Patents

Literature

1428 results about "Strain measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Strain is a measure of the amount of stretch or compression along a material (Normal strains), or the amount of distortion associated with the sliding of layers within a material (Shear strains). Strain measurement is a key element of materials testing.

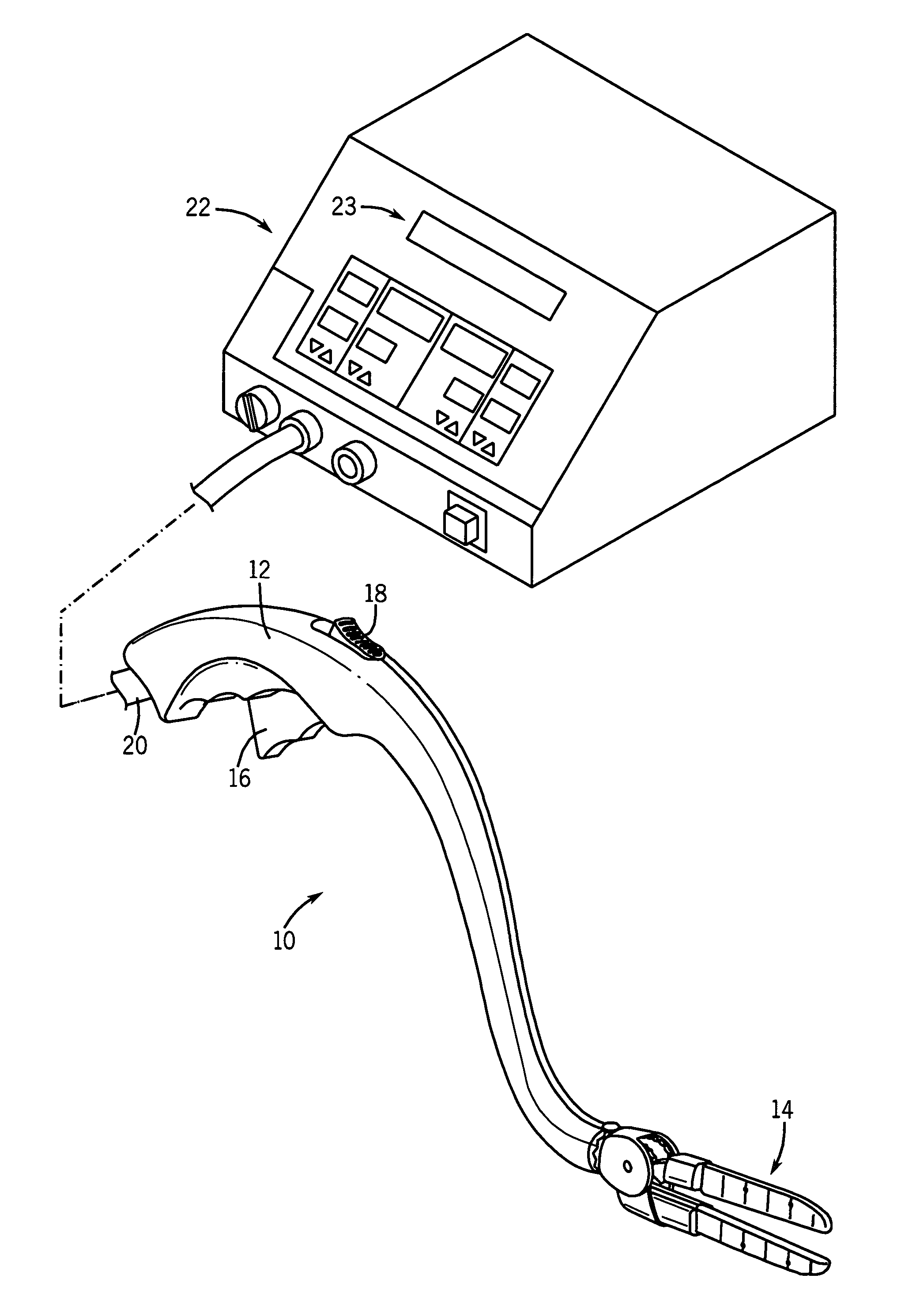

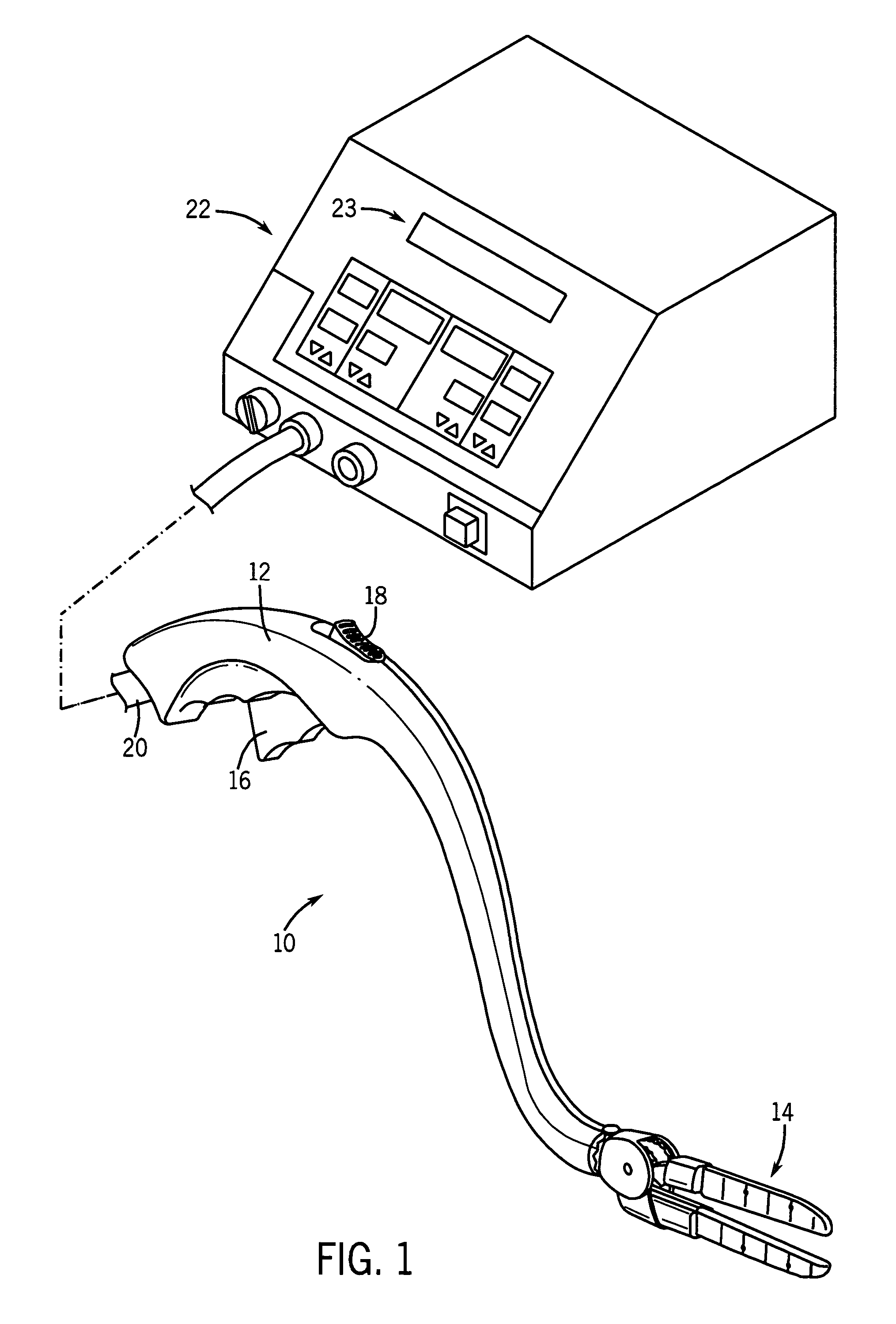

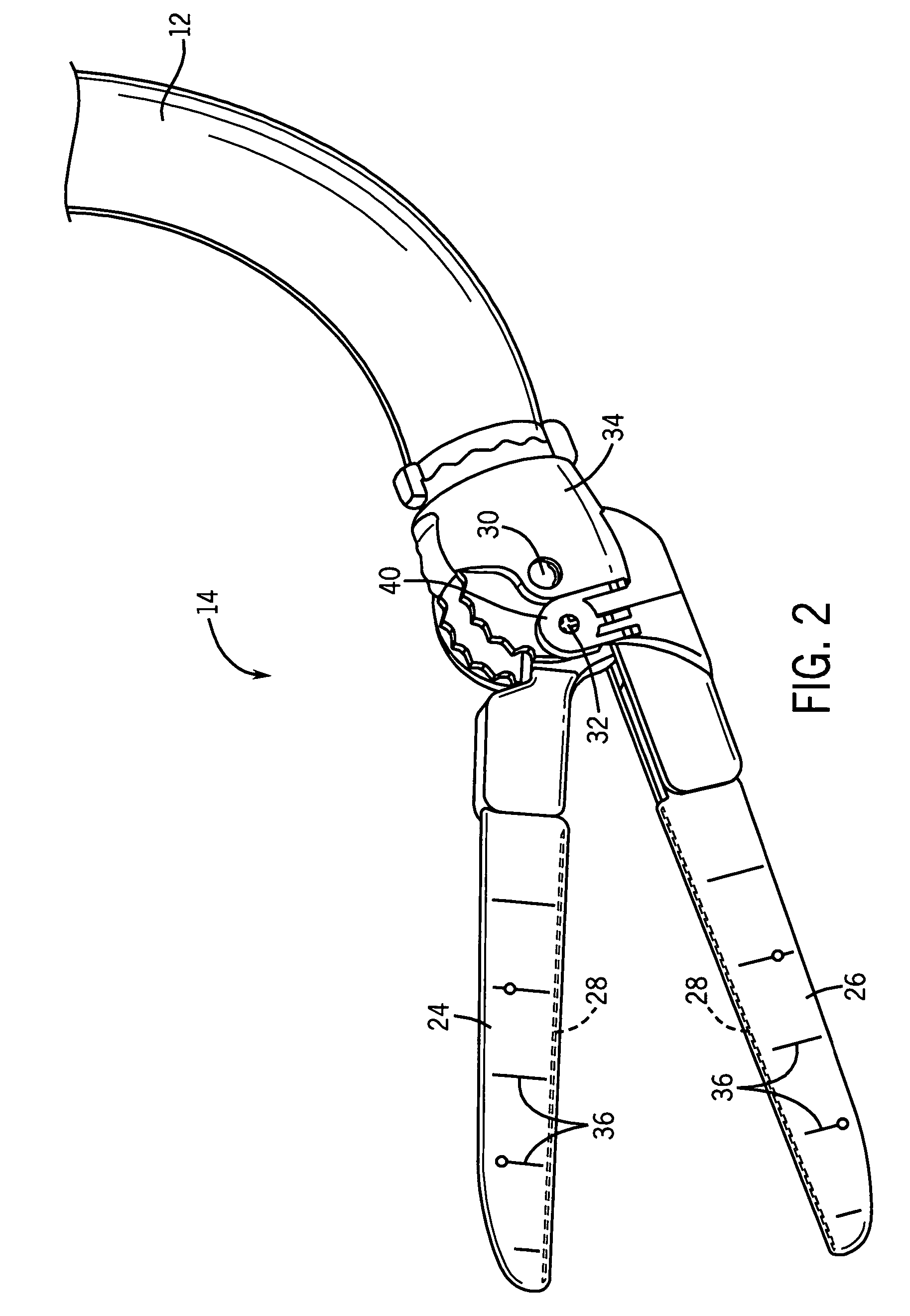

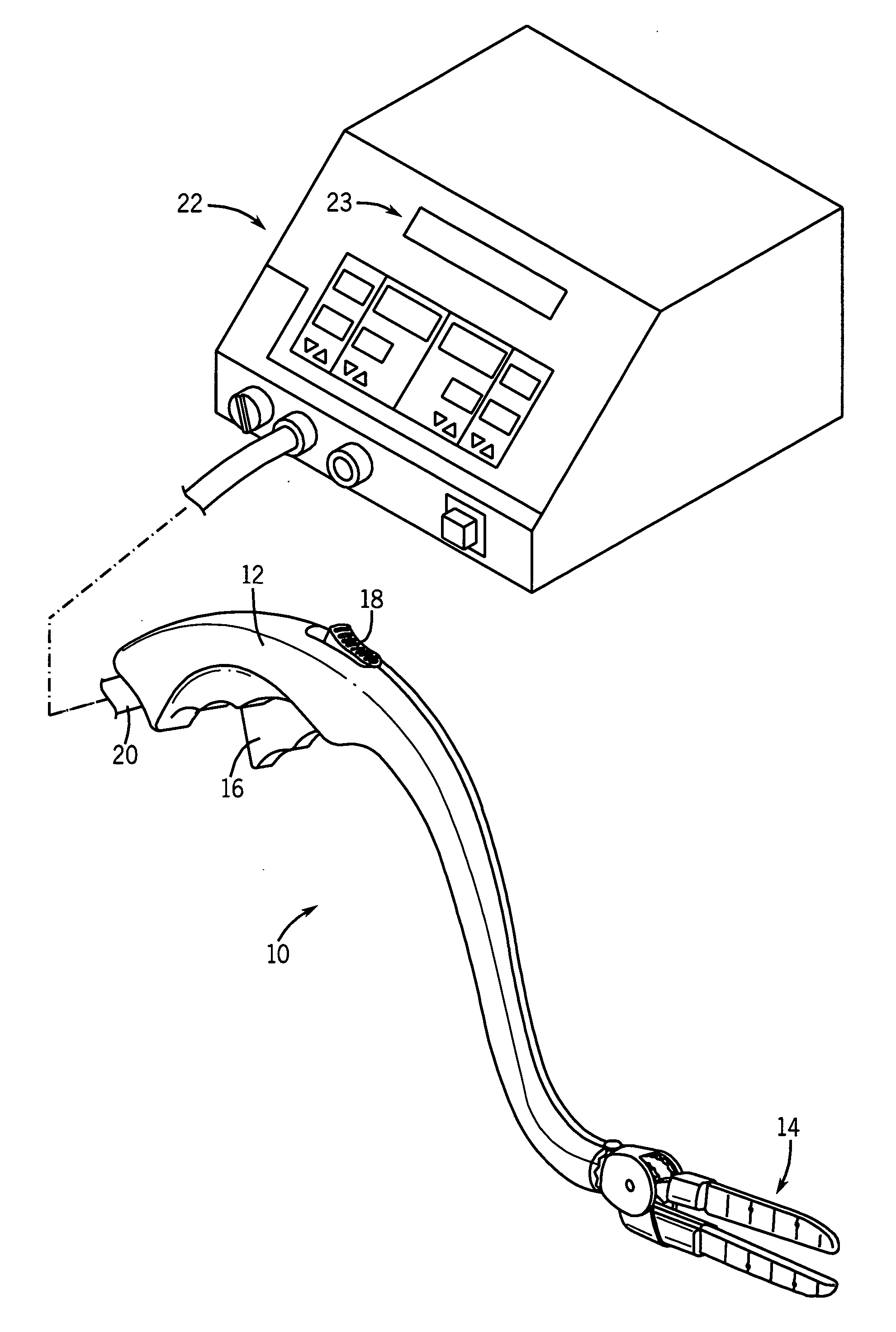

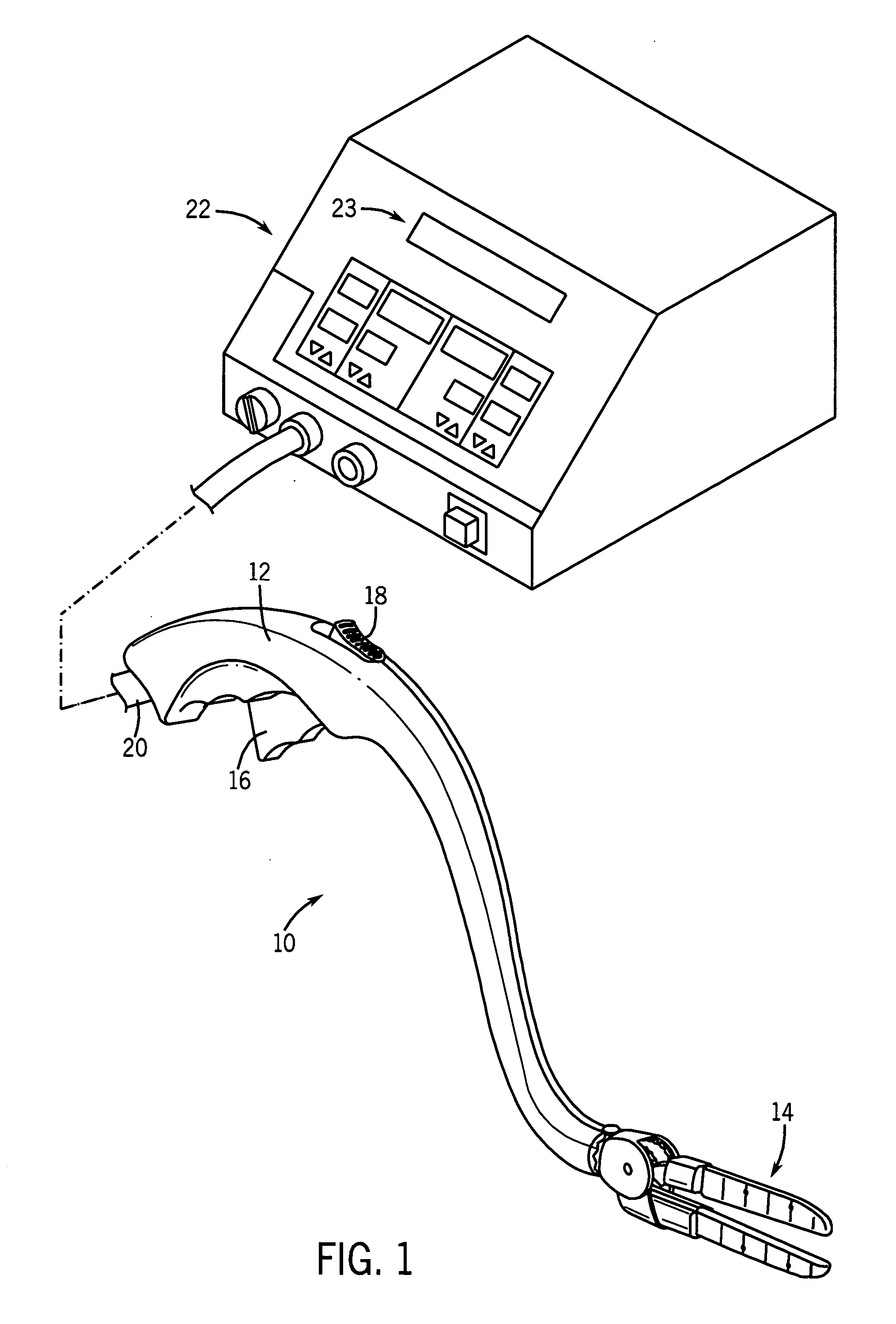

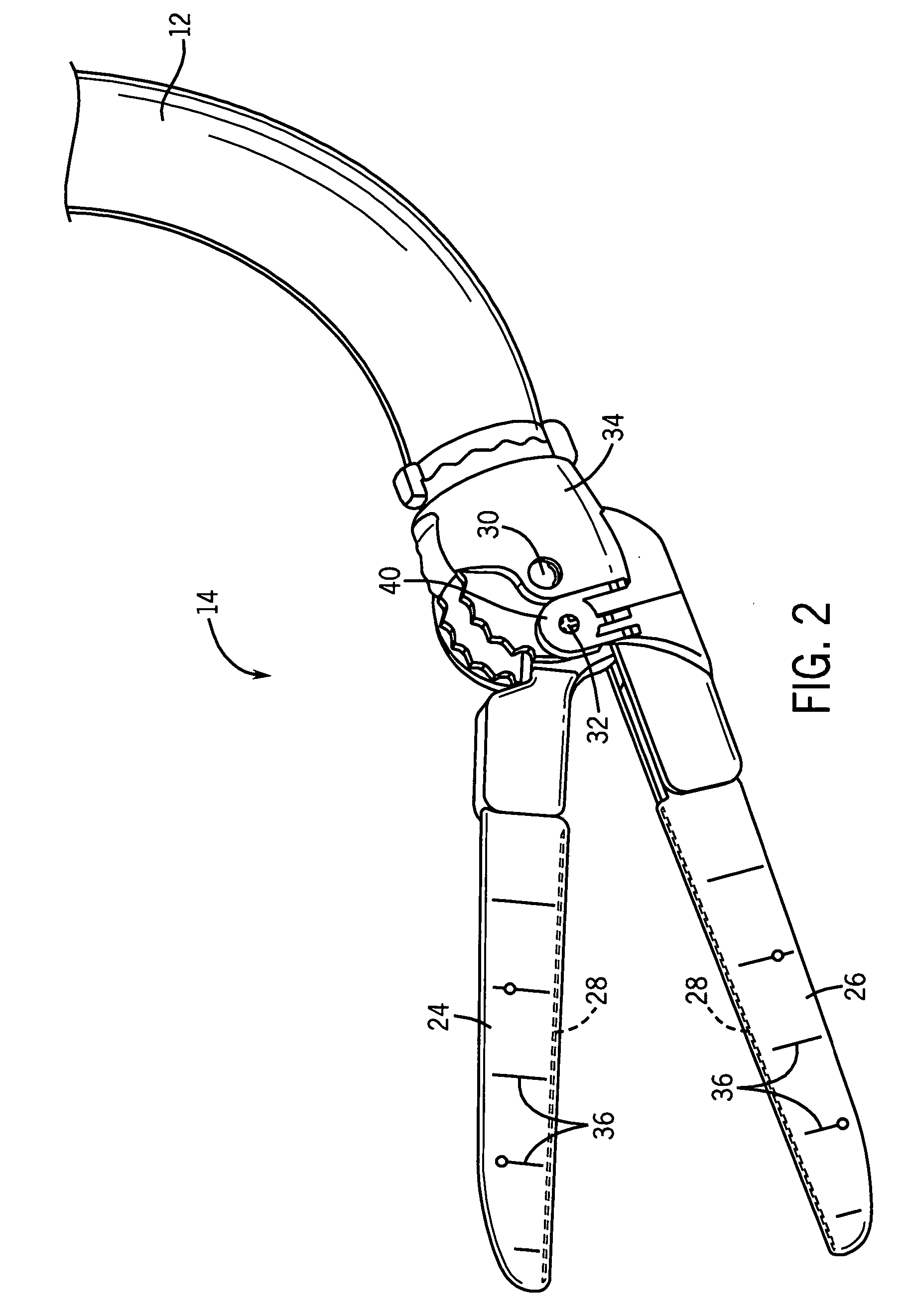

Device and method for determining tissue thickness and creating cardiac ablation lesions

A tissue ablation device has a handle and an ablation head coupled to the handle. The ablation head has a first jaw, a second jaw, and an ablative element coupled to at least one of the first and second jaws. A thickness measurement device may be coupled to the ablation device to indicate the distance separating the first and second jaws. Further, a force measurement device may be coupled to the ablation device to measure the force being applied by the first and second jaws to a piece of tissue. Further, a strain measurement device may be coupled to the ablation device to indicate the strain resulting in a piece of tissue disposed between the first and second jaws when a stress is applied to the tissue.

Owner:MEDTRONIC INC

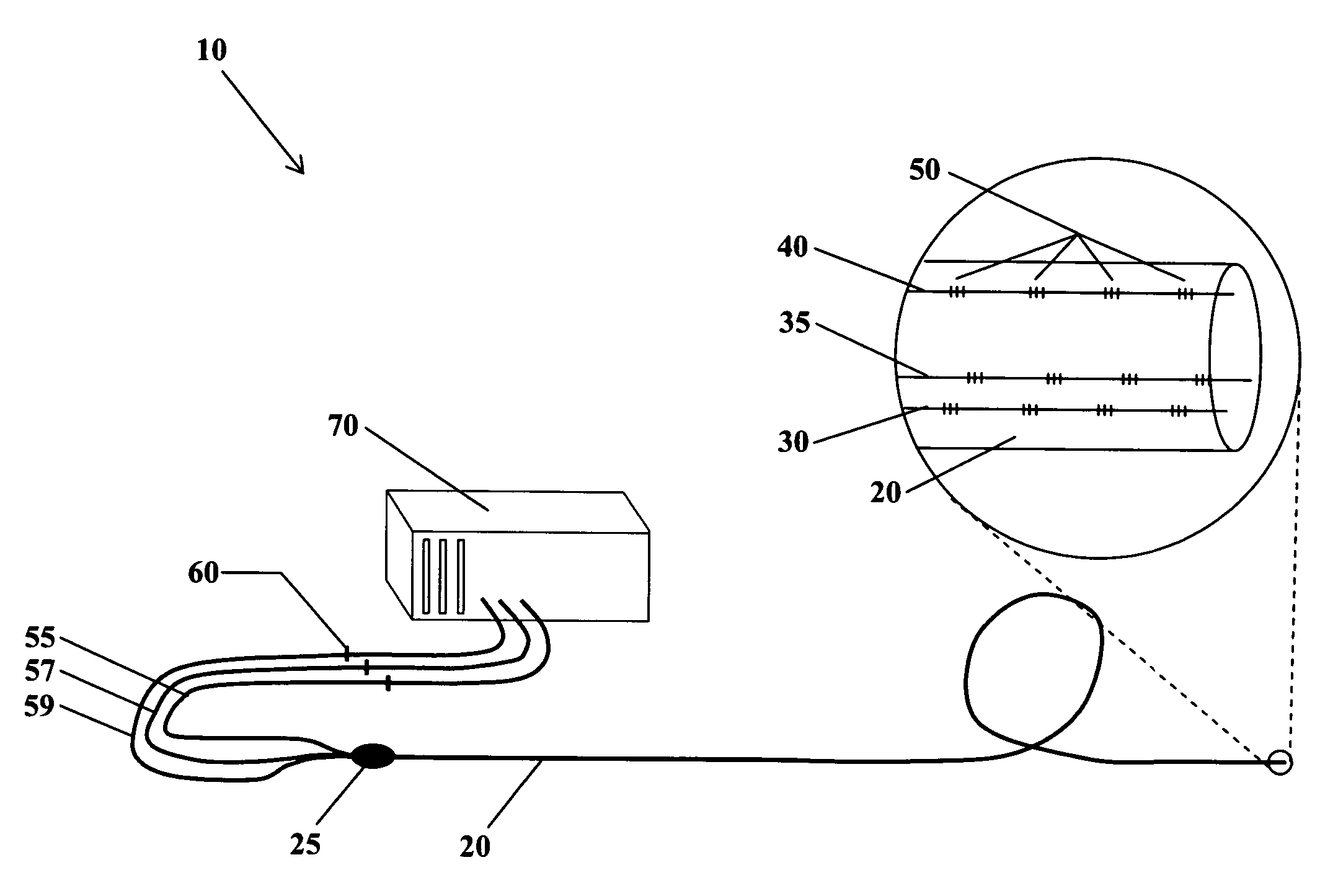

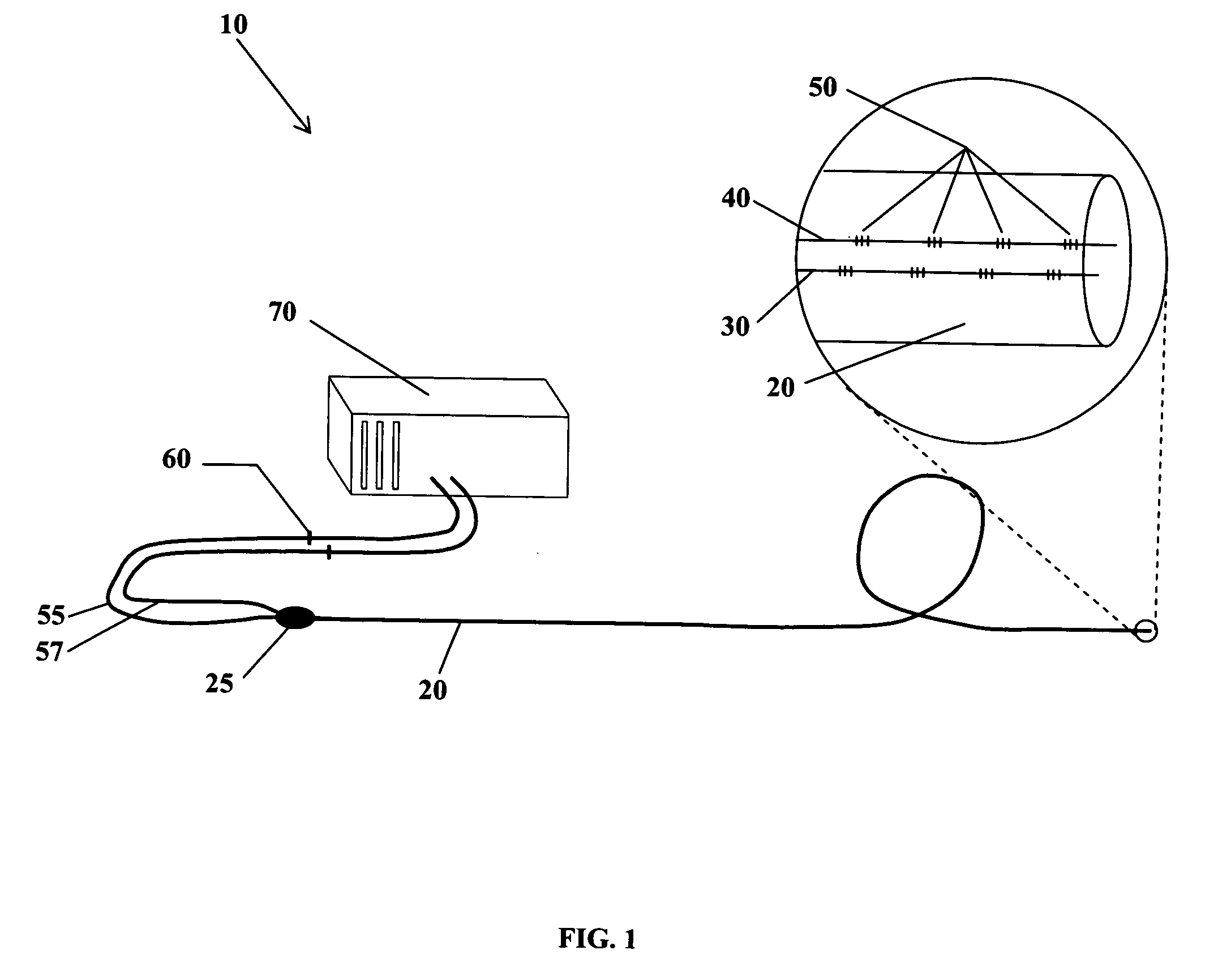

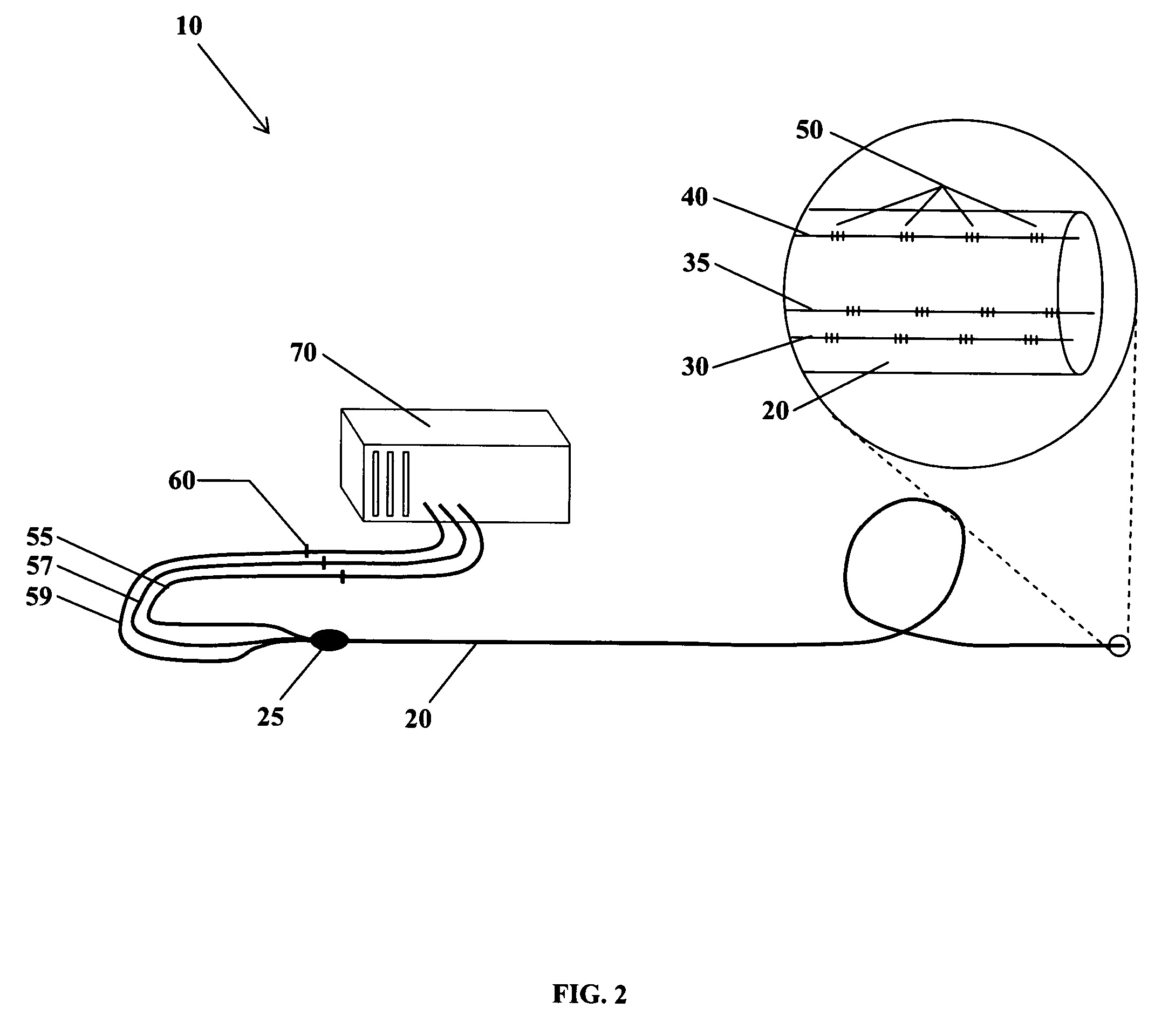

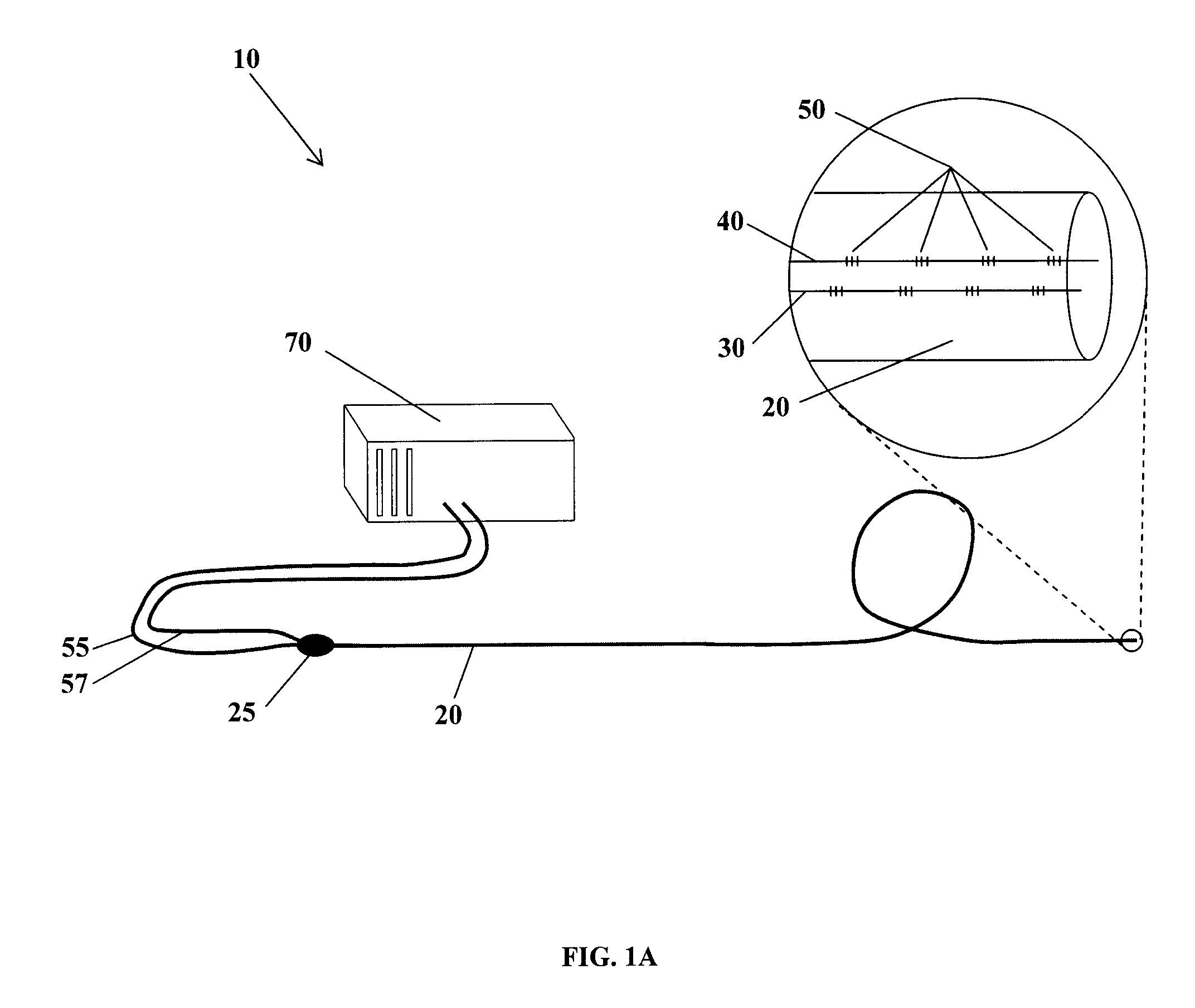

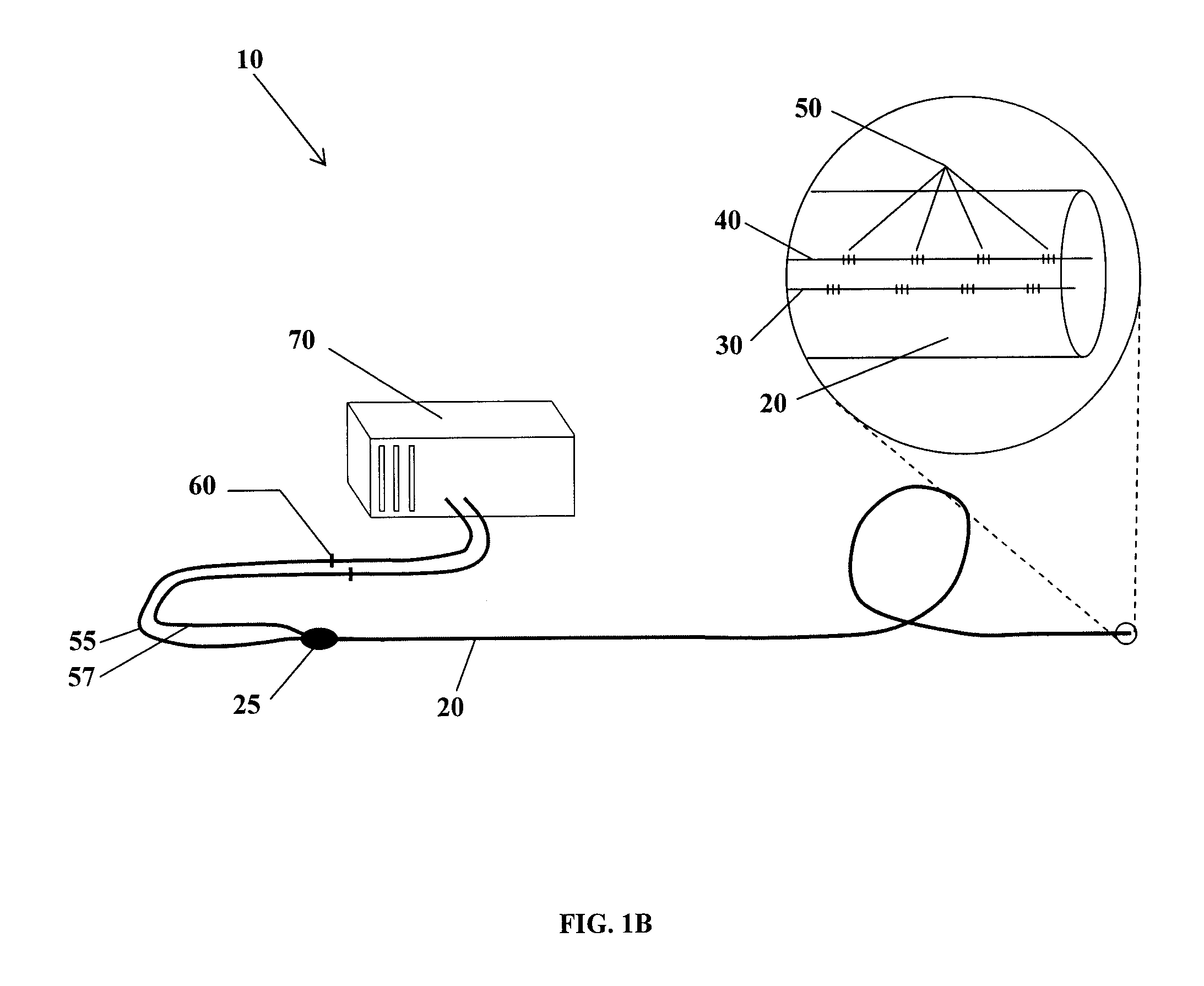

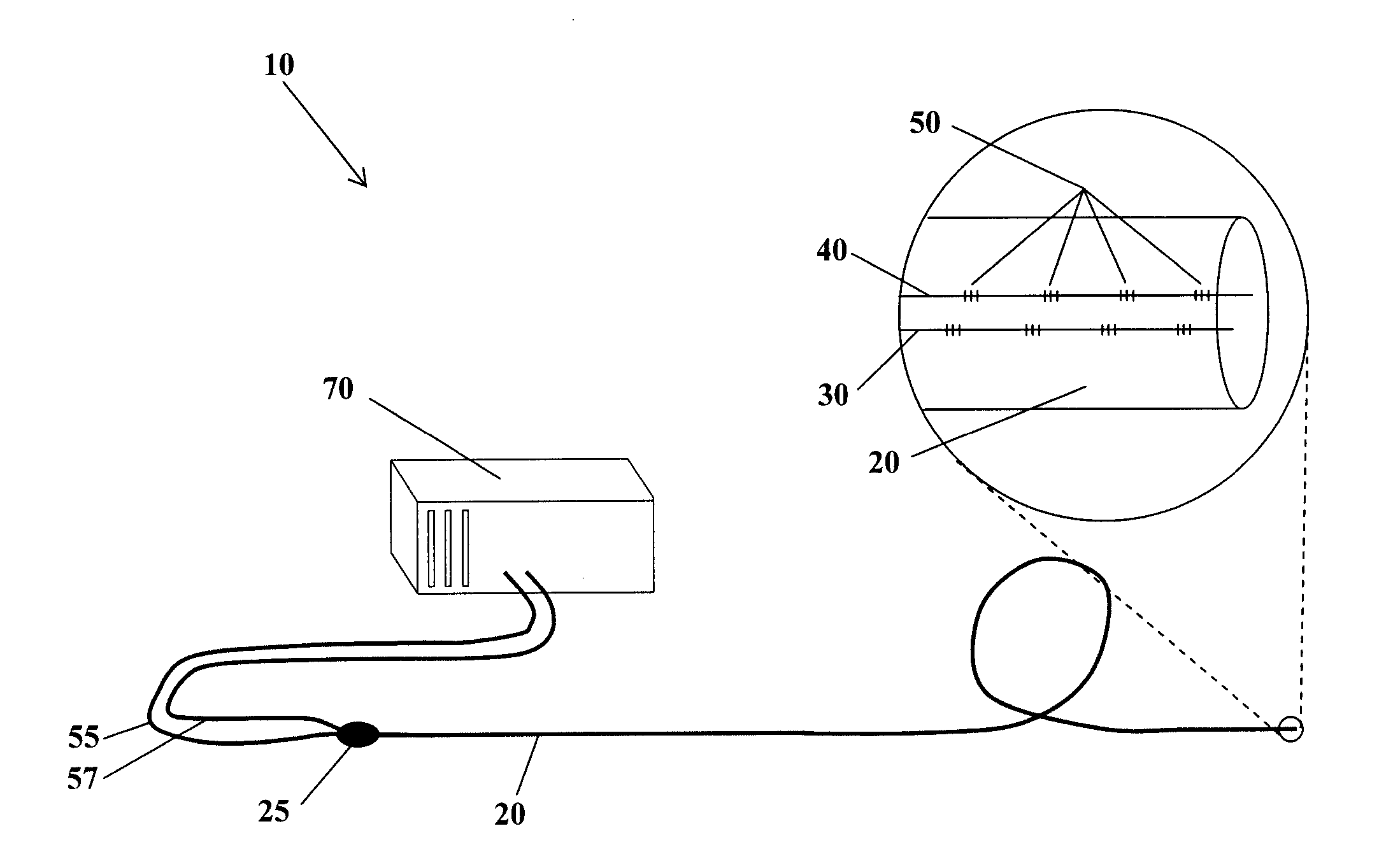

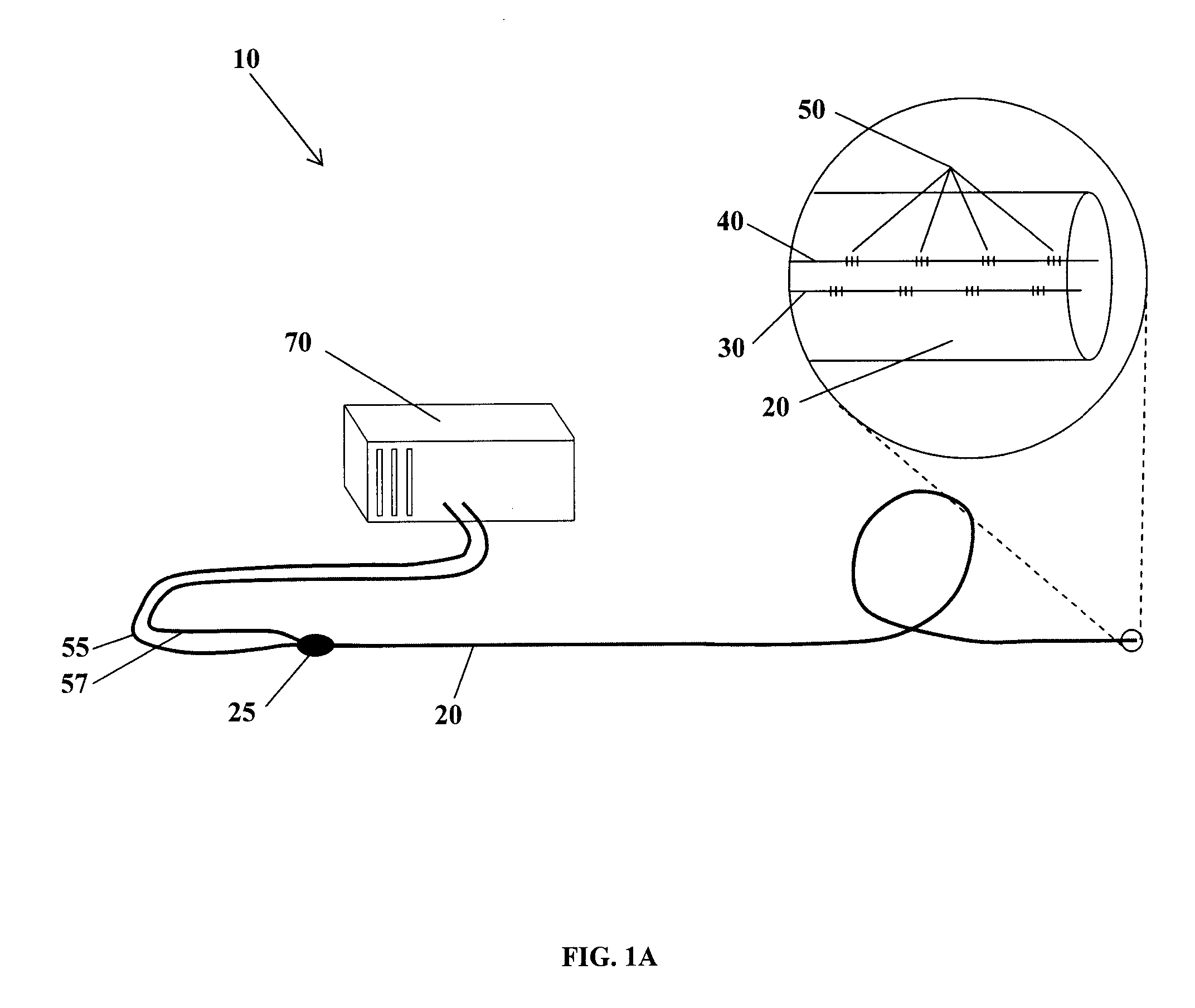

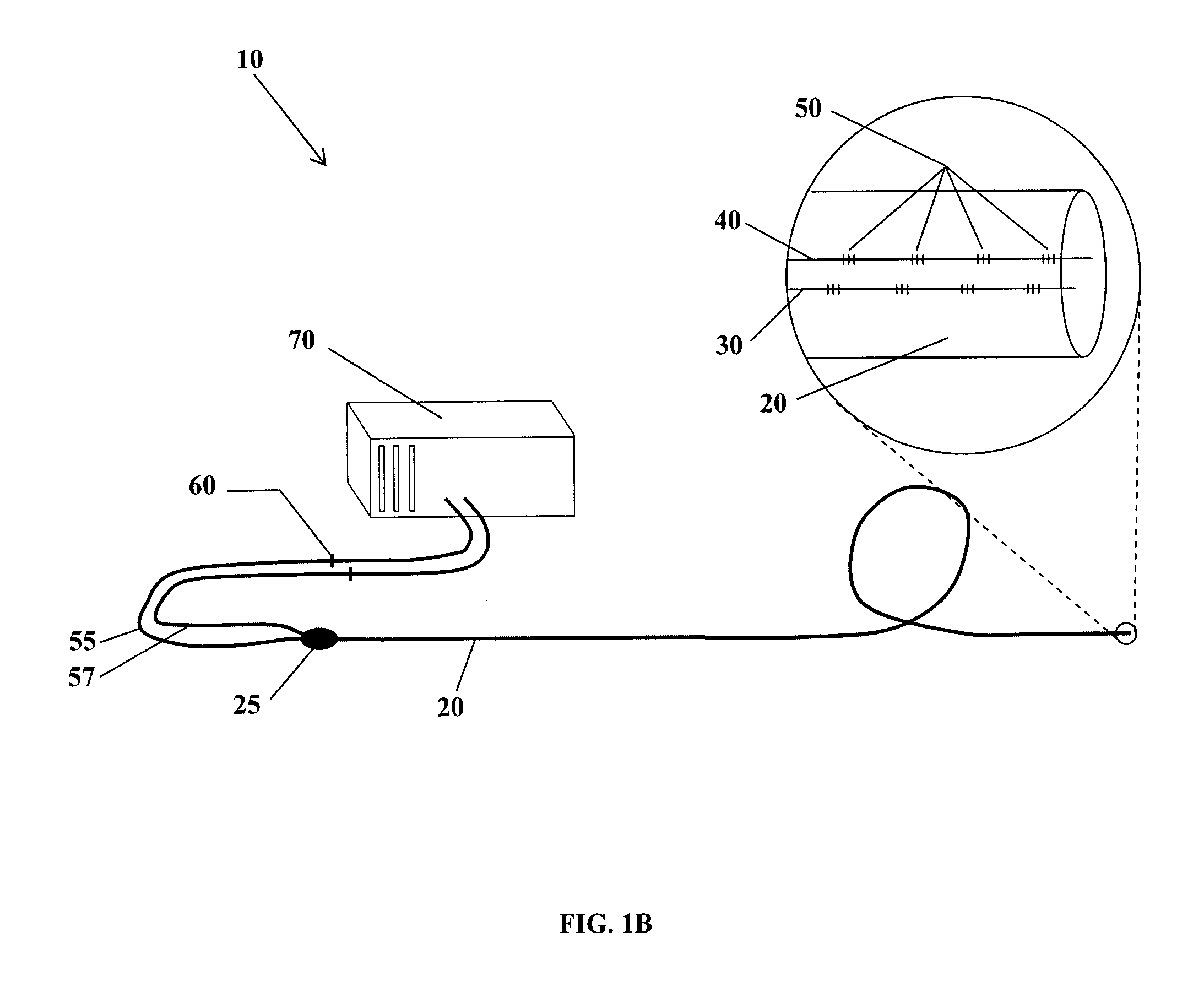

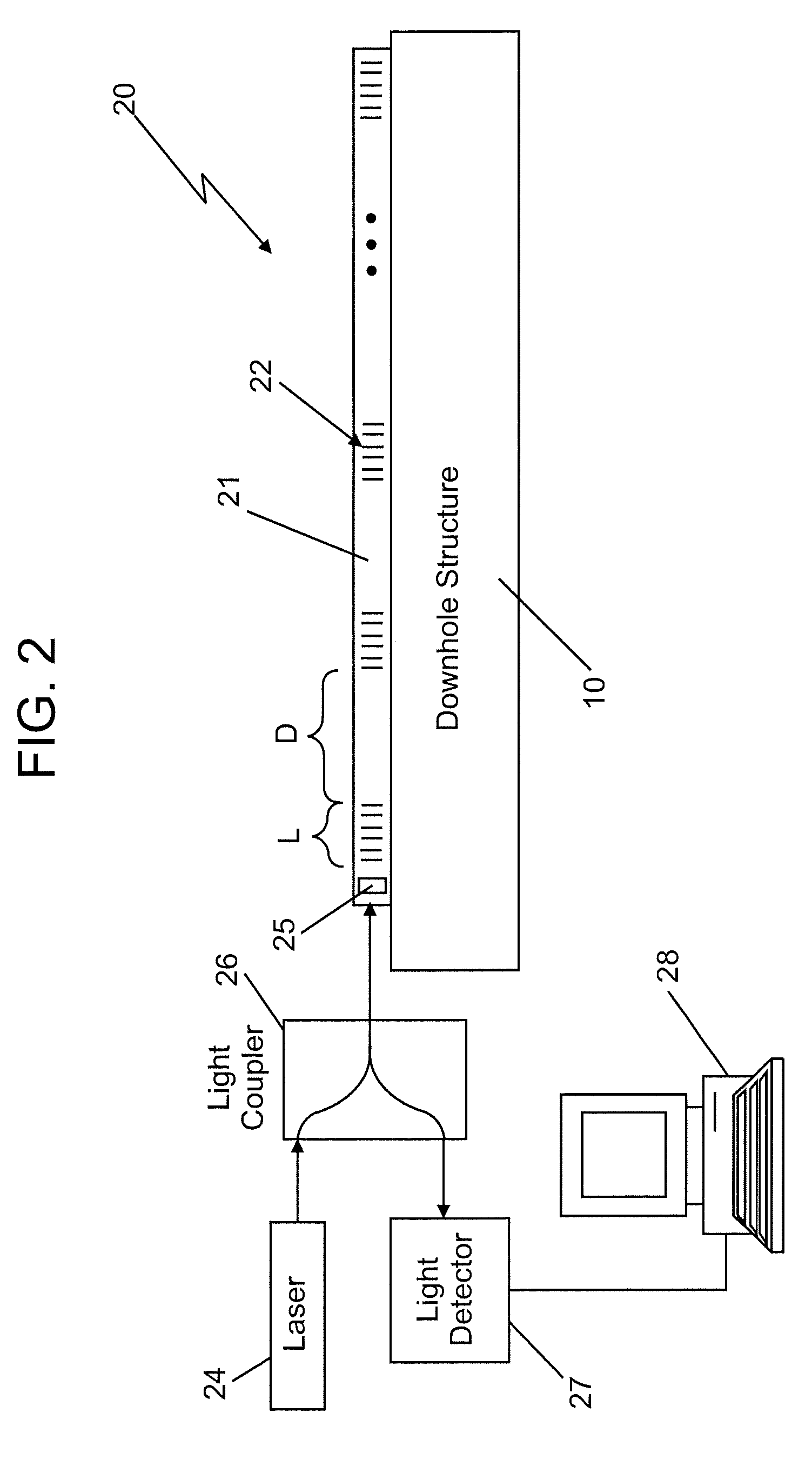

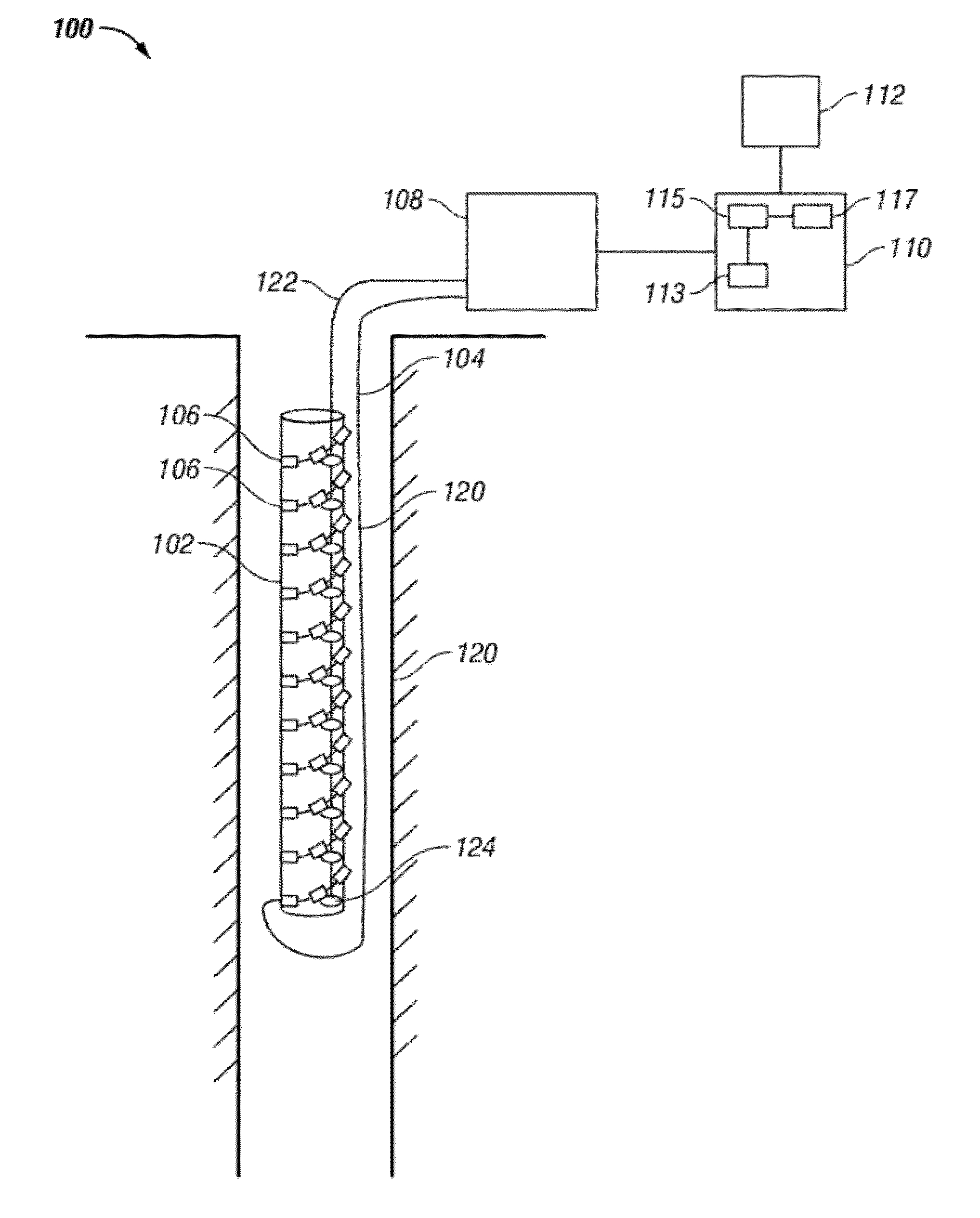

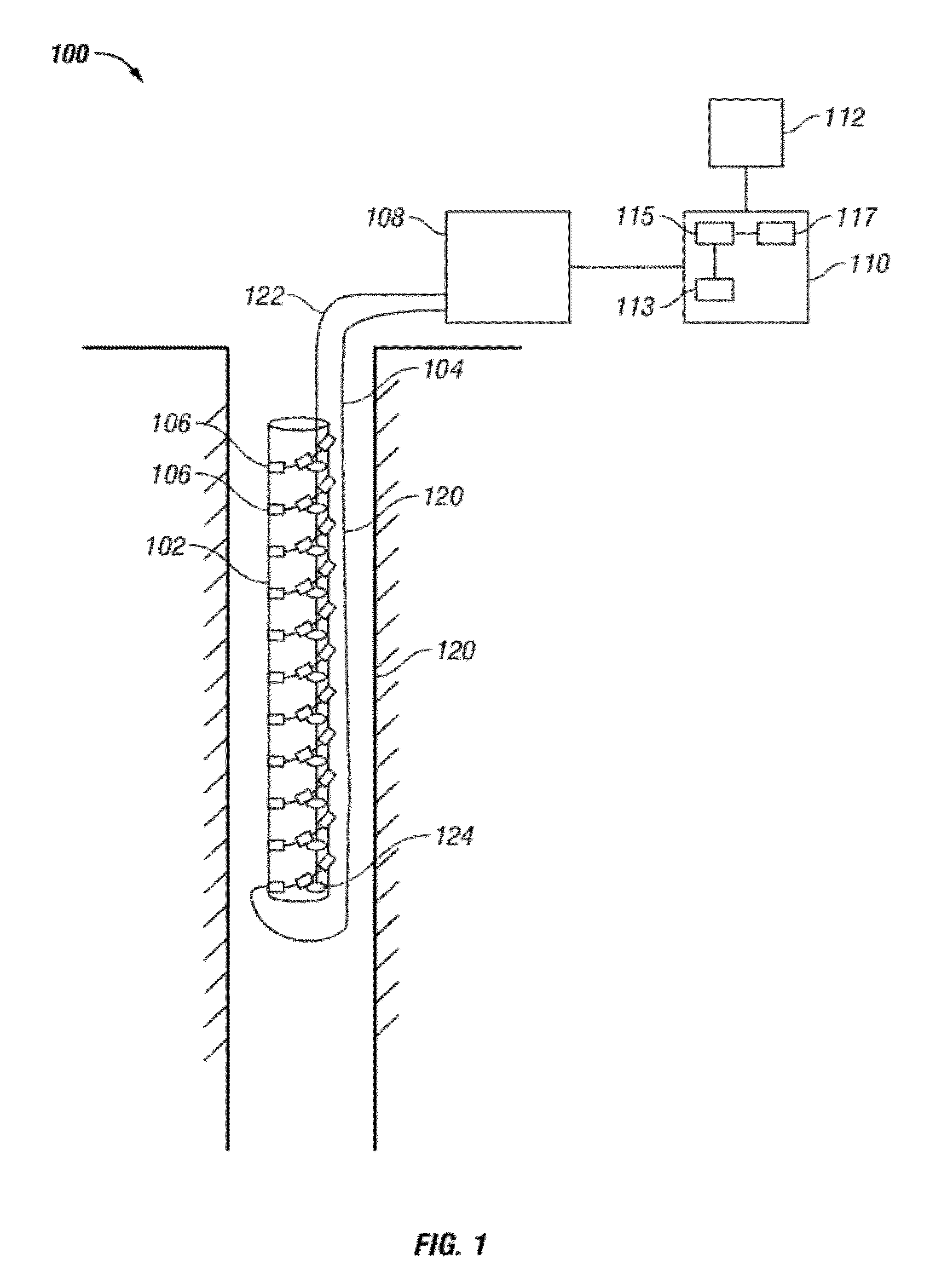

Fiber optic position and shape sensing device and method relating thereto

The present invention is directed toward a fiber optic position and shape sensing device and the method of use. The device comprises an optical fiber means. The optical fiber means comprises either at least two single core optical fibers or a multicore optical fiber having at least two fiber cores. In either case, the fiber cores are spaced apart such that mode coupling between the fiber cores is minimized. An array of fiber Bragg gratings are disposed within each fiber core. A broadband reference reflector is positioned in an operable relationship to each fiber Bragg grating wherein an optical path length is established for each reflector / grating relationship. A frequency domain reflectometer is positioned in an operable relationship to the optical fiber means. In use, the device is affixed to an object. Strain on the optical fiber is measured and the strain measurements correlated to local bend measurements. Local bend measurements are integrated to determine position or shape of the object.

Owner:LUNA INNOVATIONS

Device and method for determining tissue thickness and creating cardiac ablation lesions

A tissue ablation device has a handle and an ablation head coupled to the handle. The ablation head has a first jaw, a second jaw, and an ablative element coupled to at least one of the first and second jaws. A thickness measurement device may be coupled to the ablation device to indicate the distance separating the first and second jaws. Further, a force measurement device may be coupled to the ablation device to measure the force being applied by the first and second jaws to a piece of tissue. Further, a strain measurement device may be coupled to the ablation device to indicate the strain resulting in a piece of tissue disposed between the first and second jaws when a stress is applied to the tissue.

Owner:MEDTRONIC INC

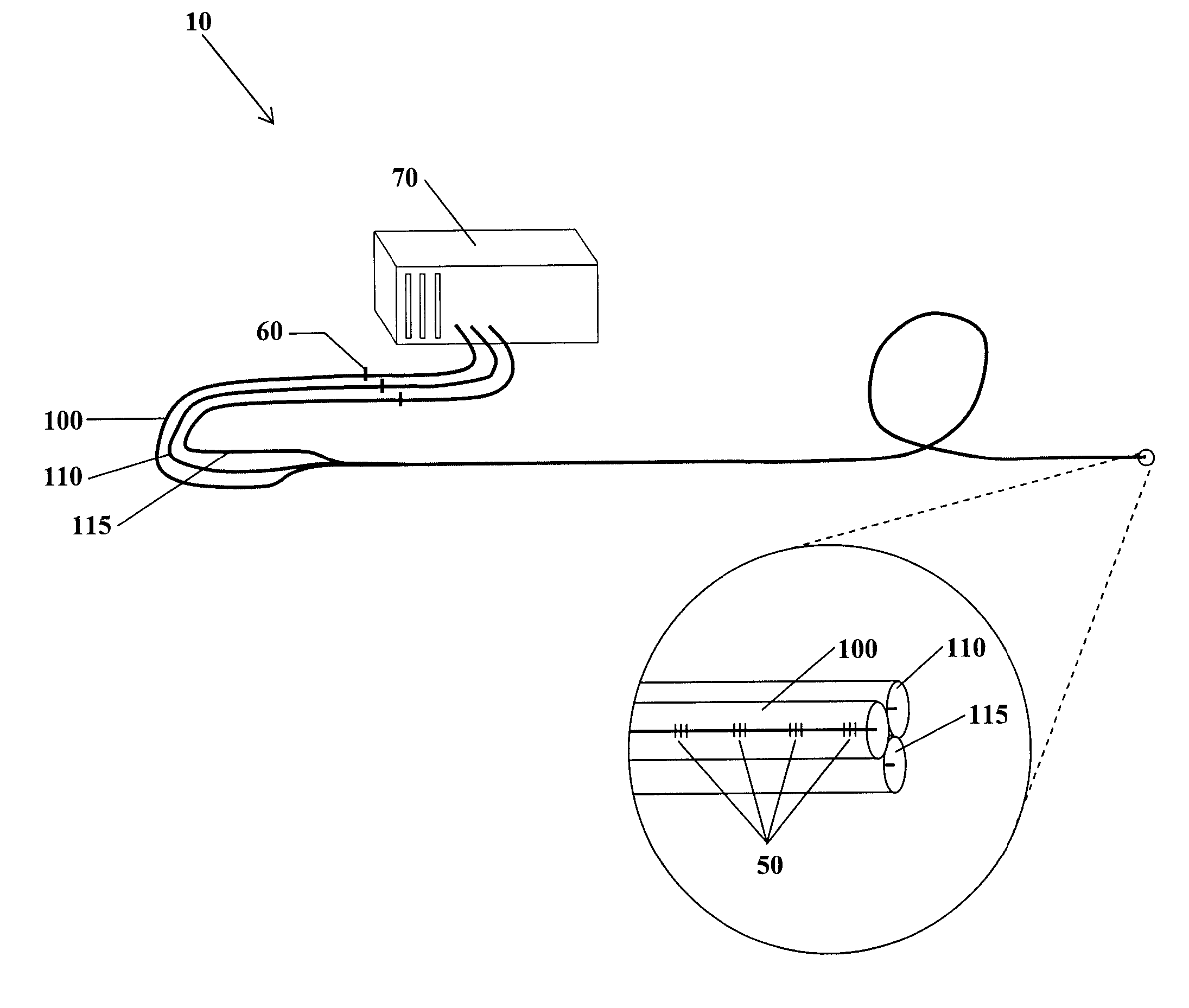

Fiber optic position and shape sensing device and method relating thereto

The present invention is directed toward a fiber optic position and shape sensing device and the method of use. The device comprises an optical fiber means. The optical fiber means comprises either at least two single core optical fibers or a multicore optical fiber having at least two fiber cores. In either case, the fiber cores are spaced apart such that mode coupling between the fiber cores is minimized. An array of fiber Bragg gratings are disposed within each fiber core and a frequency domain reflectometer is positioned in an operable relationship to the optical fiber means. In use, the device is affixed to an object. Strain on the optical fiber is measured and the strain measurements correlated to local bend measurements. Local bend measurements are integrated to determine position and / or shape of the object.

Owner:INTUITIVE SURGICAL OPERATIONS INC

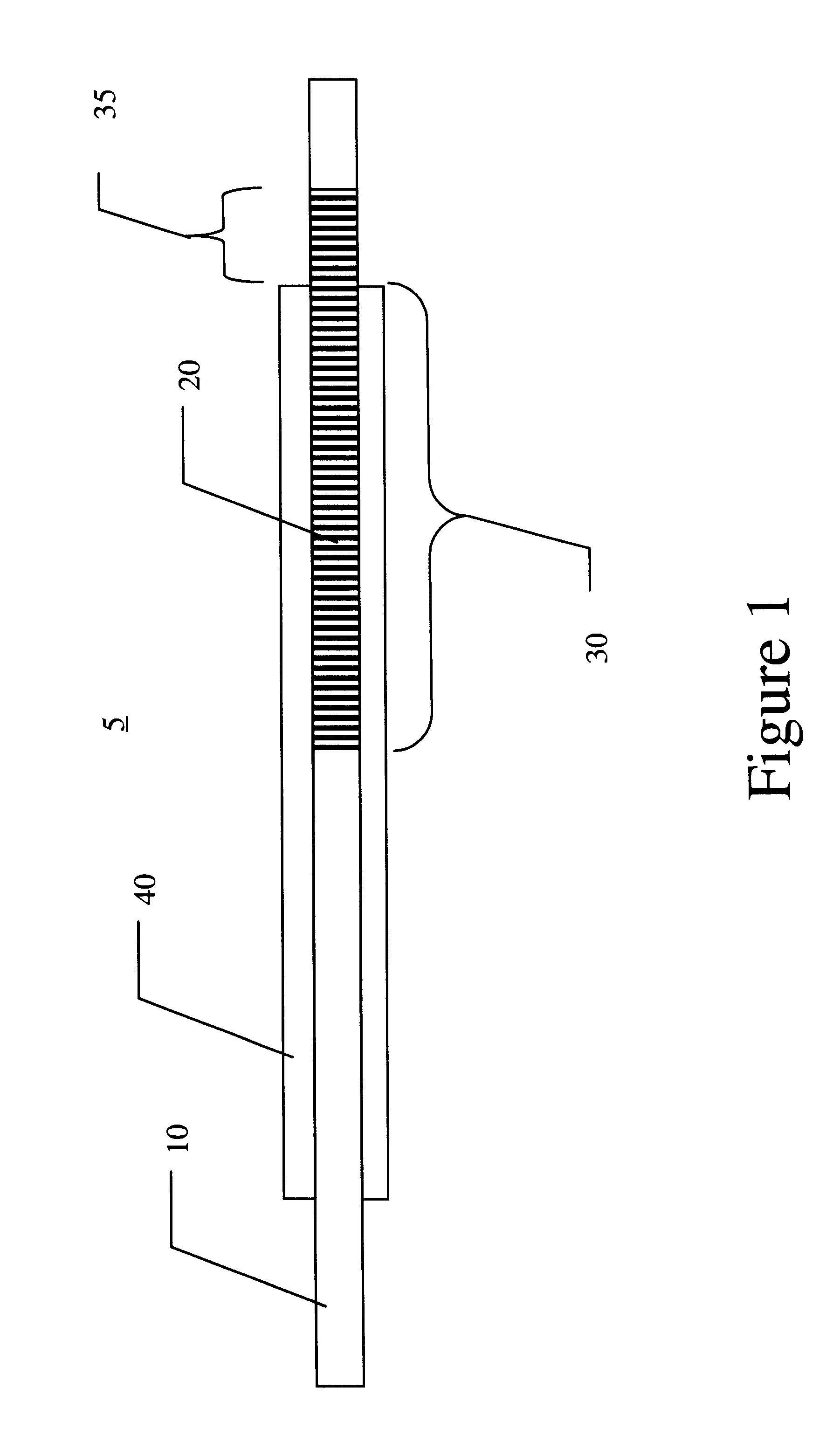

Fiber Optic Position and Shape Sensing Device and Method Relating Thereto

ActiveUS20070065077A1Improve spatial resolutionImprove accuracyRadiation pyrometryEndoscopesFiberGrating

The present invention is directed toward a fiber optic position and shape sensing device and the method of use. The device comprises an optical fiber means. The optical fiber means comprises either at least two single core optical fibers or a multicore optical fiber having at least two fiber cores. In either case, the fiber cores are spaced apart such that mode coupling between the fiber cores is minimized. An array of fiber Bragg gratings are disposed within each fiber core and a frequency domain reflectometer is positioned in an operable relationship to the optical fiber means. In use, the device is affixed to an object. Strain on the optical fiber is measured and the strain measurements correlated to local bend measurements. Local bend measurements are integrated to determine position and / or shape of the object.

Owner:INTUITIVE SURGICAL OPERATIONS INC

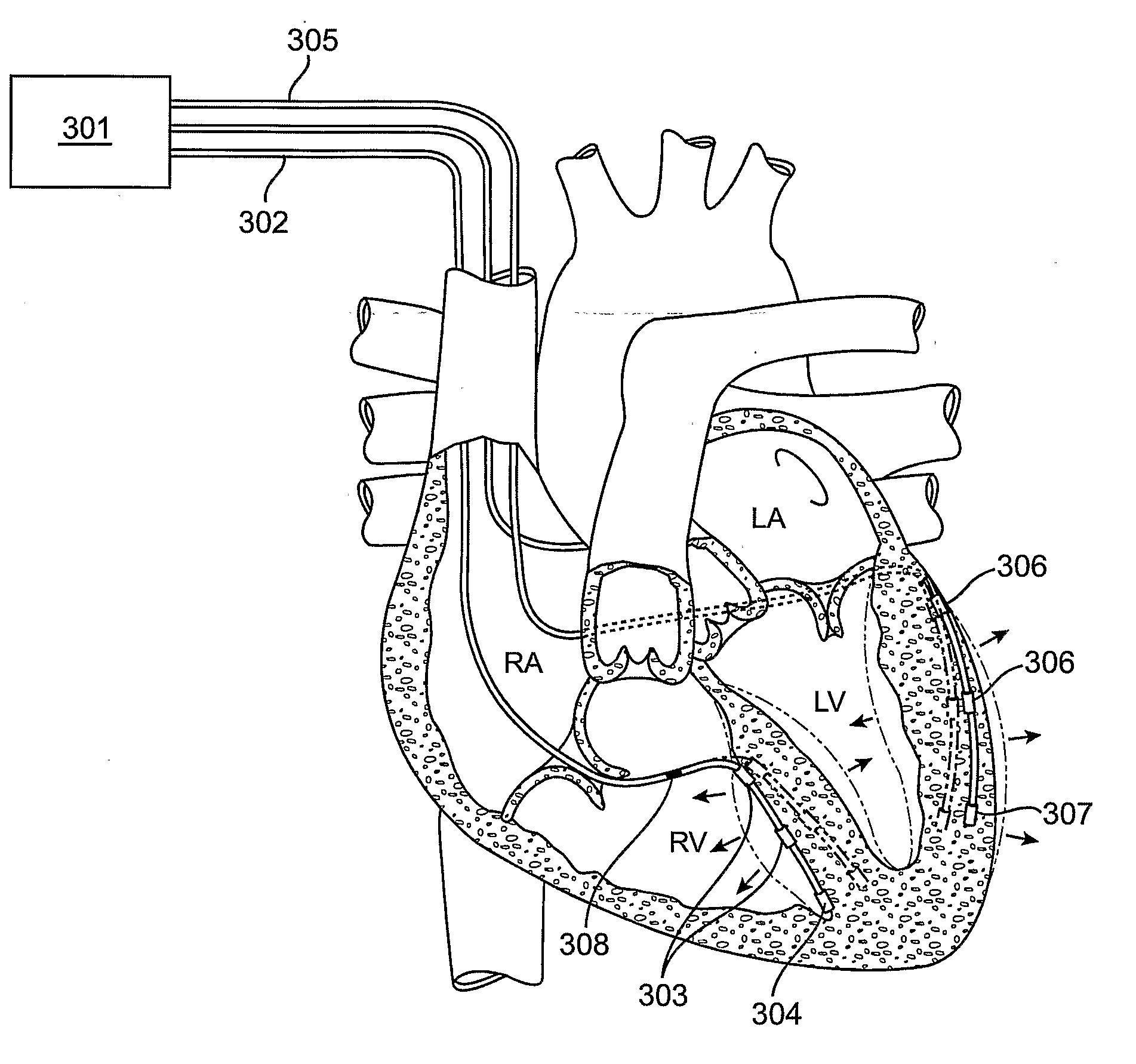

Cardiac Motion Characterization by Strain Measurement

Methods for evaluating motion of a cardiac tissue location, e.g., heart wall, are provided. In the subject methods, timing of a signal obtain from a strain gauge stably associated with the tissue location of interest is employed to evaluate movement of the cardiac tissue location. Also provided are systems, devices and related compositions for practicing the subject methods. The subject methods and devices find use in a variety of different applications, including cardiac resynchronization therapy.

Owner:PROTEUS DIGITAL HEALTH INC

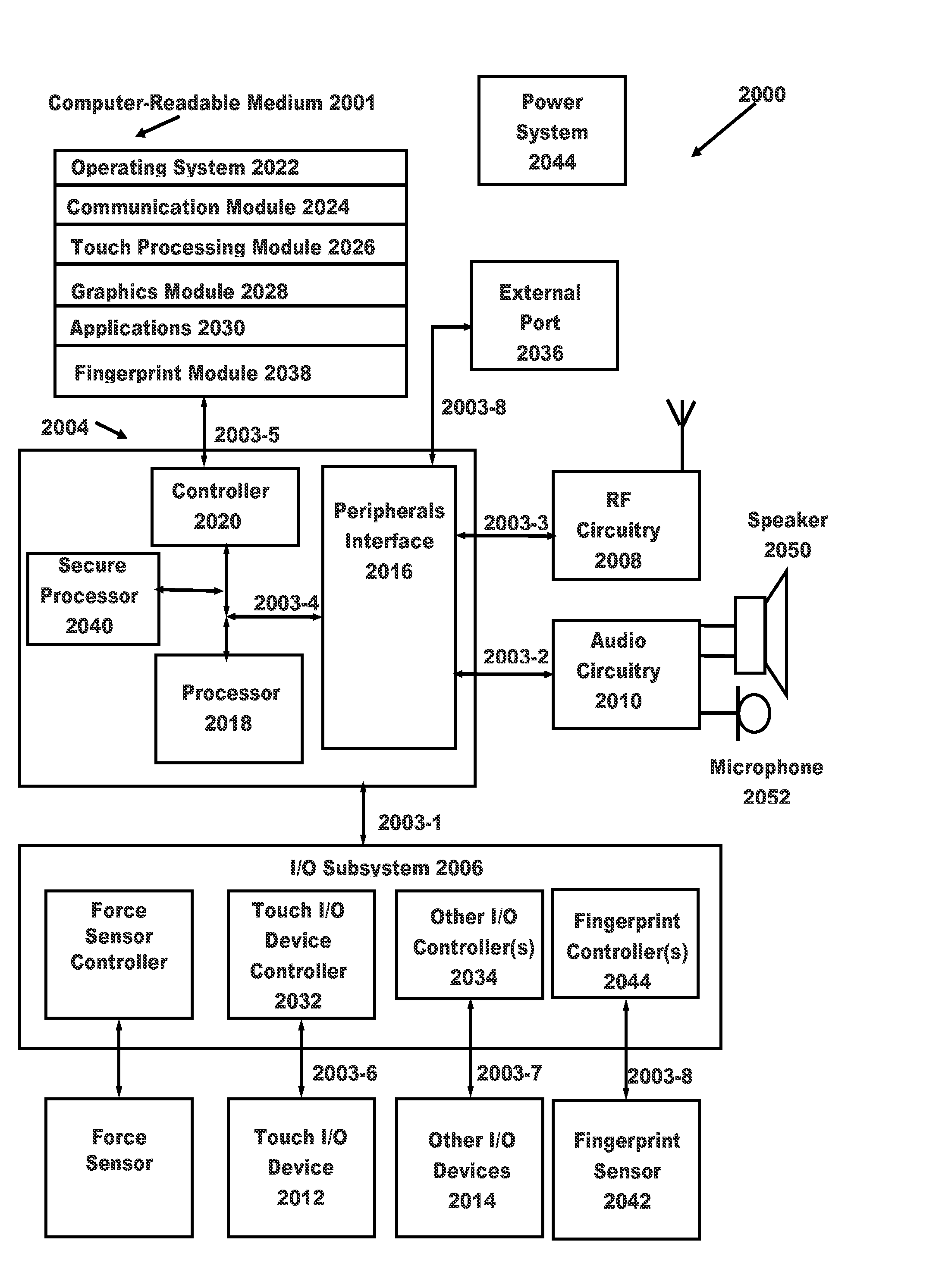

Force Sensing Using Bottom-Side Force Map

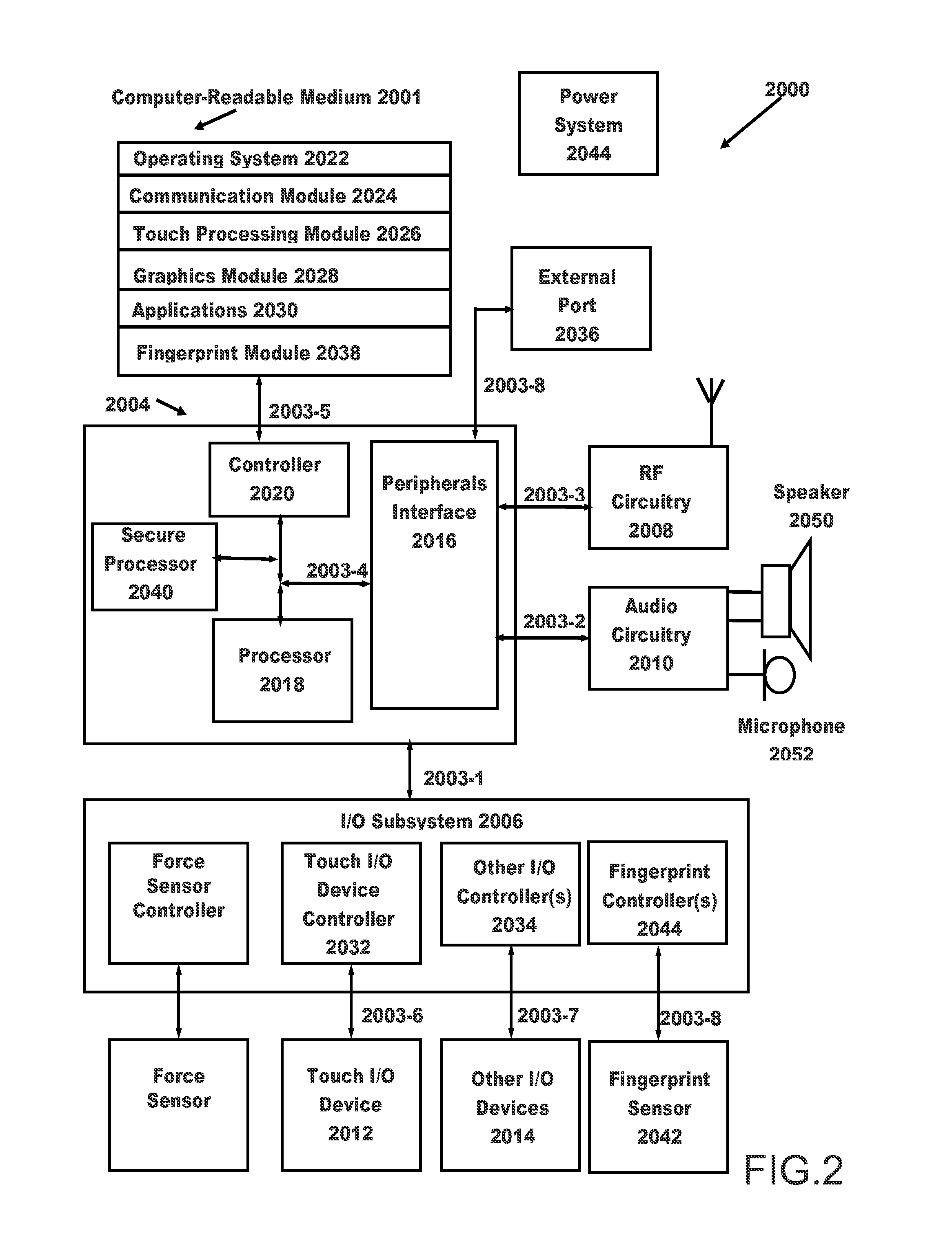

A force sensor incorporated into a touch device, measuring deflection in a device stack, including compressible elements disposed between the device stack and the frame element. When the device stack is deformed, applied force is measured using the compressible elements, using capacitive sensing or strain measurements. The force sensitive sensor provides an applied force image for the touch device's surface. The applied force location [X, Y] can be determined from measures of cover glass tilt, force at particular points, and capacitive sensing of touch location.

Owner:APPLE INC

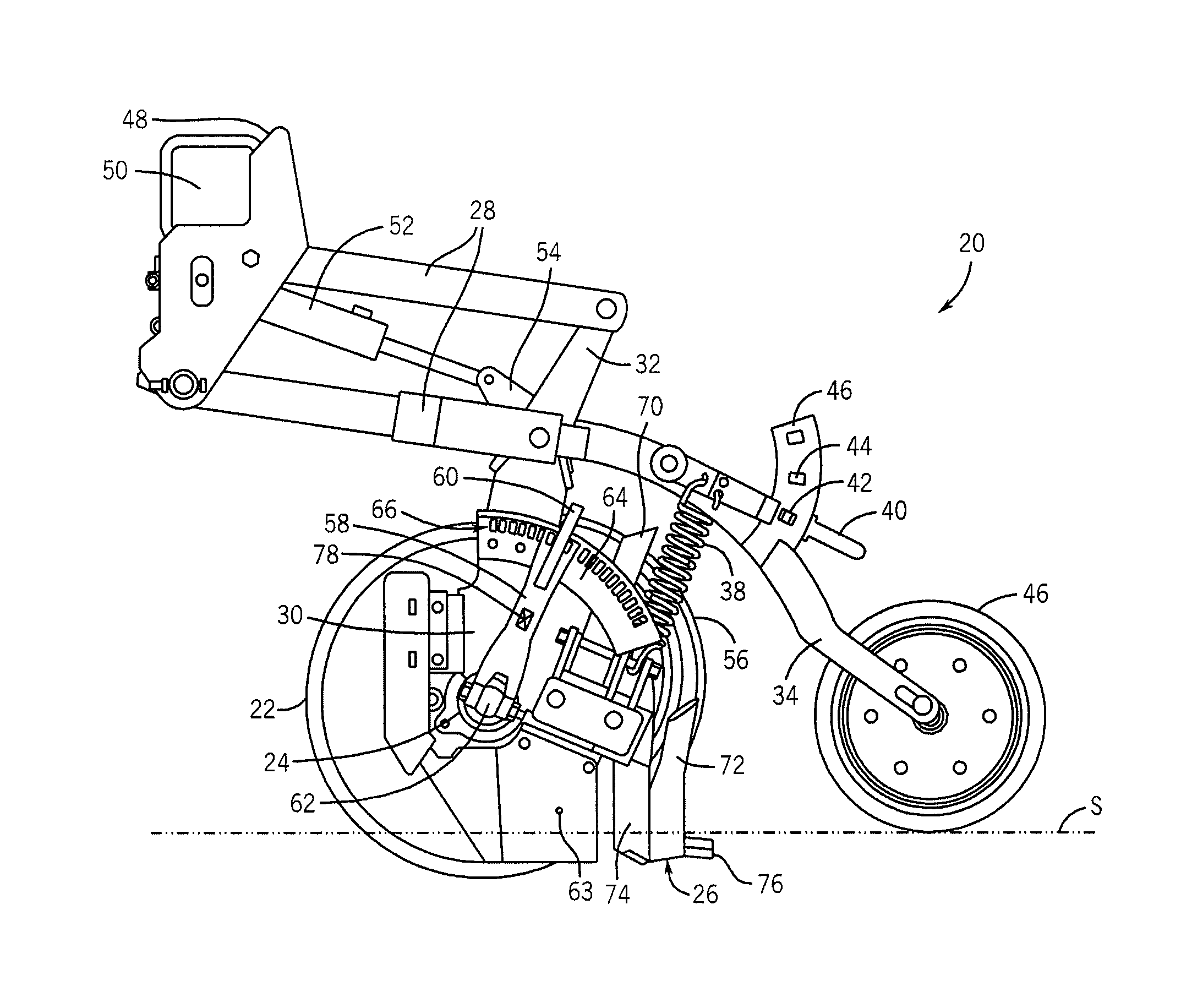

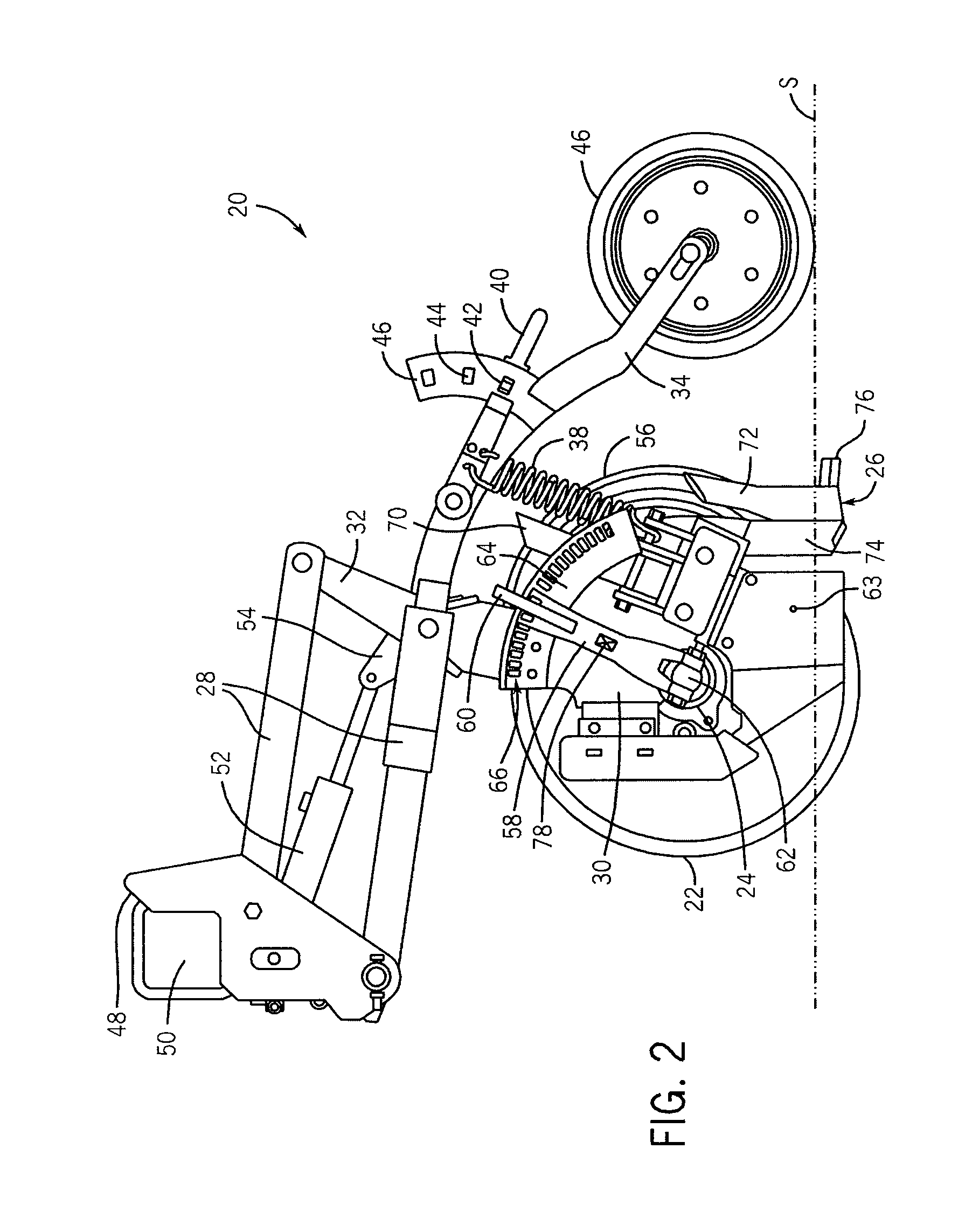

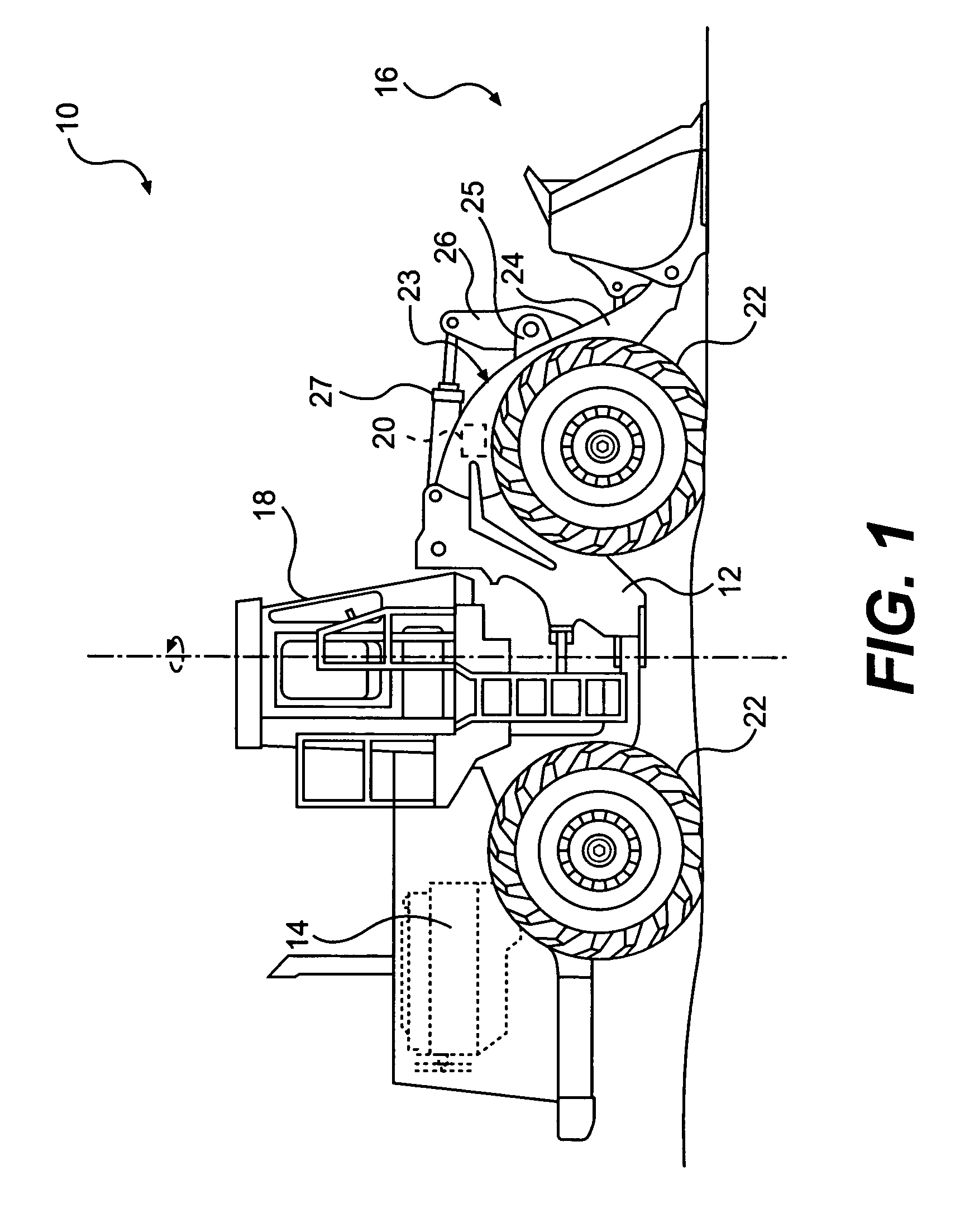

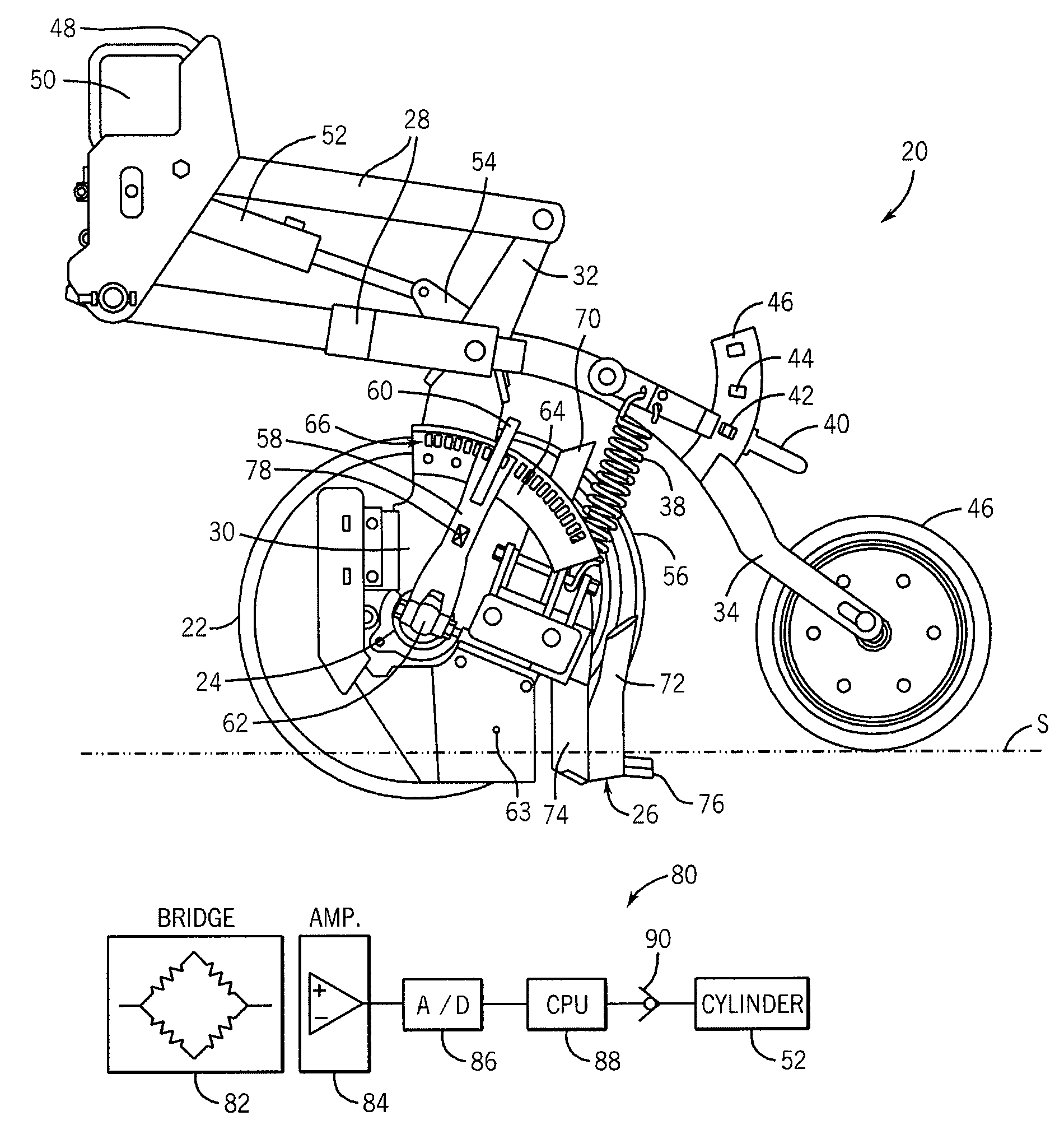

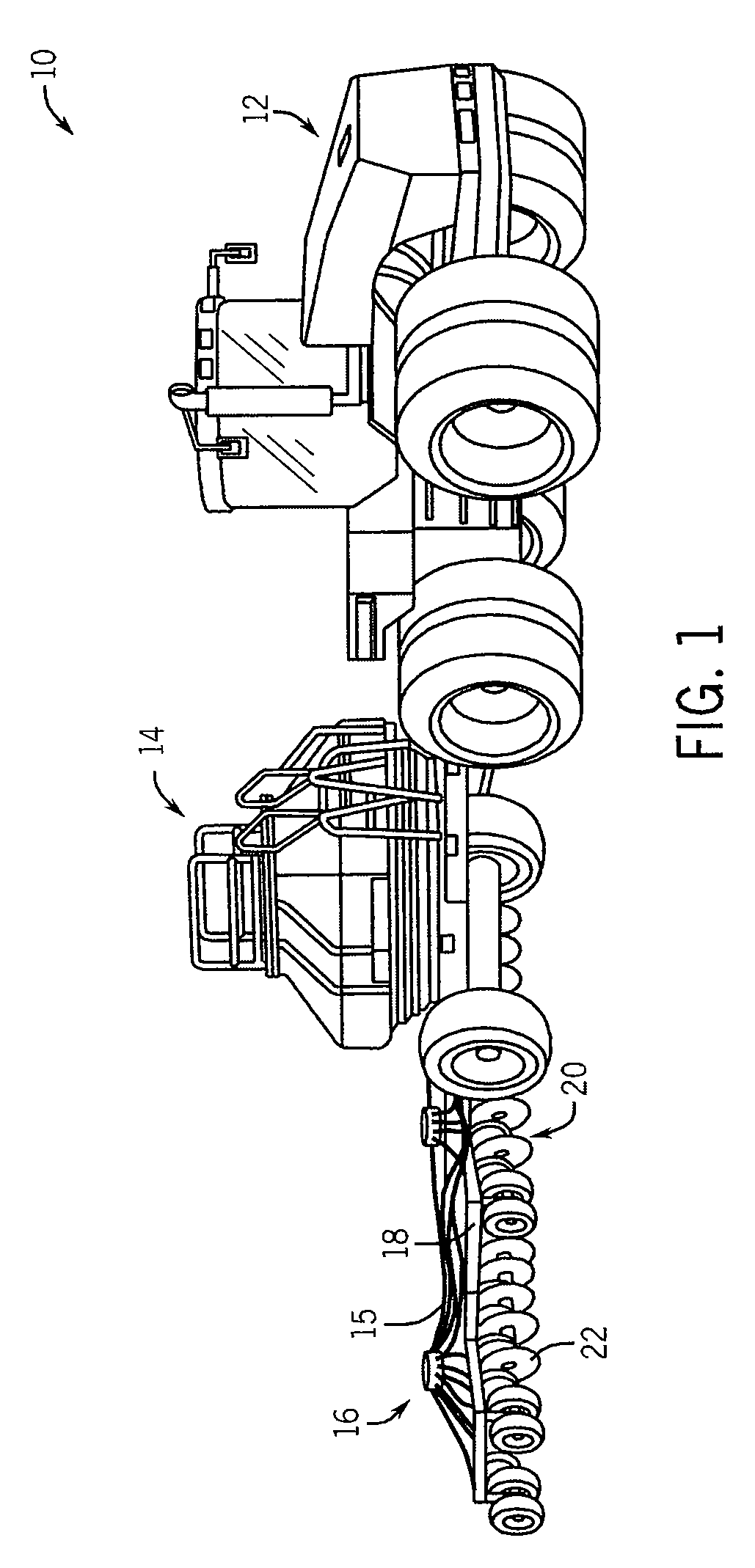

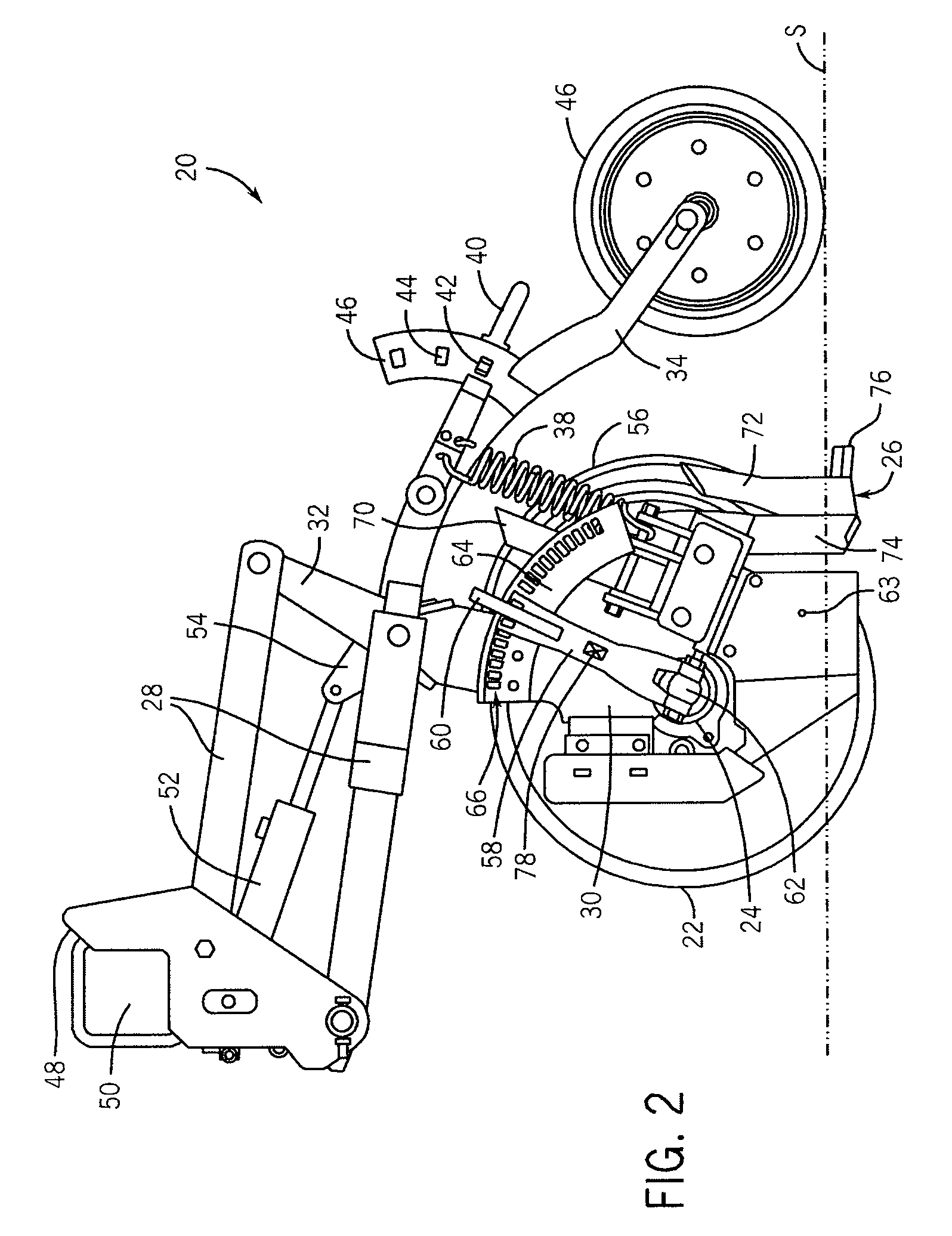

Down Pressure Adjustment Device And Method For Use With A Disc Opener Assembly Of An Agricultural Implement

A disc opener unit for an agricultural implement has a down pressure adjustment device that automatically adjusts the amount of down pressure applied on a furrowing disc based on strain measurements taken by a strain gauge or load cell. The strain gauge, which may be mounted to an arm that is used to set the position of a depth setting gauge wheel, provides feedback to a processor that in turn controls the amount of hydraulic fluid in a hydraulic cylinder to adjust the down force applied on the disc. The amount of down pressure is therefore adjusted in substantially real-time in response to changes in field conditions, which improves furrow depth consistency and reduces wear on the gauge wheel and its components.

Owner:CNH IND CANADA

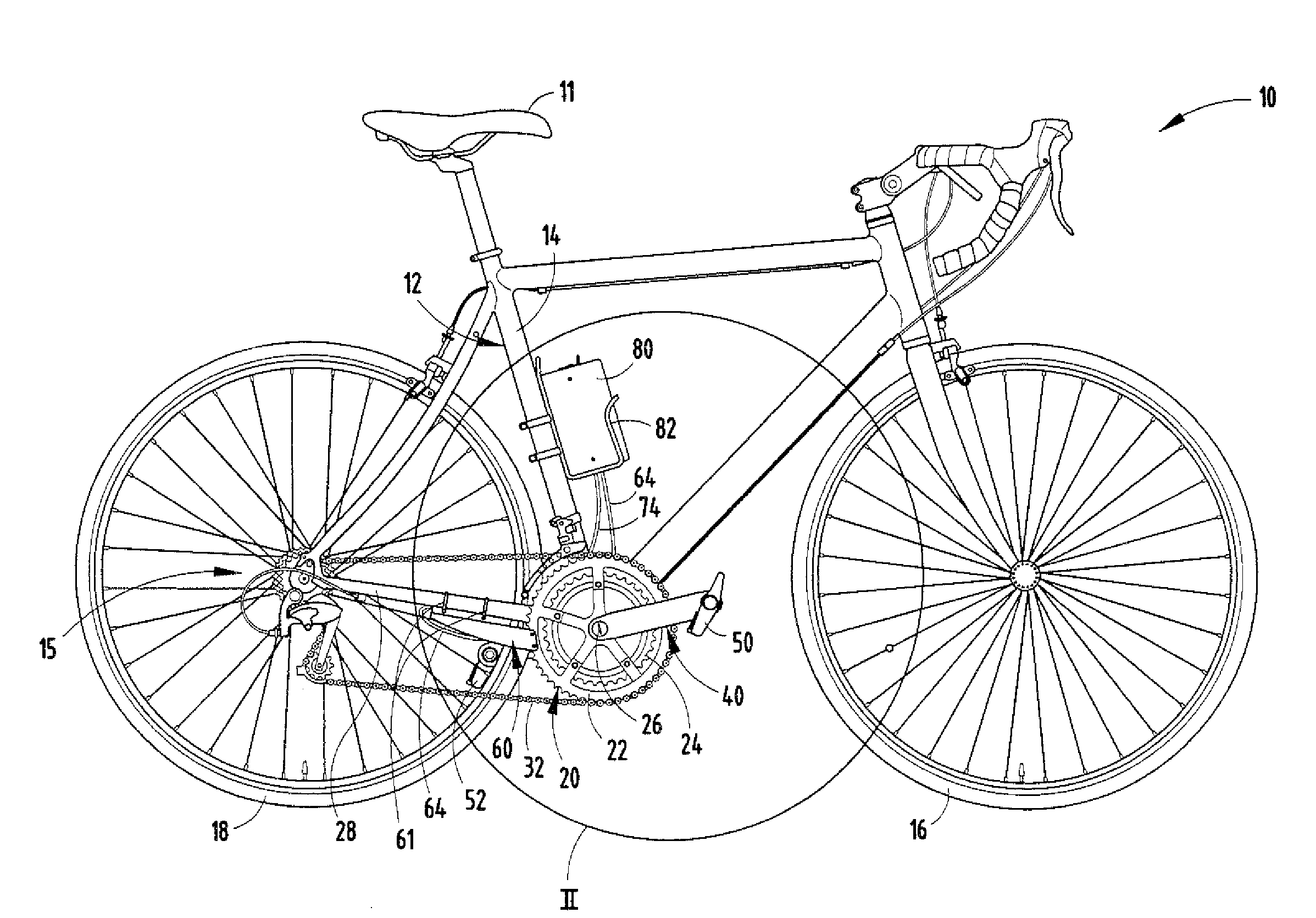

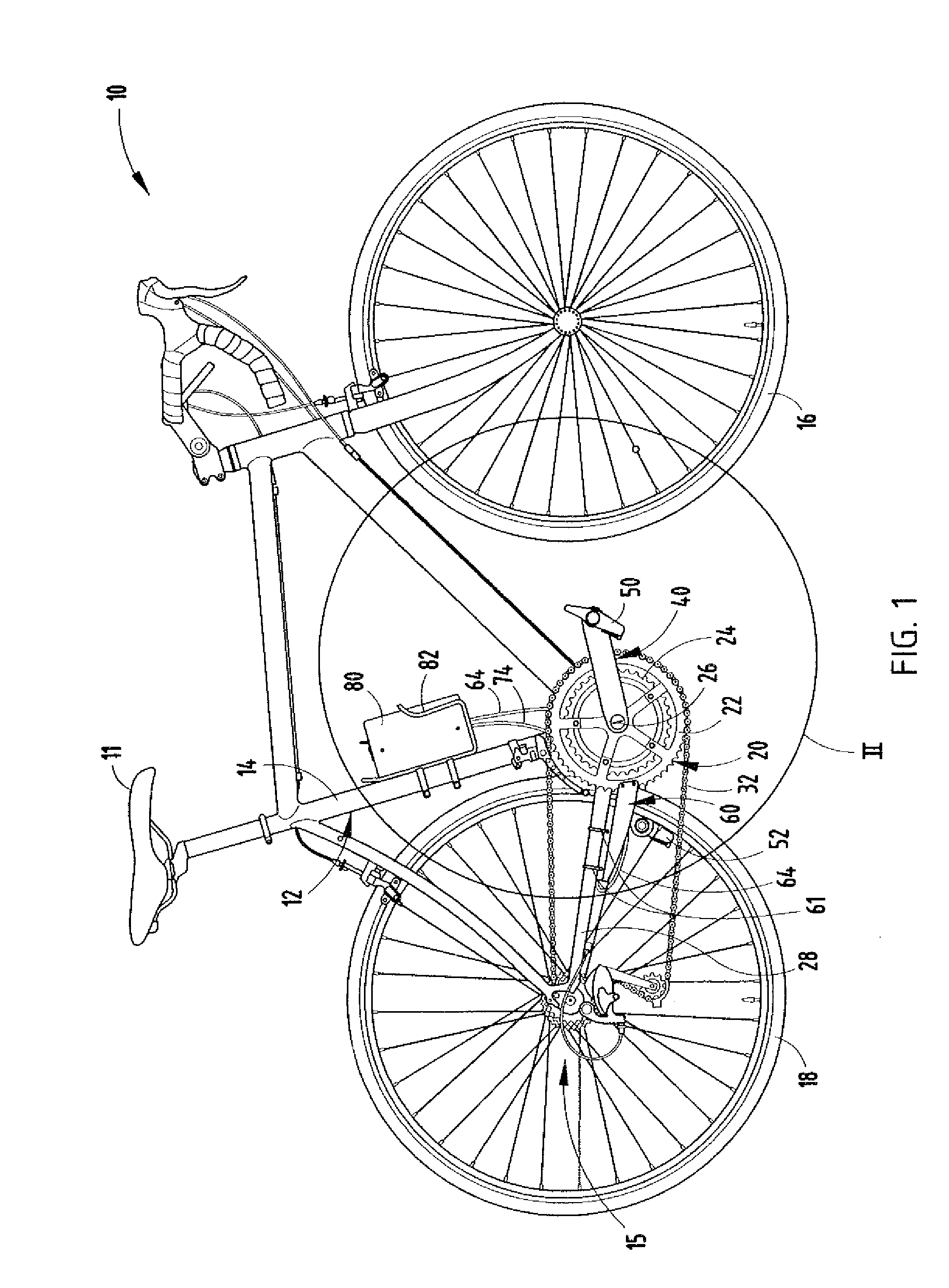

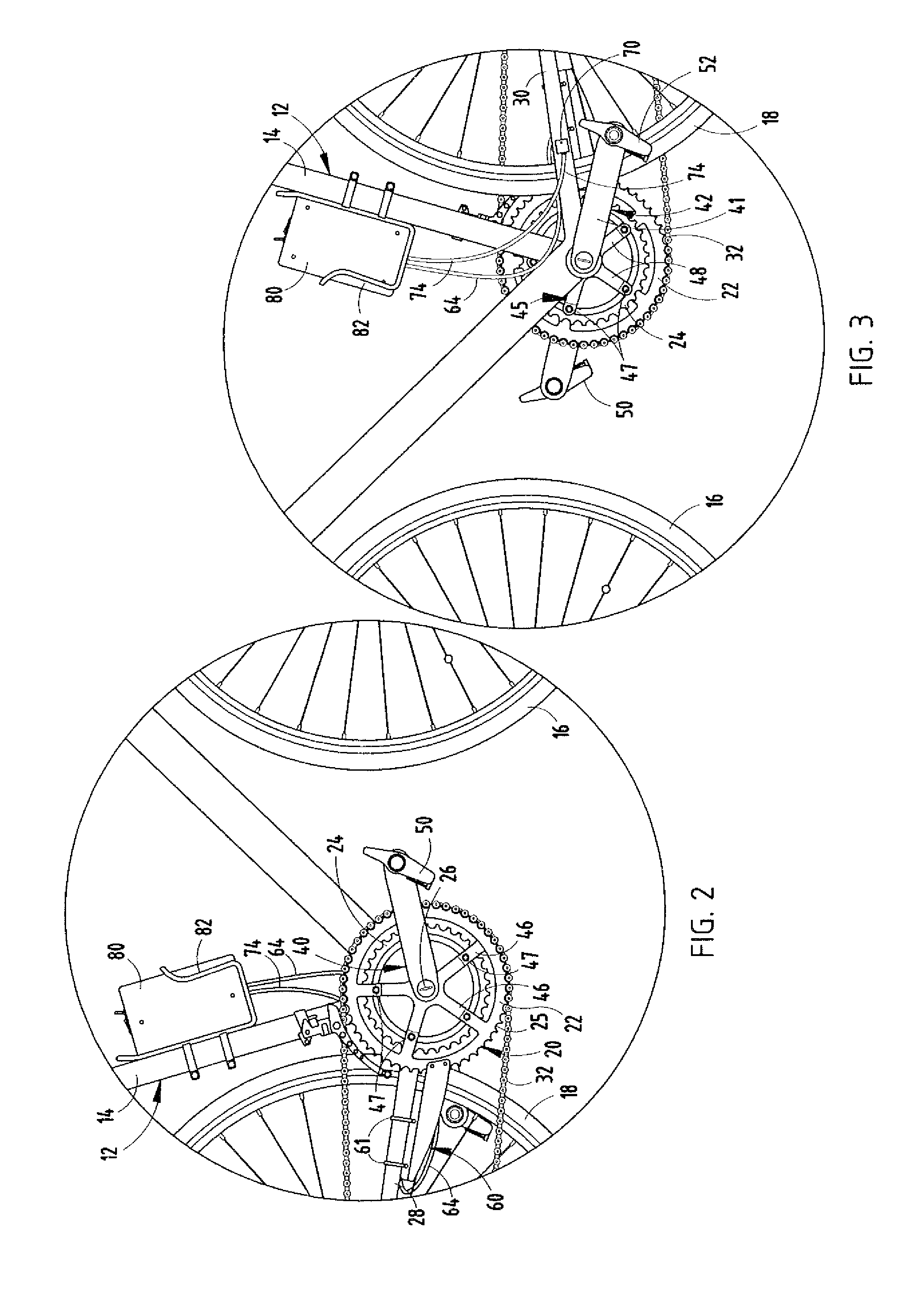

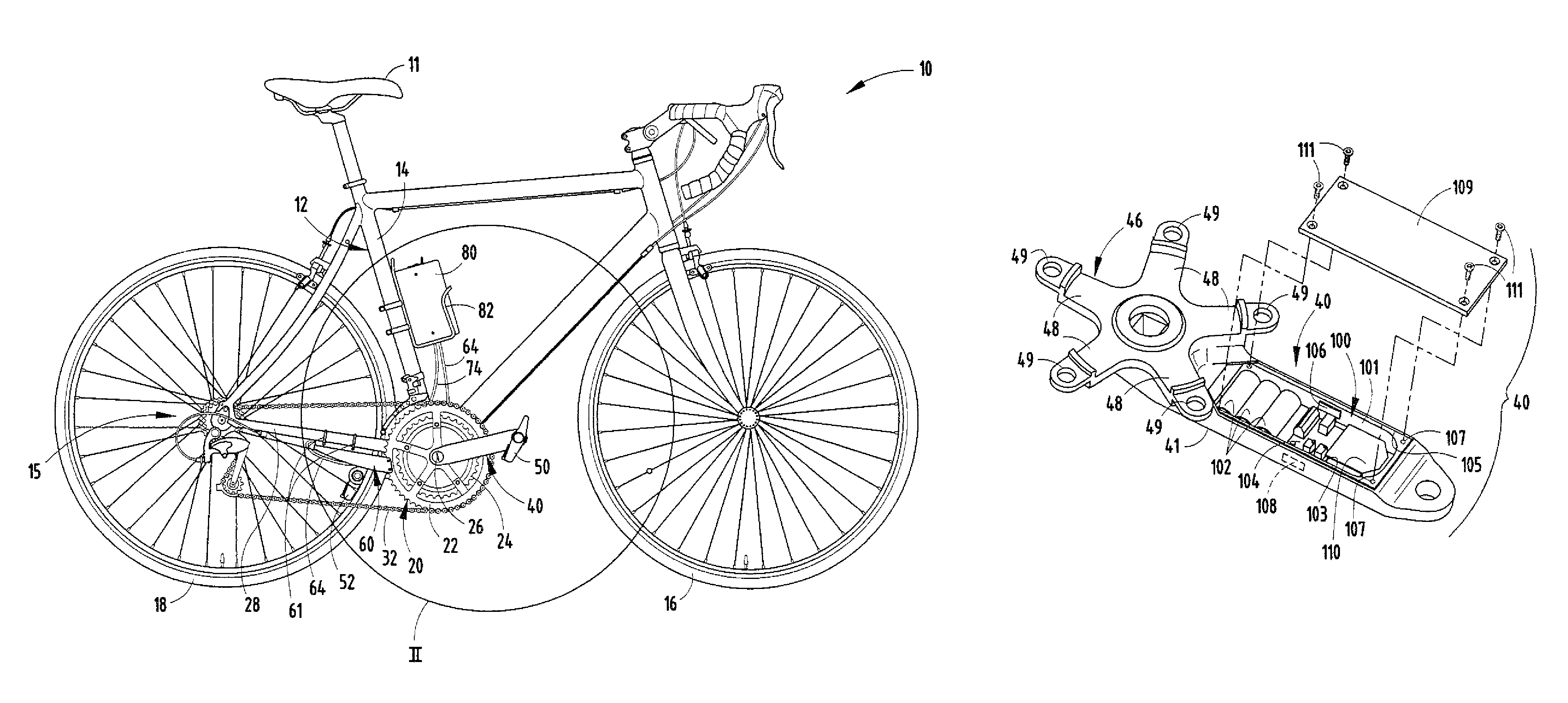

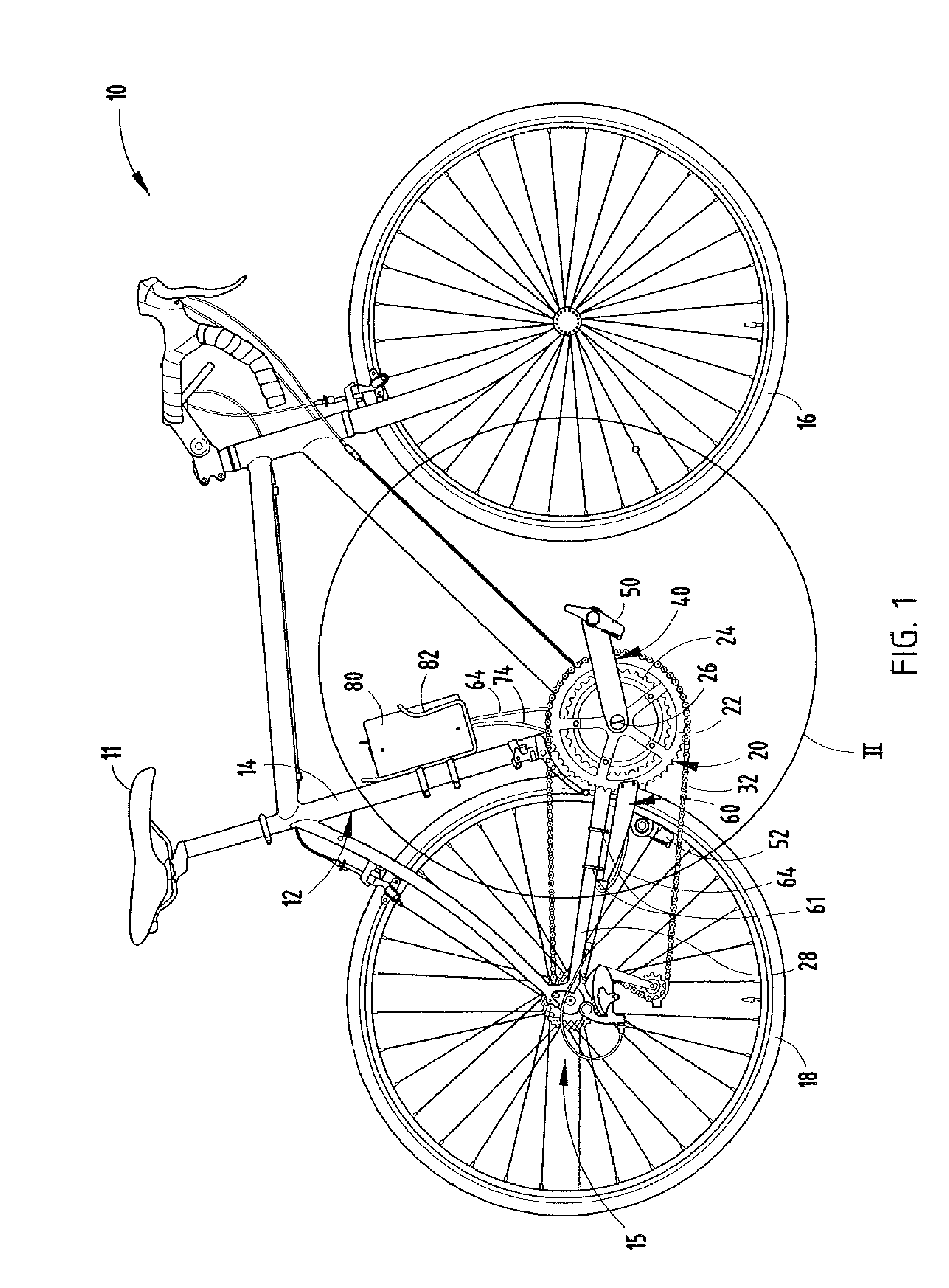

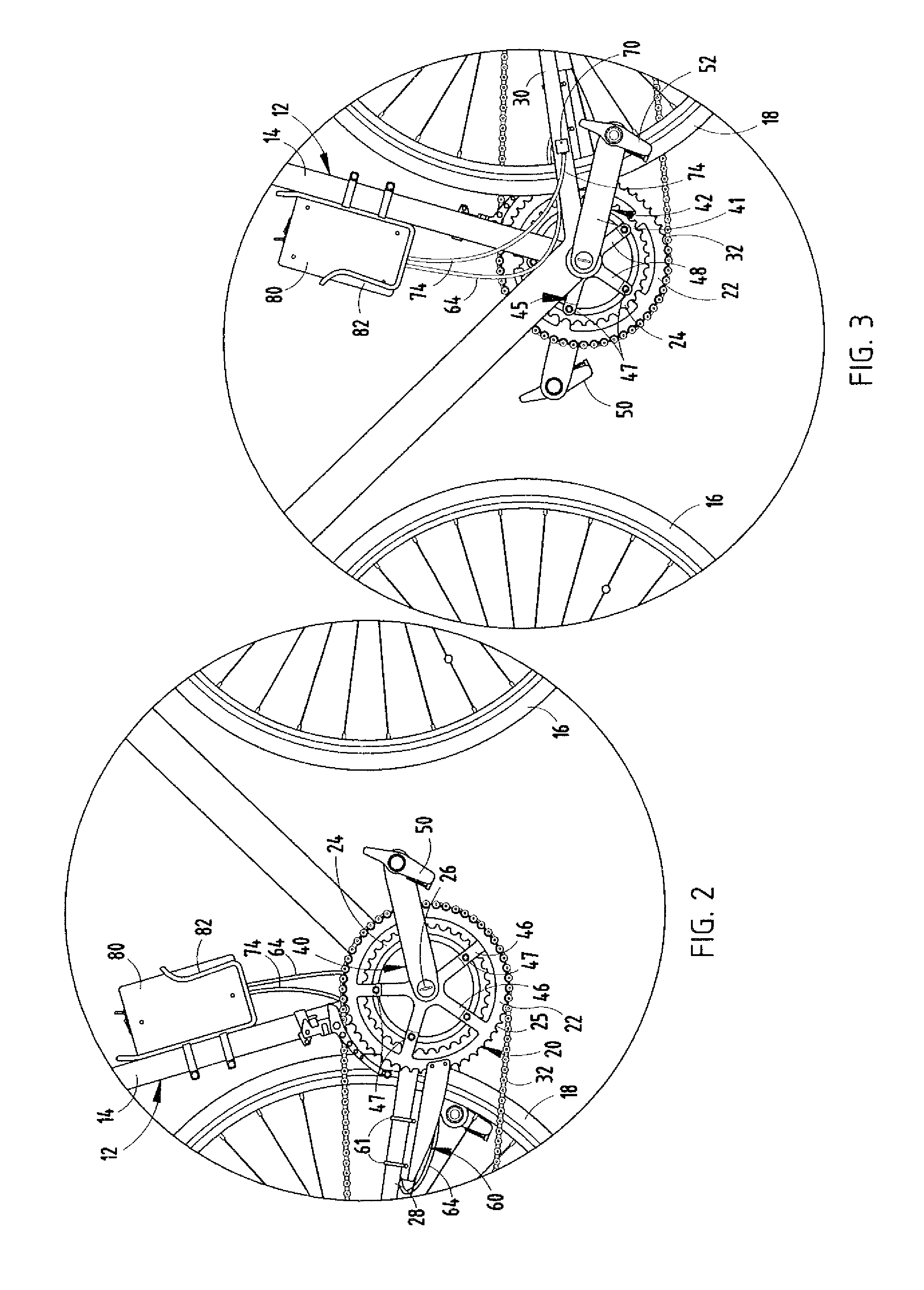

Bicycle torque measuring system

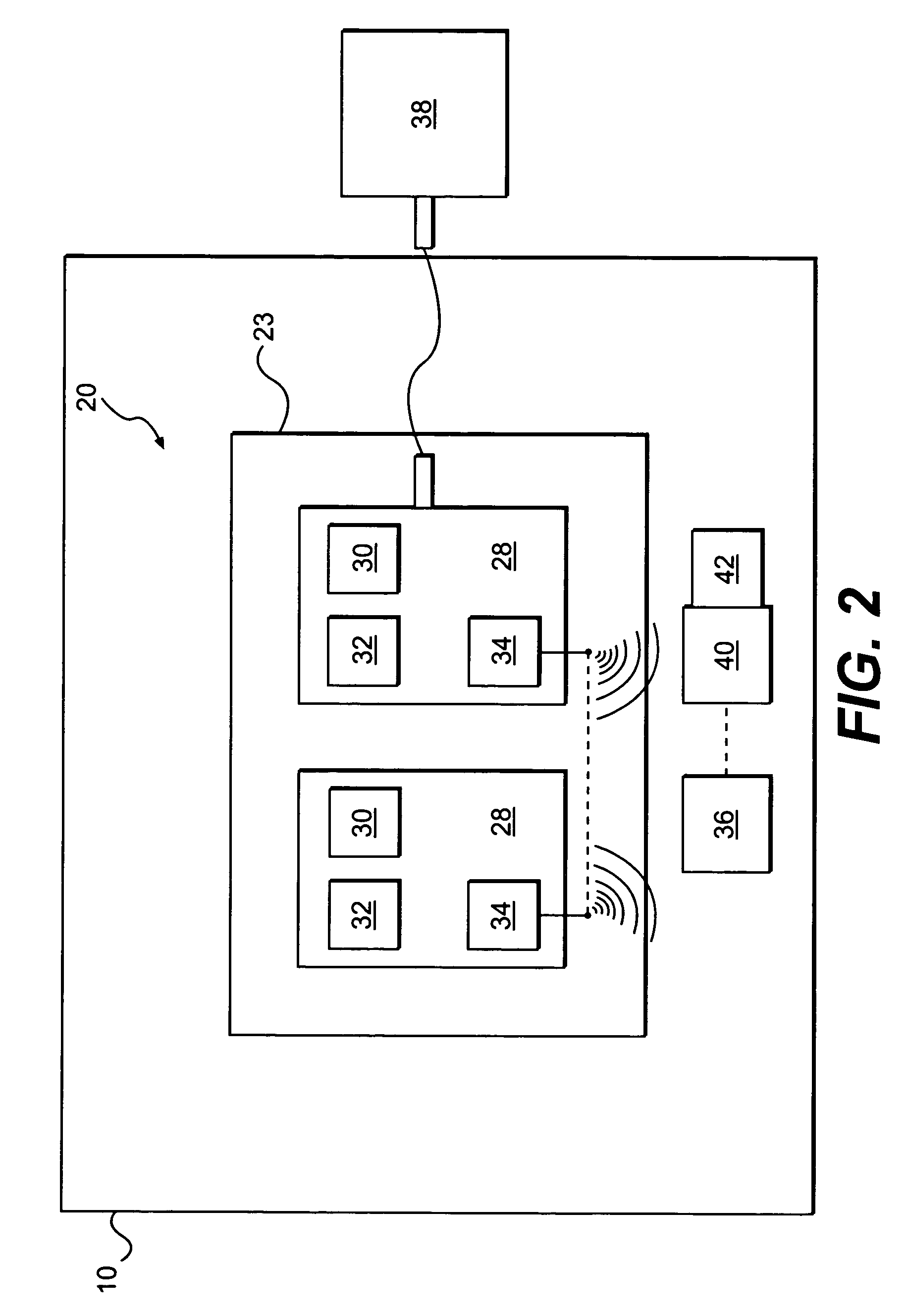

Strain gauges are mounted on each crank arm of the bicycle and provide a measure of the torque applied to each crank arm. In a preferred embodiment, strain gauges are mounted on opposite edges of each crank arm, which includes a self-contained power, electrical circuitry, and a wireless transmitter for transmitting the strain measurement information to a main controller. The main controller includes a wireless transceiver for transmitting and receiving data from both the left and right crank arms and external devices. Memory is also included for storing such data for subsequent analysis to determine the individual leg performance of a cyclist during a race or training session.

Owner:MAGNUM ENG

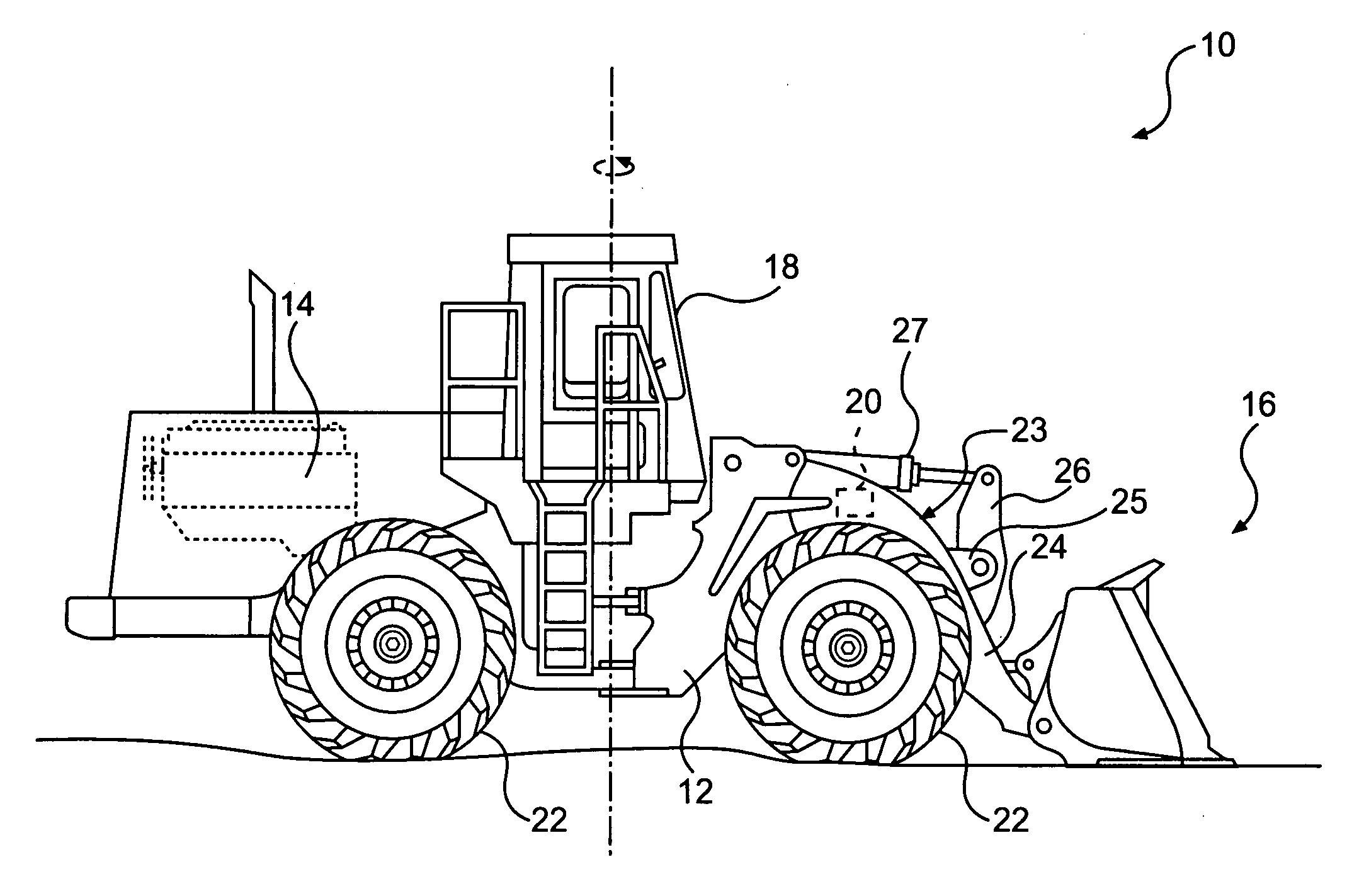

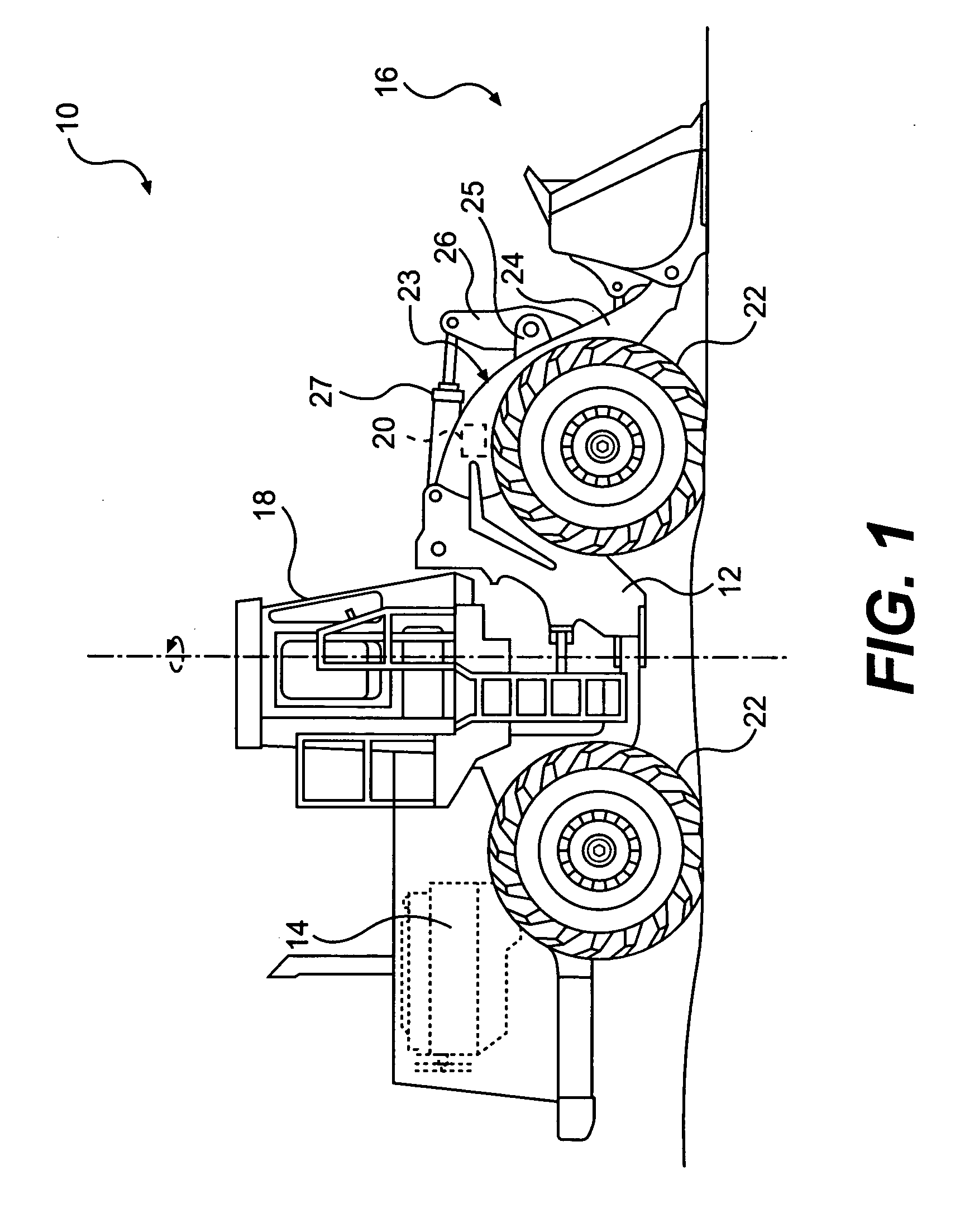

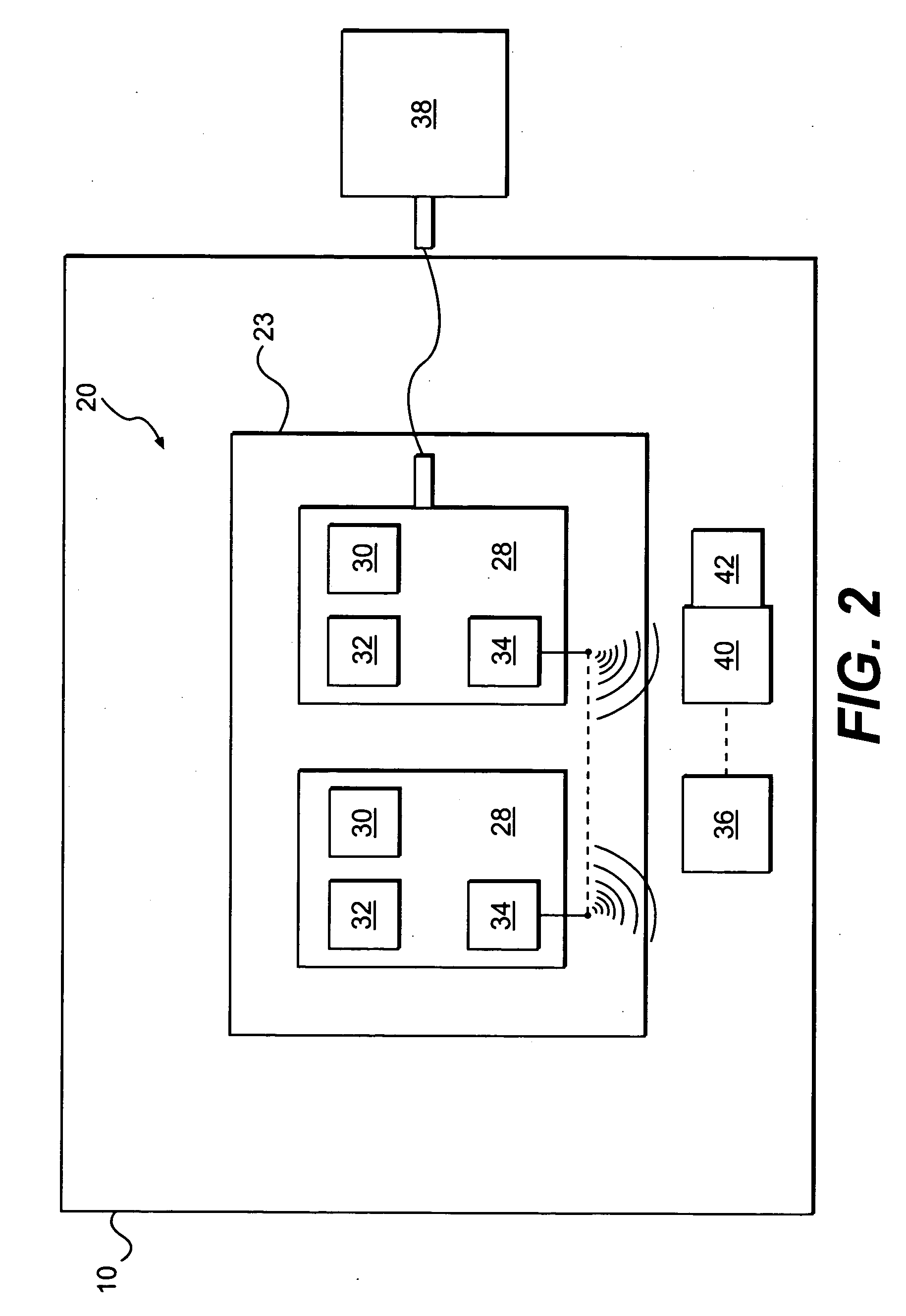

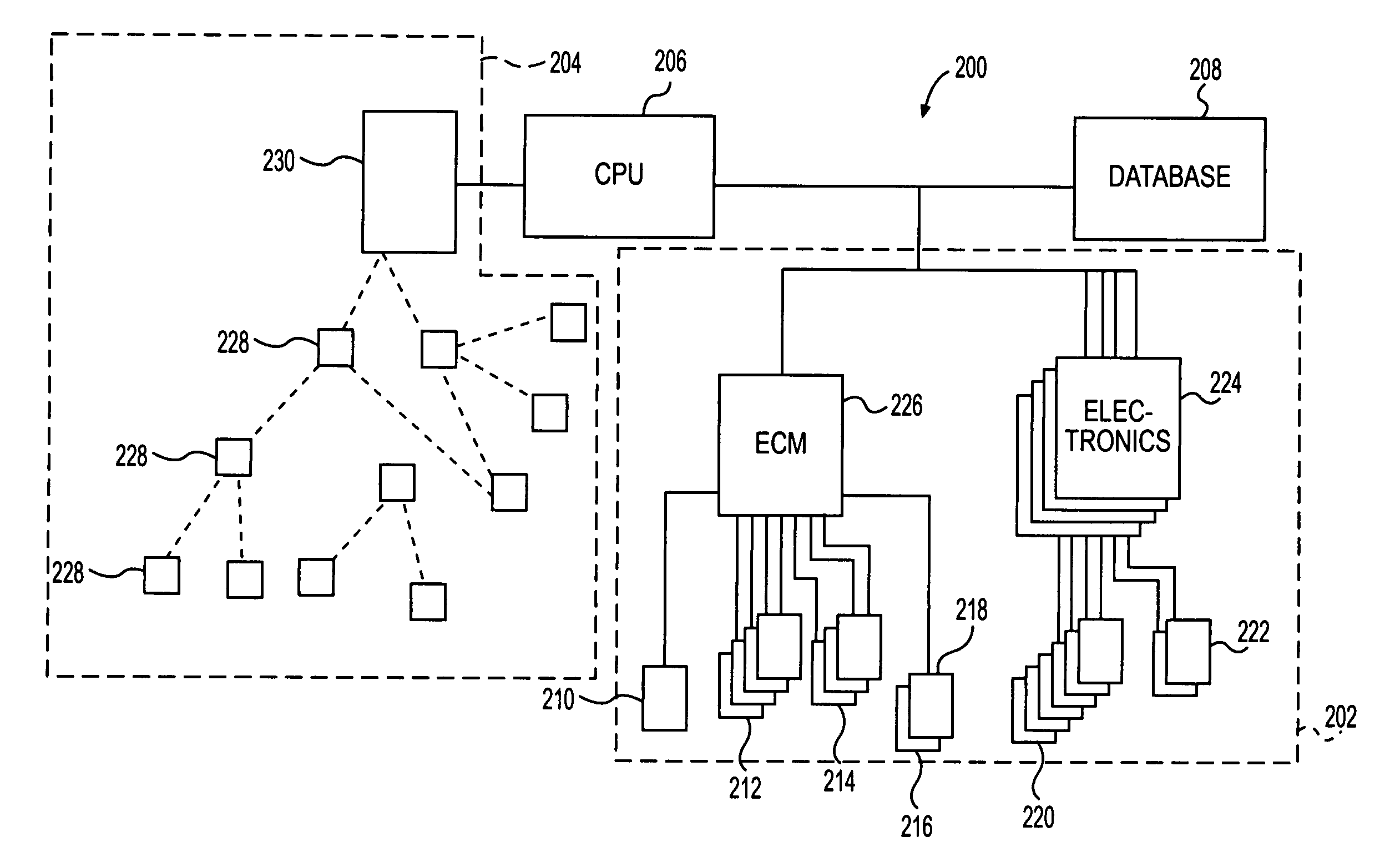

Monitoring system

A monitoring system is provided, which may include a structural component configured to undergo mechanical loading and a wireless node attached to the structural component. The node may include a strain sensing device configured to measure strain experienced by the structural component at the location of the node. The node may also include a processor configured to predict, based on the strain measurements, fatigue life of the structural component.

Owner:CATERPILLAR INC

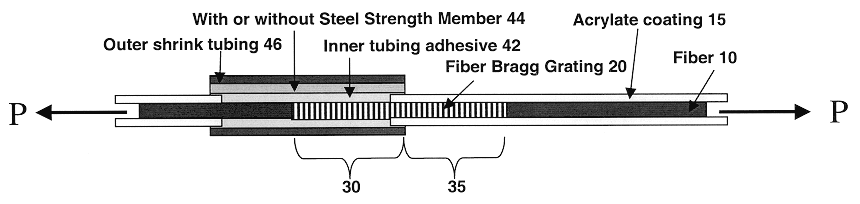

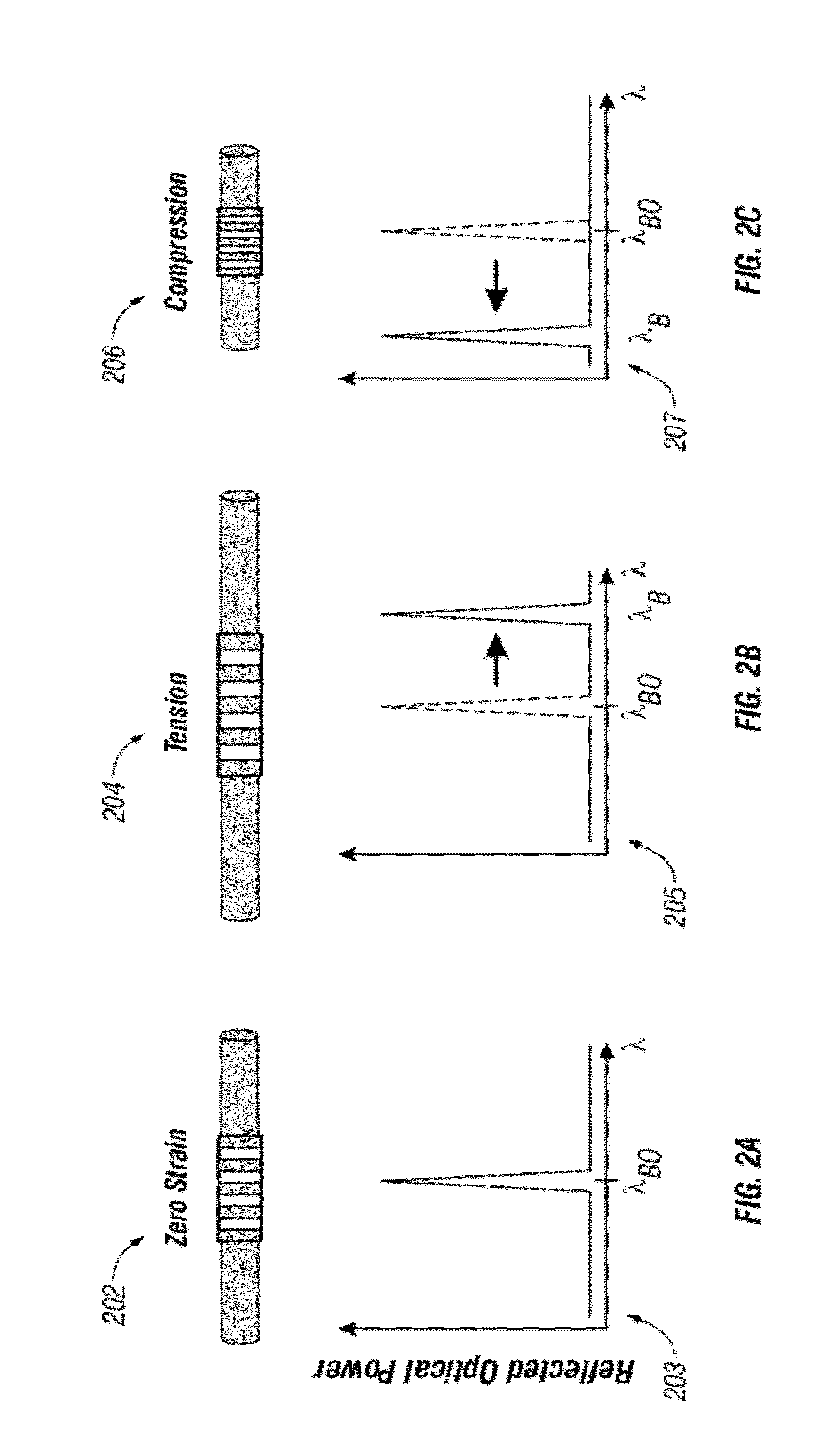

Fiber-Bragg-grating-based strain measuring apparatus, system and method

InactiveUS6337737B1Radiation pyrometryForce measurement by measuring optical property variationFiberGrating

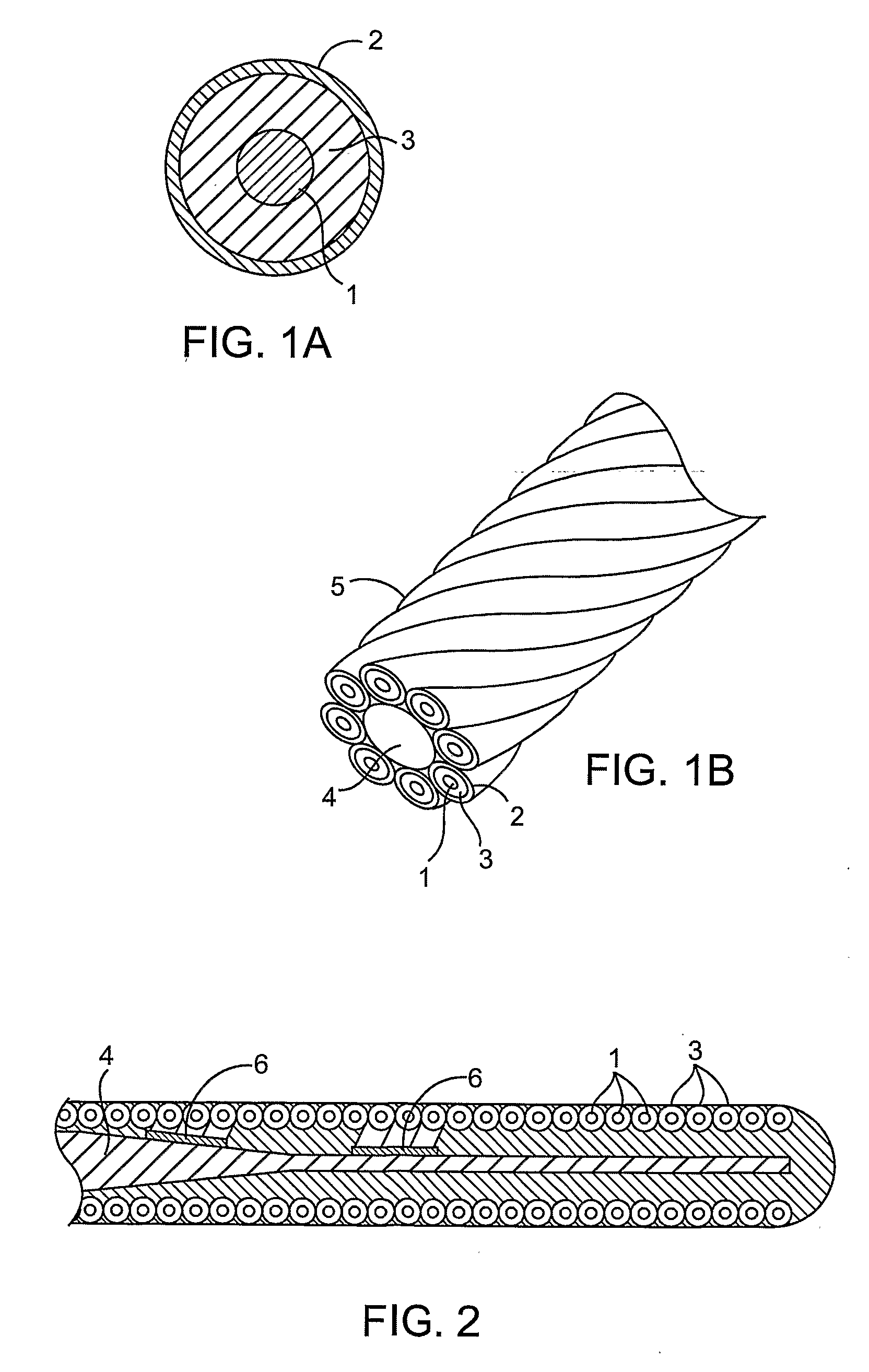

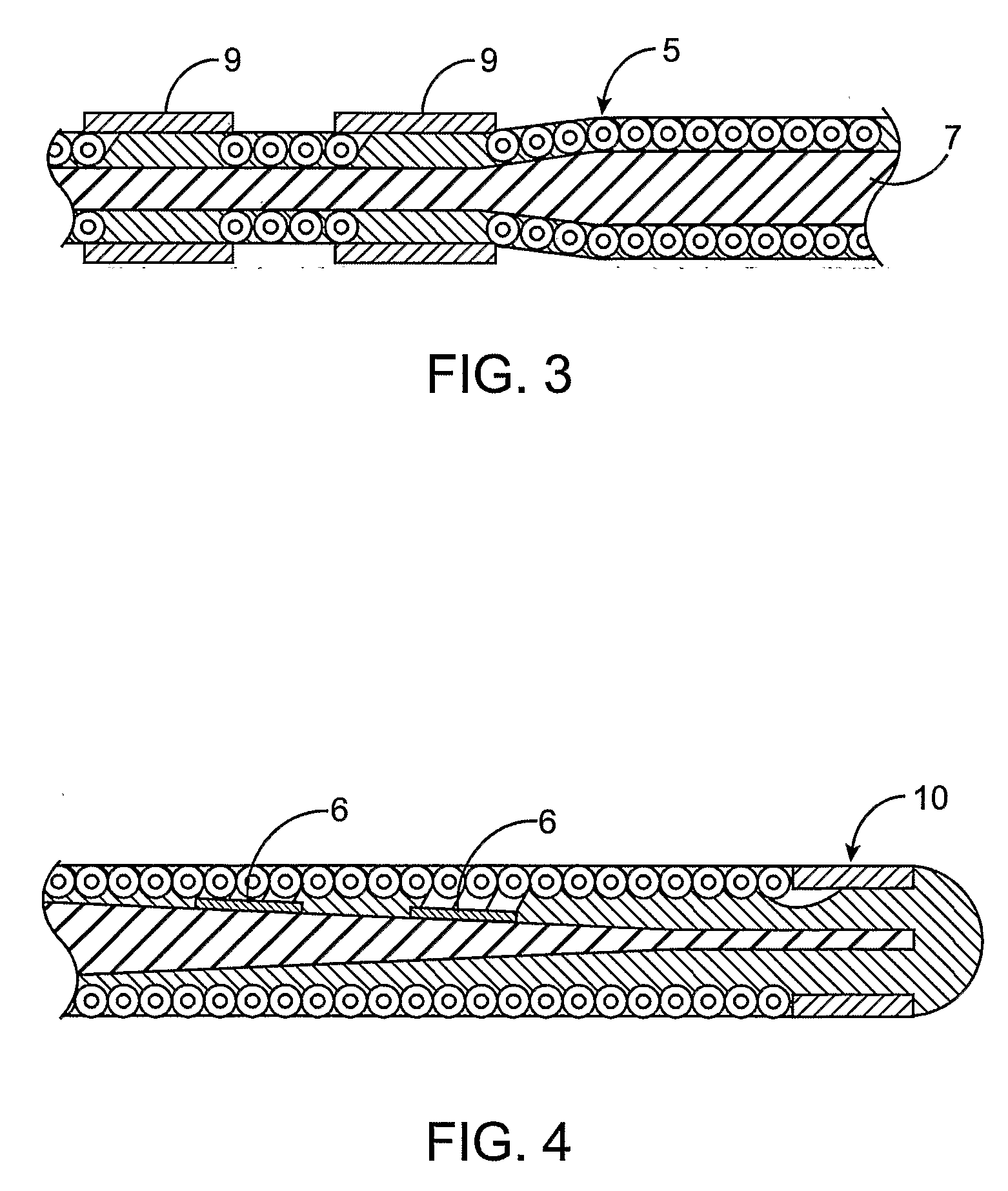

The invention was originally developed to determine the strain-relief capability of a fusion splice protector as well as the compressive stress imparted to a fusion splice by the splice protector. The invention also permits performance and comparative analyses of splice protectors as well as any package in which the optical fiber is at least partially disposed. To those ends a fiber Bragg grating (FBG) is axially arranged relative to the package such that a free or reference section of the FBG protrudes from the package while a shielded section lies within the package. Broadband light is supplied to the FBG which reflects certain wavelengths that are measured by an optical spectrum analyzer. The FBG reflected spectra will be split into two peaks as the reference and shielded sections experience different amounts or types of stress thereby providing a powerful analysis tool. A wavelength shift in the reflected spectra reveals the amount of stress experienced by the reference and free sections and permits a qualitative and quantitative analysis of the stress applied by the package and the package's ability to protect fiber from stress (e.g. such as that imposed by a tension pull test). Measurements may be made after a variety of conditions are changed such as splice protector curing, axial tension application, axial tension release, time, and age accelerating environments. Comparative studies and various other calculations may also be performed to evaluate different packages.

Owner:CIENA

Bicycle torque measuring system

Strain gauges are mounted on each crank arm of the bicycle and provide a measure of the torque applied to each crank arm. In a preferred embodiment, strain gauges are mounted on opposite edges of each crank arm, which includes a self-contained power, electrical circuitry, and a wireless transmitter for transmitting the strain measurement information to a main controller. The main controller includes a wireless transceiver for transmitting and receiving data from both the left and right crank arms and external devices. Memory is also included for storing such data for subsequent analysis to determine the individual leg performance of a cyclist during a race or training session.

Owner:MAGNUM ENG

Monitoring system

A monitoring system is provided, which may include a structural component configured to undergo mechanical loading and a wireless node attached to the structural component. The node may include a strain sensing device configured to measure strain experienced by the structural component at the location of the node. The node may also include a processor configured to predict, based on the strain measurements, fatigue life of the structural component.

Owner:CATERPILLAR INC

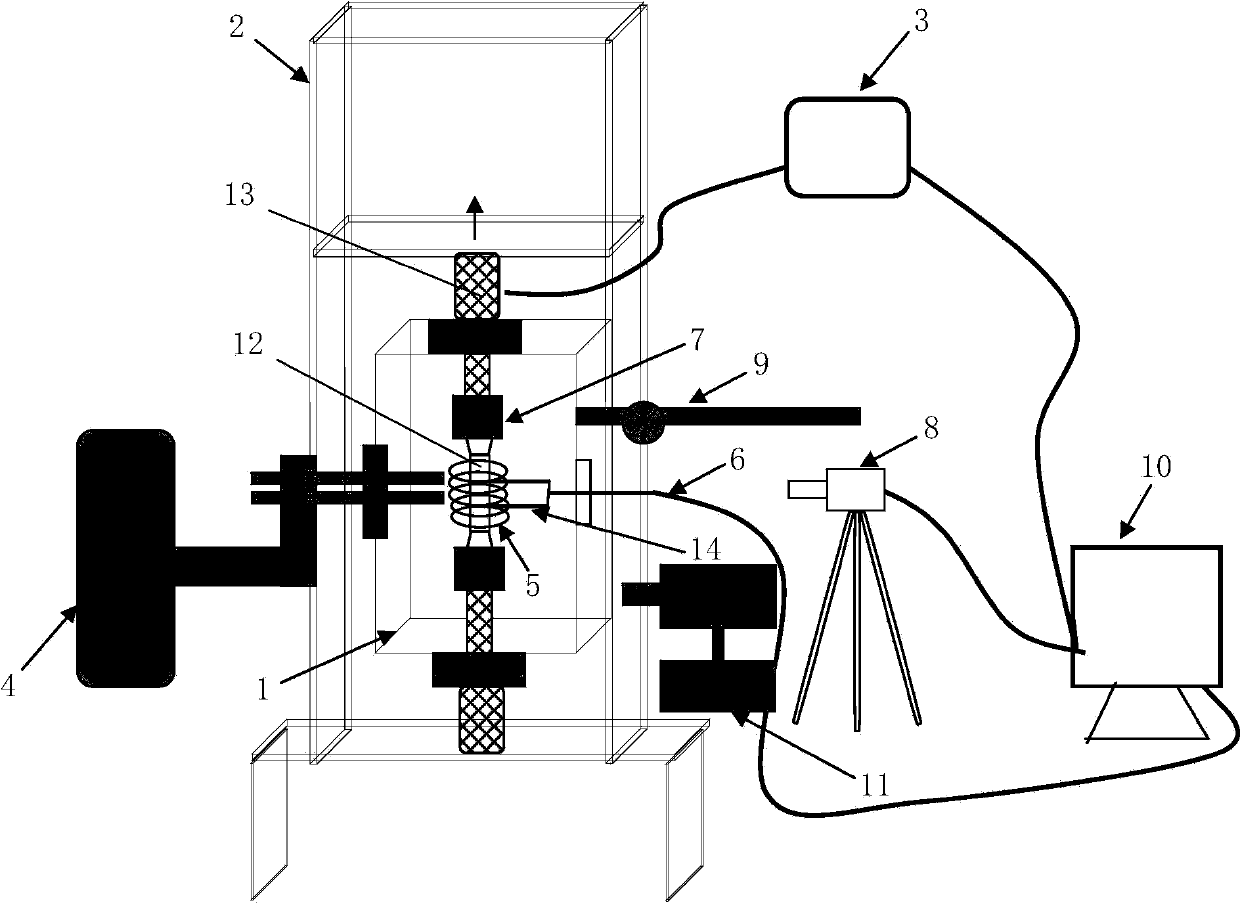

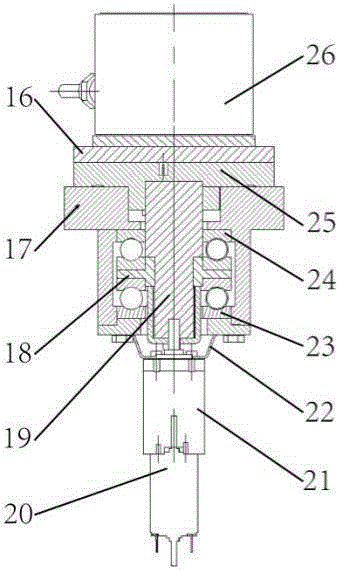

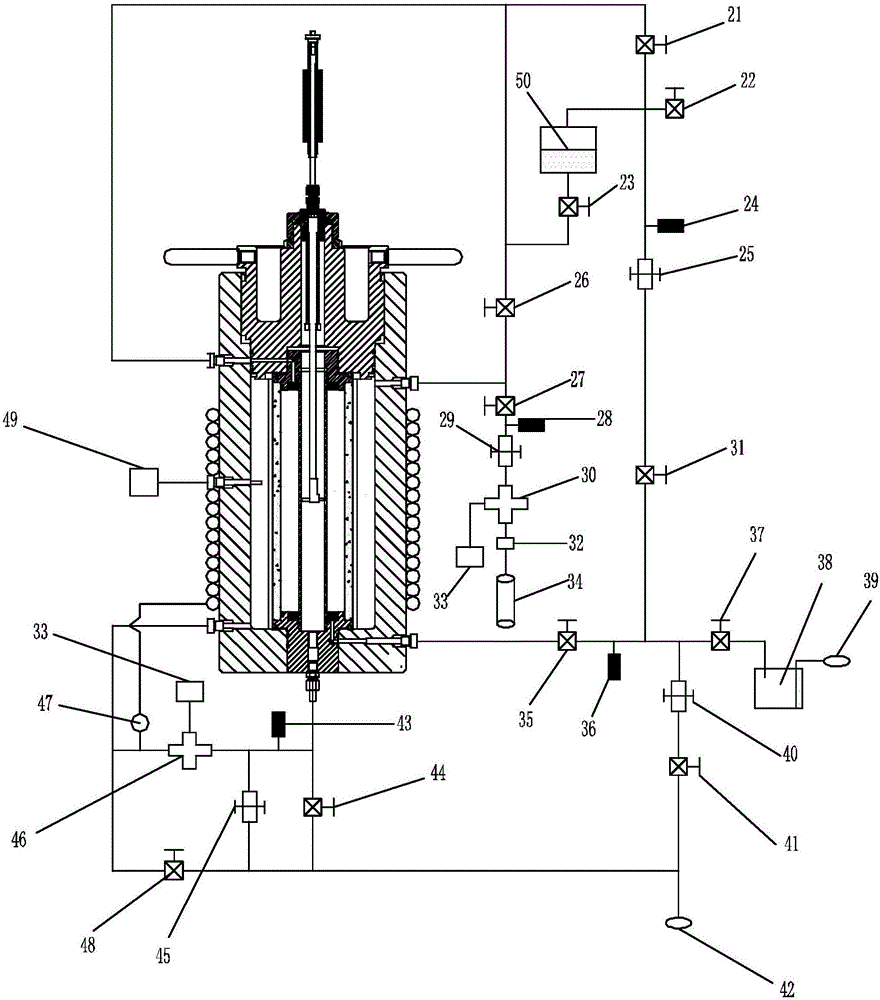

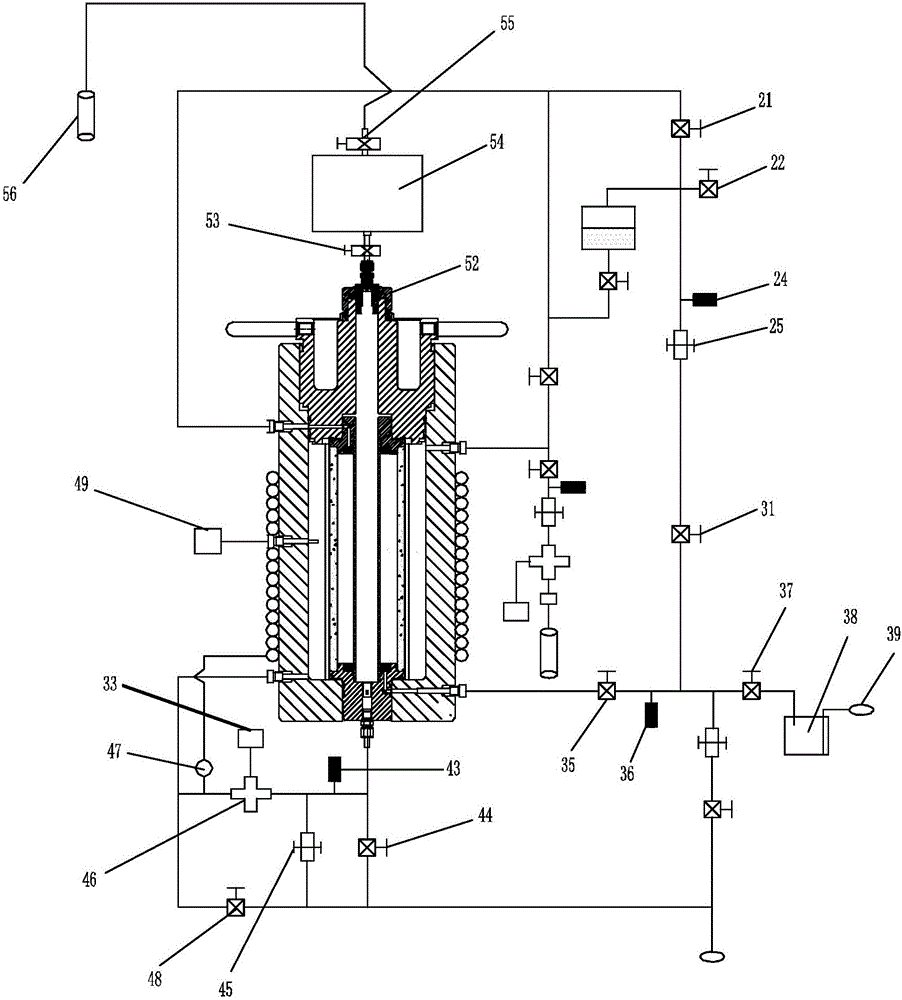

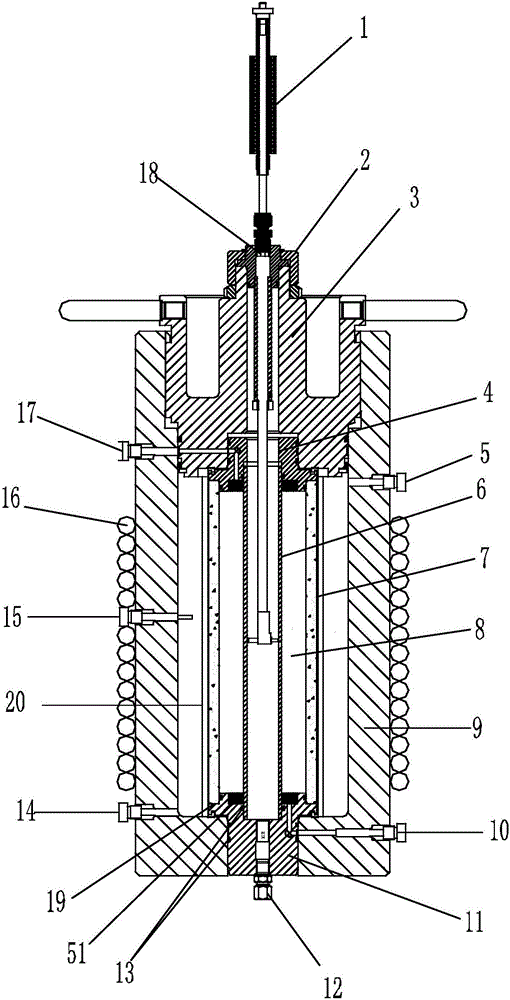

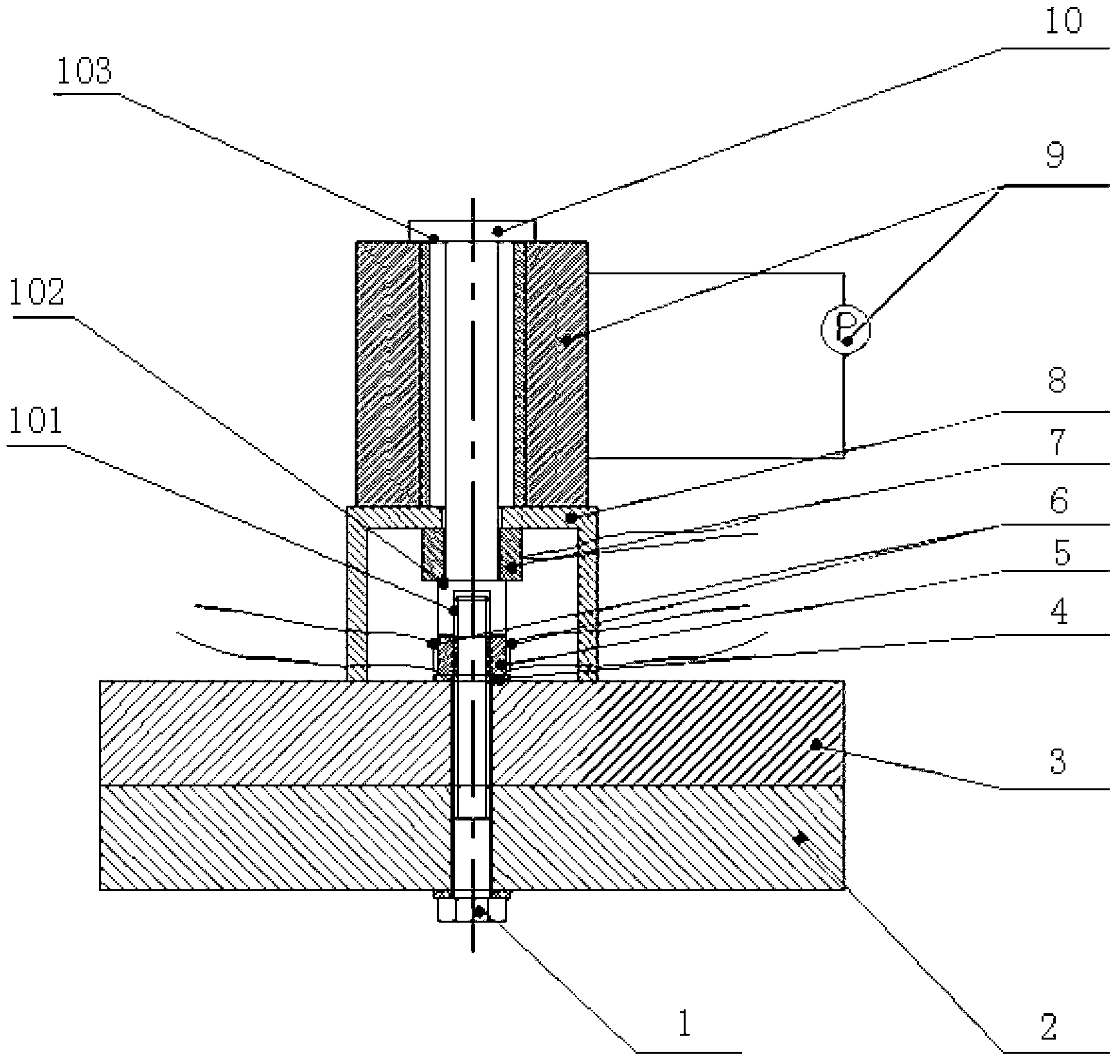

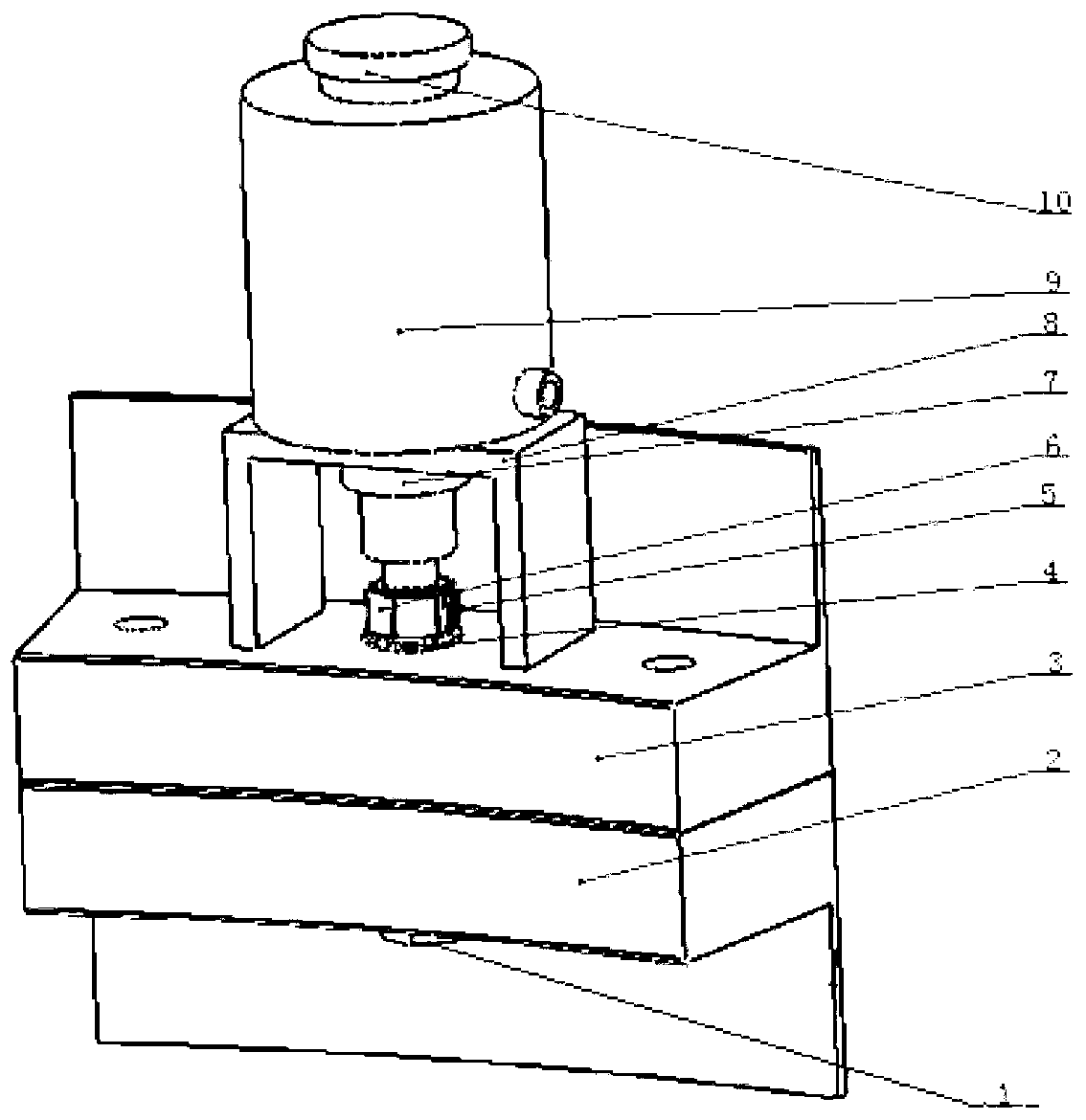

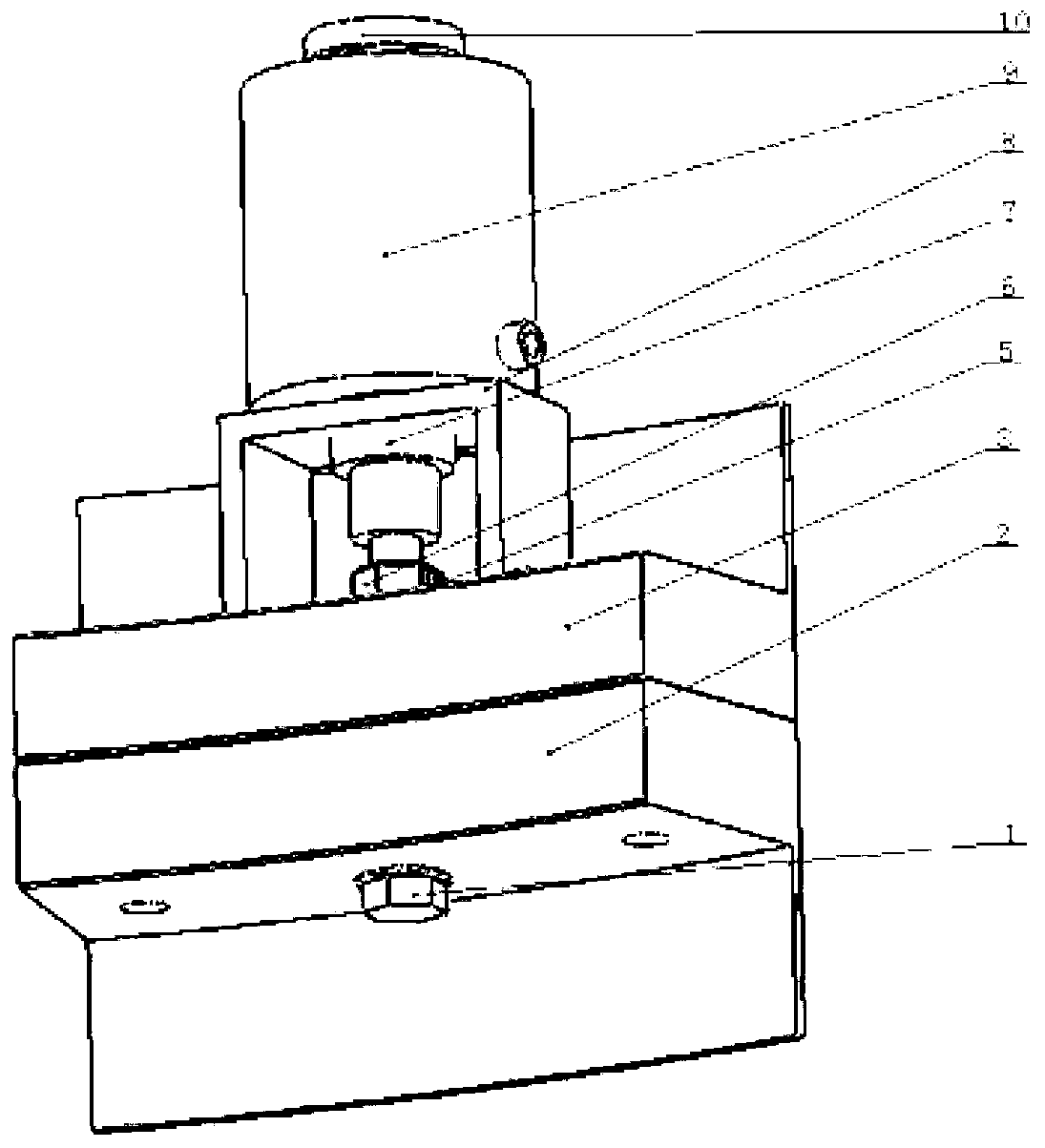

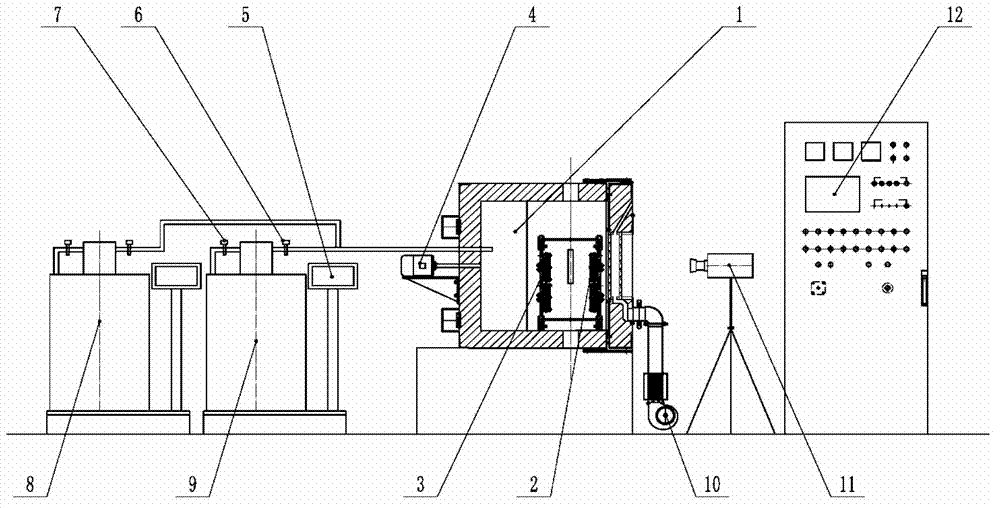

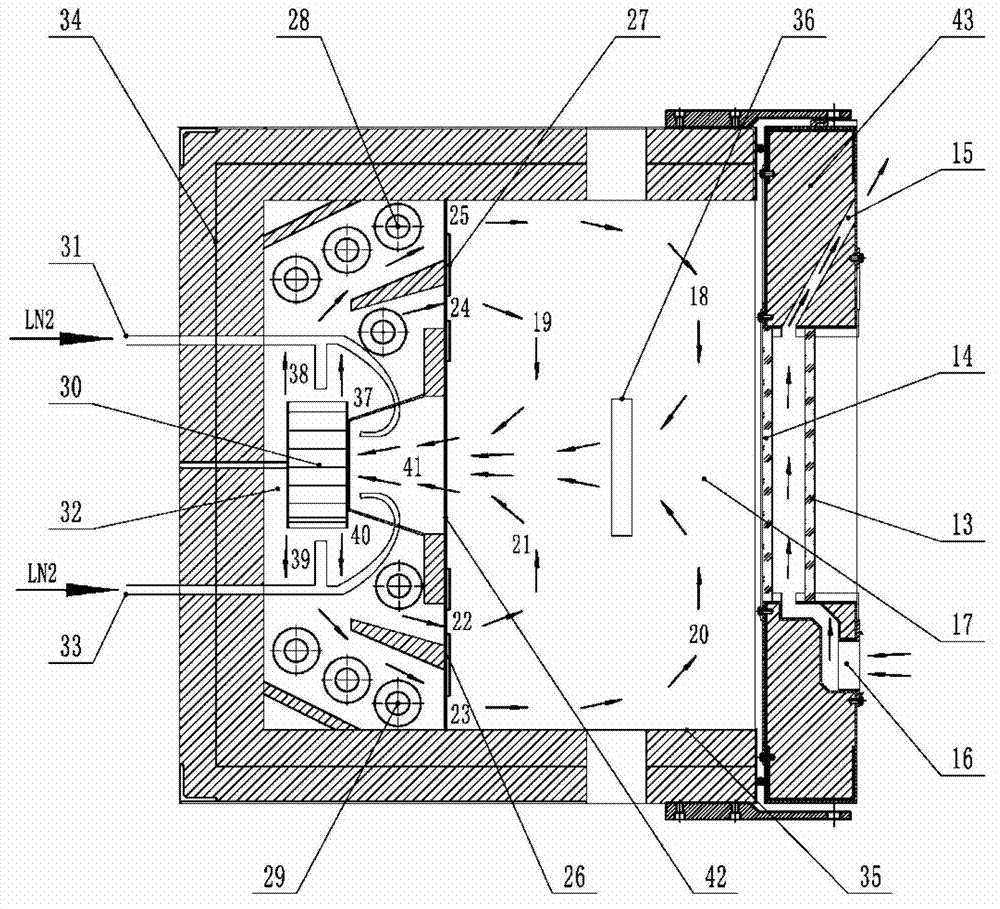

Thermo-mechanical-environmental coupling effect testing device and application from room temperature to ultrahigh temperature

ActiveCN104215521APrecise temperature controlTestable tensile strengthWeighing by removing componentMaterial strength using tensile/compressive forcesPower control systemTest fixture

The invention relates to the field of test of mechanical properties of materials and in particular relates to a thermo-mechanical-environmental coupling effect testing device and application from room temperature to ultrahigh temperature. The device comprises an electronic universal testing machine, a loading control system, a power supply control system, an induction heater, a strain measurement system, a sample clamp, a temperature measuring system, a pressure control system, a display and analysis system and a vacuum system, wherein a vacuum cavity in the electronic universal testing machine is in a fully water-cooled design, and various functional windows, such as a sensor connector of the clamp and the electronic universal testing machine, an infrared or thermocouple temperature measuring opening of the temperature measuring system, a pressure control opening of the pressure control system, an induction power supply introduction opening of the power supply control system, an extensometer introduction opening of the strain measurement system and a connector of the vacuum system and the vacuum cavity, are reserved in different parts of the vacuum cavity. The device disclosed by the invention can quantitatively research the thermo-mechanical-environmental coupling effect and has the advantages of diversified tested mechanical property parameters, high sample heating and cooling speed and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Automatic down pressure adjustment system for set of ganged disc openers

A disc opener unit for an agricultural implement has a down pressure adjustment device that automatically adjusts the amount of down pressure applied on a furrowing disc based on strain measurements taken by a strain gauge or load cell. The strain gauge, which may be mounted to an arm that is used to set the position of a depth setting gauge wheel, provides feedback to a processor that in turn controls the amount of hydraulic fluid in a hydraulic cylinder to adjust the down force applied on the disc. The amount of down pressure is therefore adjusted in substantially real-time in response to changes in field conditions, which improves furrow depth consistency and reduces wear on the gauge wheel and its components.

Owner:CNH IND CANADA

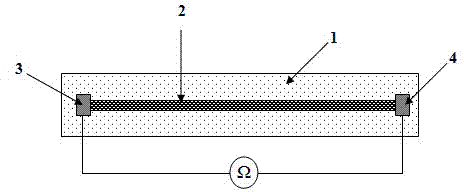

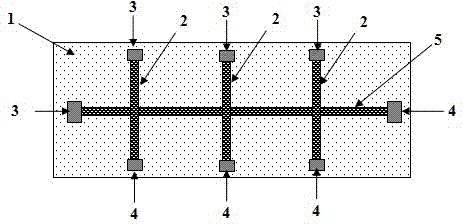

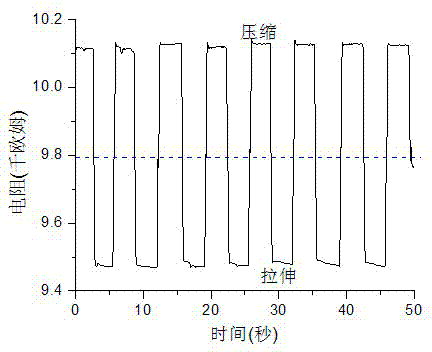

Graphene-based strain measuring and motion sensing device and manufacturing method thereof

InactiveCN102506693AEasy to prepareStable structureUsing electrical meansIndication/recording movementBiological motionEngineering

The invention discloses a graphene-based strain measuring or motion sensing device. The device is formed by the following steps: a layer or a plurality of layers of graphene film layers are combined on a flexibly insulating substrate; two ends of the graphene film layer are led out through electrodes and connected with ohmmeters, wherein the device is closely combined on the surface of an object to be detected, or a plurality of the devices are closely combined on the surface of the object to be detected, so that the strain variation measurement or motion monitoring can be realized. The device disclosed by the invention has the advantages of simple manufacturing method and capabilities of being suitable for large-scale production such as surface mounting and the like, and being applied to various types of environments and deformed surfaces; especially, the influence on the object to be detected is small, so that contactless measurement can be realized, and the device is suitable for monitoring biological motion. The invention further discloses a manufacturing method and a measuring method for the device.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

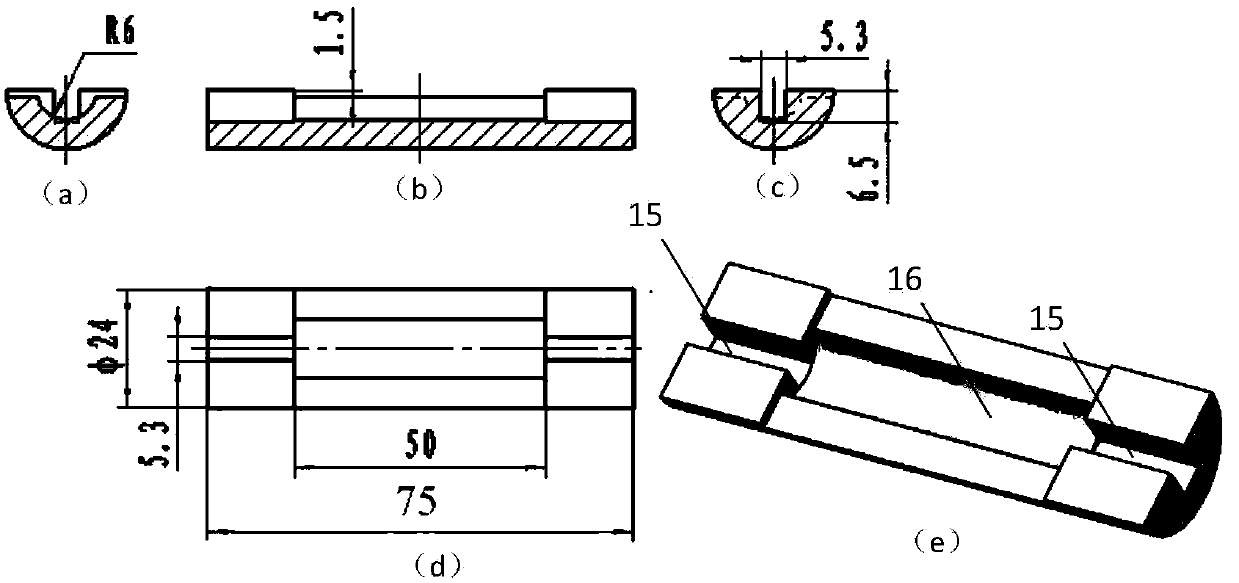

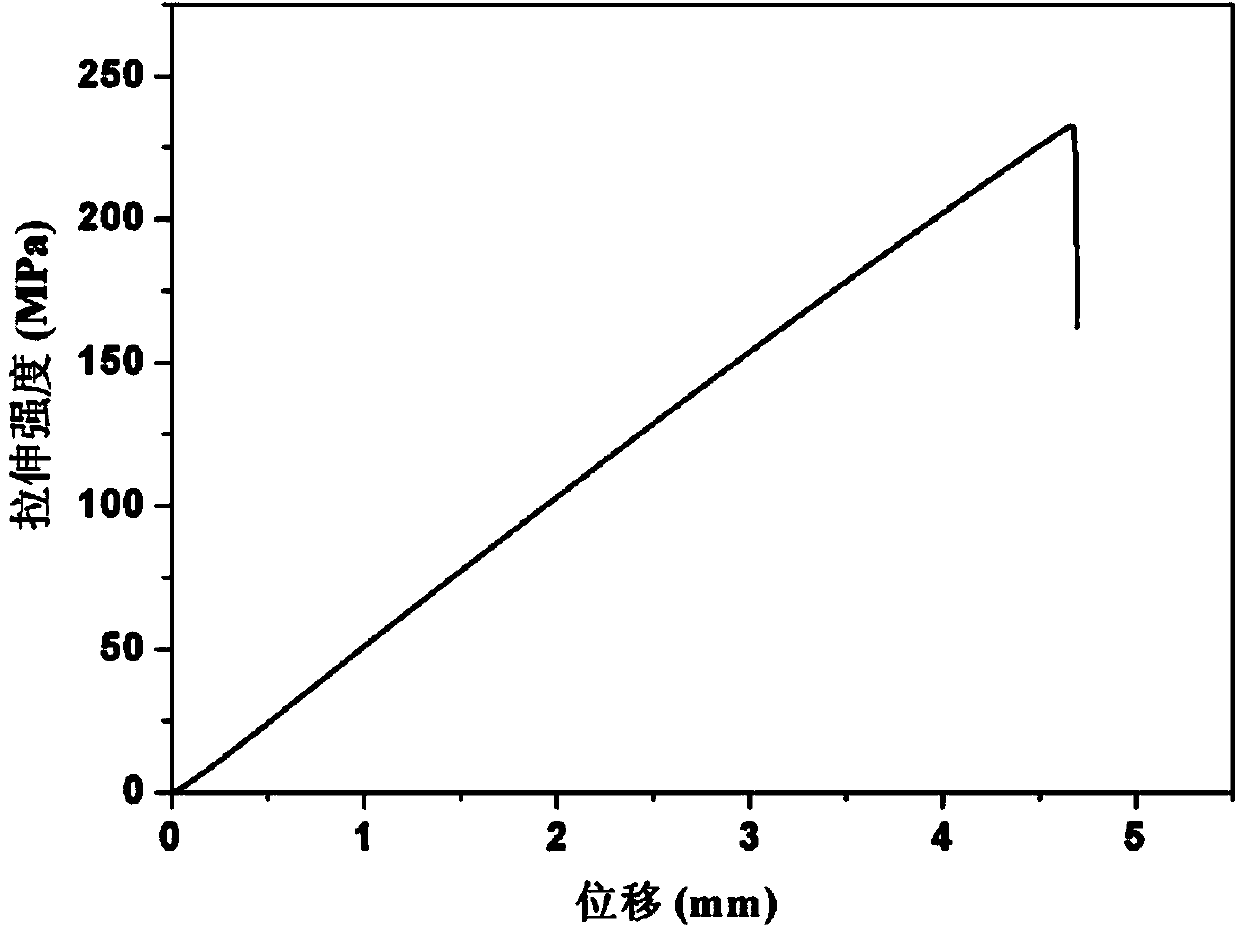

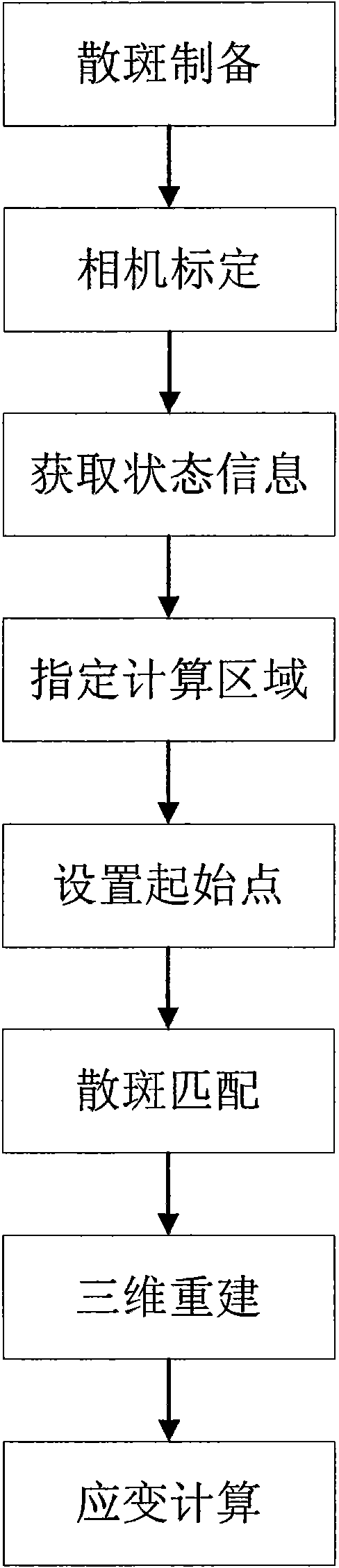

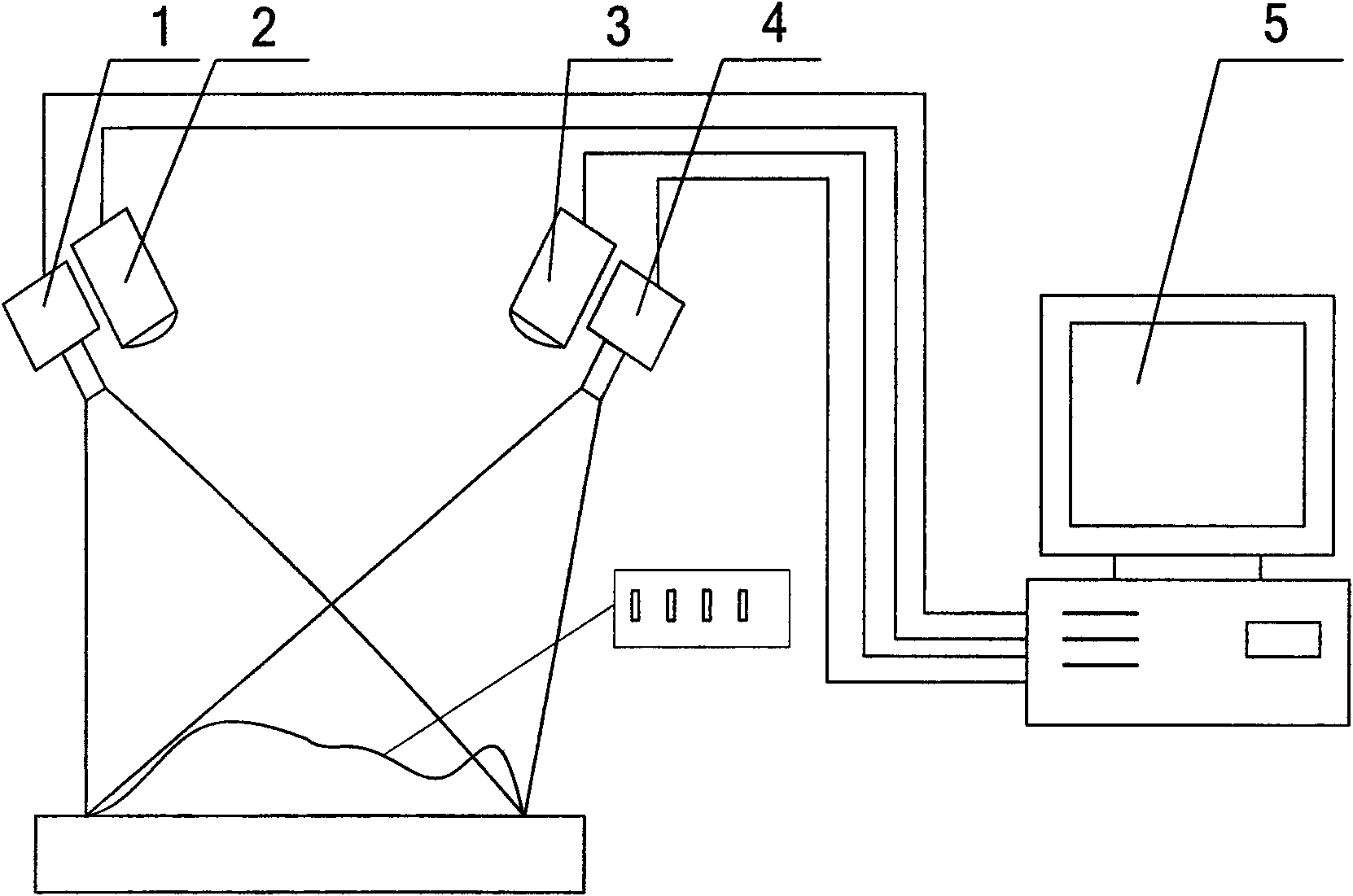

Three-dimensional speckle strain measurement device and measurement method thereof

ActiveCN101655352AHigh measurement accuracySimplify requirementsUsing optical meansVibration measurementFracture mechanics

The invention discloses a three-dimensional speckle strain measurement method, comprising: (1) speckle preparation; (2) camera calibration; (3) state information acquisition; (4) computational domaindesignation; (5) initial point setting; (6) speckle matching; (7) three-dimensional reconstruction; and (8) strain computation. By the above operation steps, the invention provides a three-dimensionalspeckle strain measurement method, which can effectively obtain high preciseness measurement results in measurements of material characteristic parameters such as full-field vibration measurement, dynamic strain measurement, high speed deformation measurement, fracture mechanics, impact excitation and dynamic material experiments. The invention has the characteristics of convenient measurement operation, high automation degree, exact and reliable results, high efficiency and non-contact measurement.

Owner:XI AN JIAOTONG UNIV

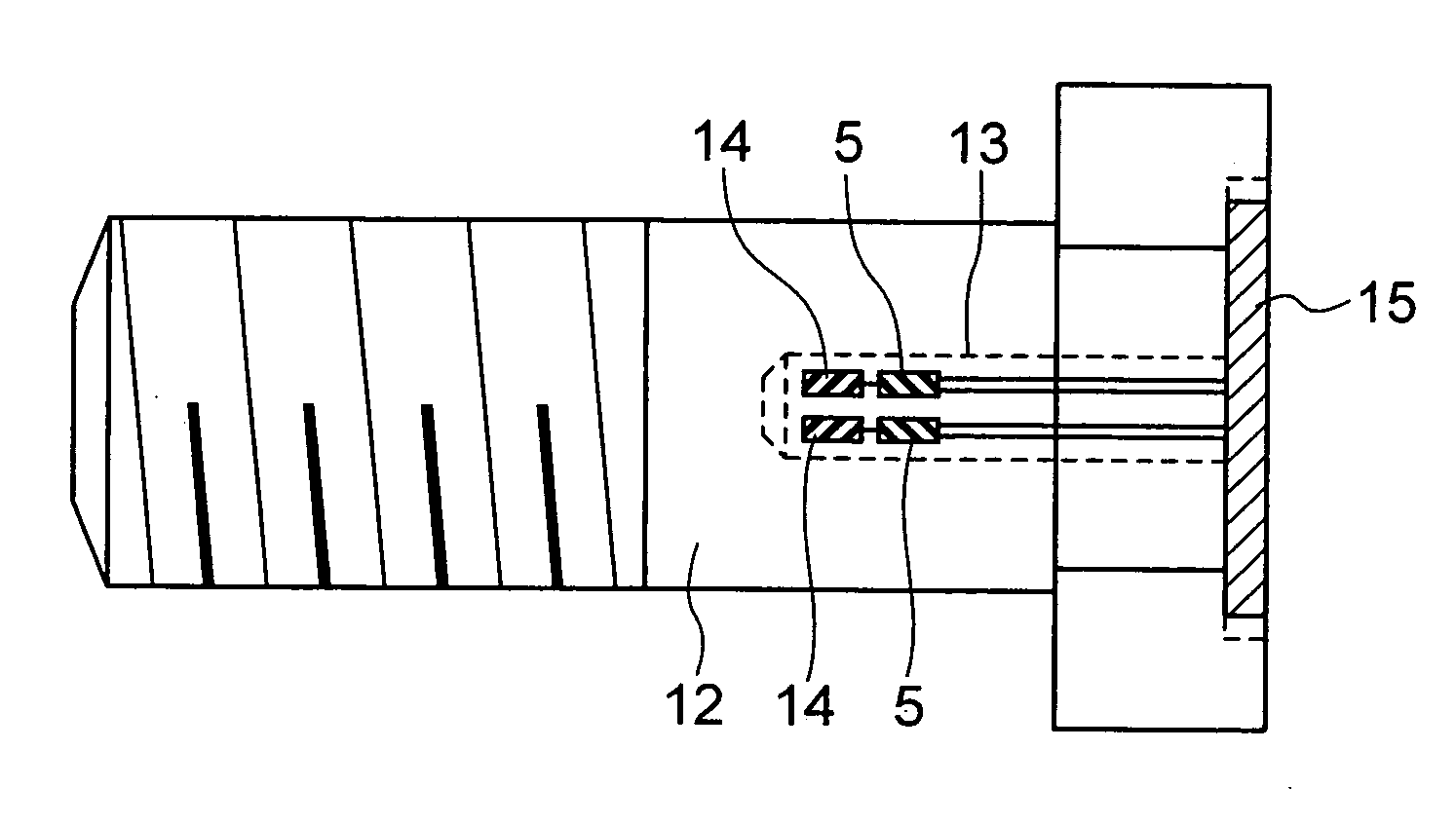

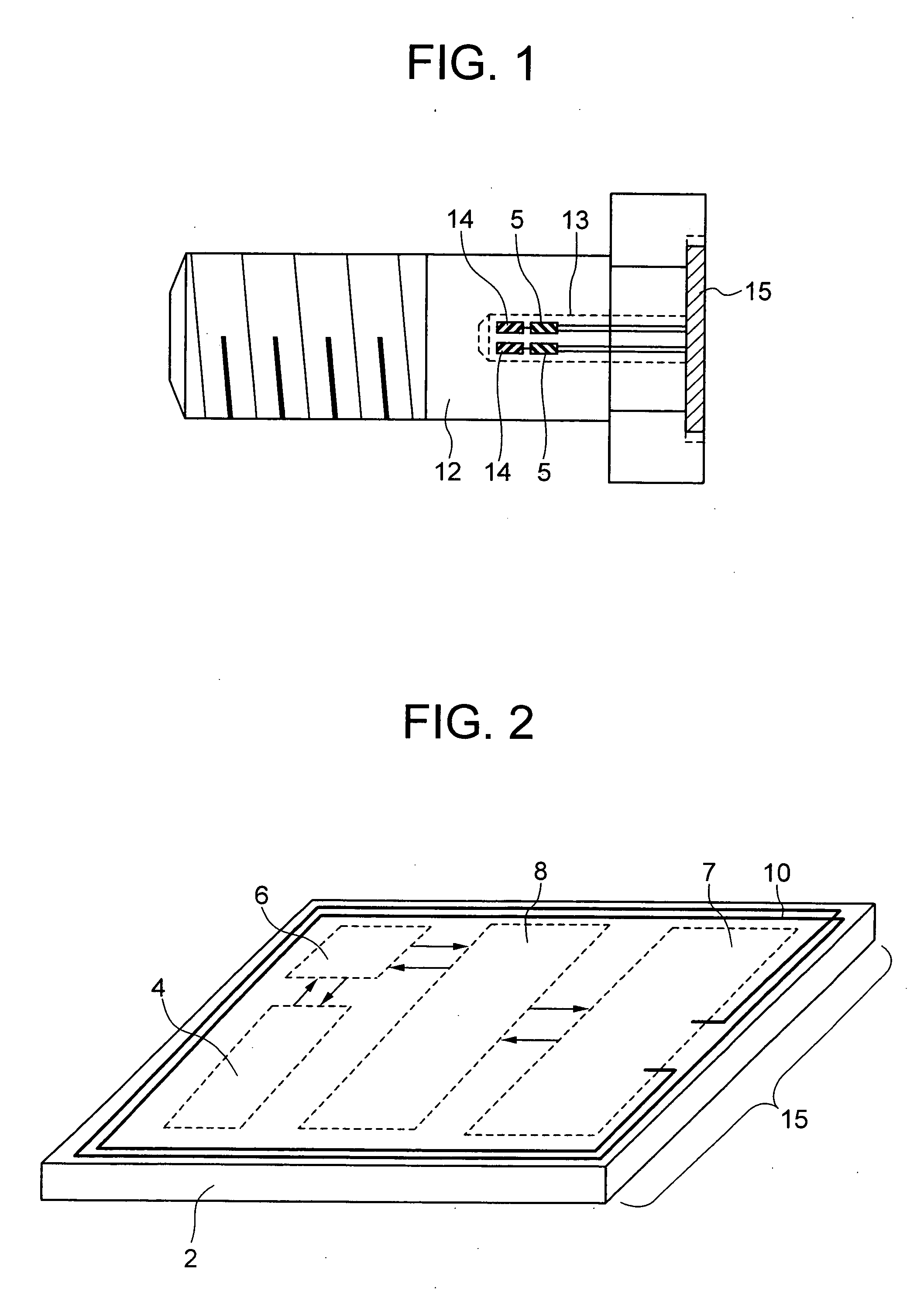

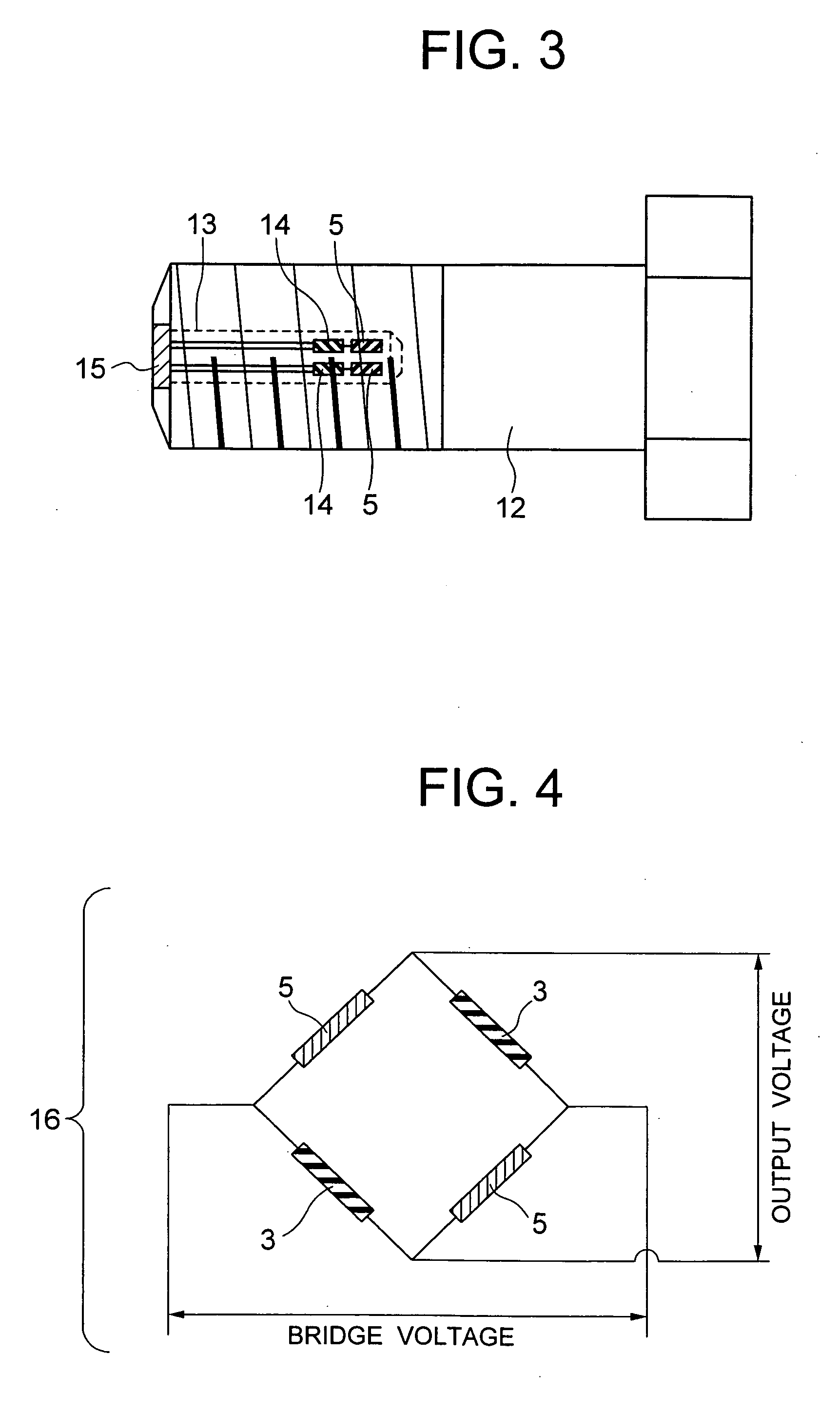

Bolt with function of measuring strain

ActiveUS20070017295A1Improve accuracyHigh precision measurementAcceleration measurement using interia forcesTesting/calibration apparatusElectrical resistance and conductanceEngineering

A bolt with a function of measuring strain, comprising a Wheatstone bridge circuit comprising a strain sensor and a dummy resistor, a translate circuit that amplifies a signal from the Wheatstone bridge circuit to convert the same into a digital signal, a transmitting circuit that transmits the digital signal outside the bolt, and a power circuit, by which electromagnetic wave energy received from outside the bolt is supplied as a power source for at least any one of the circuits.

Owner:HITACHI LTD

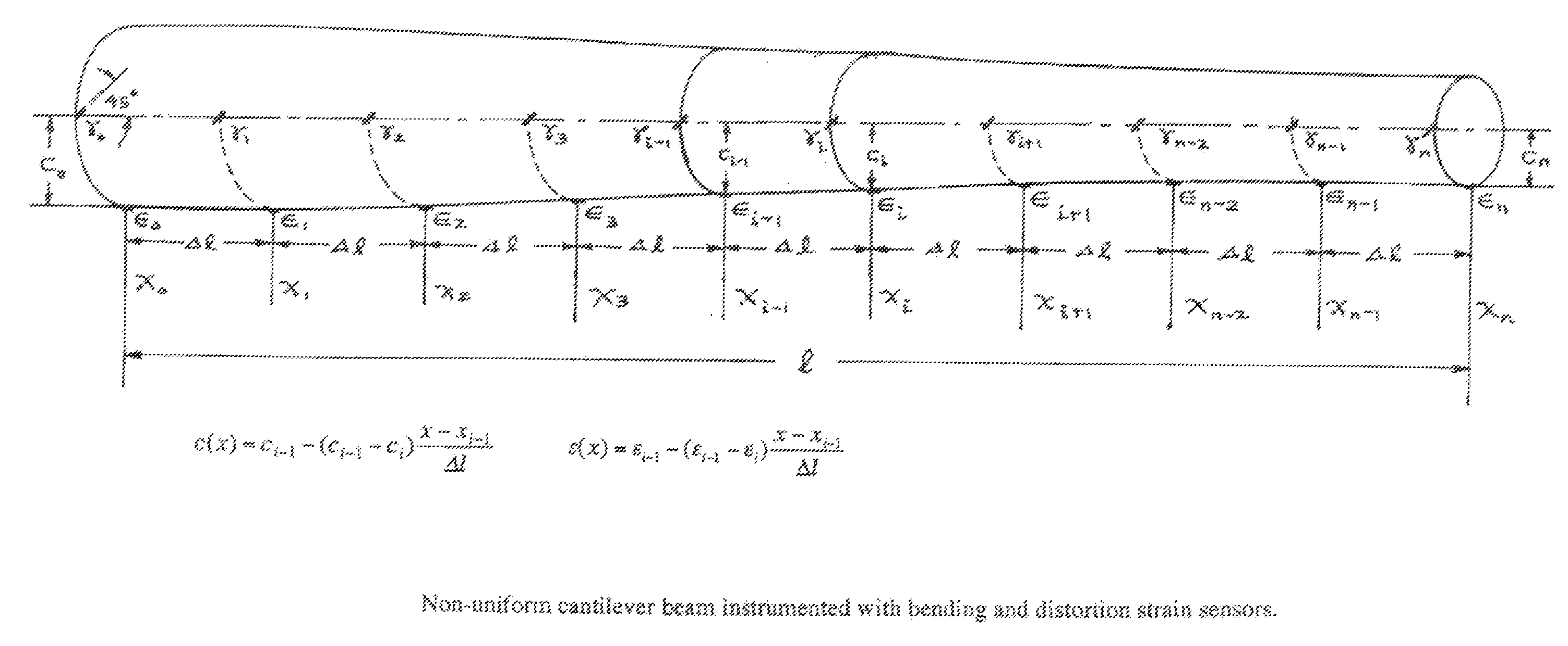

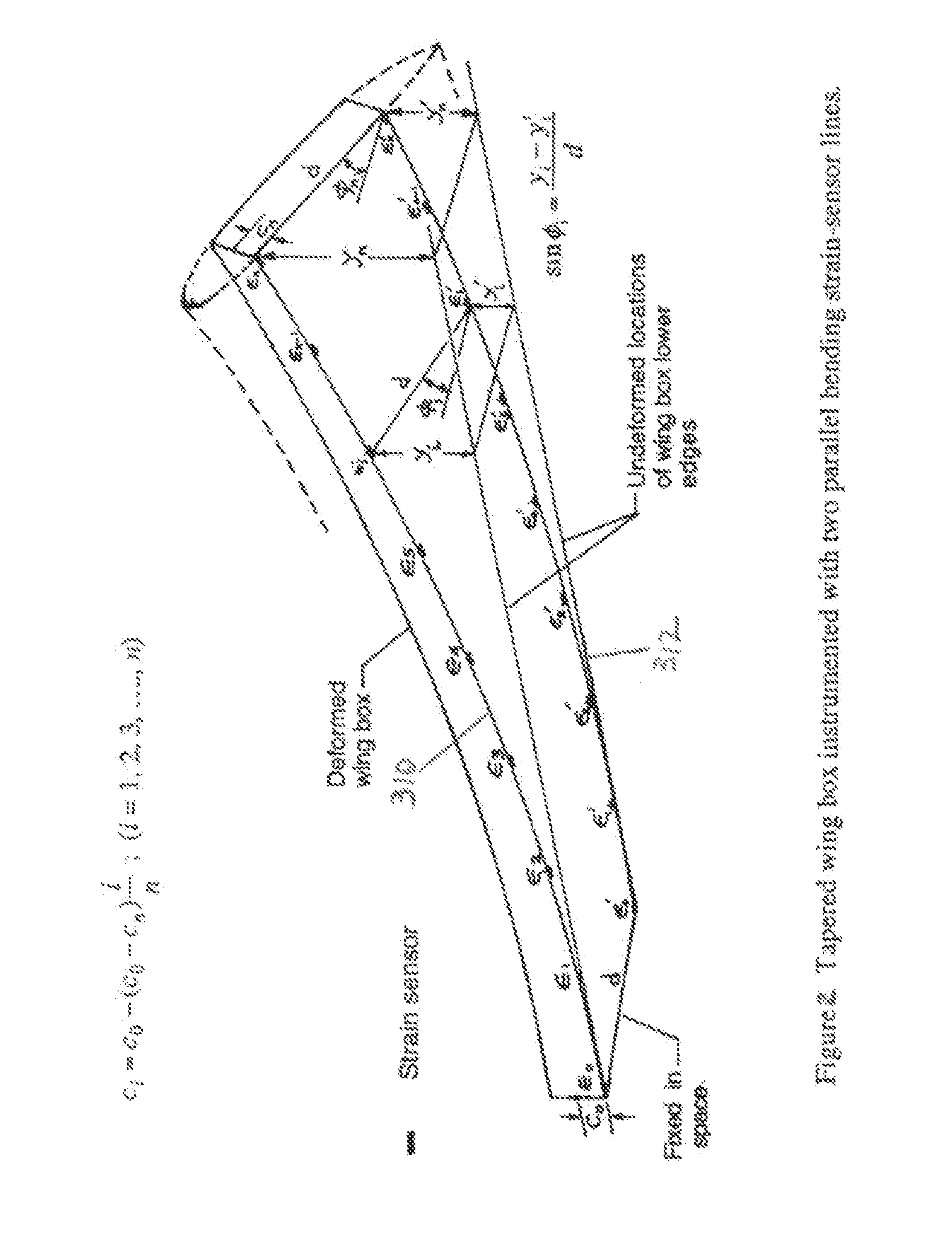

Method for real-time structure shape-sensing

InactiveUS7520176B1Force measurement by measuring optical property variationOptical apparatus testingTime structureEngineering

The invention is a method for obtaining the displacement of a flexible structure by using strain measurements obtained by stain sensors. By obtaining the displacement of structures in this manner, one may construct the deformed shape of the structure and display said deformed shape in real-time, enabling active control of the structure shape if desired.

Owner:NAT AERONAUTICS & SPACE ADMINISTATION UNITED STATES OF AMERICA AS REPRESENTED BY THE DIRECTOR OF

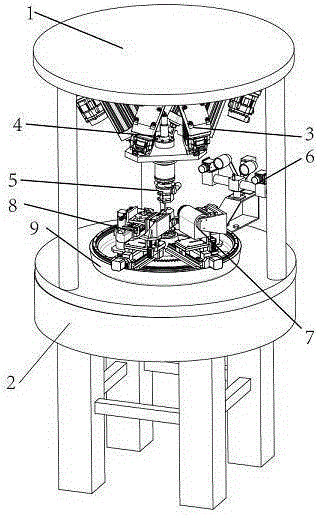

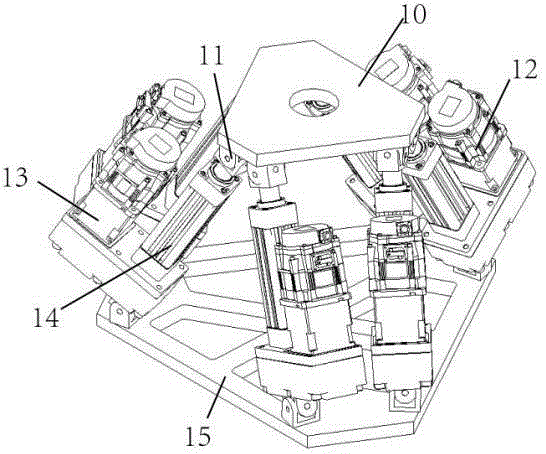

Material in-situ detection device and method under multi-load multi-physical field coupling service conditions

ActiveCN105223076ANovel structureCompact layoutMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesPhysical fieldScientific instrument

The invention relates to a material in-situ detection device and method under multi-load multi-physical-field coupling service conditions, and belongs to the field of precise scientific instruments. The material in-situ detection device is composed of a precise six-degrees-of-freedom composite load loading module, a precise torsion module, a precise indentation module, a clamp module and a control module which work together to complete a composite-load multi-physical-field coupling experiment, a digital speckle strain measurement and infrared thermal imaging module and a microscope observation module are integrated, and in-situ observation and quantitative characterization are carried out on material deformation behaviors and damage mechanism phenomena in a composite-load multi-physical-field loading process. The device and the method have the advantages that the composite-load loading can be realized, and a novel loading method such as 'cantilever type pure bending, cantilever type tensile / compression-torsion, and cantilever type bending-torsion' is carried out. Silicon nitride ceramic heating sheets, Peltier tiles and current loading are used for achieving simulation of cold / hot-electricity and other multiple physical fields, and an improvement innovative experimental testing method is provided for material micromechanical property tests close to the serving conditions.

Owner:JILIN UNIV

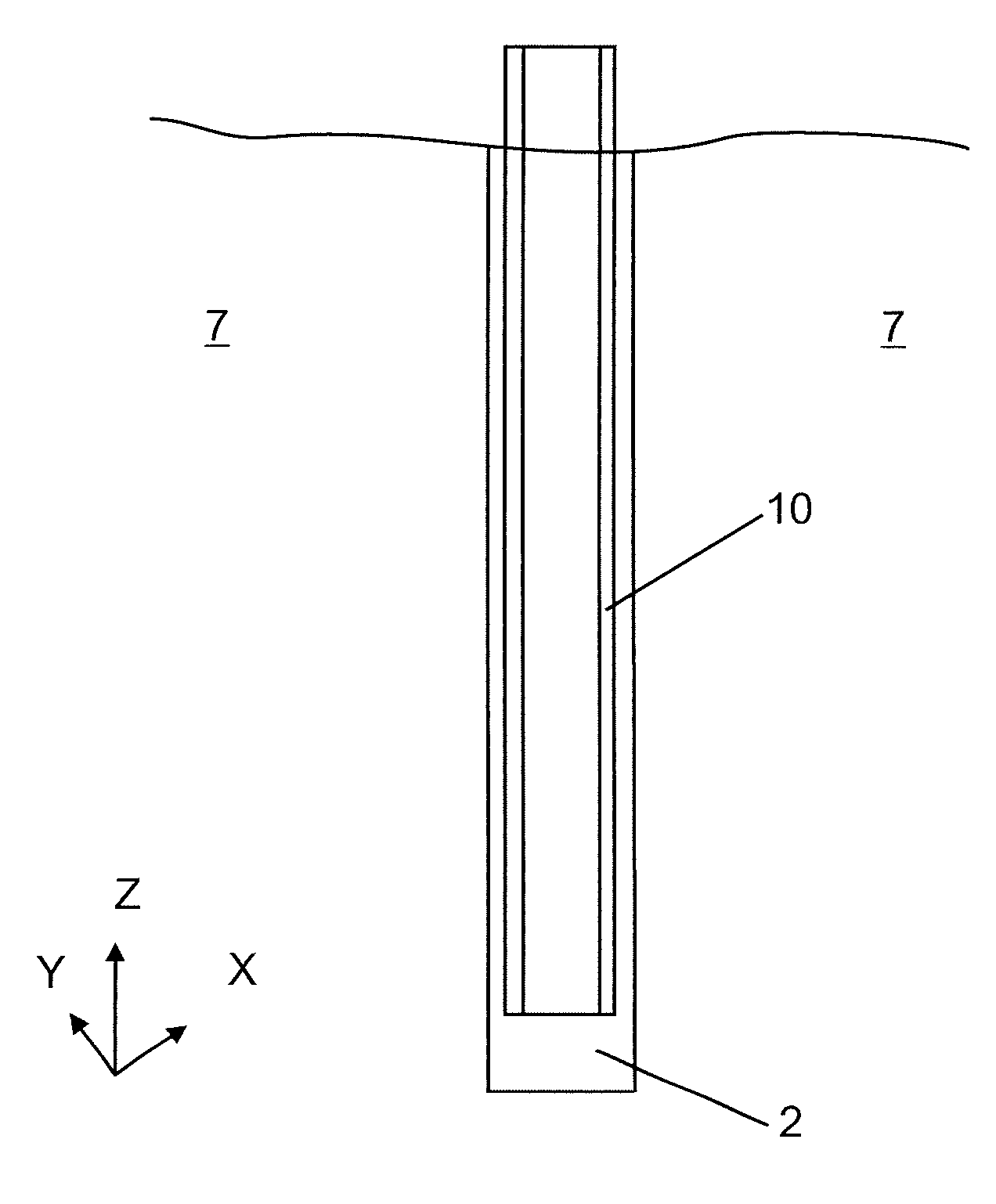

Oil/gas well cement sheath sealing integrity testing device and method for carrying out evaluation through device

PendingCN106522923AAchieving Seal IntegrityAchieving Sealing CapabilityConstructionsEngineeringCement sheath

The invention relates to an oil / gas well cement sheath sealing integrity testing device. The testing device comprises a pressure kettle and a simulation wellbore located in the pressure kettle. The testing device further comprises a pressure control system, a temperature control system, a fluid channeling detection system, a strain measuring system and a mud cake simulation system. The simulation wellbore comprises a casing pipe and a core located on the periphery of the casing pipe. An annular gap is formed between the sleeve and the core, and a cement sheath is formed in the annular gap. The upper ends and the lower ends of the casing pipe and the core are provided with an upper end cover and a lower end cover respectively. The temperature borne by the cement sheath under different downhole working conditions and complex loads from the casing pipe and a stratum can be truly simulated, and the process range covers well cementation at the oil / gas well drilling and completion stage and pressure tests, producing tests, circulating injection production, fracturing and other improvement working conditions in the production process. The influence rule of the cement sheath sealing integrity can be evaluated by changing the thickness of the cement sheath, the character of mud cakes, the maintenance temperature and other factors.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

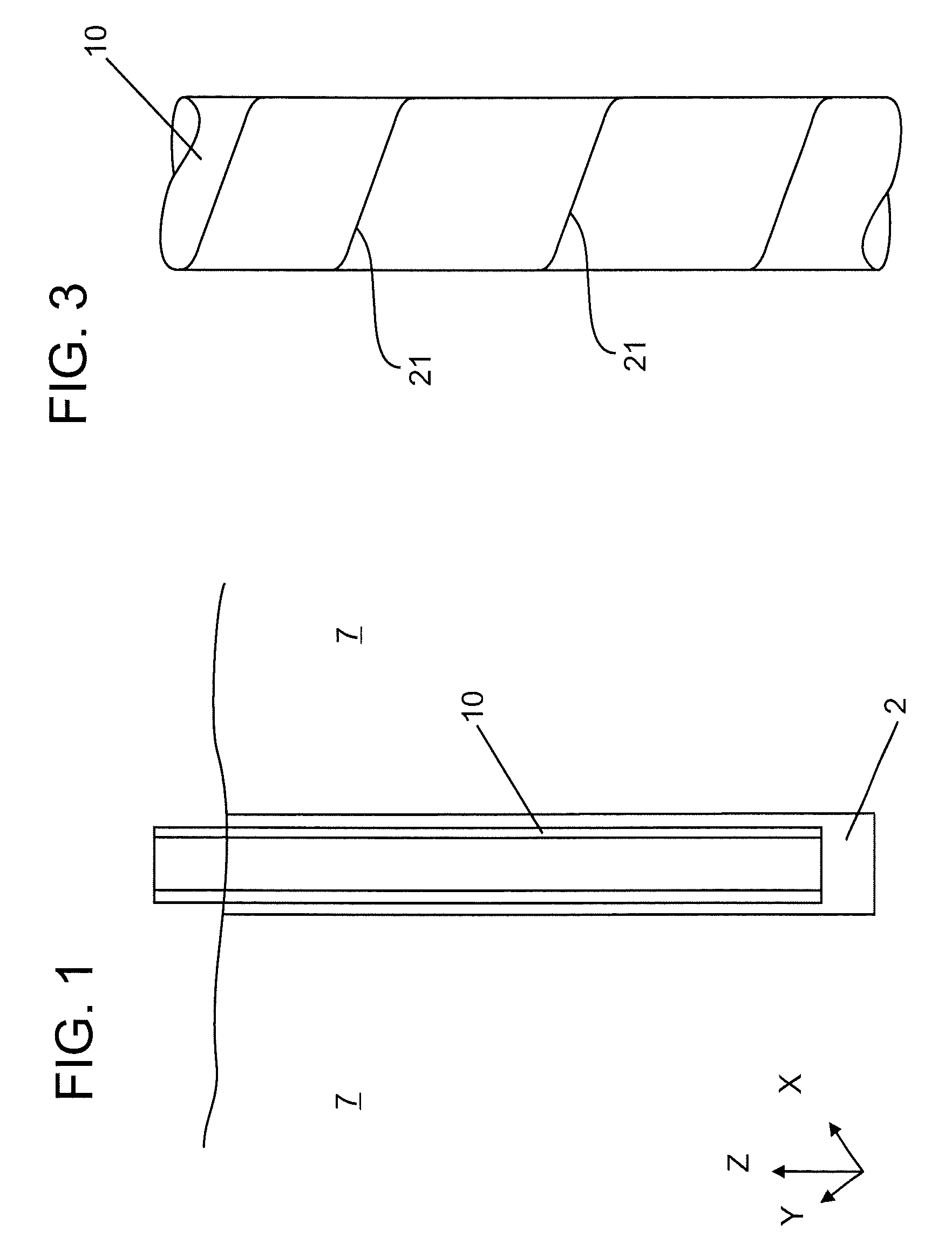

Method for analyzing strain data

ActiveUS20090254280A1Electric/magnetic detection for well-loggingDigital computer detailsPosition dependentEngineering

A method for estimating a shape, the method including: selecting a structure comprising a plurality of strain sensors inoperable communication with the structure, each strain sensor configured to provide a strain measurement; placing the structure in a borehole; receiving the strain measurements from the plurality of strain sensors; creating a mesh grid having nodes, each node related to a location of one strain sensor and assigned a strain value measured by the one strain sensor; creating an additional node for the mesh grid wherein a strain value assigned to the additional node is derived from the strain value corresponding to at least one adjacent node; and performing an inverse finite method using the mesh grid with the assigned strain values to estimate the shape.

Owner:BAKER HUGHES INC

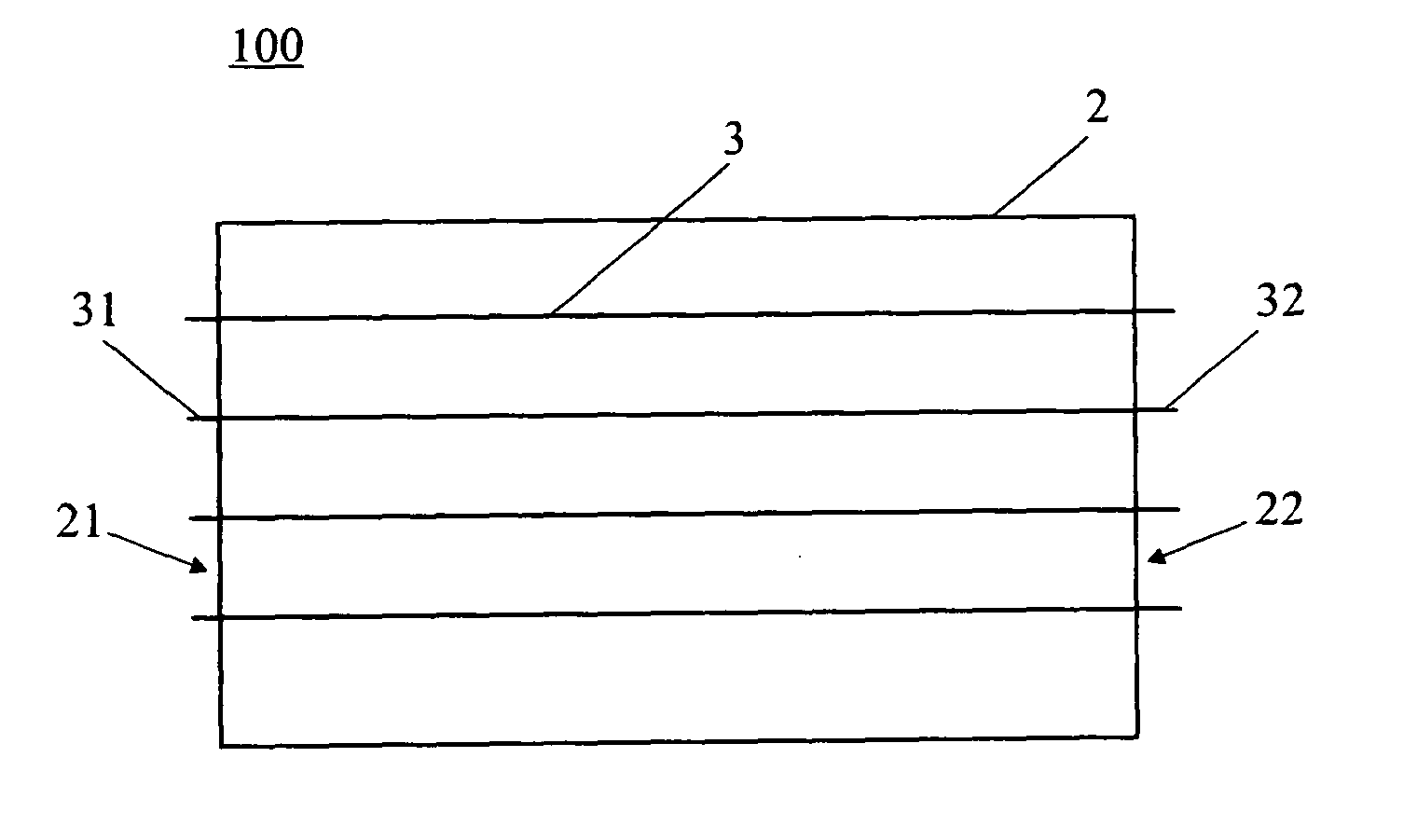

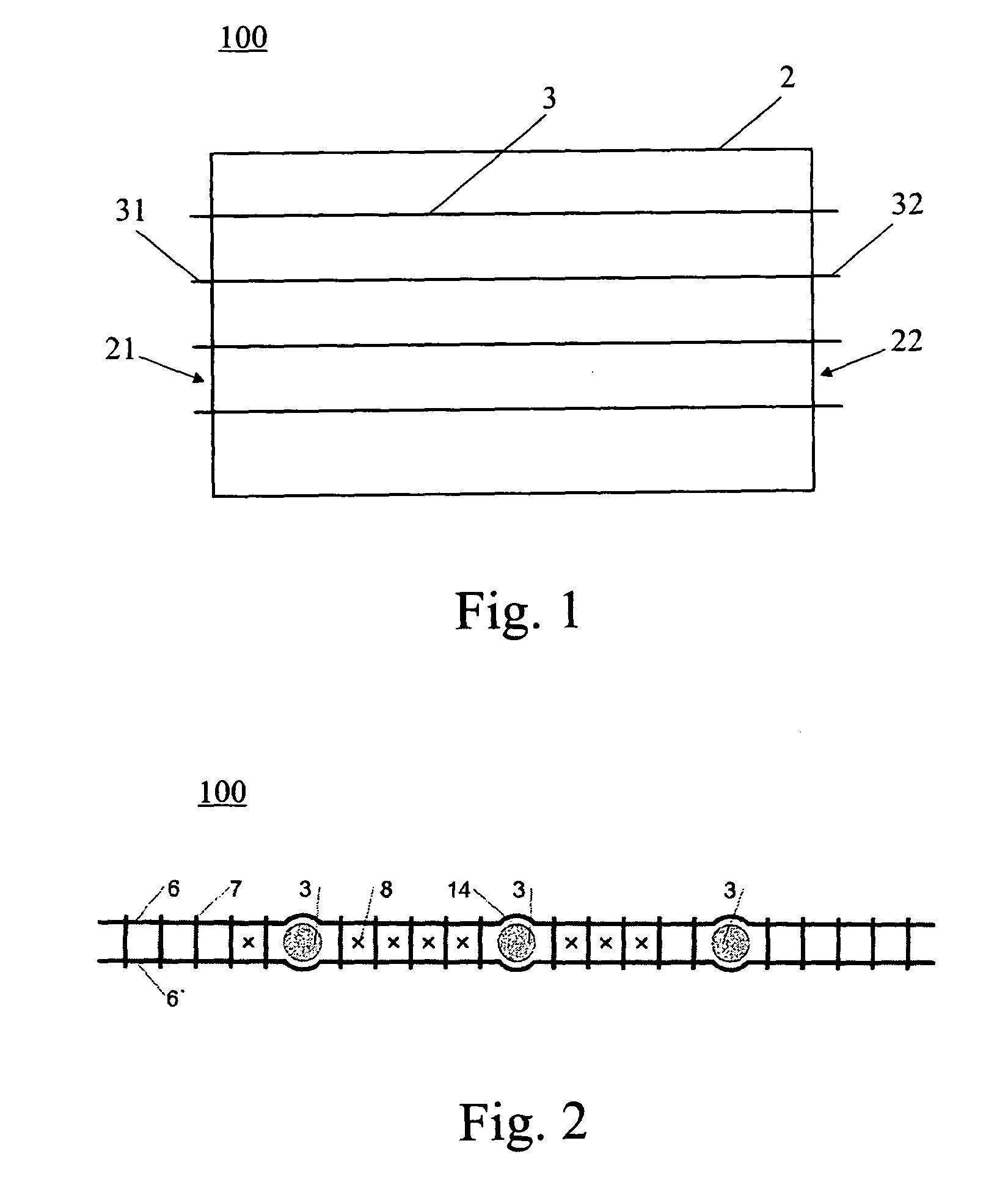

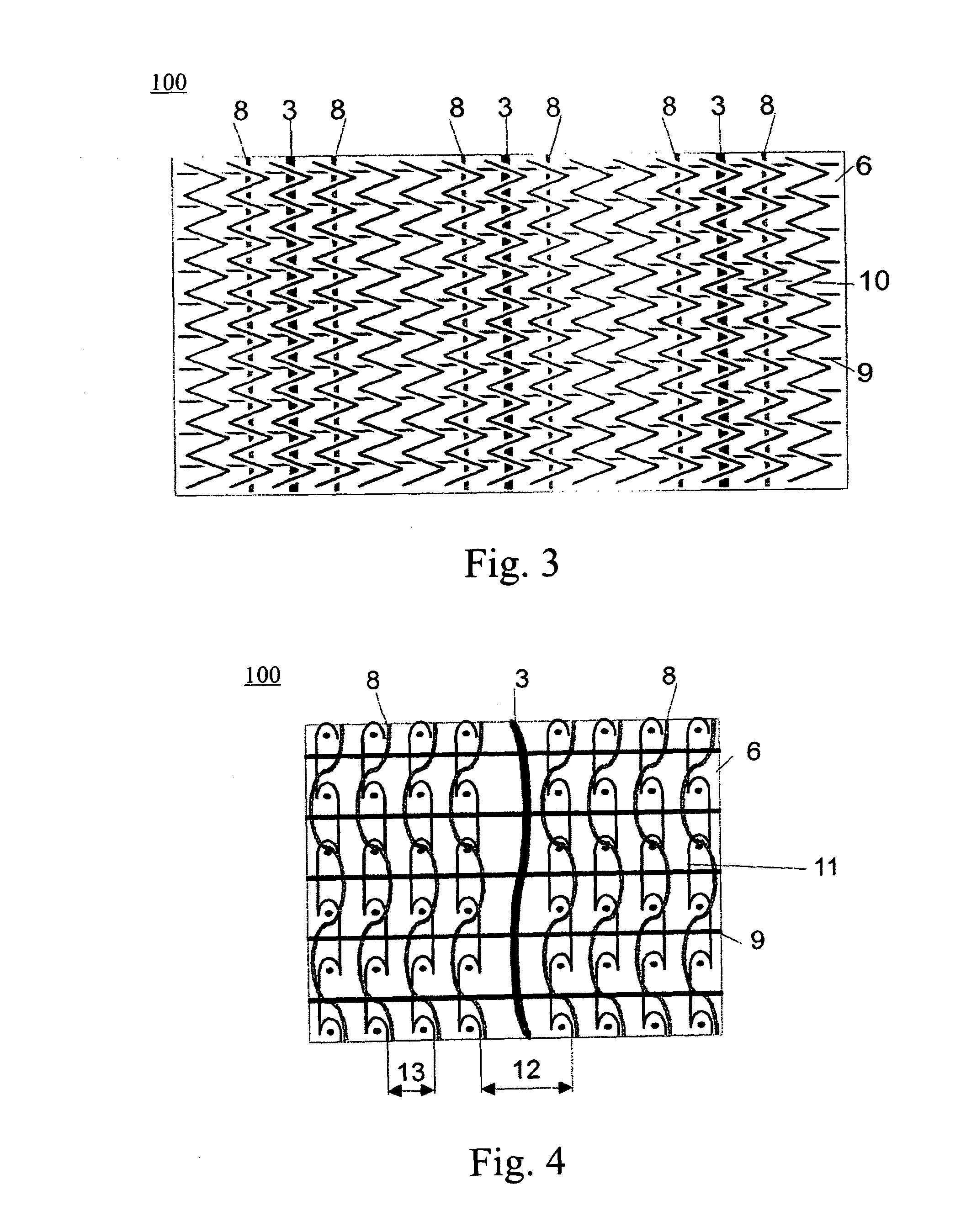

Reinforcement Element With Sensor Fiber, Monitoring System, And Monitoring Method

A reinforcement element, comprises at least one sensor fiber adapted for strain measurements based on stimulated Brillouin scattering within said sensor fiber. Furthermore, a system for monitoring strain within a structure comprises a reinforcement element comprising at least one sensor fiber adapted for strain measurements based on stimulated Brillouin scattering within said sensor fiber, a pump laser for coupling in laser radiation of a pump frequency into said at least one sensor fiber, a Stokes laser for coupling in laser radiation of a Stokes laser radiation into said at least one sensor fiber, wherein the pump frequency and the Stokes frequency are different from one another and wherein the frequency difference between the pump and Stokes frequencies is within the range of acoustical phonons within said sensor fiber, a sensor adapted to obtain a stimulated Brillouin backscattering signal, and a network analyzer adapted for determining the complex transfer function of the sensor fiber to determine a spatially resolved strain measurement.

Owner:GLOTZL GES FUR BAUMESSTECHN +2

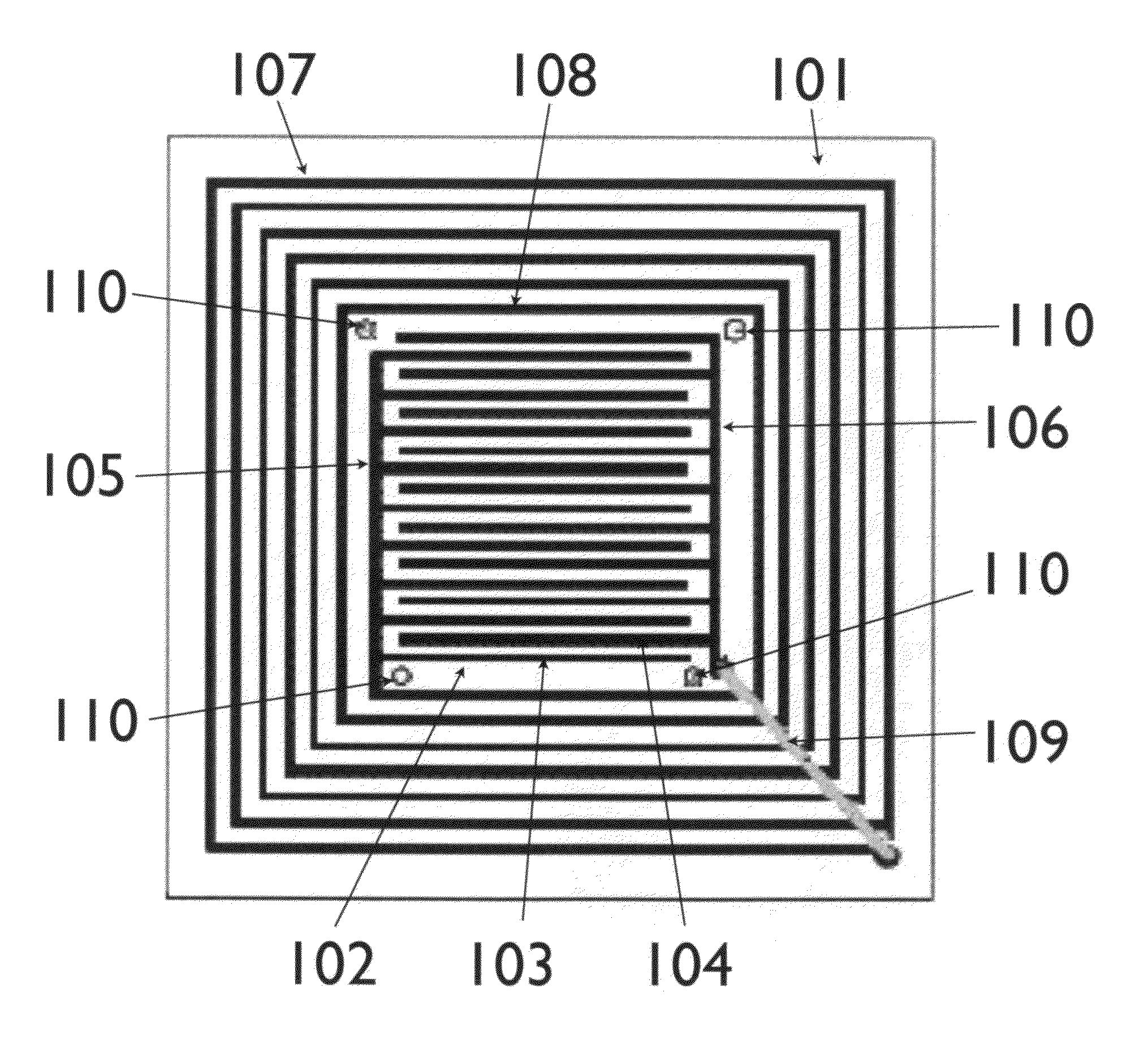

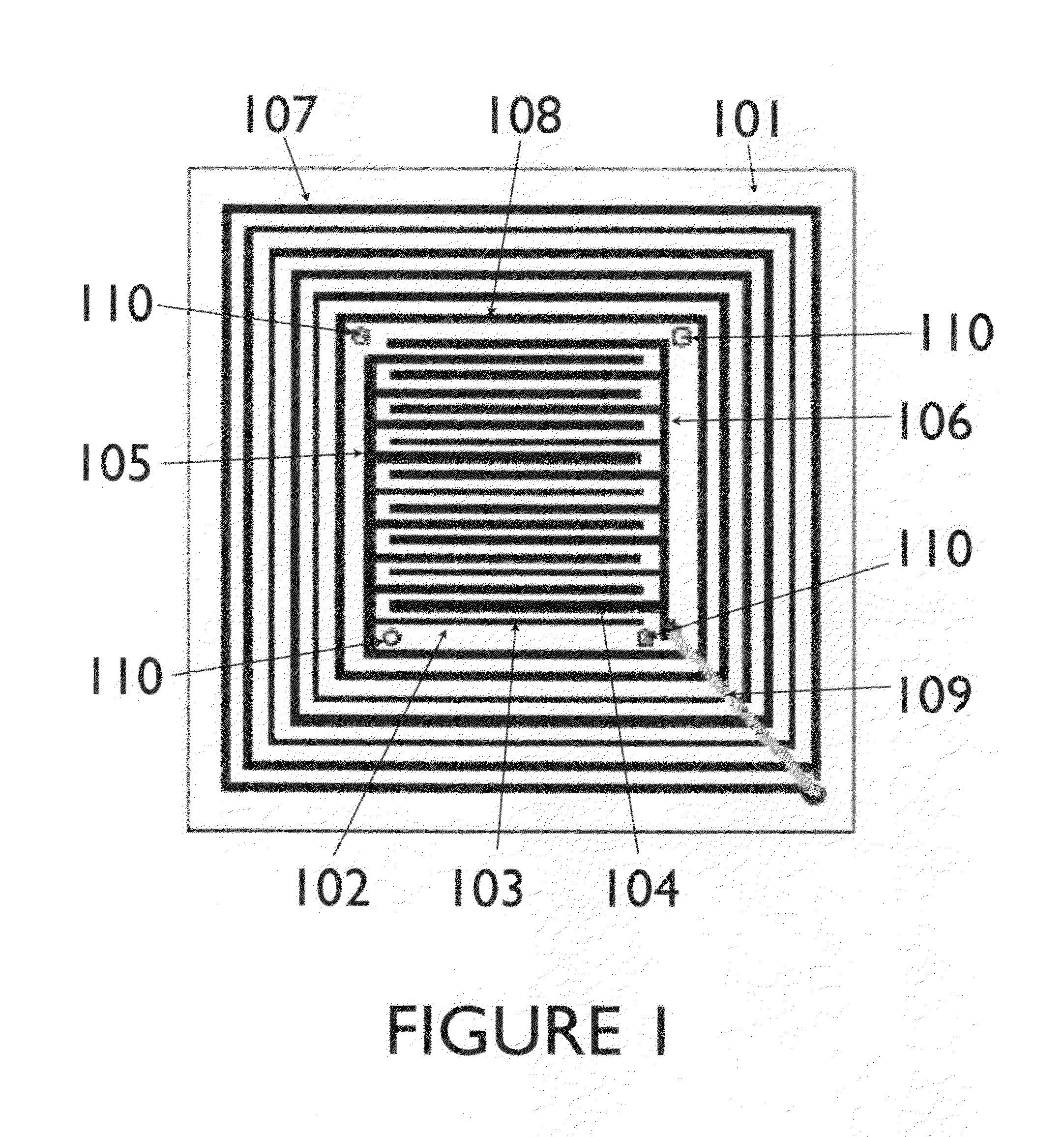

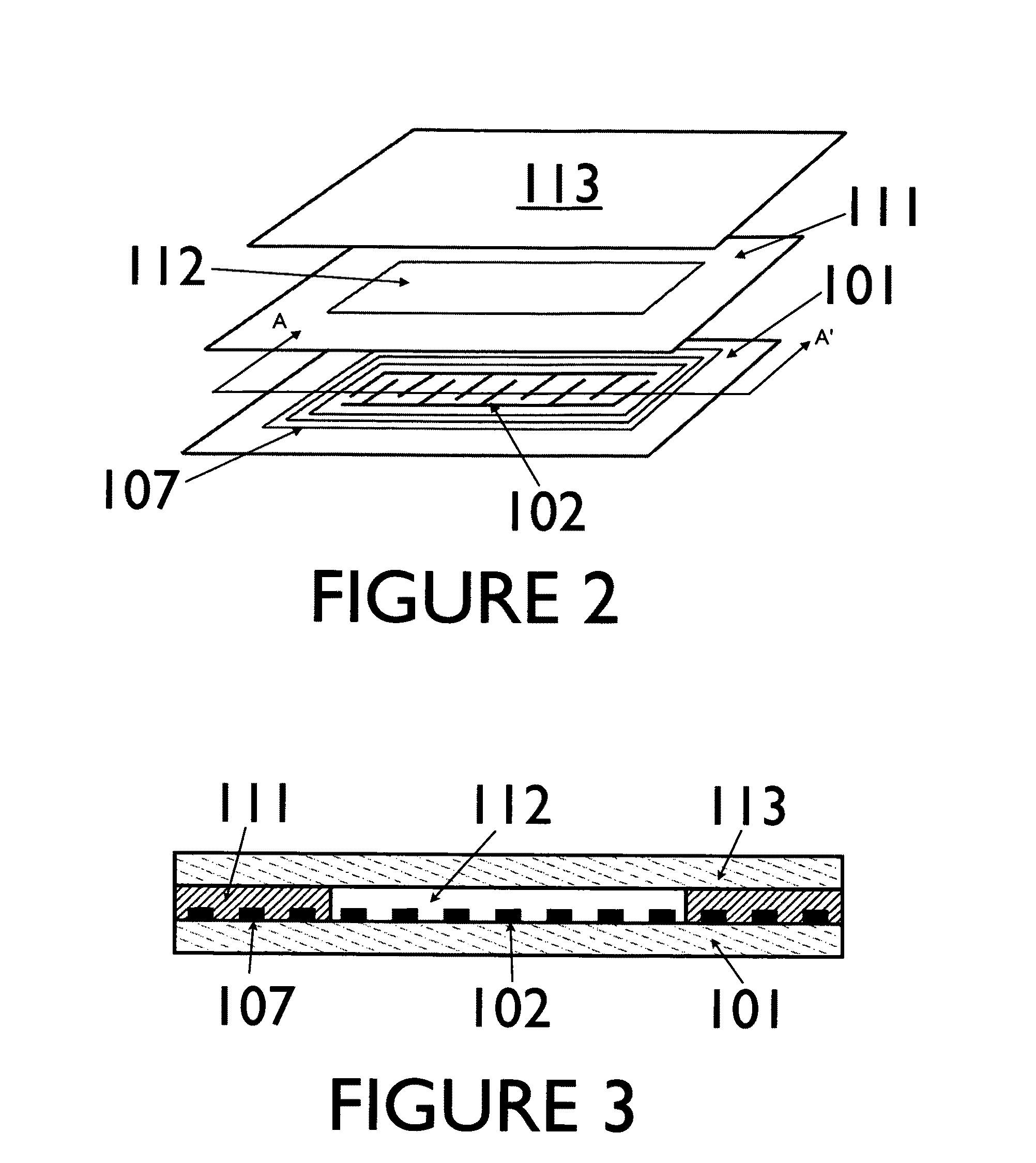

High sensitivity passive wireless strain sensor

ActiveUS8104358B1Easy to manufactureStable characteristicsFluid pressure measurement by electric/magnetic elementsForce measurementCapacitanceMeasuring instrument

A high sensitivity strain sensor that utilizes a micro-scale cavity built in a multi-layer structure, with a pair of interdigitalized capacitor incorporated on one of the layers, is described in this document. The device's capacitance changes produced by unattended deformations of the cavity can be used to measure the associated strain without using any movable electrodes. The sensor can be remotely energized from a radio frequency wave sent by a reader antenna to construct a battery-free wireless instrument. Changes on the sensor's resonant frequency are remotely detected so that a strain level is measured from fluctuations in the received signal. This detection method provides a simple, reliable and sensitive technique to measure small strain changes down to the pico-scale. Materials with a highly strain-dependant permittivity are integrated in the sensor to enhance its sensitivity. The proposed sensor consists of a simple planar structure. It can be used as the main component on low-cost, accurate and highly stable strain measuring instruments capable of monitoring very small strain levels. Furthermore, the sensor is passive, may be operated wirelessly, and can, thus, be used for remote long-term embedded strain detection.

Owner:PUERTO RICO UNIV OF

High-strength bolt axial force measuring device and measuring method

InactiveCN103245452AHigh measurement accuracyReduce adverse effectsMeasurement of torque/twisting force while tighteningMeasurement deviceProper time

The invention discloses a high-strength bolt axial force measuring device and measuring method. The measuring device comprises a pull rod, an axial force sensor, a force providing part and a support; the close end of the pull rod is provided with a connecting part for being connected with a high-strength bolt thread end, and the close and far ends of the pull rod are provided with a first match part and a second match part respectively; the first match part is in match contact with the close end face of the axial force sensor, the second match part and the far end of the force providing part act in a match mode, the far end of the support is mounted between the force providing part and the axial force sensor, and the close end of the support is used for being supported on a part connected with a high-strength bolt; and the high-strength bolt axial force measuring device also comprises a strain measuring part arranged on a nut. The measuring method comprises the steps of (1) mounting the strain measuring part on the axial outer face of the nut; 2, connecting the pull rod with the thread end of the high-strength bolt in the match mode; and 3 starting the force providing part to read the value of the axial force sensor at proper time according to the changing condition of the stain measuring part. The high-strength bolt axial force measuring device and method are accurate in measuring by directly measuring the axial force of the high-strength bolt.

Owner:LONGYUAN BEIJING WIND POWER ENG TECH

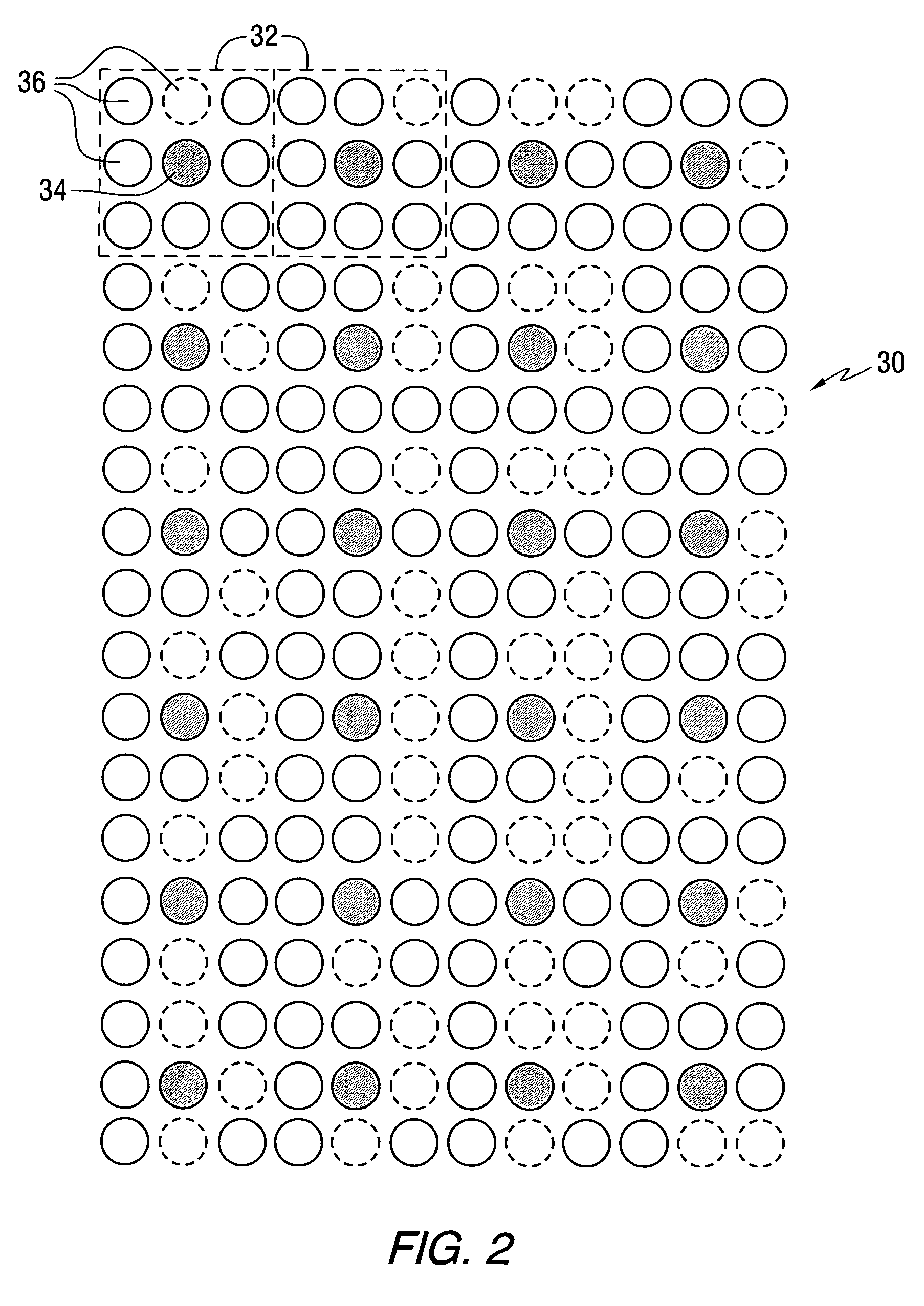

In-situ large area optical strain measurement using an encoded dot pattern

ActiveUS20070209447A1Force measurement by measuring optical property variationTest sampleComputational physics

Owner:NORTHROP GRUMMAN SYST CORP

High-low temperature dynamic cold-hot circulation thermodynamic test system

InactiveCN102879278ARealize two-way cooling and heating cycleLow temperatureMaterial strength using tensile/compressive forcesLiquid nitrogen containerEngineering

The invention discloses a high-low temperature dynamic cold-hot circulation thermodynamic test system suitable for mechanics performance testing under a high-low temperature environment. A test box adopts a design of an inner cavity and an outer cavity; inner and outer cavity baffles are provided with four air outlets from top down and air suction holes in the center; the test box further comprises an optical strain observation window, a defrosting air heater and a multi-point direct-current illumination source; and in addition, the test system further comprises a dual-output PID (Proportion Integration Differentiation) controller, a DIC (Digital Image Correlation) full strain measurement instrument and an automatic switchover liquid nitrogen refrigerating system. According to the high-low temperature dynamic cold-hot circulation thermodynamic test system, the defects that the conventional thermal steady state test system has no thermal transient state and thermal circulation functions and liquid nitrogen cannot be fed without interruption due to limitation of liquid nitrogen container volume on low-temperature refrigeration are solved, and the technical problems of interference and the like of high-temperature hot wave impact and low-temperature frost fog on full strain measurement are solved at the same time, so that the purposes of obtaining the mechanical performance of a test material under the high-low temperature environment in the processes of thermal steady state, thermal transient state, cold-hot circulation and the like and synchronously measuring a sample strain field are achieved.

Owner:TSINGHUA UNIV

Interpretation of Real Time Compaction Monitoring Data Into Tubular Deformation Parameters and 3D Geometry

A method, apparatus and computer-readable medium for determining a deformation strain distribution of a member corresponding to a selected deformation mode is disclosed. Strain measurements are obtained at a plurality of sensors, wherein each strain measurement is related to a strain at a location of the member. A component of the strain related to a selected deformation mode for the obtained strain measurements is determined and a principal strain component and a secondary strain component for each of the determined components of the strain is determined. The determined principal strain component and secondary strain component are mapped to a surface of the member to determine the deformation strain distribution.

Owner:BAKER HUGHES INC

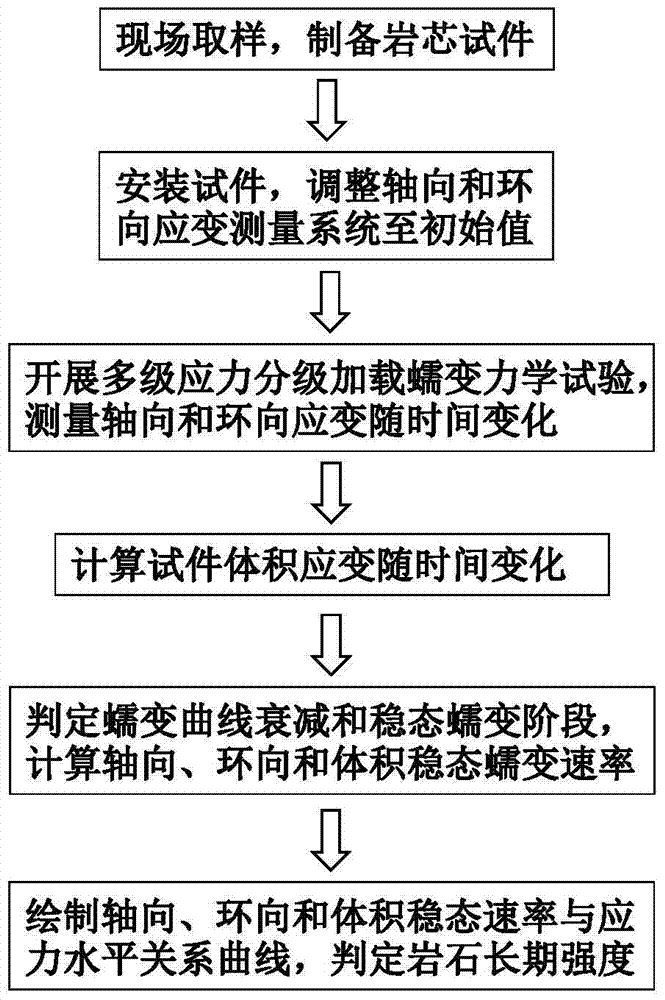

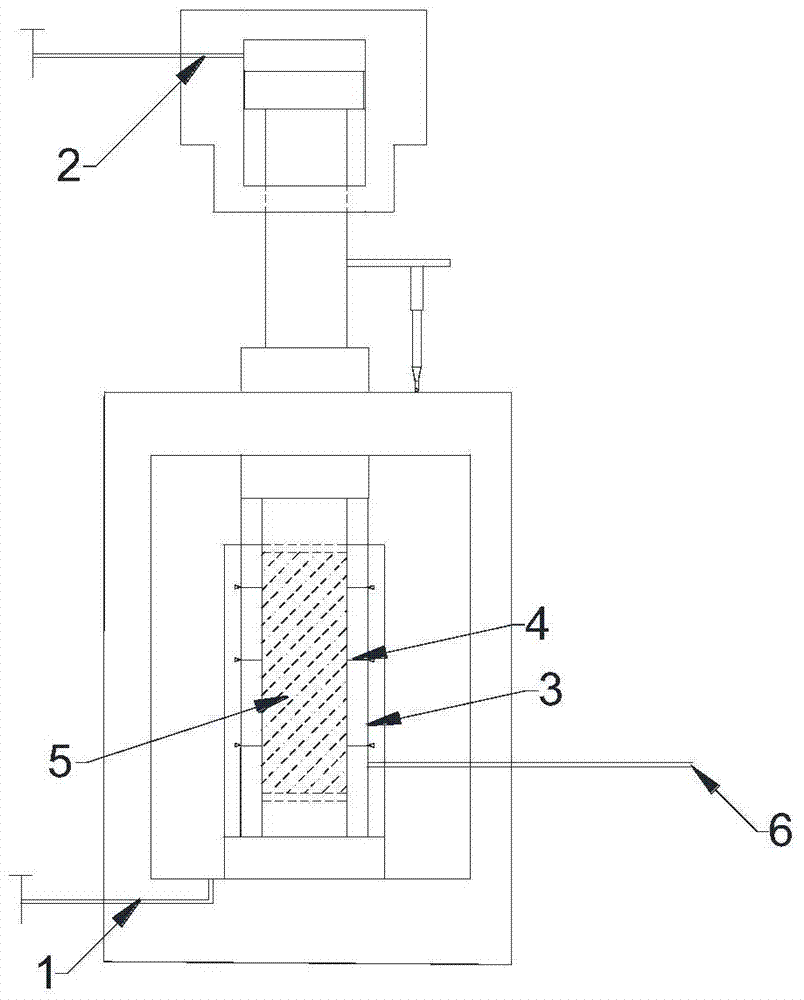

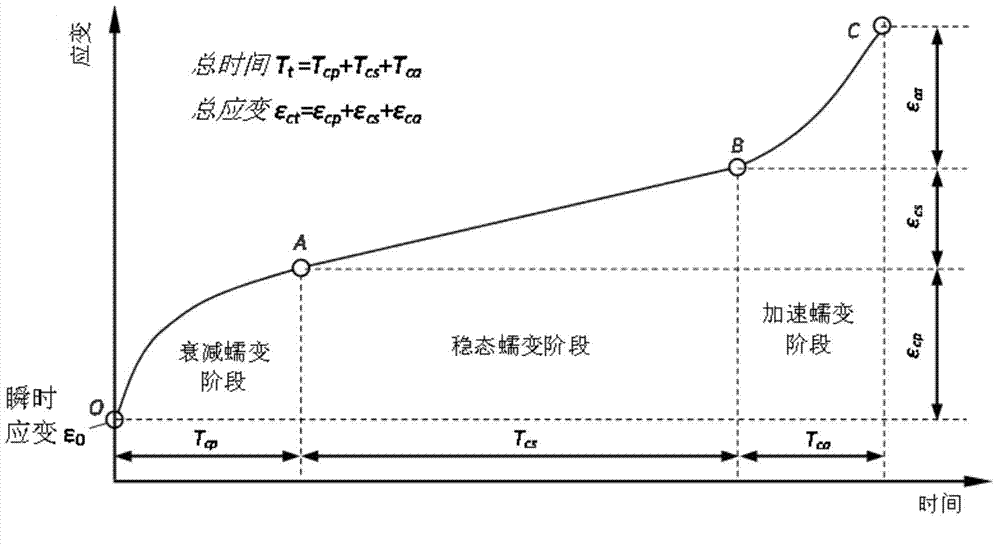

Method for determining long-period strength of rock through multistage stress staged loading creep mechanic test

InactiveCN104849134ARemove subjective judgmentThe method is simple and reliableStrength propertiesRock coreTemporal change

The invention discloses a method for determining the long-period strength of rock through a multistage stress staged loading creep mechanic test. The method comprises the following steps that the in-site sampling is carried out, and a rock core test piece is manufactured; the test piece is arranged into a rock three-axis rheological mechanic test instrument, and an axial stress and annular stress system is regulated to an initial value; the test piece is subjected to multistage stress staged loading creep mechanic test in a stress load control mode until a specimen is damaged, and in the process, the change of the axial compression stress and the annular volume expanding stress along with the time in the whole test process under the effects of different stress is measured; the change of the size of the test piece along with the time is calculated; a rock creep curve is drawn, and the weakening creeping stage and the steady-state creep stage of the creep curve under the effect of each stage stress load are judged; the steady-state creep speed under the effect of each stage of stress load is calculated, the relationship curve of the change of the axial, annular and size steady-state creep speed along with the stress level is drawn, a crossing point is determined, and the stress corresponding to the crossing point is the long-period intensity of the rock.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

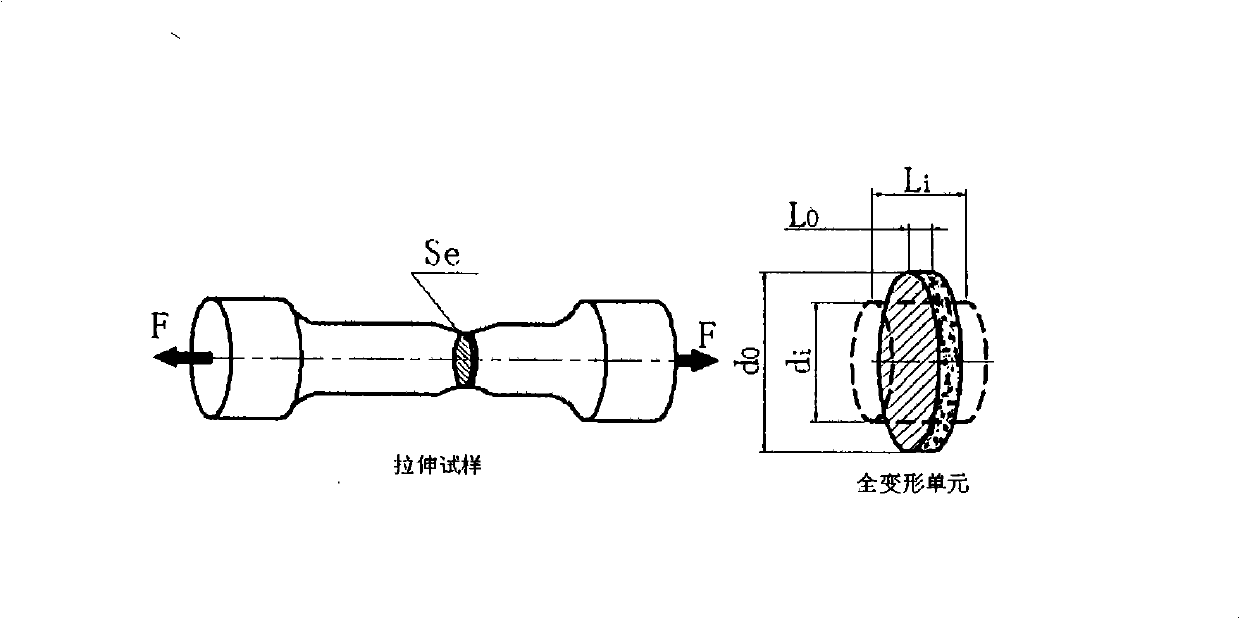

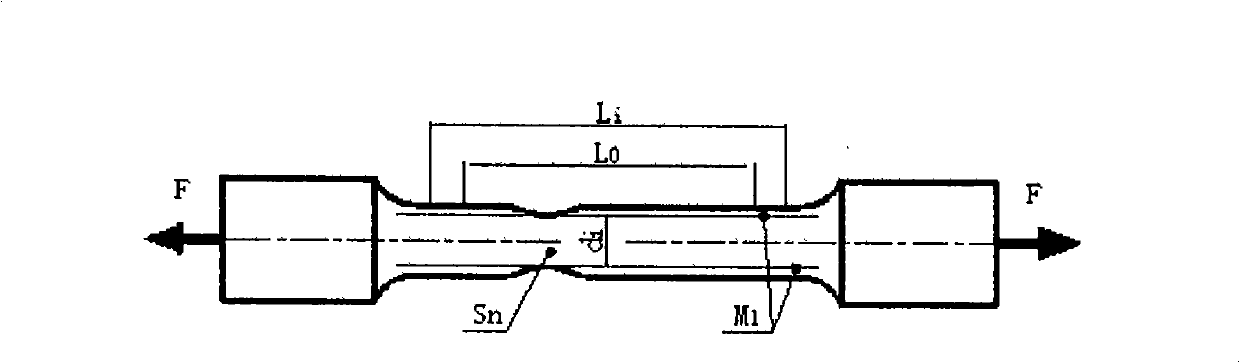

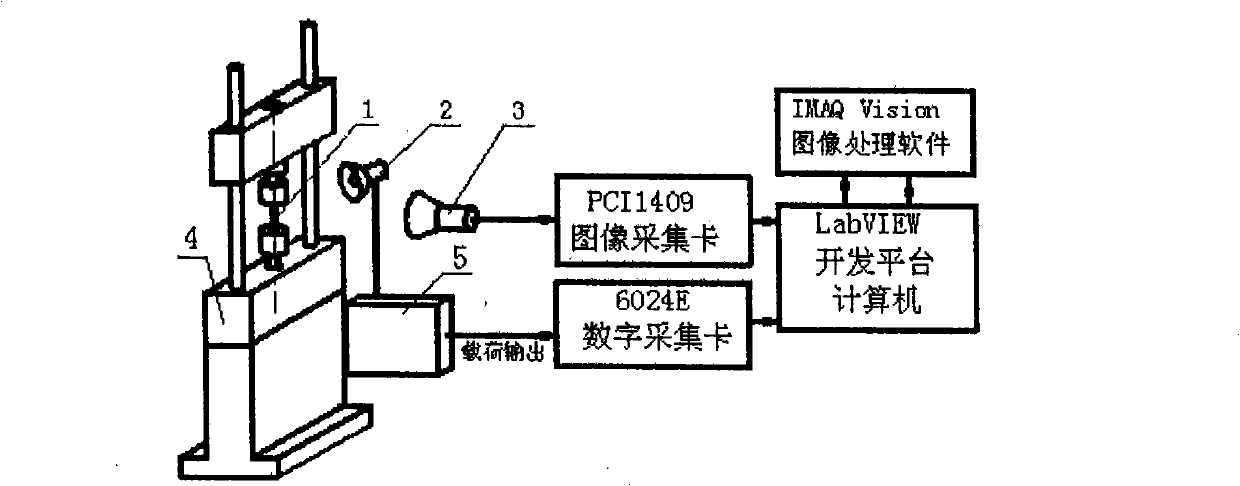

True stress-true strain computation model and test system

InactiveCN101319977AAccurate performance characteristics of mechanical behaviorExpress mechanical behavior characteristicsSpecial data processing applicationsStrength propertiesVisual technologySoftware system

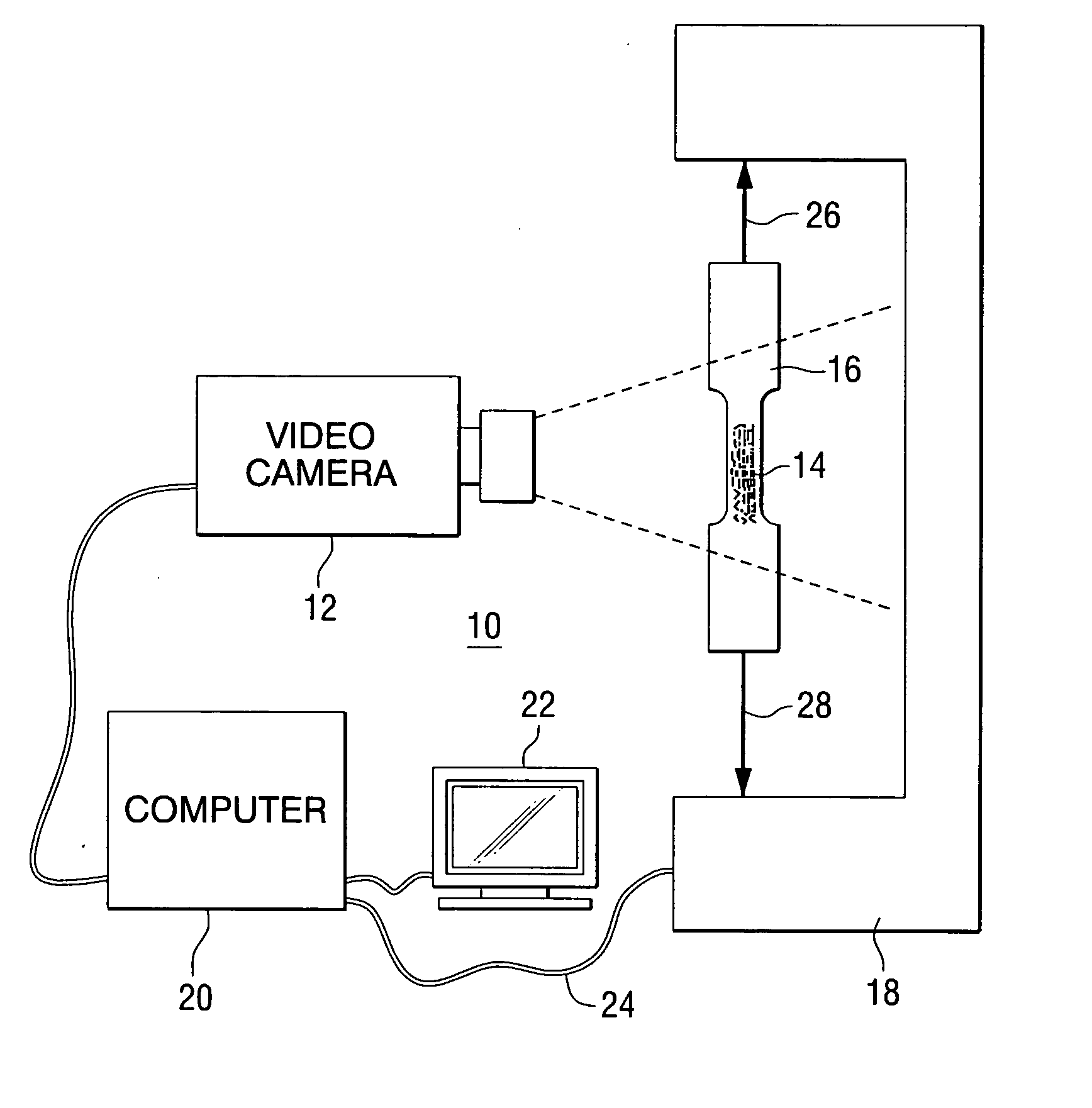

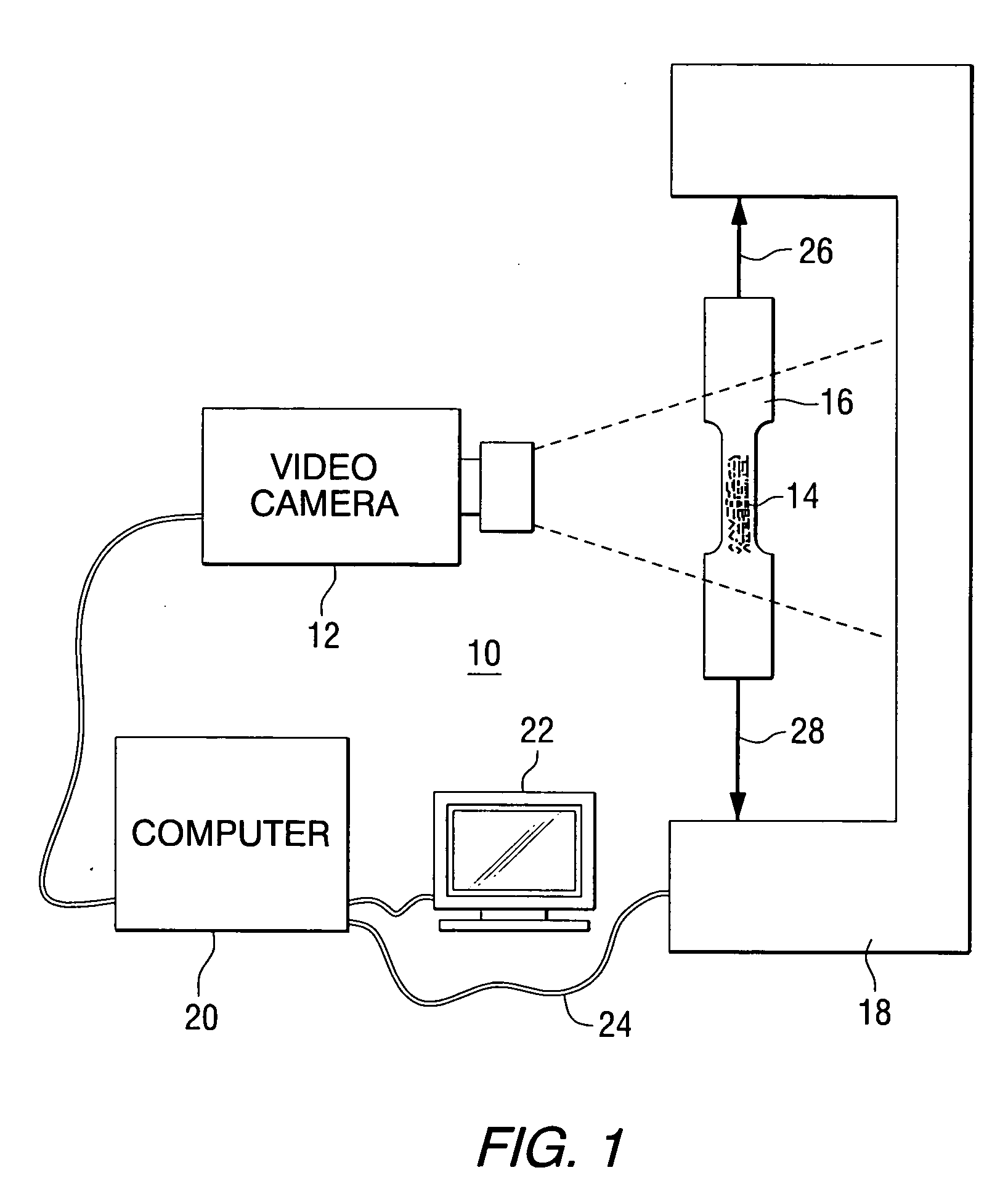

The invention researches the substantive characteristics of material deformation to aim at the practical problem of measuring real stress-real strain and discloses a real stress-real strain calculating model and a practical testing system: 1, based on the analysis on the deformation of a tension specimen, taking a unit body the special part of which is provided with characteristics as the object for the stress-strain analysis, building a unique full-deformation unit model, firstly solving the theory analysis problem of real stress-real strain, establishing a theory foundation and building a novel real stress-real strain calculating formula: Sigma i is equal to 4Fi / Pi d<2>I and Epsilon is equal to (d<2>0 / d<2>i) minus 1; 2, adopting a machine visual technology and an image processing method to develop a practical software system and a practical hardware system that are compatible with the machine visual technology and the image processing method, and realizing the direct non-contact real stress-real strain measuring in real meaning; 3, the testing system includes a light source (1), CCD camera (2), an image acquisition card (3), a data acquisition card (4) and a material testing machine (5); 4,the software includes image capturing program, load data acquisition program and comprehensive calculation analysis program.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com