Preparation method of novel antioxidant for high-temperature rubber

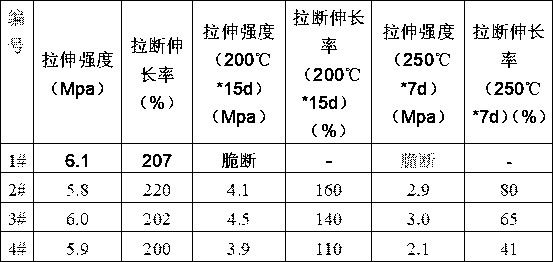

An antioxidant and high-temperature technology, which is applied in the field of preparation of new high-temperature rubber antioxidants, can solve the problems of weakening the effect of alkylated diphenylamine, compatibility and adverse effects of volatility, and achieve tensile strength and fracture High elongation retention rate, shorten synthesis time, improve formation speed and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: a kind of preparation method of novel high temperature rubber antioxidant, comprises the following steps:

[0043] Step 1. Add 5mmol ZrCL4, 5mmol terephthalic acid, 0.8ml concentrated HCL (37%) to 30mLN , In N-dimethylformamide;

[0044] Step 2. After dissolving, add 5mL of deionized water dissolved with a certain amount of CA (citric acid) and CTAB (cetyltrimethylammonium bromide) into the above solution, mix well and transfer to a tank equipped with PTFE. Crystallize at 120°C for 24 hours in an ethylene-lined autoclave;

[0045] Step 3, after the reaction kettle is cooled to room temperature, the white colloidal product obtained is sprayed with N , N-dimethylformamide solution and methanol solution were washed three times respectively, and then refluxed with methanol at 70° C. for 4 h;

[0046] Step 4. Transfer the sample to a constant temperature oven and dry it overnight.

Embodiment 2

[0047] Embodiment 2: a kind of preparation method of novel high-temperature rubber antioxidant, comprises the following steps:

[0048] Step 1. Add 10mmol ZrCL4, 10mmol terephthalic acid, 1.6ml concentrated HCL (37%) to 30mLN , In N-dimethylformamide;

[0049] Step 2. After dissolving, add 5mL of deionized water dissolved with a certain amount of CA (citric acid) and CTAB (cetyltrimethylammonium bromide) into the above solution, mix well and transfer to a tank equipped with PTFE. Crystallize at 120°C for 24 hours in an ethylene-lined autoclave;

[0050] Step 3, after the reaction kettle is cooled to room temperature, the white colloidal product obtained is sprayed with N , N-dimethylformamide solution and methanol solution were washed three times respectively, and then refluxed with methanol at 70° C. for 4 h;

[0051] Step 4. Transfer the sample to a constant temperature oven and dry it overnight.

Embodiment 3

[0052] Embodiment 3: a kind of preparation method of novel high temperature rubber antioxidant, comprises the following steps:

[0053] Step 1. Add 5mmol ZrCL4, 5mmol terephthalic acid, 0.8ml concentrated HCL (37%) to 30mLN , In N-dimethylformamide;

[0054] Step 2. After dissolving, add 10mL of deionized water dissolved with a certain amount of CA (citric acid) and CTAB (cetyltrimethylammonium bromide) into the above solution, mix evenly and transfer to a tank equipped with PTFE. Crystallize at 120°C for 24 hours in an ethylene-lined autoclave;

[0055] Step 3, after the reaction kettle is cooled to room temperature, the white colloidal product obtained is sprayed with N , N-dimethylformamide solution and methanol solution were washed three times respectively, and then refluxed with methanol at 70° C. for 4 h;

[0056] Step 4. Transfer the sample to a constant temperature oven and dry it overnight.

[0057] The TGA spectra of the novel antioxidants for high-temperature ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com