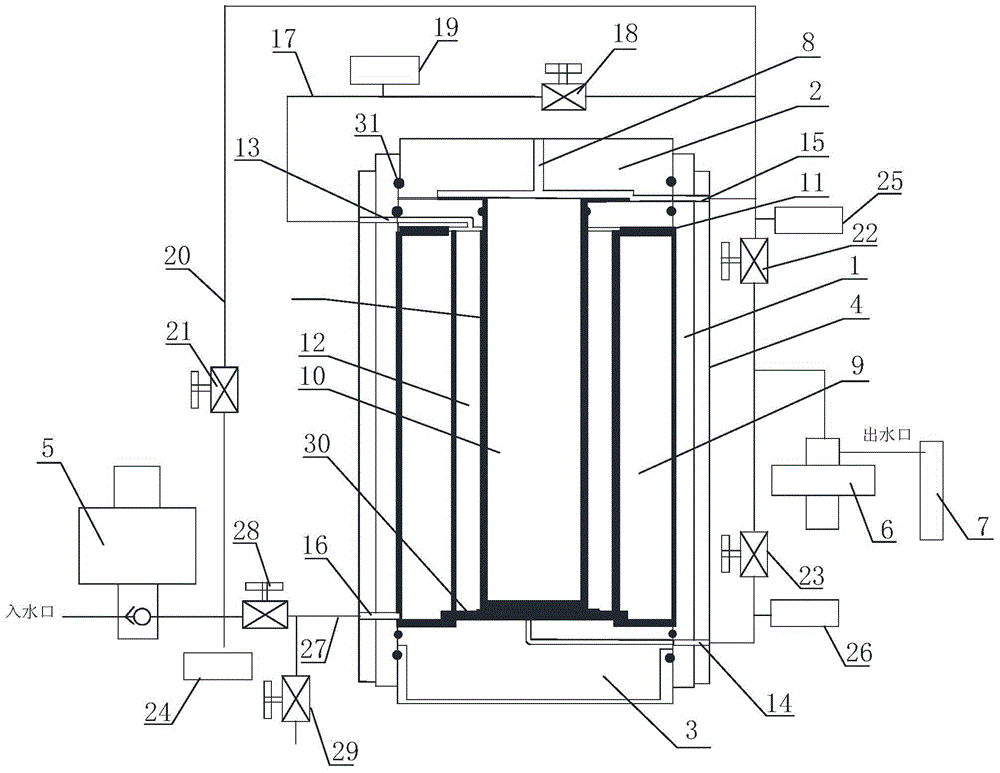

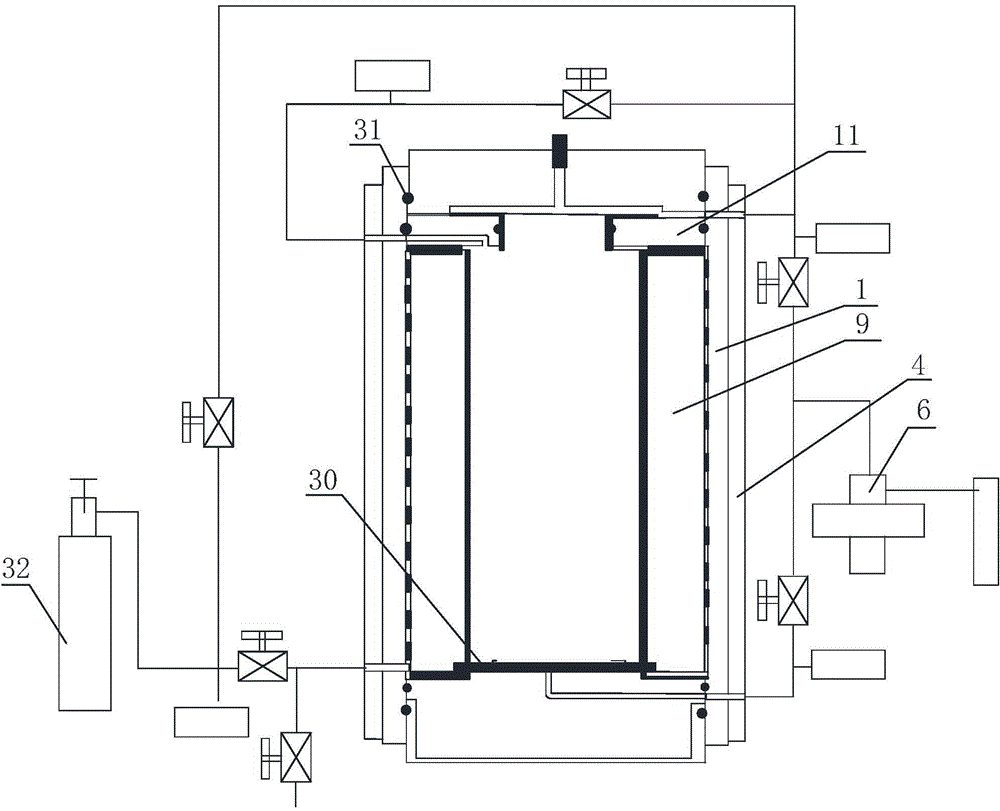

Oil-gas well cement sheath seal characteristic simulation test device and test method

A simulation test, cement sheath technology, applied in construction and other directions, can solve problems such as difficulty in obtaining hydraulic isolation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] After the cement sheath is injected, oil, gas, and water channel in the annular space and oil and gas are emitted from the wellhead, which is still a cementing quality problem that has not been well resolved at home and abroad, especially in the adjustment wells of high-pressure oil and gas layers. This phenomenon is particularly prominent. The pressure in the annular space is an important factor affecting the safe production of oil and gas wells. The evaluation of the sealing characteristics of the cement sheath is an important basis for the formulation of production measures and the evaluation of wellbore integrity. In addition, fracturing is currently the most important technology for developing low-permeability oilfields, but the channeling between thin interlayers during fracturing has seriously restricted the subdivision and stimulation of thin reservoirs by fracturing technology. The compressive strength of the rock is about 70-100MPa, and the interlayer itself is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com