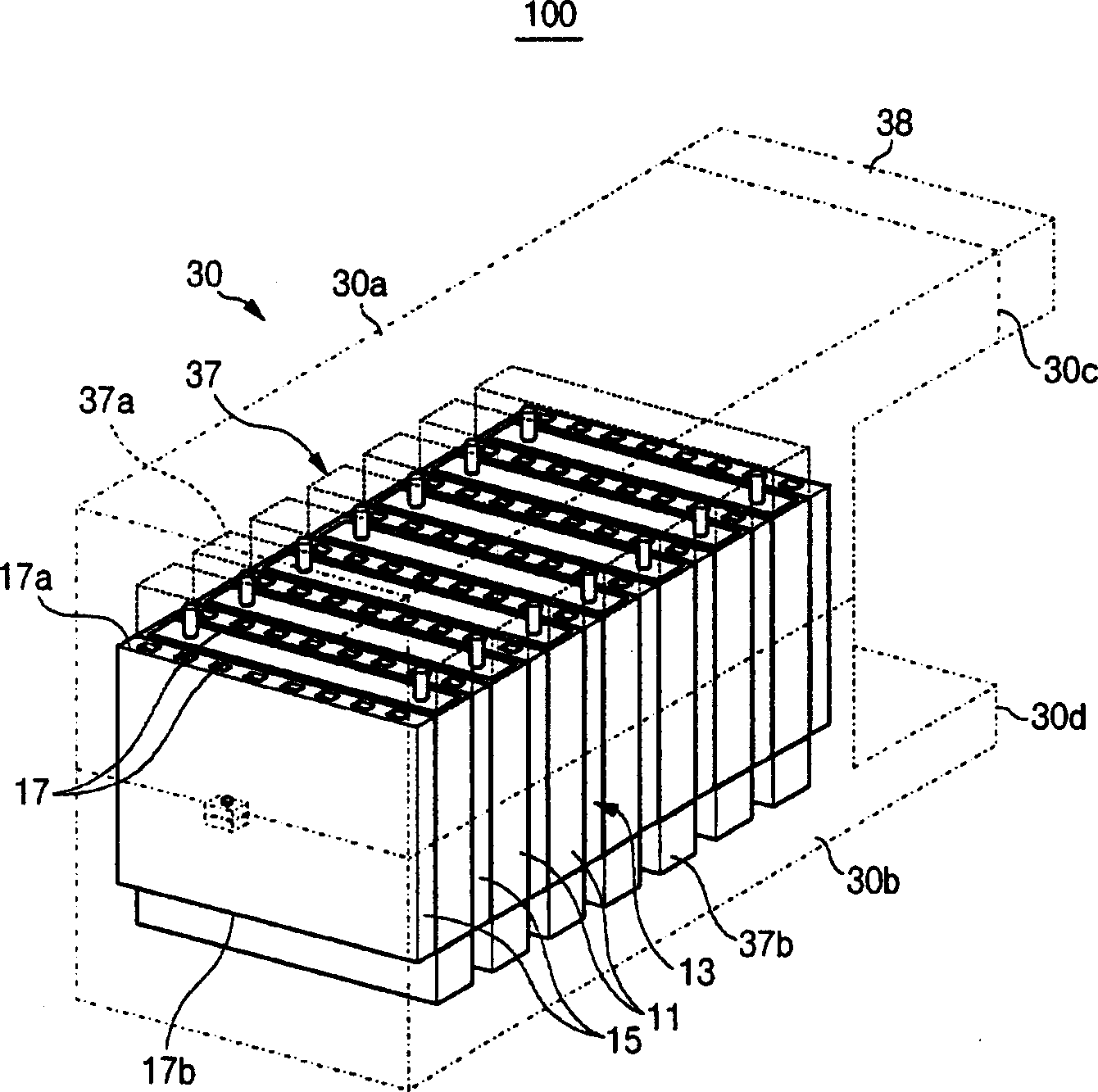

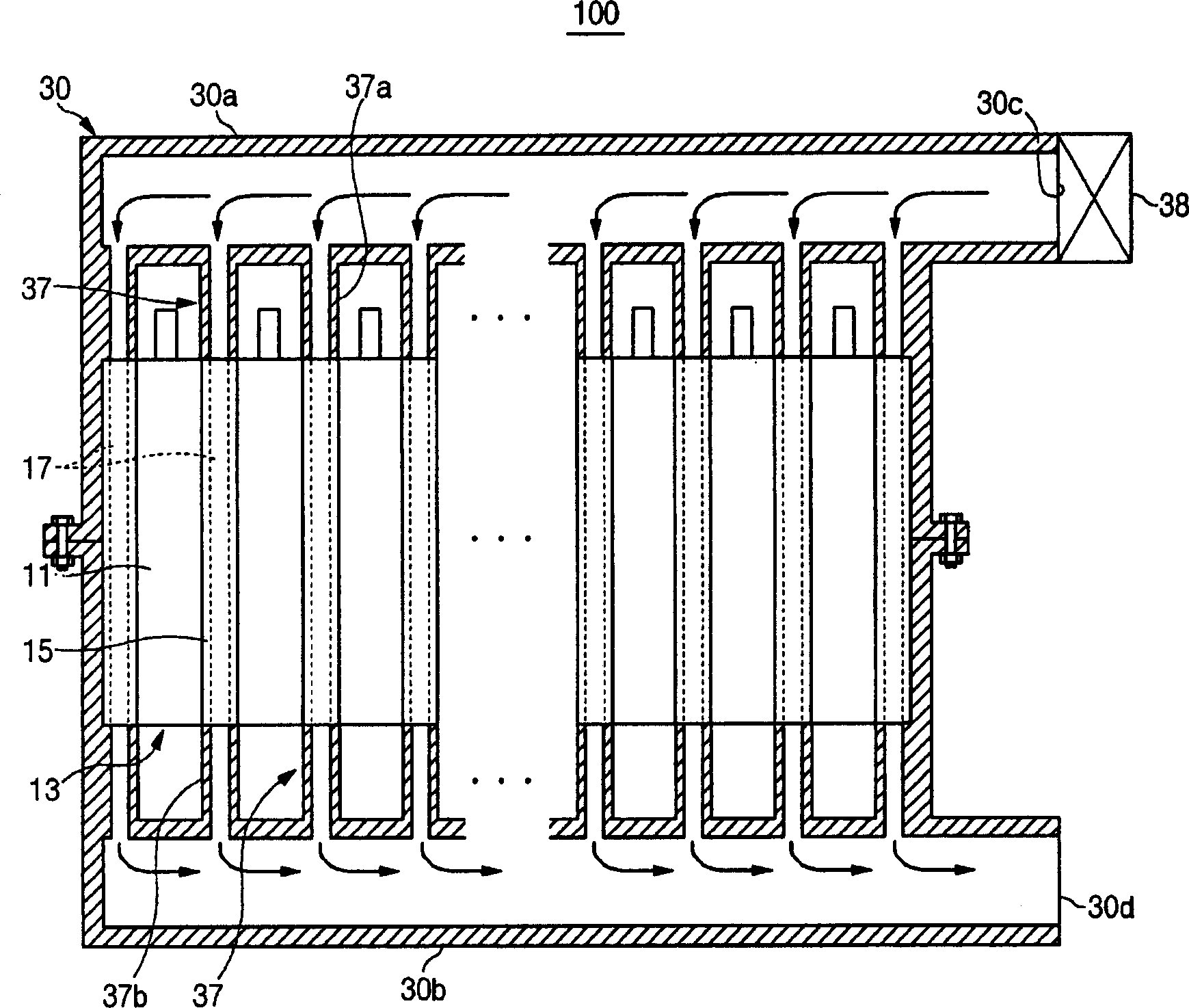

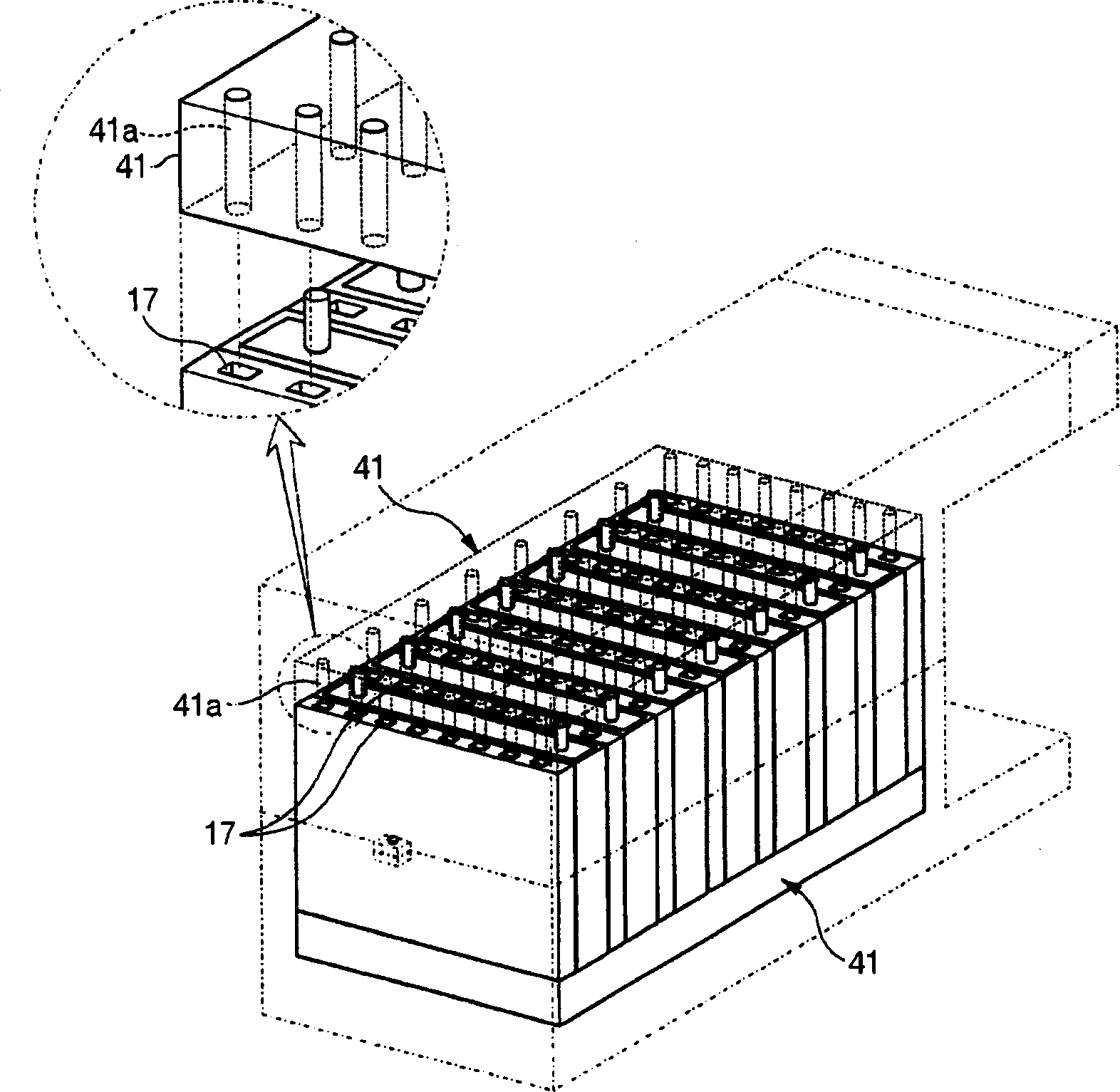

Secondary battery module

InactiveCN1790803AImprove cooling efficiencyImprove charge and discharge efficiencyCell temperature controlCell component detailsTemperature controlCharge and discharge

The invention discloses a secondary battery module, which comprises a unit cell assembly having a plurality of unit cells spaced apart from each other; a case suitable for accommodating the unit cell assembly; and a communication part installed in the case, the communication part It is suitable for the cooling medium to flow into the case between the plurality of unit cells. The casing includes an inlet for temperature-controlled air to flow into the unit cell assembly, an outlet for air to flow out through the unit cells, and communication members arranged perpendicular to the direction of air inflow and outflow with respect to the inlet and outlet so as to communicate with the unit cells, respectively. The flow channel is connected. The secondary battery module of the present invention can optimize the cooling efficiency of the entire unit battery assembly, thereby further improving charge and discharge efficiency.

Owner:SAMSUNG SDI CO LTD

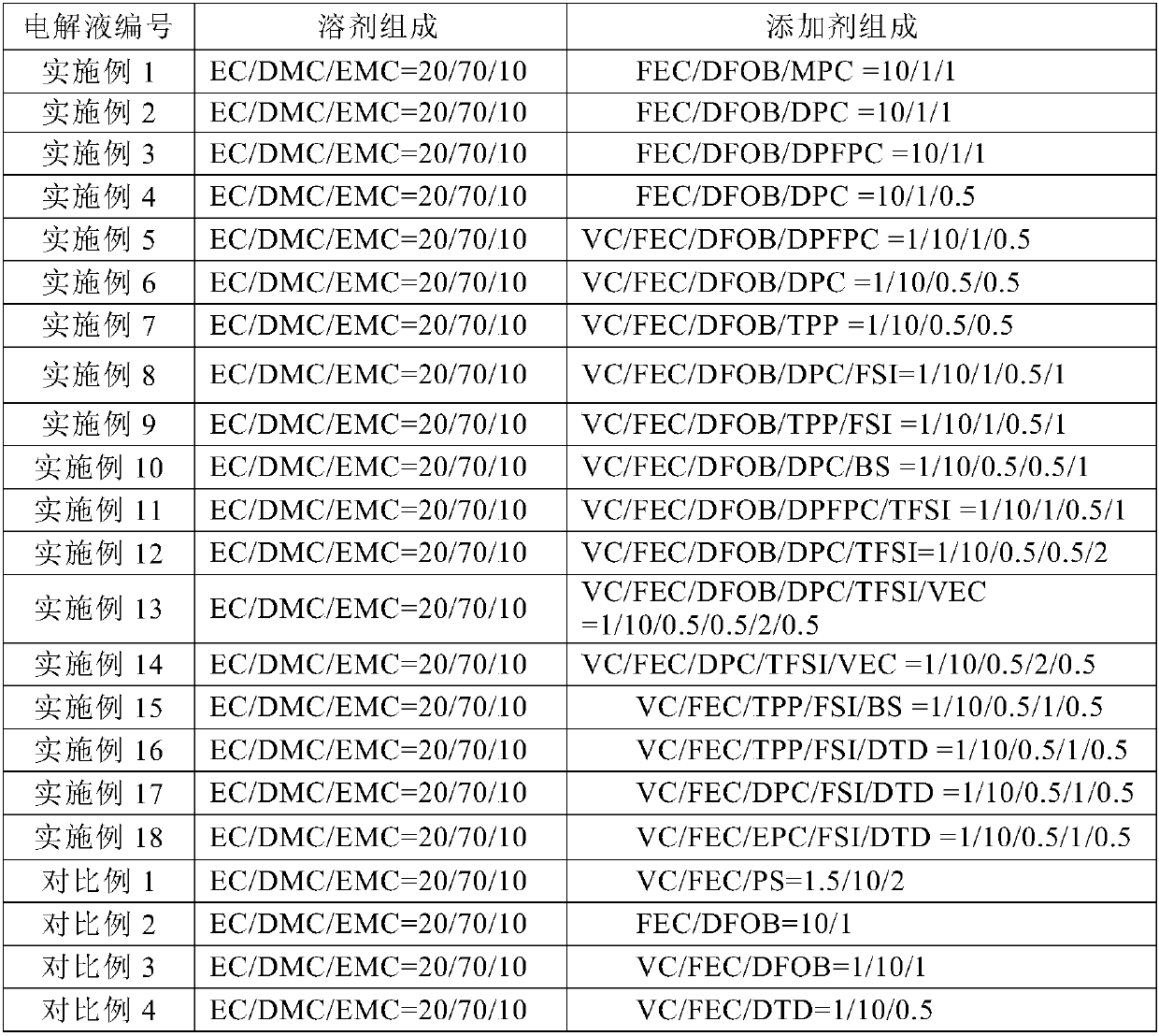

Lithium-ion battery electrolyte and lithium-ion battery

InactiveCN107834110AImprove cycle performanceImprove charge and discharge efficiencySecondary cells servicing/maintenanceHigh temperature storageCyclic process

The invention belongs to the technical field of lithium-ion batteries, in particular to a lithium-ion battery electrolyte and a lithium-ion battery. Three additives, namely an additive A, an additiveB and an additive C, are added in the in the electrolyte, wherein the additive A can improve the cycle performance of a high-nickel material battery and inhibit the battery from increasing internal resistance in high-temperature storage and cyclic processes, the charging and discharging efficiency of the battery in charging and discharging processes can be improved, and self-discharging is reduced; the additive B can form a thin and compact SEI membrane on a negative electrode interface, so that a high-nickel material has relatively low interface impedance when matching with a high-volume high-compaction negative electrode material, and lithium-ions are favorably diffused; the additive C can inhibit a high-nickel battery from producing too much gas so that a battery explosion-proof valveis sprung in the long-term storage process at high temperature, and meanwhile has positive influence on the cycle life of the battery; therefore, the electrolyte guarantees that the battery has a relatively good cyclic life, the internal resistance of the battery in the use process is reduced, and when the battery is used at high temperature, potential safety hazards, which appear as the explosion-proof valve is sprung, are avoided.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

Lithium ion battery and negative pole piece thereof

ActiveCN103022414AImprove low temperature performanceImproved magnification performanceSecondary cellsNon-aqueous electrolyte accumulator electrodesDischarge efficiencyLithium carbonate

The invention provides a lithium ion battery and a negative pole piece thereof. The negative pole piece of the lithium ion battery comprises a negative pole current collector and a negative pole active material layer which is arranged on the negative pole current collector. The negative pole piece of the lithium ion plate is characterized by further comprising a hard carbon material layer which contains hard carbon and is arranged on the negative pole active material layer. The hard carbon material layer also contains lithium salt which has mixture of lithium carbonate, lithium sulfide, lithium carbonic ester, alkoxy lithium, lithium sulphonate and alkyl diester lithium. The lithium ion battery comprises a positive pole piece, a negative pole piece which adopts the negative pole piece of the lithium ion battery, an isolating membrane arranged between adjacent positive and negative pole pieces, and electrolyte. By utilizing the lithium ion battery and the negative pole piece, the low temperature performance and the safety performance of the battery are effectively improved, and the rate capability and the discharge efficiency of the lithium ion battery are improved, the service life of the lithium ion battery is prolonged.

Owner:WUXI FUHONG TECH +1

Preparation method of nitrogen and oxygen in-situ doped porous carbon electrode material and application thereof

ActiveCN105575673AIncrease surface areaBest charge capacityHybrid capacitor electrodesHybrid/EDL manufacturePorous carbonApatite

The invention relates to a preparation method of nitrogen and oxygen in-situ codoped porous carbon electrode material and an application thereof. The nitrogen and oxygen in-situ codoped porous carbon electrode material is excellent in conductivity, great in chemical stability, three-dimensional and abundant in pore channels. An animal bone, such as an ox bone, a swine bone and a goat bone, is adopted to act as a carbon precursor. The organic component of collagen in the bone acts as a carbon and nitrogen source, and the inorganic component acts as a natural template to act as supporting material in the carbonization process and a pore channel regulating structure for controlling change and size of hydroxyapatite crystals so that the material is prepared. The porous carbon electrode material is abundant and prosperous in pore structures and has micropores, mesopores and macropores with the specific surface of being 1000-3000m<2>g<-1> so that the porous carbon electrode material can be used as supercapacitor electrode material.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com