Patents

Literature

277 results about "C constant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A C constant is usually just the written version of a number. For example 1, 0, 5.73, 12.5e9. We can specify our constants in octal or hexadecimal, or force them to be treated as long integers.

Method for preparing VOCs catalytic combustion catalyst

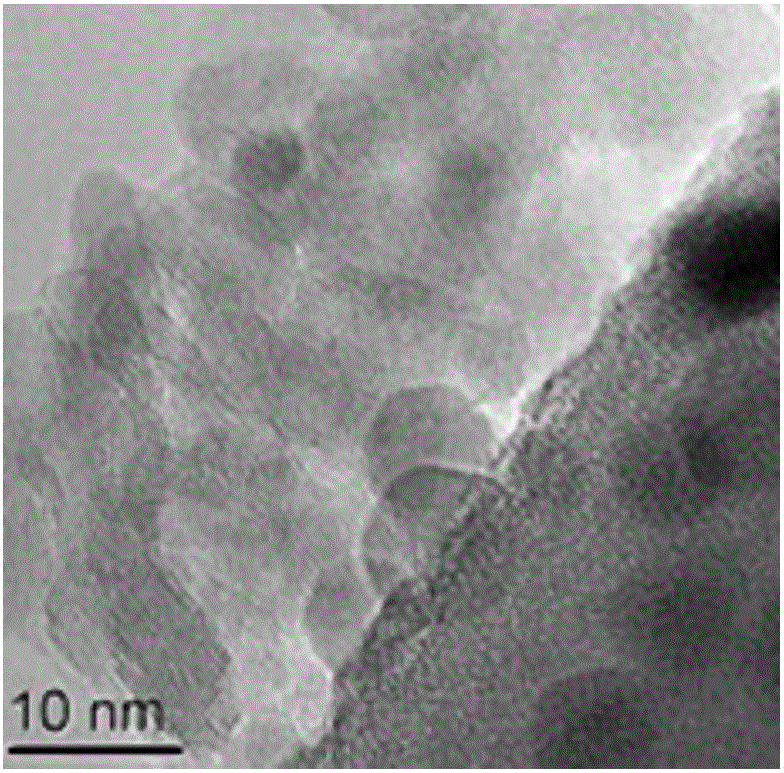

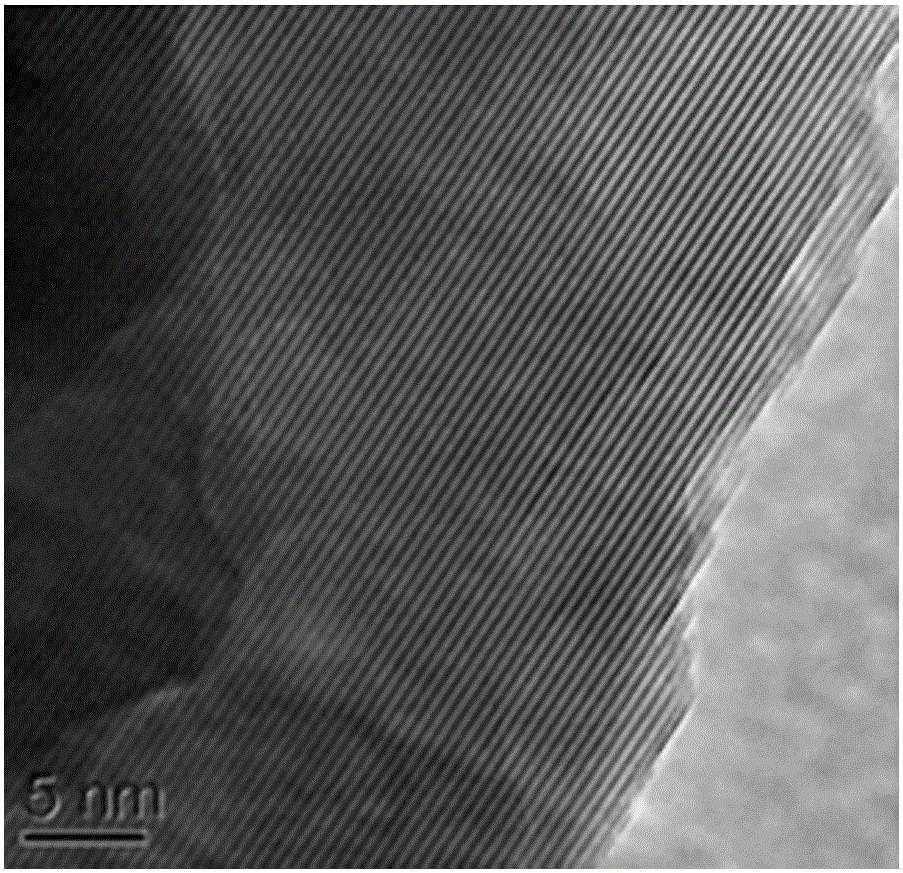

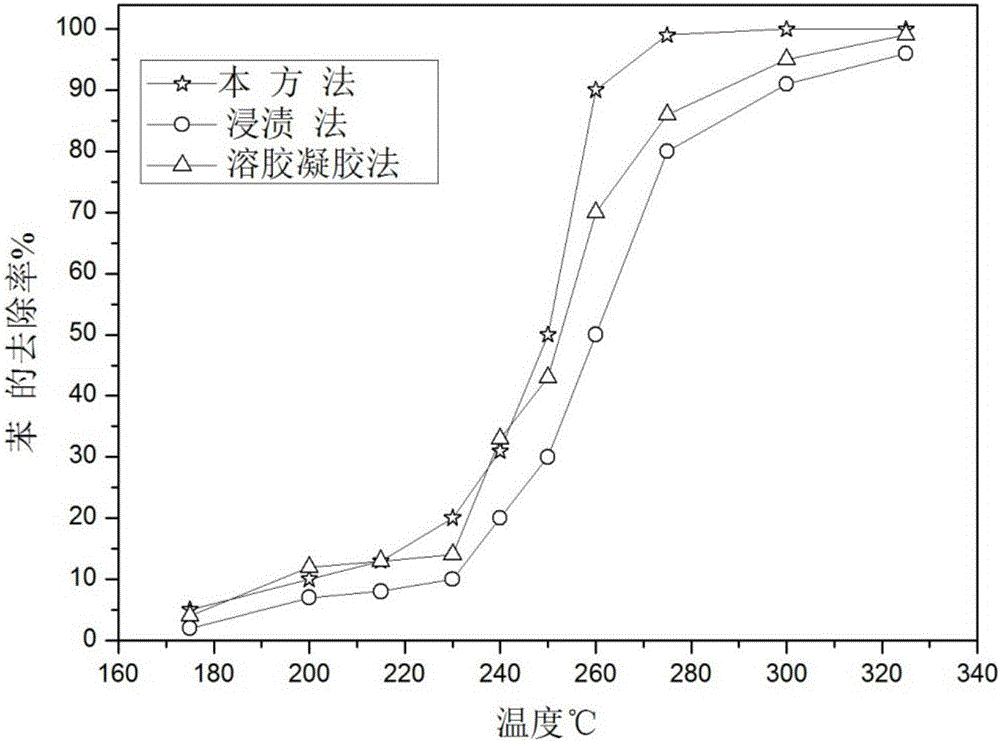

ActiveCN106064087AIncrease loadEvenly distributedMolecular sieve catalystsHeterogenous catalyst chemical elementsCarboxylic acidIon

A method for preparing a VOCs catalytic combustion catalyst comprises the following steps: preparing a solution A containing at least one metal compound, preparing a solution B contain organic ligand, adding the solution B to the solution A, and stirring the solution B and the solution A to obtain a mixed solution, wherein the organic ligand is at least one of carboxylic acid or imidazole organic matters; putting a carrier in the mixed solution, and carrying out 50-200DEG C constant temperature impregnation for 2-8h to obtain an MOF / carrier material; preparing a solution C containing at least one metal compound, and loading the treated MOF / carrier material in the solution C to carry out loading; ageing the above prepared material for 12h, drying the aged material at 60-100DEG C for 3-5h, and roasting the dried material in 500-800DEG C air for 4-8h; and washing the roasted material with distilled water or deionized water, and drying the washed material at 60-110DEG C for 8-24h to obtain the metal oxide catalyst.

Owner:南京朗科环保科技有限公司

Catalyst for hydrolyzing carbonyl sulfur and preparation method thereof

InactiveCN101559379AWide concentration rangeHigh desulfurization precisionDispersed particle separationCatalyst activation/preparationMass ratioHydrolysis

The invention discloses a catalyst for hydrolyzing active carbon-based COS under the condition of low temperature and a preparation method thereof, wherein a carrier of the catalyst is active carbon, and active compositions of the catalyst are alkali materials and metal oxide. The catalyst can remove COS in air at a low temperature (between 30 and 100 DEG C) and remove H2S generated by hydrolysis together. The preparation method comprises the following steps: firstly, using running water and distilled water to wash the active carbon, and drying the active carbon for 2 to 4 hours at a temperature of between 110 and 180 DEG C, wherein the active carbon can be coal and coconut husks; secondly, using a 1 mol / L KOH solution to boil the washed active carbon for 1.5 to 2 hours, performing modification treatment, and using distilled water to wash the solution until the pH value is approximately 6.0; thirdly, selecting one or more metallic salt solutions to soak the active carbon, performing modification treatment, and performing ultrasonic soakage for 0.5 to 1 hour, wherein the content of a soaking liquid is 10 to 90 percent of the mass ratio of the active carbon, and the volume of the soaking liquid is as follows: 20 milliliters of the soaking liquid is added into 10 grams of the catalyst; fourthly, drying the soaked active carbon for 2 to 6 hours in a 120 DEG C constant-temperature drying cabinet, and activating the catalyst for 2 to 4 hours under the protection of 300 to 600 DEG C N2; and fifthly, performing ultrasonic soakage on the activated catalyst in the fourth step in an alkali solution for 0.5 to 1 hour.

Owner:KUNMING UNIV OF SCI & TECH

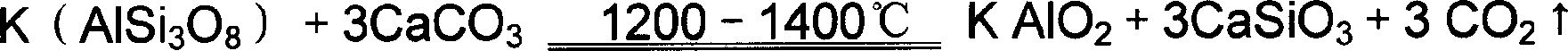

Method for preparing potash manure (kali salt) from potassium-rich rock using hydrothermal chemical reaction

InactiveCN1508092AHigh potassium dissolution rateSimplified separation and purification processAlkali metal carbonatesAlkali metal sulfites/sulfatesChemical reactionLiquid ratio

The method for preparing potash fertilizer (kaili salt) by using potassium-rich rock through the process of hydrothermal chemical reaction is characterized by that its adopted alkaline raw material can be lime or light-burned magnesia or dolomite lime and gypsum, and said method includes the following steps: coarse-crushing and medium crushing the above-mentioned raw materials to below 3 mm; according to the ratio of that potassium-rich rock; lime or light-burned magnesia or dolomite lime; gypsum is 1:0.8-1:0.2-0.25 feeding the above-mentioned raw materials into vibration grinding machine and grinding them to below 200 meshes, uniformly mixing them, conveying obtained mixture material into storage tank device, adding water, regulating solid-liquid ratio to 1:1-3, stirring and mixing, transferring said material into high-pressure reactor, introducing high-pressure steam, making hydrothermal reaction at 130-250 deg.C constant temperature for 5-24 hr. so as to obtain the invented prdouct.

Owner:ZHONGKE JIANCHENG MINERAL TECH BEIJING

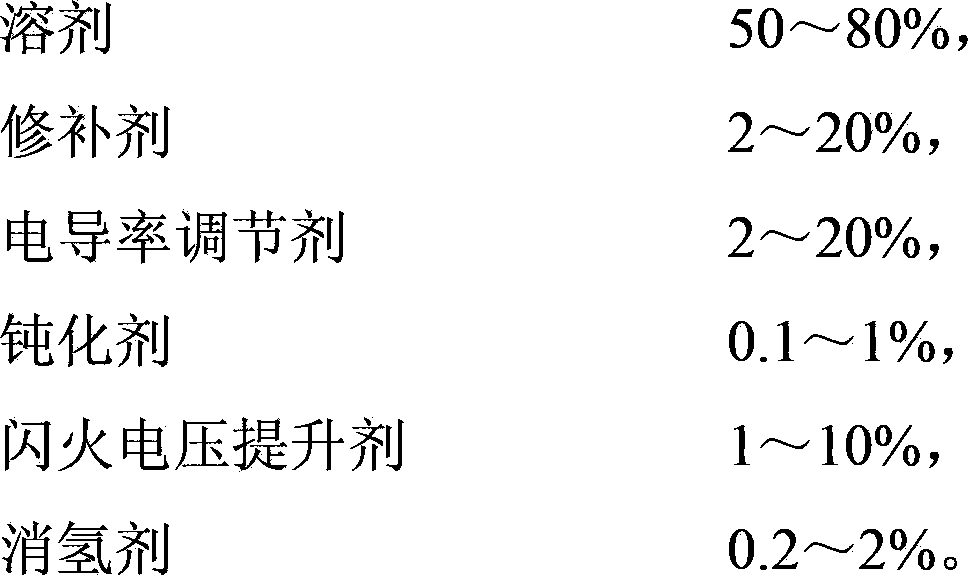

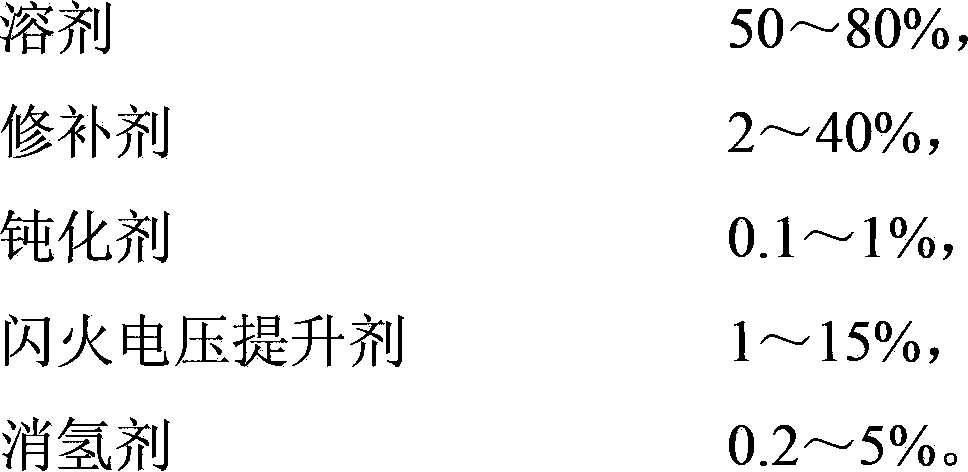

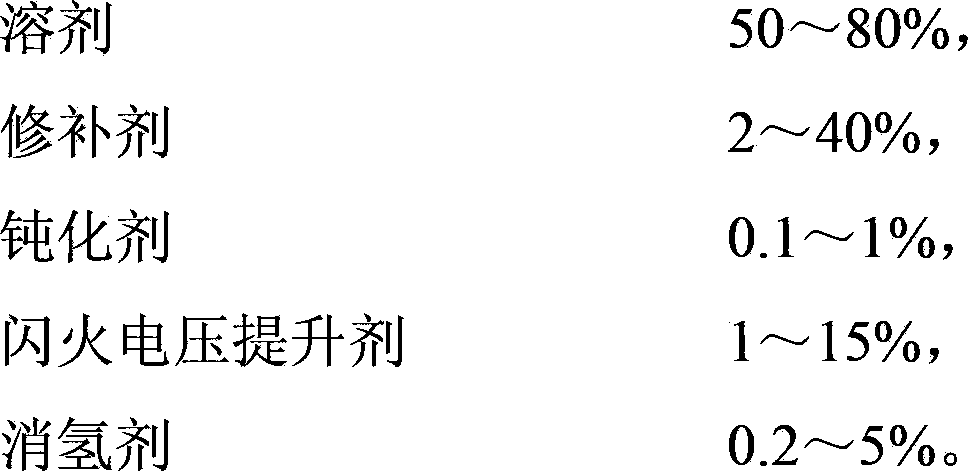

High-conductivity boron series-free working electrolyte and preparation method thereof

ActiveCN103632851AImprove conductivityImprove the ability to repair the oxide film of aluminum foilElectrolytic capacitorsHydrogenC constant

The invention discloses a high-conductivity boron series-free working electrolyte and a preparation method thereof. The electrolyte comprises, by weight, 50% to 80% of a solvent, 2% to 20% of a healant, 2% to 20% of a conductivity conditioning agent, 0.1% to 1% of a passivator, 1% to 10% of a spark voltage improving agent, and 0.2% to 2% of a hydrogen elimination agent. The preparation method comprises the following steps: S1, carrying out weighing; S2, adding the solvent and the healant into a container, carrying out stirring and heating to raise the temperature to 50 DEG C, stopping heating, and carrying out stirring until full dissolving; S3, dripping the conductivity conditioning agent into the solution obtained by the step S2 and stirring 20 to 40 mins; S4, adding the spark voltage improving agent, the passivator, and the hydrogen elimination agent into the solution obtained by the step S3 successively, stirring, and raising the temperature to 110 DEG C, and carrying out 110-DEG C constant temperature processing for 50 to 70 mins; and S5, carrying out cooling on the solution obtained by the step S4 to the room temperature and obtaining an electrolyte. The beneficial effects are as follows: the electrolyte does not contain boric acid or borate; the conductivity of the electrolyte is high; and the service life is long.

Owner:江西联晟电子股份有限公司

Active anti-swelling and swelling-shrinkage agent and preparation method and application thereof

InactiveCN105647509AImprove surface activityImprove permeabilityDrilling compositionEthylenediamineC constant

The invention provides an active anti-swelling and swelling-shrinkage agent and a preparation method and application thereof. Water is added to a closed container, cation modified starch, dimethyl diallyl ammonium chloride and epoxy chloropropane are sequentially added, a reaction is conducted for 3 h under the 100-DEG-C constant-temperature condition, after the container is cooled to 40 DEG C, ethidene diamine, potassium peroxodisulfate and urea are added, the mixture is stirred to be uniform, and raw materials are obtained; the raw materials are taken, potassium chloride or ammonium chloride is added, 1-2 parts of fluorinated surfactant is added, the balance is water, the mixture is stirred to be uniform, and a product is obtained; the product is diluted into a solution with the mass concentration of 2-5%, and the solution is injected into an oil layer to be used. The active anti-swelling and swelling-shrinkage agent has an obvious anti-swelling effect, water injection efficiency is improved, and the water injection amount meets injection allocation requirements.

Owner:XI'AN PETROLEUM UNIVERSITY

Temperature-sensitive and salt-sensitive copolymer gel and preparation method thereof

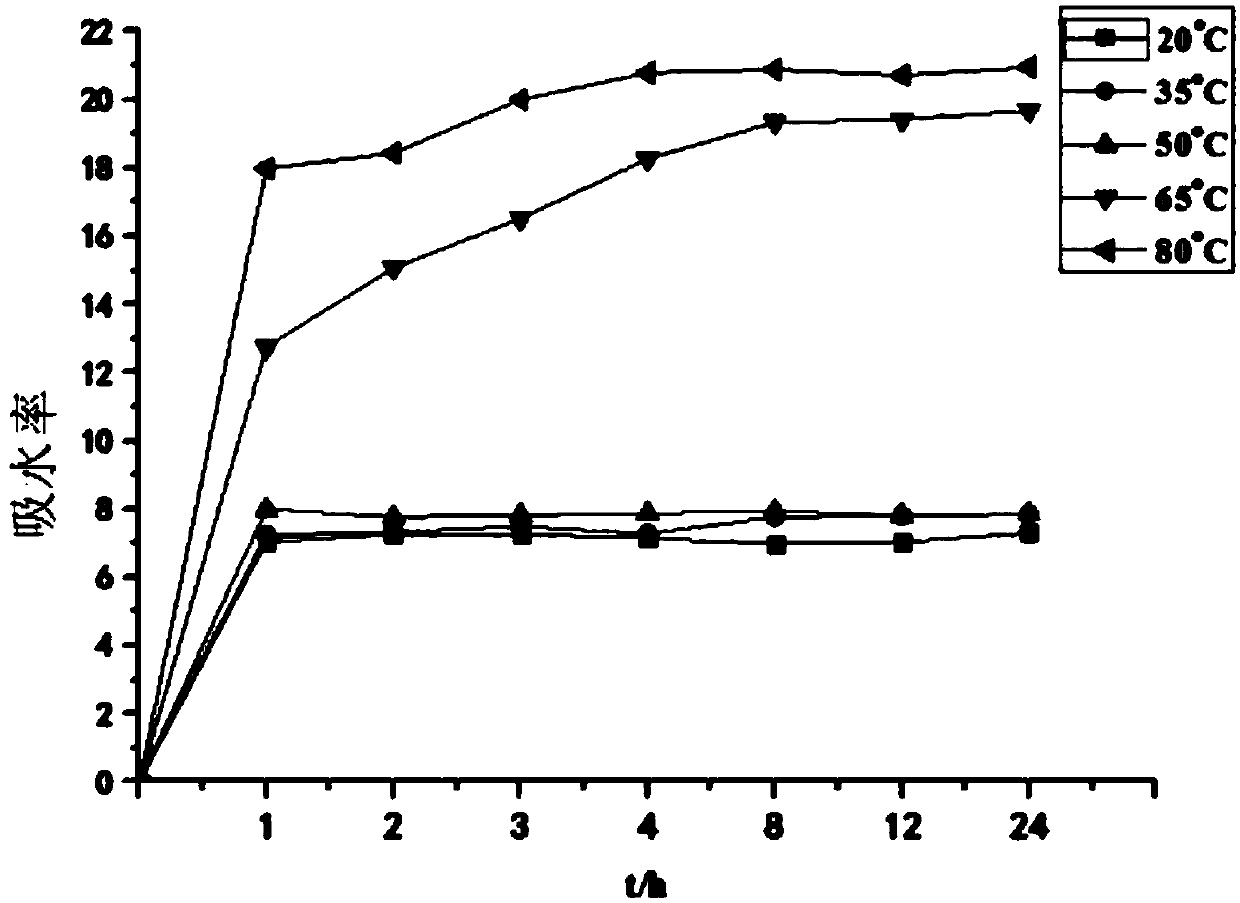

InactiveCN107814881AExcellent temperature sensitive performanceImprove salt toleranceDrilling compositionWater bathsFunctional monomer

The invention discloses a temperature-sensitive and salt-sensitive copolymer gel. The temperature-sensitive and salt-sensitive copolymer gel is prepared from the following raw materials of acrylamide,functional monomers and starch through crosslinking and polymerizing. The temperature-sensitive and salt-sensitive copolymer gel is prepared by the following steps of (1) adding the starch into water, stirring, and pasting to the complete transparent state in a 75-DEG C constant-temperature water bath pot, so as to obtain a starch water solution; (2) adding the acrylamide and the functional monomers into the starch water solution, so as to obtain a first reaction solution; (3) adding a crosslinking agent and a free radical initiator into the first reaction solution, uniformly stirring, sealing a reaction container, and reacting for 24 to 36h at the temperature of 60 to 70 DEG C, so as to obtain a crude gel; (4) adding the crude gel into pure water, soaking and stirring for 12h, and drying, so as to obtain the temperature-sensitive and salt-sensitive copolymer gel. The synthesized temperature-sensitive and salt-sensitive copolymer gel has the characteristics that the temperature-sensitive and salt-sensitive properties with high expansion rate at high temperature and high salt condition are realized, and the like; by using the starch as a substrate for grafting and copolymerizing, the degradability of the gel is realized; the damage to stratum is little, the environment-friendly effect is realized, and the modern green development value is met.

Owner:SOUTHWEST PETROLEUM UNIV

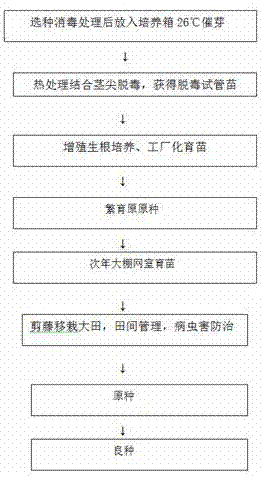

Factory propagation method for detoxified red sweet potato

InactiveCN107455262AReduce breeding costsEasy plantingPlant tissue cultureHorticulture methodsShoot apexGreenhouse

The invention relates to a factory propagation method for detoxified red sweet potato. The method comprises the step of detoxifying test-tube plantlets, breeder seeds, stock seeds and improved variety. The method specifically comprises the following steps: firstly, cleaning potato blocks, using 800-times diluted solution of 50% carbendazim for disinfecting for 20min and then performing 26 DEG C constant temperature sprouting; adopting a high / low temperature alterative treating mode of treating for 16 hours at 26 DEG C and treating for 8 hours at 35-40 DEG C in each day for continuously treating for about 30 days when the buds grow to 0.1-0.5cm; performing stem apex detoxification, rapid tissue culture propagation, rooting and seedling hardening, rapid water culture propagation, potato vine transplanting and breeder seeds propagation; and using the breeder seeds for rowing potato and seedling in the greenhouse with a fly net in the next year; transplanting into field, performing field management, controlling pests, timely harvesting and storing the stock seeds before frosting and propagating the excellent stock seeds. According to the invention, the detoxified seedlings can be subjected to factory propagation within a short period of time, the production cost of the detoxified seedlings can be reduced and the lastly acquired detoxified improved variety is convenient for the peasant to plant, transport and store.

Owner:牛力立

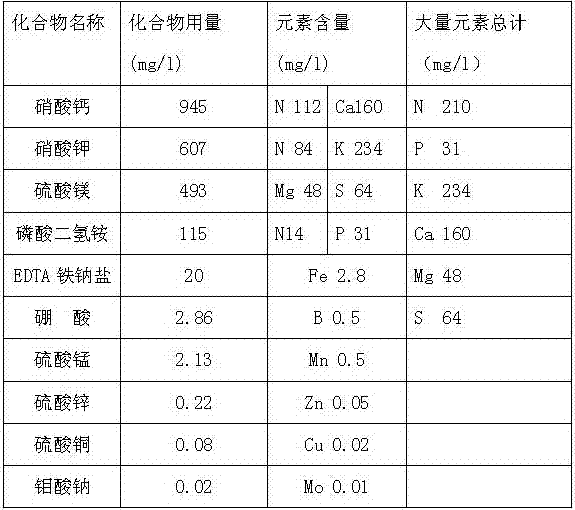

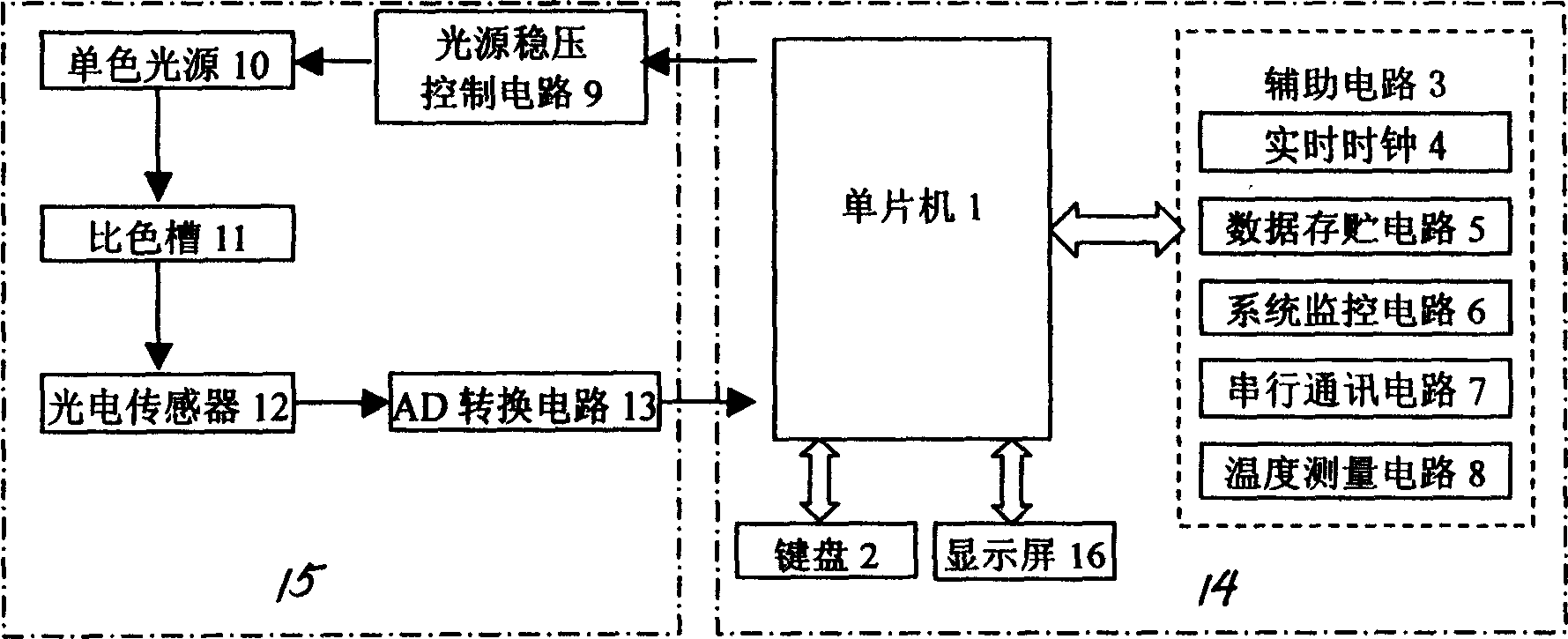

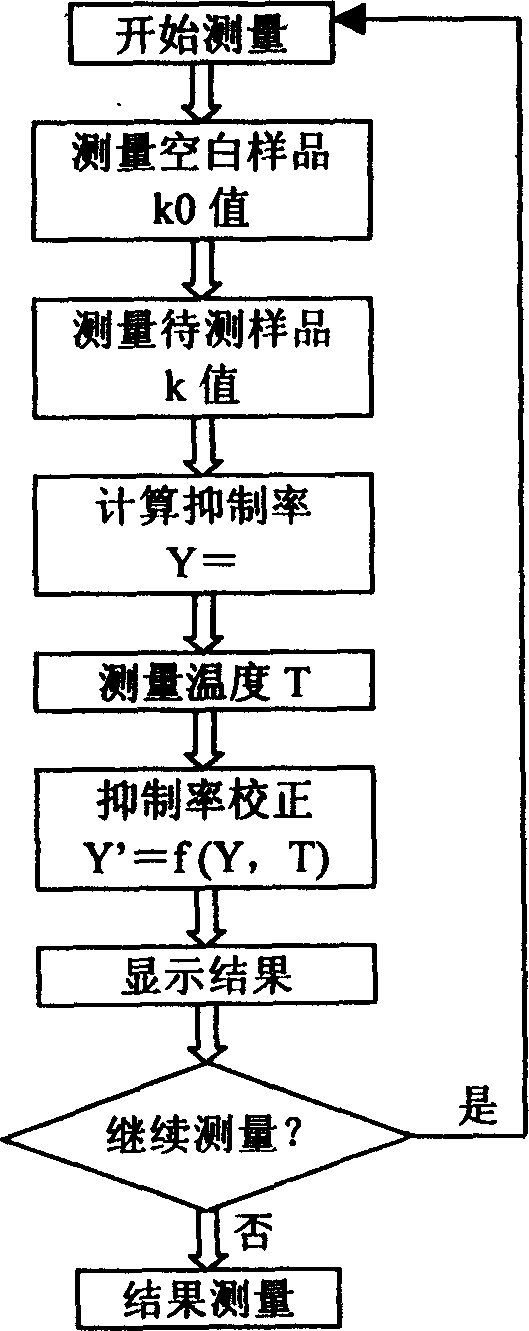

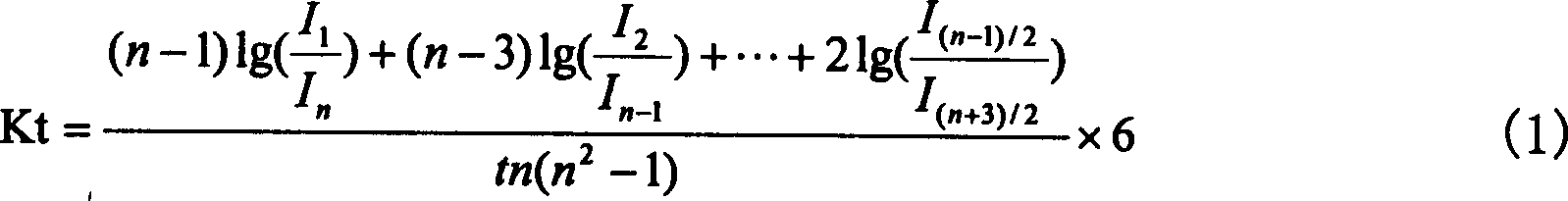

Method for checking pesticide residue and portable detecting instrument thereof

InactiveCN1544916ASimple structureReduce volumeMaterial analysis by optical meansObservational errorMicrocontroller

The invention discloses a pesticide residue detecting method and its portable detector. It omits the step of correcting instrumental light source I0 and reduces measuring error source; advances a temperature correcting model, omits 37 deg.C constant-temperature measuring condition, and needs no more heavy constant-temperature devices like water bath tank, etc. The detector: under the control of light source voltage stabilizing control circuit, the monochromatic light source generates monochromatic light; the monochromatic light beam passes through colorimetric tank holding the solution inside to be detected to irradiate a photoelectric sensor; the sensor converts the detected light intensity value to a voltage value, and then transmits the voltage to an A / D converter to convert into a digital signal, then the digital signal is inputted in a MCU system for data processing, a temperature measuring circuit converts the detected temperature signal to a digital signal to send into the MCU for temperature correction. It is especially suitable for the requirement of field fast screening or semiquantitative determination. It has simple structure, small bulk, and convenient use and can directly indicate the toxicity of pesticide residue.

Owner:HUAZHONG UNIV OF SCI & TECH

Sorting method for self-discharge performance of high-capacity lithium battery

ActiveCN110165319AMature technologyGood value for moneyFinal product manufactureSecondary cells charging/dischargingLithium-ion batteryConstant current

The invention provides a method for sorting the self-discharge performance of a high-capacity lithium battery, and belongs to the technical field of lithium ion batteries. The method comprises the following steps: taking a lithium battery which is filled with liquid and aged at the high temperature of 45 DEG C for 2 days, and performing constant-current charging for 90 minutes at the temperature of 0.05-0.1 DEG C; performing constant-current charging for 90 minutes at the temperature of 0.1-0.2 DEG C; employing 0.3 C constant-current constant-voltage formation, wherein the upper limit protection voltage is 4.3 V, and the cut-off current is 0.01 C; testing OCV1 by adopting a tester with the voltage precision of 0.0001 V, standing for 3 days at the high temperature of 40-45 DEG C, standing for 12 hours at the normal temperature, and testing the OCV2; screening the battery with large self-discharge difference through calculating the difference value of the OCV1-OCV2; according to the conventional 0.5 C charging and discharging detection capacity of a lithium battery, performing 0.5 C constant-current charging for 60 minutes, carrying out the voltage limiting for 4.2 V, finishing a cabinet test OCV3, testing the OCV4 after placement at normal temperature for 7 days, and controlling the difference value of OCV3-OCV4 to be less than or equal to 9mv, wherein the battery with the difference value being less than or equal to 9mv is qualified. According to the lithium battery manufactured by the method, the number of secondary capacity grading batteries can be reduced, and meanwhile,the consistency and the safety of subsequent lithium battery grouping use are improved.

Owner:HENAN FUSEN NEW ENERGY TECH

Preparation of magnetic fluid for ultra-high vacuum sealing device

ActiveCN101388270AHigh strengthImprove stabilityMagnetic liquidsIron compoundsWater bathsUltra-high vacuum

The invention relates to a method for preparing magnetic fluid for a ultrahigh vacuum sealing device, which uses the following steps: A) Fe2+ soluble salt and aqueous solution of Fe3+ soluble salt are mixed according to the molar ratio of Fe2+ and Fe3+, which is 1:2. B) obtained mixed solution is placed in 80 DEG C constant temperature water bath, excessive ammonia is added to generate Fe3O4 particles, oleic acid is added, thereby obtaining magnetic nano Fe3O4 particles which are coated with the oleic acid. C) the magnetic nano Fe3O4 particles which are coated with the oleic acid are dispersed in dioctyl sebacate and is placed in 100 DEG C constant temperature water bath, modified polyoxyethylene ether is added after being stirred for 30min, the temperature is increased to 150 DEG C, emulsification pretreatment is done for 60min, the temperature is reduced below 60 DEG C, thereby obtaining the magnetic fluid for the ultrahigh vacuum sealing device. The method for preparing the magnetic fluid for the ultrahigh vacuum sealing device has lower requirements for experiment instruments and operation conditions, the prepared magnetic fluid is very steady, the saturated vapor pressure is very low, and the startup torque is also low.

Owner:浙江微磁精密技术股份有限公司

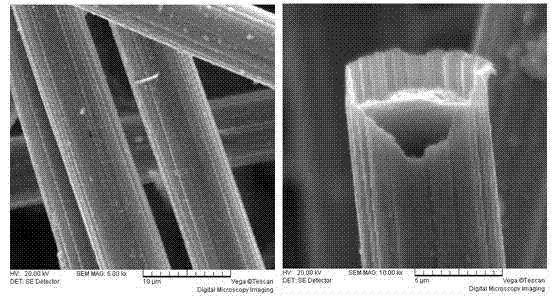

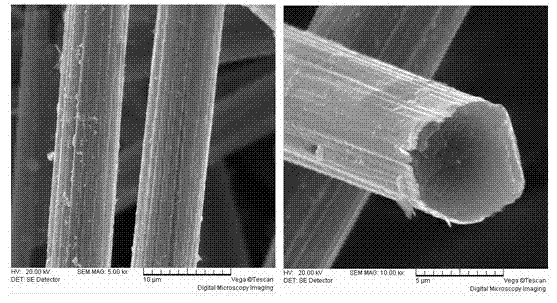

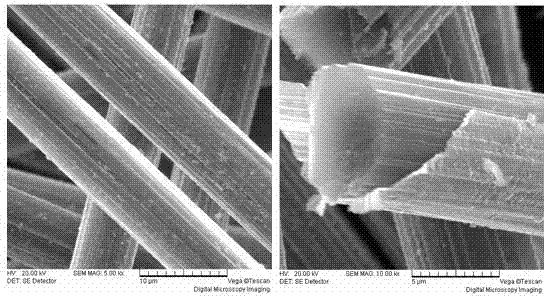

Method of nickel-copper-phosphor ternary alloy plating on carbon fiber surface

InactiveCN102226276ASimple processLiquid/solution decomposition chemical coatingArtificial filament chemical after-treatmentFiberWater baths

The invention discloses a method of nickel-copper-phosphor ternary alloy plating on a carbon fiber surface. The method comprises steps of degumming; coarsening; sensitizing-activating; putting a carbon fiber treated with sensitization-activation in a nickel-copper-phosphor plating solution for plating until end of reaction, removing, washing and drying; and placing the nickel-copper-phosphor solution in a 80 DEG C-85 DEG C constant temperature water-bath for insulation. A formula of the nickel-copper-phosphor solution comprises nickel sulfate 25-30g / L, copper sulfate 2.0-2.5g / L, sodium hypophosphate 24-27g / L and a complexing agent sodium citrate 55-60g / L, wherein a pH is 8.0-8.5. According to the method, a nickel-copper-phosphor ternary alloy plating on the carbon fiber surface can be obtained at one time, so that the method can not only simplify a nickel-copper-phosphor alloy plating technology, but also can be applied to metallization processing of other composite reinforcement.

Owner:CHONGQING UNIV

Salt shrinking finishing method of silk fabrics

InactiveCN104233778AGood salt shrinkage effectSoft texturePhysical treatmentAnimal fibresWarm waterC constant

The invention discloses a salt shrinking finishing method of silk fabrics. The method comprises the following steps: carrying out plasma treatment on a silk fabric to be treated; immersing the treated silk fabric in warm water and putting the silk fabric out; preparing the finishing liquid, namely mixing calcium chloride and deionized water to enable the calcium chloride to be dissolved, continuously adding softening agents and carrying out ultrasonic agitation to obtain the finishing liquid; impregnating the treated silk fabric in the finishing liquid, and performing salt shrinking finishing in a 50-80-DEG C constant-temperature and constant-humidity chamber; and putting out the silk fabric, washing with hot water for 2-3 times, then washing with cold water for 2-3 times, and drying in an air drying oven to obtain the silk fabric after the salt shrinking finishing. The silk fabric treated by adopting the method has the good salt shrinking effect, has the soft texture, and is fluffy and elastic; and the method is simple to operate and low in cost.

Owner:海门新百花印染有限公司

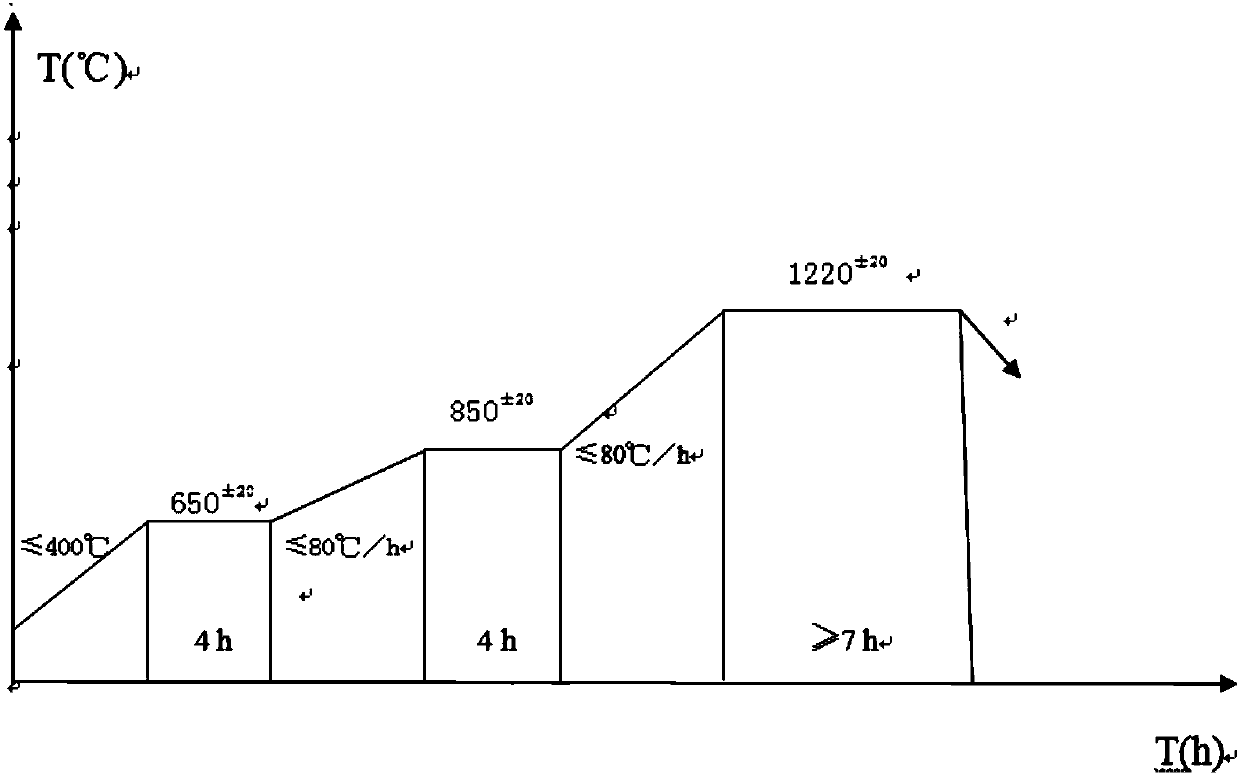

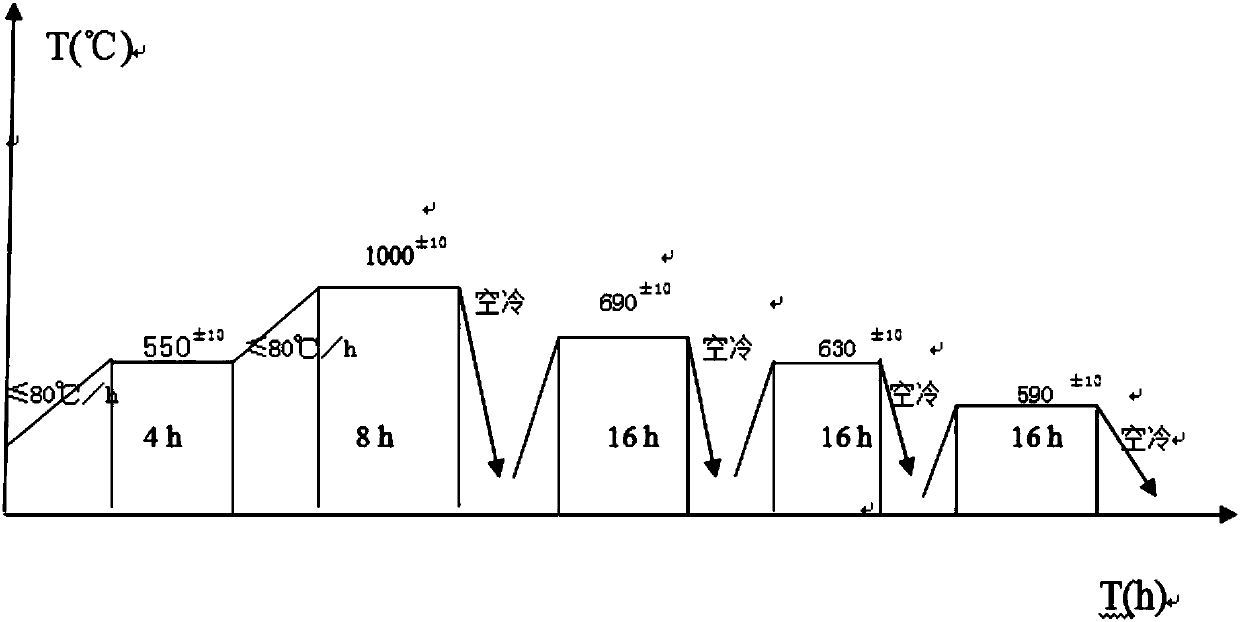

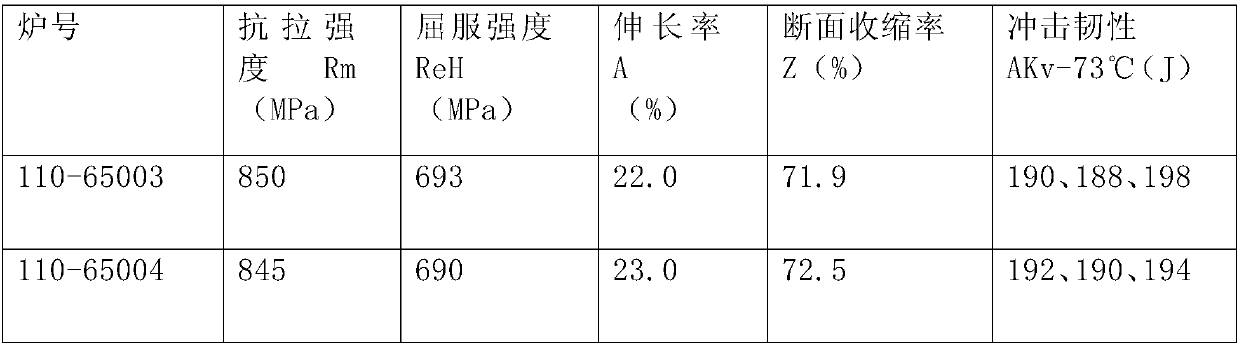

F6NM martensitic stainless steel cylinder-body forge piece and heat treatment method

ActiveCN107937828AReduce the risk of obsolescenceStable mechanical propertiesMartensitic stainless steelSS - Stainless steel

The invention relates to a F6NM martensitic stainless steel cylinder-body forge piece and a heat treatment method. According to the F6NM martensitic stainless steel cylinder-body forge piece and the heat treatment method, the high strength and the high low temperature impact toughness resistance can be met, cracks are avoided, and meanwhile, cracking and scrap of steel ingots during forging are avoided; and the F6NM martensitic stainless steel cylinder-body forge piece comprises, by mass, no more than 0. 04% of C, 0.30-0.50% of Si, 0.70-1.00% of Mn, 11.5-13.0% of Cr, 3.5-4.5% of Ni, 0.50-0.70%of Mo, 0.04-0.1% of V, no more than 0.020% of P and no more than 0.010% of S. The F6NM martensitic stainless steel cylinder-body forge piece has the advantages that the F6NM martensitic stainless steel cylinder-body forge piece after being subjected to component optimization adopts sectional-type constant-temperature slow heating, the charging temperature, the heating speed and the heat preservation time are strictly controlled, forging is strictly executed according to the new forging process, and heat treatment adopts the special heat treatment process of 550 DEG C constant-temperature heating, 1000 DEG C air quenching and three times of tempering at 690 DEG C, 630 DEG C and 590 DEG C. After production, product inspection dimensions confirm to the customer drawing requirements, a sampleis sampled and sent to a third party for being tested, the mechanical properties meet the index requirements, after multiple times of production, the mechanical properties of the F6NM martensitic stainless steel cylinder-body forge piece are all very stable, and the F6NM martensitic stainless steel production scrap risk is greatly reduced.

Owner:BAODING TECH CO LTD

Method for cage culture of frogs

The invention discloses a method for cage culture of frogs, particularly a method for artificially breeding frogs in a sealed pond, which is disinfected at fixed period, by utilizing cages. The method comprises the steps of selecting parent frogs, spawning, cultivating tadpoles, and breeding young and adult frogs, and is characterized by comprising the steps of: (1) selecting parent frogs: selecting healthy and strong parent frogs which are cultivated for 2-5 years, and breeding in a 20-30 DEG C constant-temperature humidity-retention water tank; (2) spawning: placing male and female frogs in the tank at a ratio of 1:(0.5-1), mating, spawning, and transferring out the parent frogs after spawning; (3) cultivating tadpoles: breeding incubated tadpoles in small-pore cages in the pond, and feeding with tadpole powder until the tadpole tails break; and (4) breeding adult frogs: transferring the tadpoles of which the tails break to the cages in which foam boards and wood board are placed, feeding with frog feed, and harvesting until each frog is 0.25-0.5kg. The method has the advantages that the operation is simple and convenient, the water pollution is reduced, the survival rate of the frogs is improved, the insect pests are effectively removed and microorganisms are not destroyed, and the water, manpower and expense are saved.

Owner:蒙有恳

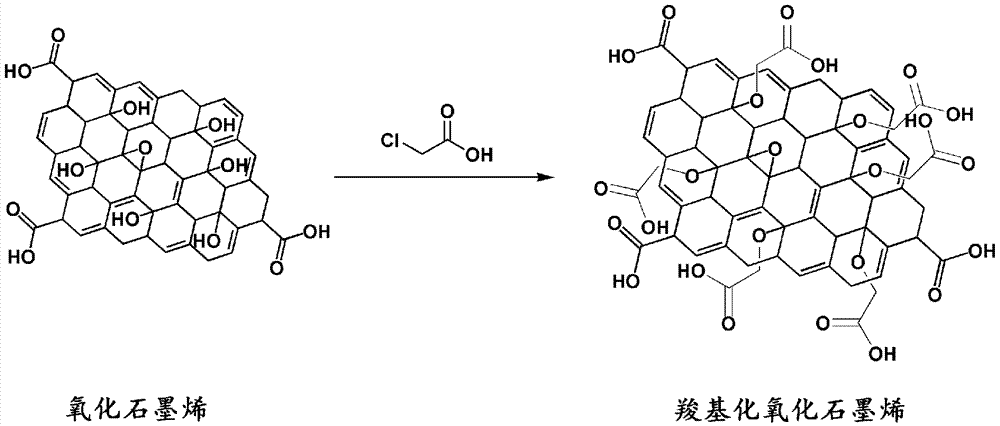

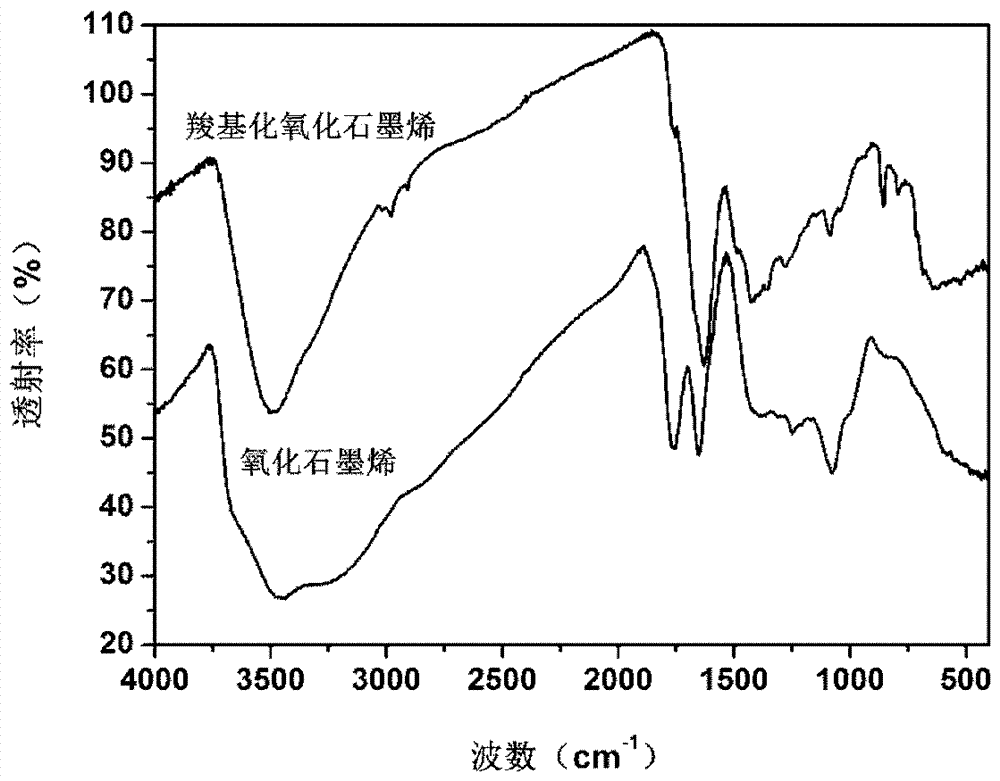

Application of carboxylation graphene oxide serving as adsorbent in metal ion adsorption

InactiveCN107537445AEasy to prepareRaw materials are easy to getOther chemical processesWater contaminantsWater bathsSorbent

The invention provides application of carboxylation graphene oxide serving as an adsorbent in metal ion adsorption and belongs to the technical field of wastewater treatment. The application comprisesthe steps of utilizing a classical Hummers method to prepare graphene oxide, then mixing the graphene oxide with chloroacetic acid under the alkali condition, stirring in 25 DEG C constant-temperature water bath, centrifugally washing and drying to prepare the carboxylation graphene oxide. The carboxylation graphene oxide has the advantages of simple preparation method, raw materials easy to obtain, moderate reaction conditions, simple treatment technology and further good performance in a wastewater treatment aspect.

Owner:信阳学院

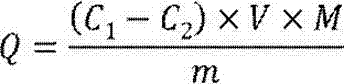

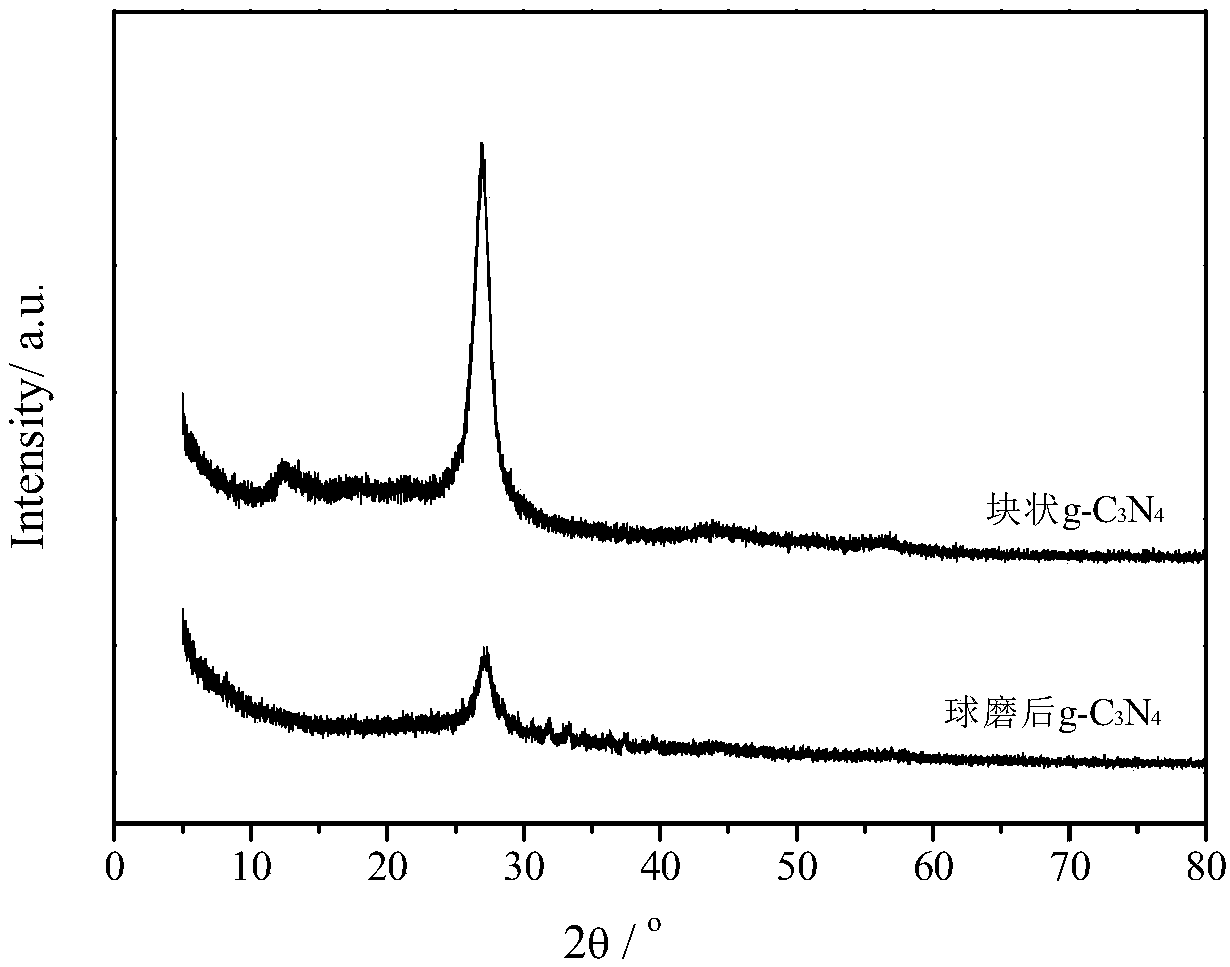

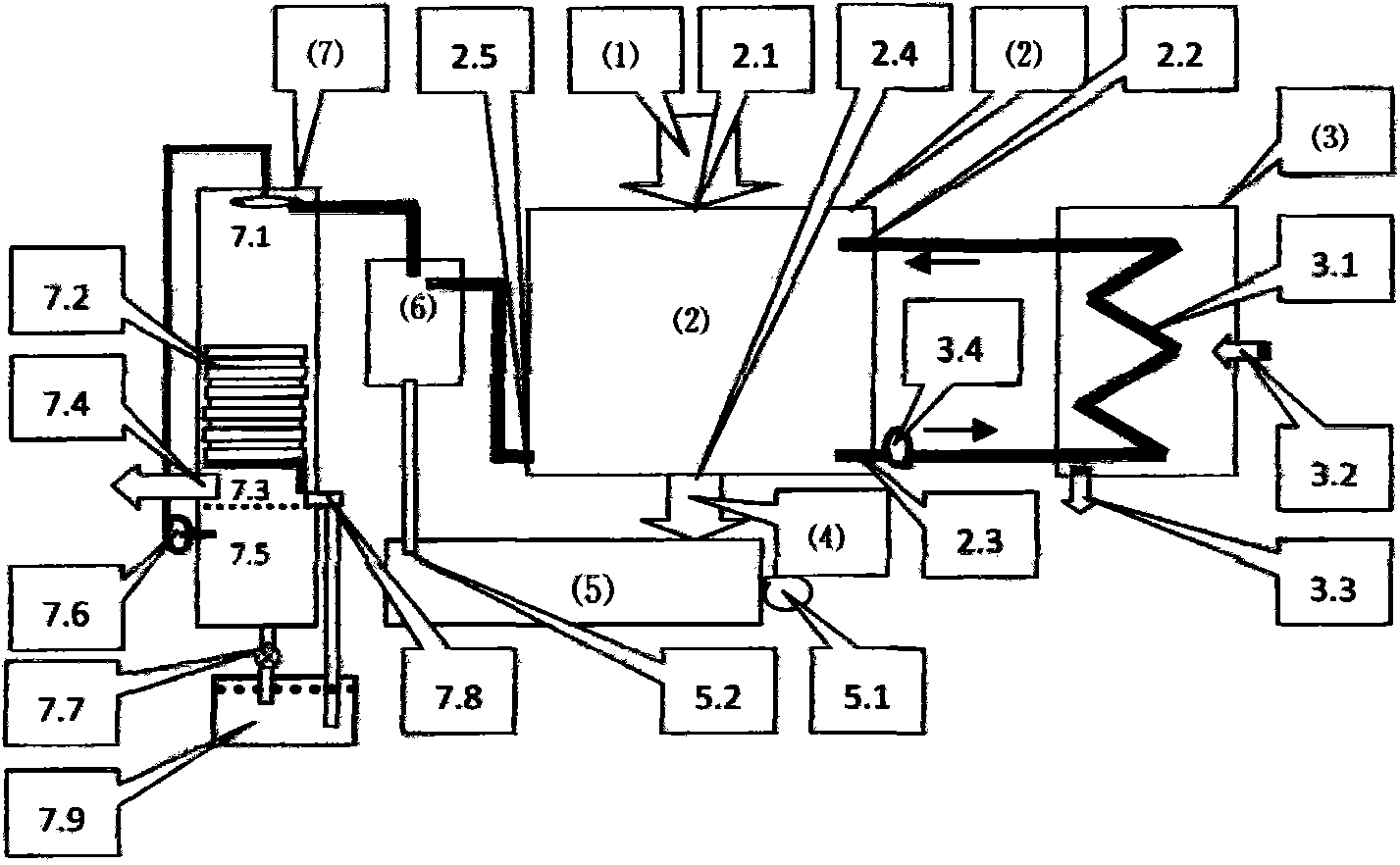

Carbon nitride and graphene composite material modified by organic dye and application of carbon nitride and graphene composite material

ActiveCN107649159AHigh surface areaHigh yieldOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsOrganic dyeWater vapor

The invention discloses a carbon nitride and graphene composite material modified by organic dye. A method for preparing the carbon nitride and graphene composite material includes ultrasonically uniformly mixing g-C3N4 alcoholic solution and graphene alcoholic solution with each other, keeping the temperature of 100-240 DEG C constant for 8-24 h, centrifugally removing ethyl alcohol and carryingout vacuum drying on obtained precipitates to obtain g-C3N4 / r-graphene compositions; ultrasonically uniformly mixing the g-C3N4 / r-graphene compositions, the organic dye and organic alcohol C with oneanother, carrying out centrifuging, washing precipitates by the aid of organic alcohol C and then drying the precipitates under dark conditions to obtain the carbon nitride and graphene composite material modified by the organic dye. The carbon nitride and graphene composite material has the advantages that the carbon nitride and graphene composite material is provided with mesoporous structures and has large specific surface areas, the hole-charge separation speeds, the light absorption rate and the light utilization rate can be increased, the photocatalytic performance of the carbon nitrideand graphene composite material is higher than 8 times the photocatalytic performance of graphite-phase carbon nitride if the carbon nitride and graphene composite material is used for carrying out reduction on carbon dioxide and water vapor in visible light to obtain methanol.

Owner:ZHEJIANG UNIV OF TECH

Method for preparing phenol from benzene through one-step process

InactiveCN102463124AHigh activityHigh selectivityOrganic chemistryPhysical/chemical process catalystsWater bathsFiltration

The invention relates to a method for preparing phenol from benzene through a one-step process. According to the method, a catalyst treats coal-based active carbon as a carrier and a ferric salt as an active component, and the carrier of the catalyst is processed according to the following steps: 1, adding 100g of the coal-based active carbon washed by water to a flask, adding 250ml of a nitric acid solution with the concentration of 2-12mol / L, connecting a condenser tube to the flask, carrying out reflux processing for 10h in a 25-90DEG C water bath, absorbing a tail gas with an NaOH or Na2CO3 solution, fully washing the coal-based active carbon with tap water until the pH value is unchanged, leaching the coal-based active carbon with distilled water three times, carrying out pumping filtration, and drying the coal-based active carbon in a 110DEG C constant temperature drying box; and 2, dipping the coal-based active carbon in 20-50mL of an aqueous Fe2(SO4)3 solution with the concentration of 0.04-0.20mol / L, laying them aside for 0.5-24h at room temperature, carrying out pumping filtration, and drying the coal-based active carbon in the 110DEG C constant temperature drying box. The catalyst has the advantages of high activity, high selectivity, high stability, production cost reduction, and product quality improvement.

Owner:PETROCHINA CO LTD +1

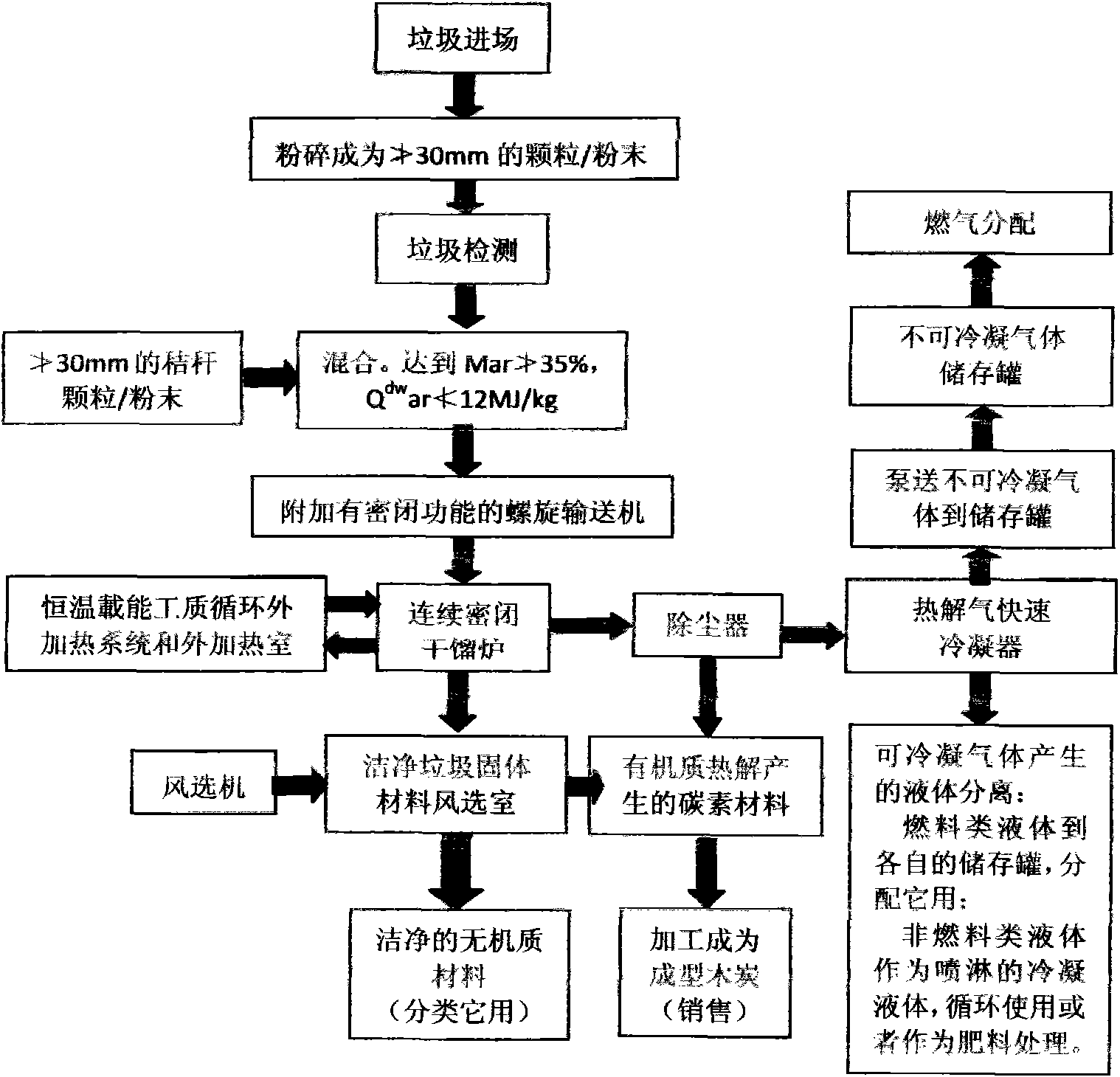

Method of harmless and recycle treatment of garbage

InactiveCN102247966ASolid waste disposalSpecial form destructive distillationRefuse-derived fuelClassification methods

Garbage generated in our country has a large amount of household meal residuals, so garbage has obvious characteristics of a high moisture as received (Mar is not less than 50%) and a low lower heating value (Q<dw>ar is not more than 5MJ / kg). A method of increasing biomass energy is employed by the invention. First, garbage is conversed to garbage derivative fuel, and a method of complete isolation from air and external heating is adopted to realize drying, deodorizing, disinfecting and carbonization and pyrolysis of garbage material under a 300-6000 DEG C constant temperature working condition; at last, a rapid condensation method is conducted to rapidly separate condensable gas components and incondensable gas components in gas generated from pyrolysis; and solid materials are separated through an air classification method and answer the purpose intended. According to the garbage treatment method of the invention, no extra processing on the received garbage is needed; and no dioxins or even little secondary pollution is generated; so that various substances in the garbage can be recycled by 100%.

Owner:许绍良

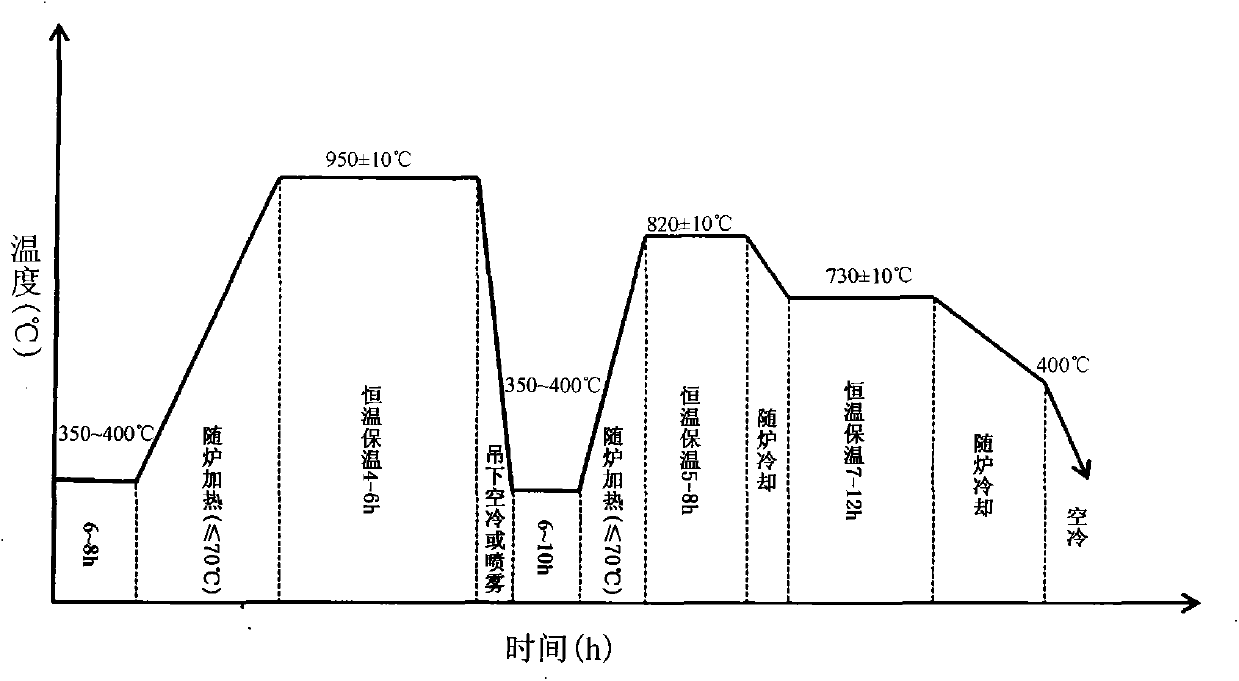

After-forged heat treatment technique of 9Cr2MoV chilled roll steel

InactiveCN103468889AReduce distortionReduce crackingFurnace typesHeat treatment furnacesC constantCarbide

The invention relates to an after-forged heat treatment method of 9Cr2MoV chilled roll steel. The after-forged heat treatment method is characterized in that a chilled roll is made of 9Cr2MoV steel, the after-forged heat treatment method comprises the steps of normalizing and spheroidizing annealing, wherein the normalizing technique is performed at the temperature of 950 DEG C, higher temperature facilitates the dissolution of carbide and ensures the homogeneity of compositions. When normalization cooling is performed, the chilled roll is hoisted and cooled by atomizing water so as to prevent formation of continuous network carbide on grain boundary; in the spheroidizing annealing, fine carbide is easily molten from the middle through 820 DEG C insulation, so as to form a great amount of diffusely distributed carbide particles; carbide, as heterogeneous nucleus, is continuously separated out by austenite through retarded cooling, a carbon enrichment region of the austenite is formed into carbide crystal nucleus grown crystal grains, finally, the carbide crystal nucleus grown crystal grains are gathered and grown into particular cementite with certain size through 730 DEG C constant temperature, so that an excellent spheroidized structure can be obtained.

Owner:MAANSHAN CHENXU MASCH MFG CO LTD +2

Vehicle fuel and preparation method thereof

ActiveCN105885970AImprove stabilityGuaranteed combustion efficiencyLiquid carbonaceous fuelsFuel additivesDetonatorCombustion

The invention provides a vehicle fuel and a preparation method thereof. The vehicle fuel comprises the following components in parts by weight: 5-10 parts of diesel oil, 30-80 parts of polymethoxy dimethyl ether, 1-5 parts of an alcohol combustion improver, 1-5 parts of a corrosion inhibitor, 1-10 parts of an anti-detonator, 1-5 parts of a catalysis combustion improver, 1-10 parts of a stabilizer, 1-5 parts of an anti-oxidant, 0.1-5 parts of a dispersing agent and 5-10 parts of solvent oil. The preparation method comprises the following steps: sufficiently stirring and mixing the diesel oil, the polymethoxy dimethyl ether and the solvent oil at normal temperature to obtain a first mixture; under the stirring state, adding the alcohol combustion improver, the corrosion inhibitor and the catalysis combustion improver into the first mixture to obtain a second mixture; under a stirring and 35-60 DEG C constant-temperature condition, adding the stabilizer, the anti-detonator, the anti-oxidant and the dispersing agent into the second mixture, wherein the time interval of addition between adjacent substances is 1-2 hours; and preserving the heat and standing for 3-5 hours after stirring for 1-2 hours. The vehicle fuel provided by the invention is good in stability, and the utilization rate of the polymethoxy dimethyl ether is high.

Owner:SHANDONG CHENXIN NEW ENERGY

Florfenicol-beta-cyclodextrin inclusion complex and preparation method thereof

InactiveCN106177983AHigh inclusion rateHigh yieldAntibacterial agentsOrganic active ingredientsWater bathsAlcohol

The invention provides a florfenicol-β-cyclodextrin inclusion compound and a preparation method thereof, wherein the preparation method is: A. Add distilled water to β-cyclodextrin, heat and dissolve to make a saturated solution A; B. Add ethanol to Florfenicol to prepare solution B; C. Place solution A on a magnetic stirrer, and gradually drop solution B into solution B at a constant temperature of 75-85°C at a constant speed of 500r / min to obtain clathrate solution; The combined liquid container is placed in a water bath and stirred to room temperature; D. After the cooled clathrate solution was refrigerated for 24 hours, the precipitate was obtained after suction filtration, and the precipitate was washed with ethanol, and then dried at 55°C to obtain the florfenicol-β-cyclodextrin inclusion compound. The preparation method is simple in operation and high in preparation efficiency, and the prepared florfenicol-β-cyclodextrin inclusion compound has a high inclusion rate and a greatly improved yield, and is suitable for large-scale production for preventing and controlling aquatic animals. bacterial disease.

Owner:FOSHAN UNIVERSITY +1

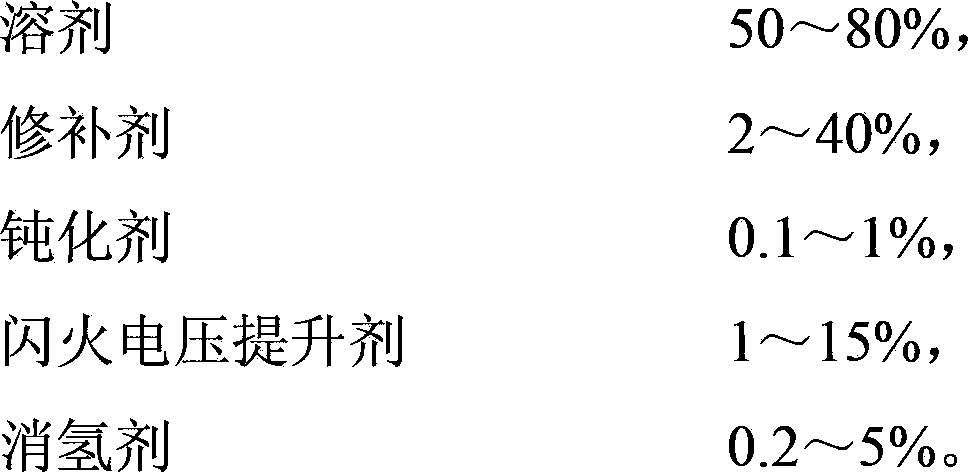

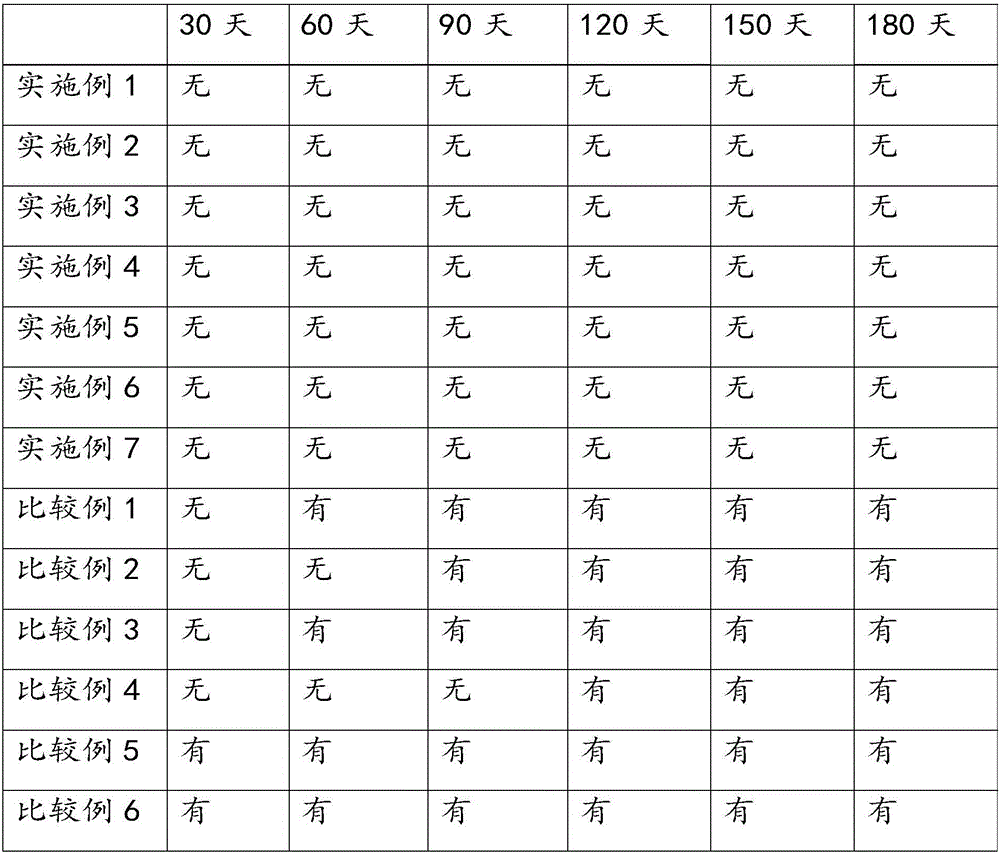

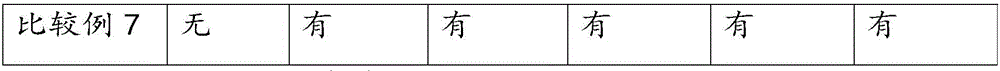

High-sparking voltage boron series-free working electrolyte and preparation method thereof

ActiveCN103632850AIncrease the flash voltageImprove performanceElectrolytic capacitorsHydrogenC constant

The invention discloses a high-sparking voltage boron series-free working electrolyte and a preparation method thereof. The electrolyte comprises, by weight, 50% to 80% of a solvent, 2% to 40% of a healant, 0.1% to 1% of a passivator, 1% to 15% of a sparking voltage boosting agent, and 0.2% to 5% of a dehydrogenation agent. The preparation method comprises the following steps: S1, carrying out weighing; S2, adding the solvent, the healant and the sparking voltage improving agent into a container, carrying out heating to raise the temperature to 140 DEG C, stirring to realize full dissolving, stopping heating and stirring continuously, and cooling to the temperature of 110 DEG C; S3, successively adding the passivator and the hydrogen elimination agent into the 110-DEG C solution obtained in the step S2 and carrying out 110-DEG C constant temperature processing for 50 to 70 mins; and S4, cooling the solution obtained in the step S4 to the room temperature to obtain an electrolyte. The beneficial effects are as follows: the electrolyte does not contain boric acid or borate; the sparking voltage of the electrolyte is high and thus security and stability of the electrolyte can be realized beneficially due to the high sparking voltage; and the service life is long.

Owner:江西联晟电子股份有限公司

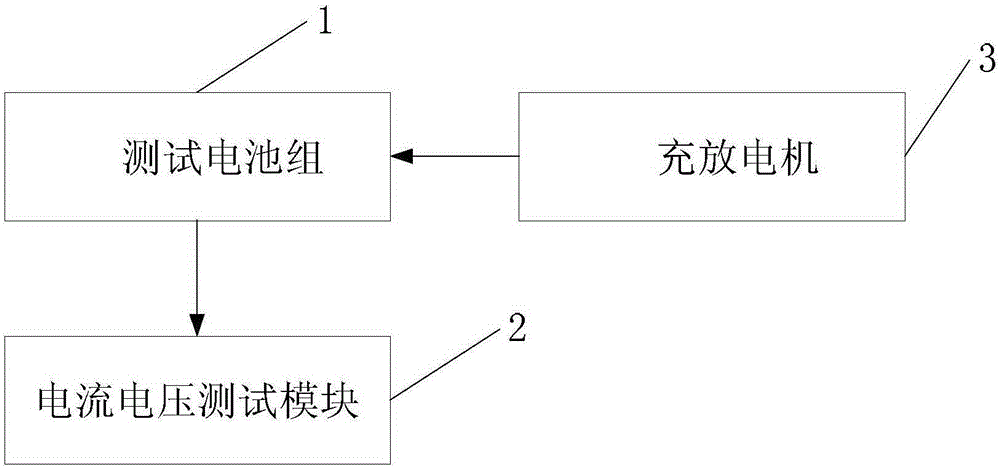

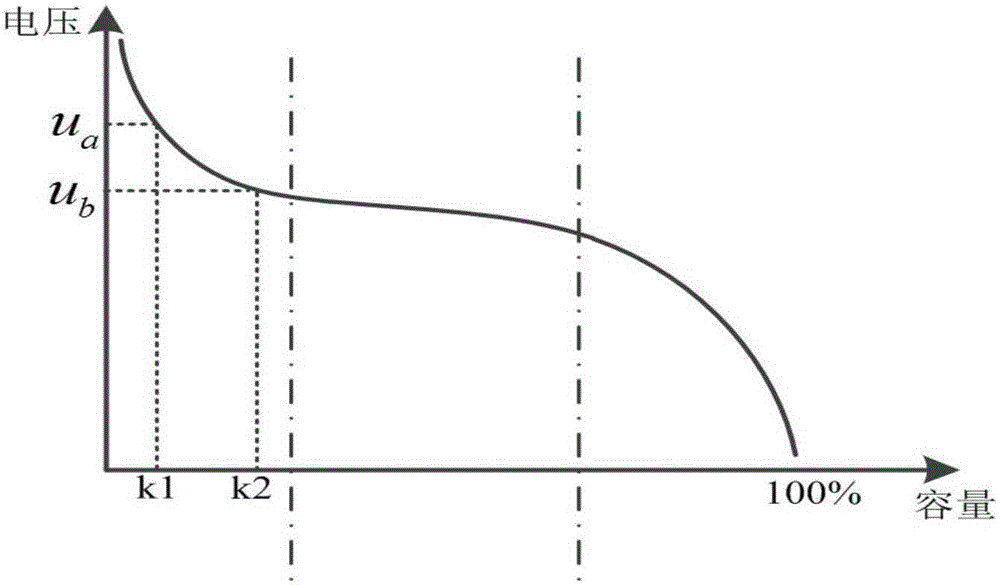

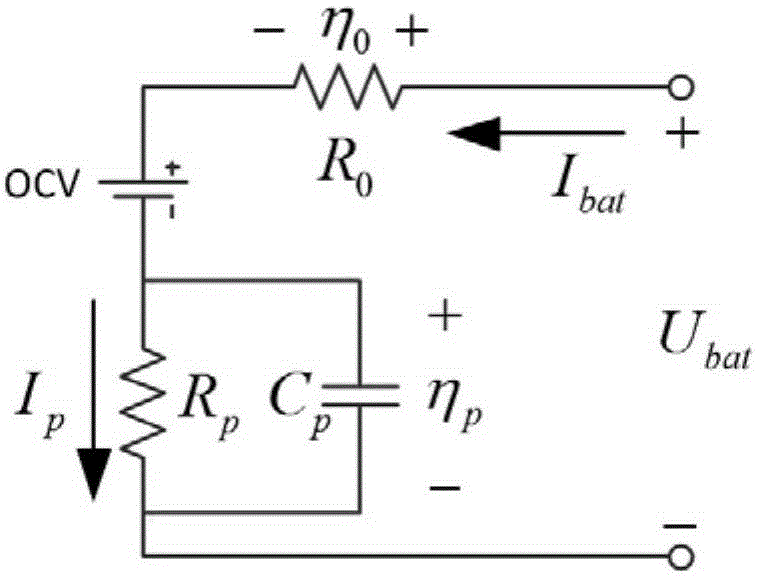

Energy storage battery detection method

The invention relates to the technical field of battery management, in particular to an energy storage battery detection method. The method solves the problem that the working performance of a battery pack under actual working conditions can not be detected through an existing battery pack detection technology. The method includes the set test steps that under given working conditions, a battery pack is kept static for 5 min, constant-current discharge is performed till discharge cut-off voltage U1 is reached, the battery pack is kept static for 1 h, constant-current charge is performed till charge cut-off voltage U2 is reached, constant-voltage charge is performed till the current is smaller than charge cut-off current, the battery pack is kept static for 1 h, discharge is performed under the working conditions till cut-off voltage U3 is reached, 0.05 C constant-current discharge is performed till cut-off voltage U4 is reached, and 0.5 C constant-current discharge is performed till discharge cut-off voltage U1 is reached. The evaluation parameters including open-circuit voltage, polarization internal resistance, polarization capacity, ohmic internal resistance, capacity parameters and power parameters of a battery module can be obtained by detecting the parameters including end voltage and total current and adopting an online parameter identification method, and then the parameters can be utilized for evaluating the battery pack. The method is mainly used for detecting the battery pack.

Owner:STATE GRID CORP OF CHINA +3

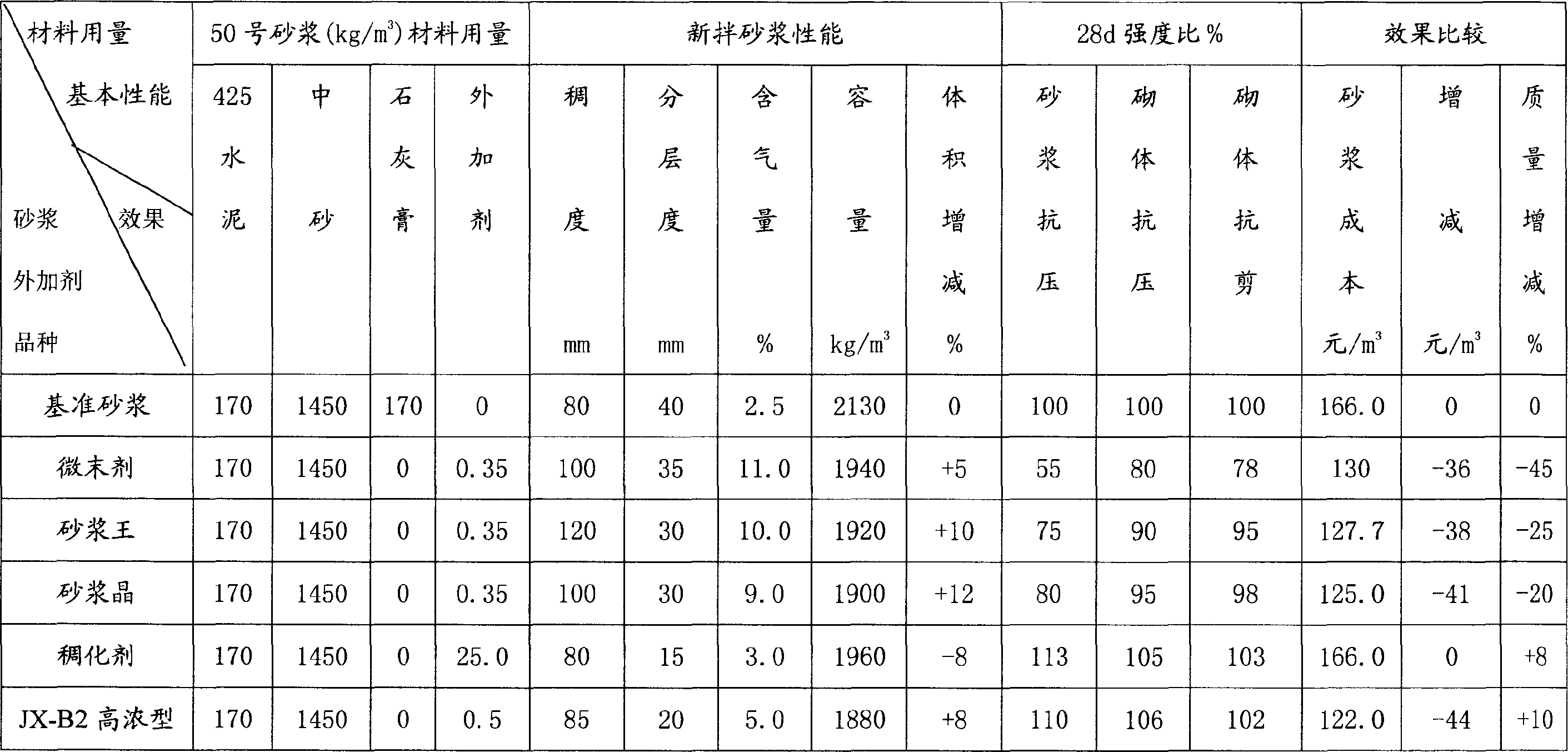

Efficient mortar plasticizer base material and its efficient mortar plasticizer composition

This invention relates to a basic material of a high efficient mortar DBP to be prepared by the following method: a, adding 11-14% rosin polymers into 45-55% water of 80-120deg.C slowly and mixing them in a kettle continuously to be solved fully, then adding 4-6% inorganic alkali and dissolving them completely under the 60-80deg.C constant to the complete reaction, b, adding 8-10% sulfosalt while mixing, 1-2% polyalcohol under 40-60 deg.C constant to the complete reaction, c, adding 10-11% DBP to be dissolved fully under 30-50 deg.C to be cooled to normal temperature, d, spraying and drying them to powder particles then to be matched with 3-5% DBP and 9-11% silicon powder to get the basic material of high efficient mortar DBP. This invention also relates to its compound.

Owner:四川铁科新型建材有限公司

Method for preparing porous biological glass scaffold

The invention relates to the technical field of preparation of inorganic chemical materials, and concretely relates to a method for preparing a porous biological glass scaffold. The method for preparing the porous biological glass scaffold comprises the following steps: 1, preparing sol; 2, preparing wet gel; 3, preparing xerogel; 4, preparing bioactive glass; and 5, preparing the bioactive glass porous scaffold. The above bioactive porous material with high amount of porosity, good connectivity and controllable aperture can be prepared through using a 58S biological glass slurry to dip polyurethane foam adopted as a template, the apparent porosity of the porous scaffold obtained after dipping is carried out once is about 93%, the apparent porosity of the porous scaffold after being dipped twice decreases to about 80%, and the porous scaffold has high bioactivity in a 37DEG C constant temperature SBF solution.

Owner:SHAANXI SHENGMAI PETROLEUM

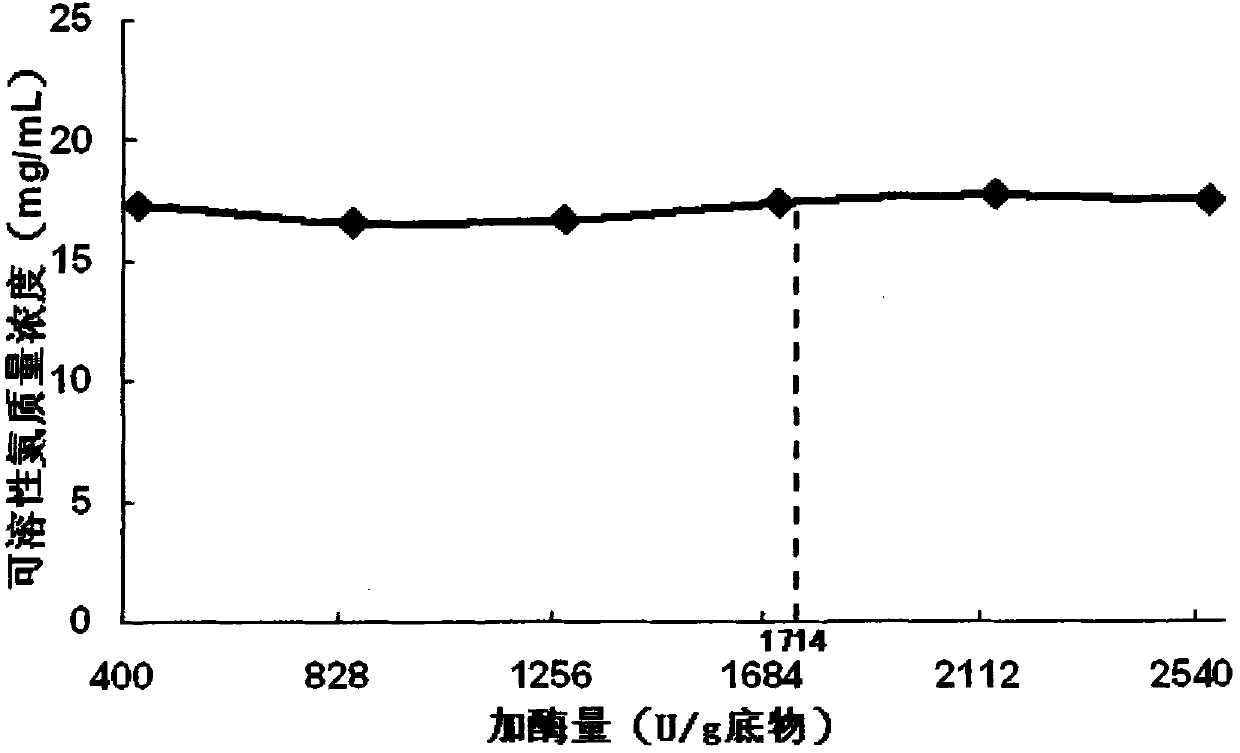

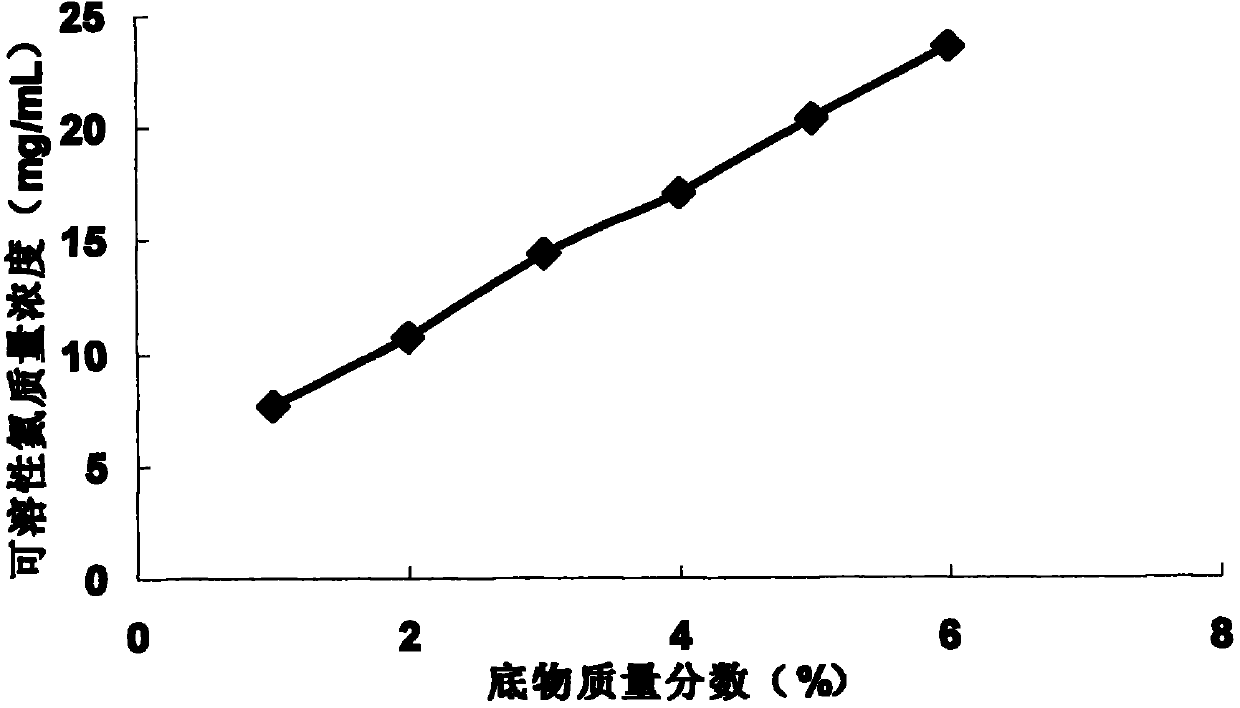

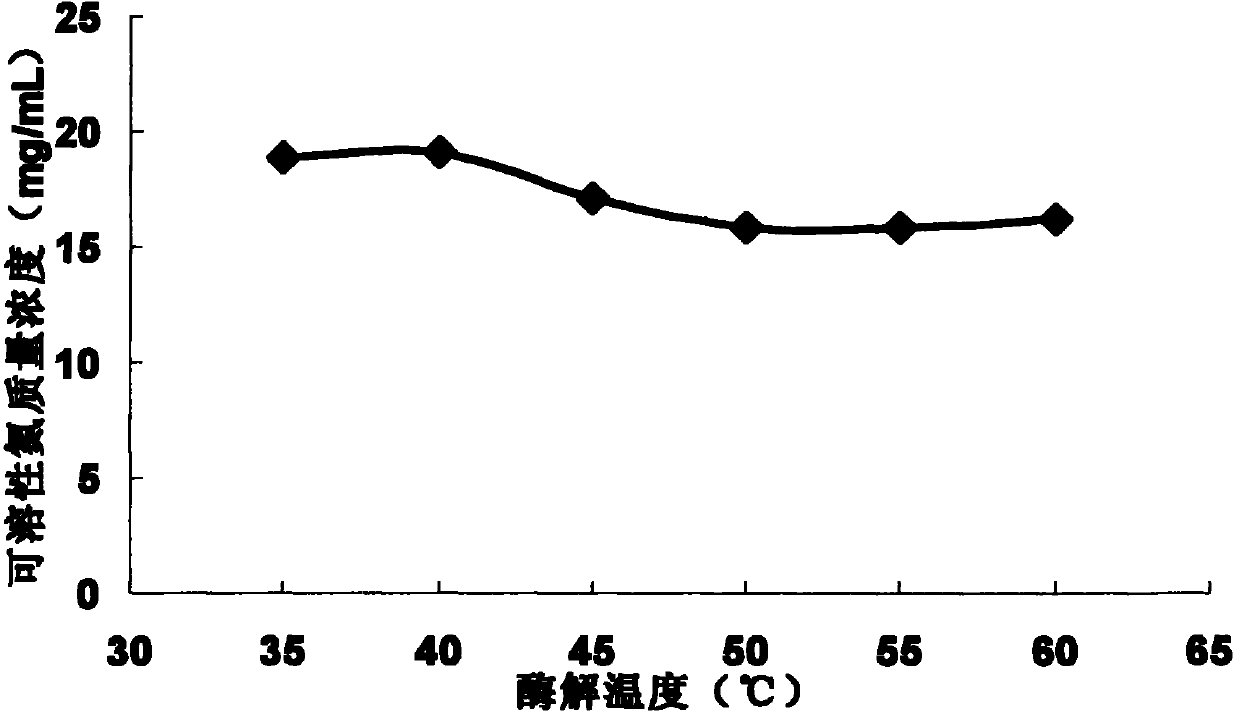

Method for preparing peanut peptide by fractional bienzyme hydrolysis

InactiveCN101999513AReduce manufacturing costHigh yieldProtein foodstuffs working-upProtein solutionWater baths

The invention relates to a method for preparing peanut peptide by fractional bienzyme hydrolysis, belonging to the technical field of peanut protein processing methods. The method is characterized by comprising the following steps of: dissolving the peanut protein powder in distilled water, then placing the dissolved peanut protein powder into a 9 DEG C constant-temperature water bath, and preserving for 20min so as to passivate separated peanut protein; taking out the separated peanut protein after passivation, regulating the pH value of the protein solution to be 8.0, adding incision enzyme, and reacting for 120min in a 5 DEG C constant-temperature water bath oscillator; after reaction, regulating the pH value of the protein solution, adding flavourzyme, evenly mixing, reacting for a certain period of time in a constant-temperature water bath oscillator with a certain temperature, taking out after the reaction, placing into a 1 DEG C water bath, preserving for 5min, and cooling with cold water to obtain the peanut peptide after cooling. The invention has the advantages of low preparation cost, high peanut peptide yield, high purity, short preparation time, simple preparation method, and mild production conditions, and the mass concentration of soluble nitrogen in an enzymolysis product is high.

Owner:SHANDONG PEANUT RES INST

Composite of food-grade compound calcium sulfonate-base lubricating grease and preparation method thereof

InactiveCN102899134AImprove high temperature resistanceImprove shear stabilityThickenersCalciteStearic acid

The invention relates to a composite of food-grade compound calcium sulfonate-base lubricating grease and a preparation method of the composite. The preparation method comprises the following steps of: feeding mixture of 40-60% synthesized calcium sulfonate with high base number, water and ethanol into a reaction kettle, stirring and heating to 60-80DEG C, adding 0.5-2% of acetic acid to convert calcium carbonate with a calcite structure, adding 1-5% of calcium hydroxide and 2-5% of stearic acid under 90-100 DEG C after 1h of constant temperature, carrying out saponification reaction for 120min, rising temperature after saponification, adding 1-5% of calcium borate after 1h of 130-140 DEG C constant temperature, rising the temperature to 180-200DEG C keeping constant temperature for 5-10min, cooling the temperature to 100-110DEG C, adding 0.2-1.5% of antioxygen, homogenizing, adjusting thickness by adding base oil, degassing in a filtering way, and filling to form finished products. The dropping point of the composite provided by the invention is more than 300DEG C, the 0.1-milliom times shear difference value is within 20, and the PD (potential difference) value is not less than 400kg.

Owner:CHINA PETROLEUM & CHEM CORP

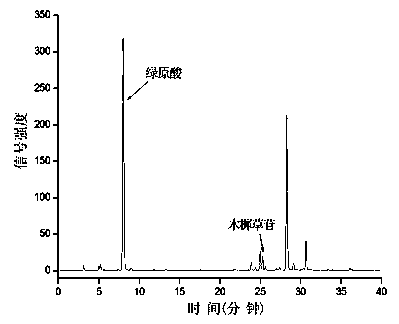

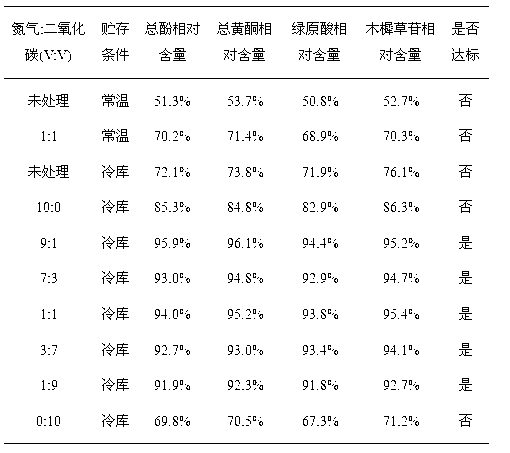

Storage and fresh preservation method of honeysuckle

The invention discloses a storage and fresh preservation method of honeysuckle. The method comprises the steps that dried honeysuckle is put into a packaging bag for controlled atmosphere treatment, and then sealed and packaged. Gas used for the controlled atmosphere treatment is mixed gas of nitrogen and carbon dioxide. The sealed honeysuckle is placed in a 0-6 DEG C constant-temperature refrigeratory for storage. The method is simple in technology; the batch storage of the honeysuckle is achieved; oxidation of effective components such as chlorogenic acid and flavone of the honeysuckle, and loss of aroma components can be prevented effectively; and the storage time and quality of the honeysuckle are prolonged and improved greatly.

Owner:SHANDONG ANALYSIS & TEST CENT

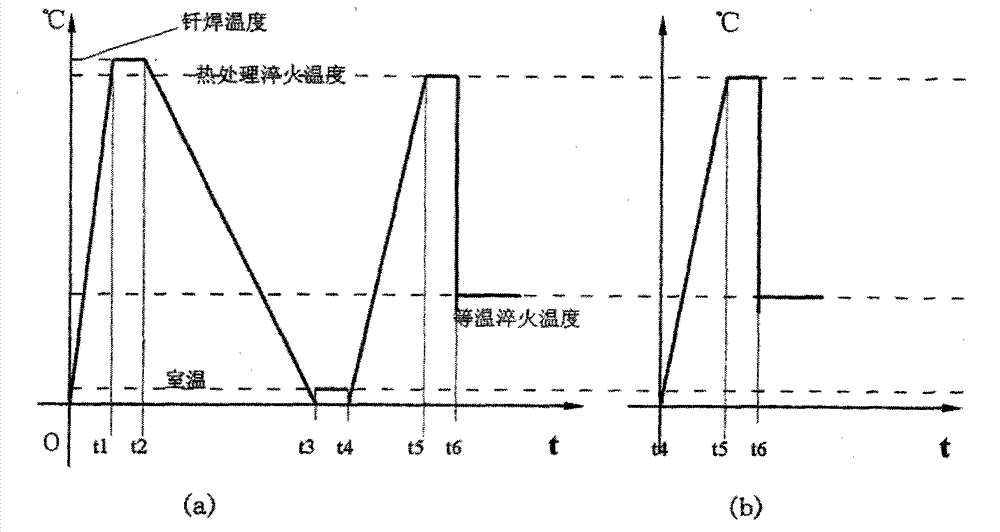

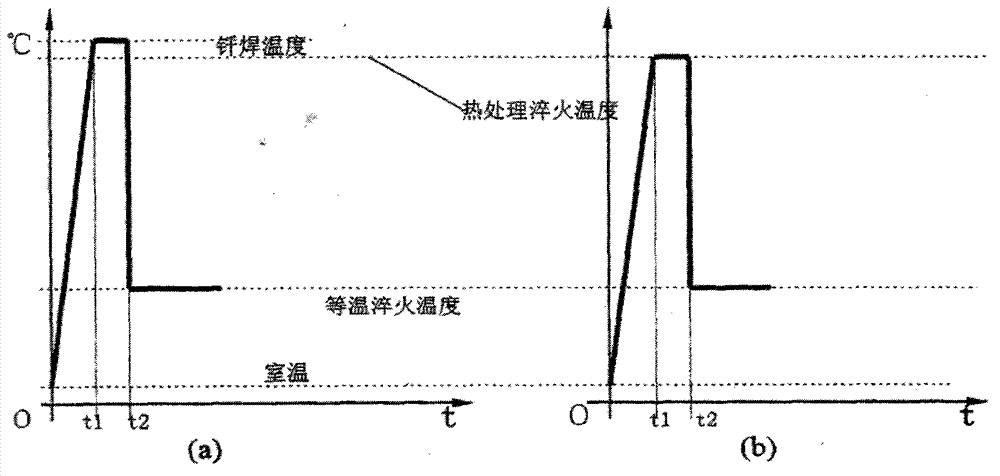

Production method of cutting picks of coal mining machine

The invention discloses a production method of cutting picks of a coal mining machine. The production method comprises the following steps of: enabling the cutting picks which are well matched to sequentially enter a heating area of an inductor, and controlling the automatic feeding meter at 12 seconds-14 seconds; enabling the cutting picks to enter a welding area, firstly supplementing borax at the upper part of an alloy gear head, tightly shaking an alloy for a plurality of times after melting of copper, performing heat treatment when the temperature of an isothermobath is not less than 230 DEG C, gradually clamping out the well welded cutting picks, arranging into a hanging hook, rapidly lifting the hanging hook with the hand, immersing the cutting picks into a saline solution of the isothermobath, swinging left and right for 3 times, then hanging a cross rod, totally immersing the gear head alloy in the saline solution, and rapidly starting to supply water for cooling when temperature achieves 265 DEG C during feed-discharge balance; staying the cutting picks for not less than 30 minutes under the state that the variation in the isothermobath does not exceed a 20-DEG C constant temperature zone; and lifting out the cutting picks, performing salt leaching, and then washing and cooling. The difference between the production method disclosed by the invention and the prior art is that two times of heating are combined into a whole and can be completed once, thus the brazing quality is ensured, and the heat treatment quenching quality is also improved.

Owner:安徽省皖江机电设备制造有限公司

Preparation method for novel high temperature resisting organic fire prevention heat insulating material

InactiveCN101544014AHigh temperature resistantDimensionally stableCeramic shaping apparatusMass ratioSolvent

The invention provides a preparation method for novel high temperature resisting organic fire prevention heat insulating material. The preparation method comprises the following steps: mixing an organic silicon resin and alumina micropowder according to the mass ratio of 25-35:75-65, adding an organic solvent so as to make the raw materials be evenly mixed, adding the mixture into a 110 to 130 DEG C constant temperature oven and performing heating preservation for 3 to 12 hours so as to remove the solvent, transferring the mixture into a heating die while the mixture is still hot, carrying out the forming according to a staged temperature rise die stamping process system, and adding the material into a constant temperature oven at 200 to 250 DEG C after decompression and die ejection and carrying out the treatment for 5 to 10 hours. The prepared organic fire prevention heat insulating material has the advantages of conventional inorganic and organic fire prevention materials. The material shows the characteristics of resin material and has enough mechanical strength at a room temperature; and the material is converted into ceramic material at a high temperature, still meets the requirement of enough mechanical strength, and has stable external dimensions without deformation in the heating process. The material has a simple preparation process, and can be used for making covers and protecting cases meeting various requirements on the shape through die stamping. The method is suitable for the industrialized production.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com