Patents

Literature

30results about How to "Not easy to break the knife" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

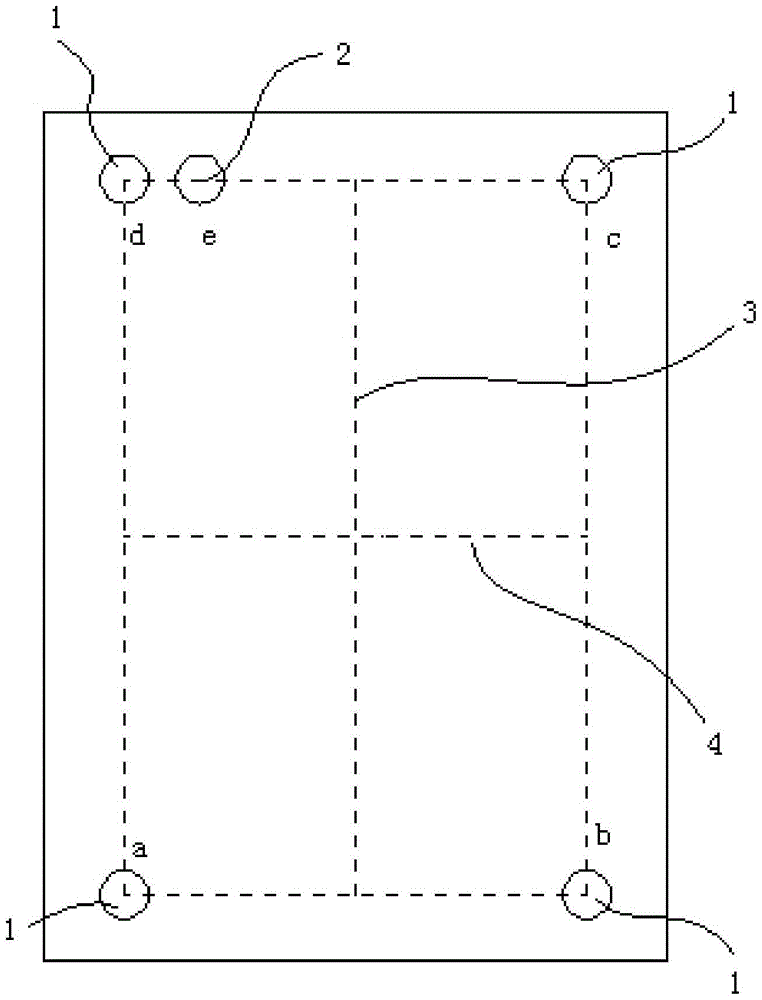

Drilling method for circuit board

ActiveCN103752882AGuaranteed coincidenceHigh precisionPrinted circuit manufactureDrill holeDiameter ratio

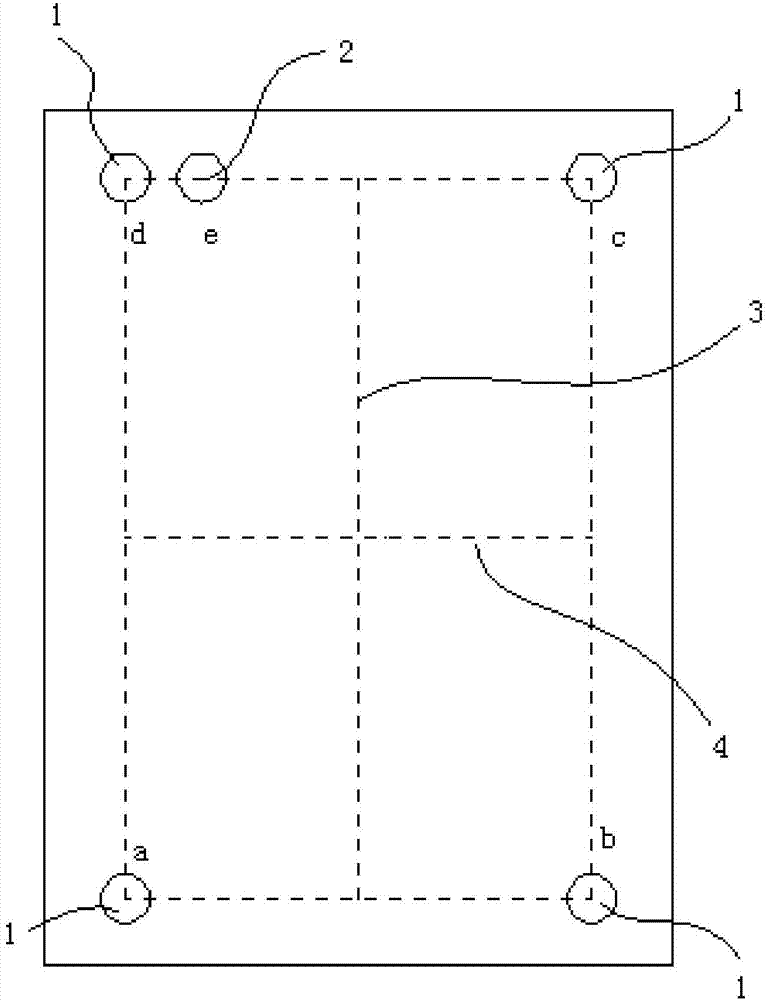

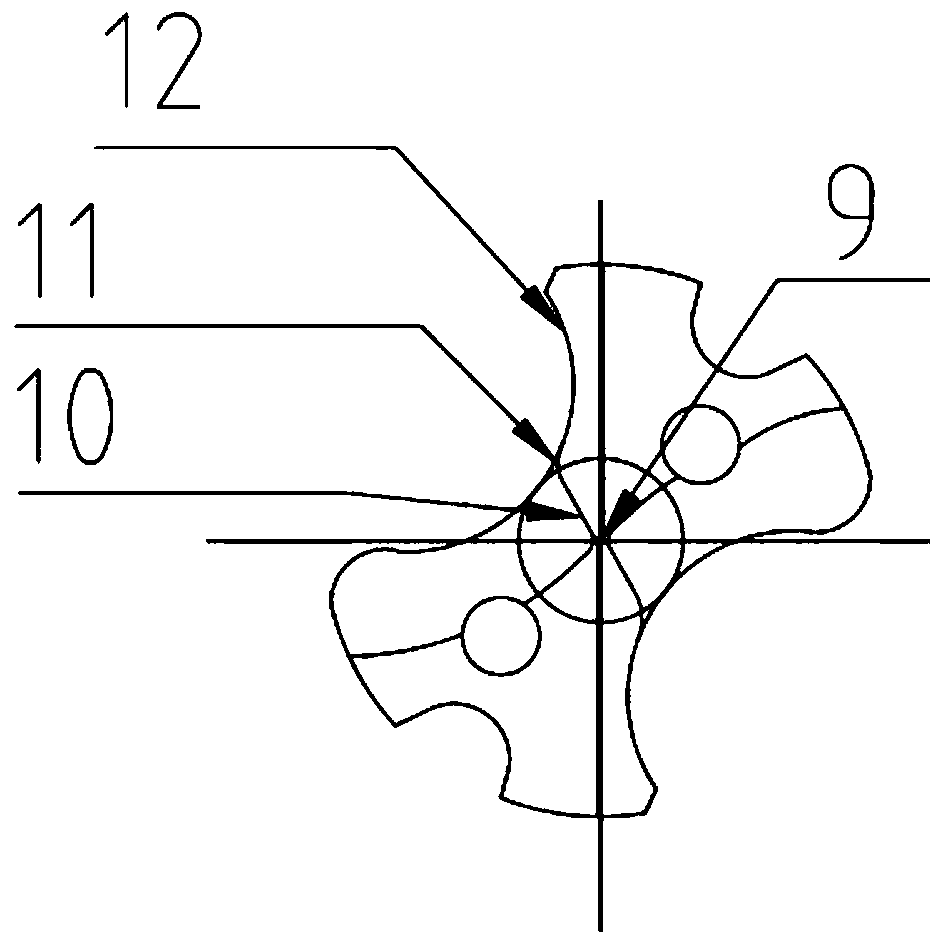

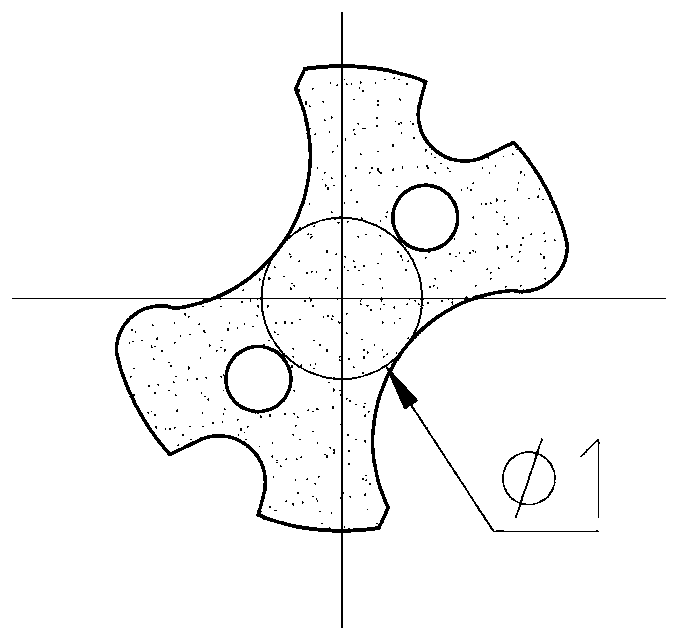

The invention discloses a drilling method for a circuit board and belongs to the technical field of circuit board production. The drilling method comprises the following steps of setting a positioning target and a directional target on the circuit board, drilling a positioning hole in the positioning target and drilling a directional hole in the directional target; enabling the number of the directional target to be one and arranging the directional target in an area which is outside a horizontal central line and a longitudinal central line; identifying the direction of the circuit board through the directional hole, enabling a pin to penetrate the positioning hole and installing and fixing the circuit board and a cover plate; drilling the circuit board in the front side and the rear side and enabling the drilled holes in the front side and the rear side to be through holes. The drilling method for the circuit board can achieve circuit board drilling with the high thickness-diameter ratio and obtain high accuracy hole location.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

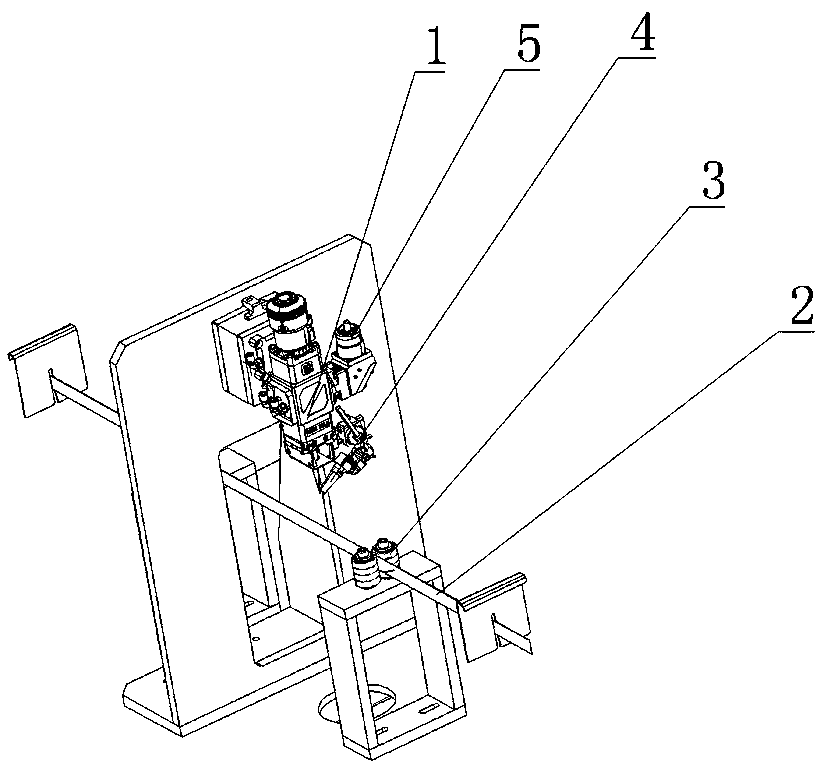

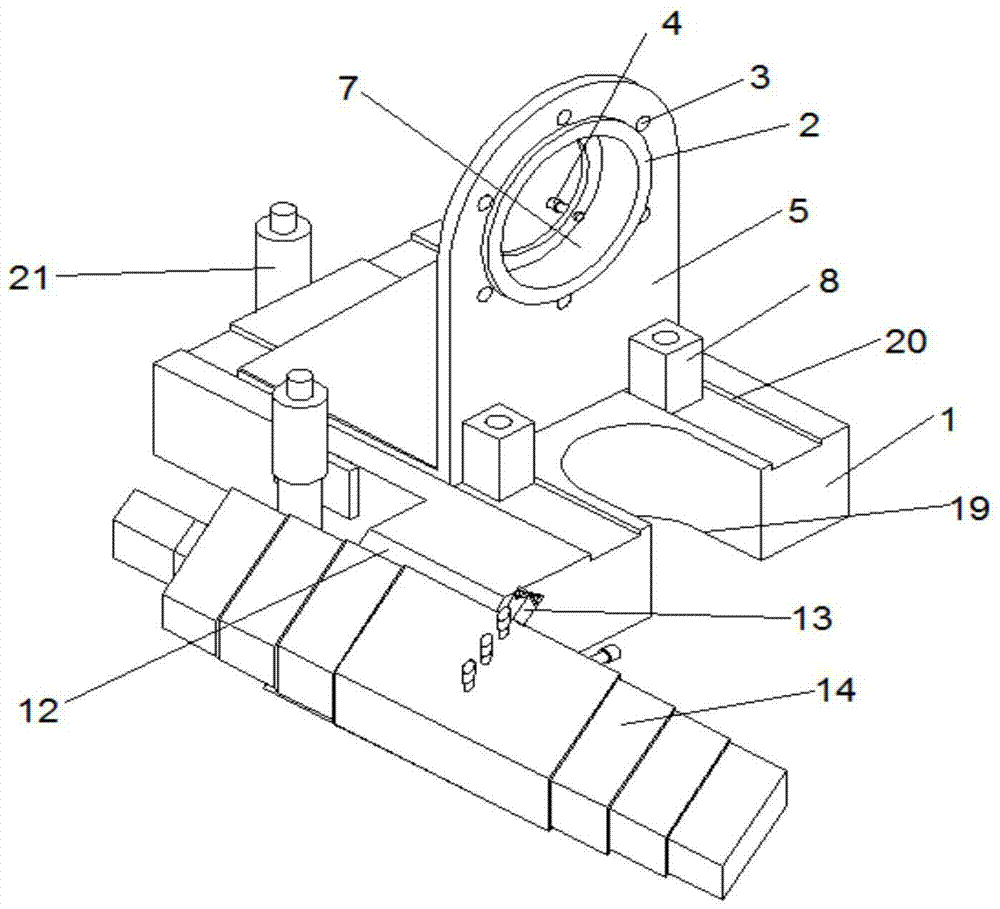

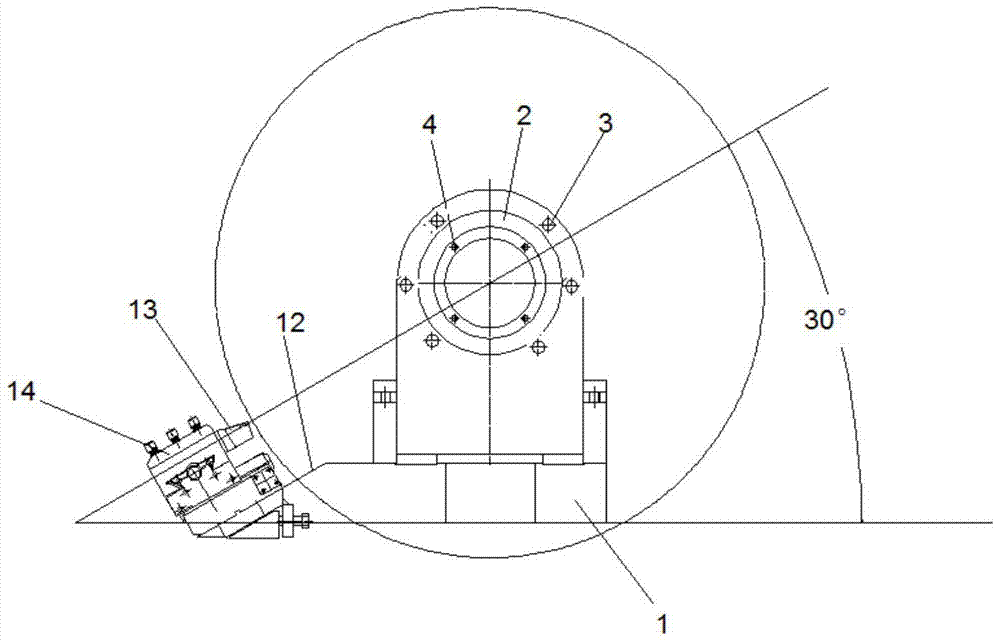

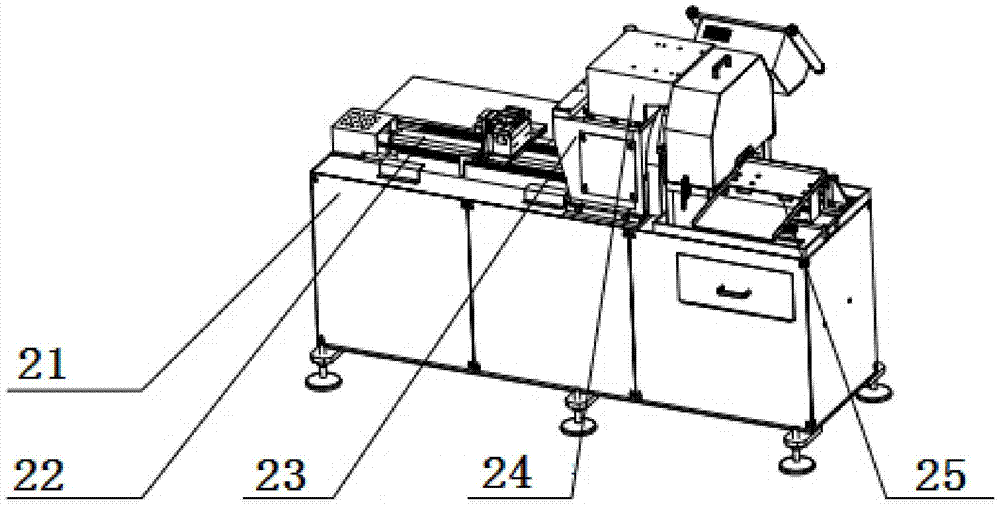

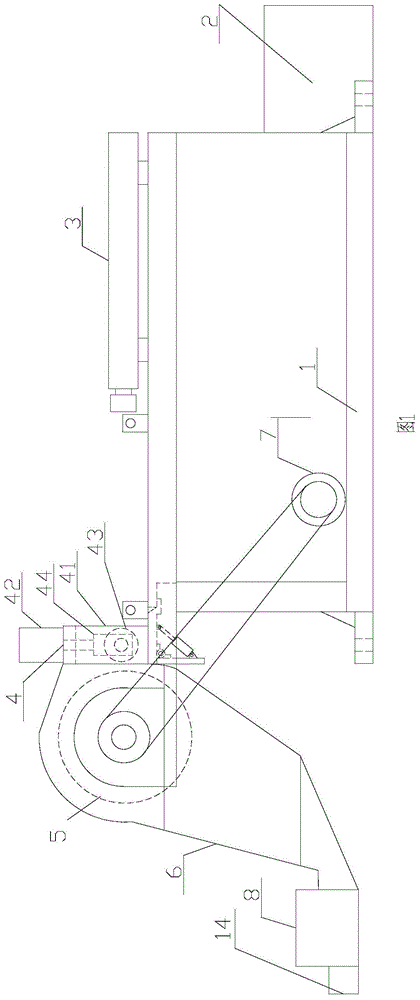

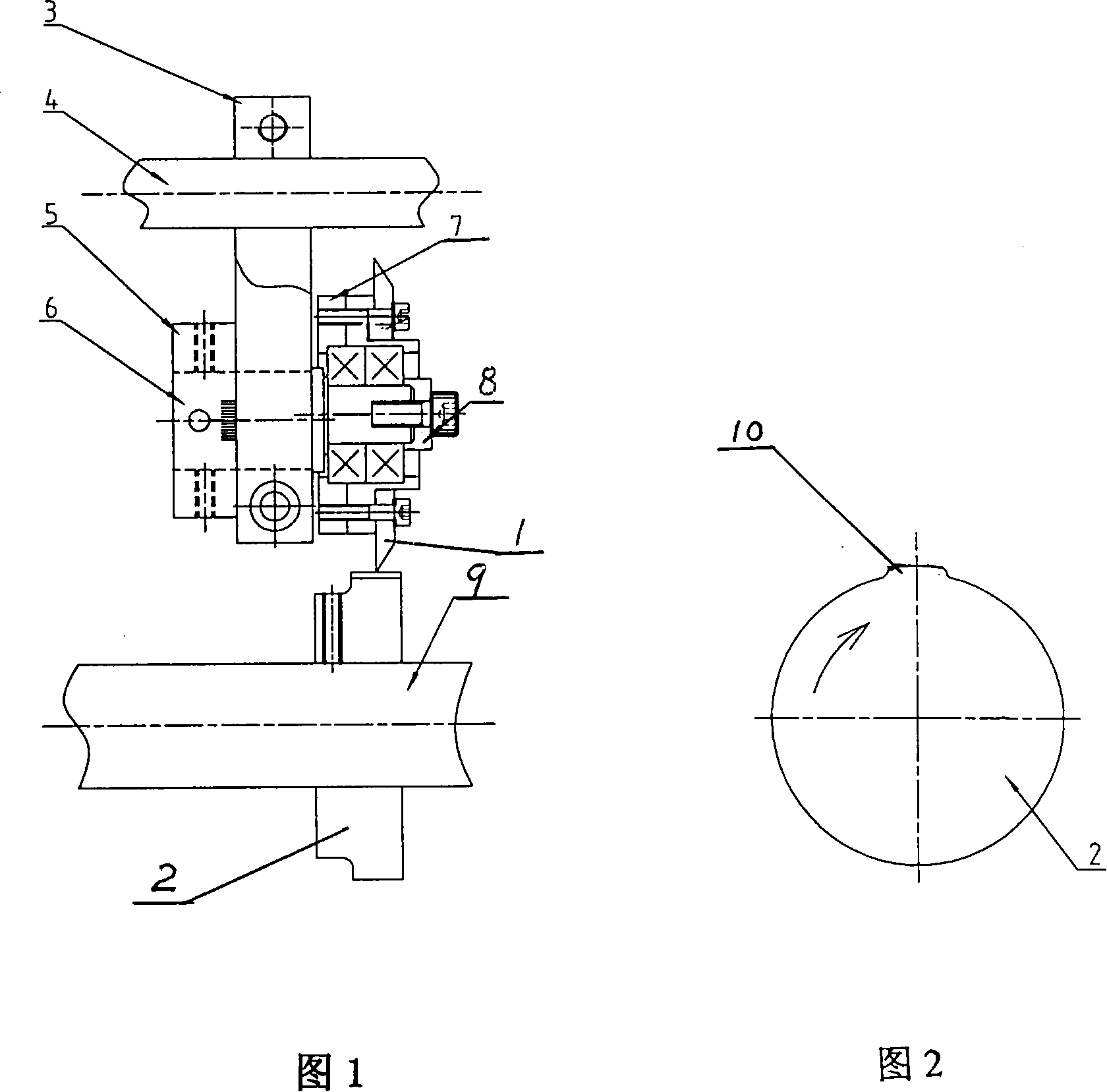

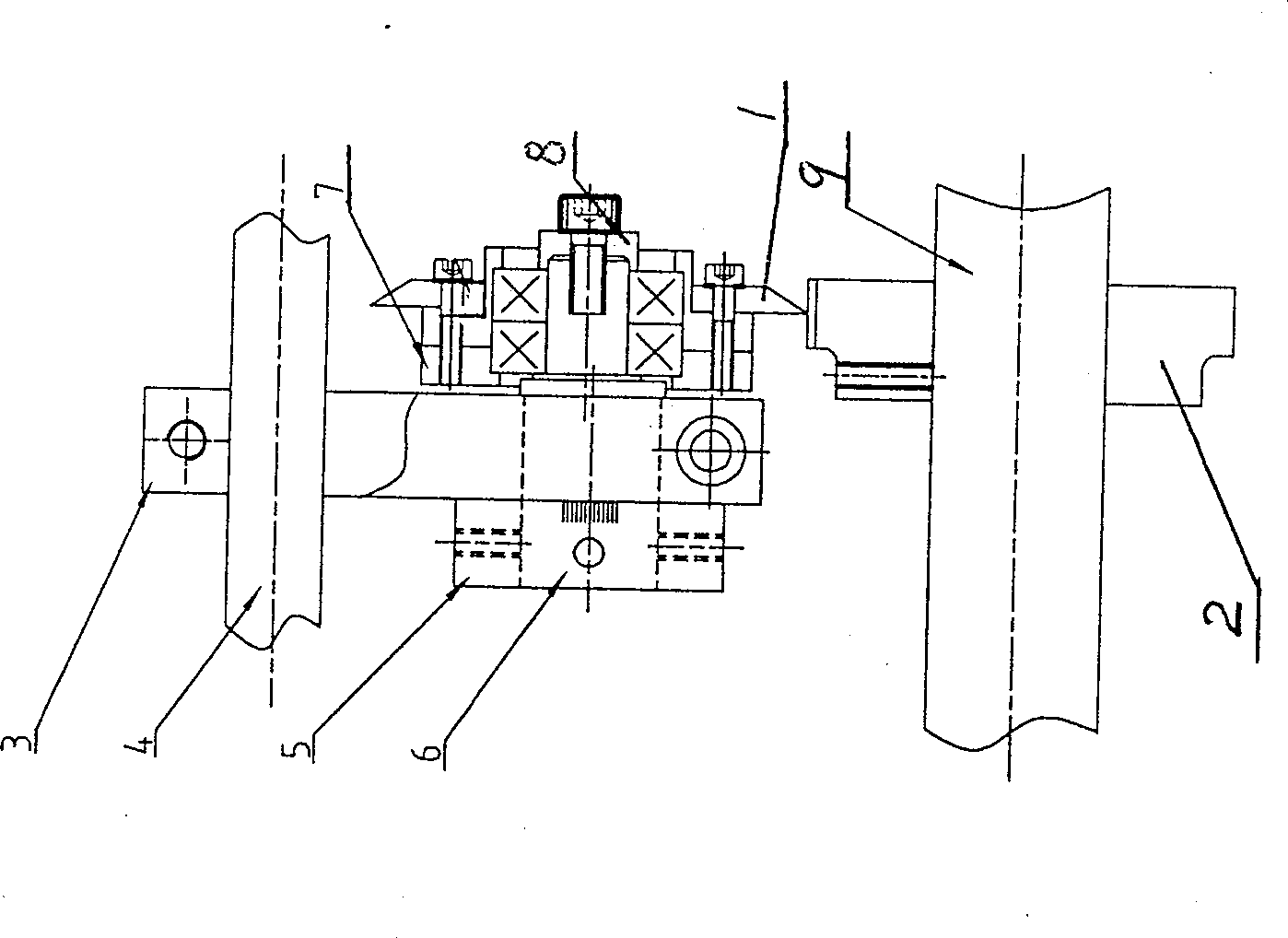

Locomotive wheel numerical control lathing device

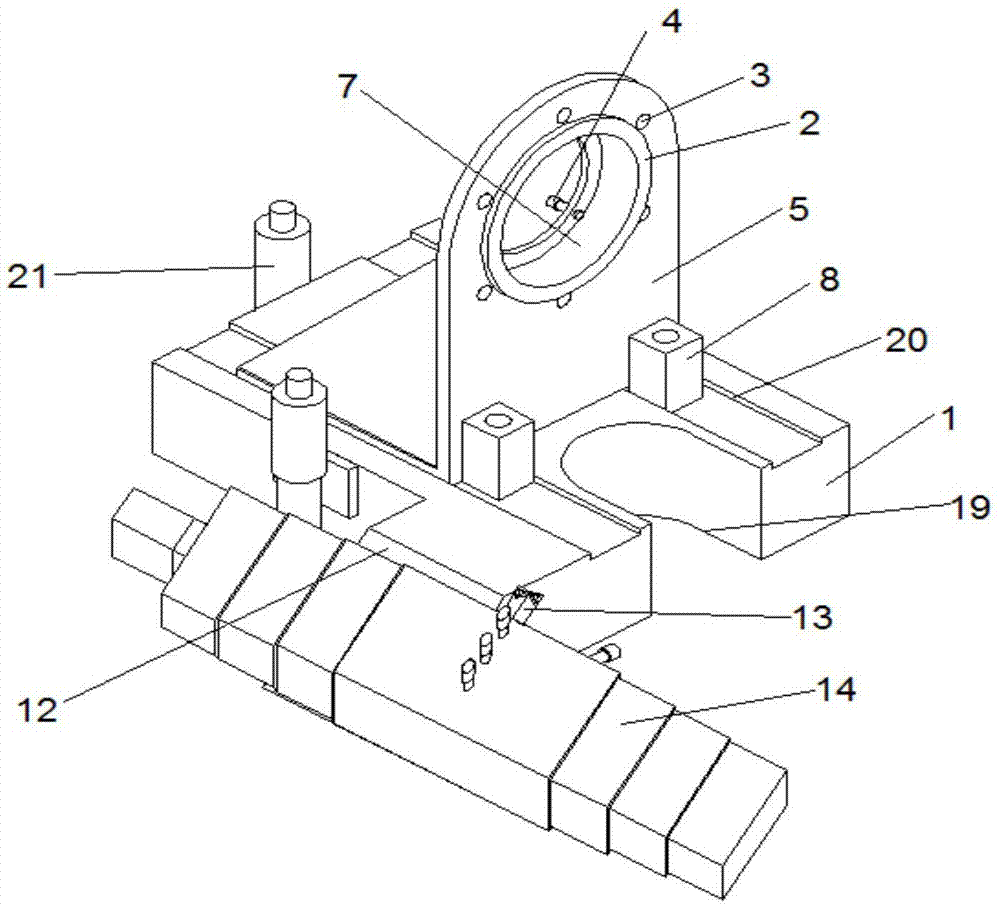

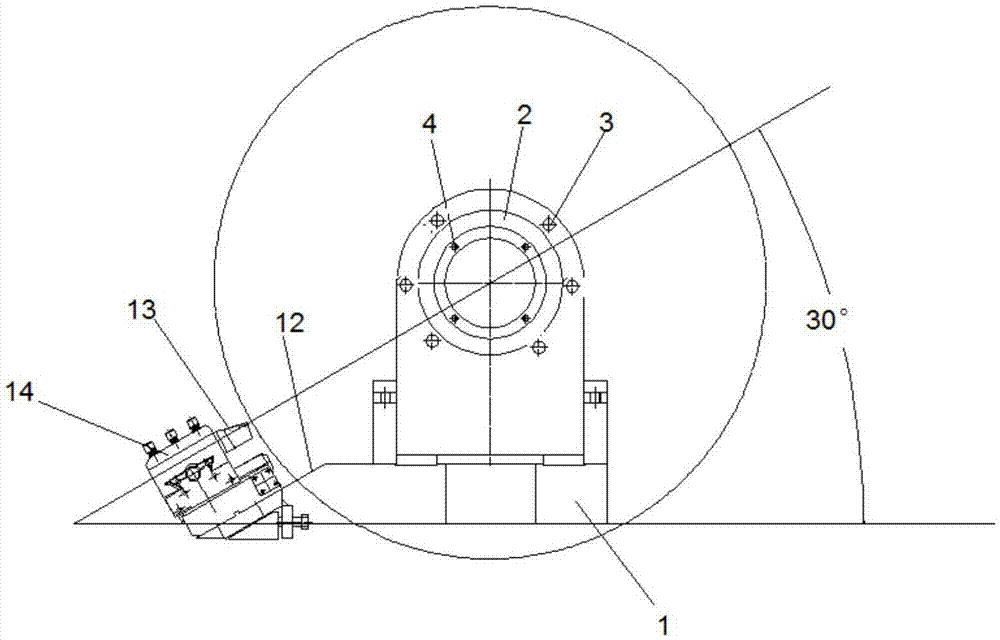

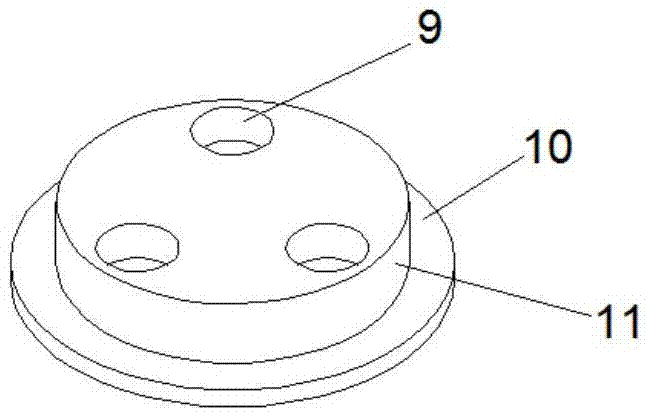

The invention relates to the technical field of railway equipment. A manufacturing unit and a support unit are integrated onto the same supporting platform by utilizing a pair of engine bases. The locomotive wheel numerical control lathing device provided by the invention is characterized in that a tool supporting structure, a shaft end positioning device and a shaft end supporting device are arranged on the same platform base (1), the shaft end positioning device comprises a positioning bending plate (5) and a connection plate (6) which are provided with a positioning boss (2), a mounting bolt hole (3) and an axial clearance adjustment bolt (4), and a concentric stepped hole (7) is arranged in the positioning boss (2); the positioning bending plate (5) is lengthways fixed on the platform base (1) along the center line of the rounded positioning boss (2); the tool supporting structure is of an inclined plane (12) formed by forward extended one side of the front end of the platform base (1), wherein the inclined plane (12) is parallel to a plane formed by the axial line of the positioning boss (2) and the radius of a working point. The device is light in weight, simple in structure and operation, high in working efficiency, and low in investment cost, is applied to locomotive wheel lathing operation in a railway locomotive department, and is particularly applied to the wheel lathing operation without the wheel lathing condition.

Owner:JINAN WUXING ELECTROMECHANICAL TECH CO LTD

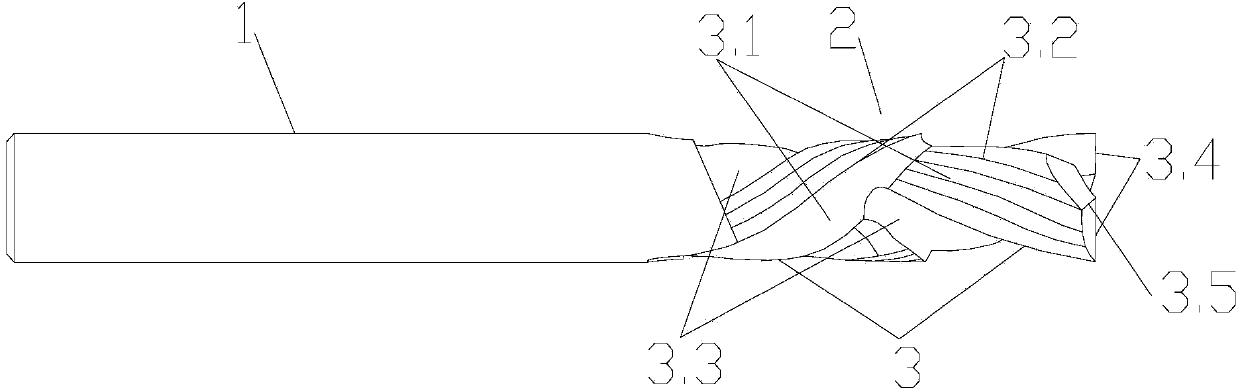

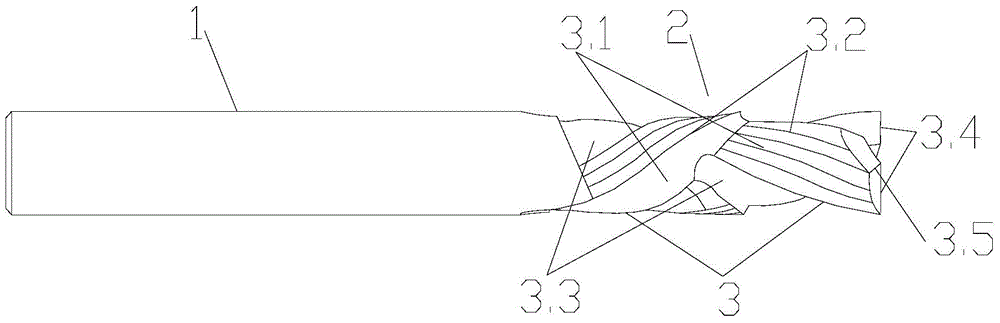

Two-edge pressure-type end mill

ActiveCN104191020AUniform distribution of cutting edgesEvenly distributedMilling cuttersMilling cutterSinistral and dextral

The invention relates to the technical field of a cutter for cutting machining, in particular to a two-edge pressure-type end mill. The two-edge pressure-type end mill comprises a cutter handle and an edge part which is arranged on the front end of the cutter handle, wherein the edge part is formed by a plurality of sections of spiral structures which are identical in structure and are connected with one another from front to rear, each spiral structure is formed by screwing a left-handed edge body and a right-handed edge body relative to the same axis for half circle, a plurality of spiral scale backs are uniformly arranged on the back surface of each spiral cutter body, a seamed edge of each spiral cutter body and a seamed edge of each scale back are respectively provided with a cutting edge, a spiral cutter withdrawing groove is formed between the two spiral cutter bodies, the seamed-edge side edges of all the spiral cutter bodies form a spiral cutting edge of the two-edge pressure-type end mill, and the front end edges, on the front end of the edge part, of the spiral cutter bodies are intersected to form a mill end edge. The two-edge pressure-type end mill is specially used for cutting a composite material, is free of layering, burrs and the like in the machining process, and is high in machining quality.

Owner:CHANGZHOU CHUANGWEI TOOL MFG

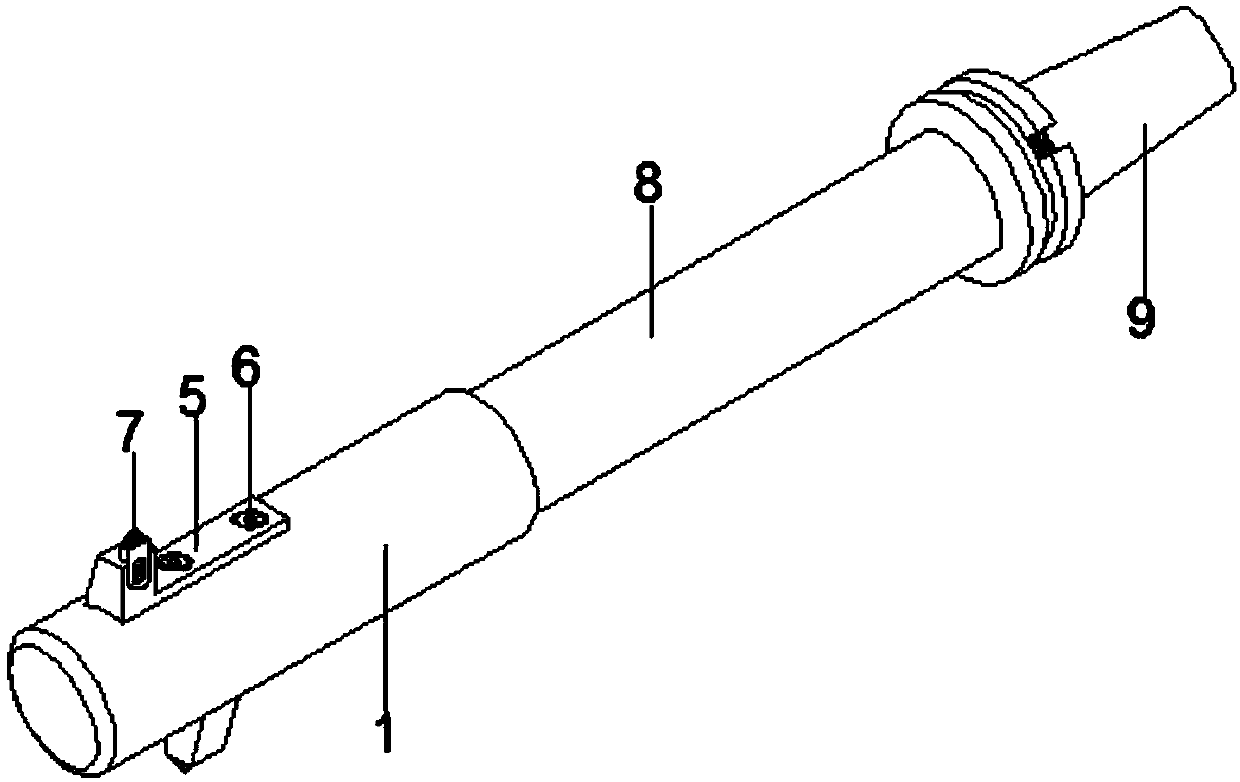

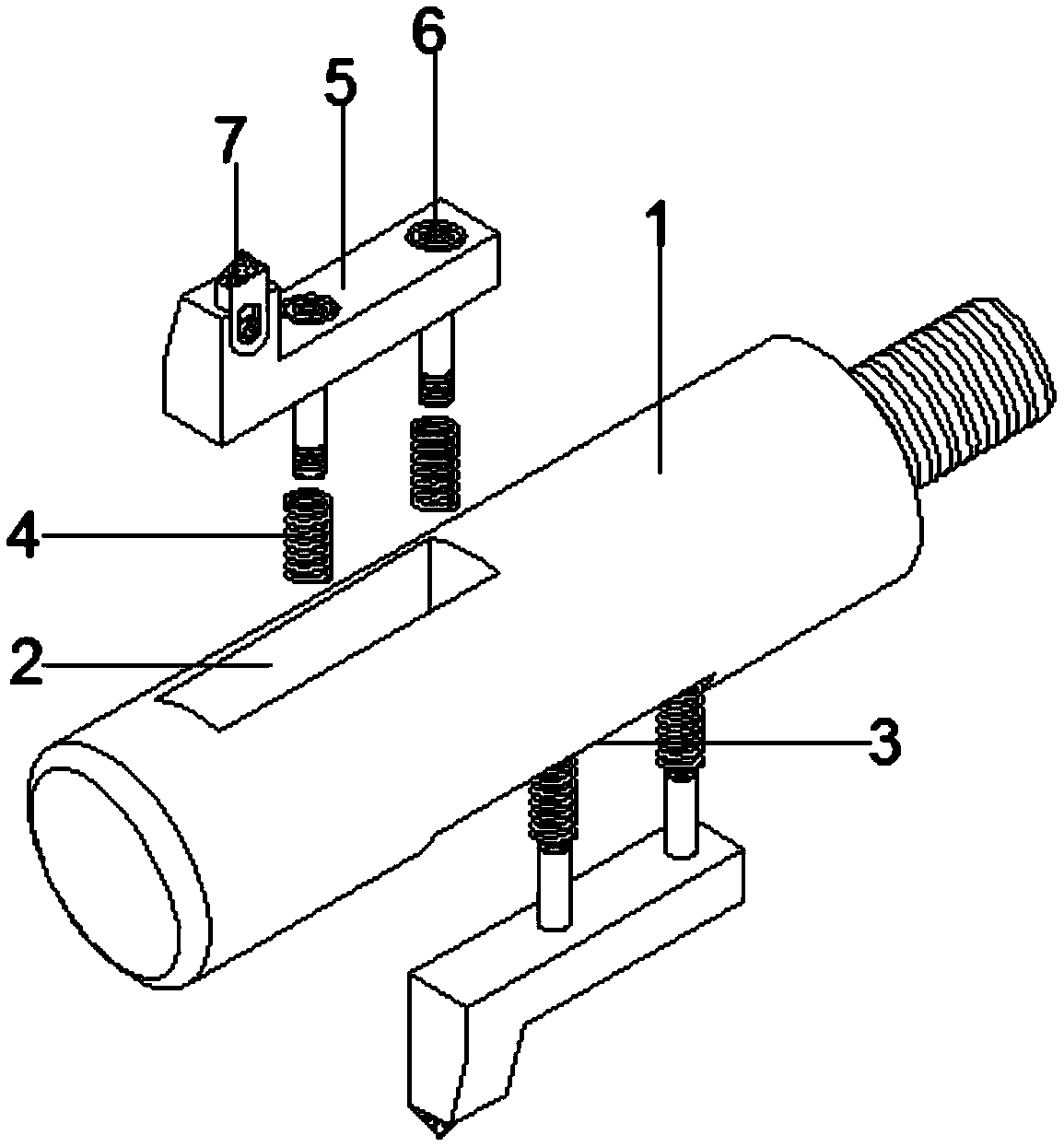

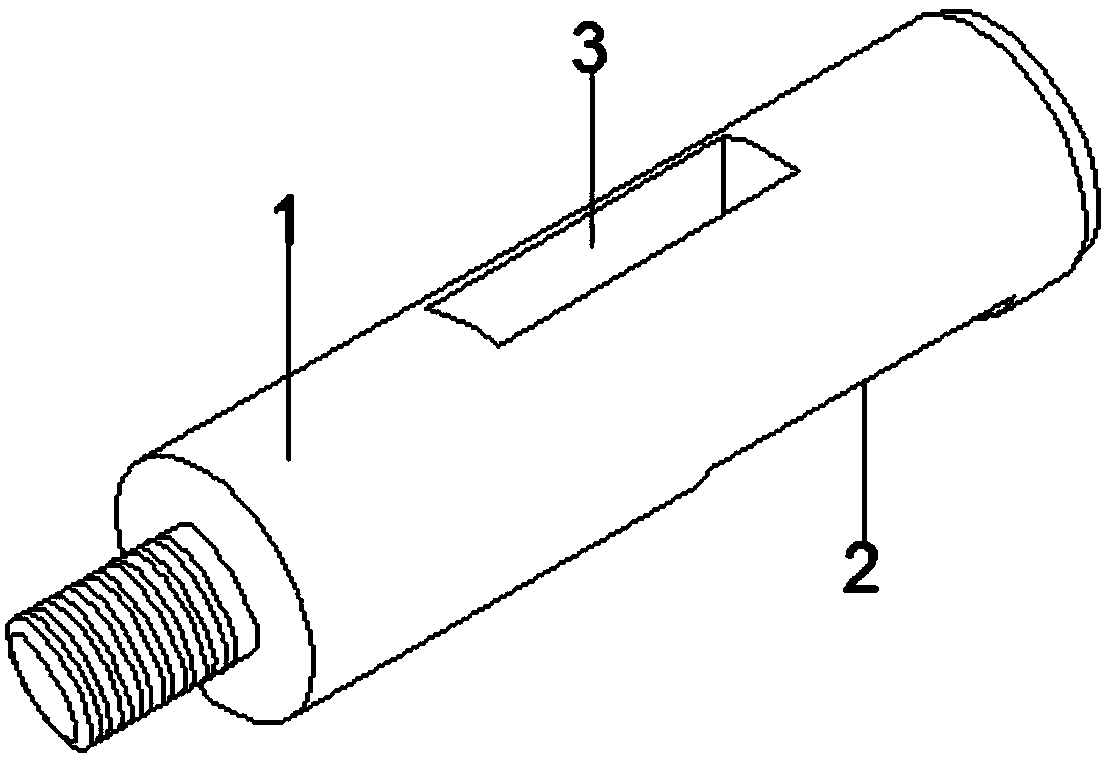

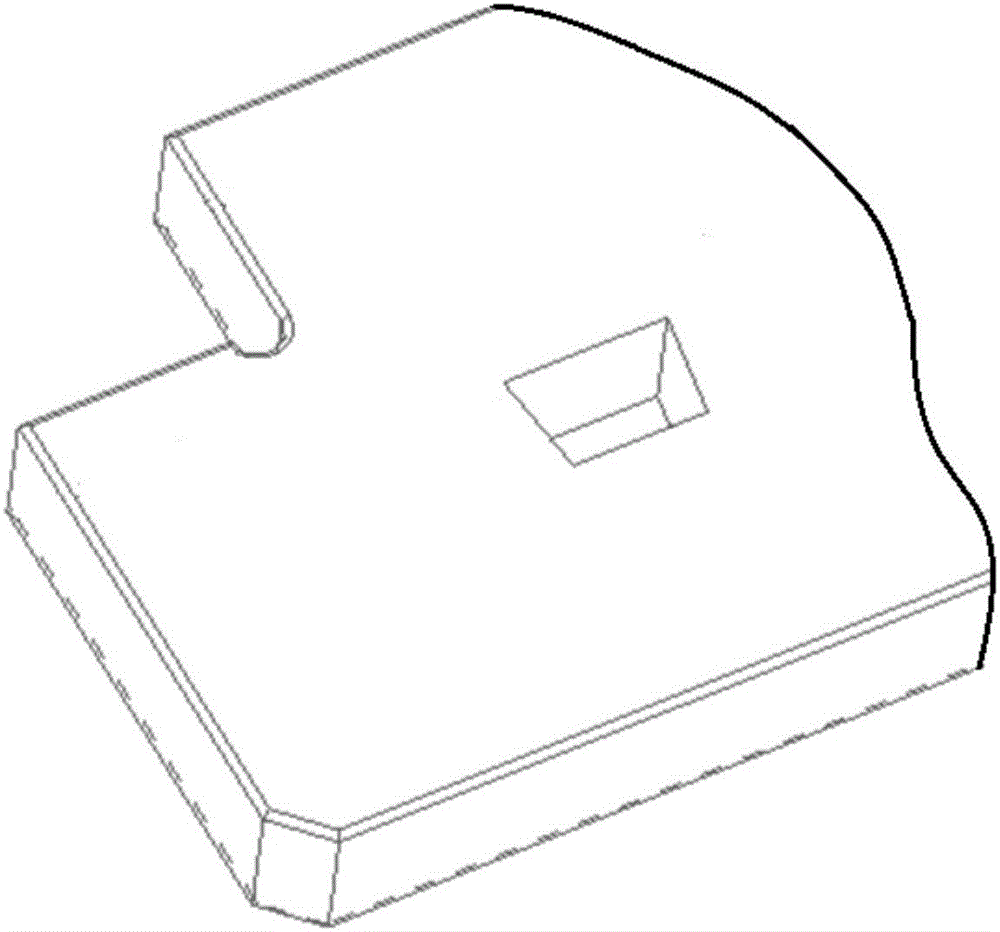

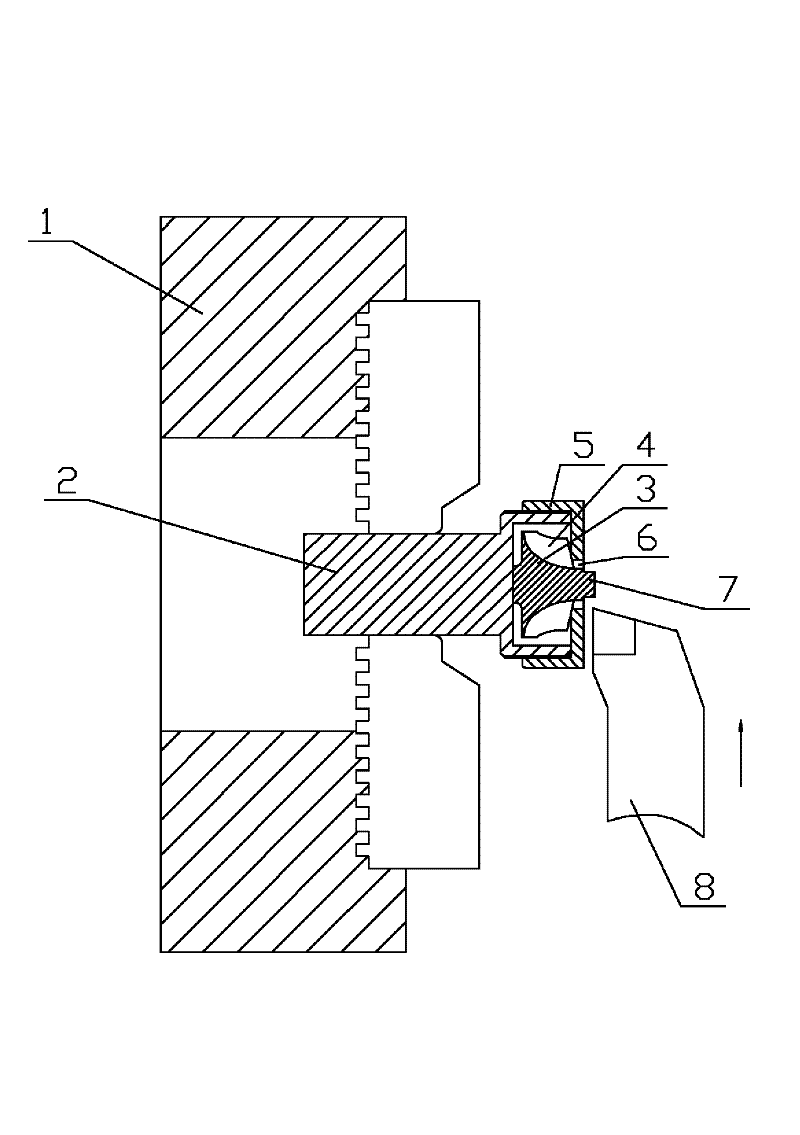

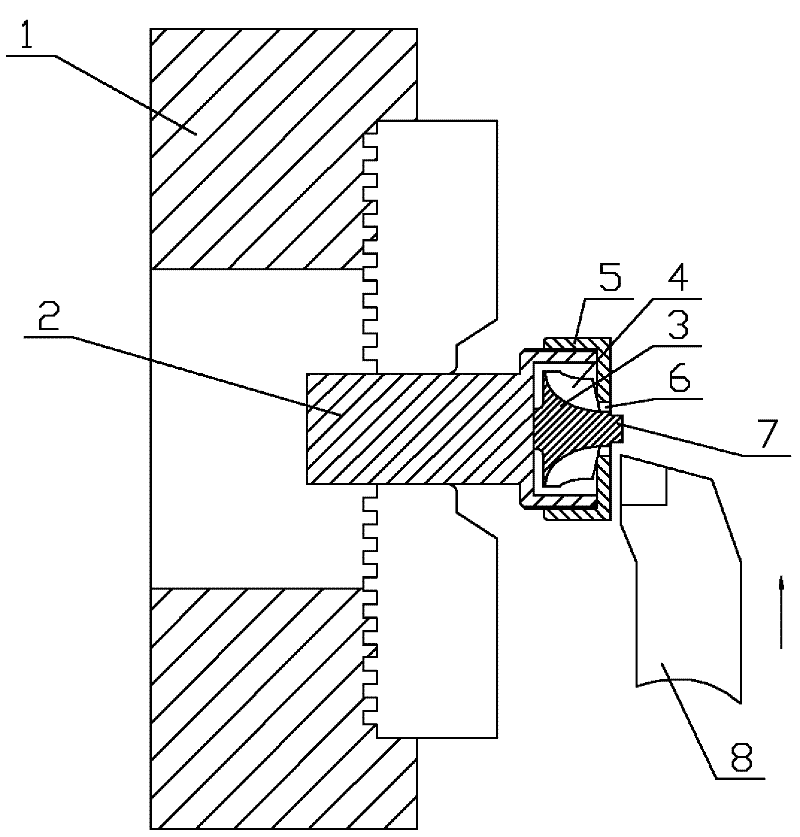

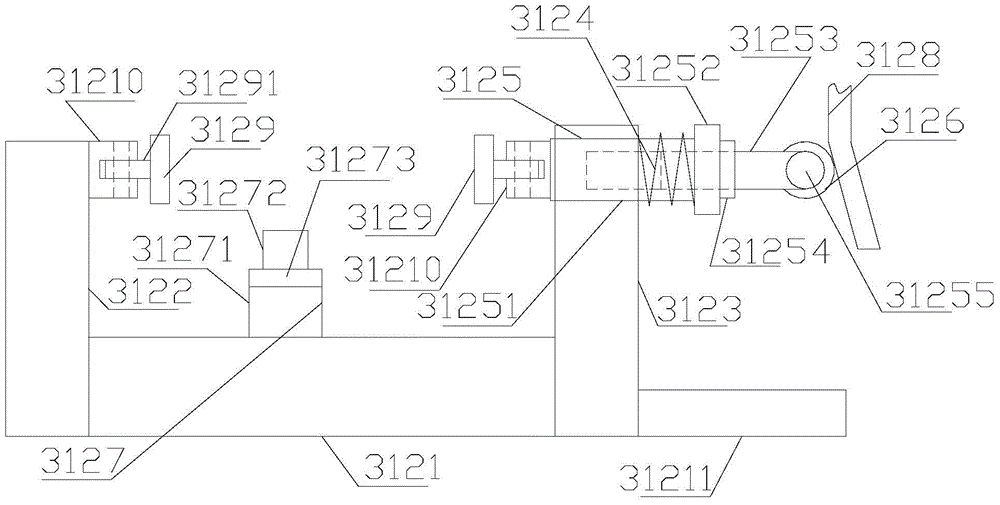

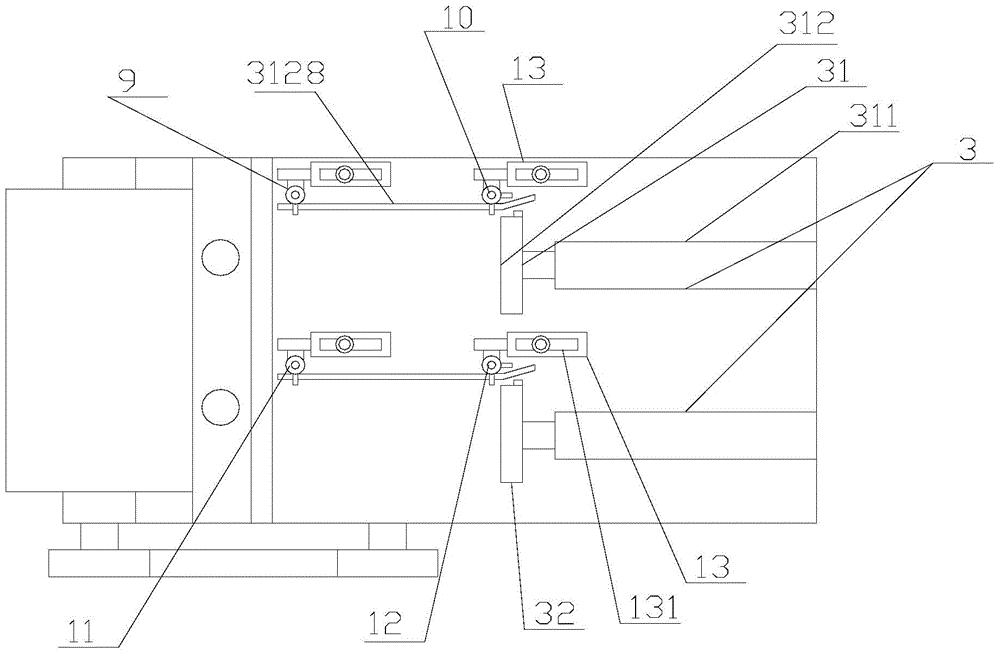

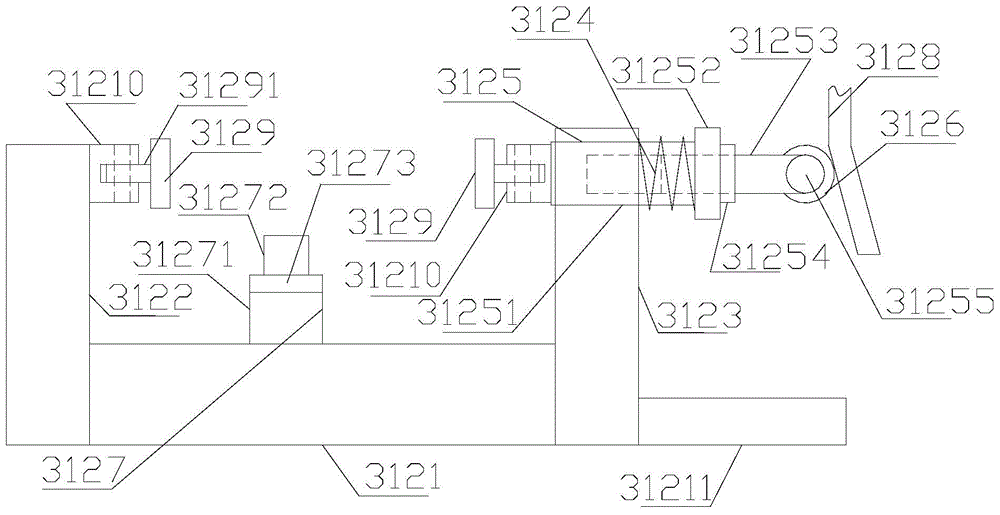

Floating boring tool structure for inner wall of steel tube

InactiveCN108672732AAvoid problems that affect machining accuracyEasy to disassembleTool holdersEngineeringMachining

The invention provides a floating boring tool structure for the inner wall of a steel tube. The floating boring tool structure comprises a tool bar, a first tool groove and a second tool groove. The first tool groove is formed inside the portion above the tool bar, and the first tool groove and the tool bar are of an integrated structure. The second tool groove is formed inside the portion below the tool bar, and the second tool groove and the tool bar are of an integrated structure. Springs are mounted inside the first tool groove and the second tool groove and connected with the first tool groove and the second tool groove in a penetrating manner through half-shaft bolts correspondingly. Tool aprons are mounted inside the first tool groove and the second tool groove and connected with the first tool groove and the second tool groove in a penetrating manner through half-shaft bolts correspondingly. The floating boring tool structure is structurally improved, therefore, the structure has the advantages that tools are not likely to be broken, the structure is convenient to dismount when being replaced for repair, the rough machining and finish machining integrated operation functionis achieved, and machining precision and machining efficiency are improved; and thus, problems in the background art are effective solved, and defects in the background art are effectively overcome.

Owner:惠州市豪美仕智能技术有限公司

Minimally inVasiVe spine endoscope piezosurgery head deVice and processing method thereof

InactiveCN108670358AHigh hardnessImprove wear resistanceEndoscopic cutting instrumentsAbrasive surgical cuttersUltrasonic sensorSurface layer

The inVention discloses a minimally inVasiVe spine endoscope piezosurgery head deVice and a processing method thereof. The minimally inVasiVe spine endoscope piezosurgery head deVice comprises a grinding head and a piezosurgery rod; the grinding head is arranged at the lower end of the piezosurgery rod through a first connecting piece, and a second connecting piece is fixedly arranged on the upperend of the piezosurgery rod; the grinding head, the first connecting piece, the piezosurgery rod and the second connecting piece form an integrated structure and are integrally arranged; the second connecting piece is diVided into a connecting part connected with the piezosurgery rod and a joint part connected with an ultrasonic transducer; the joint part is arranged on the upper end of the connecting part. The processing method of the minimally inVasiVe spine endoscope piezosurgery head deVice completes processing of the piezosurgery head deVice through multiple steps. The deVice can be usedin a minimally inVasiVe spine endoscope passage, and the use is conVenient, efficient and safe; the surface layer of the piezosurgery head deVice is high in hardness, abrasiVe resistance and fatiguestrength, so that the piezosurgery rod cannot be easily bended; the toughness of a core part is high, so that the piezosurgery deVice can bear impact loading and cannot be easily broken.

Owner:林浩

Quenching strengthening process of thin blade cutting edge

InactiveCN111286596AHigh hardnessImprove toughnessFurnace typesOther manufacturing equipments/toolsLaser quenchingEngineering

The invention discloses a quenching strengthening process of a thin blade cutting edge. The process is characterized in that after a thin blade is integrally quenched by a traditional quenching process, the integrally-quenched thin blade is subjected to rough sharpening; the roughly-sharpened thin blade is moved at a high speed, the relative moving speed is 100-400 mm / s, when the thin blade moves,a high-power-density laser light spot is adopted to irradiate the cutting edge, the power density is larger than or equal to 150 W / mm<2>, the cutting edge forms a laser quenching layer, and finally fine sharpening is carried out, so that the thin blade with the quenched-strengthened cutting edge is obtained. A high-power-density laser device is matched with the fast-moving thin blade, so that thecutting edge of the thin blade is protected from being melted, the quenching effect is achieved, the sharpness, the wear resistance and the service life of the thin blade are improved, and the best performance of the material of the thin blade is played.

Owner:浙江久恒光电科技有限公司

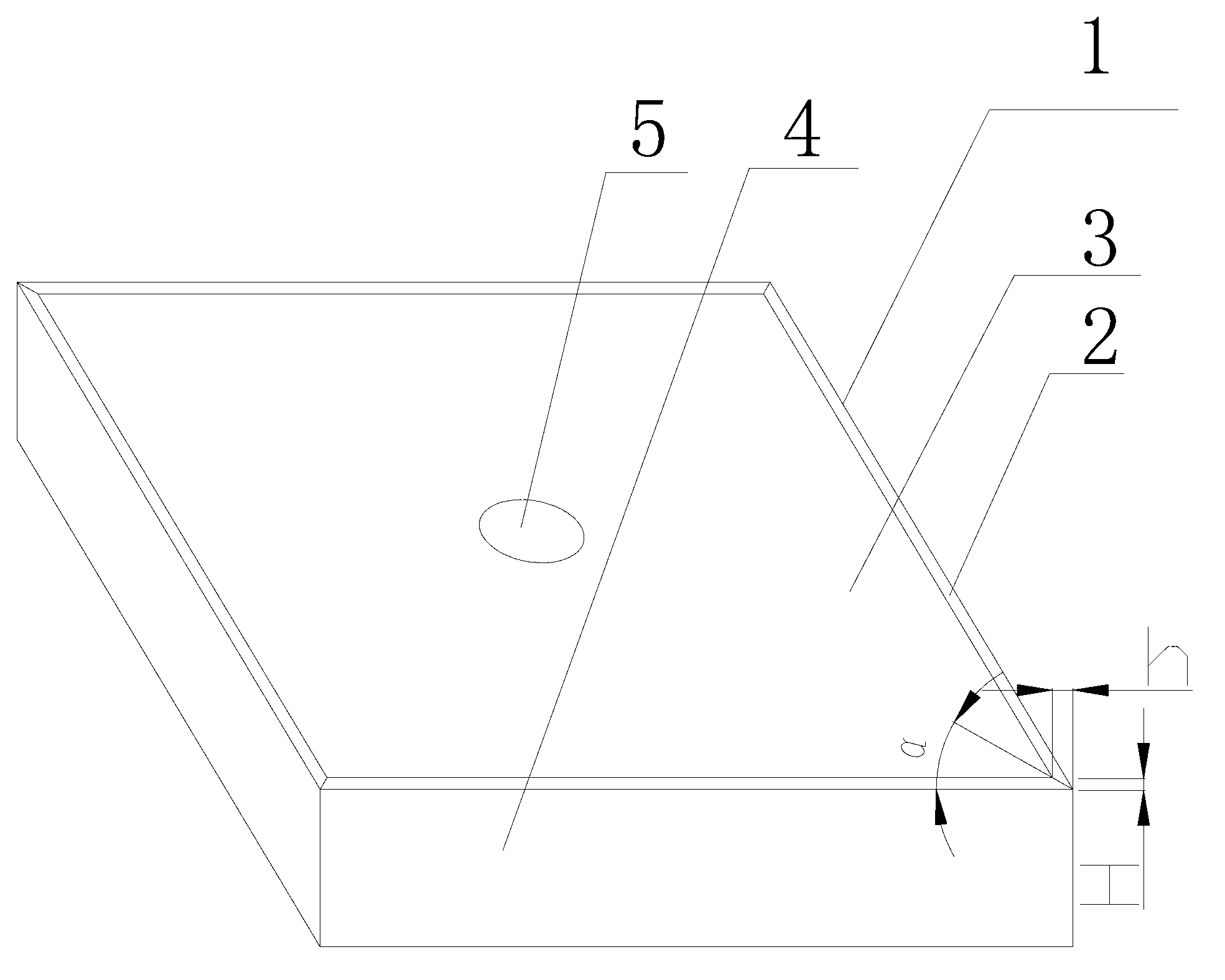

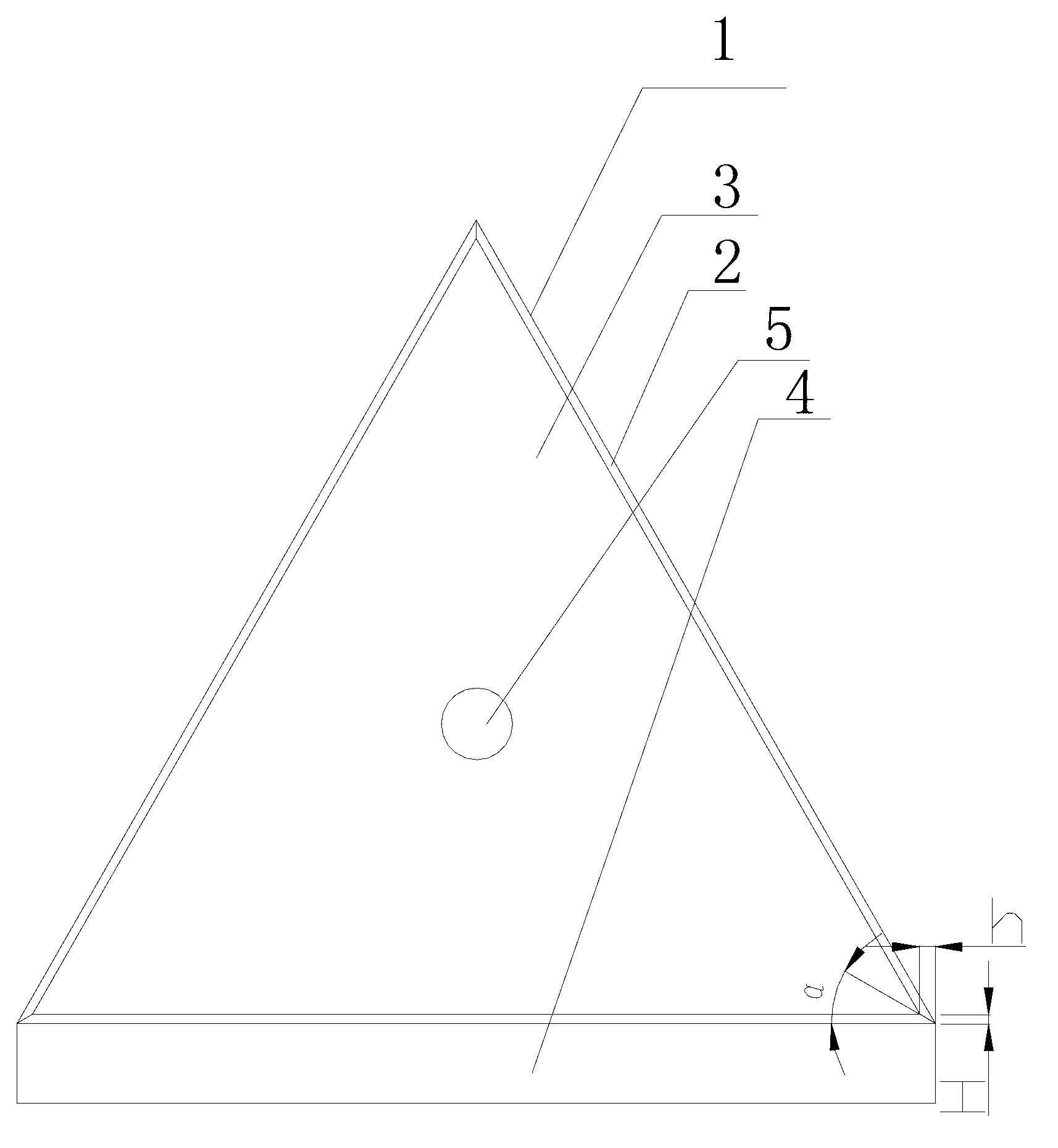

Cutting blade and processing method thereof

InactiveCN103008699AReduce cutting resistanceIncreased cutting resistanceTurning toolsPulp and paper industryKnife blades

The invention discloses a cutting blade and a processing method thereof. The cutting blade comprises a blade body; an edge is arranged on the blade and is of a chamfering structure; the chamfering structure forms an inclined plane; the two ends of the inclined plane are respectively connected with a front blade face and a rear blade face of the blade; and the width of the chambering structure is 0.15-1 mm. The cutting blade and the processing method disclosed by the invention has the beneficial effects that the cutting resistance of the cutting blade is small, the workpiece processing accuracy is high, the processing method of the cutting blade is simple, and the production cost is low.

Owner:ZHUZHOU PURUIKE CEMENTED CARBIDE

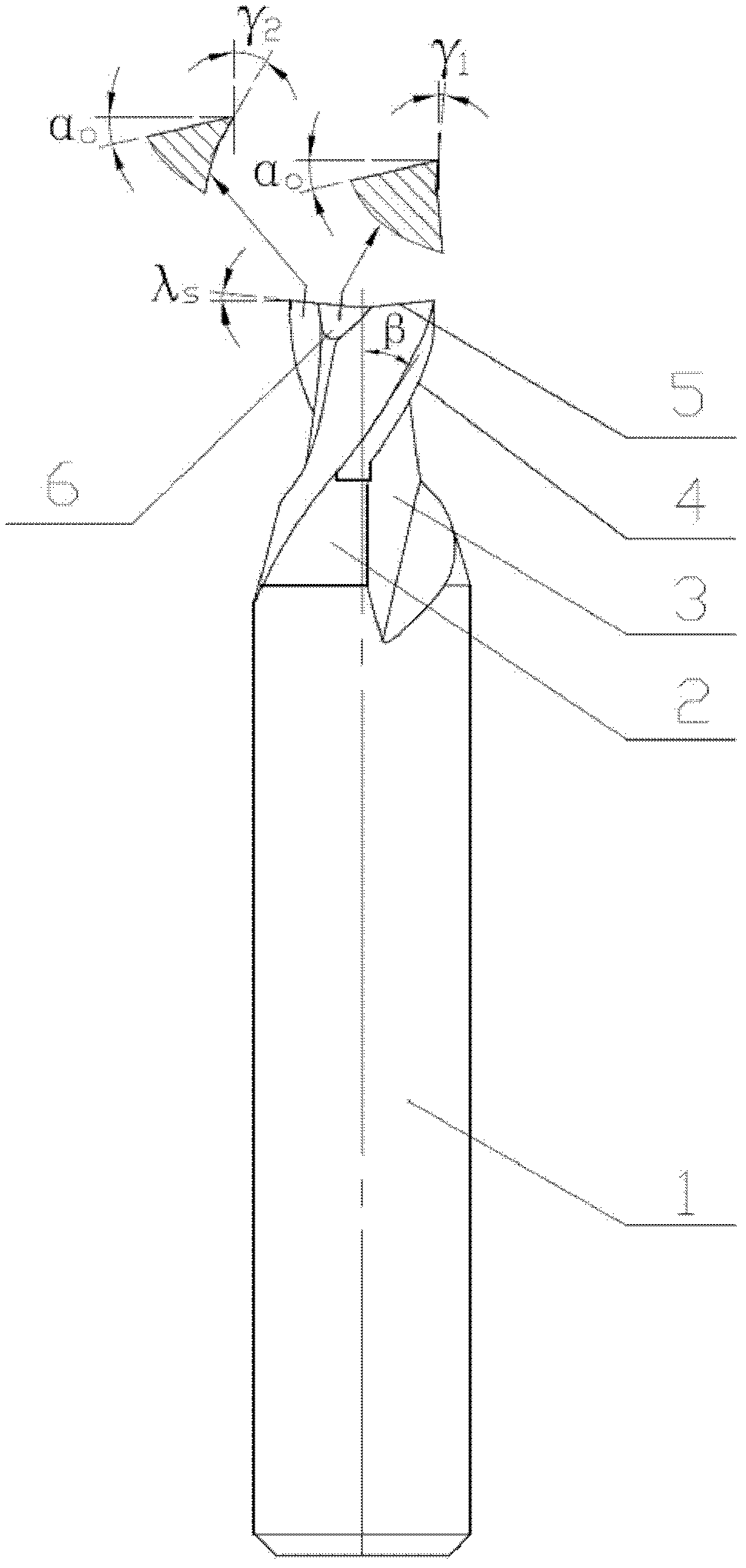

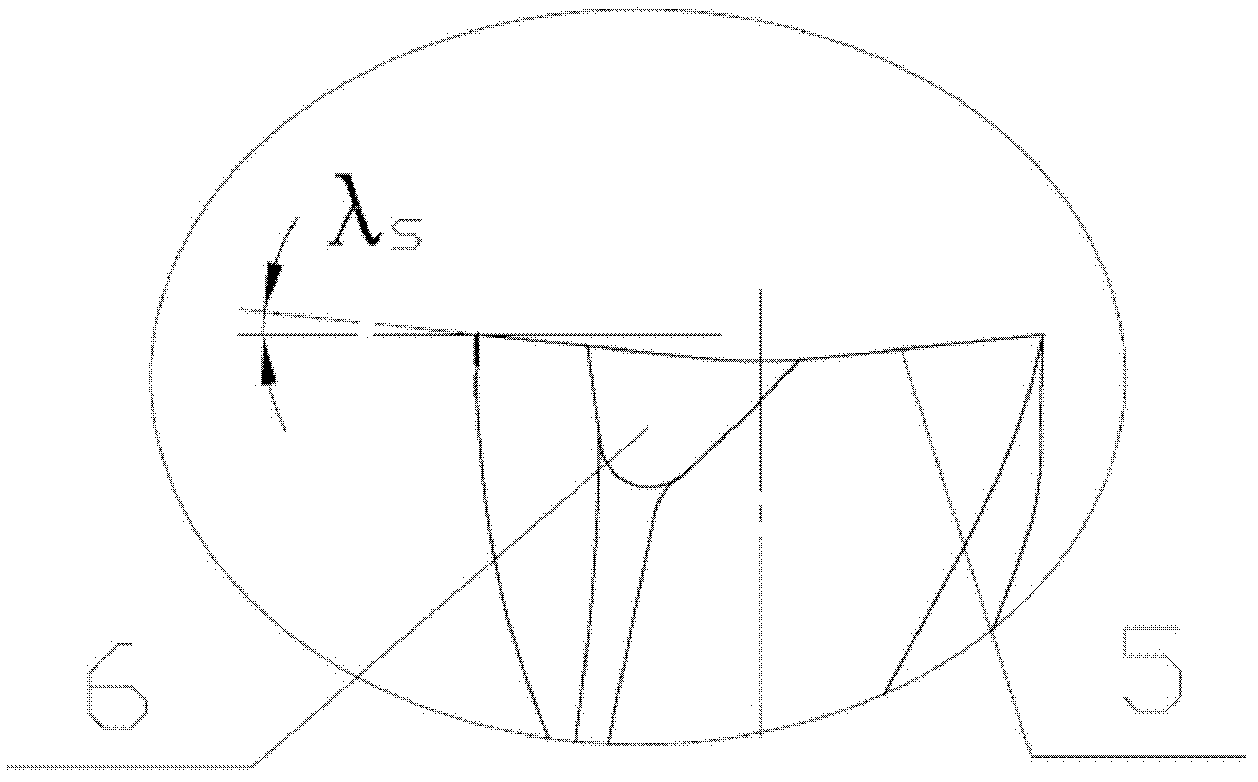

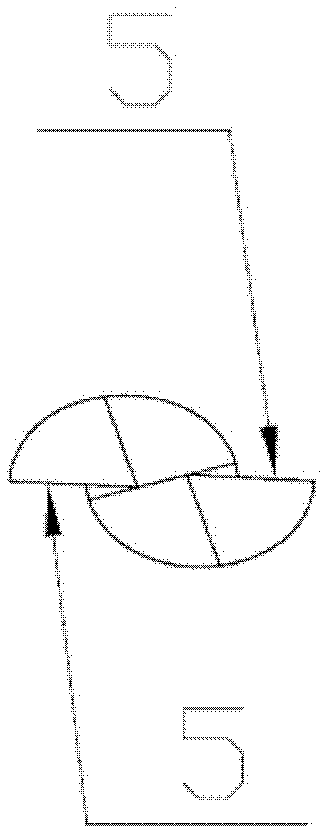

Two-edge special end milling cutter for through groove

The invention discloses a two-edge special end milling cutter for a through groove, which comprises a cutter handle and a cutter body. The cutter body consists of a spiral groove, a side edge, an end surface cutting edge and a chip discharge groove. The two-edge special end milling cutter is characterized in that the end surface cutting edge is arranged at the top end of the cutter body and the inclination angle lambda s is equal to 3-8 degrees; and the chip discharge groove is arranged on the spiral groove adjacent to the central part of the end surface cutting edge, the front angle gamma 1 of the internal side of the end surface cutting edge is equal to 0-10 degrees, the front angle gamma 2 of the external side of the end surface cutting edge is equal to 30 degrees, the rear angle alpha 0 of the end surface cutting edge is equal to 12-15 degrees and the spiral angle beta of the spiral groove is equal to 30 degrees. The end milling cutter has the advantages that the cutting edge is sharp, the chips are discharged smoothly, the processing efficiency is high, the problems that the groove bottom quality is poor and the cutter is apt to be broken when the common two-edge end milling cutter is used for milling through grooves are solved, and the end milling cutter is suitable for processing all kinds of through grooves.

Owner:合肥波林新材料股份有限公司

CNC cutting tool and CNC machining method

InactiveCN106583534ANot easy to break the knifeFast processingPerforating toolsDrill bitMilling cutter

The invention discloses a CNC cutting tool. The CNC cutting tool comprises an integrated body and a cutting edge. One end of the body is the fixing end of the cutting tool, and the other end of the body is the cutting end; and the outer contour of the cutting end is the same with the contour of a to-be-machined aperture, the cutting edge is the last edge of the cutting end, and the end face of the cutting end is an internal concave hook face. According to the CNC cutting tool, the invention further provides a CNC machining method. The CNC machining method comprises the following steps that (1), through a common drill or a milling cutter, a to-be-machined part is subjected to rough treatment; (2), main shaft rotation is stopped, the CNC cutting tool is switched, and the orientation of the CNC cutting tool is positioned; (3), the cutting tool falls quickly to conduct punching; and (4), the cutting tool is raised up, and machining is finished. According to the CNC cutting tool and CNC machining method, tool breaking is not prone to happening, so that a defective product owing to tool breaking is not produced, the machining speed is quick, and the service life of the cutting tool is long.

Owner:GUANGDONG EVERWIN PRECISION TECH

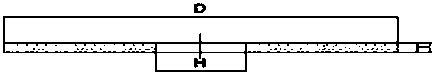

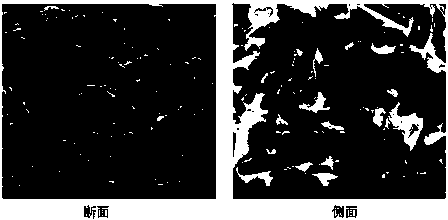

An ultra-high cutting verticality integral ultra-thin resin grinding wheel and its preparation method

ActiveCN105437090BImprove axial strengthHigh modulusBonded abrasive wheelsGrinding devicesFiberGlass fiber

The invention relates to an integrated type ultrathin resin grinding wheel with ultrahigh cutting perpendicularity. The grinding wheel comprises, by volume, 10-25 part of abrasive materials, 40-50 parts of resin binders and 10-40 parts of padding. Chopped fibers composed of carbon fibers and / or glass fibers are adopted as the padding, wherein the diameter of each chopped fiber is 5-20 micrometers, the length of each chopped fiber is 50-500 micrometers, and the length-diameter ratio of each chopped fiber is (10-100):1. Compared with an integrated type ultrathin resin grinding wheel made of traditional padding, the cutting perpendicularity of the integrated type ultrathin resin grinding wheel is obviously improved, a kerf can be reduced at least by about 0.01 mm, and the cutting perpendicularity is improved at least by about 28.6%; the grinding wheel is not prone to breakage, the dimension of a cut workpiece is good, and the cutting quality is greatly improved.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

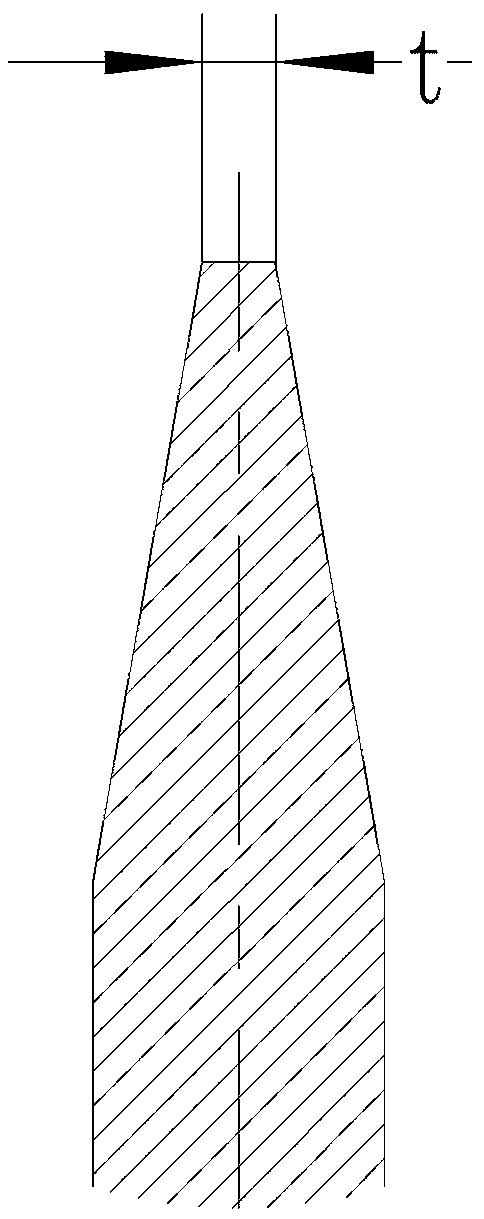

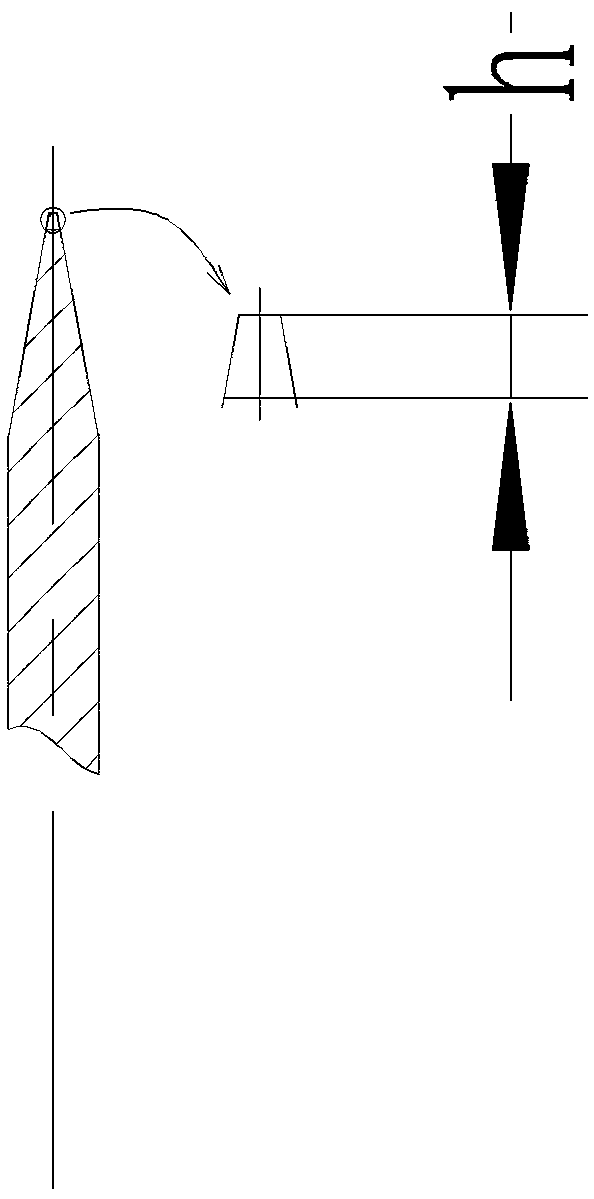

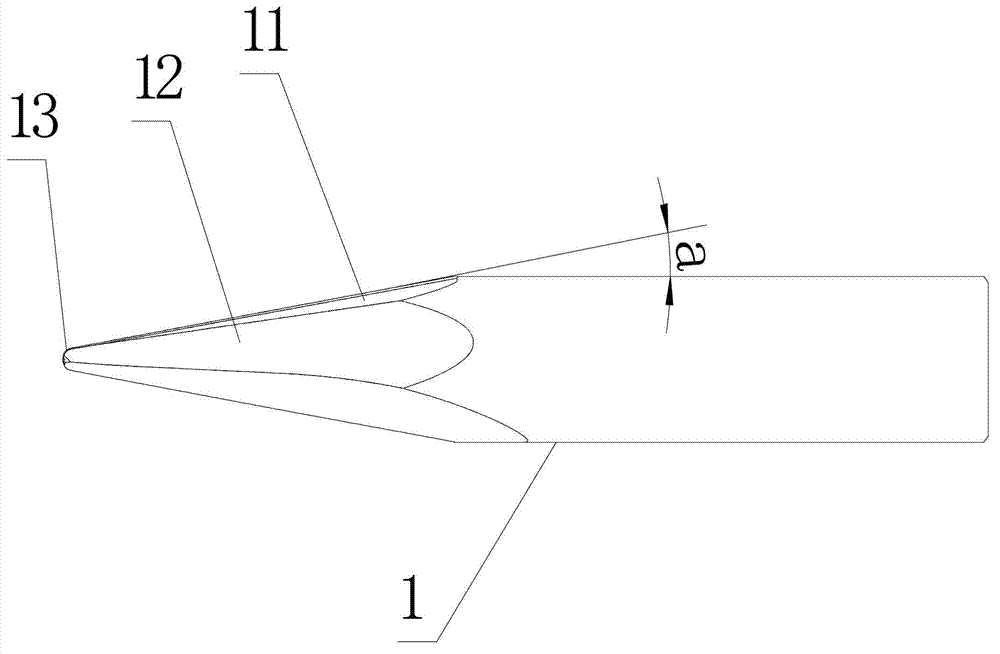

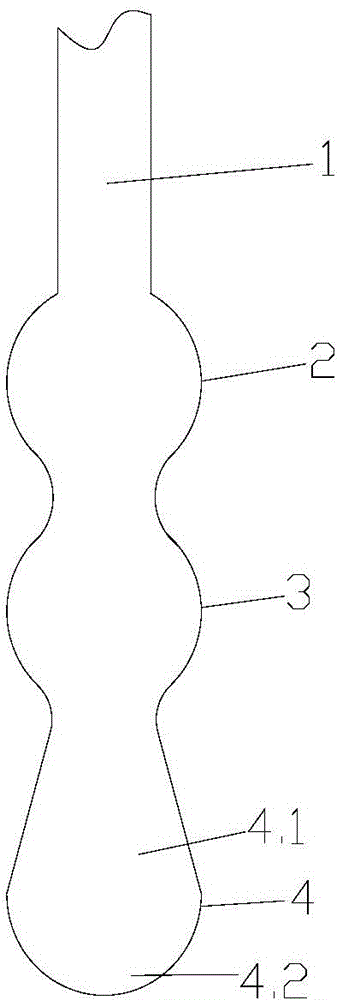

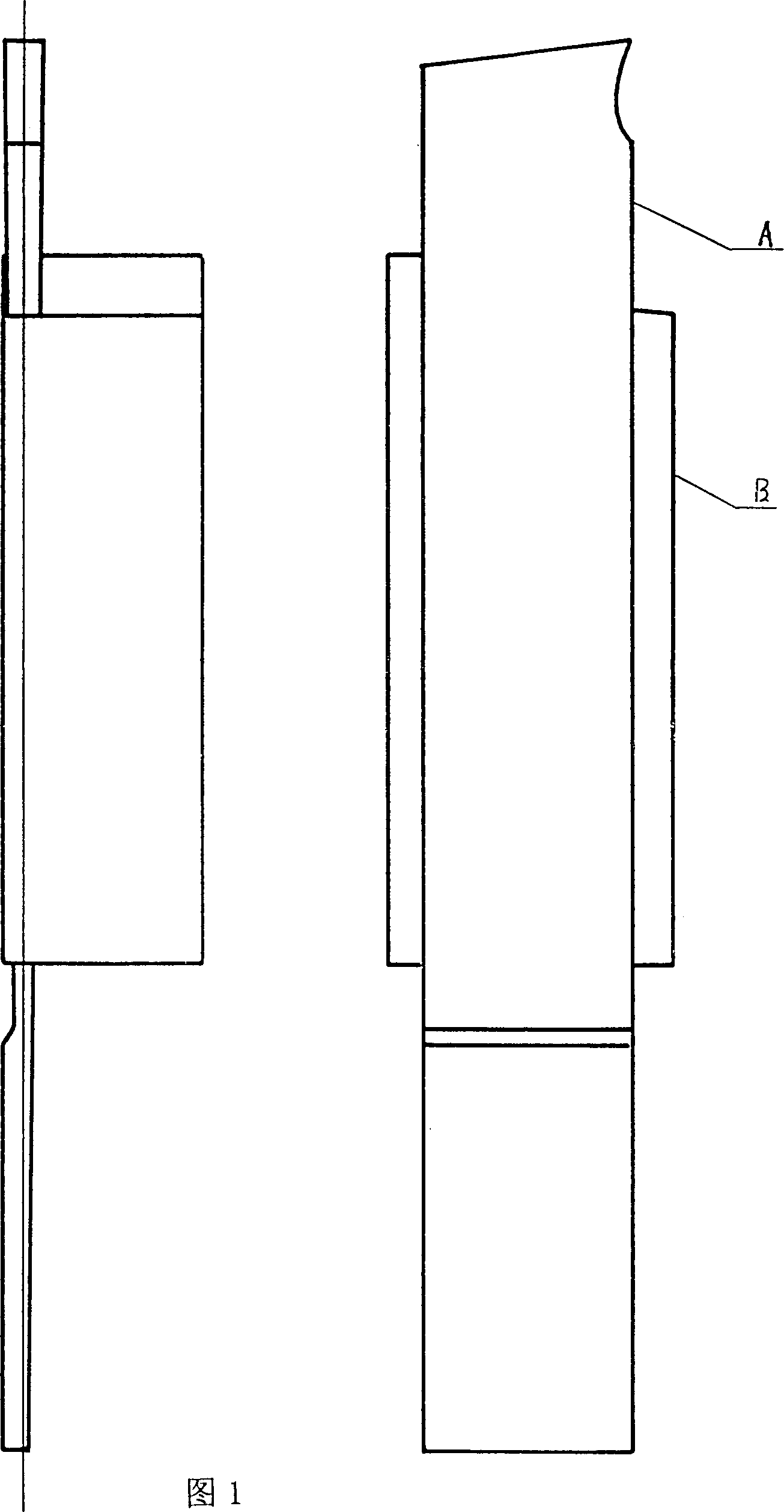

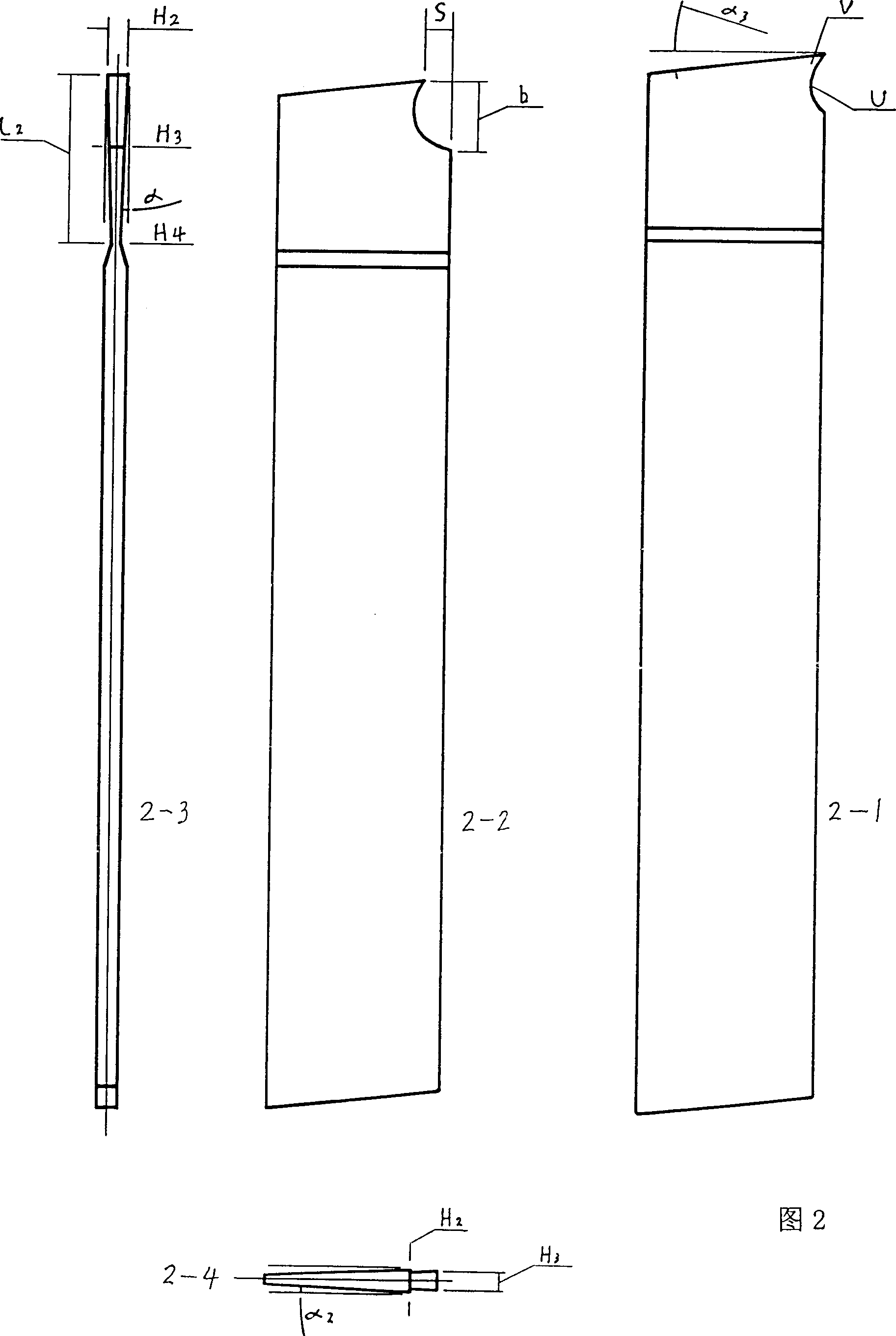

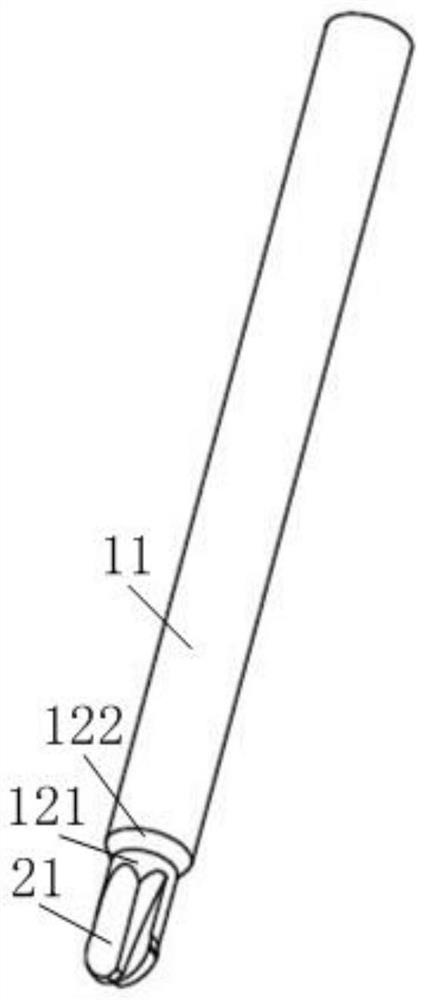

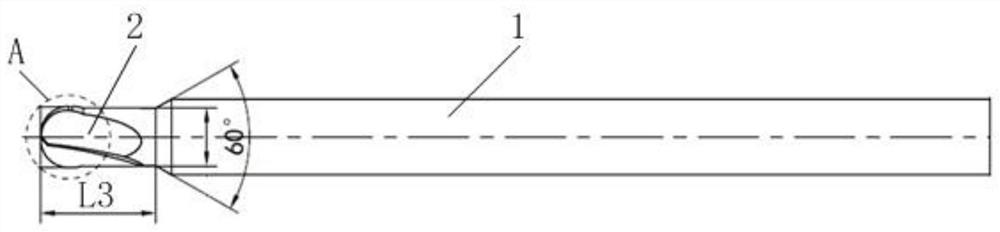

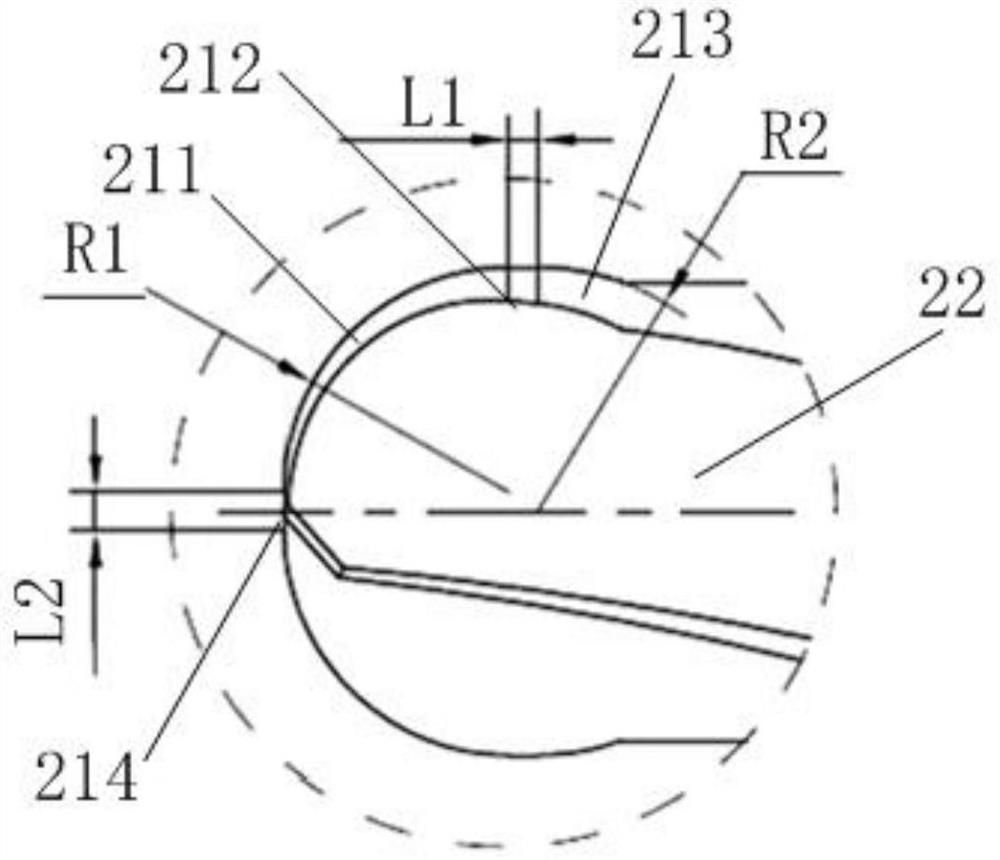

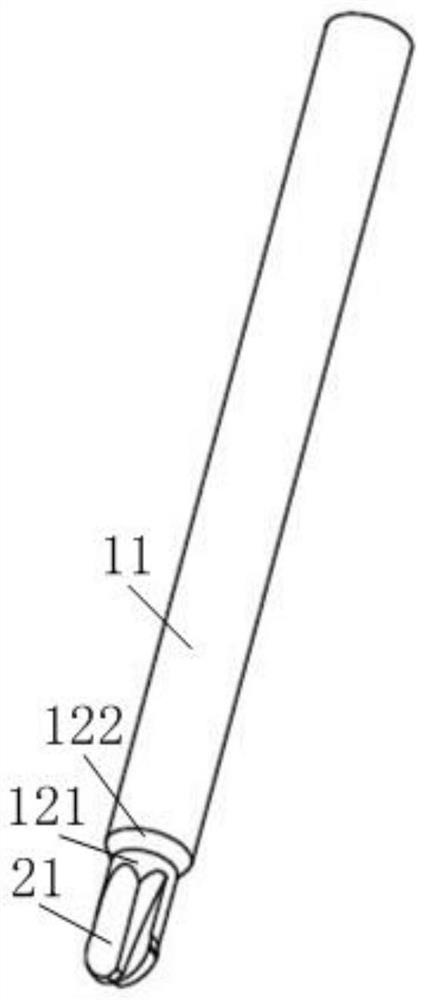

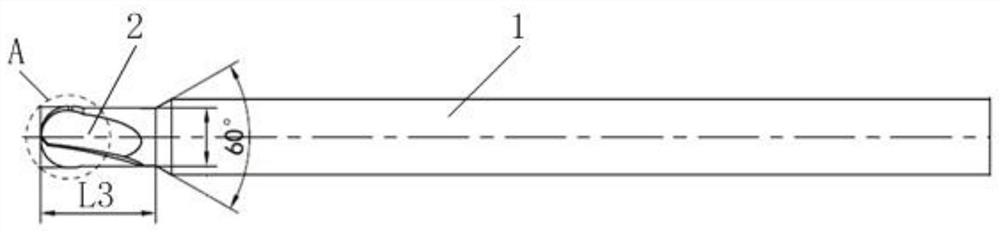

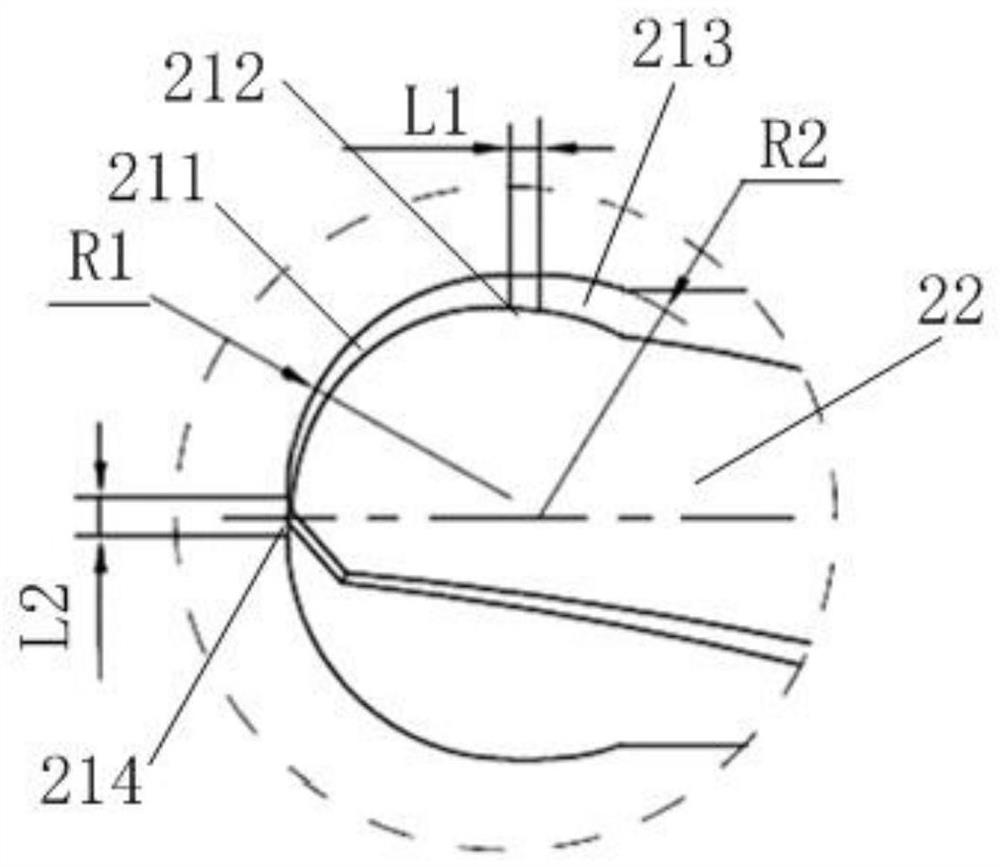

Micro-diameter both-edge tapered ball cutter

InactiveCN102962871AEasy to processNot easy to break the knifeSaw bladesEngineeringMechanical engineering

The invention relates to micro-diameter both-edge tapered ball cutter which comprises a cutter body, wherein two cutter edges are arranged on the cutter body; a straight groove is formed in the middle of the two cutter edges; a tapered included angle formed among the two cutter edges and a horizontal plane of the cutter body is 3-7 DEG; a ball head is arranged at the front end of the cutter body; and the ball head is 0.3-0.5mm in diameter. The ball cutter has the advantages that the two cutter edges and the cutter body are arranged in a tapered manner; a lateral folding force of the micro-diameter cutter in the cutting process is dispersed; the processing effect of the cutter body is improved with the adoption of the ball head arranged on the cutter body; the cutter body is not easy to break; the chip removal effect is improved; the processing effect is good; and the cutting efficiency is high.

Owner:东阳市速博数控刀具有限公司

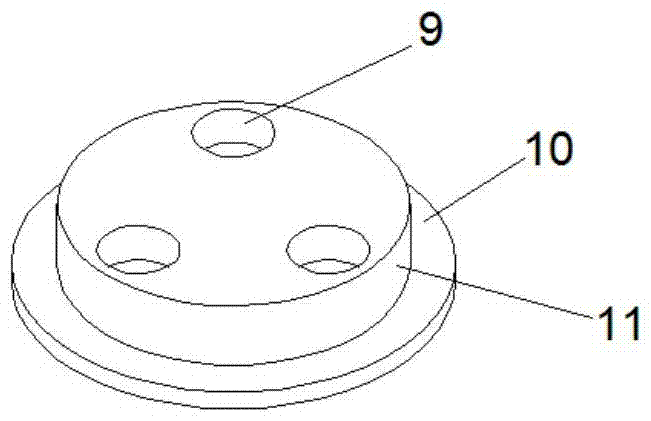

Clamp special for flat turbine head end face

InactiveCN102380785AReduce jumpingImprove processing efficiencyPositioning apparatusMetal-working holdersEdge surfaceMachined surface

The invention provides a clamp special for a flat turbine head end face. By using the clamp, the clamping positioning of a three-jaw chuck meets a clamping requirement, the machining efficiency is high, a machined surface is smooth, a fracture phenomenon is not easy to cause, and the centre beat of a machined component is low. The clamp special for the flat turbine head end face comprises the three-jaw chuck, a base and a flat turbine, and is characterized in that: the upper part of the base is provided with an open cavity body; the flat turbine is arranged in the cavity body; an end cover is covered on the outer end surface of the cavity body; a centre hole is formed in the end cover; the head end surface of the flat turbine is exposed from the centre hole of the end cover; the outer circumference of a worm wheel of the flat turbine is adhered to the inner end surface of the cavity; and the three-jaw chuck clamps the outer edge surface of the base.

Owner:WUXI MINGZHU TURBOCHARGER MFG

Locomotive wheel CNC turning repair equipment

The invention relates to the technical field of railway equipment. A manufacturing unit and a support unit are integrated onto the same supporting platform by utilizing a pair of engine bases. The locomotive wheel numerical control lathing device provided by the invention is characterized in that a tool supporting structure, a shaft end positioning device and a shaft end supporting device are arranged on the same platform base (1), the shaft end positioning device comprises a positioning bending plate (5) and a connection plate (6) which are provided with a positioning boss (2), a mounting bolt hole (3) and an axial clearance adjustment bolt (4), and a concentric stepped hole (7) is arranged in the positioning boss (2); the positioning bending plate (5) is lengthways fixed on the platform base (1) along the center line of the rounded positioning boss (2); the tool supporting structure is of an inclined plane (12) formed by forward extended one side of the front end of the platform base (1), wherein the inclined plane (12) is parallel to a plane formed by the axial line of the positioning boss (2) and the radius of a working point. The device is light in weight, simple in structure and operation, high in working efficiency, and low in investment cost, is applied to locomotive wheel lathing operation in a railway locomotive department, and is particularly applied to the wheel lathing operation without the wheel lathing condition.

Owner:JINAN WUXING ELECTROMECHANICAL TECH CO LTD

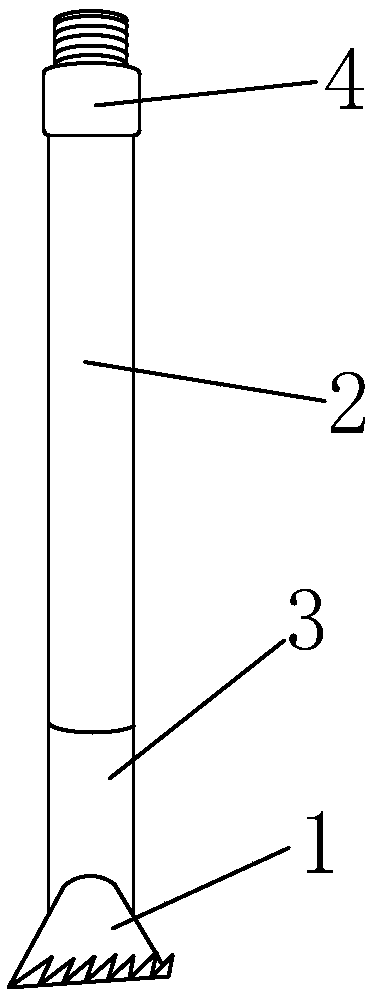

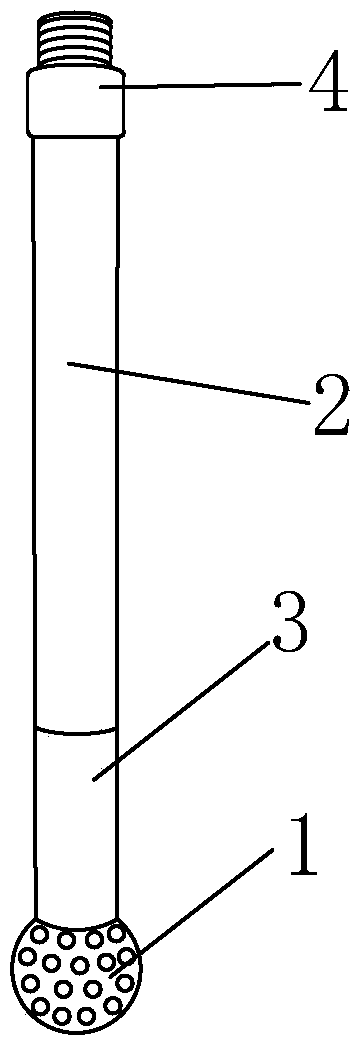

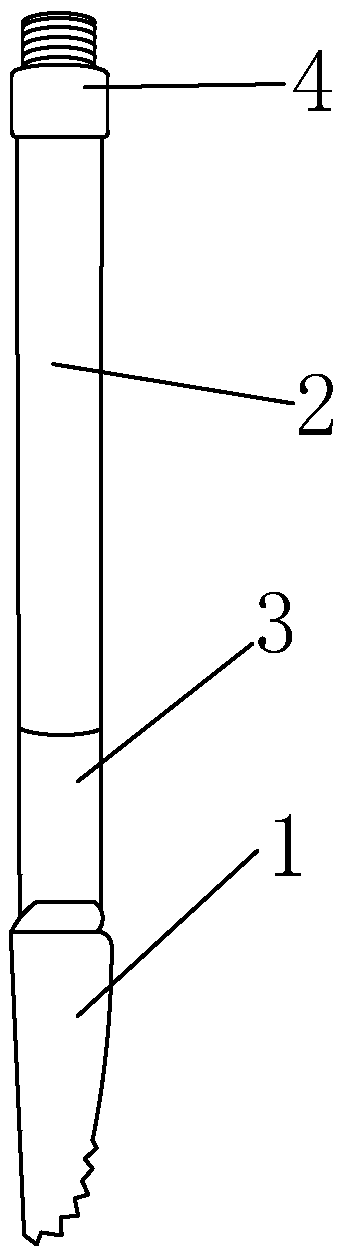

Deep hole forming tool

InactiveCN104475830AReduce contact areaAvoid breakingTransportation and packagingTrepanning drillsEngineeringDeep hole

The invention relates to the technical fields of cutting tools, particularly to a deep hole forming tool. The deep hole forming tool comprises a tool shank and a cutting module at the front end of the tool shank, wherein the cutting module is composed of a third cutting unit connected with the tool shank, a second cutting unit at the front end of the third cutting unit, and a first cutting unit at the front end of the second cutting unit; the third cutting unit and the second cutting unit are in a ball shape and are connected through a transitional smooth curved surface; the first cutting unit is composed of a taper unit connected with the second cutting unit, and a ball unit at the front end of the taper unit, and the small-diameter end of the taper unit is smoothly connected with the second cutting unit; the cutting module is provided with at least three screw cutting edges uniformly distributed in the circumferential direction of the cutting module, and the screw cutting edges are correspondingly provided with screw flutes and converge in the center of the front end of the first cutting unit. According to the deep hole forming tool, during a cutting process, the contact area between the cutting module and hole walls can be small, so that the possibility of tool tipping due to radial movement can be greatly reduced.

Owner:常州华尔澜工具有限公司

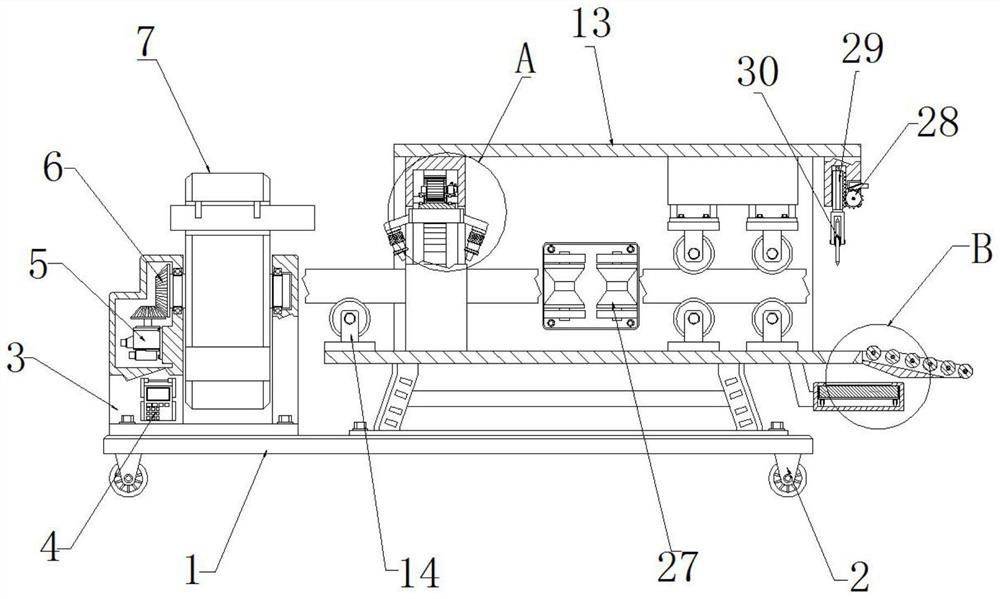

Batch cutting device for twisted steel production

The invention discloses a batch cutting device for twisted steel production, which comprises a base body, the appearance of the base body is of a cuboid platy structure, the surface of the base body is provided with chamfers, and the base body is provided with a convenient-to-move mechanism; and the first motor is arranged on the left side of the upper end of the base body, the first motor is provided with a waterproof structure, and the first motor is provided with an automatic feeding mechanism. The batch cutting-off device for twisted steel production is provided with the scrap iron collecting mechanism, scrap iron generated during steel bar cutting can be uniformly recycled, pollution and waste caused by scrap iron scattering are avoided, environment protection is facilitated, resource recycling is achieved, meanwhile, the correcting mechanism is arranged, bending correction can be conducted on steel bars before cutting, and the quality of the steel bars is improved. The steel bar bending correcting device can correct bending degrees of steel bars in the horizontal direction and the vertical direction, the machined steel bars can be straight, the attractiveness of the steel bars is further improved, the machining quality of the steel bars is guaranteed, and practicability is improved.

Owner:南京政迪科技有限公司

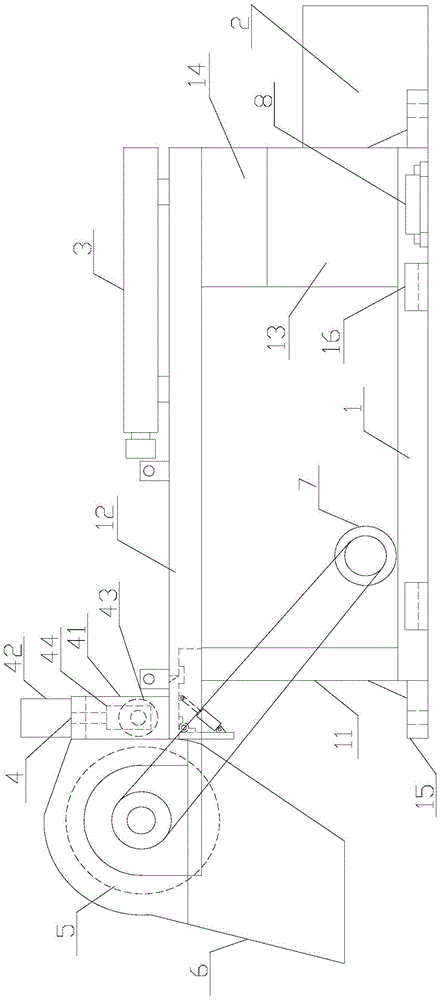

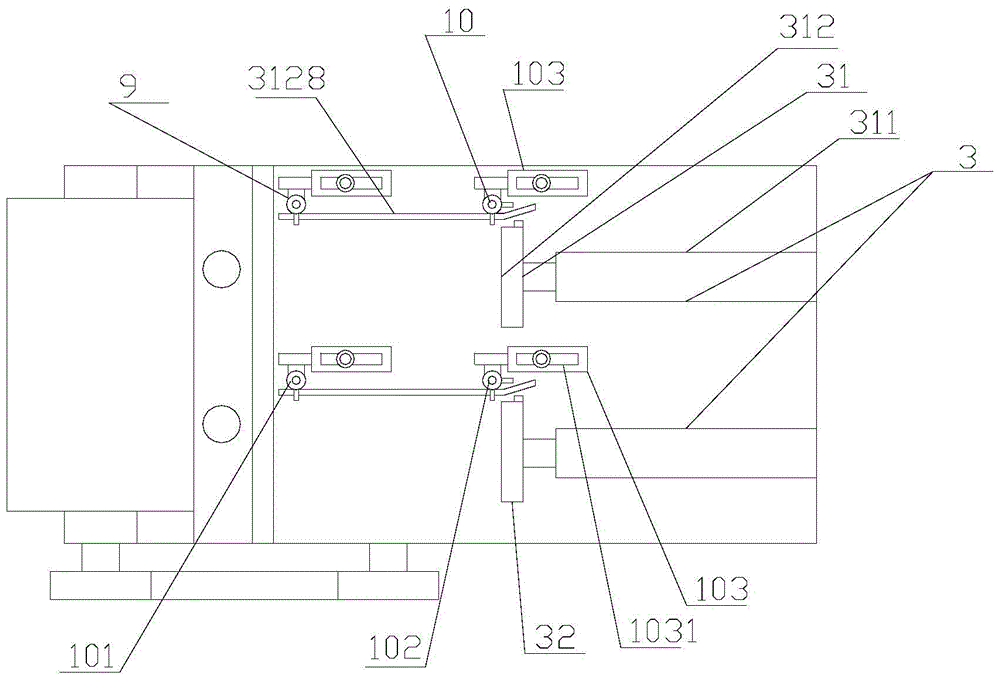

Pipe Chipless Cutting Machine

The invention discloses a scrap-free pipe cutting machine. The scrap-free pipe cutting machine comprises a main cutting shaft. A chuck for clamping a pipe is arranged inside the main cutting shaft in the axial direction. One end of the main cutting shaft is sleeved with a rotating sleeve, a cutter disc is fixed to the end face of the rotating sleeve, a blade sliding block and a supporting roller sliding block are installed on the cutter disc, the end face, far away from the main cutting shaft, of the blade sliding block and the end face, far away from the main cutting shaft, of the supporting roller sliding block are slopes, the blade sliding block is connected with a cutting blade through a bearing, and the supporting roller sliding block is connected with a supporting roller through a bearing. The outer side of the rotating sleeve is sleeved with a sliding outer sleeve. The inner wall of the sliding outer sleeve is in contact with the slope of the blade sliding block and the slope of the supporting roller sliding block, and under guiding of the slope of the blade sliding block and the slope of the supporting roller sliding block, the blade sliding block and the supporting roller sliding block are pressed by the sliding outer sleeve to move towards the center of the pipe. By means of the pipe cutting machine, the technical problem that a cut pipe opening of a cut pipe in the prior art has many waste scraps and burrs can be solved.

Owner:浙江长兴和良智能装备有限公司

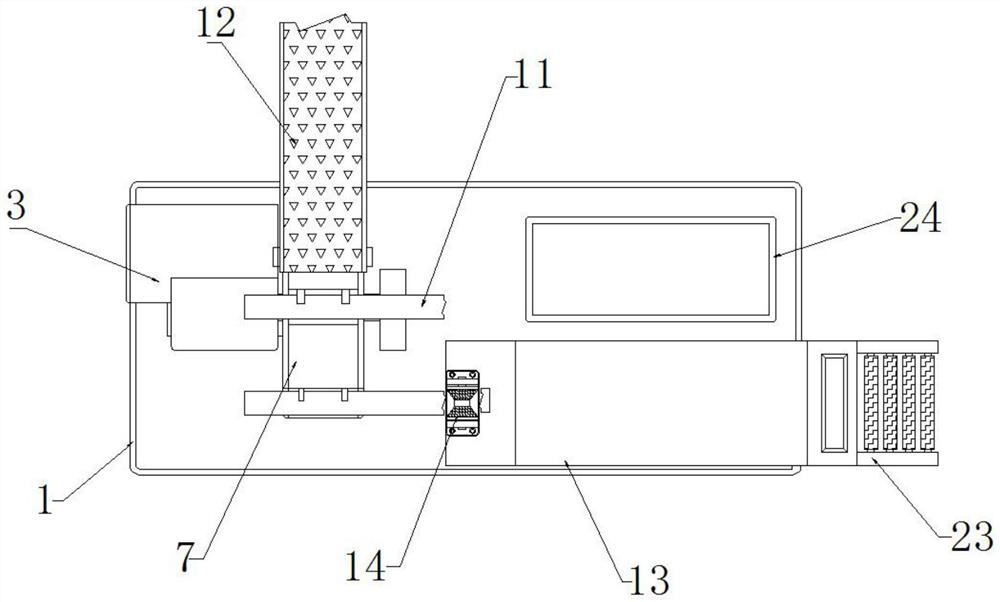

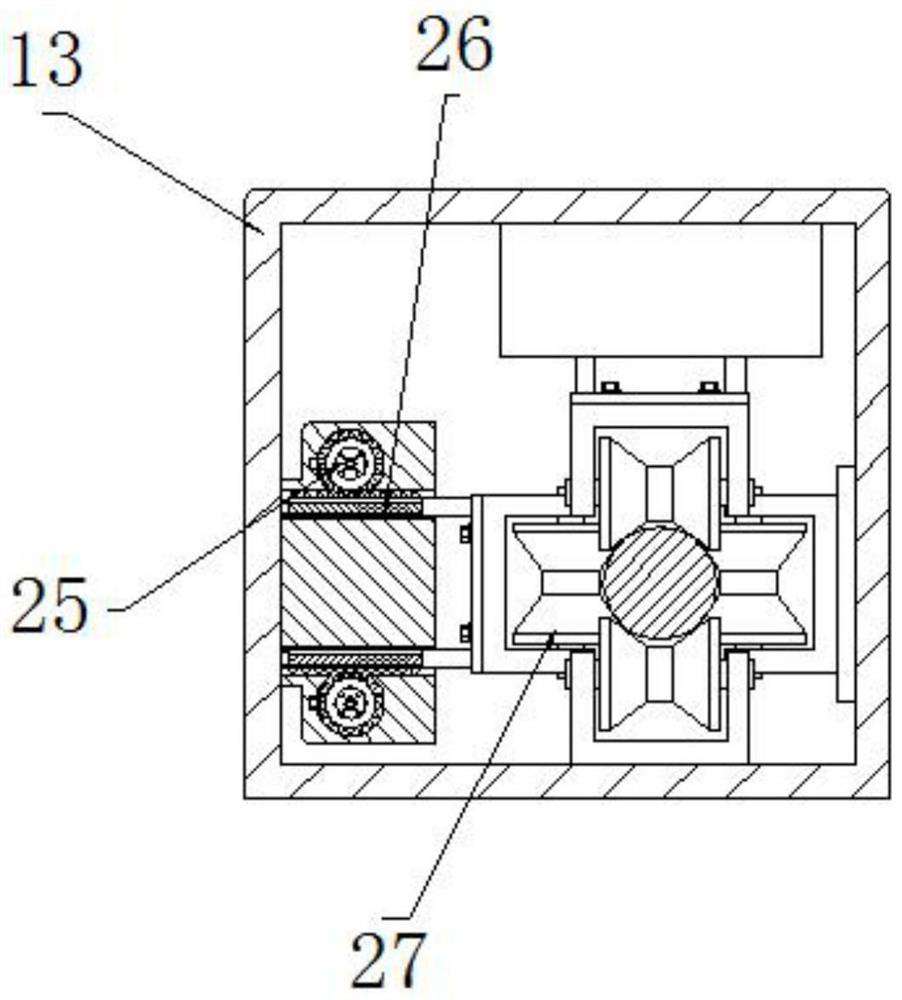

A hydraulic magnesium ingot cutting machine

ActiveCN104551257BEasy to removeEasy to install and debugTailstocks/centresPositioning apparatusPulp and paper industryIngot

The invention discloses a hydraulic magnesium ingot cutting machine. The hydraulic magnesium ingot cutting machine comprises a machine frame, a hydraulic station, a material push device, a material press mechanism, a knife roller, a material collection hopper, a motor and an adapter plate, wherein the knife roller and the material collection hopper are arranged at the front end of the machine frame, the material collection hopper is arranged below the knife roller, the knife roller is in transmission connection with the motor, the material press mechanism is arranged on a platform of the machine frame, and is tightly close to the knife roller, the material push device is arranged on the rear portion of the platform of the machine frame, the adapter plate is arranged on the lower rear portion of the machine frame, the hydraulic station is connected with the adapter plate through an oil pipe, and the adapter plate is connected with the material push device and the material press mechanism through oil pipes. Compared with the prior art, the hydraulic magnesium ingot cutting machine has the advantages that installation and debugging are convenient, the attractiveness cannot be affected, the time is saved, clamping is convenient and rapid, operating noise is low, stability is good, inclined iron can be conveniently disassembled, the cutting capacity is improved, the knife breakage phenomenon cannot easily happen, the production cost is reduced, processing is easy, and the structure is simple.

Owner:日照美鑫机械有限公司

PCB (printed circuit board) drilling process

PendingCN114126227AGuaranteed yieldGuaranteed reliabilityPrinted circuit manufactureEngineeringMachining process

The invention discloses a PCB (printed circuit board) drilling process, which adopts a plurality of cutters to sequentially perform two different processing modes such as multi-stage drilling and compensation milling to process a through hole of a PCB, and ensures that the deformation in the through hole processing process is small, so that the processing efficiency of the PCB is improved, and the processing quality of the PCB is improved. The drilling hole position precision and the through hole diameter are within a preset tolerance range. According to the PCB drilling technology, the through holes of the PCB are machined in two different machining modes of multi-stage drilling, compensation milling and the like in sequence through multiple cutters, so that deformation in the through hole machining process is small, the drilling hole position precision and the through hole diameter are both within the preset tolerance range, and the machining precision of the PCB is improved. The problems that through holes are large in top and small in bottom and different in diameter in conventional machining are completely eradicated, multiple tools share milling pressure in turn in the machining process, the tools are not prone to being broken, and the reliability of the machining technology and the yield of PCB machining are guaranteed.

Owner:苏州烁点电子科技有限公司

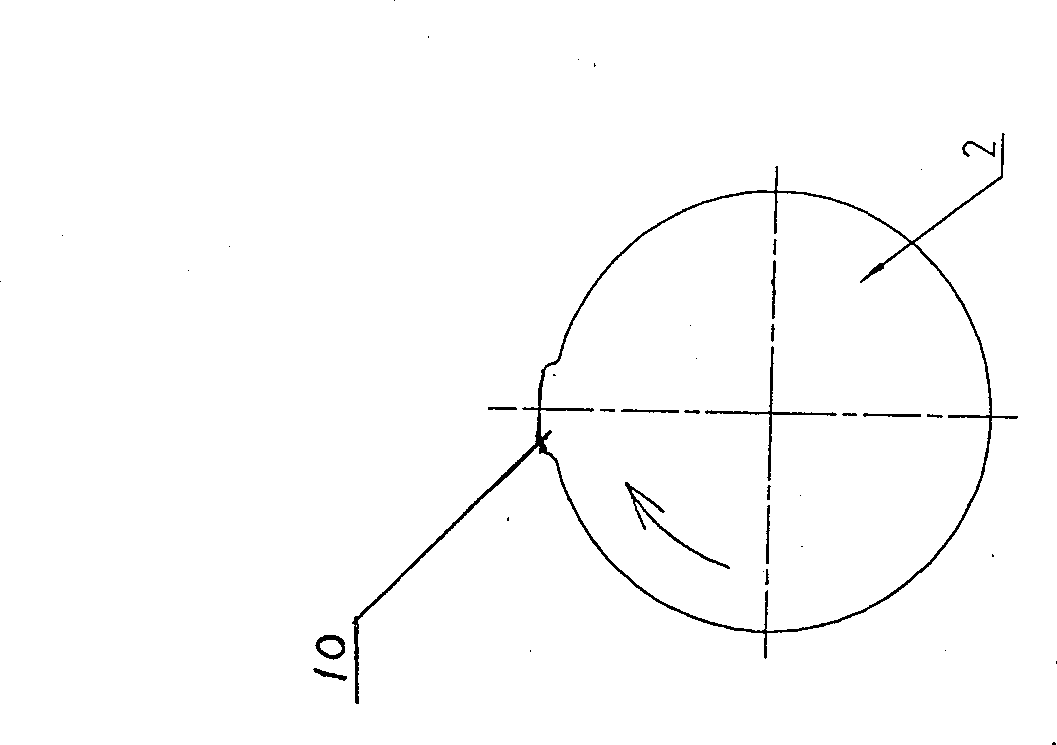

Drilling method of circuit board

ActiveCN103752882BReduce drilling depthReduce depthPrinted circuit manufactureDiameter ratioHole drilling method

A drilling method for a circuit board, comprising the following steps: arranging positioning targets (1) and a direction target (2) on a circuit board, and drilling positioning holes at the positioning targets (1) and a direction hole at the direction target (2), using the direction hole to identify the direction of the circuit board; drilling respectively from the front side and the rear side of the circuit board, so that the drill holes of the front side and the rear side form through holes. The present drilling method can achieve drilling of a circuit board with a high thickness to diameter ratio, and can obtain high accuracy hole positions.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

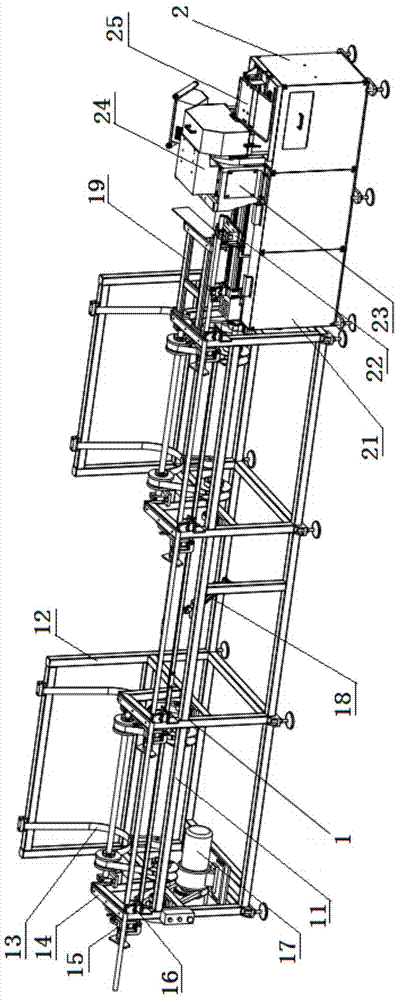

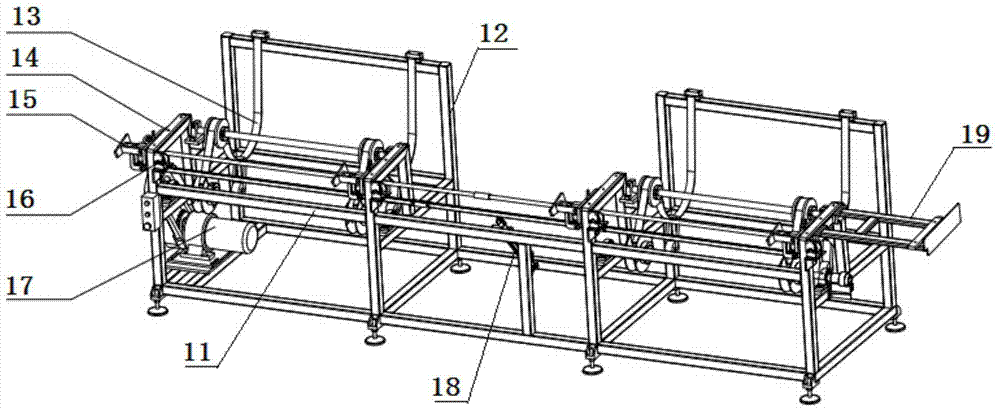

A magnesium ingot processing unit

Owner:重庆中科誉明机器人有限公司

Combined forming cutter

The combined forming cutter specially for metal cutting lathe includes cutter comprising cutting section and reinforced tail section and elastic fixture. The cutter is formed wholly, needs no grinding when used,and has long service life. The cutter may be manufactured in different specification for lathe operator to select.

Owner:田根旺

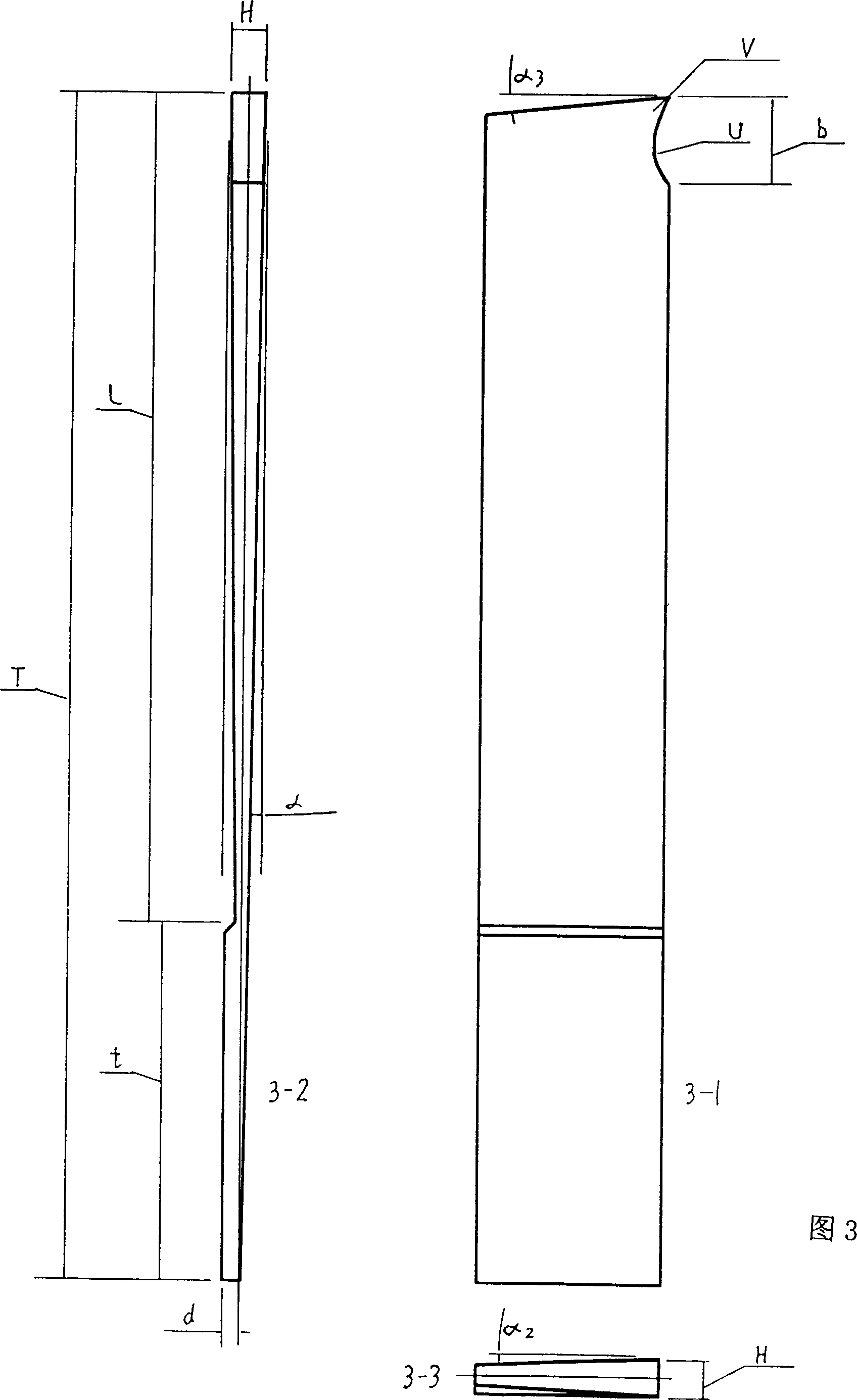

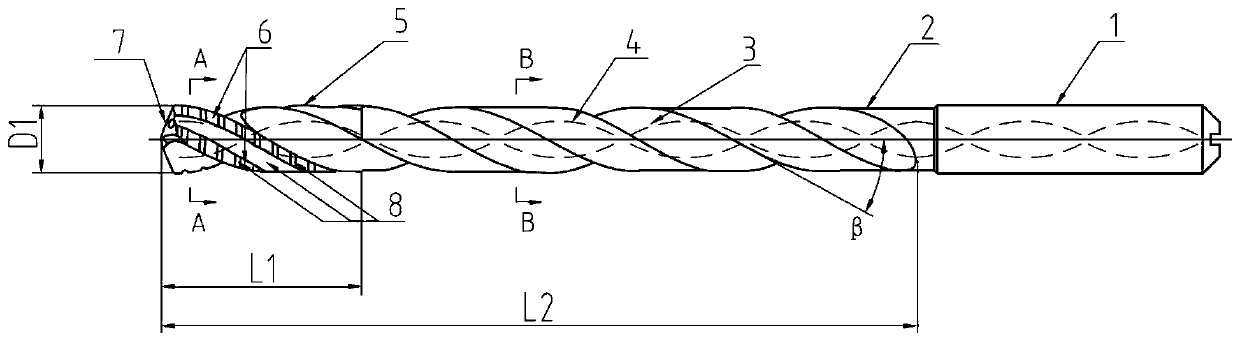

Ultra-long hard alloy deep hole twist drill for deep hole processing

InactiveCN111168127AStable supportEnhanced cooling and lubricationTransportation and packagingTwist drillsEngineeringHelix angle

The invention discloses an ultra-long hard alloy deep hole twist drill for deep hole processing. The ultra-long hard alloy deep hole twist drill comprises a handle part and a blade part which are coaxially arranged, wherein two spiral chip grooves are formed along a central axis on the blade part, and the two chip grooves define a back part; a supporting surface is arranged on the upper surface ofthe blade part; the supporting surface guides for drilling; a U-shaped cooling slot is formed in the supporting surface, a vortex angle which is a cutting edge is arranged at the left side of the blade part, a transverse blade, a secondary blade and a primary blade are arranged on the cutting edge, a crossed part of the primary blade and the secondary blade is provided with a transition blade through circular-arc transition; and the secondary blade, the transition blade and the primary blade are sequentially connected to form continuous cutting edges which are symmetrically distributed with respect to a center cross line, and are connected through the transverse blade. According to the ultra-long hard alloy deep hole twist drill for deep hole processing disclosed by the invention, the supporting surface for a drill bit, spiral angles of the chip grooves, a slot shape, a core thickness, and a circular-arc transition shape of a cutting edge hole are designed in a targeted mode, so thatdrill bit rigidity, chip removal performance and edge hole strength are perfectly unified, and therefore, precision is improved by 100%, and the service life of a tool is prolonged by 8-20 times.

Owner:SUZHOU AHNO PRECISION CUTTING TECH CO LTD

Drilling method for printed circuit board (PCB)

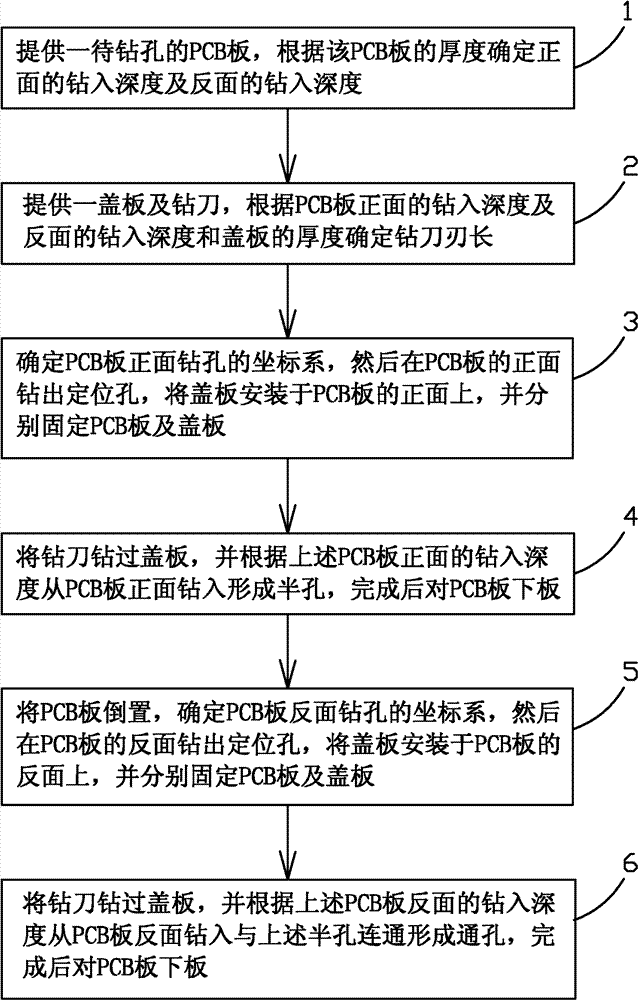

ActiveCN102036492BReduce procurement costsImprove rigidityPrinted circuit manufacturePrinted circuit boardGeotechnical engineering

The invention provides a drilling method for a printed circuit board (PCB). The method comprises the following steps of: 1, providing a PCB to be drilled, and determining drilling depth of a front surface and drilling depth of a back surface according to the thickness of the PCB; 2, providing a cover plate and a drilling cutter, and determining the length of a blade of the drilling cutter according to the drilling depth of the front surface and the drilling depth of the back surface of the PCB and the thickness of the cover plate; 3, determining a coordinate system for drilling on the front surface of the PCB, drilling positioning holes on the front surface of the PCB, arranging the cover plate on the front surface of the PCB and fixing the PCB and the cover plate respectively; 4, drilling through the cover plate by using the drilling cutter, drilling from the front surface of the PCB to form a half hole according to the drilling depth of the front surface of the PCB, and then feedingthe PCB; 5, inverting the PCB, determining a coordinate system for drilling on the back surface of the PCB, drilling positioning holes on the back surface of the PCB, arranging the cover plate on theback surface of the PCB and fixing the PCB and the cover plate respectively; and 6, drilling through the cover plate by using the drilling cutter, drilling from the back surface of the PCB to be communicated with the half hole to form a through hole according to the drilling depth of the back surface of the PCB, and feeding the PCB. In the method, a short-blade long drilling cutter is used for drilling from the two ends of the front surface and the back surface of the hole respectively, so a thicker PCB can be drilled through; and the method has the advantages of lower cost, higher drilling position accuracy and difficulty in breaking the cutter.

Owner:DONGGUAN SHENGYI ELECTRONICS

Skipping line-rolling device

The jumping thread cutting device consists of a cutting blade screwed to a bearing, a cam anvil tube below the fixed blade, a connecting block, a fixing shaft over the connecting block, a locating cap, an eccentric cutter shaft inside the hole in the lower part of the connecting block and with one end fixed by the locating cap and the other end with bearing, a bearing, a gland for fixing the center of the cutting blade, and an anvil tube shaft penetrating the cam anvil tube to fix it. The present invention has the advantages of compact structure, high reliability, low cost, high longitudinal cutting precision and capacity of regulating the pressure to the longitudinal cutter during operation.

Owner:SHANGHAI XINMIN TAIYO KIKAI

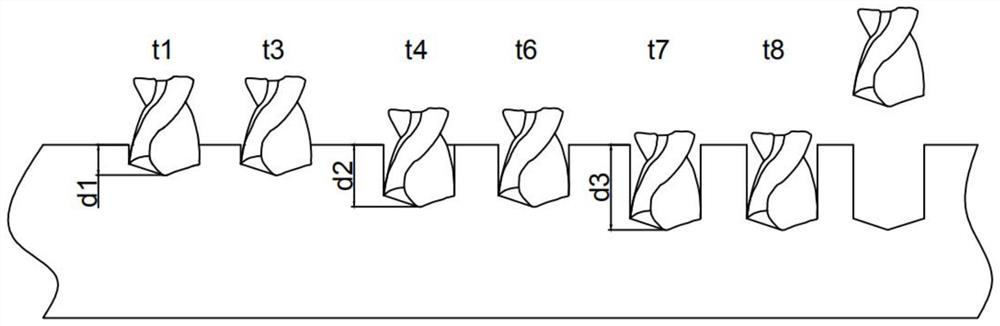

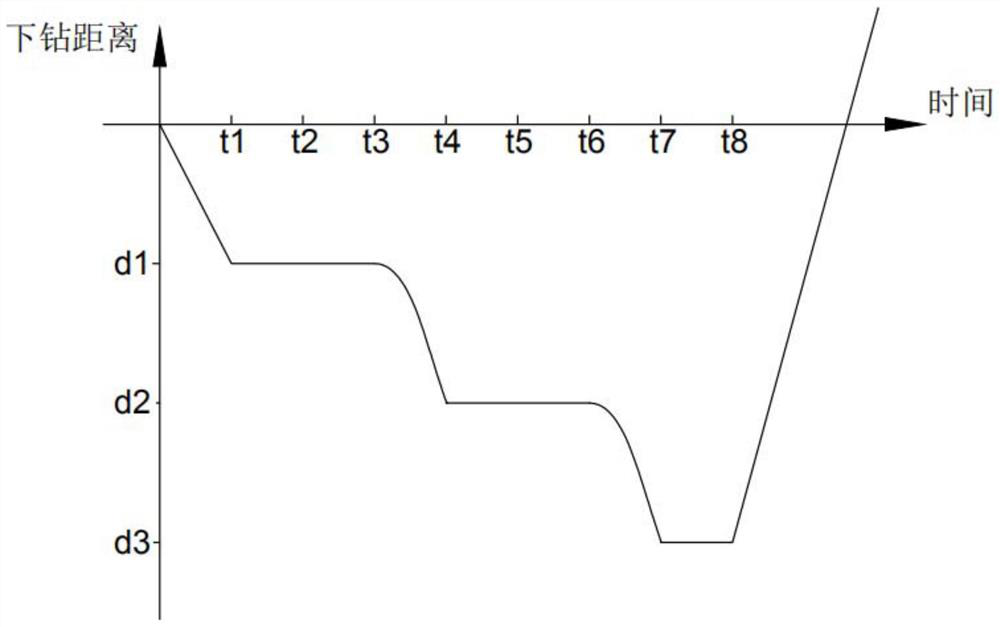

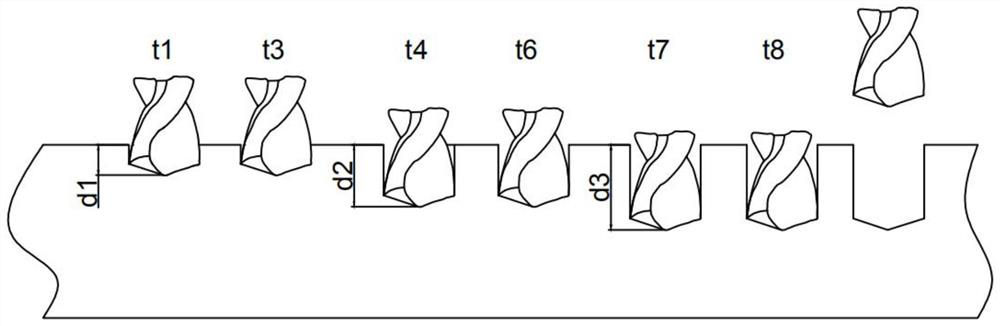

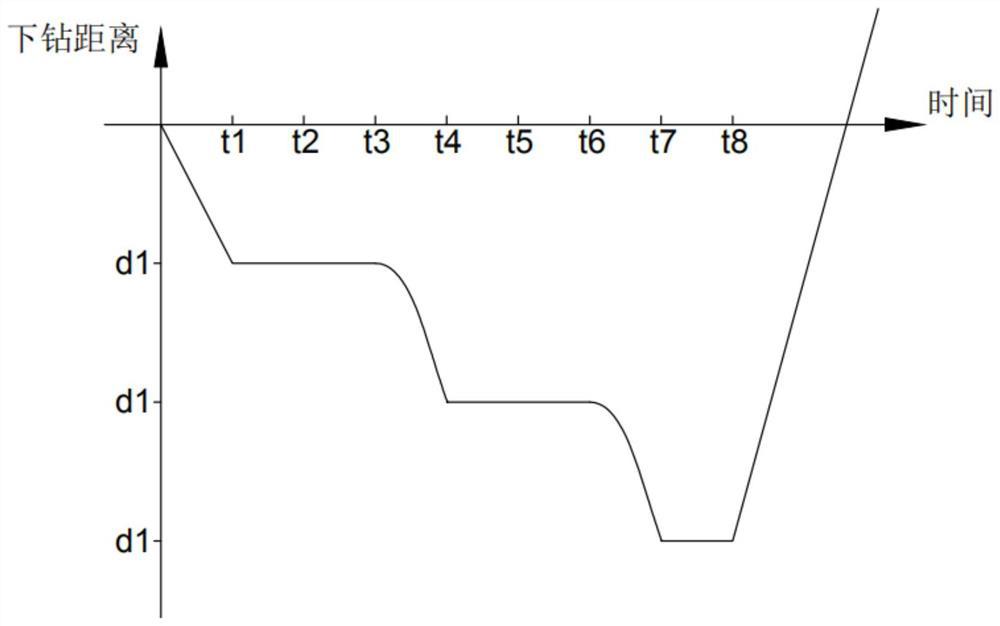

Segmental drilling method and drilling machine for thick plate

ActiveCN112170879BIncrease drilling speedReduce axial force impactBoring/drilling machinesThick plateStructural engineering

The invention belongs to the technical field of thick plate drilling, and discloses a thick plate segmental drilling method and a drilling machine. The thick plate drilling method includes the following steps: Step 1: The tool drills into the plate for a certain distance at the first rotational speed, and keeps The position of the tool and maintain the first speed for a period of time; Step 2: While the tool is drilling into the plate, gradually increase the drilling speed of the tool until the set drilling speed is reached. The tool continues to drill into the plate for a certain distance, maintain the position of the tool and maintain the first speed Rotate for a while; cycle step 2 until the tool drills down to the final depth. By not returning the tool in each segment, the smoothness of the hole wall is guaranteed; by gradually increasing the drilling speed while drilling into the plate, the speed of the tool’s refeeding acceleration in the plate is small, which can reduce the axis of the tool when it cuts into the plate Direct impact to avoid breaking the knife. This method can realize less sub-section machining, not only is not easy to break the knife, but also can achieve the effect of greatly improving the machining efficiency.

Owner:SUZHOU VEGA TECH CO LTD

Thick plate segmented drilling method and drilling machine

ActiveCN112170879AIncrease drilling speedReduce axial force impactBoring/drilling machinesThick plateEngineering

The invention belongs to the technical field of thick plate drilling, and discloses a thick plate segmented drilling method and a drilling machine. The thick plate segmented drilling method comprisesthe following steps of step 1, a cutter drills into a plate for a certain distance at a first rotating speed, and the position of the cutter is maintained for a period of time at the first rotating speed; 2, while the cutter drills into the plate, the drilling speed of the cutter is gradually increased till the set drilling speed is reached, the cutter continues to drill into the plate for a certain distance, and the position of the cutter is kept for a period of time at the first rotating speed; and the step 2 is repeated until the cutter drills down to the final depth. The smooth finish of ahole wall is ensured by not returning the cutter in each segmentation; and the drilling speed is gradually increased while the plate is drilled, the speed of accelerating the cutter to feed again inthe plate is small, the axial force impact borne by the cutter when the cutter cuts into the plate can be reduced, and cutter breaking is avoided. By means of the method, less segmented machining canbe achieved, cutter breaking is not likely to happen, and the effect of greatly improving the machining efficiency can be achieved.

Owner:SUZHOU VEGA TECH CO LTD

A heat pipe groove forming knife and forming method for a 5G base station equipment shell

ActiveCN111702234BExtend your lifeFirmly connectedMilling cuttersMilling equipment detailsEngineeringHeat pipe

Owner:ZHUHAI RUNXINGTAI ELECTRICAL

Heat pipe groove forming tool and method for 5G base station equipment shell

ActiveCN111702234AExtend your lifeFirmly connectedMilling cuttersMilling equipment detailsEngineeringHeat pipe

The embodiment of the invention discloses a heat pipe groove forming tool for a 5G base station equipment shell. The forming tool comprises a tool handle and a cutting portion which are integrally formed. The tool handle and the cutting portion have the same center axis. The cutting portion comprises a cutting blade and a chip groove. The cutting blade comprises a lower arc cutting blade, a linearcutting blade and an upper arc cutting blade which are sequentially connected from bottom to top. The tool handle comprises a tool handle body and a connecting transition portion. The cutting portionis connected with the tool handle body through the connecting transition portion. The embodiment of the invention further discloses a heat pipe groove forming method for the 5G base station equipmentshell. By adopting the forming method, it can be ensured that when the forming tool rotates, the cutting surface keeps line contact with materials, abrasion is not likely to be caused, and the service life of the tool is prolonged. The tool handle body and the cutting portion are connected firmly, and the tool is not likely to be broken. In the milling process, the cutting portion can stretch into materials to be machined through the transition portion, the forming technology for heat pipe grooves of different depths can be achieved, and the universality is high.

Owner:ZHUHAI RUNXINGTAI ELECTRICAL

Double edge compression end mill

ActiveCN104191020BUniform distribution of cutting edgesEvenly distributedMilling cuttersMilling cutterSinistral and dextral

The invention relates to the technical field of a cutter for cutting machining, in particular to a two-edge pressure-type end mill. The two-edge pressure-type end mill comprises a cutter handle and an edge part which is arranged on the front end of the cutter handle, wherein the edge part is formed by a plurality of sections of spiral structures which are identical in structure and are connected with one another from front to rear, each spiral structure is formed by screwing a left-handed edge body and a right-handed edge body relative to the same axis for half circle, a plurality of spiral scale backs are uniformly arranged on the back surface of each spiral cutter body, a seamed edge of each spiral cutter body and a seamed edge of each scale back are respectively provided with a cutting edge, a spiral cutter withdrawing groove is formed between the two spiral cutter bodies, the seamed-edge side edges of all the spiral cutter bodies form a spiral cutting edge of the two-edge pressure-type end mill, and the front end edges, on the front end of the edge part, of the spiral cutter bodies are intersected to form a mill end edge. The two-edge pressure-type end mill is specially used for cutting a composite material, is free of layering, burrs and the like in the machining process, and is high in machining quality.

Owner:CHANGZHOU CHUANGWEI TOOL MFG

Skipping line-rolling device

The jumping thread cutting device consists of a cutting blade screwed to a bearing, a cam anvil tube below the fixed blade, a connecting block, a fixing shaft over the connecting block, a locating cap, an eccentric cutter shaft inside the hole in the lower part of the connecting block and with one end fixed by the locating cap and the other end with bearing, a bearing, a gland for fixing the center of the cutting blade, and an anvil tube shaft penetrating the cam anvil tube to fix it. The present invention has the advantages of compact structure, high reliability, low cost, high longitudinal cutting precision and capacity of regulating the pressure to the longitudinal cutter during operation.

Owner:SHANGHAI XINMIN TAIYO KIKAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com