Pipe cutter

A technology of pipe cutting machine and cutting mechanism, which is applied in the direction of pipe shearing device, shearing device, metal processing machinery parts, etc., can solve the problems of high labor intensity, high processing cost, low production efficiency, etc., and achieve high degree of automation and labor efficiency. The effect of low strength and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

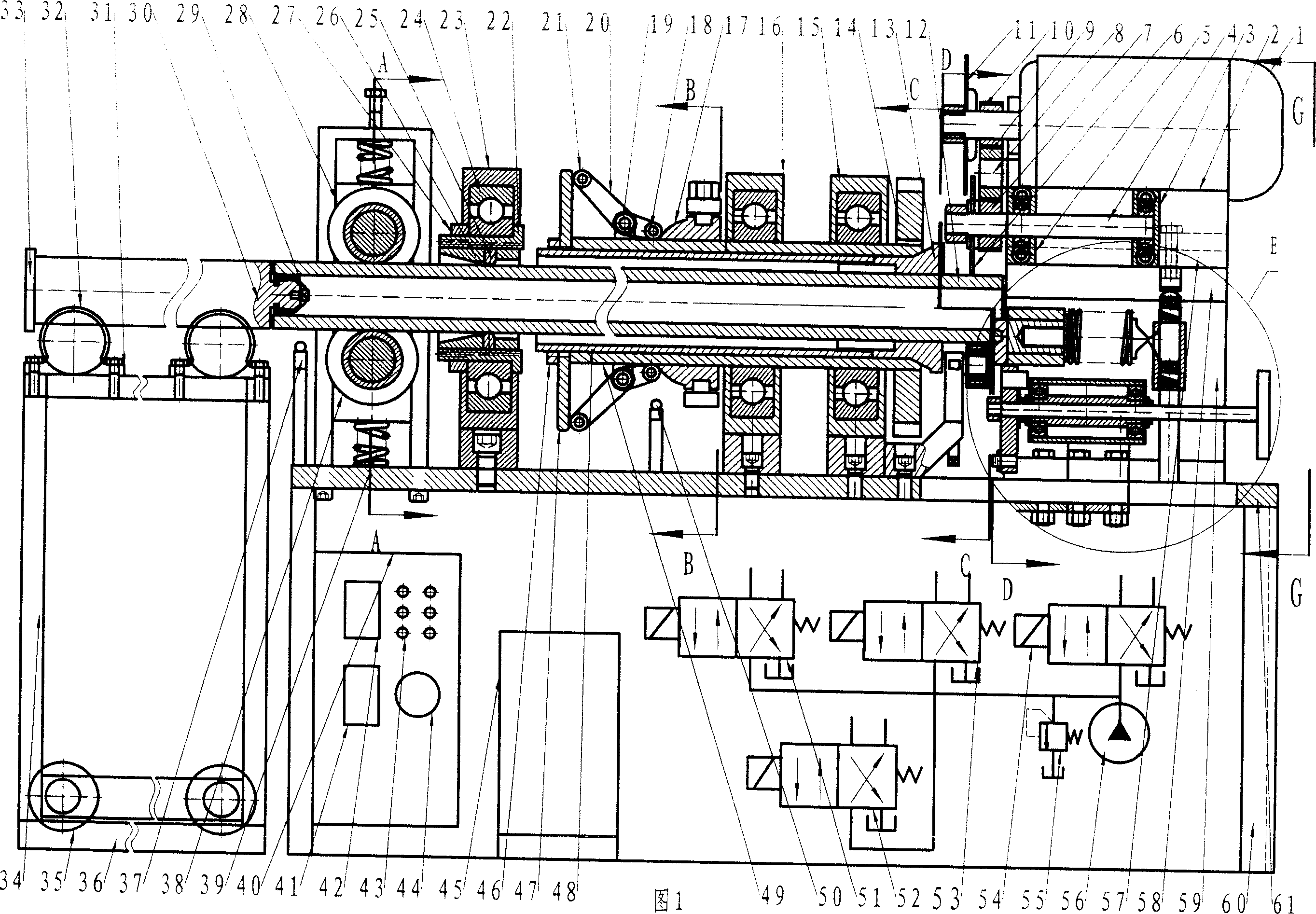

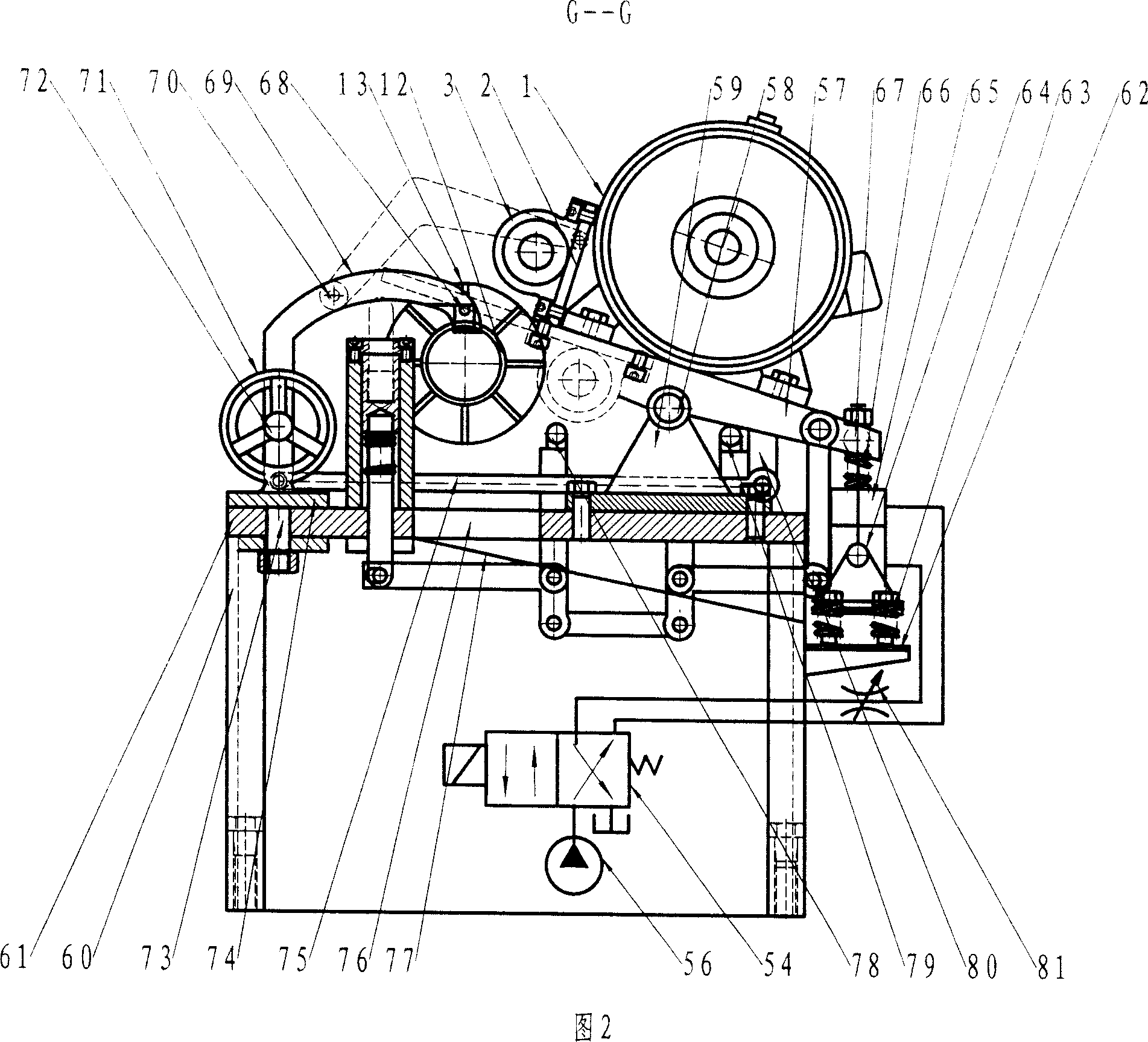

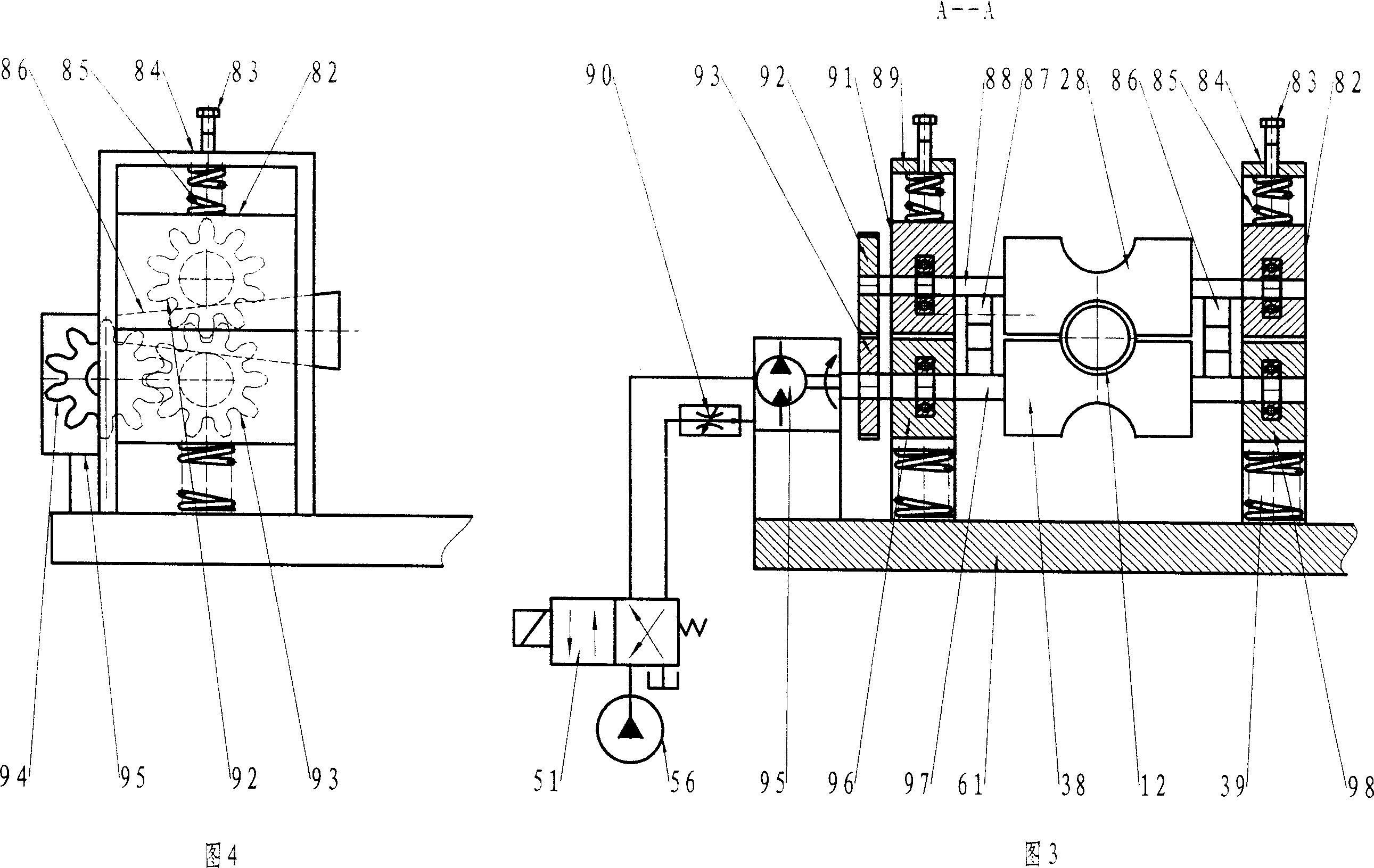

[0026] As shown in Figure 1 and Figure 14 (all the descriptions below refer to these two figures).

[0027] The pipe cutting machine includes a frame 60, a worktable 61, an air pressure or hydraulic device, a connecting pipe valve, and a cutting motor 1 axially installed at one end of the workbench 61. The valves of the pneumatic or hydraulic device include control valves 81 , 90 , 109 , 120 , overflow valve 55 , cooling valve 110 and the like. It also includes power and electrical control circuits. The electric control box 40 is arranged on the frame 60, and the main power switch 42, the control button 43, the counter 41, the buzzer 44, etc. are arranged on the positive side of the electric control box 40.

[0028] It also includes a cutting mechanism driven by a cutting motor 1 . The worktable 61 and the frame 60 are provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com