Patents

Literature

666 results about "Air stripping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air stripping is the transferring of volatile components of a liquid into an air stream. It is an environmental engineering technology used for the purification of groundwaters and wastewaters containing volatile compounds.

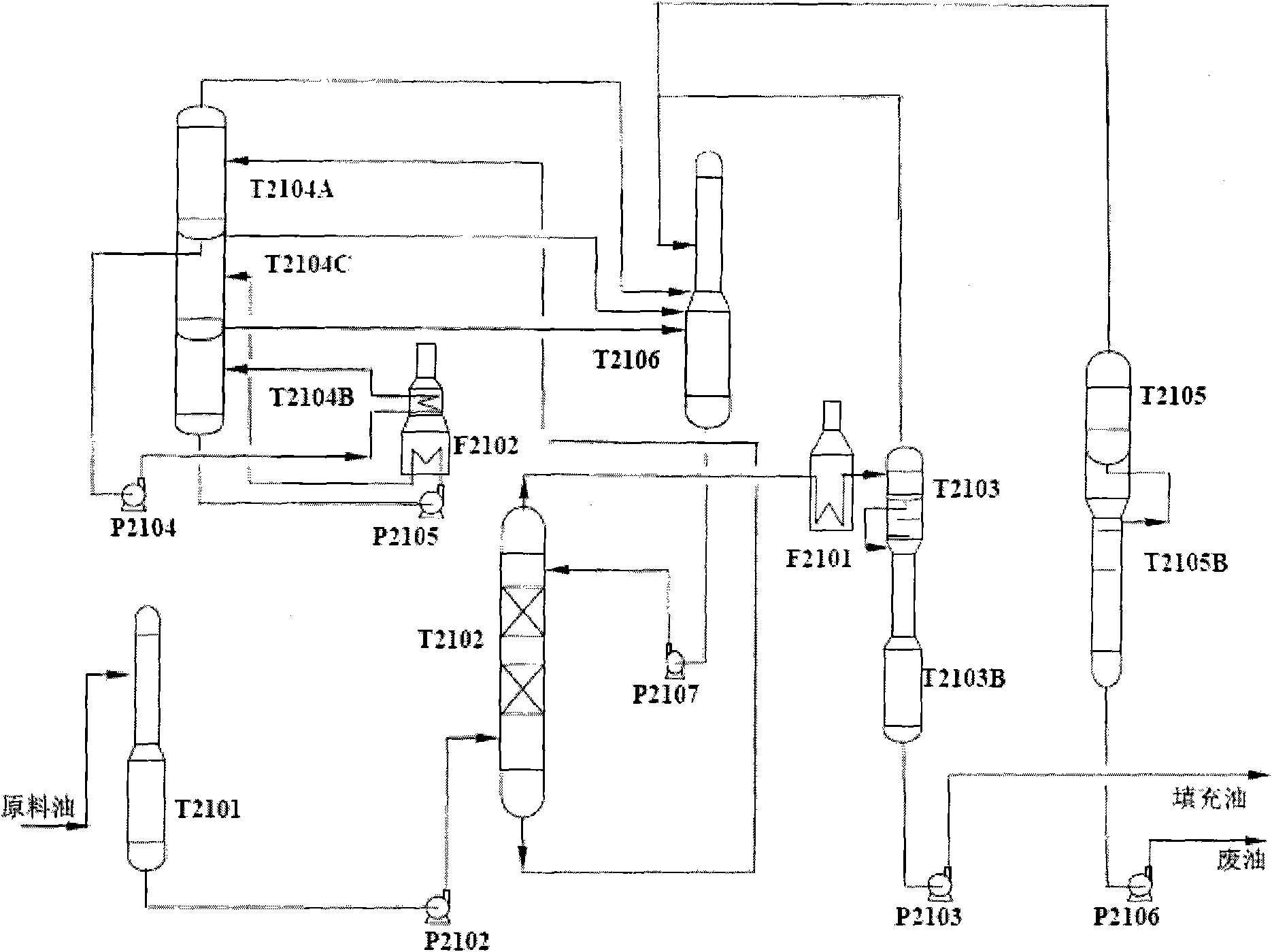

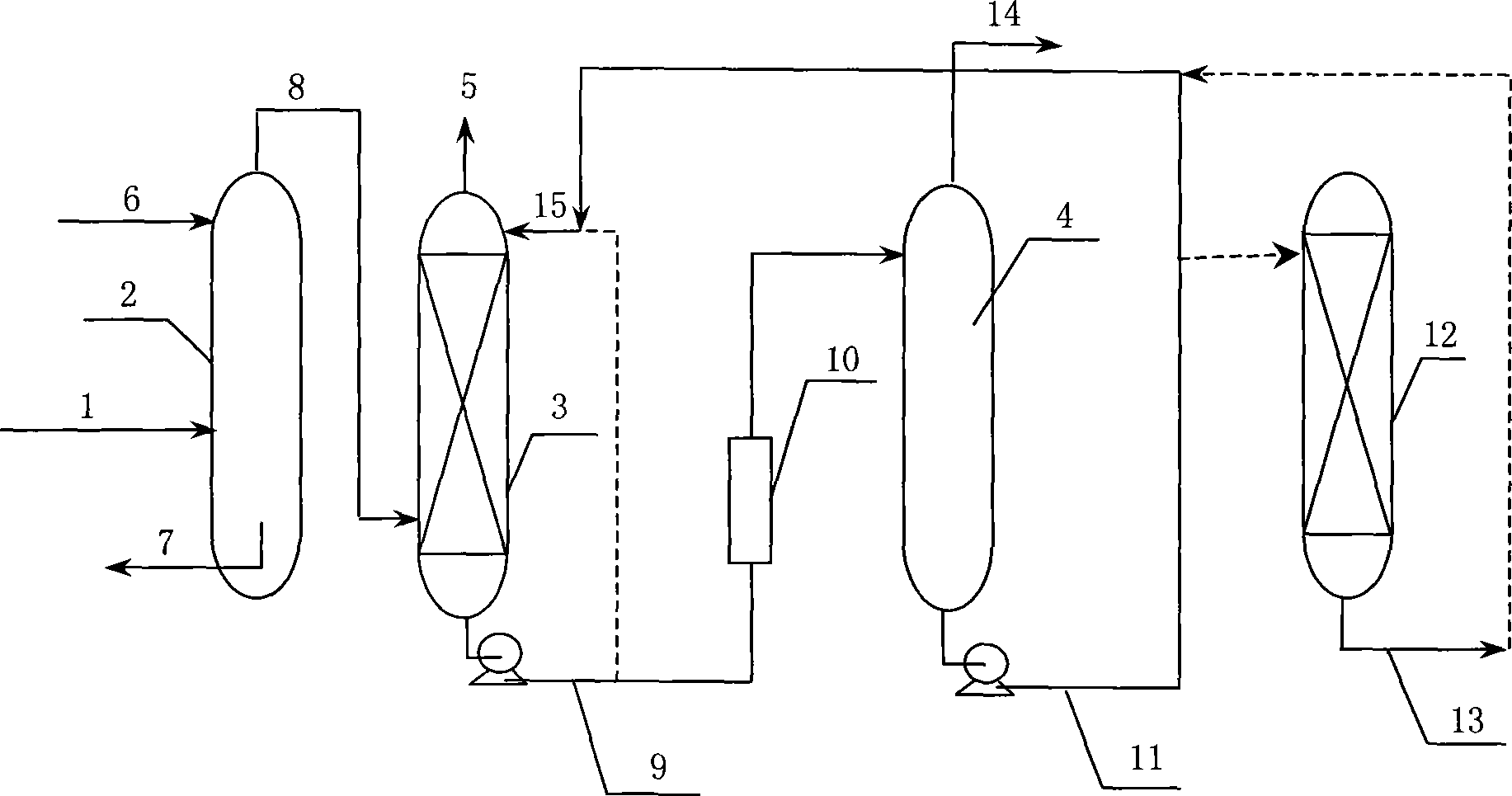

Method for preparing high-quality ethylene raw material with petroleum naphtha hydrogenation

ActiveCN101343557AImprove qualityIncrease productionOrganic chemistryBulk chemical productionVegetable oilPetroleum naphtha

The invention relates to a method for generating the high quality ethylene raw material through naphtha hydrogenation. The method takes naphtha fraction and animal and vegetable oil as the raw material oil, under the condition of hydrofining, the raw material oil and hydrogen are mixed and passed through a hydrofining reaction area, the hydrogen-rich gas recycling utilization can be acquired through separating the hydrofining generated oil, and low Sulfur, low hydrogen and low aromatic naphtha can be acquired through removing hydrogen sulfide of the separated liquid with an air stripping tower. Compared with the prior art, the method has the advantages that the oil is mixed in the naphtha hydrogenation raw material, the quality of the product as the ethylene cracking raw material, in particular to aromatic long chain hydrocarbon nC16 to 18 and propane acquired through the animal and vegetable oil hydrogenation, can be remarkably improved, the cracking furnace ethylene output can be increased and the cracking furnace life can be prolonged through adding the aromatic long chain hydrocarbon nC16 to 18 and propane in the ethylene cracking raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for decreasing the amount of cholesterol in a marine oil using a volatile working fluid

ActiveUS7678930B2Lower cholesterol levelsPoint becomes highCosmetic preparationsNervous disorderWorking fluidFree form

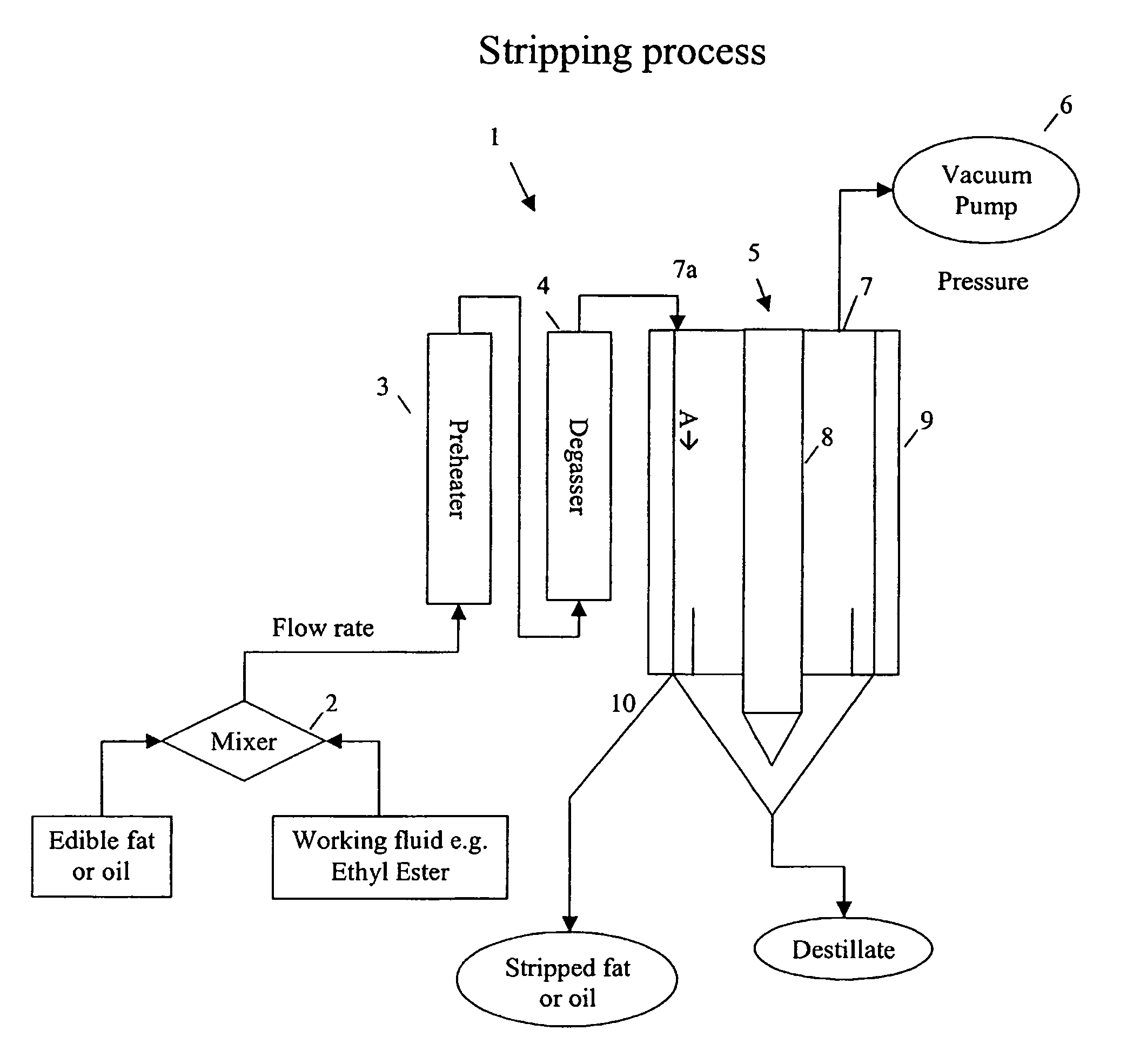

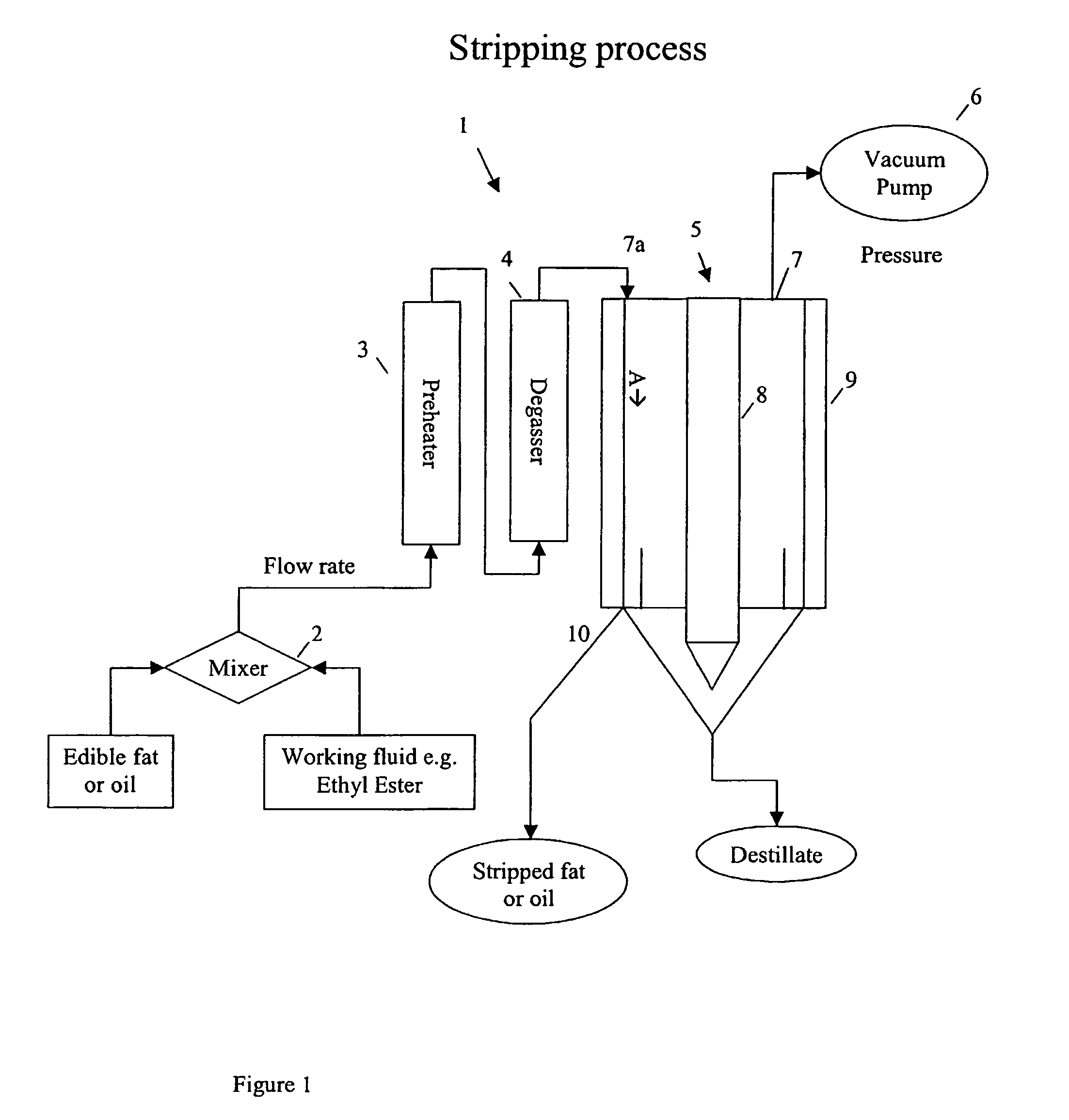

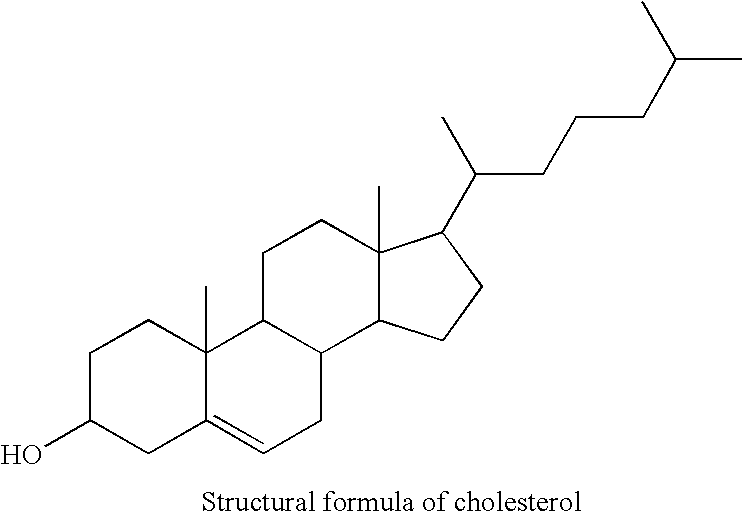

The invention relates to a process for decreasing the amount of cholesterol in a mixture comprising a marine oil, the marine oil containing the cholesterol, which process comprises the steps of adding a volatile working fluid to the mixture, where the volatile working fluid comprises at least one of a fatty acid ester, a fatty acid amide and a hydrocarbon, and subjecting the mixture with the added volatile working fluid to at least one stripping processing step, in which an amount of cholesterol present in the marine oil in free form is separated from the mixture together with the volatile working fluid. The present invention also relates to a volatile cholesterol decreasing working fluid and a health supplement and a pharmaceutical, based on a marine oil, prepared according to the process mentioned above.

Owner:PRONOVA BIOPHARMA NORGE

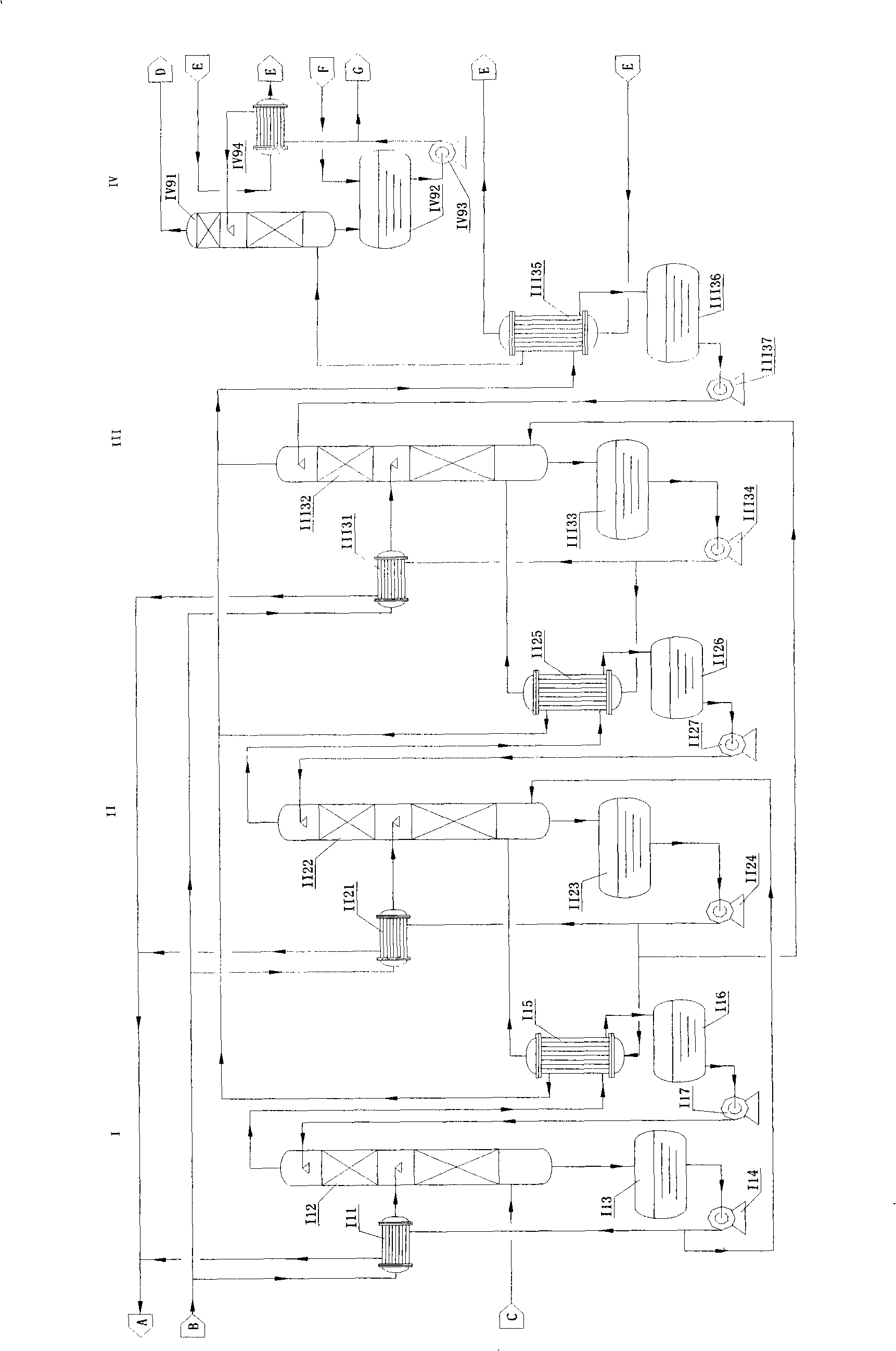

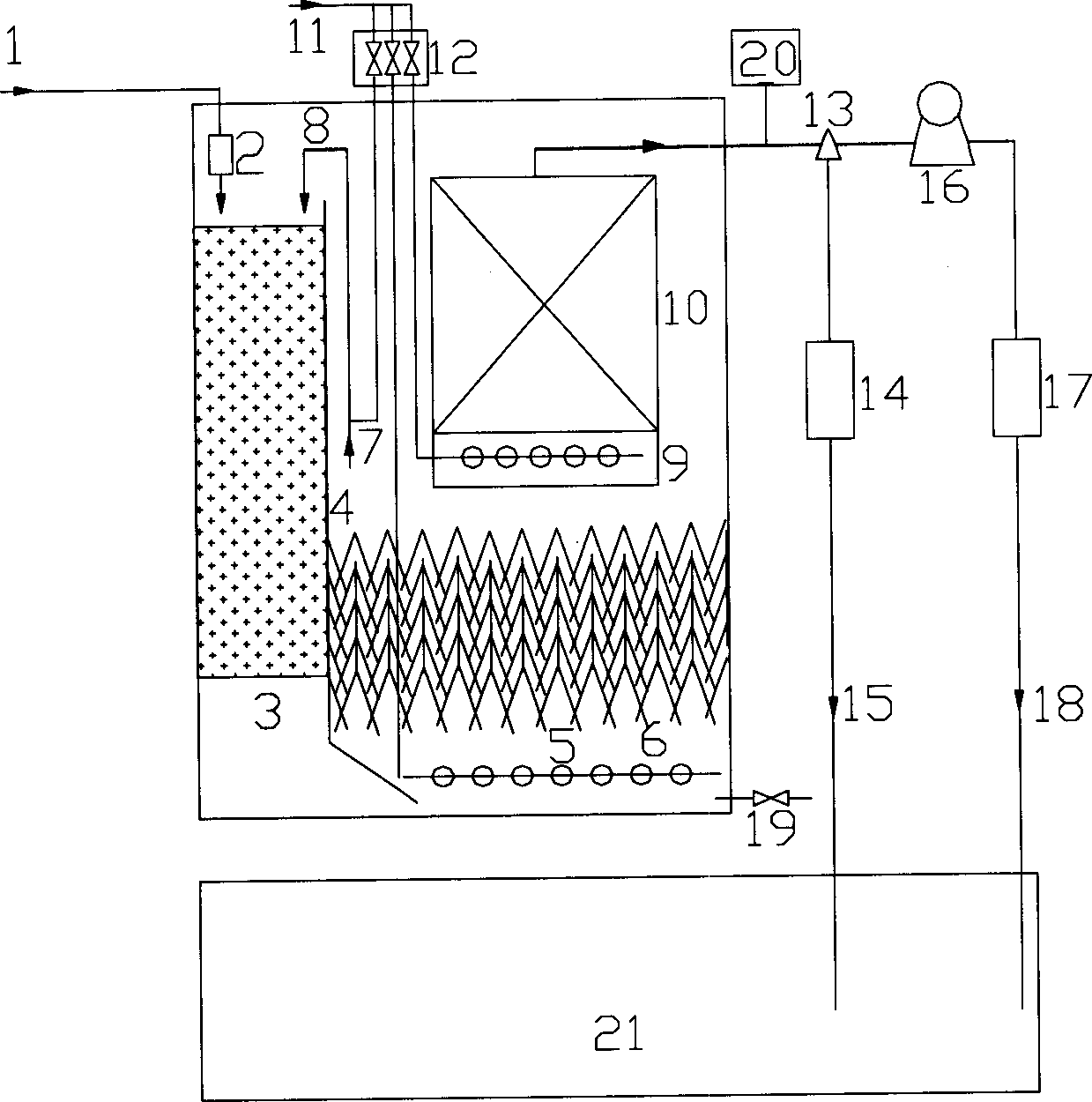

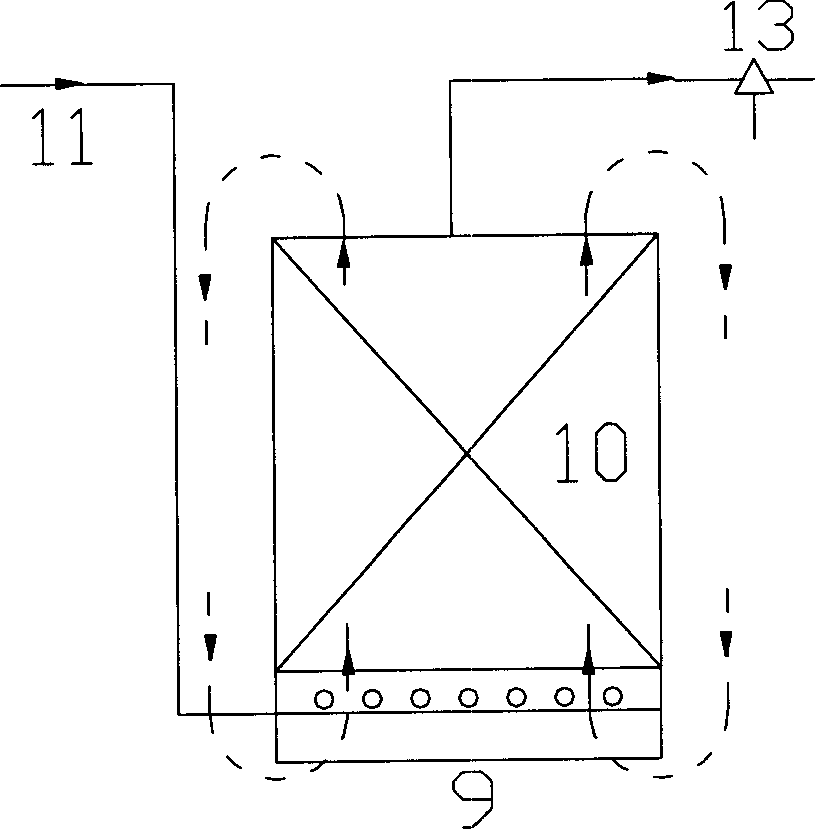

Ammonia nitrogen waste water discharge-reducing and ammonia nitrogen resource utilizing device and method

InactiveCN101264948AReduce consumptionWater/sewage treatment by degassingAfter treatmentResource utilization

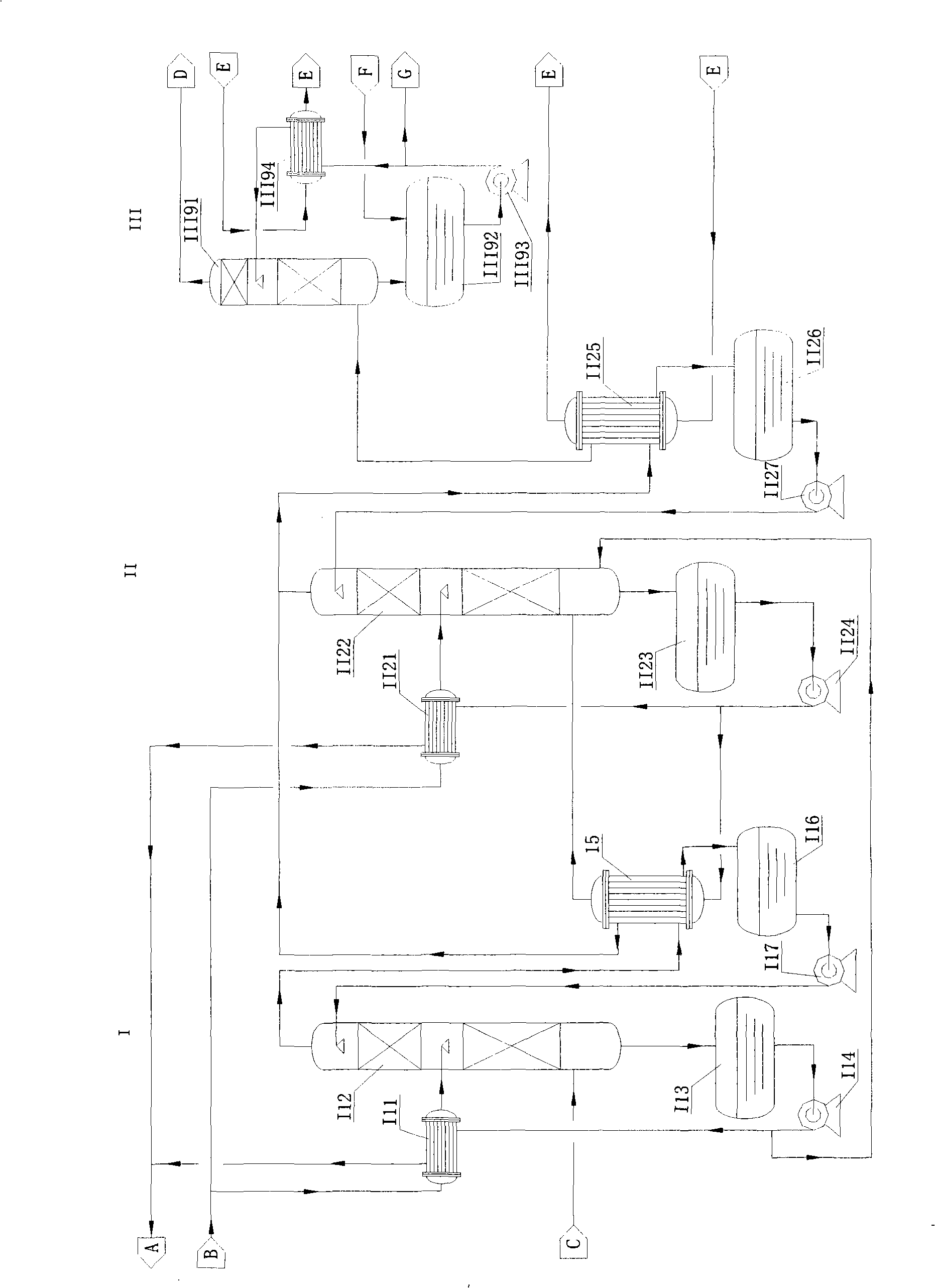

The invention relates to a device for ammonia nitrogen wastewater discharge reduction and ammonia nitrogen resource utilization and a method thereof, and belongs to the field of wastewater discharge reduction. The conventional steam blow-off method has high unit energy consumption (250-300 Kg steam / ton wastewater) in ammonia nitrogen wastewater treatment, thus resulting in very high ammonia nitrogen wastewater treatment cost. The inventive device comprises at least two stages of ammonia nitrogen stripping step and ammonia nitrogen reutilization step. The ammonia nitrogen wastewater to be treated is respectively fed into each stage of ammonia nitrogen stripping step, and the removal of ammonia nitrogen in wastewater is realized in ammonia nitrogen stripping tower and the resource utilization is realized in the ammonia nitrogen reutilization step. Except for the first stage of the ammonia nitrogen stripping tower requiring steam introduction, the steam required on other stages of ammonia nitrogen stripping tower is obtained by vaporization of a part of the tower bottom liquid in each tower by using the heat released via condensation of a part of steam in the upper stage tower and flash evaporation of the tower bottom liquid in the upper stage tower, so as to remarkably reduce steam consumption. The inventive device and method have the advantages of high ammonia nitrogen content wastewater treatment, low ammonia nitrogen content in wastewater after treatment, low steam consumption, and low treatment cost.

Owner:BEIJING UNIV OF CHEM TECH

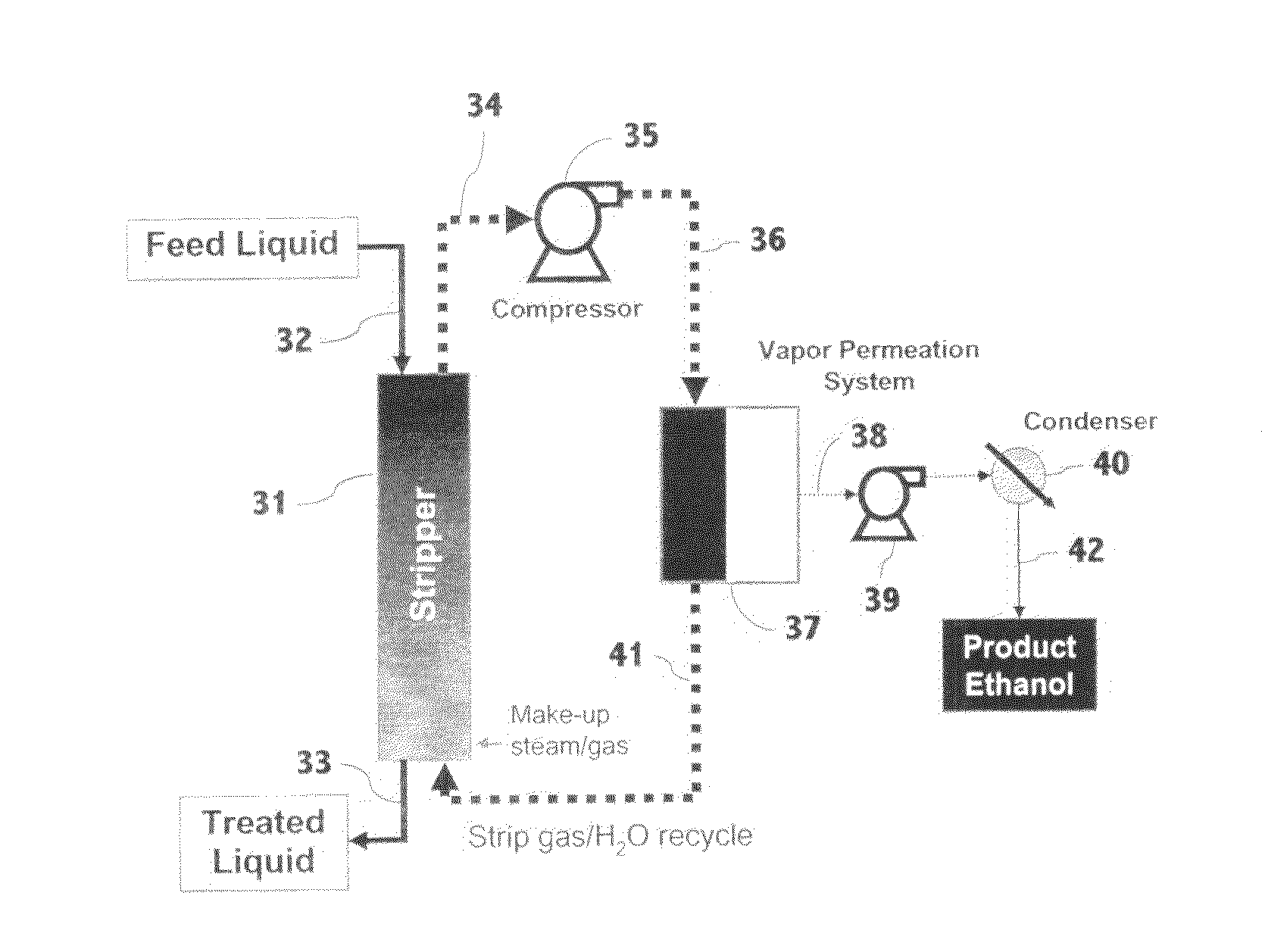

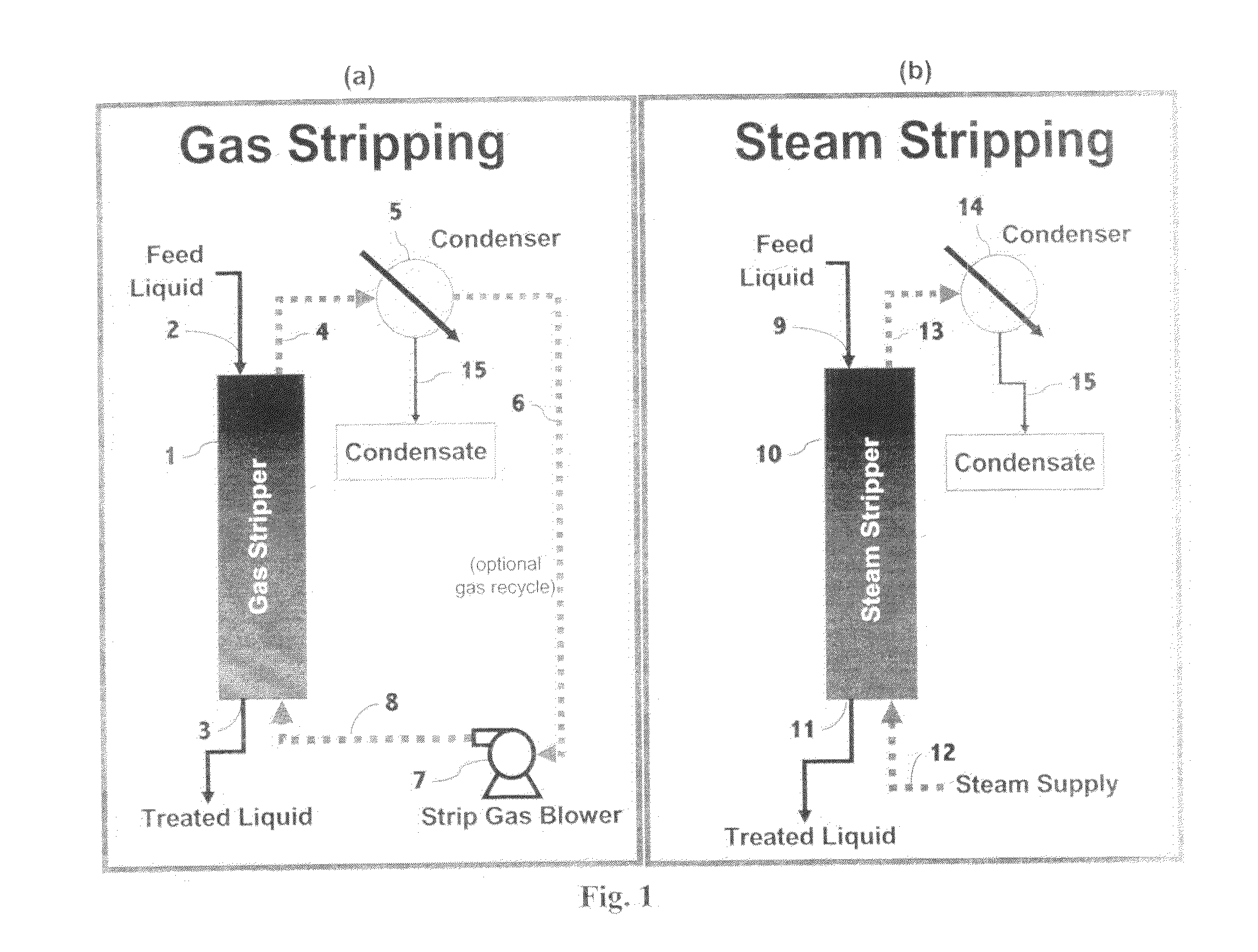

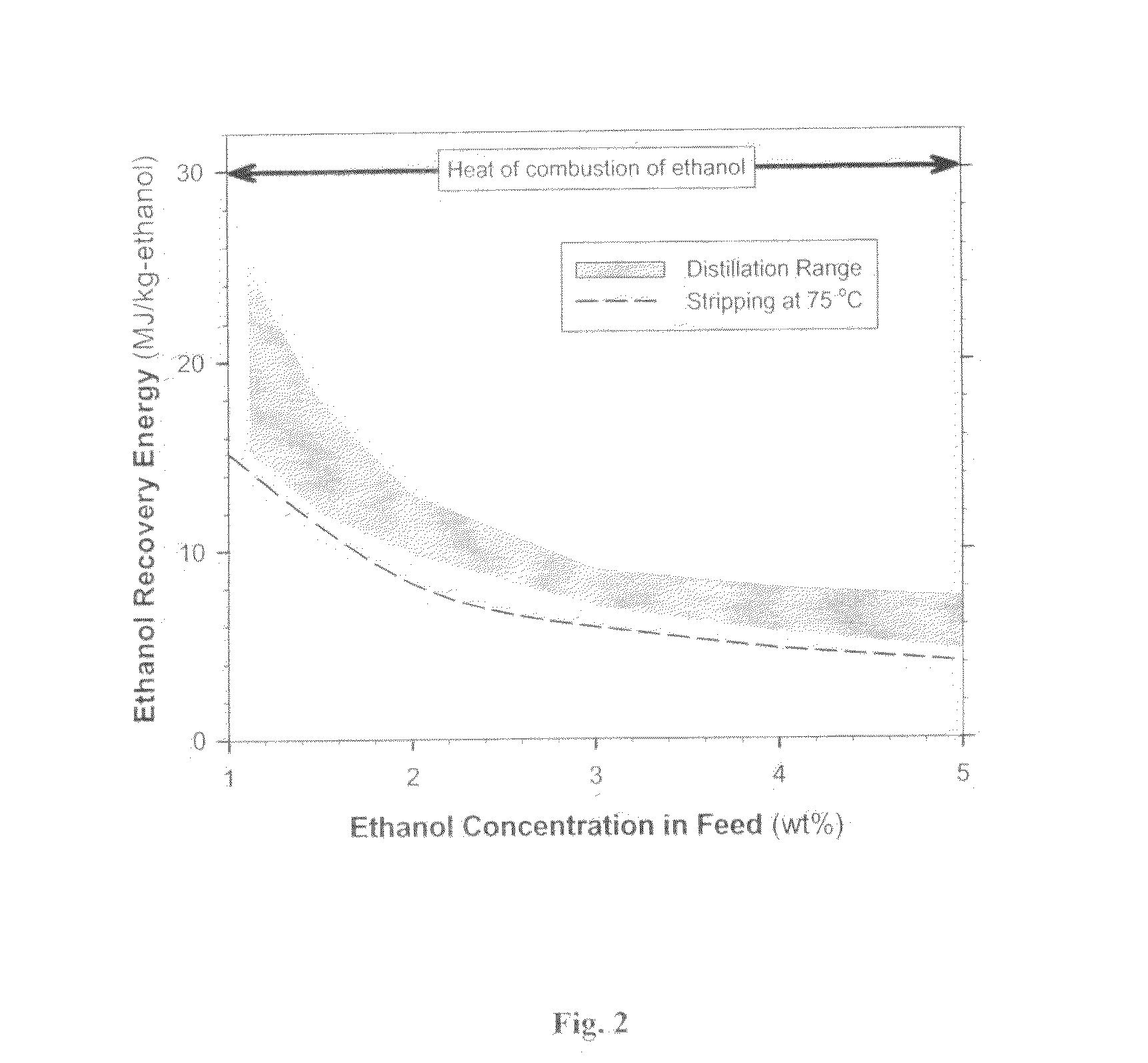

Liquid separation by membrane assisted vapor stripping process

InactiveUS20090057128A1Distillation regulation/controlUsing liquid separation agentImproved methodPermeation

An improved process for separation of liquid mixtures involves vapor stripping followed by mechanical compression of the vapor which is then exposed to a permeation membrane for separation of the compressed vapor.

Owner:VANE LELAND +1

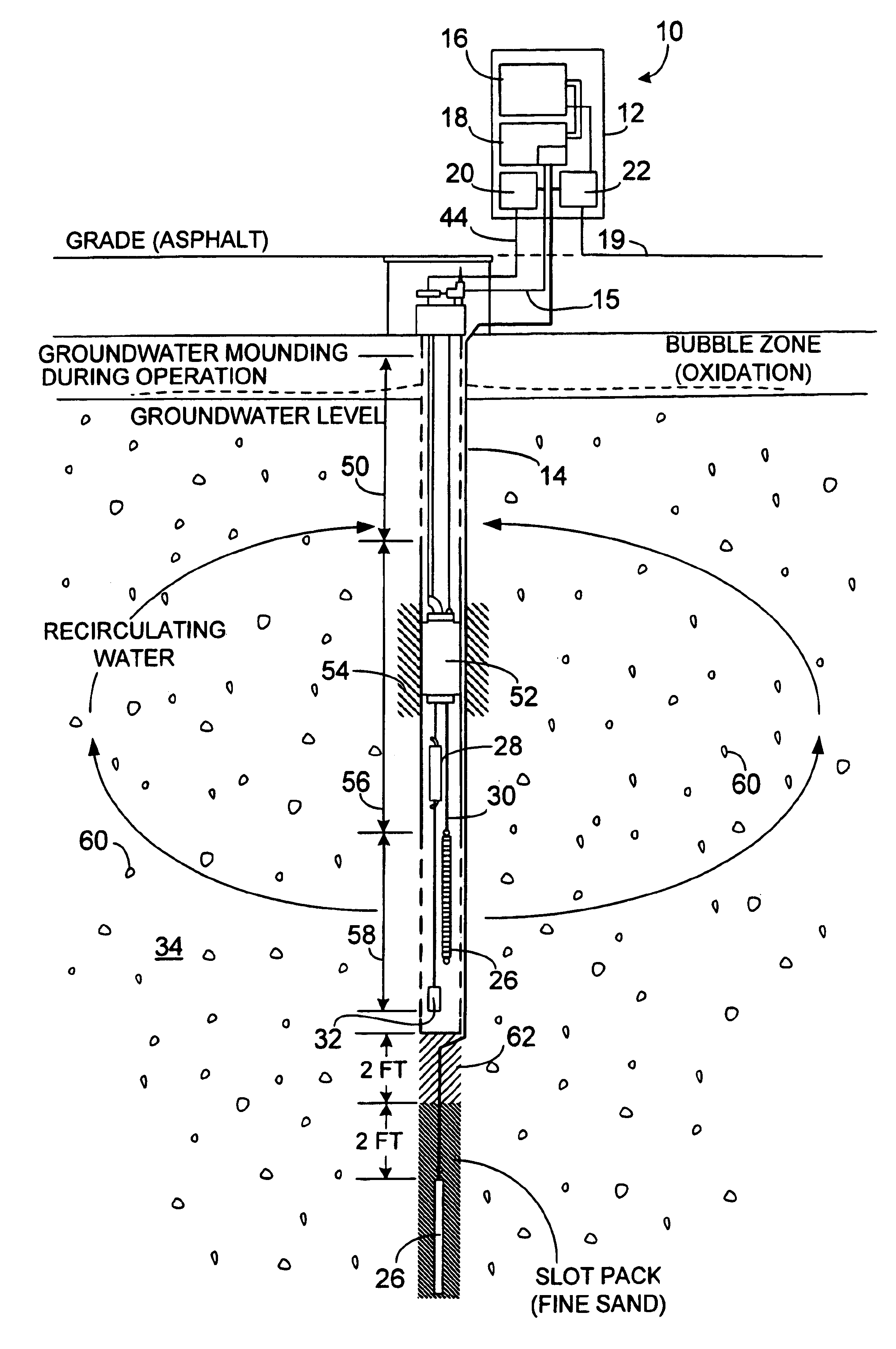

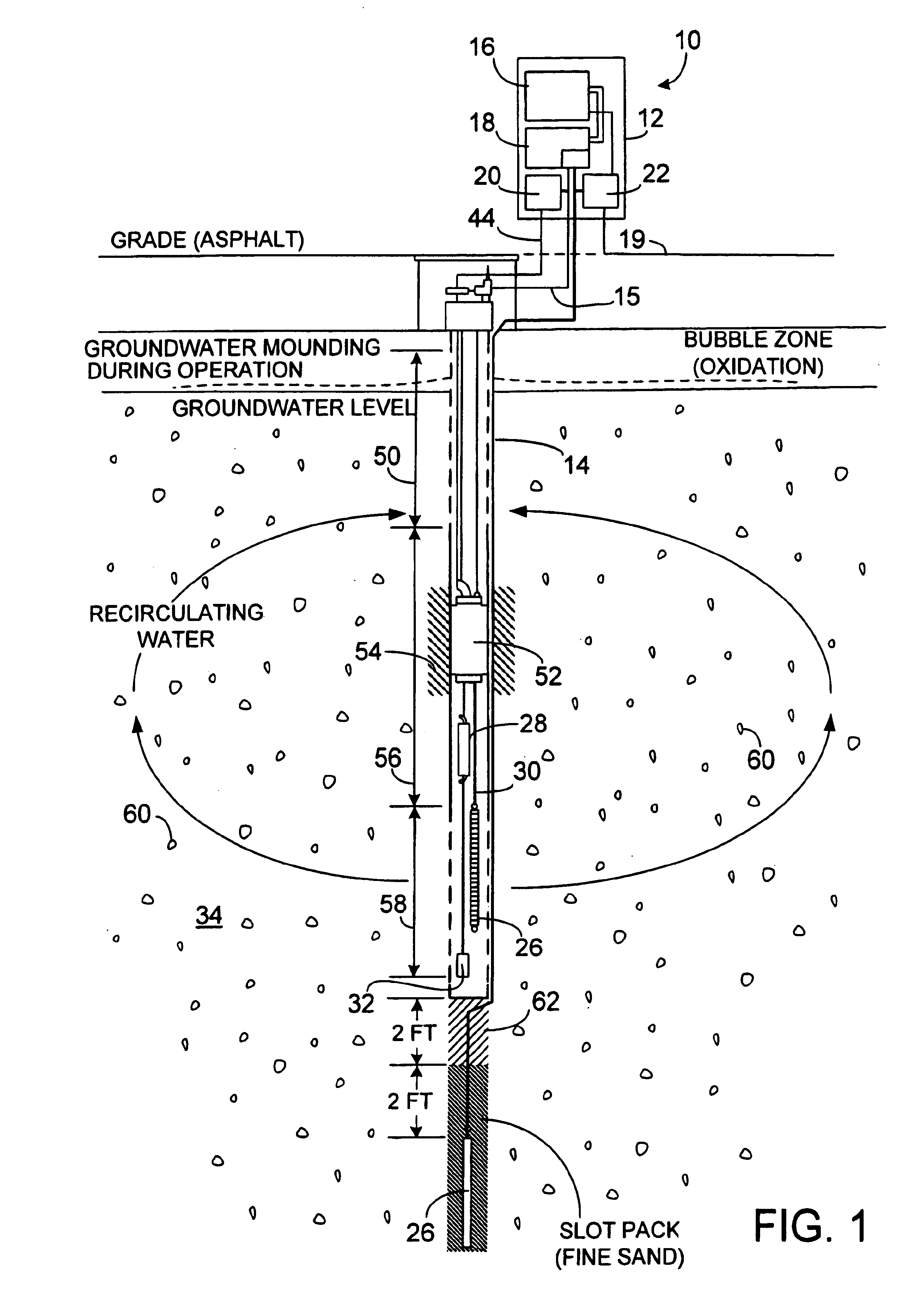

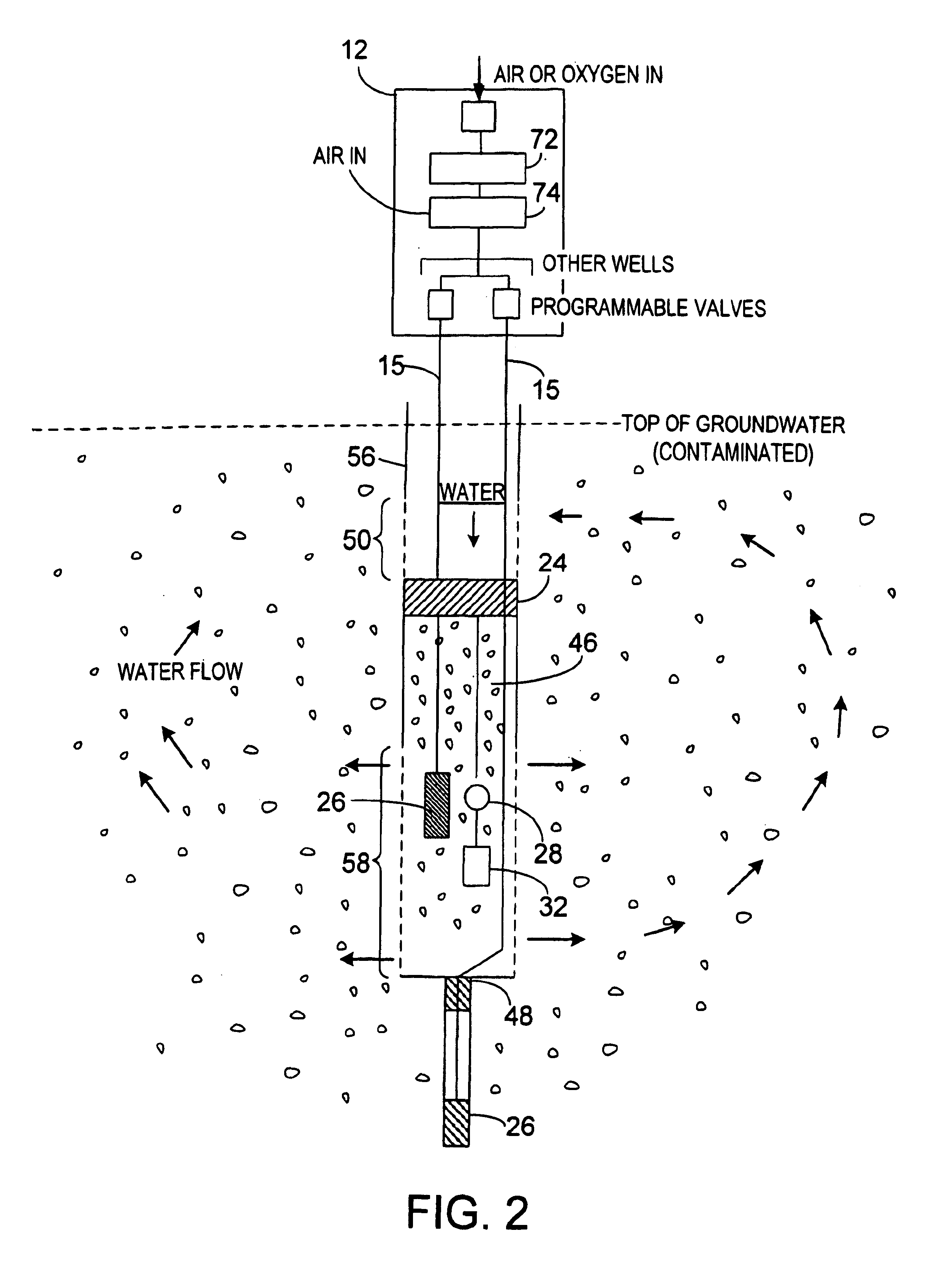

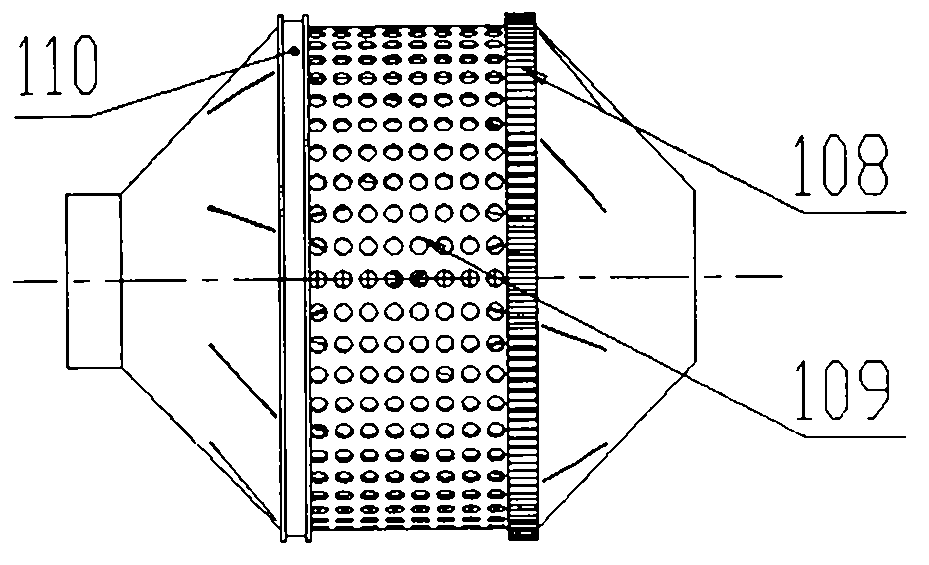

Microporous diffusion apparatus

InactiveUS6872318B2Efficient removalTreatment using aerobic processesTransportation and packagingDecompositionBioremediation

Apparatus for active in situ multi-element gas sparging for bioremediation or physico-chemical degration for removal of contaminants in a soil formation containing a subsurface groundwater aquifer or a substantially wet unsaturated zone, the multi-gas contained in bubbles, wherein the apparatus includes a plurality of injection wells extending to a depth of a selected aquifer; introducing an oxidizing agent comprising ozone mixed with ambient air to provide a multi-element gas by means of microporous diffusers, without applying a vacuum for extraction of stripped products or biodegration by-products, wherein said diffusers form micro-fine bubbles containing said multi-element gas that oxidizes, by stripping and decomposition, chlorinated hydrocarbons from the aquifer and surrounding saturated soil formation into harmless by-products; also including a pump for agitating water in the well selecting microbubbles, injecting them into the aquifer and effective to alter the path of micro-fine bubbles through a porous solid formation whereby enhanced contact between the oxidizing agent contained in each said bubble by stripping pollutant from solution in ambient water into the mini-atmosphere of each bubble effective to increase the efficiency and speed of remediation of a site.

Owner:KERFOOT TECH

Method for producing environment-friendly rubber filling oil

The invention relates to a method for producing environment-friendly rubber filling oil, which comprises the following steps: performing extraction through back flow and sufficient contact in an extraction tower by using the specific gravity difference of raw oil and a solvent; dissolving polycyclic aromatic hydrocarbon in the raw oil into the solvent, and depositing the polycyclic aromatic hydrocarbon to the bottom area of the tower automatically; raising the raw oil after the extraction to the top of the tower automatically; performing solvent recovery through a steam stripping process; and removing the carried solvent to obtain the environment-friendly rubber filling oil. The method has the advantages that the environmental protection of an oil product meets European Union requirements, the oil product has good compatibility with rubber, and the adopted solvent recovery process has the advantages of high solvent recovery rate, easily achieved conditions and the like.

Owner:NO 2 OIL PRODION PLANT HENAN OIL FIELD BRANCHCORP SINOPEC

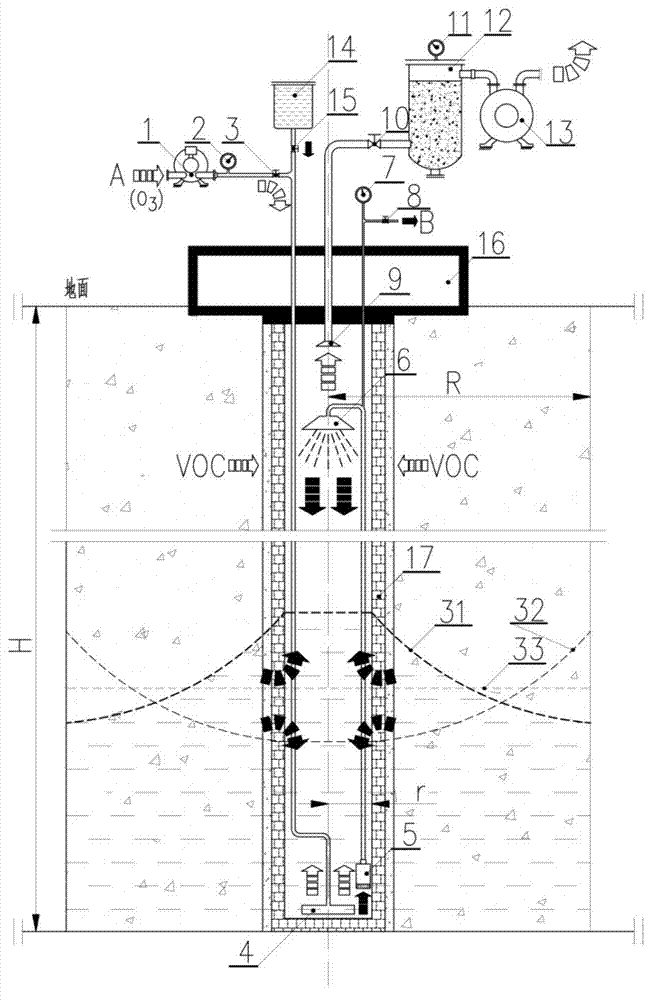

Circulation well method and device for removing pollutants in underground water

ActiveCN103112915AWell mixedWide adaptabilityWater/sewage treatment by irradiationWater contaminantsSoil propertiesAir pump

The invention relates to a circulation well method for removing pollutants in underground water. The circulation well is arranged in a polluted place and is in a continuous plum-blossom-shaped, square or hexagonal layout according to soil property, pollution level and radius of influence on soil by equipment. The circulation well is characterized in that 1-N water wells of which the diameter is not smaller than 100 mm and the depth is greater than one meter are drilled, and treatment processes of aeration, air stripping, extraction and dosing are performed to treat the polluted water in the well, wherein the air stripping treatment process: the well water (i.e. underground water) is lifted to the top of the well and is then sprayed downwards through a spray head; in the aeration and extraction treatment processes: the in-well aeration and the air-emptied extraction increase the air-liquid mass transfer interface and enhance the air stripping effect, and the dissolved oxygen content in the underground water is increased in the in-well aeration process, so that the polluted water is placed in an aerobic environment; and in the dosing treatment process: according to different pollution levels and pollutants, oxidizer, a microbial preparation, ozone or / and flocculant are added at an air inlet A of a high-pressure air pump for aeration or in a special dosing pipe.

Owner:JIANGSU DDBS ENVIRONMENT REMEDIATION

Regeneratable wet fuel gas desulfurizing technology

InactiveCN101185838AReduce lossesLarge absorption capacityDispersed particle separationLoss rateFlue gas

The invention discloses a reproducible wet flue gas desulfurization technique, which solves the problems of the prior art of high operation cost and high loss rate when absorbent is in use. The invention is characterized in that after going through a washing tower, flue gas containing gas SO< X > is then connected with the absorbent in a reverse flow in an absorption tower; the purified flue gas is discharged into the atmosphere; a portion of pregnant solution absorbent directly returns to the absorption tower for circular application, wherein SO2 of the flue gas is absorbed by the pregnant solution; a portion of air stripping is used circularly after a regeneration. The invention has the advantages that the energy consumption and operation cost of the technique are low, and loss of the absorbent is small.

Owner:CHINA PETROCHEMICAL CORP +1

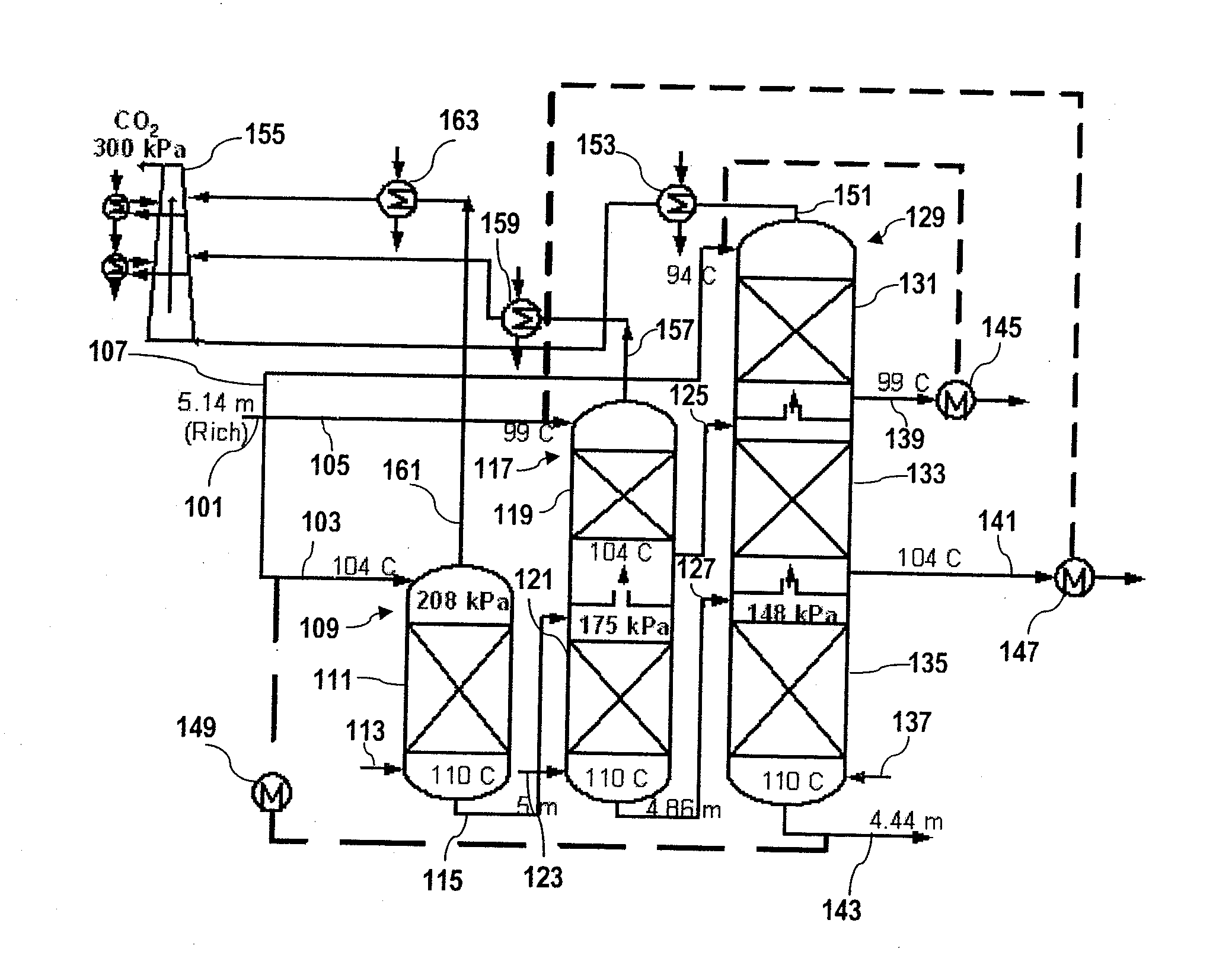

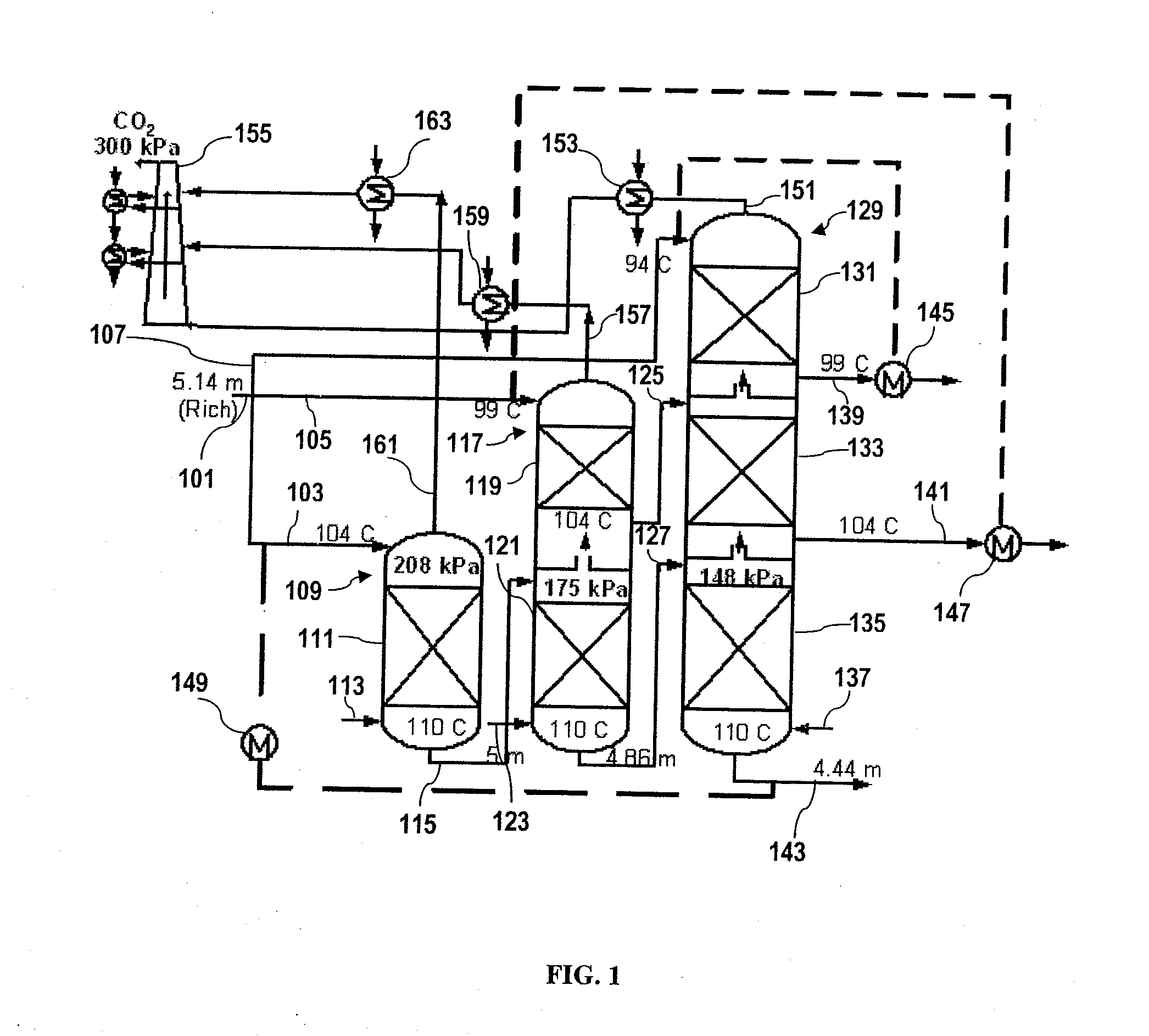

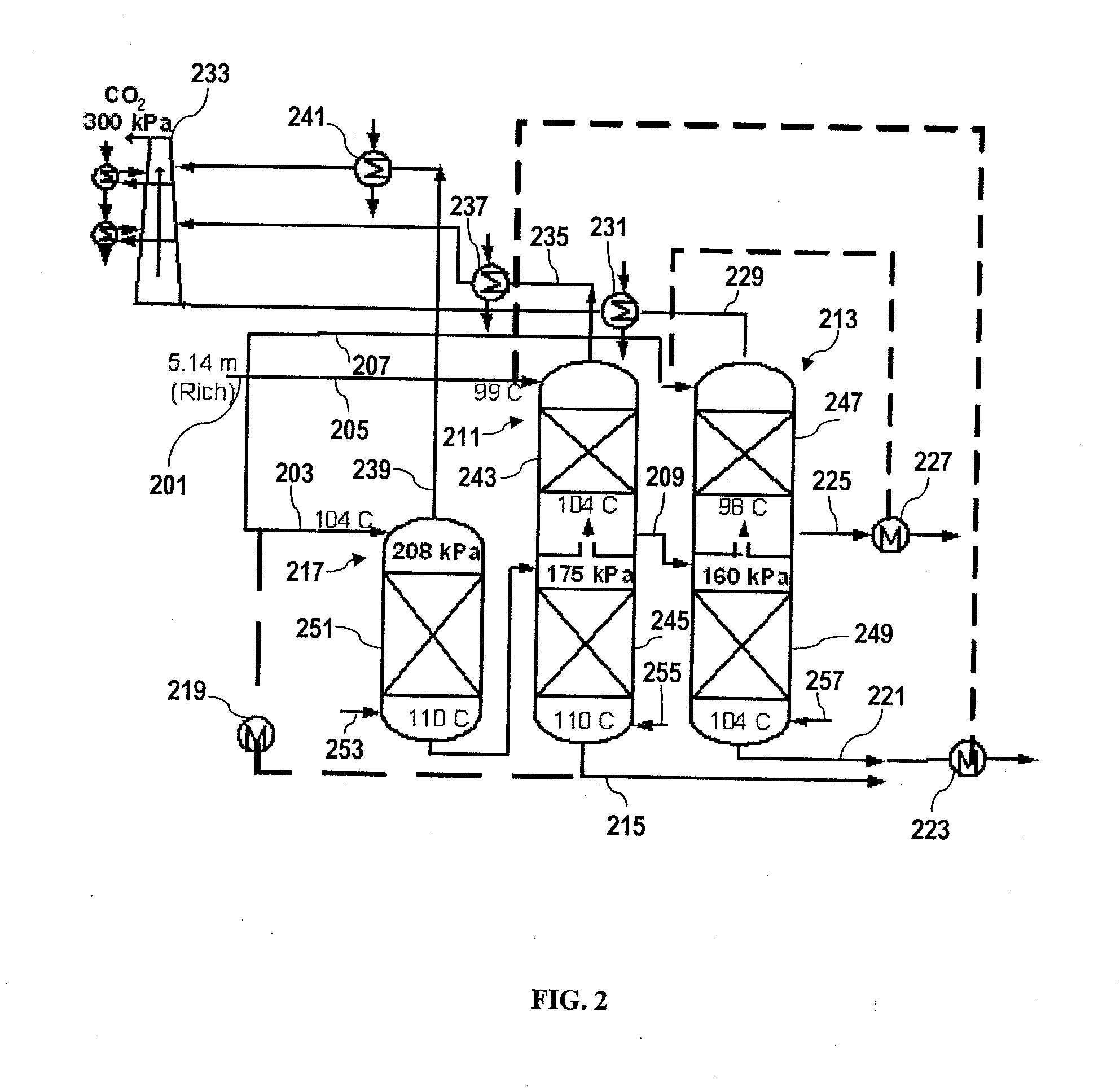

Regeneration of an Aqueous Solution from an Acid Gas Absorportion Process by Matrix Stripping

Carbon dioxide and other acid gases are removed from gaseous streams using aqueous absorption and stripping processes. By replacing the conventional stripper used to regenerate the aqueous solvent and capture the acid gas with a matrix stripping configuration, less energy is consumed. The matrix stripping configuration uses two or more reboiled strippers at different pressures. The rich feed from the absorption equipment is split among the strippers, and partially regenerated solvent from the highest pressure stripper flows to the middle of sequentially lower pressure strippers in a “matrix” pattern. By selecting certain parameters of the matrix stripping configuration such that the total energy required by the strippers to achieve a desired percentage of acid gas removal from the gaseous stream is minimized, further energy savings can be realized.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Composite denitrification agent for treating medium concentration ammonia nitrogen wastewater and denitrification method

ActiveCN101475251ANo secondary pollution purposeHigh removal rateWater/sewage treatmentSoil organic matterKetone

The invention discloses a composite denitrifier for treating medium concentration ammonia nitrogen wastewater and a denitrification method. The composite denitrifier is compounded by organic matter and inorganic matter, wherein the organic matter consists of organic ketone, a surfactant and a macromolecular polymer, wherein the organic ketone accounts for 10 to 60 percent; the surfactant accounts for 10 to 60 percent; the macromolecular polymer accounts for 10 to 60 percent; the inorganic matter accounts for 10 to 70 percent; the composite denitrifier prepared in proportion is added to the medium concentration ammonia nitrogen wastewater, wherein the addition amount is between 10 and 50 ppm; the PH value of the wastewater is regulated between 7.0 and 13.0; and the wastewater is aerated for 1.0 to 2.0 hours. As long as the composite denitrifier is added to the wastewater, the denitrification can be carried out in an aeration pool or an air stripping tower, and can reduce the medium concentration ammonia nitrogen wastewater from 10,000mg / L to less than 0.5mg / L; and the removing rate reaches as high as 99.99 percent. The composite denitrifier has available raw materials and small dosage; and the denitrification method is simple.

Owner:溧阳常大技术转移中心有限公司

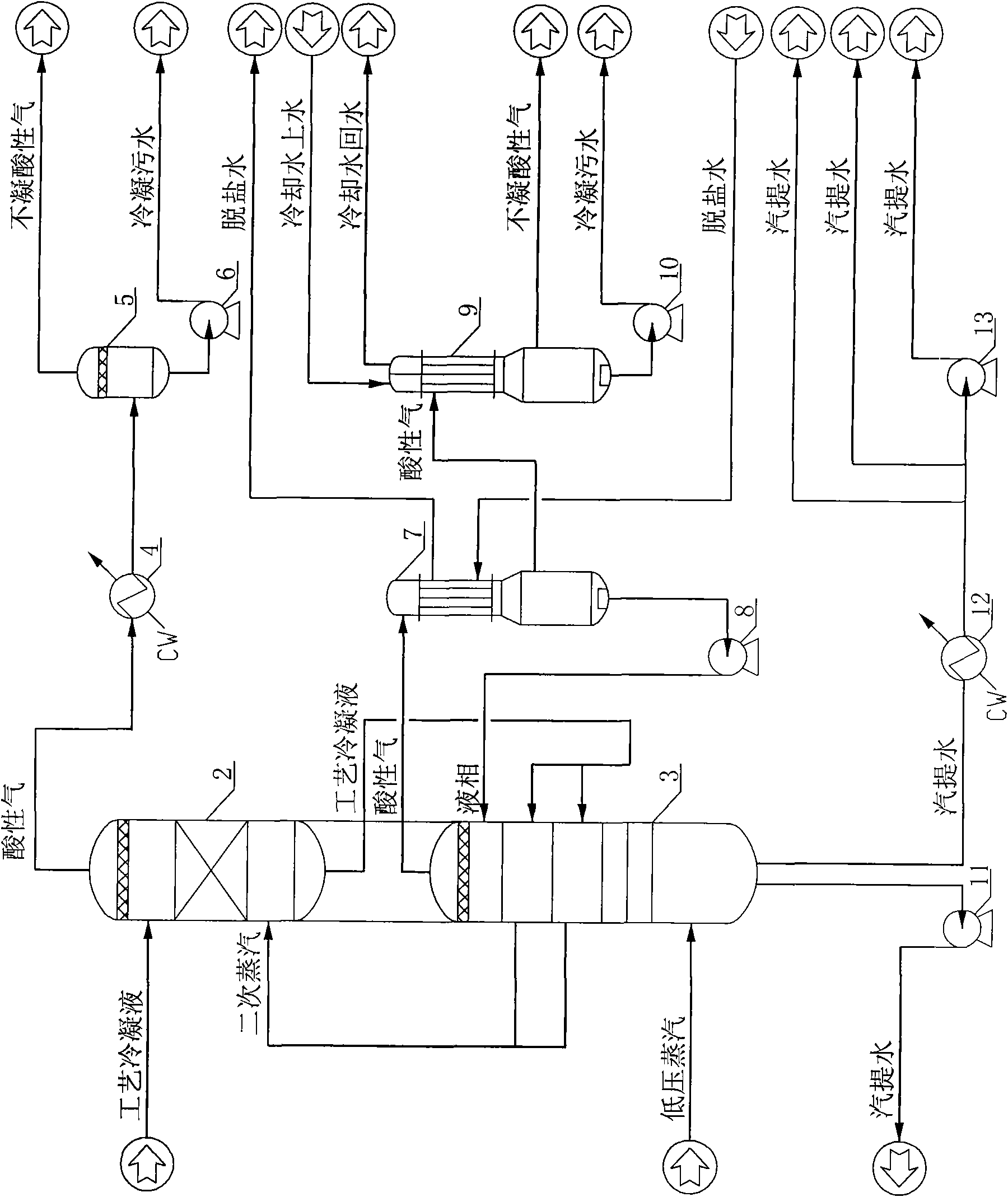

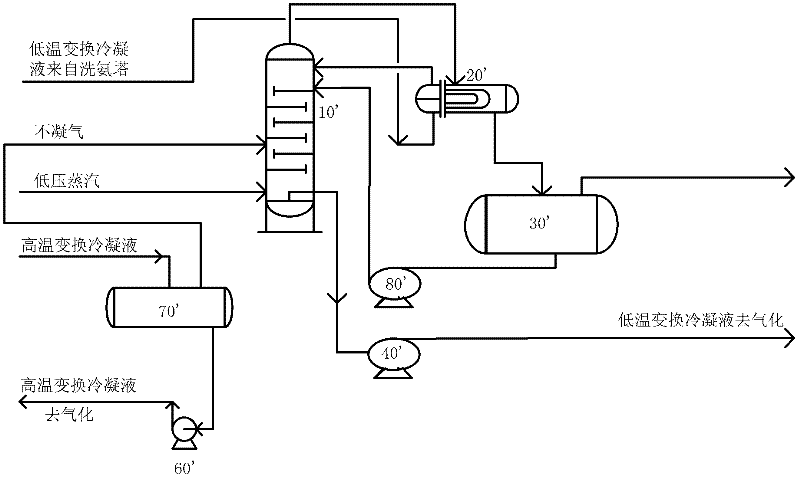

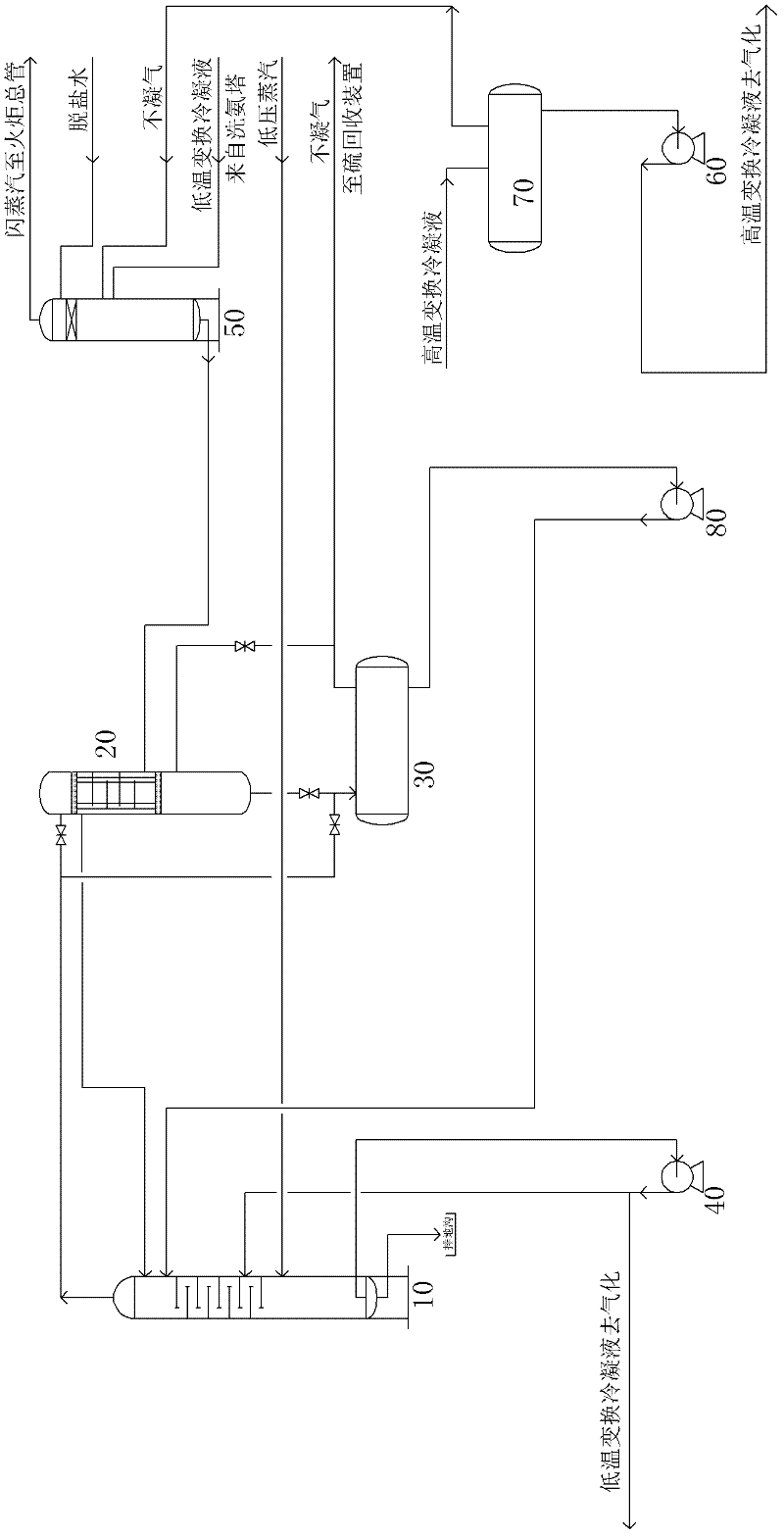

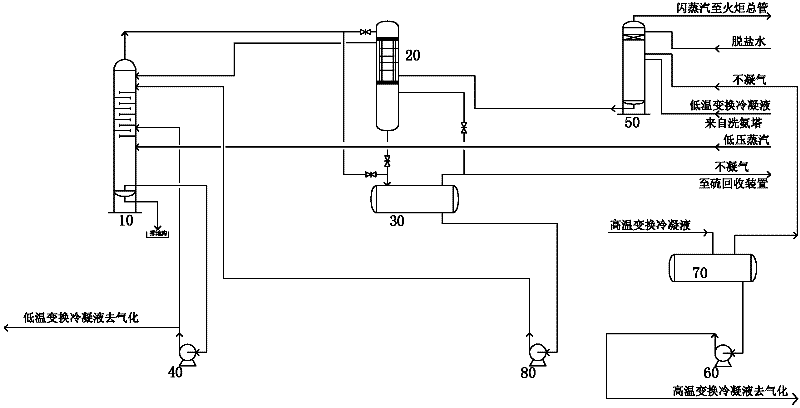

Steam stripping method of process condensate in CO conversion

ActiveCN101570350AAvoid the possibility of simultaneousSolve the blockageWater/sewage treatment by heatingWater/sewage treatment by degassingGas phaseEvaporation

The invention relates to a steam stripping method of process condensate in CO conversion. The invention is characterized in that the process condensate firstly enters the upper part of a carbon dioxide steam stripping tower for flashing evaporation; secondary steam from the upper part of an ammonia-evaporated steam stripper tower enters the bottom part of the carbon dioxide steam stripping tower and steam strips carbon dioxide by countercurrent contacting with the process condensate after flashing evaporation; the process condensate after flash evaporation and the steam stripped carbon dioxide carry out countercurrent contact; the process condensate after flash evaporation and steam stripping enters the upper part of the ammonia-evaporated steam stripper tower from the bottom part of the carbon dioxide steam stripping tower and is steam-stripped by low-pressure steam entering from a kettle of the ammonia-evaporated steam stripper tower; gas phase is treated by secondary condensation to obtain non-acid-coagulated gas and condensate sewage; and steam stripping water is obtained from the bottom part of the ammonia-evaporated steam stripper tower. The invention carries out steam stripping on the upper and lower towers to carbon dioxide and ammonia in the process condensate respectively, thus avoiding the possibility of coexistence of carbon dioxide and ammonia in a condensing system, effectively solving the problem that the steam stripping system of the process condensate in the conversion procedure occurs ammonium salt crystallization blockage and prolonging the period of stable operation of a conversion device.

Owner:CHINA PETROCHEMICAL CORP +2

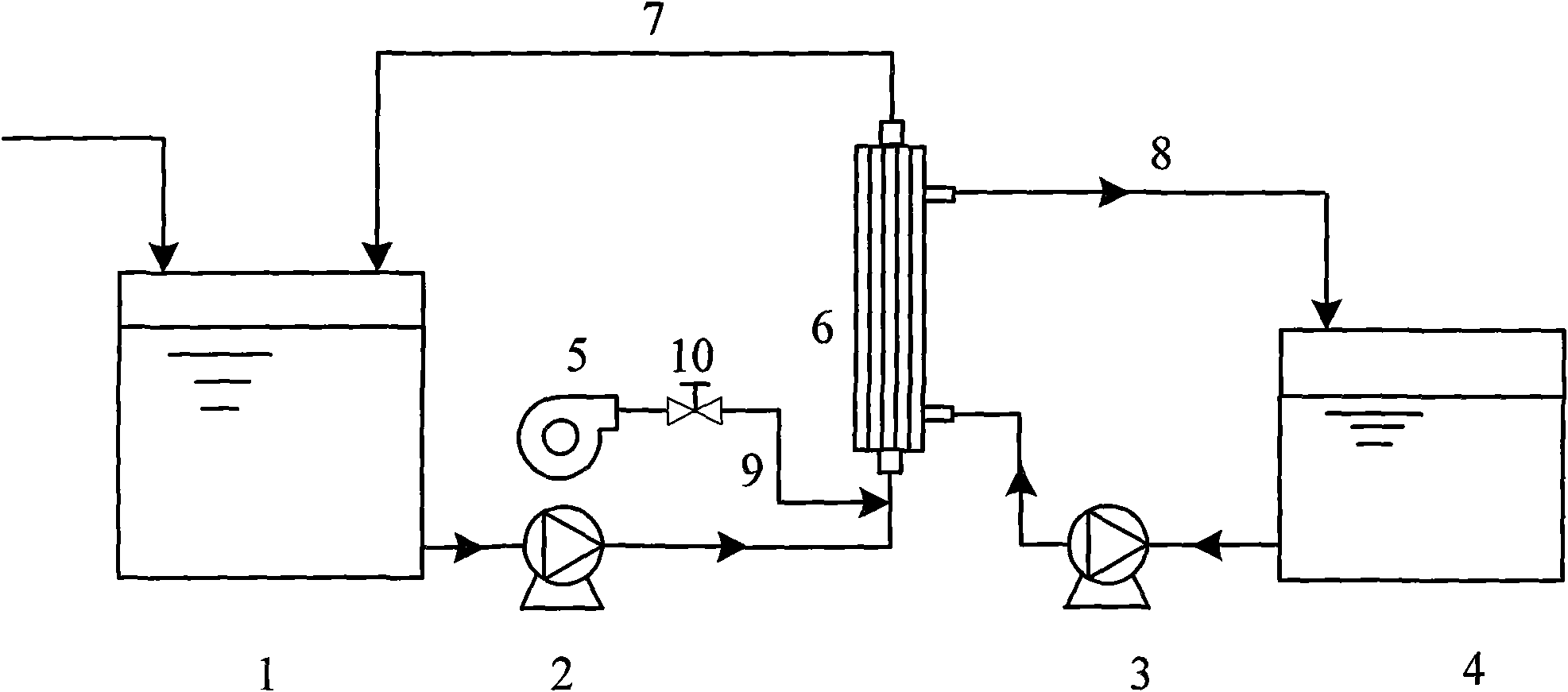

Method for treating high-salt water by air stripping type membrane distillation

ActiveCN101659451AReduce concentration polarizationIncreased turbulenceWater/sewage treatment bu osmosis/dialysisEnergy based wastewater treatmentHigh concentrationConcentration polarization

The invention provides a method for treating high-salt water by air stripping type membrane distillation. In the method, an air compressor is arranged in the system, a hydrothermal circulation pump and the air compressor jointly generate a gas-liquid two phase flow on a high-temperature side of a hydrophobic membrane, an electromagnetic valve is arranged on an air pipe, and pulse air intake is formed by the intermittent opening and closing of the electromagnetic valve. The method can effectively control membrane pollution and ensures the stable and high-efficiency operation of a membrane distillation device. The method has the main advantages of effectively relieving the concentration polarization of membrane distillation and preventing the formation of a gel layer due to the scraping effect of air bubbles on membrane surfaces in the gas-liquid two phase flow, and improving the turbulence scale of the membrane surfaces, increasing the membrane surface flow rate, reducing the concentration of membrane surface salt solution and increasing membrane permeation flux due to the adoption of pulse air intake. Air passing through a membrane component can be used for cooling membrane distillation penetrating fluid. The method of the invention can treat salt water with an extremely high concentration.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

Sewage storage tank exhaust air-release purification processing method

ActiveCN101143297AEfficient removalEfficient recyclingDispersed particle separationWater/sewage treatment by heatingSolventStorage tank

The invention relates to a purification processing method of the discharge gas of an acid waste water tank, belongs to waste gas purification treatment technology. The invention makes the discharge gas of the acid waste water tank process two-stage purification treatment: the first stage purification treatment uses segregation liquid in the process of rich ammonia segregation in the acid waste water stripping process or stripping purified water as absorption liquid; the purification treatment in the second stage uses property stable and high boiling point solvent oil and so on as absorbent. The invention organically combines the acid waste water stripping process with the purification treatment process of the acid waste water tank discharge gas, which not only can remove the odorous substances in the acid waste water tank discharge gas, but also can effectively reclaim hydrocarbon substances. The invention has simple devices and low operation cost, and has no potential safety hazard.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composition for stripping photoresist and organic materials from substrate surfaces

InactiveUS6368421B1Reduce capacityEfficient removalNon-ionic surface-active compoundsNon-surface-active detergent compositionsSolventPhotoresist

The invention relates to the field of microelectronics, such as integrated circuits, and more particularly to compositions and methods of removing photoresists or other organic materials from the surfaces of substrates used in the fabrication of integrated circuits. In particular the present invention relates to amine-free stripping compositions comprising solvent and surfactant that can effectively remove organic materials without corroding the underlying substrate, and the invention also relates to methods for removing these organic materials with the novel stripping composition.

Owner:MERCK PATENT GMBH

Composite membrane bioreactor

InactiveCN1785829ALighten the decarbonization loadSimple structureWater/sewage treatment bu osmosis/dialysisTreatment with aerobic and anaerobic processesTreatment effectNitrogen

The present invention relates to sewage treatment equipment in the concrete, it is a composite membrane biological reactor capable of simultaneously removing carbon, nitrogen and phosphorus and having good treatment effect. It is characterized by that the reactor can be divided into anoxybiotic zone and aerobic zone by means of baffle plate, in said two zones the filling material is held respectively, the aerobic zone is divided into upper and lower two portions, the membrane box is placed in the upper portion of aerobic zone, the mixed liquor of aerobic zone is passed through air stripping device and back-flowed into anoxybiotic zone.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

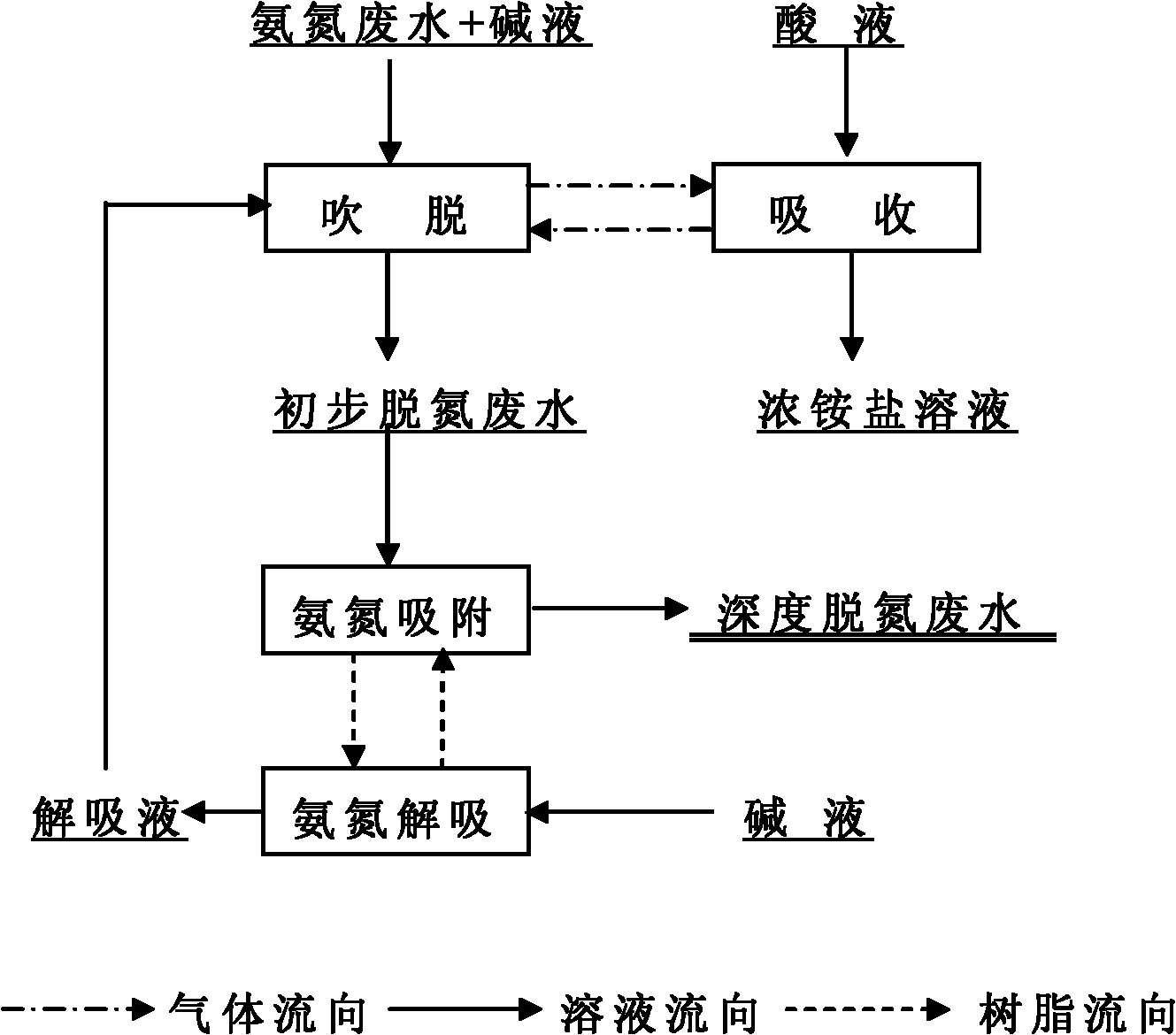

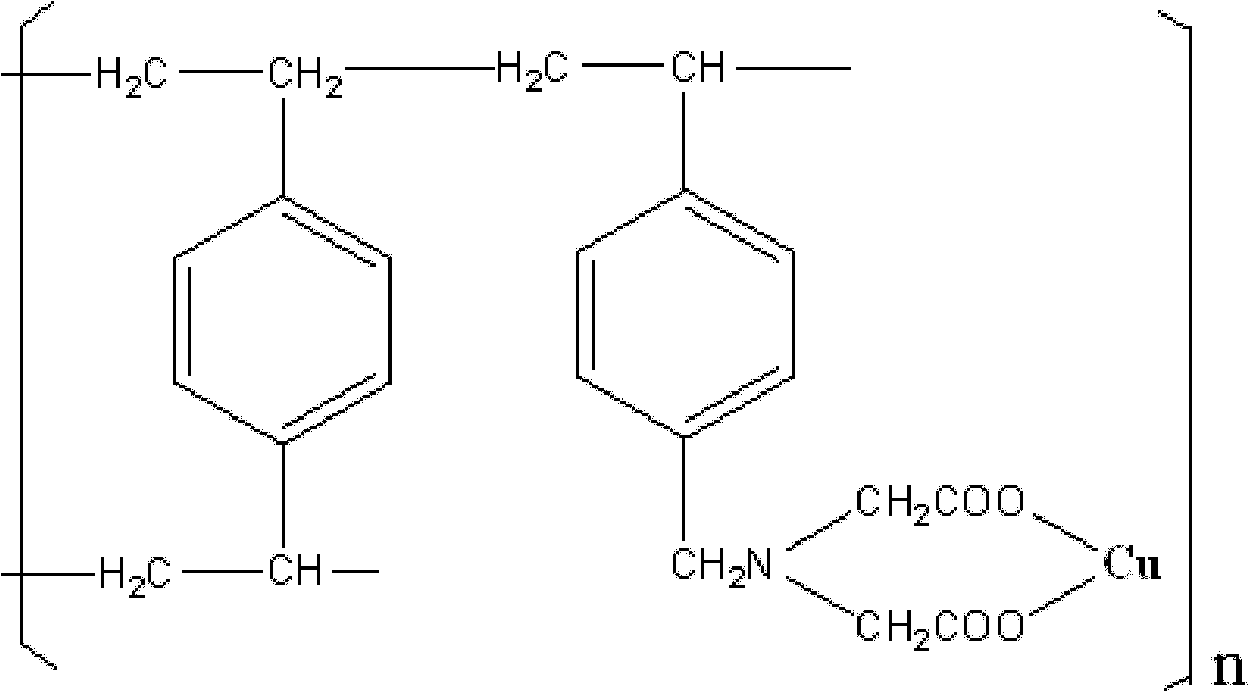

Treatment method of ammonia nitrogen wastewater

ActiveCN102030438ALow costLess investmentMultistage water/sewage treatmentHigh concentrationIon exchange

The invention discloses a treatment method of ammonia nitrogen wastewater. The method comprises the following steps: contacting the ammonia nitrogen wastewater is contacted with air under an alkaline condition so as to enter an air stripping procedure for preliminary denitrification; transferring the preliminarily denitrified wastewater to an ion exchange column containing ammonia nitrogen adsorbing resin for deep denitrification, and absorbing NH3 gas generated in the air stripping procedure with hydrochloric acid solution or sulfuric acid solution, wherein, the ammonia nitrogen adsorbing resin used in the ion exchange denitrification procedure is aminocarboxylic acid chelating cation exchange resin loaded with copper ions; and NaOH is taken as a desorbent so as to regenerate the resin, and then stripping liquid returns to the air stripping procedure. By utilizing the treatment method of the invention, the defect of a simple air stripping method such as low efficiency in the case of low ammonia nitrogen concentration is overcome, and meanwhile the problem of worse treatment capability while treating the high-concentration ammonia nitrogen wastewater by a simple ion exchange resin adsorption method is solved; and by taking alkali as a resin desorbent instead of acid, drug consumption and treatment cost are reduced. The treatment method of the invention is simple in process, economical, efficient and environmentally friendly, and is applicable to treating the ammonia nitrogen wastewater.

Owner:湖南中金岭南康盟环保科技有限公司

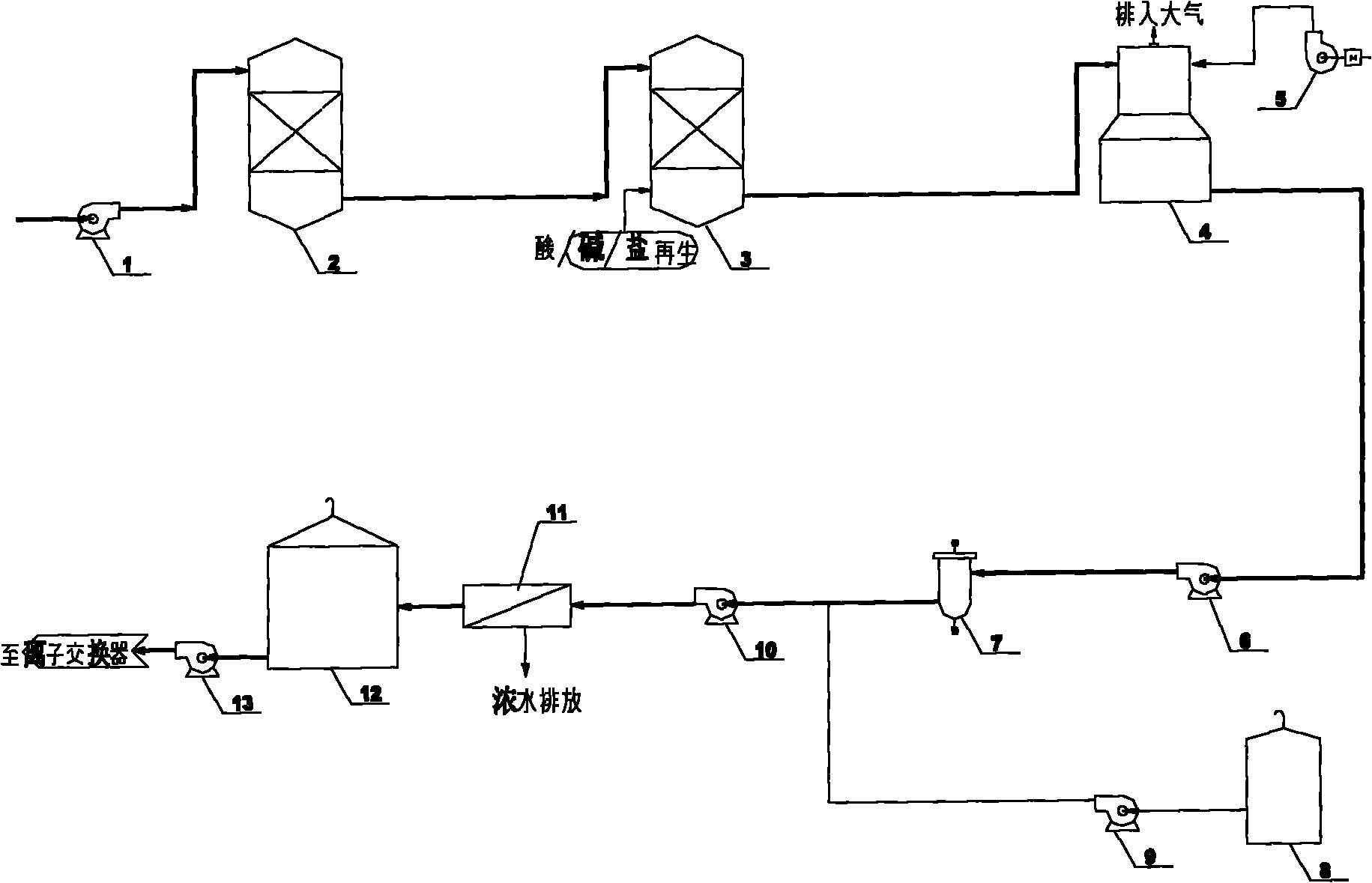

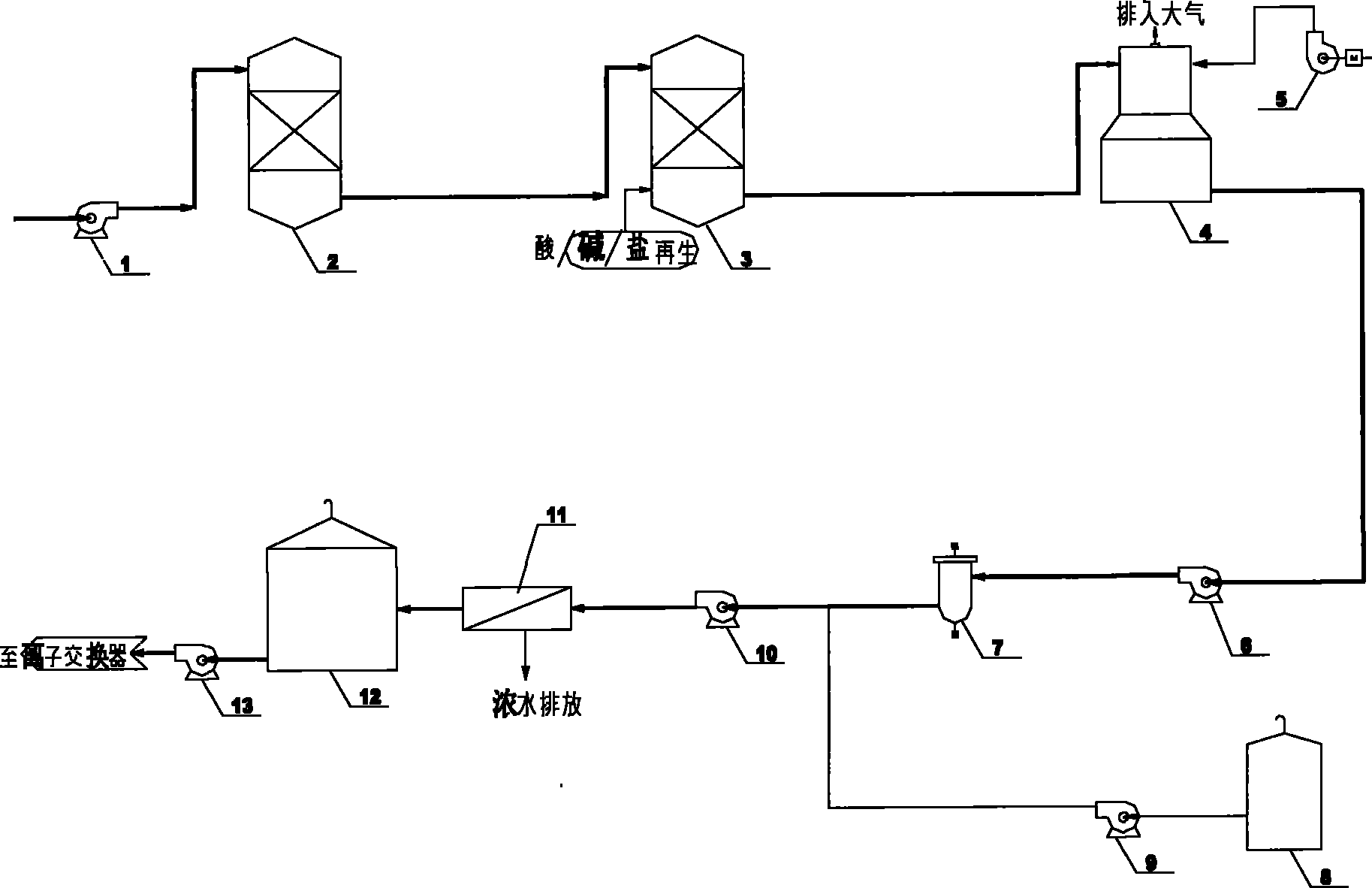

Wastewater recycling treatment process

InactiveCN101767888AImprove throughputEliminate scalingWater/sewage treatment by ion-exchangeWater/sewage treatment bu osmosis/dialysisFiltration membraneReverse osmosis

The invention discloses a wastewater recycling treatment process, which comprises the following steps: leading raw water to pass through a filter for removing suspended matters and solid particles in the raw water, leading outlet water of the filter to enter into an ion exchanger, removing calcium and magnesium ions in the raw water through ion exchange, further removing the hardness in the water, leading the outlet water of the ion exchanger to enter into a decarbonizing tower, and removing the alkalinity of the raw water under the air stripping action of a rotary fan; leading the raw water out of the decarbonizing tower to enter into a precision filter under the action of a lifting pump, lifting the outlet water of the precision filter to a nano-filtration / reverse osmosis system which is mainly formed by parallel connection and / or series connection of a nano-filtration membrane and a reverse osmosis membrane under the action of a high pressure pump, leading the nano-filtration / reverse osmosis system to discharge concentrated water, leading the nano-filtration / reverse osmosis system to drain produced water into a produced water tank, and becoming the final outlet water. The process can effectively avoid the membrane pollution, improve the recycling rate, further greatly reduce the discharge amount of wastewater, simultaneously reduce the using amount of membranes due to the improvement of running conditions of a membrane system and further reduce the investment and the running cost.

Owner:郑理慎

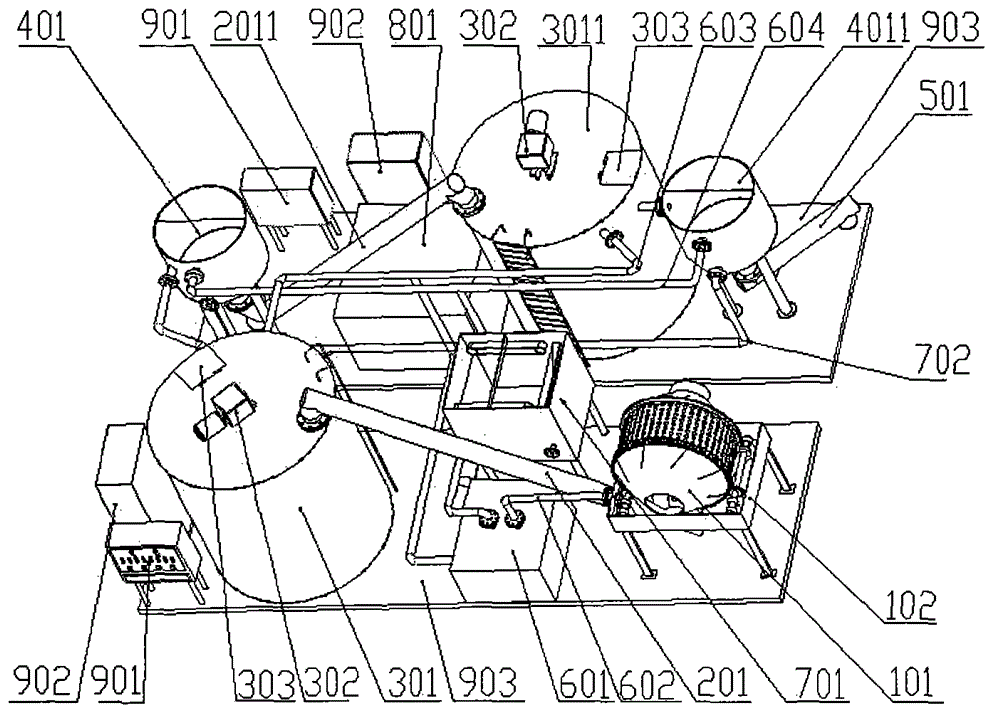

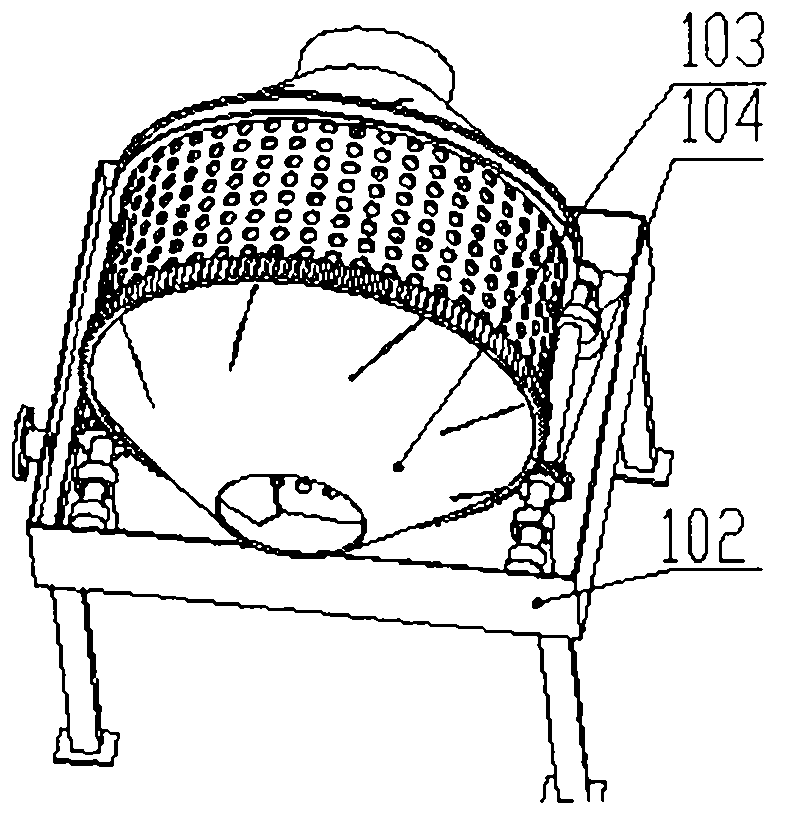

Oily sediment treatment method and device

ActiveCN102718375AAchieve the purpose of protectionImprove throughputSludge treatmentMedicineSediment

The invention provides an oily sediment treatment method and device. The method comprises the following steps of screening by a rotary screen; carrying out two times of ultrasonic washing and two times of air stripping; and utilizing the corresponding oily sediment treatment device. The oily sediment treatment method and device disclosed by the invention have the advantages of less investment andconvenience for transportation; the oily sediment can be movably, conveniently and rapidly cleaned, so that not only oil sand grains with the diameter of more than 80 mm can be washed cleanly, but also the aims of carrying out a plurality of steps of washing on the oil sand grains with the diameter of more than 80 mm and protecting the environment are achieved; and the oil content of the treated oily sediment completely achieves an environment-friendly discharge standard.

Owner:中洁环淼(江苏)环境科技有限公司

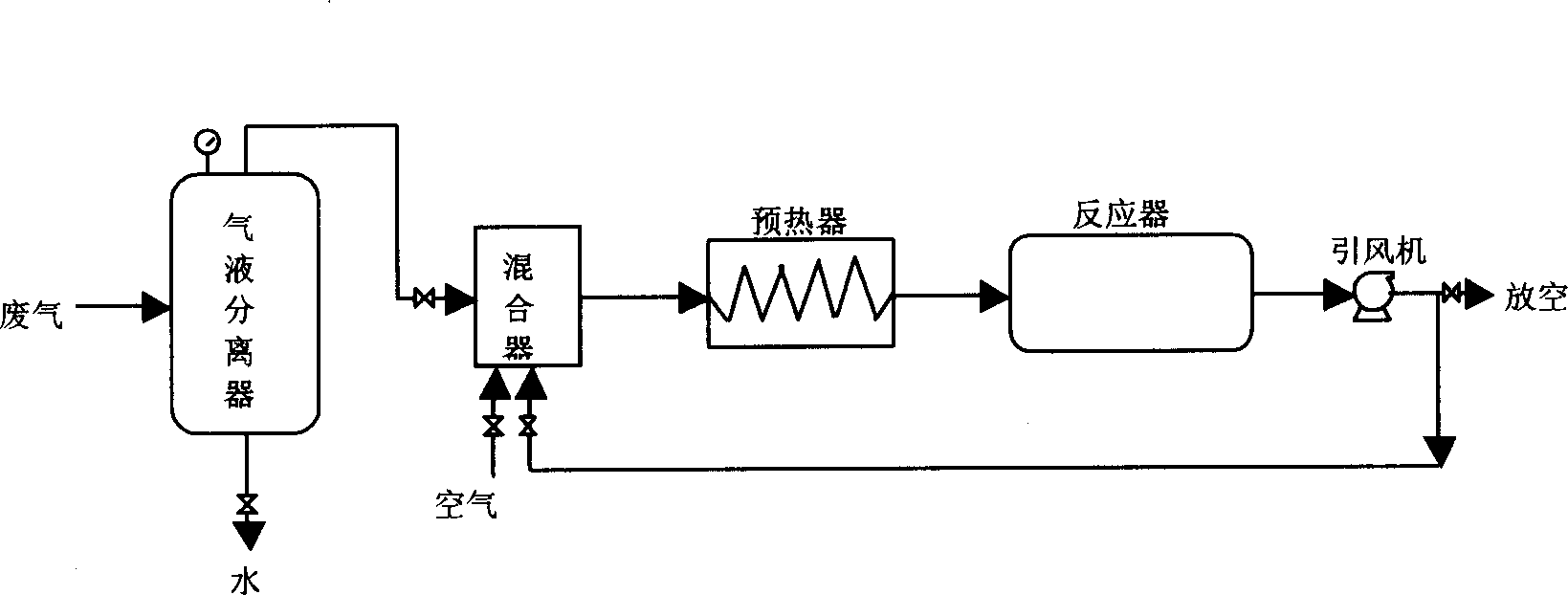

Waste polyester gas purification

InactiveCN1817417AReduce heatingAvoid overheatingDispersed particle separationIncinerator apparatusPolyesterPolyethylene terephthalate

A process for treating the waste polyester gas generated by preparing poly-ethanediol terephthalate (PET) includes such steps as gas-liquid separation for removing the most of water, diluting it by mixing it with air, preheating, catalytic reaction under the action of catalyst which is the cellular blocks carrying noble metal, and returning the resultant tail gas back to diluting step and using it as the diluting gas.

Owner:CHINA PETROLEUM & CHEM CORP

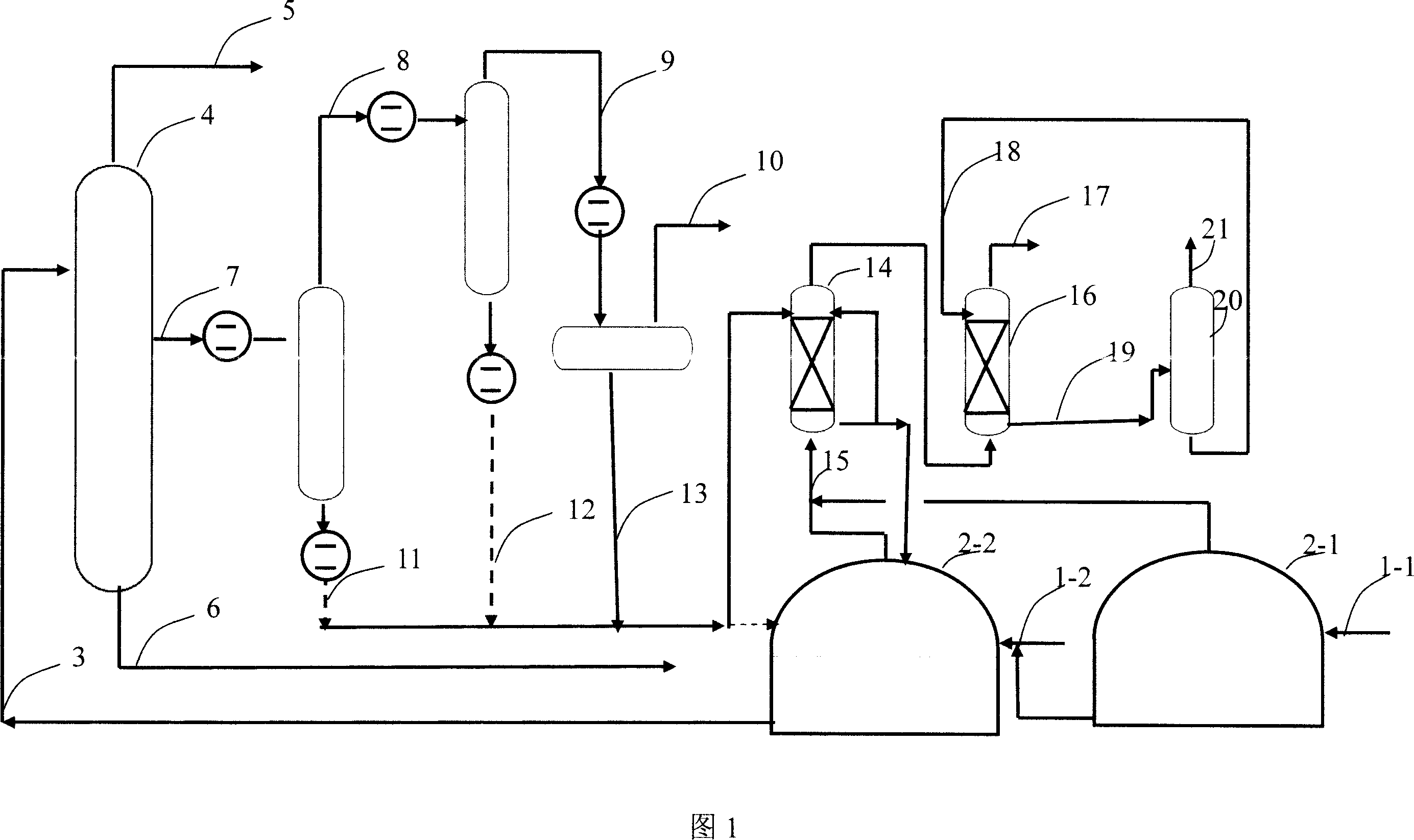

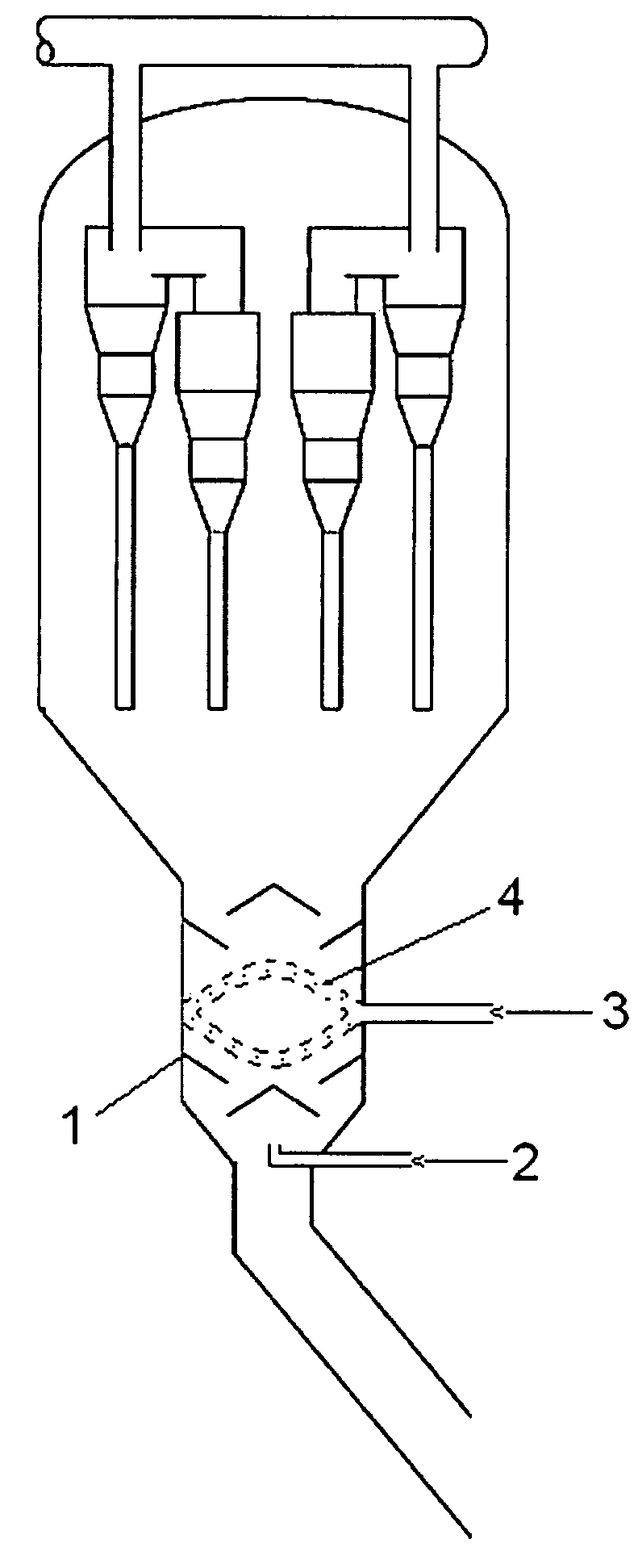

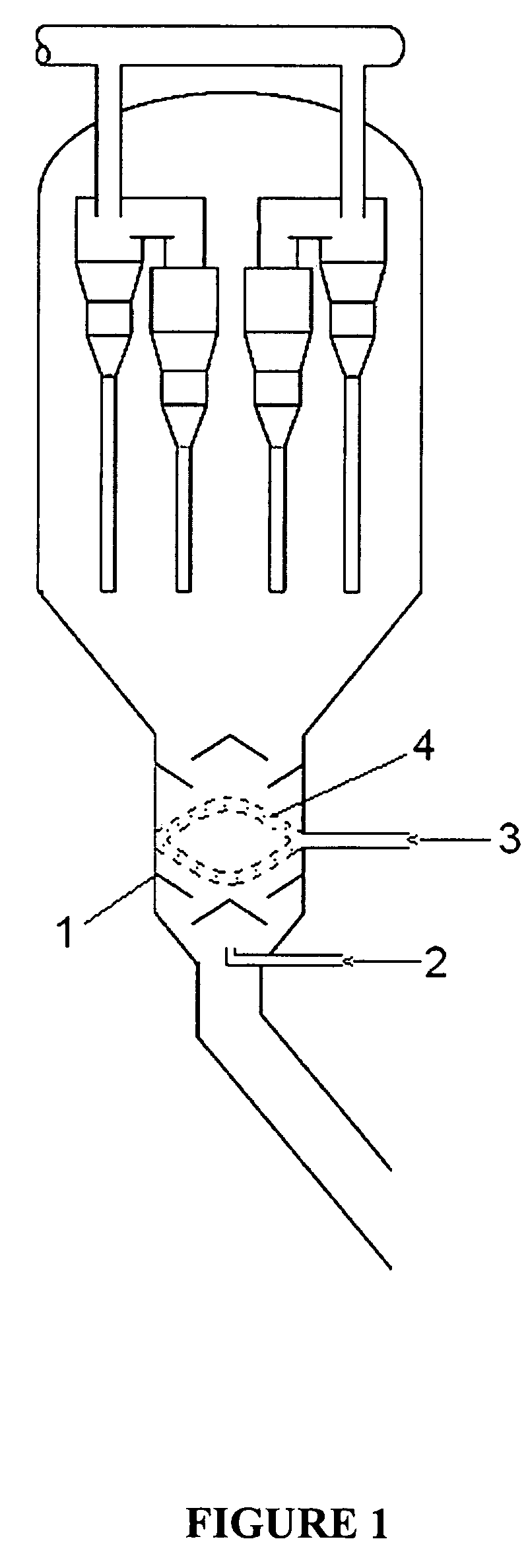

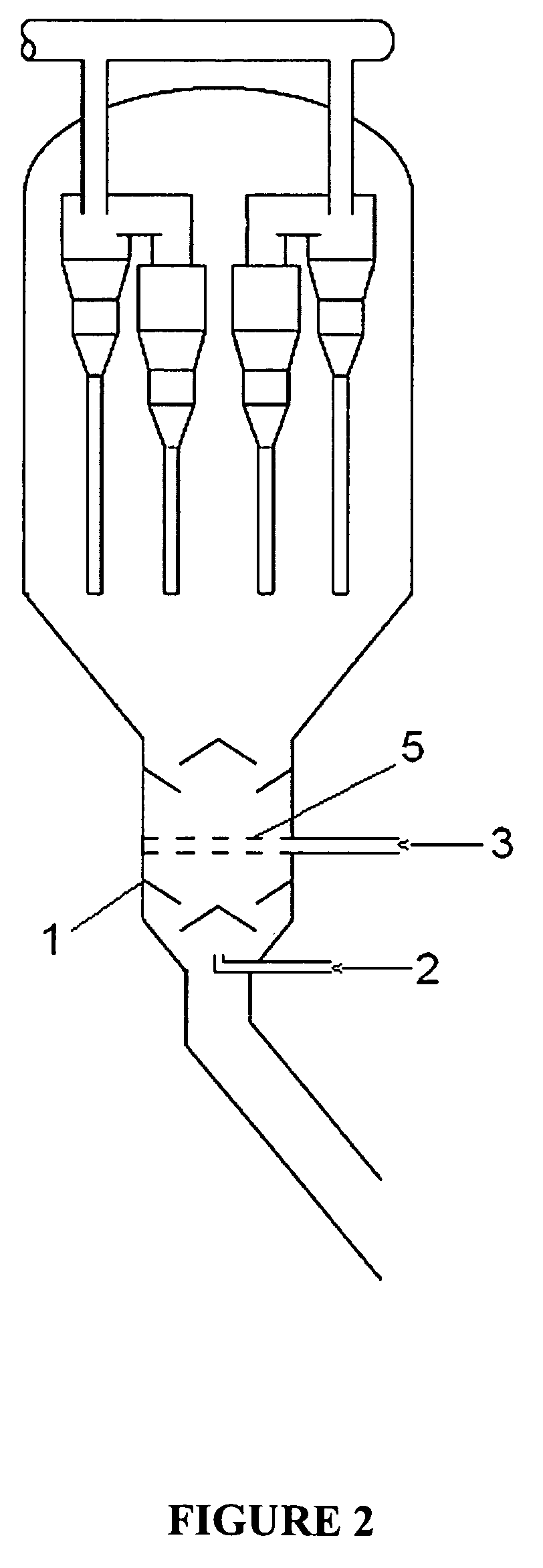

Process and device to optimize the yield of fluid catalytic cracking products

ActiveUS7658837B2Not compromise conventional stripping efficiencyCatalytic crackingTreatment with plural parallel cracking stages onlyGlobal distributionReaction zone

A process and device to optimize the yield of fluid catalytic cracking products through a reactive stripping process are disclosed. One or more hydrocarbon streams (3) are introduced in an intermediary region of the stripper (1) of a fluid catalytic cracking unit (FCC), from a device that allows a homogeneous distribution with adequate dispersion. This / these stream(s) react(s) with the catalyst of FCC, although its activity is reduced due to the adsorption of hydrocarbons in the reaction zone, generating products that improve and / or change the global distribution of products, providing a refinery profile adequate to meet quality demands and requirements.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

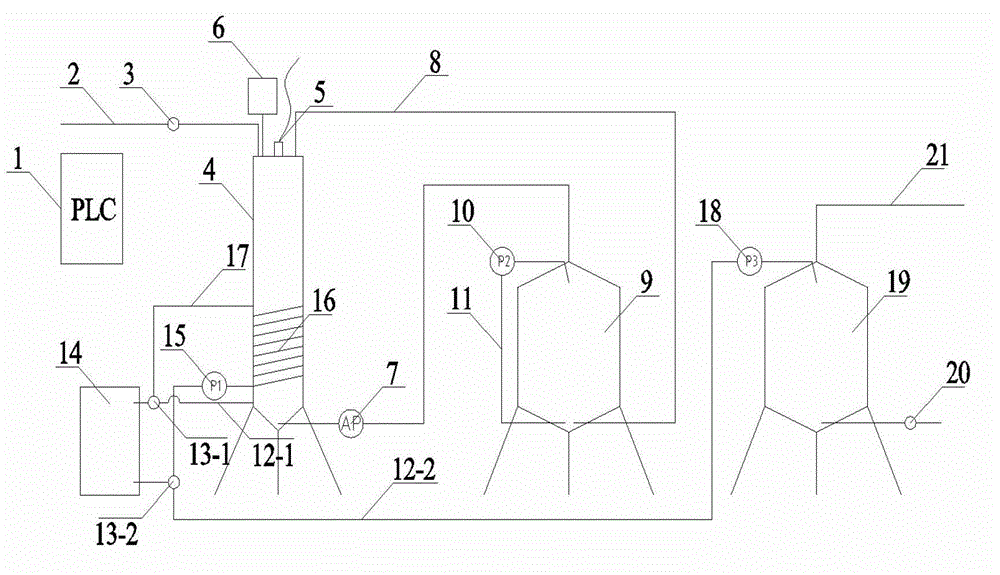

Method and system for combined air stripping biogas slurry depth treatment and biogas purification and desulfurization

ActiveCN102942973AEfficient removalIncrease the use of added valueGaseous fuelsScale removal and water softeningHigh concentrationThermal energy

The invention belongs to the technical field of waste water multilevel processing and particularly relates to a method and a system for combined air stripping biogas slurry depth treatment and biogas purification and desulfurization. Under the regulation of an additive, high-concentration ammonia nitrogen in the biogas slurry is removed by recycle gas through an air stripping mode, the gas after the air stripping is absorbed through acid liquid and serves as ammonium fertilizer to be applied, the use added value of the biogas slurry is improved, the system operation cost is reduced, the additive is added in an air stripping device, phosphorus and organic matters in the biogas slurry are subjected to flocculating settling, and the biogas slurry serves as slow release fertilizer to be applied after being collected and processed. Fecal coliform in the biogas slurry is eliminated effectively, the waste heat is used for heating the air stripping device, the air stripping efficiency of ammonia nitrogen is improved, and the optimized use of the system heat is improved. The biogas slurry after air stripping and sterilization is directly used for absorbing hydrogen sulfide and carbon dioxide in biogas, the biogas purification and desulfurization can be achieved, and the potential of hydrogen (PH) and the hardness of the processed biogas slurry can be reduced.

Owner:CHINA AGRI UNIV

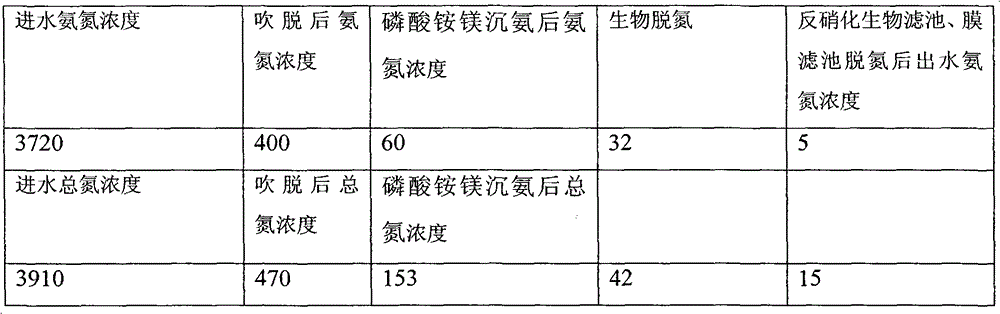

Deep denitrification process for wastewater

InactiveCN102910788AUndisturbedLow costMultistage water/sewage treatmentHigh concentrationMagnesium ammonium phosphate

The invention provides a deep denitrification process for wastewater. The deep denitrification process comprises the following specific steps of: firstly, performing microwave irradiation and coagulating sedimentation on the wastewater, wherein a certain quantity of NaOH is added into the high-concentration ammonia-nitrogen wastewater to adjust the pH value of the wastewater to 11-13, and a flocculant and a coagulant are added into the wastewater at an alkaline condition to perform the coagulating sedimentation, thus obtaining supernatant liquor; secondly, introducing the supernatant liquor obtained in the first step into an air stripping tower, wherein a sprayer is arranged at the top of the air stripping tower, multiple packing layers are arranged in the middle in a tower body, after passing through the sprayer, the wastewater becomes fine flow and flows through the packing layers, an air blower introduces air into the tower through an aeration port at the bottom of the tower, the air is in contact with the fine flow on the surface of packing, and exhaust for air stripping enters an absorption cell containing waste hydrochloric acid or waste sulphuric acid absorption liquid to absorb a part of ammonia nitrogen; thirdly, performing continuous circulating ammonia sedimentation on pyrolysis products of magnesium ammonium phosphate (MAP), and after the sedimentation of the MAP, processing effluent by a biological nitrogen removal process; fourthly, performing anaerobic (A)-anoxia (4)-oxic (O) biological nitrogen removal process on the effluent in the third step; and fifthly, performing denitrification on the left less nitrogen by a denitrification biofilter and a membrane filter. Therefore, ammonia nitrogen and total nitrogen of the effluent of the processed wastewater can reach a first-level A standard in the discharge standard of pollutants for municipal wastewater treatment plants (GB18918-2002).

Owner:NANJING UNIV

Treatment method for cobalt-nickel waste water

ActiveCN105384277AEasy to removeReduce dosageWater contaminantsWater/sewage treatment by ion-exchangeIn process controlCobalt

The invention relates to a treatment method for cobalt-nickel waste water, and belongs to the field of sewage treatment. The treatment method includes the steps of pretreating, wherein suspended solids and oil of the cobalt-nickel waste water are pretreated; ammonia nitrogen steam stripping and air stripping, wherein treatment is completed through ammonia nitrogen steam stripping and air stripping; deep oil removing through oxidization, wherein the oil is decomposed in an oxidization aeration mode; heavy metal ion precipitating, wherein heavy metal ions are precipitated by adding alkali; deep impurity removing, wherein activated carbon and ion exchange resin are used for deep impurity removing. The treatment method for the cobalt-nickel waste water is simple in process, low in cost and simple in process control, and the treated waste water can be discharged in an up-to-standard mode.

Owner:RIZHAO HENGTONG WATER TREATMENT EQUIP

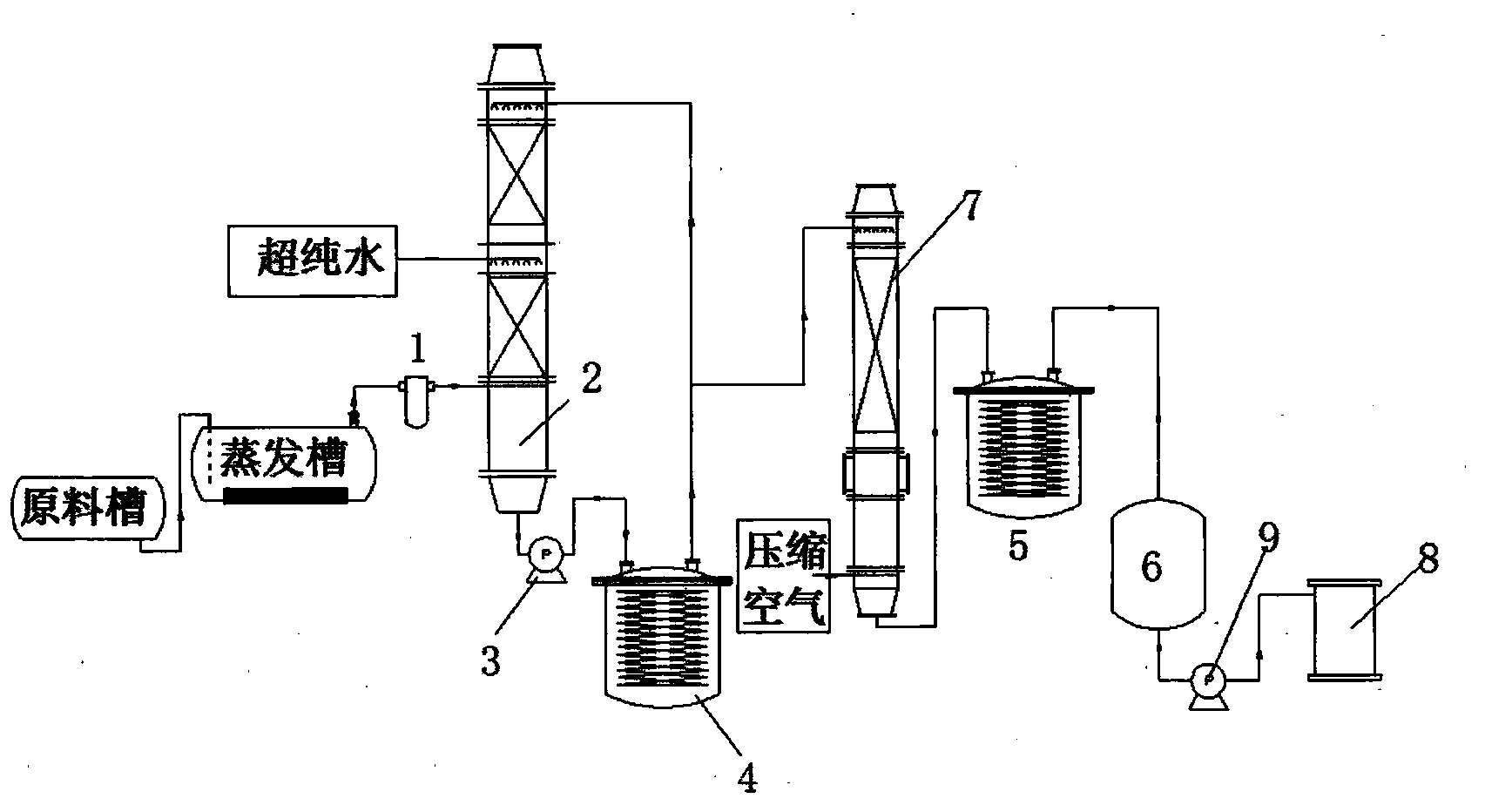

Production method of electronic-grade sulphuric acid

ActiveCN103407972AHigh temperature resistantBring pollutionSulfur compoundsUltrafiltrationDistillation

The invention discloses a production method of electronic-grade sulphuric acid. The production method comprises the following steps in sequence: industrial-grade sulfur trioxide raw materials are provided and placed into a raw material storage tank; the sulfur trioxide raw materials are conveyed into an evaporator tank; the evaporator tank is heated; sulfur trioxide steam generated by heating enters into an absorption tower through a filter; the sulfur trioxide steam is absorbed by electronic-grade ultrapure water in the absorption tower, the concentration of absorption liquid is controlled, and the absorbed solution enters into a degassing tower after cooled by a cooler; air stripping is performed on a sulfuric acid solution by the degassing tower through compressed air; the sulfuric acid solution enters into a finished product storage tank after cooled; finally, the final electronic-grade sulphuric acid applied to the integrated circuit industry is obtained after ultrafiltration to remove particles. The operating temperature of the technology, compared with a conventional technology, is lower than 120 DEG C. Therefore, the technology is safer than a high-temperature distillation technology which takes industrial-grade sulfuric acid as raw material, and in addition, compared with adopting equipment made of quartz glass, non-pollution to electronic-grade sulphuric acid products is guaranteed from equipment material.

Owner:SHANGHAI ZHENGFAN TECH +1

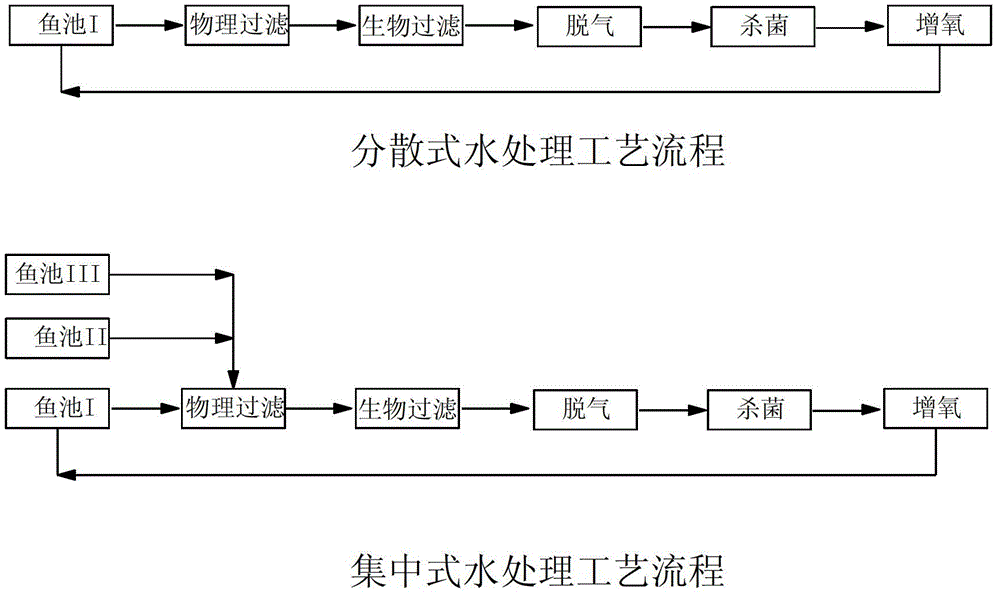

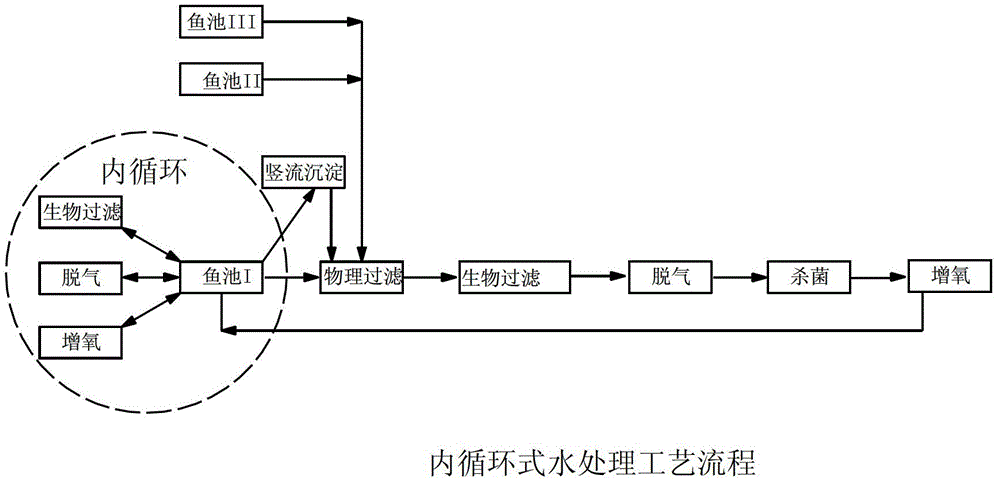

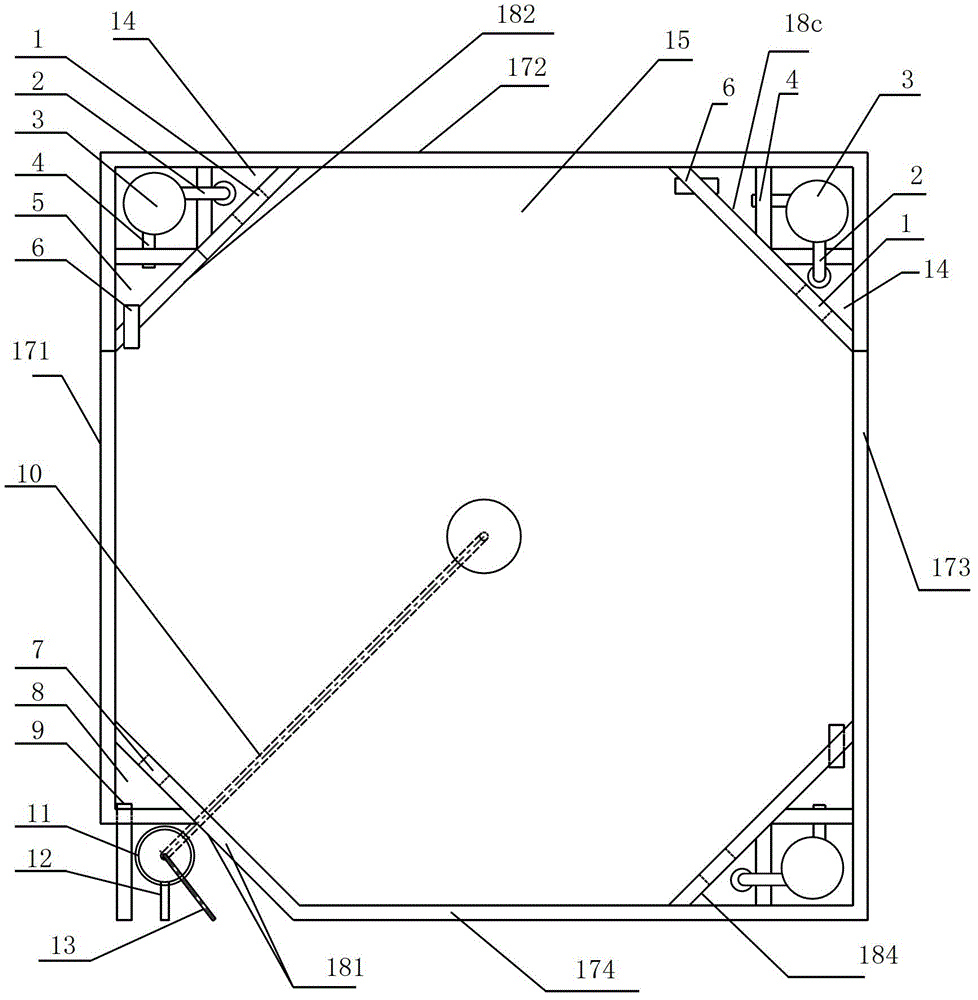

Internal circulation fishpond and circulating water treatment process

The invention relates to the technical field of aquaculture, and discloses an internal circulation fishpond and a circulating water treatment process. According to the internal circulation fishpond and the circulating water treatment process, an air striping device, a physical filtration device and a biological filtration device are arranged in vacant regions, such as corners of the fishponds; multiple functions, such as plug flow, oxygenation, degassing, solid filtration and biological filtration, are integrated in the design of the fishpond; through arranging an air stripping pump, a moving bed biofilter and a vertical flow precipitator and the like, the water treatment function of the fishpond is perfected and enhanced, and the fishpond has the functions of oxygenation, degassing, physical filtration and biological filtration; the circulating speed of a water body is reduced while the solid utilization rate is improved; through reducing the treatment load amount of a water treatment system, the circulating speed of the water body and the operating energy consumption of a circulating water pump are reduced.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

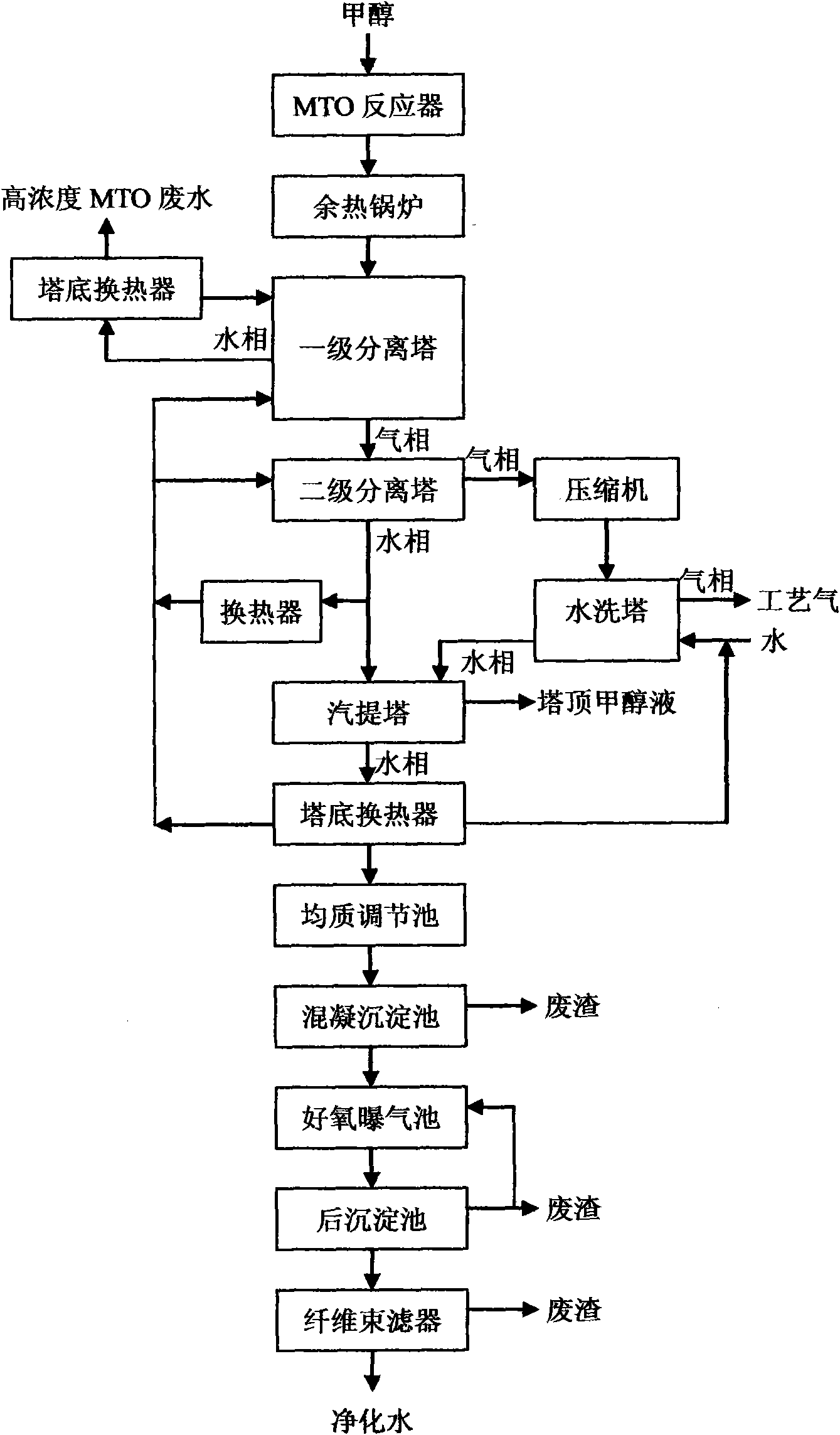

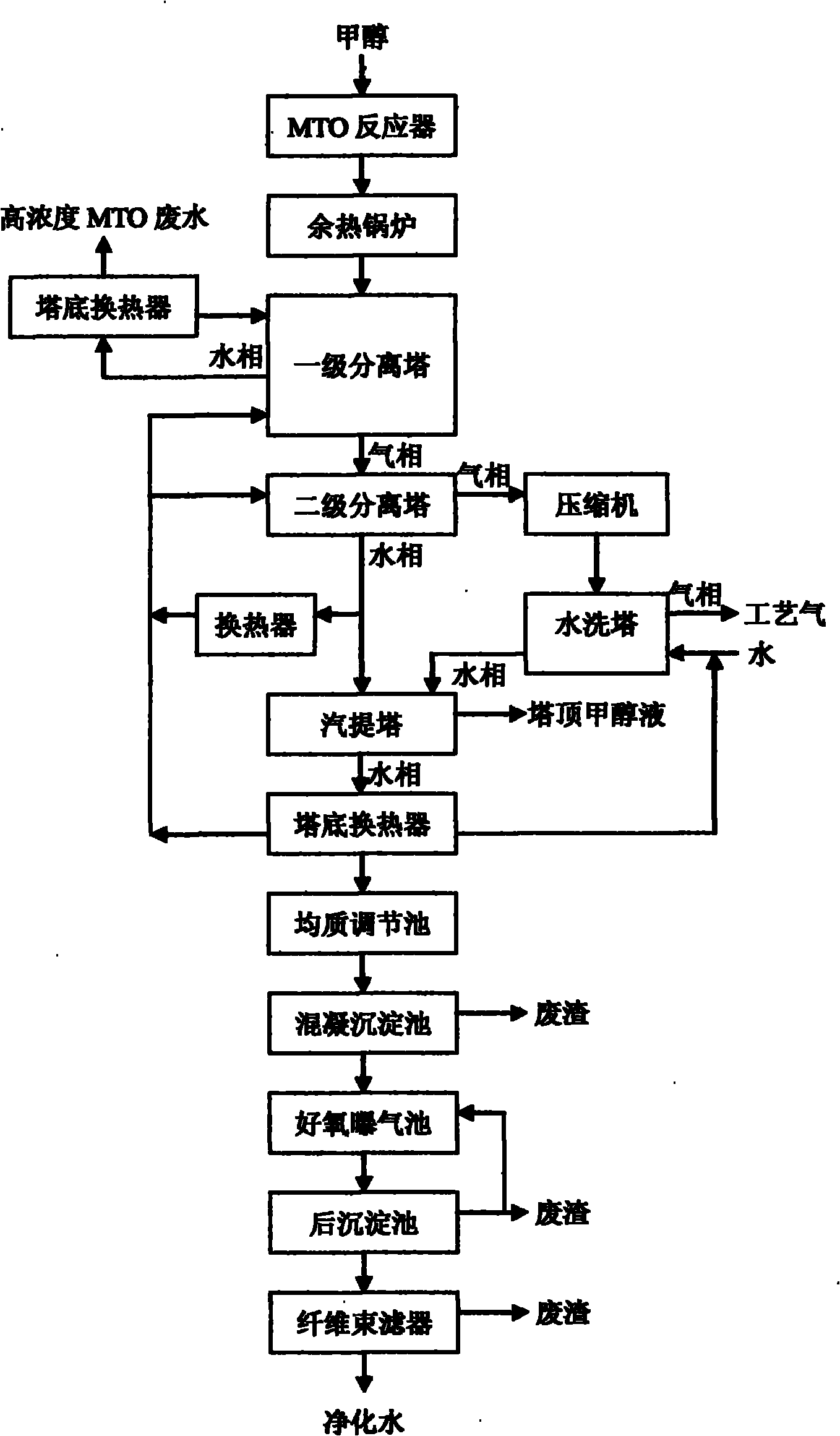

Treatment and reuse method of waste water in methanol-to-olefin process

ActiveCN102050548AEfficient use ofReduce dosageChemical industryHydrocarbon from oxygen organic compoundsHigh concentrationFiltration

The invention relates to a treatment and reuse method of waste water in a methanol-to-olefin (MTO) process. The method comprises the following steps: (1) an effluent from an MTO reactor is subjected to the waste heat recovery through a waste heat boiler and then cooled and separated through a separation tower to generate high concentration MTO waste water; (2) the effluent from the MTO reactor is further cooled, a water phase is generated at the bottom of the separation tower, an olefin gas is generated at the top of the separation tower, and the olefin gas is further purified by compression and water scrubbing; (3) the water phase from the bottom of the separation tower and a water phase from bottom of a water scrubbing tower are treated by steam stripping, and a water phase generated at the bottom of a steam stripping tower is cooled through a tower bottom heat exchanger to generate low concentration MTO water; (4) the low concentration MTO water is homogenized; (5) the low concentration MTO water is subjected to the coagulating sedimentation treatment after the homogenization; (6) the low concentration MTO water is subjected to the aerobic aeration treatment after the coagulating sedimentation treatment; (7) the effluent water is settled after the aerobic aeration treatment; and (8) the effluent water is subjected to the flocculation filtration treatment after the settlement. The method can not only reduce the consumption of the fresh water in the MTO production, but also reduce the discharge of pollutants to the environment in the MTO production.

Owner:CHINA PETROLEUM & CHEM CORP +1

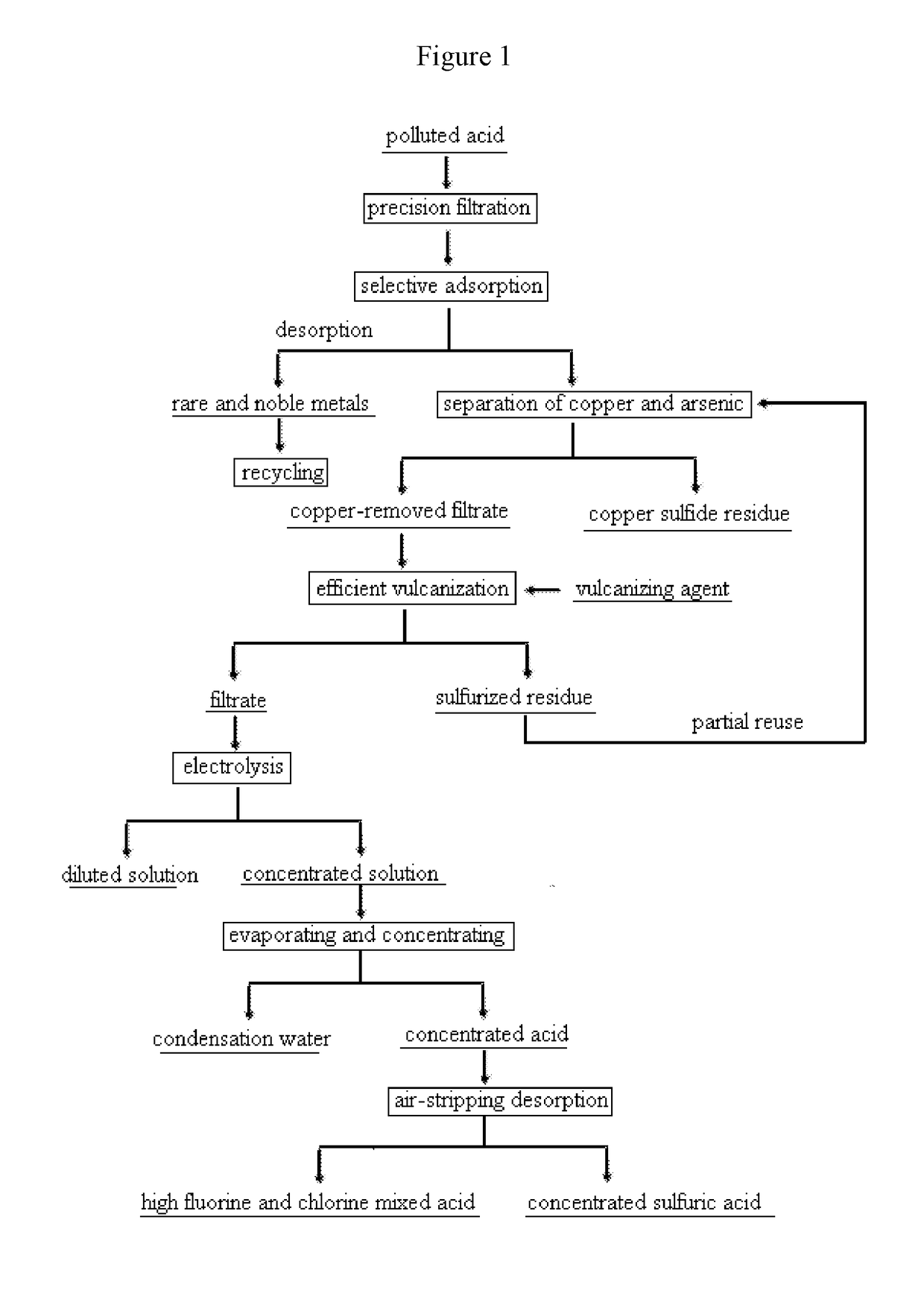

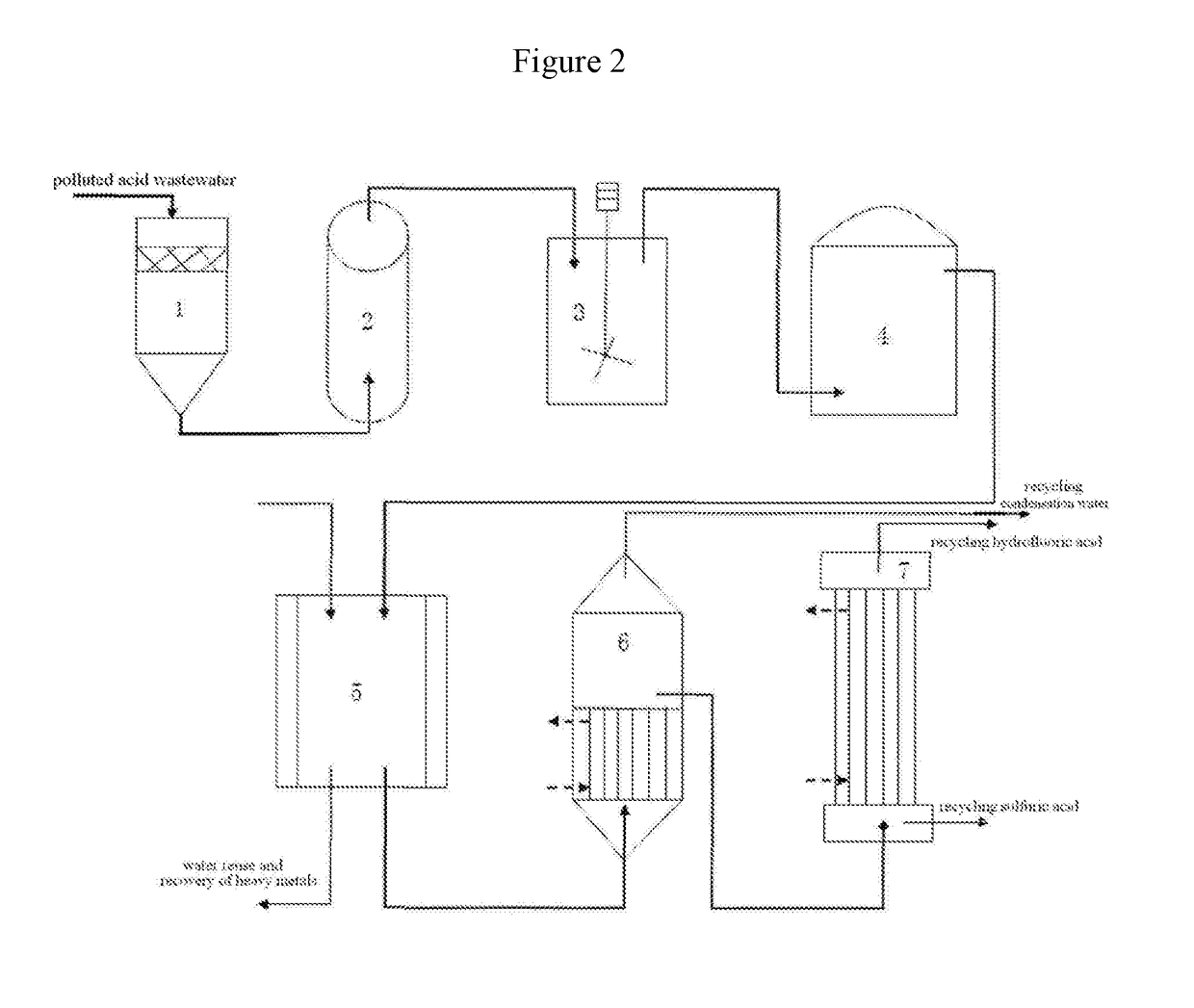

Method and apparatus for the recovery and deep treatment of polluted acid

ActiveUS20190023585A1Easy to separateStrong impact resistanceTreatment involving filtrationWaste water treatment from metallurgical processRheniumVulcanization

A method and an apparatus for recovery and deep treatment of a polluted acid. The method comprises the following main steps: (1) selectively adsorbing rare and noble metals, such as rhenium, selenium and the like; (2) separating copper from arsenic to recover the copper; (3) carrying out efficient vulcanization to perform deep arsenic removal; (4) carrying out electrodialysis to pre-concentrate acid; (5) evaporating and concentrating the acid; (6) carrying out an air-stripping method to remove fluorine and chlorine. The polluted acid treatment apparatus mainly comprises a precision filtering tank, a special adsorbing tank, a copper-arsenic separation device, a vulcanization device, an electrodialysis device, an evaporative concentration device, and an air-stripping device. The method and the apparatus can implement efficient recovery of valuable elements in polluted acid wastewater and separate treatment harmful elements, has obvious economical, social and environmental benefits, and has wide application prospects.

Owner:CENT SOUTH UNIV

Device and method for steam stripping of condensate in water gas conversion process

ActiveCN102642881AReduce pressureSuppression reduces the load on the stripperWater/sewage treatment by heatingWater/sewage treatment by degassingSaline waterSalt water

The invention discloses a device and a method for steam stripping of condensate in a water gas conversion process. The device comprises a conversion condensate tank, a flash tank and a condensate stripping tower. The conversion condensate tank is communicated with a high-temperature condensate outlet of a water gas and water separator. The flash tank is respectively communicated with an ammonia washing liquid outlet at the bottom of an ammonia washing tower and a non-condensable gas outlet of the conversion condensate tank, a desalted water spraying device and a flash steam outlet are arranged at the top of the flash tank, and the bottom of the flash tank is provided with a condensate port. The condensate stripping tower is communicated with the condensate port of the flash tank. Using the device reduces corrosion of a top plate and a top condenser of the stripping tower, pipeline blockage and stripping tower pressure build-up, and lessens load of the stripping tower. Therefore, the device can be stably operated for a long period, maintenance frequency and cost are effectively reduced, and air pollution of an evacuation area caused by overpressure evacuation of a condensate stripping system is avoided.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

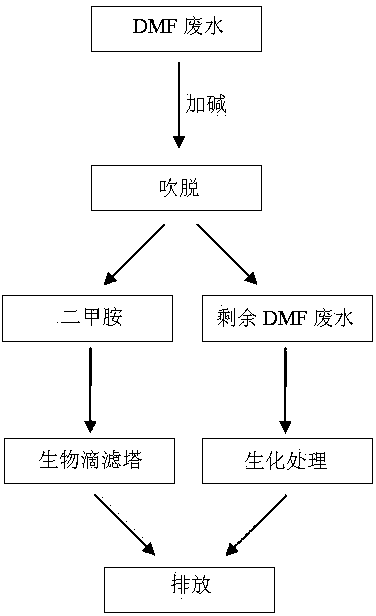

Combined treatment method of N, N-dimethylformamide (DMF) wastewater

InactiveCN103449662AAvoid secondary pollutionImprove biodegradabilityWater contaminantsMultistage water/sewage treatmentN dimethylformamideExisting Treatment

The invention discloses a combined treatment method of N, N-dimethylformamide (DMF) wastewater, relates to the field of environment protection and water pollution treatment, and in particular relates to a combined treatment method for treating the N, N-DMF wastewater. The method specifically comprises the following steps: firstly decomposing the DMF wastewater into dimethylamine and formate under an alkali condition, then carrying out air stripping, introducing the dimethylamine waste gas generated in the air stripping into a bio-trickling tower for treatment, and directly carrying out biochemical treatment on the air-stripped wastewater. According to the combined treatment method disclosed by the invention, a physic-chemical method and a biological method are combined, a feasible process for treating the DMF wastewater is provided, the toxicity of the DMF wastewater is reduced by means of the physical-chemical method, the biodegradability of the DMF wastewater is improved, and the generated dimethylamine organic waste gas and wastewater are subjected to advanced treatment by means of the bio-chemical method. By adopting the combined treatment method disclosed by the invention, the effective and economical treatment of the DMF wastewater is achieved, and the problems of secondary pollution, difficult regeneration, low efficiency and the like easily caused by the existing treatment methods of adsorption, extraction, chemical oxidization and the like are solved.

Owner:NANJING TECH UNIV

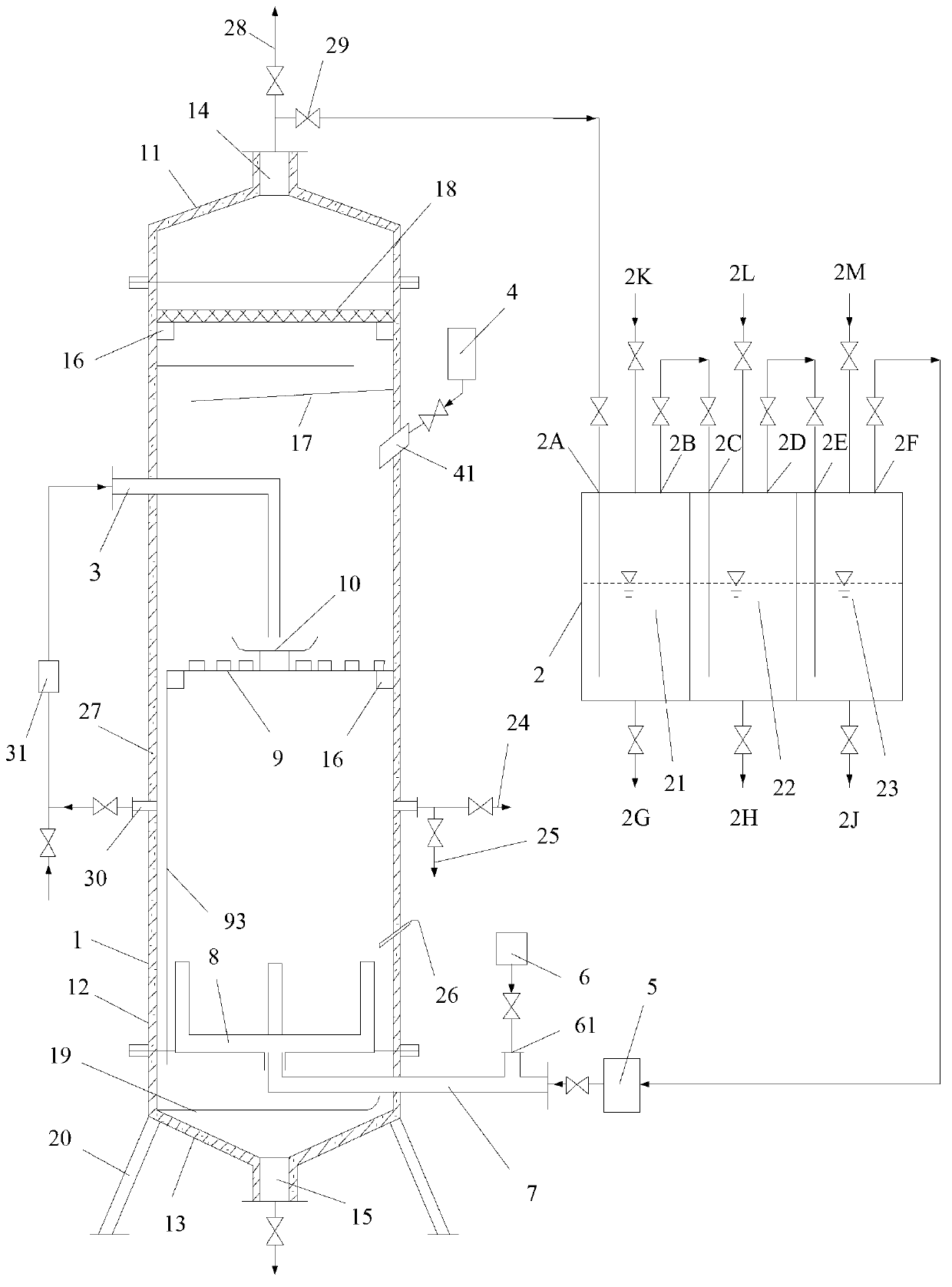

Cycle closed type filler-free high-efficiency ammonia nitrogen removing and nutrient recovery device of biogas slurry

InactiveCN103274549ALow input costRaise the pHMultistage water/sewage treatmentRecovery methodAir pump

The invention discloses a cycle closed type filler-free high-efficiency ammonia nitrogen removing and nutrient recovery device of biogas slurry, comprising the following steps: connecting an air striping tower and an absorption device through an air pump, a valve and a pipeline to form a gas circulation loop, inflating the bottom of the air stripping tower by the air pump so as to realize air stripping of a dissolved gas and ammonia nitrogen in a biogas slurry, filtering acidic gases (such as CO2 and H2S, etc.) in a recycle gas by an alkali absorption pot when the recycle gas passes through the absorption device, absorbing ammonia gas (NH3) by a primary acid absorption pot, absorbing steam in a tail gas by a secondary acid absorption pot, and sending the recycle gas by the air pump into the biogas slurry in the air stripping tower so as to continuously repeat the air stripping process. The method provided by the invention has advantages of simple processing technology, stable and reliable stripping performance, easy operation management and maintenance and the like, and is suitable for up-to-standard discharge processing of various raw materials of biogas slurries.

Owner:CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com