Roller bearing backing ring assembly

A technology for bearing components, backing rings, applied in the field of roller bearings, which can solve the problems of accelerated bearing component and journal wear, shaft or bearing failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

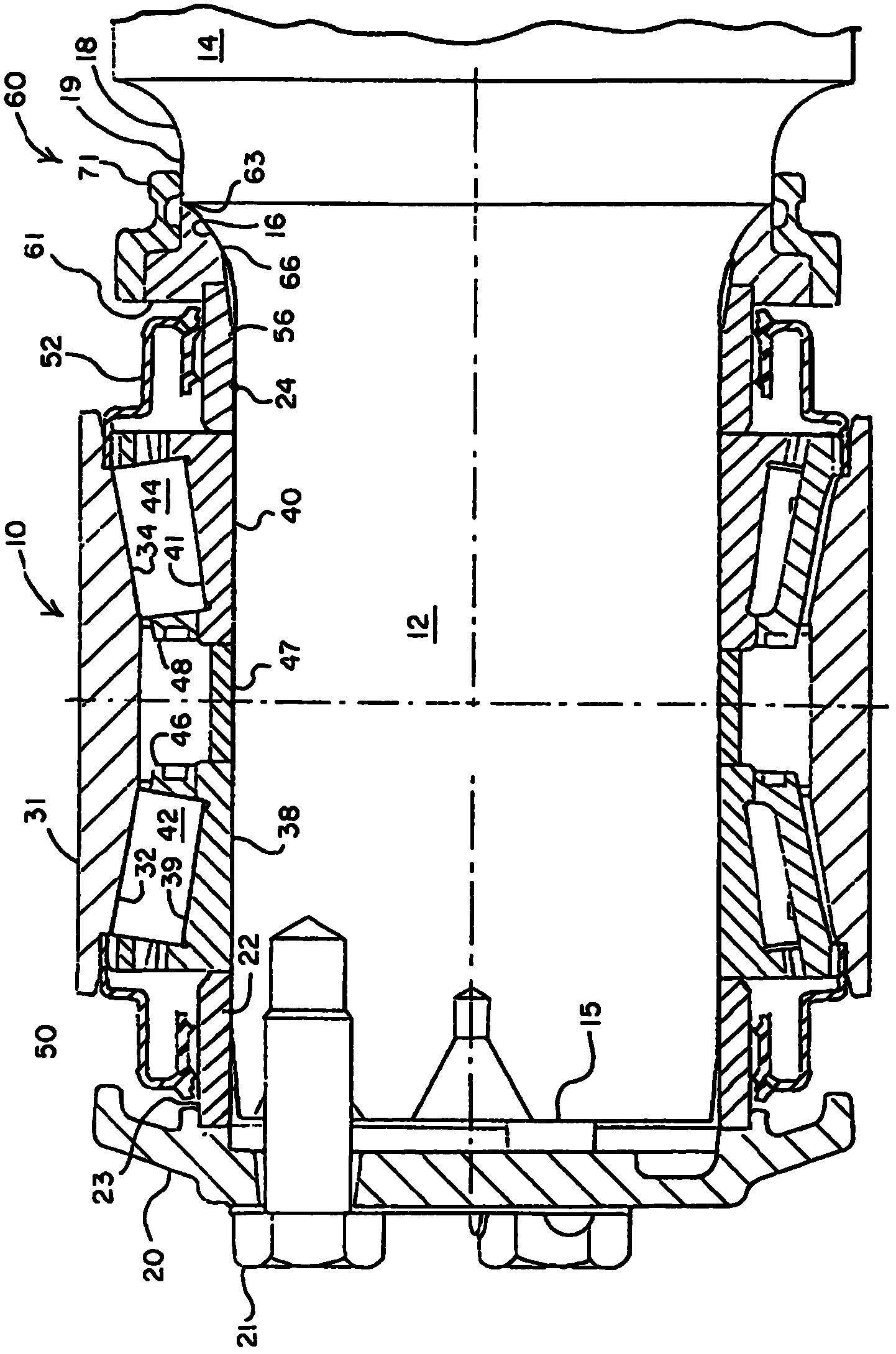

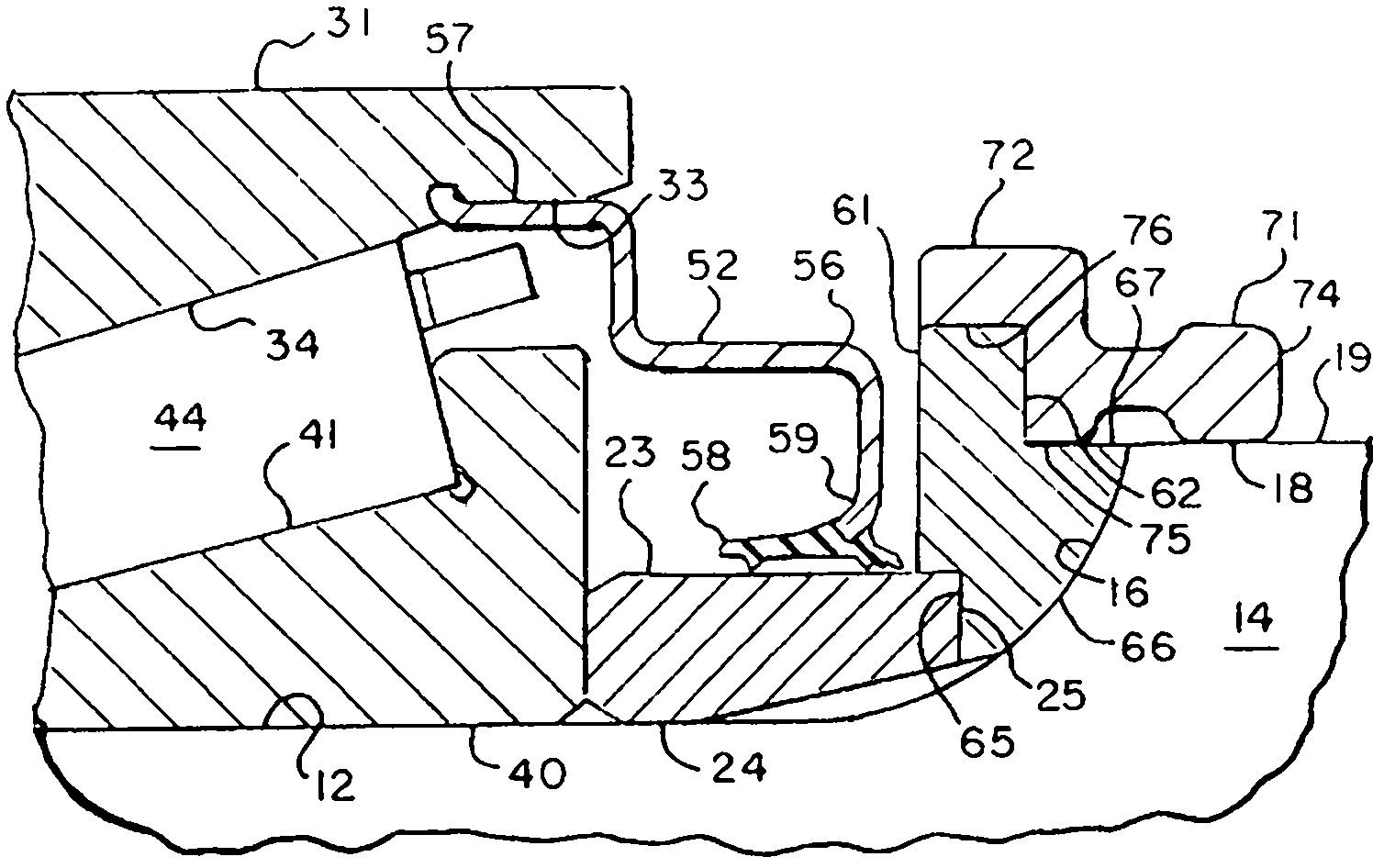

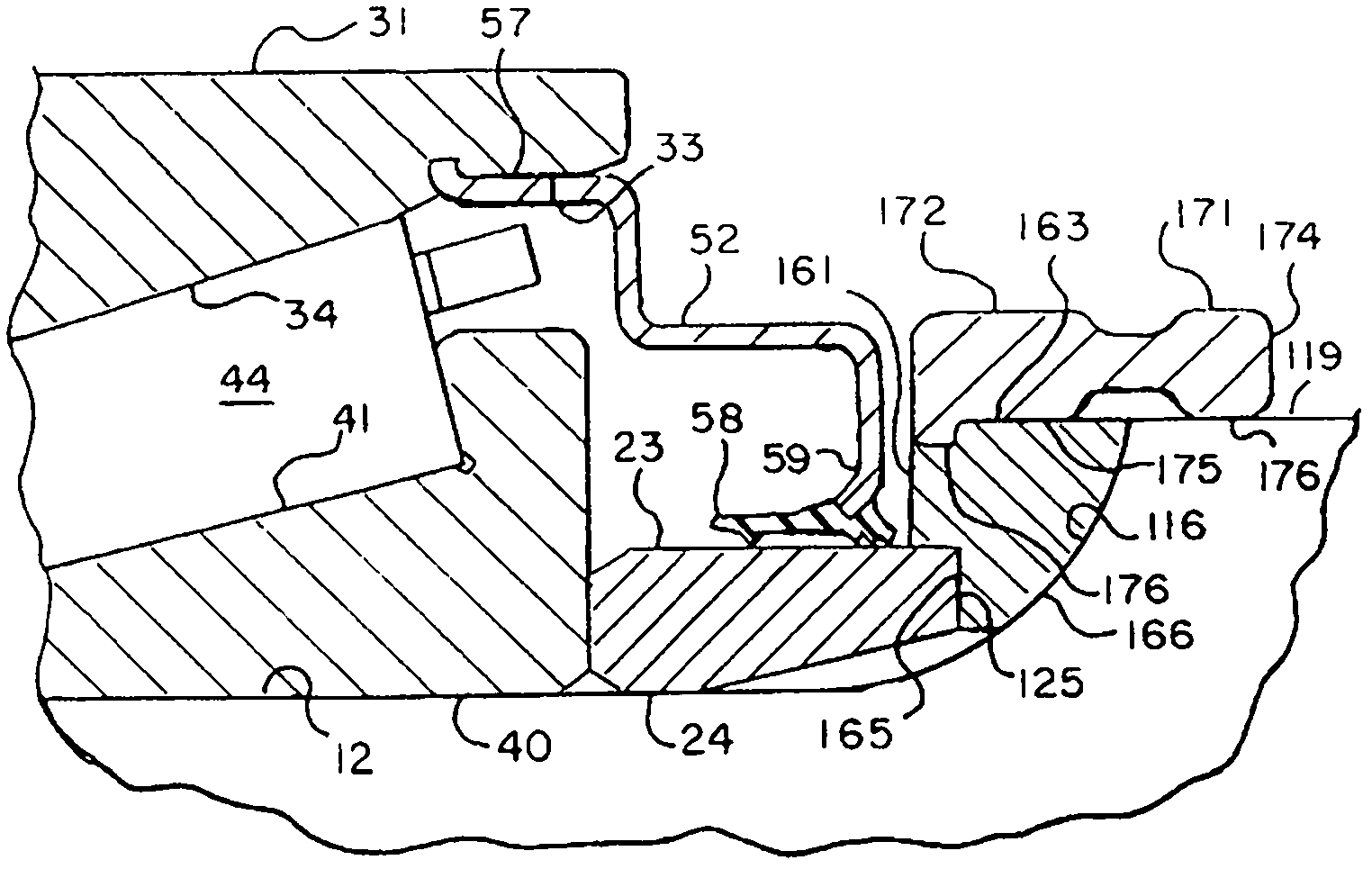

[0016] refer to figure 1 , shows one embodiment of a grommet assembly. In this embodiment, bearing assembly 10 is a tapered roller bearing of the type often used to support railcar wheels on axles in railroad applications.

[0017] Bearing assembly 10 is typically pre-assembled prior to installation on railcar axle 14 . At each free end of the axle 14, the journal 12 terminates in a slightly conical section 15 to facilitate mounting the bearing assembly 10 thereon. Bearing assembly 10 is pressed against journal 12 of axle 14 to form an interference fit.

[0018] A dust shield 18 having a larger diameter than the journal 12 is positioned axially inward from the journal 12 . Axially inwardly from dust shield 18, shaft 14 extends to its largest diameter. The weight of the railcar is transferred to the axle through the bearing assembly 10 and further to the rails through railcar wheels (not shown) fitted inside the dust shields on the axle.

[0019] Some bearing assemblies 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com