Patents

Literature

1066results about How to "Improve verticality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

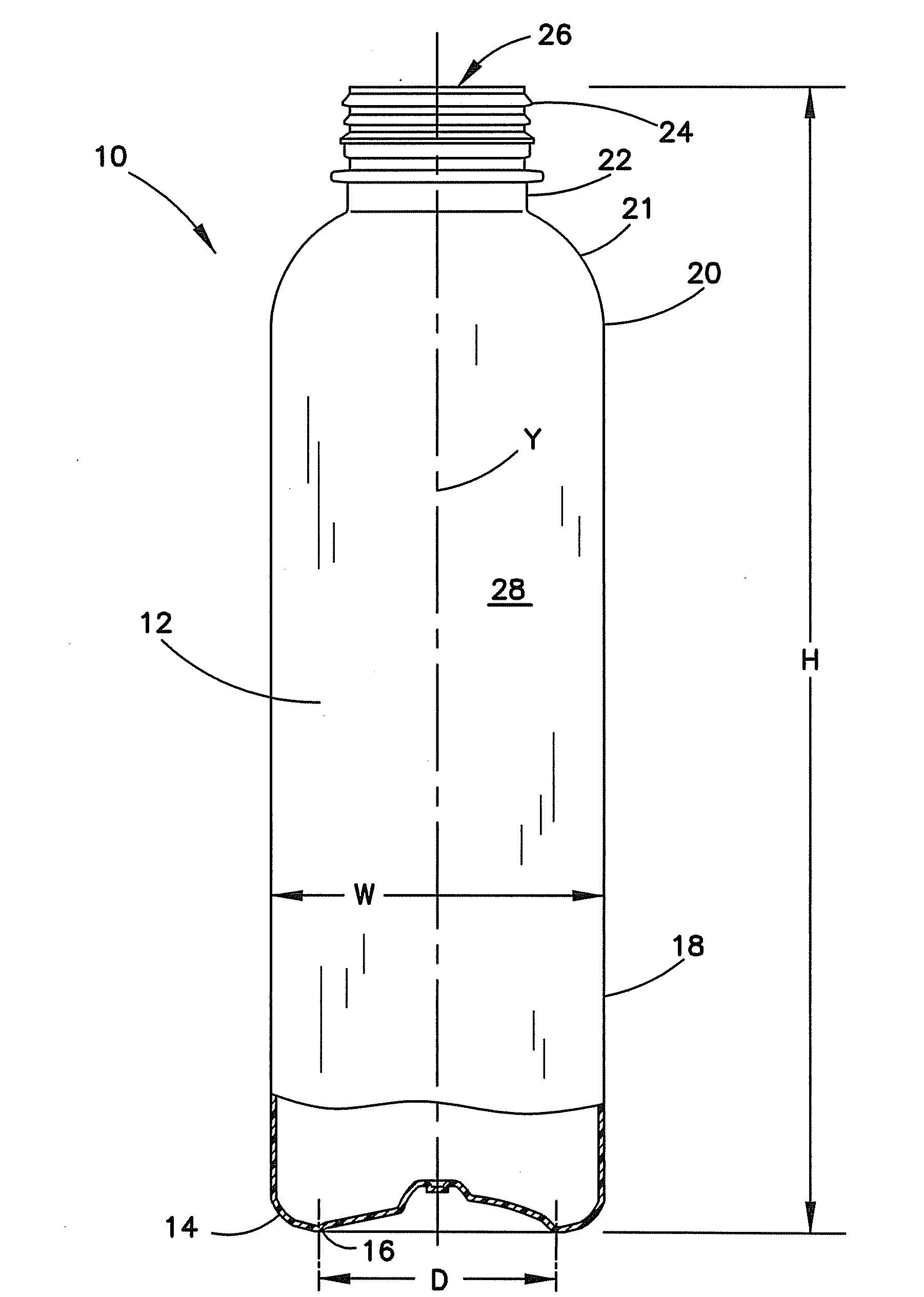

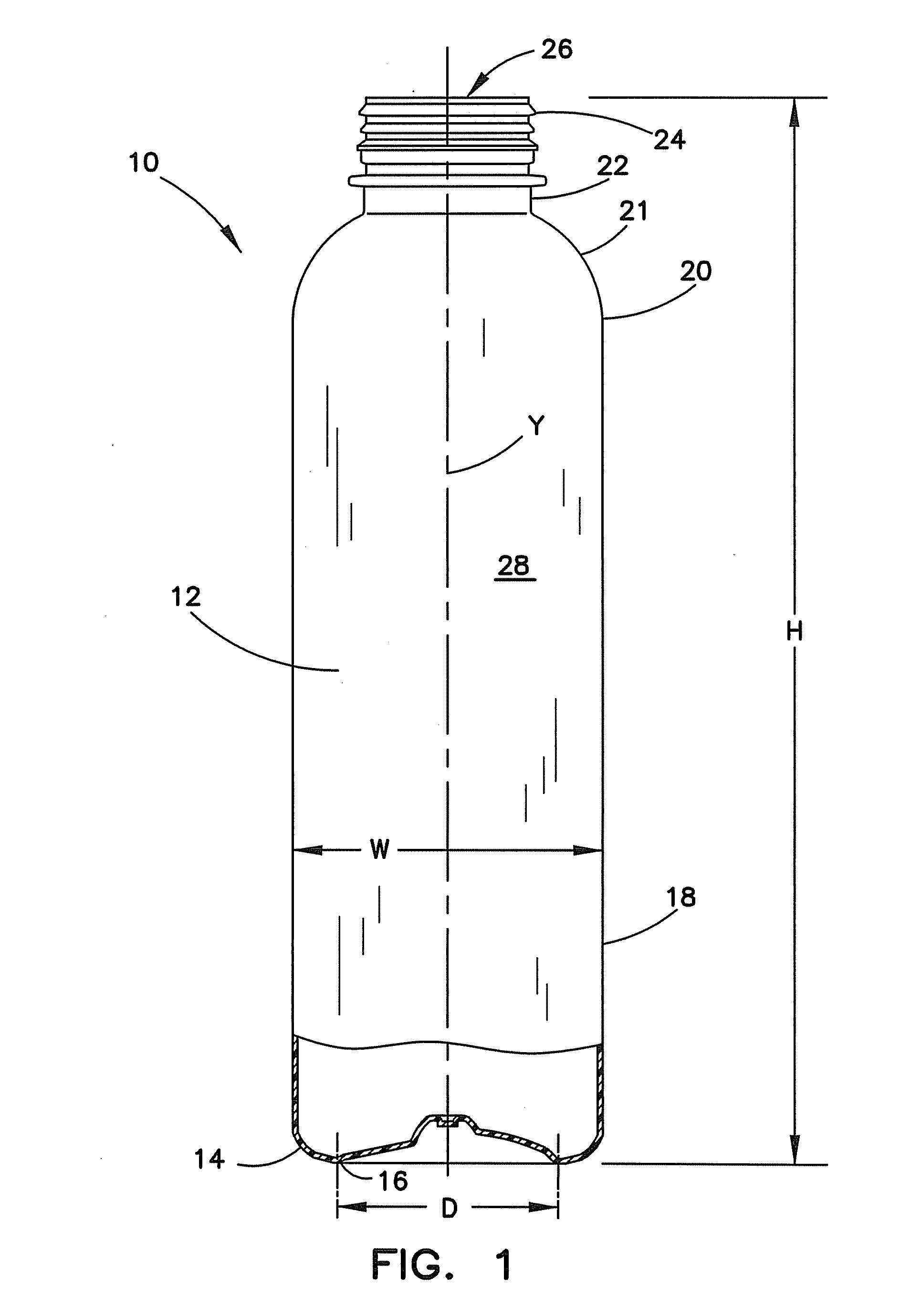

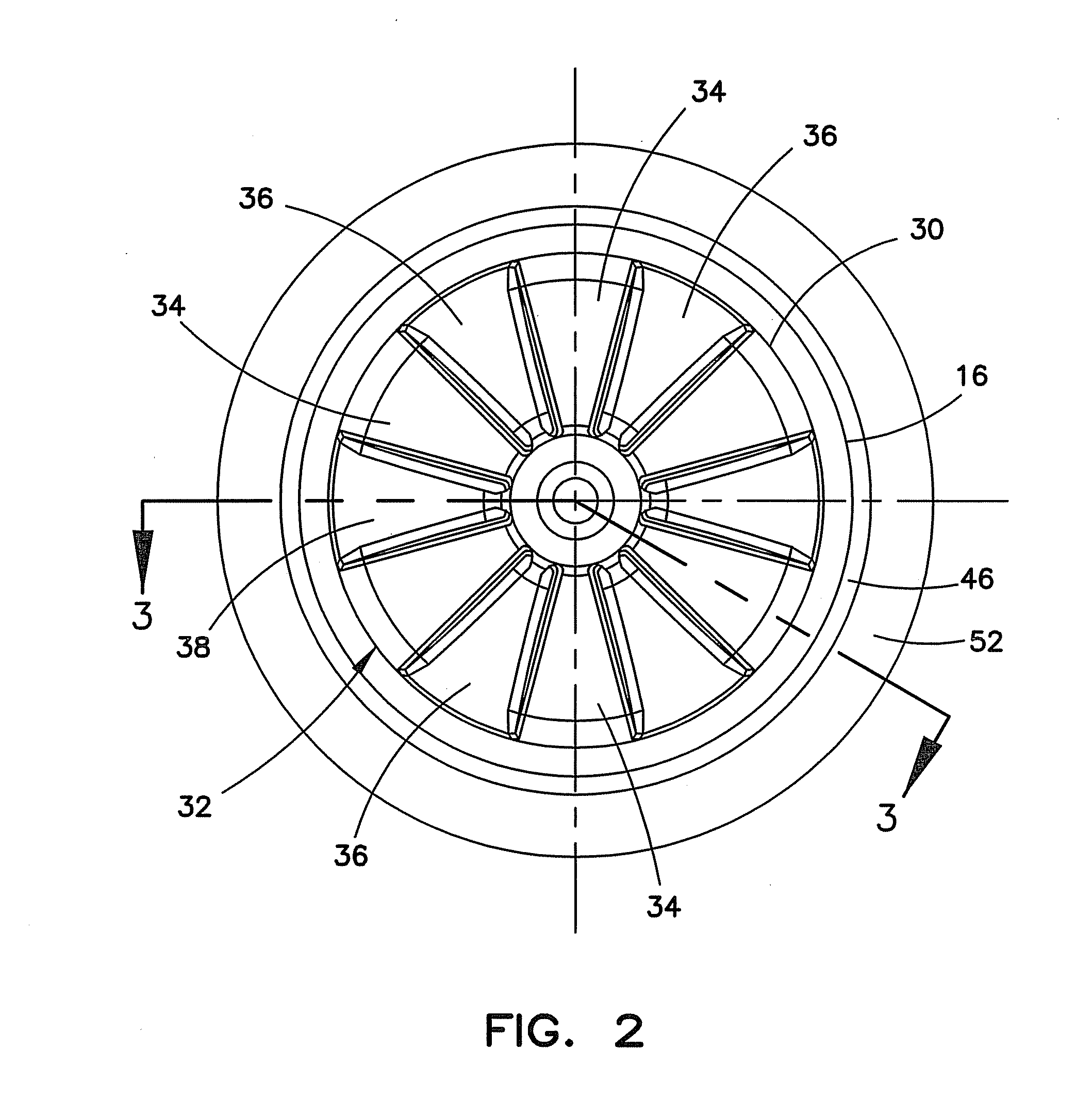

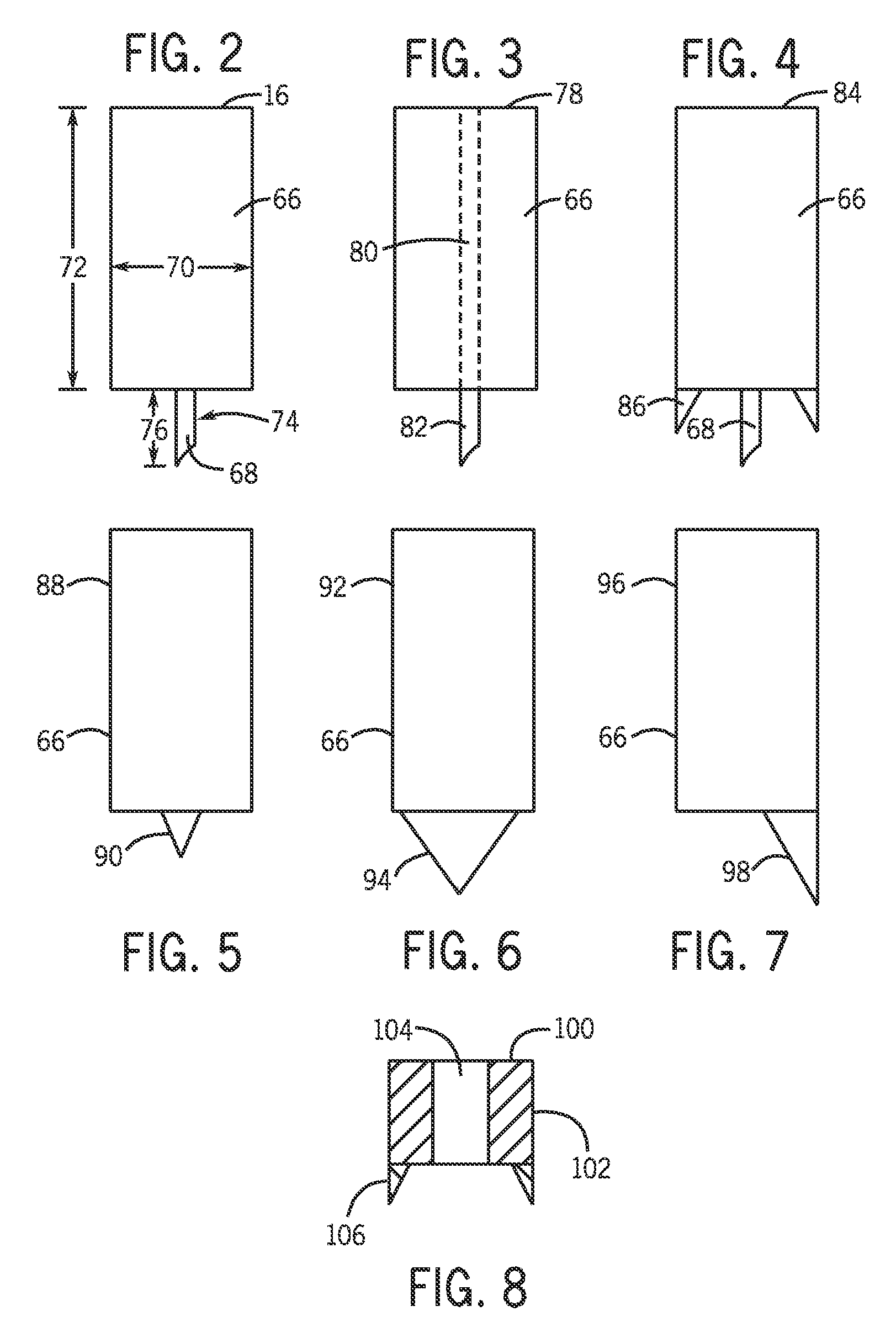

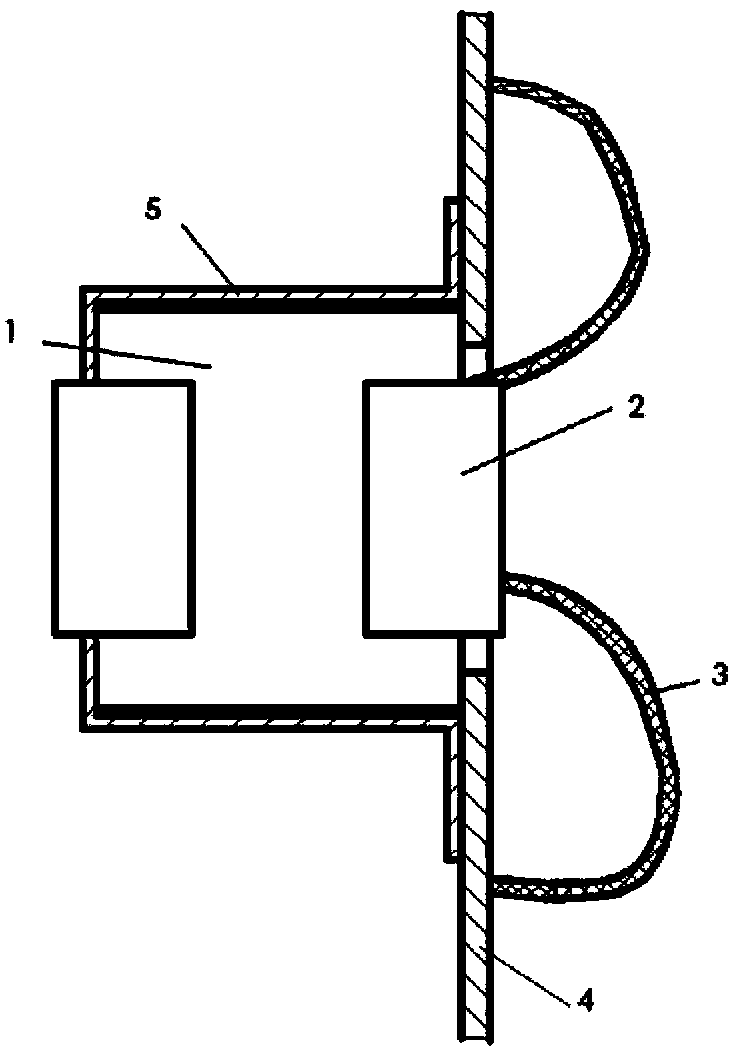

Base for pressurized bottles

InactiveUS20110049083A1Enhance vertical alignment and perpendicularityImprove verticalityLarge containersRigid containersEngineeringInternal zone

A plastic bottle with a base centered on a vertical axis, a continuous standing ring to support the bottle, a side wall formed unitarily with the base extending from the base upward to an upper side wall end, and a neck connected to the side wall upper end, the neck including a finish adapted to receive a cap to close an opening into the bottle interior. The bottle base standing ring is defined in vertical cross-section by a continuous curve bounded on a radial inside by an interior region that can include a plurality of concave domed wedge-shaped sections interspaced with buttress sections having substantially planar inclined outer portions. The bottle base standing ring has a diameter less than 80% of the maximum side wall width and is bounded on a radial outside by a conic section portion centered on the vertical axis having an apex angle of less than 1600 to improve the perpendicularity of the bottle.

Owner:AMCOR RIGID PLASTICS USA

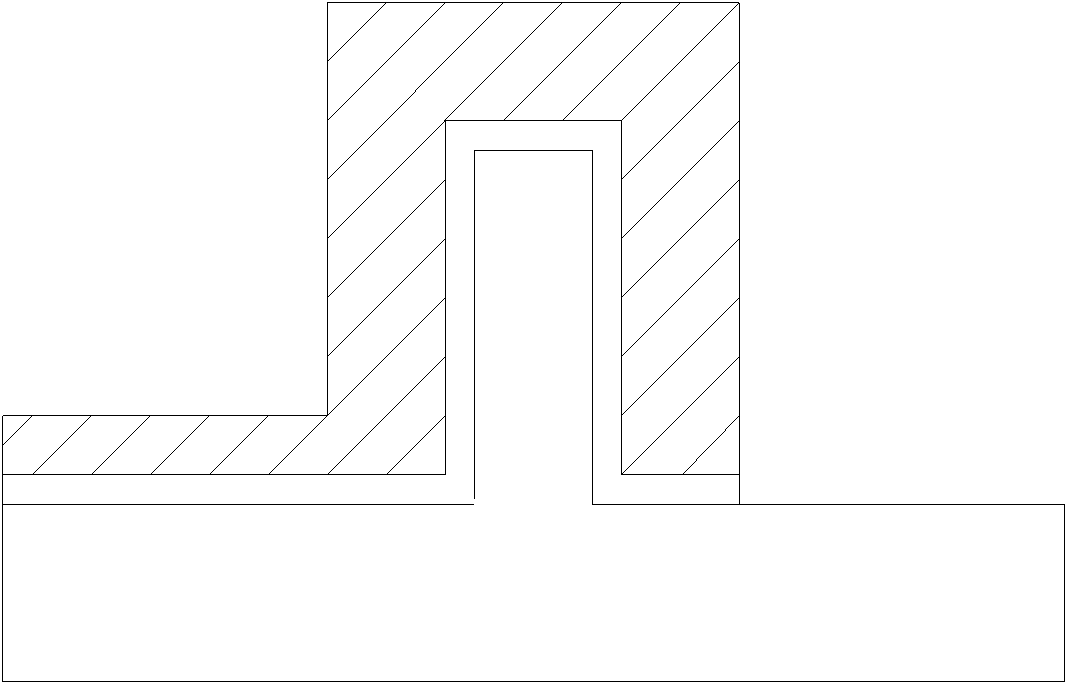

Method for manufacturing a compound semiconductor device having an improved via hole

InactiveUS20070082427A1Increase etch rateImprove verticalitySolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveEngineering

In a method for manufacturing a compound semiconductor device, a principal surface of a SiC wafer, on which a compound semiconductor device is located, is bonded to a support substrate with an adhesive having a softening point higher than 200° C. A via hole is formed dry etching, including supplying a fluorine-containing etching gas to a rear side of the SiC wafer. Thereafter, the support substrate and the adhesive are removed. Preferably, the adhesive is formed by reacting one material coating the principal surface of the SiC wafer, and another material coating the support substrate.

Owner:MITSUBISHI ELECTRIC CORP

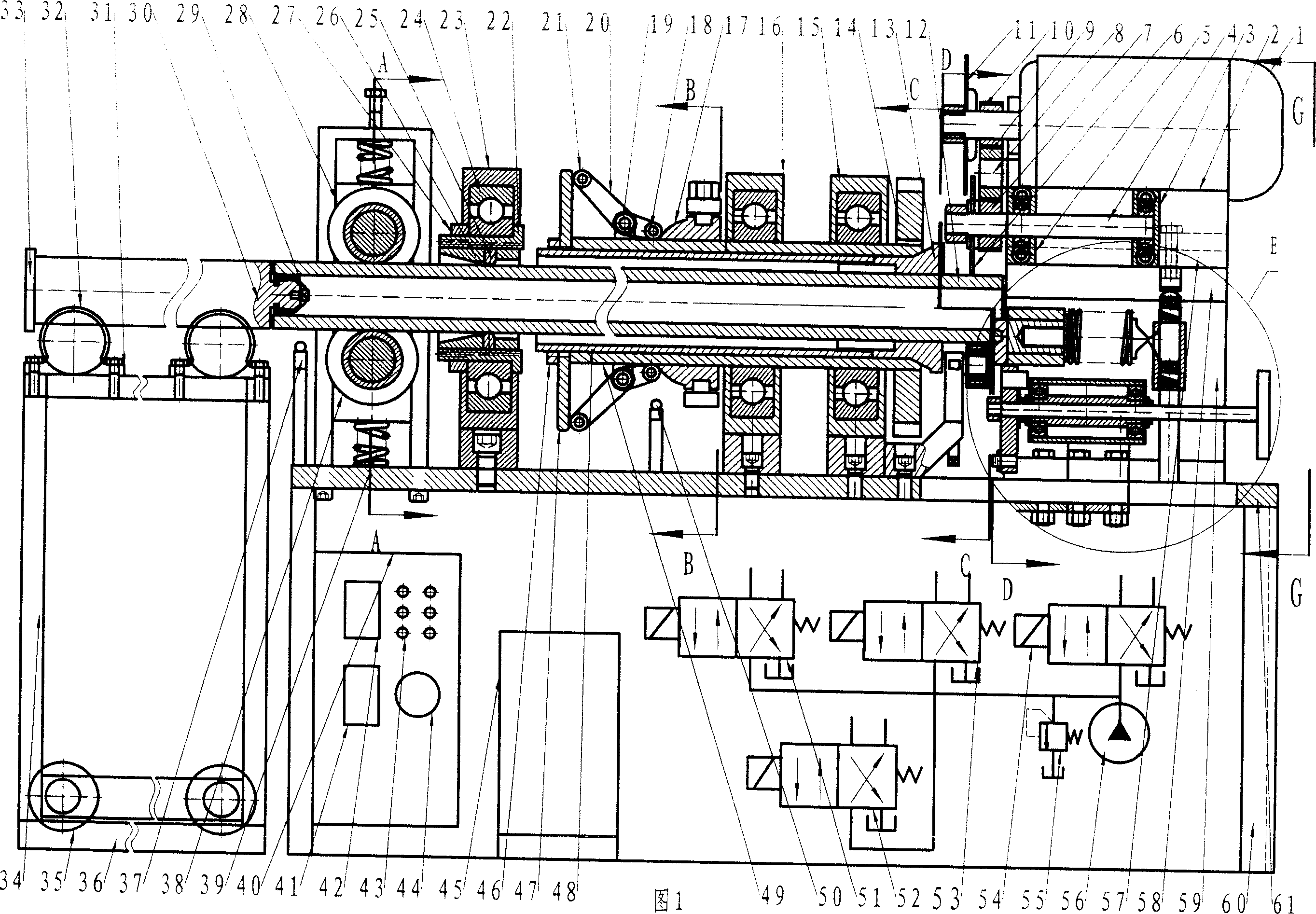

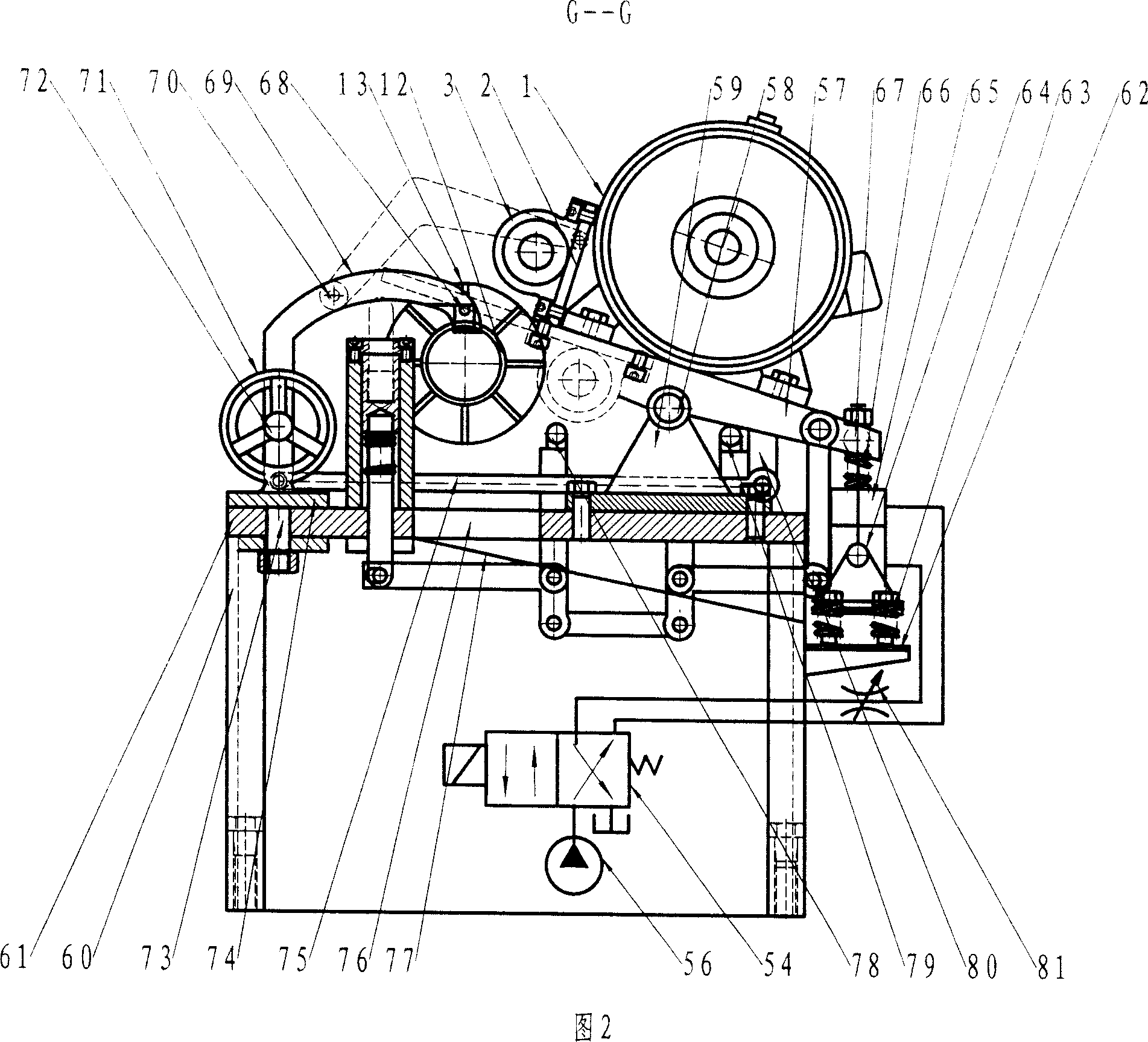

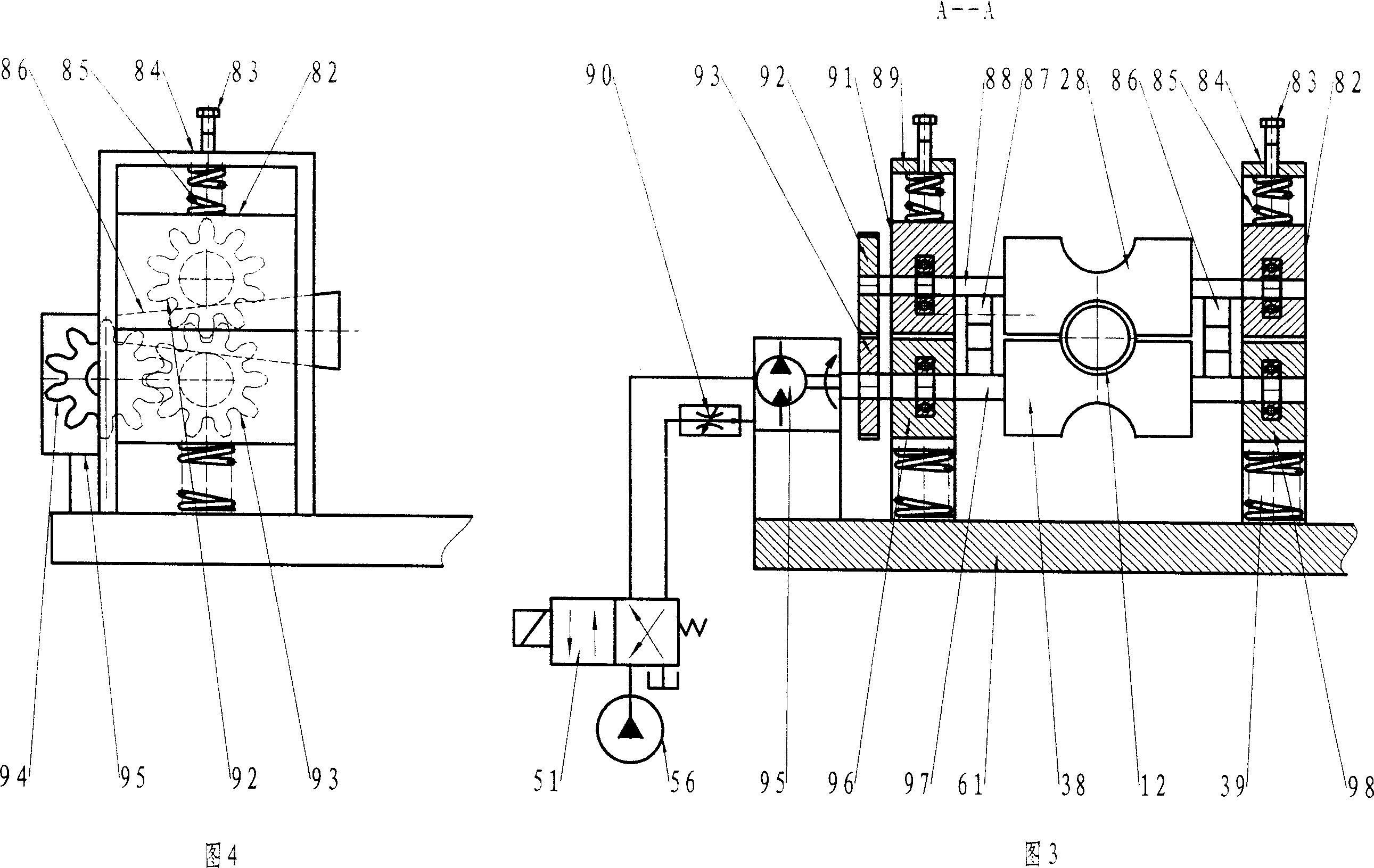

Pipe cutter

InactiveCN1951616AImprove verticalityImprove machining accuracyMetal-working feeding devicesOther manufacturing equipments/toolsSizingIndustrial engineering

The invention relates to a pipe cutter, which comprises: frame (60), work table (61), aerated or hydraulic device, connecting tube valve, cutting motor (1) axially mounted at one end of work table (61), and the cutter driven by said motor (1). Wherein, the work table (61) and frame (60) are mounted with a device for moving cutting motor (1) and cutter up and down, and a device for rotating the pipe (12) around its axle; the end of work table (61) far from the motor (1) has automatic pipe feeder; the work table (61) between cutter and pipe feeder is mounted with pipe guide support and pipe automatic clamper; one side of motor (1) has pipe (12) automatic sizing device under. The invention has high vertical degree between cutting surface and pipe axle, with high efficiency and low cost.

Owner:陈永真

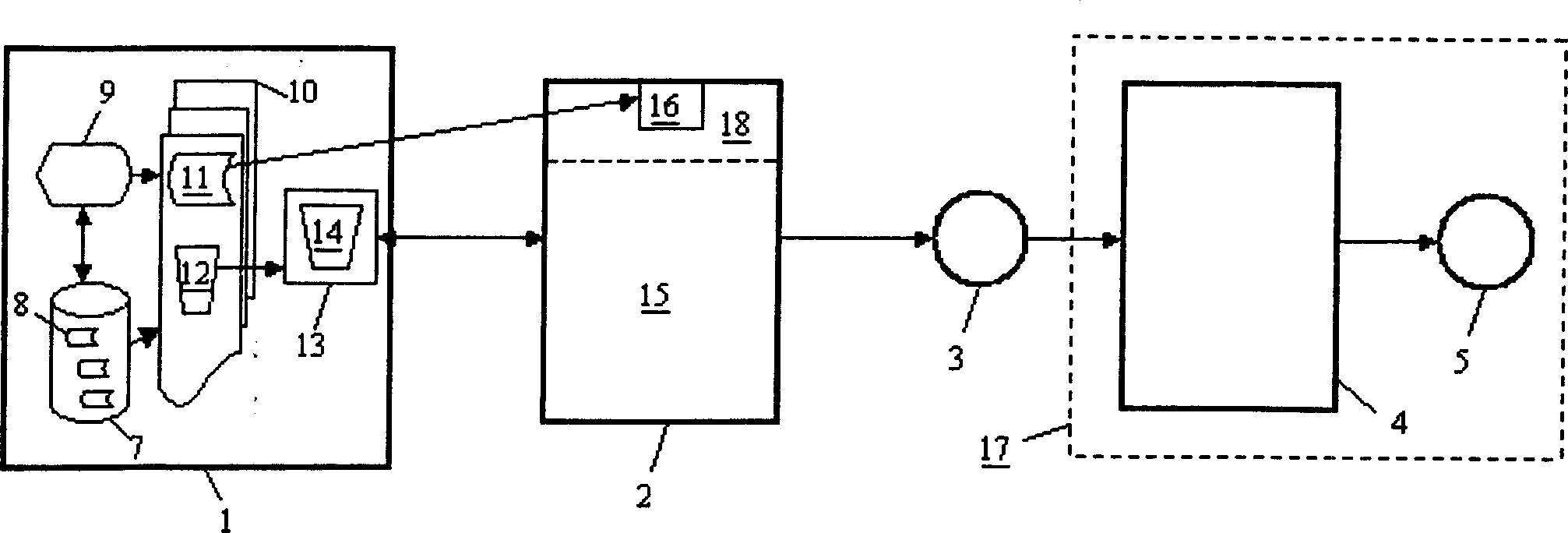

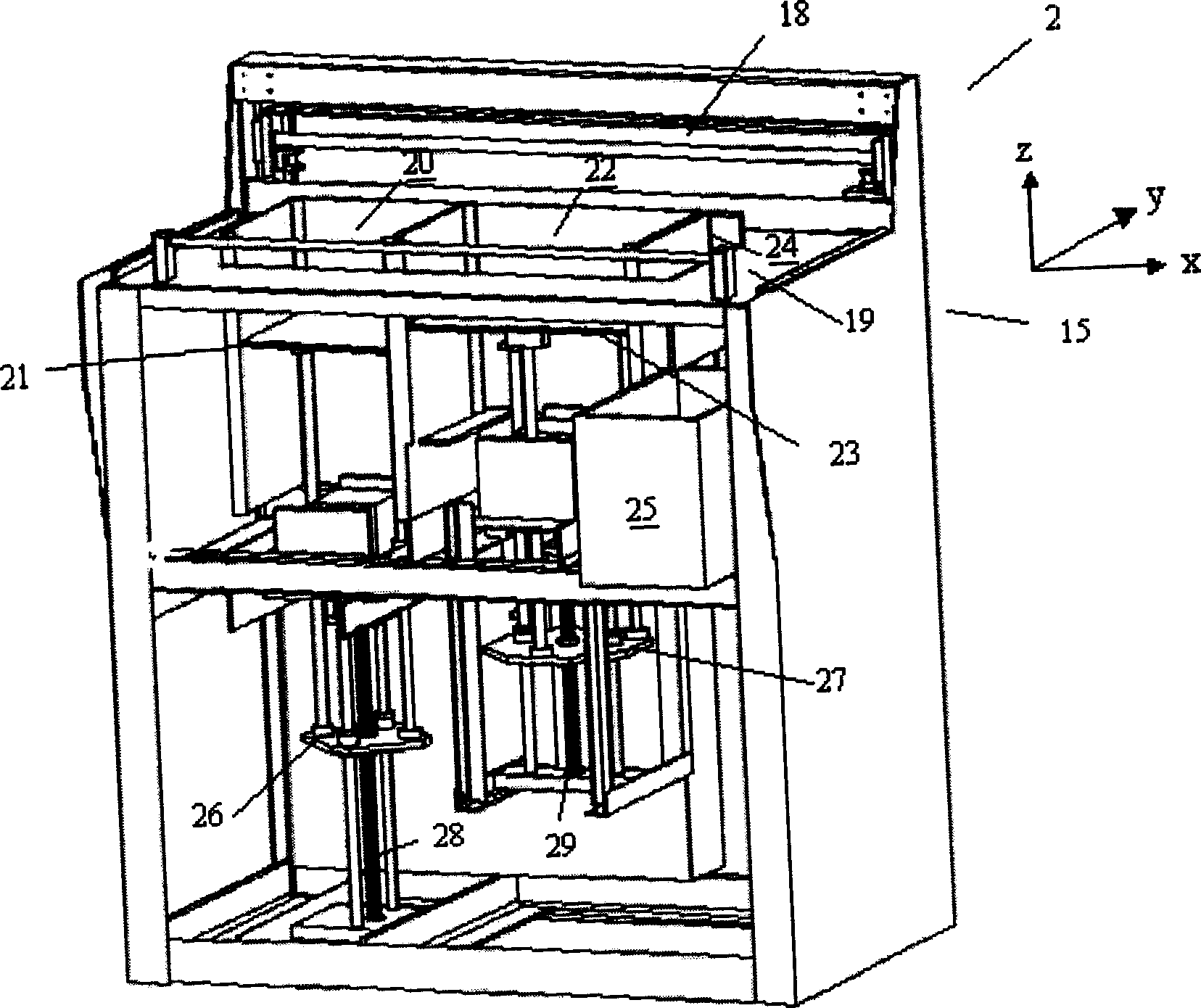

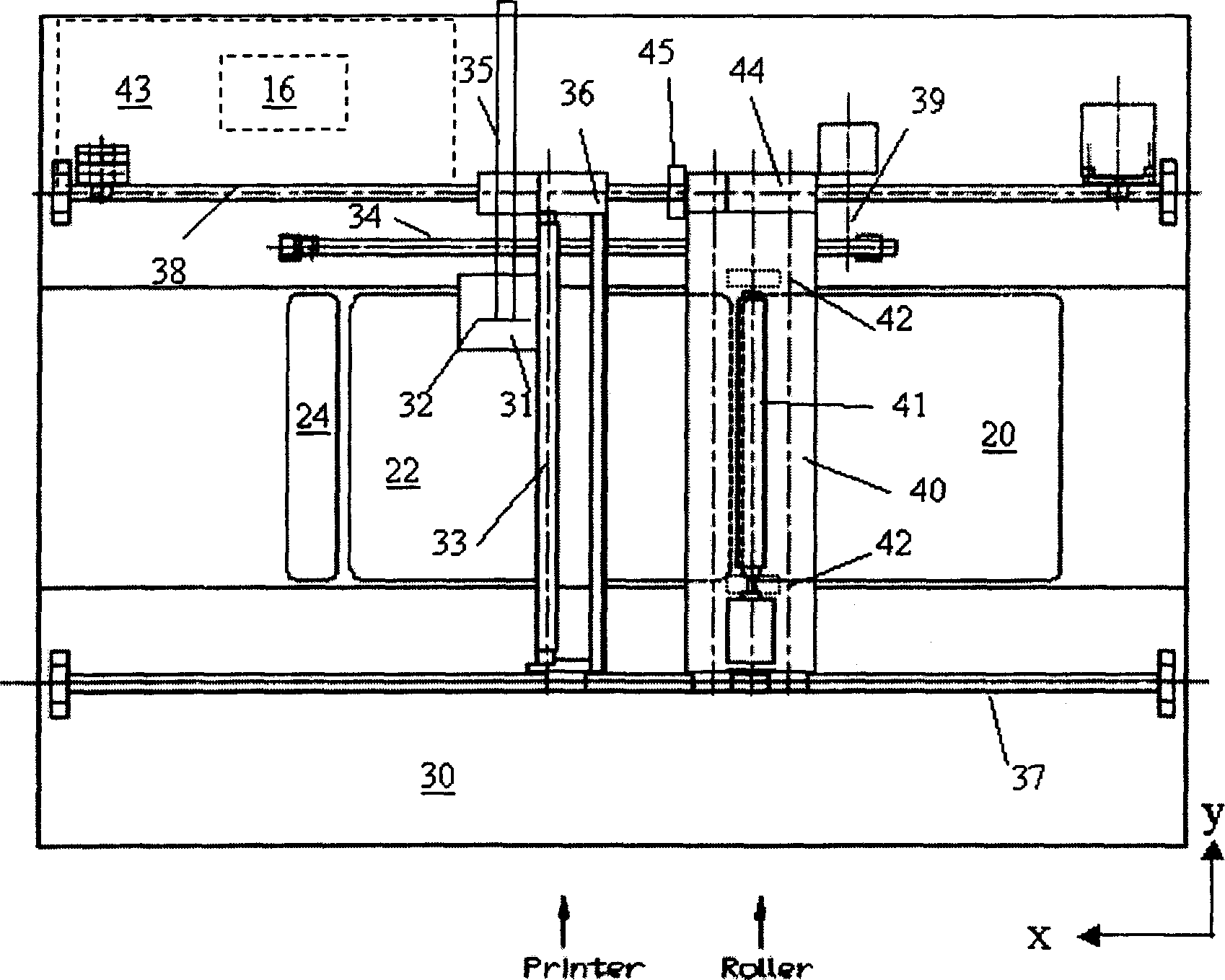

Fast shaping device for making body from image of computer and with printing machine

InactiveCN1911635AImprove stabilityImprove printing accuracyCoatingsPrintingEngineeringRapid prototyping

The present invention is one fast forming apparatus, in which the virtual image stored in the memory of computer is tomographically treated and the tomographical treatment obtained contours are jet printed one layer by one layer with fluid onto the powder in the constituting platform for combining with powder so as to form stereo real object. The fast forming apparatus includes the jet printing mechanism and firmware interfaces of a printer or a plotter, one work platform with tomographically operating software and jet printing control firmware, and one computer with memory with stored virtual image.

Owner:赖维祥 +1

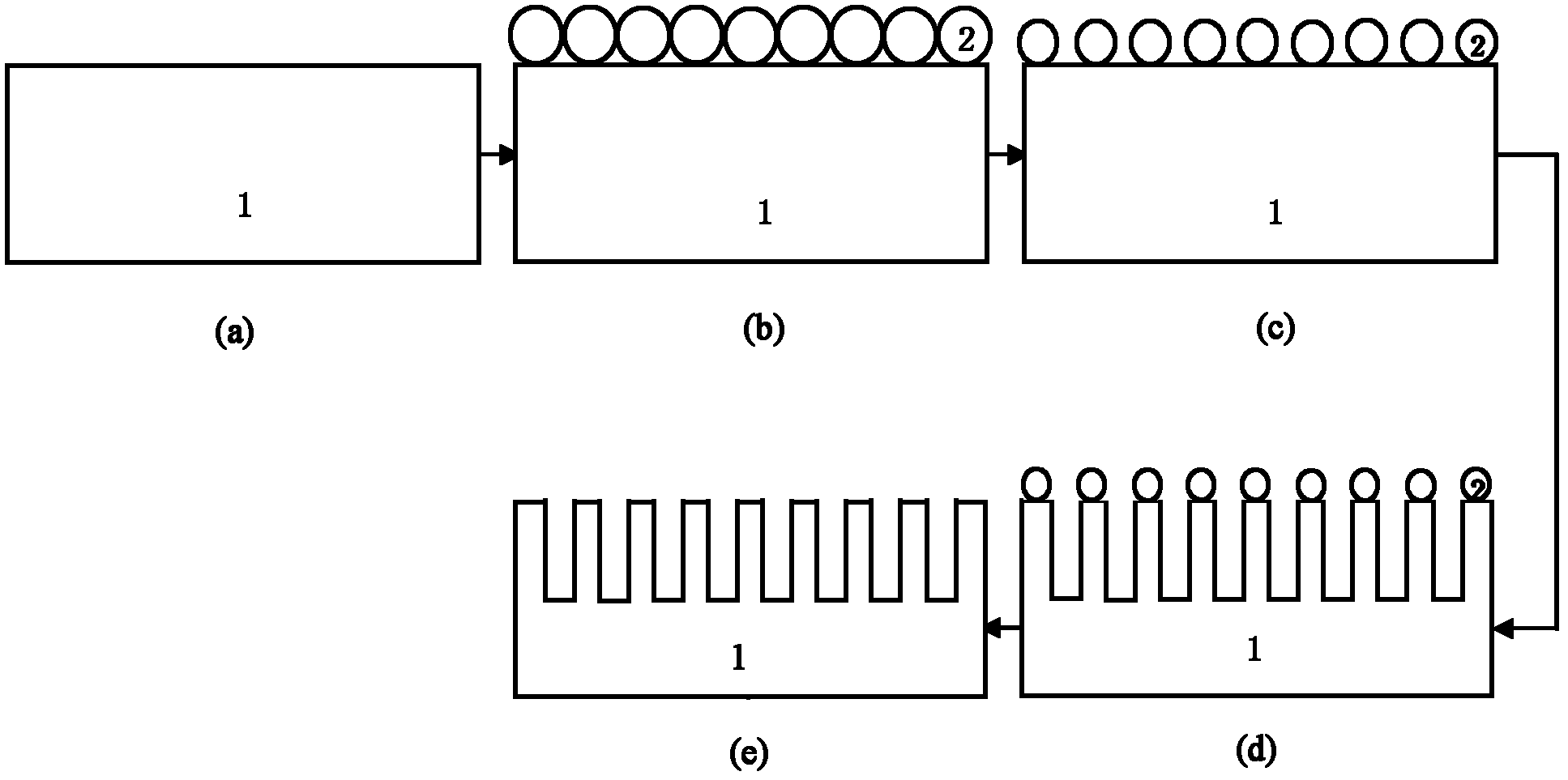

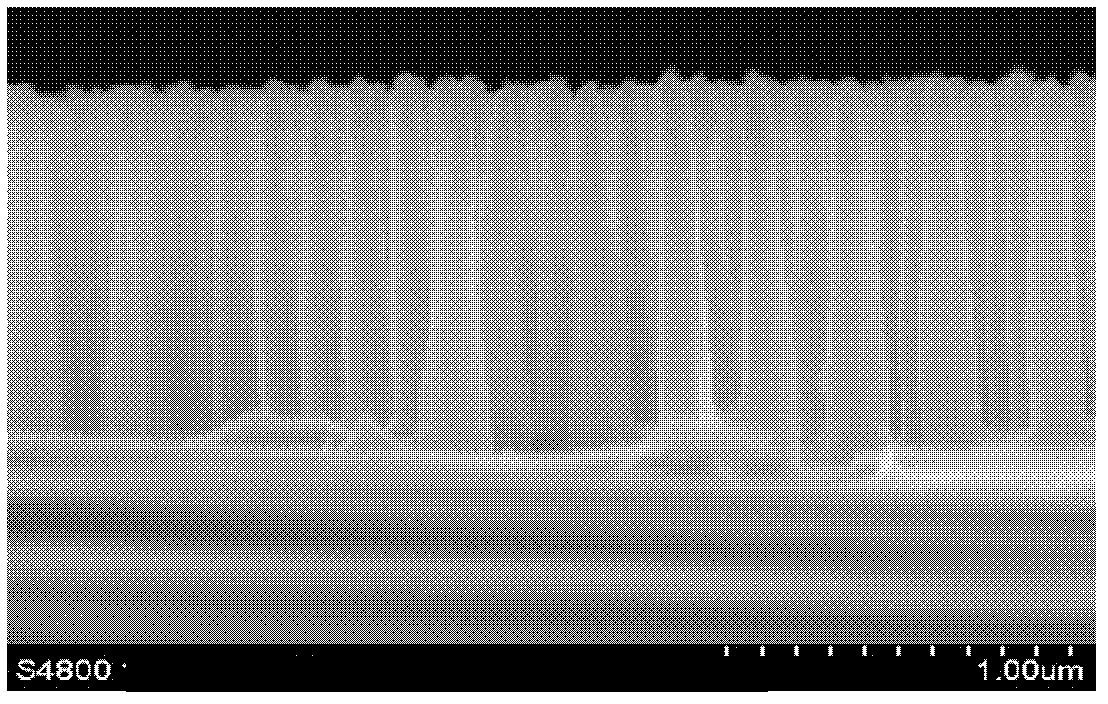

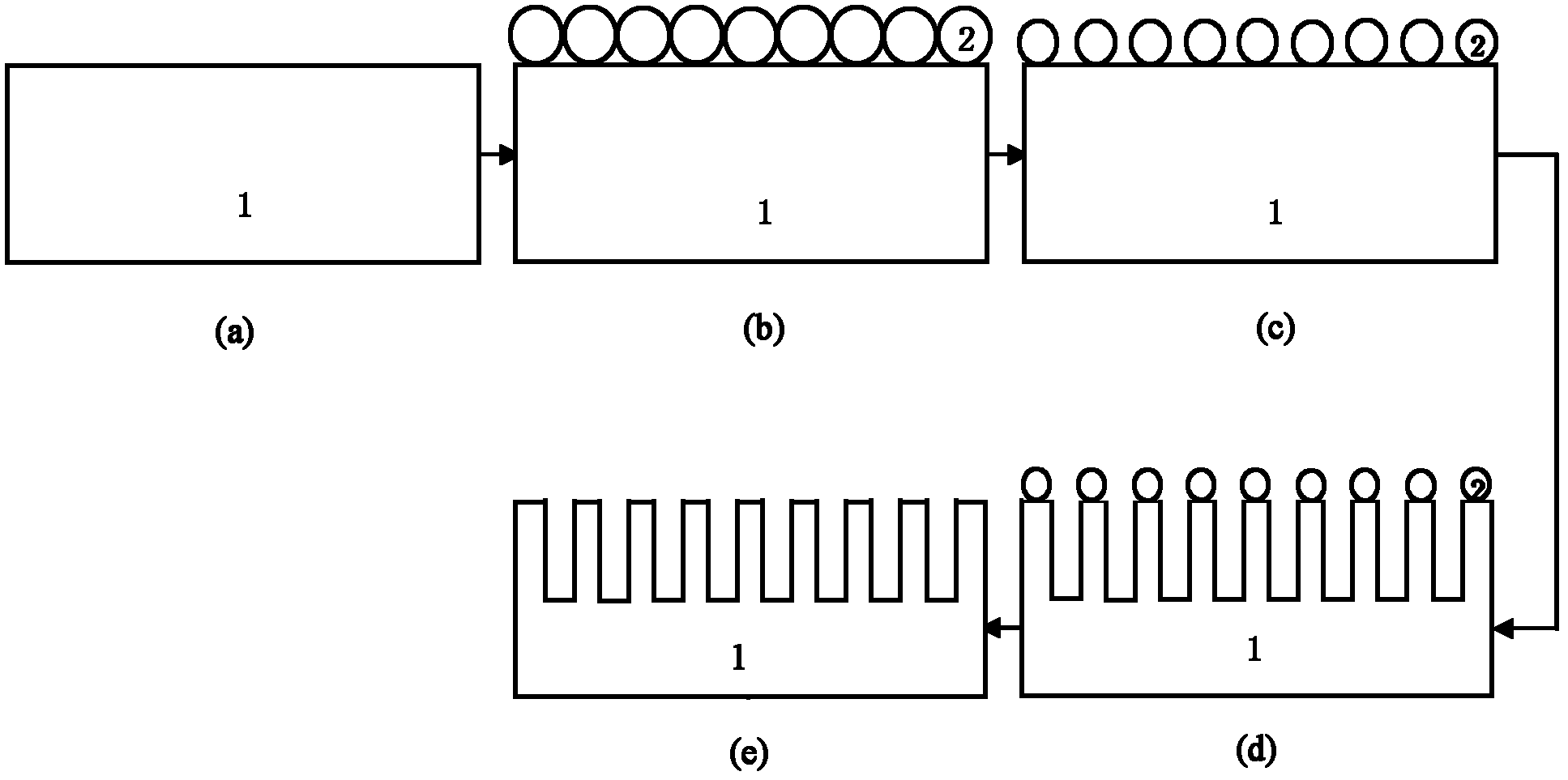

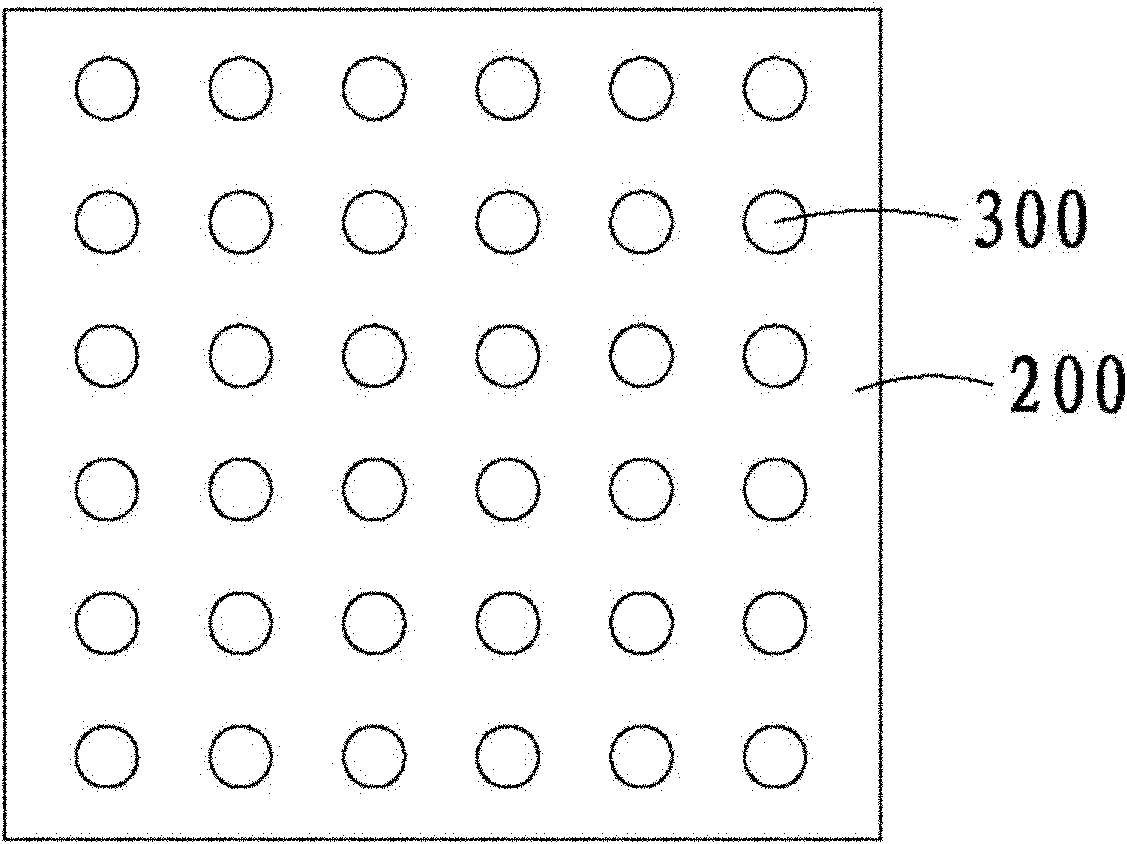

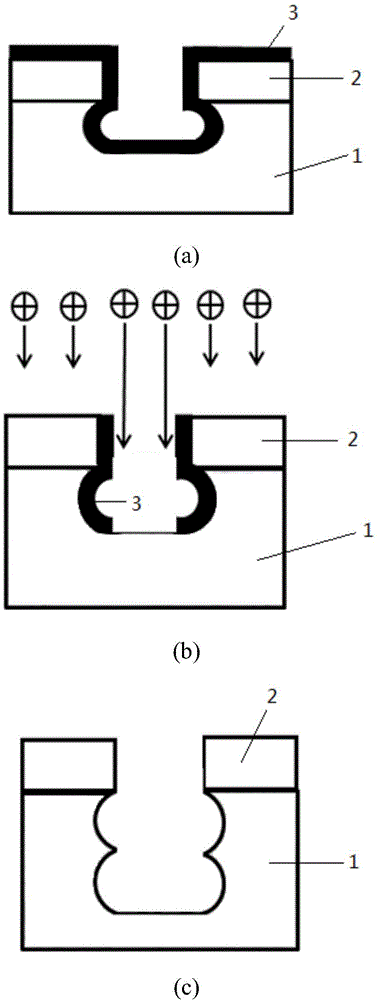

Method for preparing silicon nano-pillar array based on nanosphere etching technology

InactiveCN102633230AQuality improvementHigh feasibilityDecorative surface effectsChemical vapor deposition coatingNano structuringSelf assemble

A method for preparing a silicon nano-pillar array based on nanosphere etching technology relates to a Si nano-structure. The method comprises the following steps of: after cleaning a silicon slice, performing activation treatment on the silicon slice by means of a reactive ion etching system, thereby obtaining a silicon slice surface with hydrophilicity; self-assembling single-layer polystyrene nanospheres on a silicon substrate by a spin coating method; regulating and controlling the diameters of the single-layer polystyrene nanospheres by means of the reactive ion etching system, thereby obtaining the single-layer polystyrene nanospheres different in diameter; taking the single-layer polystyrene nanospheres as masks, performing etching by means of the masks and by inductively coupled plasma etching technology, and performing etching and sidewall protection by alternately using SF6 and C4F8; and removing the masks and by-products produced in the etching process by using an organic reagent, thus finally obtaining the silicon nano-pillar array.

Owner:XIAMEN UNIV

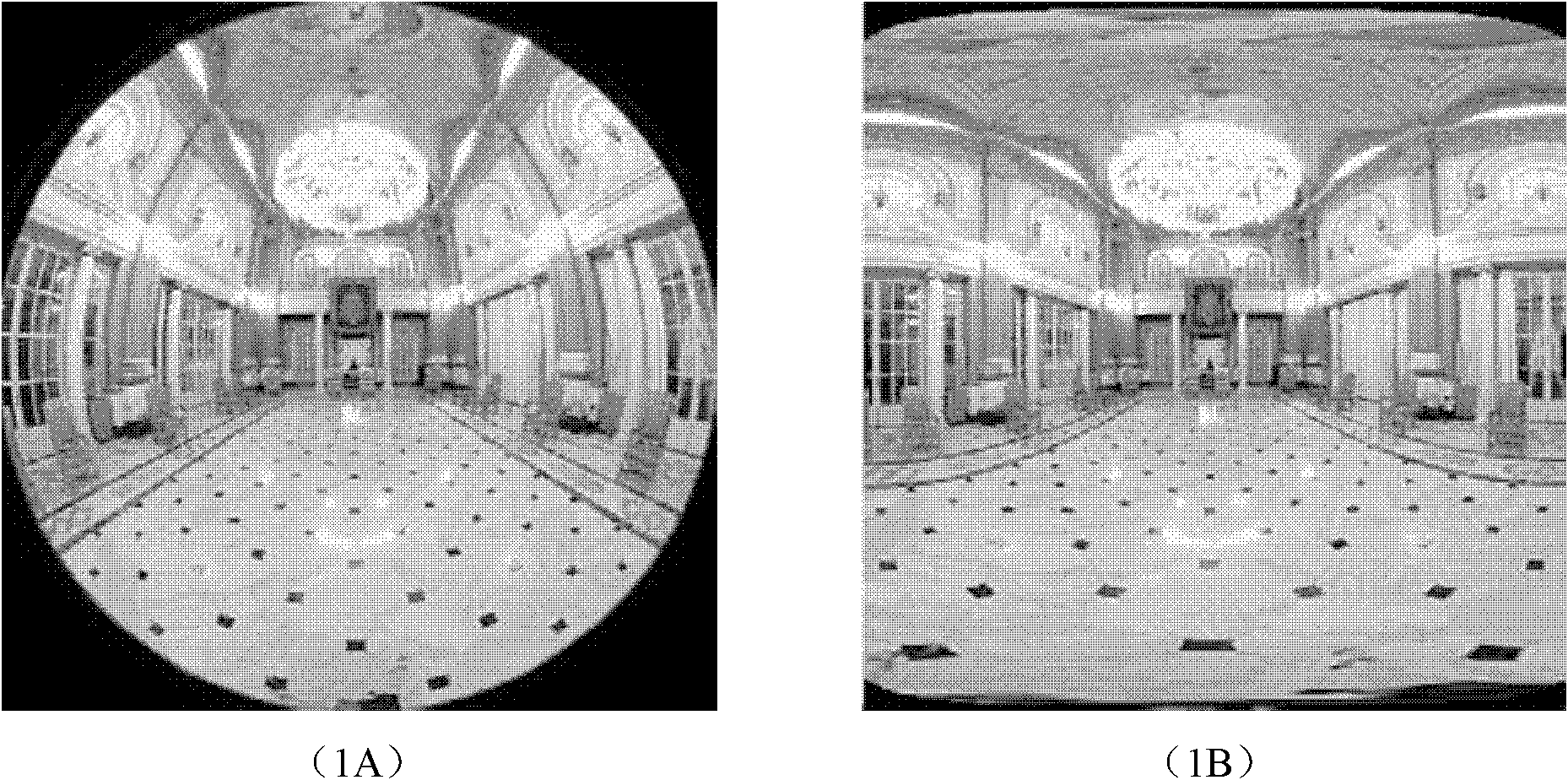

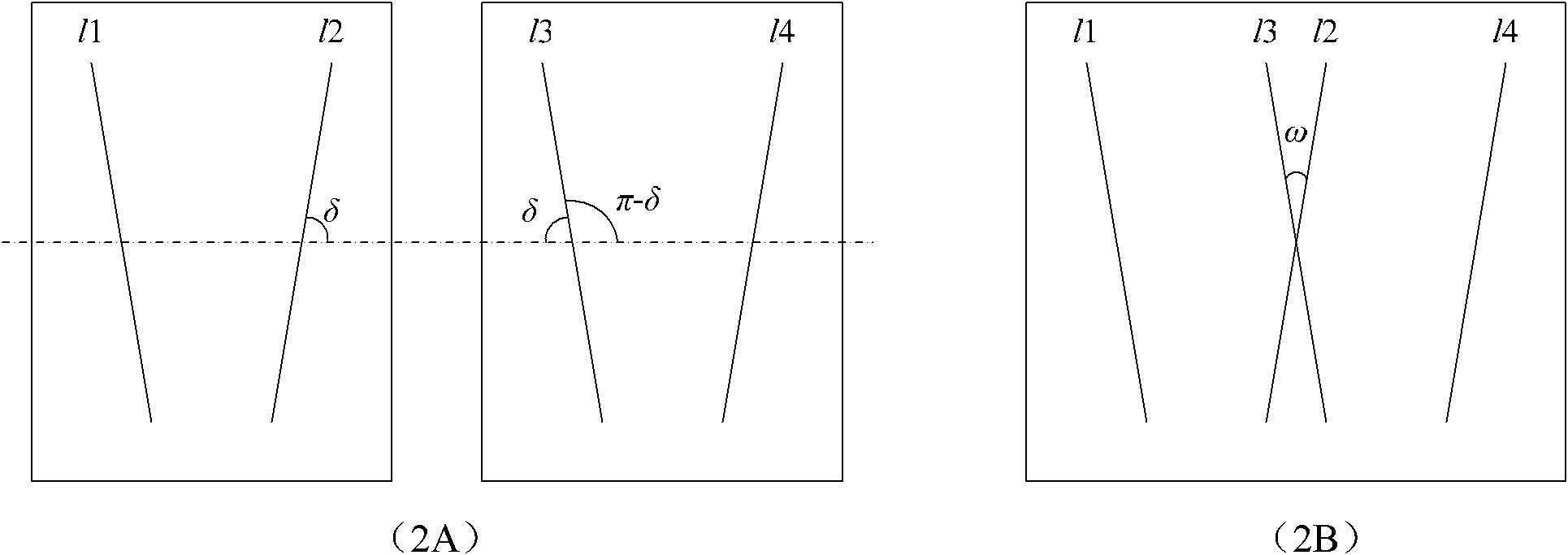

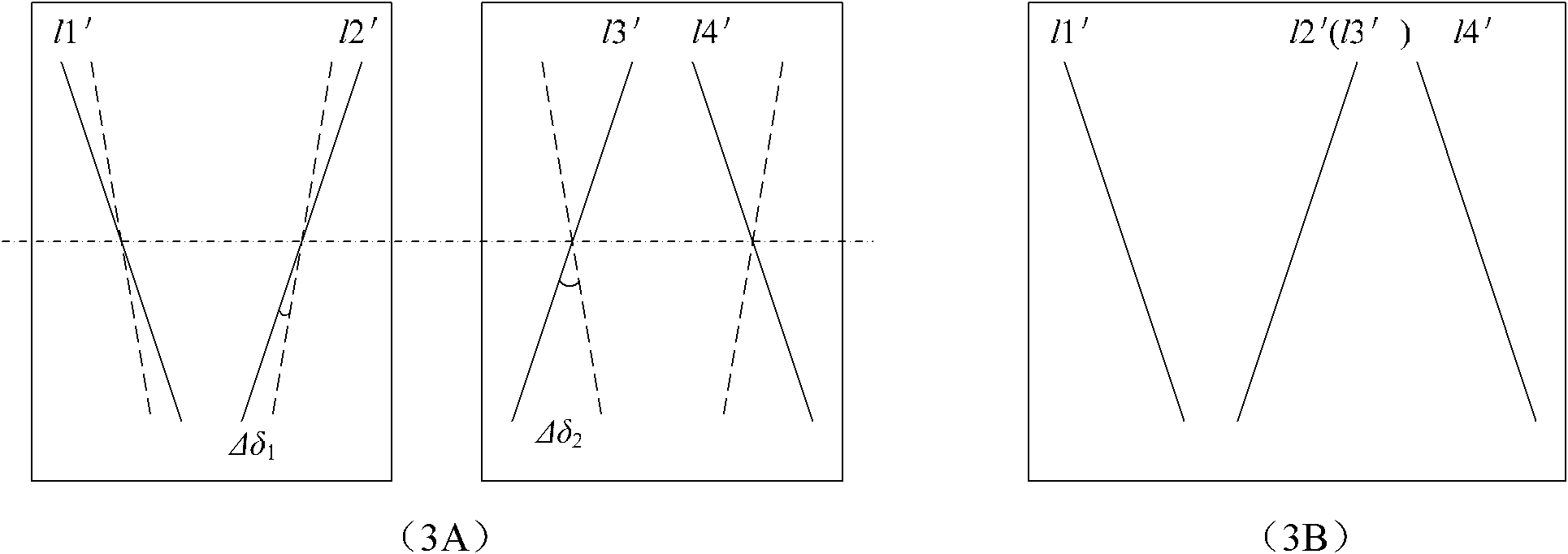

Fisheye image correcting method for image stitching

The invention provides a fisheye image correcting method for image stitching. The method corrects two fisheye images partially overlapped with each other through a computer, and finds out a splicing angle of stitching caused by pitch angles during shooting between the two fisheye images by adopting an unique correction principle and utilizing matched pixels in the two fisheye images so as to obtain the pitching angle formed during the shooting of the two fisheye images through backstepping; and the method also avoids adverse impacts, such as inclination, ghosting, and the like, of errors of the pitch angles formed during the shooting on the panorama stitching of the fisheye images through pitching conversion mapping treatment, and has the advantages of better robustness and high accuracy in computation.

Owner:CHONGQING UNIV

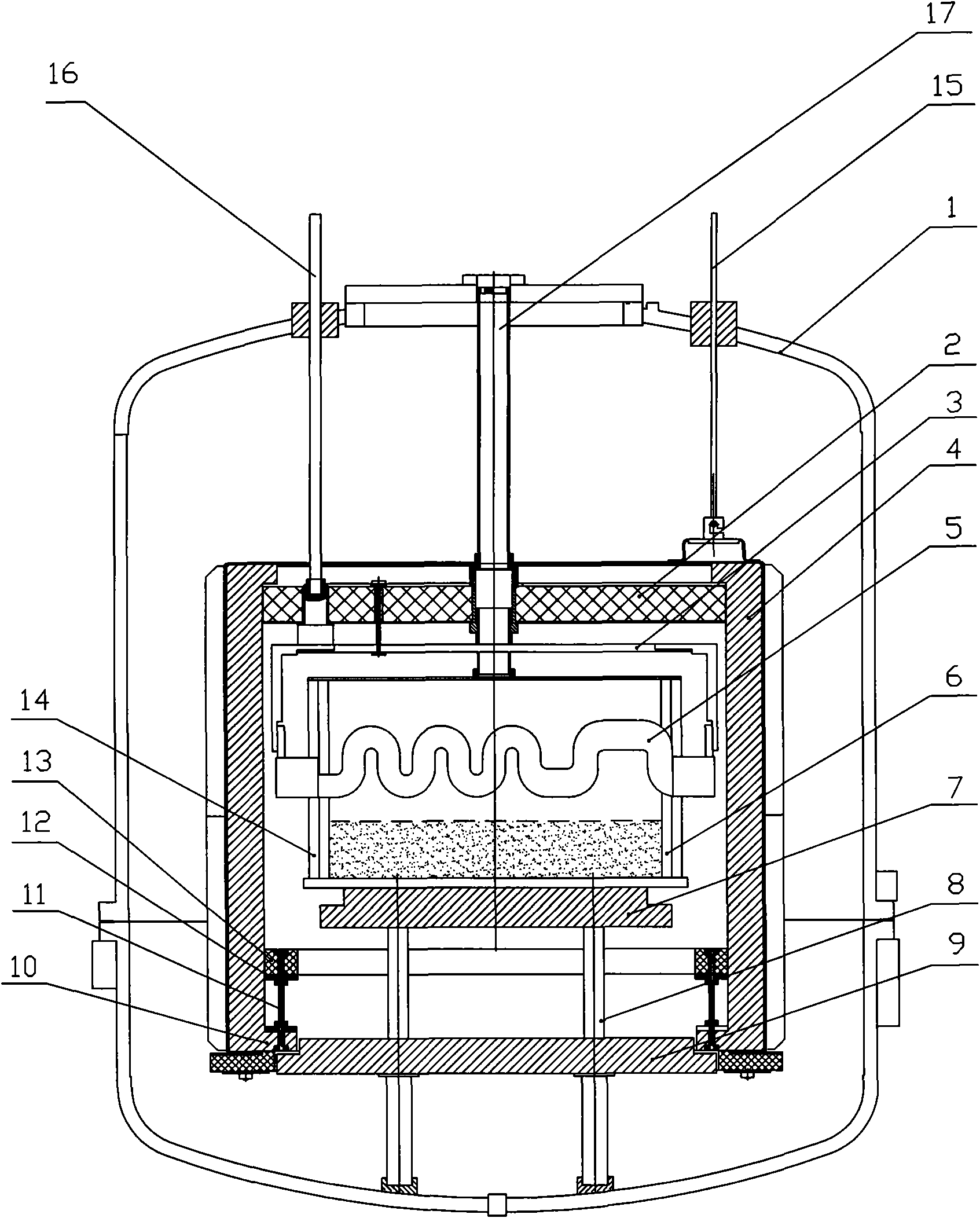

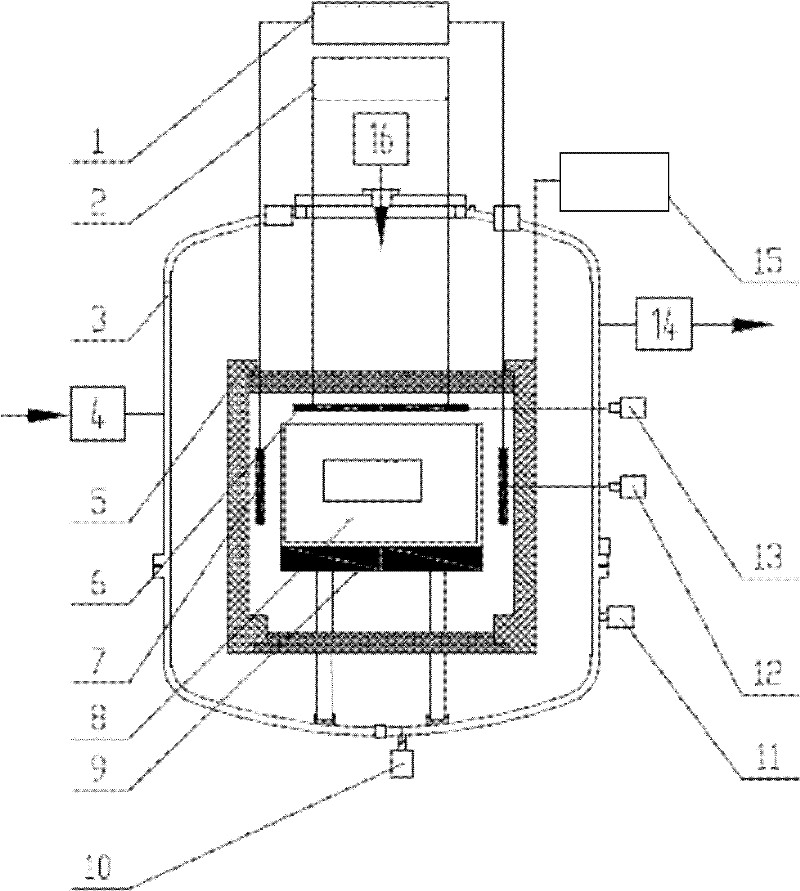

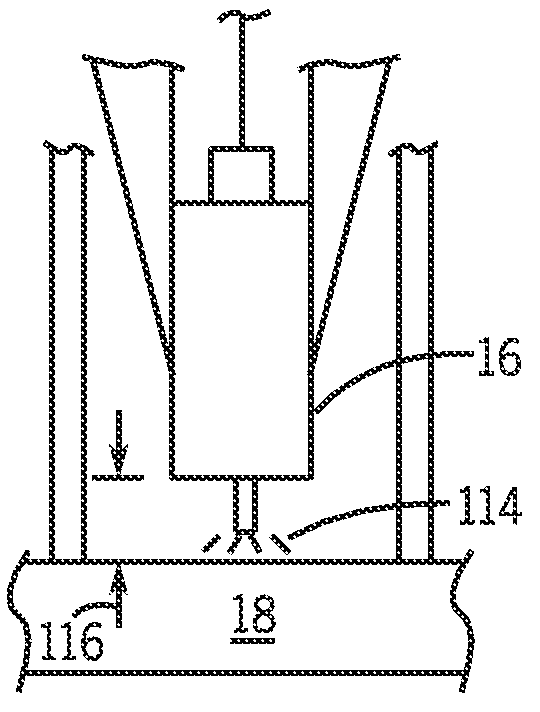

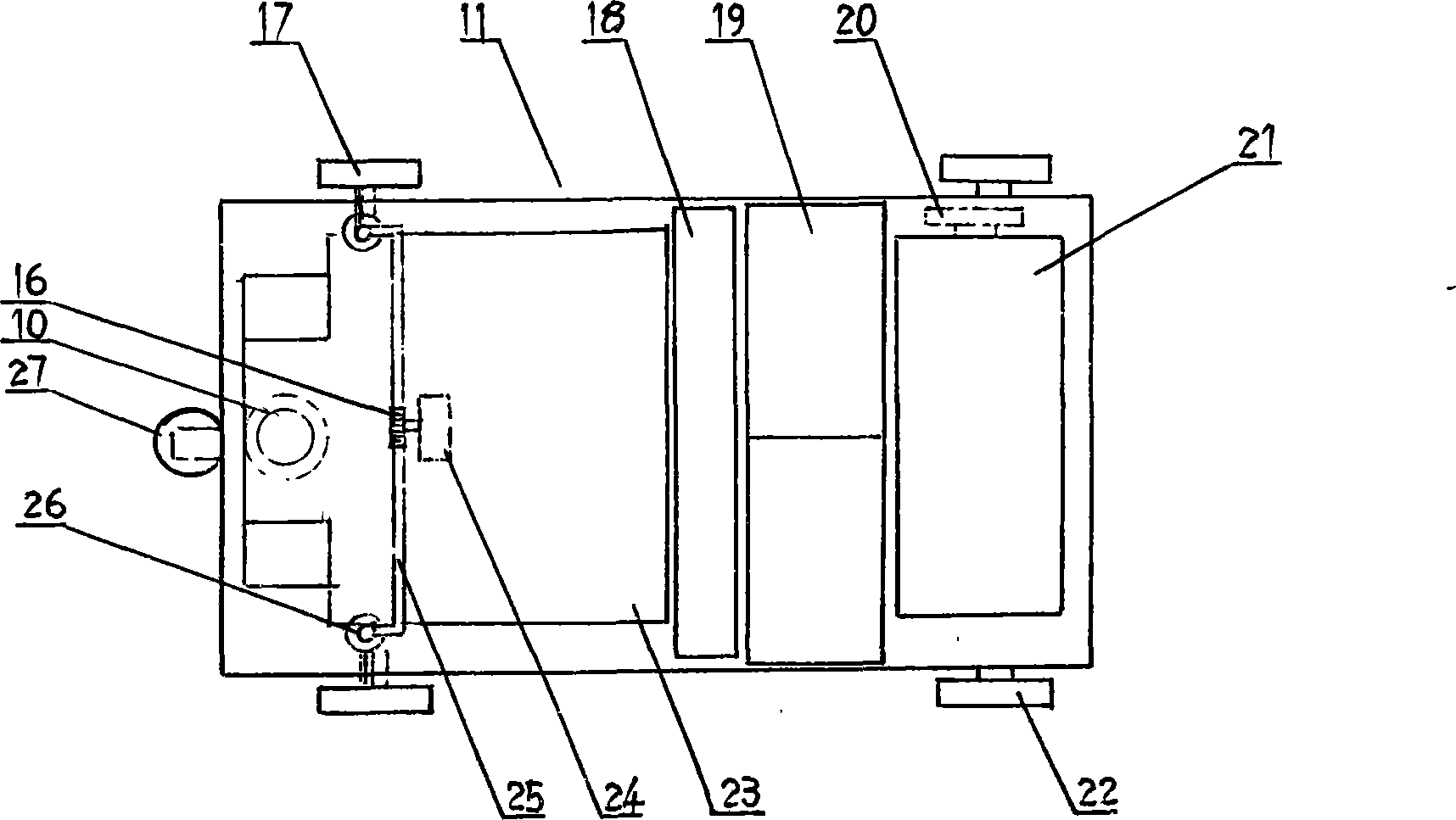

Follow-up heat insulation ring thermal field structure for vertical oriented growth of polysilicon

InactiveCN101775641ACrystal solidification process controlImprove temperature gradient distributionBy pulling from meltManufacturing technologyThermal insulation

The invention relates to the technical field of polysilicon ingot furnace designing and manufacturing, and aims to provide a follow-up heat insulation ring thermal field structure for the vertical oriented growth of polysilicon. The thermal field structure comprises a furnace chamber with a side surface enclosed heat insulation cage body, a crucible and a thermal field are arranged in the heat insulation cage body, and the upper end of the heat insulation cage body is connected with a lifting device; the upper part and the lower part of the heat insulation cage body are respectively provided with a top heat insulation board and a lower heat insulation body, wherein the top heat insulation board is fixedly suspended on an electrode, the lower heat insulation board and a heat exchange are fixed on a support column, the top heat insulation board and the upper end of the heat insulation cage body are movably connected, and the lower heat insulation board and the lower end of the heat insulation cage body are movably connected; and a circular follow-up heat insulation ring is fixed in the heat insulation cage body through a plurality of connecting devices. The follow-up heat insulation ring thermal field structure for the vertical oriented growth of polysilicon has reasonable design, can increase the grain size of polysilicon, reduce grain boundary and improve the verticality of the growing direction of polysilicon so as to improve the quality of polysilicon ingots, and simultaneously the follow-up heat insulation ring also plays the role of energy consumption reduction.

Owner:NINGBO JINGYUAN SOLAR ENERGY +1

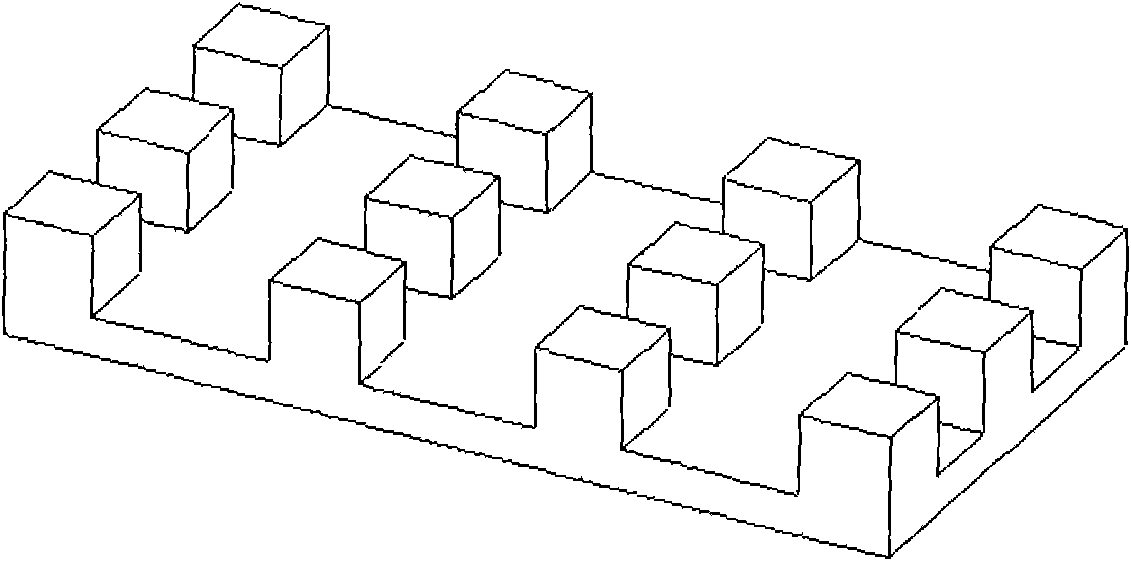

Super-hydrophobic silicon micron-nano composite structure and preparation method thereof

InactiveCN102167280AControllable graphicsLow costMaterial nanotechnologyDecorative surface effectsSurface modificationComposite structure

The invention discloses a super-hydrophobic silicon micron-nano composite structure and a preparation method thereof, which belong to the nano material preparation field. The structure is a micron-nano composite structure composed of square column array micron structures on the surface of silicon and columnar nano structures on each micron structure. The preparation method is relatively low is cost, can realize the controllable preparation of the periodic array silicon micron-nano composite structure, and is compatible with micro-electronic and micro-electro-mechanical technologies, thereby providing an effective means for the deep research on the influence of geometrical morphology on wettability; and the preparation method omits surface modification, and the super-hydrophobic property can be obtained by simply changing the structural topography of the surface, thereby laying the foundation for the application of the surface of the super-hydrophobic silicon micron-nano composite structure in the field of micro-electro-mechanical systems and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

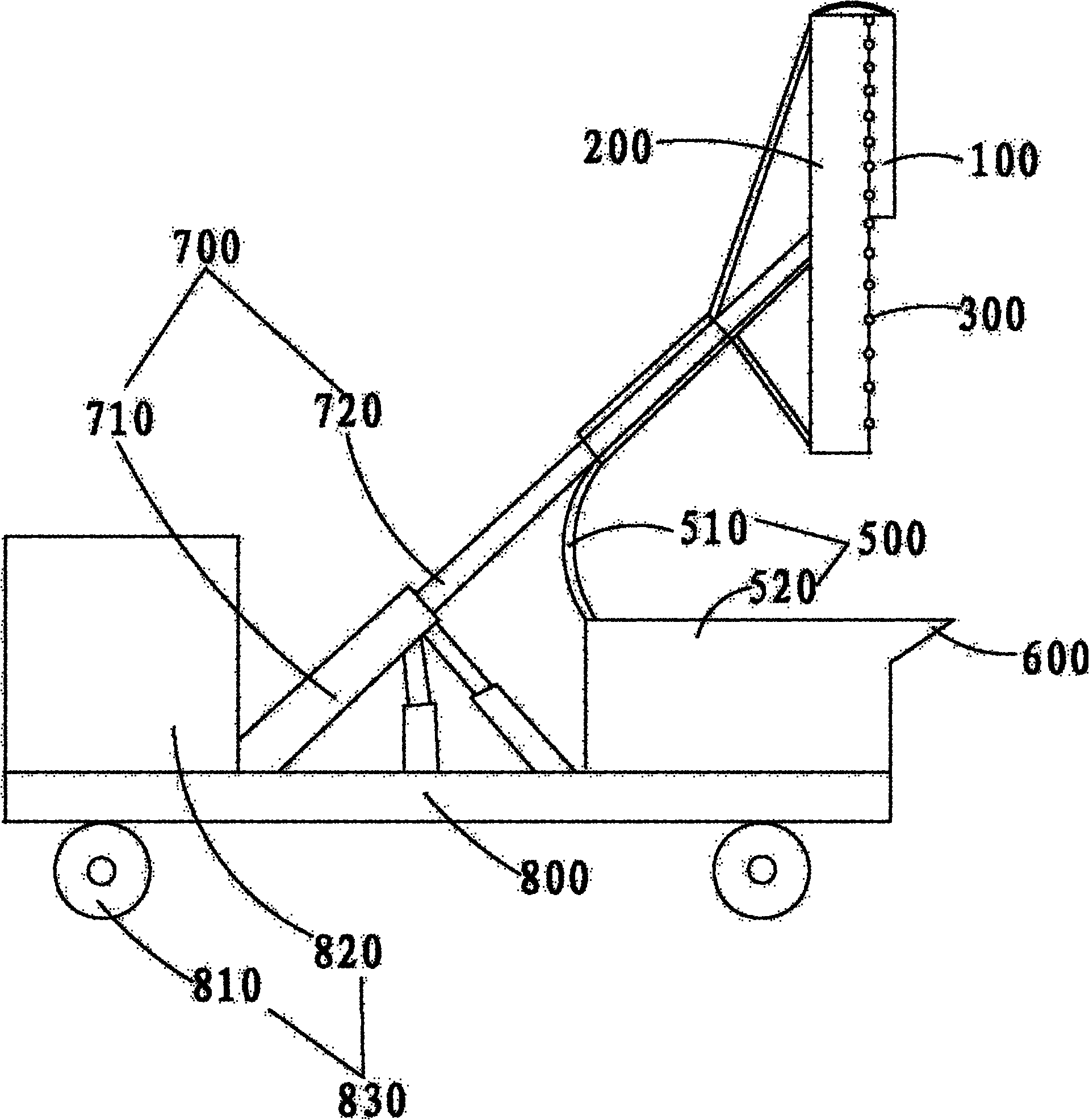

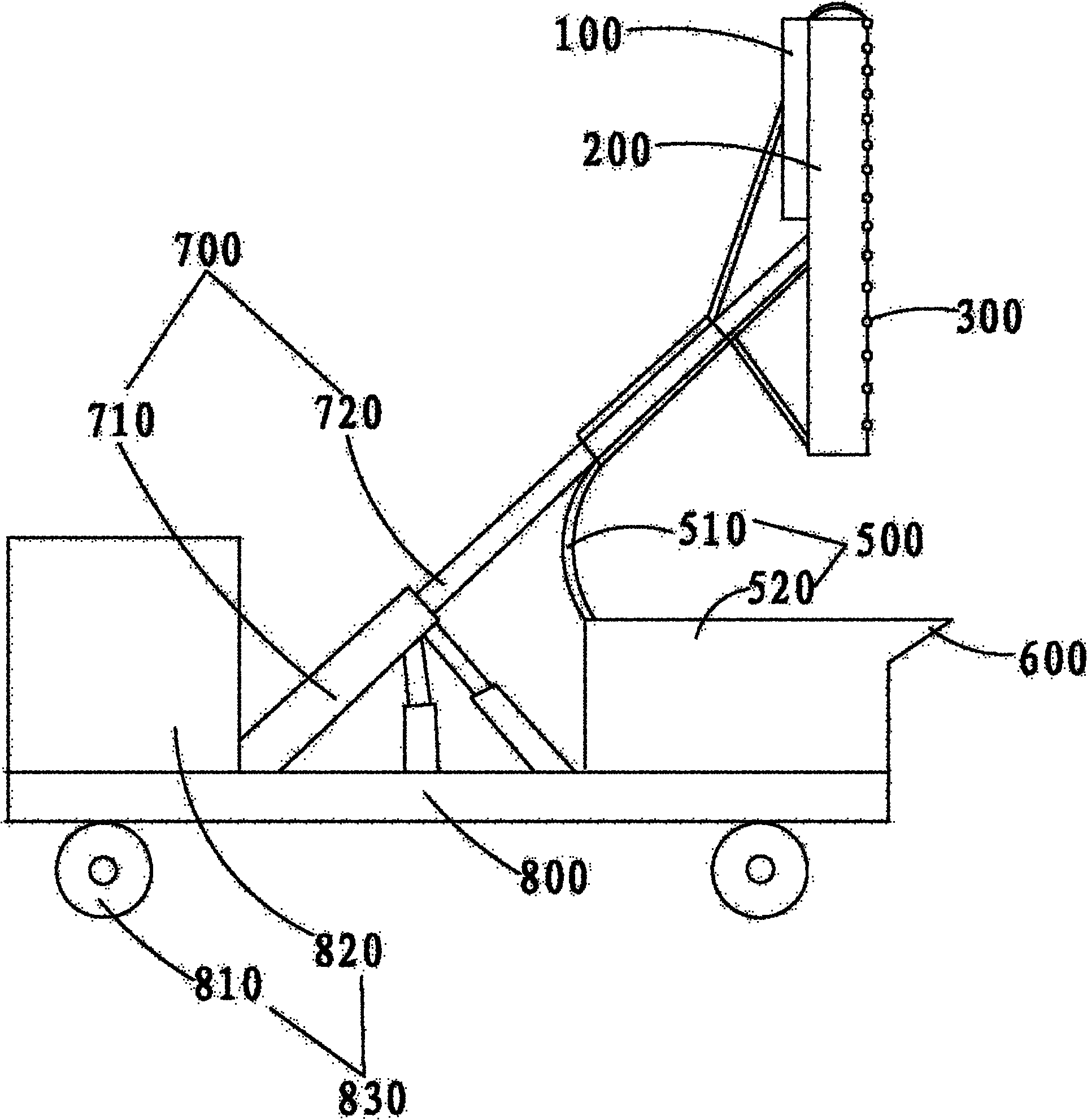

Plastering device

The invention discloses a plastering device, which is applicable to the field of construction machinery. The plastering device comprises a chassis, a screeding plate capable of screeding a slurry, and a slurry conveying part capable of conveying the slurry to an accommodating cavity, wherein the accommodating cavity is arranged in the screeding plate; the slurry conveying part is arranged on the chassis; a slurry outlet communicated with the accommodating cavity is reserved on the front face of the screeding plate; the screeding plate is moveably arranged on the chassis; the screeding plate is driven by a driving device; and a traveling part capable of driving the chassis to travel is arranged on the chassis. By arranging the screeding plate driven by the driving device and capable of screeding the slurry onto a wall, the plastering device has the advantages of high automation degree, high working performance, low requirements on skill of workers, low labour intensity and high working performance of workers, good planeness and perpendicularity of wall plastering, and high plastering quality.

Owner:朱长江

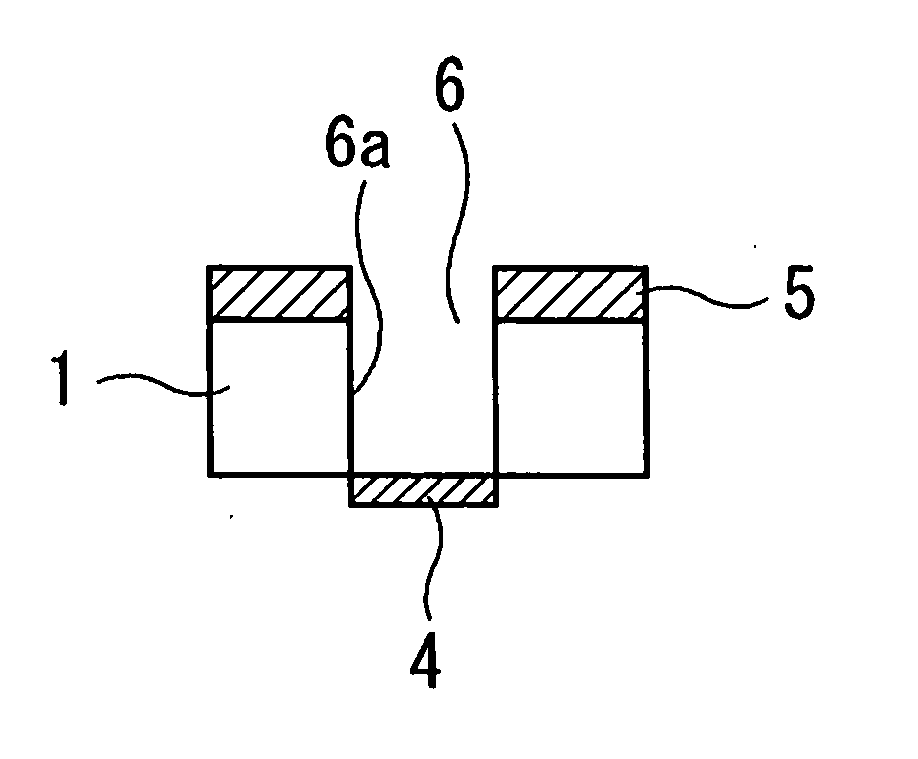

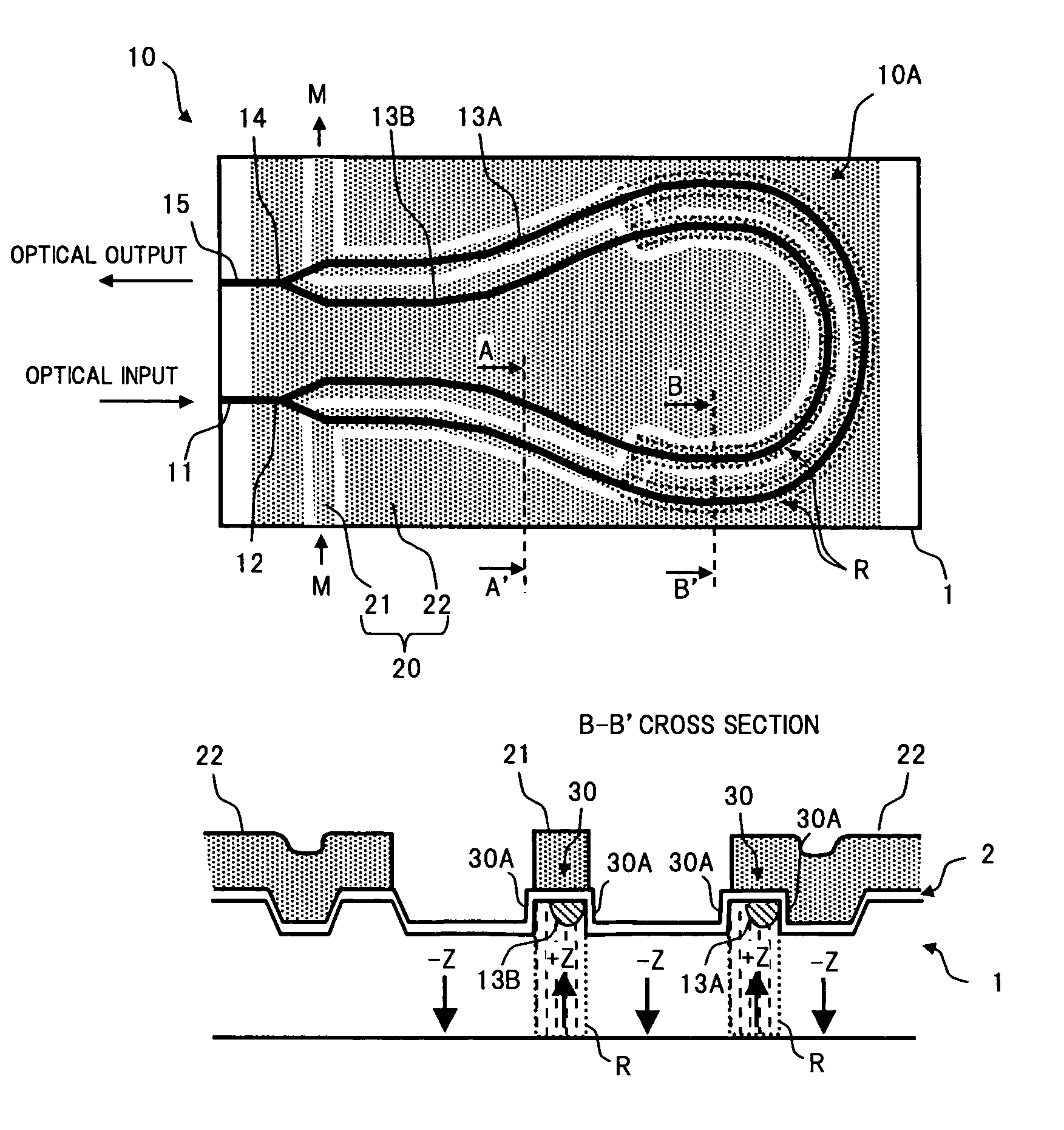

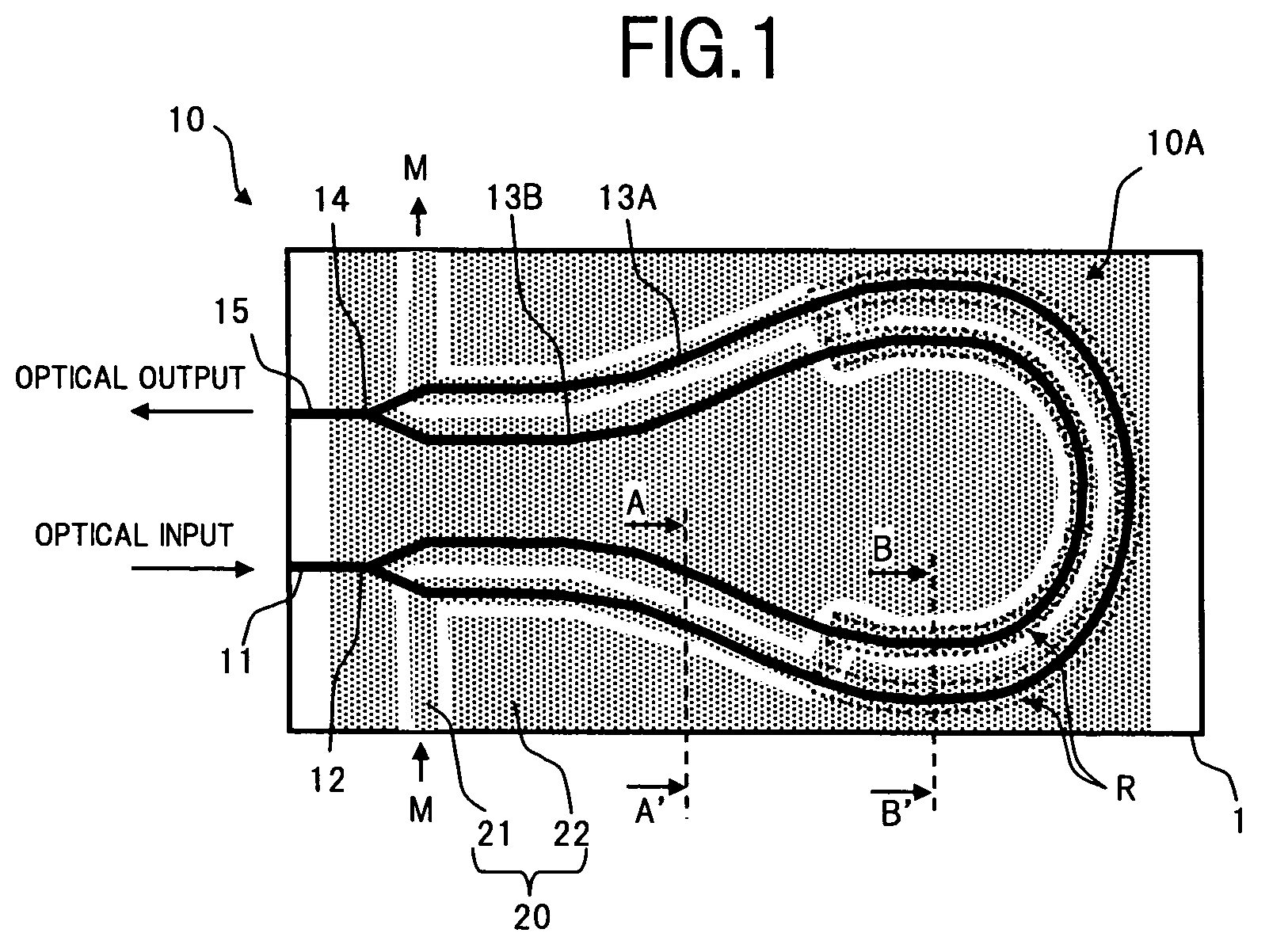

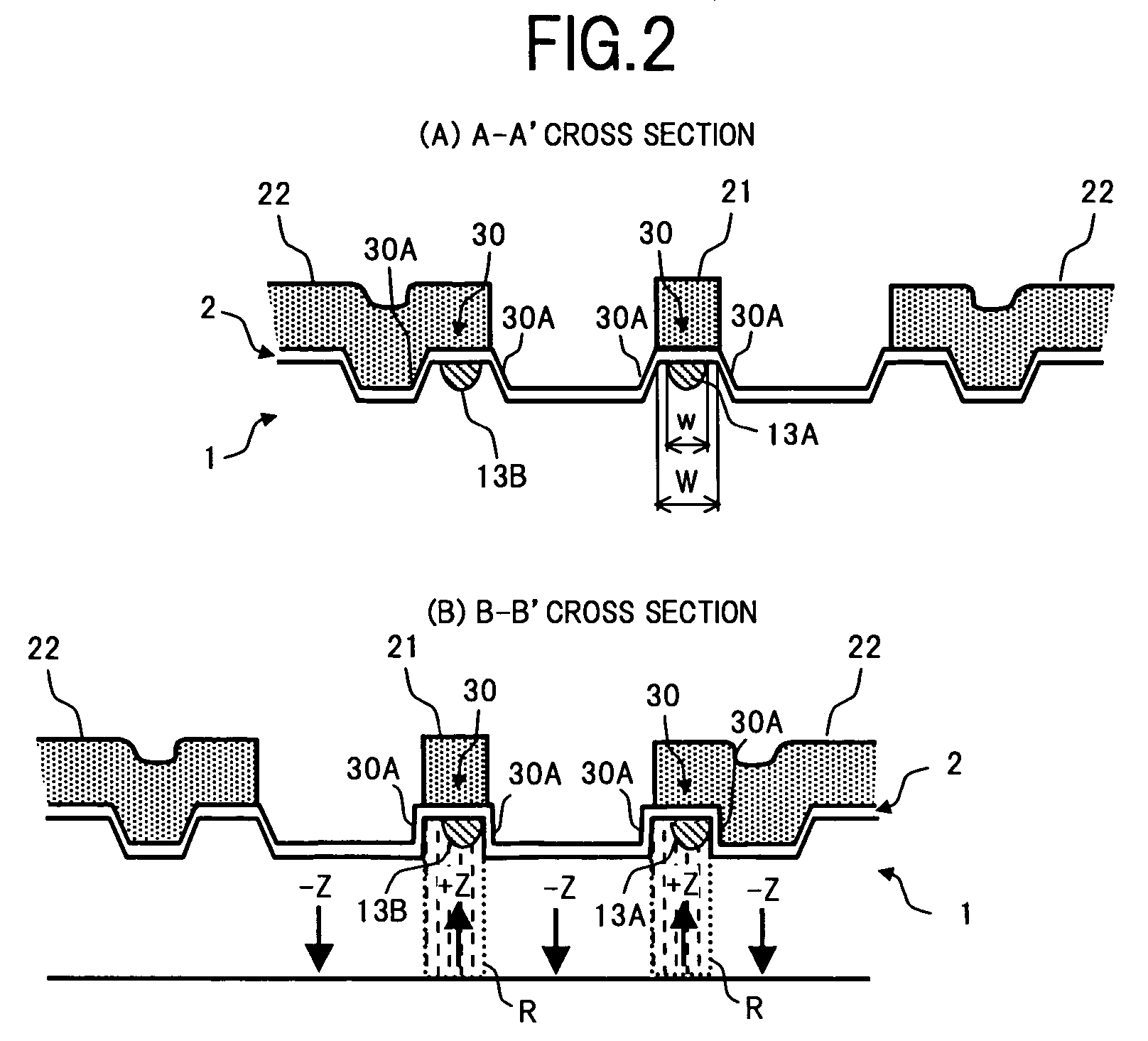

Optical modulator

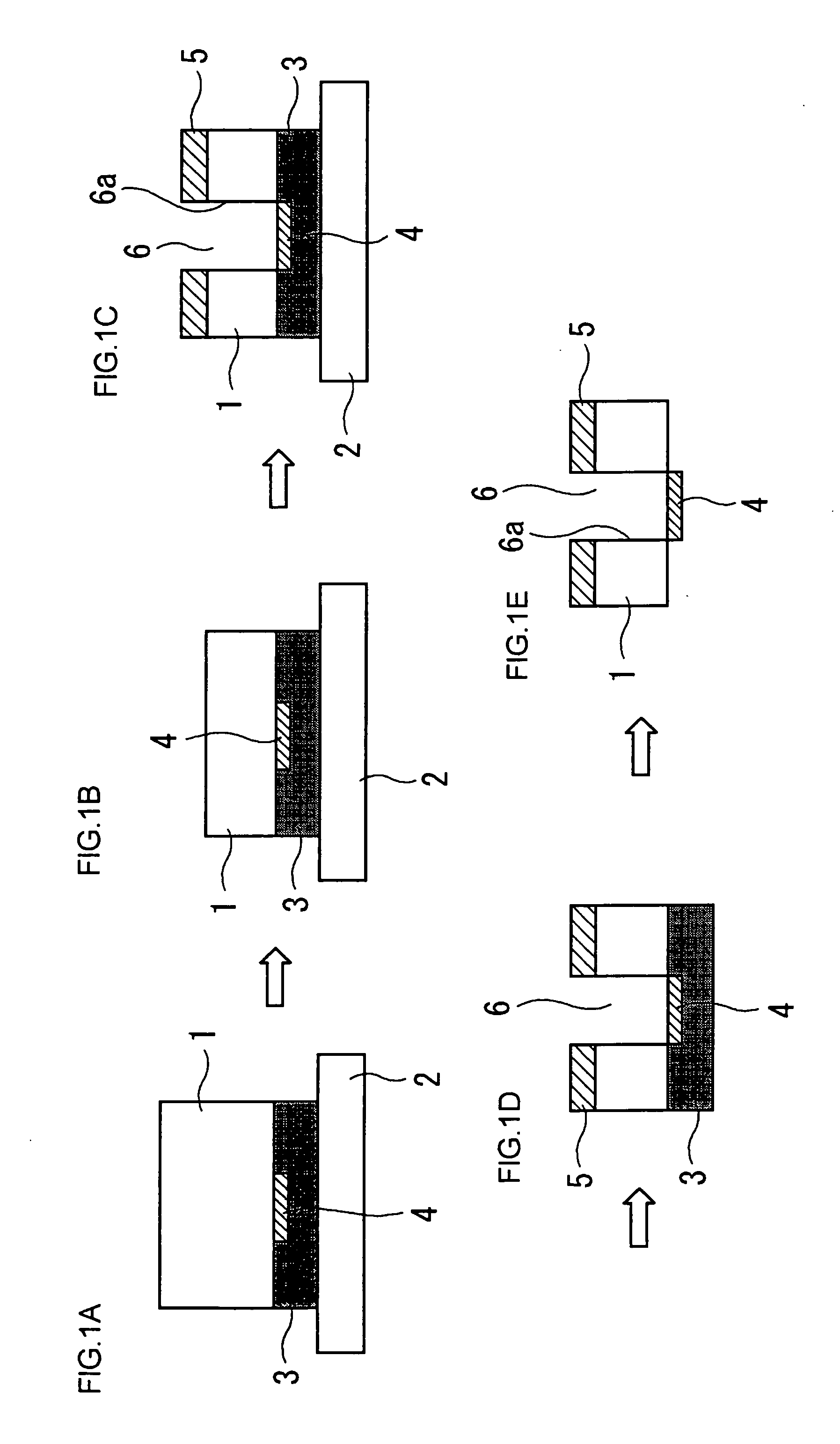

ActiveUS7088875B2Reduce wavelength chirp occurringReduce light lossCoupling light guidesNon-linear opticsLength waveWaveguide

An object of the invention is to provide a Mach-Zehnder type optical modulator that can reduce wavelength chirp occurring in a modulated light, and also can reduce an optical loss with a small sized configuration. To this end, according to the present Mach-Zehnder type optical modulator, in a configuration where optical waveguides and a coplanar electrode are formed on a substrate having an electro-optical effect, a polarization inversed region is formed in a part of an interaction portion of the substrate, and a signal electrode is arranged above one of parallel waveguides in a polarization inversed region and is arranged above the other parallel waveguide in a non-inversed region. Furthermore, a surface area of the substrate positioned on both sides of each of the parallel waveguides is lowered to provide a ridge structure section, and a buffer layer is formed on a ridge side face thereof.

Owner:FUJITSU LTD

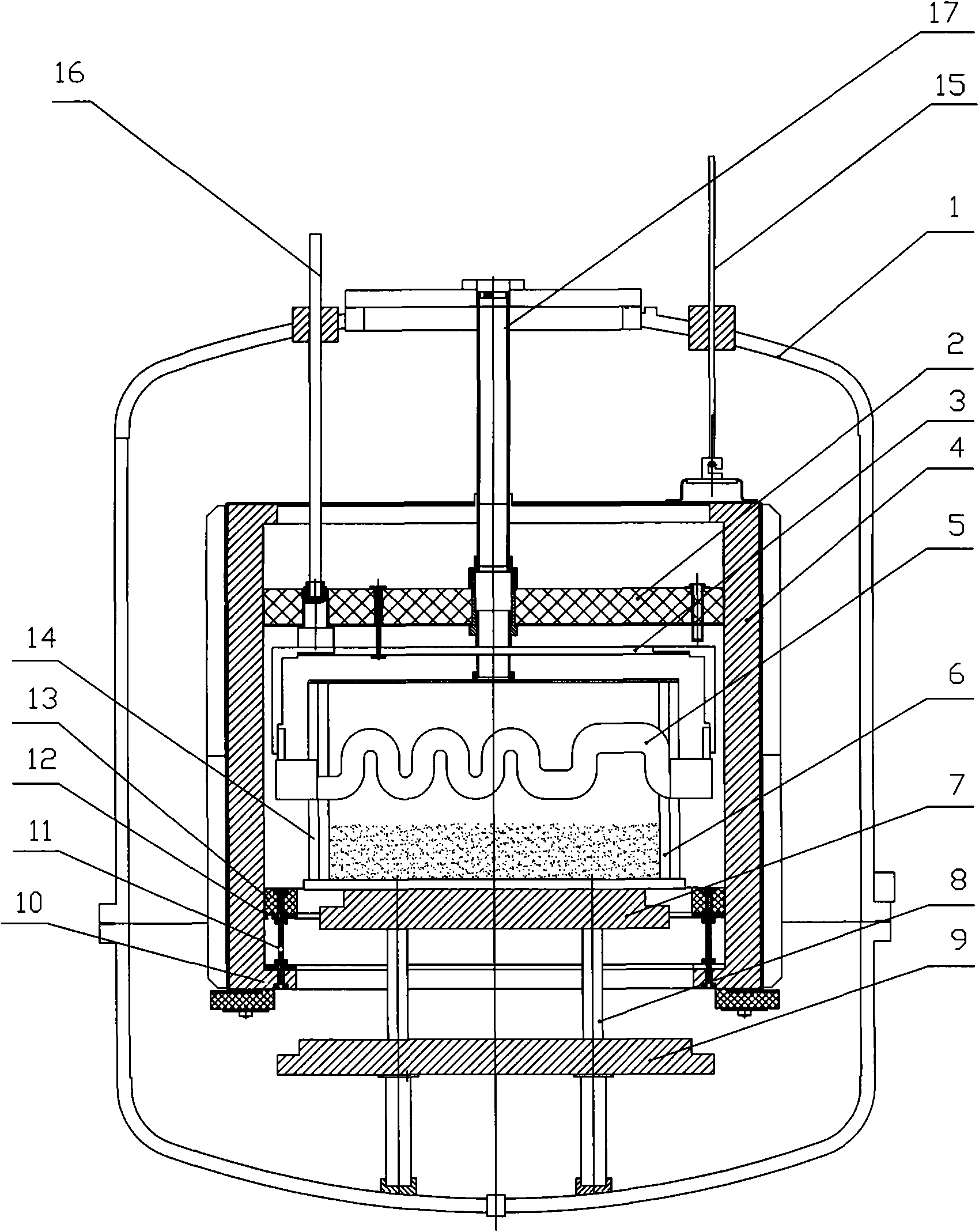

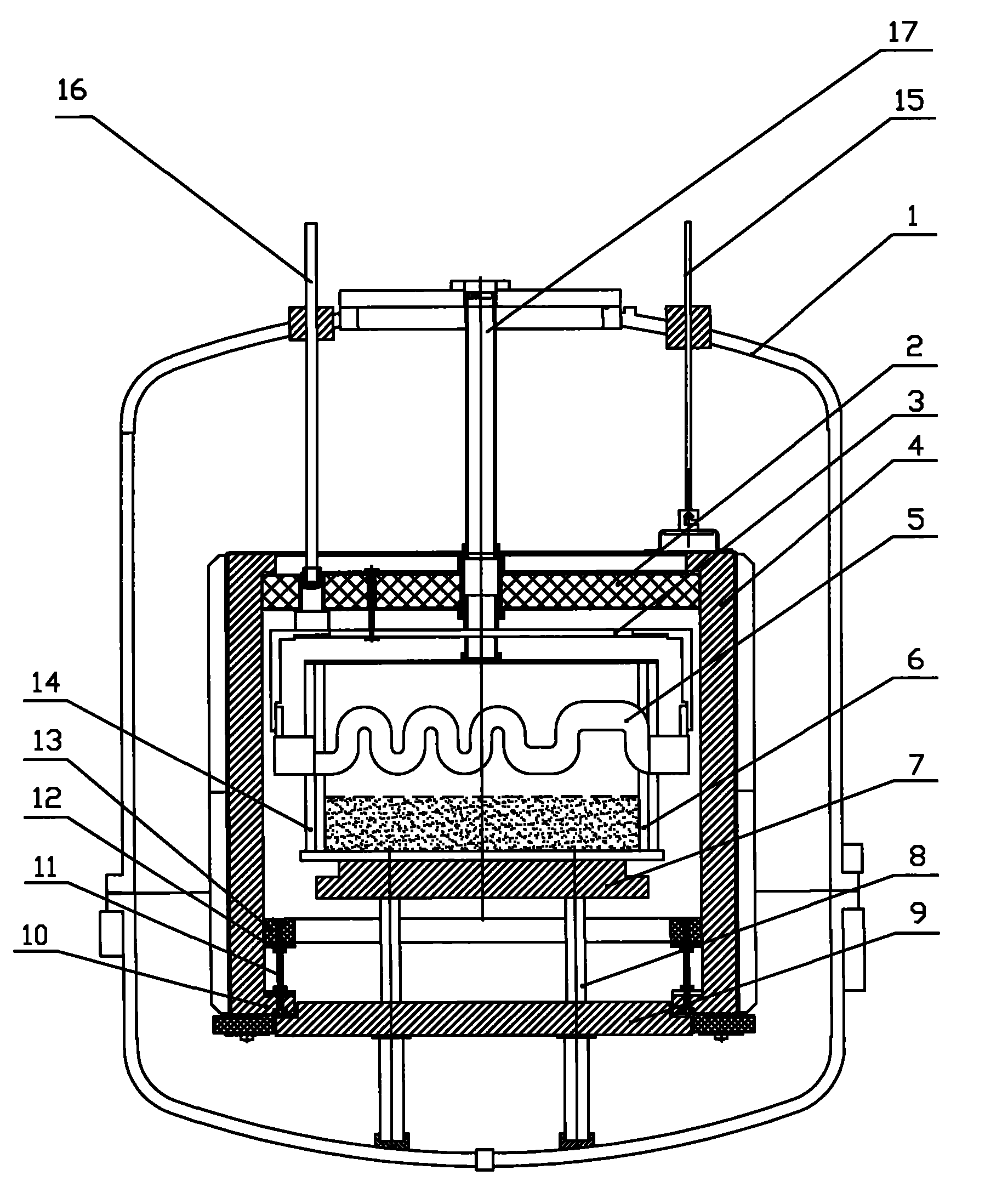

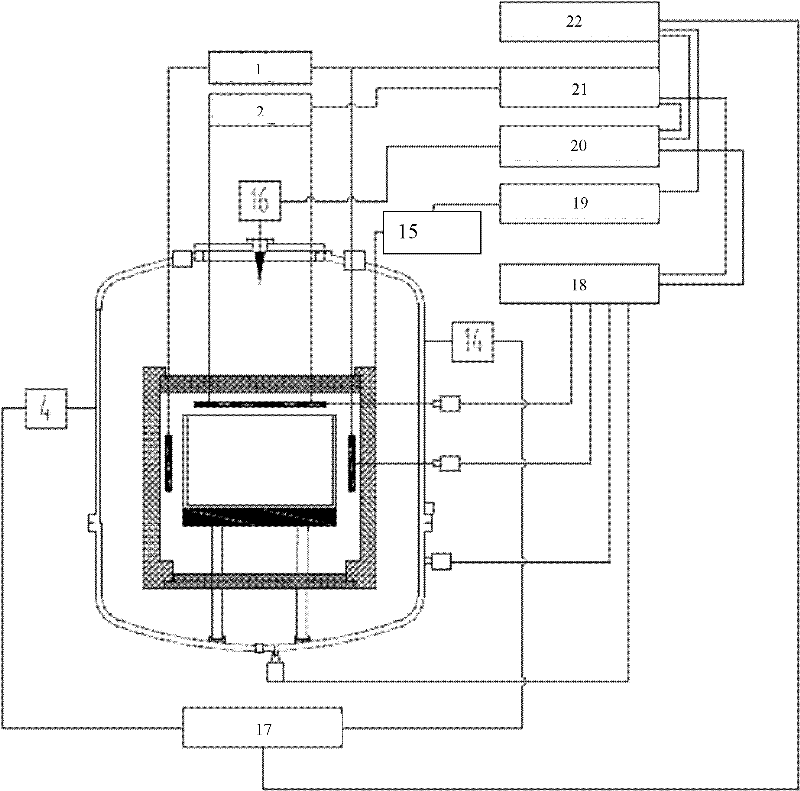

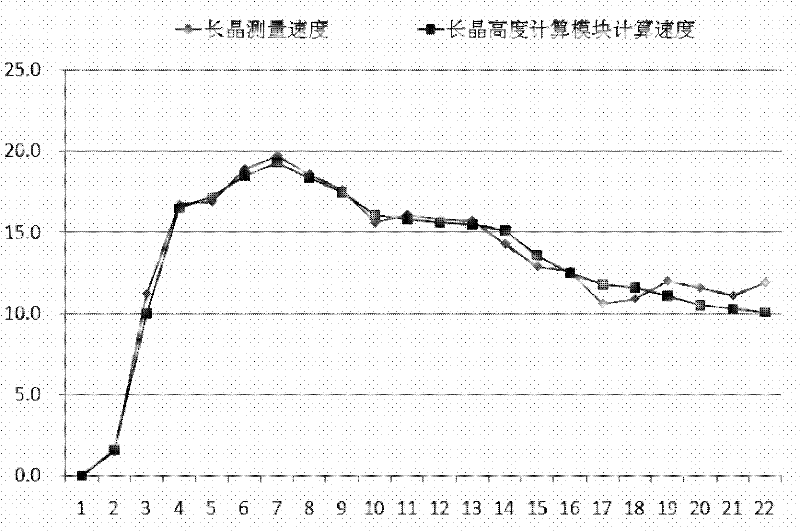

Heating control system and method for polycrystalline silicon ingot furnace based on separate control of top and side

InactiveCN102289235AFast crystal growthShorten the crystal growth timePolycrystalline material growthAuxillary controllers with auxillary heating devicesDistribution controlPolycrystalline silicon

The invention relates to production control of a polycrystalline silicon ingot casting furnace and aims at providing a heating control system and a method based on a top separated control polycrystalline silicon ingot casting furnace. A side heater in the system is connected with a side power supply, a top heater is connected with a top power supply, the side power supply and the top power supplyare connected to a power distribution control module through conducting wires, in addition, the heat control system is provided with a central control module, a heating control module, a crystal growing height calculation module, a temperature control sensor, a lower water temperature flow rate sensor, a side water temperature flow rate sensor, a side heater temperature sensor and a top heater temperature sensor, and the temperature control sensor, the lower water temperature flow rate sensor, the side water temperature flow rate sensor, the side heater temperature sensor and the top heater temperature sensor are arranged on the top of a furnace chamber. Compared with the prior art, the system and the method have the advantages that the crystal growing speed is accelerated, the crystal growing time is shortened, the crystal growing speed and the crystal growing height can be precisely calculated, the crystal growing process is precisely controlled, the total power of the heater power is reduced, in addition, the energy consumption is obviously reduced because the crystal growing time is shortened, the crystal growing interface is more smooth, the crystal grain verticality is better, in addition, the crystal favorably grows, and the crystal quality is improved.

Owner:NINGBO JINGYUAN SOLAR ENERGY

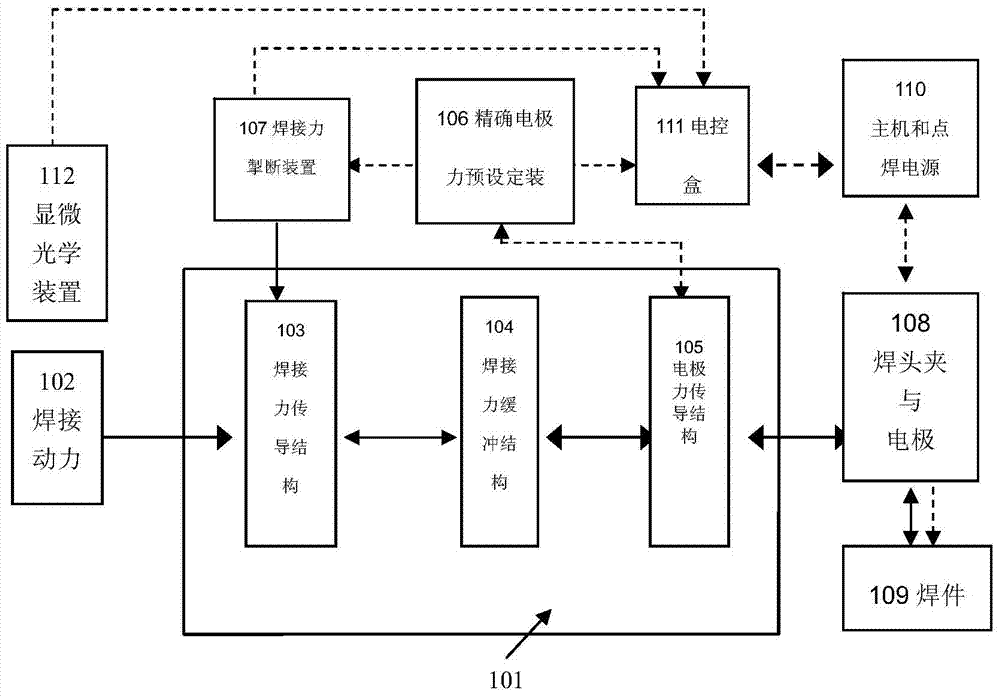

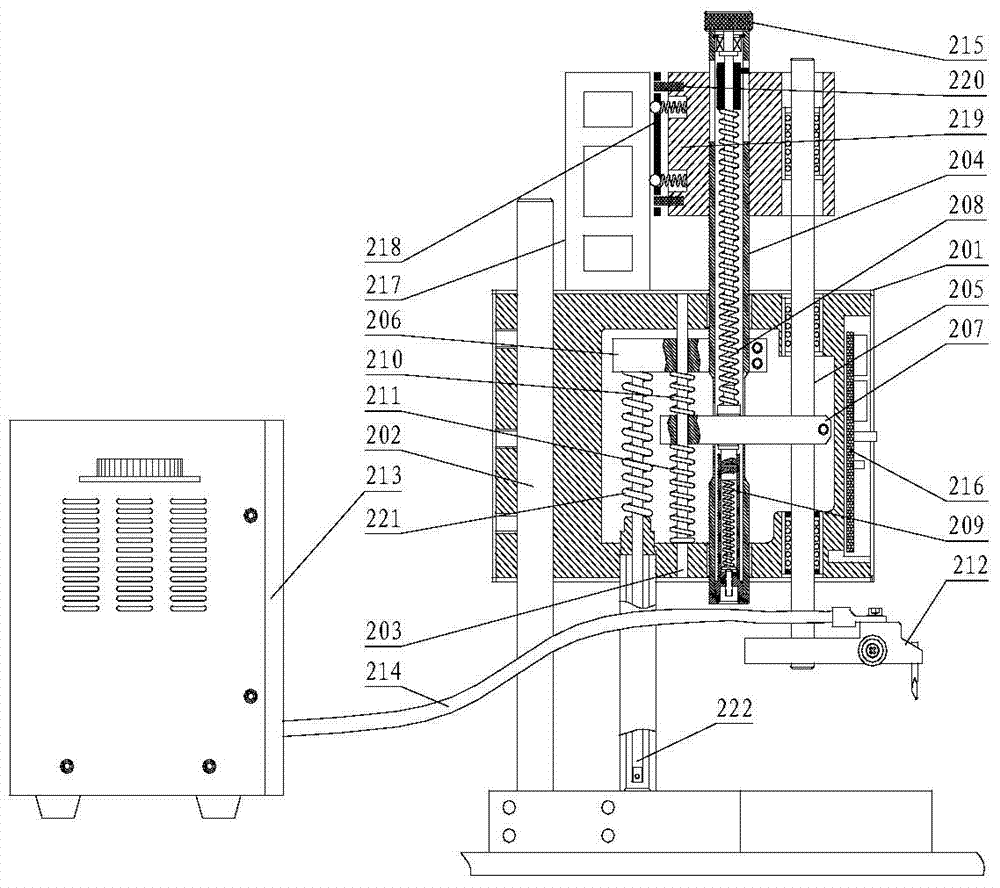

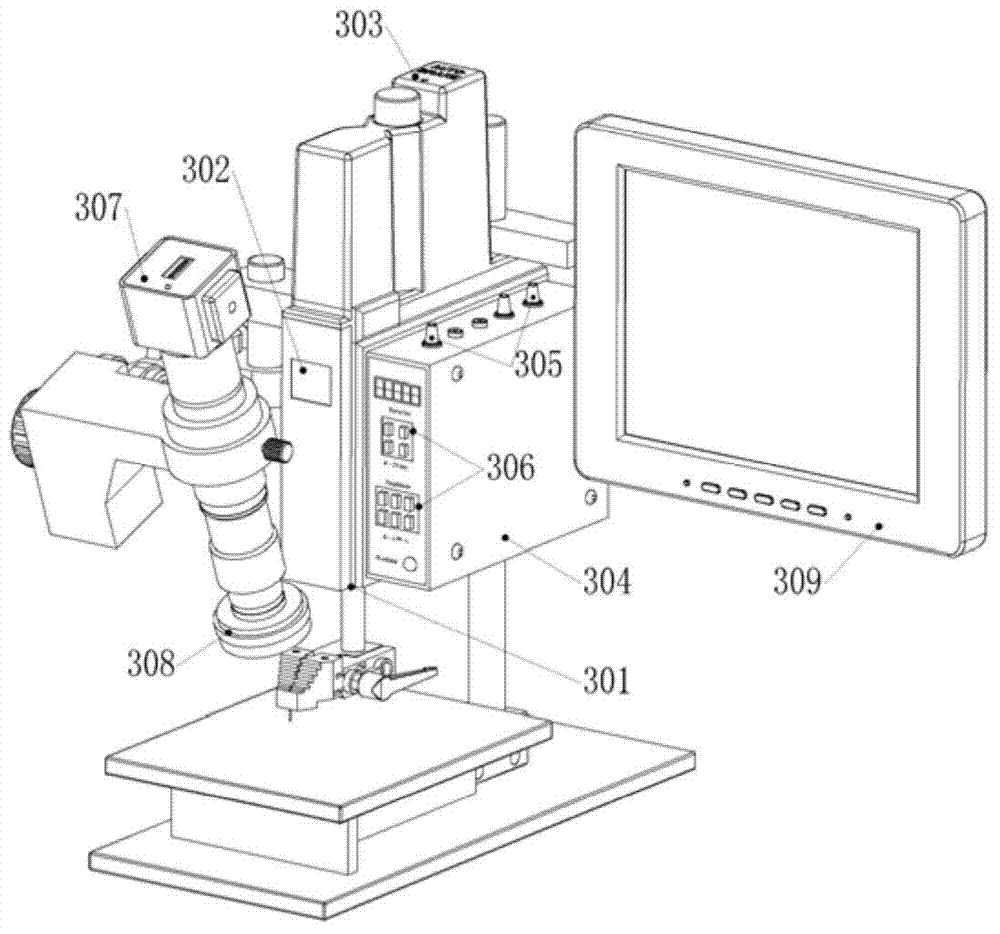

Electric resistance welding micro-welding spot welding machine

ActiveCN103920981ASimplify and reduce electrical connectionsImprove verticalityResistance electrode holdersWelding monitoring devicesElectricityElectrical resistance and conductance

The invention discloses an electric resistance welding micro-welding spot welding machine and mainly relates to noses. A mechatronics accurate electrode force pressurizing system is mounted on a nose frame, and electrode force is kept in a preset range and relatively constant during whole spot welding by the synergy and interaction of a welding acting force transmission device, an accurate electrode force presetting device and a welding force switching off device. A spot welding machine nose structure with an electric control box is provided, and nose feed and spot welding power supply output presetting are performed through the electric control box. A plastic nose frame and a stepped welding head clamp structure are provided to guarantee accurate torque transmission. A nose and a microscopy optical device are integrated, and the brand new electric resistance welding micro-welding spot welding machine is provided with the unique optical mechatronics spot welding machine nose.

Owner:GUANGZHOU MICRO WELDING EQUIP

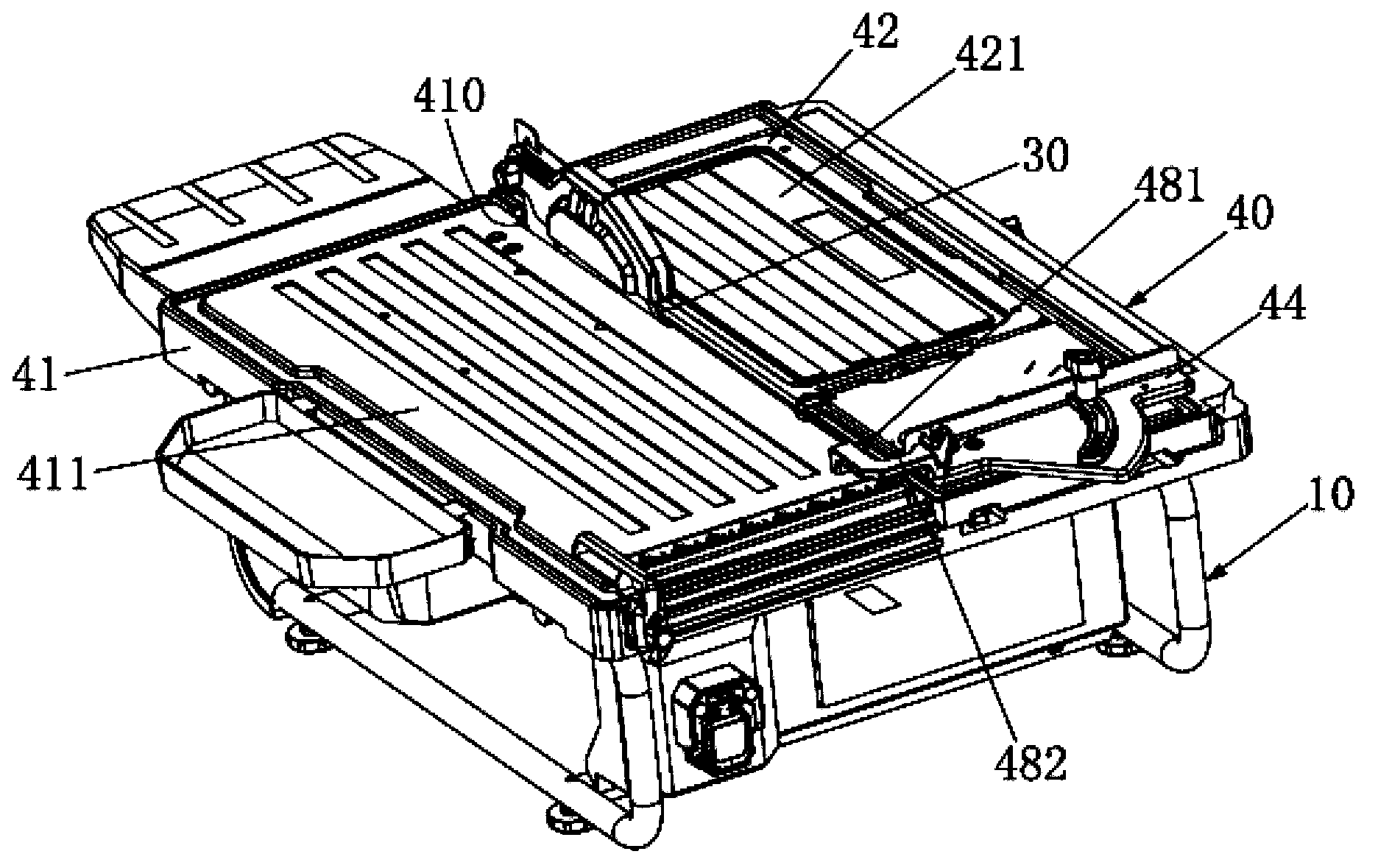

Stone cutter

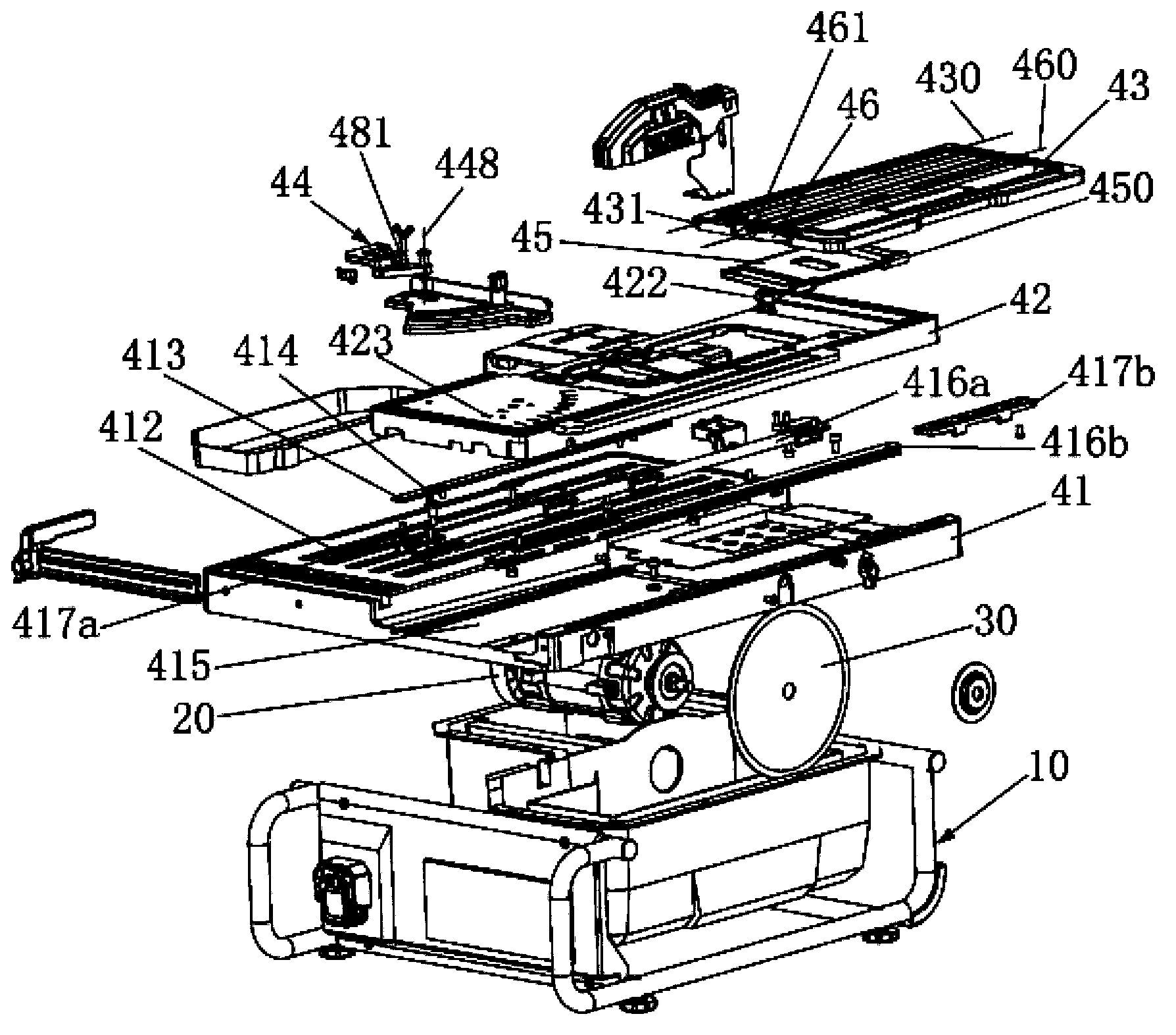

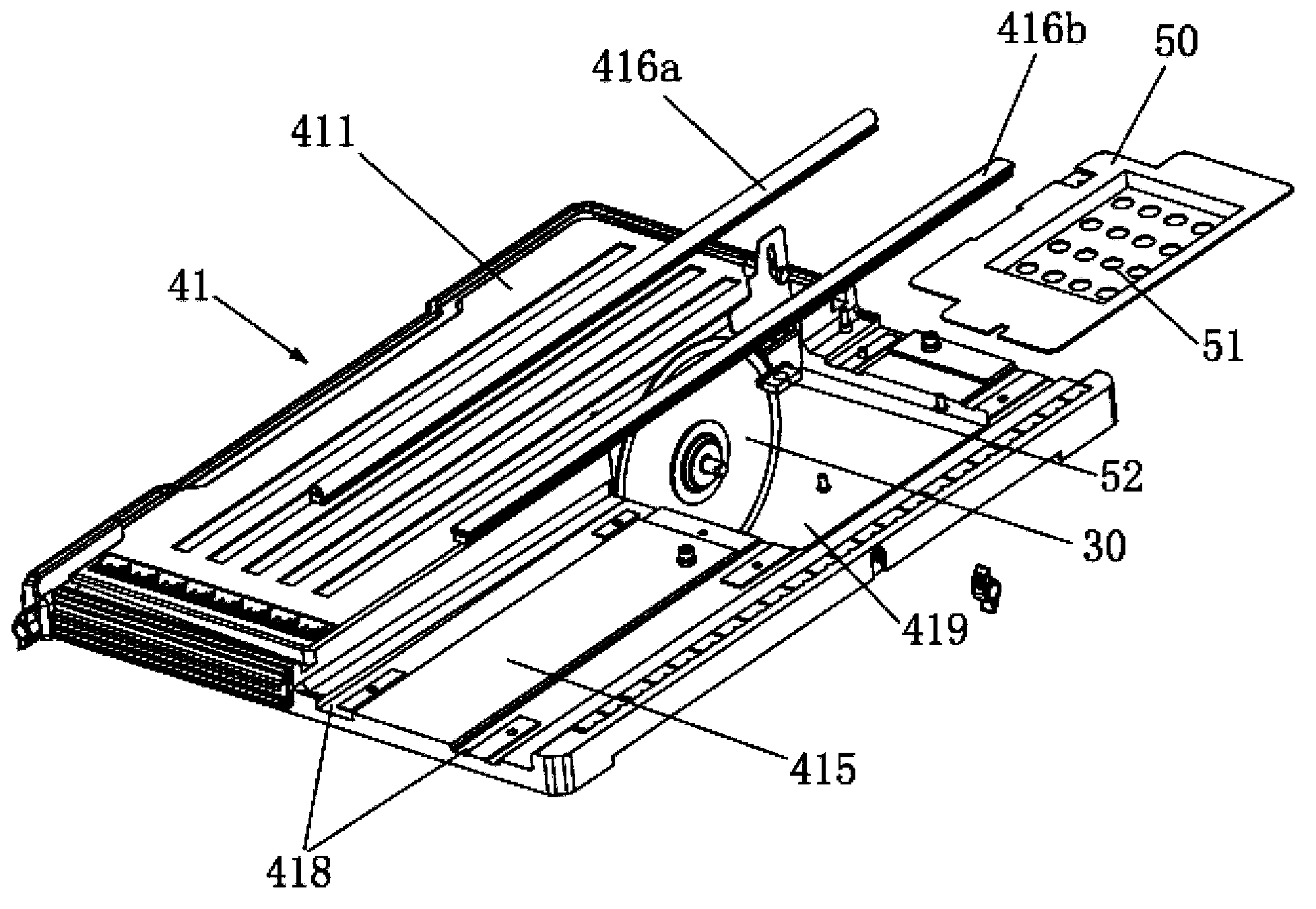

ActiveCN104275749AReduce scratchesImprove straightnessWorking accessoriesStone-like material working toolsSTONE CUTTEREngineering

A tile cutting machine comprises a base, a motor accommodated in the base, a blade driven to rotate by the motor, and a working table supported on the base, wherein the working table comprises a fixed working table fixedly mounted to the base. A movable working table is slidably mounted to the fixed working table in a sliding direction parallel to a plane of the blade. The movable working table comprises a pivoting plate pivotally mounted to the movable working table about a pivoting axis parallel to the plane where the blade is located and a fence assembly mounted to the movable working table. The tile cutting machine can effectively enhance the ability to produce straight and / or square cuts.

Owner:NANJING CHERVON IND

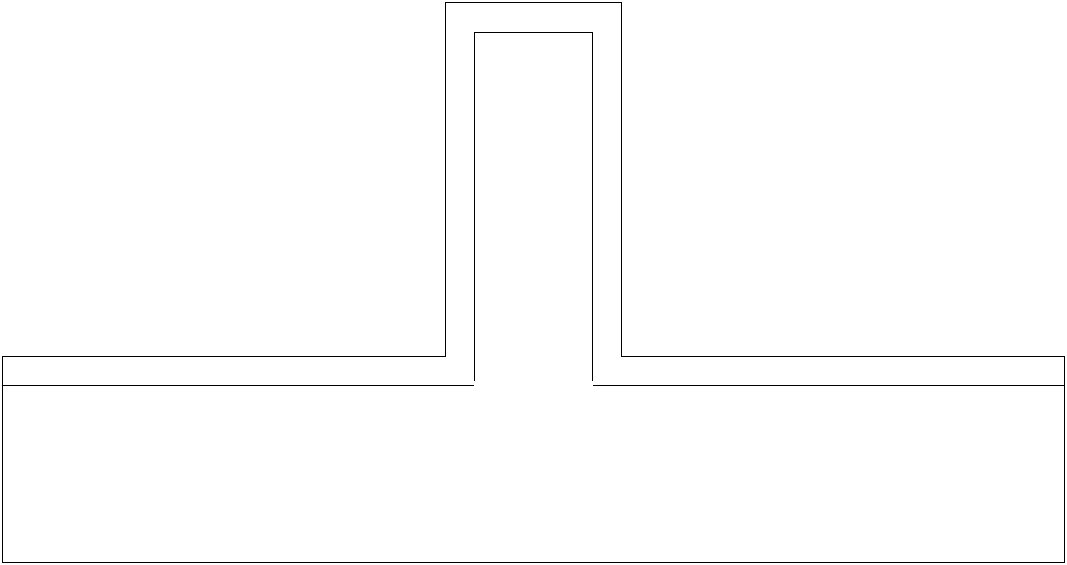

Preparation method of silicon nano-wire field-effect transistor

InactiveCN102214586AEasy to controlSmooth and steep etch effectSemiconductor/solid-state device manufacturingNanotechnologySilicon nanowiresField effect

The invention relates to the field of microelectronic apparatus manufacture, and discloses a top-down preparation method of a vertical silicon nano-wire gate field-effect transistor. The vertical silicon nano-wire gate field-effect transistor includes a semiconductor substrate, a nano-wire channel region vertically arranged on the semiconductor substrate and an annular grid conductive layer arranged out of the channel. The nano-wire channel region is provided with an active conductive layer; the upper part is doped with n impurity to serve as a source end n area; the semiconductor substrate contacting with the bottom of the drain conductive layer is doped with n impurity to serve as a drain end n area; and a non-symmetrical Halo-doped structure p+ region is added between the source end and the channel. The method for preparing the vertical silicon nano-wire gate field-effect transistor can well control the consistency of the position and size of the nano-wire, thus simplifying the manufacture process and reducing the manufacture cost.

Owner:XI AN JIAOTONG UNIV

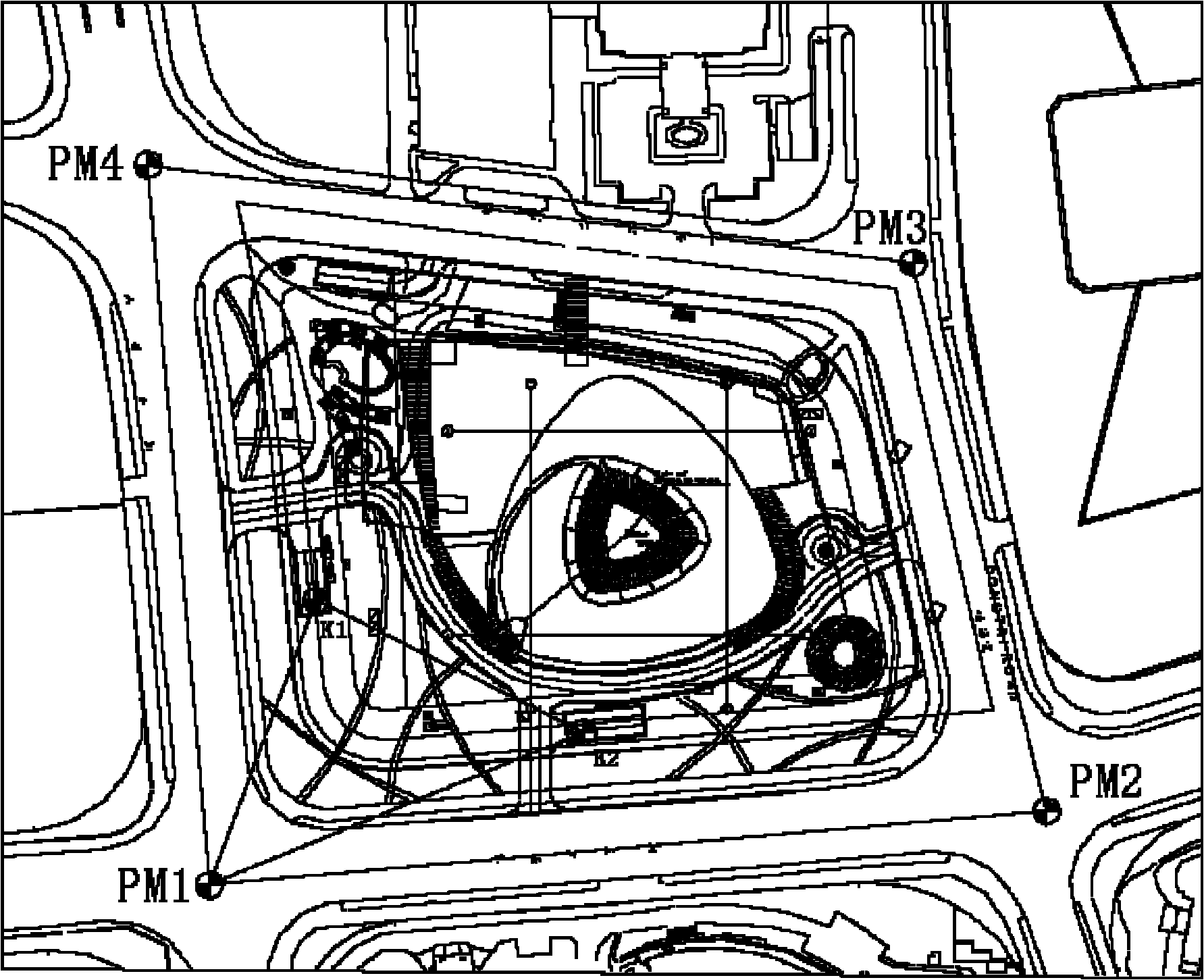

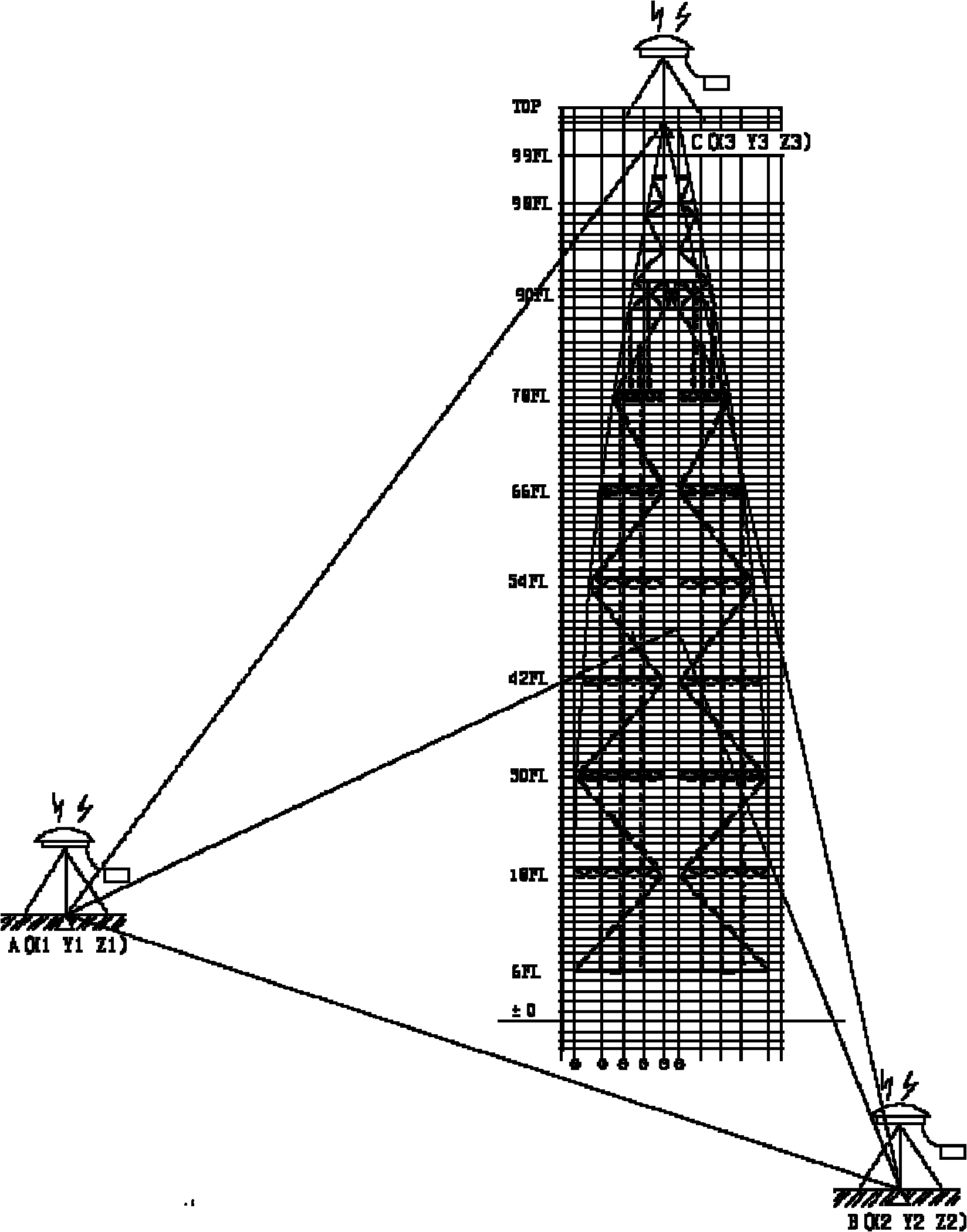

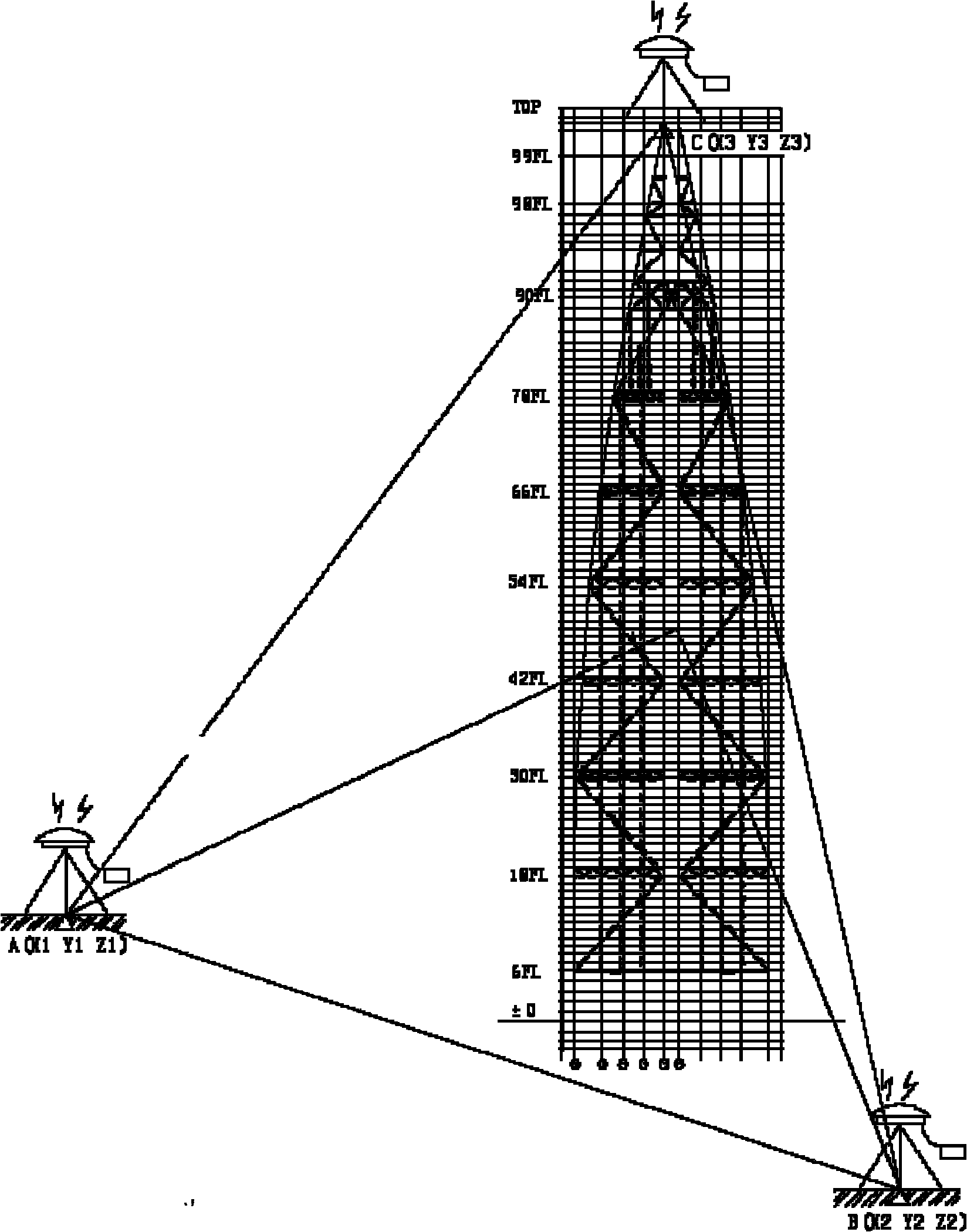

Super-high-rise building verticality measuring and controlling method based on GPS (Global Positioning System)

ActiveCN102080960AEliminate cumulative errorsImprove verticalityMeasuring points markingFixed angles setting outControl networkEngineering

The invention discloses a super-high-rise building verticality measuring and controlling method based on a GPS (Global Positioning System). A high-accuracy GPS static measurement mode is adopted, two base stations are placed on a base control network point on the ground, one mobile station is placed on any position of a construction floor surface, a first floor measurement control point is obtained through timing observation, a second floor measurement control point is obtained by using the same method, one of the two control points is used as a station measuring point and the other is used as a rear view point for checking a measuring point, and a floor axis control point is set out after no errors exist. By adopting the invention, accumulated errors in the traditional method can be eliminated, and the verticality of the building structure is improved. In addition, because each measurement is started from a base control network on the ground, no accumulated errors exist, and the maximum error source of the super-high-rise floor verticality control is eliminated.

Owner:SHANGHAI CONSTR NO 1 GRP

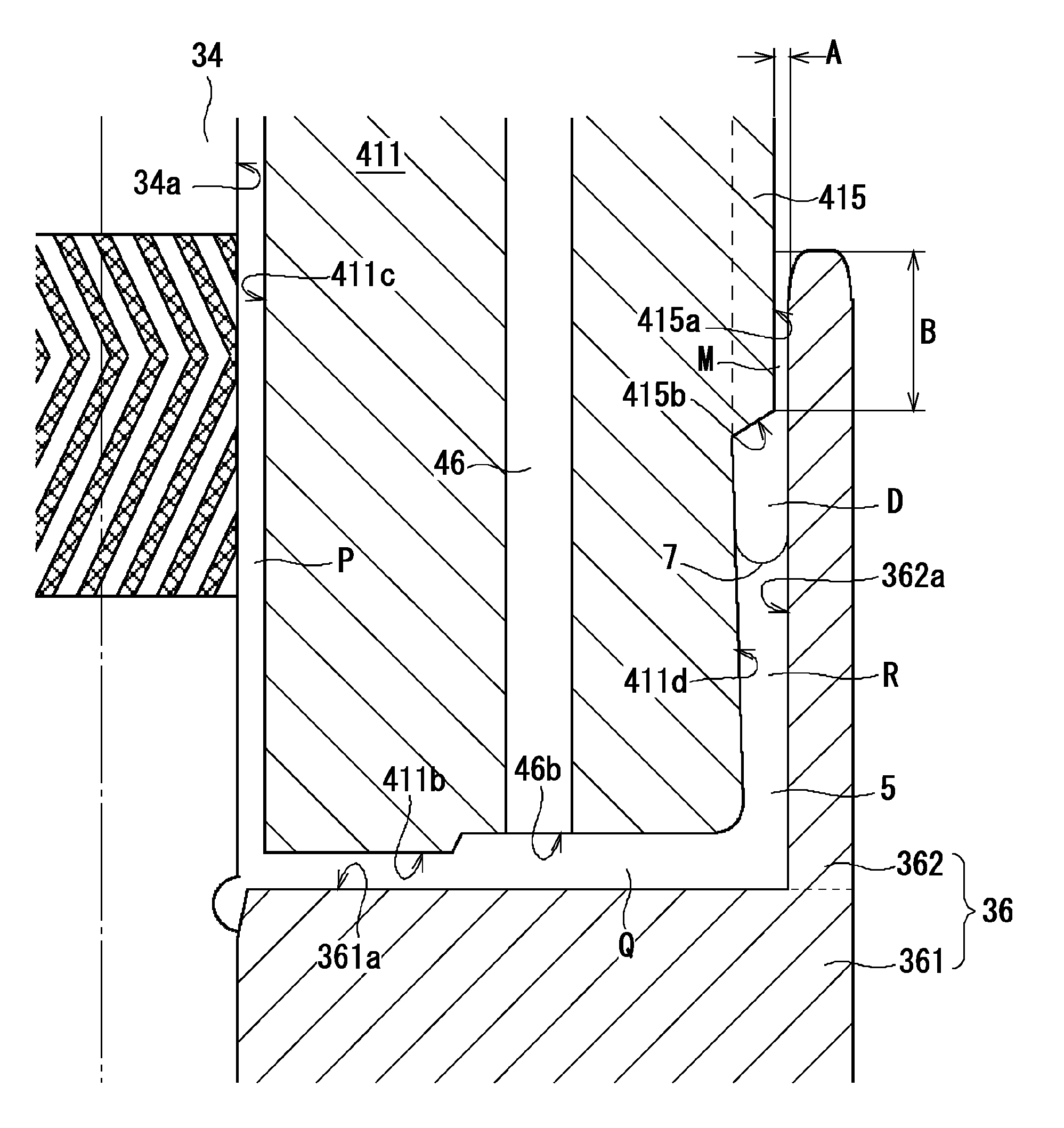

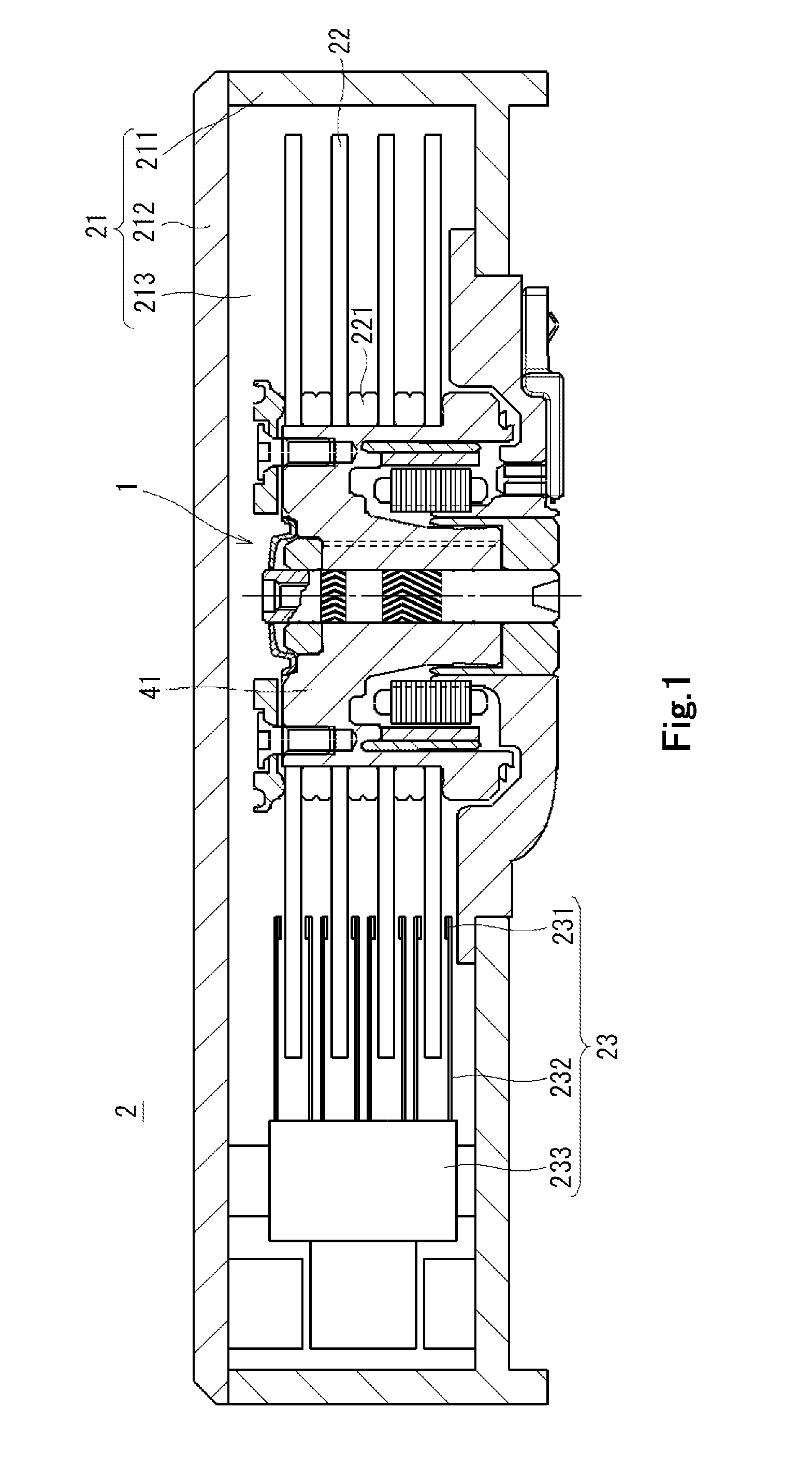

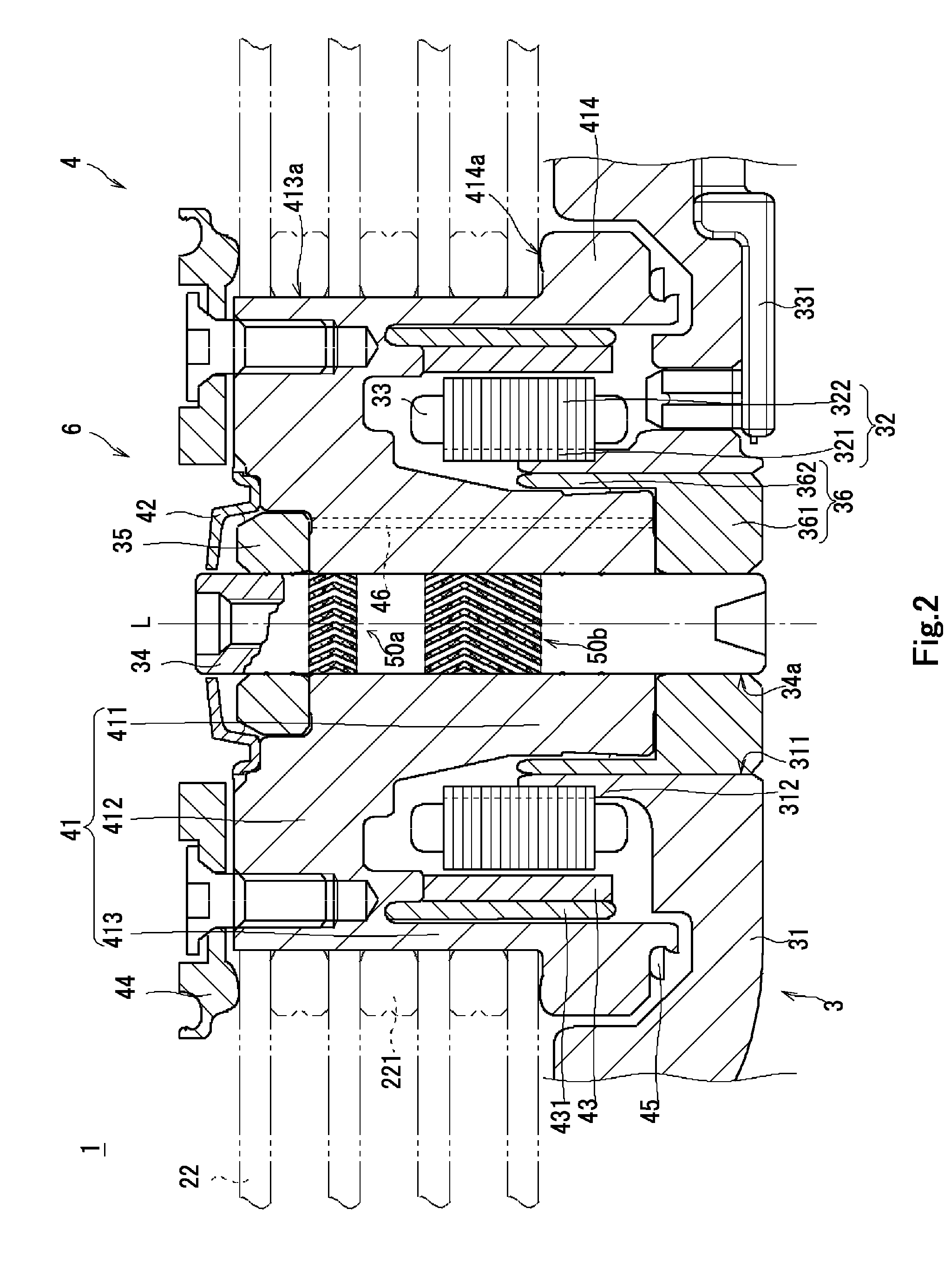

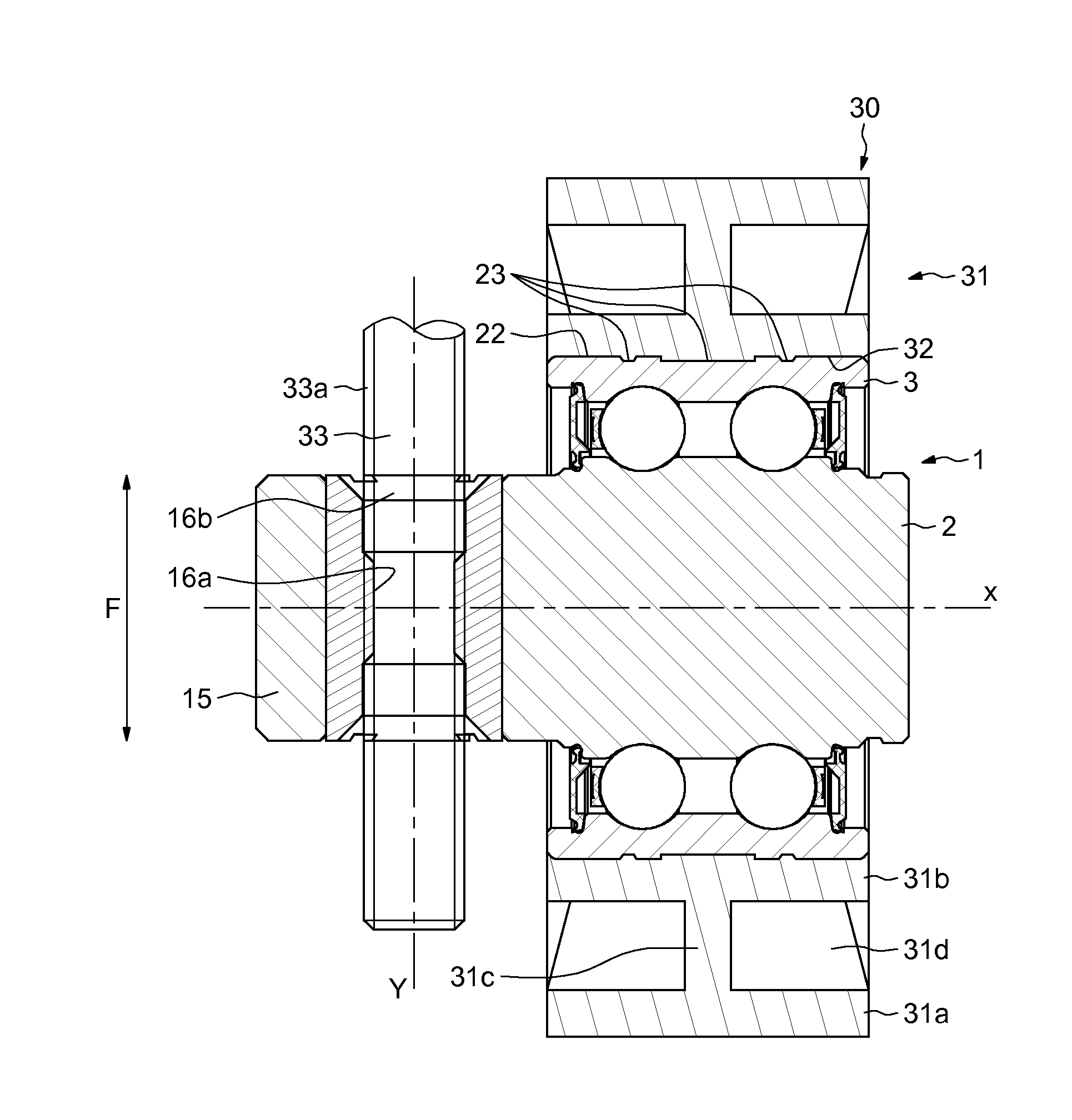

Fluid dynamic bearing apparatus, spindle motor, and disk drive apparatus

ActiveUS20120063030A1Prevent leakageImprove perpendicularityShaftsRecord information storageEngineeringAir bubble

In a fluid dynamic bearing apparatus, an oil buffer is defined between a thrust gap and a pumping gap. The oil buffer has an axial dimension greater than that of the thrust gap, and / or has a radial dimension greater than that of the pumping gap. An air bubble generated in the thrust gap due to cavitation, for example, when a fluid dynamic bearing apparatus experiences a vibration can be dissolved in lubricating oil provided within the oil buffer. This prevents leakage of the lubricating oil due to the air bubble residing in the fluid dynamic bearing apparatus.

Owner:SEAGATE TECH LLC +1

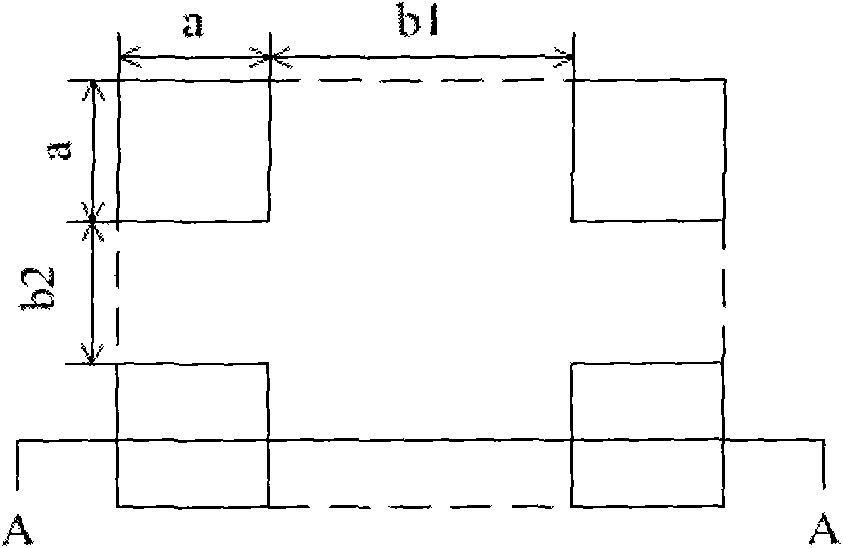

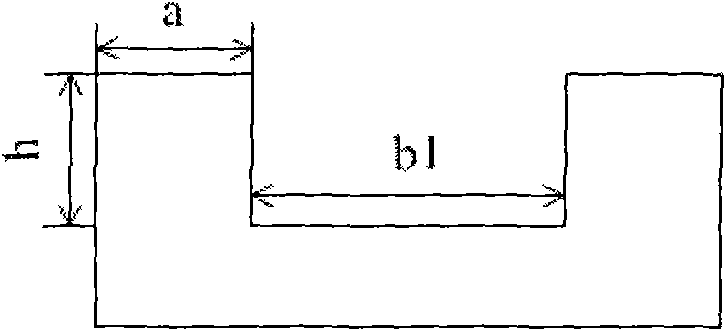

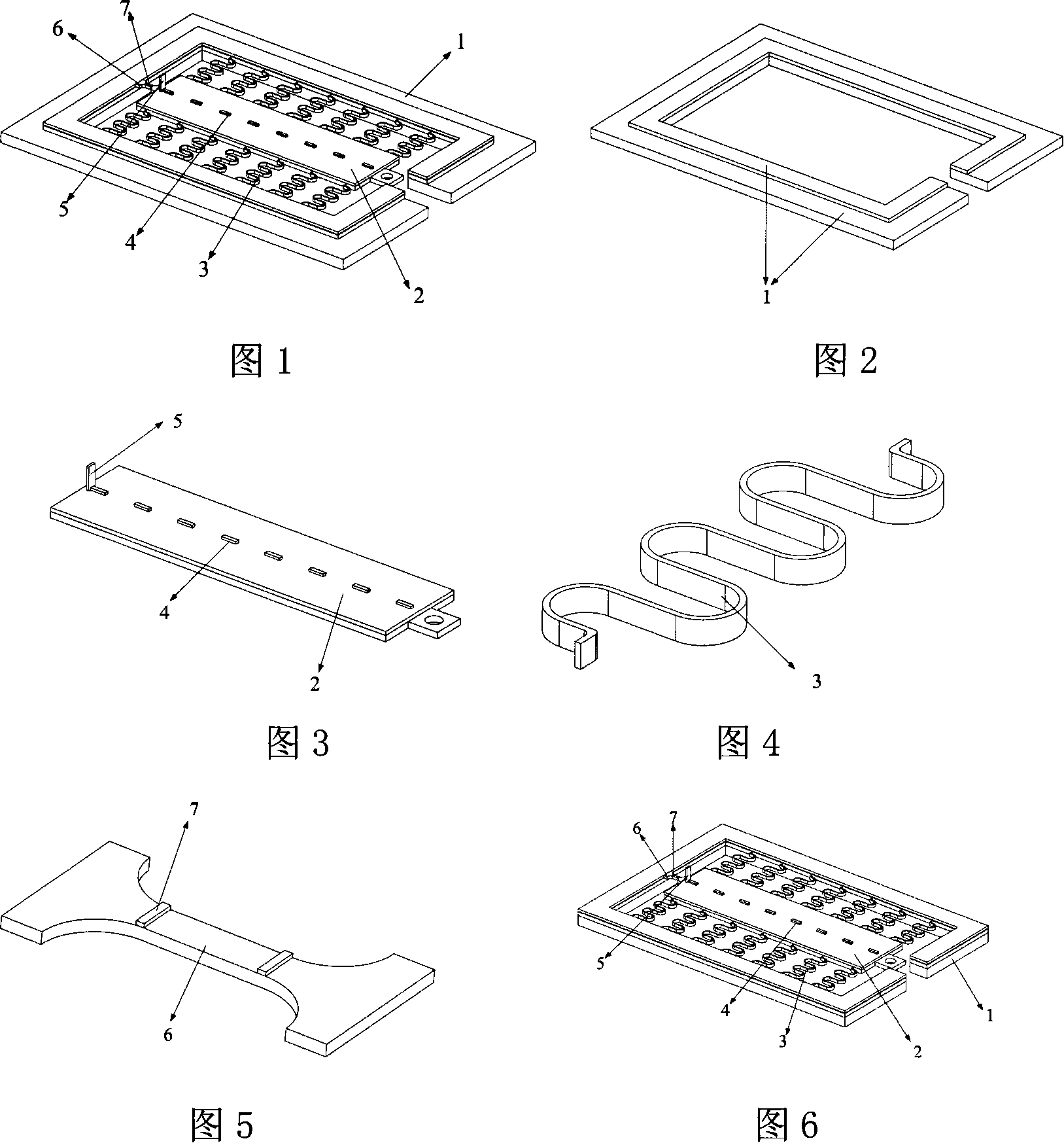

Uniaxial micro-tensile test piece for thin film mechanical performance test

InactiveCN101149317AEasy assemblyImprove verticalitySurface/boundary effectStrength propertiesEngineeringPlastic property

The single -shaft micro tensile test piece to test the film dynamic performance includes the U shpe supporting platform, movable platform, the snake supporting spring, centring marker, displacement marker. The snake supporting spring is connected with the U shape supporting platform and movable platform; the U shape supporting platform and movable platform are connected with two suspended ends of the film sample; the centring marker is on the top of the movable platform; the displacement marker is pasted to the tail to movable platform and near to the film sample. Compared to the present test piece, the process is available, it has good repeatability and high yield; also it has avoided the test error generated by the supporting girder deformation in tension process. The test piece of invention is proper for the film micro dynamic performance test of single metal, alloy and compound material.

Owner:SHANGHAI JIAO TONG UNIV

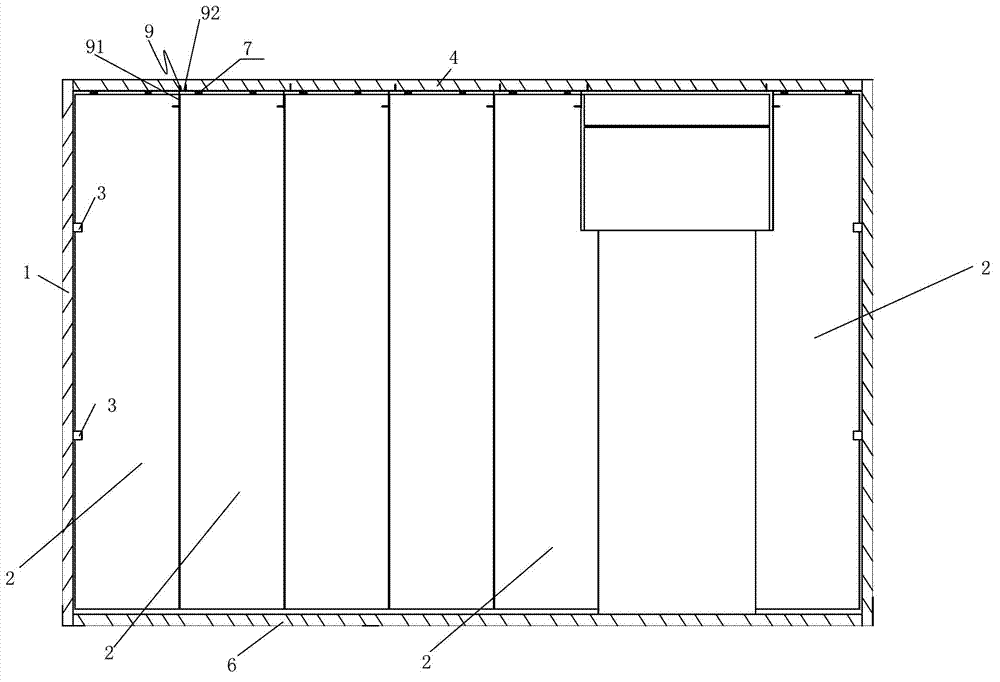

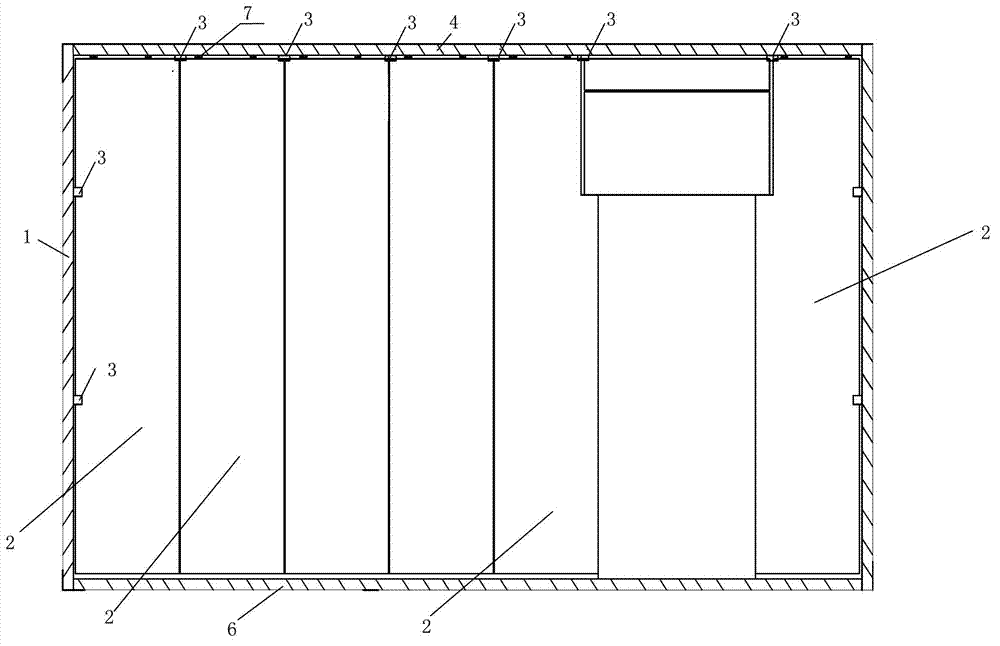

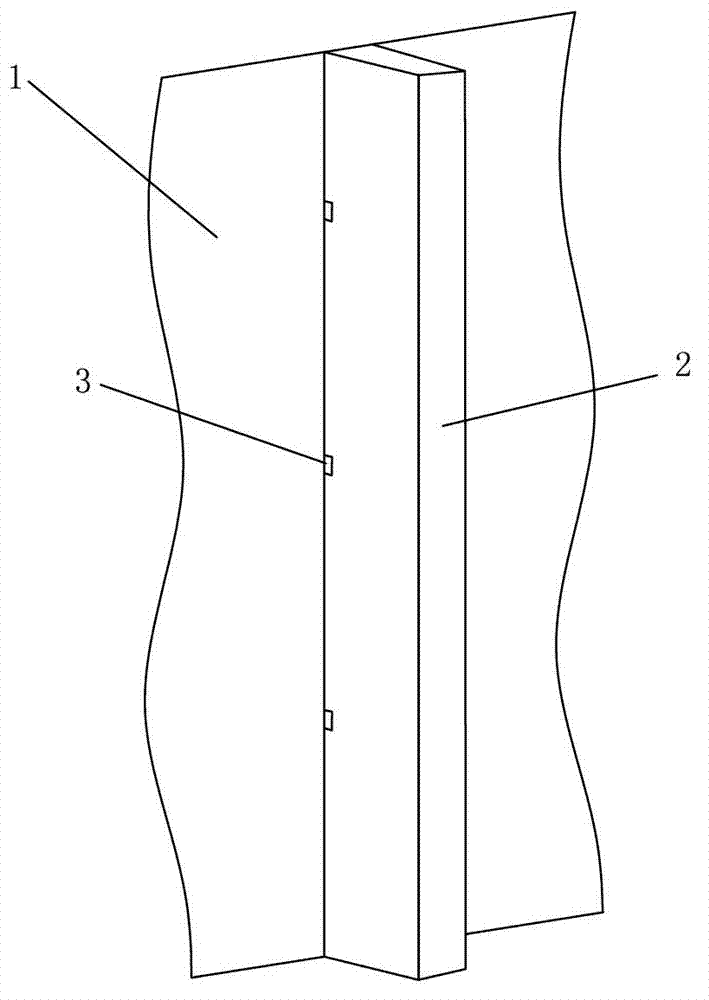

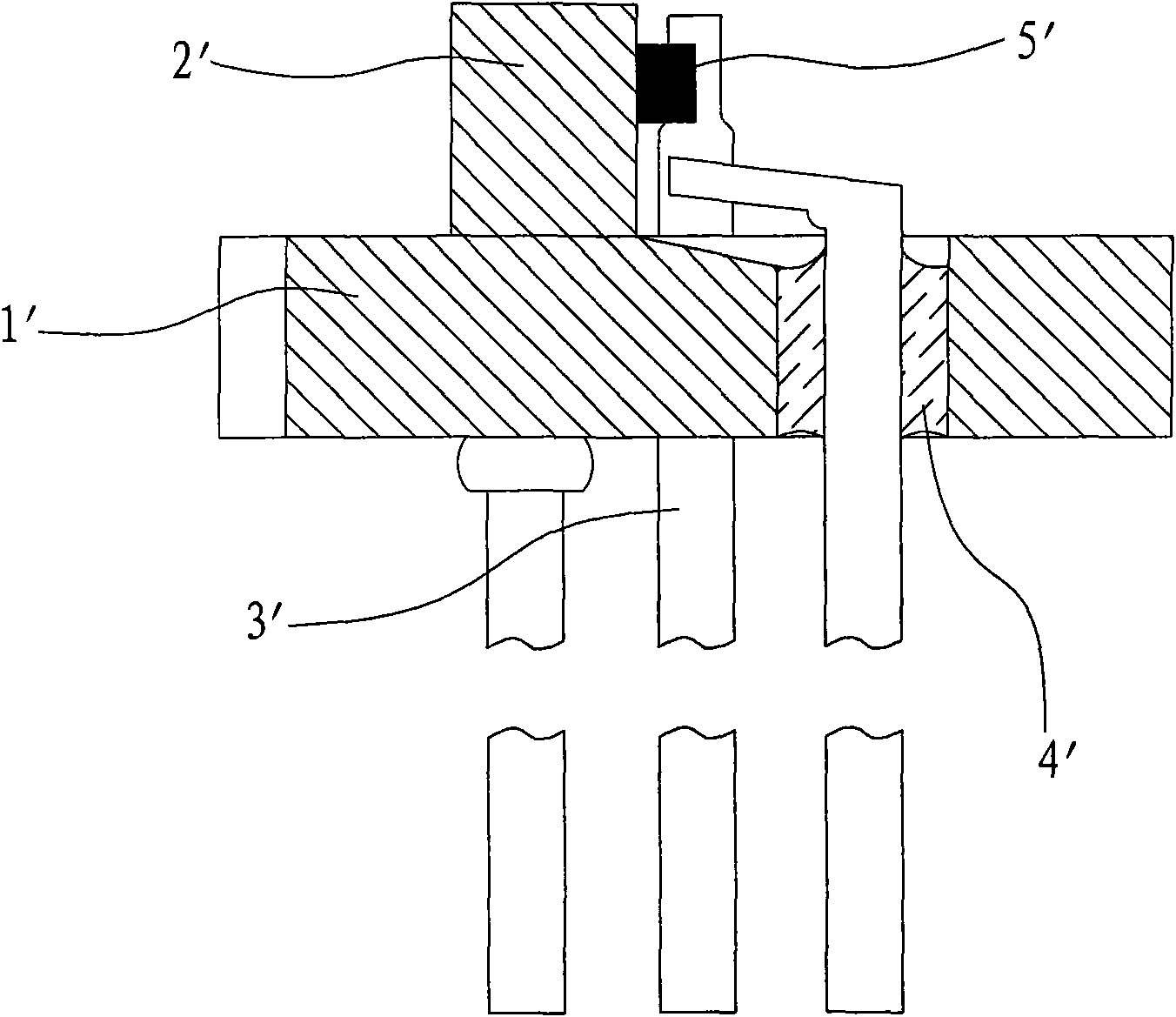

Installation technology of inner separation wall body

InactiveCN102777041ARapid positioningGuaranteed flatnessWallsBuilding material handlingStructural engineeringEngineering

Owner:中山建华墙体材料有限公司

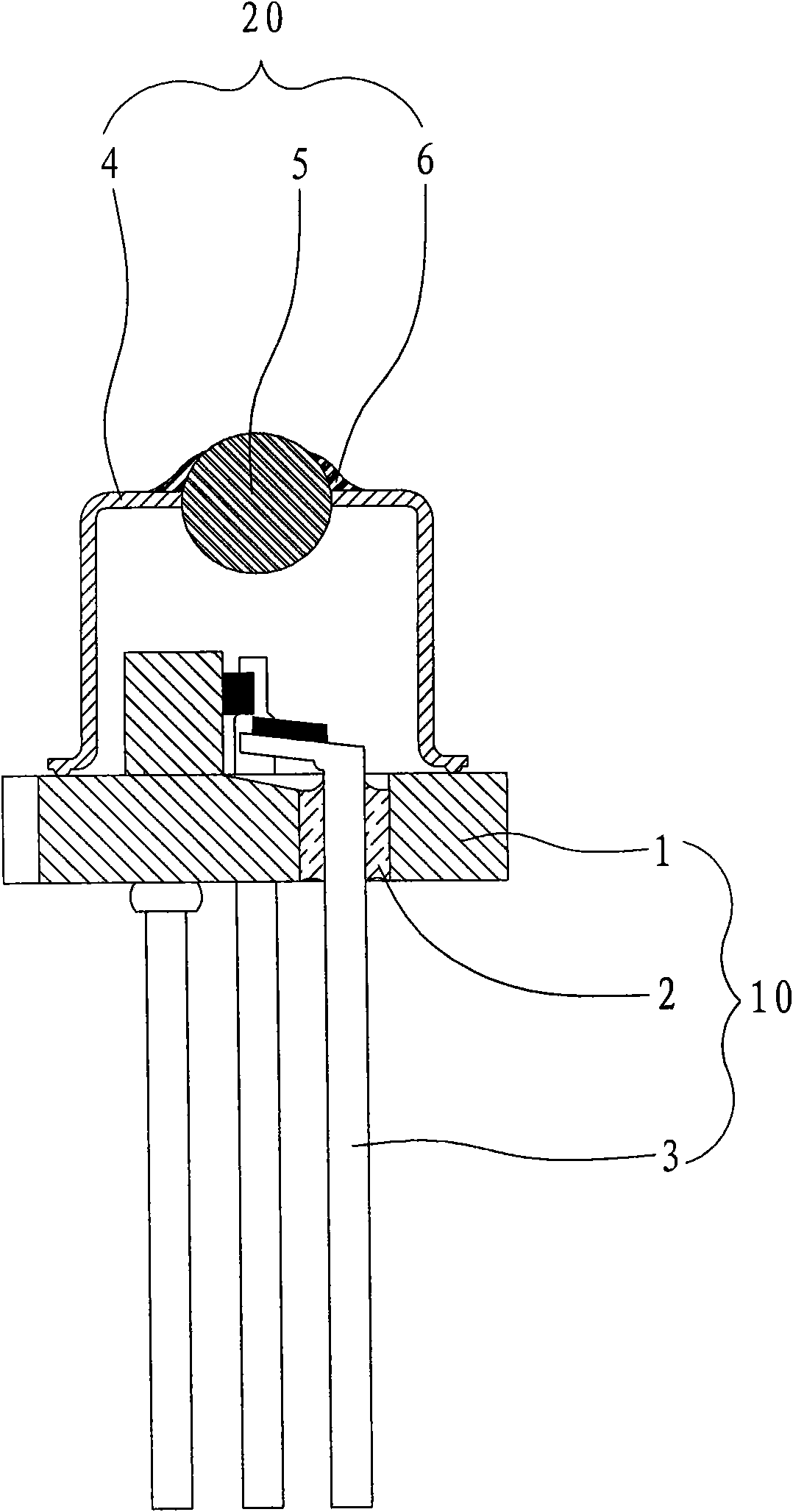

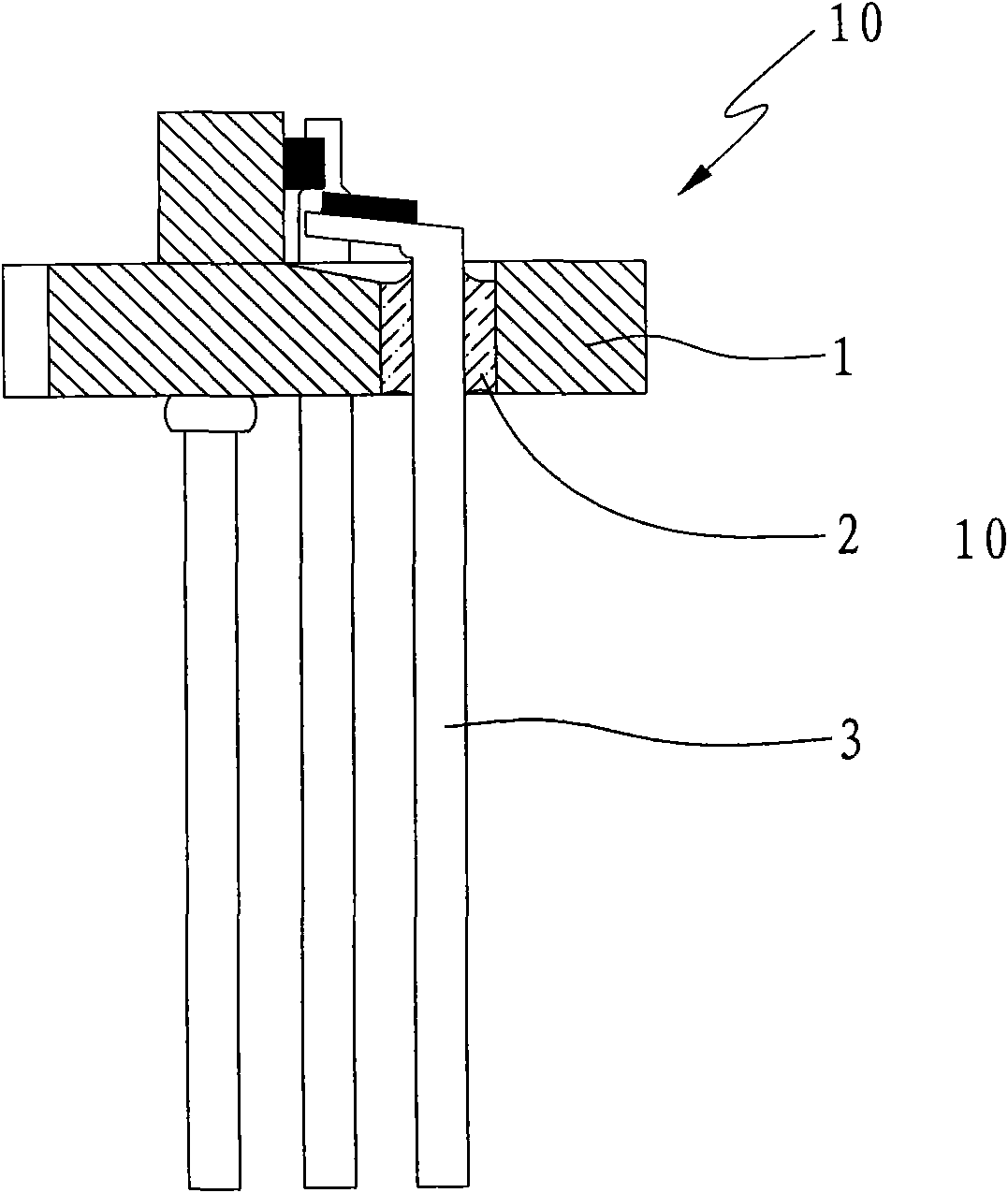

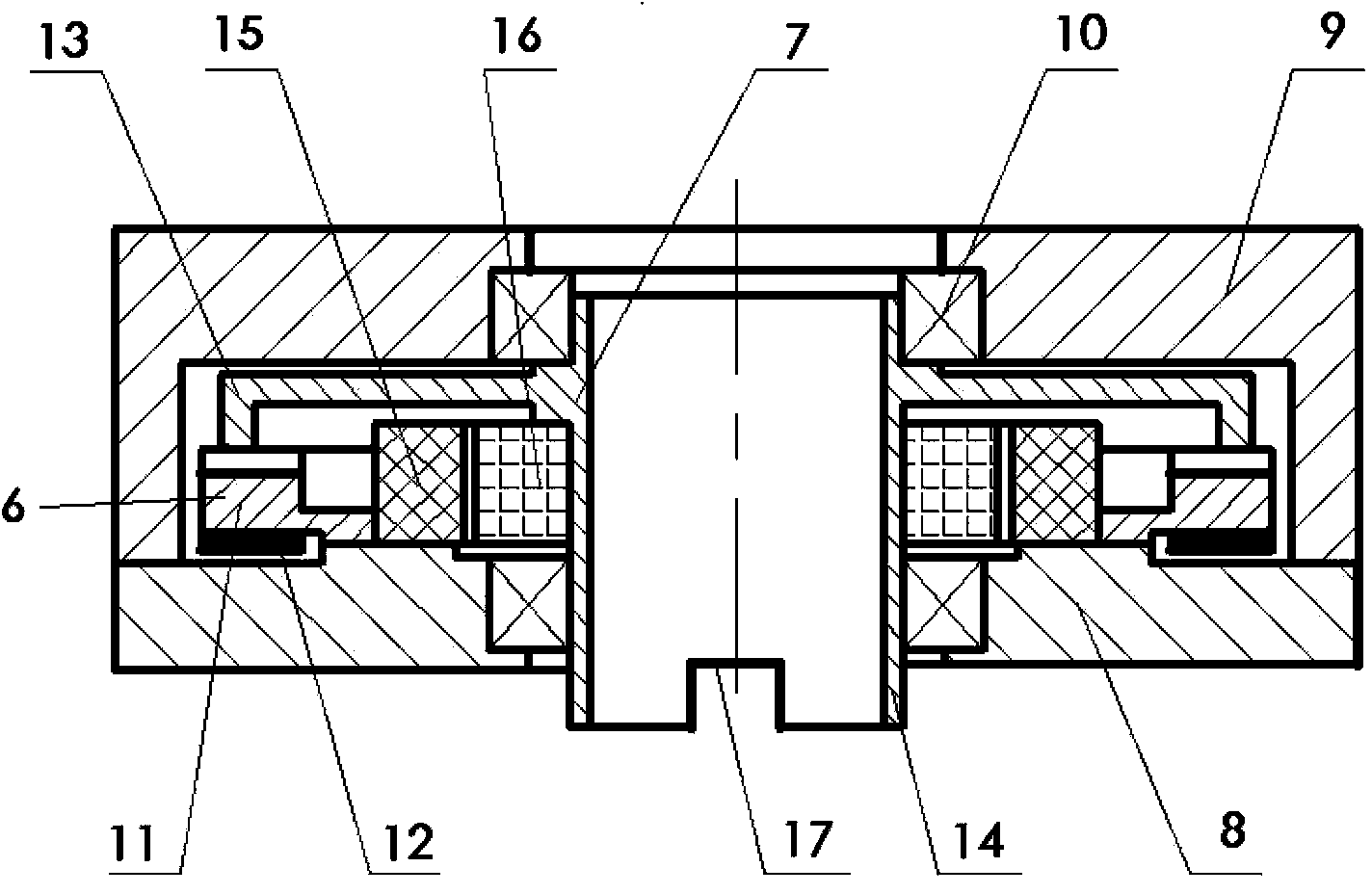

Preparation method of laser diode packaging case

InactiveCN101888057AHigh positioning machining accuracyImprove verticalityLaser detailsSemiconductor lasersEngineeringElectroplating

The invention discloses a preparation method of a laser diode packaging case, which comprises the following steps of: cleaning before sintering, and sintering, fusing and sealing a diode seat; fixing the form of a product; electroplating, and pretreating a diode cap for sintering; sintering, fusing and sealing a diode cap, and plating the bell-shaped round metal case; and assembling the diode cap and the diode seat to form the laser diode packaging case, and the like. Because a bottom plate is processed by adopting a powder metallurgy injection forming mode, the accuracy and the positioning of a metal boss on the bottom plate can be strictly controlled by adopting the casting insert polishing technology in powder metallurgy, and mass production can be realized without die trimming. The positioning processing accuracy, the verticality and the glossiness of the centre line of the metal boss on the bottom plate from the metal bottom plate are high, and the requirements of the product can be met completely.

Owner:湖北讯科光电封装技术有限公司

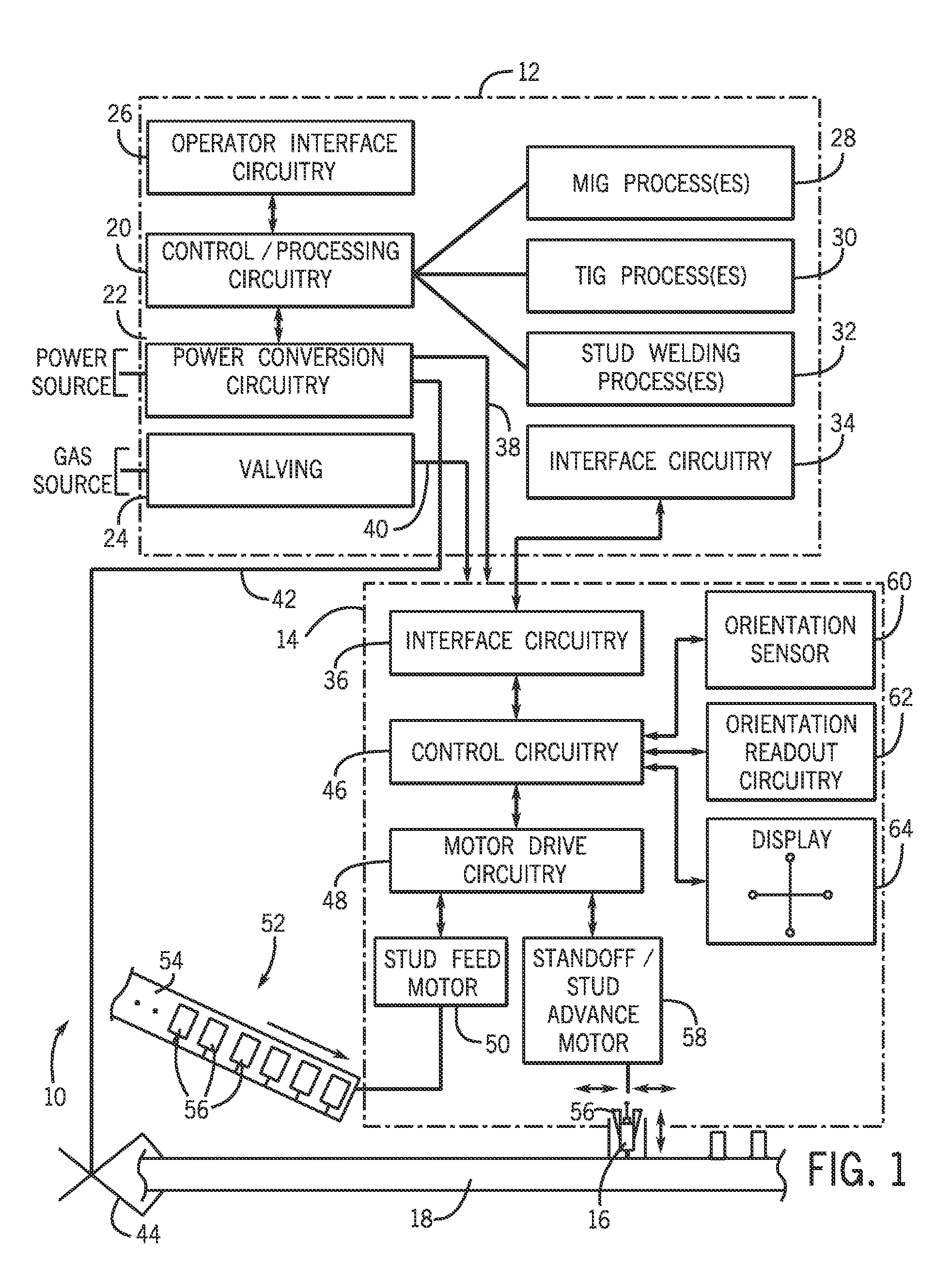

Stud welding system, consumables, and method

ActiveUS20130015163A1Reduce weight and sizeImprove verticalityArc welding apparatusWelding/cutting media/materialsStud weldingEngineering

A stud welding process may be performed by a power supply that is adapted for other welding processes, such as MIG, TIG, and so forth. A stud welding gun may receive studs preloaded in a magazine or other support. Studs are charged into the chuck of a stud welding gun and positioned where desired over a surface. An extension, such as a wire-type electrode may extend from the stud and aid in establishing the welding arc. The stud may be shielded by a nozzle or other shield to obviate the need for ceramic ferrules. Orientation of the stud welding gun may be detected, displayed and used as a basis for initiating and completing the stud welding process once the gun and / or stud is properly positioned.

Owner:ILLINOIS TOOL WORKS INC

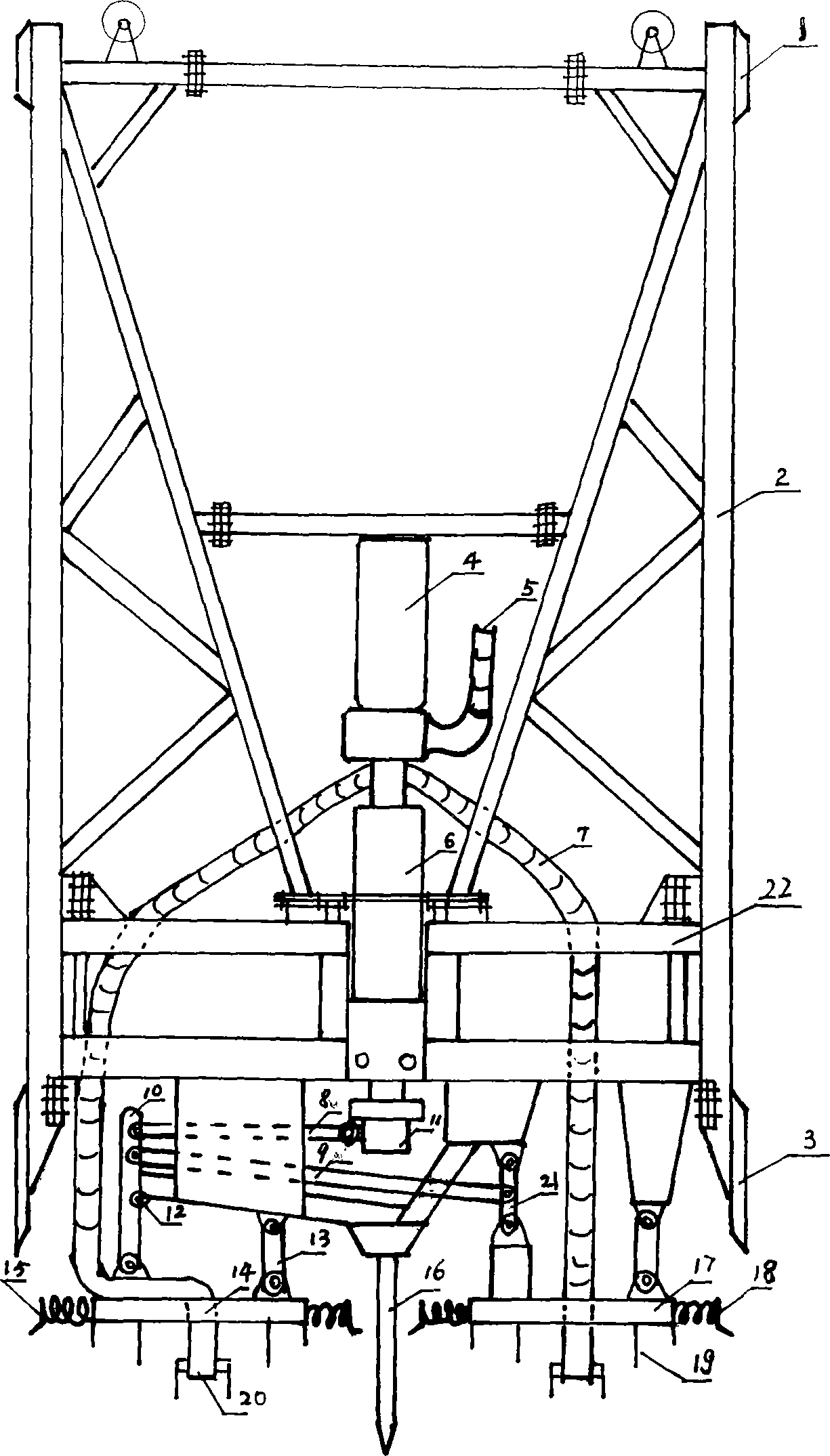

Saw grooving machine

InactiveCN101074564ALow costImprove efficiencySoil-shifting machines/dredgersSlurry wallElectric machine

The invention discloses an under ground continuous saw notching machine which includes the horizontal frame, the leader with vertical two sides, the diving electric engine in the frame center, the diving sandstone pump. The special part is: the blower of the diving electric machine is set with the brace which is set with the cutter arbor A and B on two sides, the brace is connected with the connecting rod A which is connected with rocker A which the end is connected with the cutter arbor A; the upper of the rocker A is connected to the connecting B which is connected with the rocker B which the end is hinged with cutter arbor B. it can be used in building the dyke cut-seep wall in river, reservoir and the lake and the underground continuous wall of building, port, dock, subway and the underground station.

Owner:李辉

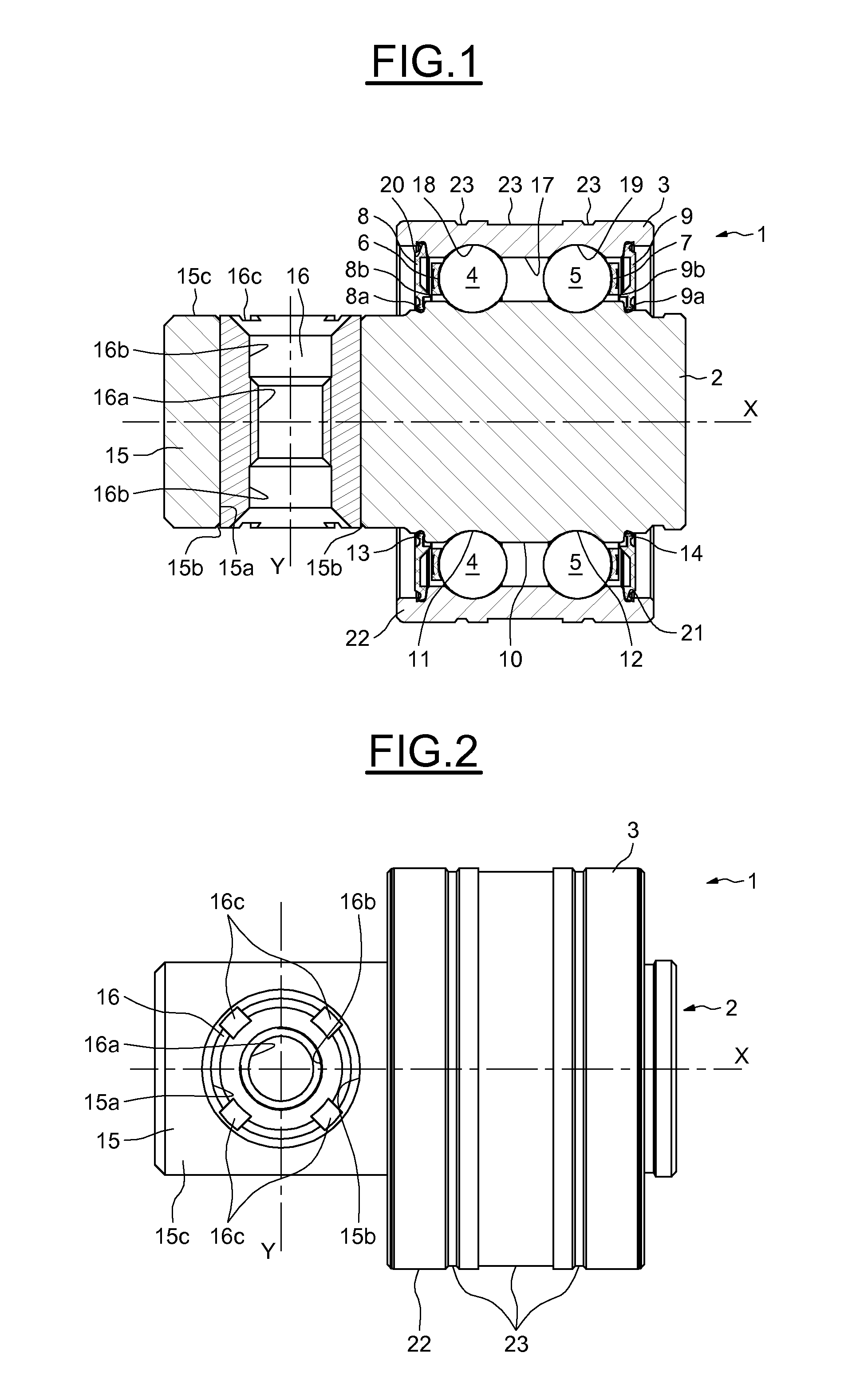

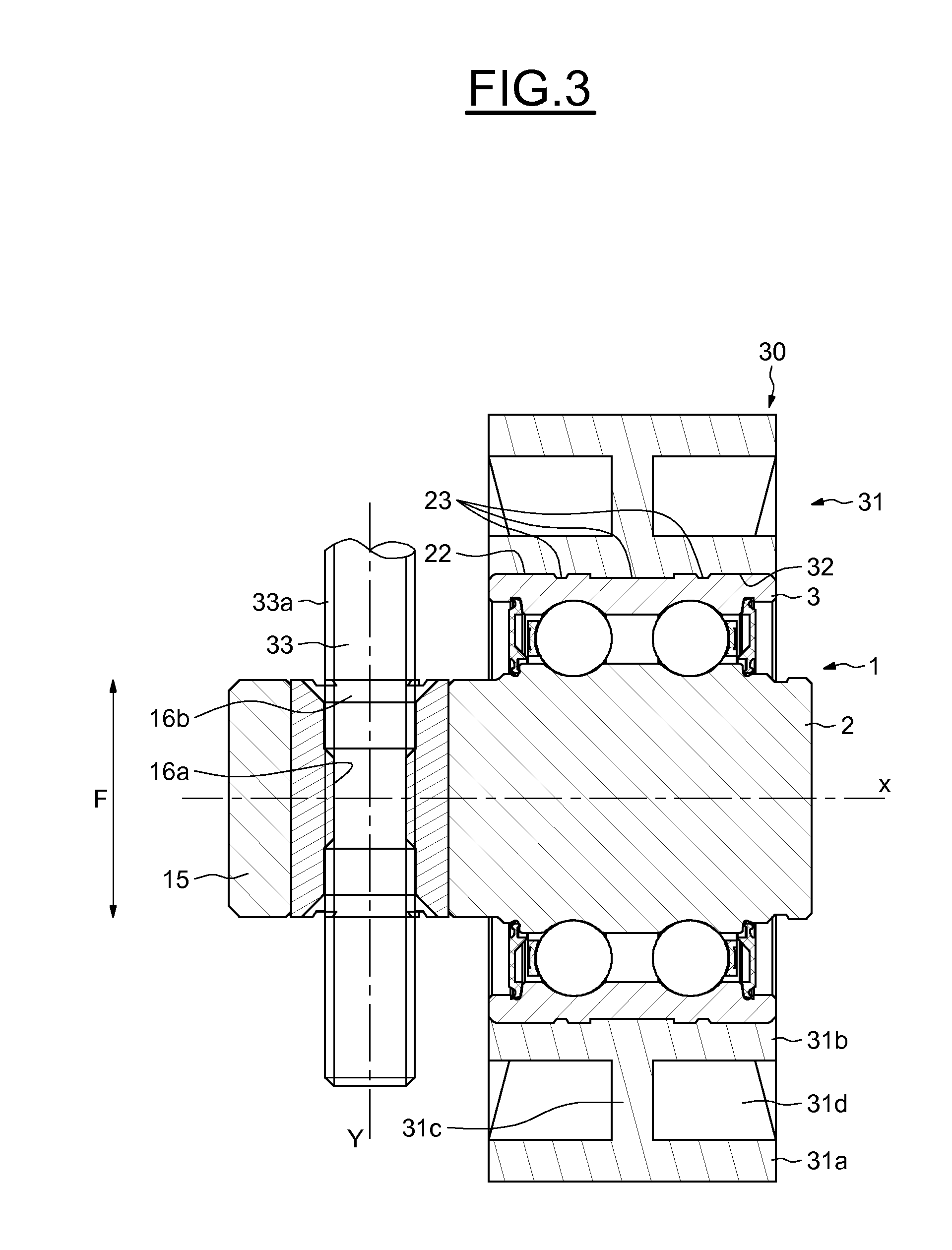

Rolling bearing for tensioning roller device and associated tensioning roller

InactiveUS20120142468A1Easy to processEasy to assembleGearingShaftsRolling-element bearingEngineering

Owner:AB SKF

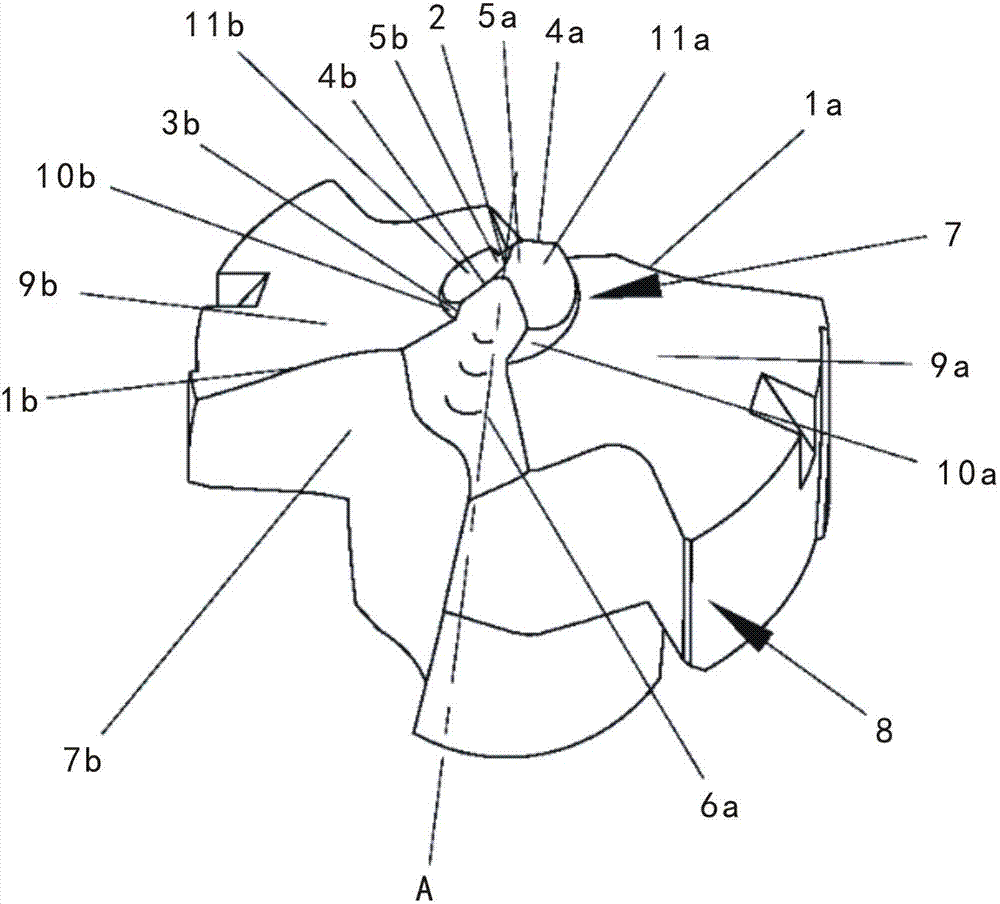

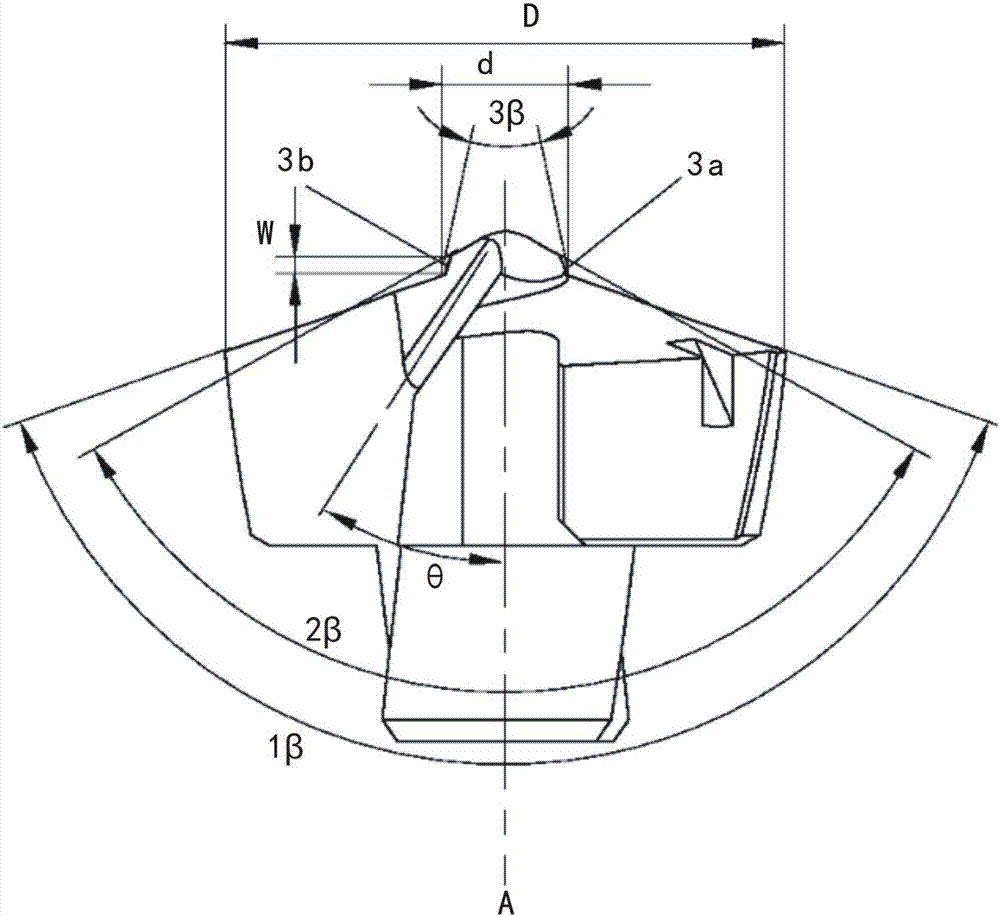

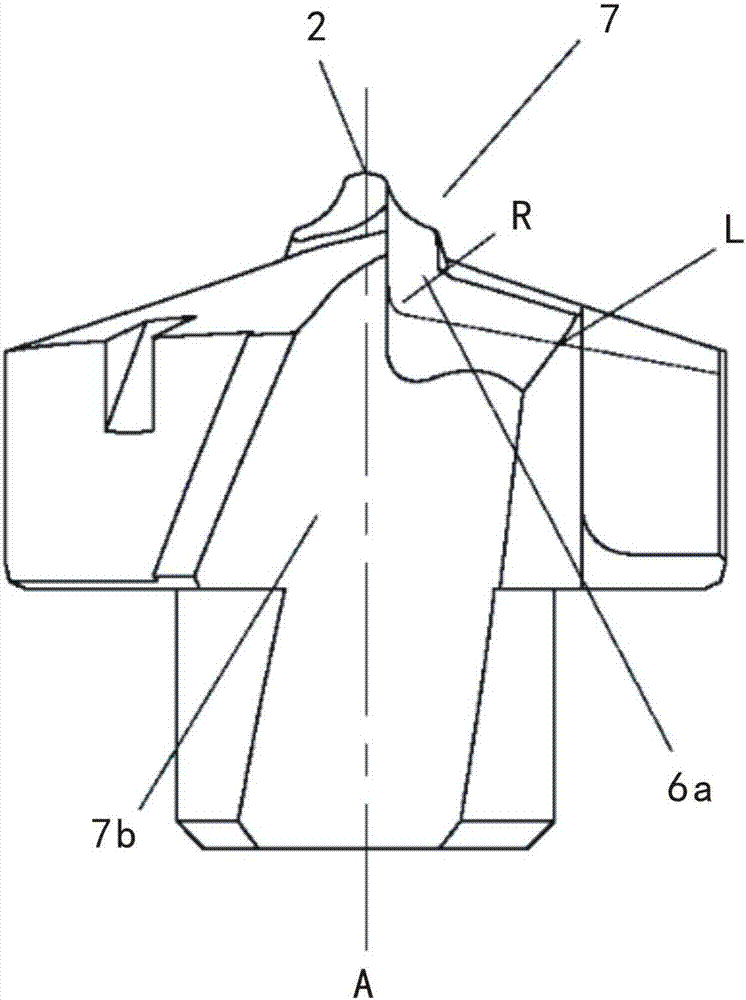

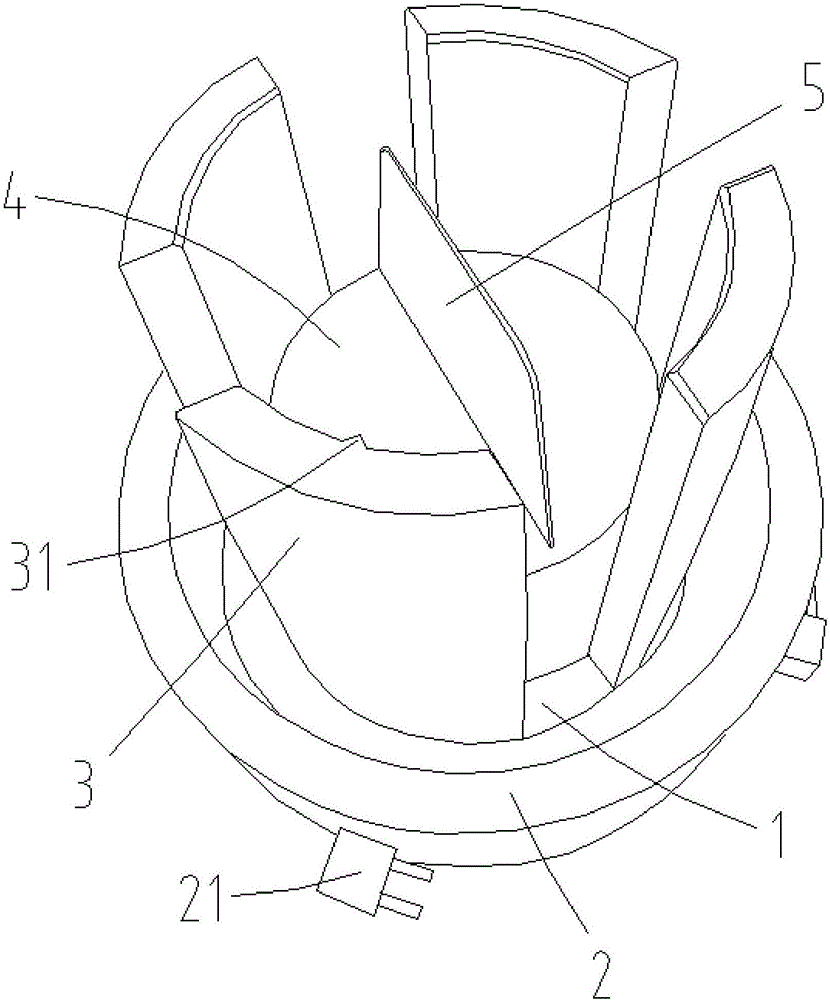

High-stability self-centering drill bit

ActiveCN107081457APrecise positioningAvoid Radial WobbleTransportation and packagingTrepanning drillsEdge surfaceEngineering

The invention discloses a high-stability self-centering drill bit. The two sides of high-stability self-centering drill bit are symmetrically provided with two chip discharge grooves, the tip of the drill bit faces upward, the center portion of the drill bit protrudes upward along the center line of the drill bit to form a central bit part, the surfaces, located outside the two sides of the central bit parts, of the upper portion of the drill bit refer to outside rear tool surfaces, the top of the central bit part is a linear chisel edge, the two sides of the chisel edge extends outward and downward to form two chisel edge surfaces, two inside rear tool surfaces and two inclined rear tool surfaces, two transition surfaces are formed between the two ends of the chisel edge and the two chip discharge grooves, the outsides of the two ends of the chisel edge are sequentially connected with two inside blades, two inclined blades and two outside blades, and the inclined blades are formed through interconnection of a straight-line blade in the middle and arc line blades at the two ends. By arranging the central bit part and arranging the chisel edge, the inside blades, the inclined blades, the chisel edge surfaces, the inside rear tool surfaces and the inclined rear tool surfaces, the positioning effect of the drill bit is significantly improved, pre-drilling is not needed, drilling can be directly conducted, and deep hole processing can be efficiently completed.

Owner:CHENGDU FENGYI YINHU CNC TOOL CO LTD

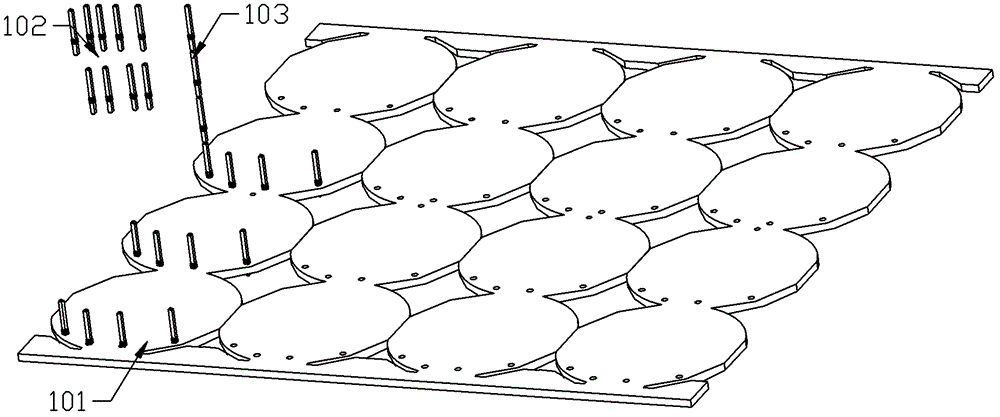

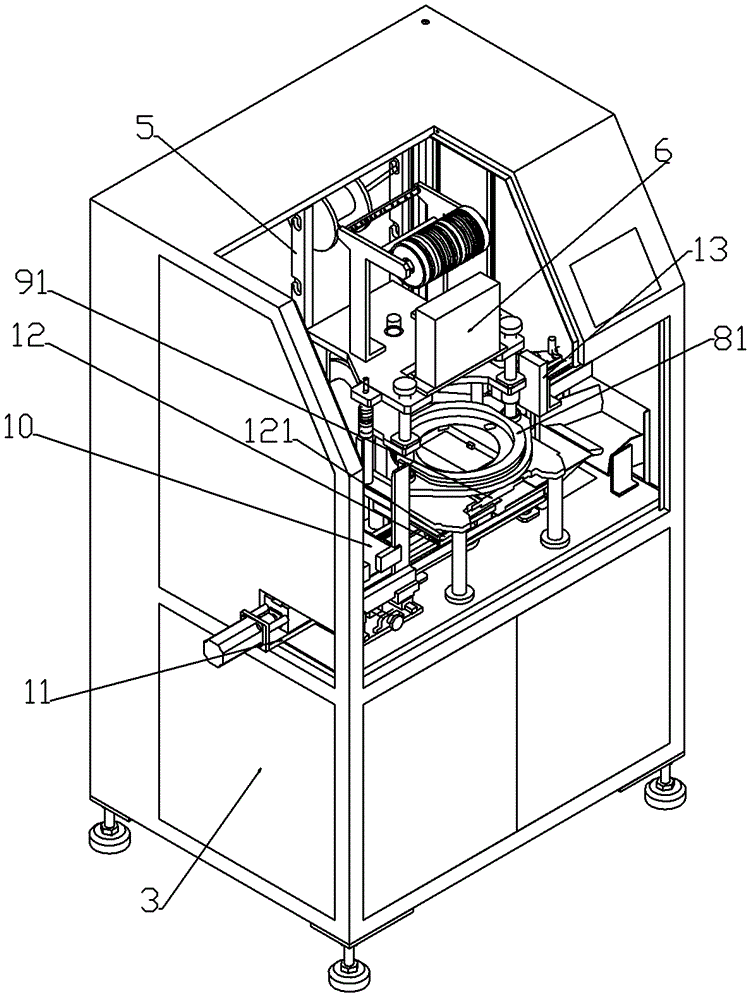

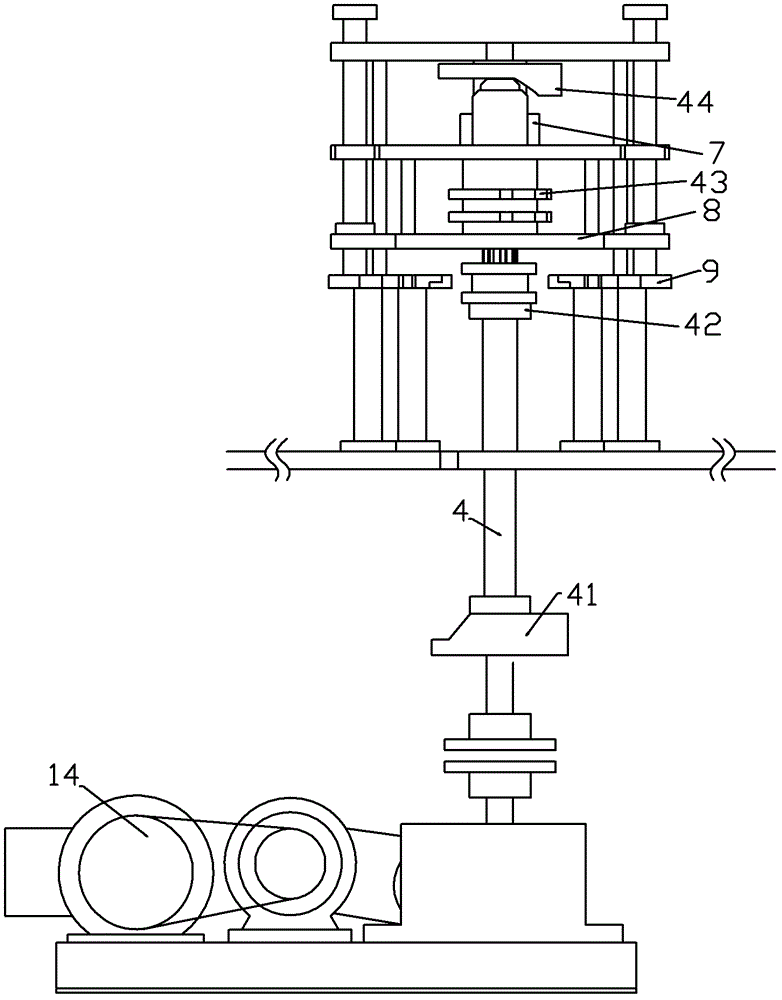

Automatic pin machine of PCB board

ActiveCN102724816AAccelerateIncrease productionPrinted circuit assemblingCutting needleTransmission system

The invention discloses an automatic pin machine of a PCB board. The automatic pin machine of the PCB board comprises a frame, a power system, a main shaft transmission system, a wire rod clamping relaxing module, a cutting needle module, a plate putting warehouse, a numerical control division plate system, a numerical control shift plate positioning system and an automatic material returning system. The automatic pin machine of the PCB board possesses a completely automatic production function which comprises that: the automatic division plate, the automatic shift plate, the automatic positioning and automatic plate returning can be achieved; a main shaft transmission mechanism drives the machine to automatically clamp a wire, send the wire and be cut off after automatic insertion. A plurality of pins are simultaneously inserted at once. A speed is fast, an output is high, cost is low and pin efficiency is high. In addition, the pins have a same length during a pin process. Verticality of the pins is good and pin quality is high, which provides a solid foundation for a subsequent automatic production technology. The wire rod used by the pin machine is a whole roll of steel wire which is automatically cut into the pins through the machine so that secondary processing cost of processing the wire rod into the pins can be saved. The raw material cost can be substantially reduced.

Owner:颍上县永安塑业有限公司

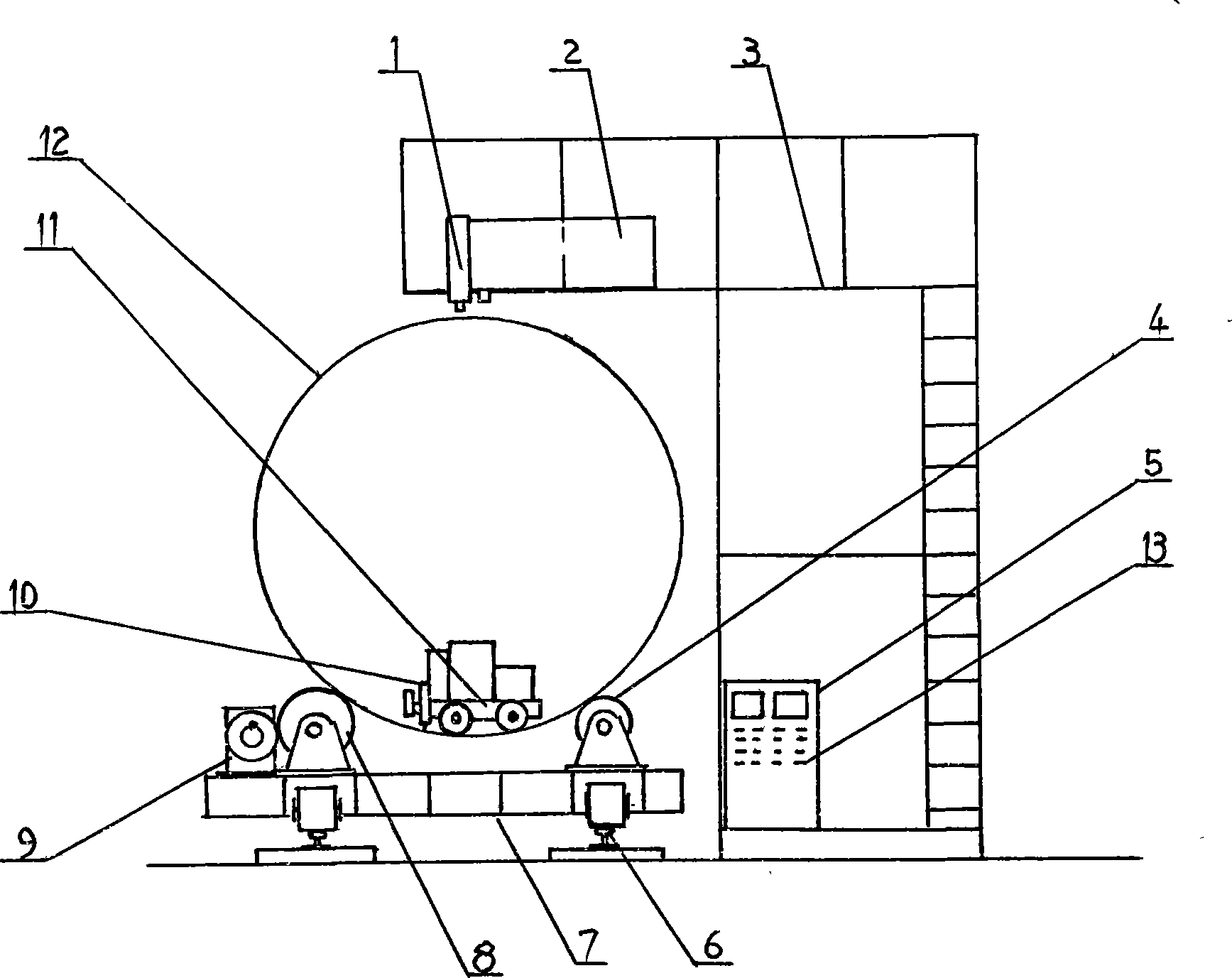

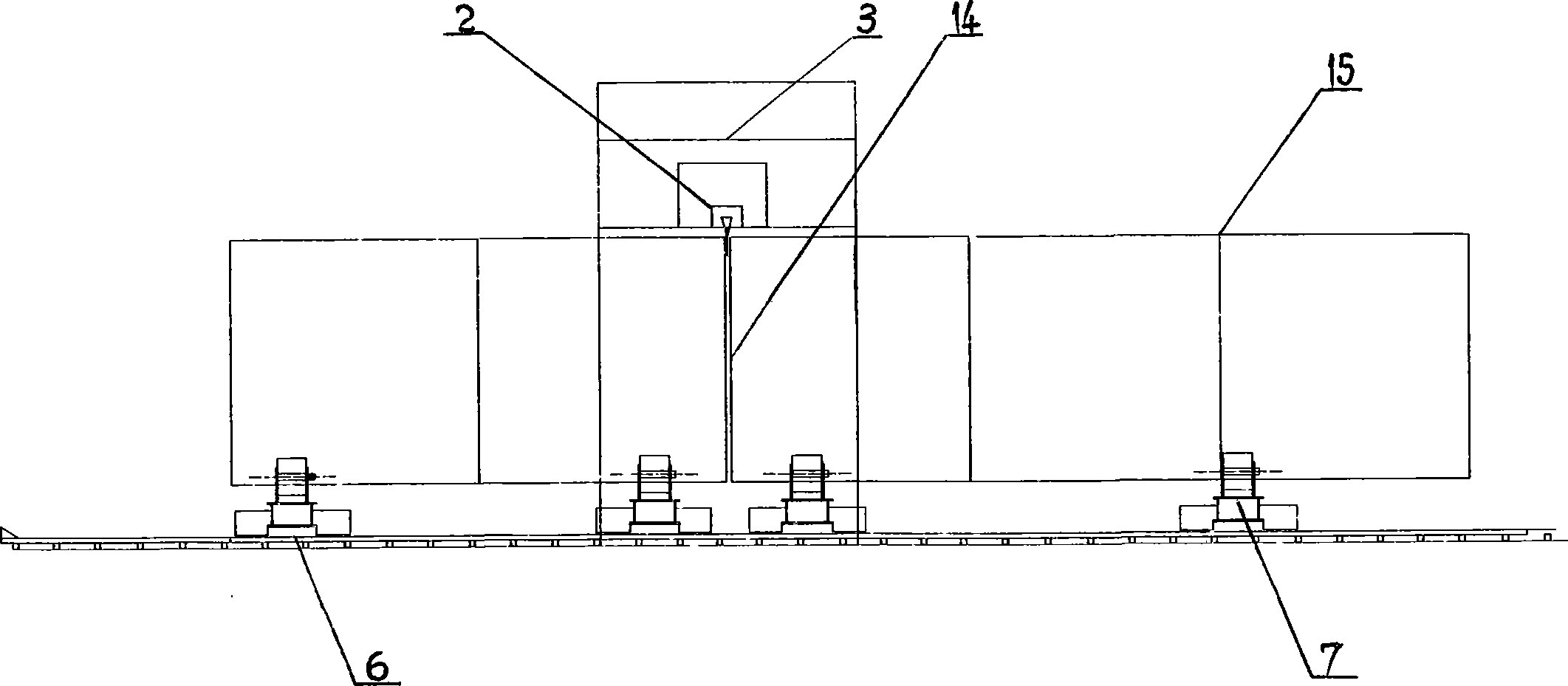

Assembly welding method for producing large diameter extremely thick steel pipes through rotary walking rail and device thereof

InactiveCN103264243AEasy to weldSame smoothnessWelding/cutting auxillary devicesAuxillary welding devicesArchitectural engineeringEnergy conservation

The invention discloses an assembly welding method for producing large diameter extremely thick steel pipes through a rotary walking rail and a device thereof. The assembly welding method for producing the large diameter extremely thick steel pipes through the rotary walking rail comprises paving the rail; arranging a waling flat vehicle on the rail; arranging an operational platform which can be extended to the upper end on the exteriors of the steel pipes to be welded on the rail edge; and arranging an automatic welding machine which is controlled through a computer on the operational platform. The device for producing the large diameter extremely thick steel pipes through the rotary walking rail comprises the computer, the rail, the automatic welding machine, a walking platform, an automatic welding vehicle and the operational platform. The assembly welding method for producing the large diameter extremely thick steel pipes through the rotary walking rail has the advantages of enabling welding of the large diameter extremely thick steel pipes in construction fields to be convenient and good in quality and being feasible and safe. The device for producing the large diameter extremely thick steel pipes through the rotary walking rail has the advantages of being simple and practical in structure, high in construction speed, time and labor saving, low in construction cost, good in construction quality and good in energy conservation and environmental protection effect.

Owner:NO 1 ENG CO LTD OF FHEC OF CCCC

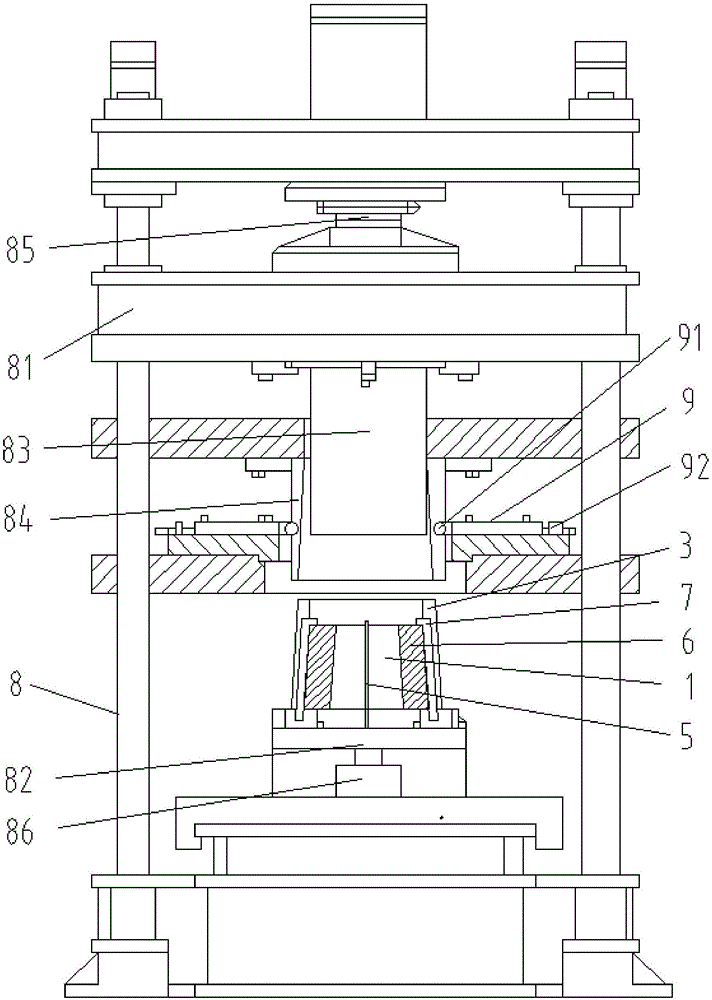

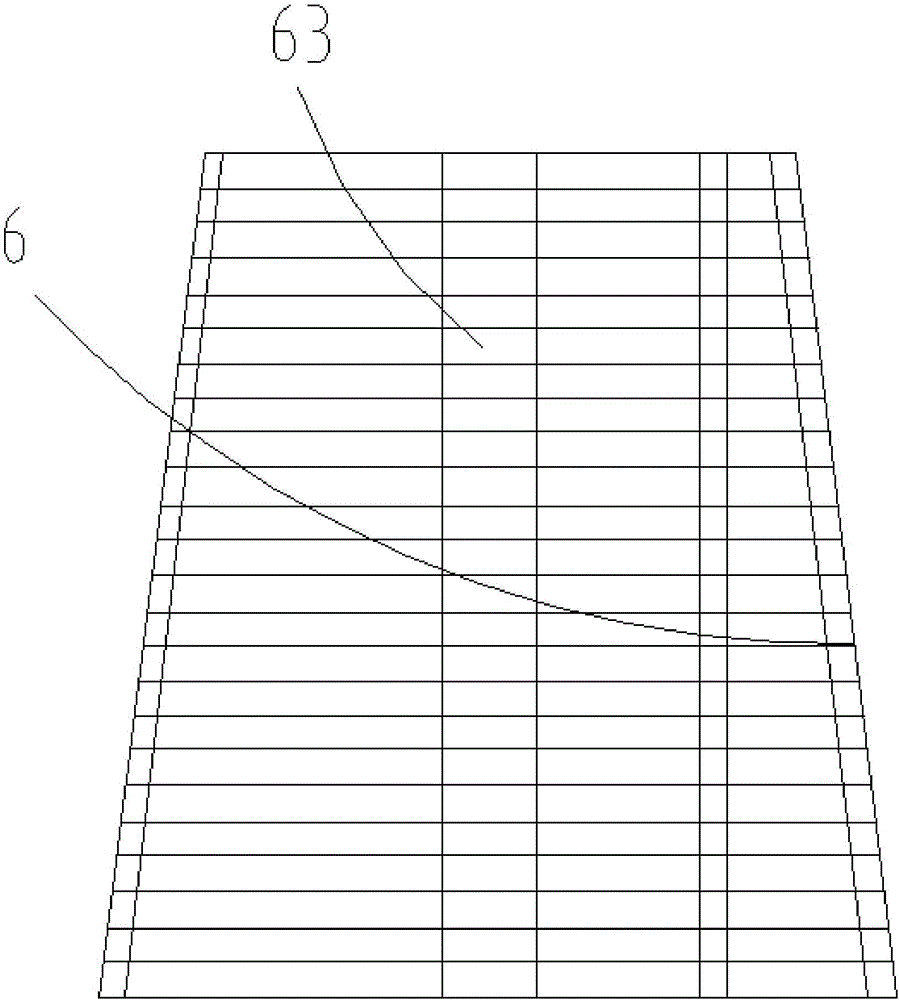

Buckle piece lamination device of conical stator punching sheet

ActiveCN106533079AImprove alignmentEasy alignmentManufacturing stator/rotor bodiesPunchingEngineering

The invention discloses a buckle piece lamination device of a conical stator punching sheet. The buckle piece lamination device comprises a stator punching sheet lamination device, a leveling device and a buckle piece lamination device, wherein an expansion sleeve, lower external cone tools and a stator punching sheet fixing seat are arranged on the stator punching sheet lamination device and are in clearance fit with one another, a trapezoidal plate is fixedly arranged on the stator punching sheet fixing seat and is arranged vertically, inclined surfaces of two sides of the trapezoidal plate can be inserted into two corresponding inner grooves of each stator punching sheet, the leveling device comprises a flattening tool, an upper internal cone tool sleeves the flattening tool, the flattening tool and the upper internal cone tool can downwards press on the stator punching sheet lamination device under the push of a leveling air cylinder, the buckle piece lamination device comprises a roller capable of transversely moving and a roller air cylinder, the roller transversely mover under the driving of the roller air cylinder, and an upper end and a lower end of a buckle piece are respectively bent and are attached onto an upper surface and a lower surface of a conical stator so that the stator punching sheets forming the conical stator can be fixed together. The buckle piece lamination device has the advantages of good perpendicularity in each stator punching sheet, stack compactness, stator inner groove orderliness and high appearance cylindricality.

Owner:安徽金箔机电产业集团股份有限公司

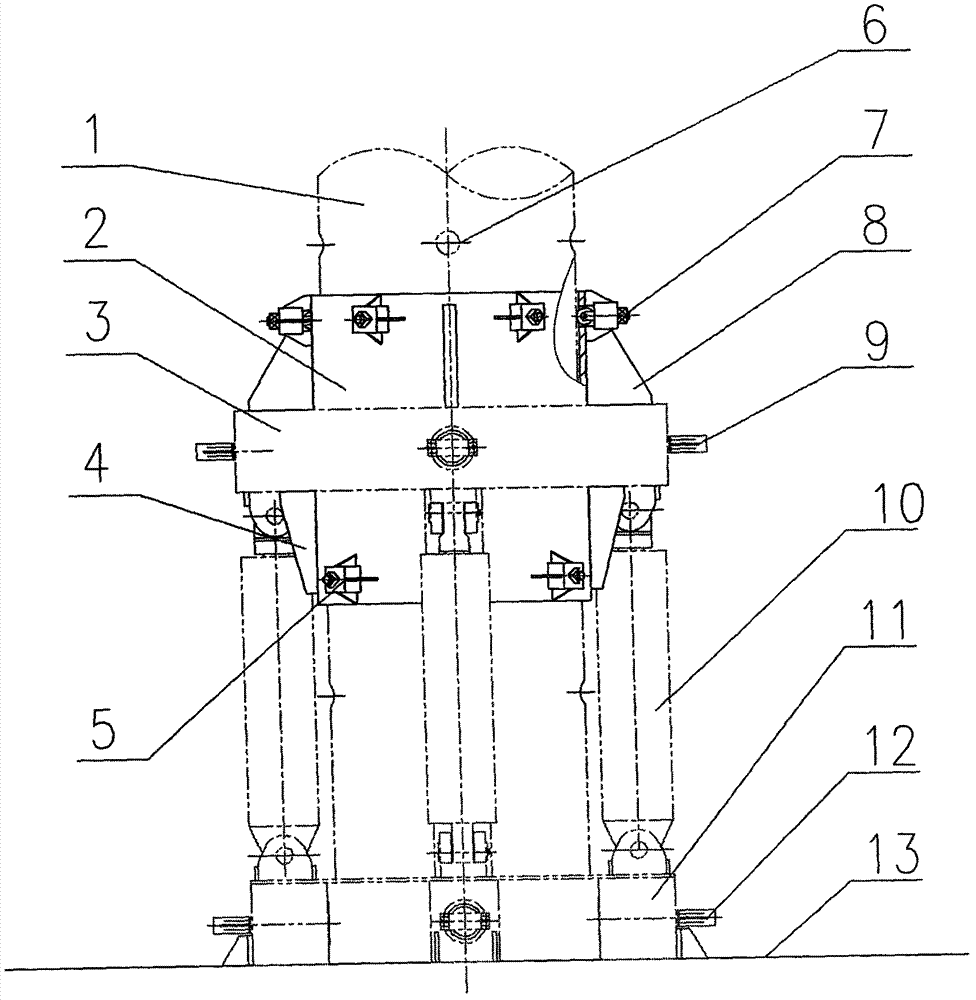

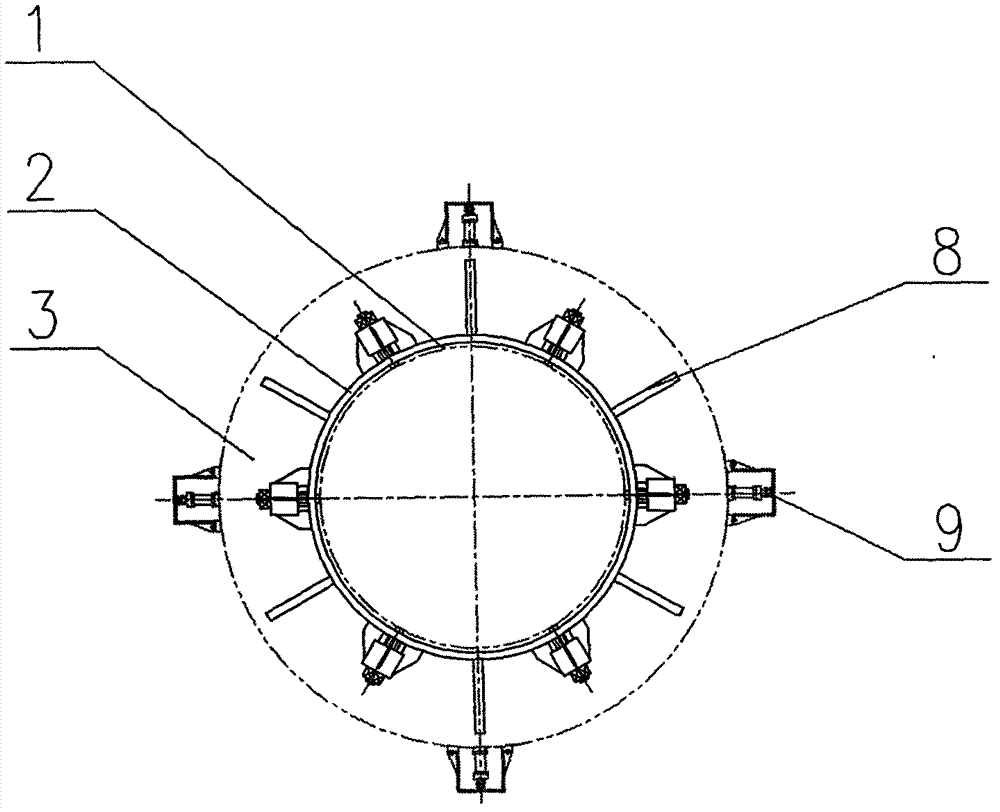

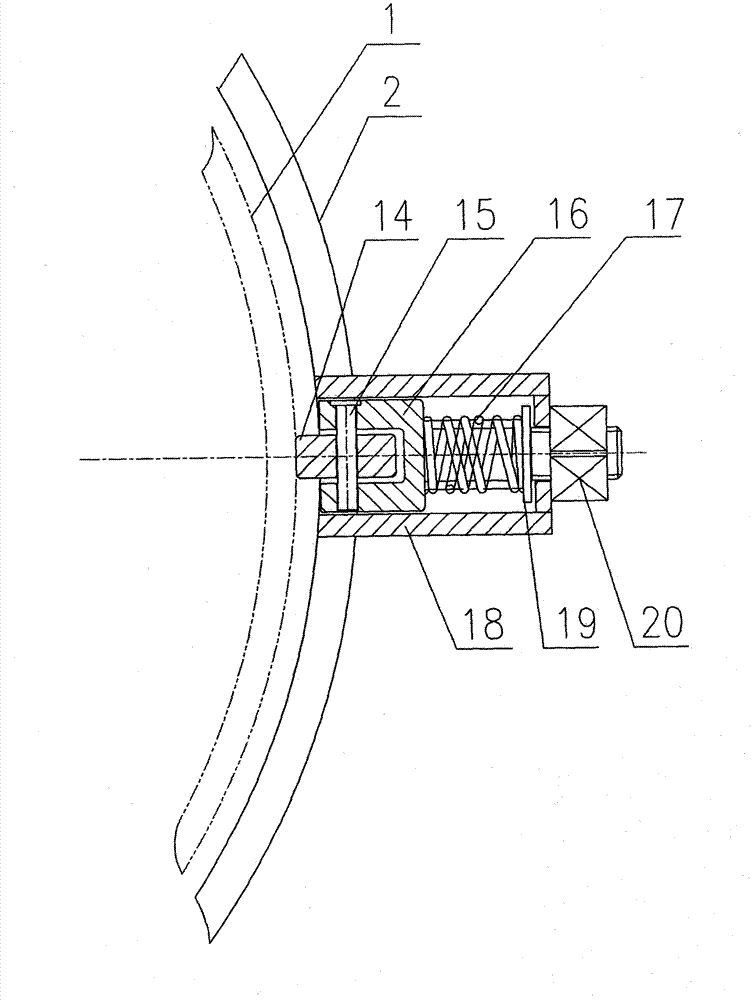

Hydraulic lifting pile righting guide device for offshore jack-up platform

InactiveCN102787590AImprove verticalityStable pressureArtificial islandsUnderwater structuresStructural engineeringPetroleum exploration

A hydraulic lifting pile righting guide device for offshore jack-up platform includes a platform support pile, a platform lifting oil cylinder, a lifting ring girder, upper and lower hydraulic bolts, and a fixed lower ring girder. A righting guide sleeve is fitted outside the platform support pile, the lifting ring girder is fitted outside the righting guide sleeve and fixed with the righting guide sleeve, the fixed lower ring girder is fitted outside the platform support pile, the lifting ring girder and the fixed lower ring girder are connected by the platform lifting oil cylinder, the fixed lower ring girder is fixed on the platform body, matching bolt holes are processed at the platform support pile and the righting guide sleeve, the hydraulic bolts are evenly distributed and mounted at the circumferences of the lifting ring girder and the fixed lower ring girder, and a righting adjustment roller group is mounted outside the righting guide sleeve. As a result, the platform support pile is limited in up-and-down movement and can only operate according to the design requirements of people to therefore reduce inclination of the platform support pile, reduce resistance to pile insertion and pullout and improve working efficiency. The invention falls into the field of design and manufacturing process of jack-up platform lifting systems for exploration and exploitation of offshore oil.

Owner:CHINA PETROCHEMICAL CORP +1

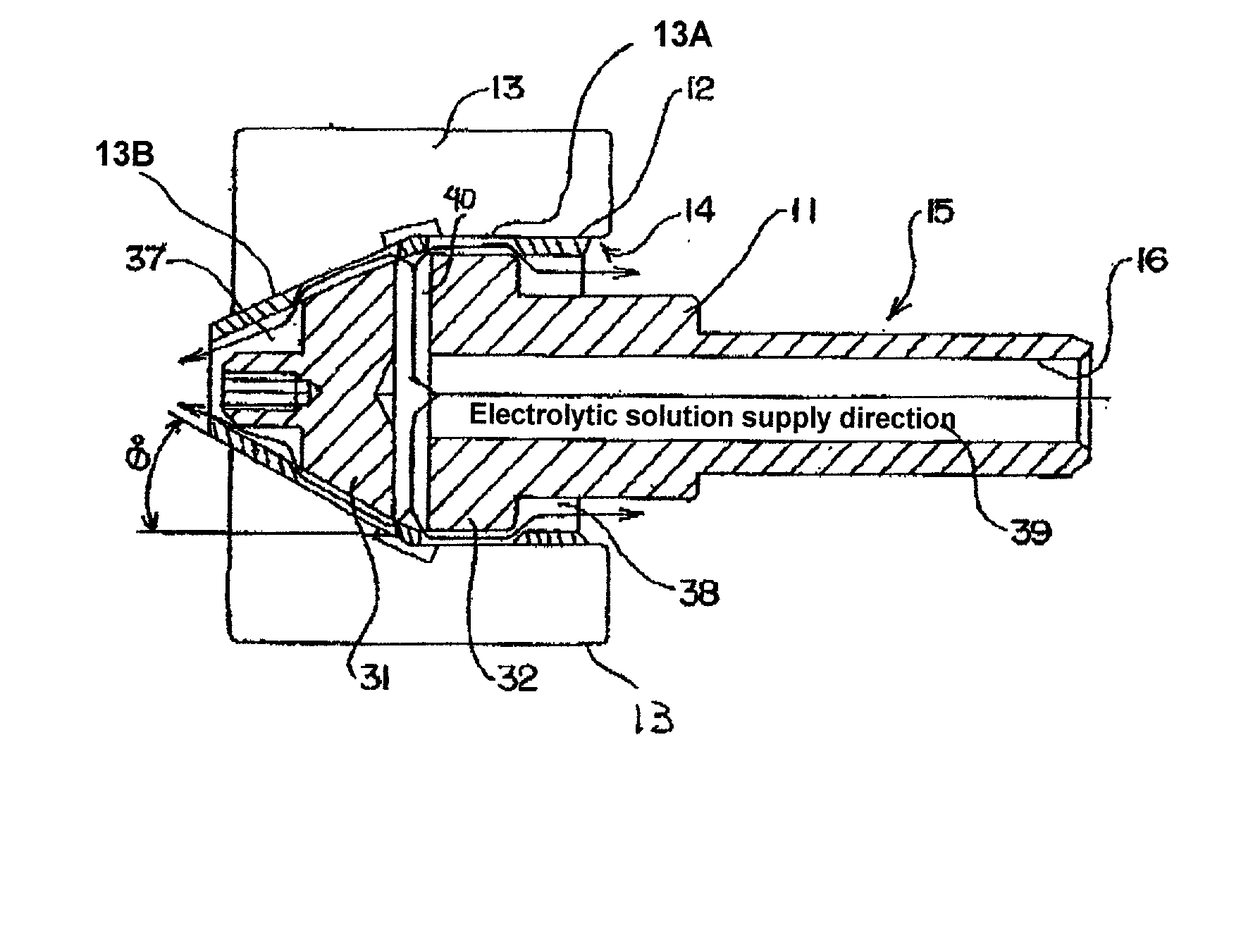

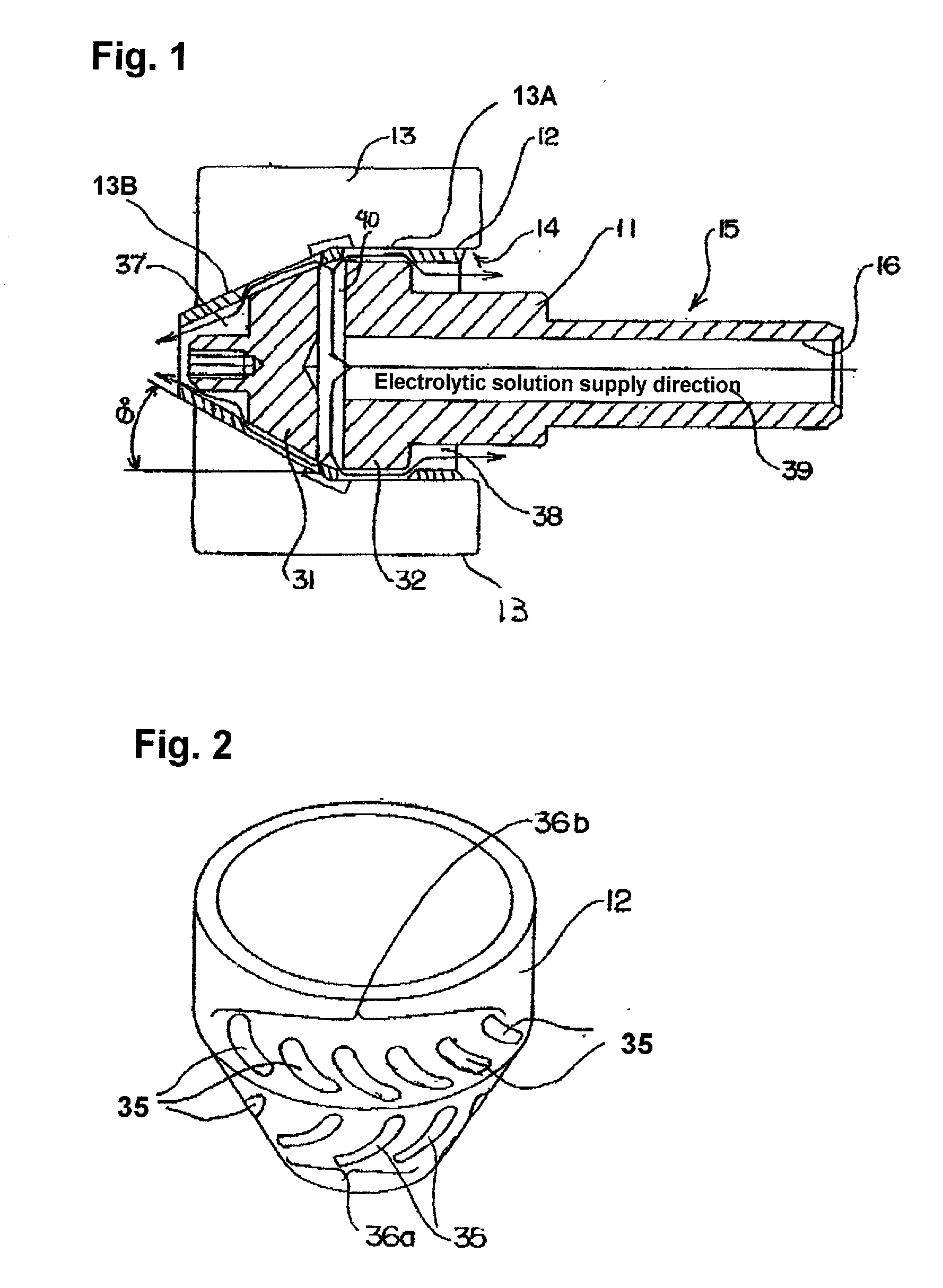

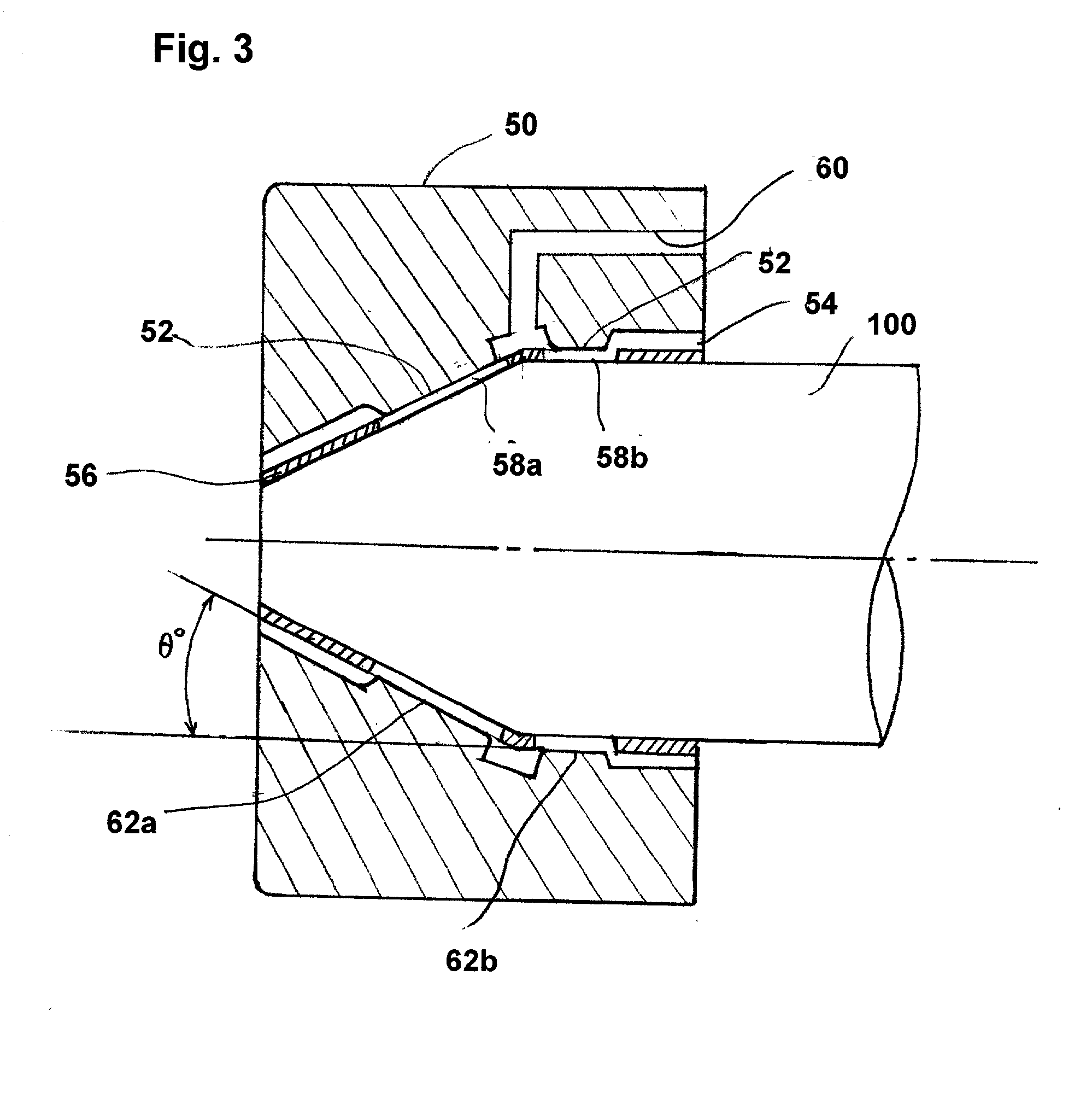

Method for manufacturing fluid bearing and fluid bearing manufactured by the method

InactiveUS20020126923A1Improve verticalityQuality improvementMachining electrodesElectrolysis componentsEngineeringFluid bearing

A method for manufacturing a fluid bearing is provided. A mask member having at least two sets of grooves provided at least two places along an axial direction is affixed to an outer surface of an electrode section of a fluid bearing manufacturing tool. Each of the groove sets consists of multiple grooves in a shape corresponding to designed fluid bearing grooves on a work piece, such as, for example, a sleeve section of the fluid bearing. The fluid bearing manufacturing tool is inserted into a hole created in the work piece, wherein a power source for electrolytic machining is connected between the fluid bearing manufacturing tool and the work piece. An electrolytic solution between the manufacturing tool and the work piece is allowed to flow to form fluid bearing grooves on an inner surface of the work piece through electrolytic machining.

Owner:SANKYO SEIKI MFG CO LTD

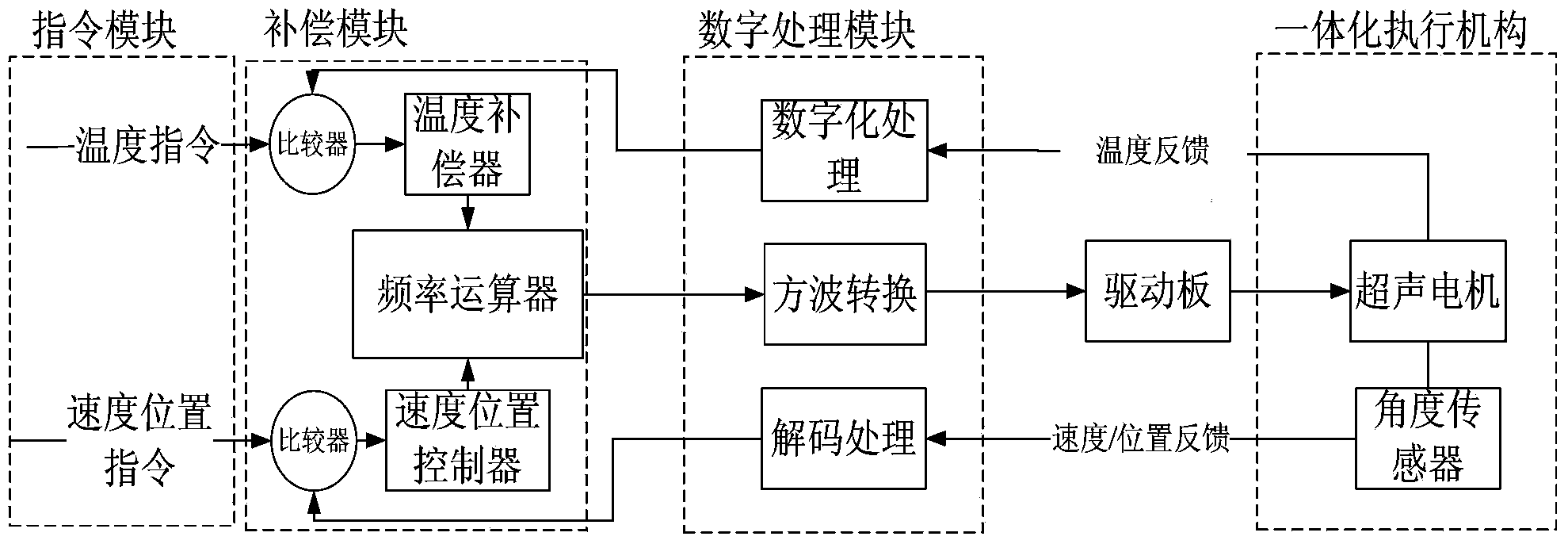

Internally-arranged angle sensor all-in-one ultrasonic motor servo control system

ActiveCN103414376APrecise closed-loop controlAffect speedPiezoelectric/electrostriction/magnetostriction machinesControl signalControl system

The invention discloses an internally-arranged angle sensor all-in-one ultrasonic motor servo control system and relates to servo control over ultrasonic motors. The internally-arranged angle sensor all-in-one ultrasonic motor servo control system comprises a command module, a compensation module, a digital processing module, a drive panel and an all-in-one actuating mechanism. The command module sends out commands to the compensation module, and the compensation module converts the commands into frequency control signals and transmits the frequency control signals to the digital processing module; the digital processing module processes the frequency control signals into square signals and transmits the square signals to the drive panel, the drive panel amplifies the square signals and then inputs the square signals to the all-in-one actuating mechanism, the all-in-one actuating mechanism is a hollow ultrasonic motor with an internally-arranged angle sensor, the angle sensor feeds back speed and position information, the speed and position information reaches the compensation module after passing through the drive panel and the digital processing module, through comparison, compensation and conversion, newly-generated frequency control signals are transmitted to the drive panel, and therefore closed-loop control is achieved. The internally-arranged angle sensor all-in-one ultrasonic motor servo control system has high reliability, high precision and good environmental suitability, and is especially suitable for being used as shaft end servo control systems of platforms with multi-degrees of freedom.

Owner:BEIJING PULIMEN ELECTRO MECHANICAL HIGH TECHN CO

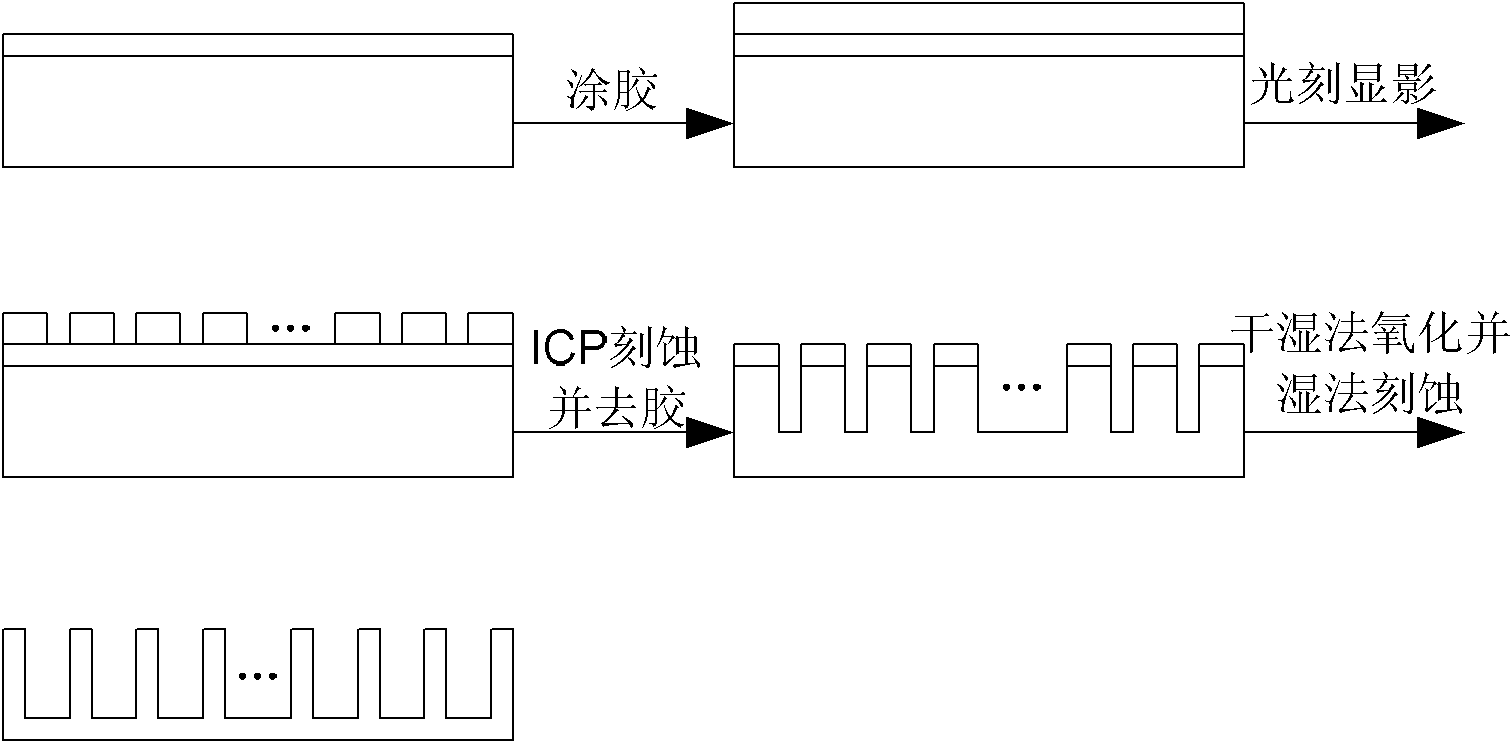

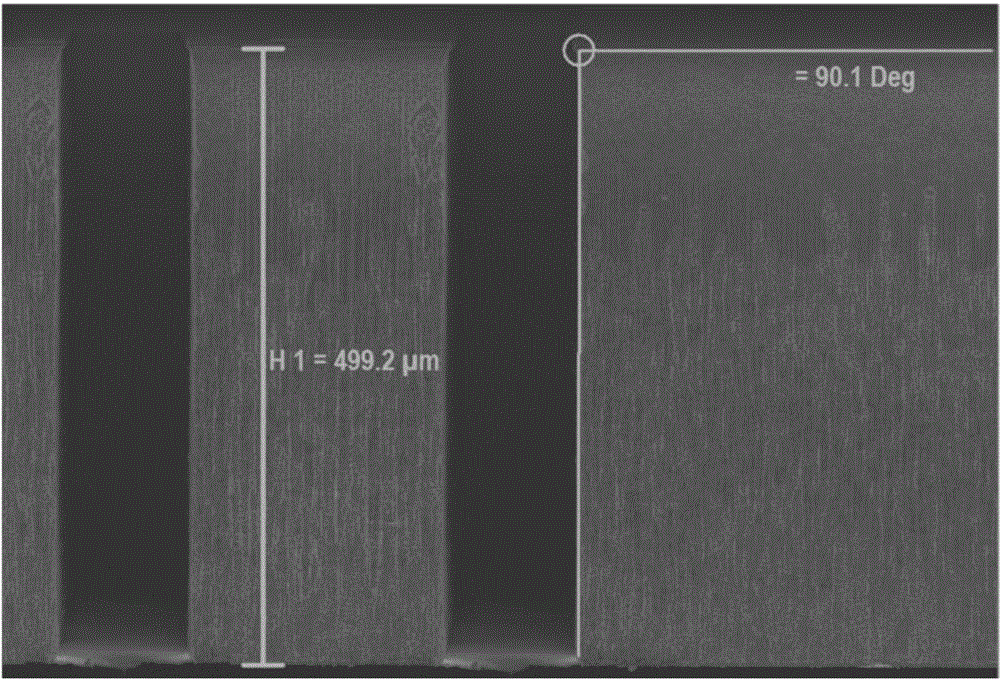

Deep silicon etching method

ActiveCN103950887AAchieve physical bombardmentReduce physical bombardmentDecorative surface effectsChemical vapor deposition coatingInductively coupled plasmaSilicon etching

The invention discloses a deep silicon etching method which comprises the following steps: (1) preparing a graphic photoresist mask on a silicon chip surface; (2) performing deep inductively coupled plasma dry etching of the silicon chip, wherein the etching is divided into several phases, each etching phase is completed in a inductively coupled plasma machine, and is completed through alternate circular processing of three steps of passivation, bombardment, and etching, and with the increase of the etching depth, the bombardment intensity in the bombardment step of each etching phase increases gradually. The method of the invention effectively solves the problems of difficult control of sidewall verticality and roughness, and difficult realization of large etching depth in the prior art, both improves the etching efficiency and increases the selection ratio or photoresist, and is high in etching groove sidewall verticality, low in roughness, and large in etching depth.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com