Patents

Literature

125results about How to "Reduce the risk of obsolescence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

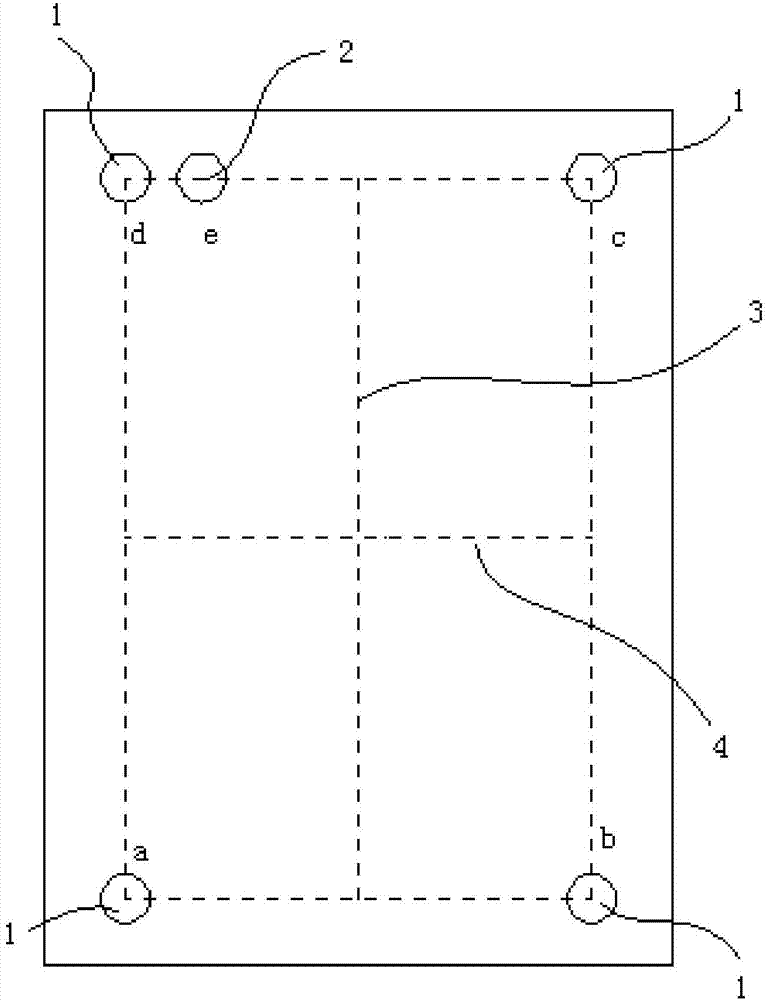

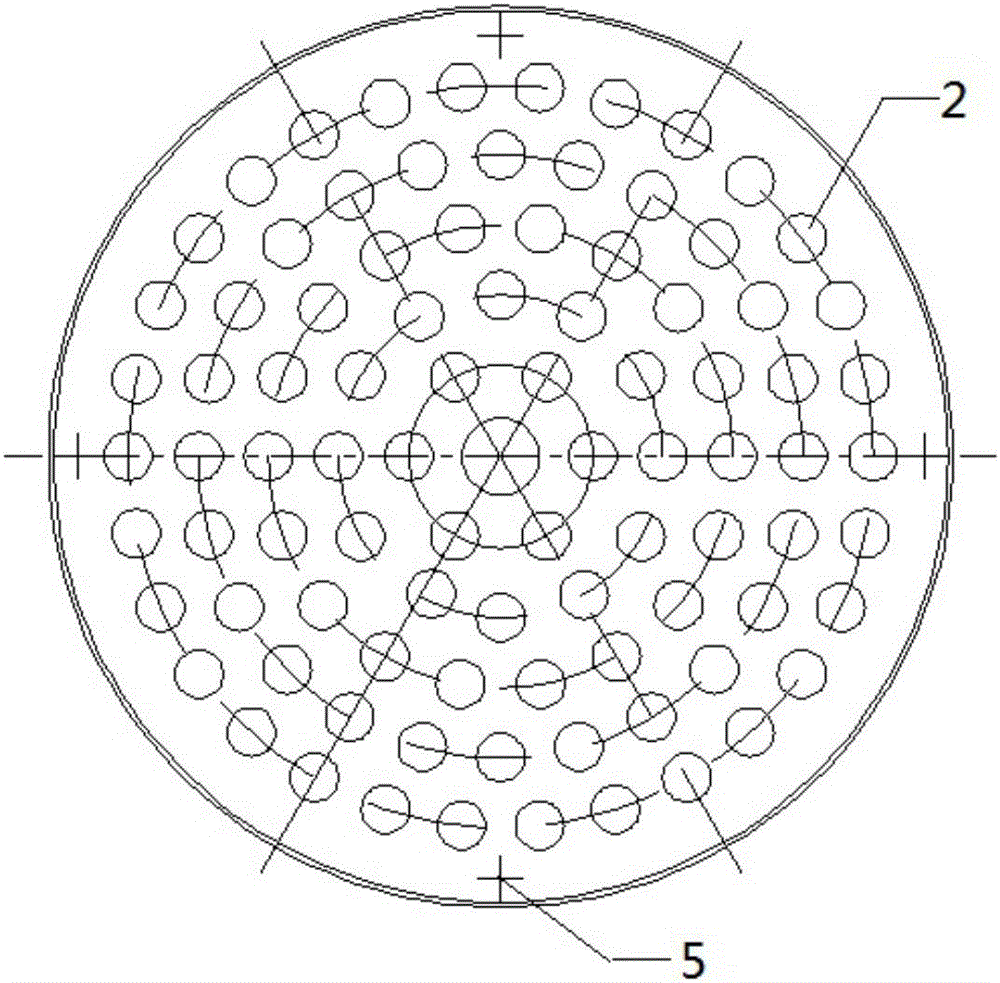

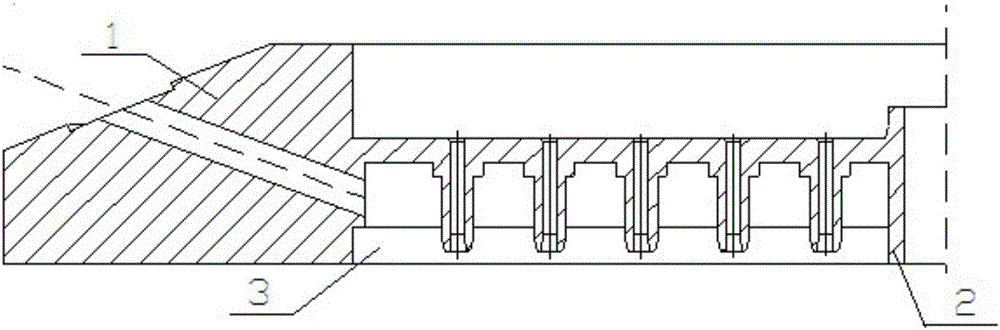

Drilling method for circuit board

ActiveCN103752882AGuaranteed coincidenceHigh precisionPrinted circuit manufactureDrill holeDiameter ratio

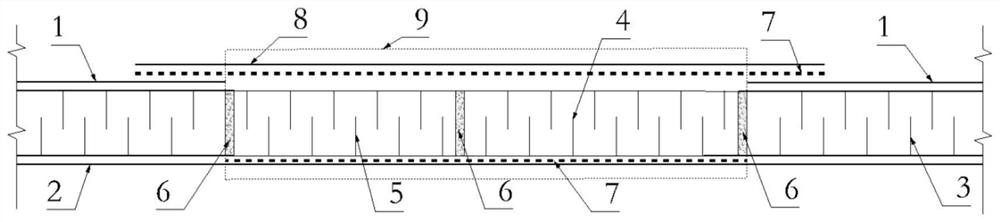

The invention discloses a drilling method for a circuit board and belongs to the technical field of circuit board production. The drilling method comprises the following steps of setting a positioning target and a directional target on the circuit board, drilling a positioning hole in the positioning target and drilling a directional hole in the directional target; enabling the number of the directional target to be one and arranging the directional target in an area which is outside a horizontal central line and a longitudinal central line; identifying the direction of the circuit board through the directional hole, enabling a pin to penetrate the positioning hole and installing and fixing the circuit board and a cover plate; drilling the circuit board in the front side and the rear side and enabling the drilled holes in the front side and the rear side to be through holes. The drilling method for the circuit board can achieve circuit board drilling with the high thickness-diameter ratio and obtain high accuracy hole location.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

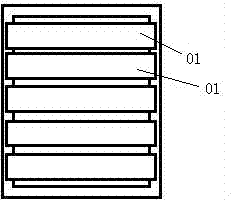

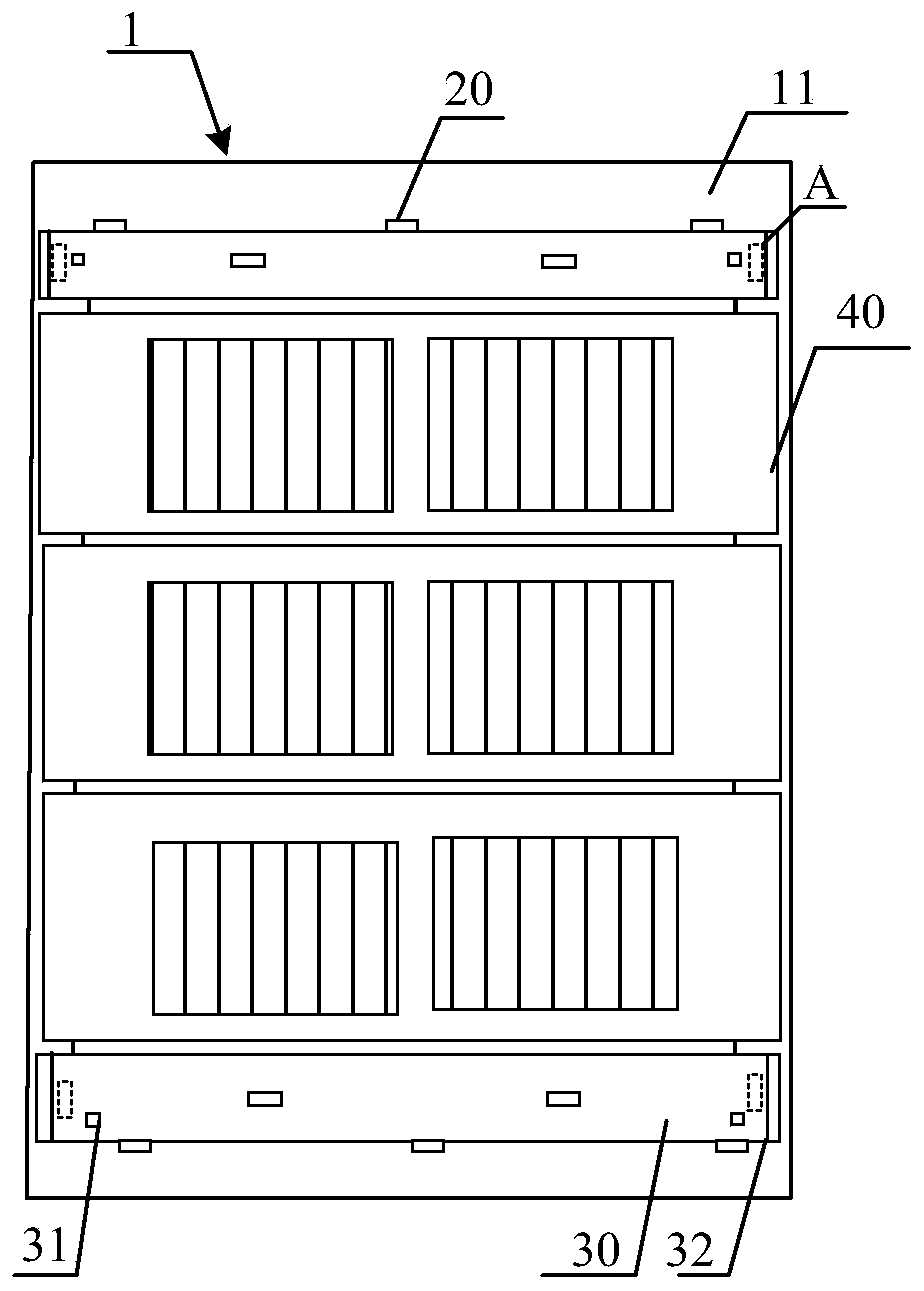

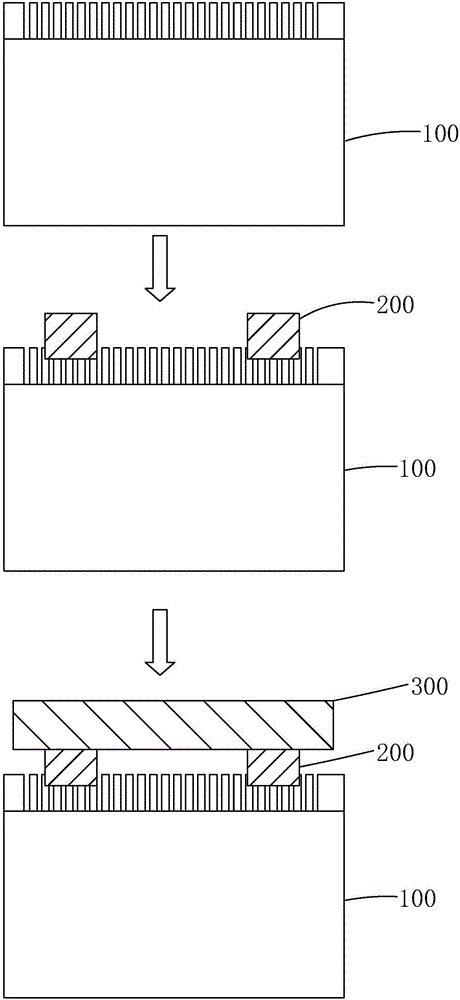

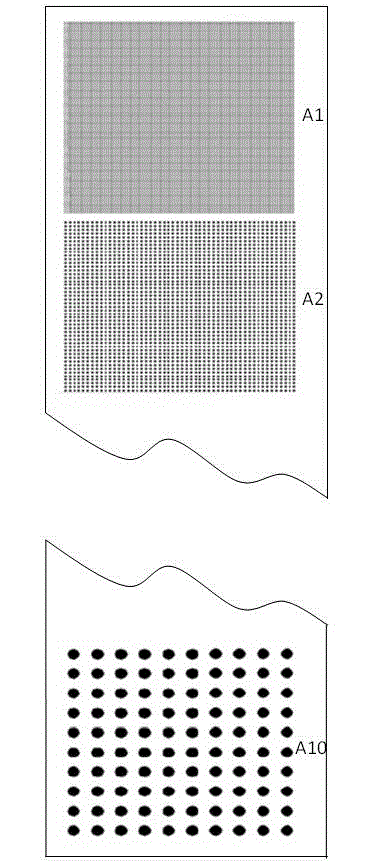

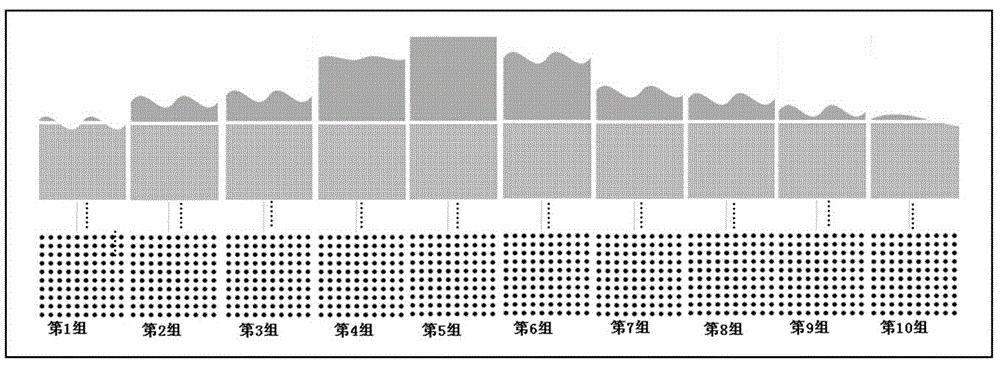

Metal mask plate structure and manufacturing method thereof

InactiveCN104846329ASpread riskLow costVacuum evaporation coatingSputtering coatingAgricultural engineeringFixed position

The invention discloses a metal mask plate structure. The metal mask plate structure comprises a plurality of divided daughter mask plates with equal or unequal areas, wherein the plurality of daughter mask plates can form a complete mask plate through splicing. The invention also discloses a manufacturing method for the metal mask plate. The manufacturing method comprises the following steps: step 1, providing a mask plate frame used for bearing the daughter mask plates and the above-mentioned plurality of daughter mask plates, wherein the mask plate frame is provided with fixed position clips used for fixing the daughter mask plates; step 2, placing the plurality of daughter mask plates on the fixed position clips on the mask plate frame and fixing the daughter mask plates via the fixed position clips; and step 3, splicing the plurality of daughter mask plates into a complete mask plate through welding or hinging. According to the metal mask plate structure provided by the invention, a segmented mask plate can be further divided into a plurality of daughter mask plates, so manufacturing difficulty of the mask plate can be abated, manufacturing cost for the mask plate can be reduced, the risk of scrapping of the whole mask plate can be lowered down, the recycle life of the mask plate can be prolonged, and manufacturing precision of each segment of the mask plate can be improved.

Owner:TRULY HUIZHOU SMART DISPLAY

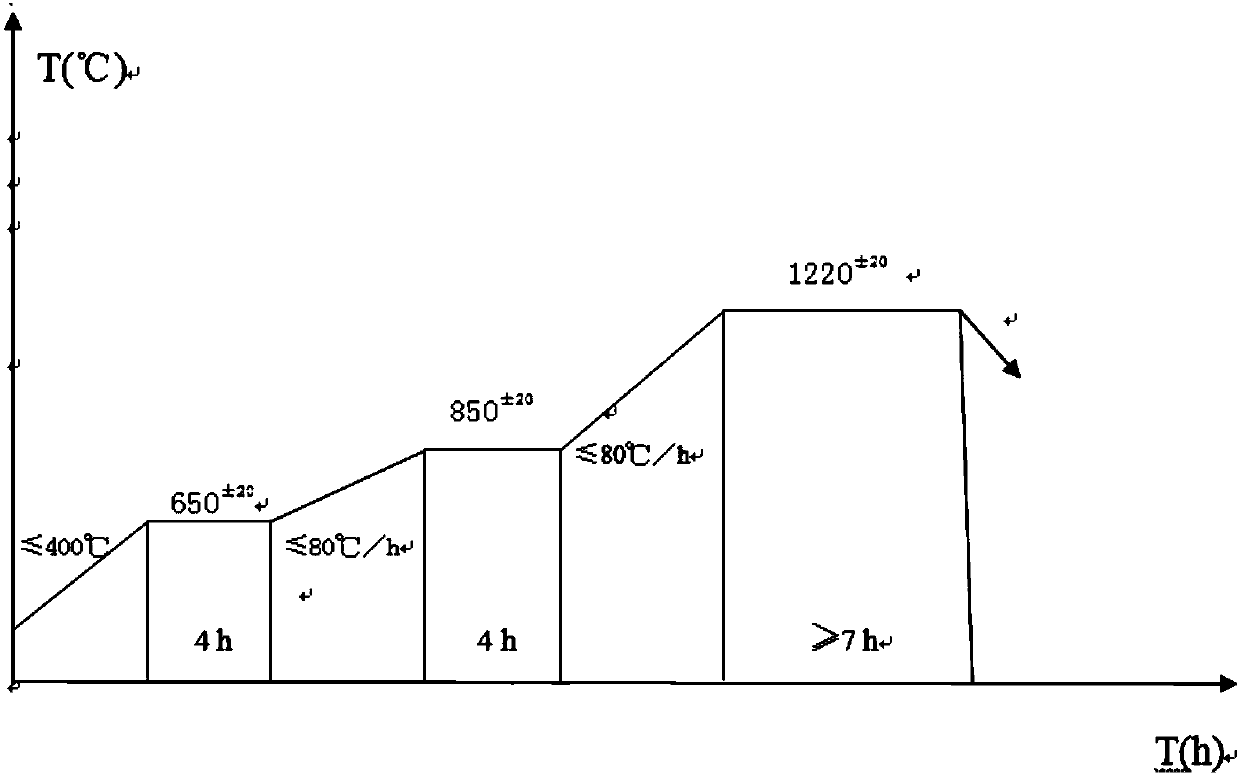

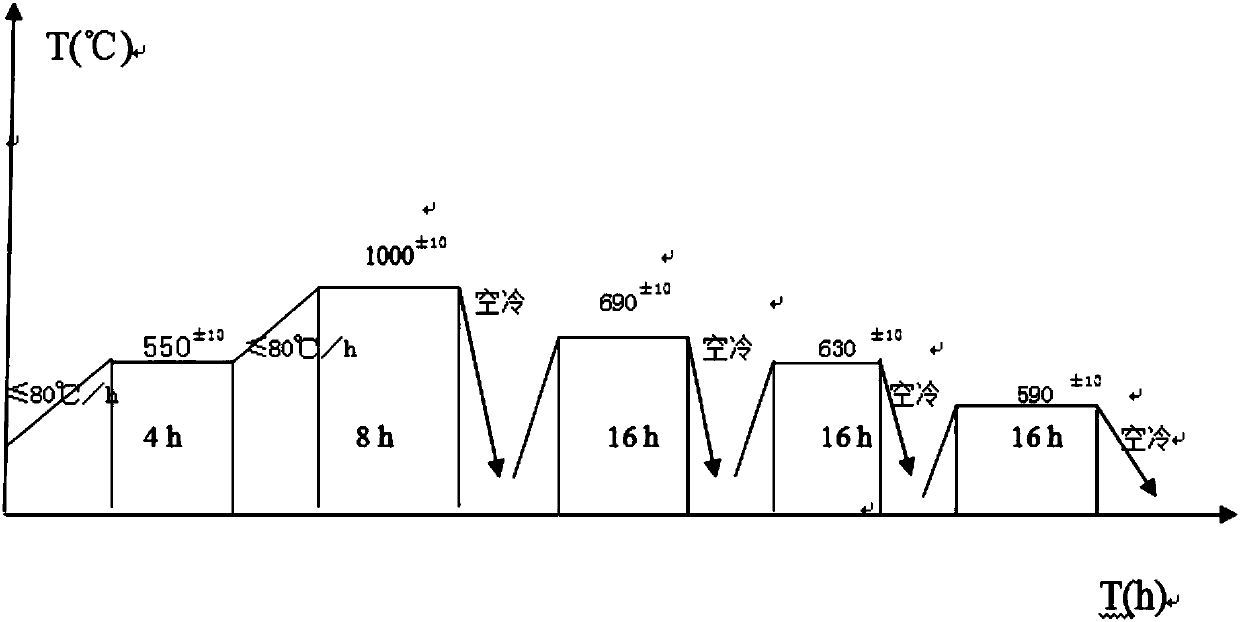

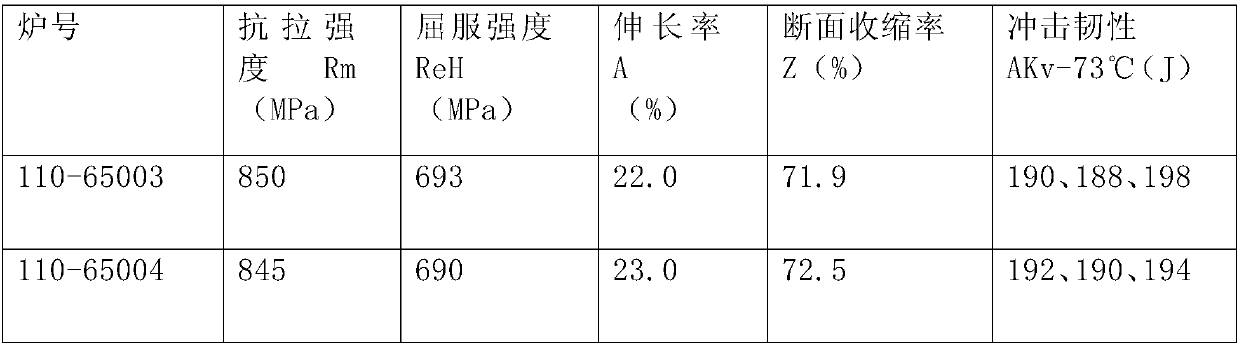

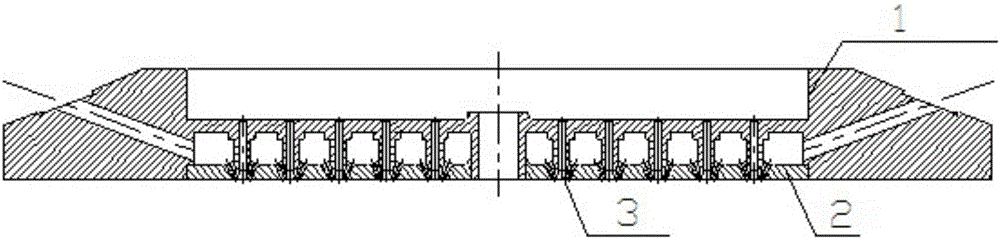

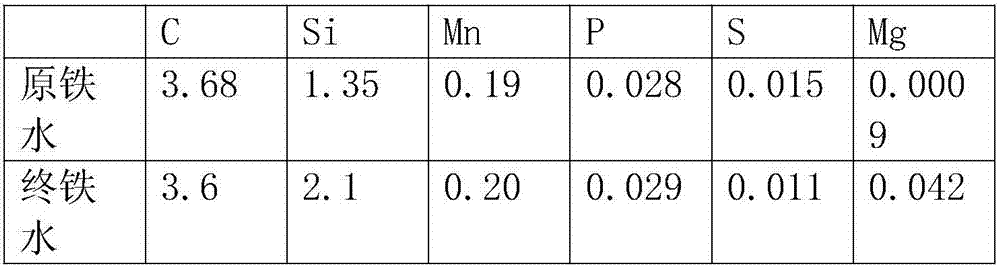

F6NM martensitic stainless steel cylinder-body forge piece and heat treatment method

ActiveCN107937828AReduce the risk of obsolescenceStable mechanical propertiesMartensitic stainless steelSS - Stainless steel

The invention relates to a F6NM martensitic stainless steel cylinder-body forge piece and a heat treatment method. According to the F6NM martensitic stainless steel cylinder-body forge piece and the heat treatment method, the high strength and the high low temperature impact toughness resistance can be met, cracks are avoided, and meanwhile, cracking and scrap of steel ingots during forging are avoided; and the F6NM martensitic stainless steel cylinder-body forge piece comprises, by mass, no more than 0. 04% of C, 0.30-0.50% of Si, 0.70-1.00% of Mn, 11.5-13.0% of Cr, 3.5-4.5% of Ni, 0.50-0.70%of Mo, 0.04-0.1% of V, no more than 0.020% of P and no more than 0.010% of S. The F6NM martensitic stainless steel cylinder-body forge piece has the advantages that the F6NM martensitic stainless steel cylinder-body forge piece after being subjected to component optimization adopts sectional-type constant-temperature slow heating, the charging temperature, the heating speed and the heat preservation time are strictly controlled, forging is strictly executed according to the new forging process, and heat treatment adopts the special heat treatment process of 550 DEG C constant-temperature heating, 1000 DEG C air quenching and three times of tempering at 690 DEG C, 630 DEG C and 590 DEG C. After production, product inspection dimensions confirm to the customer drawing requirements, a sampleis sampled and sent to a third party for being tested, the mechanical properties meet the index requirements, after multiple times of production, the mechanical properties of the F6NM martensitic stainless steel cylinder-body forge piece are all very stable, and the F6NM martensitic stainless steel production scrap risk is greatly reduced.

Owner:BAODING TECH CO LTD

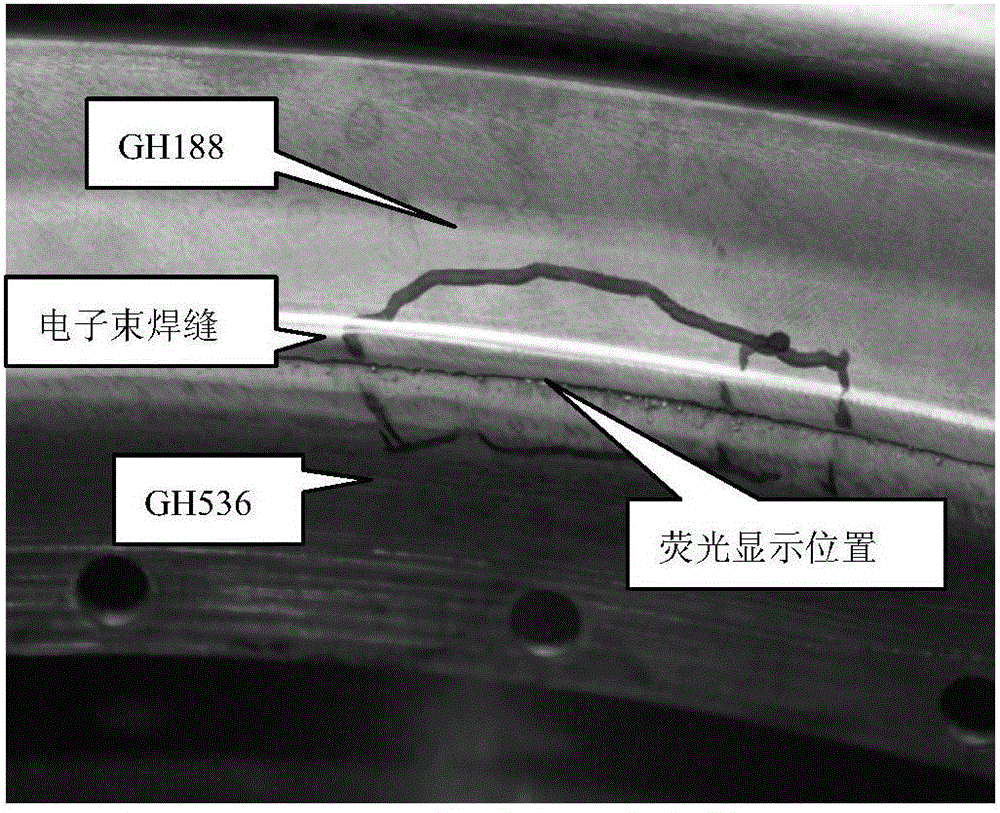

Welding method for multi-part structure of head injector in thrust chamber of liquid-propellant rocket engine

InactiveCN106735829AImprove reliabilityImprove welding qualityElectron beam welding apparatusThrust chamberPre treatment

The invention discloses a welding method for a multi-part structure of a head injector in a thrust chamber of a liquid-propellant rocket engine. According to the method, welding for the head injector in the thrust chamber of the liquid-propellant rocket engine is completed through welded part machining, welding reference machining for nozzle units, welded part pre-treatment, welded part assembly, welded part welding, nozzle unit welding, welding joint detection and drying. According to the method disclosed by the invention, a welding process method for a complex injector structure is optimized to be vacuum electron beam welding adopting a welding method which is more advanced, higher in reliability, higher in welding quality and lower in welding risk from traditional braze welding; and moreover, repair welding is hardly carried out once the traditional braze welding is failed, and local repair welding can be carried out in the vacuum electron beam welding, so that the product scrap risk is lowered.

Owner:湖北三江航天江北机械工程有限公司

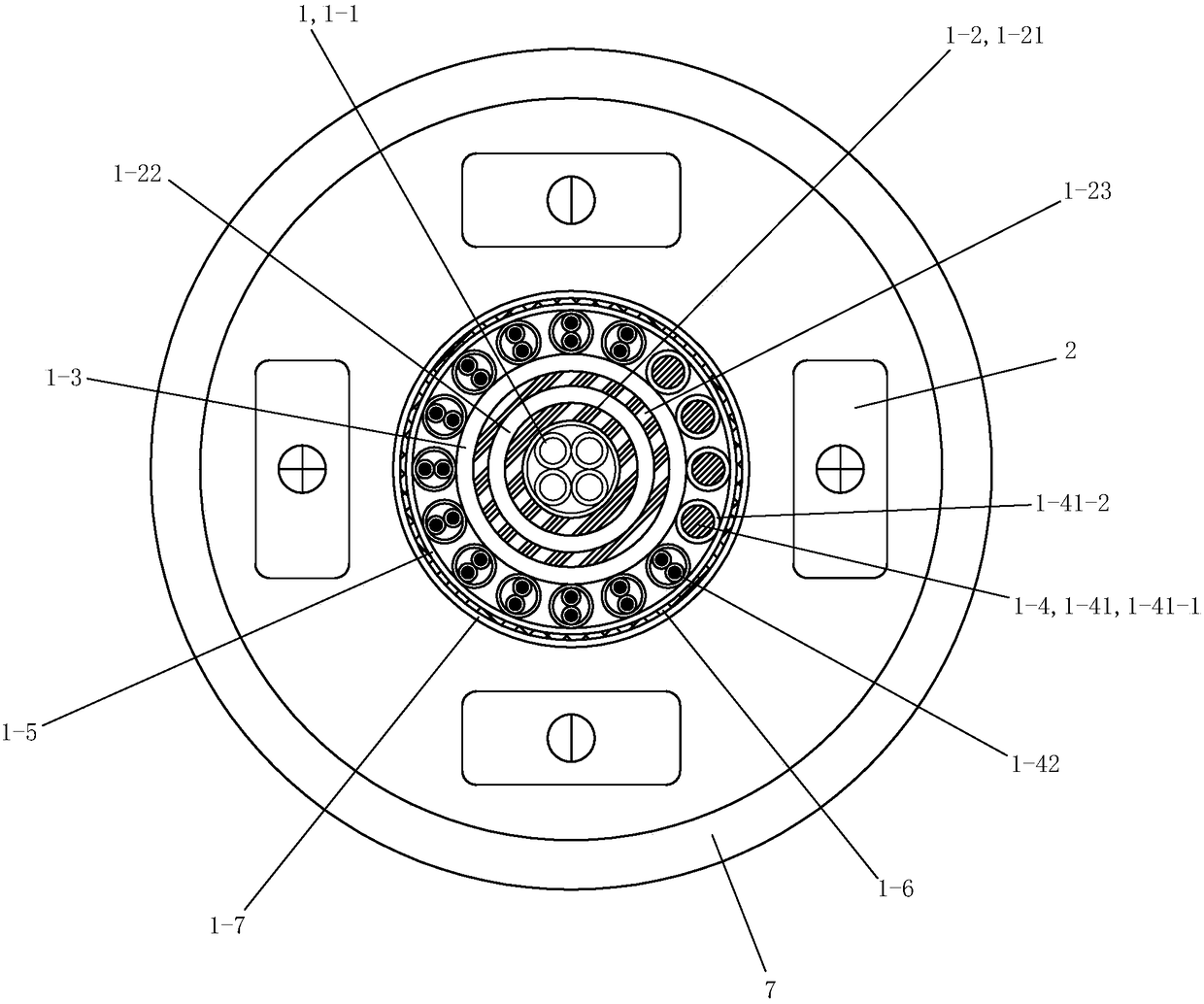

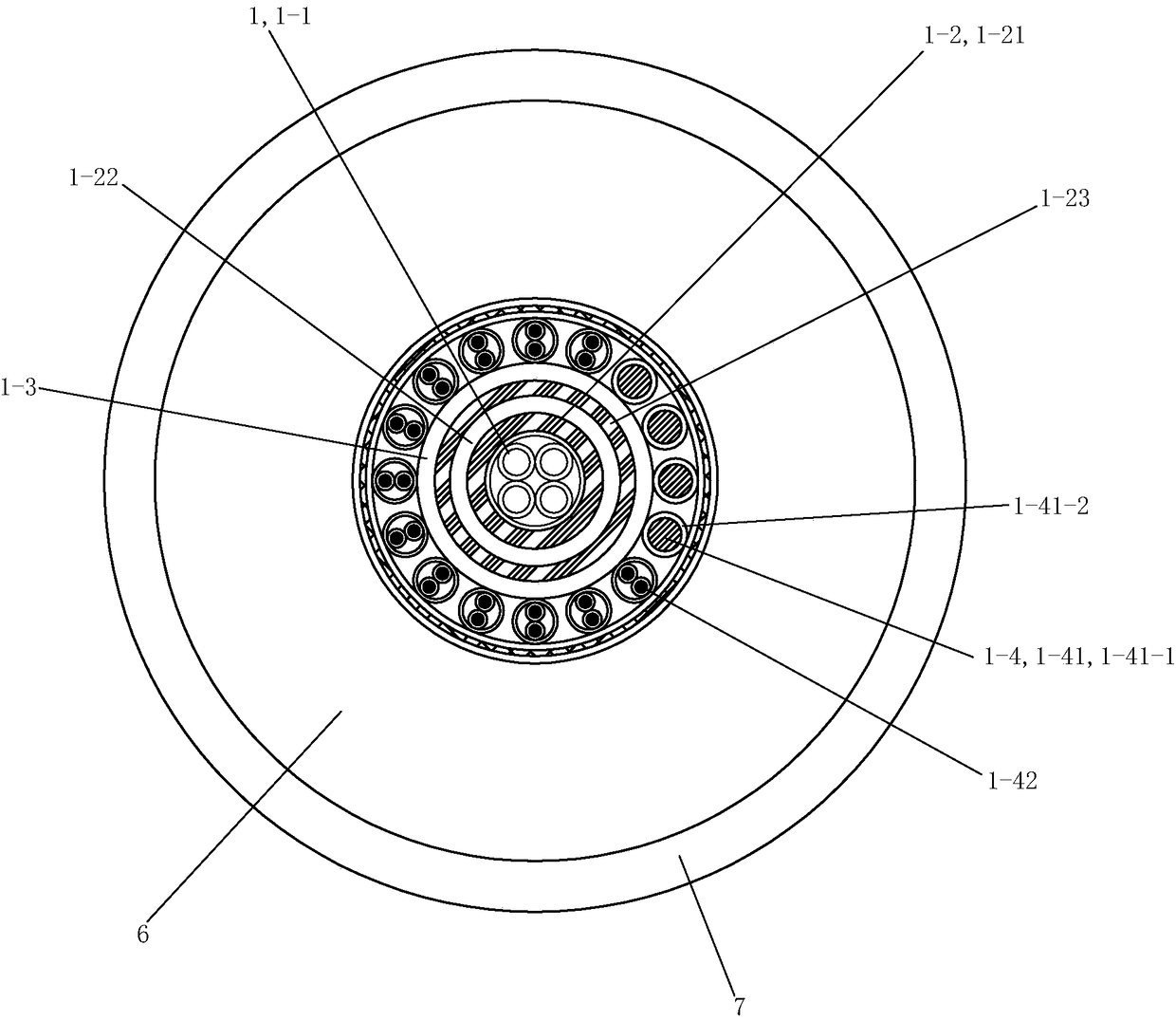

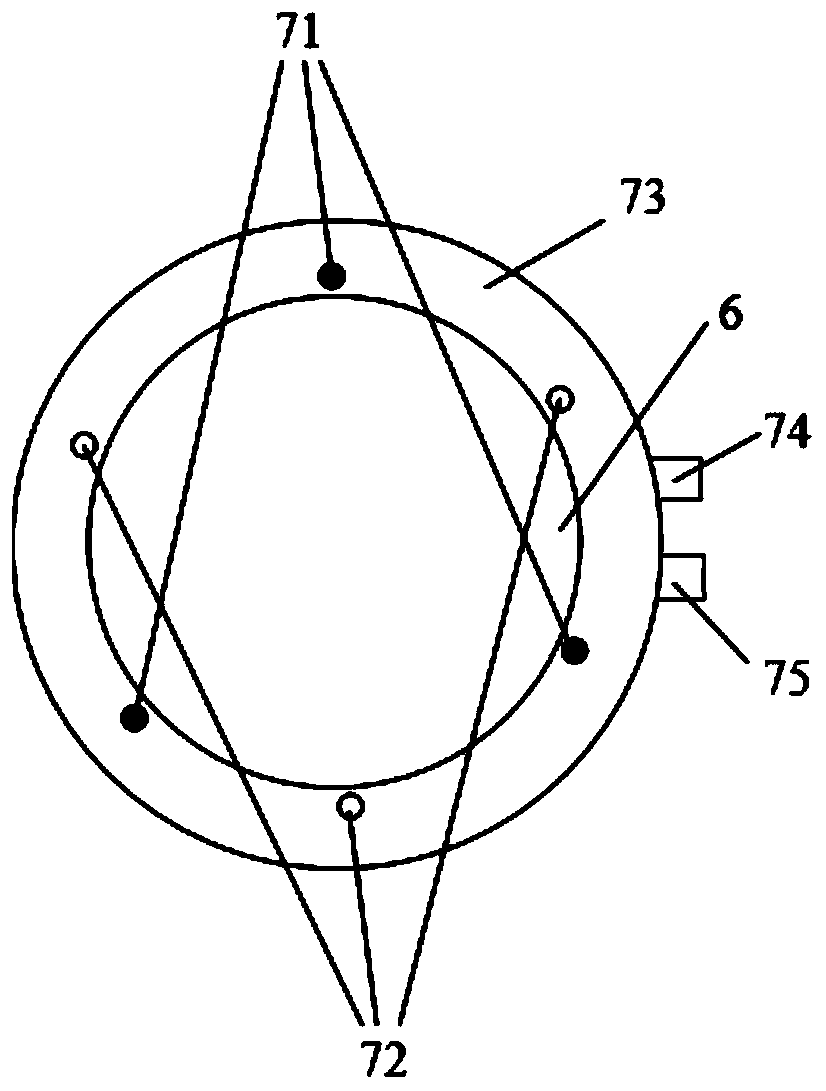

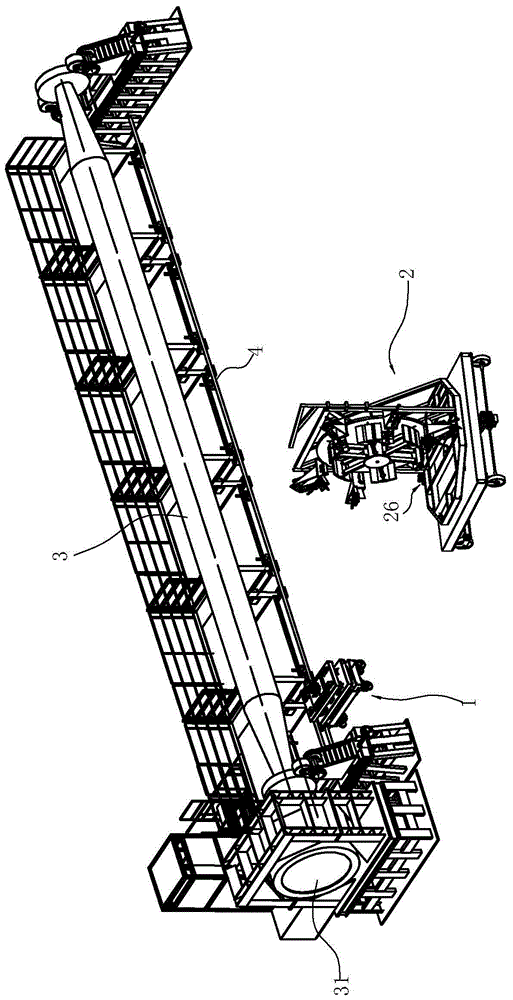

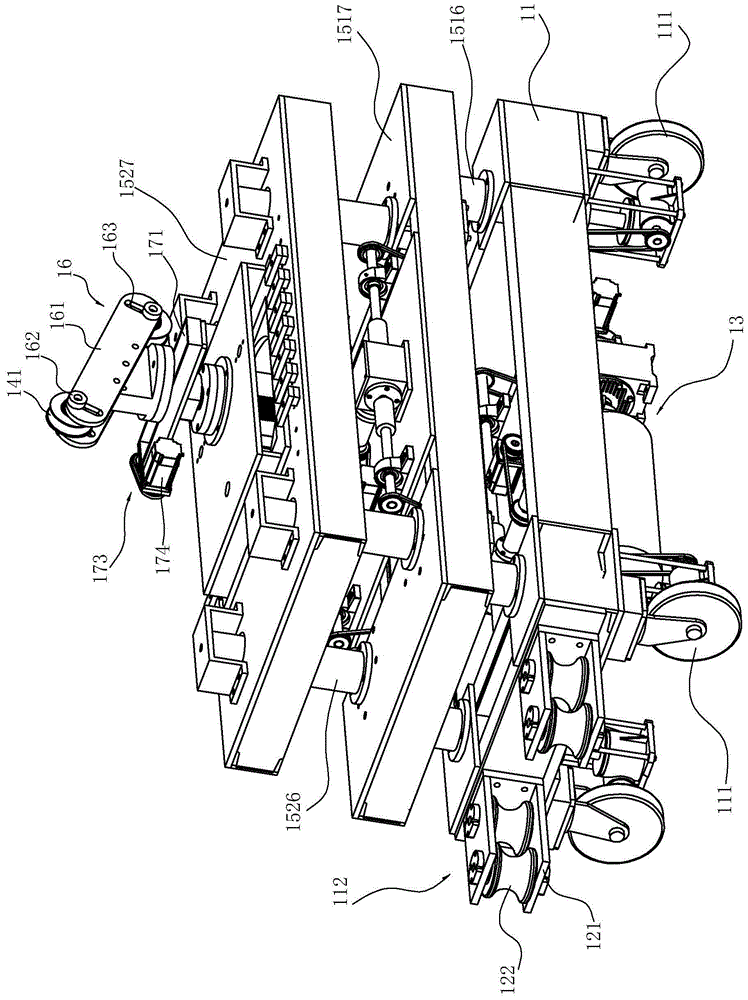

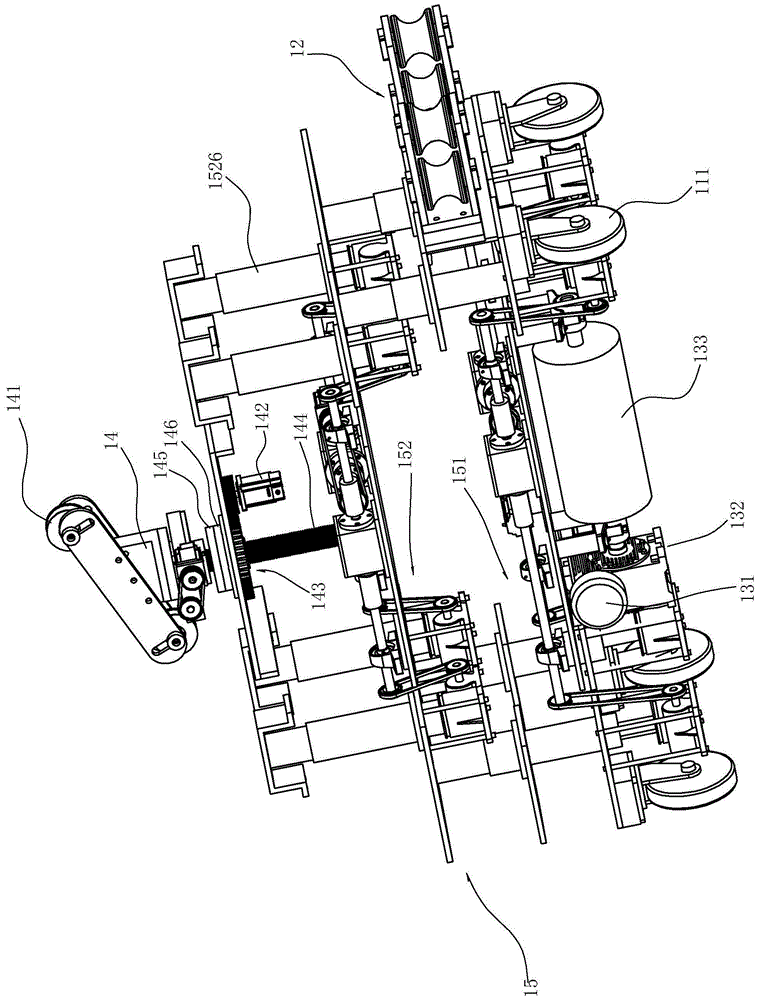

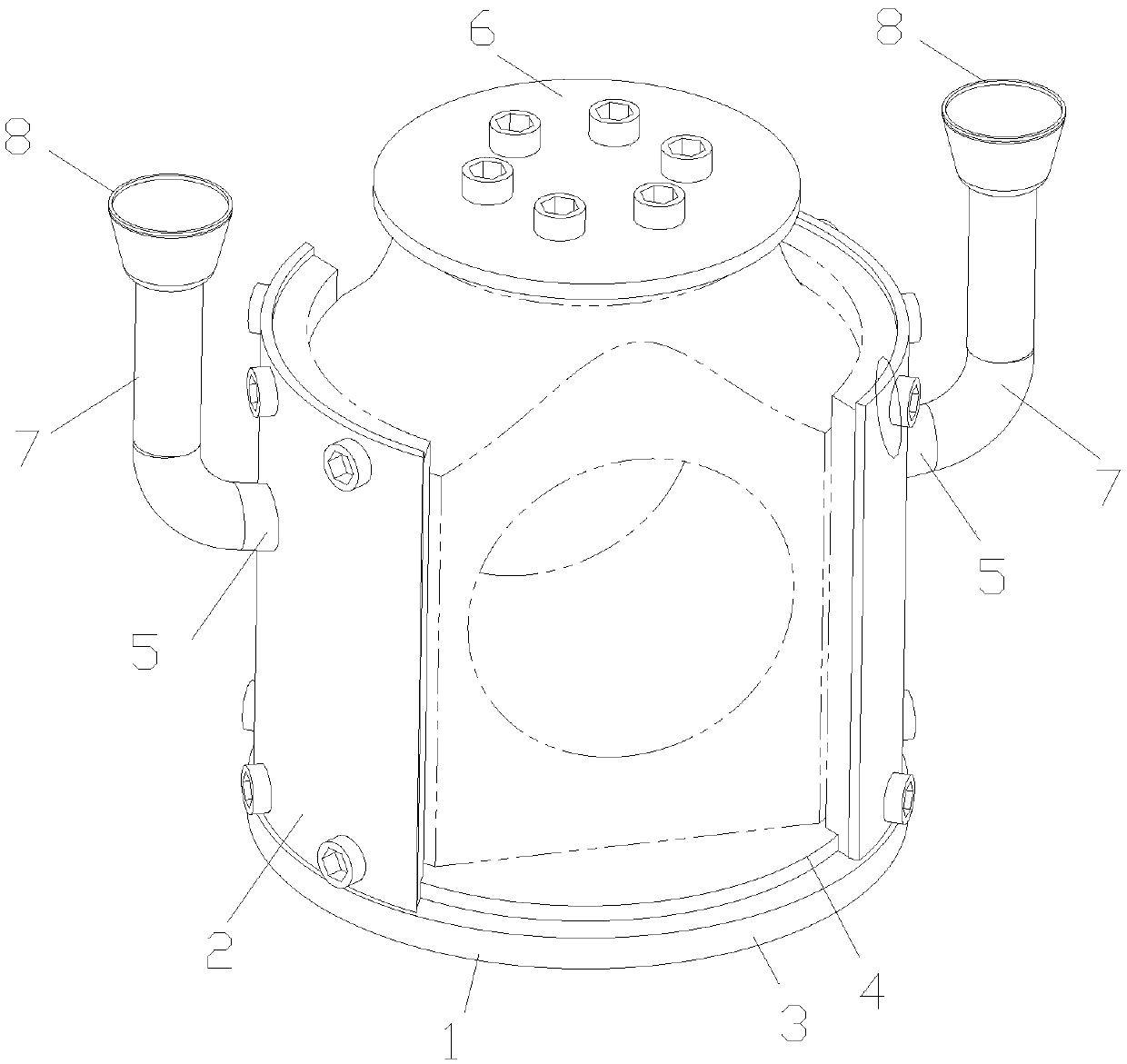

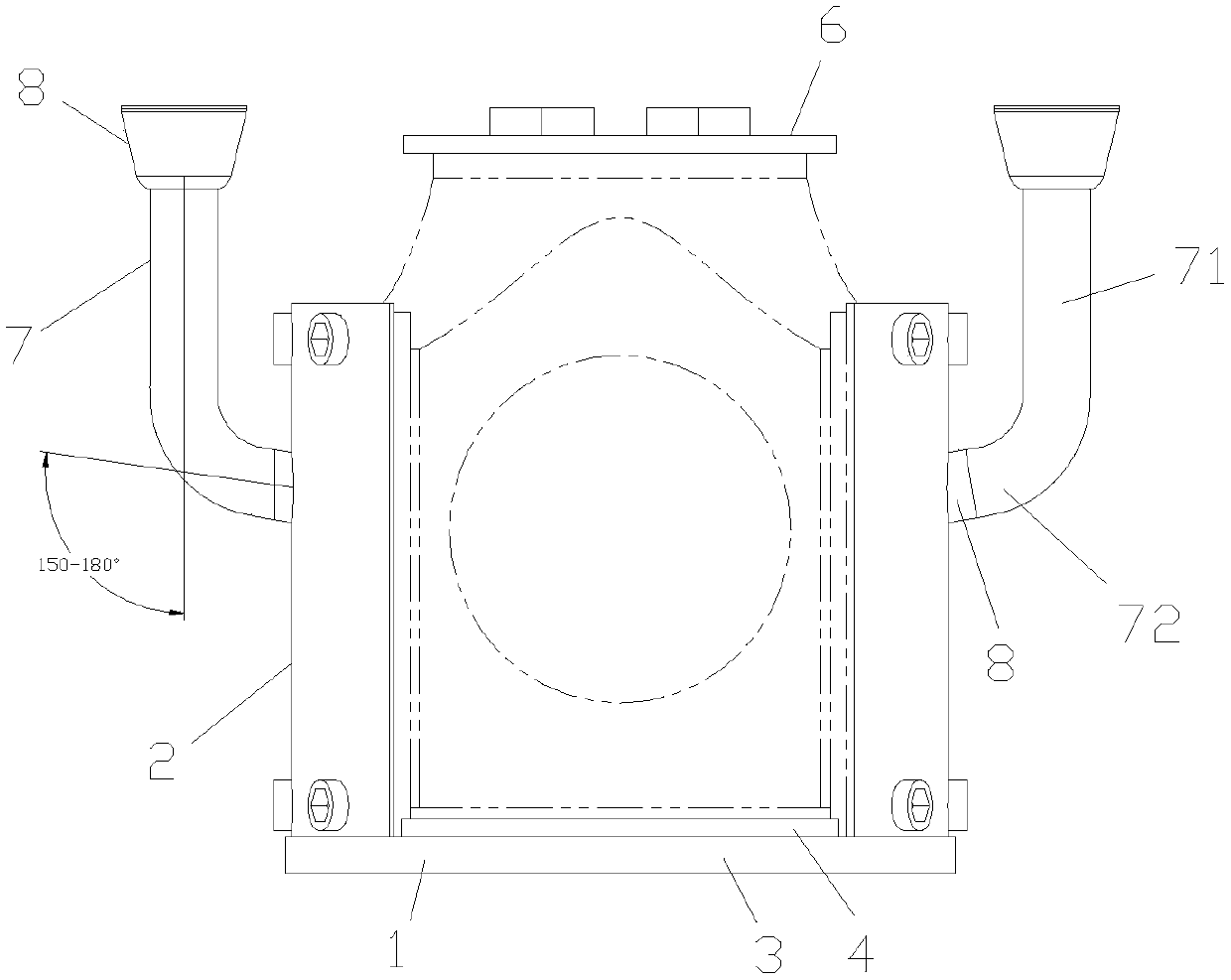

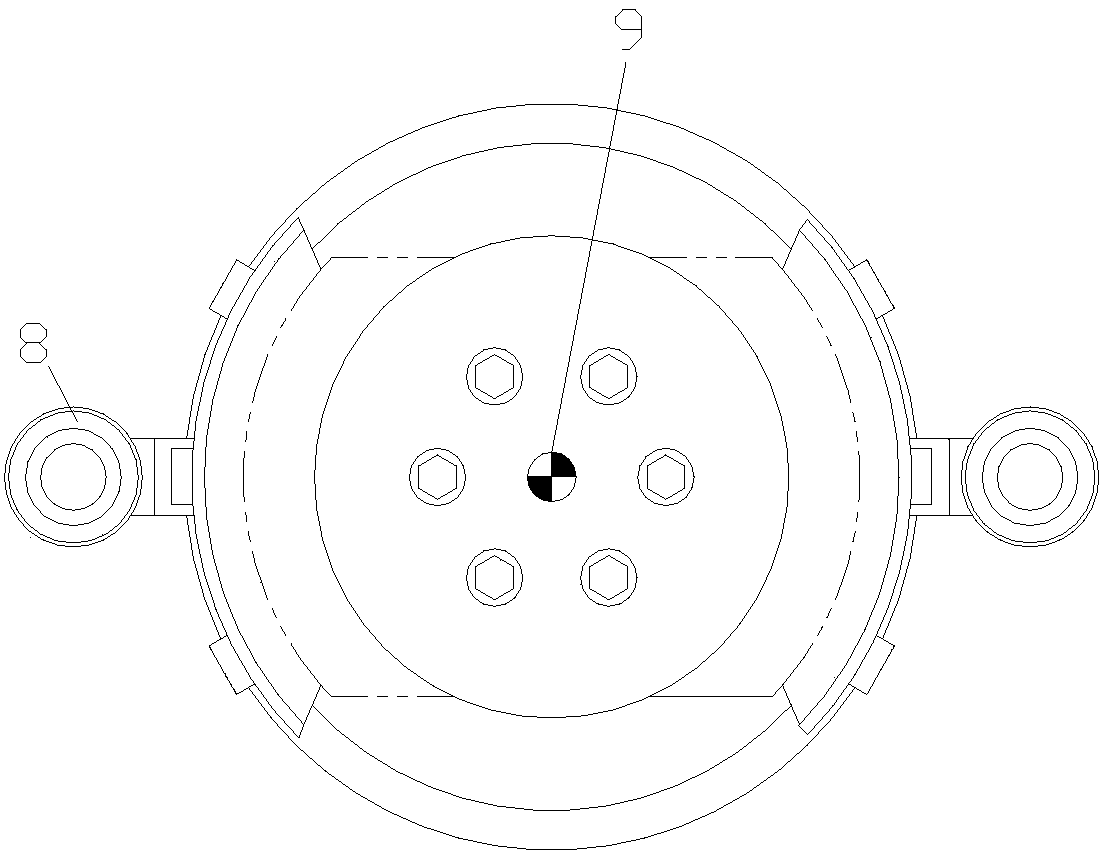

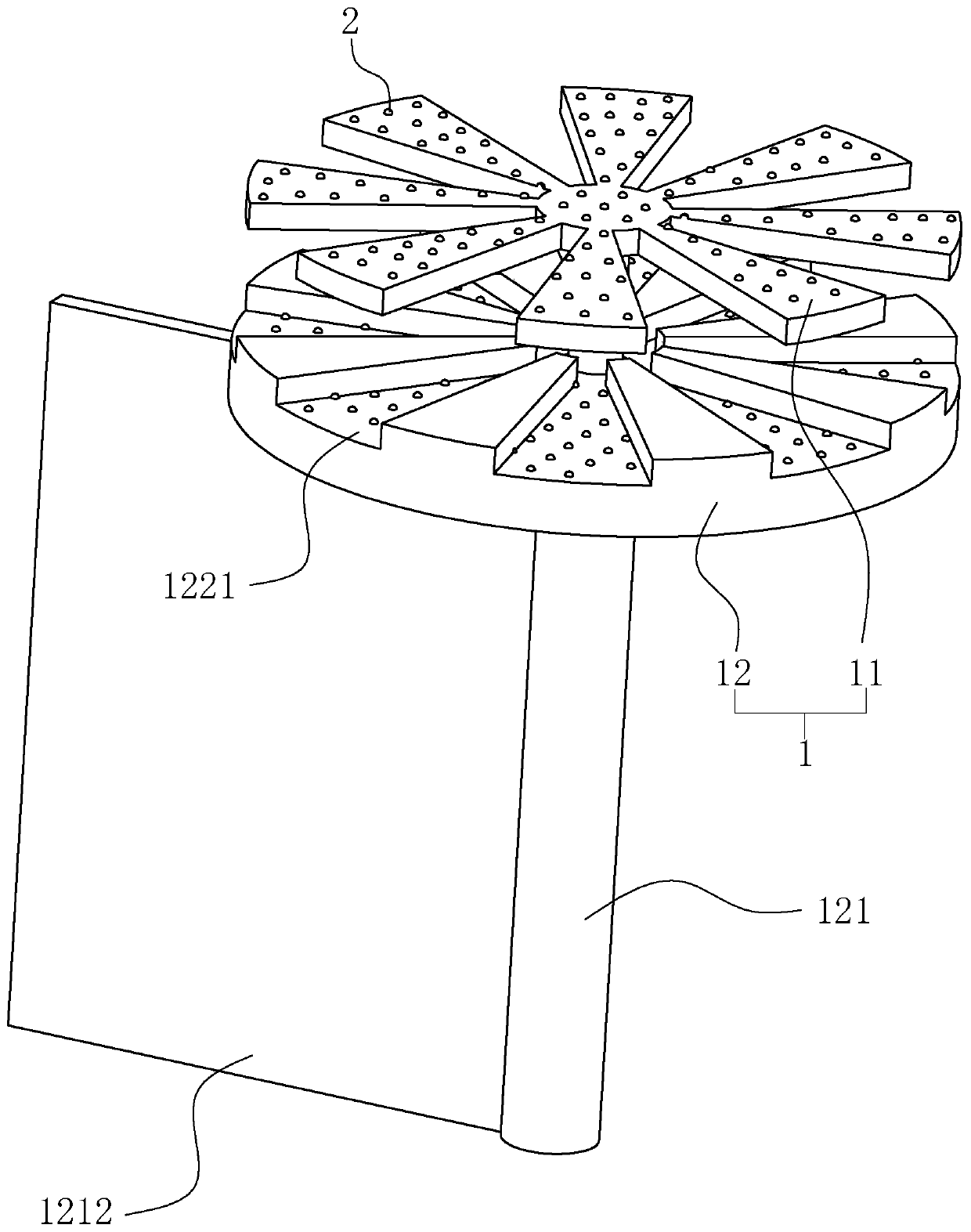

Pipe coiler

ActiveCN104444563ASimple structureGood anti-shrink functionFilament handlingControl systemEngineering

The invention relates to a pipe coiler. The pipe coiler comprises a riding wheel used for bearing a pipe to be coiled and is characterized by further comprising a pipe conveying device and a pipe uncoiling device, wherein the pipe conveying device sequentially comprises a pipe conveying base, a lifting mechanism, a fine adjustment mechanism, a supporting base, a radial adjusting mechanism and a riding wheel from bottom to top, the pipe uncoiling device comprises a pipe uncoiling base, a base plate is arranged on the pipe uncoiling base and provided with a support, and the support is provided with a rotating disk which is provided with an axial clamping mechanism, a radial clamping mechanism, a telescopic sleeve, an anti-shrinking mechanism, sensors and a control system. Through the pipe coiler, the pipe feeding position can be tracked in real time, the pipe conveying height, the pipe conveying angle and the pipe conveying speed can be adjusted in real time, the pipe coiling quality is guaranteed, the scrap risk is reduced, the labor intensity of workers is relieved, and manual cost is saved; due to the design of the pipe uncoiling device, it is effectively prevented that in the pipe distributing process, a coiled pipe bundle loosens, the loosened pipe bundle overlaps and is knotted, the pipe can go out smoothly, pipe distribution quality is guaranteed, and product quality is good.

Owner:ZHENHAI PETROCHEM JIANAN ENG

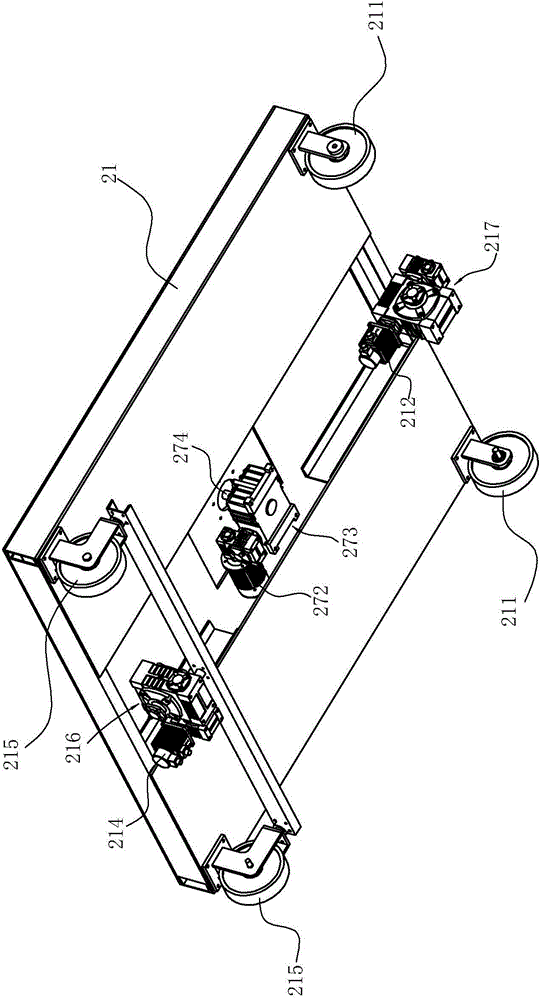

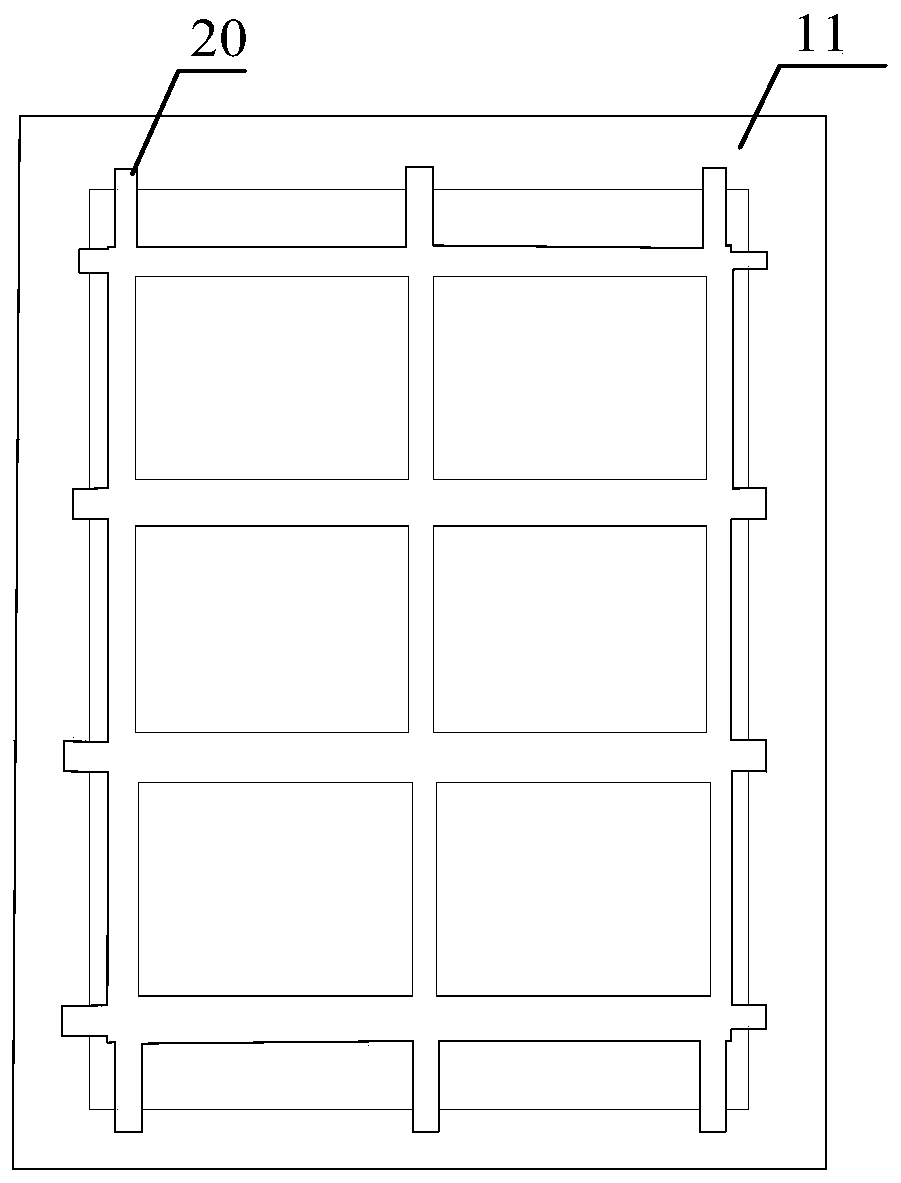

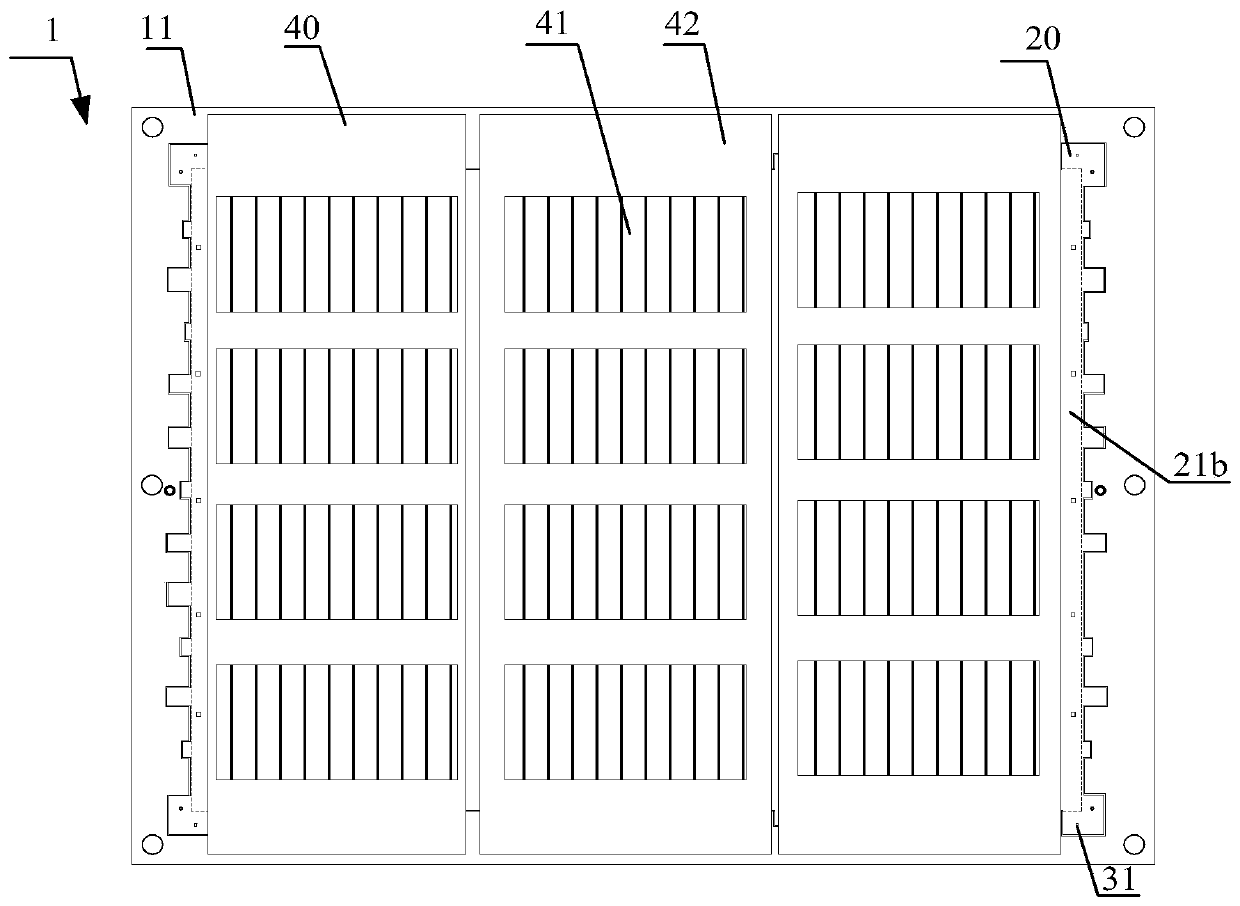

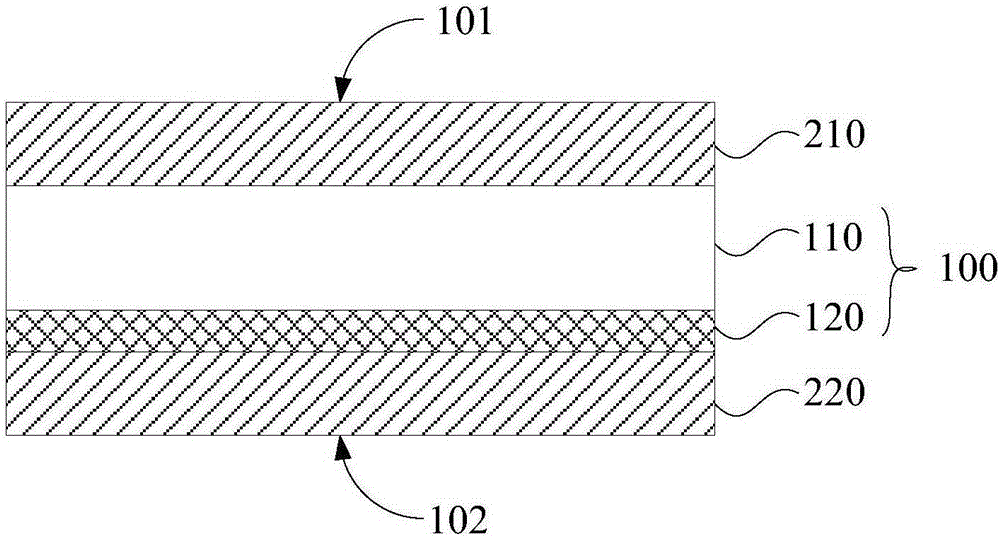

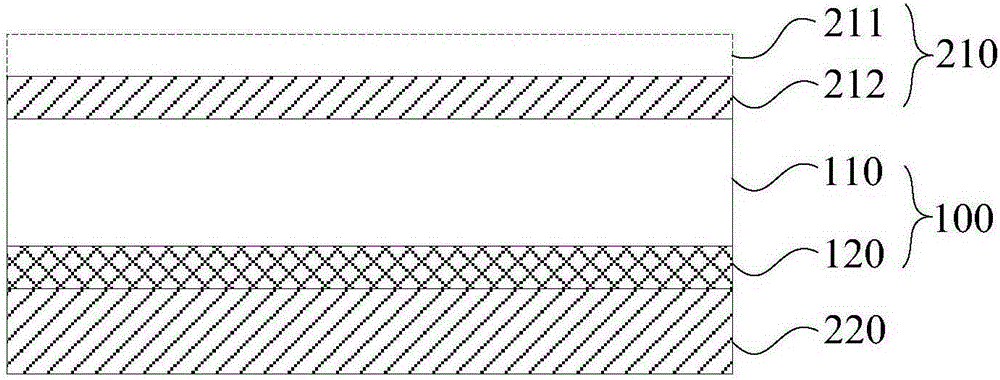

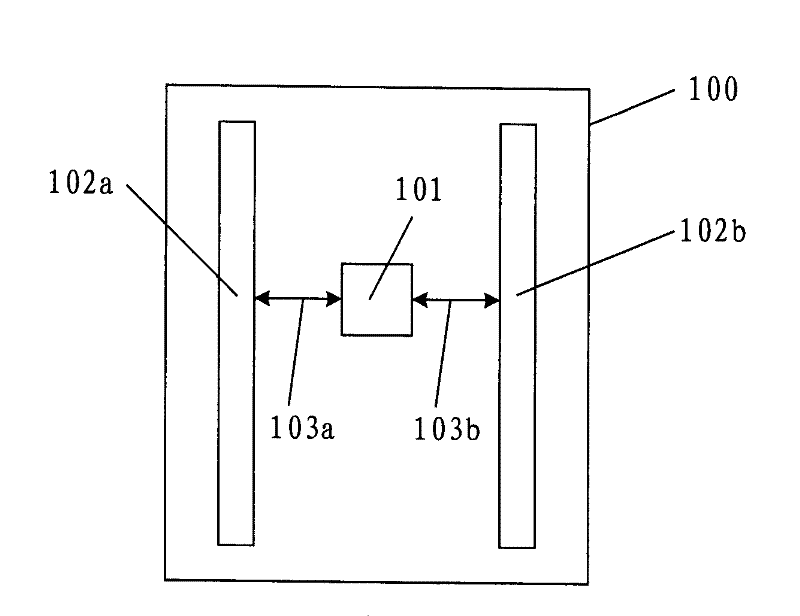

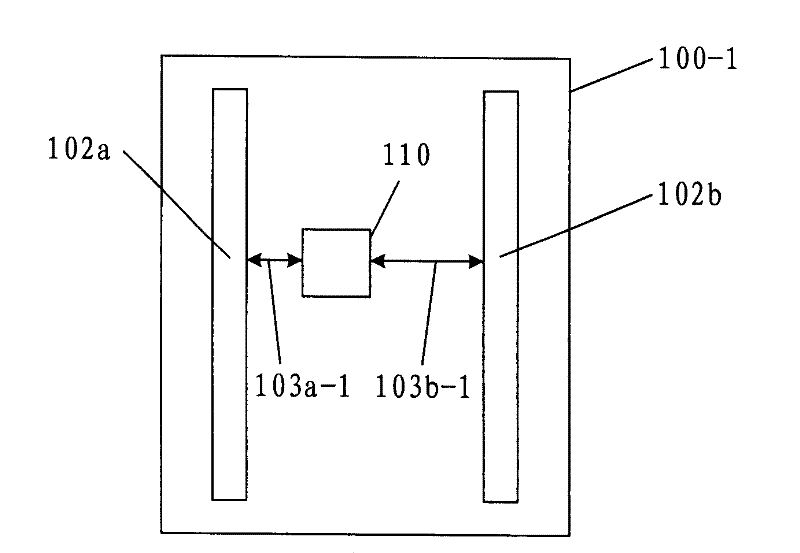

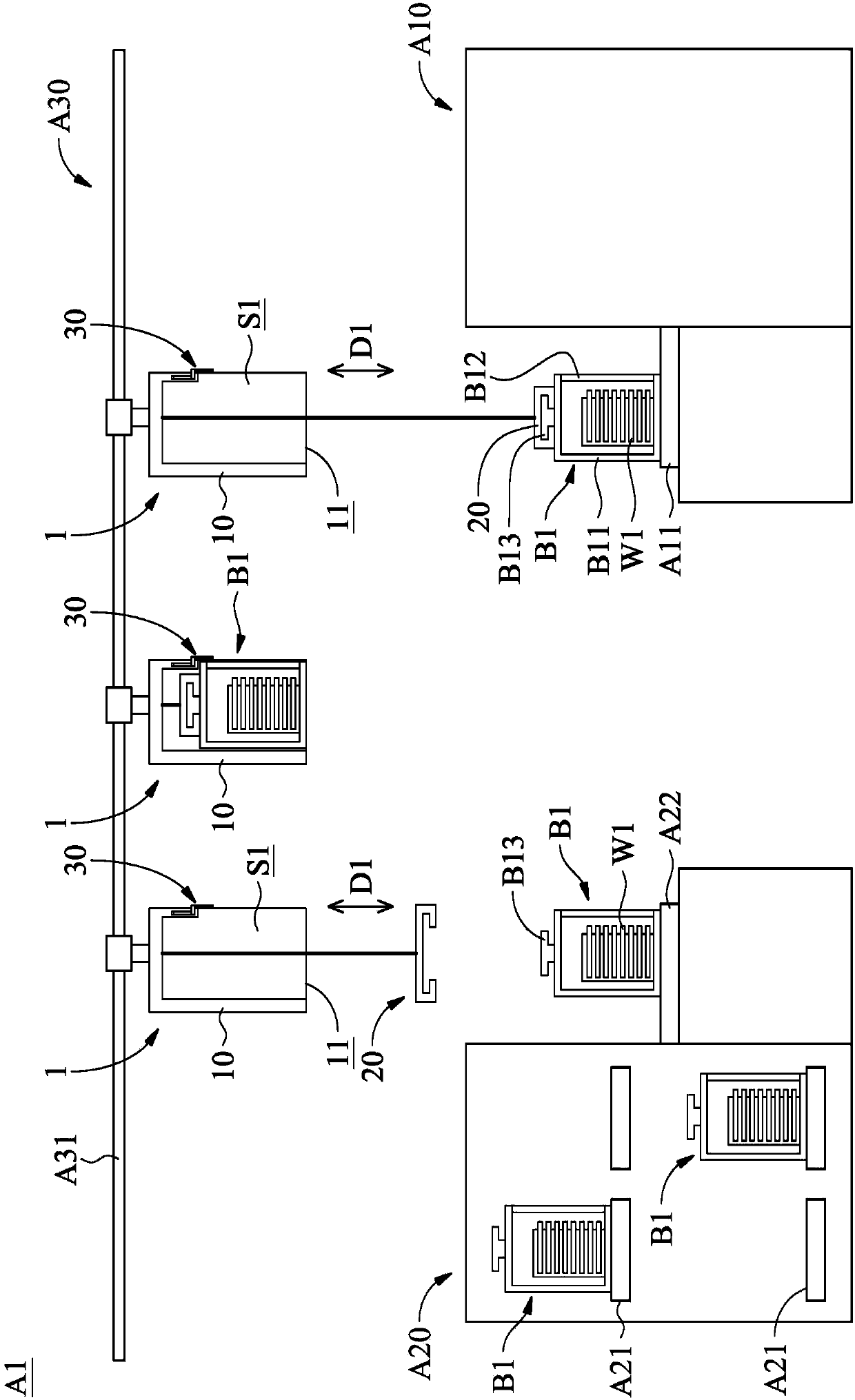

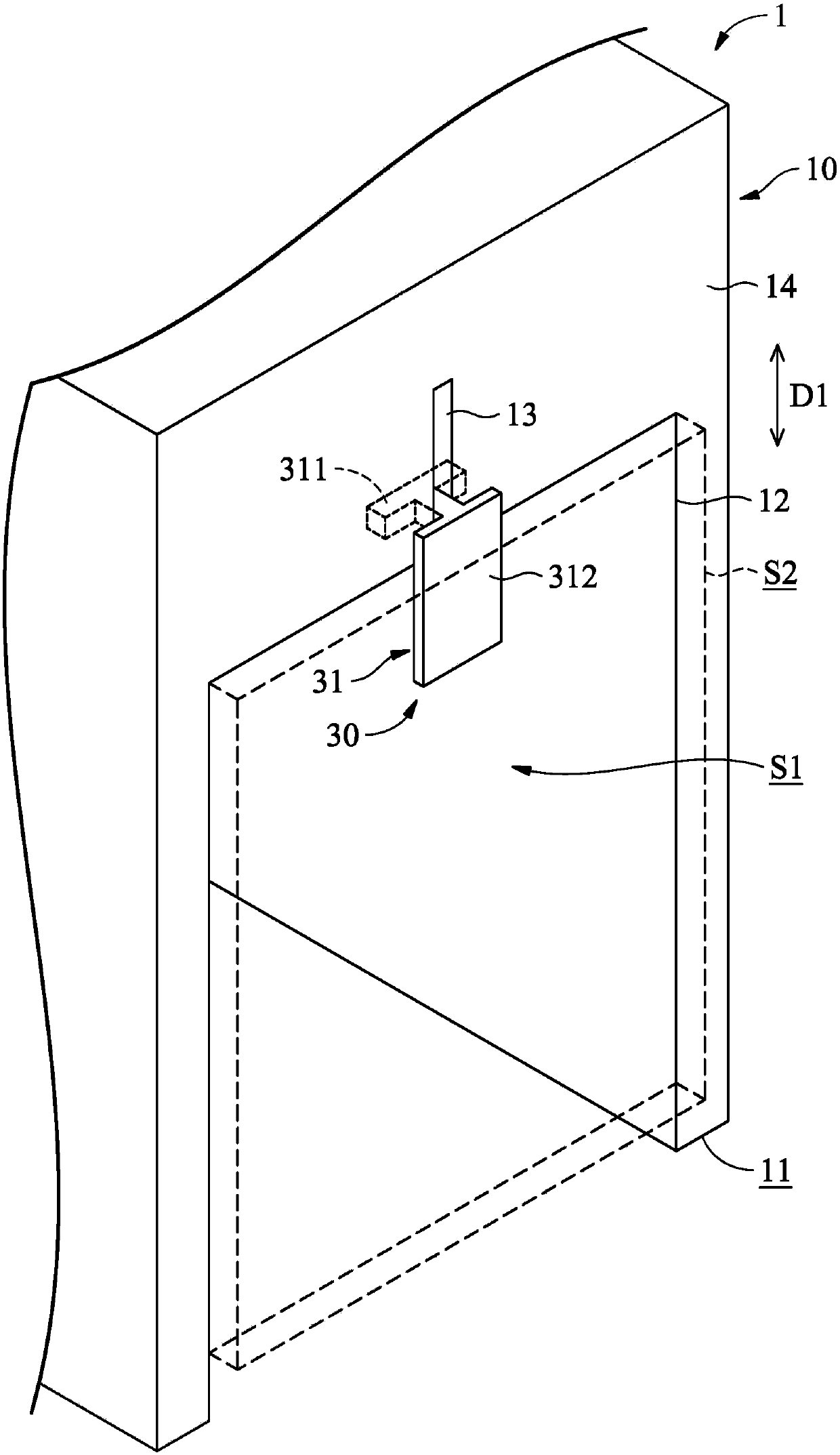

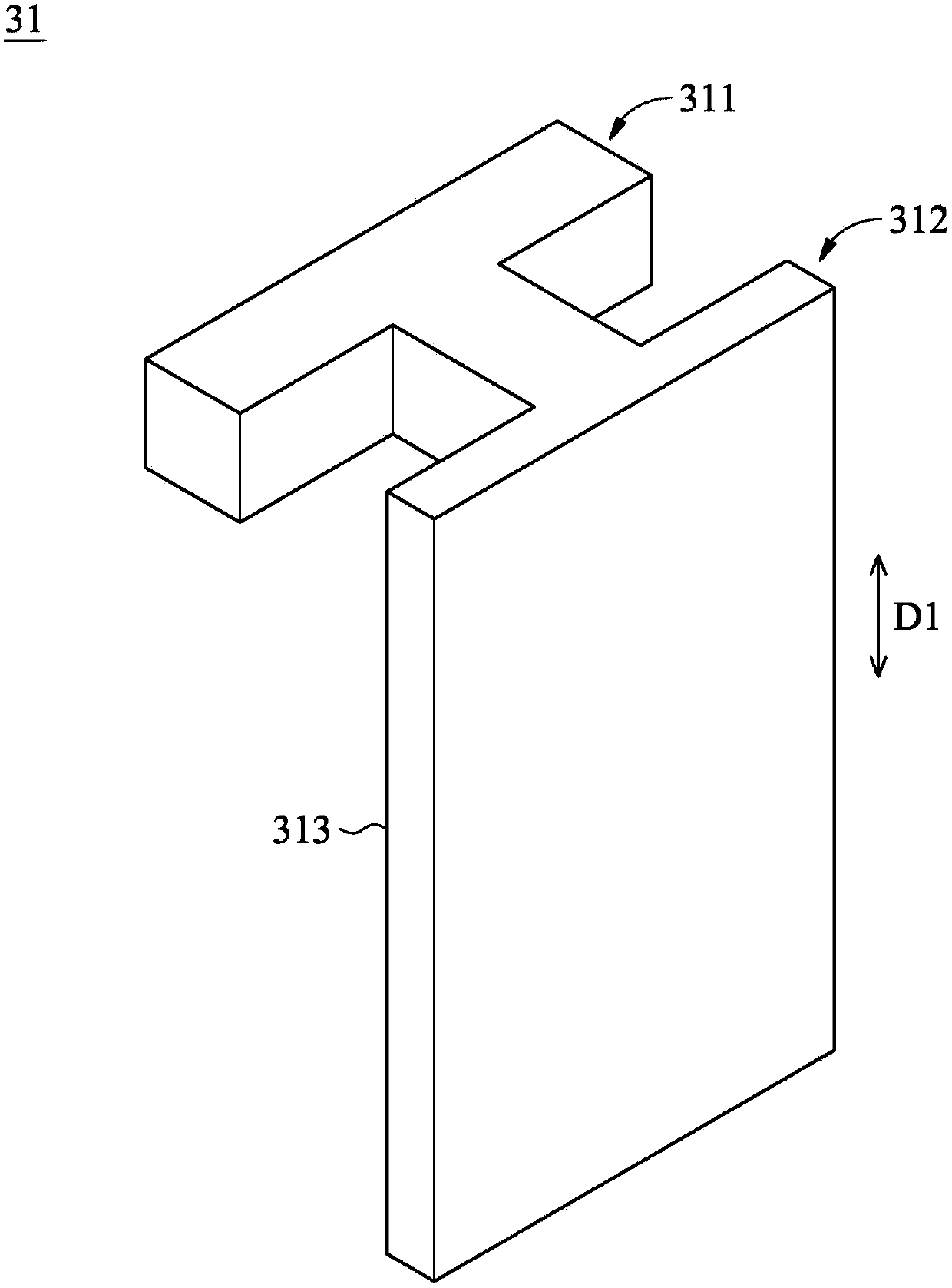

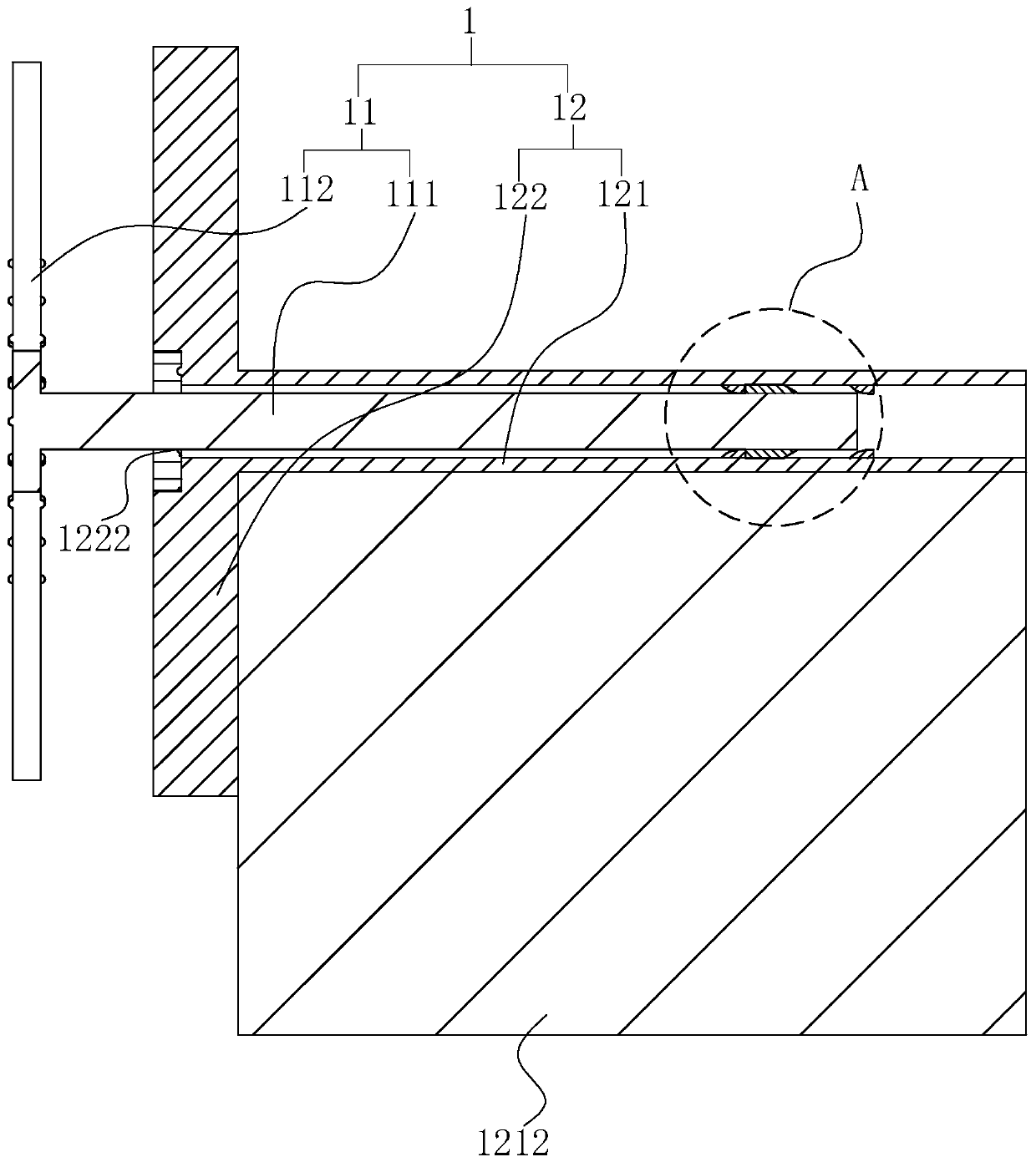

Supporting frame, fixing frame and mask plate

PendingCN111286695AAvoid failureAvoid precisionSolid-state devicesVacuum evaporation coatingFixed frameSupport plane

The invention discloses a supporting frame, a fixing frame and a mask plate, and relates to the technical field of display. The supporting frame comprises a supporting frame, supporting strips and multiple of extending parts; an evaporation area is defined in the supporting frame; the supporting strips are arranged on the supporting frame and located in the evaporation area; and the extending parts are arranged in the circumferential direction of the supporting frame and extend in the direction away from the evaporation area, and alignment marks used for aligning the mask plate with a substrate in the evaporation process are arranged on the extending parts. According to the embodiment, the extending parts are arranged on the supporting frame, and the alignment marks are arranged on the extending parts, so that the alignment marks are effectively prevented from losing efficacy or reducing the precision, the stability of the alignment marks is improved, and the product scrap risk is reduced.

Owner:CHENGDU BOE OPTOELECTRONICS TECH CO LTD +1

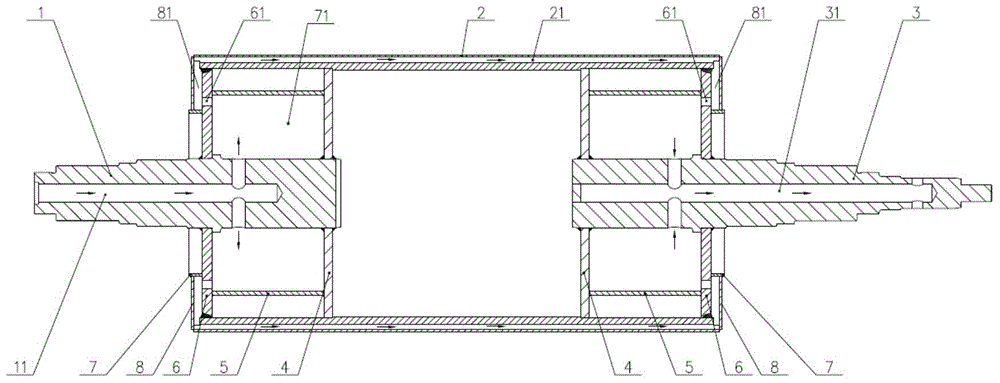

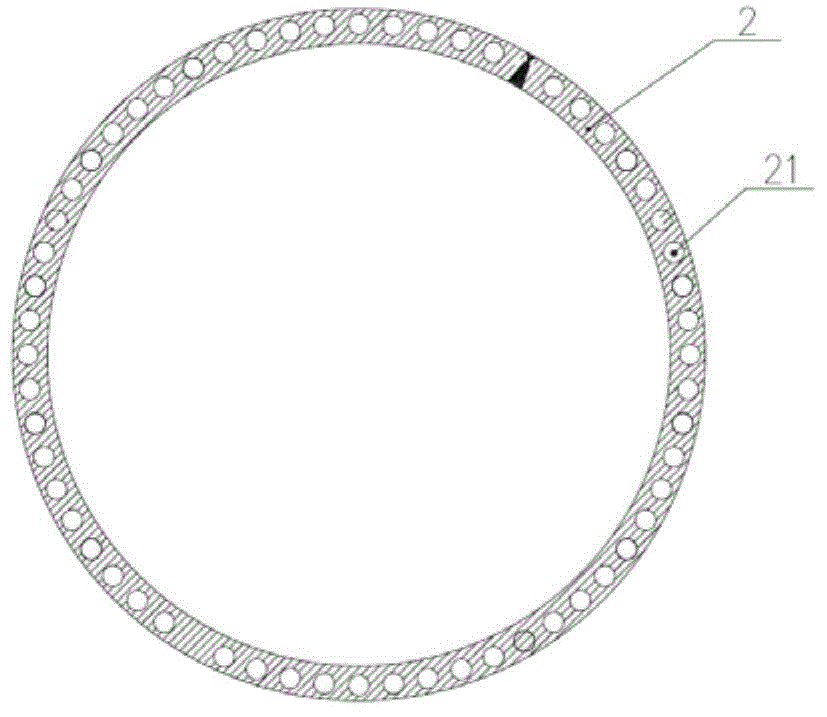

Water cooling roller

ActiveCN104561465AReduce usageReduce manufacturing costFurnace typesHeat treatment furnacesWater channelStrip steel

The invention relates to a water cooling roller. The water cooling roller comprises an operating side shaft, a transmission side shaft and a roller, wherein inner plates, outer end plates and inner end plates are arranged on the operating side shaft and the transmission side shaft; a cylinder is arranged between the inner end plate and the outer end plate; a cover plate is arranged between the inner plate and the roller; the inner end plate, the outer end plate and the cylinder form an inner cavity; the inner plate, the cover plate, the outer end plate and the roller form an outer cavity; holes communicated with the inner cavity and the outer cavity are uniformly formed in the outer end plate; a first water channel is formed inside the operating side shaft; a plurality of second water channels penetrating through in the axial direction are uniformly formed in the wall thickness periphery direction of the roller; a third water channel is formed inside a driven side shaft; the first water channel is communicated with the inner cavity on an operating side; the second water channels are communicated with the inner cavity on a transmission side; the third water channel is communicated with the outer cavity on the operating side and the outer cavity on the transmission side. The water cooling roller has the advantages that by performing optimization design on the structure of the water cooling roller, the application of large-section forge pieces is reduced, the equipment manufacture cost is reduced, the water cooling roller is high in cooling speed and uniform in cooling, and the strip steel shape is good.

Owner:WISDRI WUHAN WIS IND FURNACE

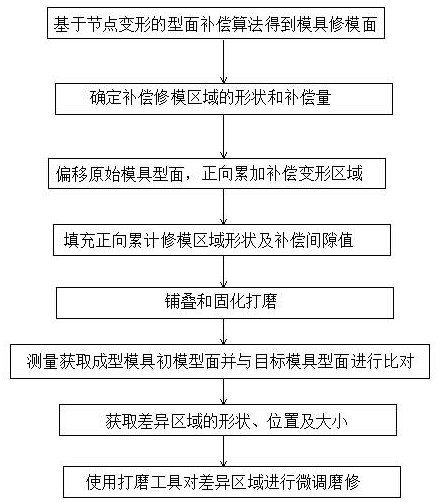

Compensation mold-repairing method for profile deformation of composite material component mold

The invention discloses a compensation mold-repairing method for the profile deformation of a composite material component mold, and belongs to the technical field of curing and forming for compositematerial components. The compensation mold-repairing method for the profile deformation of the composite material component mold is characterized by comprising the following steps: a, obtaining a moldrepairing surface based on a profile compensation algorithm for joint deformation; b, determining the shape and compensation amount of a compensation mold-repairing area, deviating from an original mold profile, and accumulating forwards a compensation deformation area; c, adopting a glass fiber reinforced plastic material for filling the shape of the forwards-accumulated mold repairing area andcompensating a gap value, and then carrying out laying and curing grinding to obtain an initial profile mold of the target forming mold; and d, obtaining the initial mold profile of the forming mold through digital measurement, comparing the initial mold profile with a target mold profile, obtaining the shape, the position and the size of a difference area, and carrying out fine adjustment and grinding on the difference area by using a grinding tool to finish mold profile qualification correction. According to the invention, the forming mold can greatly reduce the shape deviation between an actual part and a theoretical part, shorten the correction period and reduce the cost.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

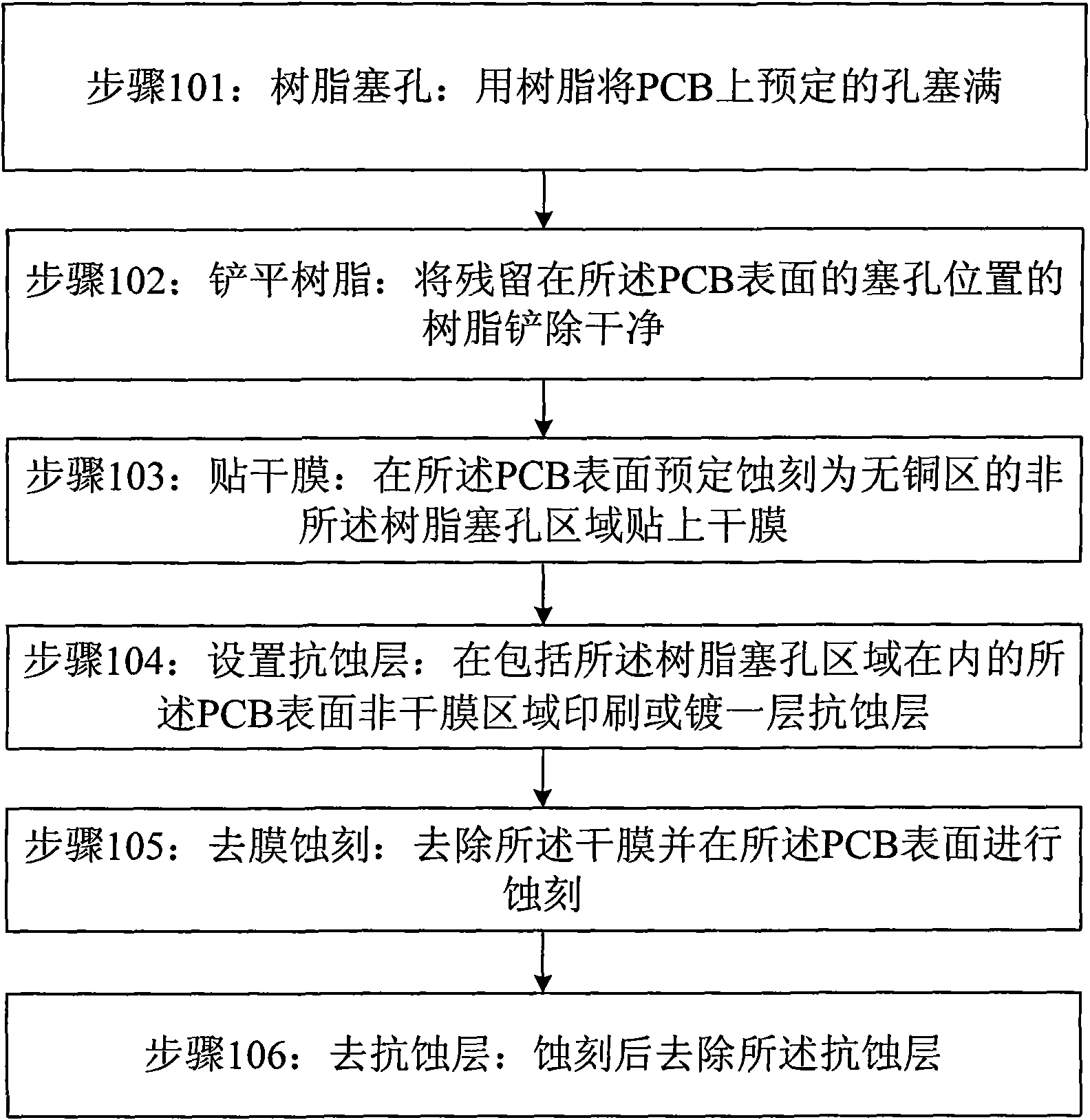

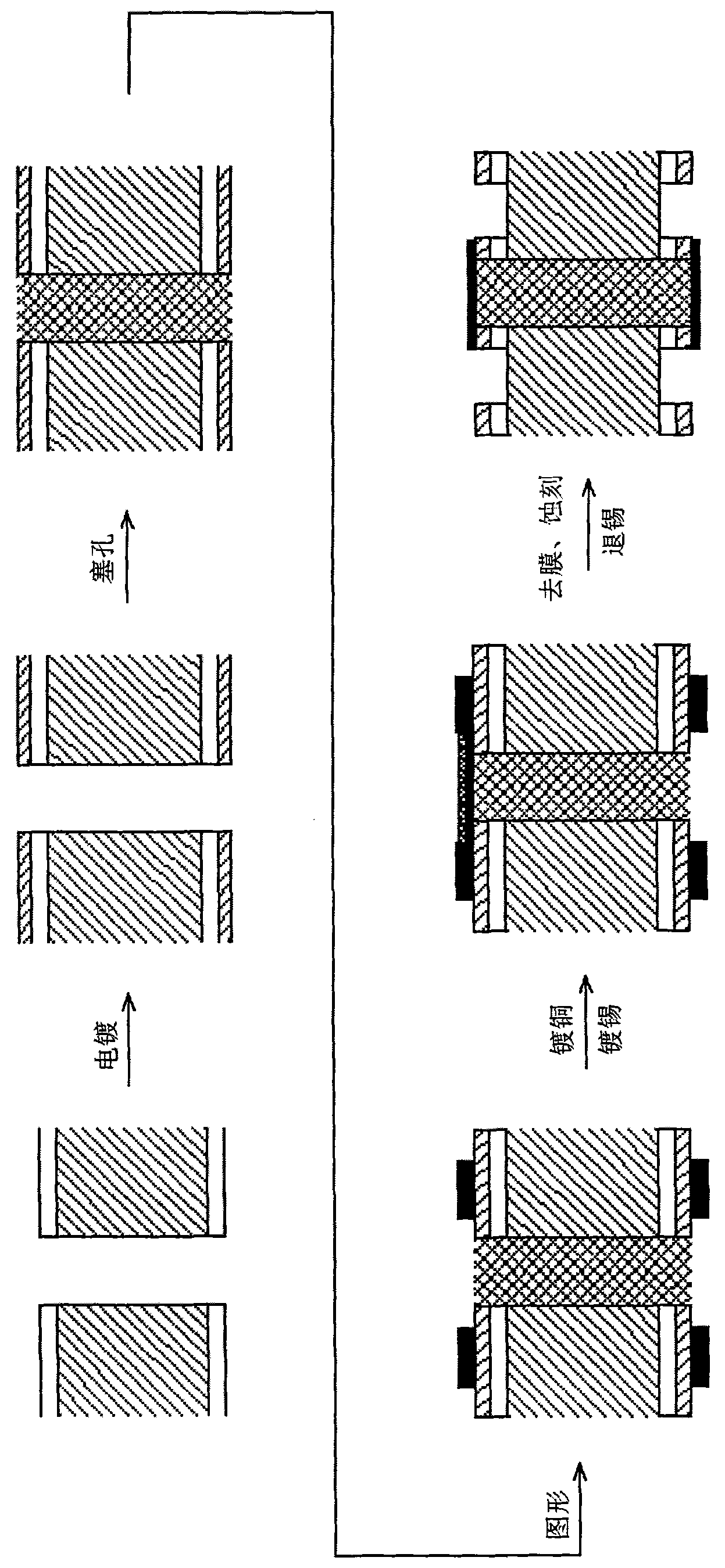

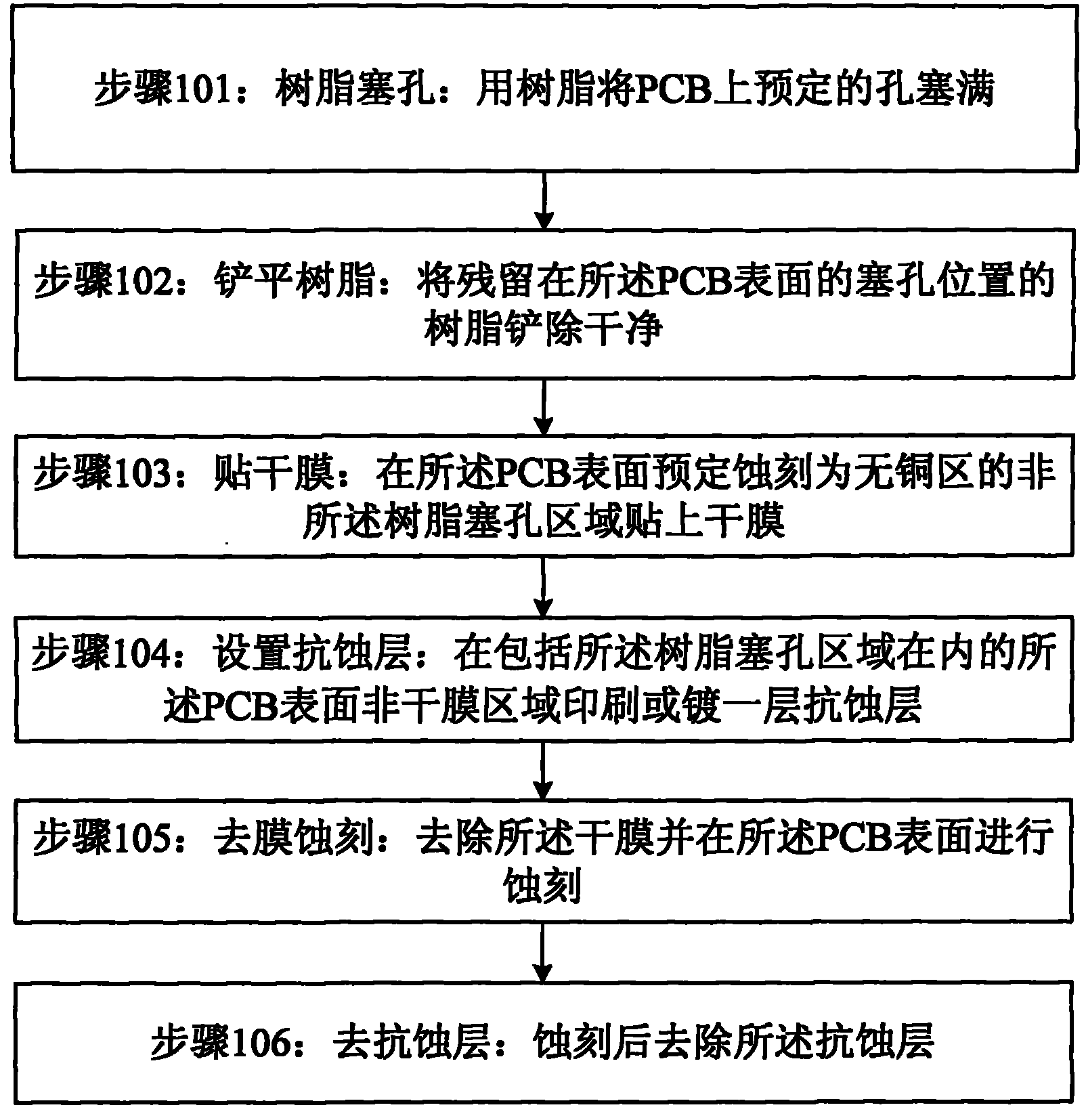

PCB (Printed Circuit Board) processing method

ActiveCN101772269AStrong process adaptabilityImprove craftsmanshipPrinted element electric connection formationEngineeringCopper

The invention discloses a PCB (Printed Circuit Board) processing method which comprises the following steps of: resin hole cramming: cramming preset holes on a PCB by using resin; resin leveling: shoveling resin left at the positions of the crammed holes on the surface of the PCB completely; drying film pasting: pasting a dry film on a non-resin hole cramming area preset to be etched into a copper-free area on the surface of the PCB; anti-corrosion layer arrangement: printing or plating an anti-corrosion layer on a non dry film area on the surface of the PCB, which comprises the resin hole cramming areas; film removing and etching: removing the dry film and etching on the surface of the PCB; and anti-corrosion layer removing: removing the anti-corrosion layer after etching. The invention has good adaptability to the resin hole cramming process and can greatly reduce the scrap cost.

Owner:SHENNAN CIRCUITS

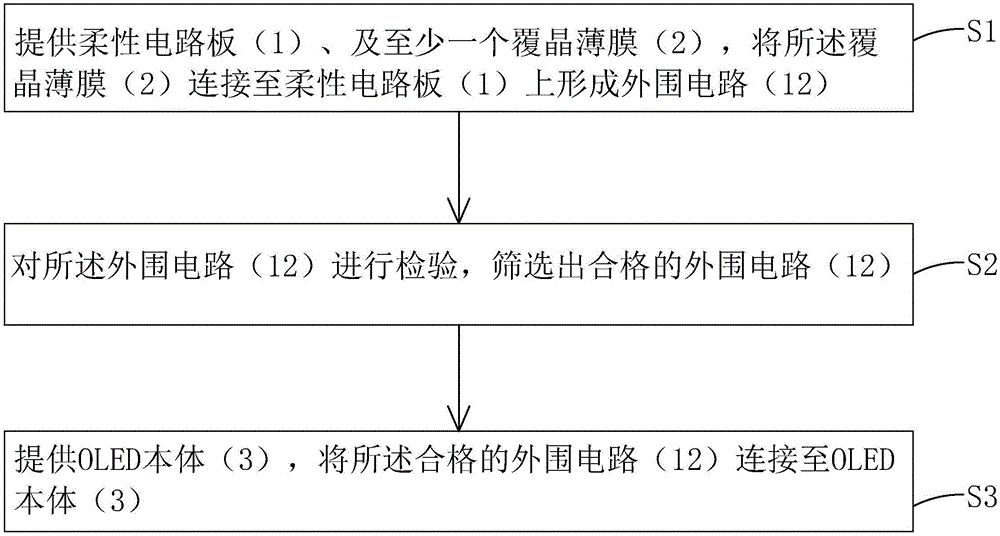

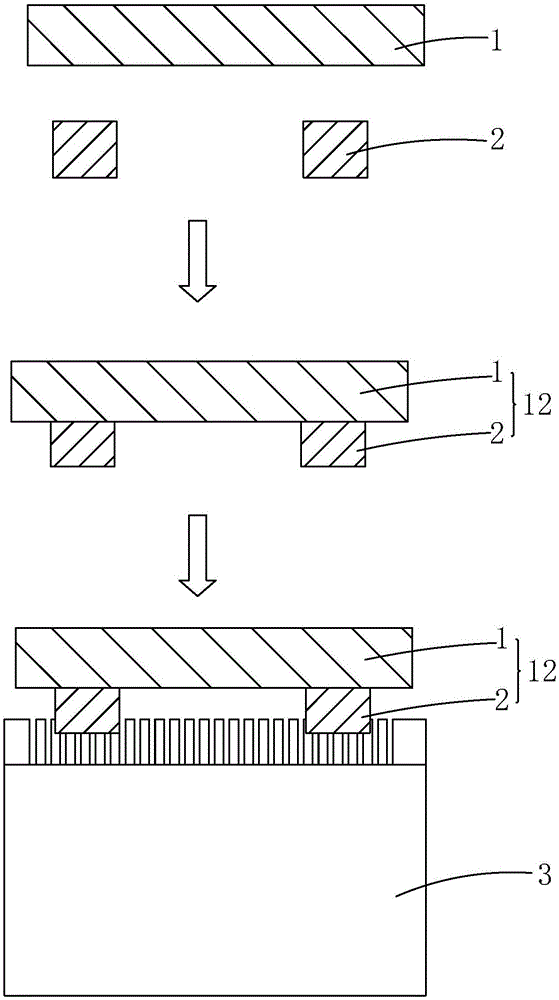

Flexible OLED display device assembling method

InactiveCN106816555AReduce the risk of obsolescenceImprove assembly yieldSolid-state devicesSemiconductor/solid-state device manufacturingFlexible circuitsDisplay device

The present invention provides a flexible OLED display device assembling method. The method comprises the steps of firstly, connecting a crystal covering film (2) to a flexible circuit board (1) to form a peripheral circuit (12), screening out the qualified peripheral circuit (12) through examination, and finally connecting the qualified peripheral circuit (12) to an OLED body (3). In this way, the scrapping risk of the OLED body (3) during the module stage is reduced, and the assembly yield is improved. The production cost is saved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

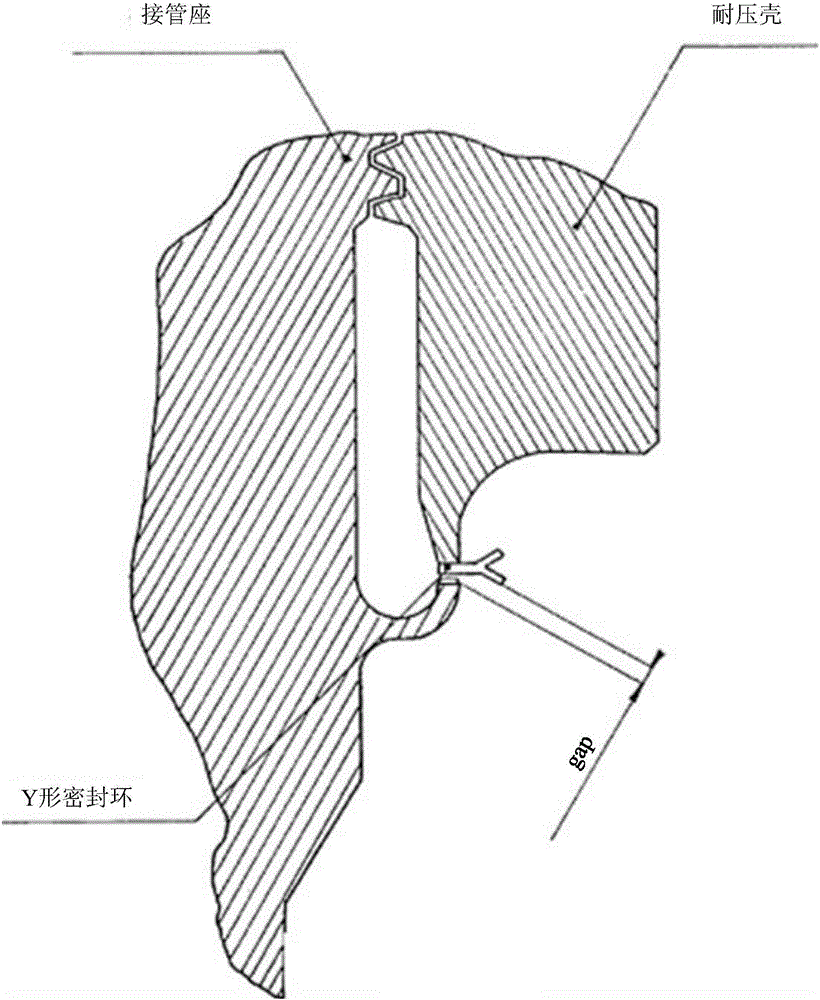

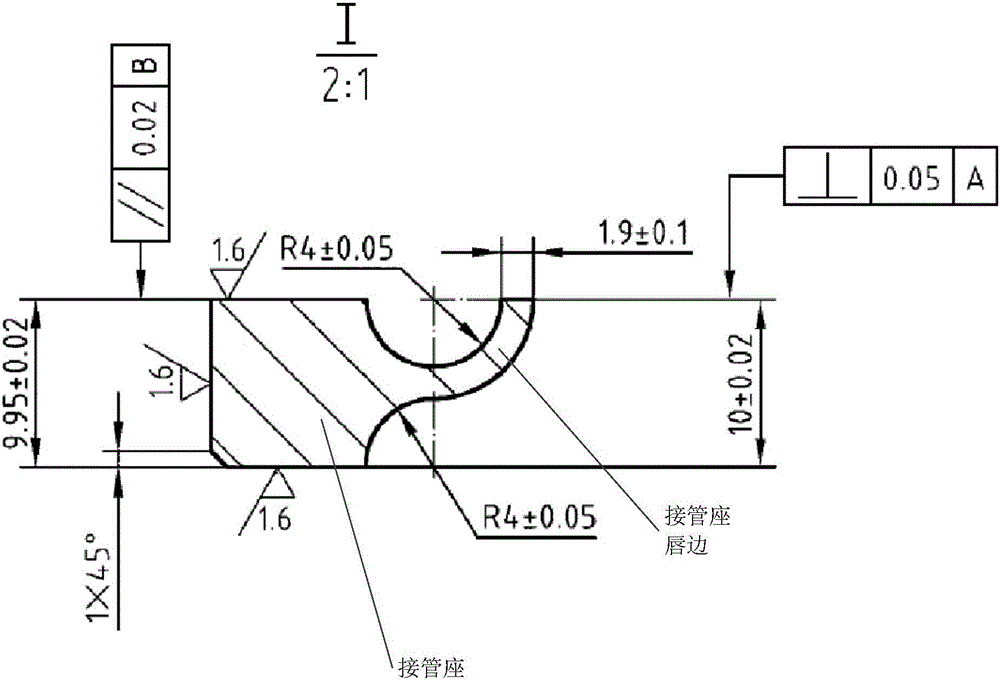

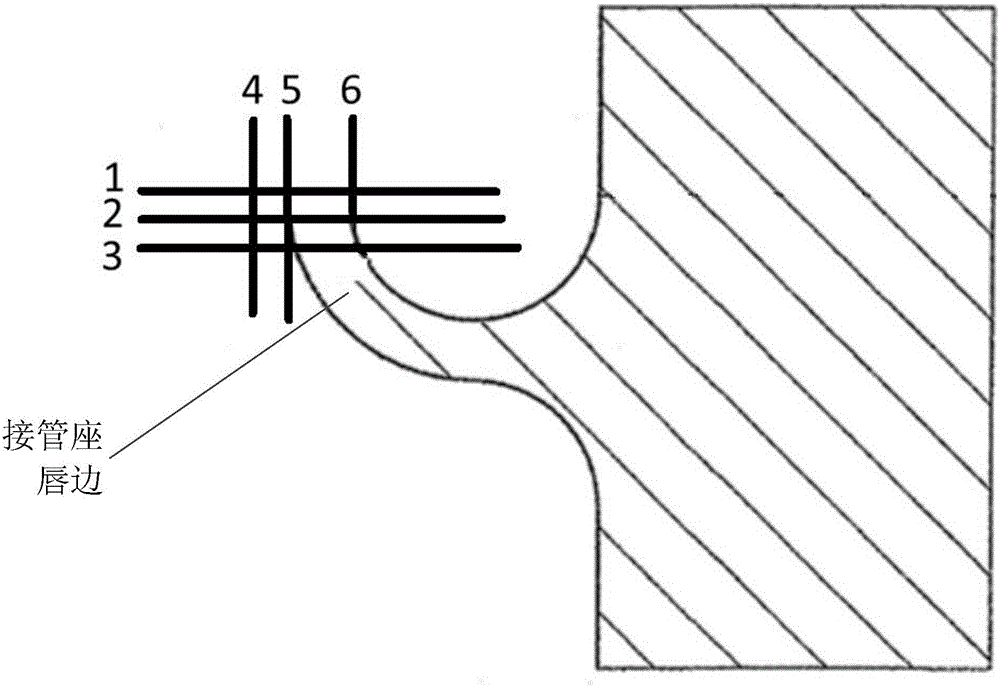

Method for machining omega weld joint groove in lower portion of CRDM of nuclear power plant and cutter

The invention discloses a method for machining an omega weld joint groove in the lower portion of a CRDM of a nuclear power plant and a cutter. The method and the cutter are used for solving the technical problems that the size of the machined omega weld joint groove in the lower portion of the CRDM of the nuclear power plant in the prior art is difficult to guarantee, reliability is low, welding quality is affected, and a construction period is prolonged. The cutter comprises a first machining blade, a second machining blade and a third machining blade. The method for machining the groove includes the steps that firstly, adjustment is performed, so that the concentricity of a cutter drive device is identical to that of a pipe connection seat and the initial position of the cutter is set; secondly, the cutter is driven to rotate around the axis of the pipe connection seat and driven to move downwards simultaneously, so that weld joint residues on the inner side, the upper portion and the outer side of the lip edge of the pipe connection seat are cut off through the first machining blade, the second machining blade and the third machining blade respectively; and thirdly, after the cutter reaches the preset position, the cutter is controlled to stop moving downwards, and the cutter moves upwards to be away from the lip edge of the pipe connection seat. By the adoption of the method and the cutter, the machining accuracy of the size of the lip edge of the pipe connection seat of a top cover of a pressure container is improved, the welding quality of a weld joint at the lower portion of the CRDM is guaranteed, and reliability is high.

Owner:中广核工程有限公司 +1

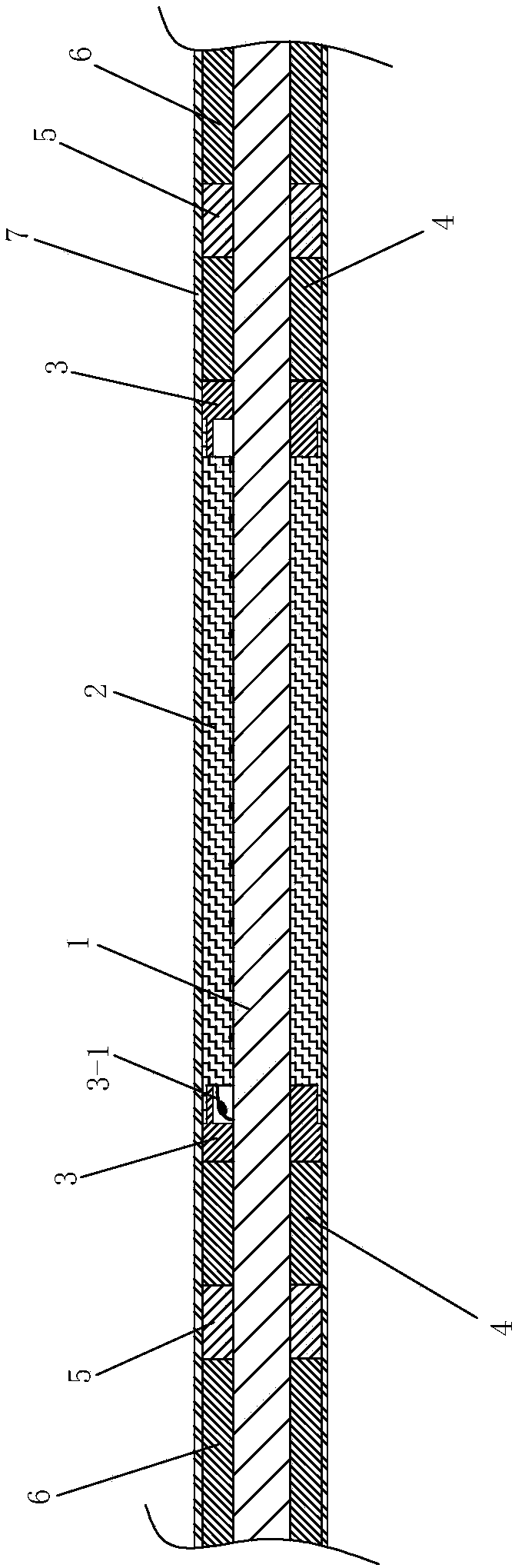

Solid towline with good dragging performance for marine seismic exploration

InactiveCN108447591AMaintain pressure resistanceWith impact resistanceNon-insulated conductorsFloating cablesYarnRubber material

The invention discloses a solid towline with good dragging performance for marine seismic exploration. The solid towline is characterized in that the solid towline comprises a main cable, hydrophones,buoyancy sleeves and an outer sheath. The hydrophones are fixedly arranged on the main cable with an equal interval. The hydrophones are electrically connected to corresponding wire cores in the maincable. Each of the buoyancy sleeves is made of a foamed polyethylene material, and foamed polyethylene is extruded on the main cable. The main cable includes the transmission wire cores, a tensile fiber layer and a conductive wire layer. The tensile fiber layer is formed by weaving aramid yarn and / or polyester yarn outside the transmission wire cores. The conductive wire layer includes a set of power lines and a set of signal lines. The power lines and the signal lines are orderly arranged with an equal interval along the circumferential direction of the main cable outside the tensile fiber layer to form the corresponding wire layer. The buoyancy sleeves are fixedly arranged on the main cable with an equal interval, and each of the buoyancy sleeves is between two adjacent hydrophones. Theouter sheath is made of a thermoplastic polyurethane elastomer rubber material and is extruded outside the hydrophones, positioning ends and the buoyancy sleeves, and the outer sheath is seamlessly bonded to the hydrophones.

Owner:CHANGZHOU MARINE CABLE

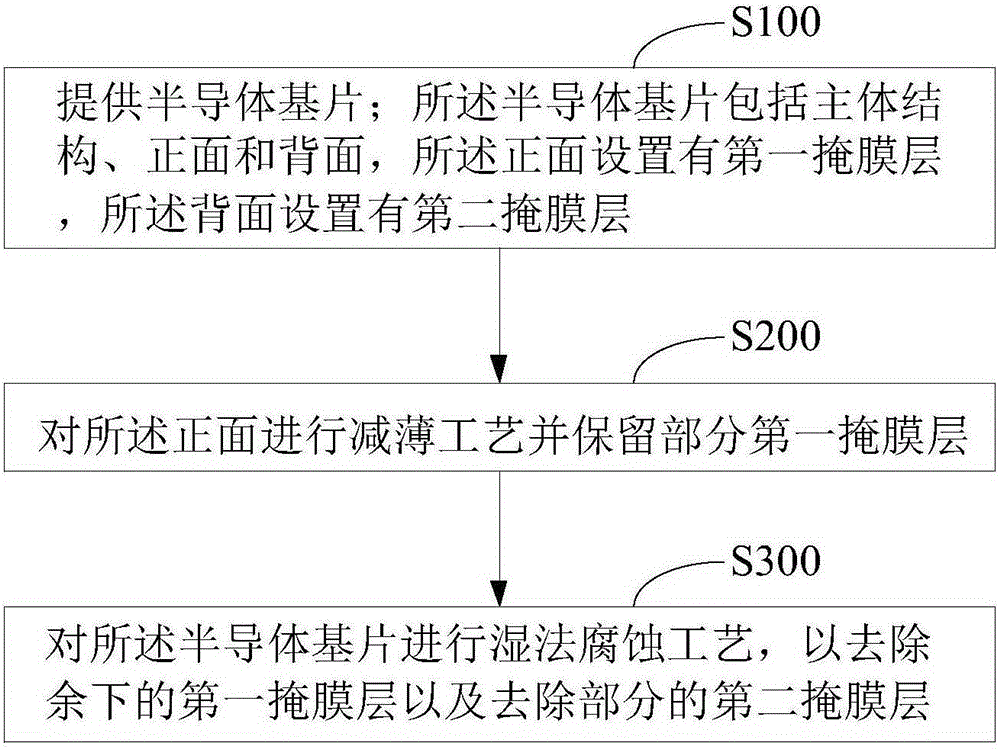

Method removing semiconductor substrate mask layer

ActiveCN106558486AImprove protectionSo as not to damageSemiconductor/solid-state device manufacturingSemiconductorMask layer

A method removing a semiconductor substrate mask layer comprises the following steps: thinning the front side of the substrate so as to remove partial the first mask layer; using wet method corrosion technology on the substrate so as to remove residual first mask layer and partial the second mask layer. An LTO structure close to the backside of the substrate is protected by the second mask layer, and cannot be damaged by the wet method corrosion technology, thus well protecting the LTO structure, preventing wafer damages, and reducing wafer discarding risks.

Owner:CSMC TECH FAB2 CO LTD

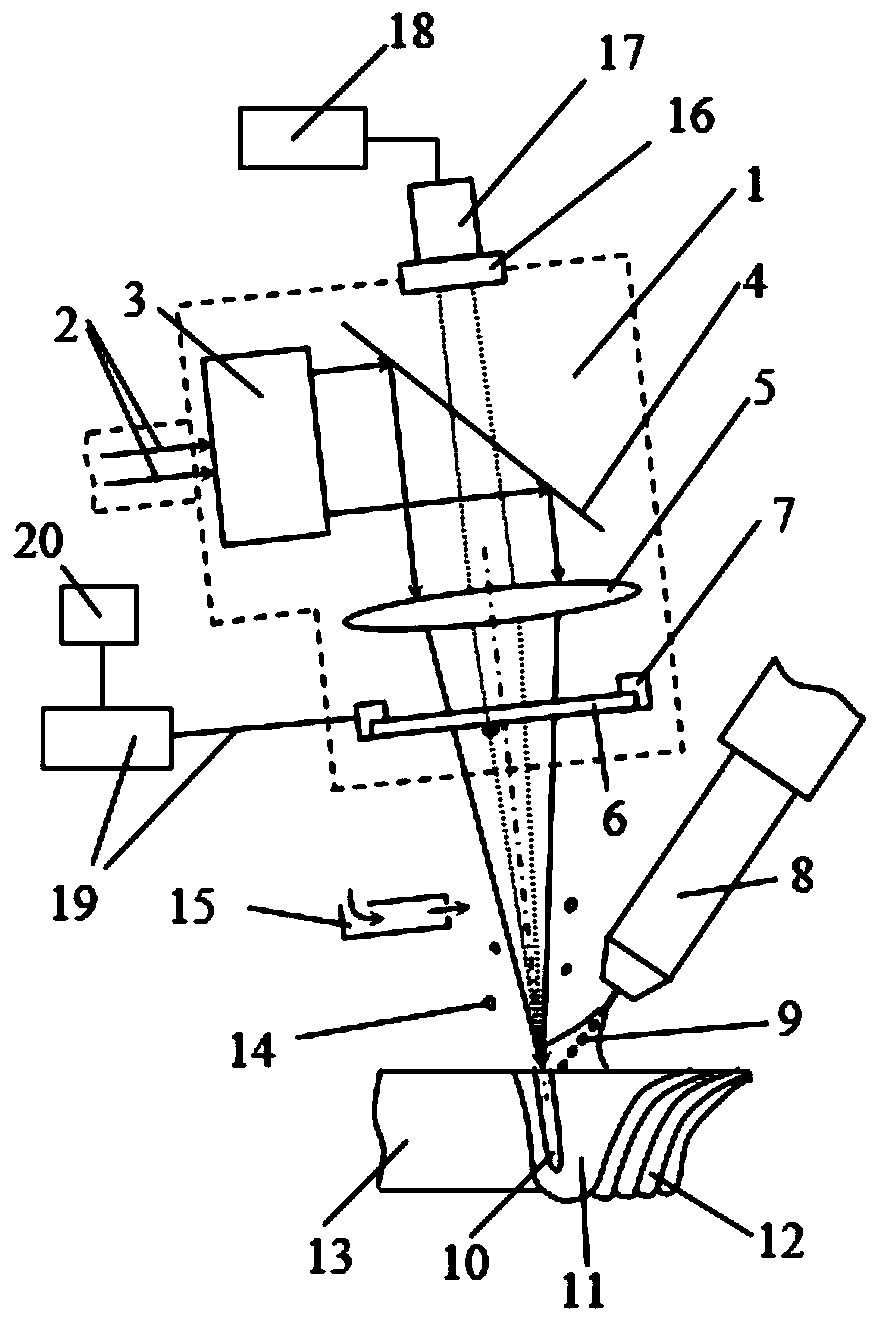

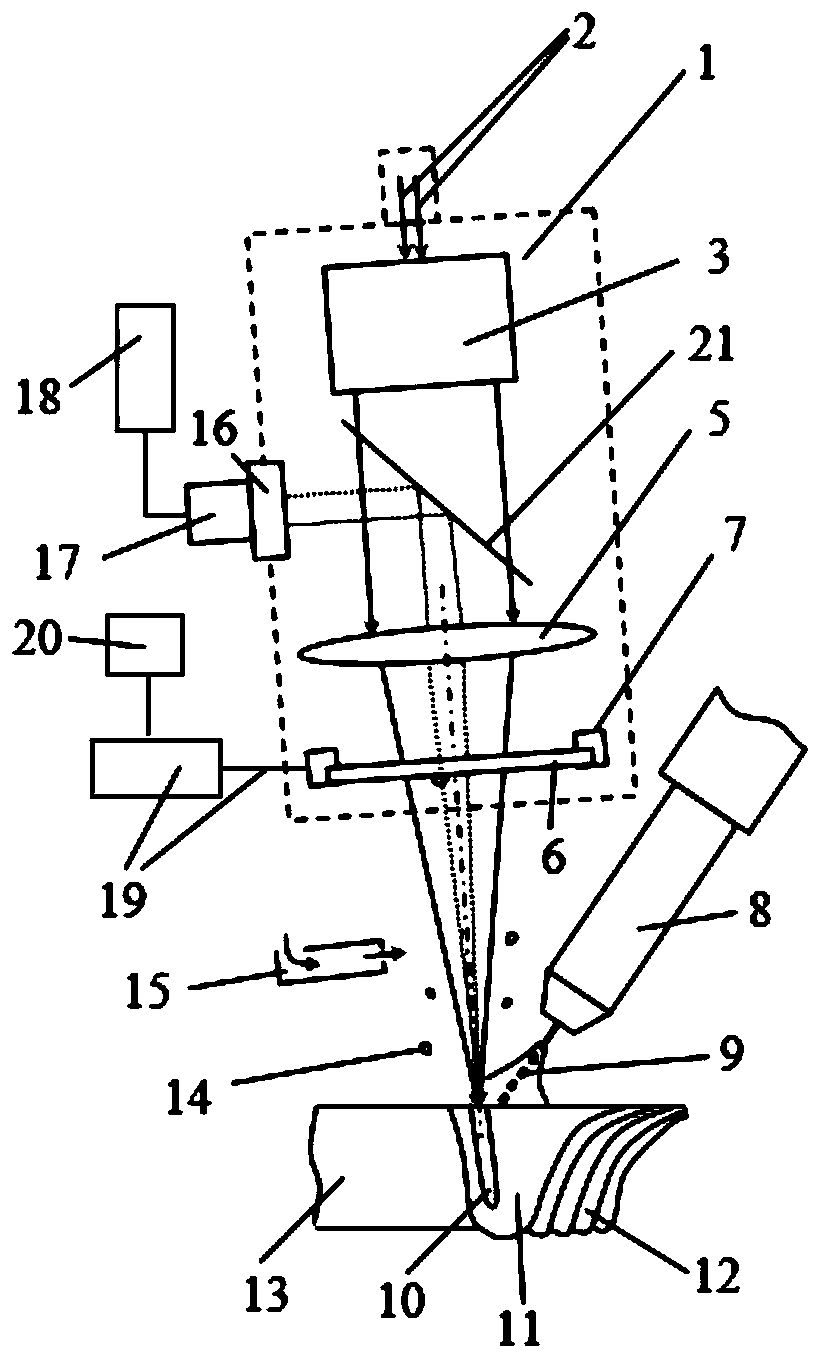

In-situ monitoring device and method for pollution of protective lens for welding laser head

InactiveCN110744213ASolving the conundrum of pollution situationsSolve only before weldingLaser beam welding apparatusEngineeringWelding defect

The invention relates to an in-situ monitoring device and method for pollution of a protective lens for a welding laser head. The in-situ monitoring device comprises the protective lens, a monitoringassembly, a data analysis assembly and an executing terminal; the monitoring assembly is used for monitoring the pollution situation of a laser transmission area on the protective lens; the data analysis assembly is used for calculating the polluted area of the laser transmission area on the protective lens in real time, and the polluted area is compared with a preset threshold value; and when thepolluted area calculated by the data analysis assembly is larger than the preset threshold value, the executing terminal executes a welding interrupt instruction, and the welding laser head stops welding. The welding process of continuous welding defects caused by serious pollution of the protective lens can be stopped in time, subsequent defect elimination and welding continuing are convenient,the obsolescence risk of weldments is lowered to the utmost extent, and the welding pass percentage is further increased.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

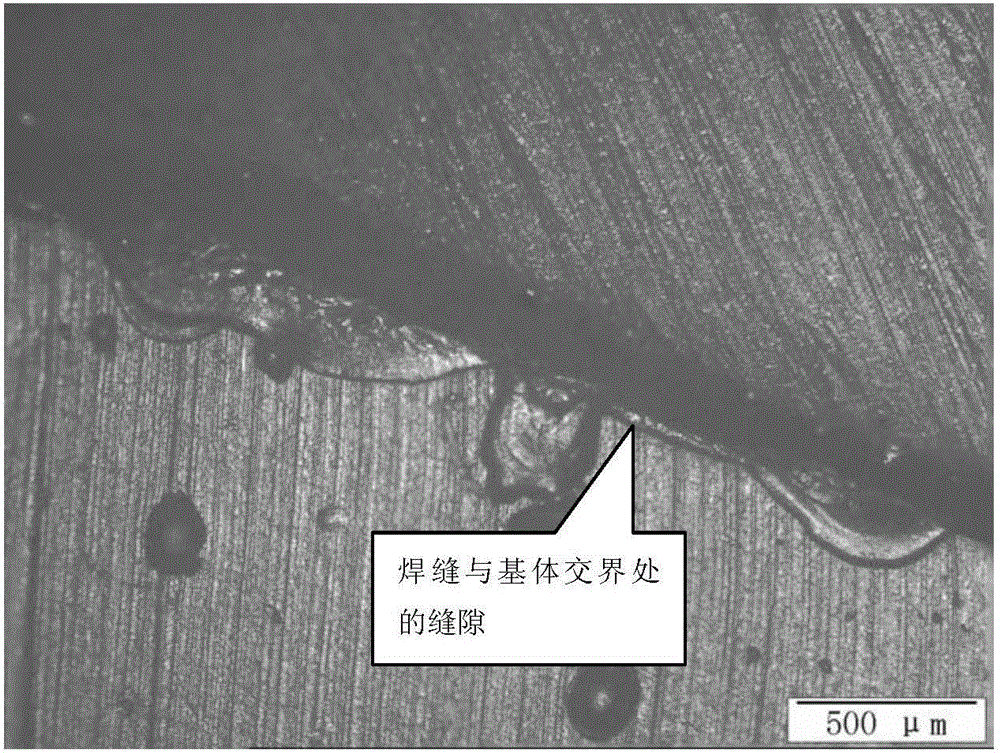

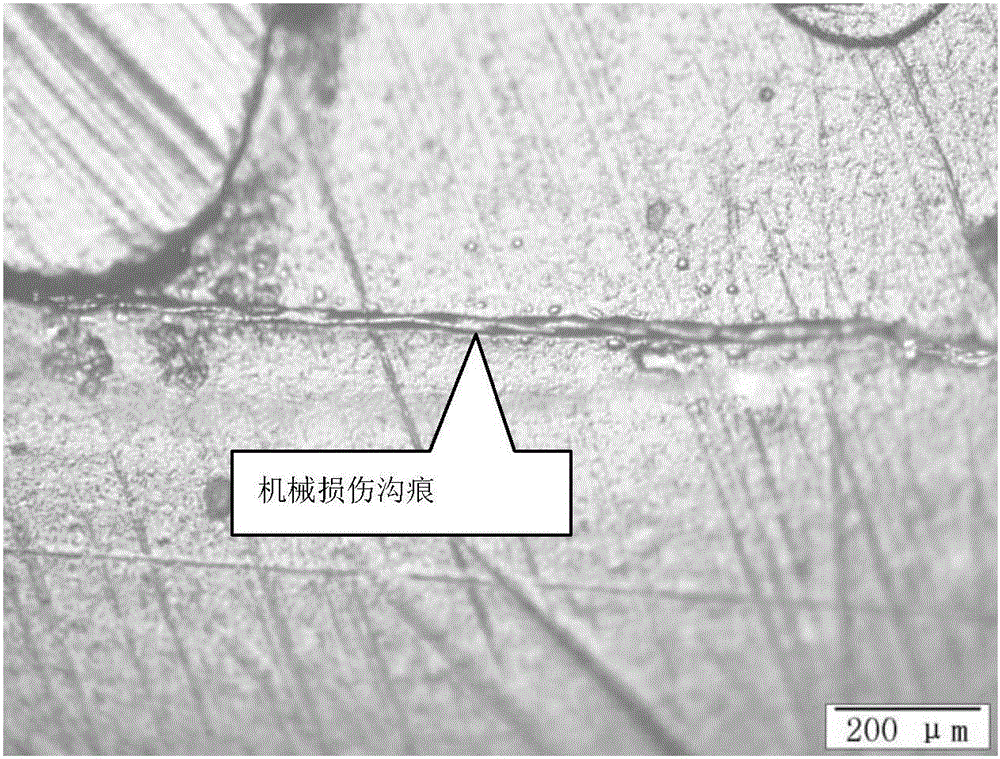

Non-destructive metal surface defect microscopic detection method

InactiveCN106248687AReduce the risk of obsolescenceRealization of Microscopic ObservationOptically investigating flaws/contaminationNon destructiveMicroscopic observation

The present invention provides a non-destructive metal surface defect microscopic detection method. According to the present invention, when the abnormal display appears on the surface of a metal part, the reason cannot be macroscopically determined, and the condition is required to be determined through the further microscopic observation, the non-destructive metal surface defect microscopic detection method is used; AC paper covers the surface of a part to develop the defect appearance so as to achieve the microscopic observation of the part surface defect and determine the defect type, such that the detection period can be effectively shortened, the parts scrap risk can be reduced, the product qualification rate can be improved, and the production cost can be reduced; and the method has characteristics of simple operation, wide application range, high promotion value, and good market prospect.

Owner:AECC AVIATION POWER CO LTD

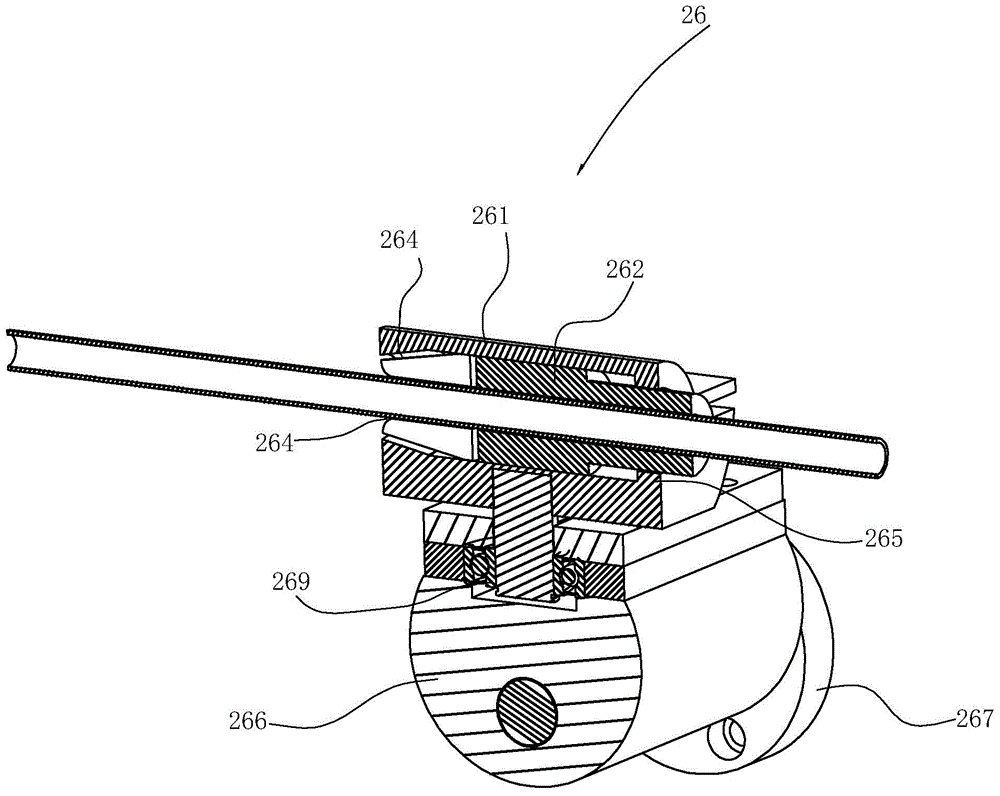

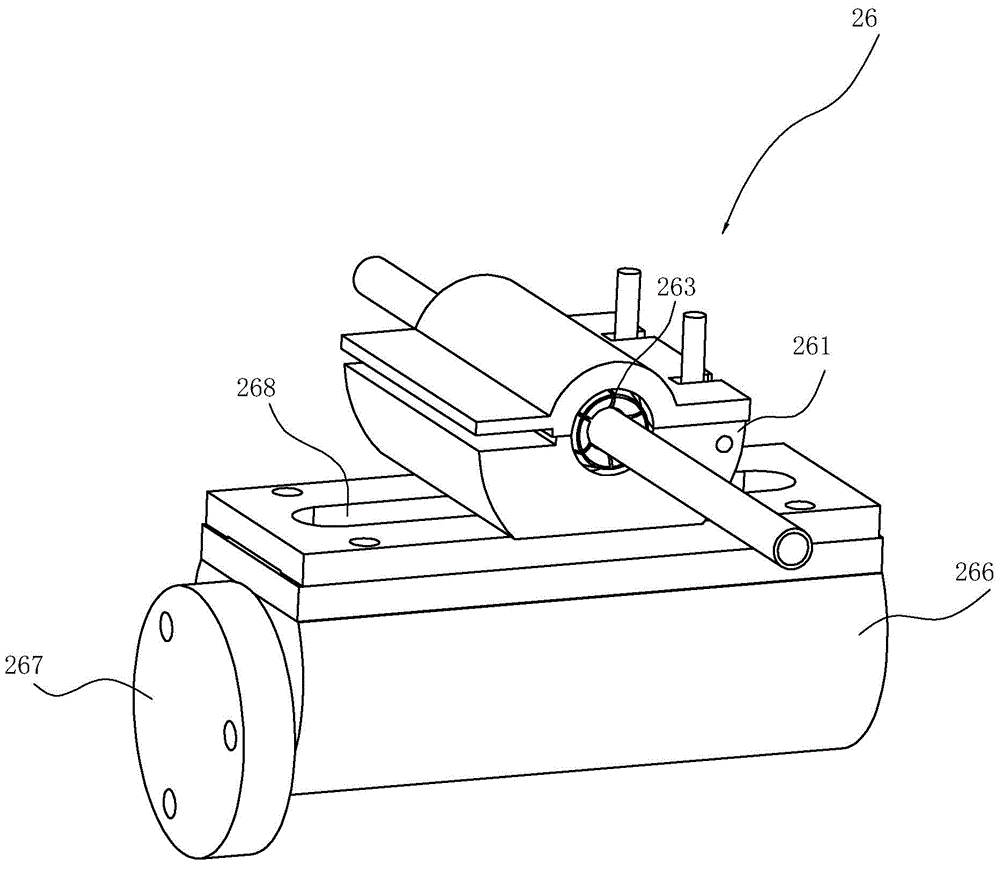

a pipe winding machine

ActiveCN104444563BSimple structureGood anti-shrink functionFilament handlingControl systemEngineering

The invention relates to a pipe coiler. The pipe coiler comprises a riding wheel used for bearing a pipe to be coiled and is characterized by further comprising a pipe conveying device and a pipe uncoiling device, wherein the pipe conveying device sequentially comprises a pipe conveying base, a lifting mechanism, a fine adjustment mechanism, a supporting base, a radial adjusting mechanism and a riding wheel from bottom to top, the pipe uncoiling device comprises a pipe uncoiling base, a base plate is arranged on the pipe uncoiling base and provided with a support, and the support is provided with a rotating disk which is provided with an axial clamping mechanism, a radial clamping mechanism, a telescopic sleeve, an anti-shrinking mechanism, sensors and a control system. Through the pipe coiler, the pipe feeding position can be tracked in real time, the pipe conveying height, the pipe conveying angle and the pipe conveying speed can be adjusted in real time, the pipe coiling quality is guaranteed, the scrap risk is reduced, the labor intensity of workers is relieved, and manual cost is saved; due to the design of the pipe uncoiling device, it is effectively prevented that in the pipe distributing process, a coiled pipe bundle loosens, the loosened pipe bundle overlaps and is knotted, the pipe can go out smoothly, pipe distribution quality is guaranteed, and product quality is good.

Owner:ZHENHAI PETROCHEM JIANAN ENG

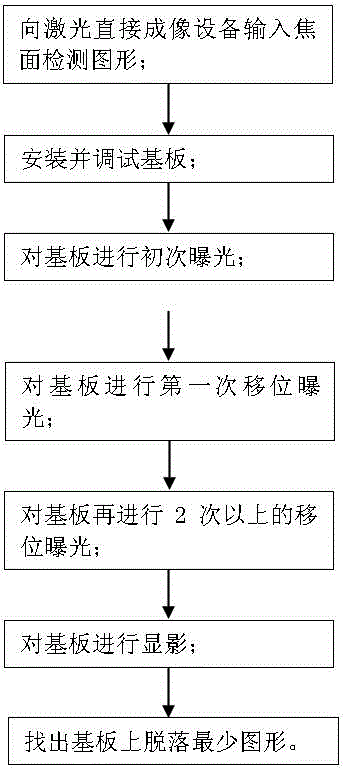

Method for acquiring optimal focal plane distance of laser direct imaging equipment

InactiveCN105549346AImprove detection efficiency and accuracyReduce the risk of obsolescencePhotomechanical exposure apparatusMicrolithography exposure apparatusLine widthExposure

In the prior art, the exposure focal plane of laser direct imaging equipment is difficult to rapidly acquire. Based on the difficult problem in the prior art, the present invention provides a method for acquiring the optimal focal plane distance of laser direct imaging equipment. The method comprises: inputting a focal plane detection pattern into laser direct imaging equipment; installing and debugging a substrate; carrying out primary exposure on the substrate; carrying out primary displacement exposure on the substrate; repeatedly performing the displacement exposure on the substrate; developing the substrate; and finding the least shedding pattern on the substrate. According to the present invention, the necessarily-used detection step for measuring the line width by using a microscope in the traditional method is eliminated, the optimal expose focal plane can be quickly, intuitively and accurately found, the detection efficieny and the accuracy of the focal plane are improved, and the PCB reject risk caused by the insufficient exposure is reduced.

Owner:HEFEI ADVANTOOLS SEMICON

2195 aluminum-lithium alloy special-shaped section structure and spinning method thereof

ActiveCN112247483ASimple processOptimize heat treatment processFurnace typesHeat treatment furnacesSpinningEngineering

The invention provides a 2195 aluminum-lithium alloy special-shaped section structure and a spinning method thereof. The special-shaped section structure is characterized in that a curved surface flanging structure is arranged in the center area of a spatial smooth profile, the flanging profile is of a curve fitting structure, the top diameter is 240 mm, and the profile precision requirement is high. The deformation amount of each pass is controlled to be in a range of 10.5-15.5% through circulating hot strong spinning forming, quenching, shape correcting, machining and artificial aging, gradient decreasing is achieved, the rotating speed of a main shaft is 25 rpm / min, and hot spinning machining integrated forming of the 2195 aluminum-lithium material special-shaped structure is achieved.The two-pass forming scheme that according to traditional forming of the special-shaped structure, a rigid die is adopted to draw a smooth molded surface firstly, and then local flanging is conductedto form the special-shaped structure is broken through, the scrap risk caused by cracks occurring in the rigid die drawing and flanging process is obviously reduced, a hot spinning integrated formingthought is created, forming of the new material special-shaped structure is realized, and a foundation is laid for new material engineering application.

Owner:TIANJIN AEROSPACE CHANGZHENG ROCKET MFGCO

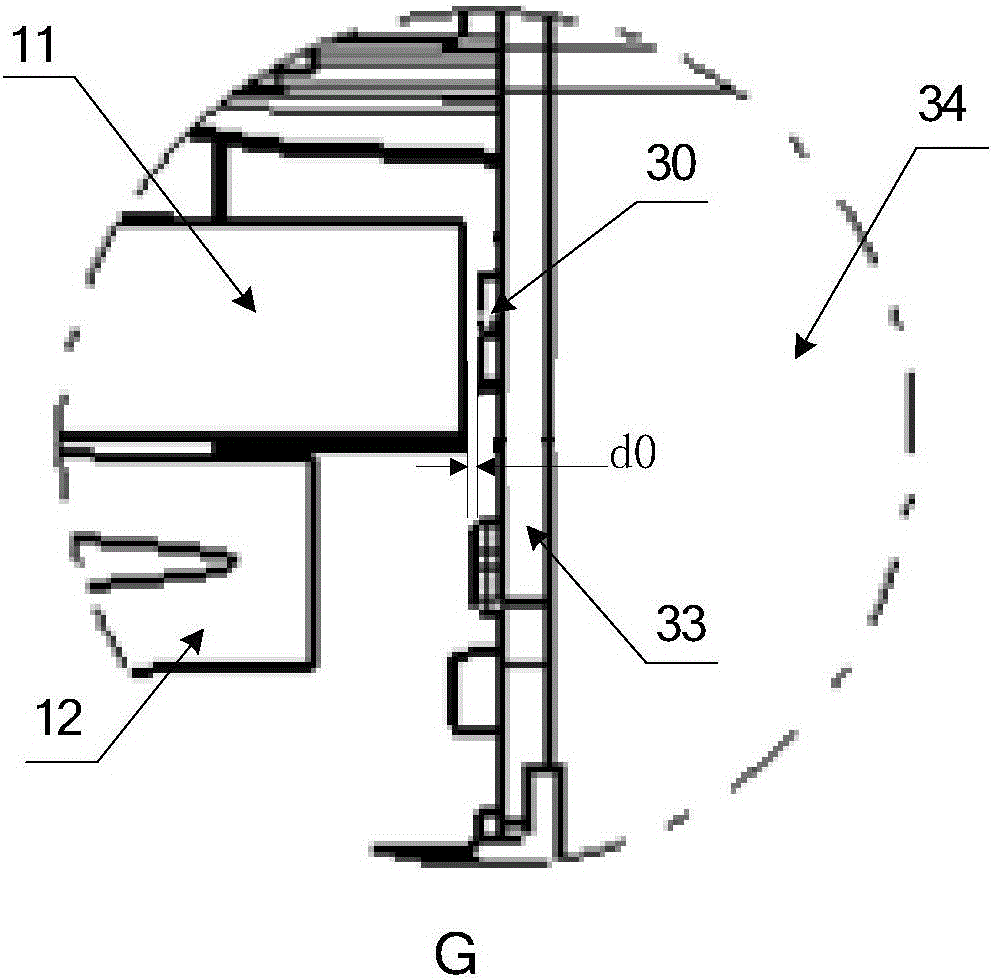

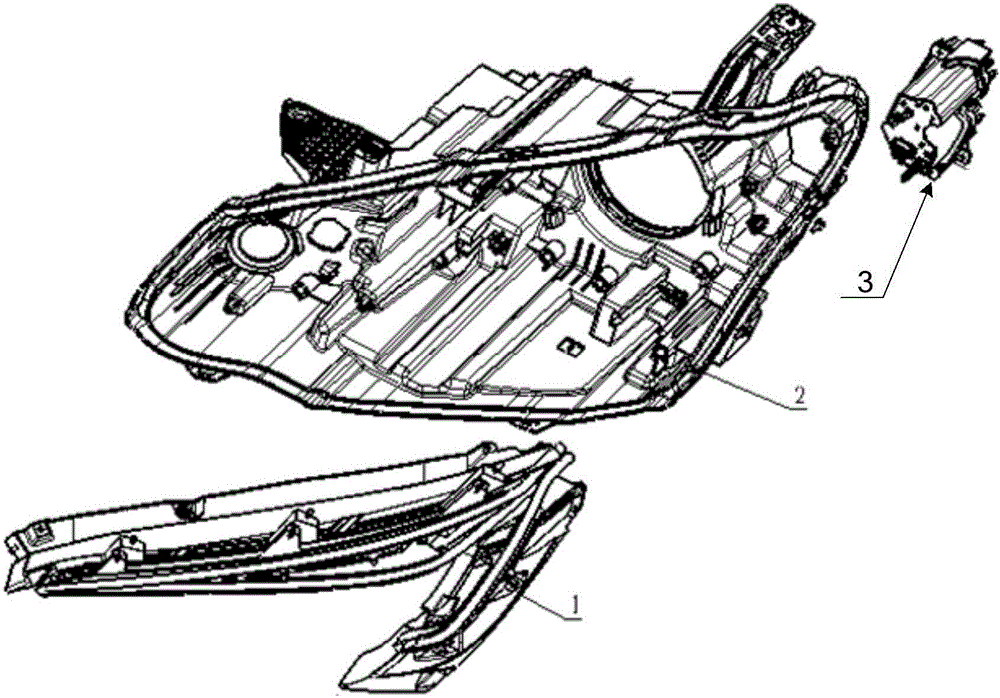

Light guide grading LED protection cover structure and light guide grading automotive lamp thereof

InactiveCN106122871ANot bruisedAvoid the risk of obsolescenceMechanical apparatusLighting heating/cooling arrangementsLight guideEffect light

The invention discloses a light guide grading LED protection cover structure and a light guide grading automotive lamp thereof, relates to arrangement of a common car lighting or signal device, in particular to the light guide grading LED protection cover structure for protecting a light guide grading automotive lamp LED chip and an automotive lamp using the light guide grading LED protection cover structure. The light guide grading automotive lamp comprises a light guide for automotive lamp grading and a circuit board mounted with an LED chip in an adhering manner; an LED protection cover surrounding the LED chip is equipped on the LED chip side of the circuit board; the height H of the LED protection cover is equal to the sum of the height h of the LED chip and the minimum protective gap d; the length and width of the LED protection cover are greater than those of the LED chip and less than those of a light inlet surface of the light guide to ensure that the light inlet surface of the light guide does not touch the semiconductor chip of the LED chip under any condition and to protect the semiconductor chip of the LED chip from being damaged, so that the light guide collides with the LED chip due to automotive vibration or deformation of the light guide to finally cause the risk that the automotive lamp is integrally scrapped.

Owner:HASCO VISION TECHNOLOGY CO LTD

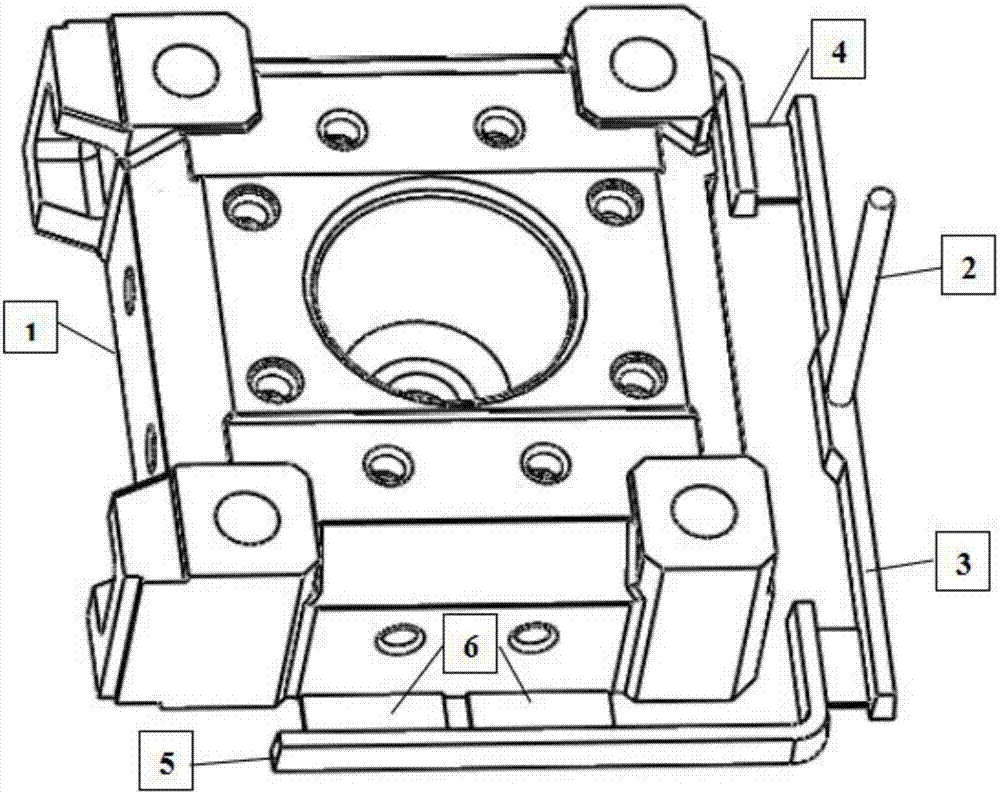

Injection molding machine super-thick large piece pouring system and pouring technology thereof

InactiveCN107350427AReduce the risk of obsolescenceLess impuritiesFoundry mouldsFoundry coresInjection molding machineIndustrial engineering

The invention discloses an injection molding machine super-thick large piece pouring system and a pouring technology thereof. Molten iron enters a first cross gate through a sprue on a casting, thin gates are arranged at the tail end of the first cross gate, and most of slag is blocked by the first cross gate; then the molten iron enters a second cross gate, the slag is blocked through thin inner gates, and the waste slag is shielded by the second cross gate; and the flow velocities of the inner gates and the thin gates are lower than 50 cm / s, and secondary oxidation slag is avoided. According to the injection molding machine super-thick large piece pouring system and the pouring technology thereof, the casting scrapped risk caused by fragments of a filter screen and a ceramic tube is reduced; the operating efficiency of staff is improved, and the cost is reduced; and impurities in foundry returns are reduced, the purity degree of the molten iron is increased, and the purity degree of reclaimed sand is increased.

Owner:JIANGSU HONGDE SPECIAL PARTS CO LTD

A laser photolithography method PCB solder resist pattern transfer and forming process

InactiveCN109041439AReduce production process linksReduce production capacityConductive material chemical/electrolytical removalResistChemical reaction

A laser photolithography PCB solder resist pattern transfer and forming process comprises that following step: 1) surface treatment of the process board: cleaning the surface of the process board to ensure that the surface is coated with ink under the condition of no impurity oxidation; 2) coat photosensitive ink: covering that surface of the whole work plate cop foil by a coating wheel to form anink with uniform thickness; 3) Ink drying: The solvent in the wet ink is evaporated through the uniform temperature of the flintlock furnace to form 18-24UM dry film; 4) laser photoresist pattern: utilizing laser and line pattern data to generate beams with different wavelengths of energy, directly scanning that work plate with photosensitive dry film, and utilizing photochemical molecular bonding principle to solidify and adhere the ink; 5) developing a solder resist pattern: for a solder resist pad pattern by chemical reaction washing of a developing liquid and an ink without molecular bonding; 6) soldering of that solder resist ink: solidifying the ink through a high-temperature oven and a drying path.

Owner:ZHEJIANG LEUCHTEK ELECTRONICS

Crosshead alloy layer pouring clamp

InactiveCN107931572AReduce the amount of processingImprove liquidityCasting apparatusCircular discAlloy

The invention discloses a crosshead alloy layer pouring fixture, which belongs to the technical field of alloy processing, and comprises a base and a stopper, and the base includes a bottom disc and an outwardly extending notch arranged on a thickness side of the bottom disc. Plug, the plug plug is a cylindrical protrusion coaxial with the bottom disc, the outer surface of the cylindrical protrusion is slidably fitted with the surface of the inner hole of the big end of the crosshead, and the stopper It is tightly sealed with the working surface of the crosshead. An alloy casting groove is arranged on the working surface. A strip-shaped arc-shaped pouring cavity, any one of the baffles is provided with a pouring sprue. In the present invention, an arc-shaped pouring cavity is formed by the inner surface of the baffle and the alloy casting groove. Compared with the square pouring cavity, the amount of alloy processing is significantly reduced, which can reduce alloy consumption and material cost.

Owner:重庆檀科科技有限公司

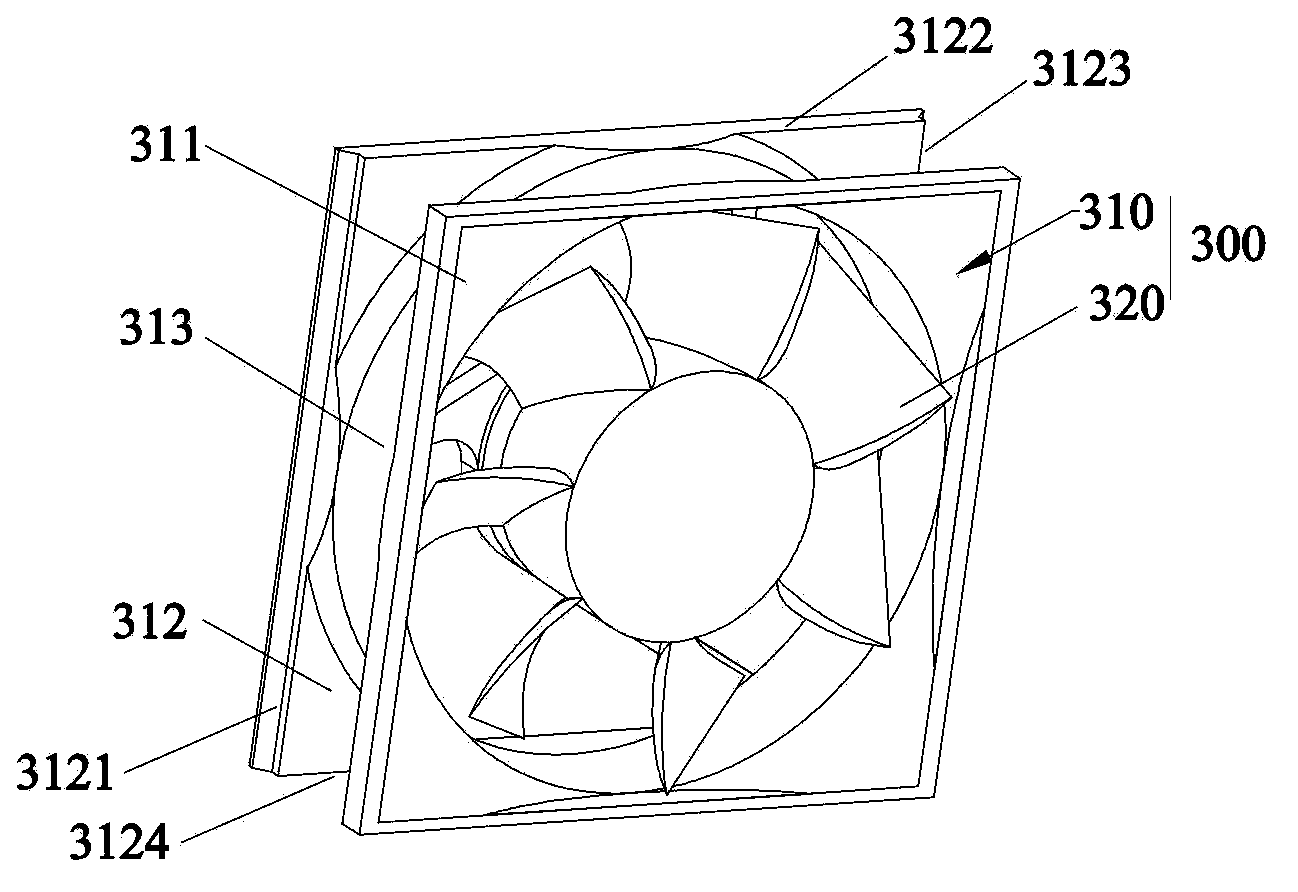

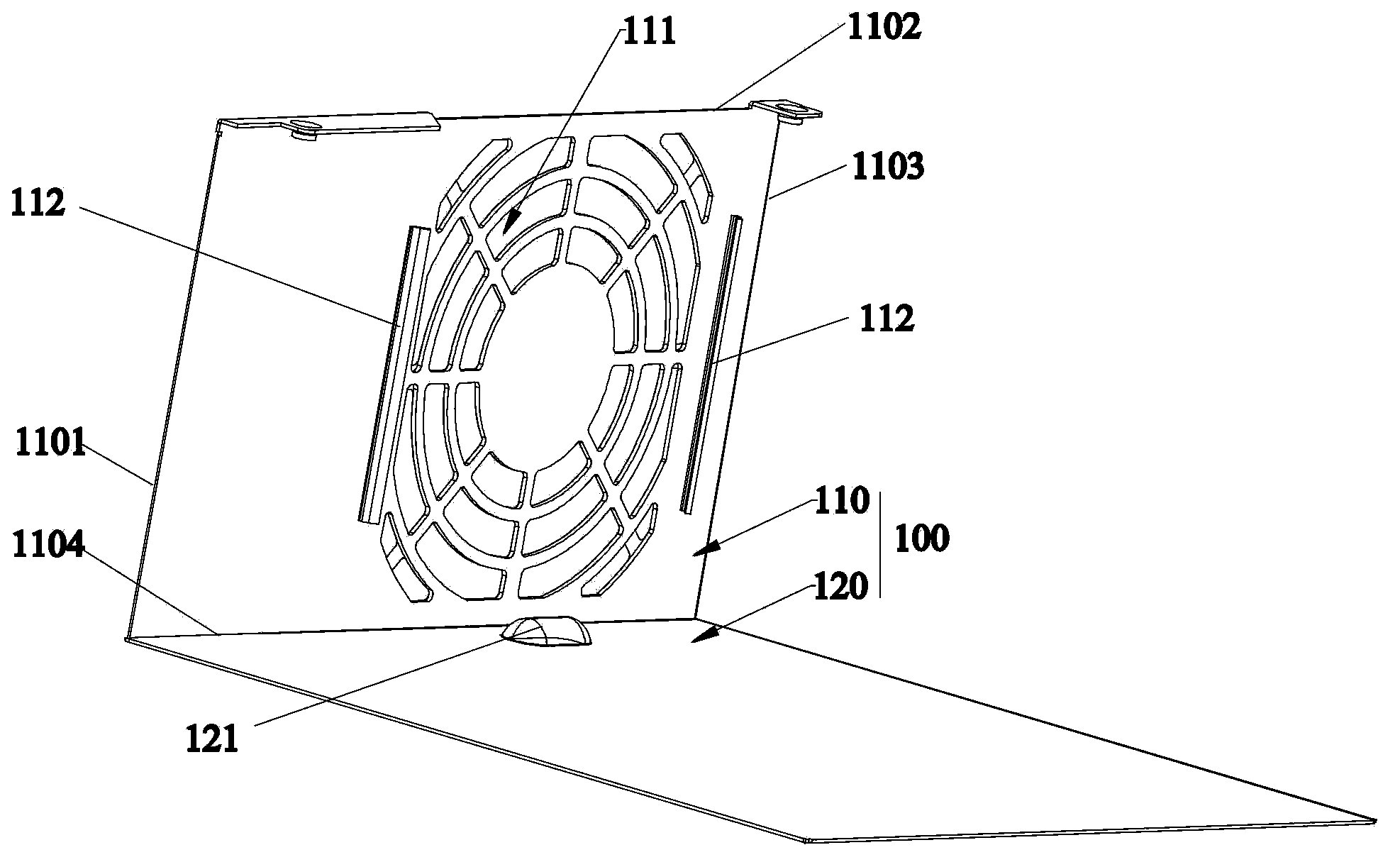

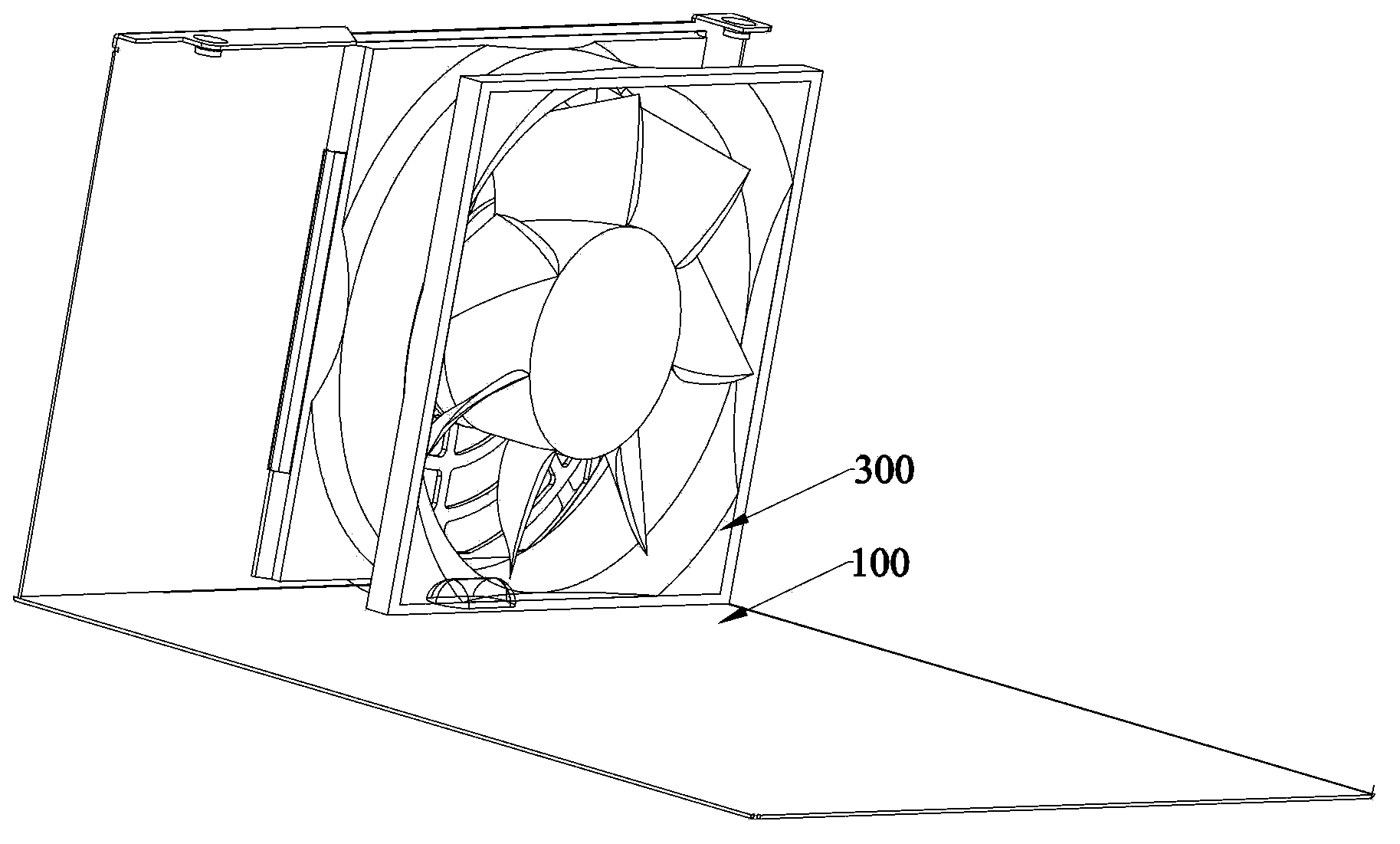

Mounting structure of fan and heat radiating device

Owner:DELTA ELECTRONICS POWER (DONGGUAN) CO LTD

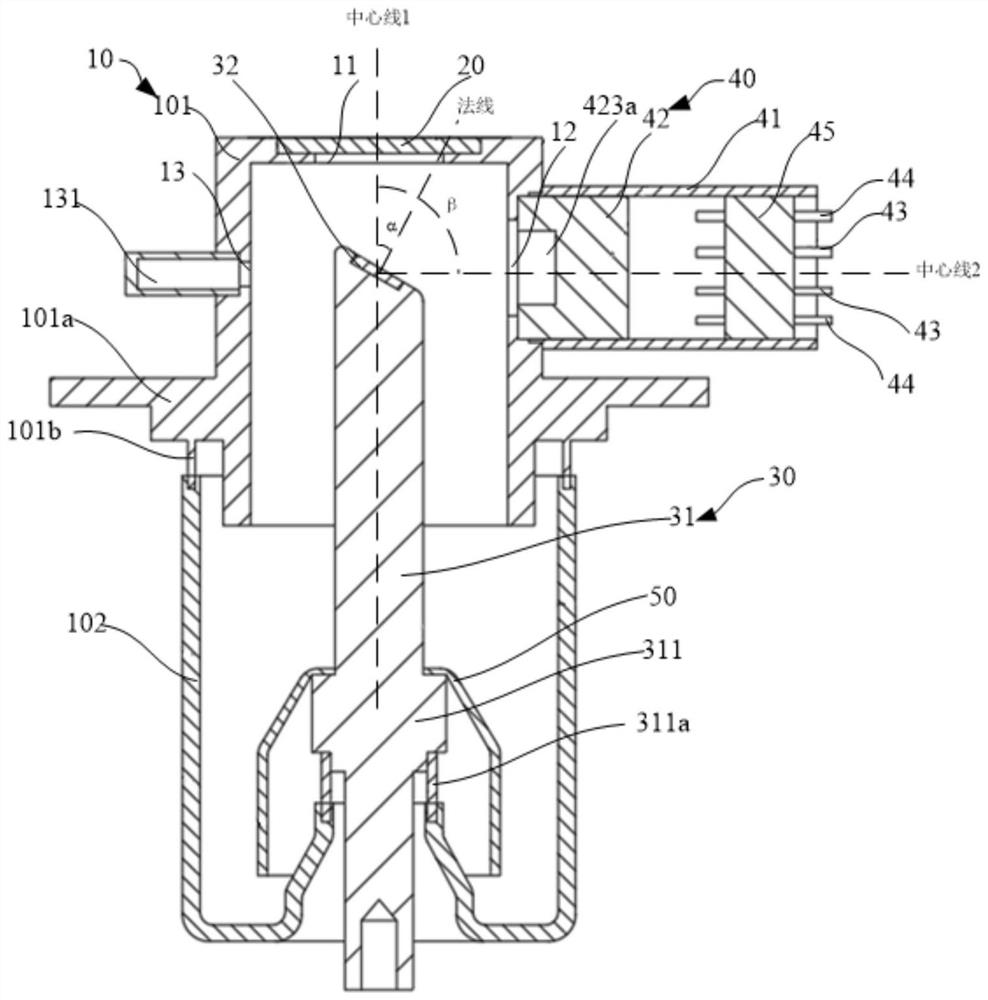

Cold cathode X-ray tube and X-ray generating device

PendingCN114551192AImprove production pass rateExtended service lifeX-ray tube electrodesX-ray tube vessels/containerCold cathodeMaterials science

The invention provides a cold cathode X-ray tube and an X-ray generating device. The cold cathode X-ray tube comprises a shell, an emergent window, an anode assembly and a cathode assembly, the shell is provided with a first mounting opening and a second mounting opening; the anode assembly comprises an anode column and an anode target; the emergent window is mounted at the first mounting opening, and the cathode assembly is mounted at the second mounting opening; or, the emergent window is mounted at the second mounting opening, and the cathode assembly is mounted at the first mounting opening; the cathode assembly comprises a fixed cover and a cold cathode, the fixed cover is connected with the shell, and the cold cathode is arranged at the corresponding mounting port and is arranged in the fixed cover; wherein the cold cathode comprises at least two emitter regions, each emitter region comprises at least one cathode single point, and the cathode single points are arranged towards the anode target. The cold cathode X-ray tube solves the problem that an existing cold cathode X-ray tube is short in service life.

Owner:海宁精奕电子有限公司

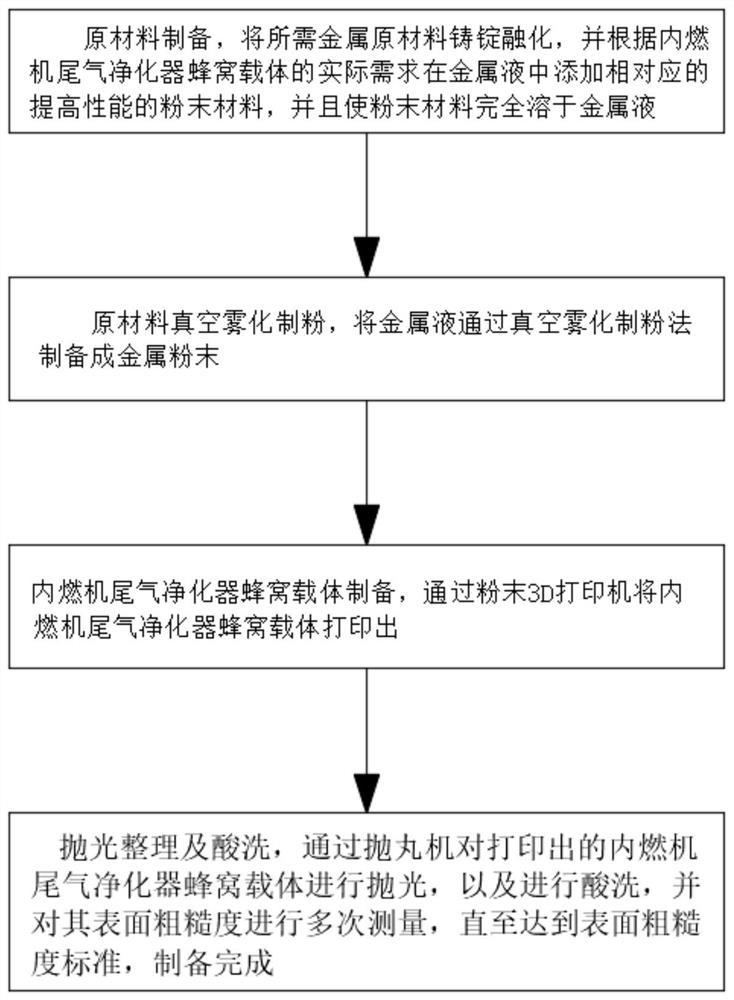

Preparation method of internal combustion engine tail gas purifier based on 3D printing technology

PendingCN112453397AUniform materialSimple processAdditive manufacturing apparatusIngot castingManufactured material

The invention discloses a preparation method of an internal combustion engine tail gas purifier based on a 3D printing technology. The preparation method comprises the following steps that S1, raw materials are prepared, specifically, ingot casting and melting are carried on required metal raw materials, and corresponding alloy is added into molten metal according to the actual requirements of a honeycomb carrier of the internal combustion engine tail gas purifier; S2, the raw materials are subjected to vacuum atomization powder preparation, specifically, the molten metal is prepared into metal powder through a vacuum atomization powder preparation method; S3, the honeycomb carrier of the internal combustion engine tail gas purifier is prepared; and S4, polishing finishing and acid pickling are conducted. Compared with an existing preparation method, the preparation method of the internal combustion engine tail gas purifier based on the 3D printing technology is simple in technologicalprocess, the finished product composition material is uniform, the product yield is high, the procedures of heat treatment, hot rolling, cold rolling and welding in an existing preparation method areomitted, the risk of product scrapping is reduced, short-process green and clean manufacturing is achieved, and energy is also saved.

Owner:安徽钢研新材料科技有限公司

Mask plate, mask plate layout design method and defect repairing method

InactiveCN101192007BSolve scrapProduction has no effectSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentGraphicsDefect repair

Owner:SEMICON MFG INT (SHANGHAI) CORP

Wafer transport carrier and wafer box detection method

ActiveCN110060939APrevent looseningReduce the risk of obsolescenceSemiconductor/solid-state device manufacturingConveyor partsElectrical and Electronics engineeringScrap

The invention provides a wafer transport carrier and a wafer box detection method. The wafer transport carrier comprises a loading device with a containing space and a detection area which is connected with the containing space, a suspension device arranged in the containing space and configured to move a wafer box into the containing space, and a detection device arranged on the loading device and configured to detect the position of a door plate of the wafer box so as to send out a warning signal when the door plate is located in the detection area. The detection device disclosed by the invention can be used for detecting whether the door plate of the wafer box is loosened relative to a shell or not in real time in a process that the suspension device moves the wafer box or in a processthat the wafer transport carrier transports the wafer box, and can be used for sending out the warning signal when detecting that the door plate is loosened relative to the shell, so that the door plate can be prevented from falling from the shell and the risk of wafer scrap can be reduced.

Owner:TAIWAN SEMICON MFG CO LTD

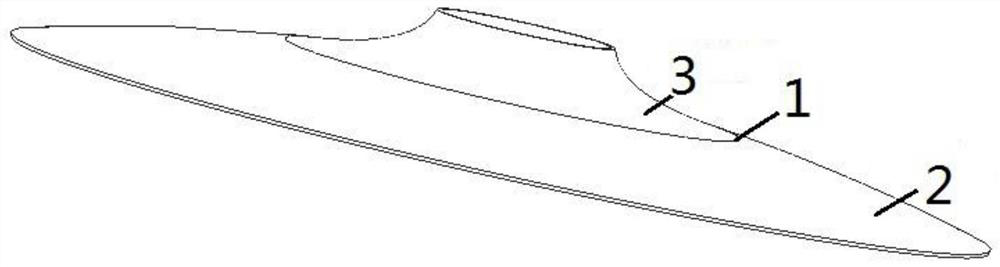

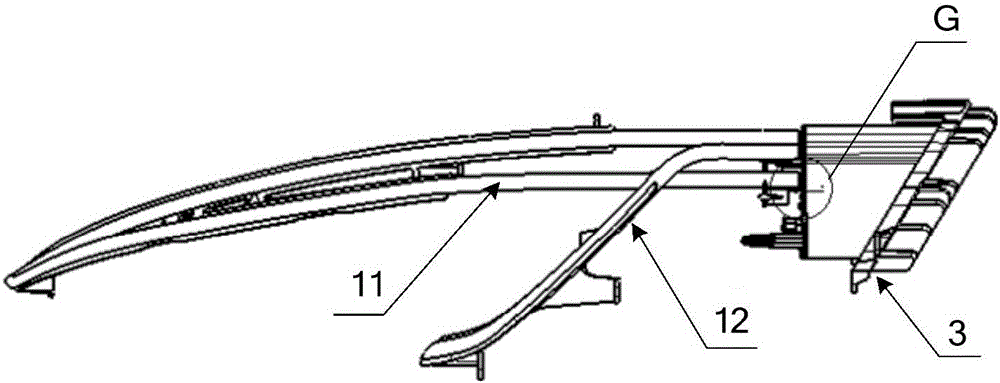

Method for repairing large-area damage of honeycomb sandwich structural part

ActiveCN112743880AReduce the risk of obsolescenceAvoid secondary damageWeight reductionDomestic articlesHoneycombEngineering

The invention provides a method for repairing large-area damage of a honeycomb sandwich structural part. The method comprises the steps of dividing a damage zone (9) into N parts according to the area of the damage zone (9); placing corresponding honeycombs at the N parts of the damage zone (9) in sequence, and curing the honeycombs according to a preset curing condition to form a spliced honeycomb; and sequentially placing a structural adhesive film (7) and a patch (8) on the upper surface of the spliced honeycomb from bottom to top, and curing the patch (8) according to a preset curing condition.

Owner:HARBIN

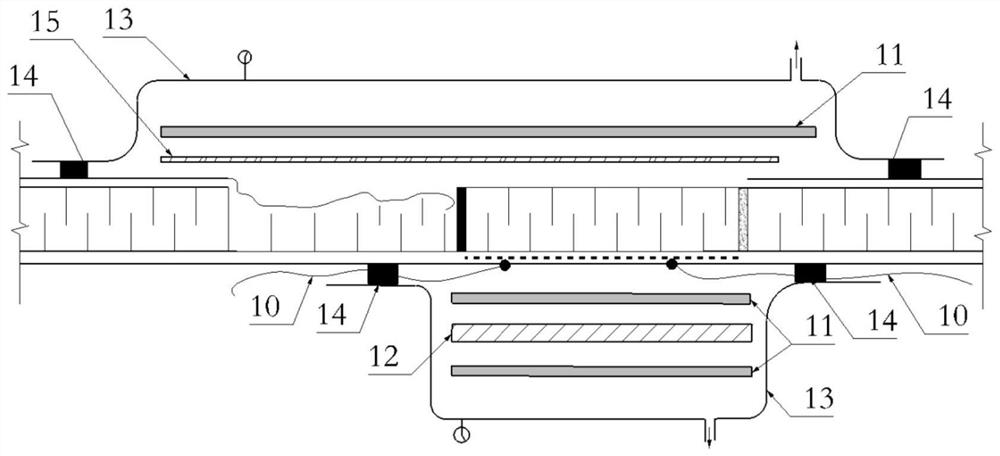

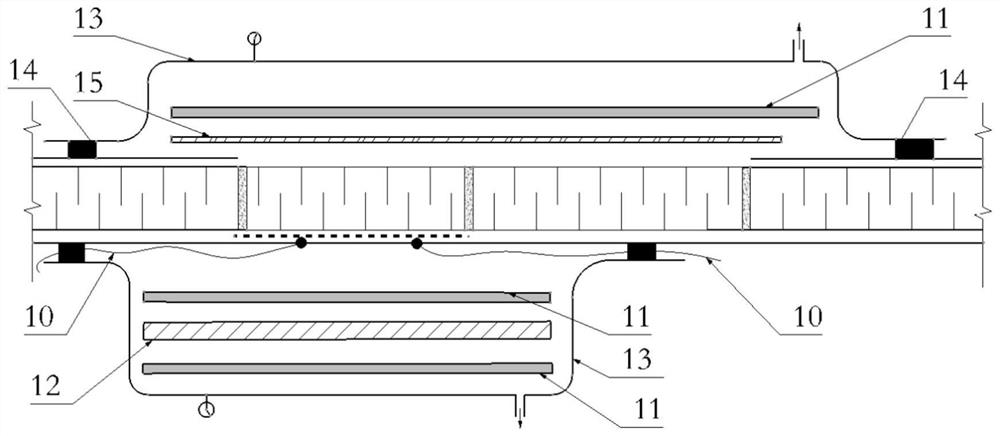

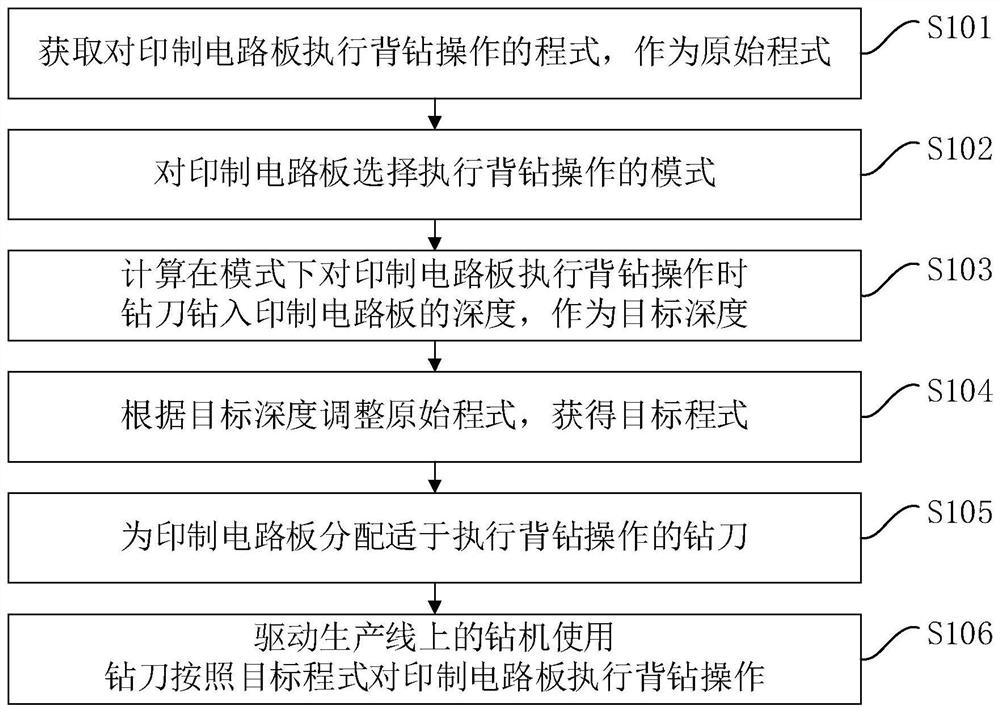

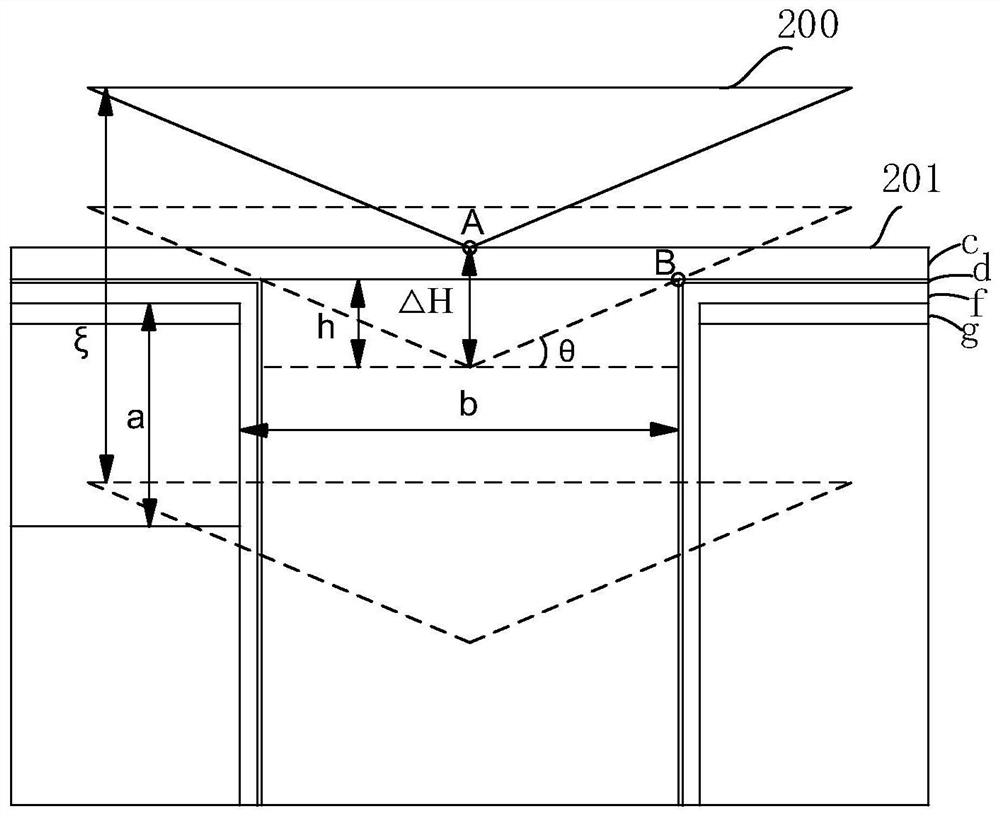

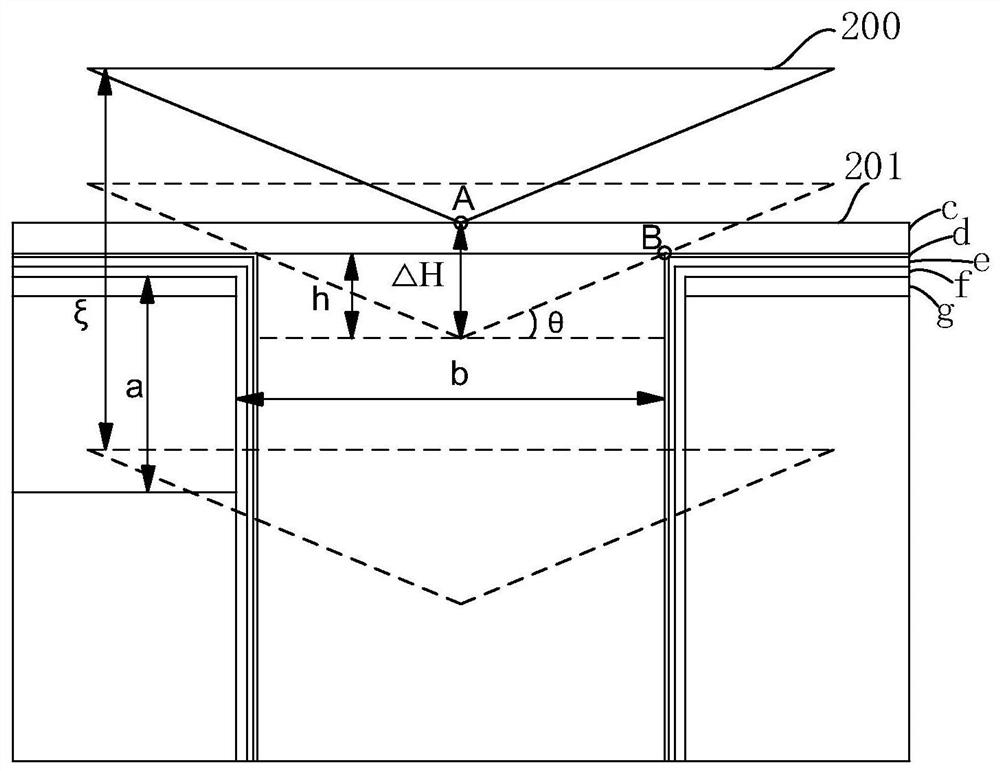

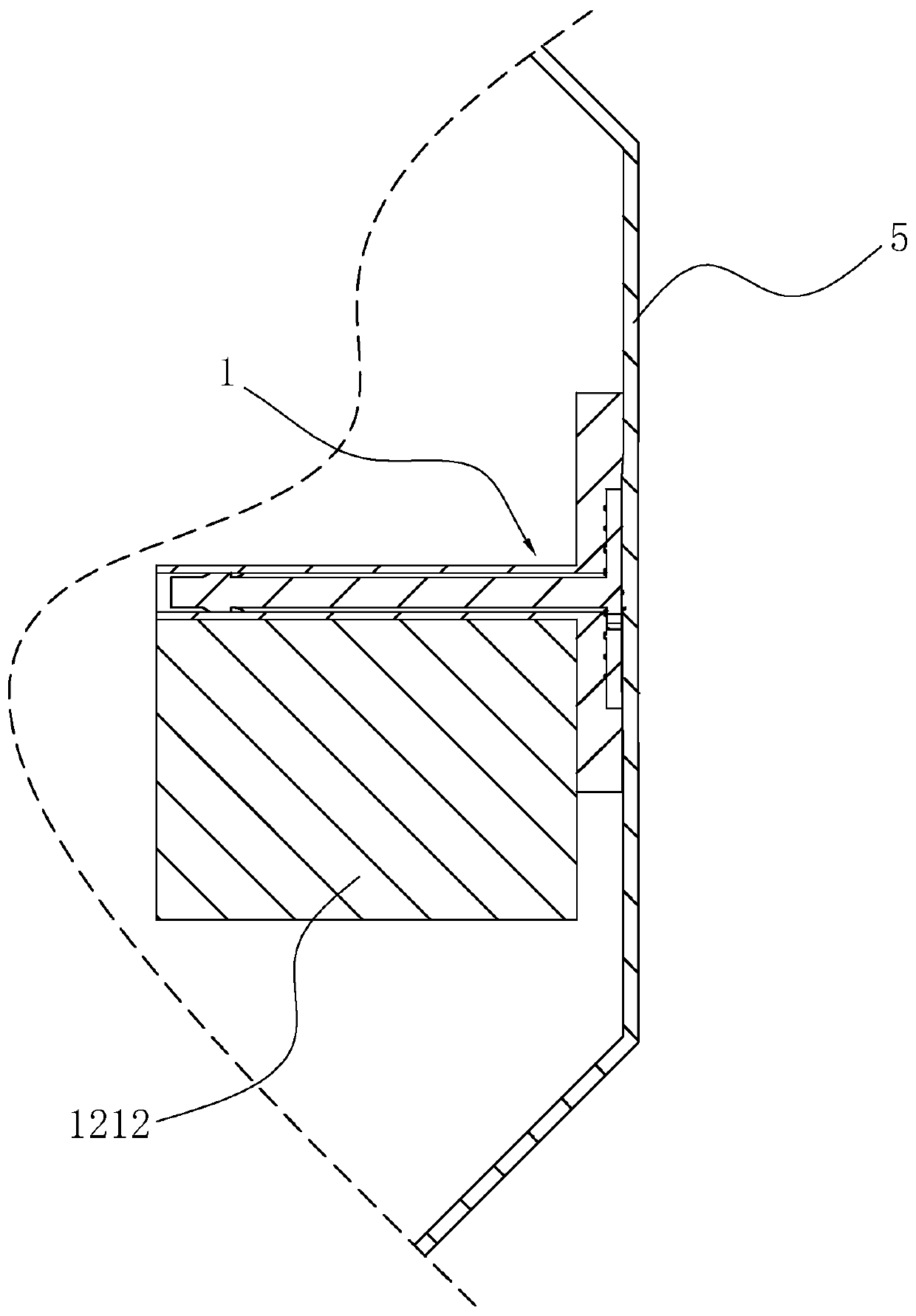

Backdrilling method, device and equipment of printed circuit board, and storage medium

ActiveCN112203426AHigh precisionReduce the risk of obsolescenceCircuit board tools positioningProduction lineProcess engineering

The invention discloses a back drilling method, device and equipment for a printed circuit board, and a storage medium. The method comprises the steps: obtaining a program for carrying out backdrilling operation on a printed circuit board, and taking the program as an original program; selecting a mode of performing backdrilling operation on the printed circuit board; calculating the drilling depth of a drilling tool into the printed circuit board when the backdrilling operation is performed on the printed circuit board in the mode, and taking the drilling depth as a target depth; adjusting the original program according to the target depth to obtain a target program; distributing a drilling tool suitable for executing backdrilling operation to the printed circuit board; and driving a drilling machine on a production line to use the drilling tool to perform backdrilling operation on the printed circuit board according to the target program. According to the method, the program requiredfor manufacturing the printed circuit board is obtained, the mode of executing the backdrilling operation is autonomously selected, the target depth of backdrilling is calculated according to different modes, the backdrilling program is adjusted according to the target depth, the printed circuit board scrap risk caused by manual misoperation is reduced, and the production efficiency is improved.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +1

Structure of pressure-resistant oil tank and manufacturing method thereof

The invention relates to a structure of a pressure-resistant oil tank and a manufacturing method thereof. According to the main points of the technical scheme, the manufacturing method of the pressure-resistant oil tank comprises the following steps that S1, a connection part is installed, an installation rod is inserted into a sleeve from one end of a matching disc during installation, and a gapis reserved between an installation disc and the matching disc; S2, the connection part is fed into a blow molding mold through a feed part, a blow molding machine blows out a molten parison, the parison is put into the mold, and the blow molding mold is closed; S3, the installation disc makes contact with the parison and presses the parison into a shaft hole, a pressing driving part pushes a shaft sleeve to move along the shaft hole and rotates at the same time, and the shaft sleeve pushes the installation disc to abut against the matching disc; and S4, the blow molding mold is opened, the feed part is taken out from the blow molding mold, then the blow molding mold is closed again, the mold is opened again after the parison is cooled, and the effect that connection strength and stabilitybetween an anti-wave plate and the inner wall of the pressure-resistant oil tank are improved is achieved.

Owner:德安福(天津)汽车技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com