Automatic side wall separating mechanism of electric connector

An automatic separation and electrical connector technology, applied in the direction of self-propelled projectiles, weapon types, projectiles, etc., can solve the problems of poor separation effect of electrical connectors, and achieve the effects of high connection reliability, improved efficiency and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

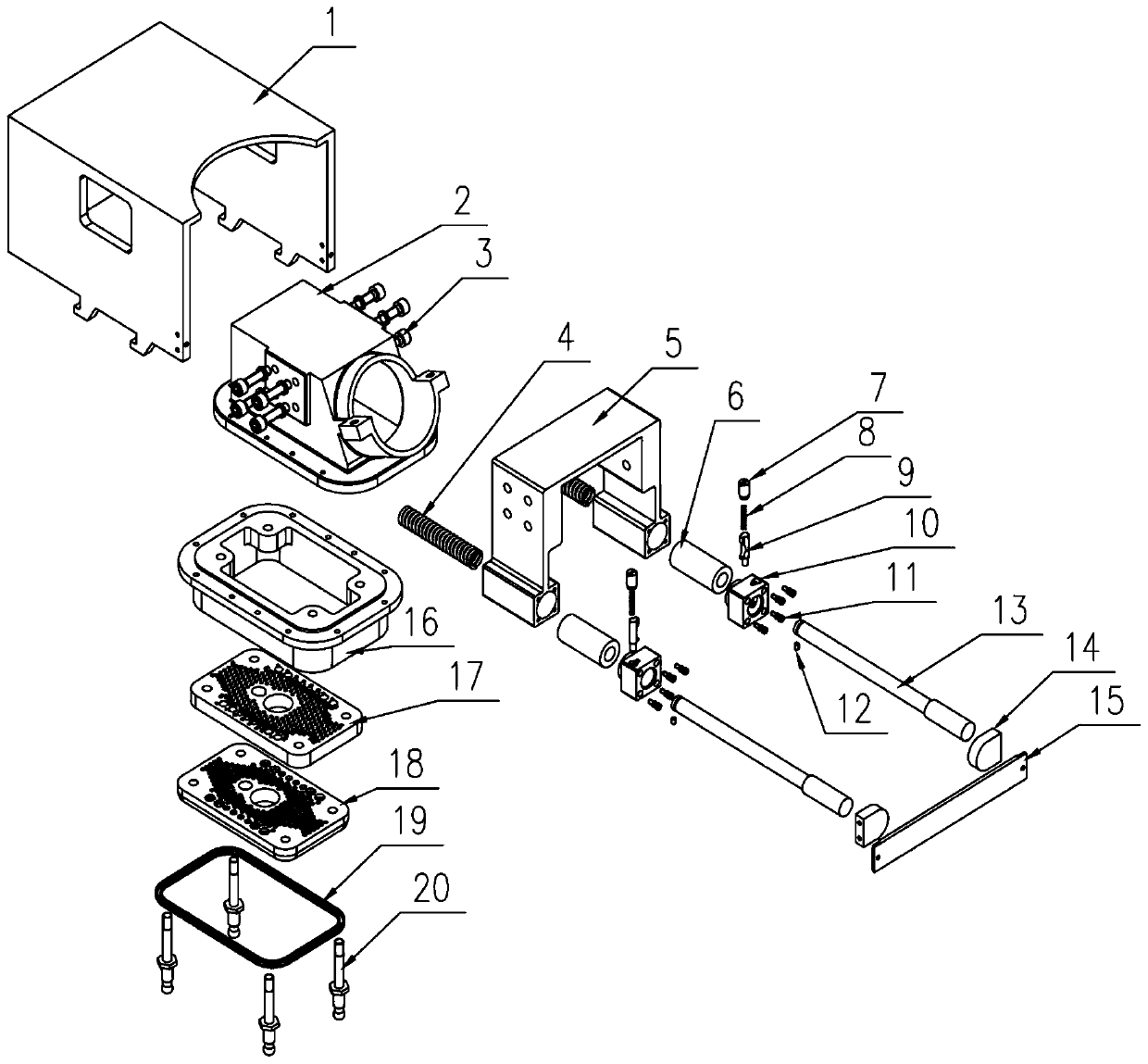

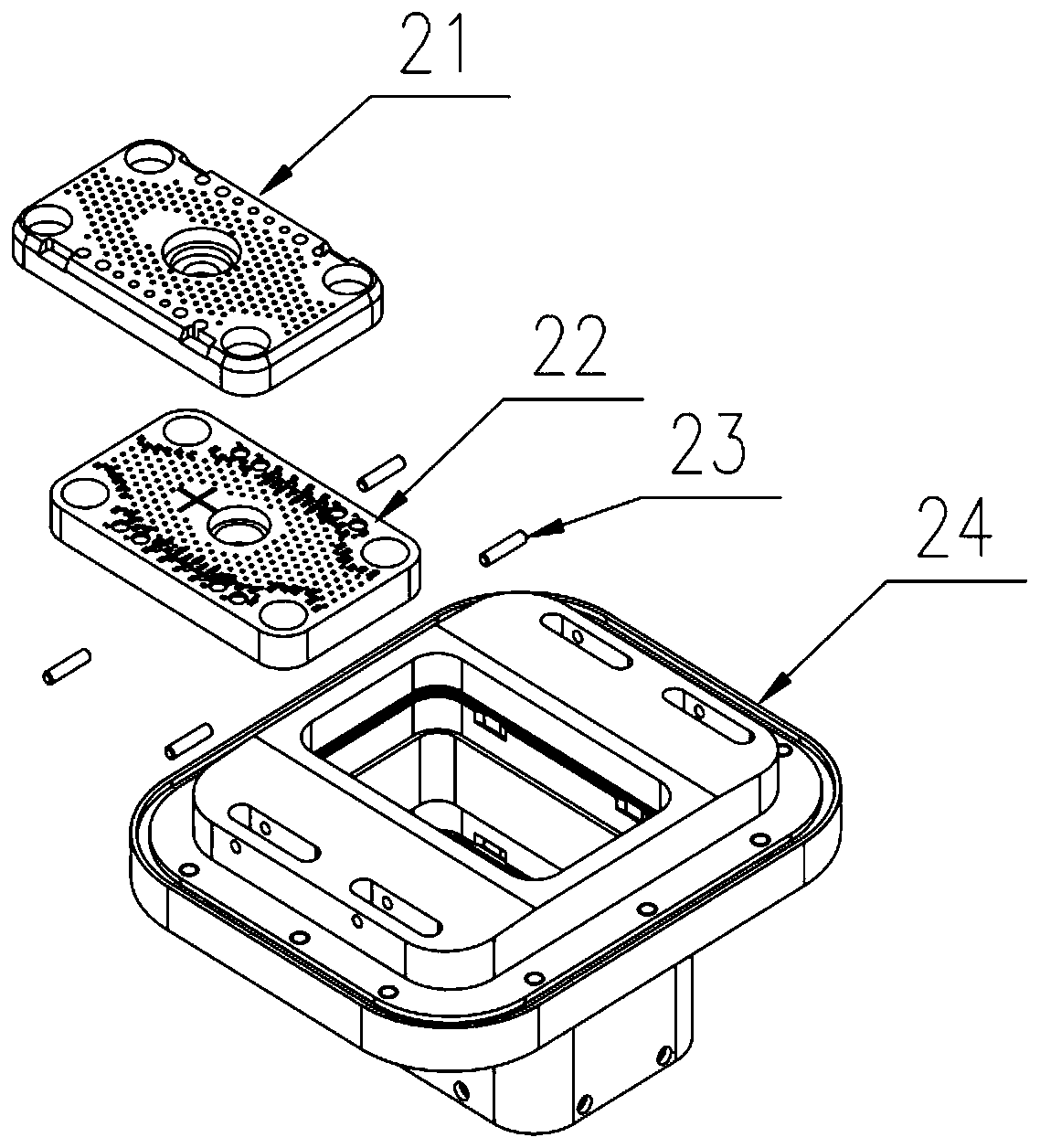

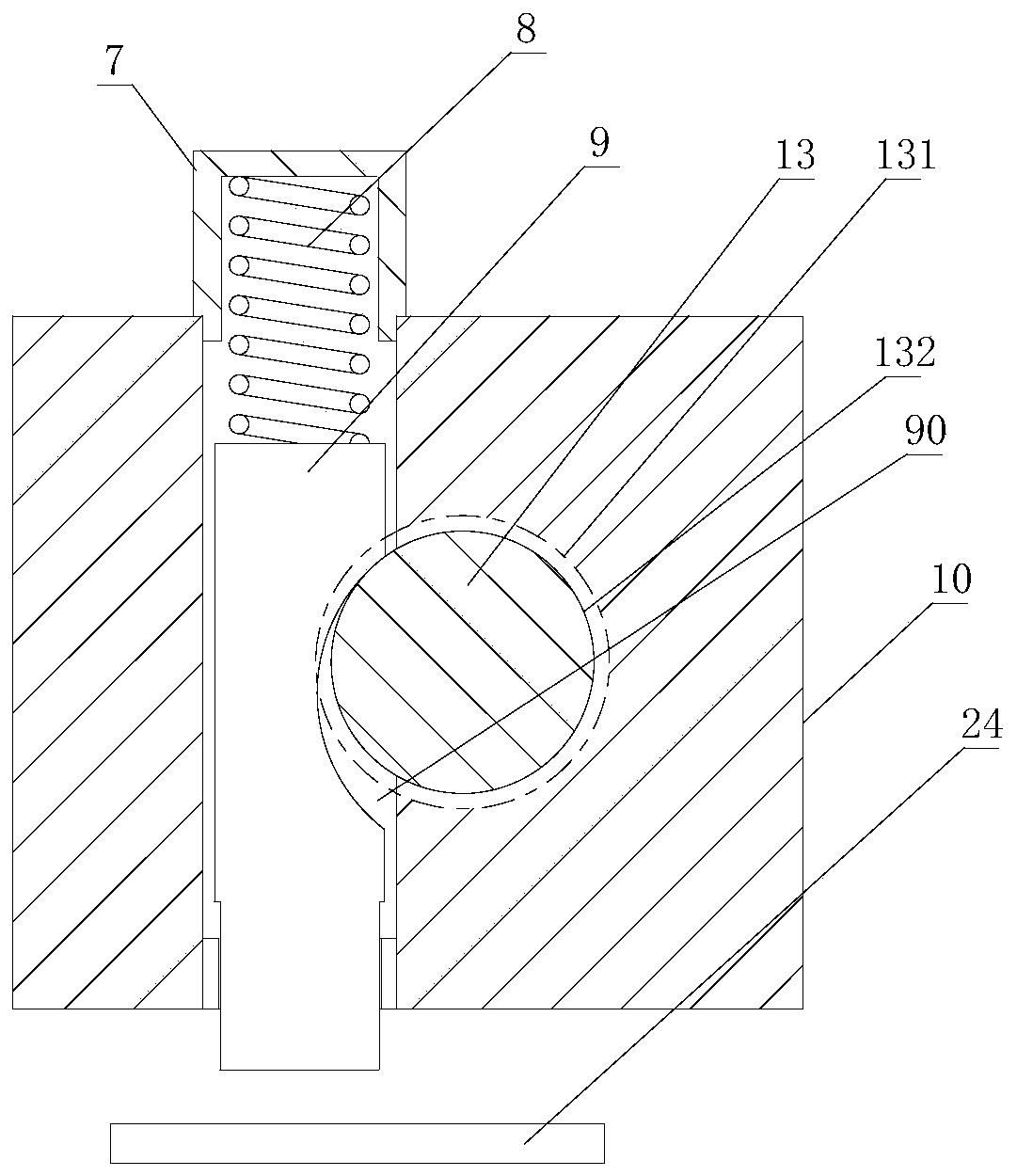

[0029] Such as figure 1 , figure 2 As shown, a side wall automatic separation mechanism of an electrical connector includes a plug and a socket, and the socket includes a socket housing 24 and a locking pin 23, and the locking pin 23 is arranged on the socket housing 24. The plug includes a shell 1, a plug cable cover 2, a fixing frame 5 and a plug housing 16, the shell 1 is provided with a cavity, the plug cable cover 2 is fixedly connected in the fixing frame 5, and the fixing frame 5 is arranged on In the cavity, the housing 1 is provided with an opening, the plug cable cover 2 is provided with threaded holes, the fixing frame 5 is provided with through holes, and the plug cable cover 2 is fixedly connected to the fixing frame 5 by bolts 3 Above, the plug cable cover 2 is fixedly connected to the plug housing 16, and the housing 1 is provided with a hook that cooperates with the locking pin 23; the fixing frame 5 is provided with a fixing block 10 fixed by screws 11 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com