Soft packaging tube sealing machine

A technology of flexible packaging and tube sealing machine, which is applied in packaging, transportation and packaging, and container manufacturing machinery, etc. It can solve the problems of low work efficiency and inconvenient use, and achieve the effects of saving space, simple structure, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

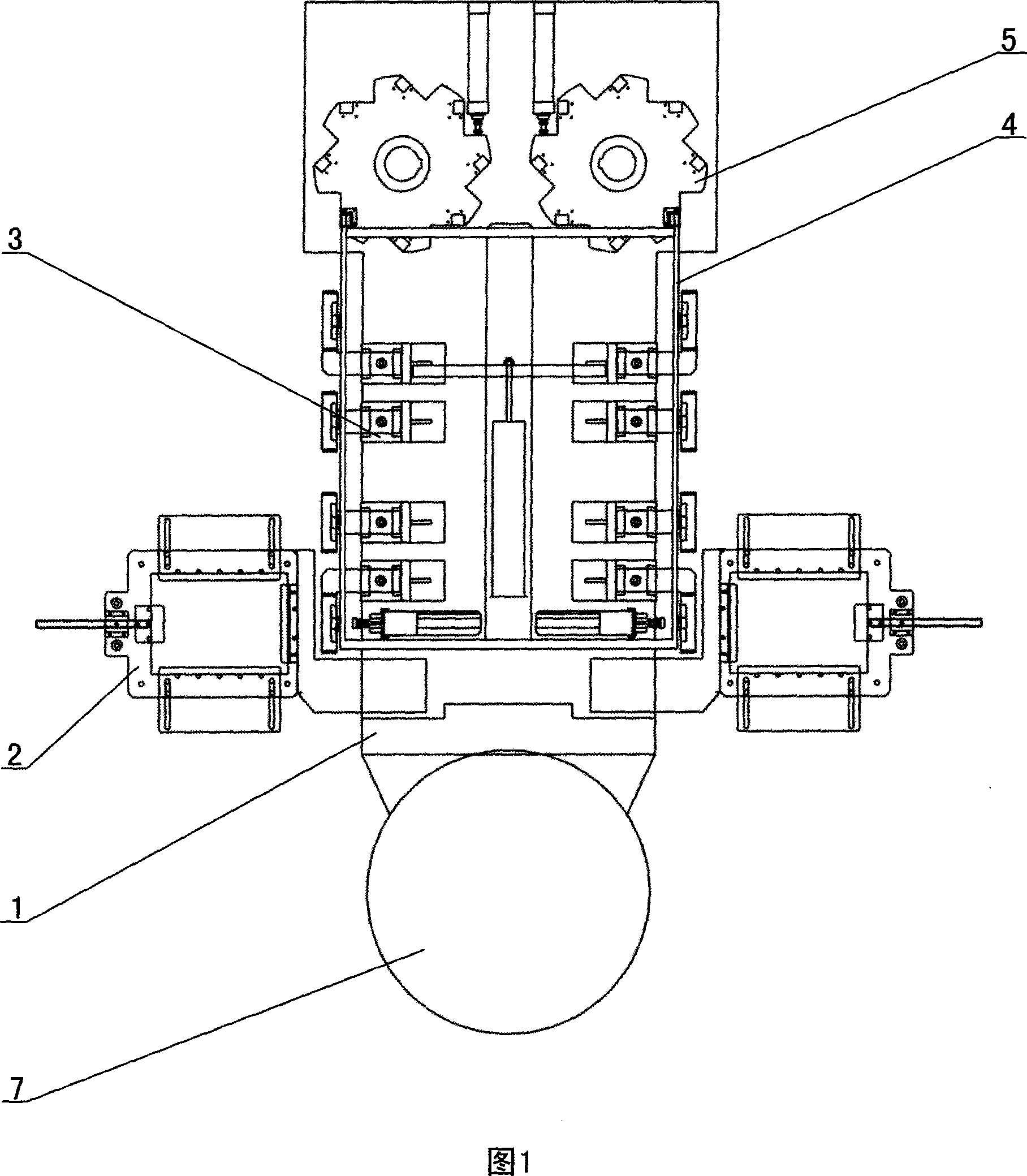

[0040] As shown in Figures 1-7, the flexible packaging tube sealing machine in this embodiment in turn includes a bag loading mechanism 7, an intubation mechanism 2, a transfer mechanism 4, 8 clamping mechanisms 3 and 2 arranged on the frame 1. Collection mechanism 5.

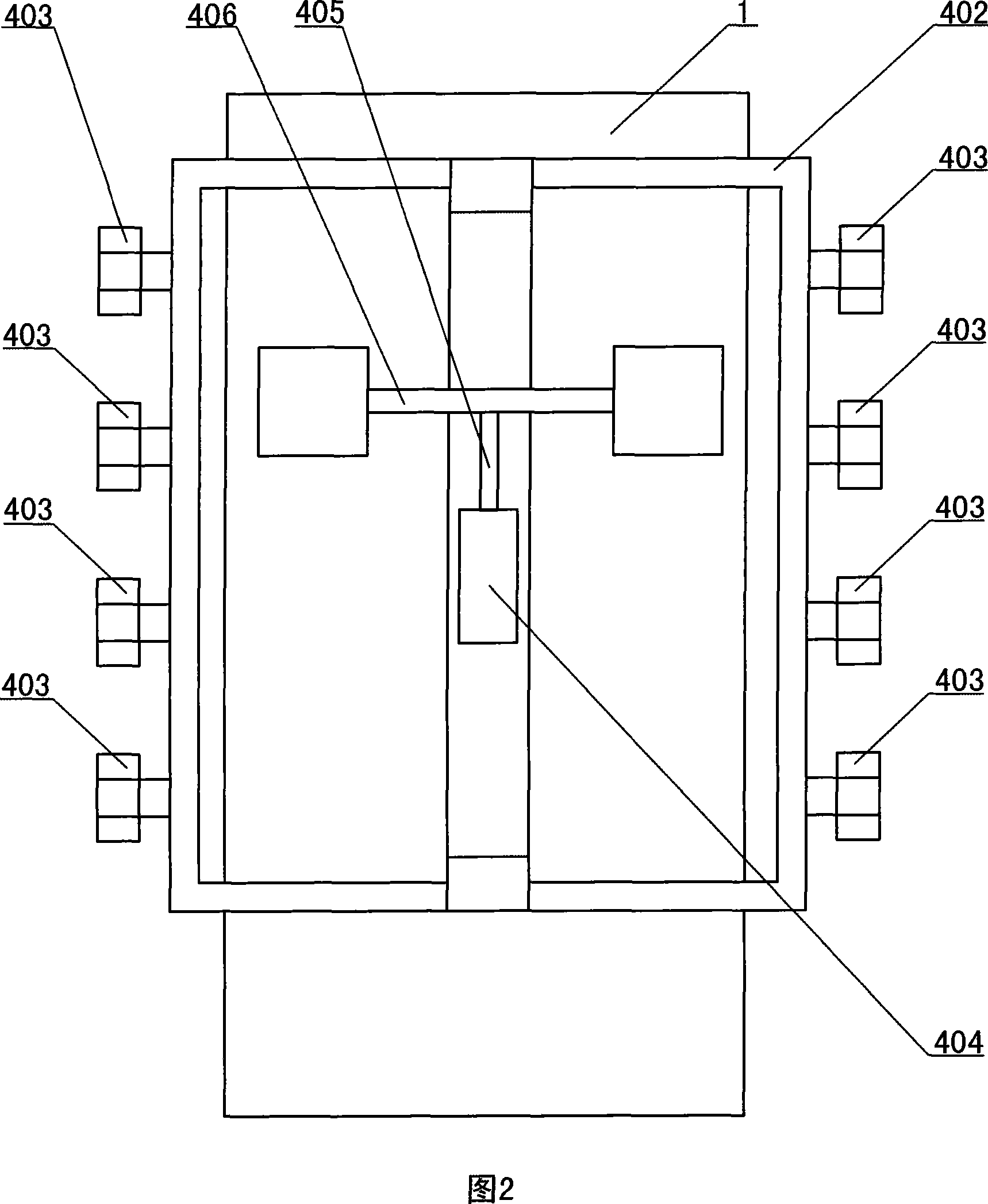

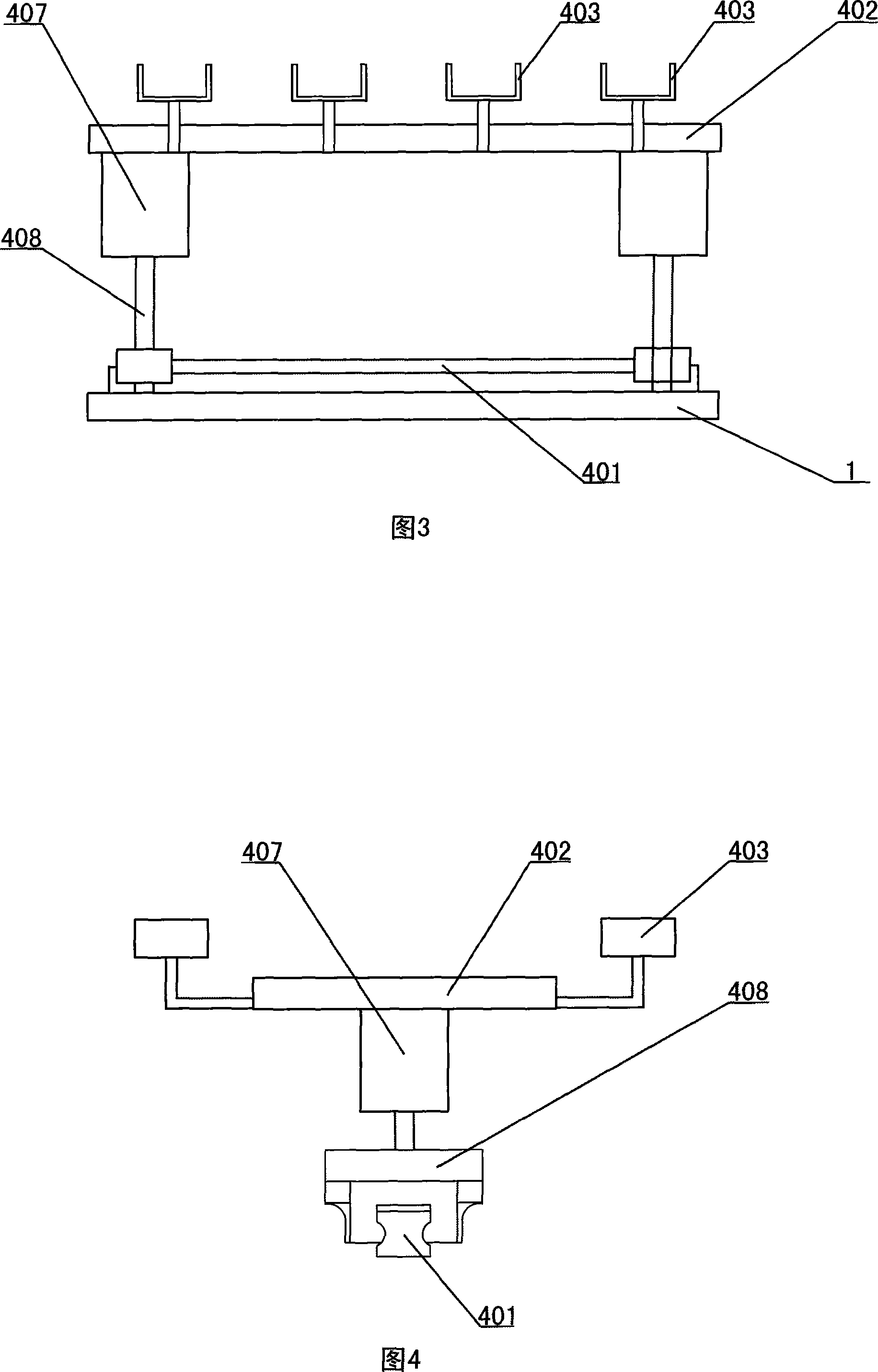

[0041] The transfer mechanism 4 includes a movable frame 402, a back and forth reciprocating mechanism and two lifting mechanisms. Two lifting mechanisms are respectively arranged at the front and rear ends of the movable frame 2. The lifting mechanism is fixed on the movable frame 2, the end of the lifting mechanism can move against the frame 1, the movable frame 402 is connected to the frame 1 through the reciprocating mechanism, and the movable frame 2 is parallel to the direction of movement of the reciprocating mechanism. There are 4 flexible packaging brackets 403 on each side. Each flexible packaging bracket 403 corresponds to a clamping mechanism 3, and the adjacent flexible packaging brackets 403 on the sa...

Embodiment 2

[0060] As shown in Figures 8-10, the flexible packaging tube sealing machine in this embodiment in turn includes a bag loading mechanism 7', an intubation mechanism 2', a transfer mechanism 4', and 8 mold clamping mechanisms arranged on the frame 1' 3'and 2 bag collection mechanisms 5'.

[0061] The difference between this embodiment and the first embodiment is that the bag-receiving mechanism 5'is different, so other mechanisms will not be described. The following is a detailed introduction to the bag-receiving mechanism 5'.

[0062] The bag receiving mechanism 5'includes a flexible packaging bracket 502' arranged on the frame 1', a series connection belt pulling mechanism and a series connection belt pressing mechanism, the series connection belt pulling mechanism is located on a flexible packaging bracket 502' On the other hand, the tandem belt pressing mechanism includes a belt pressing drive mechanism and a belt pressing member 503'. One end of the belt pressing member 503' i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com