Drilling method for circuit board

A drilling method and circuit board technology, applied in the directions of printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of inability to drill through the PCB board at one time, low hole position accuracy, and scrapped PCB boards, so as to avoid resistance to deformation. The ability is weakened, the hole position error is avoided, and the effect of high precision is guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] A method for drilling a circuit board, comprising the following steps:

[0025] 1. Setting of positioning target and direction target.

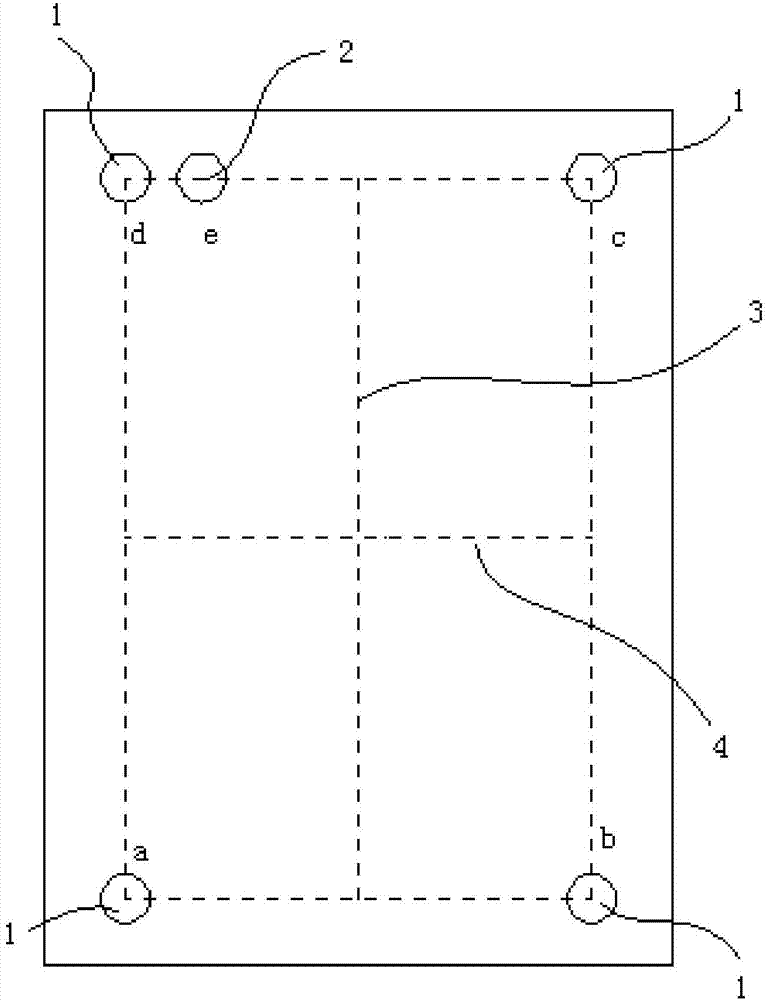

[0026] Such as figure 1 As shown, the positioning target 1 and the direction target 2 are set on the circuit board, and the positioning target 1 is four, which are respectively arranged on the four corners of the circuit board, and the four positioning targets 1 are the endpoints Positioning graphics that make up a rectangle. The direction target 2 is a positioning target located on one side of the rectangular positioning figure and close to the end point of the side, with a distance of 5-6 mm from the positioning target.

[0027] According to the above design, when making the inner layer graphics, the graphics of the positioning target and the direction target are produced on each layer of the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com