Device for simulating casing-cement sheath damage indoor test under stratum action

A simulation test, cement sheath technology, applied in wellbore/well components, earthwork drilling and production, etc., can solve problems such as the inability to truly simulate the formation sliding action, the inability to consider the casing and cement sheath as a whole, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

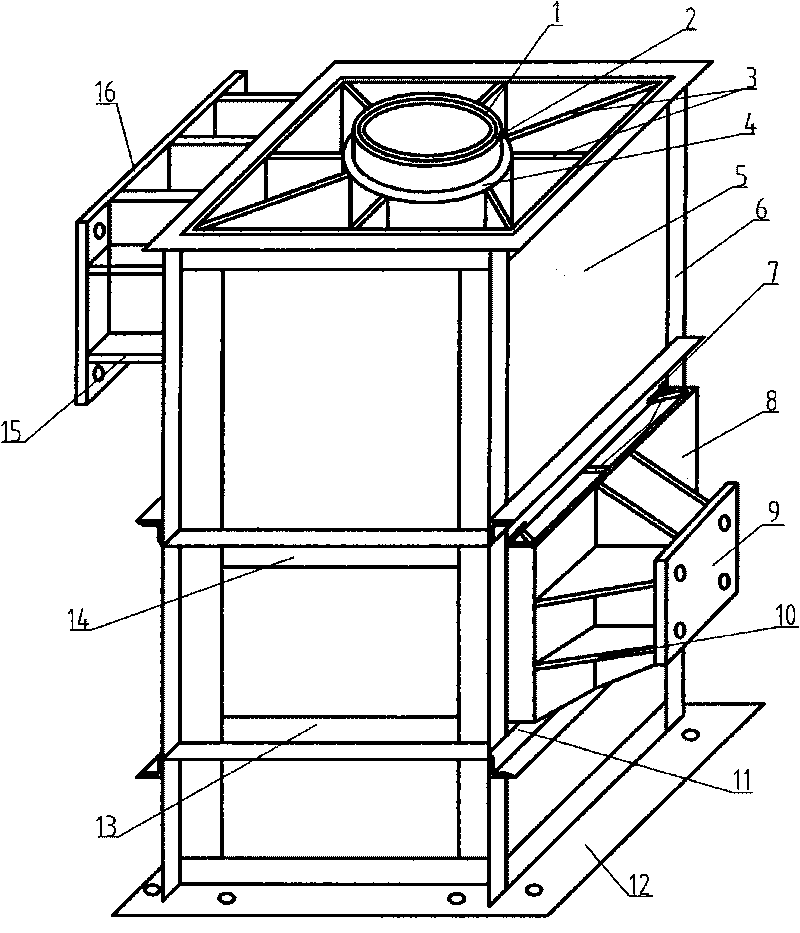

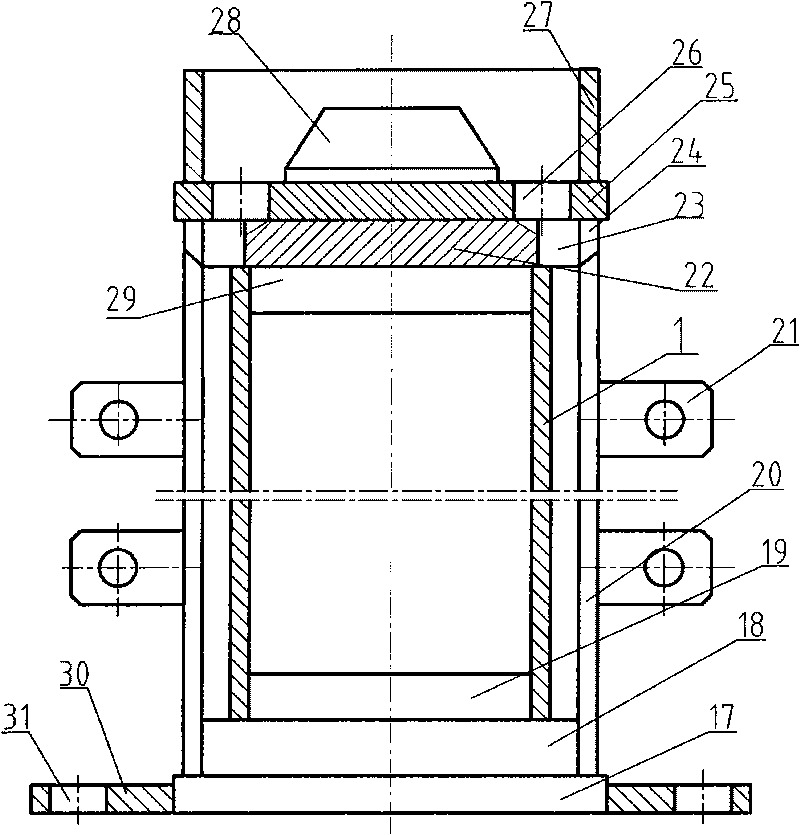

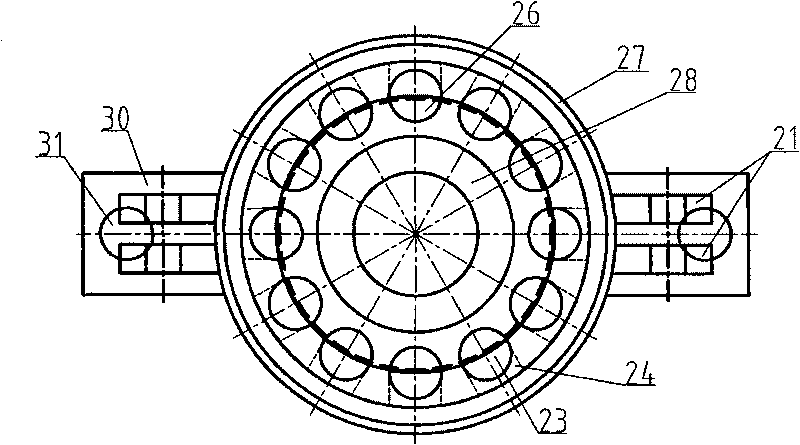

[0016] Describe the present invention in detail below in conjunction with accompanying drawing:

[0017] An indoor simulation test device for casing-cement sheath damage under formation action, see attached figure 1 , attached figure 2 And attached image 3 , in the figure: casing 1, cement sheath 2, reinforcing plate 3, reinforced steel casing 4, guard plate 5, box frame 6, upper positioning plate 7, pullable movable layer 8, actuator connector 9, Second stiffener 10, lower positioning plate 11, fixed base 12, glideway 13, upper slideway 14, first stiffener 15, reaction wall connector 16; mold base 17, base 18, lower positioning base 19, steel pipe 20. Clamping steel plate 21, circular baffle plate 22, slurry inlet hole 23, exhaust hole 24, circular support plate 25, first slurry inlet hole 26, cylindrical upper cover 27, guide column 28, upper positioning support 29 , fixed steel plate 30, reserved hole 31.

[0018] The embodiment of the present invention consists of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com