Patents

Literature

3259results about "Tube shearing machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

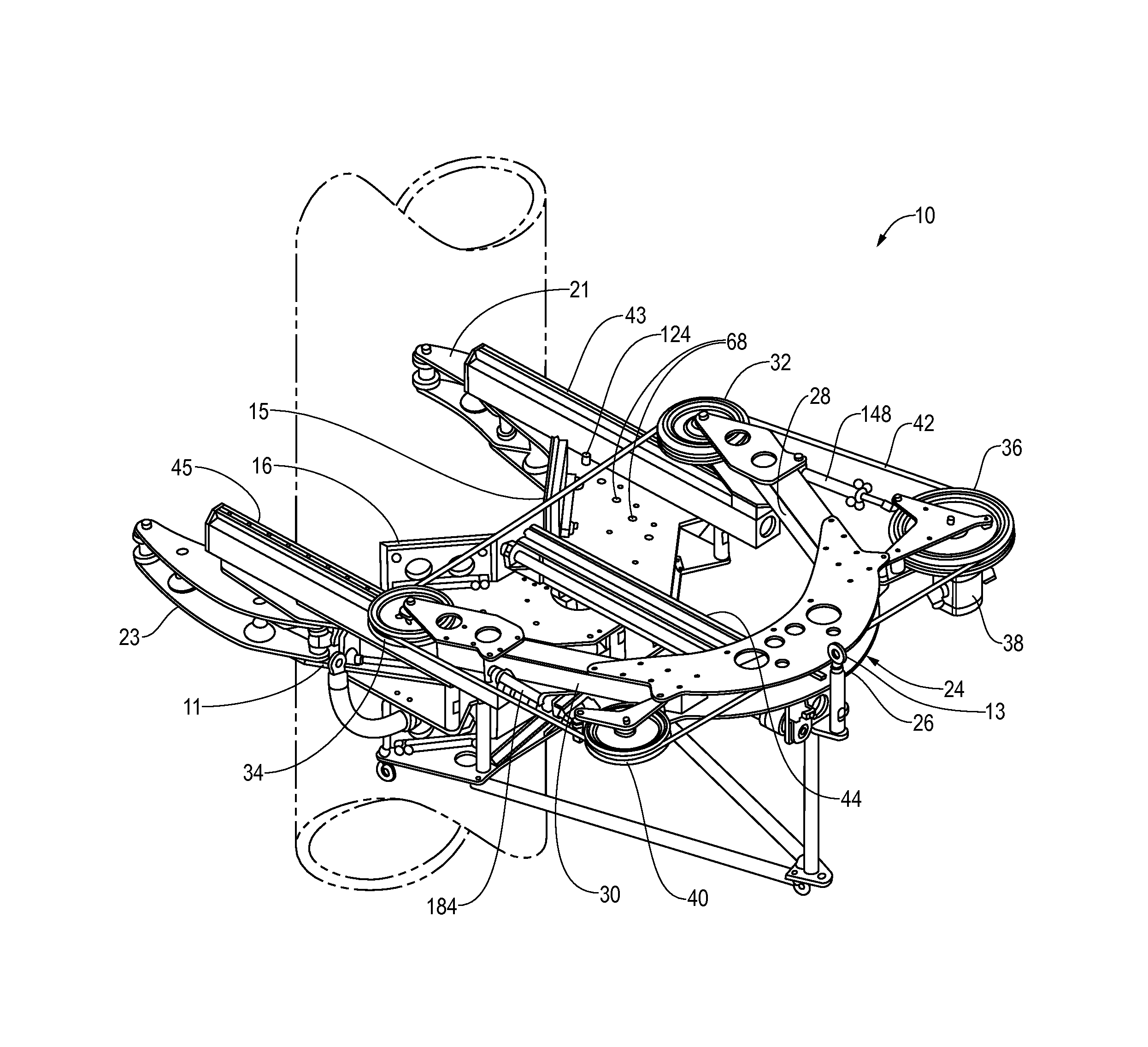

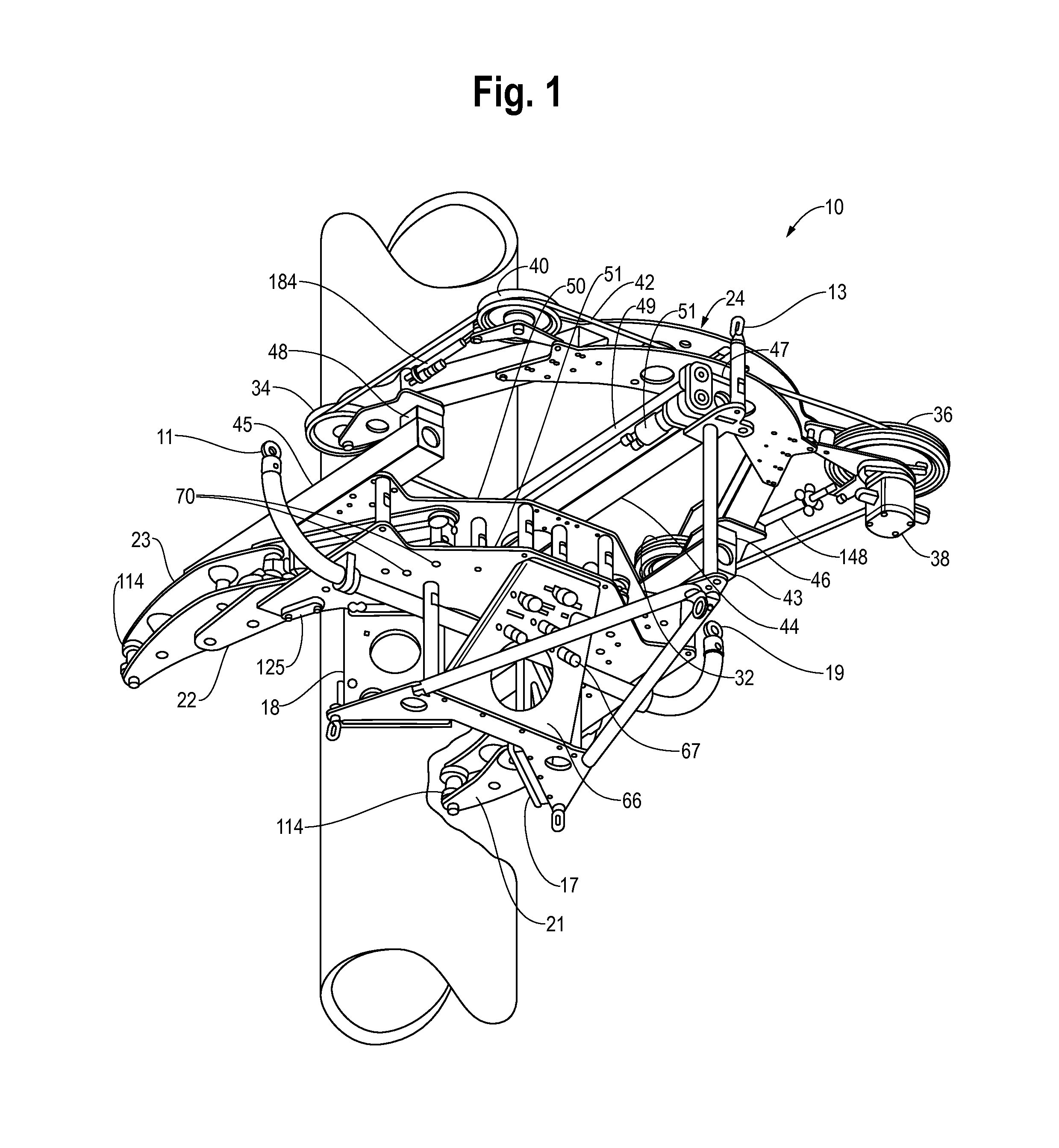

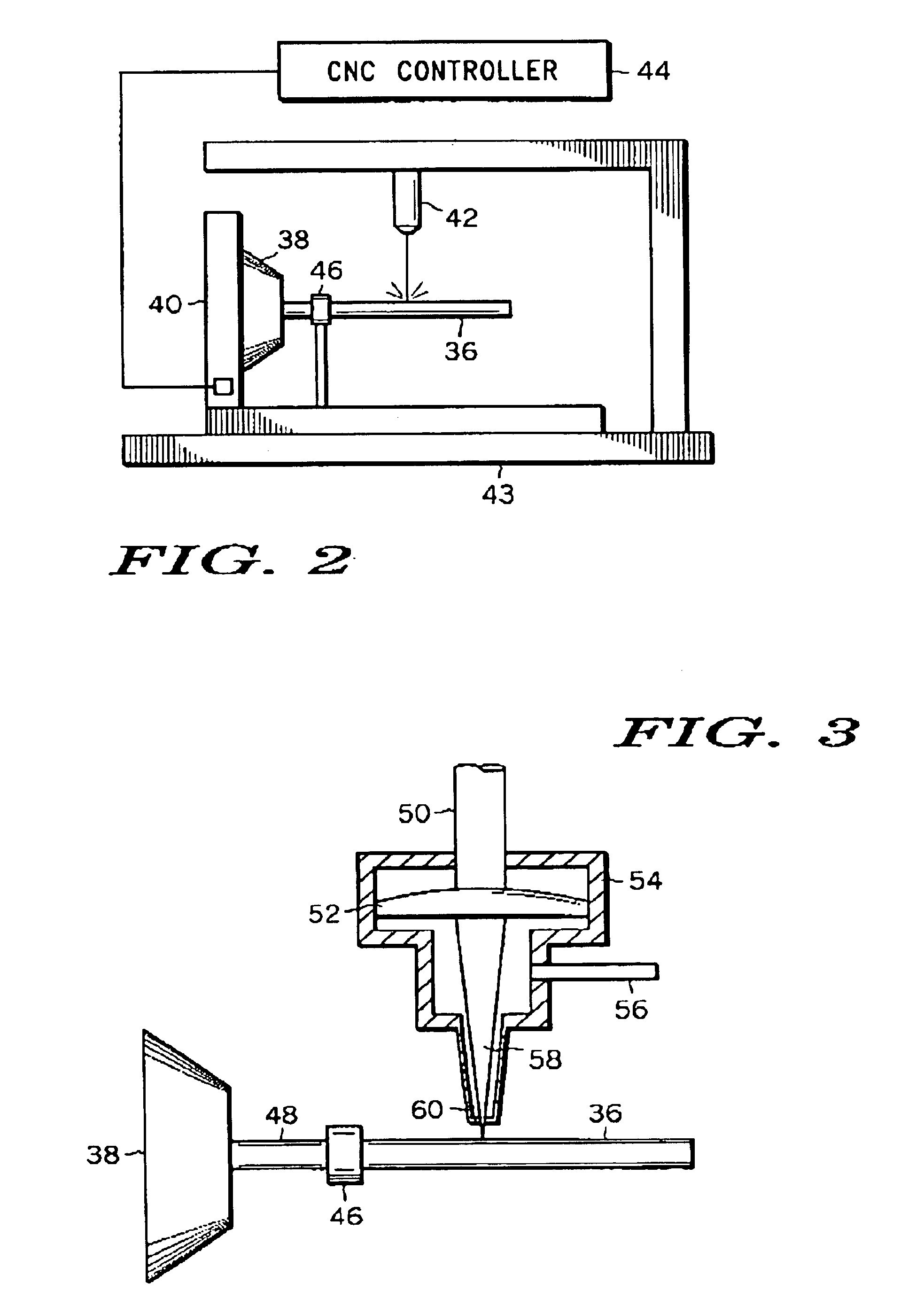

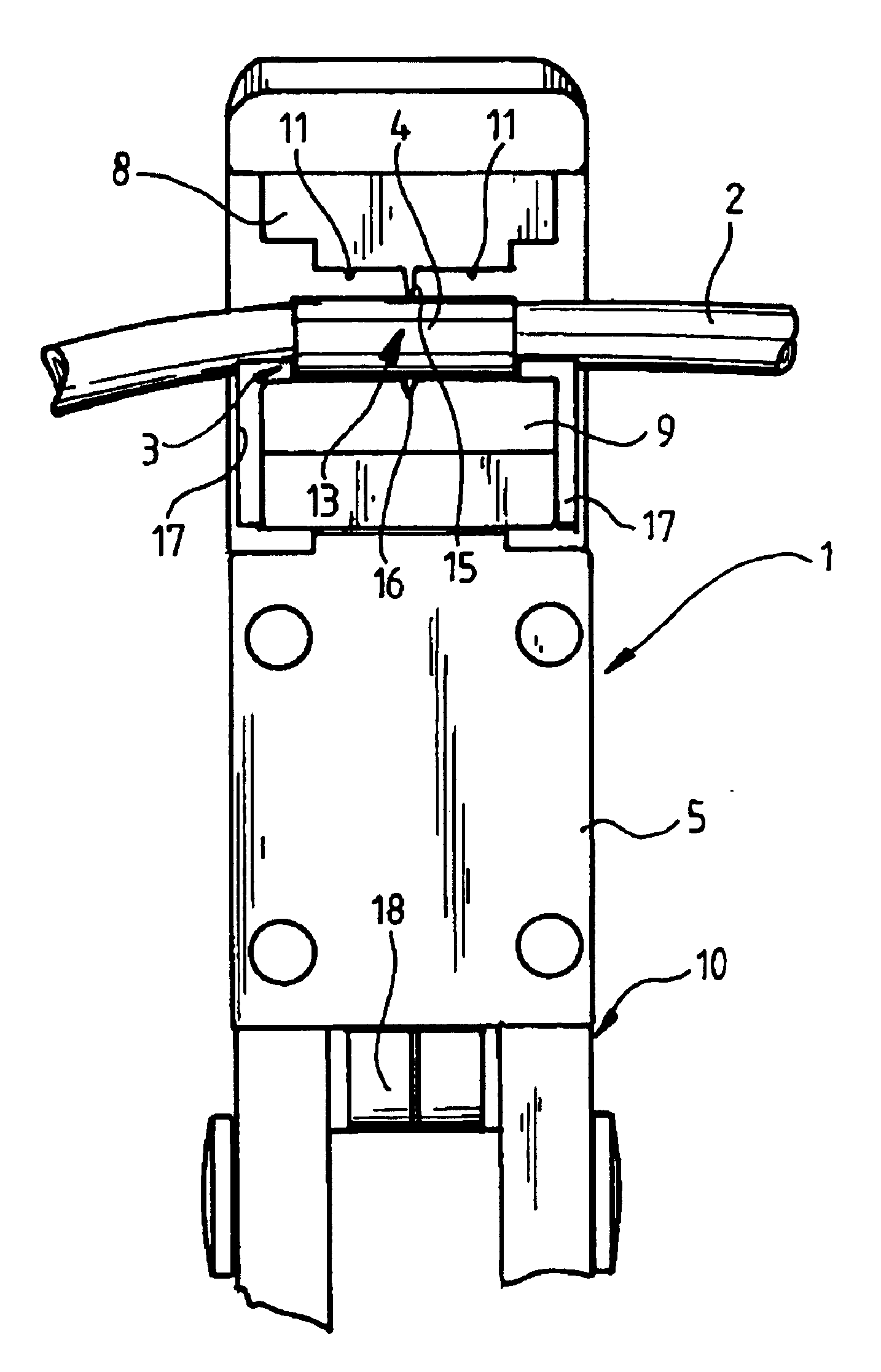

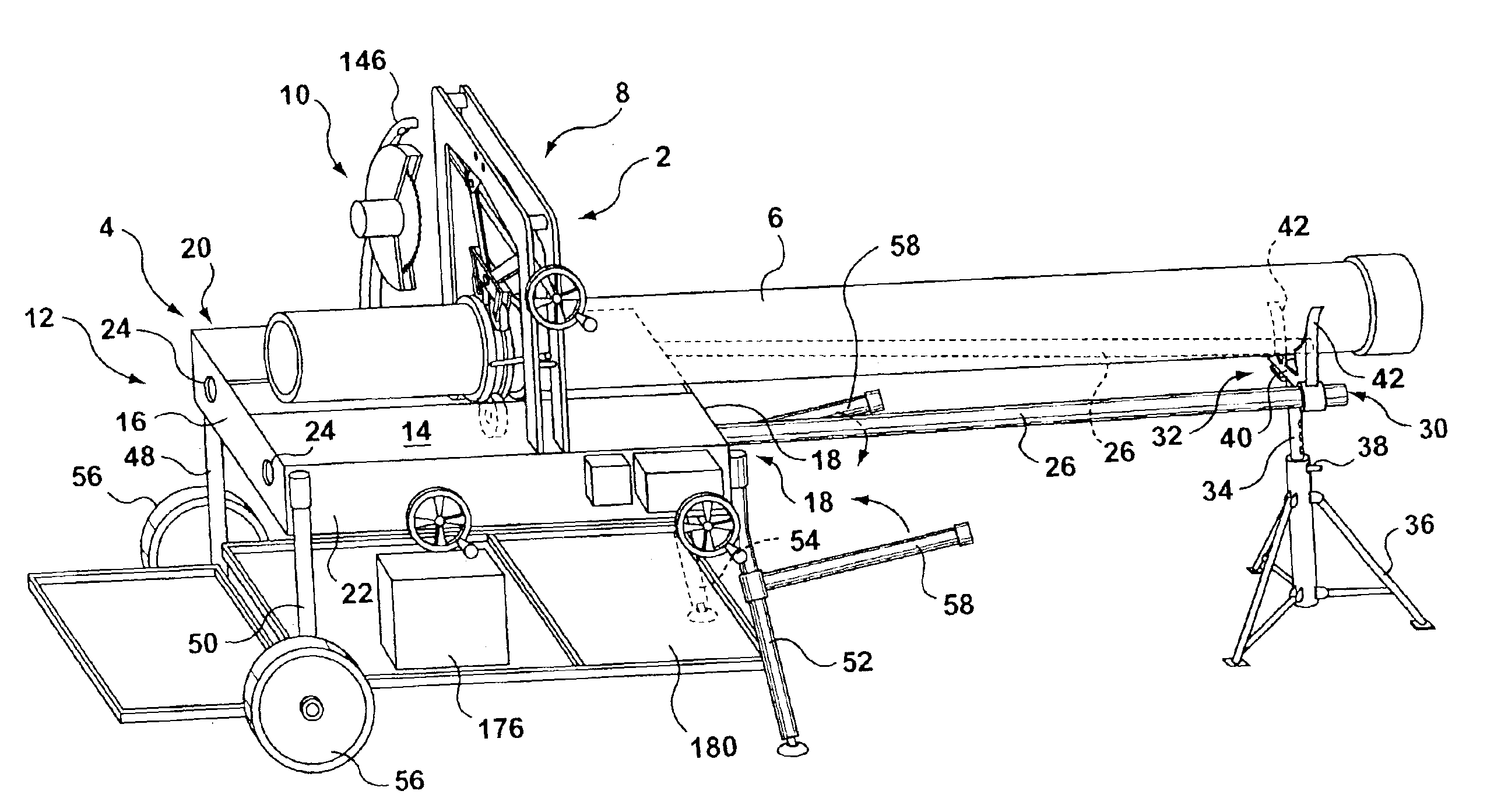

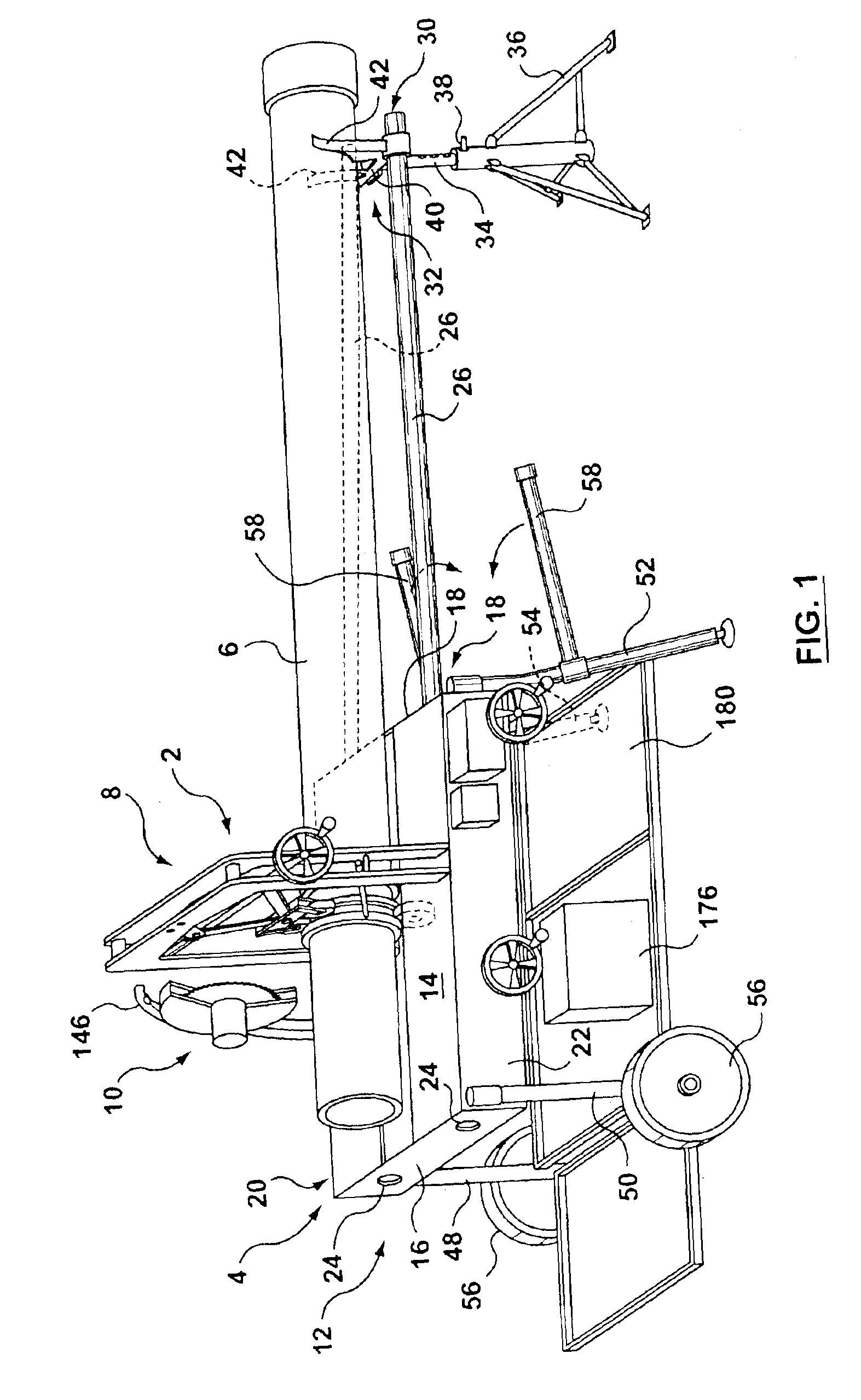

Wire saw

A device for cutting a length of pipe includes a clamp portion for clamping around a length of pipe and a bow moveable with respect to the clamp portion that retains a loop of diamond embedded wire. The device further includes a feed for driving the bow with respect to the clamp portion and a detector for detecting bending of the wire and a control responsive to the detector for controlling feed rates. The device is made of modular parts and has synchronizing arms for clamping around a length of pipe. In one embodiment, the wheels are retained in enclosures with slots through which the cutting wire passes.

Owner:ILLINOIS TOOL WORKS INC

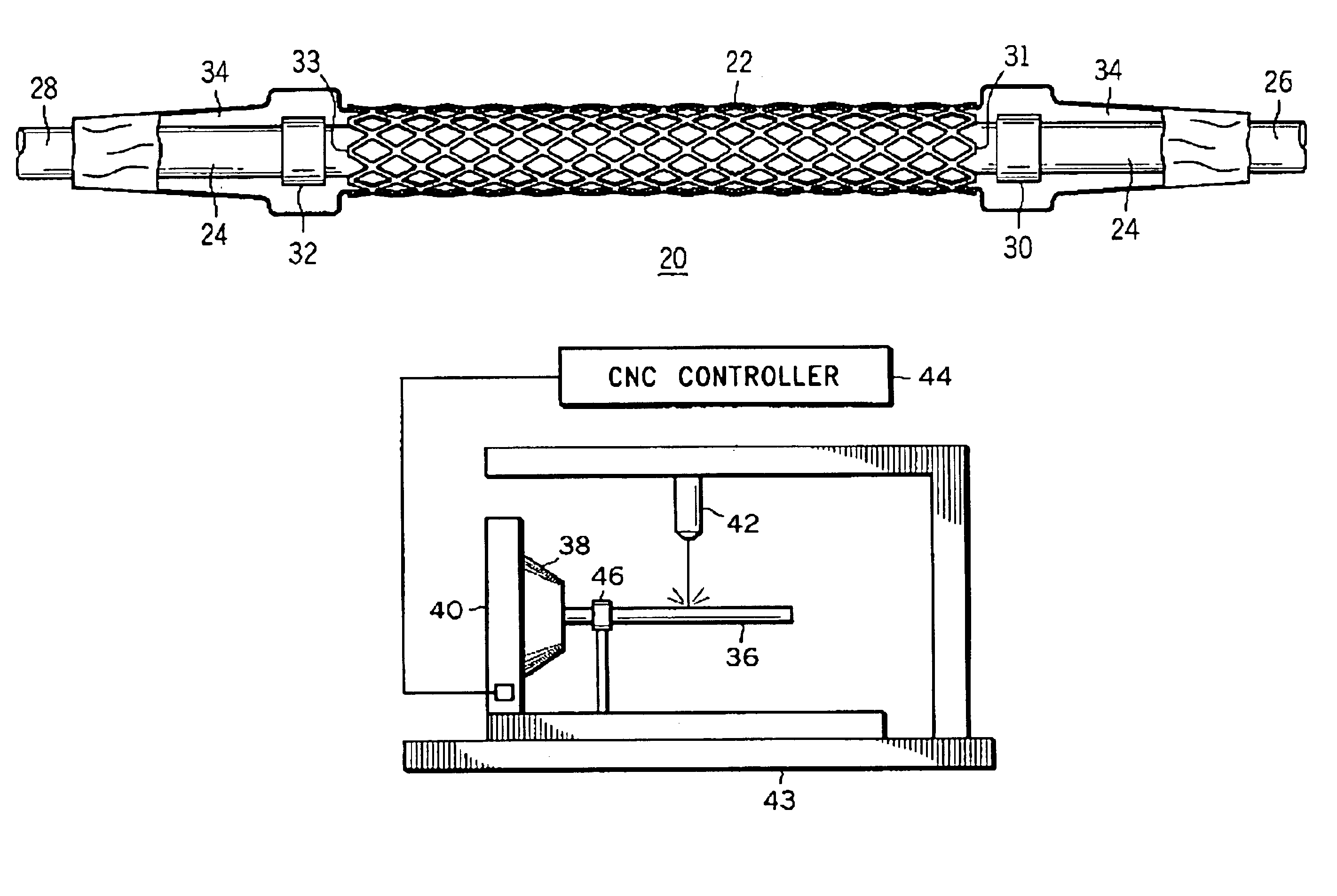

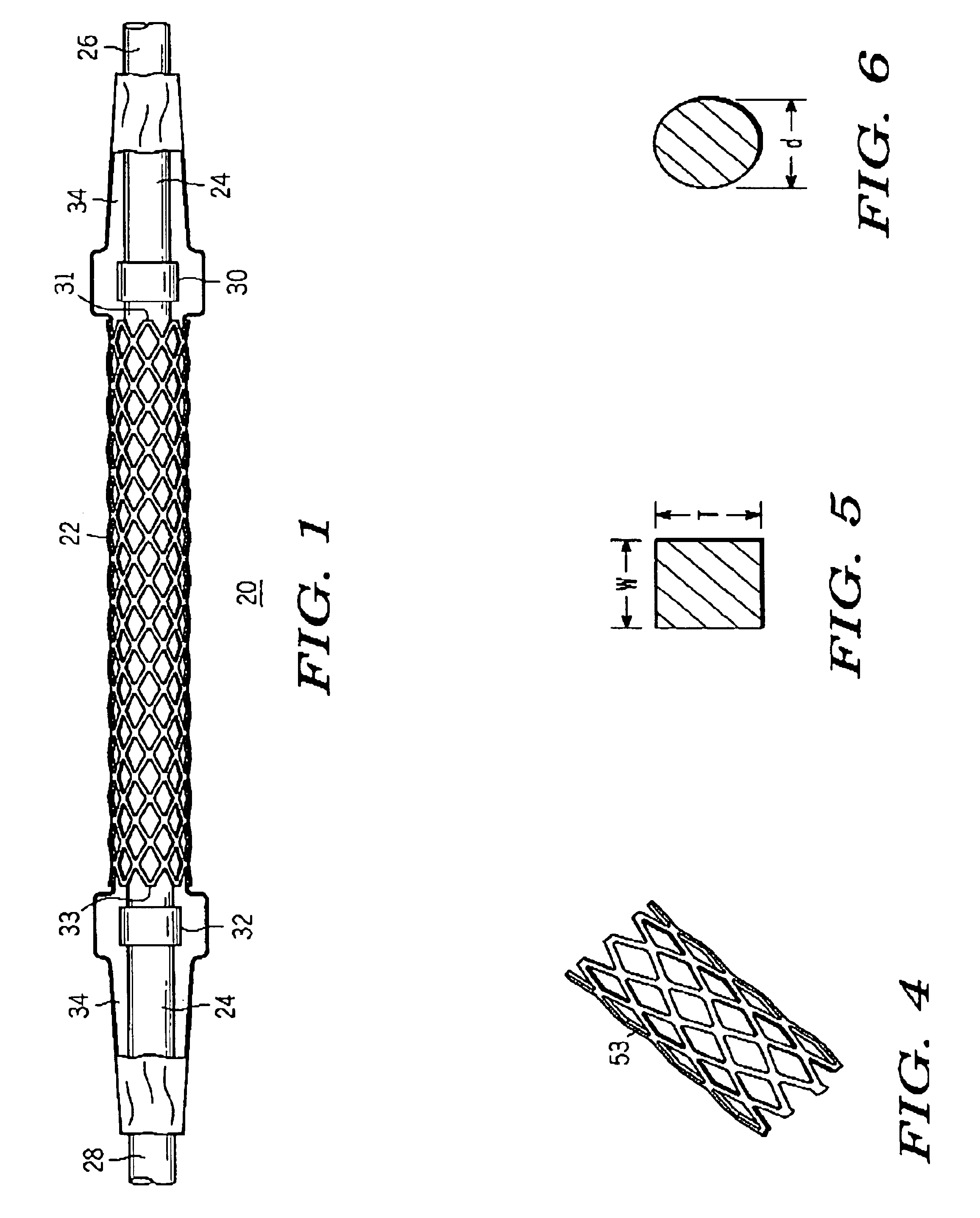

Method for manufacturing an endovascular support device

A method for manufacturing an endovascular support device comprises positioning a generally tubular member made of an implantable metal and having a generally cylindrical wall in a working relationship with a laser beam. A desired pattern is cut in the generally cylindrical wall in order to produce a stent having a plurality of openings and a plurality of edges. The stent is tumbled in a medium to round its edges and, in turn, to produce more rounded cross-sections of stent elements.

Owner:MEDTRONIC VASCULAR INC

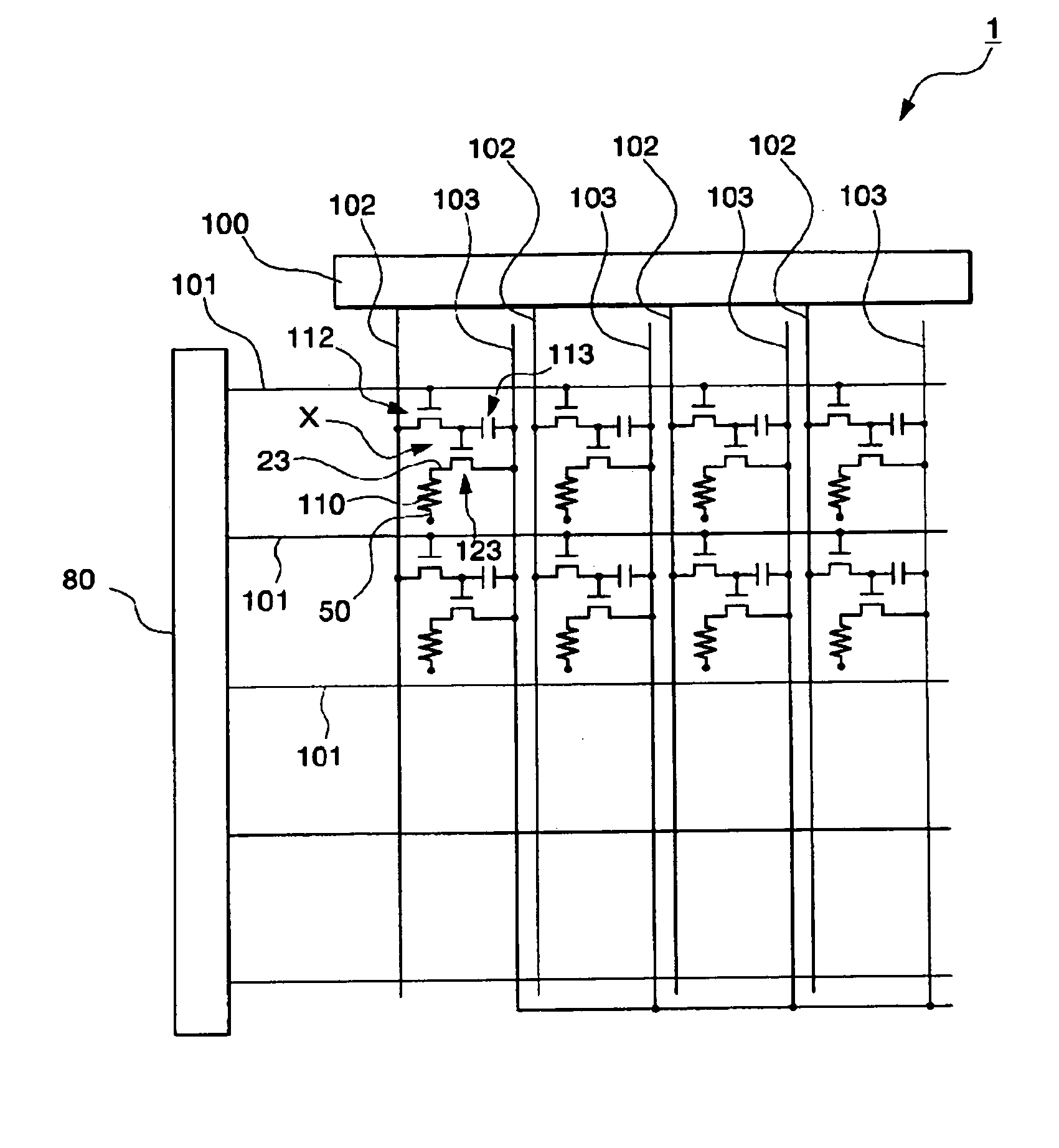

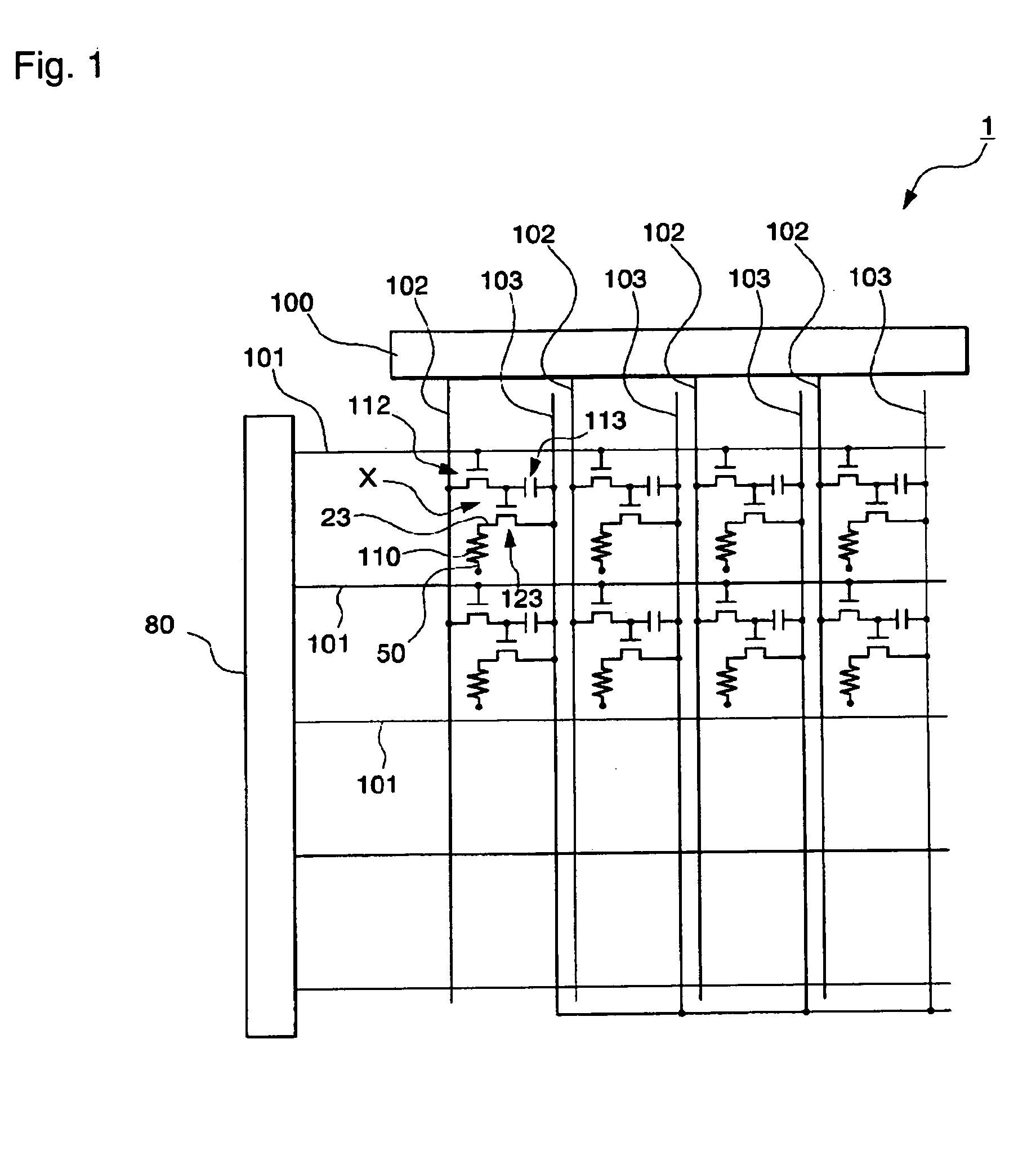

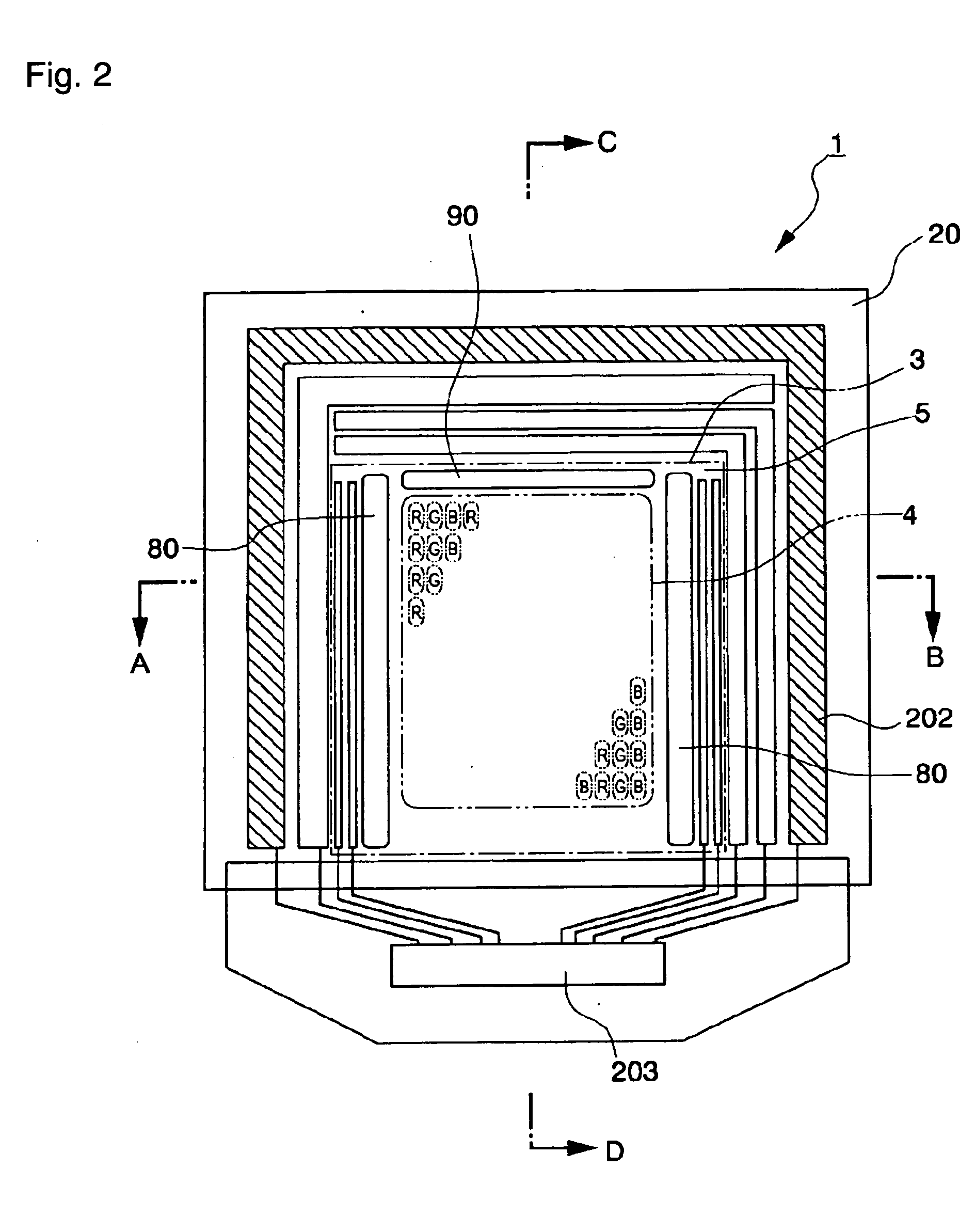

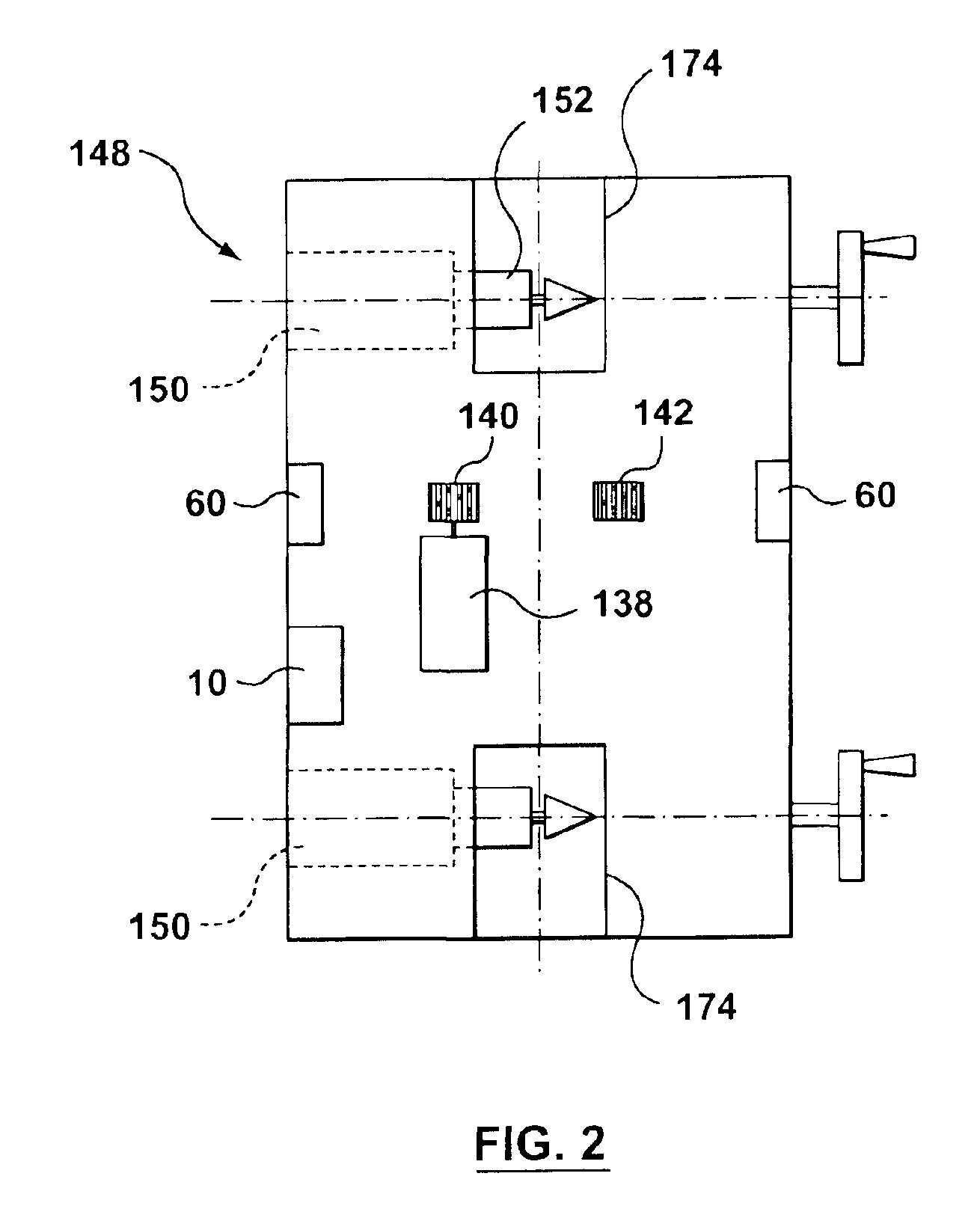

Electro-optical device, method of manufacturing the same, and electronic apparatus

ActiveUS20040212759A1Reduced or prevented from being deterioratedQuality improvementElectroluminescent light sourcesSolid-state devicesUltravioletEngineering

Owner:SEIKO EPSON CORP

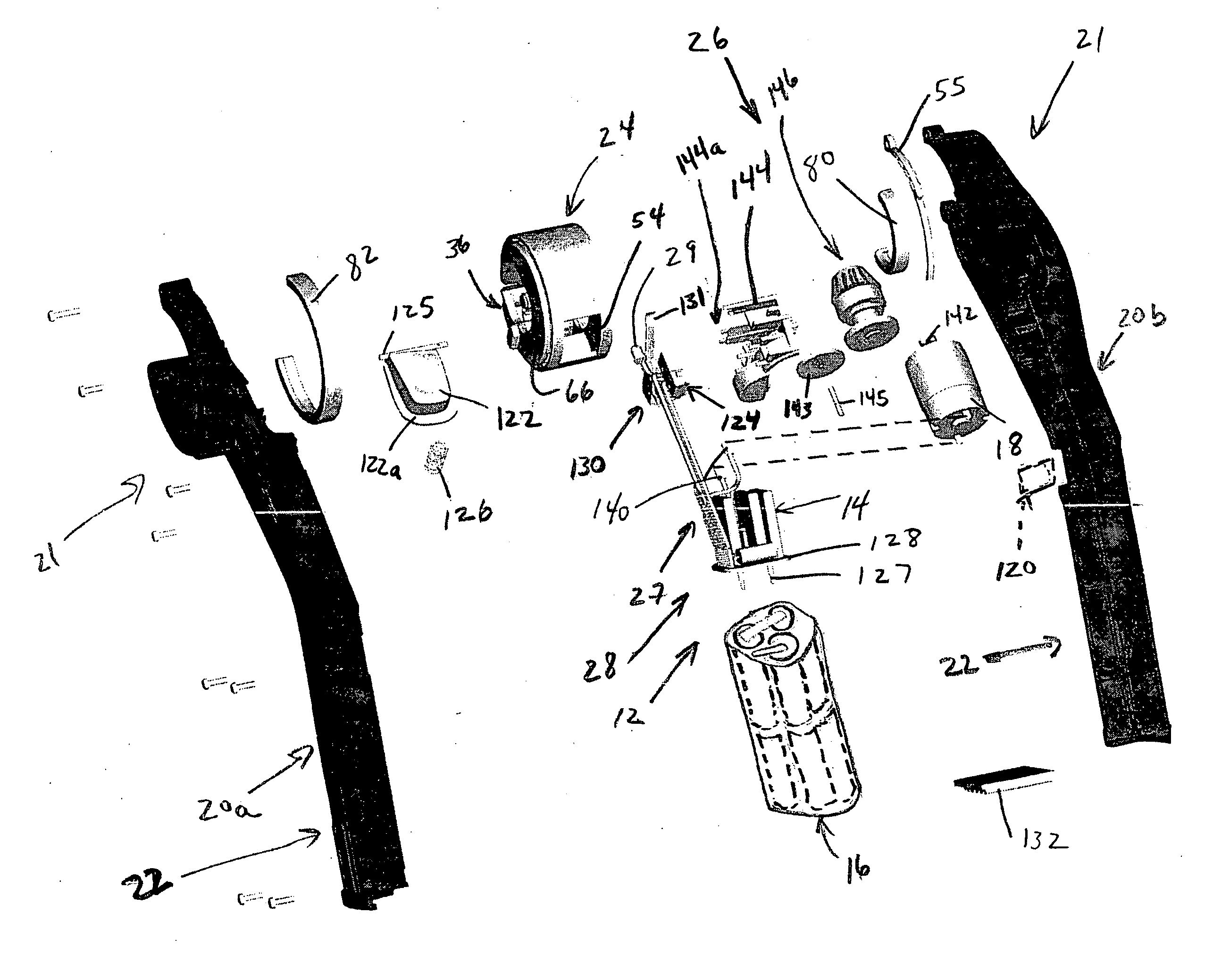

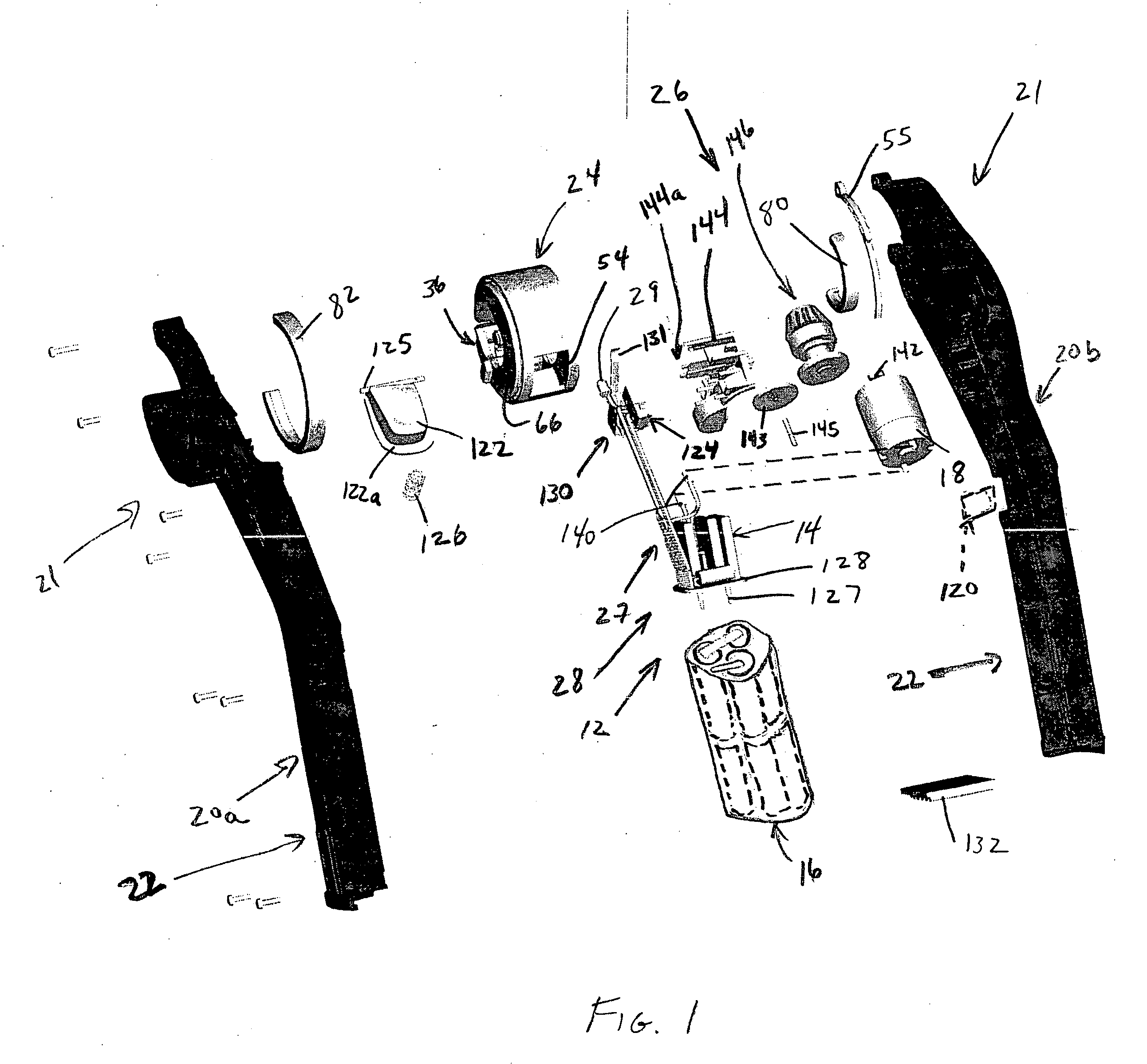

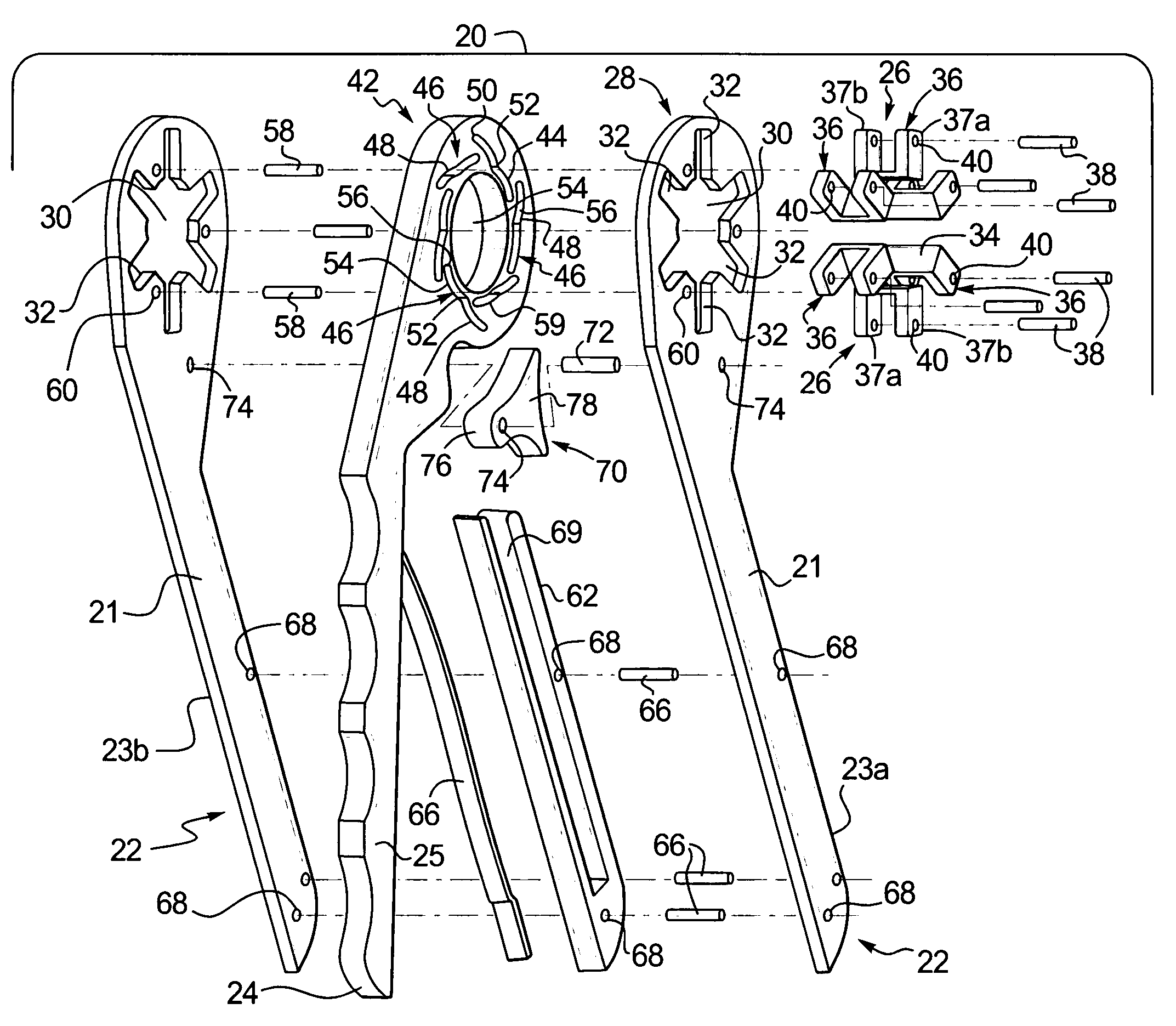

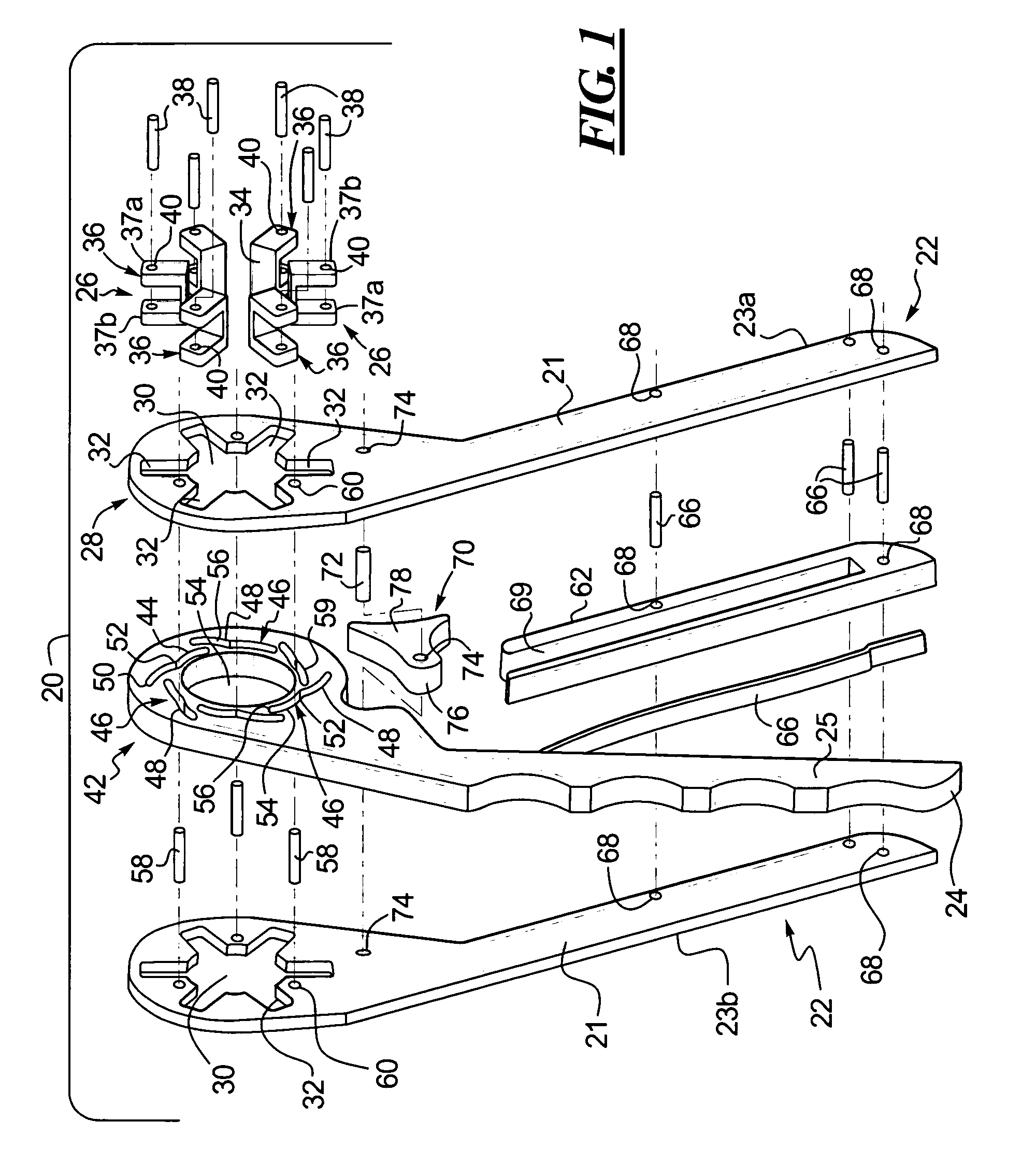

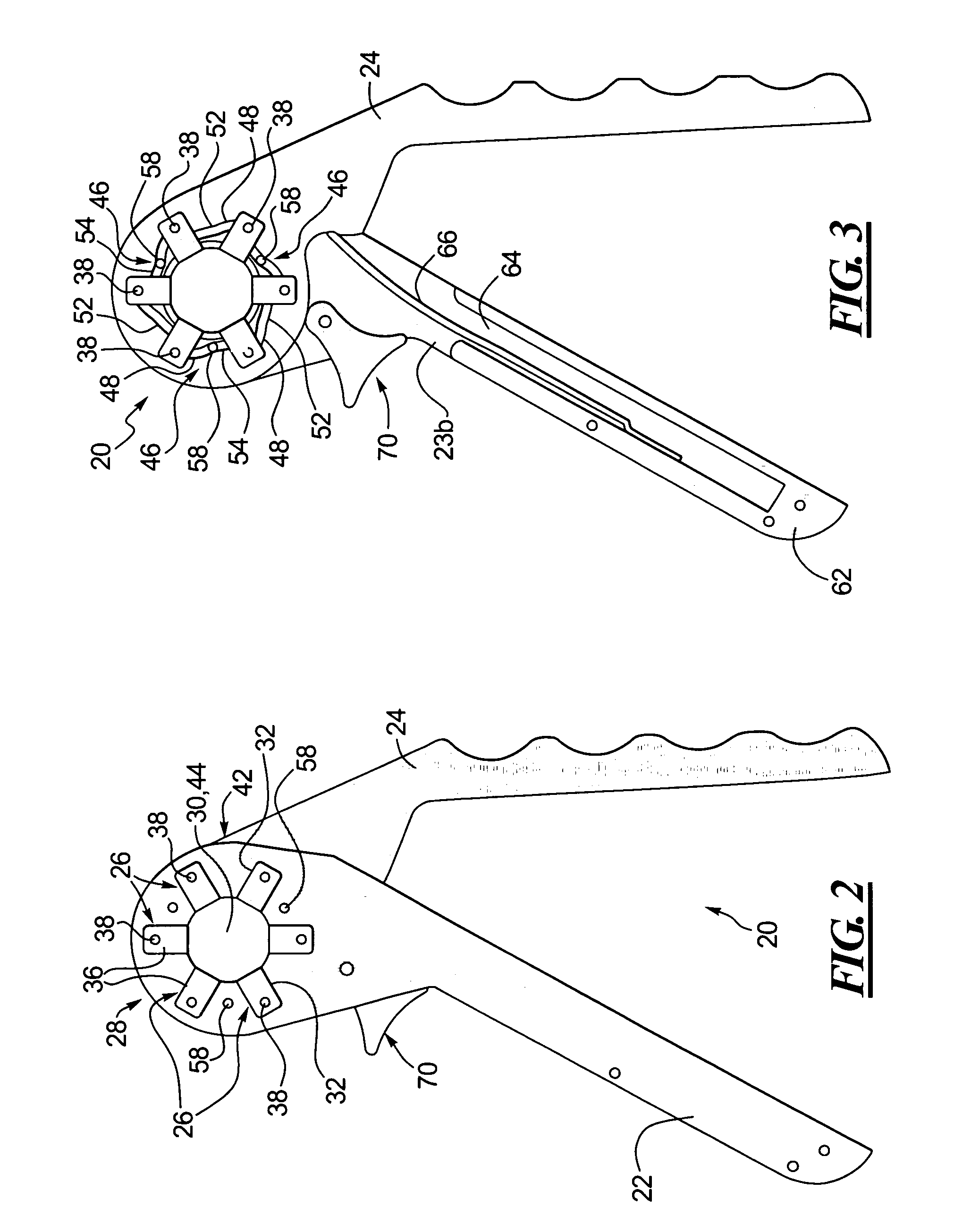

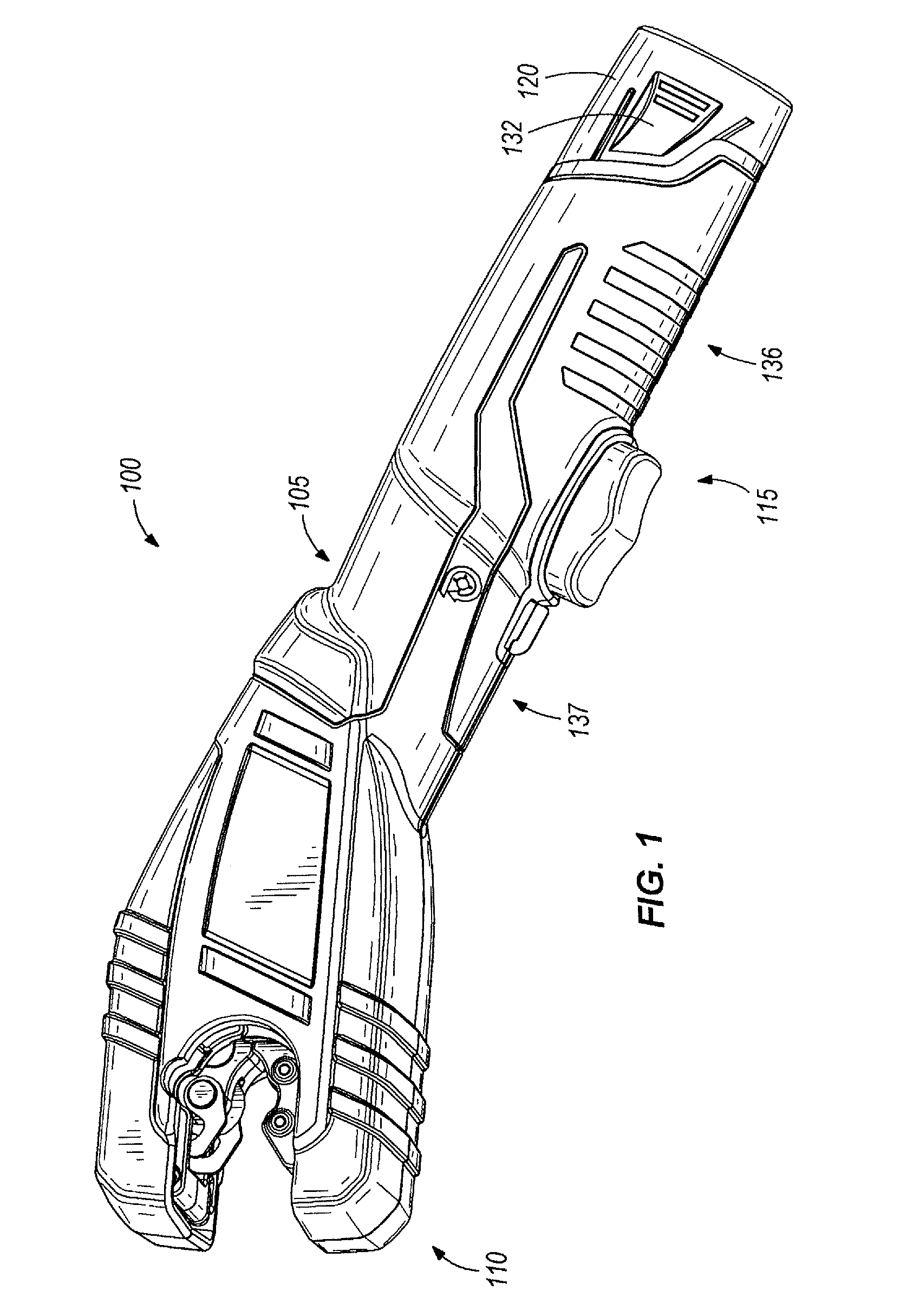

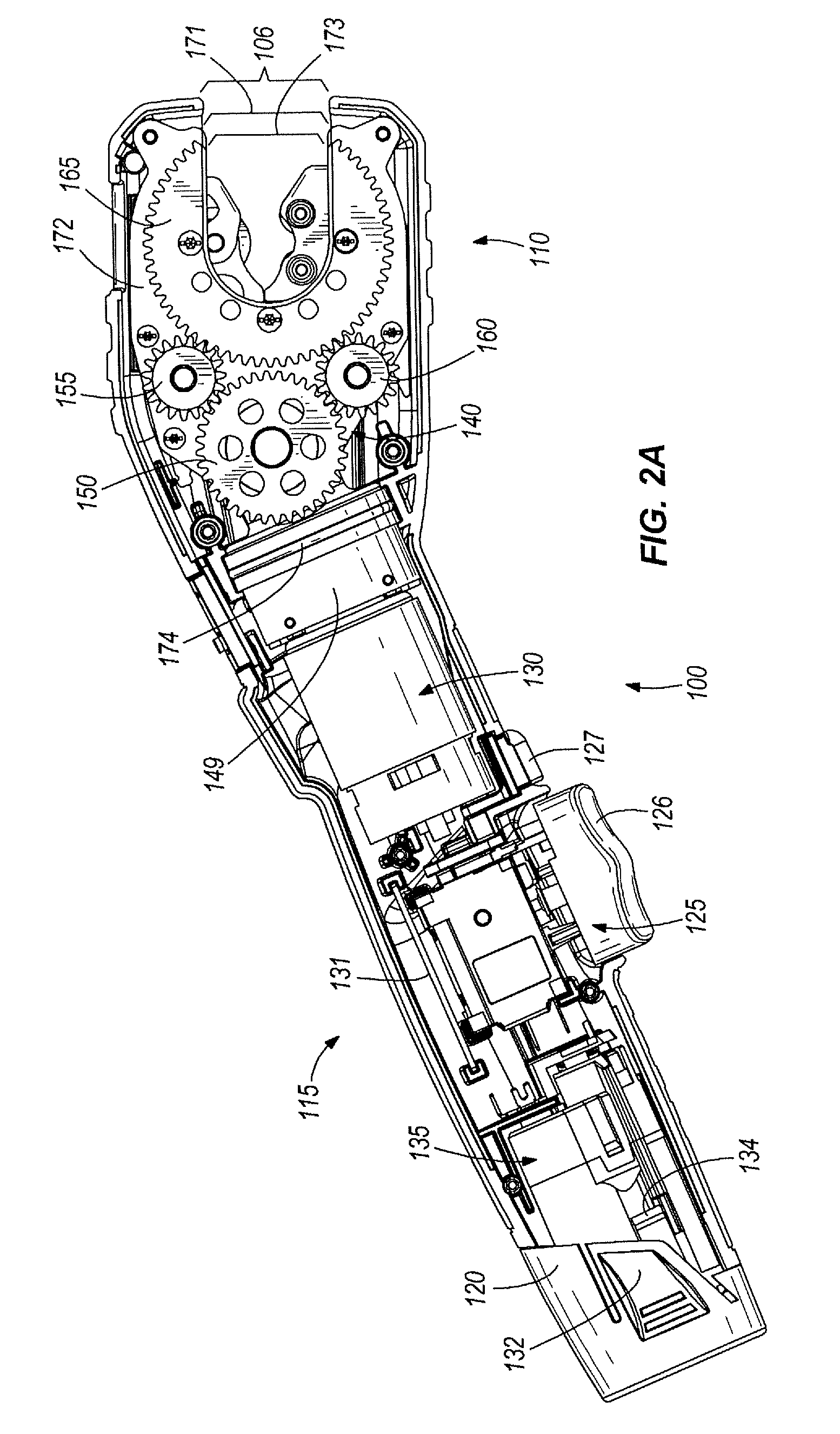

Powered hand held devices

InactiveUS20060092674A1Improved power supply arrangementReduce loadBatteries circuit arrangementsSurgeryHand heldSupercapacitor

A powered hand held device having an improved power supply with both a low power source in parallel with a high power source from ultracapacitors. The ultracapacitor power is used by the device motor during certain peak power demands which require high power to the device motor. An improved hand held tube cutter tool is provided both with and without the improved power arrangement, and includes a rotating cutter head assembly with an adjustable roller assembly providing a superior tube cut.

Owner:SUPERIOR TOOL CORP

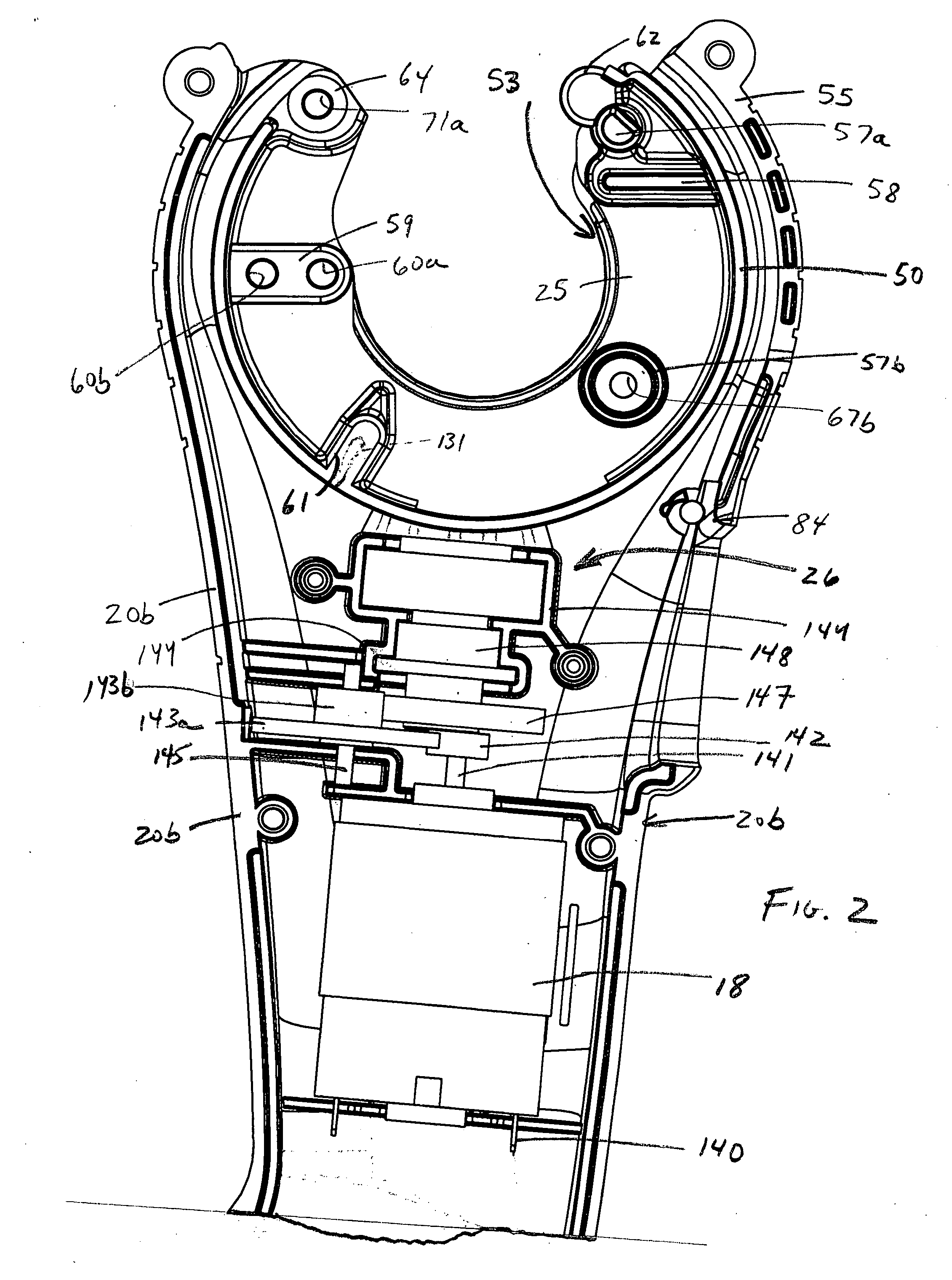

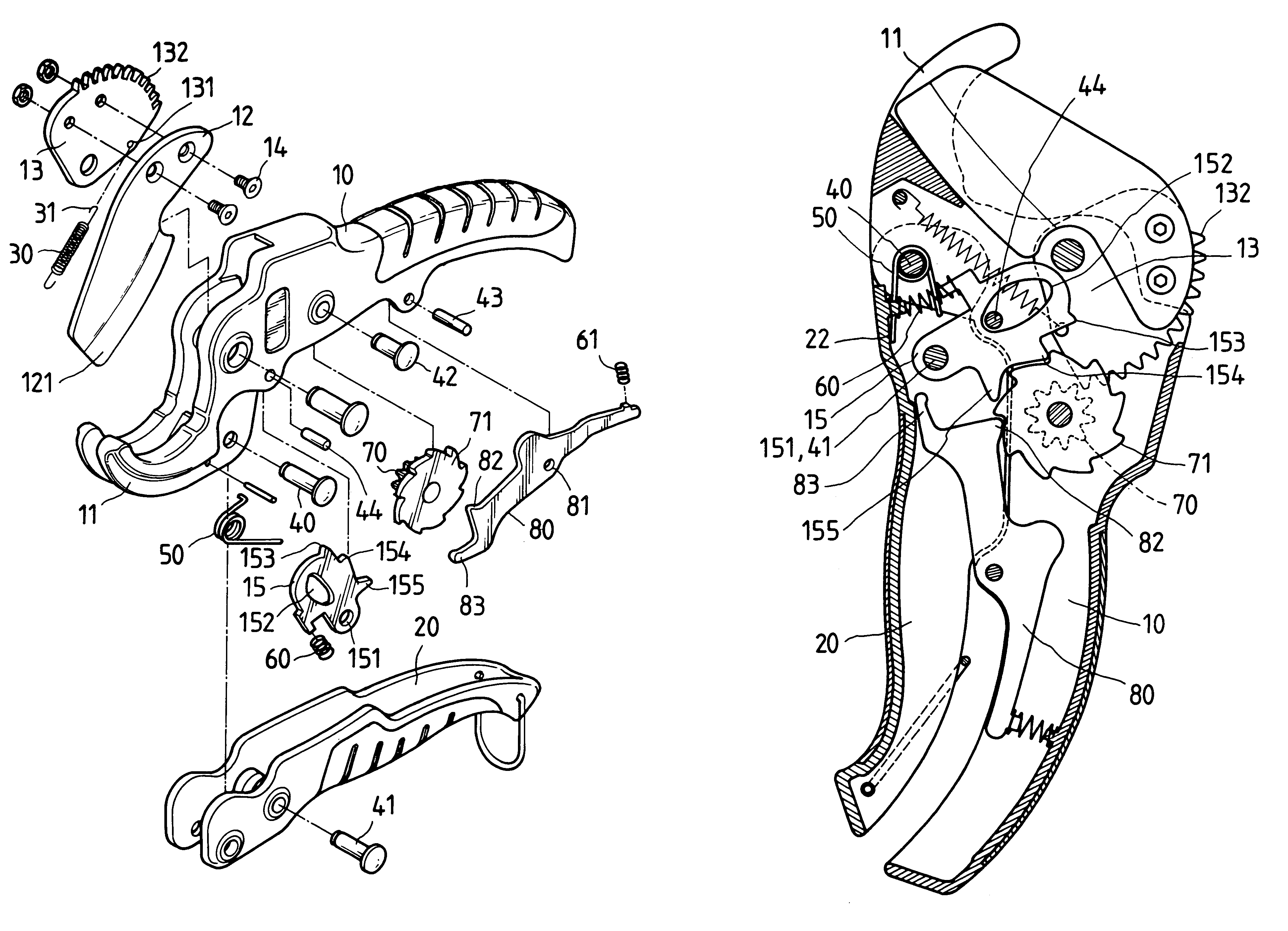

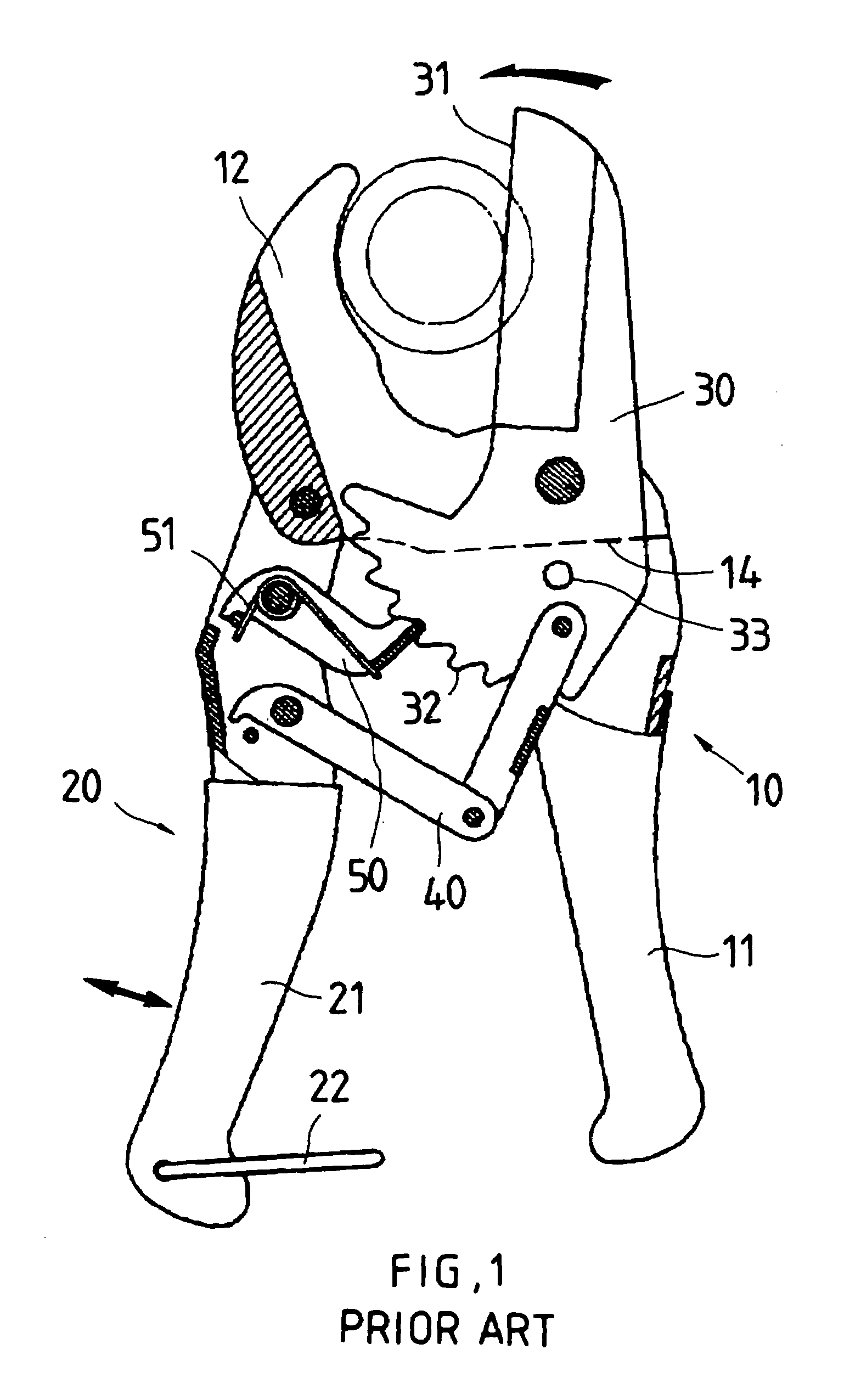

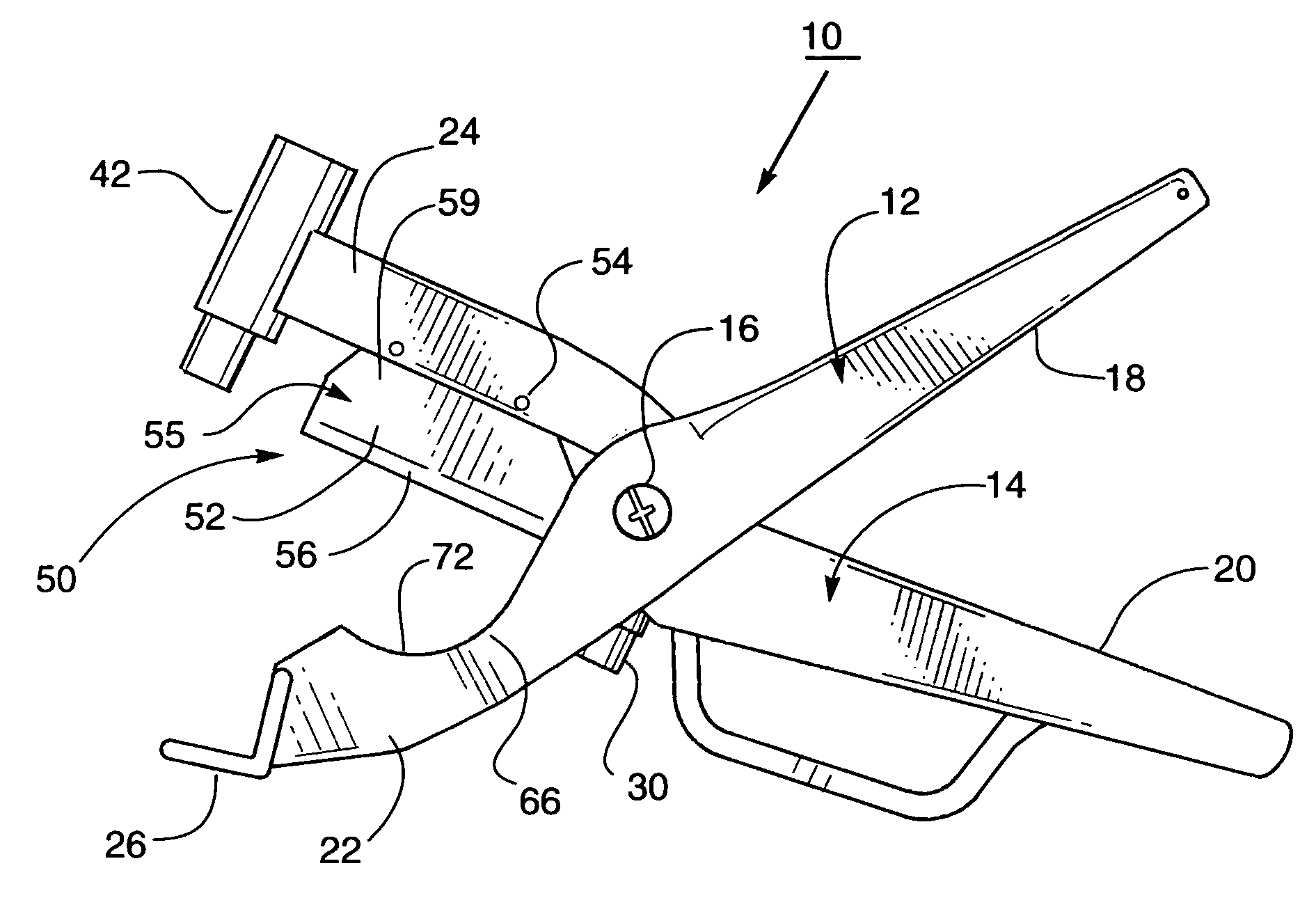

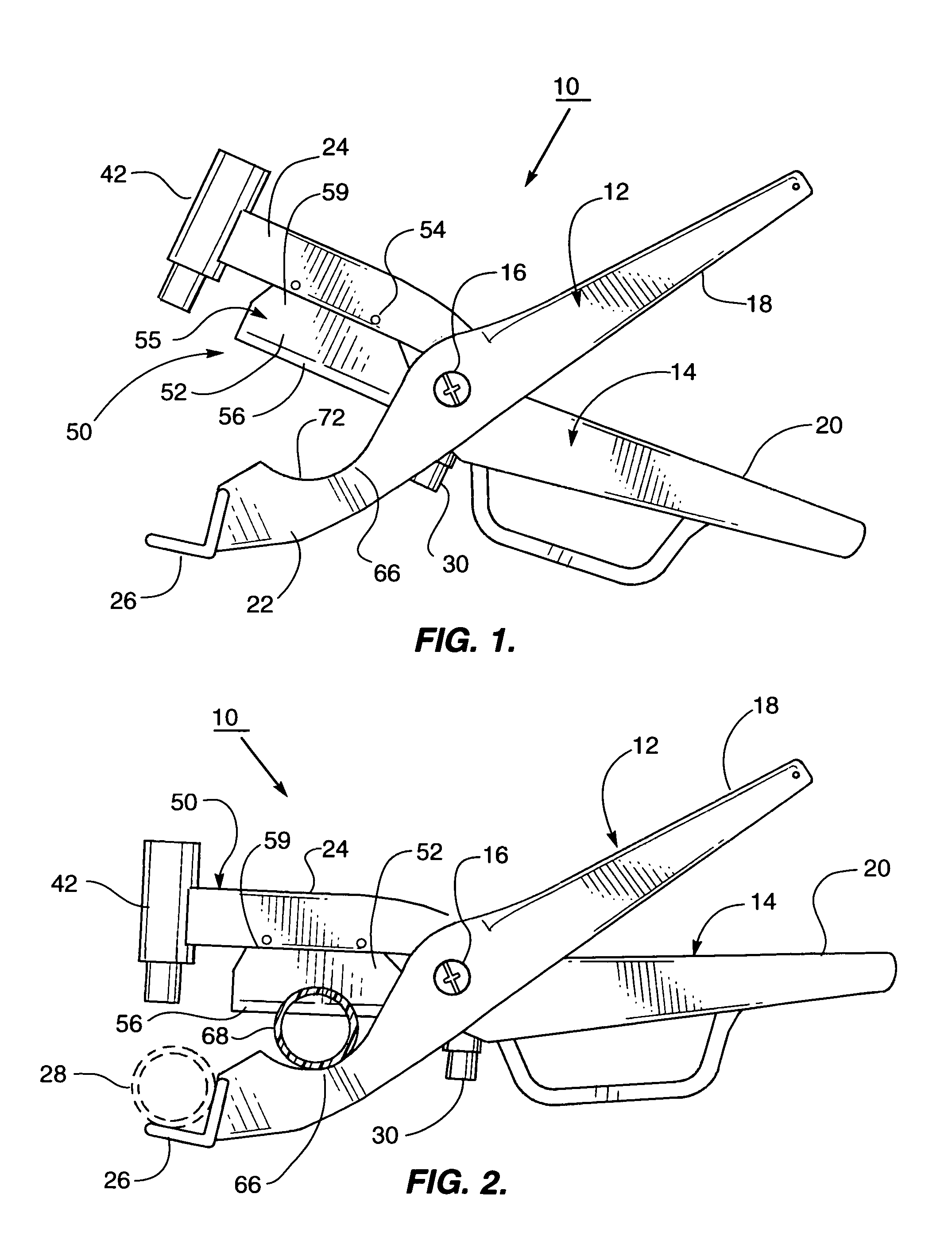

Ratchet scissors

InactiveUS7127819B1Smoothly and stepwise cuttingLabor savingTube shearing machinesMetal working apparatusClockwise

Provided is scissors comprising a movable first handle unit; a stationary second handle unit including a bifurcated jaw, a pivotal blade in the jaw, a spring biased pivotal plate member in the jaw and including teeth, a gear and ratchet wheel assembly, and a spring biased pivotal pawl; and a spring biased lever including a pawl member engaged with the ratchet wheel. Continuously pivoting the first handle unit about the second handle unit by moving the first handle unit alternately back and forth in each action of pivoting the first handle unit toward the second handle unit will pivot the first and second protrusions counterclockwise, rotate the gear and ratchet assembly clockwise, and pivot the teeth counterclockwise to cut a pipe anchored in the mouth.

Owner:HUANG YONG SHENG

Sealing appliance

InactiveUS6779575B1Simple and efficient mannerVaccination/ovulation diagnosticsGlass pressing apparatusEngineering

An appliance for sealing elastic hoses with a sleeve, which is plastically deformable and slipped onto the hose, has two jaws which are movable towards and away from each other. One jaw has two straight bars which project towards the other jaw and extend transversely of the sleeve to make two transverse indentations in the sleeve and the hose when the jaws are moving towards each other. The same jaw has a cutting edge which projects towards the other jaw and is directed transversely of the sleeve, the cutting edge making a substantially transverse cutting indication in the sleeve and the hose when the jaws are moving towards each other.

Owner:MERCK CHEM & LIFE SCI AB

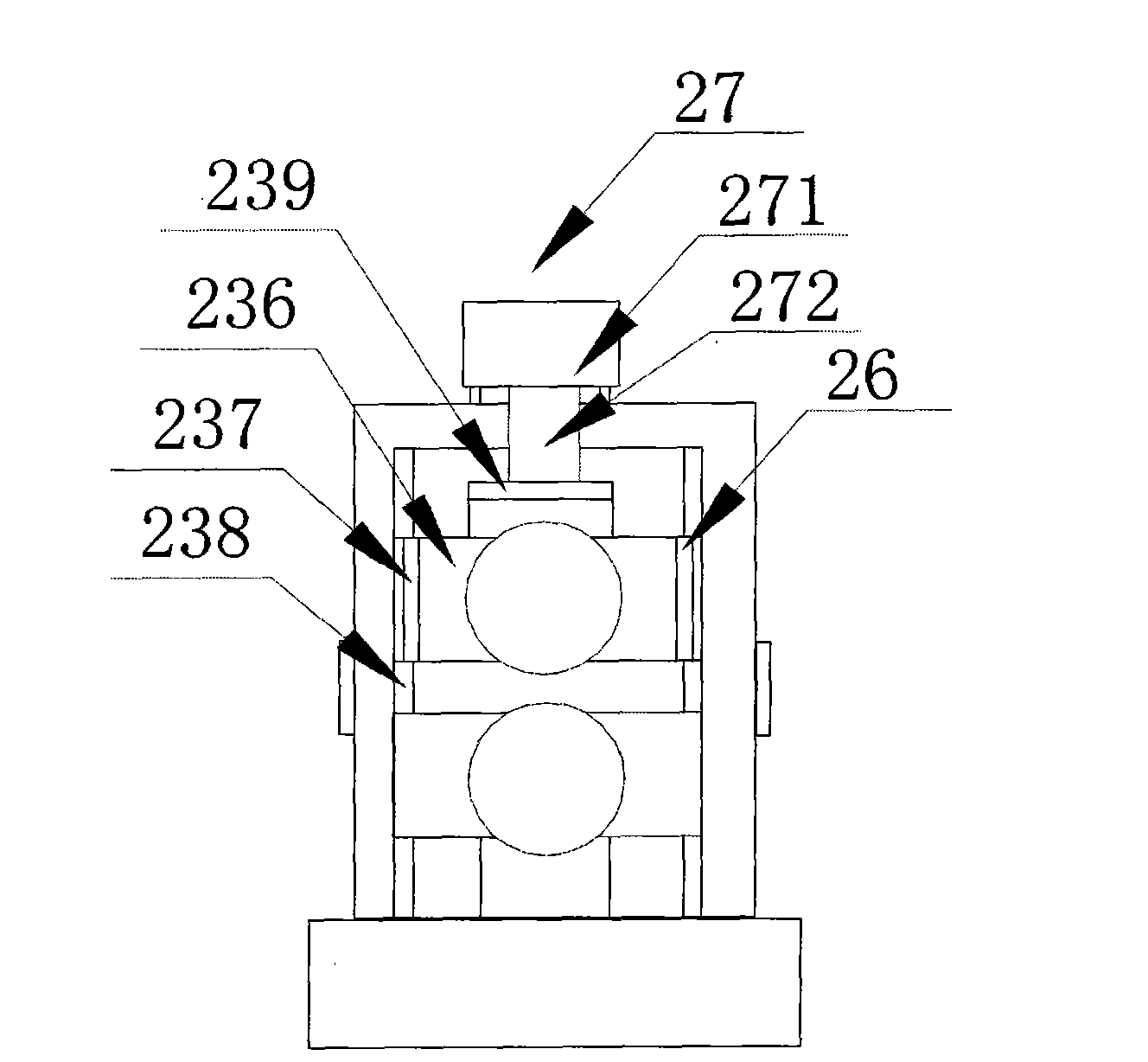

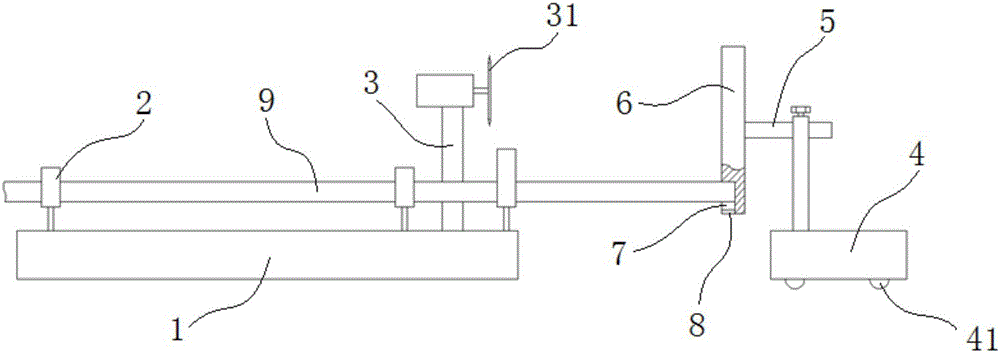

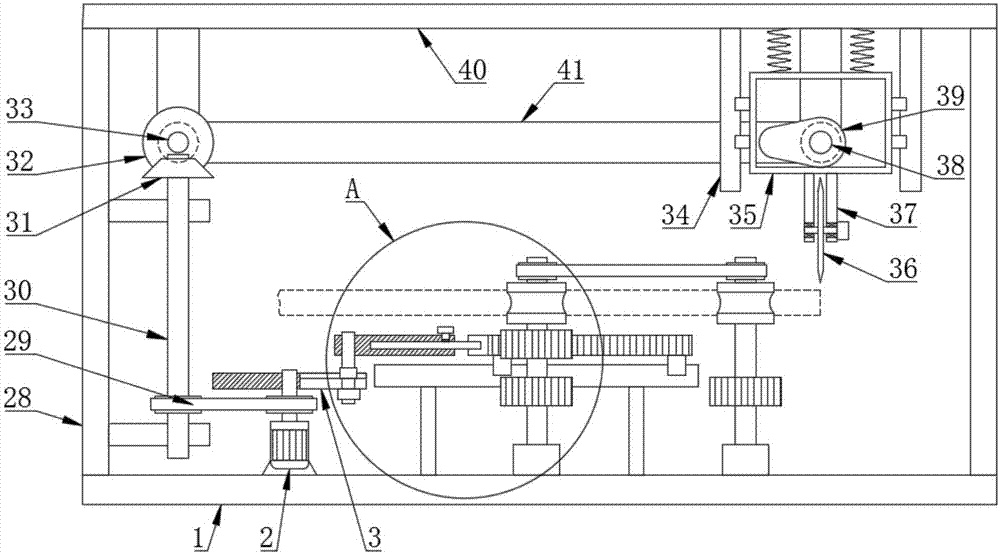

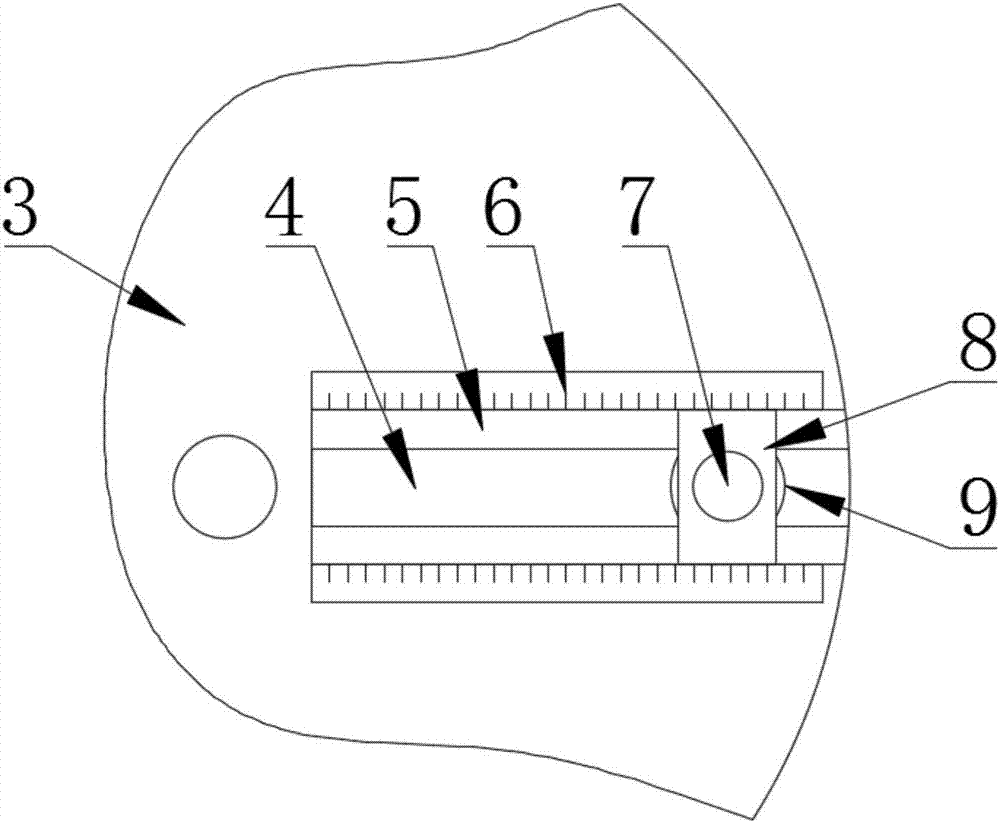

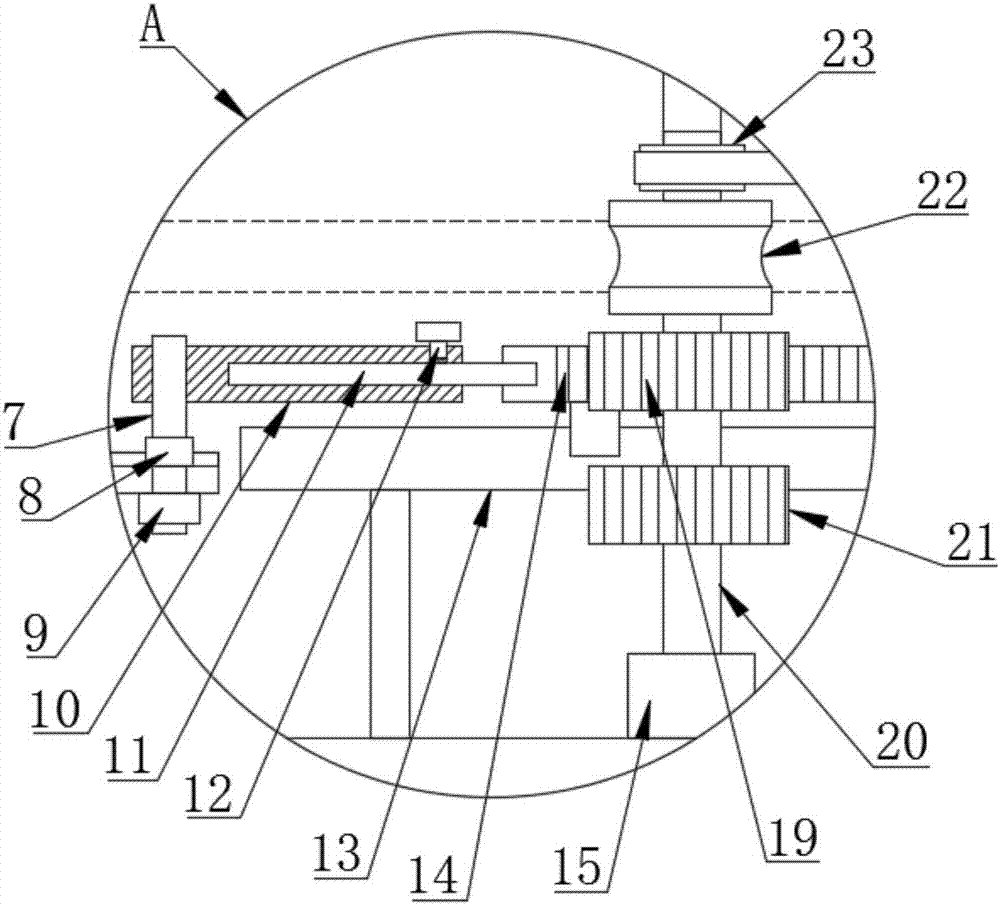

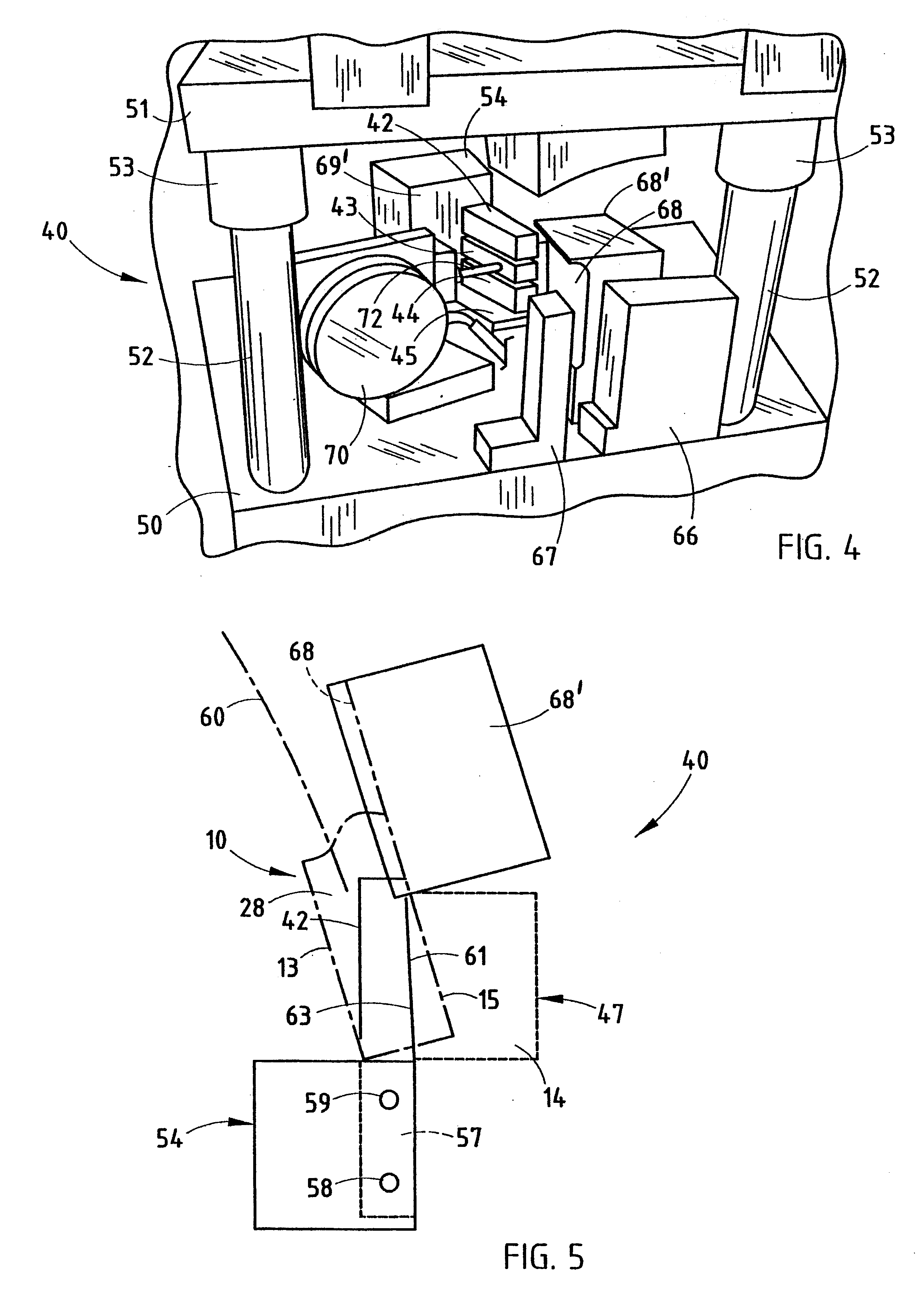

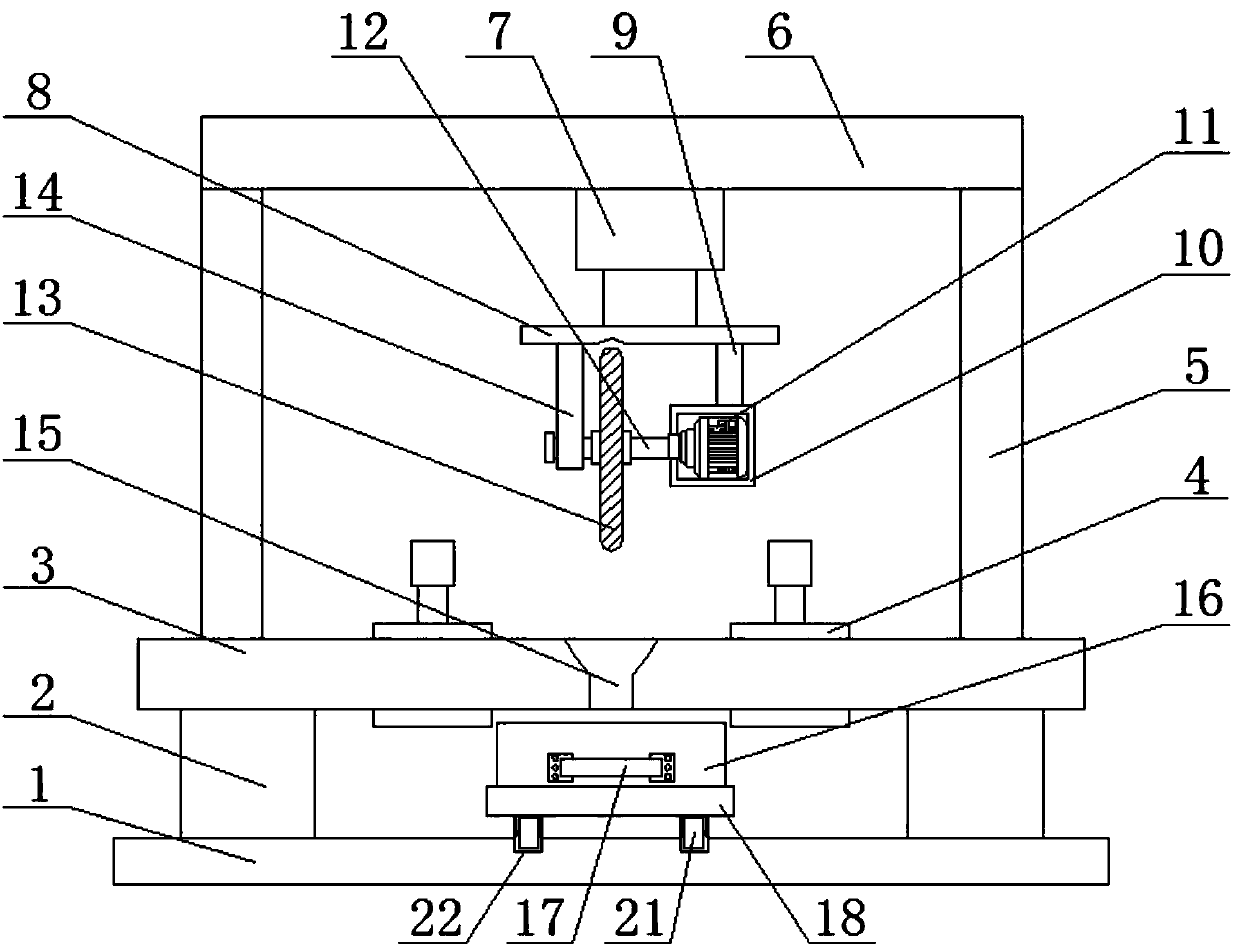

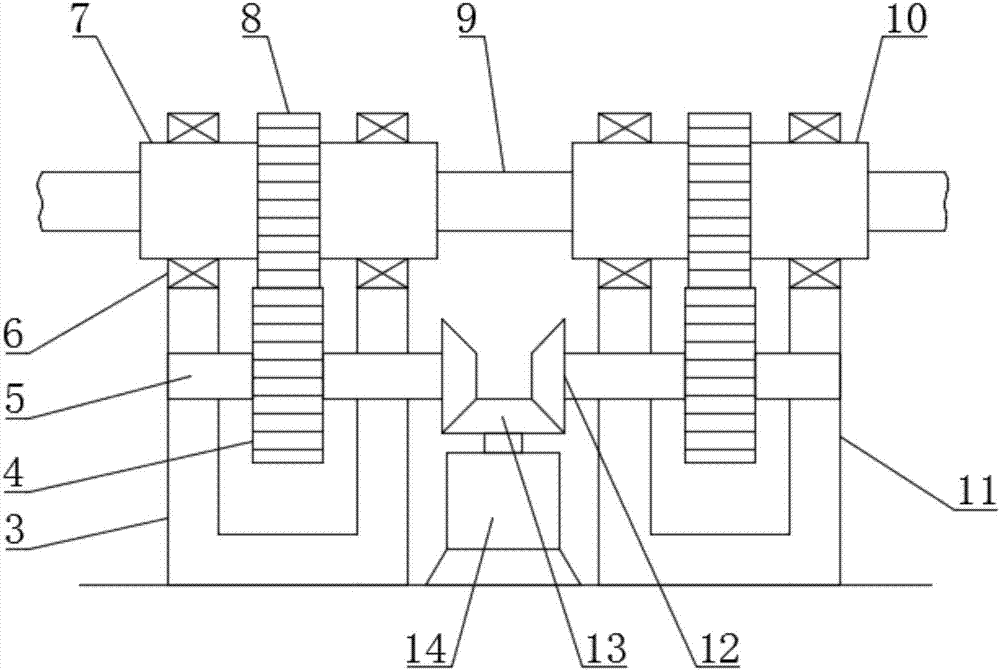

Full-automatic fixed-length cutting device of metallic hose

InactiveCN101623780ARealize fixed-length automatic cuttingIncrease productivityMetal-working feeding devicesTube shearing machinesFixed lengthMetal hose

The invention relates to a full-automatic fixed-length cutting device of a metallic hose, comprising a base, a strip conveyer and a conveying chute. The strip conveyer is used for conveying the metallic hose and is erected on the base; the conveying chute vertically penetrates through the strip conveyer which is provided with a positioning mechanism, a conveying mechanism and a clamp, wherein the conveying mechanism sends the metallic hose into the clamp and pulls the metallic hose away for a certain distance, and then, the metallic hose is cut by a cutting mechanism which is arranged on the base. The invention realizes the automatic fixed-length cutting of the metallic hose, greatly improves the production efficiency, and achieves higher consistency degree of a cut product.

Owner:严光辉

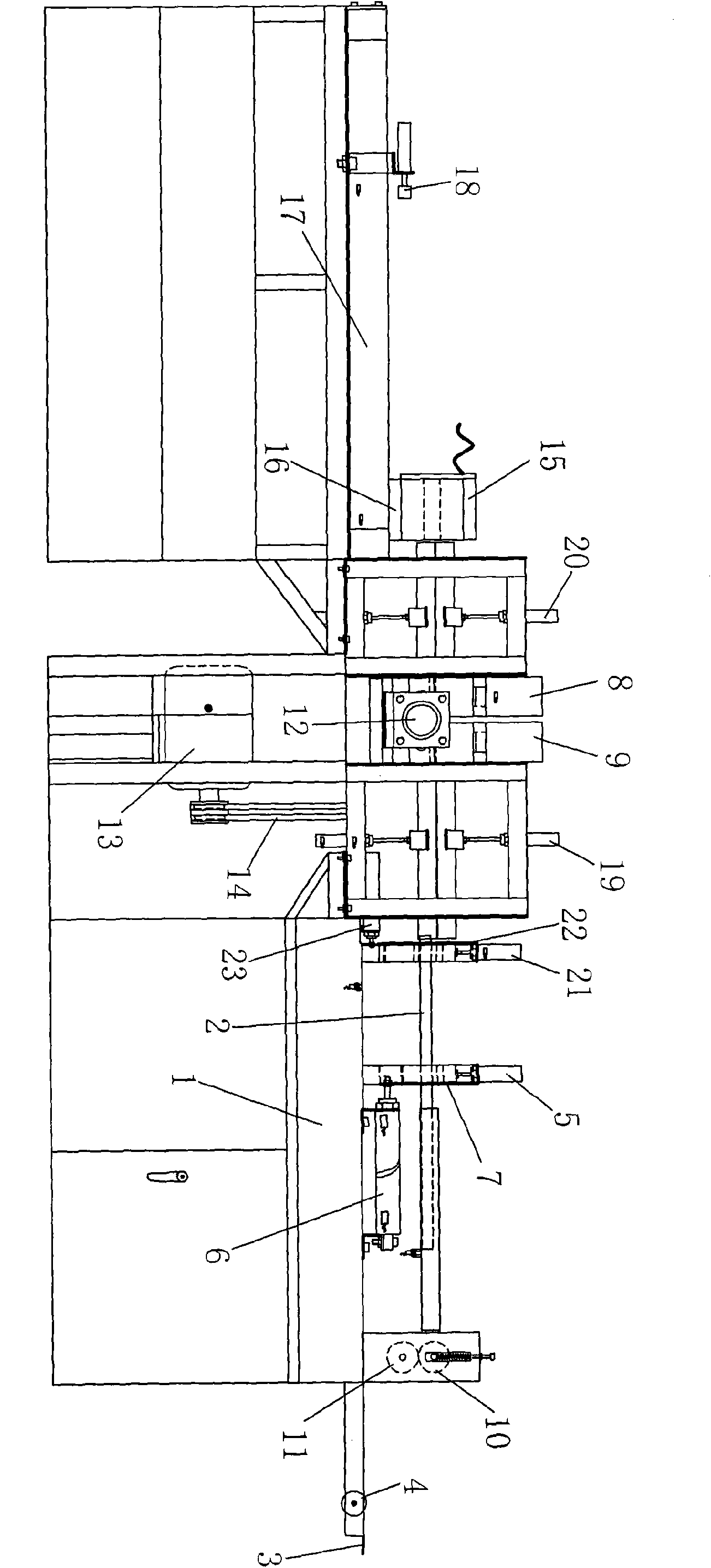

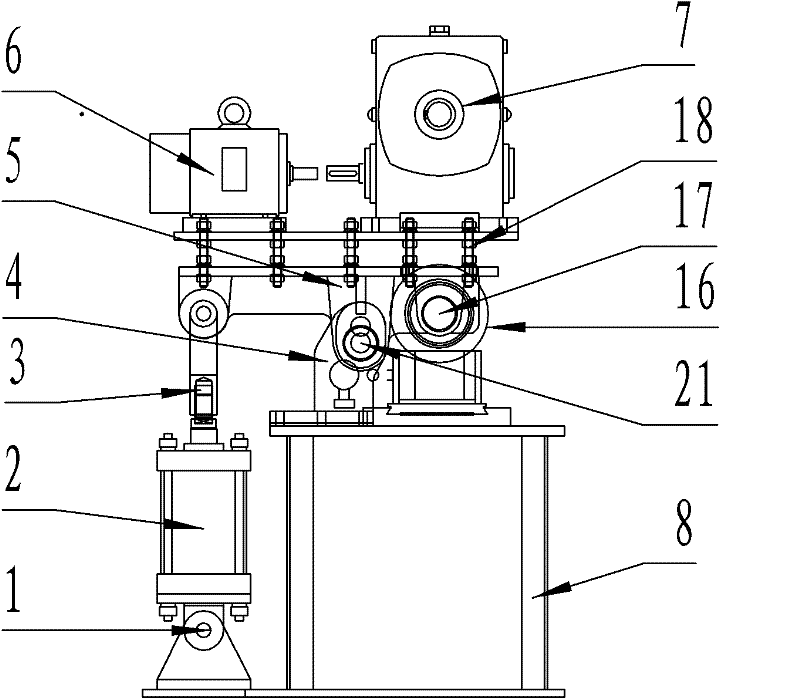

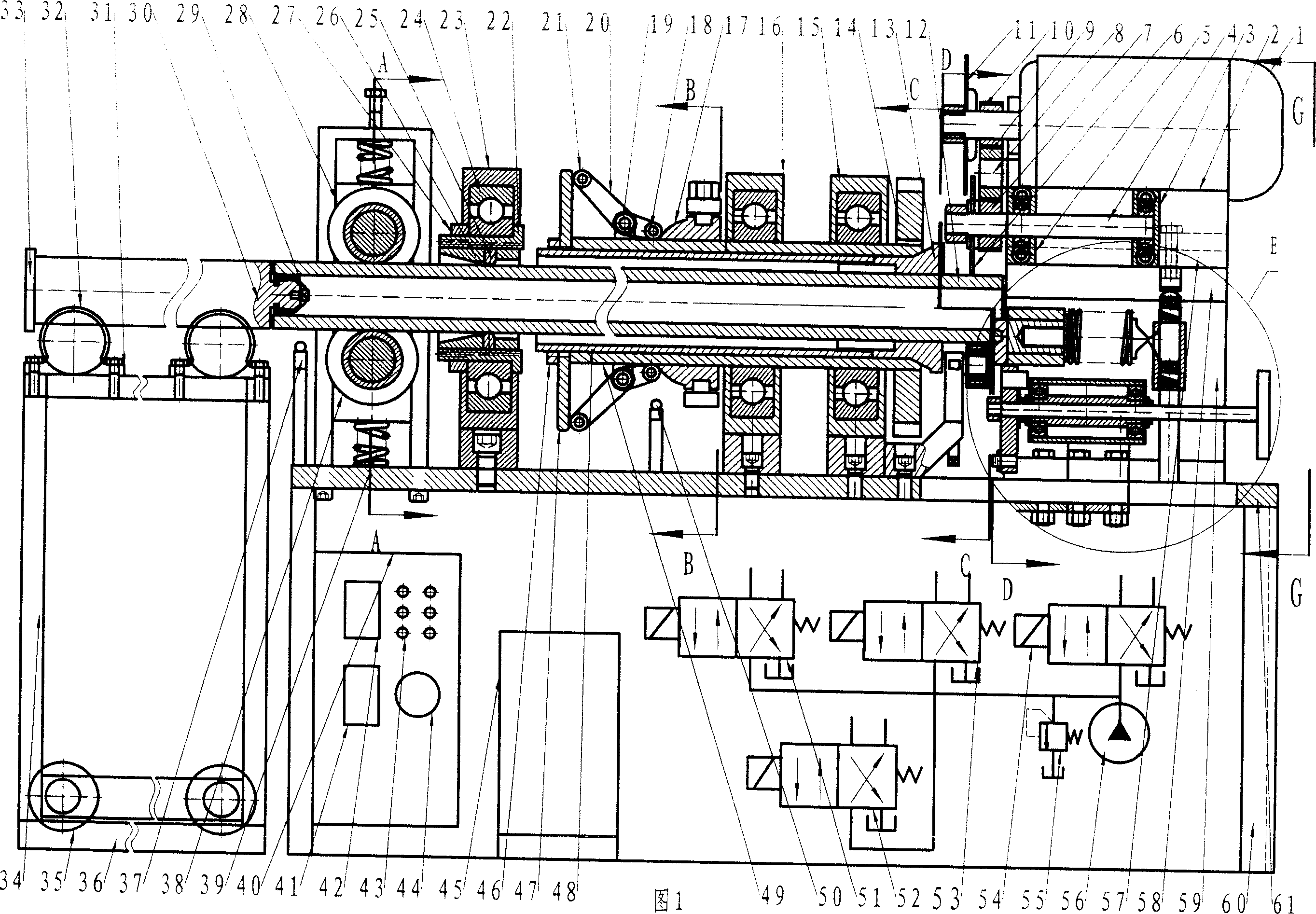

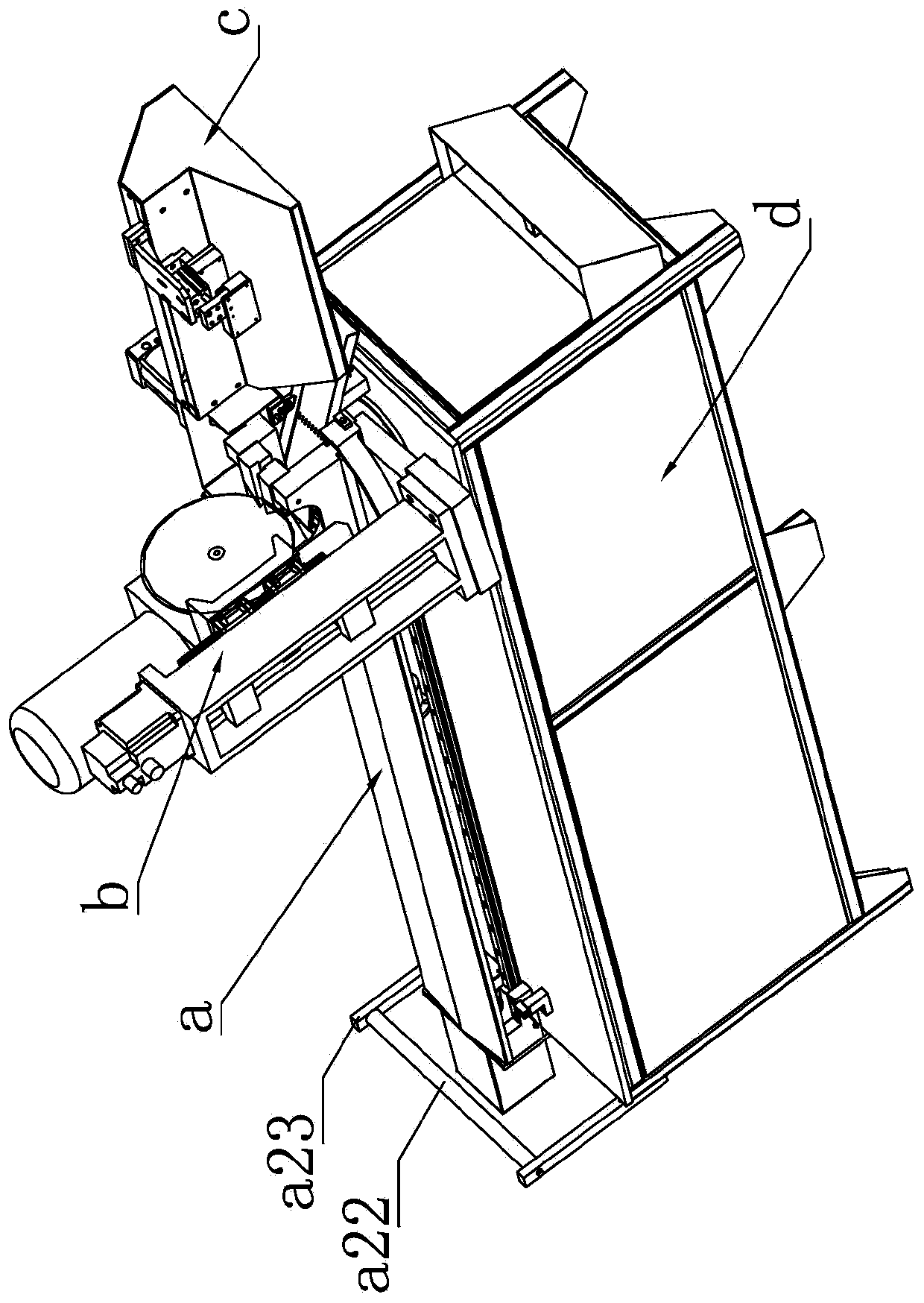

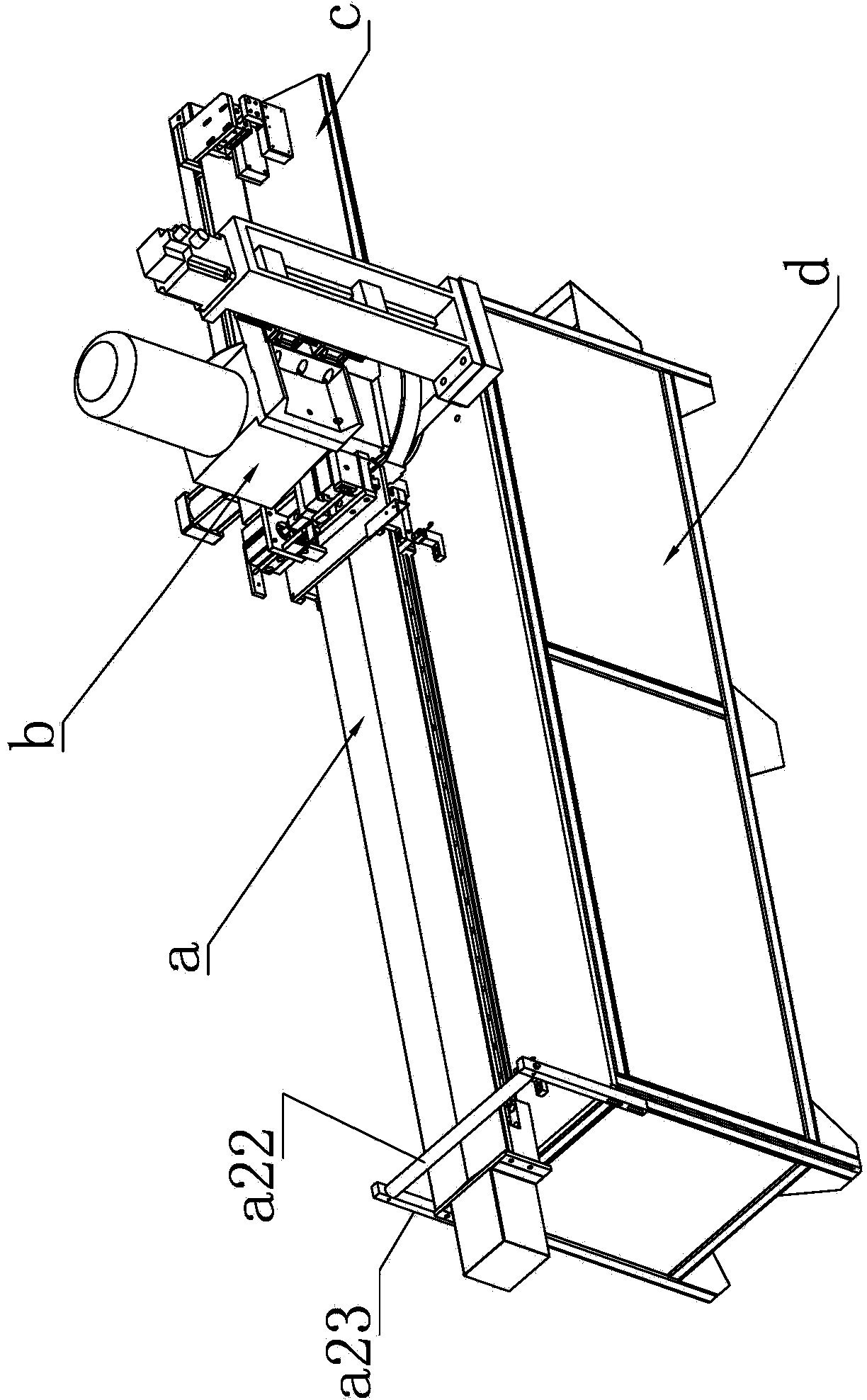

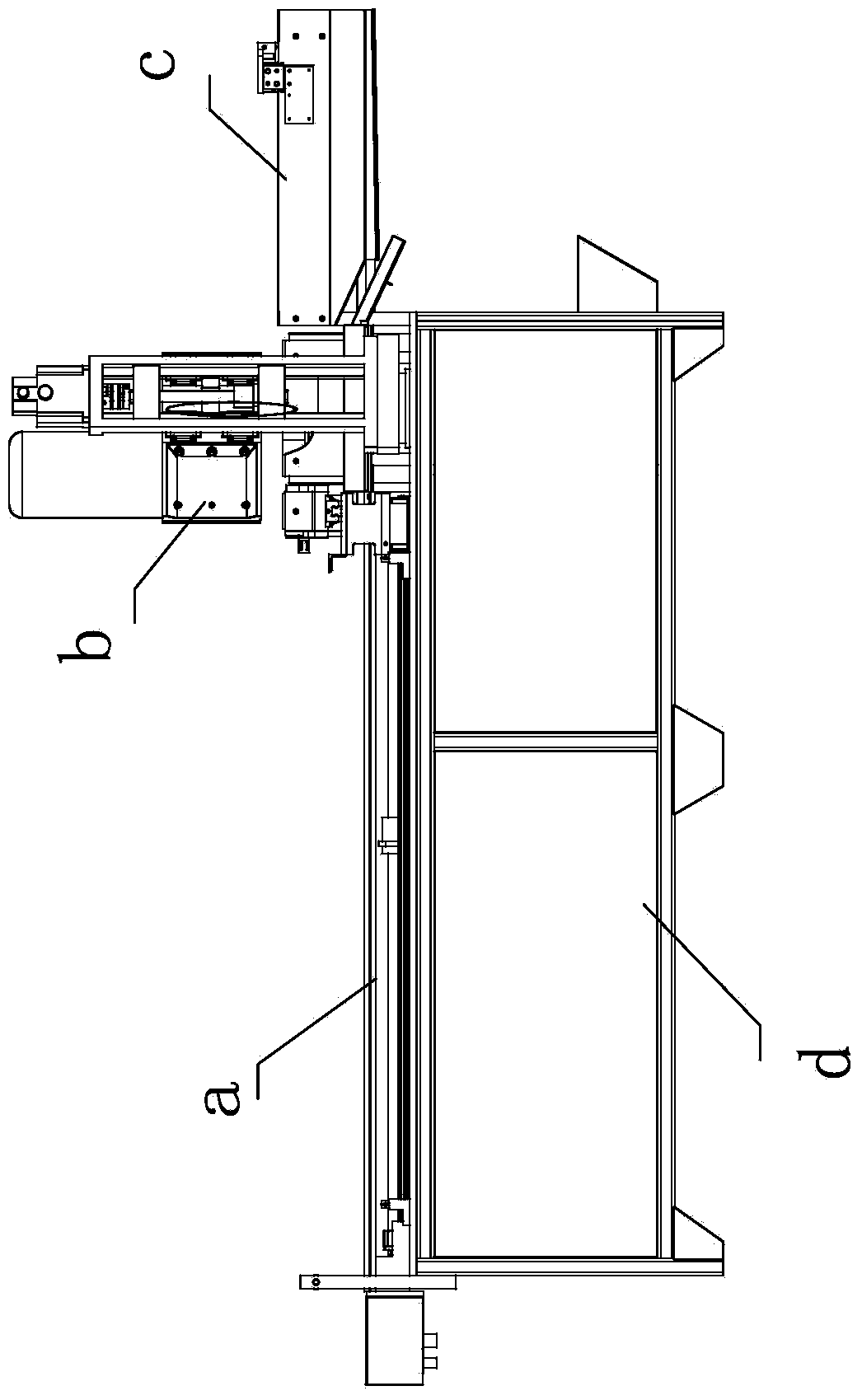

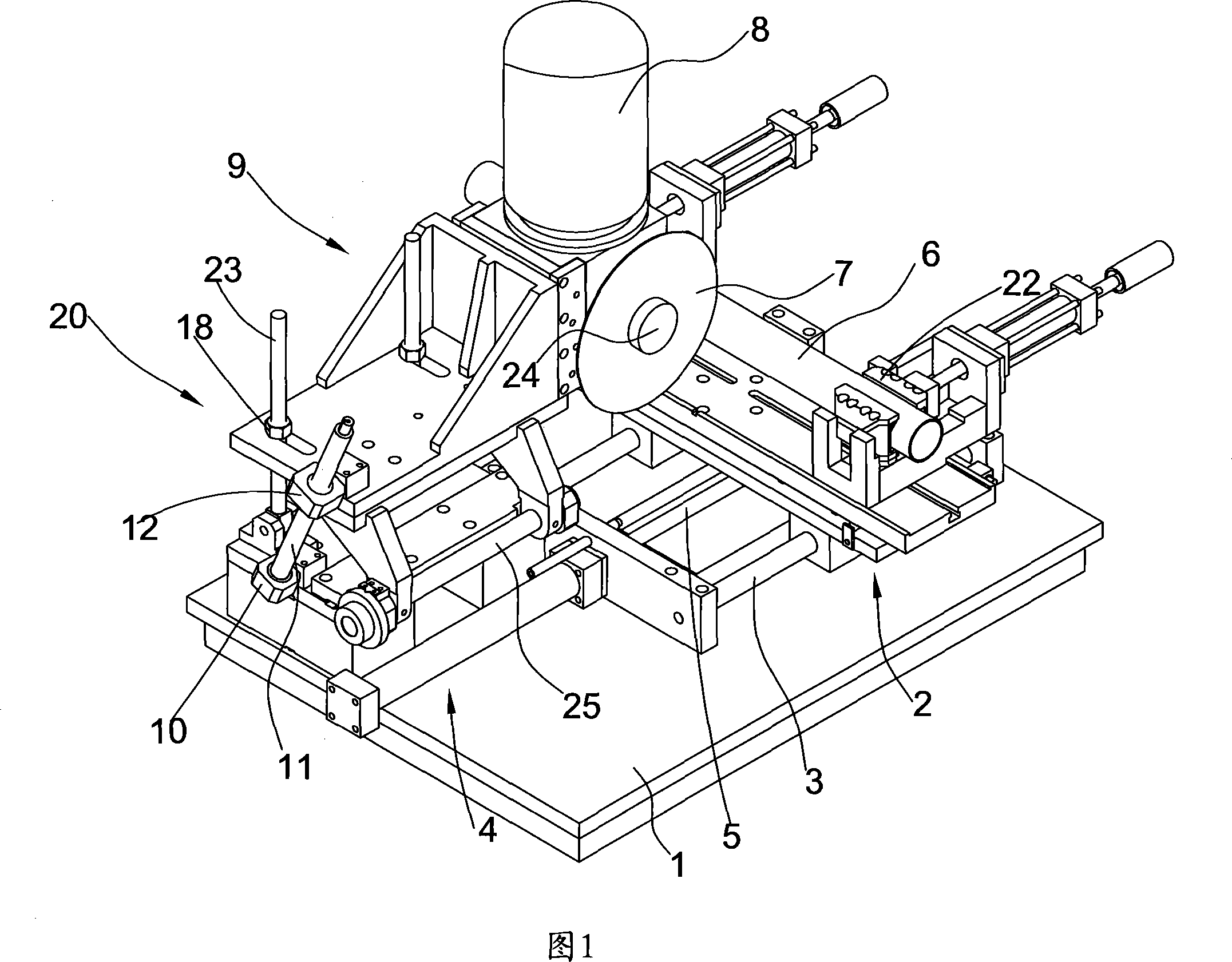

Full automatic pipe cutting machine

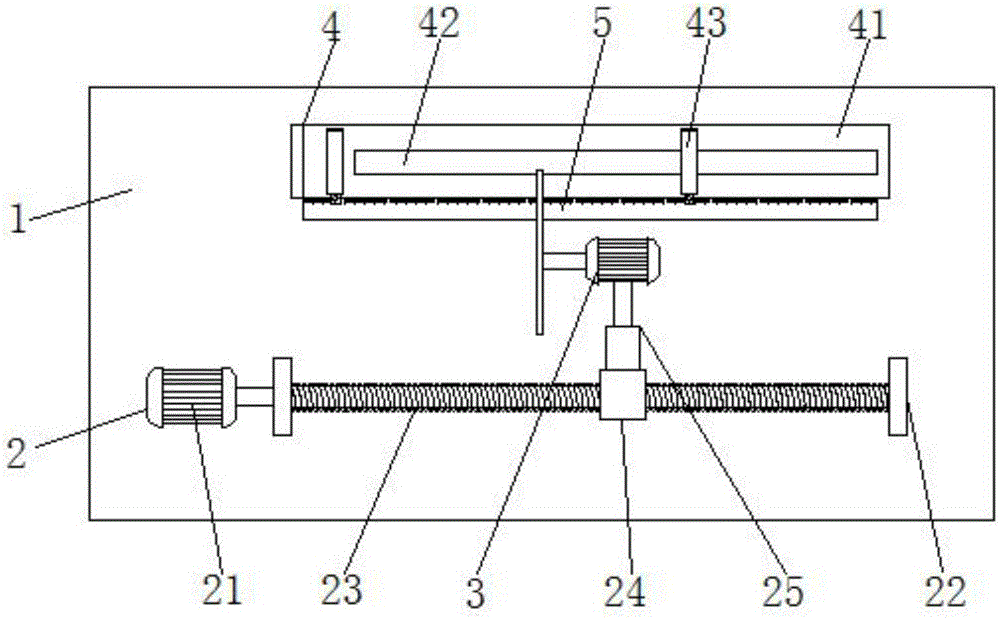

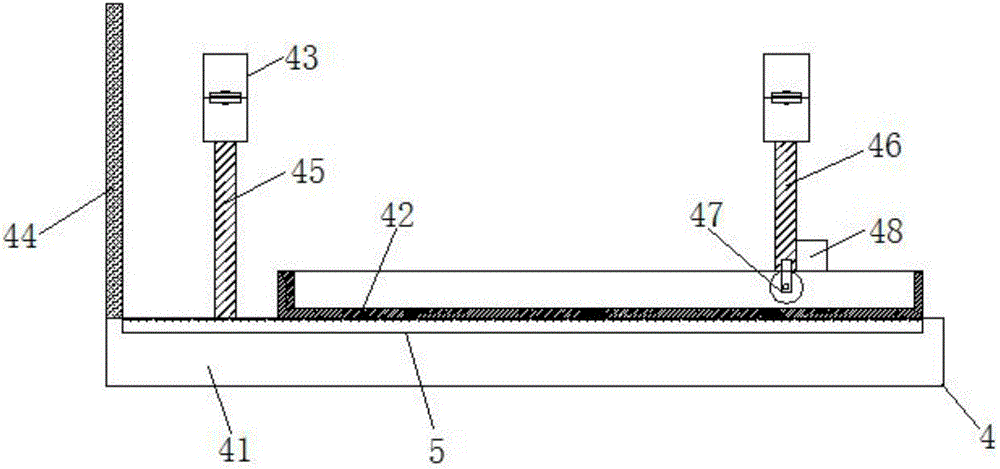

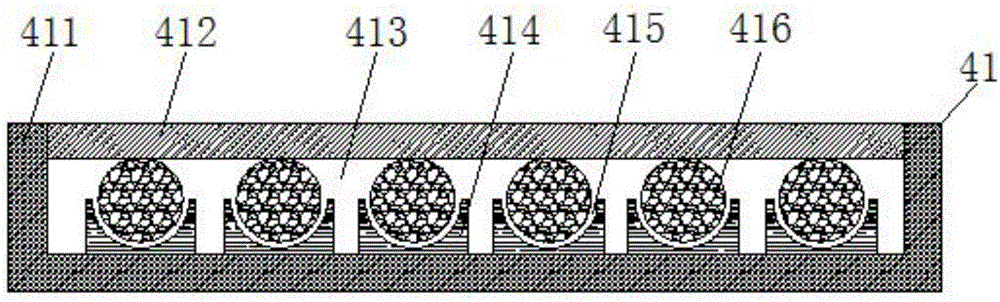

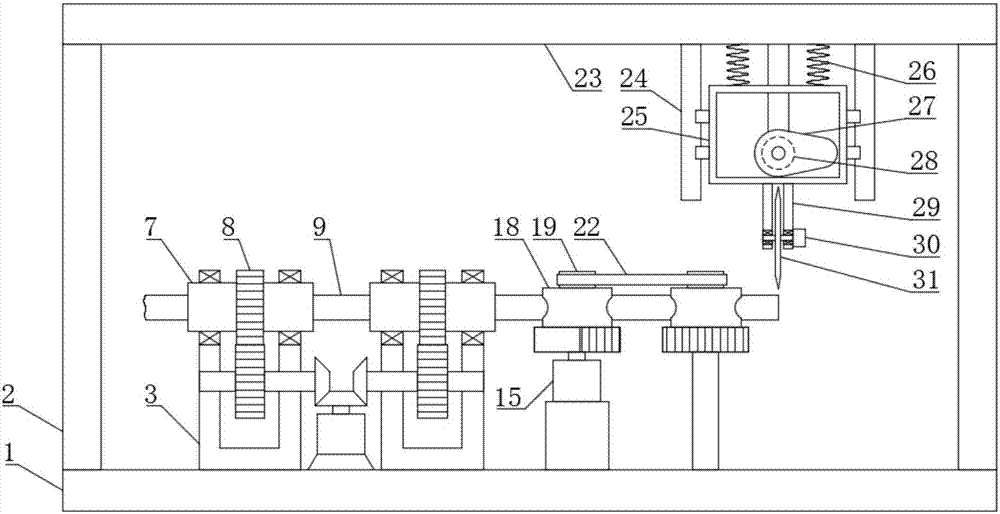

InactiveCN102179562AHigh degree of automationImprove cutting efficiencyTube shearing machinesShearing machine accessoriesEngineeringLength measurement

The invention discloses a full automatic pipe cutting machine. The pipe cutting machine comprises a feeding drive part, a cutting drive part, a pipe clamping part, a cutting part, an unloading part and a cutting measurement part which are sequentially arranged on an operating platform, wherein the feeding drive part conveys pipes to the cutting part by a driving wheel and a rolling wheel, then the pipes are cut off by a cutting tool driven by the cutting drive part; the driving wheel of the pipe cutting machine is driven by a stepping motor, and the lengths of the cut pipes can be accurately detected and controlled according to the electrical signals of stepping quantity of the stepping motor and the data of radius of the driving wheel; and in addition, the operating platform is also provided with an infrared distance measurement sensor, and the length accuracy of the cut pipe is jointly ensured by the electrical distance measurement signals and the movement detection signals of the stepping motor. By adopting the clamping feeding structure, the automatic cutting structure, the automatic clamping structure, the automatic unloading structure and the automatic cut pipe-length measurement and control mechanism, the degree of automation of the pipe cutting machine is improved.

Owner:中臻工业有限公司

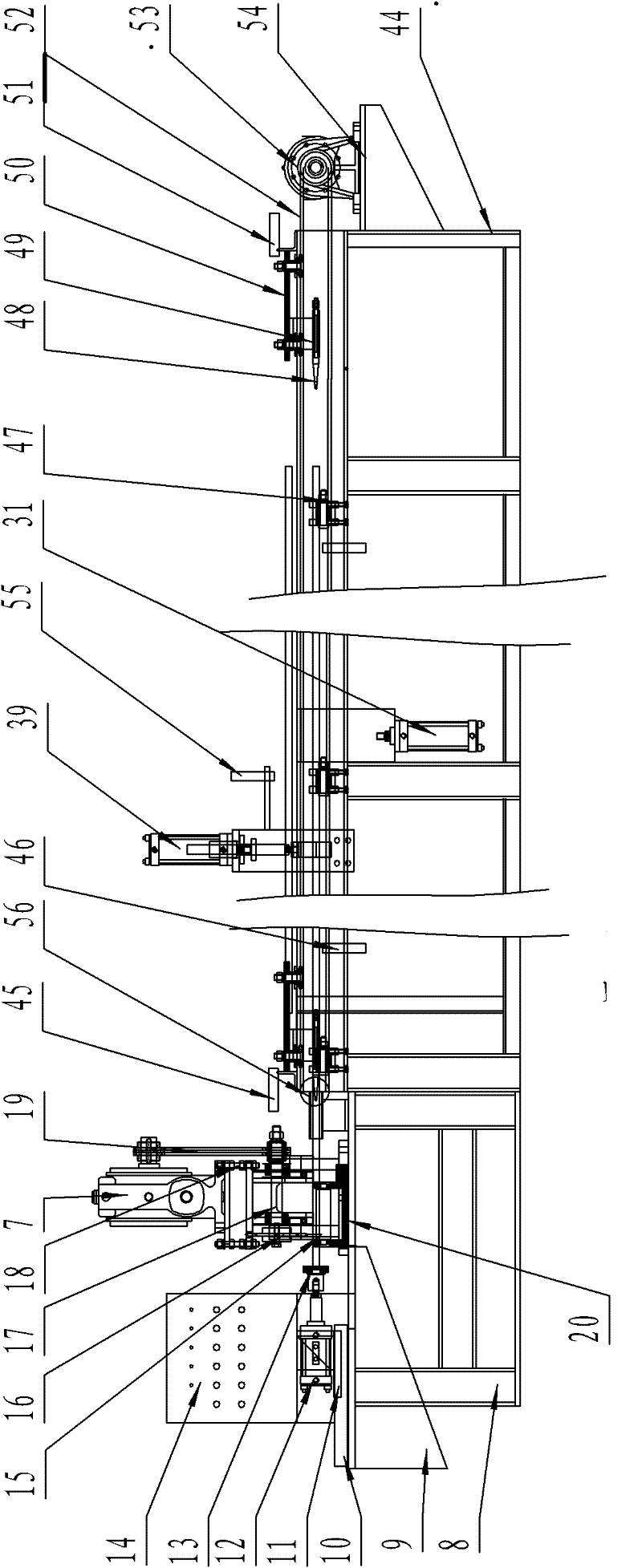

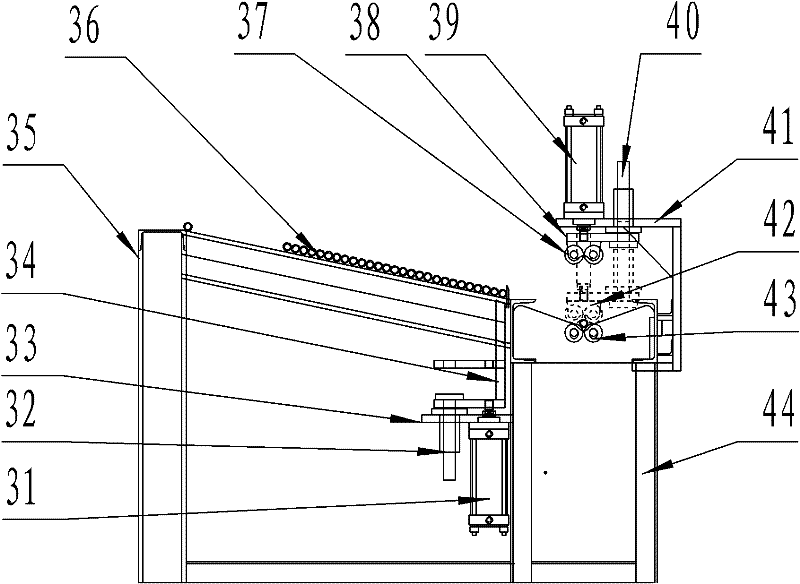

Automatic blanking machine for steel pipes

ActiveCN102126045AExact lengthFully automatedTube shearing machinesShearing machine accessoriesElectrical controlSlide plate

The invention discloses an automatic blanking machine for steel pipes, belongs to the field of cutting-off equipment of the steel pipes and particularly relates a steel pipe cutting-off device with a mechanical automatic material supply device and a cutting-off device. The automatic blanking machine for the steel pipes is characterized by mainly comprising a fixed scale cutting-off system, a steel pipe conveying system and an electrical control system, wherein the steel pipe conveying system and the electrical control system are connected with the fixed scale cutting-off system, wherein the fixed scale cutting-off system comprises a steel pipe fixed scale device mounted on a transverse sliding track at the left end of a lathe bed and the cutting-off device mounted on the lathe bed, a front positioning sliding plate is mounted on a front positioning sliding plate seat fixed on the transverse sliding track of the steel pipe fixed scale device, a steel pipe fixed scale cylinder is arranged on the sliding plate, a steel pipe fixed scale detection switch is arranged at the front end of the cylinder, and the steel pipe conveying pipe comprises a steel pipe storage device and a steel pipe feed device. The automatic blanking machine for the steel pipes has the beneficial effects of realizing automation of supply, compression and fixed scale cutting-off of the steel pipes, not only improving the working efficiency and reducing the labor intensity, but also ensuring the precise length of the steel pipes which are cut off, and being suitable for being used in occasions which need to cut the steel pipes into steel pipe sections with equal length.

Owner:济南玛钢钢管制造有限公司

Adjustable gripping tool

Owner:LOGGERHEAD TOOLS LLC

Pipe cutter

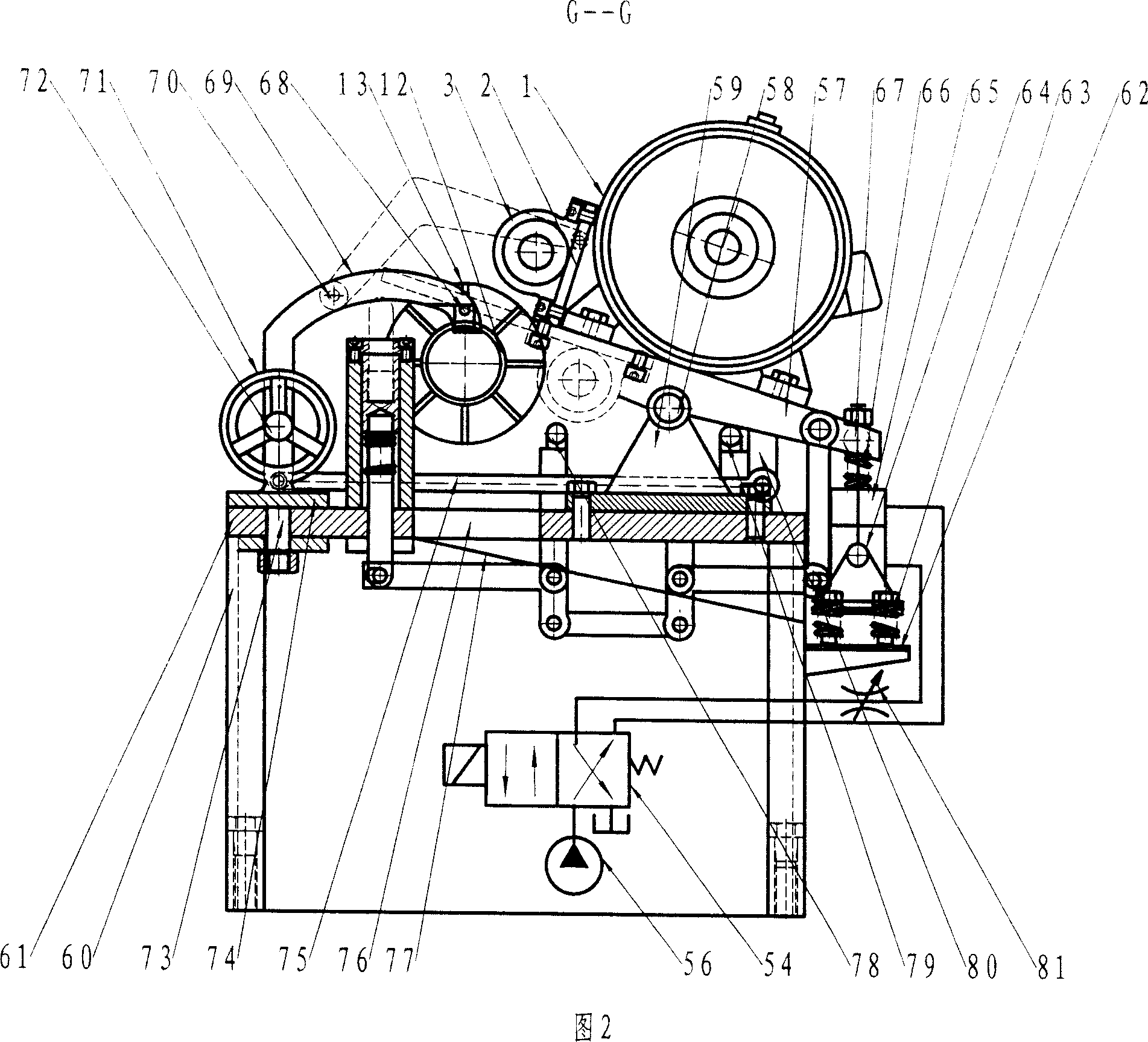

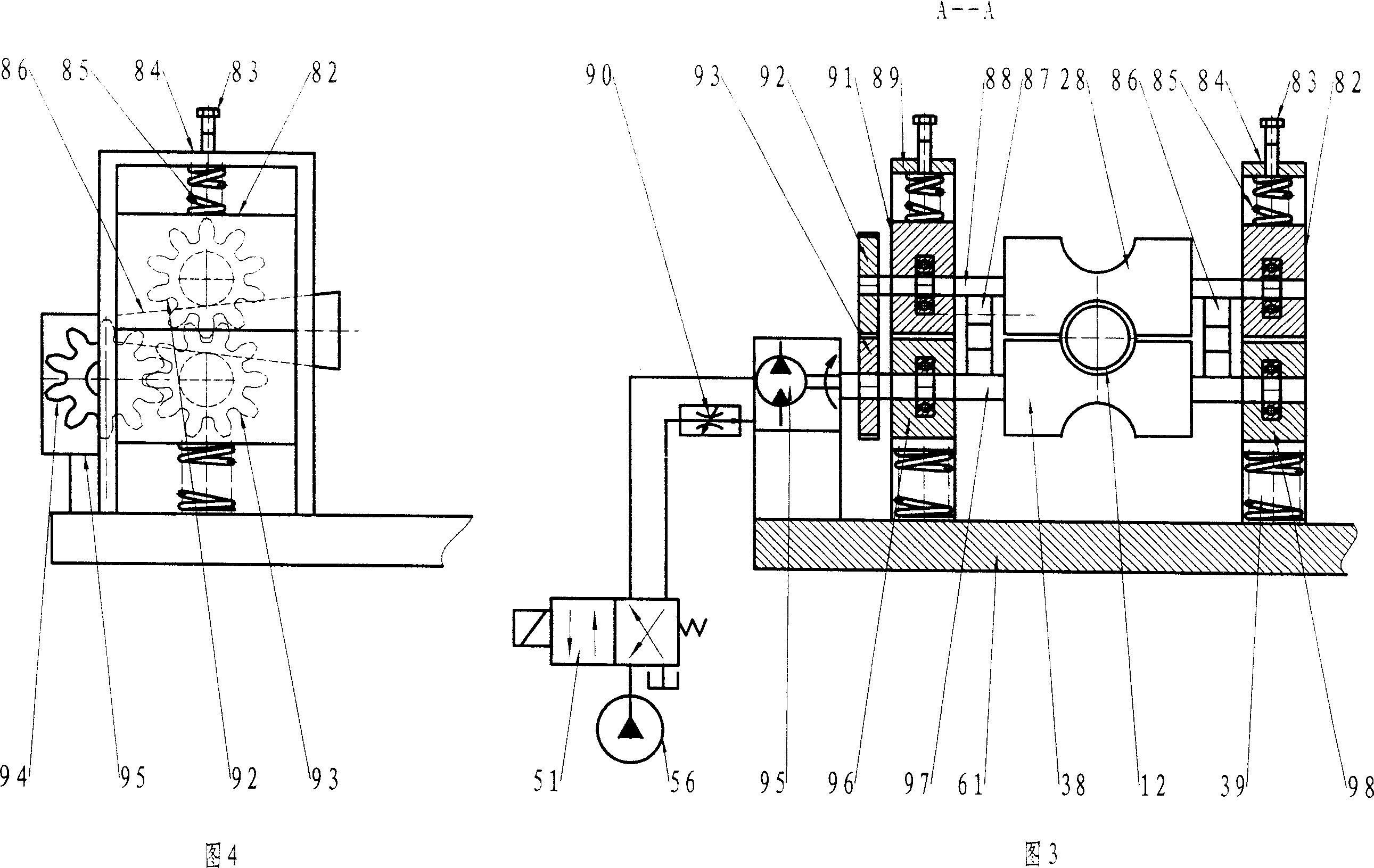

InactiveCN1951616AImprove verticalityImprove machining accuracyMetal-working feeding devicesOther manufacturing equipments/toolsSizingIndustrial engineering

The invention relates to a pipe cutter, which comprises: frame (60), work table (61), aerated or hydraulic device, connecting tube valve, cutting motor (1) axially mounted at one end of work table (61), and the cutter driven by said motor (1). Wherein, the work table (61) and frame (60) are mounted with a device for moving cutting motor (1) and cutter up and down, and a device for rotating the pipe (12) around its axle; the end of work table (61) far from the motor (1) has automatic pipe feeder; the work table (61) between cutter and pipe feeder is mounted with pipe guide support and pipe automatic clamper; one side of motor (1) has pipe (12) automatic sizing device under. The invention has high vertical degree between cutting surface and pipe axle, with high efficiency and low cost.

Owner:陈永真

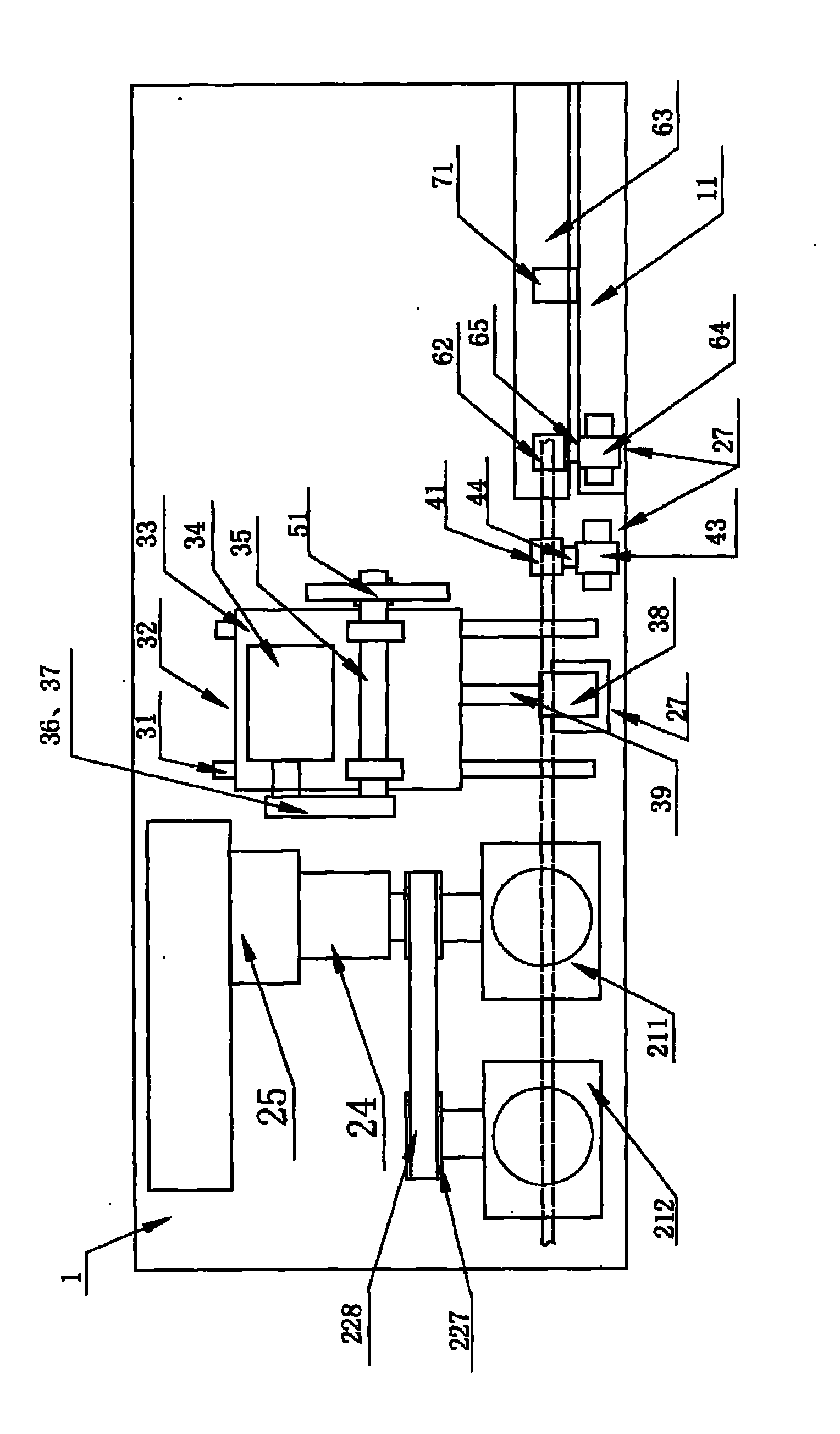

Hard pipe cutting equipment

InactiveUS20030005562A1Reduce distanceImprove holding capabilityTurning machine accessoriesOther manufacturing equipments/toolsEngineeringElectric control

The present invention relates to a novel cutting equipment, which automatically cuts hard plastic pipes produced from an extruder, having a table, an input V shape leading wheel, an input fixing clamp apparatus mechanism, a cutting mechanism, a bearing transmission mechanism, an output fixing clamp apparatus mechanism, a V shape leading plate, a leading wheel, a cuttings collector, and an electric control system, which are assembled to a novel means of a hard pipe cutting machine.

Owner:NANYA PLASTICS CORP

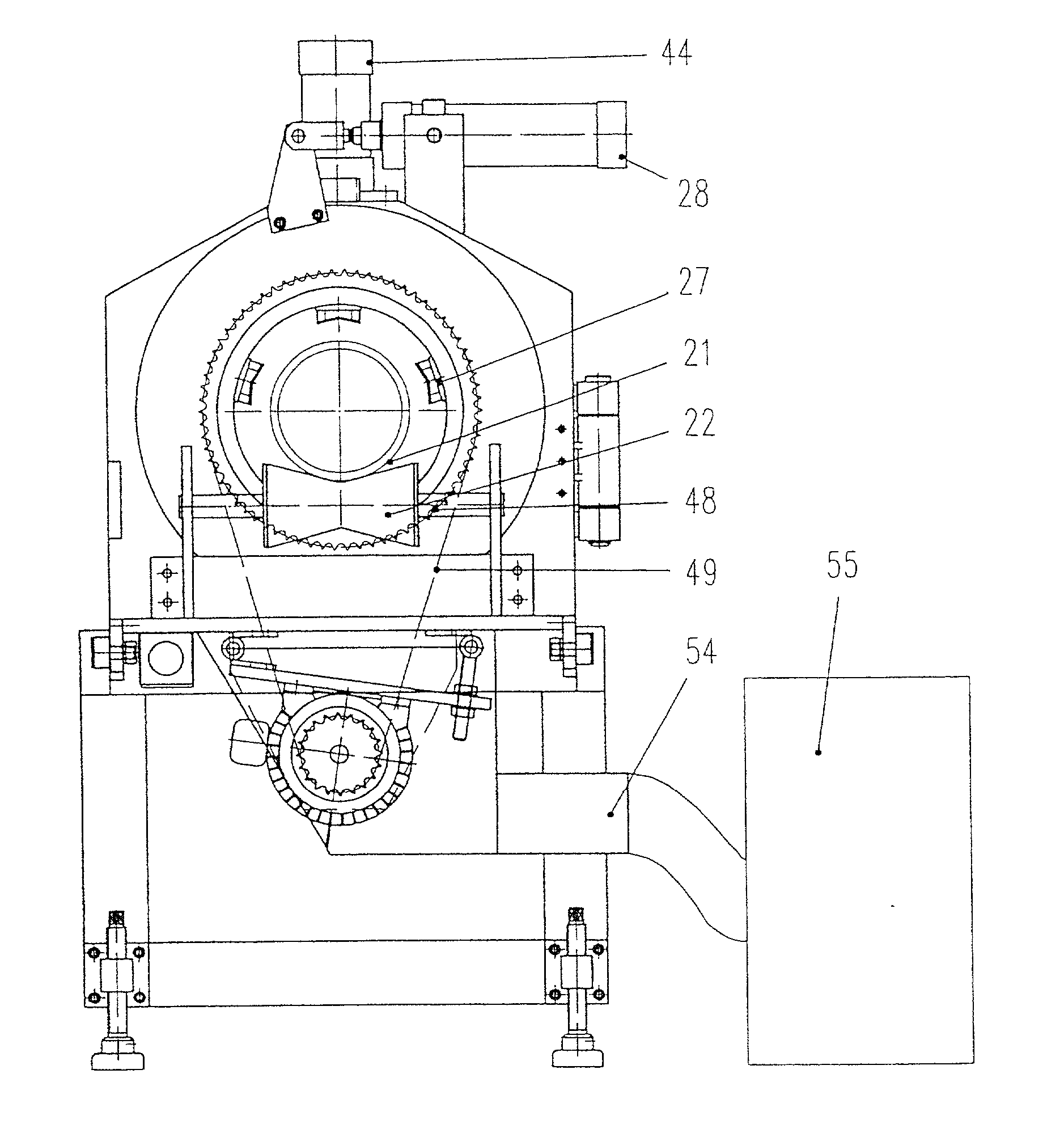

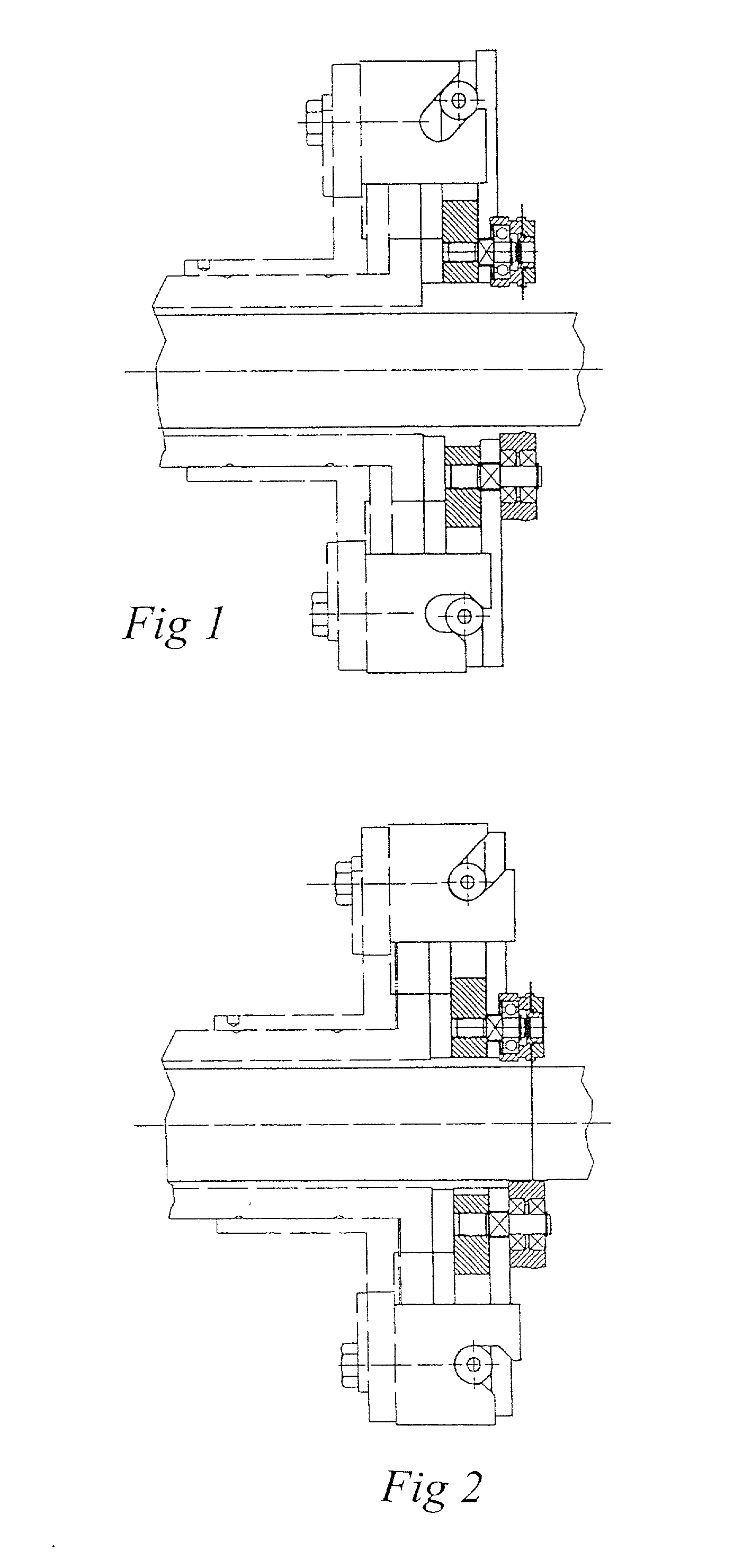

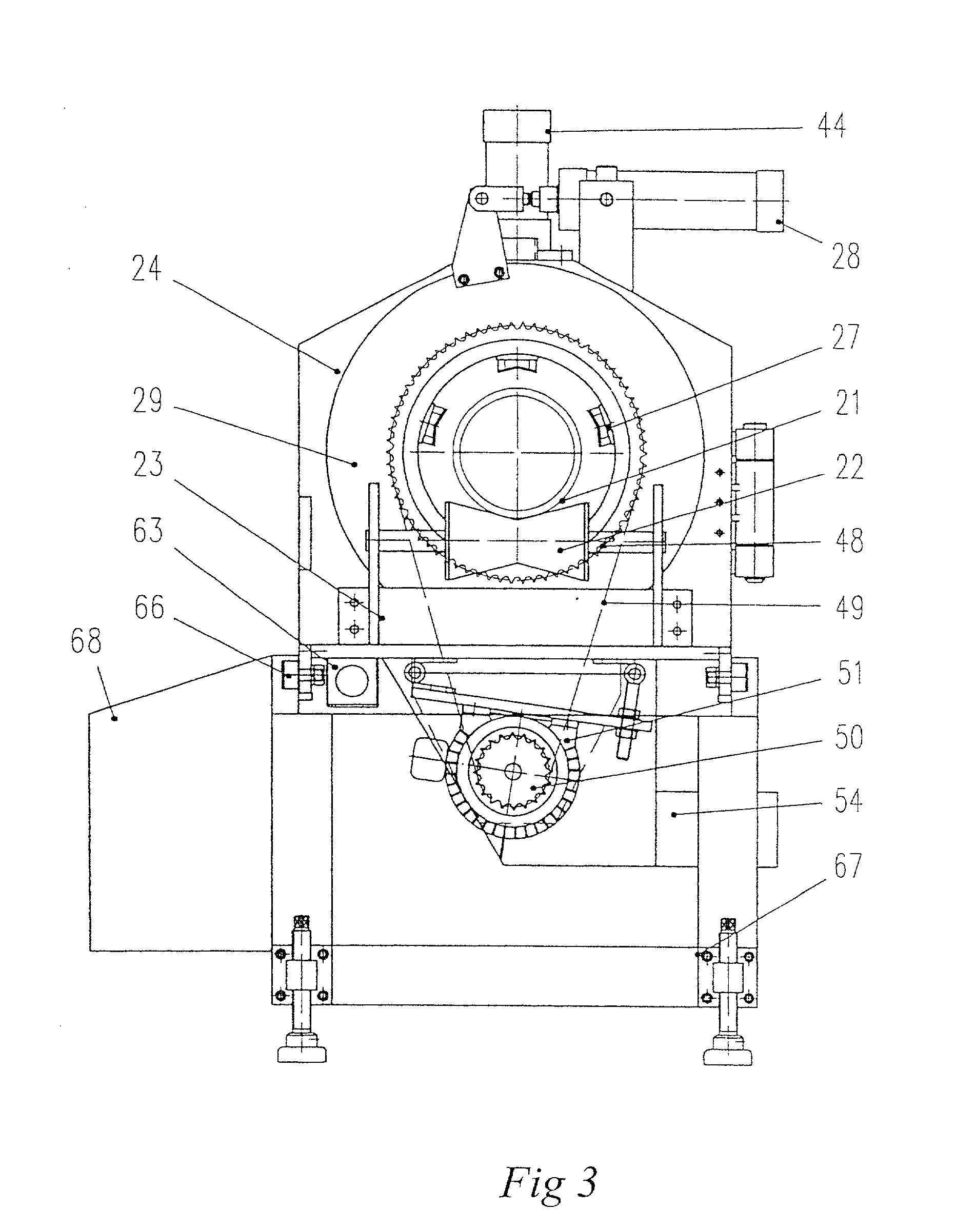

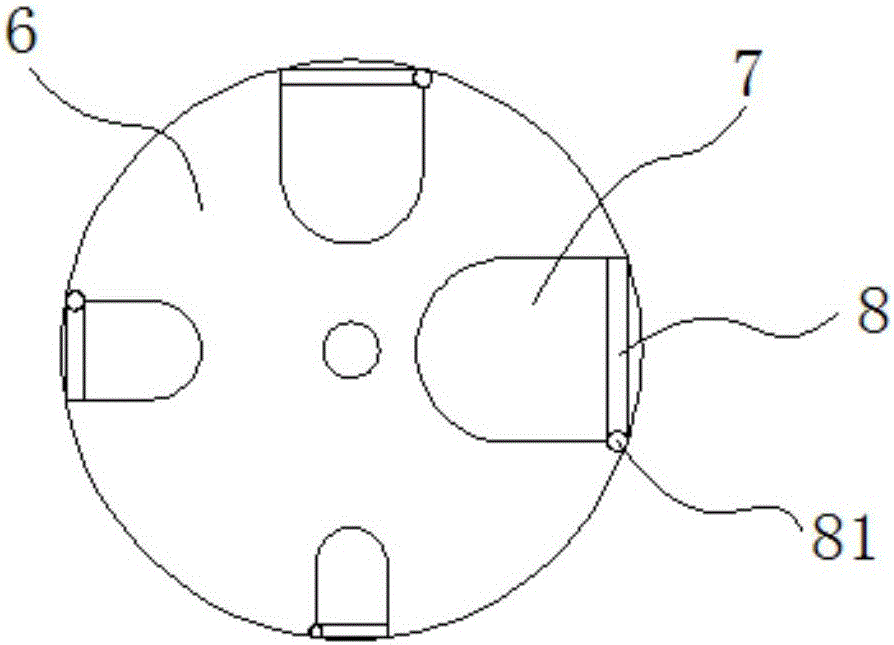

Pipe cutting machine with rotary machine head

InactiveCN104175349AGuaranteed stabilityQuality improvementTube shearing machinesMetal working apparatusEngineeringCantilever

The invention provides a pipe cutting machine with a rotary machine head, belongs to the technical field of machinery and solves the problem that the conventional pipe cutting machine is nonstandard in cutting, and the more materials are wasted. The pipe cutting machine with the rotary machine head comprises a foot stand, a feeding assembly, a rotary machine head assembly and a material discharging assembly, wherein the feeding assembly comprises feeding guide rails, a feeding base and a feeding clamp component, the feeding base can slide on the feeding guide rails, and the feeding clamp component is arranged on the feeding base; the rotary machine head assembly comprises a machine head clamp component, a rotary cantilever, a machine head sliding base and a cutting blade, the machine head clamp component is fixedly connected onto the foot stand, the rotary cantilever is rotationally connected onto the foot stand through a cutter machine and is positioned on the outer side of the machine head clamp component, the machine head sliding base is arranged on the rotary cantilever and can move up and down, and the cutting blade is arranged on the machine head sliding base; the material discharging assembly is arranged on the outer side of the rotary machine head assembly. According to the pipe cutting machine, the feeding assembly, the rotary machine head assembly and the material discharging assembly are arranged on the foot stand linearly, so that the angle cutting at the end part of the pipe can be realized, the cutting uniformity can be guaranteed, and the loss can be reduced.

Owner:ZHEJIANG YOTRIO GRP CO LTD

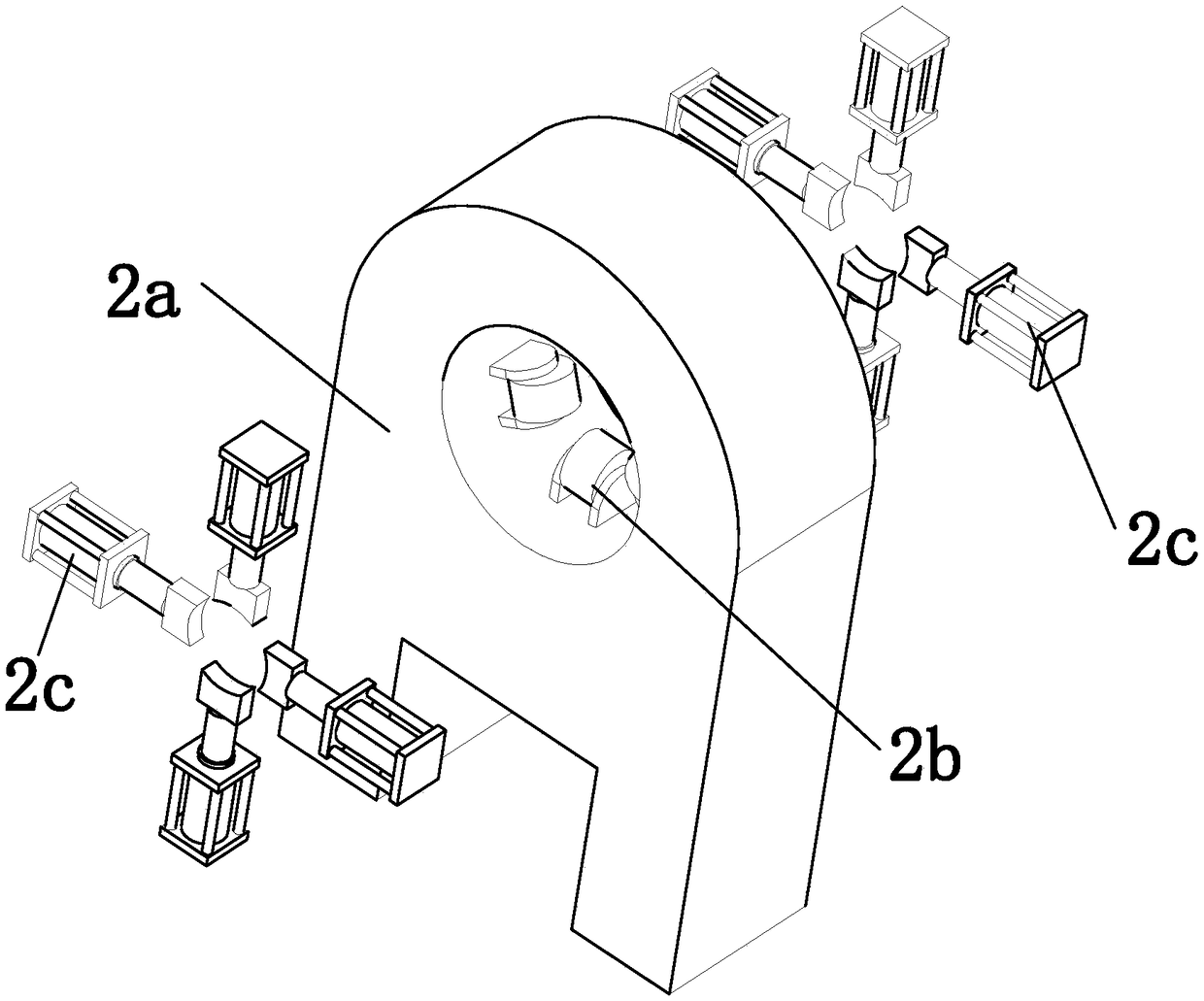

Fixed-length cutting device for tubes

ActiveCN105689788AEasy to cut to lengthImprove securityTube shearing machinesMetal working apparatusEngineeringMechanical engineering

The invention discloses a fixed-length cutting device for tubes. The fixed-length cutting device comprises a cutting table, a cutting device, support elements, a location table, a support shaft, a location disc and baffles, wherein the cutting device is arranged at the front end of the cutting table; the plurality of support elements are arranged on the cutting table along the same straight line, wherein the support element at the forefront is located in front of the cutting device; the location table is arranged in front of the cutting table; the support shaft is erected on the location table in a manner of being capable of sliding forwards and backwards; the location disc is rotatably arranged at the rear end of the support shaft in a sleeving manner, a plurality of U-shaped grooves are arranged in the rear end surface of the location disc in a sinking manner along a peripheral direction, and the opening of each U-shaped groove penetrates through the sidewall of the location disc; one baffle is arranged at the opening of each U-shaped groove in a covering manner; and one end of each baffle is hinged at one side of the opening of the corresponding U-shaped groove through a pin shaft, and a torsional spring is arranged on each pin shaft in a sleeving manner. The fixed-length cutting device disclosed by the invention is capable of conveniently carrying out fixed-length cutting on the tubes, safe and efficient in cutting process, and low in cost.

Owner:海宁经开产业园区开发建设有限公司

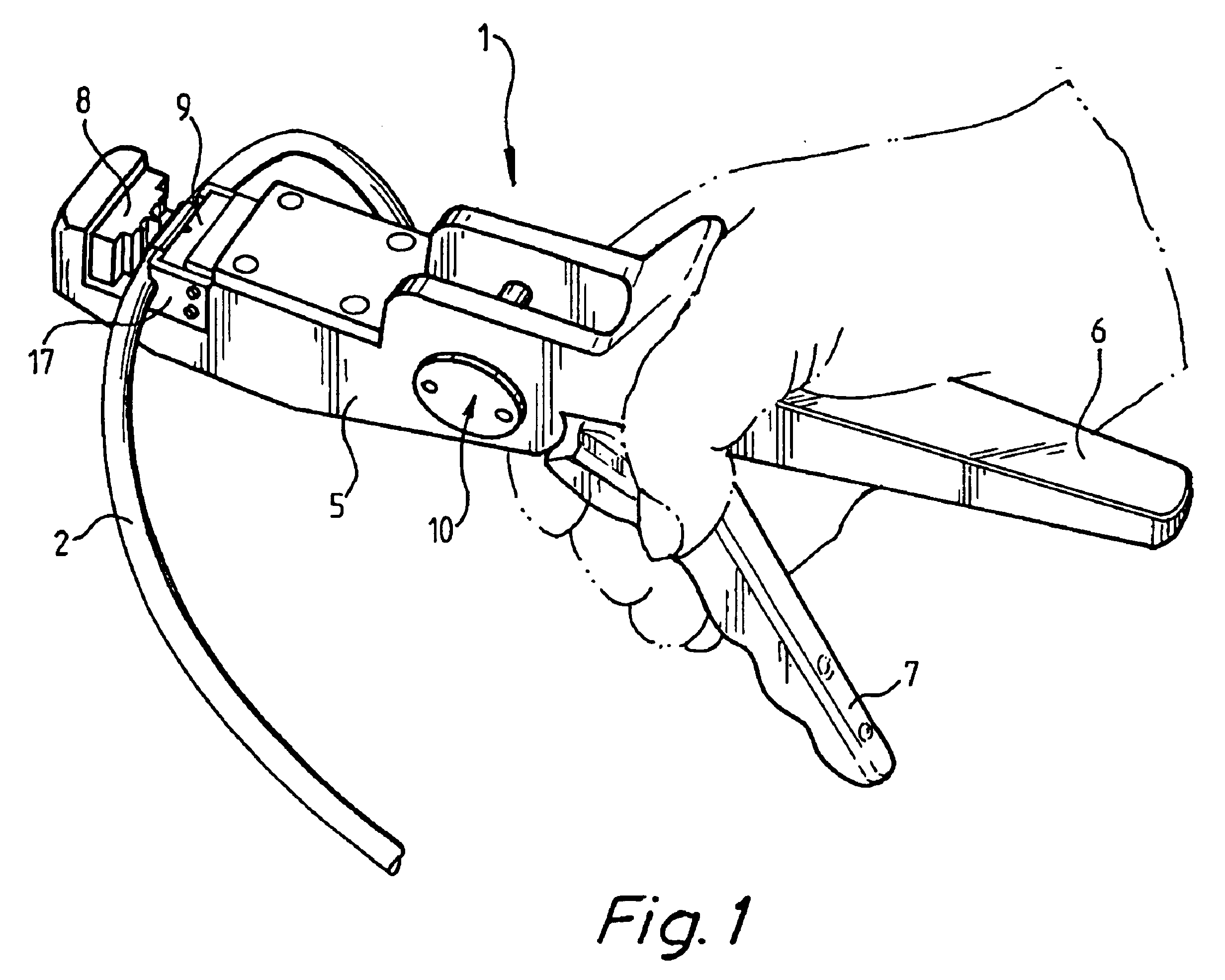

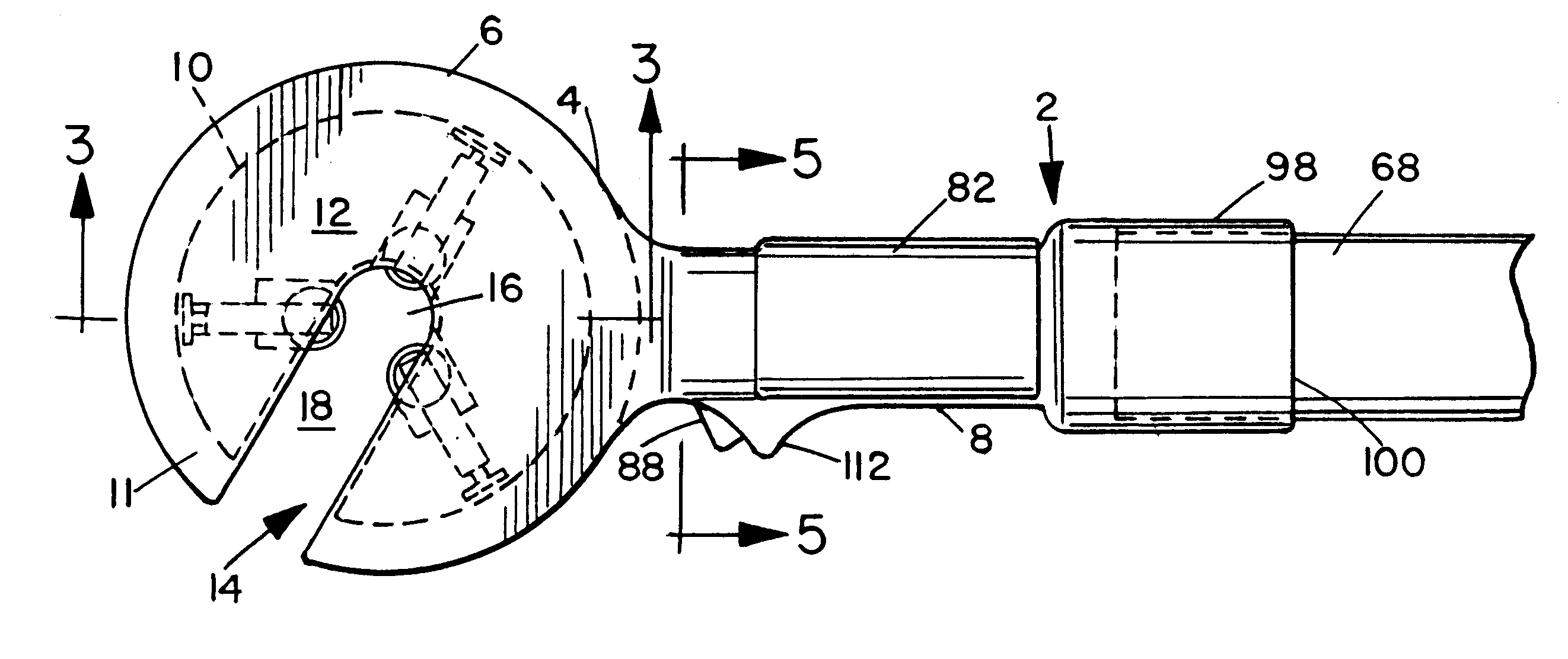

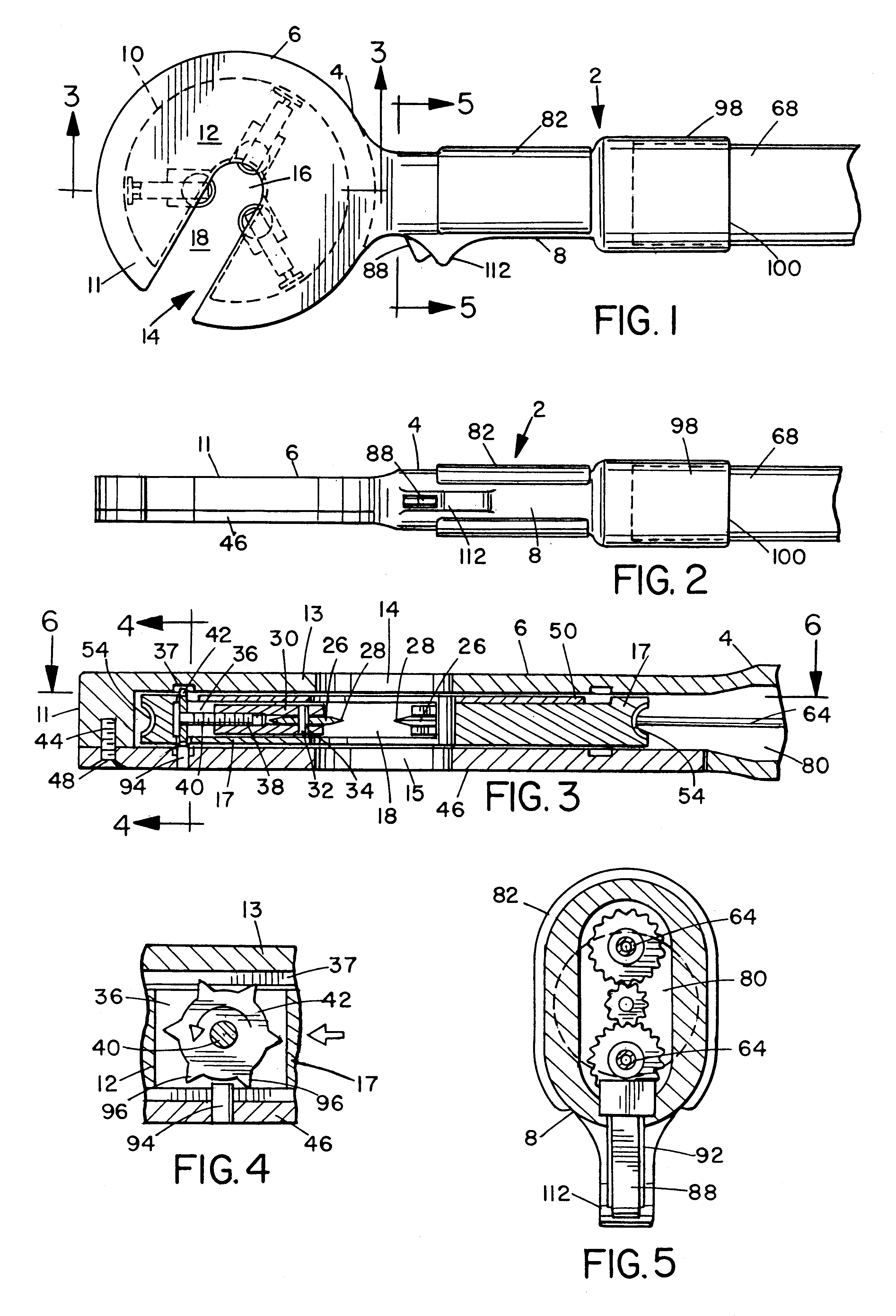

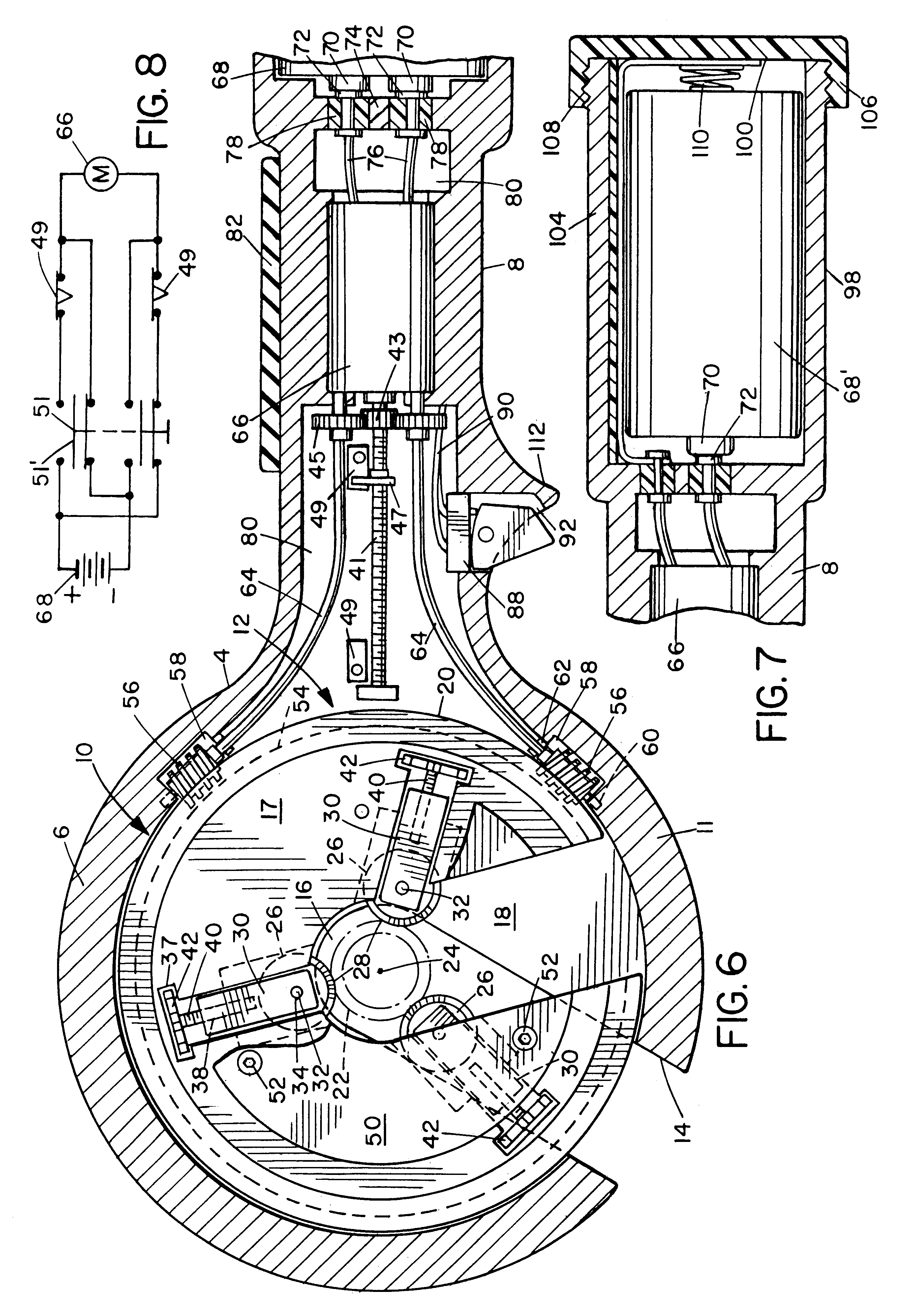

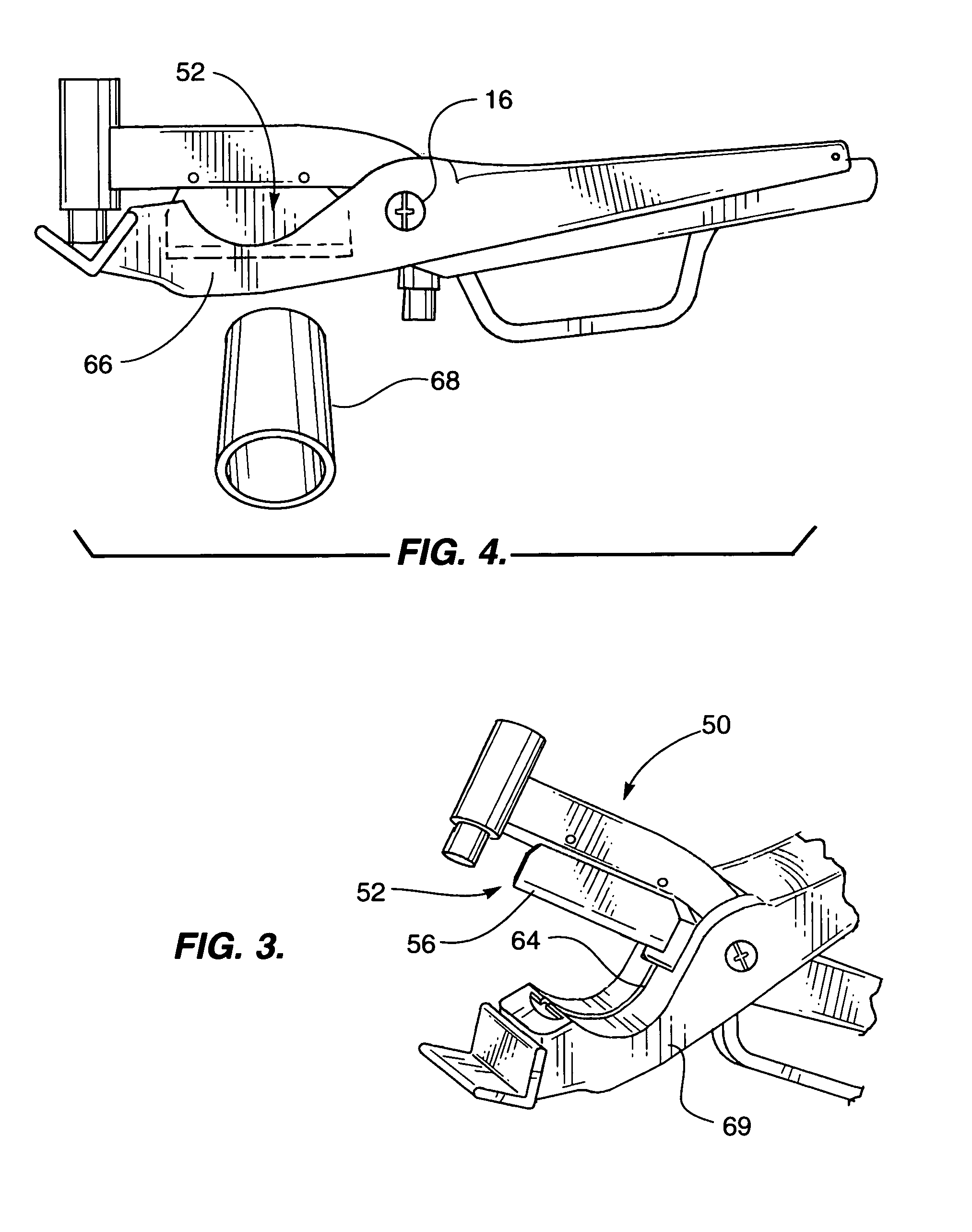

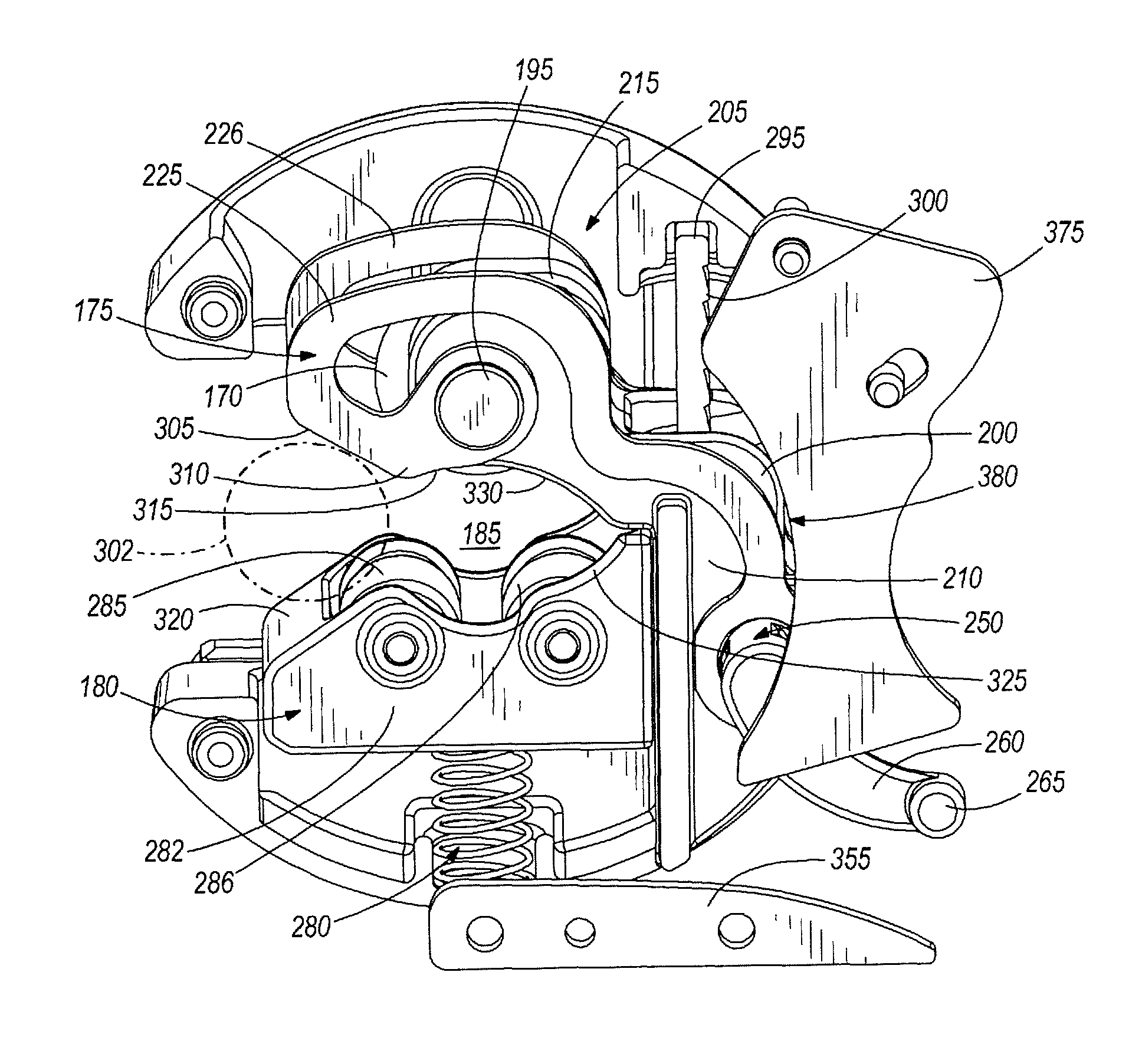

Power-driven hand-held tubing cutter

A motor driven, hand-held tubing cutter is disclosed, which can be held stationary by a worker while cutting the tubing, and does not require that the tubing be held in a vise or other clamping tool. The device is reversible, and upon completion of the cut, the device can be reset automatically to its initial position to receive a subsequent length of tubing for cutting. The tool has a motor-rotated cutting head into which the tubing to be cut is inserted, one or more cutting blades which are urged into cutting contact with the tubing wall by the motor-driven rotation of the head in cooperation with indexing bosses, and, once the tubing is cut through, reversal of the driving motors causes the blades to be retracted into the head, resetting the tool for further cutting. The tool may be used to cut any cuttable metal or plastic tubings, including tubing of aluminum, brass, copper, steel, ABS, PVC, polycarbonate, phenolic, etc.

Owner:WRATE LEONARD A

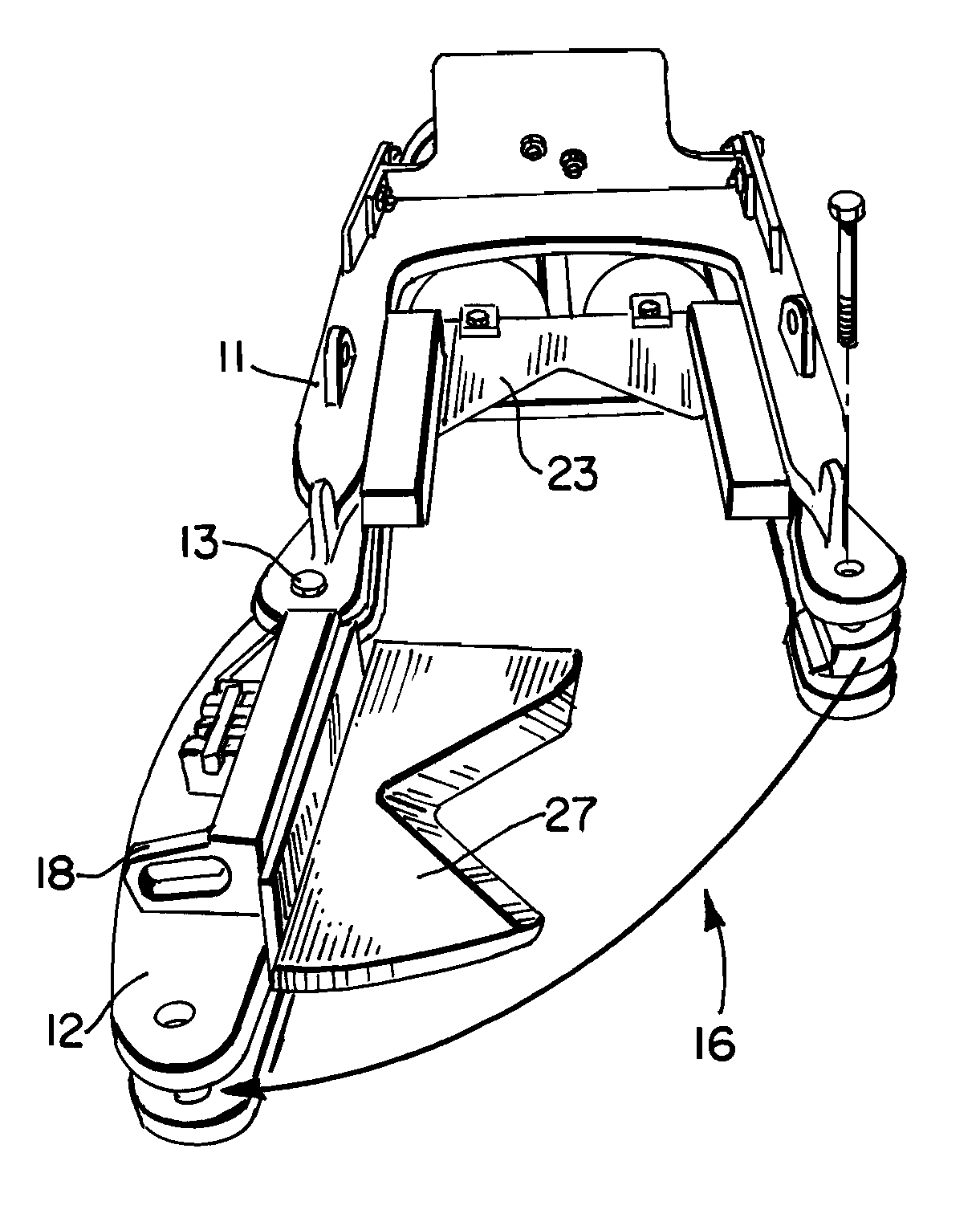

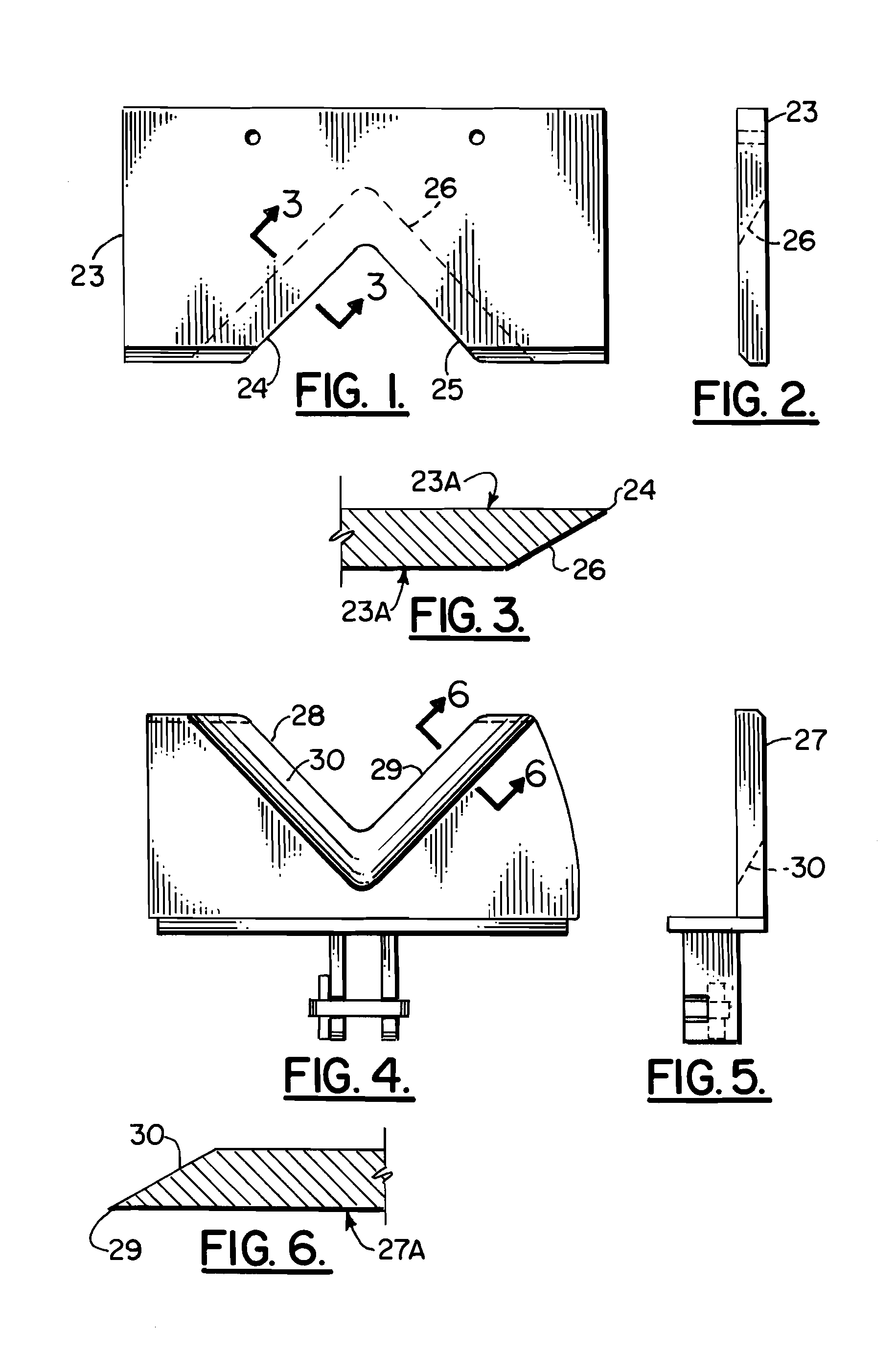

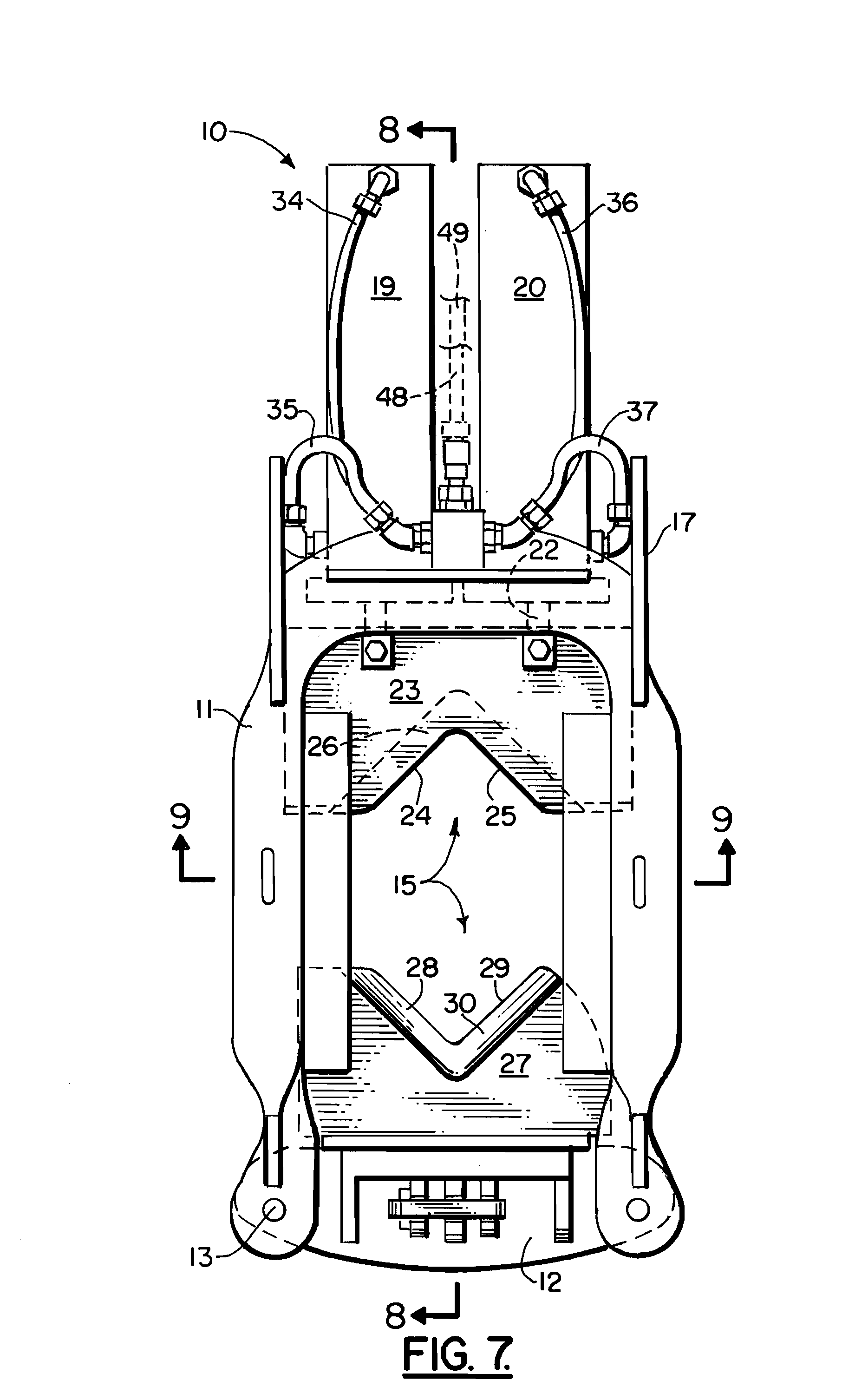

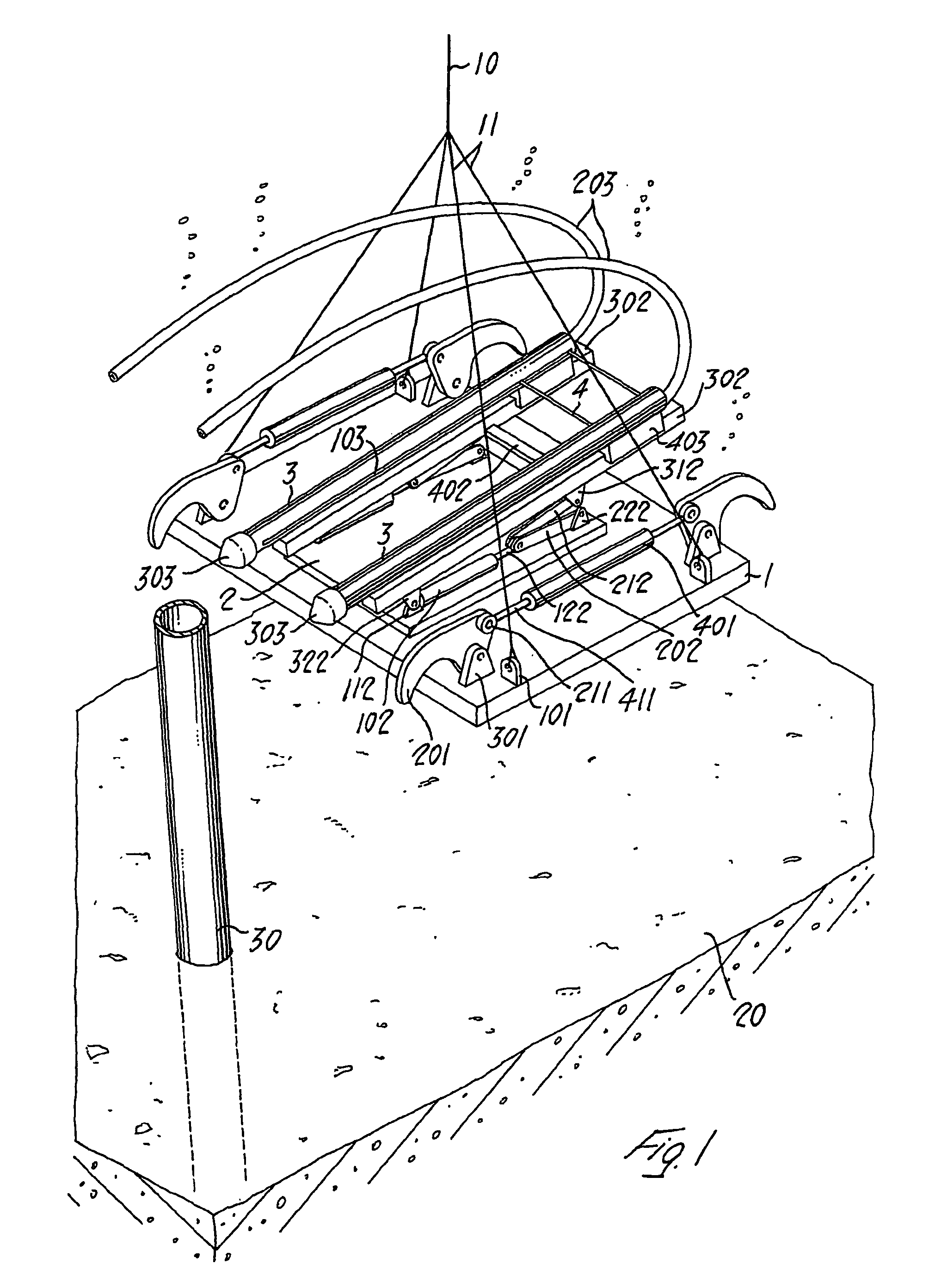

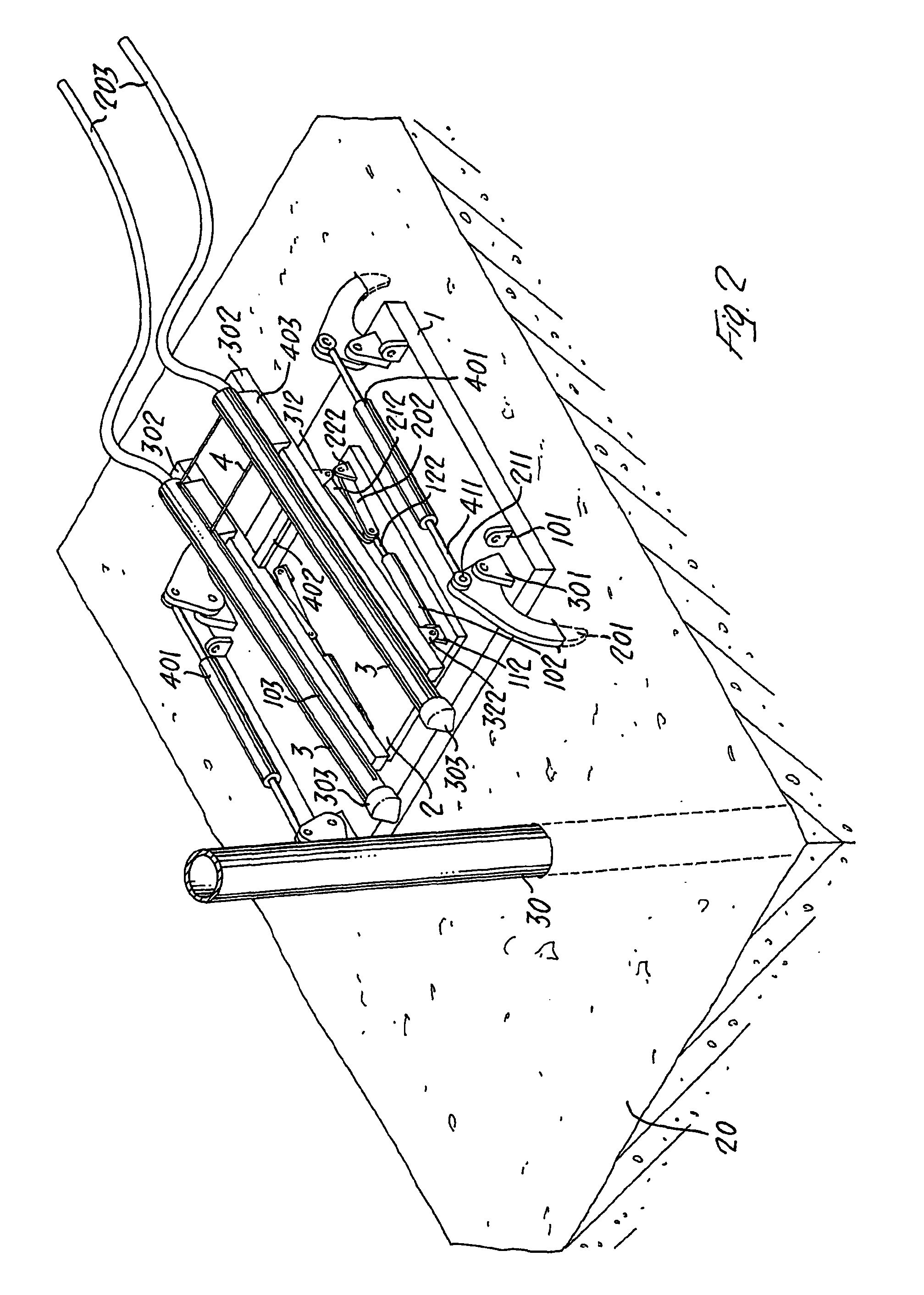

Method and apparatus for salvaging underwater pipelines

A method of salvaging a pipeline in a marine environment is disclosed. The method provides a frame having a perimeter that surrounds a pair of opposed cutting blades, the frame having a gate that enables the frame to be selectively placed around or removed from a section of pipeline to be cut. As part of the method, the frame is placed on a pipeline by first opening the gate and then closing the gate once the pipeline is in an opening that is at the center of the frame. The center opening is generally rectangular in shape once the gate is closed. The cutter blades are moved toward one another, preferably with one blade being the moving blade and the other being a fixed blade. The cutter blades move toward one another until they overlap. At the time that they overlap, the cutter blades are prevented from deflecting in a direction normal to the direction of travel by a pair of guide rails that trap the moving blade in between the fixed blade and the guide rails. The pipeline to be cut is automatically centered within respective v-notched shaped blades prior to being severed as the blades advance relative to one another.

Owner:KELLY JOHN M +1

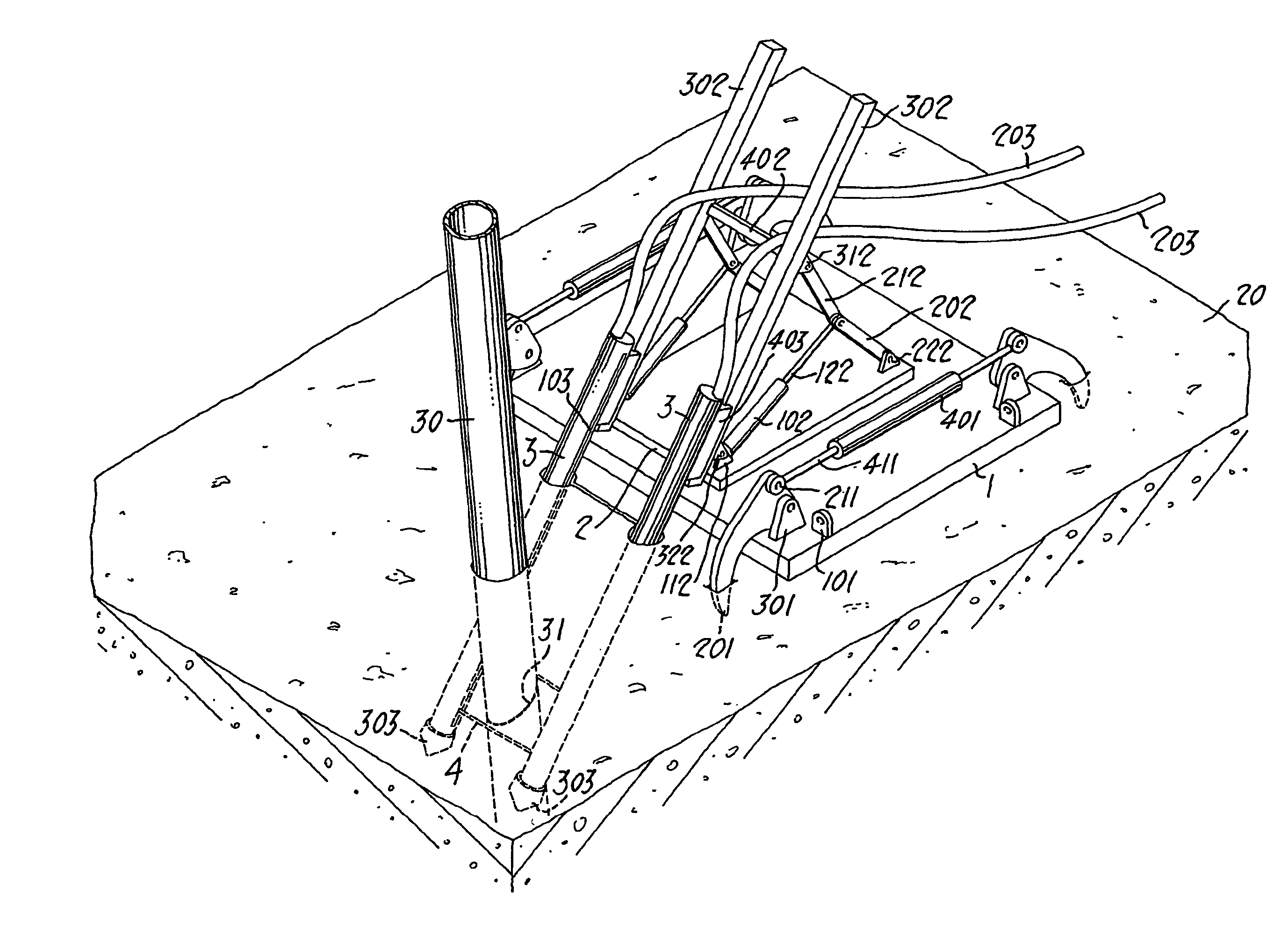

Method and apparatus for cutting underwater structures

InactiveUS7036599B2Minimum of of energyMinimum expenditureMetal sawing devicesArtificial islandsOcean bottomMarine engineering

A method for the cutting of underwater structures below the level of the sea bottom on which they are installed, comprises determining an ideal plane of cutting, having considered the characteristic features of the structure i.e. its morphology and its positioning on the bottom, the shape and consistency of the bottom itself, and the depth below the level of the bottom at which the cut must be effected; positioning and anchoring of a cutter in proximity of the cutting area; obtainment of at least one perforation or boring in proximity of the structure through the bottom at least up to the predetermined level for the cutting of the structure, along a direction parallel to the cutting direction and preferably lying on the cutting plane; and introduction of the cutter inside the perforation or boring and cutting of the structure. An apparatus for carrying out the method is also provided.

Owner:TS TECNOSPAMEC

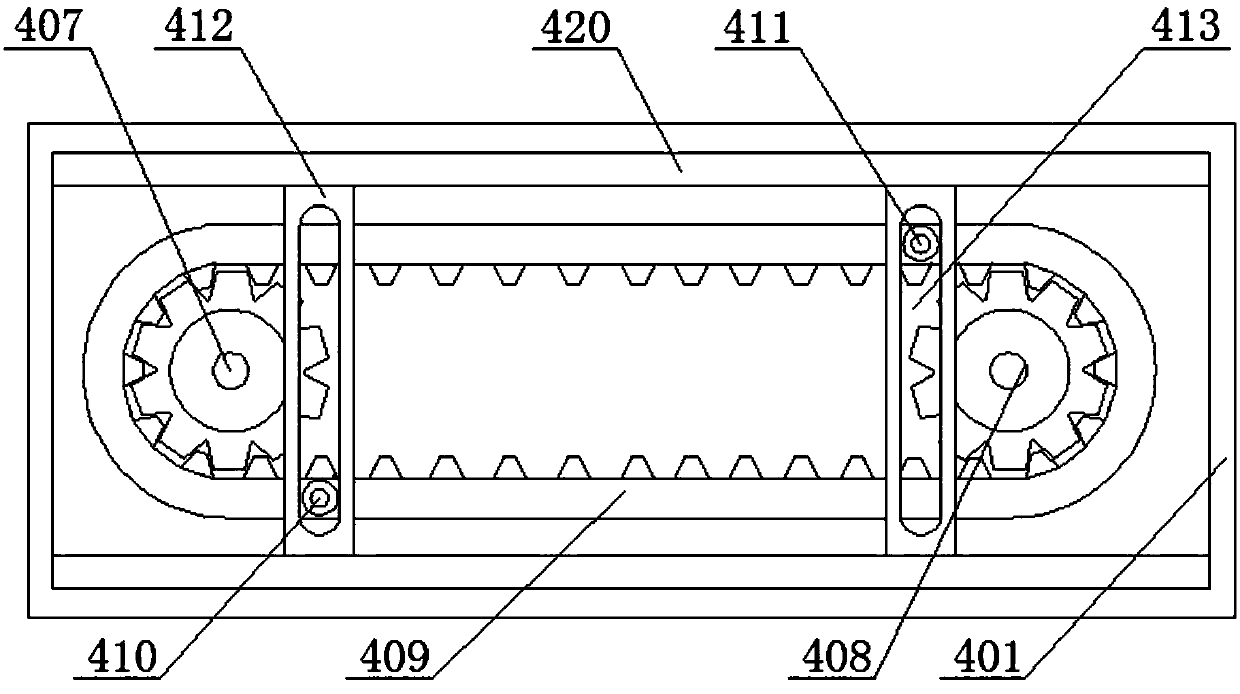

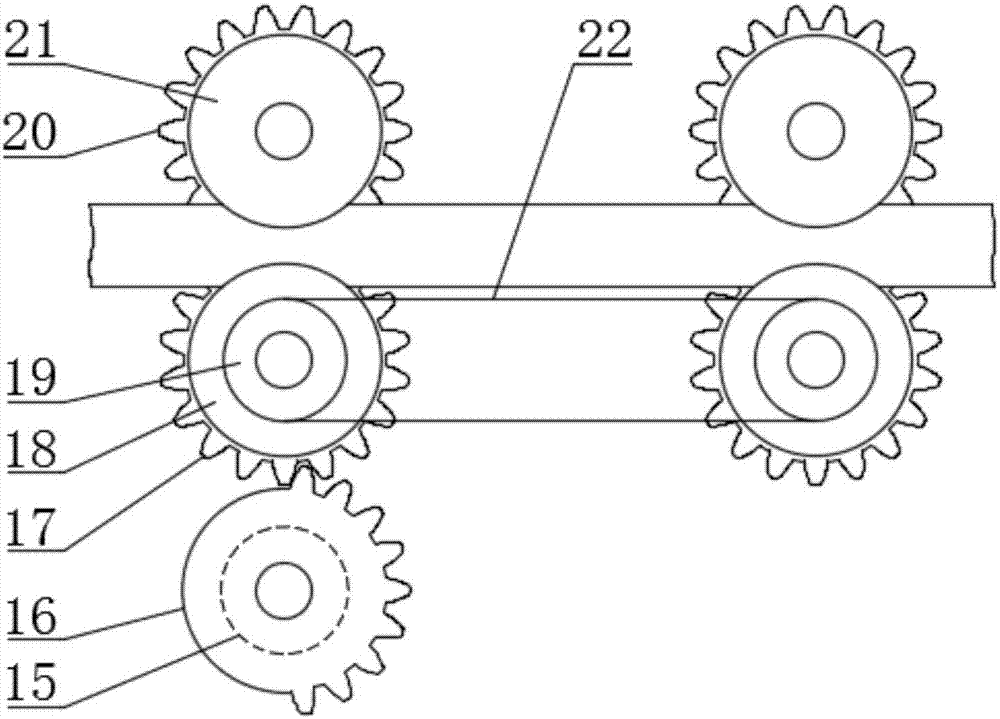

Adjustable equal-length automatic steel pipe cutting device

ActiveCN107570784AAdjust feed lengthAdjustable lengthTube shearing machinesShearing machine accessoriesTorsion springMotor shaft

The invention discloses an adjustable equal-length automatic steel pipe cutting device. A first rack on the upper side is rotationally connected with a first rotating shaft, and multiple elastic plates are evenly hinged to the positions, located at the first gear, of the side wall of the first rotating shaft through torsion springs. Inclined grooves matched with the elastic plates are evenly formed in the inner wall of the first rack of the upper side. A moving sliding rail is fixedly arranged on the top of a base through a support. The moving sliding rail is connected with a rack in a slidingmanner through a sliding block. The rack is located on the rear side of the first rack on the upper side and is engaged with the first rack on the upper side. The top of the base is further providedwith a speed reduction motor. A rotary disc is installed at the top of the speed reduction motor through a motor shaft. A bar-shaped hole is formed in the right side of the rotary disc. A sliding groove is further formed in the top of the right side of the rotary disc. A limiting block is connected to the sliding groove in a sliding manner, and a pin shaft is fixedly connected to the limiting block. By means of the adjustable equal-length automatic steel pipe cutting device, the first rack on the upper side only drives the first rotating shaft to rotate forwards, and therefore a steel pipe isdriven to be fed progressively; and due to the feeding length of the steel pipe, a plate can be covered, manual feeding control is not needed, and operation is convenient.

Owner:阪神机器(徐州)有限公司

Hot tapping plugging construction method of long natural gas delivery pipeline

ActiveCN103016893AReliable and reliableImprove economyArc welding apparatusPipe elementsProcess engineeringIndustrial engineering

The invention discloses a hot tapping plugging construction method of a long natural gas delivery pipeline. The method specifically comprises the following implementation steps of: performing non-stop tapping operation; performing non-stop plugging operation; disassembling a pipeline of a cutting section; performing end connecting operation; restoring; and performing anti-corrosive backfill. The construction process of the method has the characteristics of reliability, economy, safety, simplicity in operation of an entire construction process, light labor intensity, no influence on downstream gas utilization, short working period, cost saving, suitability for various environments and the like, so that the method is increasingly generalized and applied in natural gas reconstruction and expansion projects.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

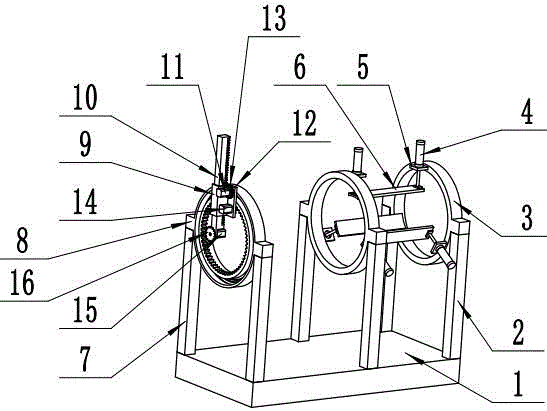

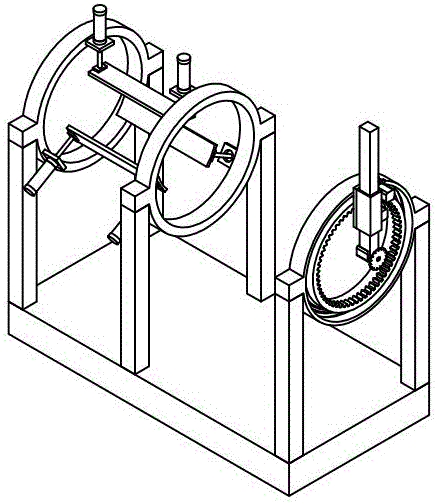

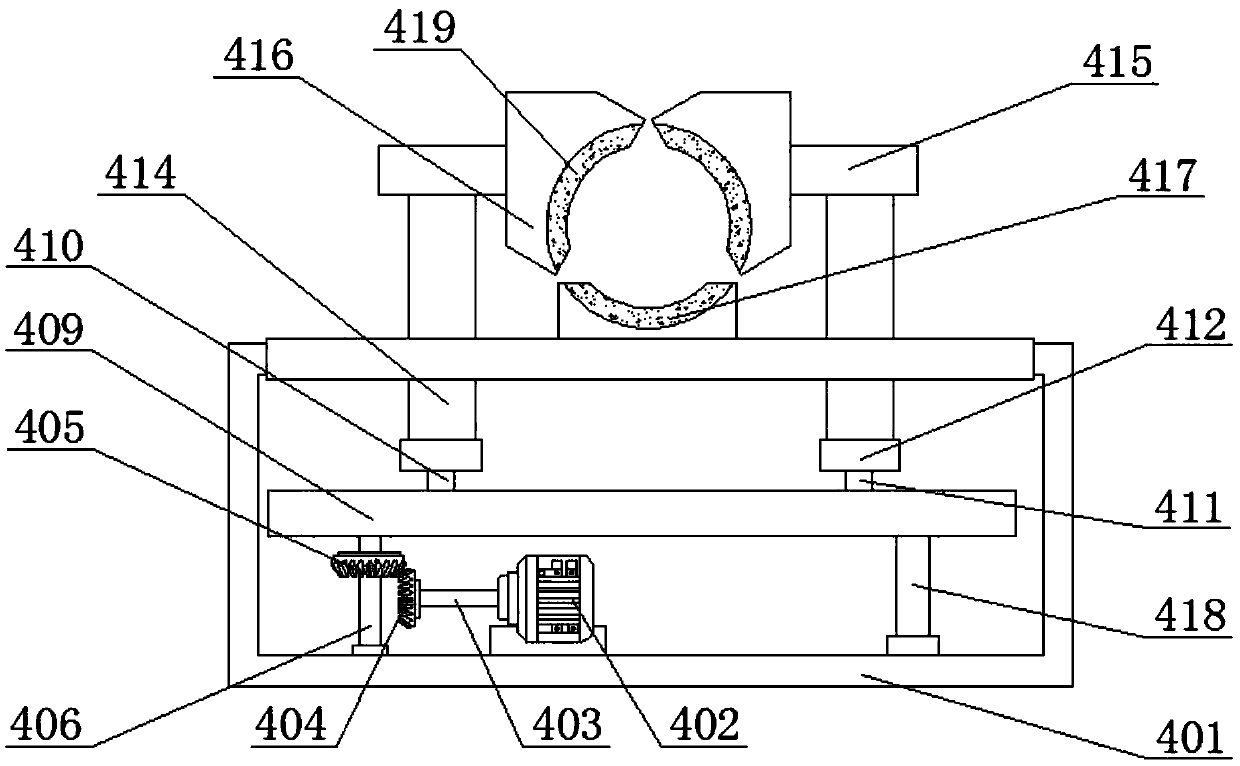

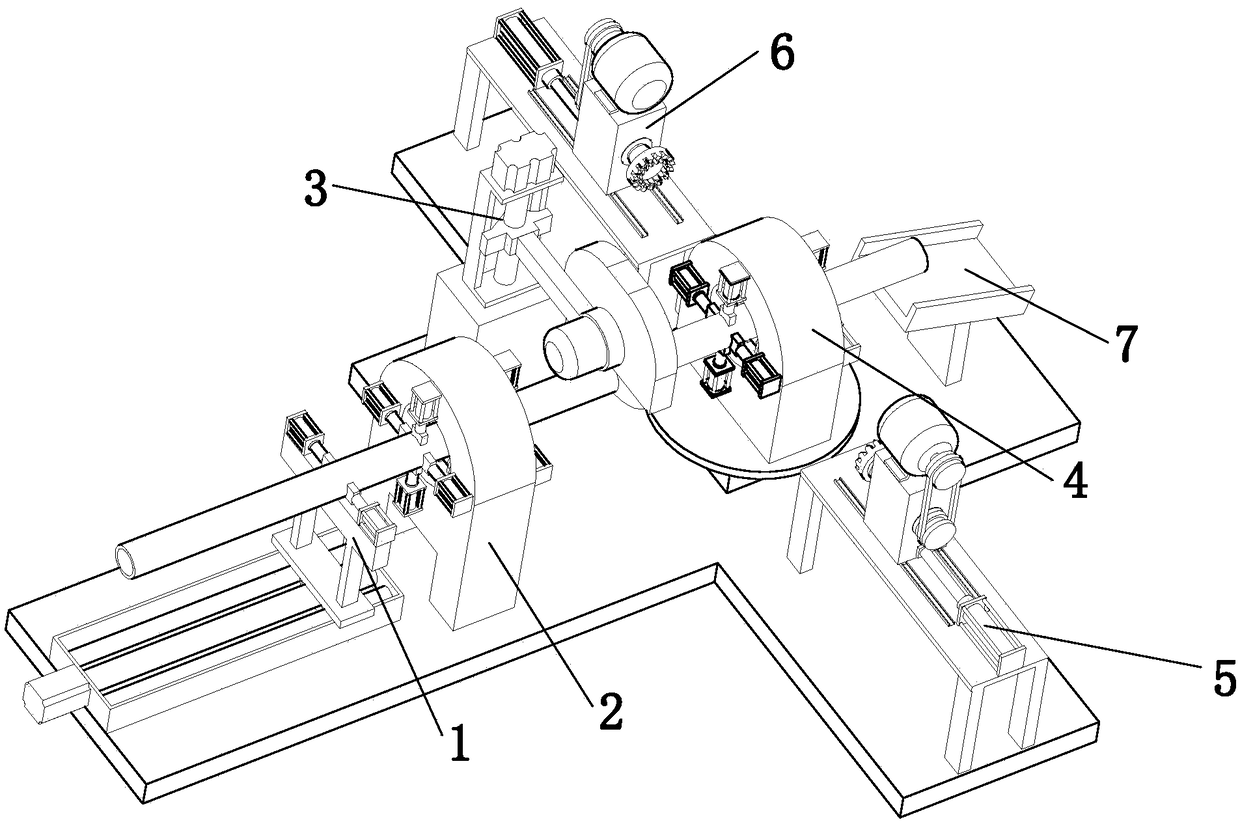

Outer-pipe circular cutting robot for steel pipe

ActiveCN106001735AImprove cutting efficiencyFast cutting speedTube shearing machinesShearing machine accessoriesGear wheelElectric machinery

The invention relates to an outer-pipe circular cutting robot for a steel pipe. The robot comprises a base, a steel pipe pressing plate, a circular cutting frame, an expansion link sleeve, an expansion link, an expansion link motor, a cutting mechanism fixing plate, a rotary motor, a cutting blade, an electric brush, an expansion link rack and an expansion link cutting motor fixing frame, wherein steel pipe frame stand columns of the expansion link motor fixing plate is fixedly arranged on the base, a steel pipe fixing sleeve is fixedly arranged on the steel pipe frame stand columns, the circular cutting frame is fixedly arranged on circular cutting frame stand columns, and the circular cutting frame stand columns are fixedly arranged on the base; the expansion link is arranged on the expansion link sleeve in a sliding way, the expansion link motor is fixedly arranged on the expansion link motor fixing plate, a stretching motor gear is fixedly arranged on an expansion link motor shaft, and the stretching motor gear is meshed with the expansion link rack; and the cutting motor is fixedly arranged on the expansion link cutting motor fixing frame, and the cutting blade is fixedly arranged on the cutting motor shaft. The robot can improve the steel pipe cutting efficiency, and is high in cutting speed, trim in notches and good in effect.

Owner:青岛昊坤机械制造有限公司

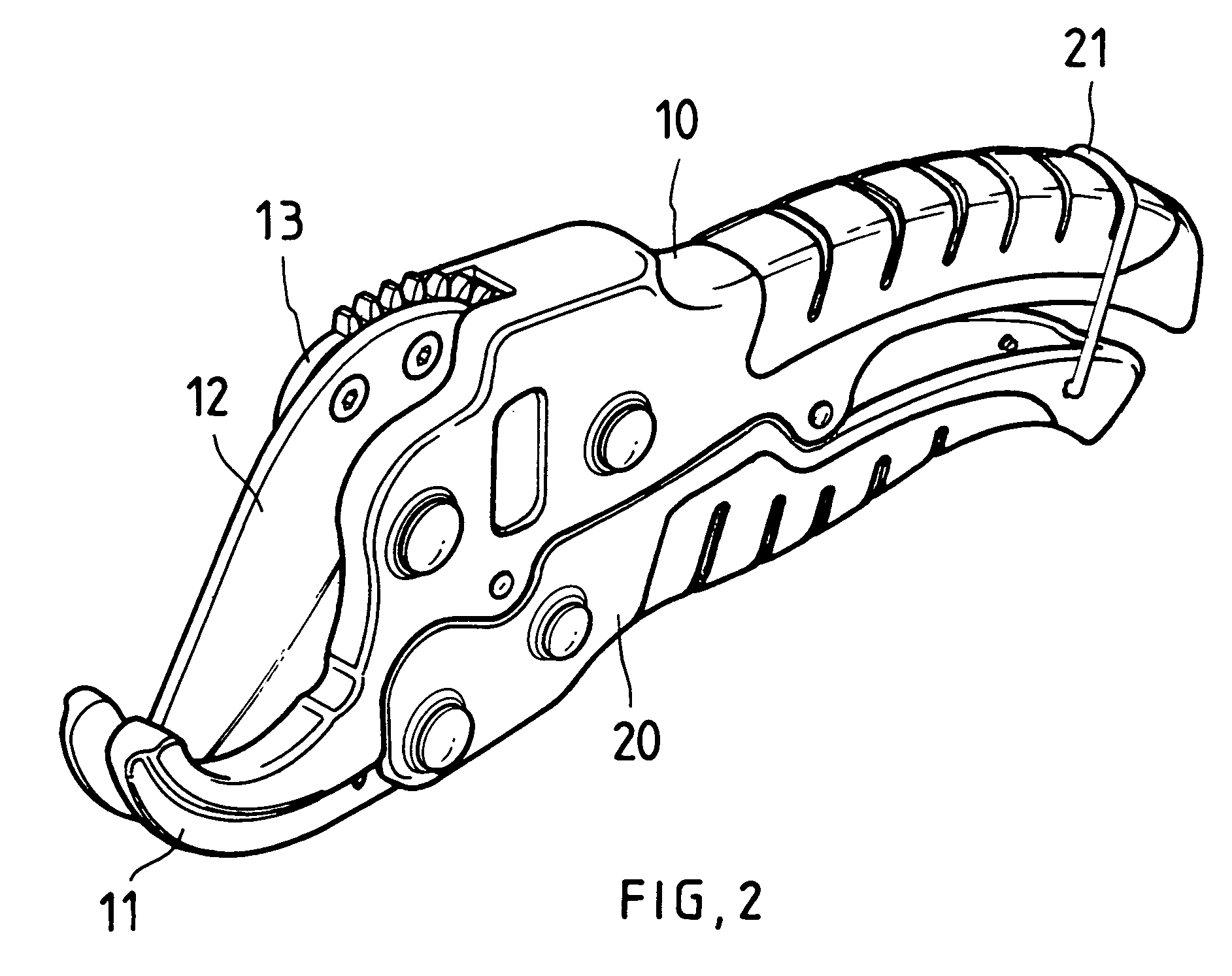

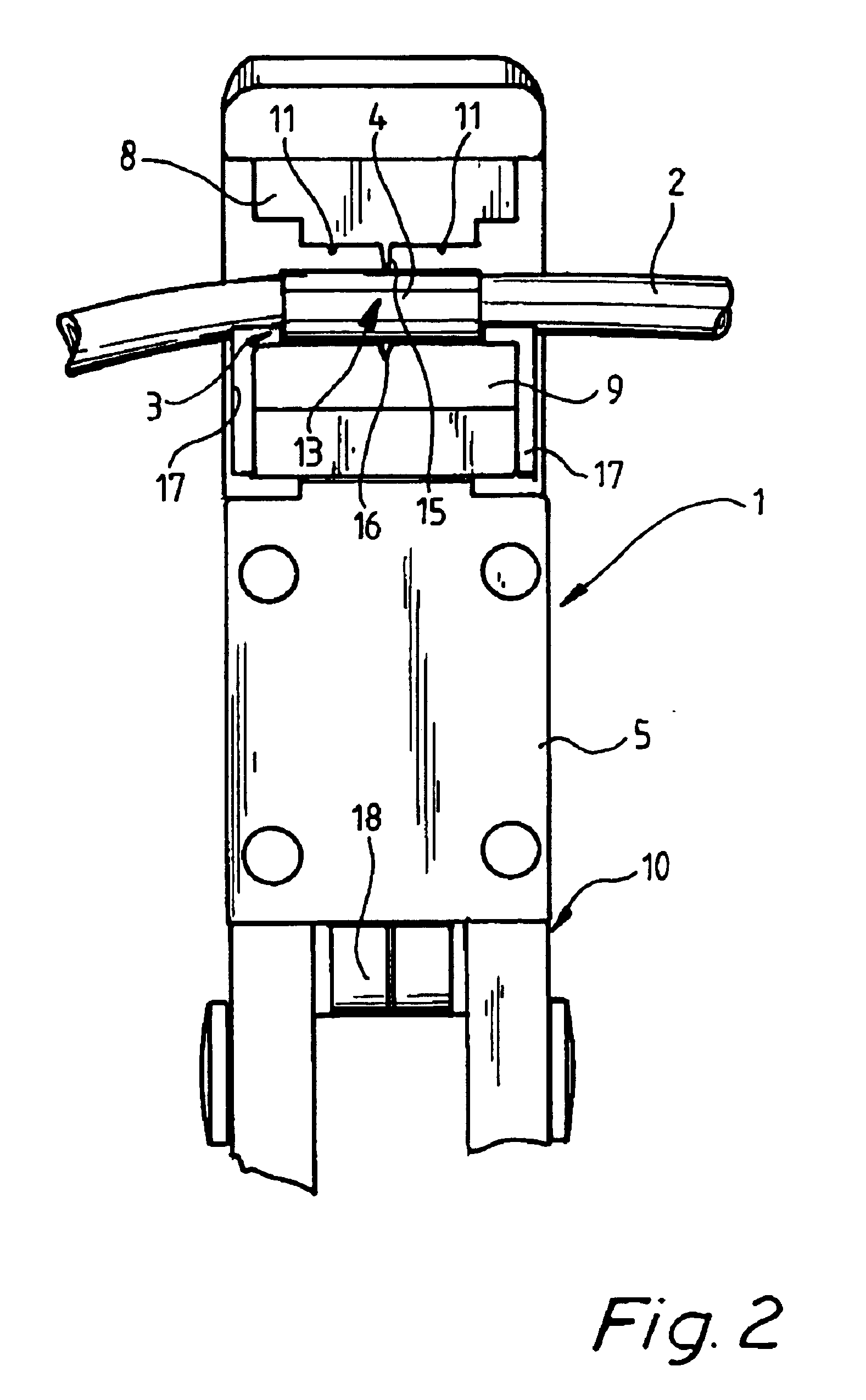

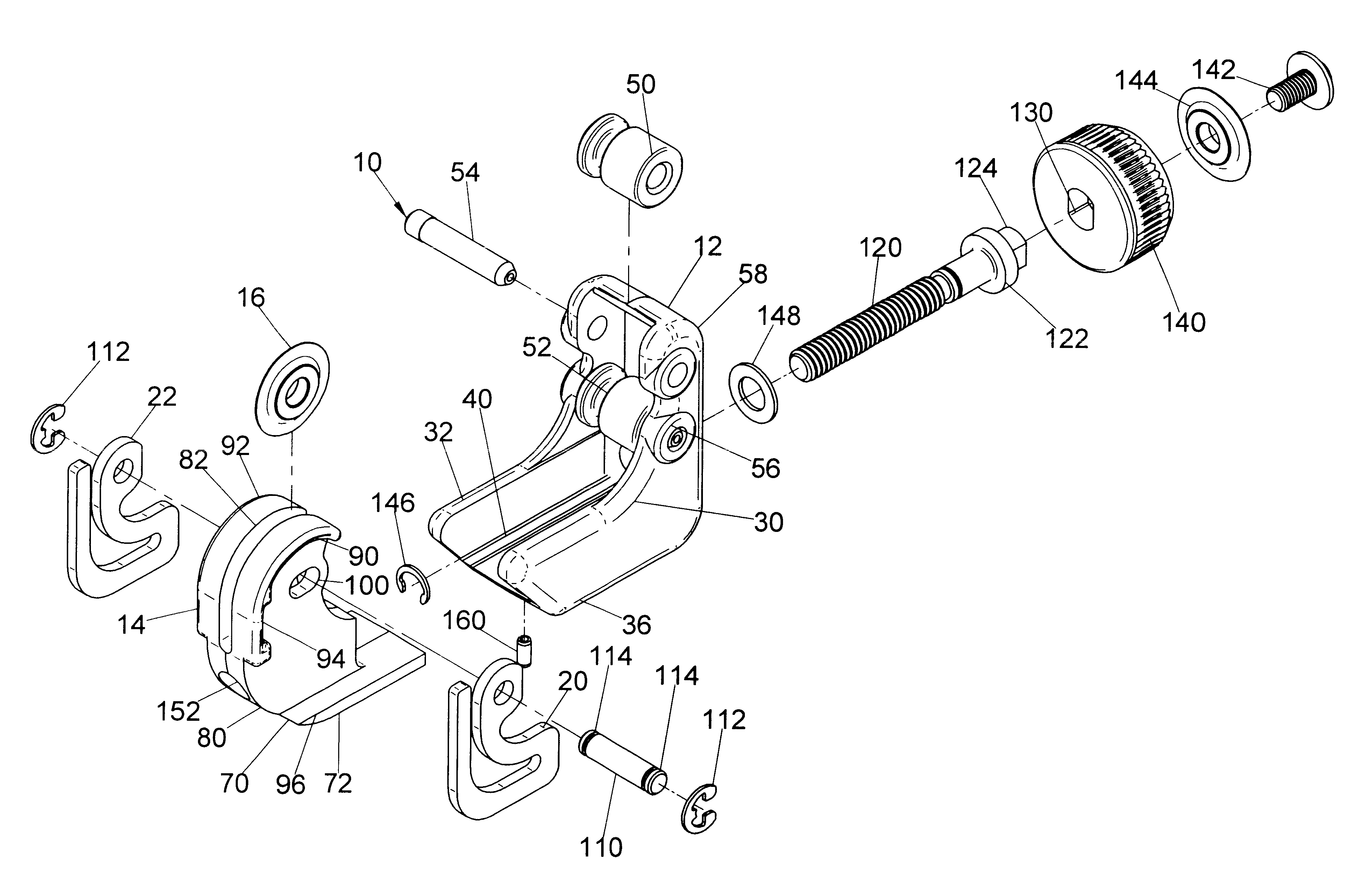

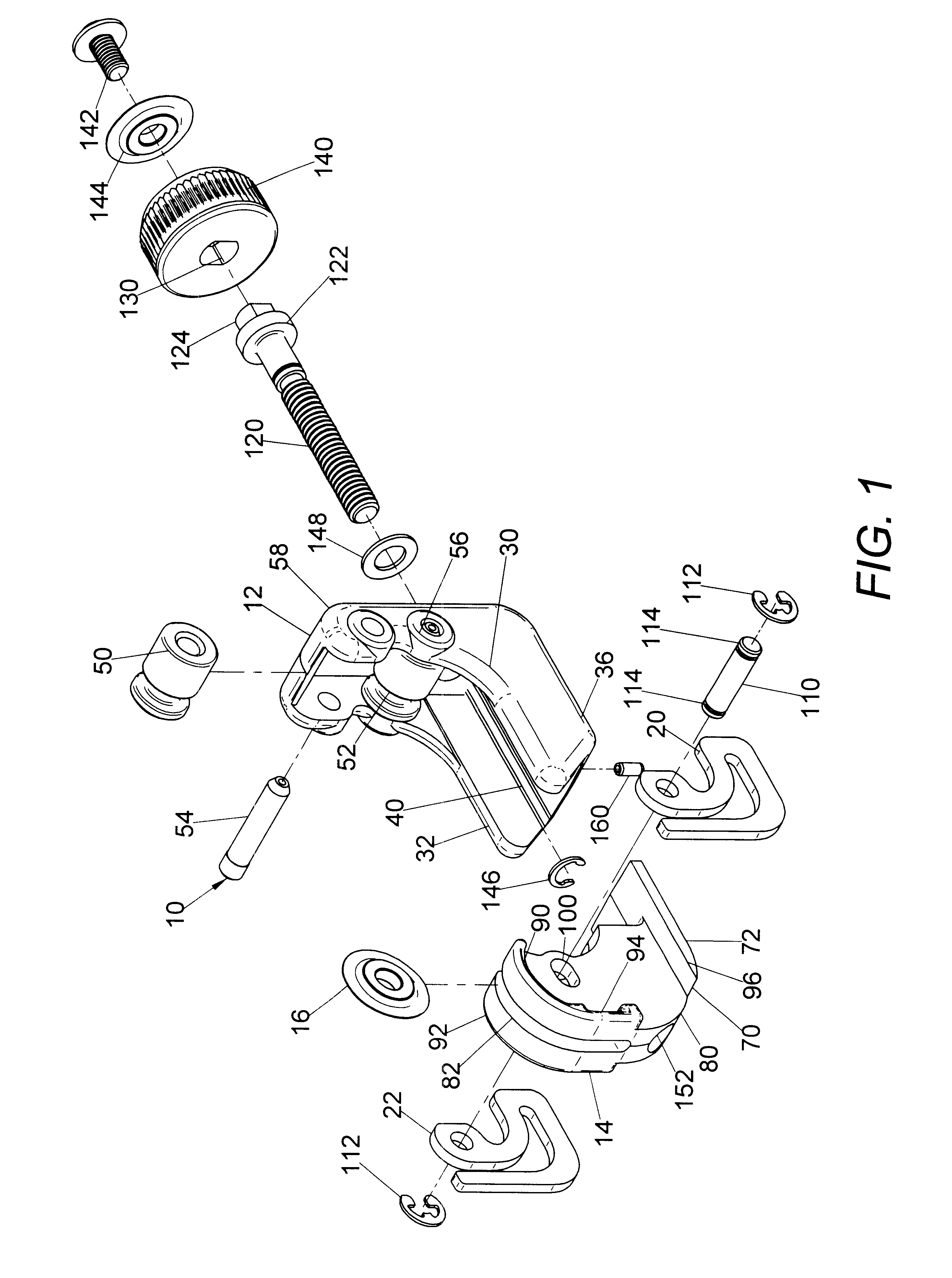

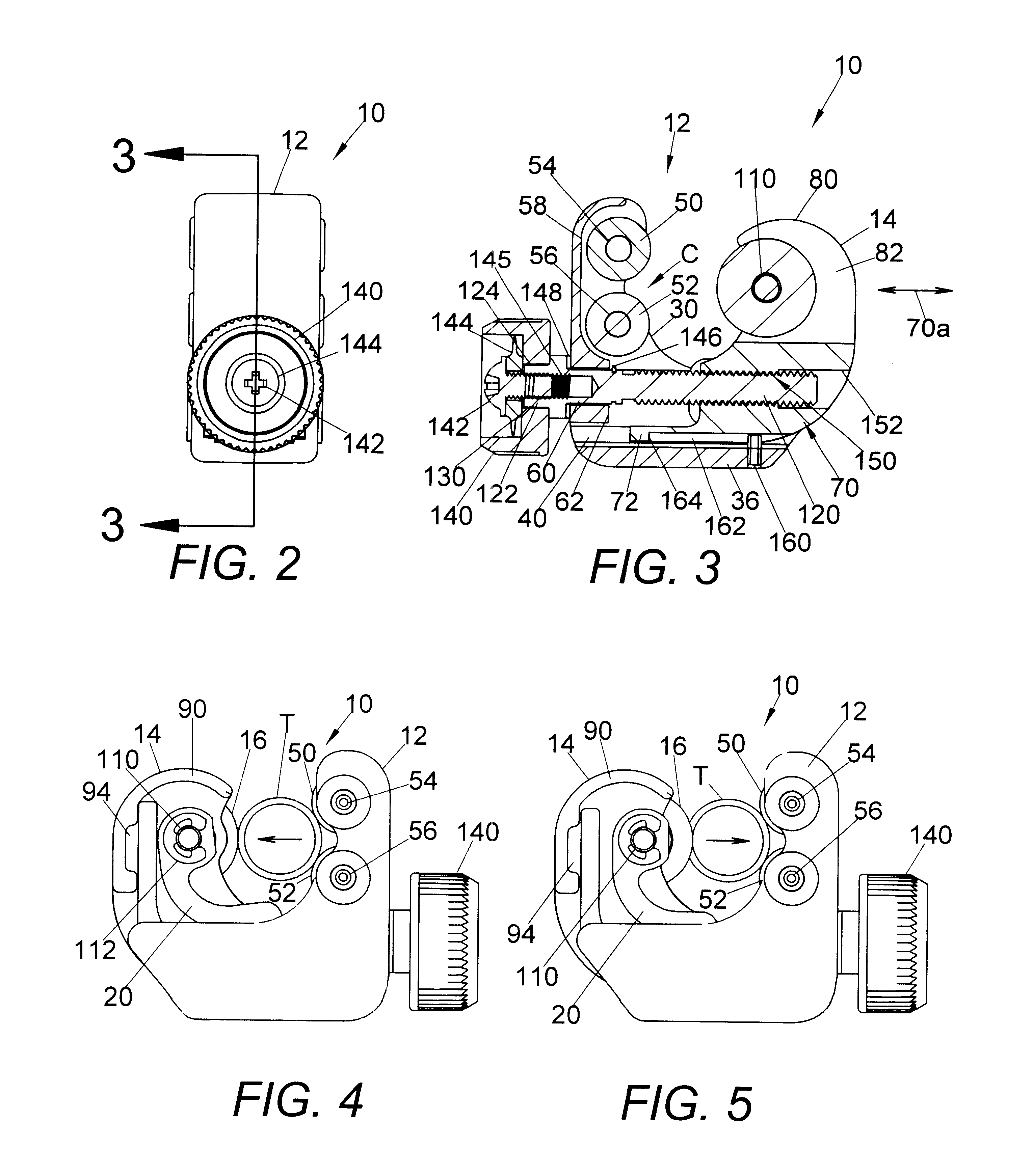

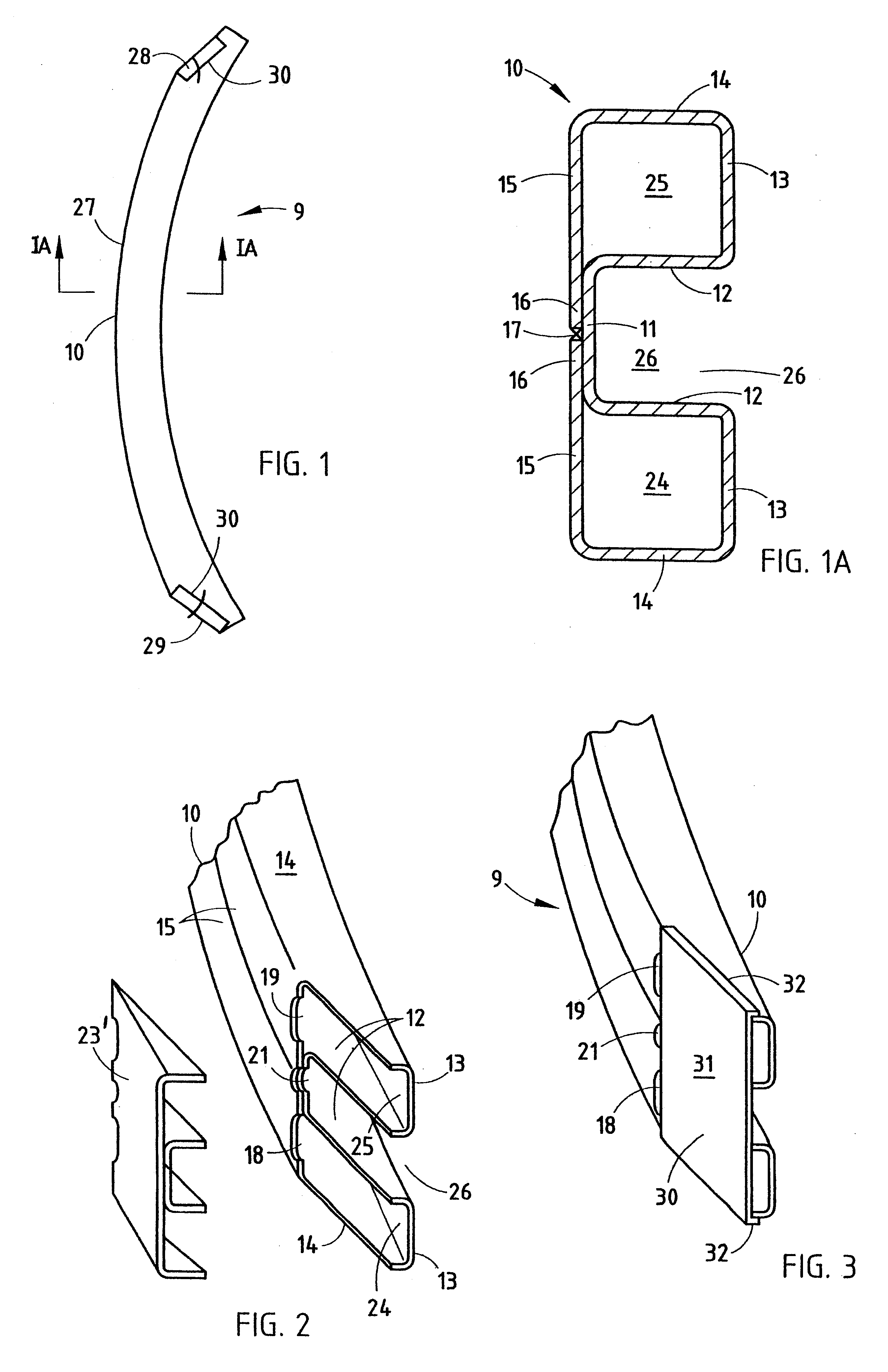

Tube cutter

InactiveUS6393700B1Reduce actionMaintain abilityTube shearing machinesMetal working apparatusEngineeringCutting force

A tube cutter for cutting a circular tube having a central tube axis, the cutter comprising: a housing with first and second parallel rollers defining a cradle for receiving a tube cut with the tube axis generally parallel to the axes of the rollers, a cutter head reciprocally mounted on the housing for sliding linearly in a direction toward and away from the rollers, the cutter head having a base and an upstanding arm supporting a cutter wheel rotatable about an axis generally parallel to the axes of the rollers and facing the tube in the cradle, a spring element biasing the cutter wheel in the stated direction and toward the rollers, and a threaded shaft between the housing and cutter head, and rotatable to move the cutter head linearly toward the housing, whereby the cutter wheel engages the tube and the spring element creates a cutting force pushing the cutter wheel against the tube for cutting the tube.

Owner:EMERSON ELECTRIC CO

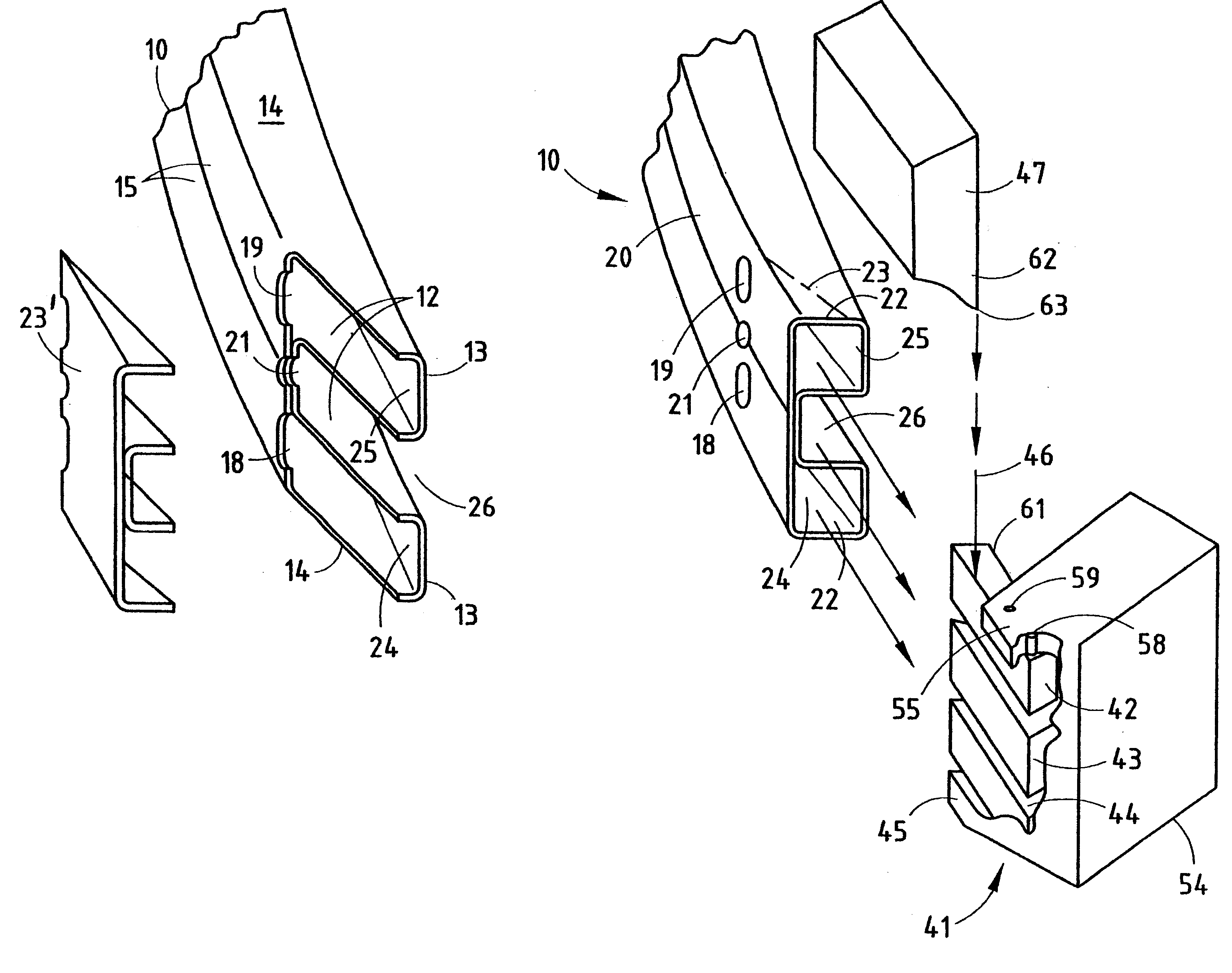

Die apparatus for cutting end of bumper bar

InactiveUS6240820B1High strengthLoad-supporting elementsTube shearing machinesEngineeringMechanical engineering

A die apparatus includes a first die configured to telescopingly engage an end section of a tubular bar, including one or more "floating" mandrels configured to extend into cavities of the tubular bar, and further including a stationary die member spaced from the mandrel(s). The mandrel(s) and the stationary die member include angled cutting edges that are aligned so that the cutting edges are engageable from a single transverse direction. The mandrel(s) is movably supported on the first die to float parallel the single direction toward and away from the stationary die member. A cutting die has a shearing punch configured to move along the single direction to sequentially engage the angled cutting edges to shear off an angled portion of the end section. The die apparatus is optimally designed for use with a rollformed swept tubular bumper bar having a B-shape and that has walls forming first and second tubular sections that define first and second cavities, with the walls further defining a third cavity between the first and second cavities. In such a die apparatus, the first die includes first, second, and third mandrels configured to extend into the first, second, and third cavities, respectively, of the B-bumper. A method related to the above apparatus is also disclosed.

Owner:SHAPE CORP

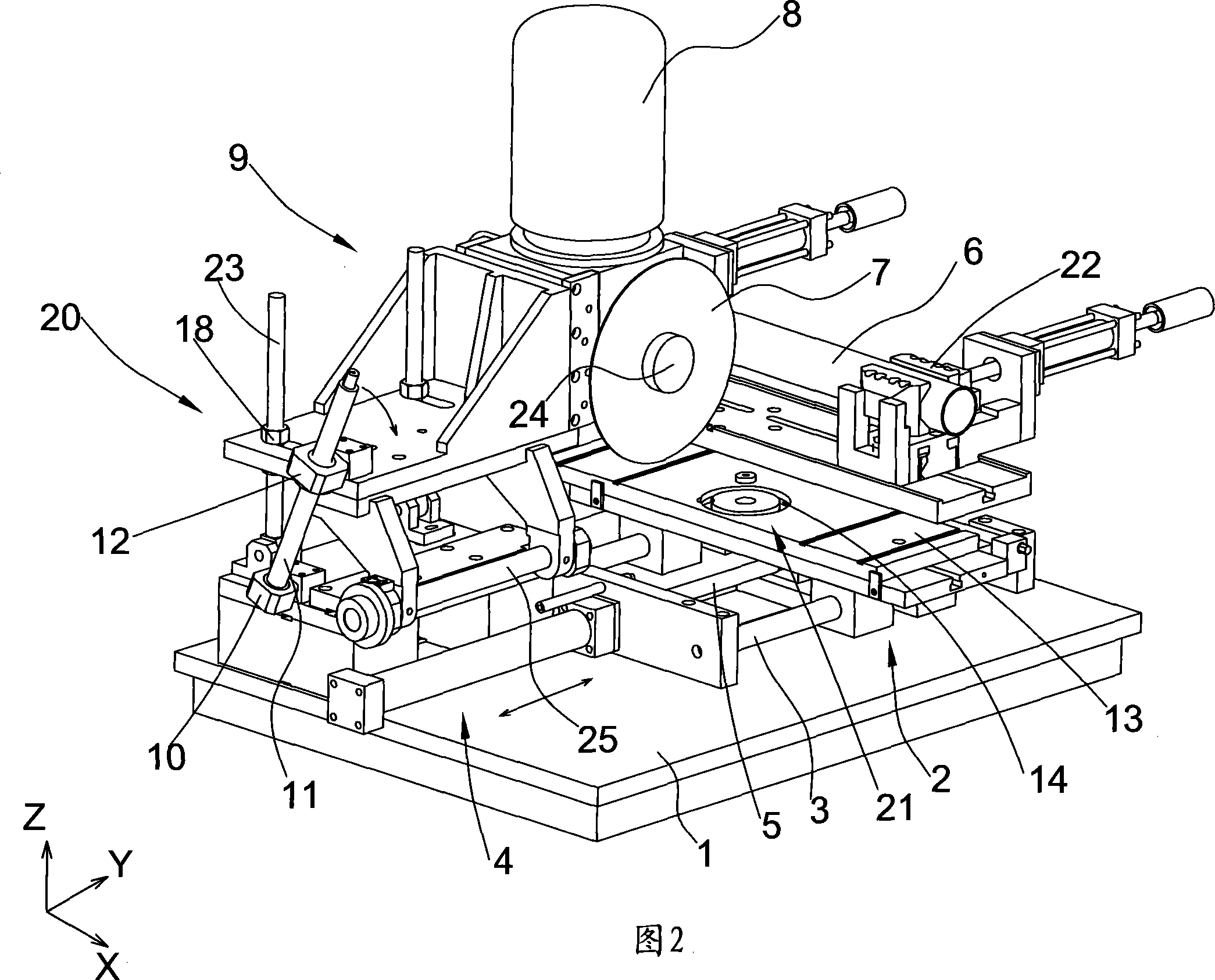

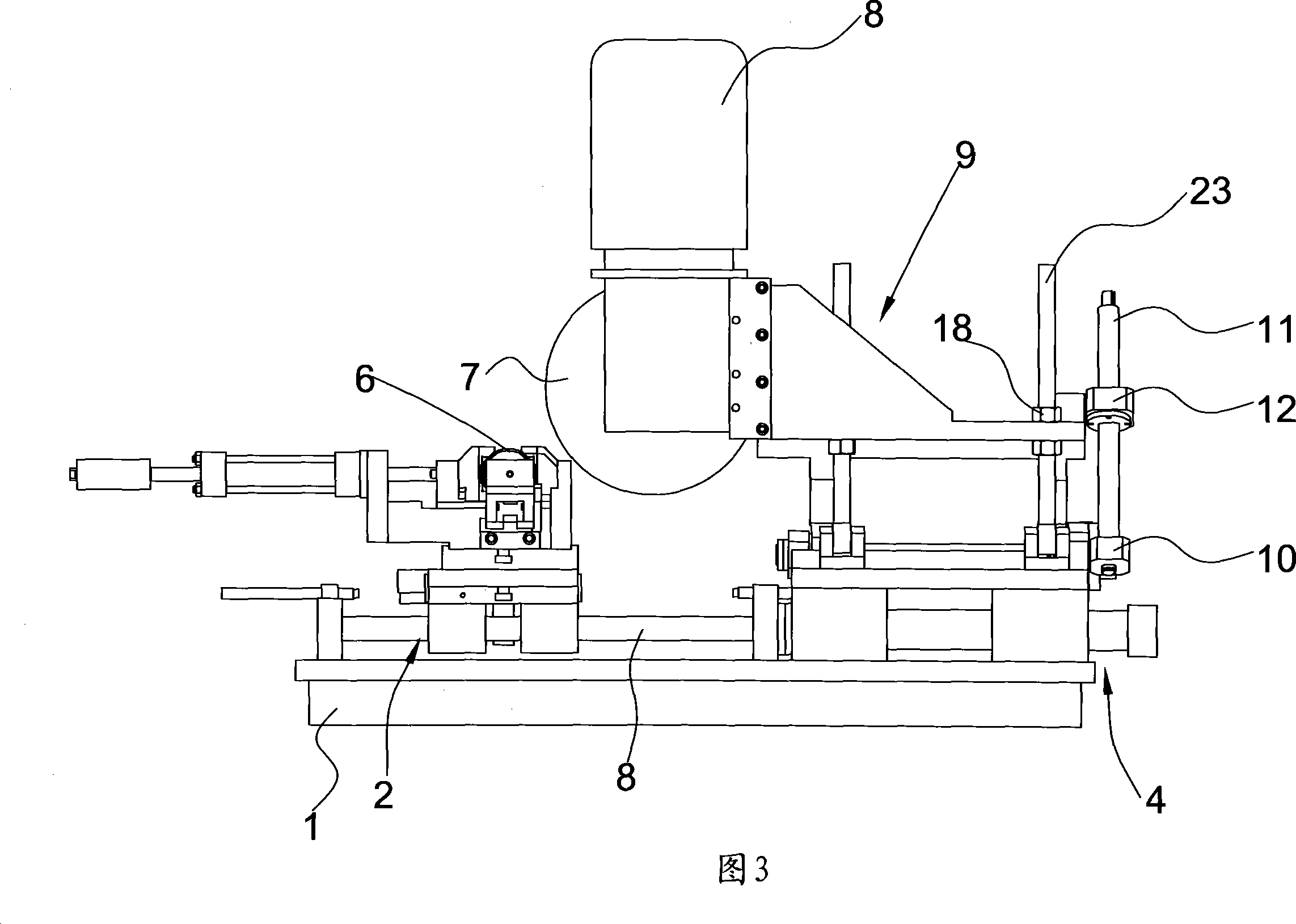

Three-dimensional pipe cutter

The invention is concerned with a kind of three-dimensional machine to cut pipe, relating to machine rack, holding equipment, fixing seat for drill. The drill connects with the fixing seat in moving, and the holding equipment sets on the machine rack in sliding. The drill connects on the first running axis extending to the axis of X and the machine rack has guiding rail extending along the level direction and the holding equipment set on this guiding rail in sliding. The machine rack has the second running axis extending along the axis of Y that being upright to axis of X and the drill seat connects with the second running axis in sliding. There is the first lock equipment between the drill fixing equipment and machine rack, and the holding equipment relates to the sliding seat connecting with guiding rail and worktable on the sliding seat moving around the axis of Z, and the sliding seat and worktable can match and slide with each other and there is the second lock equipment between the sliding seat and worktable. The three-dimensional relationship between the drill and pipe piece to cut the pipe piece from multi-angle, and the adjustment is easy to cut the strange shape of pipe piece or cut for many times.

Owner:庄添财

Installation tool for irrigation emitter barbs with cutter

A tool installs barb emitters in irrigation tubing. The tool has a cradle which receives irrigation tubing and a punch mounted opposite the cradle. The punch has a first cylinder and a second cylinder telescopically received within the first cylinder. The first cylinder has a cap at the upper end and an annular ring extending inwardly from to partially occlude the lower end. The second cylinder includes a second cap at the upper end which slidably engages the first cylinder and is resiliently urged by a spring against the annular ring. The cap has a punch holder extending downwardly therefrom. A needle has a sharp tip extending downwardly from the punch holder through the second cap to a point within the second cylinder when the spring is fully extended and beyond the second cylinder when the spring is fully compressed. One of the jaws has a knife blade extending from the other end thereof opposite. The of the jaws defines a semi-circular concave anvil at the other end. The anvil has an axially extending slot therein which receives the cutting edge of said knife blade when the handles are closed together.

Owner:MYERS MICHAEL

Pipe cutting device for automobile accessory manufacturing

ActiveCN107824869AImprove work efficiencyEasy clampingMetal-working feeding devicesTube shearing machinesMaterial resources

The invention discloses a pipe cutting device for automobile accessory manufacturing. The pipe cutting device comprises a base, wherein fixing blocks are arranged on two sides of the top part of the base, a supporting plate is arranged at the top parts of the fixing blocks, clamping devices are arranged on the two sides of the inner part of the supporting plate, supporting columns are arranged onthe two sides of the top part of the supporting plate, and a fixing plate is arranged at the top ends of the supporting columns. The invention relates to the technical field of automobile accessories.According to the pipe cutting device for automobile accessory manufacturing, clamping devices are arranged, so that the clamping performance is better; pipes do not need to be manually held by handsfor cutting, the pipes with different specifications can be clamped, so that working efficiency of the cutting device is improved; a hydraulic rod, a push plate, a placing frame, a collecting box anda material falling groove are arranged so that chippings collected by the collecting box can be processed, the use of manpower and material resources is saved, and the use effect required by a user ismet; and a rolling wheel and a sliding groove are arranged, so that the use by the user is facilitated, and the purpose of conveniently collecting the chippings is achieved.

Owner:平湖市博强机械制造有限公司

Metal pipe fixed-length cutting device

InactiveCN105834506AEase of workHigh precisionTube shearing machinesShearing machine accessoriesEngineeringMechanical engineering

The invention discloses a metal pipe fixed-length cutting device. The device comprises a working table, a drive device and a pipe clamping device are fixedly mounted on the top of the working table, the drive device is located on one side of the pipe clamping device, and the side, close to the pipe clamping device, of the drive device is connected with a cutting device; and a dividing rule is fixedly mounted on the side, close to the drive device, of the pipe clamping device. The metal pipe fixed-length cutting device has the beneficial effects that the cutting length does not need to be manually measured, working difficulties of workers are reduced, work efficiency is improved, and the fixed-length cutting precision is improved; the distance between two pipe clamping parts can be adjusted according to the length of a non-cut pipe, and the applicability of the pipe clamping device is improved; and thirdly, vibration generated in the cutting process can be relieved, errors generated by pipe cutting are avoided, and meanwhile safety of pipe cutting work is improved also.

Owner:朱华

Steel pipe rust removing and cutting integrated machine for building

InactiveCN107234293AImprove processing efficiencyGuaranteed smoothGrinding machinesTube shearing machinesGear wheelArchitectural engineering

The invention discloses an integrated machine for derusting and cutting steel pipes for construction, which comprises a base and a steel pipe. The base is provided with a first U-shaped seat and a second U-shaped seat, and the tops of the first U-shaped seat and the second U-shaped seat respectively pass through the The bearing with seat is rotatably connected with a first derusting cylinder and a second derusting cylinder, and second gears are fixedly installed on the first derusting cylinder and the second derusting cylinder; the first U-shaped seat and the second U-shaped seat also have Rotationally connected with a rotating shaft, the first gear is installed on the rotating shaft, the first gear meshes with the second gear, the right end of the rotating shaft connected with the first U-shaped seat and the left end of the rotating shaft connected with the second U-shaped seat are equipped with the second bevel gear , the base is also provided with a first motor, the motor shaft at the top of the first motor is connected with a first bevel gear, and the first bevel gear meshes with the second bevel gear. The invention rotates the derusting cylinder, and a derusting brush is arranged on the inner wall of the derusting cylinder to derust the steel pipe, and the scope of derusting is wide; there are two derusting cylinders with opposite rotation directions, so that the derusting is more thorough.

Owner:肖进兴

Pipe cutter

Owner:MILWAUKEE ELECTRIC TOOL CORP

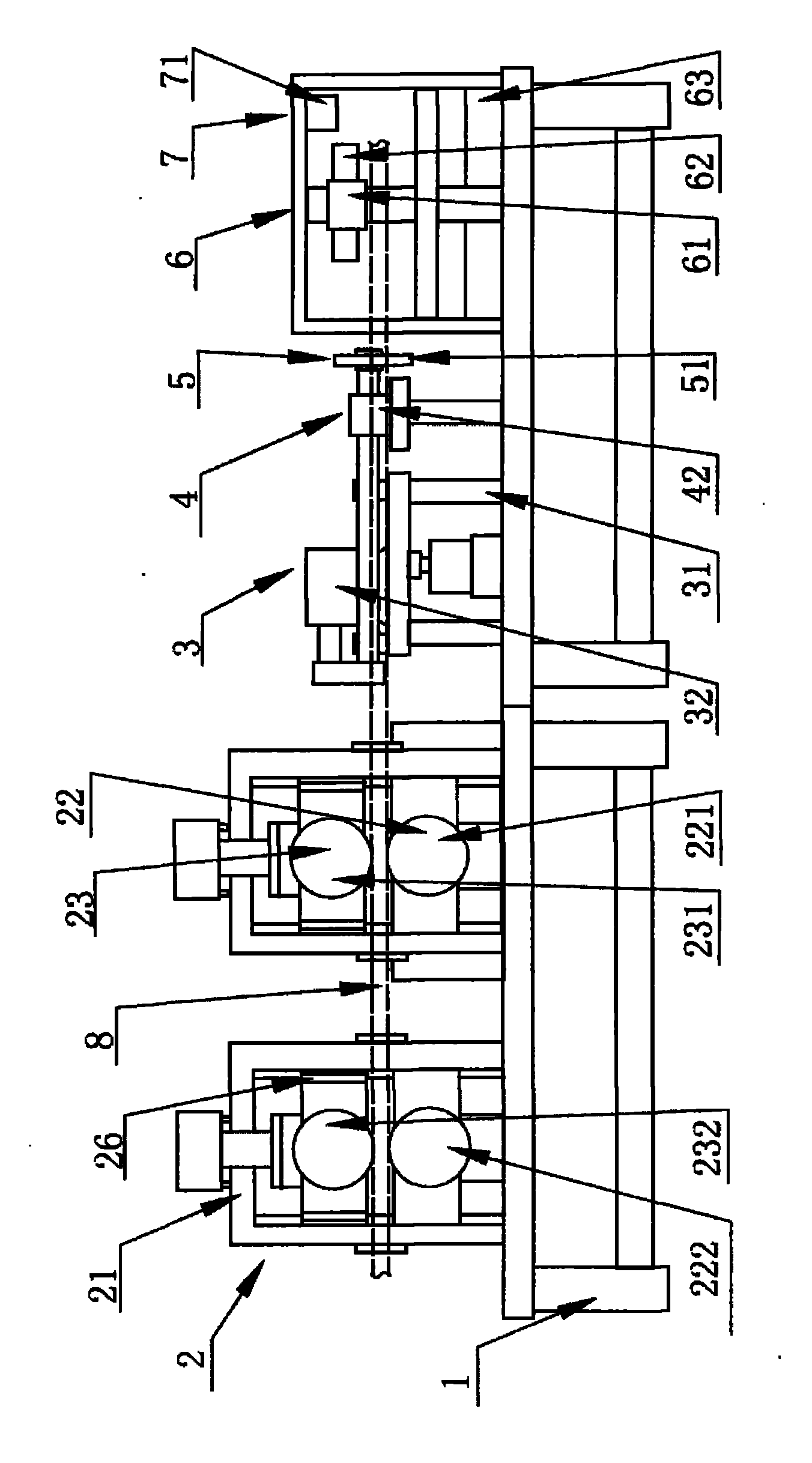

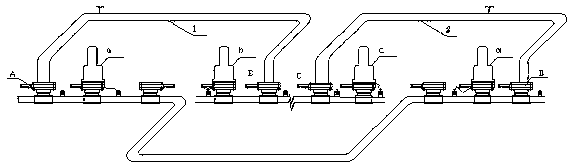

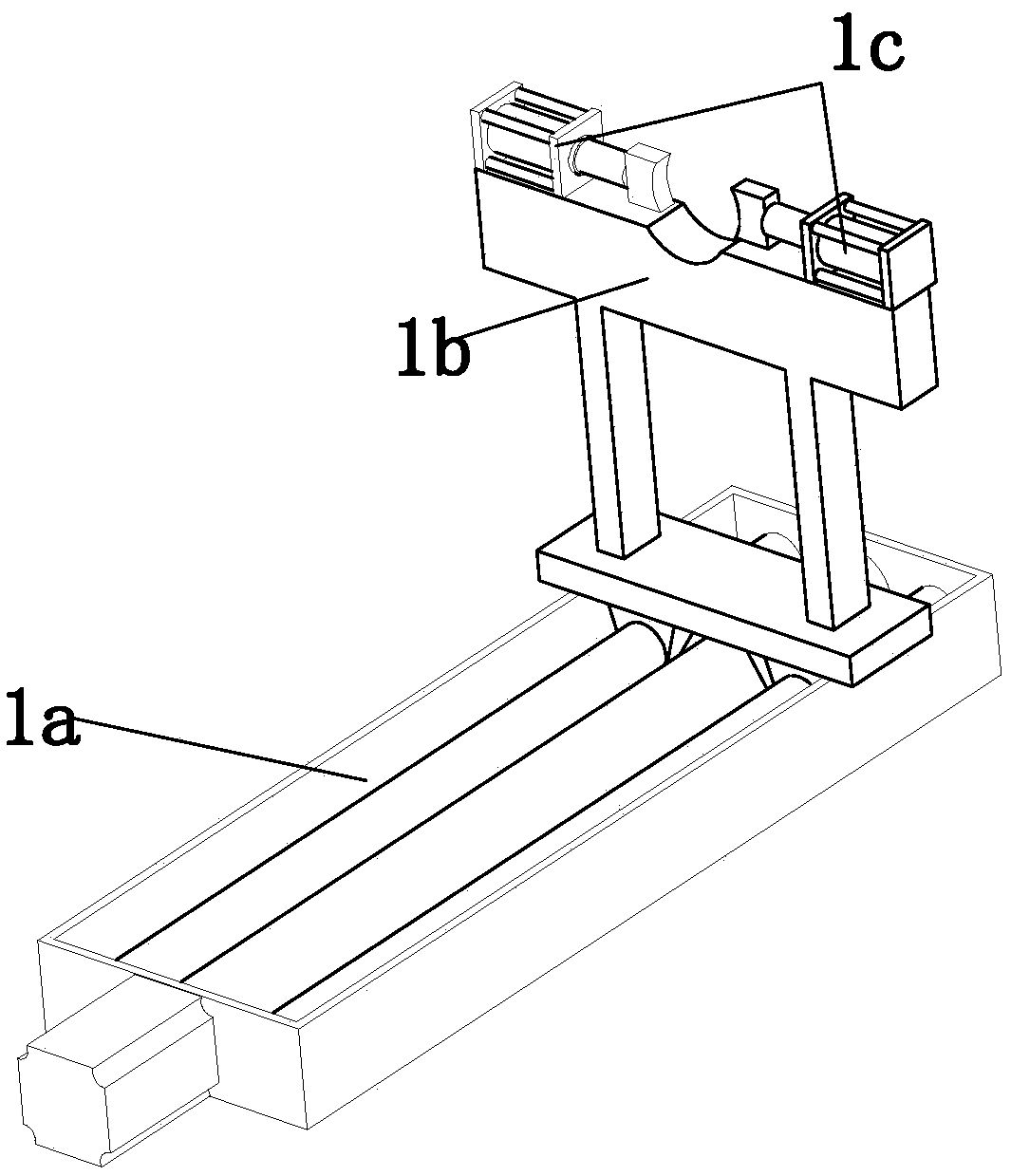

Round pipe cutting and end face grinding integrated machine

InactiveCN108746816ASolve cutting problemsSolve the disadvantages that grinding cannot be completed at one timeOther manufacturing equipments/toolsTube shearing machinesEngineeringMechanical engineering

The invention relates to the field of cutting and grinding machines, in particular to a round pipe cutting and end face grinding integrated machine. The round pipe cutting and end face grinding integrated machine comprises a bottom plate, and further comprises a feeding assembly, a first clamping assembly, a cutting assembly, a second clamping assembly, a first grinding assembly and a second grinding assembly; the first clamping assembly is located on one side of the second clamping assembly and fixedly installed on the bottom plate; the cutting assembly is located between the first clamping assembly and the second clamping assembly and fixedly installed on the bottom plate; the feeding assembly is located at the feeding end of the first clamping assembly and fixedly installed on the bottom plate; the feeding assembly, the first clamping assembly, the cutting assembly and the second clamping assembly are sequentially arranged in a linear state; the first grinding assembly is fixedly installed on the bottom plate, and the output end faces the second clamping assembly; the second grinding assembly is fixedly installed on the bottom plate, and the output end faces the output end of the first grinding assembly; the first grinding assembly, the second clamping assembly and the second grinding assembly are linearly arranged; and manpower cost is reduced.

Owner:李达

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com