Patents

Literature

304results about How to "Improve assessment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

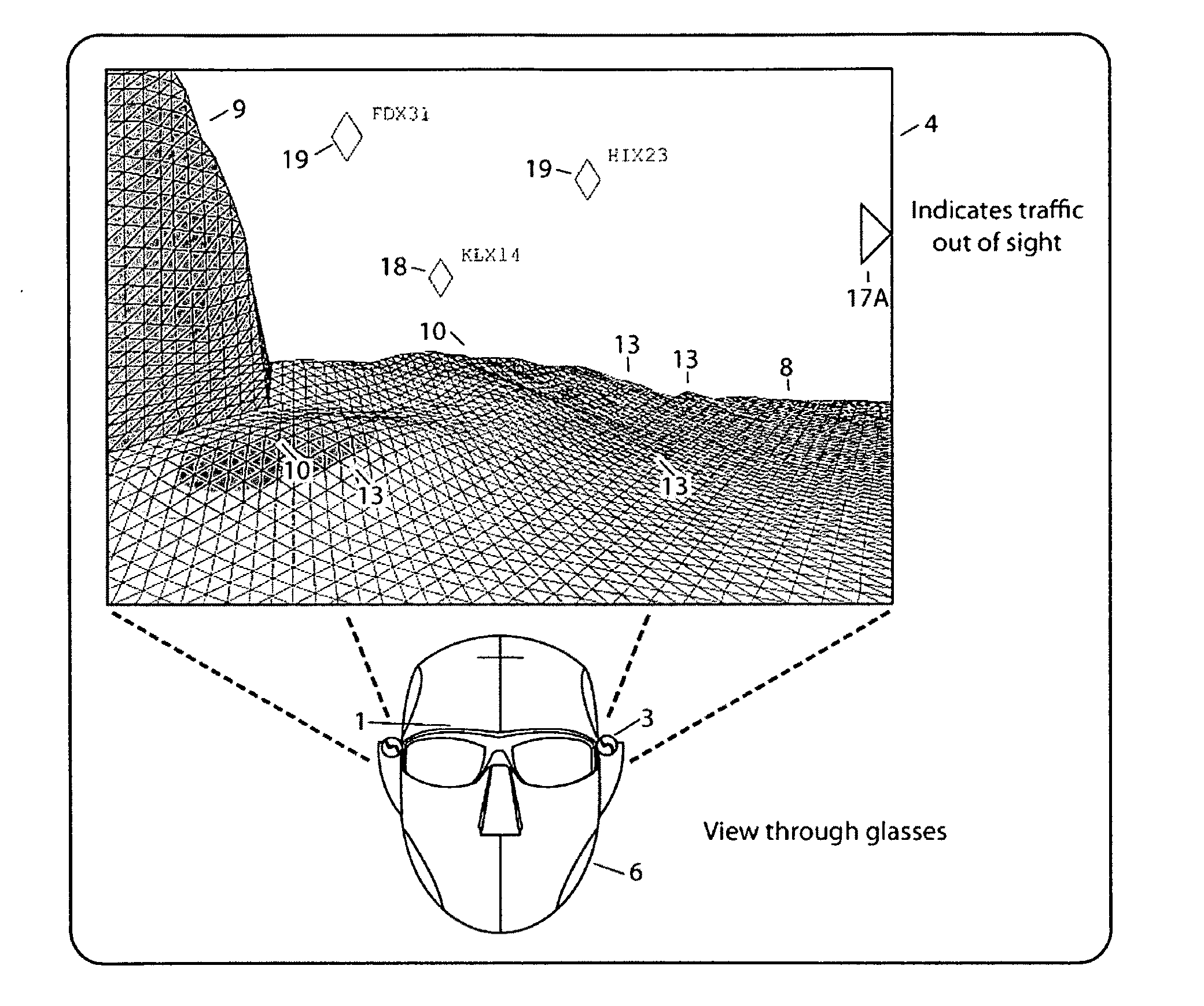

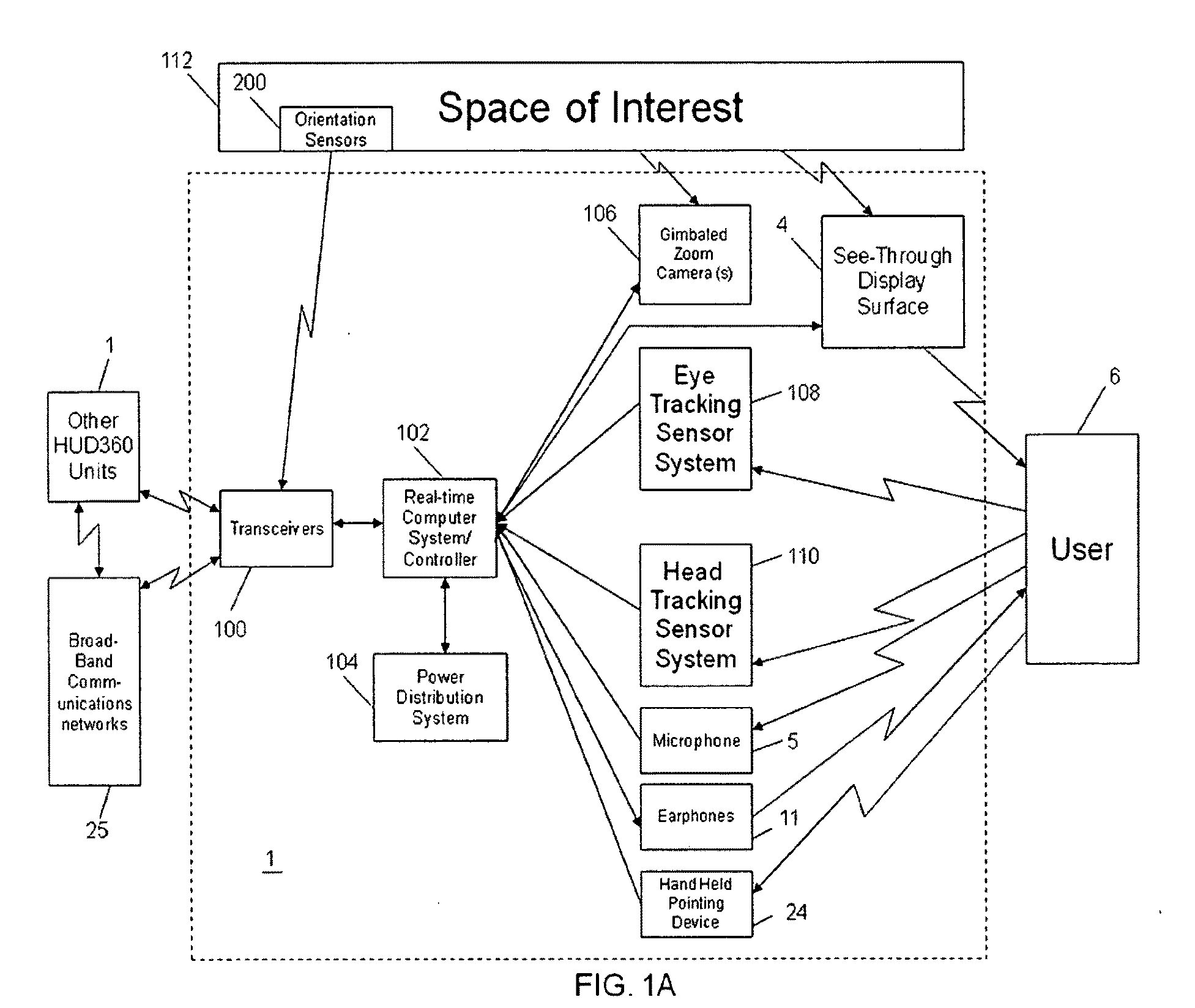

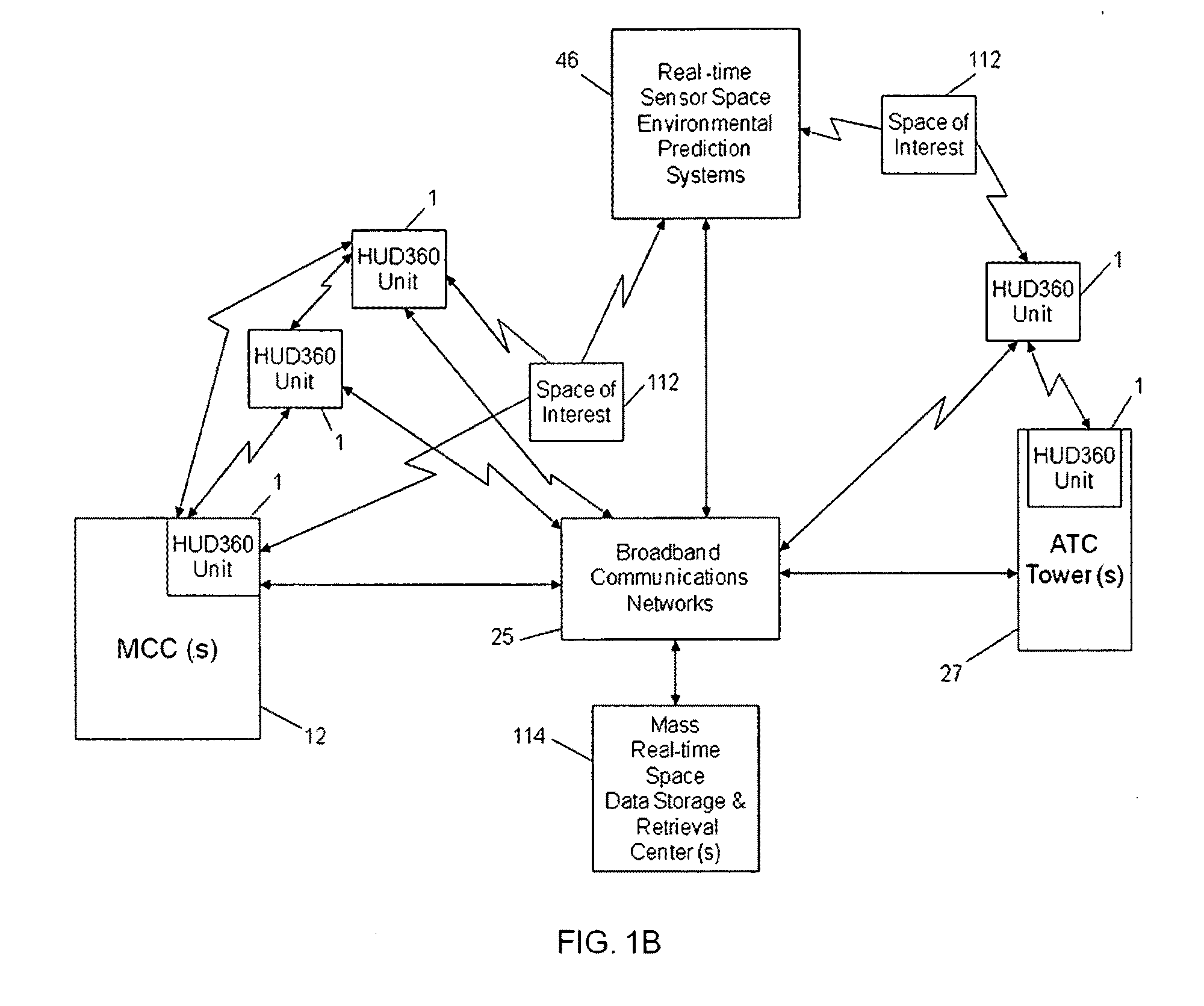

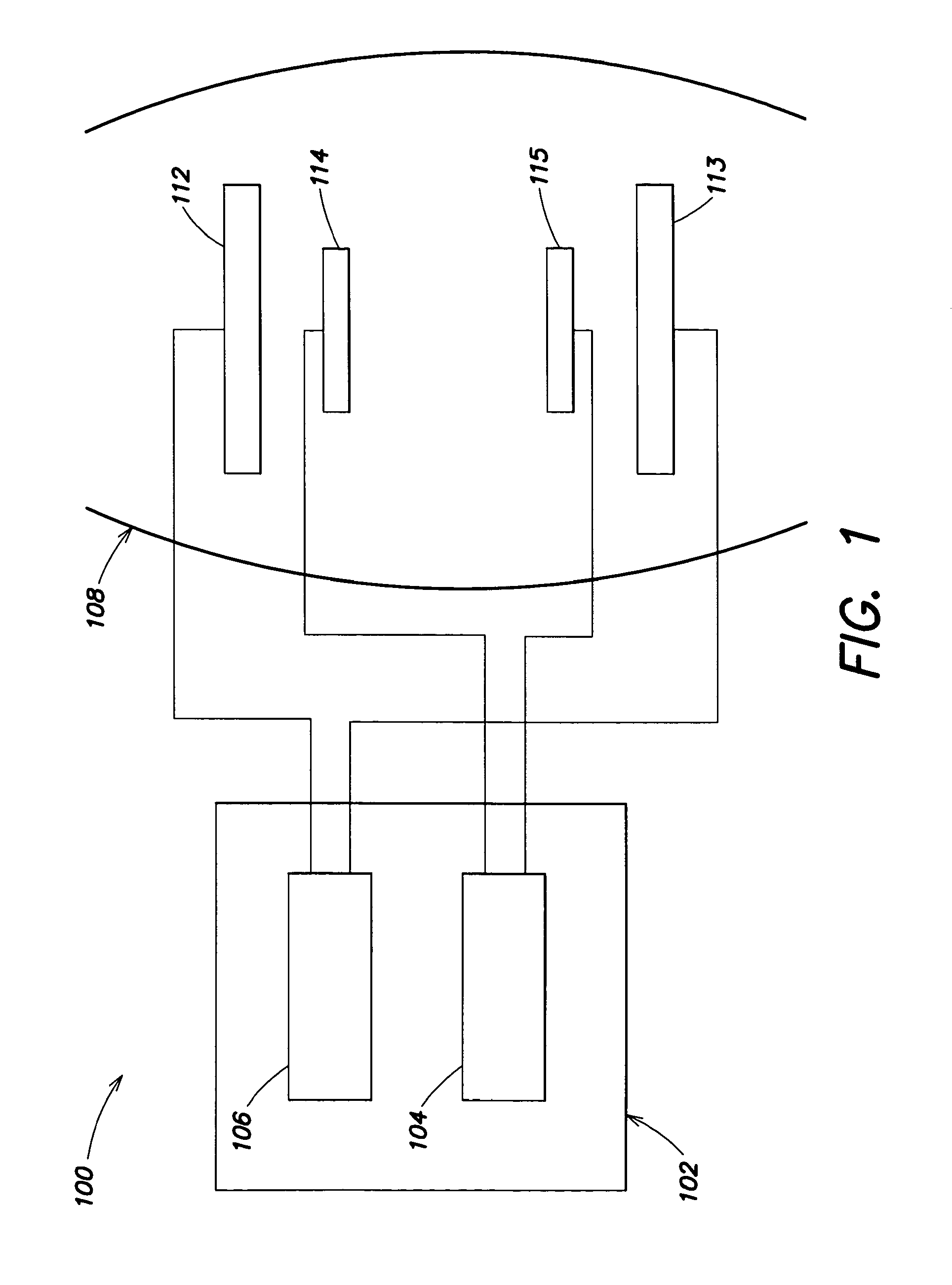

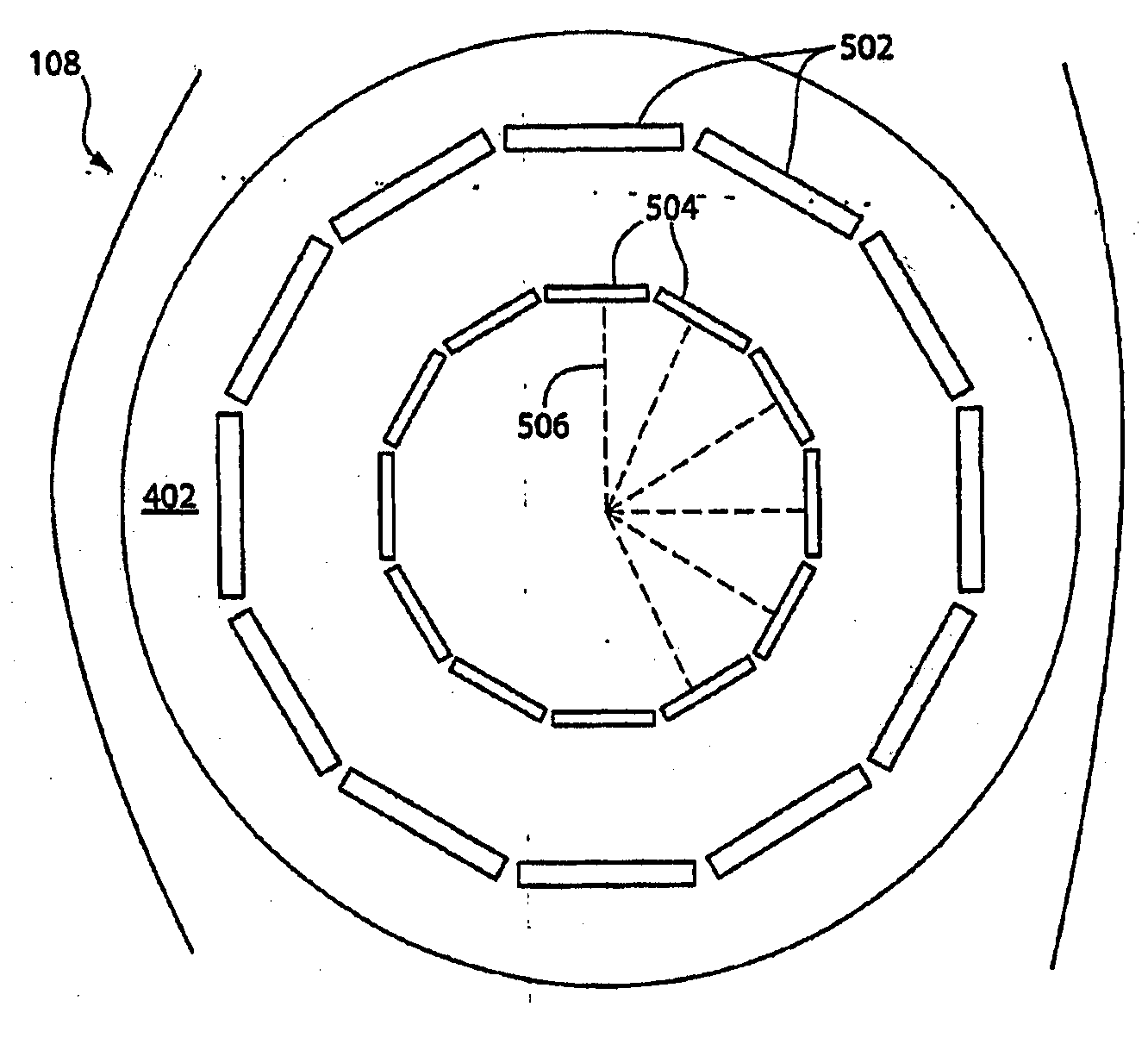

Computer-aided system for 360º heads up display of safety/mission critical data

InactiveUS20100238161A1Improve assessmentSatisfy safety performance requirementsCathode-ray tube indicatorsInput/output processes for data processingHead-up displayDisplay device

A safety critical, time sensitive data system for projecting safety / mission critical data onto a display pair of Commercial Off The Shelf (COTS) light weight projection glasses or monocular creating a virtual 360° HUD (Heads Up Display) with 6 degrees of freedom movement. The system includes the display, the workstation, the application software, and inputs containing the safety / mission critical information (Current User Position, Total Collision Avoidance System—TCAS, Global Positioning System—GPS, Magnetic Resonance Imaging—MRI Images, CAT scan images, Weather data, Military troop data, real-time space type markings etc.). The workstation software processes the incoming safety / mission critical data and converts it into a three dimensional space for the user to view. Selecting any of the images may display available information about the selected item or may enhance the image. Predicted position vectors may be displayed as well as 3D terrain.

Owner:REALTIME

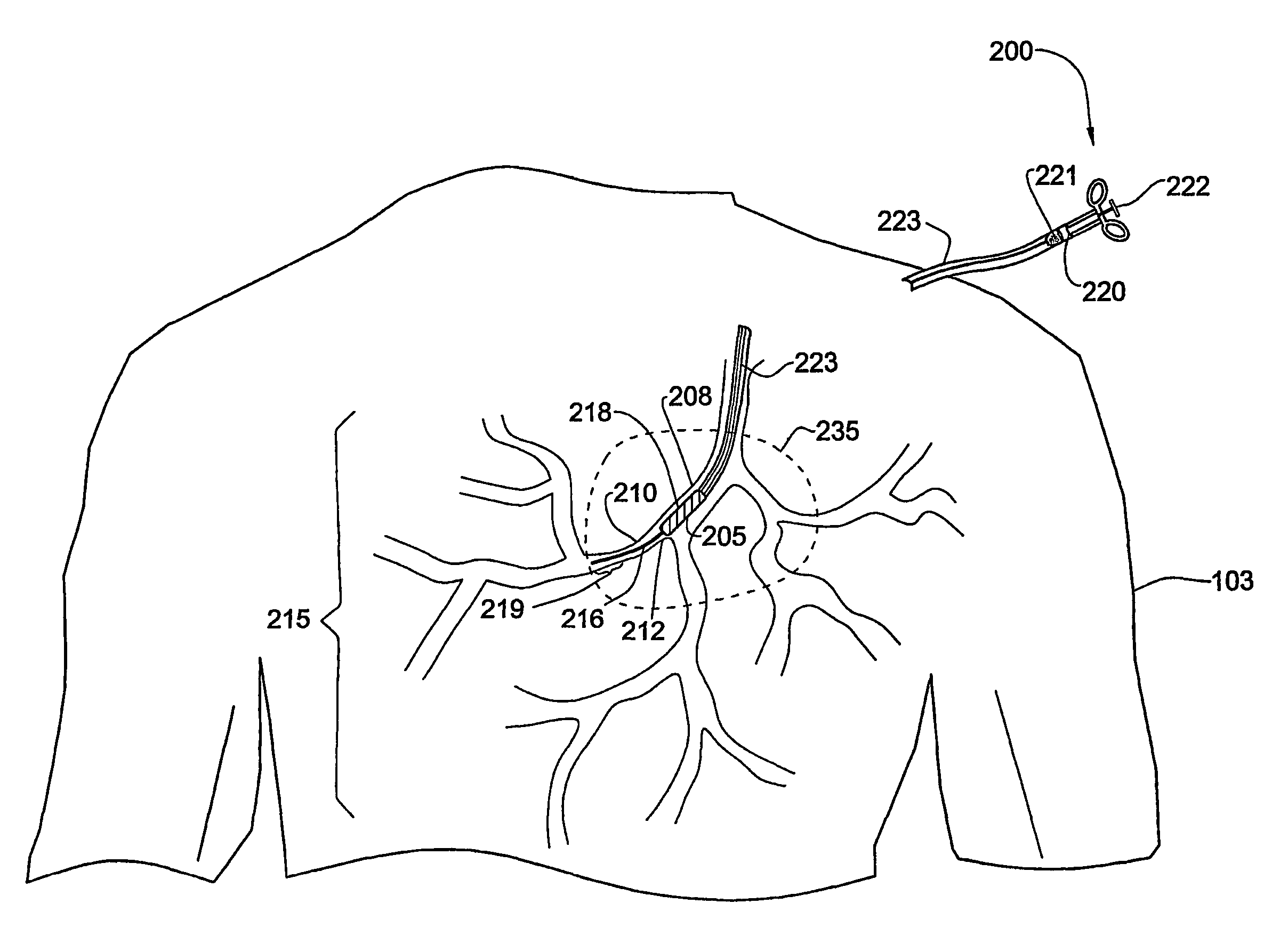

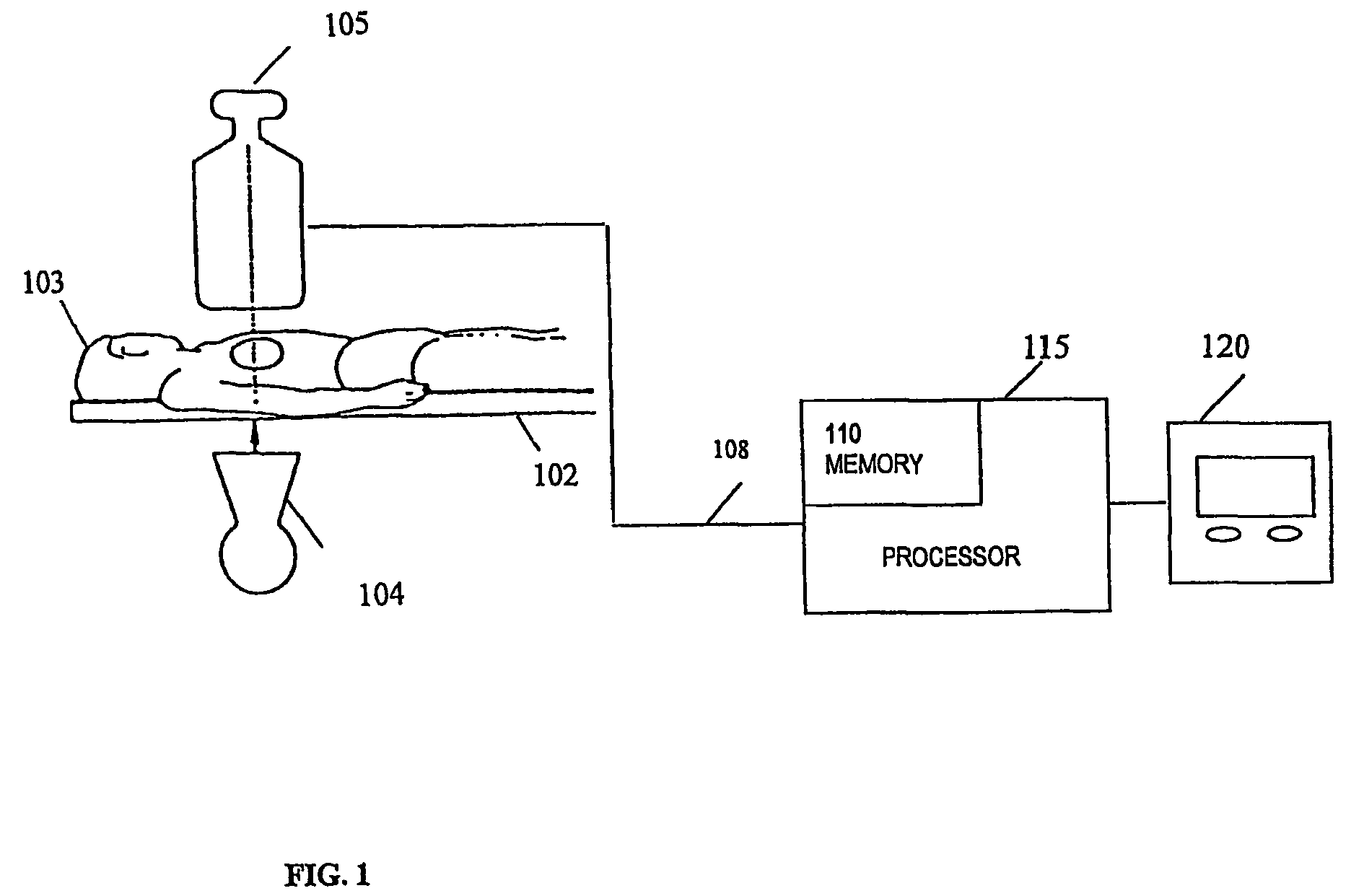

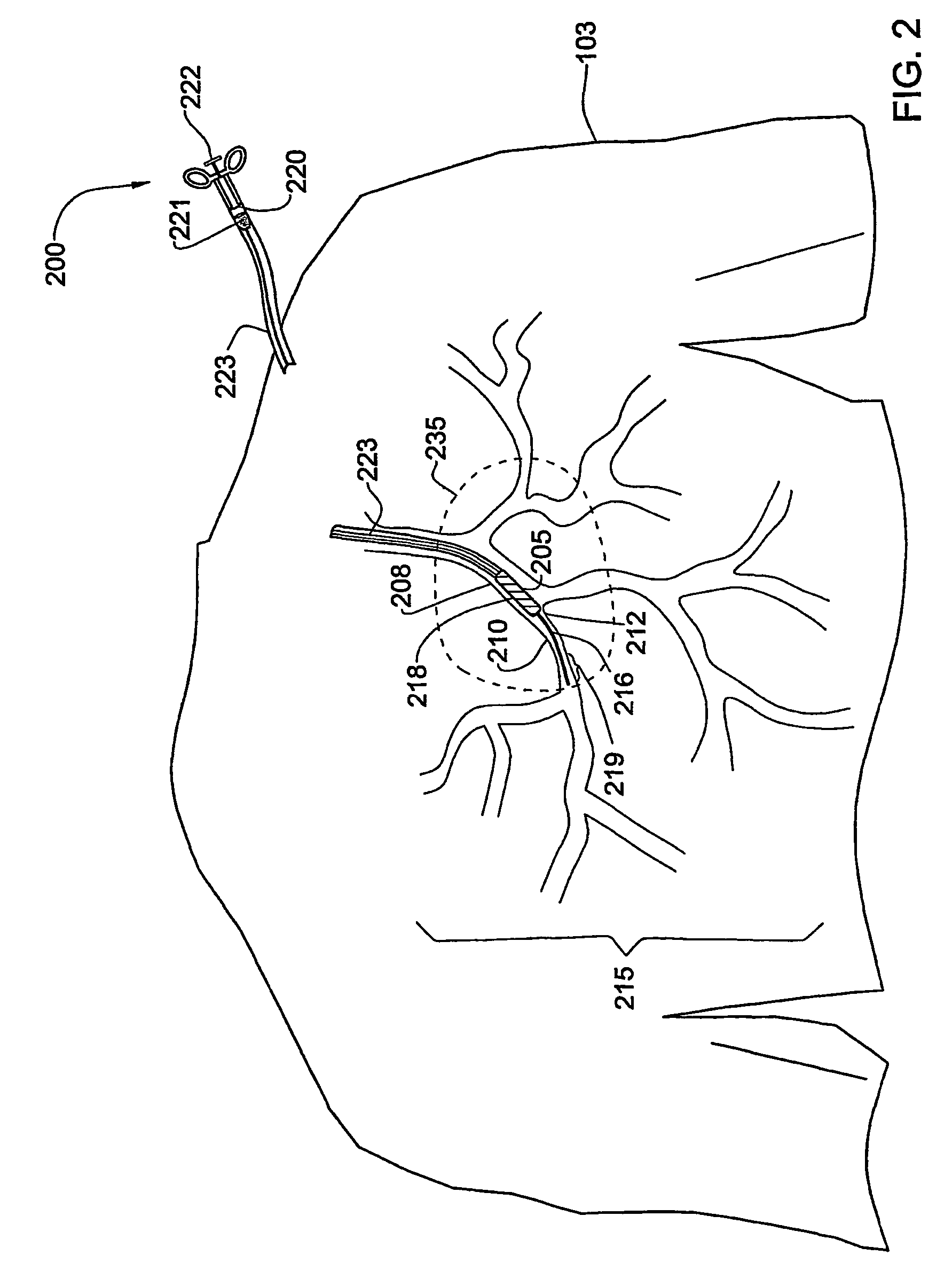

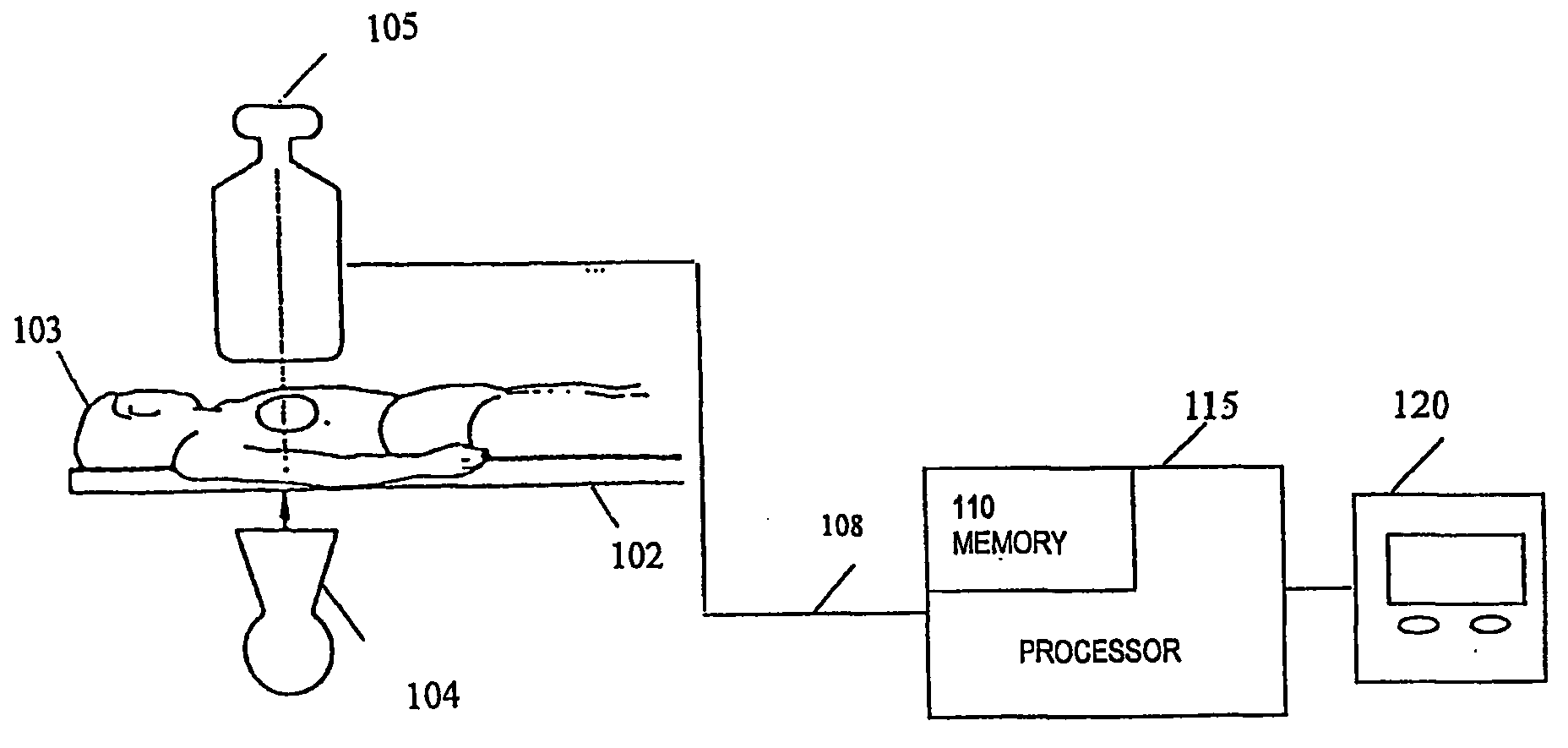

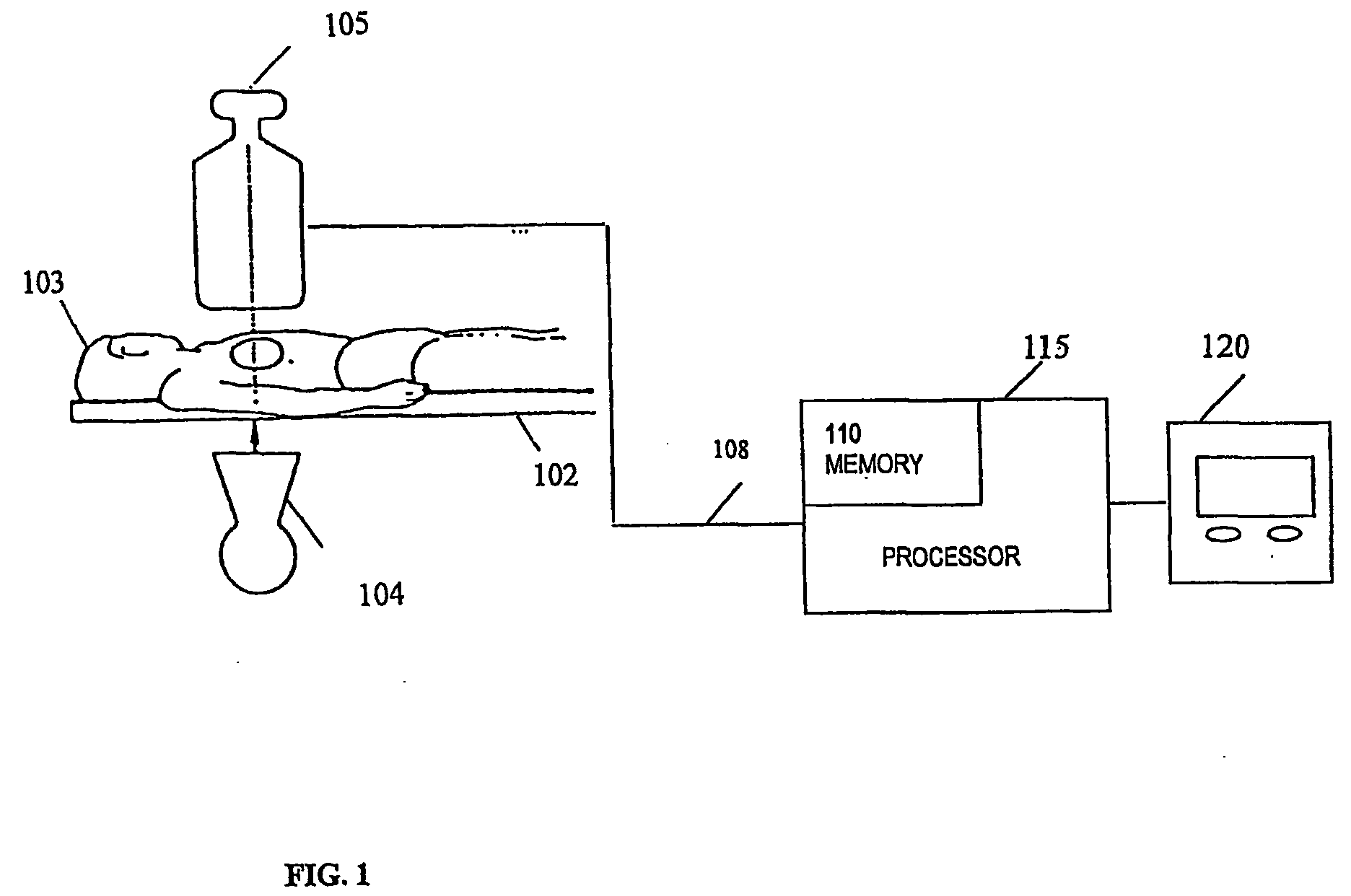

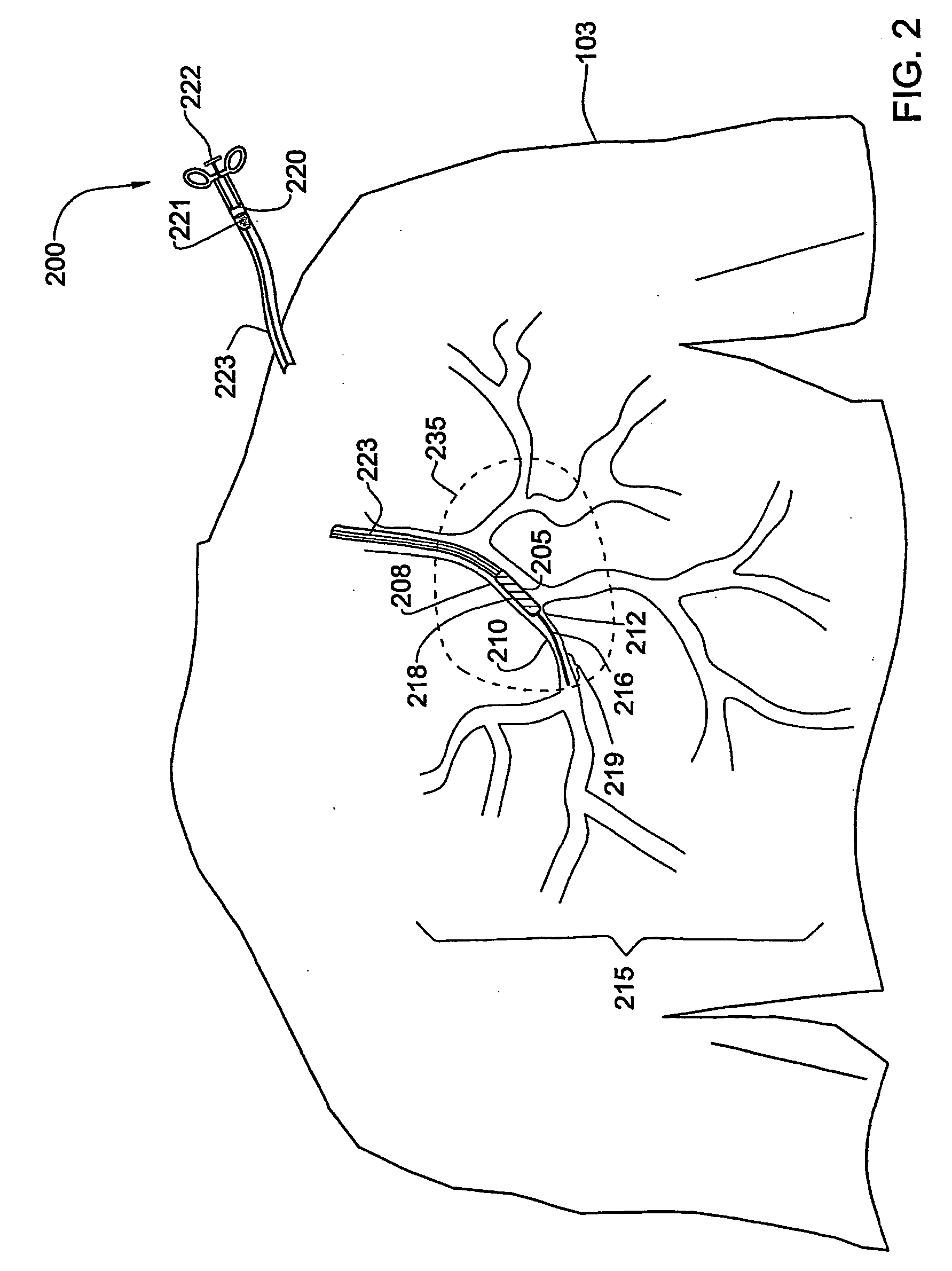

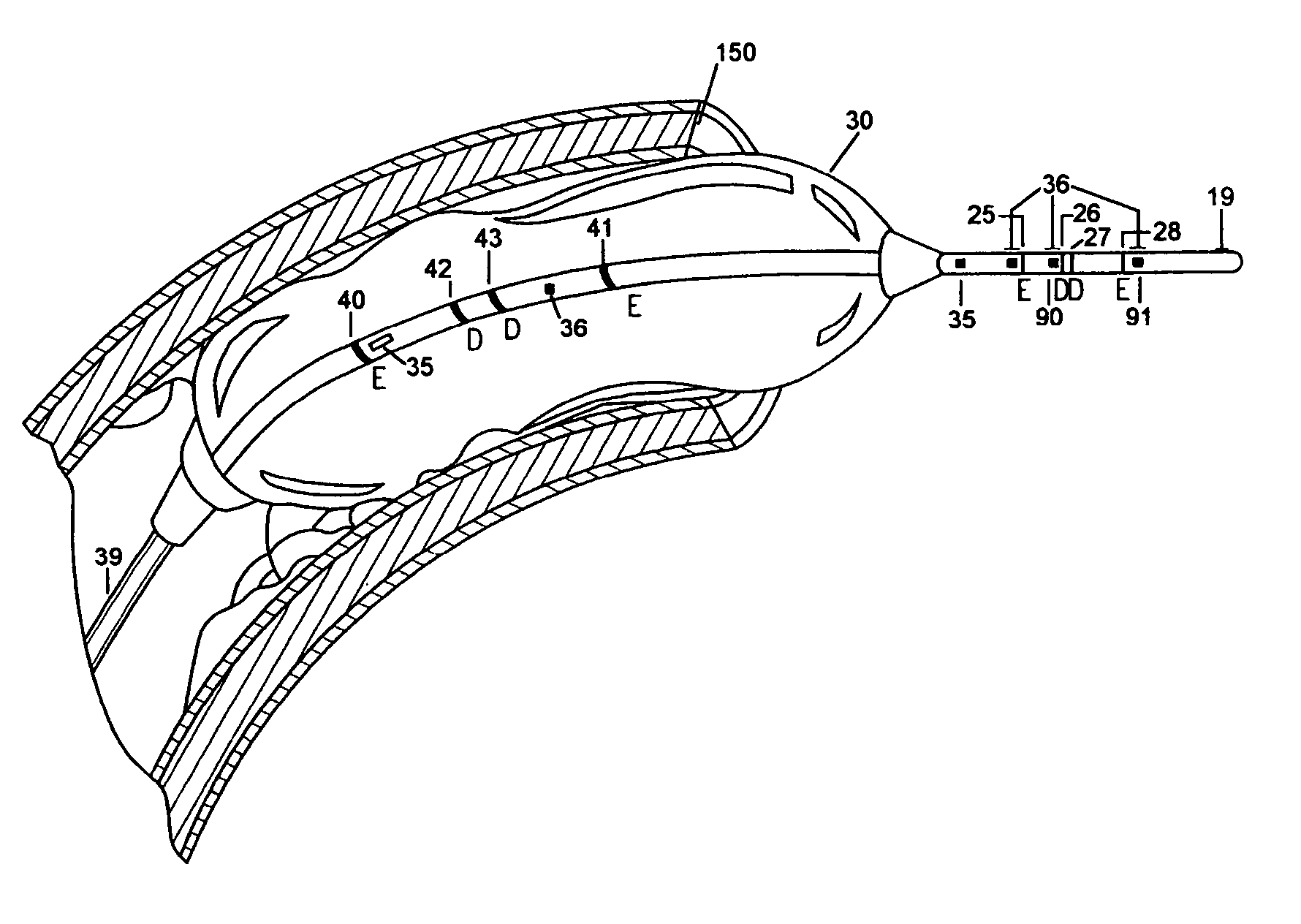

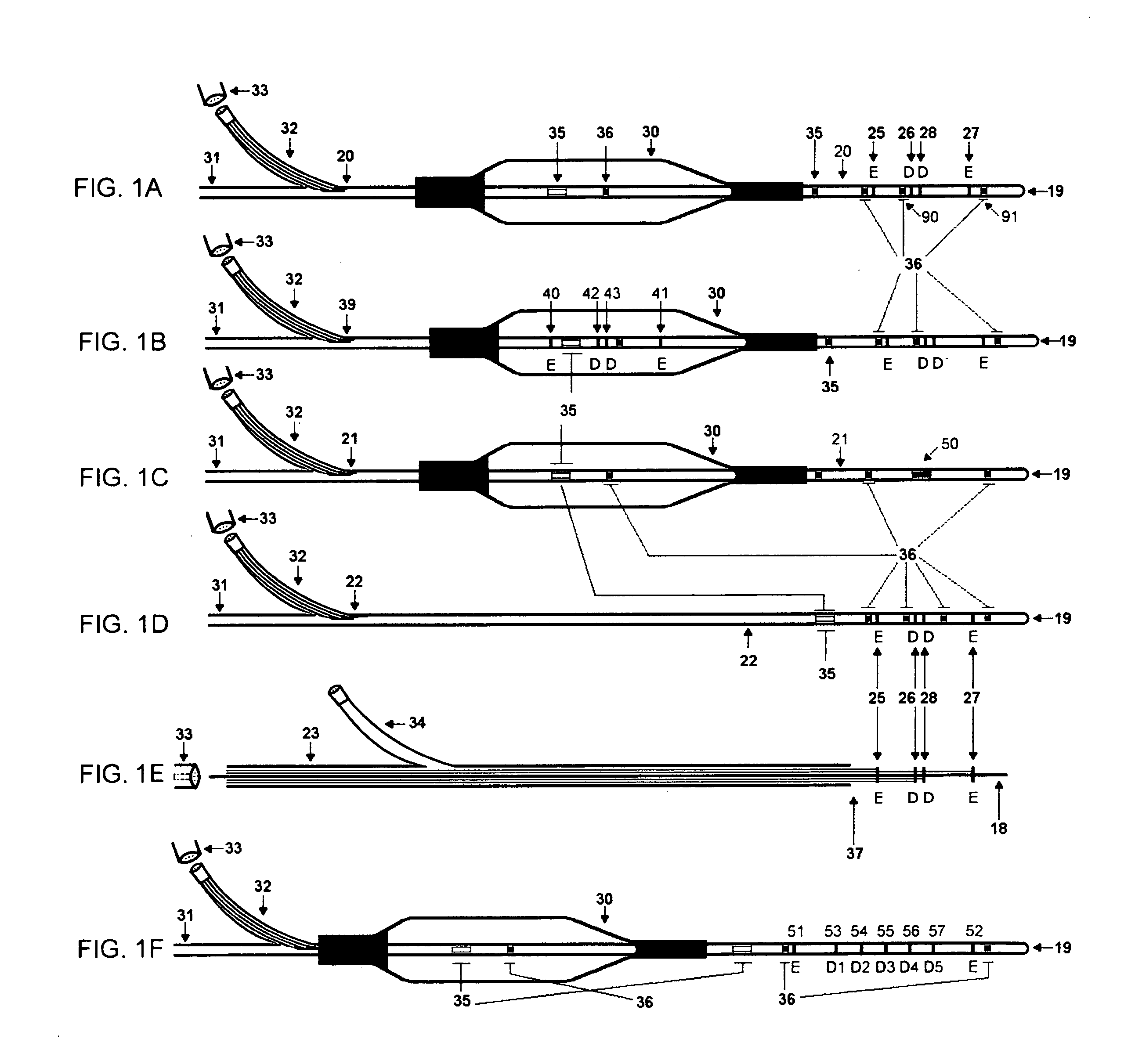

Method and system for positioning a device in a tubular organ

InactiveUS7778685B2Accurate measurementImprove assessmentDiagnostic recording/measuringSensorsComputer scienceAngle of view

A system and method for positioning a device at a desired location in a tubular organ such as an artery. A three-dimensional reconstruction of the organ is obtained, and the desired location is marked in the reconstruction. The device is inserted into the organ and an image is obtained of the device and organ. The reconstruction with the marked location is projected onto a plane from the perspective of the image and the projection and image are superimposed. If the device is not at the desired location, the device is repositioned in the organ and an additional image of the device is obtained. The reconstruction is then projected onto a plane from the perspective of the additional image and the additional image and the projection are superimposed. This process is repeated, as required, until the device is in the desired location.

Owner:PAIEON INC

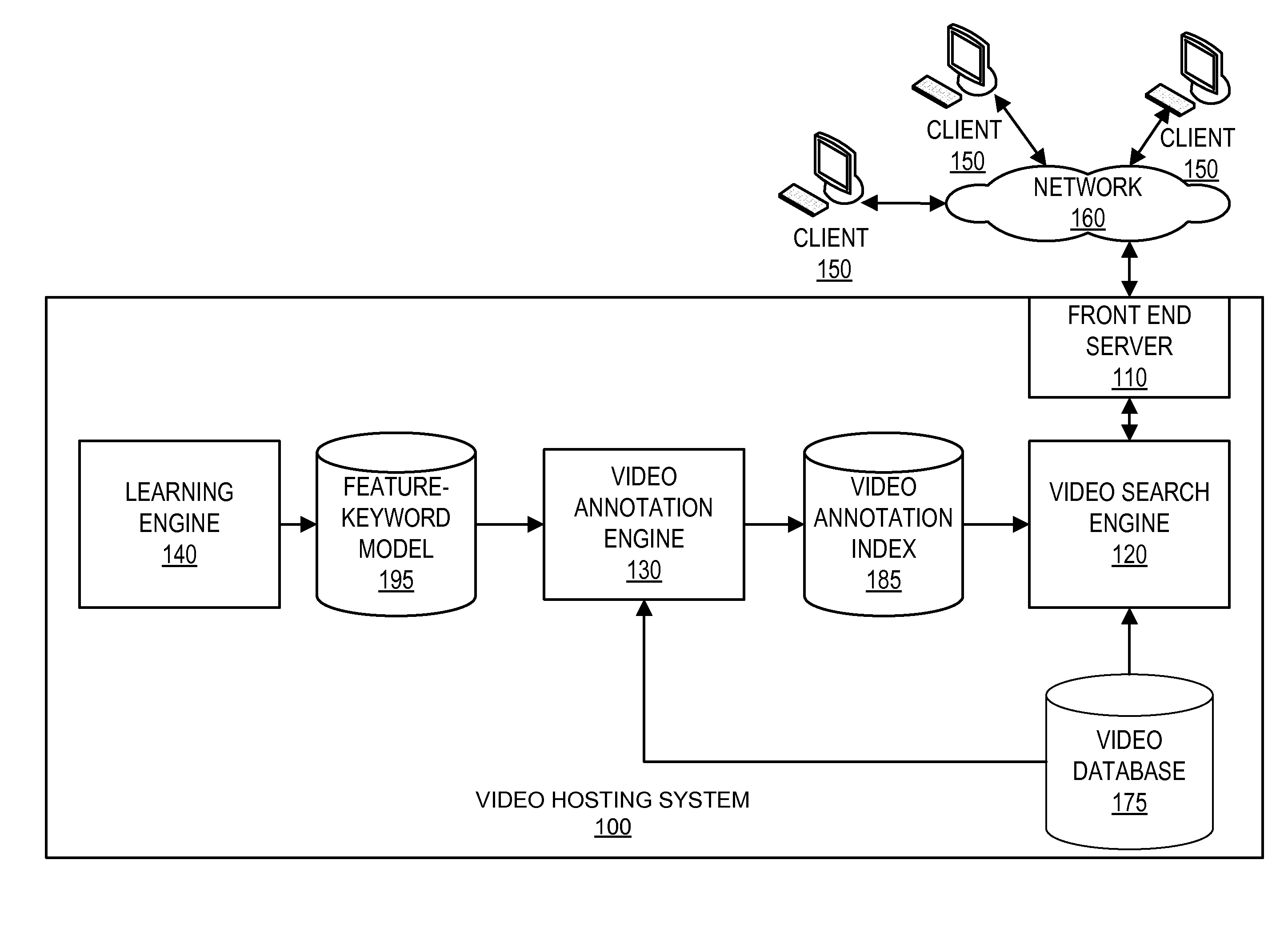

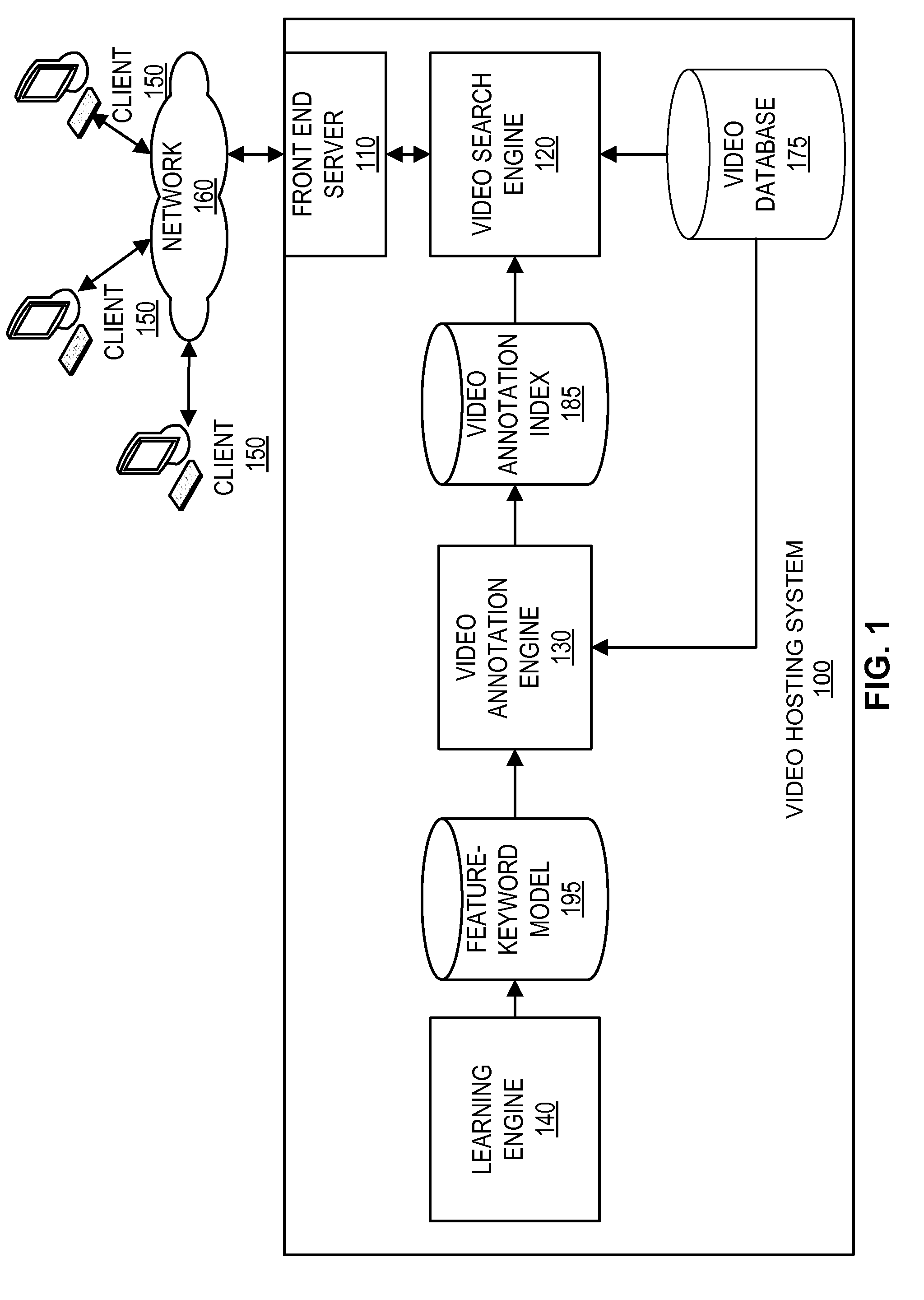

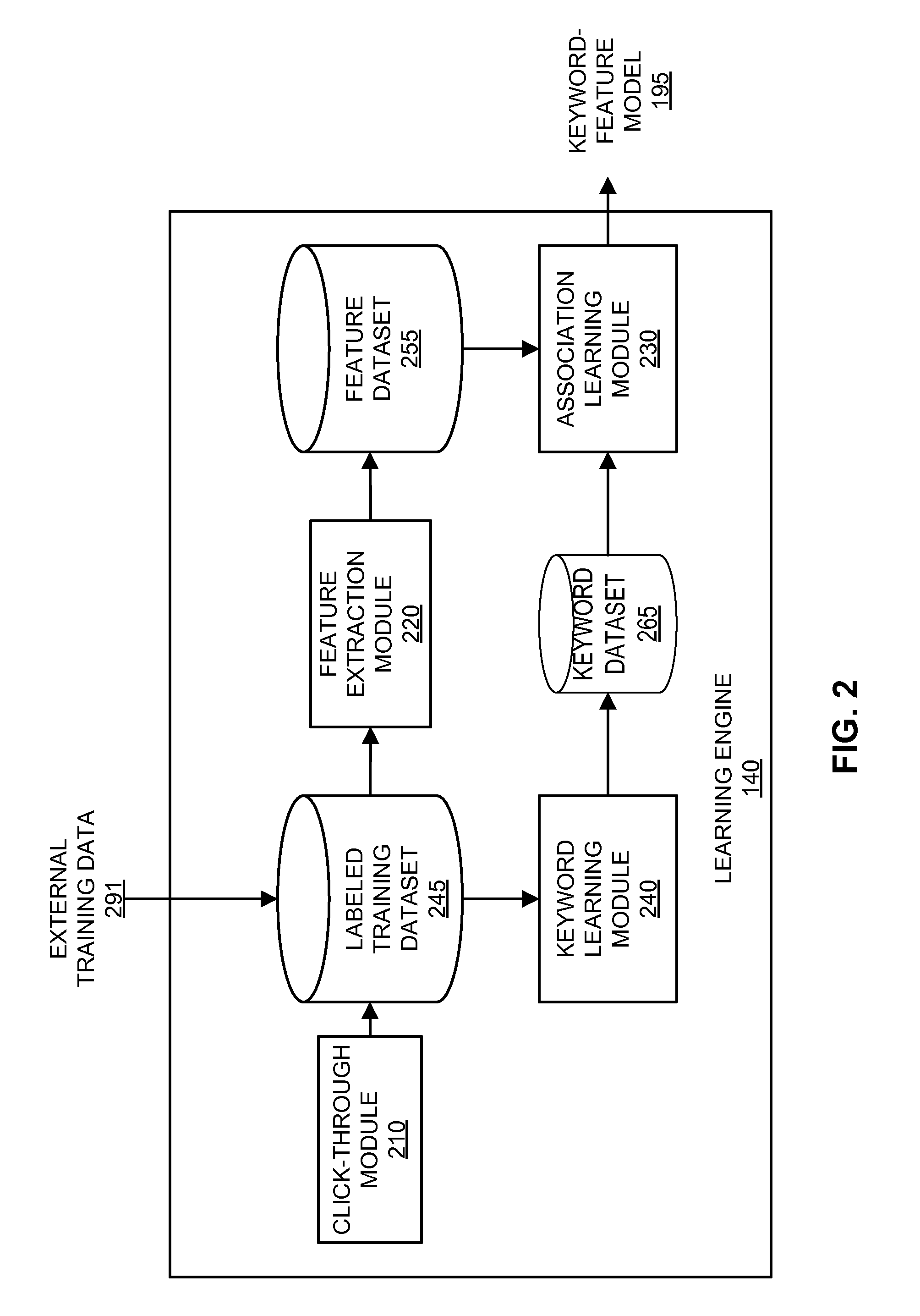

Relevance-Based Image Selection

InactiveUS20110047163A1Improve assessmentBetter assessmentDigital data processing detailsMetadata video data retrievalPattern recognitionData set

A system, computer readable storage medium, and computer-implemented method presents video search results responsive to a user keyword query. The video hosting system uses a machine learning process to learn a feature-keyword model associating features of media content from a labeled training dataset with keywords descriptive of their content. The system uses the learned model to provide video search results relevant to a keyword query based on features found in the videos. Furthermore, the system determines and presents one or more thumbnail images representative of the video using the learned model.

Owner:GOOGLE LLC

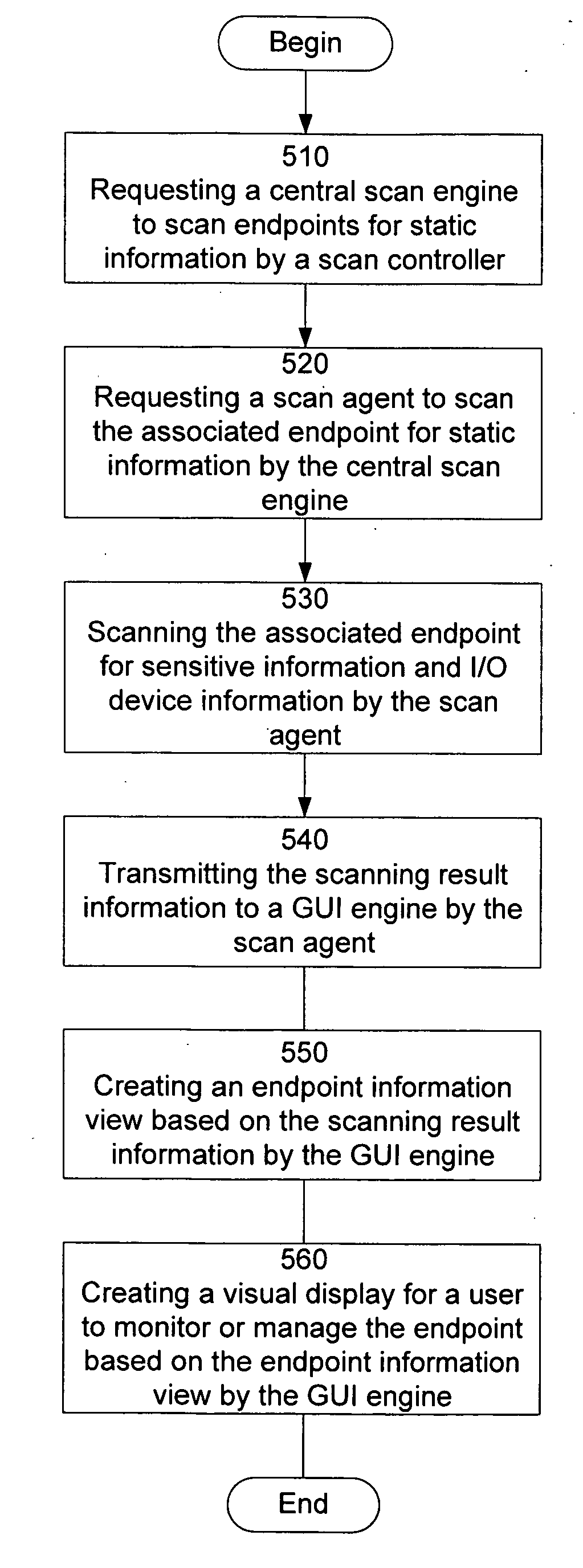

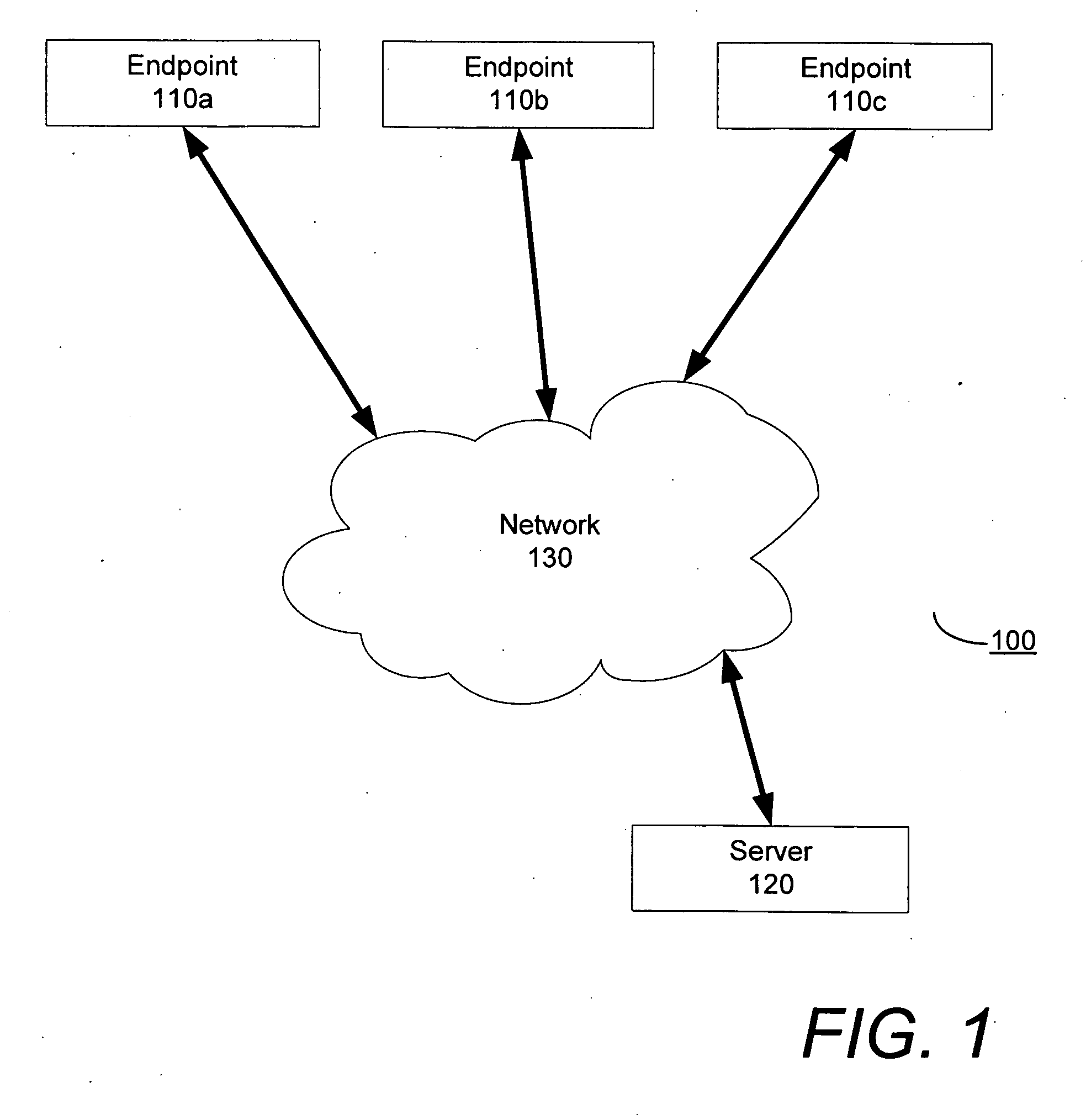

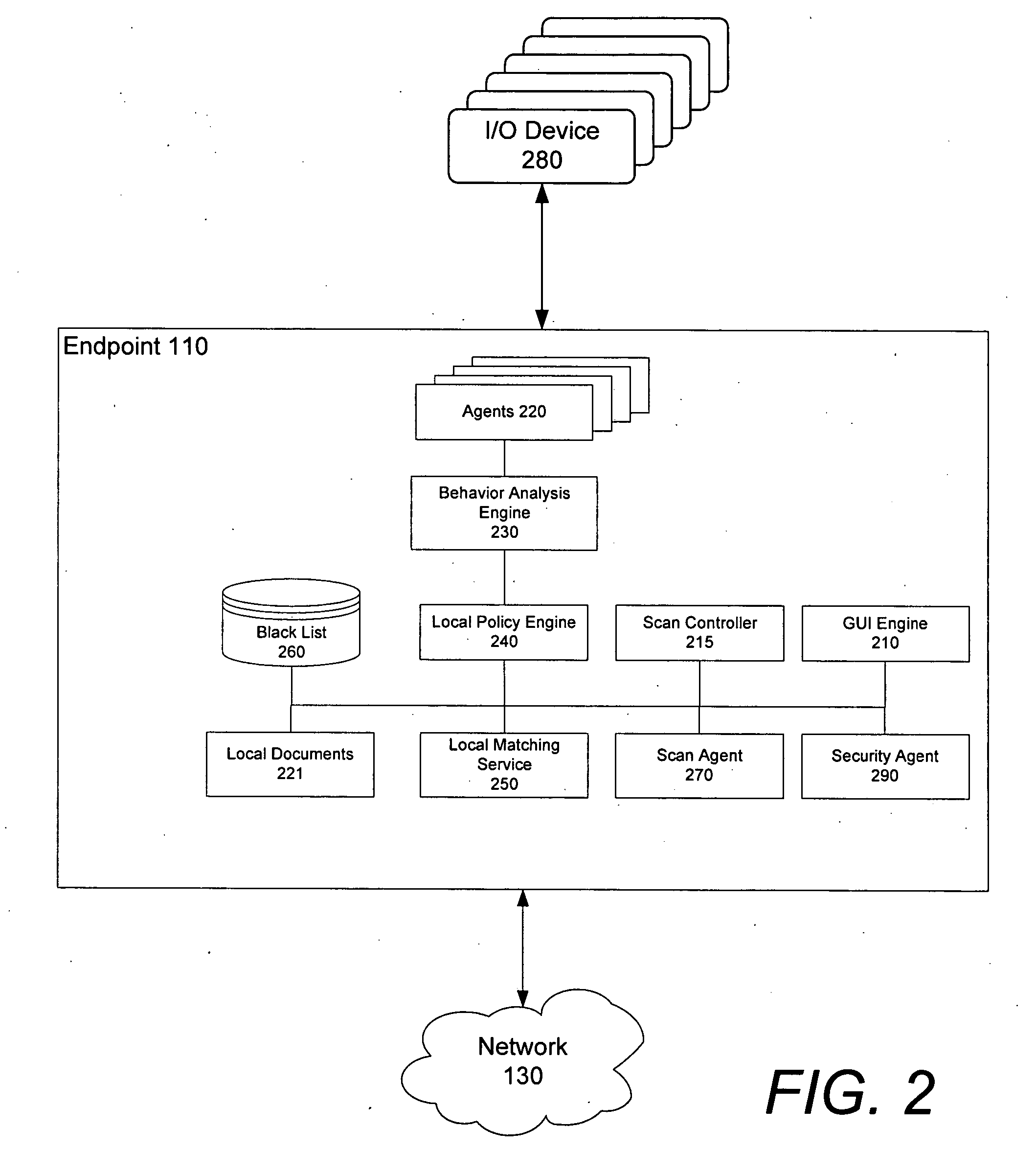

Graphical user interface based sensitive information and internal information vulnerability management system

ActiveUS20060272024A1Rapid assessmentEasy to identifyMemory loss protectionDigital data processing detailsTime informationGraphical user interface testing

A system and method provides a graphical user interface (GUI) for users to monitor and manage sensitive information within an enterprise network. The GUI can provide users with information, such as the presence of input / output devices (I / O device), the location of documents containing sensitive information (sensitive documents), and the status of local security policy. The GUI can also provide users with real-time information, such as the occurrence of local security policy violations, the life-cycle of sensitive documents, and the sensitive information dynamic flow within the enterprise network.

Owner:TREND MICRO INC

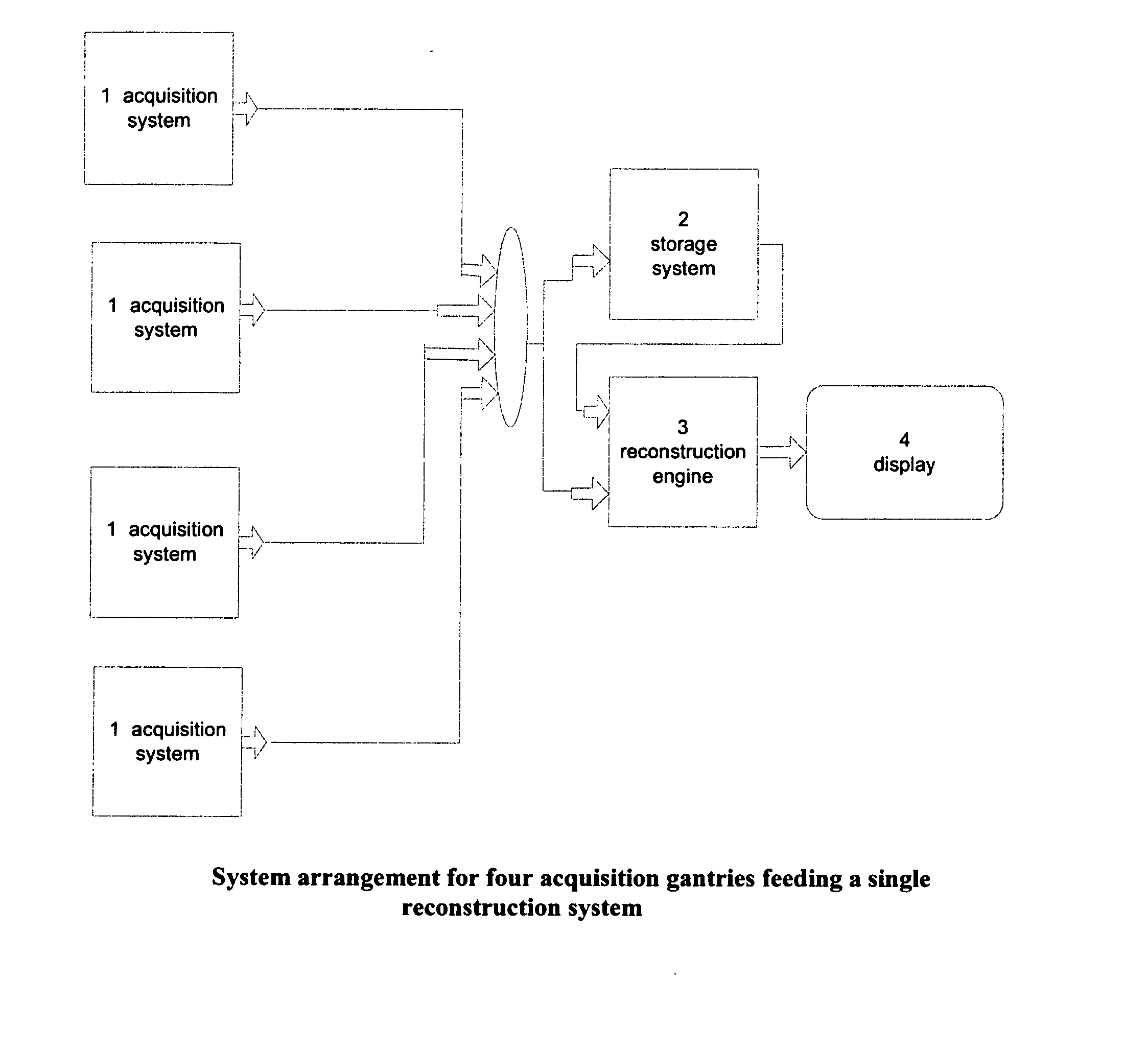

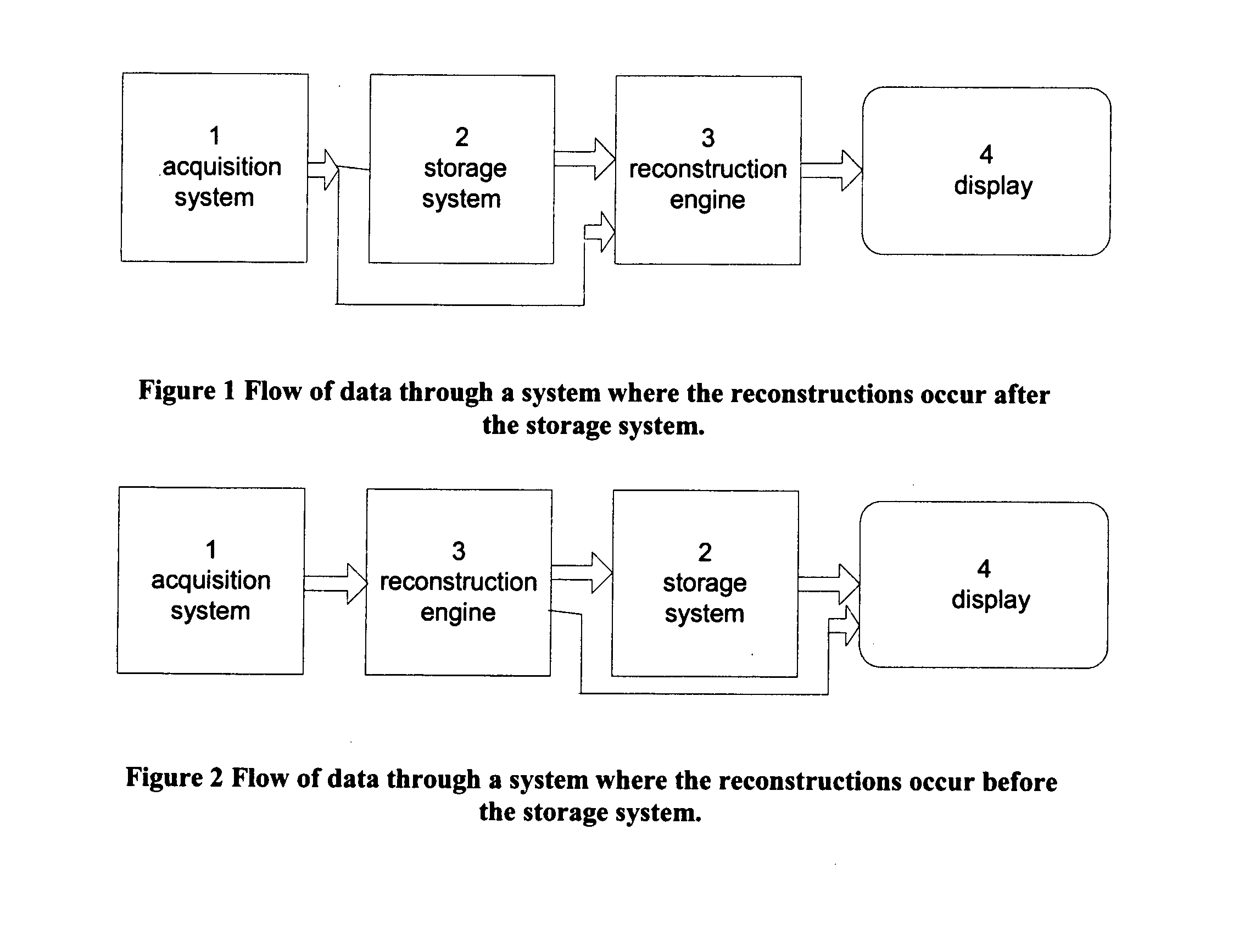

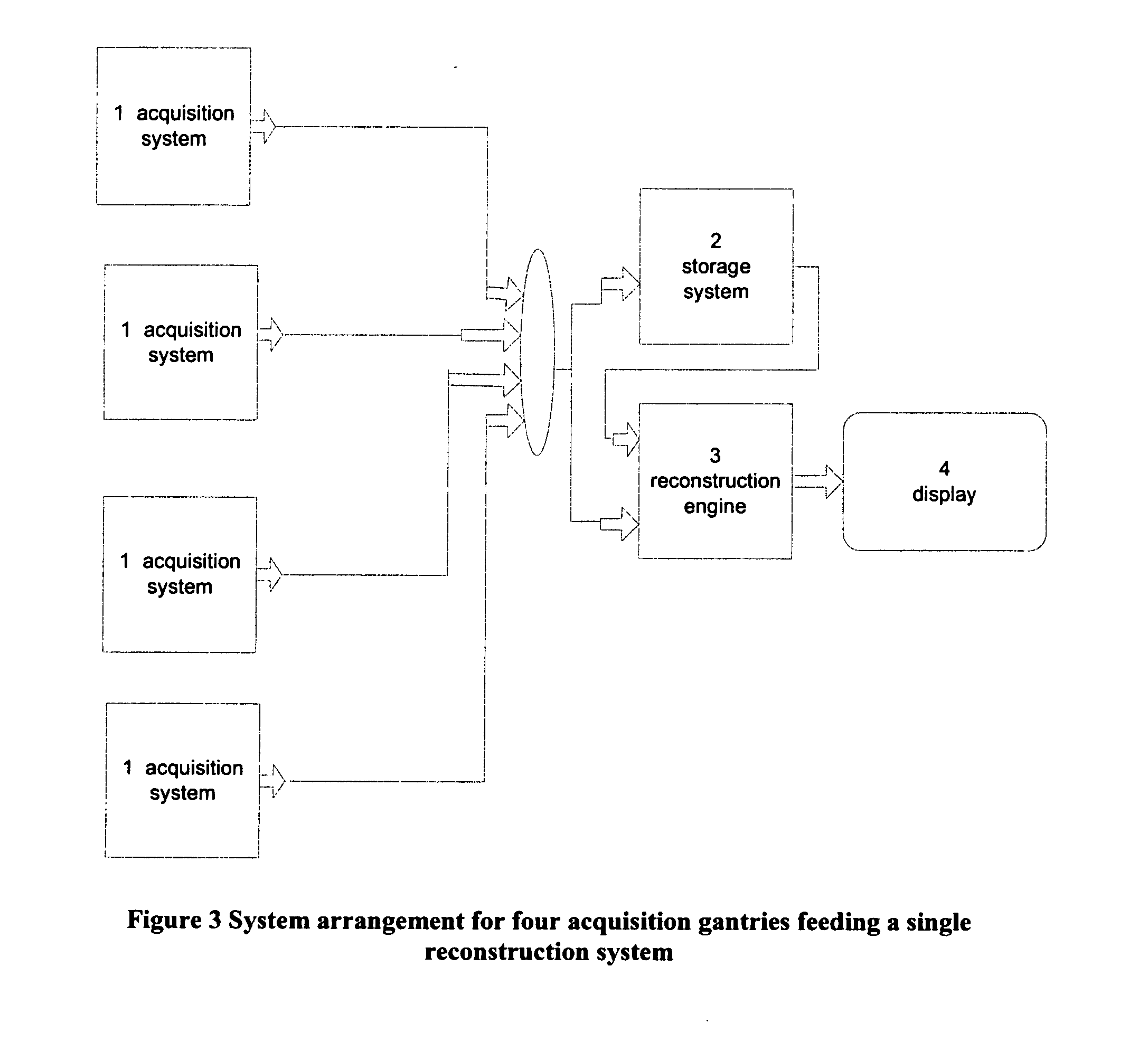

Image Handling and display in X-ray mammography and tomosynthesis

InactiveUS20080019581A1Easy to identifyImprove assessmentImage enhancementReconstruction from projectionTomosynthesisProjection image

A method and system for acquiring, processing, storing, and displaying x-ray mammograms Mp tomosynthesis images Tr representative of breast slices, and x-ray tomosynthesis projection images Tp taken at different angles to a breast, where the Tr images are reconstructed from Tp images

Owner:HOLOGIC INC

Method and system for positioning a device in a tubular organ

InactiveUS20040102697A1Accurate measurementImprove assessmentDiagnostic recording/measuringSensorsRadiologyBiomedical engineering

A system and method for positioning a device at a desired location in a tubular organ such as an artery. A three-dimensional reconstruction of the organ is obtained, and the desired location is marked in the reconstruction. The device is inserted into the organ and an image is obtained of the device and organ. The reconstruction with the marked location is projected onto a plane from the perspective of the image and the projection and image are superimposed. If the device is not at the desired location, the device is repositioned in the organ and an additional image of the device is obtained. The reconstruction is then projected onto a plane from the perspective of the additional image and the additional image and the projection are superimposed. This process is repeated, as required, until the device is in the desired location.

Owner:PAIEON INC

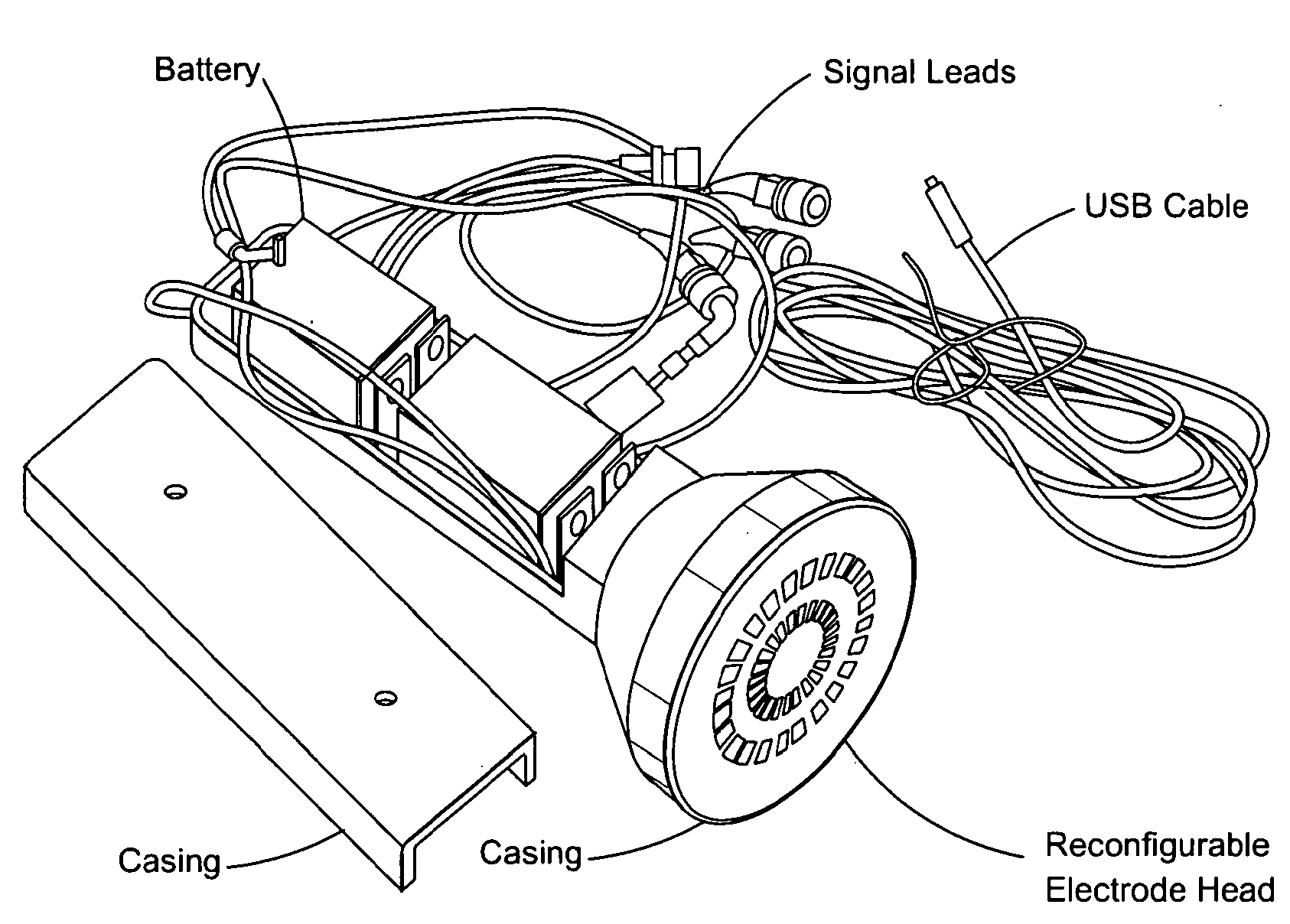

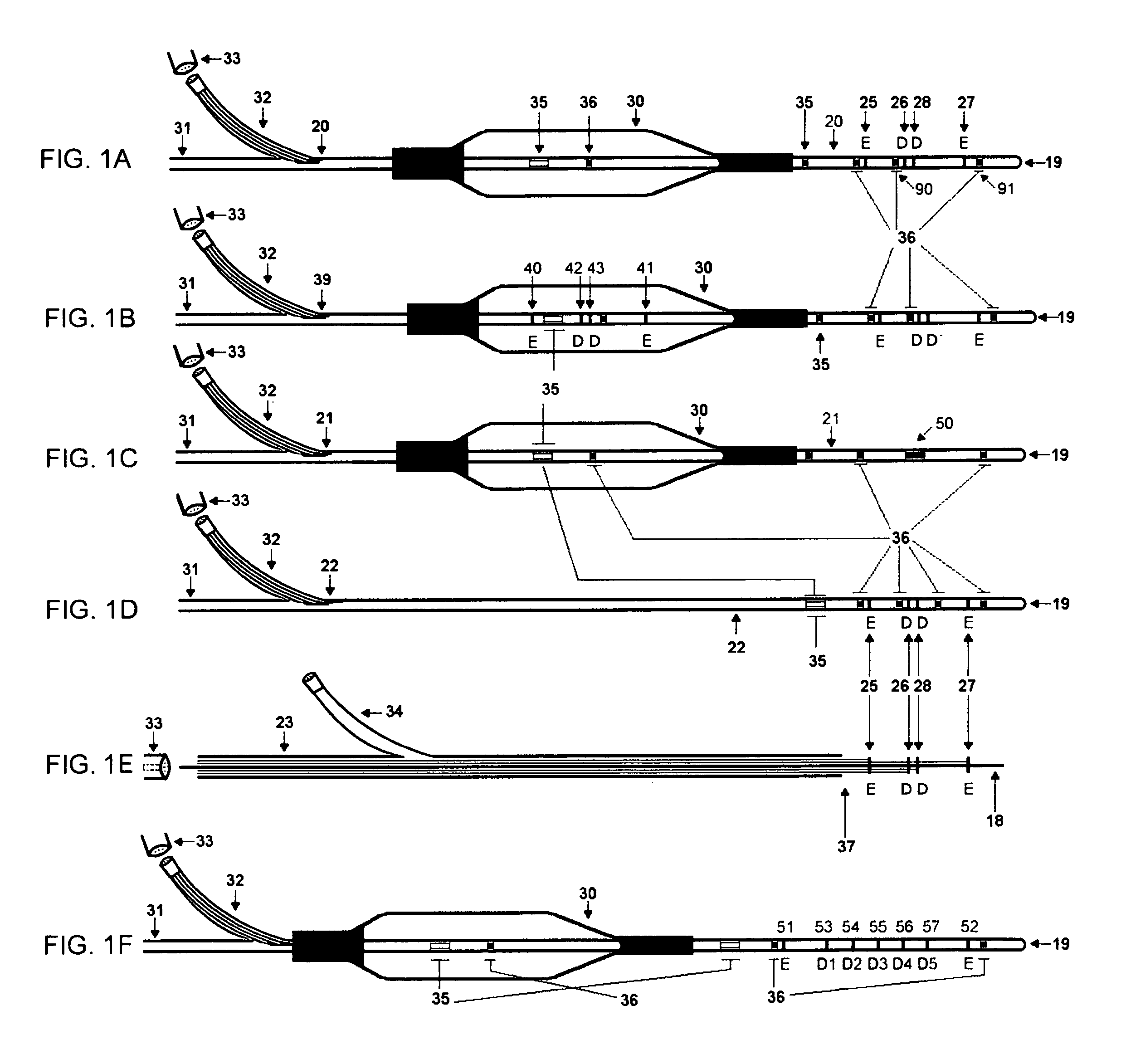

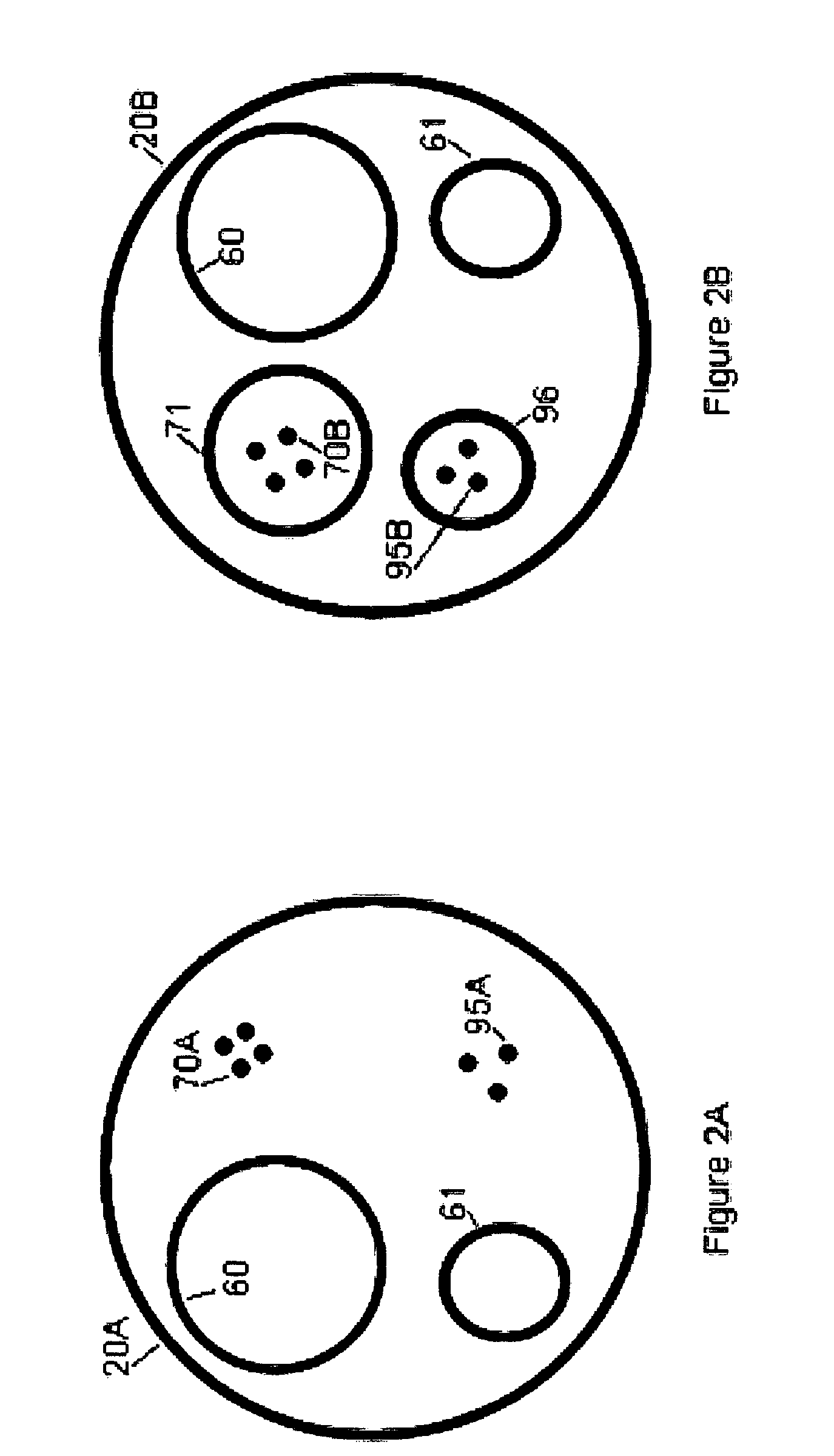

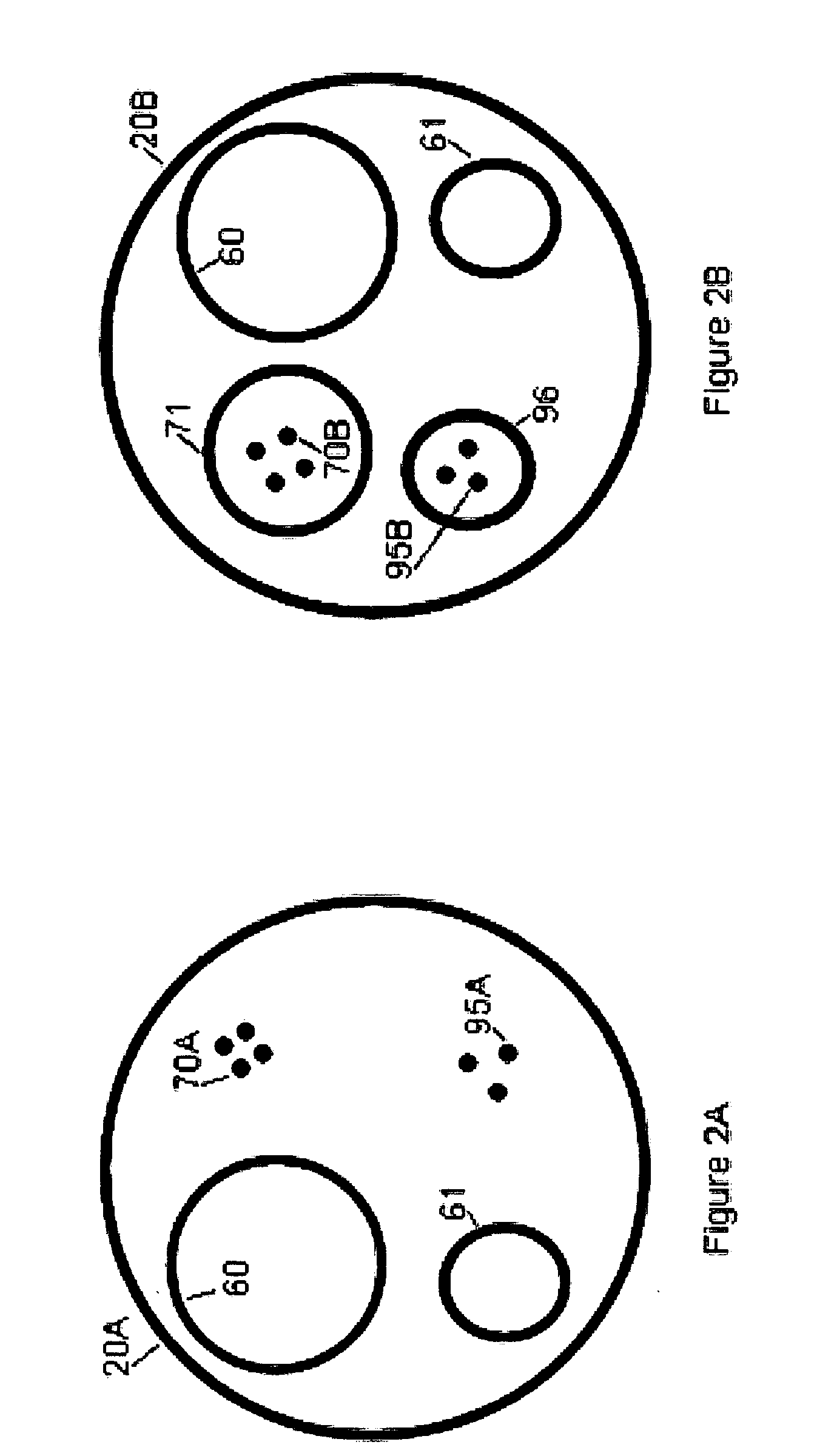

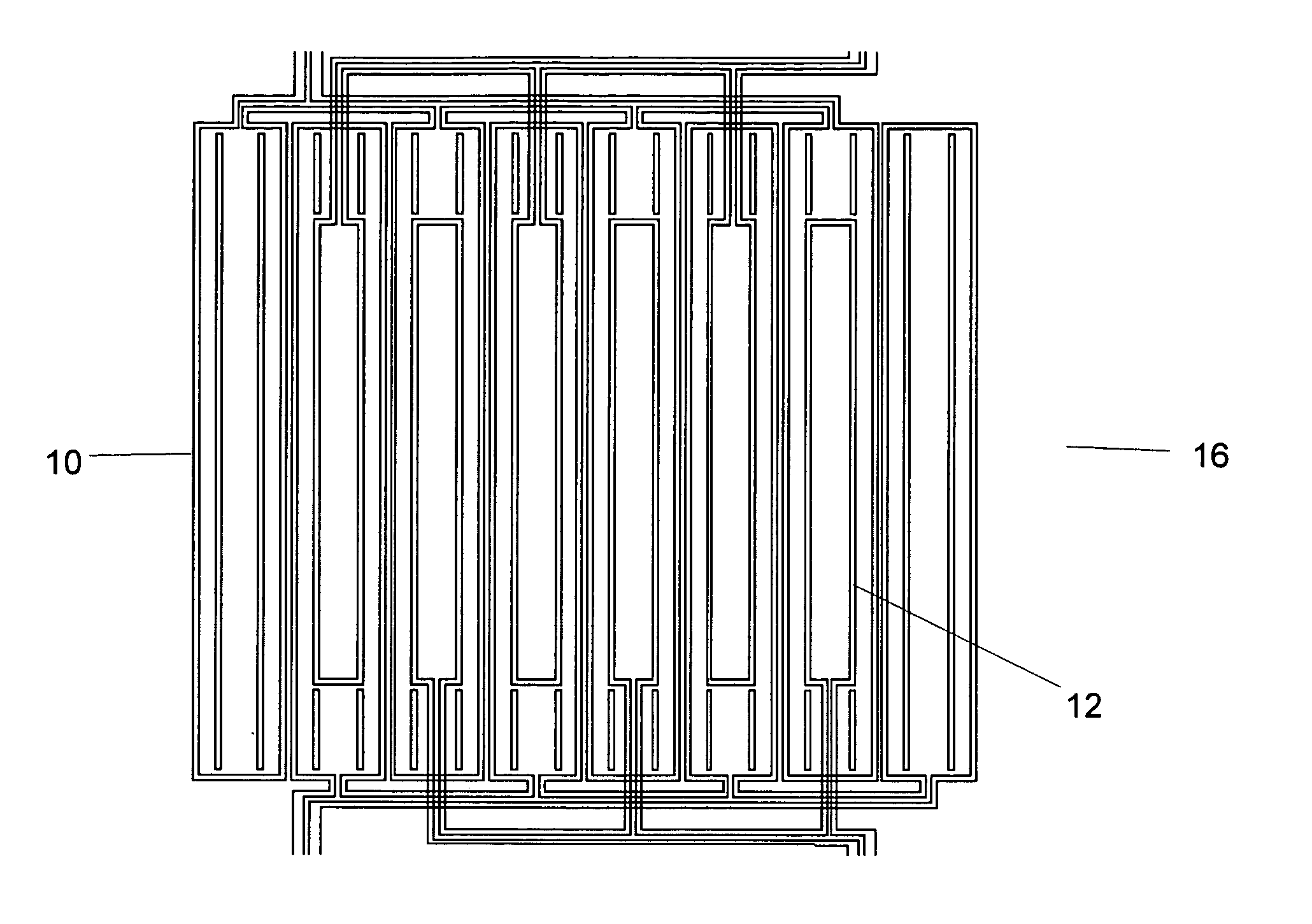

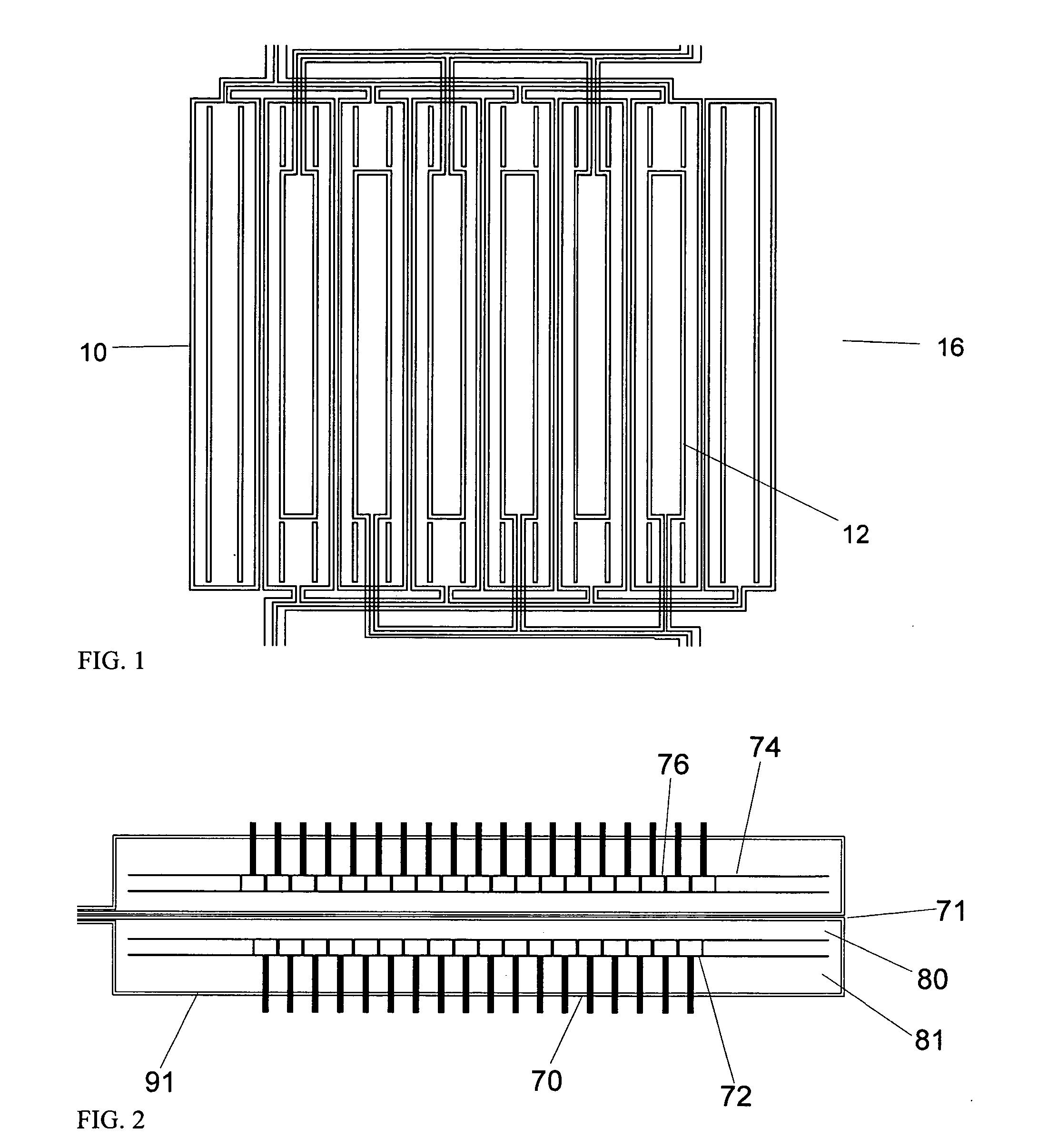

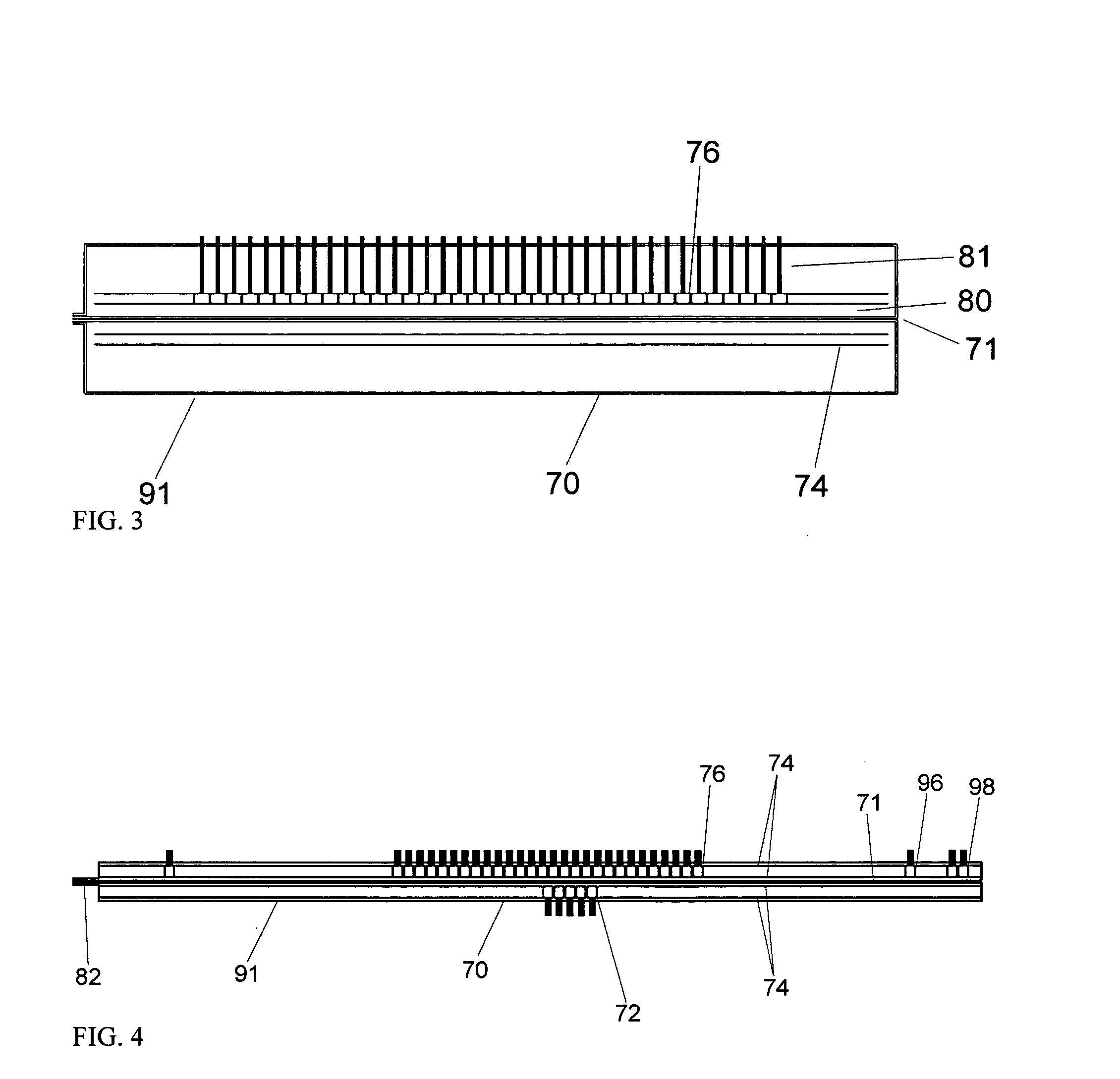

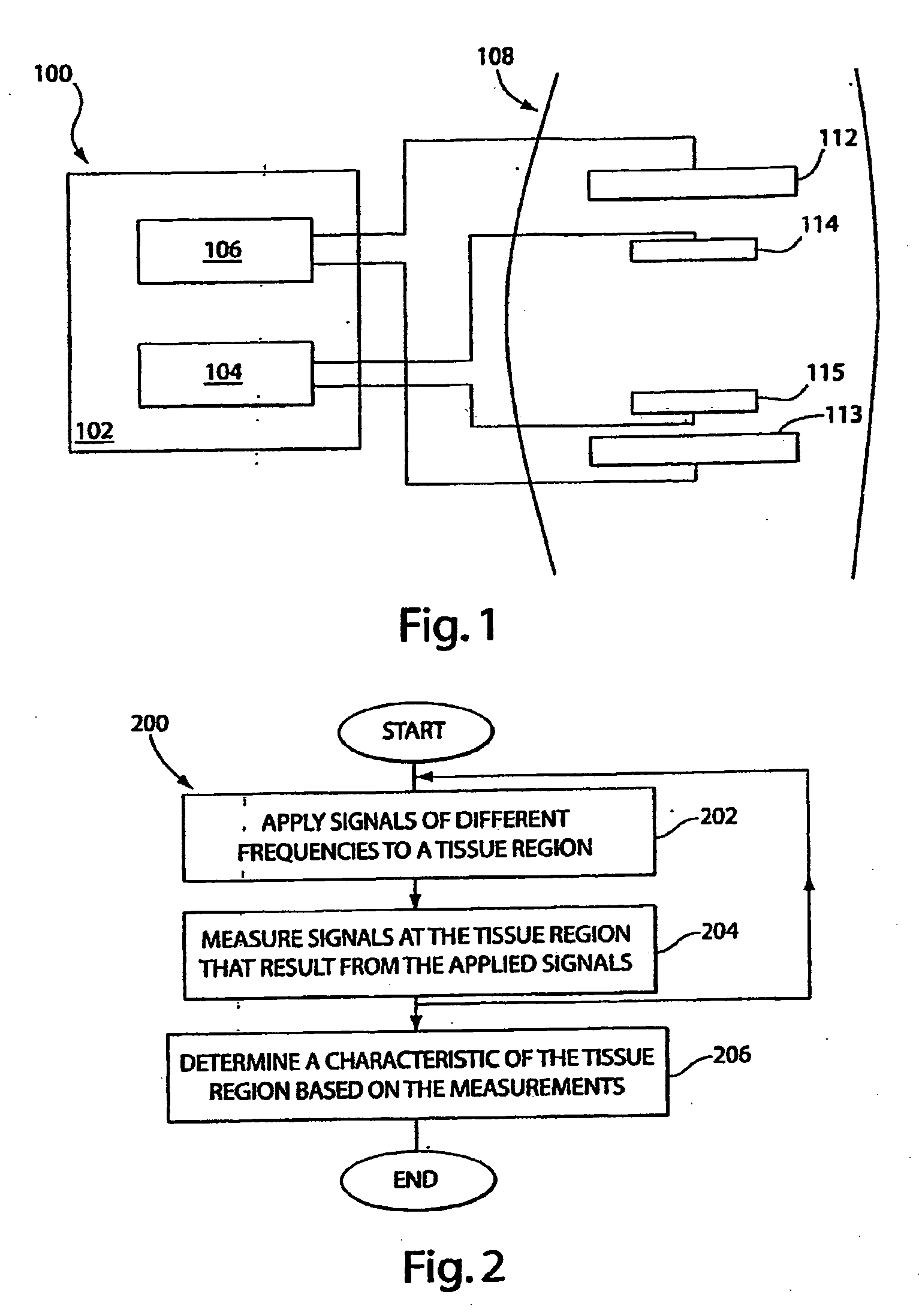

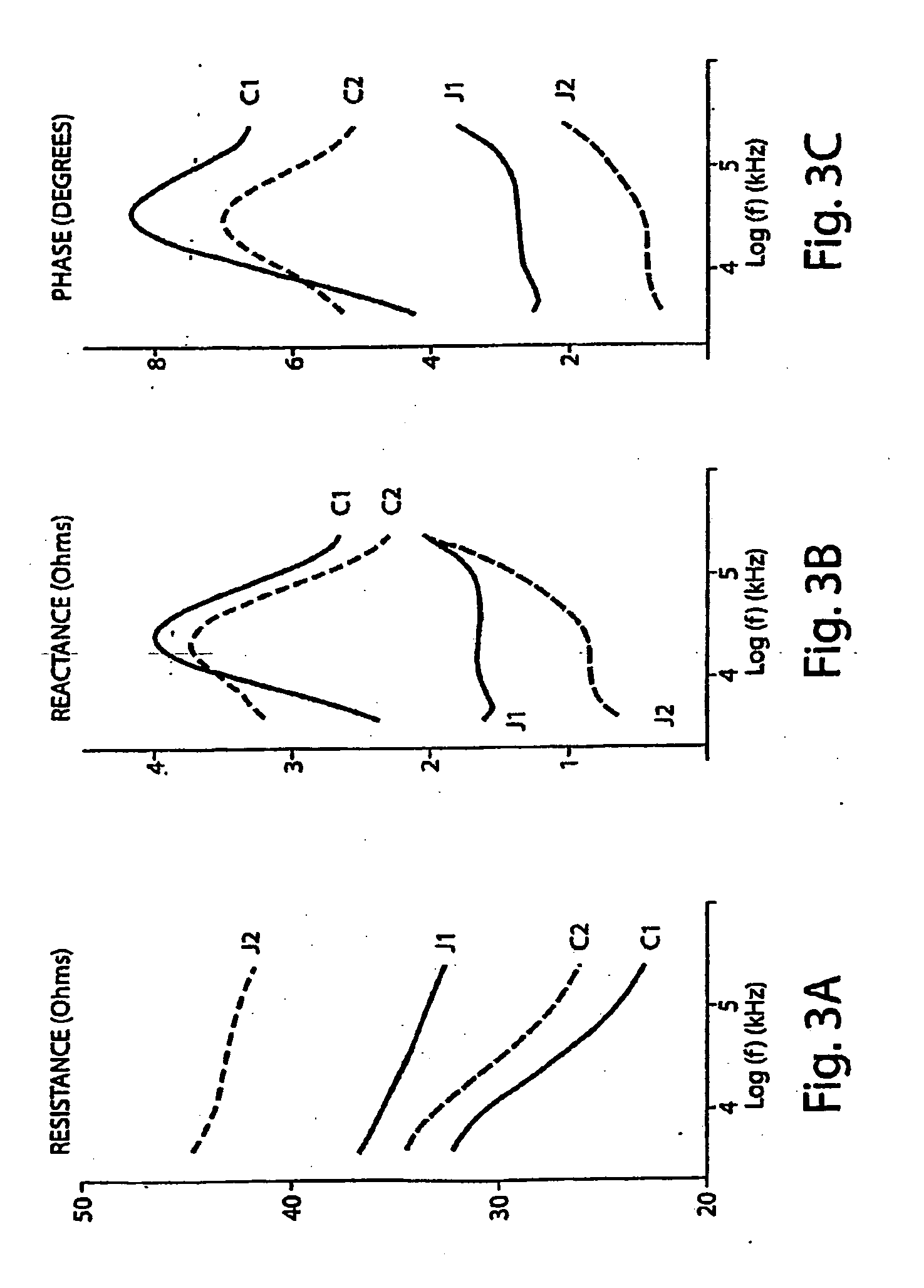

Hand-held device for electrical impedance myography

ActiveUS20120245436A1Improve assessmentEasy diagnosisUltrasonic/sonic/infrasonic diagnosticsDiagnostic recording/measuringFiberElectrical resistance and conductance

A device for determining muscle condition of a region of tissue. The device comprises an electrical impedance myography (EIM) portable probe bearing an electrode array. The electrode array comprises excitation electrodes used to apply multi-frequency electrical signals to the region of tissue and pickup electrodes that are used to collect electrical signals resulting from the application of the multi-frequency electrical signals to the region of tissue. To improve accuracy and reproducibility of EIM measurements, the electrode array is reconfigurable to select different subsets of excitation and pickup electrodes so that the electrodes are oriented differently with respect to muscle fibers. Additional devices may be associated with the EIM probe to measure such parameters as temperature, moisture content of the region, quality of contact of electrodes of the electrode array with a surface of the region and pressure with which the EEM probe is applied to the region. The EIM measurements may be adjusted based on these parameters. Also, ultrasound and electrical impedance tomography measurements may supplement the ELM measurements for more complete analysis of the muscle condition.

Owner:MASSACHUSETTS INST OF TECH +1

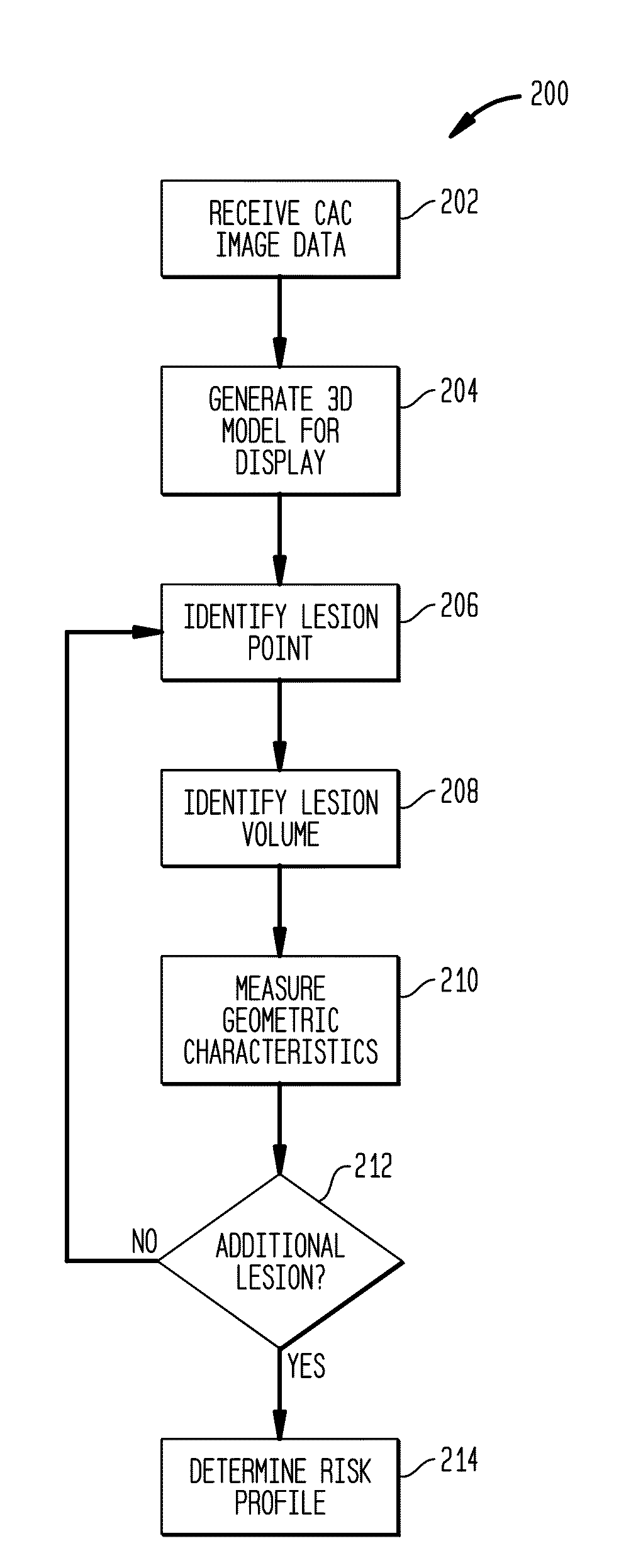

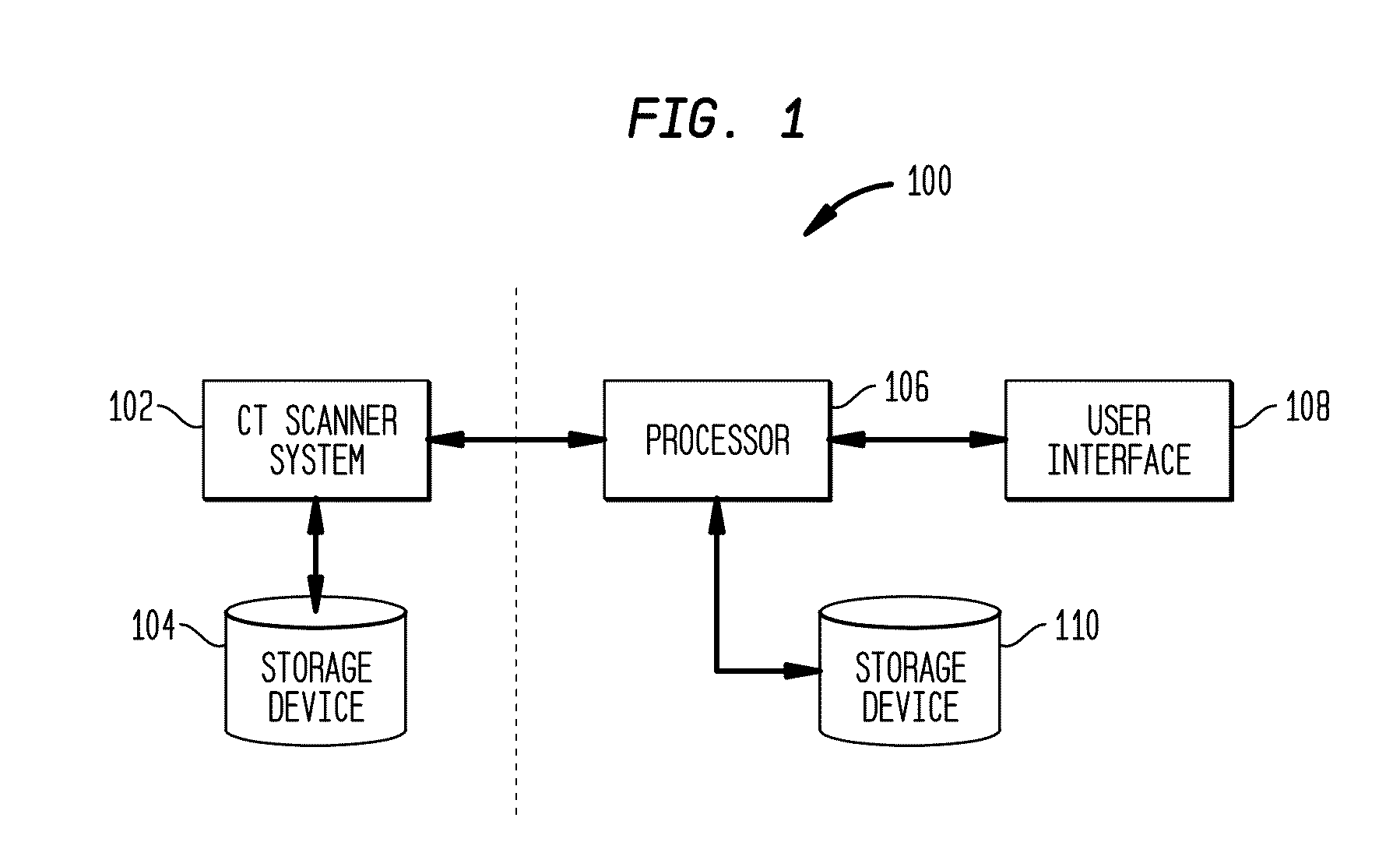

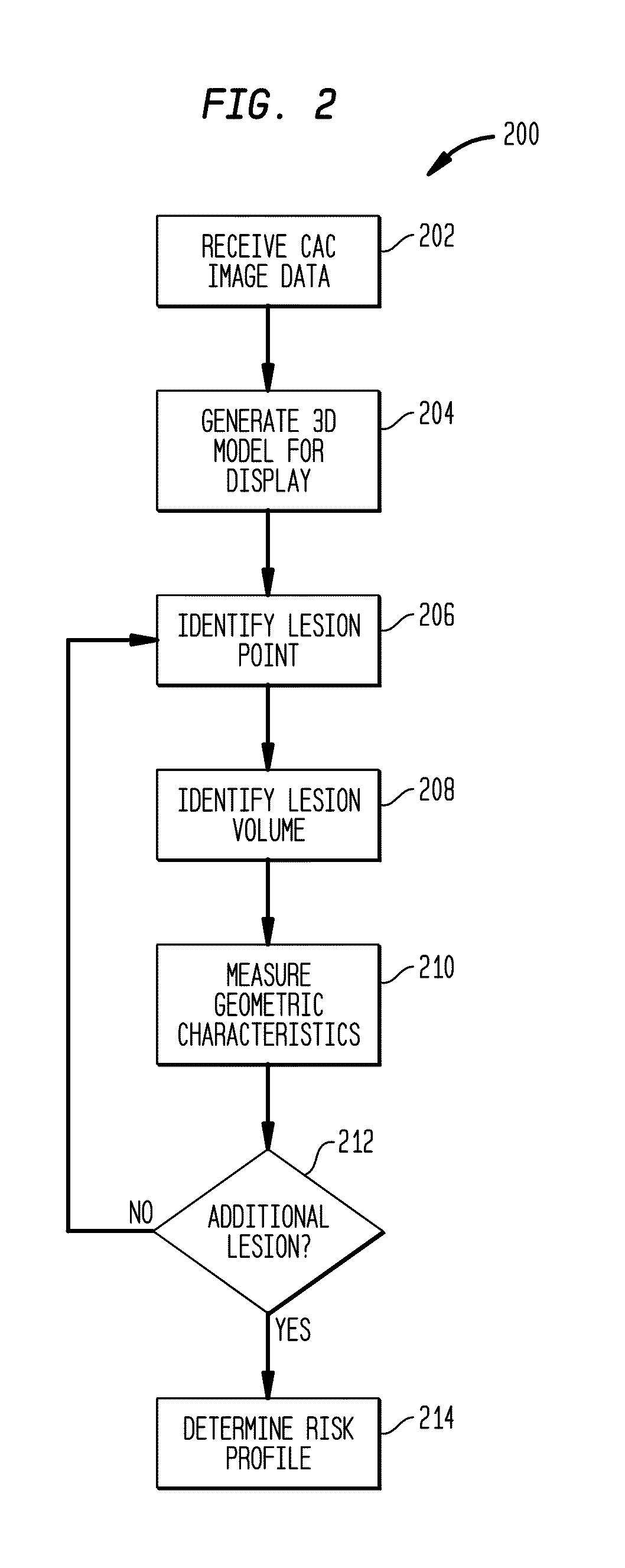

System and method for lesion-specific coronary artery calcium quantification

ActiveUS20100156898A1Predict in advanceImprove assessmentImage enhancementImage analysisRadiologyContrast enhancement

Methods and systems utilizing the data provided by a non-contrast-enhanced CAC scan that is left unused by the “whole-heart” Agatston or volume scores. Agatston and volume scores summarize overall coronary calcium burden, but do not show the number of vessels involved, the geographic distribution of the lesions, the size and shape of the individual lesions and the distance of the lesions from the coronary ostium. The methods and systems described herein extract and use the enhanced information provided by 3-D CAC scan data and significantly increases its clinical predictive value by providing vessel and lesion specific CAC scores which are superior to the whole-heart Agatston and volume scores in predicting obstructive Coronary artery disease (CAD).

Owner:VOROS SZILARD +1

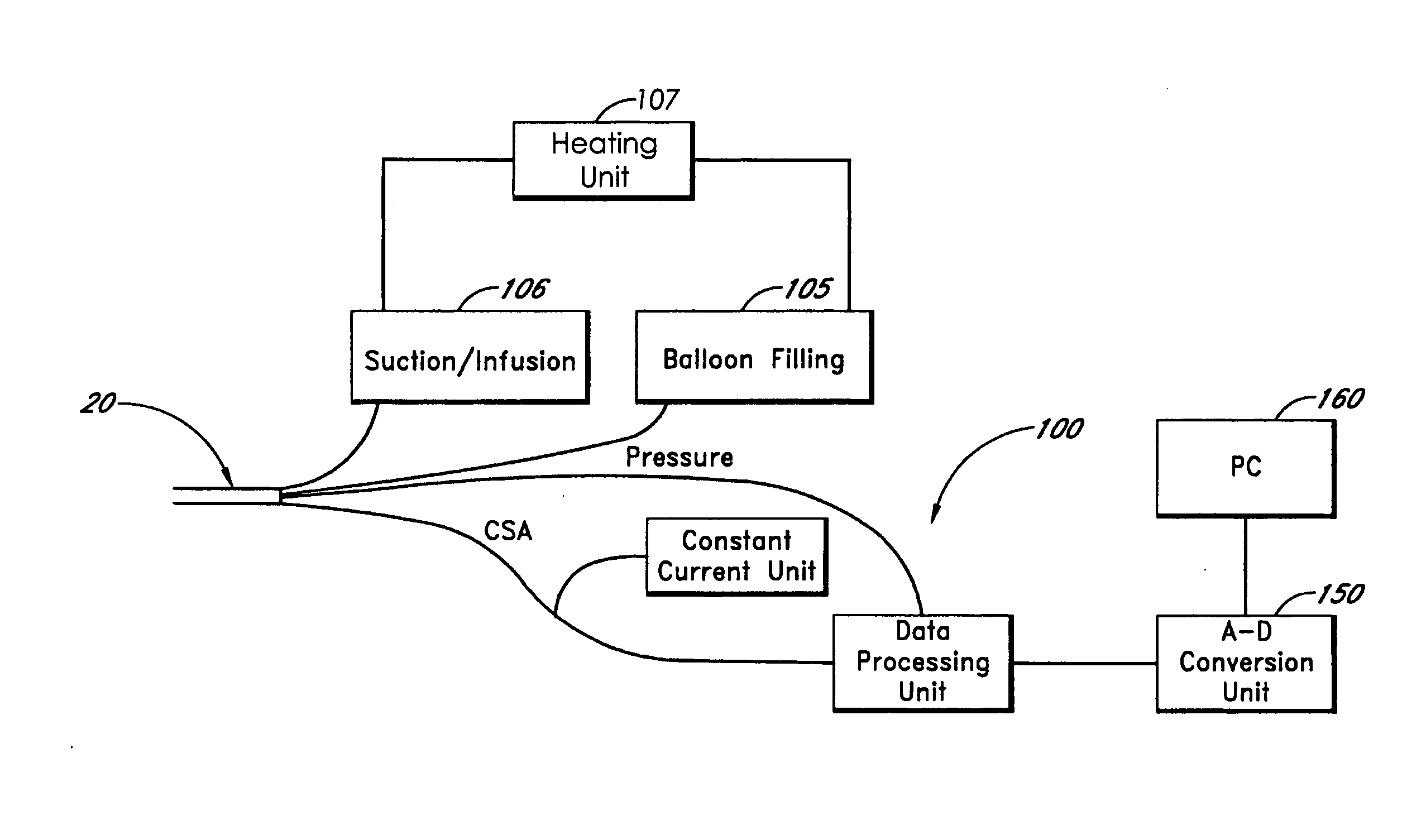

Devices, systems and methods for plaque type determination

Devices, systems and methods are disclosed for determining the composition of a plaque at a plaque site, which could be inside a blood vessel. Through a combination of fluid injection with different conductivities and measurement of the resultant conductances, a parallel tissue conductance measure is obtained that assists in determining the composition of the site plaque. Lower parallel conductance levels are determinative of a higher lipid and / or fatty plaque, which is a type that may break out of its position and cause organ injury or death.

Owner:3DT HLDG

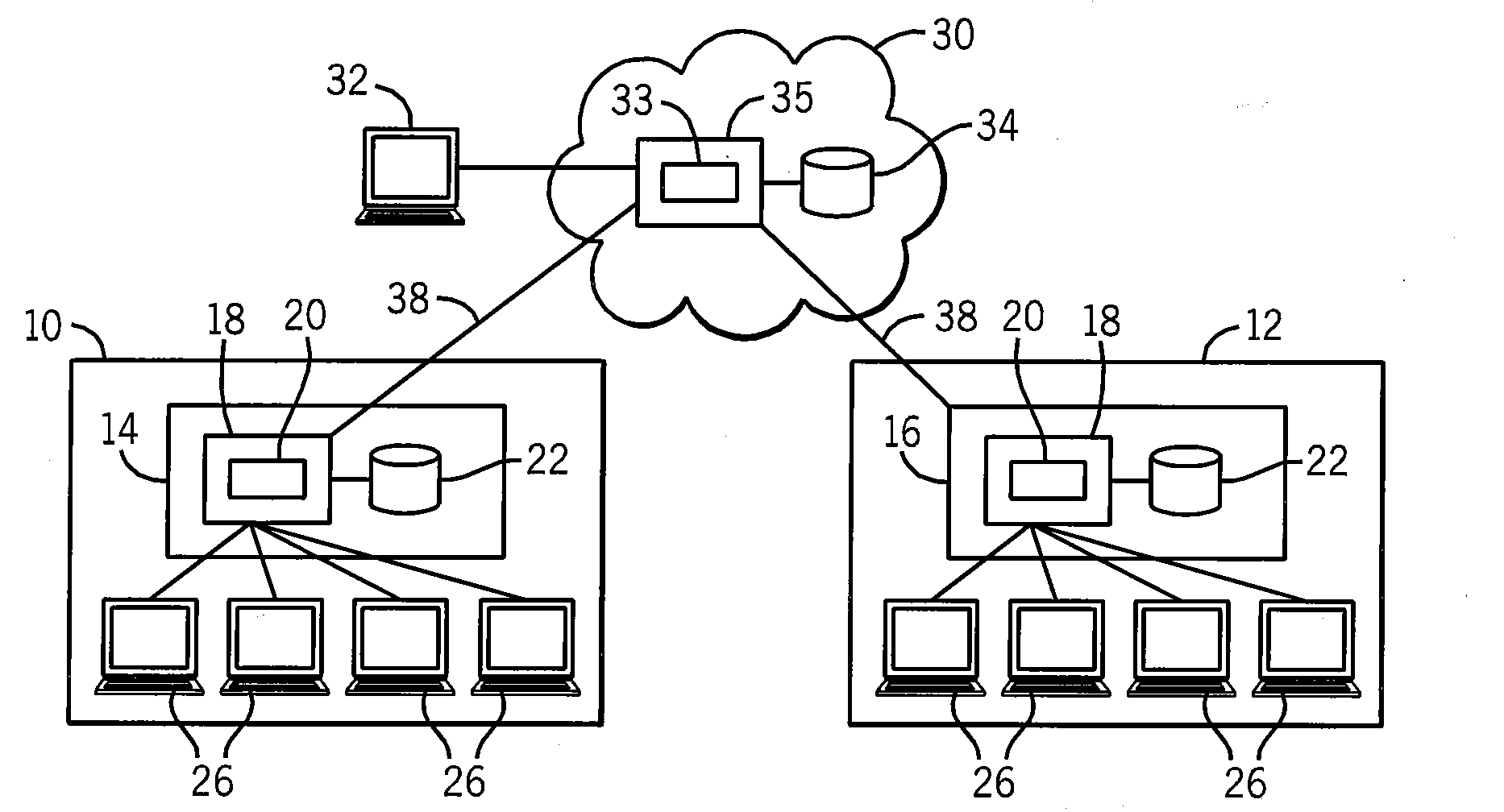

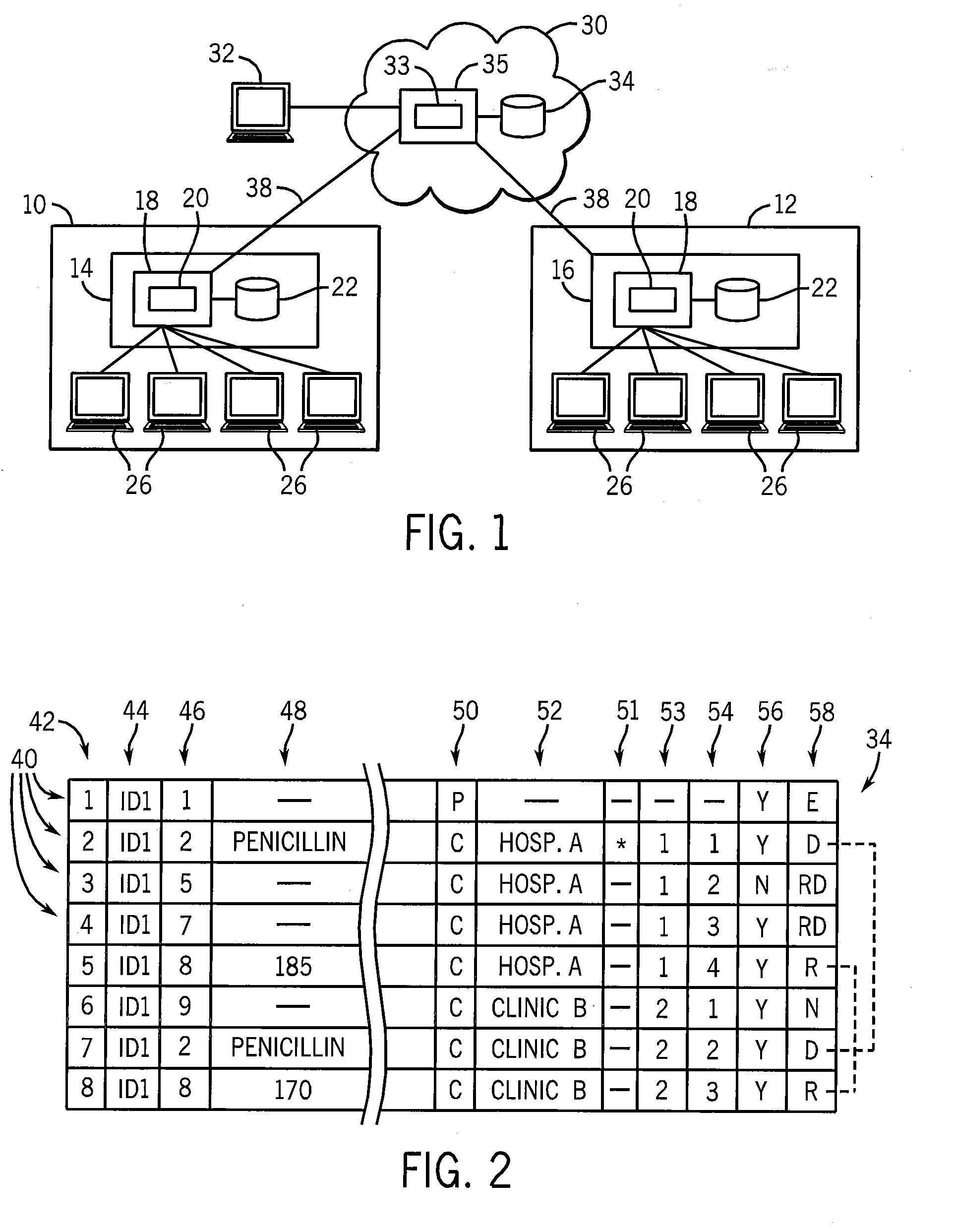

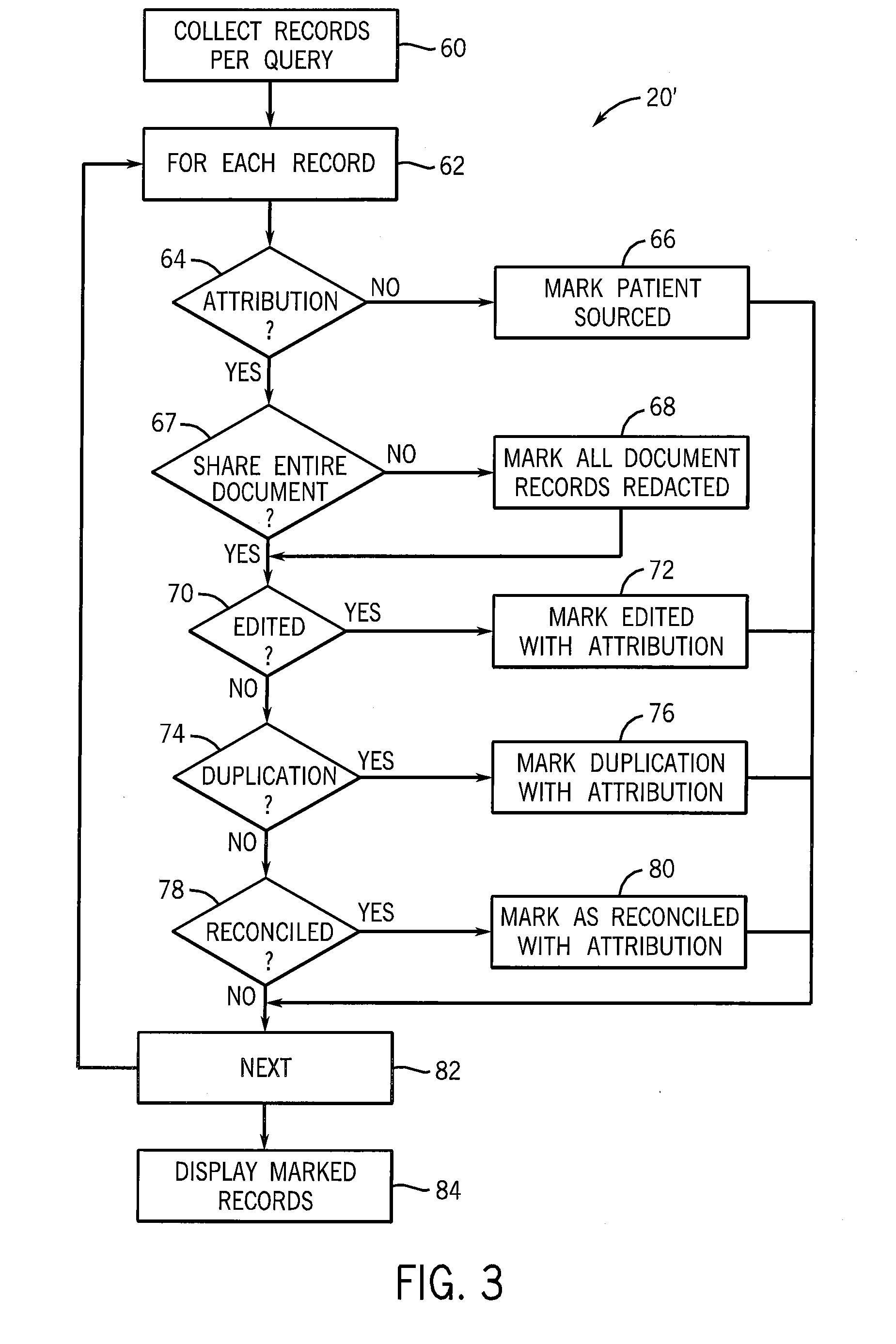

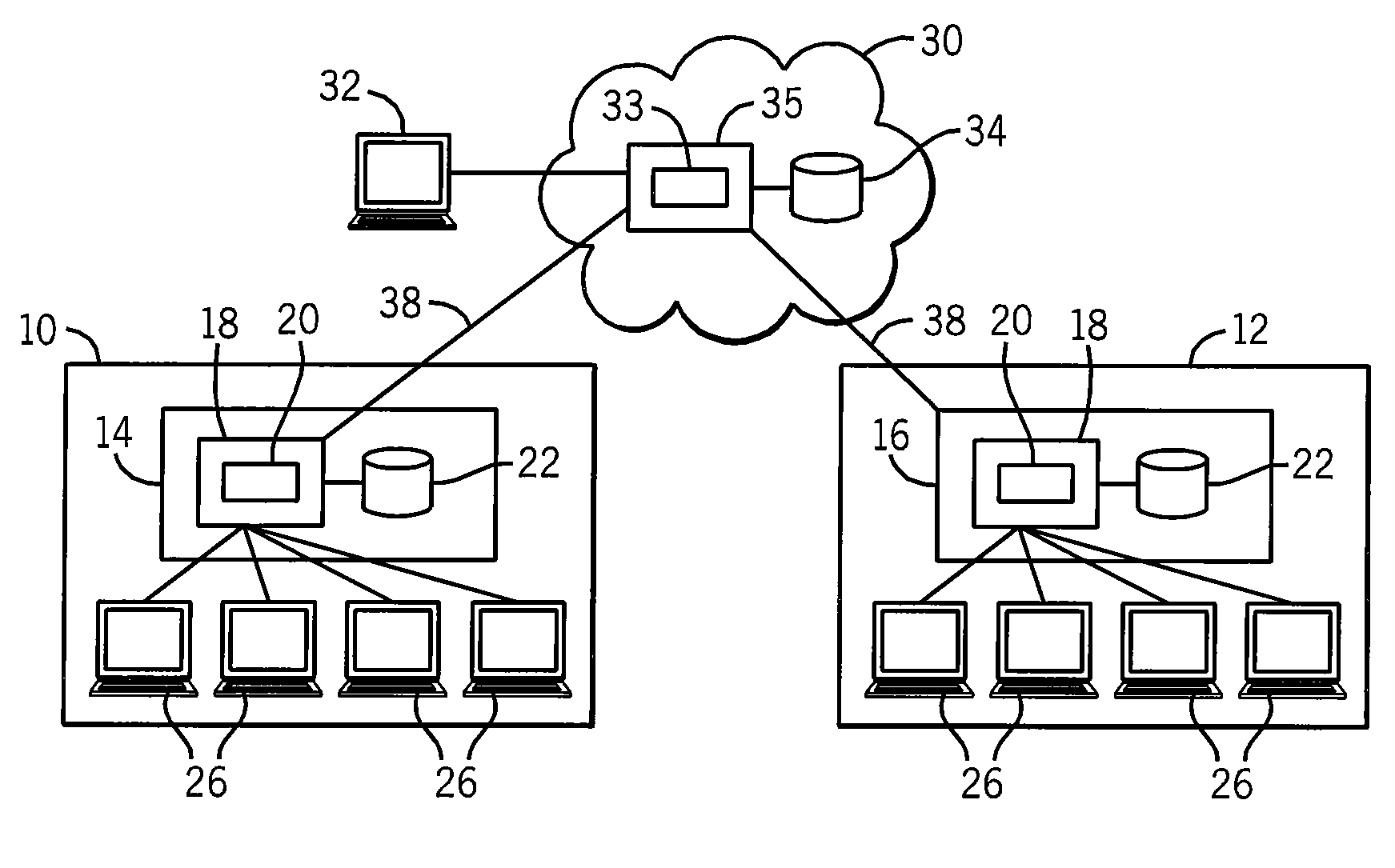

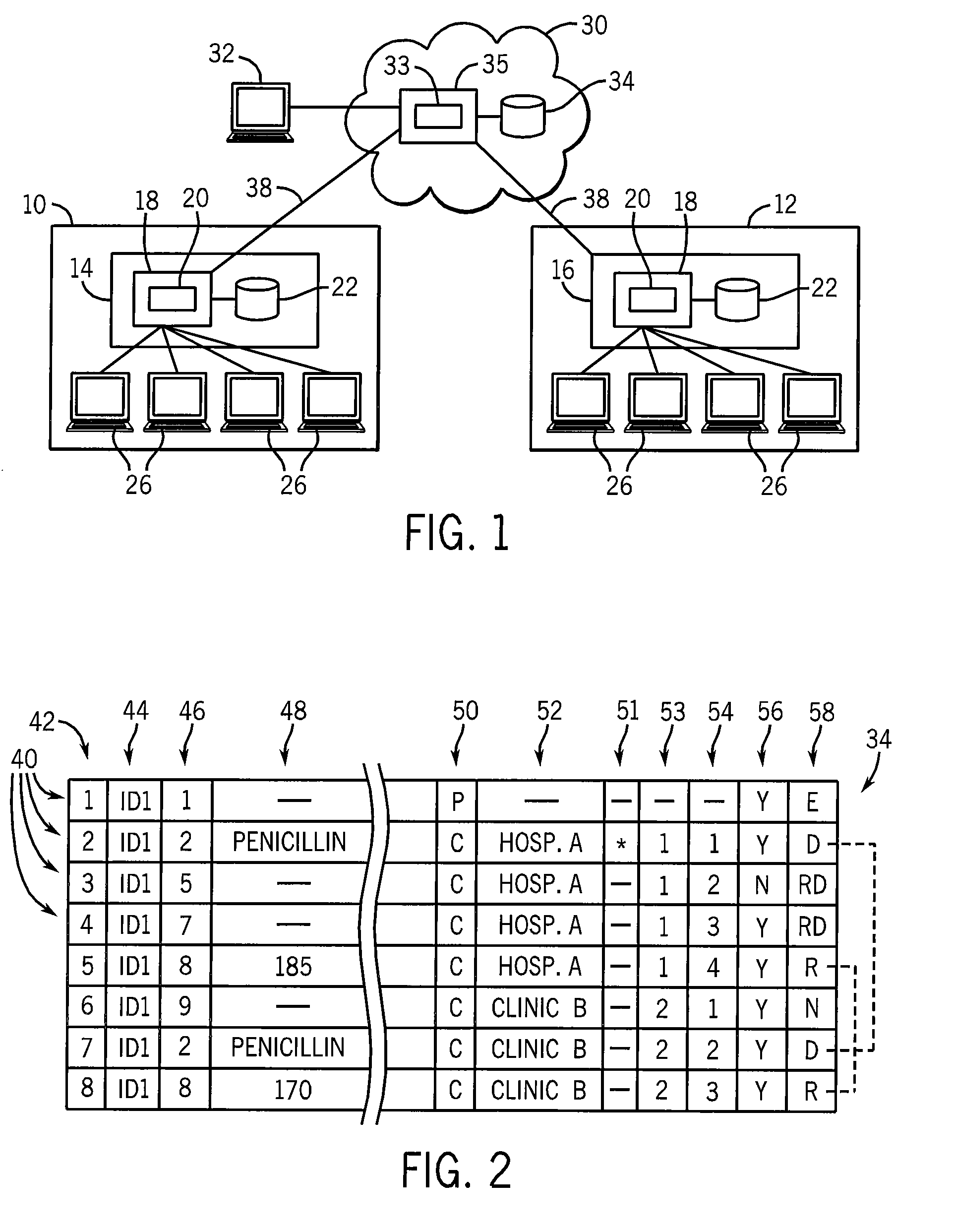

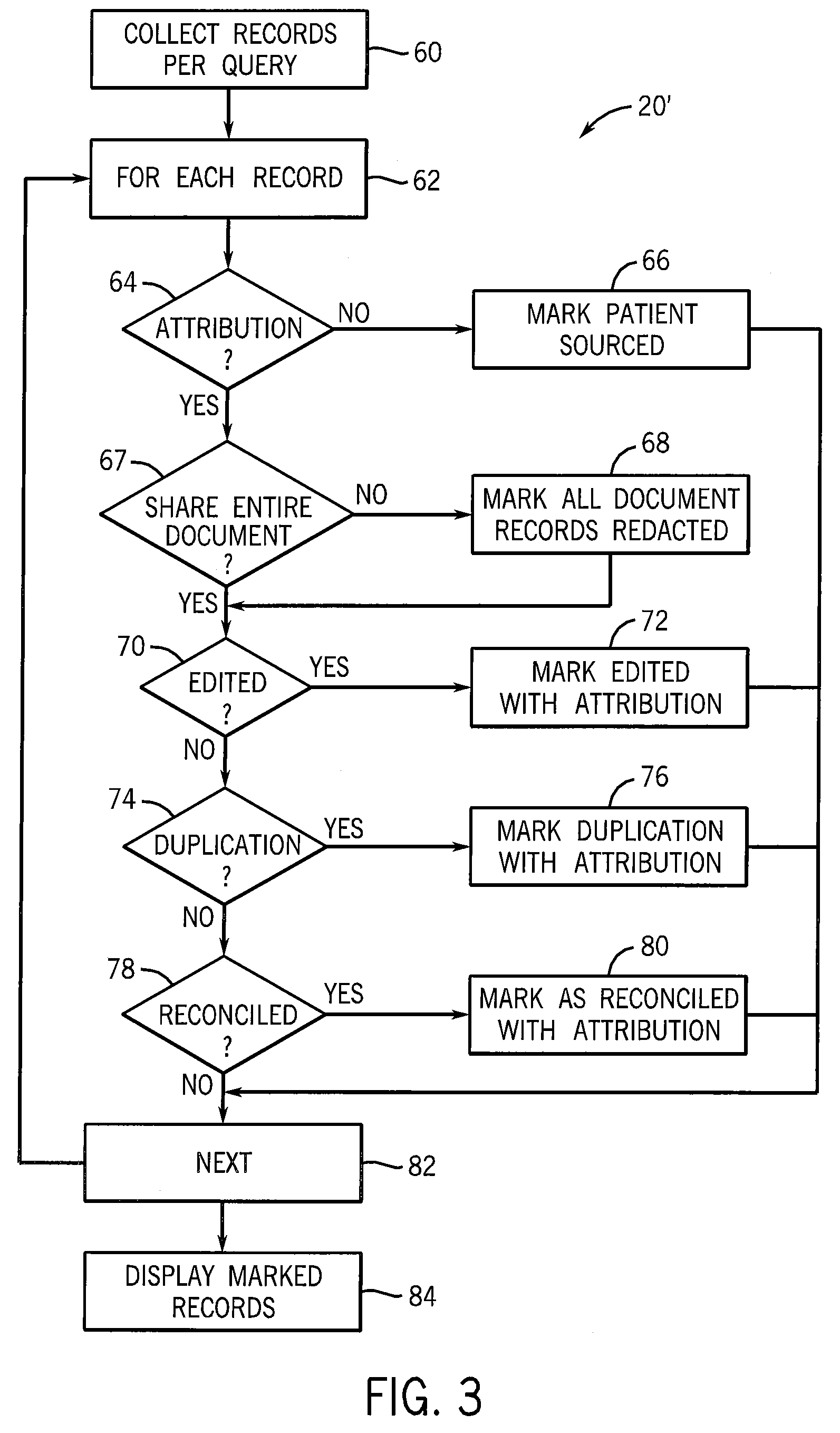

Electronic health record system utilizing disparate record sources

ActiveUS20090228303A1Simple mechanismIncrease the value of dataData processing applicationsSpecial data processing applicationsThird partyRecording system

A system for facilitating patient ownership of his or her medical data through the use of third-party health repositories that preserves the maximum information content of the medical records by displaying information relevant to the authority of the medical data as reflected by its source and types of modification as it has moved between institutions, as well as the data itself. In this way, improved use of this data is made possible.

Owner:EPIC SYST CORP (US)

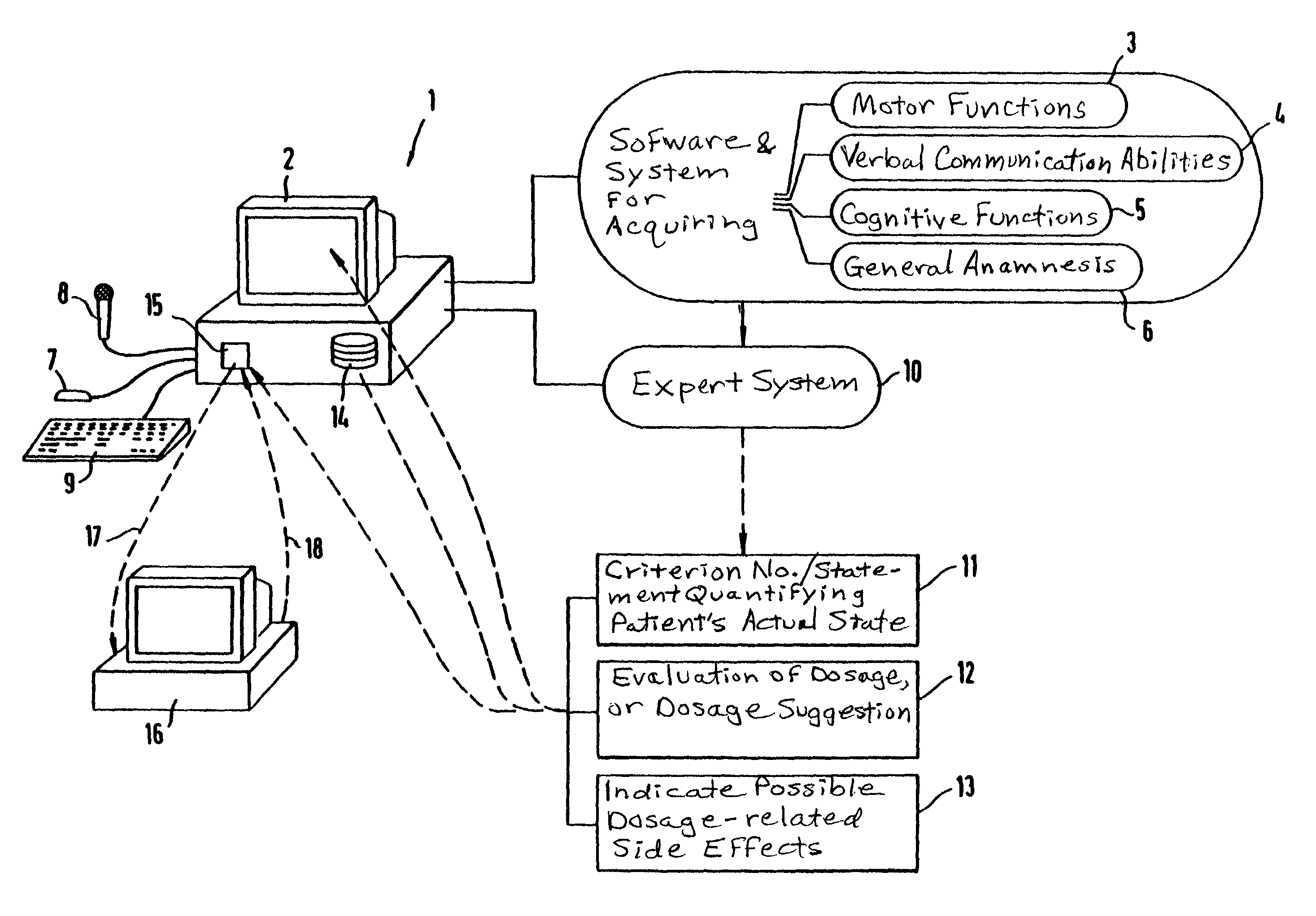

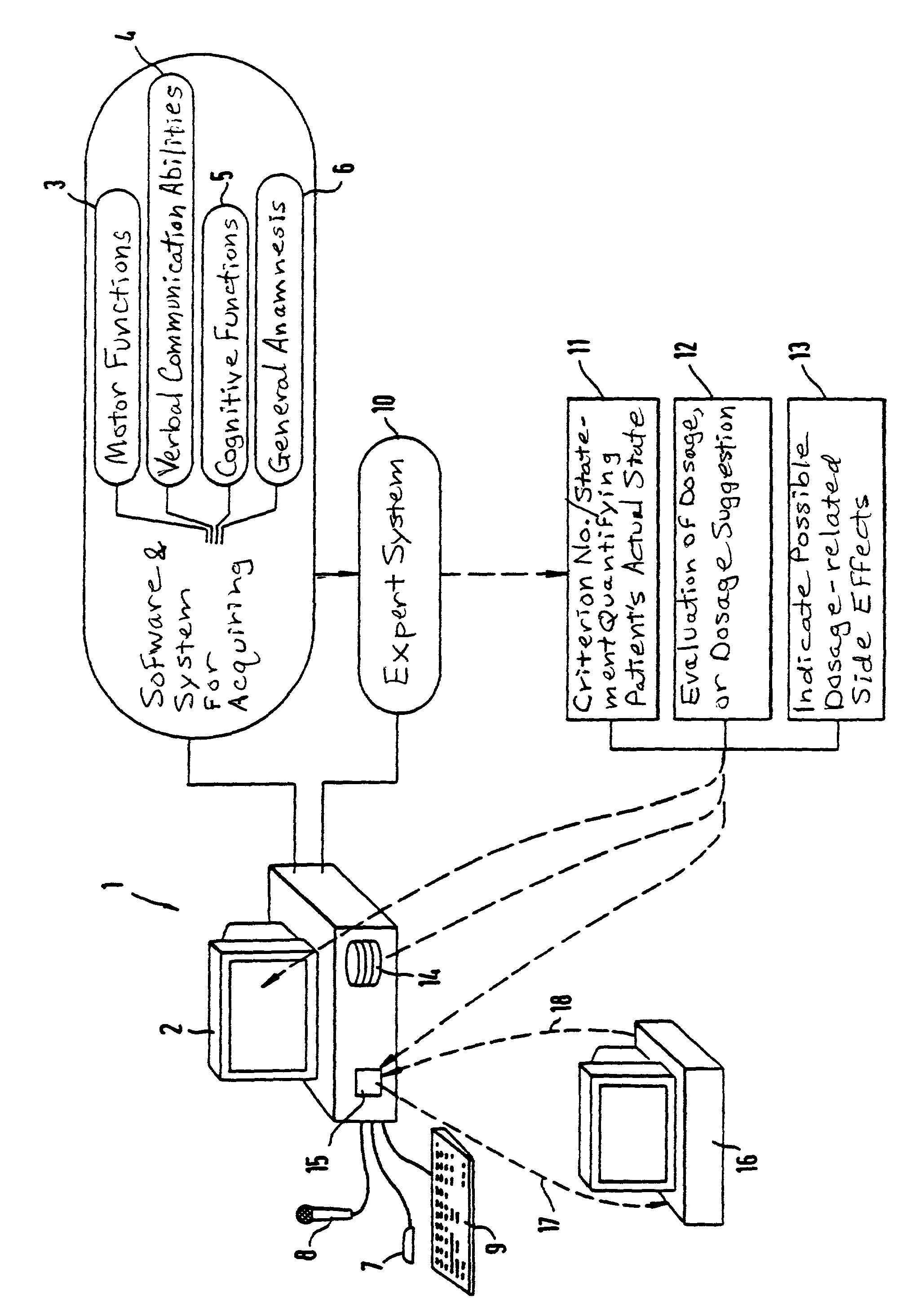

Method and system for allowing a neurologically diseased patient to self-monitor the patient's actual state

InactiveUS7890340B2Quick identificationImprove assessmentData processing applicationsDrug and medicationsNervous systemMedicine

In a method for allowing a patient suffering from a neurological disease and being treated with medication to self-monitor his or her current state, information regarding the motor functions and / or verbal and / or cognitive abilities of the patient are interactively acquired upon using a computer located for easy and repeated access by the patient, and at least one criterion number or a statement describing the state is determined on the basis of this information by an expert system at the computer and is made available to the patient by an output device at the computer.

Owner:SIEMENS HEALTHCARE GMBH

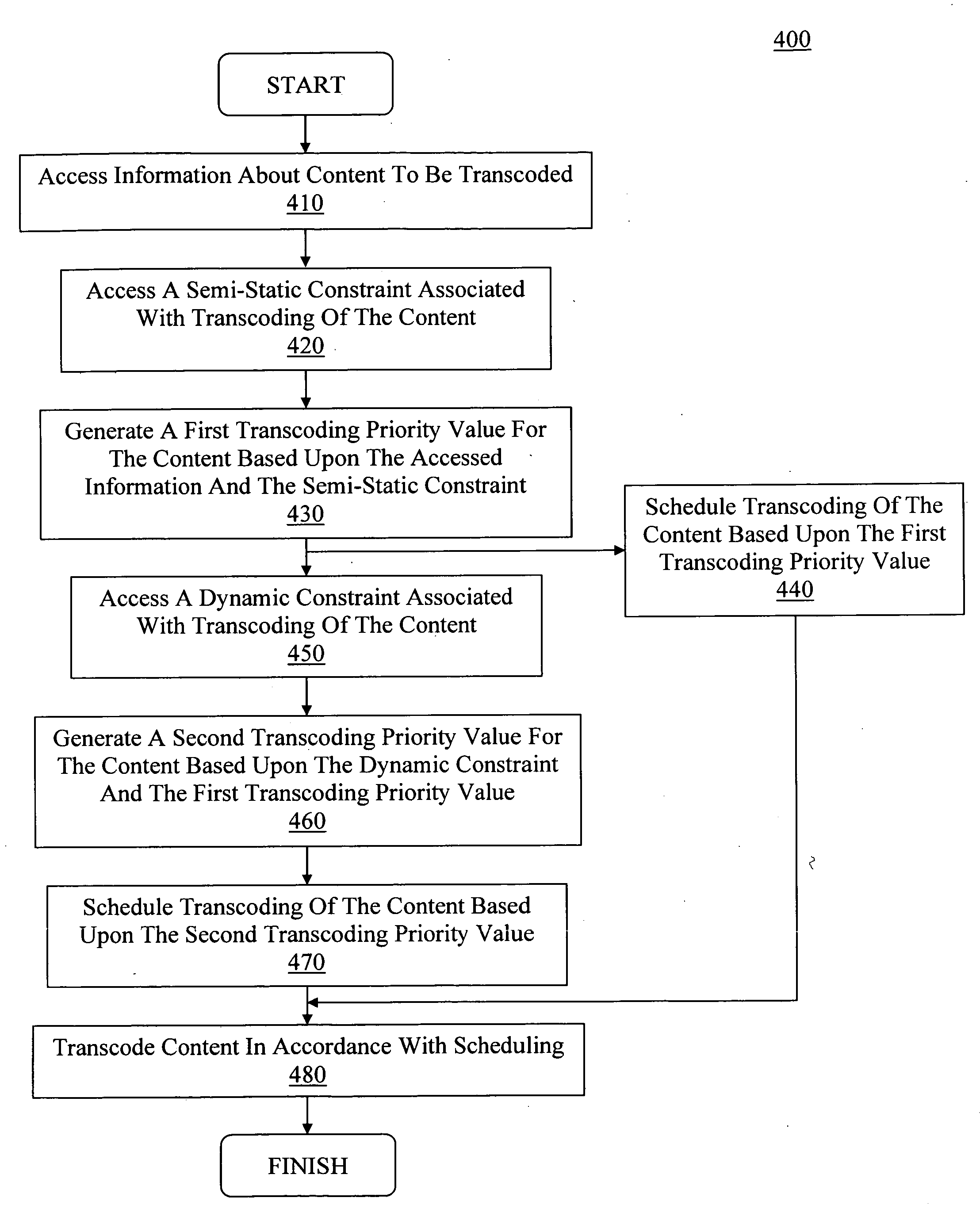

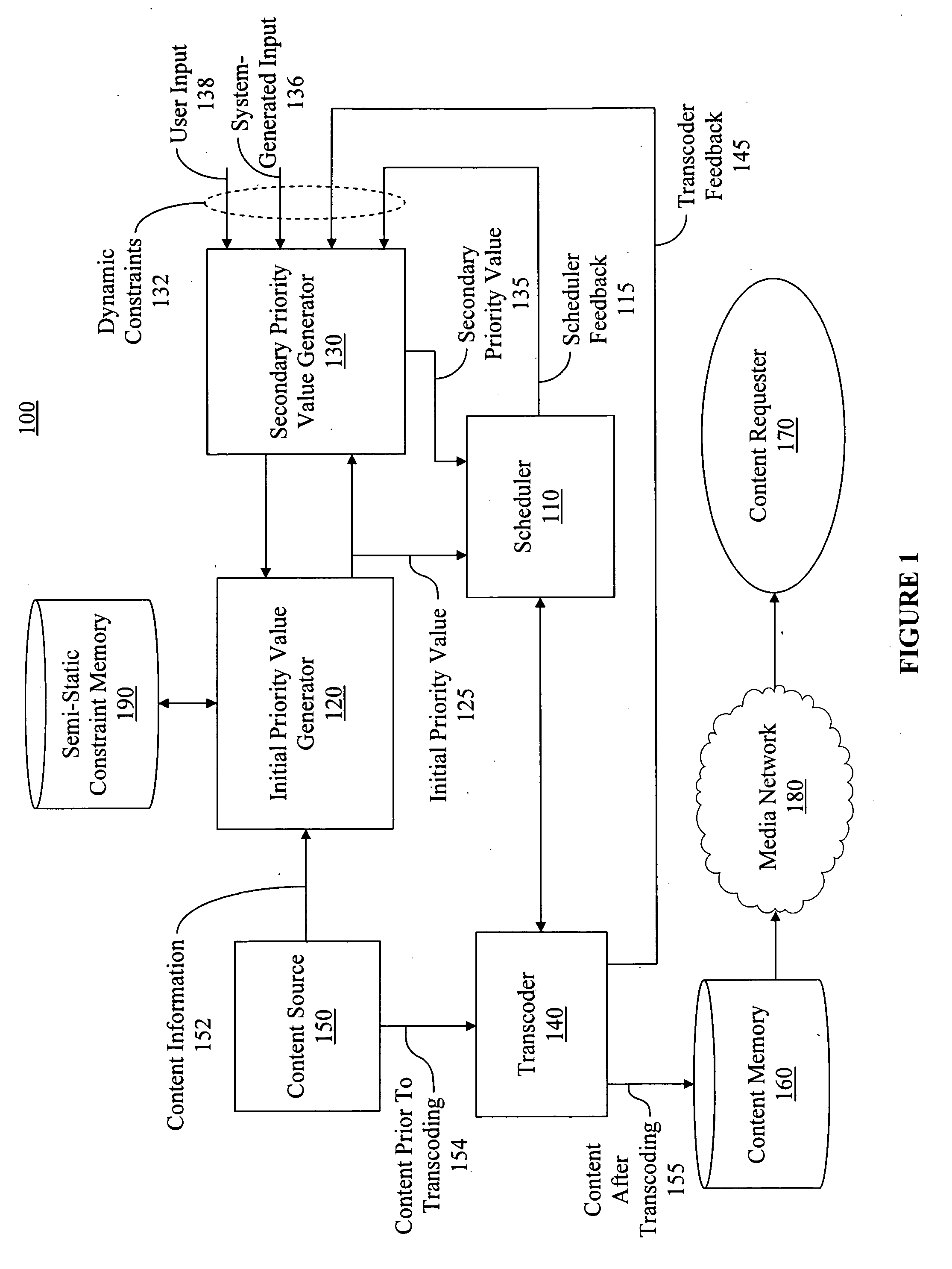

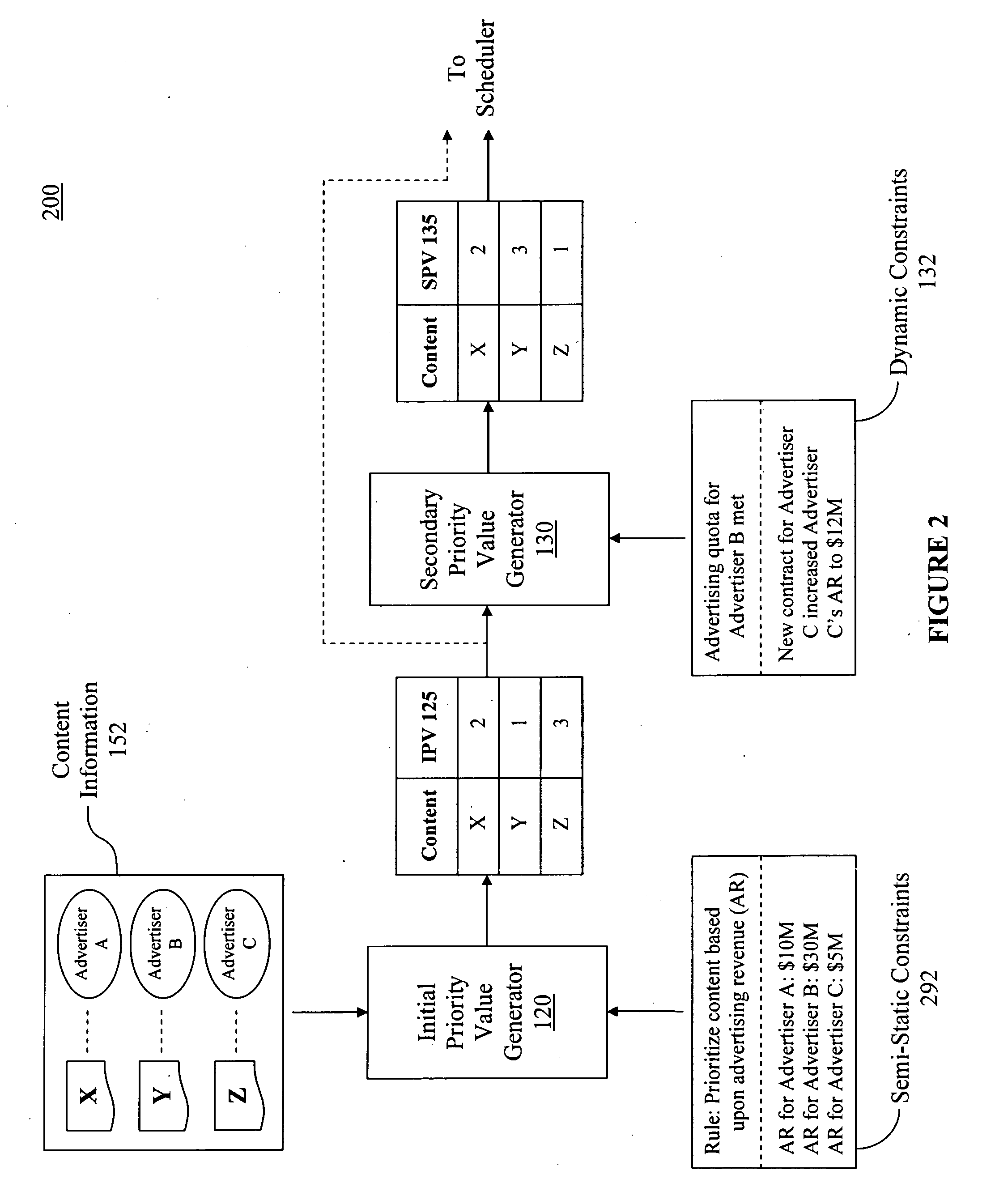

System and method for improved scheduling of content transcoding

InactiveUS20090172685A1Accurate assessmentReduce resource loadMultiprogramming arrangementsMemory systemsQuality of serviceTranscoding

A method and system for improved scheduling of content transcoding is disclosed. Embodiments are capable of generating and assigning a first transcoding priority value to a piece of content, where the first transcoding priority value is based upon information about the content and at least one semi-static constraint. A second transcoding priority value may also be generated and assigned based upon the first transcoding priority value and at least one dynamic constraint. Transcoding of the content may be scheduled using the first and / or second transcoding priority values, thereby providing scheduling of content transcoding which takes into account longer-term knowledge and / or shorter-term knowledge for better assessment of the demand for transcoding of a given piece of content. Accordingly, embodiments enable transcoding of content with reduced resource load, reduced transcoding cost, and improved quality of service.

Owner:MEVIO

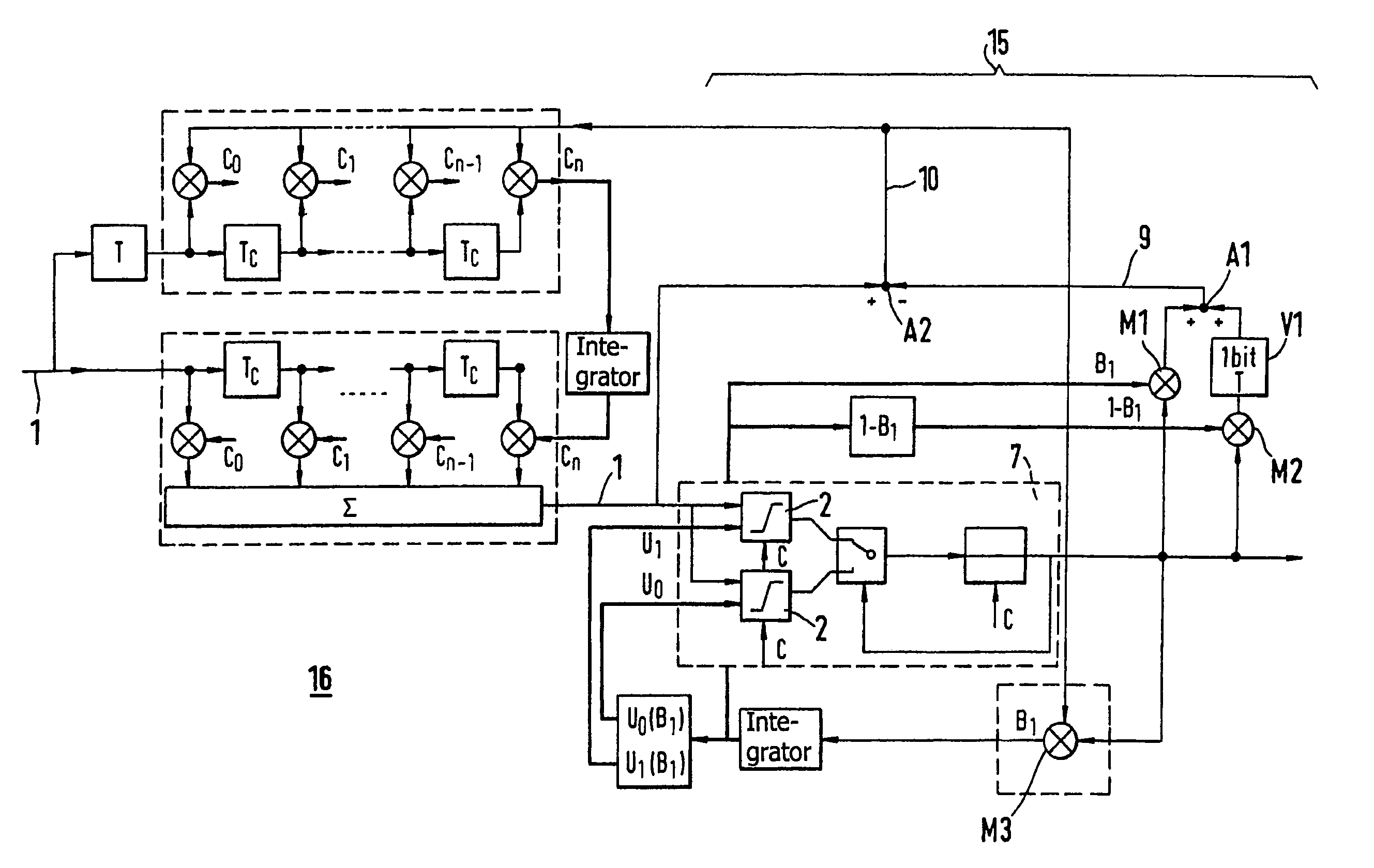

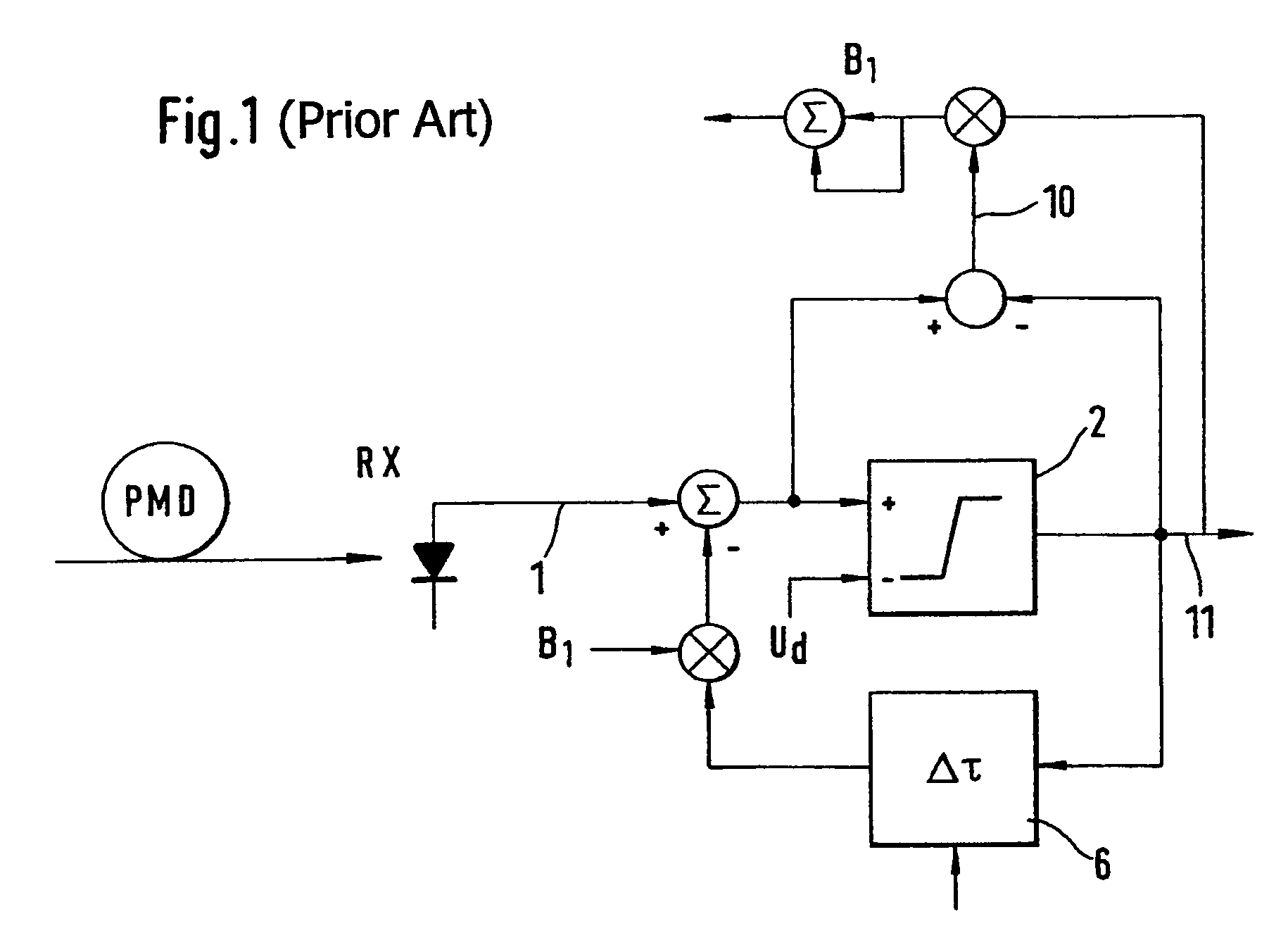

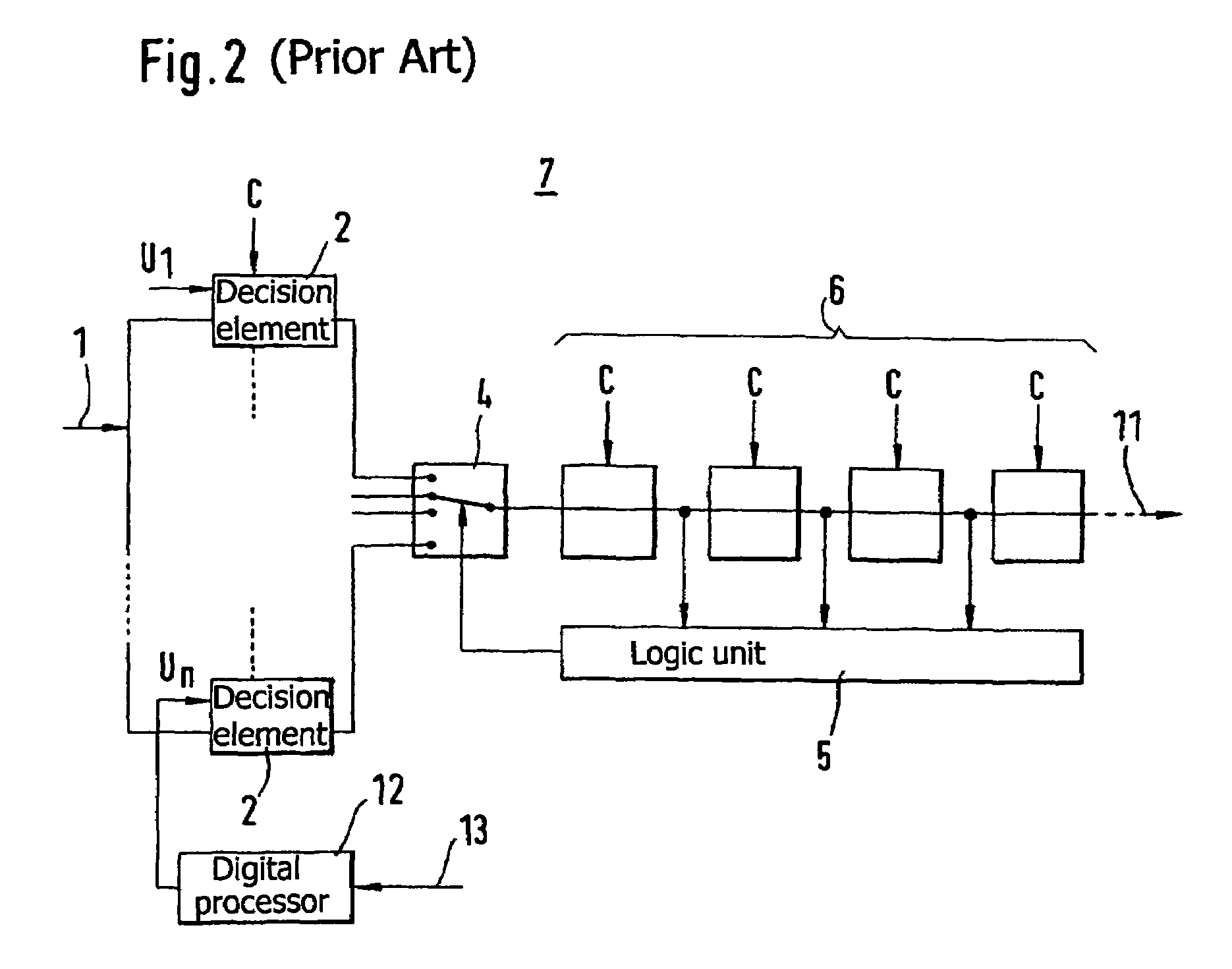

Process for recovering digital optical signals and a feedback decision circuit

InactiveUS6987804B2Simple and rapid adaptationImprove assessmentMultiple-port networksTransmission control/equlisationDecision circuitEngineering

A process is proposed for recovering disturbed digital signals, wherein the electrical signals pass through a feedback equalizer and an analogue control of the setting parameters of the equalizers is performed. A pseudo-error monitor, which facilitates a high-speed adjustment of decision element thresholds, is also provided.

Owner:ALCATEL LUCENT SAS

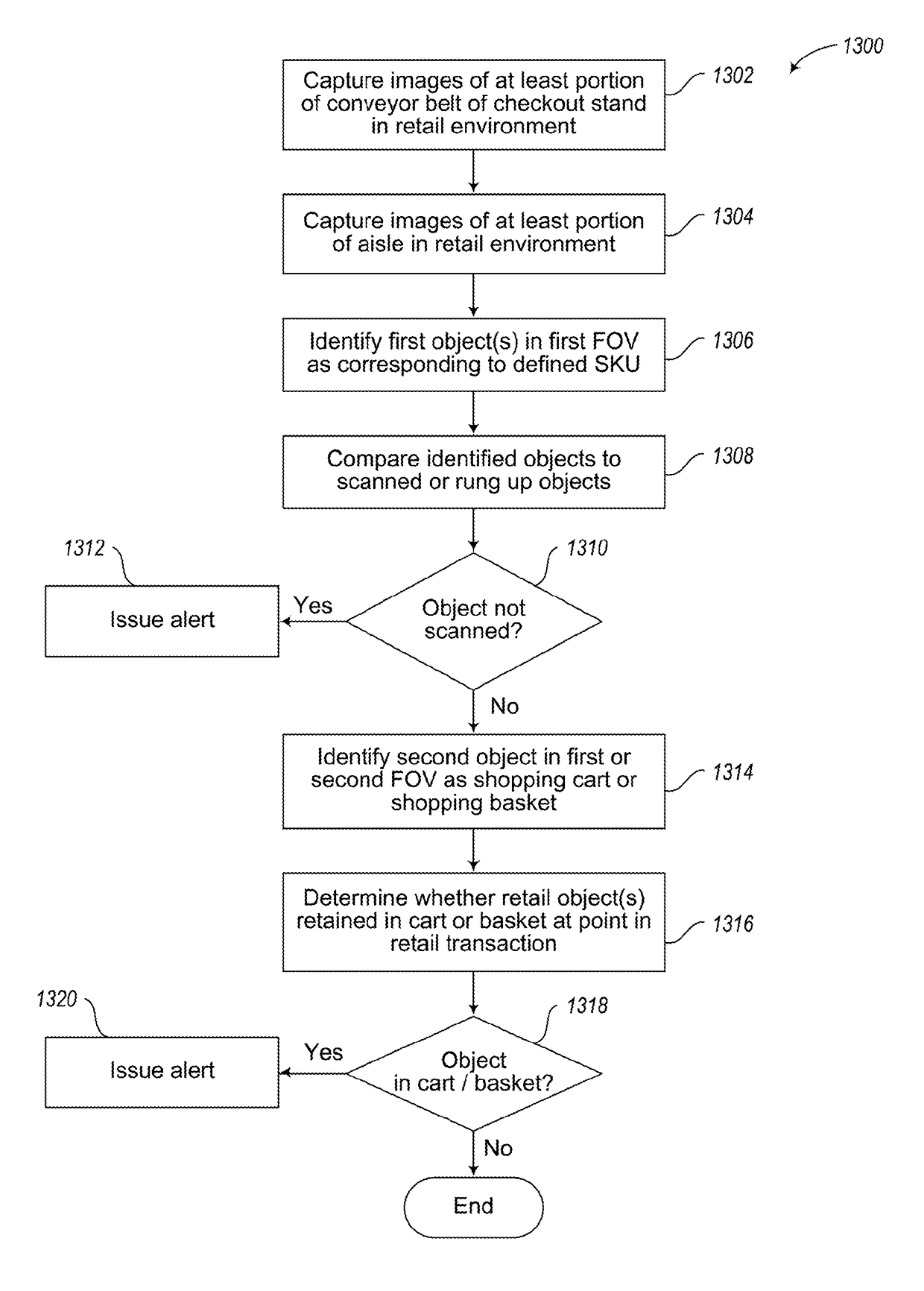

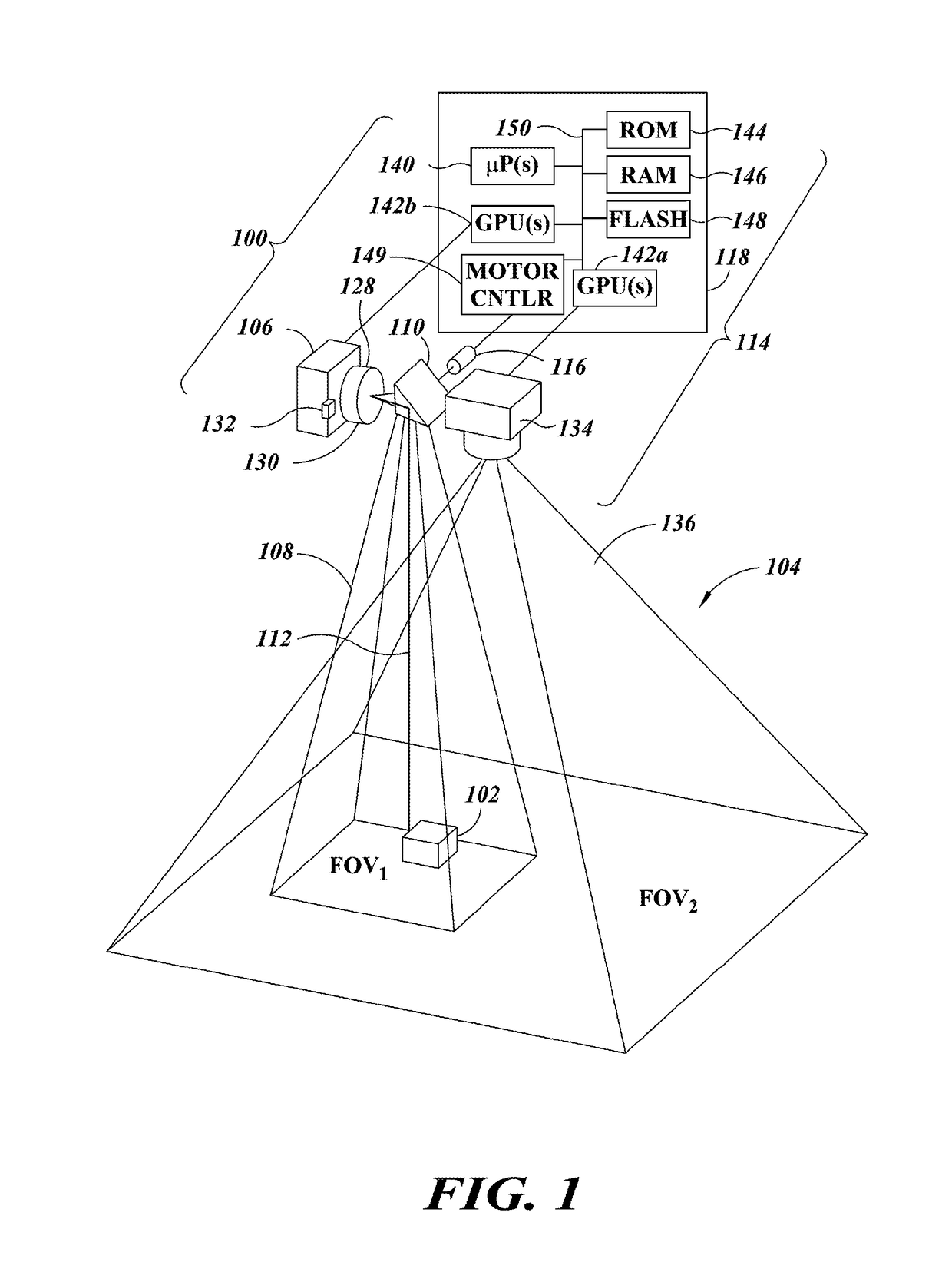

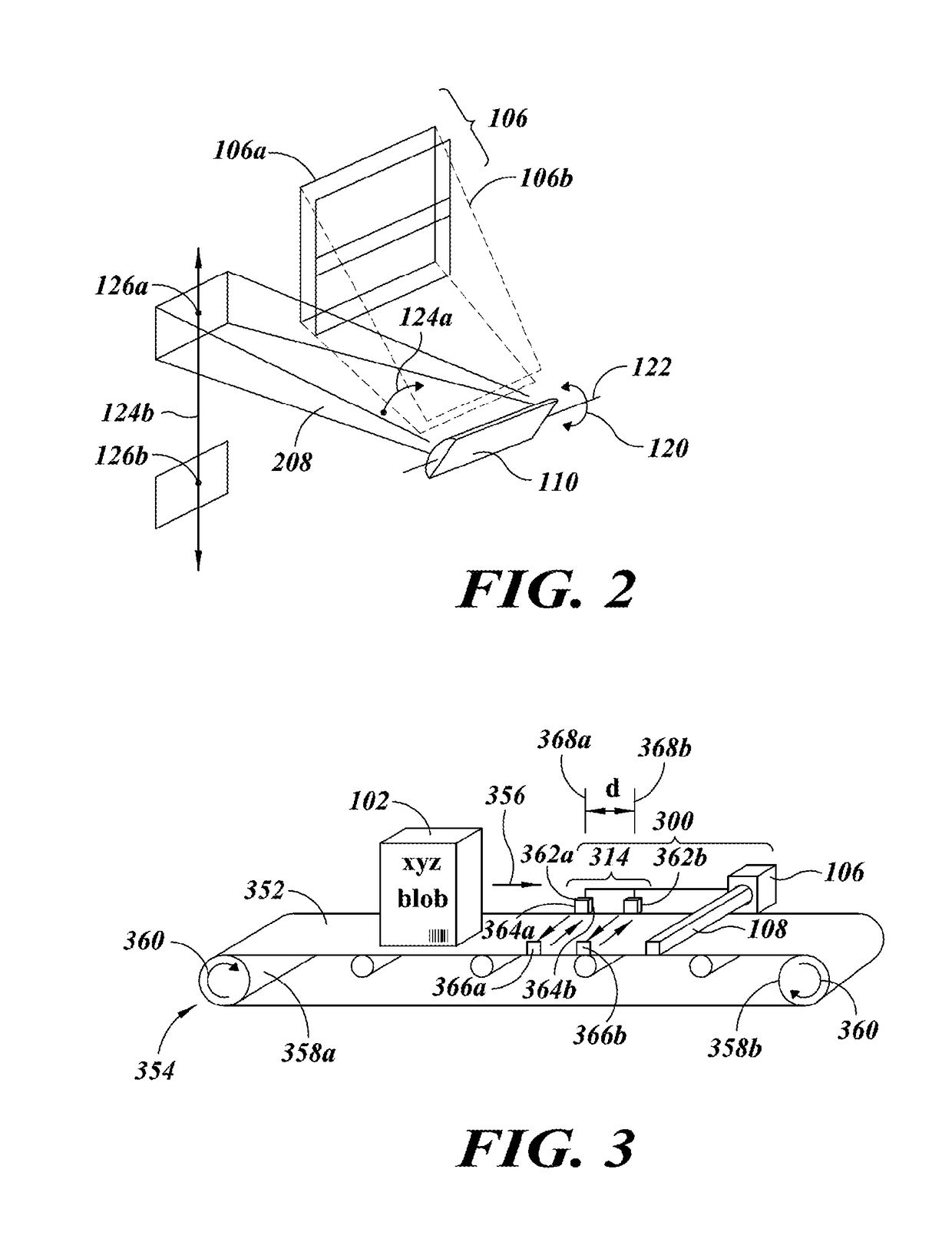

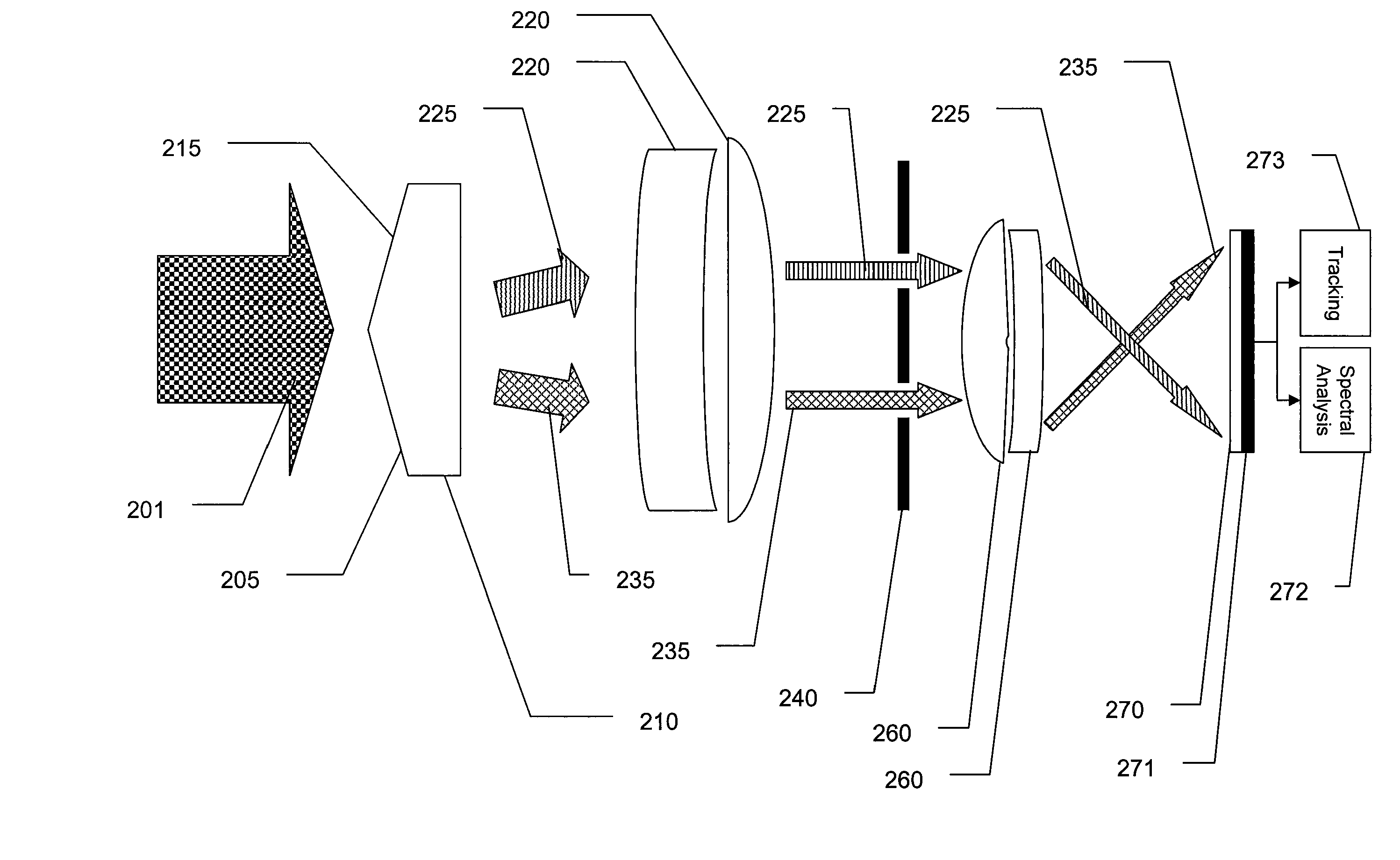

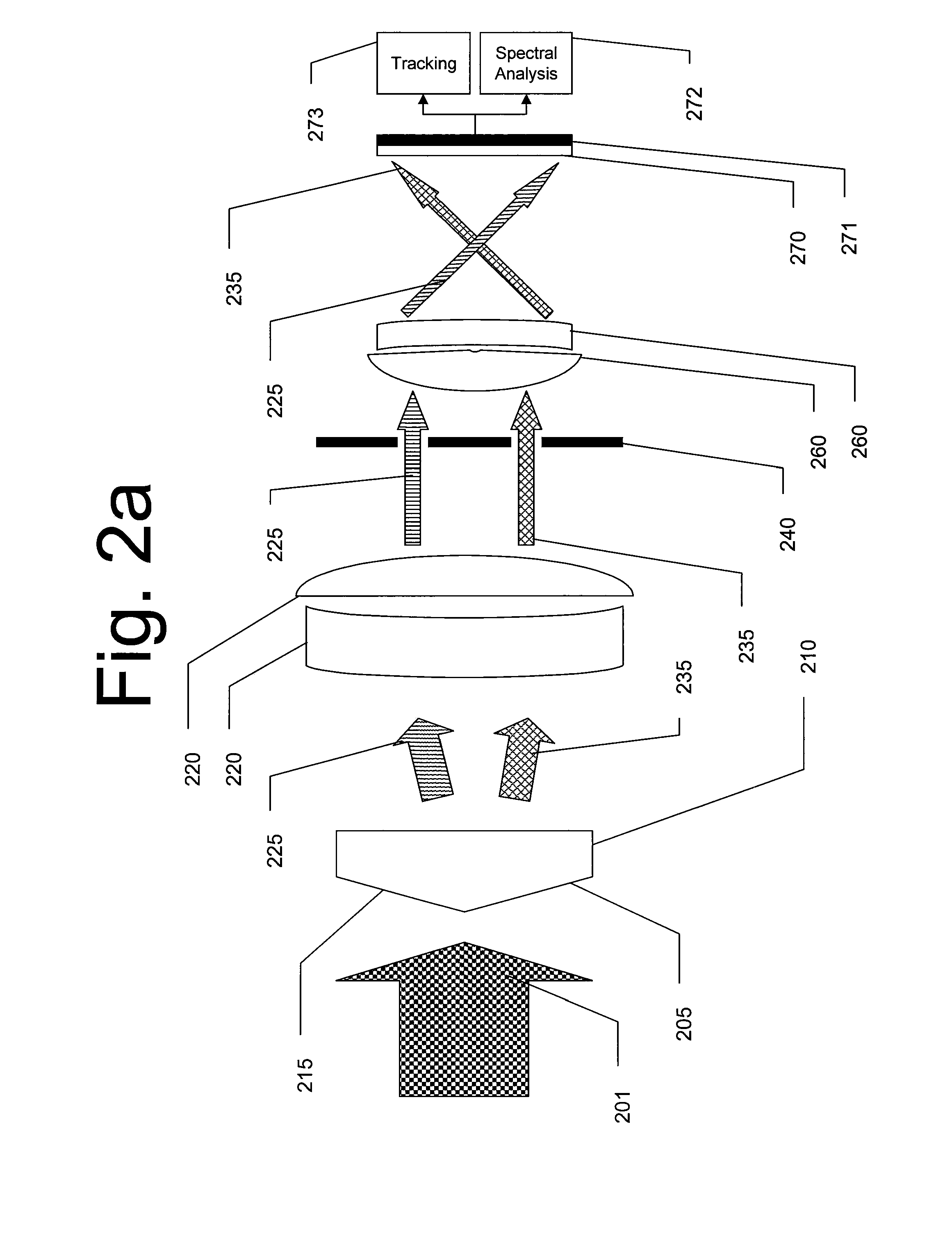

Imaging systems and methods for tracking objects

ActiveUS20180218224A1Low costFast trackCharacter and pattern recognitionCash registersImage resolutionComputer graphics (images)

A first imager has a relatively high resolution and a relatively narrow first field-of-view. Information about objects in an environment is detected or captured, and used to steer the first field-of-view of the first imager. The sensor(s) may take the form of a second imager with a relatively lower resolution and relatively wider second field-of-view. Alternatively, other types of sensors, for instance presence / absence sensors may be employed. The first field-of-view may be directed toward an object that satisfies one or more conditions, for instance matching a particular SKU. The first field-of-view may track a moving object, for instance via a tracking mirror and actuator. This approach may be employed in retail locations, for example in grocery or convenience stores, for instance to reduce various forms of theft or in industrial environments.

Owner:DATALOGIC USA INC

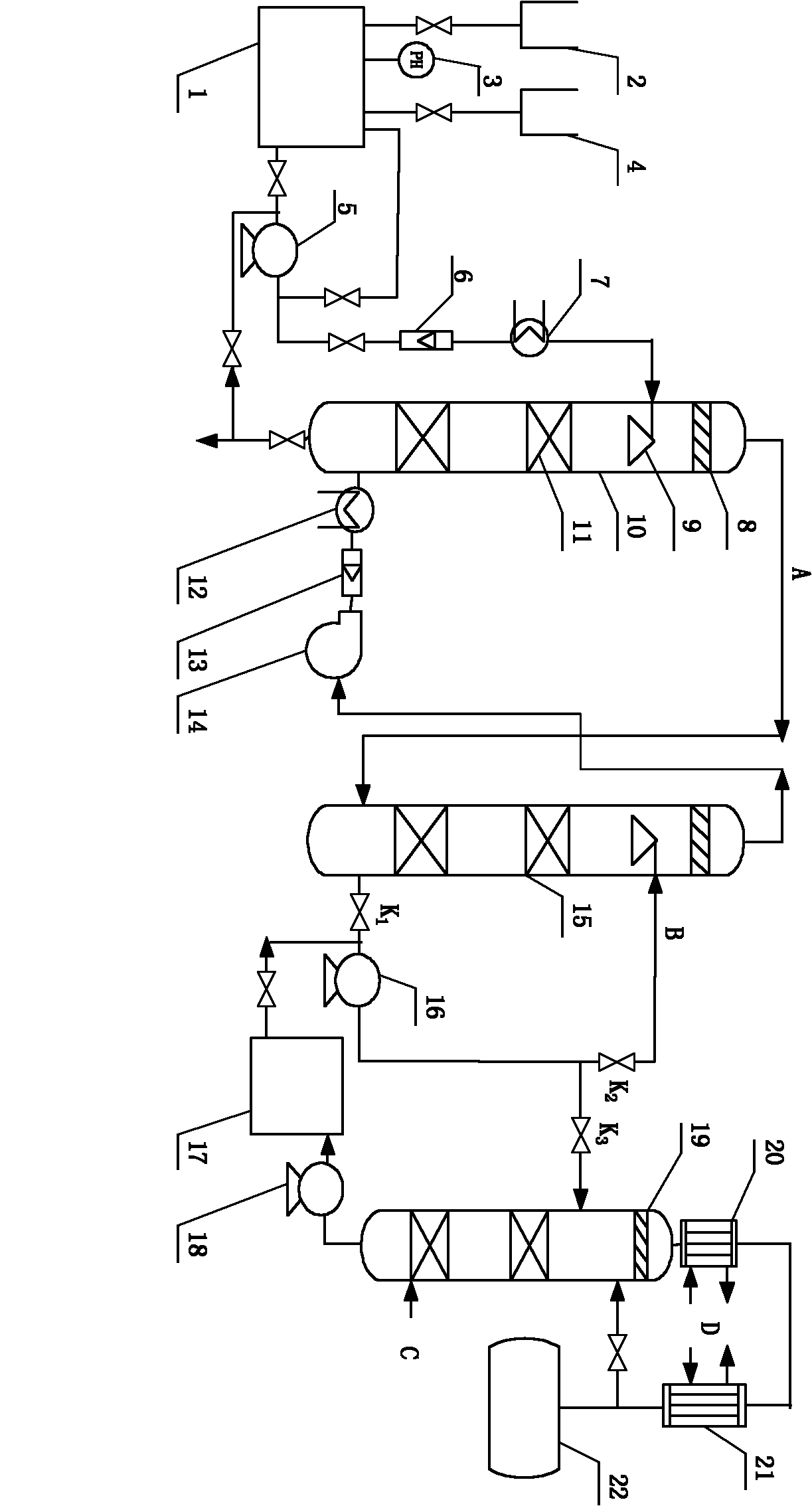

Closed-loop processing integrated process for high-efficiency air stripping and tail-gas ammonia recycling of ammonia-nitrogen wastewater

ActiveCN102060406AImprove ammonia removal efficiencyReduce the gas-liquid volume ratioChemical industryMultistage water/sewage treatmentExhaust gasProcess engineering

The invention relates to a closed-loop processing integrated process for the high-efficiency air stripping and the tail-gas ammonia recycling of ammonia-nitrogen wastewater, which is characterized in that: by selecting the types of fillers, tower internals and the like of an ammonia-nitrogen air-stripping tower and strengthening a gas-liquid mass transferring process, the ammonia removing efficiency is improved, and meanwhile, the gas-liquid volume ratio is reduced, thereby the energy consumption is markedly reduced; the invention provides a renewable ammonia-absorbing solution which can be used for efficiently absorbing the ammonia in air-stripping gas, and the ammonia is regenerated and desorbed to obtain strong ammonia water with the concentration of 10-25wt%, therefore, the high-efficiency recovery and the recycling of the ammonia in the air-stripping gas is realized, and the absorbing solution is recycled after being regenerated; the purified gas after absorption is used as the air-stripping gas for closed-loop circulating by adopting a closed-loop circulating technology, thereby the reaction heat in the absorbing process is effectively recovered, the energy consumption is further reduced, and meanwhile, the secondary pollution is eliminated; and the ammonia-removing and recycling processes of the wastewater are developed into a set of modularized process technologies by applying an integrated technology, thereby the technical requirements of industrial enterprises on processing the ammonia-nitrogen wastewater with different concentrations are satisfied.

Owner:NANJING UNIV OF TECH

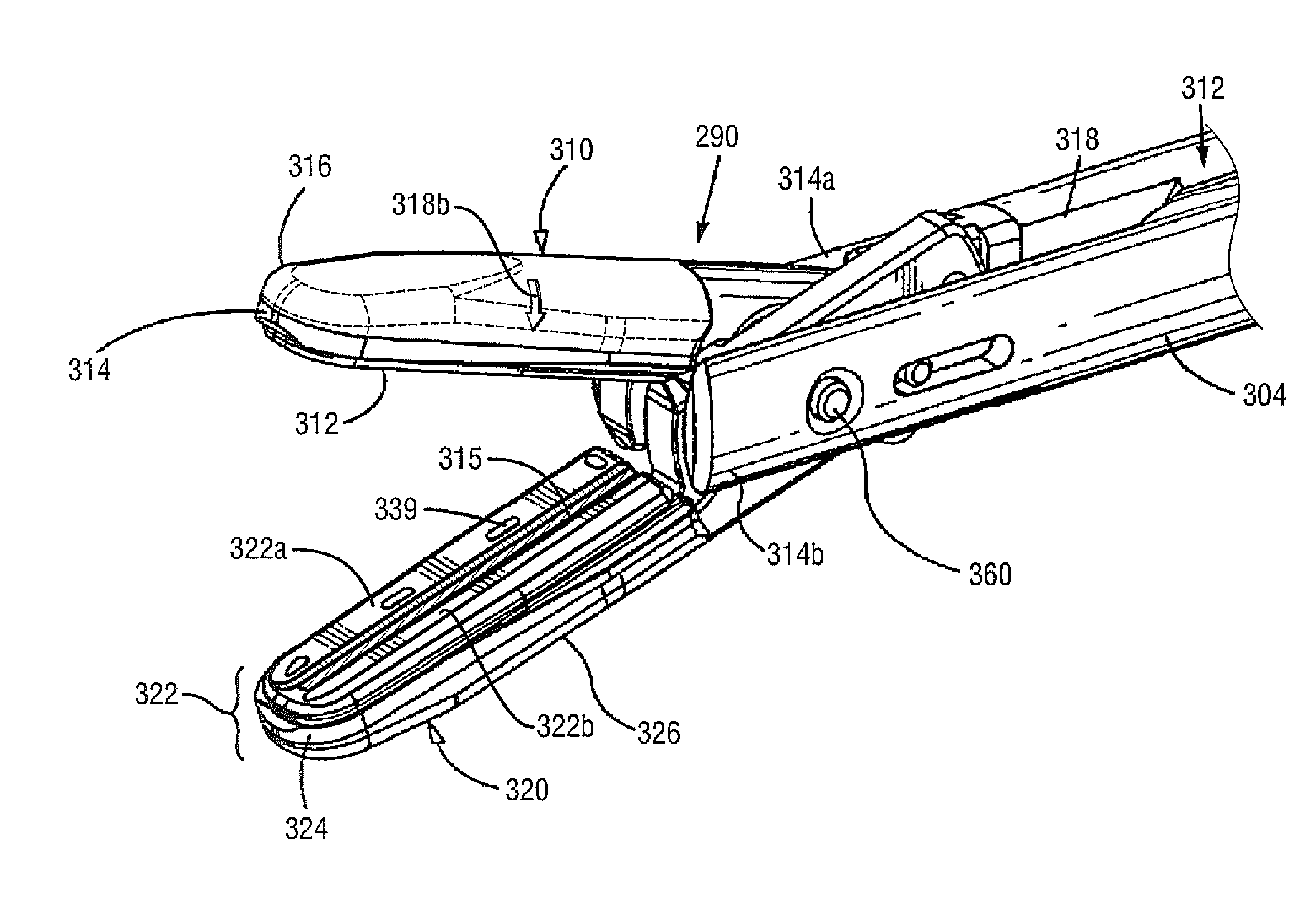

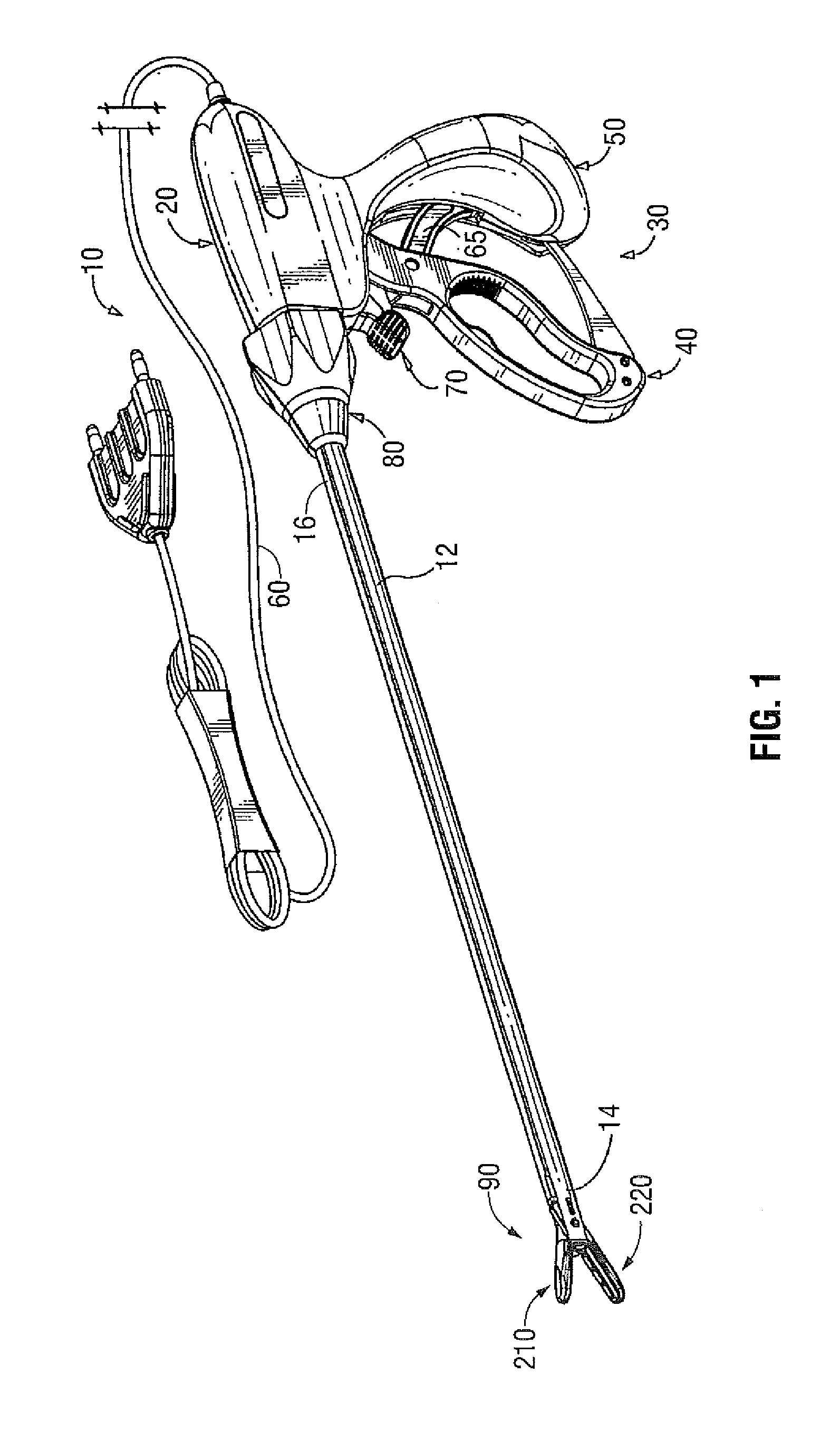

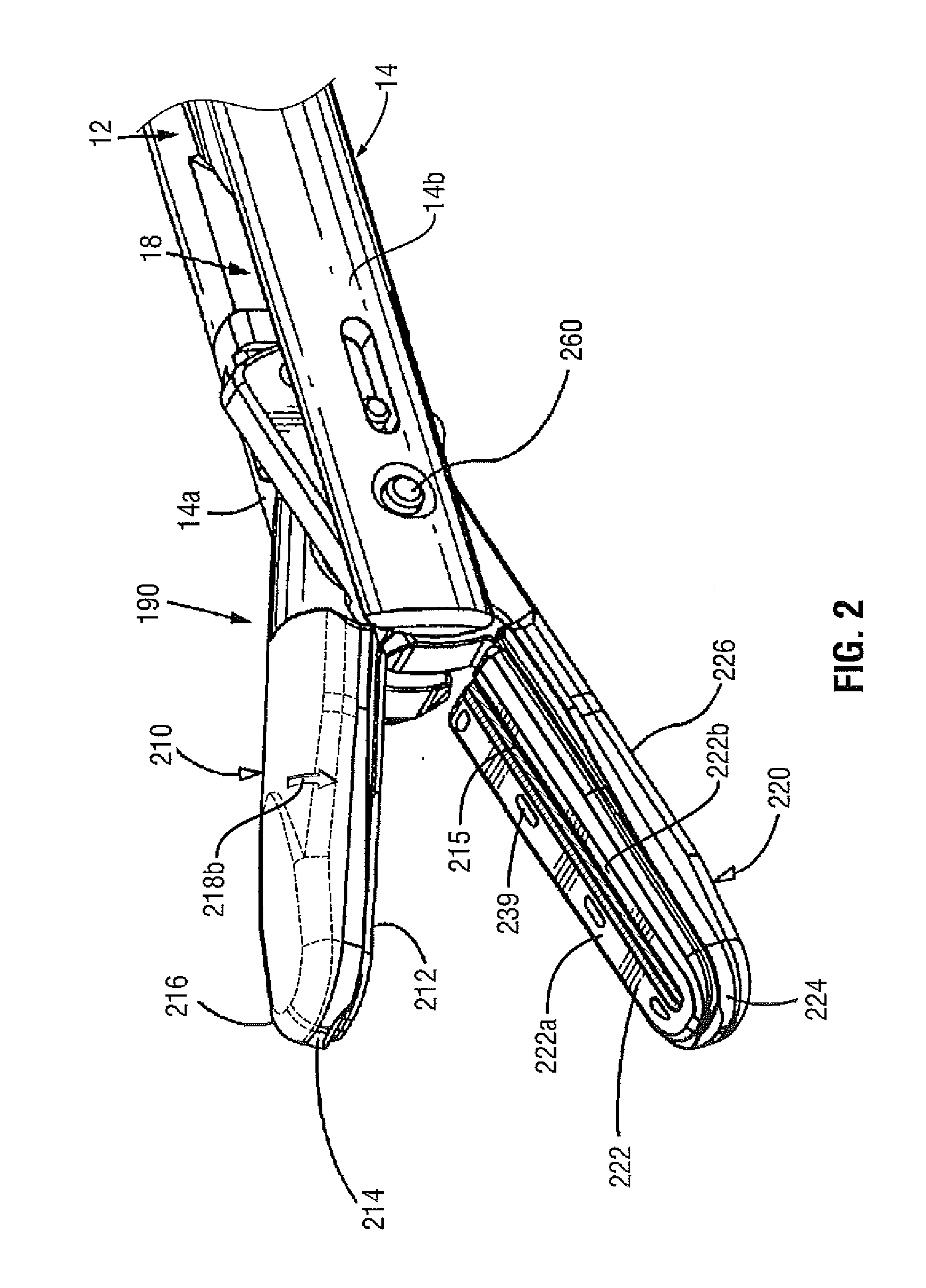

Asymmetrical electrodes for bipolar vessel sealing

ActiveUS9498278B2Improved sealing energyReduce the amount requiredDiagnosticsCatheterVessel sealingBipolar electrosurgery

Owner:COVIDIEN LP

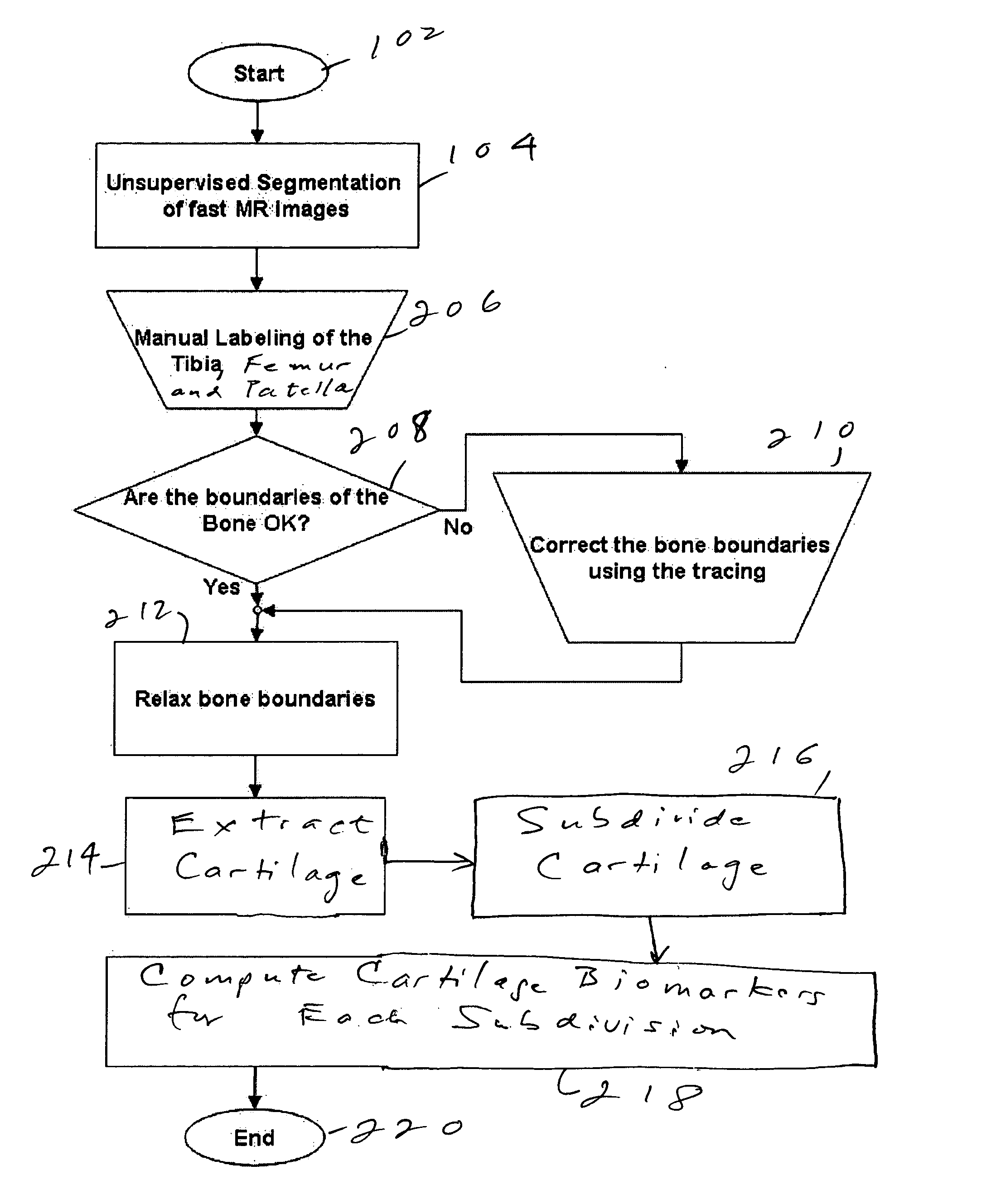

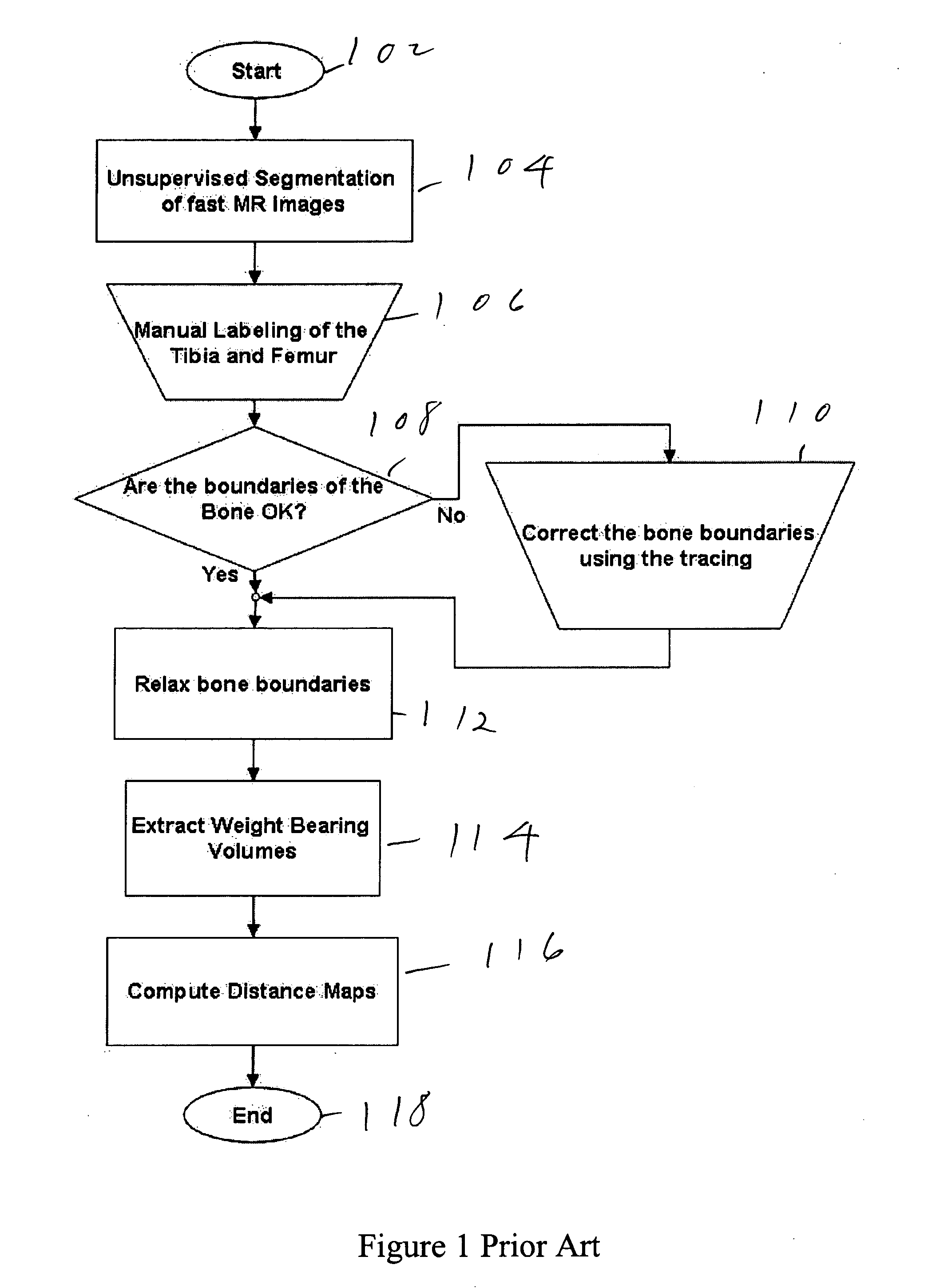

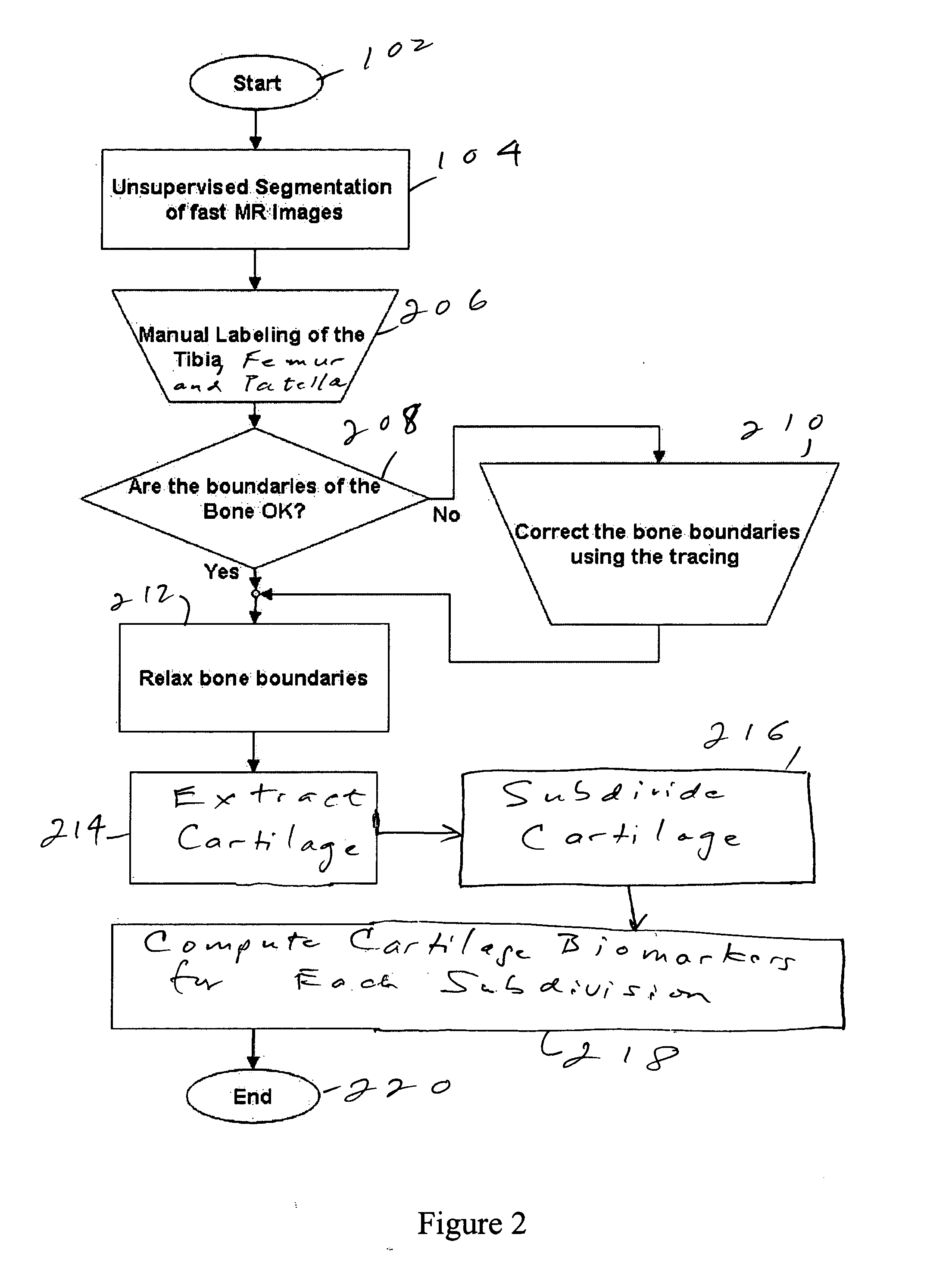

Method and system for automatic extraction of load-bearing regions of the cartilage and measurement of biomarkers

InactiveUS20050113663A1Improve assessmentImprove diagnostic capabilitiesImage enhancementImage analysisDiseaseNuclear medicine

An image is taken of a knee or other region of interest. The cartilage is extracted from the image and is subdivided into load-bearing and non-load-bearing regions. A biomarker is calculated for each of the load-bearing and non-load-bearing regions. The biomarkers can be assessed over time. The biomarkers for the load-bearing and non-load-bearing regions, and their changes, are used to assess the progress of joint disease.

Owner:VIRTUALSCOPICS

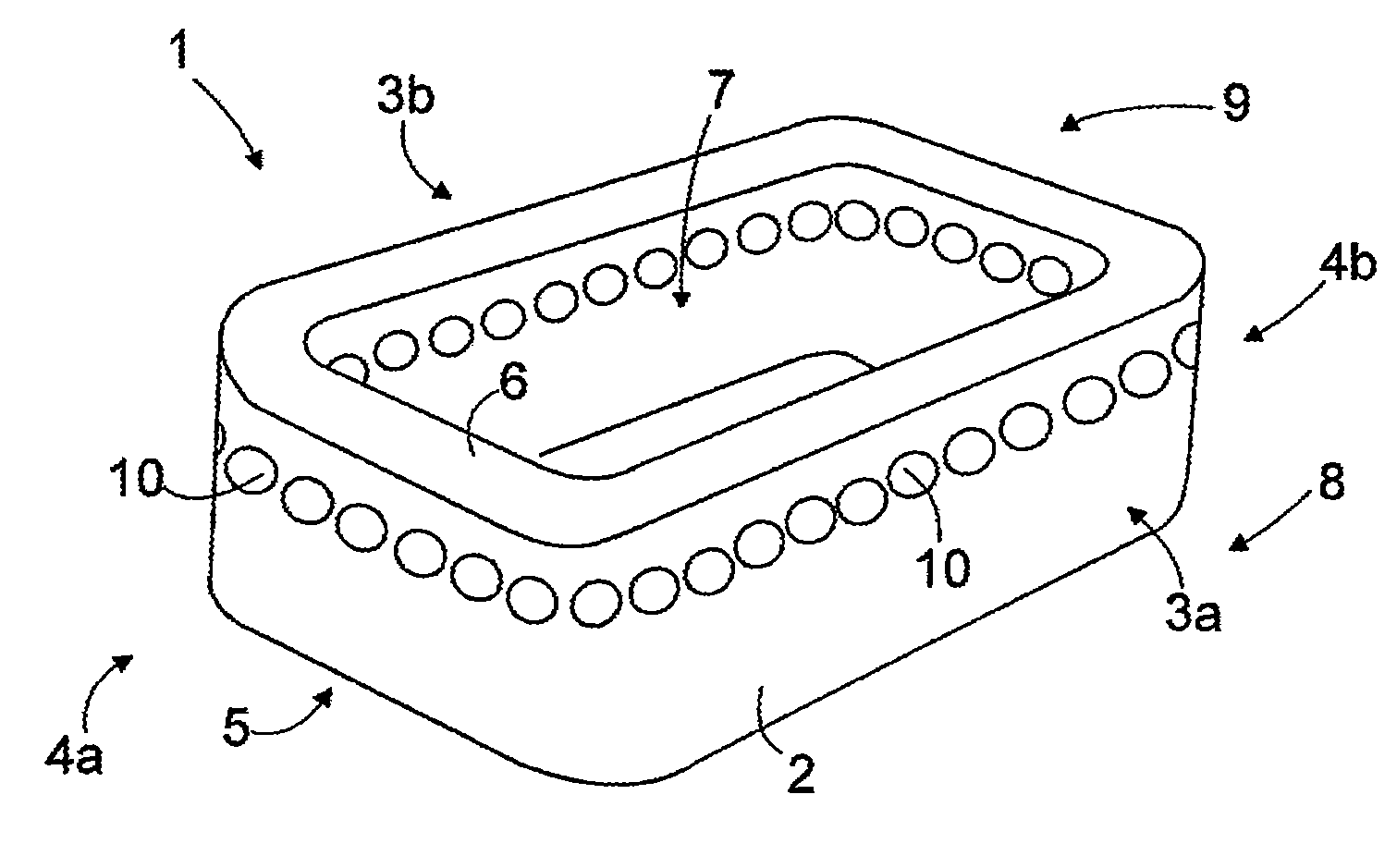

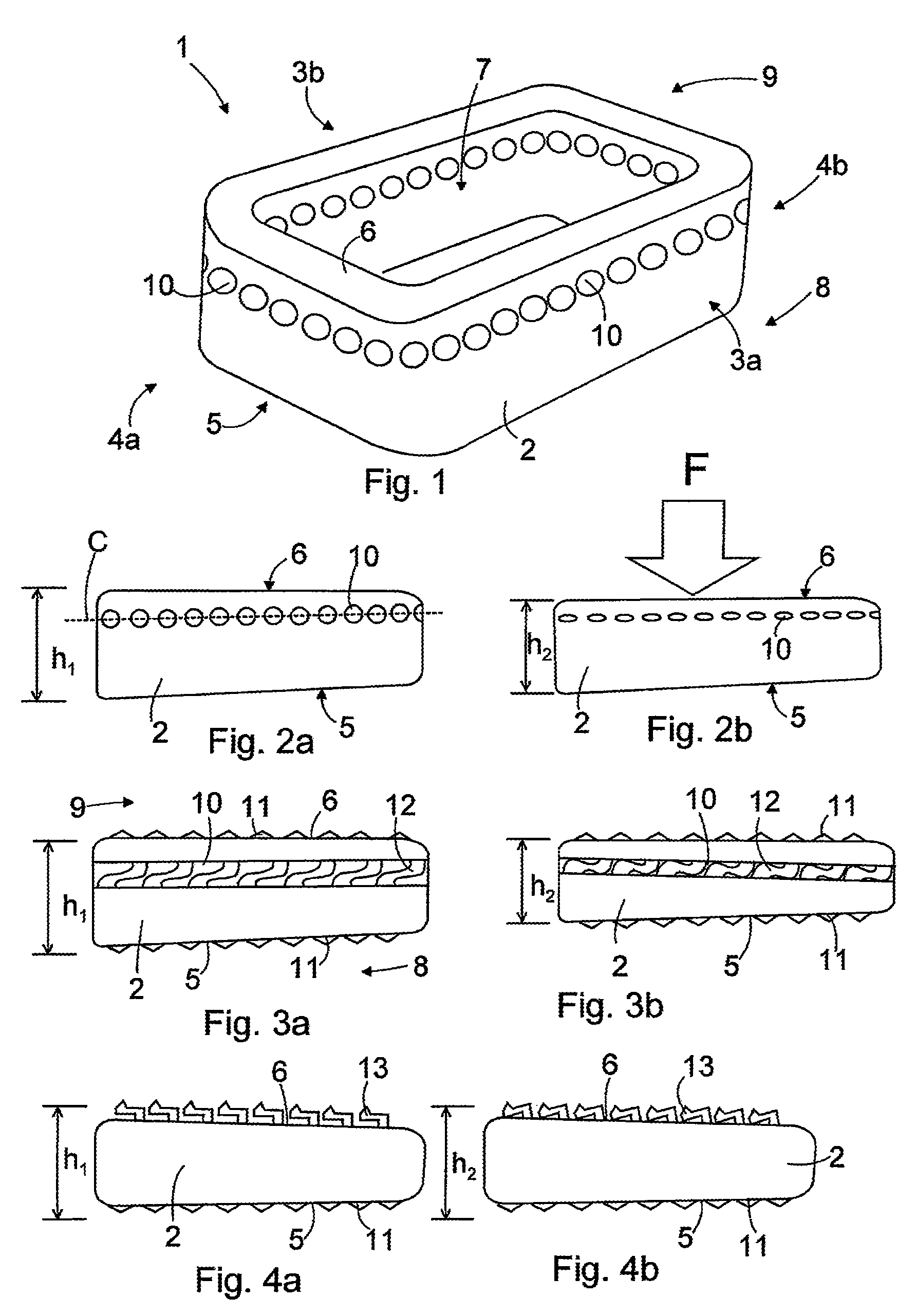

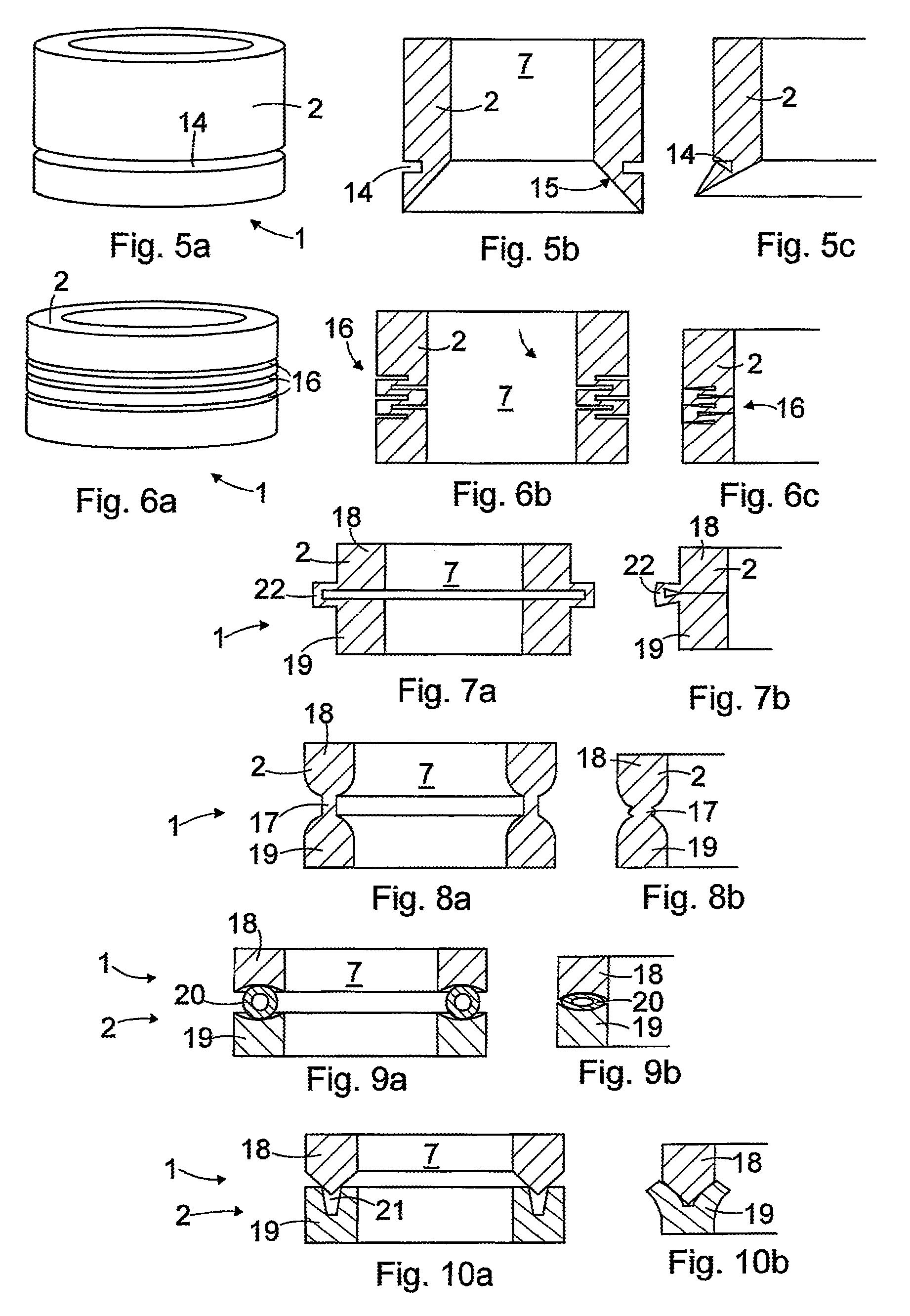

Surgical implant

InactiveUS20070185580A1Speed up the processIncrease percentageBone implantSpinal implantsIntervertebral diskBiomedical engineering

An implant to be inserted in the disk space between a lower vertebra and an upper vertebra. The implant comprises a body having a lower surface and an upper surface, and an aperture extending through the body in the direction of the height of the body from a lower side of the body to an upper side of the body. The body is arranged to reduce its height permanently under the load the body is exposed to between a lower vertebra and an upper vertebra.

Owner:INION

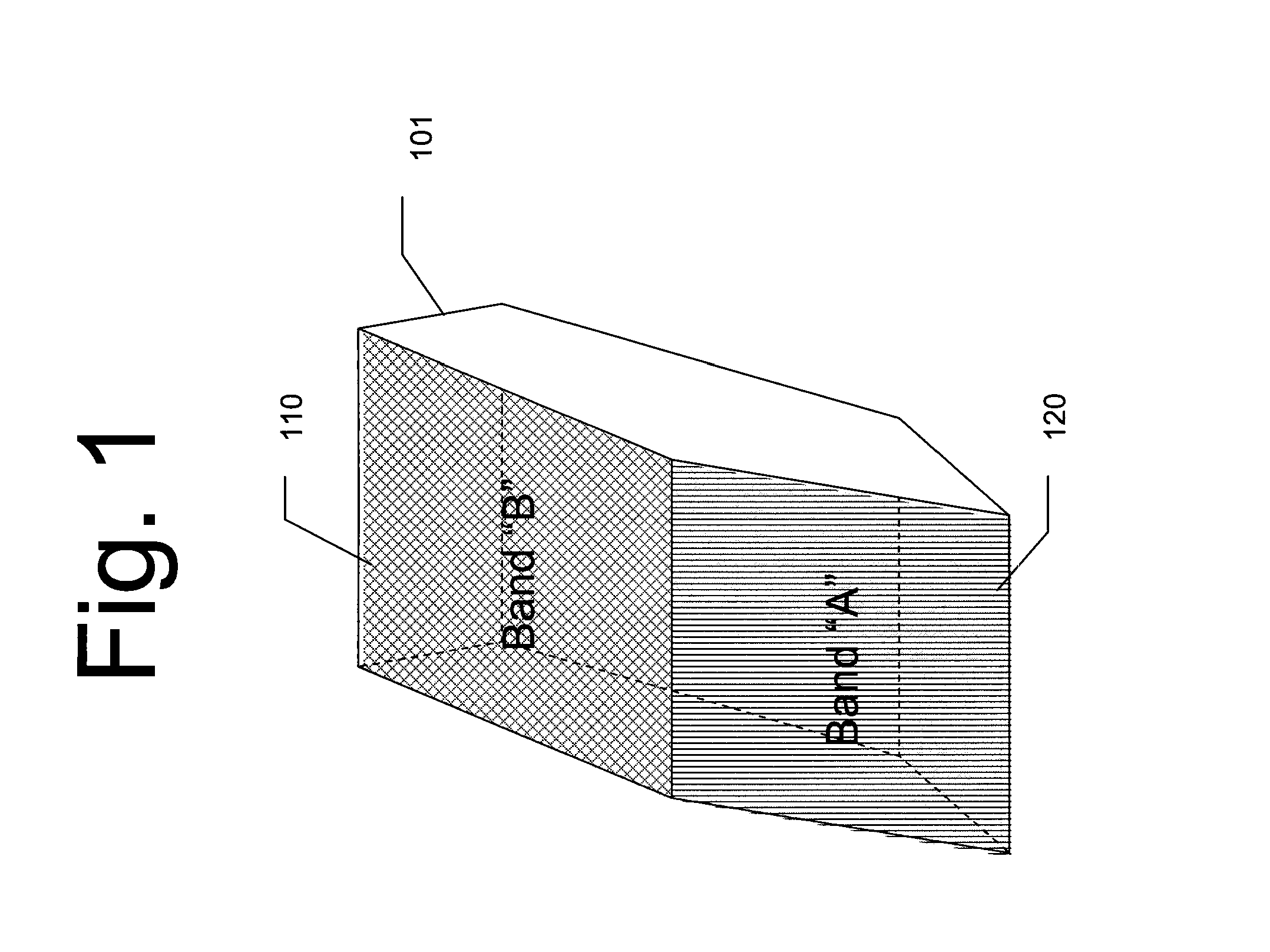

System and Method For Analysis of Image Data

ActiveUS20110002505A1Effectively halves costEffectively halves weightTelevision system detailsPrismsAridComputational physics

Owner:LOCKHEED MARTIN CORP

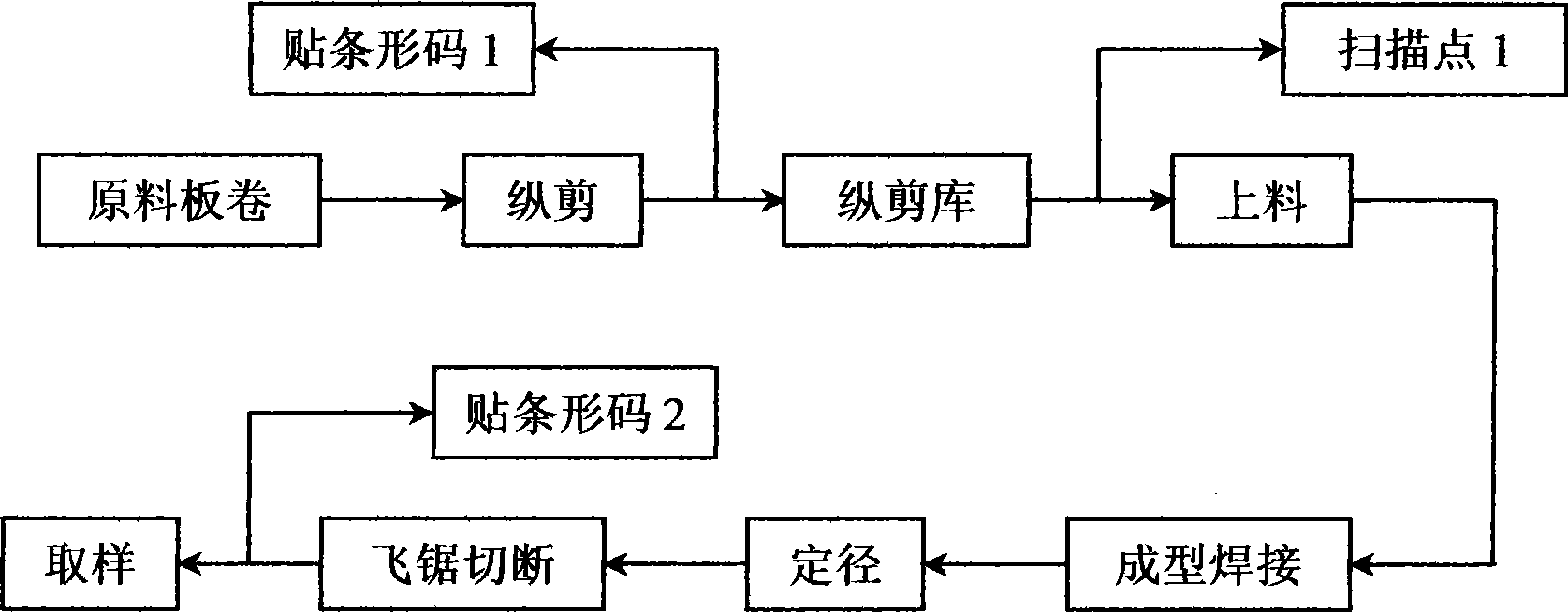

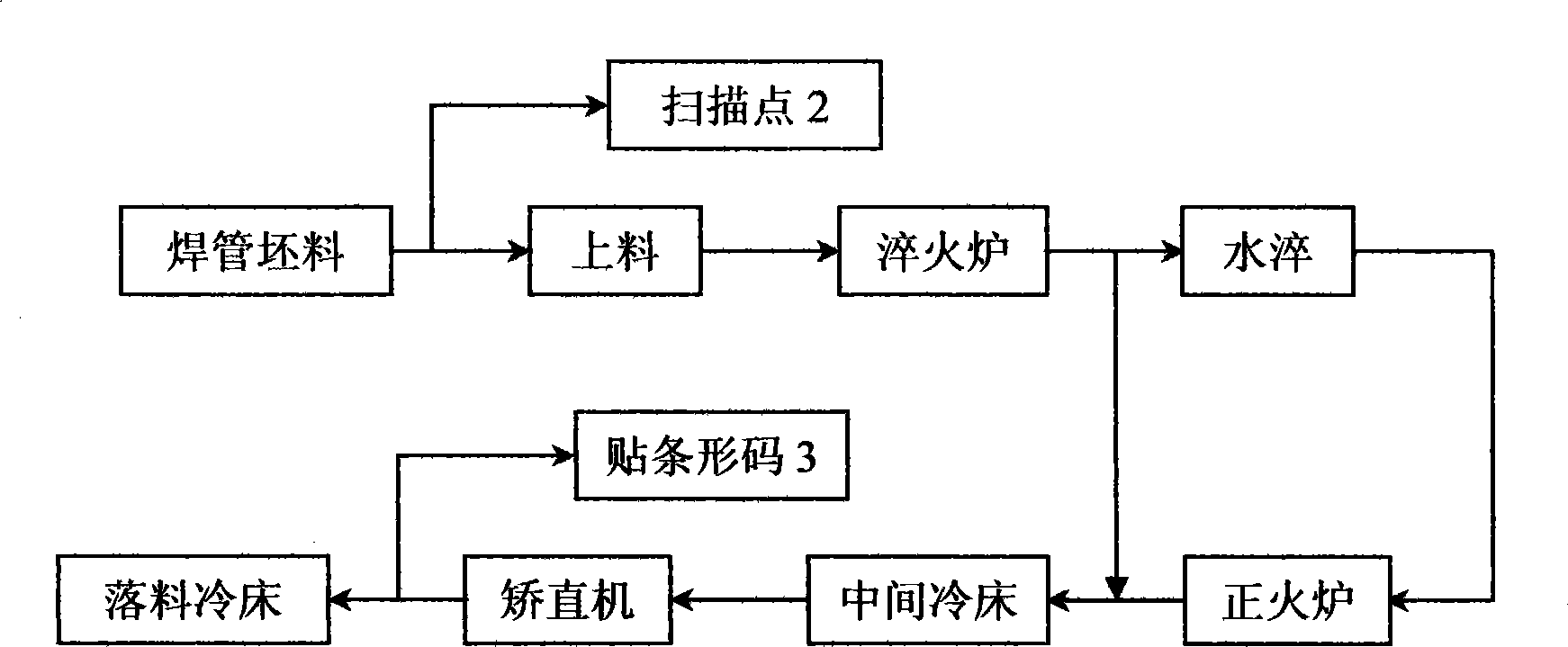

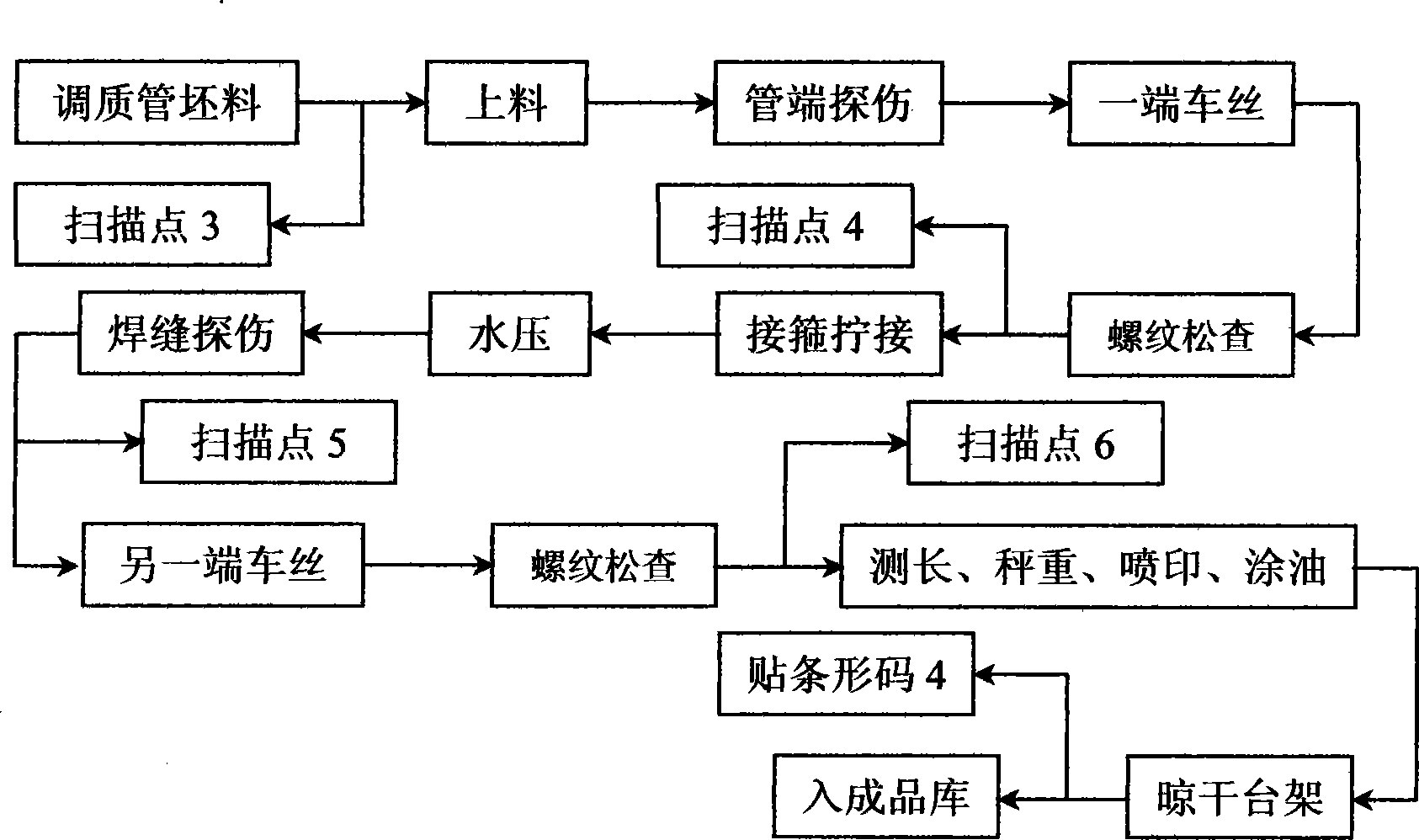

Materiel tracking system of ERW welded pipe product line

InactiveCN101482744AAvoid mixing steel and other phenomenaIncrease production capacityTotal factory controlProgramme total factory controlProduction lineWork in process

The present invention relates to a material tracking method in manufacturing process of ERW welding tube. In the manufacturing process of ERW welding tube, all production processes from raw material hot rolling bending, longitudinal shearing strips, ERW tube welding, fine-finishing after welding, wholly quenching and tempering, tube processing, etc. are executed with material welding. In the processes realized with material tracking, the facilities of bar code printing and scanning, on-line jet printing, automatic generating of sequence number of steel tube, pipe end lettering, steel tube data collecting, production management, etc. are used for recording, coding, identifying, marking and controlling each procedure in the production process of welding tube from raw material to finished tube for obtaining effectively recording main parameter of each unit assembly of each steel tube in the production process, matching with a nondestructive flow detection device for recording and marking the defect existing in the raw material, half-finished product and finished product, thereby realizing the tracking to the production process of each steel tube. The analysis to reason for the generation of defective product, the time, the personnel of production group and the contemporary process parameter can be realized. The problem can be found and settled in time. The production management and examination are facilitated.

Owner:江苏嘉宝科技制管有限公司

Self-monitoring metals, alloys and materials

ActiveUS20050083032A1Good curative effectImprove assessmentForce measurementMagnetic property measurementsTest materialObservability

Observability of damage precursor, damage and usage states, or event occurrence may be enhanced by modifying component materials to include self-monitoring materials or by processing test material to alter the surface properties. The properties of the self monitoring materials, such as magnetic permeability or electrical conductivity, are monitored with electromagnetic sensors and provide greater property variations with component condition than the original component material. Processing includes shot peening or laser welding.

Owner:JENTEK SENSORS

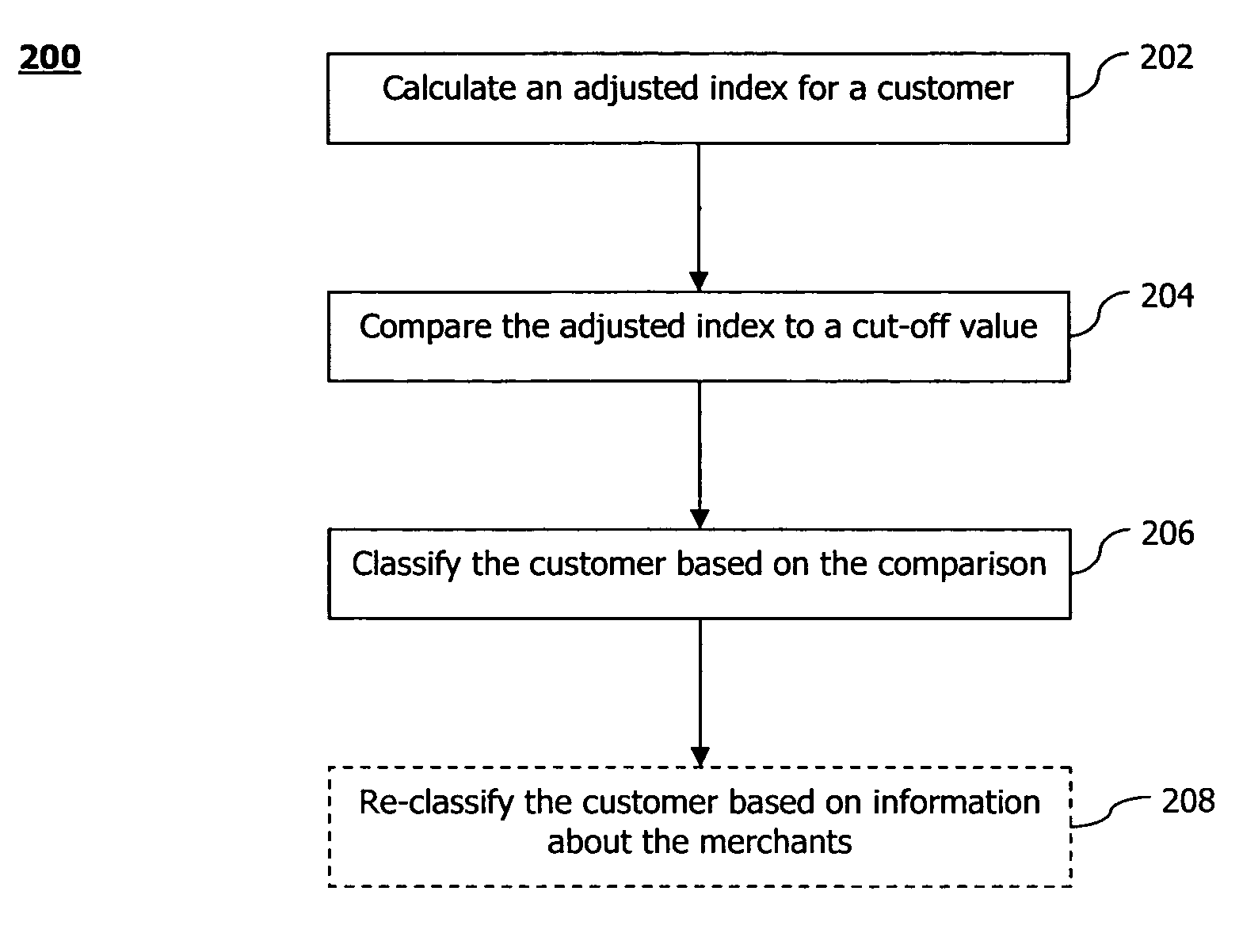

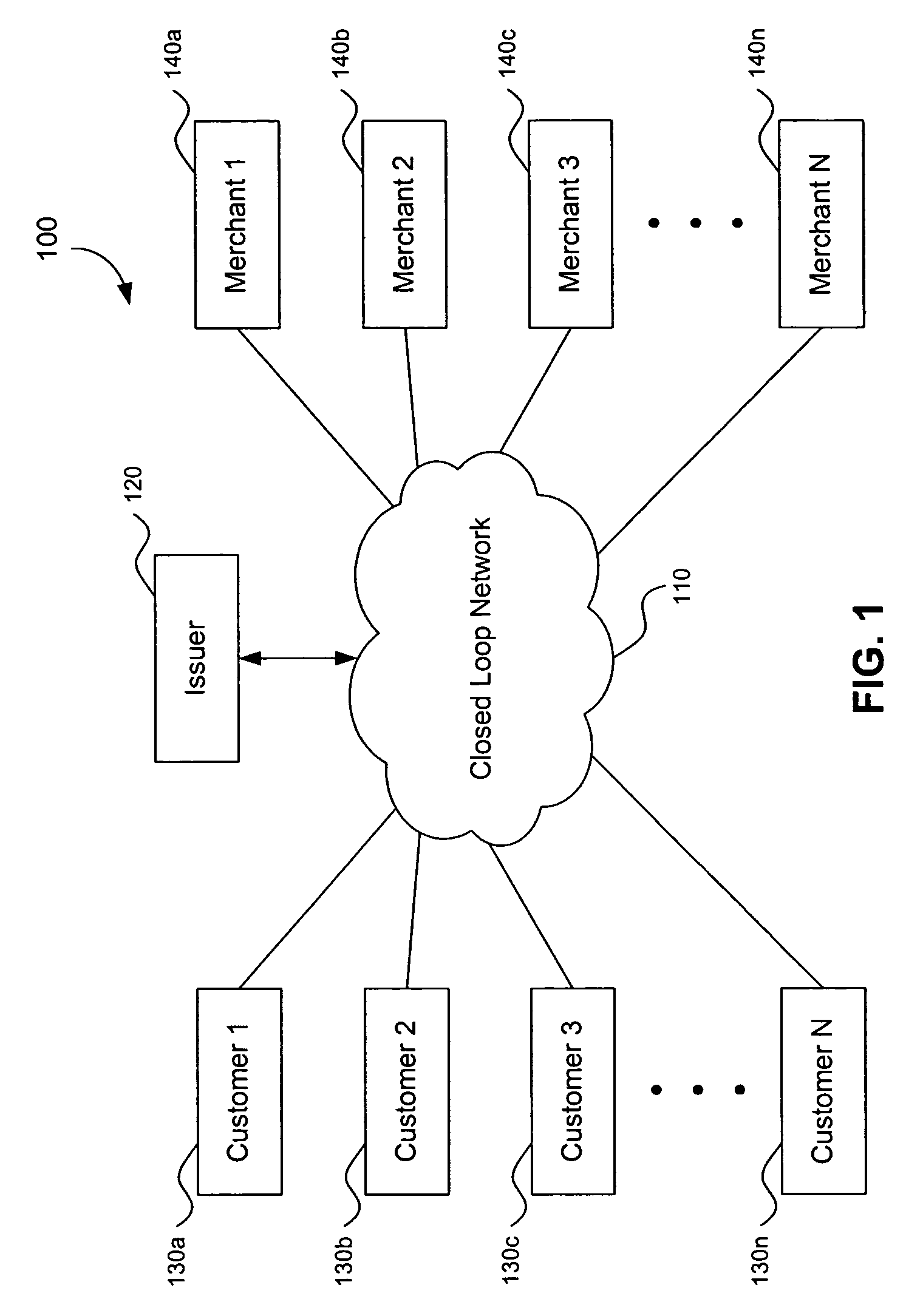

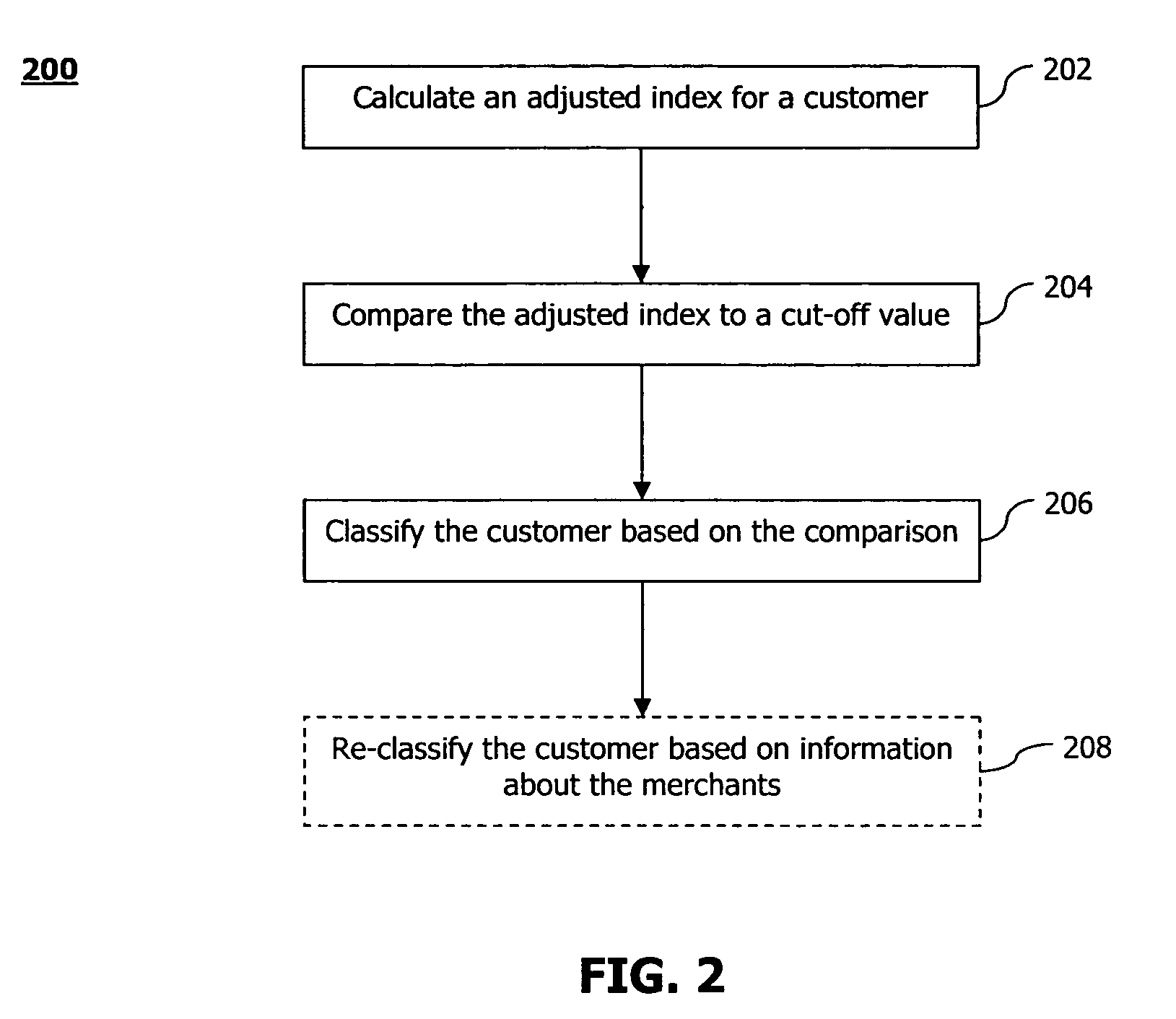

Automatic classification of credit card customers

ActiveUS7690564B2Easy to useSignificant positive effectMarket predictionsFinanceCredit cardFinancial transaction

According to embodiments of the present invention there is provided a computer-based method and a computer program product for automatically sorting customers who make purchases from merchants using a credit card. The computer-based method includes the following steps. An adjusted index is calculated for a customer based on an amount of money the customer spent across merchants during a time period. The adjusted index is compared to a cut-off value. The customer is classified based on the comparison of the adjusted index to the cut-off value. In an embodiment, the method also includes re-classifying the customer based on at least one of (i) information about the merchants, or (ii) a number of transactions in a predetermined industry.

Owner:AMERICAN EXPRESS TRAVEL RELATED SERVICES CO INC

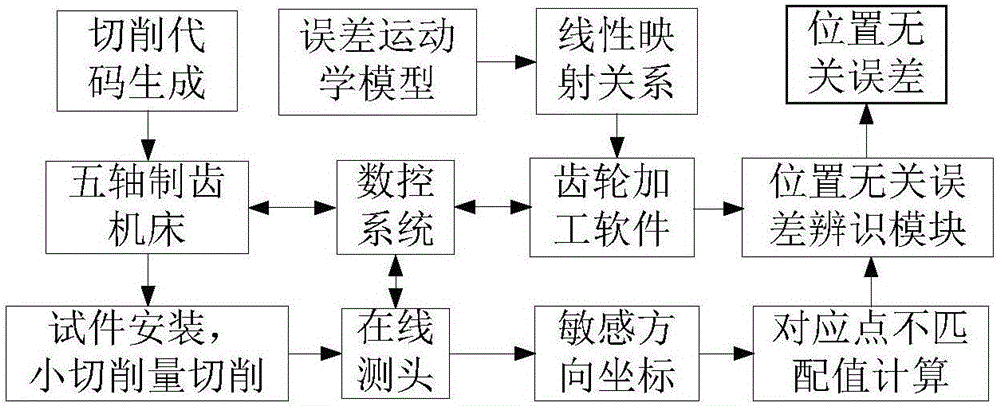

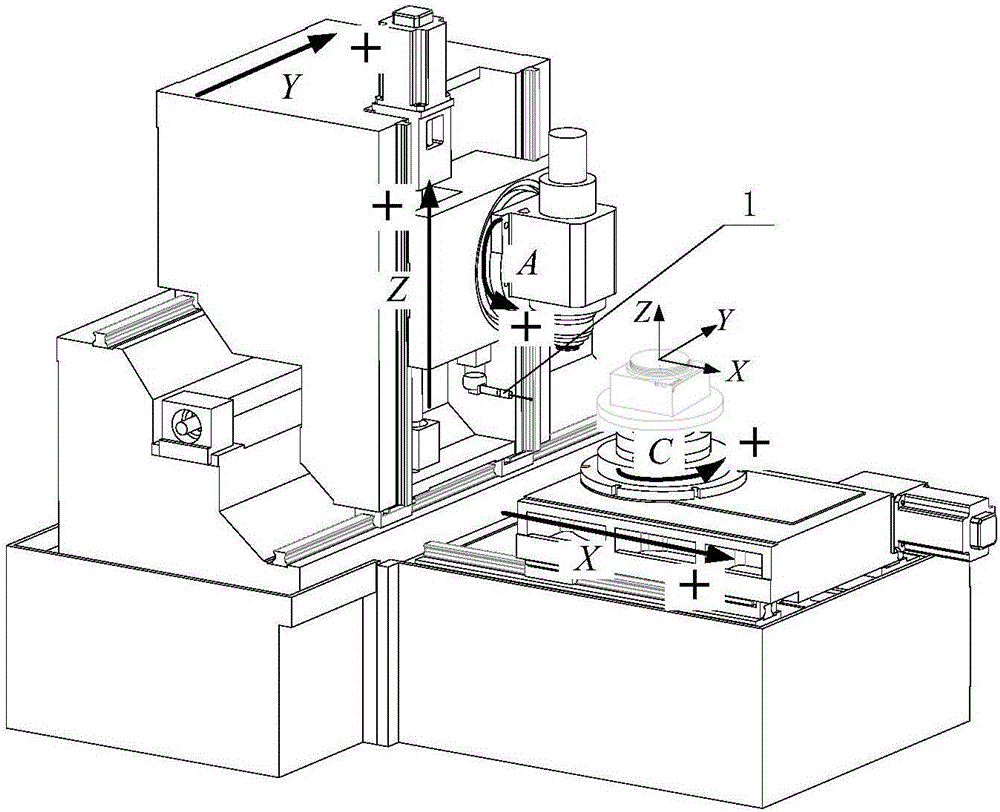

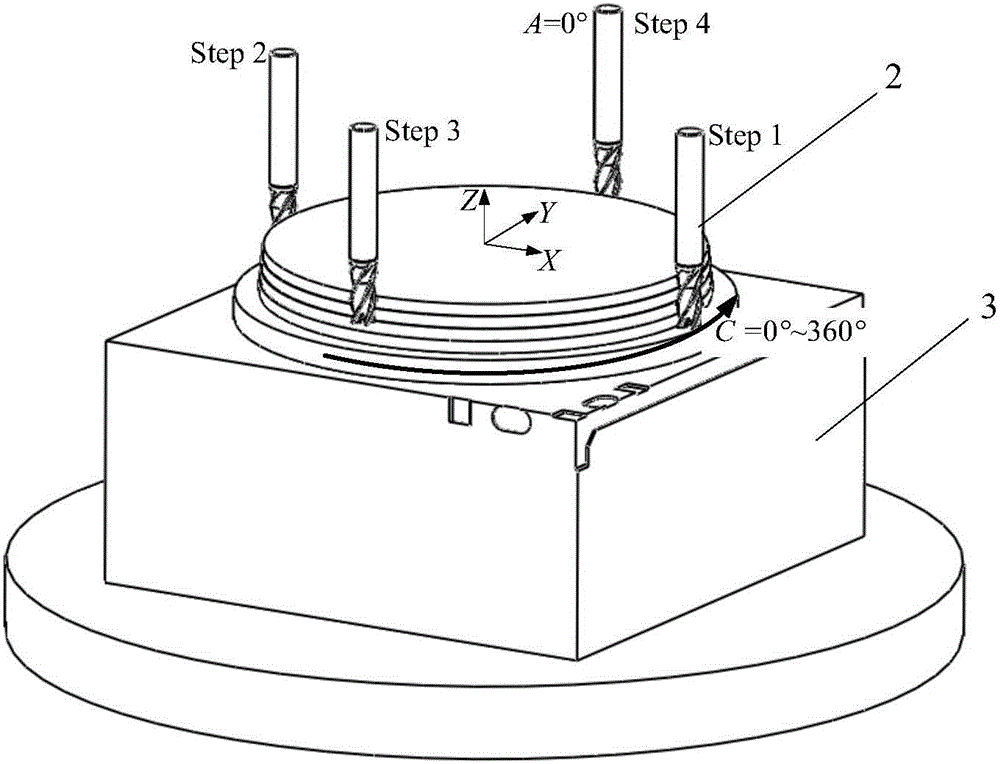

Five-axis gear making machine tool position independent error detection method based on small-cutting-amount test piece

ActiveCN106181583AAvoid influenceImprove detection accuracyMeasurement/indication equipmentsGeometric errorKinematics equations

The invention relates to the technical field of machine tool geometric error measuring and calibration, in particular to a five-axis gear making machine tool position independent error detection method based on a small-cutting-amount test piece. The detection method comprises the following steps that firstly, a track is compiled according to the shape of a designed test piece, a processing code is generated, small-amount cutting is conducted on the designed test piece, and a cutting test piece with a specific to-be-tested object is obtained; secondly, sensitive direction coordinates of the cutting surface of the specific to-be-tested object on the cutting test piece are detected and acquired by utilization of an on-line measuring head, and coordinate mismatching values corresponding to the cutting surface are calculated; thirdly, a homogeneous kinematic equation containing a position independent error is established, and the mapping relation between the coordinate mismatching values corresponding to the cutting surface, and the position independent error is determined; and fourthly, a position independent error item is obtained according to the mapping relation between the coordinate mismatching values corresponding to the cutting surface, and the position independent error. The fixe-axis gear making machine tool position independent error detecting and identifying method is efficient and easy to operate.

Owner:NANJING UNIV OF TECH +1

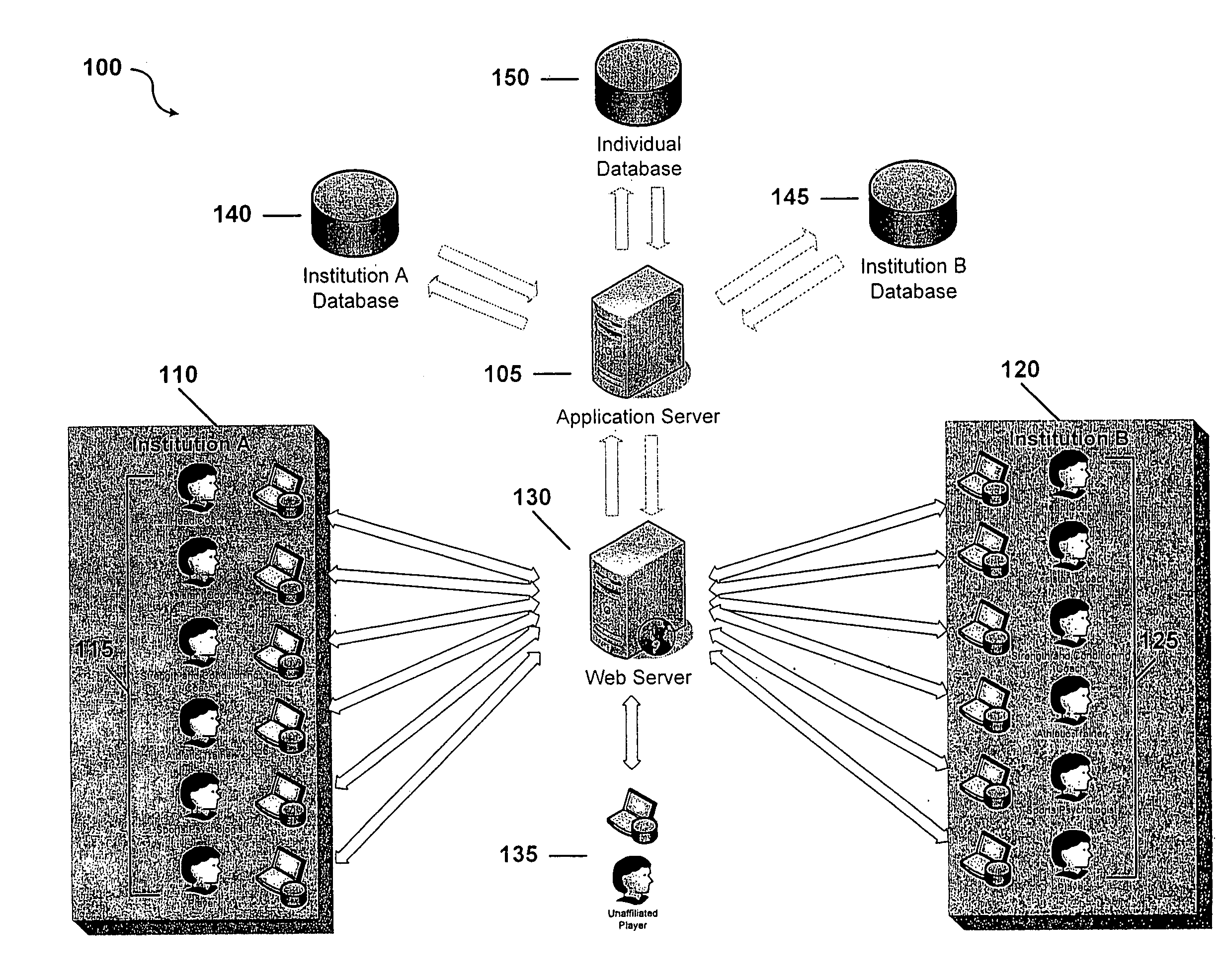

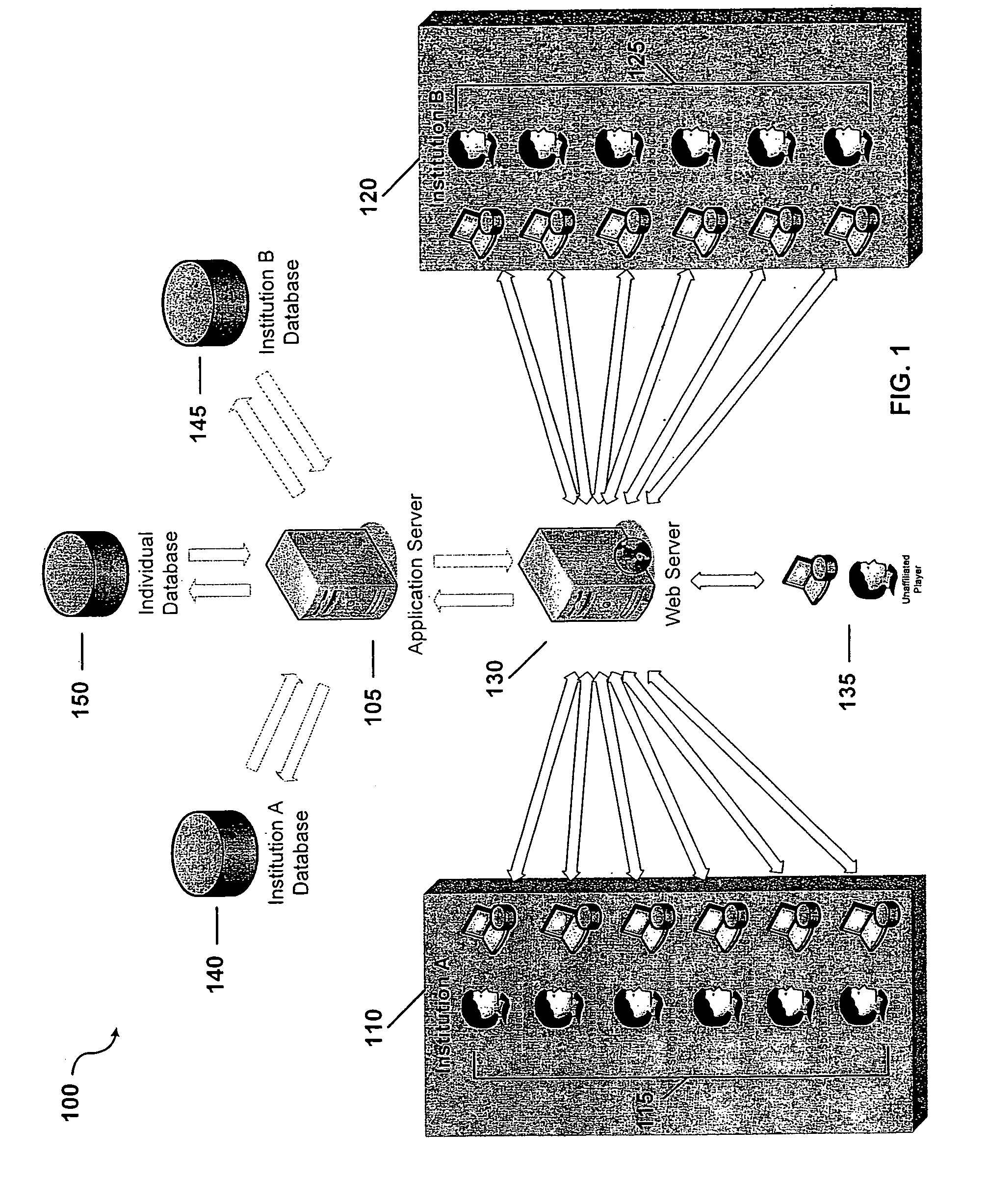

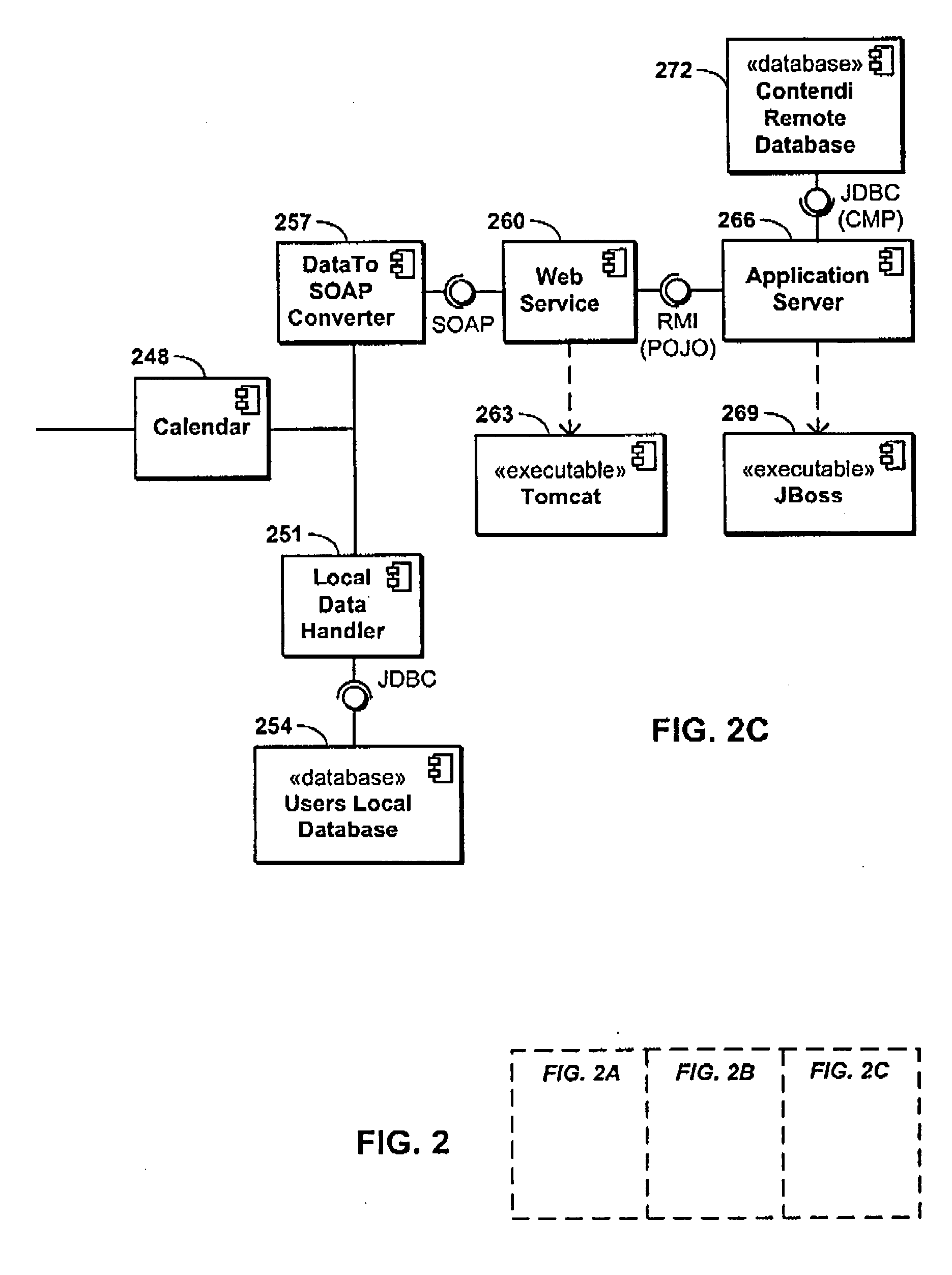

Systems and methods for integrating sports data and processes of sports activities and organizations on a computer network

InactiveUS20080147422A1Facilitate playerFacilitate team developmentOffice automationSports activityProcess integration

A system and methods are described for integrating enterprise resource planning tools in sports activities and organizations. More specifically, the system and methods provide systems and methods for integrating all data and processes of a sports organization and of member players or athletes engaged in physical activities into a unified system on a computer network. Further, the system and methods provides users of the computer network with privileged access to various team and individual data, and further, the ability to communicate and collaborate with other users to achieve individual and organizational goals.

Owner:CONTENDI

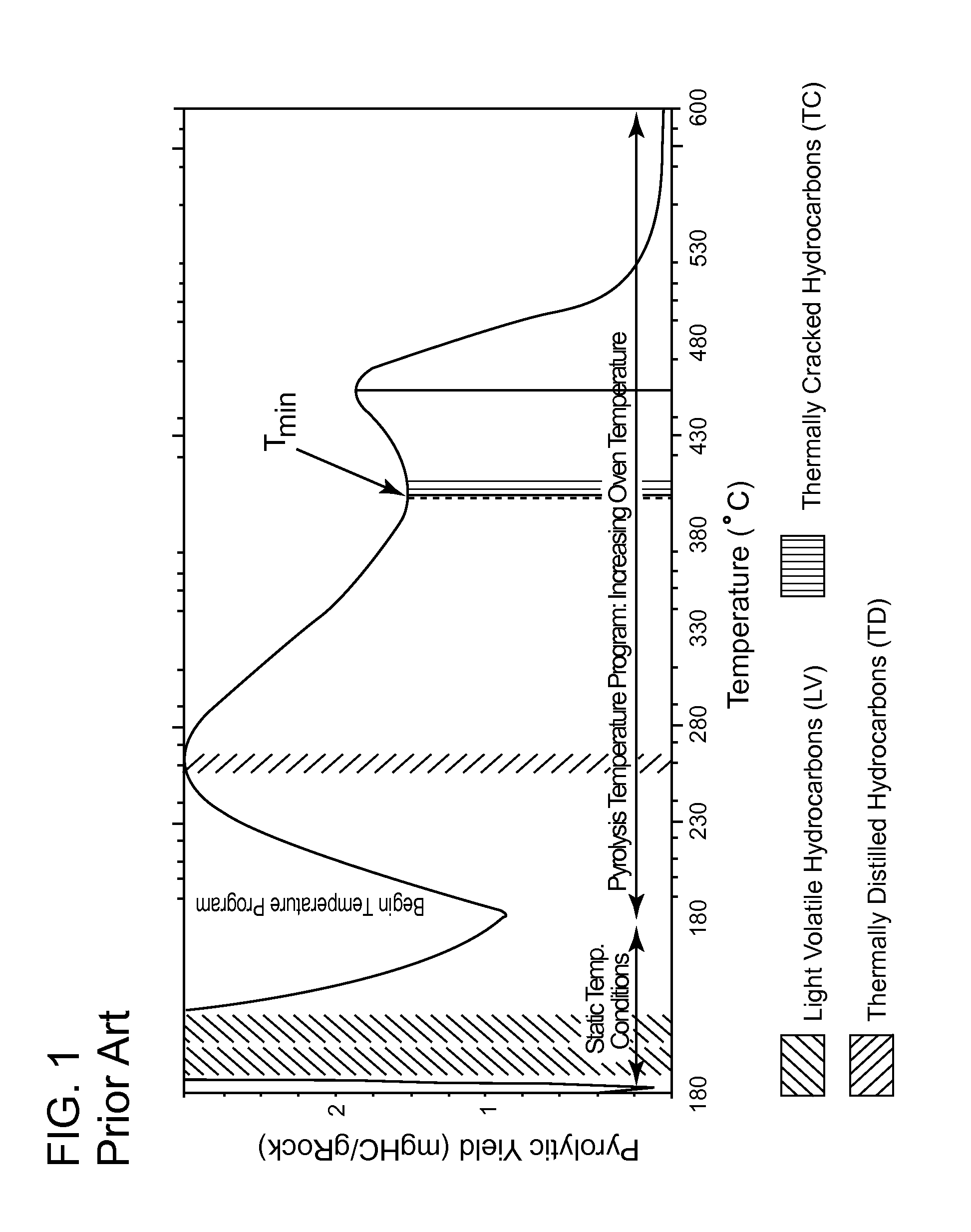

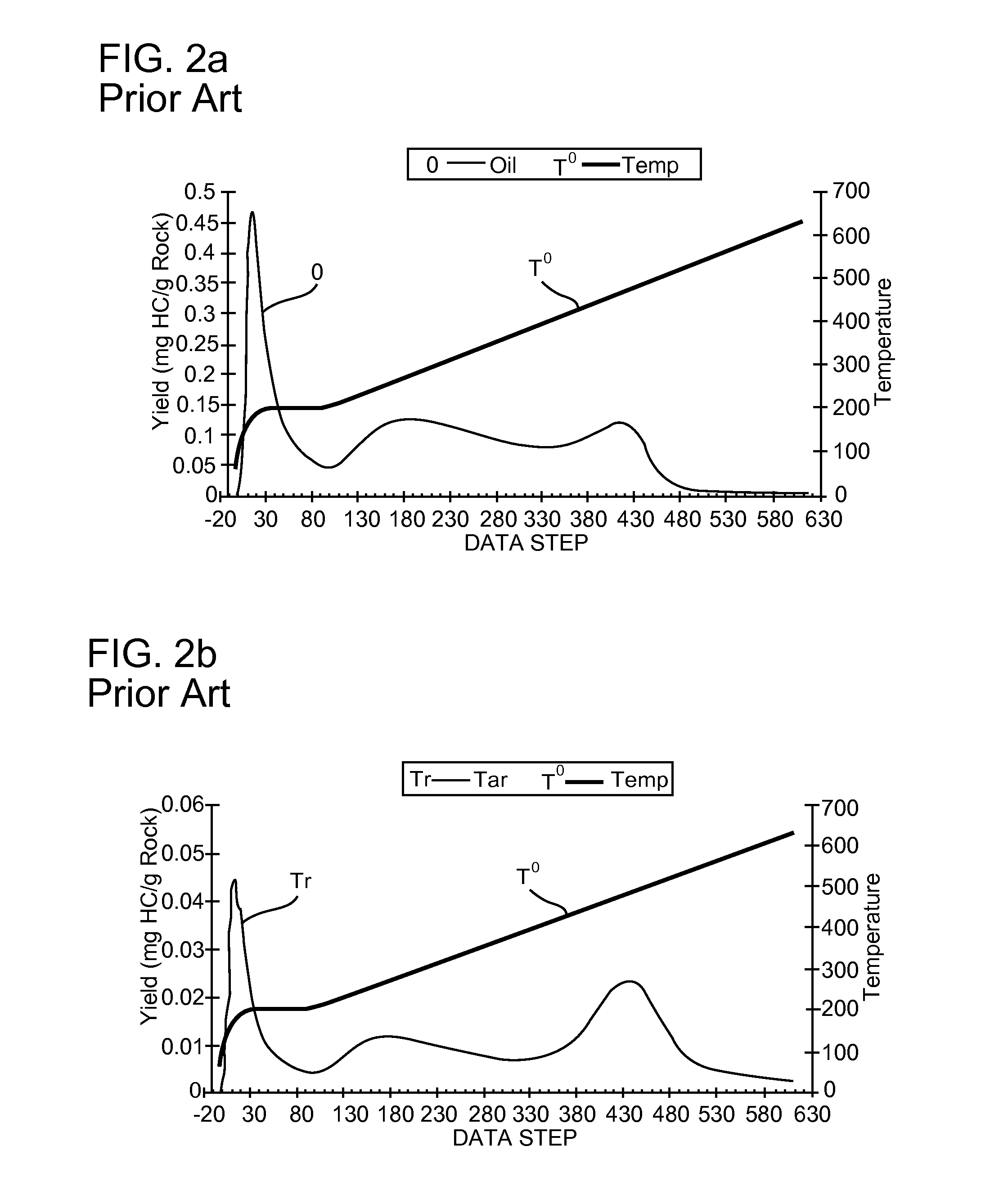

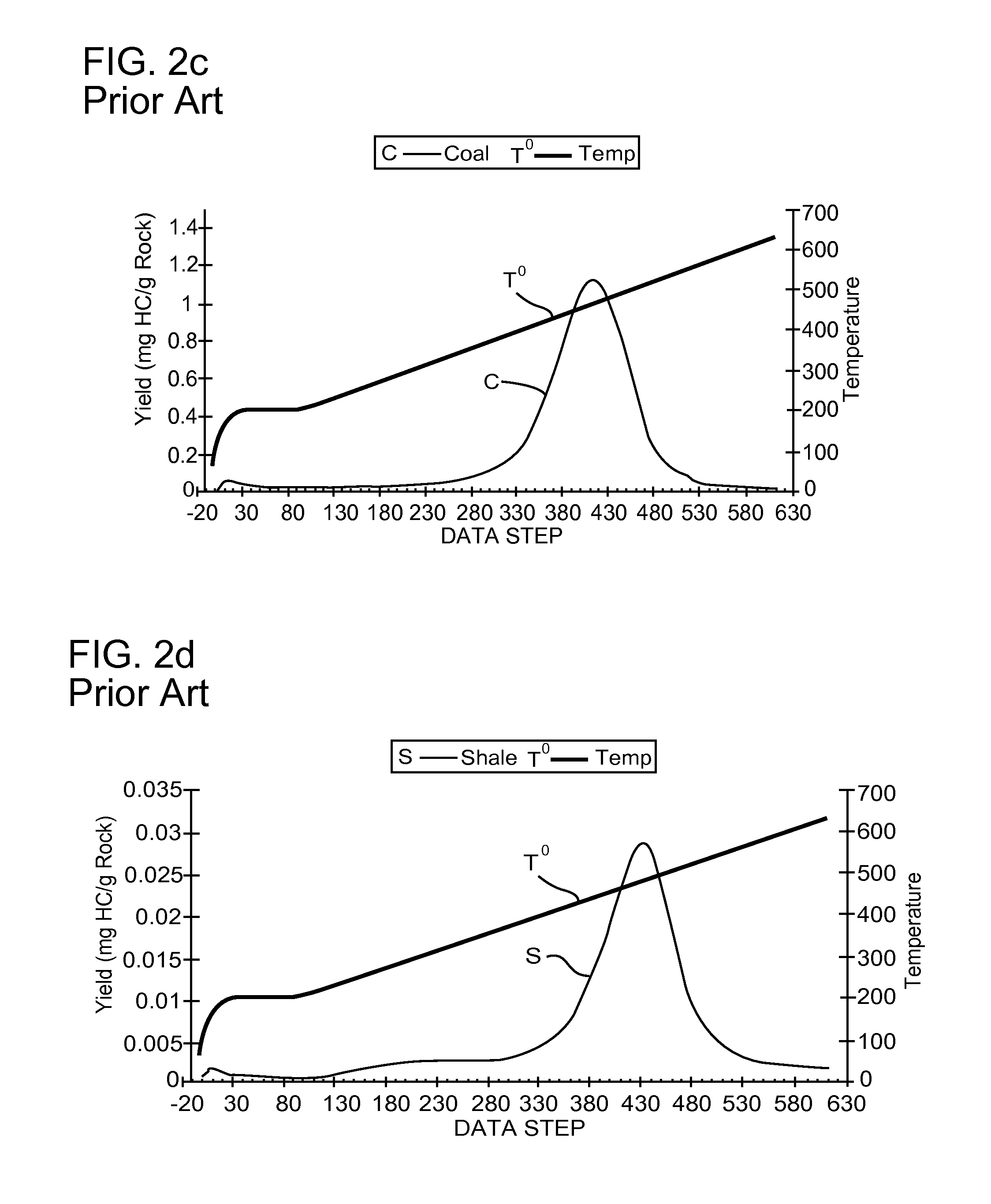

Method for reconstructing the total organic carbon content from compositional modeling analysis

ActiveUS20140114627A1Improve assessmentEarth material testingComputation using non-denominational number representationAnalysis methodTotal organic carbon

Methods are provided for utilizing the results of compositional modeling analysis to obtain accurate total organic carbon values without the need for an oxidation step or lengthy sample preparation, and also to calculate the organic carbon value attributable to contaminants, such as drilling additives.

Owner:SAUDI ARABIAN OIL CO

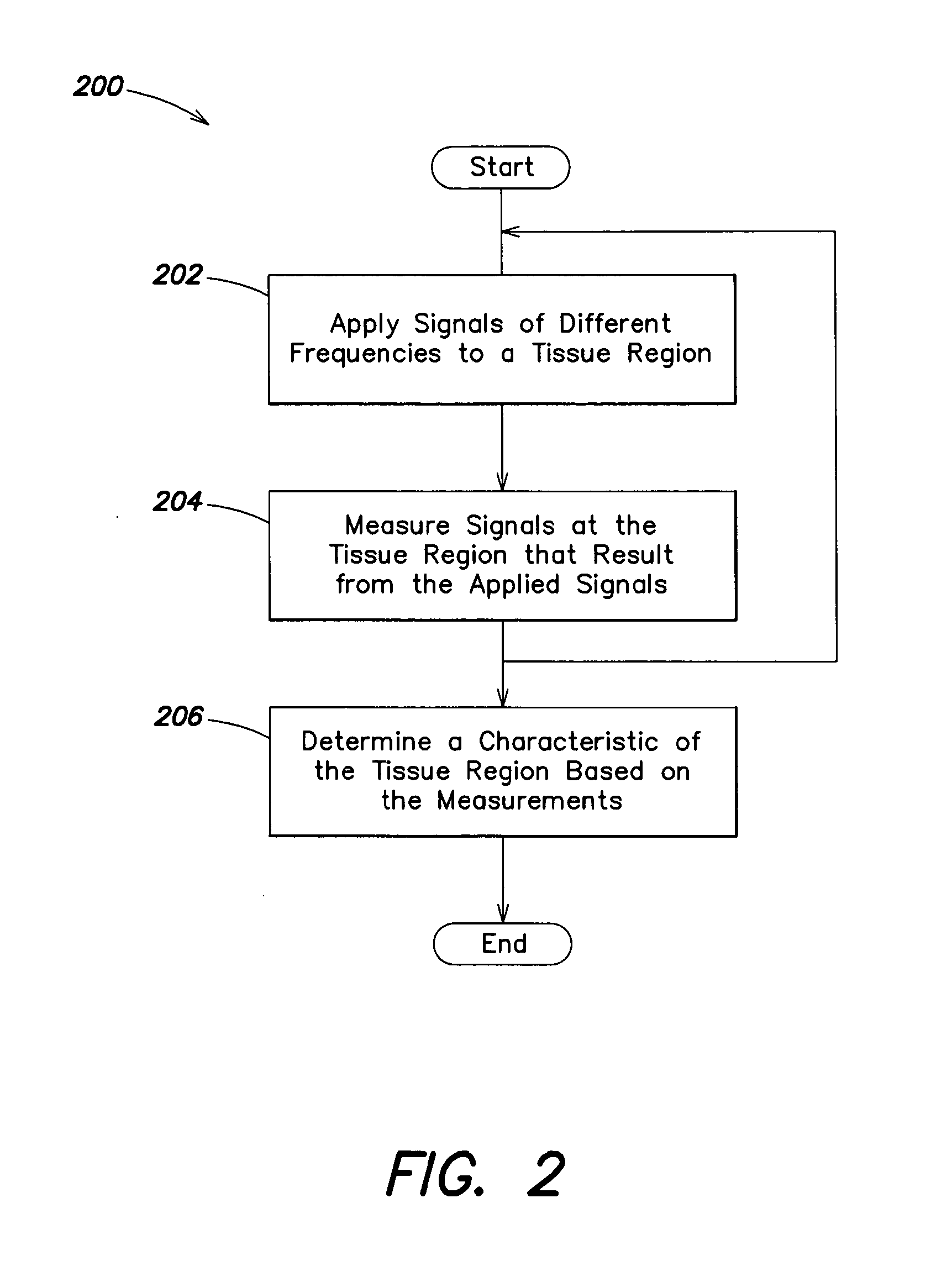

Electrical Impedance Myography

InactiveUS20100292603A1Facilitate diagnosis and treatmentImprove assessmentElectromyographySensorsElectromyographyElectrical impedance

Electrical impedance myography (EIM) can be used for the assessment and diagnosis of muscular disorders. EIM includes applying an electrical signal to a region of tissue and measuring a resulting signal. A characteristic of the region of tissue is determined based on the measurement. Performing EIM at different frequencies and / or different angular orientations with respect to a muscle can aid in the assessment and diagnosis. Devices are described that facilitate assessment and diagnosis using EIM.

Owner:NORTHEASTERN UNIV +1

Electronic health record system utilizing disparate record sources

ActiveUS8249895B2Increase the value of dataImprove assessmentData processing applicationsPatient-specific dataThird partyMedical record

A system for facilitating patient ownership of his or her medical data through the use of third-party health repositories that preserves the maximum information content of the medical records by displaying information relevant to the authority of the medical data as reflected by its source and types of modification as it has moved between institutions, as well as the data itself. In this way, improved use of this data is made possible.

Owner:EPIC SYST CORP (US)

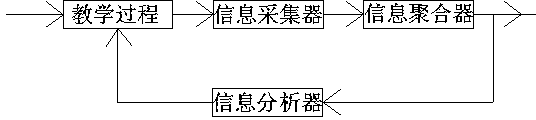

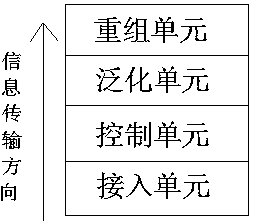

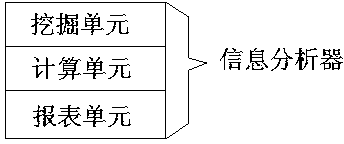

Class-type teaching evaluation system for multi-information platform polymerization and evaluation method for evaluation system

InactiveCN103400328AAchieve precise positioningPrecise positioningData processing applicationsInformation analysisInformation resource

The invention relates to a class-type teaching evaluation system for multi-information platform polymerization. The system is characterized by comprising an information collector, an information polymerizer and an information analyzer, wherein the information collector obtains teaching process data information in a normal communication process in a teaching process of a teaching participant, the information polymerizer polymerizes information interacted by the information collector to form data form which can be analyzed and the placed to an appointed database system for providing a foundation for subsequent teaching evaluation and analysis, and the information analyzer converts a single information collecting platform into multi-platform, integrates and applies multiple information technical means to polymerize information of the multi-platform into one database in a uniform manner, and dig and comb potential associated information among data by intelligence algorithm, so as to further form a true integrated data information resource.

Owner:杨安康

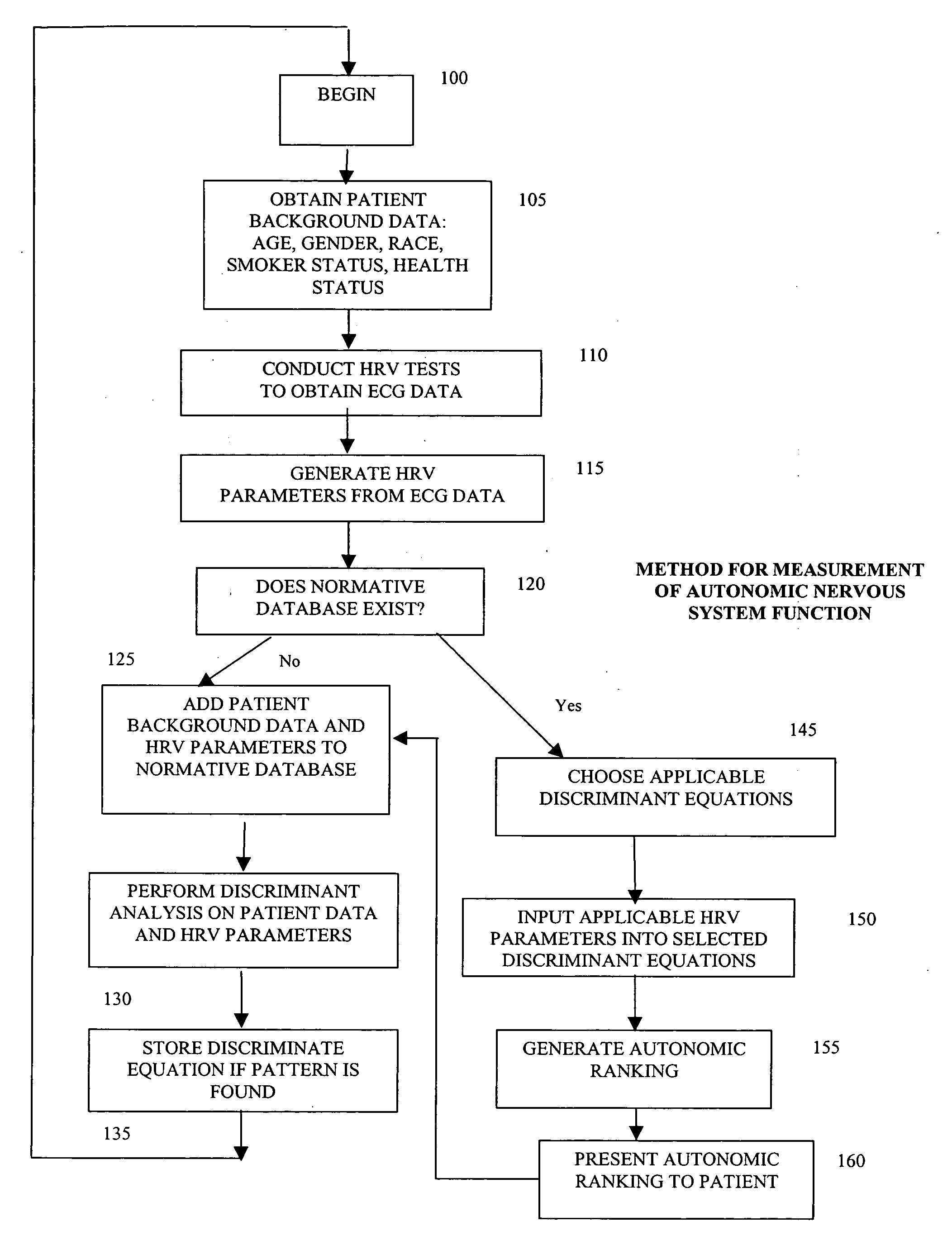

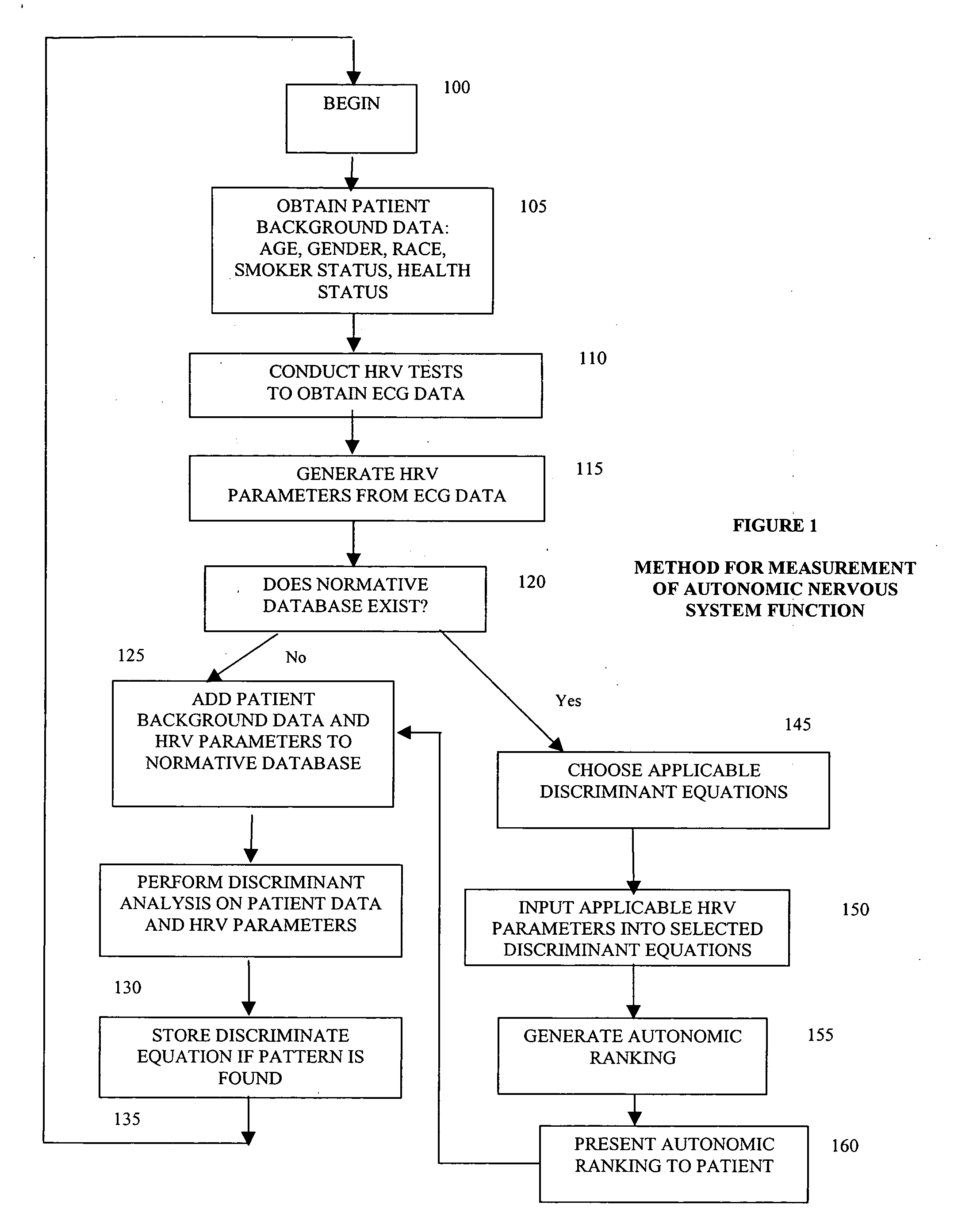

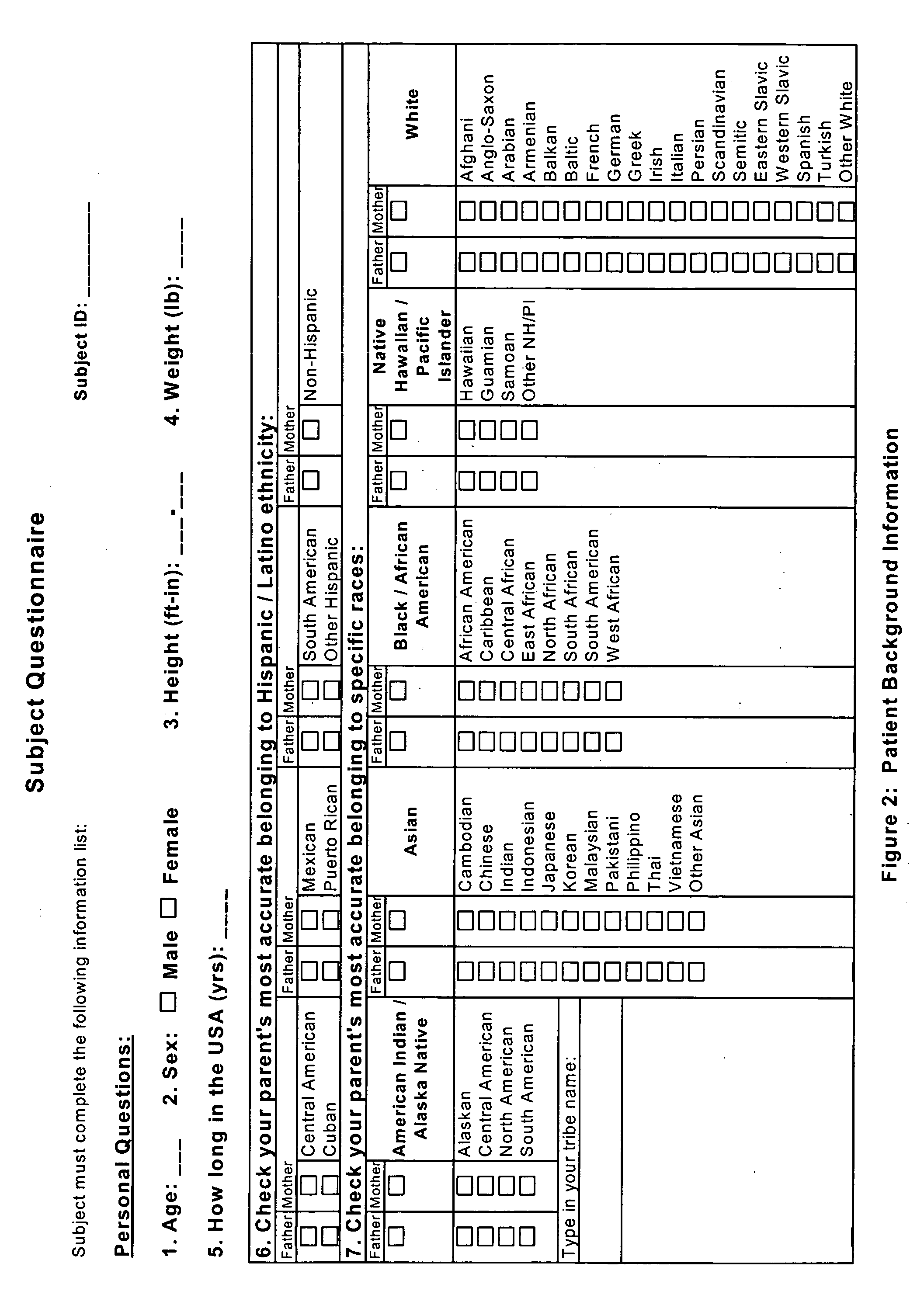

Method and apparatus for measurement of autonomic nervous system function

InactiveUS20050251054A1Improve accuracyImprove assessmentMedical data miningElectrocardiographyTime domainAutonomic bladder dysfunction

The invention analyzes relationships between factors, within a patient population, to identify autonomic dysfunction patterns. Patient test results are then compared with the identified patterns to determine the patient's autonomic function. The invention can continually amend the patient population with new test results to create increasingly accurate normative data sets from which a patient's autonomic function can be more accurately assessed. The invention may apply this concept in an application service provider model. An embodiment of the invention may use a novel method of identifying ECG R-waves. The method locates R-waves by searching for maximum slope values, in signals, that exceed threshold values. Another embodiment of the invention entails a non-provocative HRV test whereby certain time domain and frequency domain factors are analyzed to determine a patient's autonomic function.

Owner:MEDDORNA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com