Regeneratable wet fuel gas desulfurizing technology

A wet flue gas desulfurization and process technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of high absorbent loss rate and high operating costs, and achieve reduced losses, low operating costs, and high operating costs. small loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

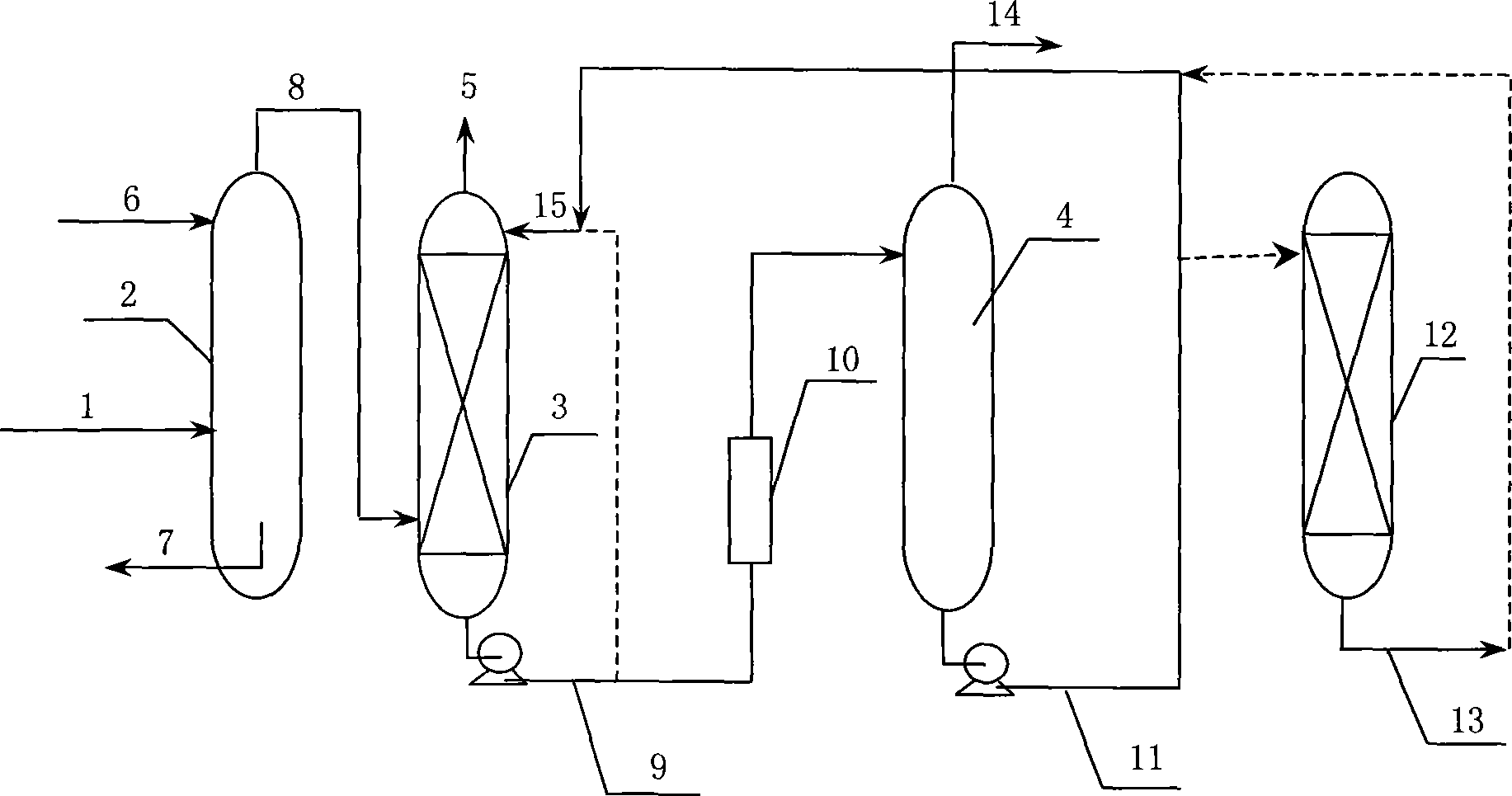

Method used

Image

Examples

Embodiment 1~4

[0027] See Table 1 for operating conditions, and Table 2 for flue gas composition and test results.

[0028] Table 1 Operating Conditions

[0029]

[0030] Table 2 Flue gas composition and test results

[0031] project

[0032] The test results show that: for different SO 2 content of flue gas, by changing the operating conditions, the desulfurization rate can reach more than 90%.

Embodiment 5

[0034] The catalyst regenerated flue gas from the catalytic cracking unit of the refinery is used as the flue gas raw material. The flue gas enters the lower part of the scrubber. In the flue gas scrubber, the flue gas is in reverse contact with the cooling water to remove the small particles of dust and a small amount of SO 3 , then the flue gas enters the lower part of the absorption tower through the blower, and contacts with the absorbent on the top of the tower countercurrently. The liquid-gas volume ratio is 0.001, and the temperature of the absorption tower is 50 ° C. 2 The rich liquid is discharged from the bottom of the tower and enters the regeneration tower. The temperature at the top of the regeneration tower is 105°C, and the temperature at the bottom of the tower is 110°C. The absorbent after the salt returns to the absorption tower, and a small amount of heat-stable salt is discharged in the form of inorganic salt. The composition and test results of the flue gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com