Lithium ion battery and negative pole piece thereof

A technology for lithium-ion batteries and negative electrodes, applied in non-aqueous electrolyte battery electrodes, secondary batteries, circuits, etc., can solve SEI film composition, structure, compactness, uniformity and stability Discharge irreversible capacity increase, reduce battery charge and discharge efficiency and battery capacity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

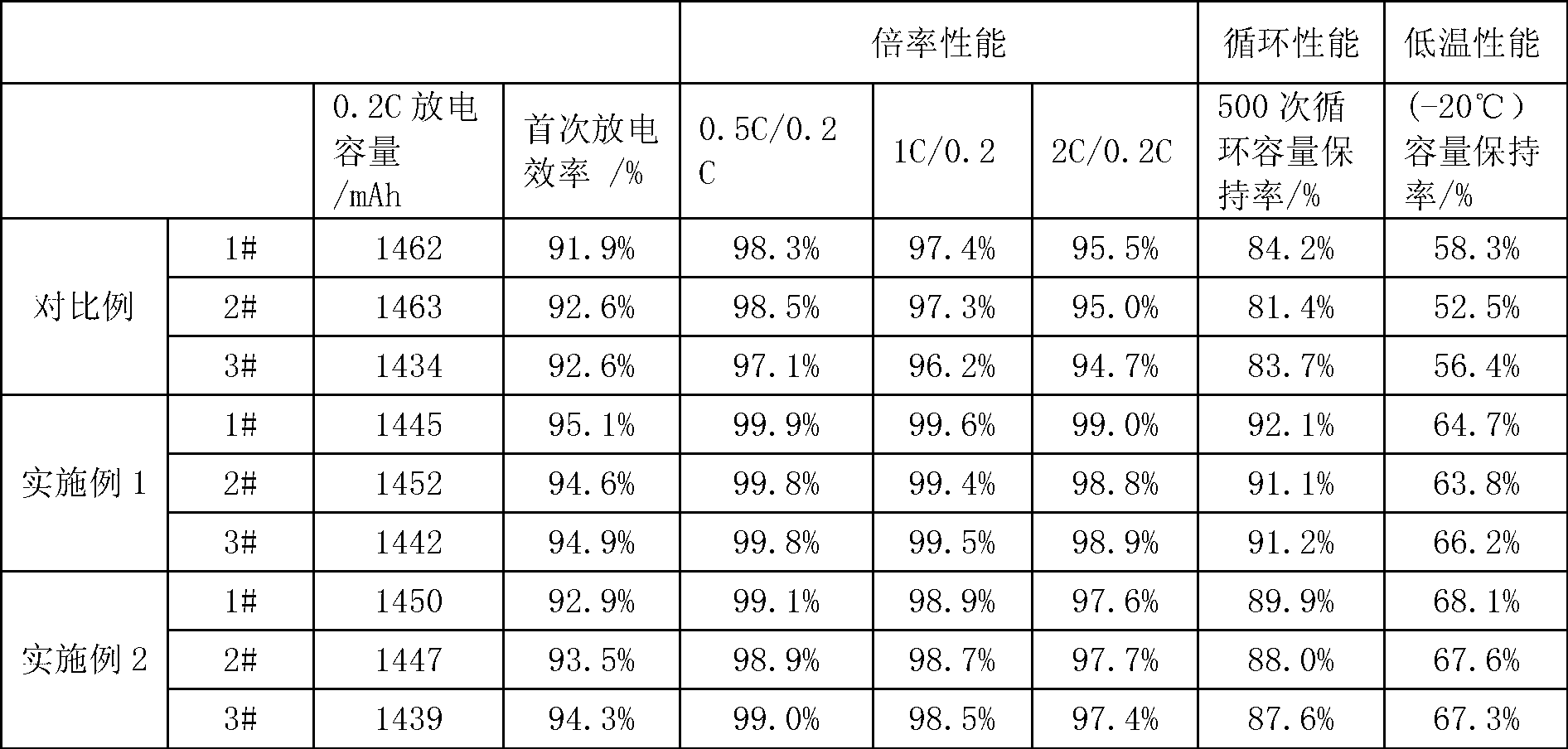

Embodiment 1

[0031] A preparation of lithium-ion battery negative electrode

[0032] 1) Preparation of negative electrode active material layer

[0033] Mix and disperse artificial graphite, Super-P (Temical), PVDF-HFP binder, and N-methylpyrrolidone at a mass percentage of 95:1.5:3.5:125 to prepare a uniform coating slurry;

[0034] Using a 9 μm thick copper foil as a substrate, the coating slurry was evenly coated on both sides of the copper foil, and dried at 120° C., and the thickness of the pole piece was 160 μm after drying.

[0035] The dried pole piece is hot rolled, the rolling temperature is 50°C, the pressure is 50MPa, the thickness of the pole piece after rolling is 105μm, and the compacted density of the pole piece is about 1.55g / cm 3 .

[0036] 2) Preparation of hard carbon material layer: Lithium carbonate (Li 2 CO 3 ), lithium methyl oxide (CH 3 OLi), lithium methyl carbonate (CH 3 OCO 2 Li), lithium methanesulfonate diester (CH 2 OSO 3 Li) 2 According to the mass p...

Embodiment 2

[0049] A preparation of lithium-ion battery negative electrode

[0050] 1) Preparation of negative electrode active material layer

[0051] Mix and disperse natural graphite, conductive agent Super-P (Temical), acrylic resin binder, and N-methylpyrrolidone at a mass percentage of 95.5:1.5:3:125 to prepare a uniform coating slurry;

[0052] Using a 9 μm thick copper foil as a substrate, the coating slurry was evenly coated on both sides of the copper foil, and dried at 120° C., and the thickness of the pole piece was 160 μm after drying.

[0053] The dried pole piece is hot rolled, the rolling temperature is 50°C, the pressure is 50MPa, the thickness of the pole piece after rolling is 100μm, and the compacted density of the pole piece is about 1.55g / cm 3 .

[0054] 2) Preparation of hard carbon material layer

[0055] Lithium carbonate (Li 2 CO 3 ), lithium sulfide (Li 2 S), Lithium carbonate diester (CH 2 OCO 2 Li) 2 , according to the mass percentage is Li 2 CO 3 :...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com