Patents

Literature

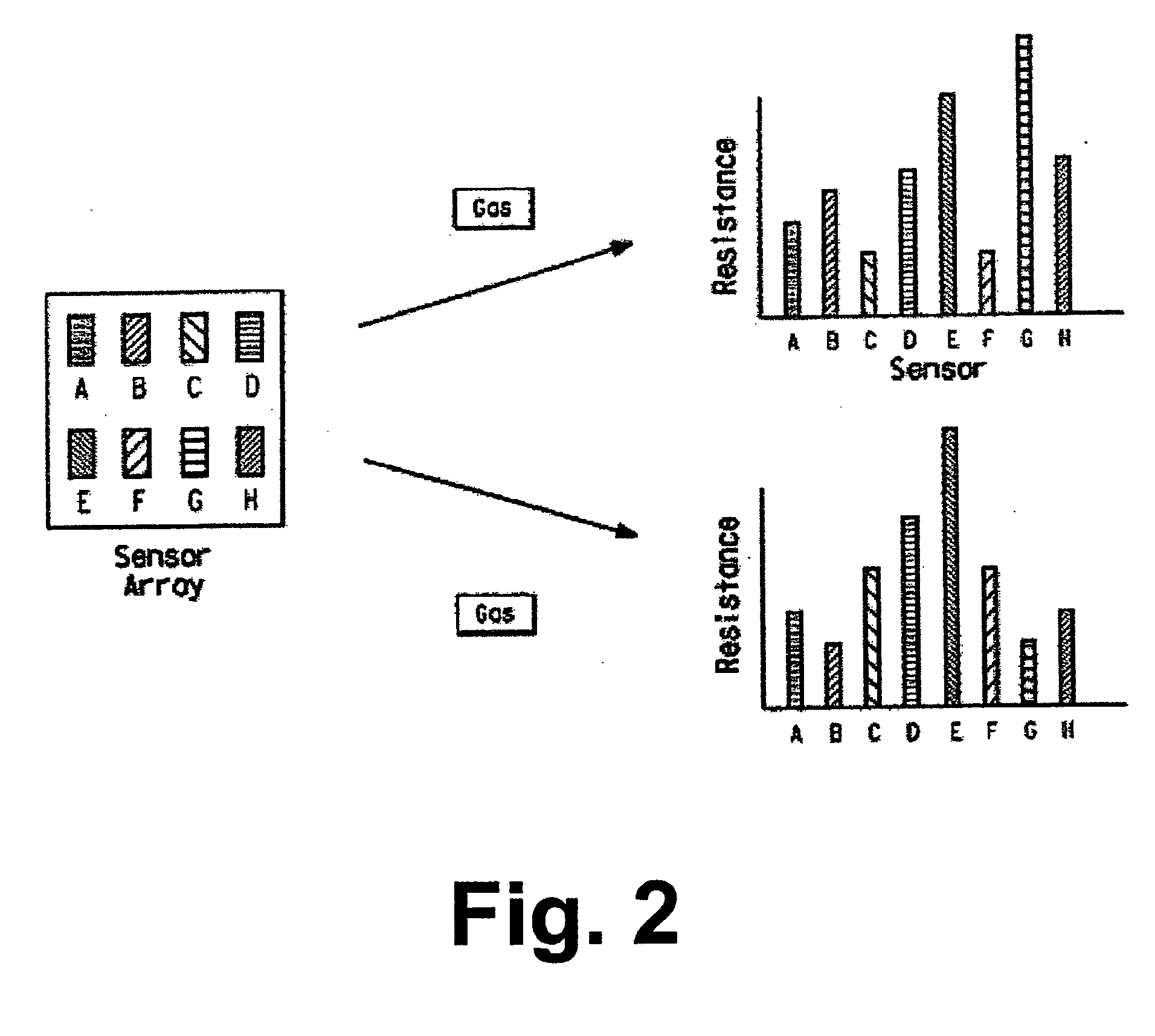

1285 results about "Gas composition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Gas composition of any gas can be characterised by listing the pure substances it contains, and stating for each substance its proportion of the gas mixture's molecule count.

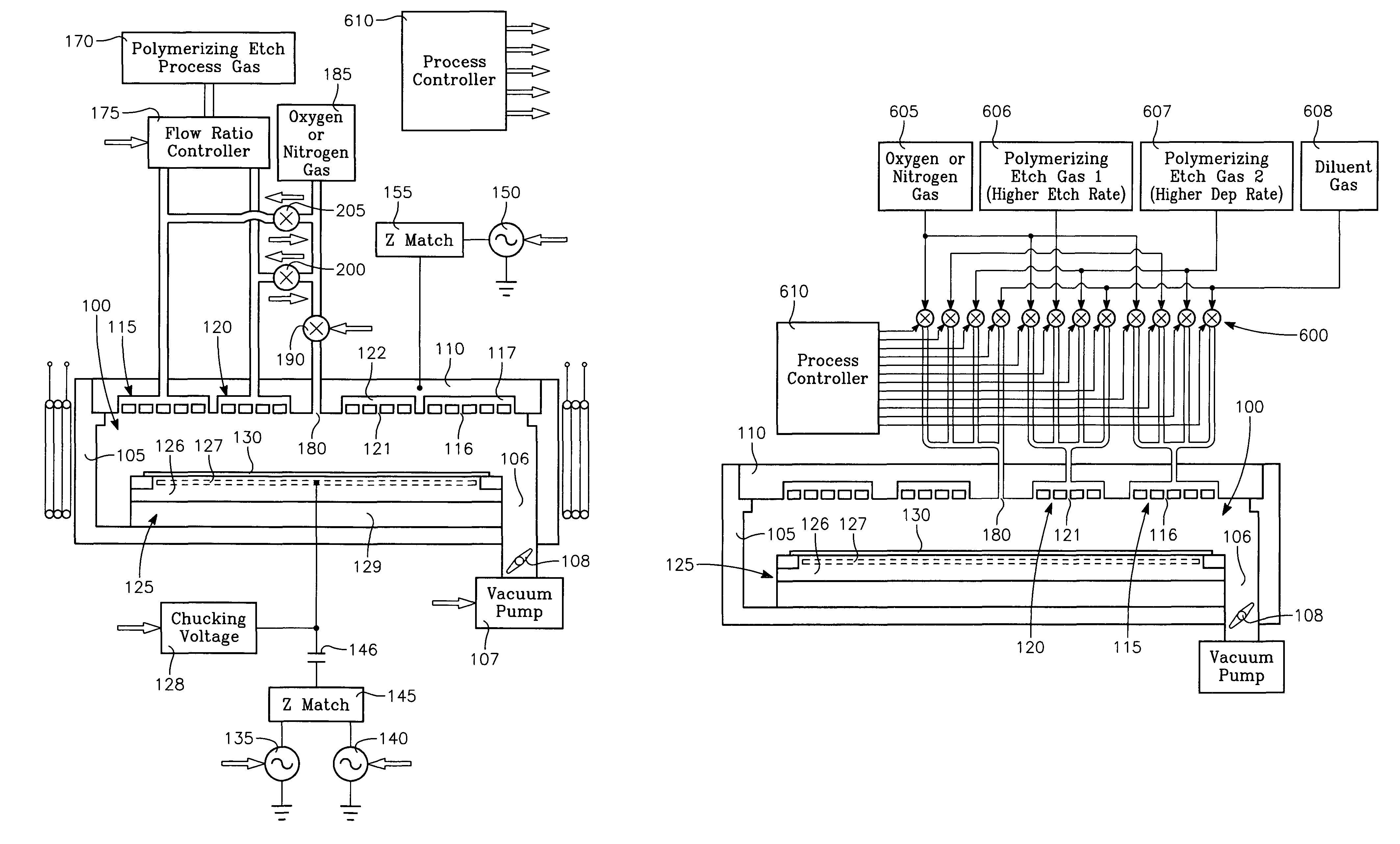

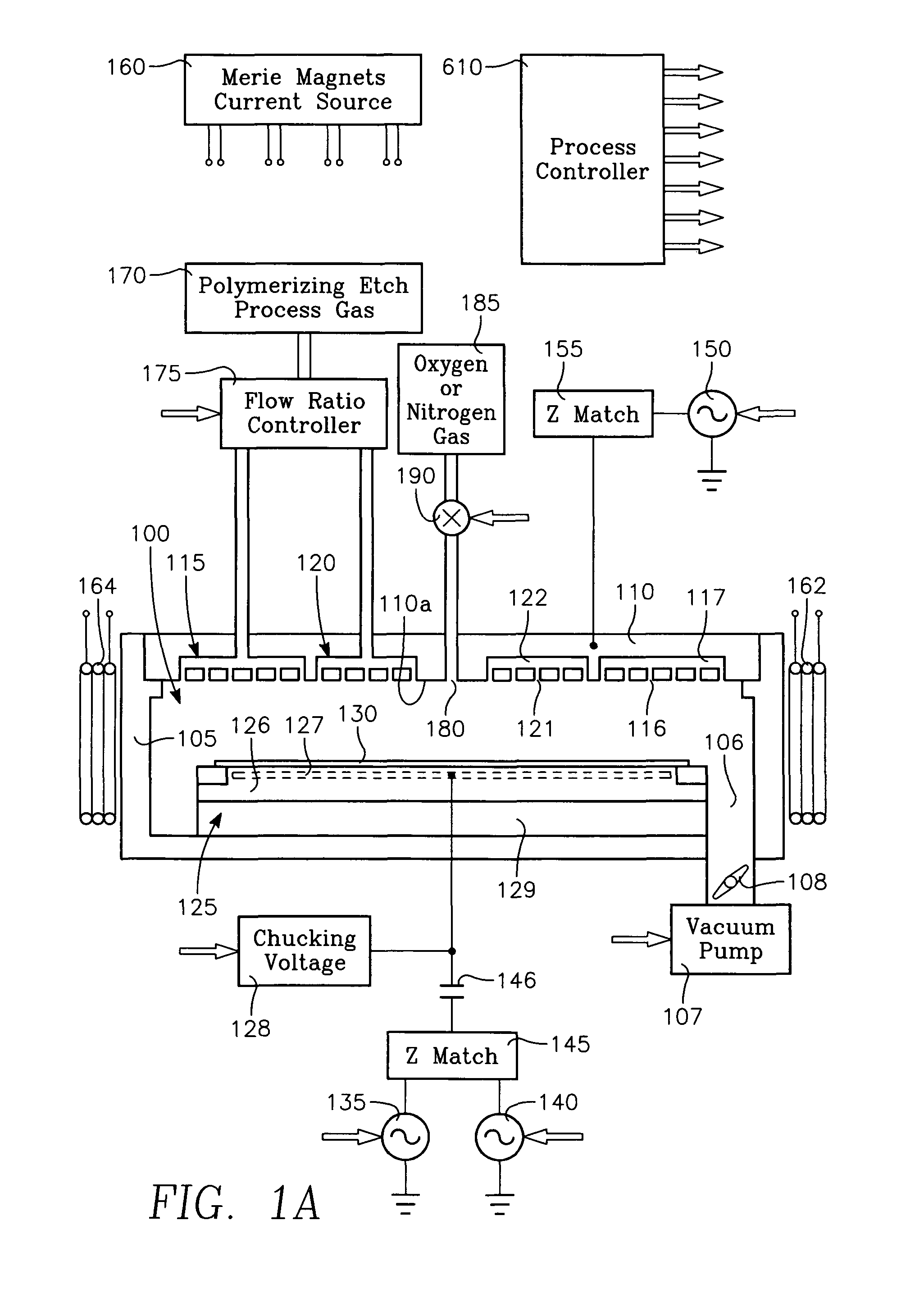

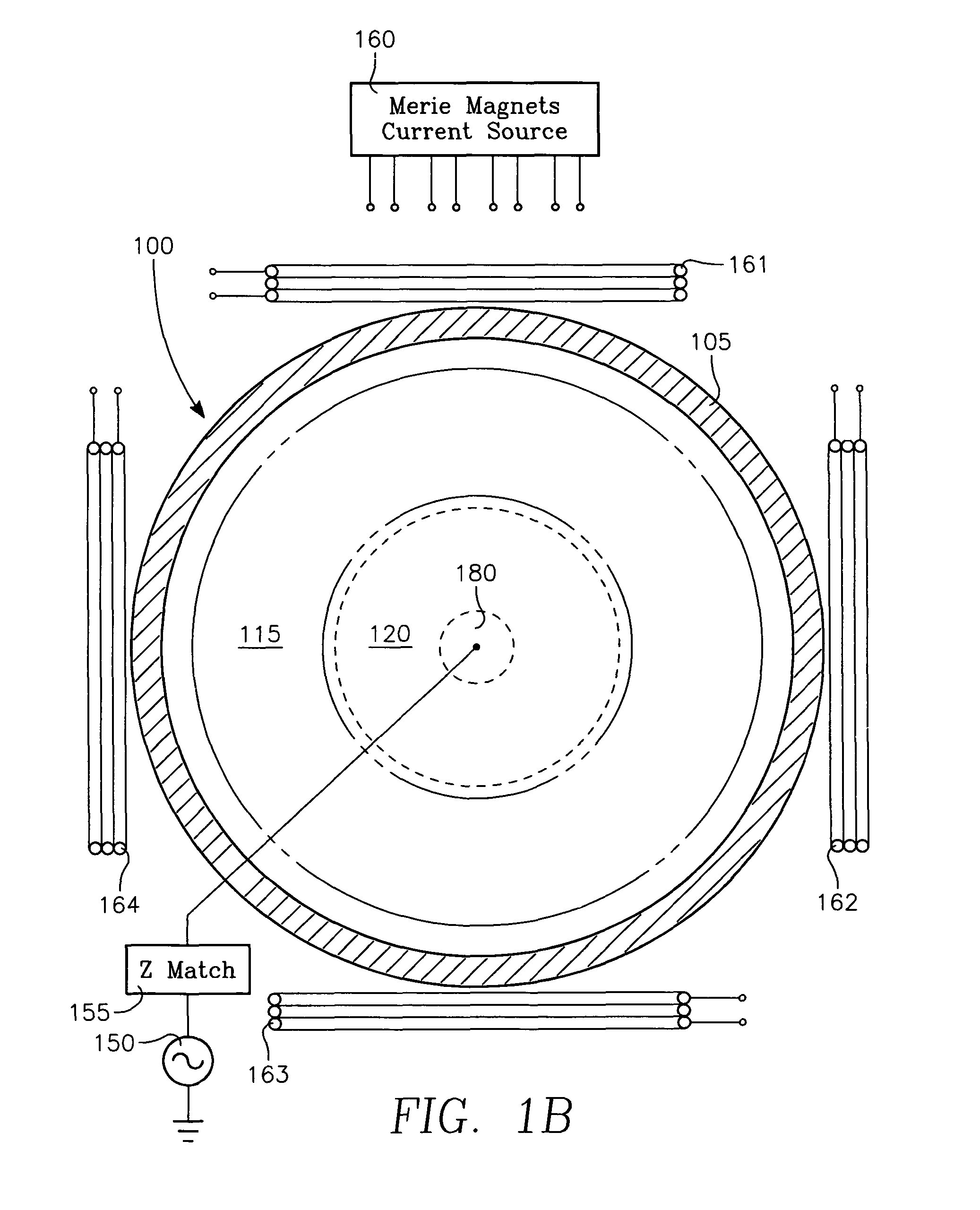

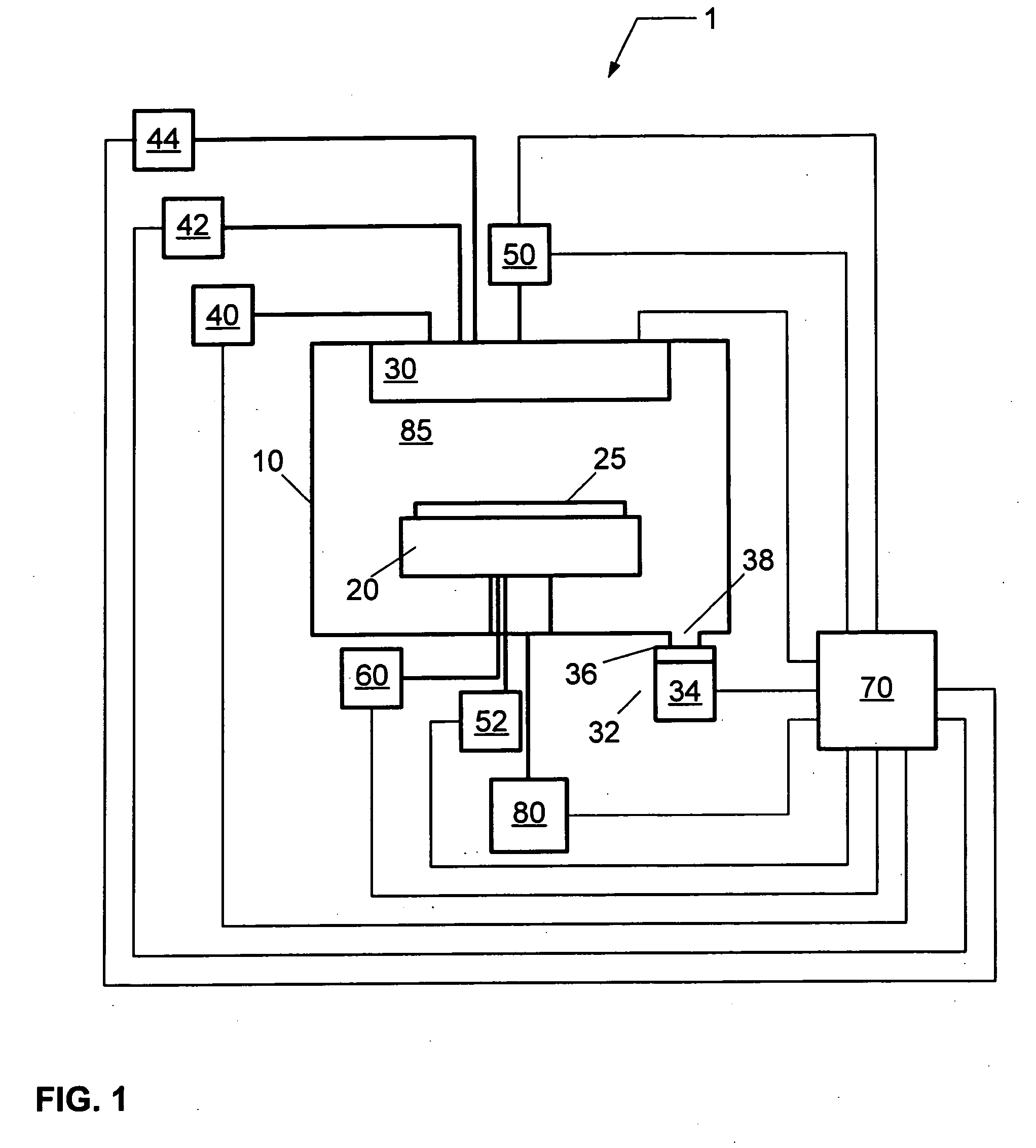

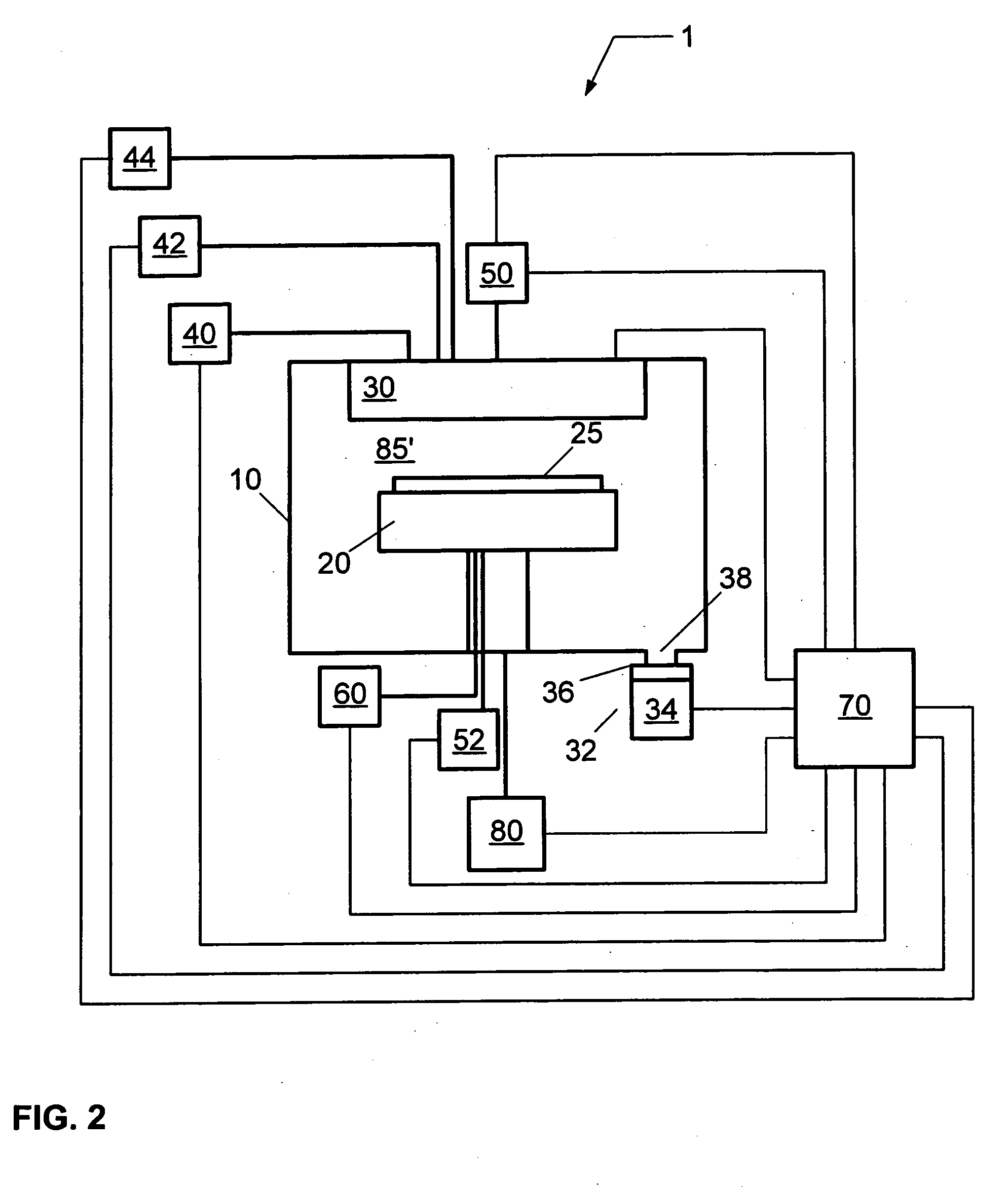

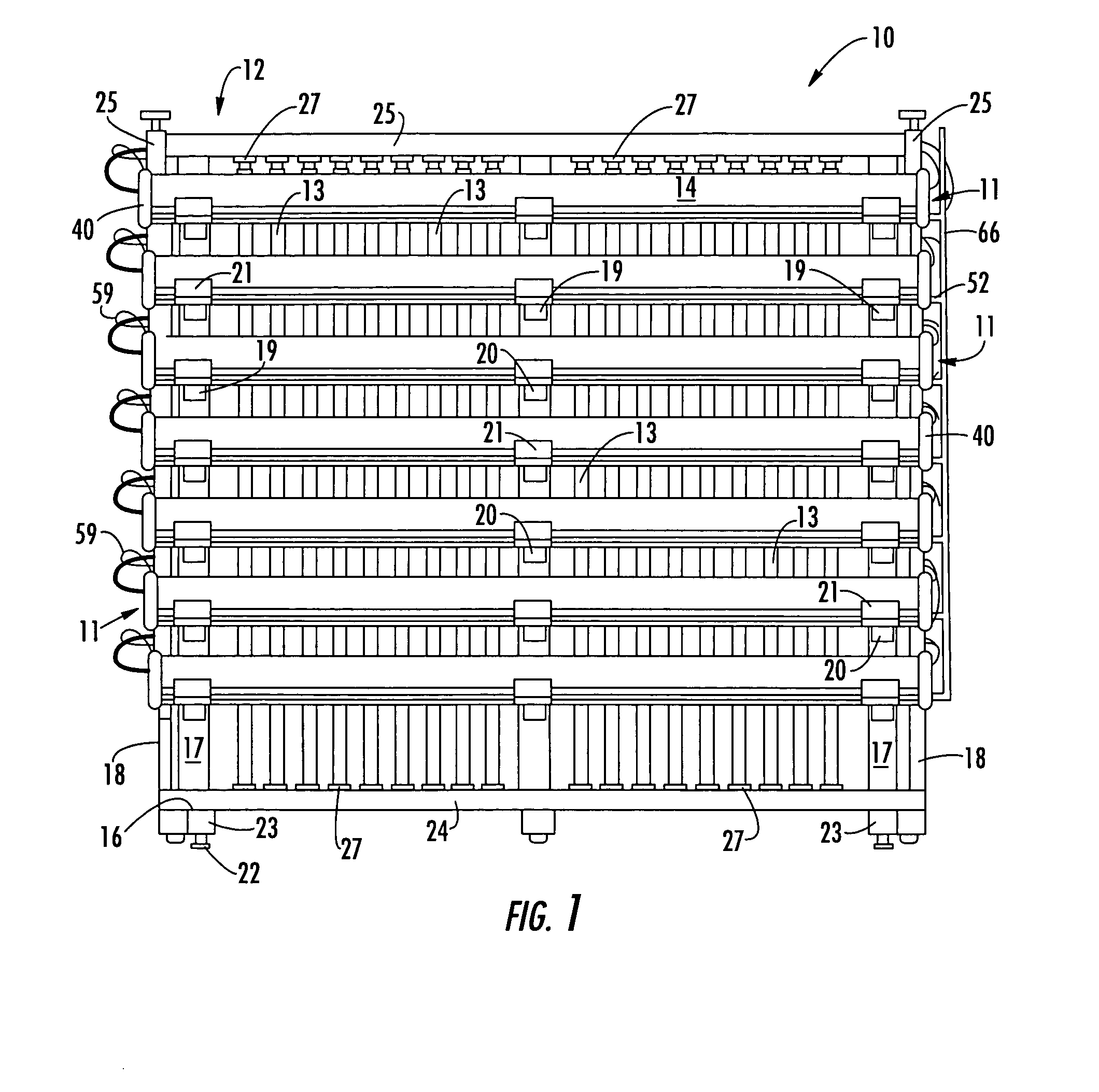

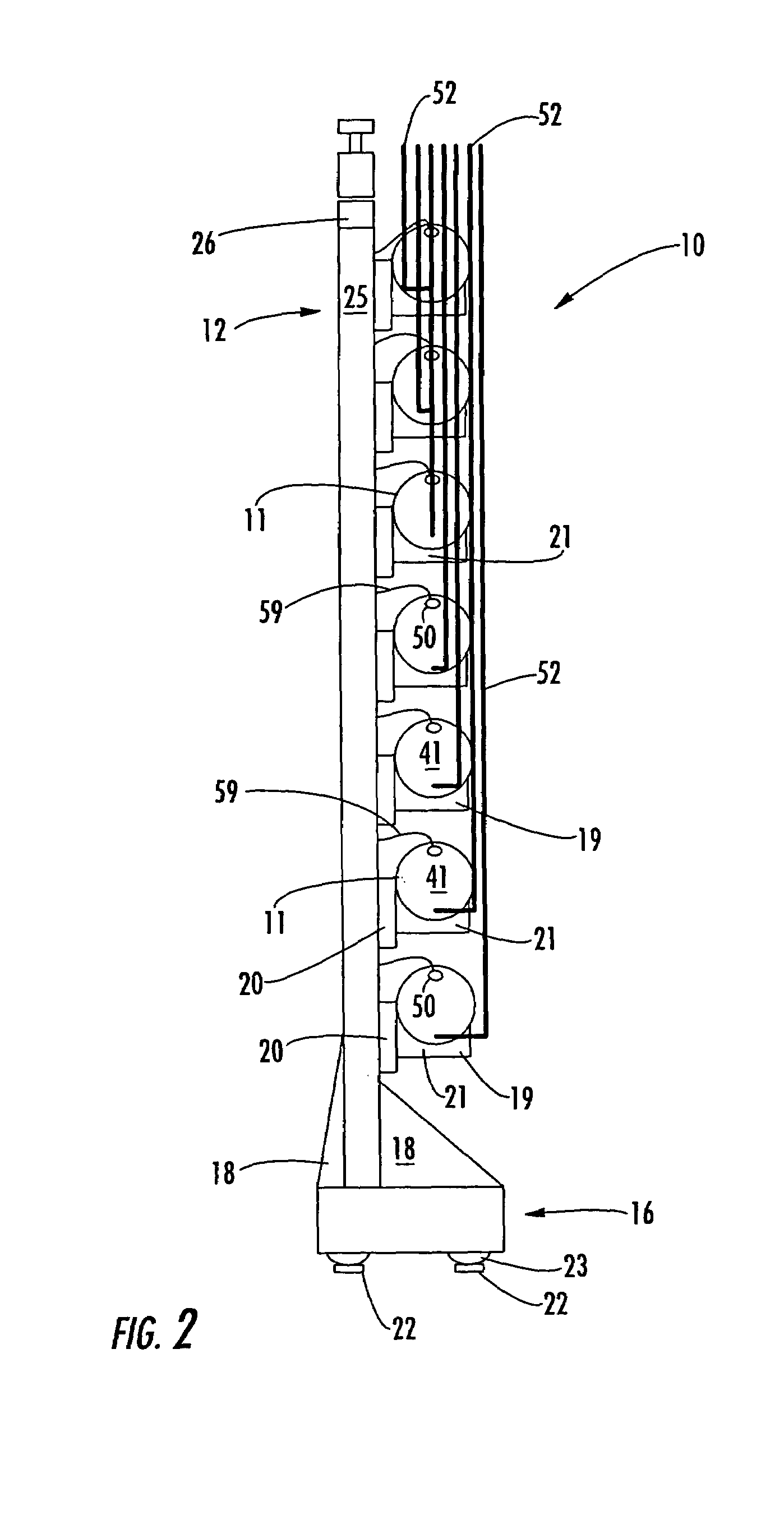

Plasma reactor apparatus with multiple gas injection zones having time-changing separate configurable gas compositions for each zone

ActiveUS8231799B2Electric discharge tubesVacuum gauge using ionisation effectsGas compositionEngineering

Owner:APPLIED MATERIALS INC

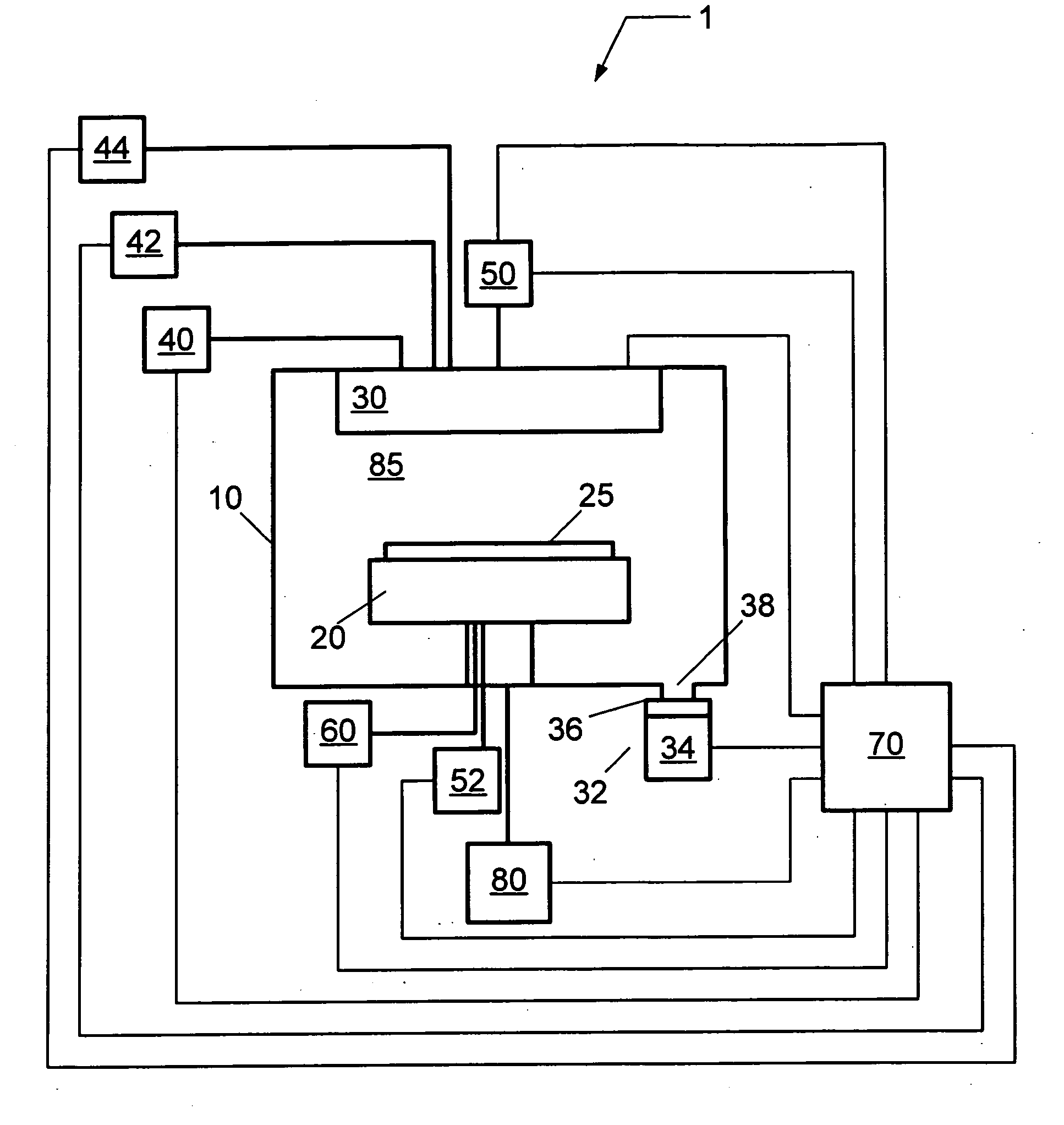

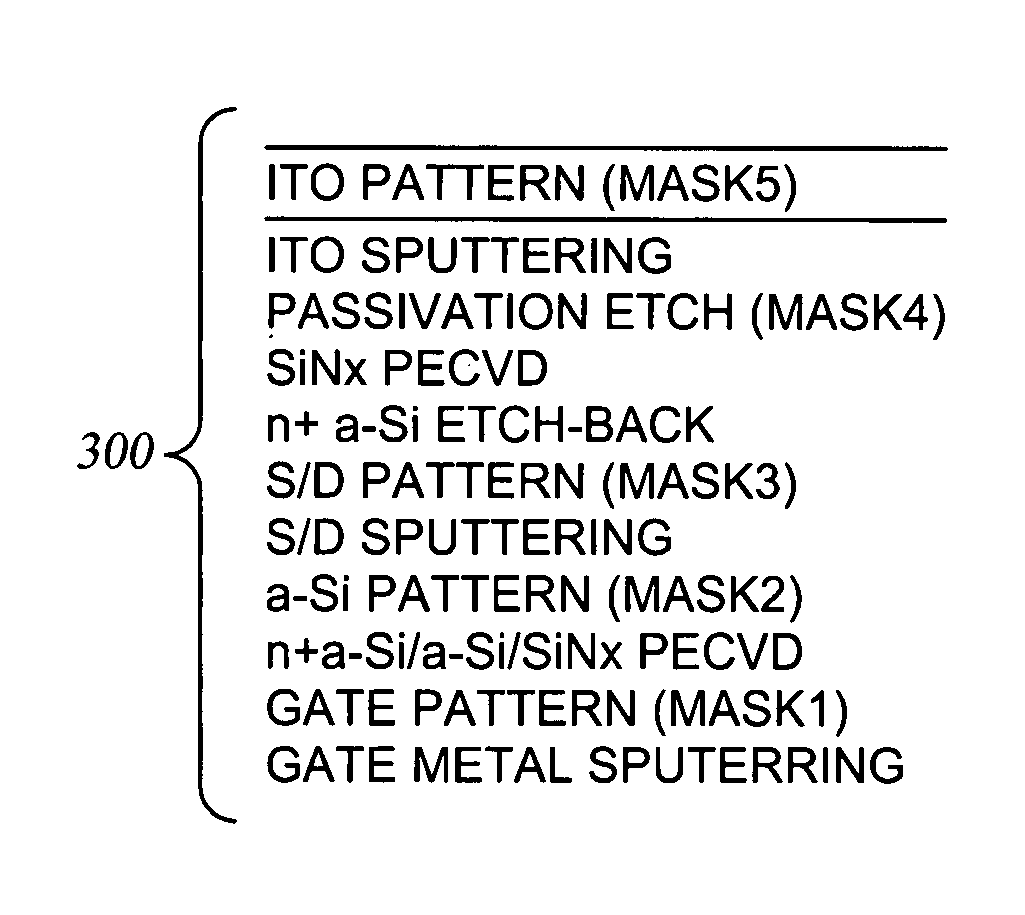

Method and system for performing different deposition processes within a single chamber

InactiveUS20070116888A1Reduce pollutionElectric discharge tubesChemical vapor deposition coatingGas phaseGas composition

A method, computer readable medium, and system for vapor deposition on a substrate that introduce a first process gas composition to a process space according to a first vapor deposition process, deposit a first film on the substrate, introduce a second process gas composition into a second process space different in size than the first process space, and deposit a second film on the substrate from the second process gas composition. As such, the system includes a process chamber including a first process space having a first volume. The process chamber further includes a second process space that includes at least a part of the first process space and that has a second volume different from the first volume. The first process space is configured for a first chemical vapor deposition, and the second process space is configured for a second chemical vapor deposition.

Owner:TOKYO ELECTRON LTD

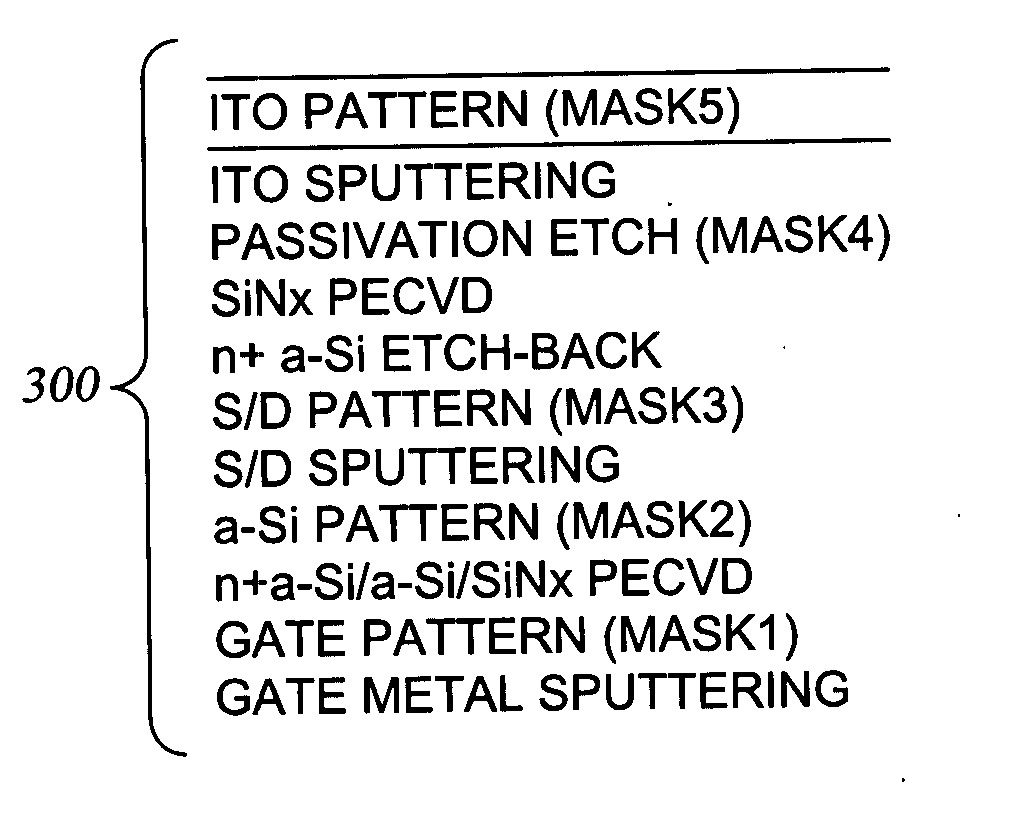

Method of controlling the film properties of a CVD-deposited silicon nitride film

InactiveUS20060019502A1Increase wet etch rateEasy to controlSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGate dielectricGas composition

We have discovered that adding H2 to a precursor gas composition including SiH4, NH3, and N2 is effective at improving the wet etch rate and the wet etch rate uniformity across the substrate surface of a-SiNx:H films which are deposited on a substrate by PECVD. Wet etch rate is an indication of film density. Typically, the lower the wet etch rate, the denser the film. The addition of H2 to the SiH4 / NH3 / N2 precursor gas composition did not significantly increase the variation in deposited film thickness across the surface of the substrate. The a-SiNx:H films described herein are particularly useful as TFT gate dielectrics in the production of flat panel displays. The uniformity of the film across the substrate enables the production of flat panel displays having surface areas of 25,000 cm2 and larger.

Owner:APPLIED MATERIALS INC

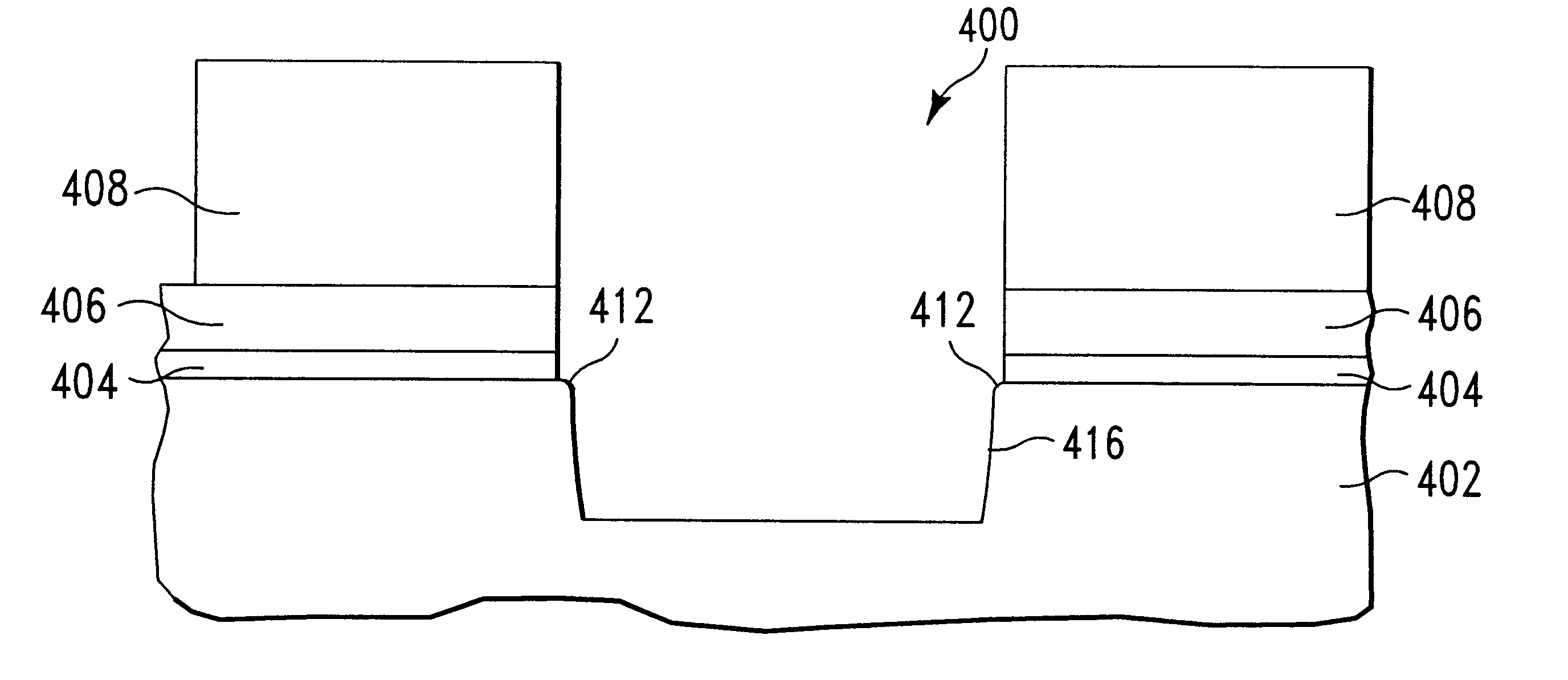

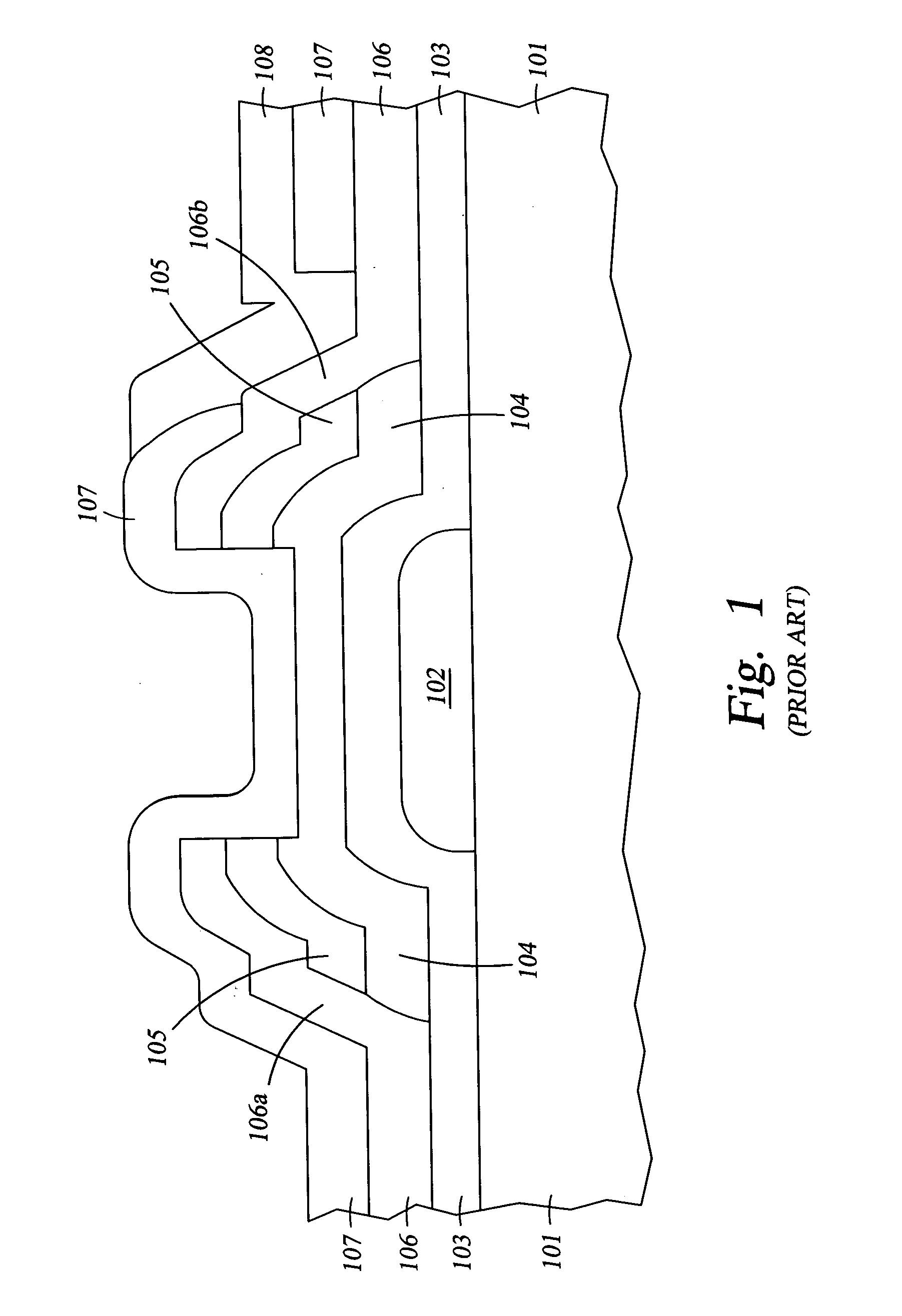

Method for etching a trench having rounded top and bottom corners in a silicon substrate

The present invention provides straight forward methods for plasma etching a trench having rounded top corners, or rounded bottom corners, or both in a silicon substrate. A first method for creating a rounded top corner on the etched silicon trench comprises etching both an overlying silicon oxide layer and an upper portion of the silicon substrate during a "break-through" step which immediately precedes the step in which the silicon trench is etched. The plasma feed gas for the break-through step comprises carbon and fluorine. In this method, the photoresist layer used to pattern the etch stack is preferably not removed prior to the break-through etching step. Subsequent to the break-through step, a trench is etched to a desired depth in the silicon substrate using a different plasma feed gas composition. A second method for creating a rounded top corner on the etched silicon trench comprises formation of a built-up extension on the sidewall of an overlying patterned silicon nitride hard mask during etch (break-through) of a silicon oxide adhesion layer which lies between the hard mask and a silicone substrate. The built-up extension upon the silicon nitride sidewall acts as a sacrificial masking material during etch of the silicon trench, delaying etching of the silicon at the outer edges of the top of the trench. This permits completion of trench etching with delayed etching of the top corner of the trench and provides a more gentle rounding (increased radius) at the top corners of the trench. During the etching of the silicon trench to its final dimensions, it is desirable to round the bottom corners of the finished silicon trench. We have discovered that a more rounded bottom trench corner is obtained using a two-step silicon etch process where the second step of the process is carried out at a higher process chamber pressure than the first step.

Owner:APPLIED MATERIALS INC

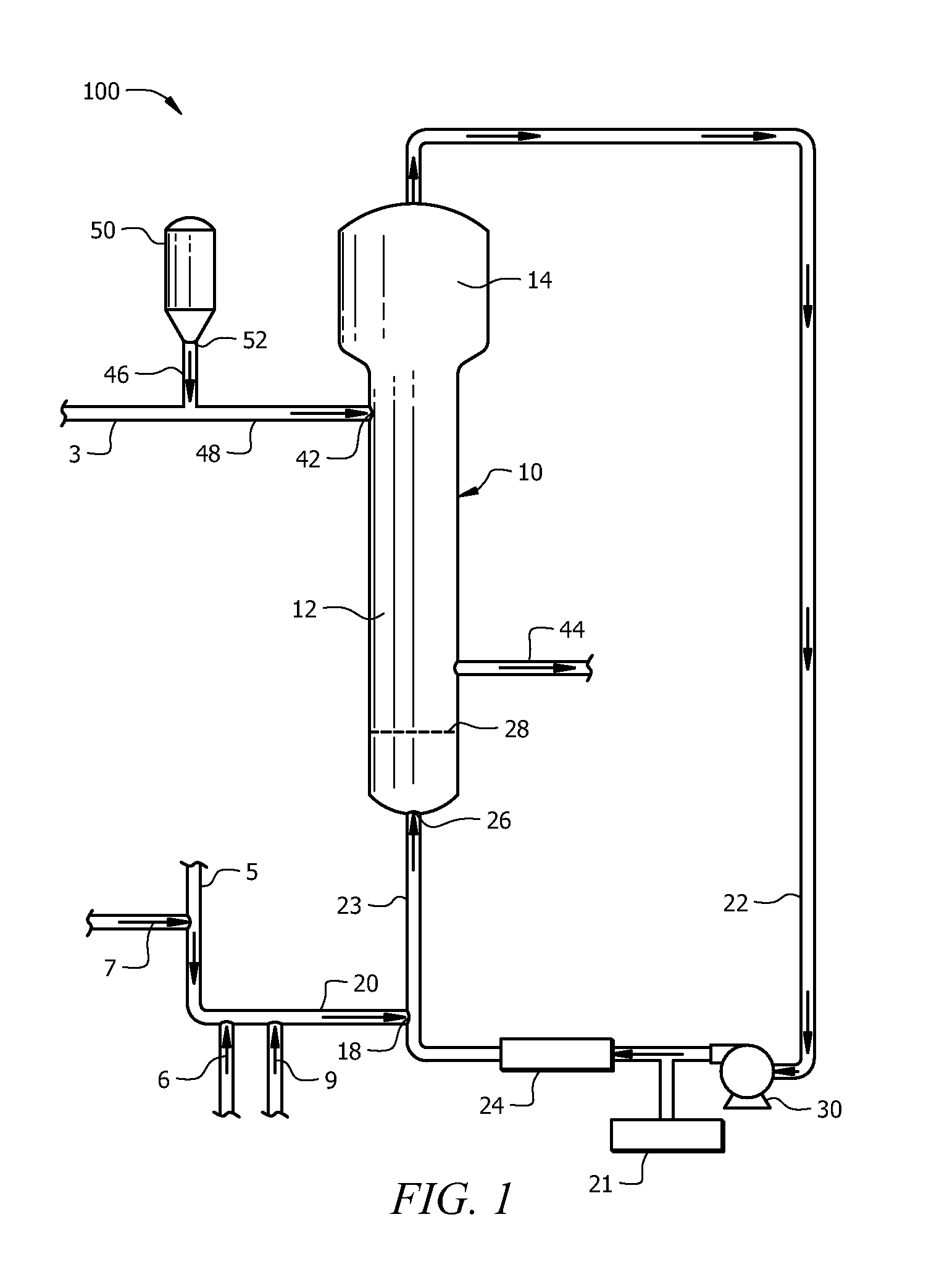

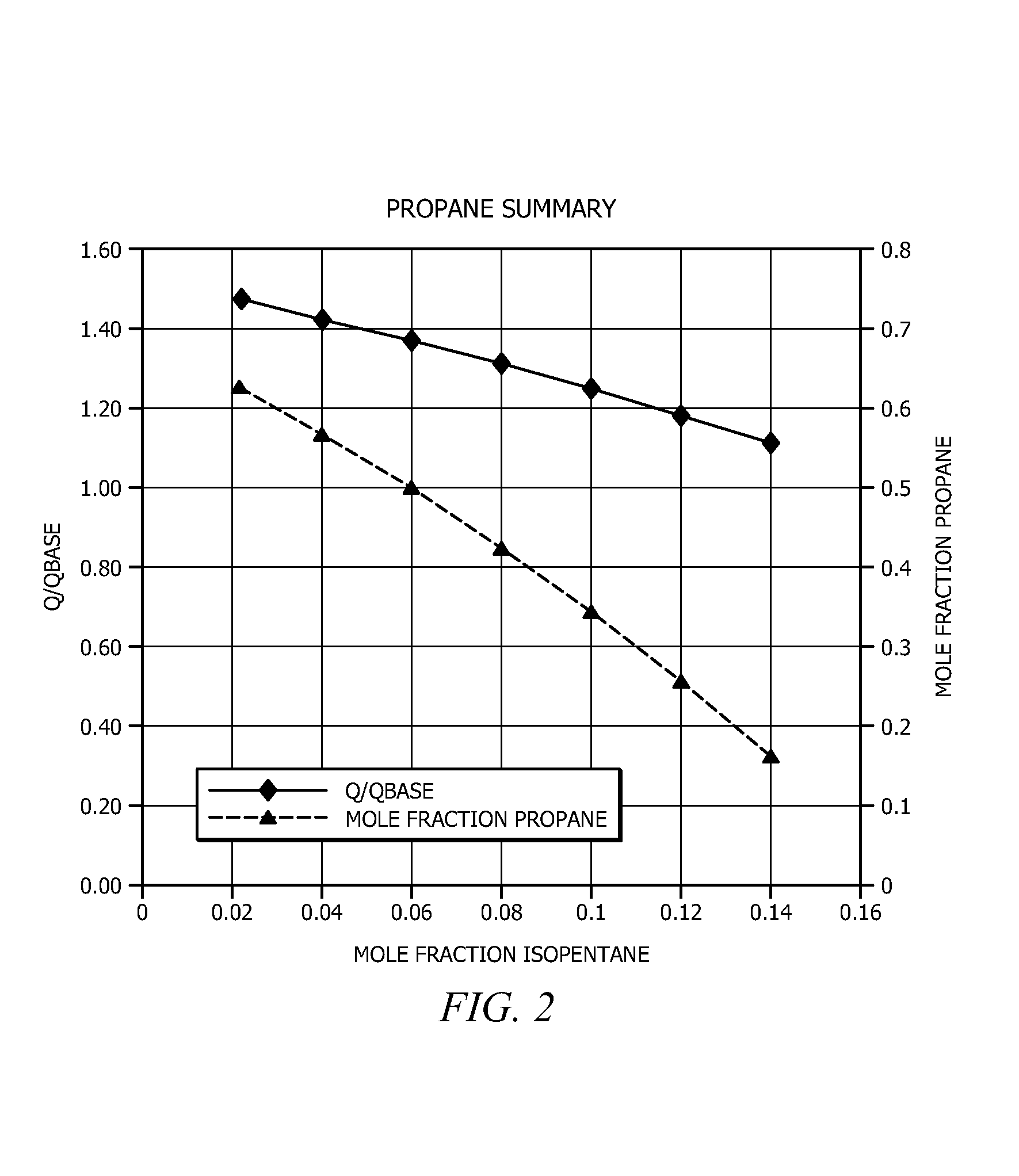

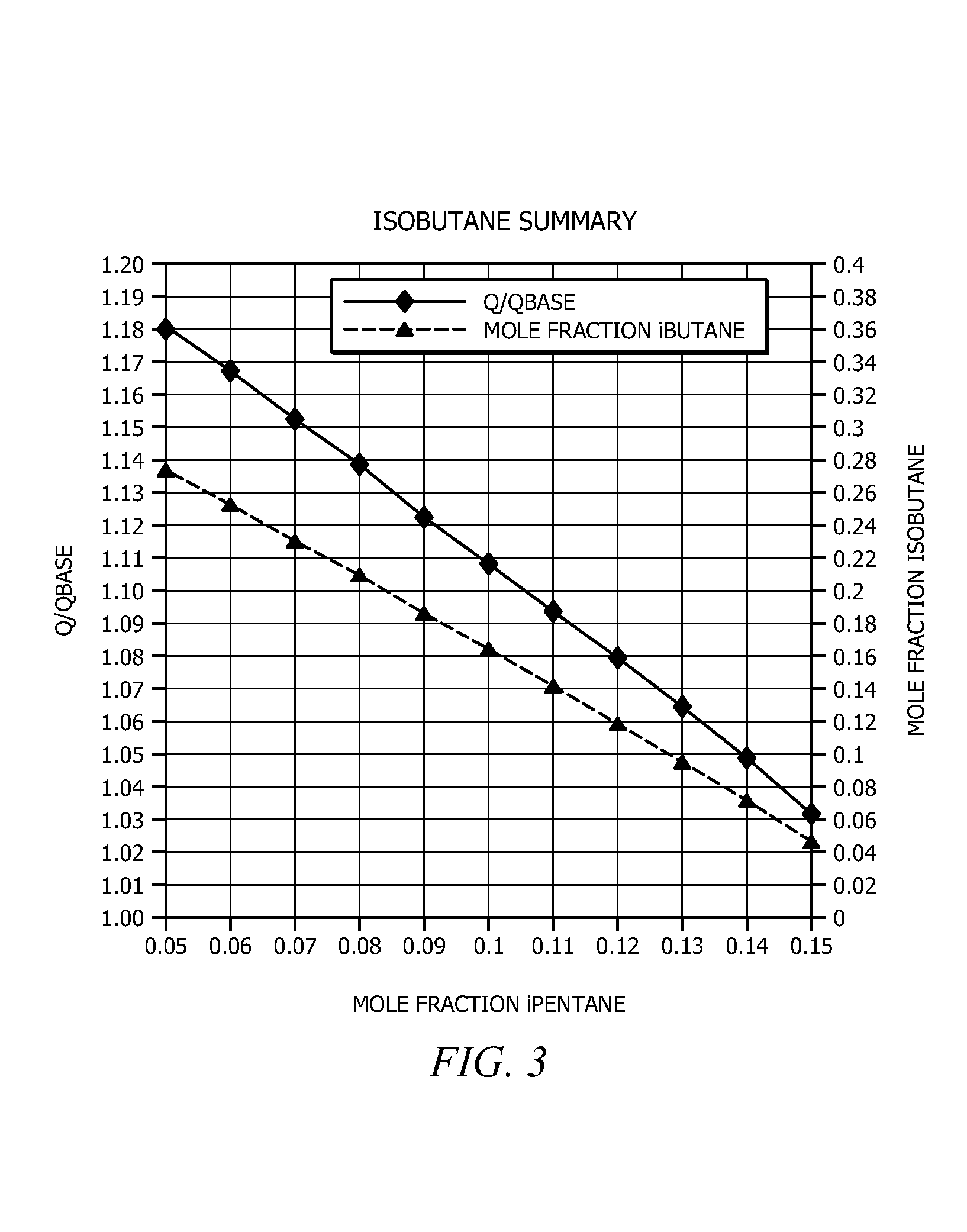

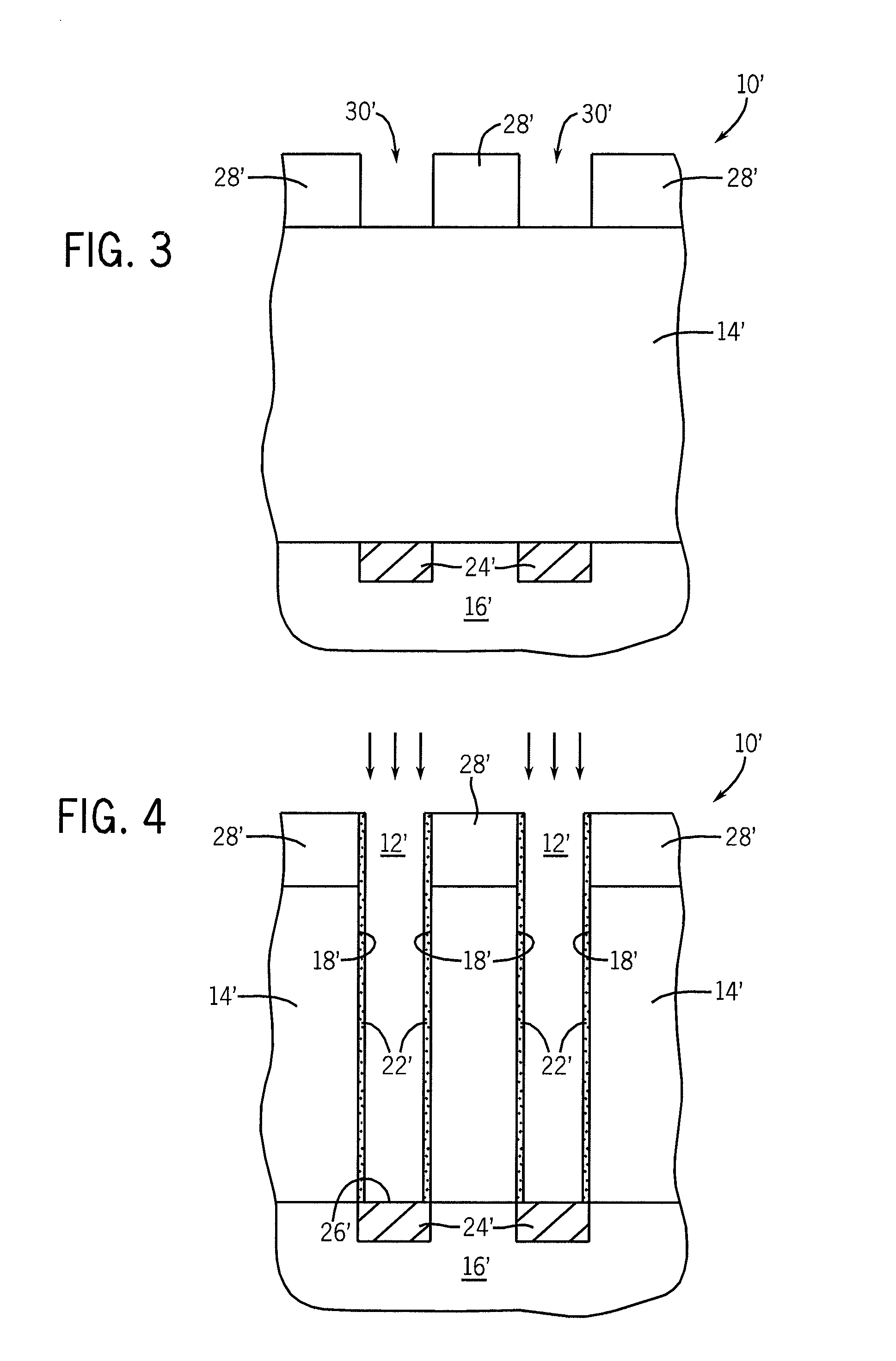

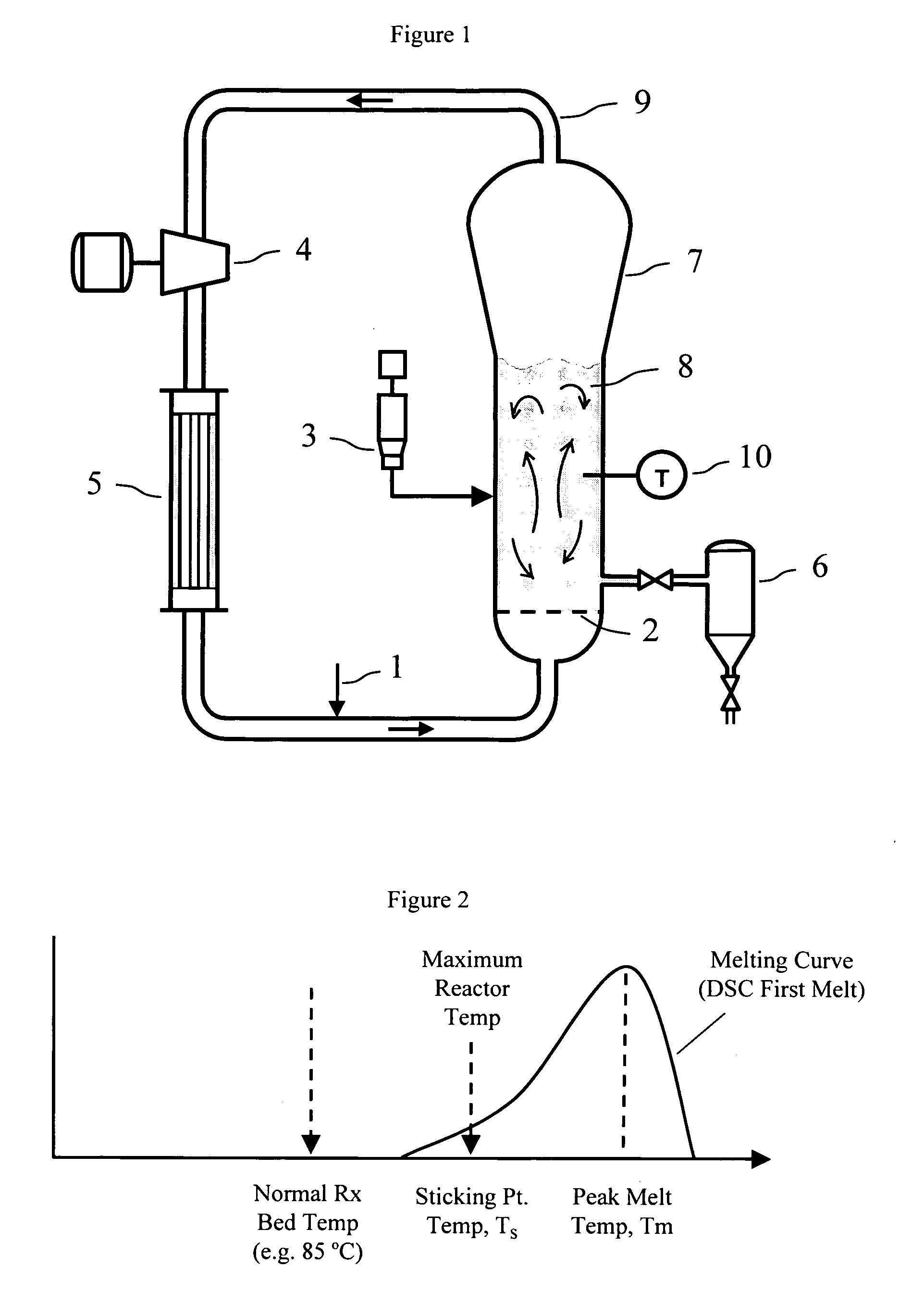

Method for operating a gas phase polymerization reactor

Disclosed herein is a method of operating a polymerization reactor for a polymerization reaction comprising modifying a recycle gas composition to increase the heat capacity of the recycle gas wherein the recycle gas composition is modified by reducing or eliminating the nitrogen concentration in the recycle gas. In an embodiment, the nitrogen concentration is reduced or eliminated by reducing or eliminating one or more nitrogen input sources to the polymerization reactor and replacing the nitrogen with an alternate inert fluid (a gas or liquid that is inert to the catalyst and reactants). The alternate inert fluid has a higher heat capacity and a higher molecular weight than nitrogen. In an embodiment, the nitrogen utilized to convey a catalyst into the polymerization reactor is replaced with an alternate inert fluid. In an embodiment, the alternate inert fluid is ethane, propane, isobutane, or combinations thereof.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

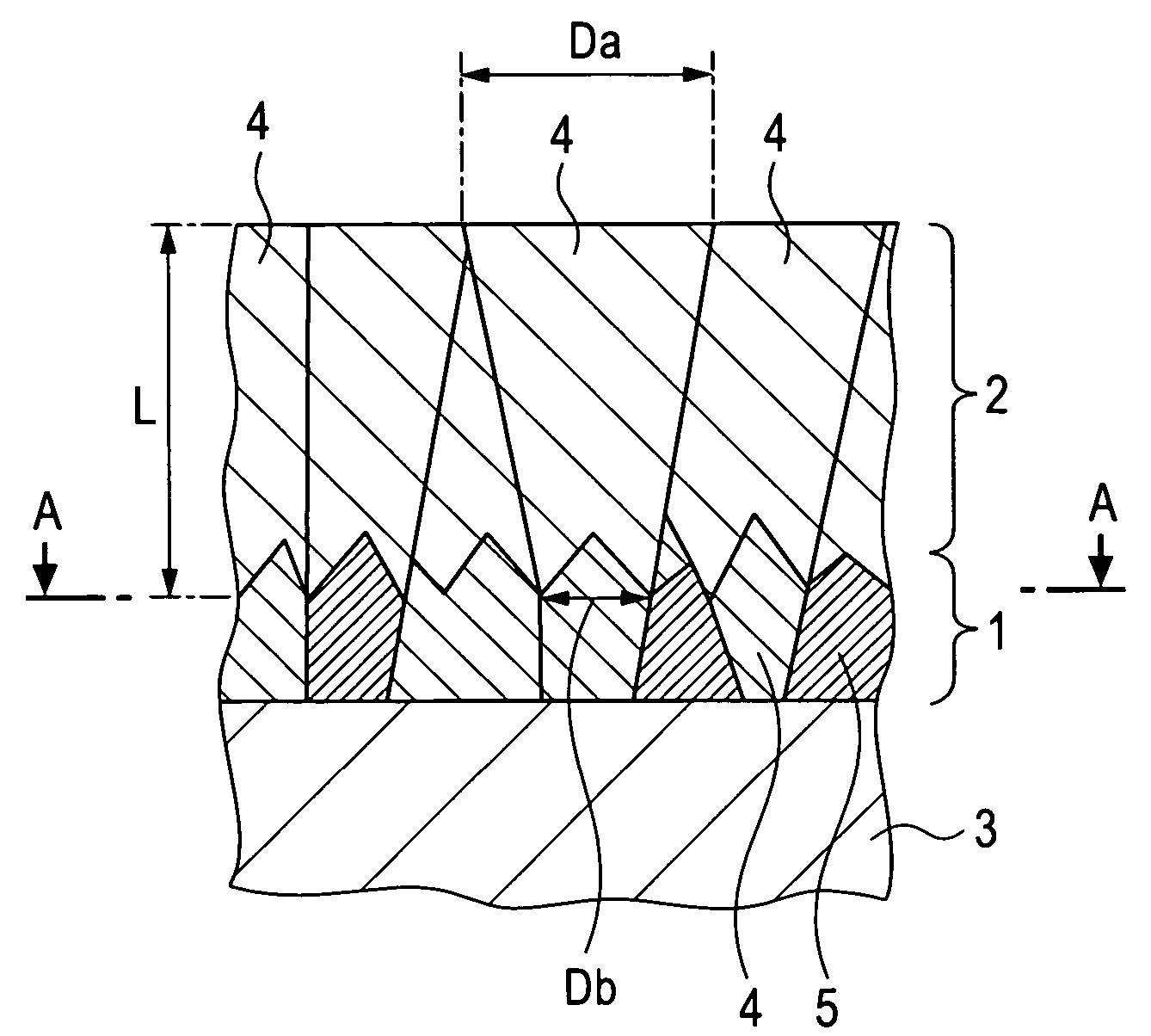

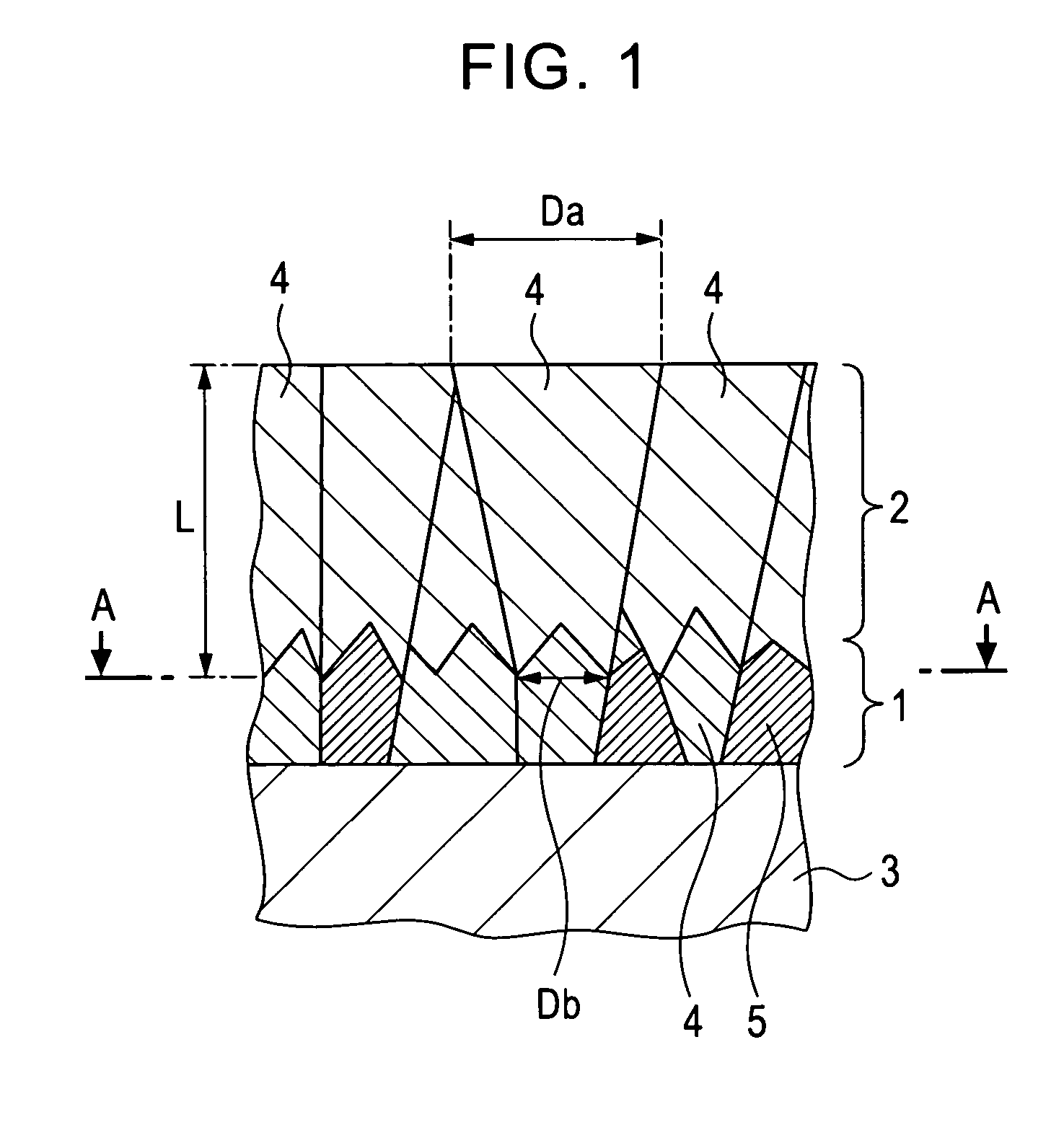

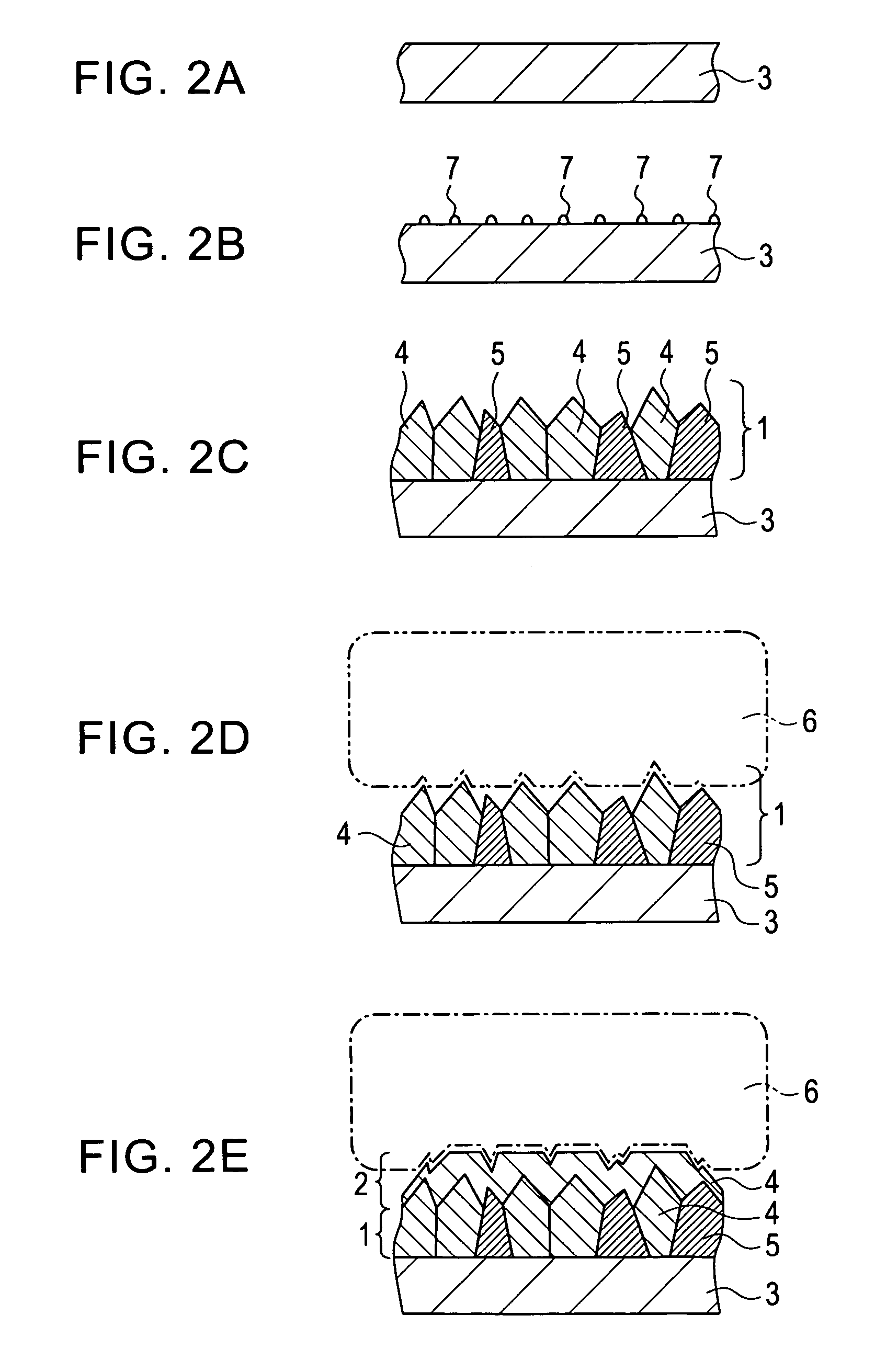

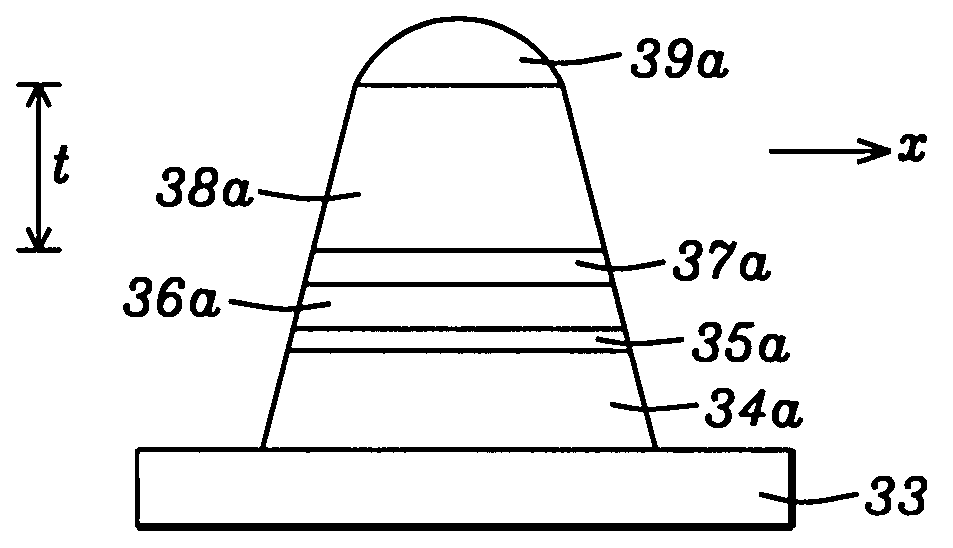

Highly-oriented diamond film, method for manufacturing the same, and electronic device having highly-oriented diamond film

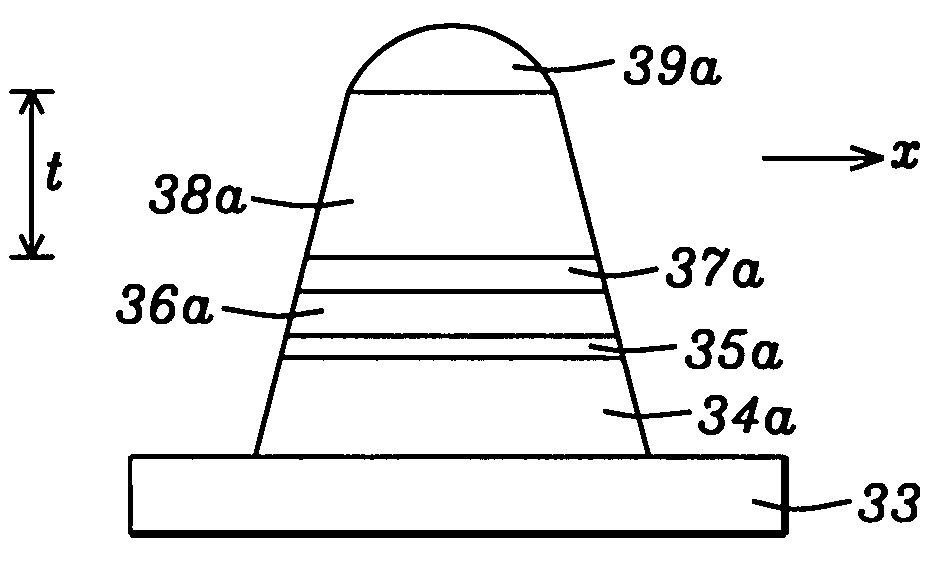

InactiveUS7311977B2Lower performance requirementsImprove performancePolycrystalline material growthFrom chemically reactive gasesHydrogenDiamond crystal

A highly-oriented diamond film which has a flat surface but does not have non-oriented crystals in the surface can be provided by depositing a first diamond layer on a substrate by {111} sector growth of diamond crystals by a CVD method using a gaseous mixture of methane and hydrogen as material gas, and then depositing a second diamond layer on the first diamond layer by {100} sector growth of diamond crystals by a plasma CVD method using a gaseous mixture of methane, hydrogen, and oxygen as material gas under the conditions that the pressure of the material gas is 133 hPa or more; the material gas composition is determined such that ([C]−[O]) / [CH3+H2+O2] is −0.2×10−2 or more and [O] / [C] is 1.2 or less; and the substrate temperature is between 750° C. and 1000° C.

Owner:KOBE STEEL LTD

Method of Etching a High Aspect Ratio Contact

ActiveUS20090176375A1Decorative surface effectsSemiconductor/solid-state device manufacturingGas compositionContact method

Methods and an etch gas composition for etching a contact opening in a dielectric layer are provided. Embodiments of the method use a plasma generated from an etch gas composed of C4F8 and / or C4F6, an oxygen source, and a carrier gas in combination with tetrafluoroethane (C2F4) or a halofluorocarbon analogue of C2F4.

Owner:MICRON TECH INC

Polymerization process

The present invention relates to a continuous gas phase process comprising polymerizing one or more hydrocarbon monomer(s) in a fluidized bed reactor in the presence of catalyst system or polymerization catalyst and a condensable fluid for a period of at least 12 hours where the bed temperature is less than the Critical Temperature and the dew point temperature of the gas composition in the reactor is within 25° C. of the bed temperature.

Owner:EXXONMOBIL CHEM PAT INC

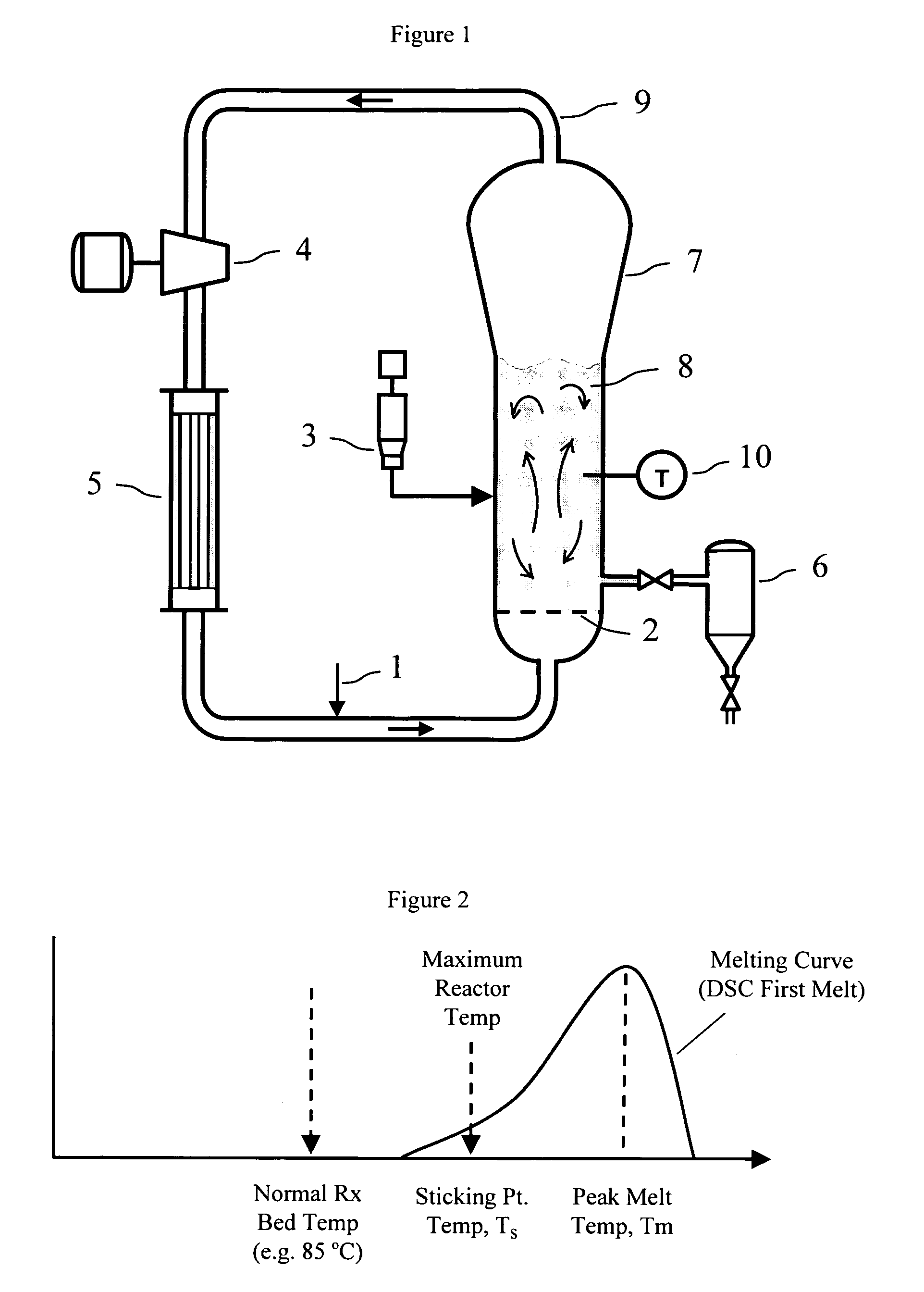

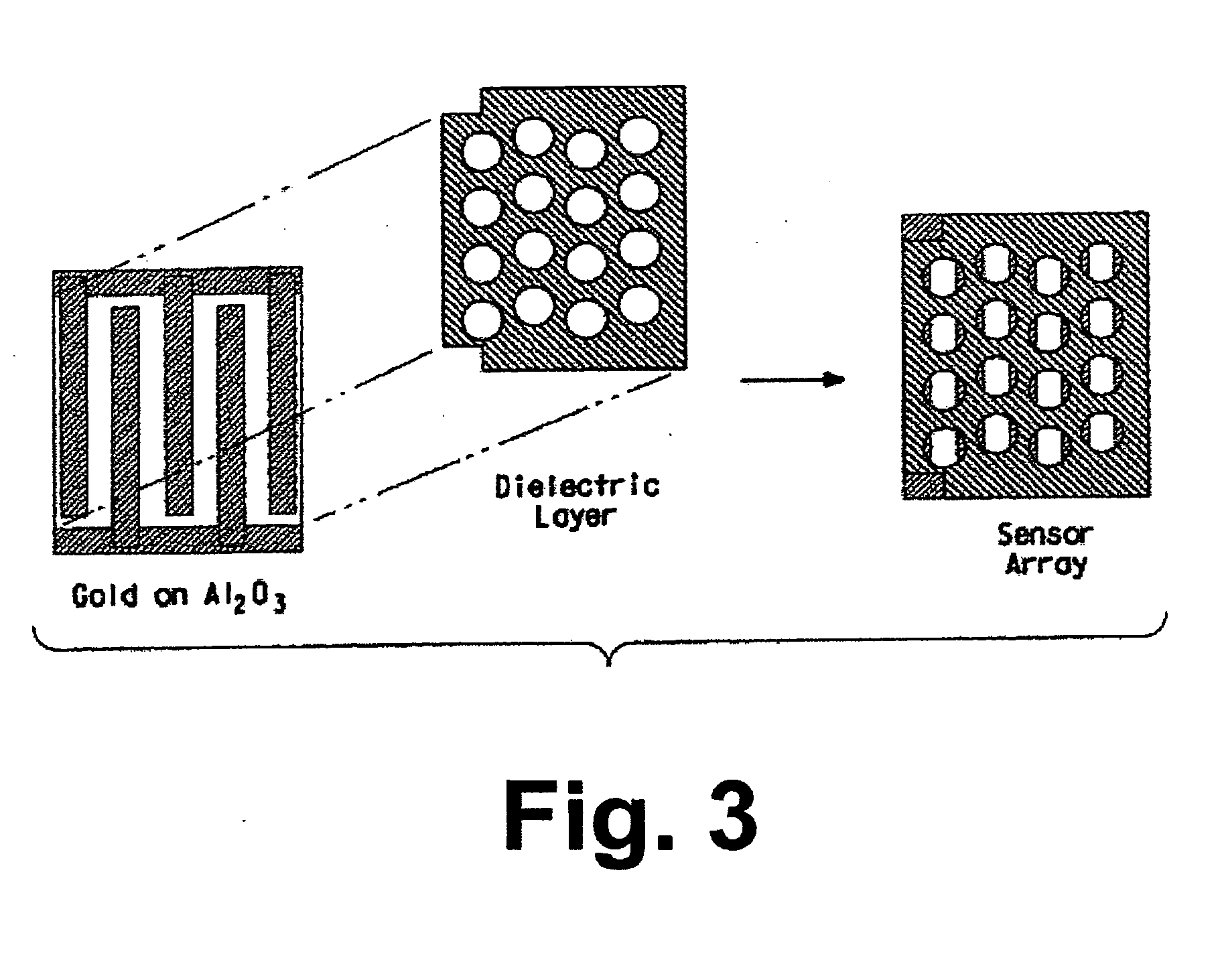

Computer-implemented system and method for analyzing mixtures of gases

InactiveUS20060155486A1Gas analyser construction detailsMaterial resistanceSensor arrayElectrical resistance and conductance

A computer-implemented system and method for converting the resistances of an array of metal oxide sensors into constituents and concentrations of a multi-component gas provided around the sensor array. The method includes preprocessing the resistances of the sensor array; selecting a model that calculates the constituents and concentrations of the multi-component gas based on the preprocessed resistances; and post-processing the constituents and concentrations of the multi-component gas generated by the selected model to provide the actual constituents and concentrations of the multi-component gas.

Owner:EI DU PONT DE NEMOURS & CO

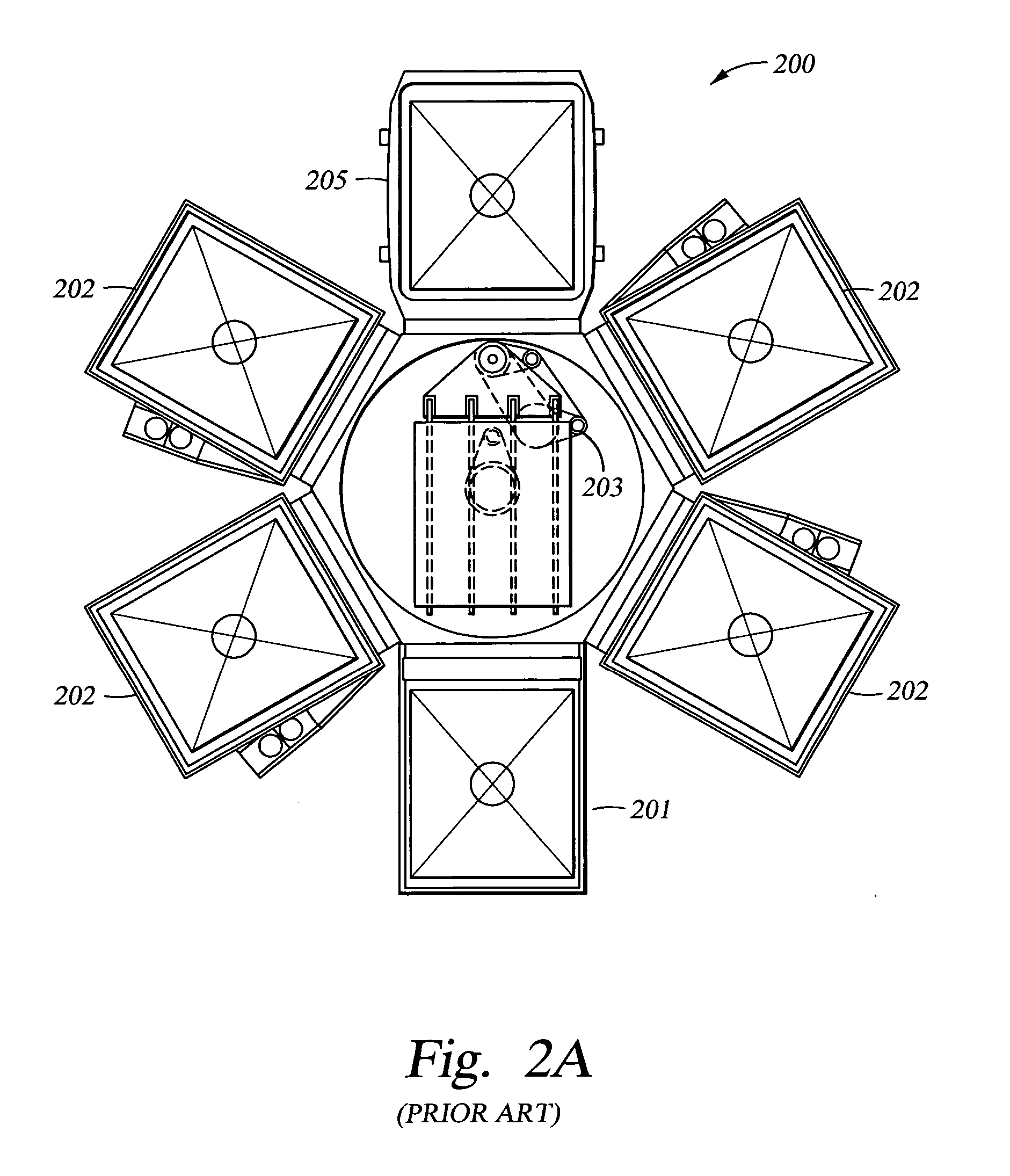

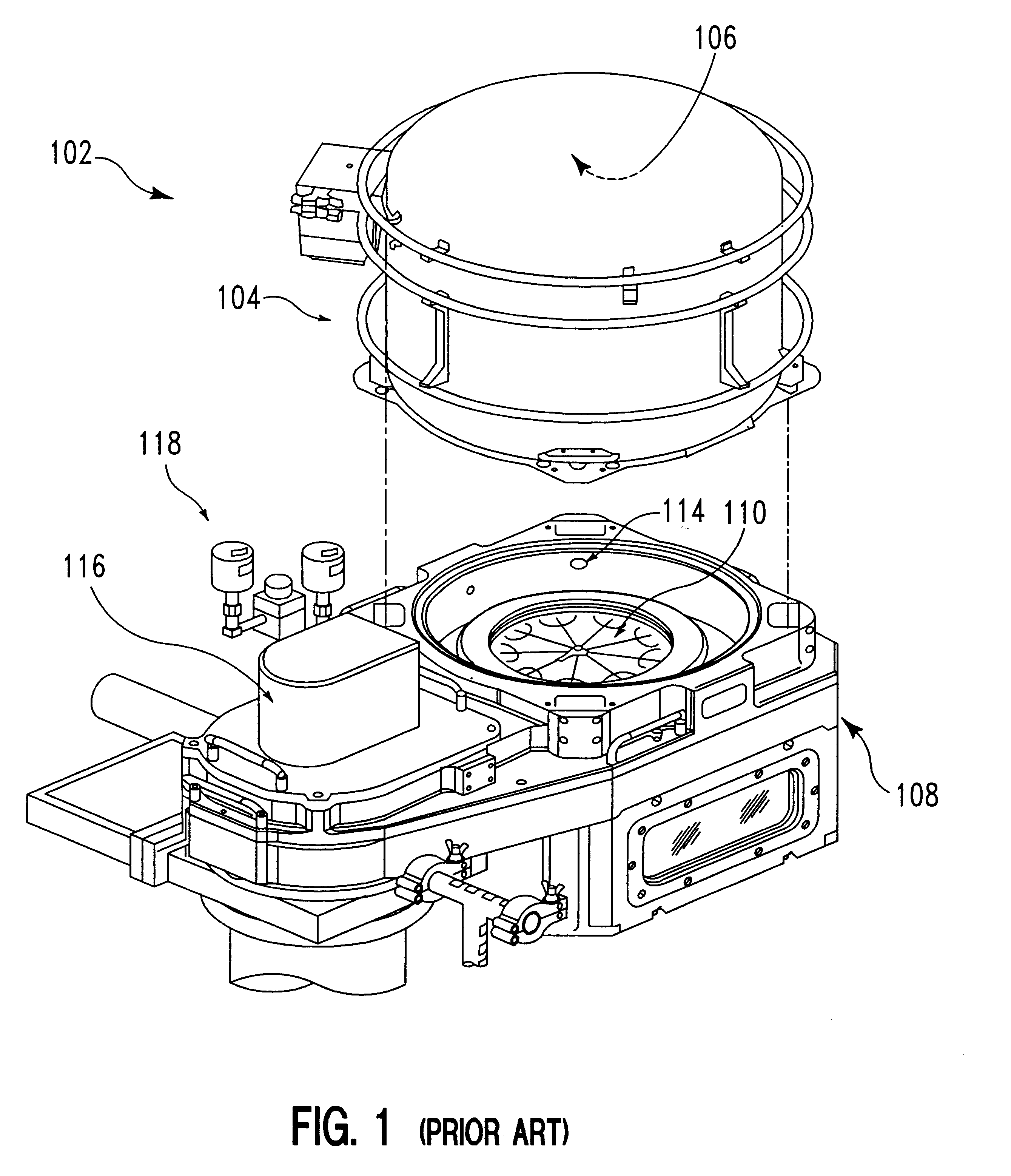

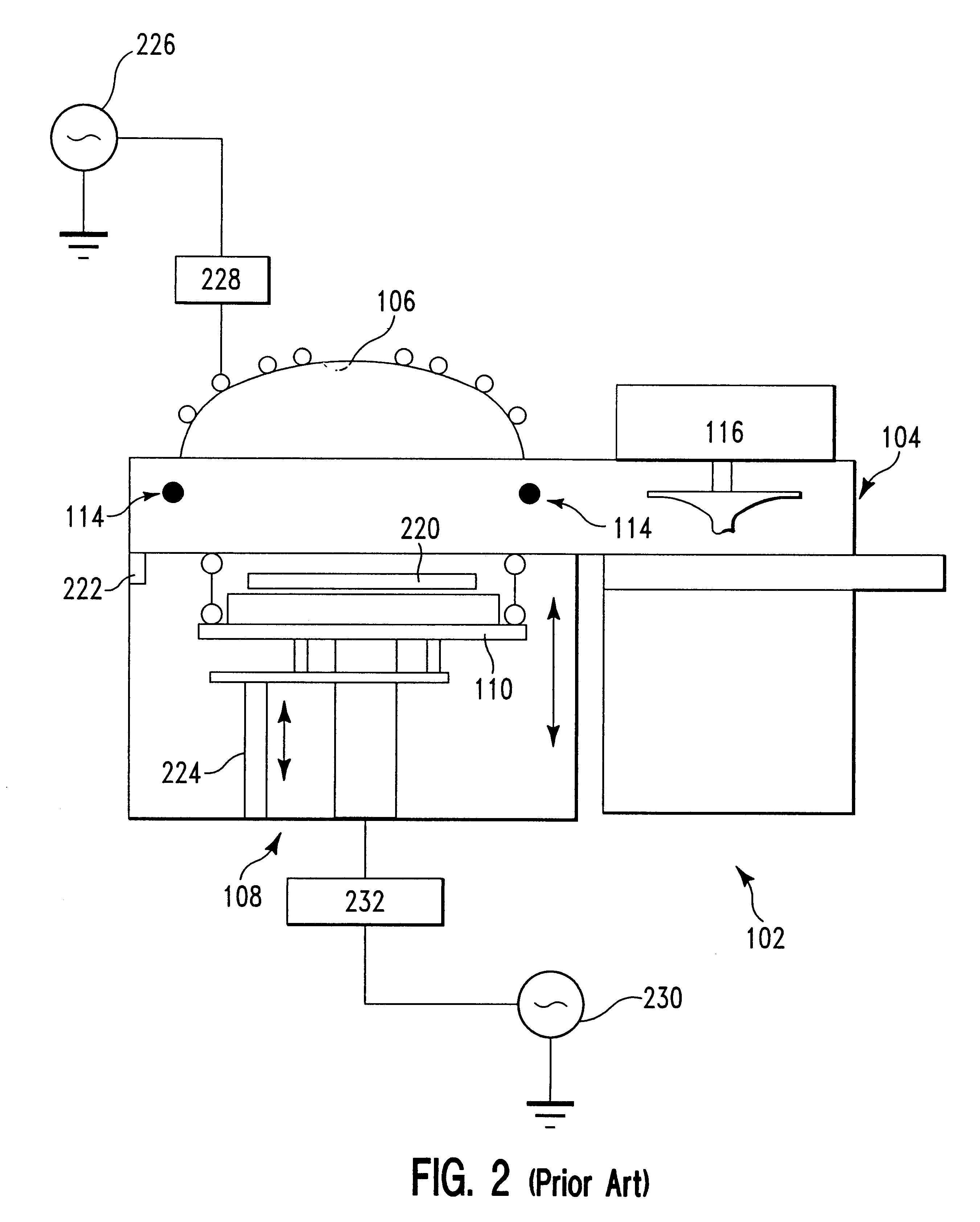

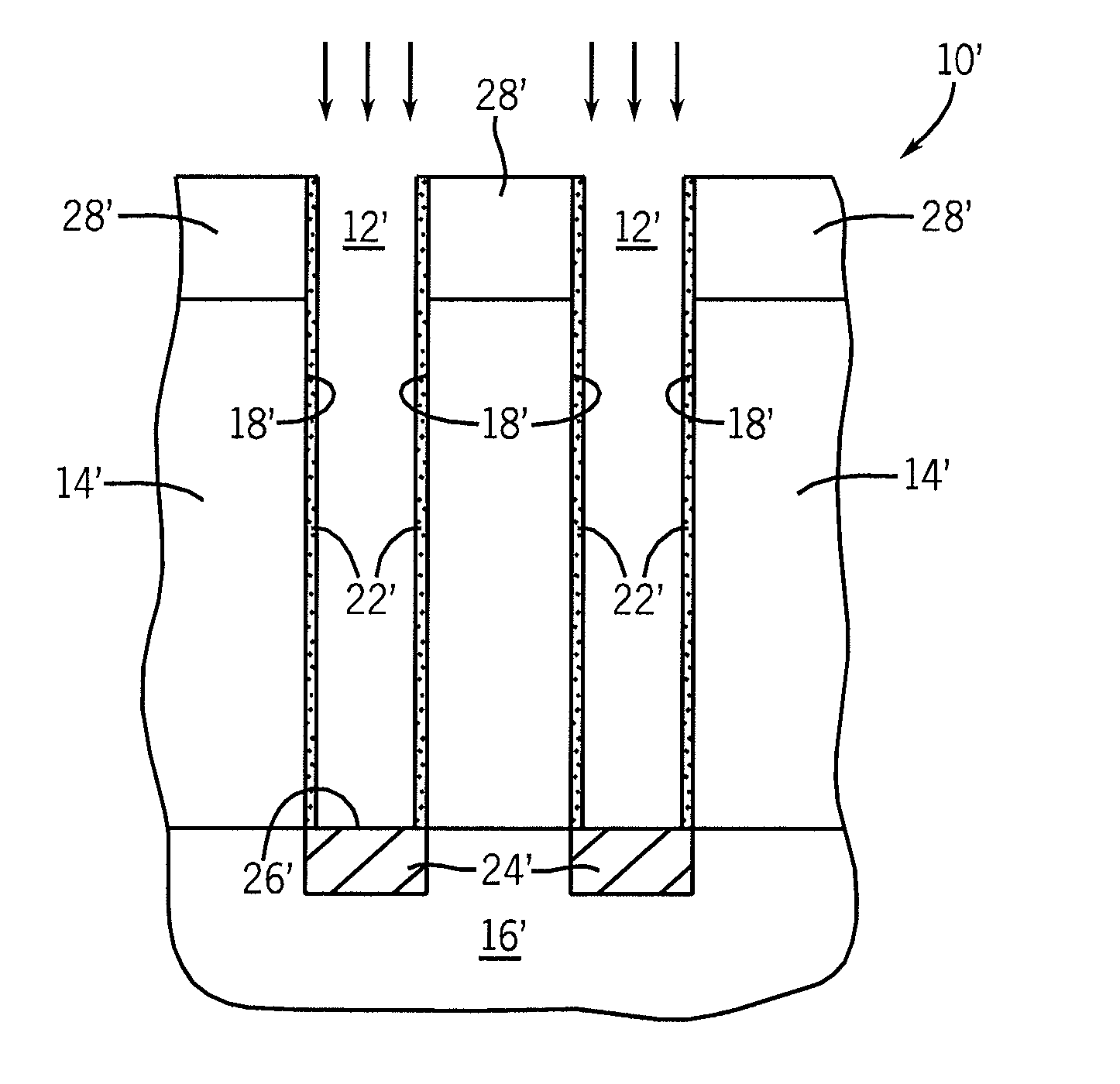

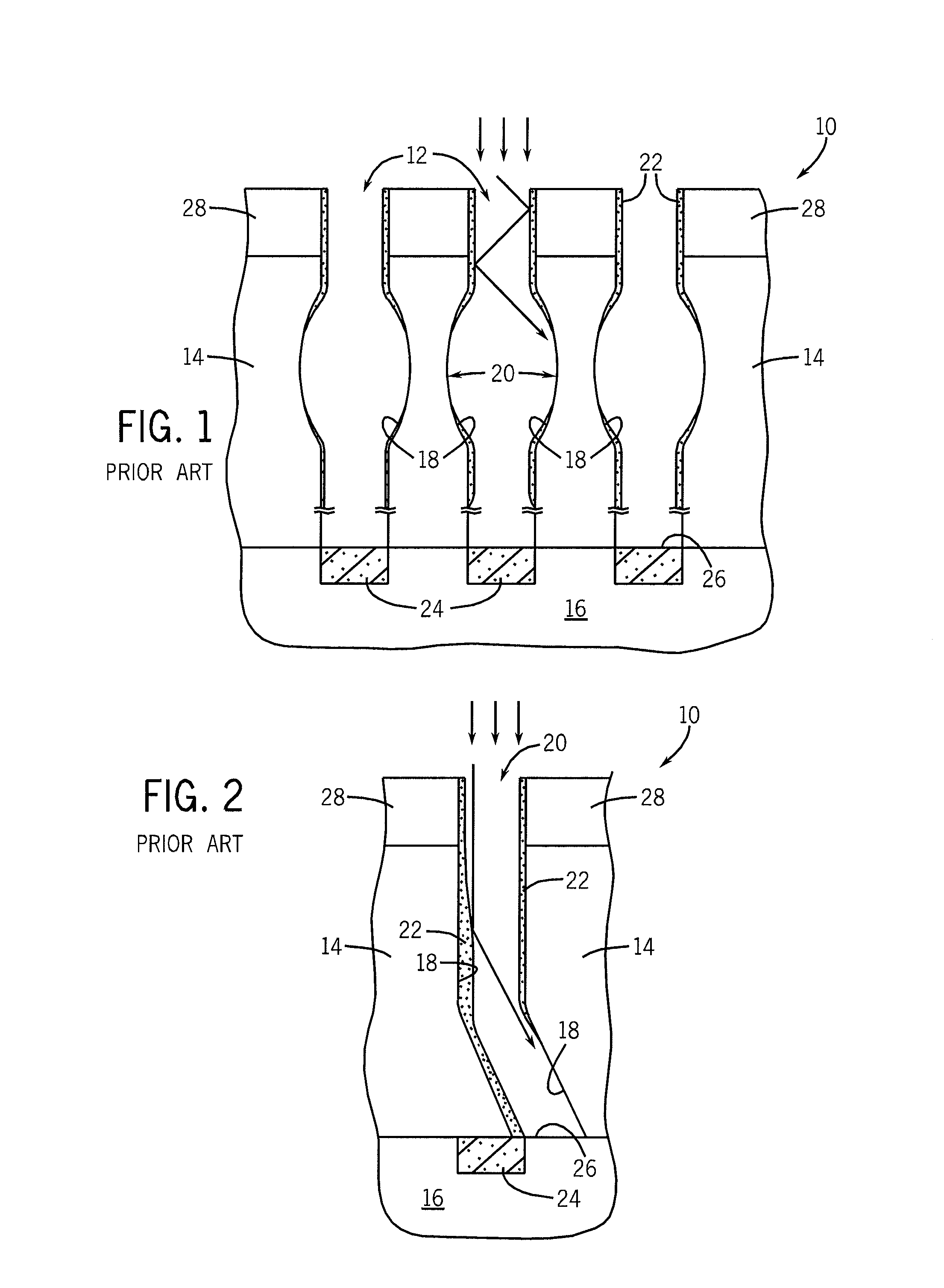

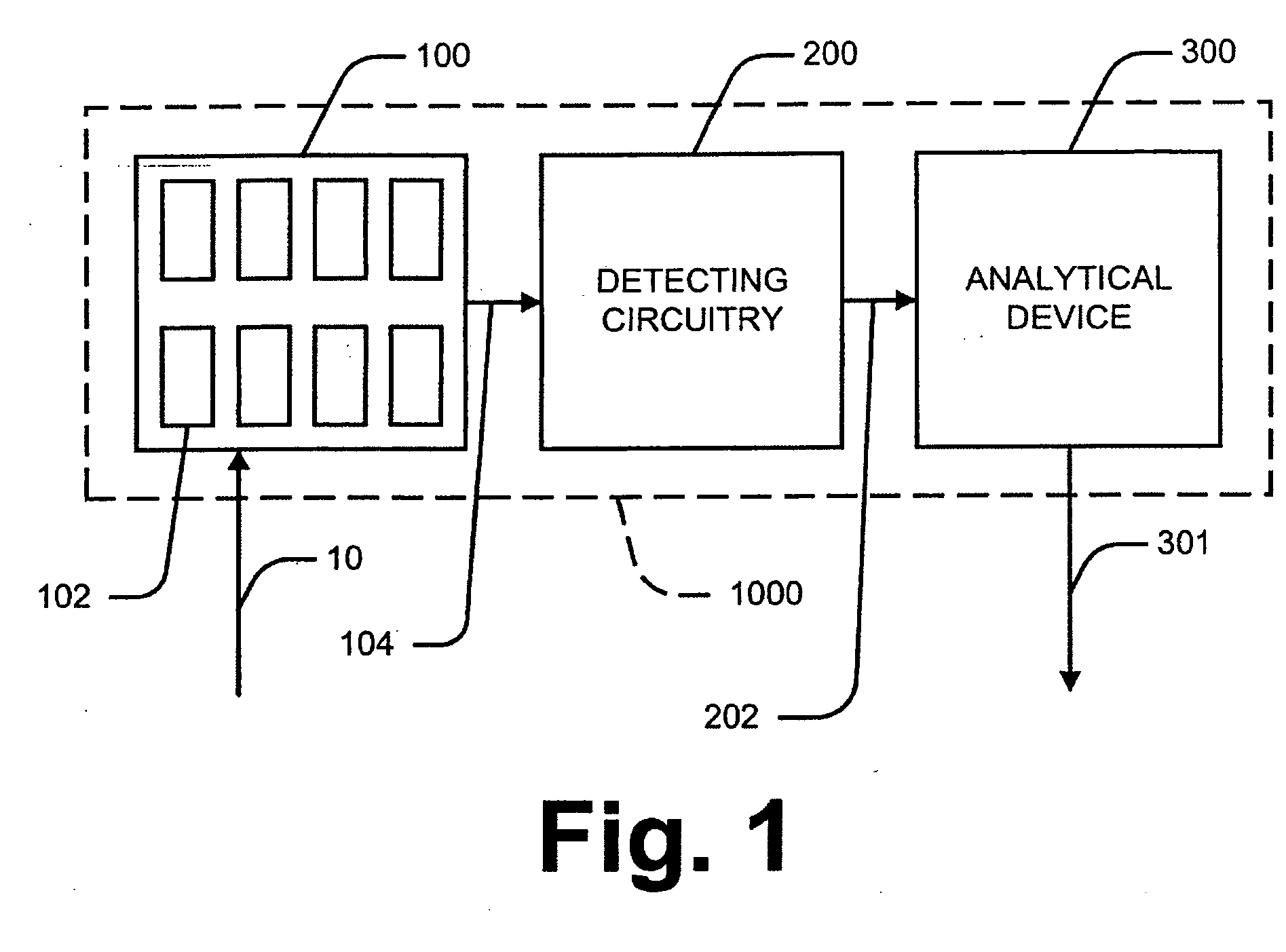

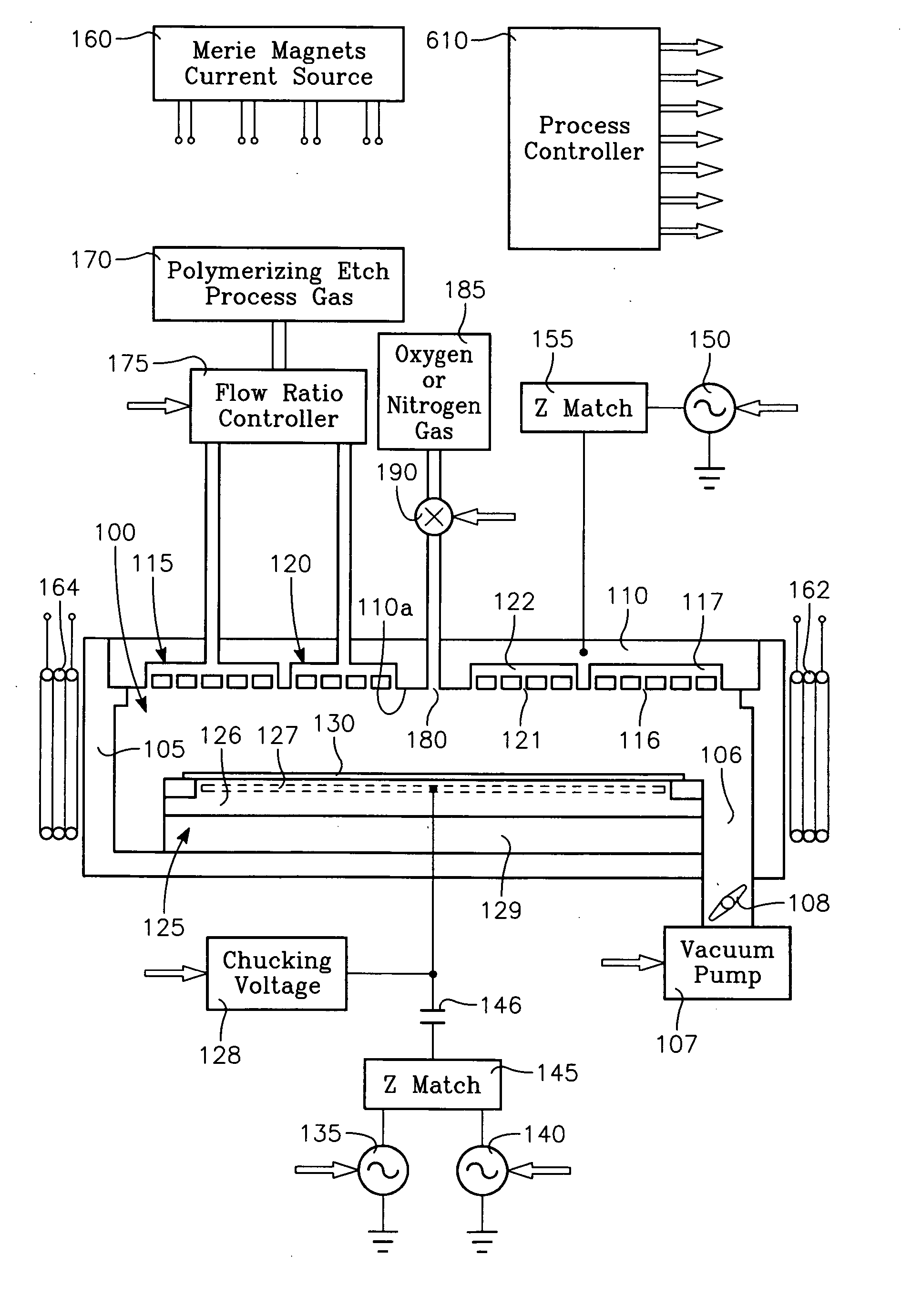

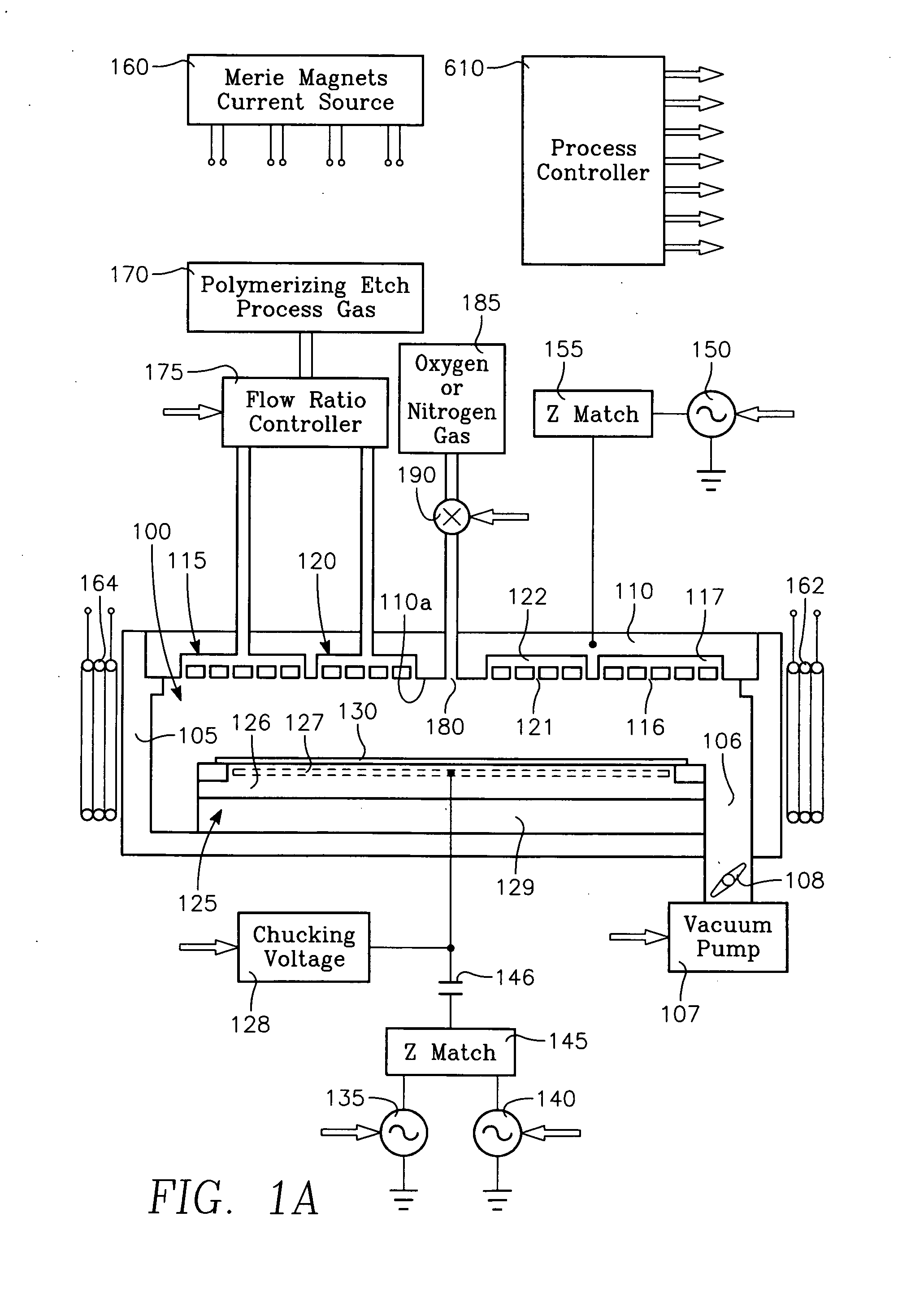

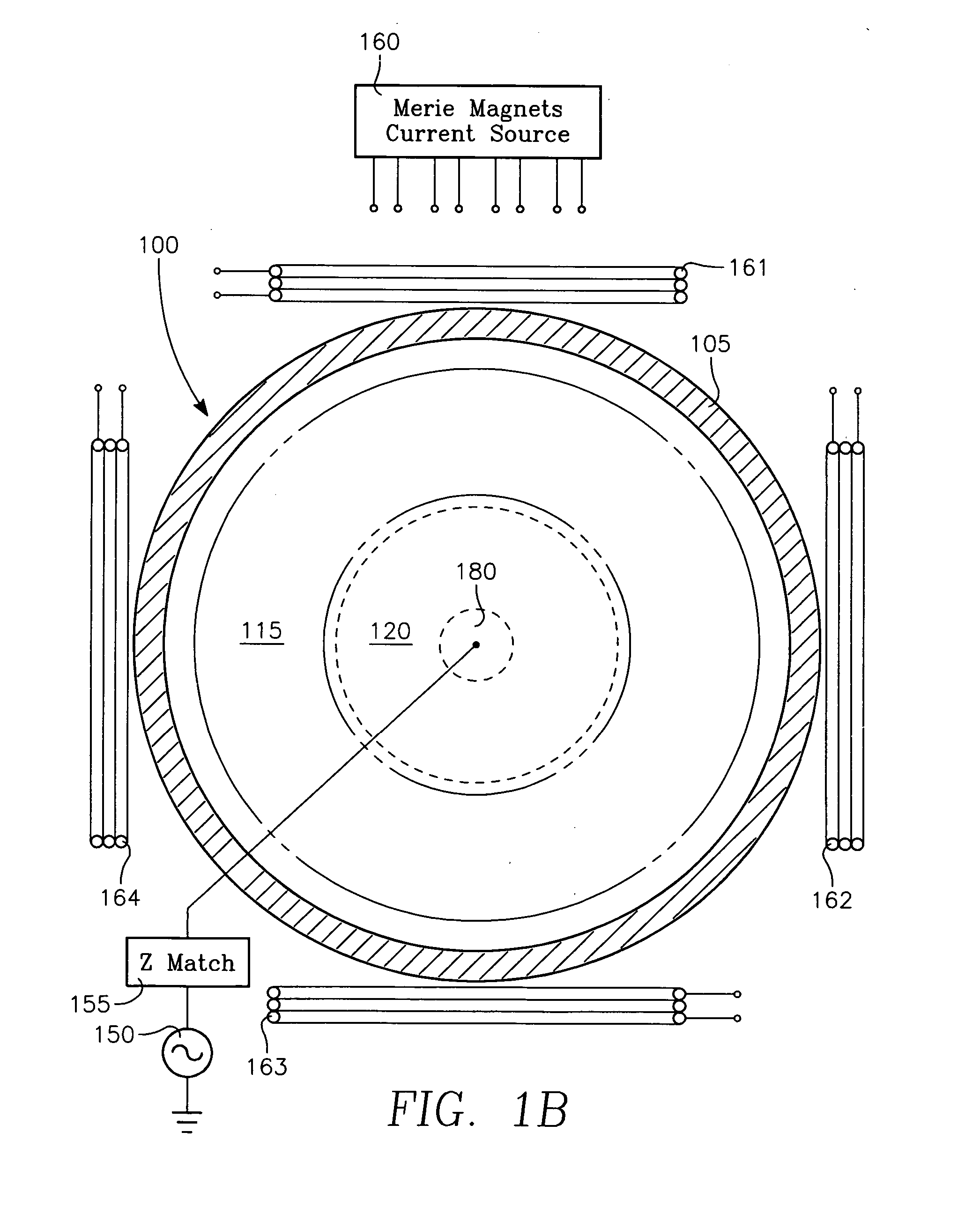

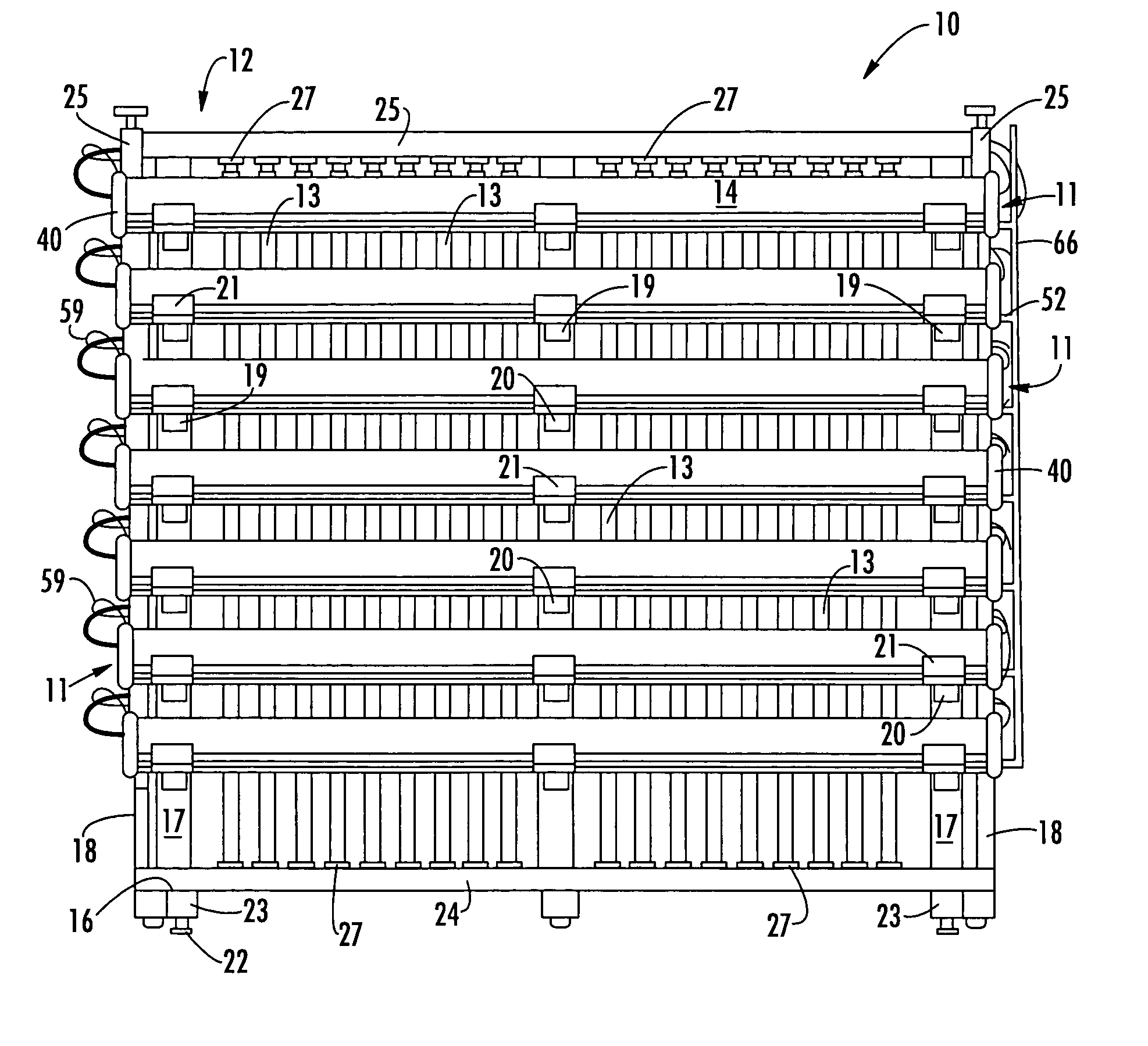

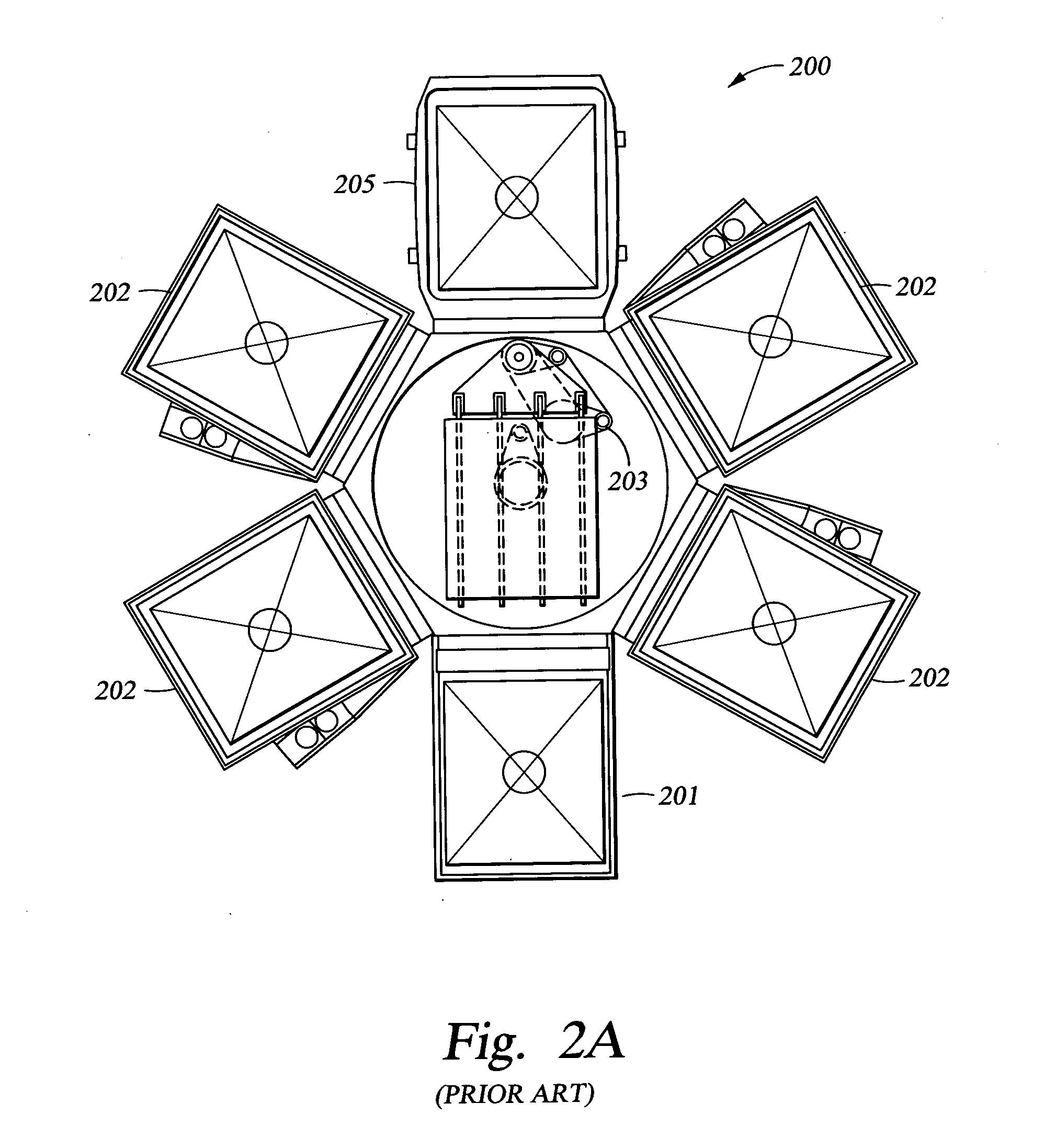

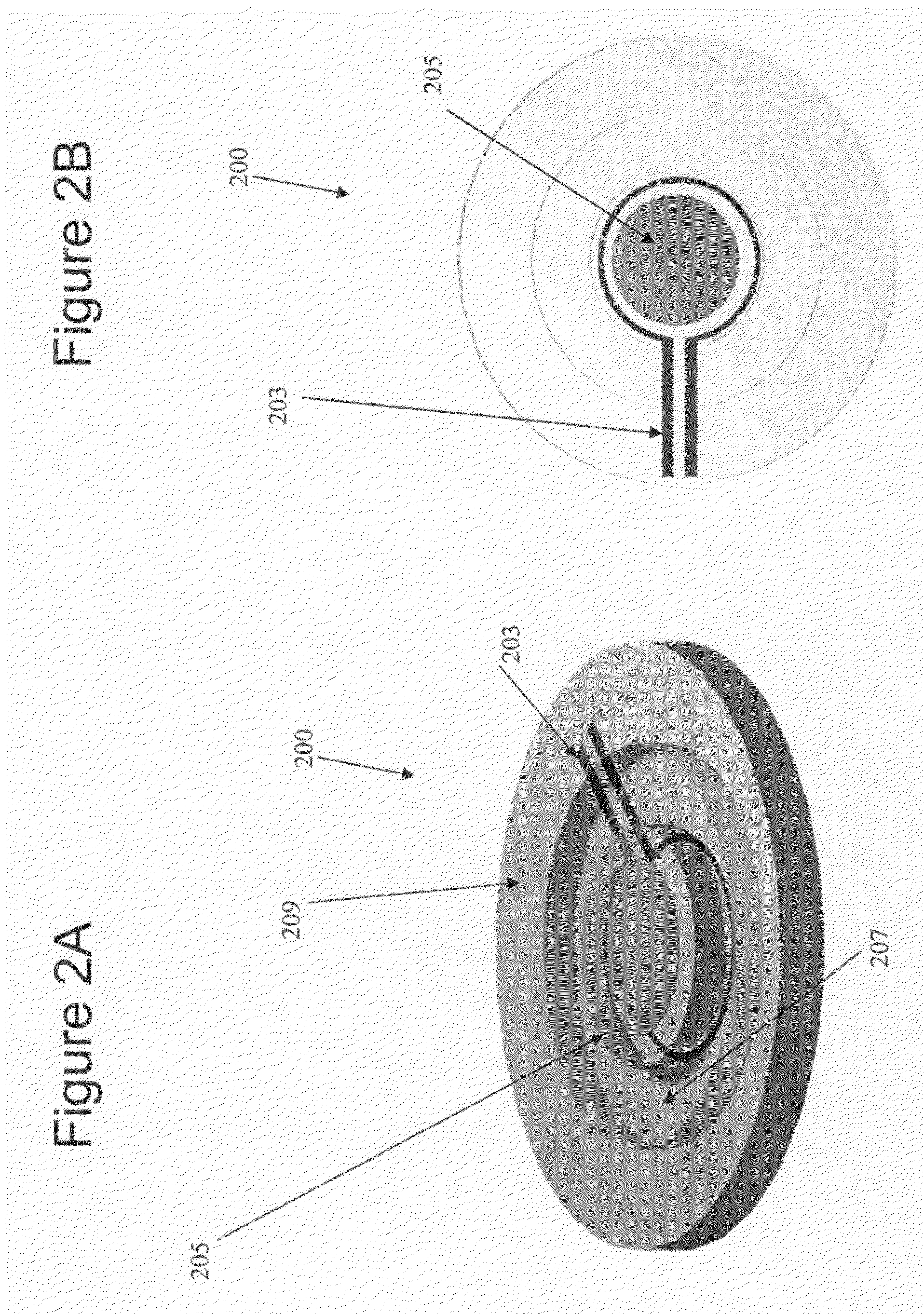

Plasma reactor apparatus with multiple gas injection zones having time-changing separate configurable gas compositions for each zone

ActiveUS20070251642A1Electric discharge tubesVacuum gauge using ionisation effectsGas compositionOxygen

A plasma reactor for processing a workpiece such as a semiconductor wafer has a housing defining a process chamber, a workpiece support configured to support a workpiece within the chamber during processing and comprising a plasma bias power electrode. The reactor further includes plural gas sources containing different gas species, plural process gas inlets and an array of valves capable of coupling any of said plural gas sources to any of said plural process gas inlets. The reactor also includes a controller governing said array of valves and is programmed to change the flow rates of gases through said inlets over time. A ceiling plasma source power electrode of the reactor has plural gas injection zones coupled to the respective process gas inlets. In a preferred embodiment, the plural gas sources comprise supplies containing, respectively, fluorocarbon or fluorohydrocarbon species with respectively different ratios of carbon and fluorine chemistries. They further include an oxygen or nitrogen supply and a diluent gas supply. The controller is programmed to produce flow of different process gas species or mixtures thereof through different ones of said plural gas injection zones. The controller is further programmed to change over time the species content of the gases flowing through different ones of said plural gas injection zones.

Owner:APPLIED MATERIALS INC

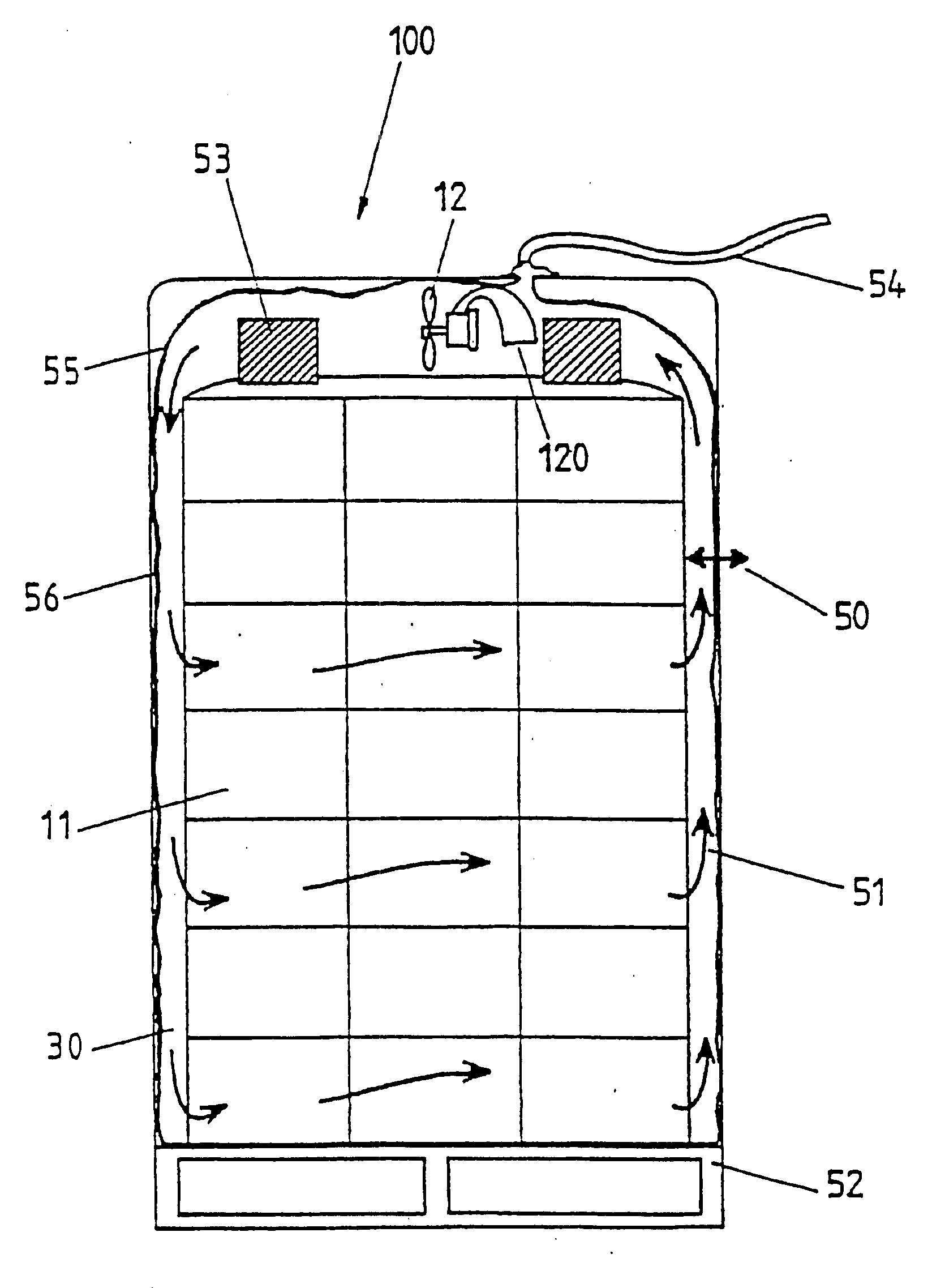

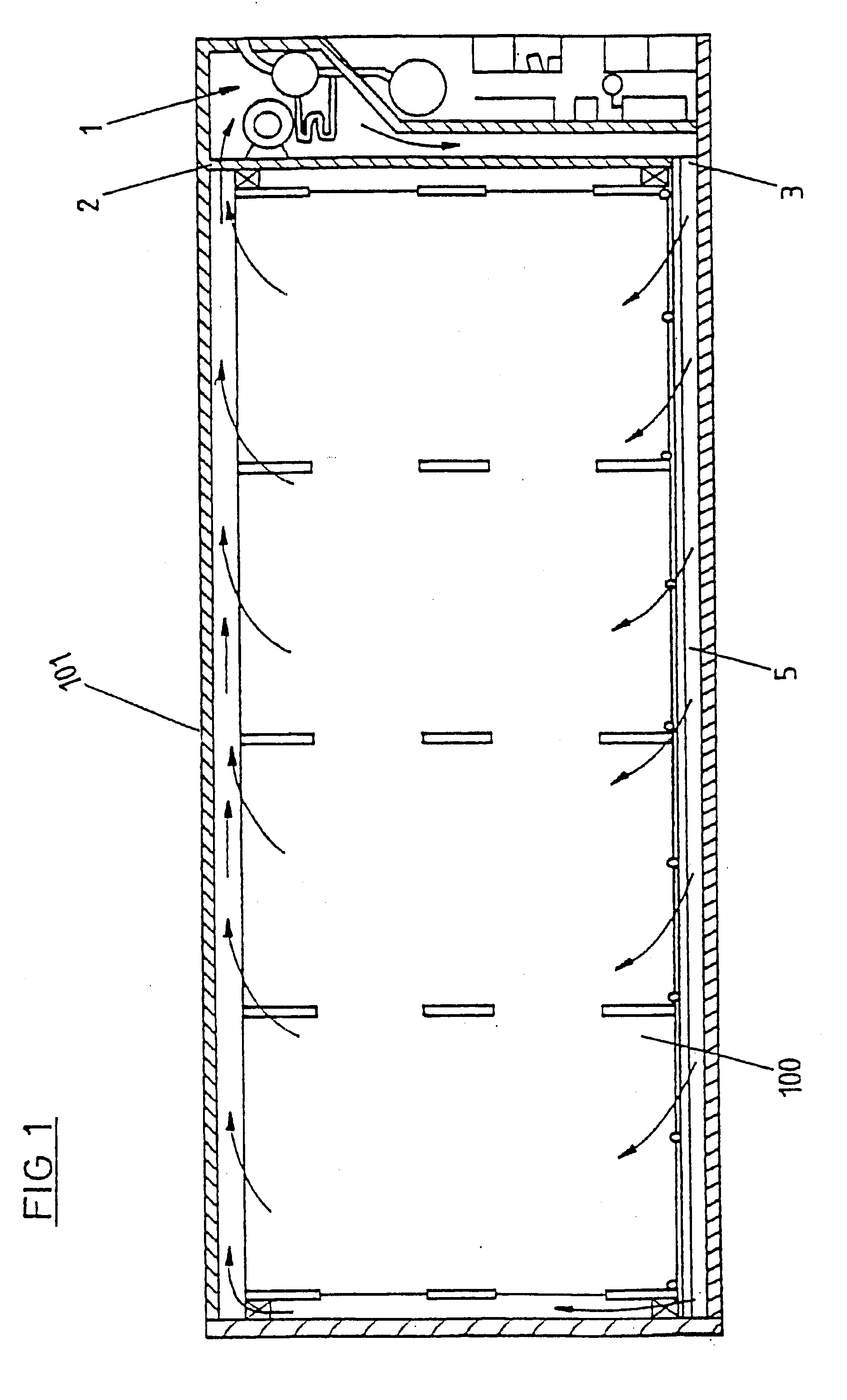

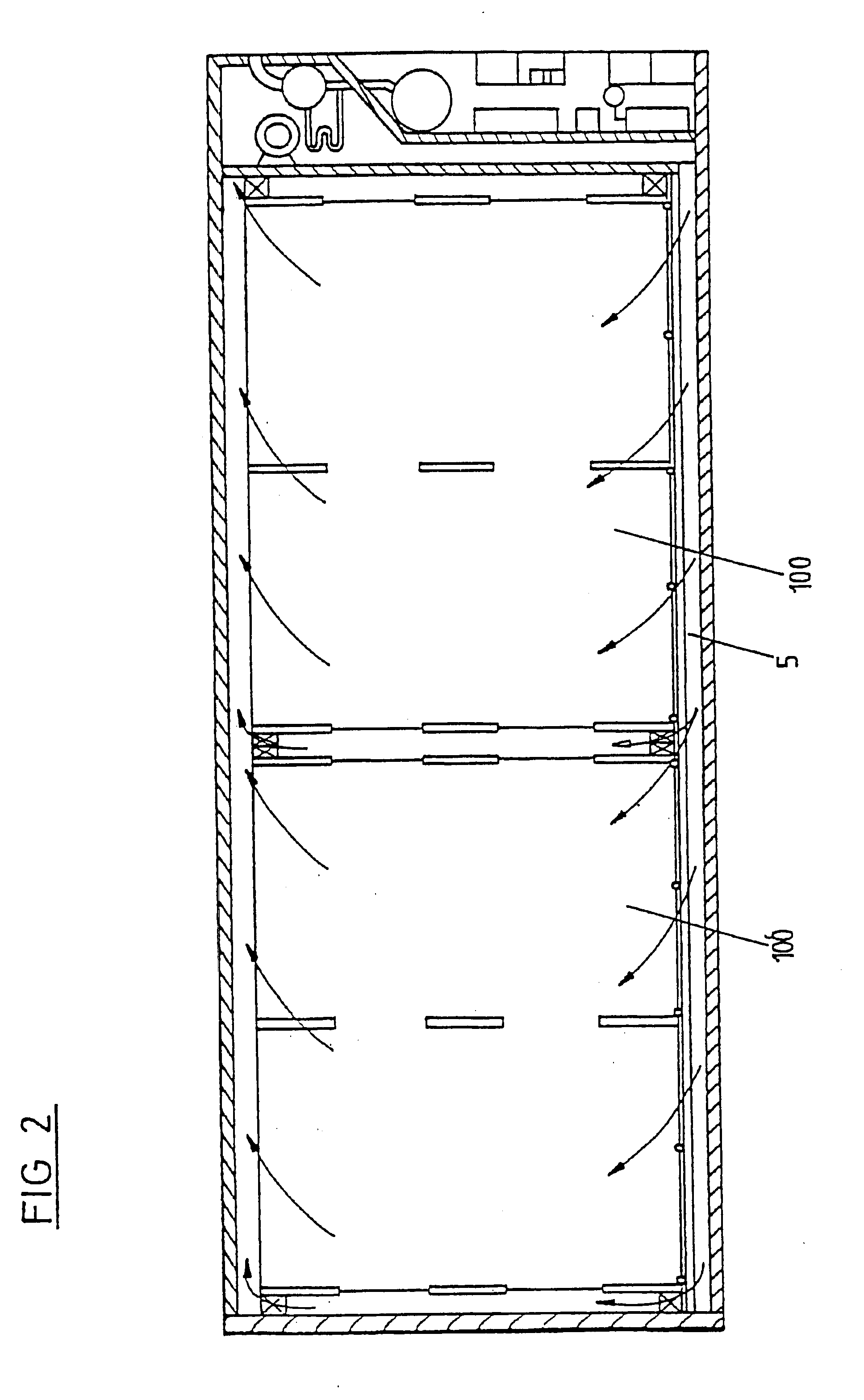

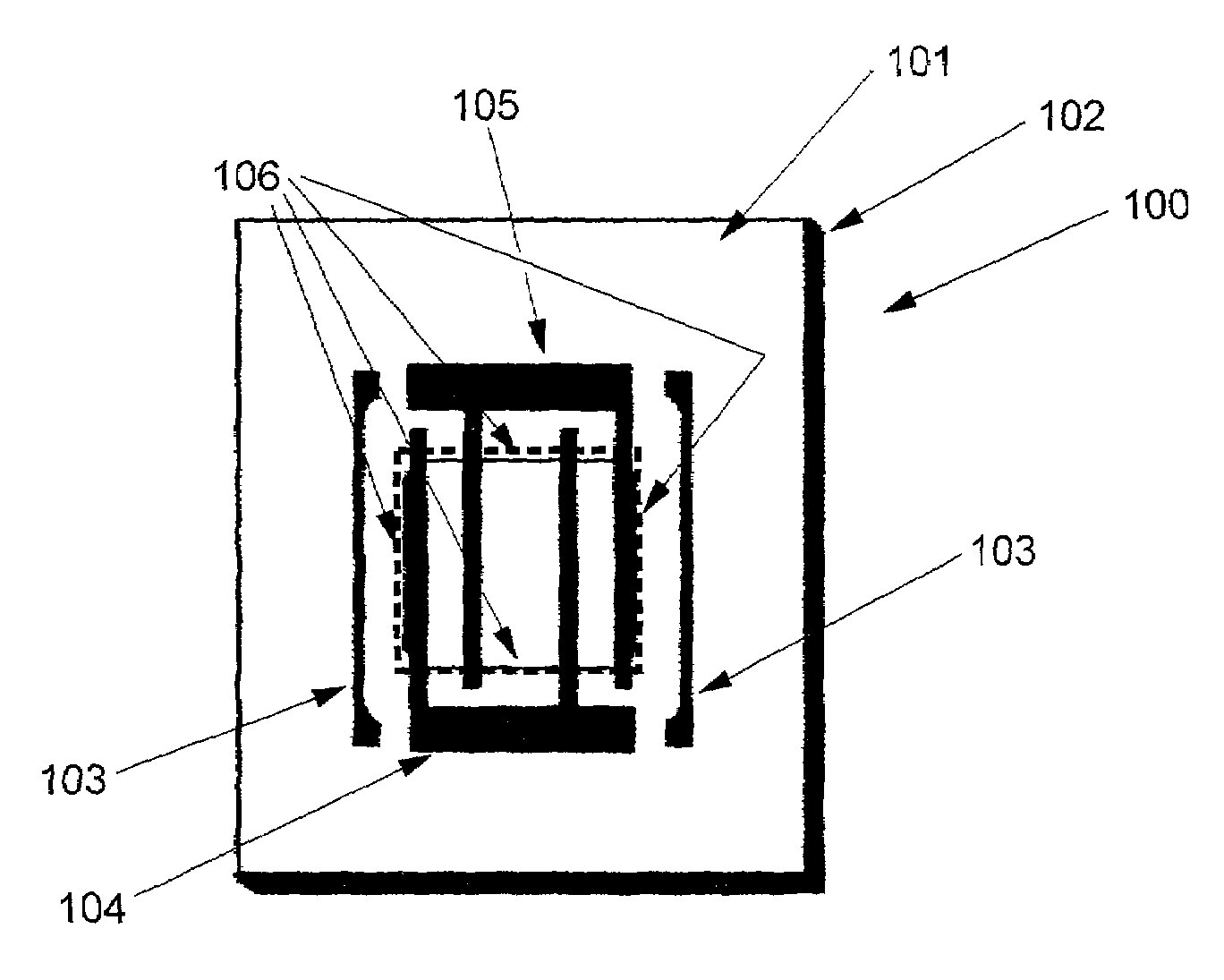

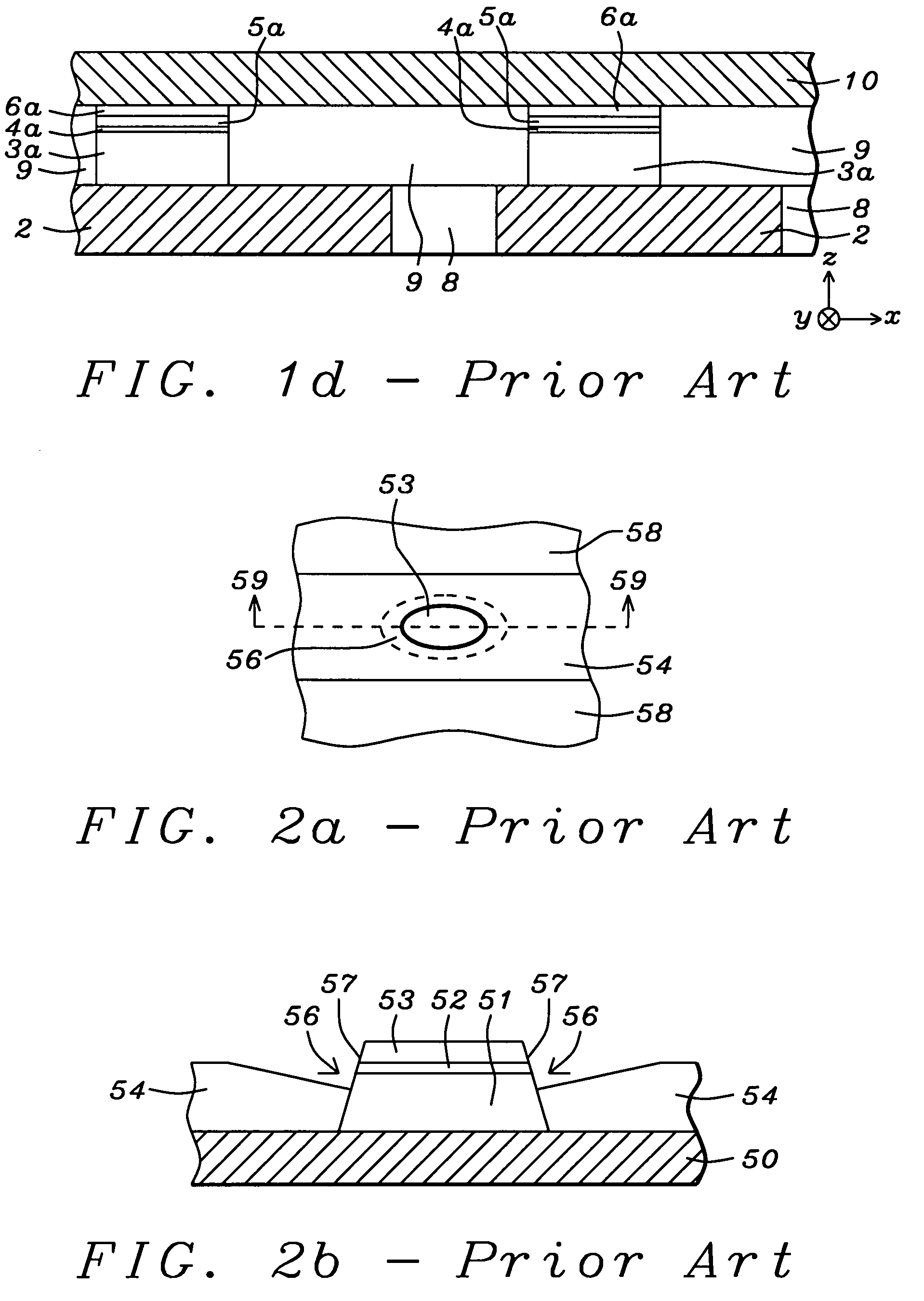

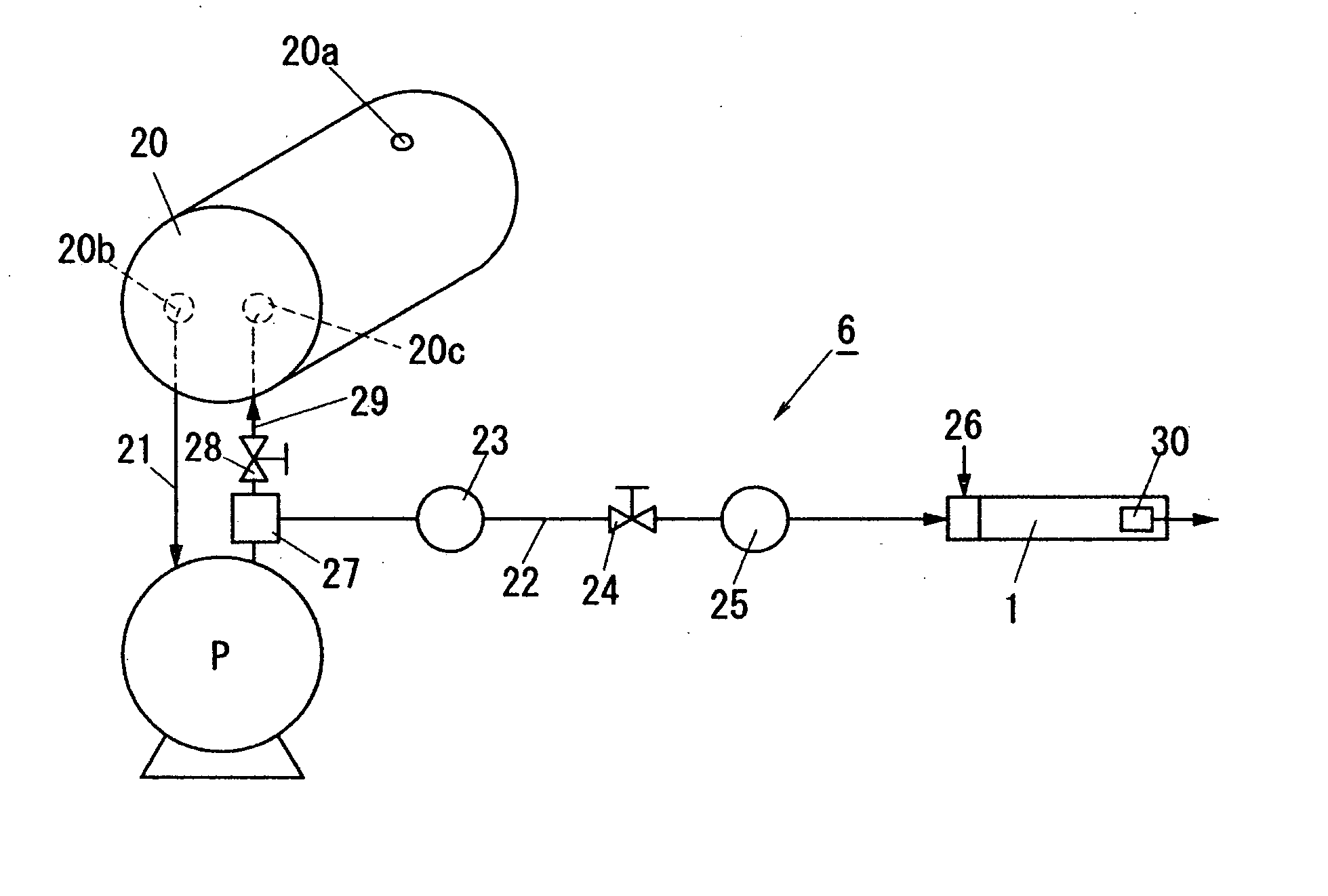

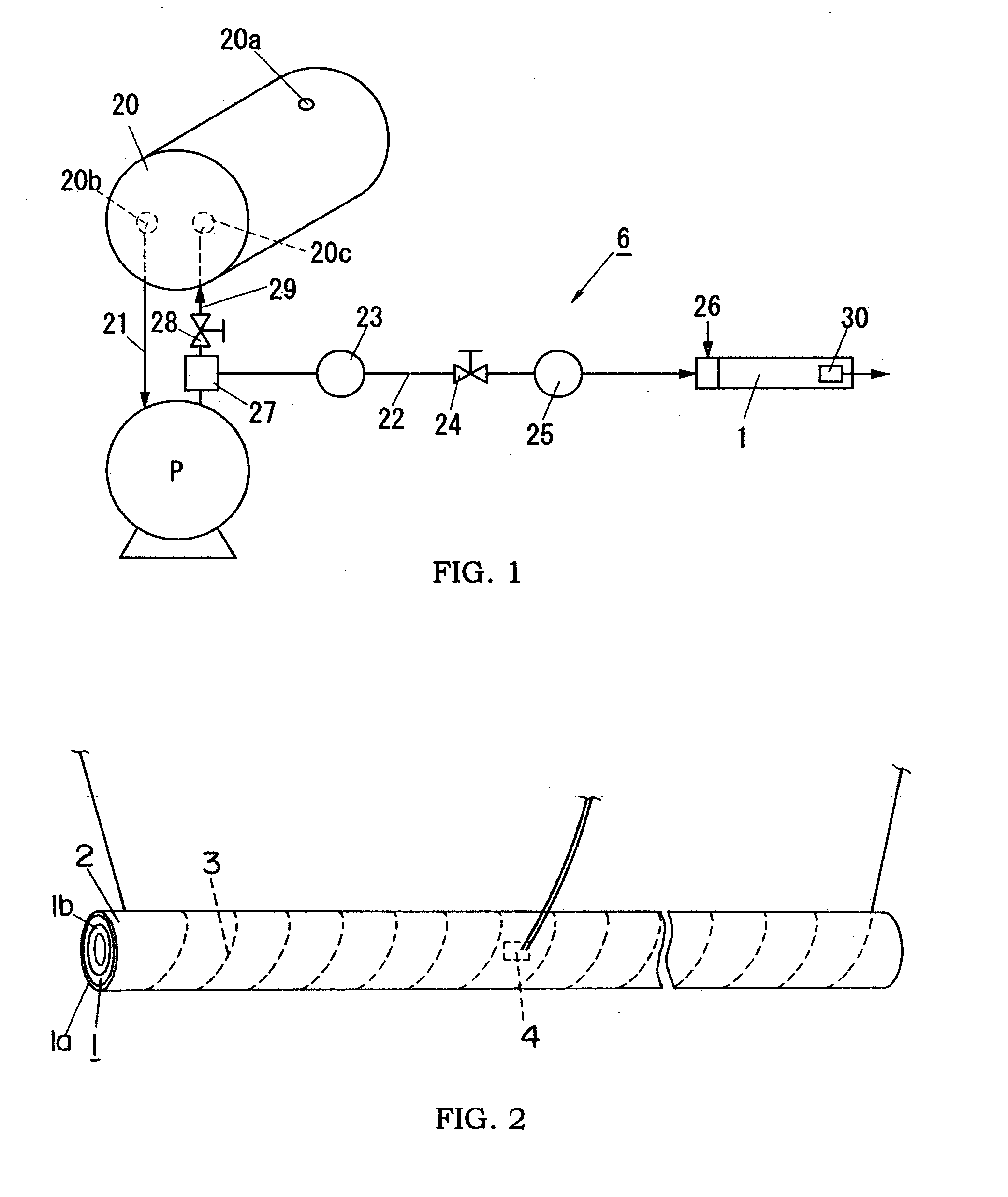

Method of transporting or storing perishable produce

InactiveUS6615908B1Convenient infusionIncrease humiditySpace heating and ventilationOperation mode of machinesGas compositionProduct gas

The invention allows cool rooms or sea containers designed for frozen goods to handle produce requiring more precisely controlled temperatures and conditions, e.g., vegetables and fruits requiring temperatures in the chilling range and often also needing control or modification of the atmosphere. Each load of produce (100) (e.g. of pallet size) is held in the sea container or cool room but is sealed from the air of the refrigerated environment by, for example, a plastics bag (56). The atmosphere within the bag is then circulated by a fan (12) (or by convection currents from a heating element) so as to pass through the load and around it via ducts (30) provided adjacent the bag (56). Heat exchange (50) between the circulating gas and the refrigerated environment, via the plastics film, serves to cool the load. However, if cooling is excessive a heating element can be used to raise the temperature of the circulating atmosphere. Gas composition of the atmosphere can be controlled by scrubbing, flushing, etc. via pipes from a central unit or at each load individually or by choosing semi-permeable plastic for the sealing bags.

Owner:TRANSPHERE SYST

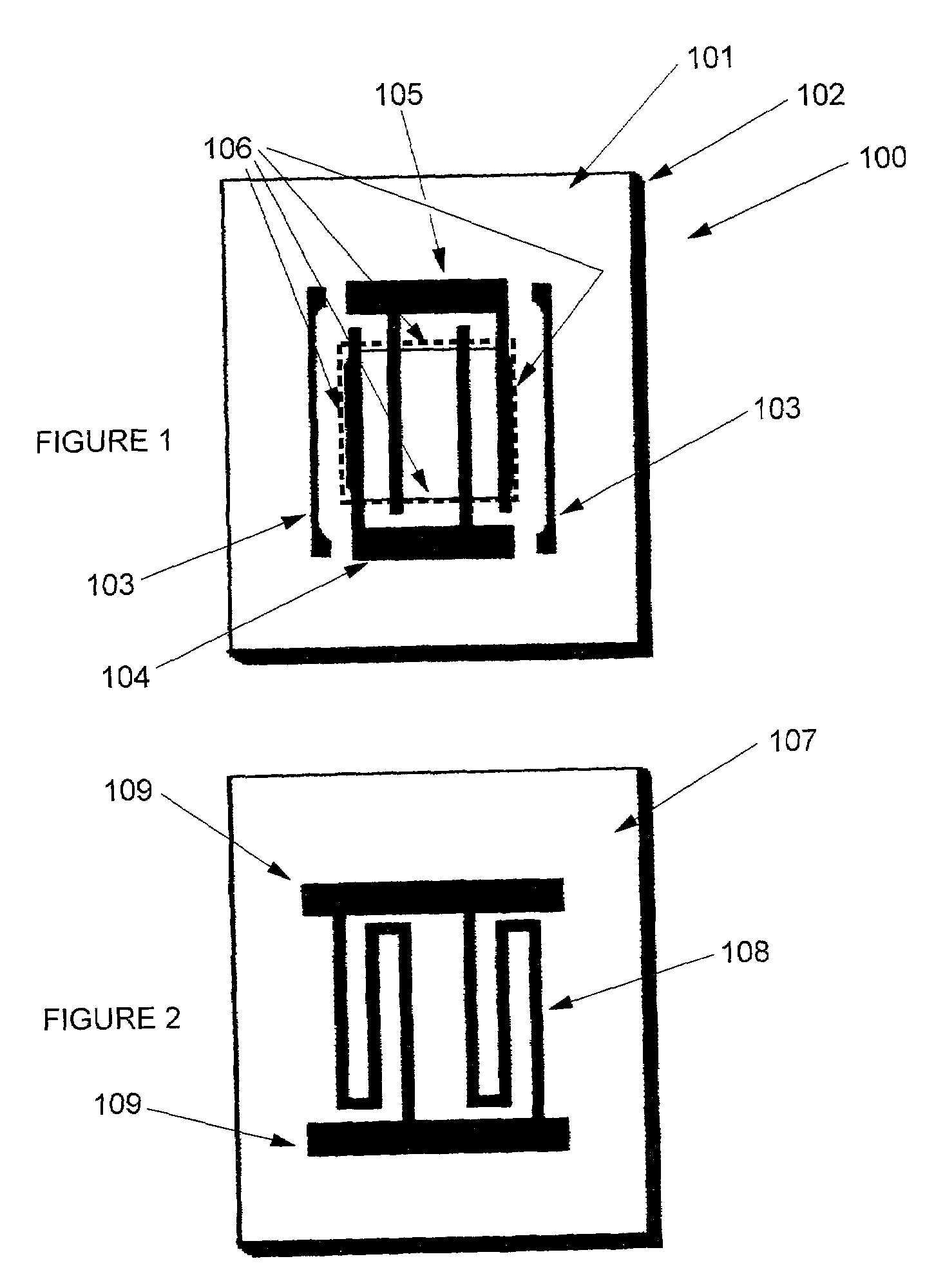

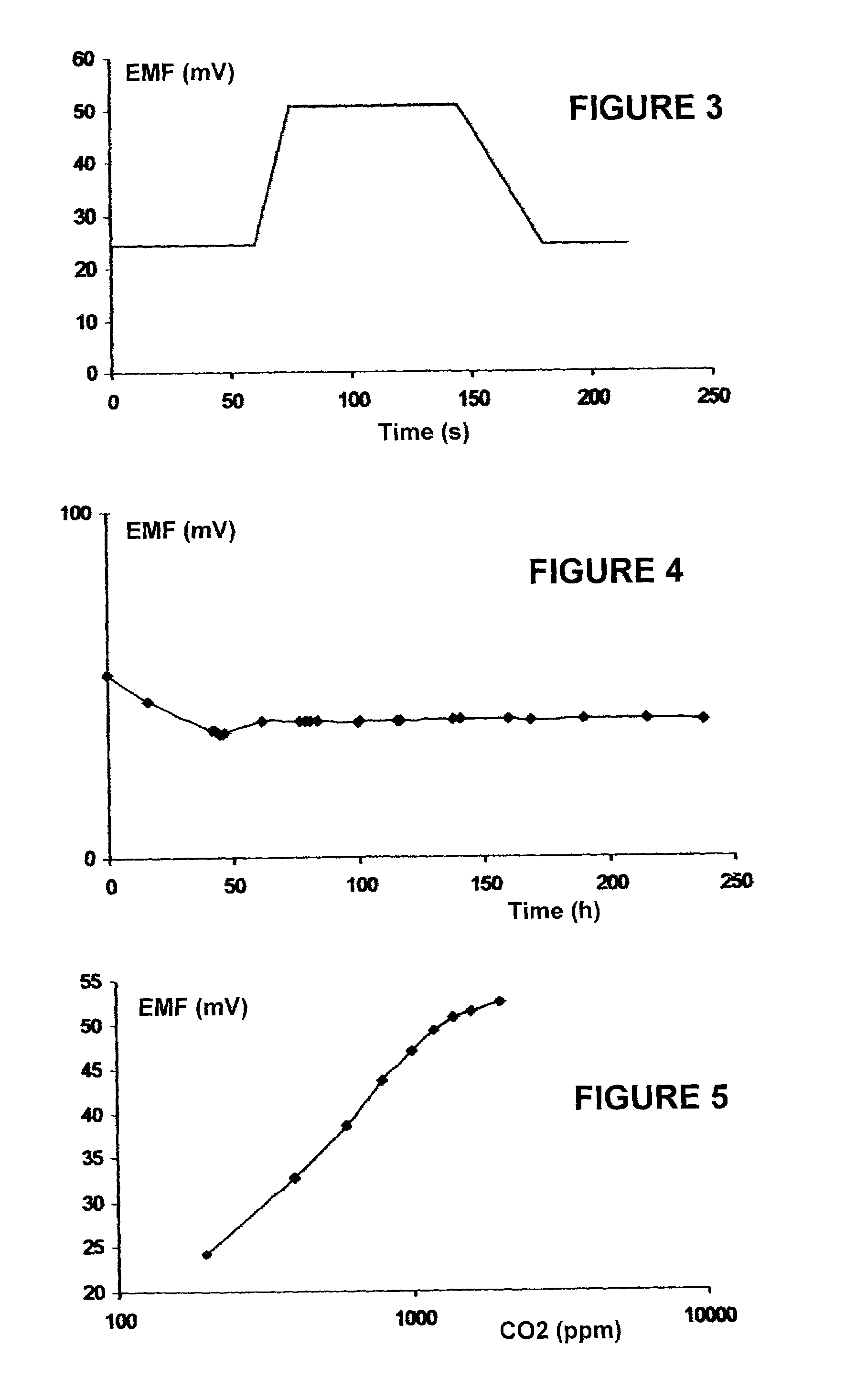

Gas component sensor for gas oxides

InactiveUS7001495B2Additional sensorExcellent chemical stability and thermal compatibilityWeather/light/corrosion resistanceElectrolytic capacitorsElectrochemical responseGas composition

The present invention is a gas component sensor comprising novel electrolyte compositions. The electrolyte compositions in bulk, sintered or thin film embodiments are capable of forming with different-metal sensing and reference electrodes a highly stable gas oxide sensors. The novel electrolyte composition changes electrochemical reactions at the sensing and reference electrodes and the overall reaction of the electrodes and electrolyte. The novel electrolyte compositions have: (1) excellent chemical stability and thermal compatibility as to the electrodes and a preferred ceramic substrate, (2) excellent chemical stability with the environment as to the reference and sensing electrodes, which need not be sealed against the atmosphere to be sensed, (3) effective adherence to the substrate and electrode metals.

Owner:AIR Q

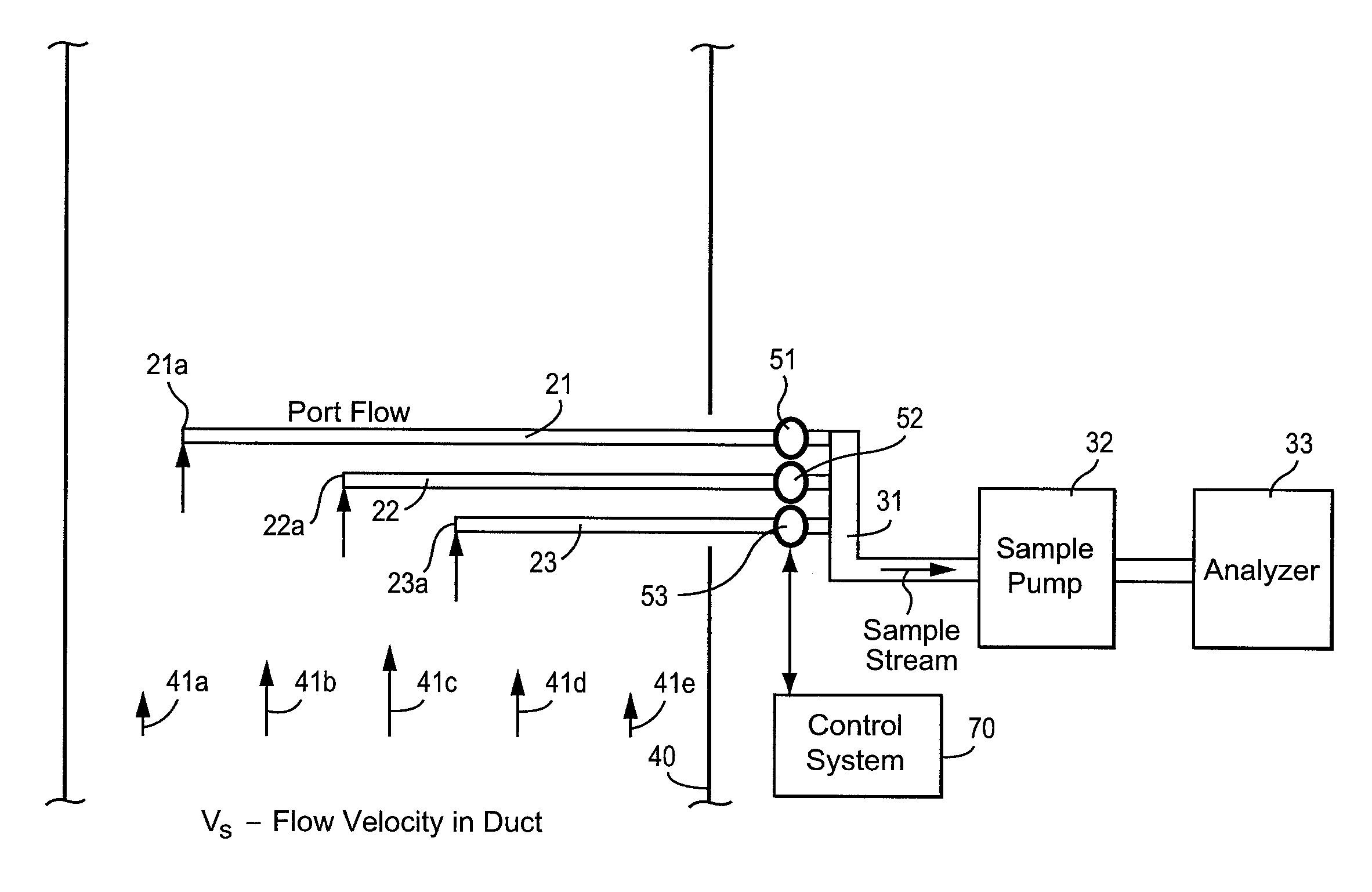

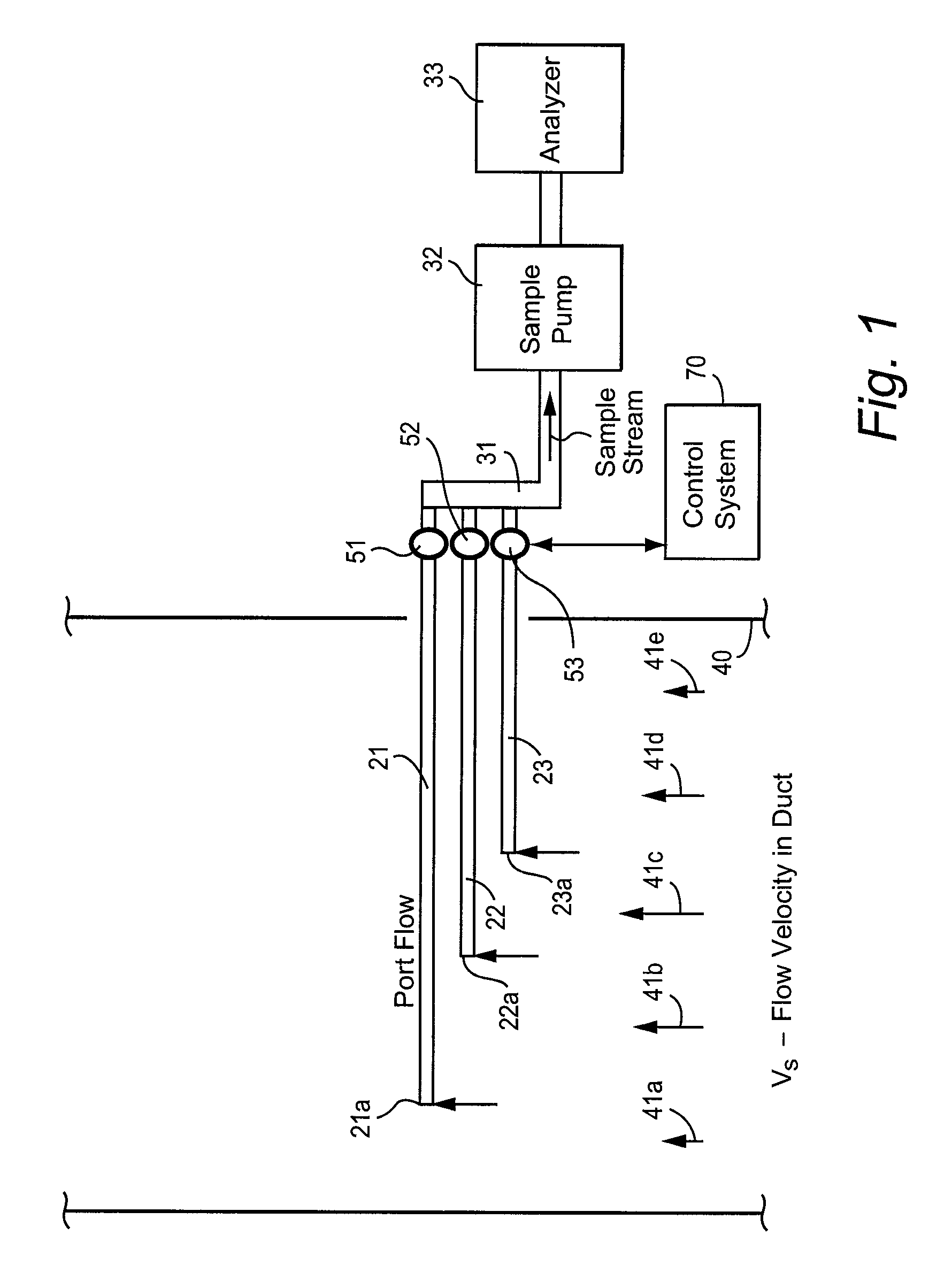

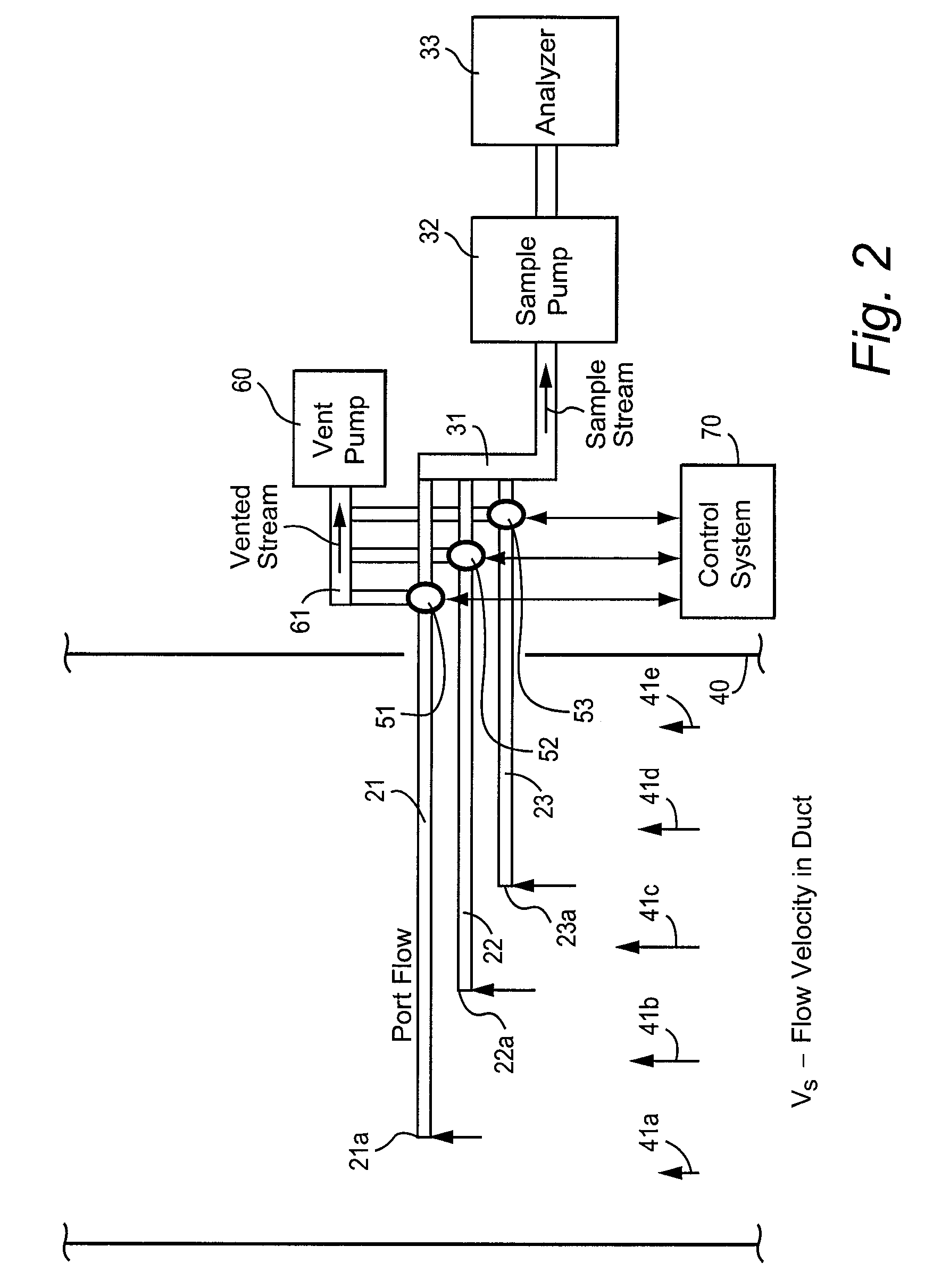

Configurable multi-point sampling method and system for representative gas composition measurements in a stratified gas flow stream

A method and system of obtaining a sample of fluid flowing through a duct comprises determining an average concentration of a component species of the fluid during a test including determining first and second concentrations of the component species at first and second respective duct locations, positioning first and second sample probes in the duct so that they receive the fluid at the first and second locations, respectively, and controlling respective flow rates of fluid received by the first and second sample probes, or alternatively first and second time amounts that the flow of fluid is received by the first and second sample probes, respectively, based on the determined first, second and average concentrations. The respective flow rates or time amounts may be controlled so that component species concentration collectively received by the first and second sample probes equals the average concentration of the component species determined during the test.

Owner:GENERAL ELECTRIC CO

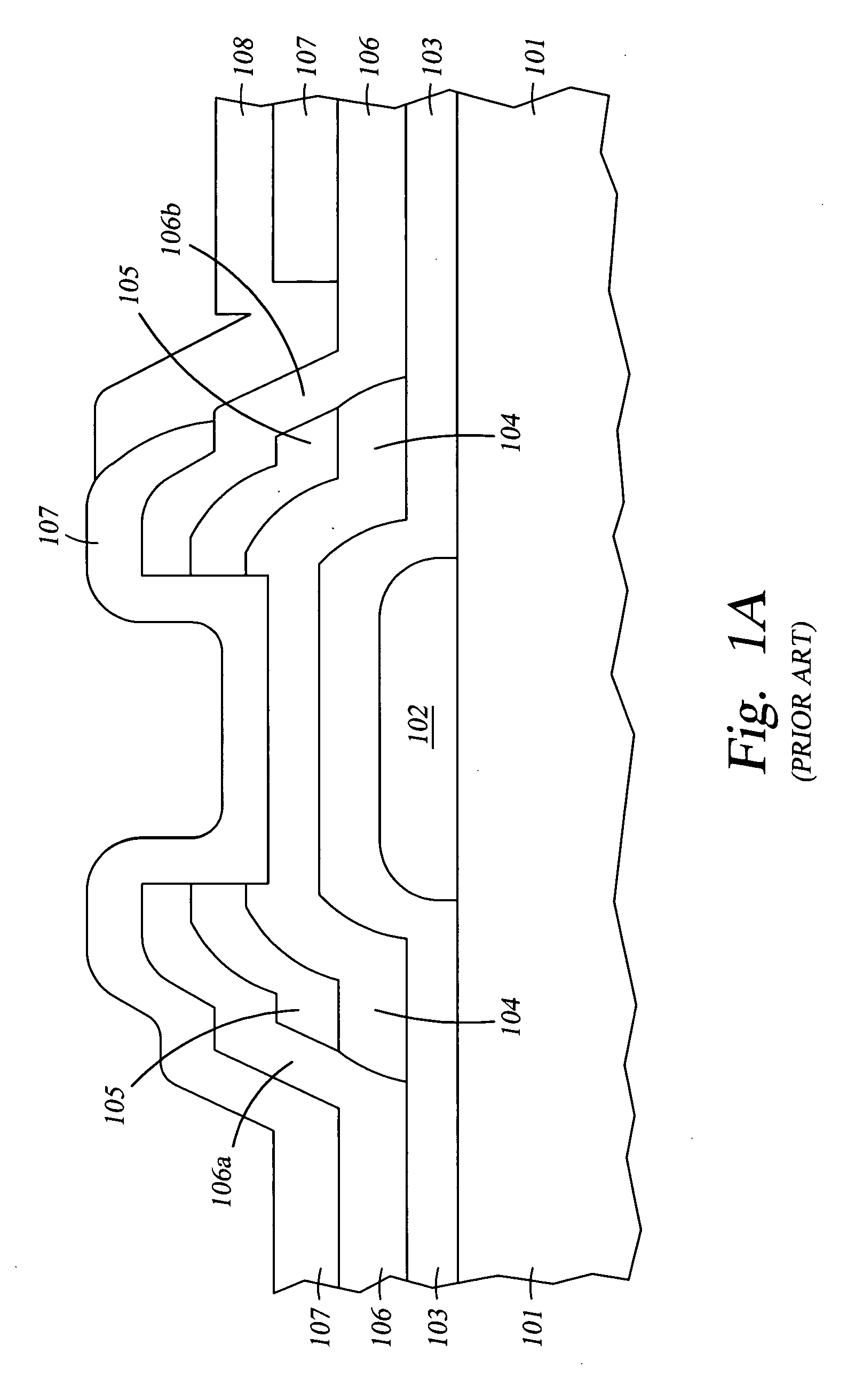

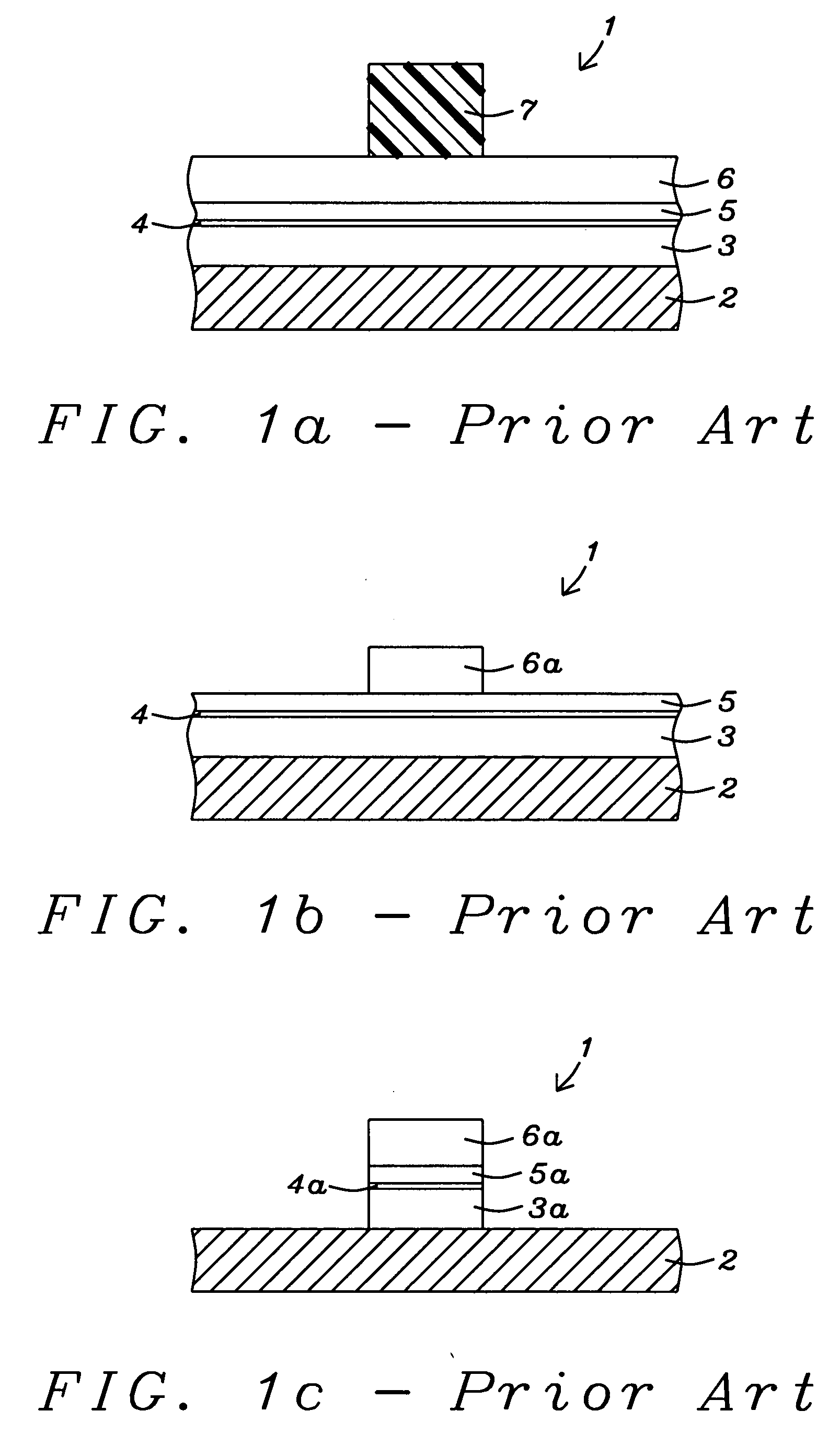

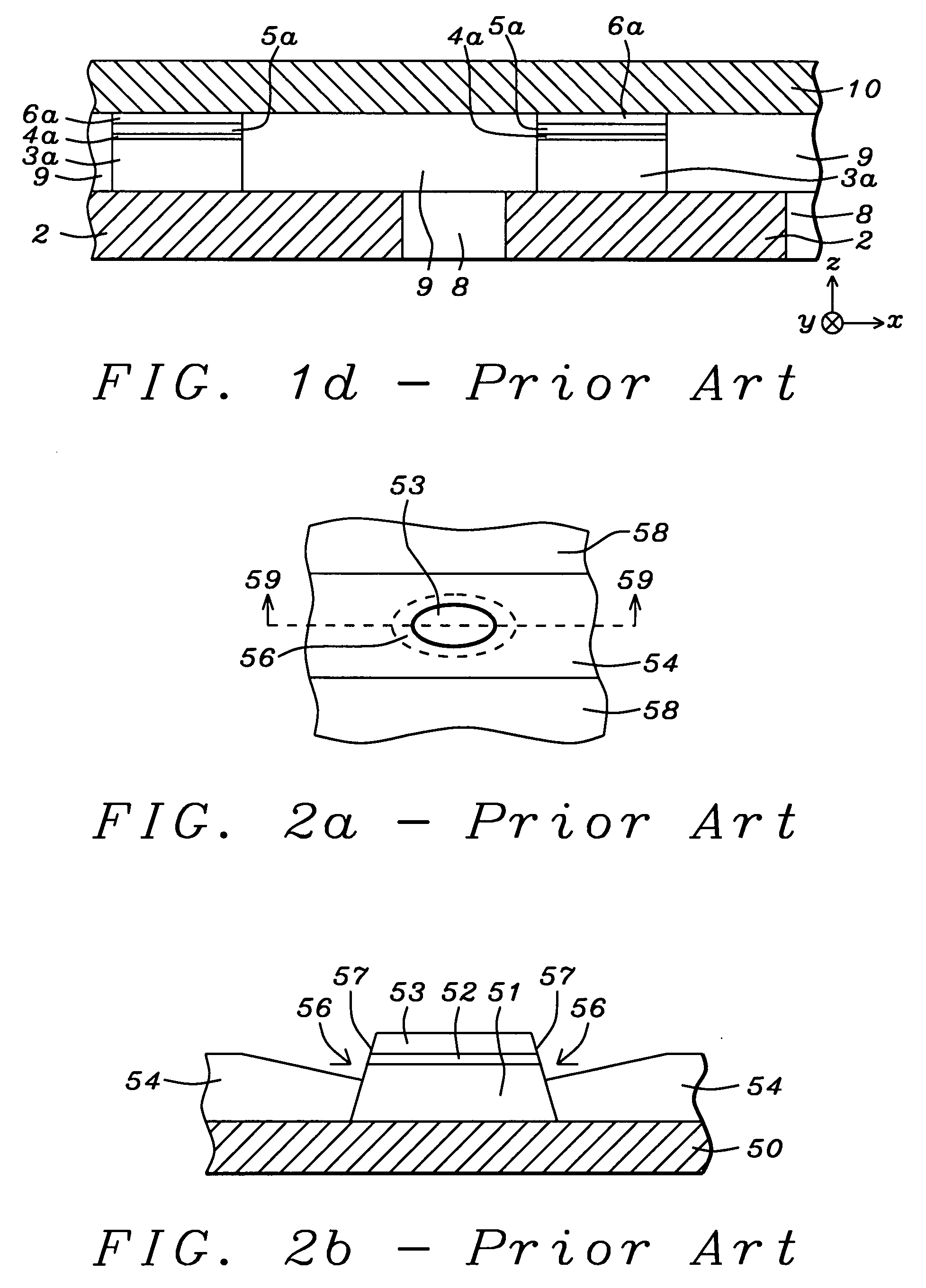

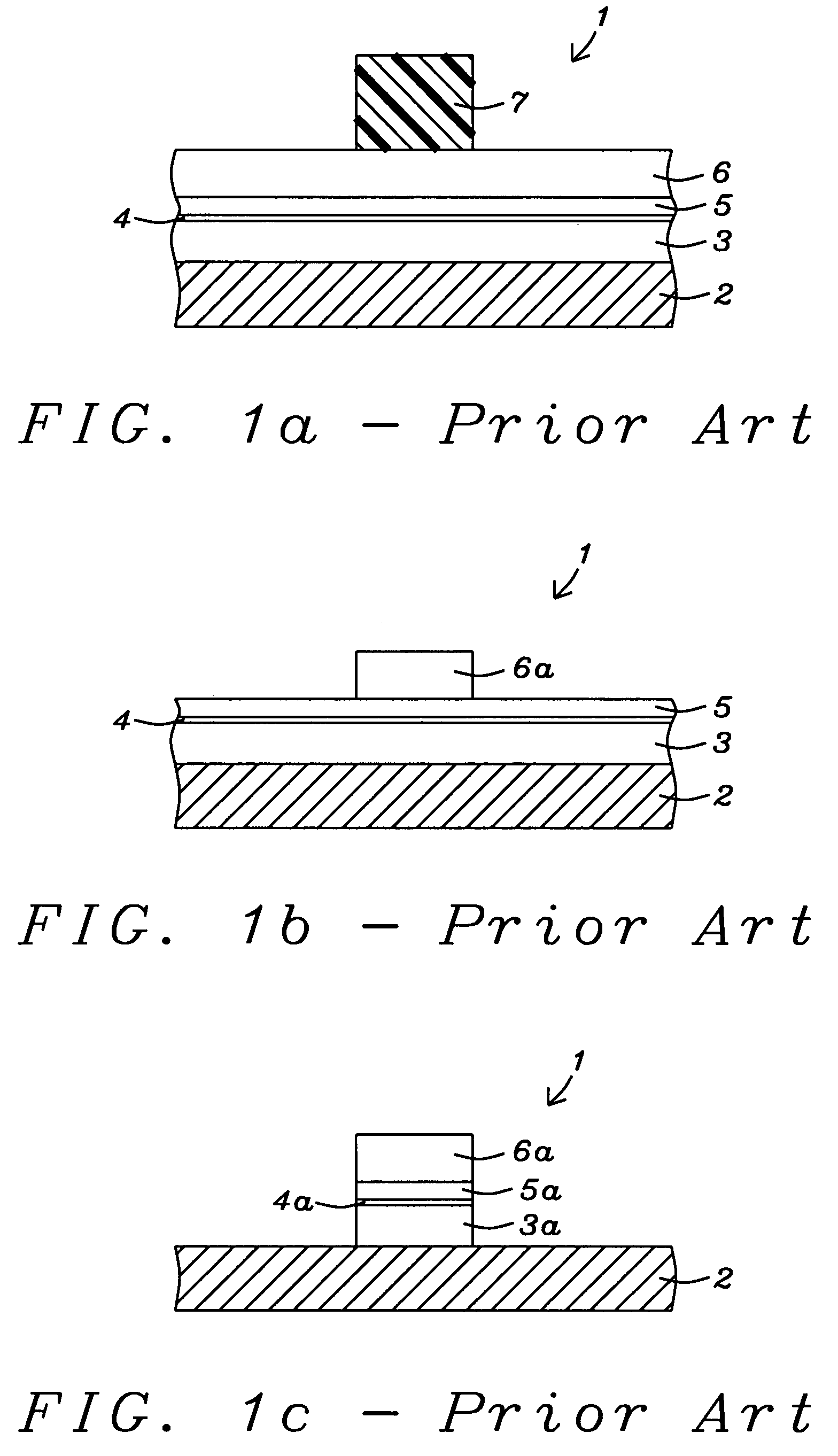

Composite hard mask for the etching of nanometer size magnetic multilayer based device

ActiveUS20090078927A1Prevent electrical shortingAvoid shortingLayered productsSemiconductor/solid-state device manufacturingBit lineEtching

A composite hard mask is disclosed that enables sub-100 nm sized MTJ cells to be formed for advanced devices such as spin torque MRAMs. The hard mask has a lower non-magnetic metallic layer such as Ru to magnetically isolate an overlying middle metallic spacer such as MnPt from an underlying free layer. The middle metallic spacer provides a height margin during subsequent processing to avoid shorting between a bit line and the MTJ cell in the final device. An upper conductive layer may be made of Ta and is thin enough to allow a MTJ pattern in a thin overlying photoresist layer to be transferred through the Ta during a fluorocarbon etch without consuming all of the photoresist. The MTJ pattern is transferred through the remaining hard mask layers and underlying MTJ stack of layers with a second etch step using a C, H, and O etch gas composition.

Owner:TAIWAN SEMICON MFG CO LTD

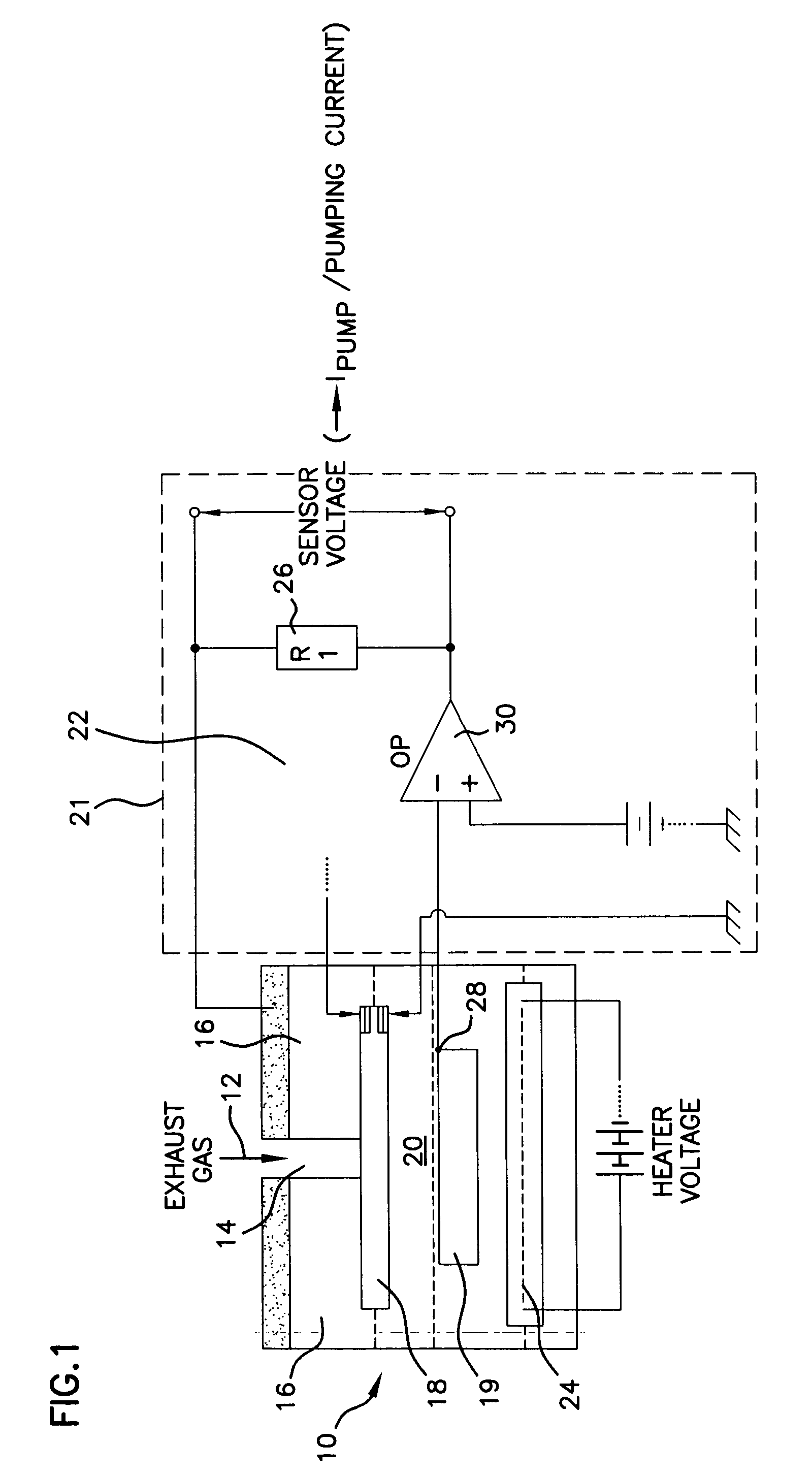

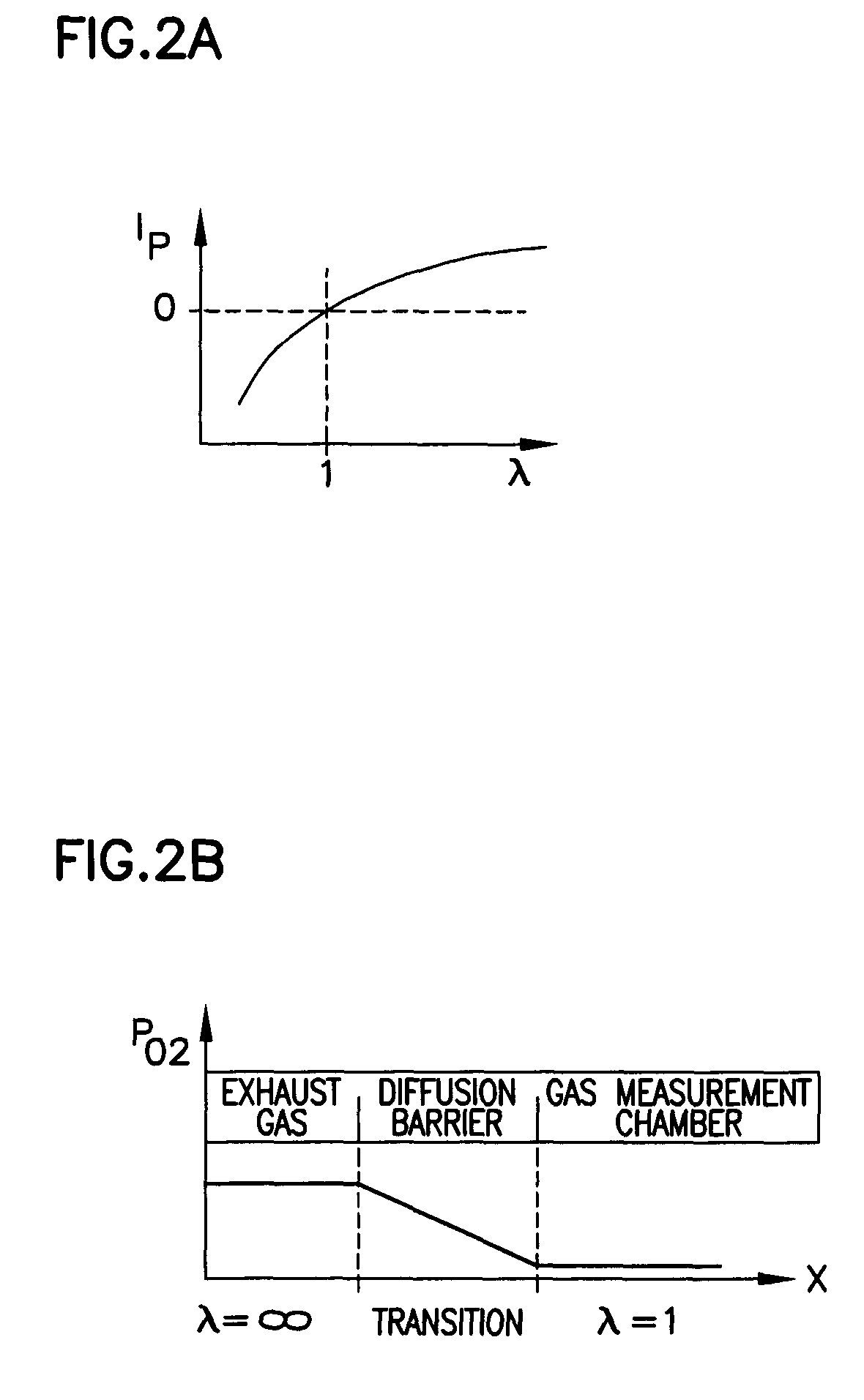

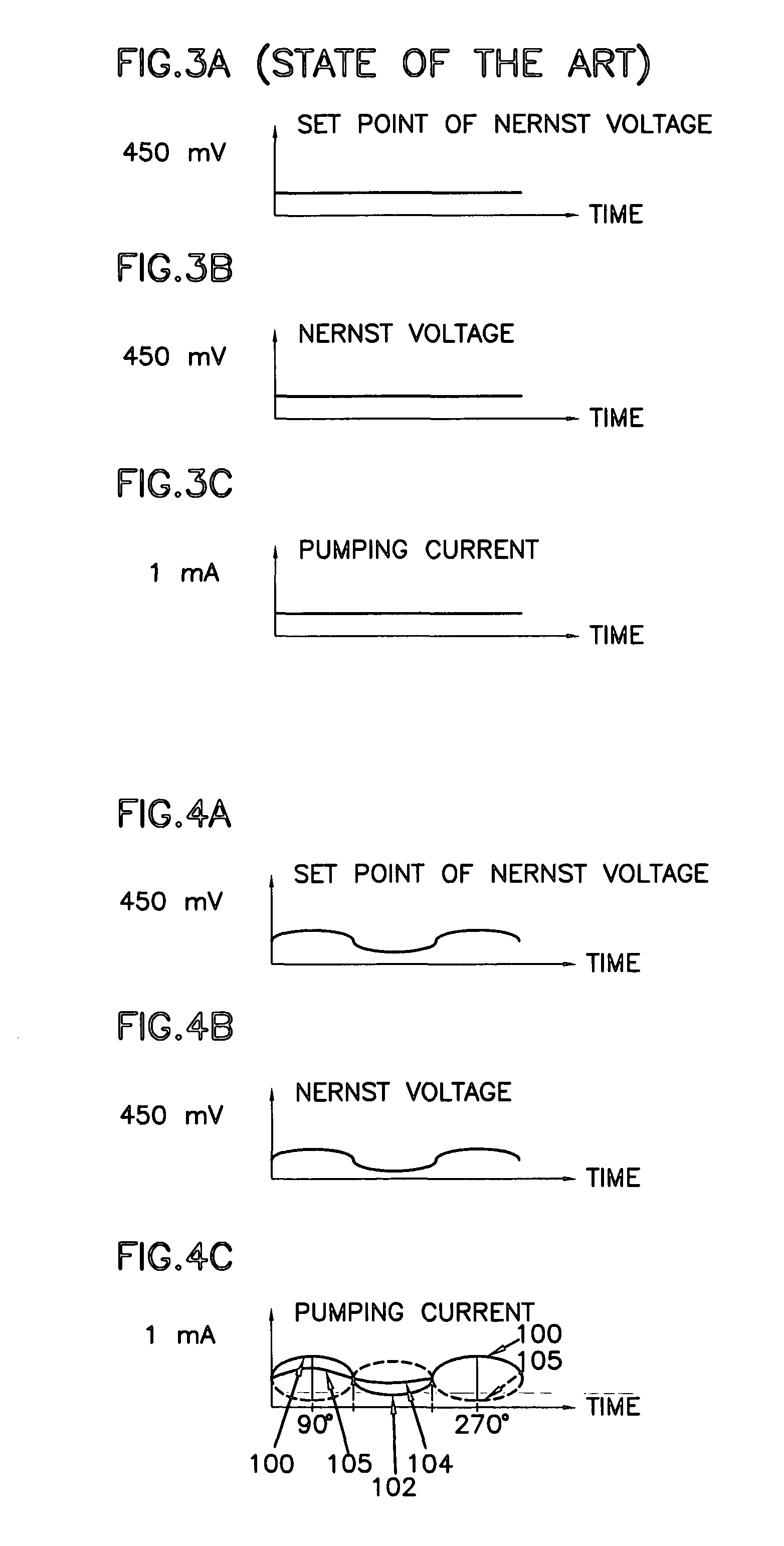

Procedure to recognize the diffusion gas composition in a wideband lambda sensor

InactiveUS7744740B2High sensitivityDiffusion coefficientWeather/light/corrosion resistanceVolume/mass flow measurementMobile vehicleDiffusion

In a procedure to recognize the gas composition of a gas mixture, which consists of at least two gases of preferably different diffusion properties, delivered to a wideband lambda sensor, especially a gas mixture of an exhaust gas of an internal combustion engine of a motor vehicle, whereby the lambda sensor has a pumping cell with at least one gas measurement chamber, provision is made for the recognition of the gas composition of the gas mixture to result by means of modulation of the gas in the gas measurement chamber. Preferably the air number in the gas measurement chamber of the pumping cell is periodically altered, whereby the sensitivity of the lambda sensor to the gases, of which there are at least two, likewise periodically changes.

Owner:ROBERT BOSCH GMBH

Polymerization process

The present invention relates to a continuous gas phase process comprising polymerizing one or more hydrocarbon monomer(s) in a fluidized bed reactor in the presence of catalyst system or polymerization catalyst and a condensable fluid for a period of at least 12 hours where the bed temperature is less than the Critical Temperature and the dew point temperature of the gas composition in the reactor is within 25° C. of the bed temperature.

Owner:EXXONMOBIL CHEM PAT INC

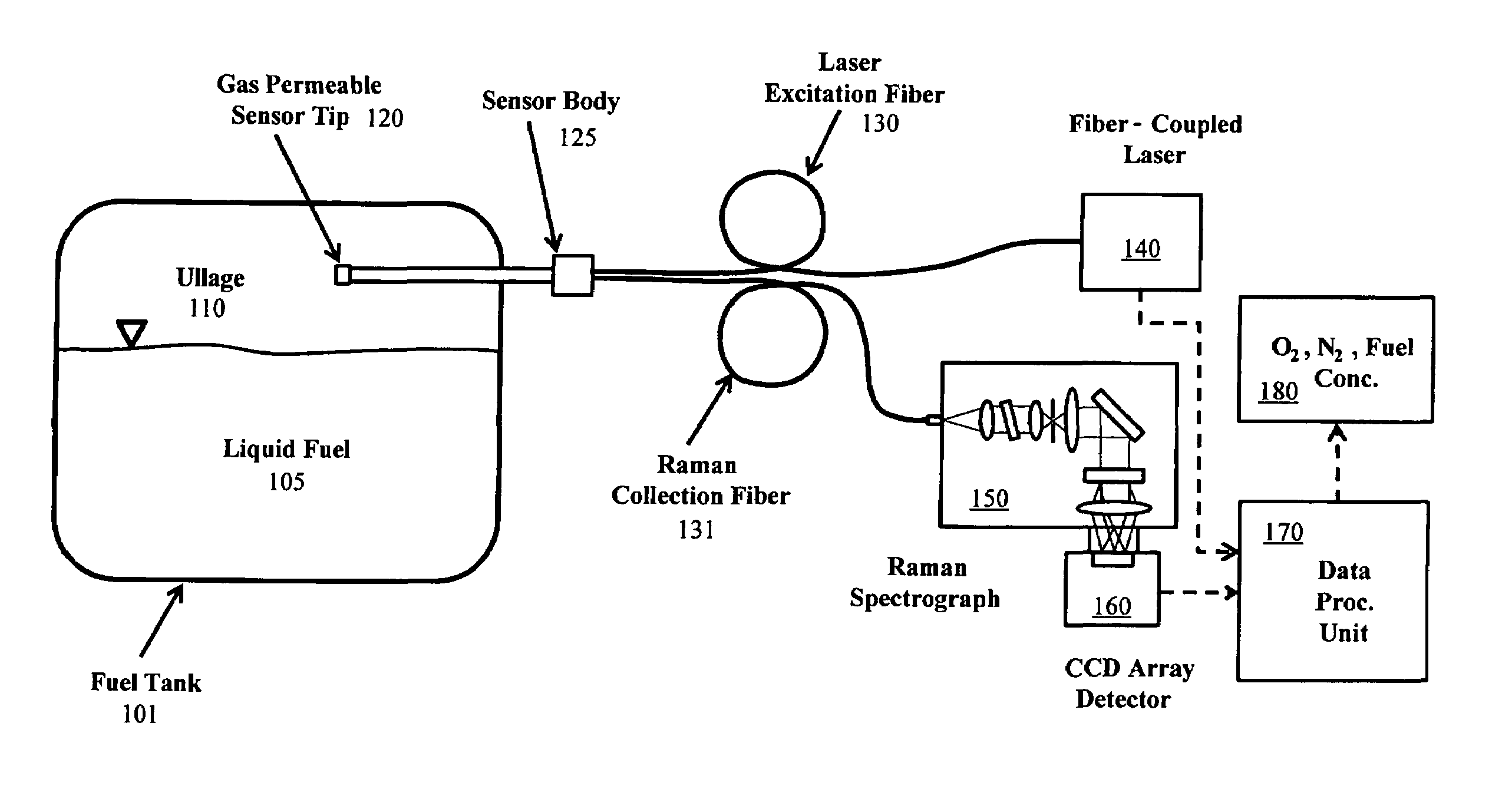

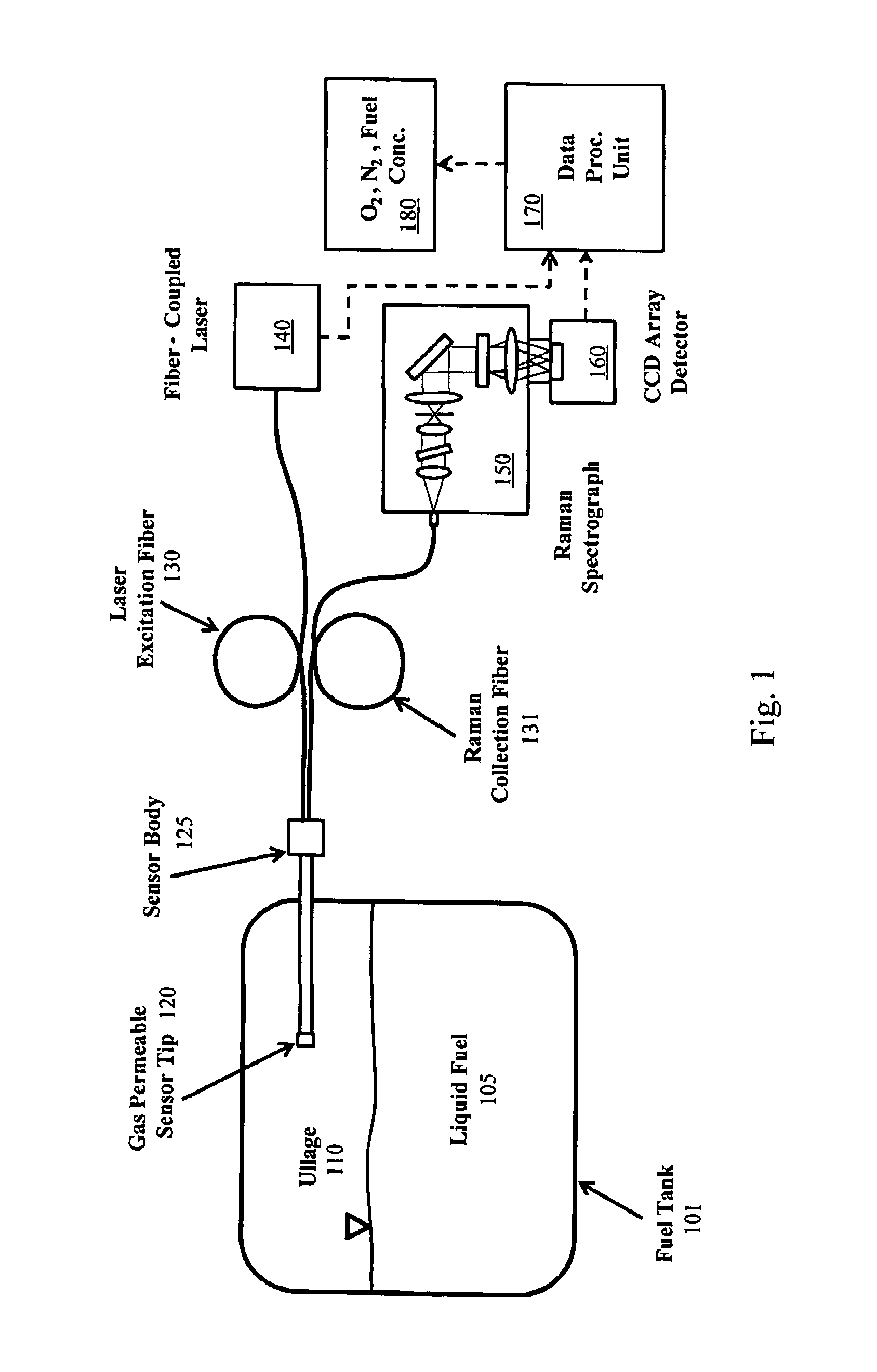

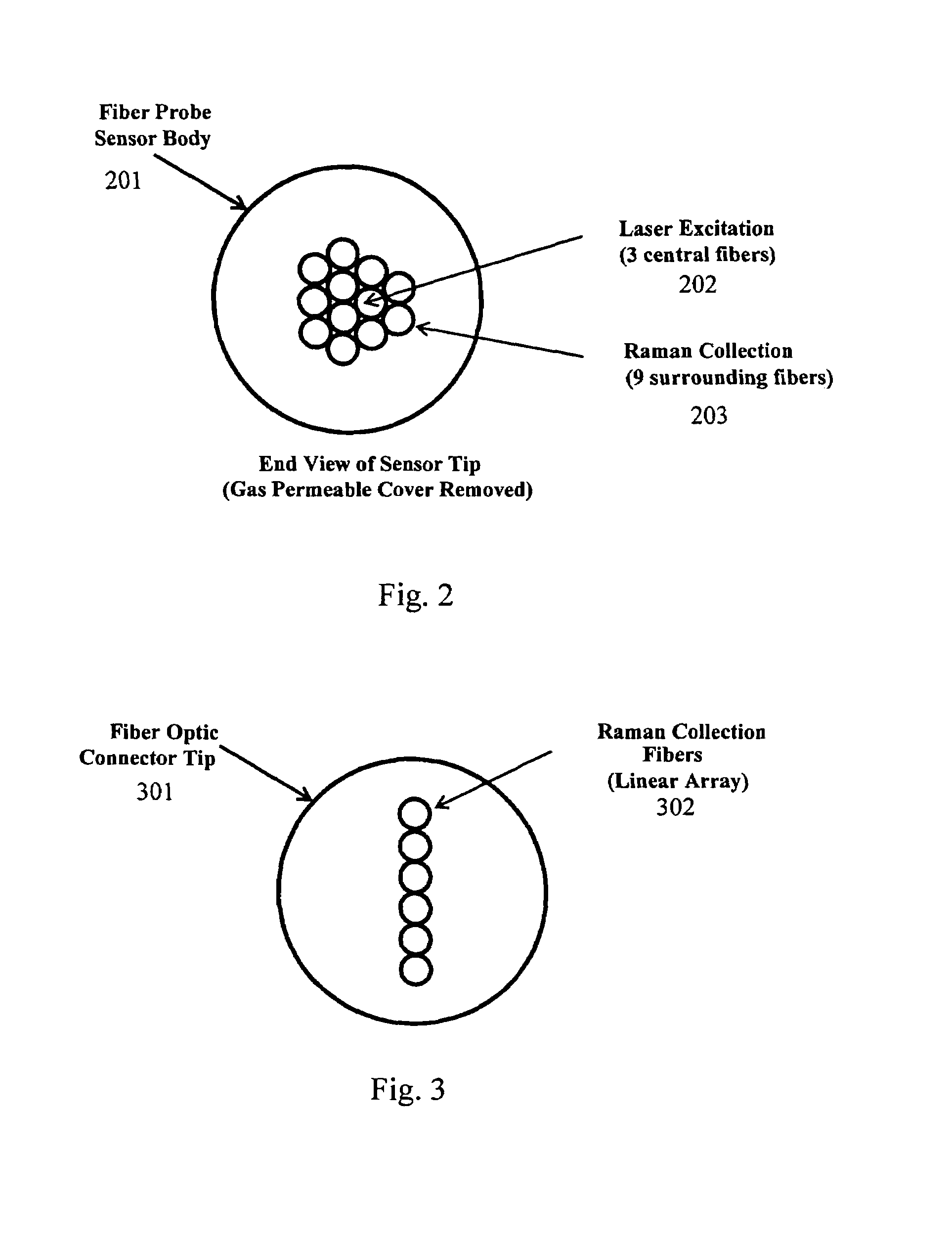

Method and system for fiber optic determination of gas concentrations in liquid receptacles

InactiveUS7385692B1Limit impingementRadiation pyrometrySpectrum investigationFiber bundleGas composition

A system for determining gas compositions includes a probe, inserted into a source of gaseous material, the probe having a gas permeable sensor tip and being capable of sending and receiving light to and from the gaseous material, a sensor body, connected to the probe, situated outside of the source and a fiber bundle, connected to the sensor body and communicating light to and from the probe. The system also includes a laser source, connected to one portion of the fiber bundle and providing laser light to the fiber bundle and the probe a Raman spectrograph, connected to another portion of the fiber bundle, receiving light from the probe and filtering the received light into specific channels and a data processing unit, receiving and analyzing the received light in the specific channels and outputting concentration of specific gas species in the gaseous material based on the analyzed received light.

Owner:NASA UNITED STATES OF AMERICA THE AS REPRESENTED BY THE ADMINISTATOR OF

Composite hard mask for the etching of nanometer size magnetic multilayer based device

ActiveUS7696551B2Avoid shortingImprove etch selectivitySemiconductor/solid-state device manufacturingGalvano-magnetic device manufacture/treatmentBit lineEtching

A composite hard mask is disclosed that enables sub-100 nm sized MTJ cells to be formed for advanced devices such as spin torque MRAMs. The hard mask has a lower non-magnetic metallic layer such as Ru to magnetically isolate an overlying middle metallic spacer such as MnPt from an underlying free layer. The middle metallic spacer provides a height margin during subsequent processing to avoid shorting between a bit line and the MTJ cell in the final device. An upper conductive layer may be made of Ta and is thin enough to allow a MTJ pattern in a thin overlying photoresist layer to be transferred through the Ta during a fluorocarbon etch without consuming all of the photoresist. The MTJ pattern is transferred through the remaining hard mask layers and underlying MTJ stack of layers with a second etch step using a C, H, and O etch gas composition.

Owner:TAIWAN SEMICON MFG CO LTD

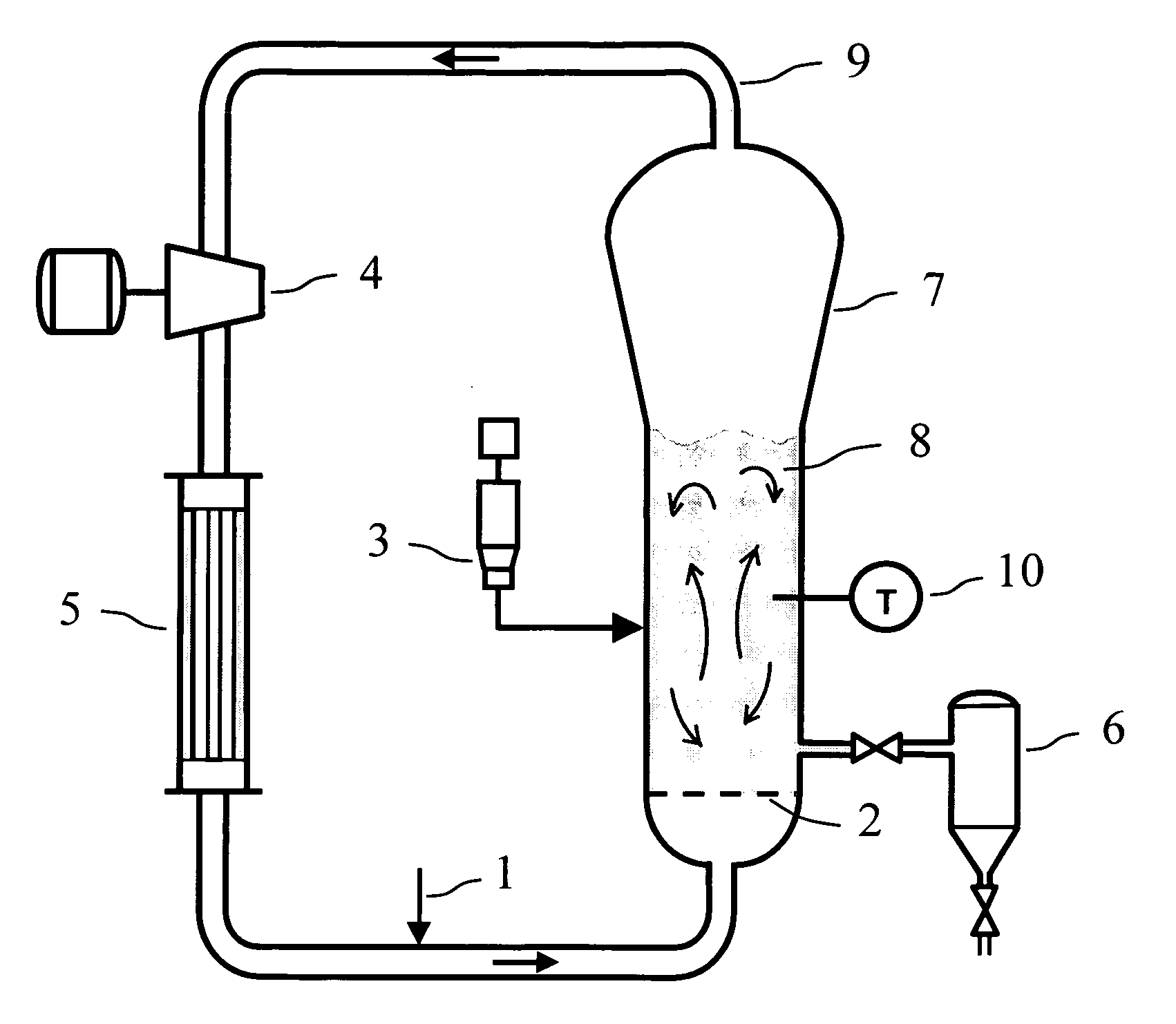

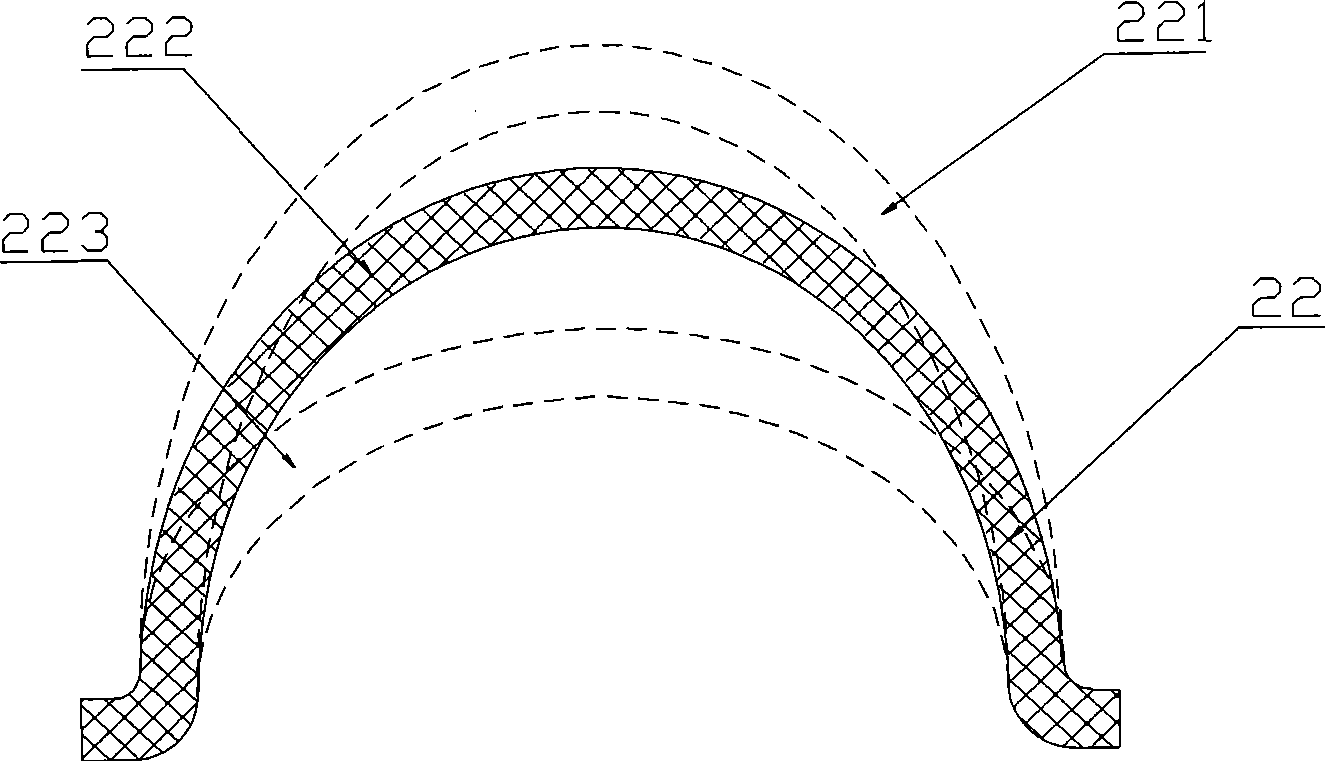

Bioreactor for growing biological materials supported on a liquid surface

InactiveUS7176024B2Promote growthMaximize growthBioreactor/fermenter combinationsBiological substance pretreatmentsGas compositionEngineering

A bioreactor assembly of the present invention for holding a media and supporting growth of a plurality of plants. The assembly includes a light source and a container having a light transmissive wall structure and defining a reservoir. A major axis of the reservoir is substantially horizontal allowing the reservoir to be filled with media to a partial level and to define a relatively large surface area for support of the plants. The assembly may also include clamps to secure and seal separate wall structure portions of the container together, and end caps to the wall portions, to define an aseptic environment. As another option, the clamps may define openings therethrough that allow passage of various devices for measuring and controlling bioreactor function such as a gas supply nozzle, a gas exit nozzle, an air temperature probe, a pH probe, a sampling drain, a gas composition probe and a media temperature probe.

Owner:SYNTHON BIOPHARMACEUTICALS BV

Gas chromatograph and expired air component analyzer

InactiveUS20050160790A1Reliable analysisStable outputAnalysing fluids using sonic/ultrasonic/infrasonic wavesComponent separationBuffer tankGas composition

A gas chromatograph having the capability of performing a reliable measurement under a condition that the baseline of a detector output is stabilized, and a breath component analyzer using the same are provided. This gas chromatograph comprises a gas separation column accommodating a member for causing a flow delay depending on gas component; air pump for supplying an air as a carrier gas into the gas separation column; gas supply port formed in a gas flow channel extending between the air pump and the gas separation column, and adapted to supply a subject gas containing a target gas component to be detected into the carrier gas flowing in the gas flow channel; buffer tank provided upstream of the gas supply port; and a detector for detecting the gas component of the subject gas supplied into the gas separation column.

Owner:FIDELITY NATIONAL INFORMATION SERVICES

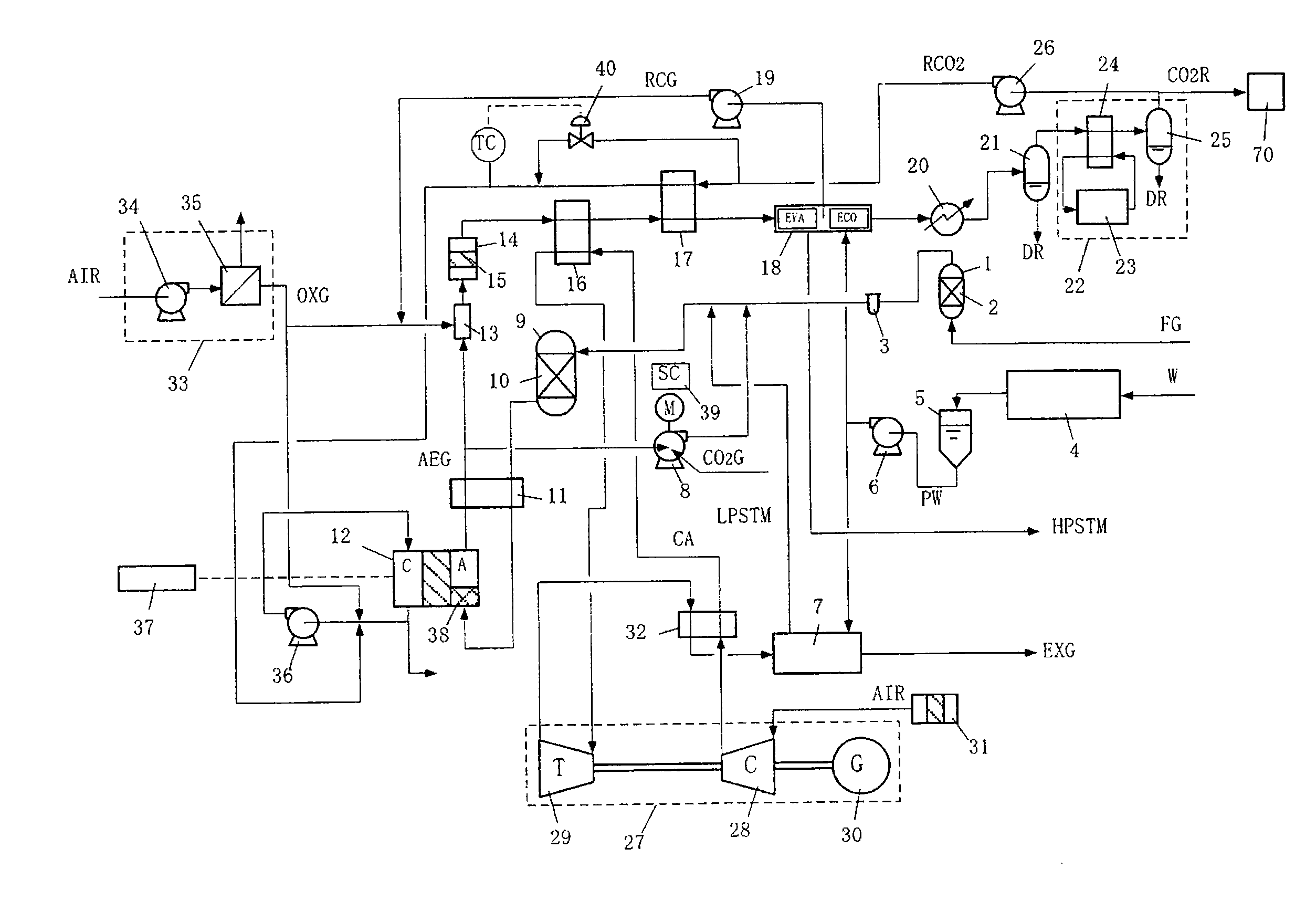

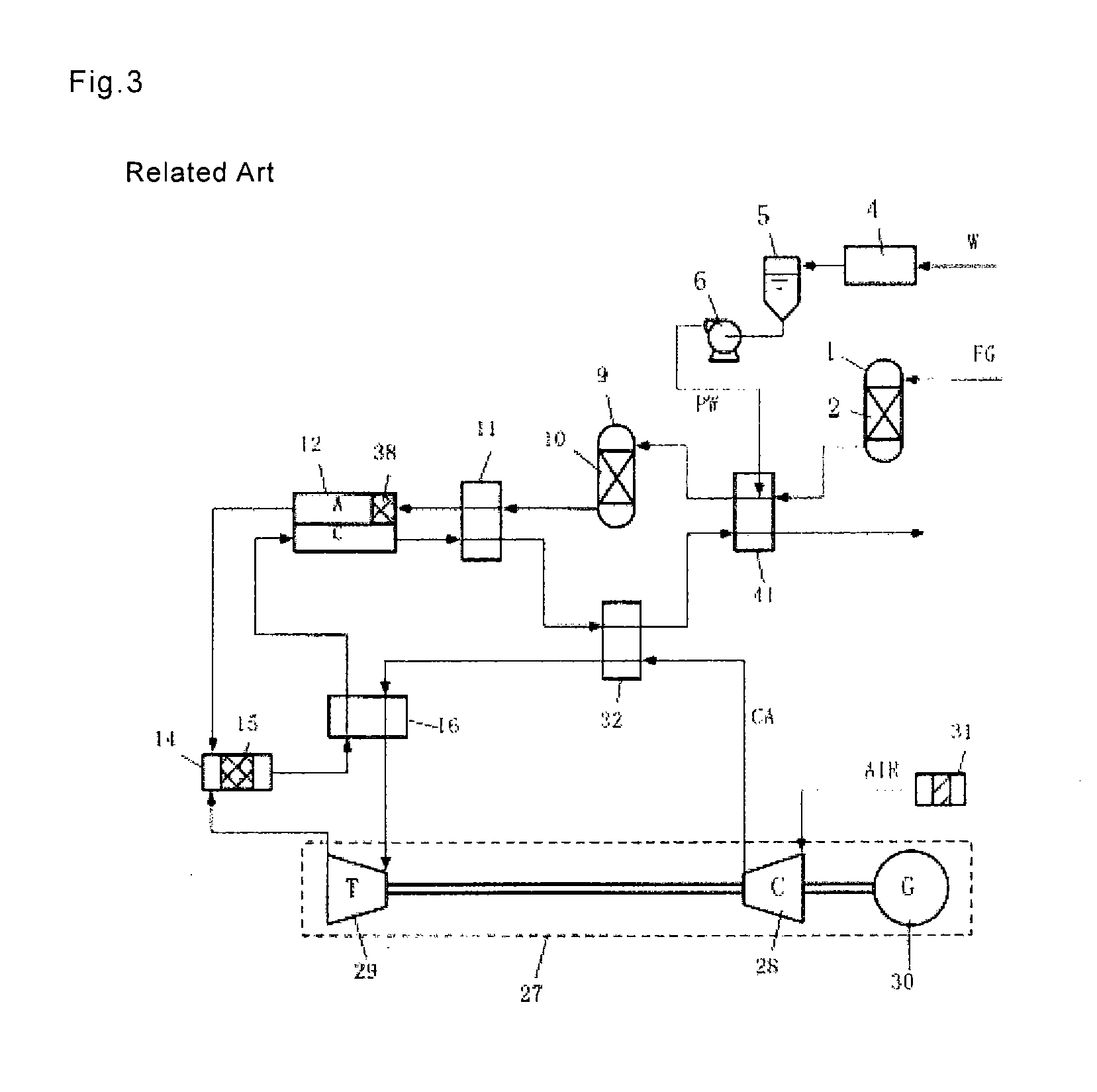

Mcfc power generation system and method for operating same

InactiveUS20110223500A1Reduce the amount of fuelReduce the amount requiredFuel cell heat exchangeRegenerative fuel cellsElectricityFuel cells

Disclosed is an MCFC power generation system and a method for operating the same enabling significant reduction of CO2 emission or substantially zero CO2 emission by minimizing the equipment added to a general power generation facility to a minimum, enabling both high power generation efficiency and high heat recovery efficiency, enabling adjustment of the voltage and output of the fuel cell in a certain range by adjusting the cathode gas composition, enabling great variation of the ratio between the heat and electricity, and thereby enabling variable thermoelectric operation. The MCFC generation system includes a cathode gas circulation system in which the cathode gas is circulated by a cathode gas recycle blower, and a closed loop is formed. Oxygen consumed by power generation is supplied from an oxygen supply plant, and CO2 is supplied from recycled CO2. Combustible components in anode exhaust are burned with oxygen, the resultant gas is cooled, and water is removed. The fuel gases in the anode exhaust is recycled.

Owner:TOKYO GAS CO LTD

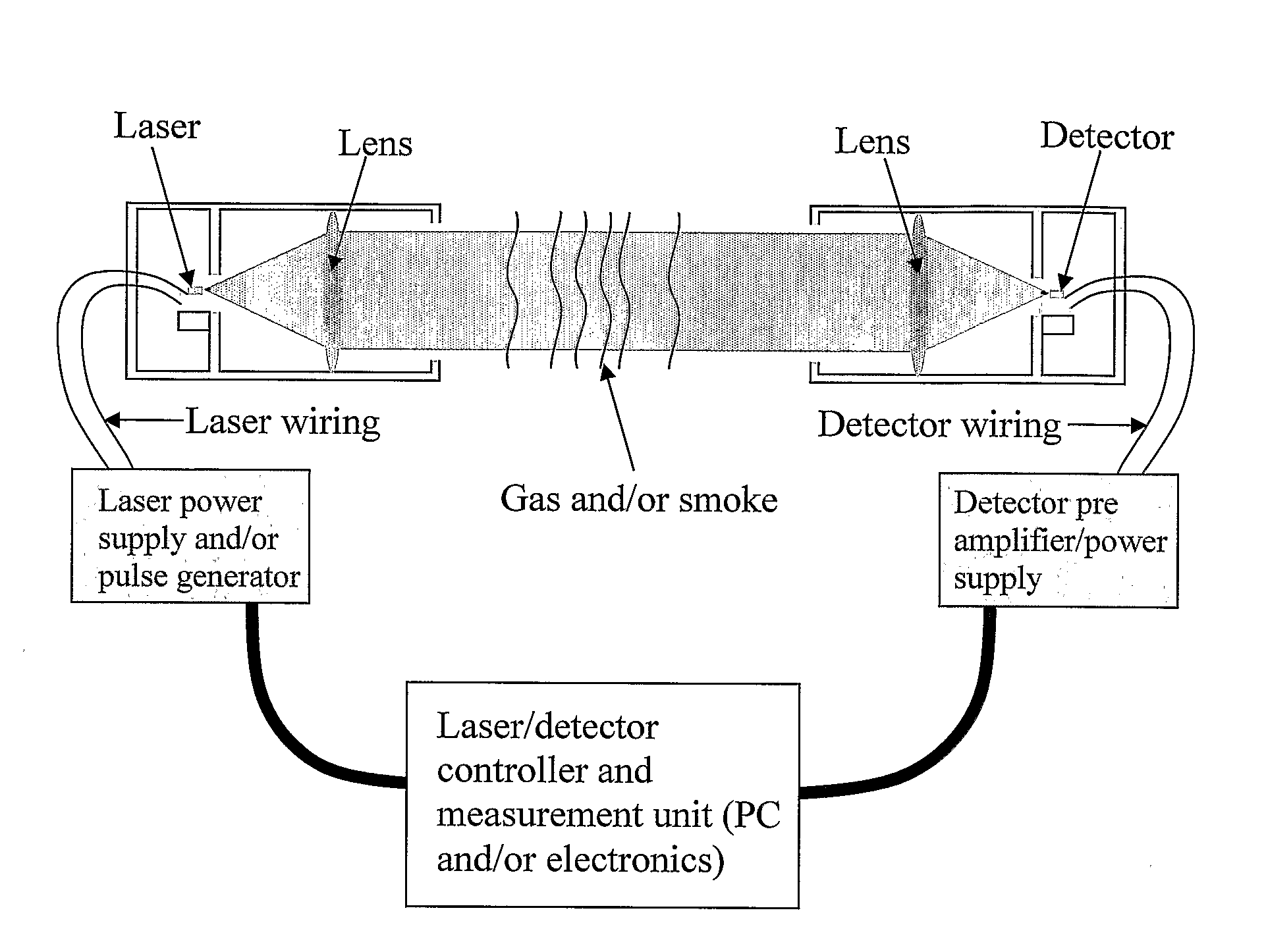

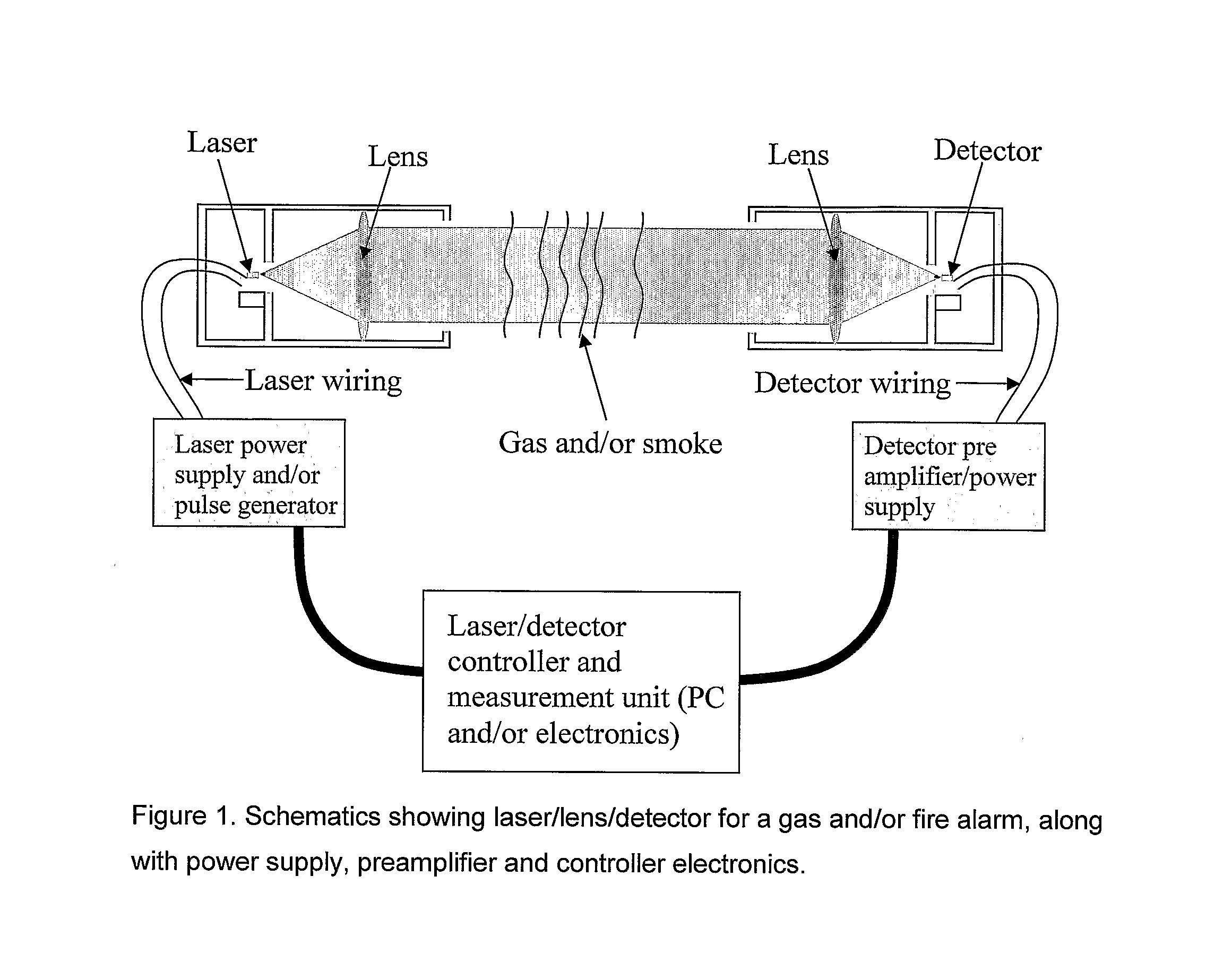

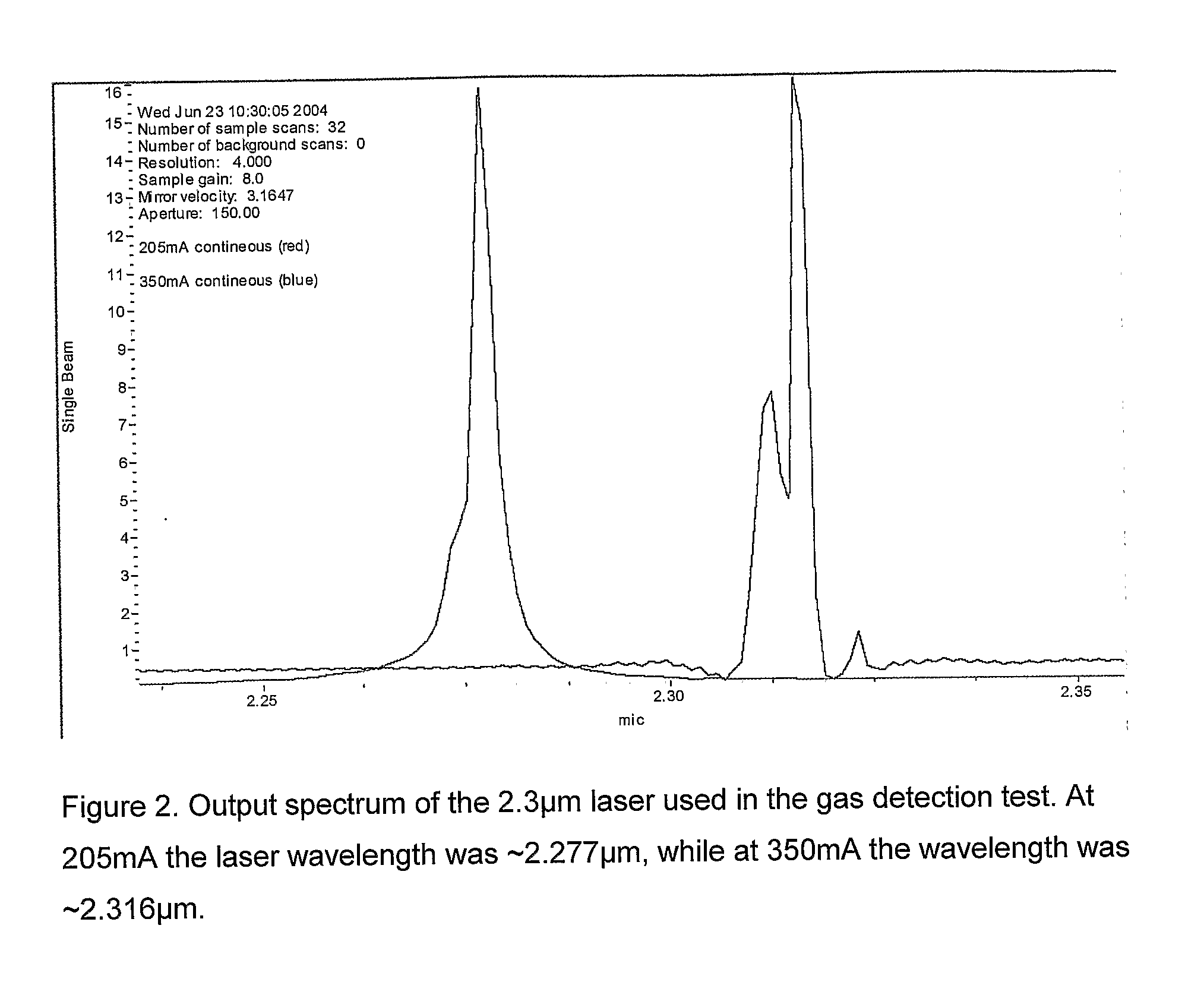

Infrared Laser Based Alarm

InactiveUS20080198027A1Avoid frostAvoid corrosion damageInvestigating moving fluids/granular solidsScattering properties measurementsGas compositionParticle density

The subject invention relates to a new alarm which is based on using a quarternary tunable Mid-IR laser to measure both particles and gas at the same time. The measurement is done within an area of which the gas of interest will absorb the Mid-IR radiation. By widely tuning the emission wavelength of the laser, several wavelengths can be measured in order to accurately find both gas composition and particle density with one laser based sensor. We tested a new device which use radiation between 2.27 μm and 2.316 μm. Methane gas reduces intensity of the radiation at certain wavelengths in this device, while particles / fog reduce intensity for all wavelengths. In this case, fog should not trigger an alarm, while methane leaks should. This can also be applied for CO and smoke in which one sensor will measure both parameters to sound an alarm instead of just one parameter.

Owner:INTEGRATED OPTOELECTRONICS

Method of controlling the uniformity of PECVD-deposited thin films

InactiveUS20050233092A1Improve performanceIncrease widthSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas compositionProduct gas

We have discovered that controlling a combination of PECVD deposition process parameters during deposition of silicon-containing thin film provides improved control over surface standing wave effects. By minimizing surface standing wave effects, the uniformity of film properties (particularly film thickness) across a substrate surface onto which the films have been deposited is improved. The process parameters which have the greatest effect on surface standing wave effects include: the spacing between the upper and lower electrodes in the plasma reactor; the RF frequency of the plasma source; the amount RF power to the plasma source; the process chamber pressure; the relative concentrations of the various components in the precursor gas composition; and the precursor gas overall flow rate relative to the substrate processing volume.

Owner:APPLIED MATERIALS INC

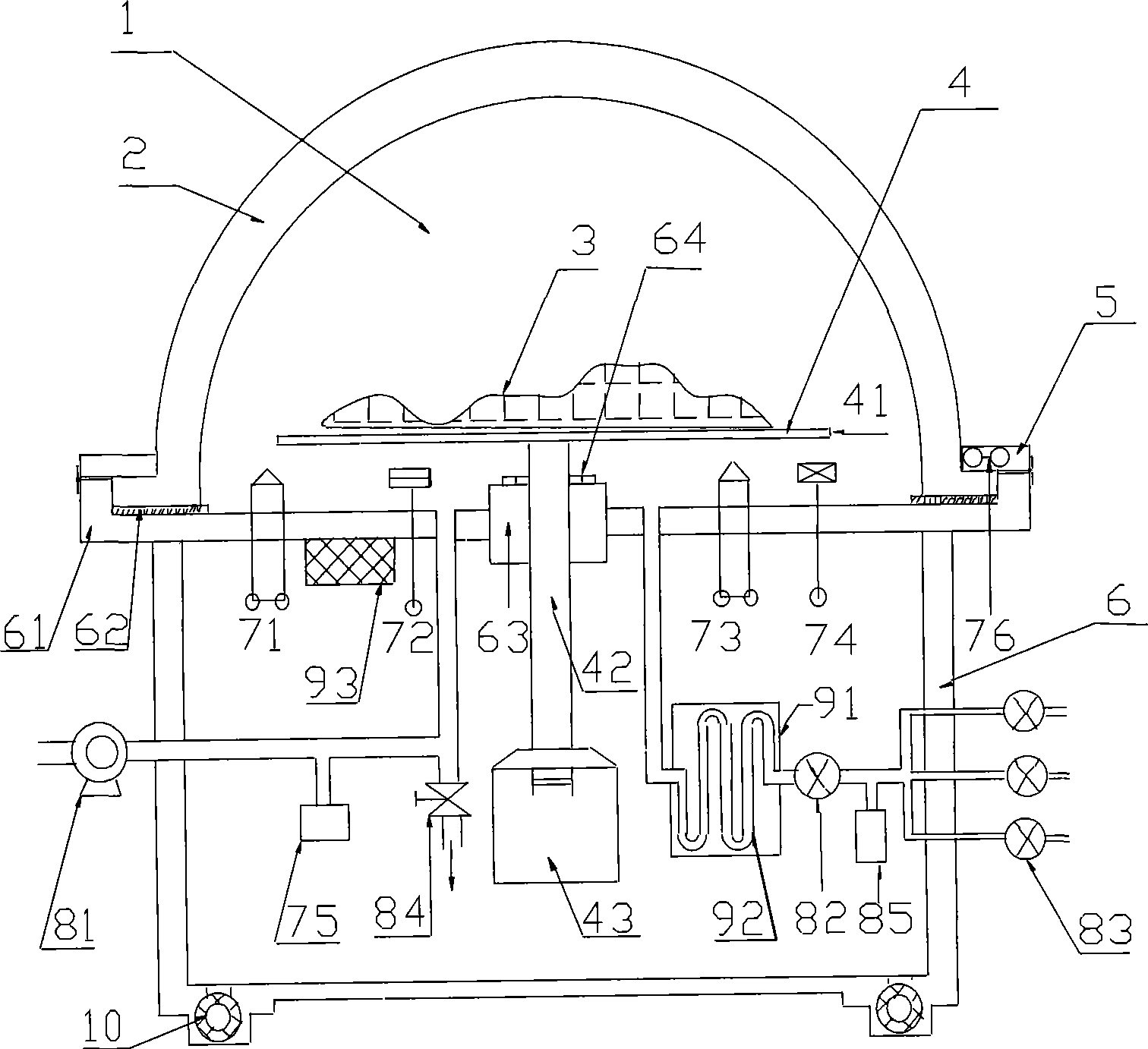

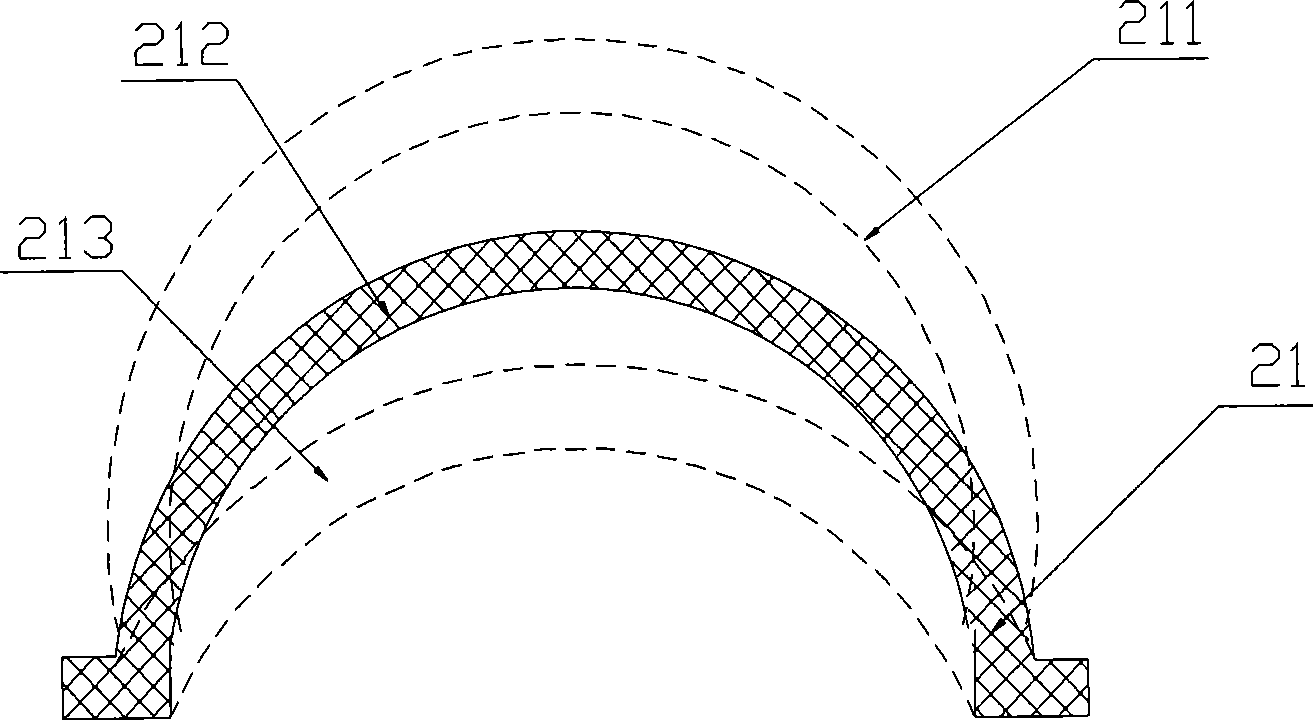

Device with culture relics exhibiting and protecting function

InactiveCN101390700APrevent oxidationInhibition of photodegradationShow cabinetsShow shelvesMicroorganismGlass cover

The invention provides a device which can exhibit and protect cultural relics. The device is characterized in that the device comprises a base; a base plate is arranged at the top of the base; the bottom of a glass cover is fixed on the base plate through a safety lock reed, and a safety alarm is arranged on the safety lock reed; a gland bush is arranged at the butt joint of the glass cover and the base plate; a rotating bushing is arranged at the middle part of the base plate and a gland bush is arranged on the rotating bushing; rotating shafts are arranged inside the rotating bushing and the base; showcase stands are arranged at the top parts of the rotating shafts, and step motors are arranged at the tail ends of the rotating shafts; a temperature sensor, a pressure sensor, a humidity sensor and a gas composition sensor are arranged at two sides of the base plate; and a cavity refrigerating / heating device is arranged at the bottom of the base plate. The device has the advantages that the device can well exhibit the cultural relics and can create a manual protecting environment without damages. The device prevents oxidation, photodegradation, overheating volatilization, mould development and microorganisms and has the function of protecting the cultural relics and the precious article inside the cavity.

Owner:DONGHUA UNIV

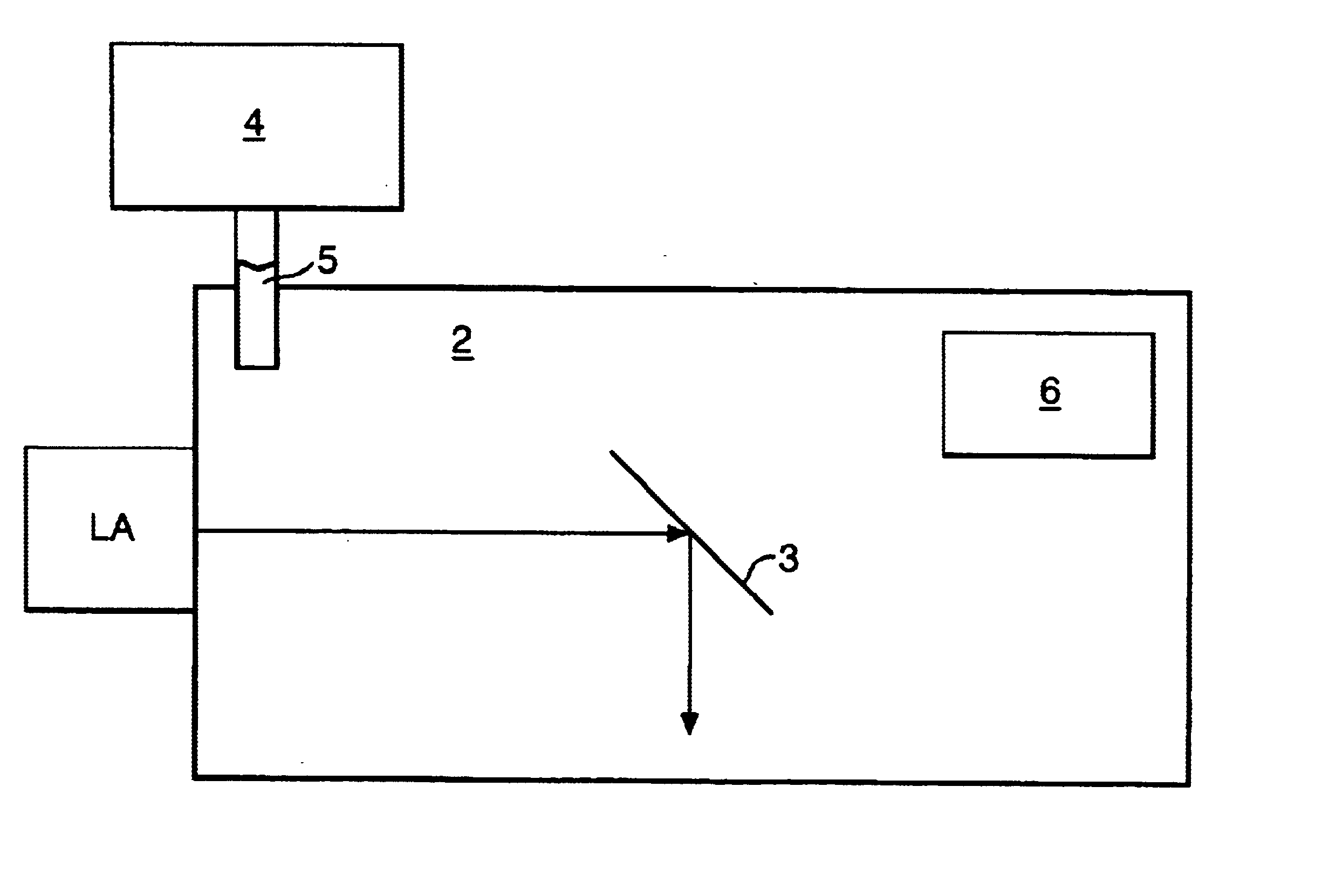

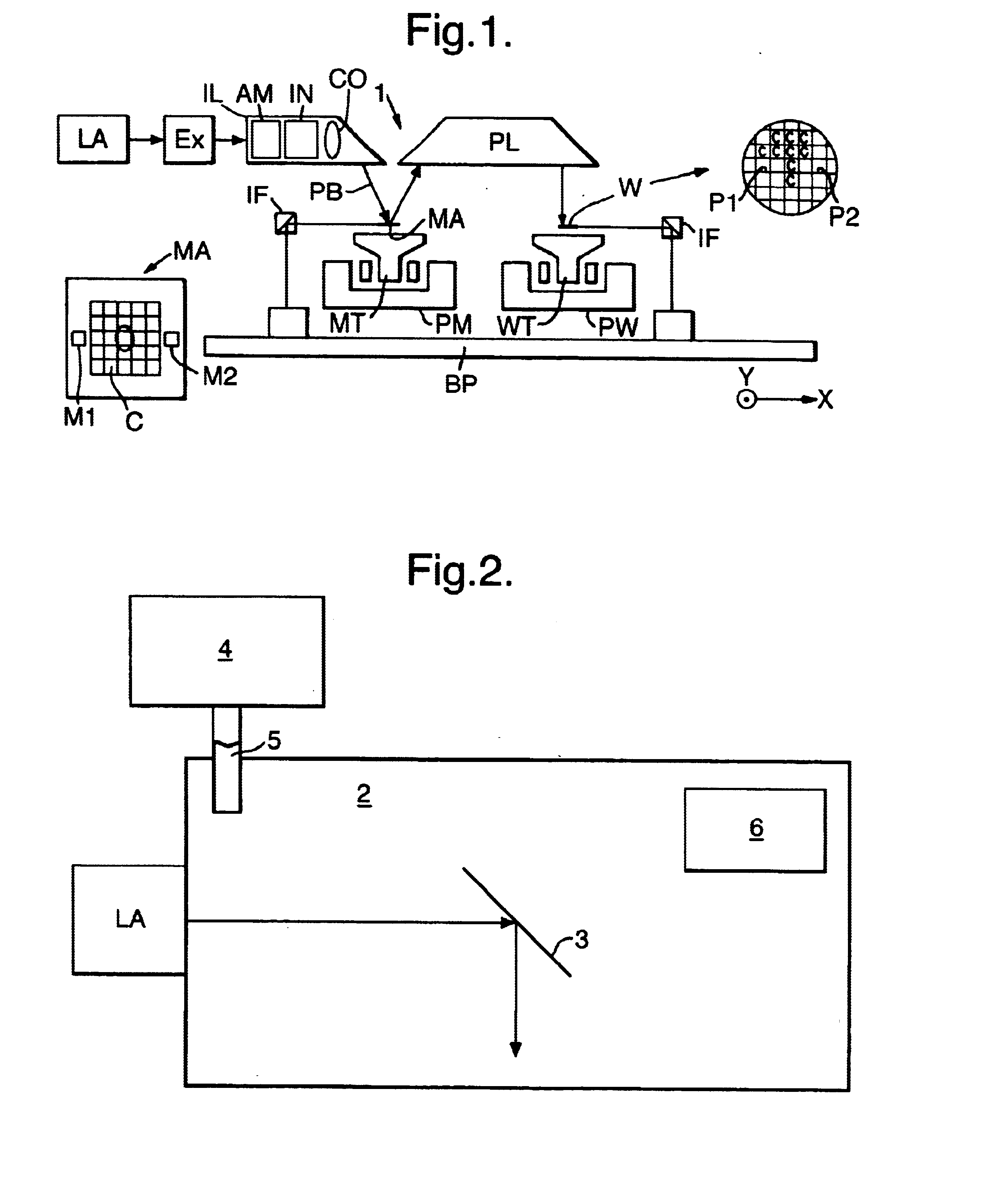

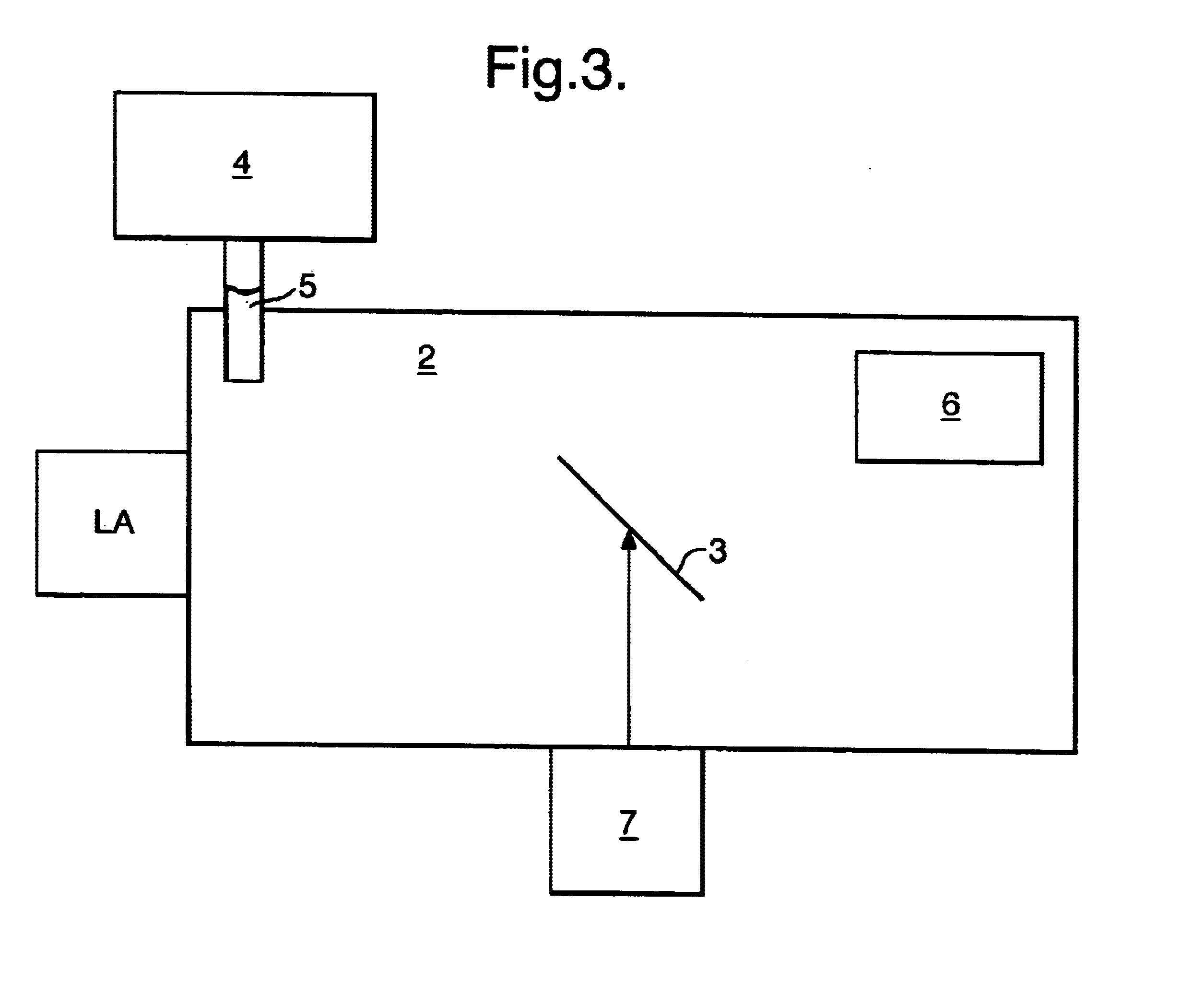

Lithographic projection apparatus, device manufacturing method, device manufactured thereby, cleaning unit and method of cleaning contaminated objects

InactiveUS6724460B2Stable cleaning materialSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusGas compositionLength wave

In-situ cleaning of optical components for use in a lithographic projection apparatus can be carried out by irradiating a space within the apparatus containing the optical component with UV or EUV radiation having a wavelength of less than 250 nm, in the presence of molecular oxygen. Generally, the space will be purged with an ozoneless purge gas which contains a small amount of molecular oxygen in addition to the usual purge gas composition. The technique can also be used in an evacuated space by introducing a low pressure of molecular oxygen into the space.

Owner:ASML NETHERLANDS BV

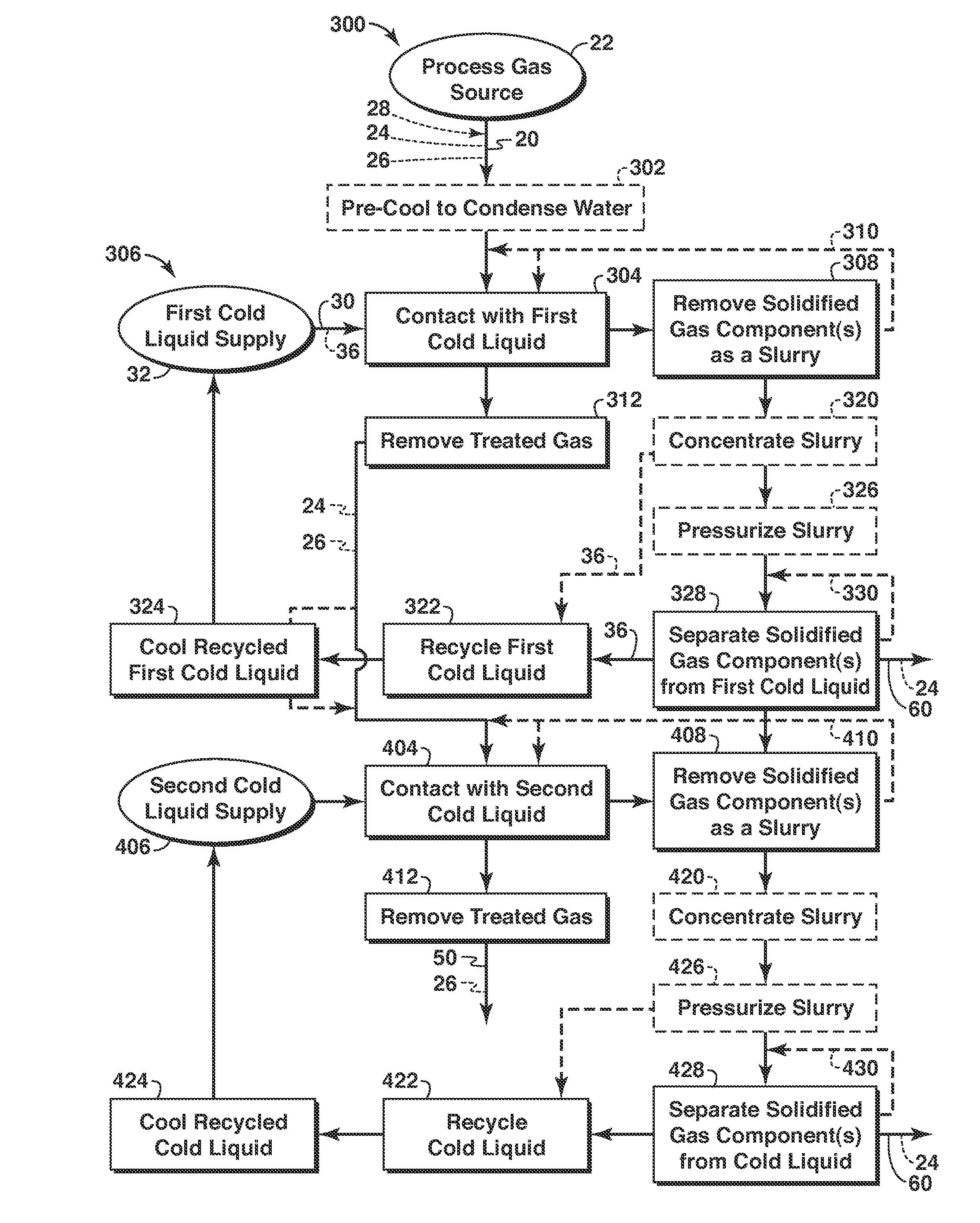

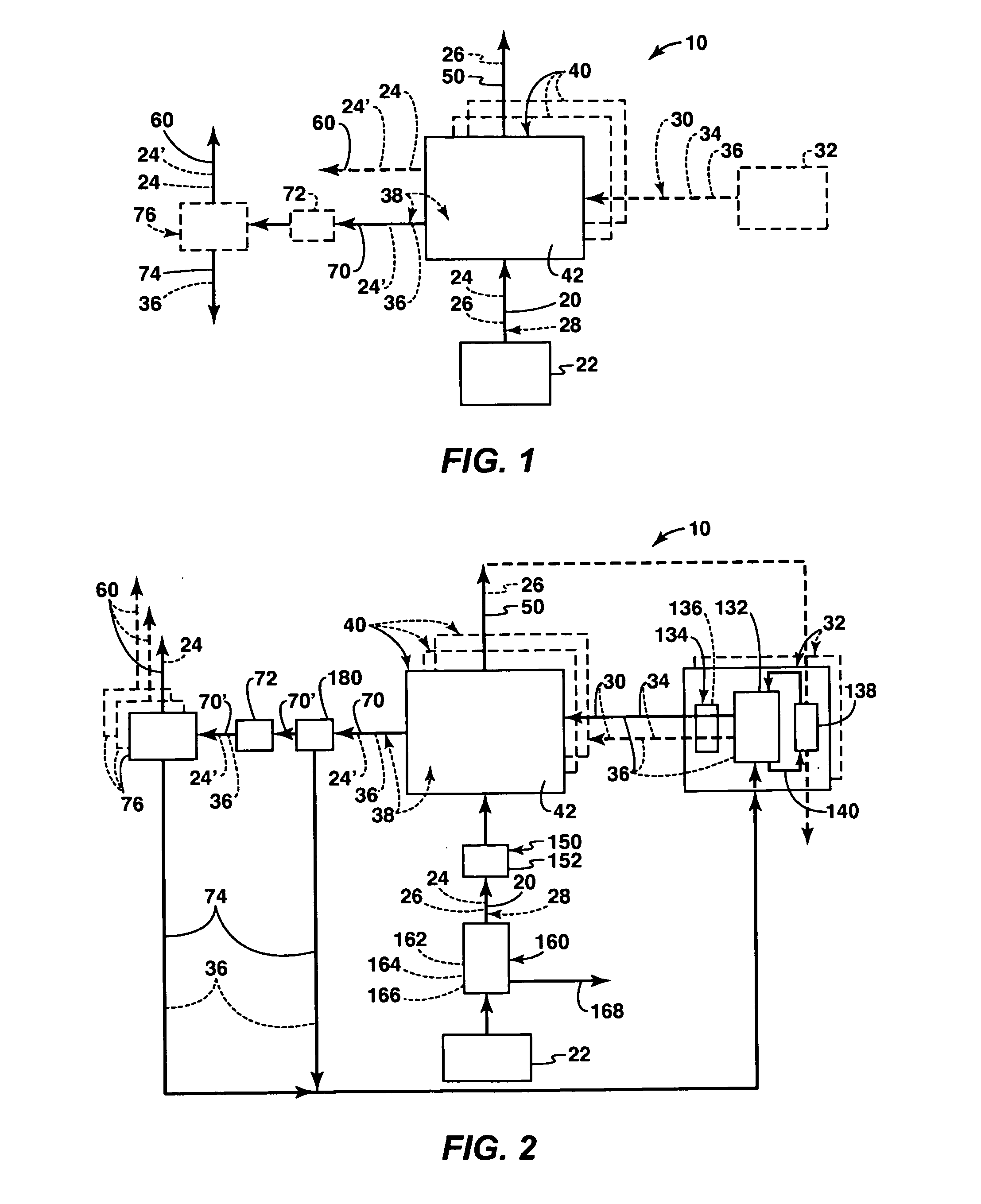

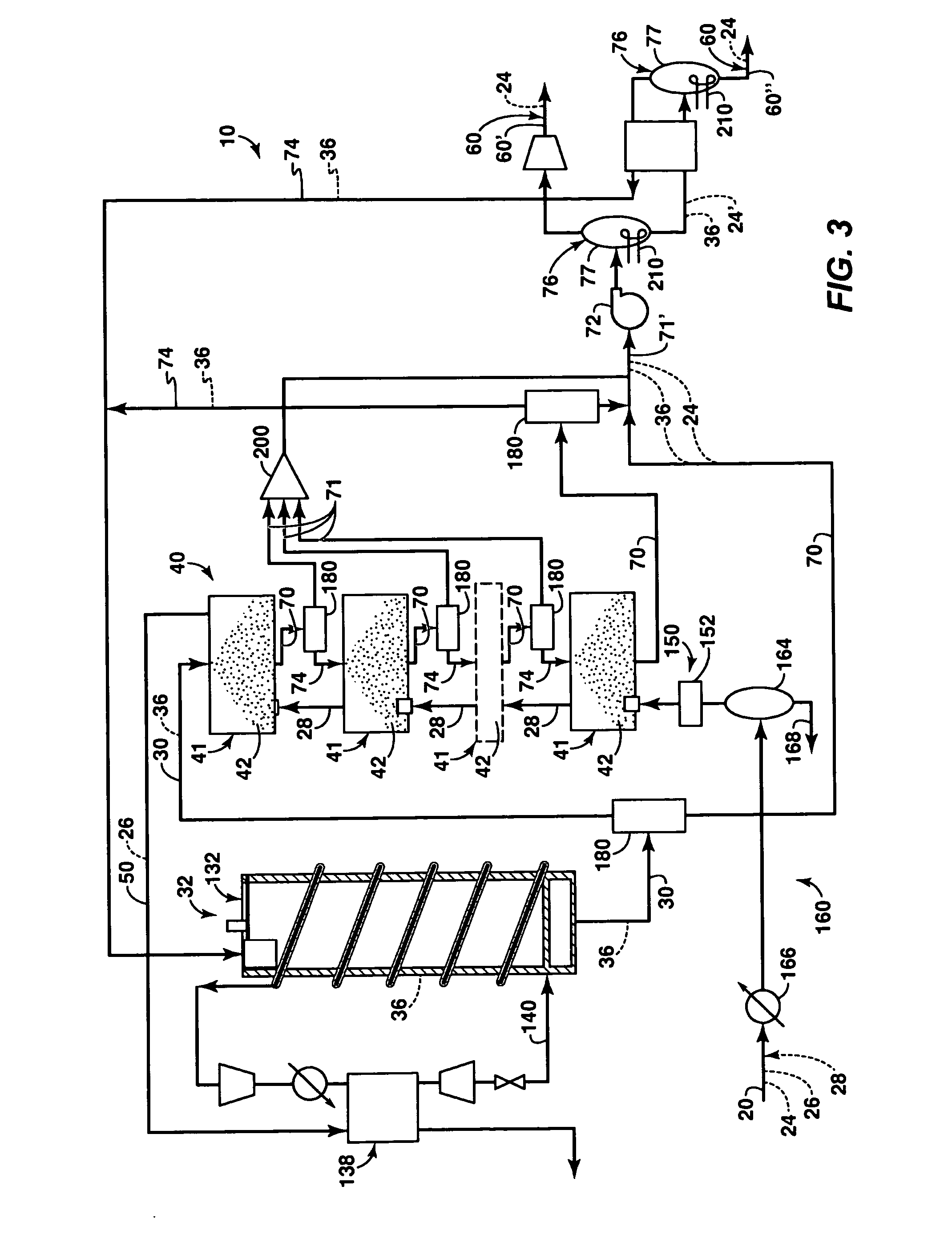

Systems and Methods For Using Cold Liquid To Remove Solidifiable Gas Components From Process Gas Streams

ActiveUS20130074541A1Increase pressureImprove concentrationSolidificationLiquefactionSlurryChemistry

Systems and methods are described for re-moving solidifiable gas from a process gas stream by direct contact with a cold liquid. The process gas stream includes at least gas that is frozen by the cold liquid while one or more other gases of the process gas stream remain in a gaseous state. The process gas stream may include water, and will have a different composition than the cold liquid. The contacting of the cold liquid with the process gas stream may be at a pressure that is less than 200 psia, and optionally less than 100 psia, 50 psia, or even 30 psia, and the solidified gas may be removed from the contacting assembly as a slurry with cold liquid.

Owner:EXXONMOBIL UPSTREAM RES CO

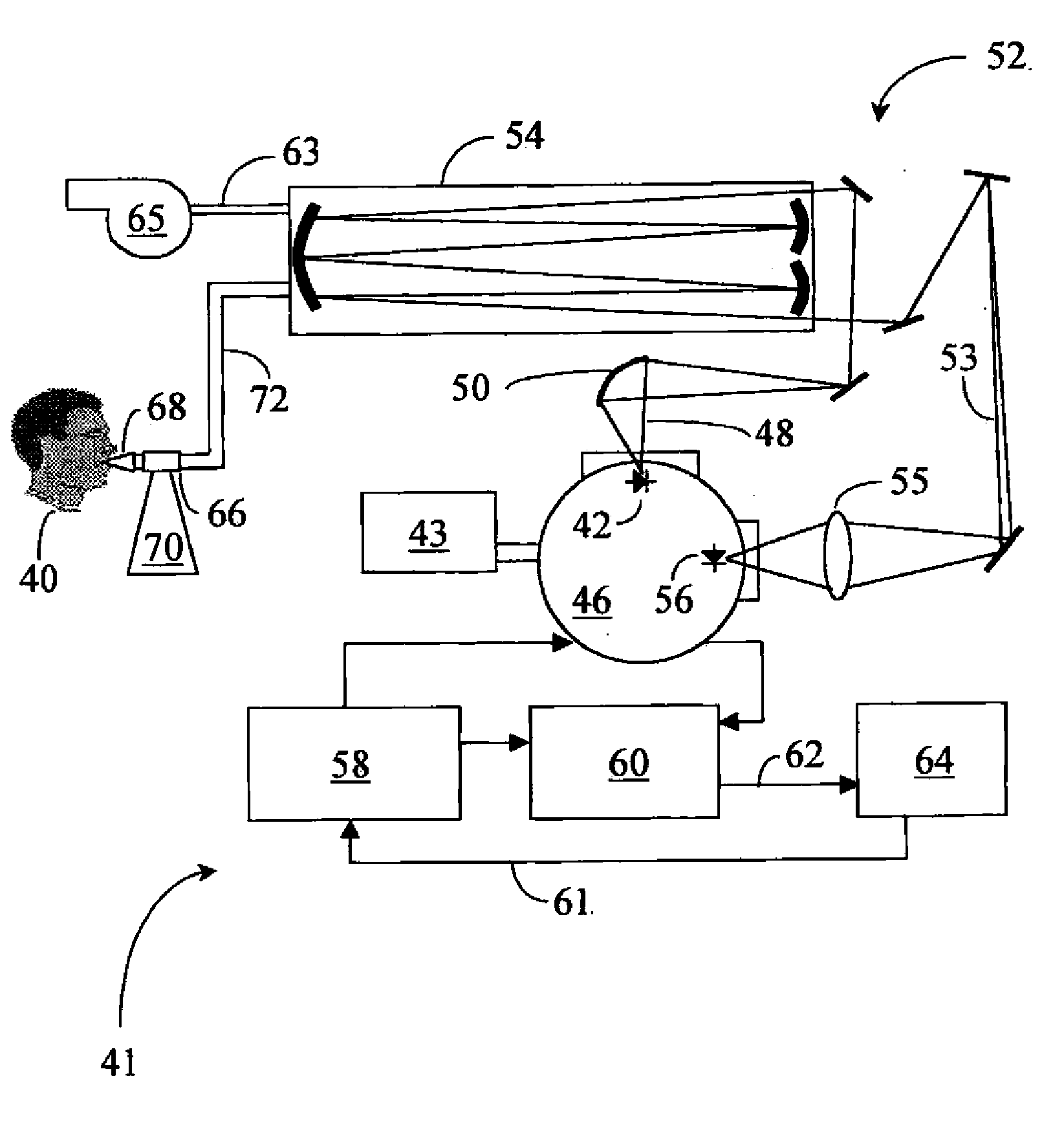

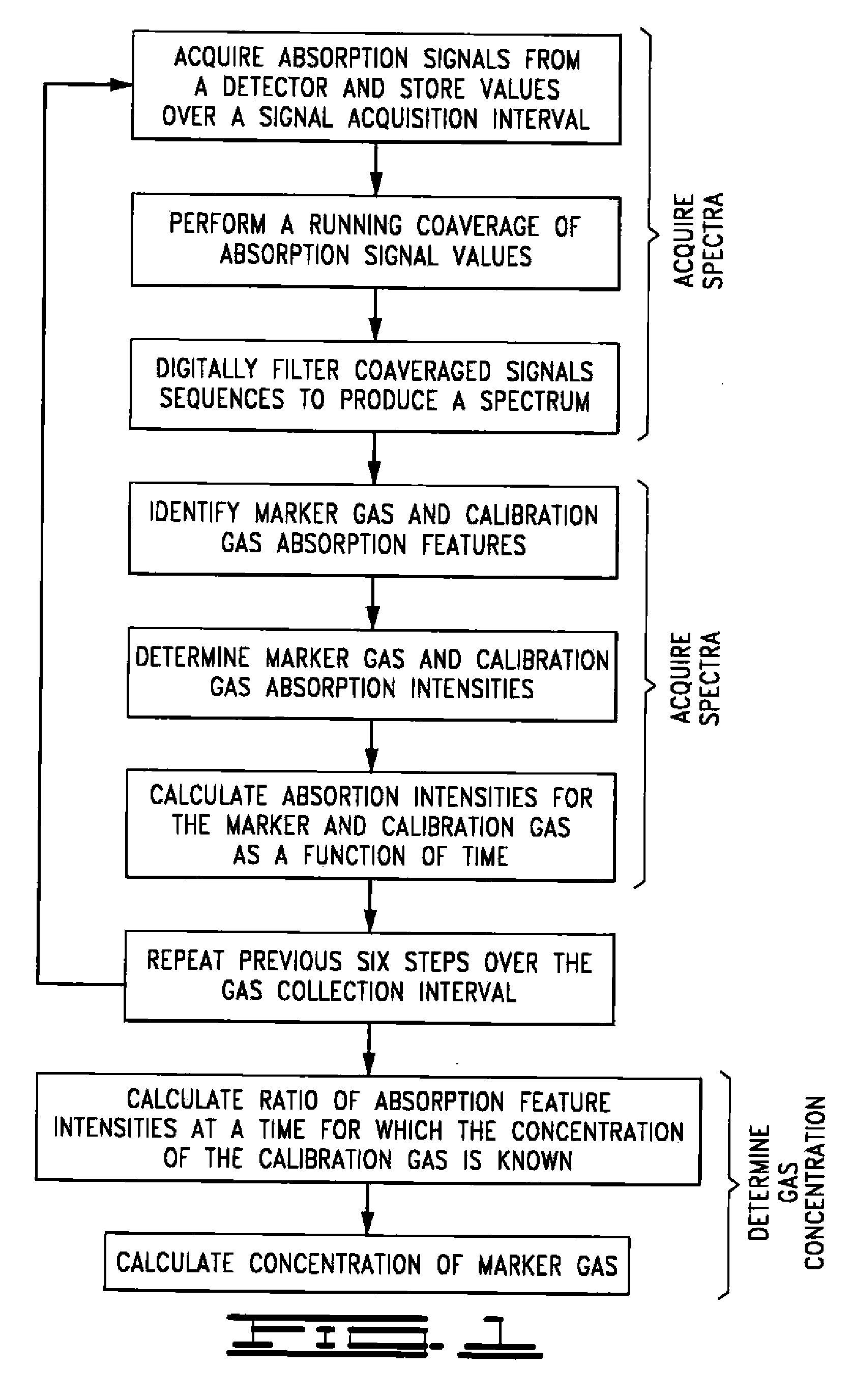

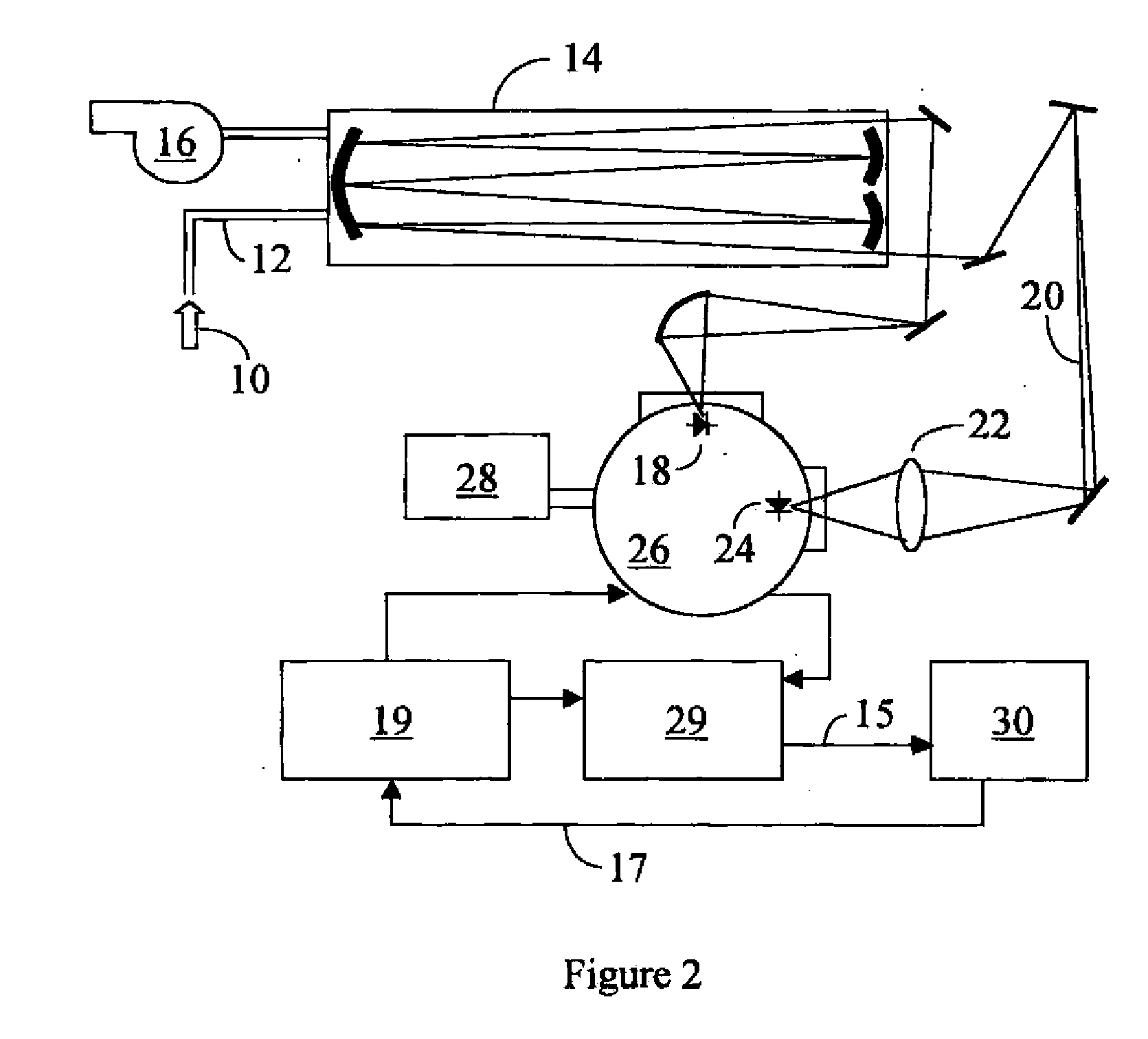

Method And Apparatus For Determining Marker Gas Concentration Using An Internal Calibrating Gas

InactiveUS20070081162A1Diagnostics using spectroscopyTransmissivity measurementsHuman airwayCalibration gas

A method and an apparatus for measuring the concentration of a specific gas component of a gas mixture including another gas whose concentration is independently known using light absorption spectroscopy are provided. A method and an apparatus for assessing human airway inflammation by measuring the concentration of exhaled NO and CO2 present in orally exhaled breath using light absorption spectroscopy are also provided. NO concentration is determined at the time during breath sampling corresponding to a known exhaled CO2 concentration. Methods and apparatus are further provided for measuring NO concentration in orally exhaled human breath that analyze breath emanating from the lower airways and lungs, while excluding breath from the nasal cavity. They include steps and apparatus for discarding initially exhaled breath, flowing breath through an analysis chamber using a vacuum pump and flowing breath through an analysis chamber using a vacuum pump at an initial flow rate and later at a flow rate higher than the initial flow rate.

Owner:EKIPS TECH

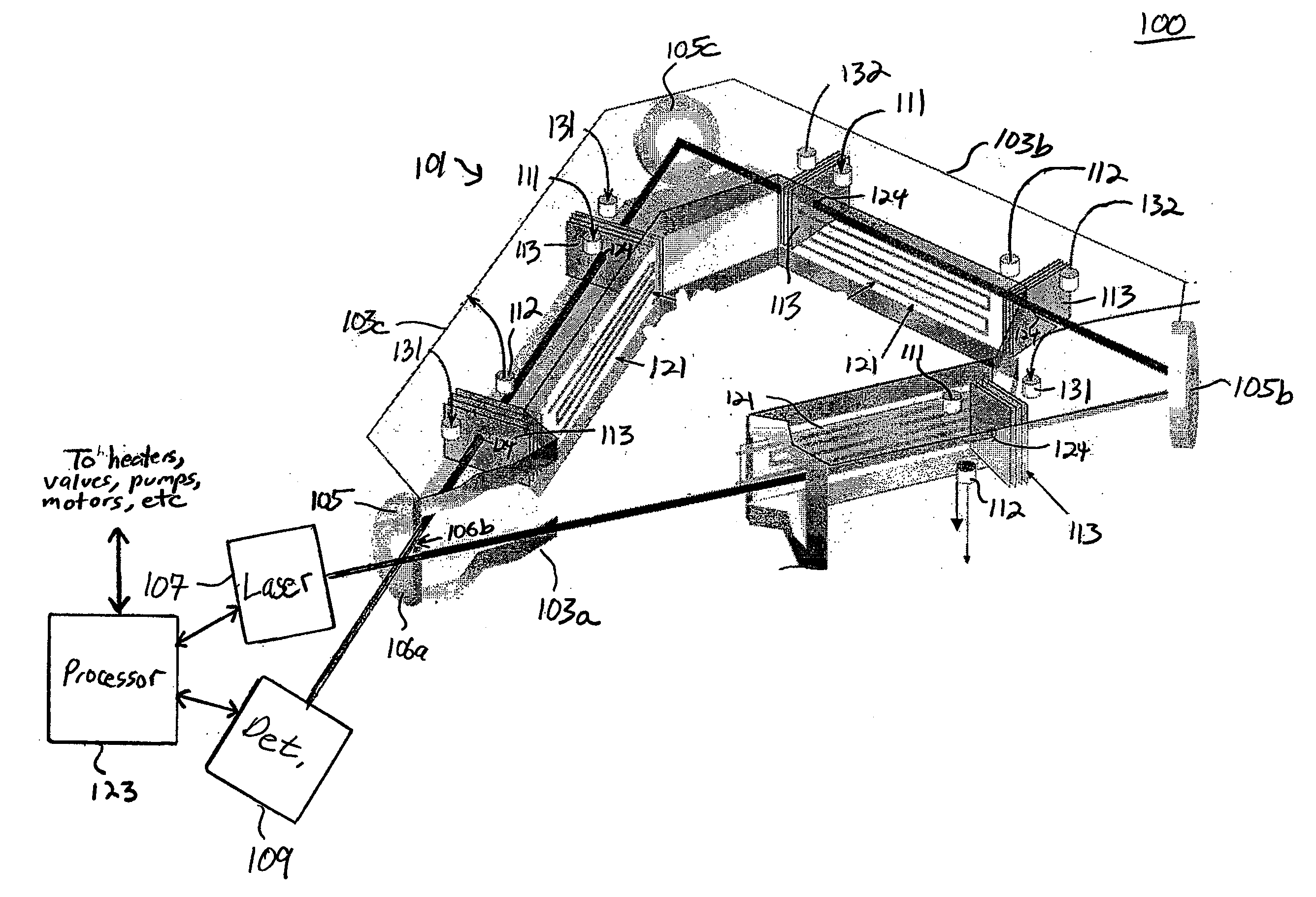

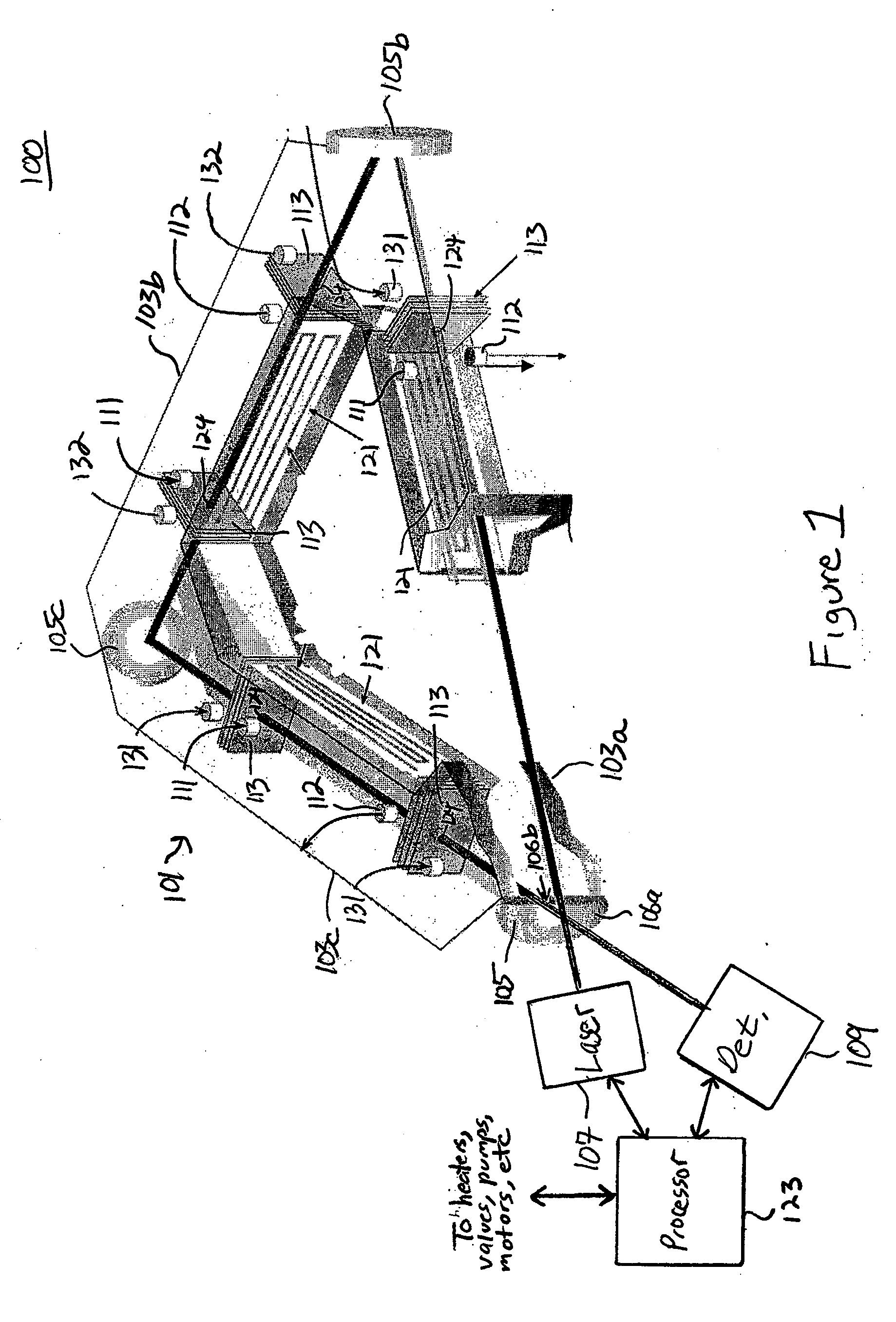

Spectroscopy Method and Apparatus for Detecting Low Concentration Gases

InactiveUS20080151248A1Reduce concentrationAbsorption/flicker/reflection spectroscopyColor/spectral properties measurementsRing downOptical cavity

The invention is a method and apparatus capable of detecting constituents of a gas at extremely low concentrations comprising providing a medium that is absorbent of at least a first particular gas under a first environmental condition and desorbent of the particular gas under a second environmental condition, exposing the medium to a sample gas for a first period of time under the first environmental condition, during a second period of time after the first period of time, exposing the medium to the second environmental condition to cause the medium to desorb gas into an optical cavity of a cavity ring down spectrometer and introducing electromagnetic radiation into the cavity, during a third period of time after the second period of time, ceasing introduction of the electromagnetic radiation into the cavity and detecting the decay of the electromagnetic radiation in the cavity, and analyzing the decay of the light in the cavity to obtain a spectral analysis of the sample gas.

Owner:HONEYWELL INT INC

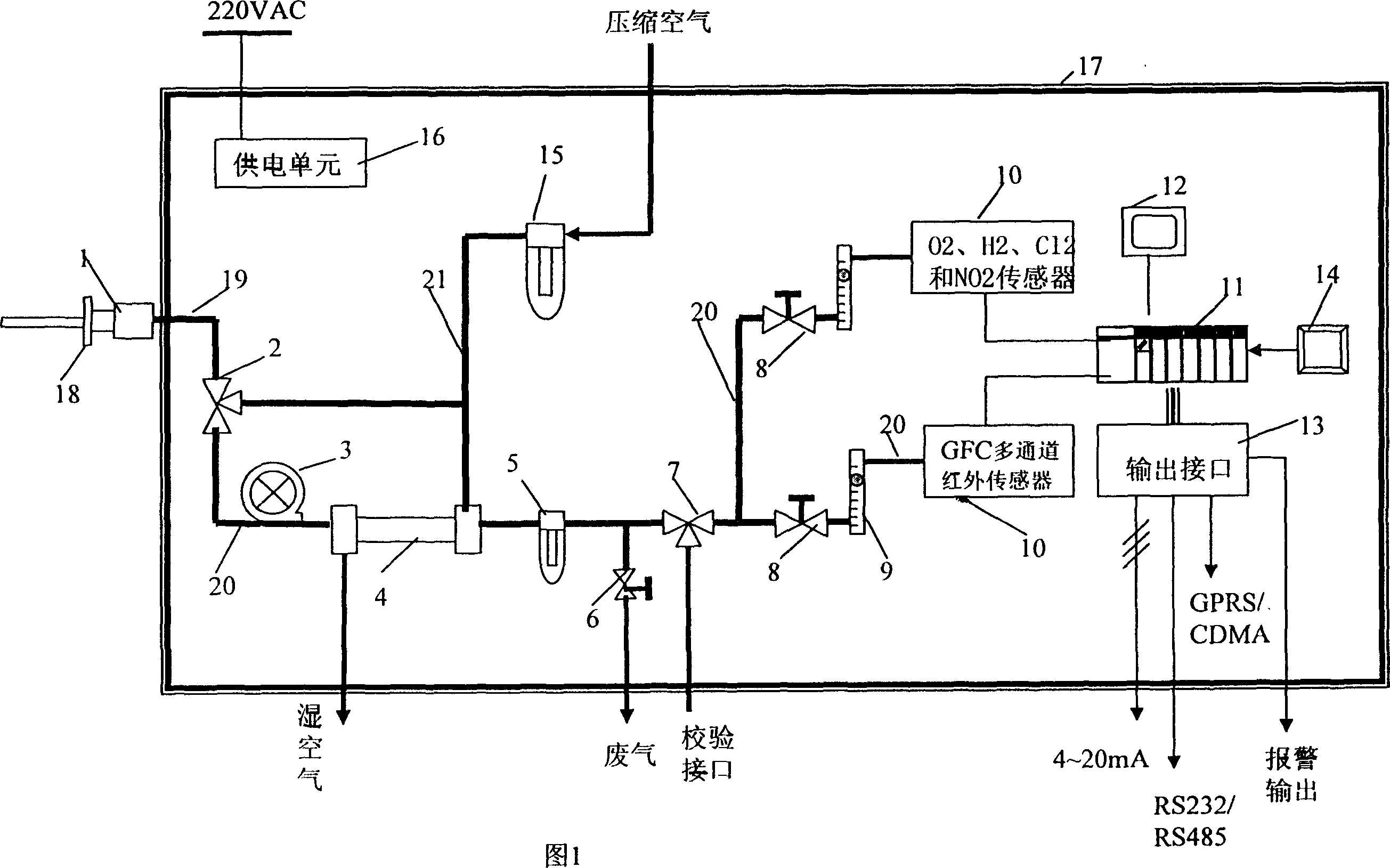

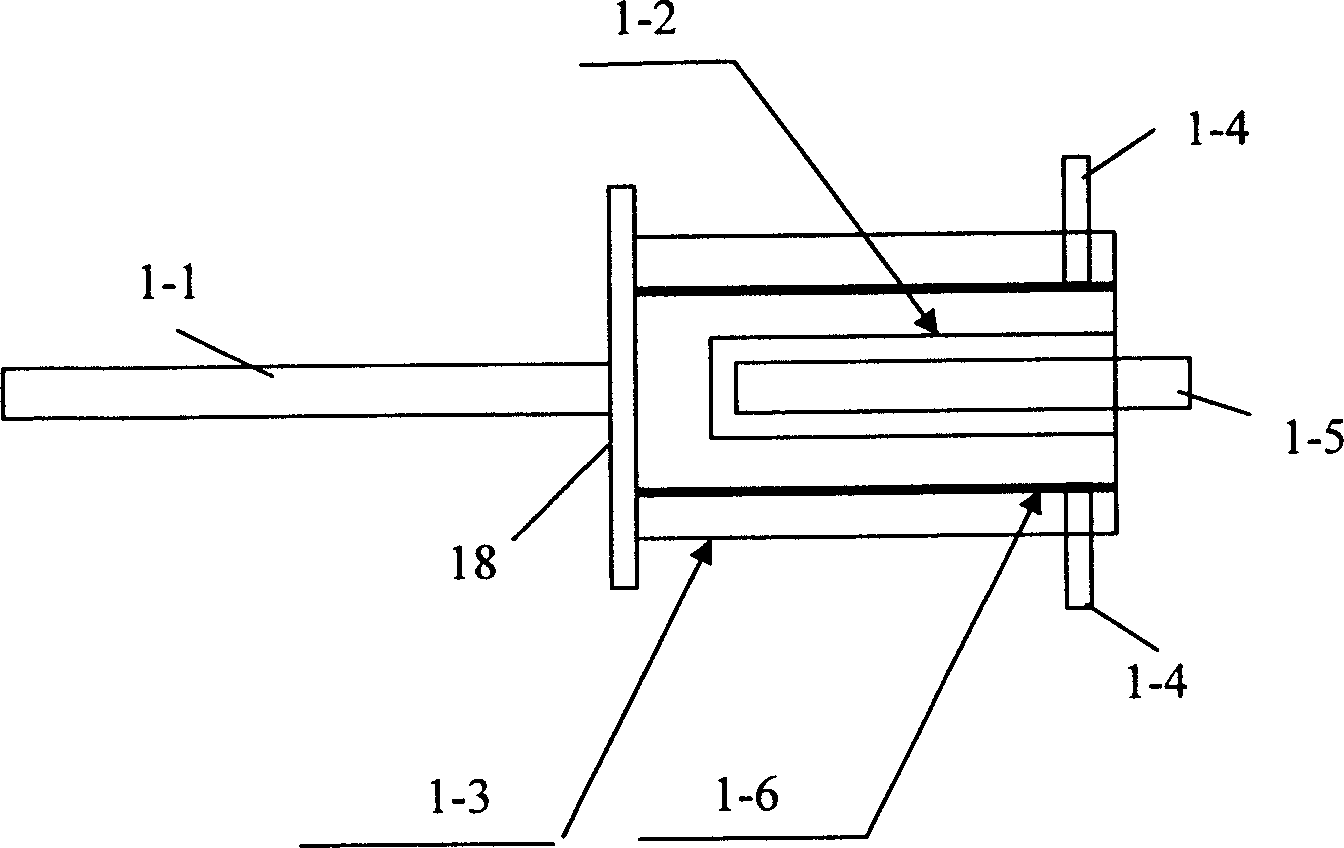

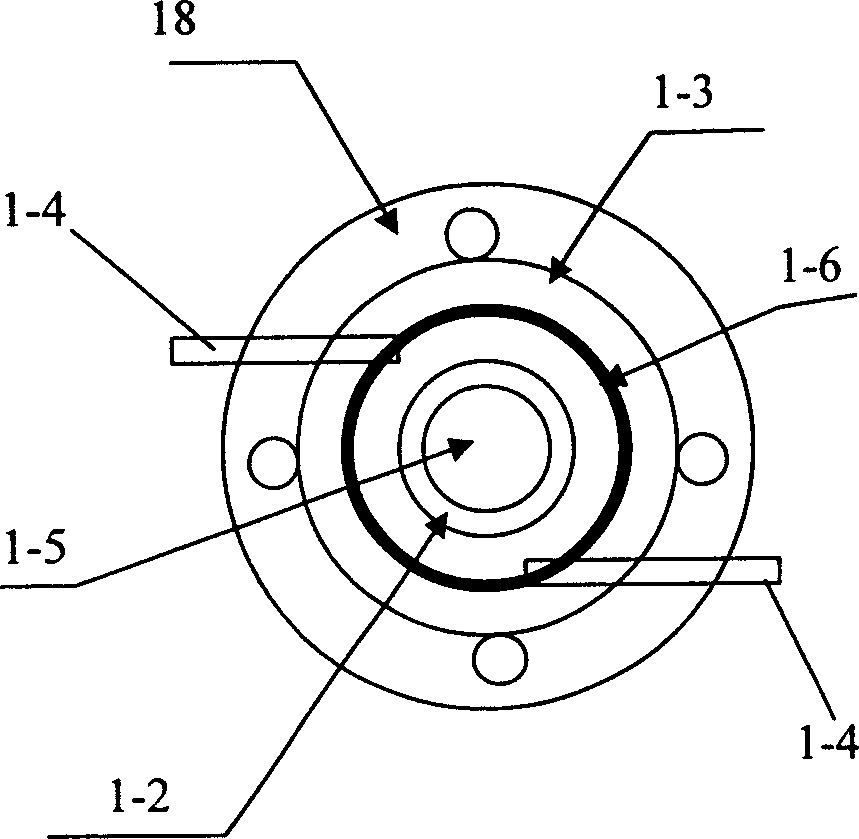

Integrated gas online detector

InactiveCN1866027ARealize simultaneous measurementAvoid long distance transportPreparing sample for investigationMaterial analysis by electric/magnetic meansGas analysisGas composition

The related integrated on-line gas detector can continual detect the content of CO, CO2, SO2, NO, NO2, N2O, CH4, HCl, H2S, HF, O2, H2 and Cl2 in smoke gas, kiln gas and furnace gas, which comprises: a sampling probe, a back-blow valve, a pump, a dehydrator, a fine filter, a bypass valve, a check valve, a stable valve, a flowmeter, a gas analysis sensor, a controller, a signal display, a signal output interface, an operation button, a drier, a power, an outdoor case, a sampling pipe, a sample-gas pipe, and a back-blow pipe. This invention has wide application.

Owner:南京卓成自动化设备有限公司

Ultracapacitor pressure control system

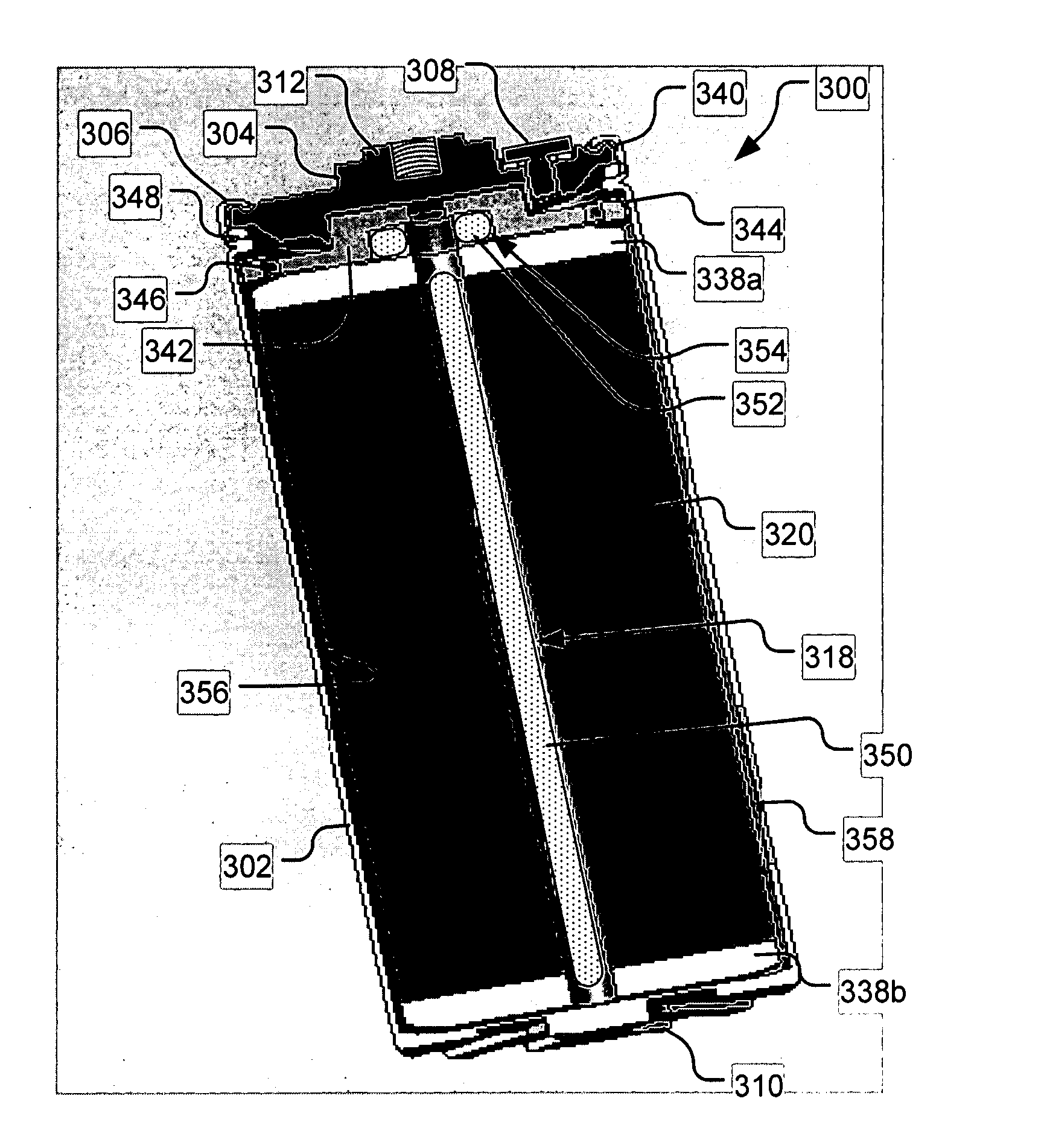

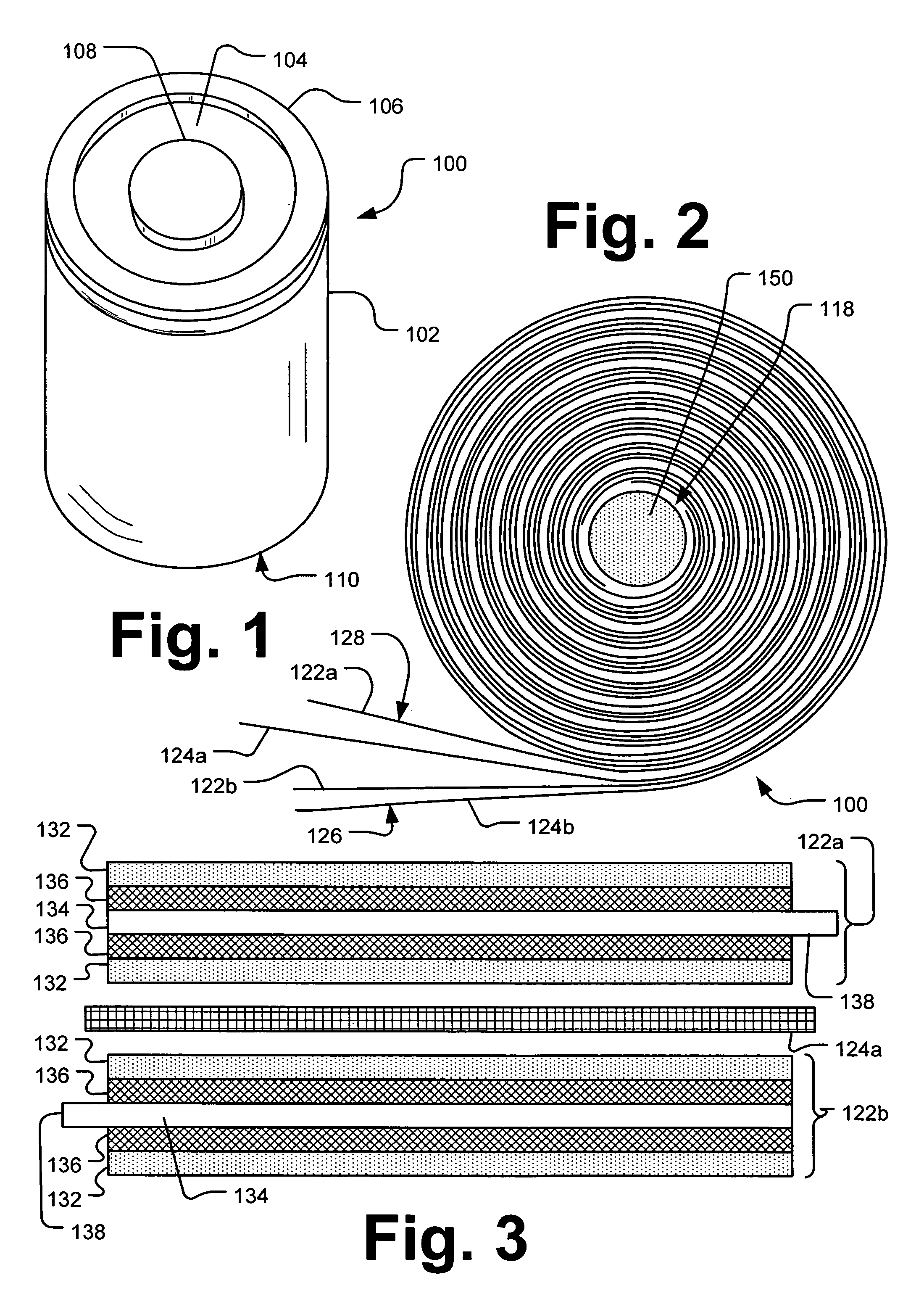

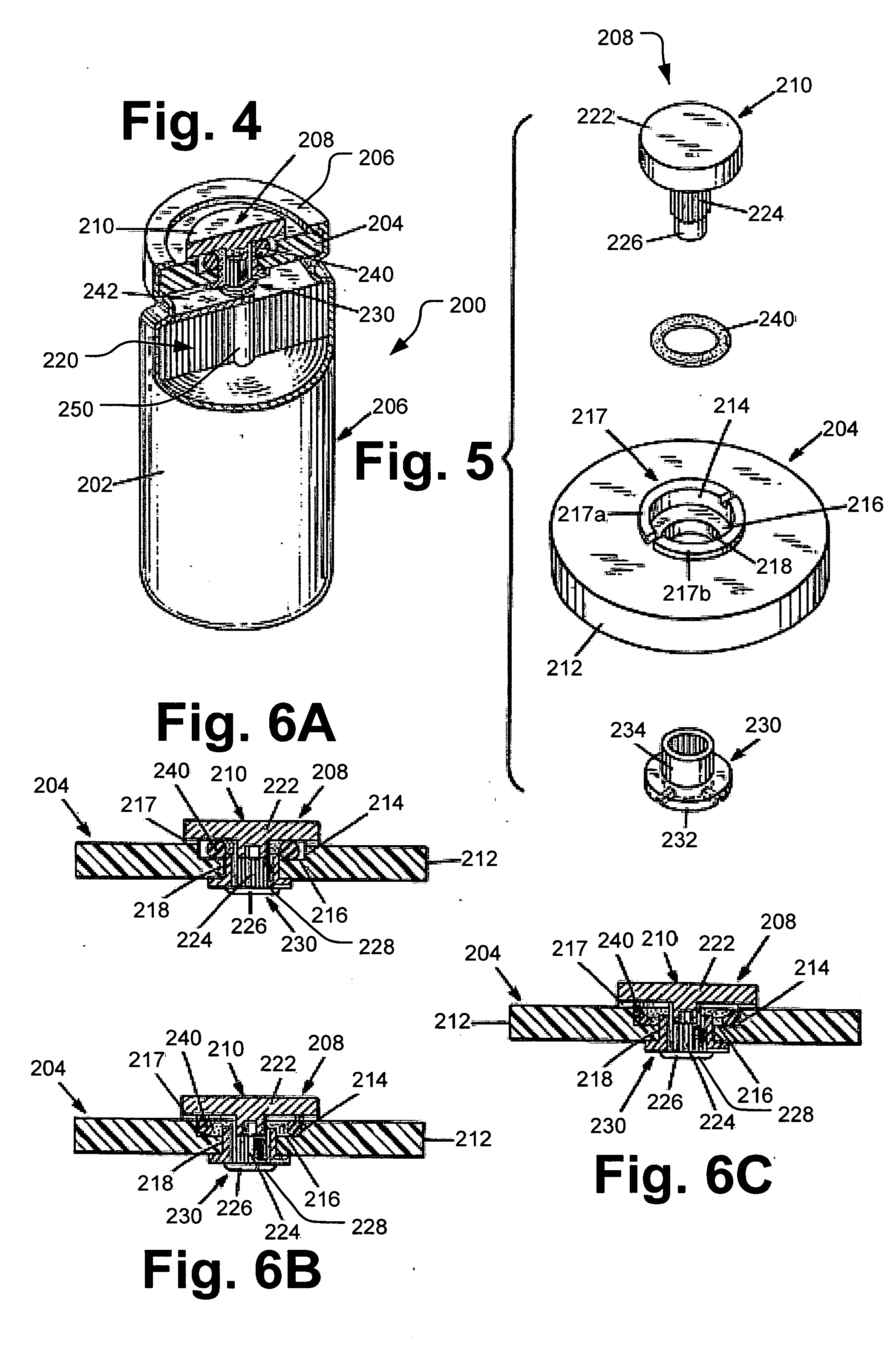

InactiveUS20070146965A1Reduce gas pressureReduce pressureProtecting/adjusting hybrid/EDL capacitorCapacitor housing/encapsulationInternal pressureGas composition

An ultracapacitor design minimizes the internal pressure of the cell package by using gas getters, either alone or in combination with a resealable vent in the package. Reducing pressure extends the life of the ultracapacitor. The primary gas types generated within a particular ultracapacitor are measured under multiple possible application conditions. Such conditions may include variables of temperature, application voltage, electrolyte type, length of use, and cycles of use. The primary gas components may be determined and suitable gas getters for different conditions may be formulated. The gas getters may be packed within the ultracapacitor packages, formulated as a negative electrode, doped into the negative current collector, or layered with the negative current collector.

Owner:UCAP POWER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com