Patents

Literature

381 results about "Cement sheath" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

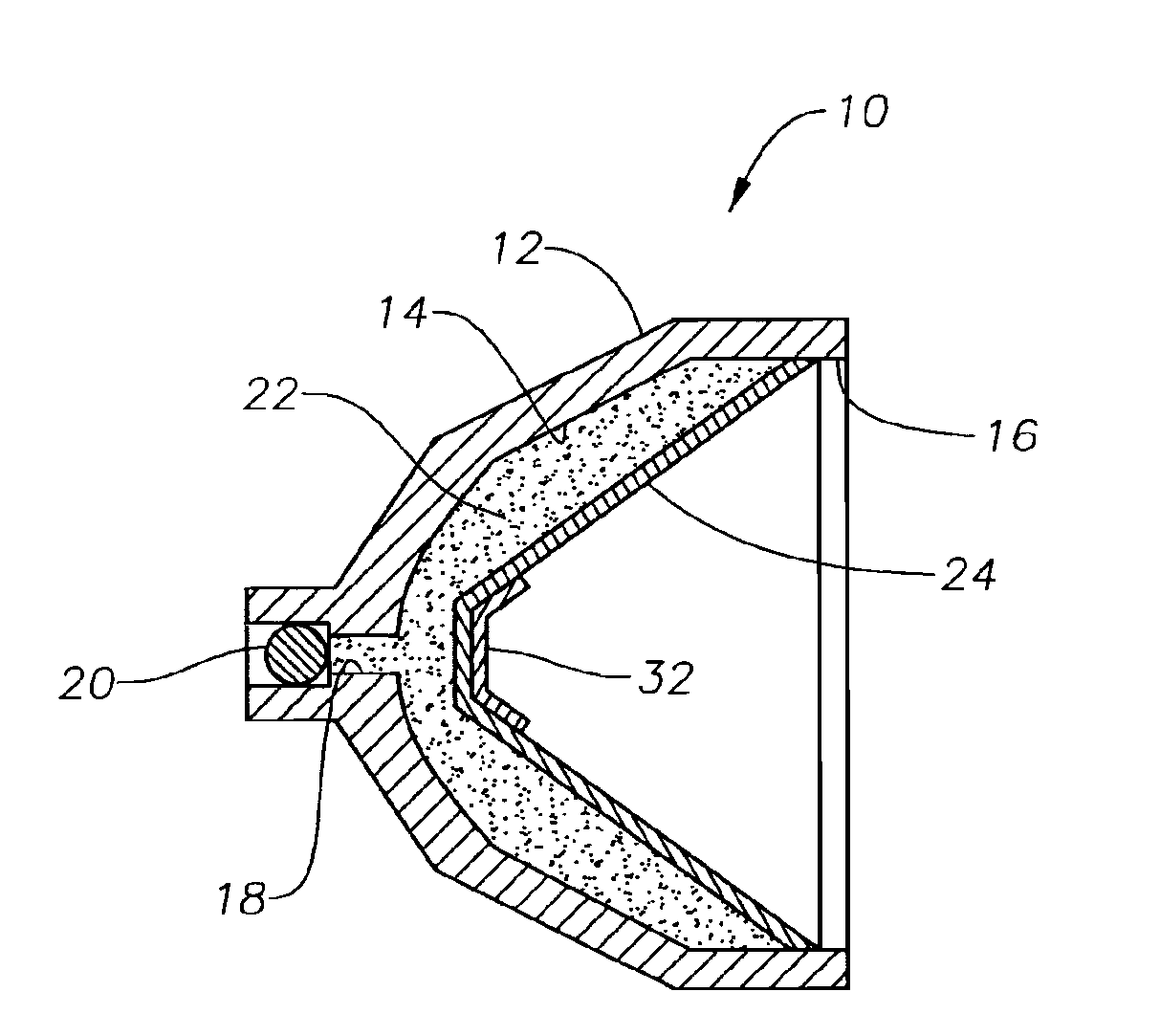

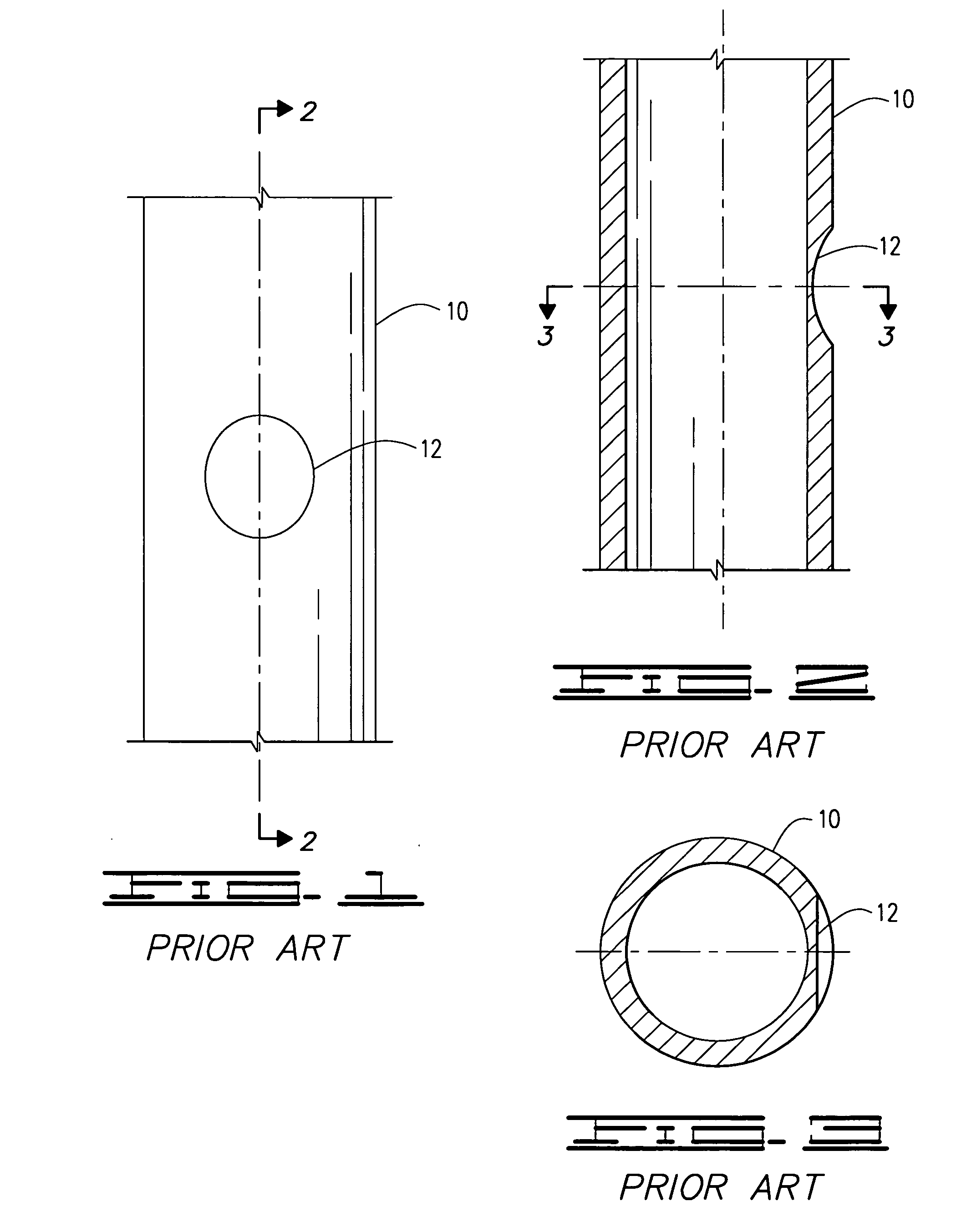

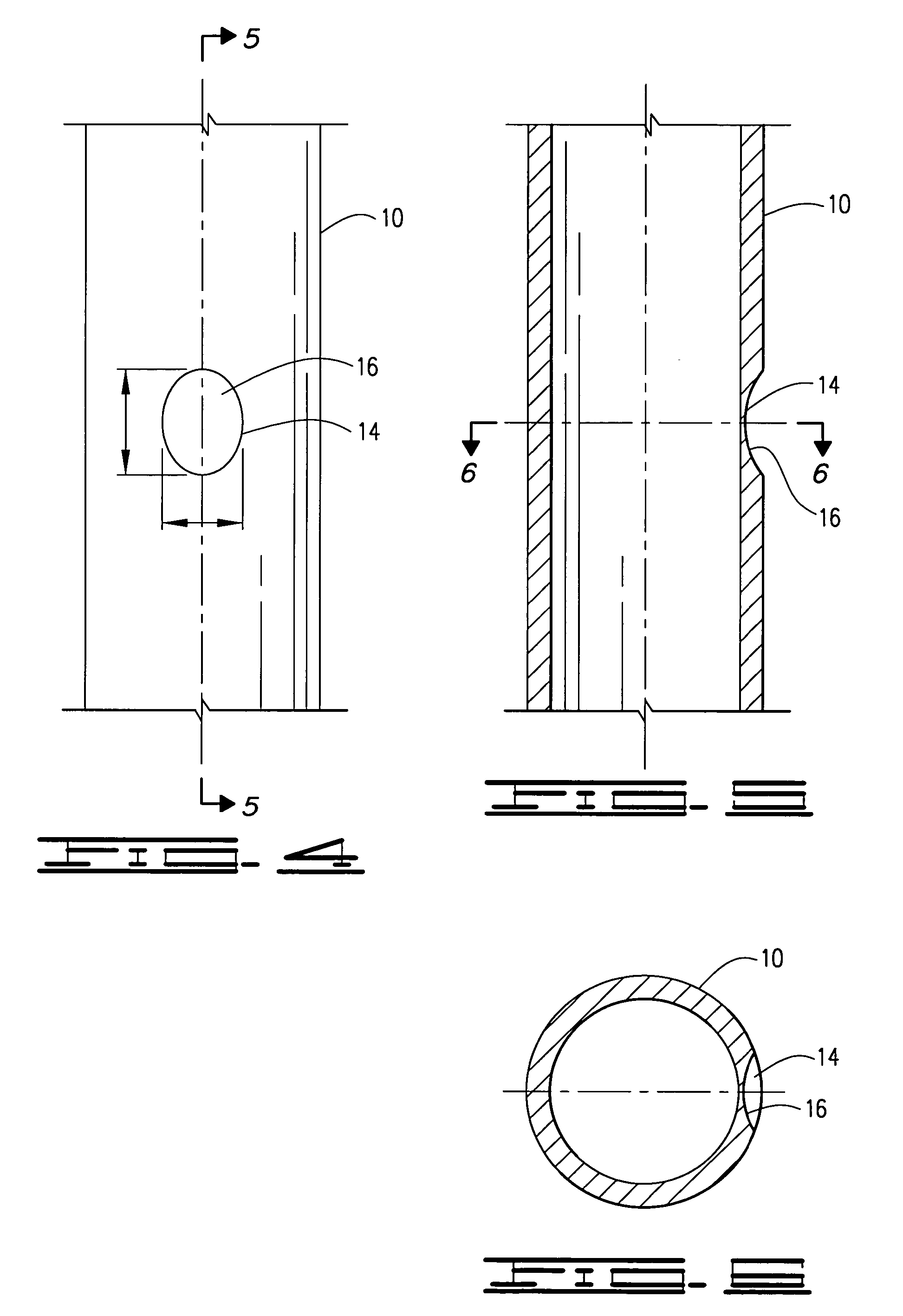

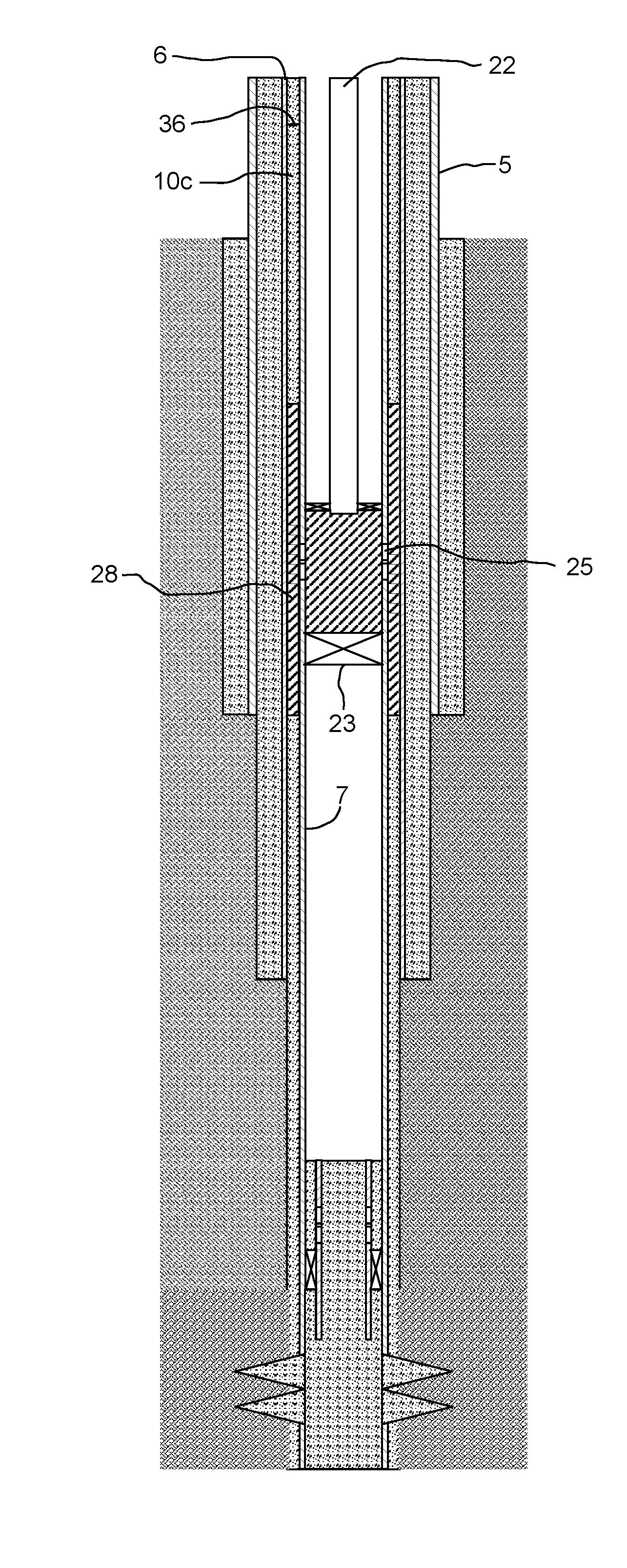

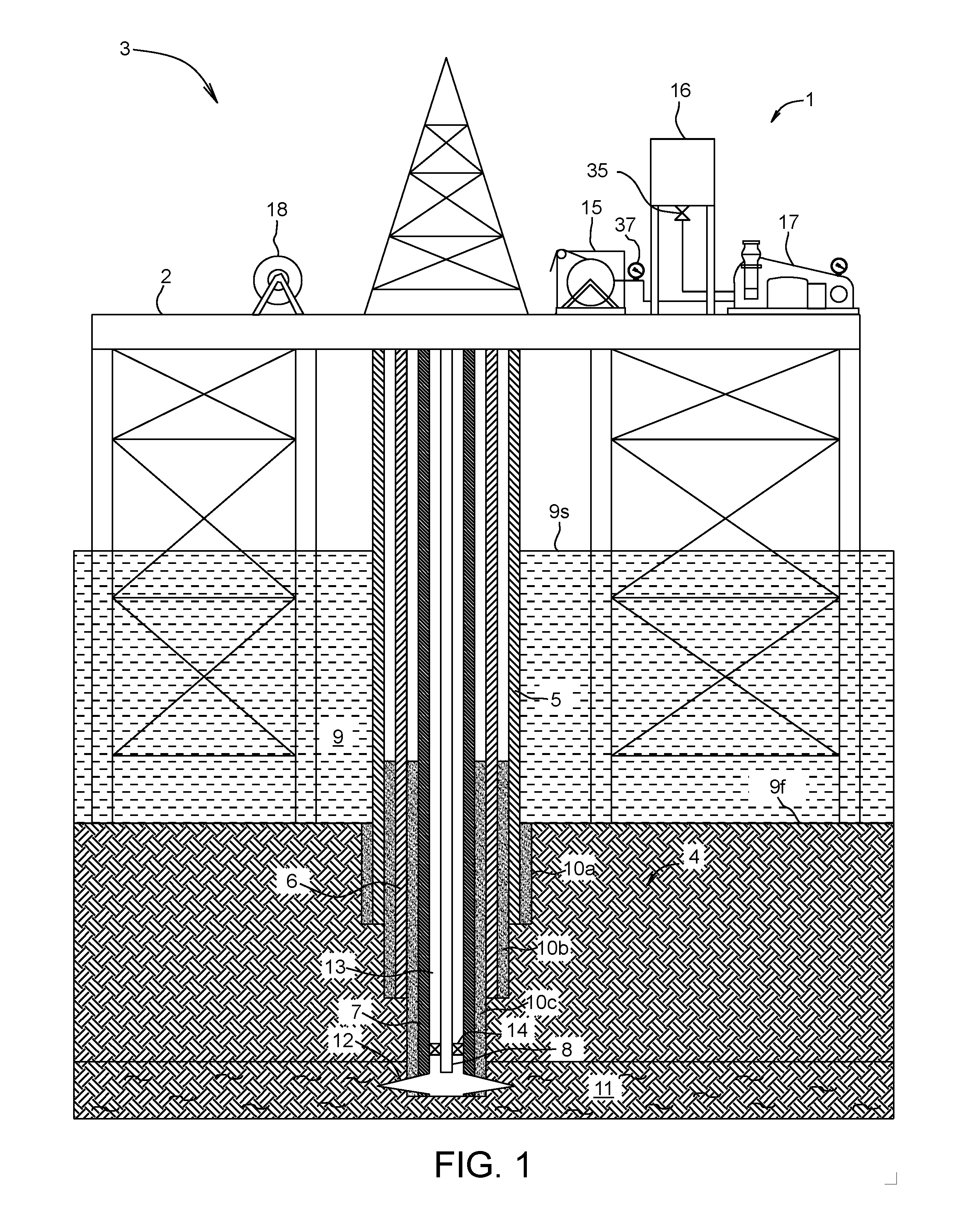

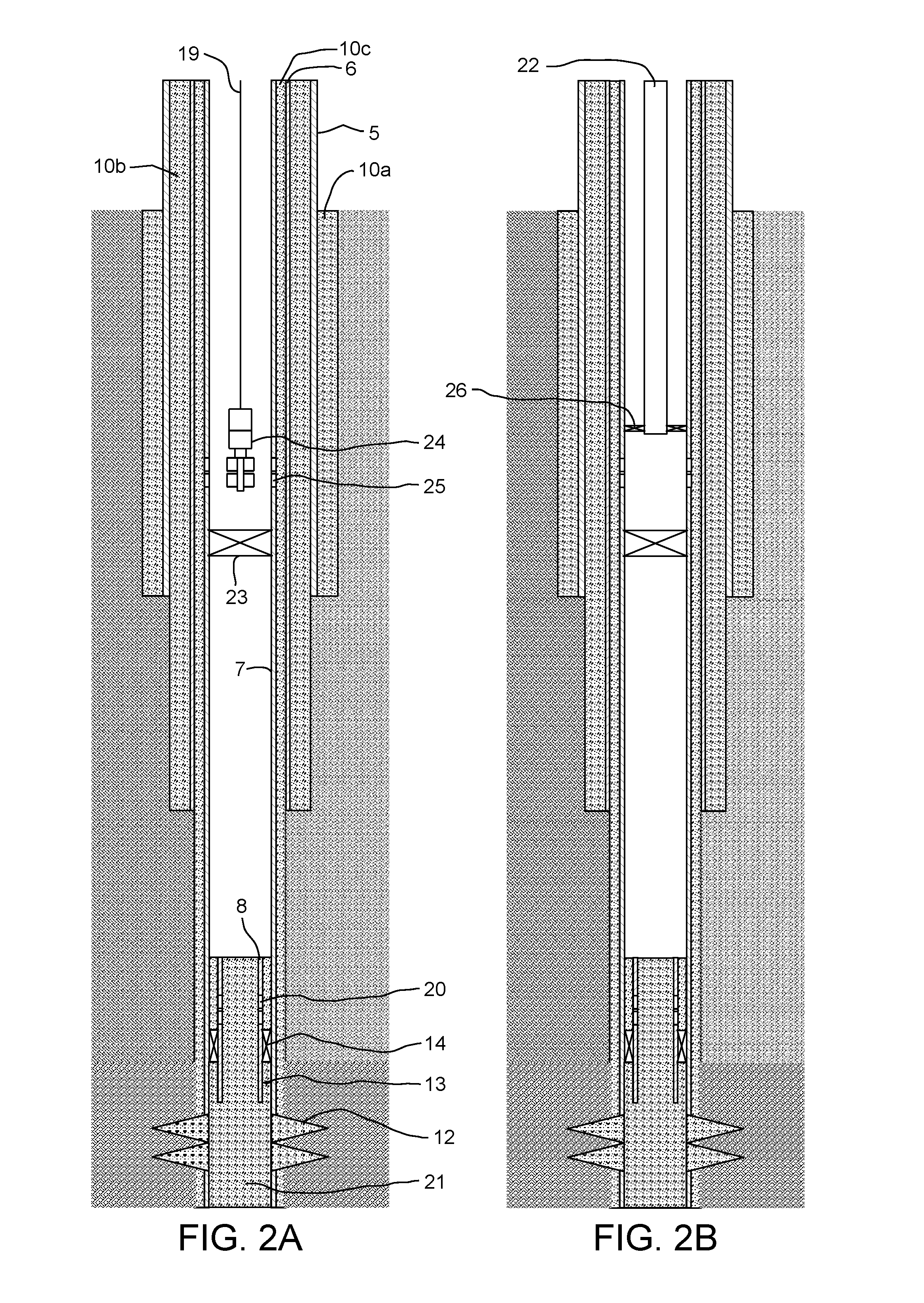

Methods and Apparatus for Completing a Well

ActiveUS20070017675A1Avoid enteringEasy to produceDrilling rodsFluid removalFracture zoneSand filter

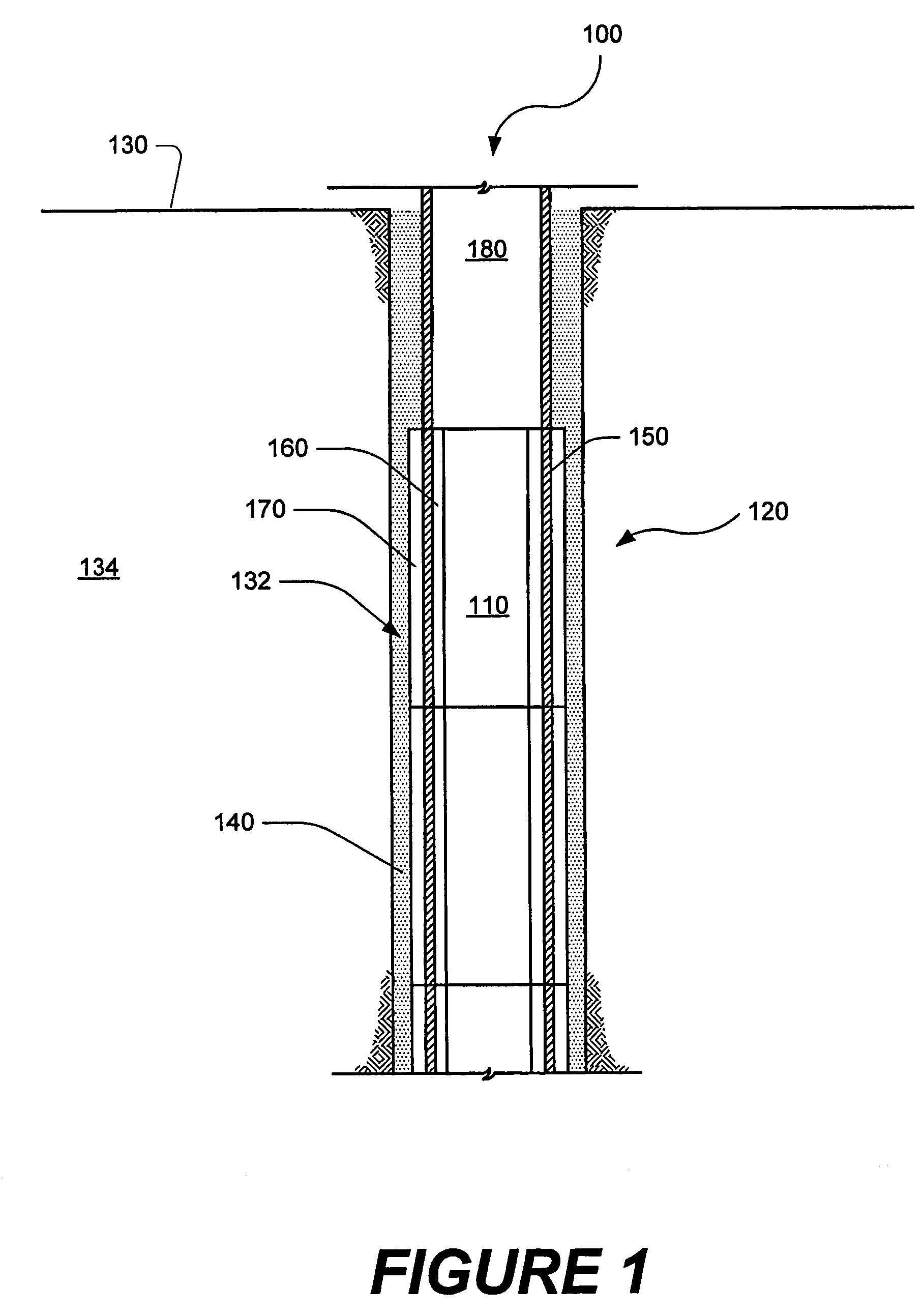

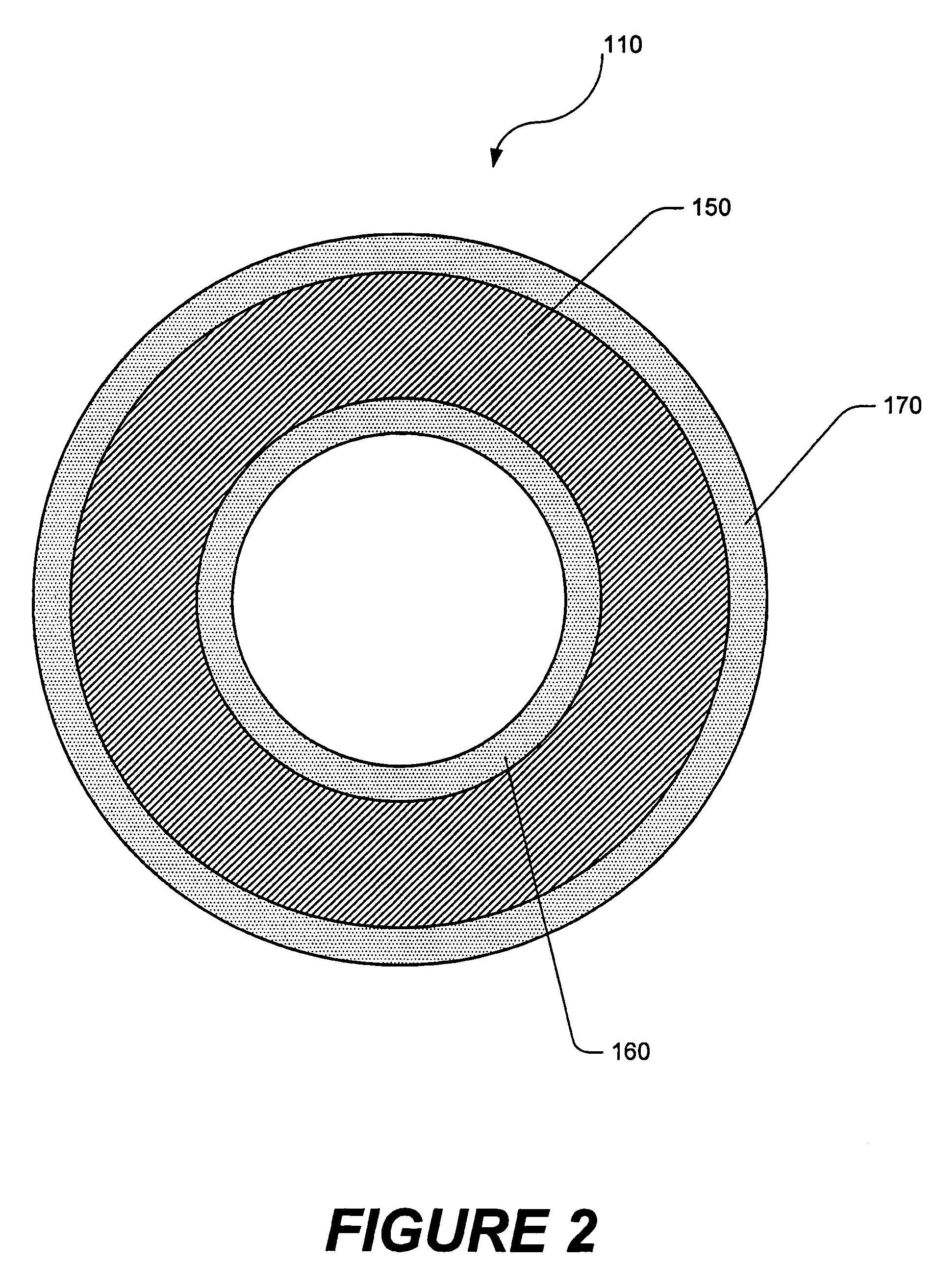

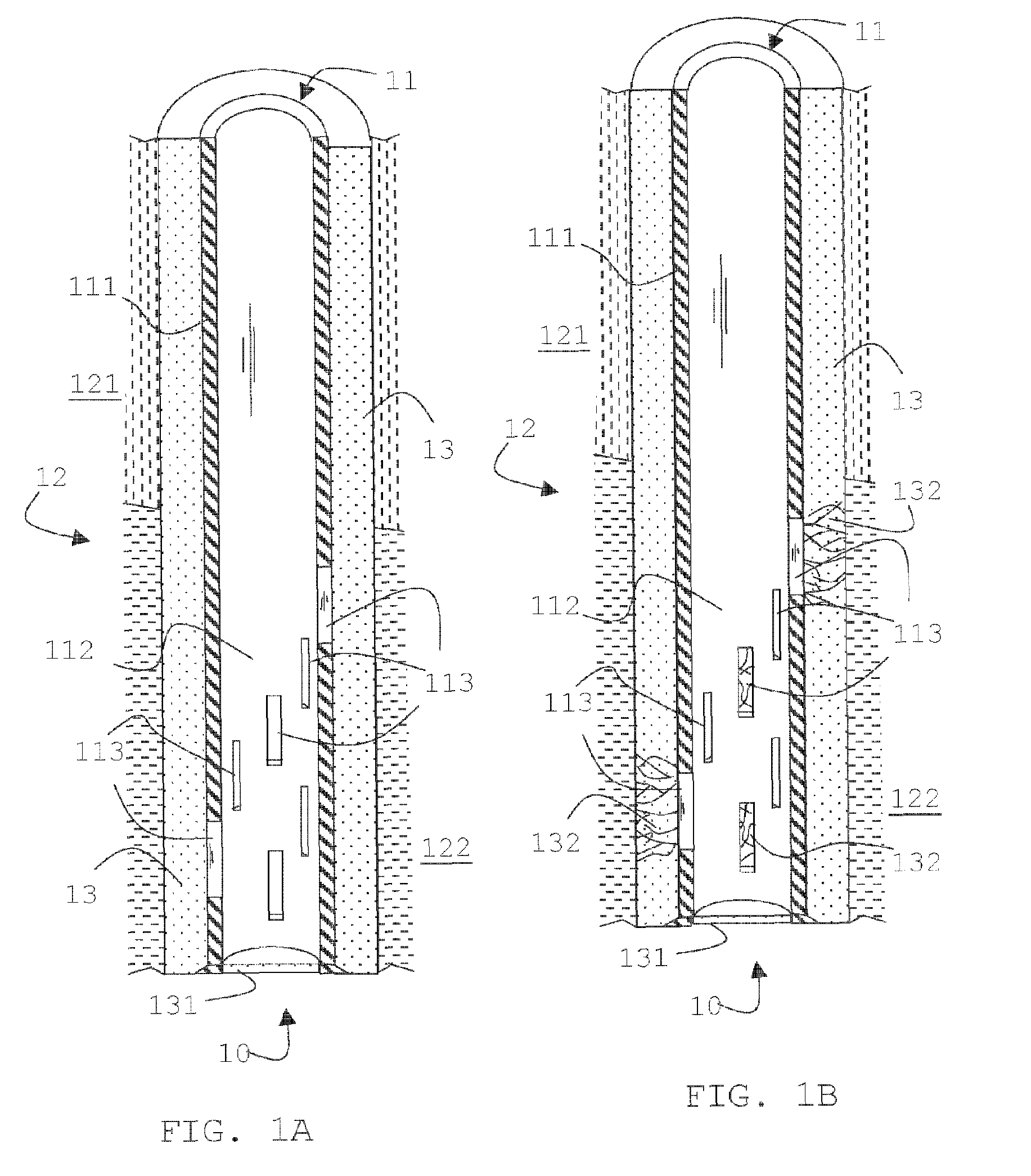

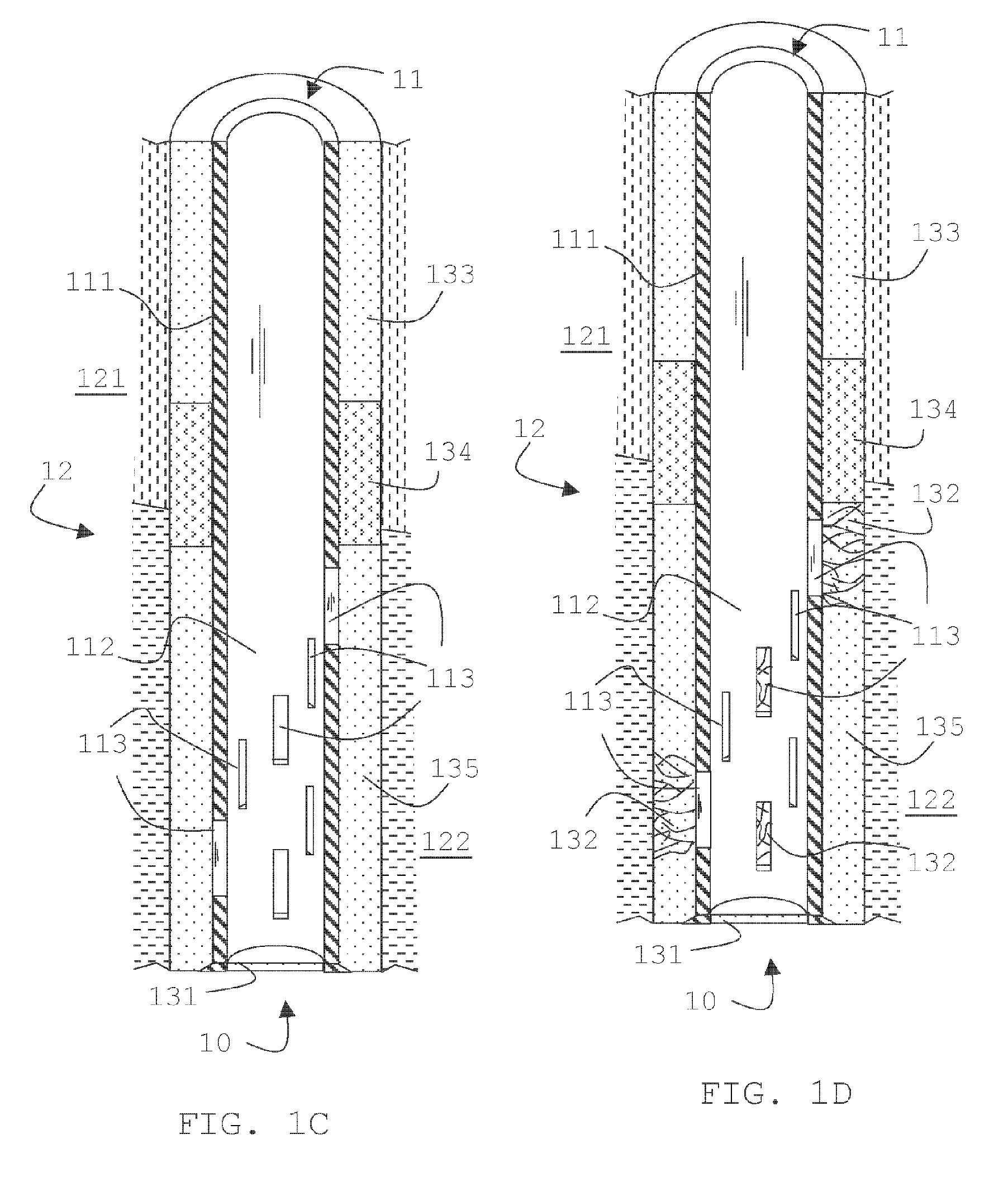

Methods and tools are described to reduce sanding including the steps of fracturing the cement sheath in a localized zone around the casing and having the fractured zone act as sand filter between the formation and openings in the casing, with the openings being best pre-formed but temporarily blocked so as to allow a conventional primary cementing of the casing. The fracturing step can also be used for remedial operation to reopen blocked formation or screens.

Owner:SCHLUMBERGER TECH CORP

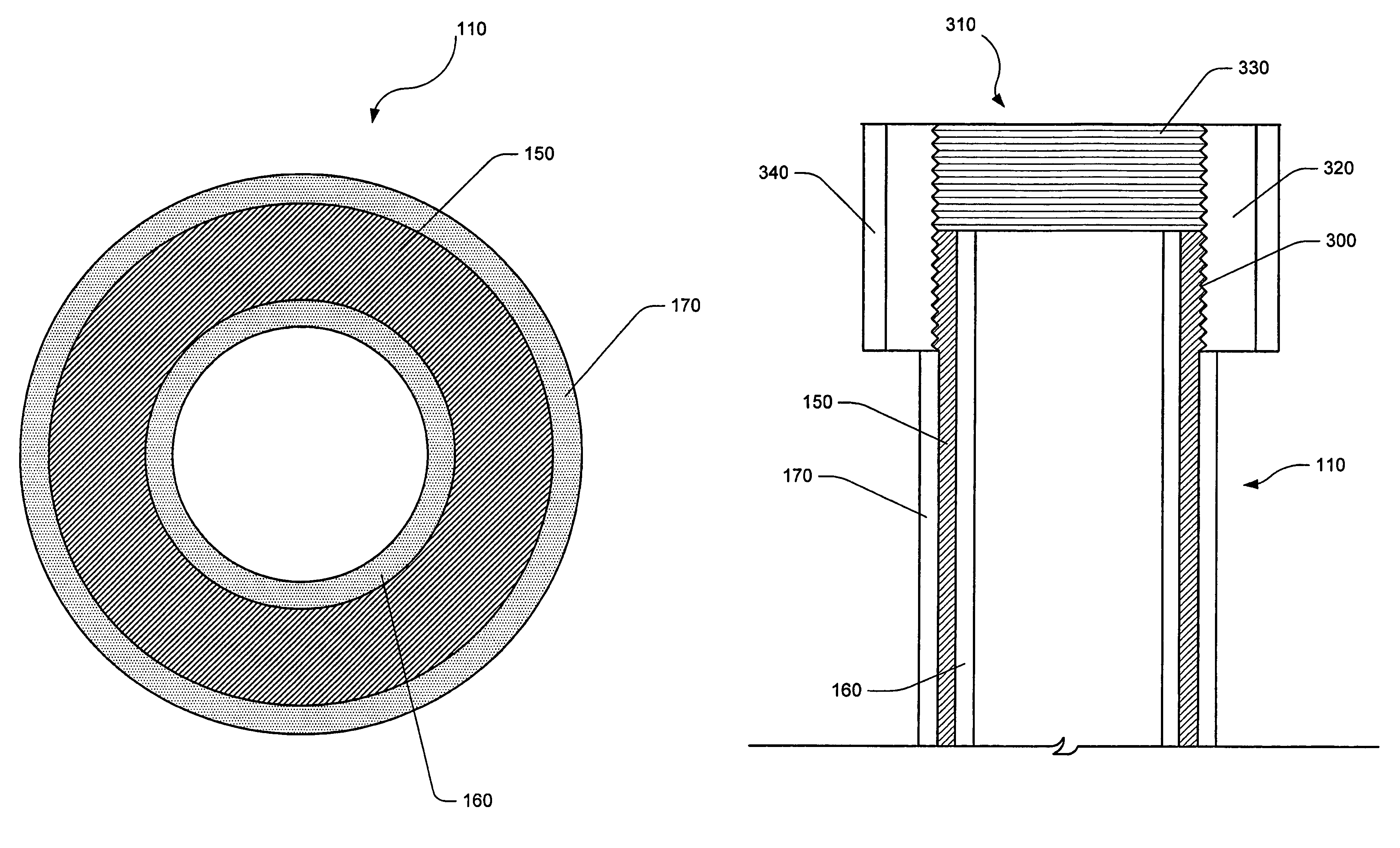

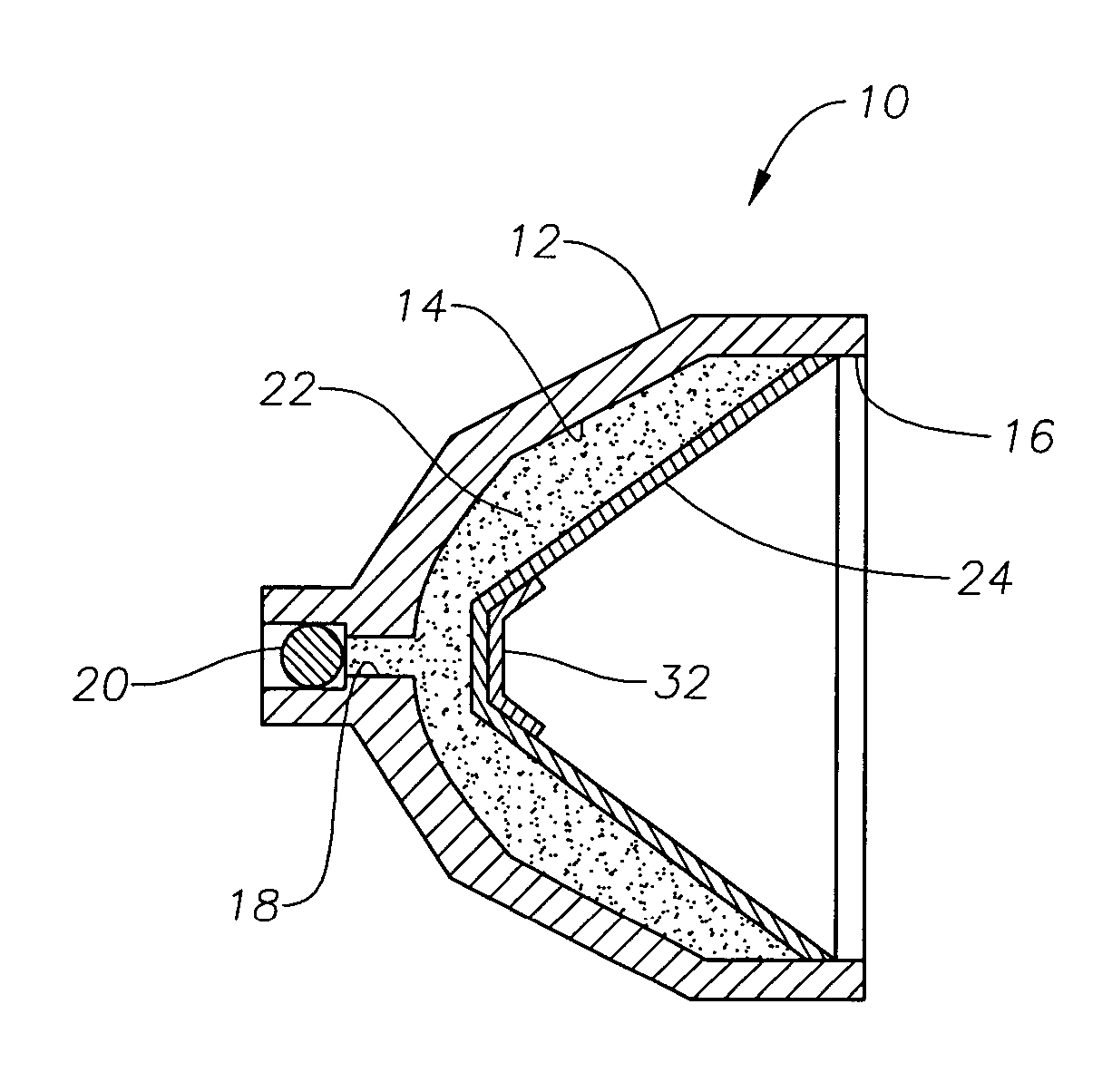

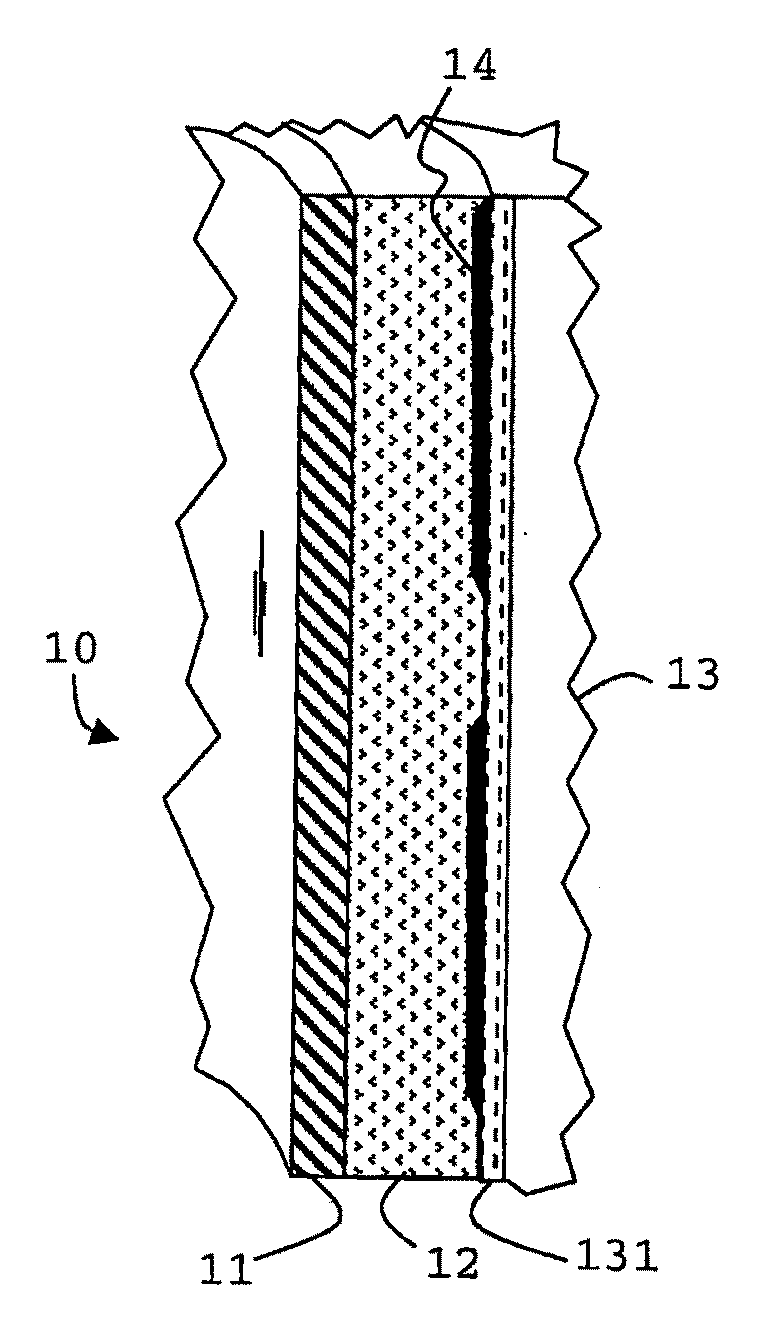

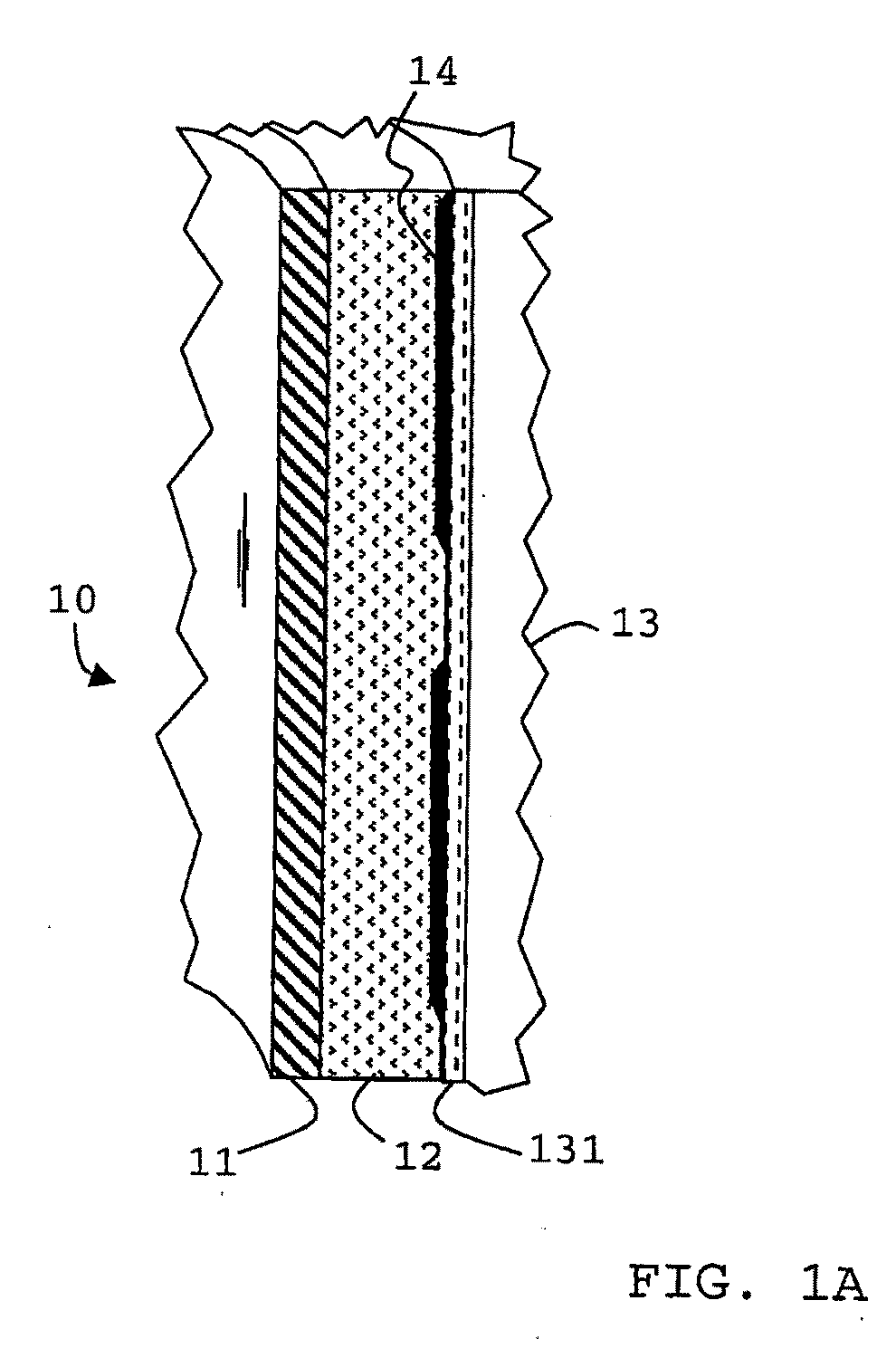

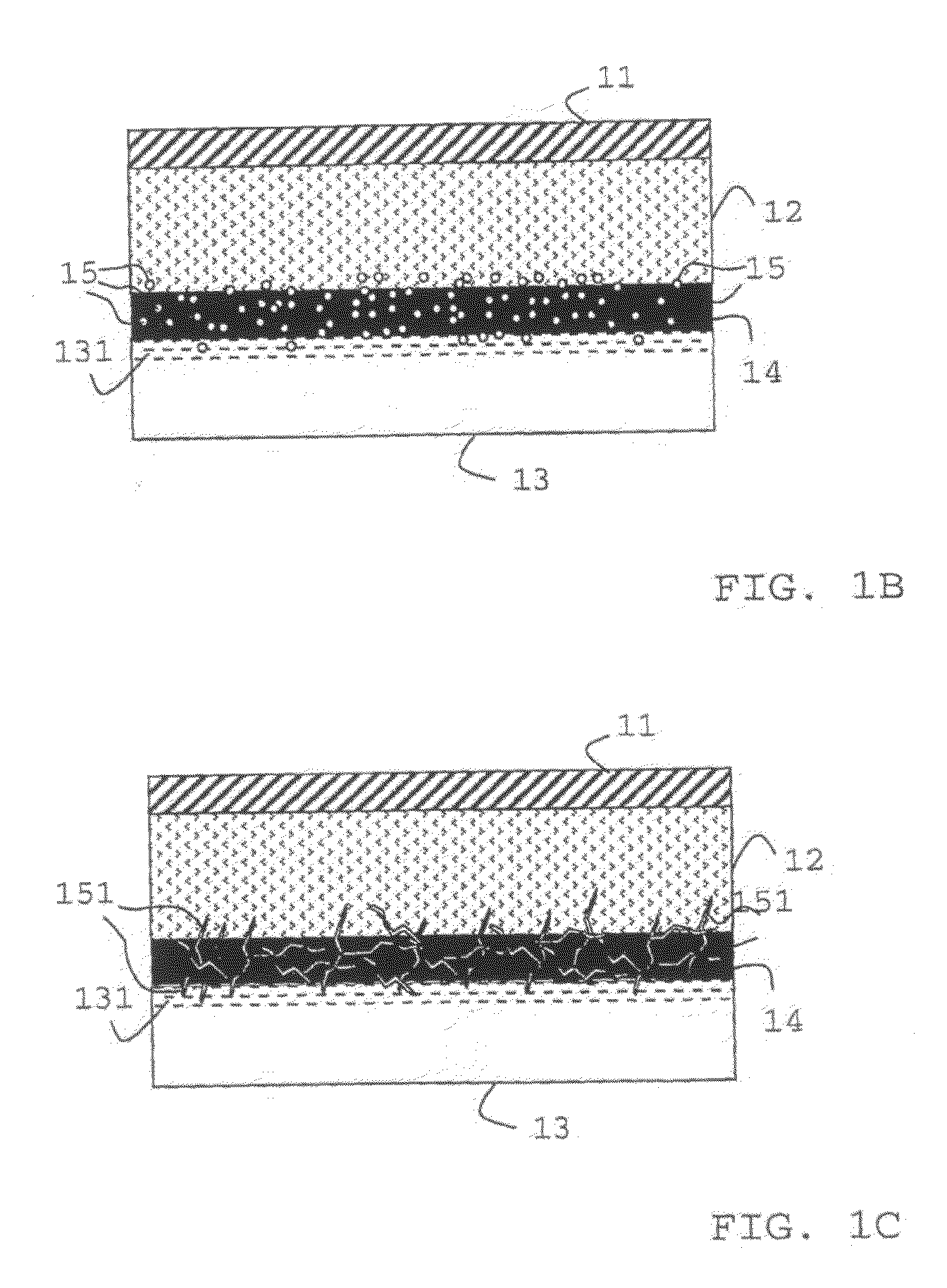

Casing comprising stress-absorbing materials and associated methods of use

The present invention relates to subterranean drilling and well completion operations, and more particularly, to improved casing that comprises stress-absorbing materials and associated methods of use. In some embodiments, the present invention discloses methods of casing a well bore that comprise the steps of providing a casing that comprises a stress-absorbing material; and placing the casing into the well bore. In other embodiments, the present invention provides improved casing that comprises stress-absorbing materials and methods of reducing the transmission of stress from a casing to a cement sheath.

Owner:HALLIBURTON ENERGY SERVICES INC

Cement Compositions and Methods of Using the Same

The present invention relates to cement compositions and their use in cementing operations. The cements comprise an aluminosilicate; a sodium aluminate, a calcium aluminate, a potassium aluminate, or a combination thereof; and water. In some cases the cement does not include Portland cement. The cement may be used in a subterranean formation having corrosive components therein, wherein the set cement sheath is resistant to degradation from the corrosive components within the subterranean formation.

Owner:HALLIBURTON ENERGY SERVICES INC

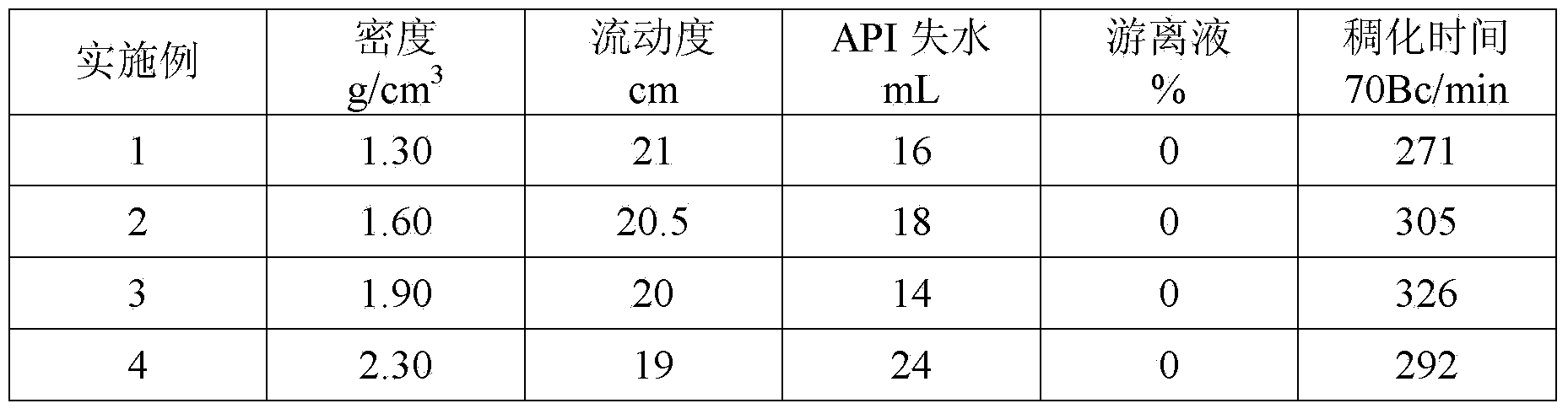

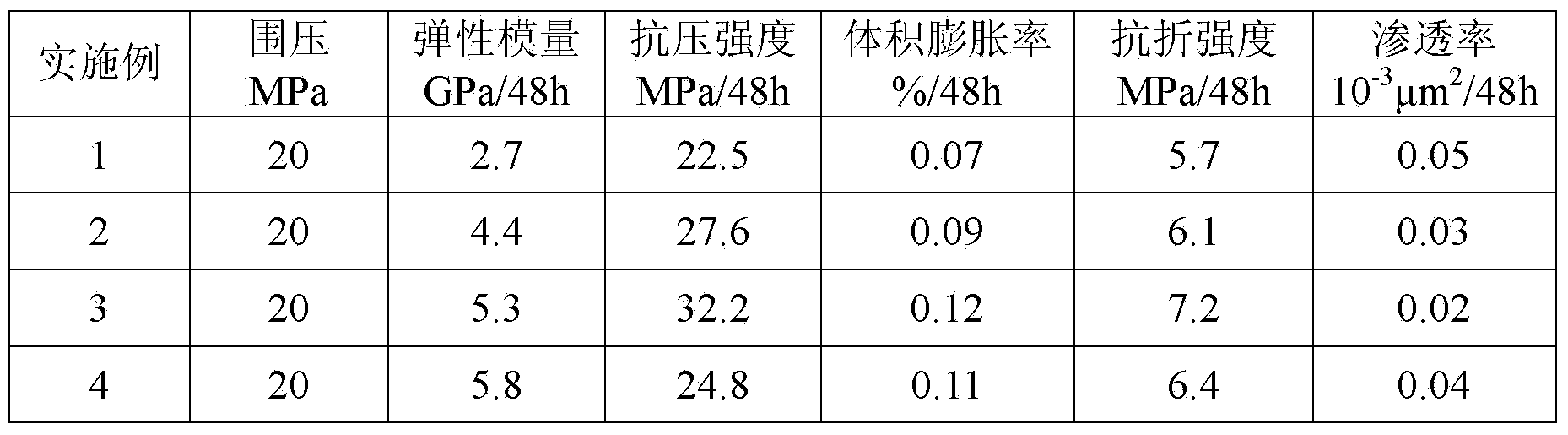

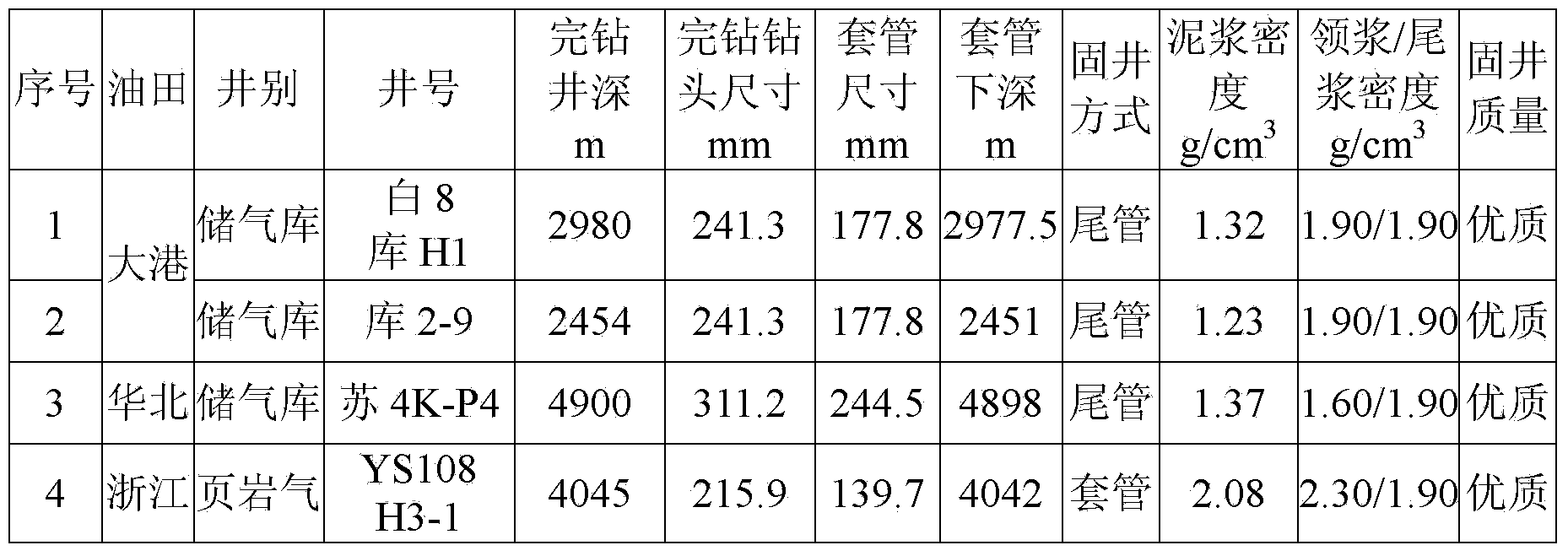

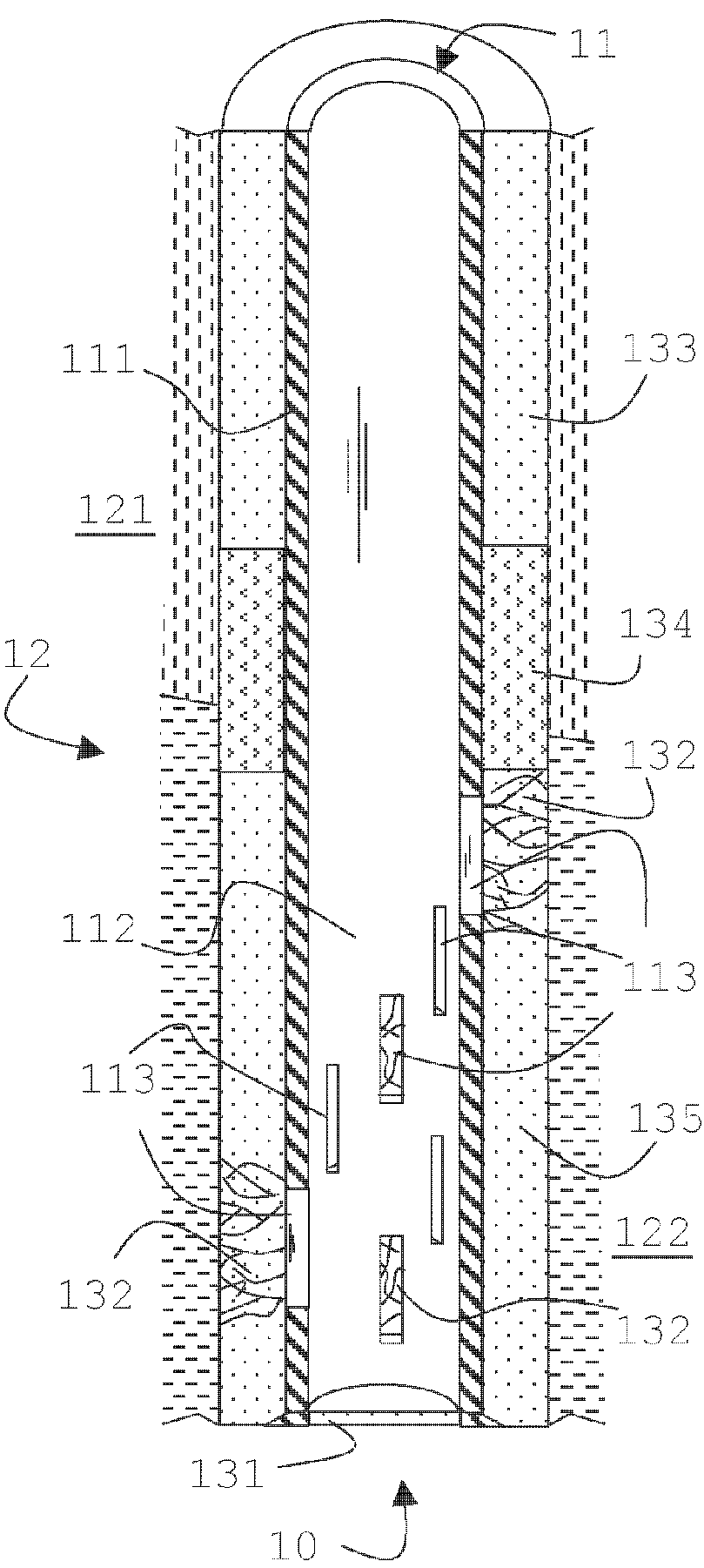

Expanded flexible well cementing grout and preparation method thereof

ActiveCN104371678ALow elastic modulusLower transfer coefficientDrilling compositionHorizontal wellsVolumetric Mass Density

The invention provides an expanded flexible well cementing grout and a preparation method thereof. The grout comprises the following components in parts by weight: 100 parts of cement, 6-14 parts of toughening material, 3-80 parts of reinforcing material, 8-120 parts of density modifier, 0.5-2.5 parts of suspension stabilizer, 20-40 parts of high-temperature stabilizer, 35-100 parts of distilled water, 0.5-2 parts of dispersant, 0.5-4 parts of fluid loss agent, 0.3-4 parts of retarder, 0.1-2 parts of foam inhibitor and 0.1-2 parts of defoamer. The invention further provides a preparation method of the expanded flexible well cementing grout. The grout has good sedimentation stability; and the set cement has the characteristics of micro expansion, high strength and low elasticity modulus, and can avoid the phenomena of micro cracks, micro annuluses, even fracture and the like caused by cement sheaths in subsequent operation of gas storage wells, shale gas wells, dense oil-gas horizontal wells and the like, thus realizing good zonal isolation and providing a technical support for long-term, safe and effective operation of oil-gas wells.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

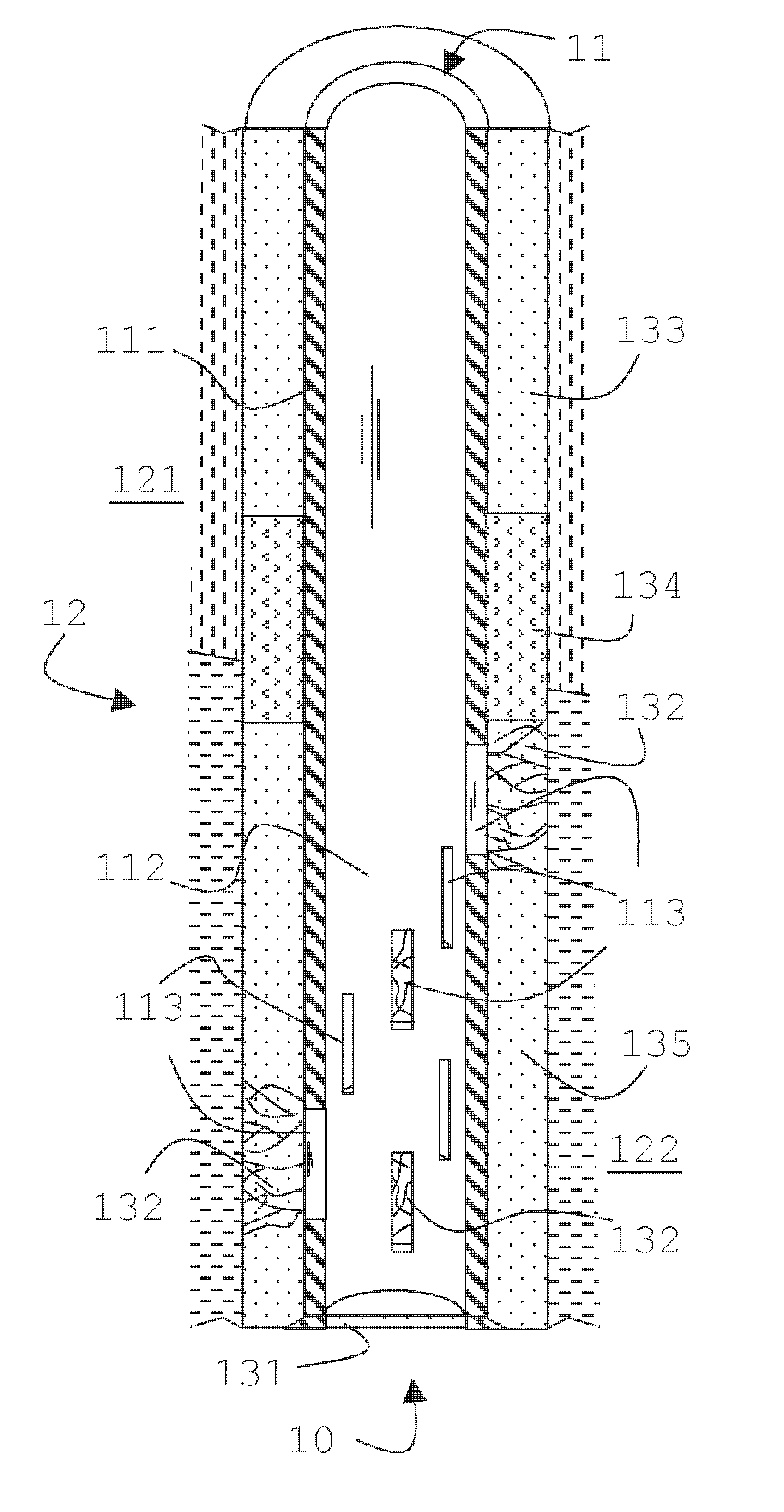

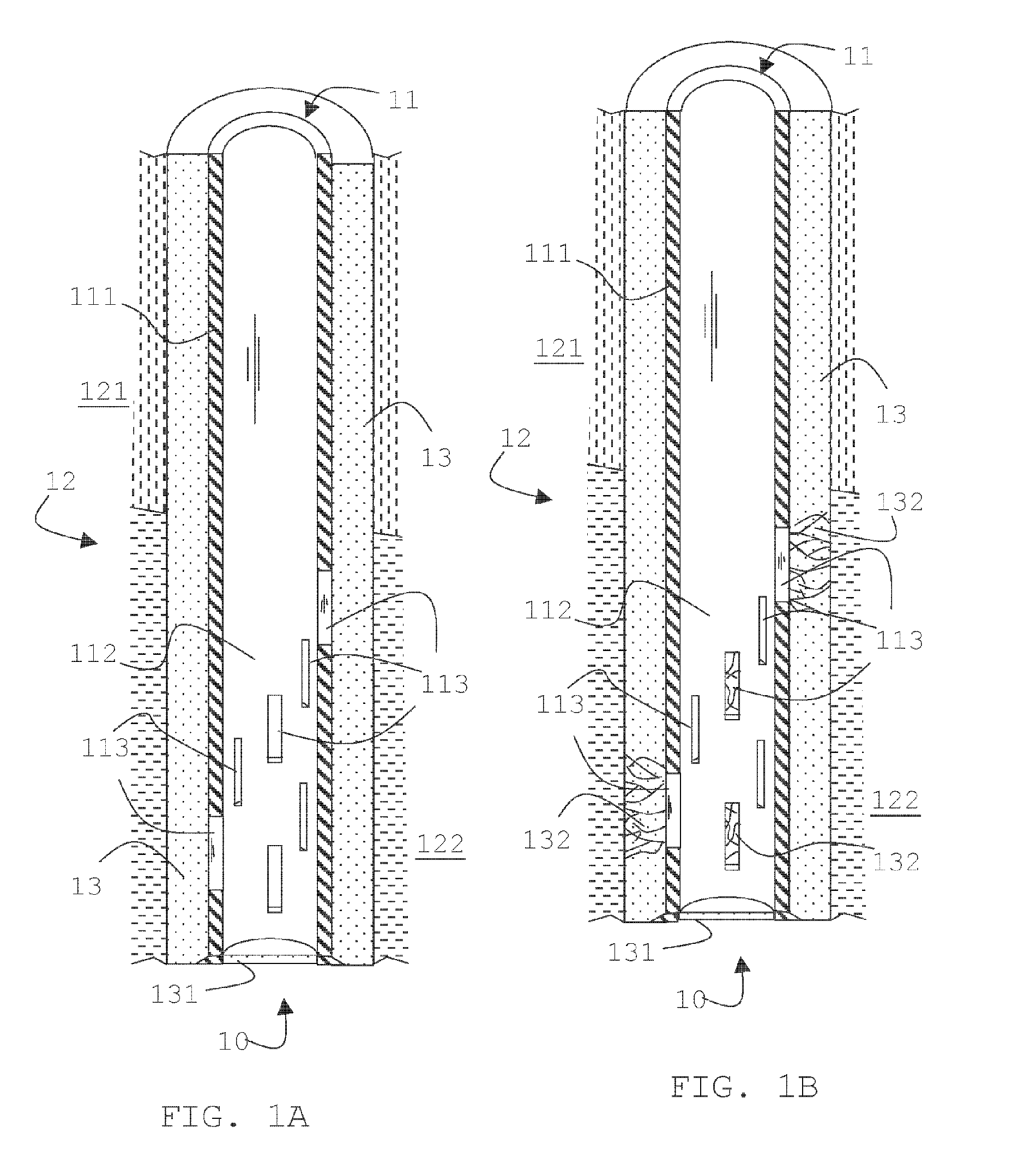

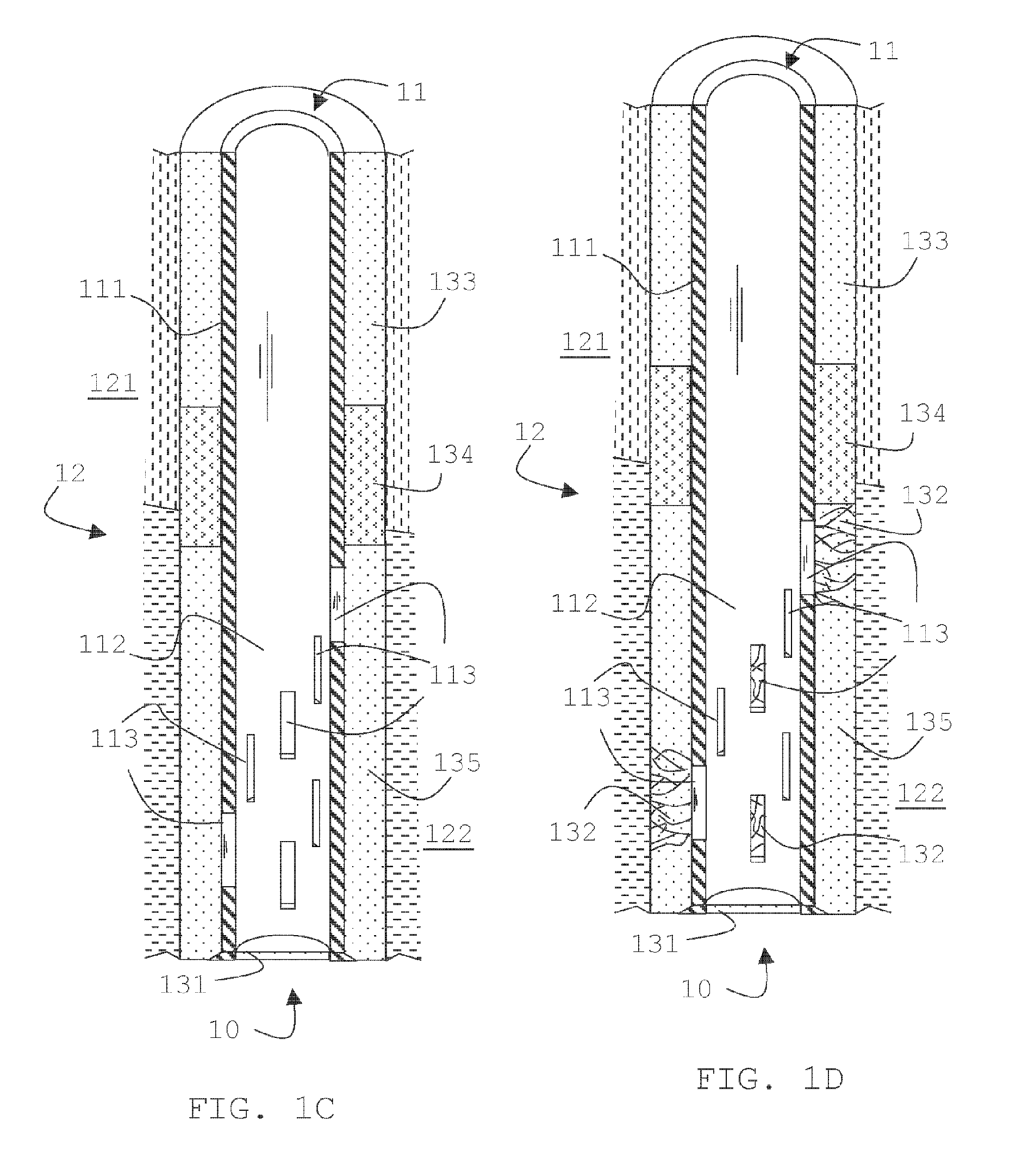

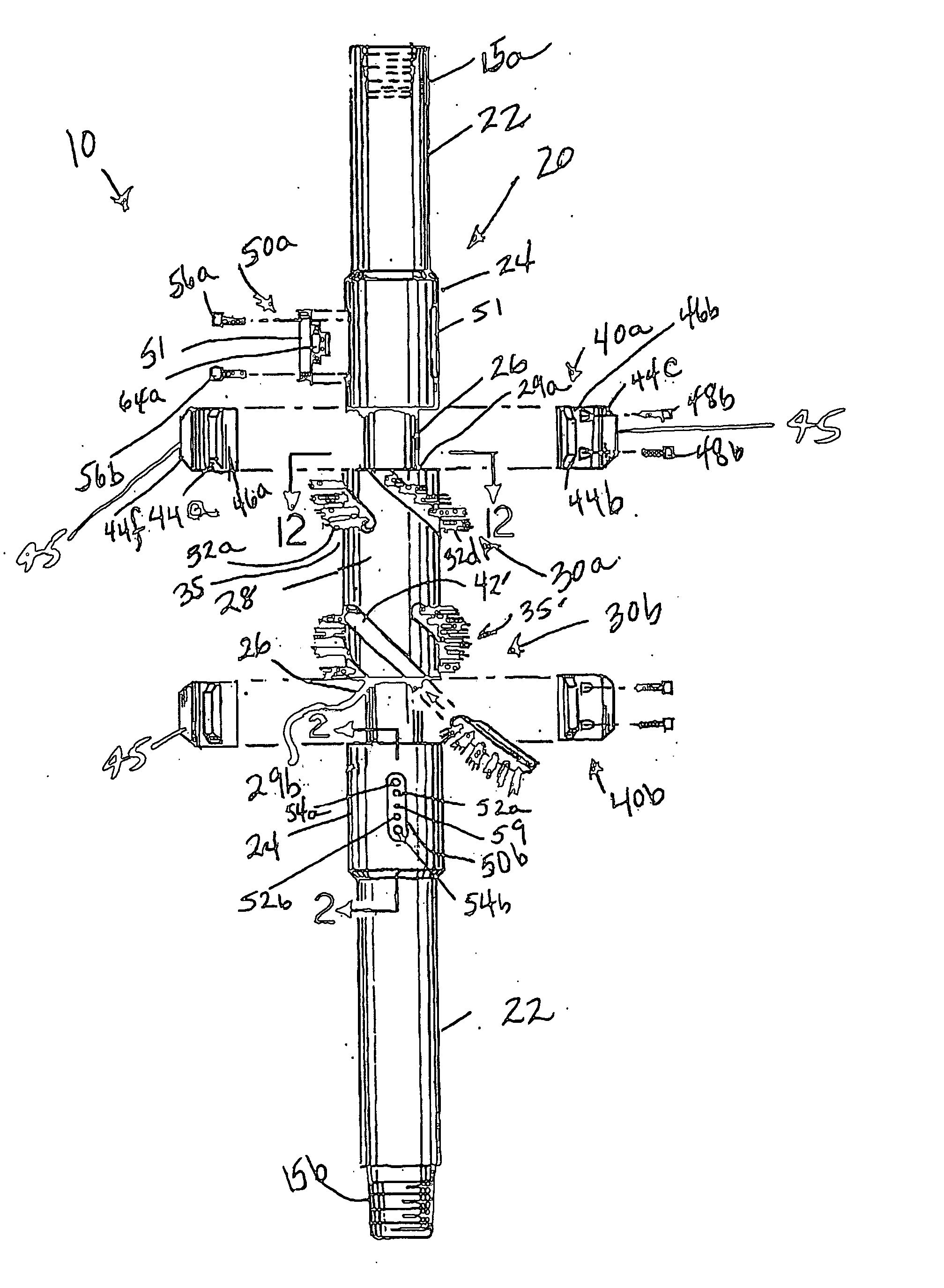

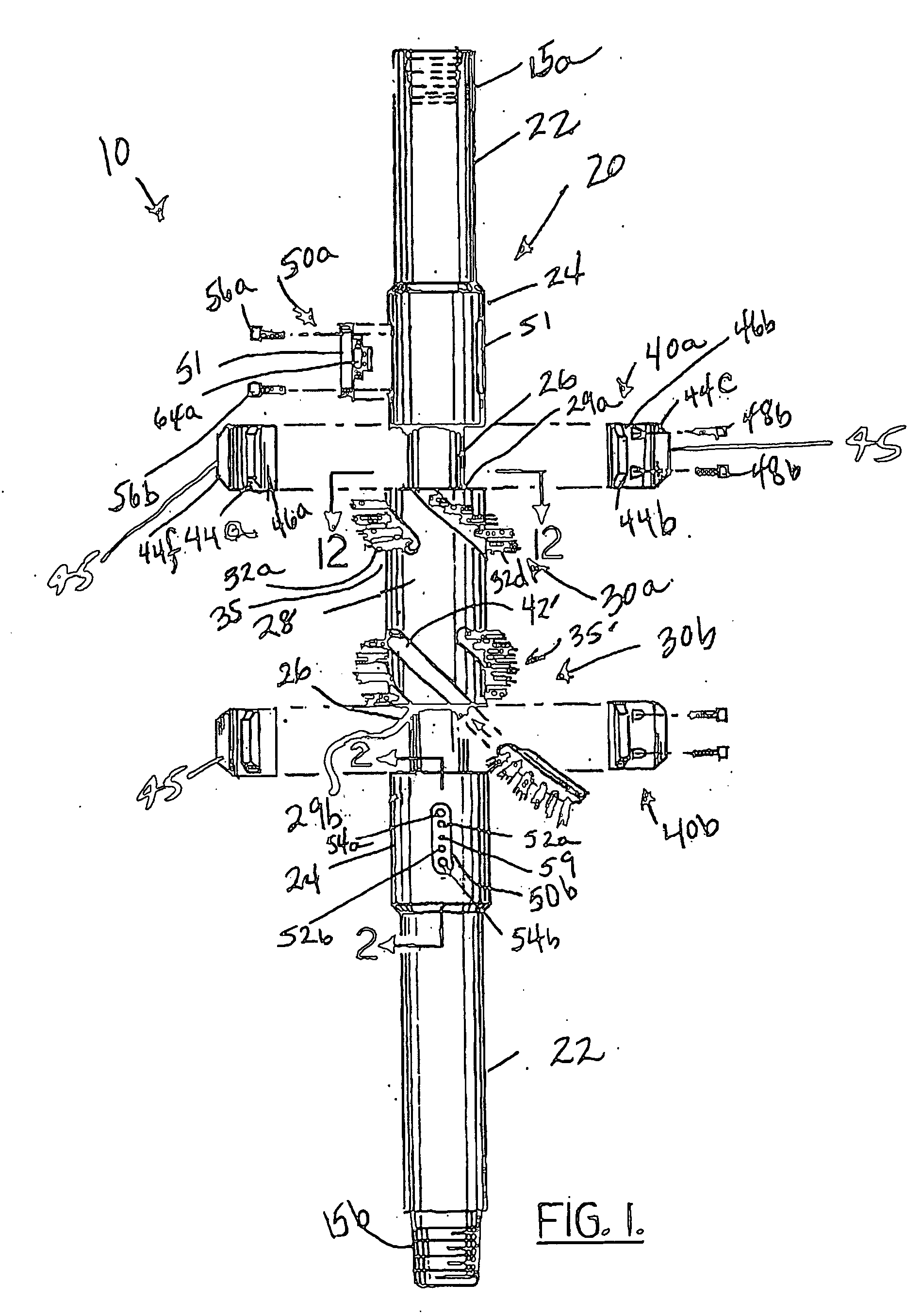

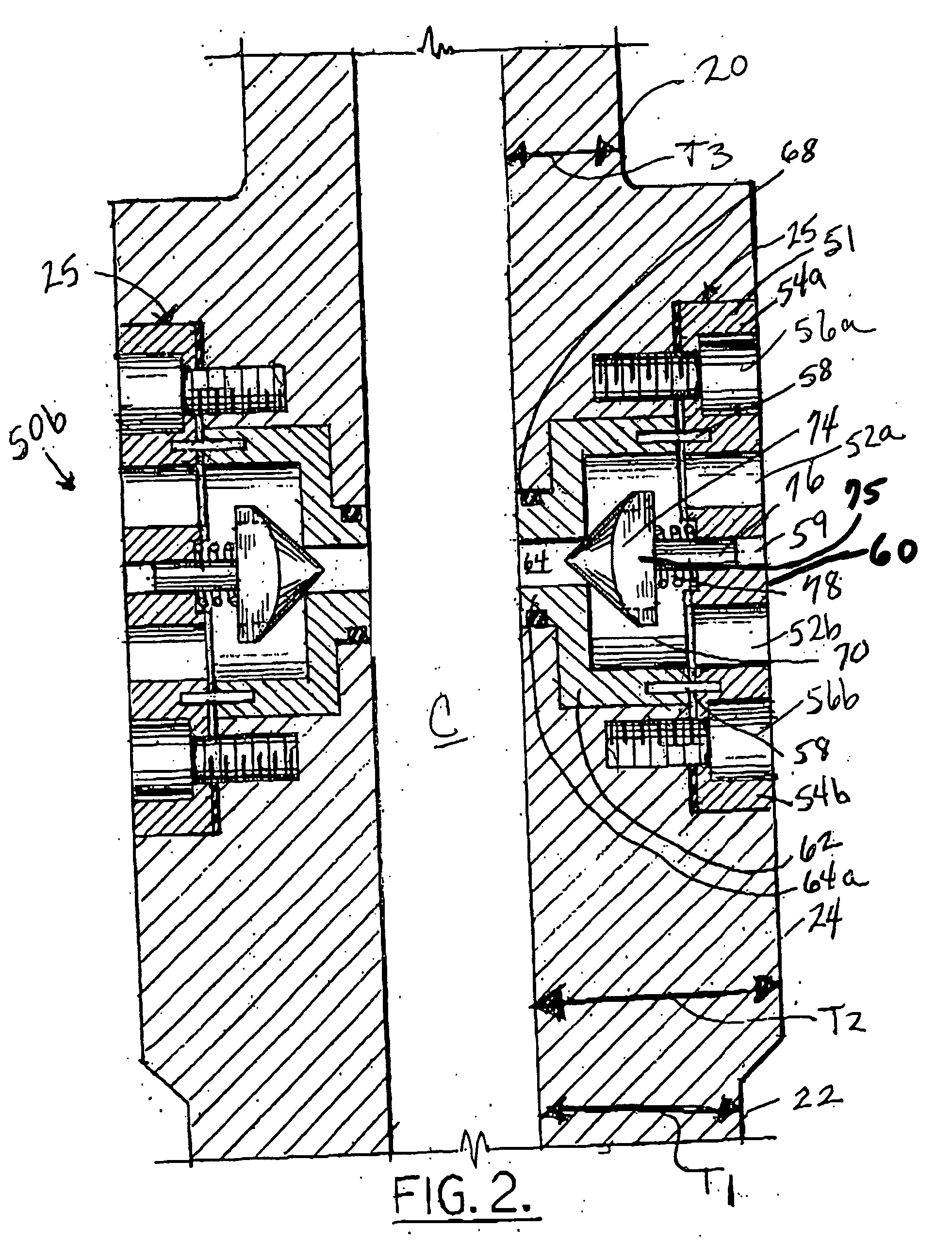

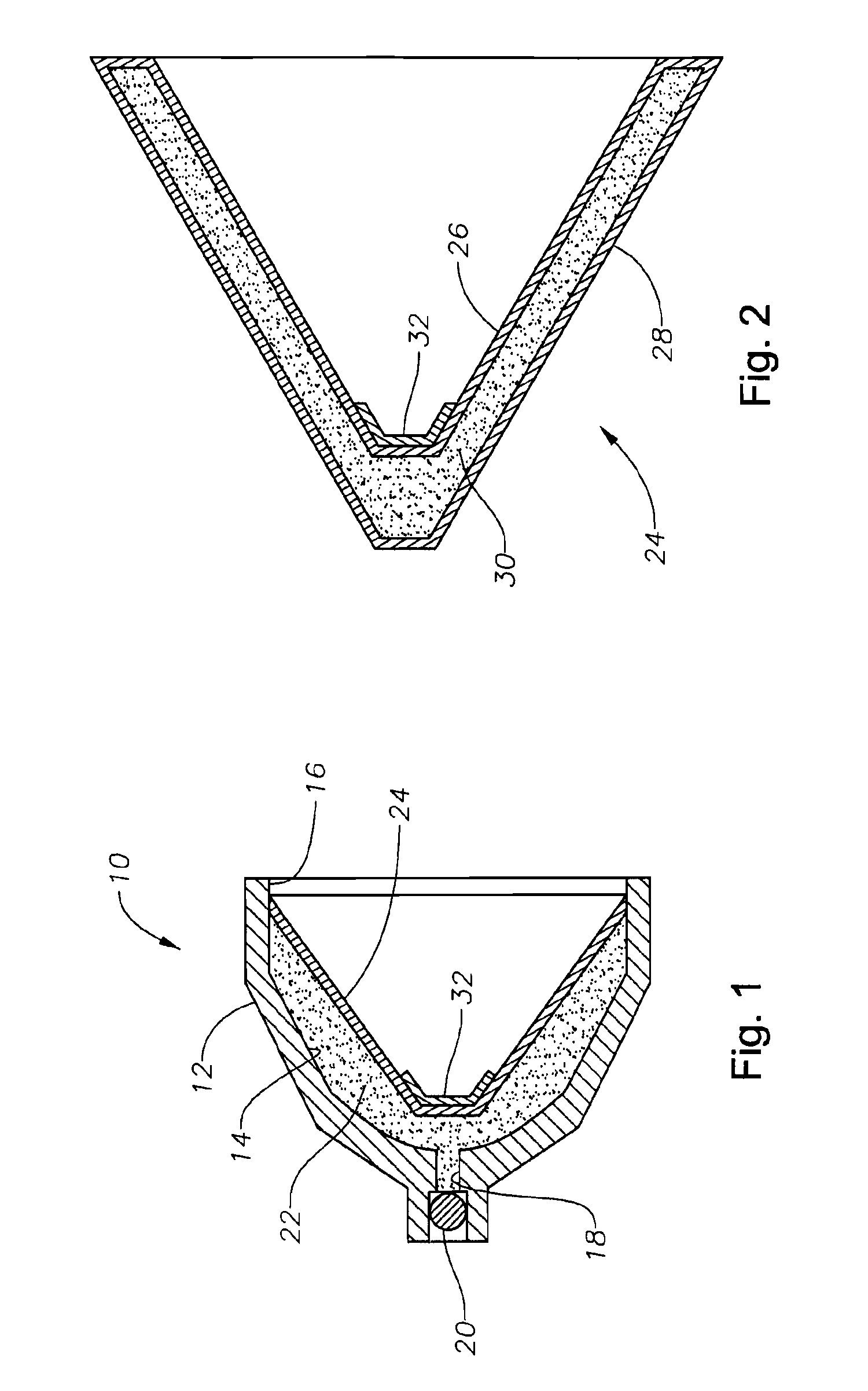

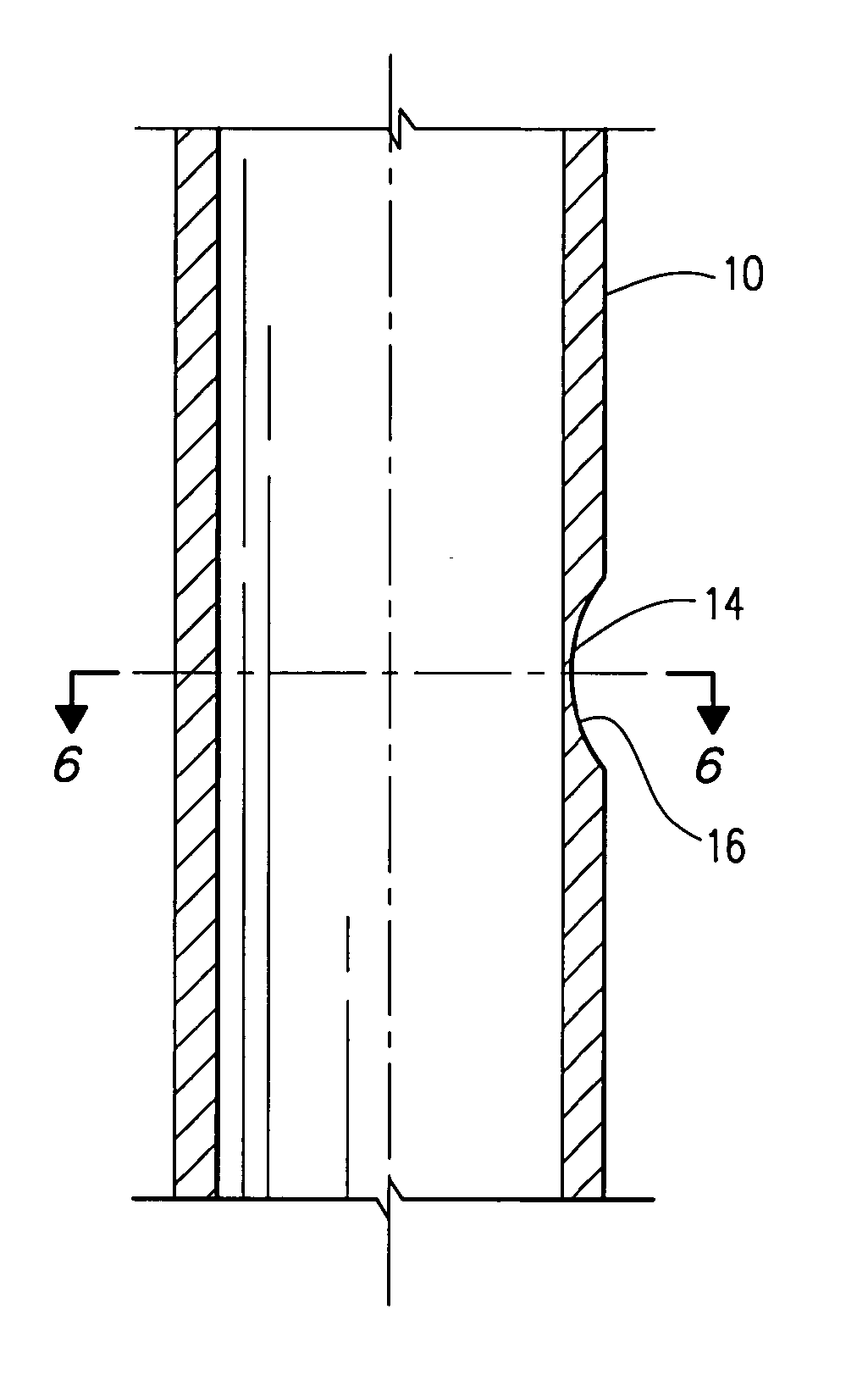

Methods and apparatus for completing a well

Methods and tools are described to reduce sanding including the steps of fracturing the cement sheath in a localized zone around the casing and having the fractured zone act as sand filter between the formation and openings in the casing, with the openings being best pre-formed but temporarily blocked so as to allow a conventional primary cementing of the casing. The fracturing step can also be used for remedial operation to reopen blocked formation or screens.

Owner:SCHLUMBERGER TECH CORP

Wellbore cleaning tool system and method of use

A wellbore cleaning tool system includes a plurality of brushes and scrappers supported by or mounted to a casing body to clean an interior wall of a wellbore. The cleaning tool system includes selectively actuated high-velocity jet sprays to aid the cleaning of the interior wall of a wellbore by enhance the loosening and releasing of mud cake, oily residue, cement sheath, and pipe scale. The jet sprays also aid in the cleaning operation performed by and efficiency of the brushes and scrappers by spraying, loosening and releasing matter (mud cake, oily residue, cement sheath, and pipe scale) adhering to or sticking on the brushes and scrapers.

Owner:WELLBORE SPECIALTIES

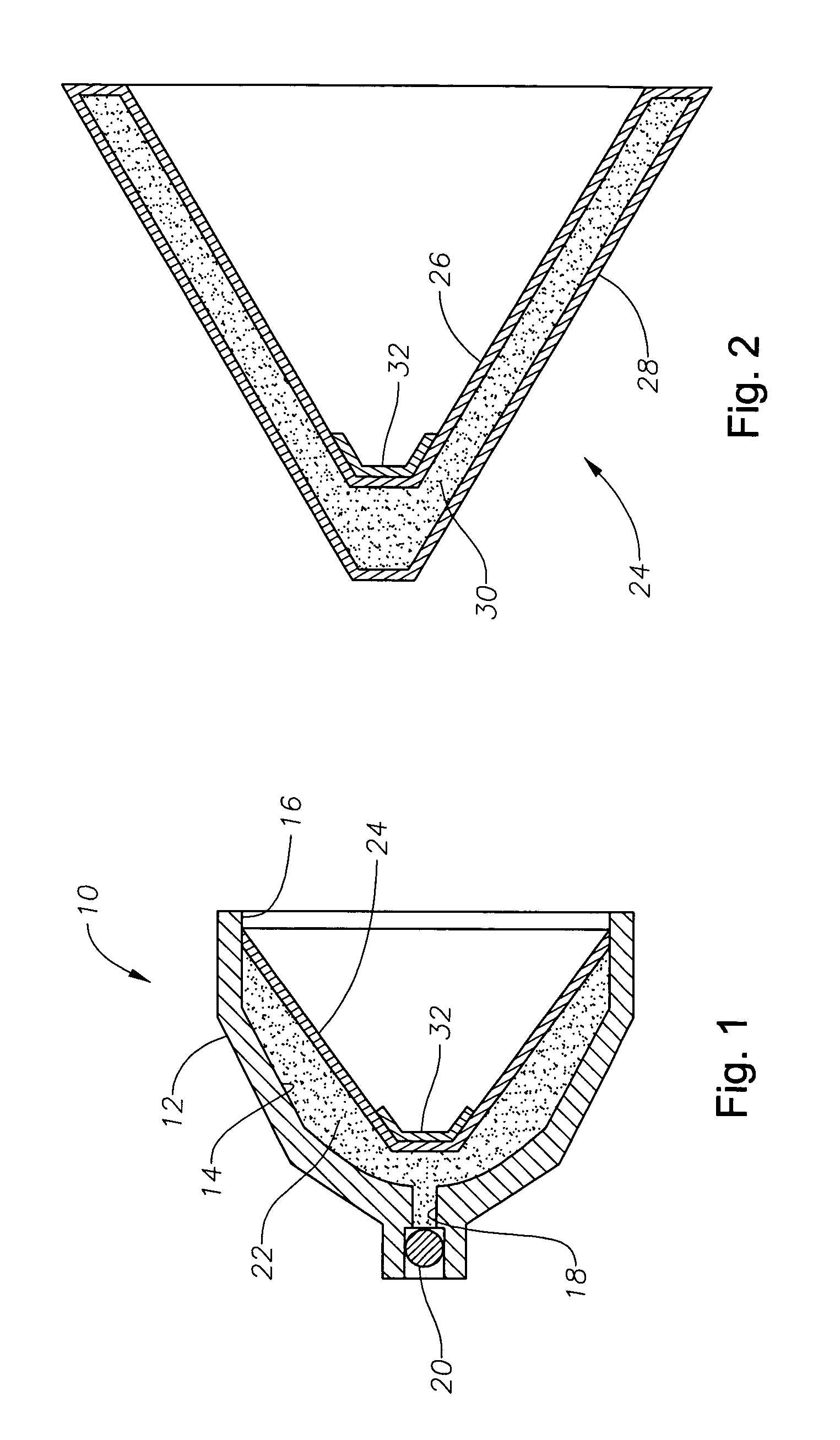

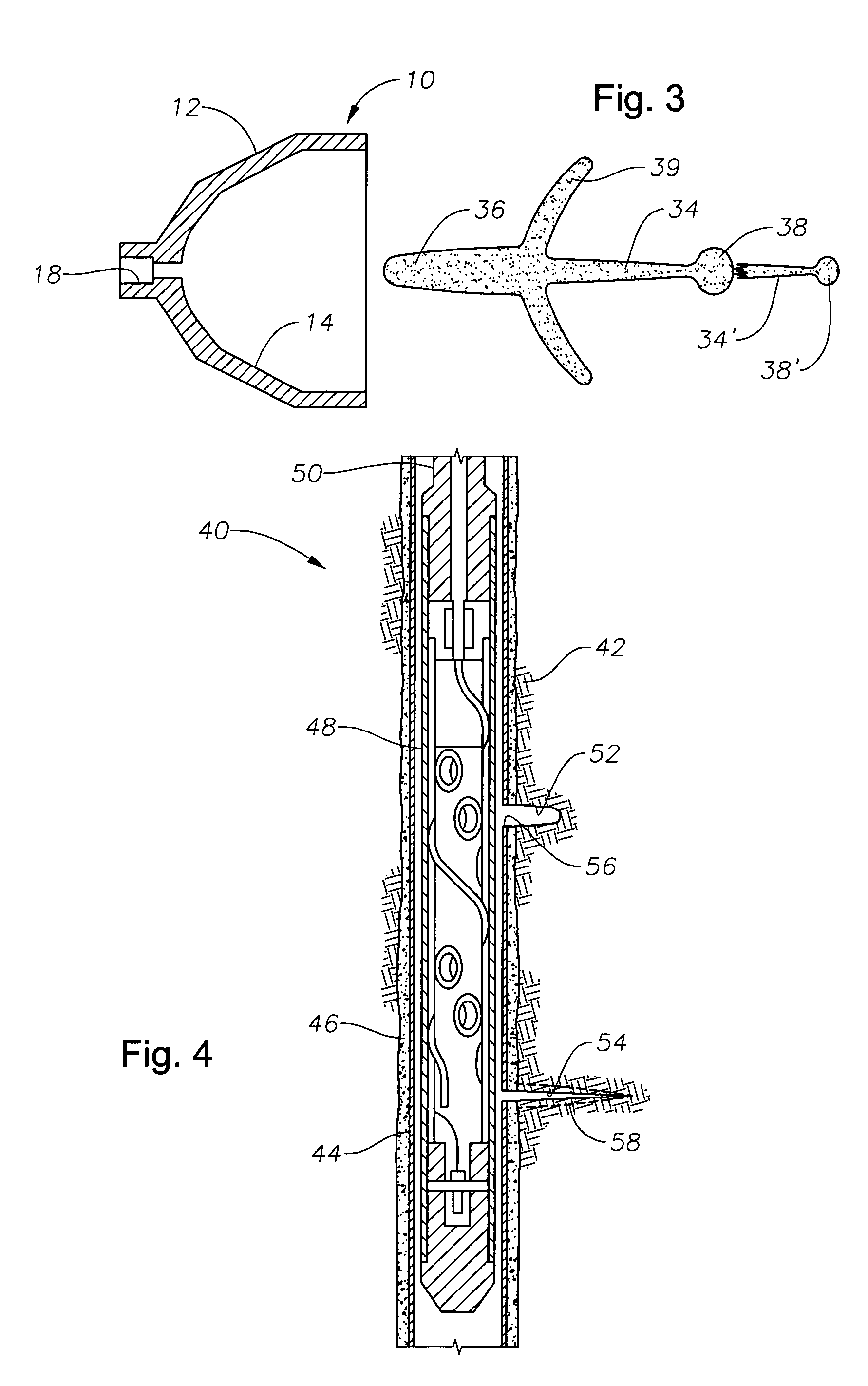

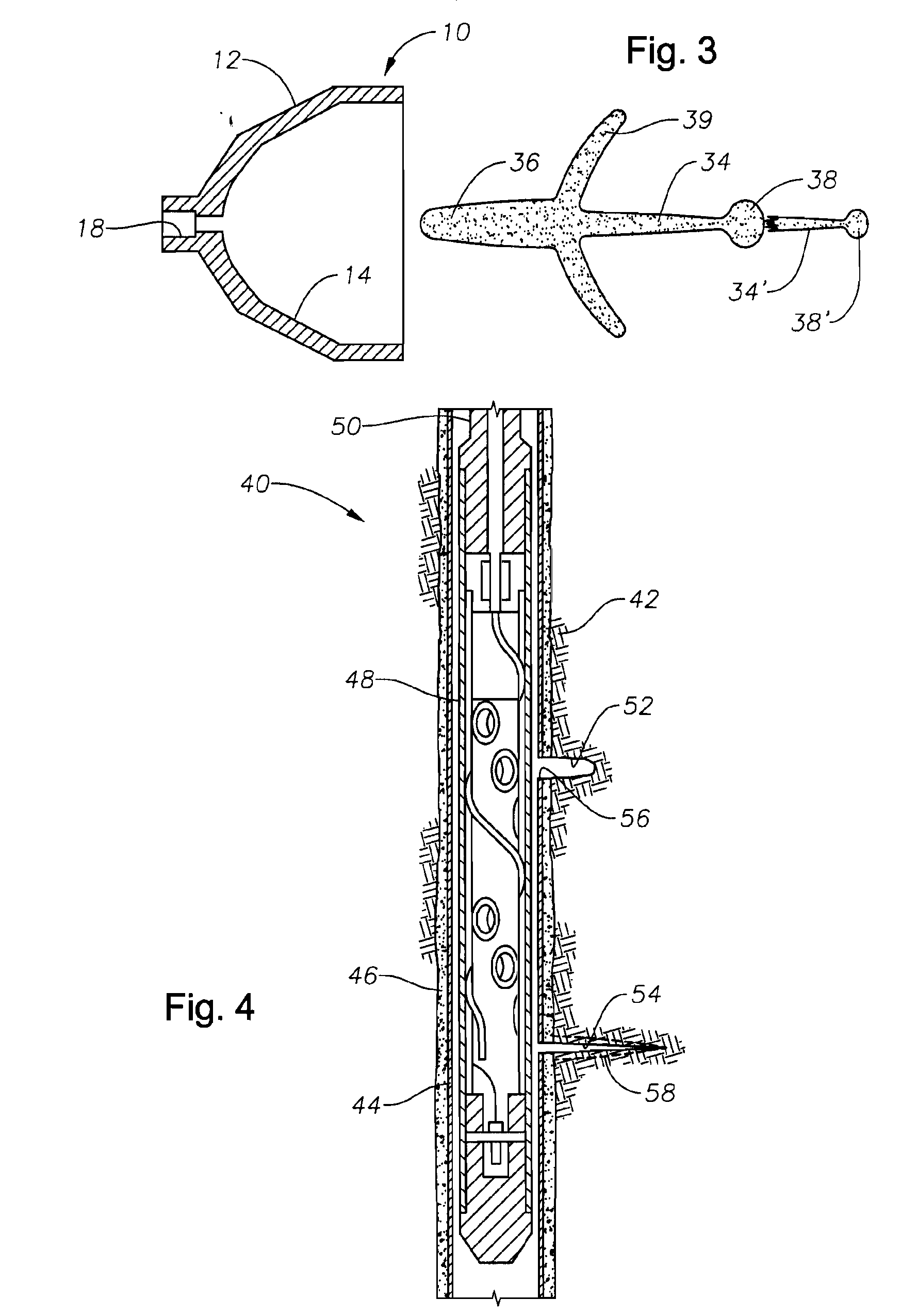

Apparatus and method for penetrating oilbearing sandy formations, reducing skin damage and reducing hydrocarbon viscosity

InactiveUS20050115448A1Excessive heatingMinimal damageExplosive chargesAmmunition projectilesPorosityPolyester

A shaped charge and a method of using such to provide for large and effective perforations in oil bearing sandy formations while causing minimal disturbance to the formation porosity is described. This shaped charge uses a low-density liner having a filler material that is enclosed by outer walls made, preferably, of plastic or polyester. The filler material is preferably a powdered metal or a granulated substance, which is left largely unconsolidated. The preferred filler material is aluminum powder, or aluminum particles, that are coated with an oxidizing substance, such as TEFLON®, permitting a secondary detonation reaction inside the formation following jet penetration. The filled liner is also provided with a metal cap to aid penetration of the gun scallops, the surrounding borehole casing and the cement sheath. The metal cap forms the leading portion of the jet, during detonation. The remaining portion of the jet is formed from the low-density filler material, thereby resulting in a more particulated jet. The jet results in less compression around the perforation tunnel and less skin damage to the proximal end of the perforation tunnel.

Owner:OWEN OIL TOOLS

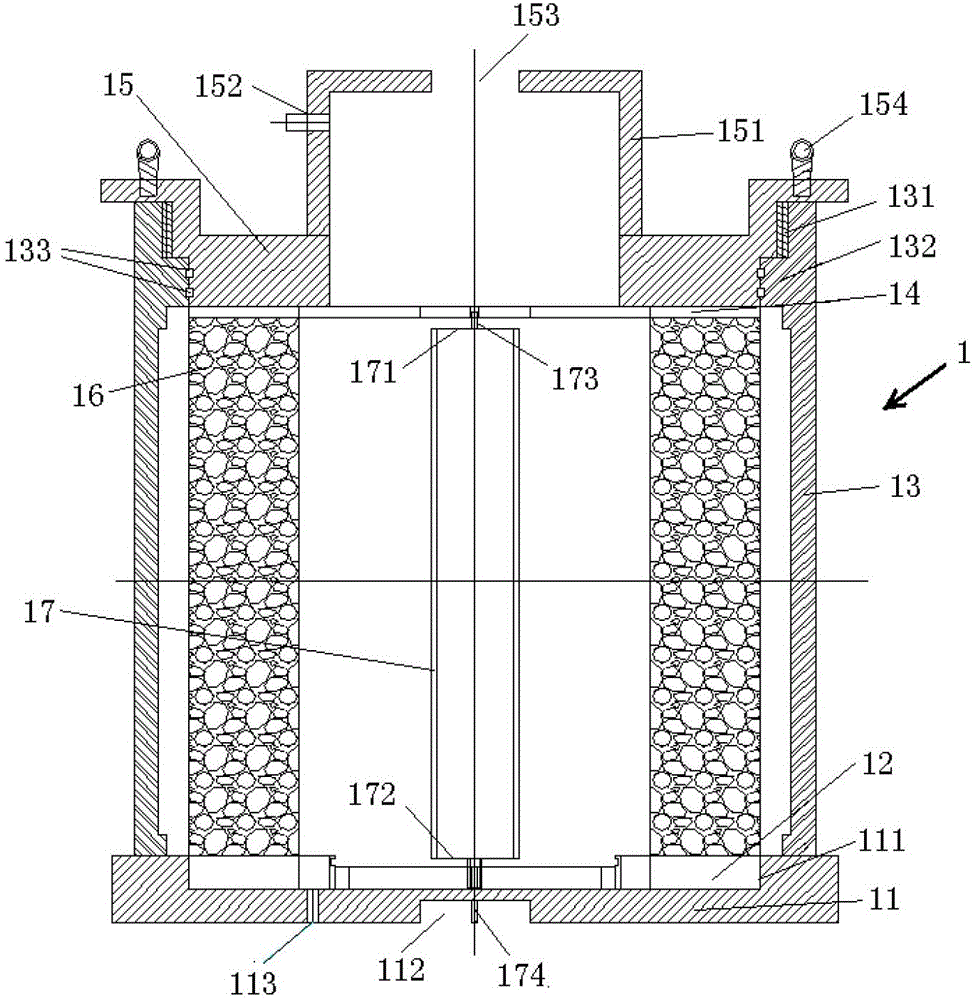

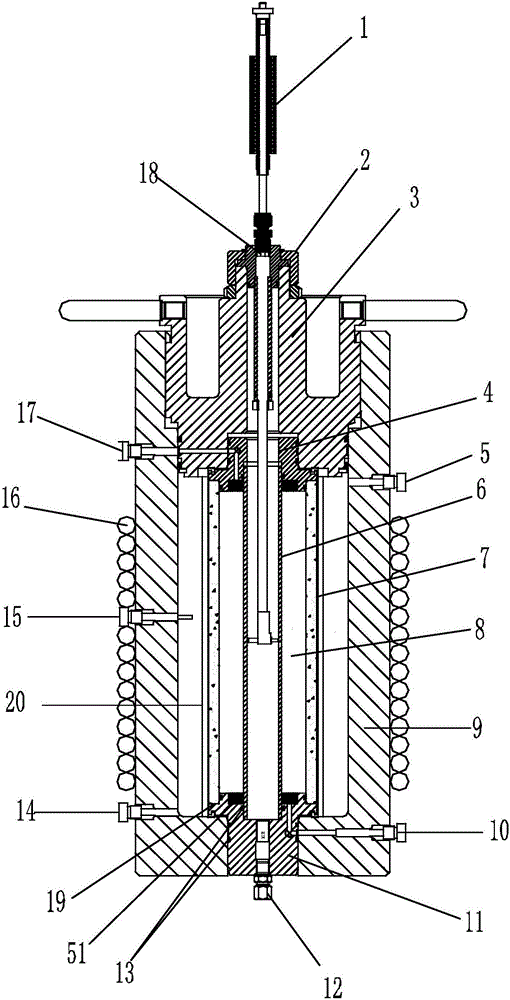

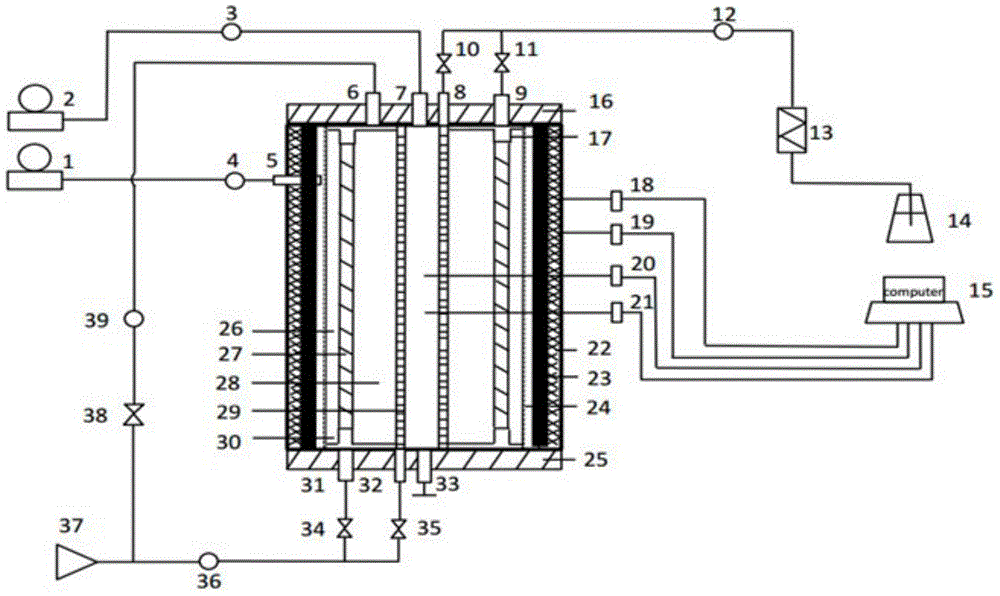

Well cementation cement sheath performance simulation experiment device and experiment method

The invention relates to a well cementation cement sheath performance simulation experiment device and an experiment method. The experiment device comprises one set of cement cake circulation device, one set of cement sheath performance detection device and one set of cementing face shearing force experiment device. The experiment method comprises the following steps of: simulating the manufacture process of a well cementation test sample under the practical underground warm-pressing condition; detecting the sealing performance and the corrosion resistance of the cement ring; detecting the sealing performance and the corrosion performance of the cement ring; and detecting cementing face shearing force between a casing pipe test sample and the cement sheath and cementing face shearing force between the cement sheath and a stratum test sample. According to the invention, because the adopted casing pipe test sample has the same size and the material with the casing pipe material applied in the practical well cementation, the adopted stratum test sample is a standard artificial stratum test sample, the porosity-permeability characteristic, the strength characteristic, and the fluid characteristic and the like of the adopted stratum test sample are same with the stratum characteristic in the practical well, the invention can be used for truly simulating the dynamic variation of full-size well cementation, and the simulation condition is accurate. The invention can be widely applied in simulation experiments of various well-cementation dynamic variations.

Owner:CHINA NAT OFFSHORE OIL CORP +1

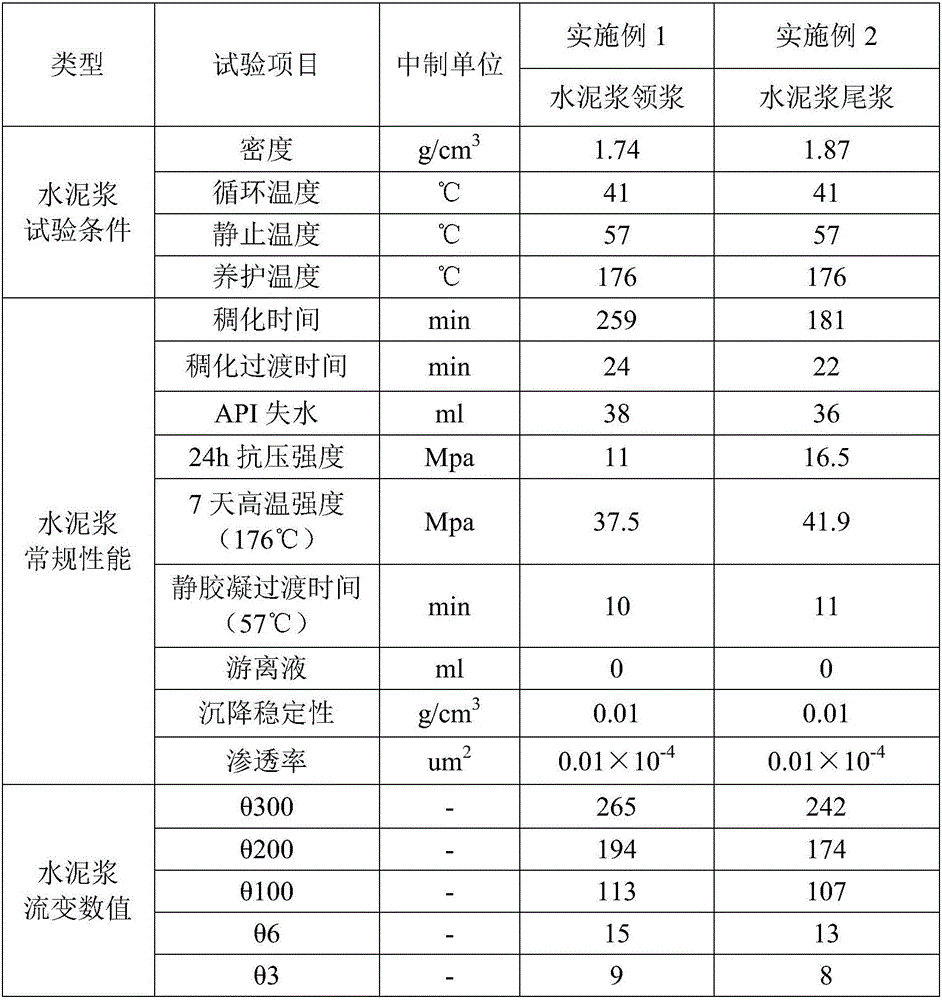

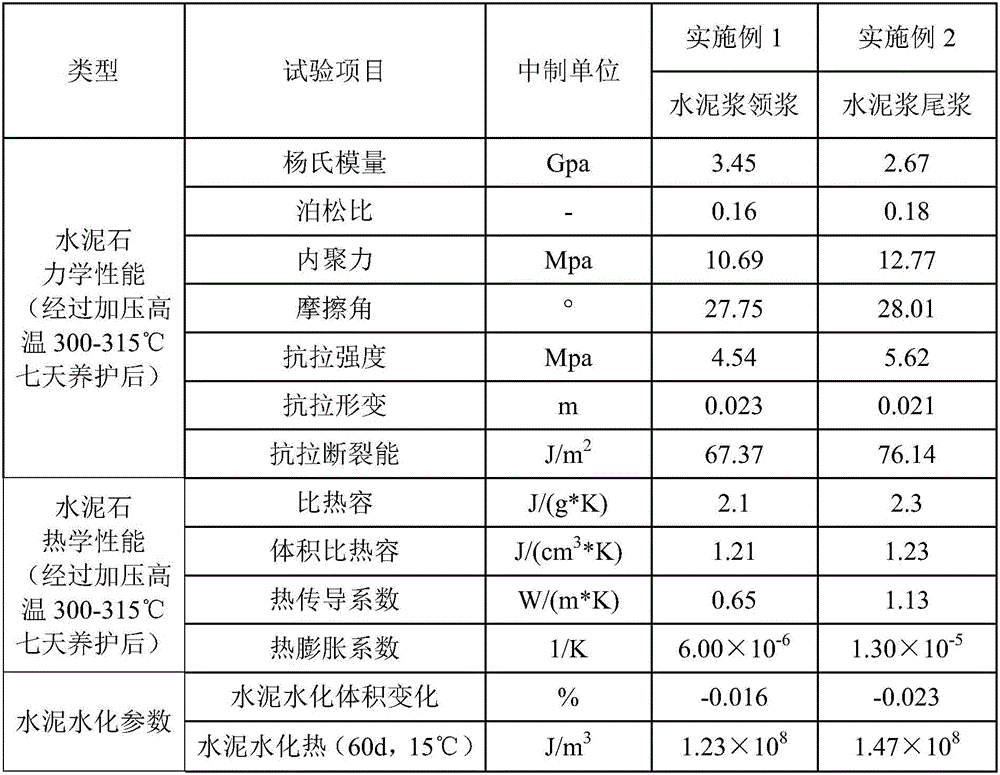

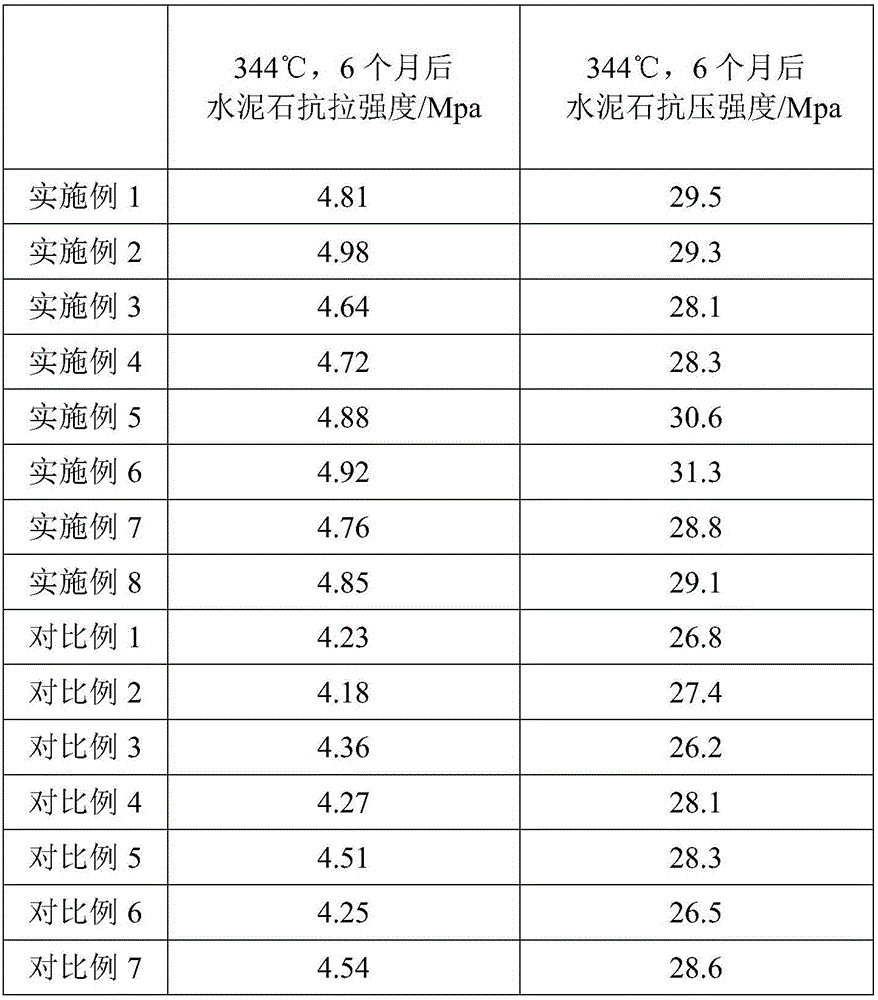

Cement slurry with long-term-integrity cement sheath for heavy-oil thermal-recovery well and preparation method thereof

ActiveCN106007545AGuaranteed general performanceEnsure that the cement slurry system has conventional comprehensive performanceDrilling compositionFiberClay minerals

The invention provides a cement slurry with long-term-integrity cement sheath for a heavy-oil thermal-recovery well. The cement slurry comprises, by weight, 100 parts of thermally responsive cement, 25 to 65 parts of water and 0.2 to 8 parts of a cement slurry aid. The thermally responsive cement comprises 30 to 60 parts of oil well cement, 10 to 20 parts of active silicon powder, 0 to 10 parts of hollow glass beads and 10 to 50 parts of a thermally responsive composite material. The thermally responsive composite material comprises 20 to 30 parts of clay mineral, 10 to 20 parts of fly ash and / or vulcanic ash, 5 to 20 parts of rubber powder and / or latex powder, 3 to 10 parts of carbon fiber, 10 to 15 parts of nanometer silicon dioxide, 5 to 10 parts of calcined magnesia, 10 to 20 parts of ultrafine superfine slag powder and 5 to 10 parts of inorganic whiskers. The cement slurry provided by the invention can solidify at normal temperature; and set cement can resist long-term high temperature, and the mechanical properties and thermal properties of the set cement in a high temperature environment are integrally adaptive to strata and casing pipes.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

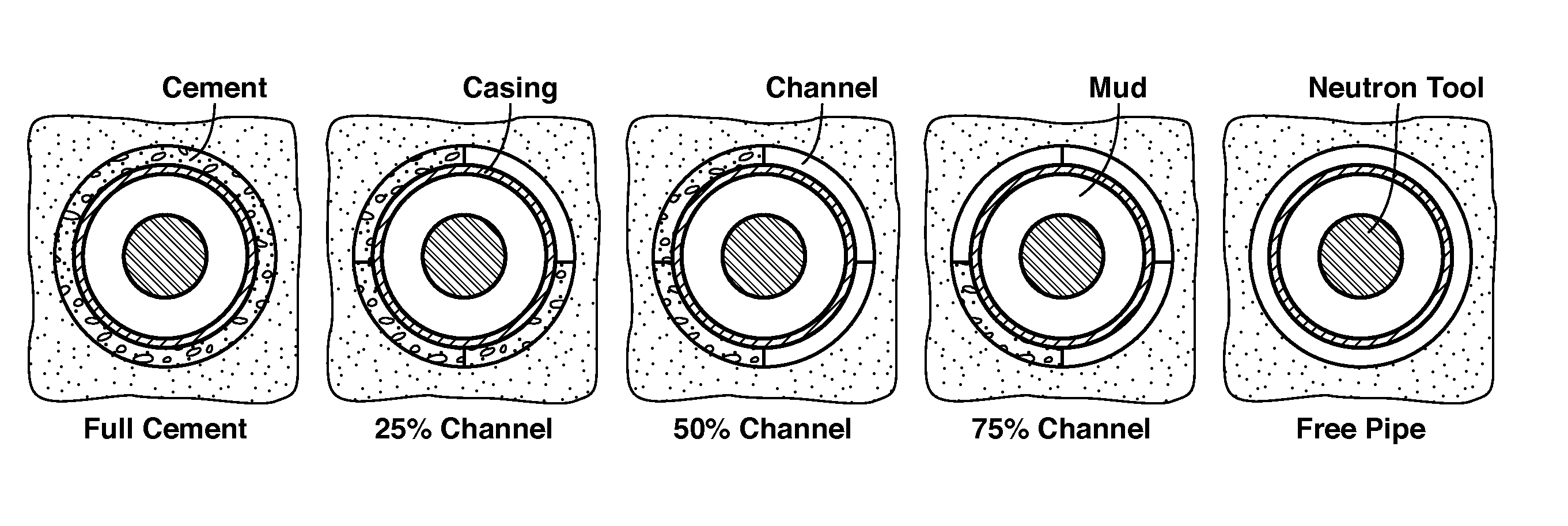

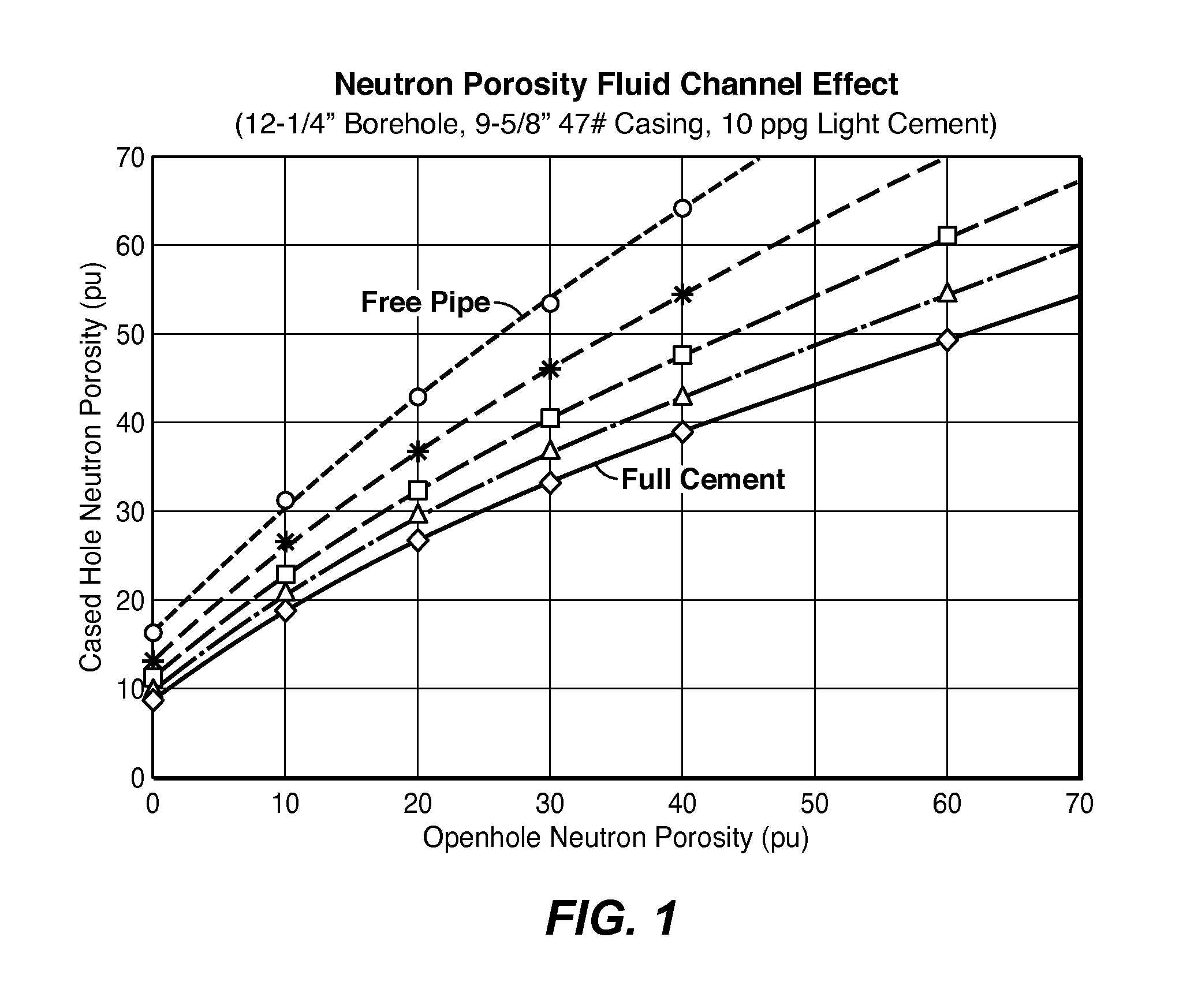

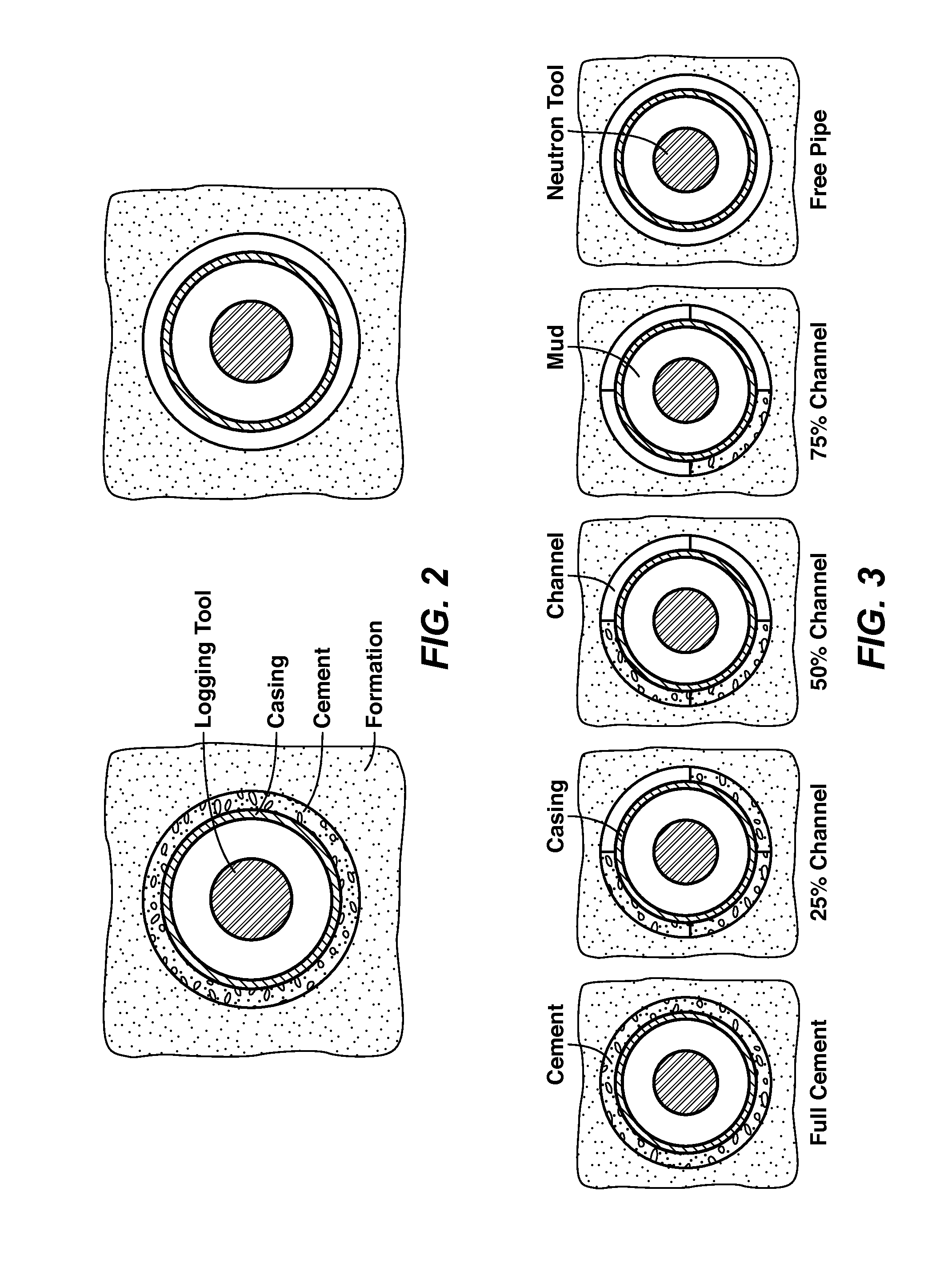

Method For Cement Evaluation With Neutron Logs

ActiveUS20130345983A1Effective approachEasy to explainElectric/magnetic detection for well-loggingConstructionsNeutron porosityMulti parameter

Method for evaluating cement integrity in a cased well environment using a logging tool that has a neutron source and one or more neutron or gamma ray detectors. Neutron porosity logs are obtained from the well before (42) and after (41) casing. This log data along with well dimensions and material composition parameters are the input quantities to a multi-parameter database (43) that is constructed by computer modeling or laboratory experiments to relate volume fraction for fluid filled channels in the cement sheath to the input quantities. The channel volume fraction (45) corresponding to the input quantities is identified or interpolated (44) from the multi-parameter database.

Owner:EXXONMOBIL UPSTREAM RES CO

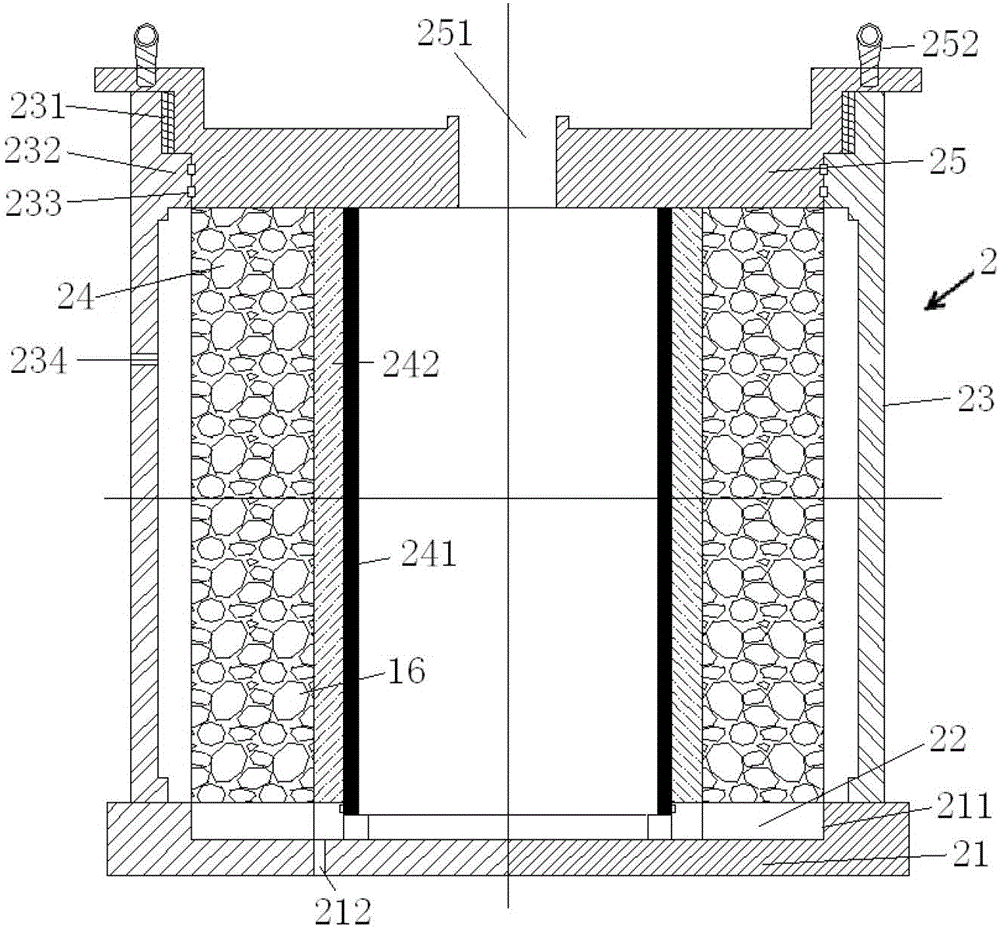

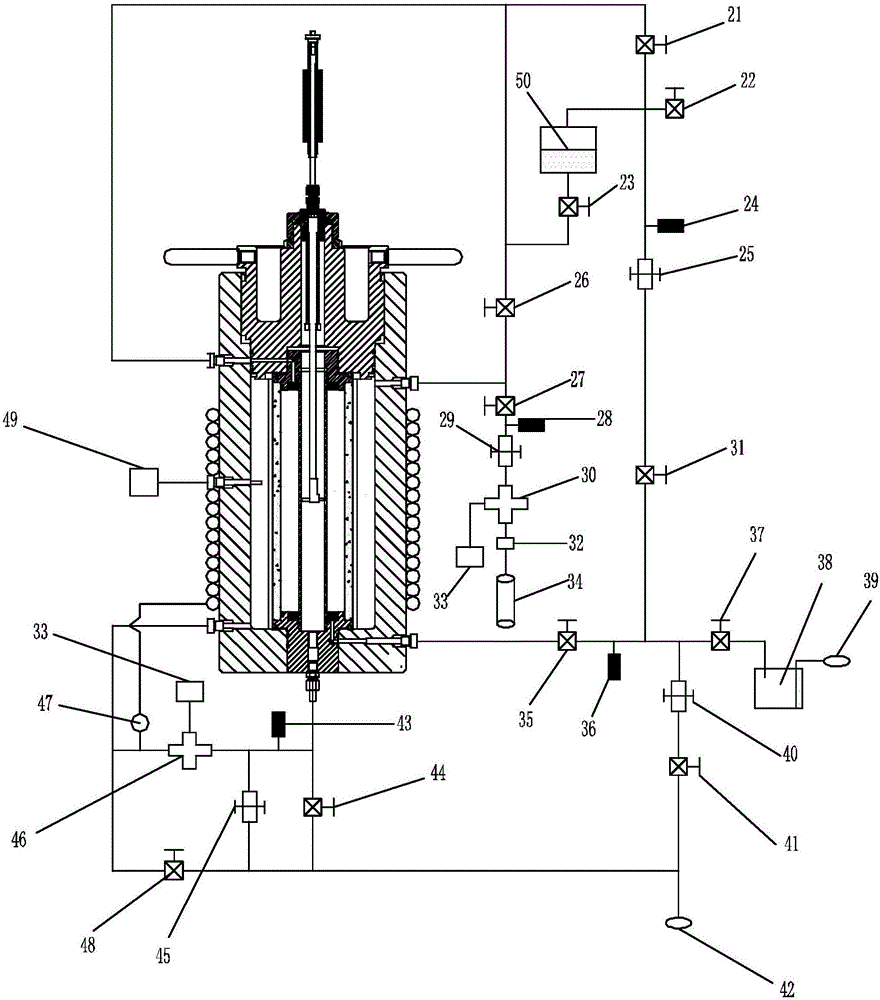

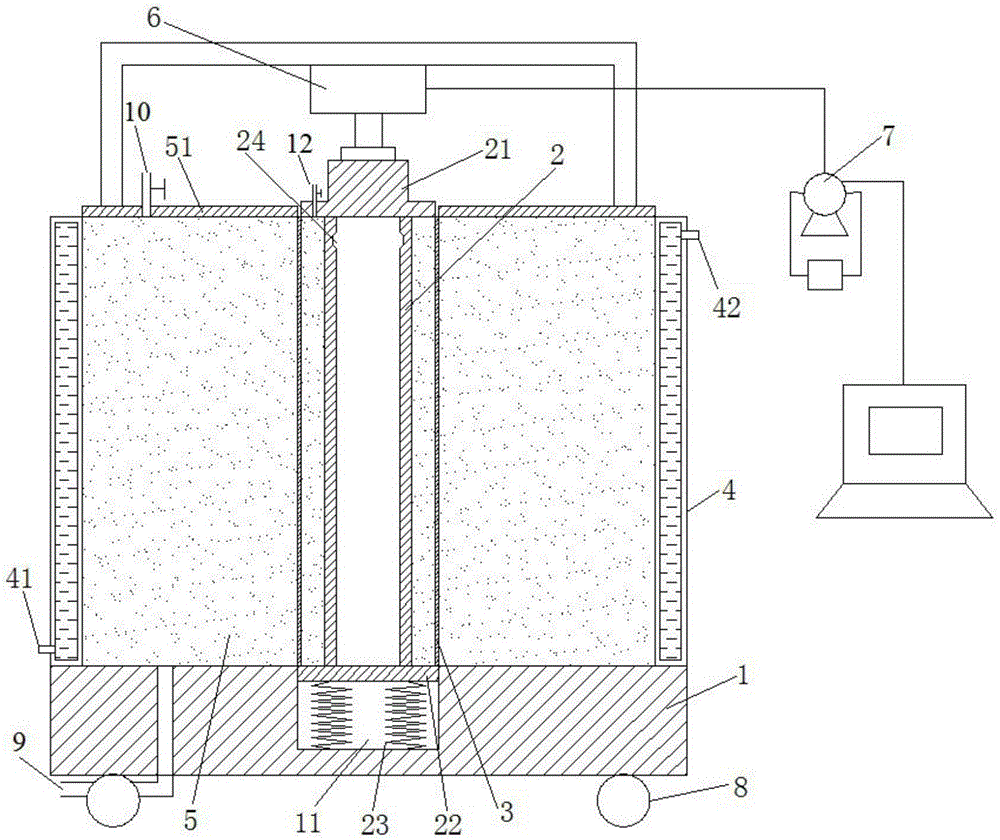

Oil/gas well cement sheath sealing integrity testing device and method for carrying out evaluation through device

PendingCN106522923AAchieving Seal IntegrityAchieving Sealing CapabilityConstructionsEngineeringCement sheath

The invention relates to an oil / gas well cement sheath sealing integrity testing device. The testing device comprises a pressure kettle and a simulation wellbore located in the pressure kettle. The testing device further comprises a pressure control system, a temperature control system, a fluid channeling detection system, a strain measuring system and a mud cake simulation system. The simulation wellbore comprises a casing pipe and a core located on the periphery of the casing pipe. An annular gap is formed between the sleeve and the core, and a cement sheath is formed in the annular gap. The upper ends and the lower ends of the casing pipe and the core are provided with an upper end cover and a lower end cover respectively. The temperature borne by the cement sheath under different downhole working conditions and complex loads from the casing pipe and a stratum can be truly simulated, and the process range covers well cementation at the oil / gas well drilling and completion stage and pressure tests, producing tests, circulating injection production, fracturing and other improvement working conditions in the production process. The influence rule of the cement sheath sealing integrity can be evaluated by changing the thickness of the cement sheath, the character of mud cakes, the maintenance temperature and other factors.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

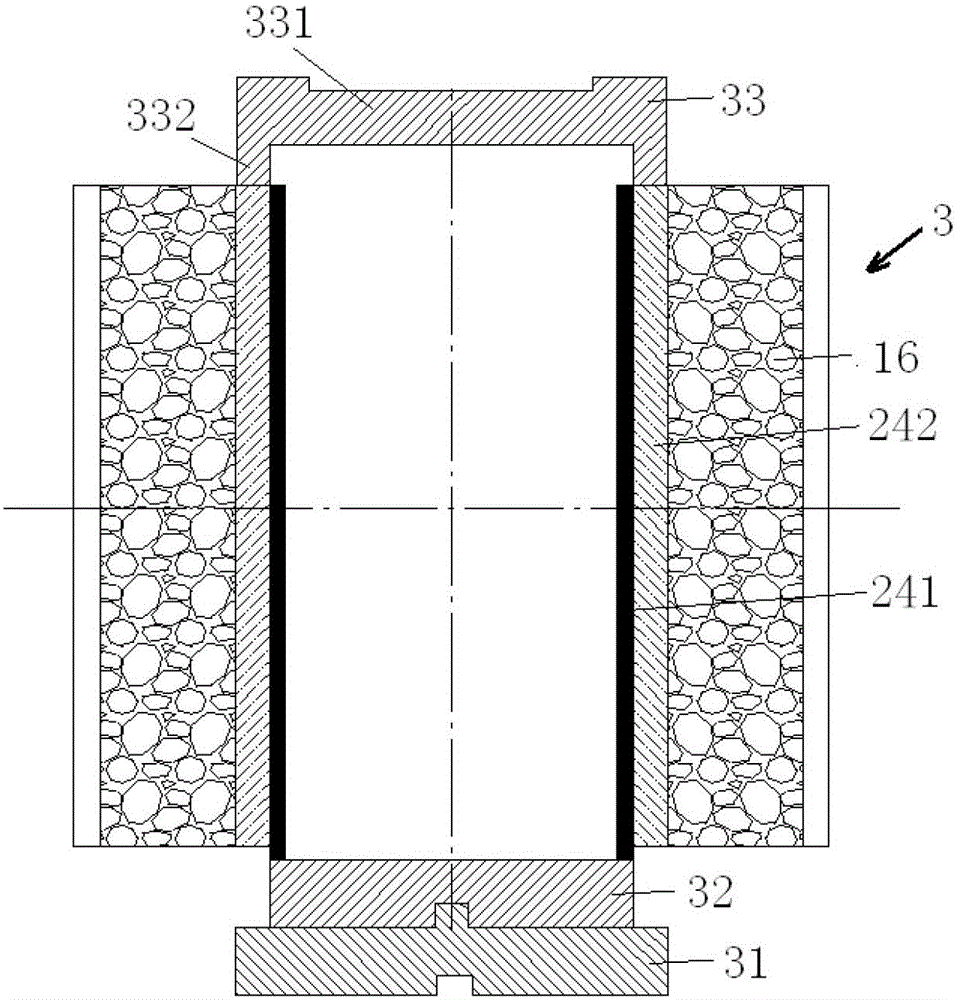

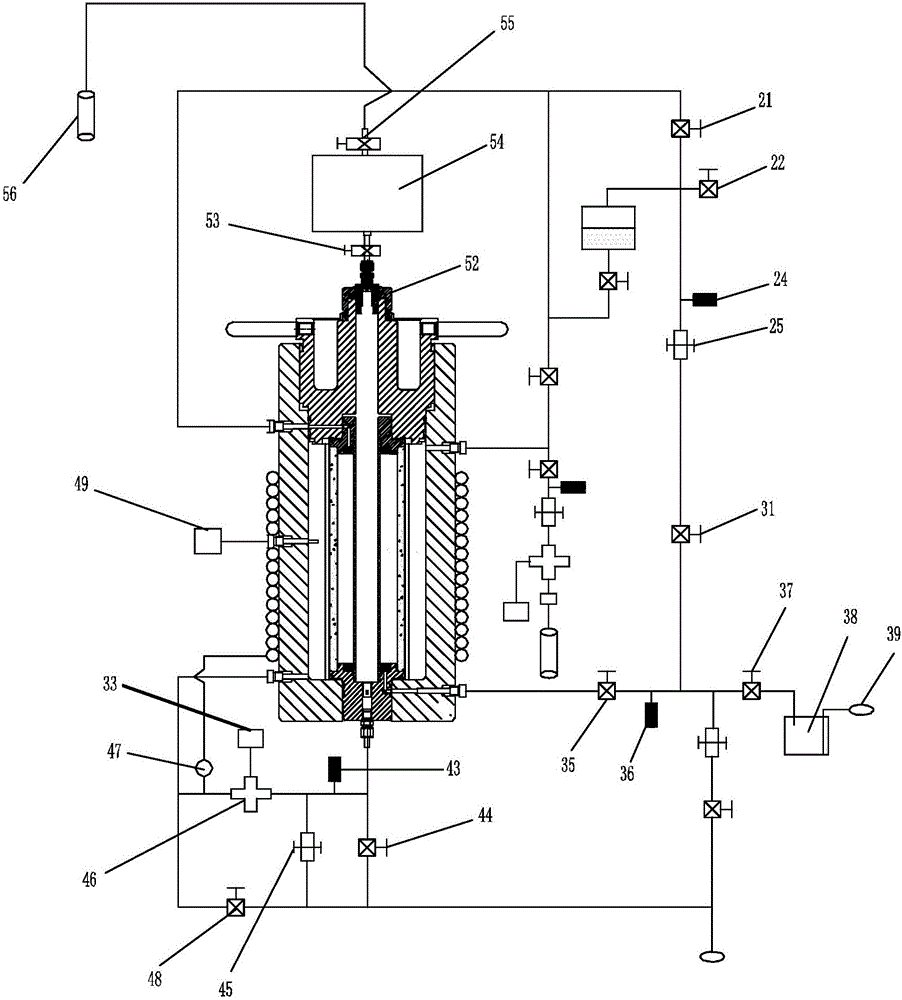

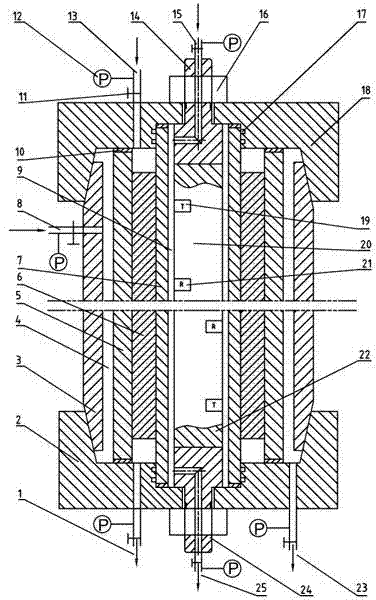

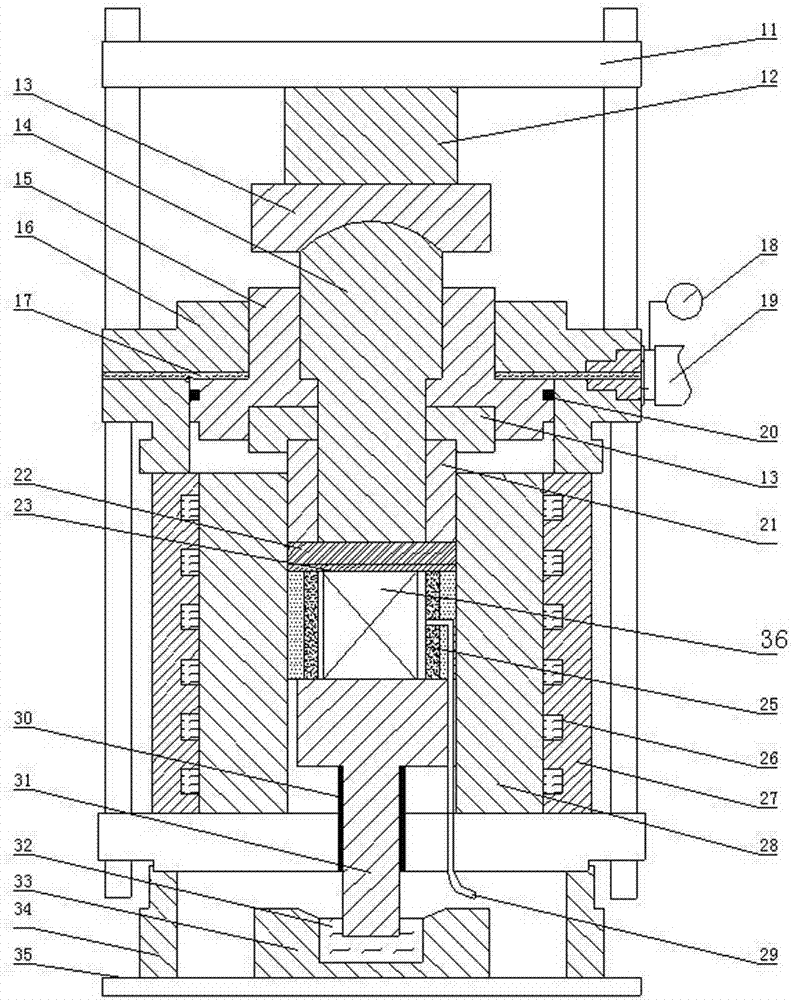

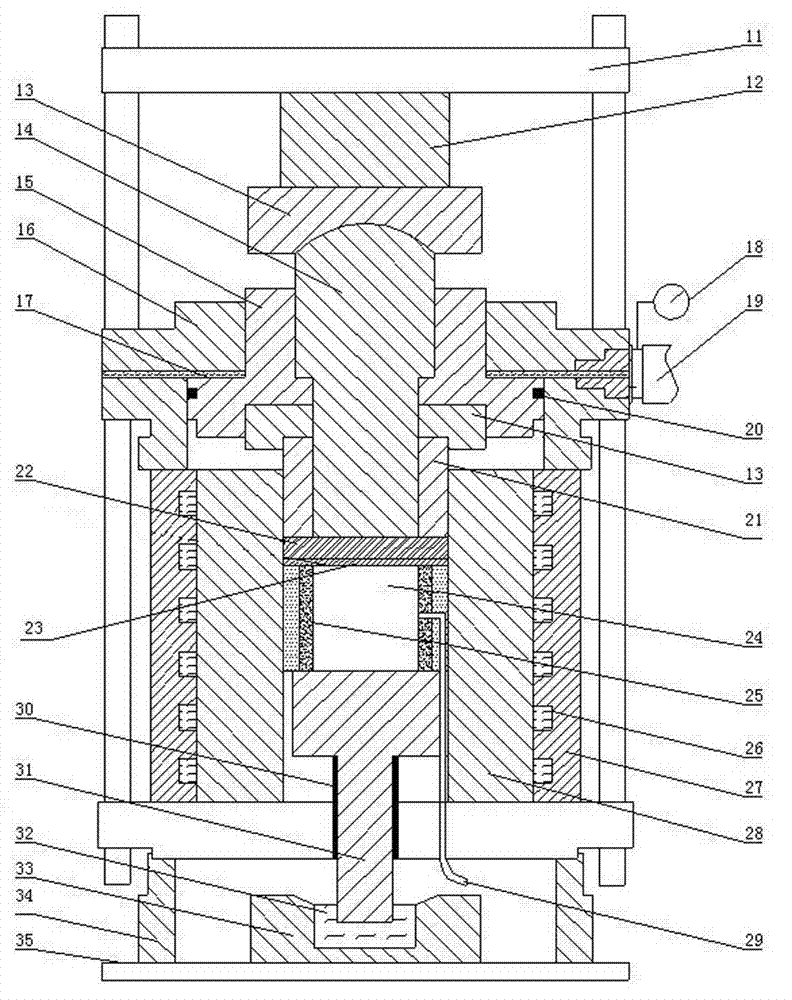

Apparatus and method for testing cementation capability of well cementation first and second interfaces under high-temperature high-pressure conditions

ActiveCN104406910AReflect the state of stressAccurate evaluation of sealing capacityUsing mechanical meansMaterial analysisEngineeringHigh pressure

The invention discloses an apparatus and a method for testing cementation capability of well cementation first and second interfaces under high-temperature high-pressure conditions. The apparatus is mainly composed of a kettle body, an outer pressure pump, an inner pressure pump, a heating belt, a surrounding pressure sleeve, an inner pressure pipe, a nitrogen source, a rotor flow meter, an observation conical flask, an outer pressure sensor, an outer galvanic couple, an inner pressure sensor, an inner galvanic couple, a gas-liquid discharge valve and a computer. The method comprises: (1) sleeving an imitated rock core with the surrounding pressure sleeve, putting in the kettle body and pouring a drilling fluid; (2) heating the kettle body, injecting a pressure P1 into the drilling fluid, and maintaining for 3 d to form an artificial mud cake; (3) pouring a cement slurry into an annular space formed by the inner pressure pipe and the imitated rock core, setting the temperature as a downhole temperature T1, pressurizing to a surrounding pressure P2 needed by an experiment, and maintaining for 3 d to form a cement sheath; and (4) pressurizing the interior of the inner pressure pipe to a pressure P3 needed by the experiment, and testing the cementation capability of the first and the second interfaces. The principle is reliable, the apparatus and the method are capable of accurately testing the cementation capability of the well cementation first and second interfaces under the high-temperature high-pressure conditions, and the evaluation result is relatively precise.

Owner:SOUTHWEST PETROLEUM UNIV

Device and method for evaluating influence of pressure change on completeness of cement sheath

The invention provides a device and a method for real simulation of underground environments, completeness maintaining of experiment equipment, and accurate and omnibearing evaluation of completeness of a cement sheath. The device mainly comprises an upper end cap, a lower end cap, an outer pipe, a middle pipe, the cement sheath, a sleeve pipe, a long source distance sector cement bond logging instrument (SBT (segmented bond tool)) and a high-temperature and high-pressure kettle. The method comprises the following steps of utilizing the high-temperature and high-pressure kettle to simulate the stratum temperature pressure of the curing and forming of the cement sheath; loading and unloading an inner annulus and an outer annulus, so as to simulate the actions of change of well shaft pressure and stratum pressure on the cement sheath under the actual working condition; utilizing a transmitting probe and a receiving probe of the SBT to continuously transmit and receive acoustic wave signals, and performing the omnibearing and high-resolution compensation type attenuation rate measurement, so as to obtain the bonding qualities of a first interface and a second interface of the cement sheath of the well cementing cement sheath under the actual stratum environment, and the amounts, sizes and bearings of cracks and channeling in the cement sheath. The device and the method have the advantage that the underground environment can be really simulated in the omnibearing way, so as to accurately and efficiently evaluate the completeness of the well cementing cement sheath, provide the new method and basis for indoor cement slurry evaluation systems and sites to take the targeted measures, and improve the well cementing quality.

Owner:SOUTHWEST PETROLEUM UNIV

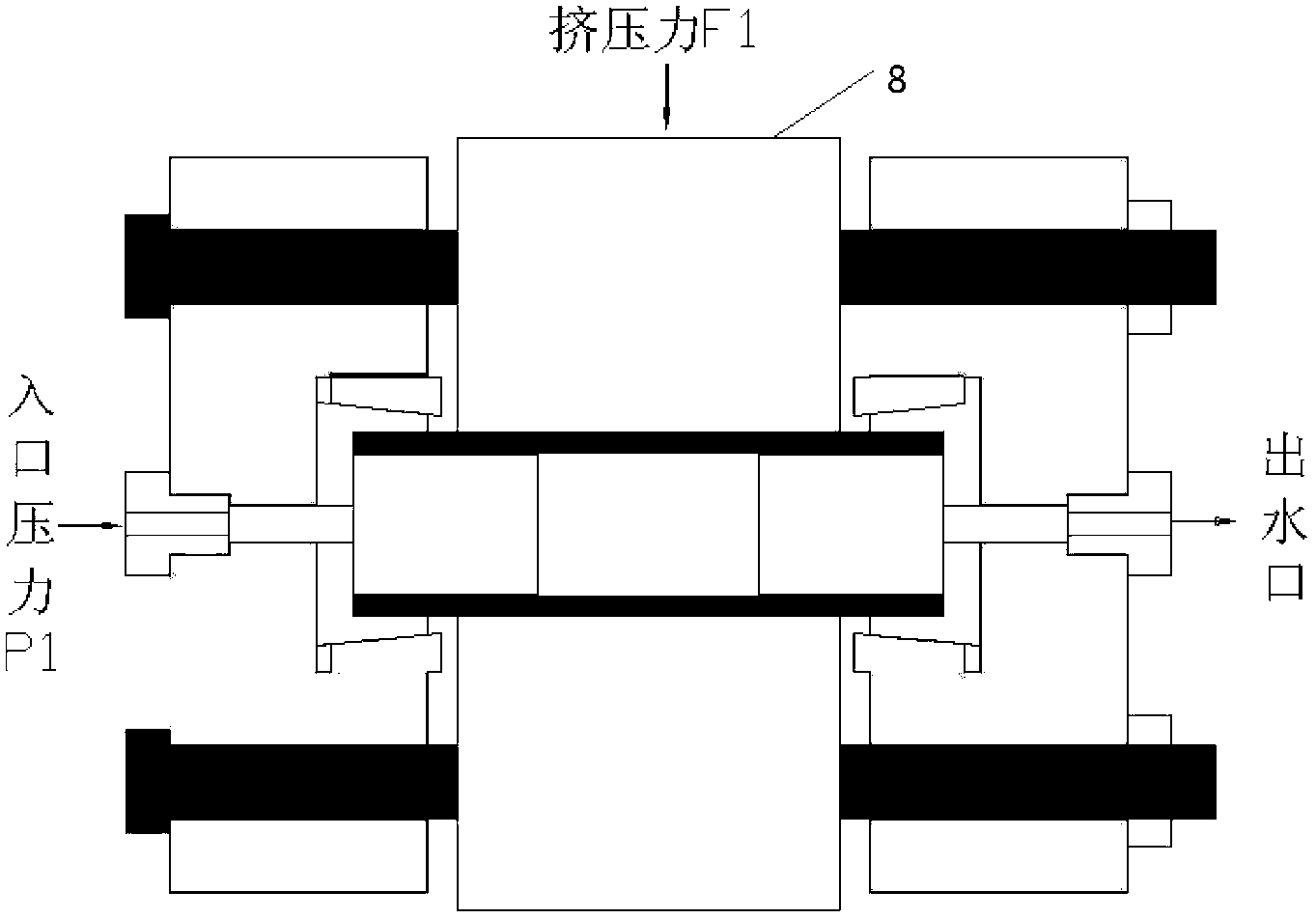

Well cementation cement sheath integrity simulation and evaluation tester

A well cementation cement sheath integrity simulation and evaluation tester includes pressing joints, wherein the pressing joints are arranged on compress packings; screwing compression rings are connected with compress discs through screw threads, and fix trapezoid rubber seal rings onto the compress discs and a steel tube; the steel tube containing a well cementation cement solidified body test sample is clamped tightly by screw rod and screw nut connecting assemblies and connected with the screw rod and screw nut connecting assemblies into a whole; pressing blocks and a mechanical pressure device are connected together to exert mechanical extrusion force to simulate the process that underground pressure variation causes damage and micro cracks to an oil well cement sheath; the pressing joints and a fluid pressing device are connected, so as to exert fluid pressure, simulate fluid pressure of the formation fluid on the well cementation cement sheath, and test and evaluate anti-channeling strength of the well cementation cement sheath; cured samples are placed in the well cementation cement sheath mechanical property simulation tester for test and analysis; and the tester can detect variation situations of the anti-channeling strength of the well cementation cement sheath under different conditions, so that impacting ductility and packing reliability of the well cementation cement sheath can be evaluated accurately.

Owner:XI'AN PETROLEUM UNIVERSITY

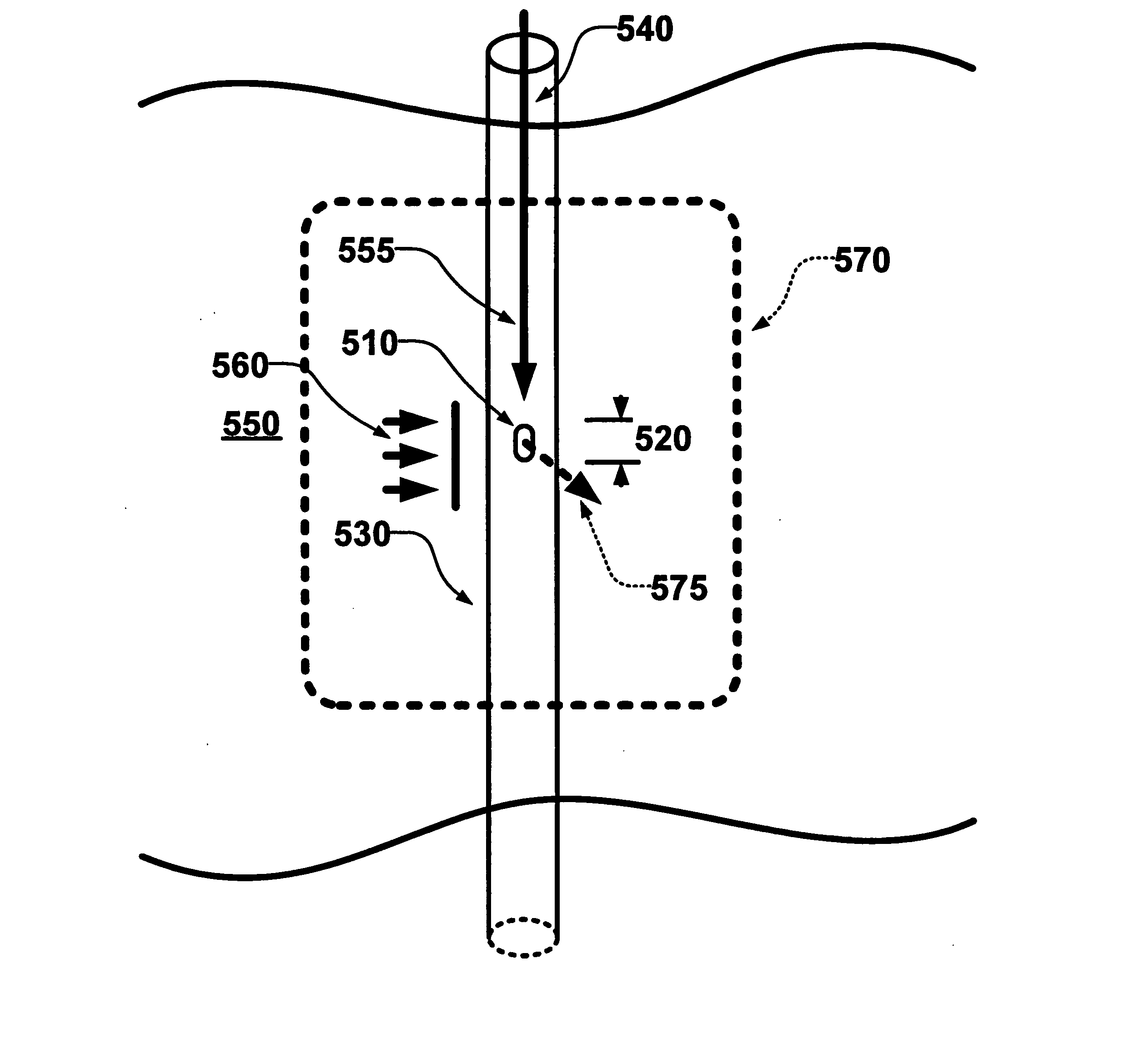

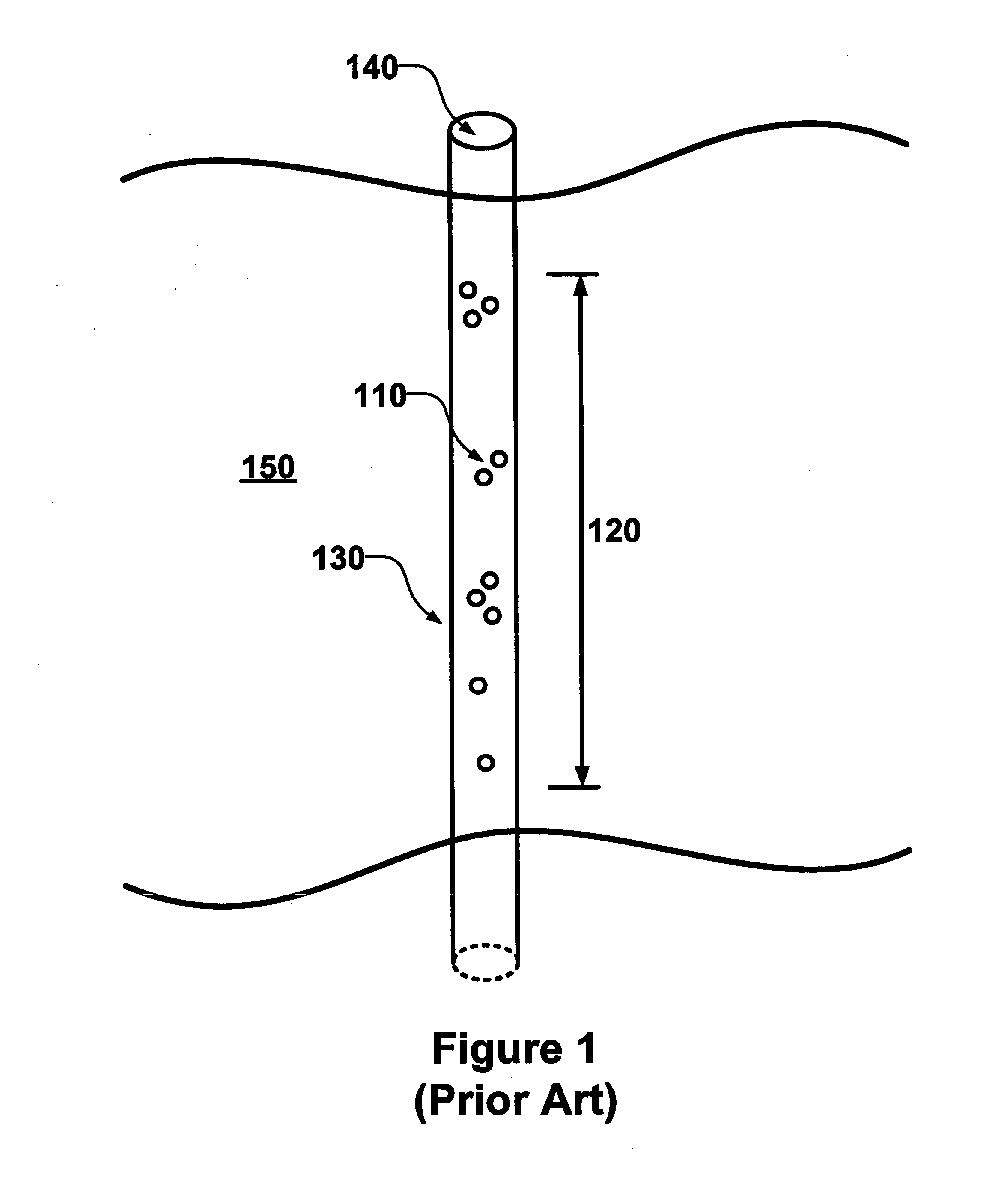

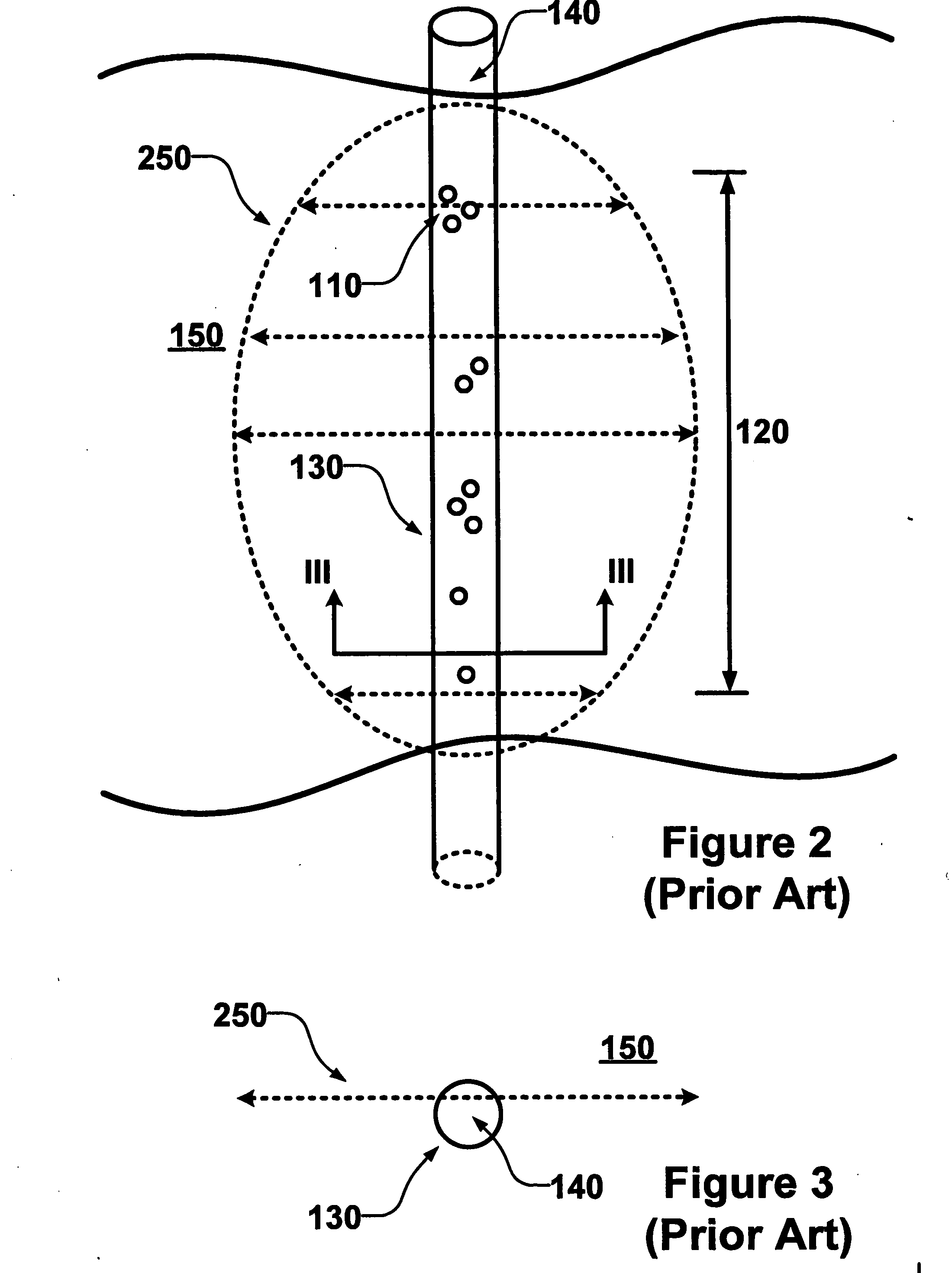

Downhole flow-back control for oil and gas wells by controlling fluid entry

InactiveUS20080000637A1Improving downhole flow-back controlEffective controlFluid removalEngineeringHydrocarbon exploration

A method and apparatus for use in hydrocarbon exploration. The method and apparatus improve downhole flow back control in oil and / or gas wells by controlling fluid entry into the well bore. Either a single limited entry opening or a small cluster of limited entry openings is provided in a well liner or casing and cement sheath allowing fluid communication between a region of a well bore and a subterranean reservoir. The method also uses the limited entry opening or the cluster during an injection treatment of the subterranean reservoir to control fluid entry. The method also provides a proppant flow back treatment following the injection treatment of the subterranean reservoir.

Owner:HALLIBURTON ENERGY SERVICES INC

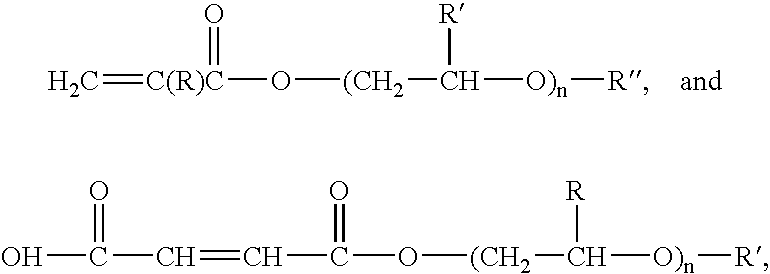

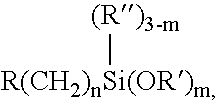

Sealant compositions comprising colloidally stabilized latex and methods of using the same

Sealant compositions comprising a colloidally stabilized latex and methods of using the same to service a wellbore are provided. The sealant compositions may include: an aliphatic conjugated diene monomer; an additional monomer comprising a non-aromatic unsaturated mono- or di-carboxylic ester monomer, an aromatic unsaturated monomer, a nitrogen-containing monomer, or combinations thereof; and a protective colloid. The foregoing sealant composition may be displaced into the wellbore to isolate the subterranean formation from a portion of the wellbore, to support a conduit in the wellbore, to plug a void or crack in the conduit, to plug a void or crack in a cement sheath disposed in an annulus of the wellbore, to plug an opening between the cement sheath and the conduit, or combinations thereof. The colloidally stabilized latex remains substantially stable when exposed to salt, which may be present in the wellbore and / or in the sealant composition itself.

Owner:HALLIBURTON ENERGY SERVICES INC

Apparatus and Method for Penetrating Oilbearing Sandy Formations, Reducing Skin Damage and Reducing Hydrocarbon Viscosity

InactiveUS20090235836A1Minimal damageSmall compressionAmmunition projectilesExplosive chargesPorosityPolyester

A shaped charge and a method of using such to provide for large and effective perforations in oil bearing sandy formations while causing minimal disturbance to the formation porosity is described. This shaped charge uses a low-density liner having a filler material that is enclosed by outer walls made, preferably, of plastic or polyester. The filler material is preferably a powdered metal or a granulated substance, which is left largely unconsolidated. The preferred filler material is aluminum powder, or aluminum particles, that are coated with an oxidizing substance, such as TEFLON®, permitting a secondary detonation reaction inside the formation following jet penetration. The filled liner is also provided with a metal cap to aid penetration of the gun scallops, the surrounding borehole casing and the cement sheath. The metal cap forms the leading portion of the jet, during detonation. The remaining portion of the jet is formed from the low-density filler material, thereby resulting in a more particulated jet. The jet results in less compression around the perforation tunnel and less skin damage to the proximal end of the perforation tunnel.

Owner:OWEN OIL TOOLS

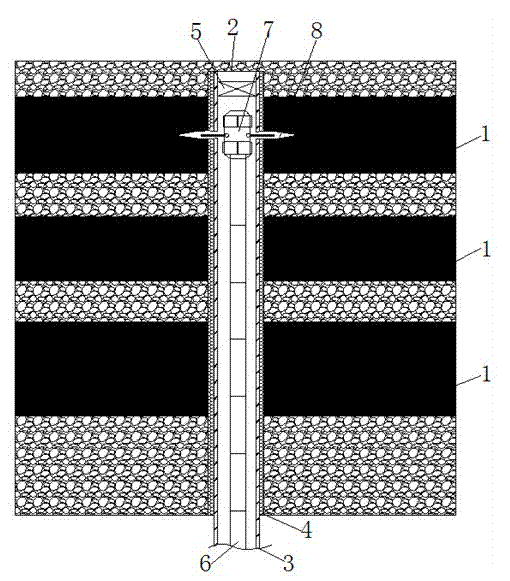

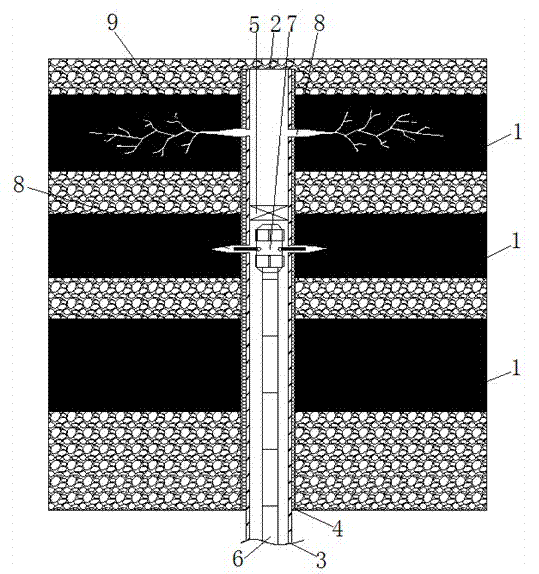

Layered hydraulic fracturing method of underground coal mine multiple coal seams

InactiveCN103174453ASolve the shortage of decompression and antireflectionFix bugsFluid removalGas removalHydraulic fracturingHigh pressure water

The invention discloses a layered hydraulic fracturing method of underground coal mine multiple coal seams. The layered hydraulic fracturing method of the underground coal mine multiple coal seams is suitable for layered air-permeability-increasing operation in soft and low-air-permeability coal seam groups and includes the following steps: (1) punching a hydraulic fracturing drilling hole penetrating all coal seams; (2) installing a coal seam hydraulic fracturing sleeve pipe in the hole, and then fixing the hole to the bottom with cement paste; (3) in the mode of hole sealing with capsules, sealing the hole to a top plate of the coal seam to be fractured, and then through a high-pressure sealing drill rod, sending a special perforating gun to the coal seam to be fractured in the hole; (4) calibrating the position of the perforating gun, aiming at the coal seam to be fractured, through the high-pressure sealing drill rod, pumping perforating liquid to the perforating gun to shoot through the sleeve pipe and a cement sheath, and a perforating orifice is formed in the coal seam; (5) taking the perforating gun and the high-pressure sealing drilling rod out of the sleeve pipe; (6) leading high-pressure water in the sleeve pipe to carry out hydraulic fracturing on the coal seam in the position of the perforating orifice; and (7) after a coal seam is fractured, repeating the steps (3) to (6) to carry out hydraulic fracturing on a next coal seam until all the coal seams are fractured. Effective pressure relief and air-permeability increasing in layered coal seam groups can be achieved, and the method of the underground coal mine multiple coal seam layered hydraulic fracturing is simple, good in effect and low in cost.

Owner:CHONGQING UNIV

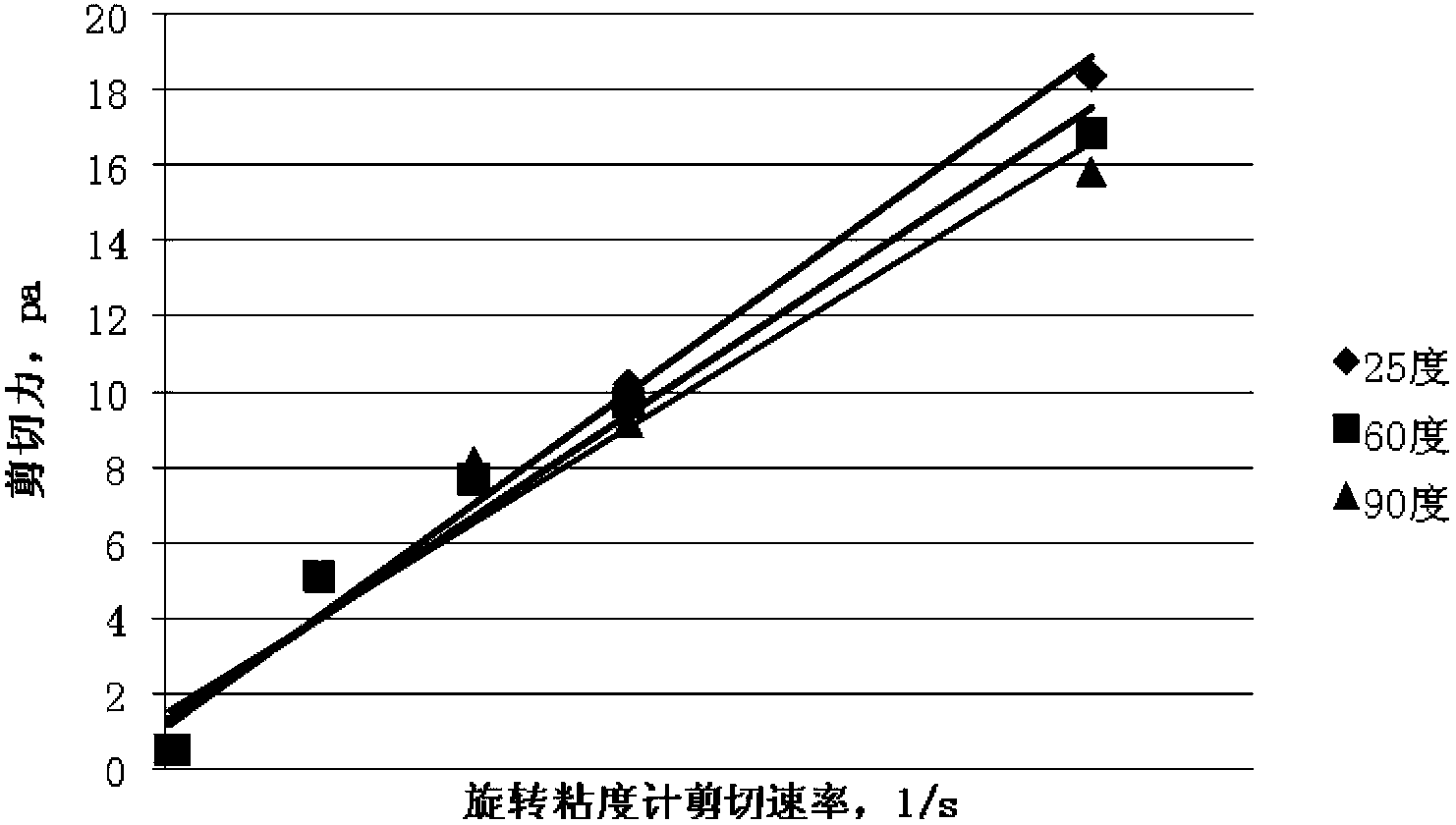

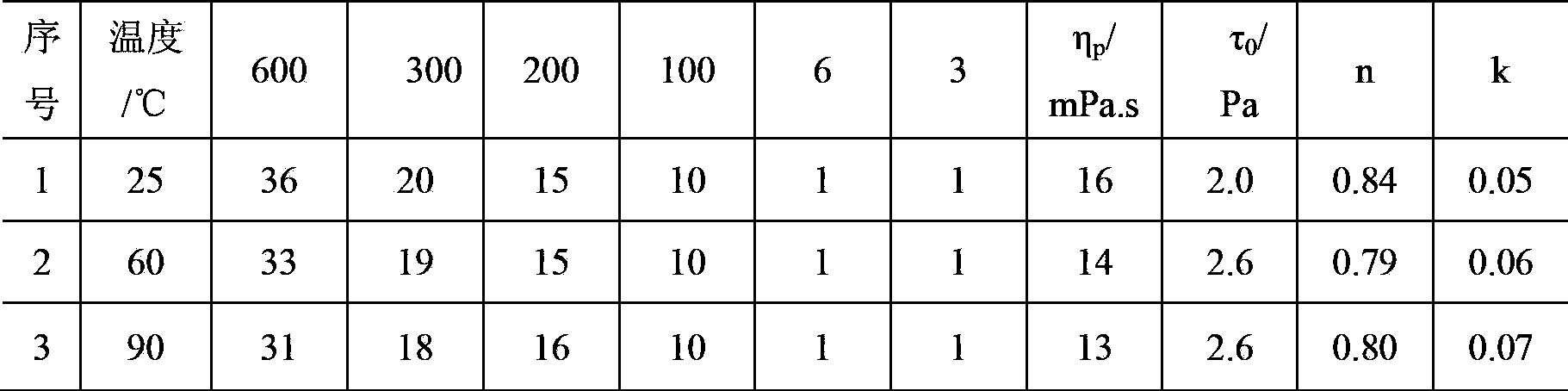

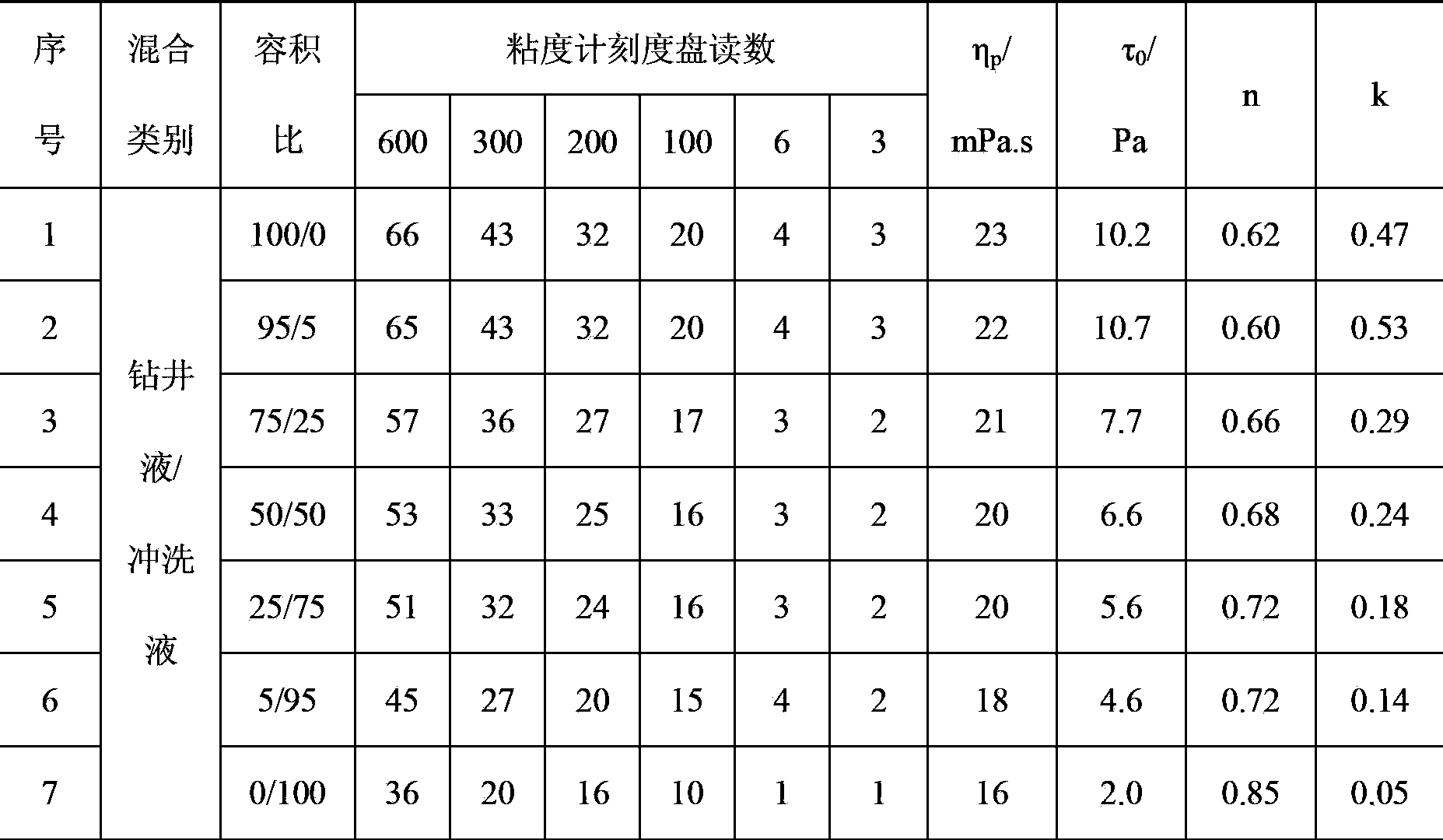

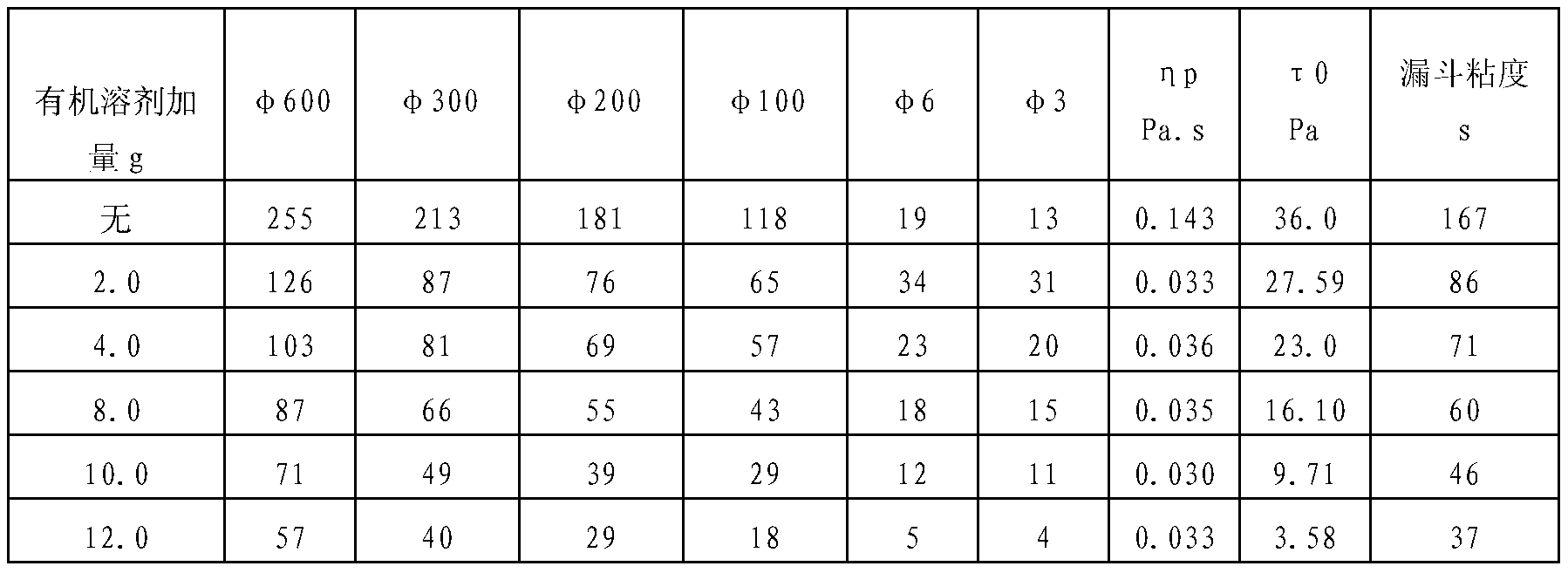

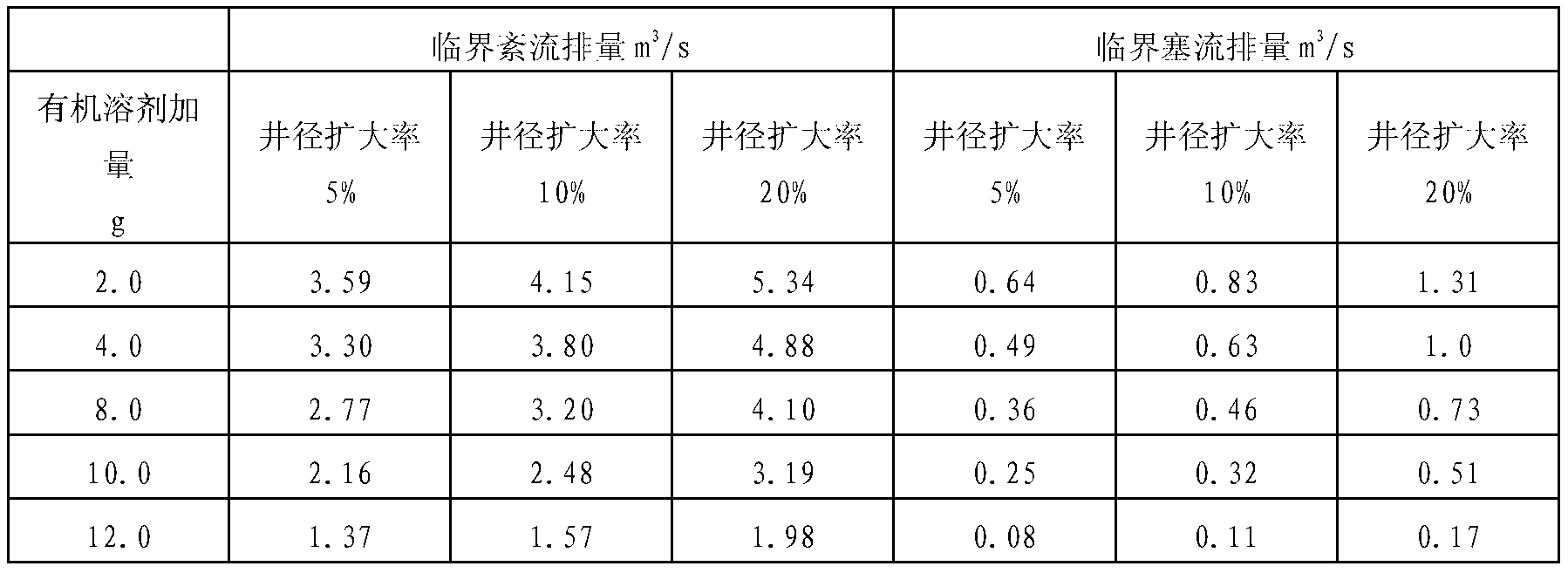

Flushing liquid for oil-based drilling fluid well cementation and preparation method thereof

ActiveCN103849364AGood physical scouring effectSystem stabilityDrilling compositionSuspending AgentsSlurry

The invention relates to a flushing liquid for oil-based drilling fluid well cementation and a preparation method thereof. The preparation method of the flushing liquid comprises: adding 1 part by weight of a suspending agent into 70 parts by weight of fresh water, stirring for 3 min with a speed of 4000 rpm, and dissolving for 30 min; adding 1-3 parts by weight of a chelating agent and 1-6 parts by weight of a cleaning auxiliary agent, and stirring for 10 min with a speed of 4000 rpm; with the stirring speed of 4000 rpm, adding 20 parts by weight of solid particles within 20 s, and stirring for 1 min; weighing 30 parts by weight of 40 DEG C fresh water, dissolving 5-15 parts by weight of a cleaning agent into the water; and finally uniformly mixing the cleaning agent solution with the above prepared solution, so as to prepare the flushing liquid. The flushing liquid has the characteristics of relatively strong permeation effect, oil flushing property and the like, used to flush oil slurry and oil films attached to well wall and casing pipe wall, helps to improve the affinity of a drilling fluid with a cement sheath and enhance the cementation property between the cement sheath and well cementation first and second interfaces, has the compatibility with conventional cement paste and oil-based drilling fluids, and is capable of improving and enhancing the rheological property of a drilling fluid system.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

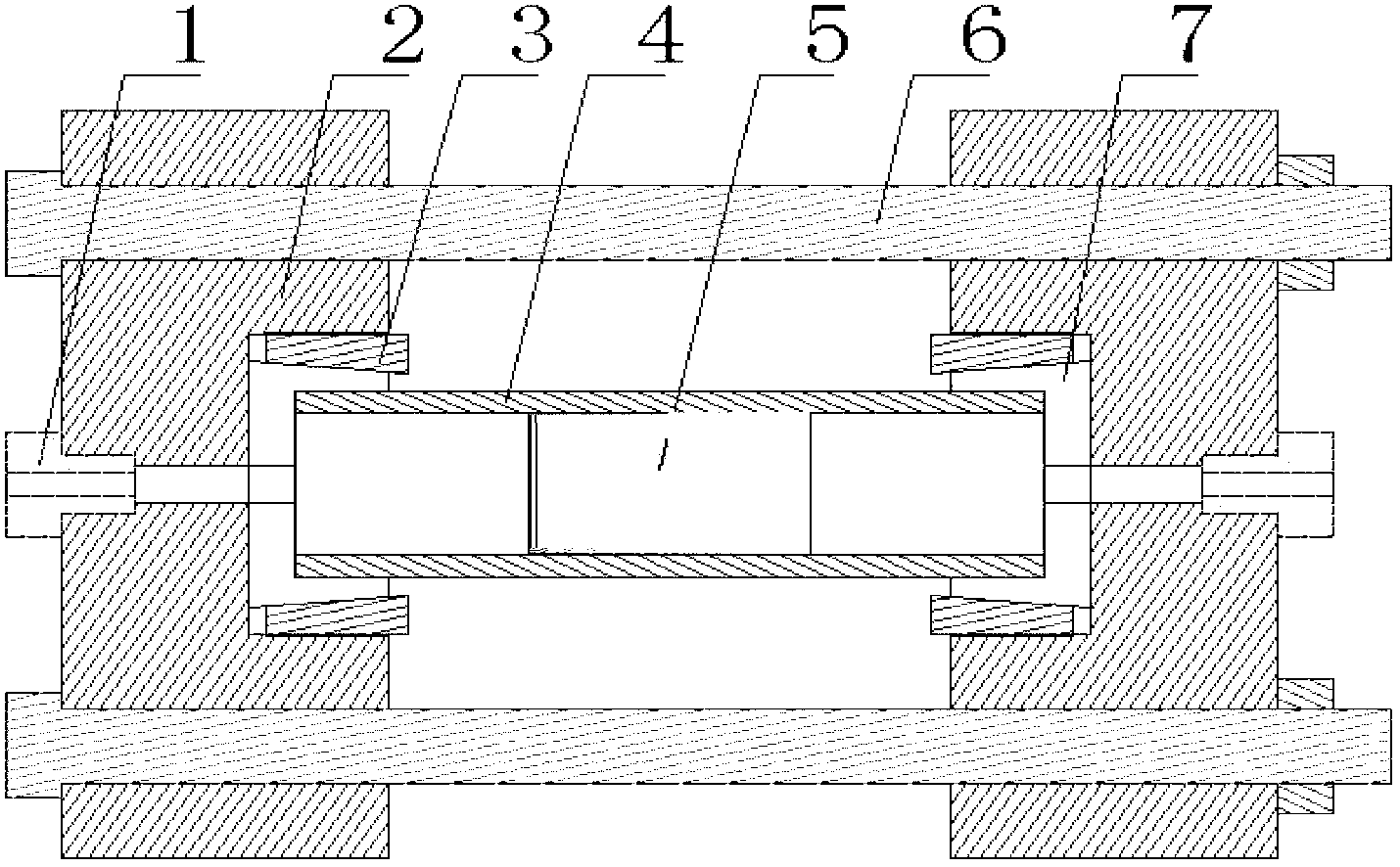

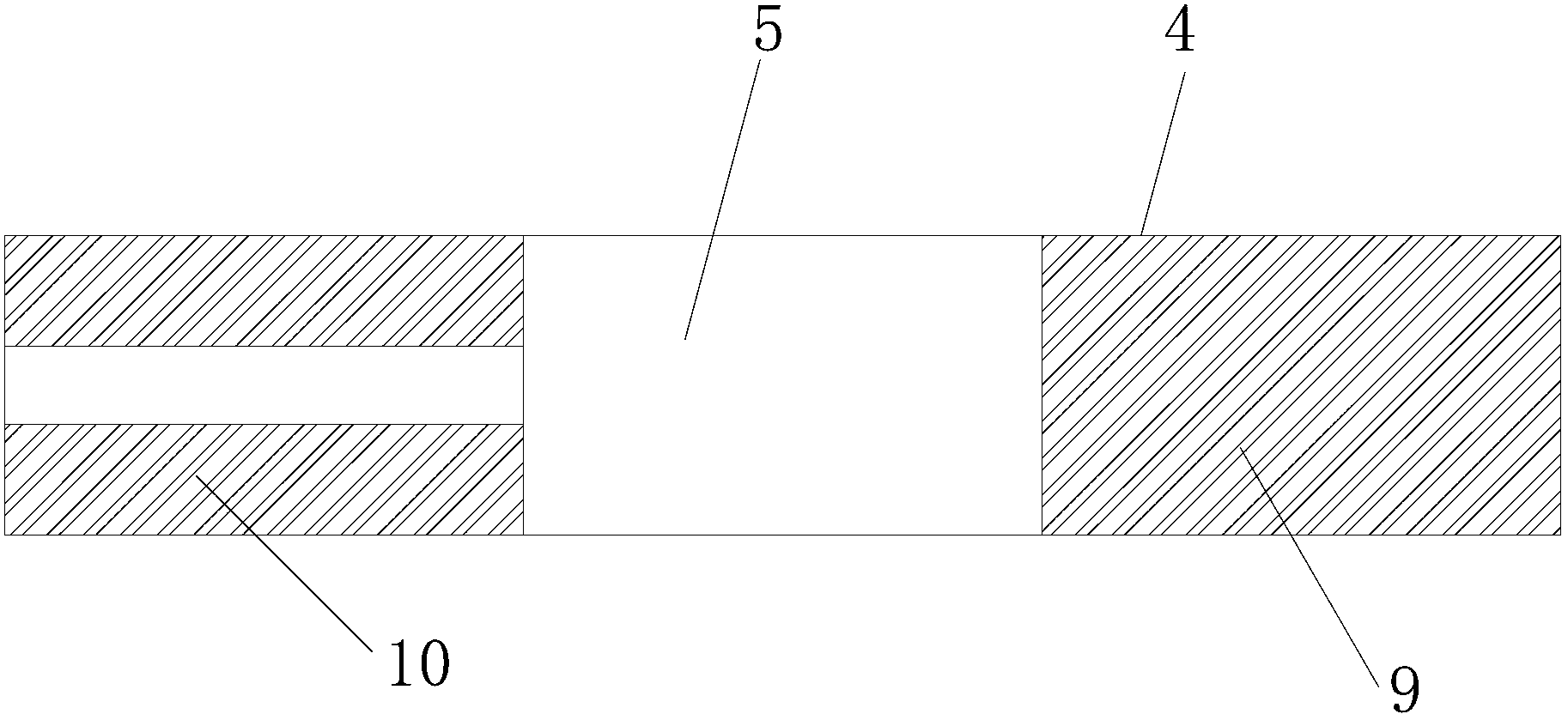

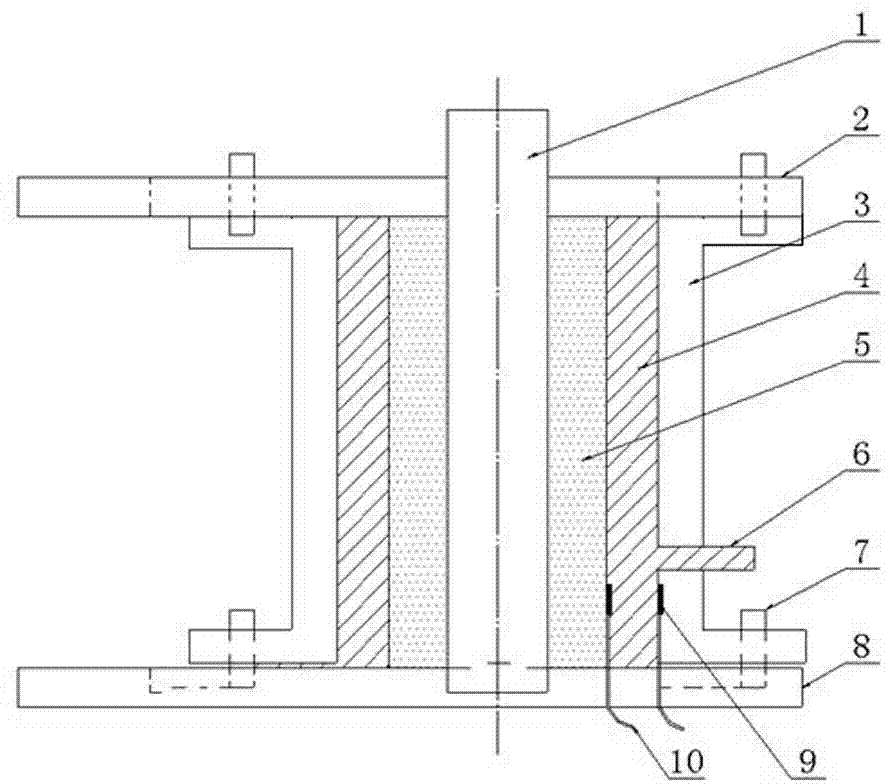

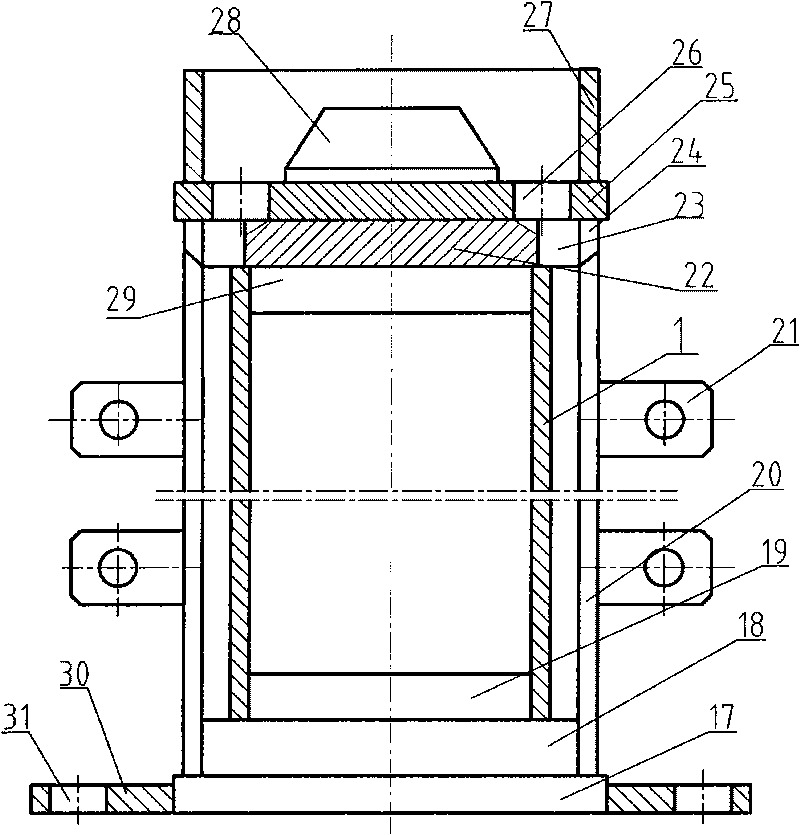

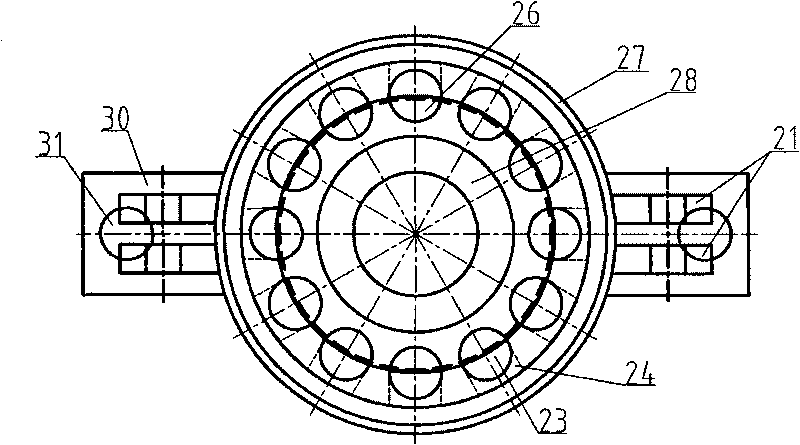

Cement sheath structural integrity mechanics experiment device

The invention relates to a cement sheath structural integrity mechanics experiment device which is composed of a cement sheath maintenance die and a three-shaft stress maintenance kettle. The cement sheath maintenance die is arranged inside an inner cavity of the three-shaft stress maintenance kettle. The cement sheath maintenance die comprises an adjustable eccentricity upper flange cover, a simulation well wall, a simulation well wall outer protective barrel, a casing pipe and an adjustable eccentricity lower flange plate. The three-shaft stress maintenance kettle comprises a barrel-shaped container, a confining pressure oil cylinder, an oil cylinder piston, an axial load piston, a confining pressure piston, an annular heating element and an electrode. The confining pressure piston is arranged inside the barrel-shaped container, the confining pressure oil cylinder is arranged on the upper end face of the barrel-shaped container in a sitting mode, a silicone oil cavity is formed between the confining pressure oil cylinder and the oil cylinder piston, an axial load sensor is connected with the axial load piston, a pressing machine upper plate is arranged at the upper end of the axial load sensor, the annular heating element is arranged inside the barrels-shaped container, the lower end face of the annular heating element presses the electrode, and the annular heating element is connected with a thermoelectric coupler. The cement sheath structural integrity mechanics experiment device can simulate the actual working condition of the oil-gas well construction, and the measured cement strength of a cement interface conforms to the actual site work better and more accurately.

Owner:NORTHEAST GASOLINEEUM UNIV

Two-interface cementing strength testing device of cementing sheath containing hydrates and ice stratum

InactiveCN105484729ASimple structureEasy to operateConstructionsTemperature controlPolyvinyl alcohol

The invention discloses a two-interface cementing strength testing device of a cementing sheath containing hydrates and an ice stratum. The testing device comprises a kettle shell base and a simulation sleeve which is vertically arranged in the middle of the kettle shell base. A polyvinyl alcohol membrane tube is arranged on the periphery of the simulation sleeve, an annular cavity is formed between the simulation sleeve and the polyvinyl alcohol membrane tube, a temperature control circulating bath sealing cover is arranged on the outer edge of the top of the kettle shell base in a surrounding mode, the position between the temperature control circulating bath sealing cover and the polyvinyl alcohol membrane tube is filled with a simulation stratum, the top of the simulation stratum is covered with a stratum kettle cover, the top of the simulation sleeve is covered with a pressurizing kettle cover which covers the top of the cavity, and a pressure device for pressurizing the pressurizing kettle cover is arranged above the pressurizing kettle cover. The testing device has the advantages that the structure is simple, installing and using are convenient, production cost is low, and a detection result is accurate and reliable.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

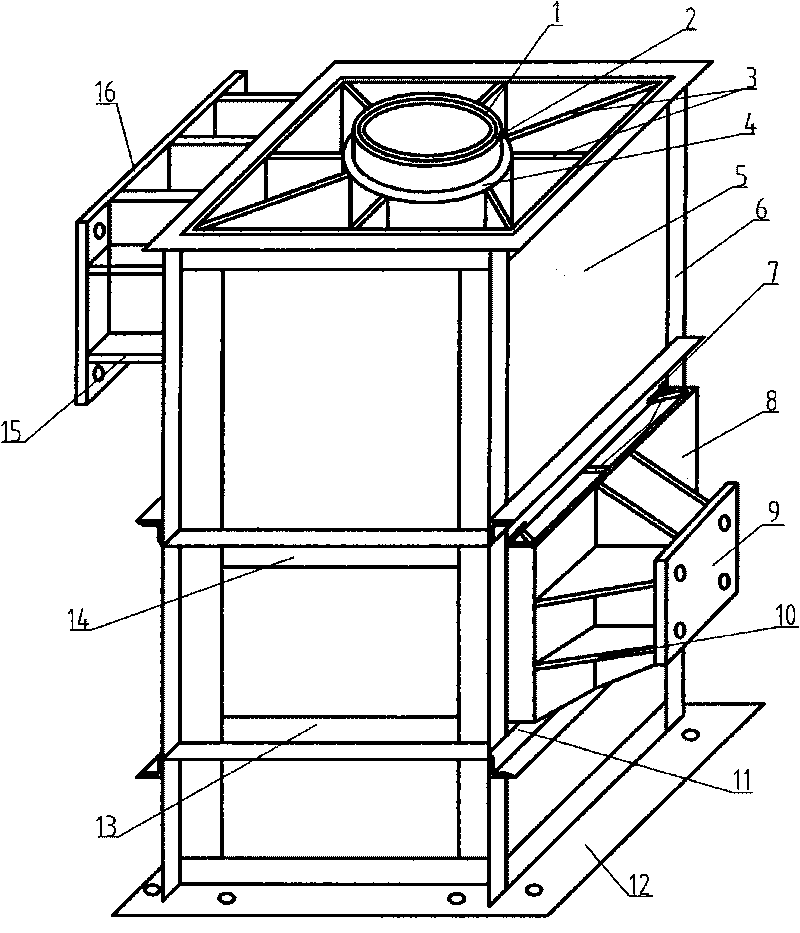

Device for simulating casing-cement sheath damage indoor test under stratum action

The invention relates to a simulation test device in petroleum extraction industry, in particular to a device for simulating a casing-cement sheath damage indoor test under stratum action. The device comprises a stratum action simulator and a well cementing casing-cement sheath indoor simulation maker. A case frame is connected with a multi-layer case formed by cover sheets; the bottom layer and the top layer of the multi-layer case are fixed layers, and the middle layer is a drawable movable layer; the internal space of the case frame is provided with a reinforcing steel casing by a reinforcing plate connected with the case frame, wherein the reinforcing steel casing is arranged section by section, and the number of the sections is coincident with that of the layers of the multi-layer case; a mould base is provided with a steel tube; a packing space is reserved between the casing and the steel tube; the casing is supported with a circular baffle on which slurry inlet holes and gas vents are evenly arranged; a tubular upper cover is arranged above a support plate; and the gyration centre of the support plate is provided with a guide post. The invention can simulate the casing-cement sheath damage indoor test under stratum action, thereby providing the test basis for the cause of formation of oil well casing damage.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

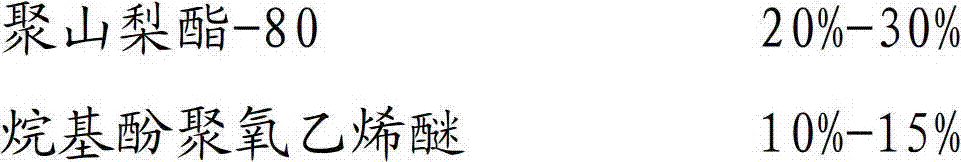

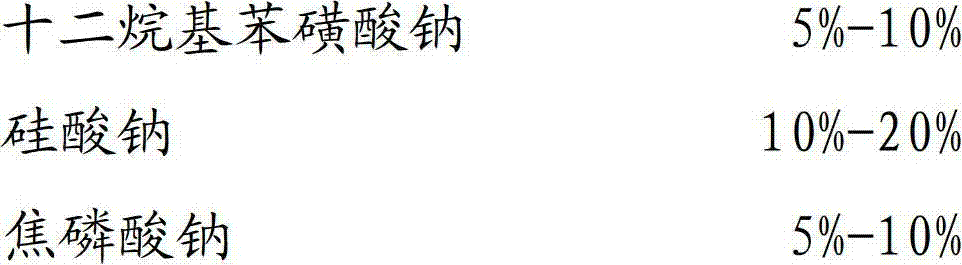

Organic and inorganic composite flushing liquid as well as preparation method and applications thereof

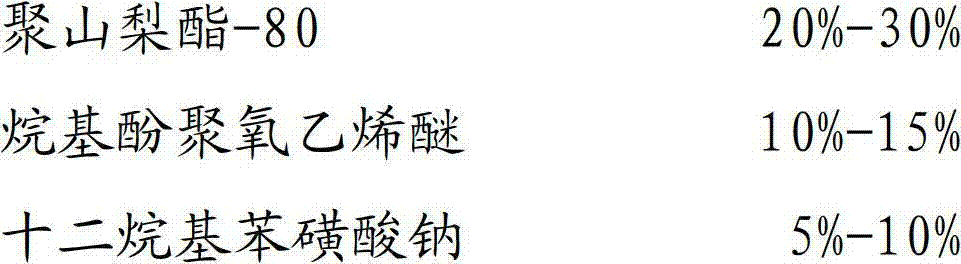

ActiveCN102732239AImprove the interface bonding strengthImprove flushing efficiencyDrilling compositionWater basedPolyethylene glycol

The invention discloses a preparation method of an organic and inorganic composite flushing liquid, and belongs to the technique of oil well cement well cementation. The flushing liquid comprises the following components: polysorbate-80, alkyl phenol polyethylene glycol ether, dodecyl benzene sulfonic acid sodium, sodium silicate, sodium pyrophosphate and water, wherein the mass ratio of each component is as follows: 20%-30% of polysorbate-80, 10%-15% of alkyl phenol polyethylene glycol ether, 5%-10% of dodecyl benzene sulfonic acid sodium, 10%-20% of sodium silicate, 5%-10% of sodium pyrophosphate and the balance of water. The flushing liquid is suitable for both the oil-based mud and water-based mud, has high flushing efficiency, improves the replacement efficiency of a well drilling liquid and cement sheath interfacial cementation quality, and can be used under the condition of 50 DEG C-200 DEG C.

Owner:天津科力奥尔工程材料技术有限公司

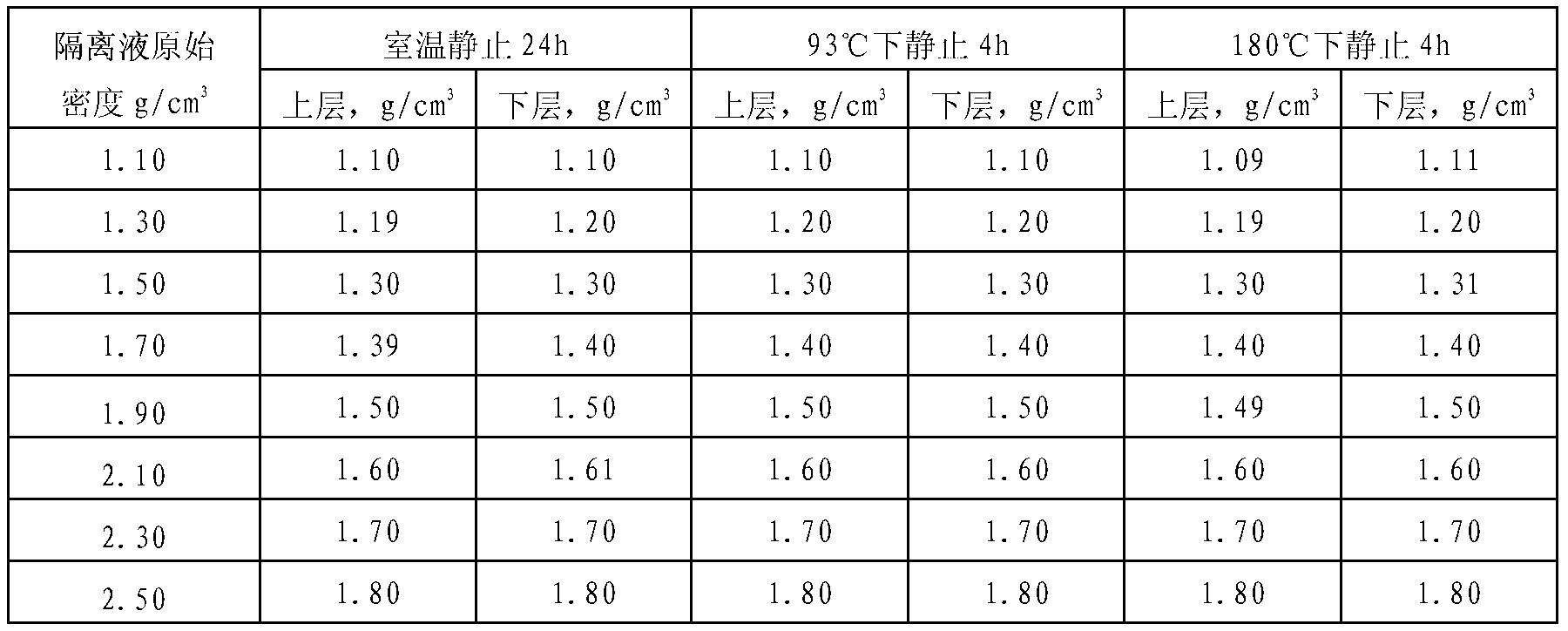

Dual-effect well cementing pad fluid using suspending agent as surfactant

ActiveCN103224774AWide range of density adaptationImprove cleanlinessDrilling compositionActive agentDual effect

The invention relates to a dual-effect well-cementing pad fluid using a suspending agent as a surfactant, and mainly solves problems that present well-cementing pad fluid is added with high-molecular polymer grade inorganic suspending agent which can influence compatibility and cement sheath cementation and thus influence sealing effect of well cementing and exploitation operation in a later stage. The dual-effect well-cementing pad fluid comprises the following components by weight parts: 12-20 parts of a flushing suspending agent, 0.2-1 part of an antifoaming agent, 0-420 parts of a weighting agent and 100 parts of water. The dual-effect well-cementing pad fluid using a suspending agent as a surfactant can eliminate adverse influences of inorganic soil and the high-molecular polymer in the well-cementing pad fluid on the compatibility and the cement sheath cementation, improve flushing and displacing effects on a drilling fluid, and guarantee quality of well cementing and the exploitation operation in the later stage.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Minimal resistance scallop for a well perforating device

InactiveUS20050139352A1Lower energy requirementsImprove structural strengthNuclear explosivesFluid removalDepth of penetrationStructural engineering

The present invention is an improvement in the design of a perforating gun to perforate the casing in oil and gas wells. Perforating guns have a cylindrical body member with explosive charges at specified intervals designed to shoot outwardly through the body member, the well casing, cement sheath, and into the rock formation. There are recessed areas, scallops, on the outer surface of the body member where the perforating jets, formed by the explosive charges, exit the body member. The present invention uses the strength of an arching geometric shape for the recessed area to be able to further reduce the thickness of steel for minimal resistance to the perforating jet. Minimizing the resistance to the perforating jet increases the depth of penetration into the rock formation and increases the hole size.

Owner:MAULDIN SIDNEY WAYNE

Method for evaluating self-repairing performance of well cementation cement sheath

InactiveCN103558363AEfficient evaluation of self-healing propertiesAccurate dataPreparing sample for investigationMaterial testing goodsWell cementingHigh pressure

The invention discloses a method for evaluating self-repairing performance of a well cementation cement sheath. The method sequentially comprises the following steps: (1) preparing self-repairing cement paste for well cementation, pouring the self-repairing cement paste into a bending-resistant and splitting tensile mold, and maintaining for a certain time in a high-temperature high-pressure maintenance kettle, so that the cement paste is solidified into set cement; (2) testing the bending strength and tensile splitting strength of the set cement which is completely broken; (3) maintaining the tested broken set cement in a maintenance device for 24 hours, and measuring the bending strength and tensile splitting strength of the set cement again; (4) calculating a bending strength repair rate and a tensile splitting strength repair rate of the set cement; and (5) repeating the steps (2) to (4), and solving an average value of the repair rates, wherein the set cement is considered to have the self-repairing performance when the average bending strength repair rate is more than or equal to 50 percent and the average tensile splitting strength repair rate is more than or equal to 30 percent. The method has the advantages that the principle is reliable, a calculation method is simple, the repair rates of the set cement can be accurately tested, and the method is suitable for evaluating the self-repairing performance of various types of well cementation set cement.

Owner:SOUTHWEST PETROLEUM UNIV

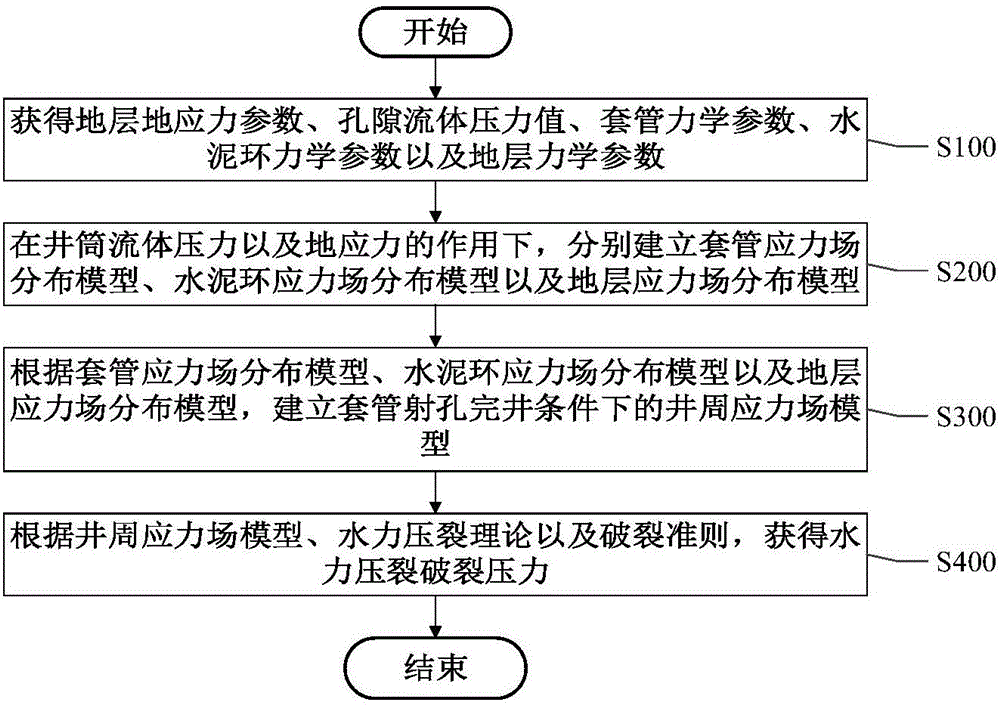

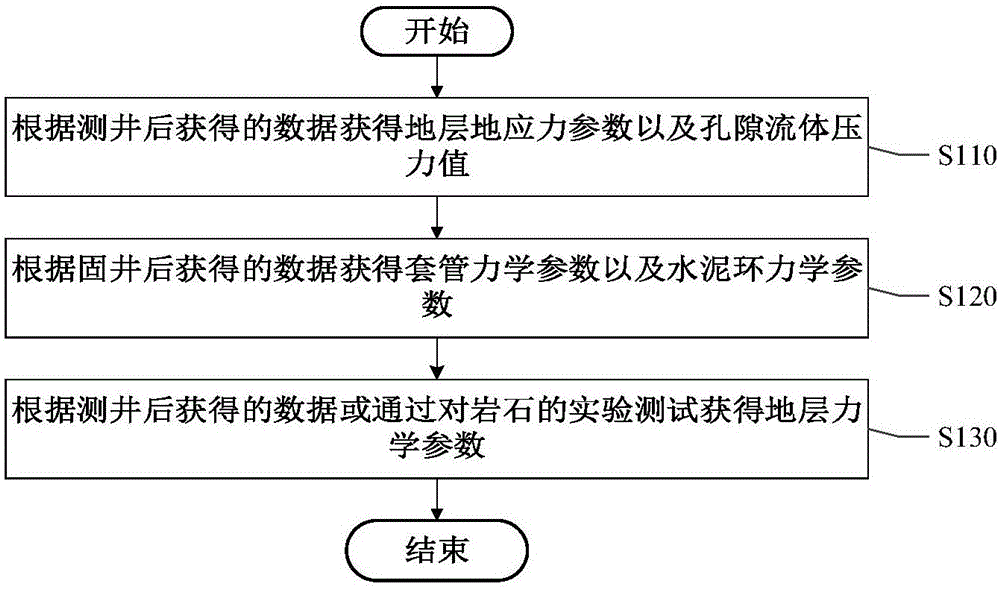

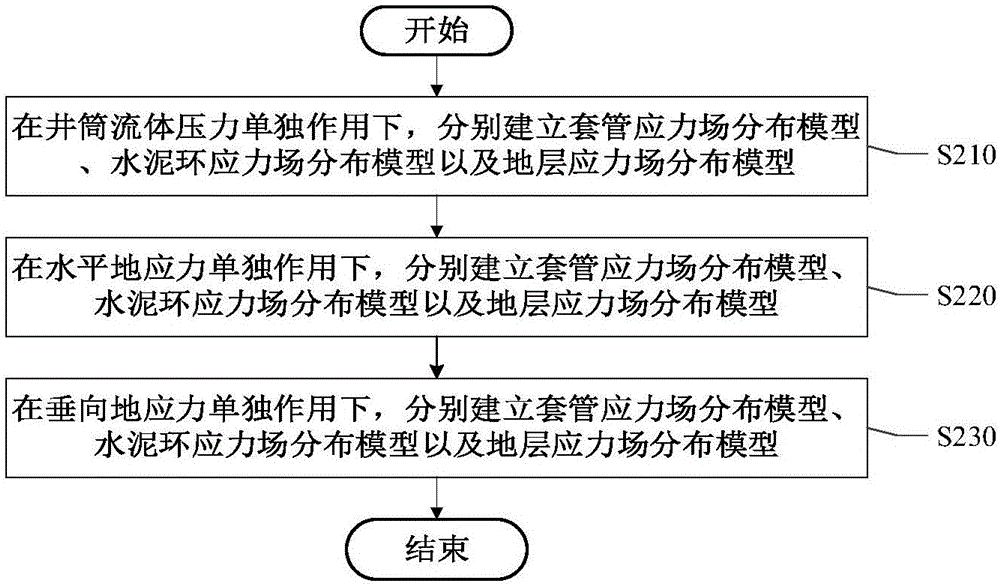

Method and device for acquiring hydrofracture bursting pressure

ActiveCN106223918AFluid removalDesign optimisation/simulationHydraulic fracturingMaterial Perforation

The embodiment of the invention provides a method and device for acquiring a hydrofracture bursting pressure, wherein a stratum ground stress parameter, a pore fluid pressure value, a casing mechanical parameter, a cement sheath mechanical parameter and a stratum mechanical parameter are obtained; and under effects of a shaft fluid pressure and ground stress, a casing stress field distribution model, a cement sheath stress field distribution model and a stratum stress field distribution model are established respectively. According to the casing stress field distribution model, the cement sheath stress field distribution model and the stratum stress field distribution model which are already established, a well-circumference stress field model under a well-cased perforation completion condition can be established; and then, the hydrofracture bursting pressure can be acquired according to the well-circumference stress field model, hydrofracture theories and bursting norms. In comparison with existing methods for acquiring the hydrofracture bursting pressure, the method for acquiring the hydrofracture bursting pressure provided by the embodiment of the invention considers more comprehensive factors and is closer to actual well completion situations.

Owner:SOUTHWEST PETROLEUM UNIV

Method of sealing wells by squeezing sealant

A method for sealing a well includes: placing an obstruction in a bore of an inner tubular string disposed in a wellbore; forming an opening through a wall of the inner tubular string above the obstruction; mixing a resin and a hardener to form a sealant; and squeezing the sealant into the bore, through the opening, and into an annulus formed between the inner tubular string and an outer tubular string, thereby repairing a cement sheath present in the annulus.

Owner:WILD WELL CONTROL

Methods and materials for zonal isolation

ActiveUS20100065273A1Improve zonal isolationReduce the impactFluid removalFlushingCross-linkWater soluble

The invention relates to the use of one or more water-soluble reactive liquid component capable of subsequent polymerization or cross-linking to form a solid to improve the zonal isolation and alleviate the impacts of cracks and fissures in the cement sheath around a completed subterranean well. It includes the steps of injecting a wellbore fluid carrying the reactive component or additive into the wellbore, injecting a cementitious composition as slurry into the wellbore and letting said reactive liquid component pass through at least one of the interfaces between cement and formation, cement and filter cake, and filter cake and formation before forming a solid of said reactive liquid component that traverses said at least one of the interfaces.

Owner:SCHLUMBERGER TECH CORP

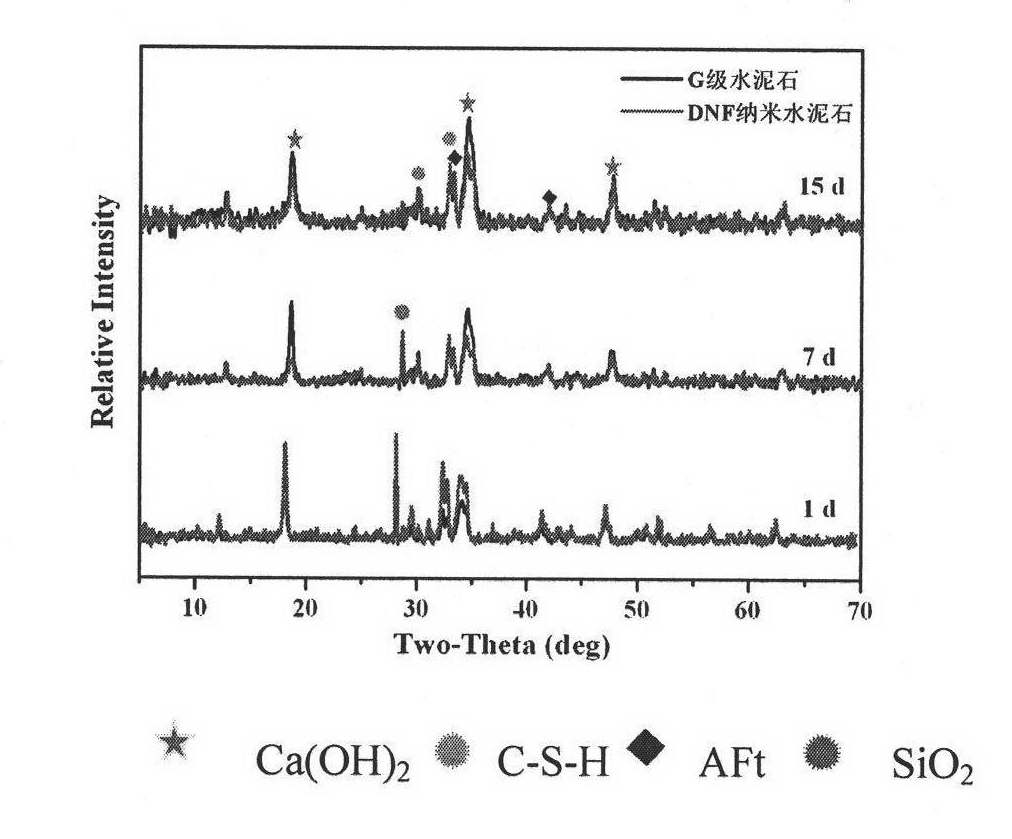

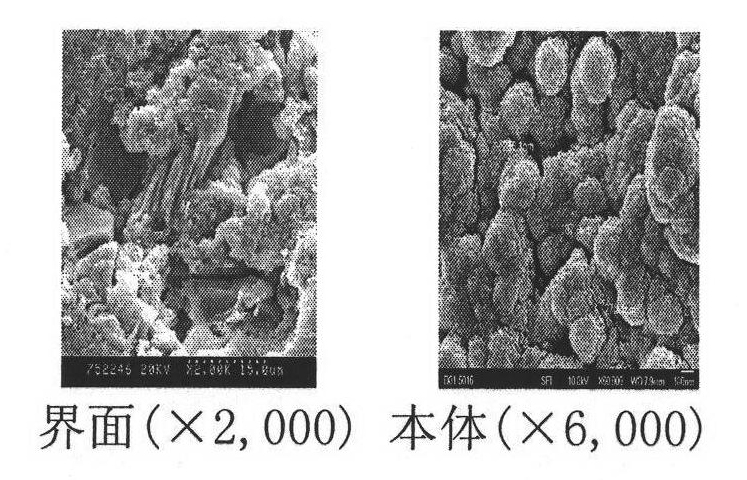

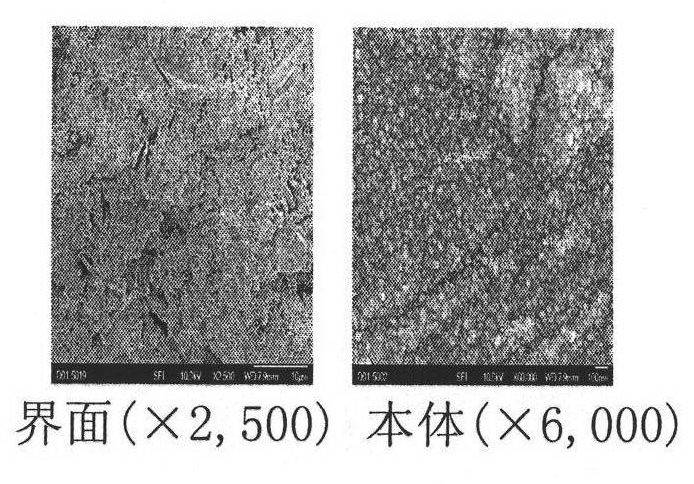

Multi-functional nanometer oil well cement slurry

InactiveCN101792660AKeep Unique PropertiesImprove cementing qualityDrilling compositionNanoparticleBond properties

The invention discloses multi-functional nanometer oil well cement slurry. The cement slurry comprises the following components in parts by weight: 2.5-3 parts of modified nanometer ferric oxide, 5-5.5 parts of modified nanometer silica, 2-2.5 parts of modified nanometer magnesium oxide, 0.2-0.5 part of dispersant Sxy and 100 parts of G-grade oil well cement, wherein the water-cement (W / C) ratio is 0.46. By using the oil well cement slurry of the invention, the blending property of nanoparticles can be increased; the flowing property of the nanometer cement slurry system can be increased; the compactness of cement can be improved, the hydrated product is optimized, and the bonding property of cement sheath interface is improved, thus increasing the cementing quality of oil and gas wells and prolonging the service life thereof.

Owner:DAQING PETROLEUM ADMINISTRATION +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com