Pipe Chipless Cutting Machine

A cutting machine and pipe technology, used in pipe shearing devices, shearing machine equipment, shearing devices, etc., can solve the problems of excessive waste and burrs in the cutting nozzle, saving resources, reducing vibration, and not easy to break Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

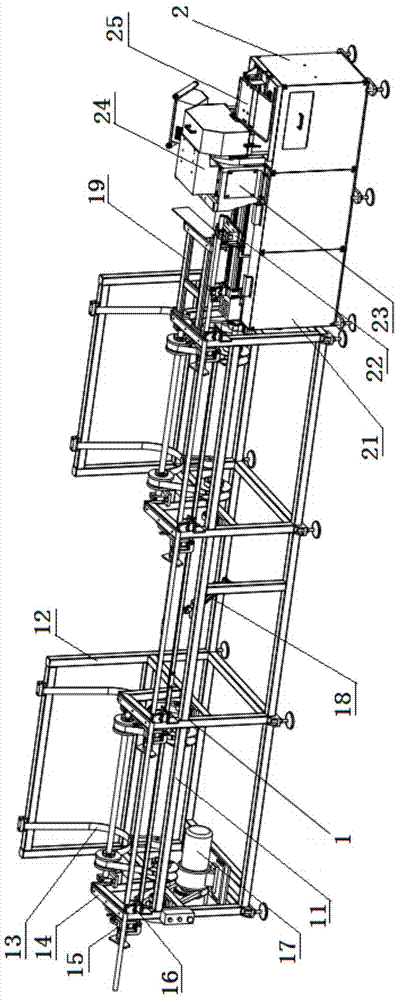

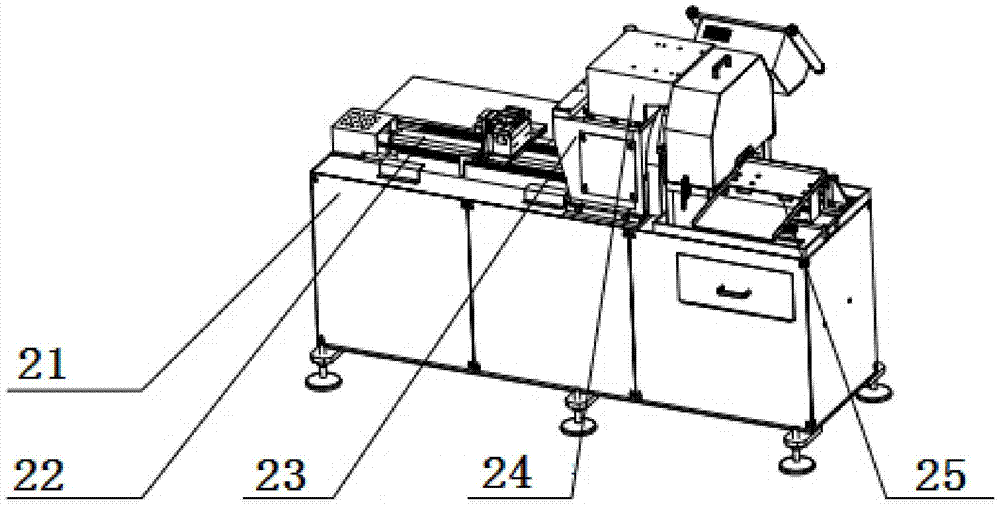

[0032] see figure 1 , The chipless cutting machine for pipes in this embodiment includes a feeding mechanism 1, a host 2 and a control system, and the right end of the feeding mechanism 1 is connected to the left end of the host 2. The cutting machine of this embodiment is especially suitable for pipes with large diameters, or steel pipes or stainless steel pipes with high hardness, and the pipe materials can be coiled pipes or straight pipes. For coiled pipes and straight pipes, the structure of the feeding mechanism 1 is different.

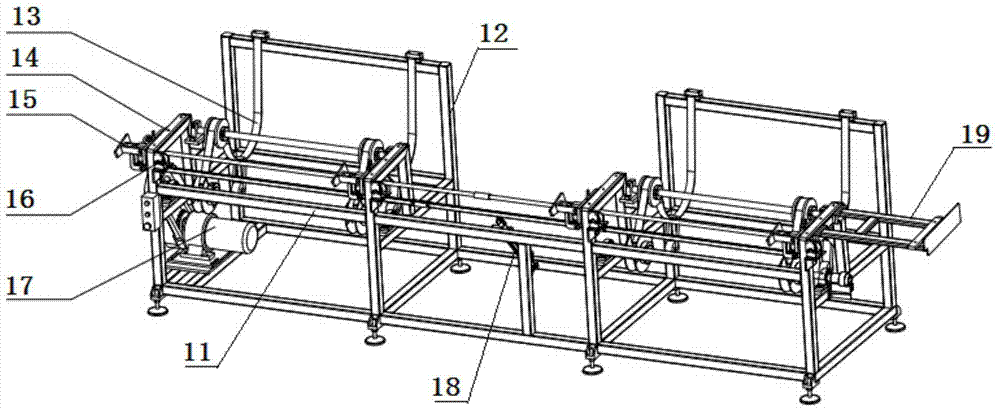

[0033] In this embodiment, the structure of the feeding mechanism is described with the transportation of straight pipes. The feeding mechanism 1 includes a support f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com