Patents

Literature

386 results about "Packaging Tube" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

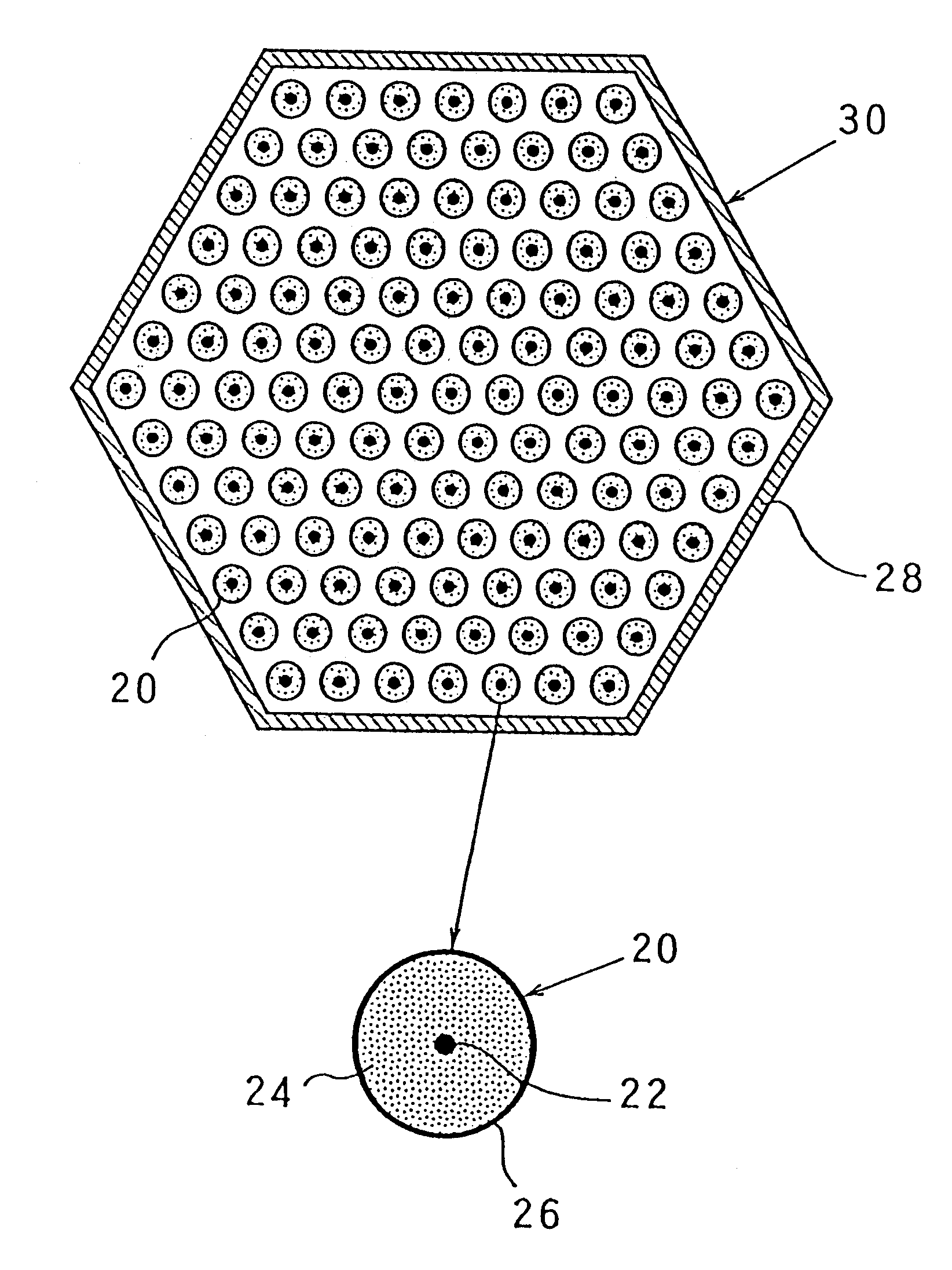

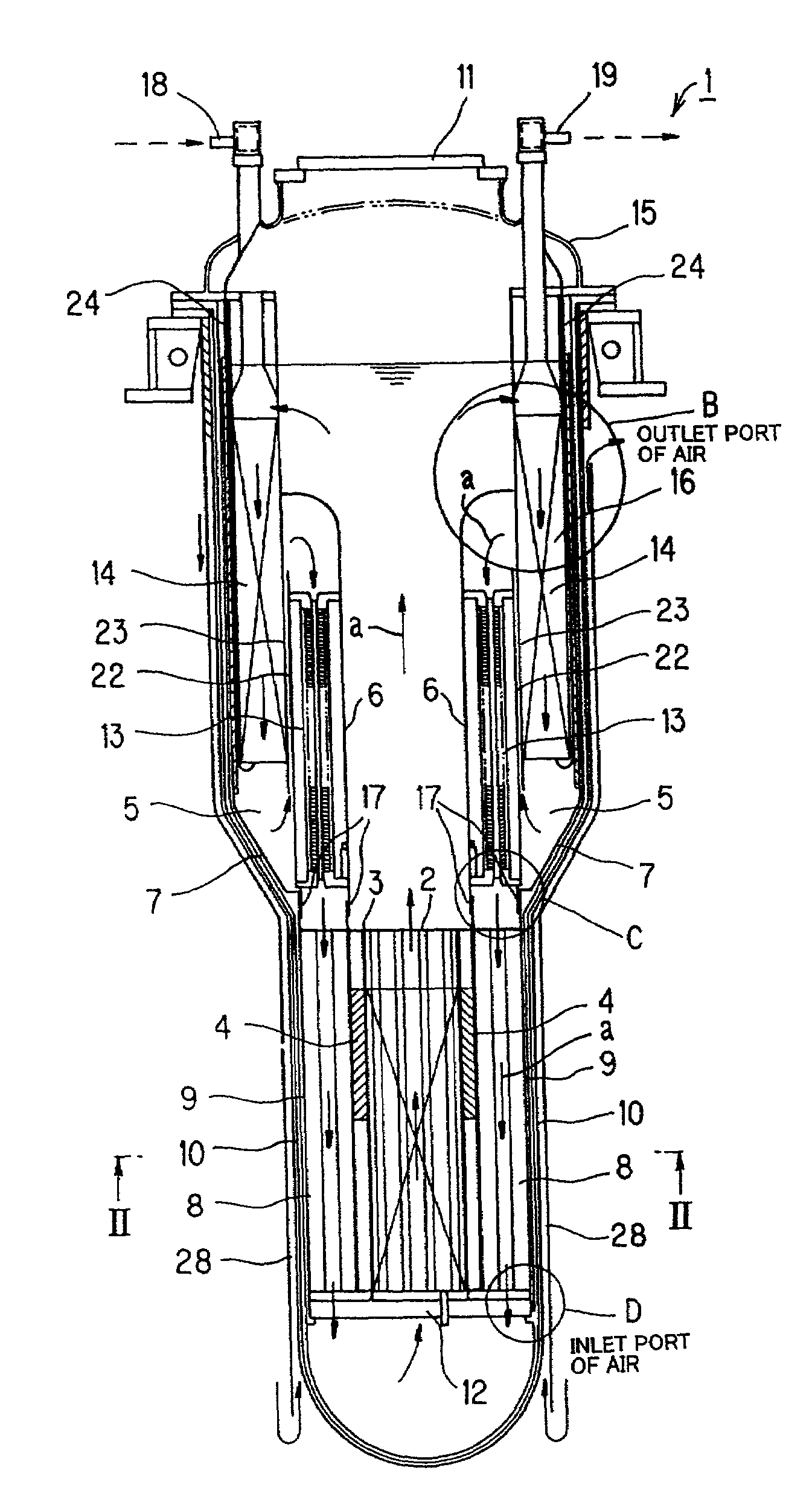

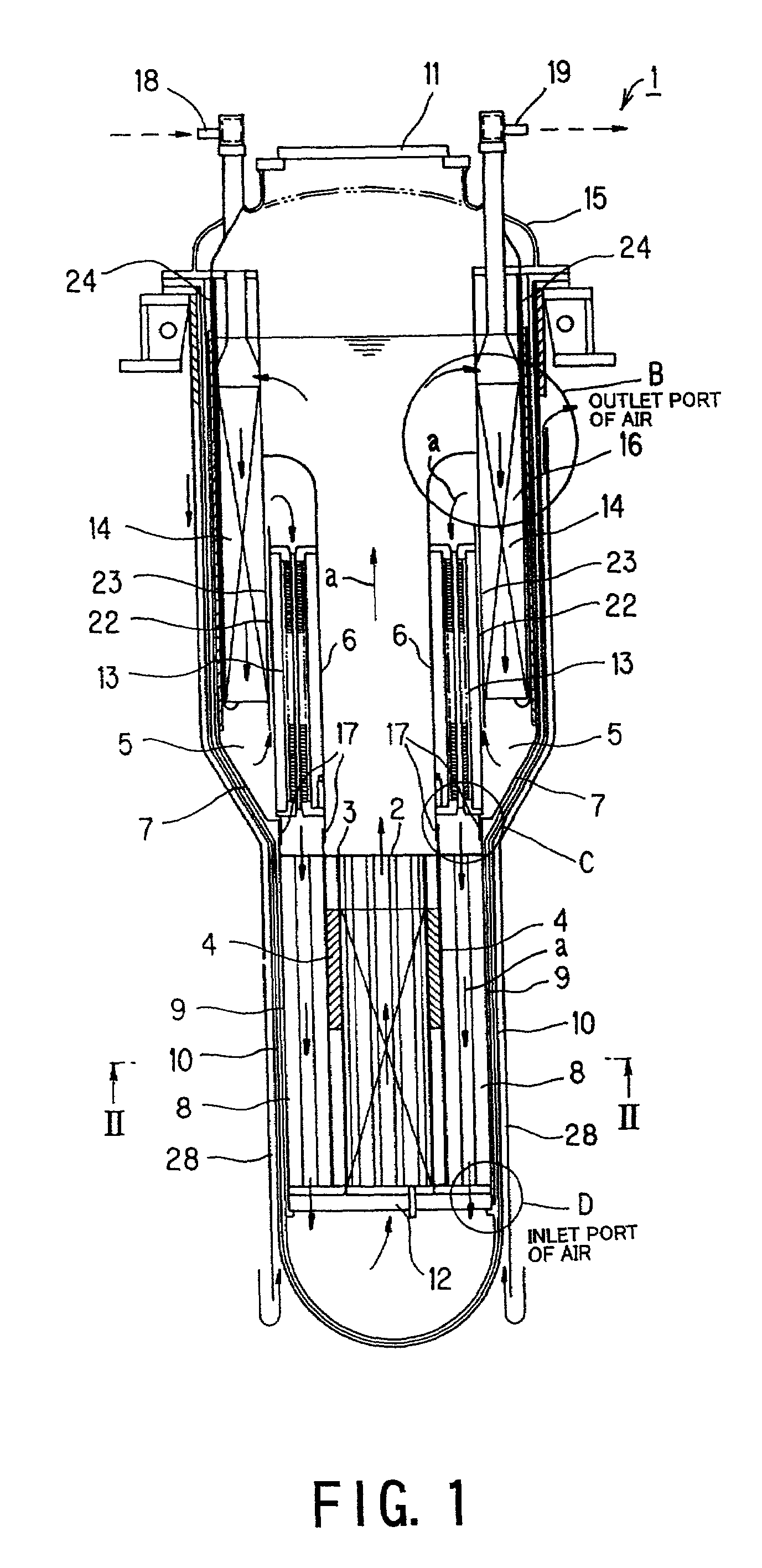

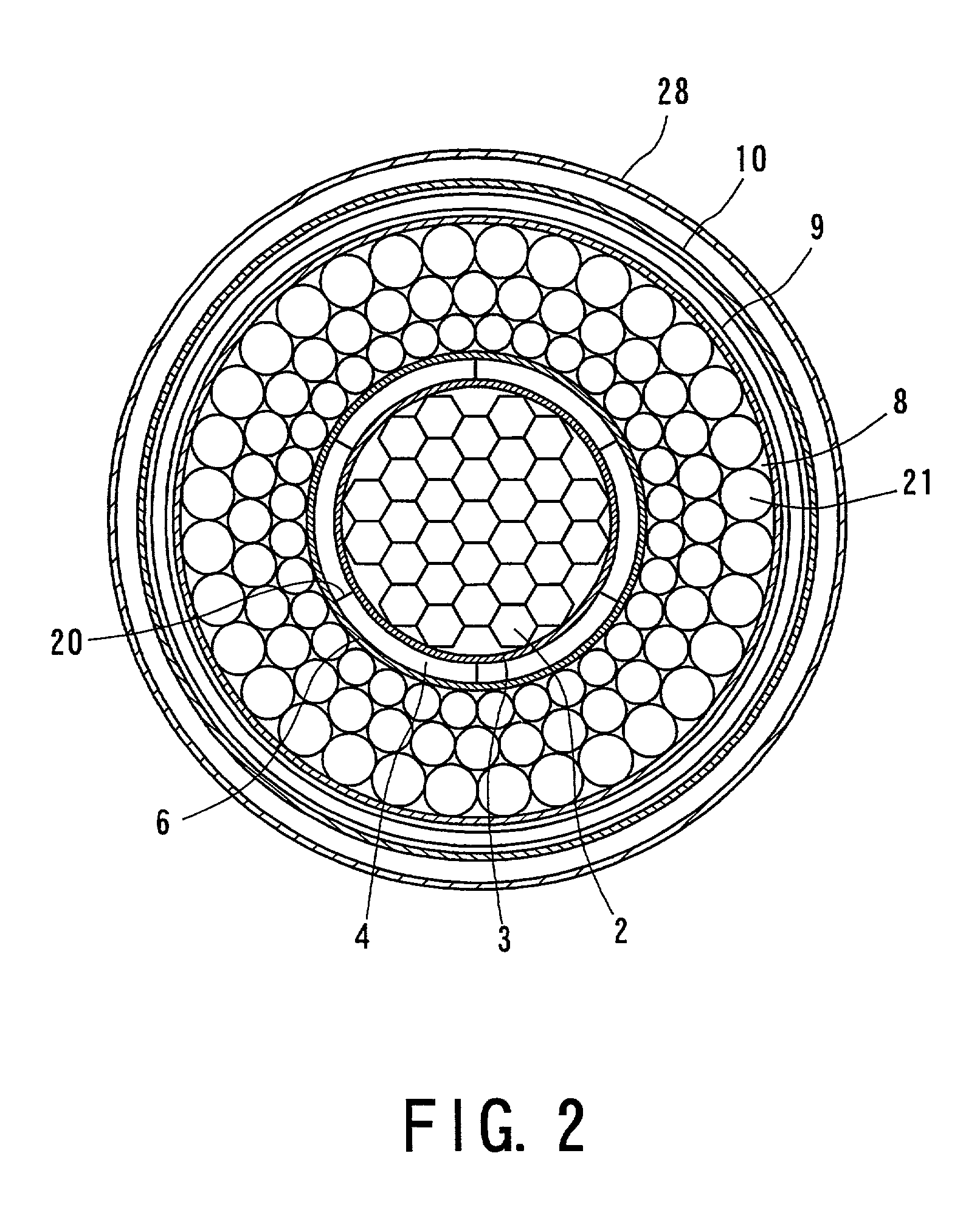

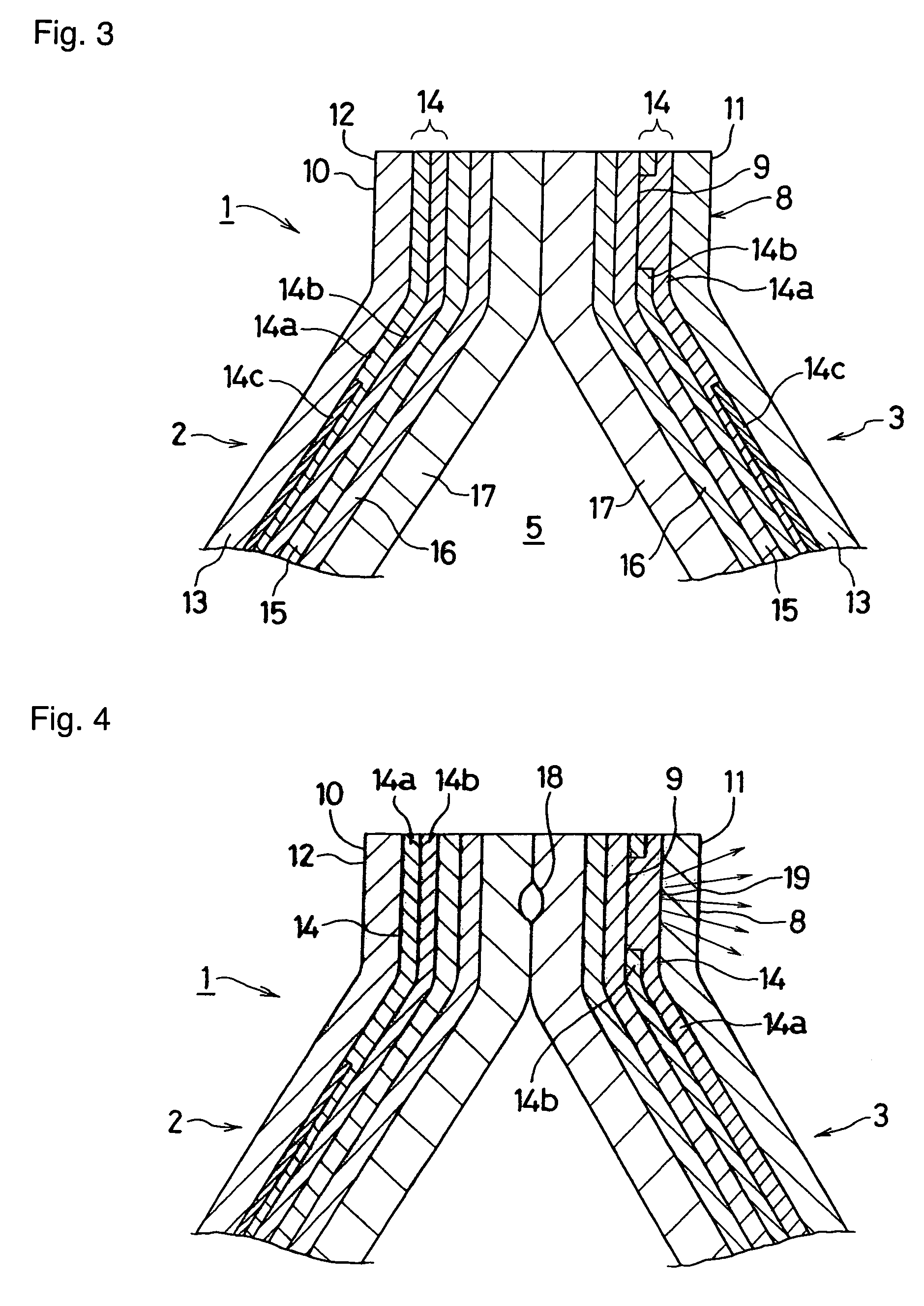

Assembly for transmutation of a long-lived radioactive material

InactiveUS6233299B1Conversion outside reactor/acceleratorsNuclear energy generationRadioactive agentTechnetium-99

A new transmutation assembly permits an efficient transmutation of a long-lived radioactive material (long-lived FP nuclides such as technetium-99 or iodine-129) which was produced in the nuclear reactor. Wire-type members of a long-lived radioactive material comprised of metals, alloys or compounds including long-lived FP nuclides are surrounded by a moderator material and installed in cladding tubes to form FP pins. The FP pins, and nothing else, are housed in a wrapper tube to form a transmutation assembly. The wire-type members can be replaced by thin ring-type members. The transmutation assemblies can be selectively and at least partly loaded into a core region, a blanket region or a shield region of a reactor core in a fast reactor. From a viewpoint of reducing the influence on the reactor core characteristics, it is optimal to load the transmutation assemblies into the blanket region.

Owner:JAPAN ATOMIC ENERGY AGENCY INDEPENDANT ADMINISTRATIVE CORP

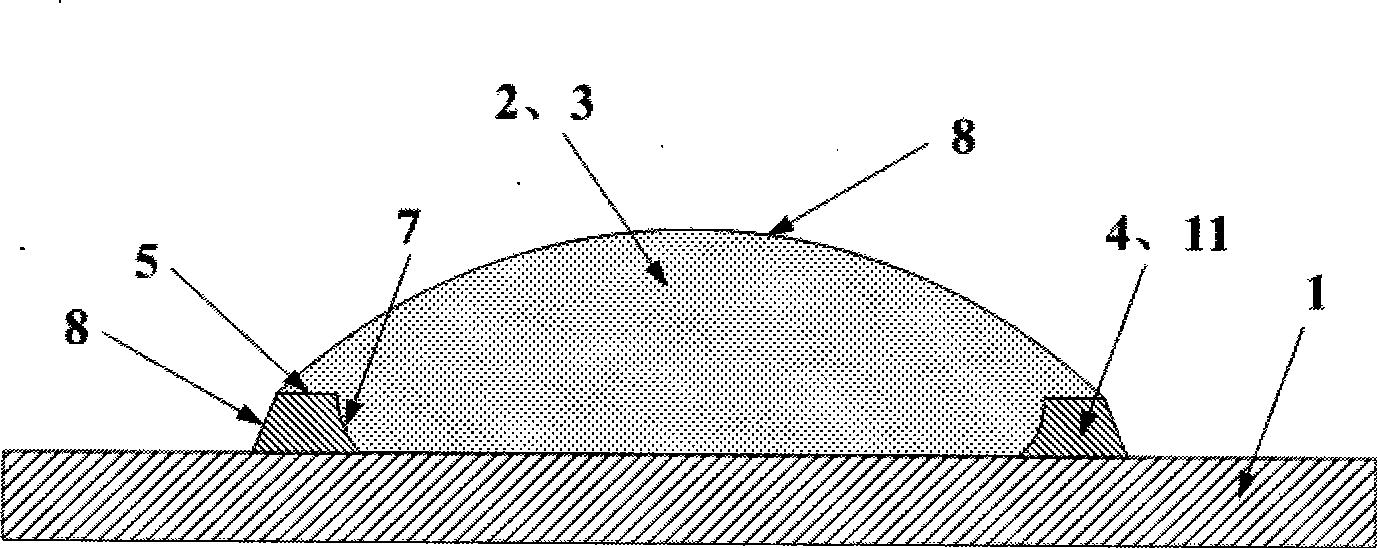

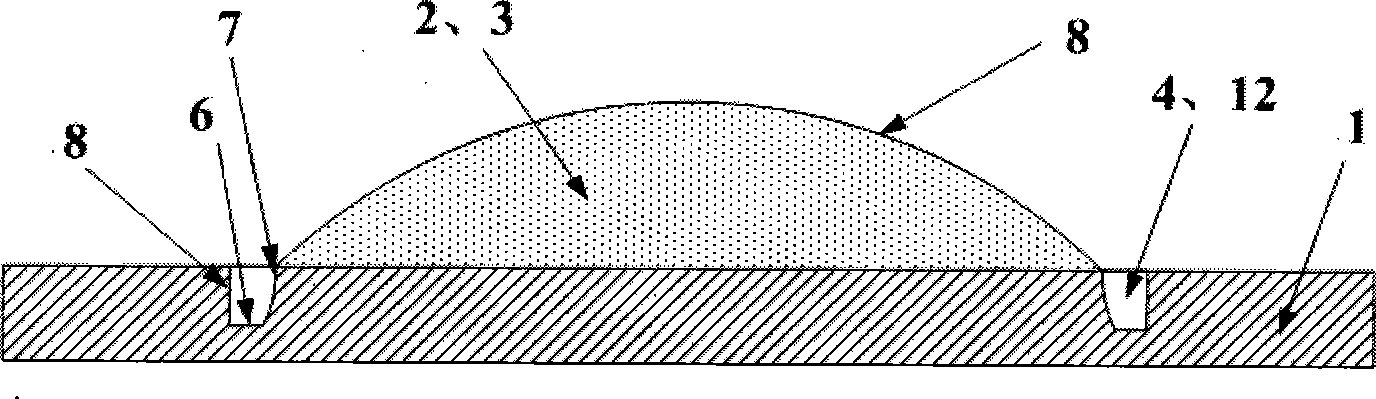

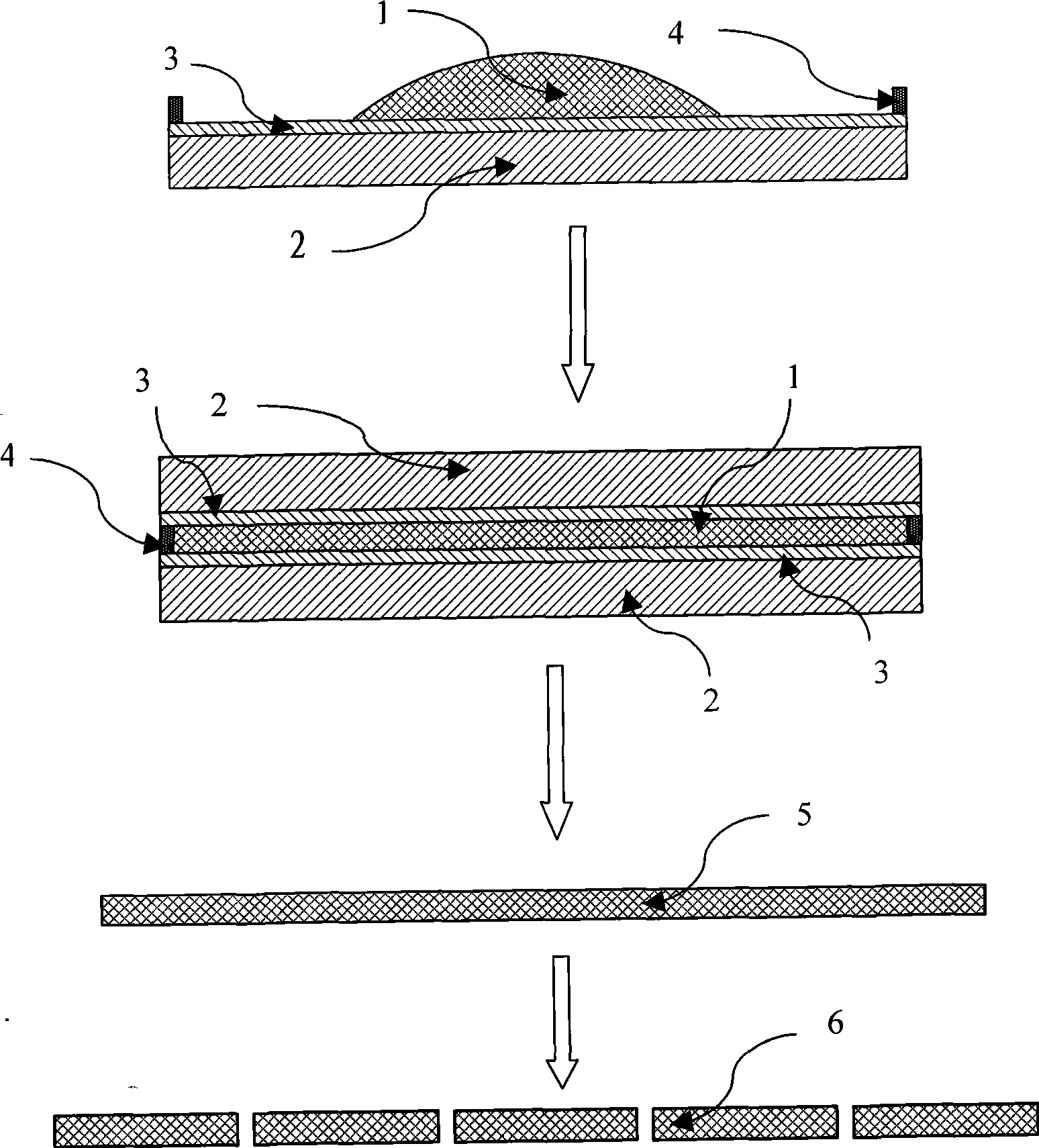

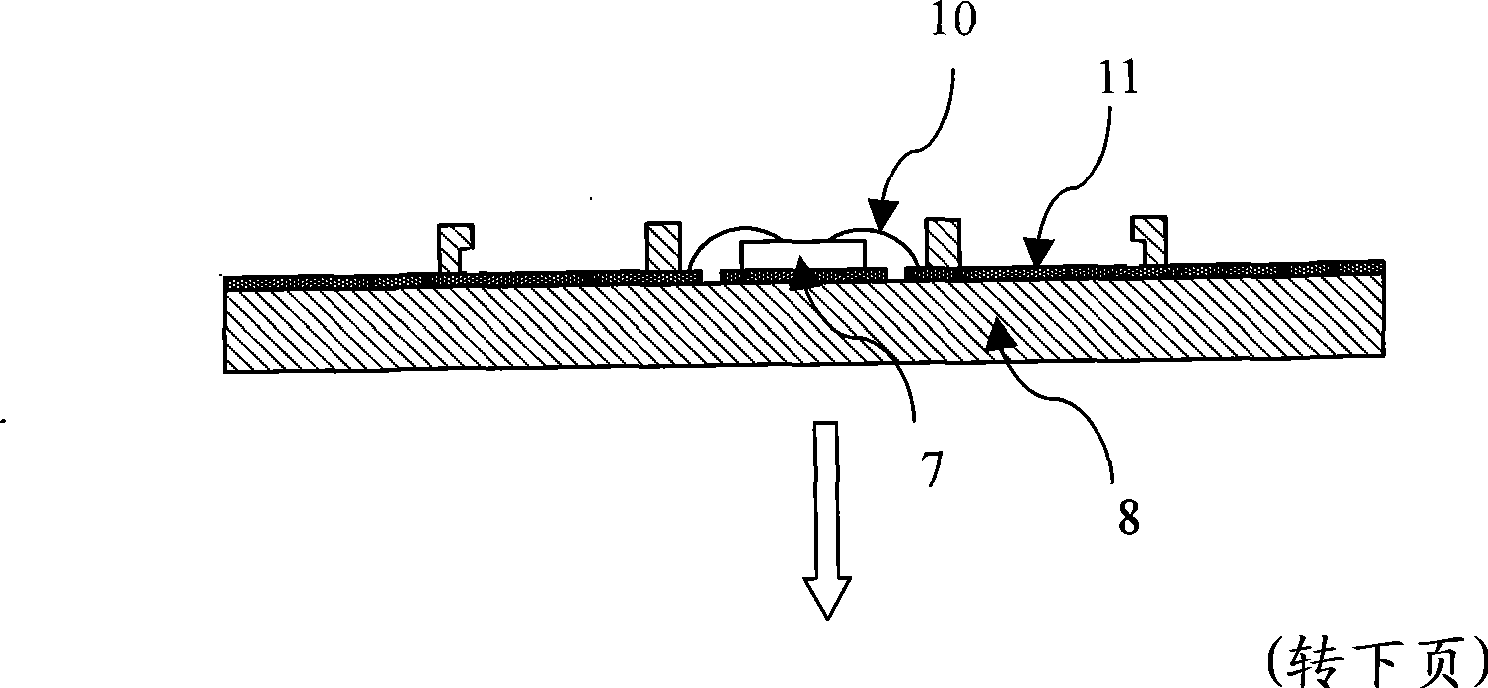

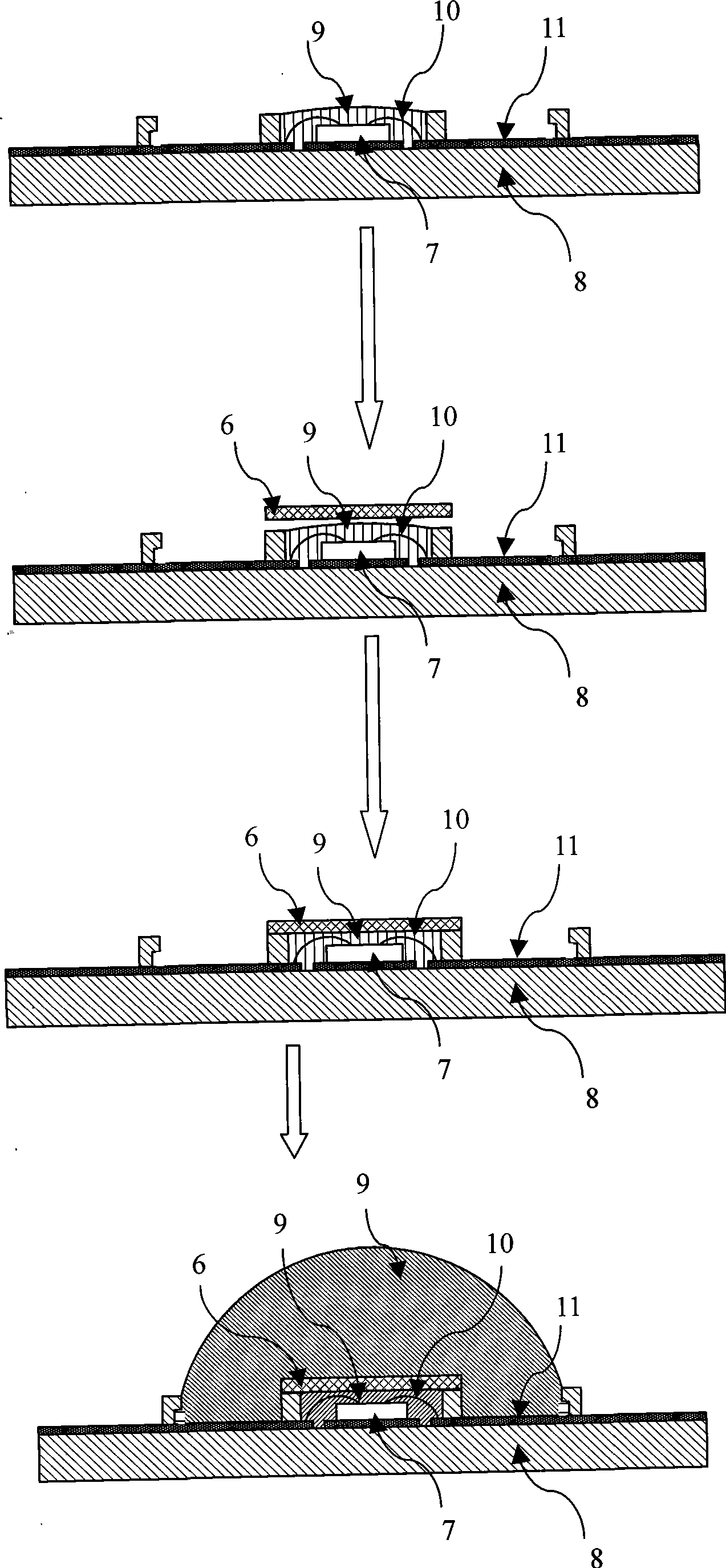

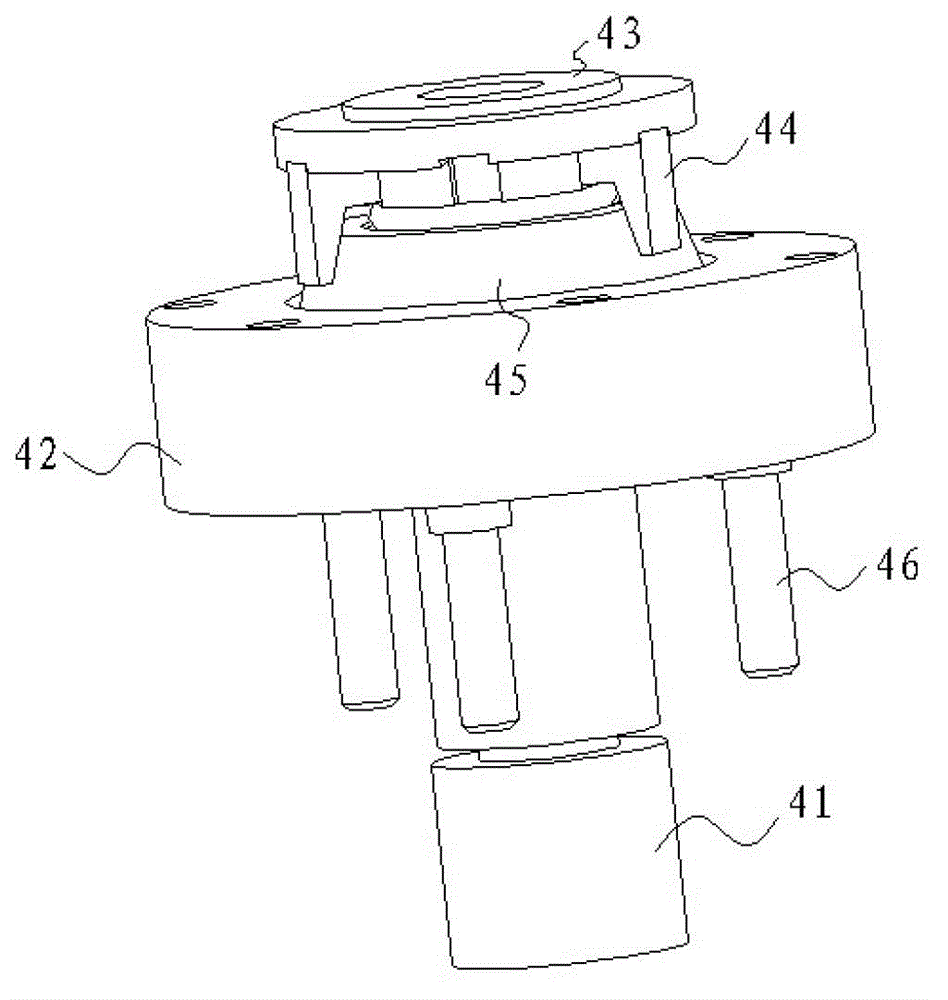

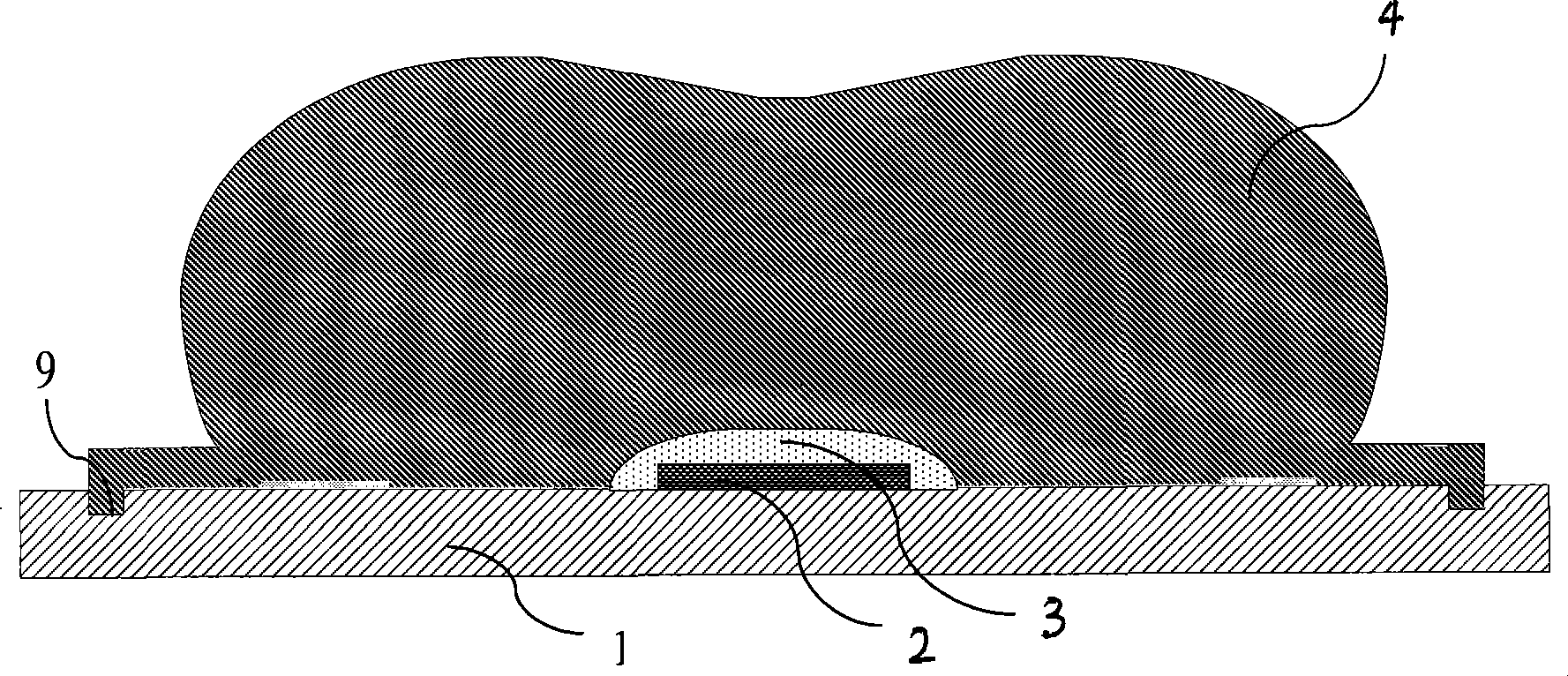

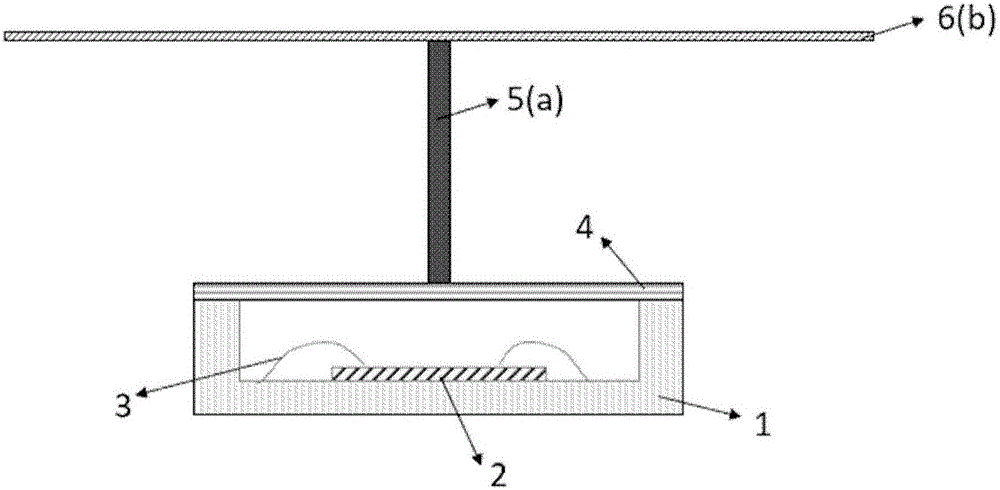

Encapsulation structure and method for white light emitting diode device

The invention provides a structure and a method for packaging white-light LED devices. The structure mainly comprises an LED chip, a packaging tube shell, packaging silica gel and phosphor gel. The structure is characterized in that the LED chip is pasted in the packaging tube shell; the LED chip is covered and packaged in the packaging tube shell by the packaging silica gel and the phosphor gel; the packaging silica gel is in a lens shape; the packaging tube shell consists of a plurality of packaging single-bodies; the periphery of each packaging single-body is provided with a convex strip or a groove; and the packaging silica gel and a phosphor layer are made into a monolayer or multilayer packaging body through the structural shape of the packaging single-bodies. The invention has the advantages of utilizing the own surface tension of the silica gel and the phosphor layer, limiting the own flowing of the silica gel and the phosphor layer through the structure on the packaging tube shell, forming the packaging body of a lens and the phosphor layer of which the surface shape meets design requirements, reducing cost and improving product quality.

Owner:GUANGDONG REAL FAITH OPTO

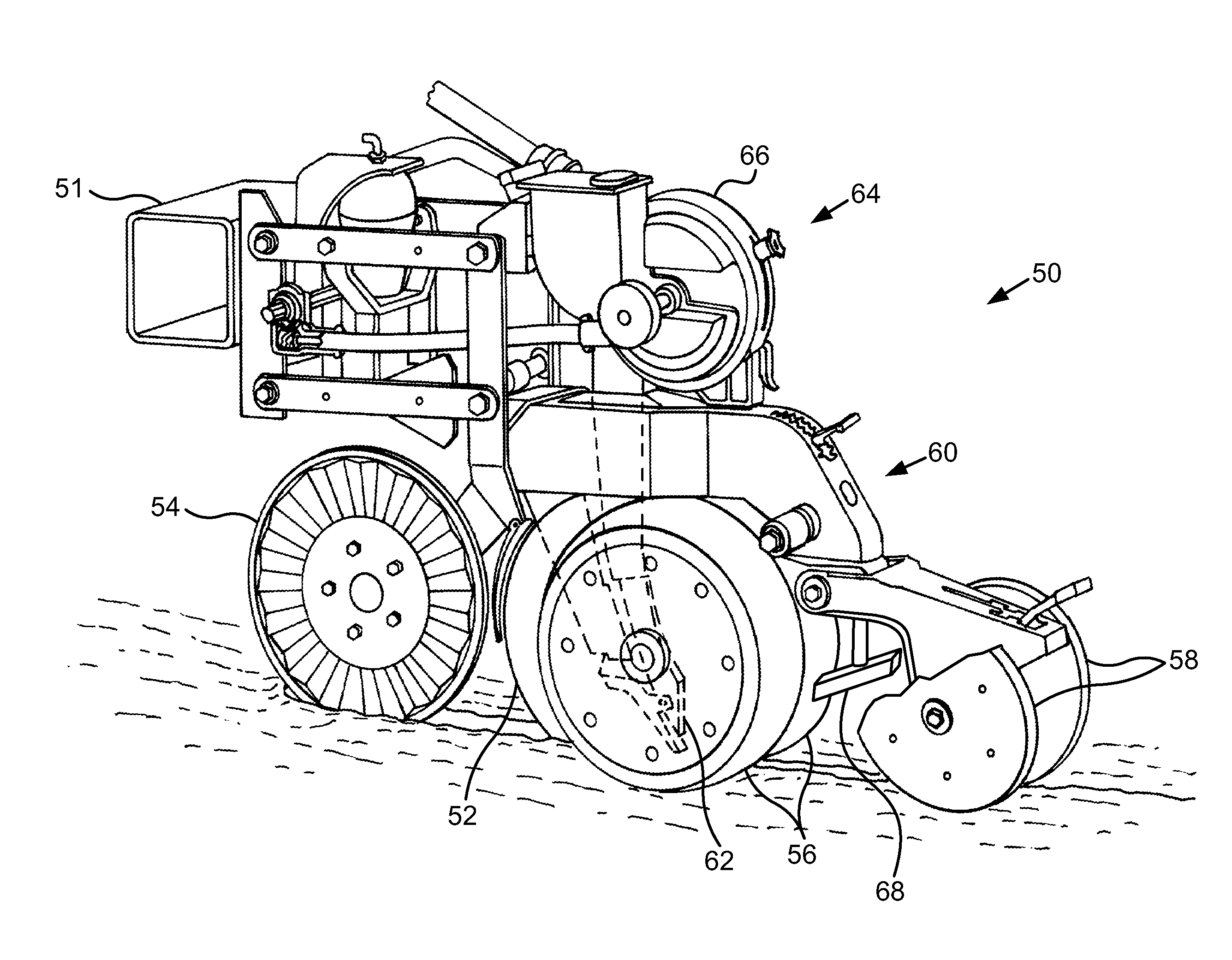

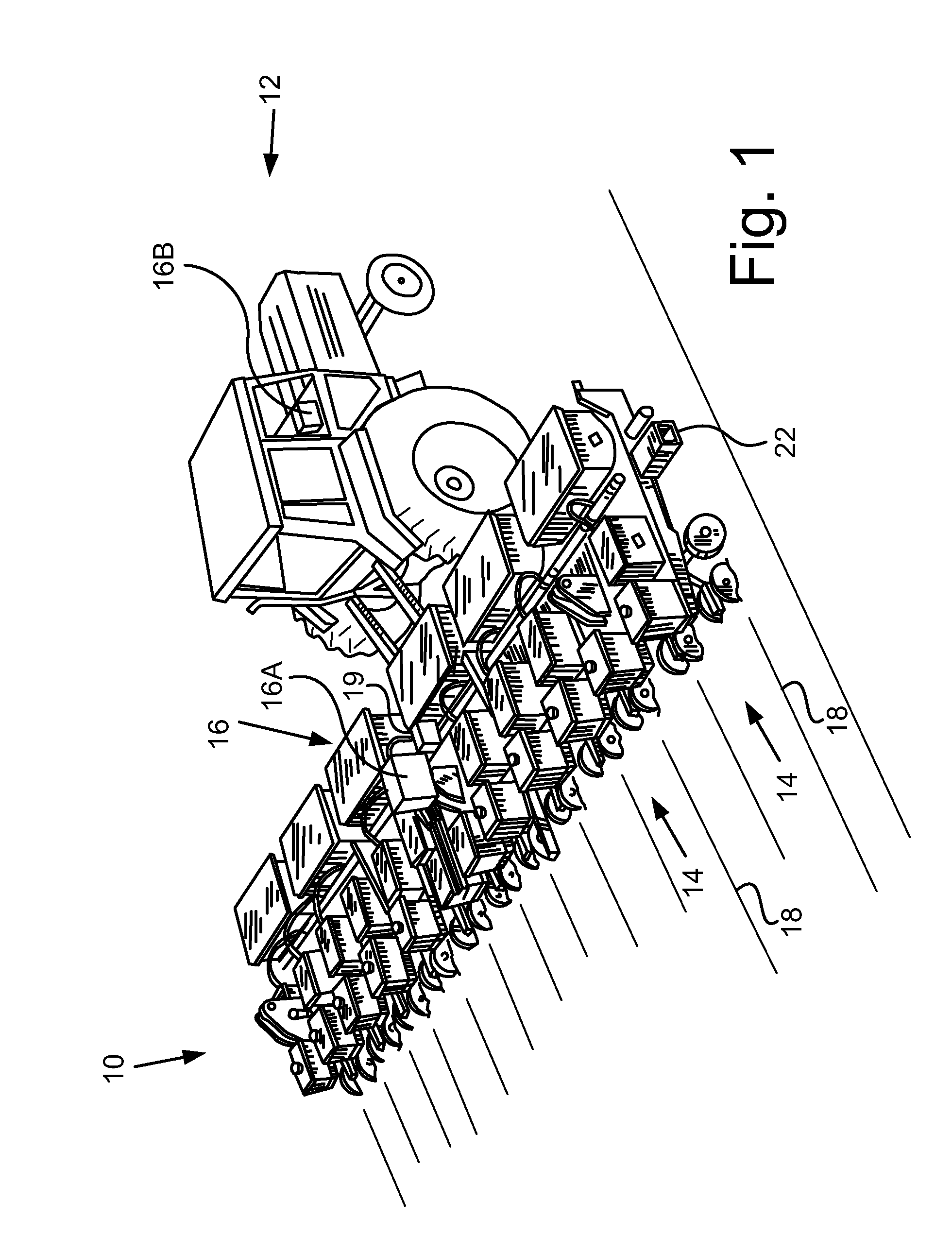

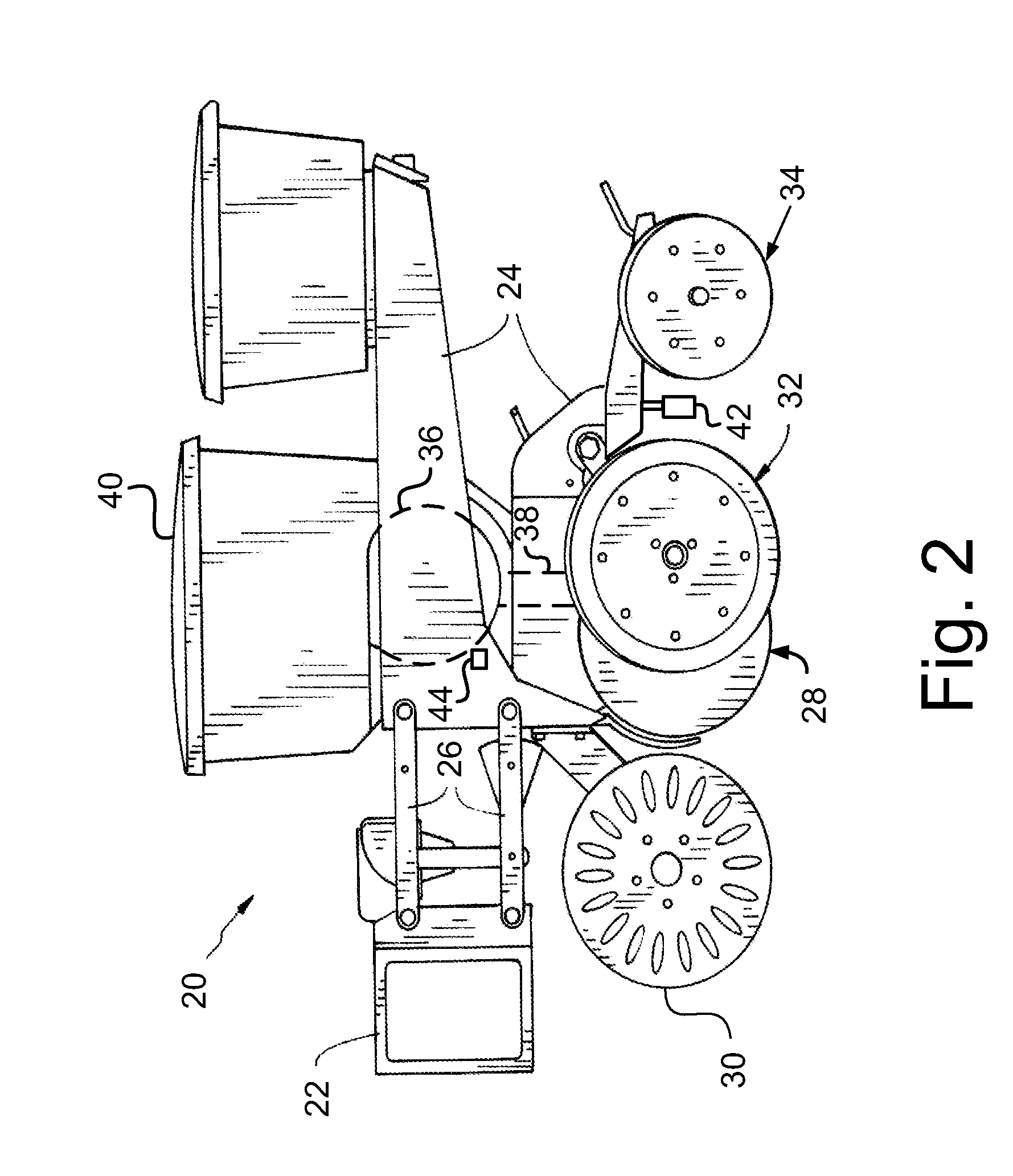

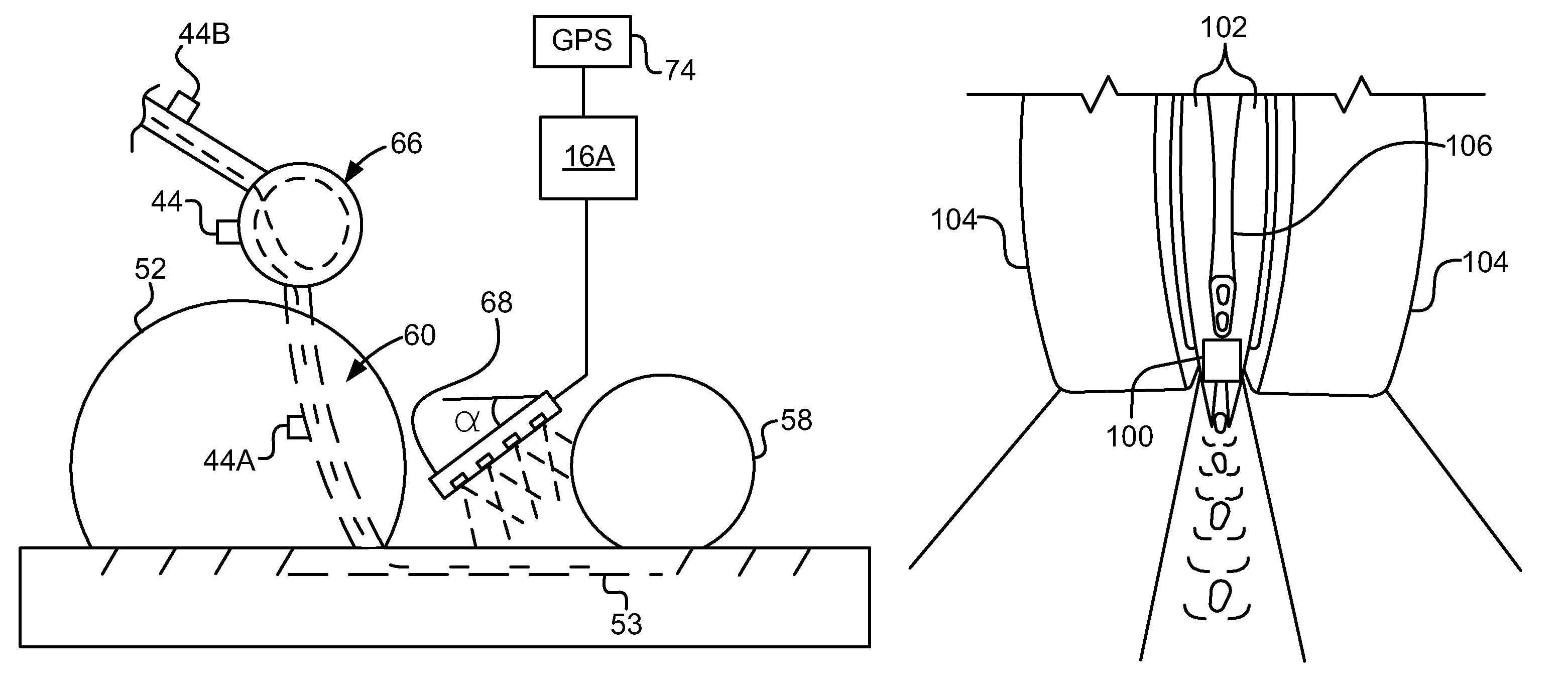

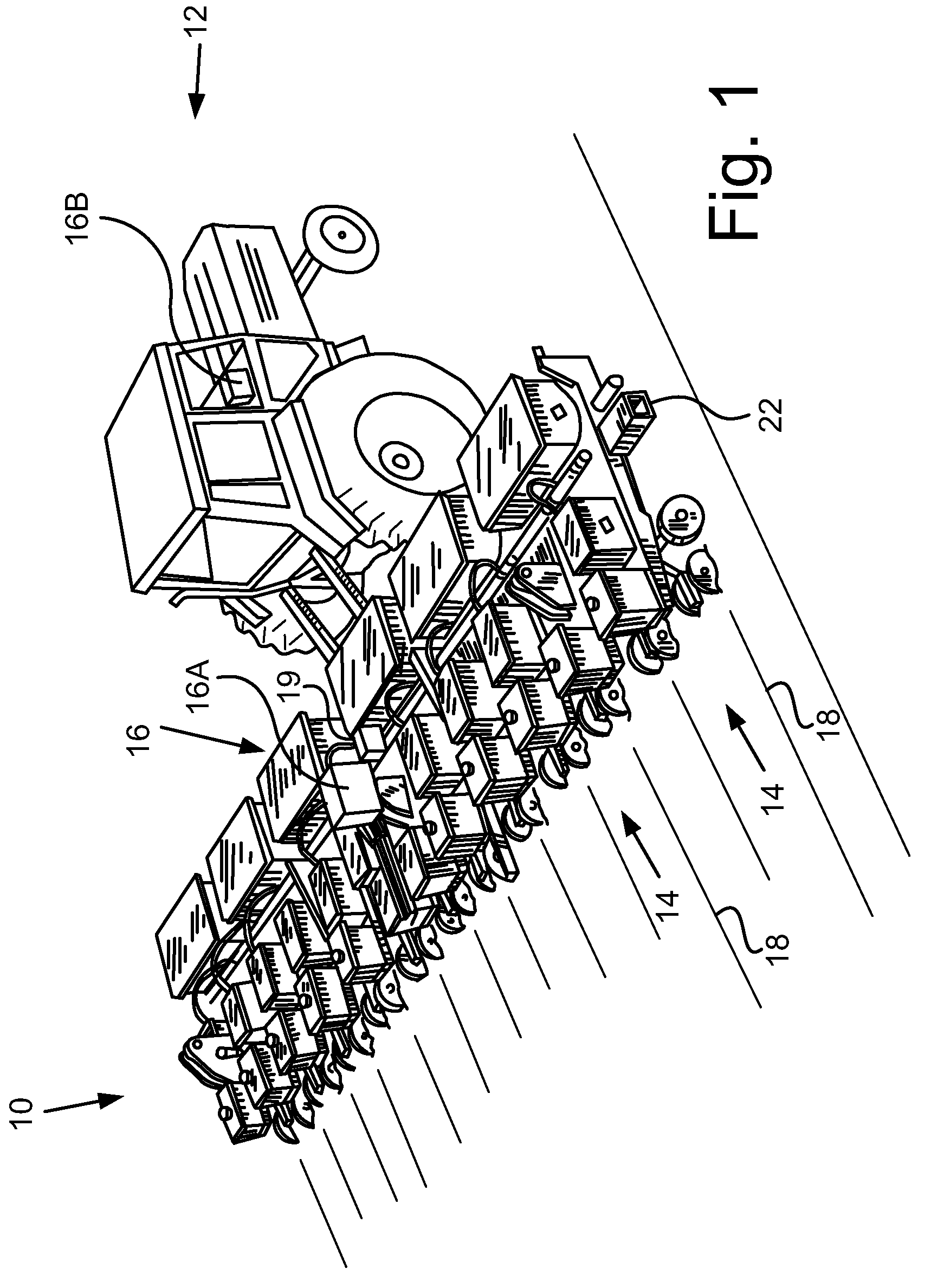

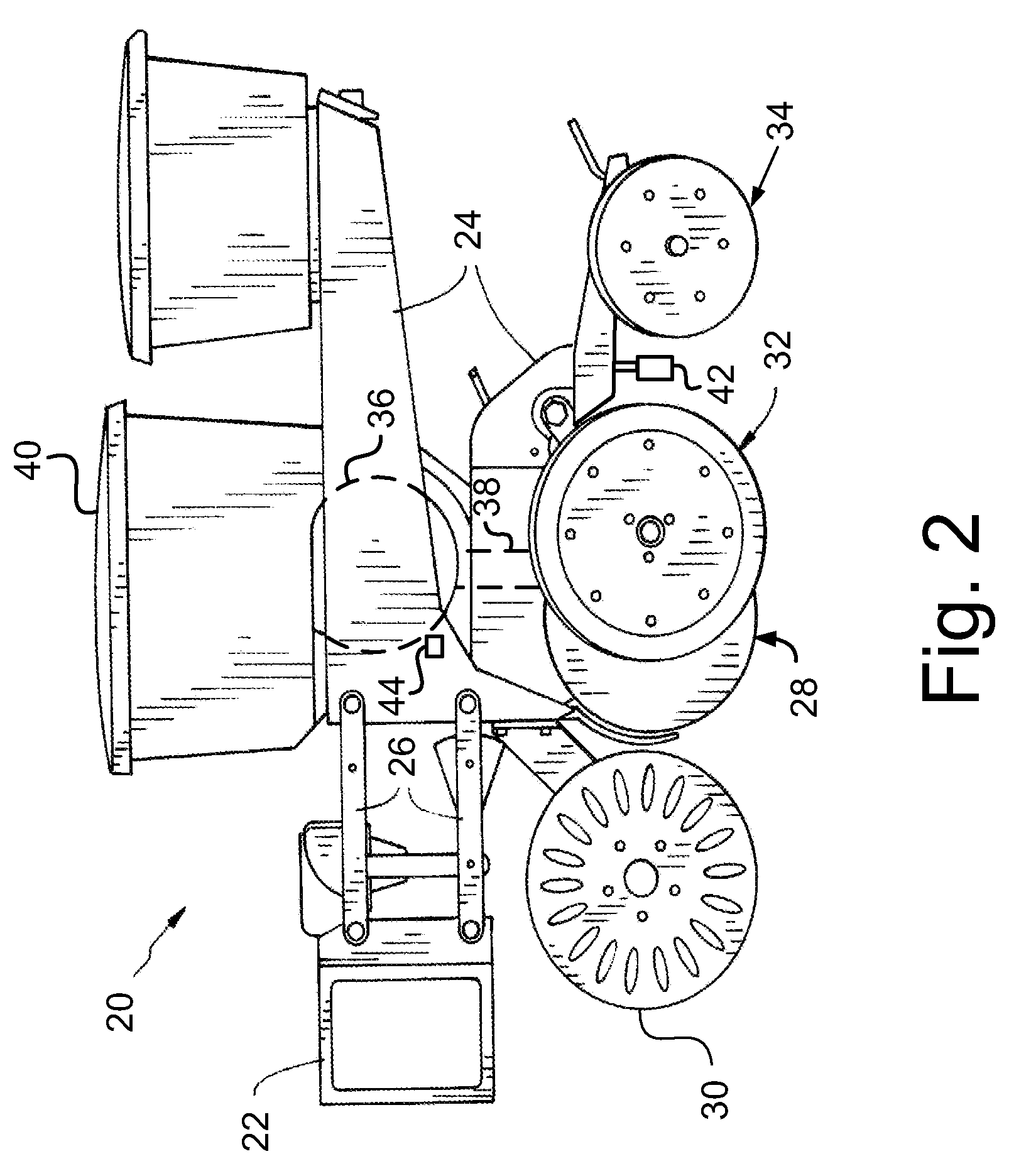

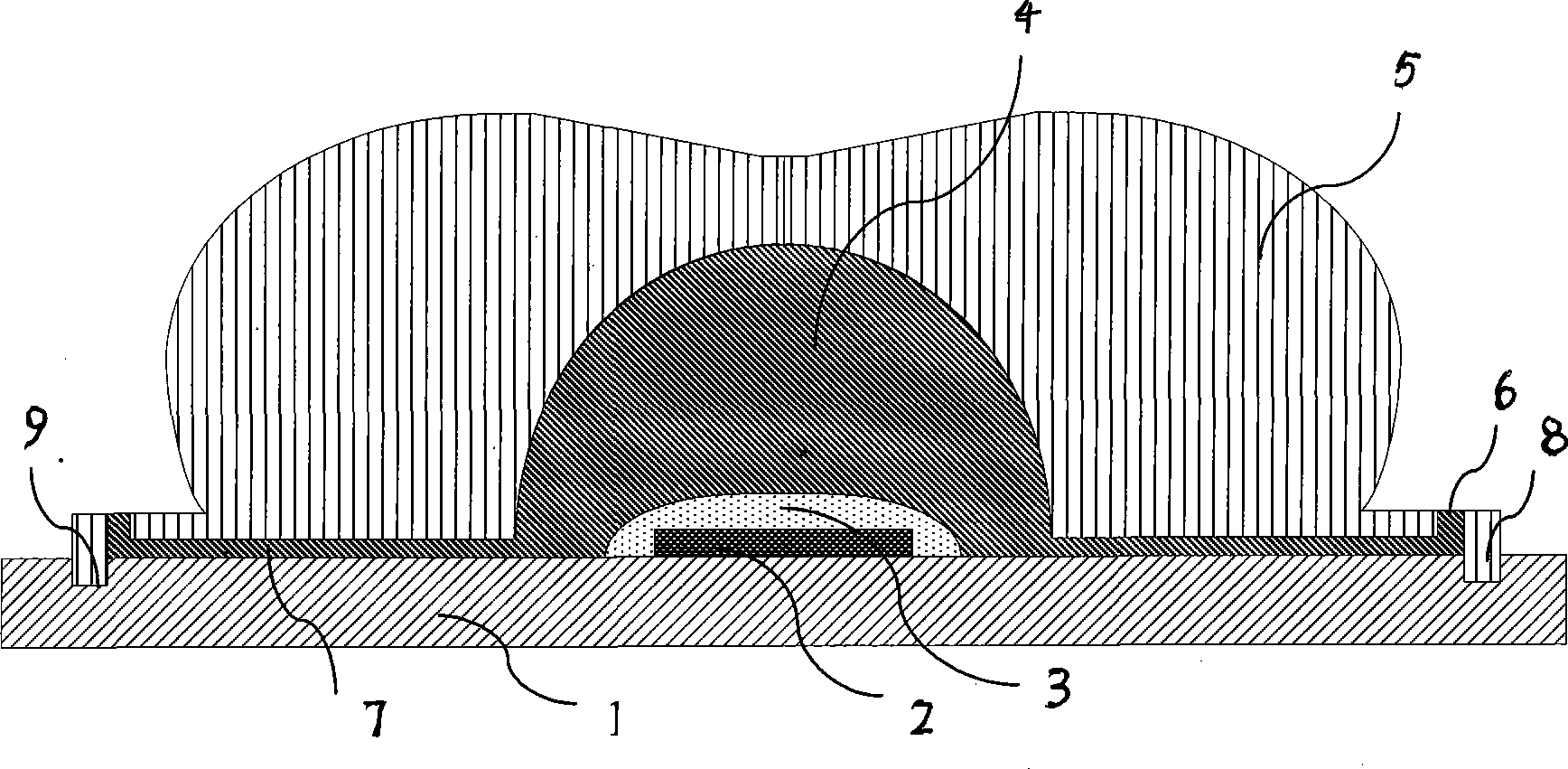

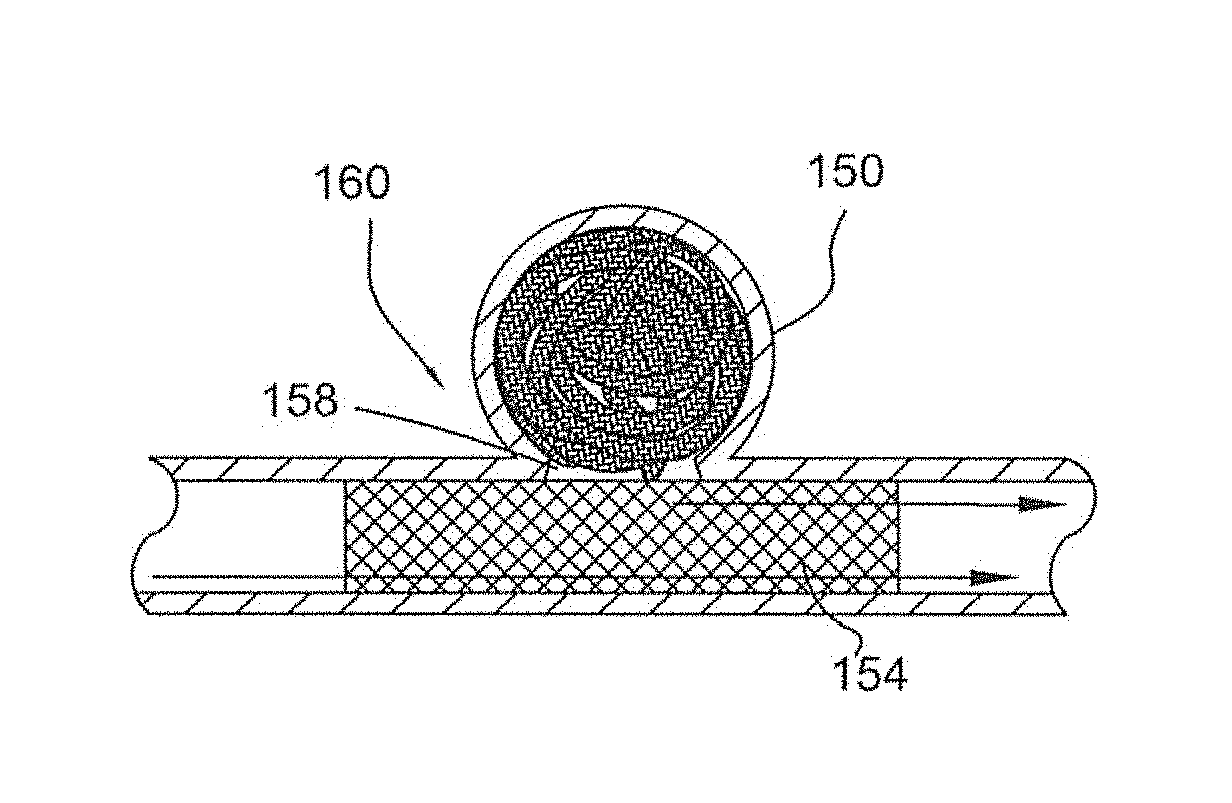

In-ground seed spacing monitoring system for use in an agricultural seeder

ActiveUS20120042813A1Reduce viewing angleHigh sensitivityRadiation pyrometryPlantingSensor arrayPositive pressure

A row crop unit for use in an agricultural seeder includes a furrow opener for opening a furrow in the soil, a seed metering system for metering seed to be placed in the furrow, and a seed placement system for placing seeds in the furrow. The seed placement system and the seed metering system are in communication with each other and at least in part define a seed travel path associated with the furrow. A furrow closer covers the seed in the furrow with soil. A seed temperature conditioner is associated with the seed travel path for varying a temperature of seed traveling through the seed travel path. A temperature sensitive sensor is positioned to sense seed which has been deposited in the furrow between the furrow opener and the furrow closer. An optional packaging tube holds a temperature sensor or sensor array. A lens is mounted with the same tube. A larger diameter tube may be positioned around the sensor packaging tube. A positive air pressure / air flow may be introduced between the two tubes. This positive air-flow forms a positive pressure and / or air flow barrier to push dust away from the sensor lens or sensor surface.

Owner:DEERE & CO

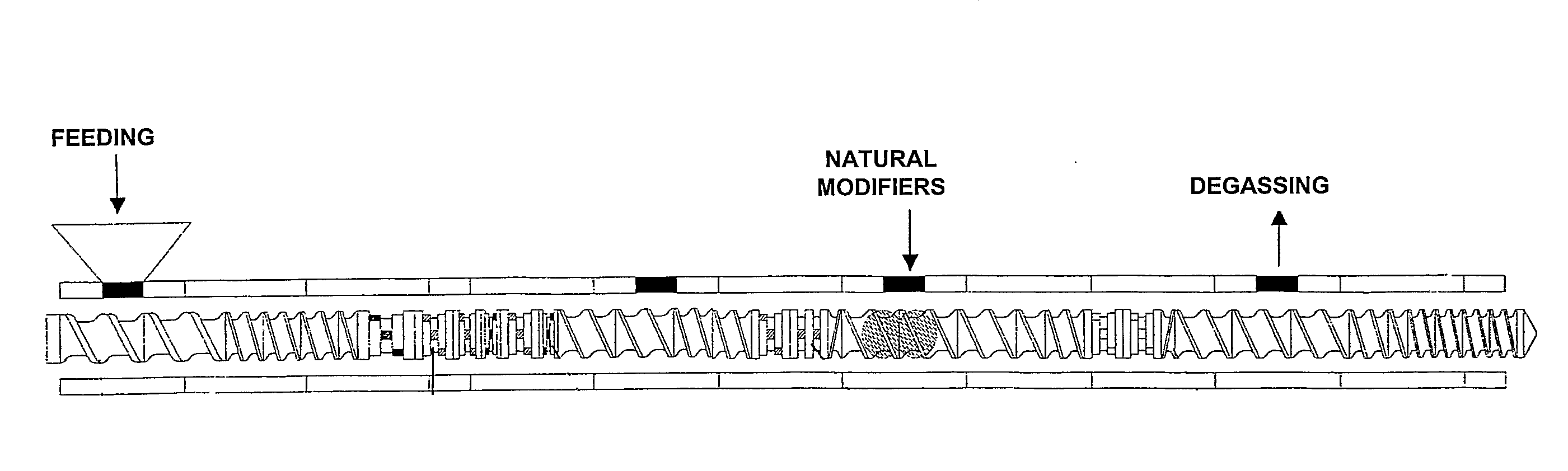

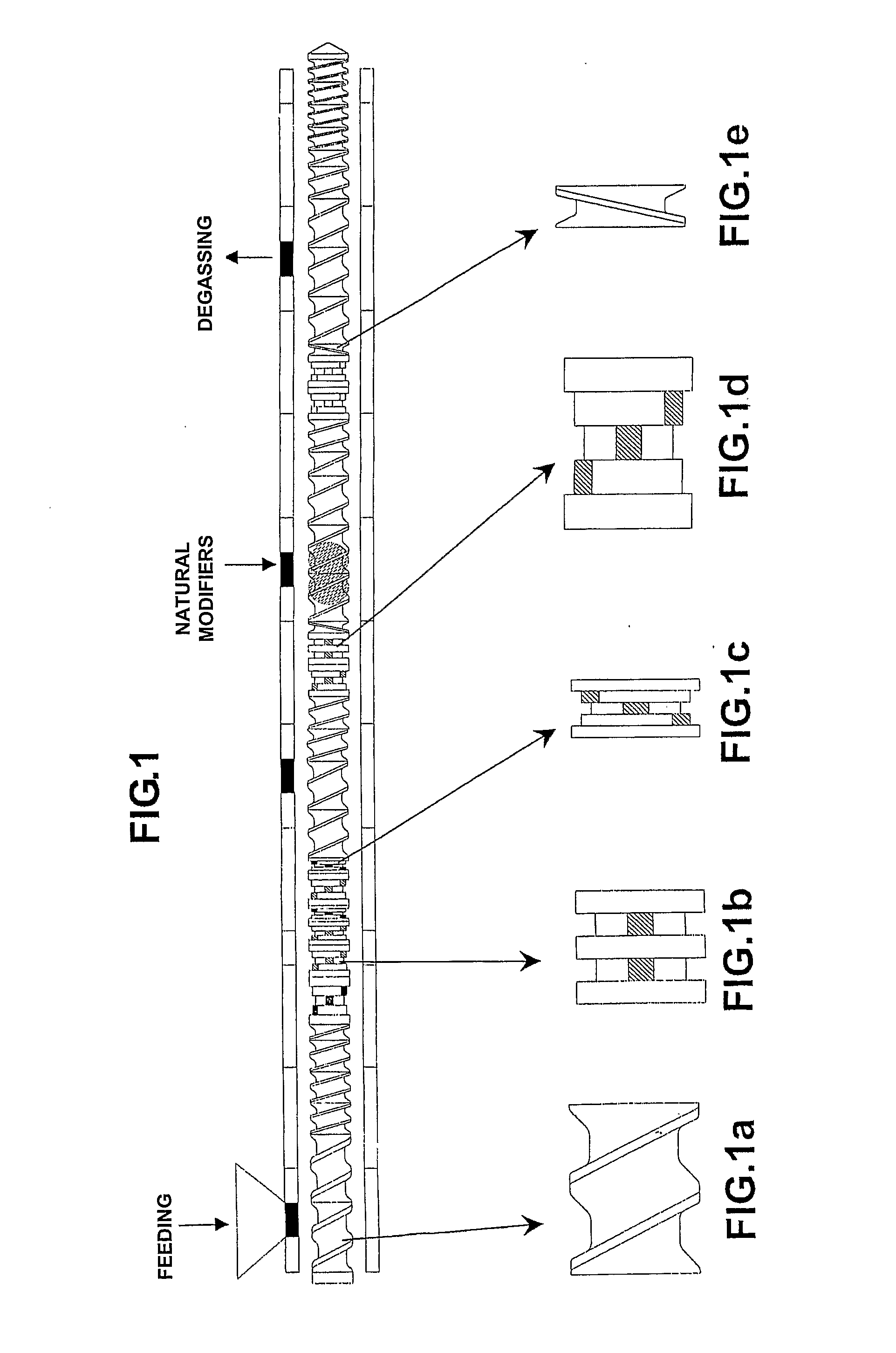

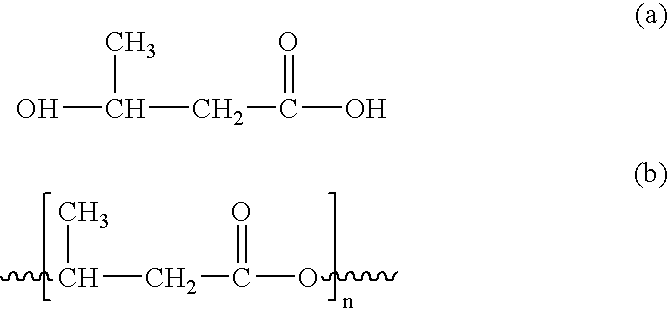

Environmentally degradable polymeric composition and process for obtaining an environmentally degradable polymeric composition

The present invention refers to a polymeric composition prepared from a biodegradable polymer defined by poly-hydroxybutyrate (PHB) or copolymers thereof, and at least one other biodegradable polymer, such as polycaprolactone (PCL) and poly (lactic acid) (PLA), so as to alter its structure, and further at least one additive of the type of natural filler and natural fibers, and, optionally, nucleant, thermal stabilizer, processing aid, with the object of preparing an environmentally degradable material. According to the production process described herein, the composition resulting from the mixture of the modified biodegradable polymer and additives can be utilized in the manufacture of injected packages for food products, injected packages for cosmetics, tubes, technical pieces and several injected products.

Owner:PHB IND

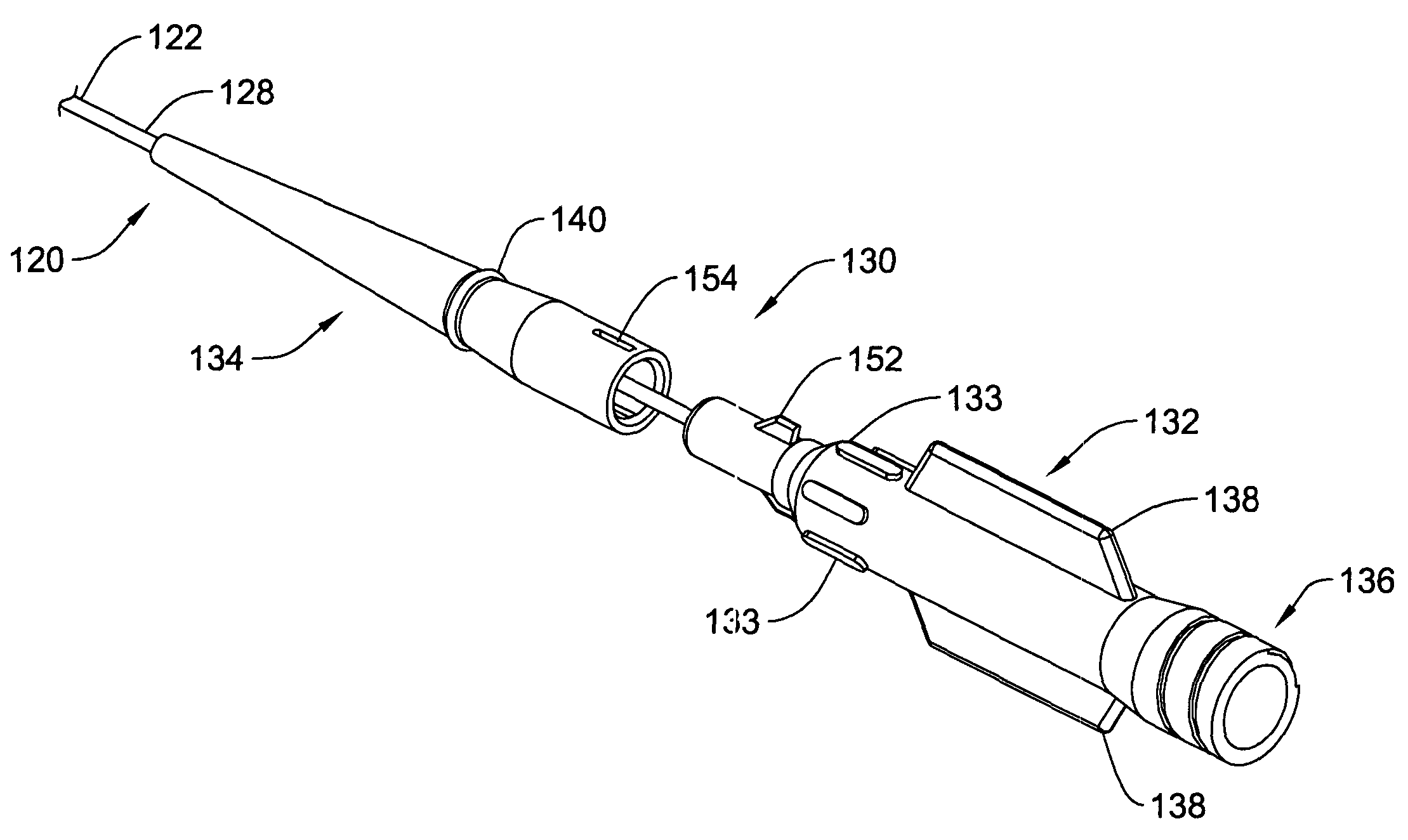

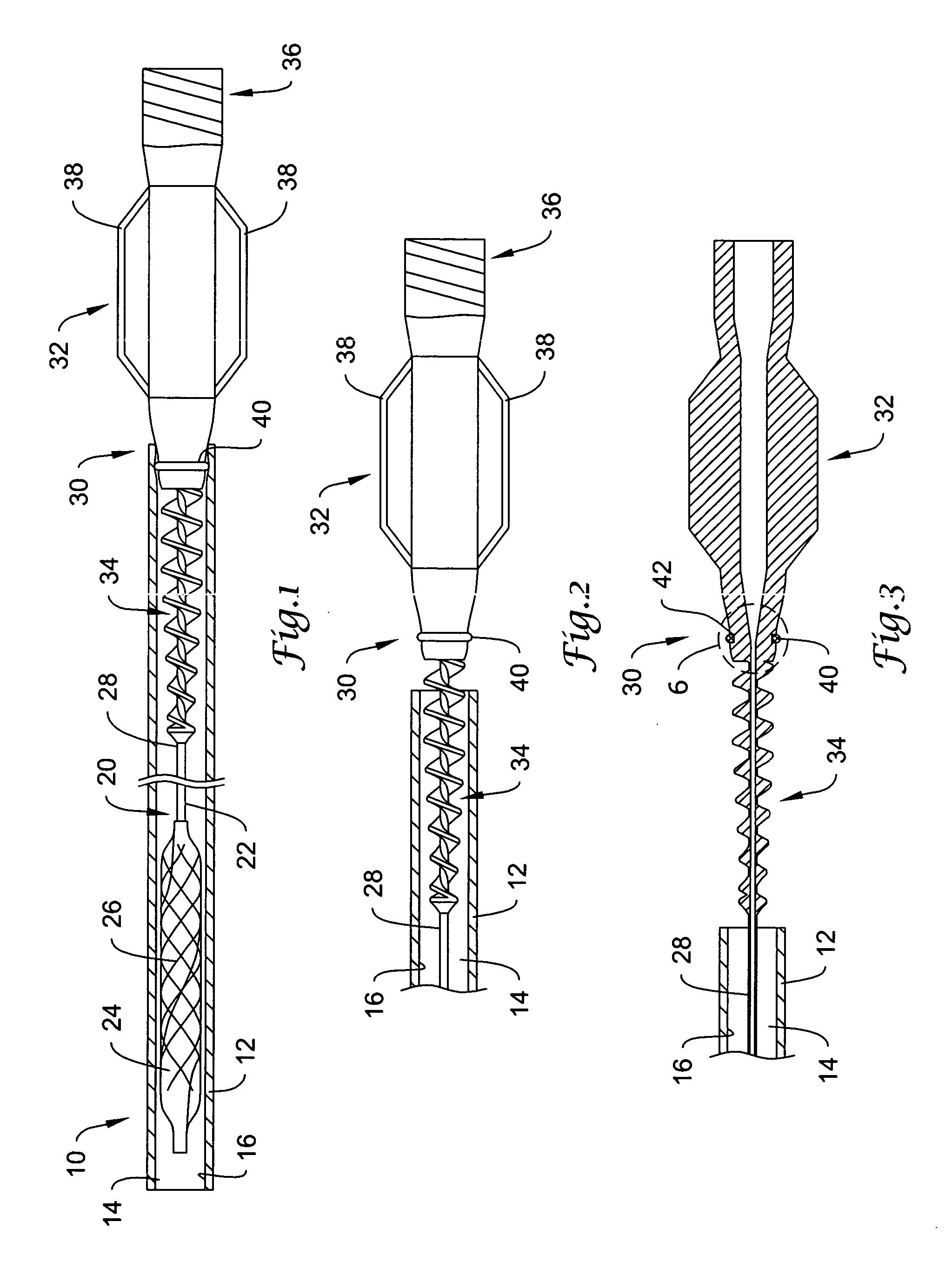

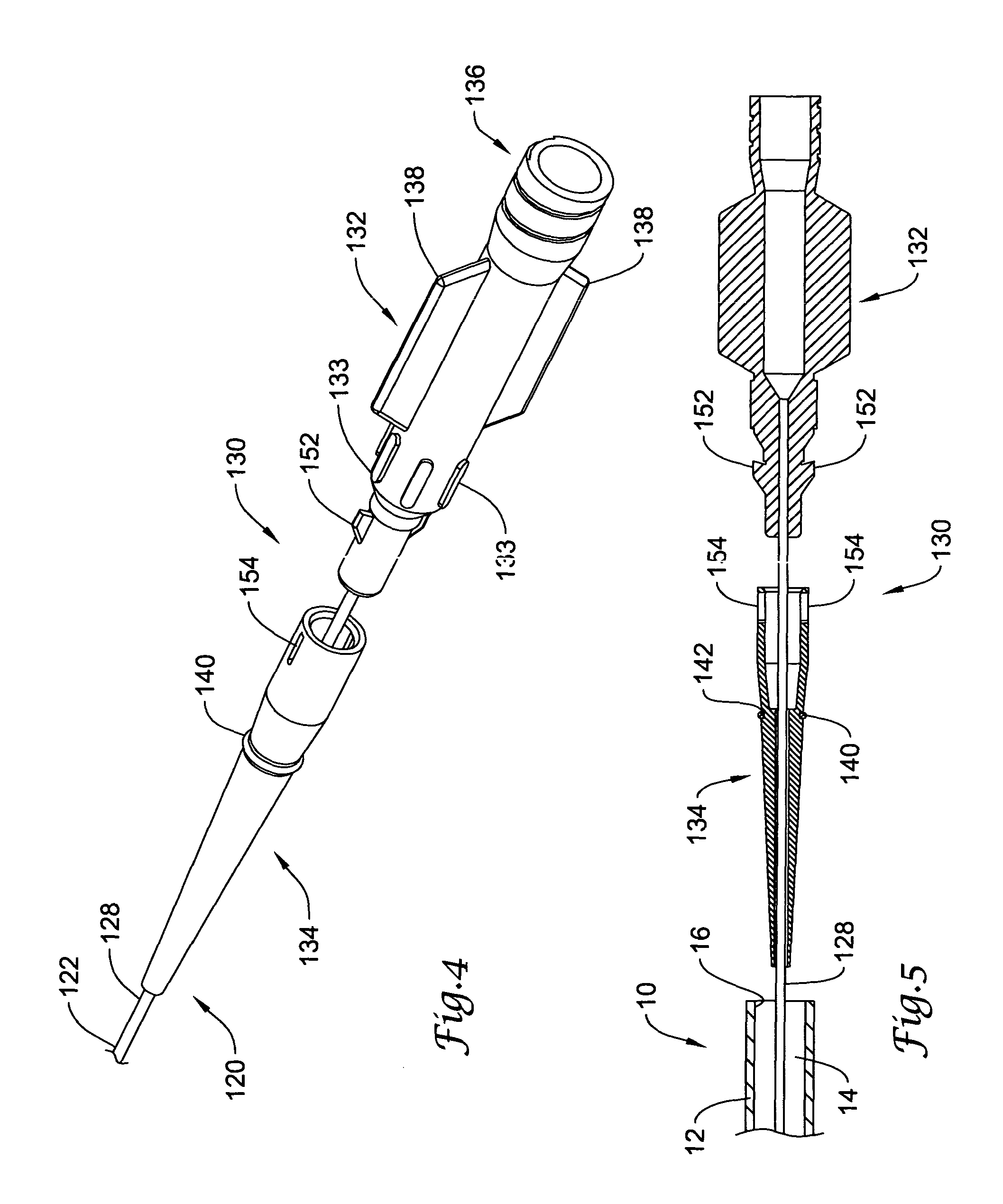

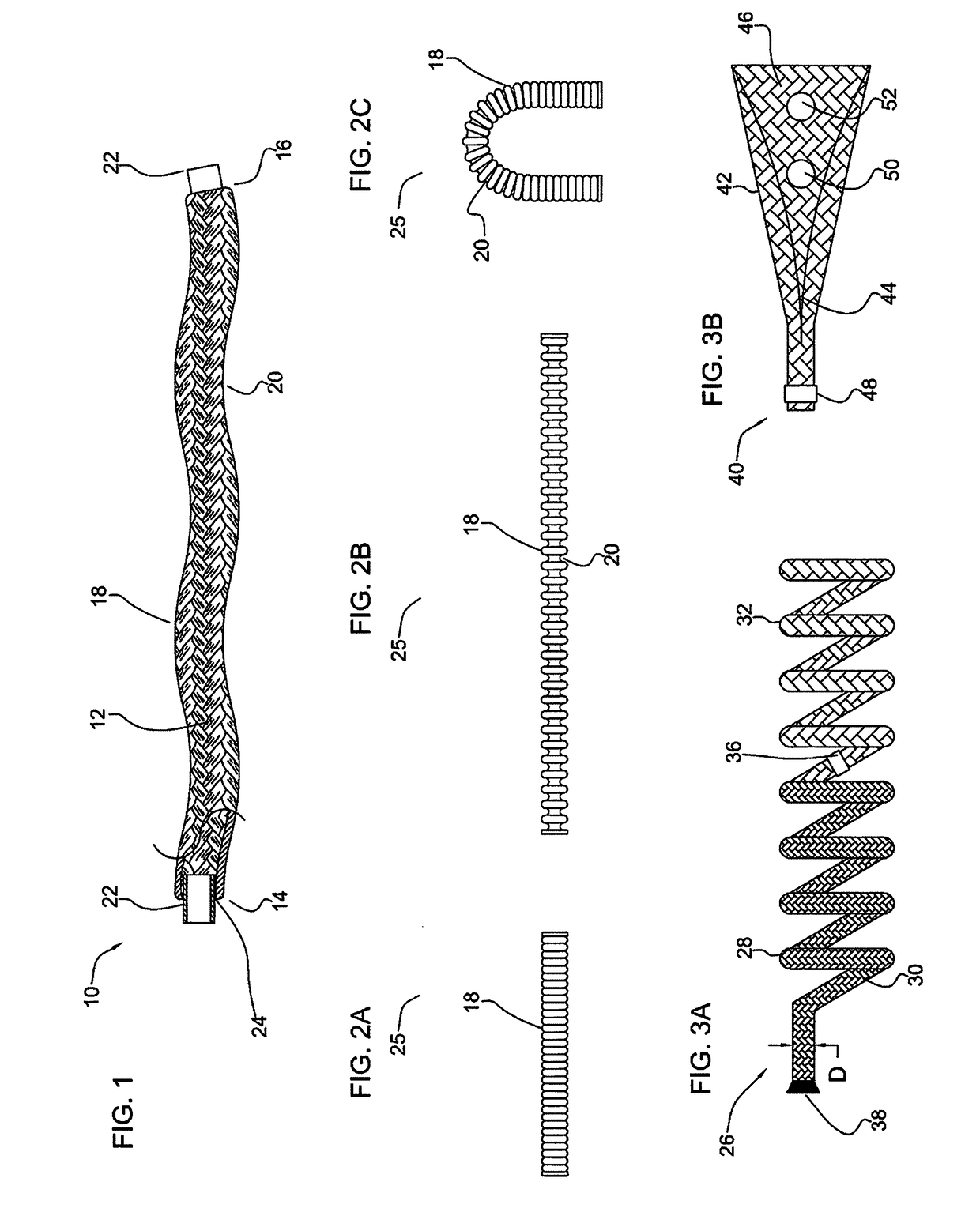

Elongate medical device having an interference fit packaging member

An elongate medical device including a hub assembly located at the proximal end. The hub assembly includes an interference fit member disposed about a portion of the hub assembly, whereby the interference fit member is configured to form an interference fit with the inner surface of a tubular packaging tube when the elongate medical device is placed in the packaging tube.

Owner:BOSTON SCI SCIMED INC

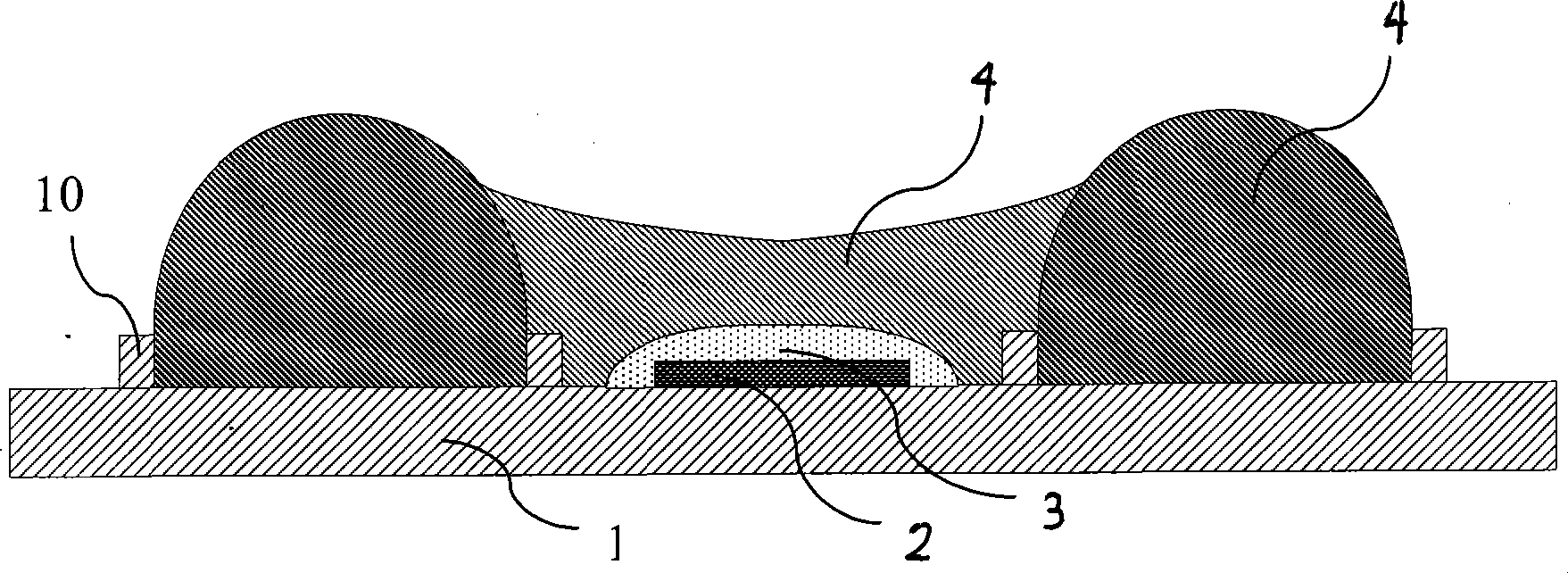

Encapsulation structure and method for white light emitting diode device

InactiveCN101452985ASolid-state devicesSemiconductor/solid-state device manufacturingPhysical chemistryThin membrane

The invention provides a packaging structure and a method for preparing white-light LED by utilizing phosphor thin films. The packaging structure and the method are characterized in that the phosphor thin films with various different parameters are prepared in advance and cut into the size needed for packaging an LED chip; after the LED chip is pasted in a packaging tube shell, the LED chip is first coated with a layer of packaging silica gel, and then the phosphor thin film with the needed parameters is placed on the silica gel through on-line detection according to the requirement on the photochromic quality of needed white light; and finally the packaging of a whole device is completed by use of the packaging silica gel. The packaging structure and the method can conveniently regulate the photochromic quality of the white light during production, simplify and shorten a color temperature regulation process for the white-light LED. In addition, the phosphor thin films prepared in advance can avoid the problem of phosphor precipitation in a dispensing process and a silica-gel solidifying process, so that the performance consistency of the white-light LED is easy to guarantee.

Owner:GUANGDONG REAL FAITH OPTO

Packing box for packing tube lamps

Owner:JIAXING SUPER LIGHTING ELECTRIC APPLIANCE

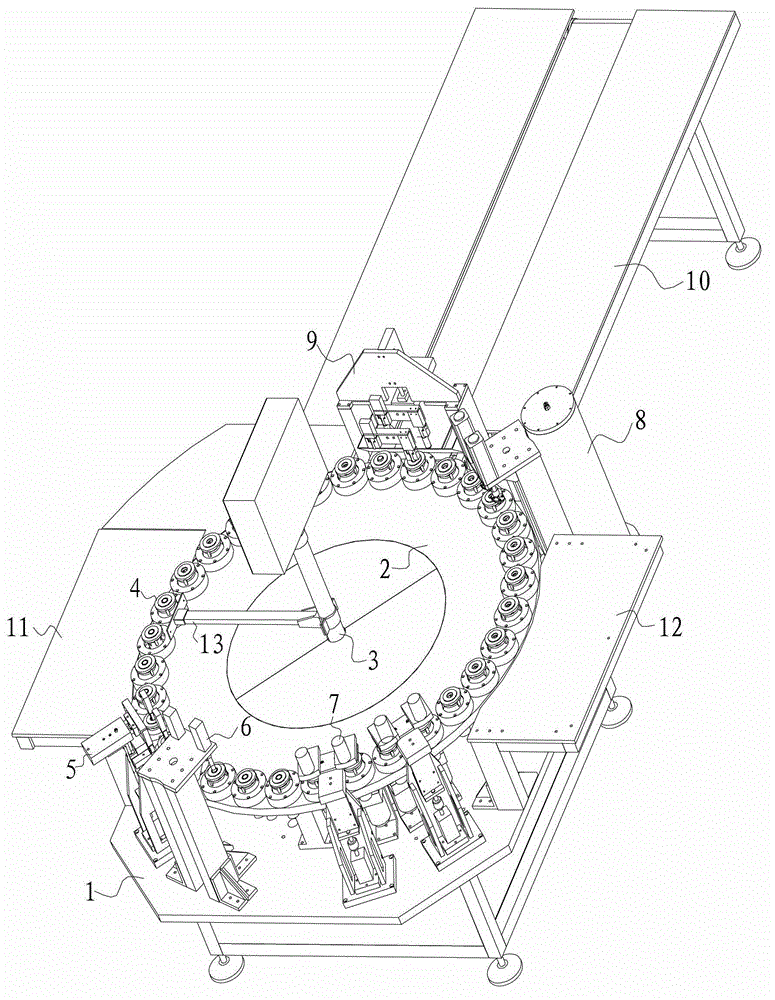

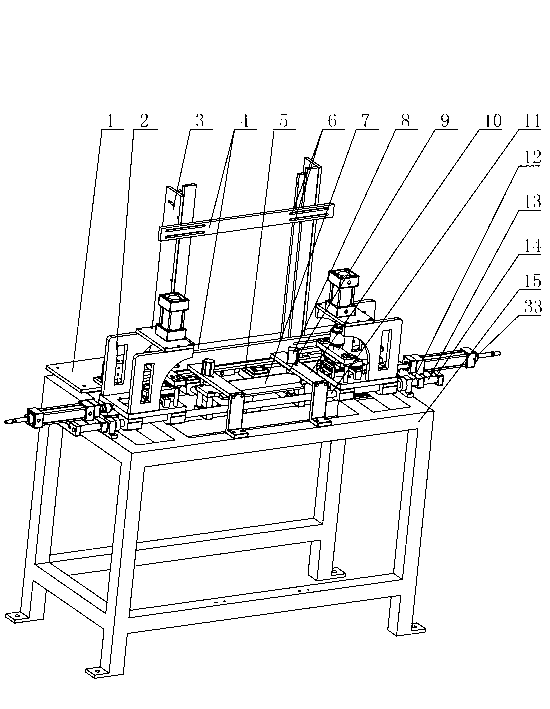

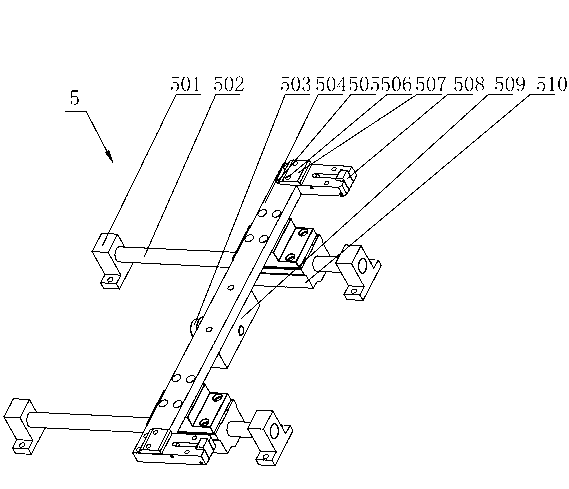

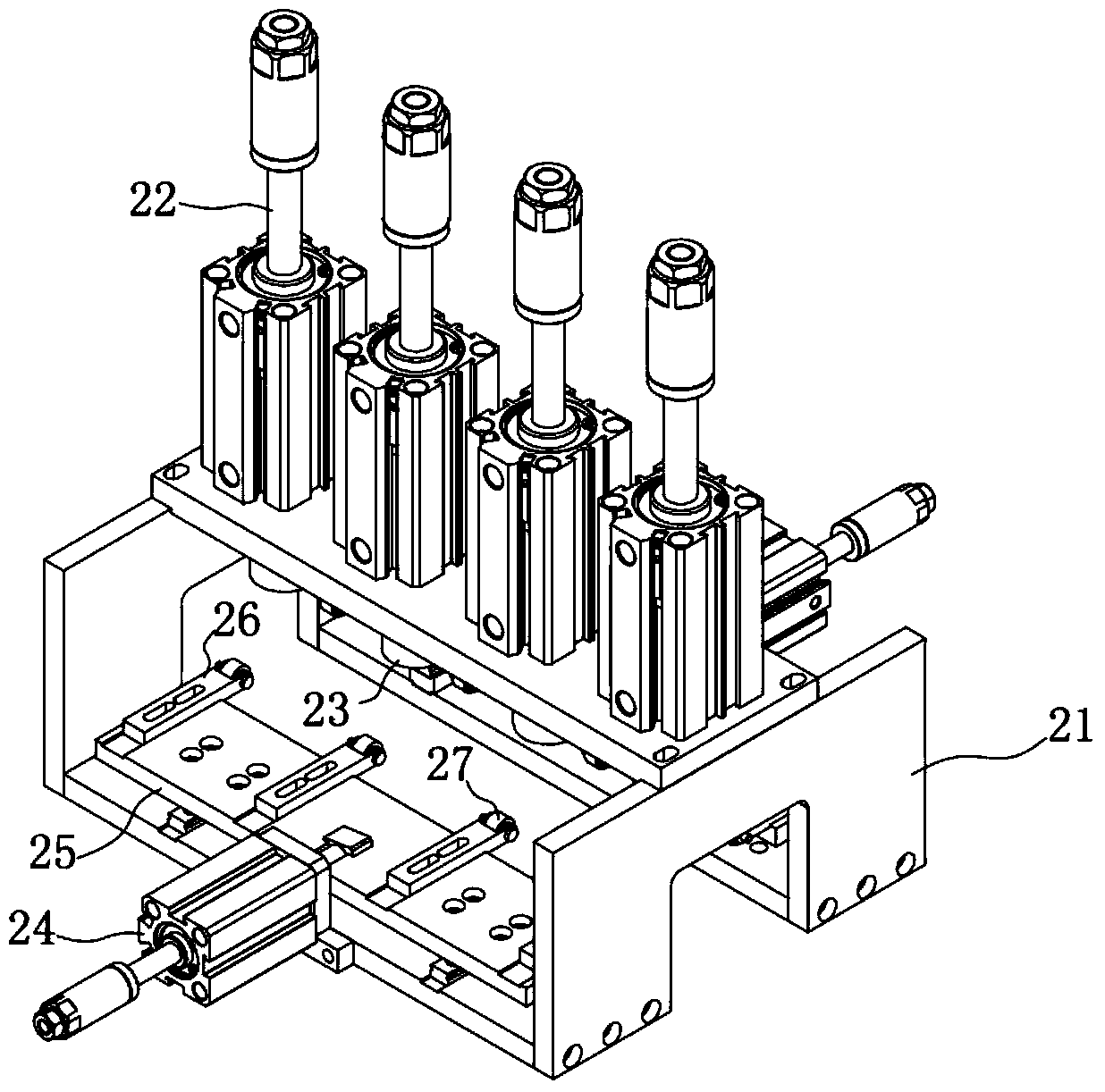

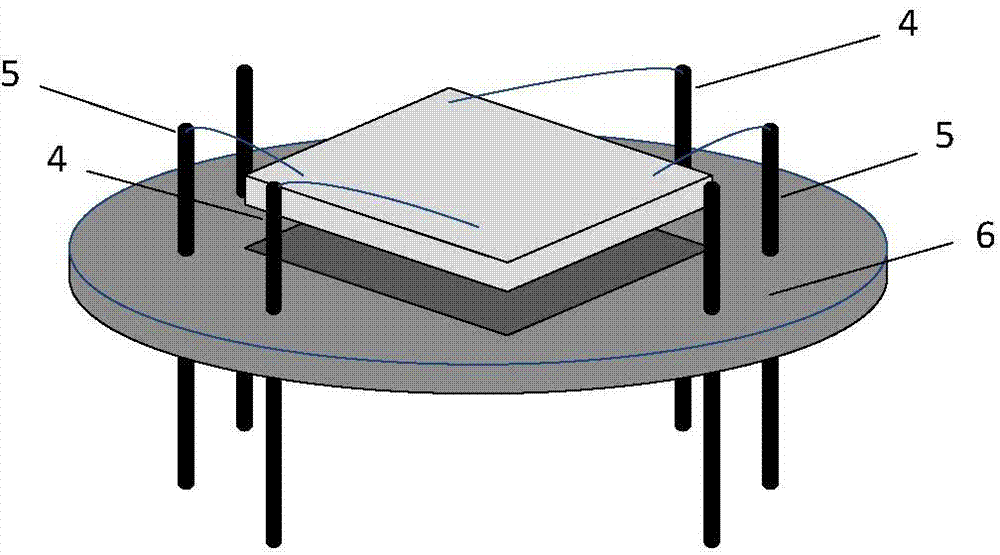

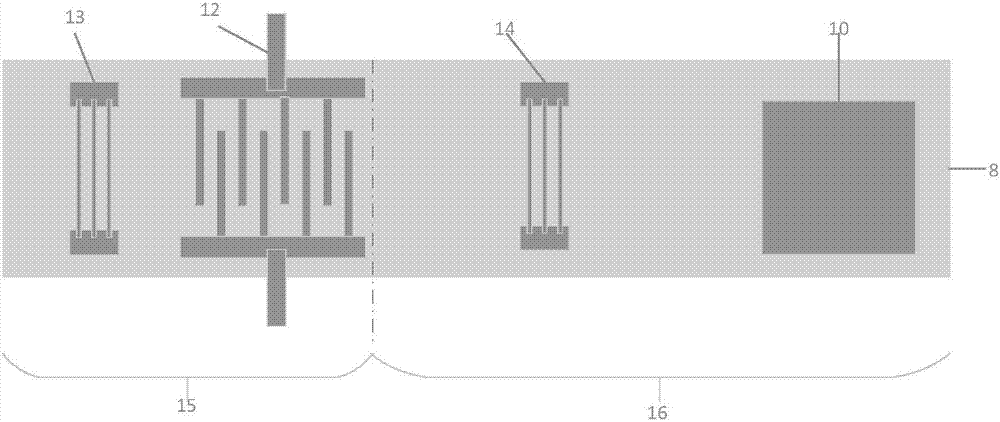

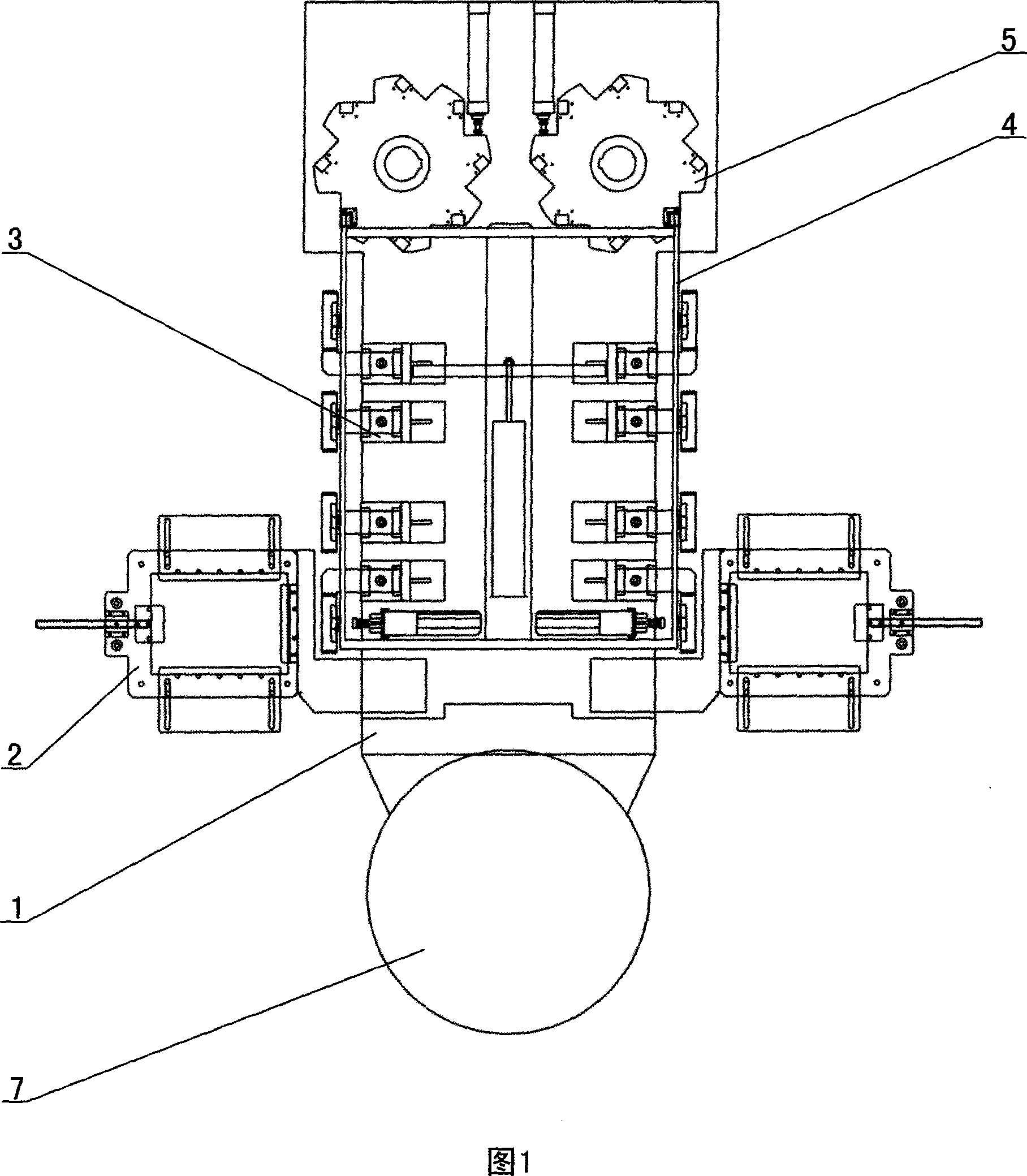

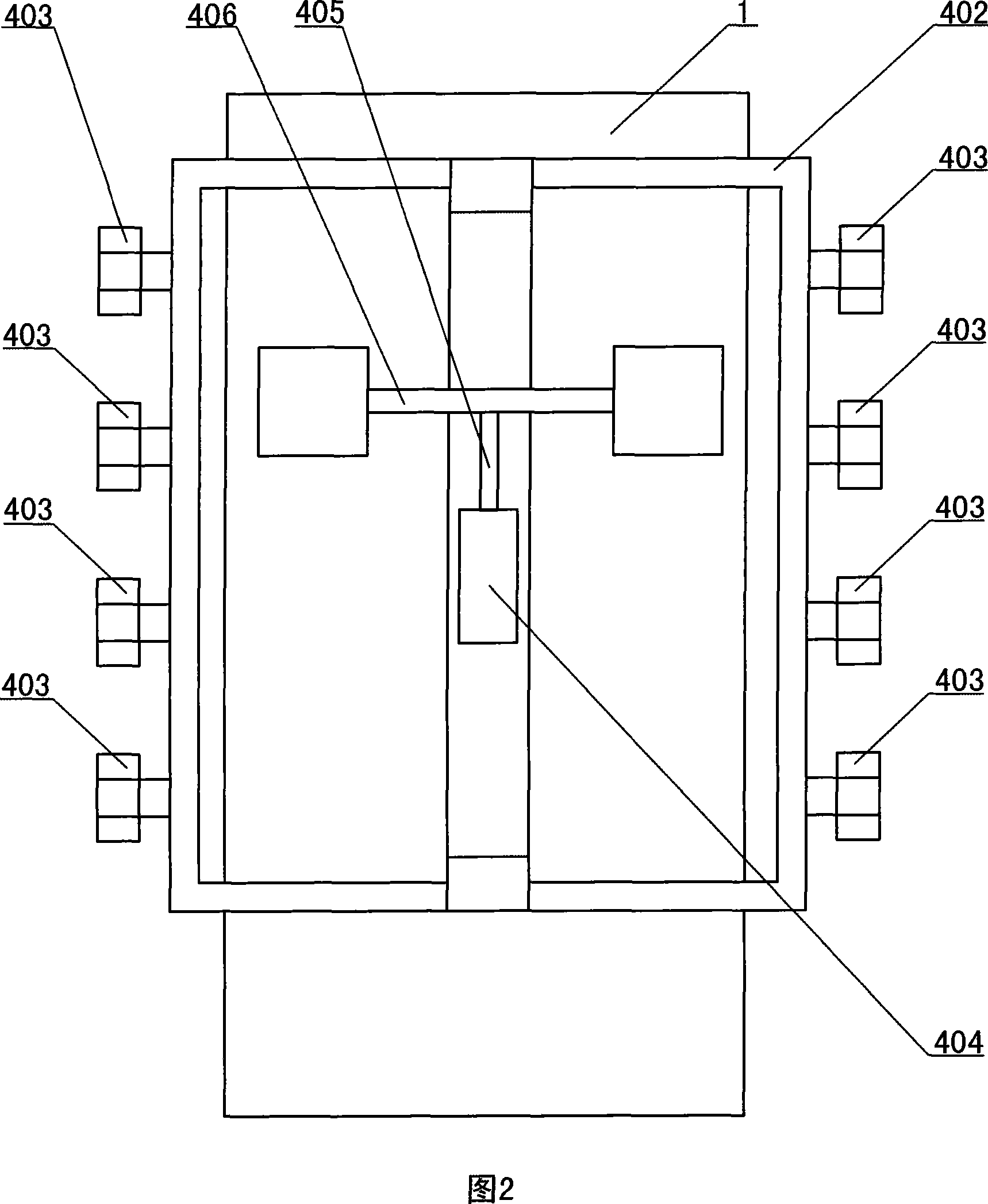

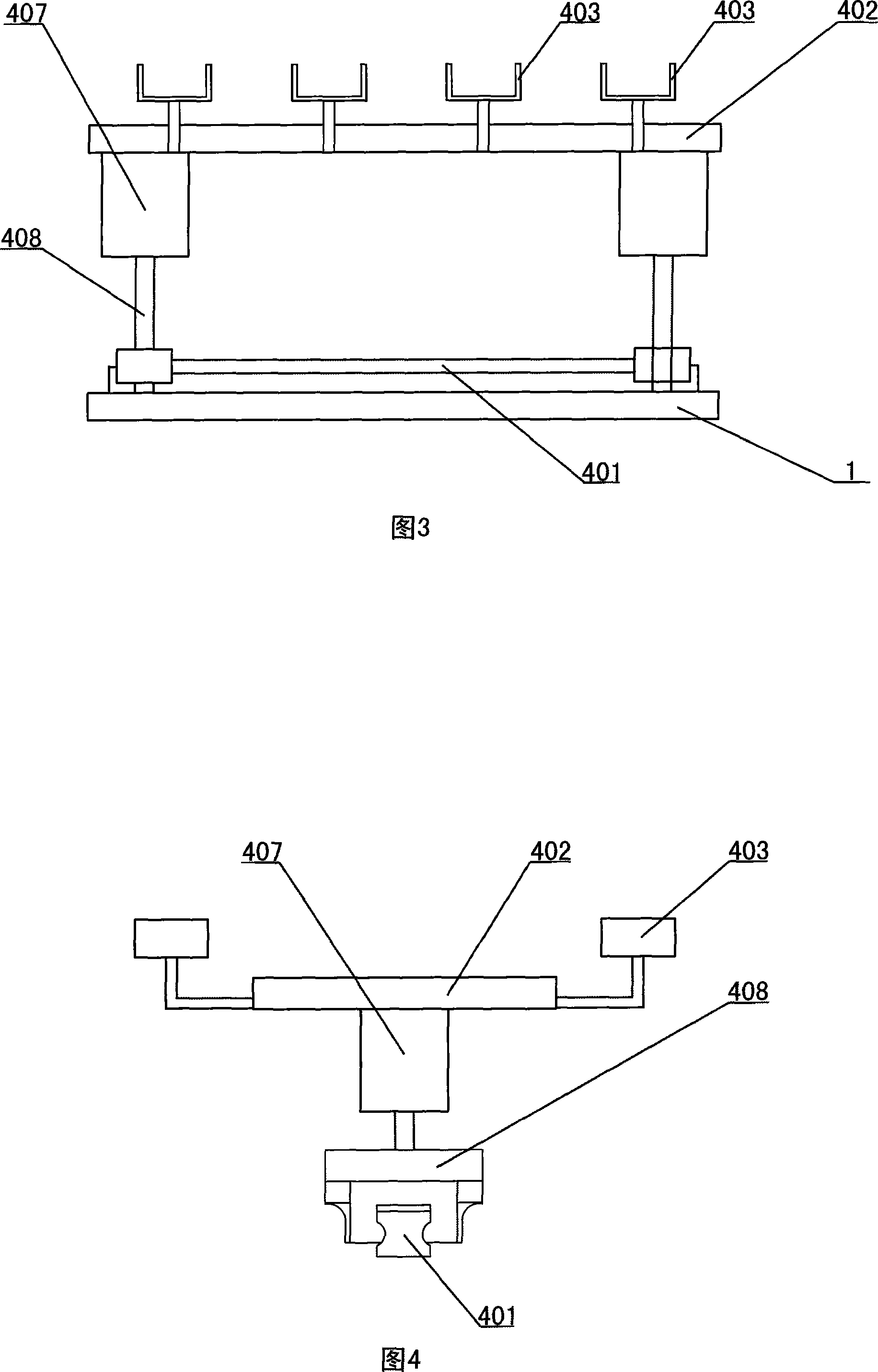

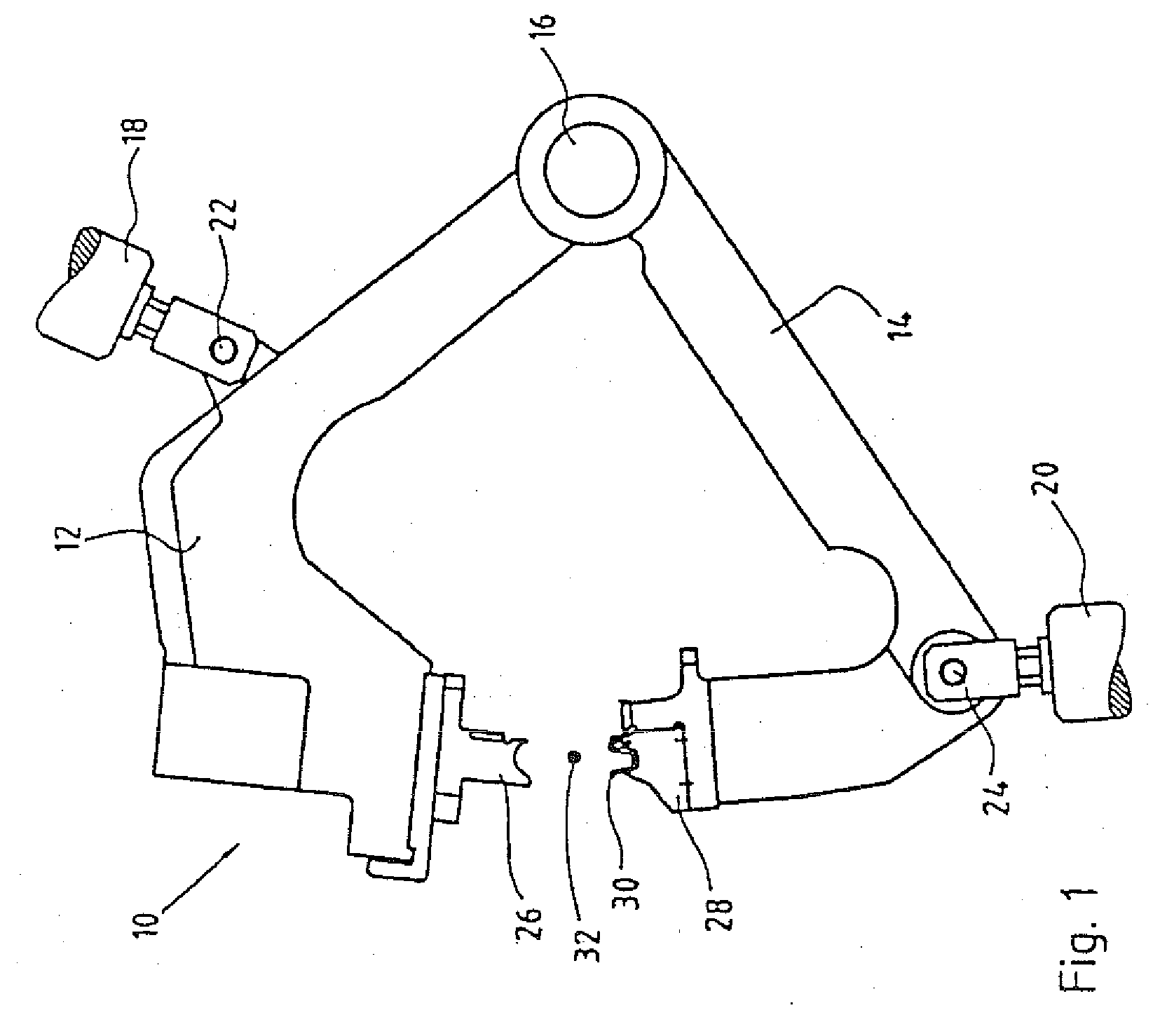

Lipstick packing tube assembling machine

ActiveCN102873536AAvoid enteringImprove assembly qualityAssembly machinesPackaging TubeAssembly machine

The invention discloses a lipstick packing tube assembling machine. A lipstick packing tube comprises an outer cover, a bush in the outer cover and a median-bundle core, and the lipstick packing tube assembling machine comprises a rack, a positioning turnplate, a plurality of fixtures, an automatic bush mounting device, a glue applying device, a compacting device and a discharging device, wherein the positioning turnplate is arranged on the rack; an outer cover mounting working area, a bush mounting working area, a glue applying working area, a median-bundle core mounting working area, a compacting working area and a discharging working area surround the positioning turnplate in sequence; a plurality of fixtures are arranged on the positioning turnplate in a ring form; the automatic bush mounting device is arranged in the bush mounting working area and used for arranging bushes in outer covers on the fixtures; the glue applying device is arranged in the glue applying working area and is used for applying glue to the outer covers with the bushes; the compacting device is arranged in the compacting working area and used for compacting median-bundle cores in the outer covers; and the discharging device is arranged in the discharging working area and used for separating the assembled lipstick packing tubes from the fixtures.

Owner:ZHEJIANG AXILONE SHUNHUA ALUMINUM IND

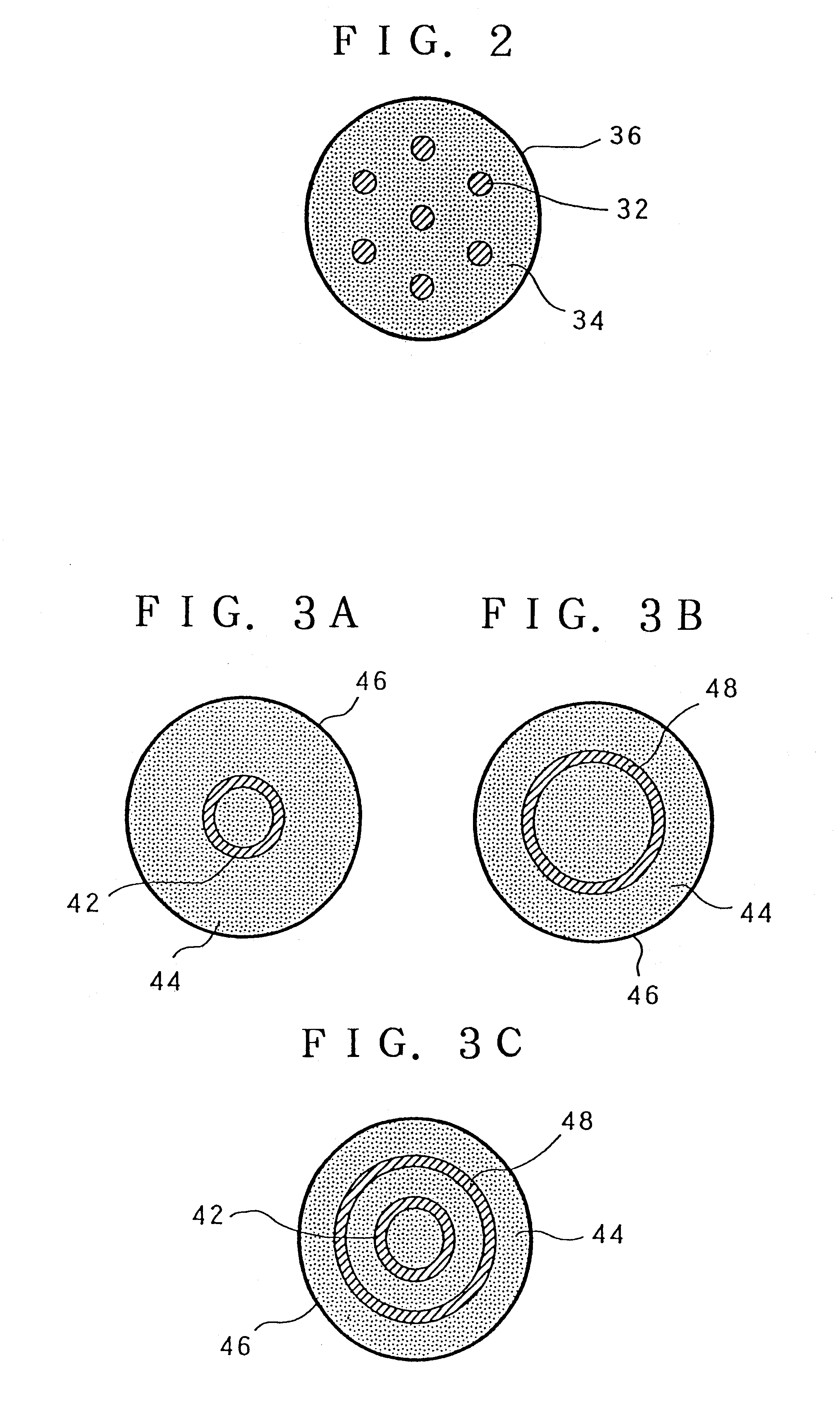

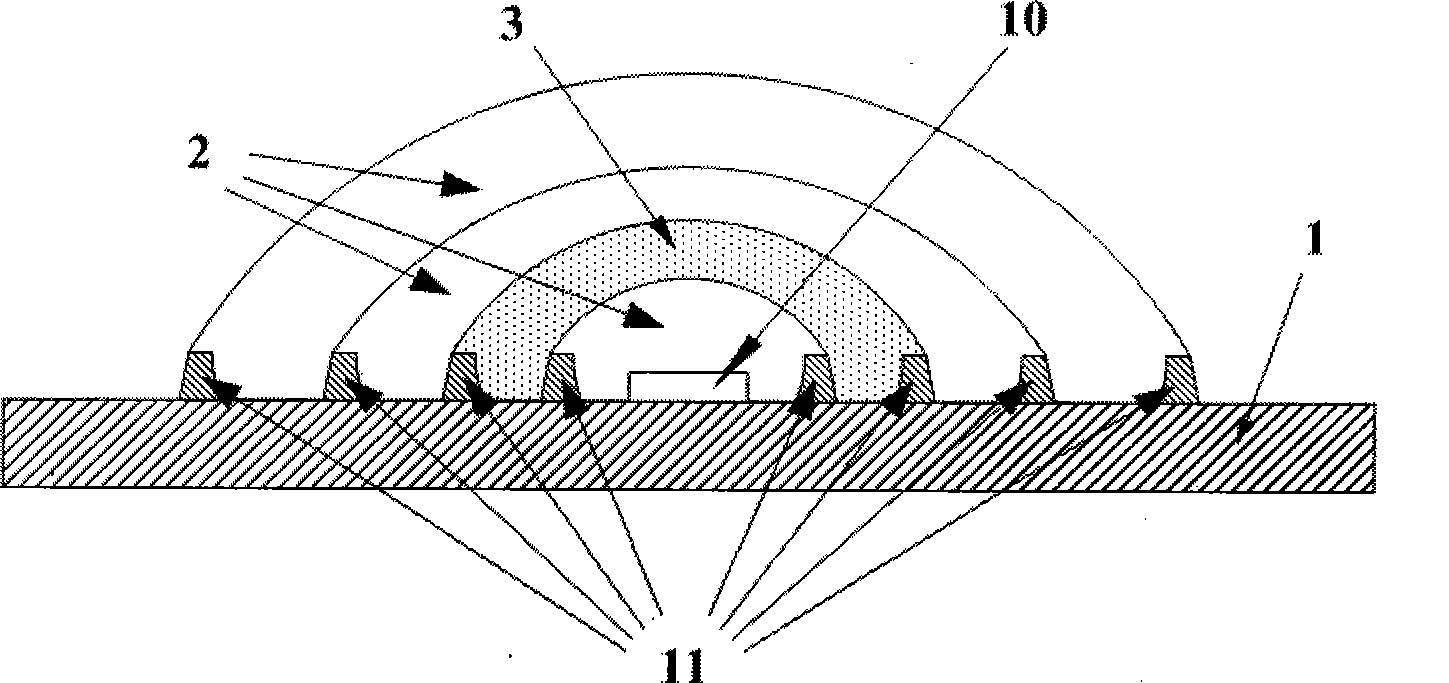

Encapsulation structure and method for applying guidance type light emitting diode device

InactiveCN101452987AImprove light extraction efficiencyImprove spot qualitySolid-state devicesSemiconductor/solid-state device manufacturingEffect lightEngineering

The invention relates to a structure and a method for packaging application-oriented LED devices. The structure comprises an LED chip, a packaging tube shell, phosphor gel, packaging colloid and a lens, wherein the LED chip is pasted in the packaging tube shell; a chip electrode is connected with a circuit layer in the packaging tube shell; the LED chip is packaged by the packaging colloid or the phosphor gel; the lens is manufactured by use of a mold or a precision machining method; at least one surface selected from the light outlet surface and the light inlet surface of the lens is a free curved surface; the lens is manufactured by pouring the packaging colloid or by a self-flow forming method; the light outlet surface of the lens is a free curved surface; and the lens is a single lens, a plurality of lens combinations or a lens array. As the invention adopts the application-oriented free-curved-surface lens to package an LED module, the LED module can be directly applied to different lighting occasions, and no other secondary optical system is needed when an LED lamp is designed. Therefore, the invention has the advantages of improving the light-emitting efficiency and spot quality of the LED module, improving the efficiency of the LED lamp, reducing the volume of the LED lamp and providing use convenience for users.

Owner:GUANGDONG REAL FAITH OPTO

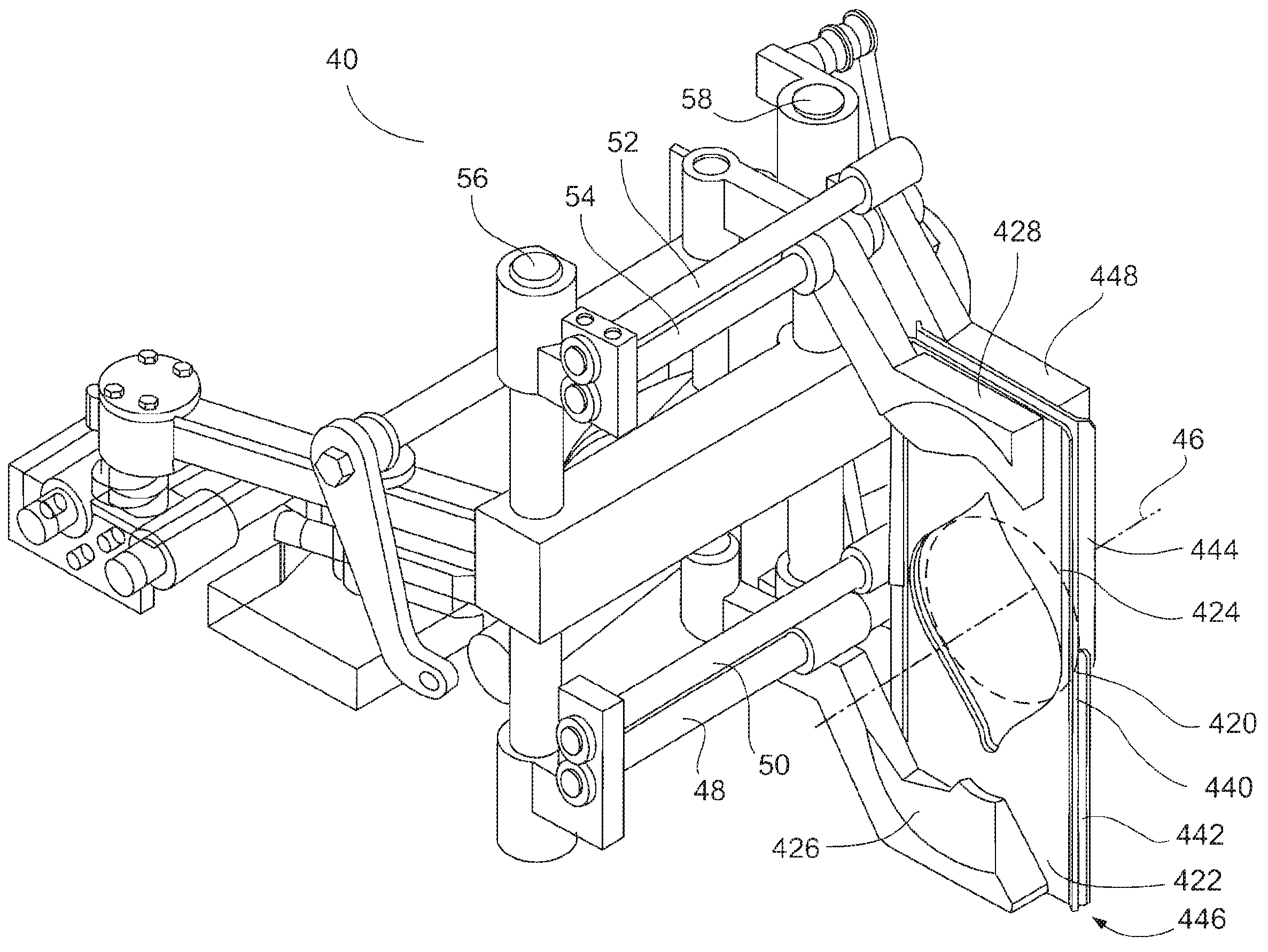

Semi-automatic punching machine for packaging tube

ActiveCN102862183AReasonable structureSimple and fast operationMetal working apparatusPunchingEngineering

The invention relates to a semi-automatic punching machine for a packaging tube, comprising a base, wherein steps are formed on the upper surface of the base, a workbench is arranged at the middle of the first step surface, a main guide rail is arranged on the lower part of the workbench, and punching mechanisms are symmetrically installed on the main guide rail and at the both ends of the workbench respectively; a bottom plate is installed on the second step surface of the base, a groove opening is formed at the middle of the bottom plate, an arranging frame is arranged at the groove opening, packaging tube limit mechanisms are arranged at the outer ends of the bottom of the arranging frame respectively, and a feeding mechanism is arranged on the lower part of the bottom plate; and a pressing mechanism is further arranged above the workbench. The semi-automatic punching machine reduces labour intensity, is high in production efficiency and reliable in working, and guarantees the product quality.

Owner:WUXI JIAXIN ELECTRONICS PRODS

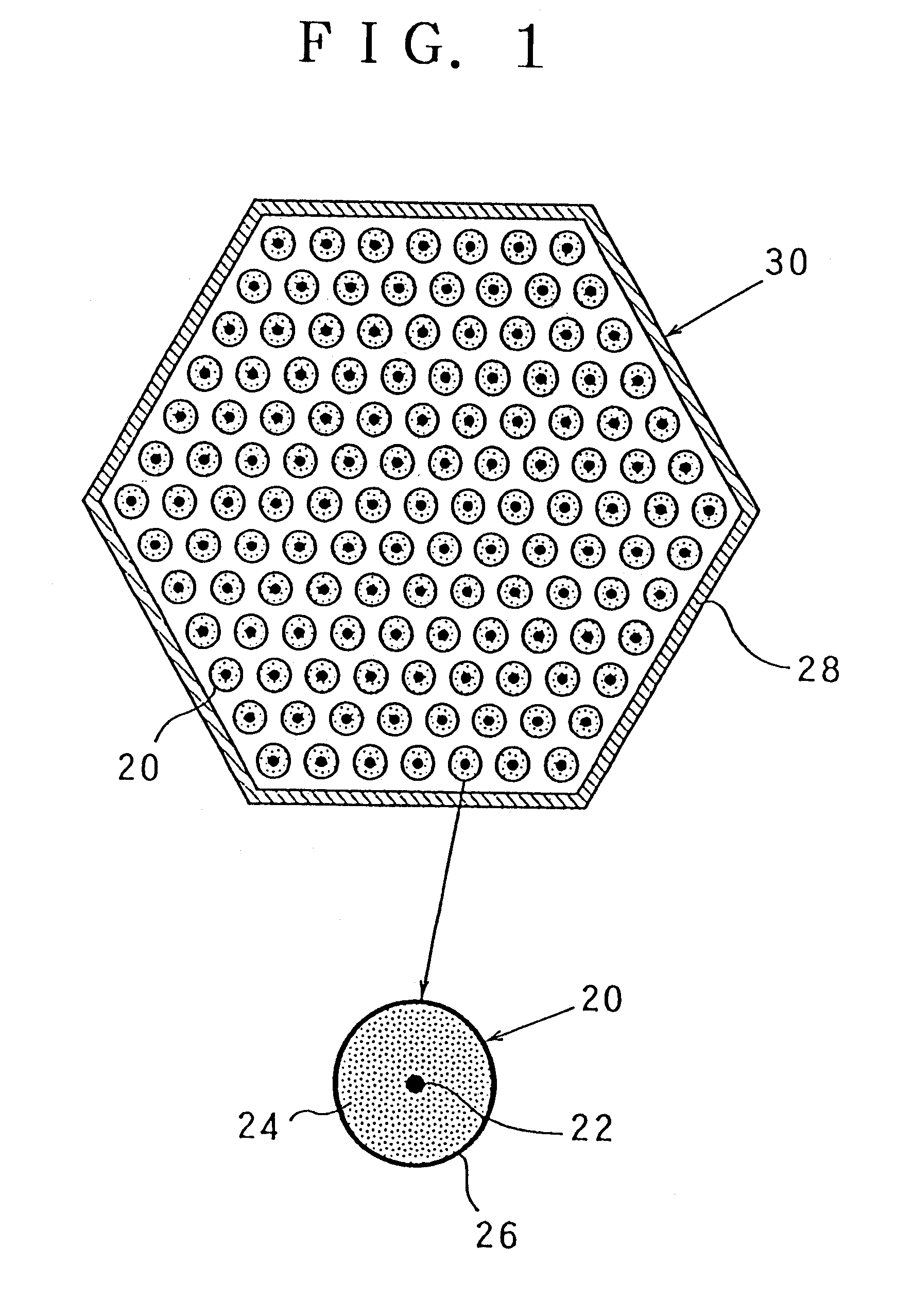

Reactivity control rod for core

InactiveUS7139352B2Prevent liquid leakageReduce the valueIntegral reactorsFuel elementsNuclear engineeringNeutron moderator

A reactivity control rod adapted to be used in a reactor core of a fast reactor and disposed at a substantially central portion of the reactor core for controlling a reactivity therein. The reactivity control rod includes a wrapper tube surrounded by a plurality of fuel rods in a reactor core, and a plurality of neutron absorber rods arranged in the wrapper tube. At least one of the plurality of neutron absorber rods includes a cladding tube and a mixture filled in the cladding tube. The mixture is composed of a neutron absorber that absorbs a neutron and a neutron moderator that moderates the neutron.

Owner:KK TOSHIBA

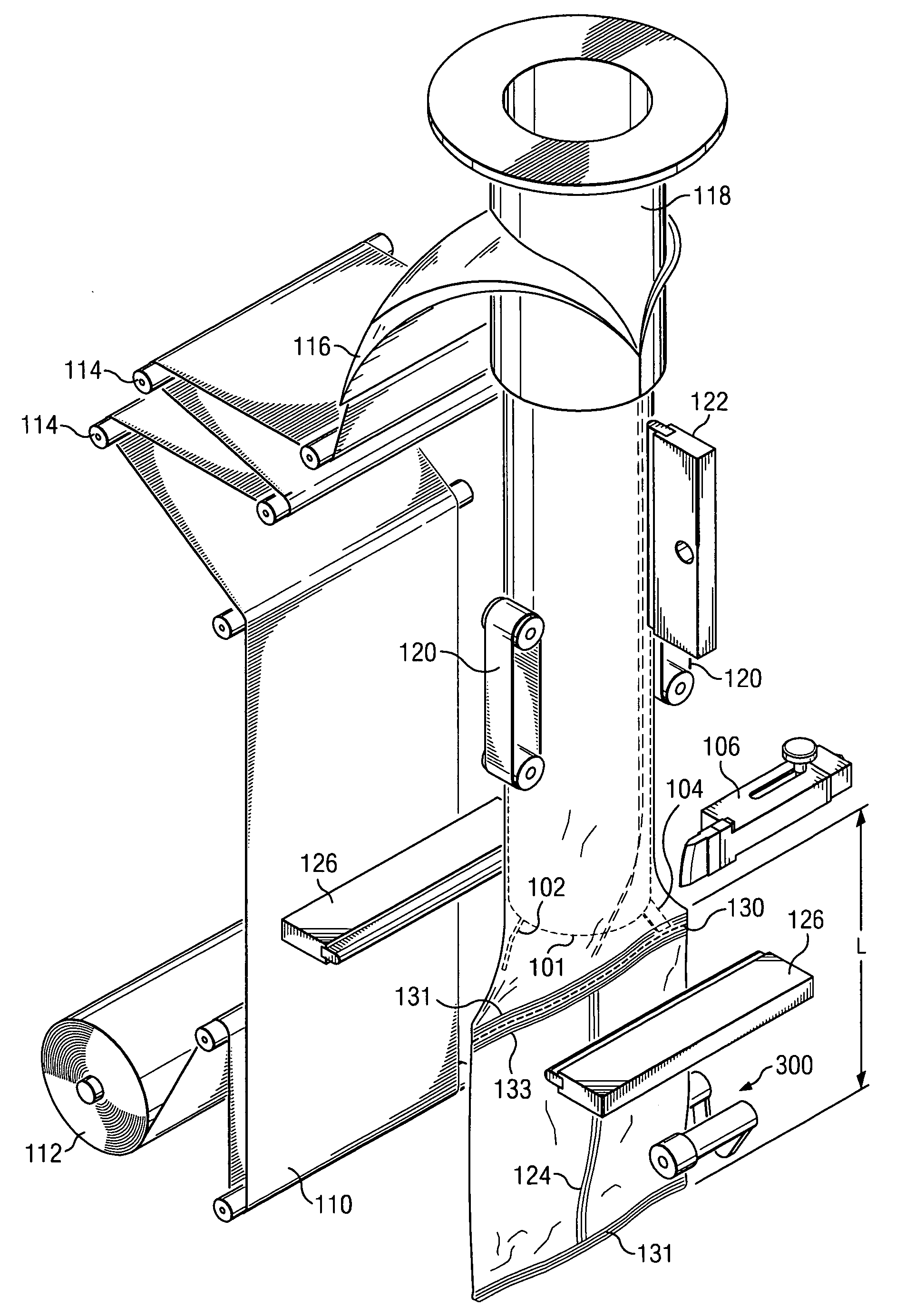

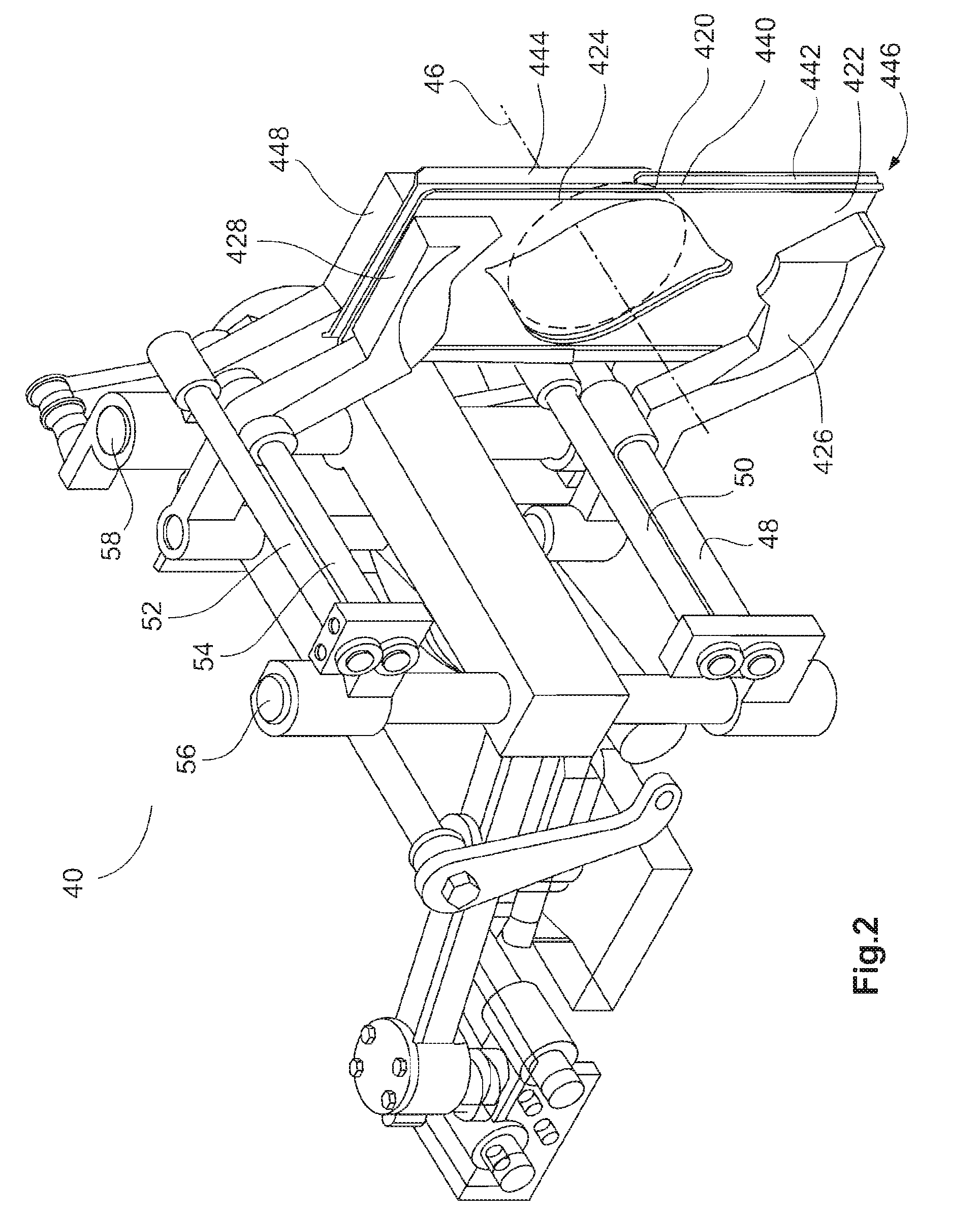

Indexing welding device for tube

ActiveUS9539760B2Inertia of the device is lowerShorten the timeConveyor partsTubular articlesEngineeringPackaging Tube

Owner:AISAPACK HLDG SA

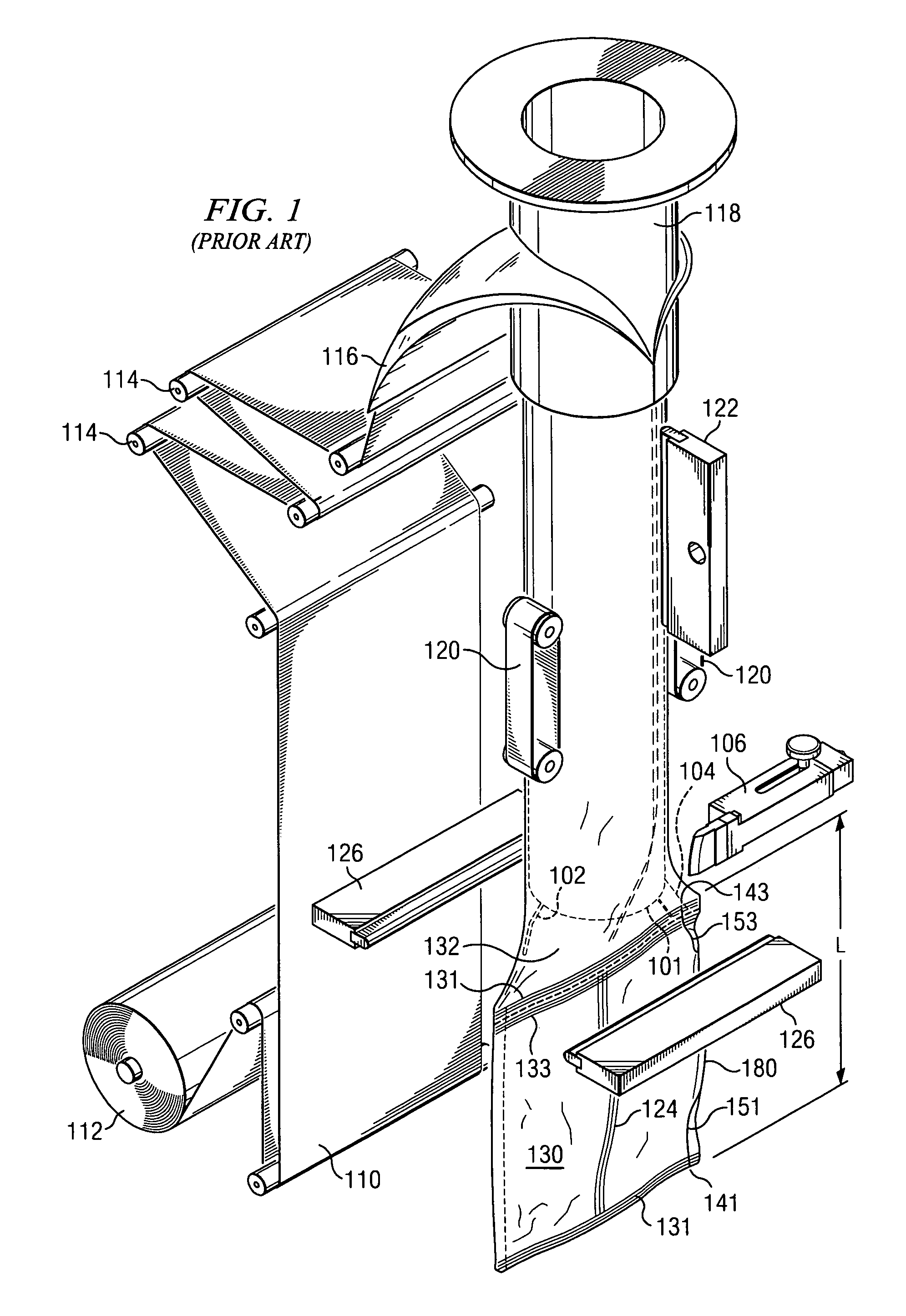

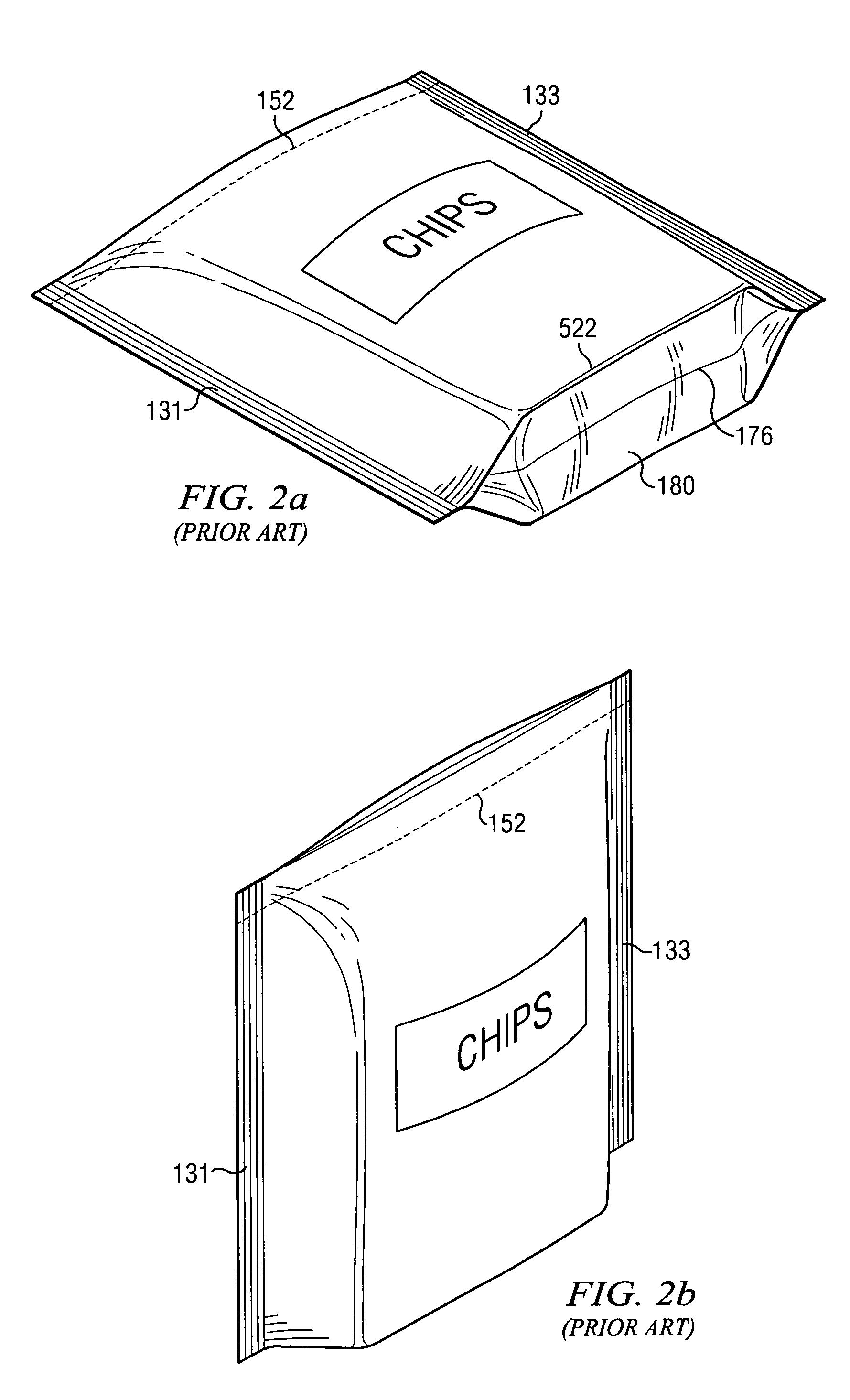

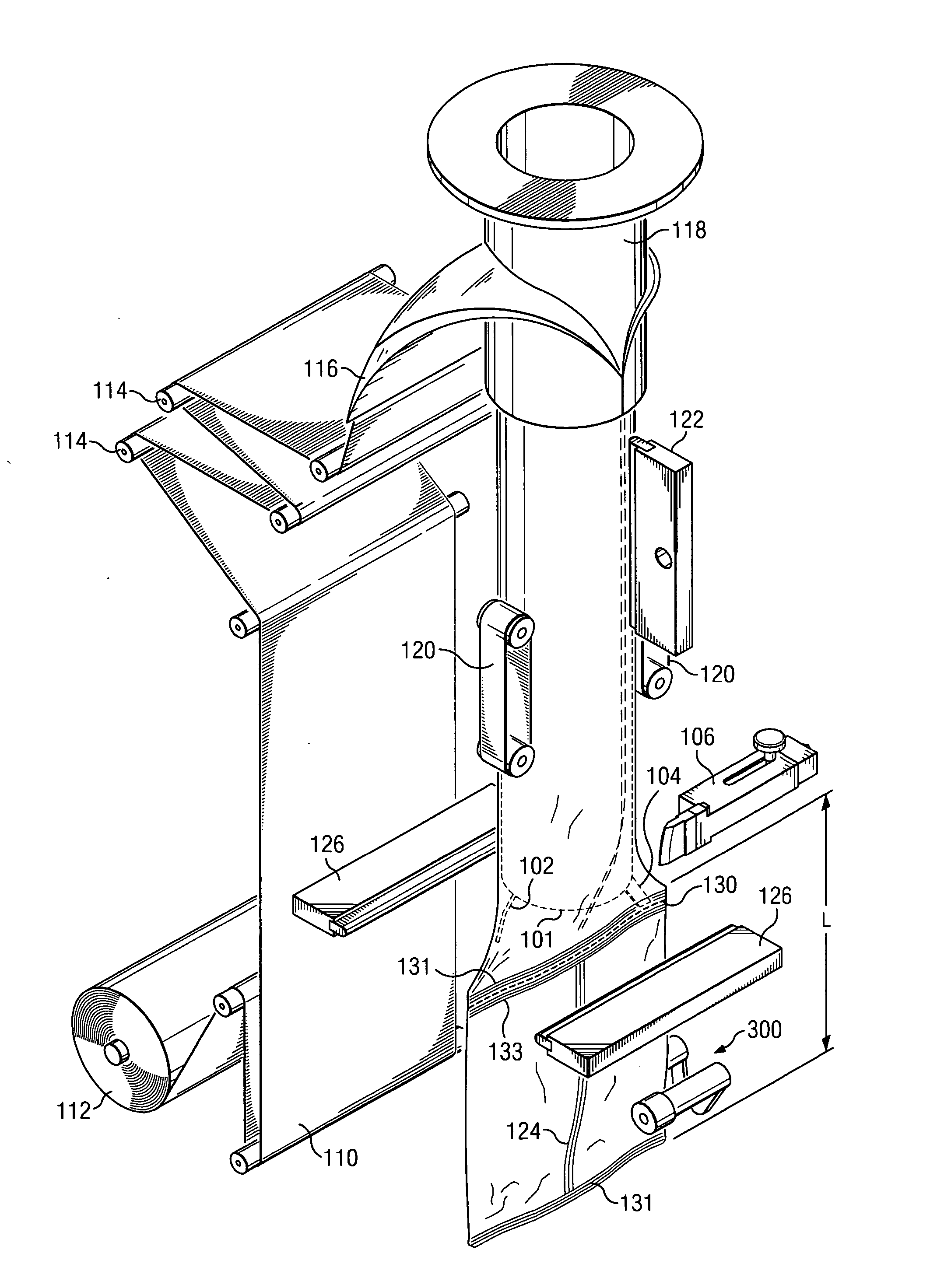

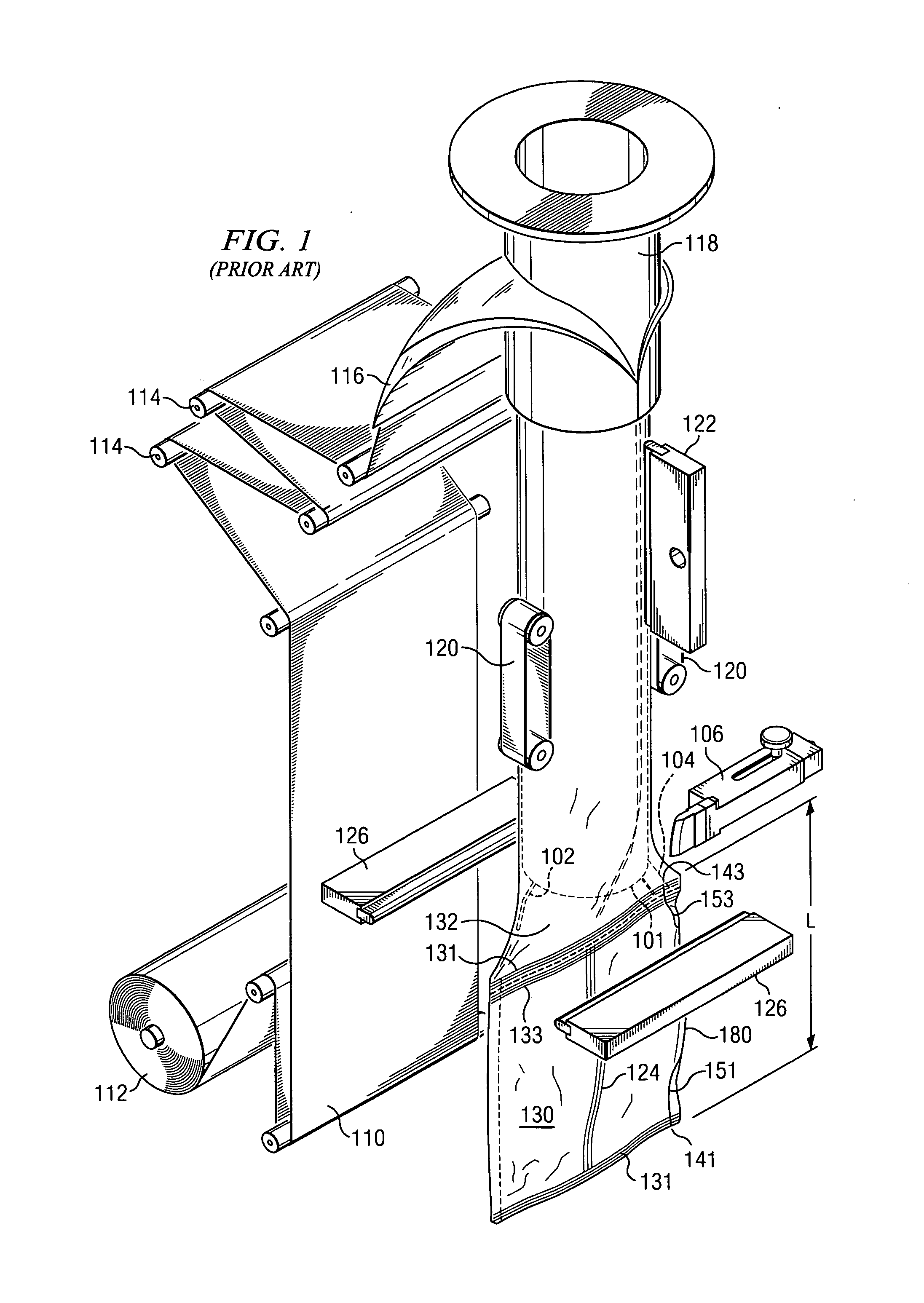

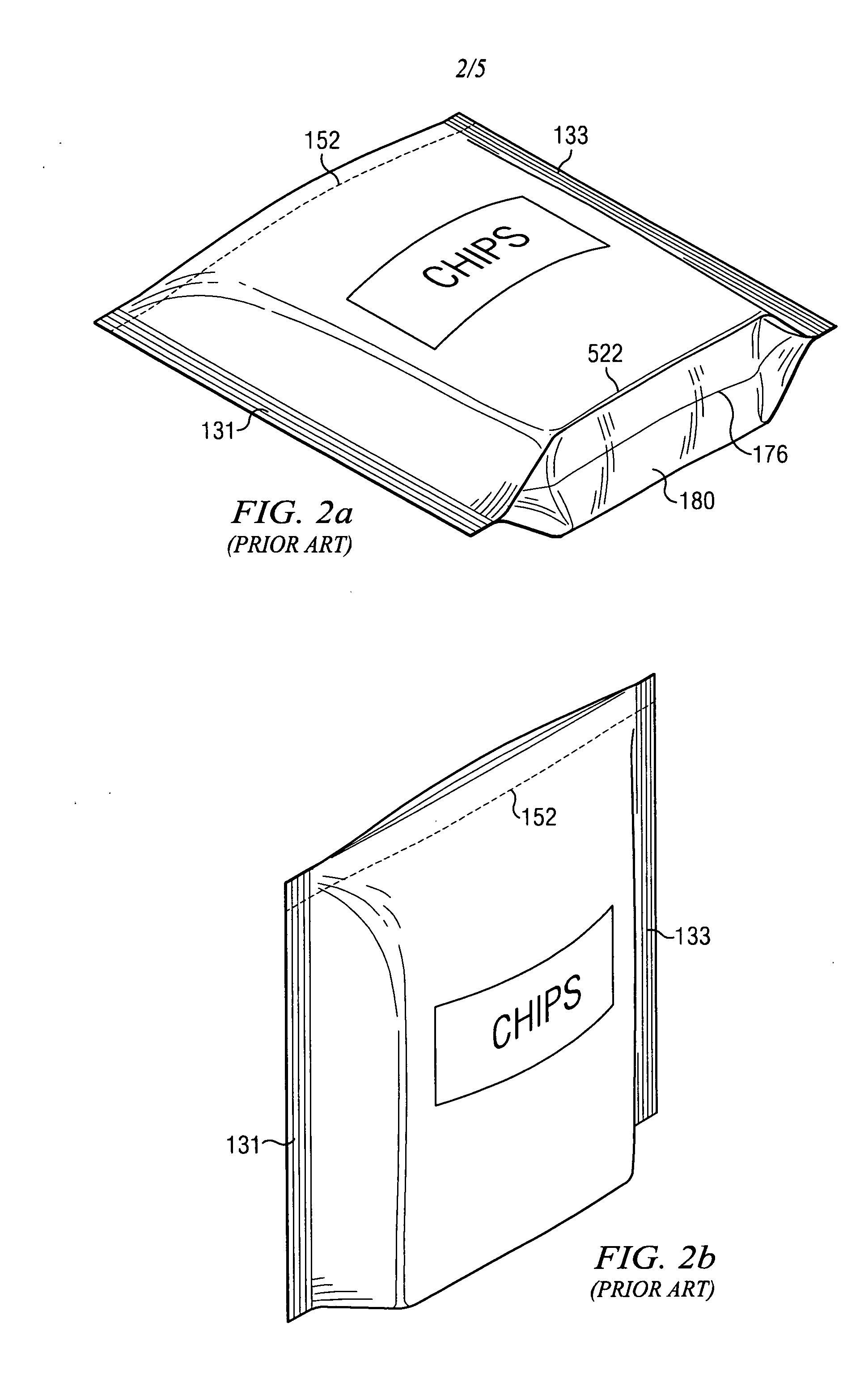

Method and apparatus for providing end seals on vertical stand-up packages

An improved method and apparatus for providing end seals on vertical stand up packages that prevents pleat formation and gusset variation. A clamping device is mounted below sealing jaws. A bottom end seal is made by the sealing jaws to form an open-ended tube. The open-ended tube is moved downward. The clamping device engages the tube to prevent twisting when product is placed into the tube. Product then enters an open-ended tube of flexible film packaging and the top seal is made.

Owner:FRITO LAY NORTH AMERICA INC

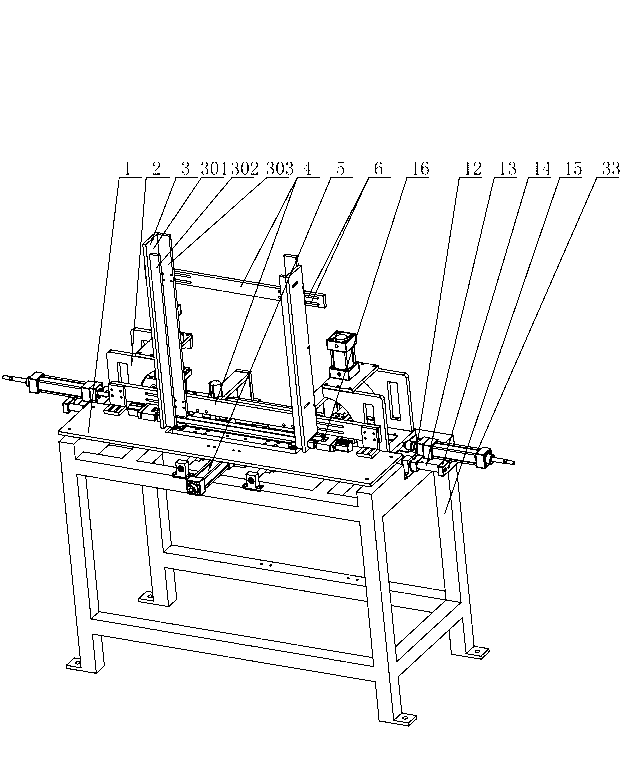

Automatic assembly machine for lipstick packaging pipes

ActiveCN104015050ASmall footprintHigh positioning accuracyAssembly machinesSmall footprintEngineering

The invention discloses an automatic assembly machine for lipstick packaging pipes. The automatic assembly machine for lipstick packaging pipes comprises a main machine frame, a workbench at the top of the main machine frame is provided with an annular guide rail groove, and the guide rail groove is internally provided with a jig board for placement of lipstick packaging pipes in a sliding fit mode. The workbench is sequentially divided into a lateral plate press-fitting working area, a shim plate installation working area, a glue touching working area, a middle bundle core press-fitting working area and a discharge working area around the guide rail groove. Each working area is internally provided with a corresponding function mechanism for assembling components of lipstick packaging pipes. The automatic assembly machine is small in occupied space, high in locating accuracy and low in cost, four working stations can operate at the same time, each working area is provided with a larger space, and later rectification and adjustment of the automatic assembly machine are facilitated.

Owner:ZHEJIANG AXILONE SHUNHUA ALUMINUM IND

Packaging material and packaging bag

Owner:TOPPAN PRINTING CO LTD +1

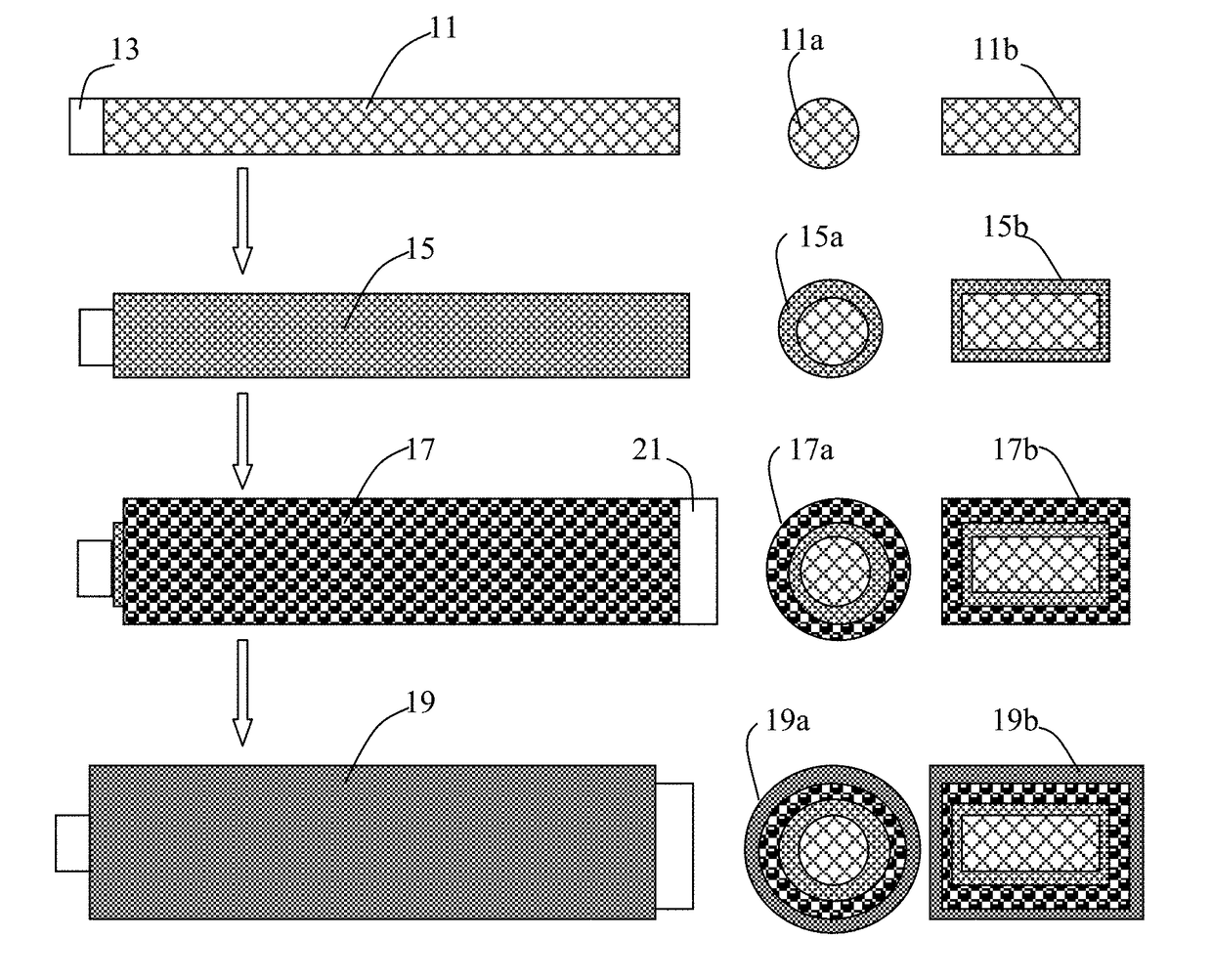

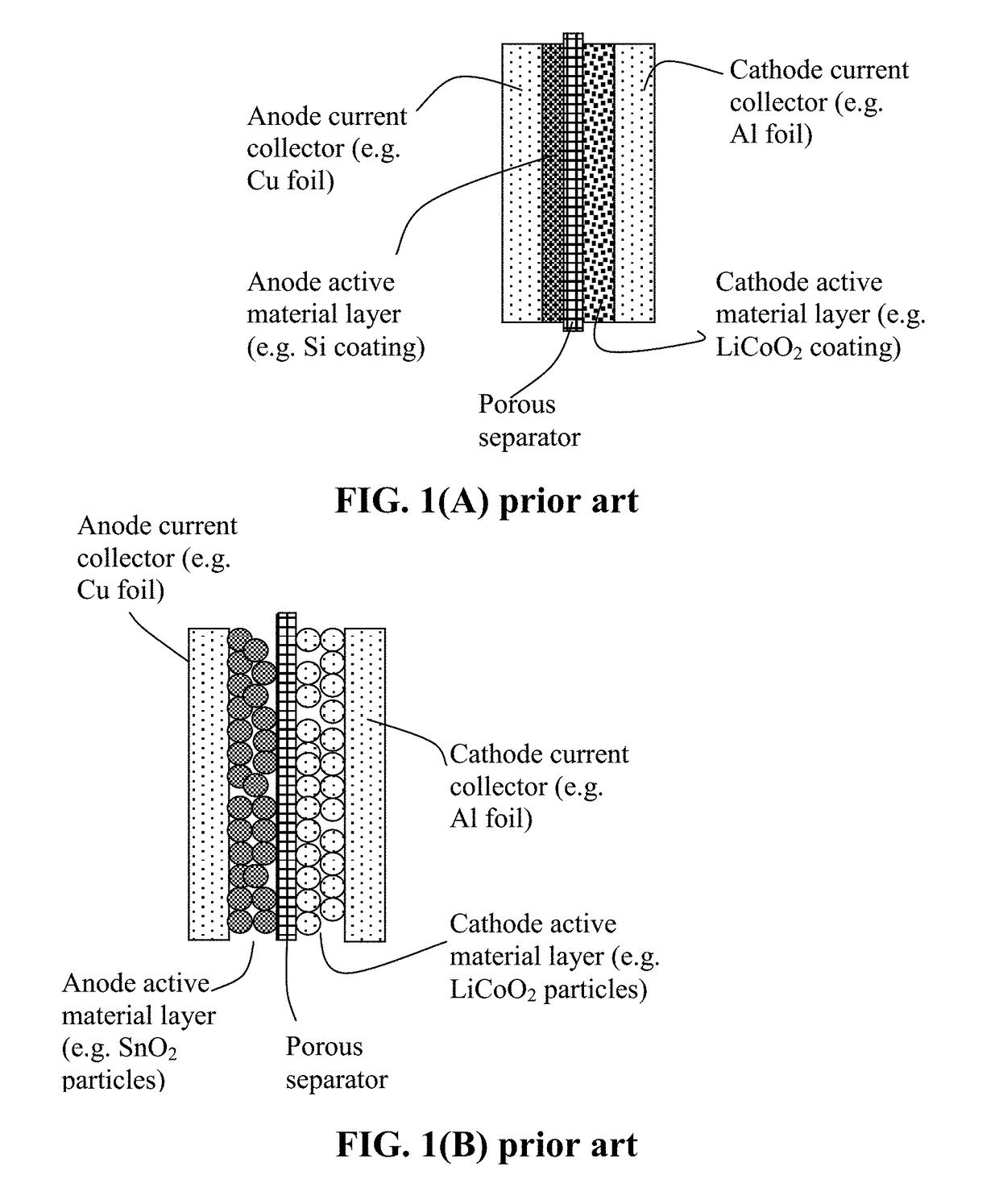

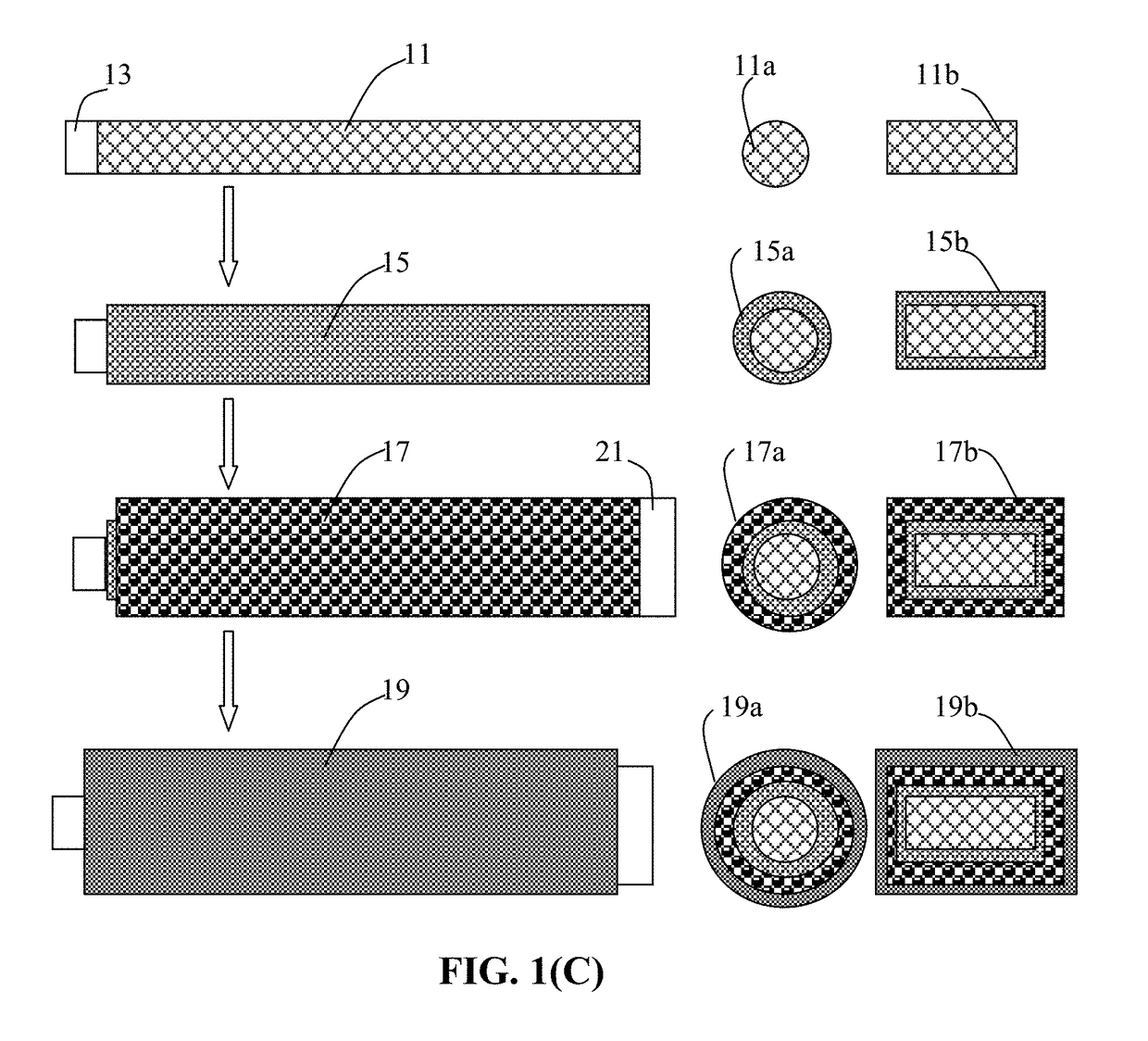

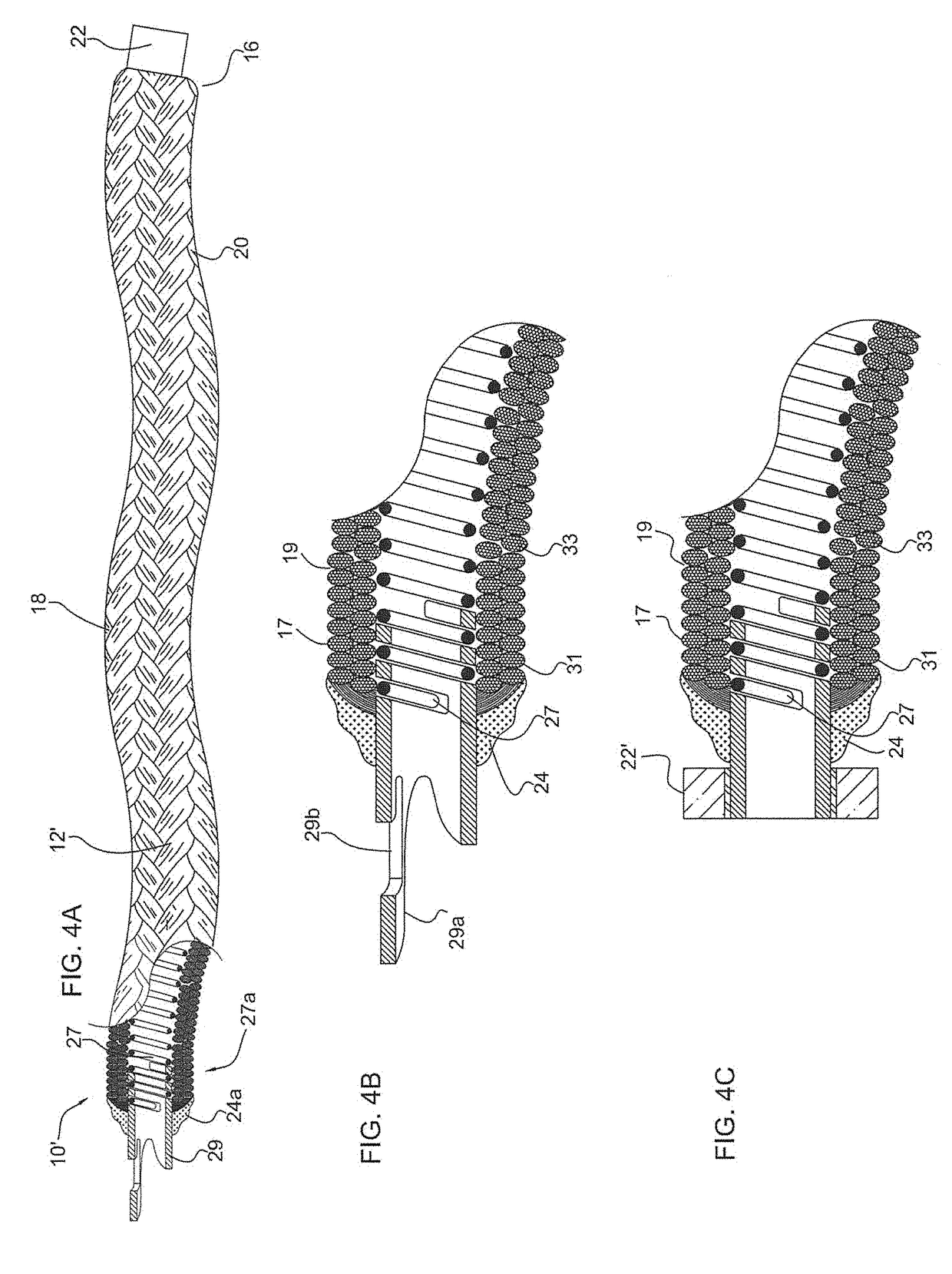

Flexible and Shape-Conformal Cable-Type Alkali Metal Batteries

Provided is a cable-shaped alkali metal battery comprising: (a) a first electrode comprising an electrically conductive porous rod having pores and a first mixture of a first electrode active material and a first electrolyte, wherein the first mixture resides in the pores of the porous rod; (b) a porous separator wrapping around the first electrode; (c) a second electrode comprising an electrically conductive porous layer wrapping around or encasing the porous separator, wherein the conductive porous layer contains pores and a second mixture of a second electrode active material and a second electrolyte, and the second mixture resides in the pores of the porous layer; and (d) a protective casing or packing tube wrapping around or encasing the second electrode.

Owner:GLOBAL GRAPHENE GRP INC

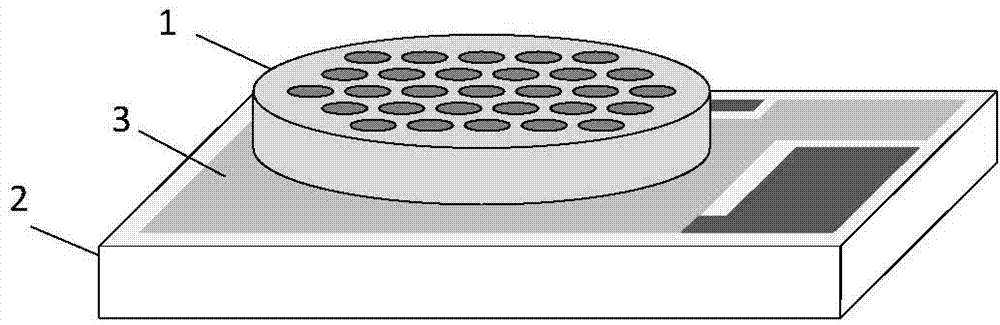

High-sensitivity gas sensor based on microchannel plate three-dimensional structure and production method of high-density gas sensor

ActiveCN103543183AHigh sensitivityHigh test sensitivityMaterial resistanceElectrical resistance and conductanceHigh density

The invention discloses a high-sensitivity gas sensor based on a microchannel plate three-dimensional structure and a production method of the high-sensitivity gas sensor. The high-sensitivity gas sensor consists of a detection module and a heating module; the detection module is bonded with the heating module through an electrically-conductive sizing agent; the detection module and the heating module are respectively provided with two lead leading-out electrodes, i.e. a detection electrode and a heating electrode, the detection module and the heating module are packaged inside a packaging tube shell, and the packaging tube shell is provided with at least four electrodes; the detection module is sequentially formed by an upper electrode, a microchannel plate and a lower electrode from top to bottom; the heating module is sequentially formed by a heat insulation substrate, a heating resistance coil and an insulation film from bottom to top. The high-sensitivity gas sensor has the beneficial effects that the effective specific surface area of a gas-sensitivity film can be improved, so that the sensitivity of the gas sensor can be improved; the porous structure of the microchannel plate favors the successful passing of detected gas, so that the test sensitivity and reaction speed of a device can be improved.

Owner:EAST CHINA NORMAL UNIV +1

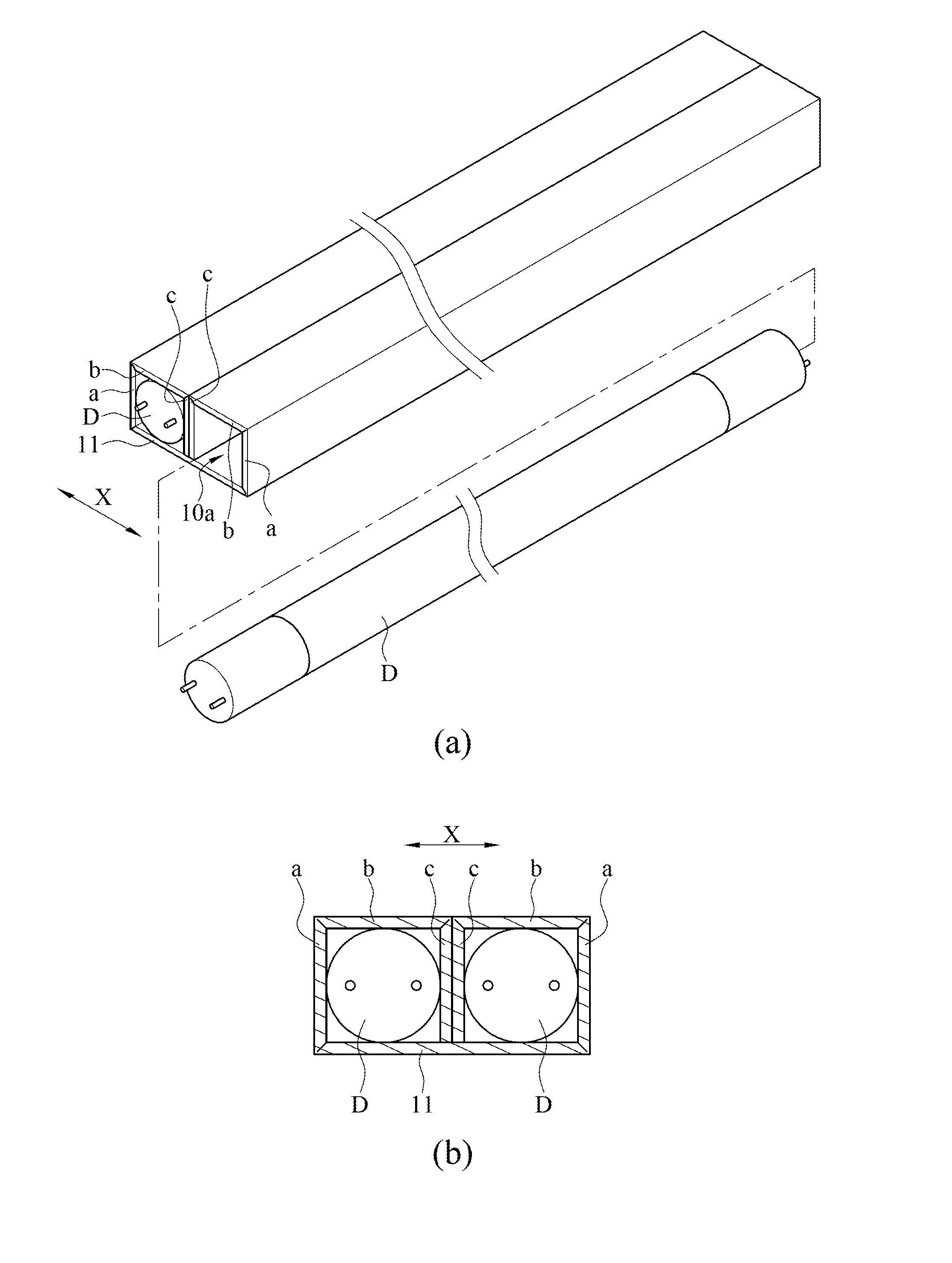

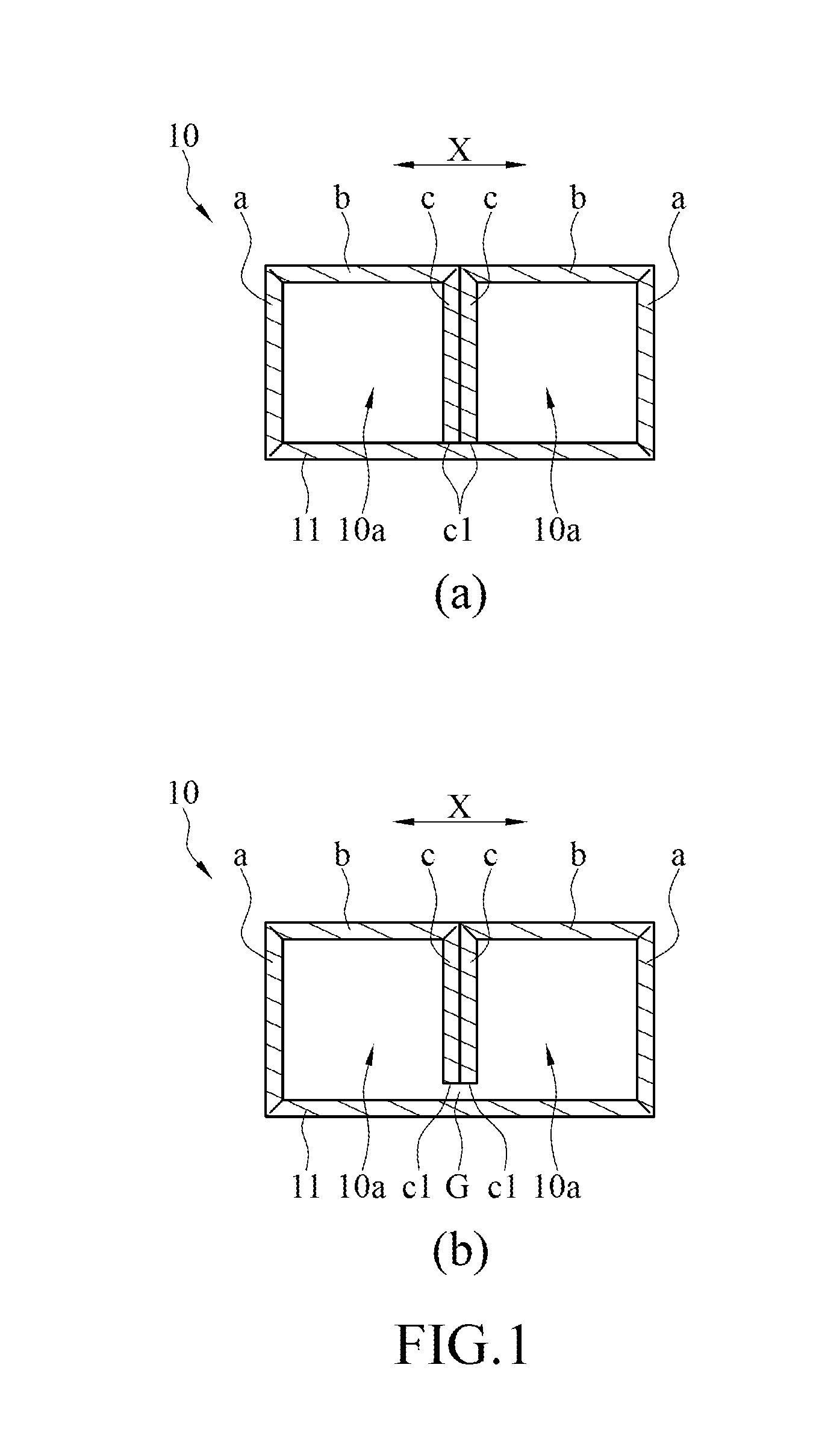

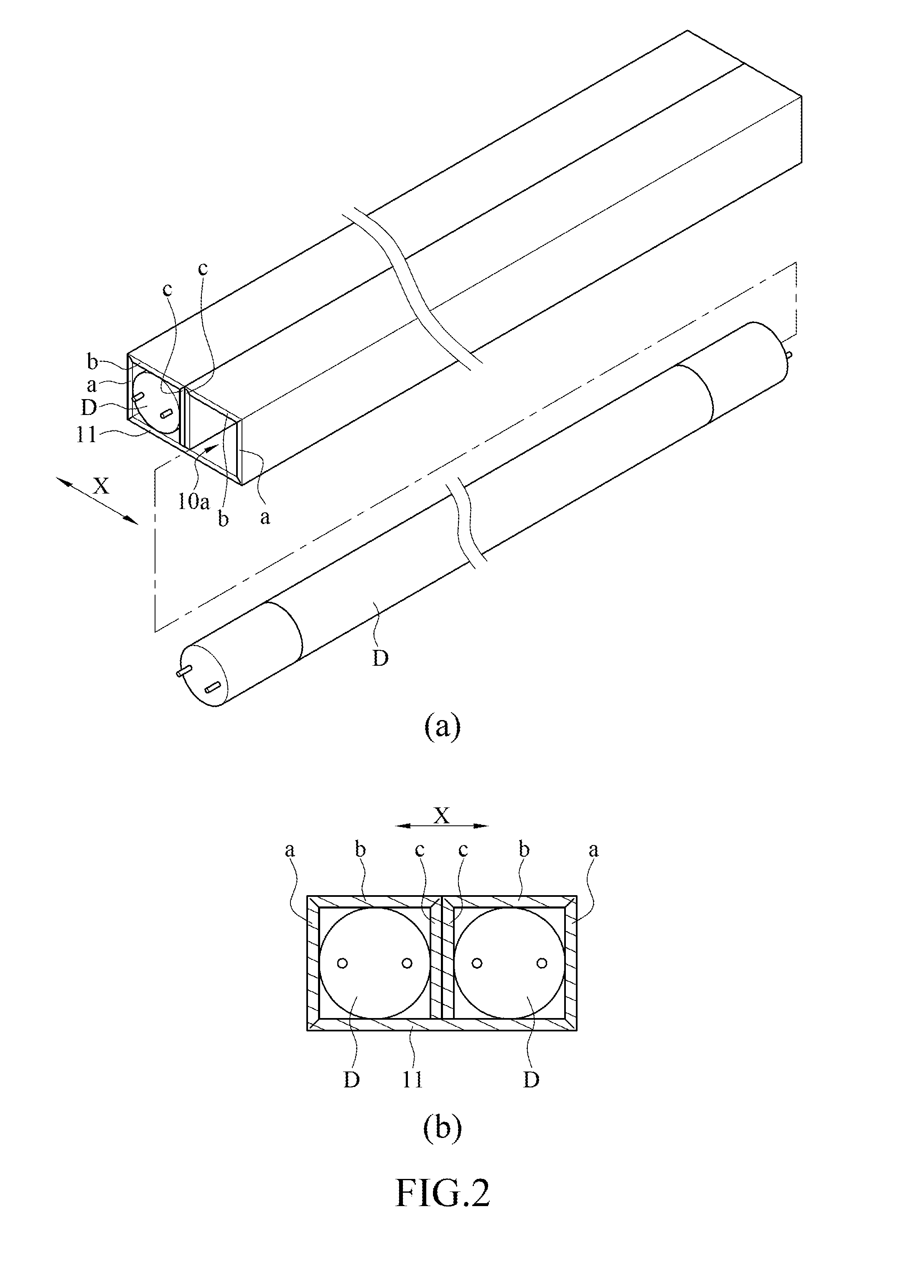

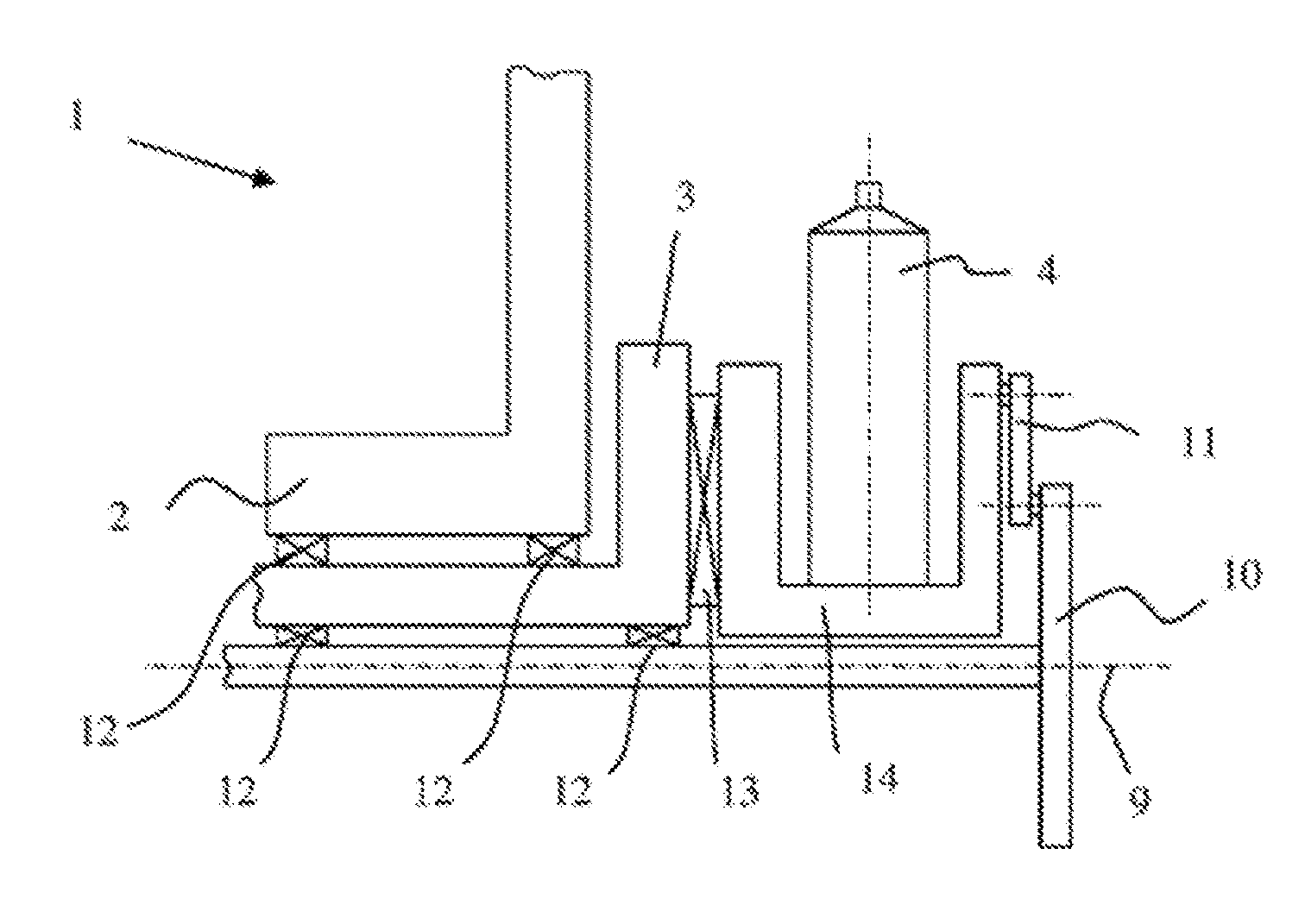

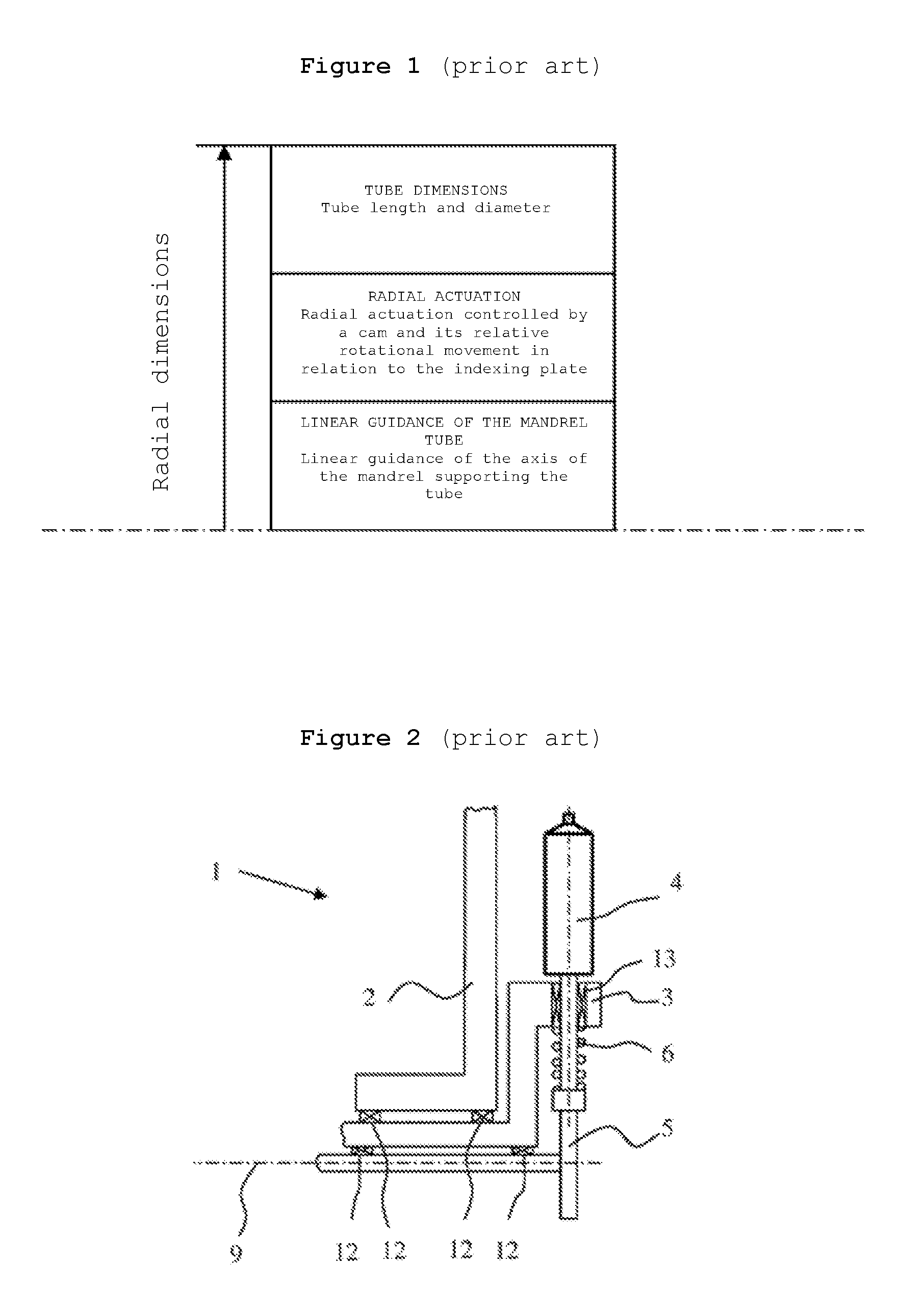

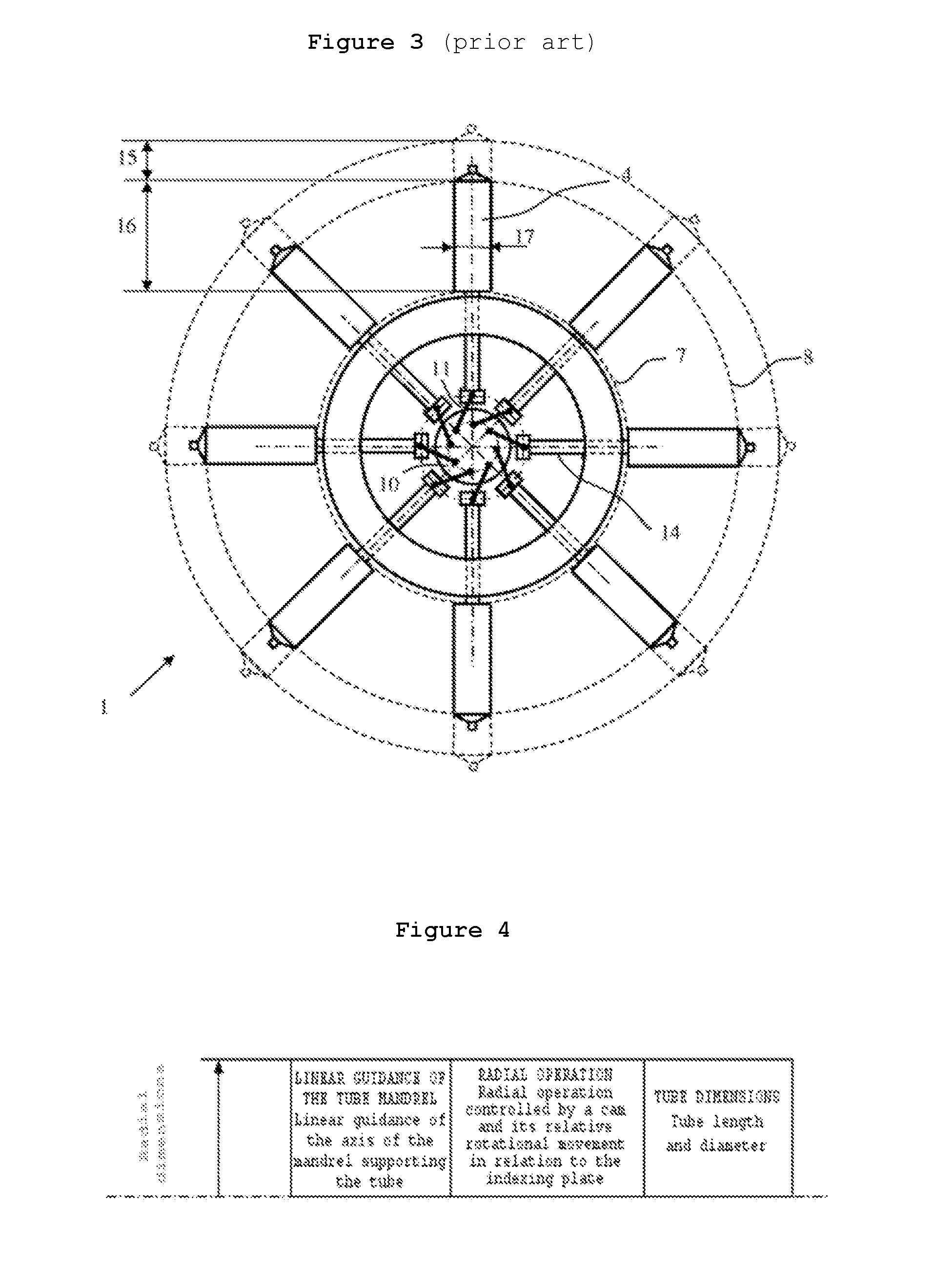

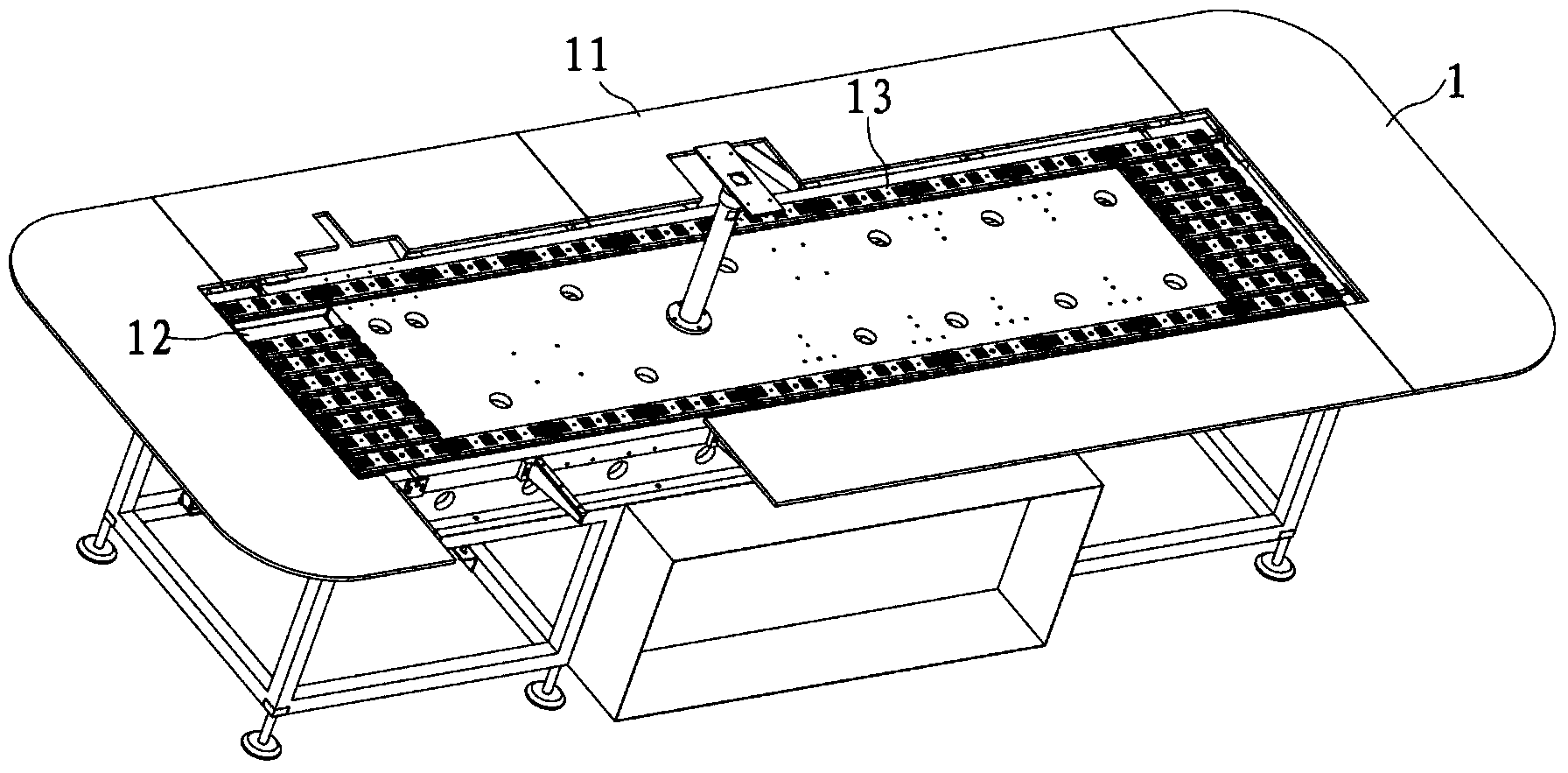

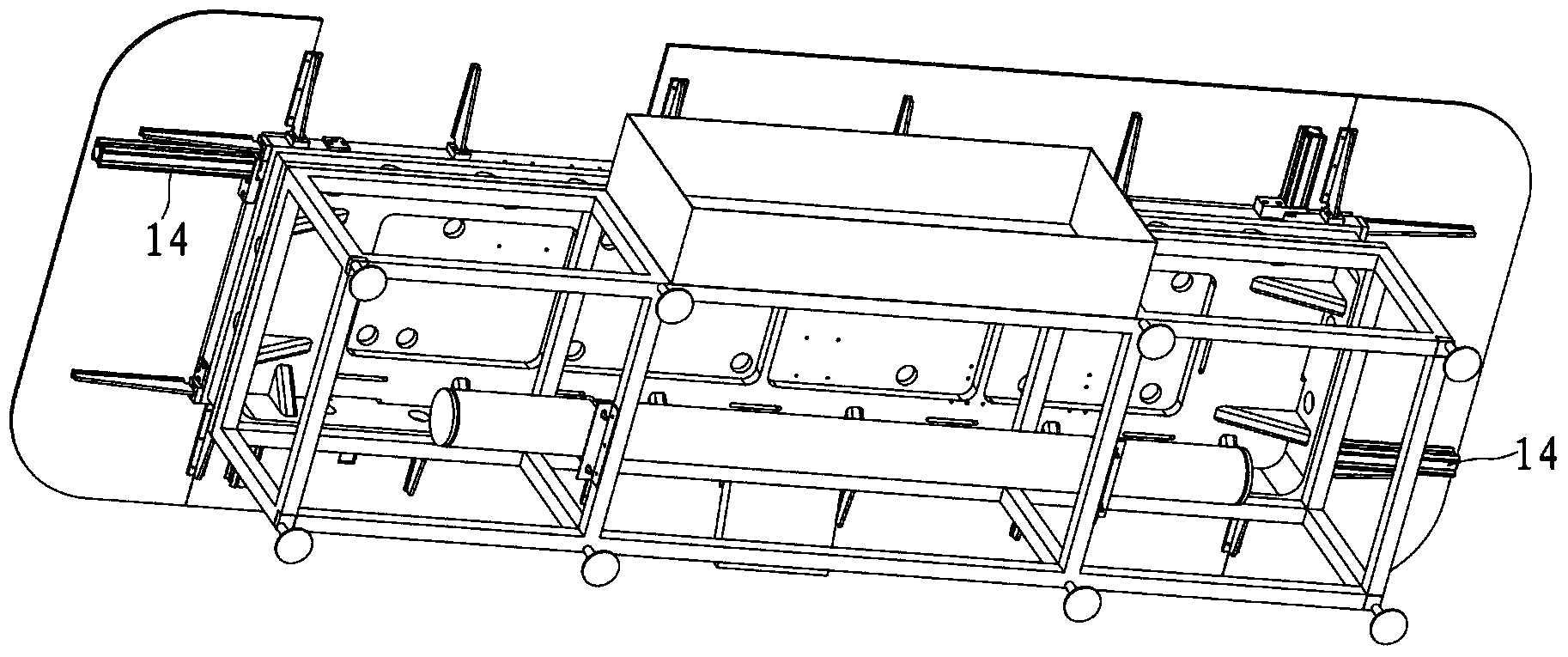

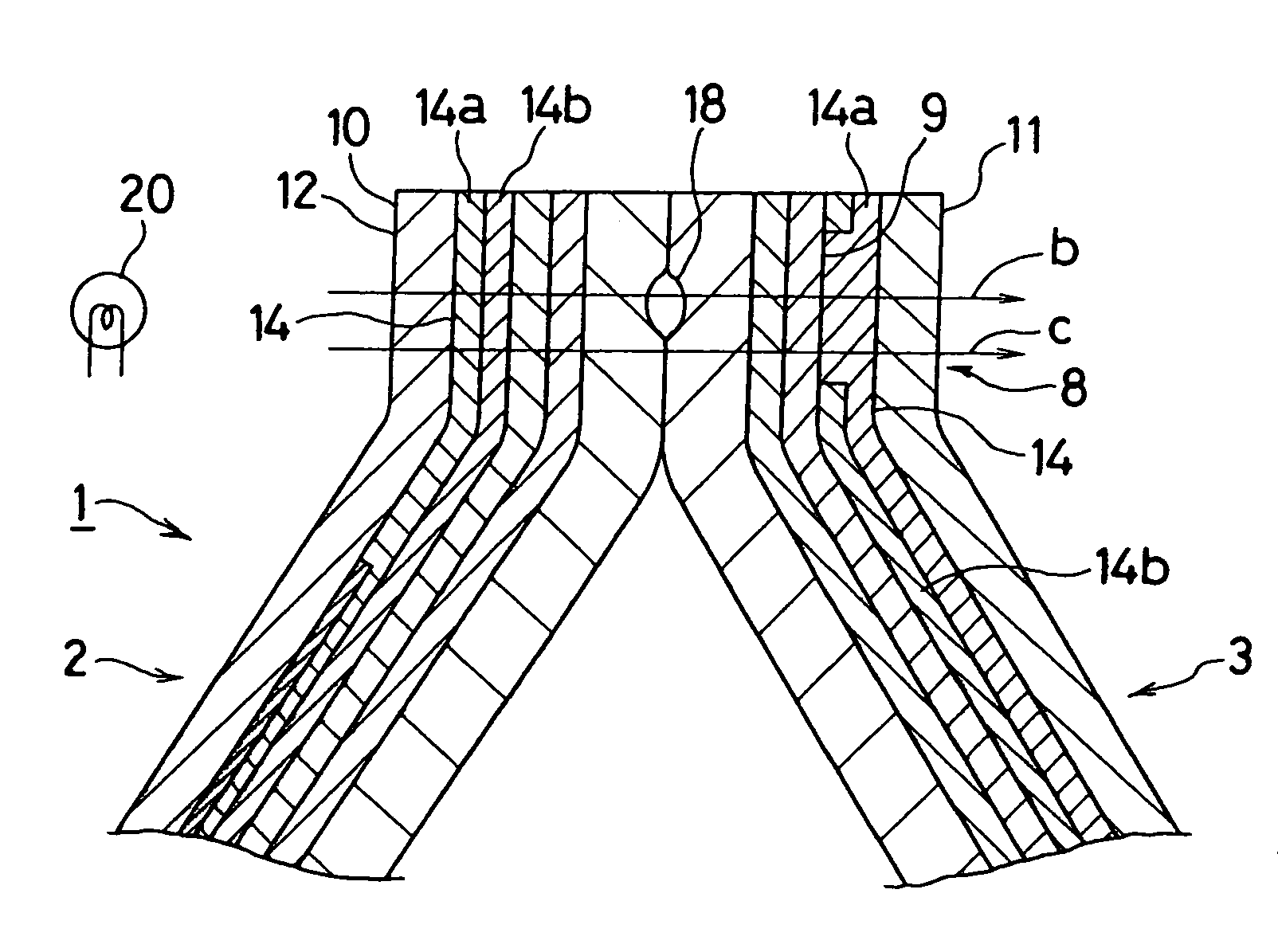

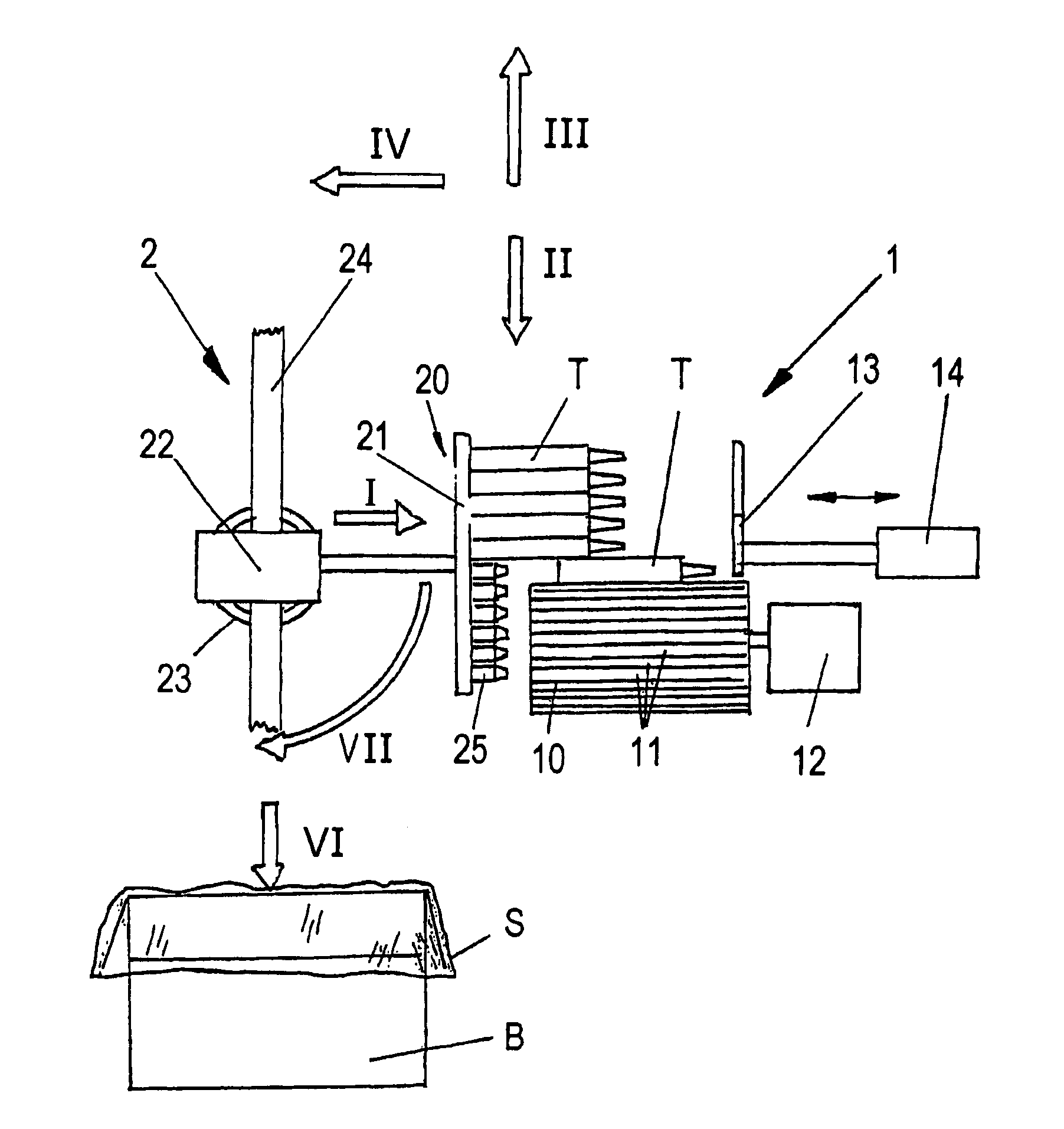

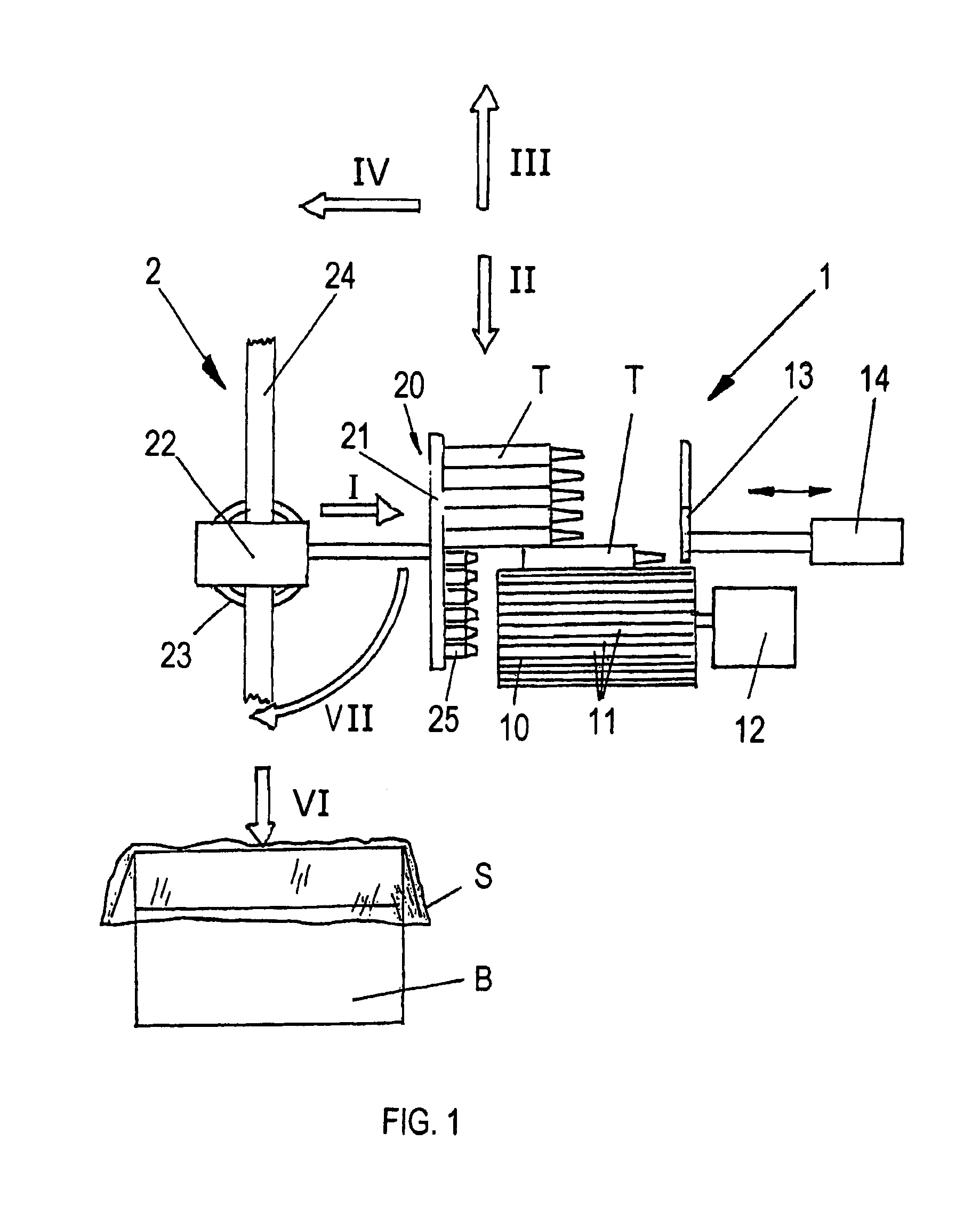

Method and device for packing tubes

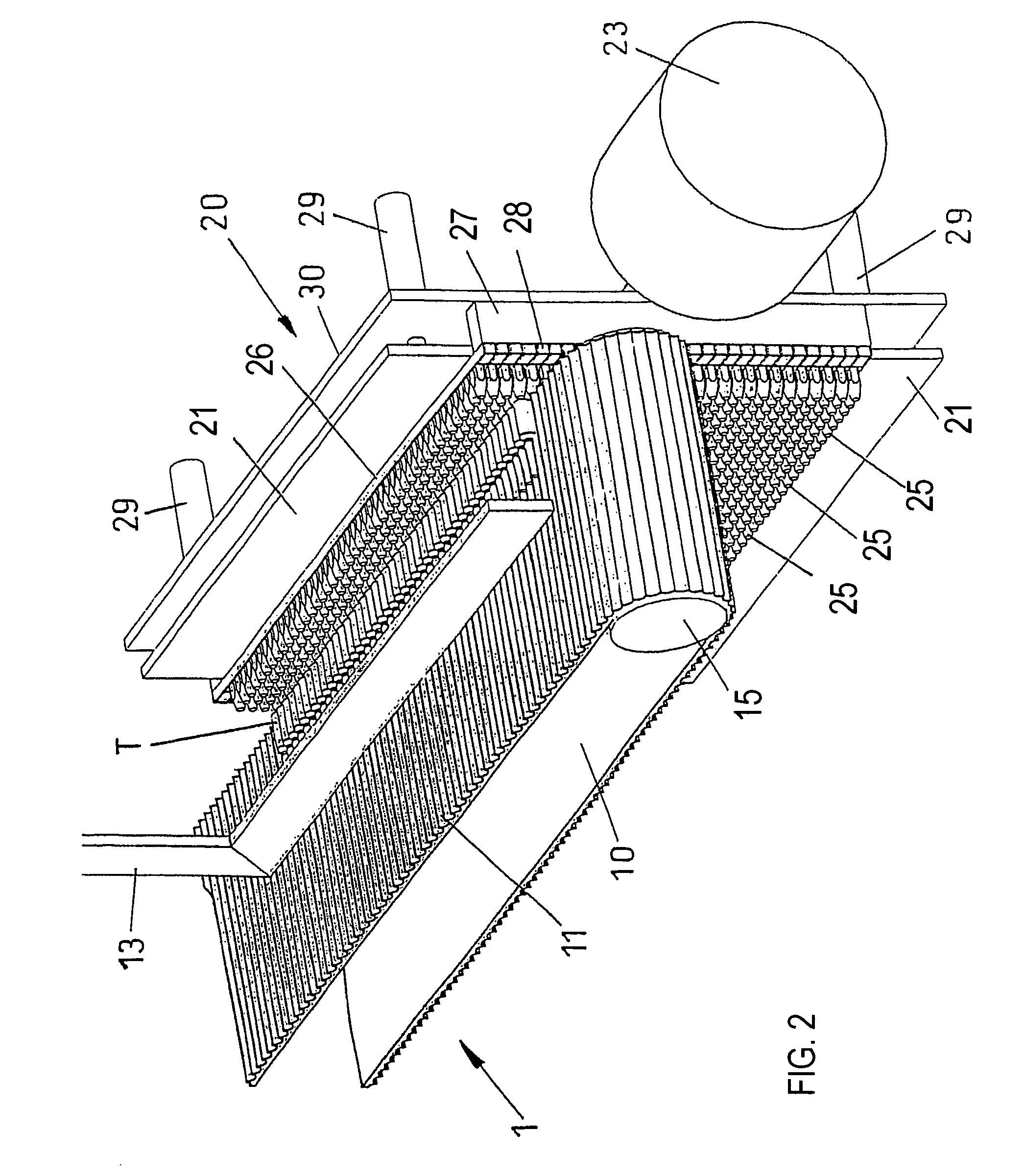

Tubes (T), coming from a production line, are supplied by means of a grouping unit (1). The grouping unit comprises a conveyor belt (10), with product holders (11) and the tubes are supplied in groups by means of a stepping motor (12). A slider (13) pushes the tubes (T) into the correct position on a mandrel support (20) of a packaging unit (2). The mandrel support (20) comprises a plate (21), which may be moved back and forth by means of a piston / cylinder unit (22) and which may be pivoted from the horizontal holding position into the vertical dispensing position. The tubes are pushed onto mandrels (25) which are mounted on the plate (21), by means of the slider (13), The tubes are thus held in exact alignment and can be filled into the carton (B) without a relative displacement or tilting of the tubes.

Owner:PACKSYS GLOBAL

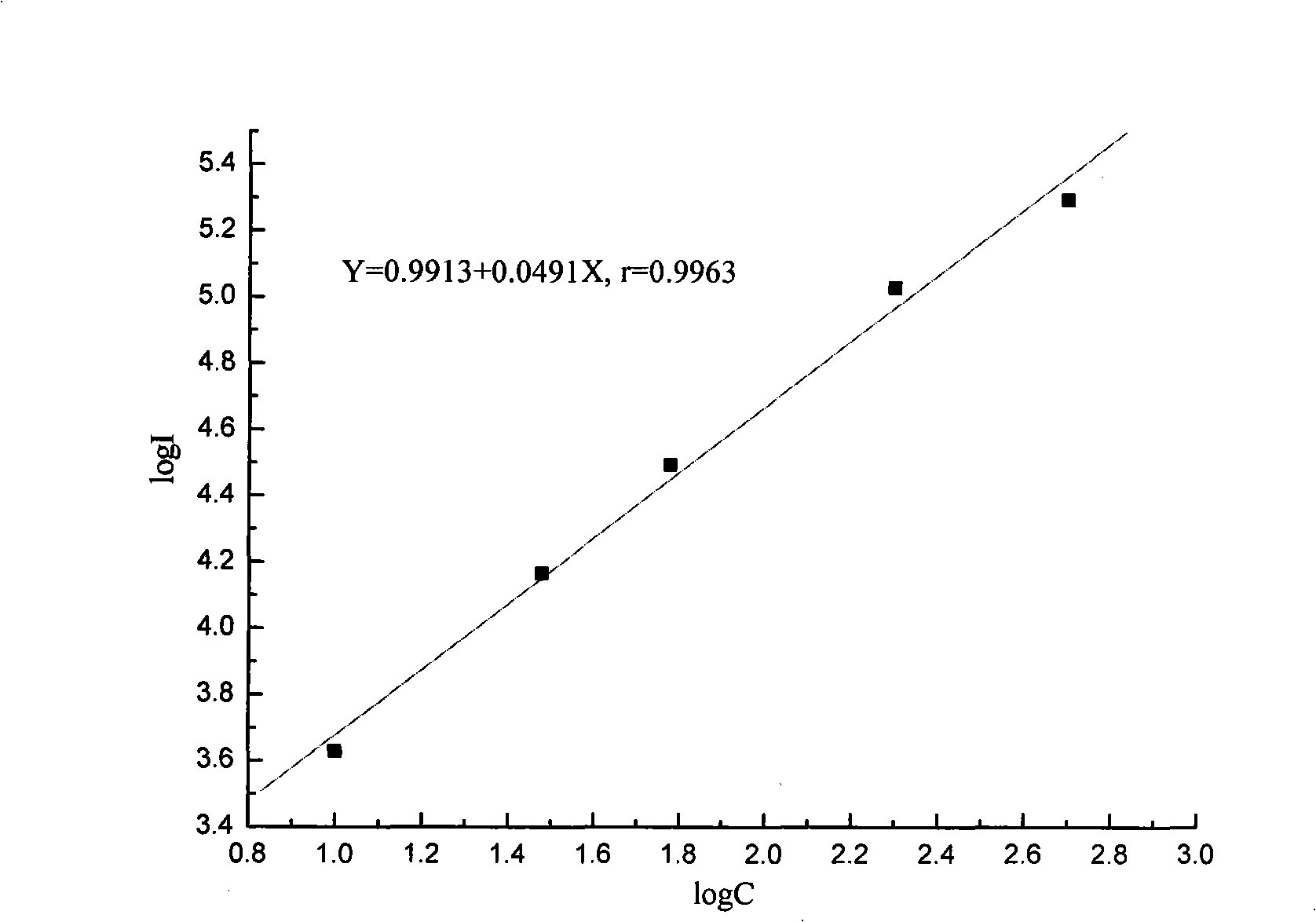

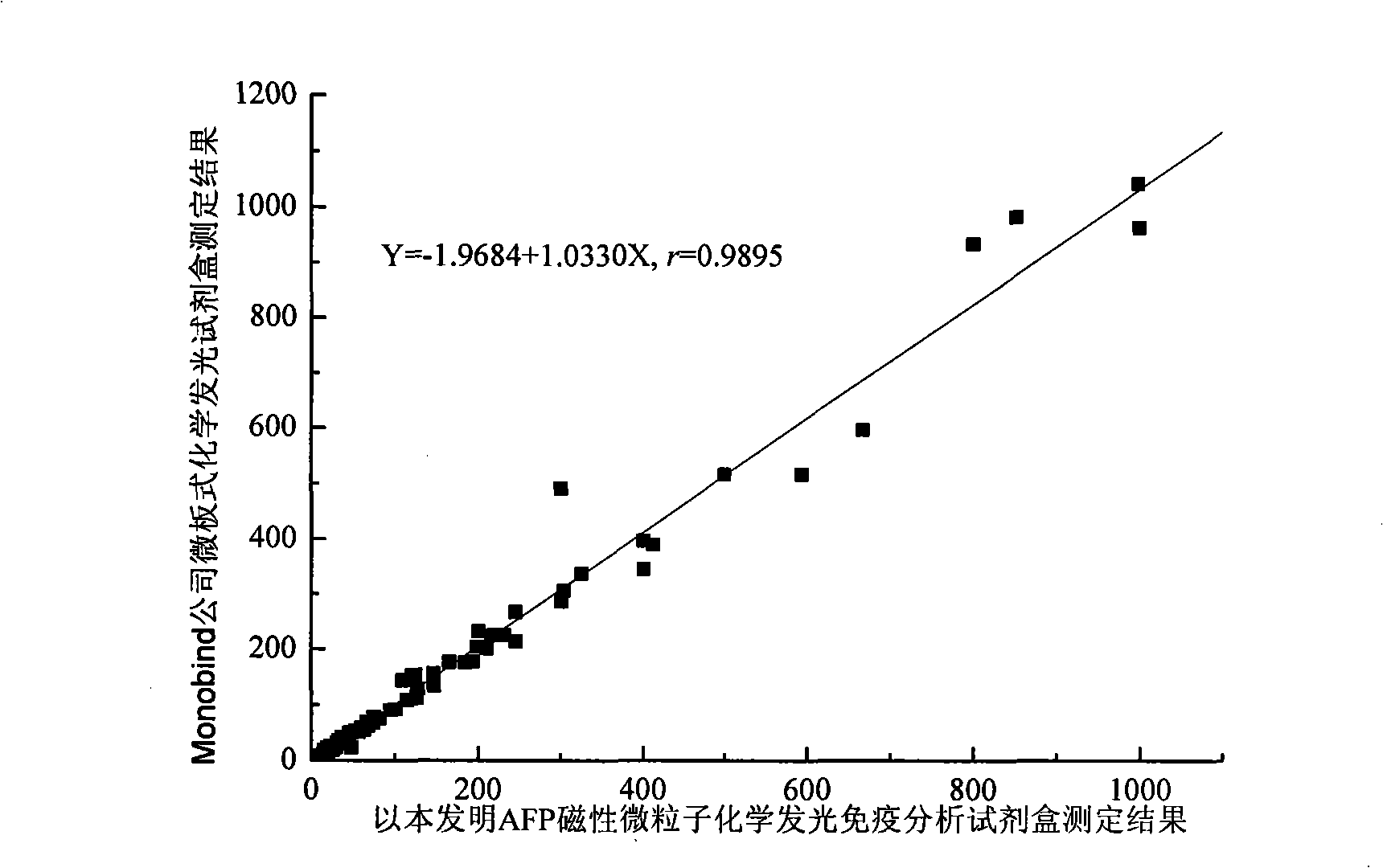

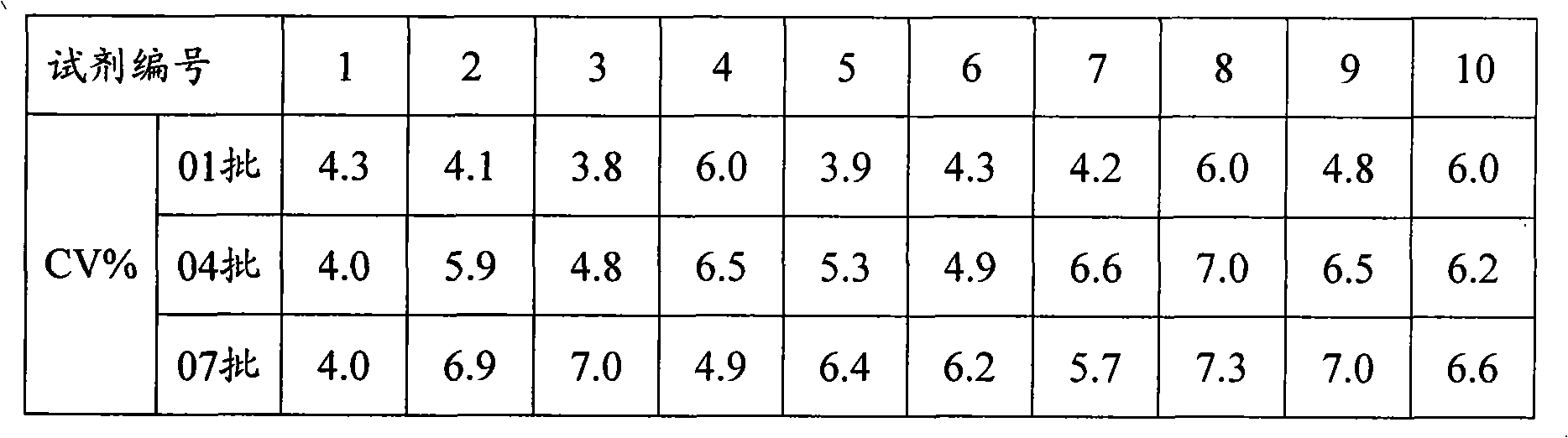

Alpha-fetoprotein magnetic particle chemoluminescence immunoassay kit and method for preparing same

InactiveCN101514991ASensitive highHighly specific detectionChemiluminescene/bioluminescenceBiological testingBiotin-streptavidin complexMicroparticle

The invention relates to the medical field of immunoassay, and in particular provides an AFP magnetic particle chemoluminescence immunoassay kit and a method for preparing the same. The kit comprises: 1) an AFP calibrator; 2) a magnetic particle solution enveloped by a fluorescein isothiocyanate (FITC) resisting monoclone antibody; 3) a mixed solution of a biotin-marked AFP monoclone antibody and an FITC-marked AFP monoclone antibody; 4) a horseradish peroxidase marked streptavidin; 5) a chemoluminescence substrate liquid; and 6) a reaction tube. Furthermore, the method for preparing the kit comprises the following steps: 1) preparing the calibrator by using an AFP pure product; 2) preparing the magnetic particle solution enveloped by the FITC antibody; 3) preparing the mixed solution of the biotin-marked AFP monoclone antibody and the FITC-marked AFP monoclone antibody; 4) marking the streptavidin with the horseradish peroxidase; 5) preparing the chemoluminescence substrate liquid; 6) packaging the calibrator, the magnetic particle solution, the mixed solution, the enzyme marked object, the chemoluminescence substrate liquid and the sub packaging tube; and 7) assembling the components into a finished product. The kit has the advantages of simplicity, fastness, flexibility, stability, and the like.

Owner:北京科美东雅生物技术有限公司

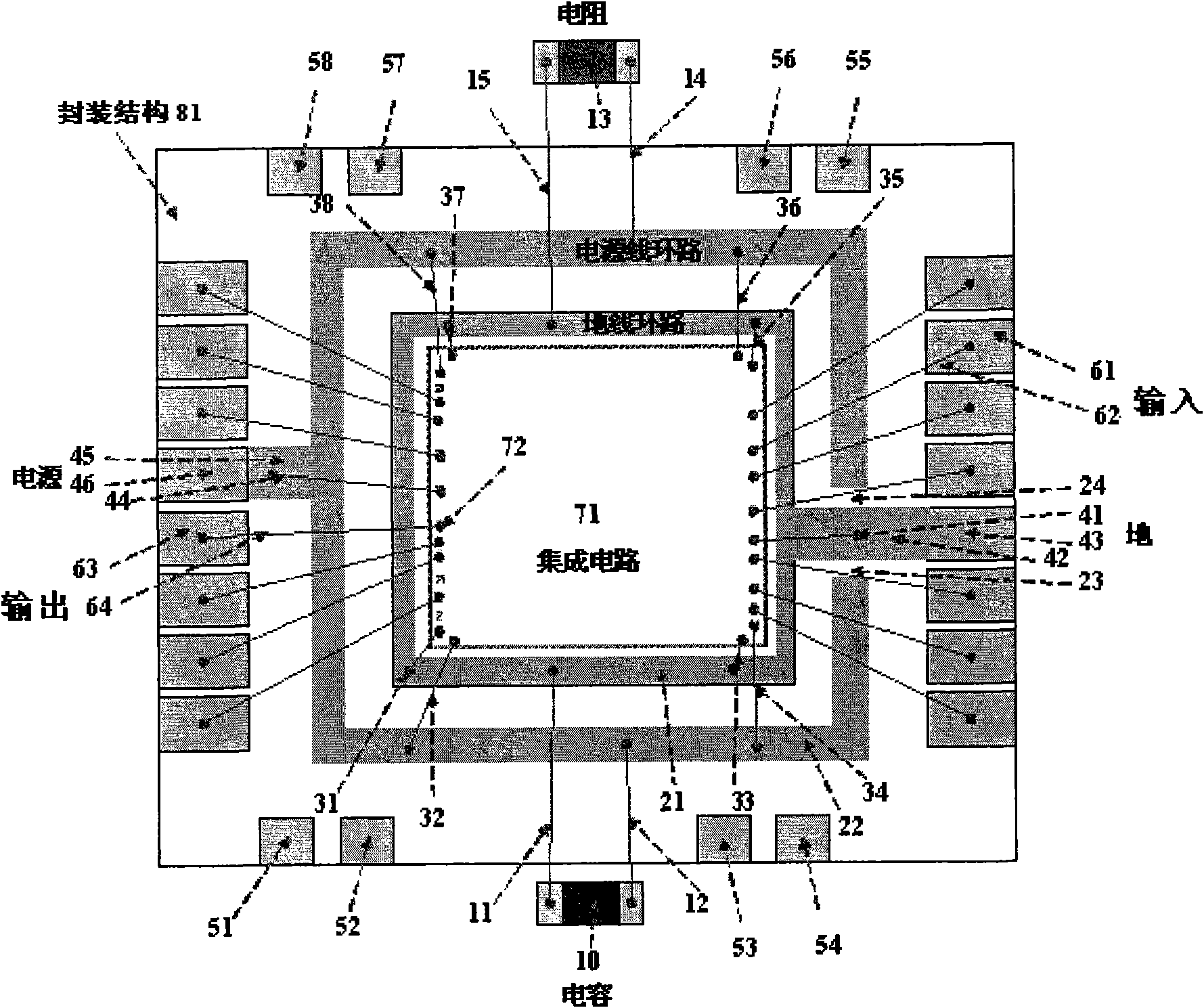

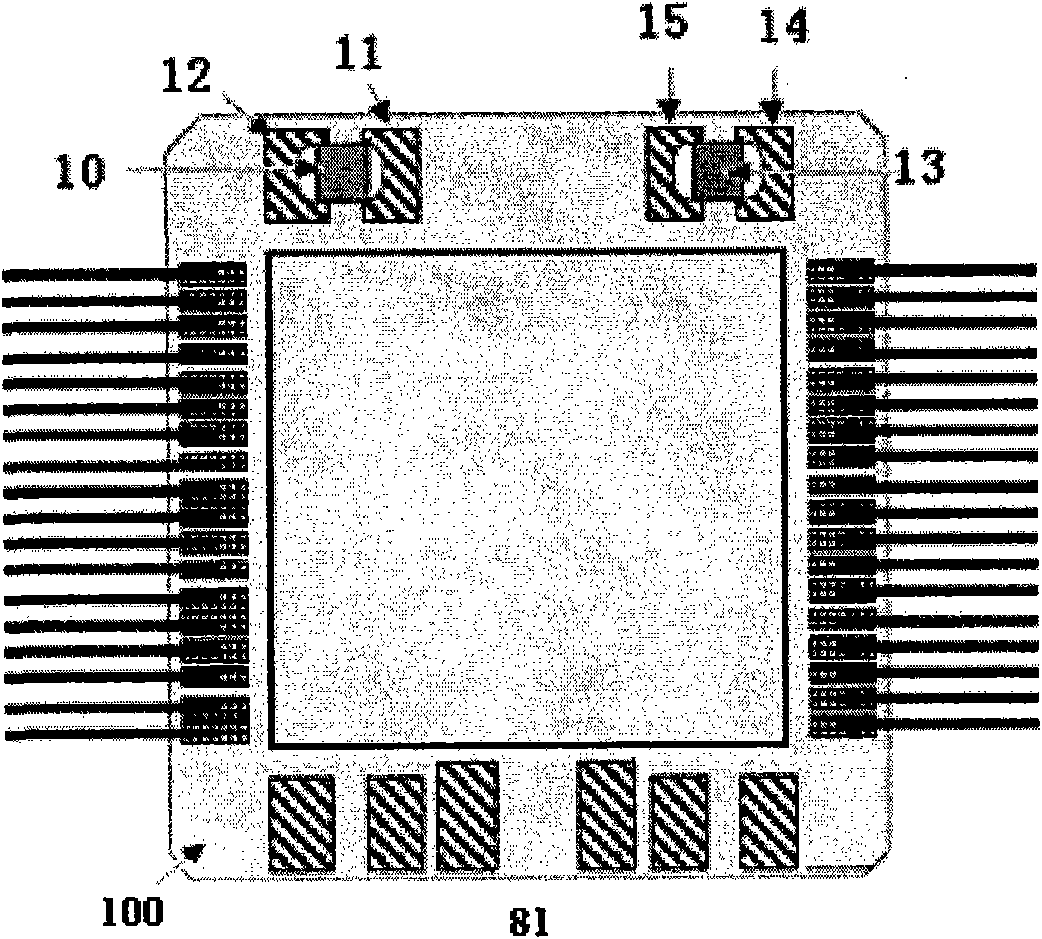

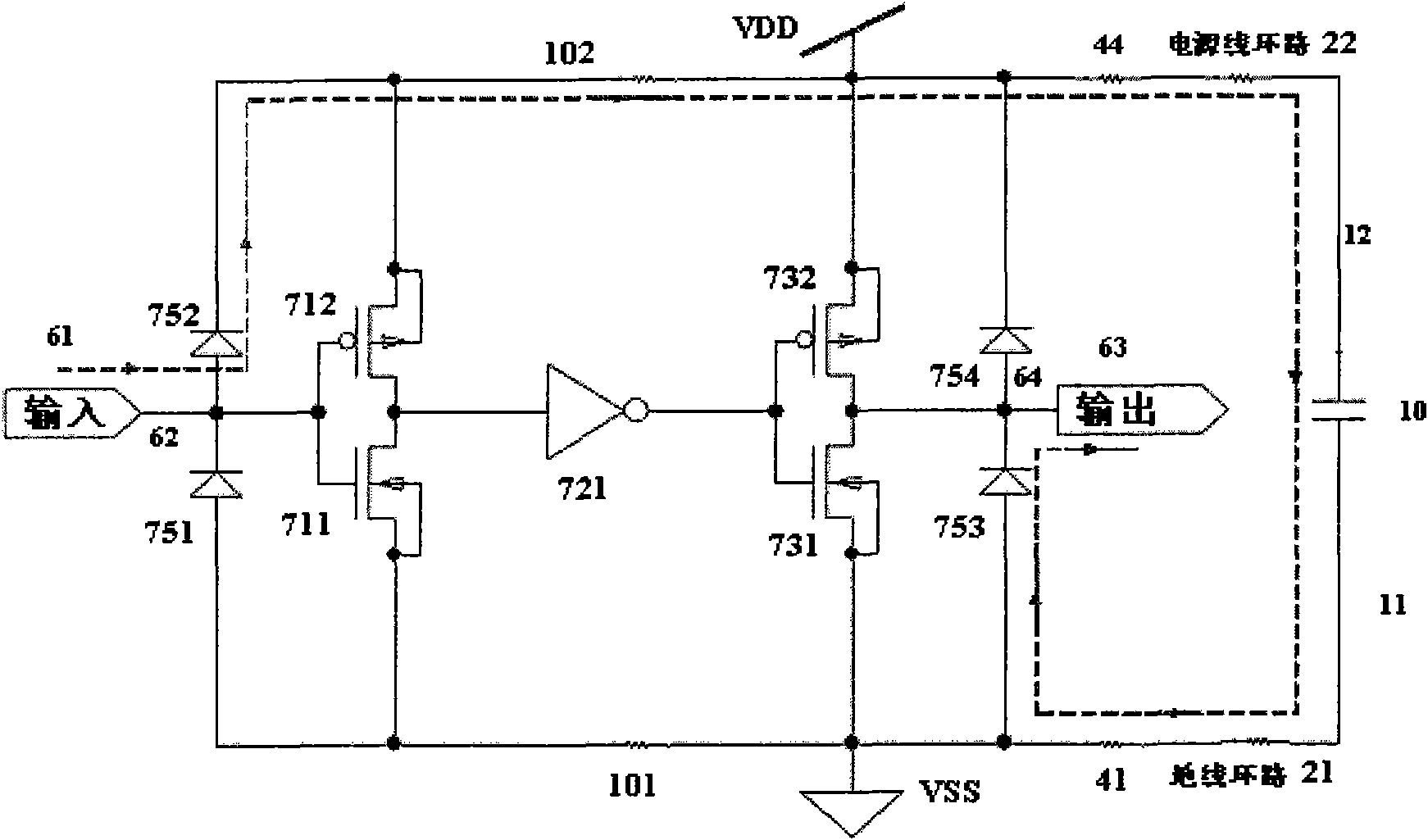

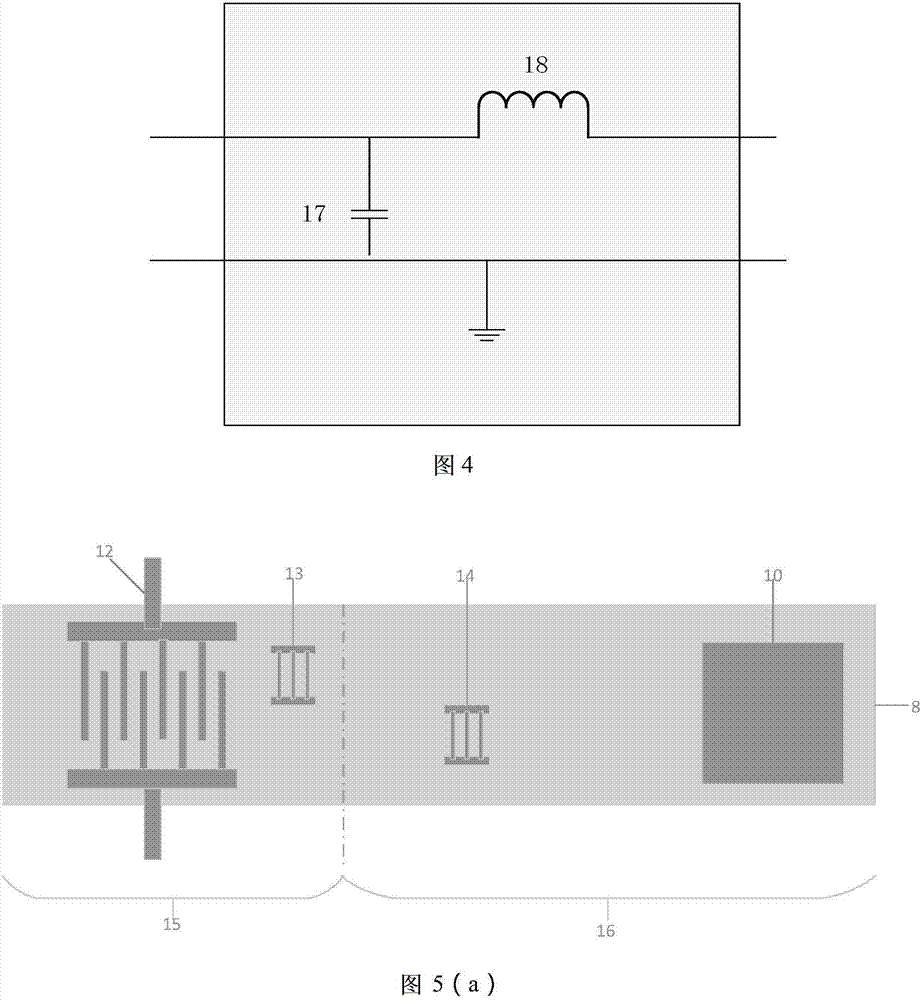

Packaging method of improving antistatic capability of integrated circuit chip

InactiveCN101562140AReduce voltage dropReduce the impact of 71 anti-ESD performanceSemiconductor/solid-state device detailsSolid-state devicesCapacitanceEngineering

The invention discloses a packaging method of improving the antistatic capability of an integrated circuit chip. The method comprises the steps: producing a power cord loop and a ground cord loop on a packaging tube shell; connecting one or a plurality of capacitors and a resistor between the power cord loop and the ground cord loop; leading one or a plurality of positions of the integrated circuit chip, which are connected with a power cord inside the chip to the power cord loop; and leading one or a plurality of positions of the integrated circuit chip, which are connected with a ground cord inside the chip to the ground cord loop. The invention enables chips with poor electrostatic discharge (ESD) protection capability inside the integrated circuit chip to reach good ESD protection capability after packaging.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

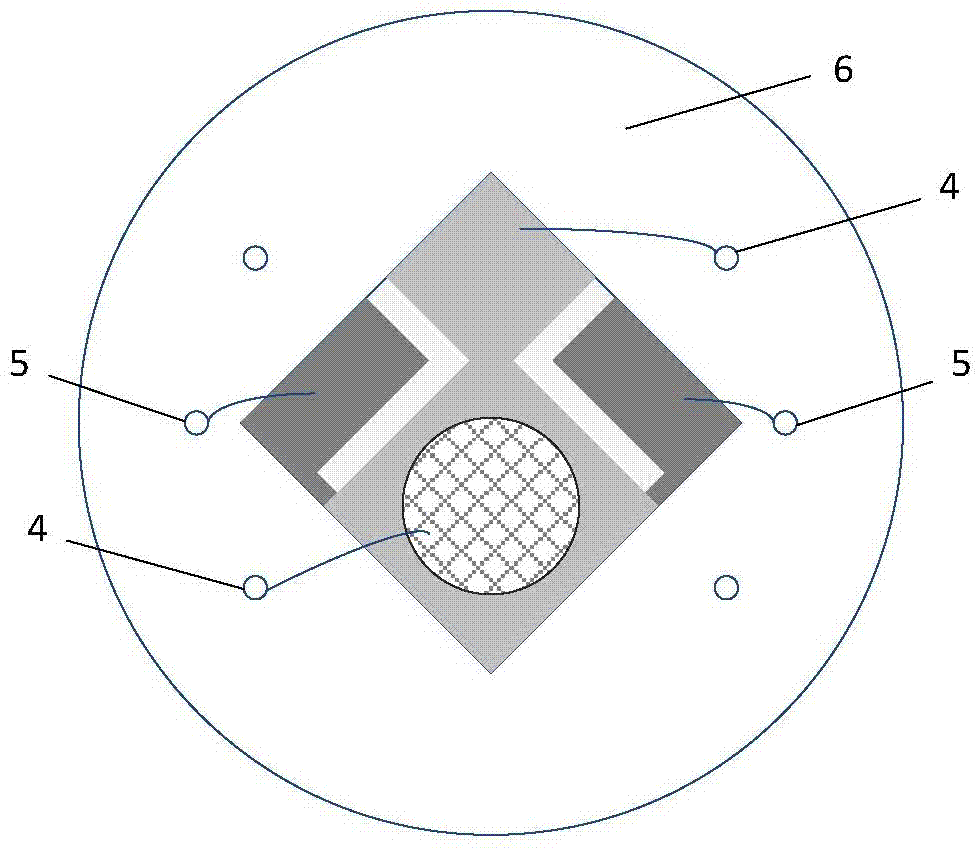

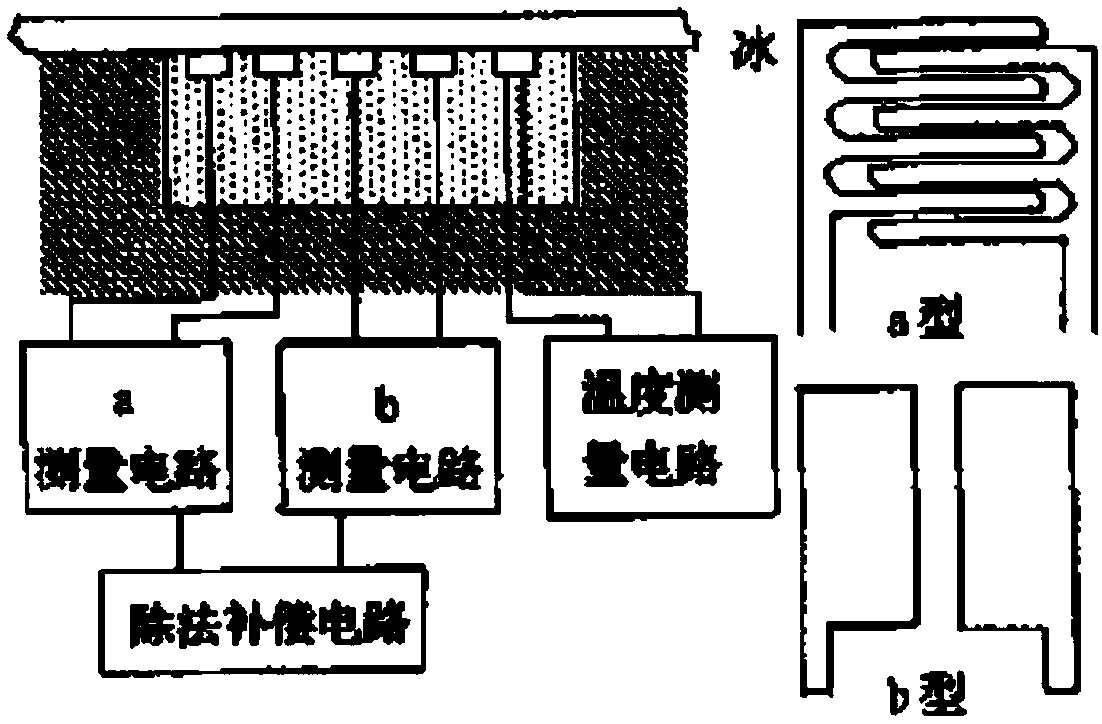

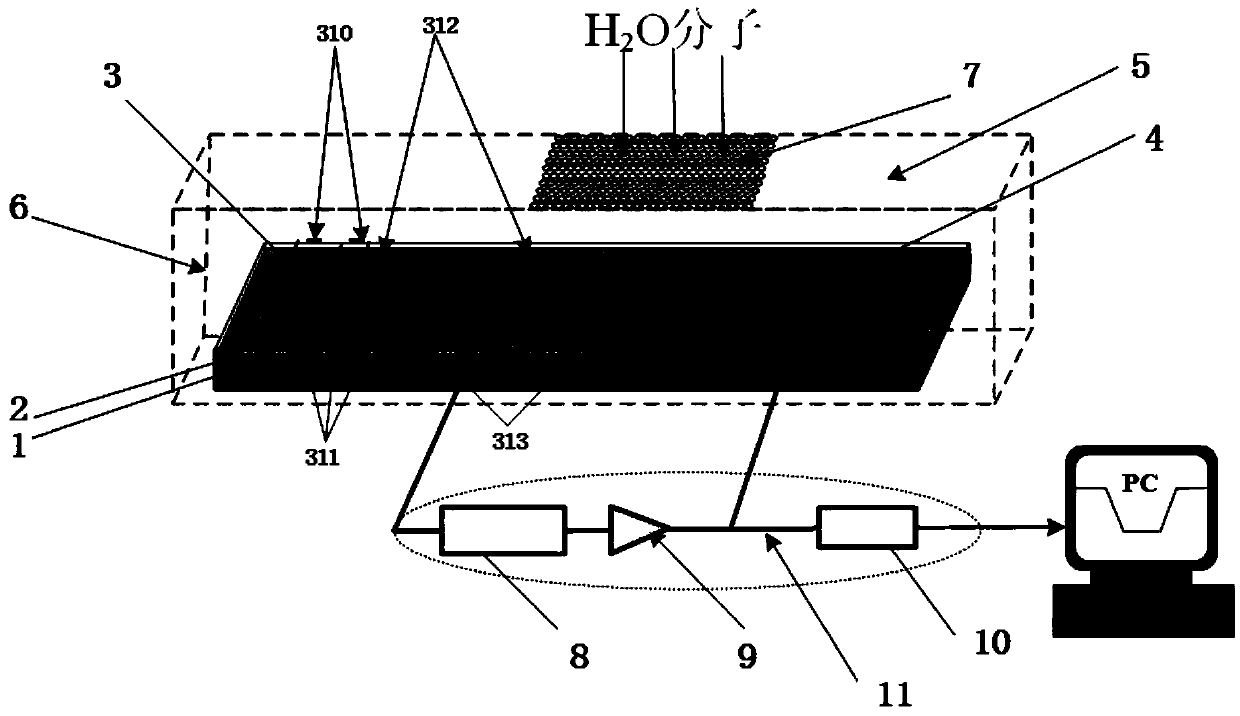

Icing sensor based on surface acoustic wave oscillator

ActiveCN111366932AHigh detection sensitivityImprove temperature stabilityICT adaptationAcoustic wave reradiationSurface acoustic wave oscillatorsSurface acoustic wave

The invention relates to an icing sensor based on a surface acoustic wave oscillator. The icing sensor comprises a surface acoustic wave device and an oscillation circuit (11), and further comprises apackaging tube shell (6) and a water permeable film (7), wherein the exterior of the surface acoustic wave device is packaged by the packaging tube shell (6), the water permeable film (7) is arrangedat an opening of the packaging tube shell (6), a surface of the surface acoustic wave oscillator is covered with a SiO2 protective thin layer (2), the surface acoustic wave device outputs an electricsignal with the changed oscillation frequency to the oscillation circuit (11), and the oscillation circuit (11) detects abrupt change of the oscillation frequency of the electric signal and outputs the oscillation frequency to realize icing early warning and monitoring. The icing sensor is advantaged in that the icing sensor has high detection sensitivity and good temperature stability, and can timely warn freezing, so the surface acoustic wave technology is easy to implement.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

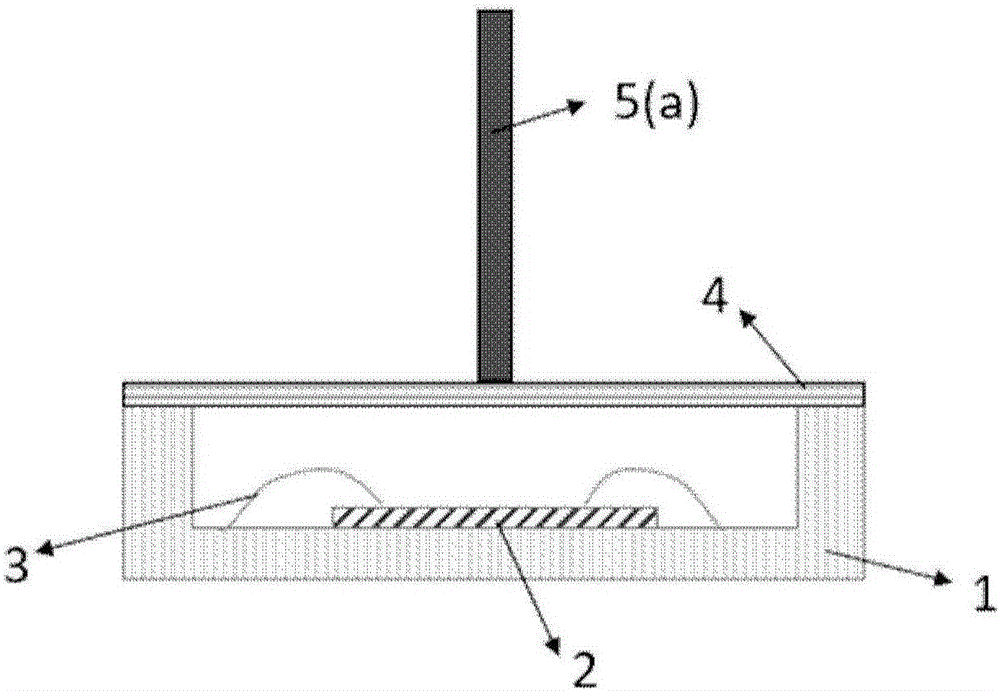

Electrode type electric field sensor packaging component and application thereof

ActiveCN106124870AImprove environmental adaptabilityHigh sensitivityElectrostatic field measurementsElectric field sensorImage resolution

The invention provides an electrode type electric field sensor packaging component comprising a packaging tube shell; an electric field sensor chip which is fixed in the packaging tube shell; a packaging cover which covers the opening of the tube shell so as to form a cavity to accommodate the electric field sensor chip; and a packaging electrode which is arranged at one side away from the cavity of the packaging cover, wherein the packaging electrode is divided into a head end, an intermediate segment and a tail end according to the near-to-distant relationship between the packaging electrode and the packaging cover. The invention also provides an application of the electrode type electric field sensor packaging component. With application of multiple designs of the packaging electrode, the spatial resolution of the electric field sensor can be enhanced, the sensitivity of the sensor can be enhanced and the environmental adaptability of the sensor can be enhanced.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

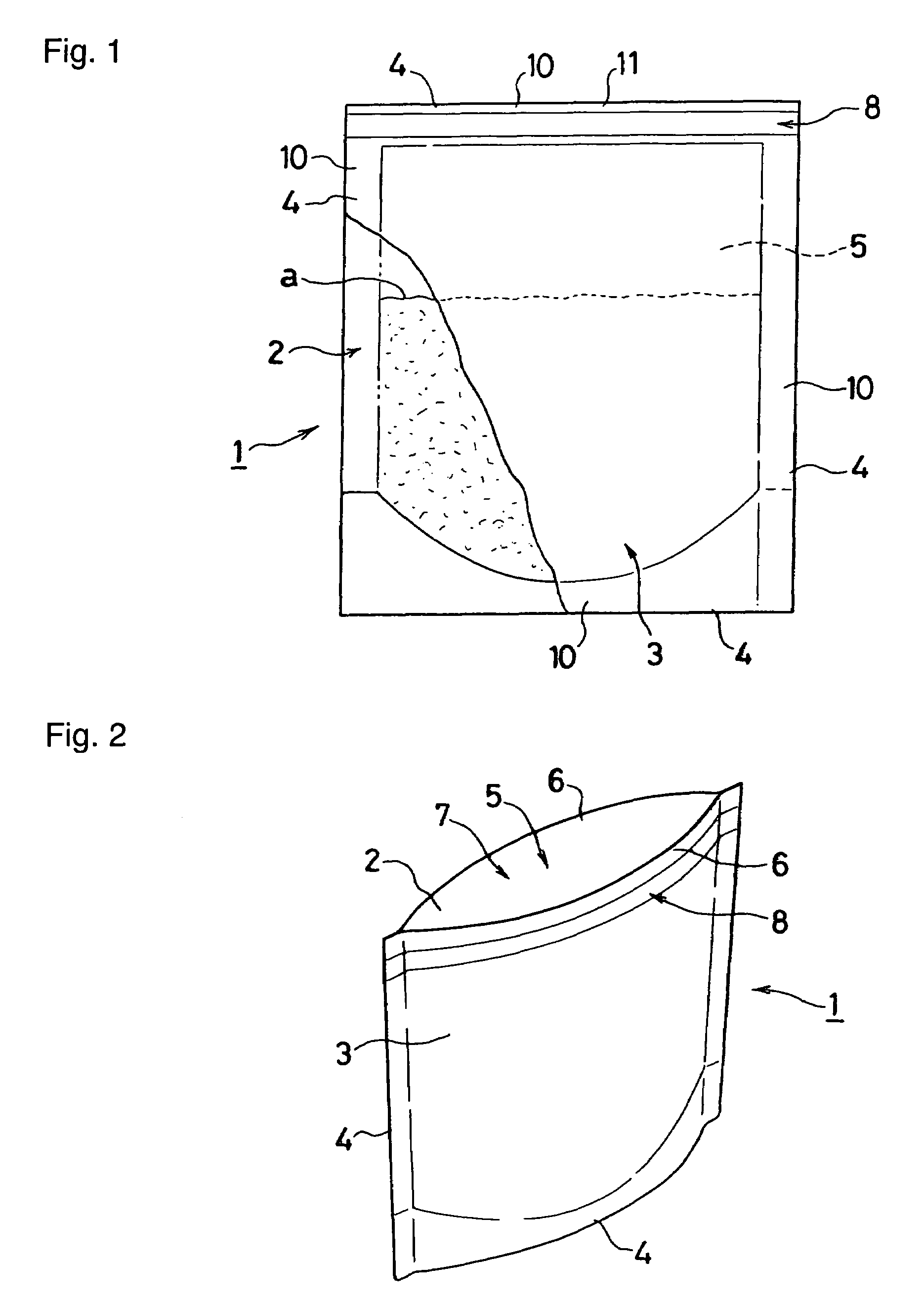

Packaging for surgical implant

ActiveUS20180289375A1Reduce horizontal sizeInhibition releaseStentsOcculdersPackaging TubeBiomedical engineering

A packaging for an implant to hold the implant in a first condition. The packaging including a first packaging tube and a container, wherein the implant is movable from the container into the first tube and maintained within the first tube in a second condition, the implant having a first transverse dimension in the first condition and a second transverse dimension in the second condition, the second transverse dimension being less than the first transverse dimension.

Owner:NEUROGAMI MEDICAL INC

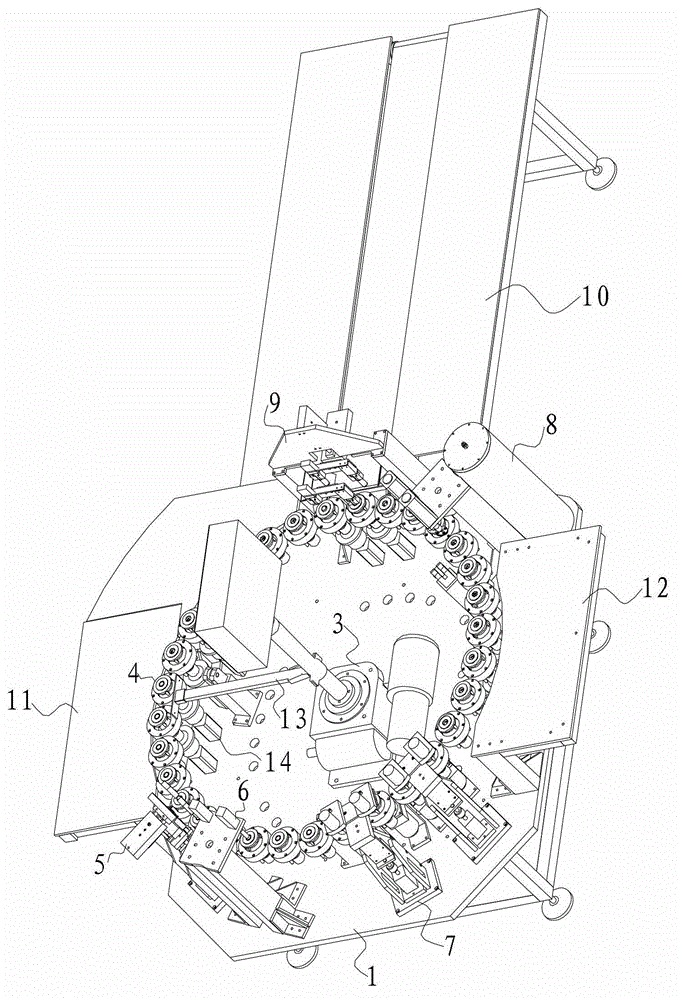

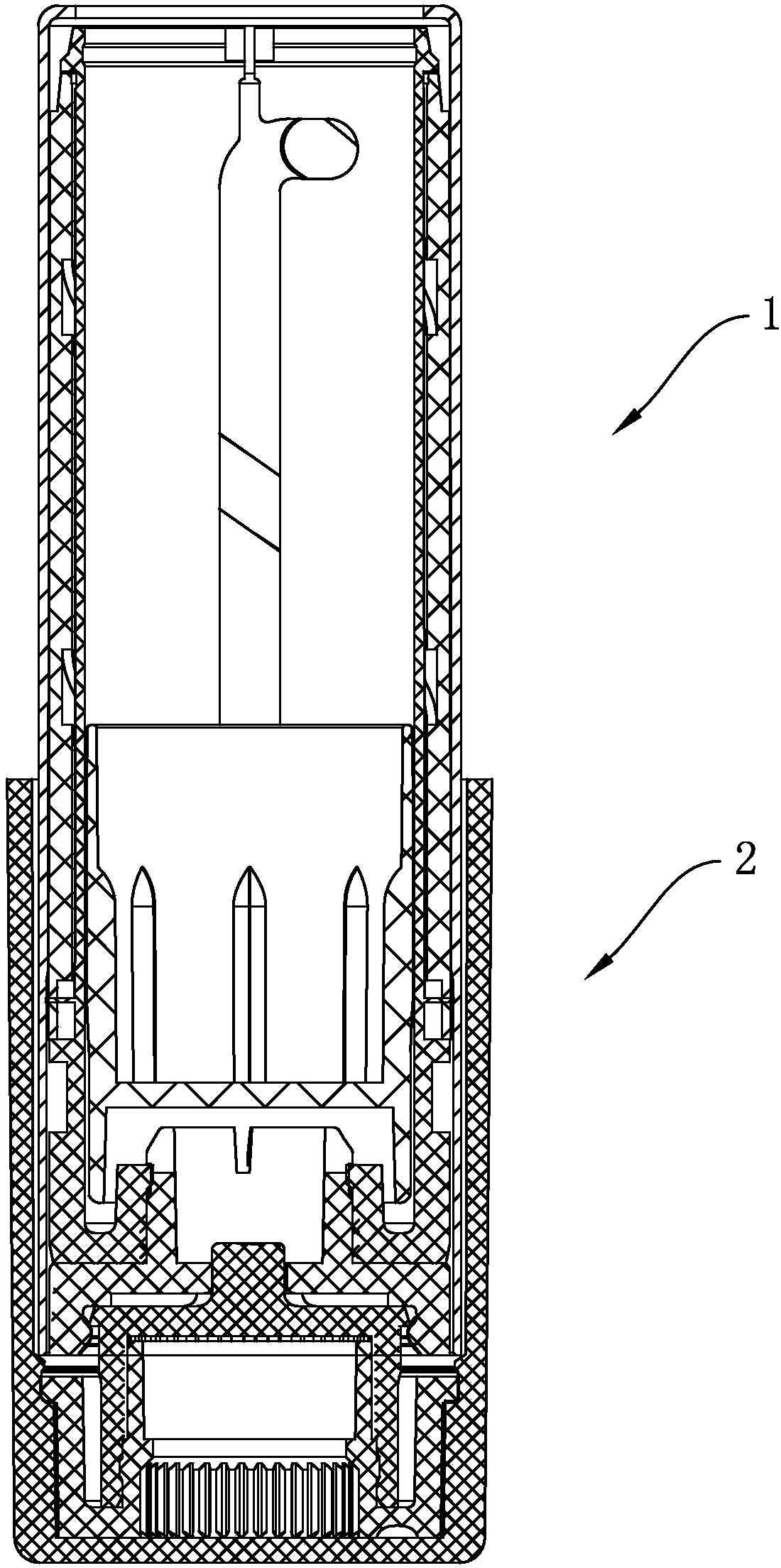

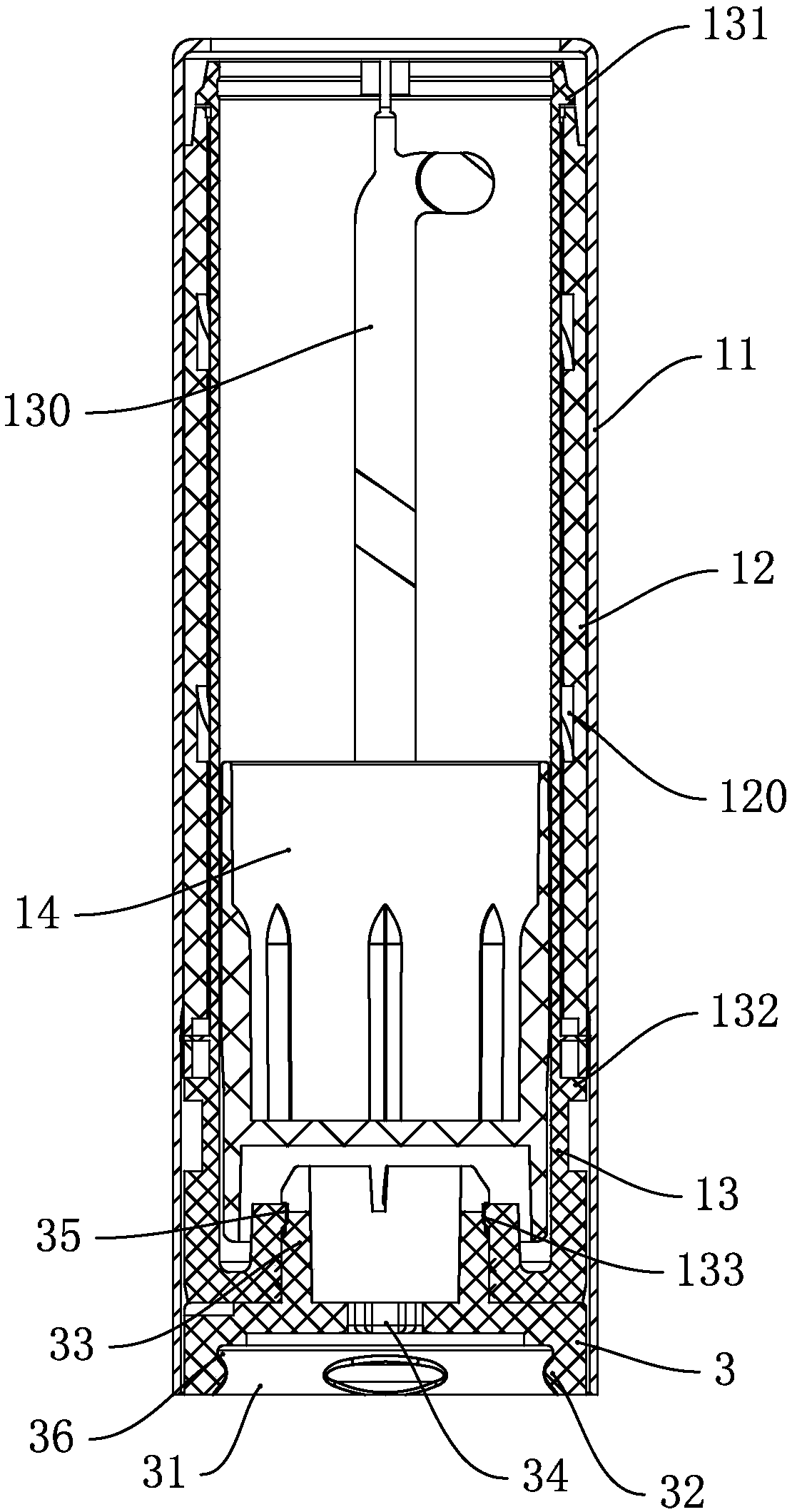

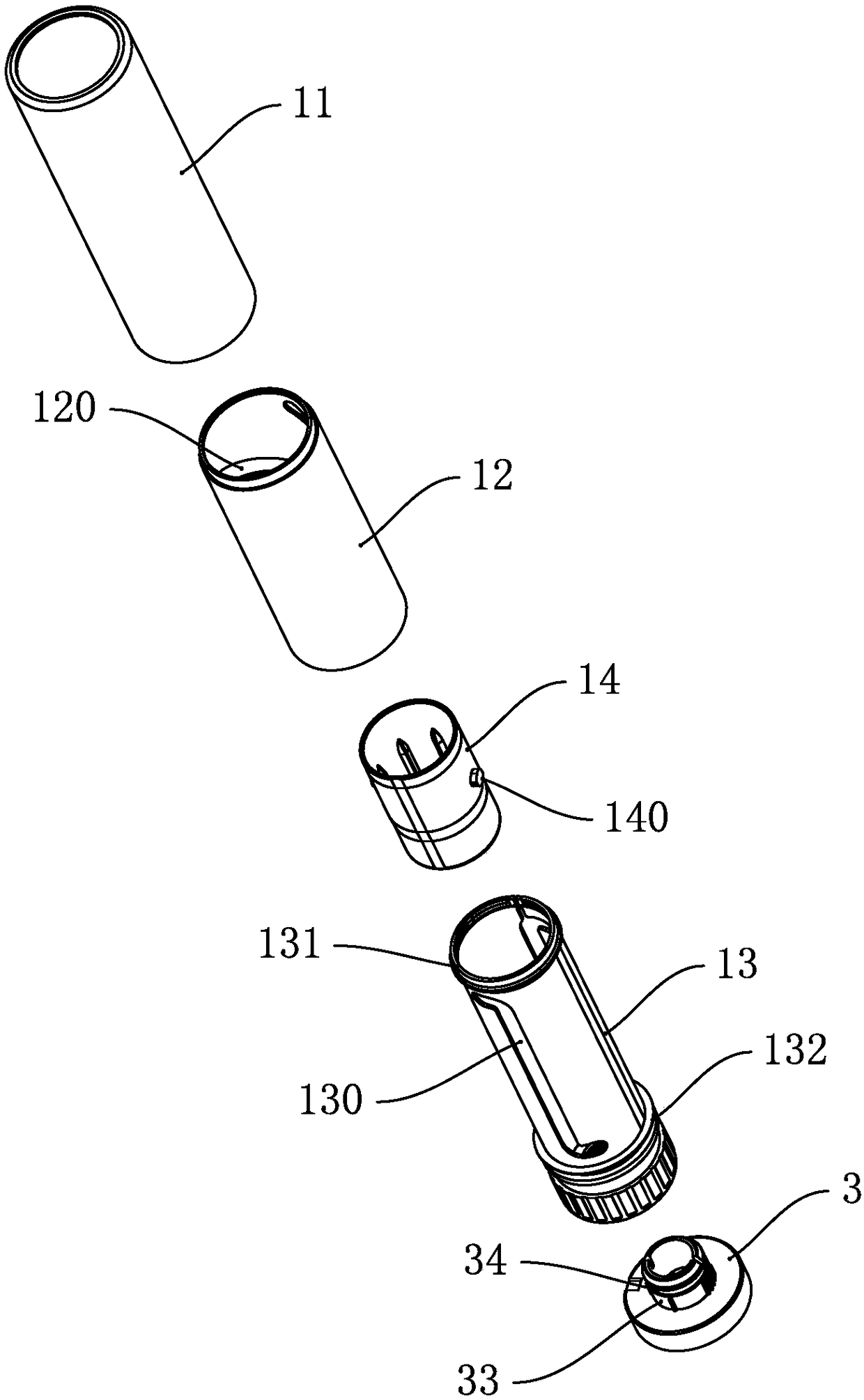

Median bundle core and packaging pipe

PendingCN108523378ANot easy to implementEasy to assemblePackaging toiletriesPackaging cosmeticsPackaging TubeHelix

The invention discloses a median bundle core and a packaging pipe. The median bundle core includes a bead, a fork, a spiral and a median bundle which are sequentially arranged from inside to outside.The bottom of the fork is provided with a connecting base, the bottom end face of the connecting base is provided with a groove, the inner side wall of the groove is provided with a clamping groove, the bottom surface of the groove is provided with a positioning hole, and the bottom of the median bundle extends in the axial direction and is close to the bottom edge of the connecting base or completely surrounds the connecting base. The packaging pipe includes a base and the median bundle core. During use, the bottom of the median bundle core is inserted in an inner chamber of the base, a connector matched with the clamping groove is disposed in the base, and the top surface of the connector is provided with a positioning block inserted in and matched with the positioning hole. The median bundle core and the base are clamped with each other, the connecting base is substantially hidden in the median bundle, the median bundle core cannot be used alone, but the median bundle core can be replaced, and the base is reused.

Owner:ZHEJIANG AXILONE SHUNHUA ALUMINUM IND

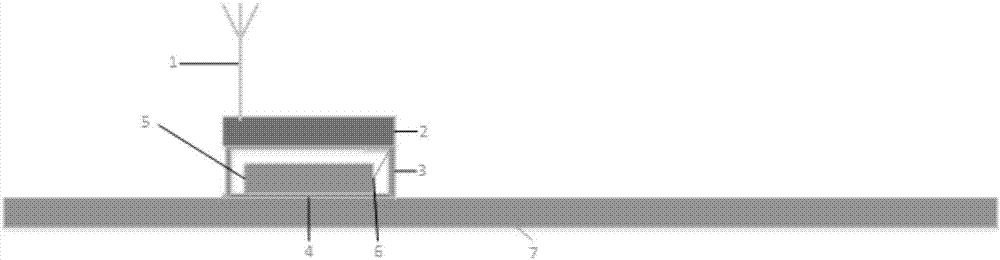

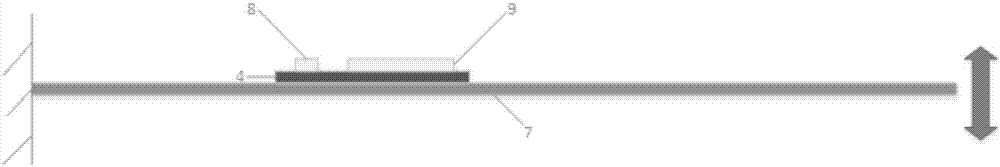

Wireless passive surface acoustic wave vibration sensor

InactiveCN107238431ASubsonic/sonic/ultrasonic wave measurementUsing electrical meansElectricityCantilevered beam

The invention provides a wireless passive surface acoustic wave vibration sensor. The wireless passive surface acoustic wave vibration sensor includes an antenna, a matching circuit, a piezoelectric cantilever beam, an SAW device with a reflective delay line structure, a mass oscillator and a cantilever beam fixing pedestal, wherein the SAW device is deposited on the piezoelectric cantilever beam through a semiconductor technology; the mass oscillator and the cantilever beam fixing pedestal are arranged at the tail end of a free end of the cantilever beam; an interdigital energy transducer and two reflectors form the SAW device; buffer materials are respectively arranged at the locations, being opposite to a packaging tube base and a packaging tube cap, on the tail end of the free end of the piezoelectric cantilever beam; when the sensor senses vibration, the mass oscillator at the free end of the piezoelectric cantilever beam enables the piezoelectric cantilever beam to generate one displacement in the force applying direction and generate curved deformation under the effect of acceleration of vibration; and the change of strain on the surface of the piezoelectric cantilever beam causes change of the SAW velocity of propagation in the reflective delay line SAW device, so that time delay and phase of the reflective delay line SAW device are changed correspondingly; and then sensing of the vibration quantity can be realized through decoupling of the sensing information.

Owner:CETC DEQING HUAYING ELECTRONICS

Method and apparatus for providing end seals on vertical stand-up packages

An improved method and apparatus for providing end seals on vertical stand up packages that prevents pleat formation and gusset variation. A clamping device is mounted below sealing jaws. A bottom end seal is made by the sealing jaws to form an open-ended tube. The open-ended tube is moved downward. The clamping device engages the tube to prevent twisting when product is placed into the tube. Product then enters an open-ended tube of flexible film packaging and the top seal is made.

Owner:FRITO LAY NORTH AMERICA INC

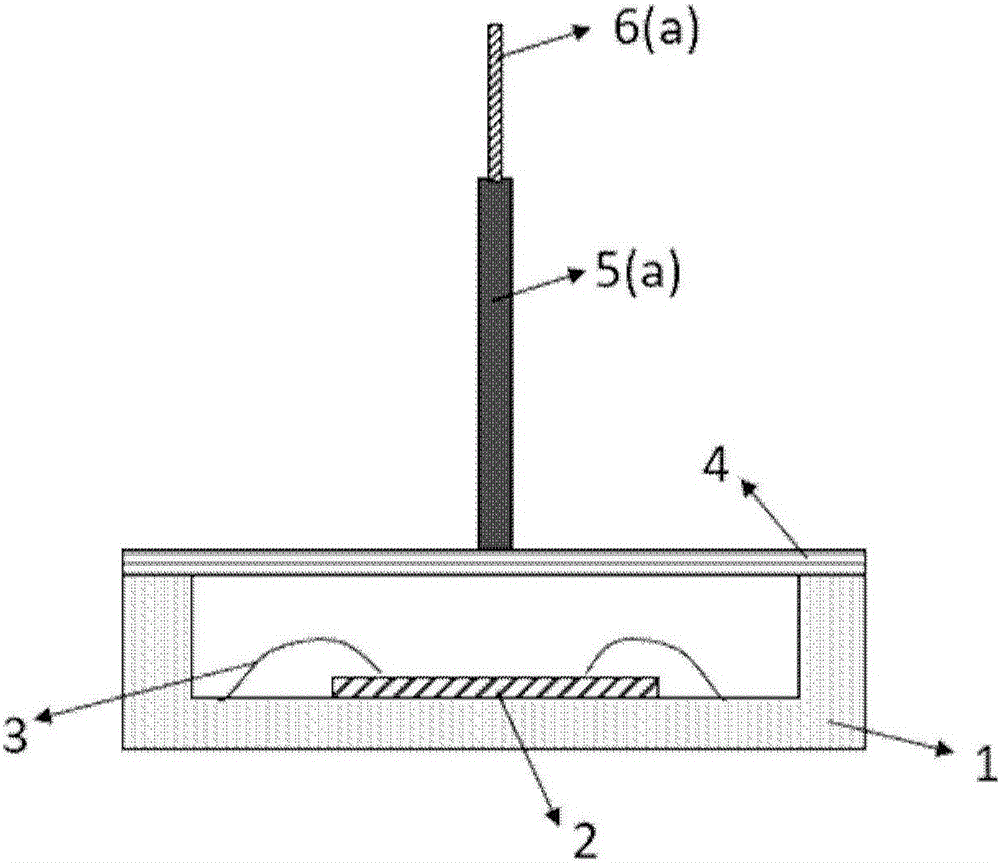

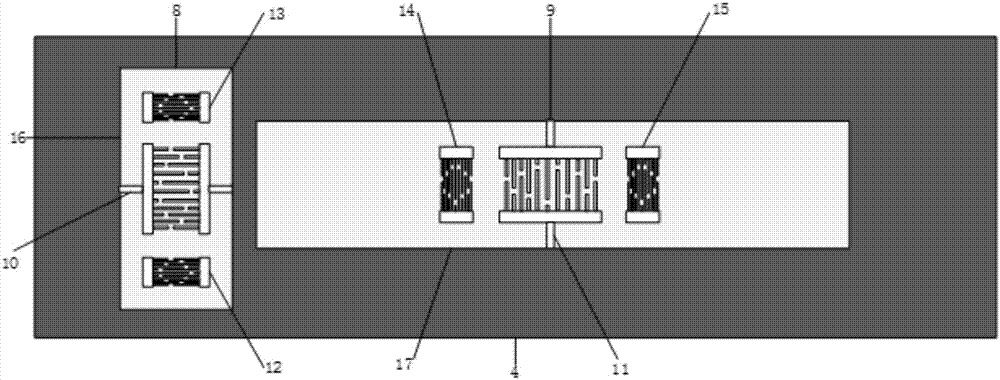

Differential resonator type wireless and passive surface acoustic wave strain sensor

The invention relates to a differential resonator type wireless and passive surface acoustic wave strain sensor, which comprises an antenna, a matching circuit, a packaging tube socket, a flexible packaging bottom sheet and a SAW sensing device, wherein the antenna is arranged on the matching circuit, the matching circuit is connected with the SAW sensing device via a signal lead wire, the SAW sensing device is packaged by means of the packaging tube socket and the flexible packaging bottom sheet, the SAW sensing device comprises a reference device and a perceiving device, the reference device is used for temperature compensation, and the perceiving device is used for strain detection. The principle of the sensor is that strain action is directly sensed by using the strain sensing device, resulting in variation of the corresponding resonance frequency, and the sensing of strain of an object to be measured can be realized through decoupling sensing information. By adopting the reference device and the perceiving device of two one-terminal-pair resonance type SAW devices, the differential resonator type wireless and passive surface acoustic wave strain sensor solves the problem of interference of environment temperature on strain measurement in a differential manner.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

Soft packaging tube sealing machine

InactiveCN101143497ASimple structureEasy to useContainer making machineryReciprocating motionEngineering

A tube sealing machine for a flexible package includes in turn a bagging mechanism arranged on the rack, an intubation mechanism, a transmission mechanism, a molding mechanism and a bag connecting mechanism. The invention has the characteristics that the transmission mechanism comprises a movable stand, a reciprocating motion mechanism and at least one lifting mechanism; the lifting mechanism is fixed on the movable stand, the end of which is arranged movably on the rack; the movable stand connects the rack through the reciprocating motion mechanism; the side of at least one movable stand parallel to the movement direction of the reciprocating motion mechanism is provided with at least one flexible package holder. The invention has the beneficial effects to the prior art of simple structure, easy use, high-yield result, effective space-saving and great production-cost reduction.

Owner:SHANTOU HONGQIAO PACKAGING IND

Clip machine

ActiveUS20080085668A1Reliable workmanshipSimple designSausage skin tying apparatusSausage filling/stuffing machinesRadial compressionEngineering

A clip machine for dividing and sealing tubular-shaped packaging filled with stuffing having at least two axially spaced pairs of radially opposed displacement elements, relating to the axis of the packaging tube, which are linked to and equipped with a linear guide, to be compressed radially towards one another and then separated axially in pairs, for the local constriction of the filled packaging and the formation of a tubular braid radially-linearly, and a pivotably arranged first sealing tool and a second sealing tool, with the first and second sealing tools being equipped to set and close at least one clamp fastener around the formed tubular braid, to be compressed radially between the axially separated displacement element pairs, the radial movement direction of displacement element pairs coincides with the radial movement direction of sealing tools.

Owner:POLY CLIP SYST

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com