Encapsulation structure and method for white light emitting diode device

A technology of light-emitting diodes and packaging structures, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as accelerating device failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

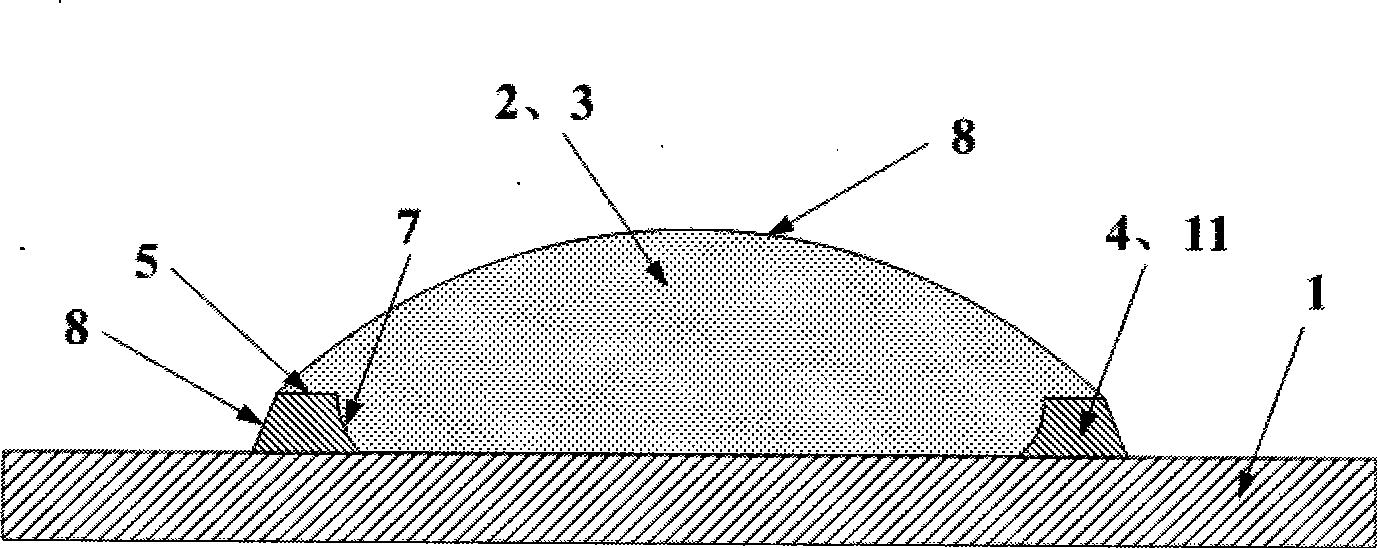

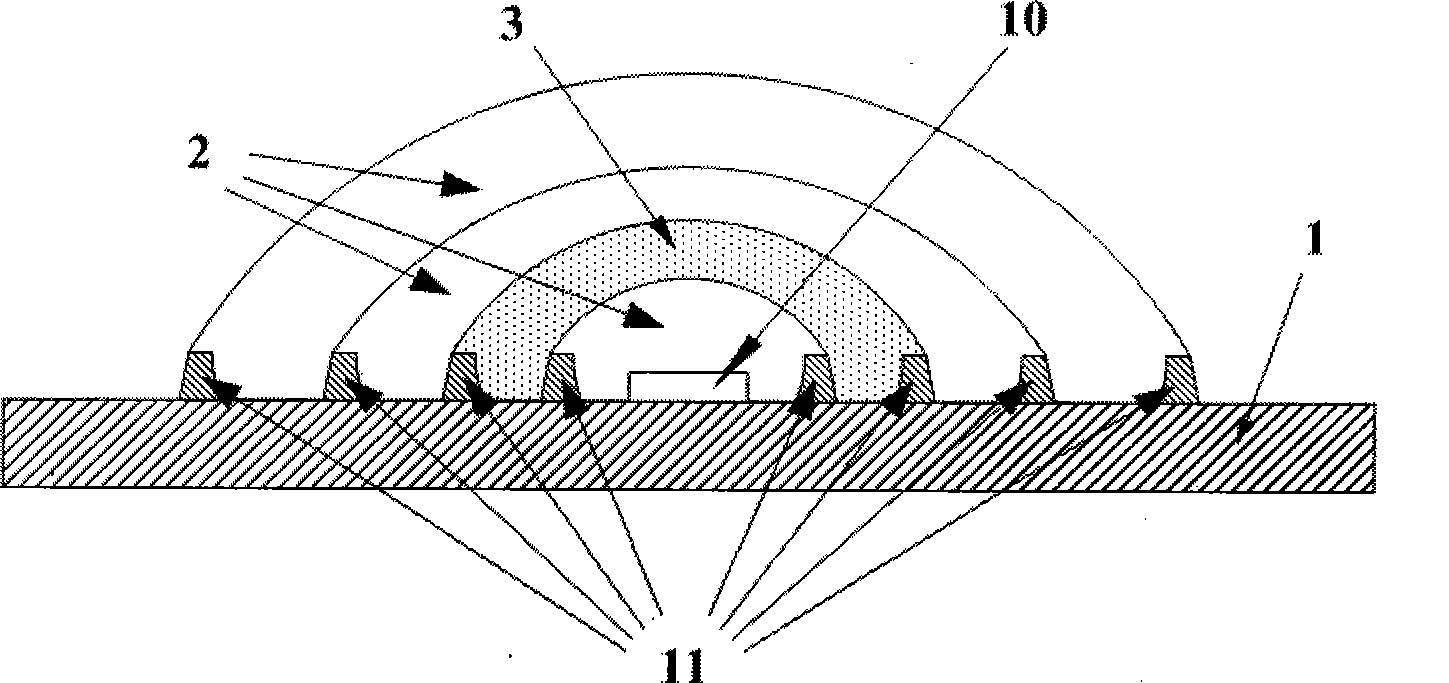

[0023] Embodiments of the present invention are further described below in conjunction with the accompanying drawings: see image 3 , the packaging structure of the white light emitting diode device is composed of a light emitting diode chip 10 , a packaging tube shell 1 , a packaging silica gel 2 , and a fluorescent powder glue 3 . The light emitting diode chip 9 is mounted in the packaging tube 1 . The packaging package 1 is in the shape of a flat plate or a structure with a reflective cup, which is flat in this embodiment. The structure of the packaging package 1 includes one or several packaging cells 4 , and a plurality of packaging cells 4 are included in this embodiment. The packaging unit 4 is a ring-shaped convex strip-shaped packaging unit 11 or a groove-shaped packaging unit 12 centered on the chip 10. The shape of the ring is a square or a circle or a regular polygon. Each packaging unit 4 can be Located on the same plane or on different planes, the multiple enca...

Embodiment 2

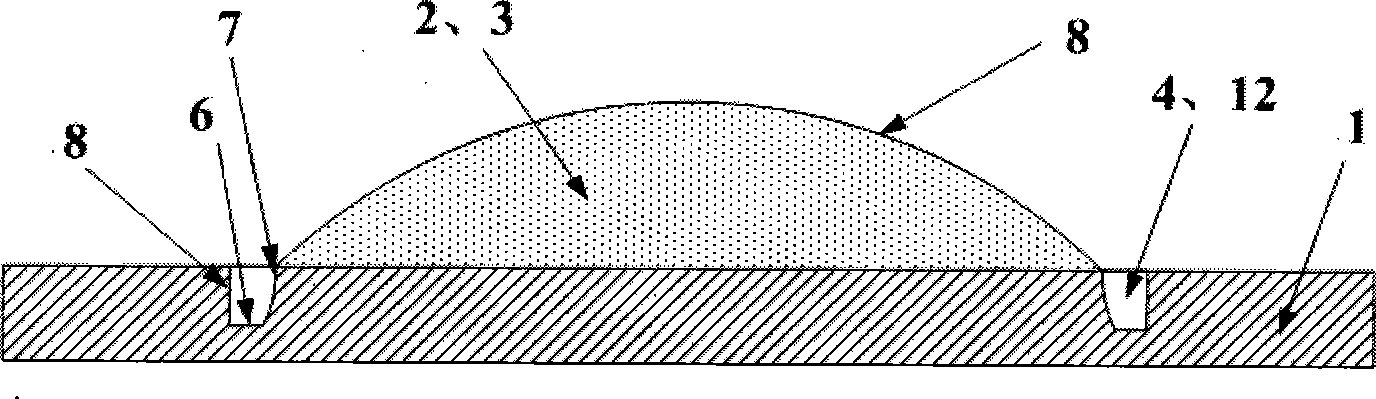

[0035] The difference between the second embodiment and the first embodiment is that the encapsulation unit 4 is a groove-shaped encapsulation unit 12, and the light-emitting diode chip 10 is first covered by the encapsulation silica gel 2, and then by the fluorescent powder glue 3, and the groove-shaped encapsulation The monomer 12 is made by precision cutting or mold manufacturing or stamping manufacturing or laser manufacturing. The outer surface 8 of each groove-shaped packaging unit 12 is a vertical plane in this embodiment, and the inner surface 7 is an arc surface in this embodiment, see Figure 4 .

Embodiment 3

[0037]The difference between the third embodiment and the first embodiment is that the package package 1 has a reflector 13, and the package package 1 contains both a convex strip-shaped package unit 11 and a groove-shaped package unit 12, see Figure 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com