Patents

Literature

45results about How to "Reduce axial movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

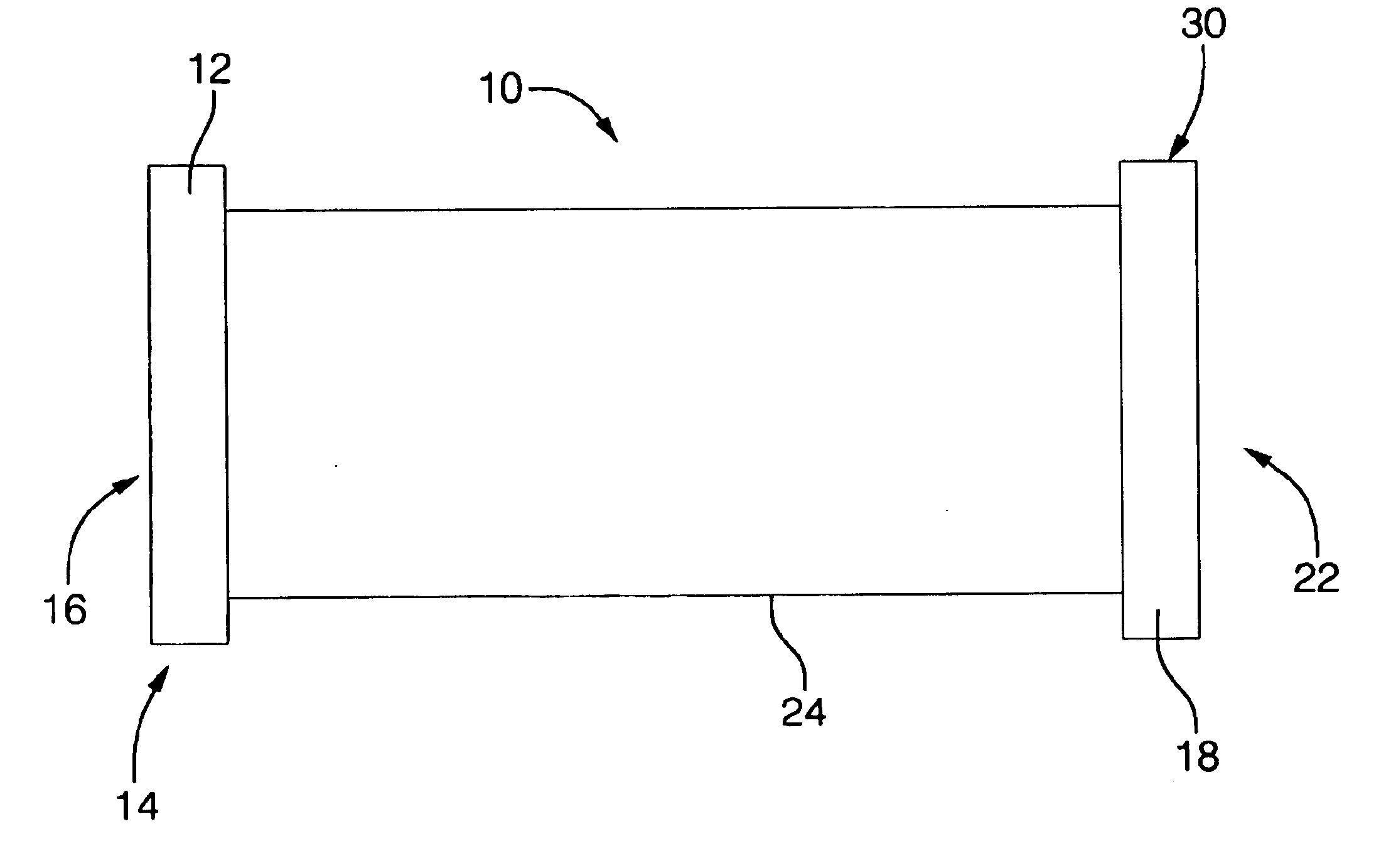

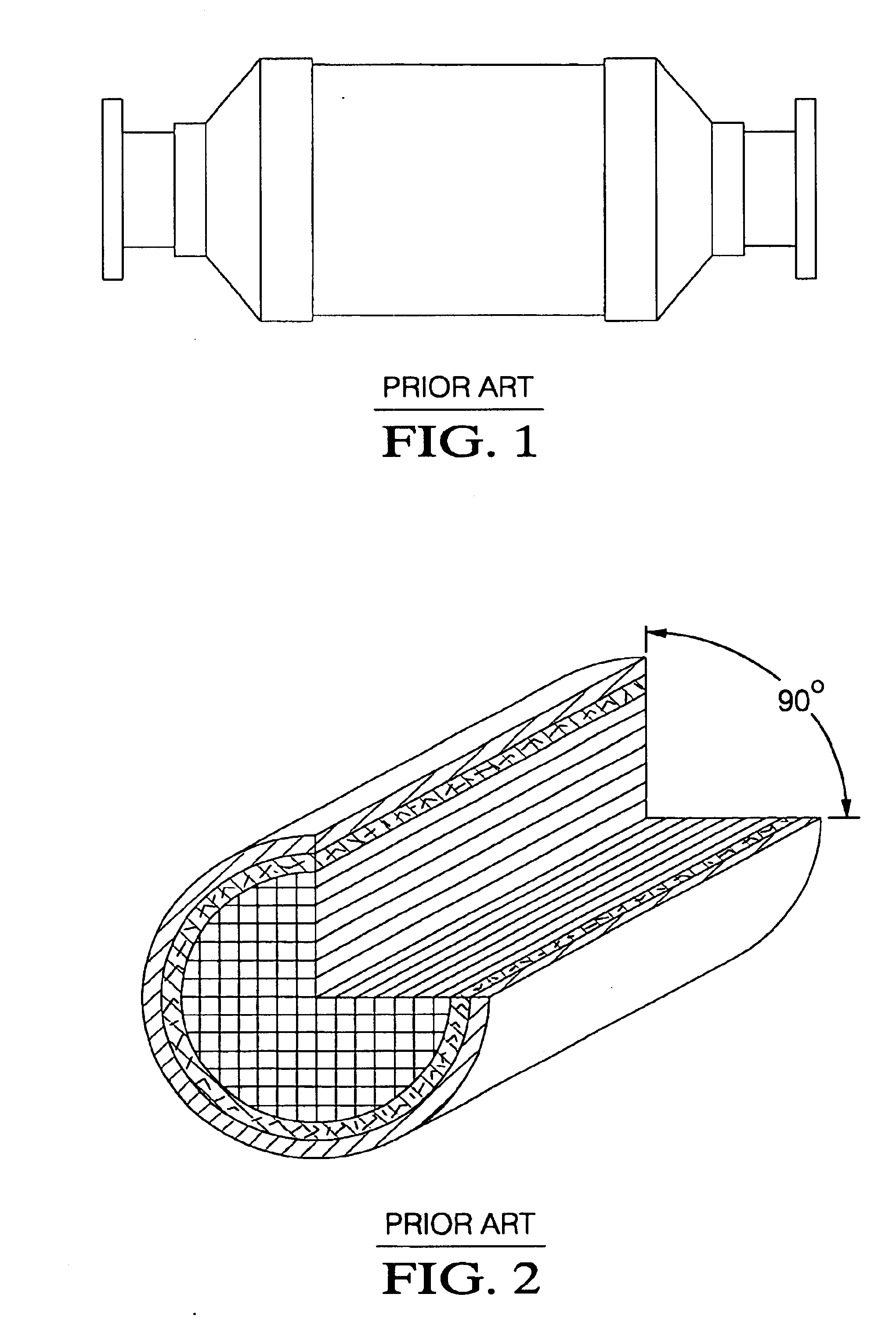

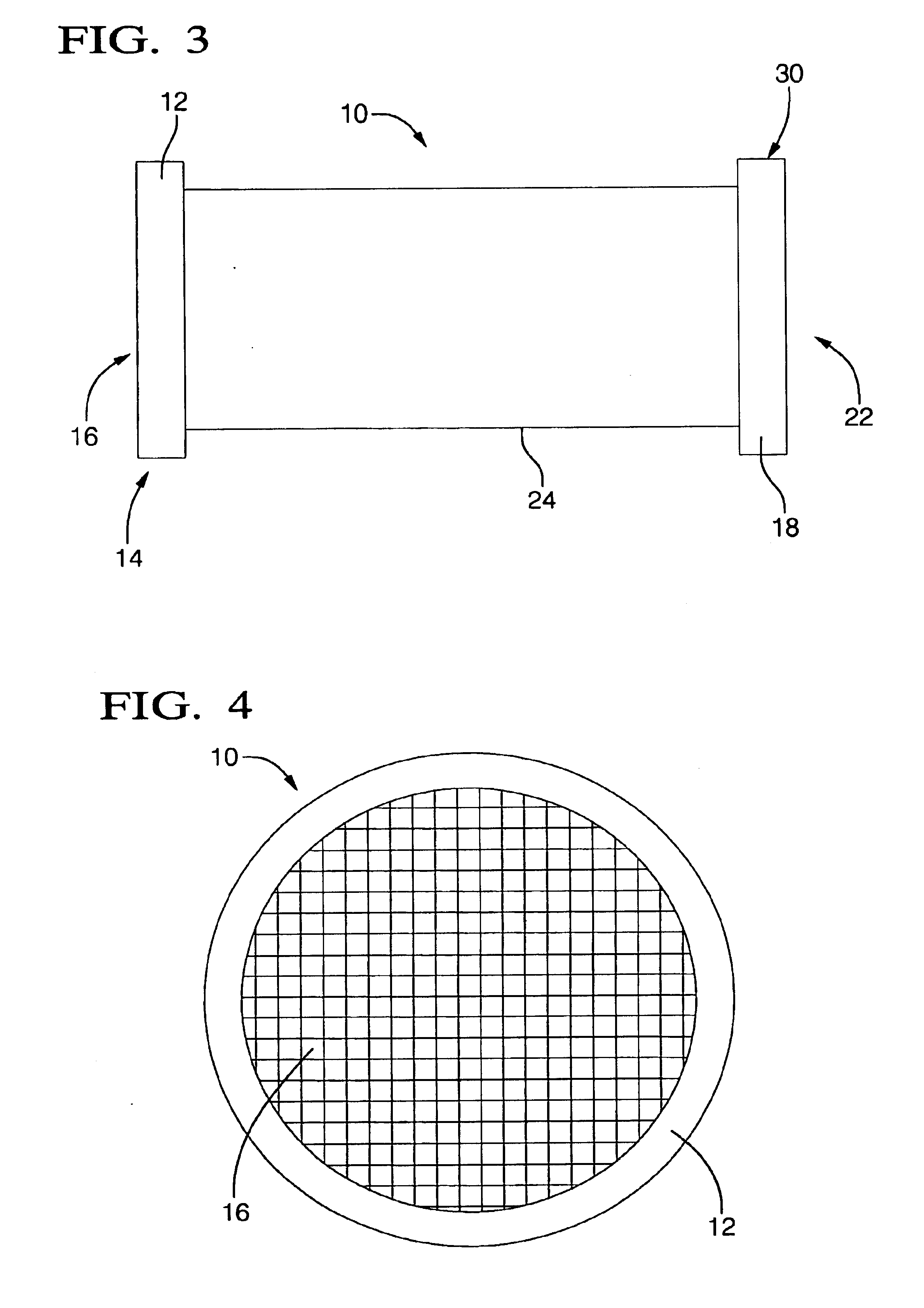

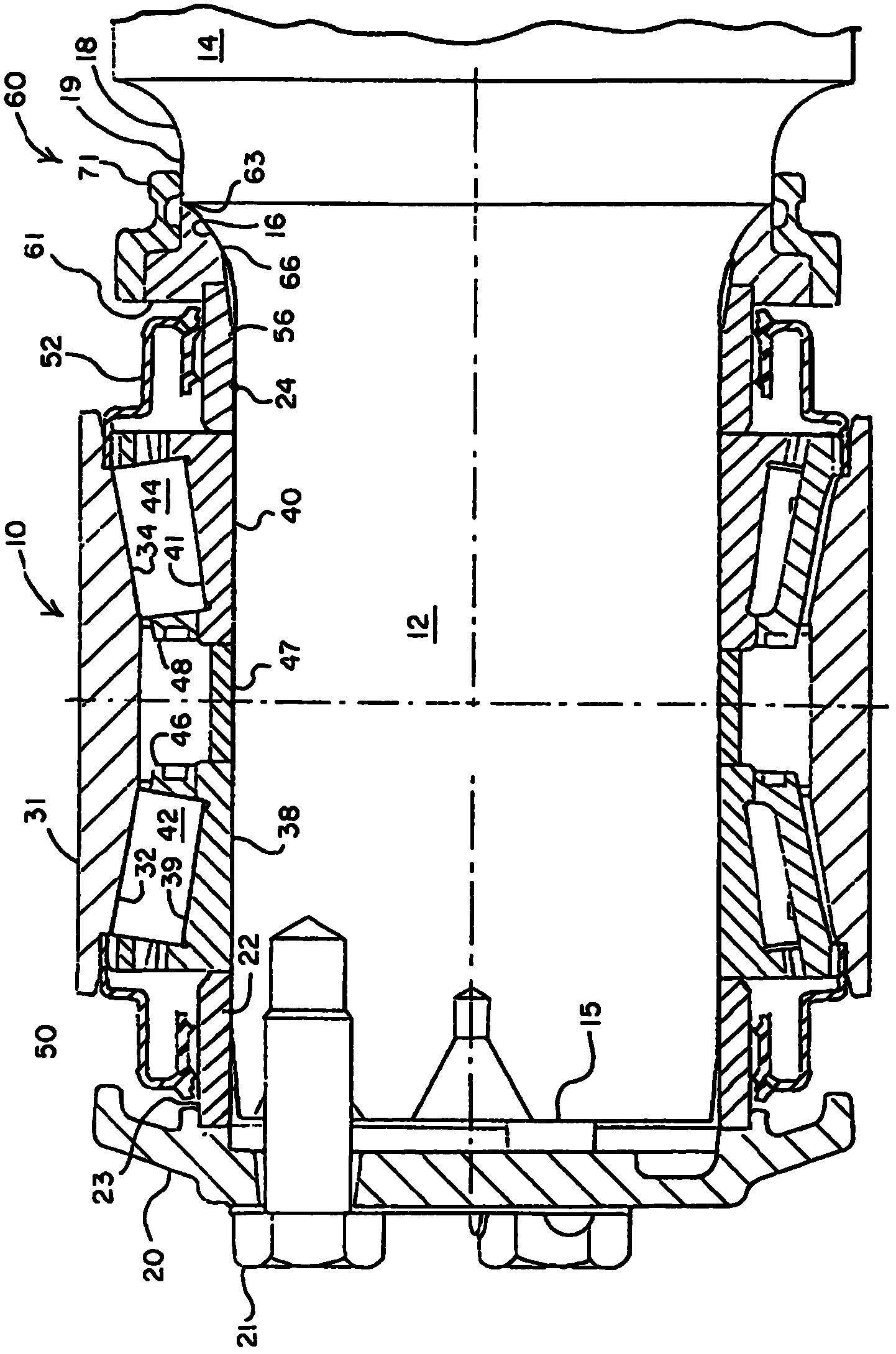

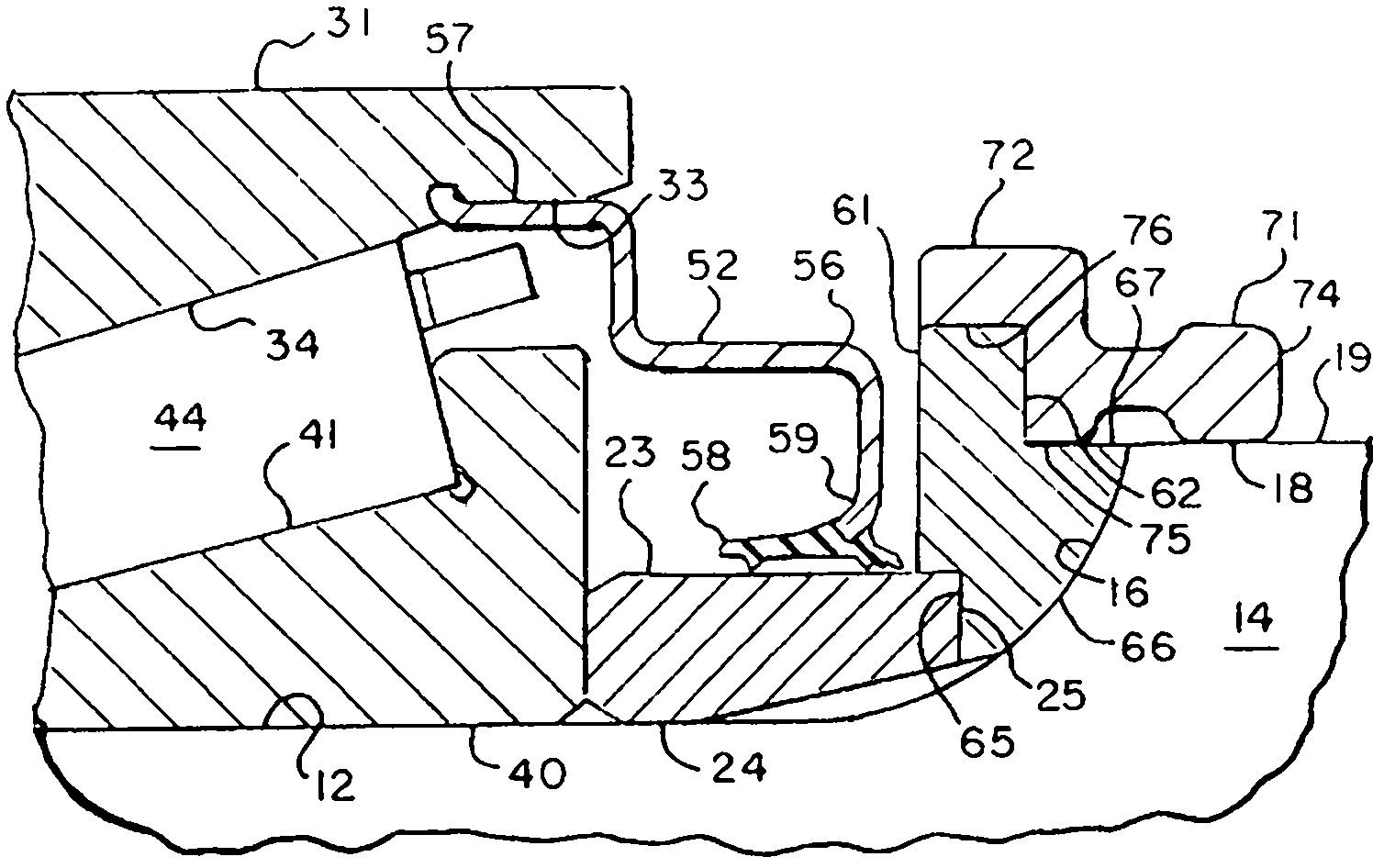

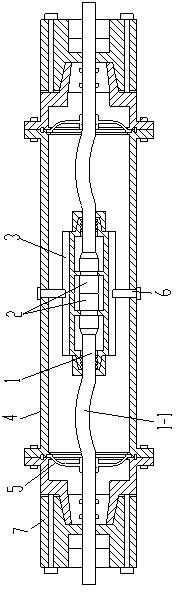

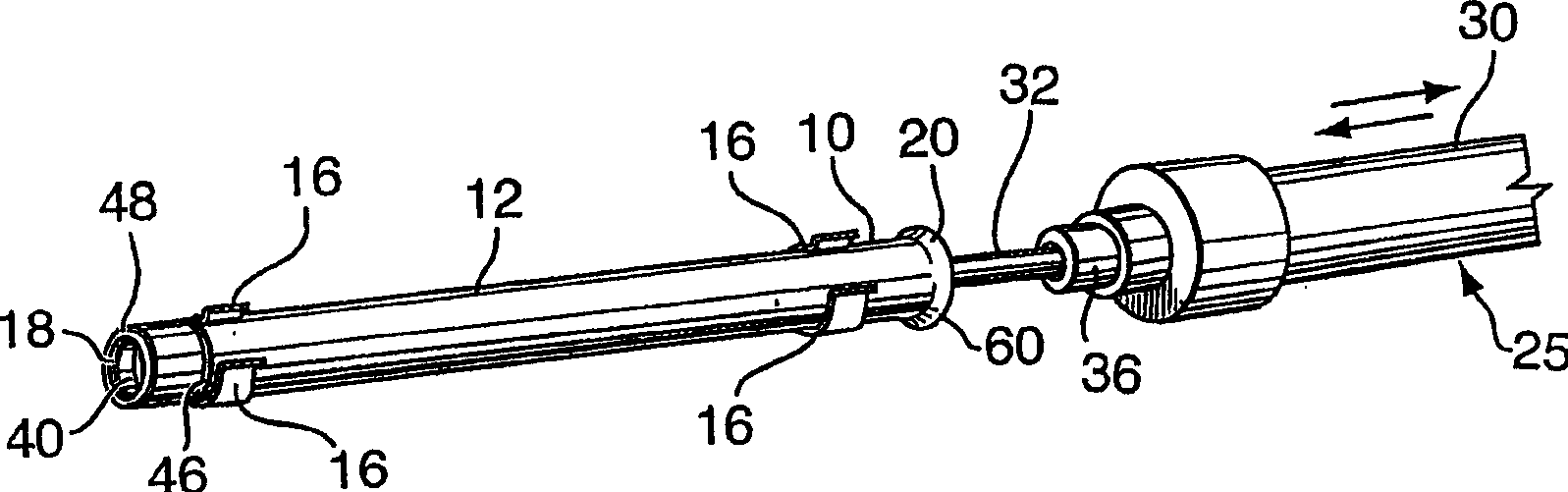

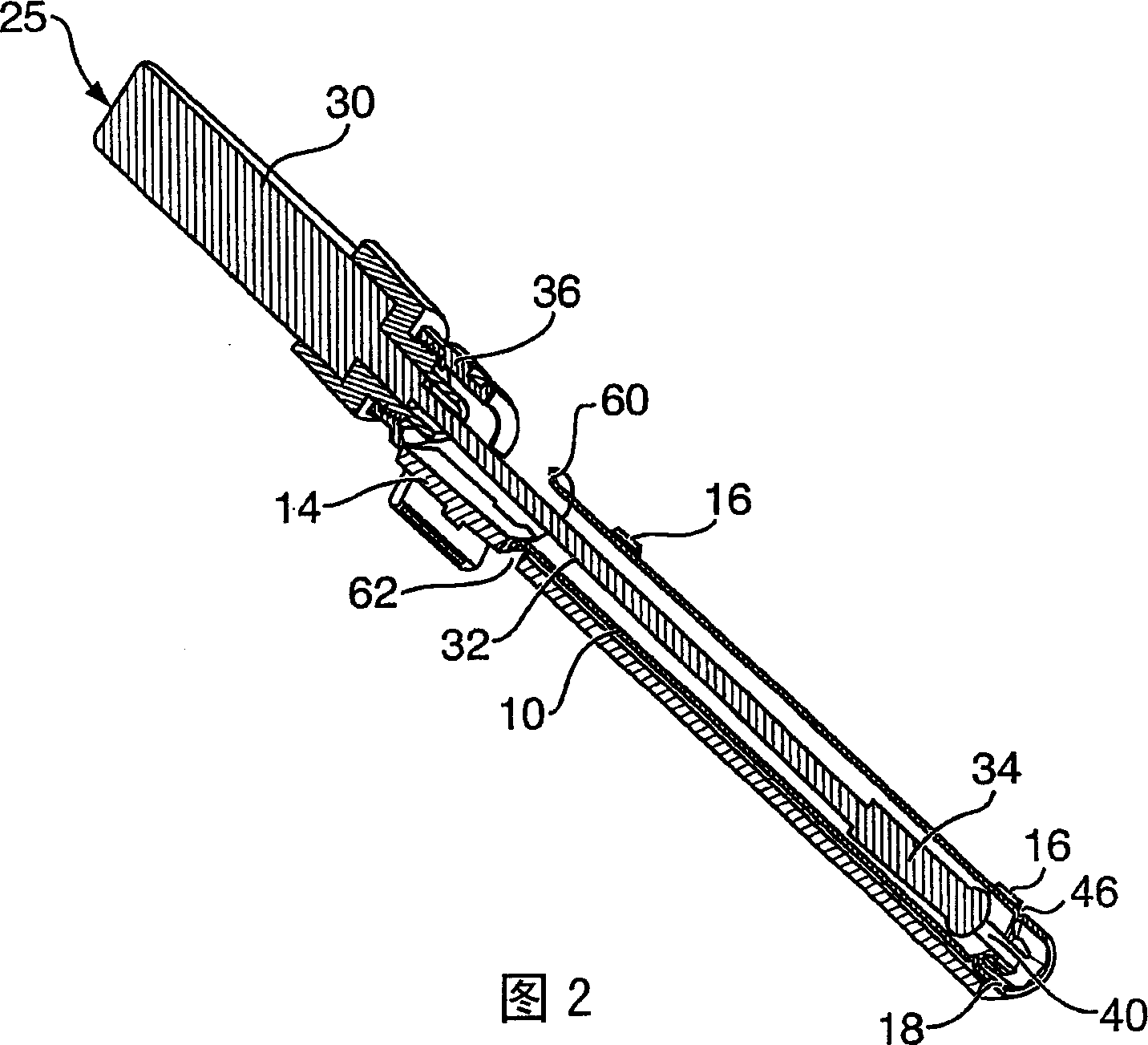

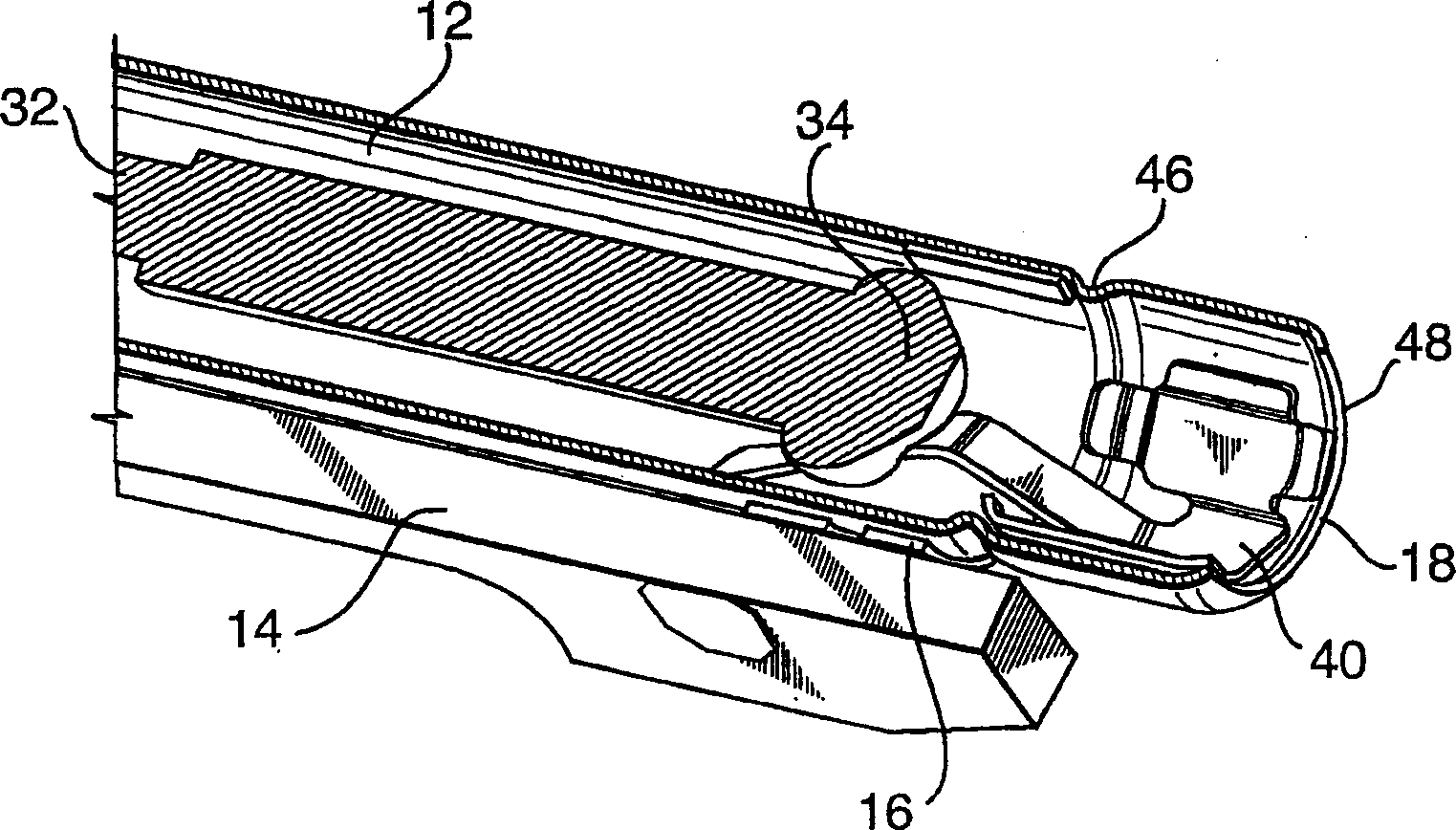

Catalytic converter

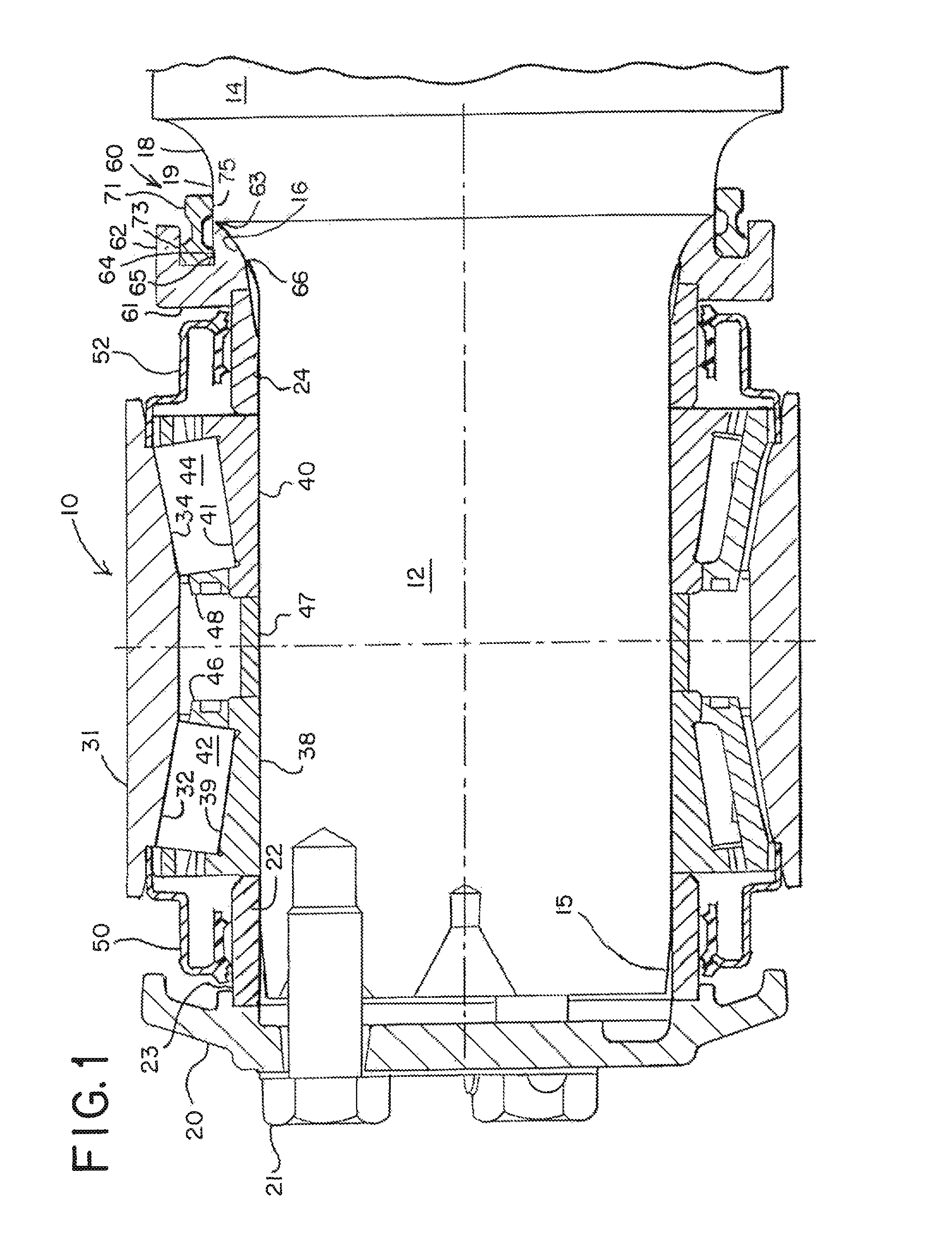

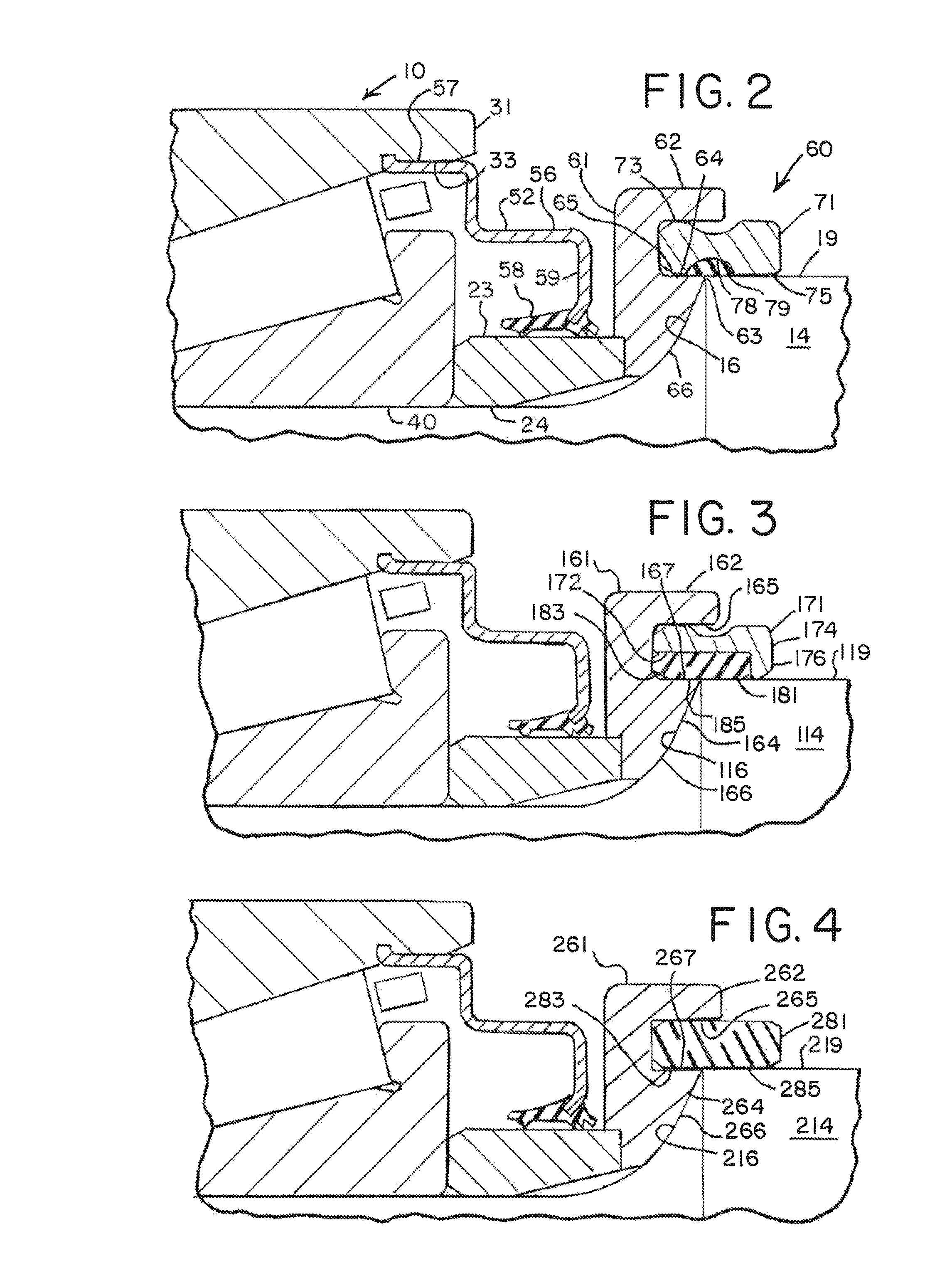

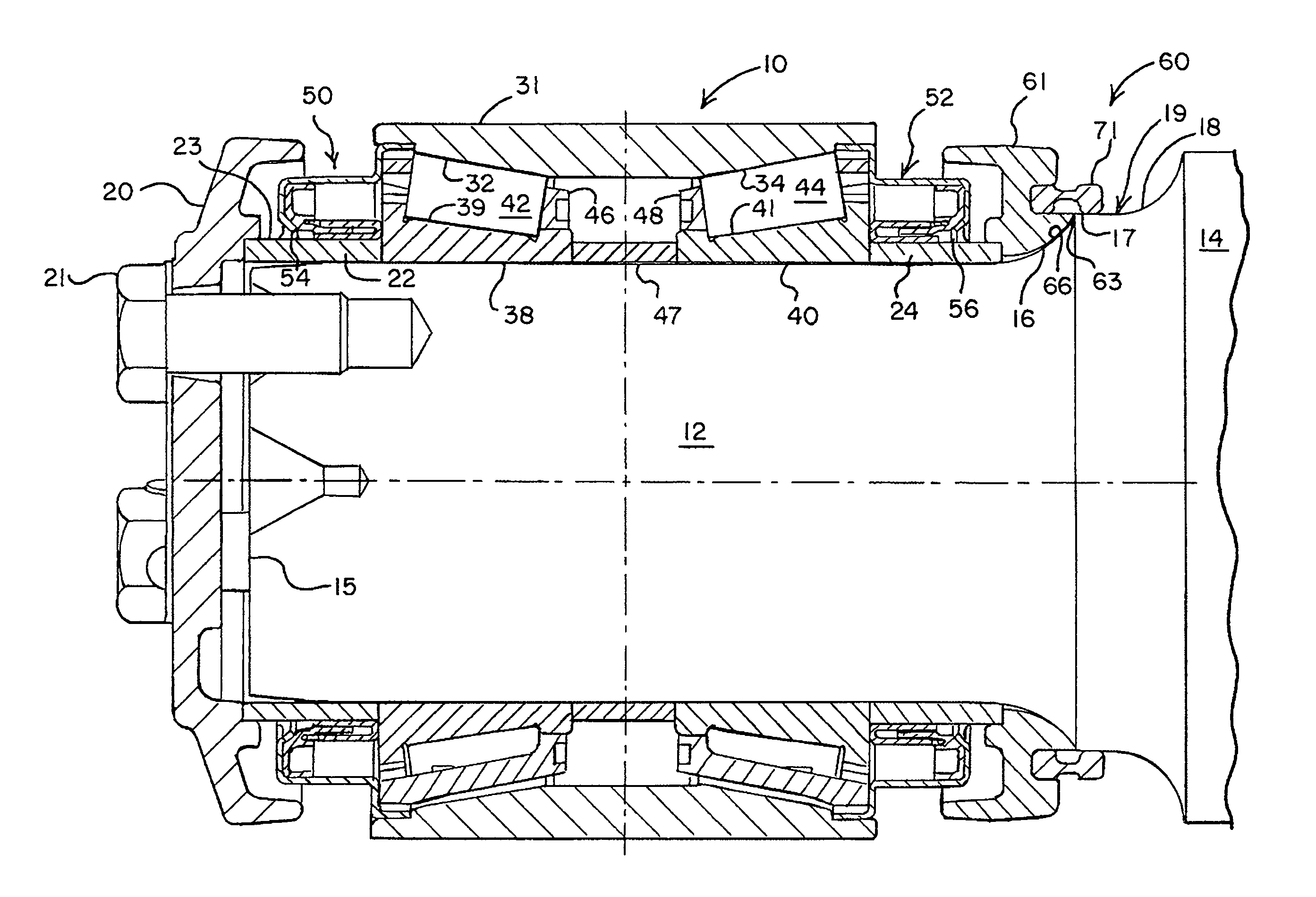

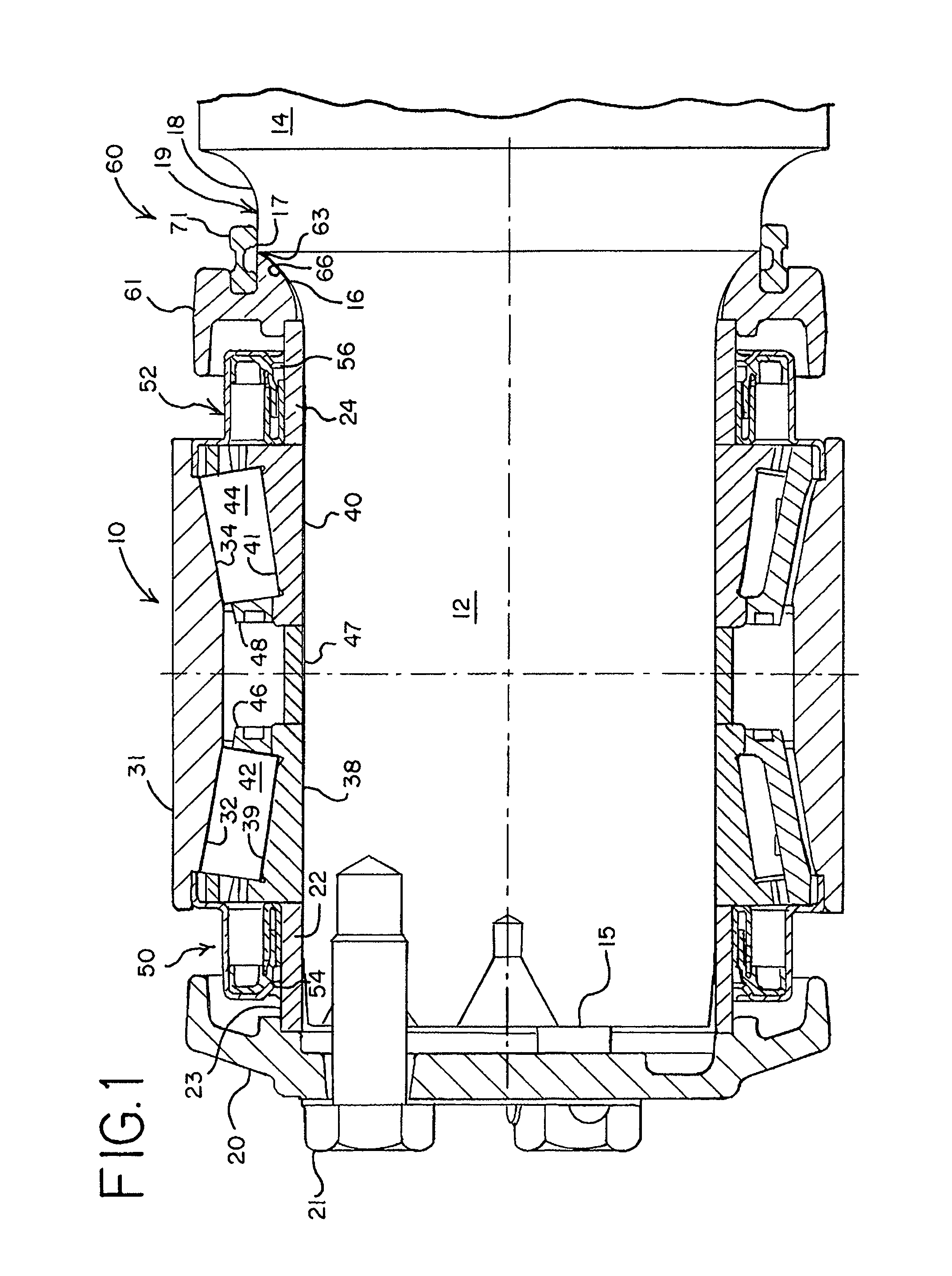

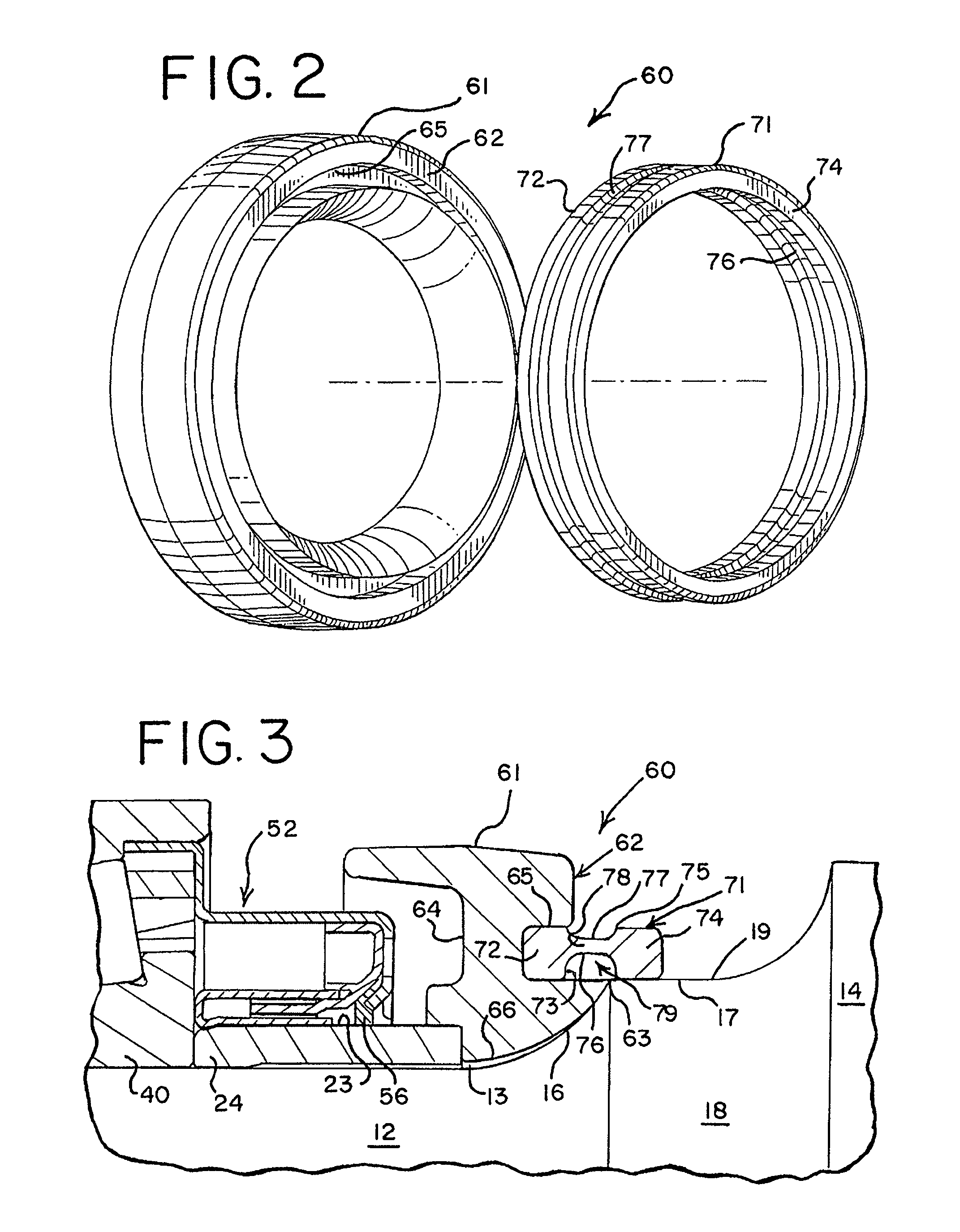

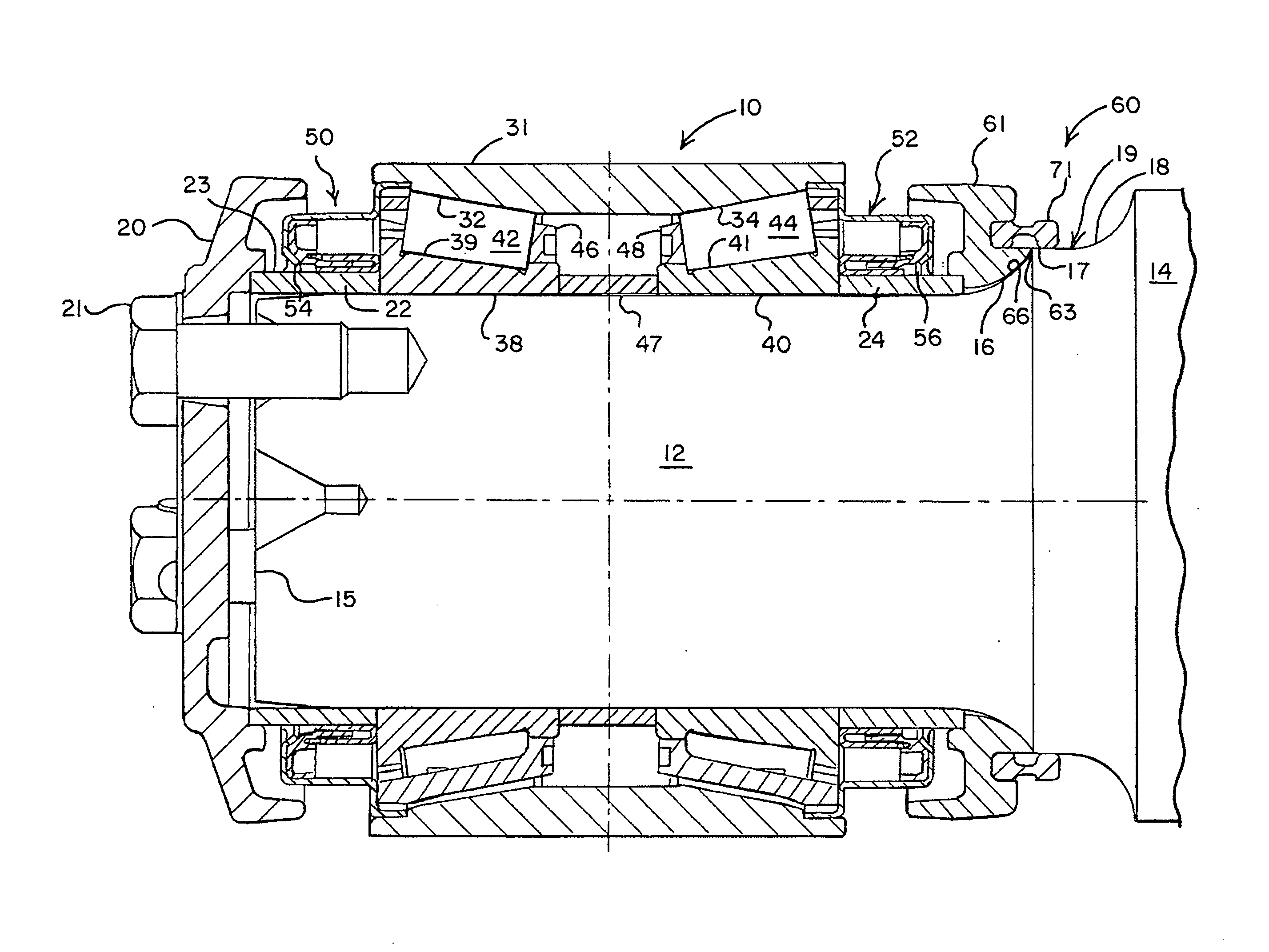

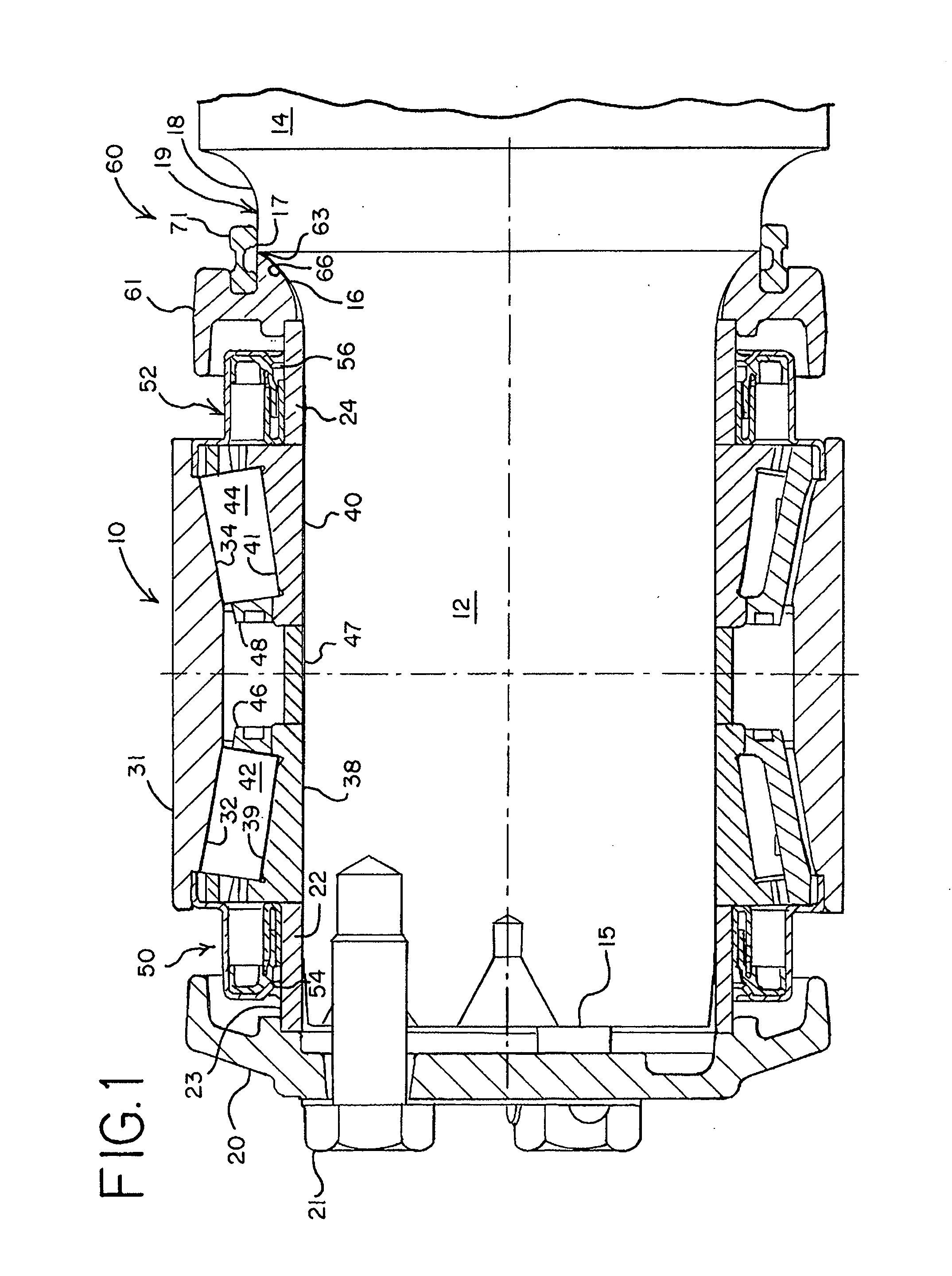

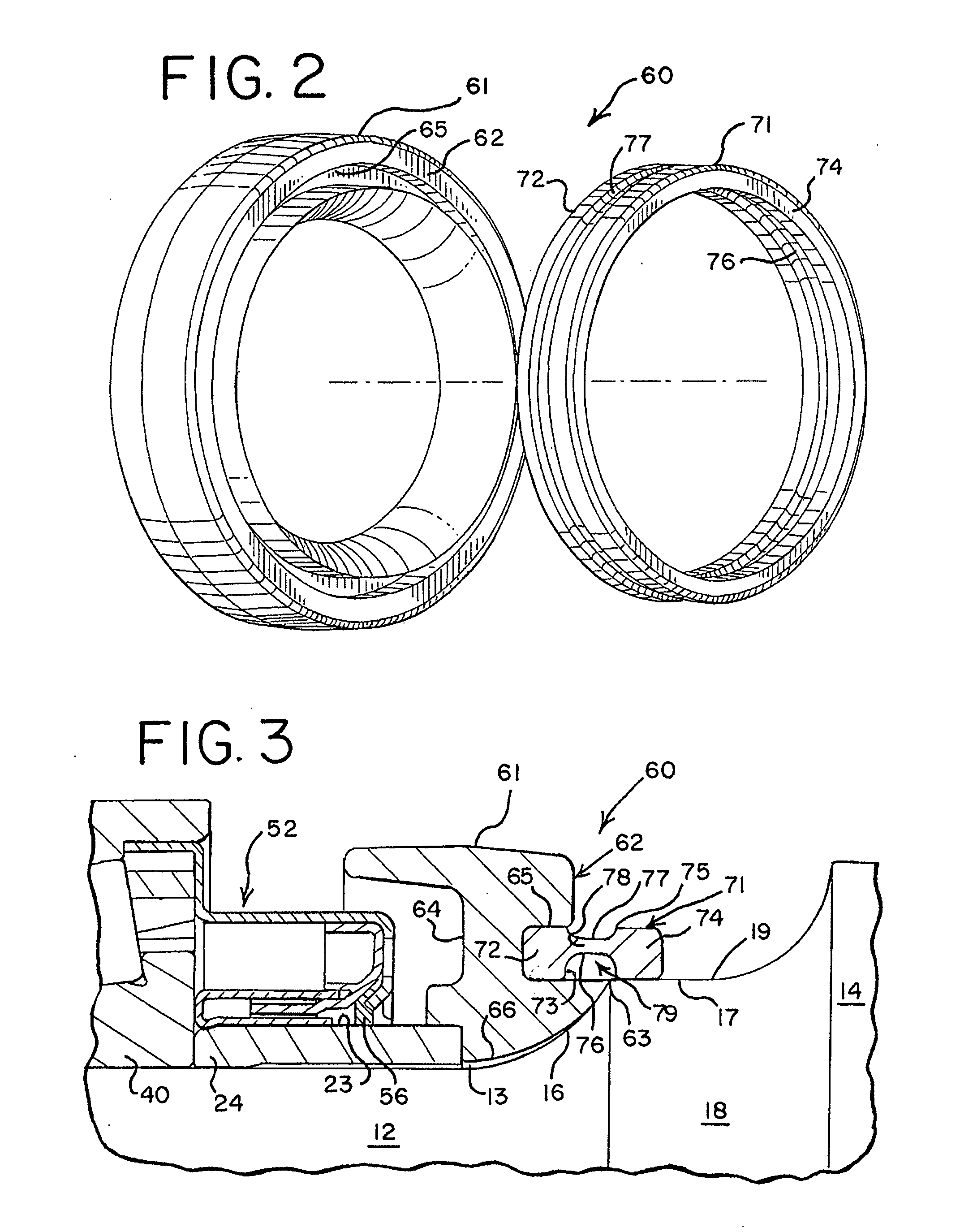

InactiveUS6919052B2Reduce exerciseReduce axial movementCombination devicesPhysical/chemical process catalystsEngineeringShear force

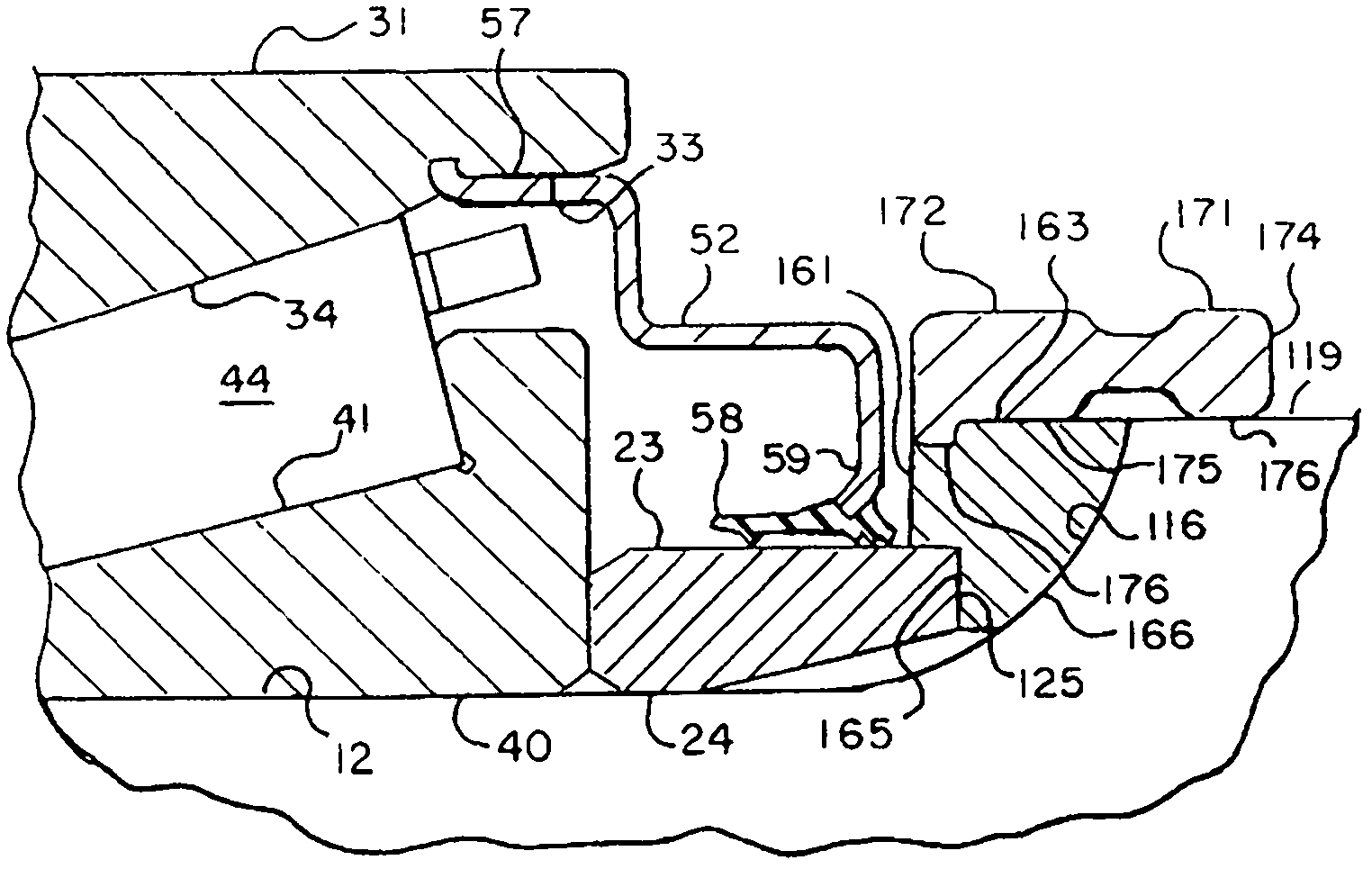

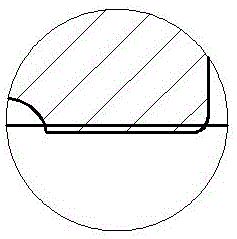

A catalytic converter comprises a catalyst substrate concentrically disposed in a shell and having a mat support material located concentrically in between the catalyst substrate and shell. The catalyst substrate includes structural features located on its outer surface that engage the mat support material. The shear forces exerted between the catalyst substrate and mat support material, in addition to the normally present frictional forces, reduce the axial movement of the catalyst substrate during assembly and operation of the catalytic converter.

Owner:DELPHI TECH INC

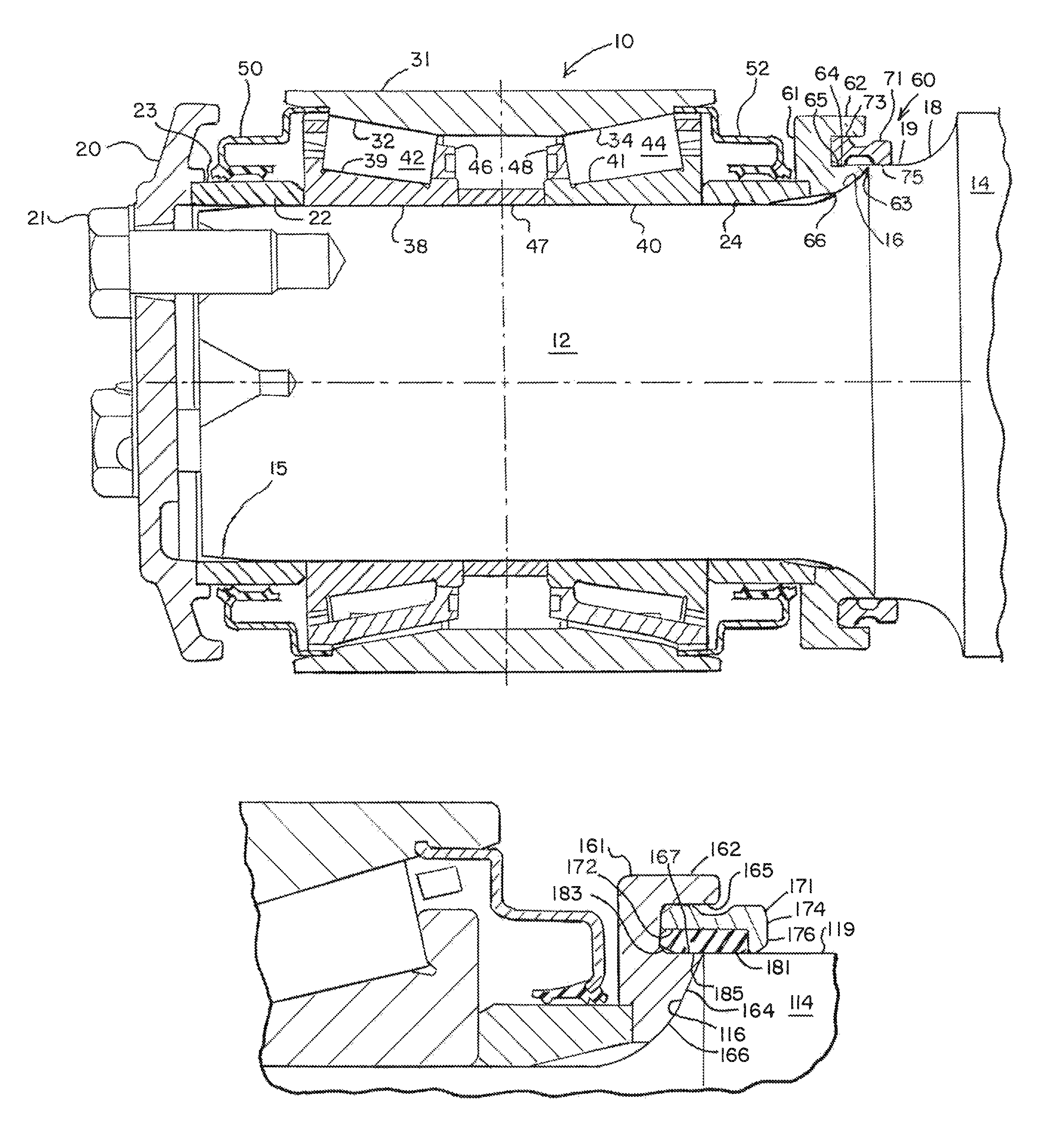

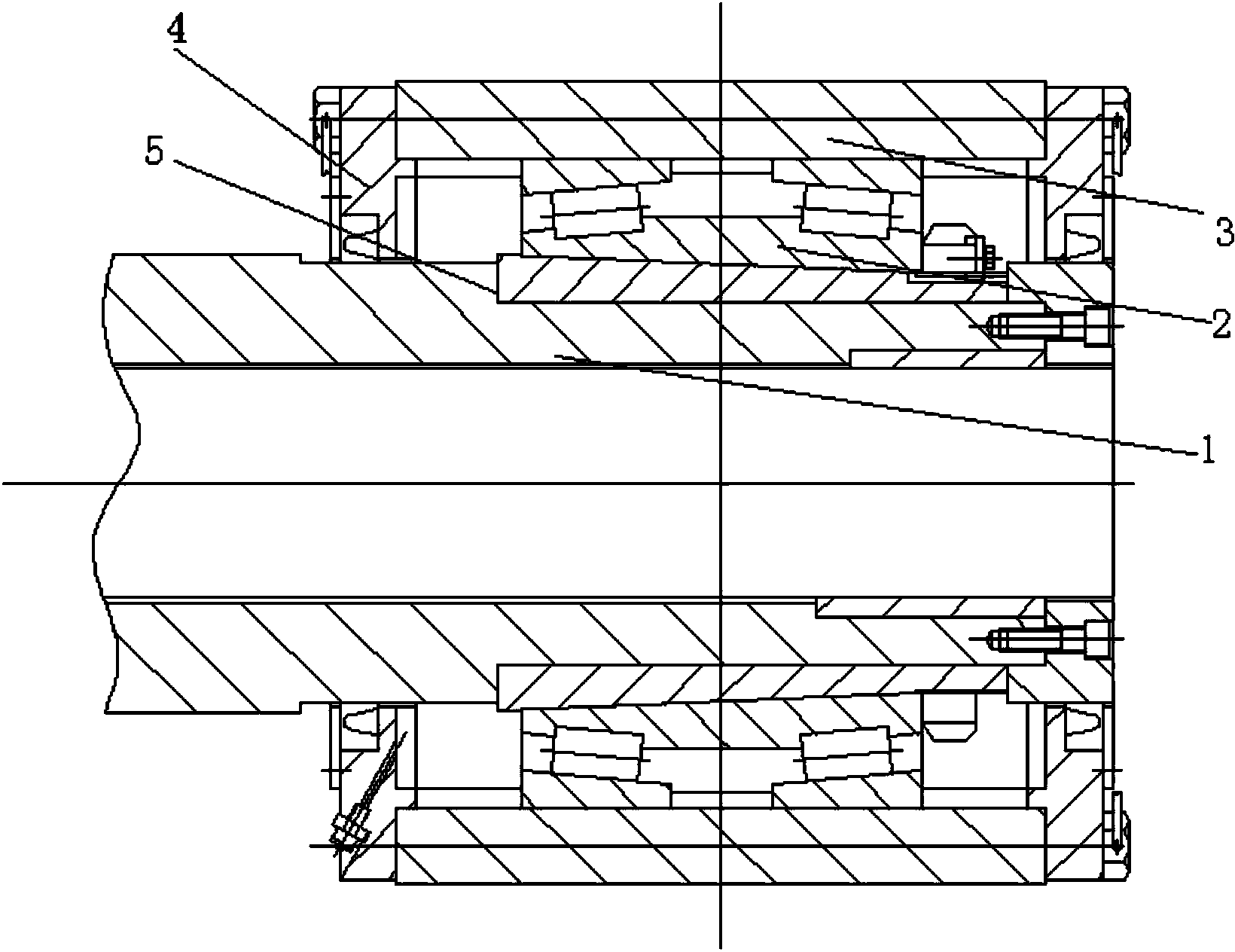

Roller bearing backing ring assembly

ActiveUS8696212B2Reduce axial movementReduced fretting wearRolling contact bearingsHubsEngineeringMechanical engineering

A novel assembly for a railcar axle bearing is presented. The assembly includes a backing ring affixed to the fillet of the journal of an axle and a locking ring for further affixing the backing ring the journal. The locking ring has an inboard end affixed to the dust guard of the axle and an outboard end for engaging the backing ring. The looking ring may include a resilient sealing ring.

Owner:AMSTED RAIL CO INC

Roller bearing backing ring

ActiveUS8226299B2Reduce axial movementReduced fretting wearRolling contact bearingsRailway vehiclesMechanical engineeringFretting wear

A novel two-piece backing ring assembly for a railcar axle is presented. The backing ring assembly has an annular body affixed to the fillet of the journal and a locking ring for further affixing the annular body into position on the journal. The locking ring has an inboard end affixed to the dust guard of the shaft and an outboard end for engaging a slot in the annular body. The locking ring assembly may be retrofitted to older generation railcar axles to increase the structural rigidity of the bearing assembly and minimize fretting wear caused by railcar axle deflection.

Owner:AMSTED RAIL CO INC

Roller bearing backing ring

ActiveUS20110064347A1Reduced fretting wearReduce axial movementRolling contact bearingsRailway vehiclesEngineeringOrbit

A novel two-piece backing ring assembly for a railcar axle is presented. The backing ring assembly has an annular body affixed to the fillet of the journal and a locking ring for further affixing the annular body into position on the journal. The locking ring has an inboard end affixed to the dust guard of the shaft and an outboard end for engaging a slot in the annular body. The locking ring assembly may be retrofitted to older generation railcar axles to increase the structural rigidity of the bearing assembly and minimize fretting wear caused by railcar axle deflection.

Owner:AMSTED RAIL CO INC

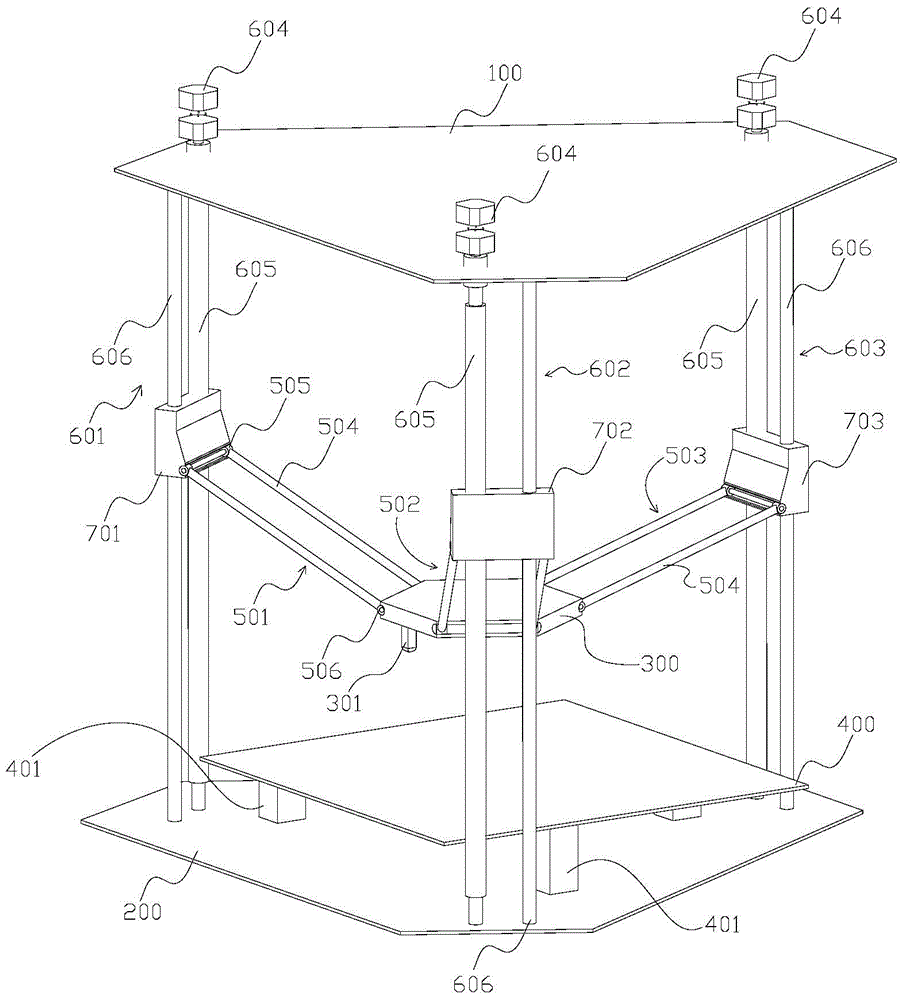

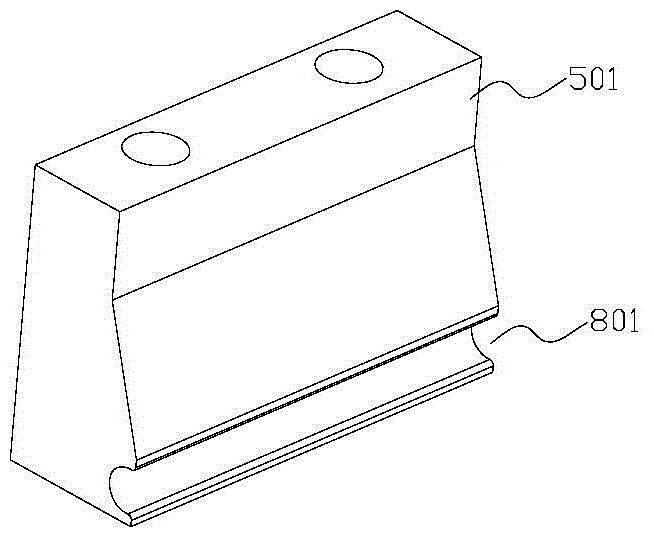

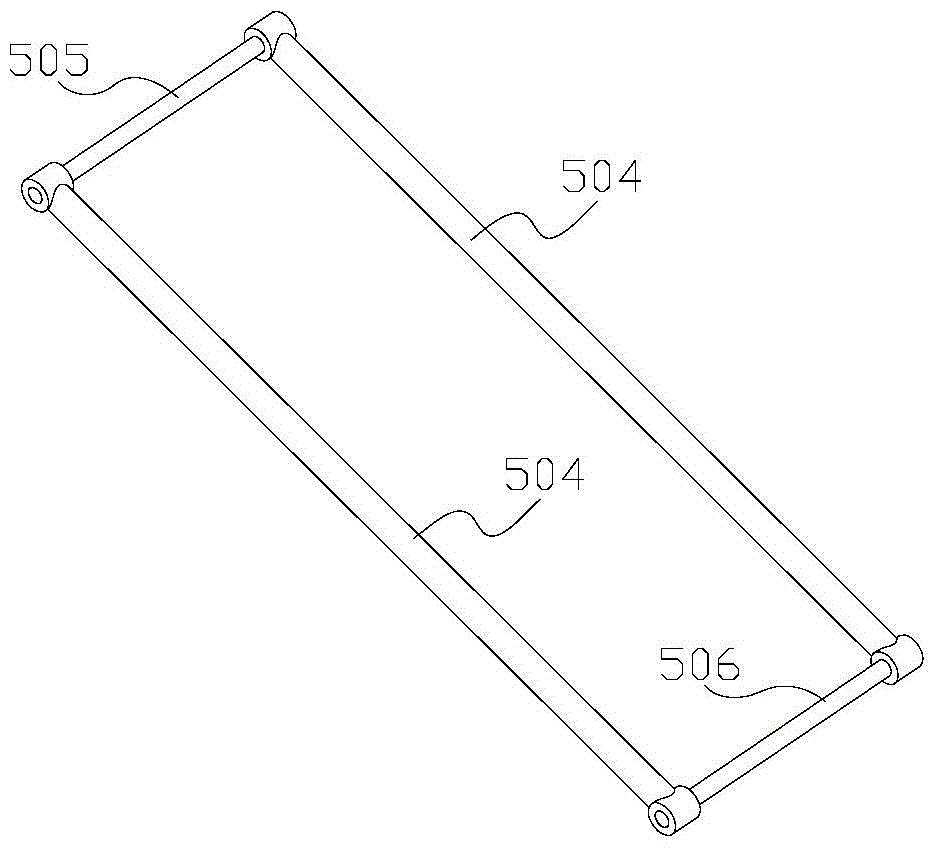

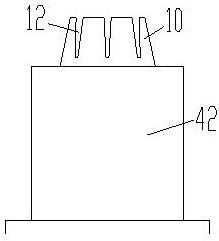

Universal movement mechanism of 3D printer

InactiveCN103552386AIncrease printing speedReduce axial movementPower drive mechanismsResonanceEngineering

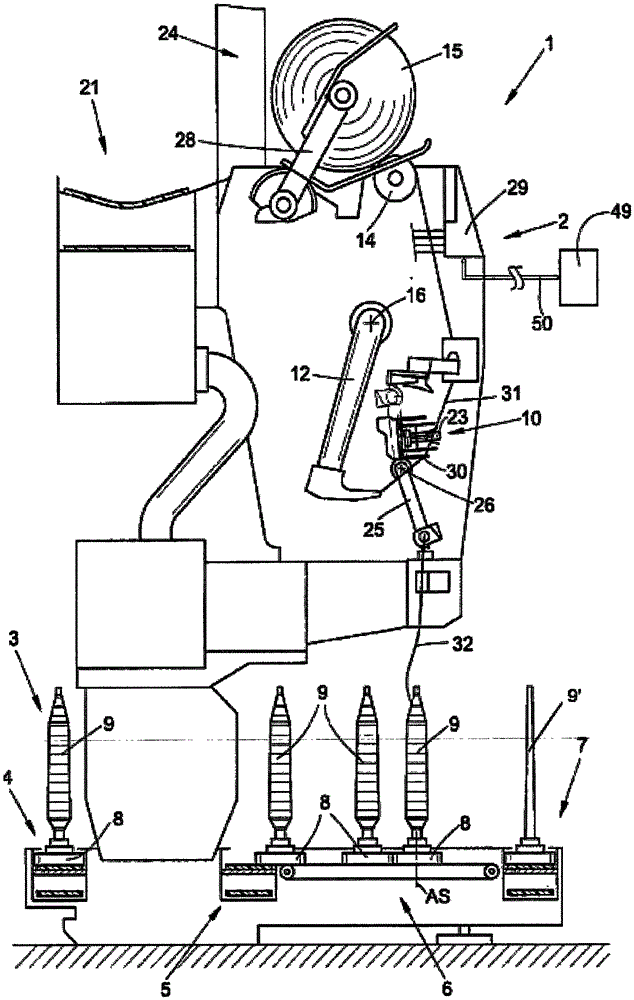

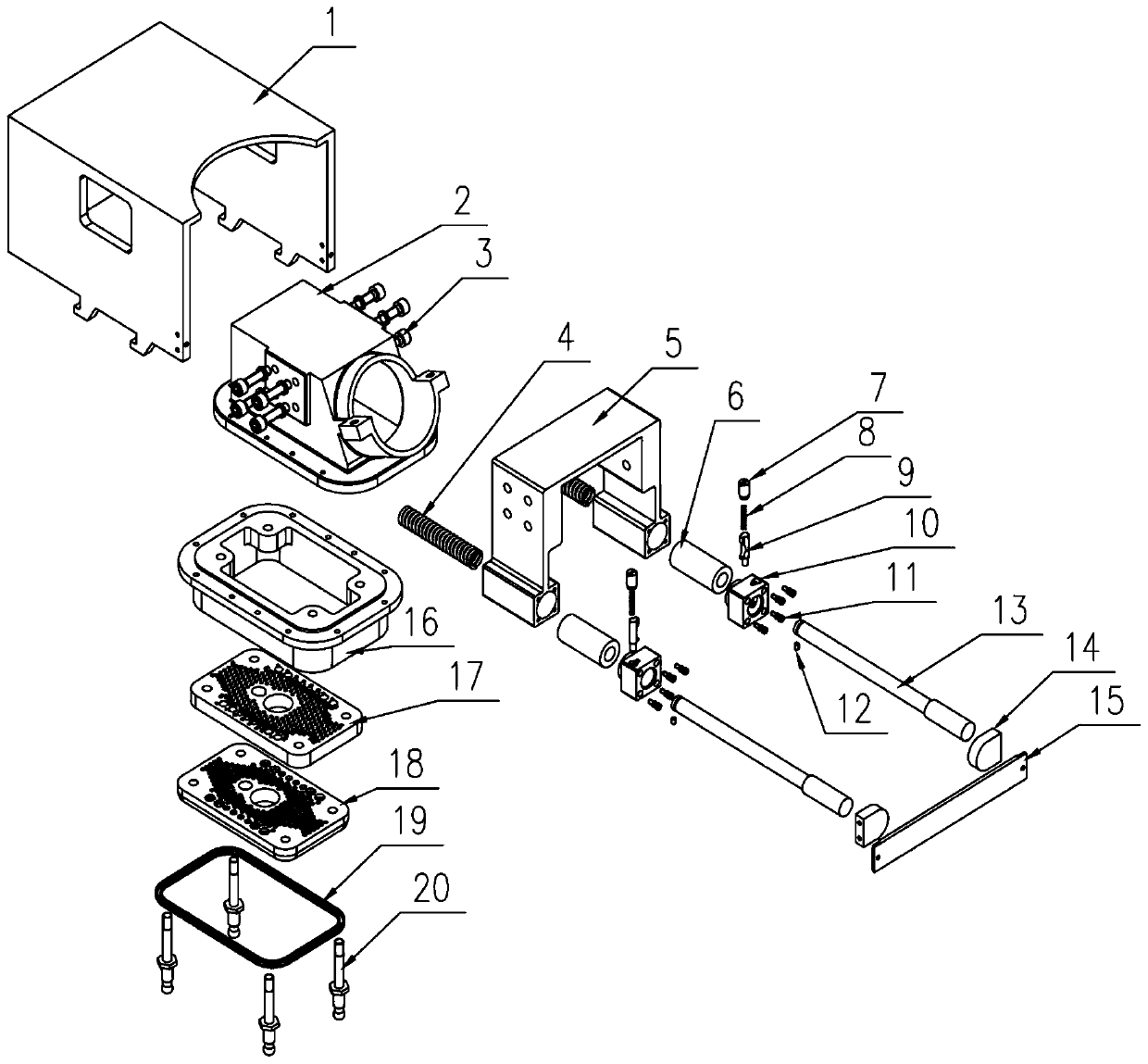

The invention discloses a universal movement mechanism of a 3D printer. The universal movement mechanism of the 3D printer comprises a mechanism top, a mechanism bottom, a material extrusion device and a workbench. The workbench is arranged between the mechanism top and the mechanism bottom, and the material extrusion device is placed above the upper surface of the workbench. Three sets of universal rotating components and three sets of transmission components are further included, and the transmission components are sleeved with sliding blocks which can slide up and down. The three sets of transmission components are installed between the mechanism top and the mechanism bottom at intervals. The sliding blocks are connected with the material extrusion device through the universal rotating components and the material extrusion device. According to the universal movement mechanism of the 3D printer, only the Z-axis direction is reserved, by the aid of the scheme, the printing speed can be increased substantially, and moreover due to the fact that two axial movements are reduced, the problems of resonance and noise are solved.

Owner:JIANGXI WOXIANG INDUSTRAL CO LTD

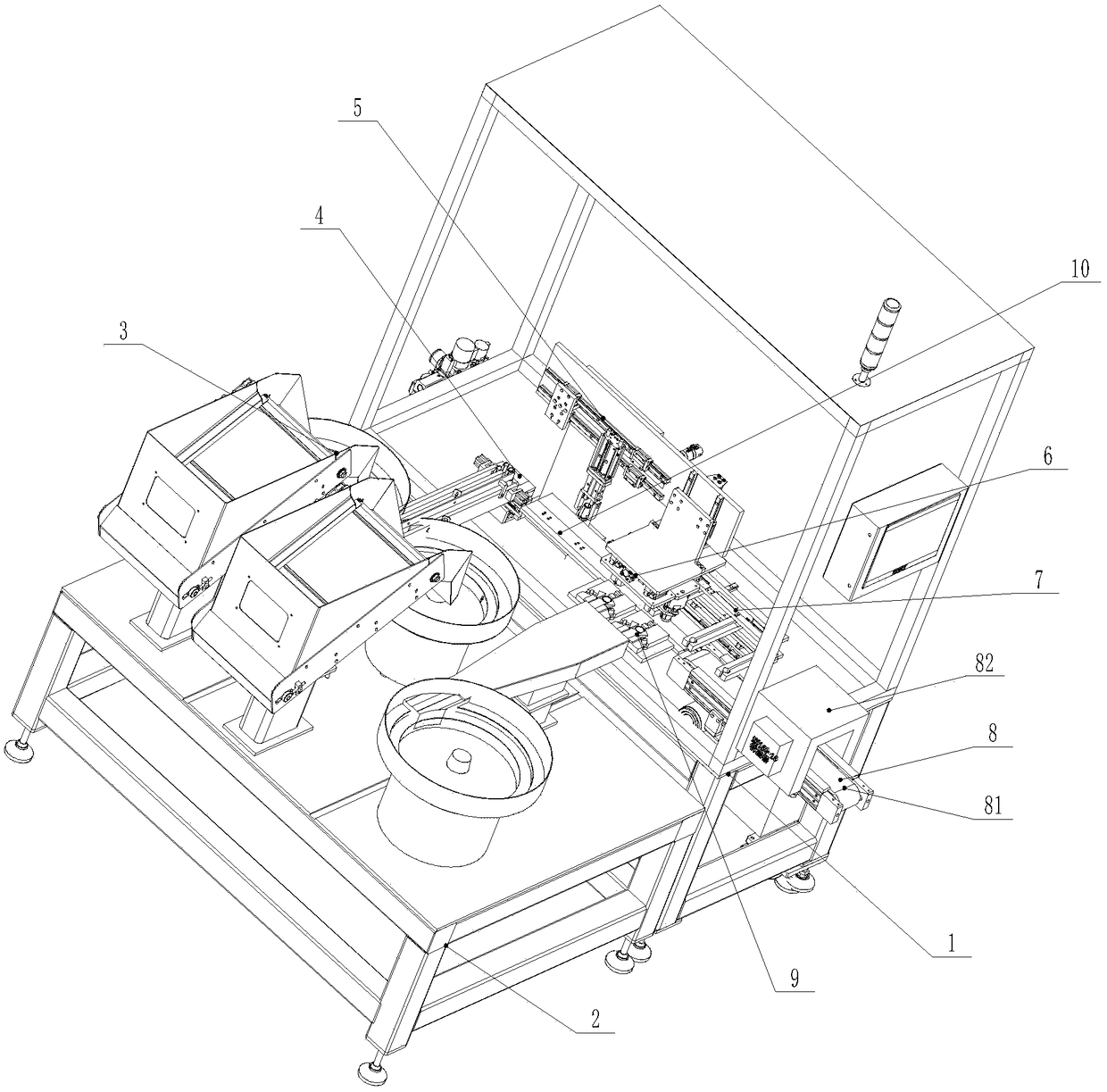

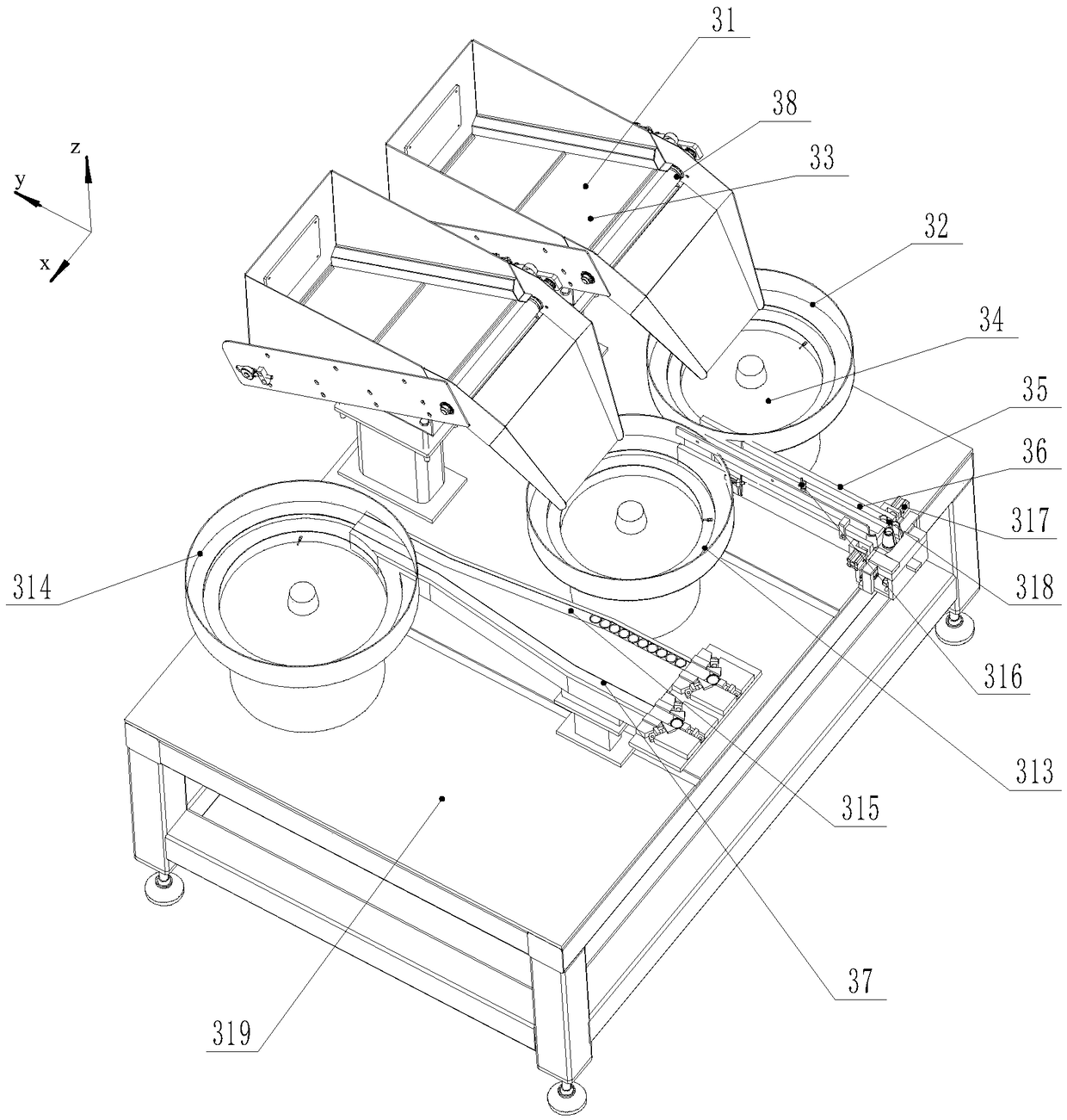

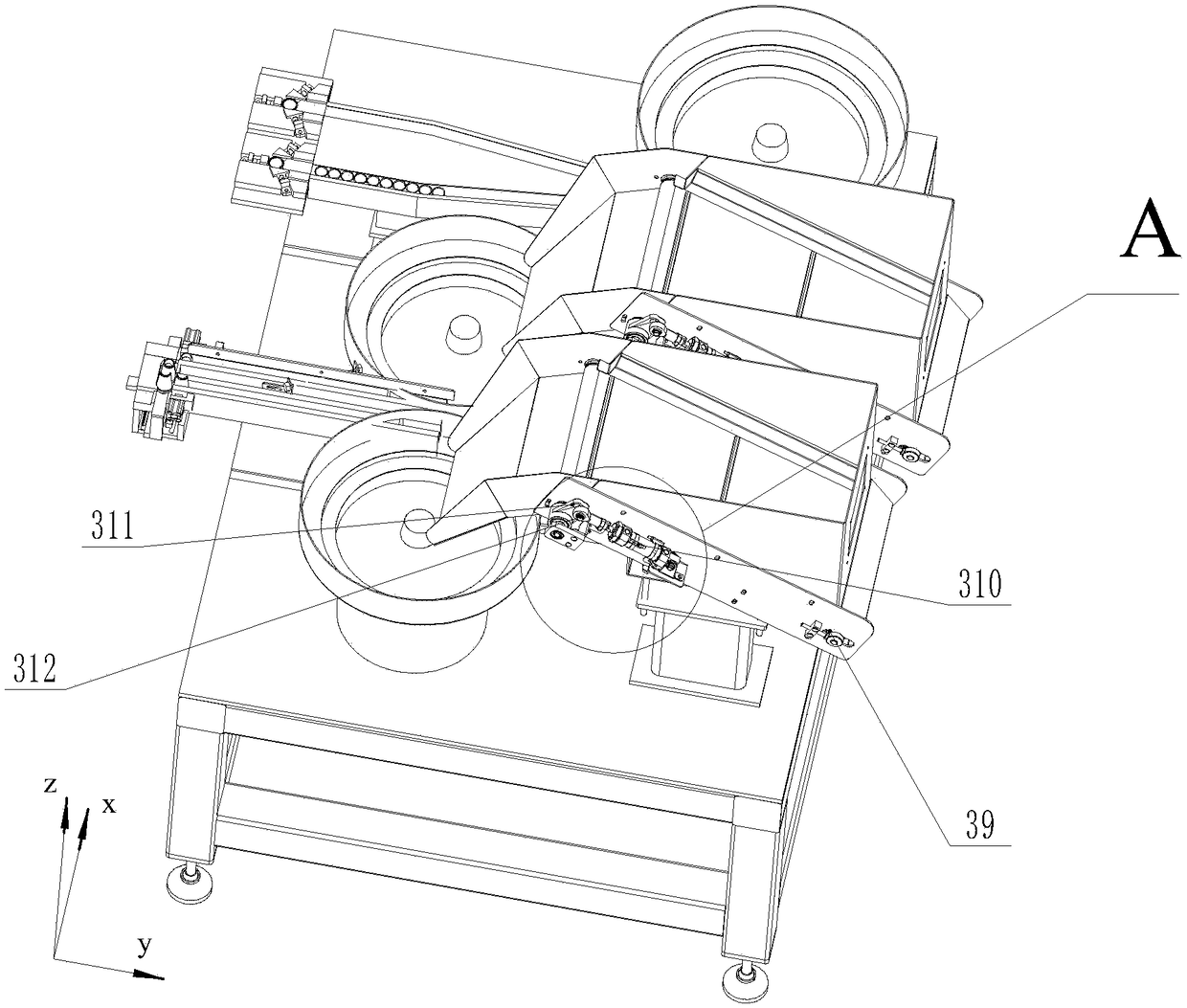

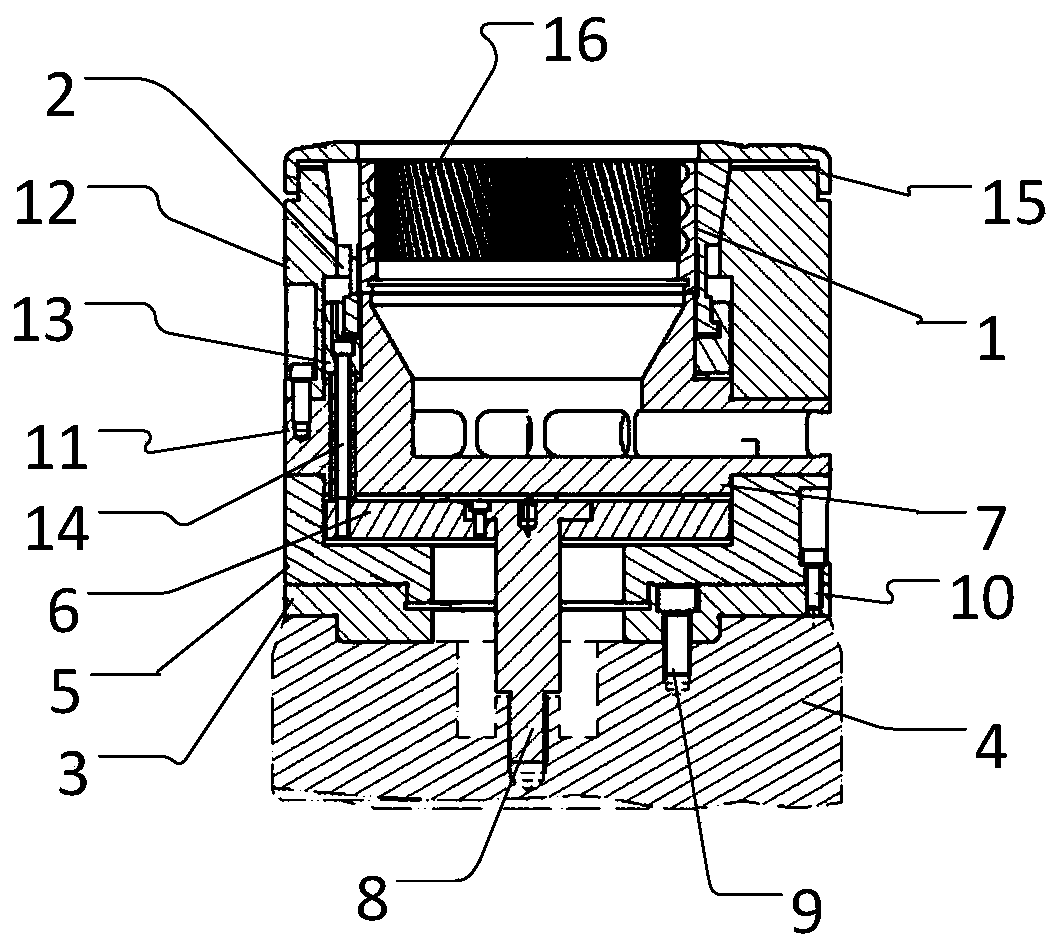

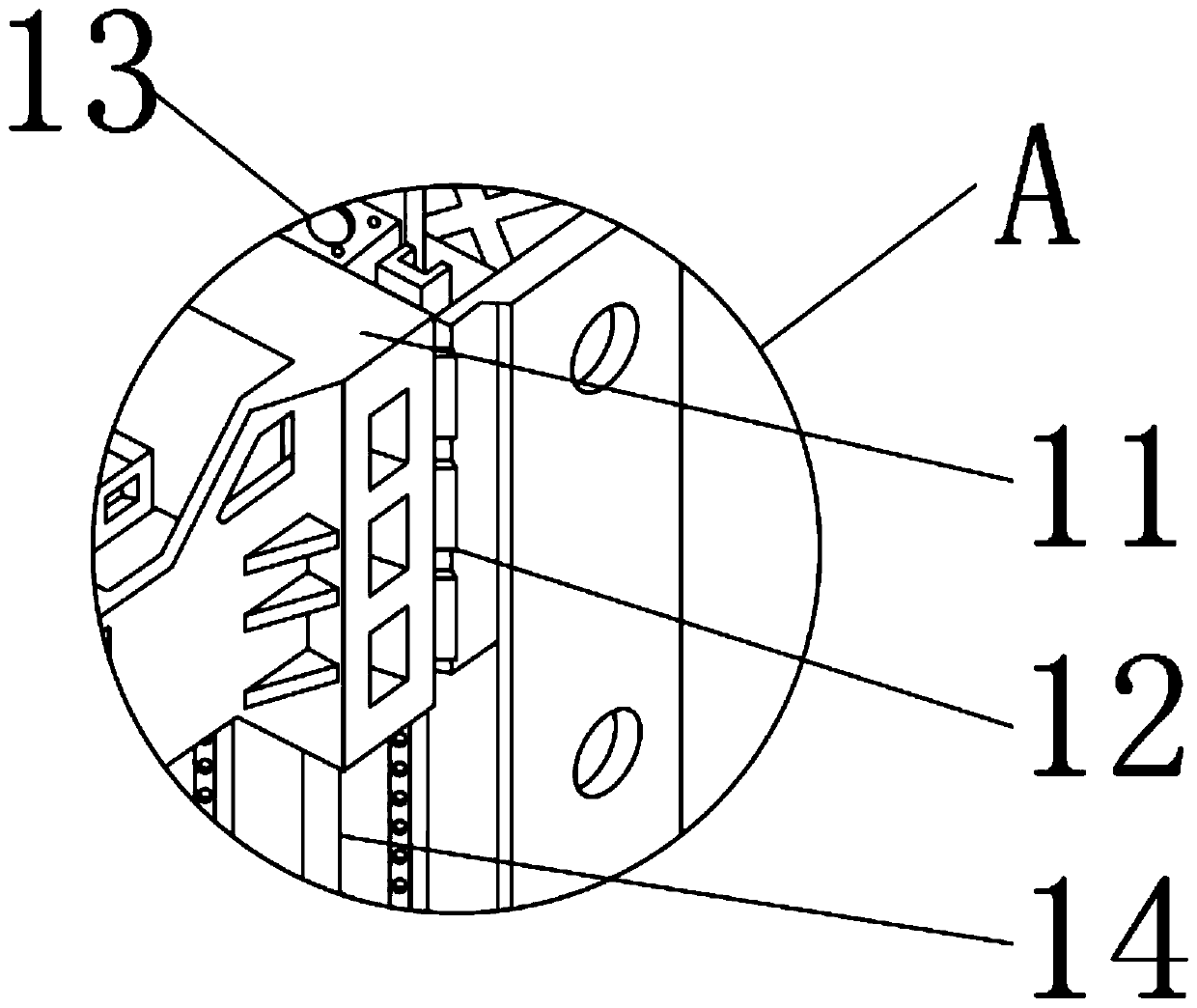

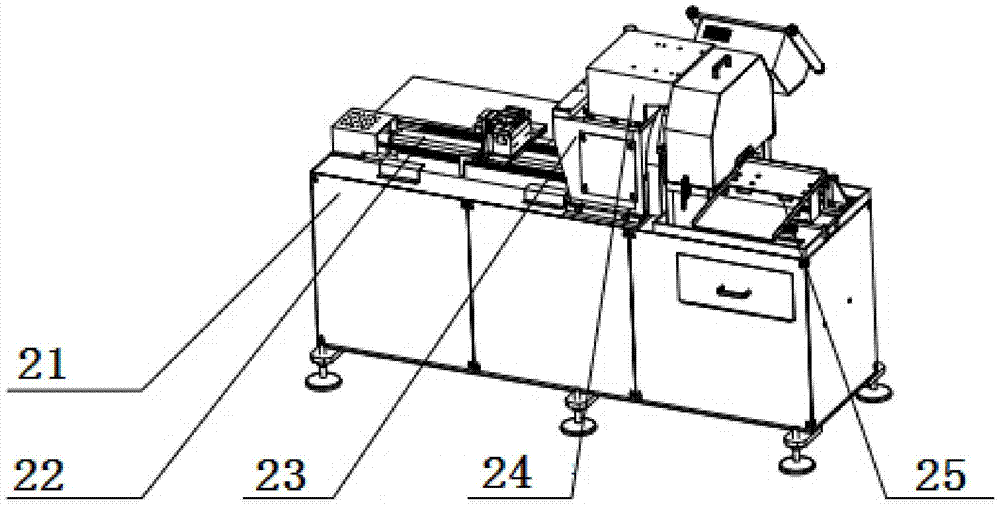

O-ring sleeving pack mechanism and operation method thereof

PendingCN109352297AReduce axial movementImprove stabilityMetal working apparatusEngineeringManipulator

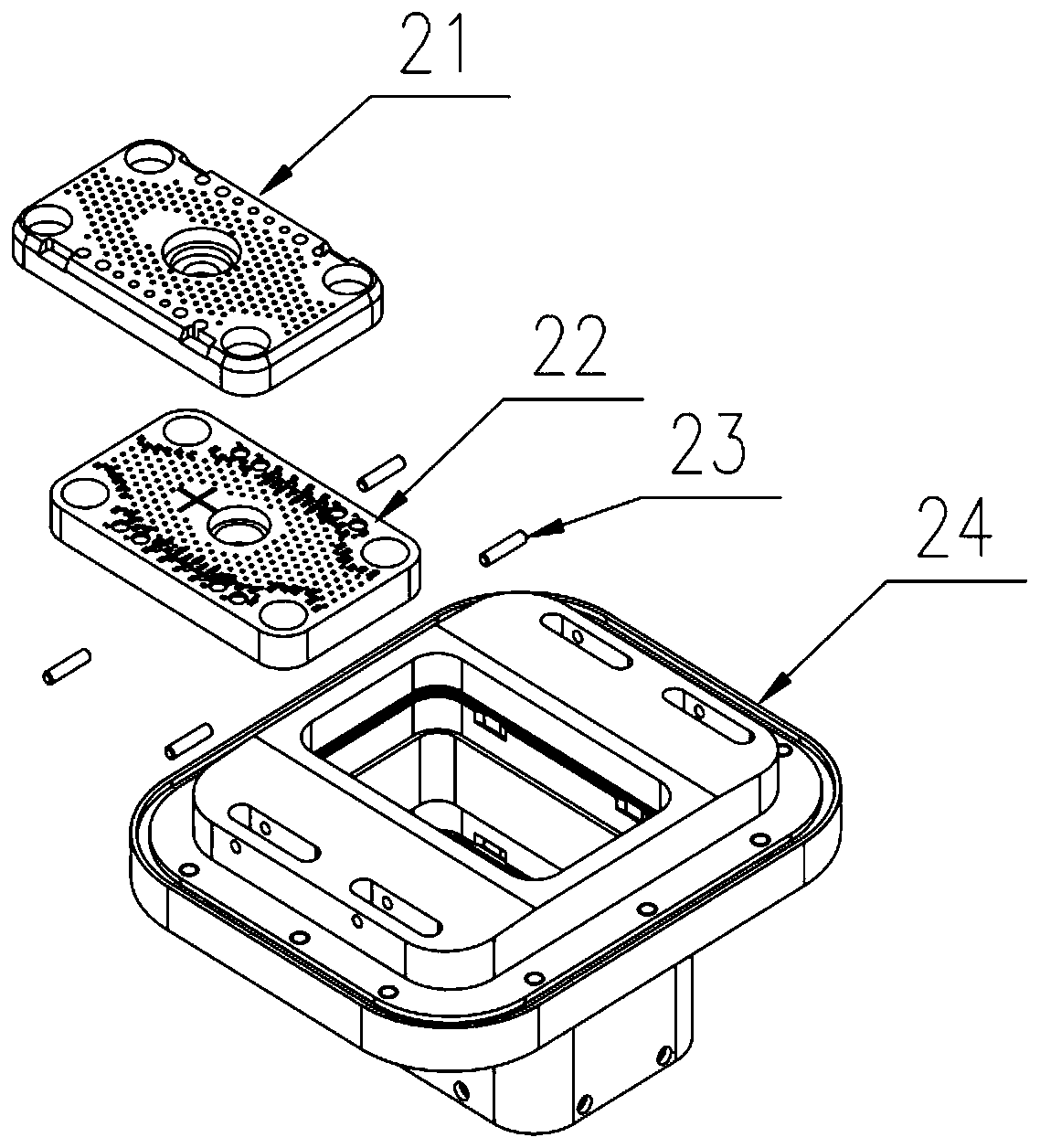

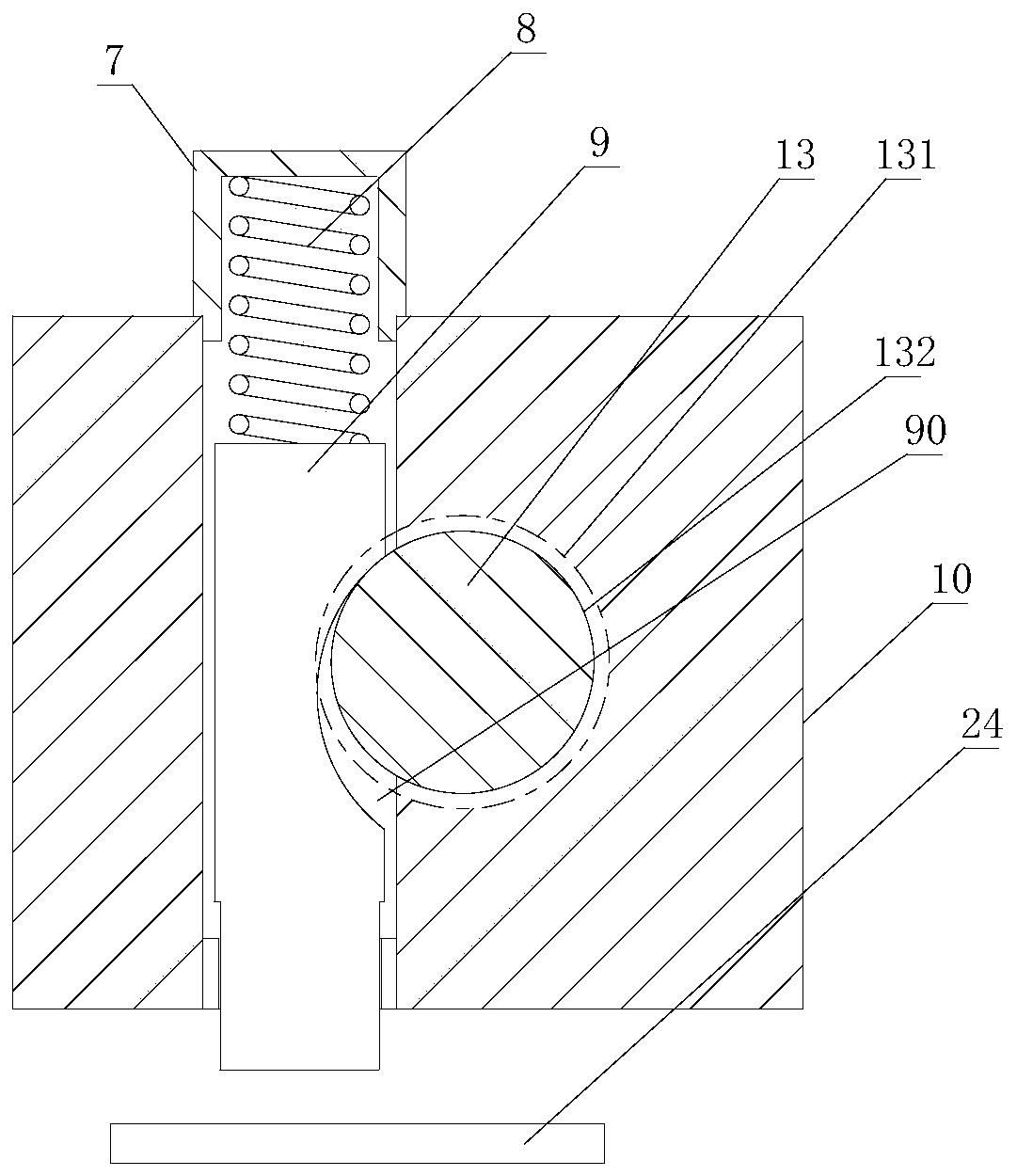

The invention provides an O-ring sleeving pack mechanism. The O-ring sleeving pack mechanism comprises a bottom support frame and an O-ring feeding platform. A manipulator mounting plate is arranged on the bottom support frame. A lifting sliding rail is in the z-axis direction, and is arranged on one surface, close to the O-ring feeding platform, of the manipulator mounting plate. A transit connecting plate is arranged on the lifting sliding rail and driven by the lifting sliding rail to slide along the lifting sliding rail. A slab is arranged on the lower portion of the transit connecting plate. A straight sliding rail extends in the direction of the z-axis, and is fixedly arranged on one surface, away from the transit connecting plate, of the slab. A three-jaw cylinder expanding mechanism used for expanding an O-ring and is connected with the straight sliding rail. A translation cylinder drives the three-jaw cylinder expanding mechanism to slide at the y-axis along the straight sliding rail. The O-ring sleeving pack mechanism has high degree of automation, high accuracy of O-ring sleeving packing, high production efficiency, and no damage to the O-ring.

Owner:湖北火爆机器人科技有限公司

Roller bearing backing ring assembly

InactiveCN102619881AReduce axial movementReduced fretting wearRolling contact bearingsRailway vehiclesMechanical engineeringRoller bearing

A novel assembly for a railcar axle bearing is presented. The assembly includes a backing ring affixed to the fillet of the journal of an axle and a locking ring for further affixing the backing ring the journal. The locking ring has an inboard end affixed to the dust guard of the axle and an outboard end for engaging the backing ring.

Owner:AMSTED RAIL CO INC

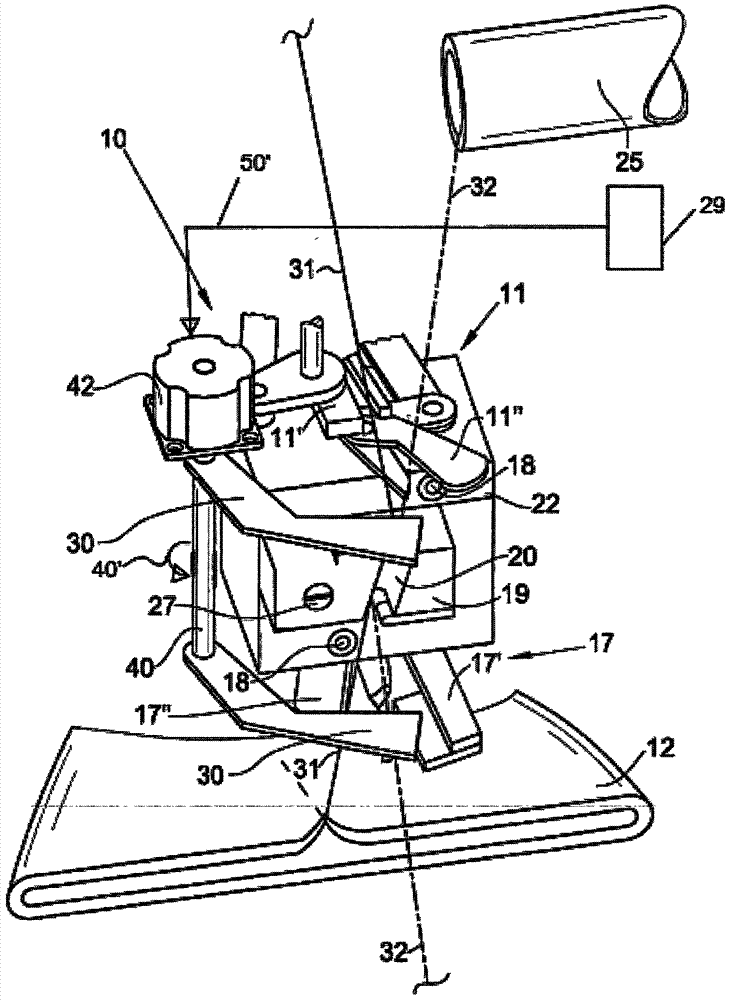

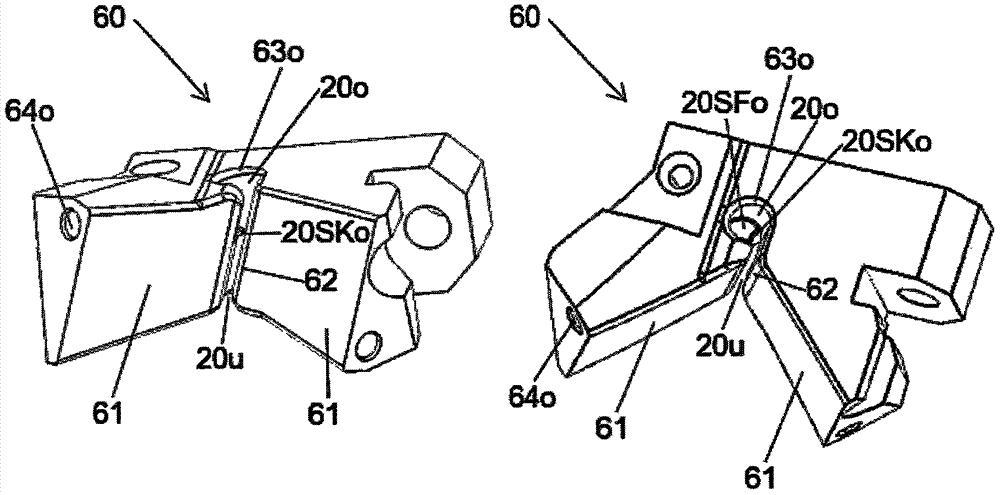

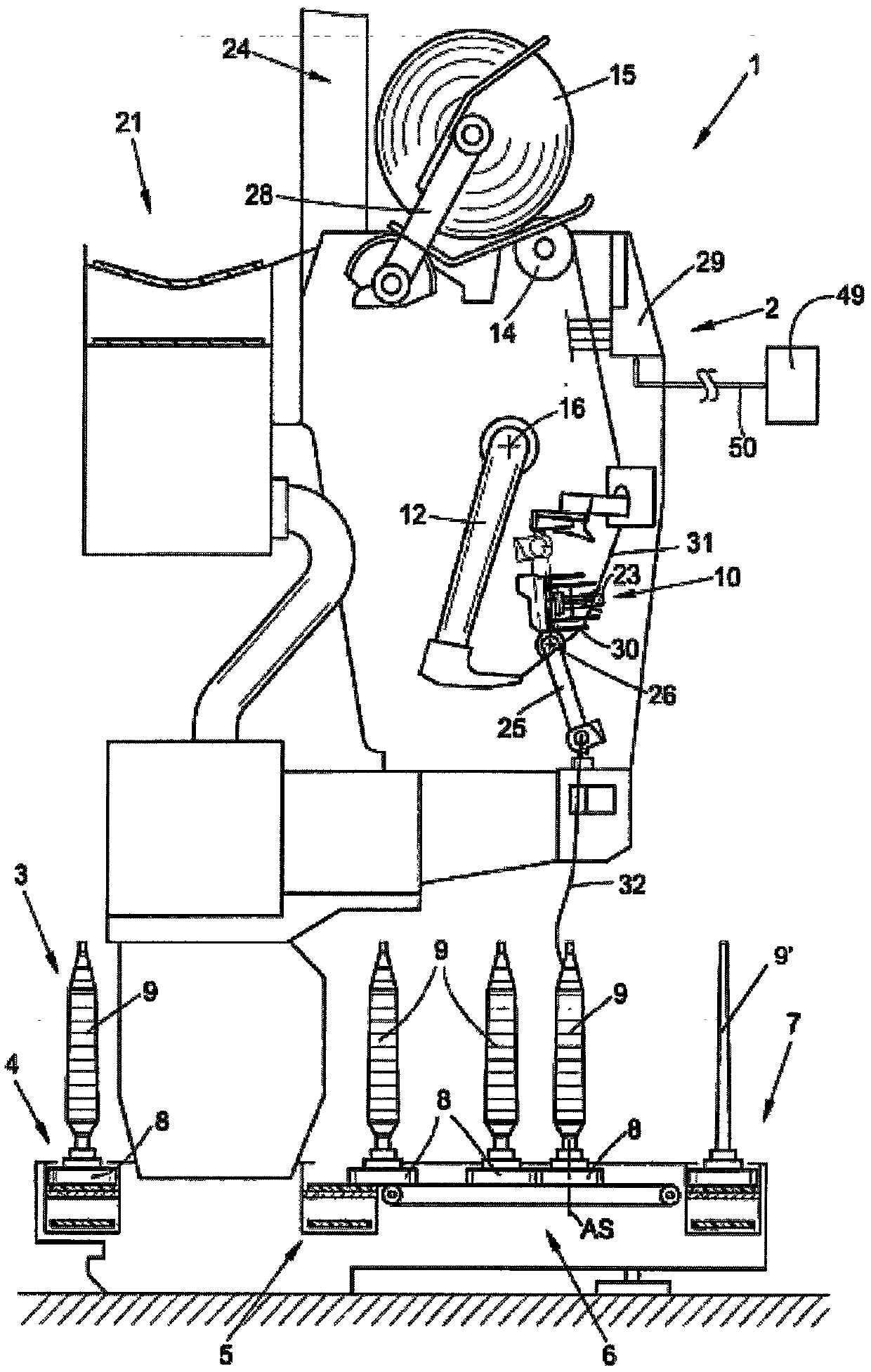

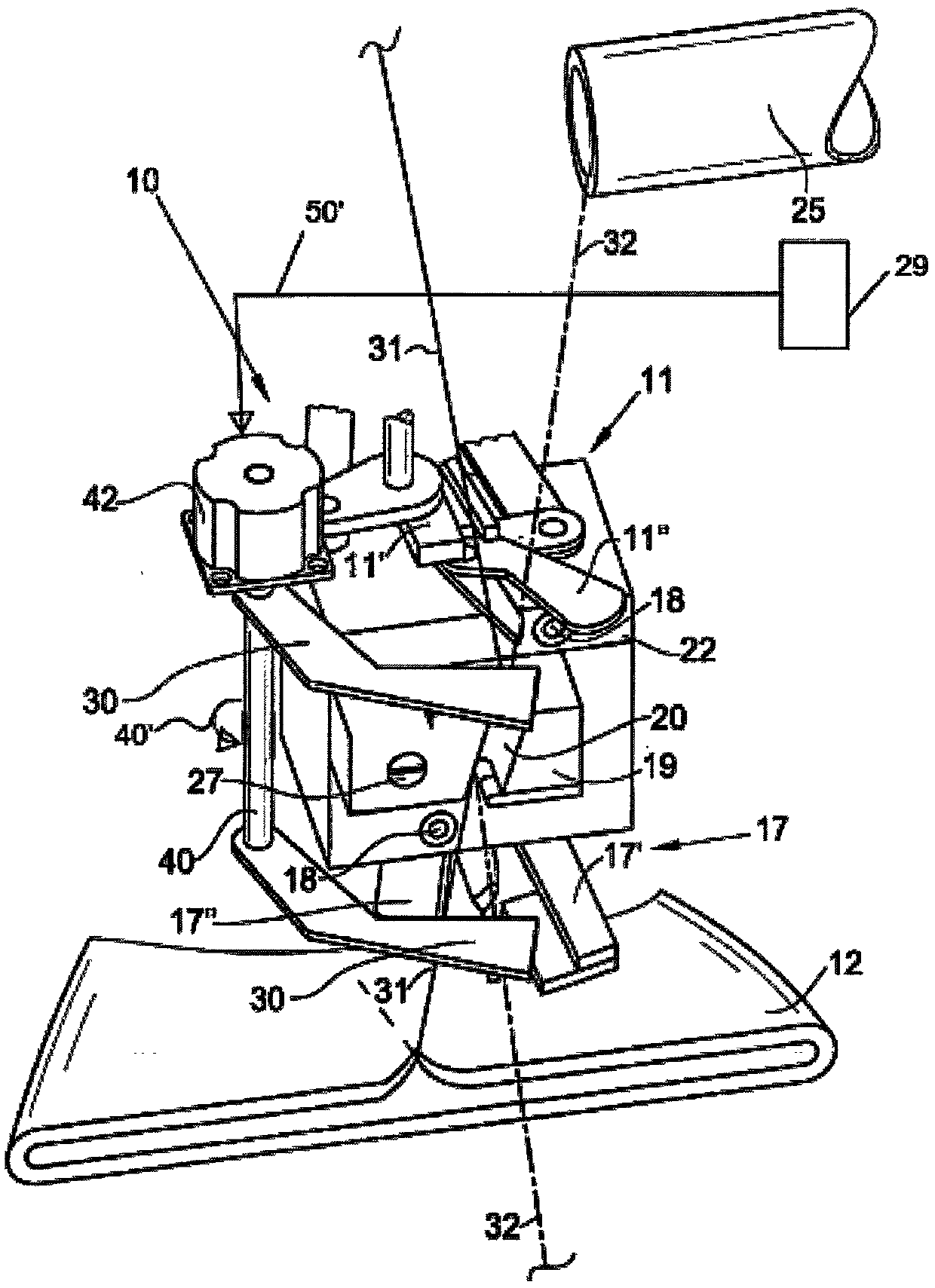

Splice channel unit, splicer and textile machine

ActiveCN105696127AReduce radialReduce riskFilament handlingContinuous wound-up machinesElectrical and Electronics engineeringTextile

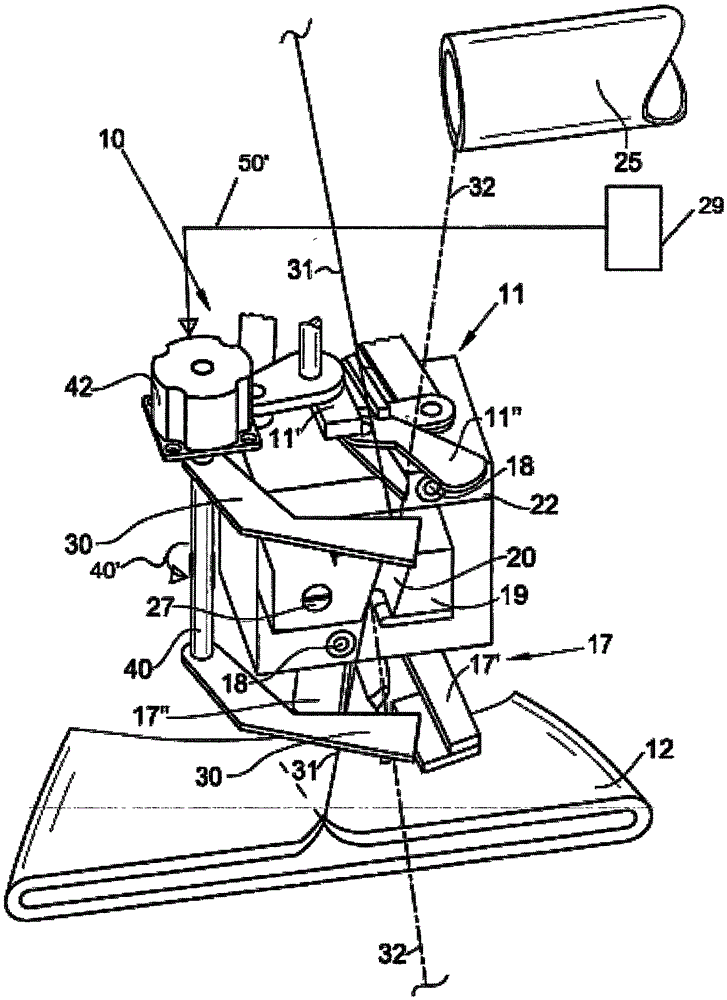

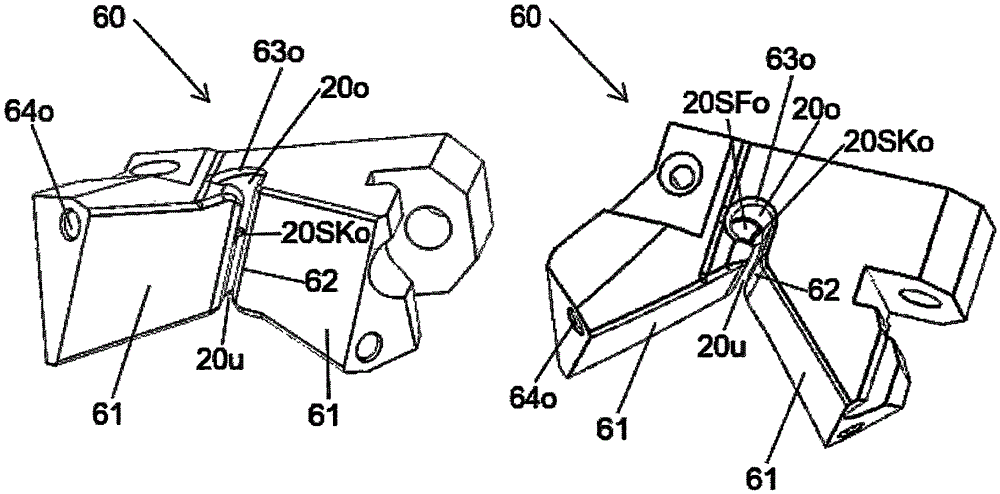

The invention relates to a splice channel unit, a splicer and a textile machine. Here, air inlet ducts (660, 66u) are especially designed to be a splice channel (20) injecting splice air into the splice channel unit (60). According to specific variants of the splice channel unit, the splice channel unit has a) the minimum of the length l of a portion (69o, 69u) near outlets and the minimum of the diameter d of the outlets (70o, 70u) communicated with the splice channel (20), b) a value of the ratio r<ld>=l / d exceeding the minimums, wherein the portion (69o, 69u) near the outlets must basically not have structures which may prevent the splice air from flowing under the condition a) and the condition b), or c) the air inlet ducts (660, 66u) designed to enable the splice air to form a laminar flow imported to the splice channel (20) before the outlets (70o, 70u) of the splice channel (20) of the air inlet ducts when the splice air flows through the splice channel.

Owner:SAURER GERMANY GMBH & CO KG

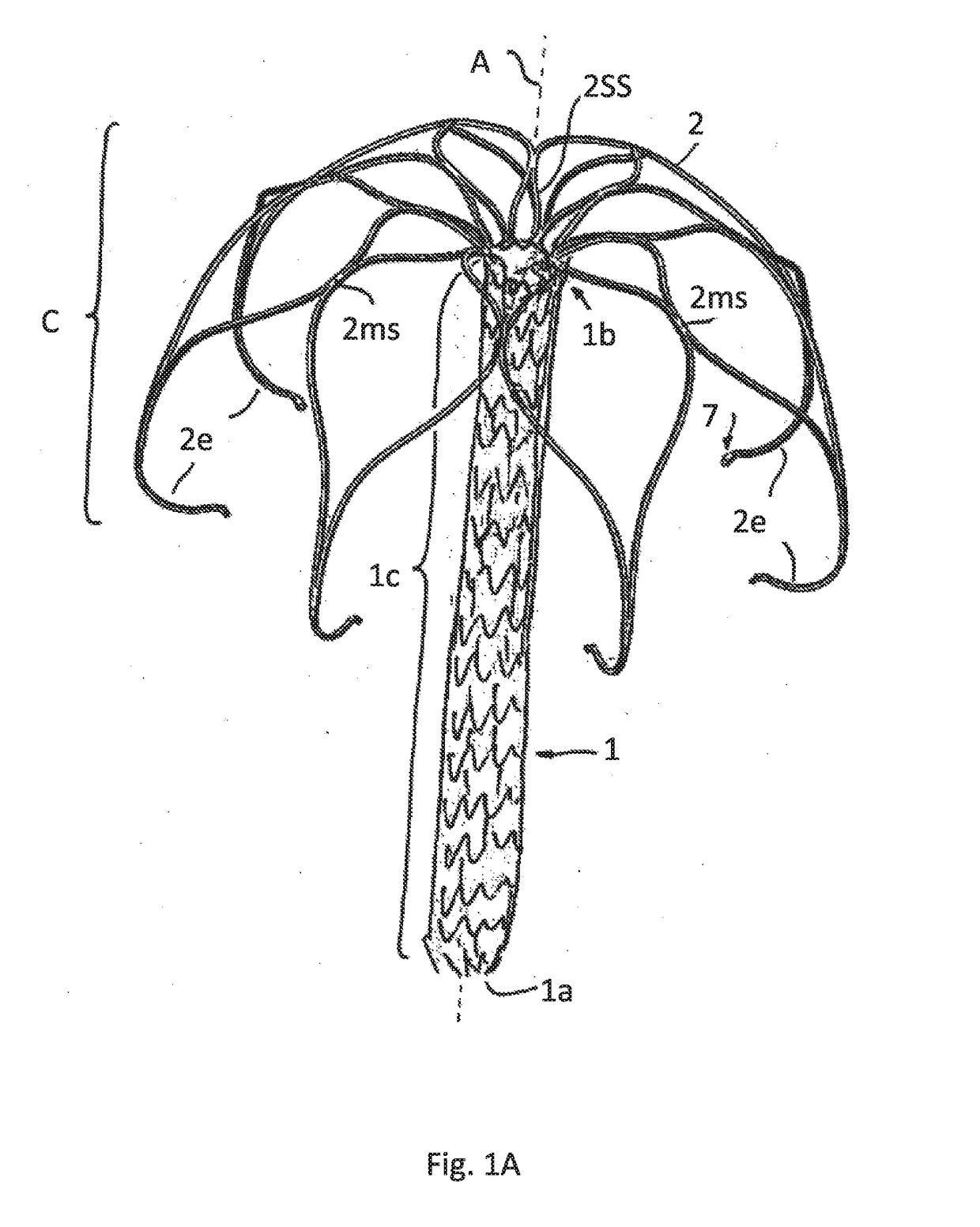

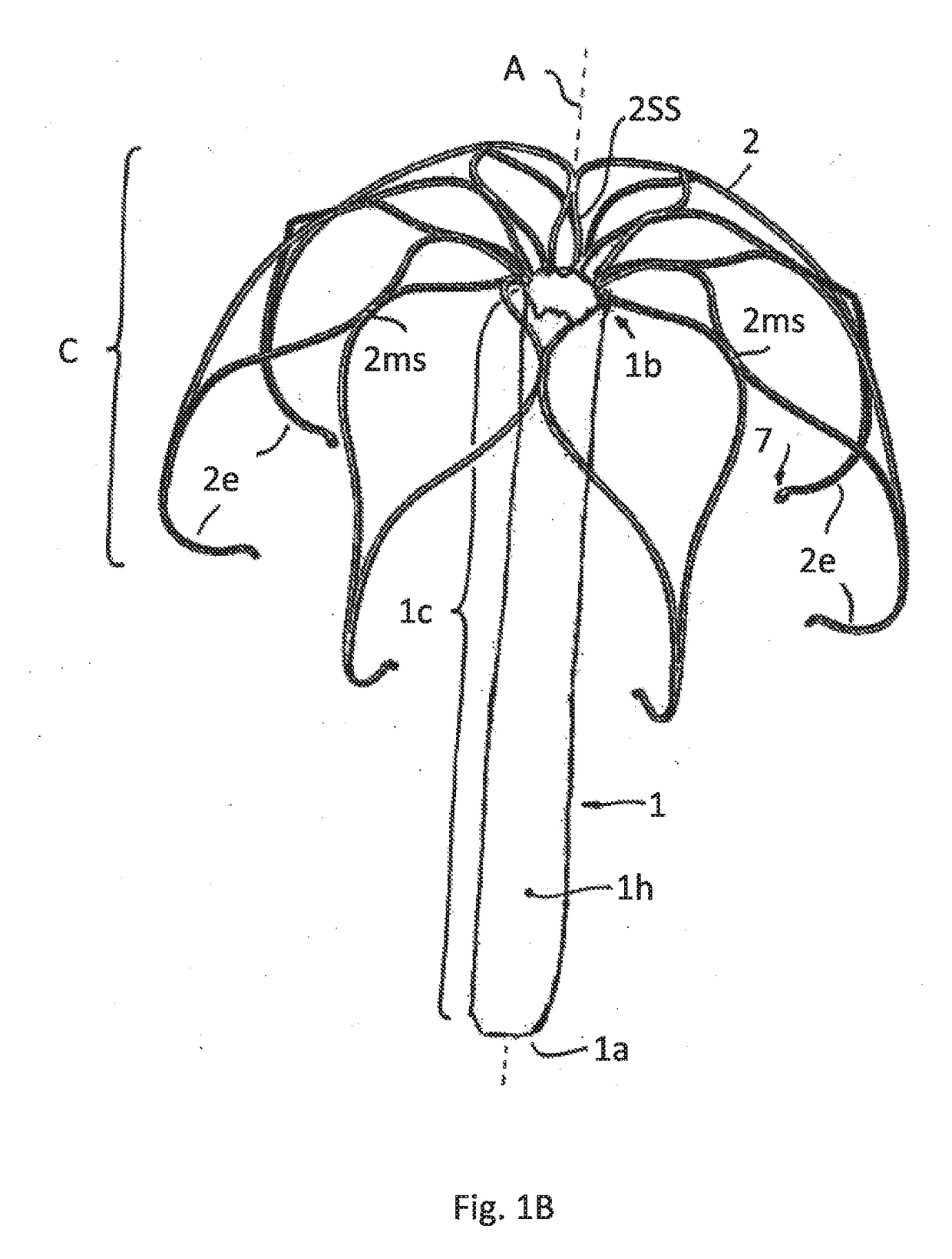

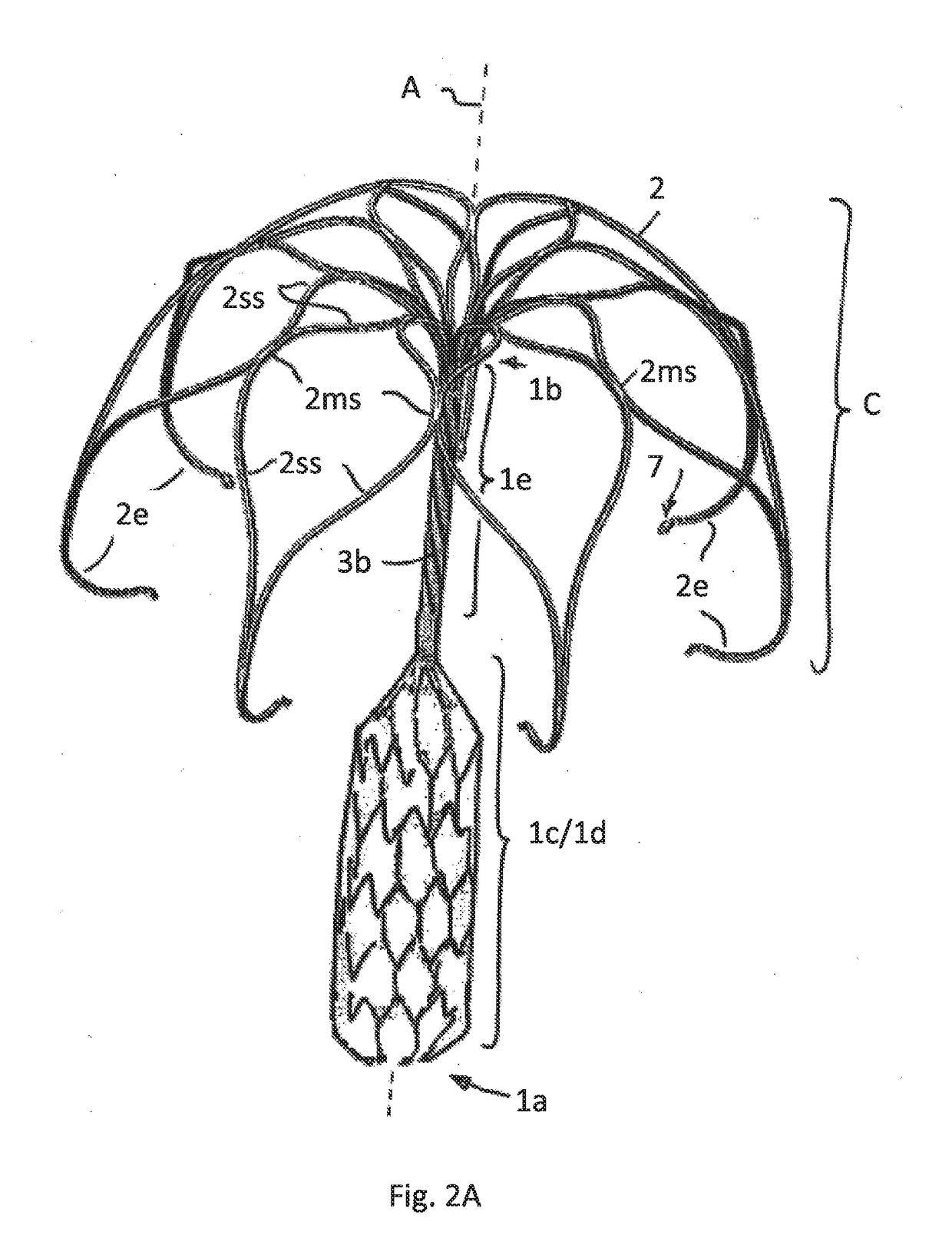

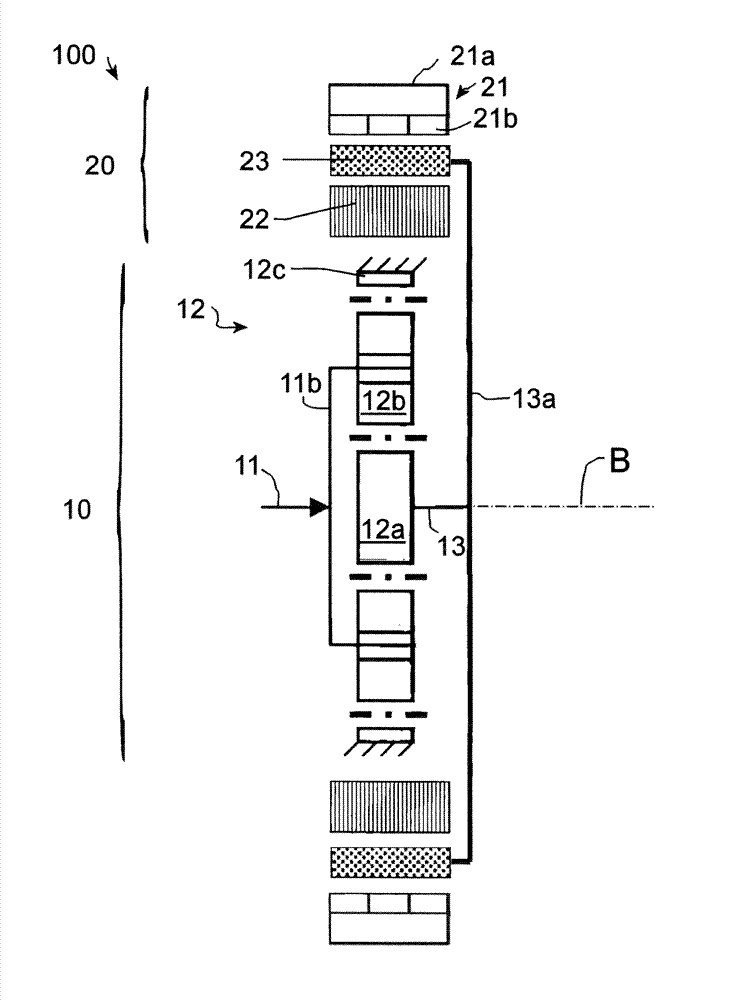

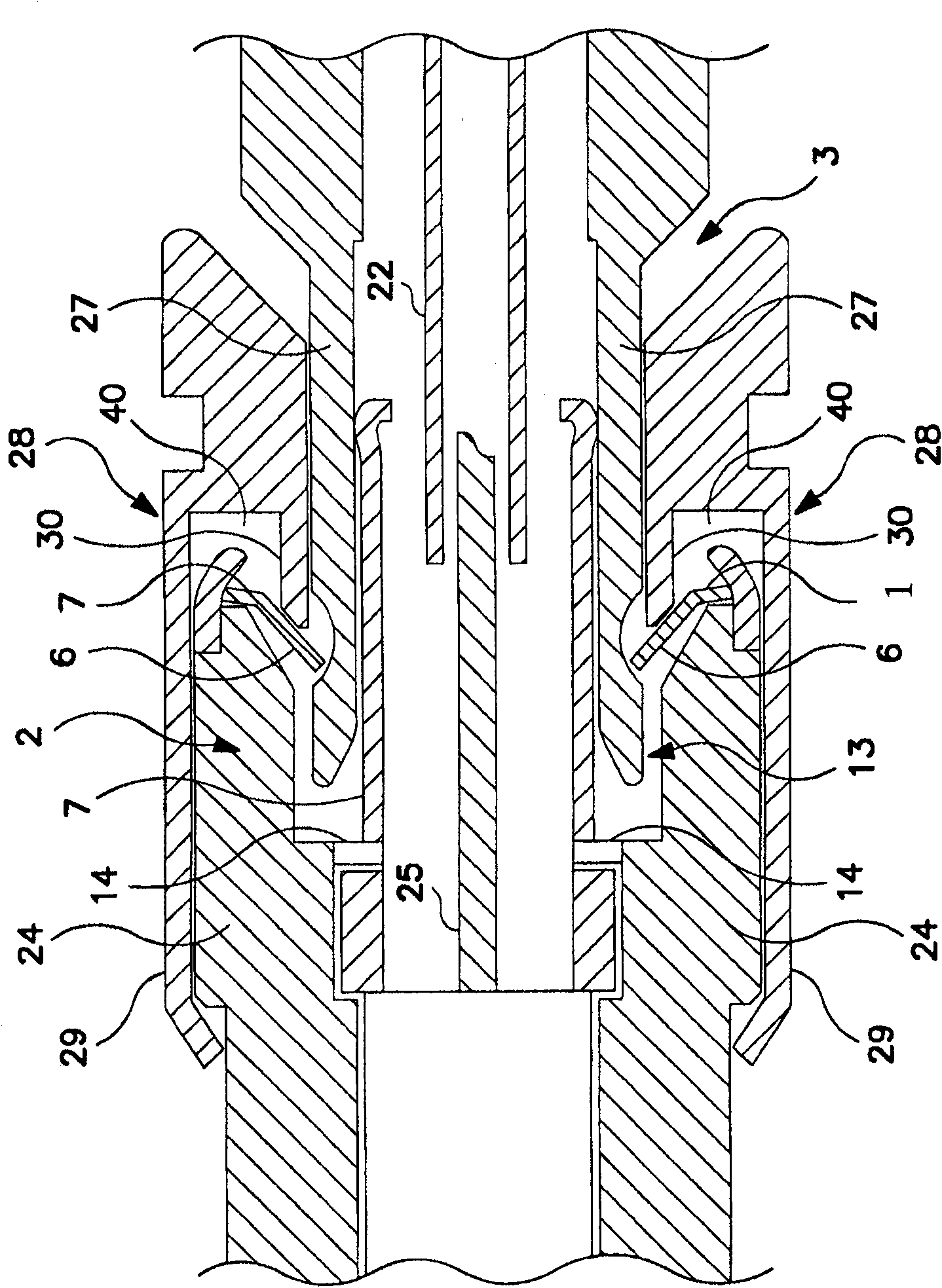

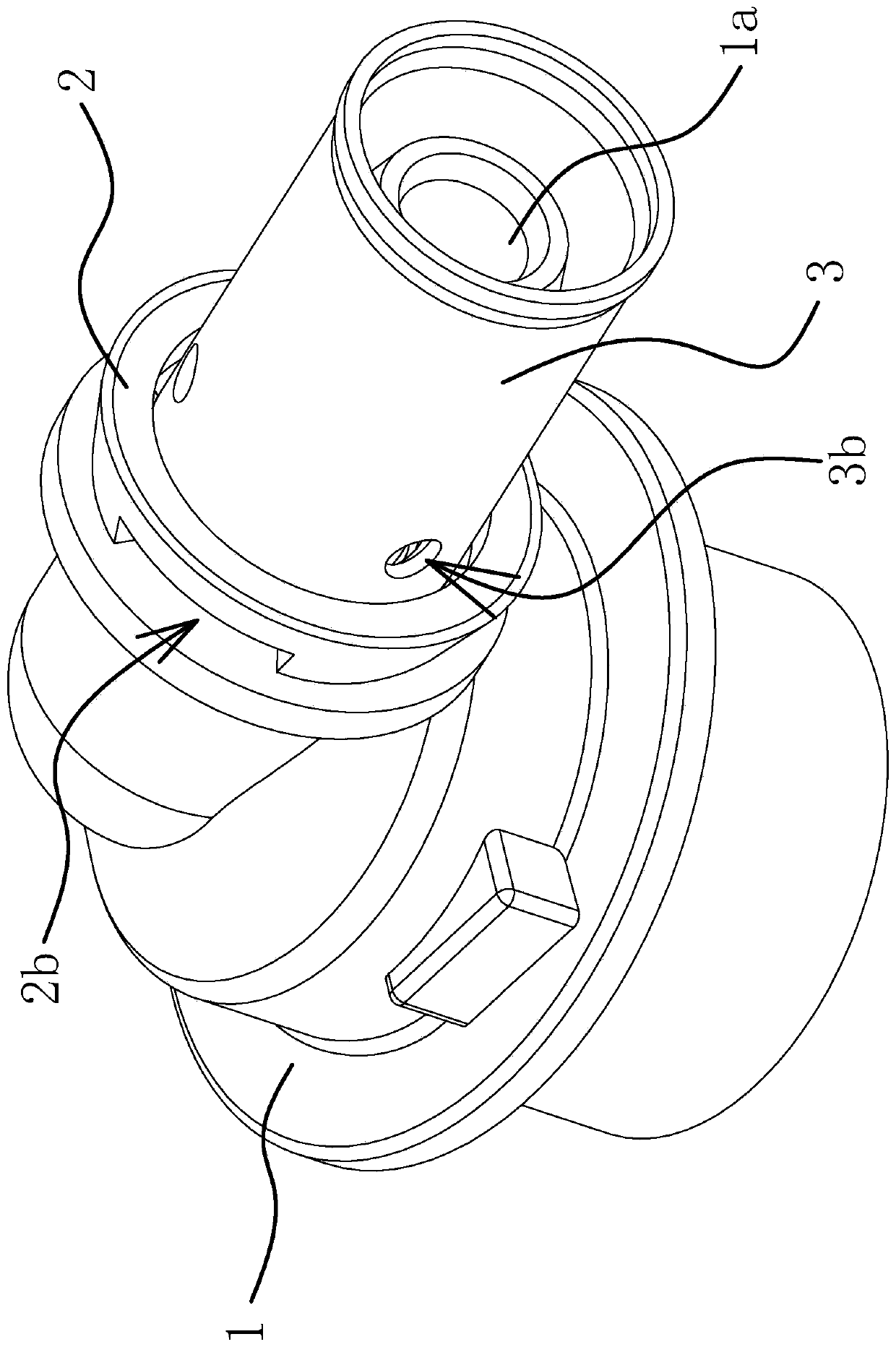

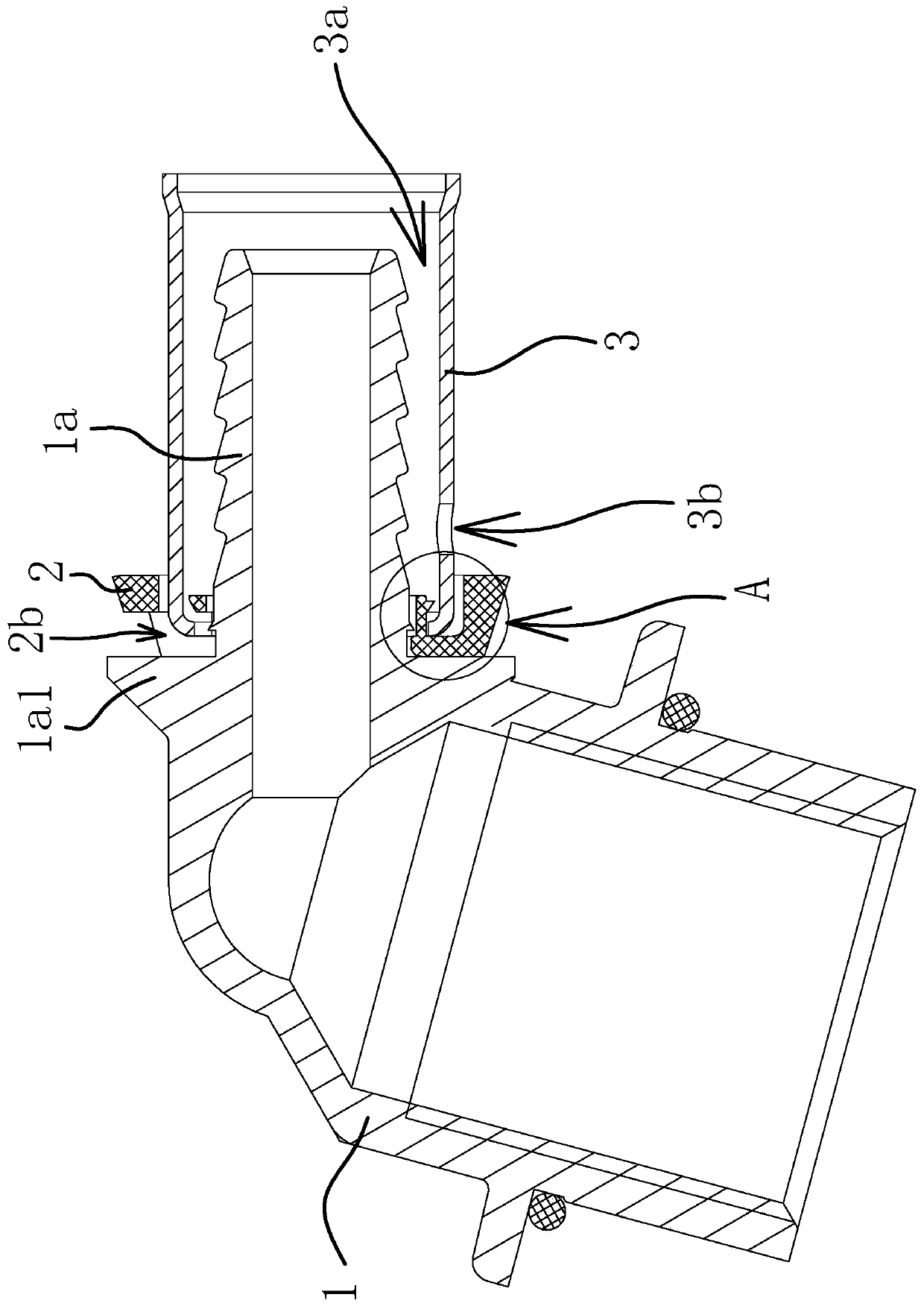

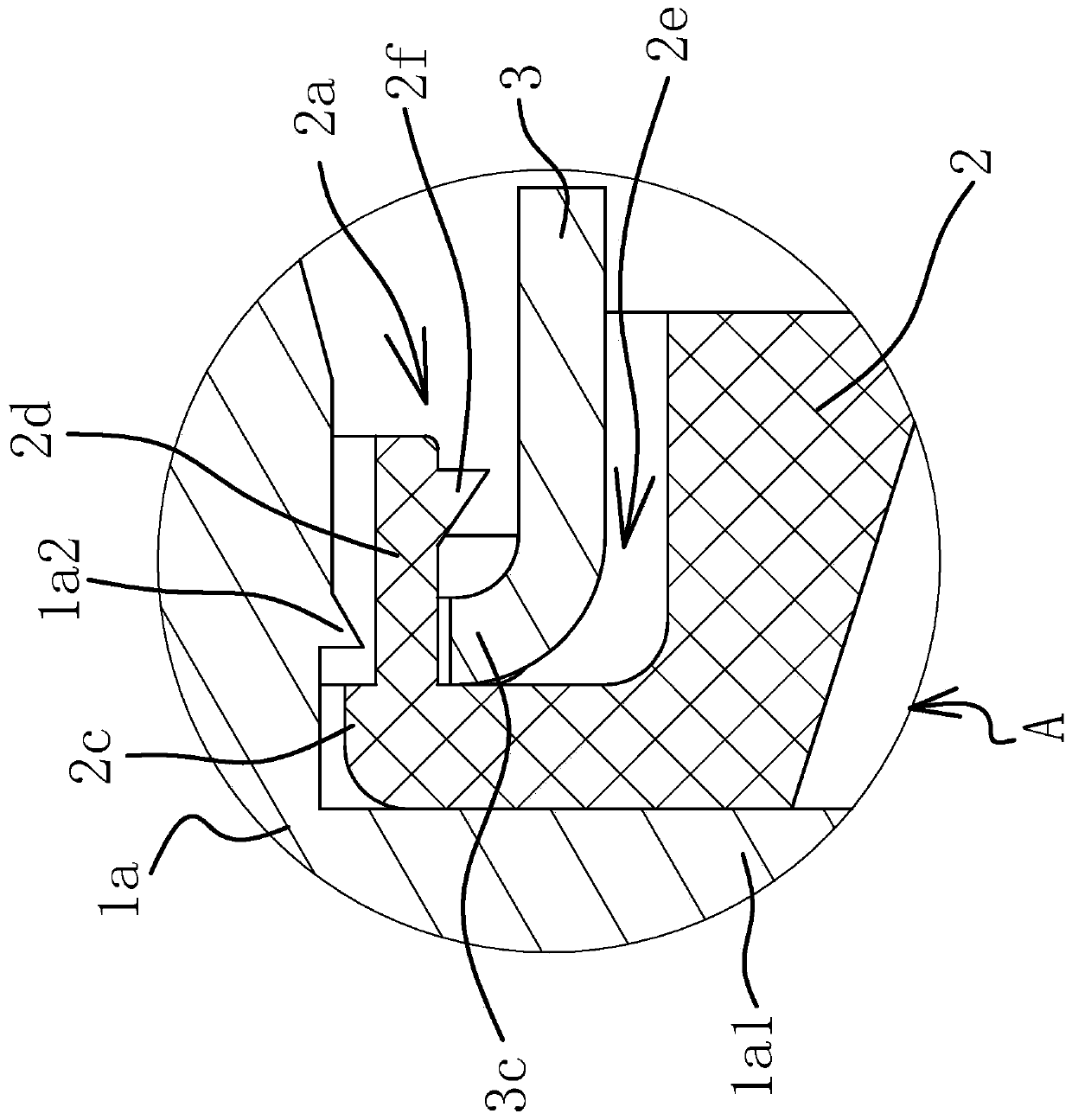

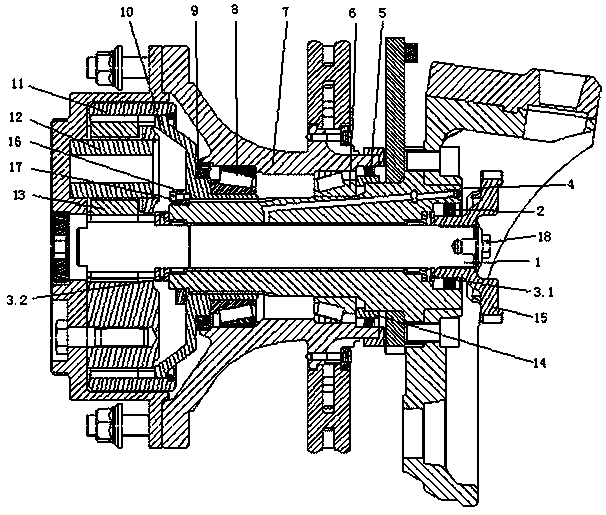

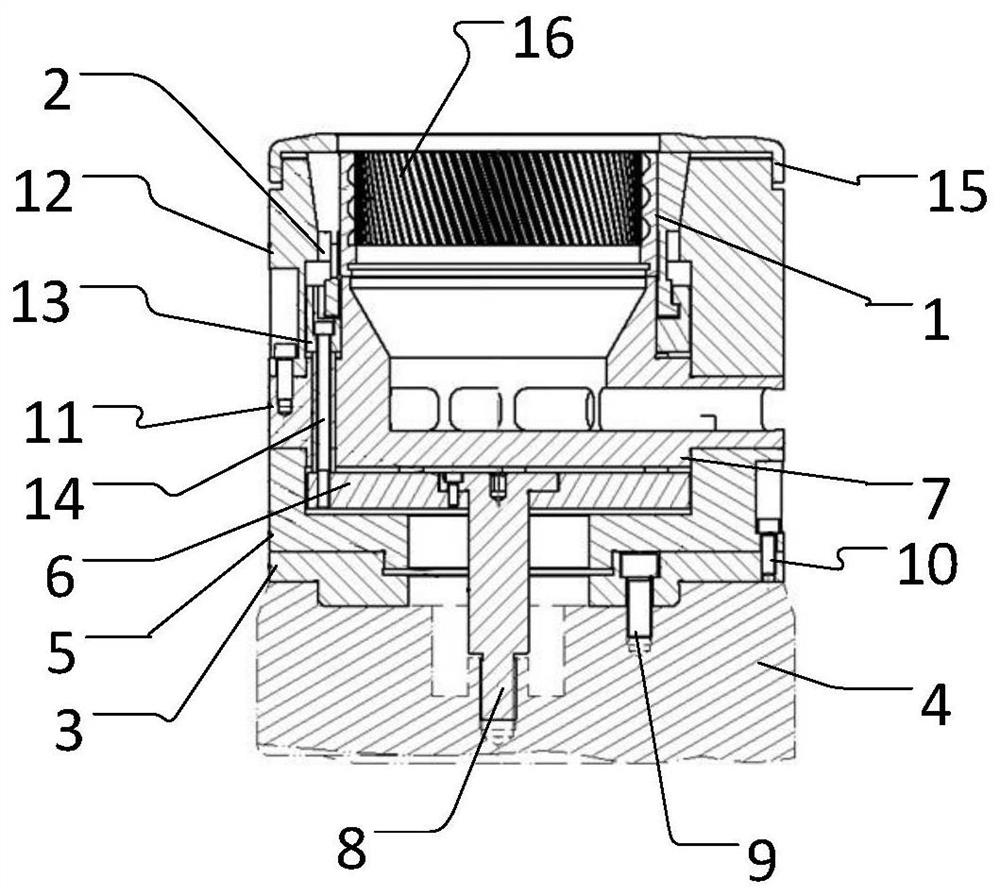

Heart implant

ActiveUS20190083238A1Improve axial stiffnessReduce axial movementHeart valvesExpandable cageBiomedical engineering

The invention relates to a heart implant comprising a tubular attachment element (1) for attaching a sheath, particularly having a sheath being coaxially positioned around at least a part of the tubular attachment element (1) and fixed to it, the tubular attachment element (1) having a lower end (1a) and an upper end (1b) and being split into several strips (2) at the upper end (1b), the strips (2) forming an expandable cage (C), particularly for fixing the heart implant to the atrium of the heart by surface contact between an exterior surface of the expandable cage (C) and an interior atrium surface, wherein in an expanded state the strips (2) extend from the upper end (1b) towards the lower end (1a) of the tubular attachment element (1) and form an expanded cage (C) being positioned around at least an upper part of the tubular attachment element (1).

Owner:CORAMAZE TECH GMBH

Photovoltaic cable joint connector

PendingCN114171987AReduce tensionEffective bufferCouplings bases/casesPhotovoltaic energy generationEngineeringStructural engineering

Owner:宝应县嘉永电器有限公司

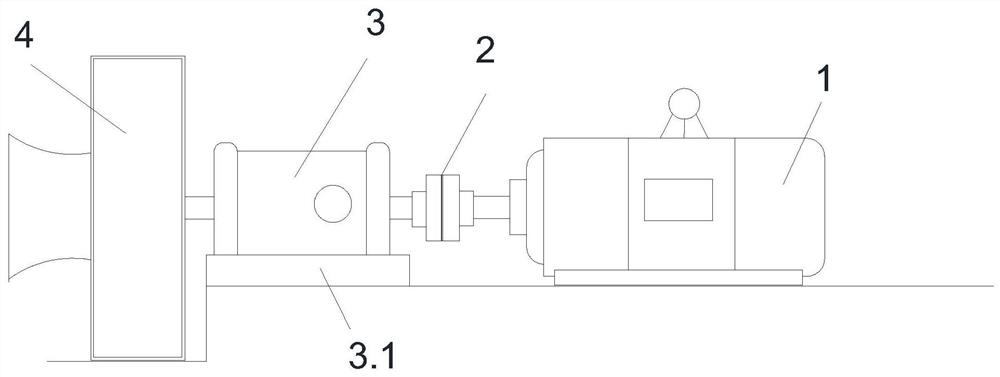

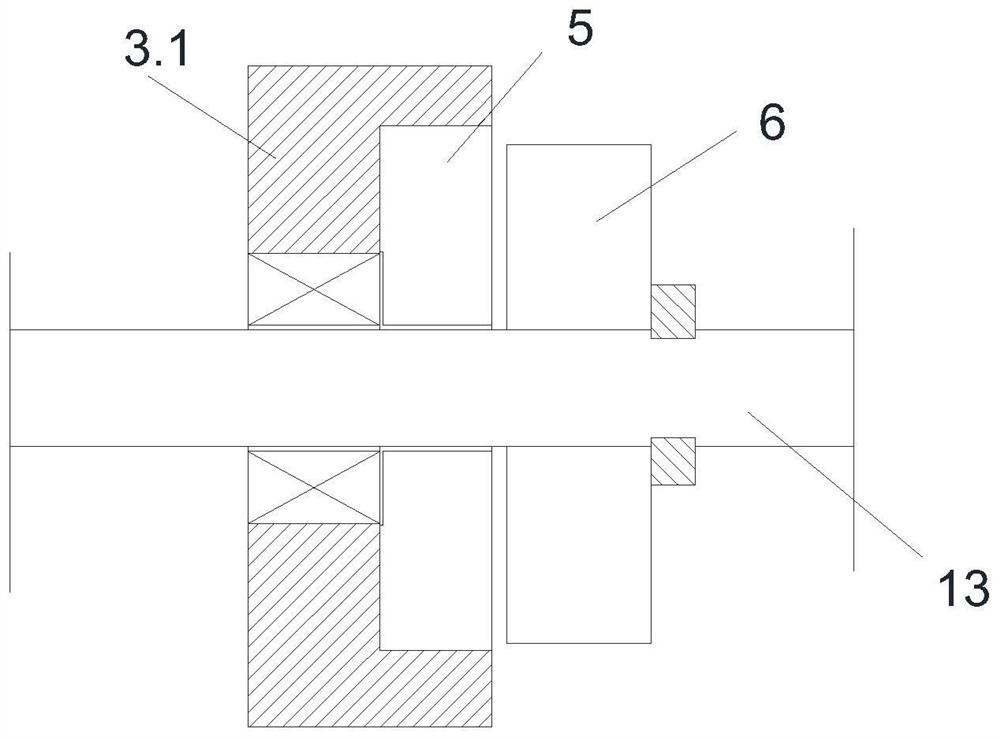

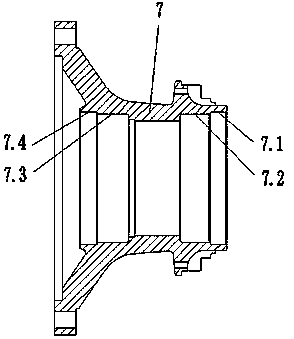

Energy-saving high-pressure fluidization fan device for circulating fluidized bed boiler

ActiveCN113323900AReduce axial movementReduce wearPump componentsPump controlElectric machineEngineering

The invention discloses an energy-saving high-pressure fluidization fan device for a circulating fluidized bed boiler. The device comprises a motor, a coupler, a transmission seat and a fan which are sequentially in transmission connection, an electromagnetic disc is arranged on a base of the transmission seat, a magnetic suction cup is arranged on a center shaft of the fan, and the electromagnetic disc and the magnetic suction cup are oppositely arranged and generate magnetic repulsive force. According to the energy-saving high-pressure fluidization fan device for the circulating fluidized bed boiler, when the center shaft axially moves due to the pulling force of the fan, the electromagnetic disc is powered on, magnetic repulsive force is generated between the magnetic suction cup and the electromagnetic disc, and the axial pulling force of the fan on the center shaft is balanced through the magnetic repulsive force, so that the axial movement of the center shaft is reduced, abrasion is reduced, and the service life is prolonged.

Owner:福建省福能龙安热电有限公司

Combination of tube assembly and clip for wireless antenna grounding

InactiveCN1717841AHigh precisionReduce axial movementAntenna supports/mountingsAntenna connectorsHand heldHand held devices

An antenna grounding assembly for a hand-held device, the grounding assembly comprising: an antenna having an antenna shaft connected between a grounding block and a protective sheath; an antenna tube affixed within the hand-held device and holding the antenna, the antenna tube having an upper end through which the antenna shaft is extended or retracted, and an inner end opposite the upper end; and a grounding clip installed into the inner end of the antenna tube, the grounding clip having a base and at least one contact pin extending axially along the antenna tube for resilient contact with the grounding block.

Owner:RES IN MOTION LTD

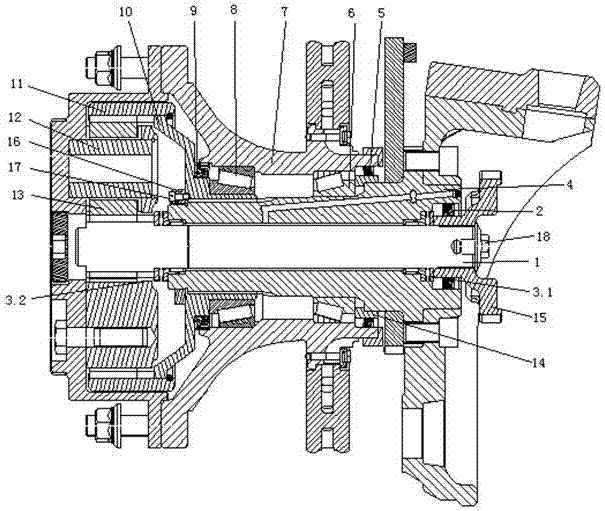

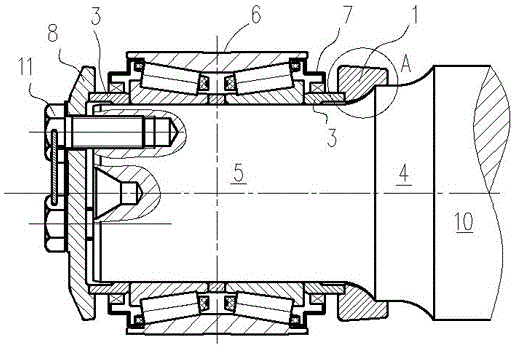

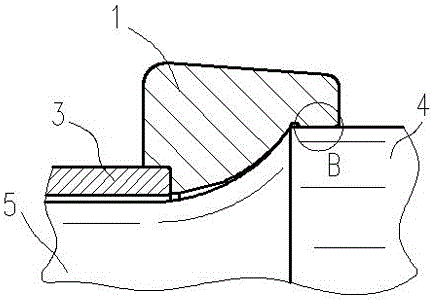

Wheel-side reducer adopting grease separating lubrication

ActiveCN107504137ARealize the purpose of separation lubricationReduce axial movementGear lubrication/coolingToothed gearingsEngineeringLubrication

The invention provides a wheel-side reducer adopting grease separating lubrication. Leakage of a gear lubricant can be reduced, and the service life of bearings can be prolonged. The wheel-side reducer comprises a planetary part, a hub and a power input part. The input part comprises an input gear shaft and a shaft head, and the planetary part comprises a plurality of planetary gears which are engaged with the input gear shaft; the planetary gear shaft is sleeved with the multiple planetary gears in a corresponding mode, and the multiple planetary gears share the same gear ring which is fixedly arranged on a gear ring support; the gear ring support is connected with the shaft head, and the planetary gears, the planetary gear shaft and the gear ring are all arranged in a wheel-side shell; the hub and the wheel-side shell are detachably connected into a whole, and the hub is supported on the shaft head and the gear ring support through the inner bearing and the outer bearing; a first oil seal is arranged between the hub and the gear ring support, and a second oil seal is arranged between the hub and the shaft head through a oil seal seat; and the inner bearing and the outer bearing are arranged in a spaced mode, and a communicating channel is arranged between the inner bearing and the outer bearing.

Owner:SINO TRUK JINAN POWER

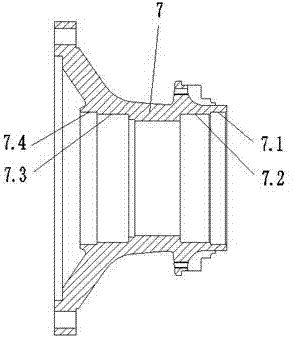

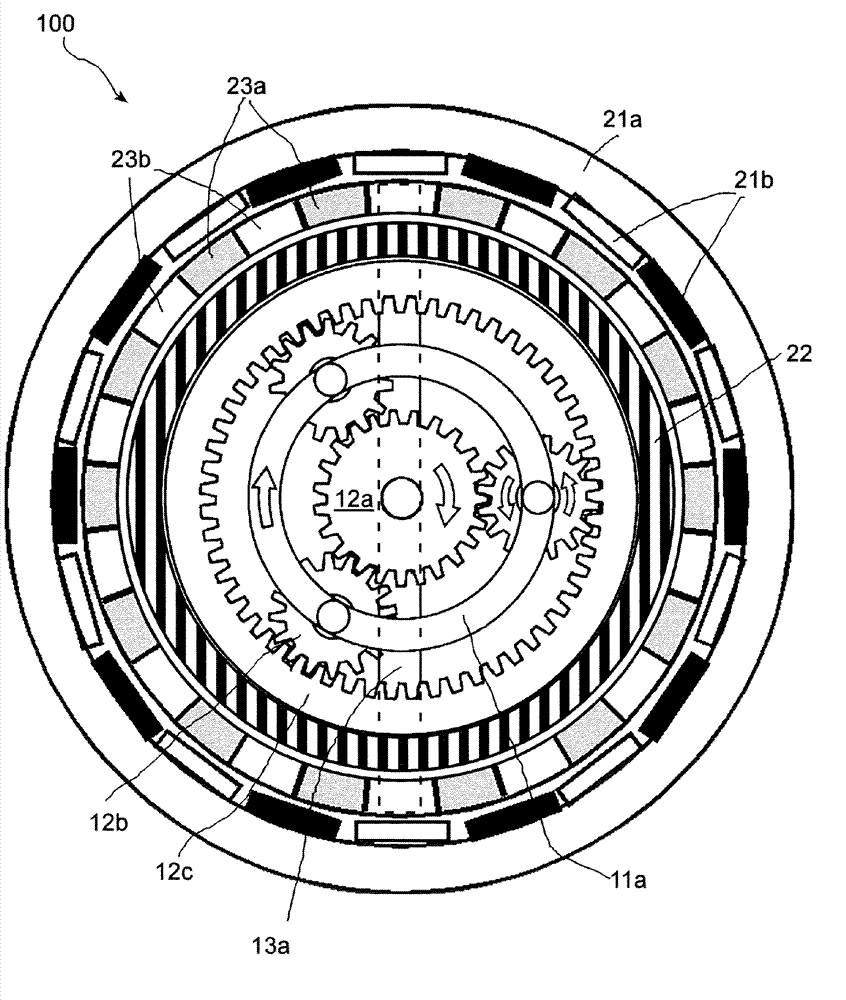

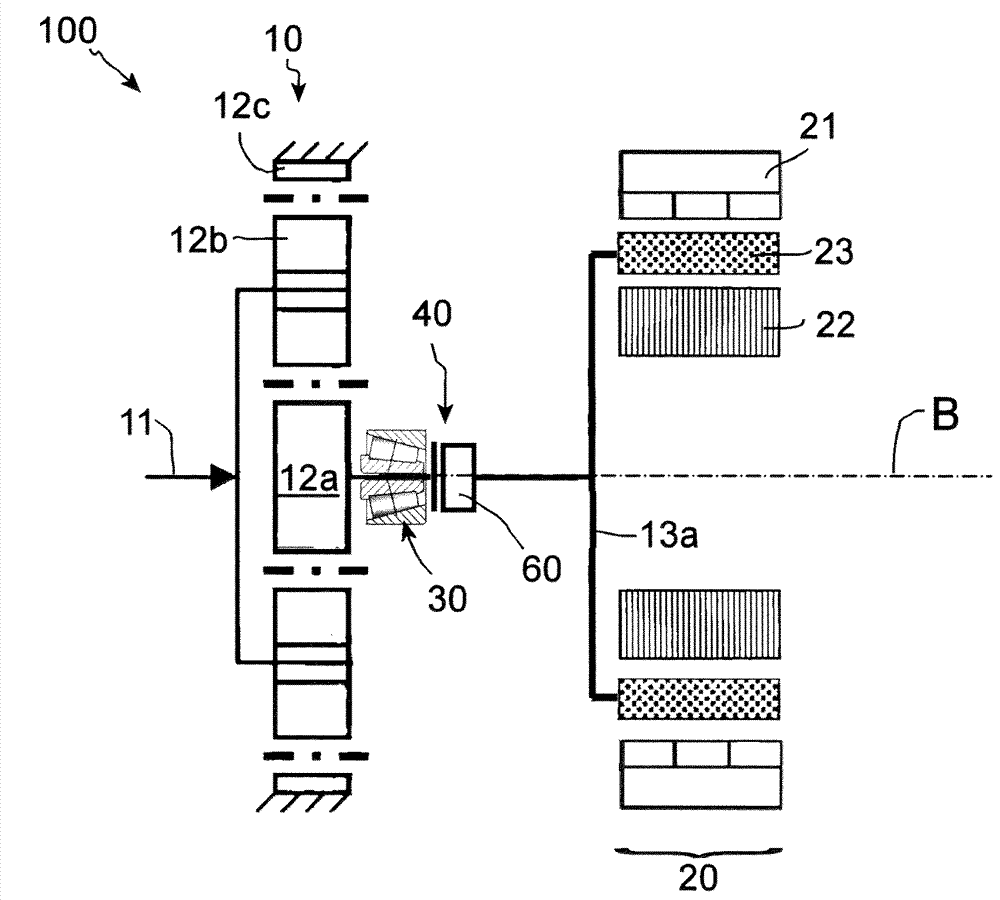

Electrical machine for a wind energy installation

InactiveCN103178677AReduce ohmic resistance lossLow costSynchronous generatorsMechanical energy handlingMagnetic fluxEngineering

The inveniton relates to an electrical machine for a wind energy installation. The electrical machine (100) includes a stationary secondary part (21) which is self-excited or externally excited, a stationary primary part (22) with a primary winding element, and a rotatably mounted magnetic modulator, which modulates a magnetic flux density. The magnetic modulator (23) is arranged between the secondary part (21) and the primary part (23) or the primary part (23) is arranged between the secondary part (21) and the magnetic modulator (23).

Owner:ROBERT BOSCH GMBH

Cold rolled uncoiler drum support roller

The invention discloses a cold rolled uncoiler drum support roller. The cold rolled uncoiler drum support roller comprises a main shaft, the end portion of the main shaft is provided with an adapter sleeve tapered roller bearing, a roller is assembled outside the adapter sleeve tapered roller bearing, and two ends of the adapter sleeve tapered roller bearing are respectively provided with a gland. The uncoiler drum support roller thoroughly solves the axial movement problem of the drum support roller, reduces the cost and improves the production efficiency.

Owner:马鞍山北光冶金机械有限责任公司

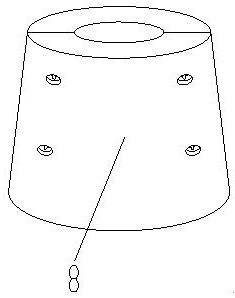

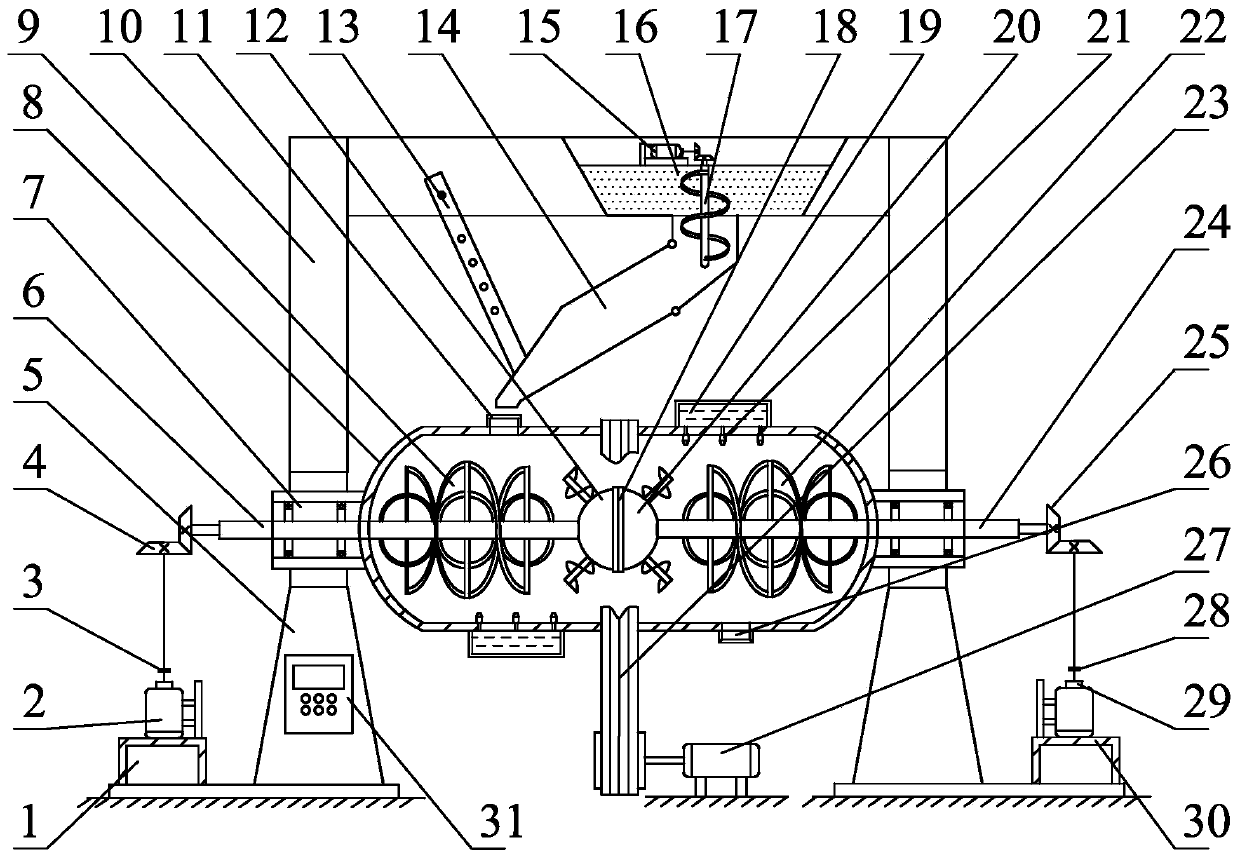

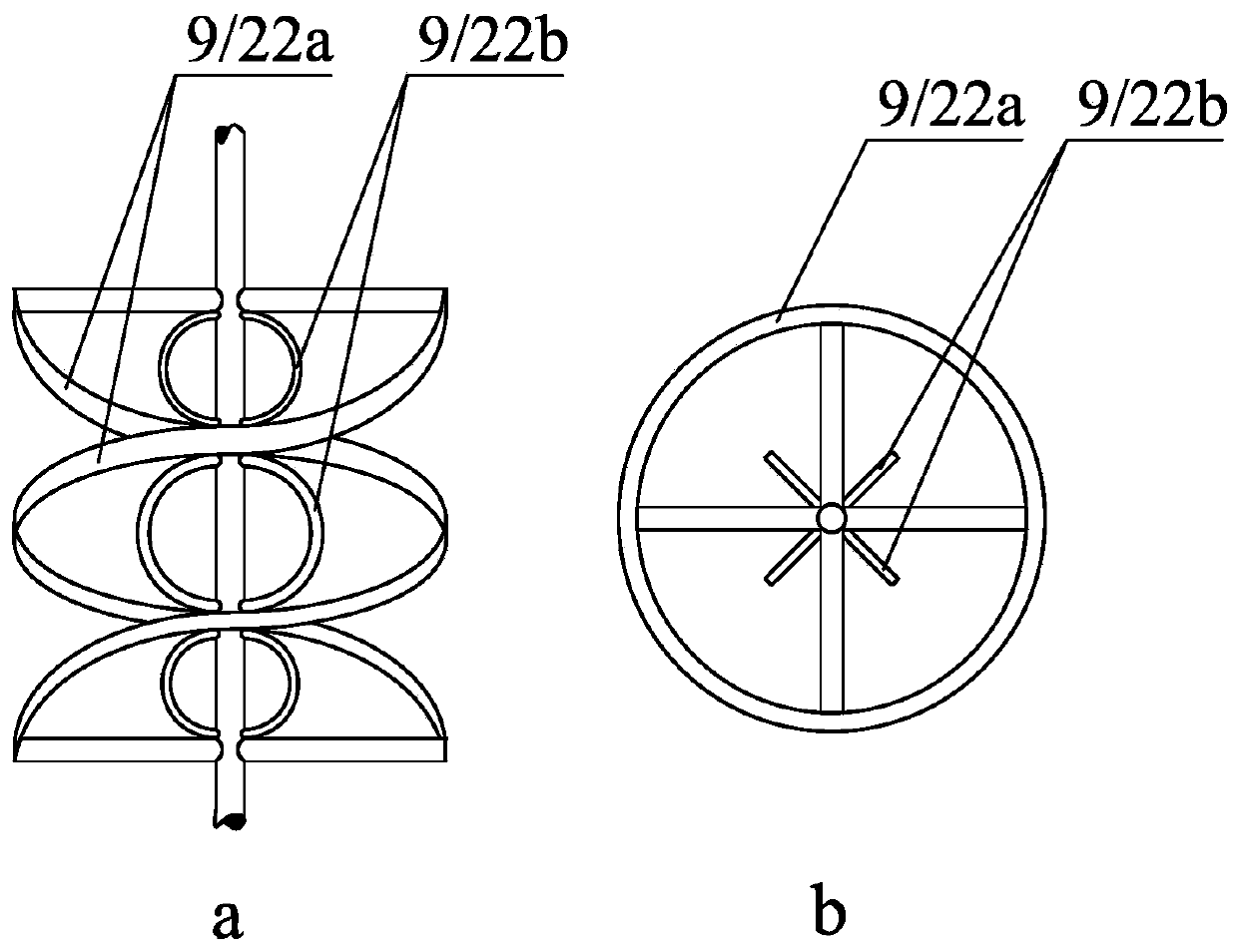

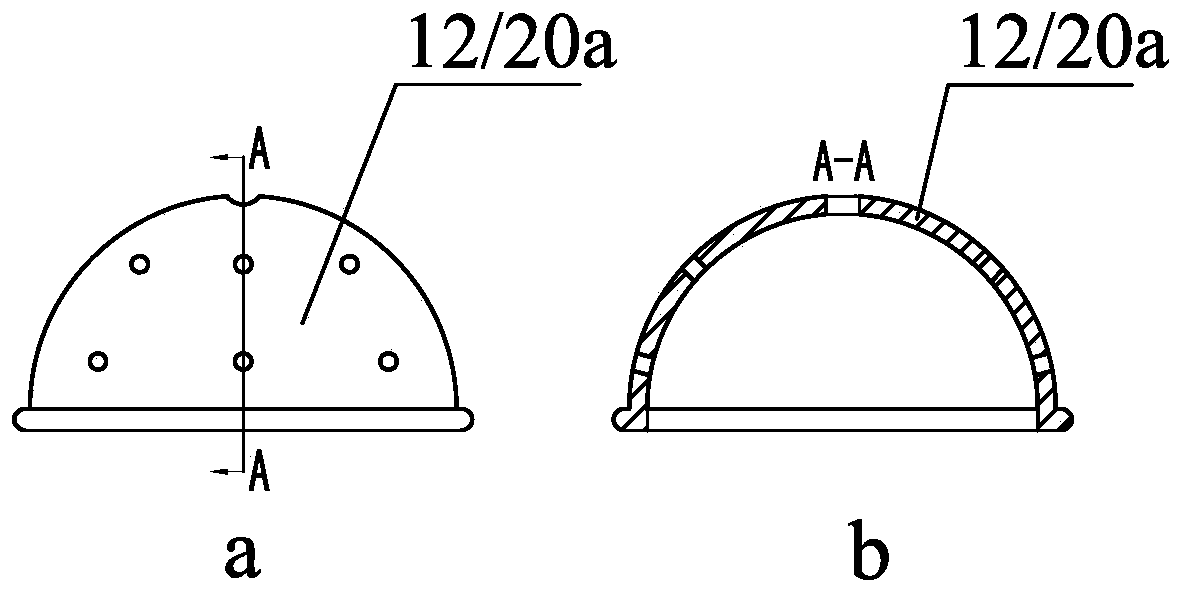

Spiral-hemisphere branch combination type intelligent silicon nitride dry granulation integrated device

InactiveCN110919813AReduce axial movementAvoid the defect of single motion pathCeramic shaping apparatusGranulation in stationary drums/troughsSupporting systemMechanical engineering

The invention discloses a spiral-hemisphere branch combination type intelligent silicon nitride dry granulation integrated device. The spiral-hemisphere branch combination type intelligent silicon nitride dry granulation integrated device comprises a support system, a stirring and granulation system, a feeding system, an atomization system and an intelligent control system. Due to the adoption ofa dual-granulation structure of a spiral-circular ring combined granulation structure and a semi-spherical branch combined granulation structure, the movement path of a powder body is expanded, the defect of the single movement path of the powder body is avoided, and the granulation effect is remarkably improved.

Owner:JINGDEZHEN CERAMIC INSTITUTE

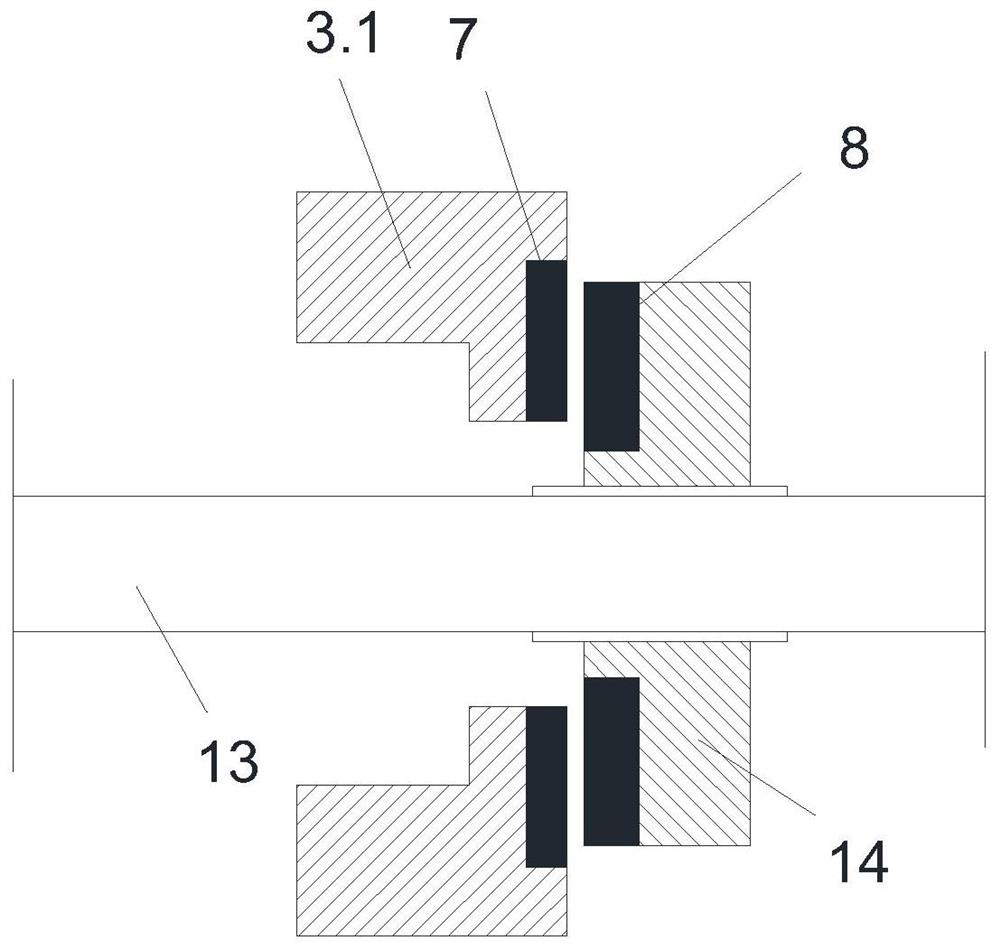

Rear retainer ring of wagon rolling bearing

InactiveCN105128883AEasy to pressReduce axial movementAxle-boxesInterference fitRolling-element bearing

The invention belongs to the technical field of bearing manufacturing, and provides a rear retainer ring of a wagon rolling bearing. The rear retainer ring (1) is provided with a rear retainer body (1-1). The inner surface of the rear retainer body (1-1) is an arc surface matched with the outer wall surface of a shaft shoulder. One side end face of the rear retainer body (1-1) is provided with an annular notch. One end of a sealing ring (1-2) is located in the annular notch in the rear retainer body (1-1), and the other end of the sealing ring (1-2) is arranged on a dust guard seat (4) in a sleeving mode. The inner diameter surface I (12) of the sealing ring is in interference fit with the outer diameter surface (14) of the dust guard seat. The inner diameter surface I (12) of the sealing ring is provided with a conical surface, and the conical surface is of a structure gradually drawing down inwards from the end, away from the rear retainer body, of the sealing ring. According to the rear retainer ring, axial movement, caused by deflection of a main shaft and a shaft neck, of the rear retainer ring is reduced, reutilization of the rear retainer ring is achieved, and the overhaul cost is lowered.

Owner:LUOYANG LYC BEARING

Automatic side wall separating mechanism of electric connector

ActiveCN109764767AQuick lockEasy to useVehicular energy storageSelf-propelled projectilesEngineeringMechanical engineering

The invention relates to an automatic side wall separating mechanism of an electric connector. The side wall automatic separating mechanism comprises a plug and a socket, wherein the socket comprisesa socket shell and a locking pin, and the plug comprises an outer shell, a plug cable cover, a fixing frame and a plug shell; the plug cable cover is fixedly connected in the fixing frame, and a clamping hook matched with the locking pin is arranged on the outer shell. The automatic side wall separating mechanism of the electric connector is characterized in that the clamping hook is arranged on the outer shell and the locking pin is arranged on the socket, when the plug and the socket can be plugged, only the downward insertion force needs to be applied to the outer shell, when the plug is incontact with the socket, a locking block is subjected to upward pressure, a pressure spring is compressed, when a groove is matched with a moving end, a guide rod moves leftwards under the acting force of a spring, the outer shell moves leftwards along with the guide rod, and when the clamping hook on the outer shell clamps the locking pin, the plug and the socket can be locked. The automatic side wall separating mechanism has the advantages of being capable of automatically separating along with elasticity, high in reliability and convenient to use.

Owner:杭州航天电子技术有限公司

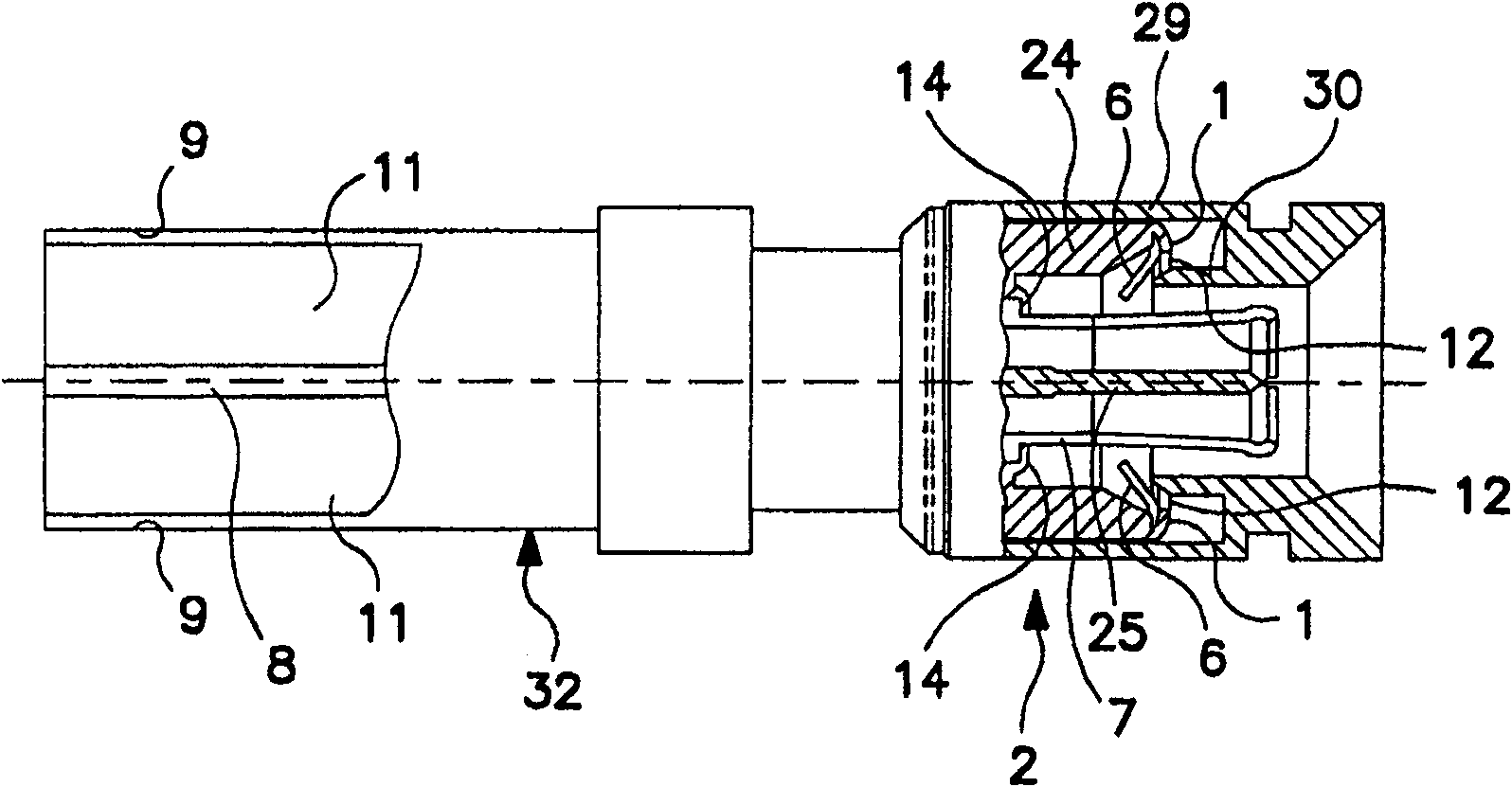

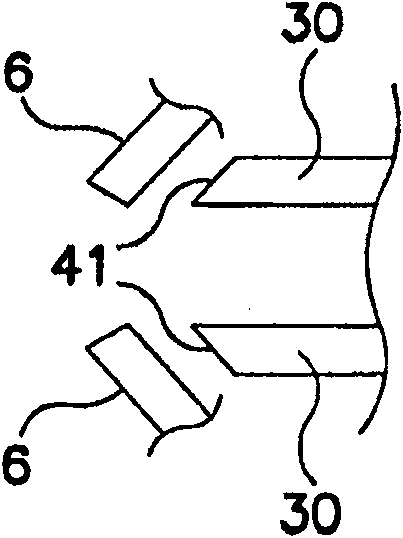

Electric connector with locking ring

InactiveCN100590936CReduce axial movementTwo pole connectionsCoupling device detailsElectrical connectionElectrical connector

An electrical connector has a first connector member, a second connector member, and a locking ring. The first connector member has a first contact and an abutment surface. The second connector memberhas a second contact for electrical connection with the first contact and a groove. The locking ring is disposed on the first connector member and has latching fingers. The latching fingers are of atleast a first type and a second type. The first type has a different length than the second type so that the first type engages the groove when the abutment surface is a first distance from the groove and the second type engages the groove when the abutment surface is a second distance from the groove when the first and second connector members are mated to lock the first connector member to thesecond connector member.

Owner:TYCO ELECTRONICS BELGIUM EC

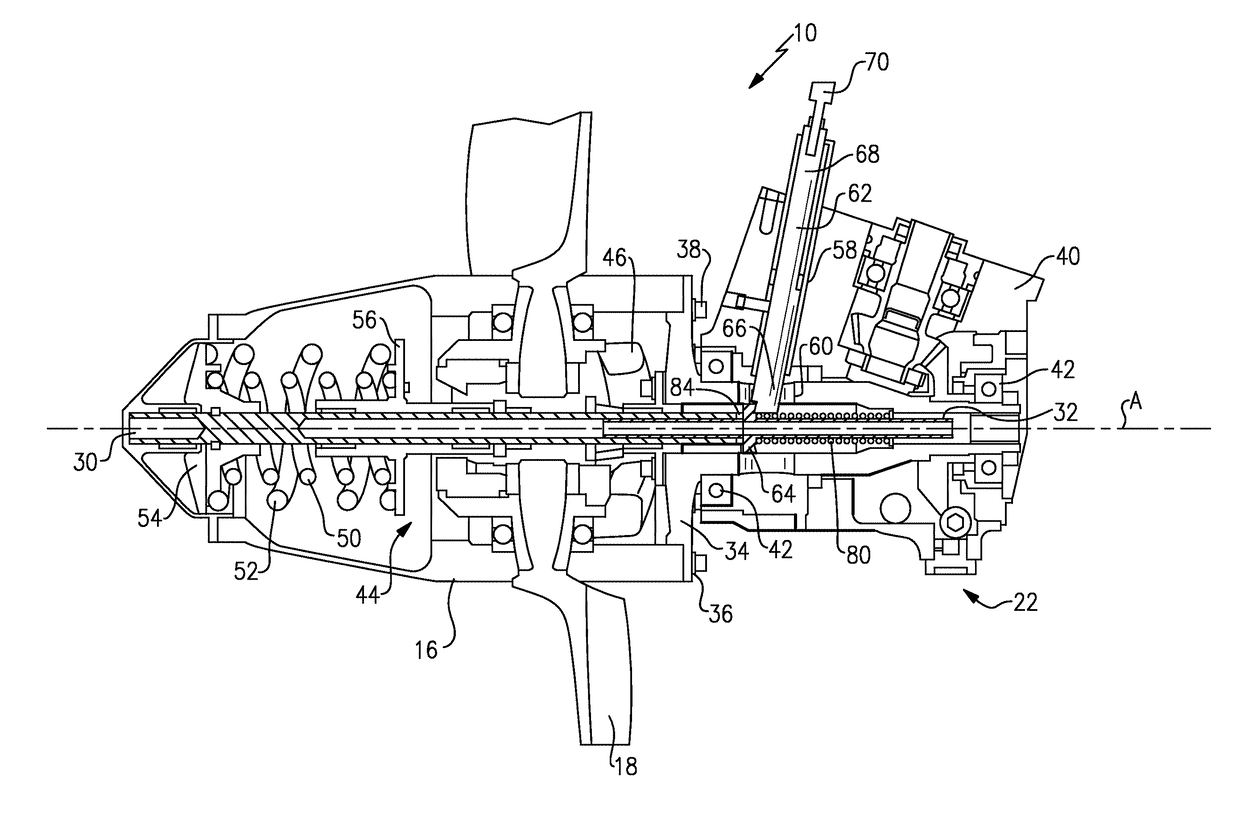

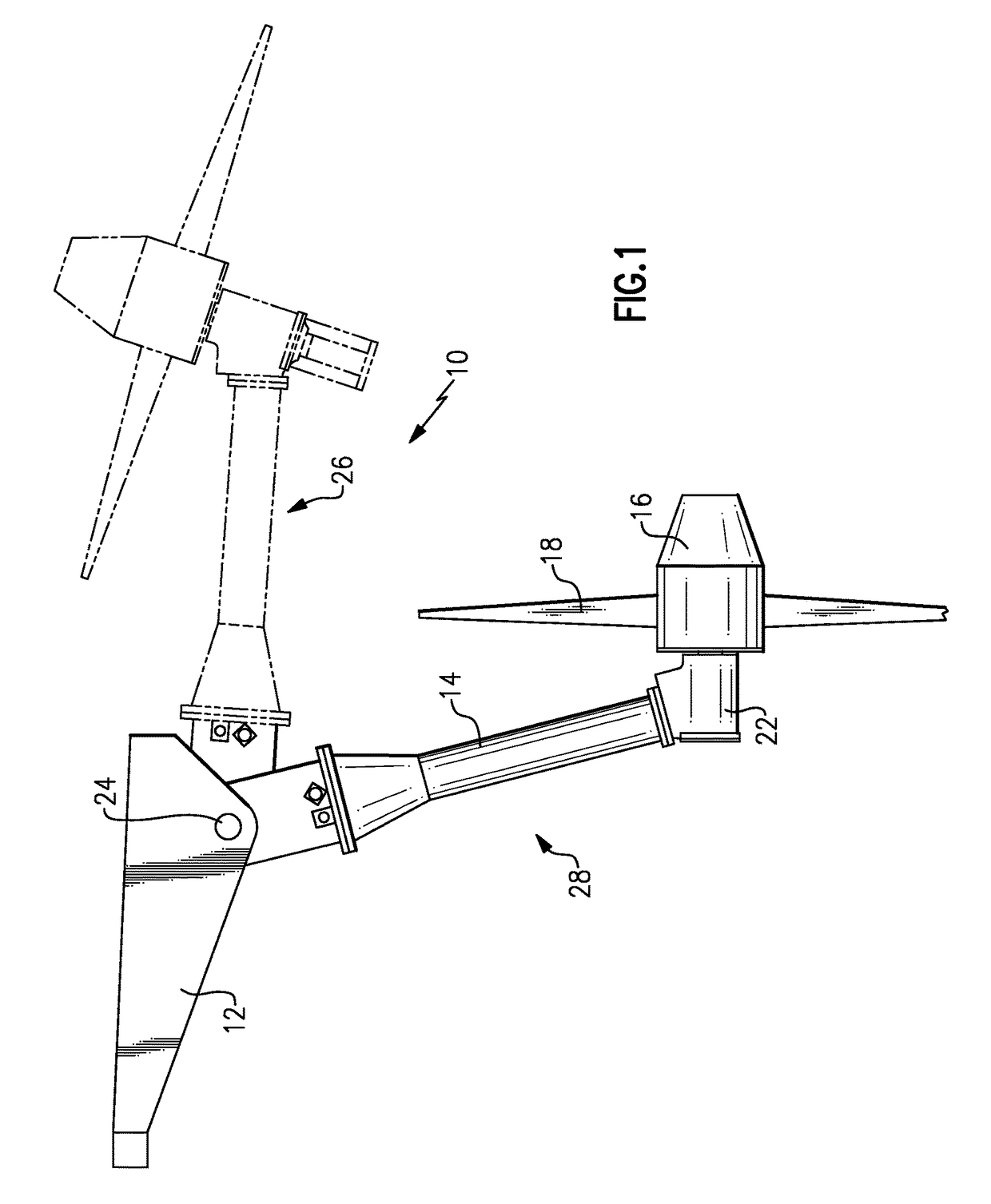

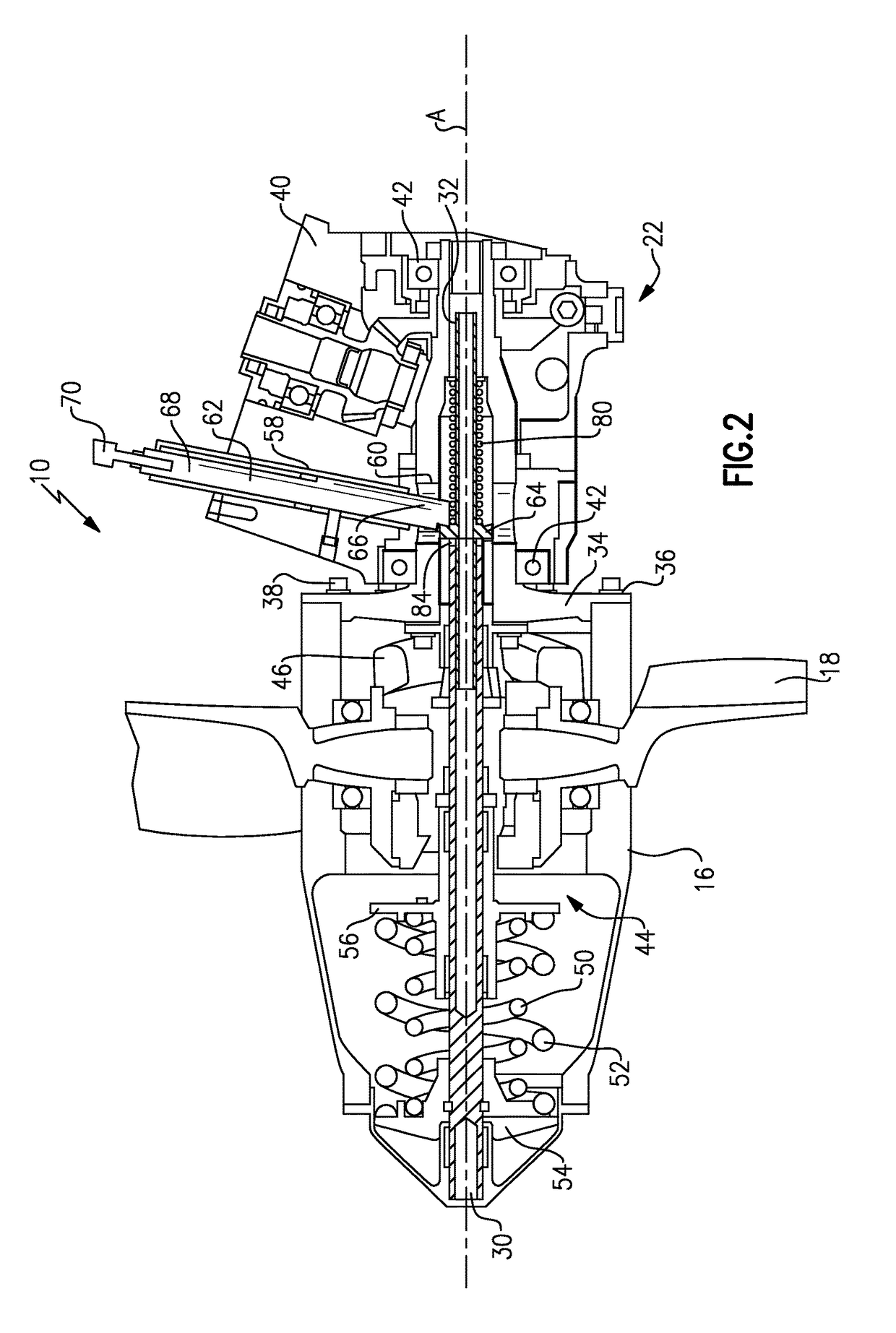

Turbine lock plunger for ram air turbine assembly

ActiveUS9598980B2Reduce axial movementPrevent rotationPropellersPump componentsEngineeringRam air turbine

A ram air turbine assembly includes a governor shaft rotatable about an axis and a stop shaft coupled for rotation with the governor shaft. A rotatable housing portion surrounds at least a portion of the stop shaft. A lock plunger extends through an opening in the rotatable housing portion to prevent rotation of the rotatable housing portion and minimize vibration impact loading when stowed.

Owner:HAMILTON SUNDSTRAND CORP

a pipe joint

Owner:RENARD FLUID INTELLIGENCE TECH JIANGSU LTD BY SHARE LTD

Skiving machine expansion sleeve type clamp

ActiveCN111230226AHigh positioning accuracyImprove gear cutting accuracyGear-cutting machinesGear teethGear wheelEngineering

The invention belongs to the technical field of machine tool clamps, and relates to a skiving machine expansion sleeve type clamp. The clamp comprises a clamp sleeve used for clamping a workpiece, wherein elastic chucks are arranged on the periphery of the clamp sleeve and apply clamping force pointing to the geometric center of the clamp sleeve to the clamp sleeve, a clamp body is arranged at oneend of the clamp sleeve and provides structural support for the clamp sleeve and the elastic chucks, the elastic chucks are symmetrically arranged on the periphery of the clamp sleeve along the geometric center line of the clamp sleeve, and the elastic chucks are of a cylindrical structure. According to the clamp, workpiece positioning precision is improved, workpiece deformation is prevented, then gear cutting precision is improved, the gear cutting service life of a cutter can be prolonged to a certain extent, the structure is simple, the rotational inertia of a skiving machine workbench isreduced, and it is guaranteed that a machine tool can be safely and stably stopped.

Owner:CHONGQING MACHINE TOOL GROUP

Splicing channel units, splicers and textile machines

ActiveCN105696127BReduce riskQuality improvementFilament handlingContinuous wound-up machinesElectrical and Electronics engineeringTextile

The invention relates to a splice channel unit, a splicer and a textile machine. Here, air inlet ducts (660, 66u) are especially designed to be a splice channel (20) injecting splice air into the splice channel unit (60). According to specific variants of the splice channel unit, the splice channel unit has a) the minimum of the length l of a portion (69o, 69u) near outlets and the minimum of the diameter d of the outlets (70o, 70u) communicated with the splice channel (20), b) a value of the ratio r<ld>=l / d exceeding the minimums, wherein the portion (69o, 69u) near the outlets must basically not have structures which may prevent the splice air from flowing under the condition a) and the condition b), or c) the air inlet ducts (660, 66u) designed to enable the splice air to form a laminar flow imported to the splice channel (20) before the outlets (70o, 70u) of the splice channel (20) of the air inlet ducts when the splice air flows through the splice channel.

Owner:SAURER GERMANY GMBH & CO KG

Grease separation lubricated wheel reducer

ActiveCN107504137BRealize the purpose of separation lubricationReduce axial movementToothed gearingsGear lubrication/coolingReduction driveGear wheel

The invention provides a wheel-side reducer adopting grease separating lubrication. Leakage of a gear lubricant can be reduced, and the service life of bearings can be prolonged. The wheel-side reducer comprises a planetary part, a hub and a power input part. The input part comprises an input gear shaft and a shaft head, and the planetary part comprises a plurality of planetary gears which are engaged with the input gear shaft; the planetary gear shaft is sleeved with the multiple planetary gears in a corresponding mode, and the multiple planetary gears share the same gear ring which is fixedly arranged on a gear ring support; the gear ring support is connected with the shaft head, and the planetary gears, the planetary gear shaft and the gear ring are all arranged in a wheel-side shell; the hub and the wheel-side shell are detachably connected into a whole, and the hub is supported on the shaft head and the gear ring support through the inner bearing and the outer bearing; a first oil seal is arranged between the hub and the gear ring support, and a second oil seal is arranged between the hub and the shaft head through a oil seal seat; and the inner bearing and the outer bearing are arranged in a spaced mode, and a communicating channel is arranged between the inner bearing and the outer bearing.

Owner:SINO TRUK JINAN POWER

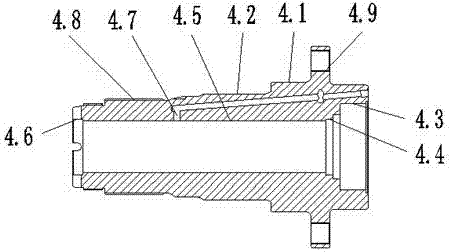

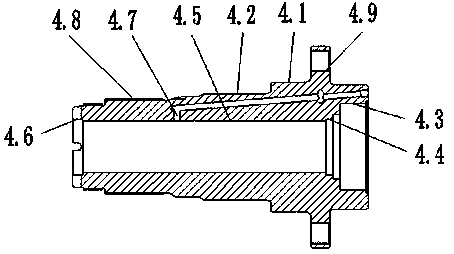

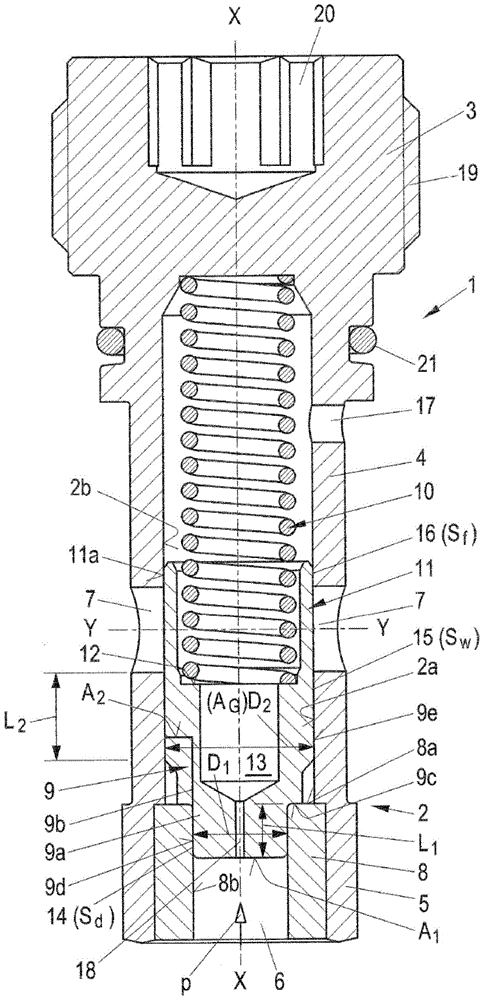

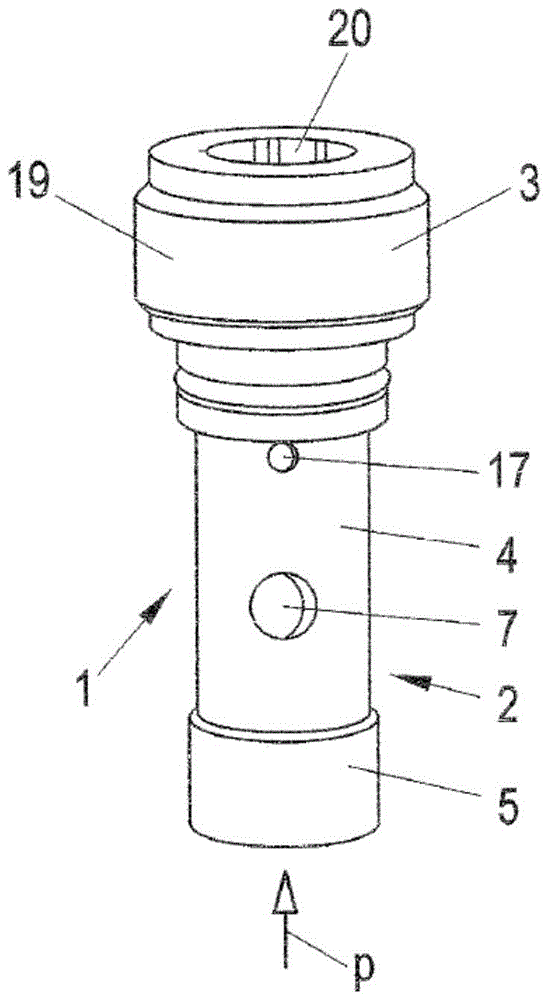

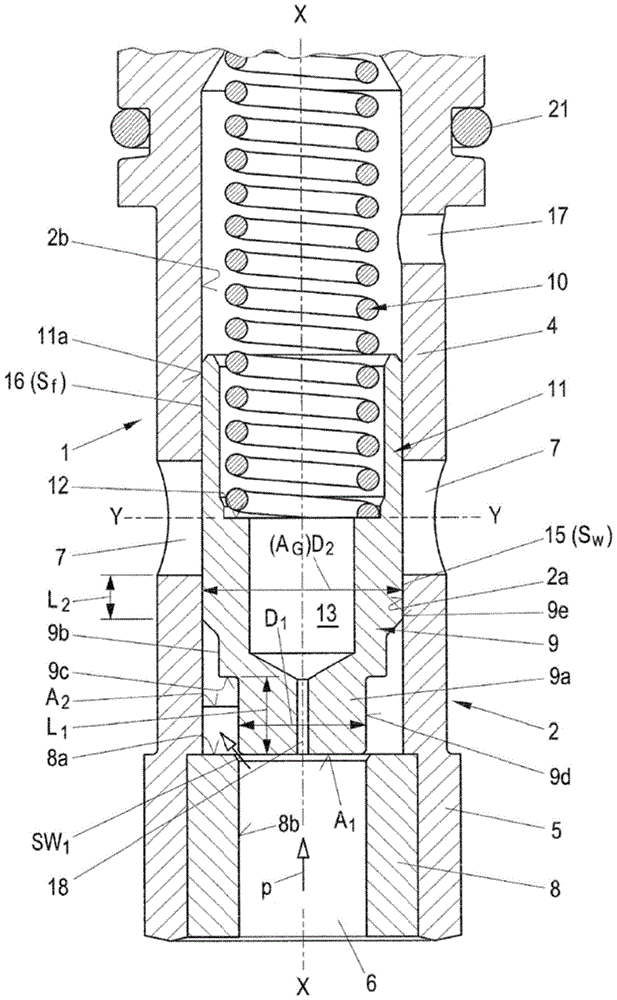

pressure limiting valve

InactiveCN104302907BPrevent movementReduce axial movementInternal combustion piston enginesCheck valvesCommon railEngineering

The invention relates to a pressure limiting valve (1), in particular for a return line installed in a common rail system of an internal combustion engine, having a valve housing (2) with a housing top (3) and a hollow cylindrical housing housing (4), wherein there is an axial inlet (6) in the valve seat (5) of the valve housing (2) and at least one axially spaced from the inlet (6) open outlet (7), where in the valve seat (5) the inner seat (8) for the valve body (9) is connected to the inlet (6) and between the valve body (9) and the return spring ( Between 10) there is an axially movable valve piston (11), the return spring (10) generating a return force against the pressure (p) acting on the inlet (6). In order to improve the functional characteristics of the valve (1), the invention proposes that the valve body (9) is constructed as a multi-stage piston, in its first step (9a) it has on its surface facing the inlet (6) A first surface (A1) capable of bearing pressure (p) in the axial direction and a first axial length (L1) through which, in a closed position, the multistage The piston forms a circumferentially extending first throttling gap (14) with its outer surface (9d) and the inner surface (8b) of the valve seat (8), and in the second step (9b) of the multi-stage piston, its has a second surface (A2) capable of bearing pressure (p) in the axial direction (X‑X), which together with the first surface (A1) constitutes the total bearing surface (AG), and, at On the entire second axial length (L2) of the second step (9b), a circumferential gap is formed between the outer surface (9e) of the multistage piston (9) and the inner surface (2a) of the housing cover (4). An extended second throttle gap (15) having a second gap width (Sw).

Owner:VOSS AUTOMOTIVE

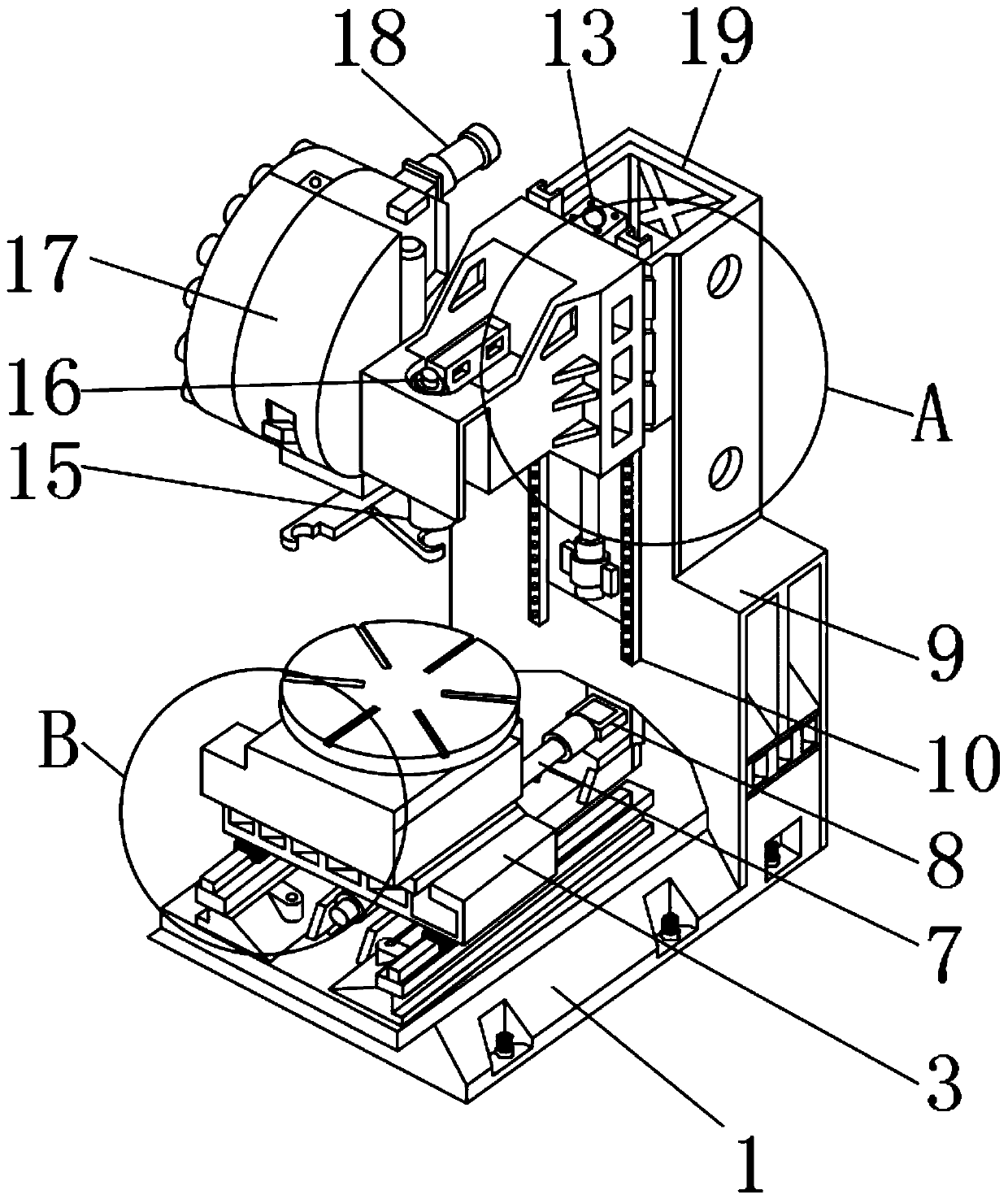

Numerical control machine tool for efficient machining of high-precision revolving body part

InactiveCN111482818ASimple designImprove machining accuracyOther manufacturing equipments/toolsNumerical controlLinear motion

The invention relates to the field of numerical control machine tools, and discloses a numerical control machine tool for efficient machining of a high-precision revolving body part. The numerical control machine tool comprises a base, the base is of a trapezoidal structure, a group of guide rails are fixedly mounted on the upper end surface of the base through bolts and parallel to each other, asliding block is in sliding connection with the surface of each guide rail, a connecting plate is mounted on the upper surface of each sliding block, and a high-precision revolving table is connectedto the upper end of each connecting plate, a first motor is mounted on the side edge of the revolving table and drives the revolving table to rotate. According to the numerical control machine tool for efficient machining of the high-precision revolving body part, the revolving table on the connecting plate is driven to do front-and-back linear motion along the guide rails through a lead screw, the revolving table is linked with a single horizontal shaft, the traditional design of a machine tool structure is simplified, an axial motion device is omitted, and accurate walking and positioning ofthe linear motion are more facilitated, so that efficient machining of the high-precision revolving body part is realized, and meanwhile, the manufacturing, assembling, maintaining and using costs ofthe equipment are reduced.

Owner:宋军杰 +4

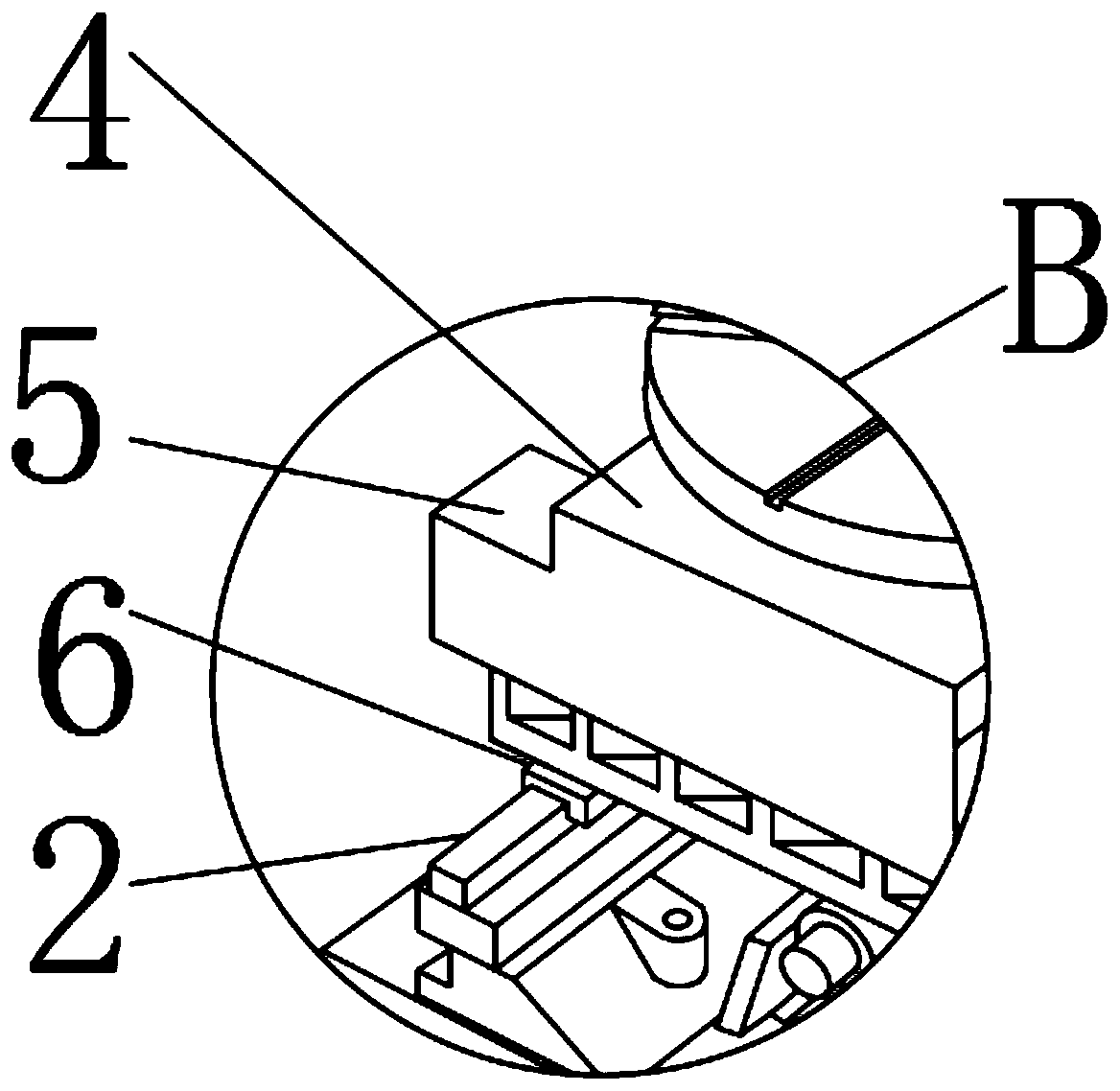

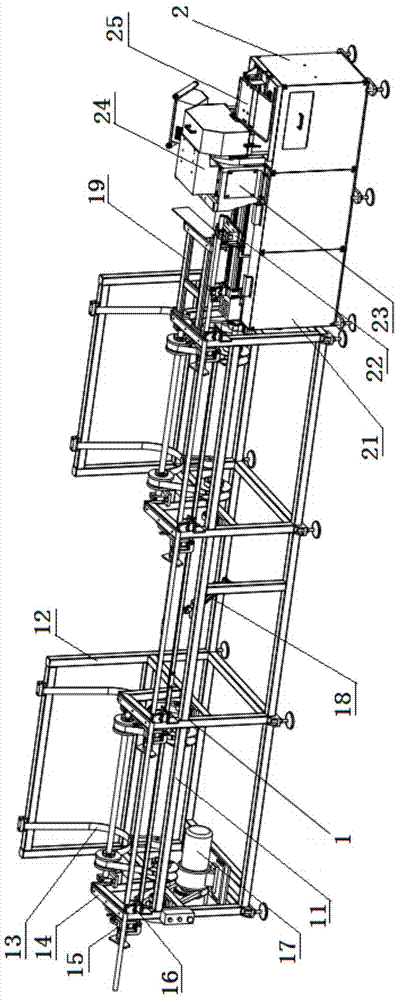

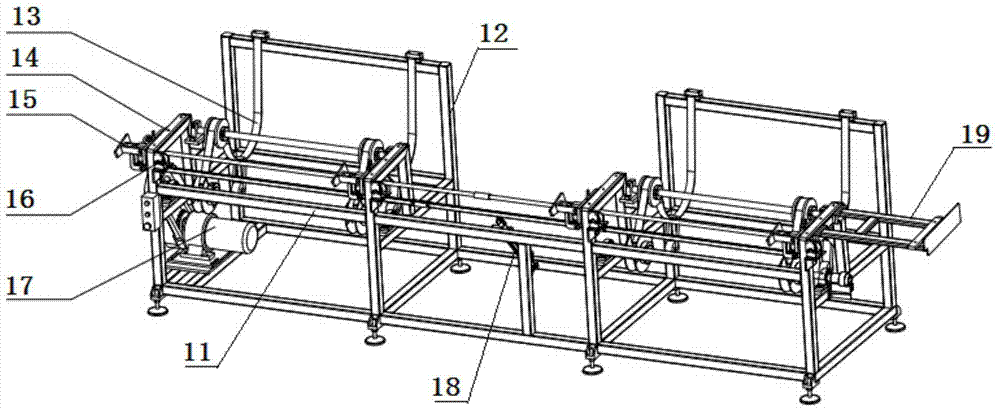

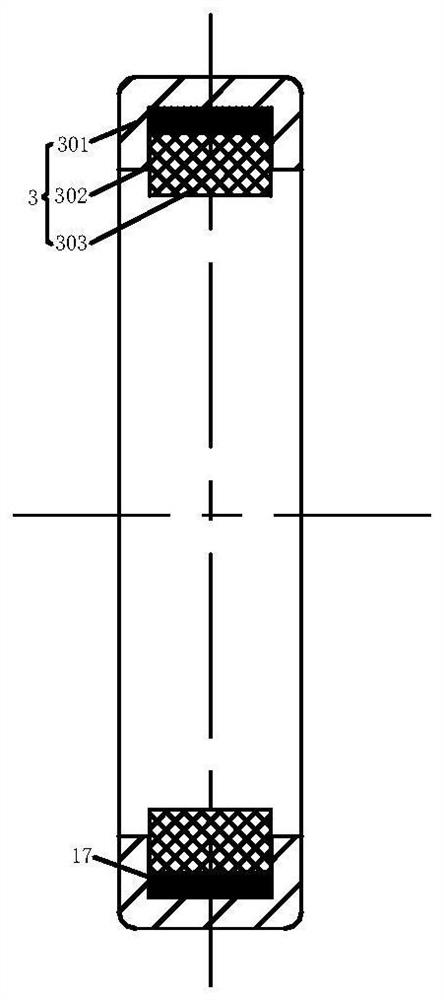

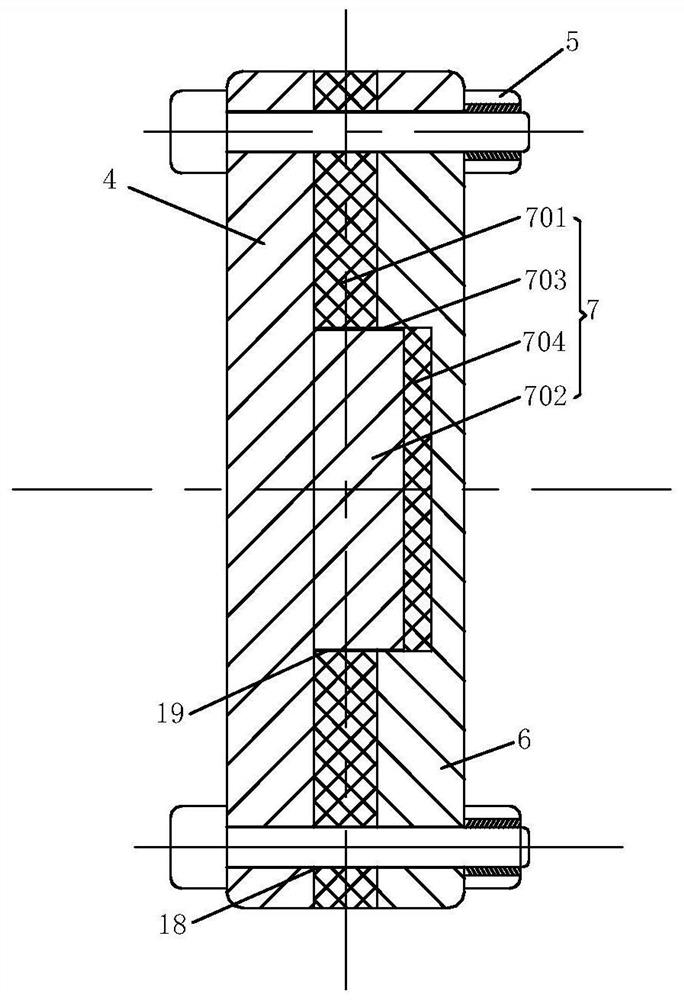

Pipe Chipless Cutting Machine

The invention discloses a scrap-free pipe cutting machine. The scrap-free pipe cutting machine comprises a main cutting shaft. A chuck for clamping a pipe is arranged inside the main cutting shaft in the axial direction. One end of the main cutting shaft is sleeved with a rotating sleeve, a cutter disc is fixed to the end face of the rotating sleeve, a blade sliding block and a supporting roller sliding block are installed on the cutter disc, the end face, far away from the main cutting shaft, of the blade sliding block and the end face, far away from the main cutting shaft, of the supporting roller sliding block are slopes, the blade sliding block is connected with a cutting blade through a bearing, and the supporting roller sliding block is connected with a supporting roller through a bearing. The outer side of the rotating sleeve is sleeved with a sliding outer sleeve. The inner wall of the sliding outer sleeve is in contact with the slope of the blade sliding block and the slope of the supporting roller sliding block, and under guiding of the slope of the blade sliding block and the slope of the supporting roller sliding block, the blade sliding block and the supporting roller sliding block are pressed by the sliding outer sleeve to move towards the center of the pipe. By means of the pipe cutting machine, the technical problem that a cut pipe opening of a cut pipe in the prior art has many waste scraps and burrs can be solved.

Owner:浙江长兴和良智能装备有限公司

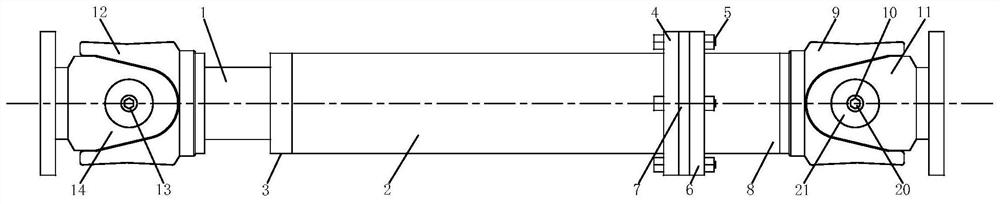

A cross universal coupling

The invention relates to the field of shaft couplings, in particular to a cross cardan coupling, comprising a spline shaft, a spline sleeve is sheathed on the right side of the spline shaft, and a spline sleeve is provided on the left side of the spline sleeve. A locking mechanism is fixedly welded, and the locking mechanism is sleeved on the outer surface of the spline shaft. The right end of the spline sleeve is fixedly connected with a first flange, and the first flange passes through the first lock. Tight bolts are fixedly connected with a second flange. The invention can effectively reduce the friction between the spline shaft and the spline sleeve through the locking mechanism, slow down the degree of wear, and further improve the service life of the spline pair, and then through the first shock pad and the second shock absorber in the buffer mechanism The shock pad can buffer and weaken the axial impact force on the cross universal coupling, reducing its damage. At the same time, the protection mechanism has a good protection effect on the first cross shaft body and the second cross shaft body, greatly The service life of the cross universal coupling is improved.

Owner:JIANGSU FORGED PIPE FITTINGS

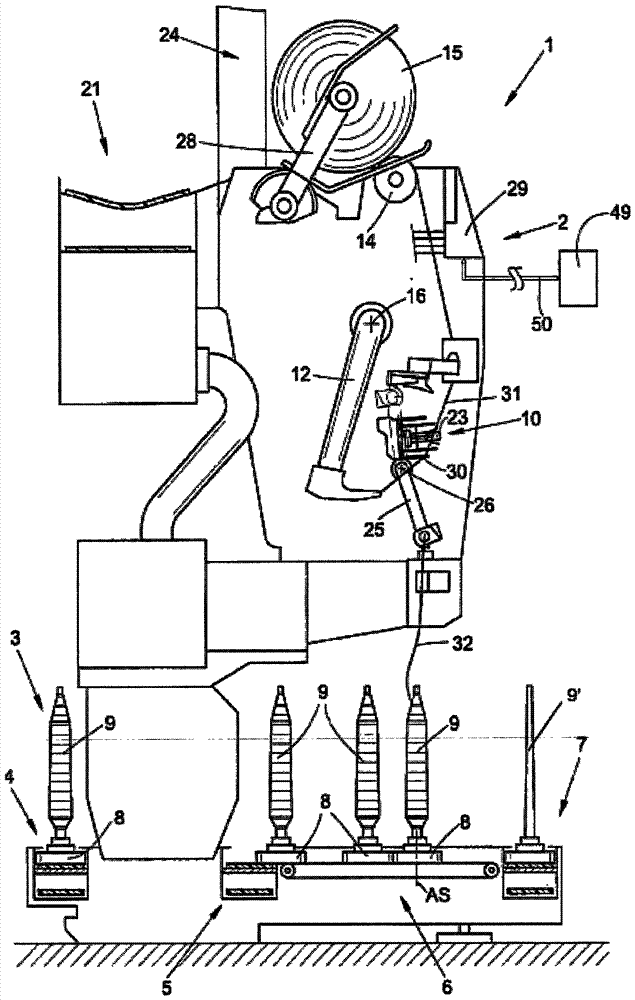

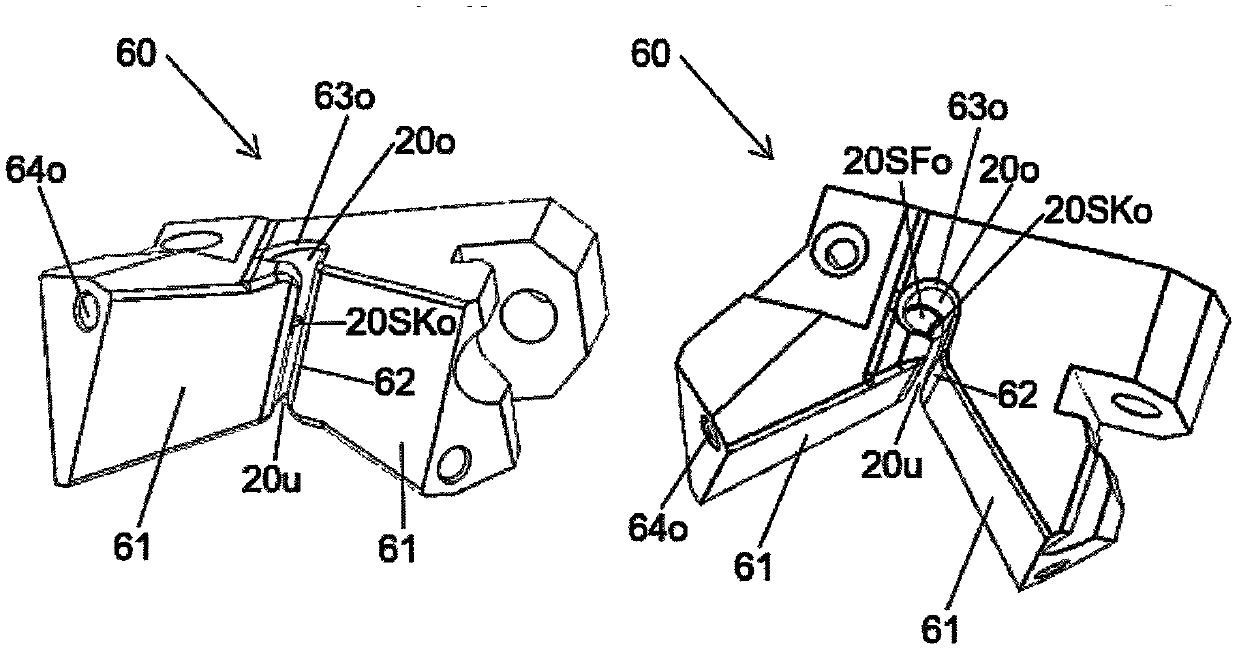

Splicing channel unit, splicer and textile machine

ActiveCN105696126BGood effectReduce axial movementFilament handlingContinuous wound-up machinesEngineeringStructural engineering

The invention relates to a splicing channel unit, a splicer and a textile machine. A splicing channel unit (60) for a splicer (10) comprises a splicing channel (20) which is divided into two splicing chambers (20o, 20u) in the axial direction of the splicing channel, the axes (76, 77) of the two splicing chambers offset from each other, and the splicing channel unit (60) is characterized in that the curvature radius (80) of the abutting intersection angles (20SKo, 20SKu) of the two splicing chambers (20o, 20u) is more than 0 mm and less than 0.35 mm. However, the invention also relates to a splicer (10) containing the splicing channel unit (60) and a textile machine (1) with such a splicer (10).

Owner:SAURER GERMANY GMBH & CO KG

A kind of expansion sleeve type fixture for gear cutting machine

ActiveCN111230226BHigh positioning accuracyImprove gear cutting accuracyGear-cutting machinesGear teethGear wheelEngineering

The invention belongs to the technical field of machine tool clamps, and relates to an expansion sleeve type clamp for a gear turning machine, including a clamp sleeve, the clamp sleeve is used to clamp a workpiece; an elastic chuck is arranged on the outer periphery of the clamp sleeve, and the elastic chuck is The clamp sleeve exerts a clamping force directed to its geometric center; a clamp body is provided at one end of the clamp sleeve, and the clamp body provides structural support for the clamp sleeve and the elastic collet. The elastic collets are arranged symmetrically on the outer periphery of the clamp sleeve along the geometric center line thereof, and the elastic collets are in a cylindrical structure. The invention improves the positioning accuracy of the workpiece, prevents the deformation of the workpiece, and further improves the gear cutting accuracy, which can prolong the cutting life of the tool to a certain extent, and has a simple structure and reduces the moment of inertia of the gear turning machine workbench, ensuring that the machine tool can be stopped safely and smoothly .

Owner:CHONGQING MACHINE TOOL GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com