Preparation method of nitrogen and oxygen in-situ doped porous carbon electrode material and application thereof

An electrode material, porous carbon technology, applied in the field of electrochemical energy storage, can solve the problems affecting the performance of supercapacitor energy density, low specific surface utilization, etc., to achieve excellent mass transfer performance, promote charge storage, and optimize charge capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Wash and clean the yellow ox bone, crush it into bone powder and dry it in an oven, then place it in a tube furnace, at a flow rate of 200mLmin -1 Under the protection of high-purity argon, with 5 oC min -1 Warm up to 400 o C carbonization, after 3 hours of heat preservation, stop heating, cool naturally to room temperature, and obtain a pre-carbonized product; weigh 5 g of the pre-carbonized product and activator KOH in a mass ratio of 1:1, grind and mix them evenly, and put them into a tube furnace. 2.5 oC min -1 Warm up to 750 o C. Cool down to room temperature naturally after heat preservation for 1h to obtain the activated carbonized product; then place the above activated carbonized product in 2molL -1 HNO 3 Stir and pickle in the solution for 12h, then wash with deionized water, 110 o After C drying for 12 hours, the porous carbon material CB-HPC-750 co-doped with nitrogen and oxygen was obtained. The pores showed a three-dimensional honeycomb network stru...

Embodiment 2

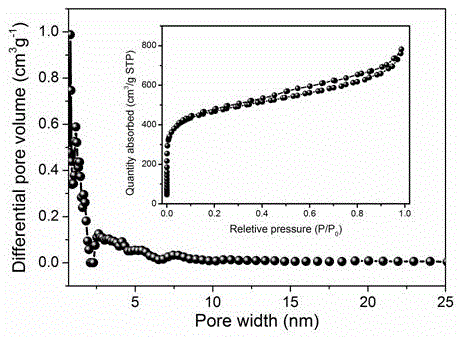

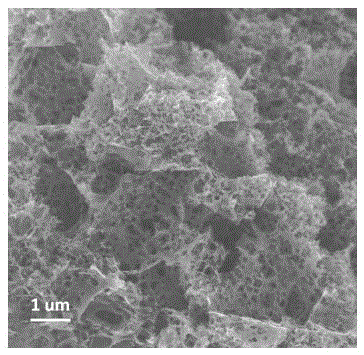

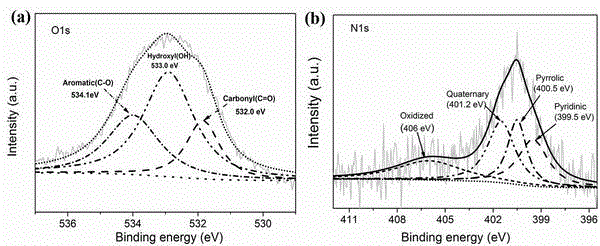

[0037] Pre-carbonization adopts the preparation process of Example 1, weighs 5g of pre-carbonized product and activator KOH, grinds and mixes them evenly in a mass ratio of 1:1, and puts them into a tube furnace. oC min -1 Warm up to 850 o C. Cool down to room temperature naturally after heat preservation for 1h to obtain the activated carbonized product; then place the above activated carbonized product in 2molL -1 HNO 3 Stir and pickle in the solution for 12h, then wash with deionized water, 110 o After C drying for 12 hours, the porous carbon material CB-HPC-850 co-doped with nitrogen and oxygen was obtained. The pores of the material showed a three-dimensional honeycomb network structure, including macropores, mesopores, and micropores. The scanning electron microscope showed figure 2 , through the nitrogen isothermal adsorption and desorption test, the specific surface area of the porous carbon reached 2520m2 by BET fitting 2 g -1 Adopting X-ray photoelectron spec...

Embodiment 3

[0039] Pre-carbonization adopts the preparation process of Example 1, weighs 5g of pre-carbonized product and activator KOH, grinds and mixes them evenly in a mass ratio of 1:1, and puts them into a tube furnace. oC min -1 Warm up to 950 o C. Cool down to room temperature naturally after heat preservation for 1h to obtain the activated carbonized product; then place the above activated carbonized product in 2molL -1 HNO 3 Stir and pickle in the solution for 12h, then wash with deionized water, 110 o After C drying for 12 hours, the porous carbon material CB-HPC-950 co-doped with nitrogen and oxygen was obtained. Through the nitrogen isothermal adsorption and desorption test, the specific surface area of the porous carbon reached 1123m2 by BET fitting. 2 g -1 ; The oxygen content measured by X-ray photoelectron spectroscopy is 9.2wt%, and the nitrogen content is 1.01wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com