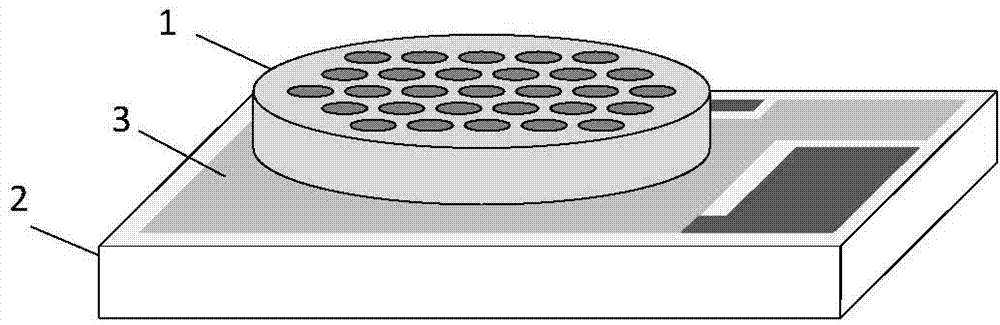

High-sensitivity gas sensor based on microchannel plate three-dimensional structure and production method of high-density gas sensor

A gas sensor, micro-channel plate technology, applied in the direction of material resistance, can solve problems such as structural reliability and stability are difficult to guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

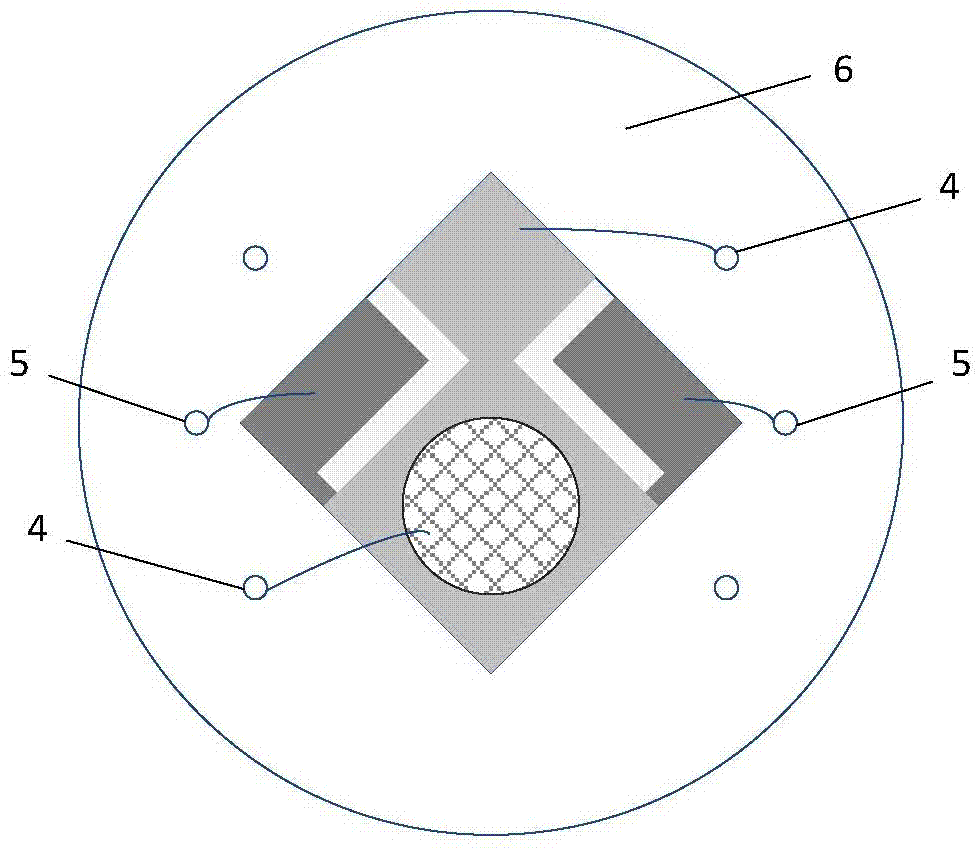

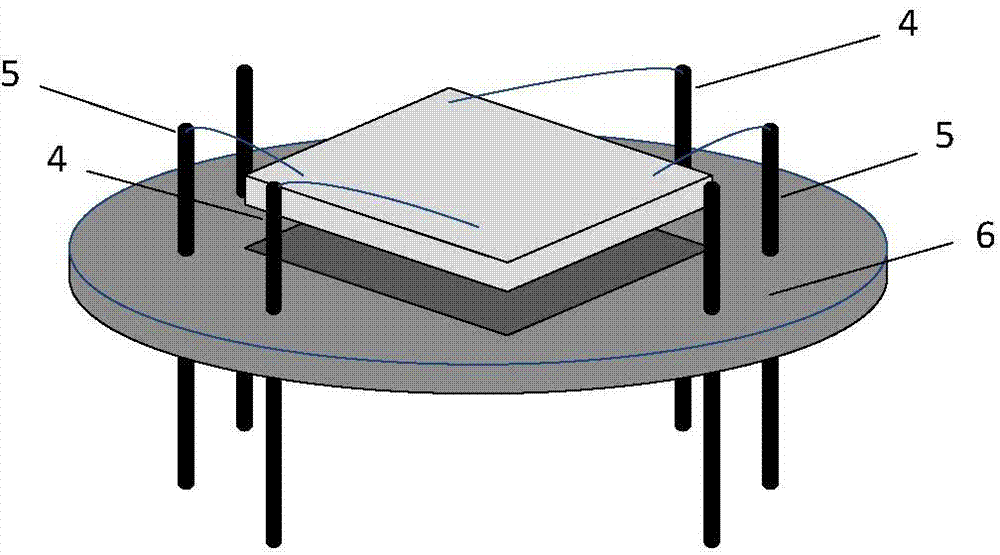

[0082] If in the detection module, the microchannel plate of glass material is used as the framework material, there is no need to prepare the side wall insulating layer 11, the material of the gas-sensitive film is tin dioxide, and the upper and lower electrodes are metal platinum. The heating module part, from bottom to top is Al 2 o 3 Ceramic sheet, metal platinum heating resistance coil, silicon nitride insulating film. The specific production process is as follows:

[0083] (1) Fabricate a microchannel plate on a glass material, each microchannel has a side length of 5 microns x 5 microns, a depth of 250 microns, and a side wall thickness of 1 micron. After laser cutting, a disc with a diameter of 3 mm is obtained;

[0084] (2) Deposit 0.5 micron tin dioxide gas-sensitive film material on the side wall of the microchannel by sol-gel method;

[0085] (3) Using the magnetron sputtering method, 0.3 micron metal platinum electrodes were deposited on the upper and lower si...

Embodiment 2

[0098] For the detection module part, the three-dimensional structure of the microchannel plate is made of silicon material, the side wall insulating layer is silicon dioxide, the material of the gas-sensitive film is tin dioxide, and the upper and lower electrodes are metal platinum. The heating module part, from bottom to top is Al 2 o 3 Ceramic sheet, metal platinum heating resistance coil, silicon nitride insulating film. The specific production process is as follows:

[0099] (1) Using the method provided by the patent 201110196442.4, and using the device provided by the patent application 201120406111.4, a silicon microchannel plate was fabricated on a 4-inch silicon wafer. Each microchannel has a side length of 5 microns x 5 microns, a depth of 250 microns, a side Wall thickness 1 micron. After laser cutting, a disc with a diameter of 3 mm is obtained;

[0100] (2) Using the method provided by patent 201210402277.8, thermally oxidize the silicon microchannel plate t...

Embodiment 3

[0115] If in the detection module part, the three-dimensional structure of the microchannel plate is made of silicon material, such as the microchannel plate is first thermally oxidized and then laser cut, the device structure is the same as that described in method 2, and the specific manufacturing process is as follows:

[0116] (1) Using the method provided by the patent 201110196442.4, and using the device provided by the patent application 201120406111.4, a silicon microchannel plate was fabricated on a 4-inch silicon wafer. Each microchannel has a side length of 5 microns x 5 microns, a depth of 250 microns, a side Wall thickness 1 micron;

[0117] (2) Using the method provided by patent 201210402277.8, thermally oxidize the silicon microchannel plate to obtain a 0.5 micron silicon dioxide sidewall insulating layer;

[0118] (3) Deposit 0.5 micron tin dioxide gas-sensitive film material on the side wall of the microchannel by sol-gel method;

[0119] (4) Using the metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Side wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com