Method of nickel-copper-phosphor ternary alloy plating on carbon fiber surface

A ternary alloy and carbon fiber technology, which is applied in the fields of fiber chemical characteristics, liquid chemical plating, metal material coating technology, etc., can solve problems such as complex processes and achieve the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

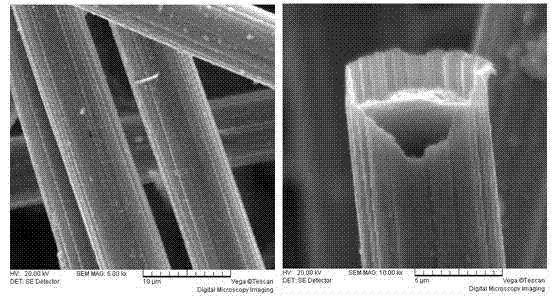

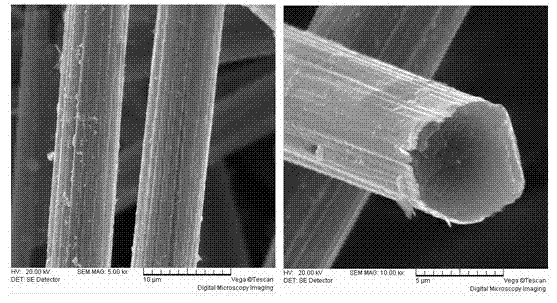

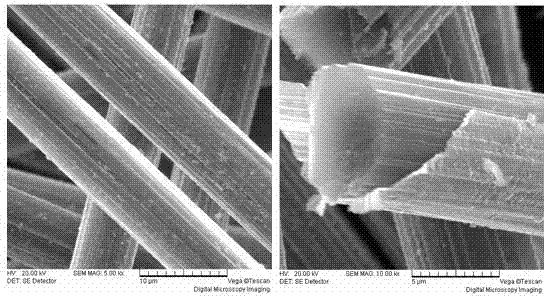

Image

Examples

Embodiment 1

[0026] Experimental raw materials include: T300 polyacrylonitrile-based carbon fiber, copper sulfate, nickel sulfate, palladium chloride, stannous chloride, acetone, hydrochloric acid, and 65% nitric acid. First use a Soxhlet extraction device to extract the carbon fiber with acetone at 70°C for 4 hours, then dry it naturally, then soak it in 65% concentrated nitric acid for 40 minutes, take it out, and then rinse it repeatedly with deionized water until the pH value of the residual solution is the same as Before cleaning, the pH value of the deionized water is close to that of the water, and it is dried in an oven at a temperature of about 80°C. Put the roughened carbon fiber into the SnCl-containing 2 Sensitize in a sensitizing solution of 20g / L and 40ml / L hydrochloric acid for 15min, take it out, wash it with distilled water once, dry it, and then put it into the sensitization solution containing PdCl 2 0.25g / L, hydrochloric acid 2.5ml / L activation solution for 15min, tak...

Embodiment 2

[0028] Experimental raw materials include: T300 polyacrylonitrile-based carbon fiber, copper sulfate, nickel sulfate, palladium chloride, stannous chloride, acetone, hydrochloric acid, and 65% nitric acid. First use a Soxhlet extraction device to extract the carbon fiber with acetone at 70°C for 4 hours, then dry it naturally, then soak it in 65% concentrated nitric acid for 40 minutes, take it out, and then rinse it repeatedly with deionized water until the pH value of the residual solution is the same as Before cleaning, the pH value of the deionized water is close to that of the water, and it is dried in an oven at a temperature of about 80°C. Put the roughened carbon fiber into the SnCl-containing 2 Sensitize in a sensitizing solution of 20g / L and 40ml / L hydrochloric acid for 15min, take it out, wash it with distilled water once, dry it, and then put it into the sensitization solution containing PdCl 2 0.25g / L, hydrochloric acid 2.5ml / L activation solution for 15min, tak...

Embodiment 3

[0030] Experimental raw materials include: T300 polyacrylonitrile-based carbon fiber, copper sulfate, nickel sulfate, palladium chloride, stannous chloride, acetone, hydrochloric acid, and 65% nitric acid. First use a Soxhlet extraction device to extract the carbon fiber with acetone at 70°C for 4 hours, then dry it naturally, then soak it in 65% concentrated nitric acid for 40 minutes, take it out, and then rinse it repeatedly with deionized water until the pH value of the residual solution is the same as Before cleaning, the pH value of the deionized water is close to that of the water, and it is dried in an oven at a temperature of about 80°C. Put the roughened carbon fiber into the SnCl-containing 2Sensitize in a sensitizing solution of 20g / L and 40ml / L hydrochloric acid for 15min, take it out, wash it with distilled water once, dry it, and then put it into the sensitization solution containing PdCl 2 0.25g / L, hydrochloric acid 2.5ml / L activation solution for 15min, take ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com