Preparation method of laser diode packaging case

A technology of laser diodes and encapsulation shells, applied in lasers, laser parts, semiconductor lasers, etc., can solve problems such as difficulty in achieving production, difficult stamping processing, and failure to meet product requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

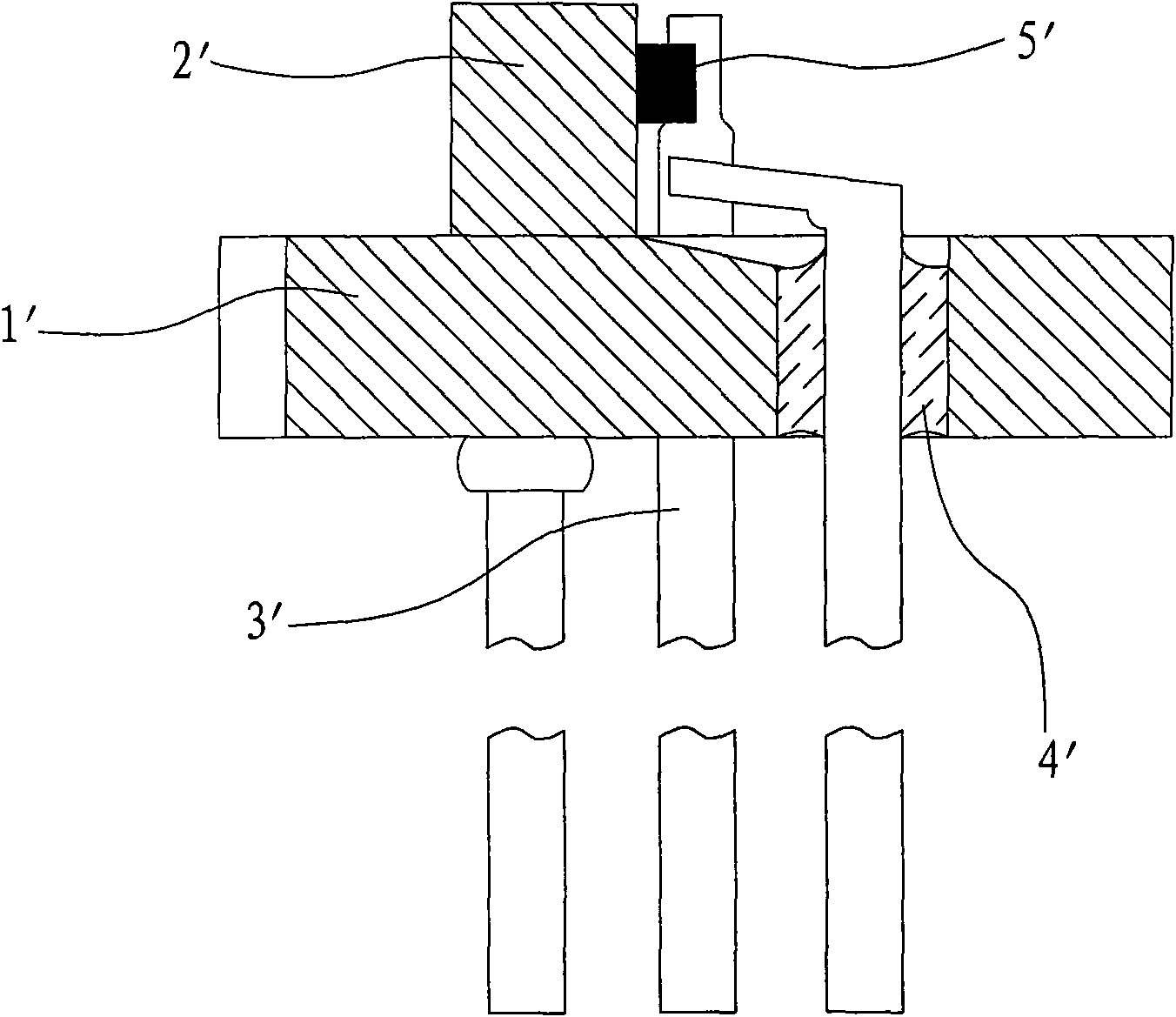

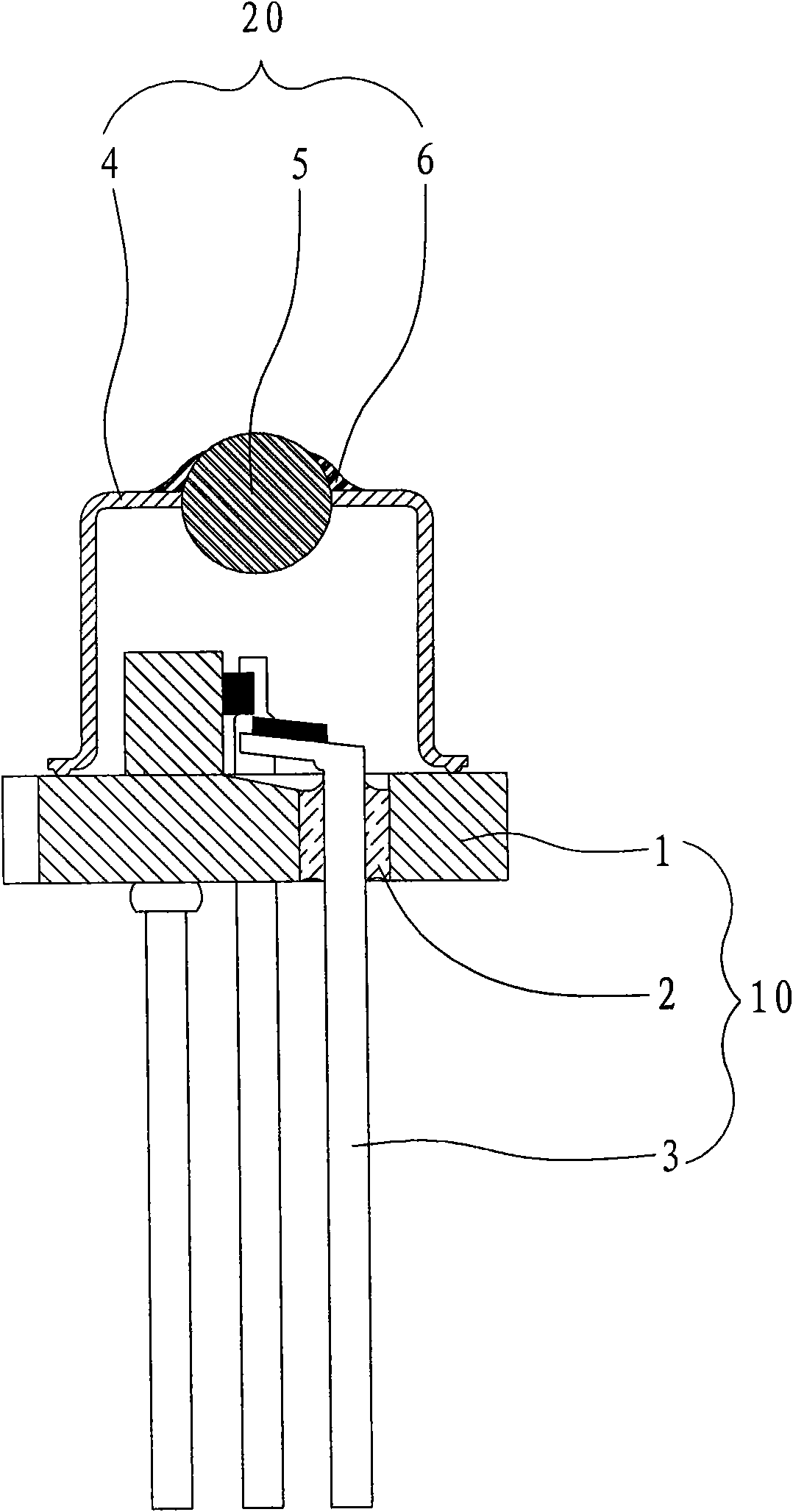

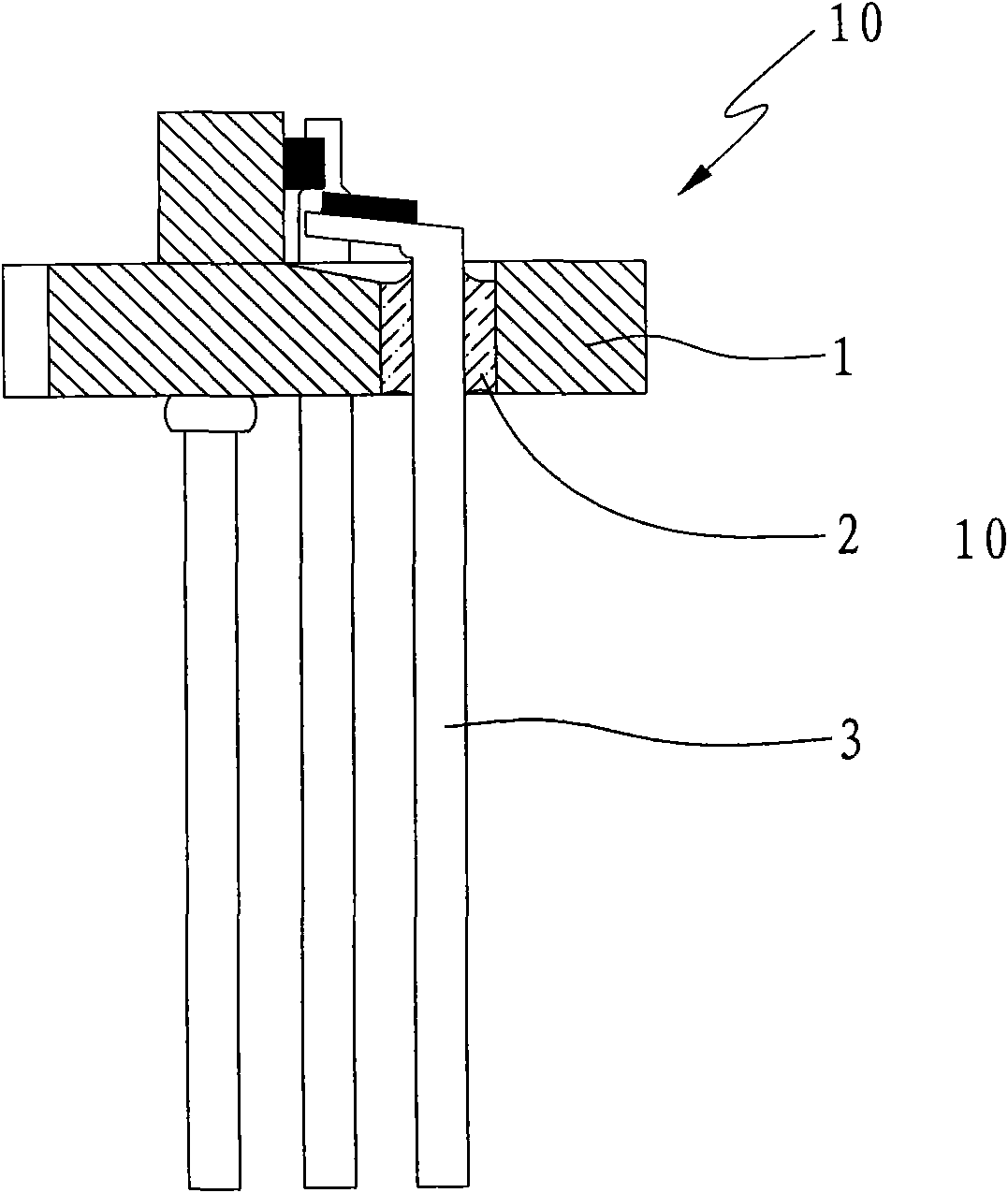

[0024] Such as figure 2 Shown is a schematic structural view of a laser diode prepared by the present invention, which consists of a stem 10 and a cap 20 . Described socket 10 (as image 3 shown) including base plate 1 (as Figure 5A , Figure 5B shown), glass insulator 2, lead wire 3; described cap 20 (such as Figure 4 Shown) comprises cover shape round metal shell 4, glass lens 5 and low temperature glass 6.

[0025] The present invention is a kind of preparation method of laser diode packaging shell, and it comprises the following steps:

[0026] (1) Cleaning treatment before sintering: (11) Ultrasonic cleaning: place the base plate 1 and the lead wire 3 in an ultrasonic cleaning solution for ultrasonic cleaning, the function is to eliminate the product performance difference caused by pollutants in the subsequent process; ( 12) Oxidation treatment: Mix nitrogen and water in the oxidation furnace to form mouse gray on the surface, in order to make the metal and glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com