Patents

Literature

69results about How to "Increase the speed of formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite Particles for Electrochemical Device Electrode, Method of Production of Composite Particles for Electrochemica Device Electrode, and Electrochemical Device Electrode

ActiveUS20090267028A1High thickness accuracyLarge thicknessElectrode manufacturing processesHybrid capacitor electrodesConductive materialsElectrochemistry

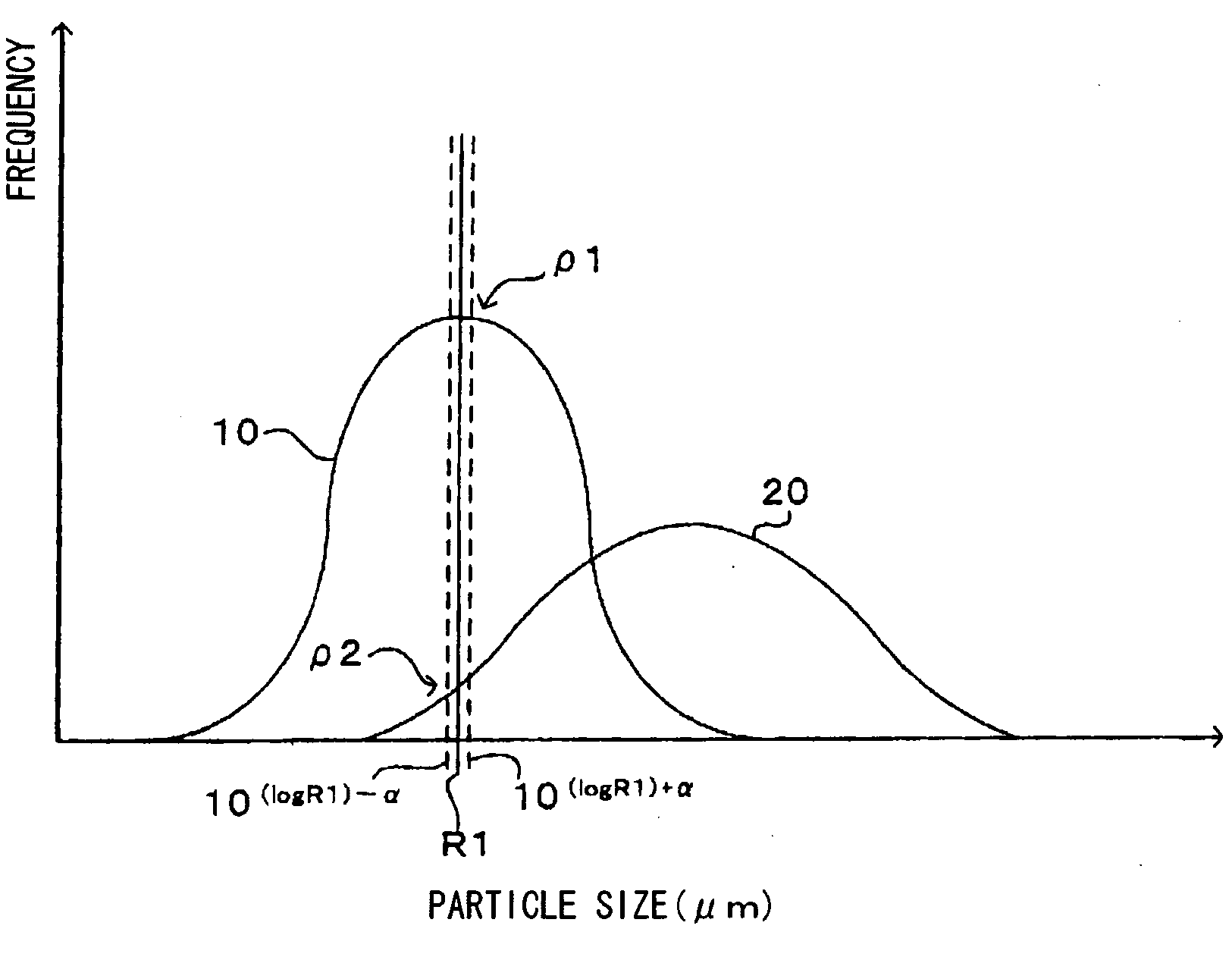

Composite particles for an electrochemical device electrode containing an electrode active material, a conductive material, and a binder, wherein primary particles of the composite particles have a volume average particle size of 1 to 500 μm and, when a relative particle amount of the primary particles having a particle size of a fine range near a mode radius R1 of the primary particles in the particle size distribution of the primary particles of the composite particles found by the volume standard is ρ1 and a relative particle amount of secondary particles having a particle size of the fine range in the particle size distribution of the secondary particles of the composite particles found by the volume standard in measurement at 23° C. is ρ2, ρ2 / ρ1 is 0.03 to 0.60.

Owner:ZEON CORP

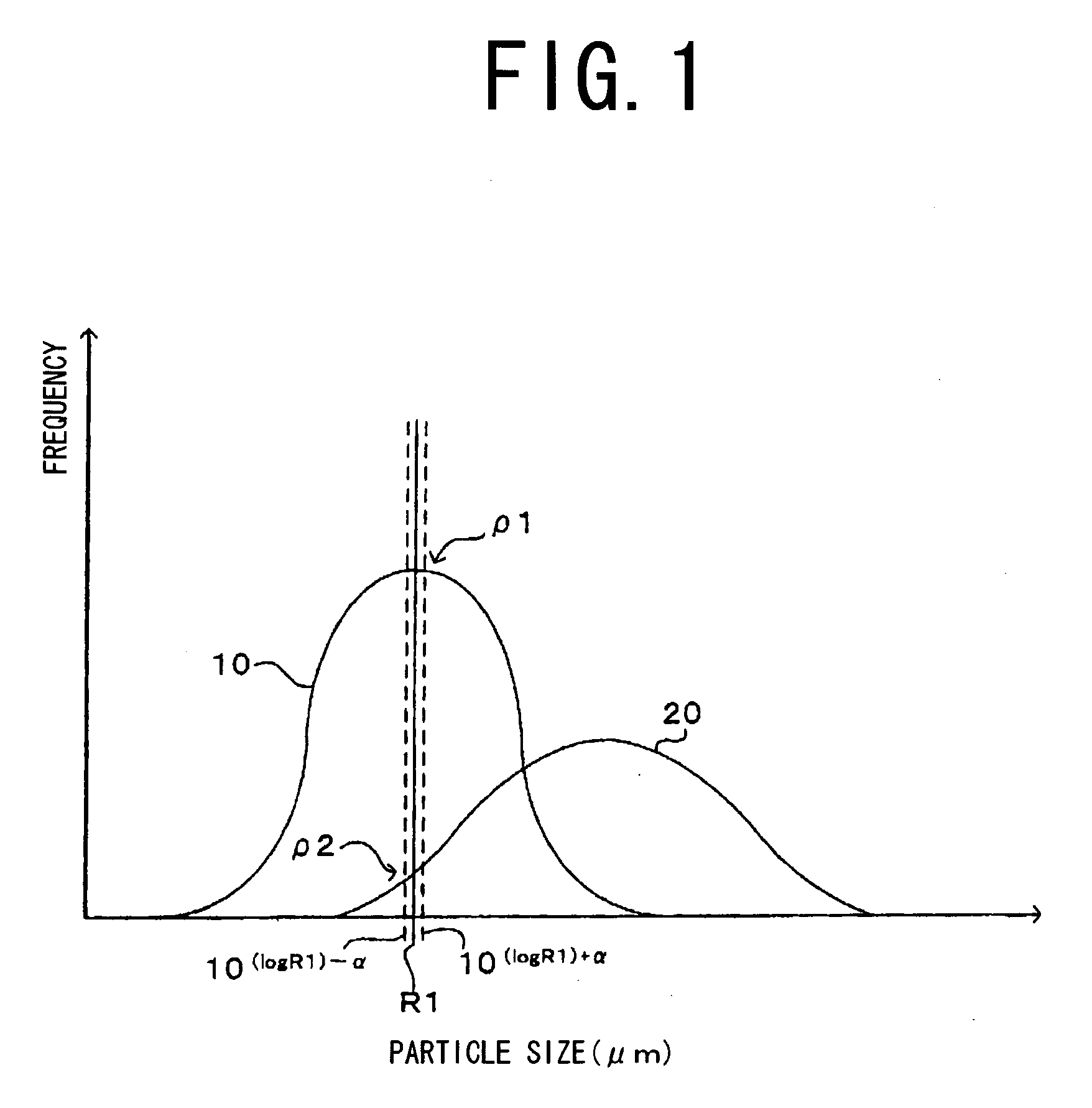

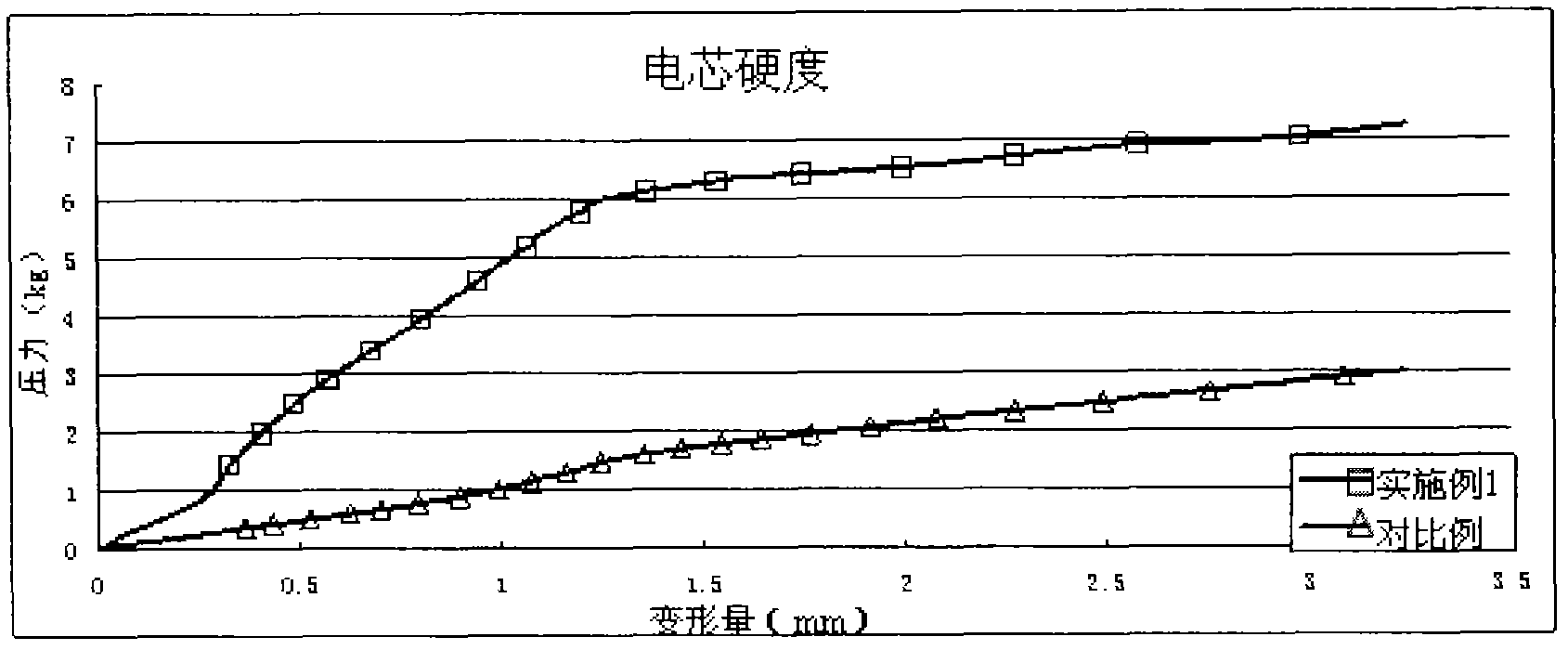

Method for improving hardness of lithium ion cell

ActiveCN102593520AFast charge and dischargeIncrease the speed of formationFinal product manufactureElectrolyte accumulators manufactureCooking & bakingLithium

The invention belonging to the technical field of lithium ion cells, and particularly relates to a method for improving hardness of a lithium ion cell by rapid formation. In the method, by adjusting the pre-baking time and temperature and the formation temperature of an electric core as well as the surface pressure on an electric core main body, the purpose of reducing the electric core polarization is achieved, high-current rapid formation is further realized, and finally the formation stopping potential is adjusted, so as to prepare the lithium ion cell with higher hardness. As compared with the prior art, the method has the following advantages: the high-temperature cramping and baking reshaping after formation is cancelled, so that the prepared electric core is higher in capacity; the electric core bears constant (or variable) pressure during the charge and discharge processes, thus the polarization in the charge and discharge processes is lower, and the capacity consistency of the prepared electric core is better; and because different temperatures and an SOC (state of charge) stopping manner are adopted for formation, the prepared electric core not only has excellent performance, but also has higher hardness.

Owner:NINGDE AMPEREX TECH +1

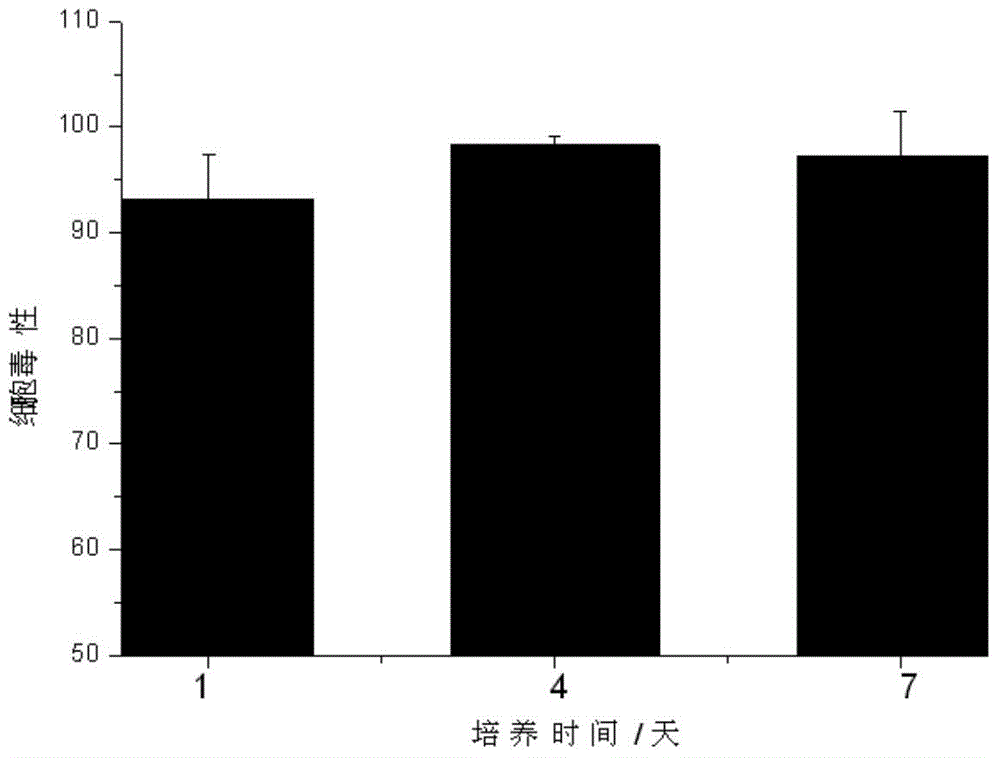

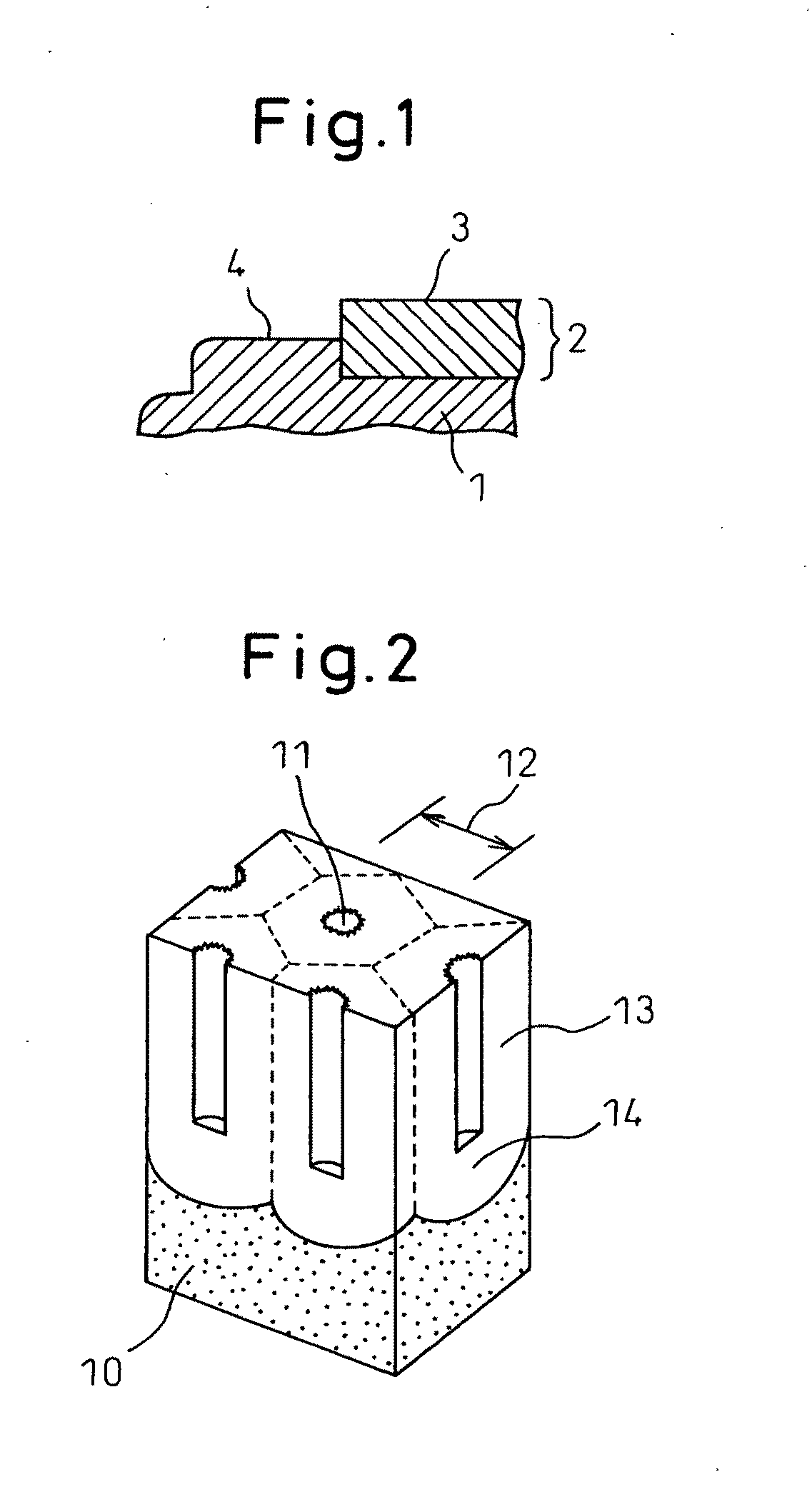

Metal bone graft material with porous structure, and preparation and application thereof

ActiveCN104818414AHigh tensile strengthHigh compressive strengthCoatingsProsthesisHuman bodyBiocompatibility

The invention relates to a metal bone graft material with a porous structure, and preparation and application thereof. The metal bone graft material is used as a filling material for transplantation after orthopaedic and oral damage and defects. The metal bone graft material contains the following trace elements in the human body by weight: 70.0 to 98.0 of Mg, 0.1 to 10.0% of Si, 0.1 to 10% of Sr and 0.1 to 10.0% of Ca, wherein the trace elements are uniformly distributed in a substrate and a coating. According to the invention, good ossification capability and matching in-vivo absorption capability are obtained by adjusting the contents of components in an alloy, controlling the shape, quantity and distribution of mesophase in metal, changing processing technology and surface coating protection of the alloy and preparing the porous structure; and the metal bone graft material has good biocompatibility and bone conduction capability, is a medical absorbent metal bone graft material with excellent mechanical properties, and is applicable to bone defects caused by wounds, malformation, bone tumors, osteomyelitis and joint displacement in clinical practice to promote bone restoration and applicable as a drug sustained release system.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

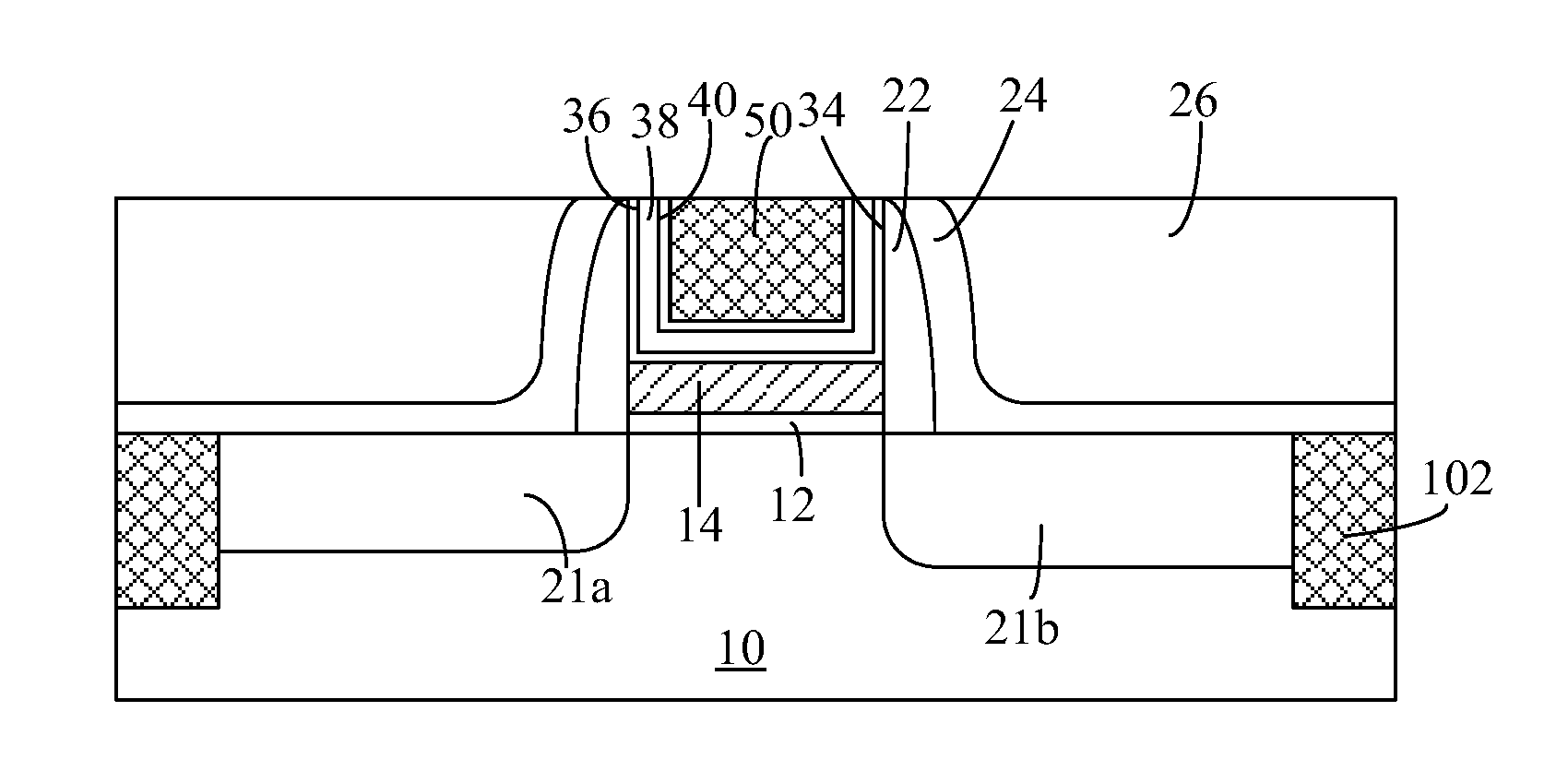

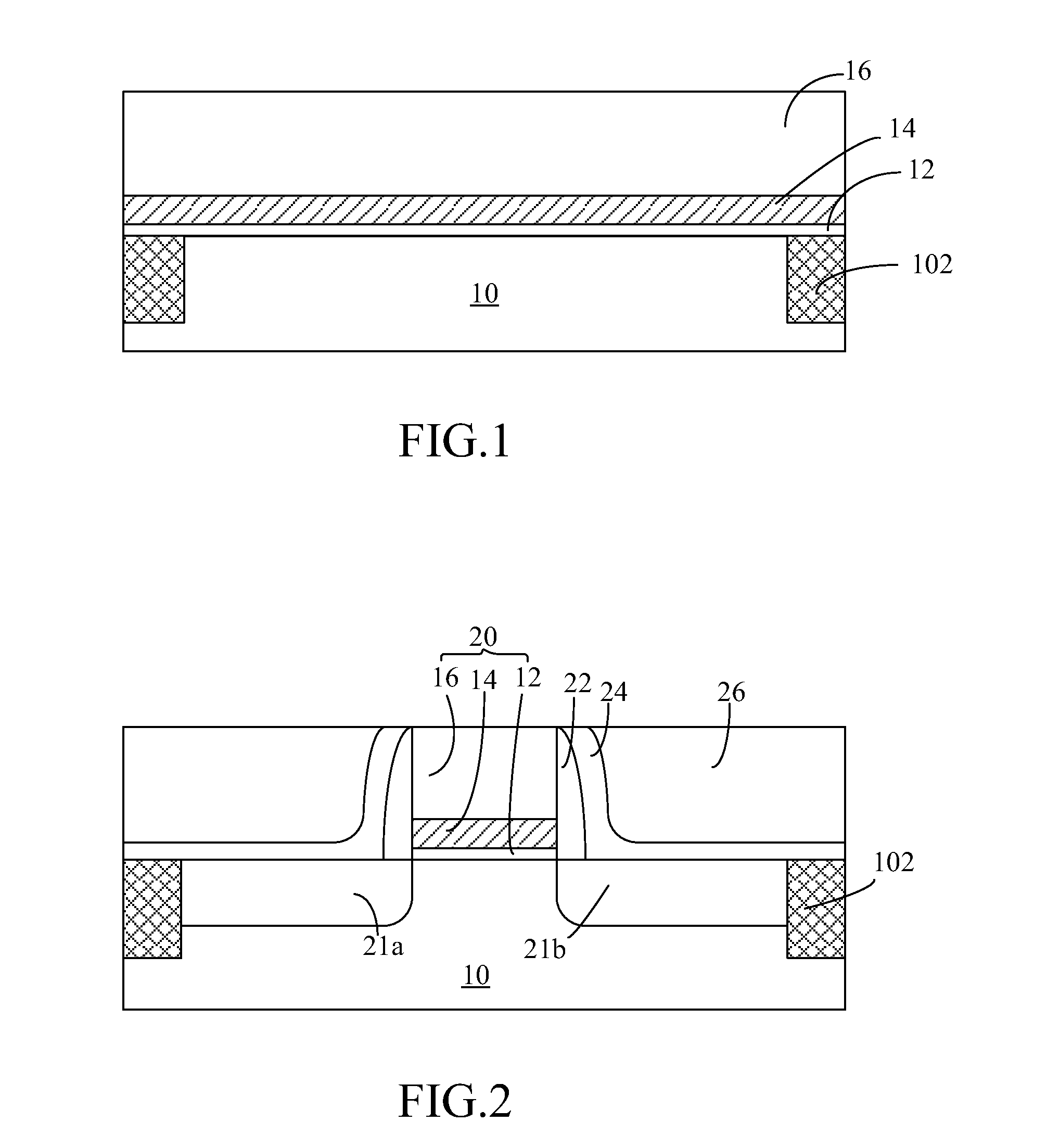

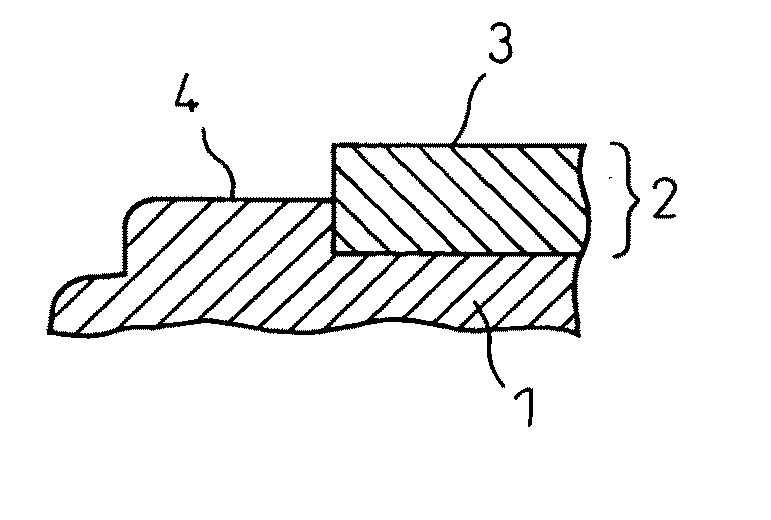

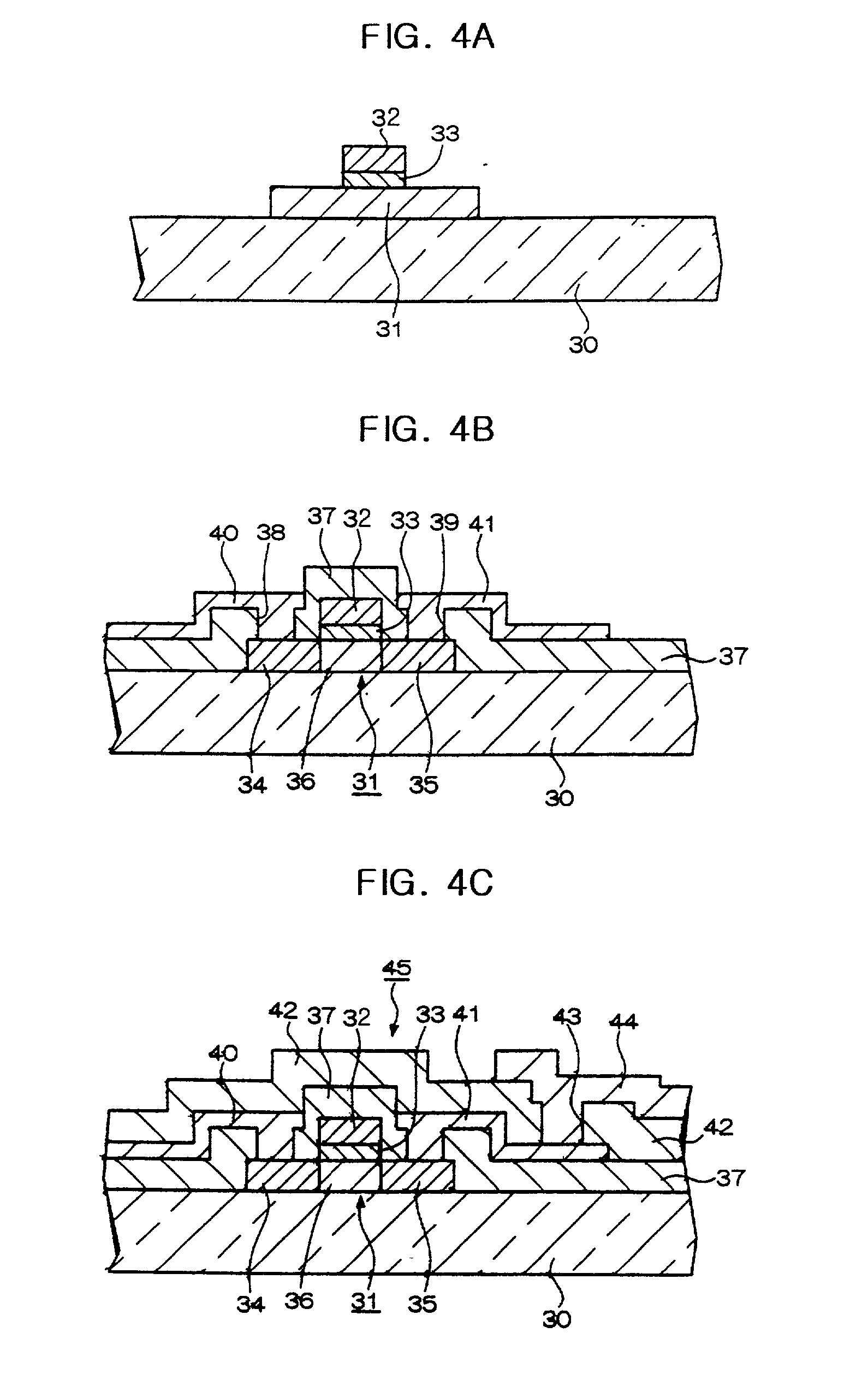

Gate stack structure with etch stop layer and manufacturing process thereof

ActiveUS20120273902A1Increase the speed of formationIncreasing the thicknessSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricGate stack

A gate stack structure with an etch stop layer is provided. The gate stack structure is formed over a substrate. A spacer is formed on a sidewall of the gate stack structure. The gate stack structure includes a gate dielectric layer, a barrier layer, a repair layer and the etch stop layer. The gate dielectric layer is formed on the substrate. The barrier layer is formed on the gate dielectric layer. The barrier layer and an inner sidewall of the spacer collectively define a trench. The repair layer is formed on the barrier layer and an inner wall of the trench. The etch stop layer is formed on the repair layer.

Owner:UNITED MICROELECTRONICS CORP

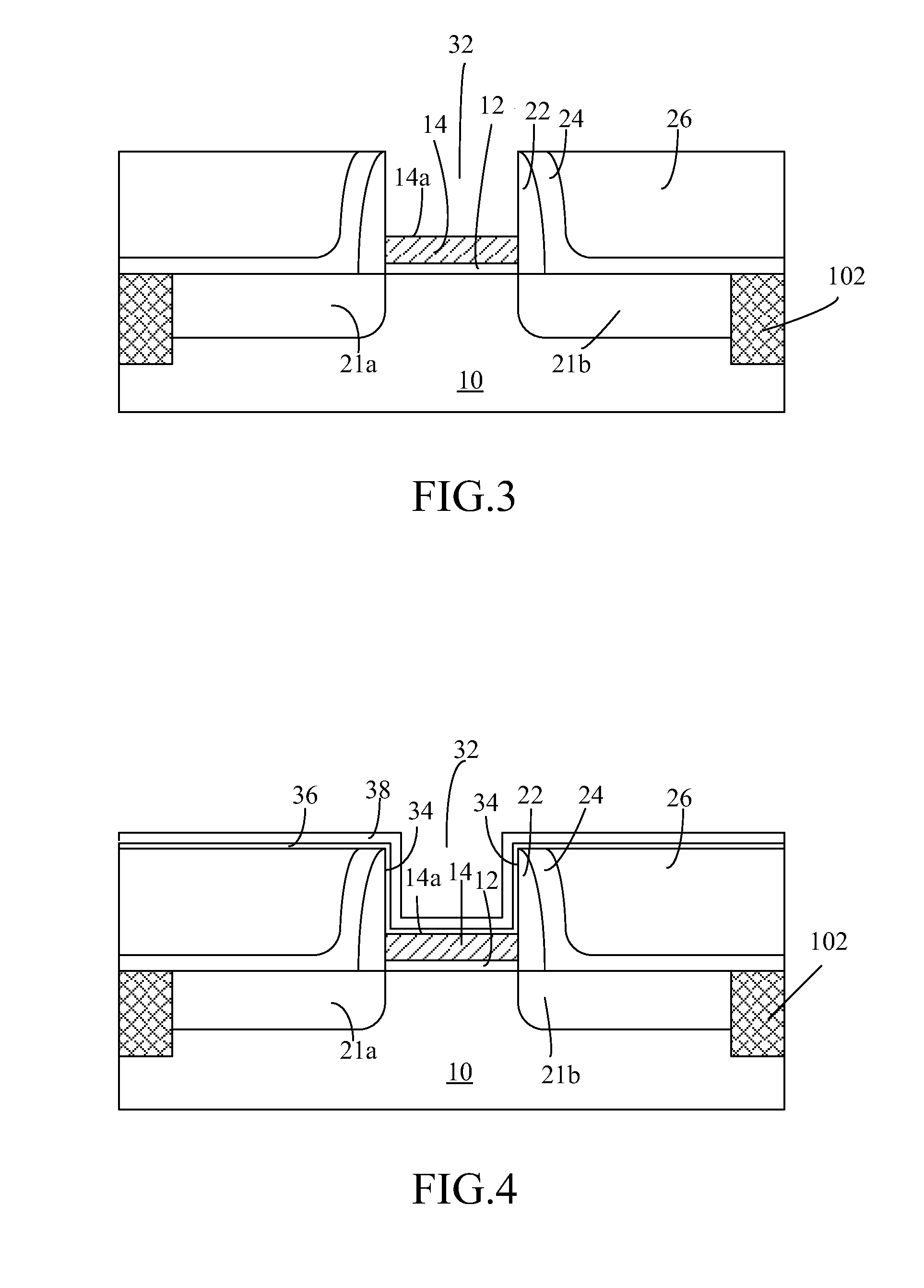

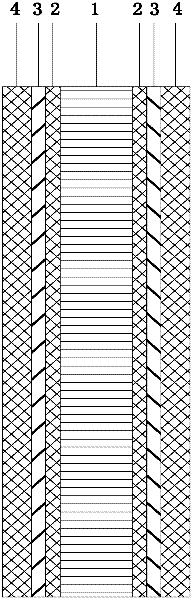

Cobalt-containing nickel plated steel strip serving as lithium battery shell material and preparation method thereof

InactiveCN102230200AImprove performanceTimely supplementCell component detailsElectrical batteryNitrogen

The invention discloses a cobalt-containing nickel plated steel strip serving as a lithium battery shell material and a preparation method thereof. The preparation method comprises the following procedures of: (1) pretreating a base material; (2) continuously electrodepositing a nickel-cobalt alloy plating layer on the pre-treated base material; (3) carrying out diffusion annealing treatment on the nickel-cobalt alloy plating layer under a protective atmosphere like high-purity nitrogen; (4) plating a nickel-cobalt alloy plating layer on the metal subjected to the diffusion annealing treatment again; and (5) rolling the plated nickel-cobalt alloy plating layer in a cold manner. The cobalt containing nickel plated steel strip disclosed by the invention is prepared by a special process of tightly combining the nickel-cobalt alloy plating layer and a low-carbon steel strip and then electroplating the nickel-cobalt alloy plating layer and the low-carbon steel strip, shows better corrosion resistance and can be used for shell materials of primary batteries, secondary batteries and lithium ion power cells such as 18650, 26650 and the like.

Owner:XIANGTAN UNIV

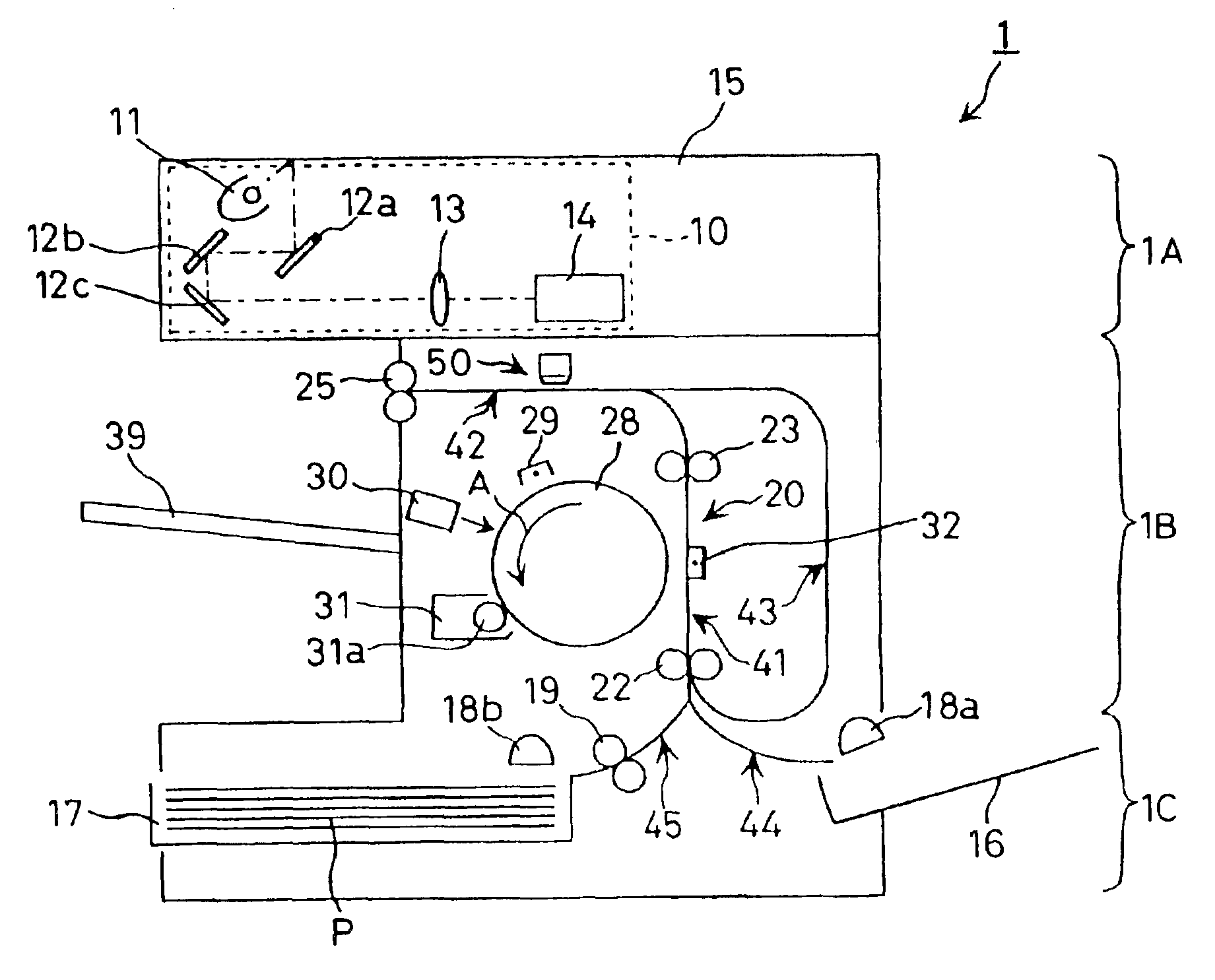

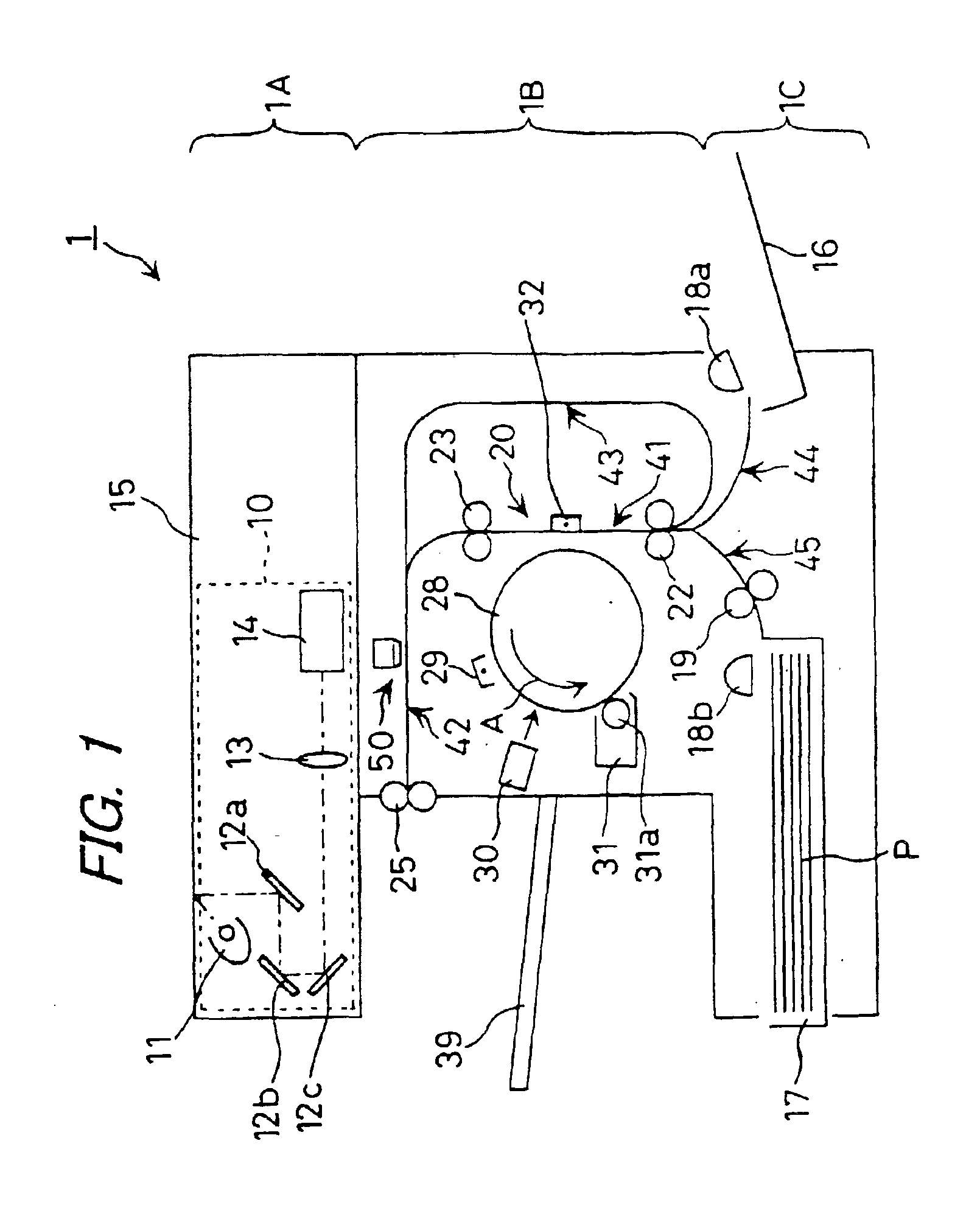

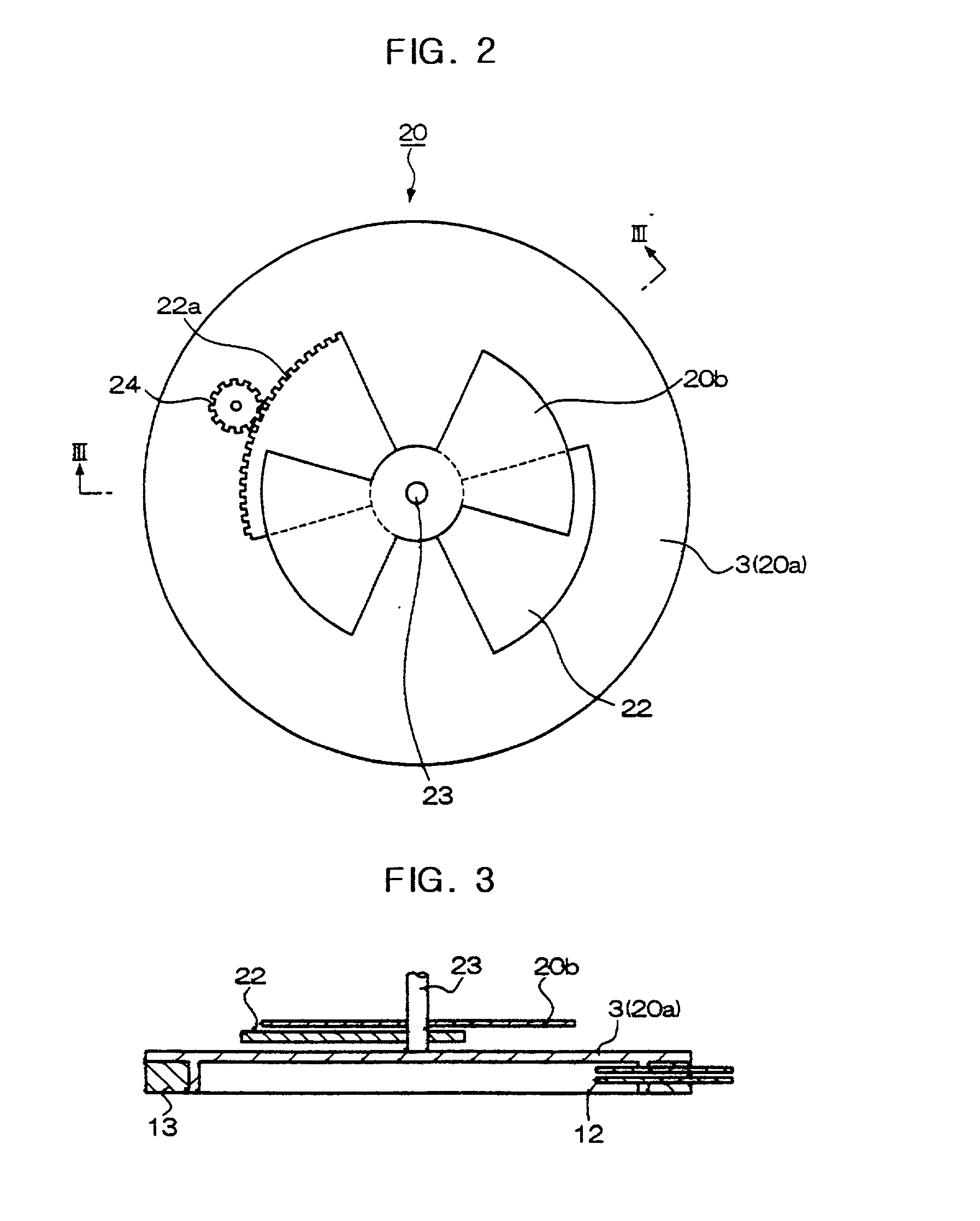

Image forming apparatus for monochromatic and color image formation

InactiveUS6889012B2Increase the speed of formationHigh color reproductionTypewritersElectrographic process apparatusColor imageImaging processing

An image forming apparatus is provided which includes a first image forming section for performing image formation based on monochromatic image data, and a second image forming section for performing image formation based on color image data. The first and second image forming sections are arranged in mutually different positions along a path for conveying recording paper. The image forming apparatus further includes an image processing section for outputting monochromatic image data and color image data, which have undergone image processing, to the first image forming section and the second image forming section respectively, at individual timings for forming images an either one or both sides of the recording paper.

Owner:SHARP KK

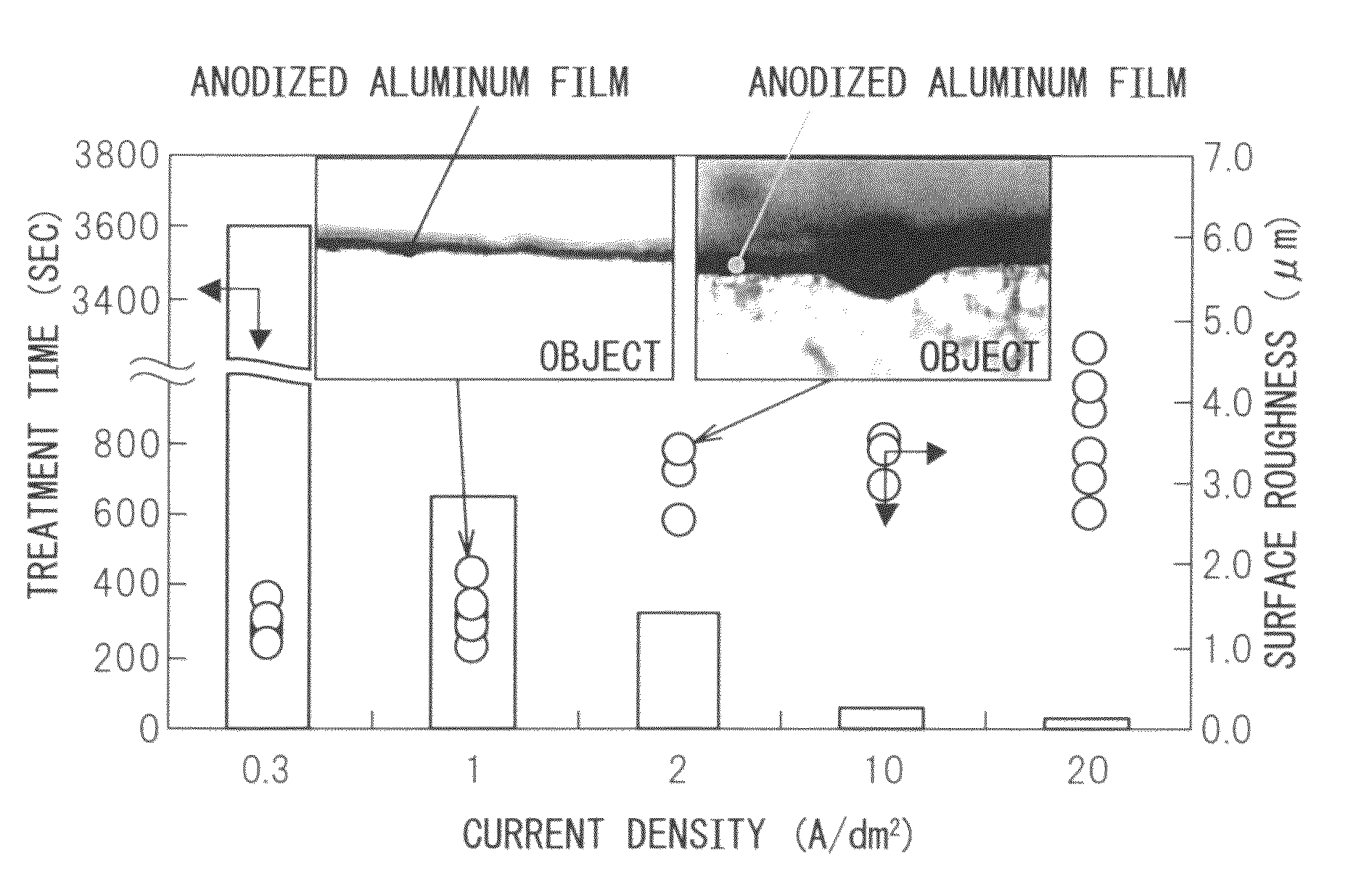

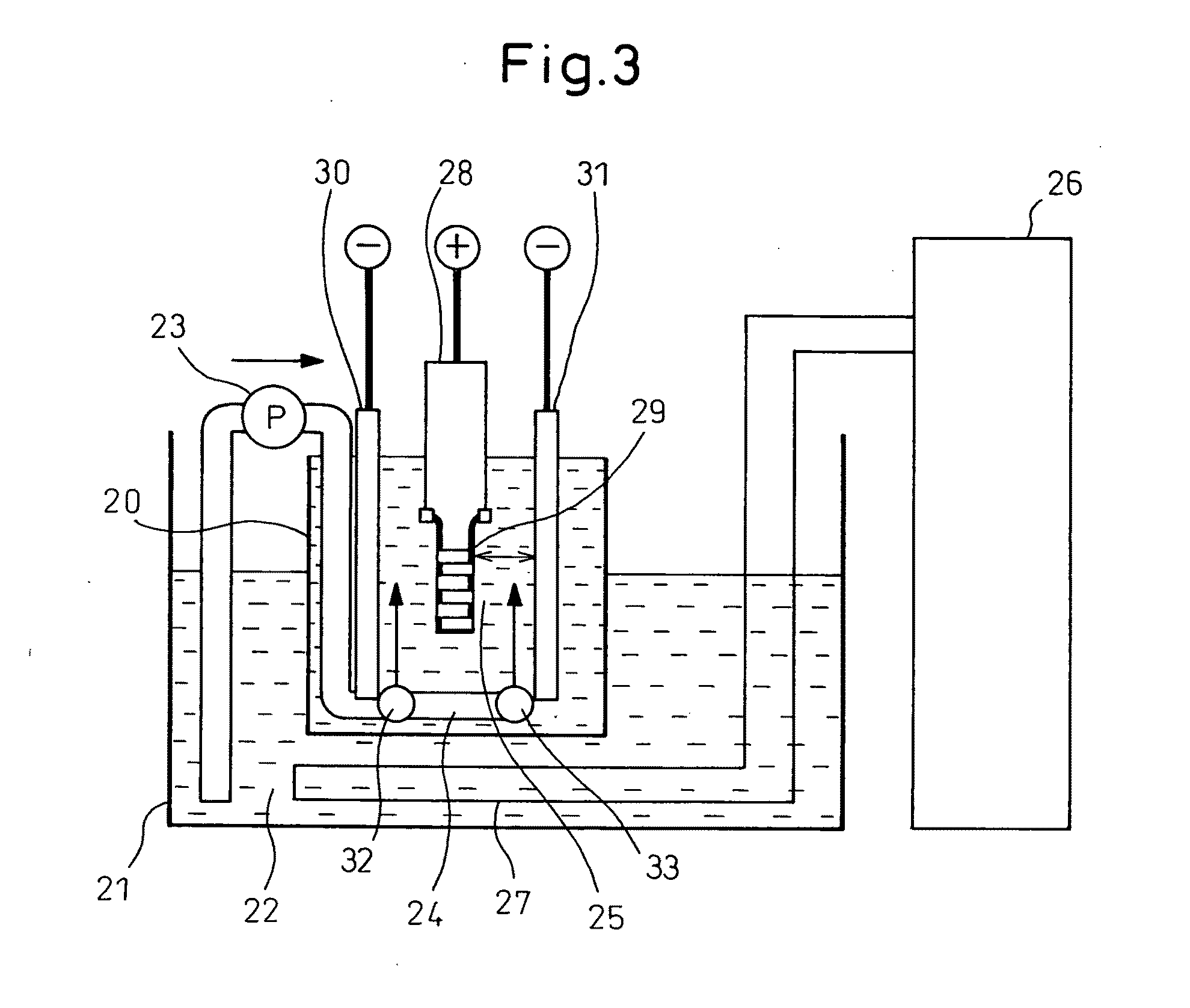

Method for anodizing aluminum and anodized aluminum

ActiveUS8691403B2Increase roughnessIncrease the speed of formationCellsAnodisationOrganic acidAnodic oxidation

Owner:DENSO CORP

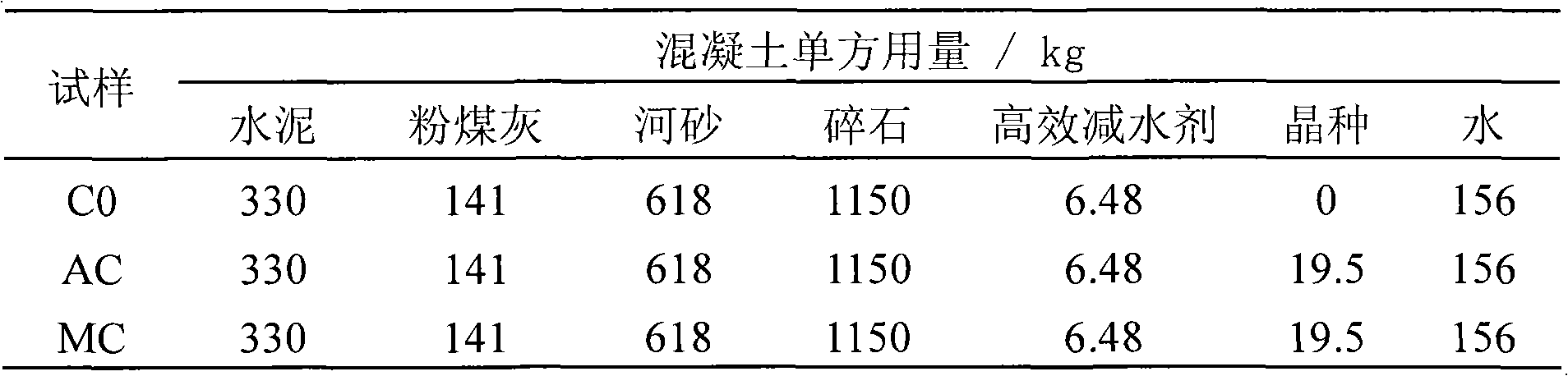

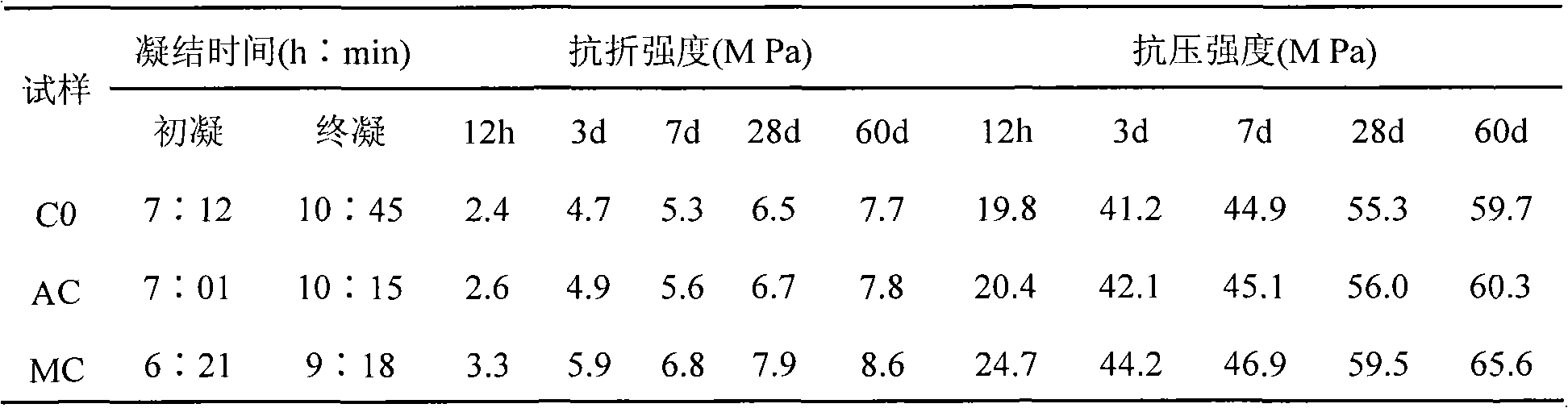

High-activity crystal seed for concrete production and preparation method thereof

InactiveCN101830660AImprove burnabilityLower firing temperatureSolid waste managementSolid waste disposalSlagSeed crystal

Owner:EAST CHINA JIAOTONG UNIVERSITY

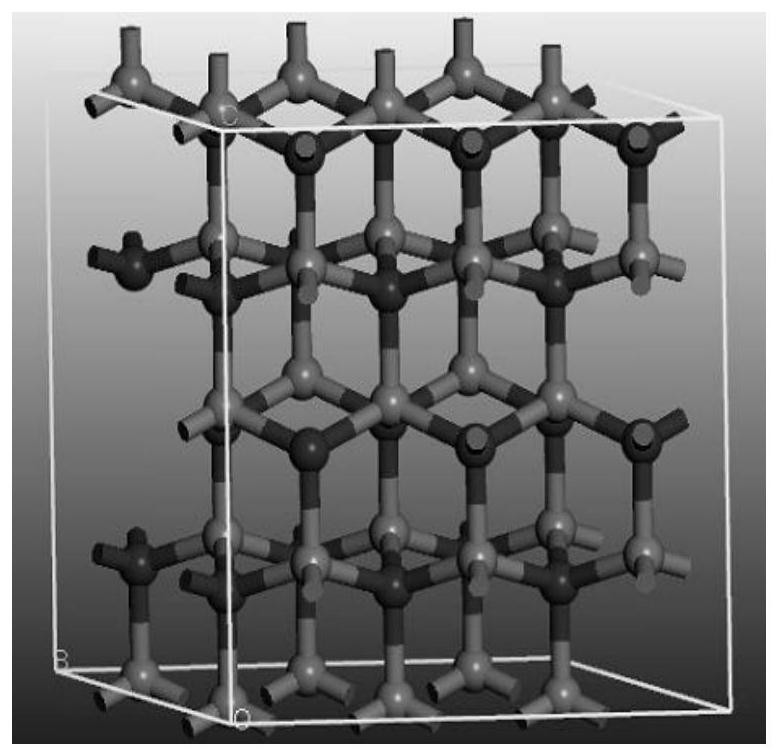

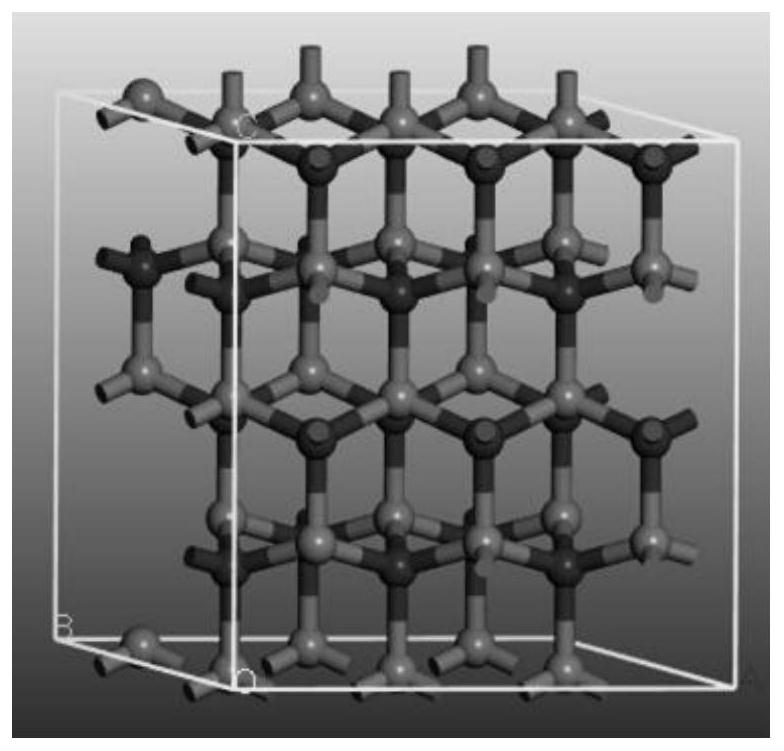

Synthetic opal and photonic crystal

InactiveUS8936683B2Rapid precipitationQuality improvementAfter-treatment apparatusFrom gel statePhotonic bandgapPhotonics

A colloidal suspension of particles is rapidly self-assembled with a minimum number of defects into a densely packed array of particles on a substrate under simultaneous sedimentation and annealing forces. The particles may be ordered as an opal structure. Optionally, the synthesized structure may incorporate an electrolyte and be used as a sacrificial form for micromolding an inverse structure. The inverse structure may exhibit a photonic band gap. Optionally, necking between particles may be adjusted after micromolding. Furthermore, a shell may alter physical properties, such as protecting a thermally stimulated photonic band gap device. These low cost methods allow more applications to become commercially viable.

Owner:PRACTICAL TECH

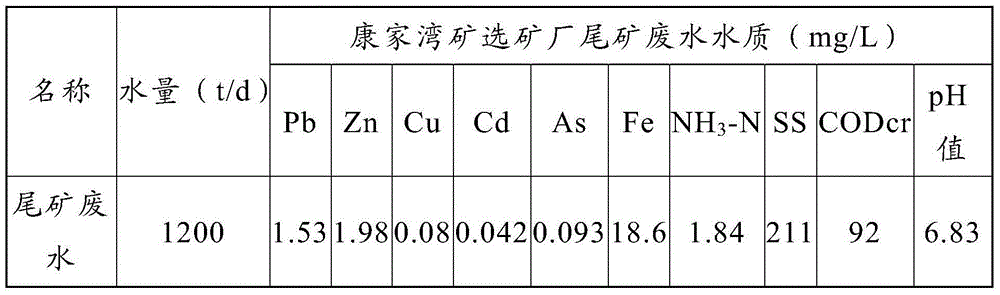

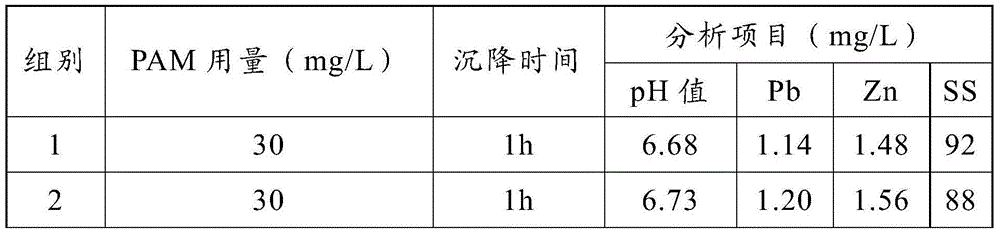

Mineral processing tailing wastewater treatment method

ActiveCN104445749AReduce the content of heavy metal ionsAchieve emission standardsMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationSuspended matterMineral processing

The application provides a mineral processing tailing wastewater treatment method. The mineral processing tailing wastewater treatment method comprises the following steps: A), mixing the mineral processing tailing wastewater and a destabilizing agent to obtain destabilized wastewater; B), mixing the destabilized wastewater and a first coagulant and sedimenting to obtain tailing wastewater supernatant and flocs; and C), mixing the tailing wastewater supernatant and a second coagulant and sedimenting to obtain purified water. During the treatment of mineral processing tailing wastewater, the wastewater is firstly destabilized so that suspended solids in the tailing wastewater is free from the steady state and then the destabilized tailing wastewater is further purified by virtue of a two-stage coagulating sedimentation method in a connected-in-series manner so as to accelerate the formation and sedimentation of coarse particle polymers, the contents of the suspended solids and heavy metal ions in the wastewater are decreased in a short time and the environmentally acceptable discharge of the wastewater is achieved.

Owner:SHUI KOU SHAN NONFERROUS METALS LTD

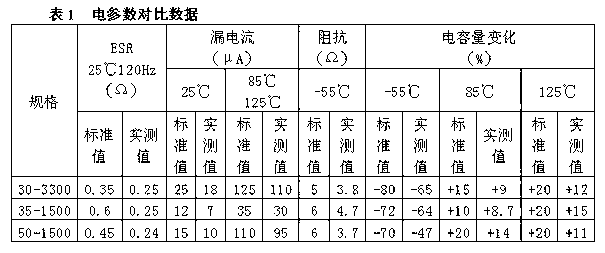

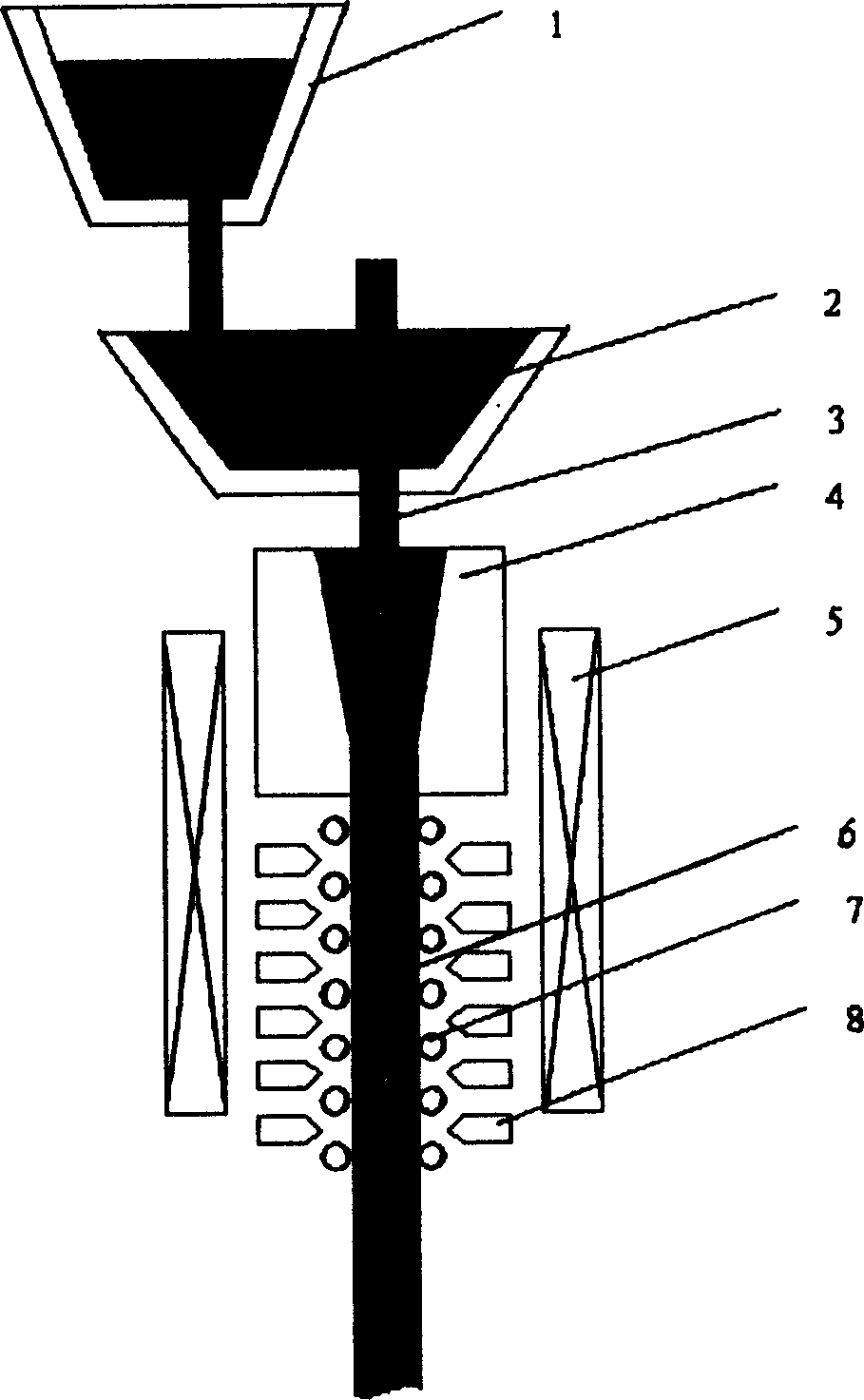

Producing method for full-tantalum-gas sealed capacitor

ActiveCN103310981AQuality improvementReduced effective resistanceElectrolytic capacitorsCapacitanceElectrolytic agent

The invention discloses a producing method for a full-tantalum-gas sealed capacitor, belongs to a capacitor manufacture method and aims to provide a manufacture method for non-solid tantalum electrolytic capacitors. The method comprises calcining a green body with the press density ranging from 5.5g / cm3 to 7.5g / cm3 into an anode tantalum block, immersing the tantalum block in an electrolyte solution to perform electrochemical treatment according to a grading boosting mode, performing vacuum heat treatment on the anode tantalum block provided with dielectric oxidation film, immersing the anode tantalum in a phosphoric acid to perform secondary electrochemical treatment, cleaning and drying the anode tantalum block which is subjected to secondary electrochemical treatment, and packaging the anode block in a tantalum casing to be prepared into a capacitor product, putting the capacitor product in an aging device to perform heating and energizing aging. The capacitor product produced through the method has the advantages of being low in equivalent series resistance and impedance, small in leakage current and capacitance change and the like.

Owner:CHINA ZHENHUA GRP XINYUN ELECTRONICS COMP ANDDEV CO LTD

Normal energy metabolism composite essential vitamin micro element and nutritive type white sugar product and manufacturing method

InactiveCN1685929AIncrease the speed of formationIncrease growth rateMetabolism disorderFood preparationB1 VitaminFood additive

A nutritive composite vitamine-trace element-white sugar necessary for normal energy metabolism for preventing and treating obesity, fatty liver, alcoholic liver, diabetes and hyperlipemia is prepared from VB1, VB2, VC, Se, Zn and white sugar. It can be used as food or food additive.

Owner:颜怀玮

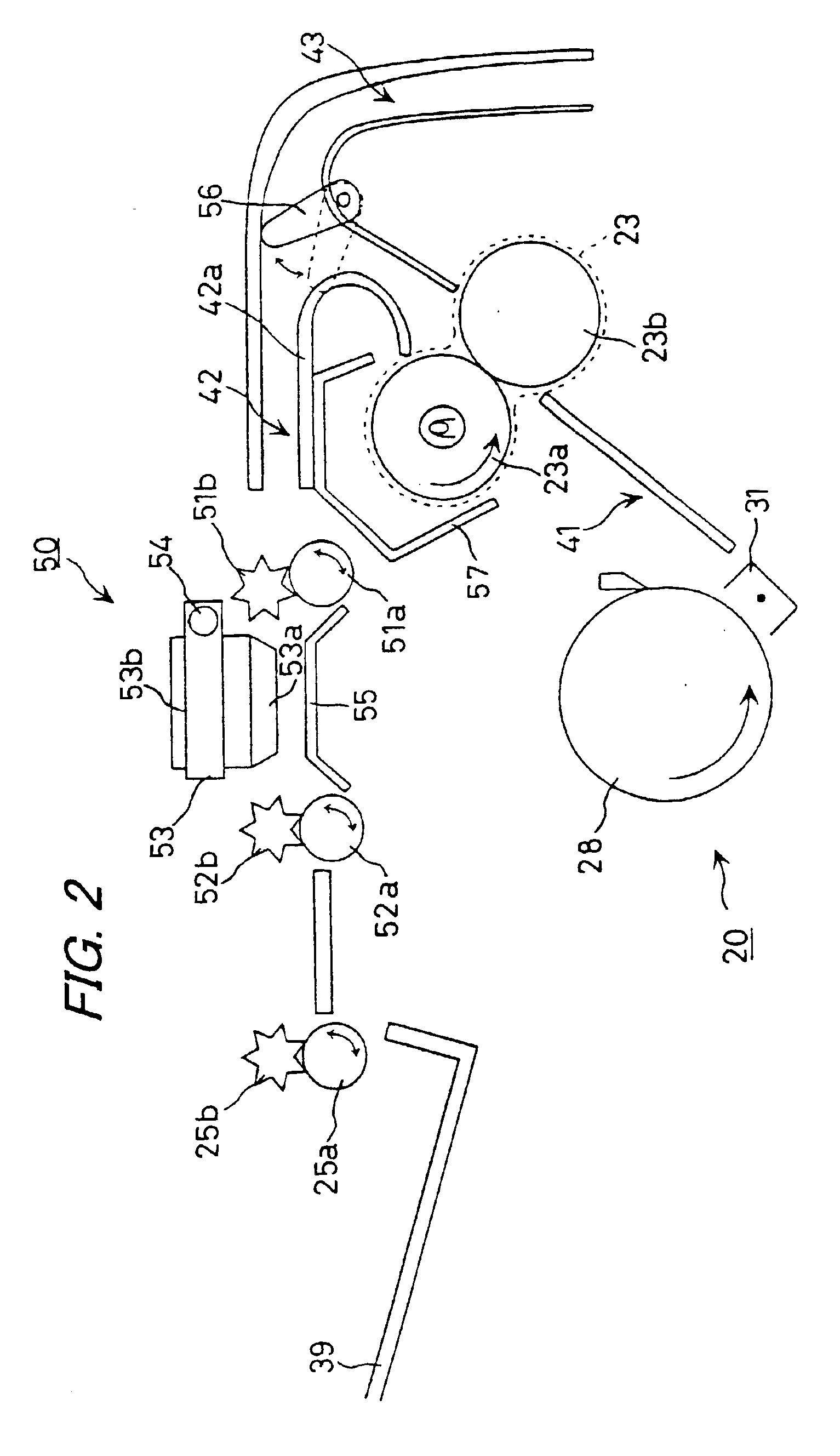

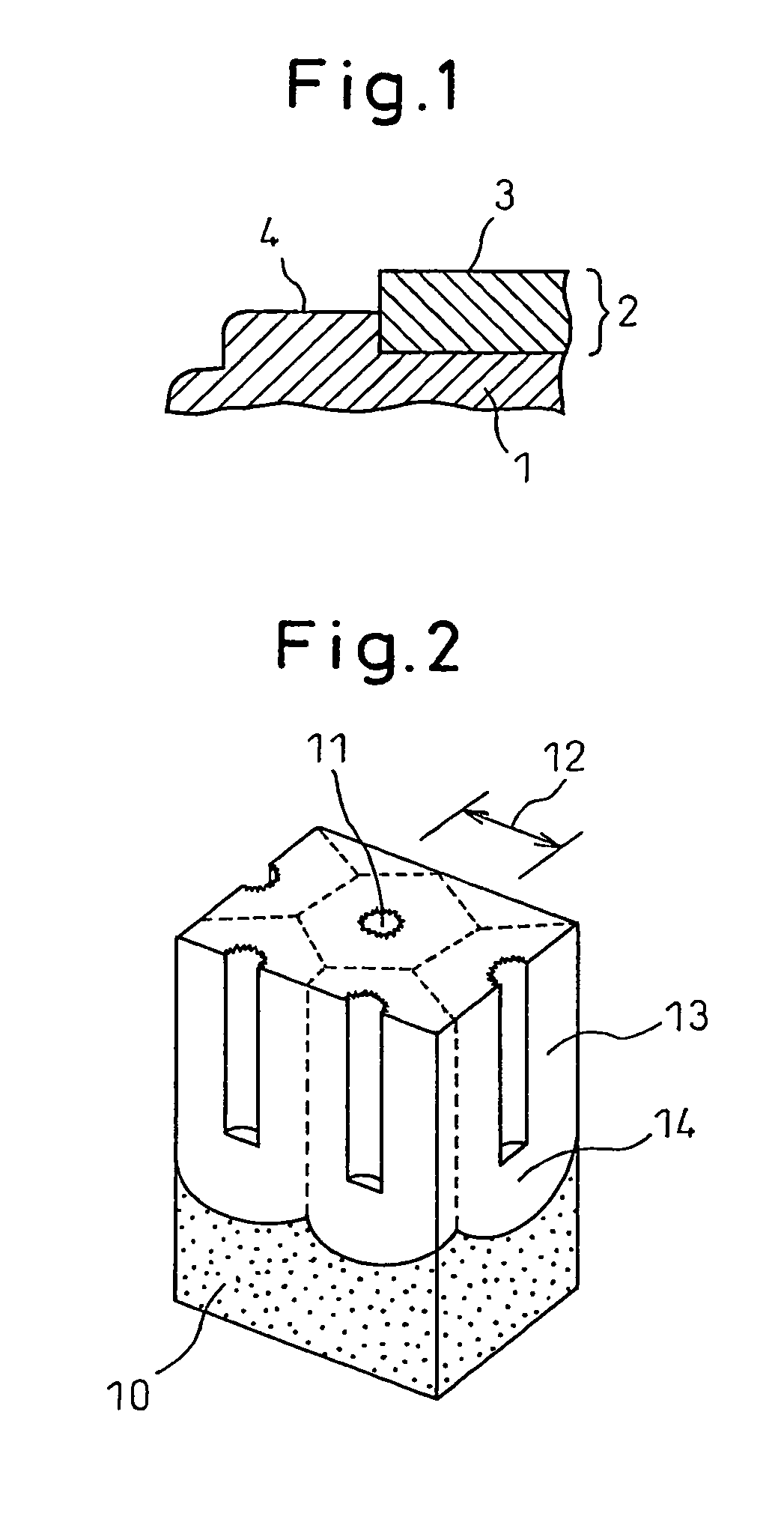

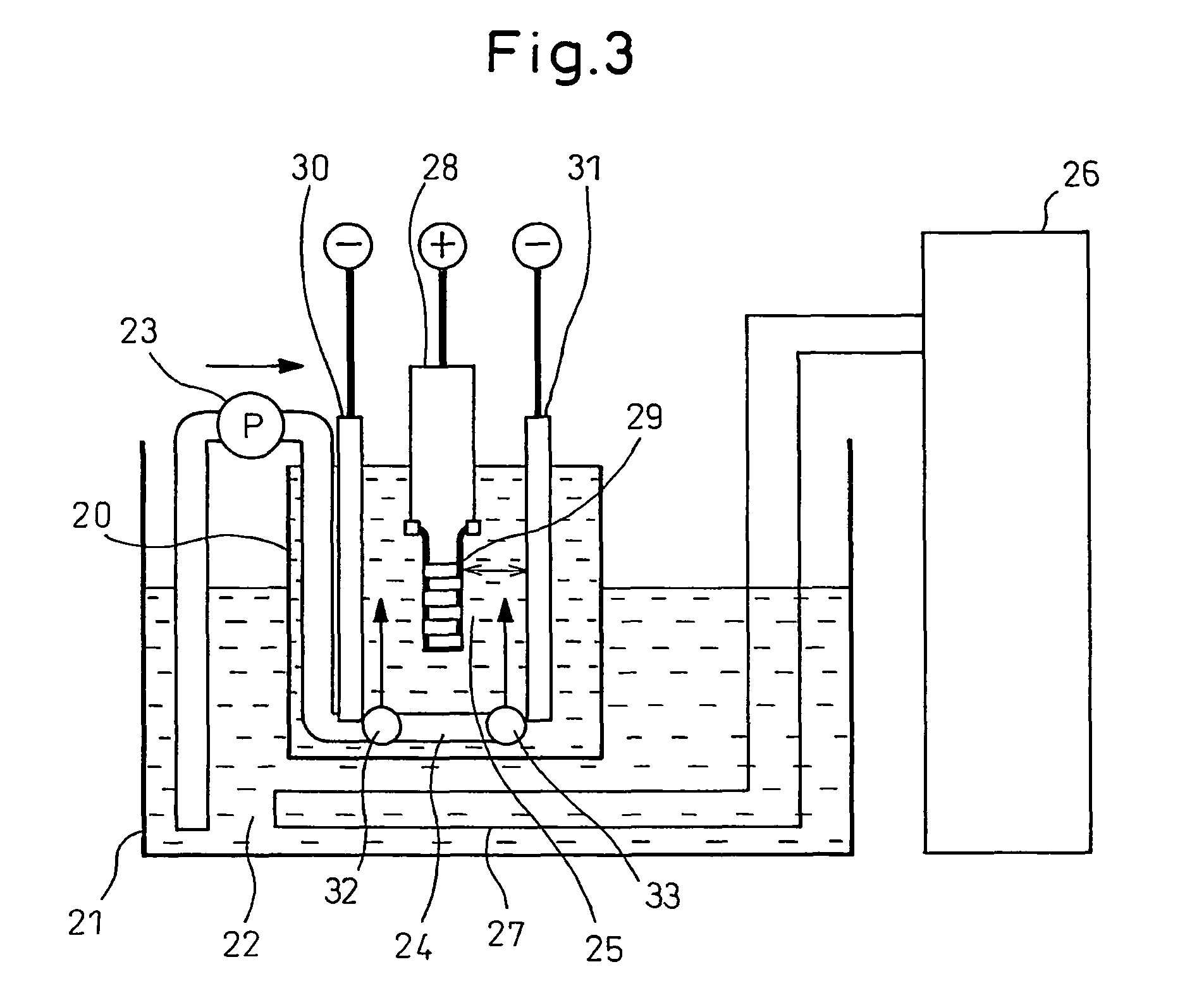

Method for anodizing aluminum and anodized aluminum

ActiveUS20110203933A1Efficiently provideUniform thicknessCellsAnodisationOrganic acidAnodic Aluminum Oxide

A method for anodizing aluminum, wherein an object (29) made of aluminum or an aluminum alloy is anodized in an electrolytic solution (25), and thereby an anodized aluminum film is formed on a surface of the object (29), is provided. The electrolytic solution (25) is comprised of at least one acid selected from organic acids having two or more carboxylic groups, moves at an average speed of 15 cm / sec or less along at least an outer surface of the object (29). The anodization is performed under conditions that a temperature of the outer surface of the object (29) is 80° C. or less, and current density is in a range from 10 to 170 A / dm2.

Owner:DENSO CORP

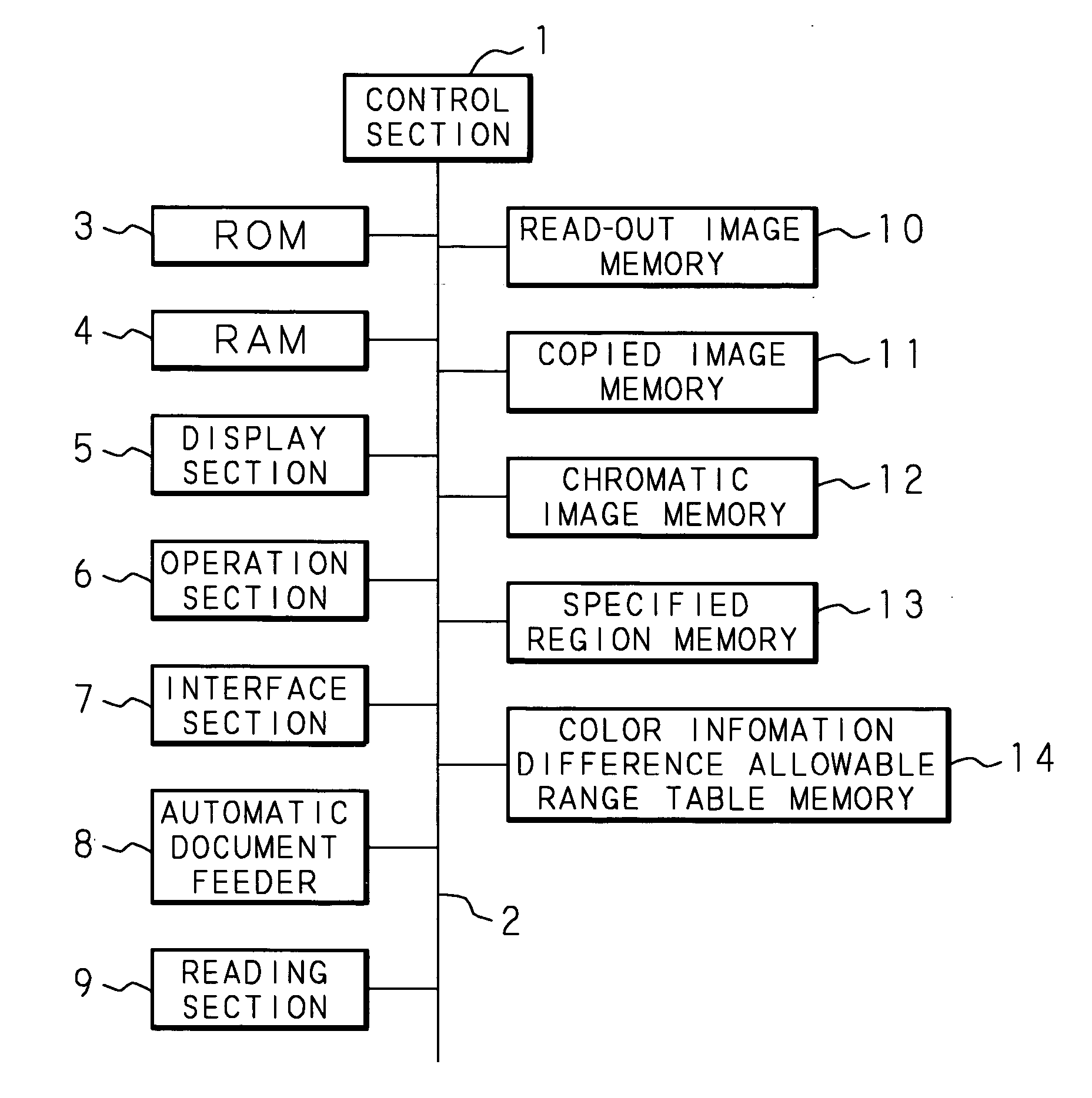

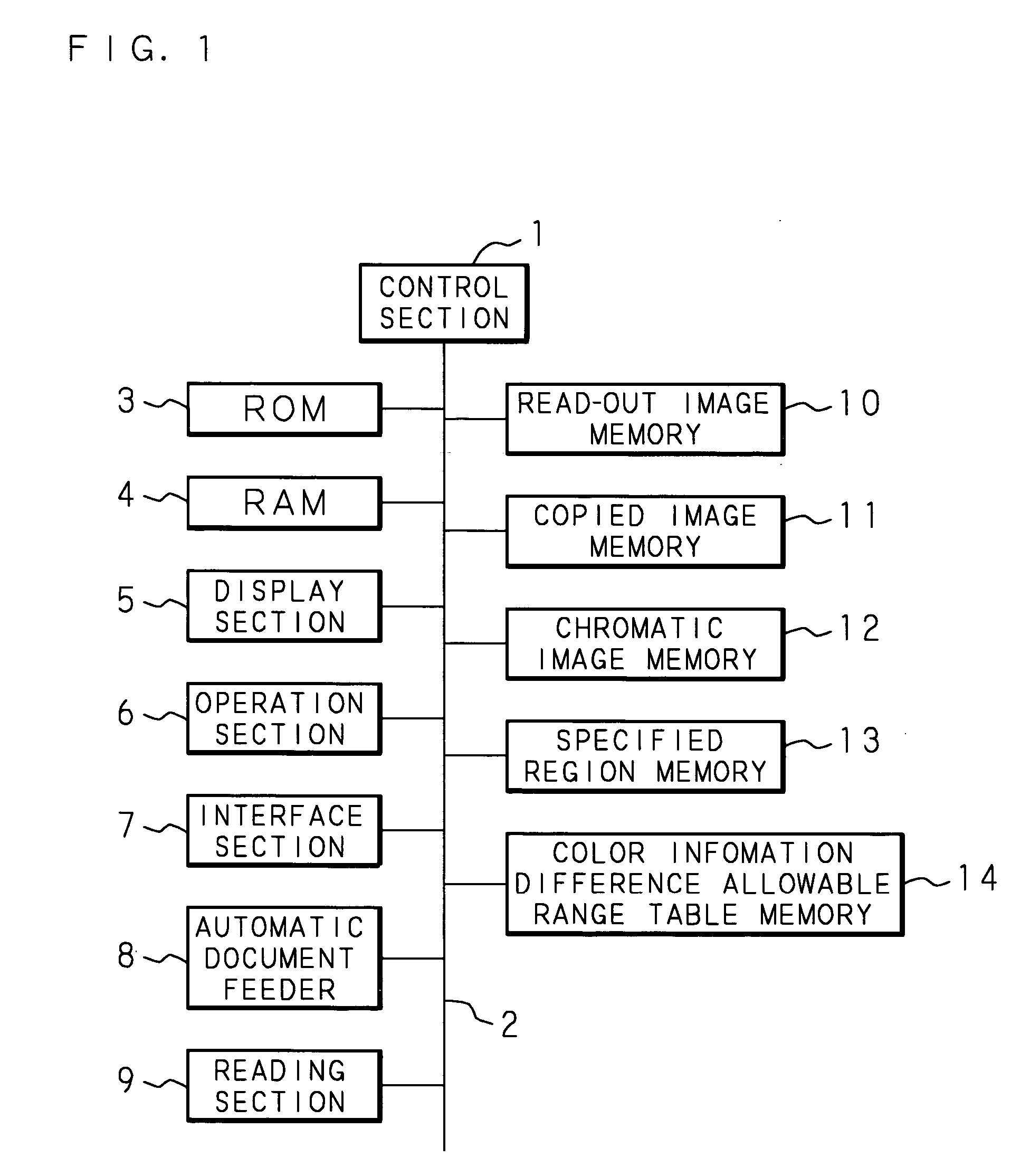

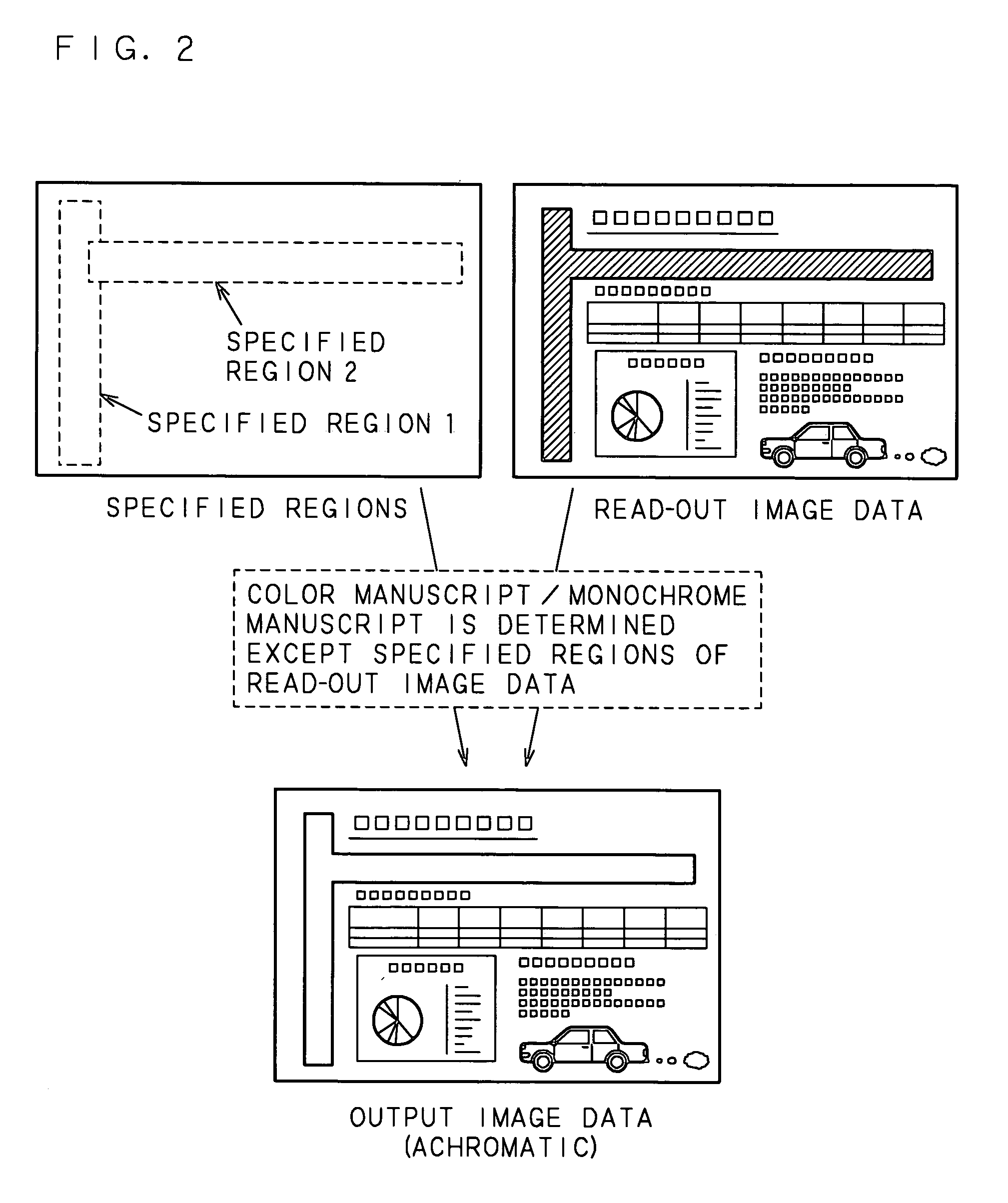

Image processing device, image formation device, and image processing method

InactiveUS20070024920A1Avoid difficult choicesEasy to operateNutsBoltsImaging processingImage formation

As for read-out image data of a manuscript, image regions not requiring color output are specified as specified regions 1 and 2. Then, it is determined whether the color information of the pixels of the read-out image data outside the specified regions 1 and 2 is achromatic. When it is determined as achromatic, the read-out manuscript is determined as a monochrome manuscript, so that processed image data in which chromatic pixels of the read-out image data in the specified regions 1 and 2 are converted into achromatic pixels is outputted as achromatic (monochrome) data. On the other hand, when it is determined as not achromatic, the read-out manuscript is determined as a color manuscript, so that the read-out image data is outputted intact as chromatic (color) data.

Owner:SHARP KK

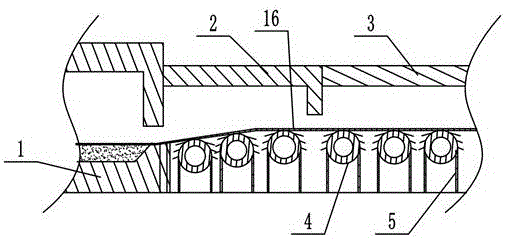

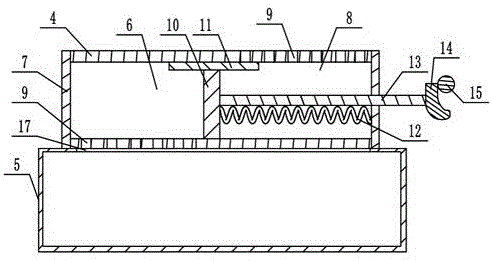

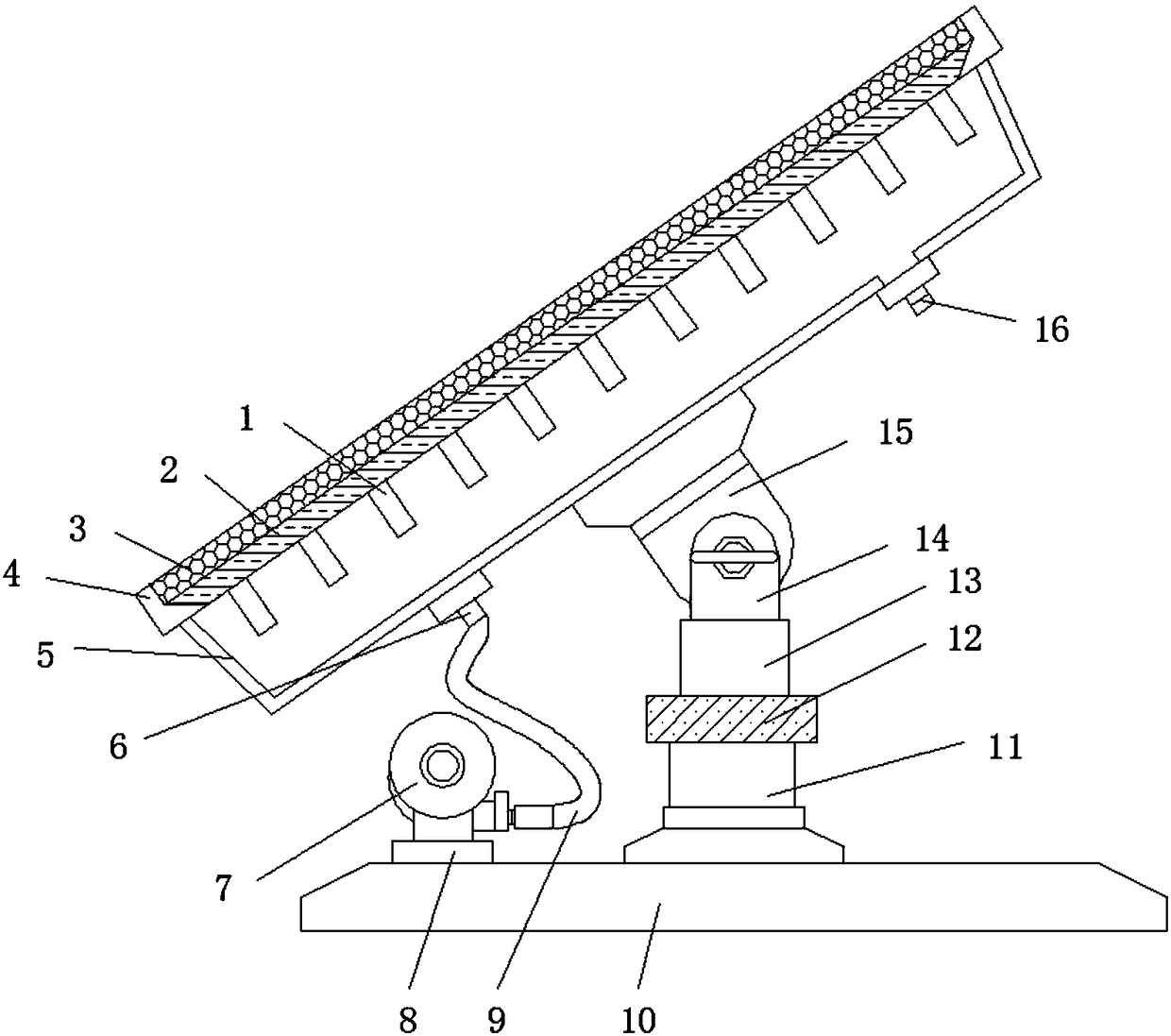

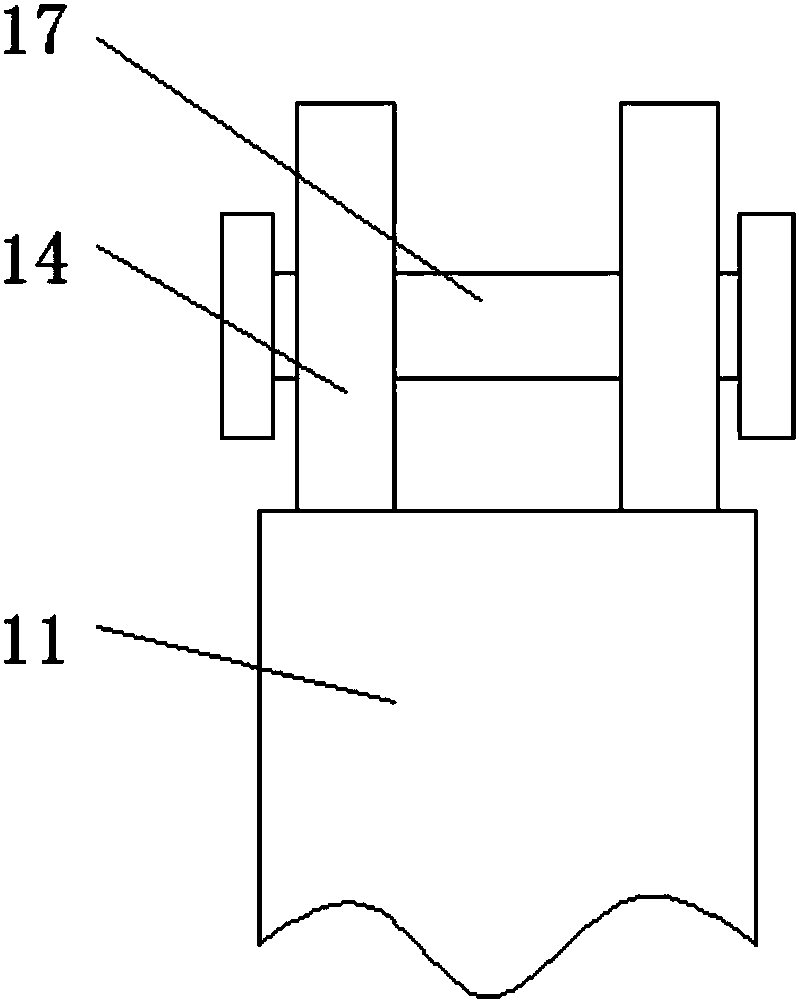

Scratch-proof float glass conveying device

ActiveCN106746577AHigh speedQuick contactGlass transportation apparatusCoatingsTectorial membraneCam

The invention belongs to the field of glass, and particularly discloses a scratch-proof float glass conveying device. The scratch-proof float glass conveying device comprises a transitional roller table and an annealing furnace which are successively connected to one side of a molten tin bath part, wherein a plurality of conveying rollers are arranged in each of the transitional roller table and the annealing furnace; the bottom sides of the conveying rollers are rotatably connected with a gas supply box; a supply opening is formed in the top of the gas supply box; each conveying roller is hollow; sealing plates are arranged at two ends of each conveying roller; an inner boss is arranged on the inner wall of each conveying roller; each inner boss is matched with a piston plate; a first compression cavity and a second compression cavity are formed by each piston plate and the corresponding conveying roller; air holes are formed in different ends of each first compression cavity and the corresponding second compression cavity; a spring is fixed between each piston plate and the sealing plate of the corresponding second compression cavity; a connecting rod is fixed at one end of each piston plate; one end, which is away from a piston of each connecting rod is statically connected with a cam; each cam comprises projections and pits; and one side of each cam is matched with an ejector rod. By the scheme, efficiency of forming a protecting film by SO2 gas and float glass can be improved, and pollution of SO2 gas to the environment can be reduced.

Owner:SHAHE ANQUAN IND CO LTD

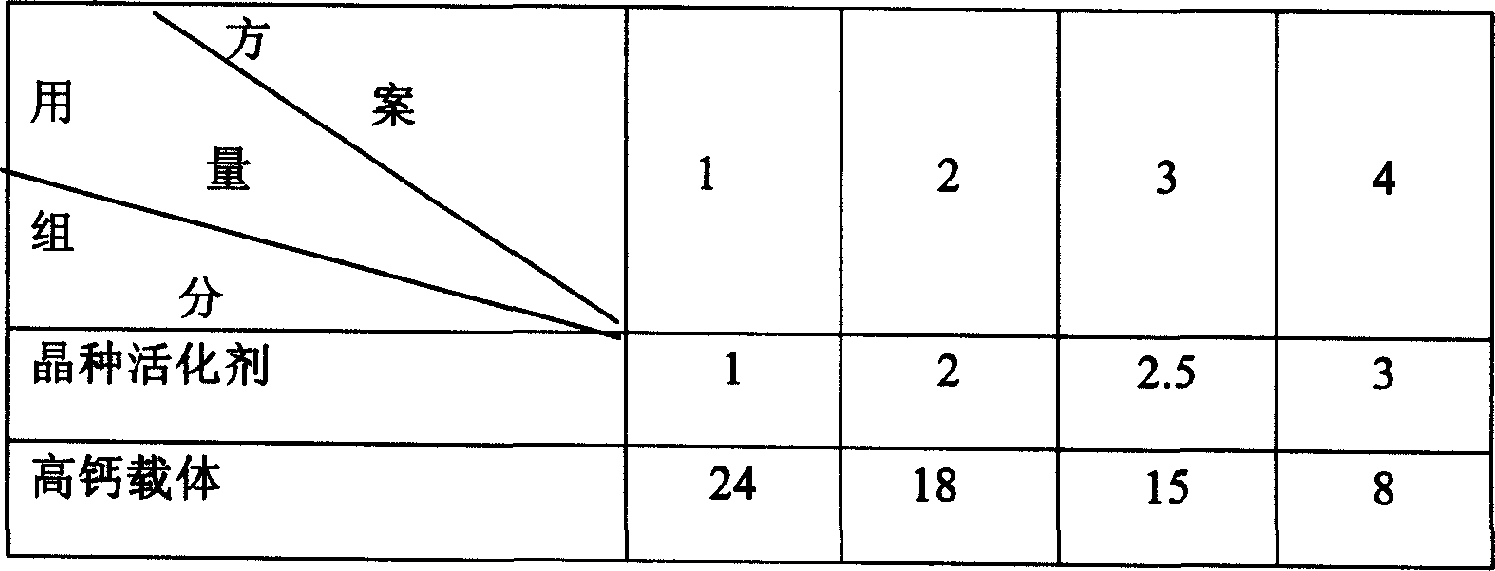

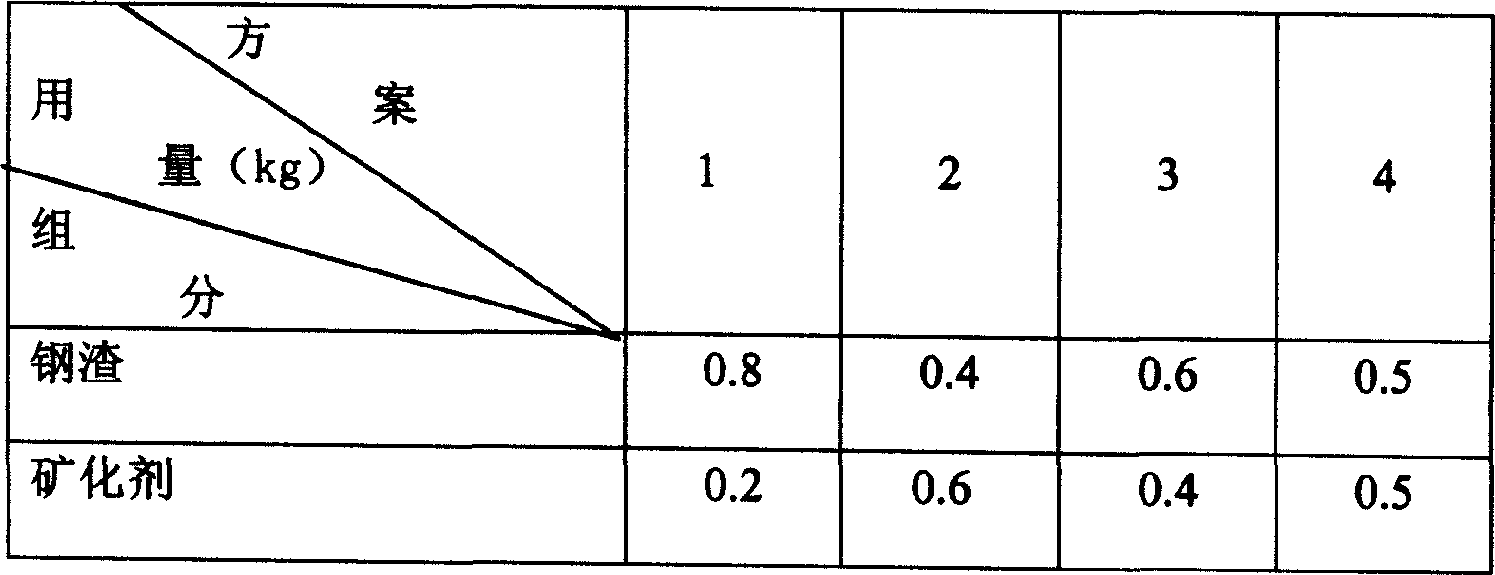

Highly active cement mineral forming promoter

The invention relates to high activity cement mineral forming accelerating agent applied to produce new type dry method cement. It is made up of seed crystal activating agent and high calcium carrier, and their proportioning by weight respectively are from one portion to three portion, and from eight portion to twenty four portion. The constituent and weight content of the seed crystal activating agent is from forty percent to eighty percent of the slag, the mineralizing agent is from twenty percent to sixty percent. The main effects of the accelerating agent supplied by the invention are that it obviously appear the seed crystal and mineralizing action, can greatly improve the raw material inflammability, reduce the fire temperature, broaden the fire range, increase the C3S content and activity of the clinker, so that increase the output and quality, as well as save resource and energy source, reduce the environment loading, and possess better economic and social benefit.

Owner:WUHAN UNIV OF TECH

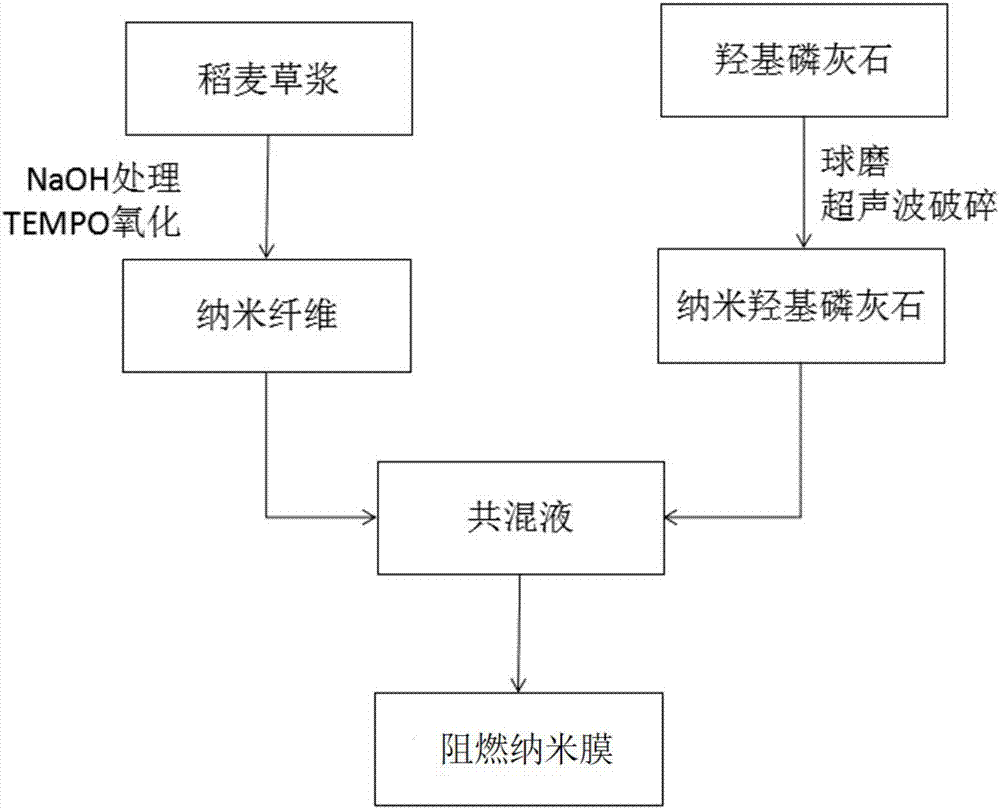

Flame-retardant nanometer film and preparation method and application thereof

ActiveCN107540857AIncrease the speed of formationIncrease char formationEmulsionBiocompatibility Testing

The invention belongs to the field of nanometer materials, and discloses a flame-retardant nanometer film and a preparation method and application thereof. The preparation method of the flame-retardant nanometer film comprises the steps that hydroxyapatite is dried and then subjected to ball milling, and after ultrasionic cell-break treatment is conducted for a period of time, nanometer hydroxyapatite emulsion is obtained; nanocellulose and nanometer hydroxyapatite are prepared into a blend solution according to certain proportion, film formation is conducted under the condition of constant temperature and humidity, and the flame-retardant nanometer film is obtained. The flame-retardant nanometer film has good flame retardance, the nanocellulose and the nanometer hydroxyapatite have the very good biocompatibility, and the flame-retardant nanometer film can be applied to the fields of flame-retardant materials, flexible electronic devices, biological and medical materials and the like.

Owner:SOUTH CHINA UNIV OF TECH

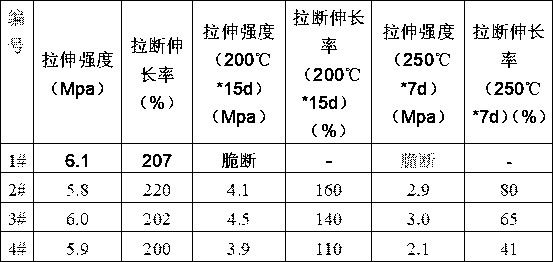

Preparation method of novel antioxidant for high-temperature rubber

InactiveCN109486199AIncrease the speed of formationImprove the ability to formN dimethylformamideAntioxidant

The invention discloses a preparation method of a novel antioxidant for high-temperature rubber. The preparation method comprises the following steps: dissolving zirconium tetrachloride and terephthalic acid, adding an acid solution, and pouring the solution into N,N-dimethylformamide; after dissolving, adding deionized water dissolved with a certain amount of citric acid and a certain amount of cetyl trimethyl ammonium bromide into the solution, uniformly mixing, transferring the solution into a high-pressure reaction kettle provided with a polytetrafluoroethylene liner, and crystallizing at120 DEG C; and after the reaction kettle is cooled to the room temperature, respectively repeatedly washing an obtained white colloidal product with an N,N-dimethylformamide solution and a methanol solution for several times, and carrying out reflux at 70 DEG C by virtue of methanol; and transferring the sample into a 100-DEG C constant temperature oven, and drying for one night, so as to obtain the antioxidant. The prepared novel antioxidant has the beneficial effects that the tensile strength and elongation at break after high-temperature thermo-oxidative aging are high, the heat resistanceis obviously increased, and the aging of silicone rubber is effectively inhibited.

Owner:中广核高新核材科技(苏州)有限公司

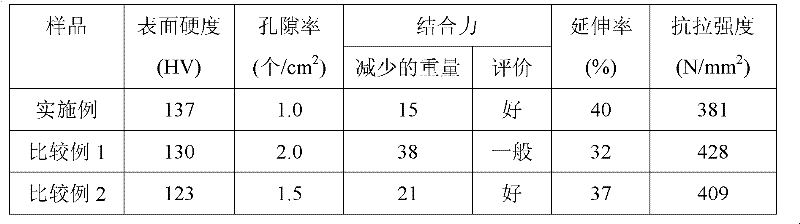

Method for performing pulse chromium plating based on trivalent chromium in sulfate system

The invention discloses a high-efficiency environment-friendly pulse plating metallurgy method for performing thick chromium plating based on trivalent chromium in a sulfate system. The method is characterized by comprising the following steps: dissolving rare earth oxides in an acid, so as to obtain a rare-earth salt solution; dissolving chromium sulfate salt, aluminum sulfate, boric acid, a complexing agent and methanol with water, and adding the rare-earth salt solution, so as to obtain a chromium sulfate salt-aluminum sulfate-boric acid-complexing agent-methanol-rare-earth salt plating solution; electroplating a to-be-plated plating piece into the electroplating solution; controlling the electroplating process conditions as follows: the distance between a pulse electroplating power supply and a plating tank is 2-3m, a wire refers to a multi-stranded core wire, and an anode refers to a Cu-matrix coating electrode plate; the current density of a connecting wire is 28-90A / dm<2> and needs to be far higher than the average current, the pH value of the electroplating solution is 2-4, the temperature refers to 25-60 DEG C, the stirring speed is 100-600rpm, the plating time refers to 30-90 minutes, the pulse frequency refers to 100-500Hz, and the duty ratio is 5-100 percent; and washing the plating piece subjected to complete electroplating, and airing. The method disclosed by the invention has the advantages of coating flatness and compactness, good adhesiveness, high current efficiency, high environmental friendliness and the like.

Owner:TIANJIN BINYONGSHENG ELECTRICAL LEAD TECH

Picea koraiensis tissue culture medium and culture method

PendingCN112470927AEffective trainingAvoid damageHorticulture methodsPlant tissue cultureBiotechnologyPicea koraiensis

The invention discloses a picea koraiensis tissue culture medium and a culture method. The method comprises the following steps: selecting picea koraiensis dormant buds, needles or tender stems as explants, and performing disinfection treatment; pretreating the explants before induction, and soaking the explants in an 8g / L NaCl solution for 3-5 minutes; performing callus tissue induction; performing proliferation of callus tissue; and inducing differentiation of buds. Based on the superiority of tissue culture, the method provided by the invention can solve the problems of low reproductive rate, low yield and the like of traditional manners of seed propagation, cutting propagation and the like to the greatest extent, and realizes the tissue culture of picea koraiensis; in addition, the success rate of taking dormant buds as the explants is the highest; and besides, the possibility of taking needles, tender stems and the like as the explants is also provided, so that the tissue cultureof the picea koraiensis is not only limited to picking the dormant buds in winter, but induction can still be performed by picking the needles and the tender stems in spring.

Owner:苏州梵时轮园艺科技有限公司

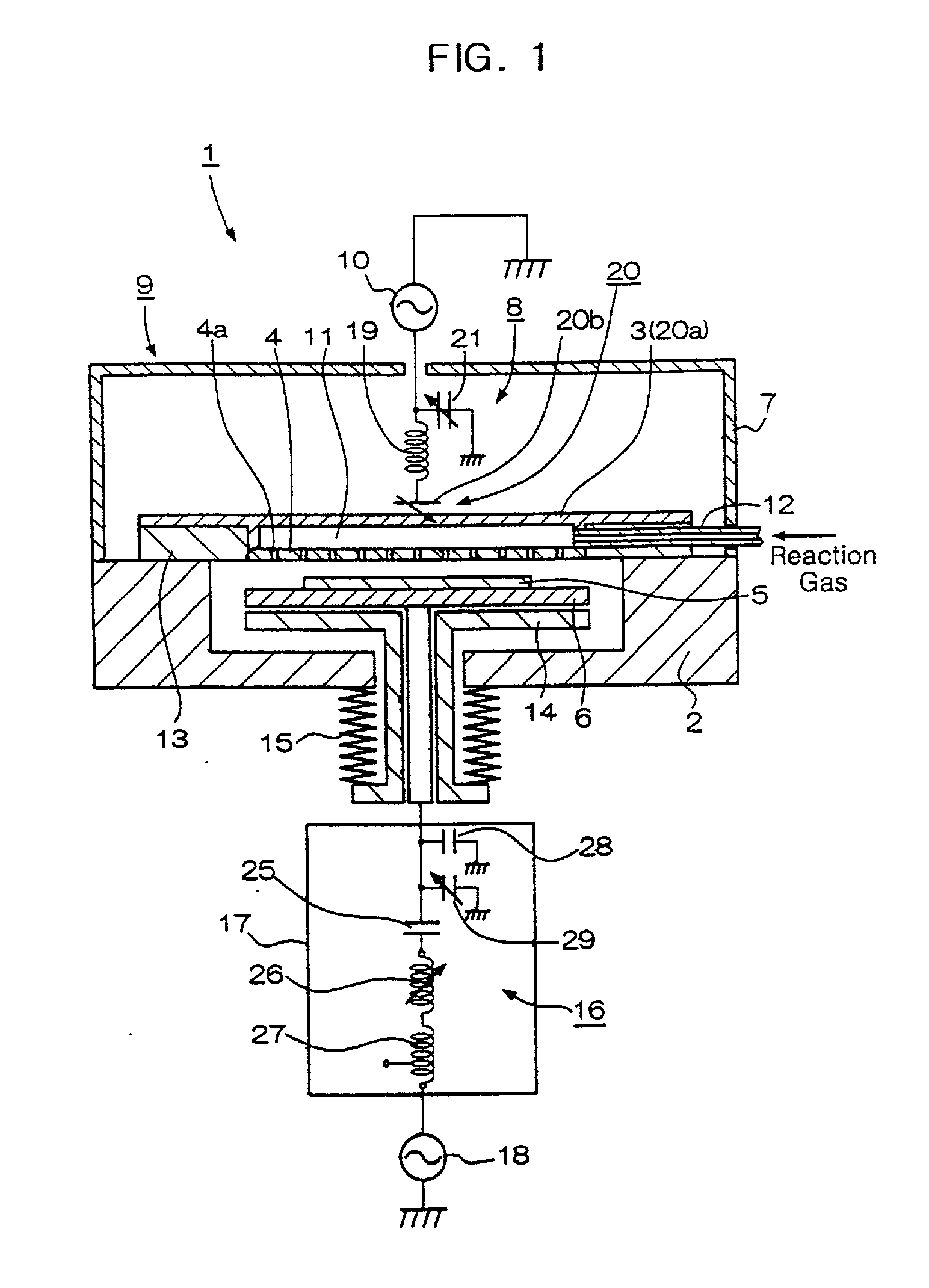

Method of forming silicon oxide layer and method of manufacturing thin film transistor thereby

InactiveUS20020019144A1Quality improvementReduce electric powerTransistorElectric discharge tubesSusceptorPresent method

The present method of forming a silicon oxide layer comprises providing two frequency excitation plasma CVD device which comprises a high frequency electrode, a susceptor electrode, and two matching box for impedance matching between the electrodes and a power supply, wherein one side electrode constituting a tuning condenser of a matching box toward the high frequency electrode is the high frequency electrode; placing a substrate on the susceptor electrode; applying high frequency electric power on the high frequency electrode and the susceptor electrode respectively; and forming a silicon oxide layer on the substrate by generating plasma with using a reaction gas of which main reaction gas is a mixing gas of monosilane and nitrous oxide.

Owner:LG DISPLAY CO LTD

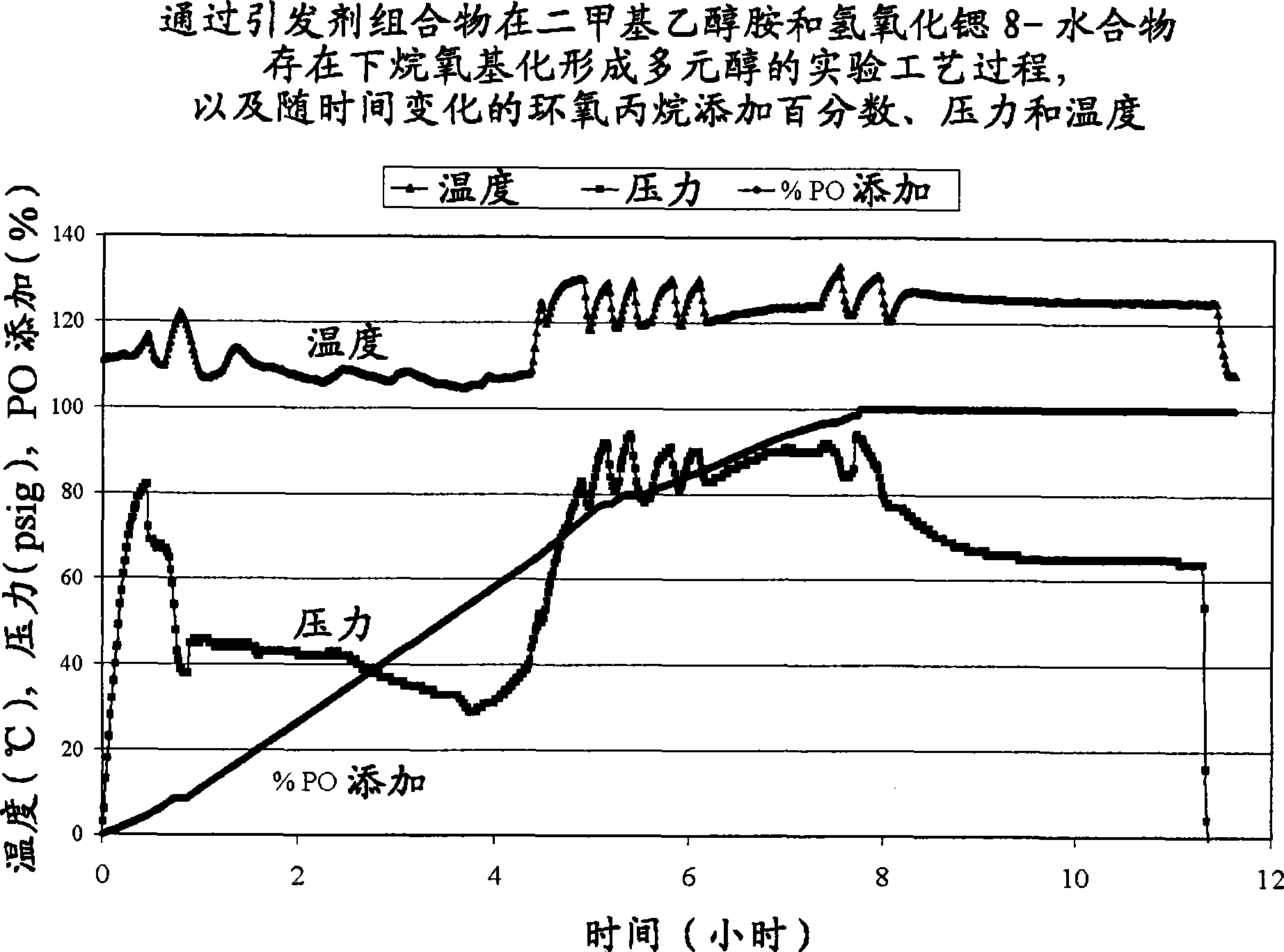

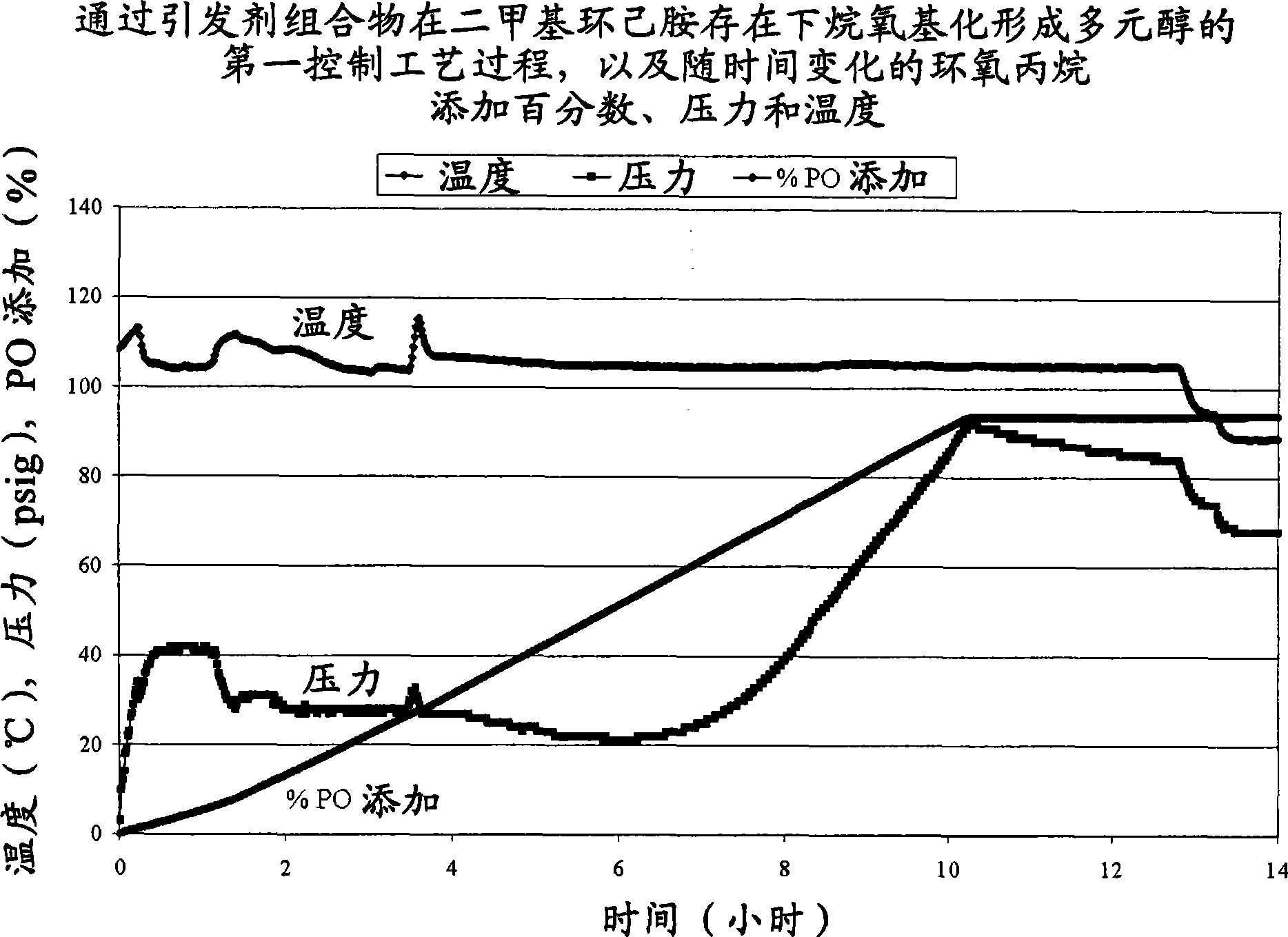

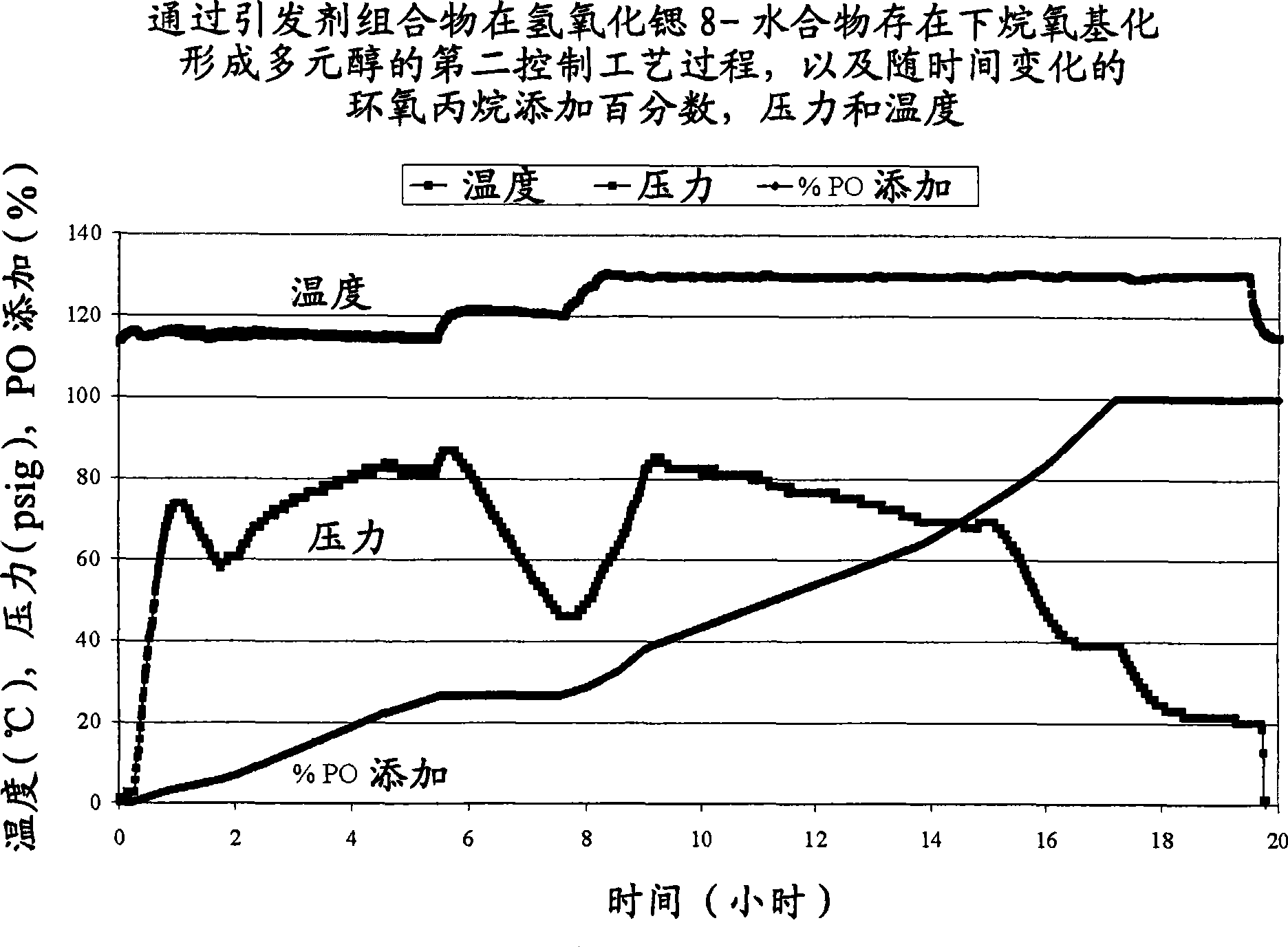

Process of forming a polyol

InactiveCN101389679AConsistent chain lengthIncrease the speed of formationSugar derivativesEther preparation from oxiranesPolyolAlkaline earth metal

A process of forming a polyol includes the steps of providing an alkylene oxide, providing an initiator composition having an average functionality of at least four, and providing an alkaline earth metal hydroxide and an amine. The process also includes the step of reacting the initiator composition and the alkylene oxide in the presence of the alkaline earth metal hydroxide and the amine to form the polyol. This allows the polyol to have consistent chain length and be formed with increased speed and in high yield, while reducing costs and maximizing efficiency. The polyol is reacted with an isocyanate and used to form a polyurethane article.

Owner:BASF SE

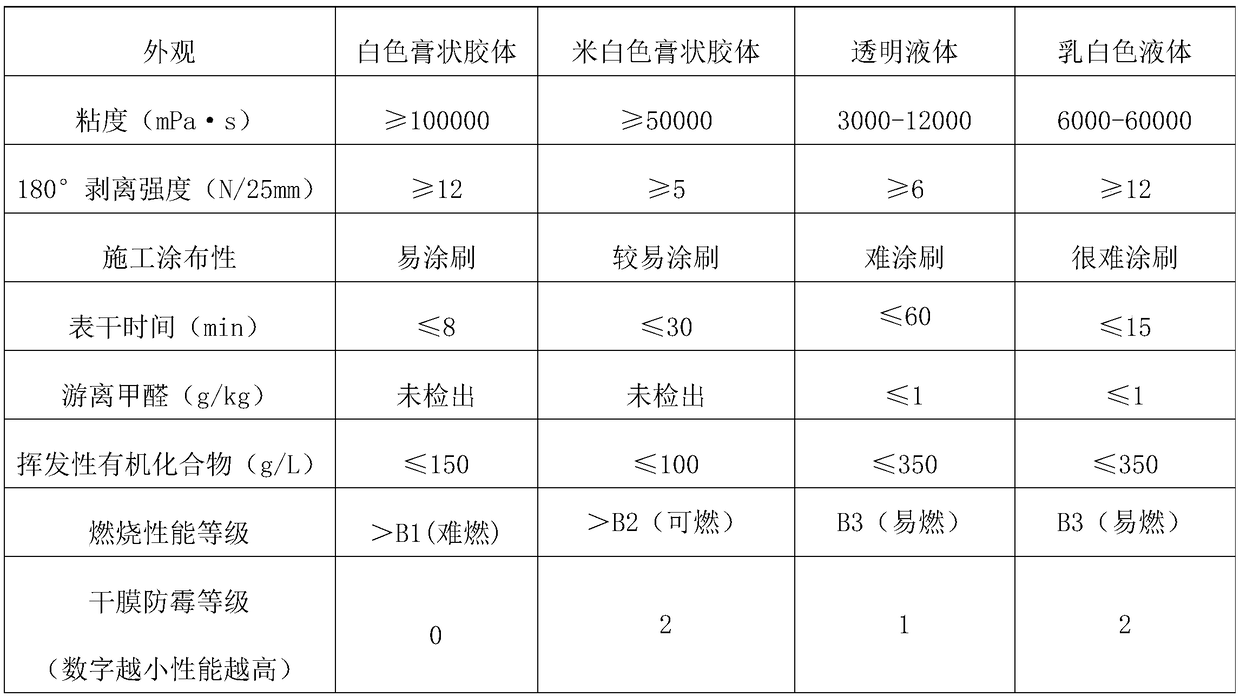

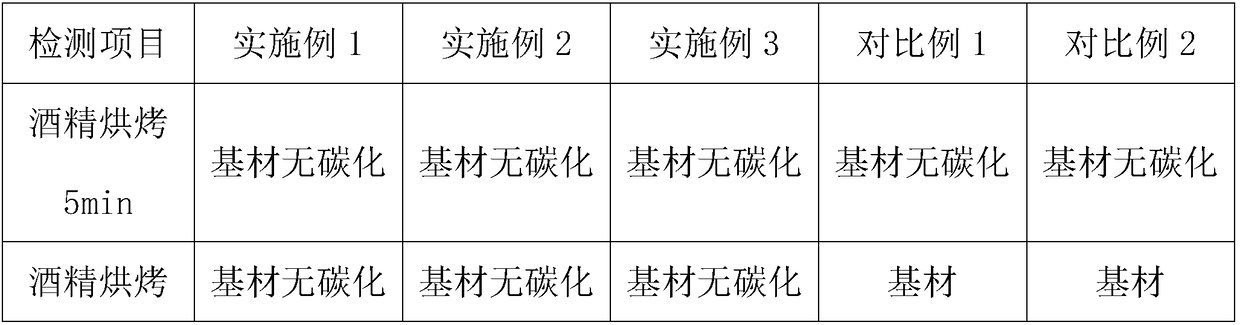

Starch-based adhesive with flame resistance function and preparation method thereof

ActiveCN109337608AReduce heat of burnPrevent the depth and spread of flamesNon-macromolecular adhesive additivesStarch adhesivesAmmonium polyphosphateChemistry

The invention discloses a starch-based adhesive with a flame resistance function. Through the organic combination of starch, kaolin and titanium dioxide, heat is firstly absorbed to form a flame retardant heat resistance residue carbon layer when the temperature is approximately risen to an ignition point, heat is continuously absorbed to form a ceramic-like coating layer, firing heat is reduced to prevent penetration and spreading of flame, the effect of quenching combustion reaction can be realized through the synergistic effect of crysticallized state ammonium polyphosphate, and the flame resistance performance of the adhesive is greatly improved through multipartite synergistic effect; adding of ultrahigh gel degree protein powder can obviously improve the density of the heat resistance residue carbon layer, and improving the formation speed and strength of the ceramic-like coating layer, thereby enhancing the flame retardant class. The adhesive is simple in production technology,obvious in flame resistance effect, safe, environmentally friendly, innocuous, harmless, easy for construction, fast to dry, and high in bonding strength, can be widely applied to bonding and construction of indoor house furnishing materials, and has a broad market application prospect.

Owner:GAREFU TECH CO LTD

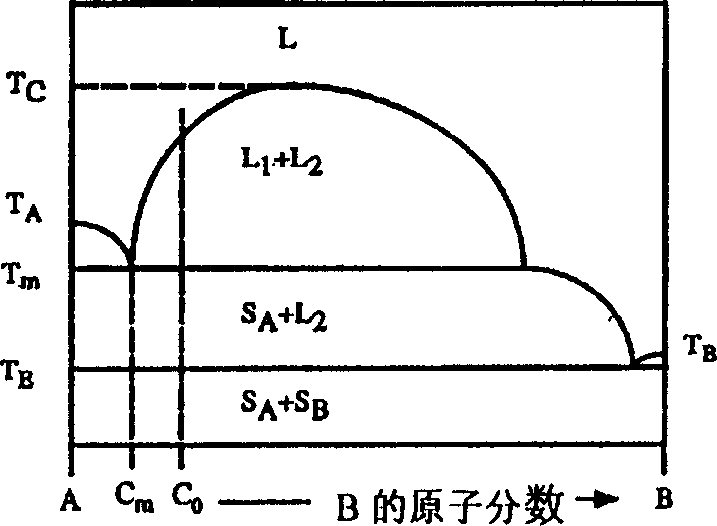

Continuous casting process of monotectic alloy sheet

The present invention relates to continuous casting technology of monotectic alloy, and is especially continuous casting process of monotectic alloy sheet. In a common continuous sheet casting apparatus, constant magnetic field of 0.3-1 tesla strength is applied to the cooling section and the crystallizing section. The constant magnetic field can increase the effective viscosity of alloy melt, retard the moving speed of dispersed phase liquid drop in liquid-liquid phase change temperature region in monotectic alloy, reduce the collision coalescence coursing speed of dispersed phase liquid drop and the separation speed of two liquid phase and decrease segregation of alloy, so that the said process of the present invention can obtain monotectic alloy with homogeneous dispersed phase particle distribution.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Composite high-efficiency solar hot wind generating device

InactiveCN108344184AWide range of applicationsImprove heat collection efficiencySolar heating energySolar heat collectors with working fluidsHeat sinkEngineering

The invention discloses a composite high-efficiency solar hot wind generating device. The composite high-efficiency solar hot wind generating device comprises a main body outer frame and a bottom plate, wherein a solar heat collecting plate is embedded on the upper surface of the main body outer frame, a heat conduction plate is laid on the back surface of the solar heat collecting plate, a radiating fin is welded on the back surface of the heat conduction plate, and a rear cover is clamped on the rear surface of the main body outer frame. An air inlet pipe is welded to one end of the surfaceof the rear cover, an air outlet pipe is welded to the other end of the surface of the rear cover, a regulator is welded to the center of the surface of the rear cover, a supporting rod is welded to the center of the upper surface of the bottom plate, and a bearing is welded on the upper portion of the supporting rod. The regulator on the surface of the rear cover in the composite high-efficiencysolar hot wind generating device is fixed on a vertical plate through a pin shaft, and the vertical plate is welded on a rotating shaft, so that the horizontal vertical angle of the rear cover can beadjusted through rotating the rotating shaft and the regulator, so as to adjust the horizontal vertical angle of the solar heat collecting plate, so that the composite high-efficiency solar hot wind generating device has wider application range and higher heat collecting efficiency.

Owner:郑州仟嘉安环保科技有限公司

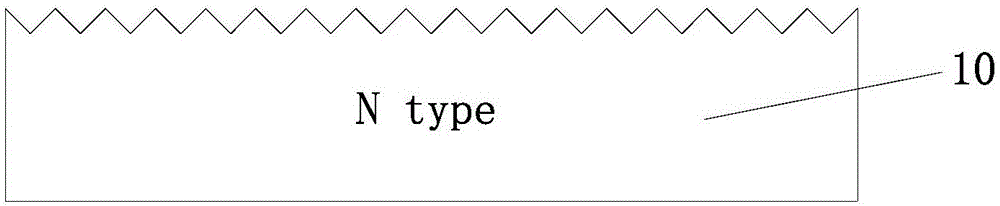

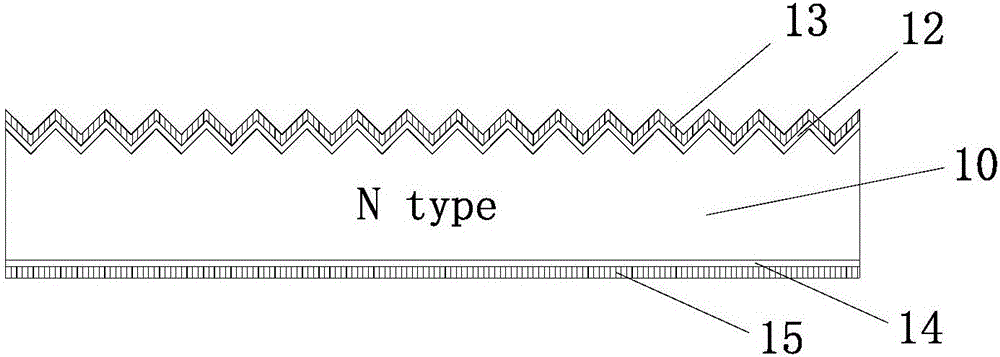

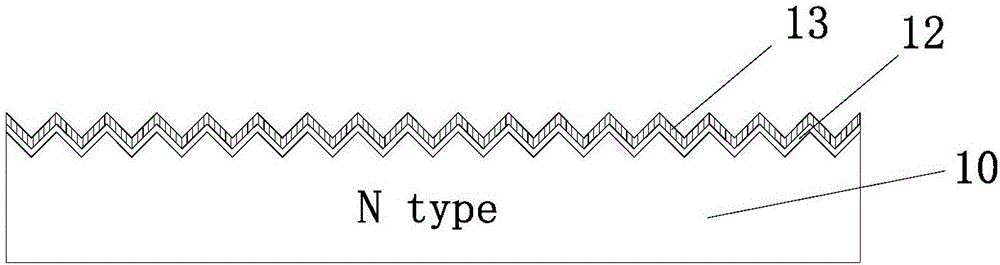

Preparation method of N-type crystalline silicon cell, cell thereof, battery and system

InactiveCN106653937ASimple preparation processIncrease the speed of formationFinal product manufacturePhotovoltaic energy generationDiffusion methodsCell fabrication

The present invention relates to a preparation method of an N-type crystalline silicon cell, a cell thereof, a battery and a system. The preparation method of the N-type crystalline silicon cell comprises the following steps of texturing, conducting the boron diffusion operation on the front surface to form a borosilicate glass layer, conducting the etching and boron diffusion operation on the back surface, enabling edge isolation, cleaning, plating a film, printing and sintering. The invention has the following beneficial effects: through adjusting the process parameters of boron diffusion, the borosilicate glass layer formed through boron diffusion has the ability of preventing the phosphorous diffusion, so that a simple N-type crystalline silicon cell fabrication process is developed; the process is simple, controllable, low in equipment investment; based on the diffusion method, formed PN junctions are less in pollution and better in quality compared with PN junctions formed through the boron- source spin coating process or the screen printing process; the diffusion coefficient of boron in silicon dioxide is higher than that of silicon, so that a thick borosilicate glass layer facilitates the reduction of the boron concentration on the surface of a p + region so as to reduce the surface recombination and improve the open-circuit voltage. The prepared N-type crystalline silicon cell is higher in open-circuit voltage and better in photoelectric conversion efficiency.

Owner:TAIZHOU ZHONGLAI PHOTOELECTRIC TECH CO LTD

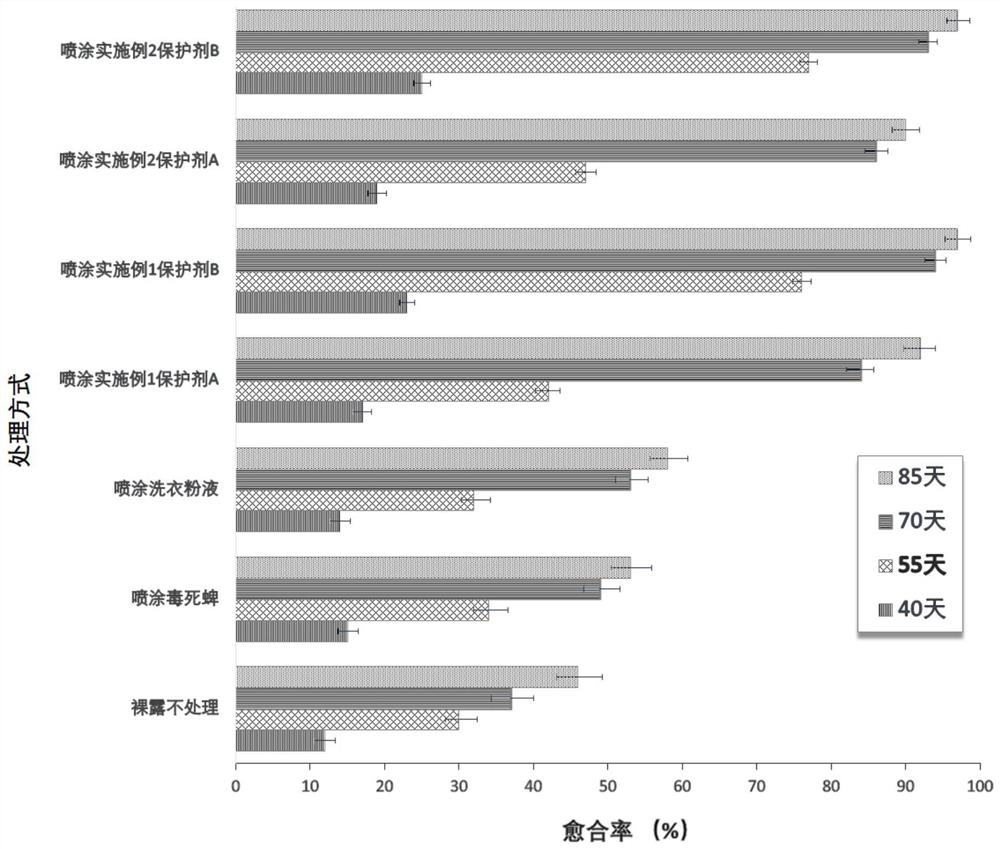

Winter jujube tree cutting opening protection agent and preparation method thereof

InactiveCN113508811ARaw materials are easy to getLow costBiocidePlant growth regulatorsAgricultural scienceAgricultural engineering

Owner:滨州市红苹果景观工程有限公司 +1

Phosphatized cold-rolled strip steel and manufacturing method thereof

ActiveCN109943777AGuaranteed cleanlinessSolve the problem that incomplete degreasing and cleaning affect the phosphating effectFurnace typesMetallic material coating processesChemical compositionStrip steel

The invention provides a phosphatized cold-rolled strip steel and a manufacturing method thereof. The phosphatized cold-rolled strip steel is composed of, by mass: 0.01-0.10% of C, 0.1-0.6% of Mn, less than or equal to 0.10% of Si, less than or equal to 0.10% of Al, less than or equal to 0.02% of P, less than or equal to 0.015% of S, and the balance Fe and impurity elements. Phosphating treatmentequipment is additionally arranged between a leveling straightening machine and an oiling machine of a continuous annealing unit; the phosphating treatment equipment consists of a phosphating section,a rinsing section and a drying box; after the strip steel is uncoiled, the strip steel enters a phosphating treatment area after being subjected to conventional treatment such as welding, cleaning, annealing, flattening and tension straightening; and the strip steel after the phosphating treatment is directly coiled into a coil without oiling. According to production of the cold-rolled phosphatized coil, the production process of the client side is simplified, the efficiency is improved, the phosphating quality is improved, and the problem that the phosphating effect is influenced due to unthorough degreasing and cleaning of the client terminal is solved.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

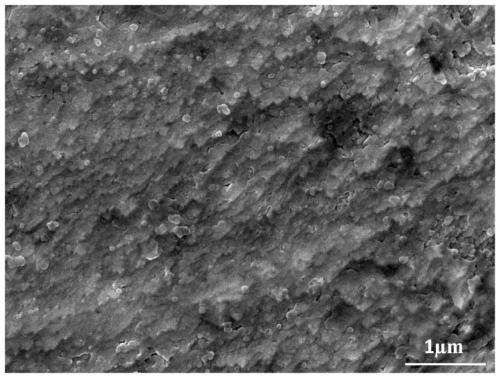

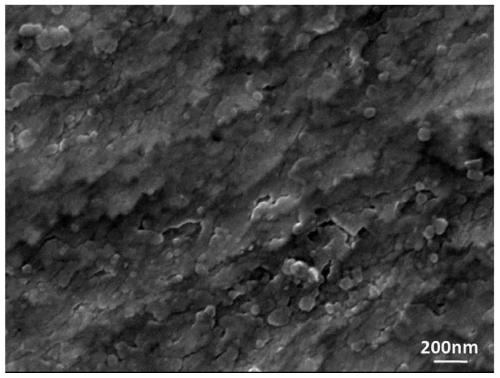

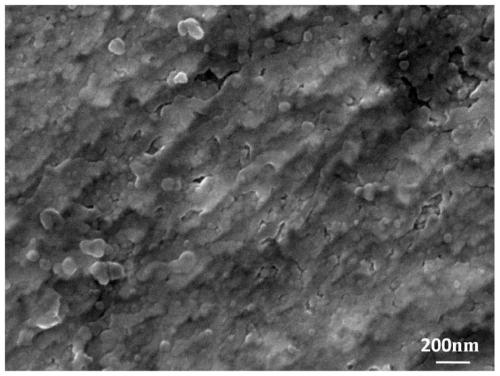

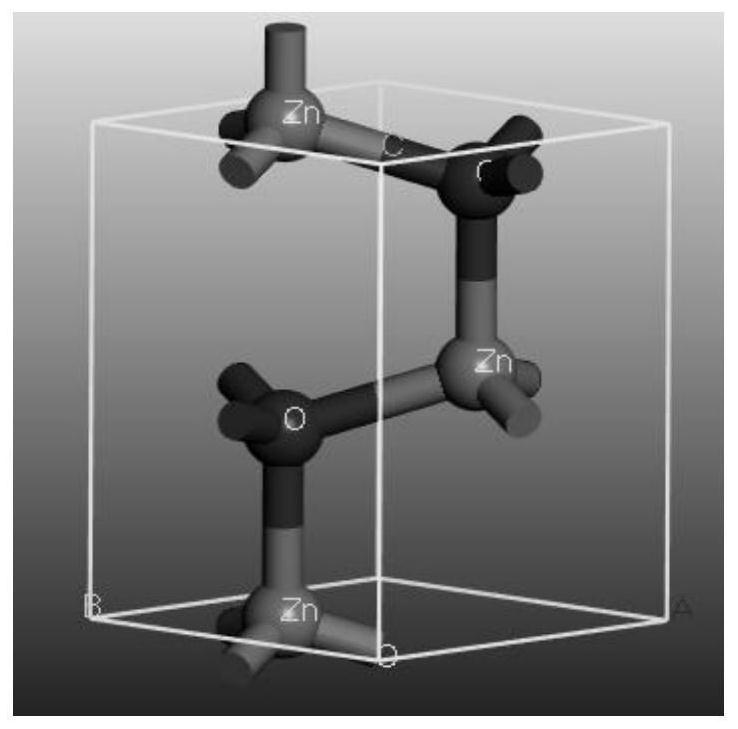

Zinc oxide resistive random access memory performance optimization method based on different vacancy concentrations

PendingCN113656950AIncrease storage capacityIncrease the speed of formationDesign optimisation/simulationSpecial data processing applicationsEngineeringMaterials science

The invention discloses a zinc oxide resistive random access memory performance optimization method based on different vacancy concentrations. The method specifically comprises the following steps: taking a resistive layer as a research object of a zinc oxide resistive random access memory; constructing a ZnO single cell model by adopting a first principle calculation method based on a density functional theory; on the basis, expanding the ZnO single cell model towards the A direction, the B direction and the C direction to obtain a 3 * 2 * 2 ZnO super cell model and a 2 * 2 * 1 ZnO super cell model; constructing a vacancy defect state on the supercell model to obtain five zinc oxide resistive layer models; based on a first principle method, reducing the energy of five zinc oxide resistive layer model systems to the minimum, and enabling the structure to be optimal, so that the performance optimization of the zinc oxide resistive random access memory is realized. According to the invention, the energy state structure of the zinc oxide resistive random access memory is researched to determine the optimal vacancy concentration of the resistive random layer, so that the formation speed of the conductive filament can be effectively increased, and the storage performance of the resistive random access memory is improved.

Owner:XIAN UNIV OF TECH

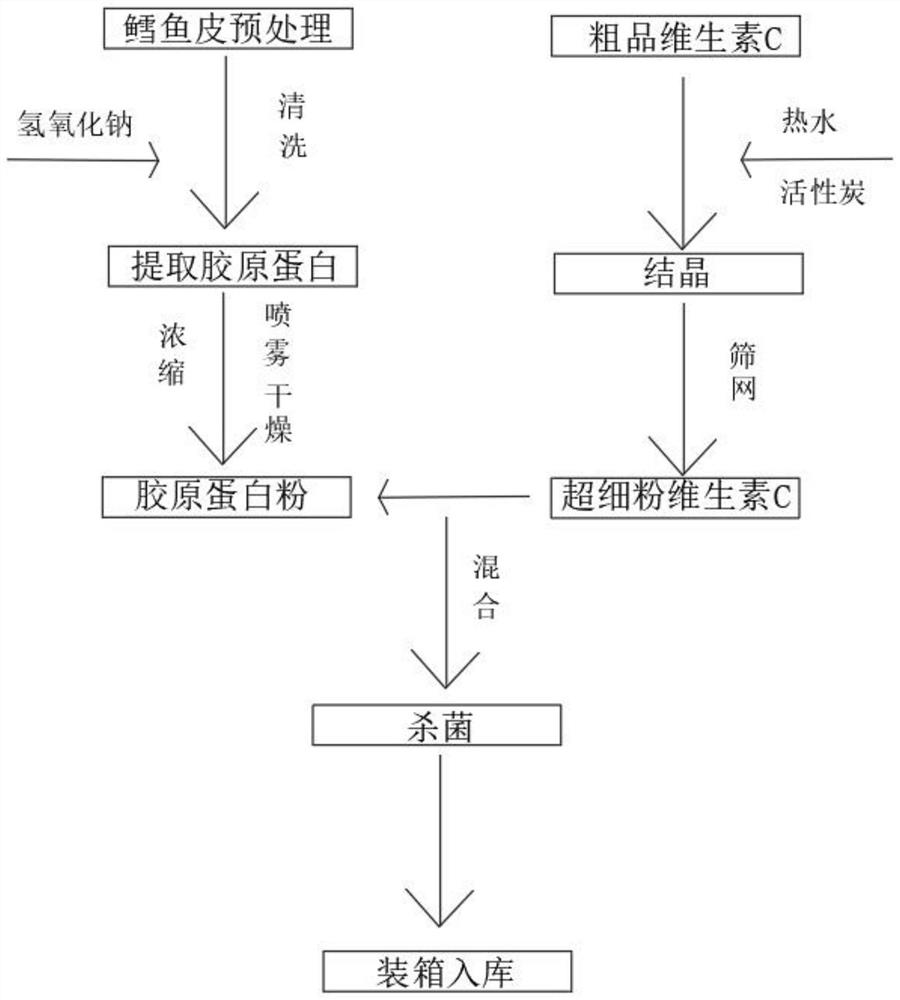

Cod small-molecular collagen peptide vitamin C powder

PendingCN112715959AHigh purityStable structureProtein composition from fishConnective tissue peptidesVitamin CCollagenan

The invention provides cod small-molecular collagen peptide vitamin C powder, which relates to the technical field of medical cosmetology, and comprises the following steps: Sp1, selecting cod skin as a raw material, and pretreating the cod skin to remove impure proteins and pigments in the cod skin; Sp2,degreasing the pretreated cod skin and removing pigment on skin; Sp3, extracting collagen in the cod skin through an acid enzyme method; Sp4, performing steps of concentration, spray drying and granulation treatment on the collagen; Sp5, preparing vitamin C ultrafine powder from the crude vitamin C; and Sp6, fully mixing the collagen particles with the vitamin C powder. The collagen polypeptide product has the advantages that the preparation process is simplified, the polypeptide yield is high, and the purity is improved. Compared with mammals, the cod skin collagen is stable in structure and high in natural activity, the cod skin is more suitable for being used as a raw material for collagen egg extraction, and the production cost is reduced.

Owner:海南省暨研抗衰老研发集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com