Patents

Literature

851 results about "Formation fluid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

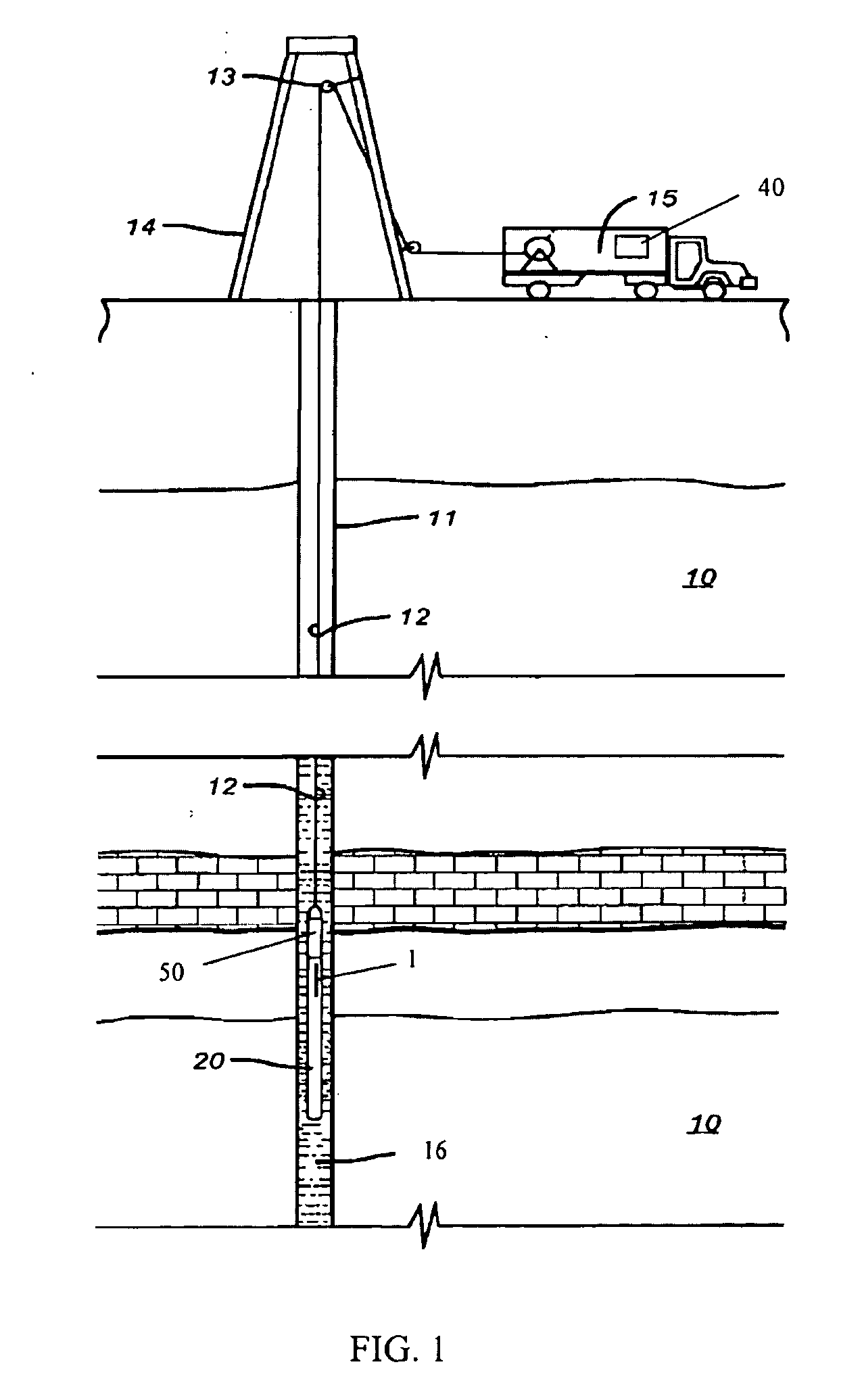

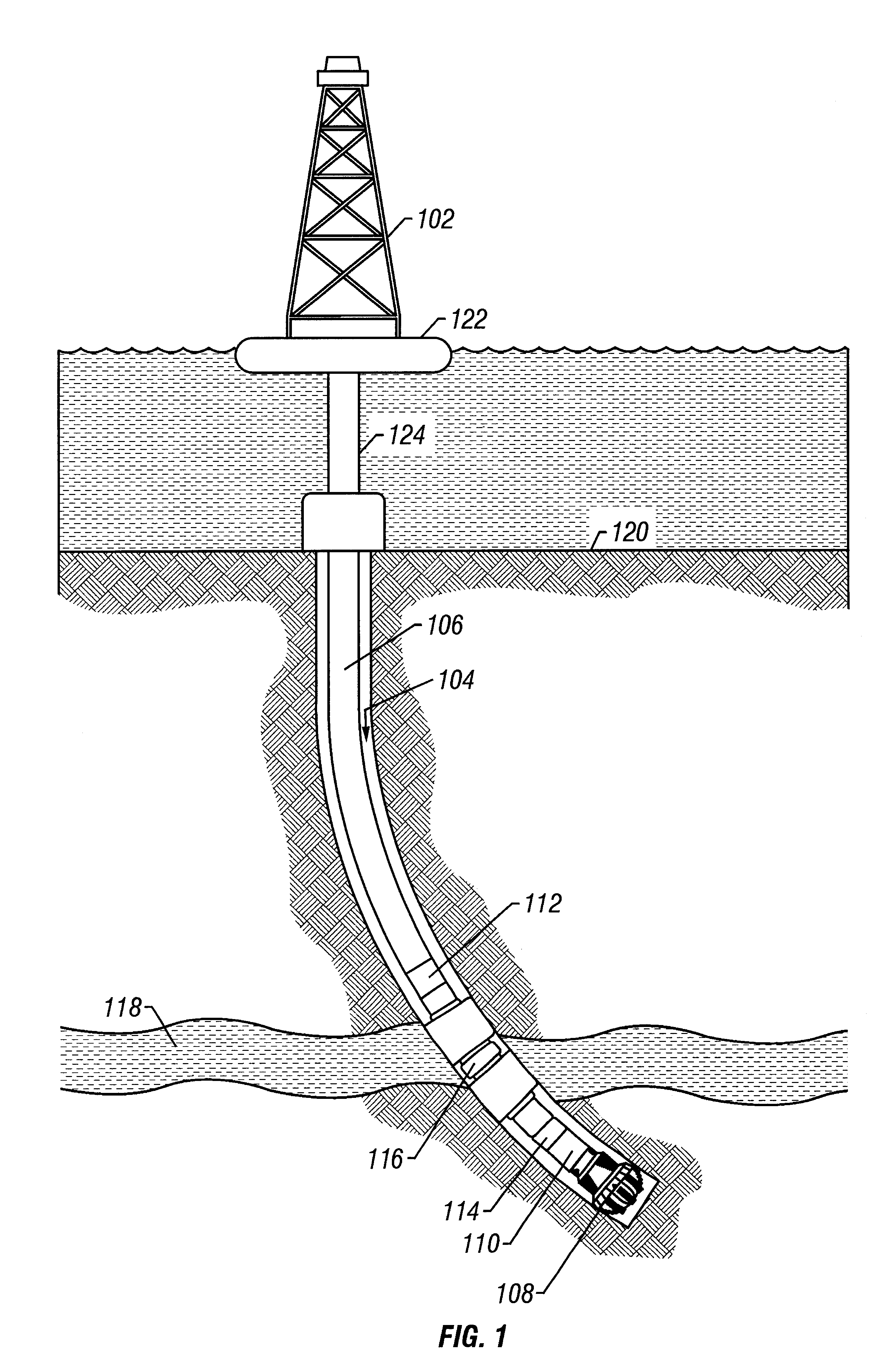

Formation fluid refers to the naturally occurring liquids and gases contained in geologic formations. Fluids introduced during the drilling process are called drilling fluids. Fluids in an oil or gas reservoir are called reservoir fluids. The fluids flowing from the wellhead of an oil or gas well are called production fluids.

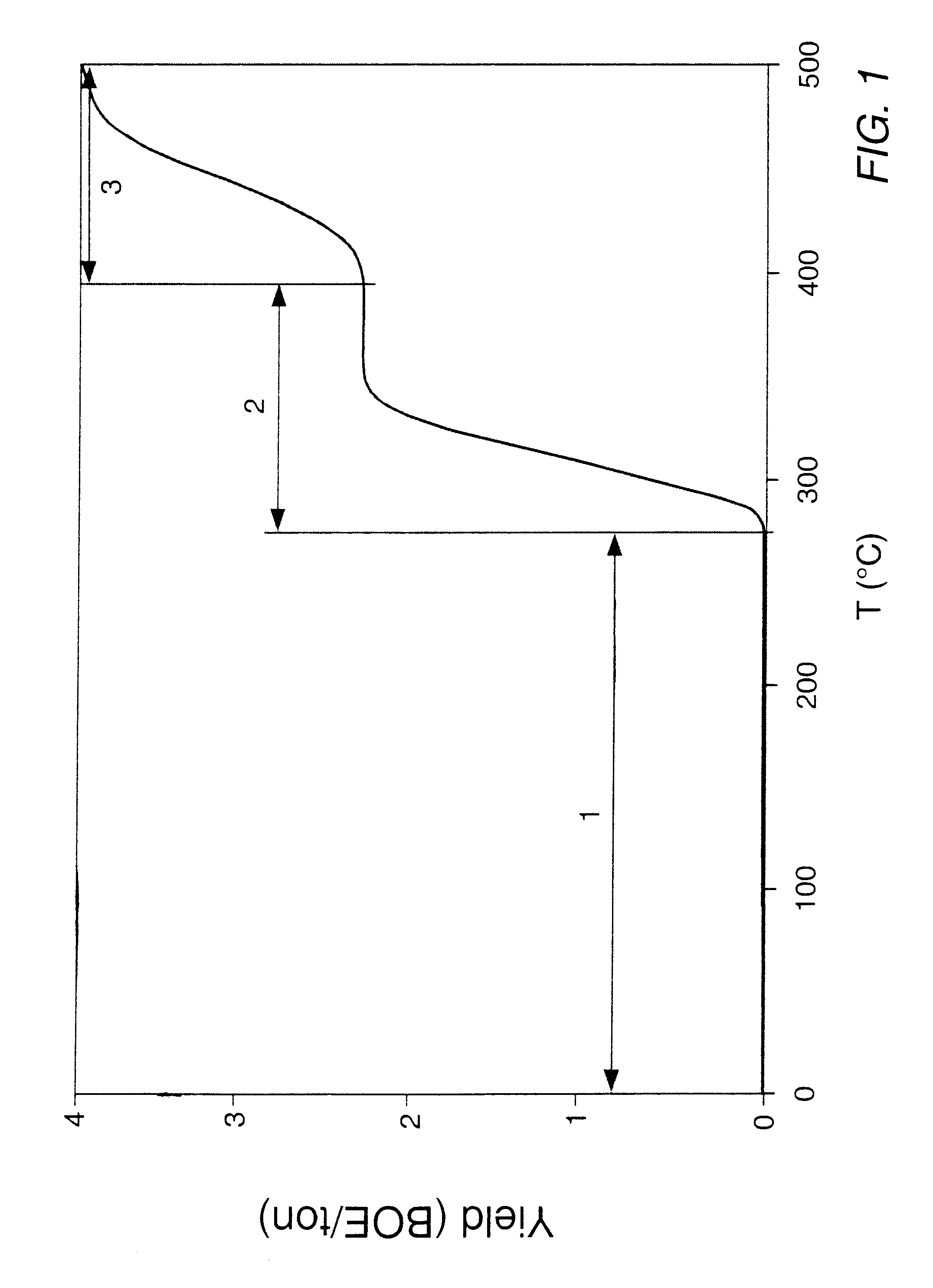

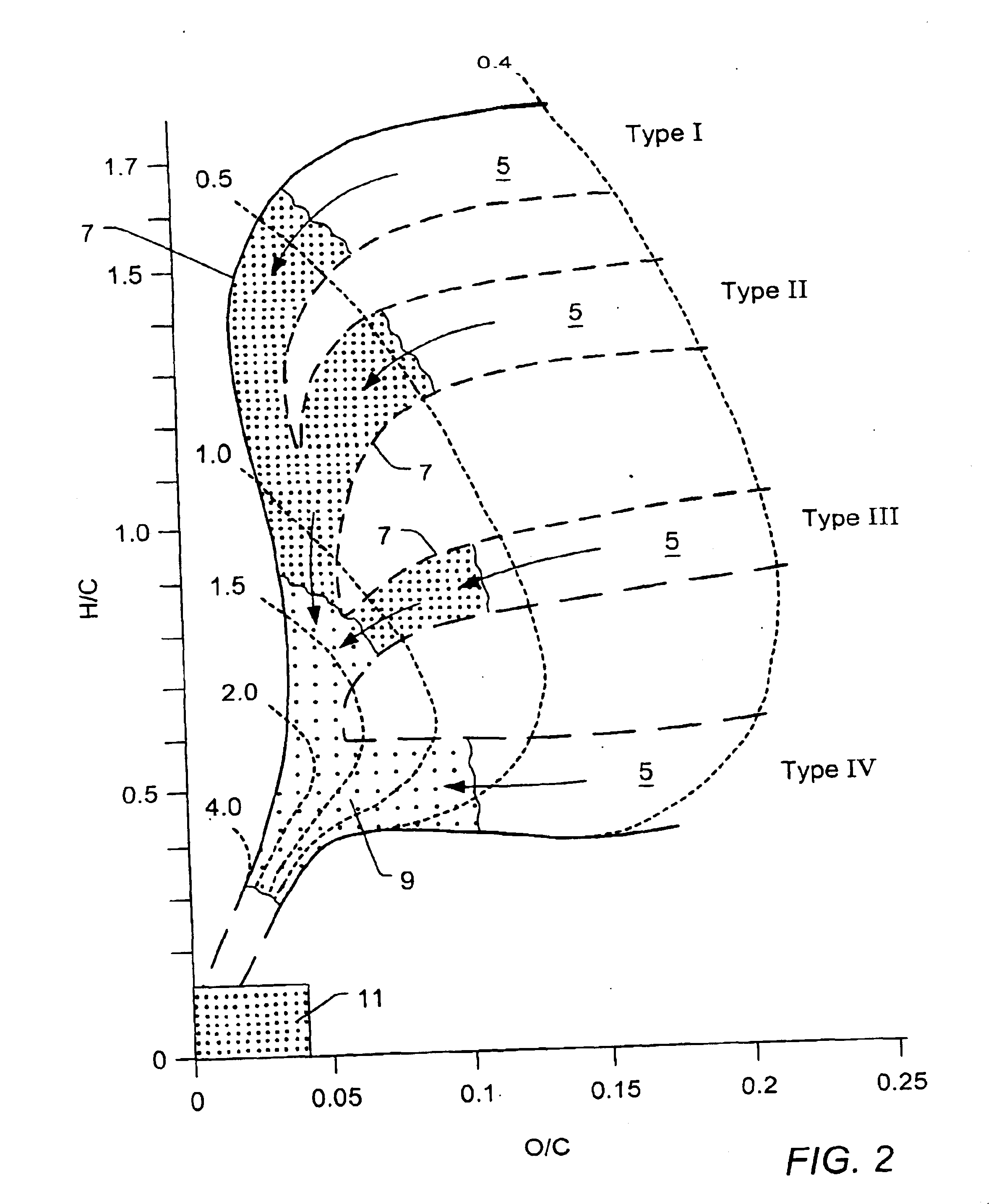

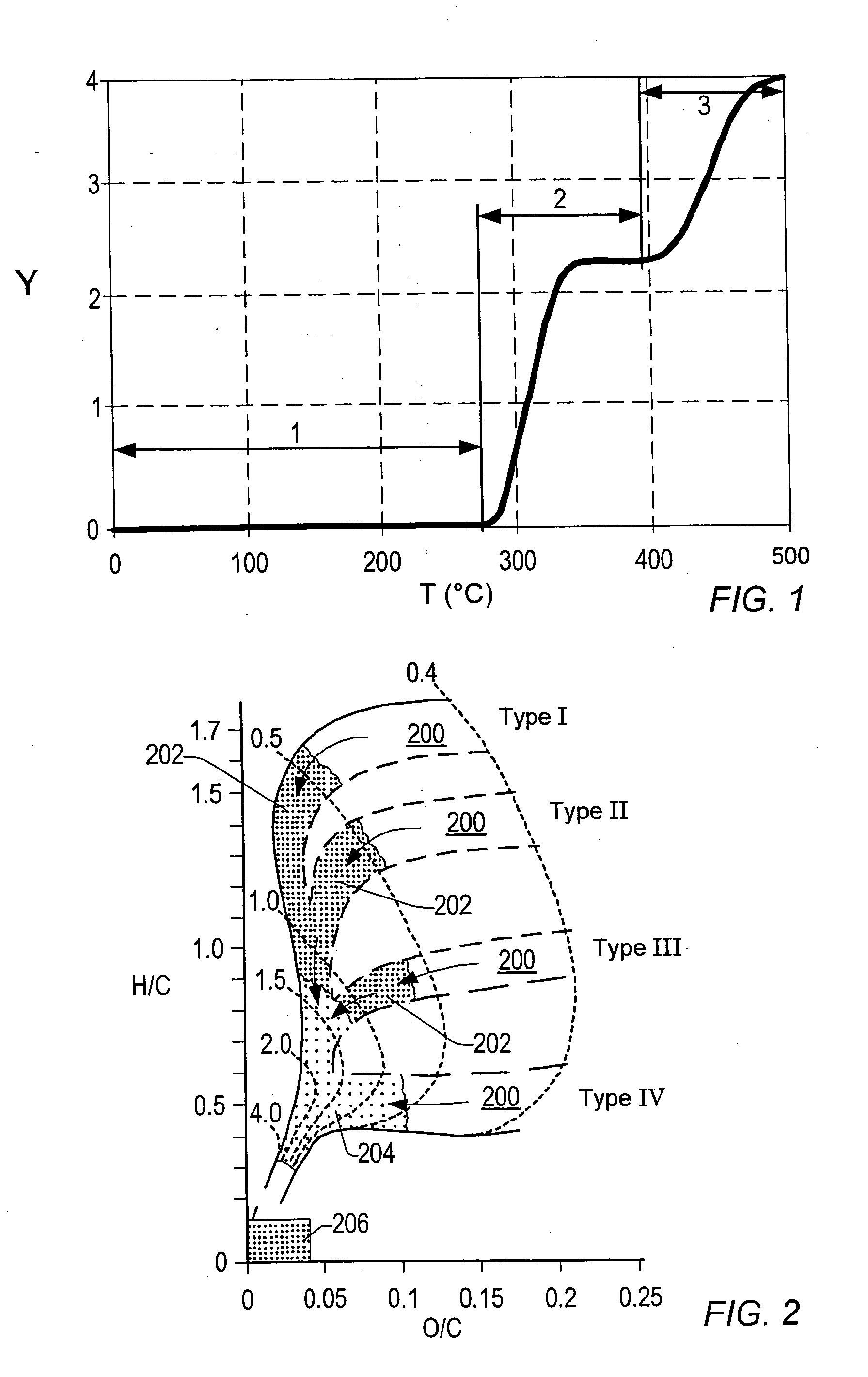

In situ thermal processing of a hydrocarbon containing formation using a controlled heating rate

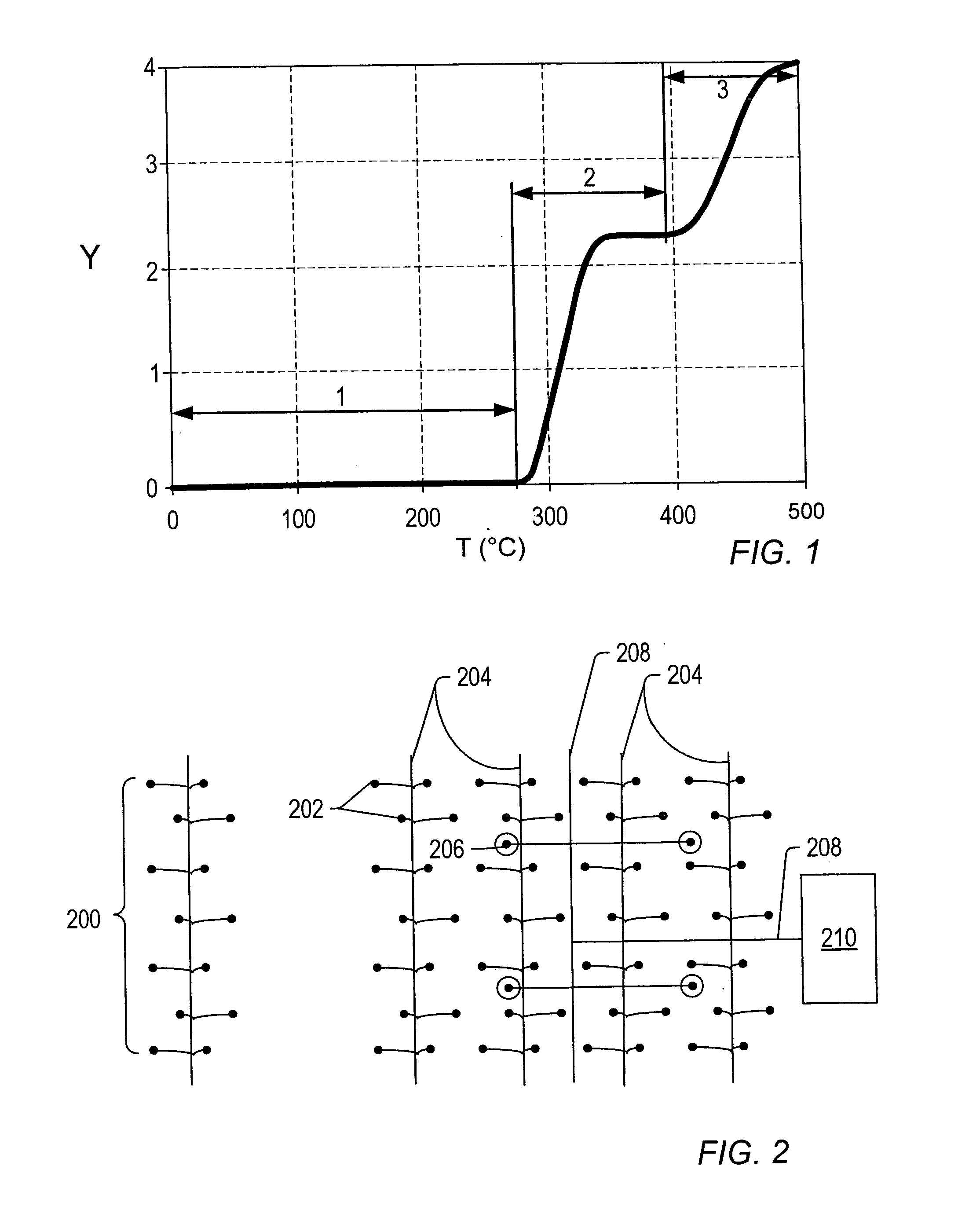

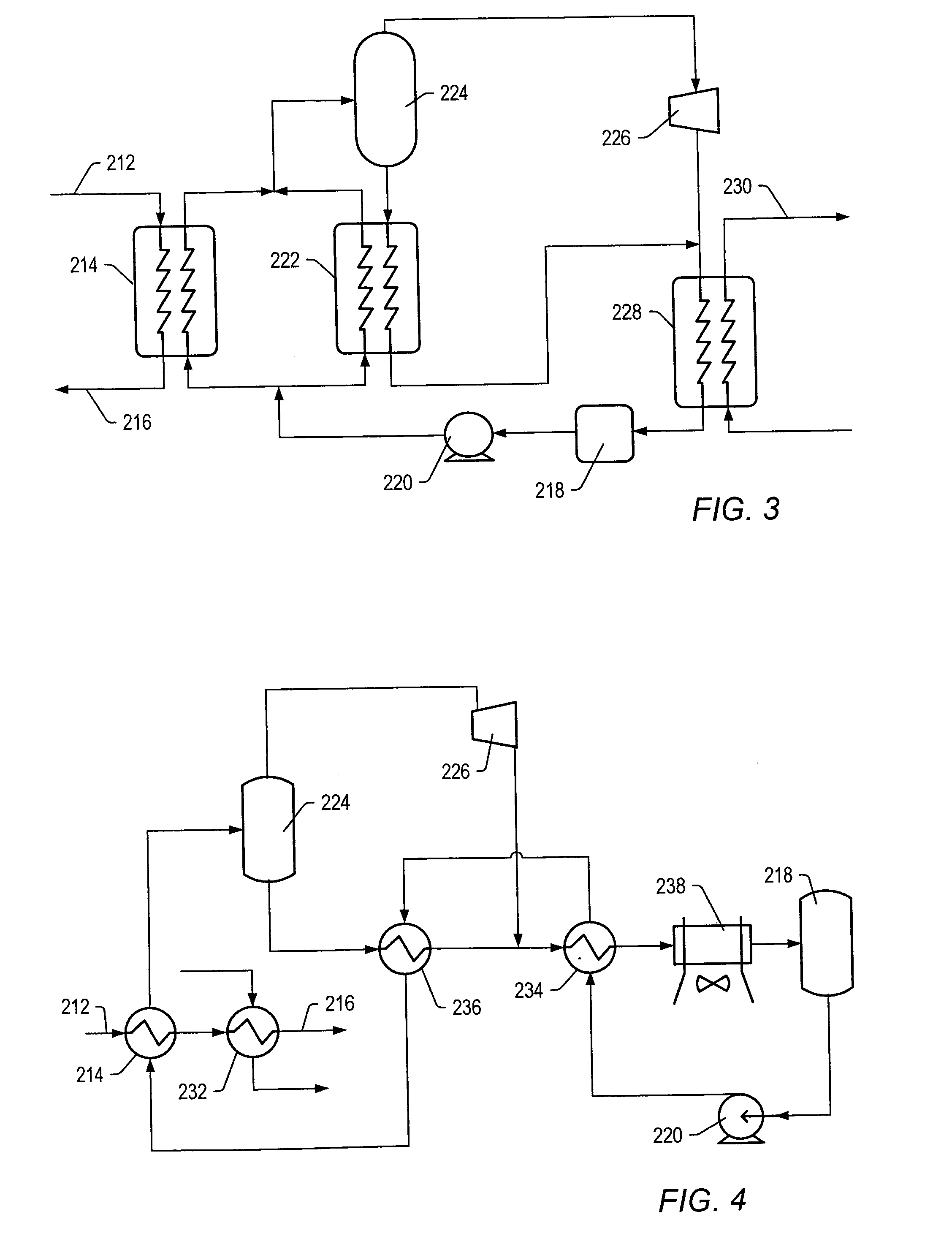

InactiveUS6745837B2High calorific valueImprove the heating effectSurveyCombustion processFormation fluidHeat energy

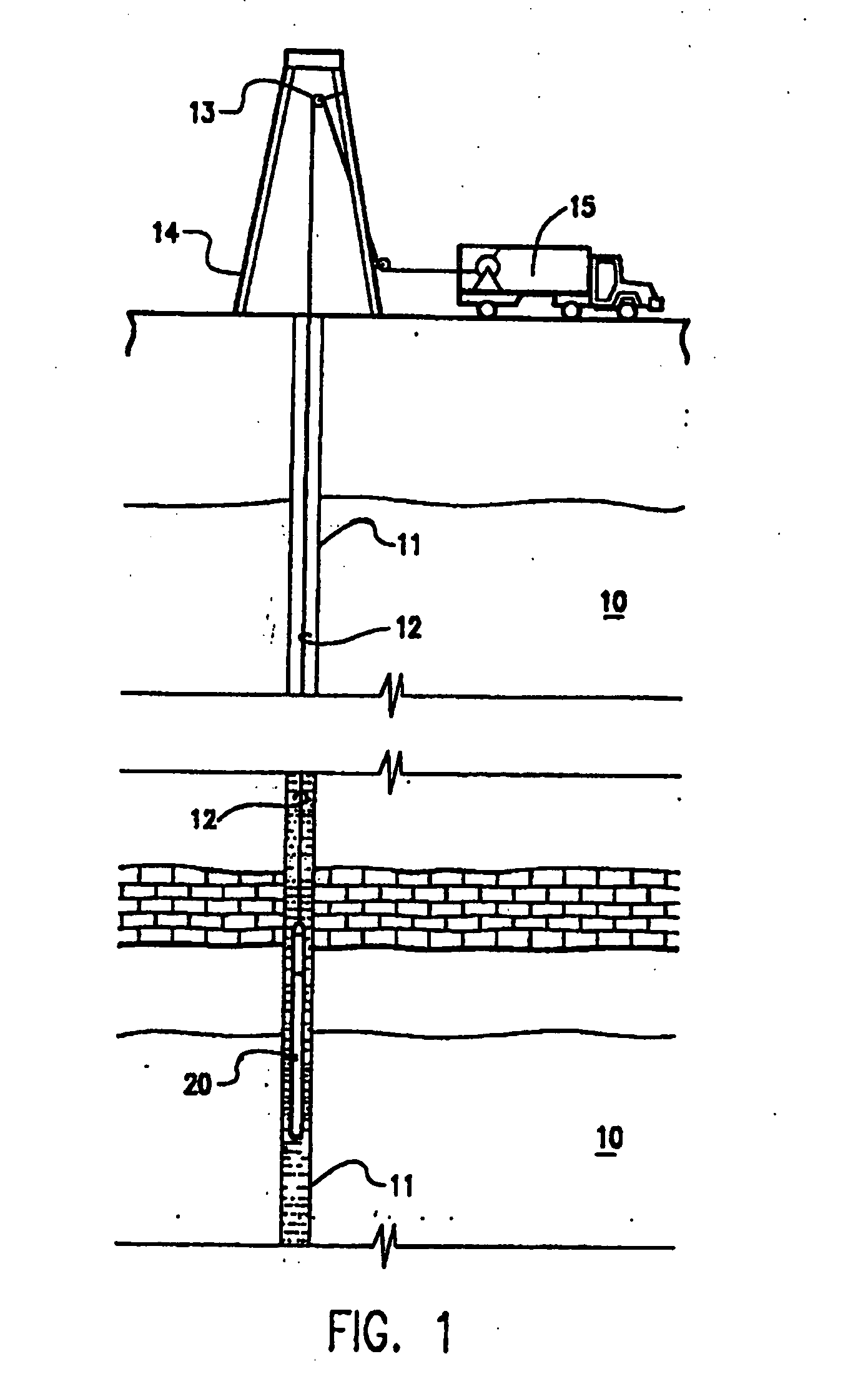

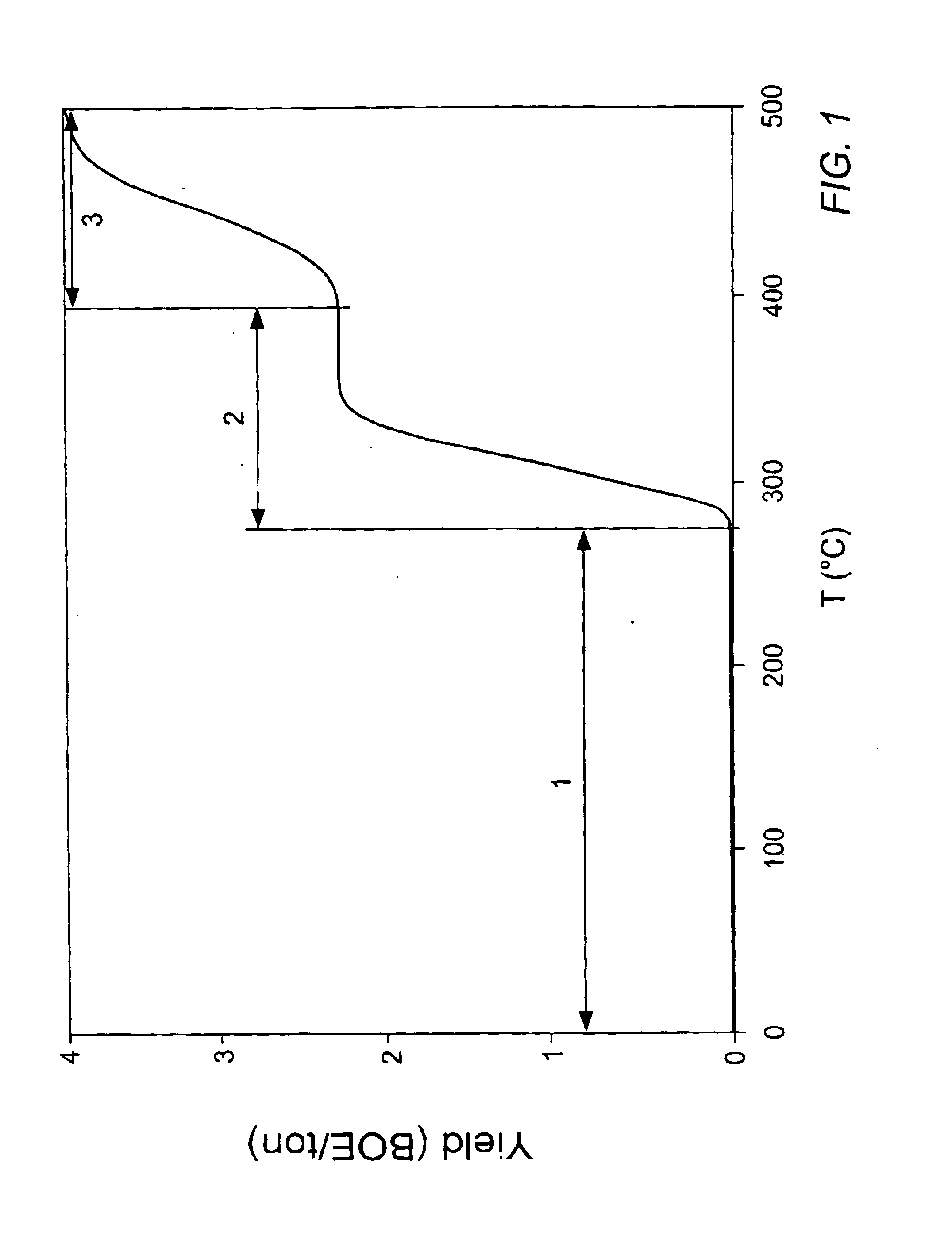

A hydrocarbon containing formation may be treated using an in situ thermal process. A mixture of hydrocarbons, H.sub.2, and / or other formation fluids may be produced from the formation. Heat may be applied to the formation to raise a temperature of a portion of the formation to a pyrolysis temperature. A heating rate to a selected volume of the formation may be controlled by altering an amount of heating energy per day that is provided to the selected volume.

Owner:SALAMANDER SOLUTIONS INC

Method and apparatus for a downhole spectrometer based on electronically tunable optical filters

ActiveUS20050099618A1High resolution spectroscopyEasy to analyze and useRadiation pyrometrySurveyGas oil ratioAPI gravity

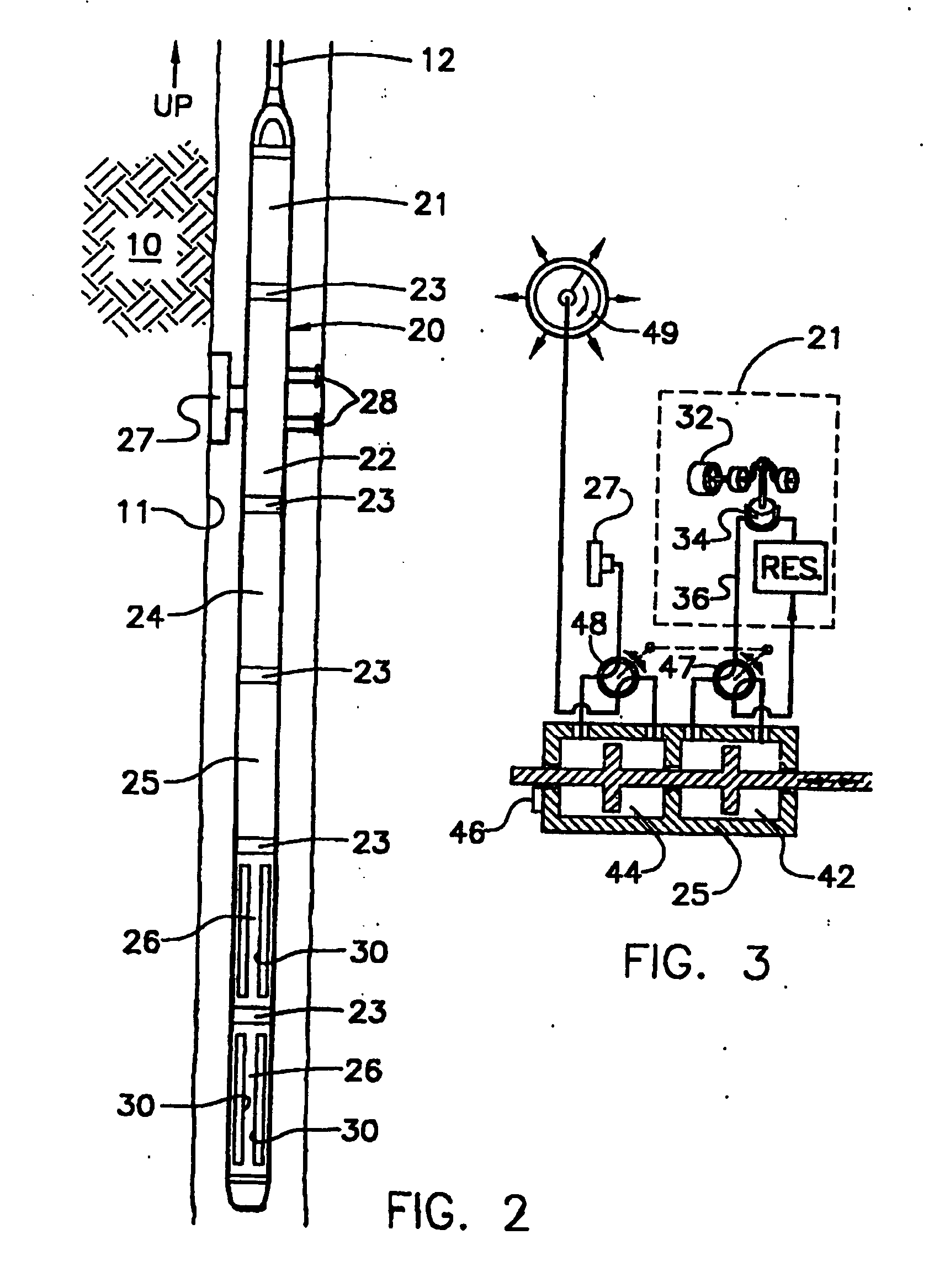

The present invention provides an apparatus and method for high resolution spectroscopy (approximately 10 picometer wavelength resolution) using a tunable optical filter (TOF) for analyzing a formation fluid sample downhole and at the surface to determine formation fluid parameters. The analysis comprises determination of gas oil ratio, API gravity and various other fluid parameters which can be estimated after developing correlations to a training set of samples using a neural network or a chemometric equation.

Owner:BAKER HUGHES INC

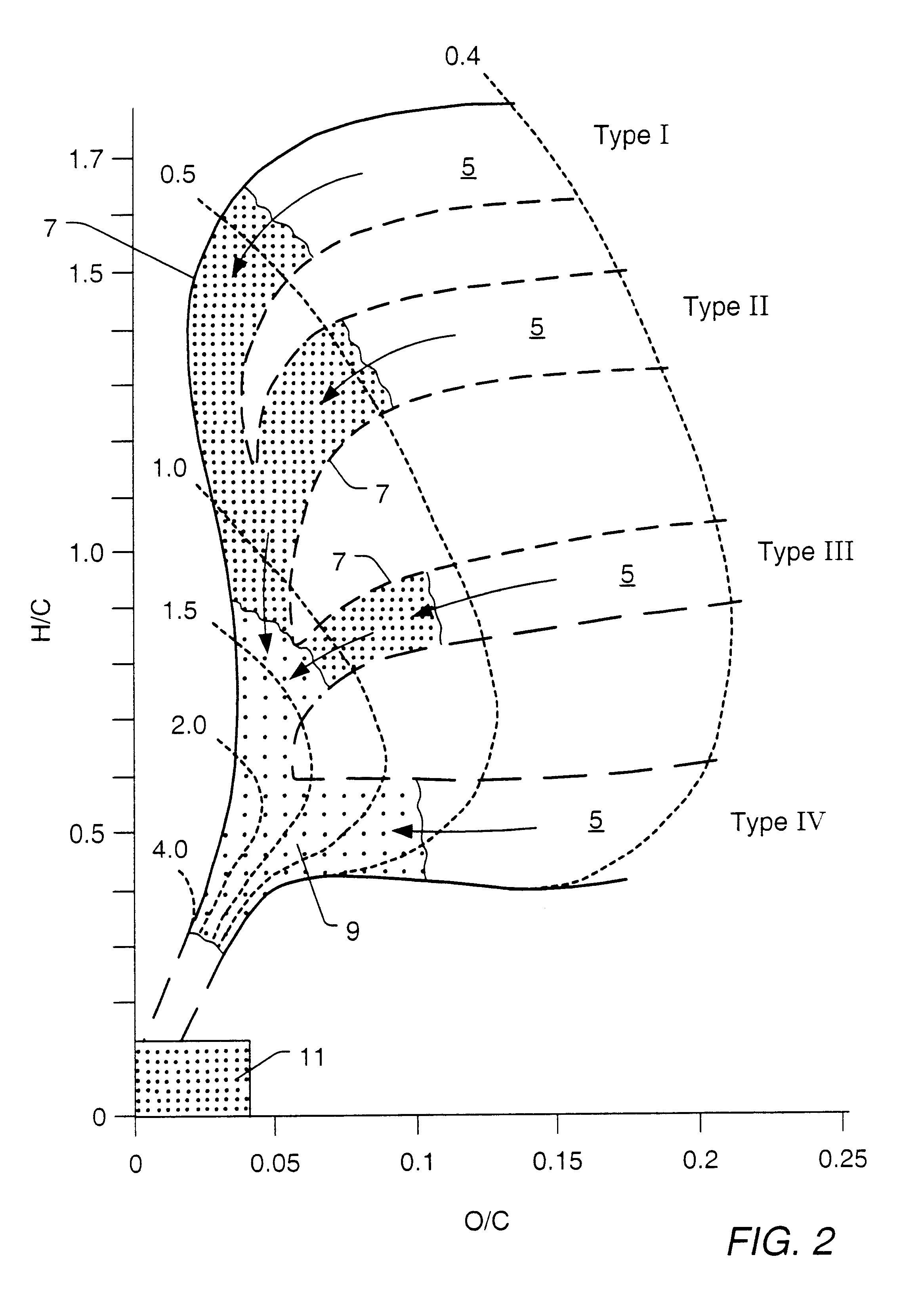

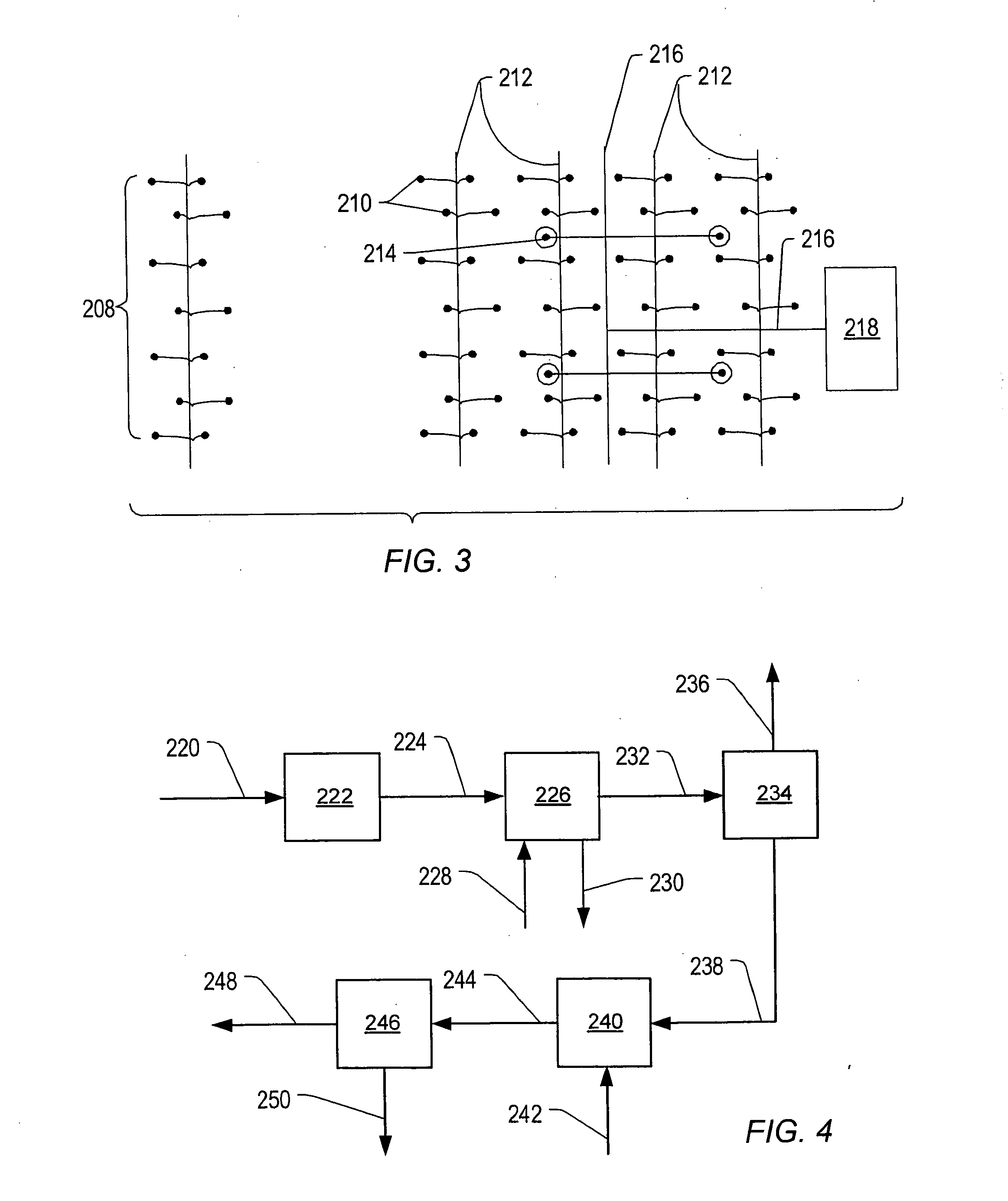

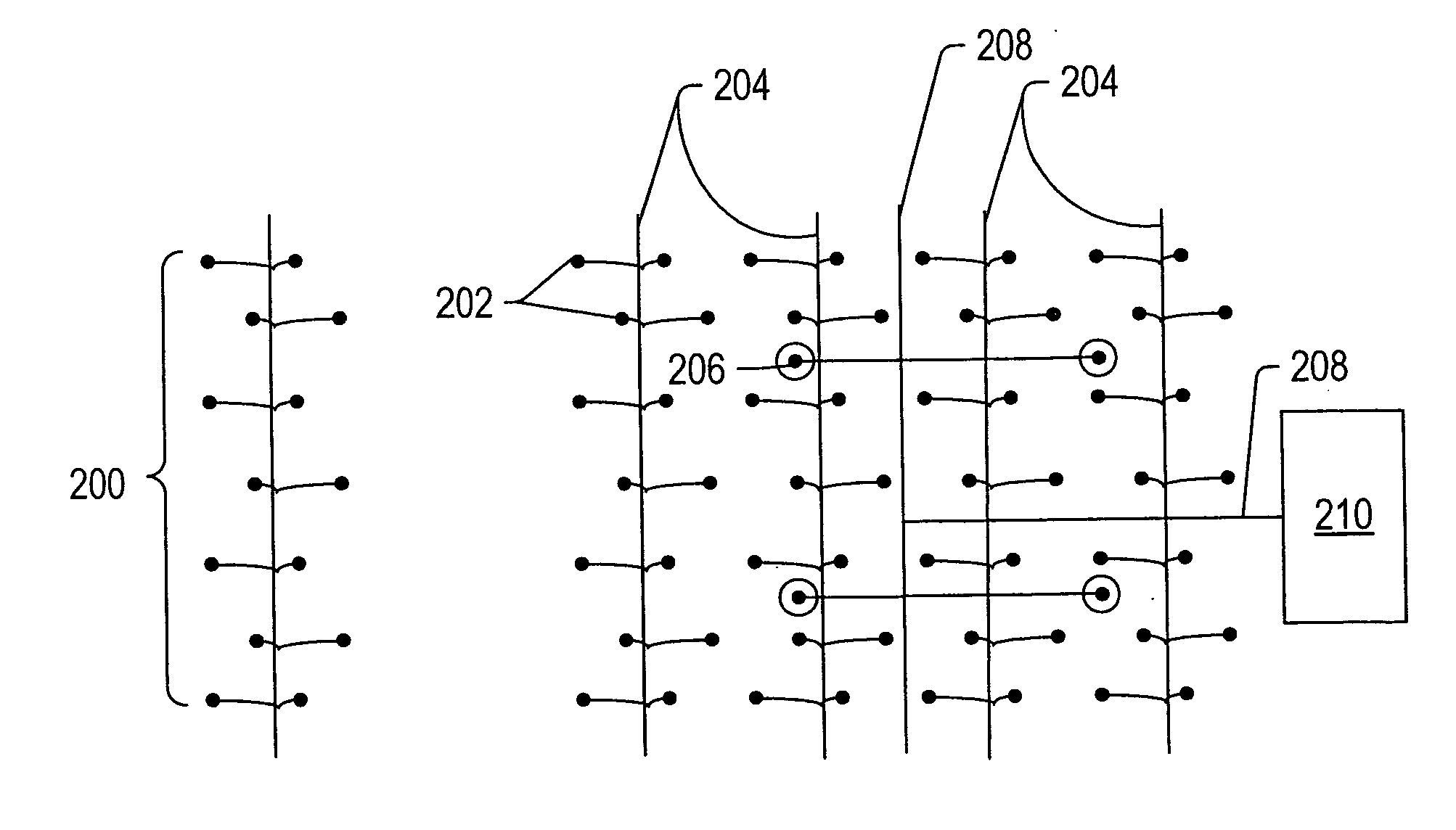

In situ thermal processing of a coal formation to increase a permeability/porosity of the formation

InactiveUS6866097B2Reduce the temperatureHigh strengthSurveyCombustion processPorosityInitial permeability

Owner:SHELL OIL CO

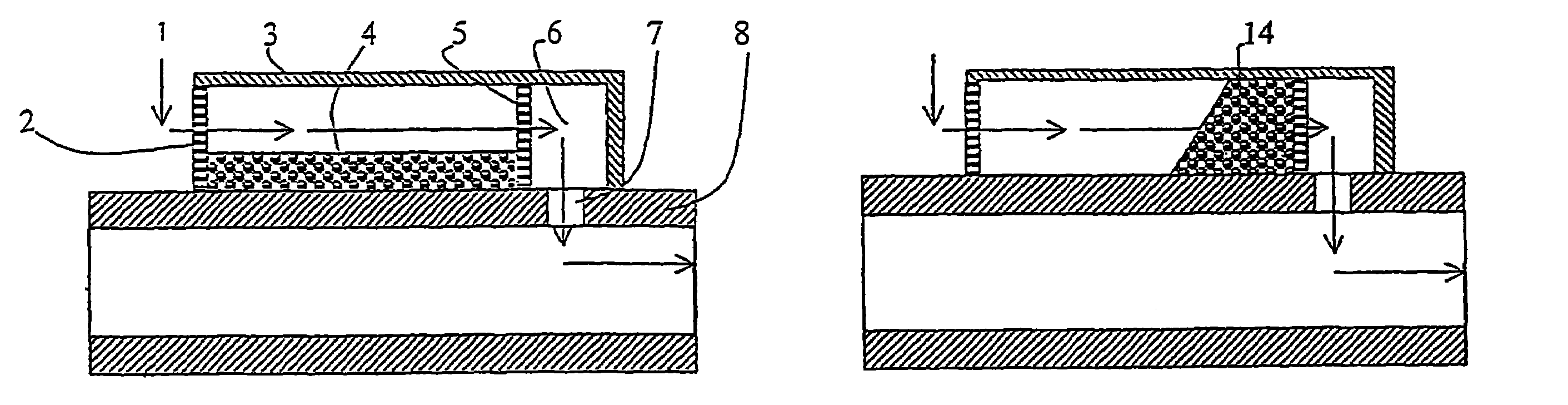

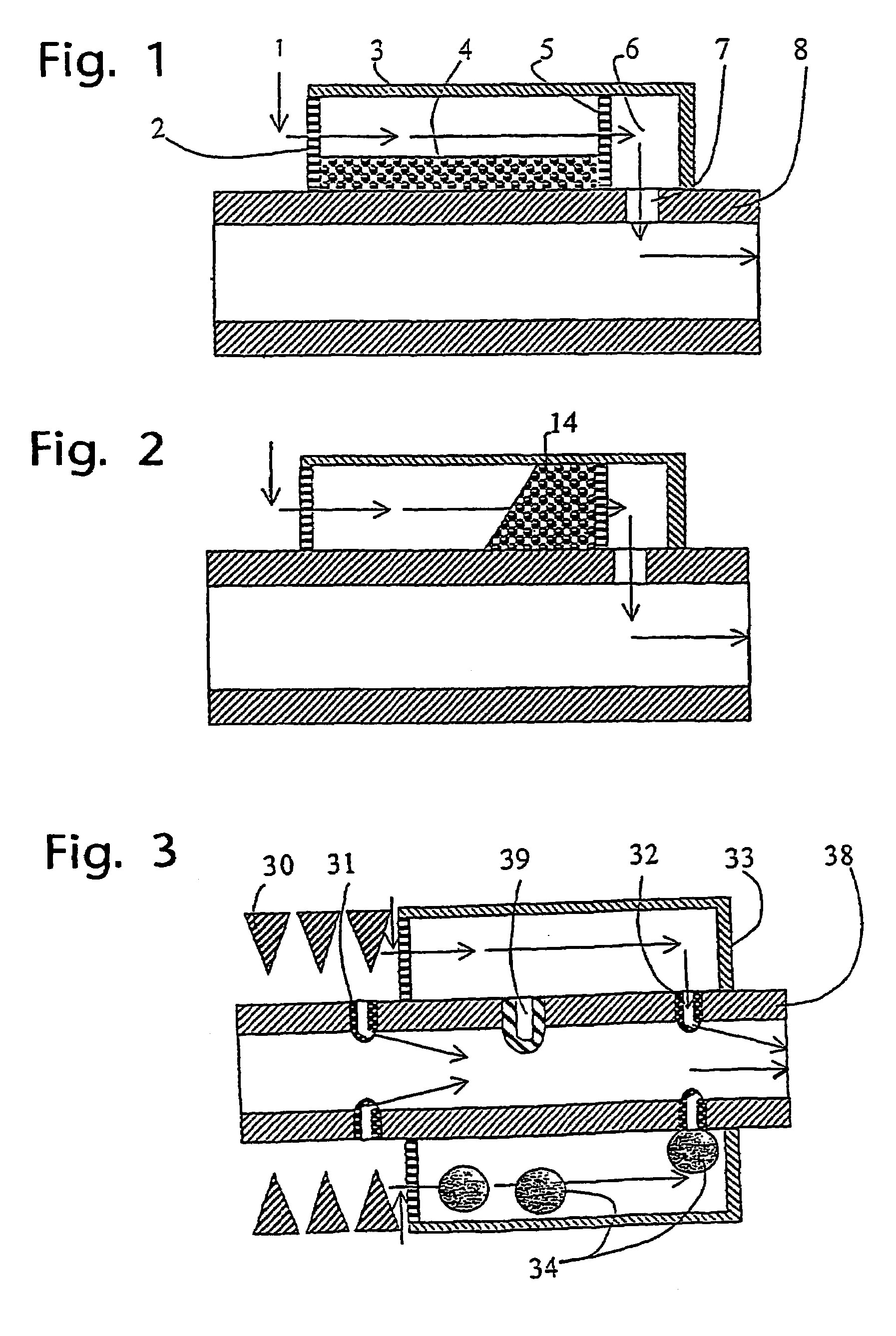

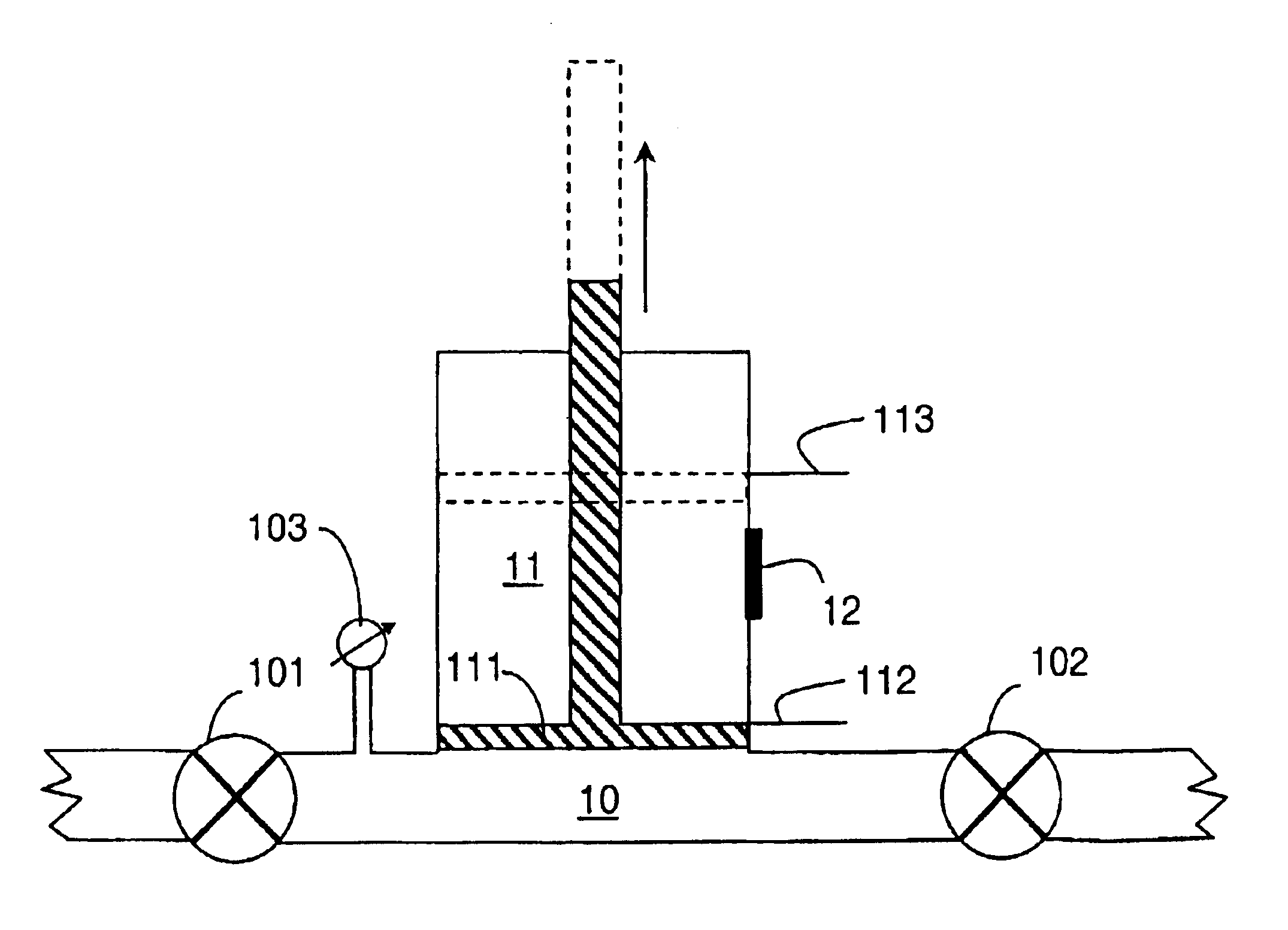

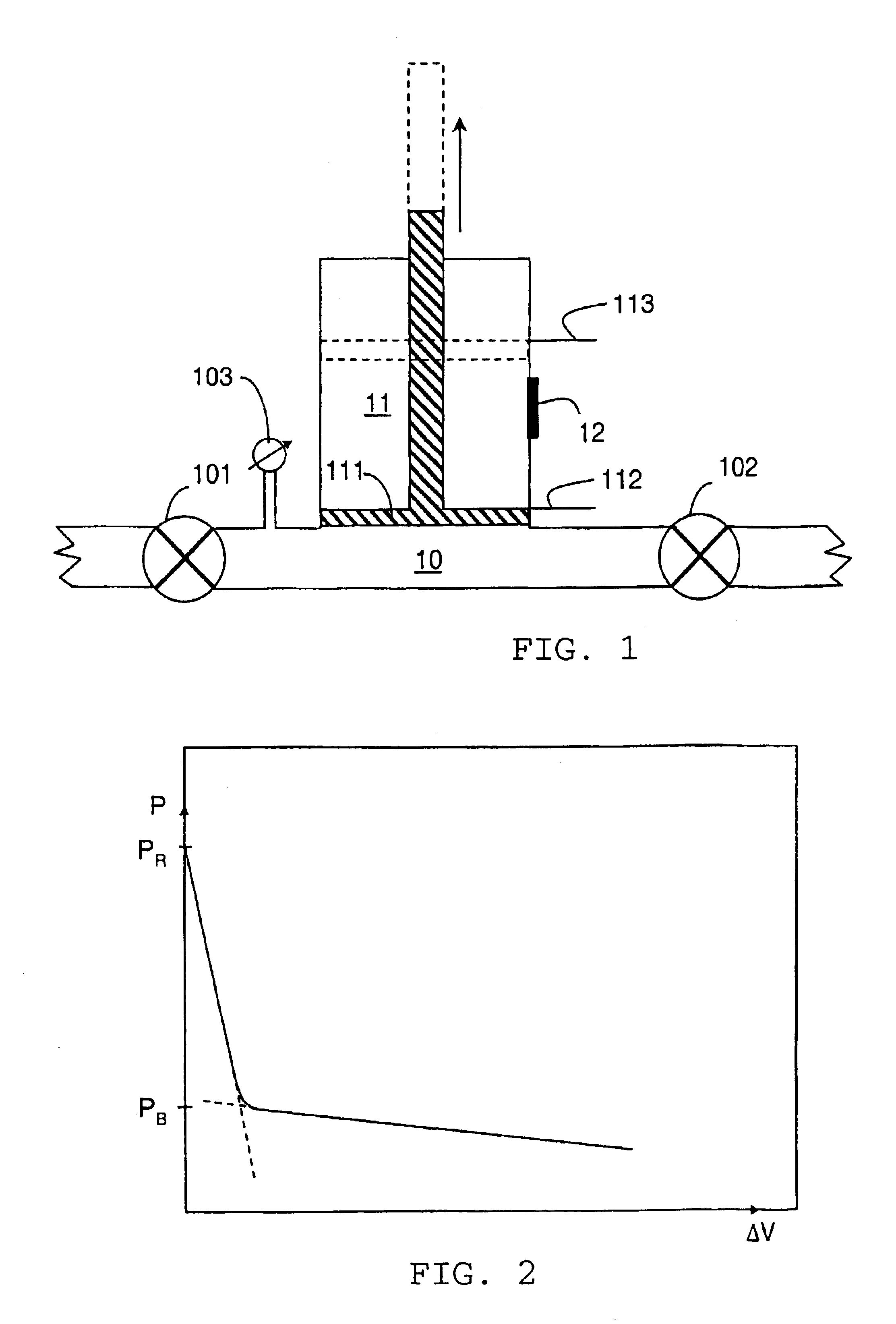

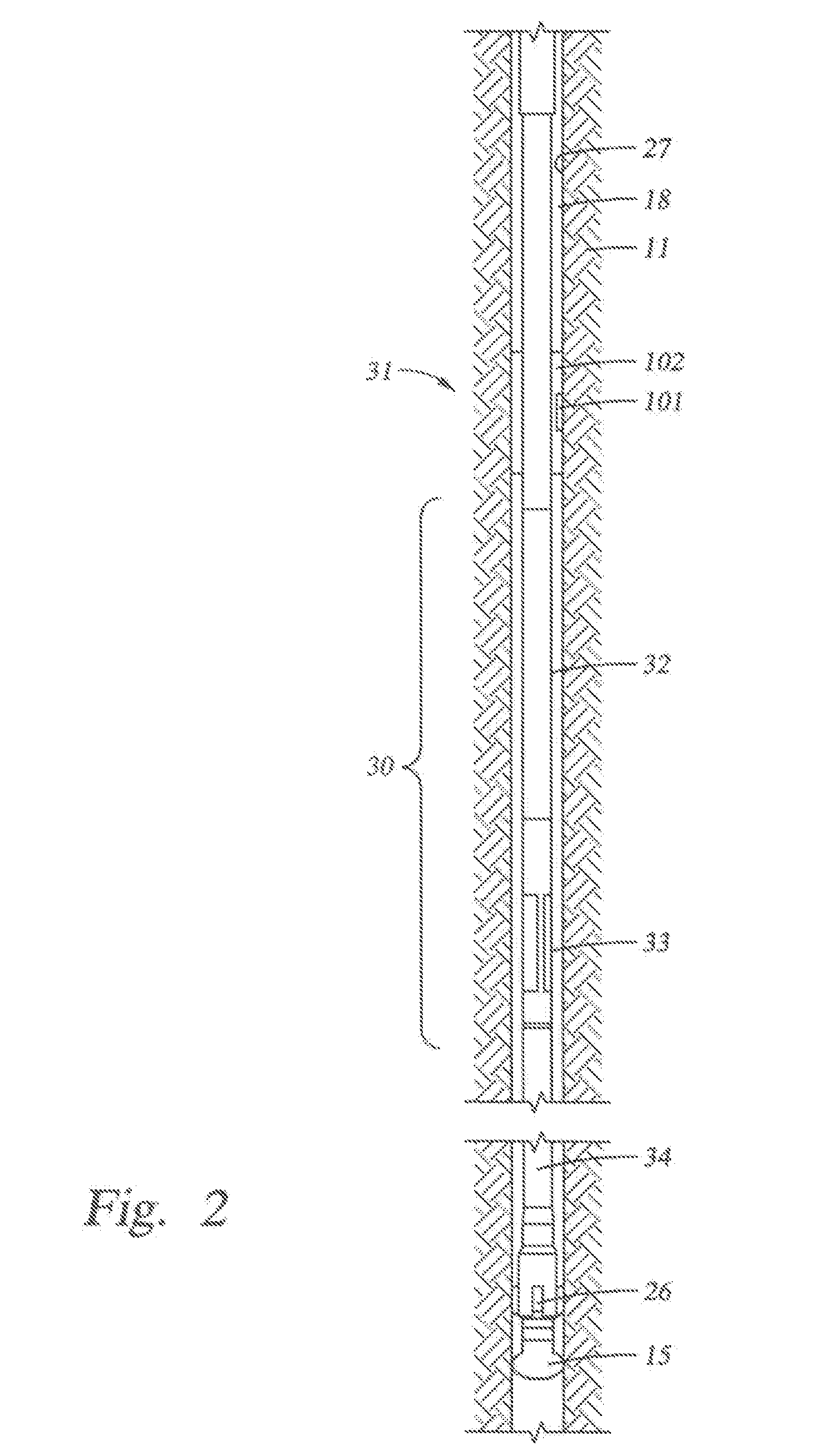

Arrangement for and method of restricting the inflow of formation water to a well

InactiveUS7185706B2Low mobilityNeutral buoyancyDrilling rodsFluid removalWater flowVolumetric Mass Density

An arrangement for restricting the inflow of formation water from an underground formation to a hydrocarbon producing well, where, between the underground formation and a production tubing (38) located in the well, there is disposed at least one flow chamber (3, 33) connected to the production tubing (38), the flow chamber (3, 33), preferably via a filter (2) in one portion, being open to inflow of formation fluid and in communication with the production tubing (38) via at least one opening (7, 32), and where the flow chamber (3, 33) is provided with at least one free-floating body (4, 34) with approximately the same density as the formation water, the at least one body (4, 34) being designed by means of the closing of at least one opening (32) or choking, to reduce the inflow of formation water to the production tubing (38).

Owner:HALLIBURTON ENERGY SERVICES INC

Protective barriers for small devices

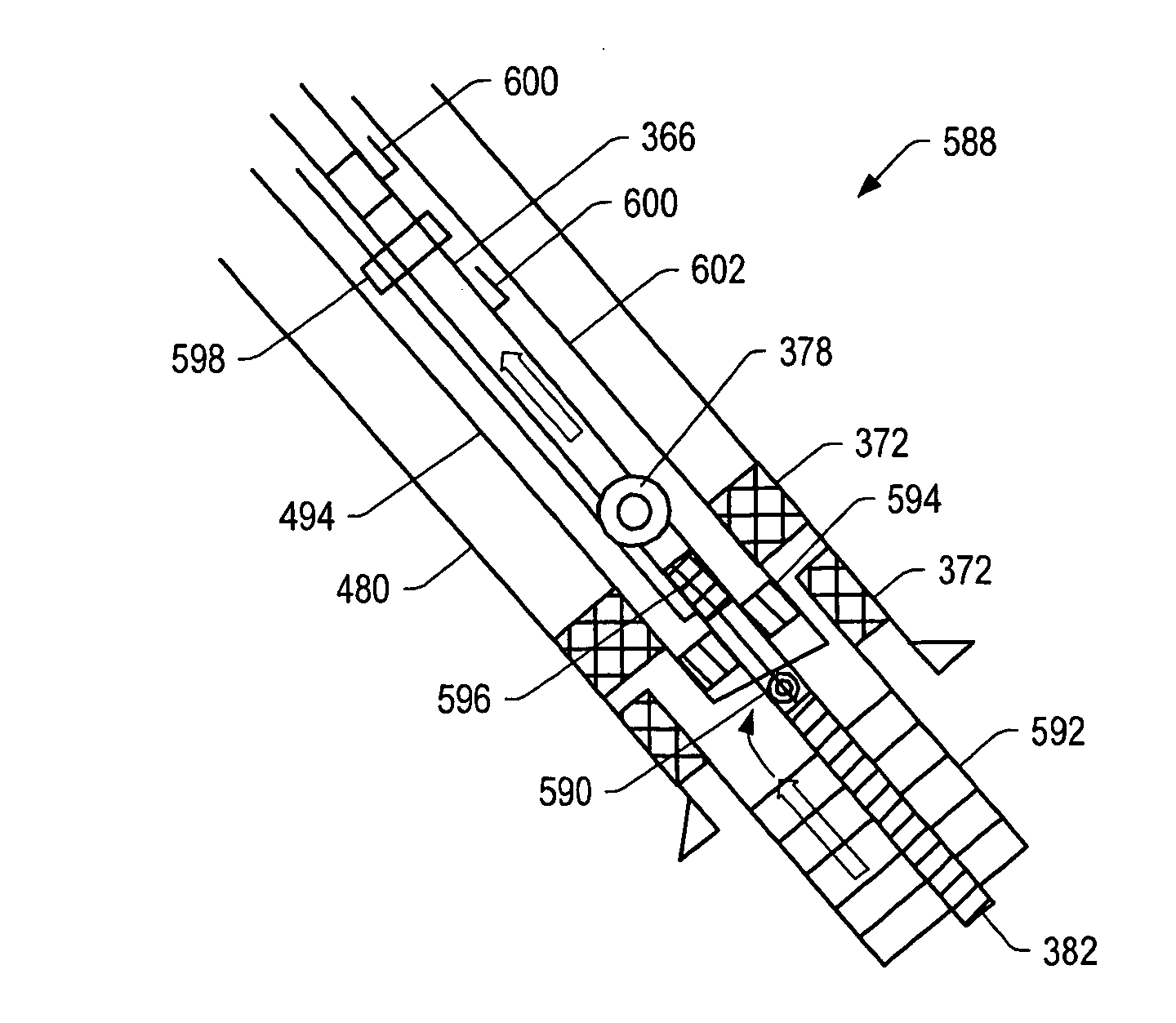

Protective barriers for small devices, such as sensors, actuators, flow control devices, among others, protect the devices from erosive and / or corrosive fluids, for example, formation fluids under harsh downhole conditions. The protective barriers include protective coatings and fluid diverting structures in the fluid flow which facilitate use of the small devices in high temperature-high pressure applications with erosive and / or corrosive fluids that are often found in downhole environments.

Owner:SCHLUMBERGER TECH CORP

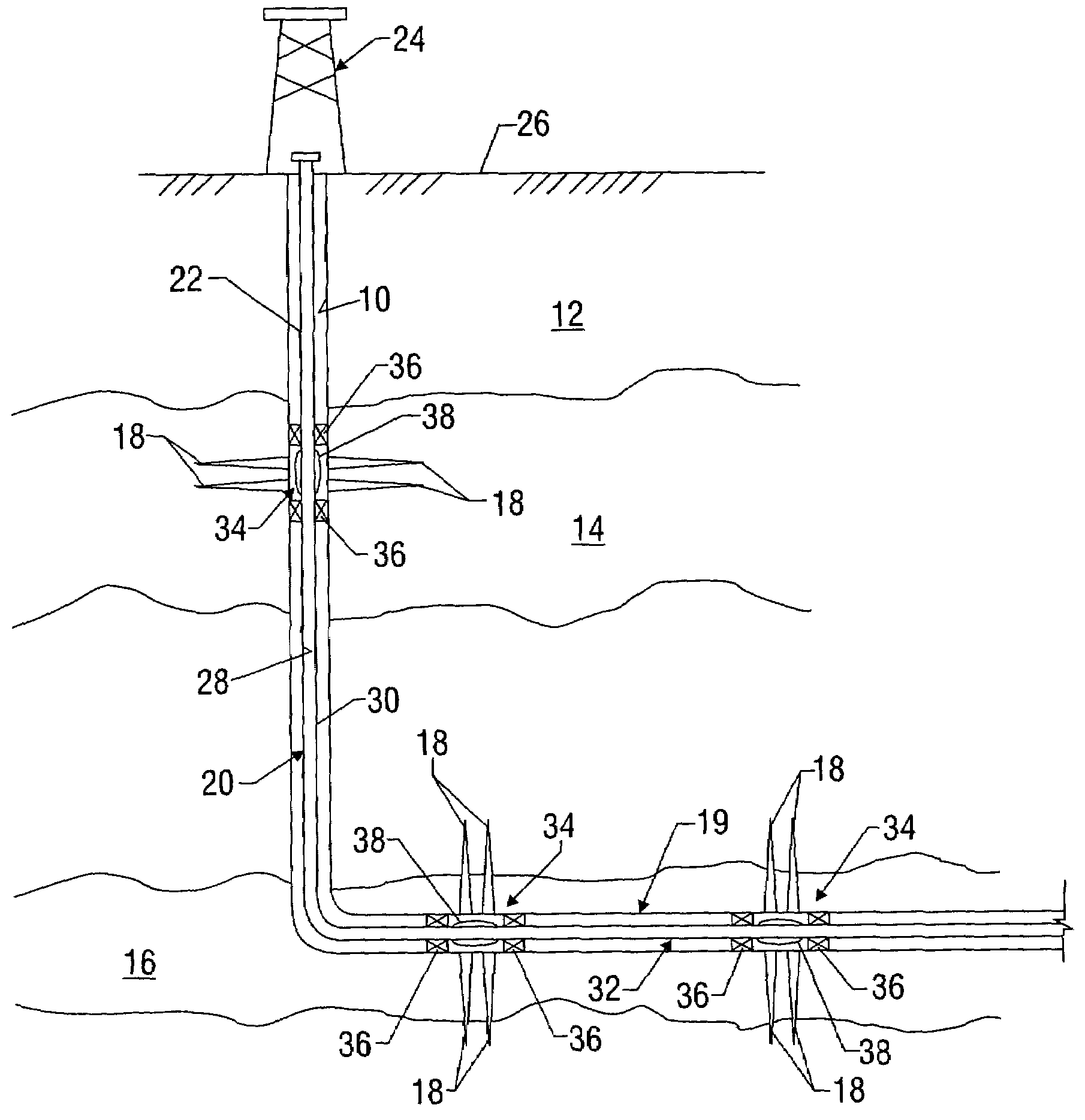

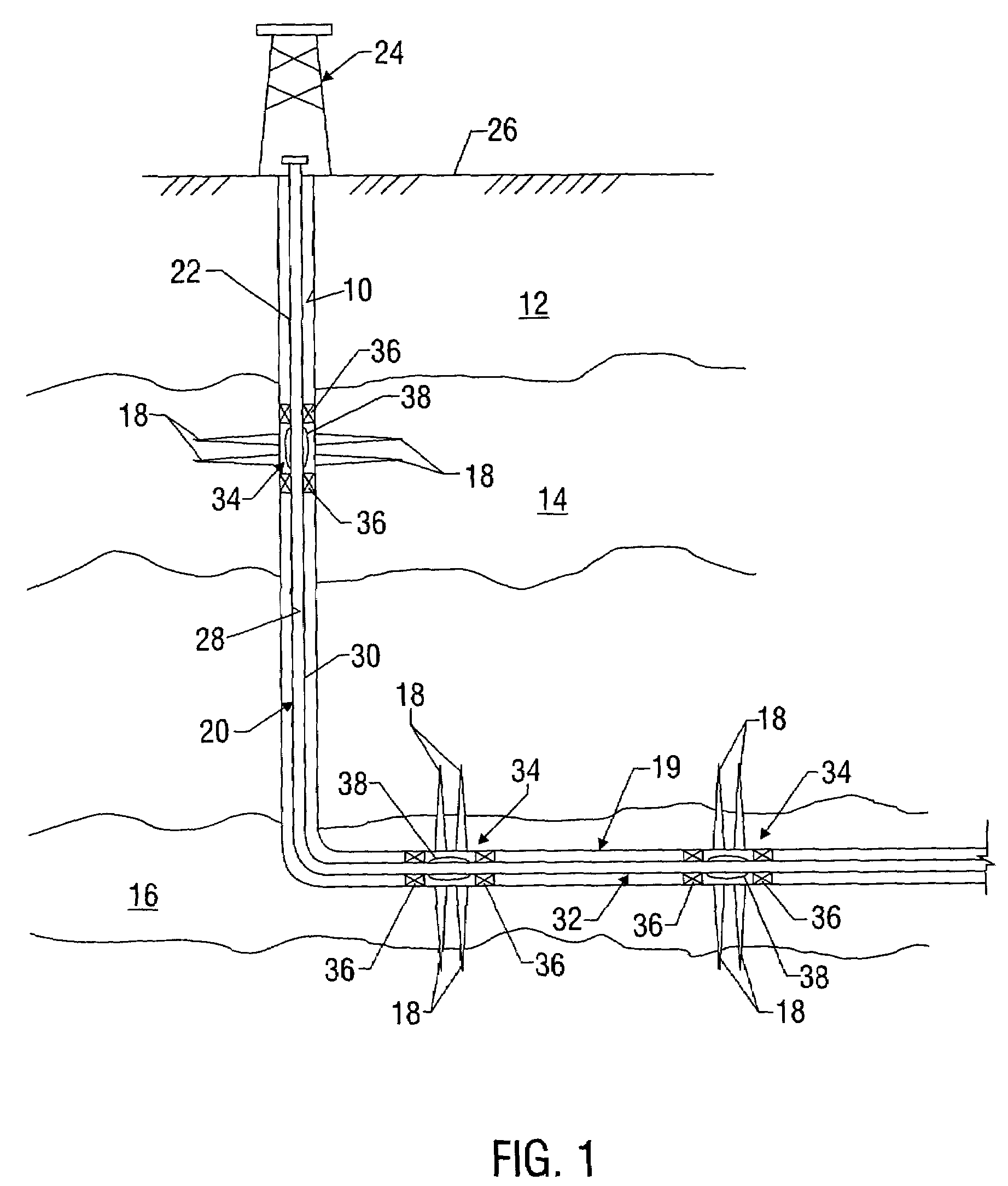

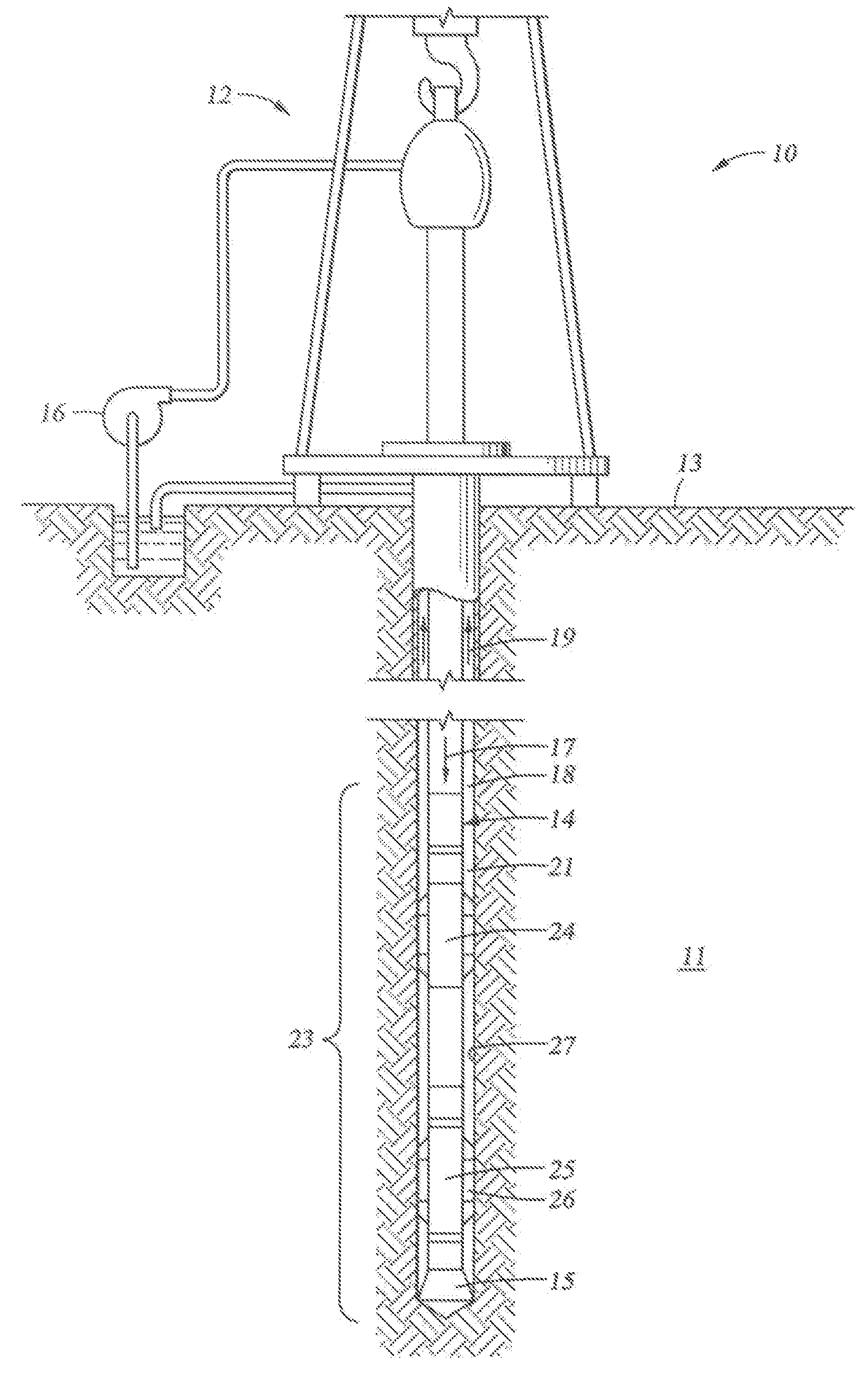

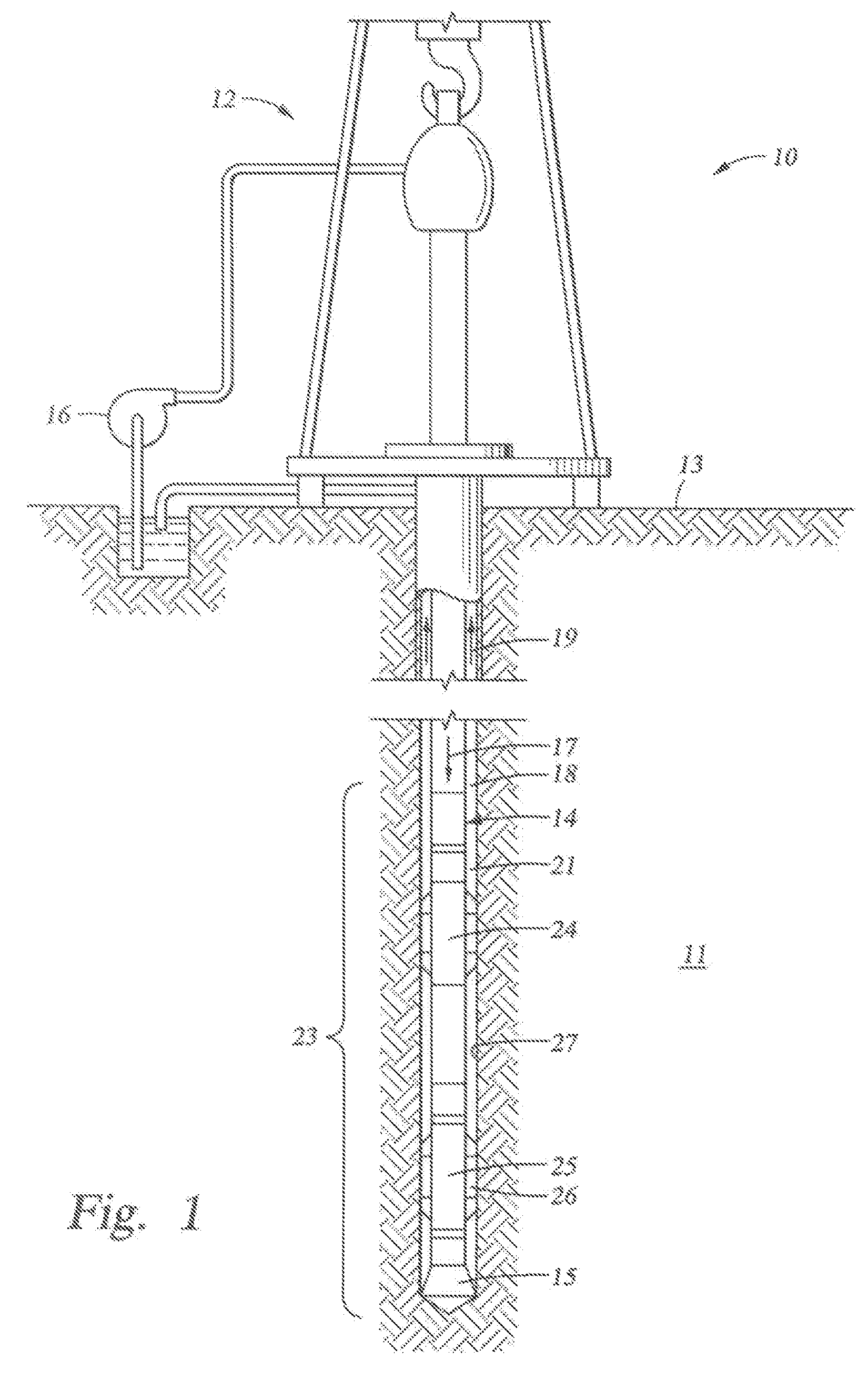

Inflow control device with passive shut-off feature

InactiveUS7290606B2Reduce gas flowConsistent service lifeSurveyConstructionsControl flowControl signal

Devices and methods for control flow of formation fluids respect to one or more selected parameter relating to the wellbore fluid. In one embodiment, a flow control device for controlling fluid flow into the production tubular uses a flow restriction member that is actuated by a character change of the formation fluid, such as liquid to gas or oil to water. The flow restriction member can be sensitive to a change in density of the formation fluid. The flow restriction member is passive, self-regulating and does not need any power source or control signal to control fluid flow. In one embodiment, the flow control device automatically rotates into a predetermined orientation upon being positioned in the wellbore. A seal disposed on the flow control devices expands into sealing engagement with an enclosure after the flow control device assumed the desired predetermined position.

Owner:BAKER HUGHES INC

Inflow control device with passive shut-off feature

InactiveUS20060076150A1Reduce gas flowConsistent service lifeSurveyConstructionsControl flowStream flow

Devices and methods for control flow of formation fluids respect to one or more selected parameter relating to the wellbore fluid. In one embodiment, a flow control device for controlling fluid flow into the production tubular uses a flow restriction member that is actuated by a character change of the formation fluid, such as liquid to gas or oil to water. The flow restriction member can be sensitive to a change in density of the formation fluid. The flow restriction member is passive, self-regulating and does not need any power source or control signal to control fluid flow. In one embodiment, the flow control device automatically rotates into a predetermined orientation upon being positioned in the wellbore. A seal disposed on the flow control devices expands into sealing engagement with an enclosure after the flow control device assumed the desired predetermined position.

Owner:BAKER HUGHES INC

Methods of introducing treating fluids into subterranean producing zones

Methods of uniformly introducing aqueous treating fluids into subterranean producing zones are provided. The methods are basically comprised of the steps of packing perforation tunnels in the producing zone with a particulate solid anhydrous borate material which degrades and dissolves in water over time. A treating fluid is then introduced into the subterranean zone by way of the packed perforation tunnels whereby the treating fluid uniformly flows into the producing zone. The particulate solid anhydrous borate material in the perforation tunnels is allowed to degrade and dissolve in an aqueous fluid in contact therewith so that the aqueous fluid and produced formation fluids freely flow into the well bore.

Owner:HALLIBURTON ENERGY SERVICES INC

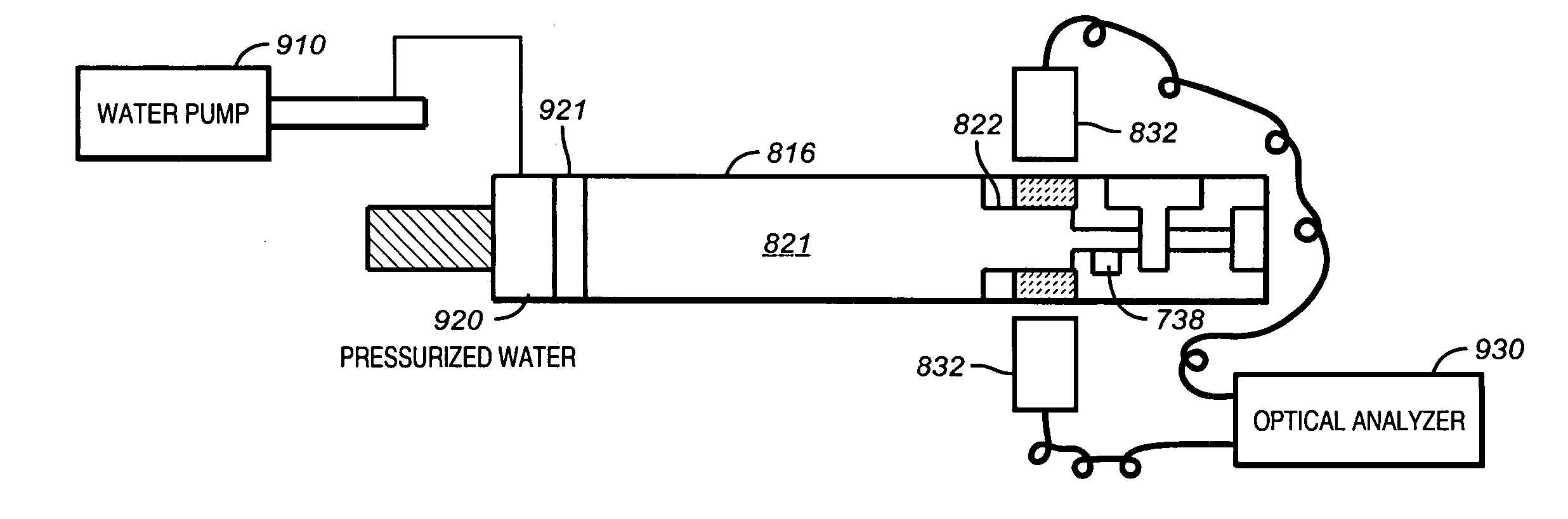

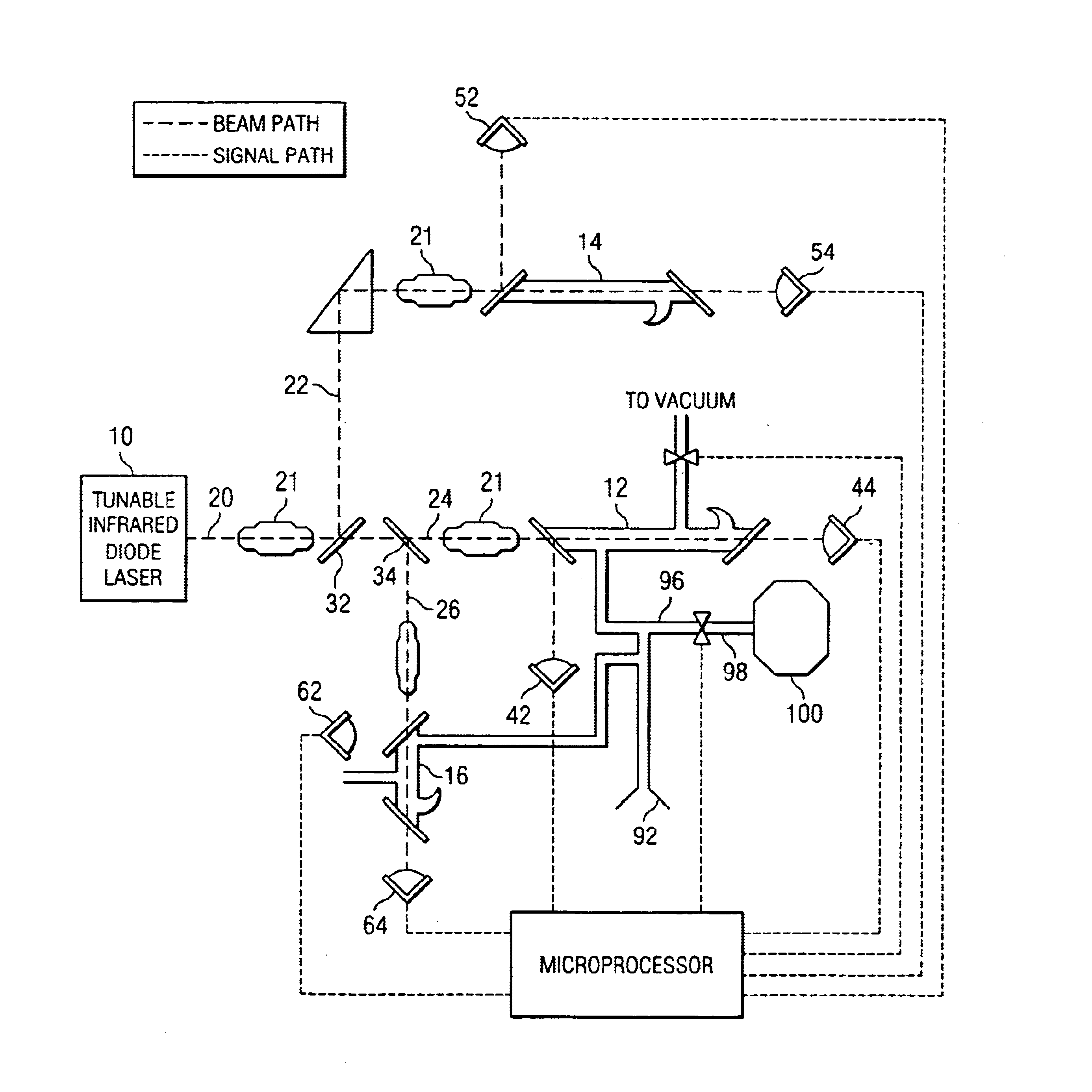

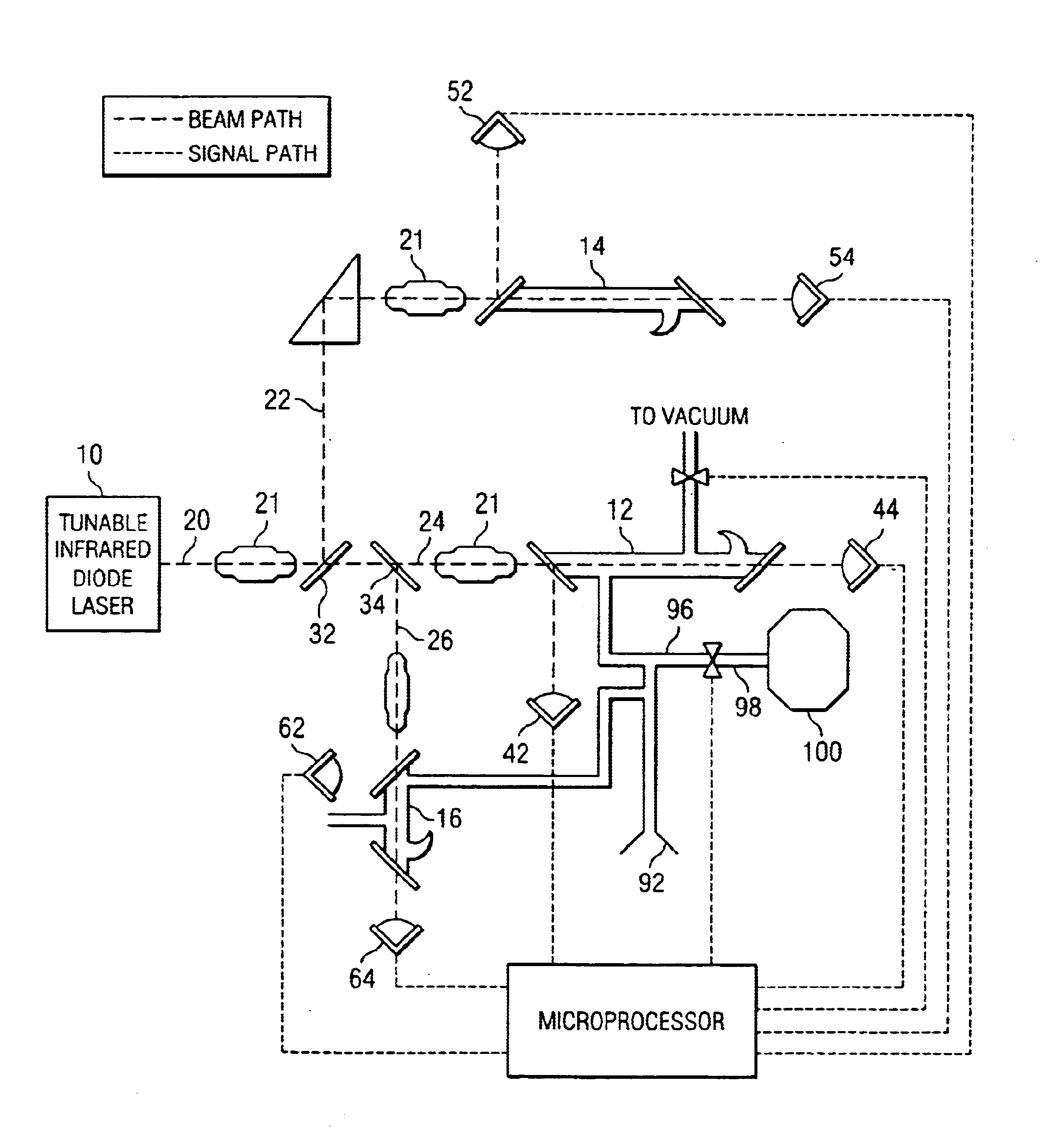

Method and apparatus for a tunable diode laser spectrometer for analysis of hydrocarbon samples

The present invention provides an down hole apparatus and method for ultrahigh resolution spectroscopy using a tunable diode laser (TDL) for analyzing a formation fluid sample downhole or at the surface to determine formation fluid parameters. In addition to absorption spectroscopy, the present invention can perform Raman spectroscopy on the fluid, by sweeping the wavelength of the TDL and detecting the Raman-scattered light using a narrow-band detector at a fixed wavelength. The spectrometer analyzes a pressurized well bore fluid sample that is collected downhole. The analysis is performed either downhole or at the surface onsite. Near infrared, mid-infrared and visible light analysis is also performed on the sample to provide an onsite surface or downhole analysis of sample properties and contamination level. The onsite and downhole analysis comprises determination of aromatics, olefins, saturates, gas oil ratio, API gravity and various other parameters which can be estimated by correlation, a trained neural network or a chemometric equation.

Owner:BAKER HUGHES INC

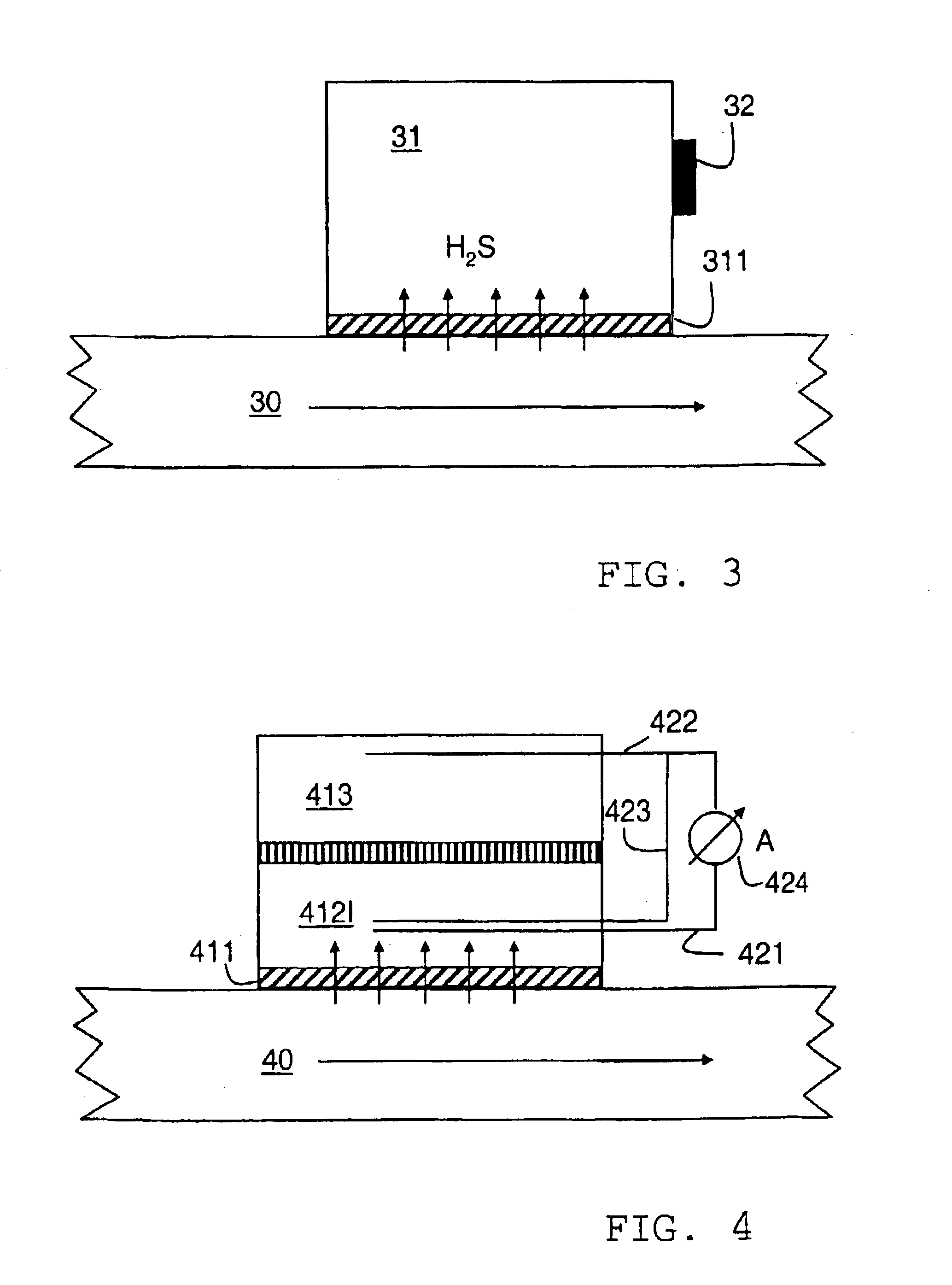

Hydrogen sulphide detection method and apparatus

Described is a downhole method and apparatus for detecting hydrogen sulphide in formation fluids produced in a hydrocarbon well. The sensor system is located within or in communication with an extraction chamber used to extract hydrogen sulphide in a gaseous state from the formation fluid and preferably equipped with renewable sensing elements.

Owner:SCHLUMBERGER TECH CORP

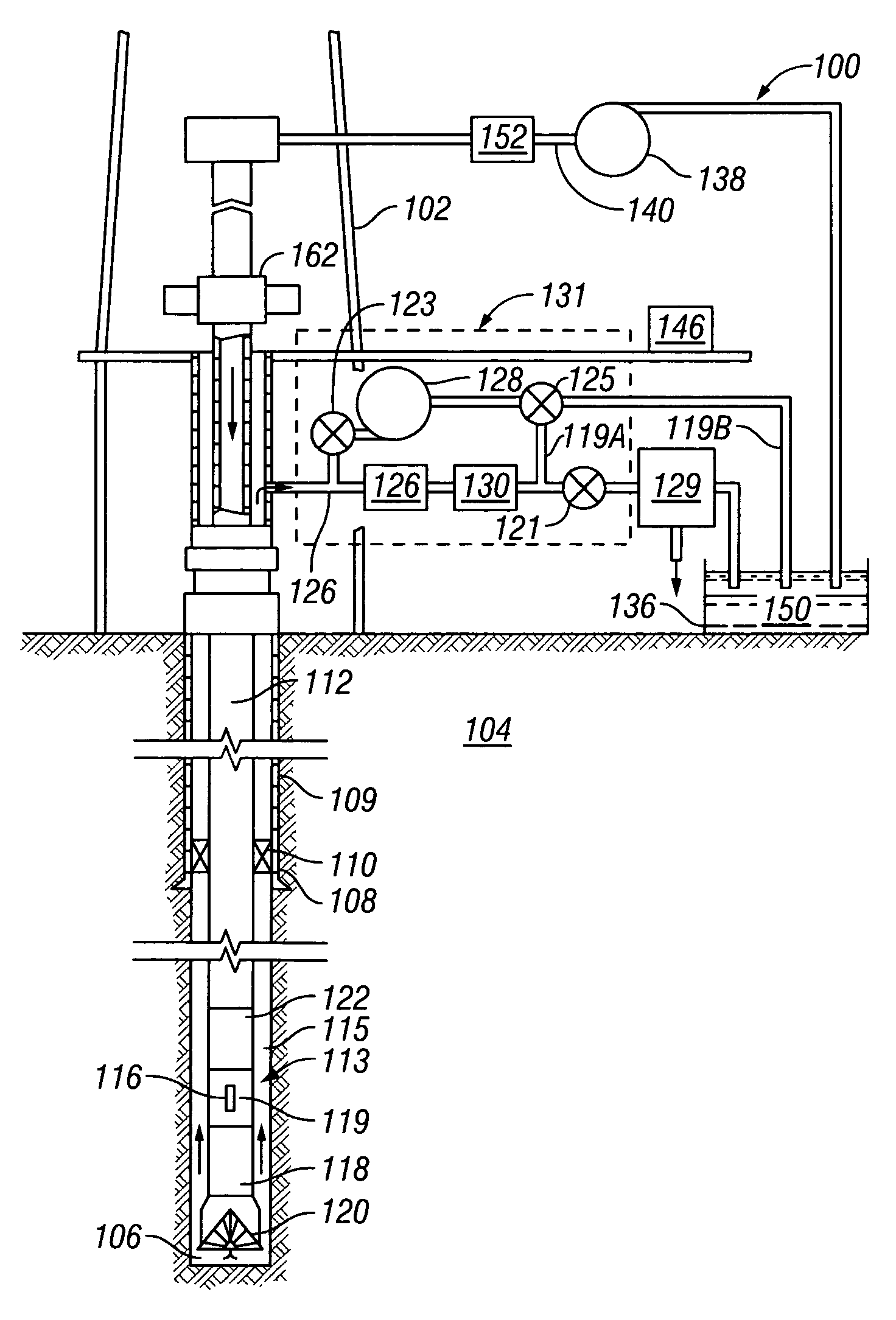

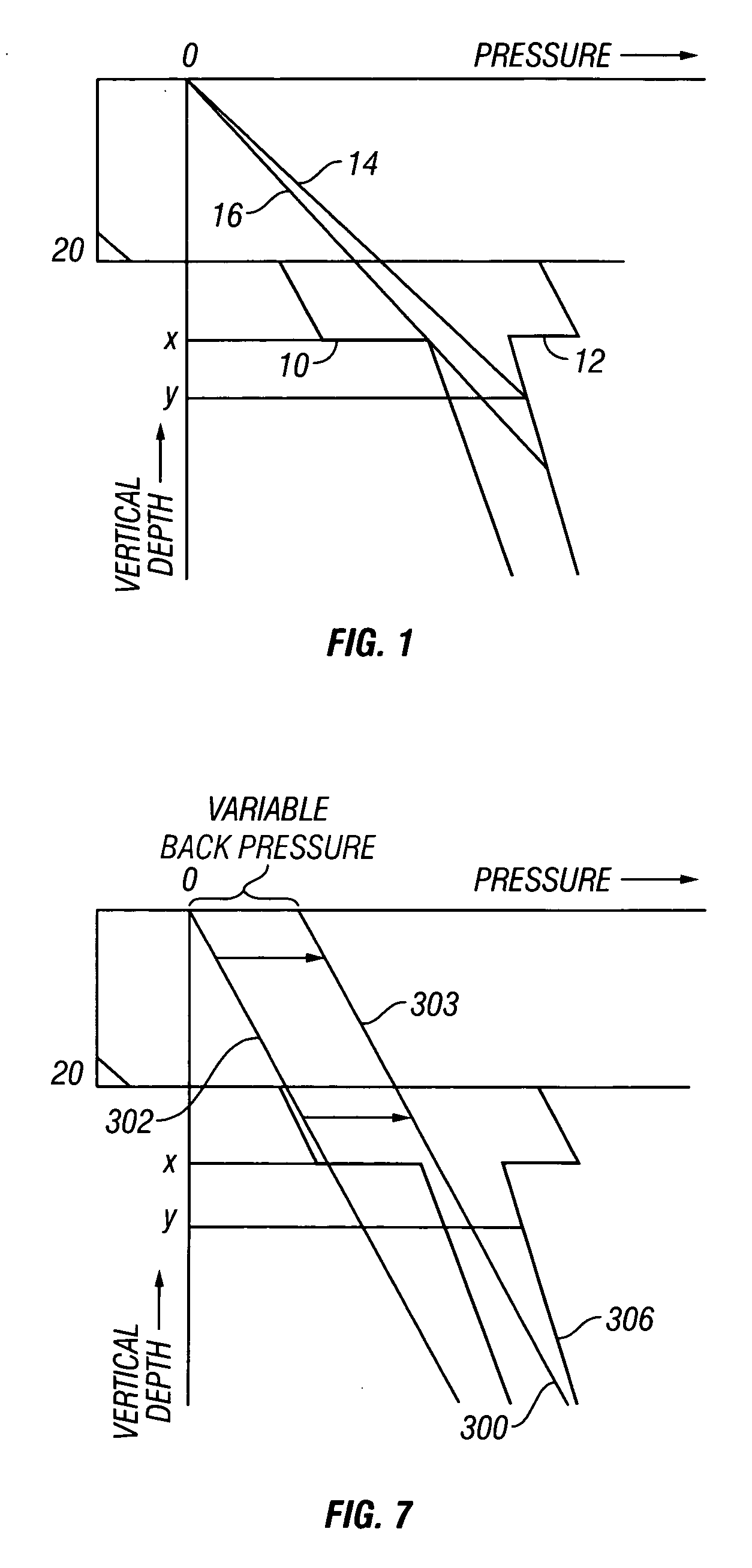

Method for determining formation fluid entry into or drilling fluid loss from a borehole using a dynamic annular pressure control system

ActiveUS20070151762A1Rate of pumping constantIncrease fluid pressureSurveyDrilling rodsDrill bitFormation fluid

A method for controlling formation pressure during drilling includes pumping a drilling fluid through a drill string in a borehole, out a drill bit at the end of the drill string into an annular space. The drilling fluid is discharged from the annular space proximate the Earth's surface. At least one of a flow rate of the drilling fluid into the borehole and a fluid flow rate out of the annular space is measured. Pressure of the fluid in the annular space proximate the Earth's surface and pressure of the fluid proximate the bottom of the borehole are measured. Pressure of the fluid proximate the bottom of the borehole is estimated using the measured flow rate, annular space pressure and density of the drilling fluid. A warning signal is generated if difference between the estimated pressure and measured pressure exceeds a selected threshold.

Owner:SMITH INT INC

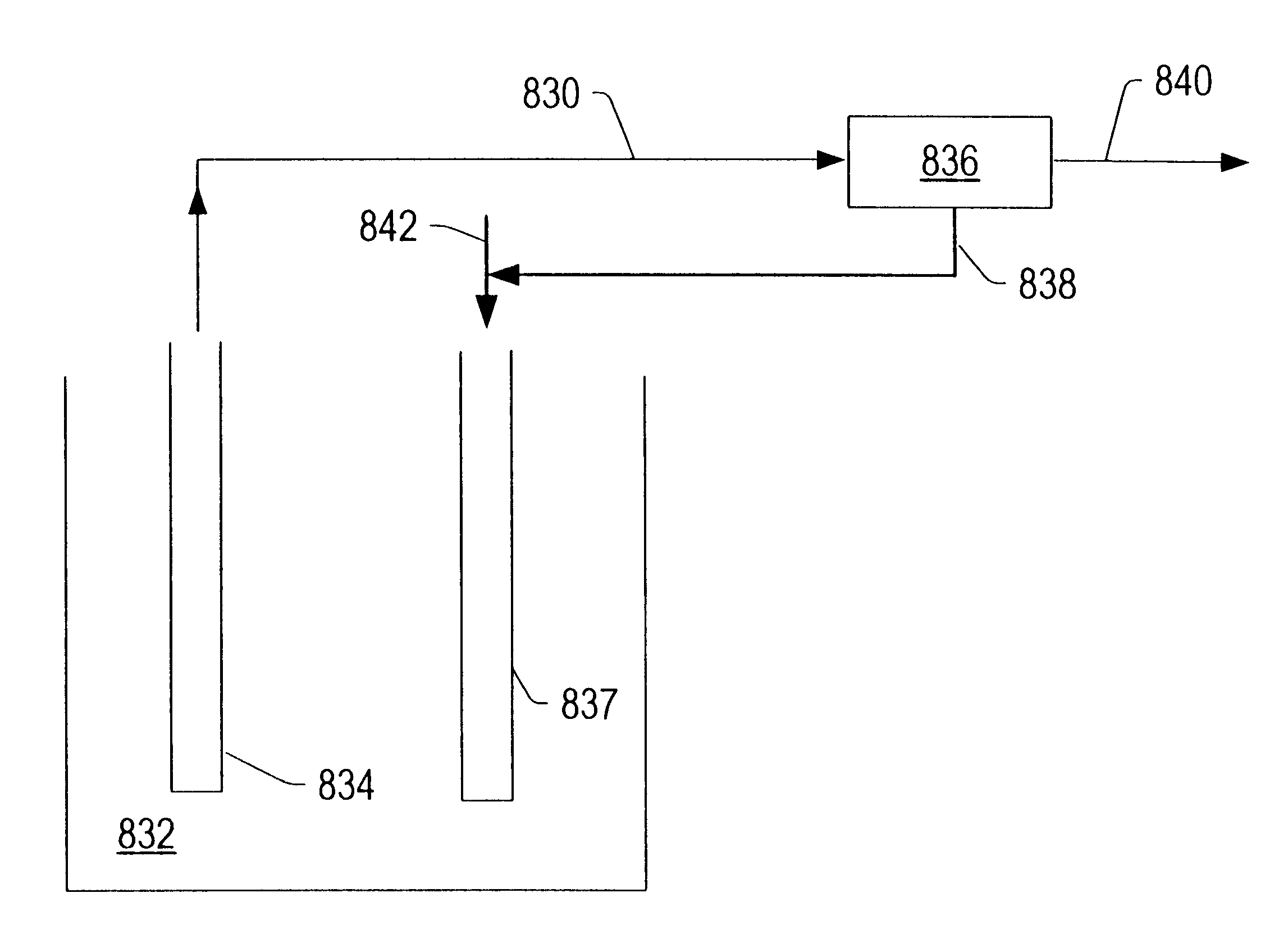

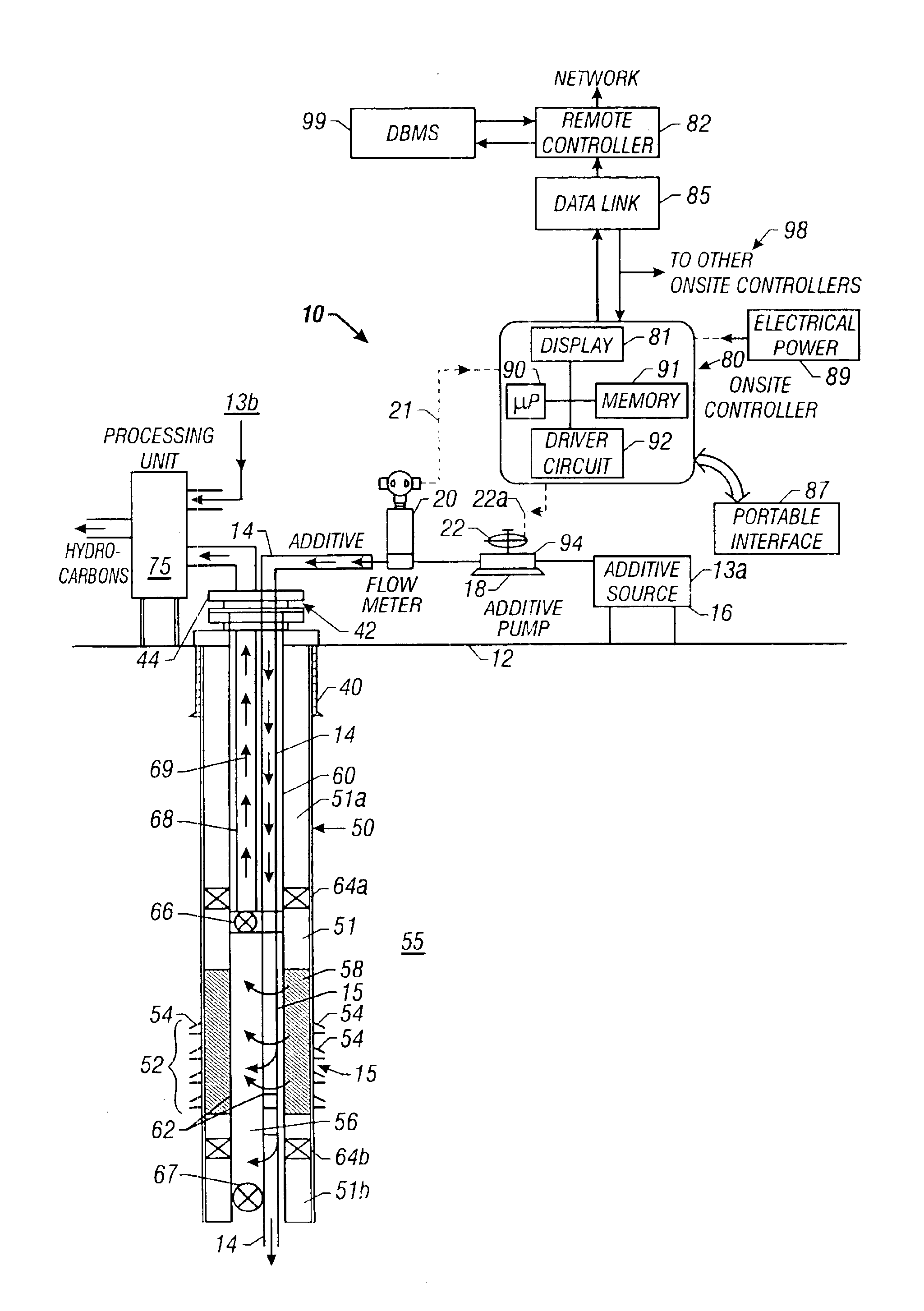

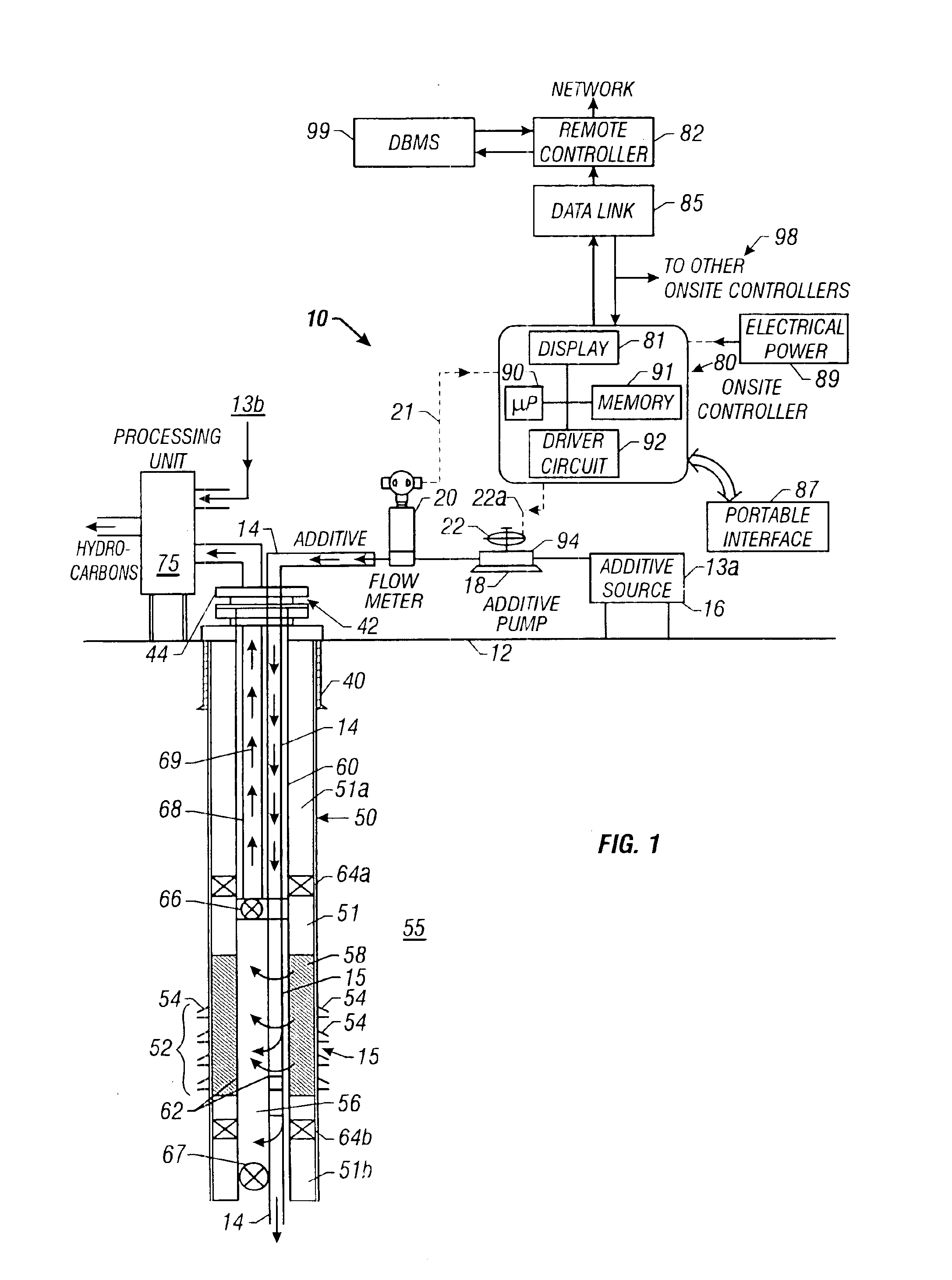

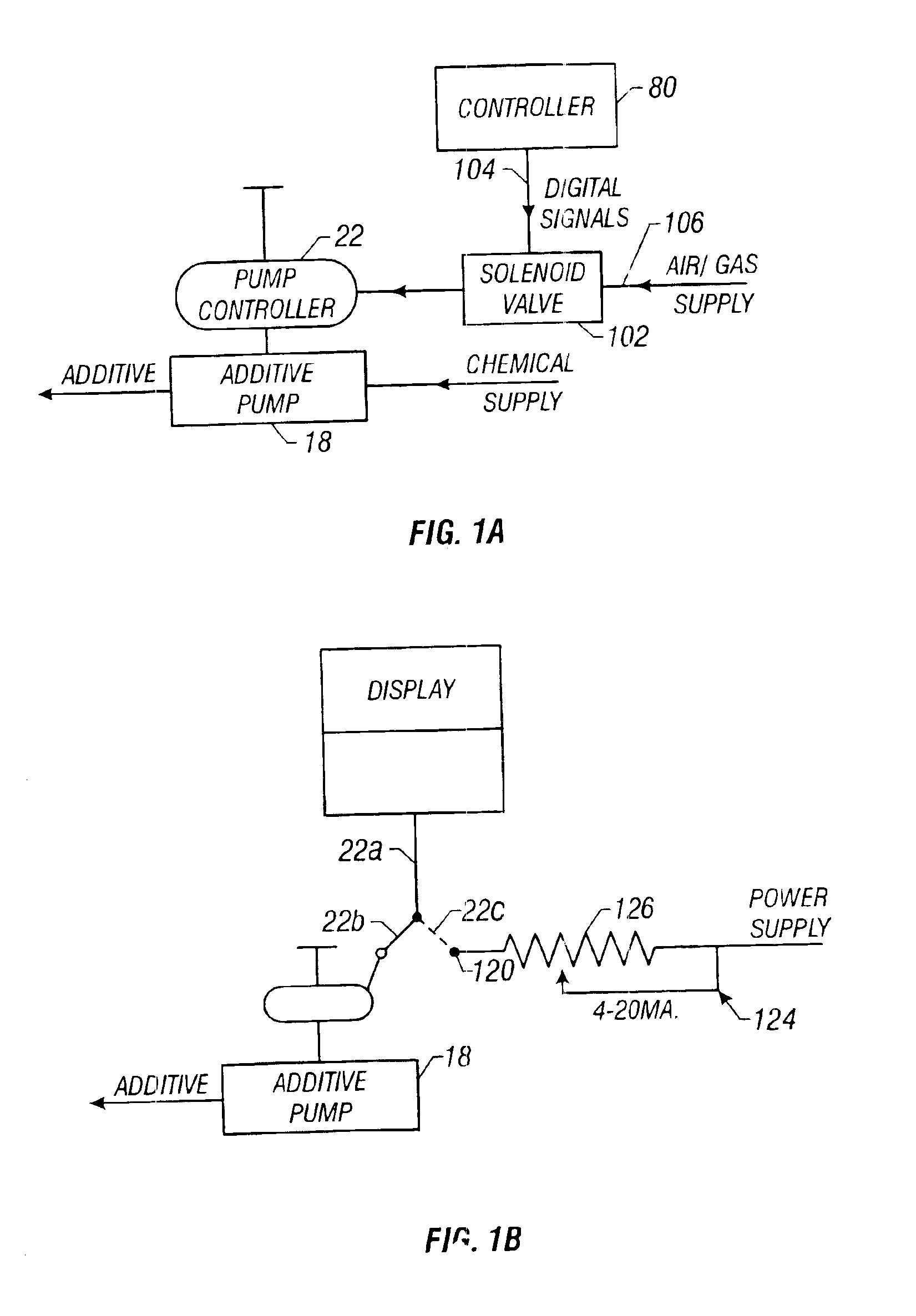

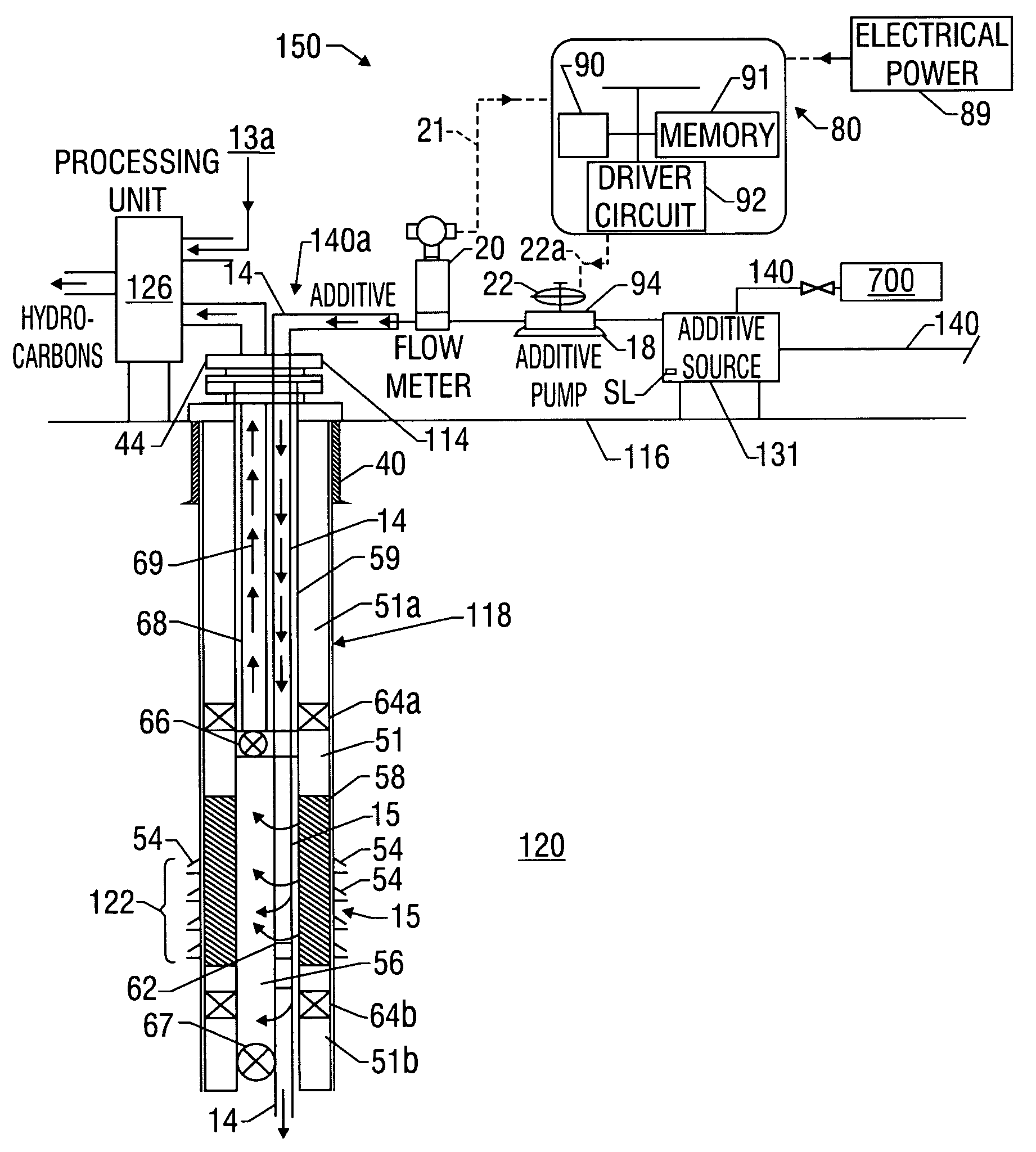

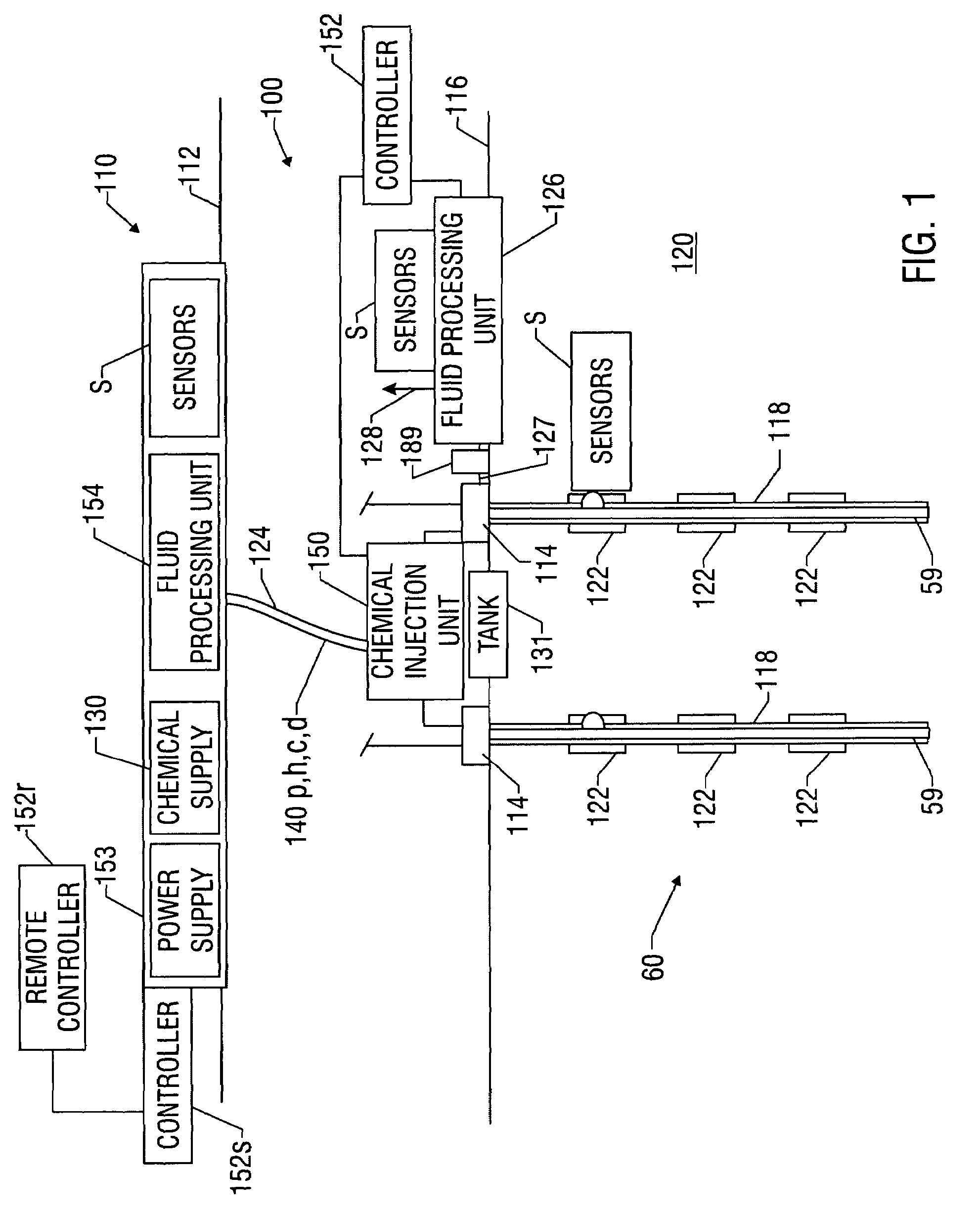

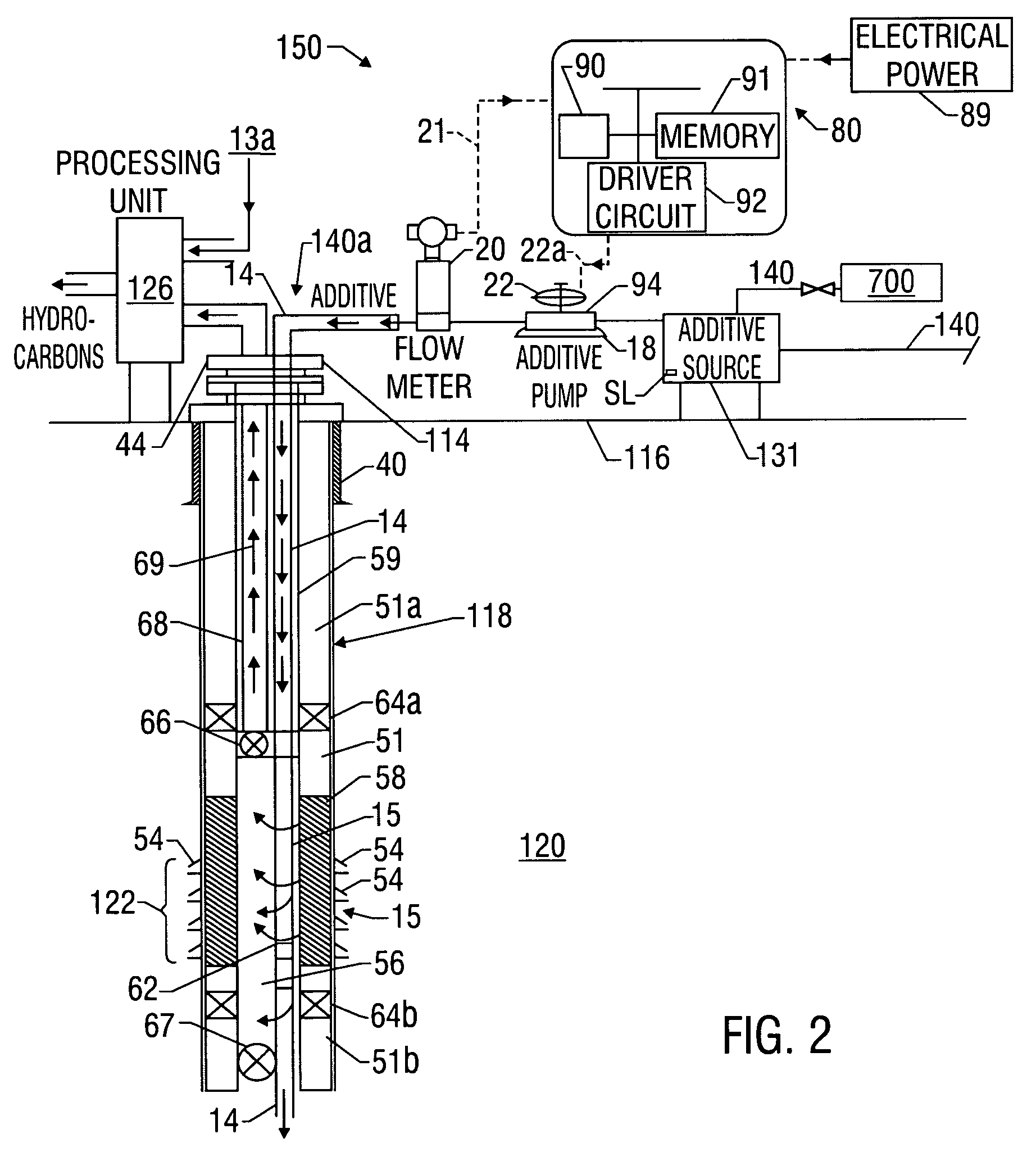

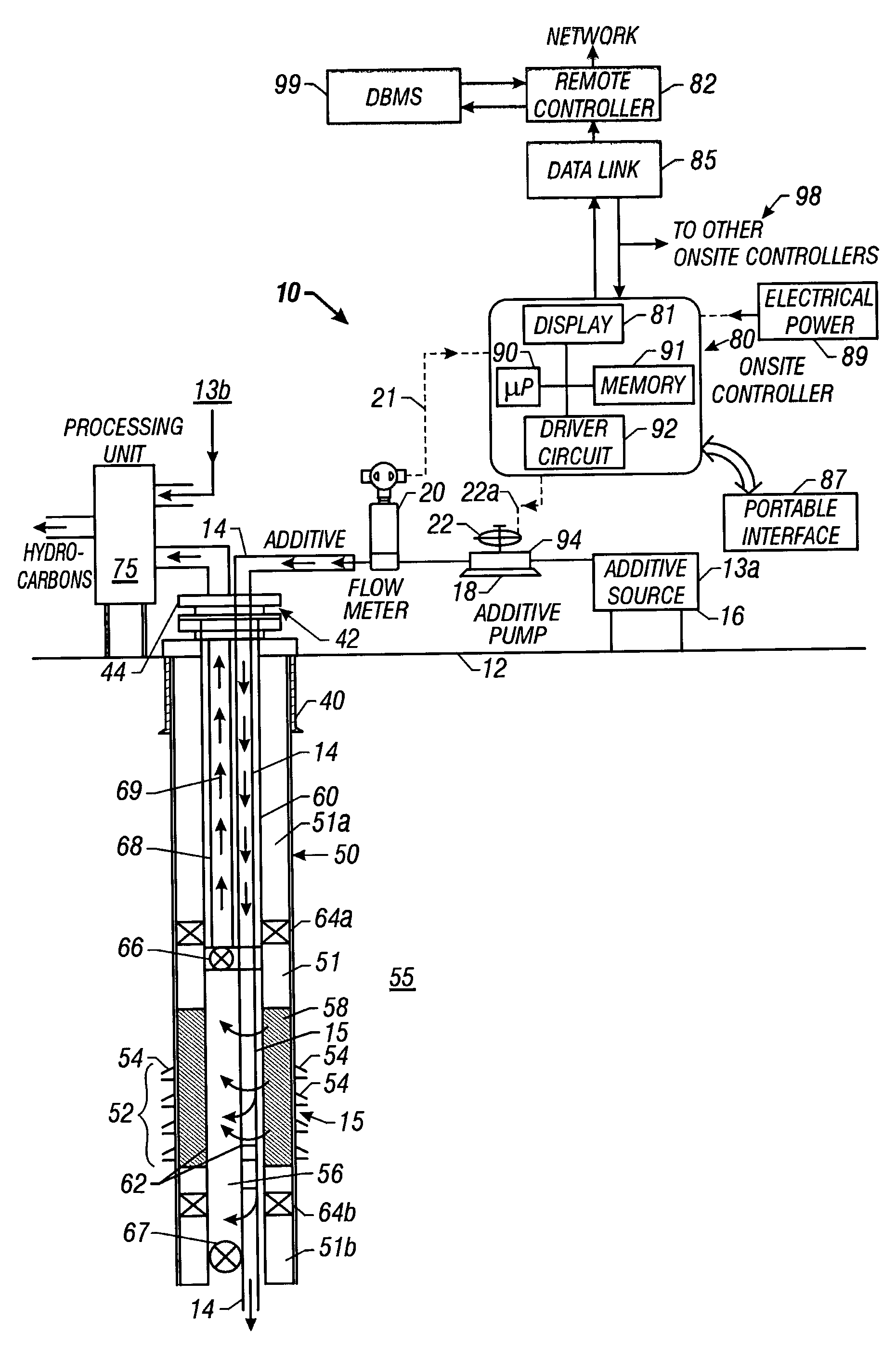

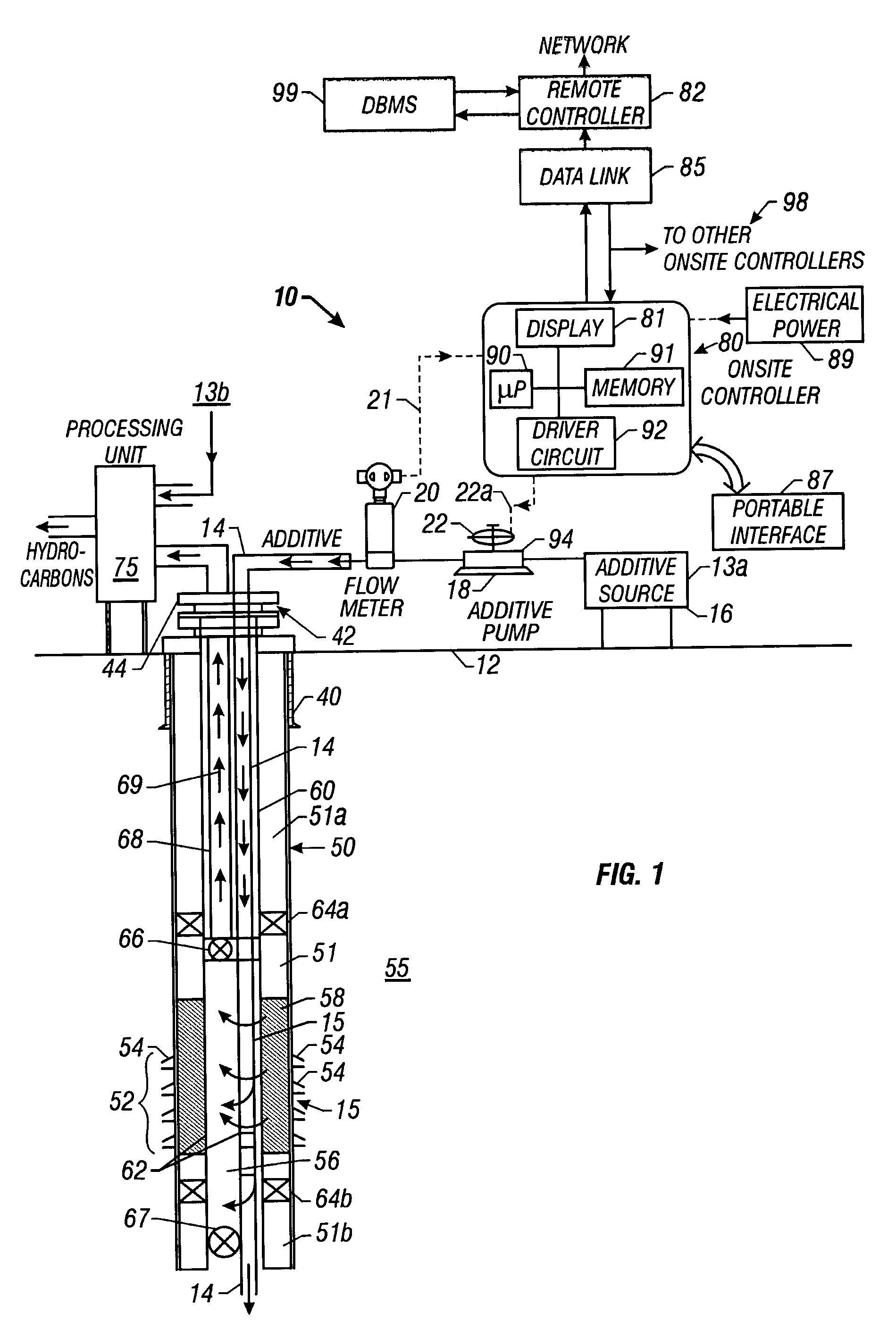

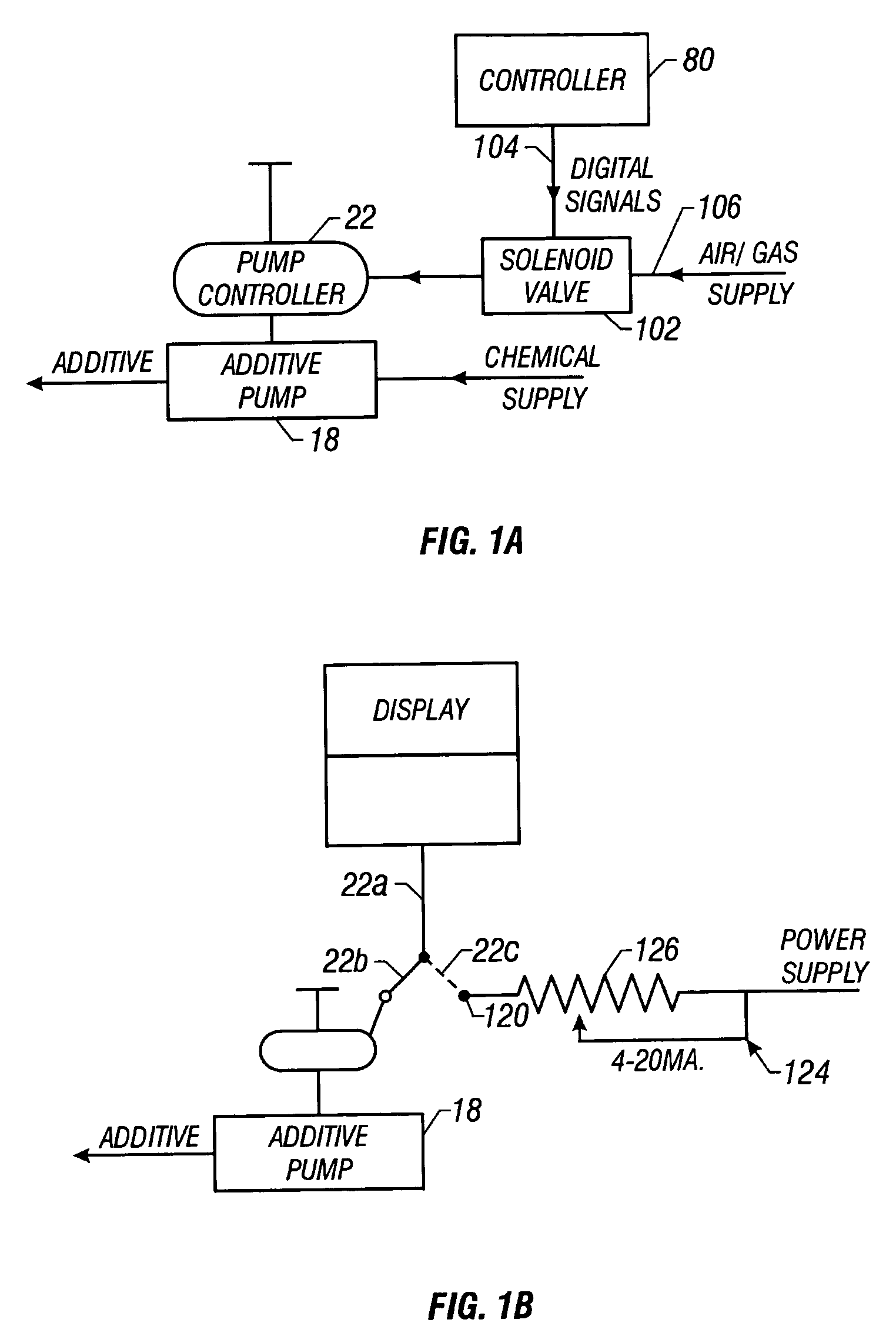

Closed loop additive injection and monitoring system for oilfield operations

InactiveUS6851444B1Realize automatic adjustmentAccurate measurementSurveyOperating means/releasing devices for valvesLine tubingMonitoring system

A system is provided that monitors at the wellsite injection of additives into formation fluids recovered through wellbores and controls the supply of such additives from remote locations. A pump supplies the selected additive from a source at the wellsite into the wellbore via a suitable supply line. A flow meter in the supply line measures the flow rate of the additive through the supply line and generates signals representative of the flow rate. A controller at the wellsite determines the flow rate from the flow meter signals and in response thereto controls the pump to control the flow rate of the additive to the well. The wellsite controller interfaces with a suitable two-way communication link and transmits signals and data representative of the flow rate, and other parameters to a second remote controller. The remote controller transmits command signals to the wellsite controller representative of any change desired for the flow rate. The wellsite controller is microprocessor based and may be programmed at the wellsite or by the remote controller to adjust the flow rate. The system of the present invention may be configured for multiple wells, with each well having a separate wellsite controller or a common wellsite controller.

Owner:BAKER HUGHES INC

Inhibiting reflux in a heated well of an in situ conversion system

Owner:SHELL OIL CO

Methods of hydrotreating a liquid stream to remove clogging compounds

A method includes producing formation fluid from a subsurface in situ heat treatment process. The formation fluid is separated to produce a liquid stream and a gas stream. At least a portion of the liquid stream is provided to a hydrotreating unit. At least a portion of selected in situ heat treatment clogging compositions in the liquid stream are removed to produce a hydrotreated liquid stream by hydrotreating at least a portion of the liquid stream at conditions sufficient to remove the selected in situ heat treatment clogging compositions.

Owner:SHELL OIL CO

Methods and apparatus of downhole fluid analysis

ActiveUS7461547B2Check of qualityQuality improvementSurveyIndirect flow property measurementReal time analysisFormation fluid

Owner:SCHLUMBERGER TECH CORP

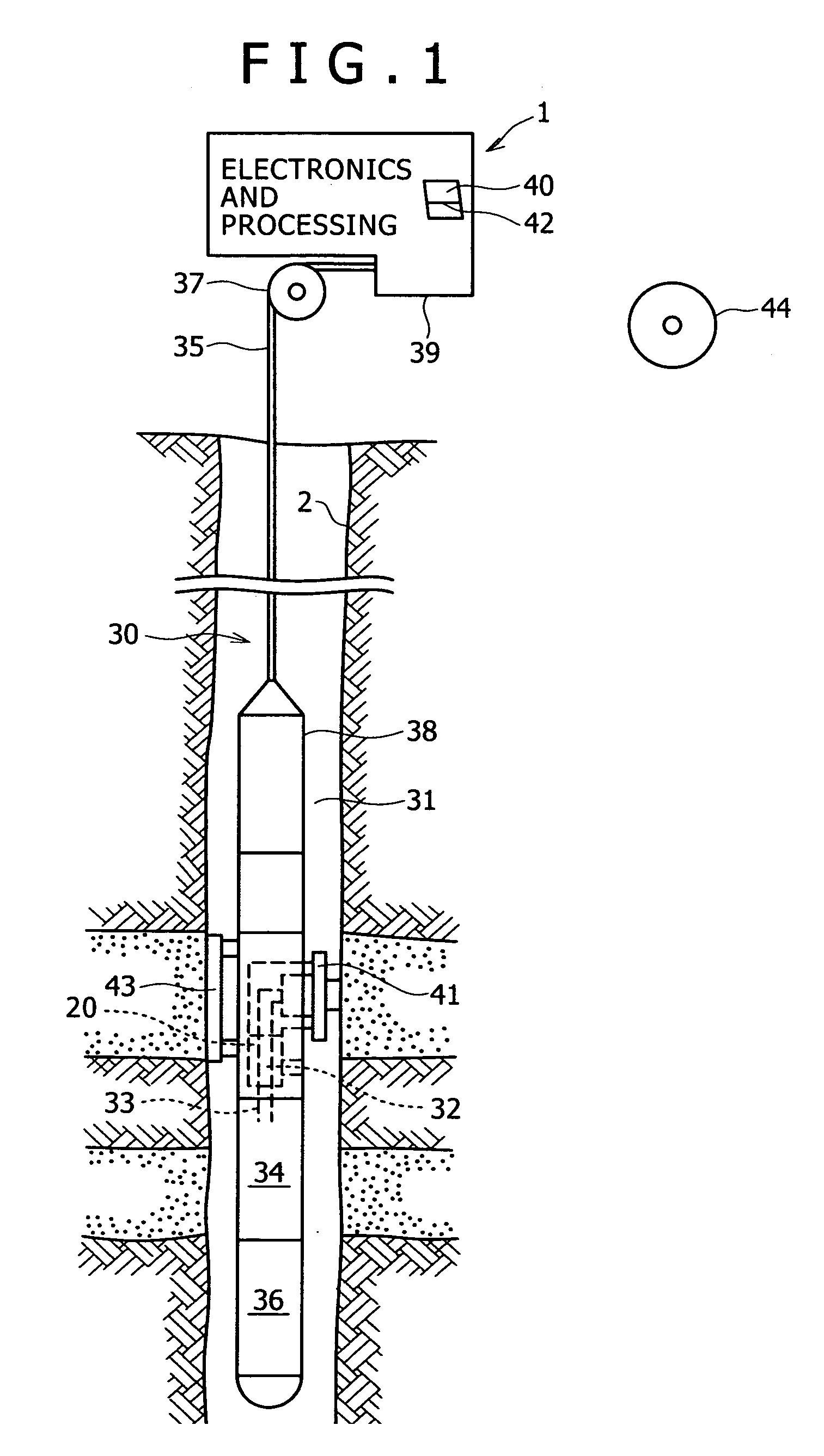

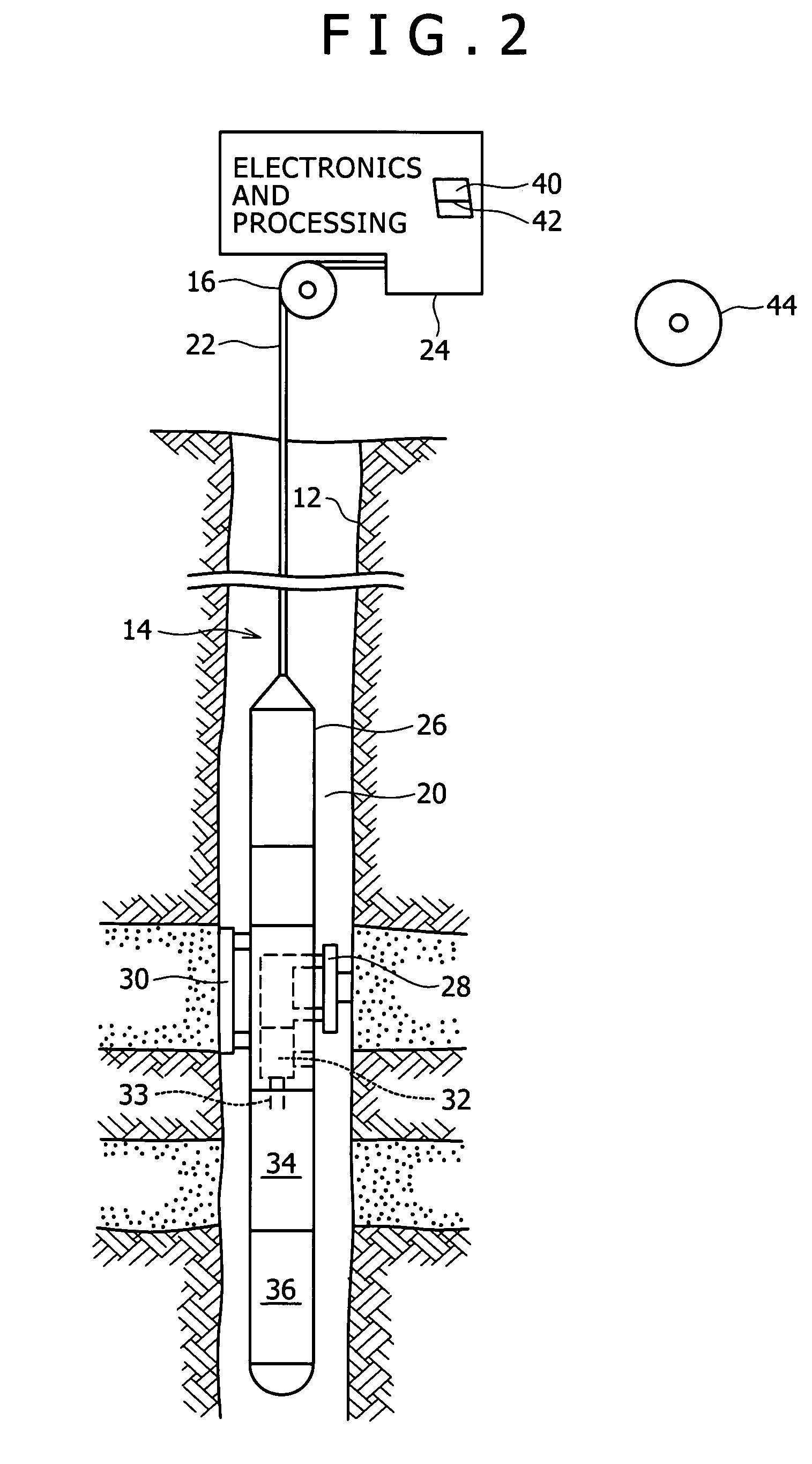

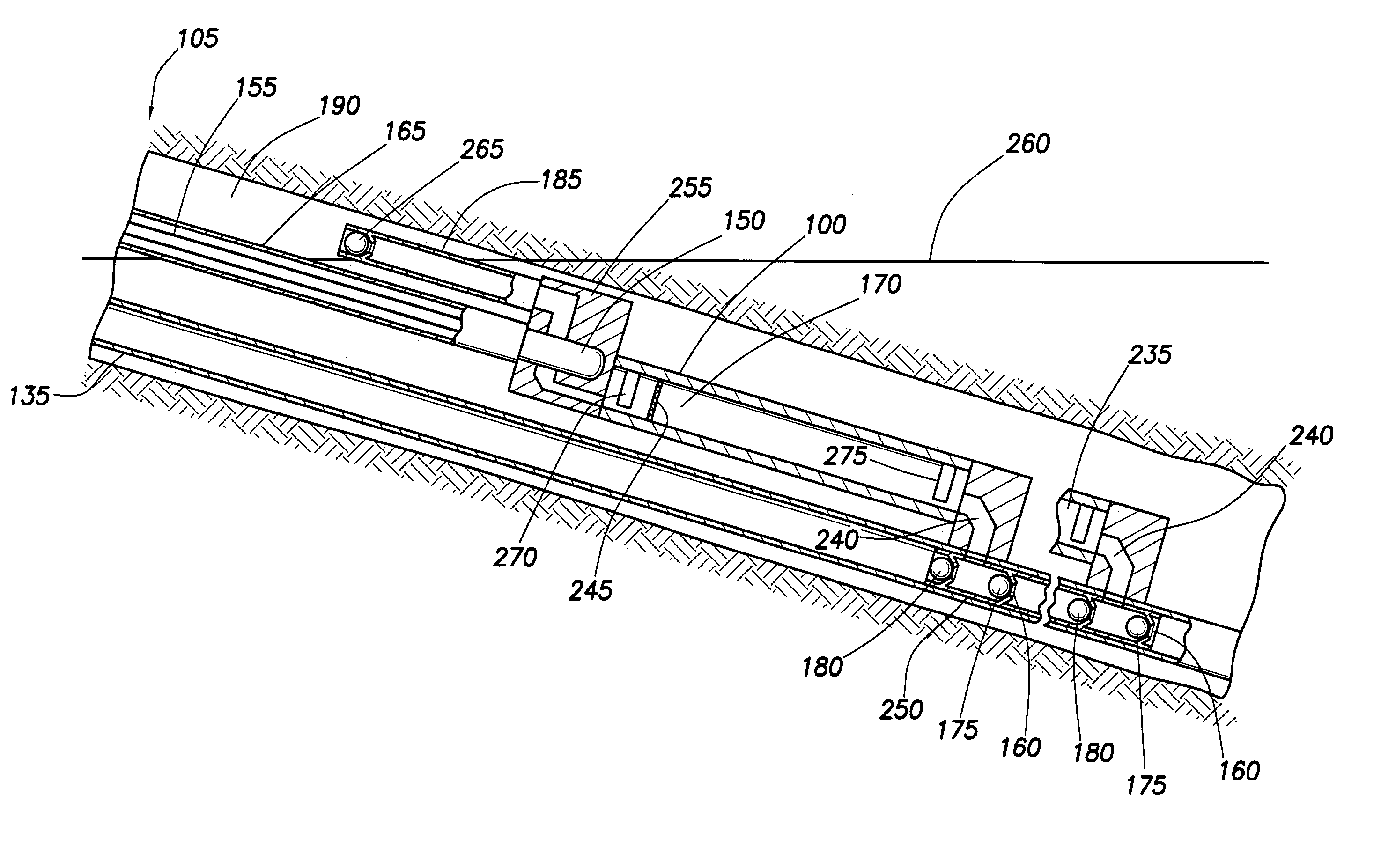

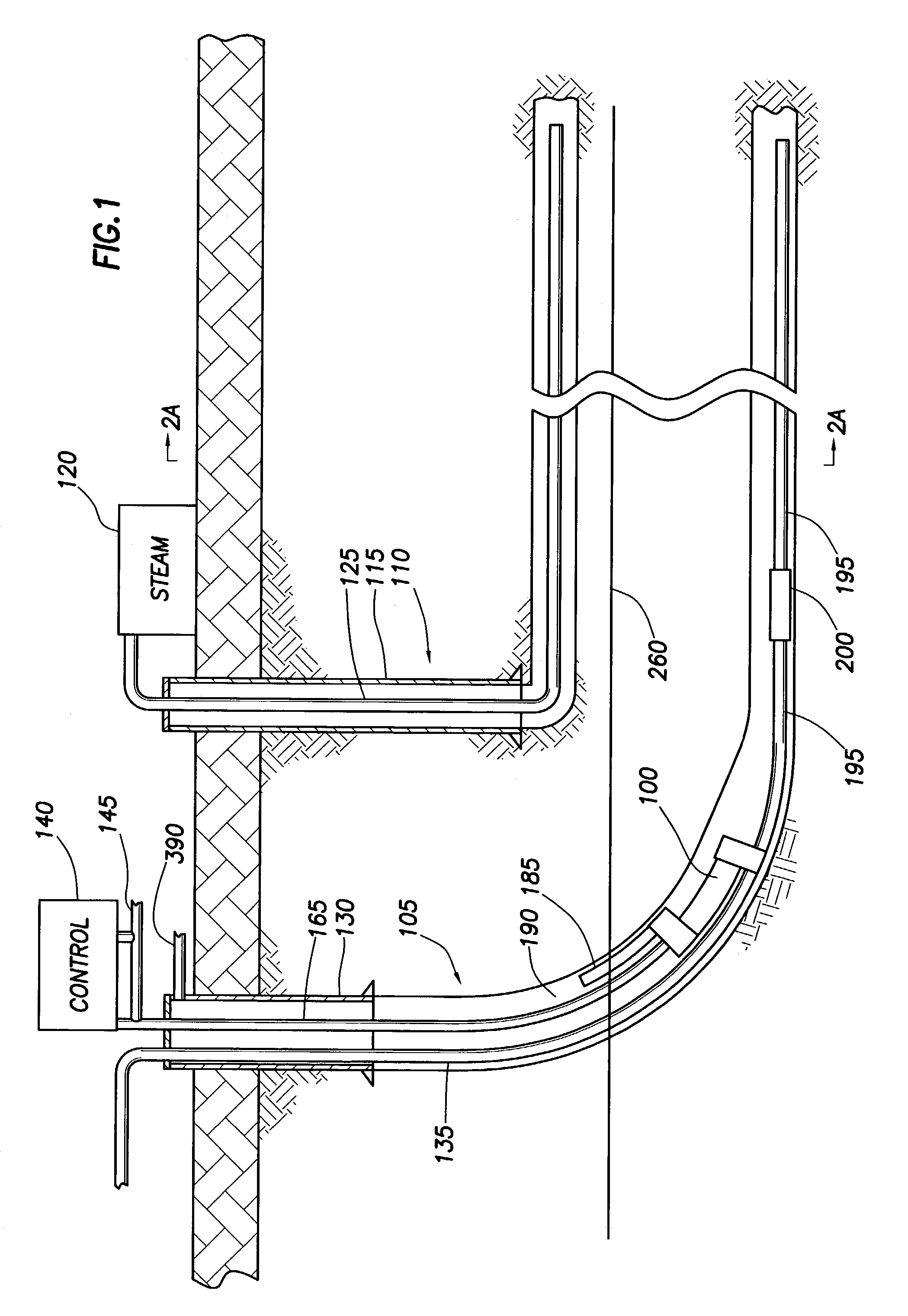

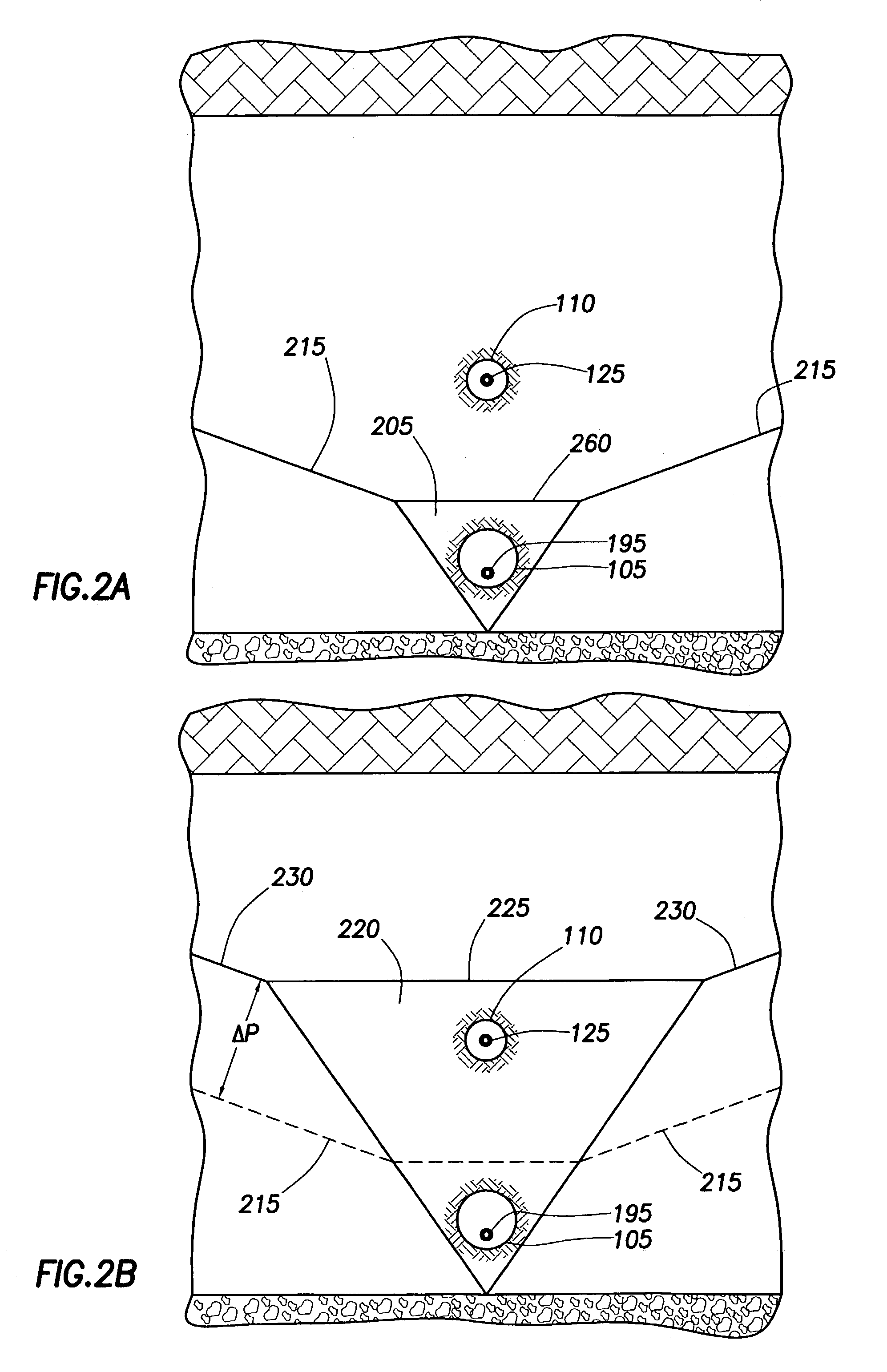

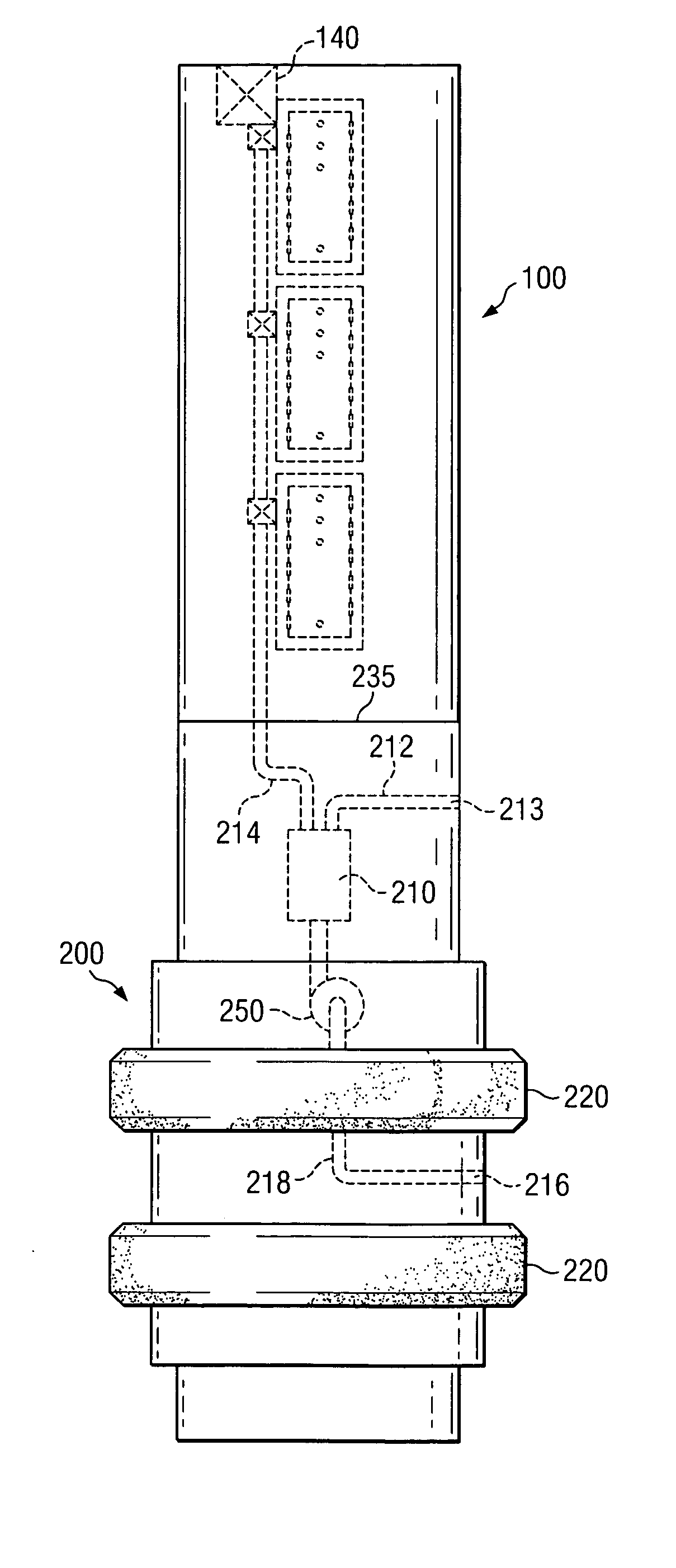

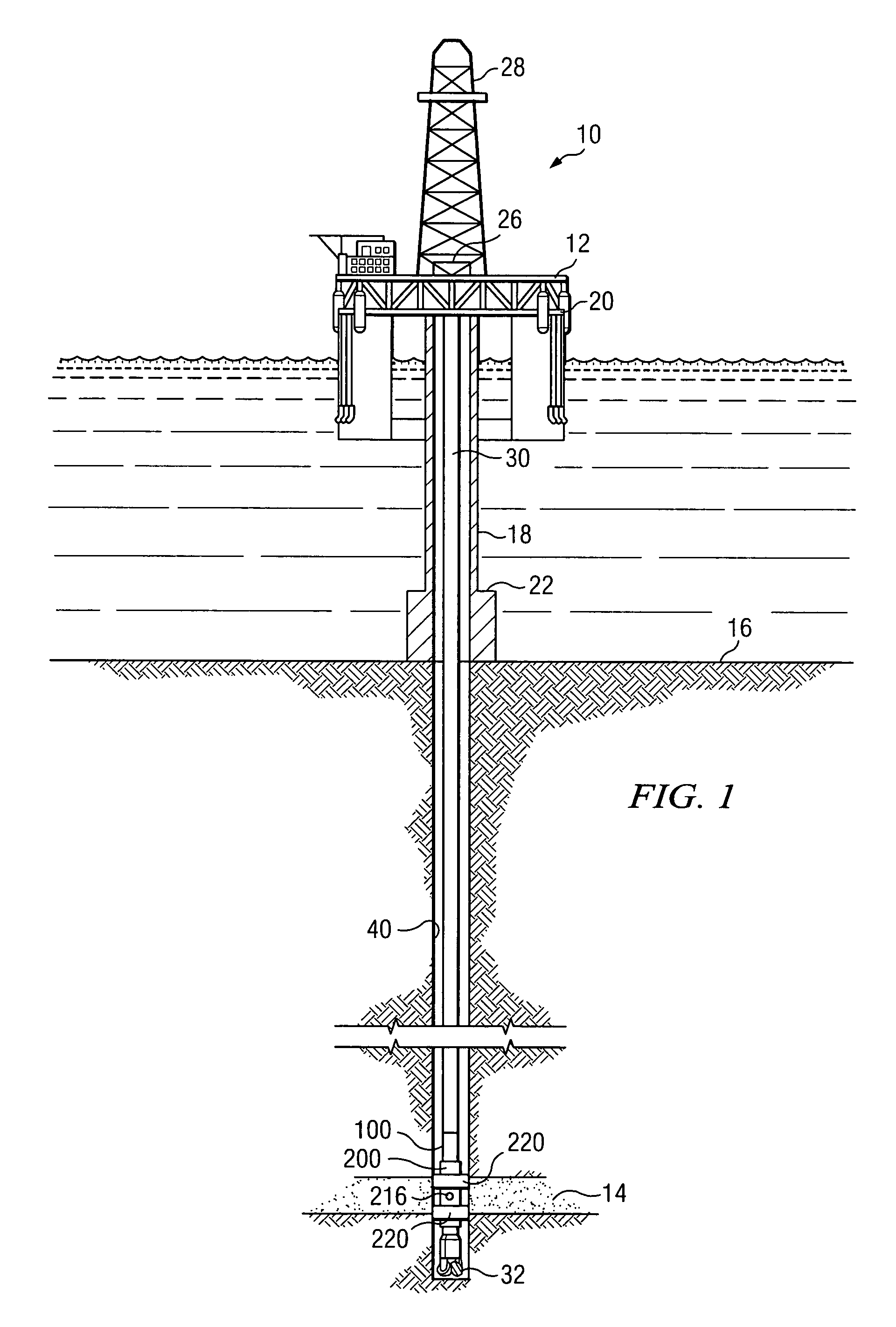

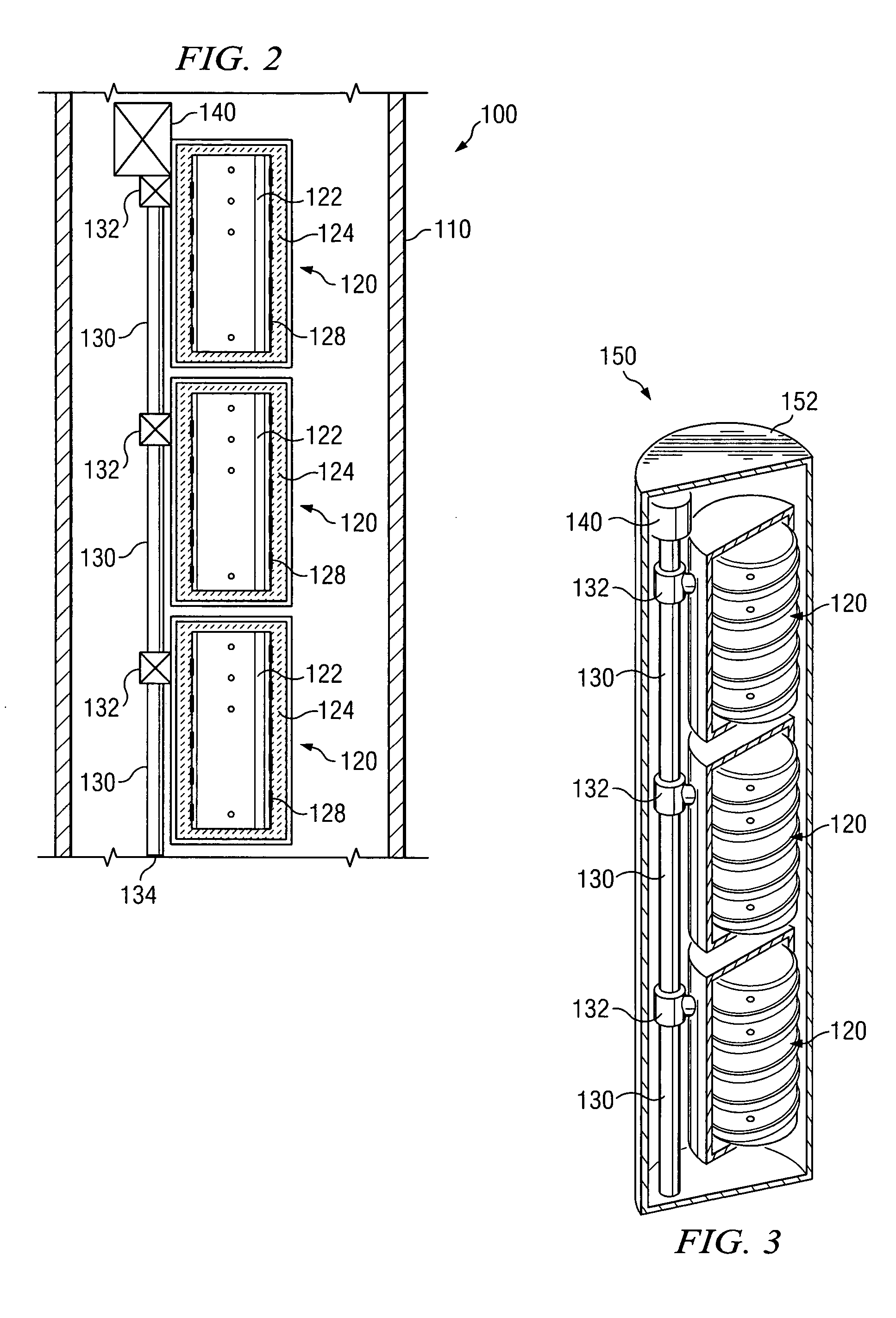

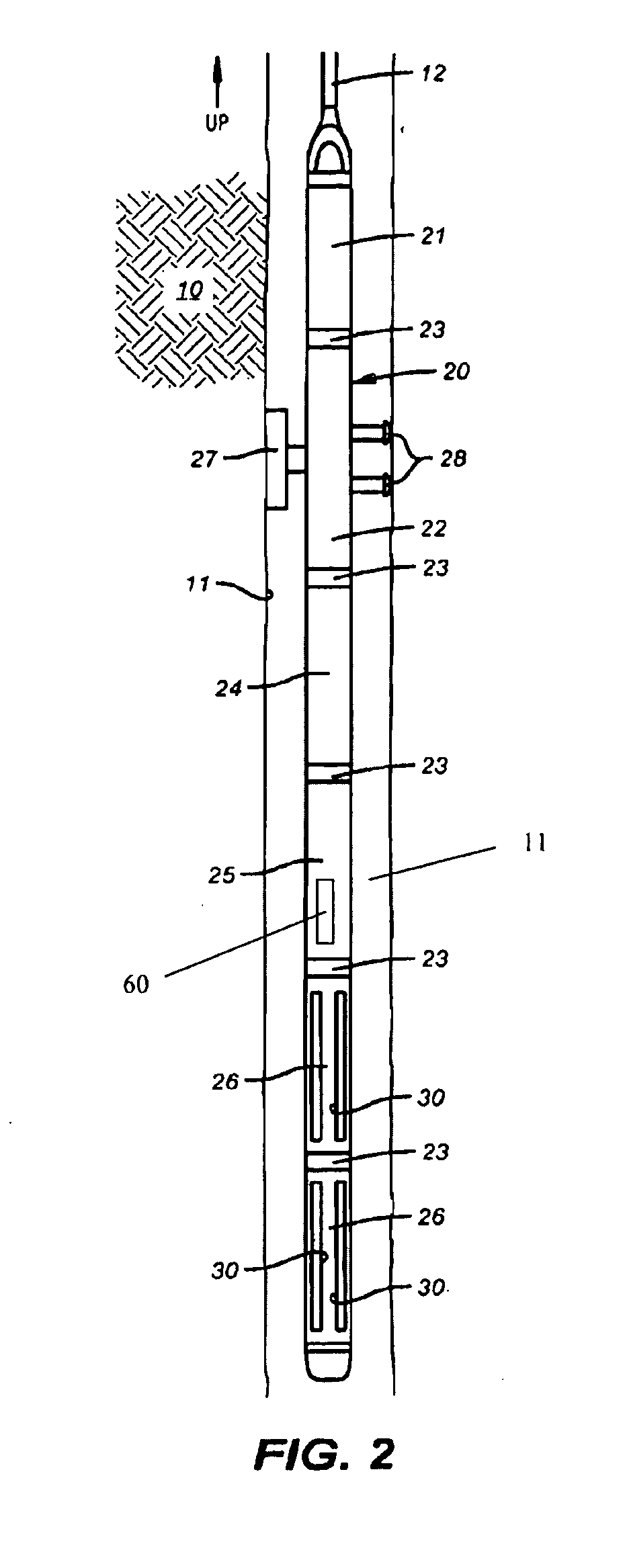

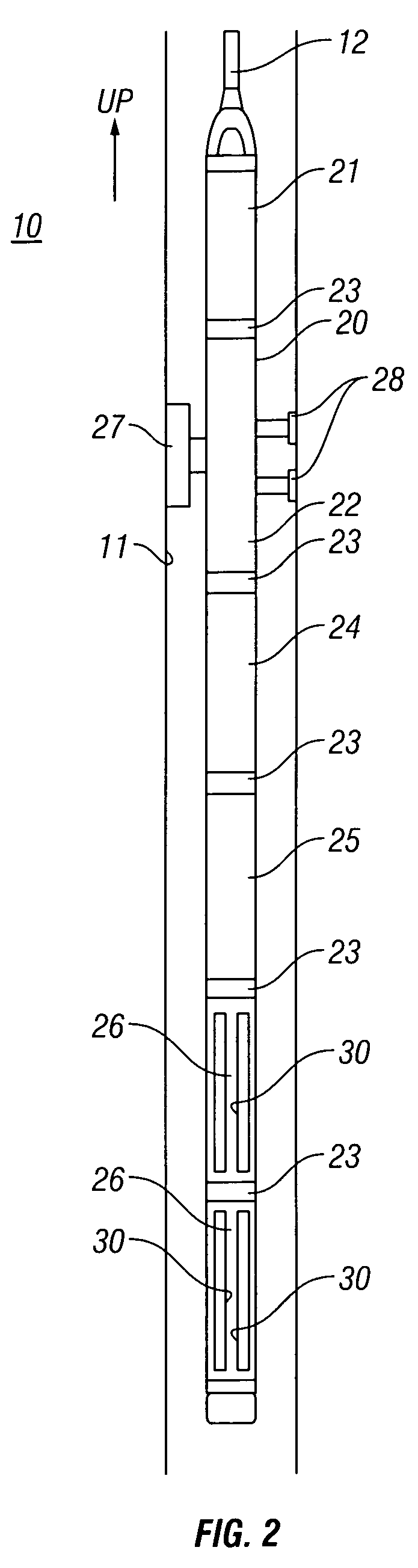

Gas operated pump for hydrocarbon wells

The present invention generally relates to an apparatus and method for improving production from a wellbore. In one aspect, a downhole pump for use in a wellbore is provided. The downhole pump includes two or more chambers for the accumulation of formation fluids and a valve assembly for filling and venting gas to and from the two or more chambers. The downhole pump further includes a fluid passageway for connecting the two or more chambers to a production tube. In another aspect, a downhole pump including a chamber for the accumulation of formation fluids is provided. In another aspect, a method for improving production in a wellbore is provided. In yet another aspect, a method for improving production in a steam assisted gravity drainage operation is provided. Additionally, a pump system for use in a wellbore is provided.

Owner:WEATHERFORD TECH HLDG LLC

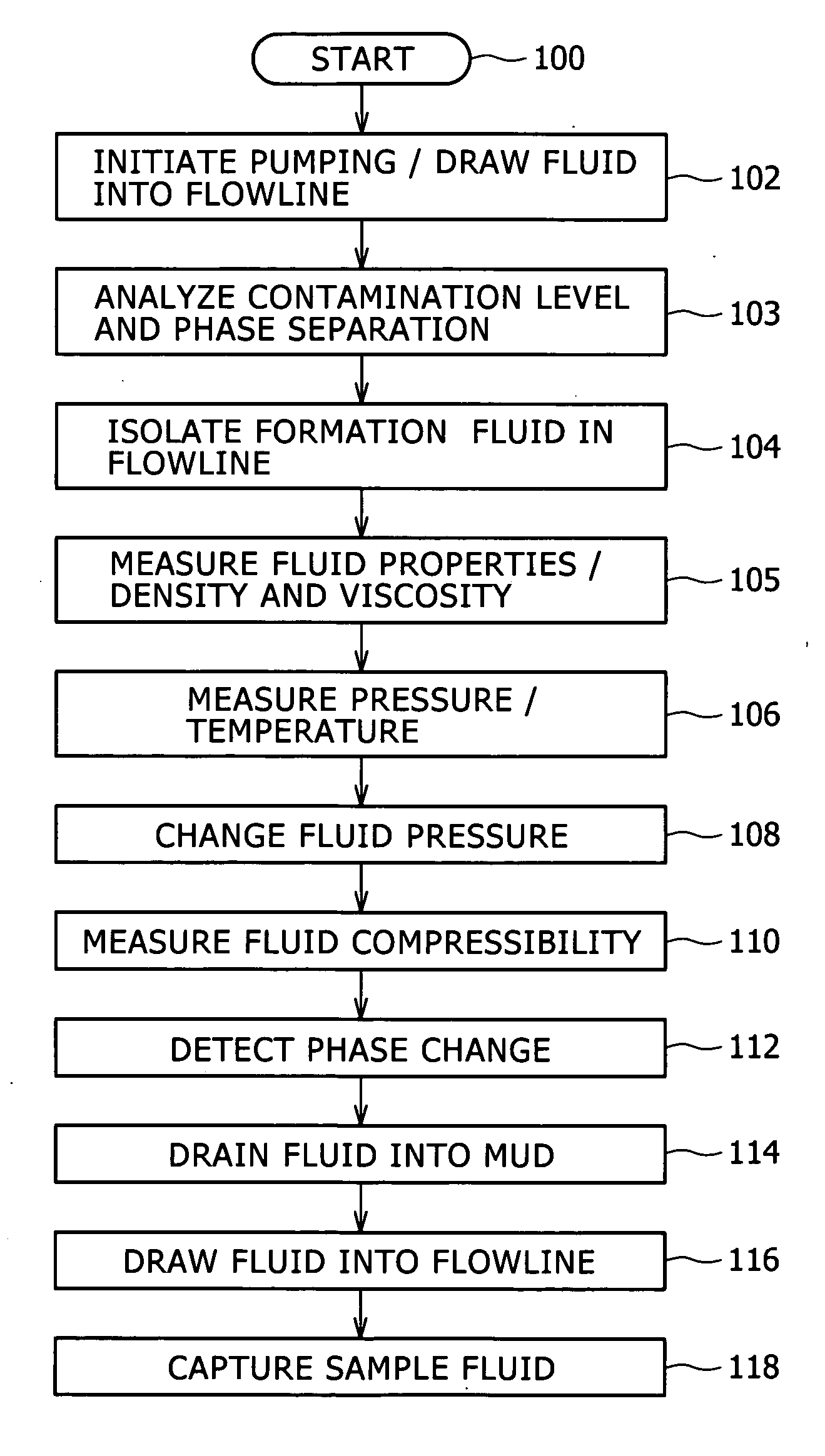

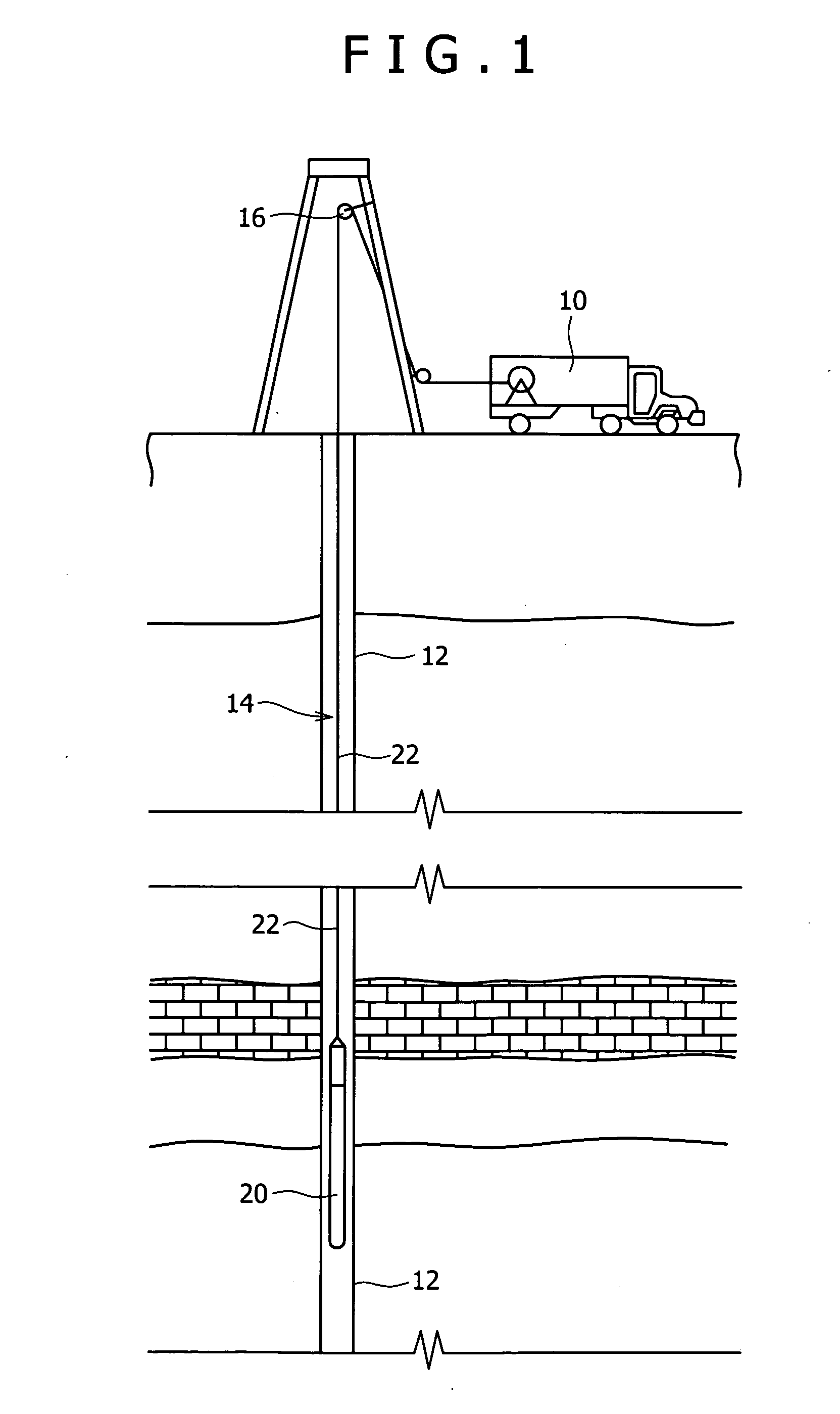

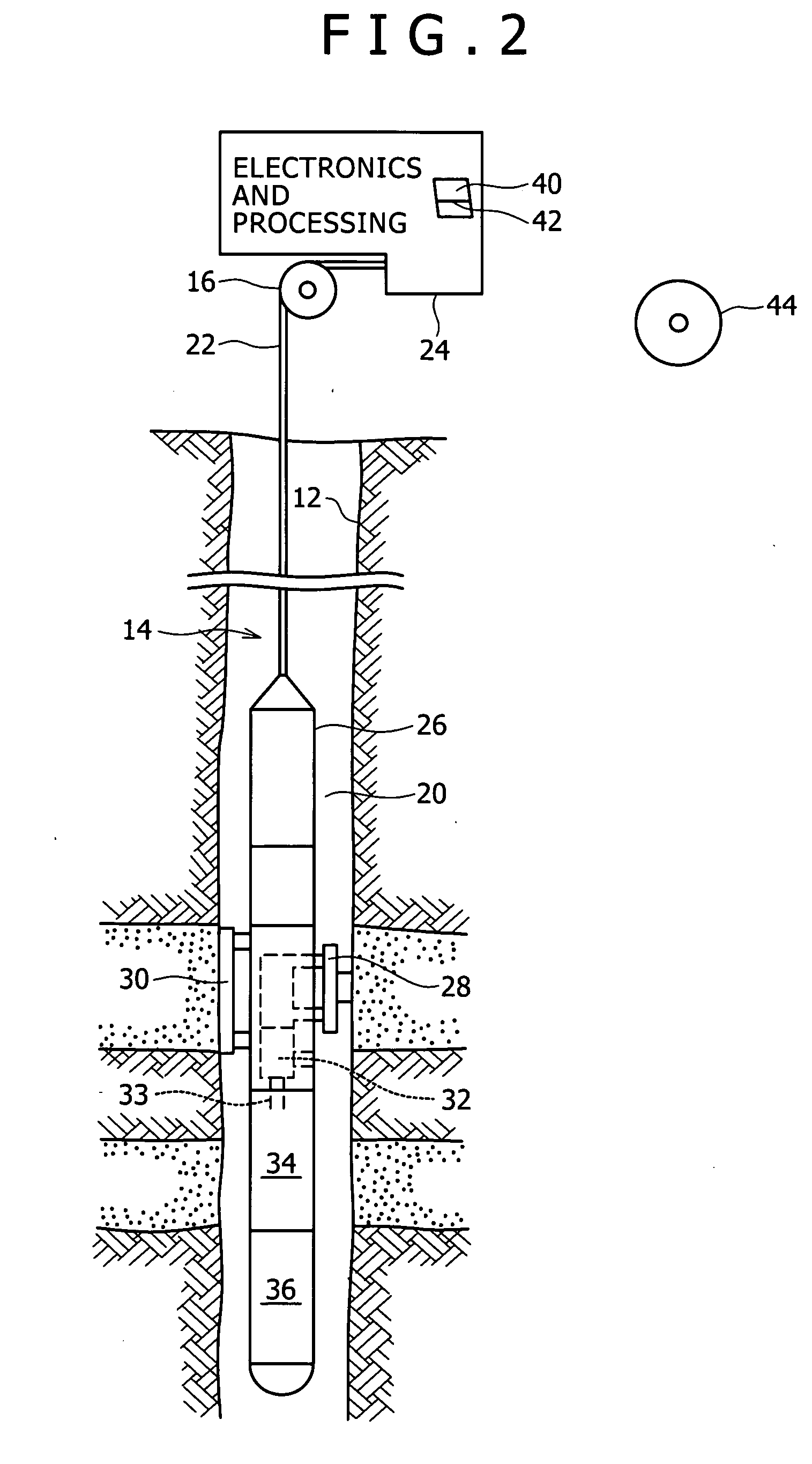

Methods and apparatus of downhole fluid analysis

ActiveUS20060243047A1Accurate representationCheck of qualitySurveyIndirect flow property measurementReal time analysisFormation fluid

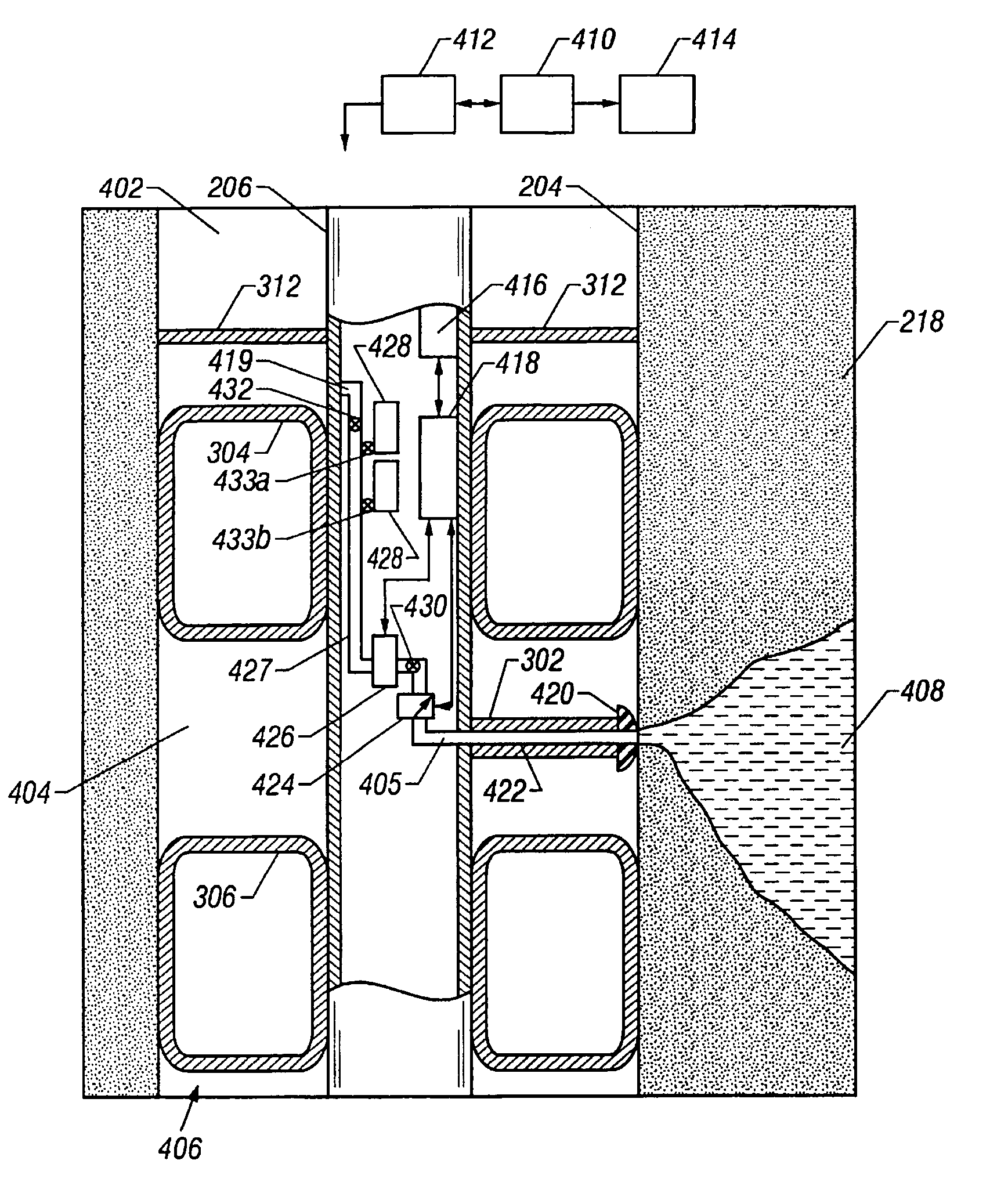

Methods and apparatus for downhole analysis of formation fluids by isolating the fluids from the formation and / or borehole in a pressure and volume control unit that is integrated with a flowline of a fluid analysis module and determining fluid characteristics of the isolated fluids. Parameters of interest may be derived for formation fluids in a static state and undesirable formation fluids may be drained and replaced with formation fluids that are suitable for downhole characterization or surface sample extraction. Isolated formation fluids may be circulated in a loop of the flowline for phase behavior characterization. Real-time analysis of the fluids may be performed at or near downhole conditions.

Owner:SCHLUMBERGER TECH CORP

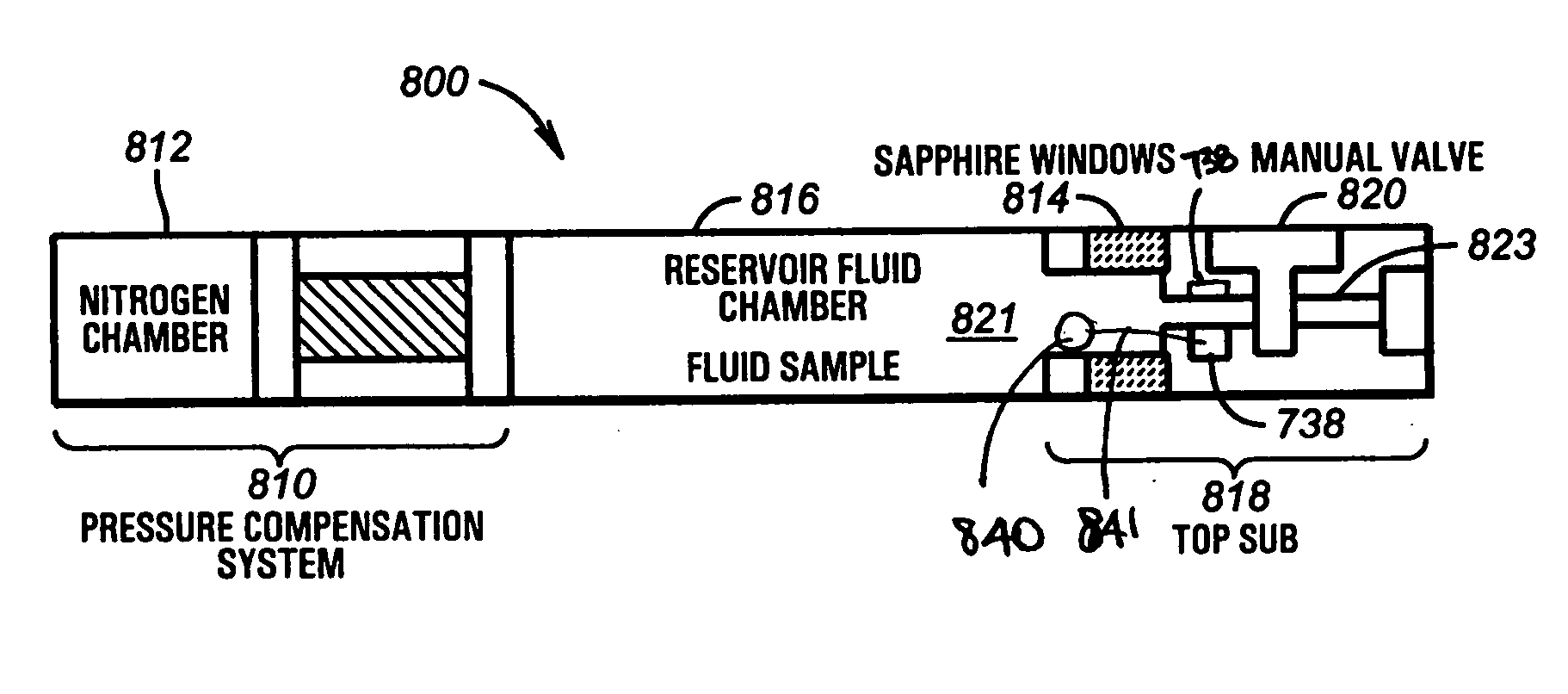

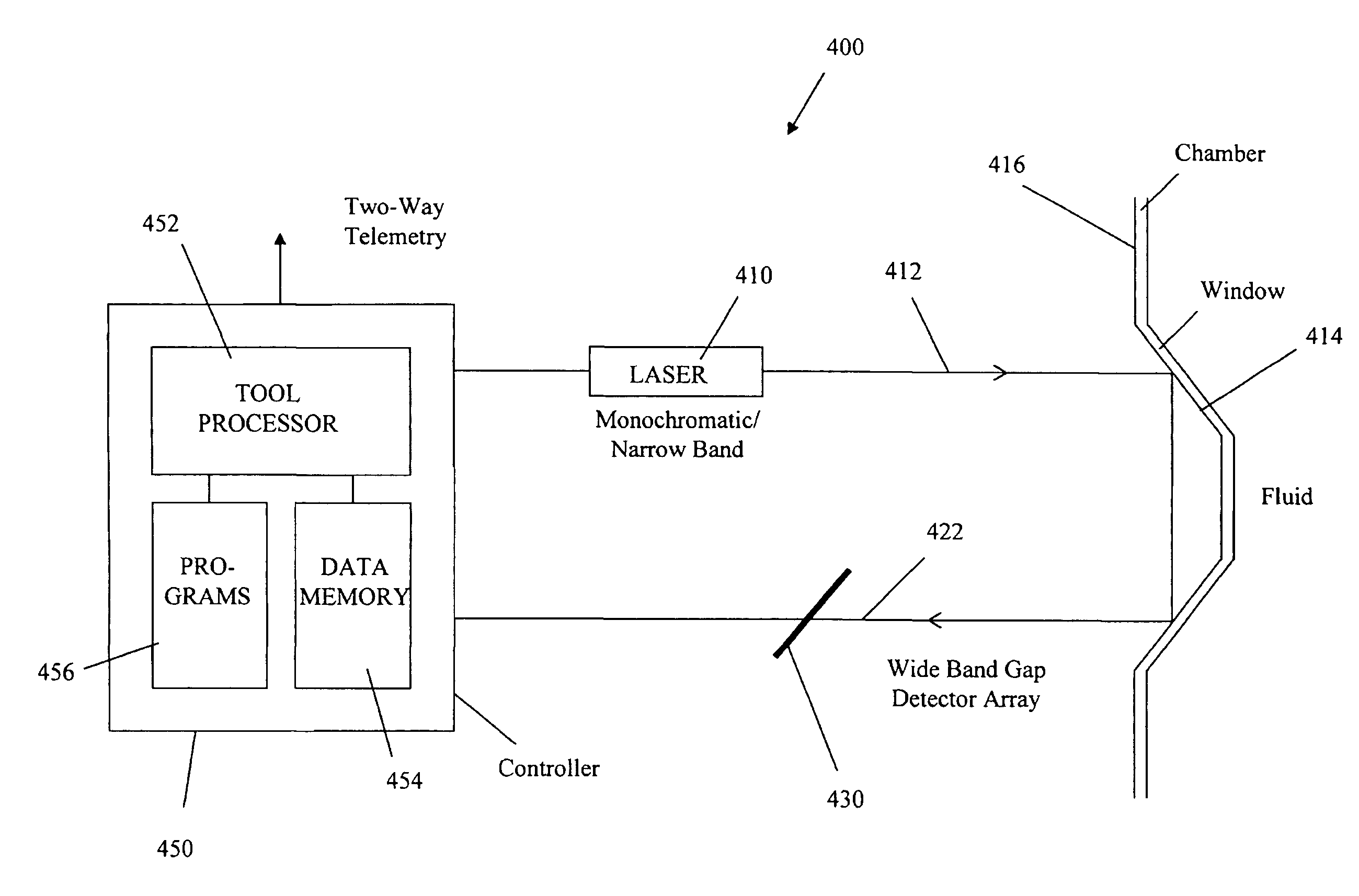

Method and apparatus for an advanced optical analyzer

ActiveUS20040218176A1Eliminate riskThe result is accurateRadiation pyrometrySpectrum investigationSmall sampleAPI gravity

The present invention provides a sample tank having a window for introduction of electromagnetic energy into the sample tank for analyzing a formation fluid sample down hole or at the surface without disturbing the sample. Near infrared, mid infrared and visible light analysis is performed on the sample to provide a downhole in situ or surface on site analysis of sample properties and contamination level. The onsite analysis comprises determination of gas oil ratio, API gravity and various other parameters which can be estimated by a trained neural network or chemometric equation. A flexural mechanical resonator is also provided to measure fluid density and viscosity from which additional parameters can be estimated by a trained neural network or chemometric equation. The sample tank is pressurized to obviate adverse pressure drop or other effects of diverting a small sample.

Owner:BAKER HUGHES INC

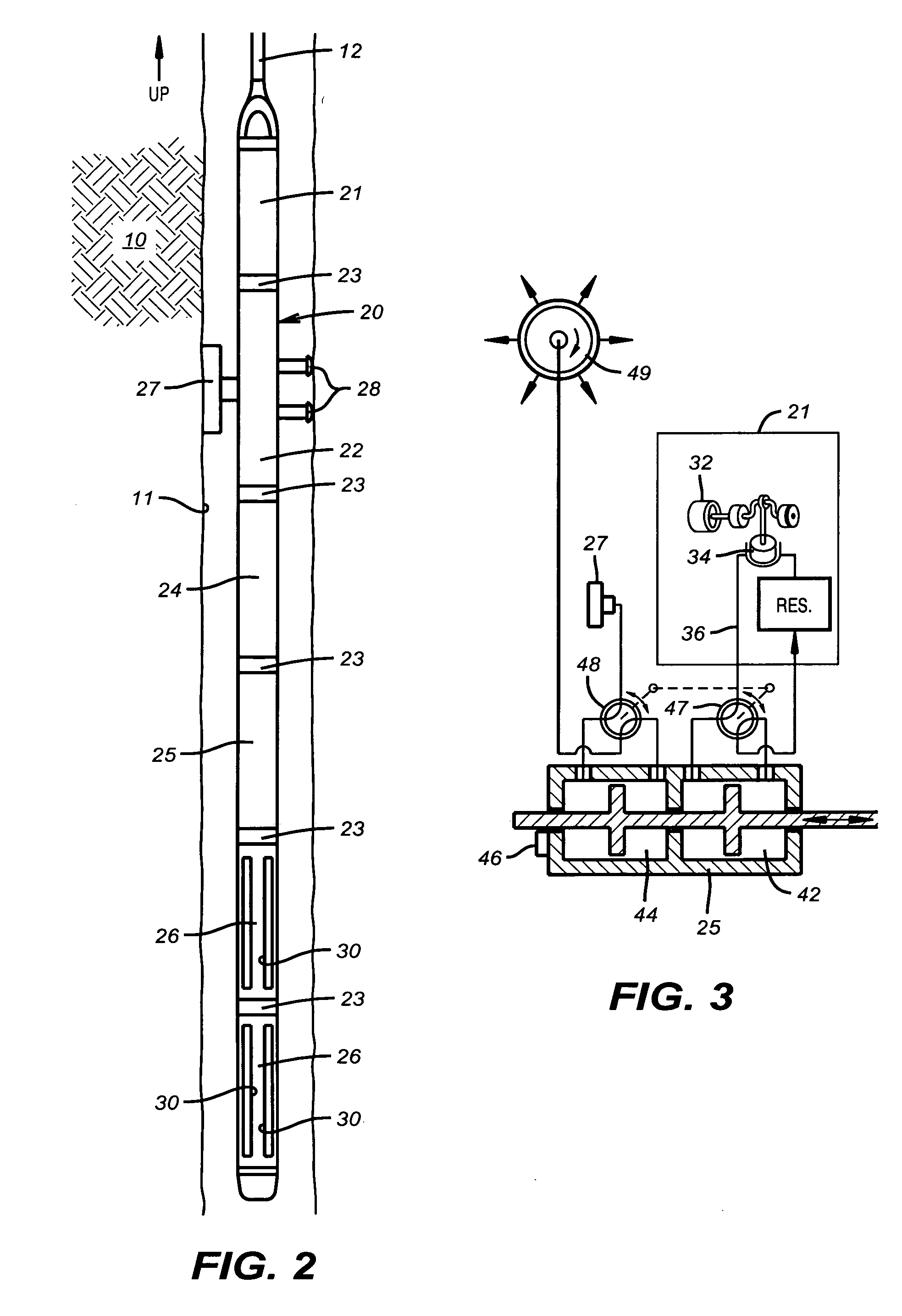

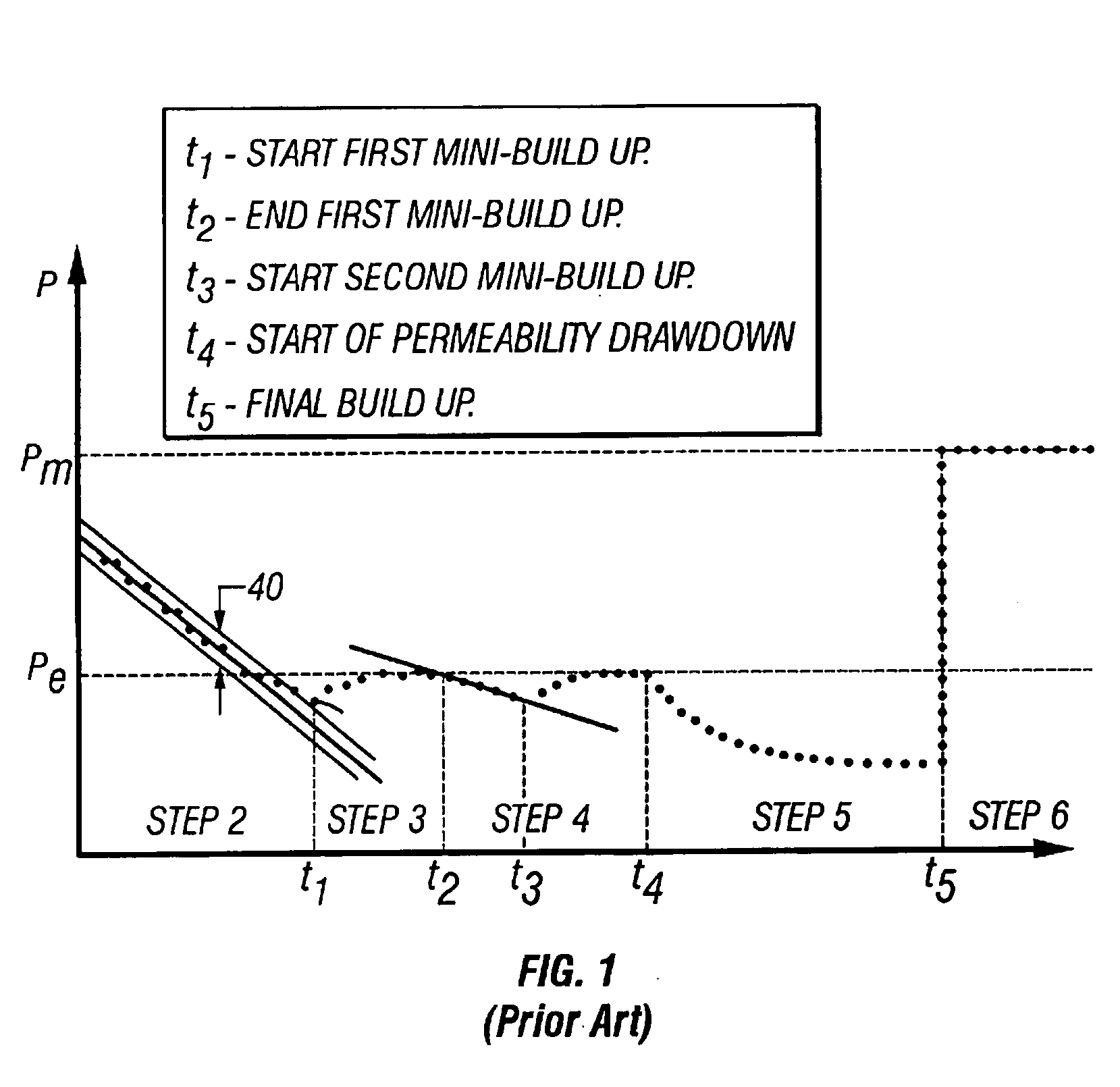

Method and apparatus for pumping quality control through formation rate analysis techniques

InactiveUS20040231842A1Enhance well operation efficiencyImprove securitySurveyFluid removalMinimum timeQuality control

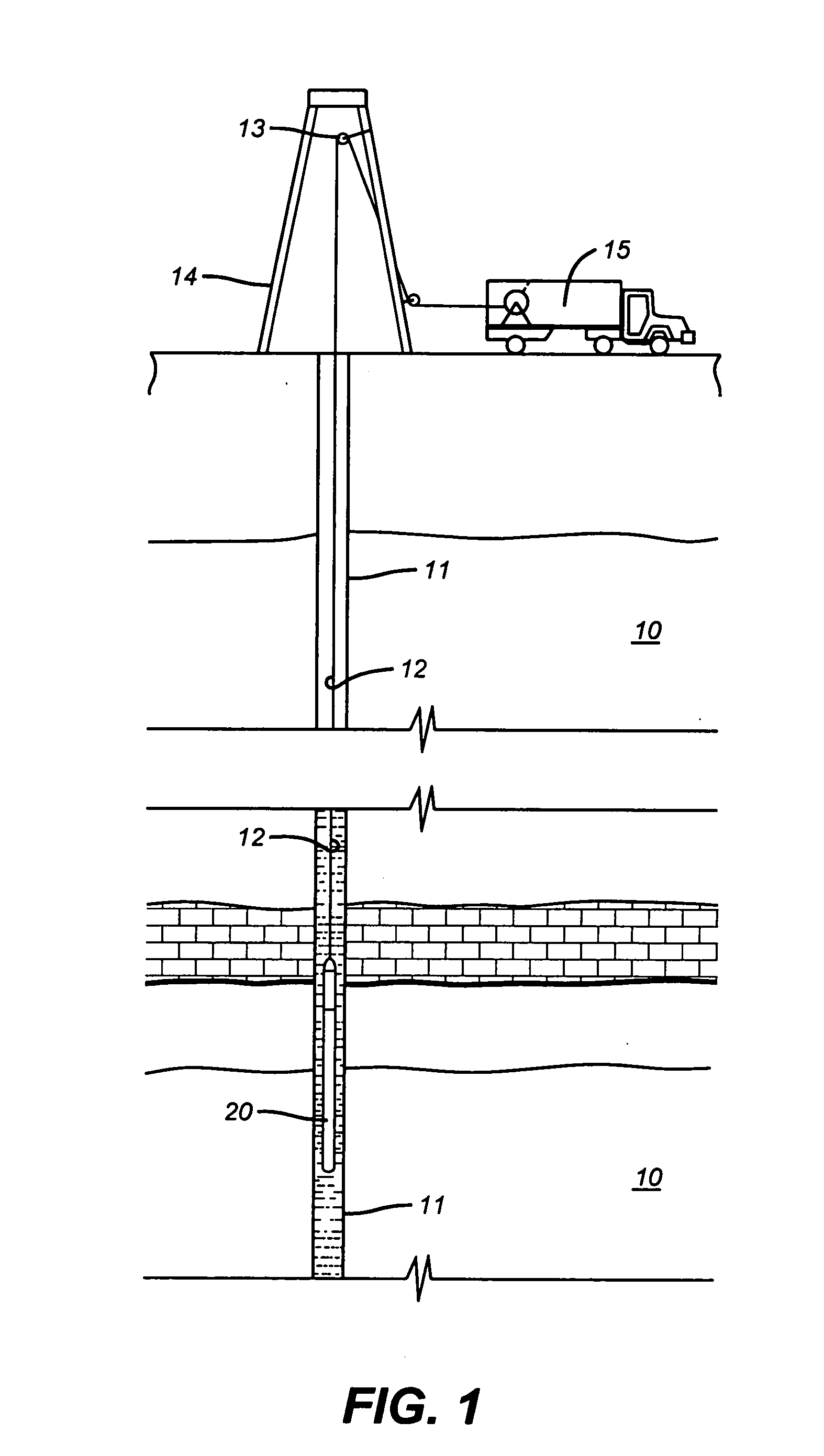

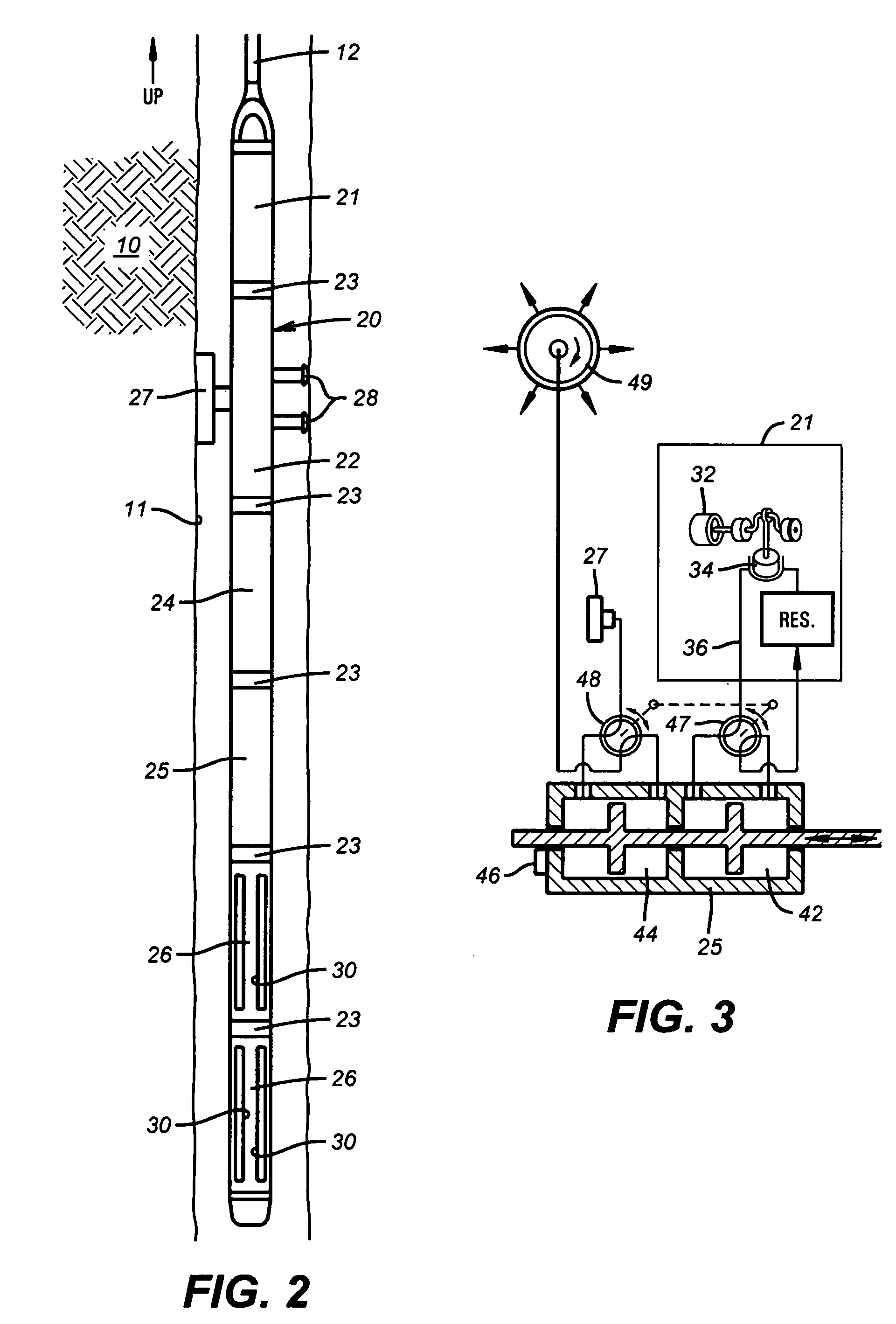

The present invention provides a method and apparatus for determination of the quality of a formation fluid sample including monitoring permeability and mobililty versus time to determine a filtrate contamination level, single phase state without gas and solids in the formation fluid, as it existed in the formation and the determination of laminar flow from the formation. The present invention also enables determination of an optimal pumping rate to match the ability of a subsurface formation to produce a single phase formation fluid sample in minimum time. The method and apparatus also detect pumping problems such as sanding and loss of seal with borehole.

Owner:BAKER HUGHES INC

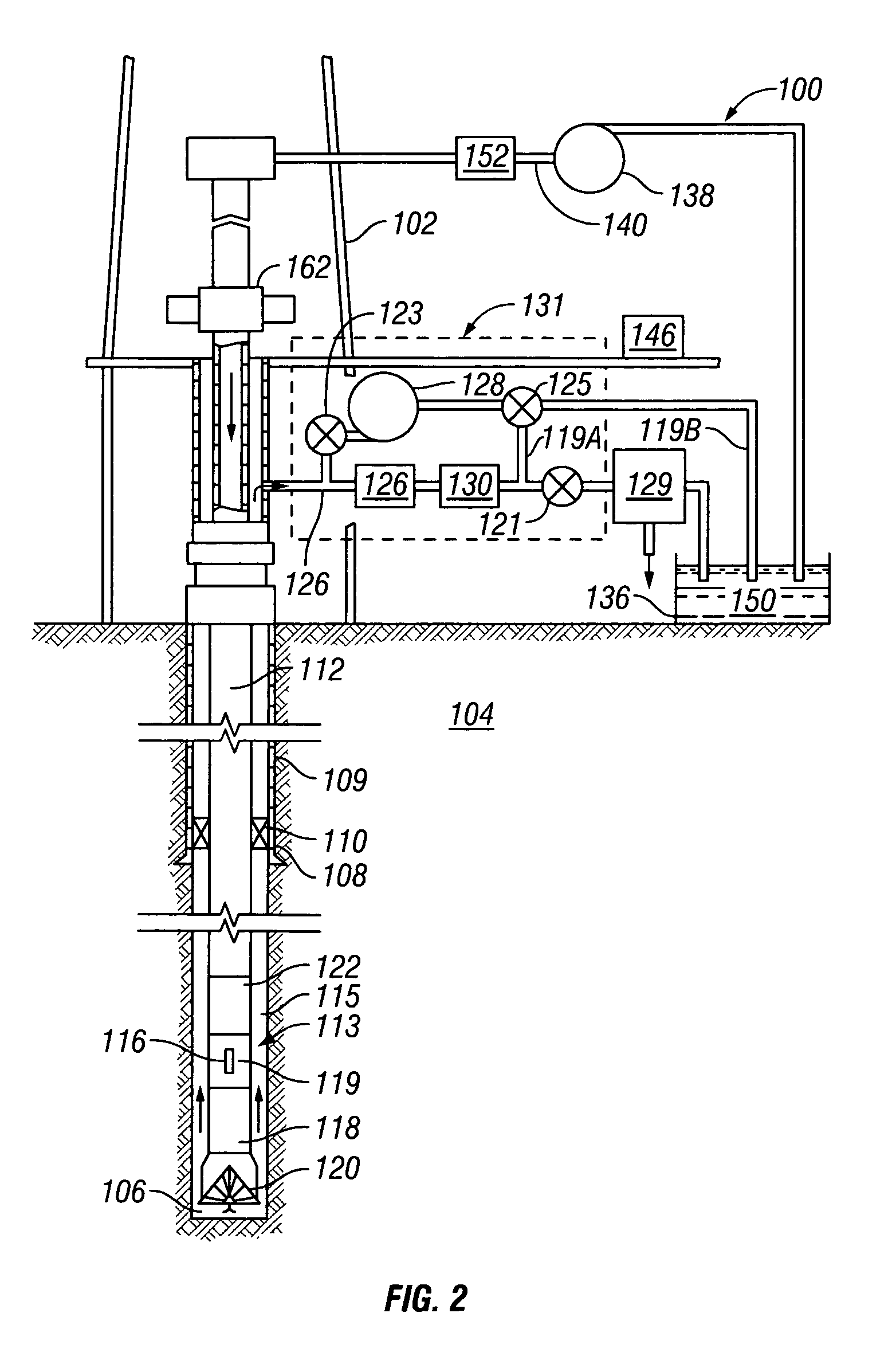

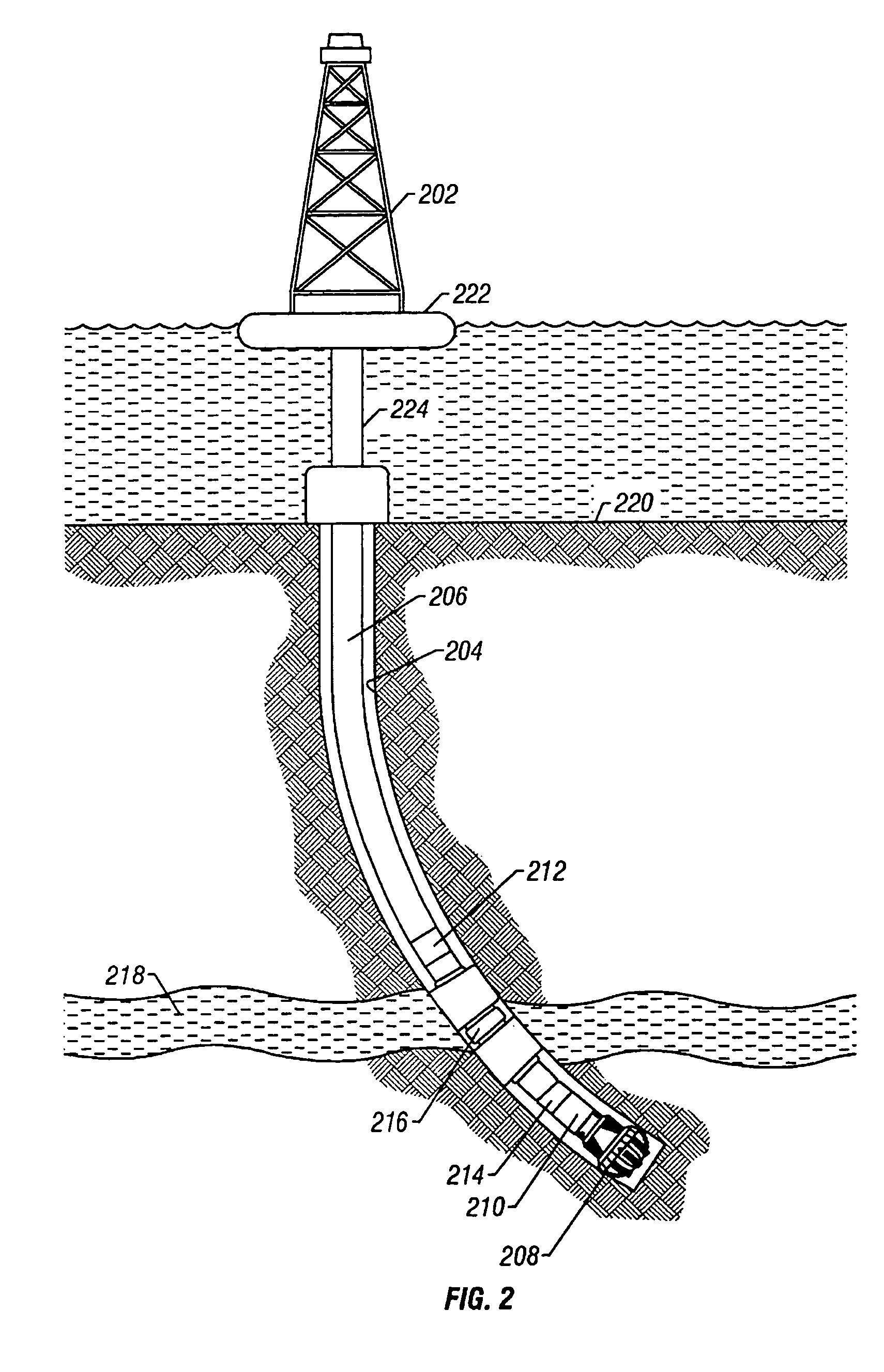

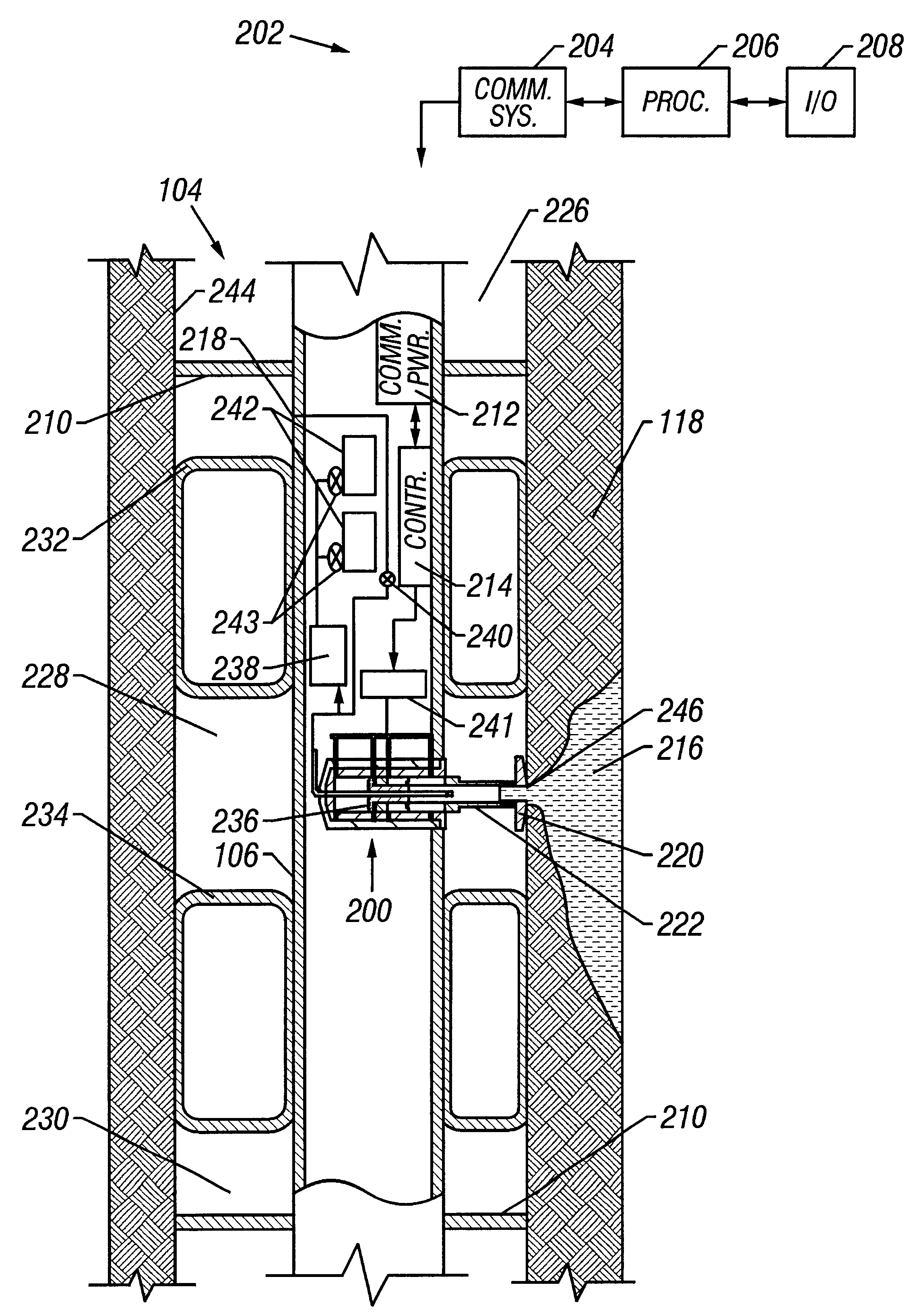

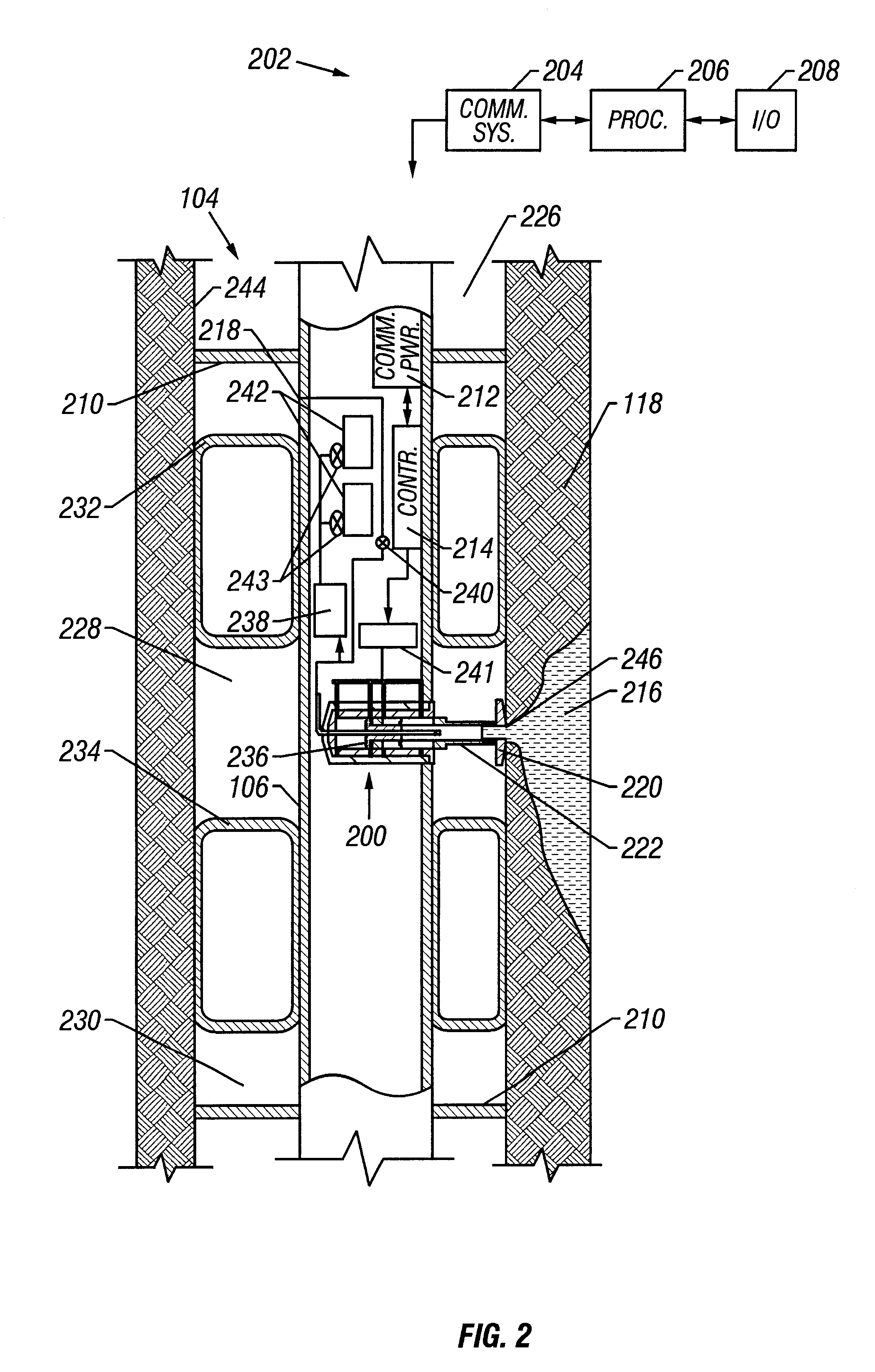

Subsea chemical injection unit for additive injection and monitoring system for oilfield operations

InactiveUS7234524B2Reduce and prevent such buildupPromote of formationDrilling rodsCleaning apparatusOcean bottomMonitoring system

A system monitors and controls the injection of additives into formation fluids recovered through a subsea well. The system includes a chemical injection unit and a controller positioned at a remote subsea location. The injection unit uses a pump to supply one or more selected additives from a subsea and / or remote supply unit. The controller operates the pump to control the additive flow rate based on signals provided by sensors measuring a parameter of interest. A one mode system includes a surface facility for supporting the subsea chemical injection and monitoring activities. In one embodiment, the surface facility is an offshore rig that provides power and has a chemical supply that provides additives to one or more injection units. In another embodiment, the surface facility includes a relatively stationary buoy and a mobile service vessel. When needed, the service vessel transfers additives to the chemical injection units via the buoy.

Owner:BAKER HUGHES INC

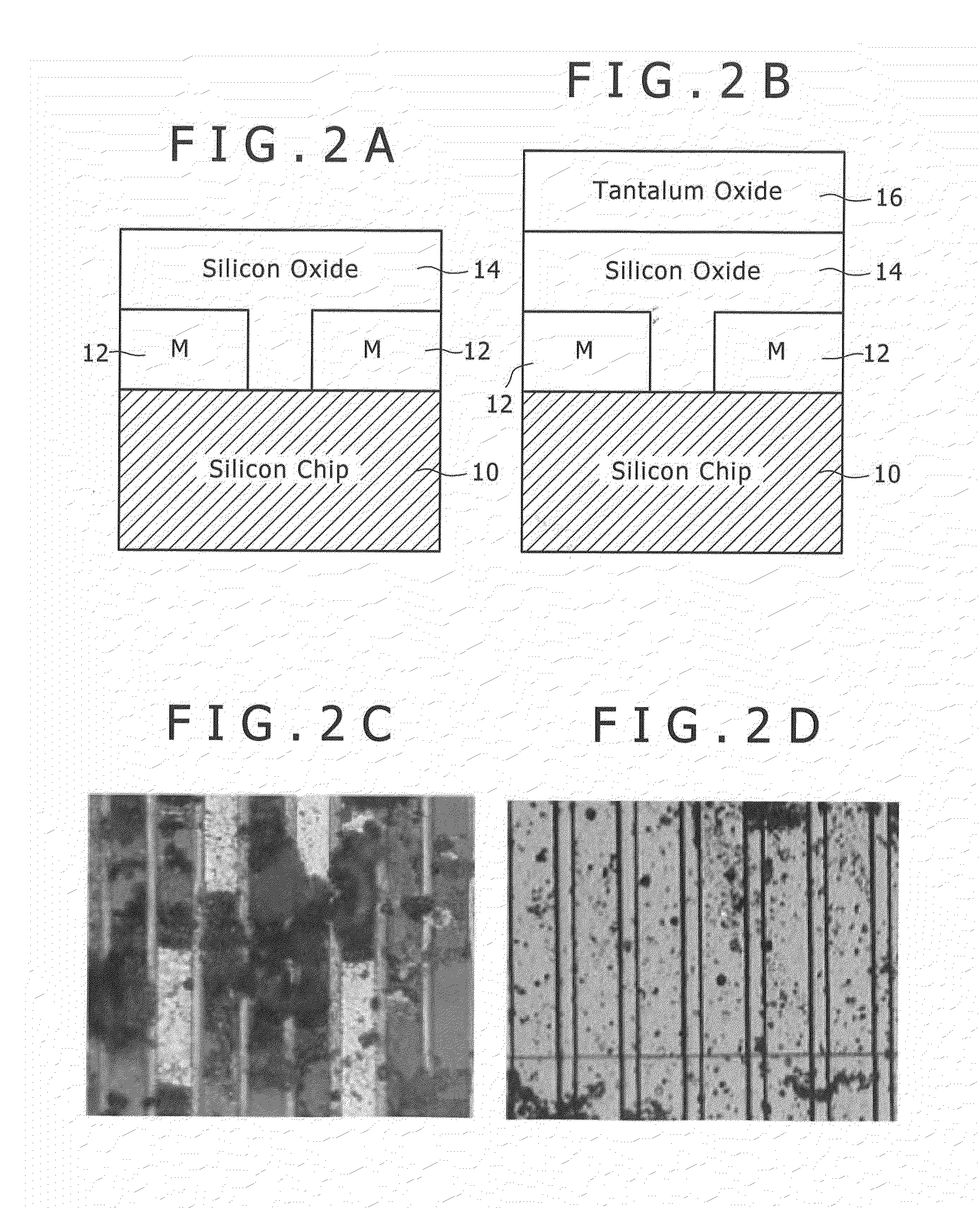

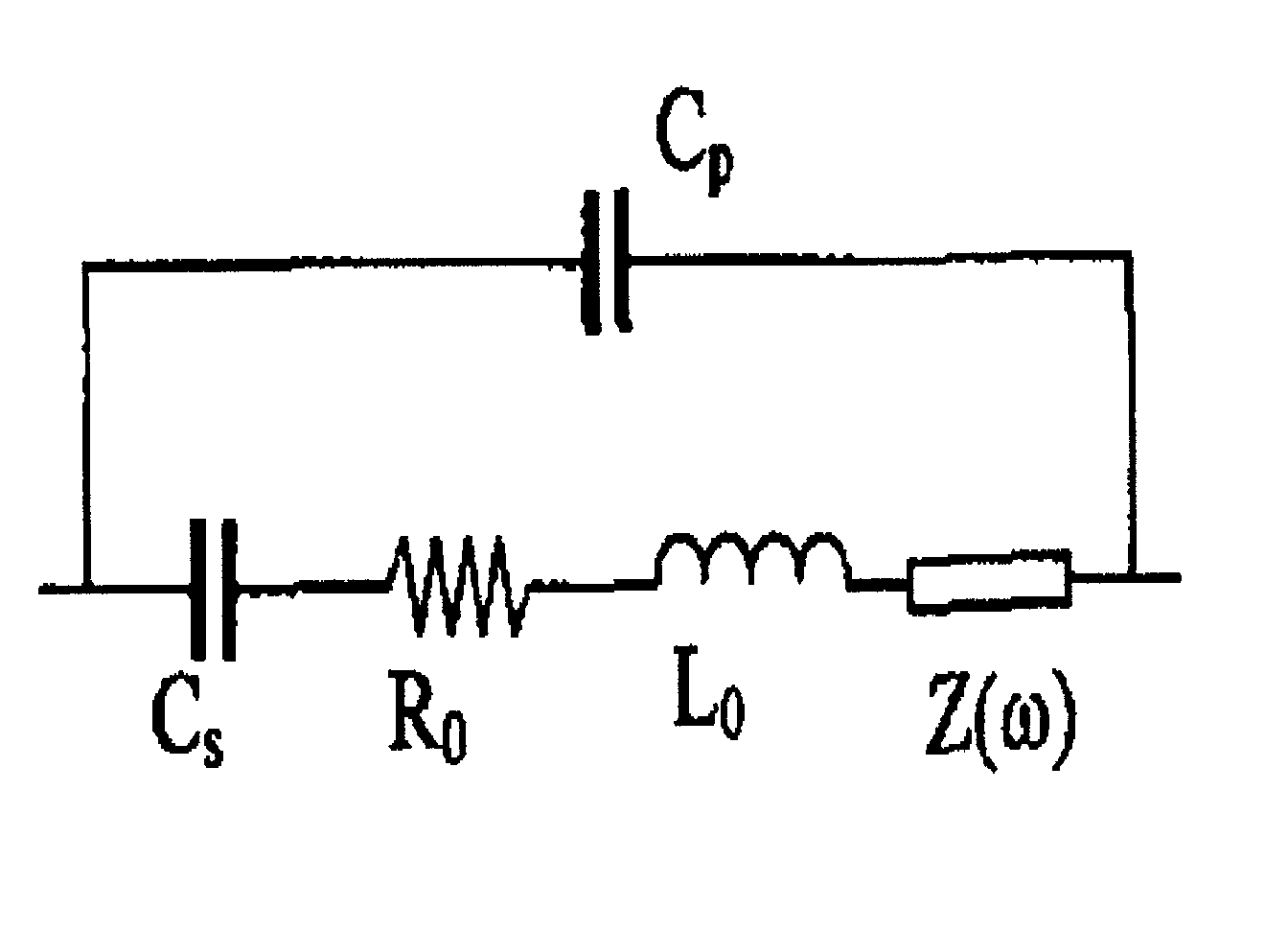

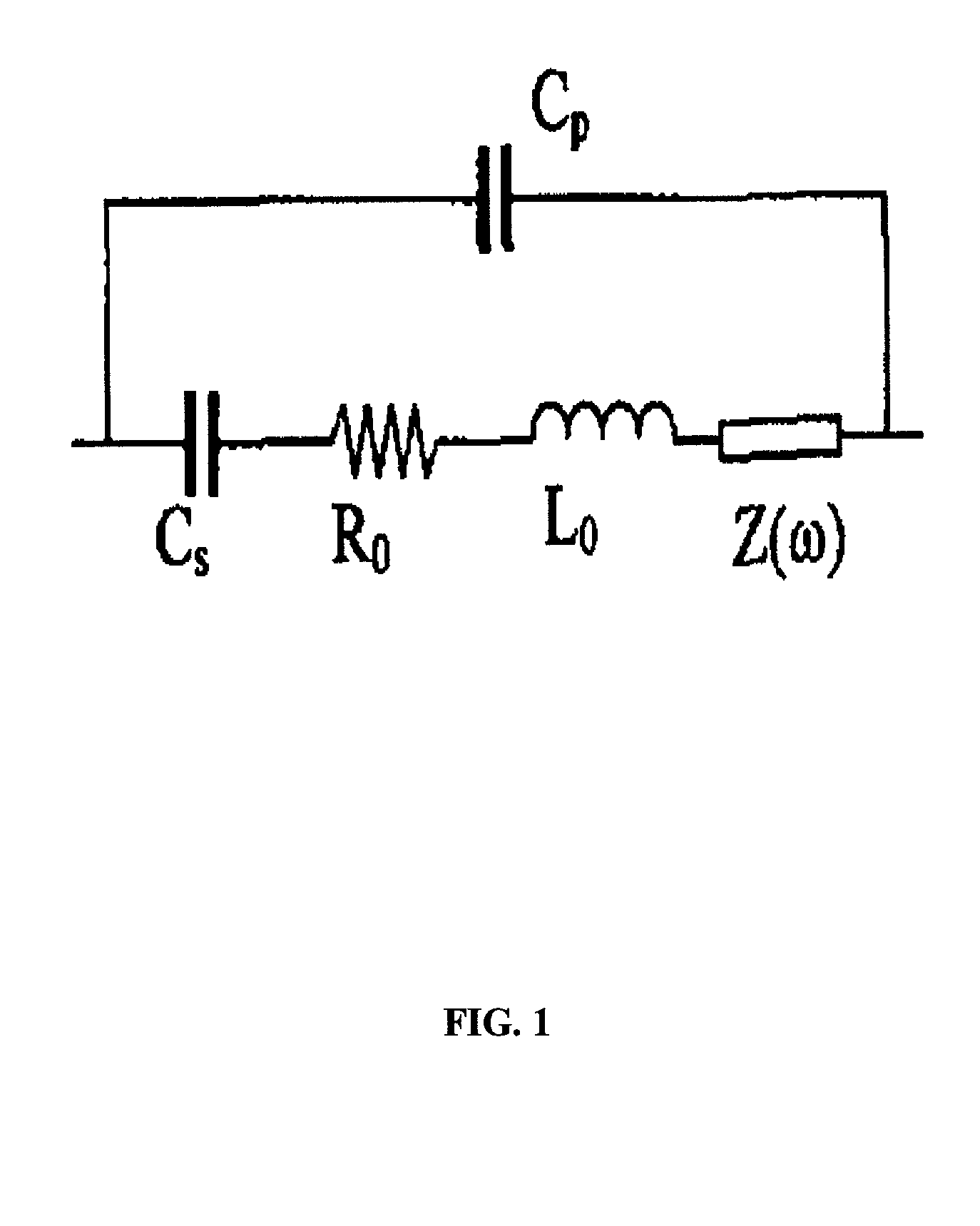

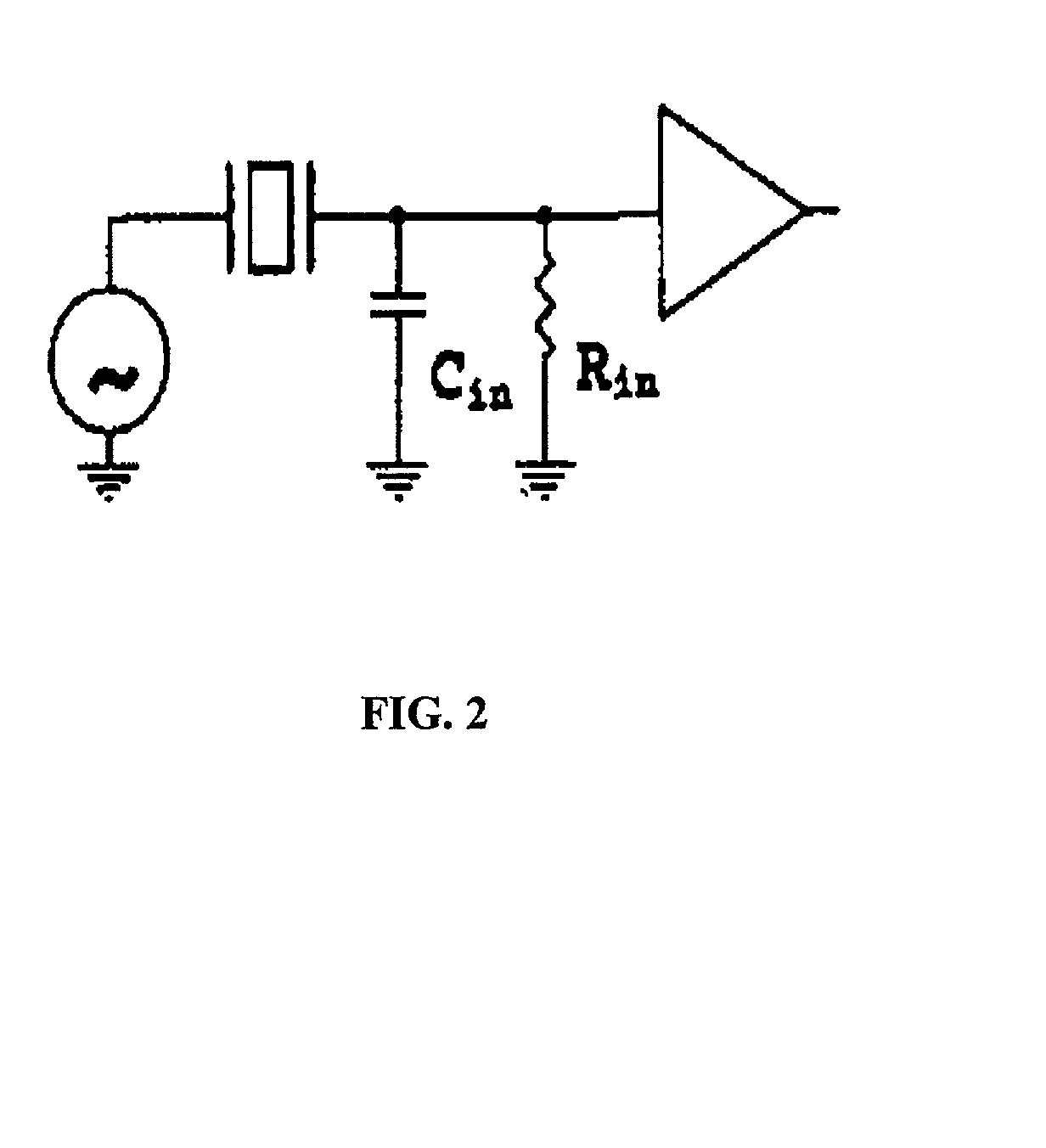

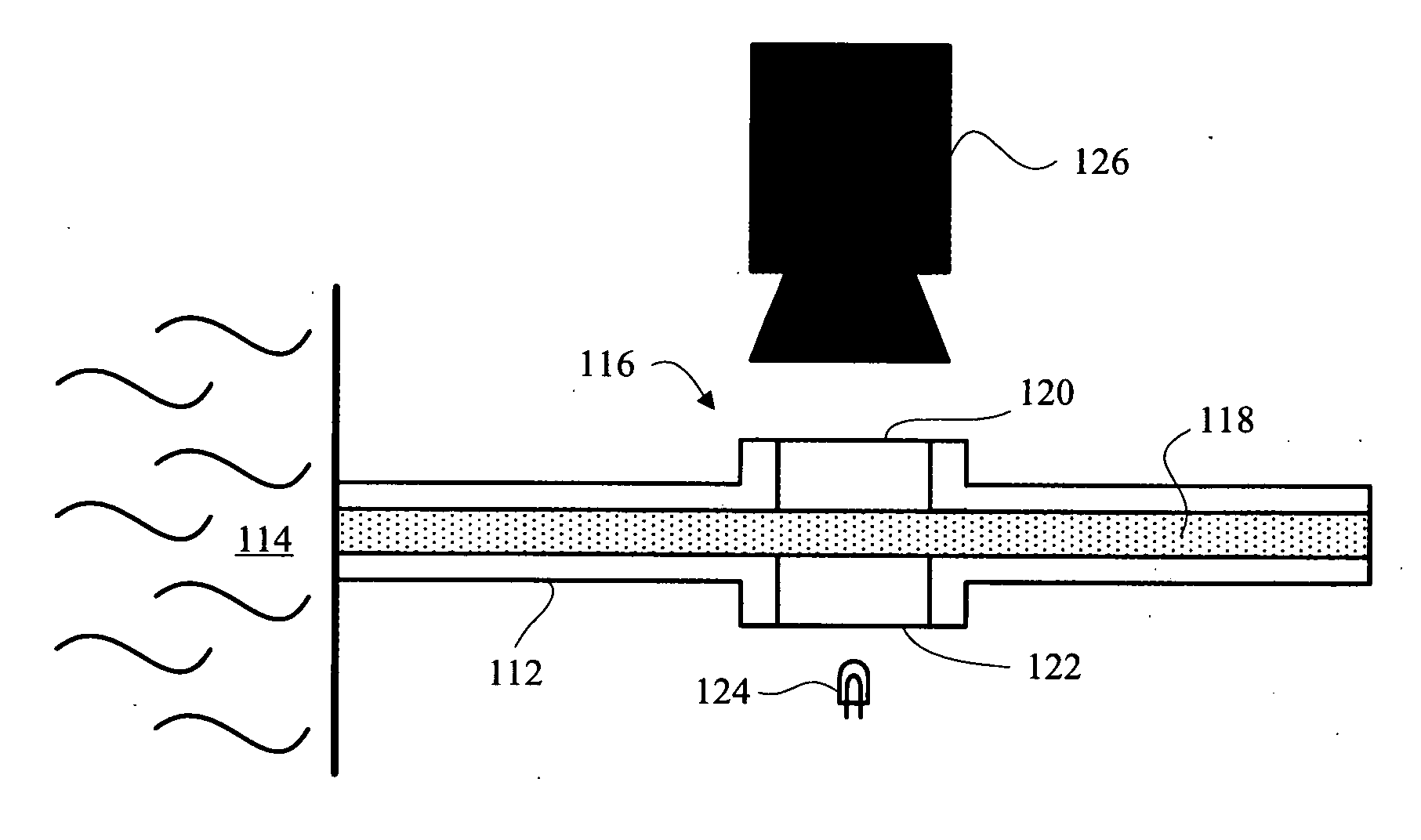

Method and apparatus for downhole fluid characterization using flexural mechanical resonators

InactiveUS20020178805A1Avoid contact corrosionProtection from damageElectric/magnetic detection for well-loggingAnalysing fluids using sonic/ultrasonic/infrasonic wavesTuning forkFormation fluid

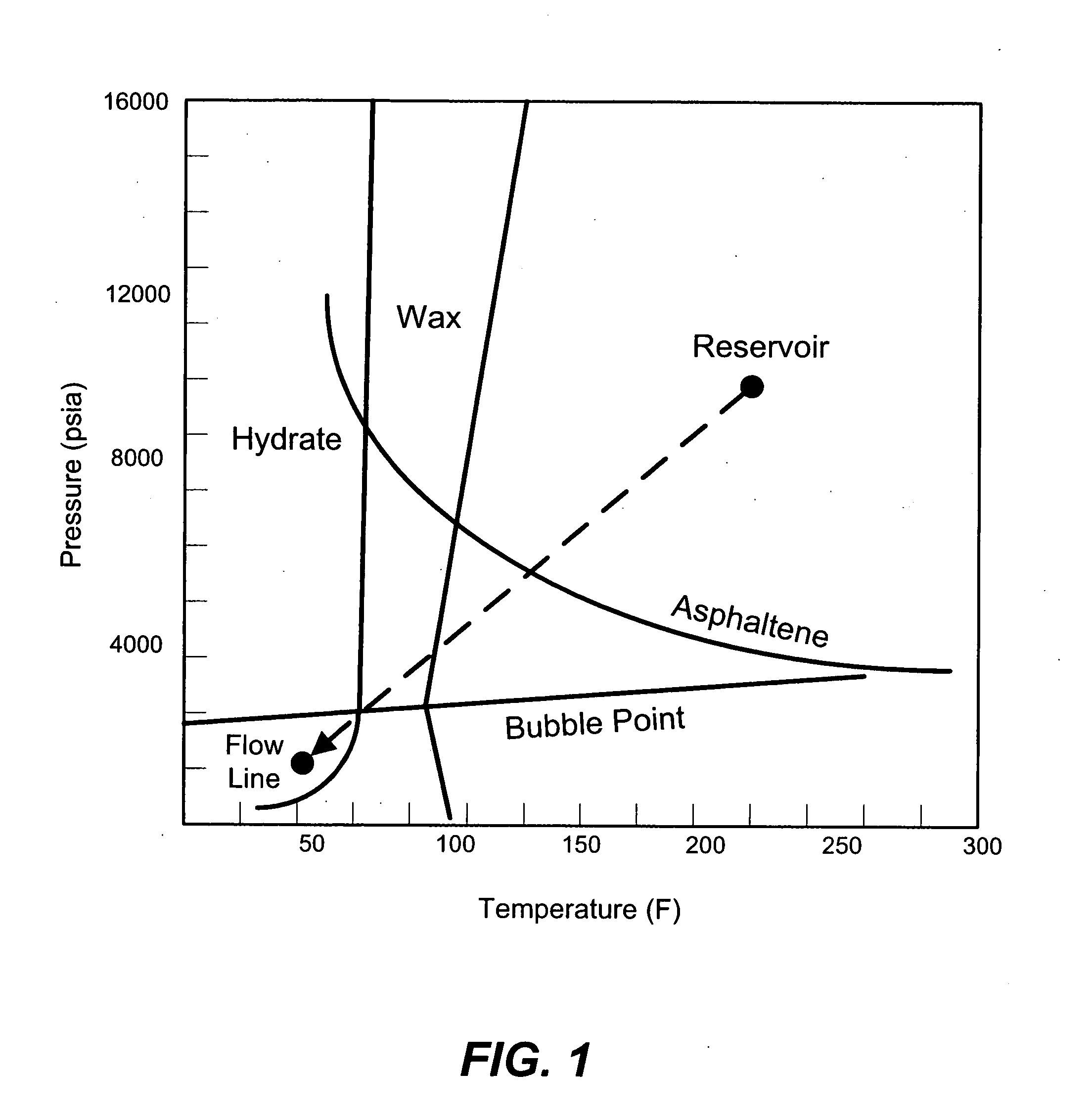

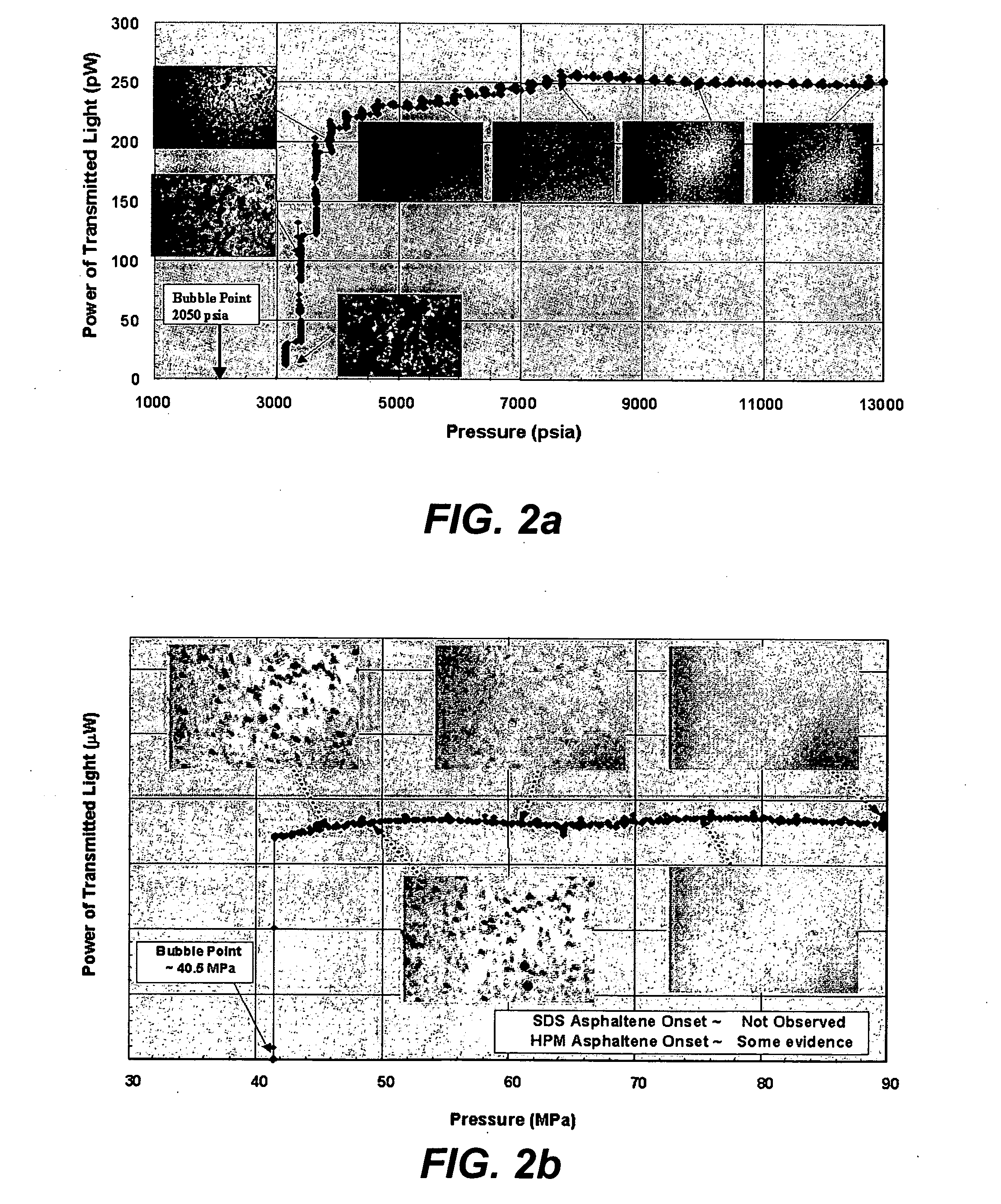

The present invention provides a downhole method and apparatus using a flexural mechanical resonator, for example, a tuning fork to provide real-time direct measurements and estimates of the viscosity, density and dielectric constant of formation fluid or filtrate in a hydrocarbon producing well. The present invention additionally provides a method and apparatus for monitoring cleanup from a leveling off of viscosity or density over time, measuring or estimating bubble point for formation fluid, measuring or estimating dew point for formation fluid, and determining the onset of asphaltene precipitation. The present invention also provides for intercalibration of plural pressure gauges used to determine a pressure differential downhole.

Owner:BAKER HUGHES INC

Spectral imaging for downhole fluid characterization

ActiveUS20070035736A1Reduce pressureConstructionsInvestigating moving fluids/granular solidsOcean bottomLine tubing

The present invention contemplates implementation of transitory downhole video imaging and / or spectral imaging for the characterization of formation fluid samples in situ, as well as during flow through production tubing, including subsea flow lines, for permanent and / or long term installations. The present invention contemplates various methods and apparatus that facilitate one-time or ongoing downhole fluid characterization by video analysis in real time. The methods and systems may be particularly well suited to permanent and periodic intervention-based operations.

Owner:SCHLUMBERGER TECH CORP

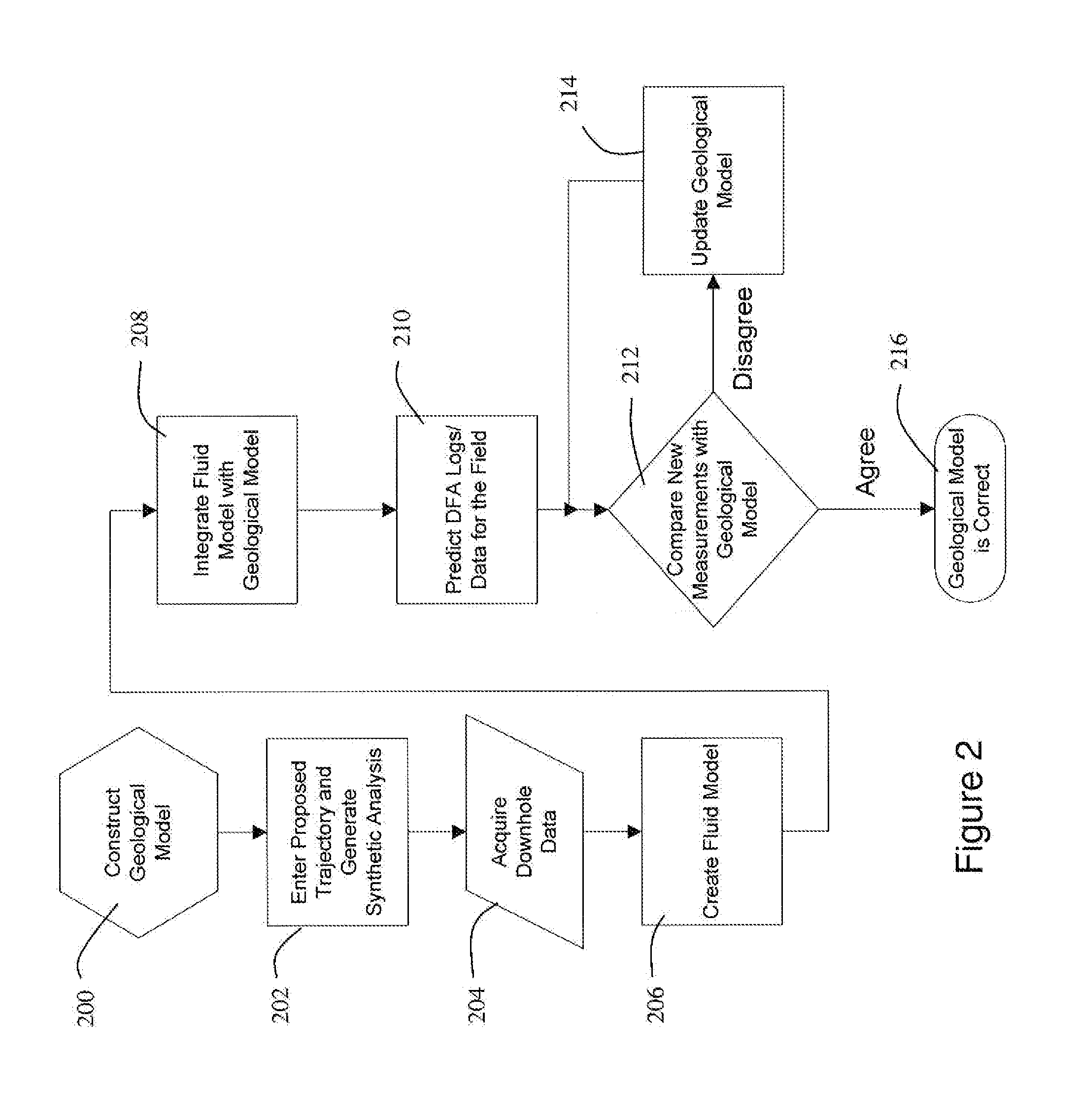

Facilitating oilfield development with downhole fluid analysis

InactiveUS20080040086A1Eliminate needSimple processElectric/magnetic detection for well-loggingSeismology for water-loggingModeling softwareData acquisition

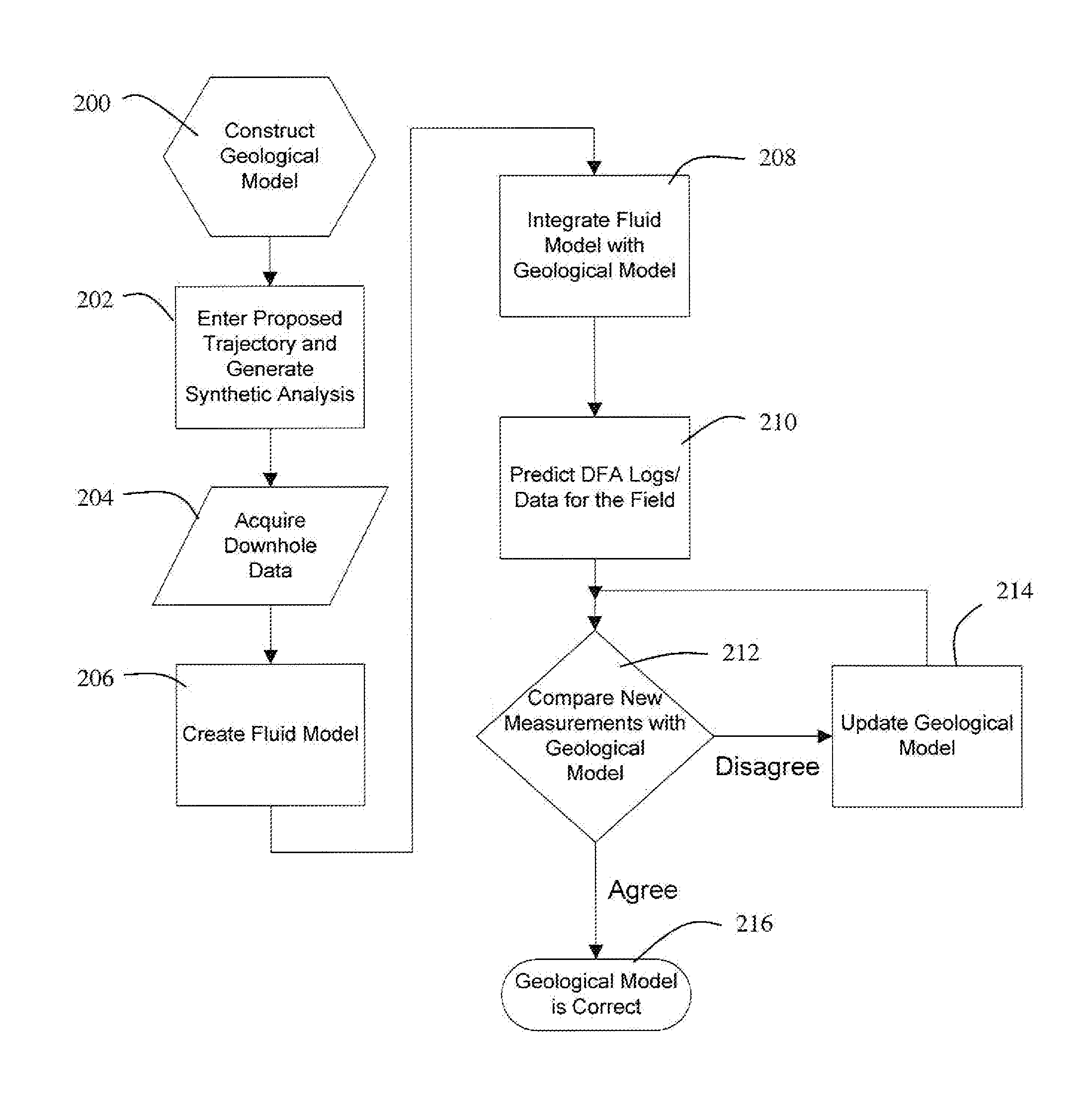

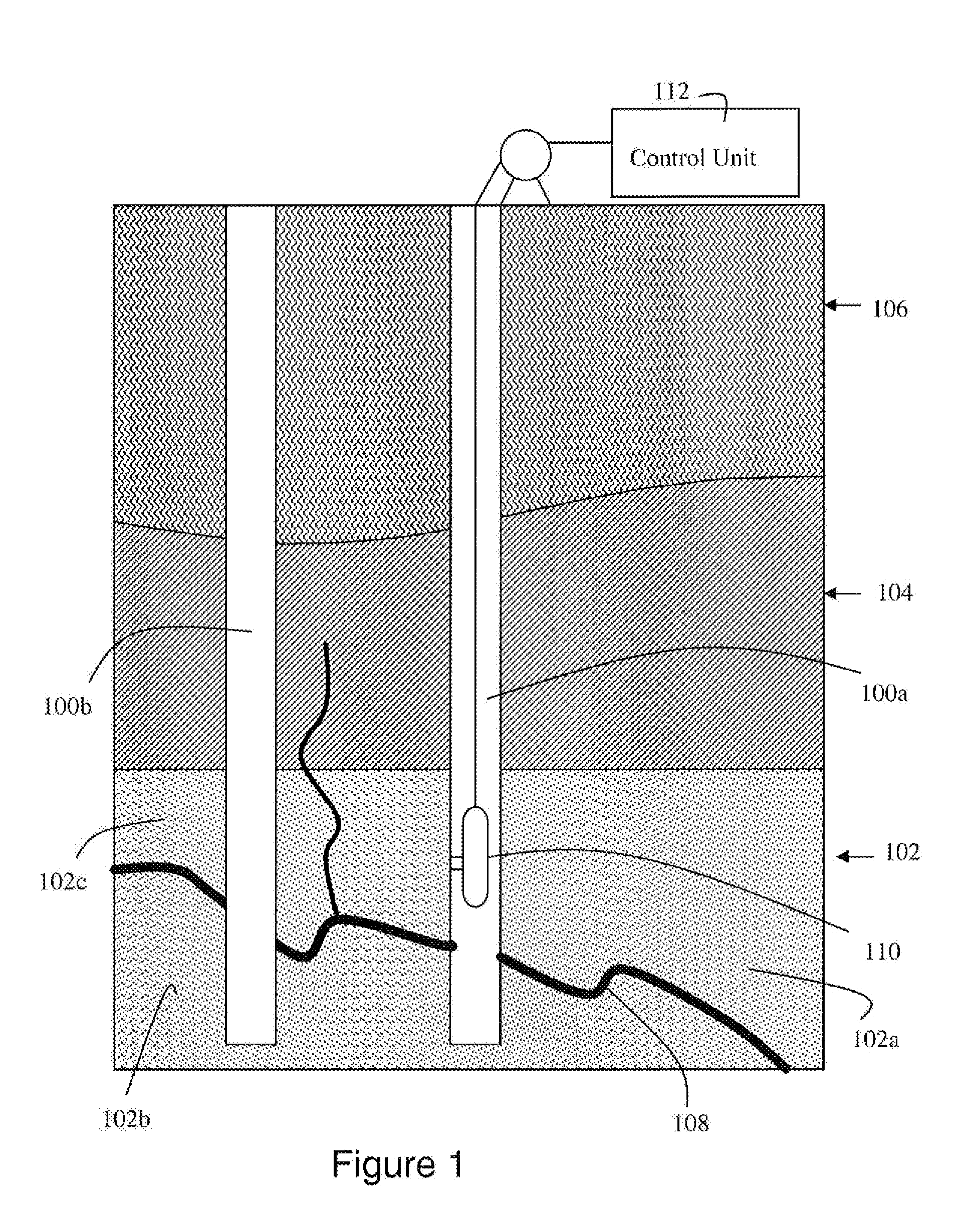

Formation fluid data based on measurements taken downhole under natural conditions is utilized to help identify reservoir compartments. A geological model of the reservoir including expected pressure and temperature conditions is integrated with a predicted fluid model fitted to measured composition and PVT data on reservoir fluid samples or representative analog. Synthetic downhole fluid analysis (DFA) logs created from the predictive fluid model can be displayed along the proposed borehole trajectory by geological modeling software prior to data acquisition. During a downhole fluid sampling operation, actual measurements can be displayed next to the predicted logs. If agreement exists between the predicted and measured fluid samples, the geologic and fluid models are validated. However, if there is a discrepancy between the predicted and measured fluid samples, the geological model and the fluid model need to be re-analyzed, e.g., to identify reservoir fluid compartments. A quantitative comparative analysis of the sampled fluids can be performed against other samples in the same borehole or in different boreholes in the field or region to calculate the statistical similarity of the fluids, and thus the possible connectivity between two or more reservoir regions.

Owner:SCHLUMBERGER TECH CORP

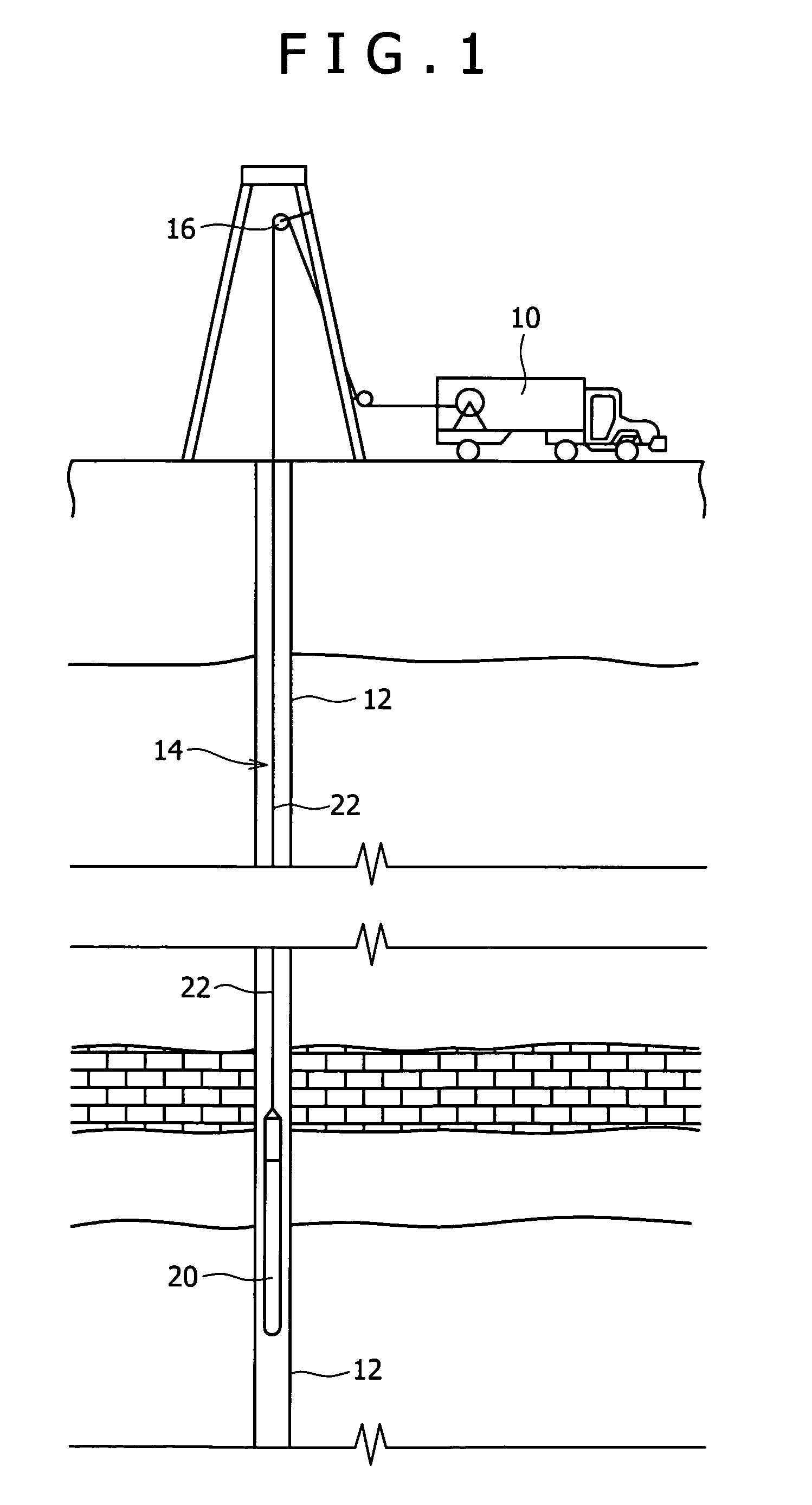

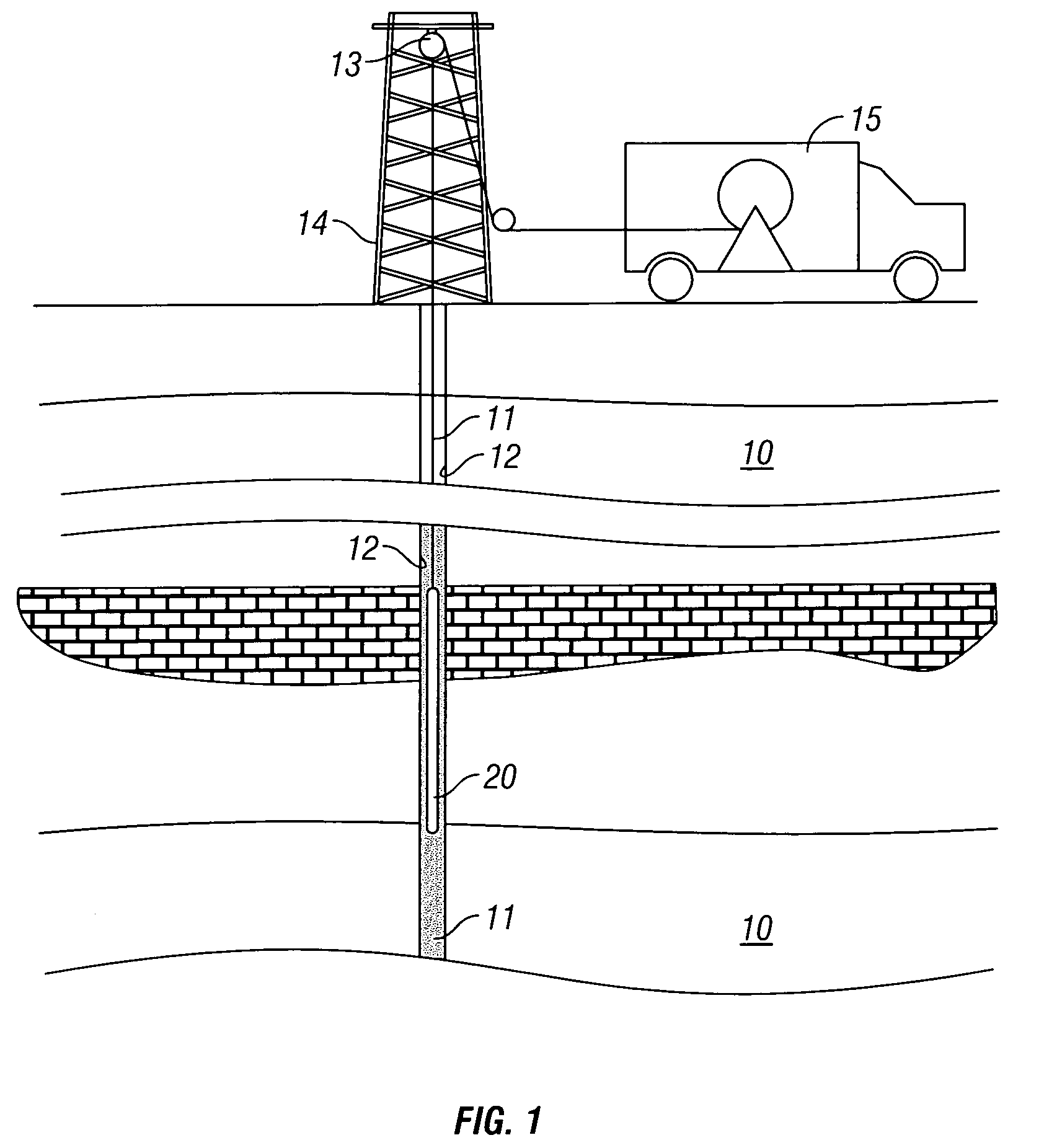

Apparatus for obtaining high quality formation fluid samples

InactiveUS20050028974A1Accurate measurementImprove assessmentSurveyInsulationEngineeringFormation fluid

A well fluid sampling tool is provided. The sampling tool includes at least one insulated sample chamber mounted in a tool collar. The tool collar may be coupled with a drill string such that, when the tool collar is deployed in a well bore, selected sample chambers may receive a fluid sample from outside the drill string without removing the drill string from the well bore (e.g., during measurement while drilling or logging while drilling operations). A heating module in thermal communication with at least one of the sample chambers is disposed to selectively heat the sample chambers in thermal communication therewith. The sampling tool may be particularly useful for acquiring and preserving substantially pristine formation fluid samples.

Owner:PATHFINDER ENERGY SERVICES

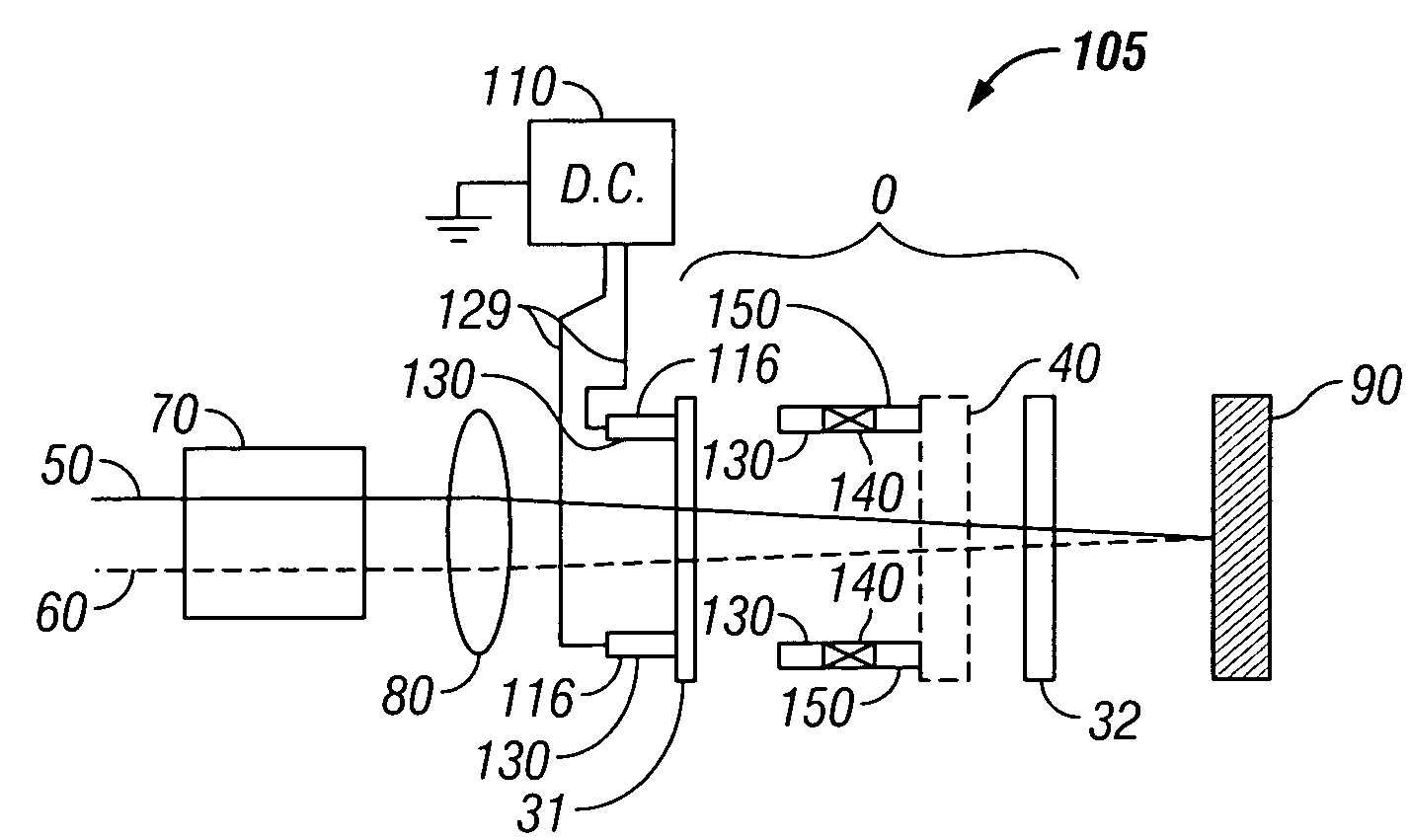

Method and apparatus for performing rapid isotopic analysis via laser spectroscopy

InactiveUS6888127B2Accurate and preciseAccurate and Precise MeasurementsRadiation pyrometryColor/spectral properties measurementsIsotopeLaser beams

Method and apparatus for providing real-time data indicative of the isotopic composition of formation fluids during drilling. The method includes the steps of: (a) providing a reference fluid having a known isotopic composition in a reference cell; (b) capturing a sample of formation; (c) providing at least one laser beam; (e) passing a beam through the reference fluid, measuring the reference-measurement beam before and after it passes through the reference fluid; (f) and passing a beam through the sample, measuring the beam before and after it passes through the sample, and calculating a first isotope concentration from those measurements. The measurements can provide information relating to the carbon isotopic composition of individual compounds in hydrocarbon gas mixtures, with the individual compounds including methane, ethane, propane, iso- or normal butane, or iso- or normal pentane.

Owner:CALEB BRETT USA

Apparatus and method for estimating filtrate contamination in a formation fluid

InactiveUS20070081157A1Enhanced Raman effectSurface-enhancing Raman effectRadiation pyrometryOptical prospectingUltravioletEffect light

The disclosure, in one aspect, provides a method for estimating a property of a fluid that includes: pumping an ultraviolet (UV) light into a fluid withdrawn from a formation downhole at a wavelength that produces light due to the Raman effect at wavelengths that are shorter than the substantial wavelengths of fluorescent light produced from the fluid; detecting a spectrum corresponding to the Raman effect light (“Raman spectrum”); and processing the detected Raman spectrum at one or more selected wavelengths to estimate a property of the fluid. In another aspect, the disclosure provides an apparatus that includes a laser that induces UV light at a selected wavelength into a fluid in a chamber, a detector that detects Raman scattered light at wavelengths shorter than the wavelengths of the fluorescent light scattered by the fluid, and a processor that analyzes a spectrum corresponding the Raman scattered light at a selected wavelength to estimate a property of the fluid.

Owner:BAKER HUGHES INC

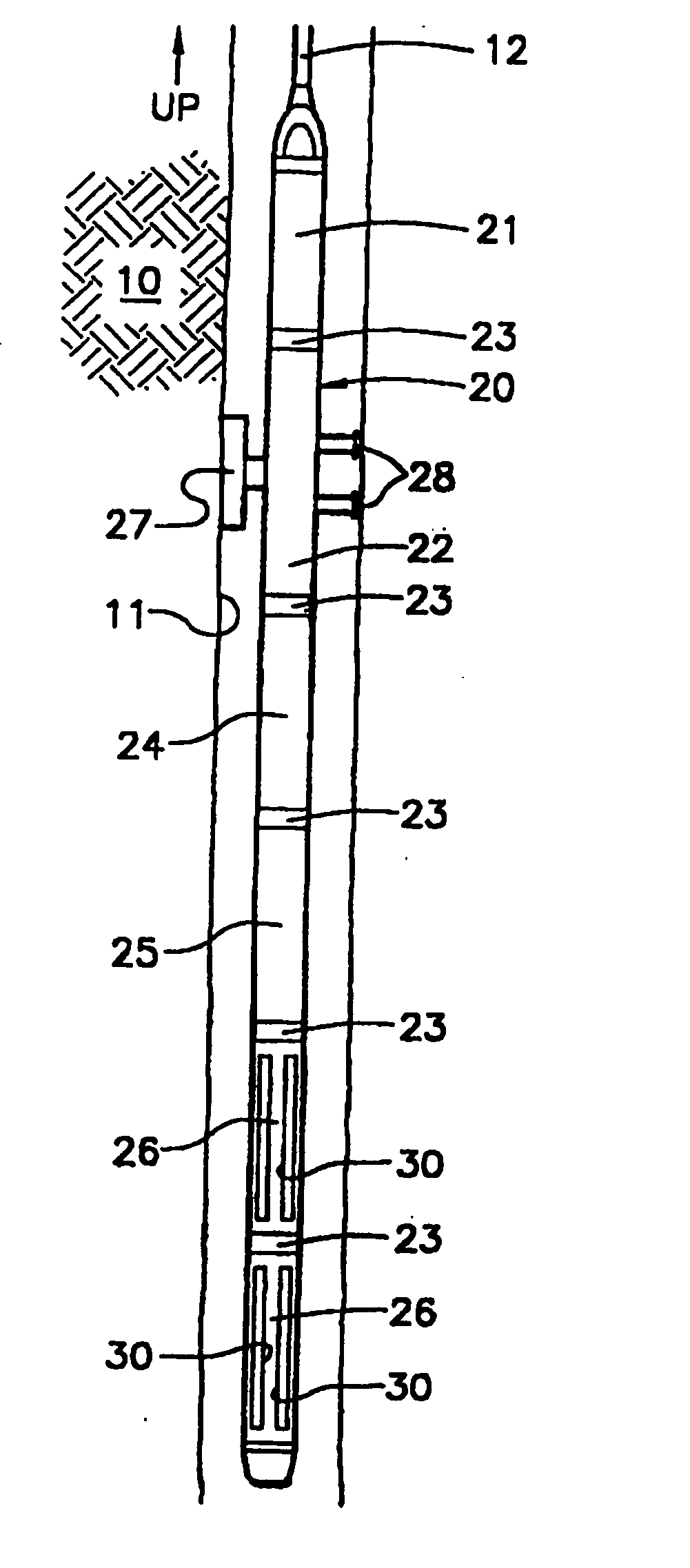

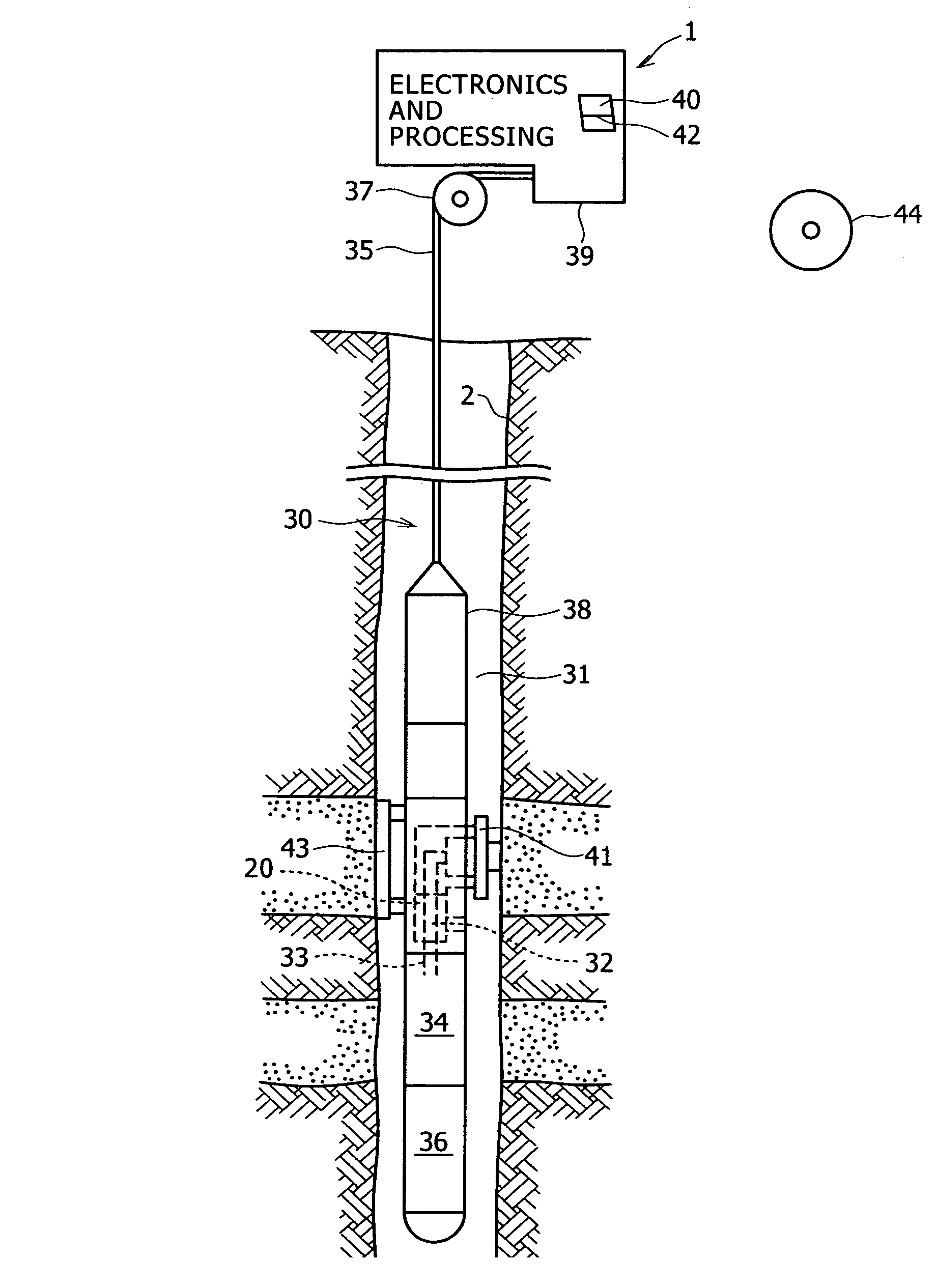

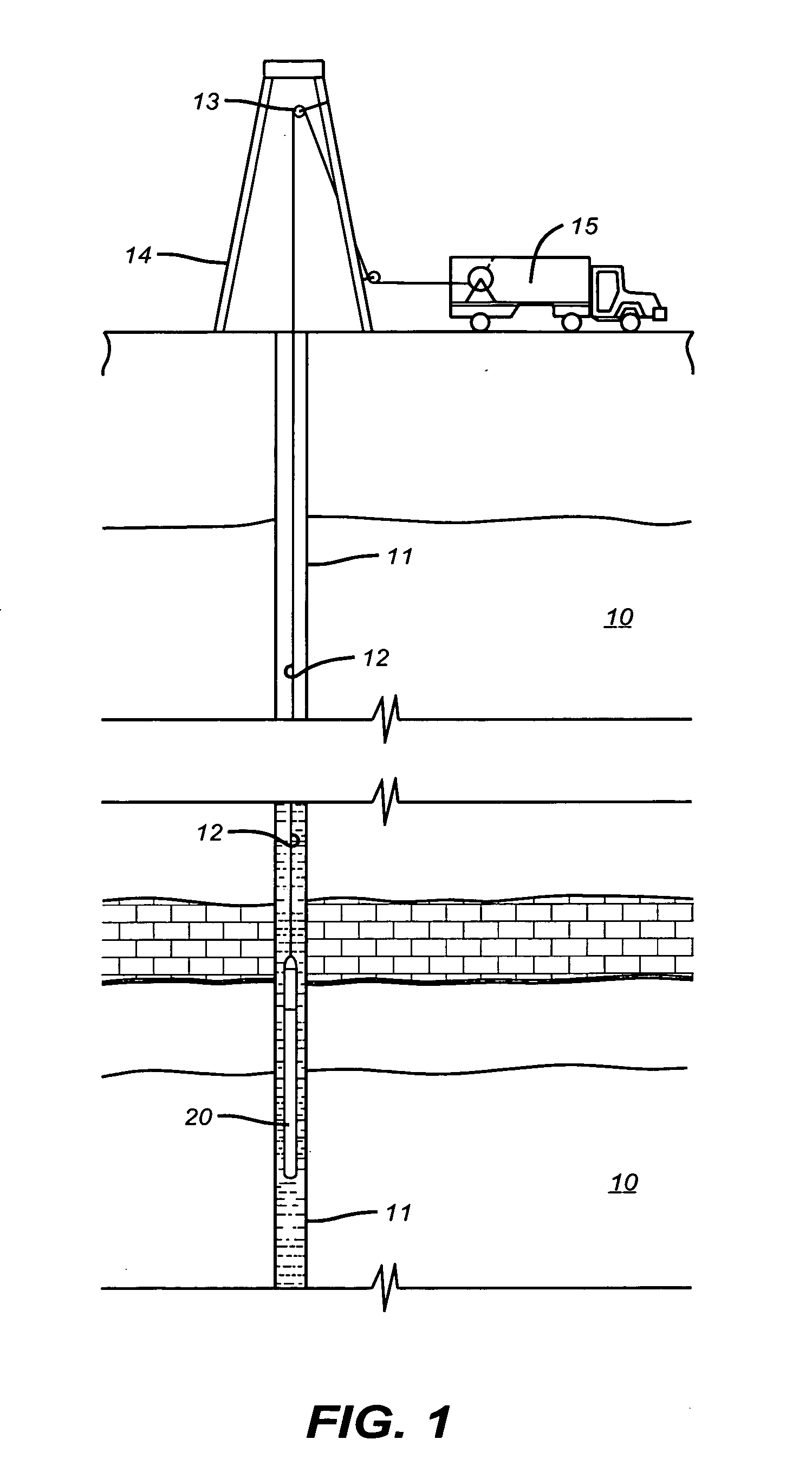

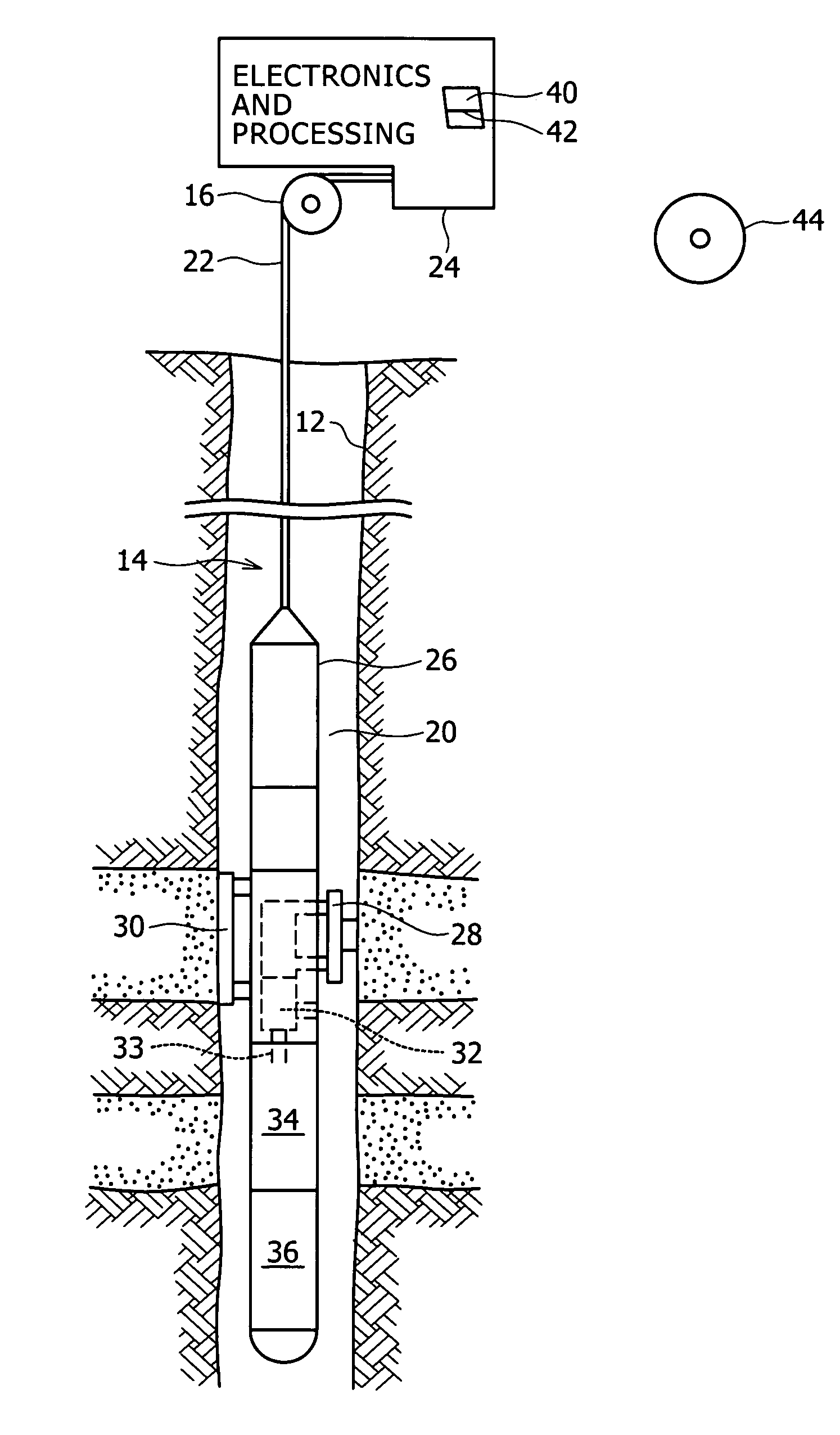

Pump Control for Formation Testing

A downhole formation fluid pumping and a sampling apparatus are disclosed that may form part of a formation evaluation while drilling tool or part of a tool pipe string. The operation of the pump is optimized based upon parameters generated from formation pressure test data as well as tool system data thereby ensuring optimum performance of the pump at higher speeds and with greater dependability. New pump designs for fluid sampling apparatuses for use in MWD systems are also disclosed.

Owner:SCHLUMBERGER TECH CORP

Method for fast and extensive formation evaluation using minimum system volume

A minimum volume apparatus and method is provided including a tool for obtaining at least one parameter of interest of a subterranean formation in-situ, the tool comprising a carrier member, a selectively extendable member mounted on the carrier for isolating a portion of annulus, a port exposable to formation fluid in the isolated annulus space, a piston integrally disposed within the extendable member for urging the fluid into the port, and a sensor operatively associated with the port for detecting at least one parameter of interest of the fluid.

Owner:BAKER HUGHES HLDG LLC

Closed loop additive injection and monitoring system for oilfield operations

A system is provided that monitors at the wellsite injection of additives into formation fluids recovered through wellbores and controls the supply of such additives from remote locations. The selected additive is supplied from a source at the wellsite into the wellbore via a suitable supply line. A flow meter in the supply line measures the flow rate of the additive through the supply line and generates signals representative of the flow rate. A controller at the wellsite determines the flow rate from the flow meter signals and in response thereto controls the flow rate of the additive to the well. The wellsite controller interfaces with a suitable two-way communication link and transmits signals and data representative of the flow rate and other parameters to a second remote controller. The remote controller transmits command signals to the wellsite controller representative of any change desired for the flow rate.

Owner:BAKER HUGHES INC

Method and apparatus for a downhole spectrometer based on electronically tunable optical filters

The present invention provides an apparatus and method for high resolution spectroscopy (approximately 10 picometer wavelength resolution) using a tunable optical filter (TOF) for analyzing a formation fluid sample downhole and at the surface to determine formation fluid parameters. The analysis comprises determination of gas oil ratio, API gravity and various other fluid parameters which can be estimated after developing correlations to a training set of samples using a neural network or a chemometric equation.

Owner:BAKER HUGHES HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com