Patents

Literature

464results about How to "Avoid corrosion damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

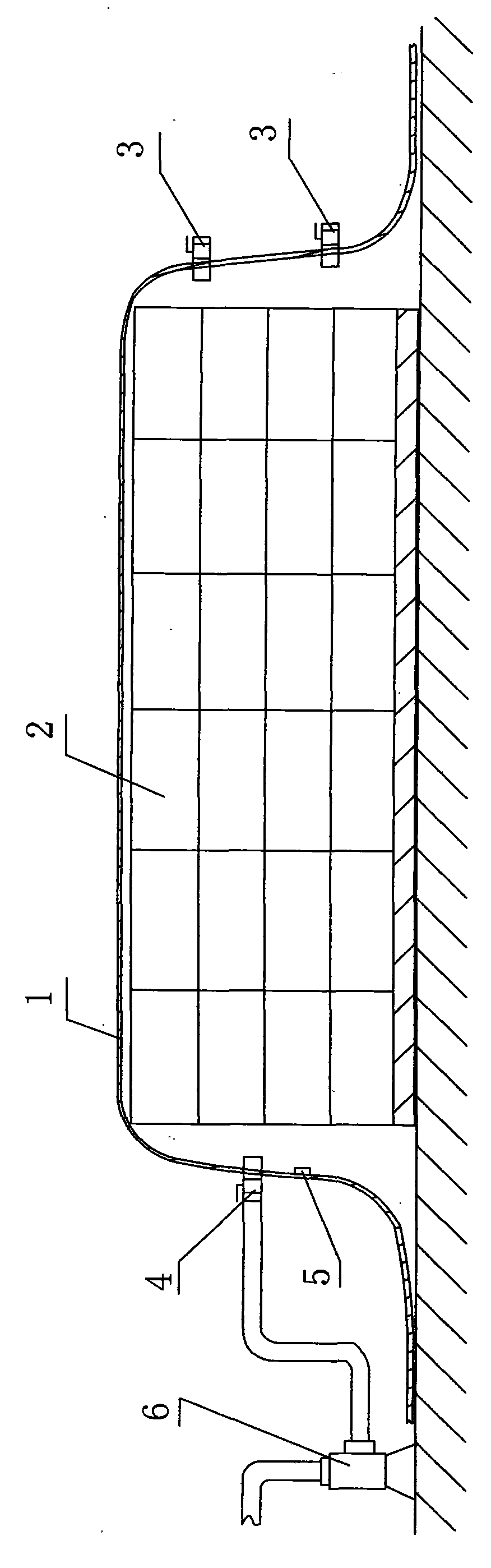

Multifunctional tobacco leaf stack sealing storage method capable of adjusting storage environment

ActiveCN101584280AImprove air tightnessImprove moisture resistanceAgriculture tools and machinesTobacco treatmentNatural ventilationInput control

The invention relates to a tobacco leaf stack sealing storage method capable of adjusting storage environment, comprising the following steps: 1) building a tobacco leaf stack sealing space capable of adjusting storage environment: covering the warehoused tobacco leaf stack using a plastic seal tent and enclosing the tobacco leaf stack in the sealed space; the sealed space enclosed by the plastic seal tent is perform air flow commutation with the outside when an air input control joint and an air output control joint are turned on and the sealed space enclosed by the plastic seal tent is at full sealed state when the air input control joint and the air output control joint are turned off; 2) gassing to disinfect; 3) filtering and purifying the steamed and disinfected noxious gas; 4) performing the daily tobacco-leaf mould proof conservation; 5) in winter, starting the plastic seal tent to perform the winder general investigation and natural ventilation and conservation of the tobacco leaf and restoring the plastic seal tent until the next early spring. The sealing storage method has low cost and environmental protection.

Owner:WUHAN DONGCHANG STORAGE TECH

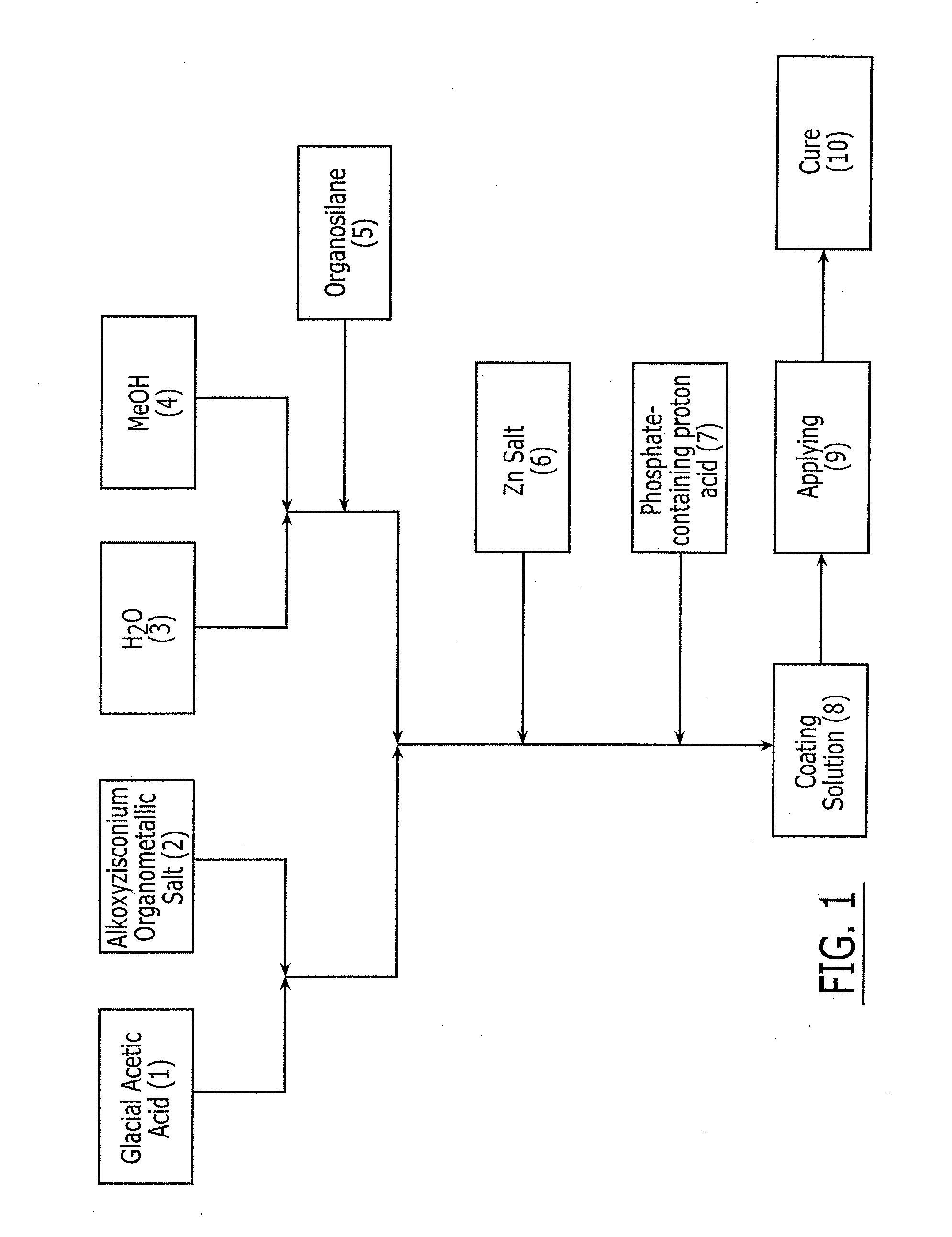

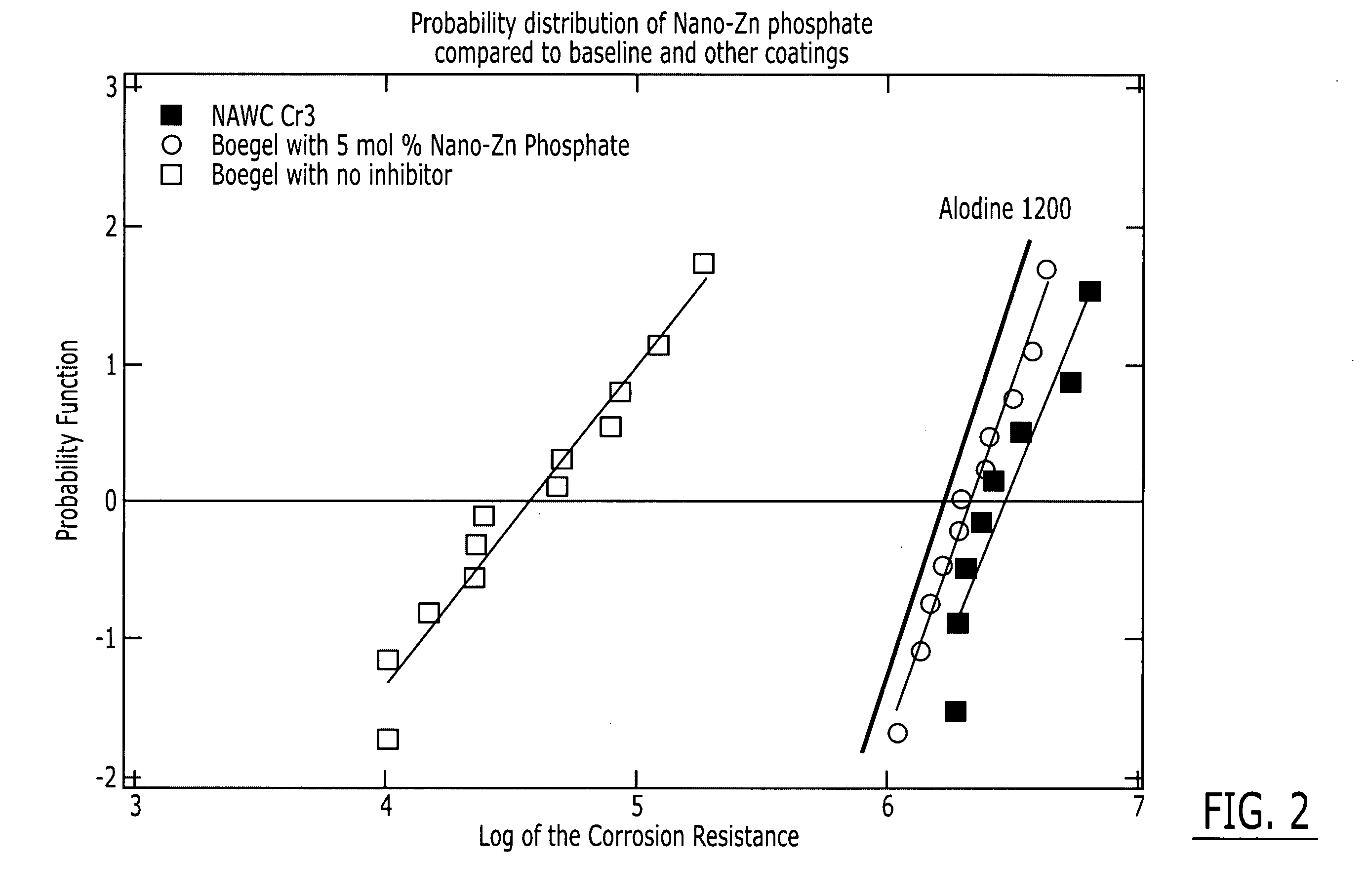

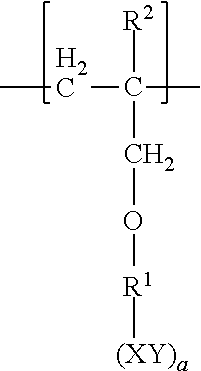

Nano-structured inorganic zinc phosphate corrosion protective coating for metal alloys

ActiveUS20090192251A1Trend downSuperior metal to resin adhesiveLiquid surface applicatorsEfficient propulsion technologiesZinc phosphateOrganic acid

A method is provided for enhancing corrosion resistance of a metal surface that includes the step of forming a sol-gel coating in which nanostructured zinc phosphate (Zn3(PO4)2) and zinc oxide (ZnO) phases are present in the mixture. The method may include the steps of mixing an organosilane, organometallic, organic acid, water, and alcohol and allowing the components of the mixture to partially hydrolyze, followed by adding at least one component having zinc functionality and at least one component having phosphate functionality to the partially hydrolyzed mixture, wherein the zinc component and phosphate component are added in a molar ratio of from about 1.5:1 to about 5:1 (Zn:PO4). The resulting mixture can be applied as a coating to a metal surface to improve the corrosion resistance of the metal and to enhance the adhesion of resinous materials to the metal surface.

Owner:THE BOEING CO

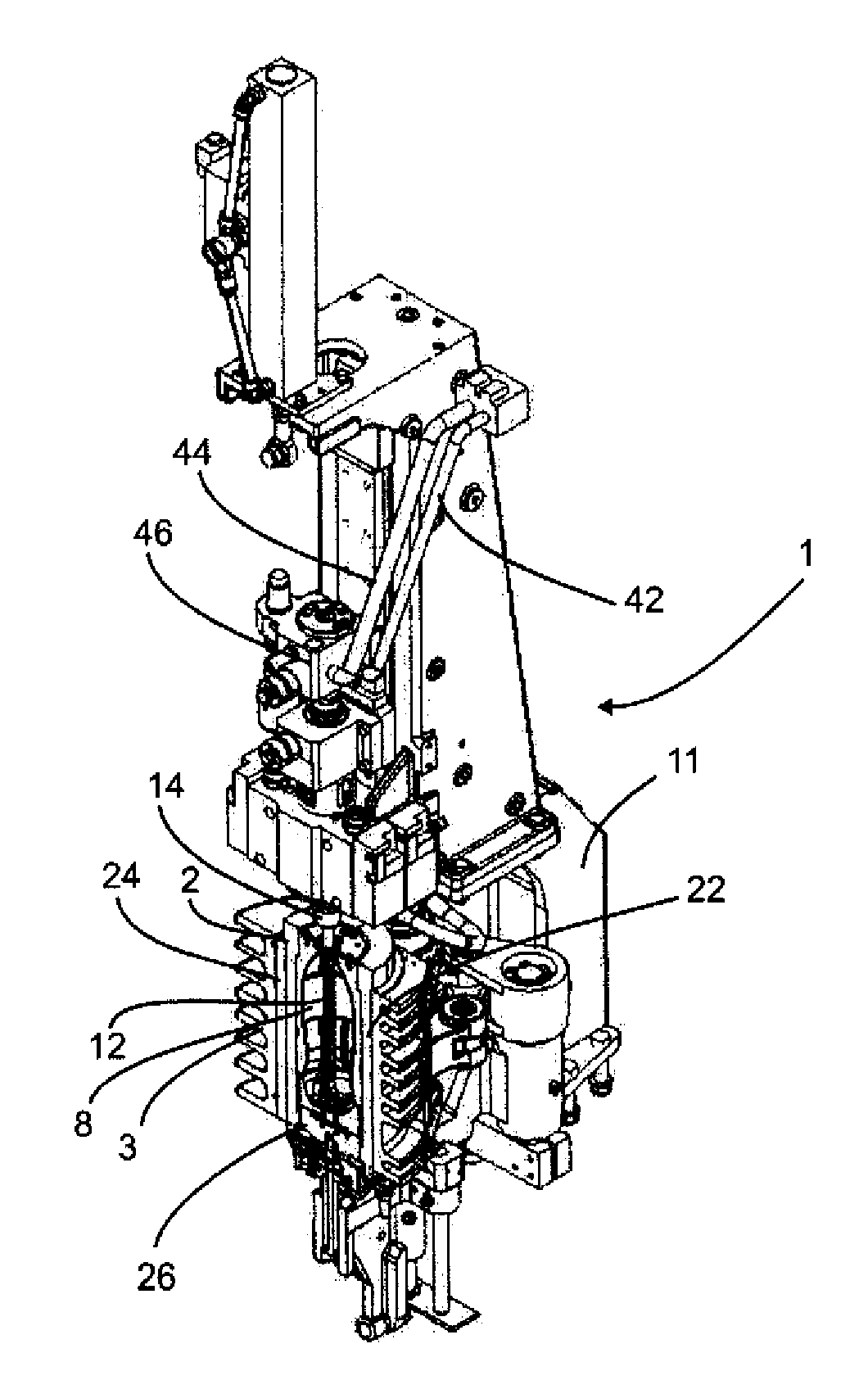

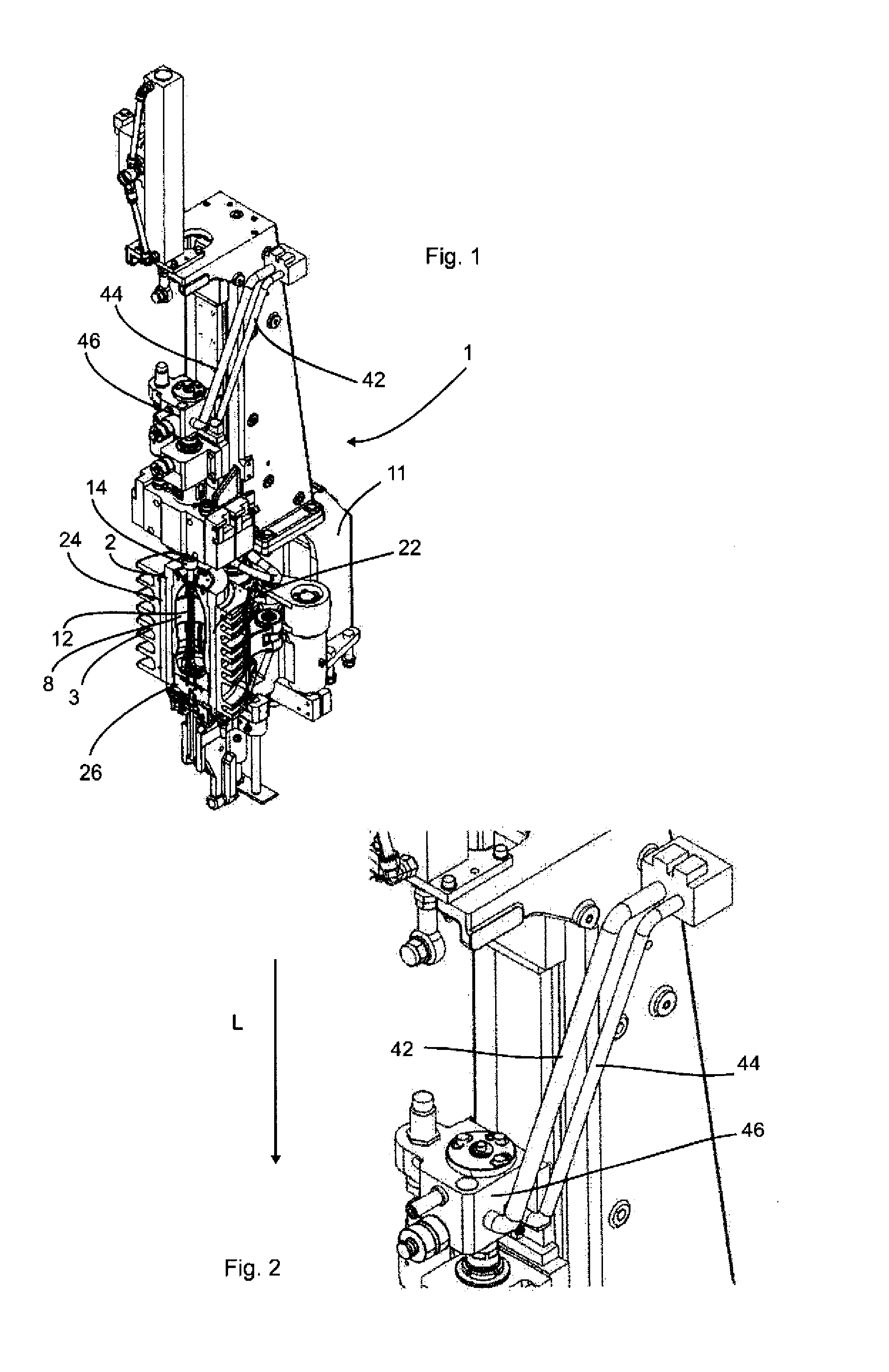

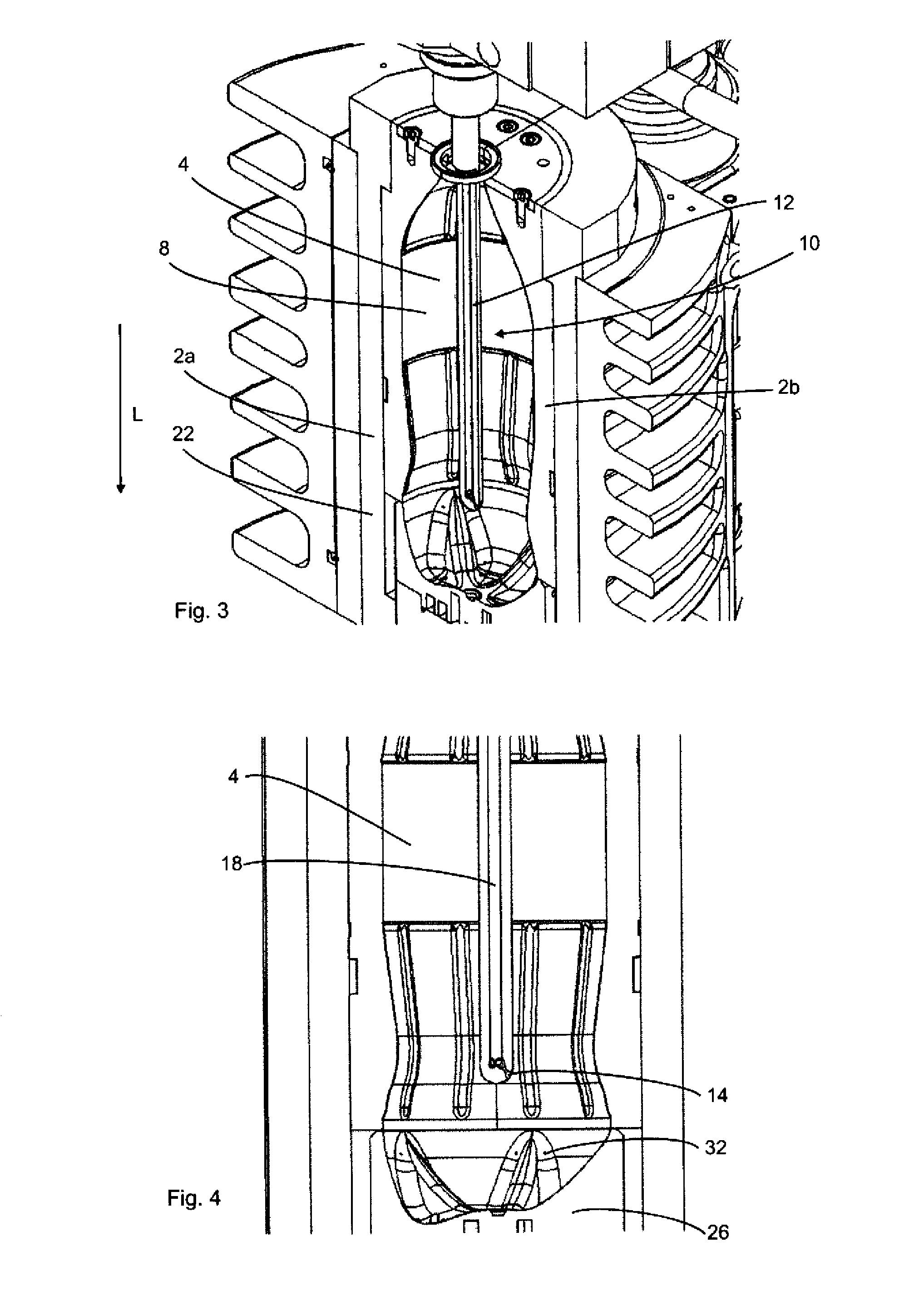

Blow moulding machine with cleaning system

InactiveUS20110037187A1Permit cleaningAvoid corrosion damageMouldsConfectioneryMechanical engineering

Owner:KRONES AG

Method for manufacturing metal surface self-cleaning high-protection film

ActiveCN104213112AGuaranteed protective effectWith self-cleaning functionMetallic material coating processesComposite filmMolybdate

The invention provides a method for manufacturing a metal surface self-cleaning high-protection film. The method comprises two steps of molybdate solution soaking treatment and plant corrosion inhibitor-low-surface-energy material collaborative modification treatment. According to the molybdate solution soaking treatment step, a composite film which is of a specific micro / nano coarse structure, has the good protection effect and is composed of metallic oxides, molybdenum oxide and metal molybdate can be formed on a metal surface, and therefore according to the plant corrosion inhibitor-low-surface-energy material collaborative modification treatment step, efficient green plant corrosion inhibitors can be introduced into the film, and the protection effect can be obviously improved. Due to the hydrophobization effect of the low-surface-energy material on the film, the film has the self-cleaning function, the pollution can be avoided, the probability of direct contact of metal materials and corrosive media can be reduced, and the protection effect of the film can be further improved. The method has the advantages of being environmentally friendly, simple in process, convenient to operate, capable of being easily and industrially produced in a large-scale mode and the like.

Owner:重庆中昆新材料科技有限公司

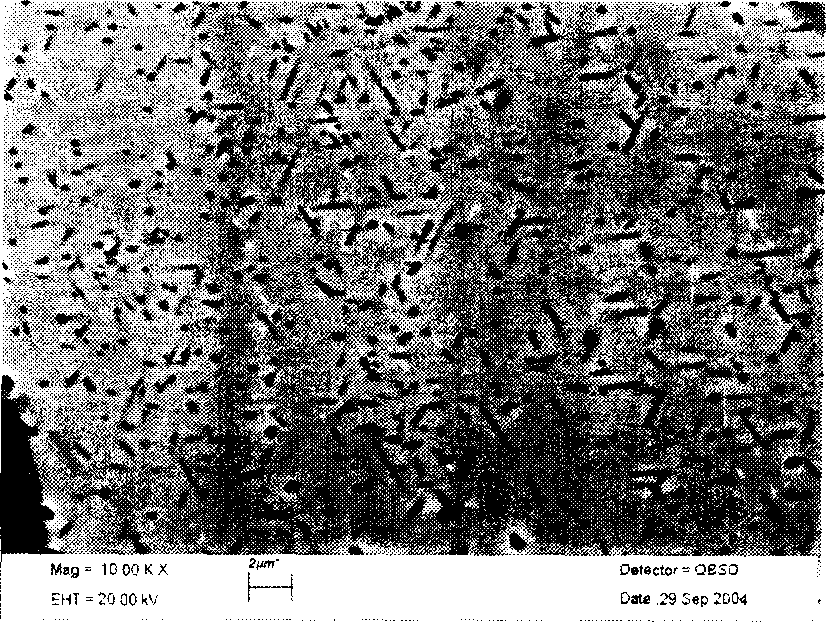

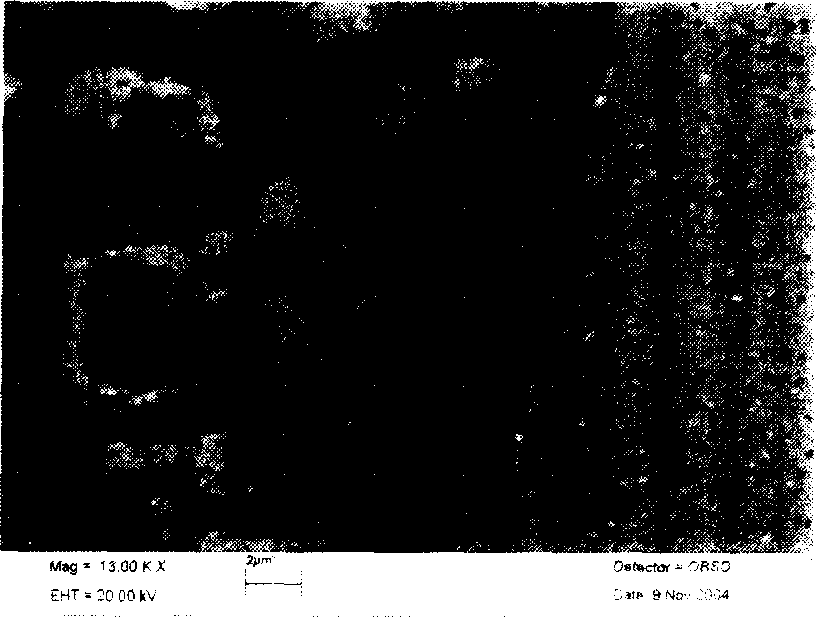

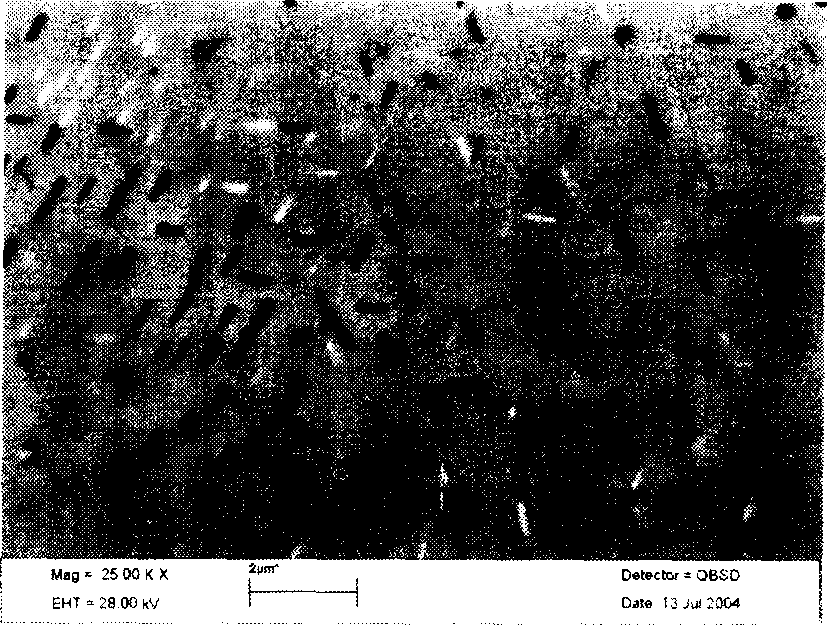

Method for observing microscopic structure of stainless steel

InactiveCN1916597AAvoid formingAvoid corrosion damageSurface/boundary effectPreparing sample for investigationElectrolysisDistilled water

A method for observing microscopic structure of stainless steel includes using alcohol, perchloric acid and so on to prepare electrolytic polishing liquid; polishing prepared test piece; using electrolytic polisher with 23v-40 voltage and 10-30deg.c electrolytic polishing liquid to carry out electrolytic polishing on test piece then washing test piece; placing electrolytic polished test piece into sample chamber of scan electronic microscope and using back scattering electronic detector to observe microstructure of test piece.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

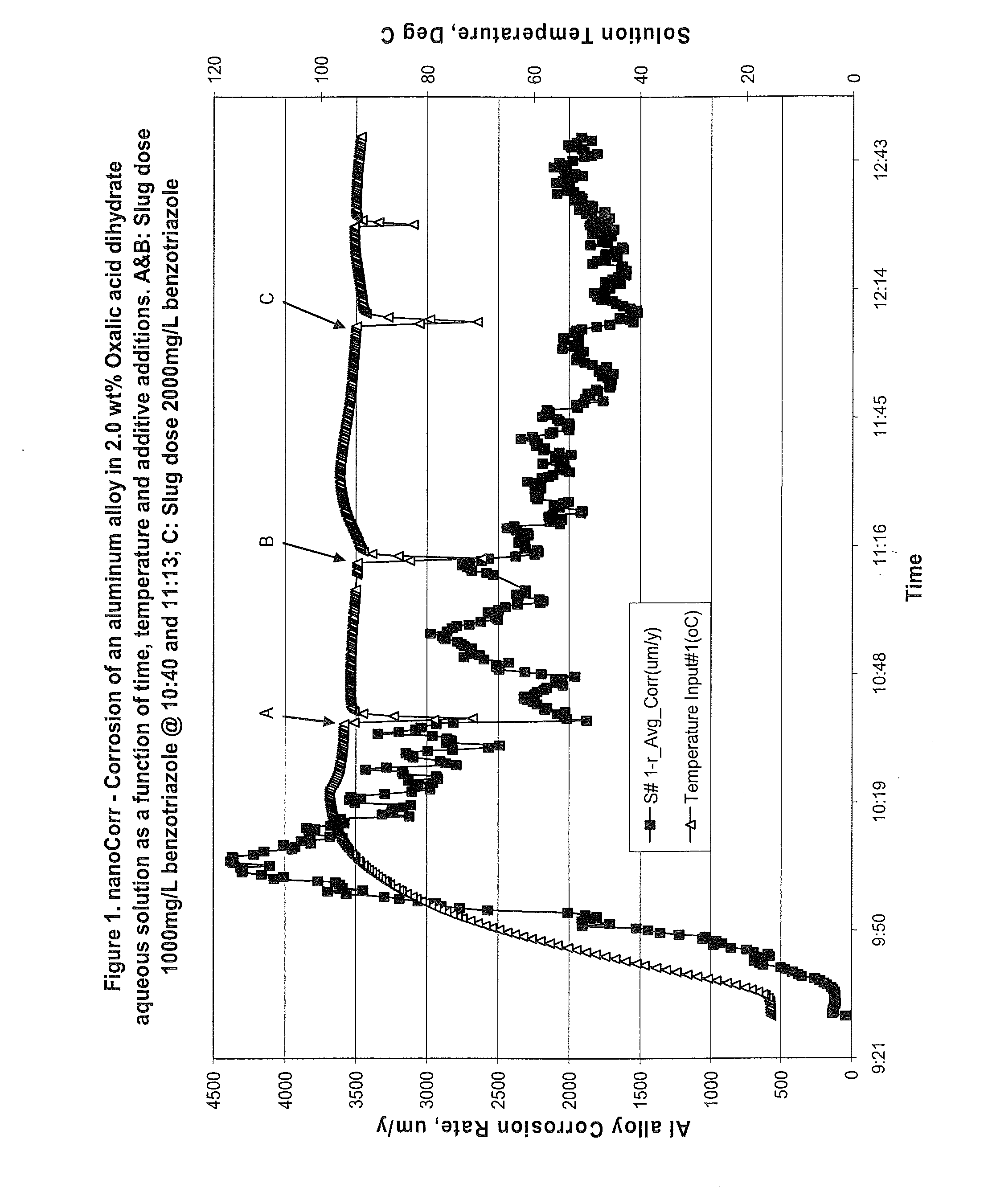

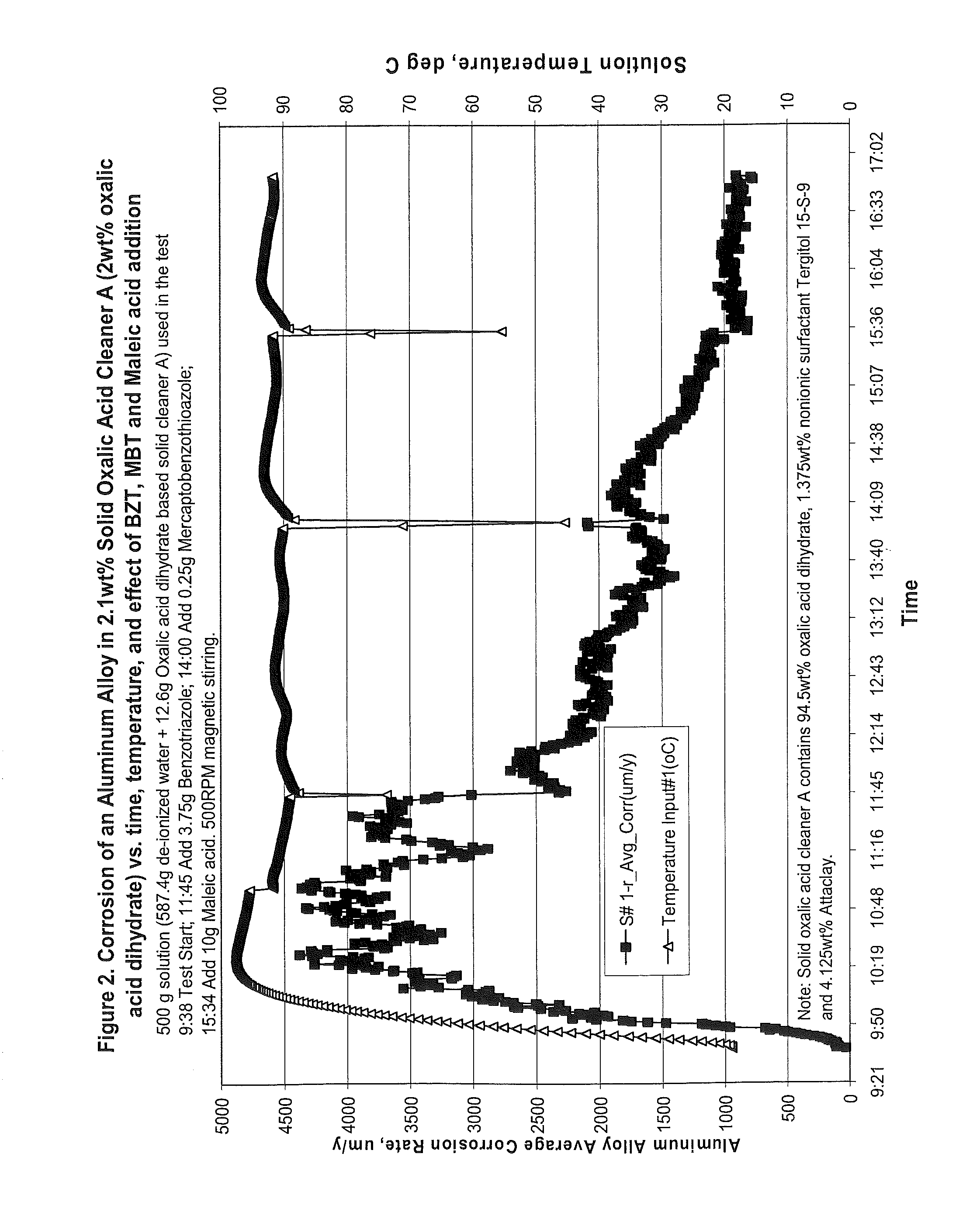

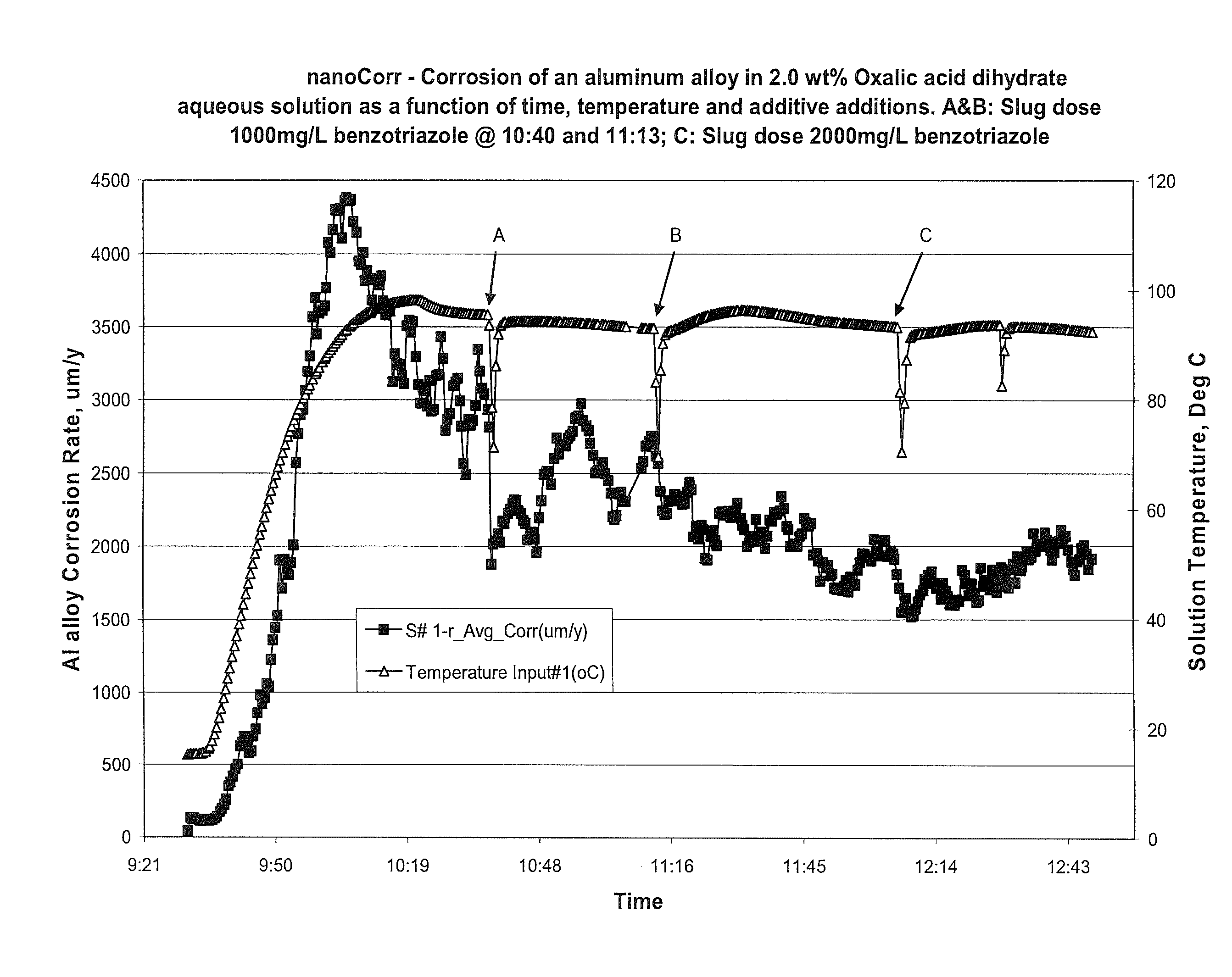

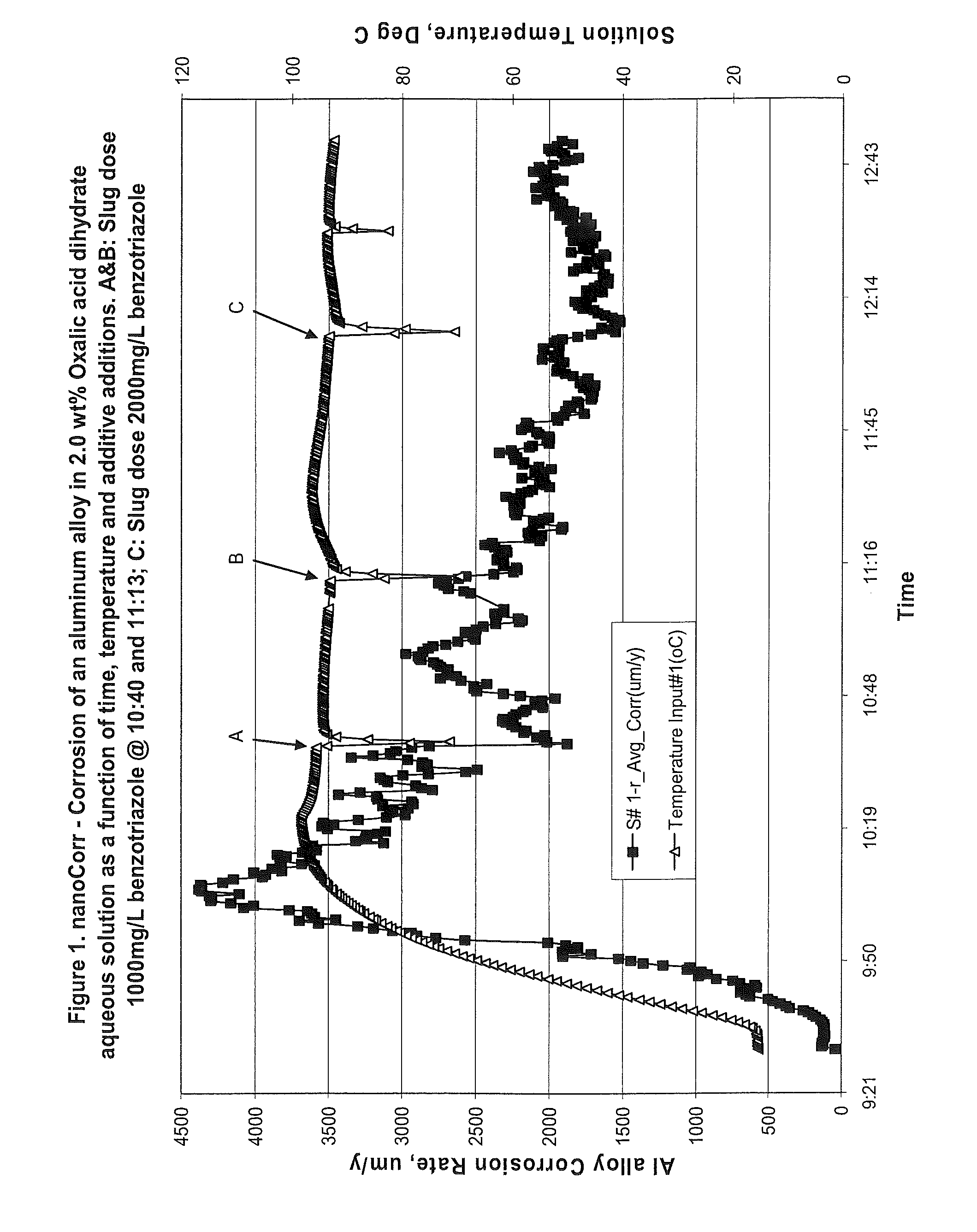

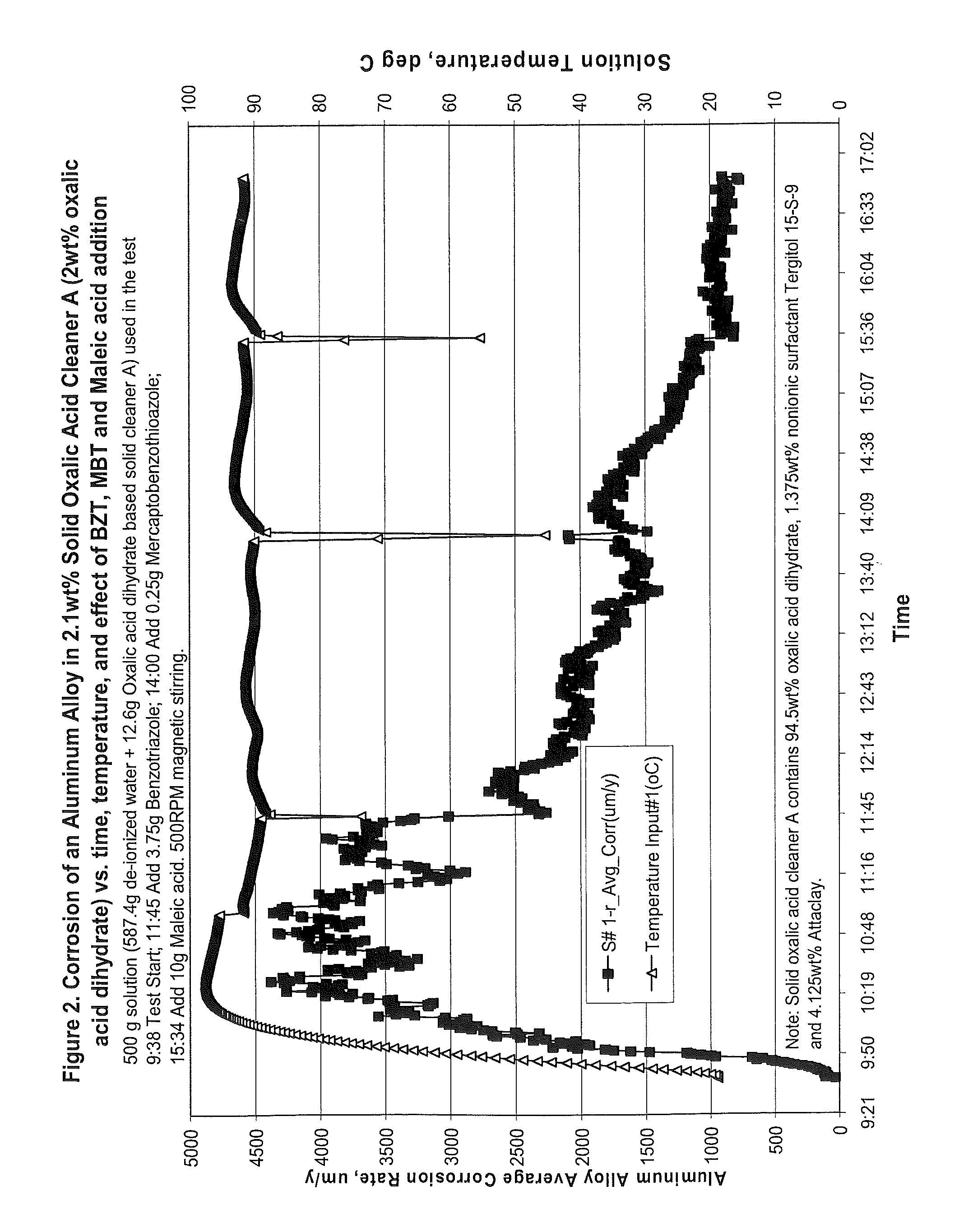

Methods and composition for cleaning a heat transfer system having an aluminum component

InactiveUS20110000505A1Prevent leaching and corrosionReduce heat transferInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsEngineeringHeat transfer fluid

Disclosed herein is a method and treatment system for rapid cleaning and protecting of automotive cooling systems containing controlled atmosphere brazed aluminum heat exchangers. The method and treatment system can optionally include a conditioning (passivating) step. The treatment system can comprise three different parts: (1) cleaner or cleaning solution; (2) conditioner or conditioning solution; and (3) compatible CAB aluminum protective heat transfer fluid.

Owner:PRESTONE PROD CORP

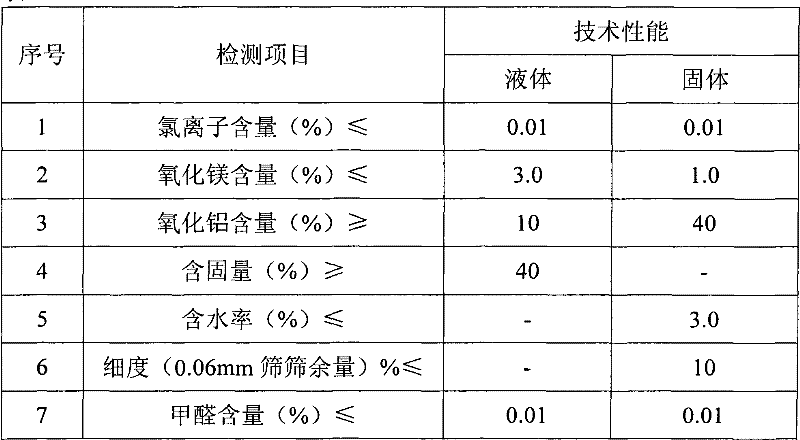

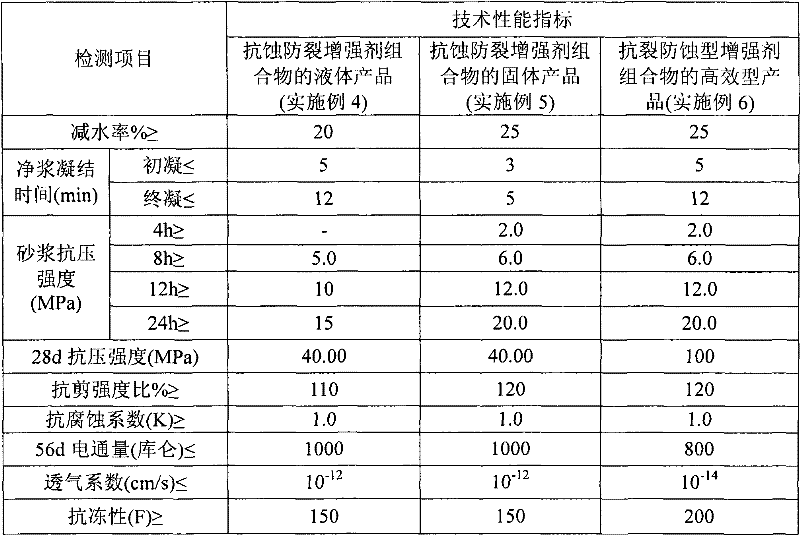

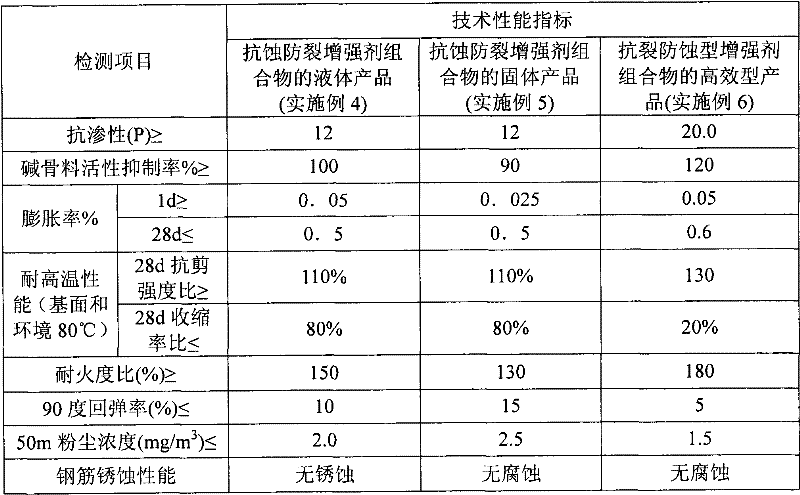

Anti-corrosion anti-cracking reinforcing agent composition and preparation method thereof

The invention relates to an anti-corrosion anti-cracking reinforcing agent composition for concrete, mortar, and net slurry used in injection (first-aid repair) engineering, and a preparation method thereof. The composition comprises the following components on a percentage basis: 2-50% of micro-expansive powder, 5-30% of reinforcing powder, 5-20% of anti-corrosion compacting agents, 10-20% of plasticizers, 1-6% of catalysts, and 10-60% of carriers. The composition of the invention prepares solid and liquid products by processes of melting refinement, polymerization, ball milling, jet milling, complex formulation, and the like, and thus meets construction process requirements of different first-aid repair endurance engineering.

Owner:四川巨星新型材料有限公司

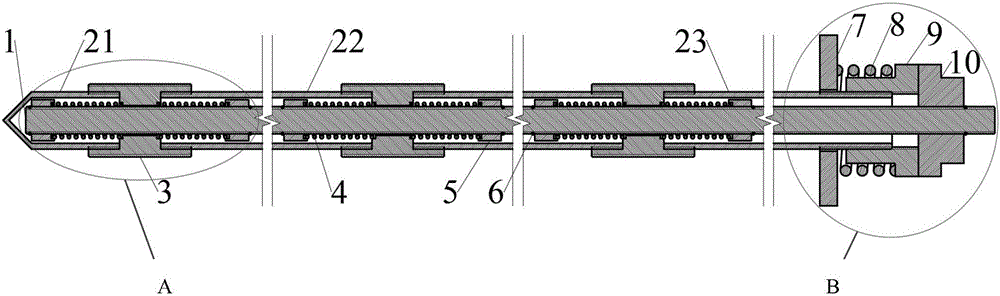

Sectional and modular combined anchor rod capable of resisting large deformation and impact and assembling method of combined anchor rod

ActiveCN105863695AAvoid destructionAvoid breakingBulkheads/pilesAnchoring boltsStructural engineeringLarge deformation

The invention discloses a sectional and modular combined anchor rod capable of resisting large deformation and impact and an assembling method of the combined anchor rod. An outer anchor module of the combined anchor rod comprises an outer anchor end, anchor tubes and anchorage piers serving as connecting parts of the anchor tubes, wherein an anchoring agent is used for bonding the outer anchor module and a drill hole wall, and the function of a total-length bonding type anchor rod is realized; an inner anchor module comprises an outer anchor end, anchorage piers, springs and screw rods, the screw rods compress the inner anchor springs under the traction of the outer anchor end, anchorage force dispersely acts on each anchorage pier, the anchorage piers transfer the acting force to the anchoring agent in a pressure form, and the function of a pressure dispersing type anchor rod is realized; the inner anchor module and the outer anchor module are in parallel before breakage of the anchor tubes, the auxiliary anchoring function on surrounding rock is realized, and buffer yield and timely secondary high-strength supporting on the surrounding rock are realized after breakage of the anchor tubes.

Owner:许国安

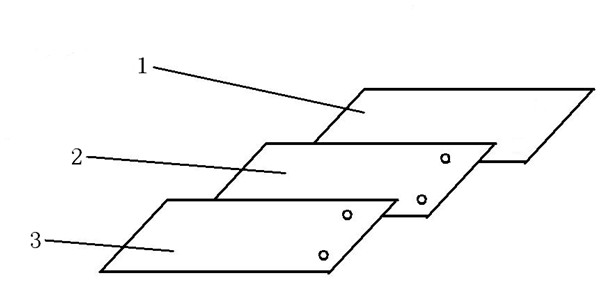

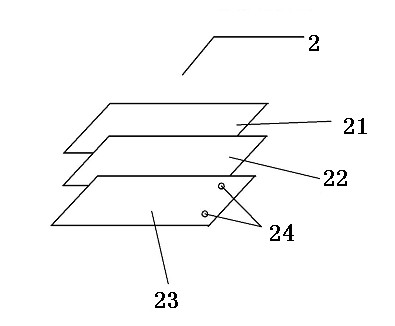

Low-temperature plane waterproof heating floor module and manufacturing method thereof

InactiveCN102383571AHigh heat conversion efficiencyImprove safety performanceLighting and heating apparatusElectric heating systemFiberEpoxy

The invention discloses a low-temperature plane waterproof heating floor module, which comprises an external decorating waterproof surface layer, a heating base material layer and an external decorating waterproof bottom layer which are sequentially overlapped and stuck, wherein the heating base material layer consists of an upper base material layer, a heating layer and a lower base material layer which are sequentially stuck; the heating layer is carbon fiber conducting paper; a pair of electrodes is arranged on the carbon fiber conducting paper; and a pair of conducting holes corresponding to the electrodes is respectively arranged on the lower base material layer and the external decorating waterproof bottom layer. According to the low-temperature plane waterproof heating floor module and a manufacturing method thereof disclosed by the invention, a heating element of the heating floor is subjected to sealing insulated treatment by using tailored epoxy resin, a polyvinyl chloride plastic board and other materials, and thereby corrosive damage of an outside material to the heating element is avoided and durable and safe use of the low-temperature plane waterproof heating floor module disclosed by the invention is ensured.

Owner:SHANGHAI RELI TECH GRP CO LTD

Methods and composition for cleaning a heat transfer system having an aluminum component

InactiveUS8216383B2Prevent leaching and corrosionReduce heat transferInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsEngineeringHeat transfer fluid

Disclosed herein is a method and treatment system for rapid cleaning and protecting of automotive cooling systems containing controlled atmosphere brazed aluminum heat exchangers. The method and treatment system can optionally include a conditioning (passivating) step. The treatment system can comprise three different parts: (1) cleaner or cleaning solution; (2) conditioner or conditioning solution; and (3) compatible CAB aluminum protective heat transfer fluid.

Owner:PRESTONE PROD CORP

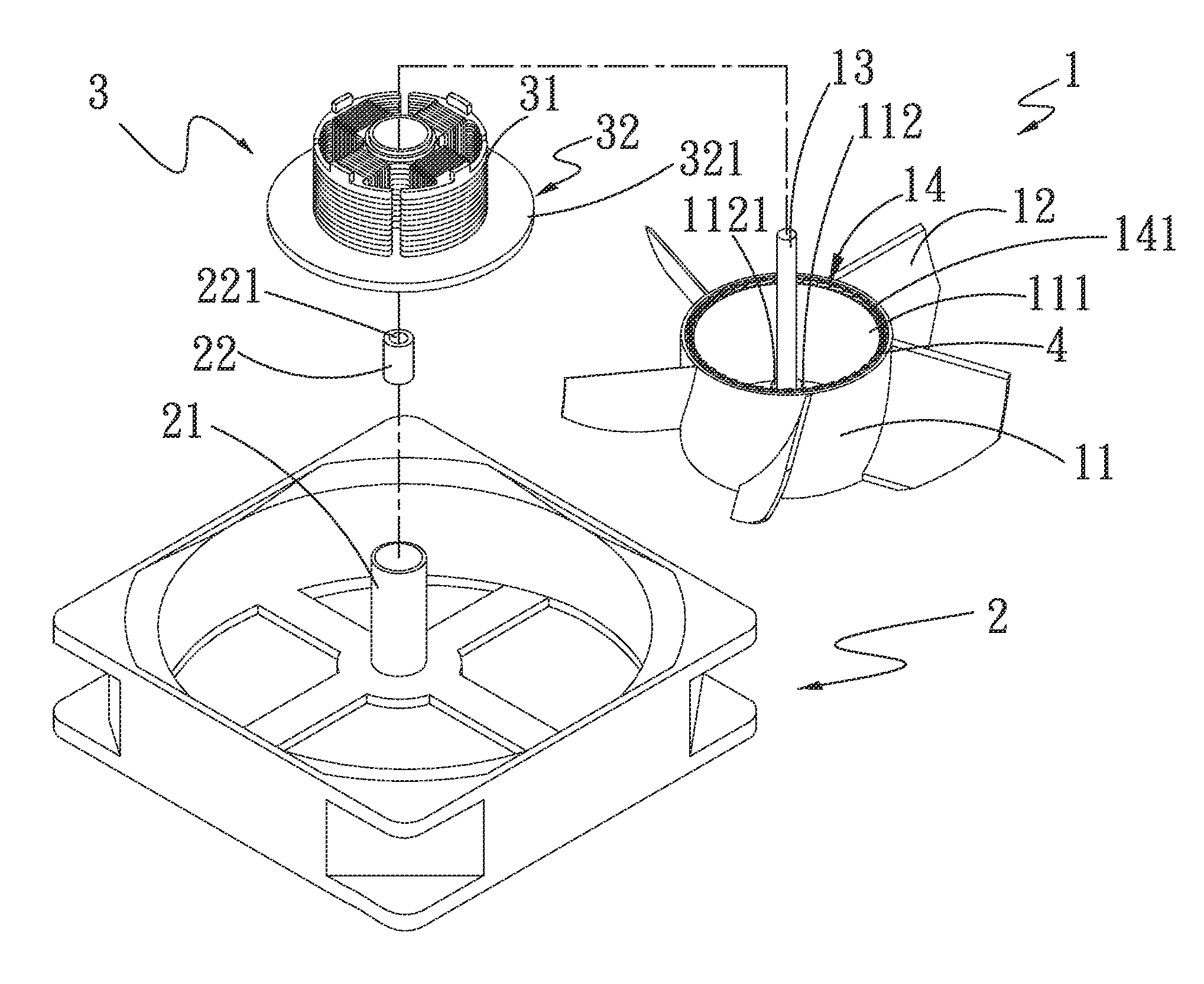

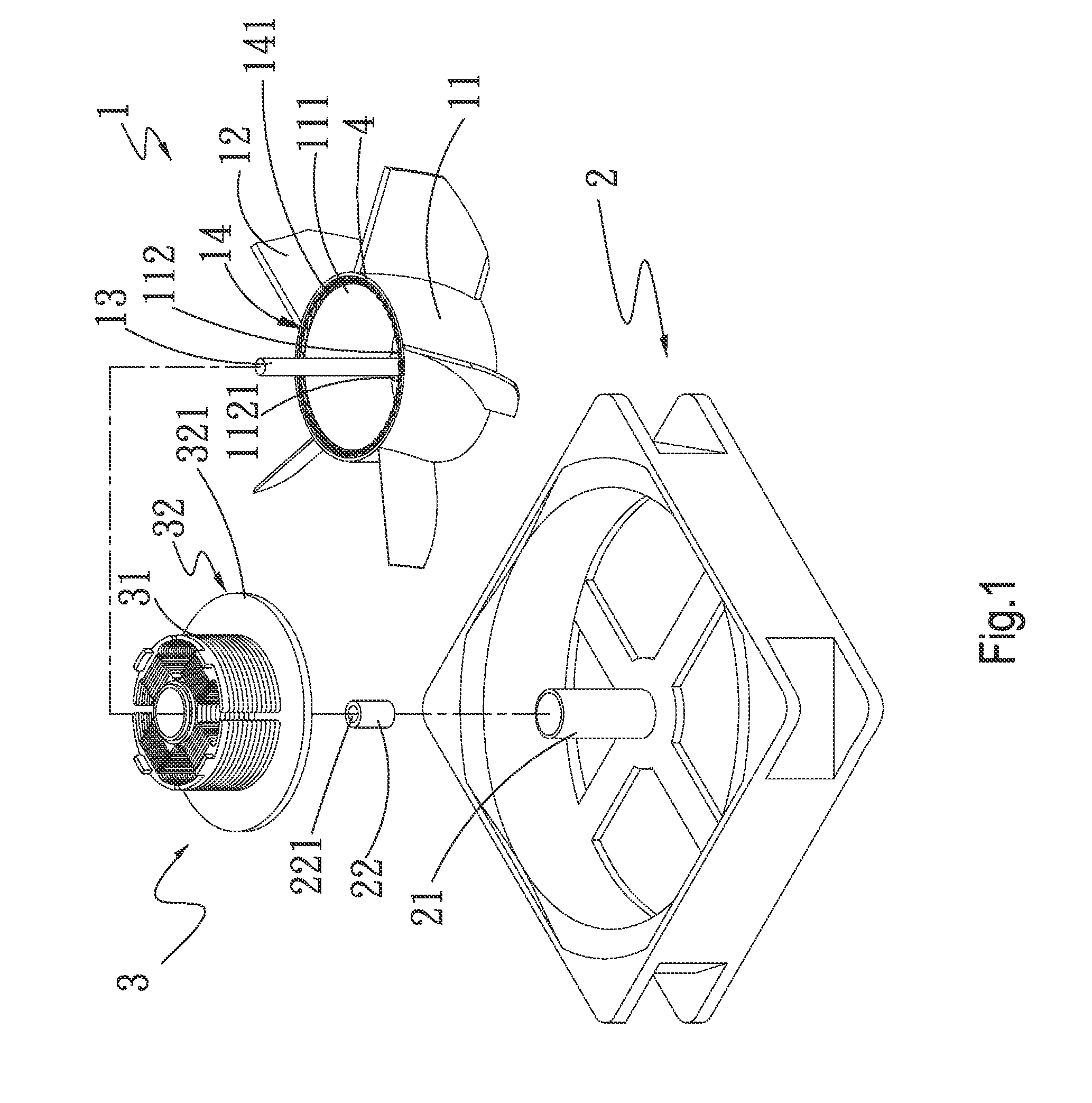

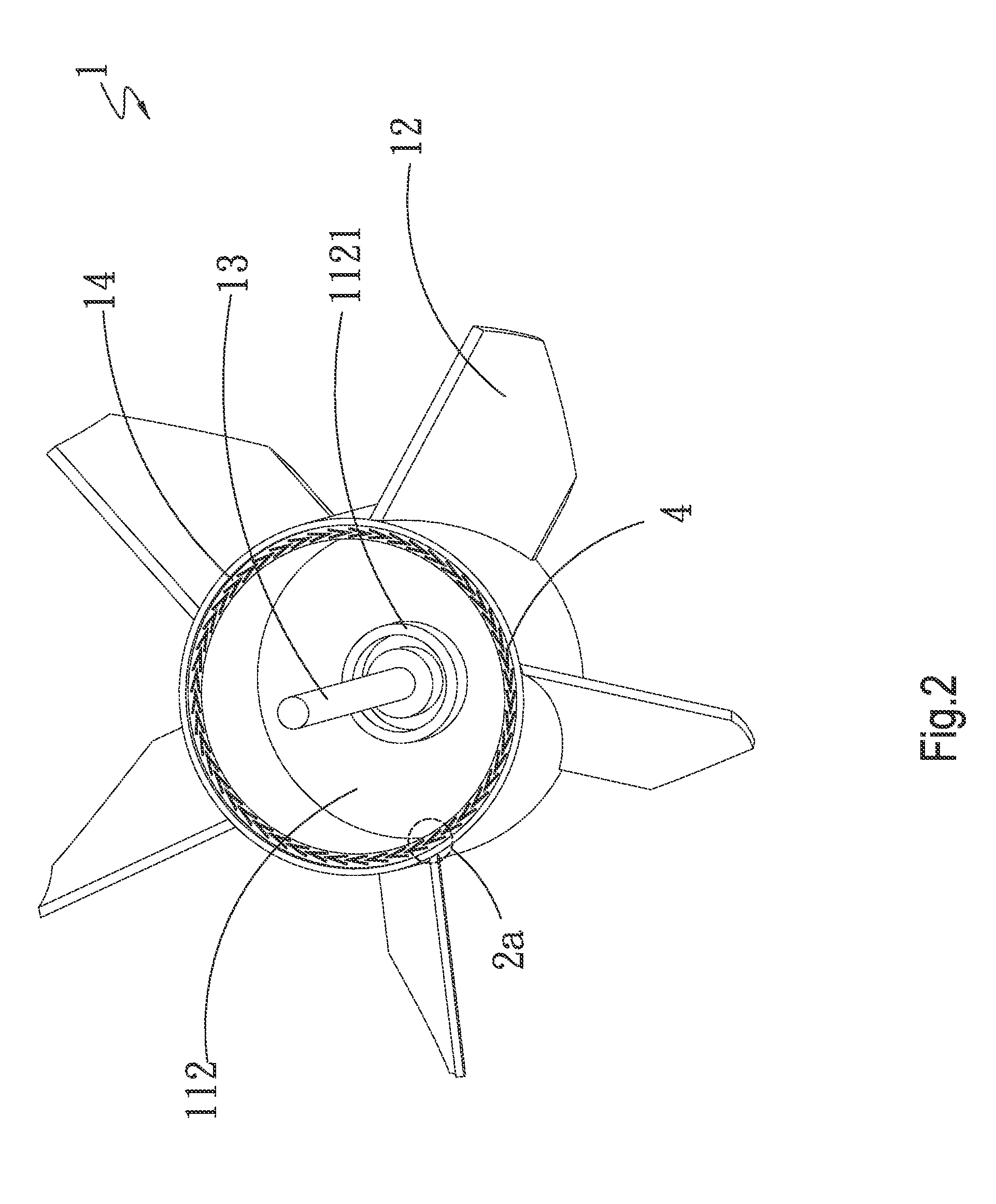

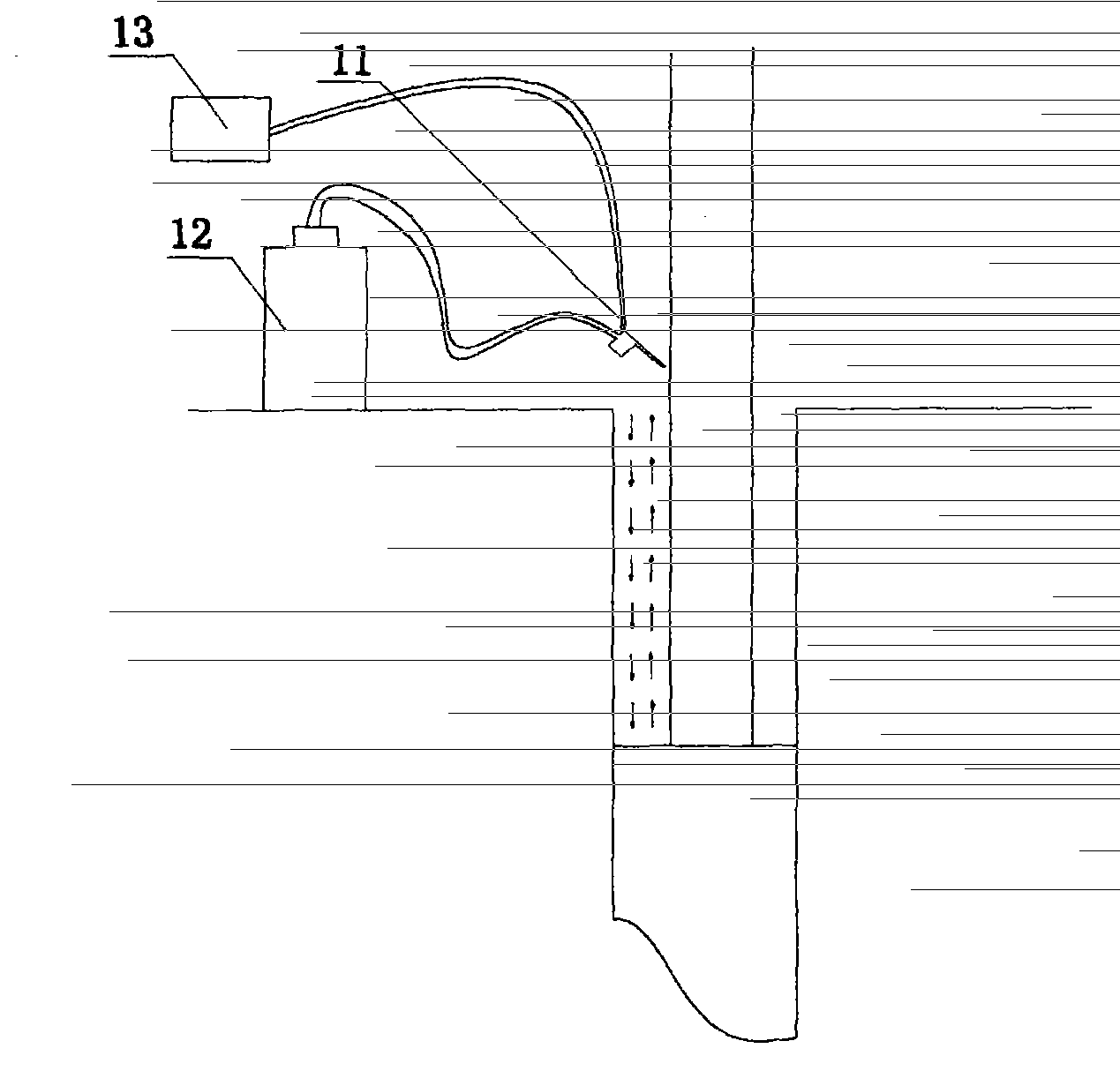

Fan with pressurizing structure

A fan with pressurizing structure includes a rotor having a main body, blades spaced on the main body, a magnetic body annularly mounted in the main body, and a shaft axially connected to an inner side of the main body; a frame having a sleeve and at least one bearing rotatably received in the sleeve, and an opposing end of the shaft being inserted into the bearing; a stator assembly fitted around the sleeve and including silicon steel plates and a base plate; and a plurality of first pressurizing sections selectively provided on one of the base plate and an end face of the magnetic body. With the first pressurizing sections, deposition of moisture and salt fog in the sleeve and the rotor can be prevented to avoid corroded and damaged bearing and rotor shaft, and the service life of the whole fan is increased.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

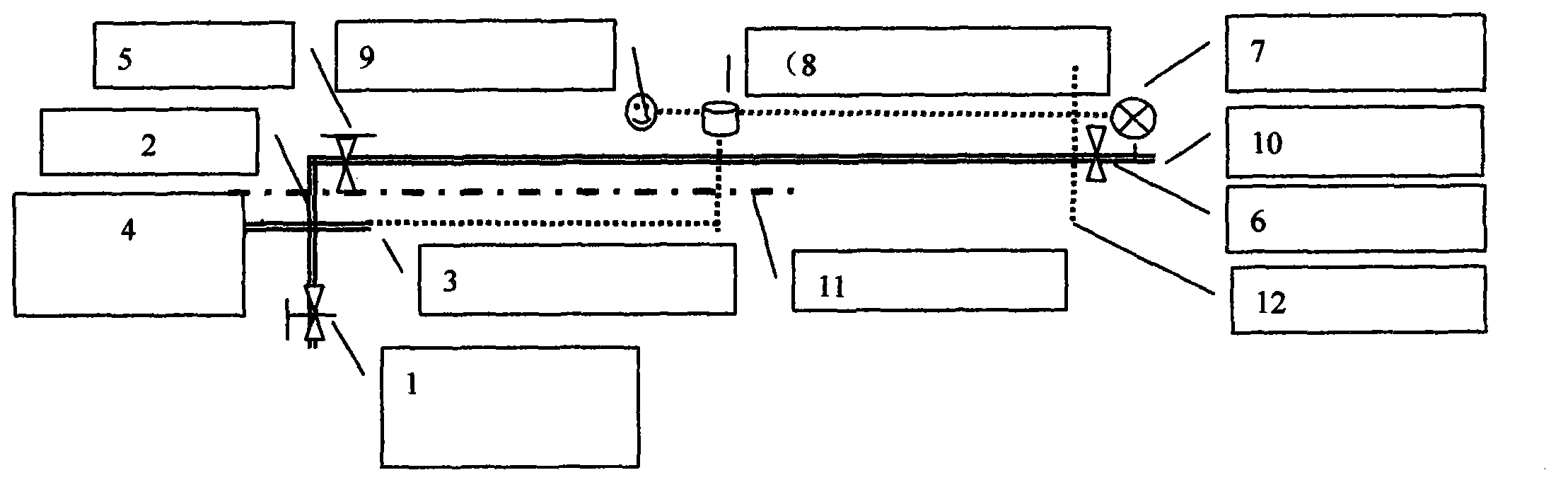

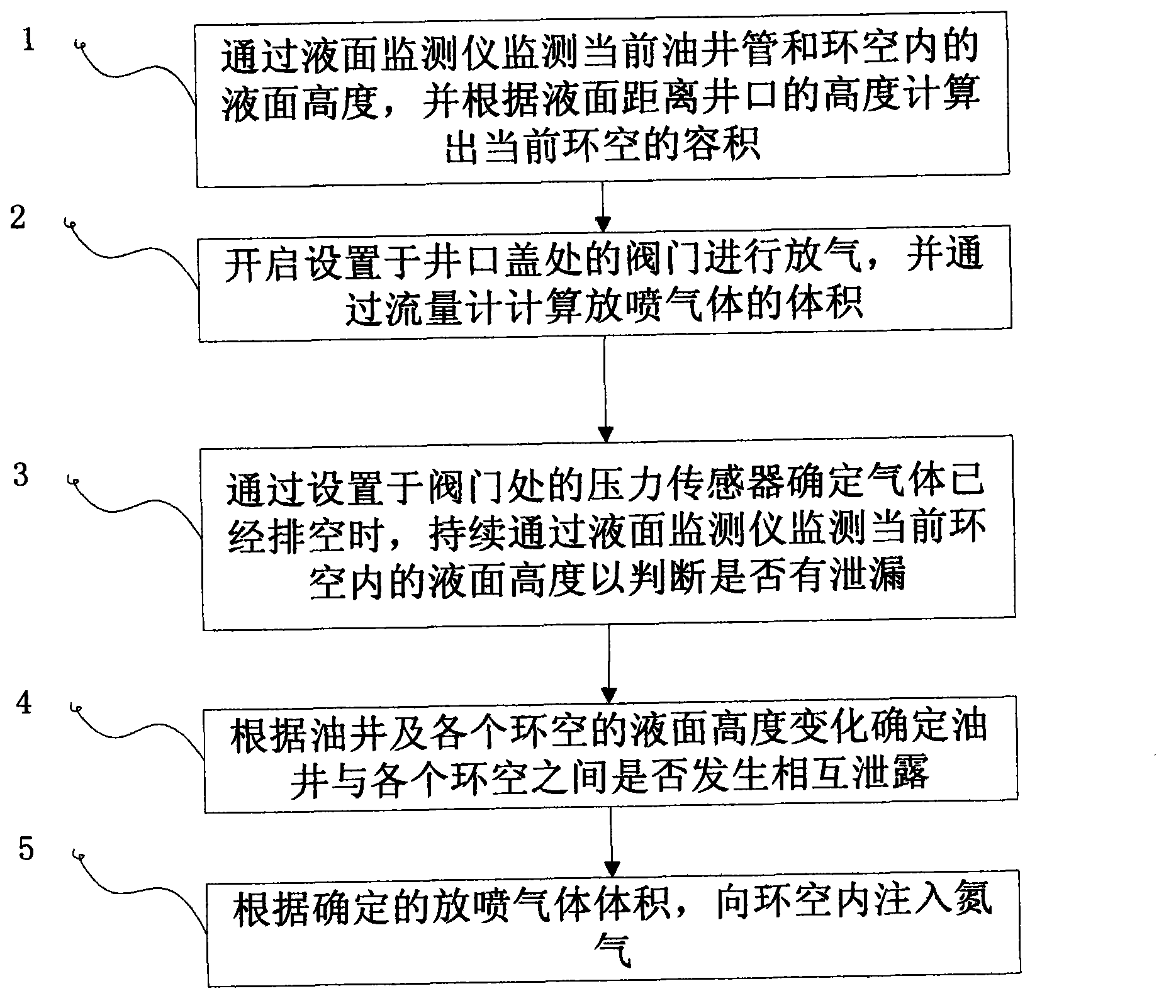

Sustained casing pressure diagnosis device and method

ActiveCN103726834AAvoid corrosion damageSimple structureSurveyConstructionsDiagnosis methodsEngineering

The invention provides a sustained casing pressure diagnosis device and method. The sustained casing pressure diagnosis device comprises a liquid level monitor for monitoring the liquid level in a sustained casing, a pressure sensor for monitoring pressure, and a flow meter for monitoring the blowout flow. A four-way joint is arranged at the position of a surface casing pressure corker and connected with a transmitting gun for monitoring the liquid level in the sustained casing, the pressure sensor for monitoring pressure and a high-pressure pipeline valve for gas blowout, and the flow meter and the pressure sensor are arranged on the high-pressure pipeline valve. The sustained casing pressure diagnosis method includes the steps of firstly, monitoring the current height of the liquid level in the sustained casing through the liquid level monitor, and calculating the current volume of the sustained casing according to the height between the liquid level and the well mouth; secondly, opening the high-pressure pipeline valve on the four-way joint of the sustained casing to conduct blowout, and calculating the volume of blowout gas through the flow meter; thirdly, monitoring the change between the pressure existing during blowout and pressure existing after blowout through the pressure sensor arranged on the high-pressure pipeline valve, and continuing to monitor the current height of the liquid level in the sustained casing through the liquid level monitor so as to judge whether leakage happens to the sustained casing or not.

Owner:SICHUAN GREDIS PETROLEUM TECH CO LTD

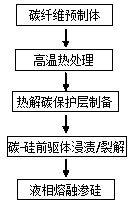

Carbon-silicon carbide double-ingredient substrate carbon fiber composite material as well as preparation method and application thereof

ActiveCN108516852AEvenly distributedImprove frictional stabilityBraking discsAdditive ingredientPorous carbon

The invention discloses a carbon-silicon carbide double-ingredient substrate carbon fiber composite material as well as a preparation method and application thereof. The method comprises the followingsteps of (1) performing weaving and high-temperature heat treatment on a carbon fiber prefabricated body; (2) preparing a porous carbon / carbon blank body; (3) introducing carbon elements and siliconelements into the carbon / carbon blank body in an impregnating mode; after the soaking and pyrolysis circulation period, obtaining a Cf / Cm-Sim porous intermediate; (4) performing embedded fusion Si seeping on the Cf / Cm-Sim porous intermediate to obtain a Cf / Cm-SiCm composite material. The inside SiC distribution of the composite is uniform; the residue Si content is 1.2 to 3.3 percent; the bendingintensity is 236 to 275MPa; the compression intensity is 322 to 364MPa; the dynamic friction coefficient is 0.32 to 0.48; the mechanical / friction performance is excellent; the thermal stability and the environment applicability are high; the material is applicable to the manufacturing of automobile braking discs / sheets.

Owner:湖南金羽先进材料有限公司

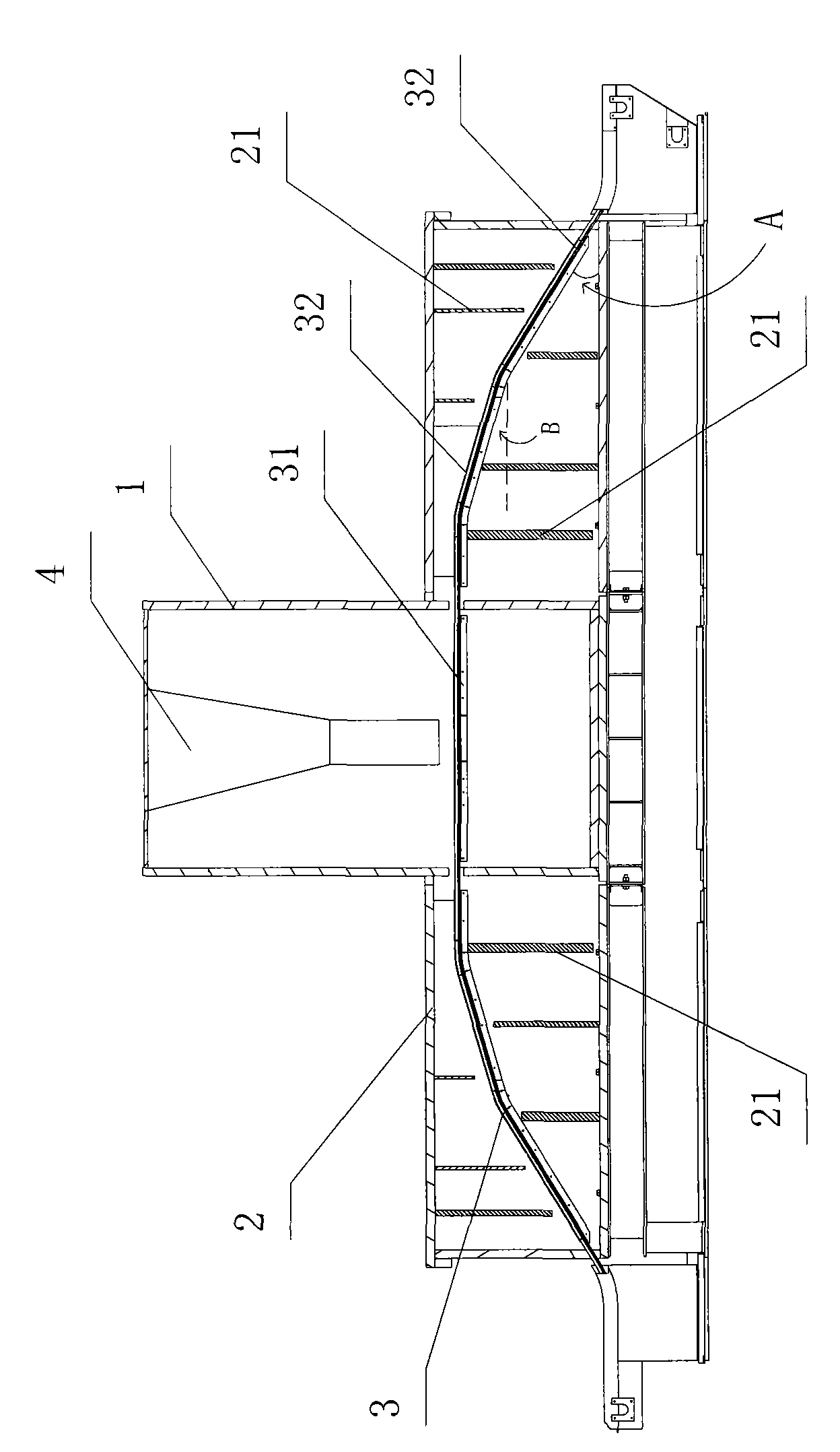

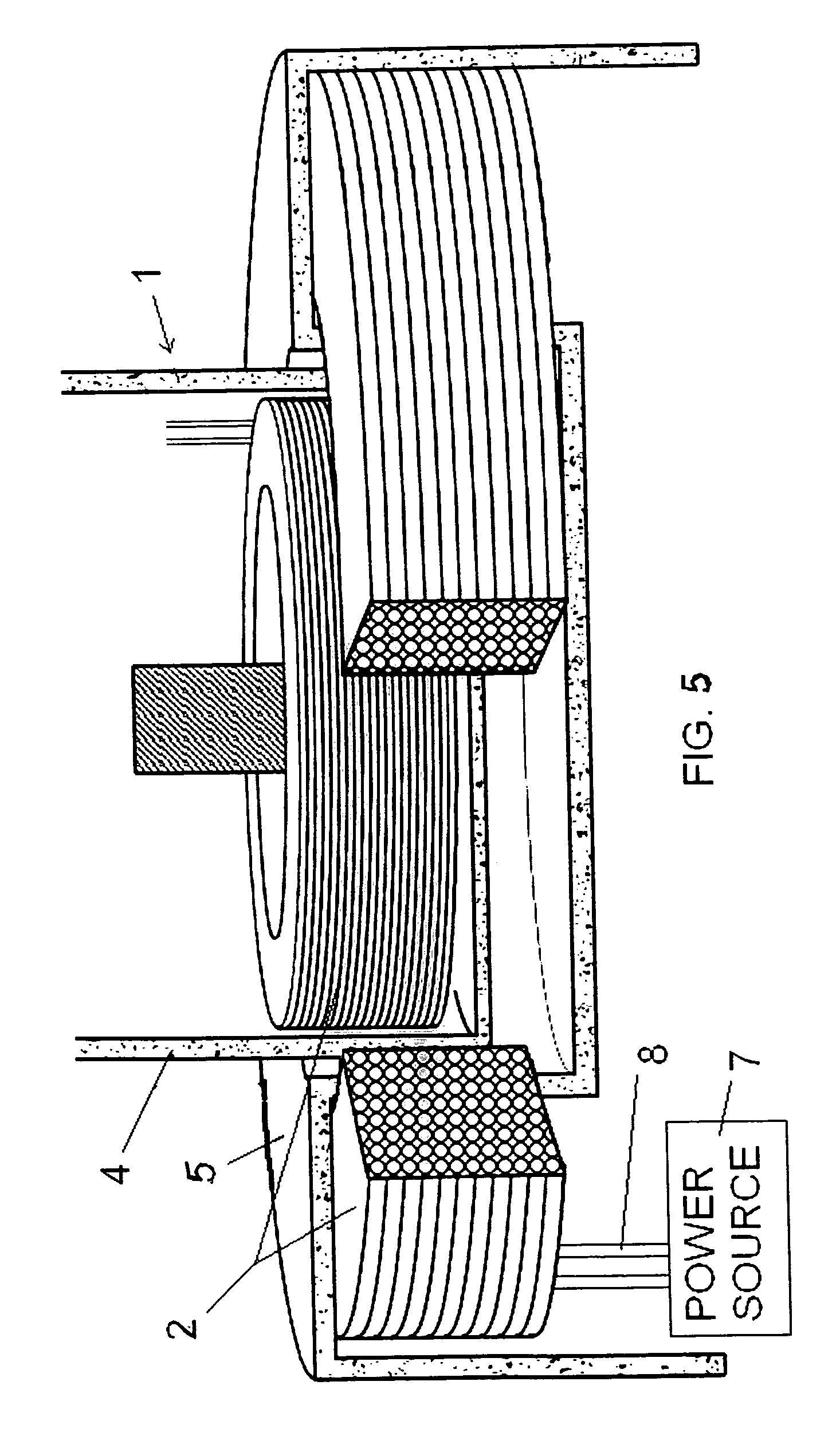

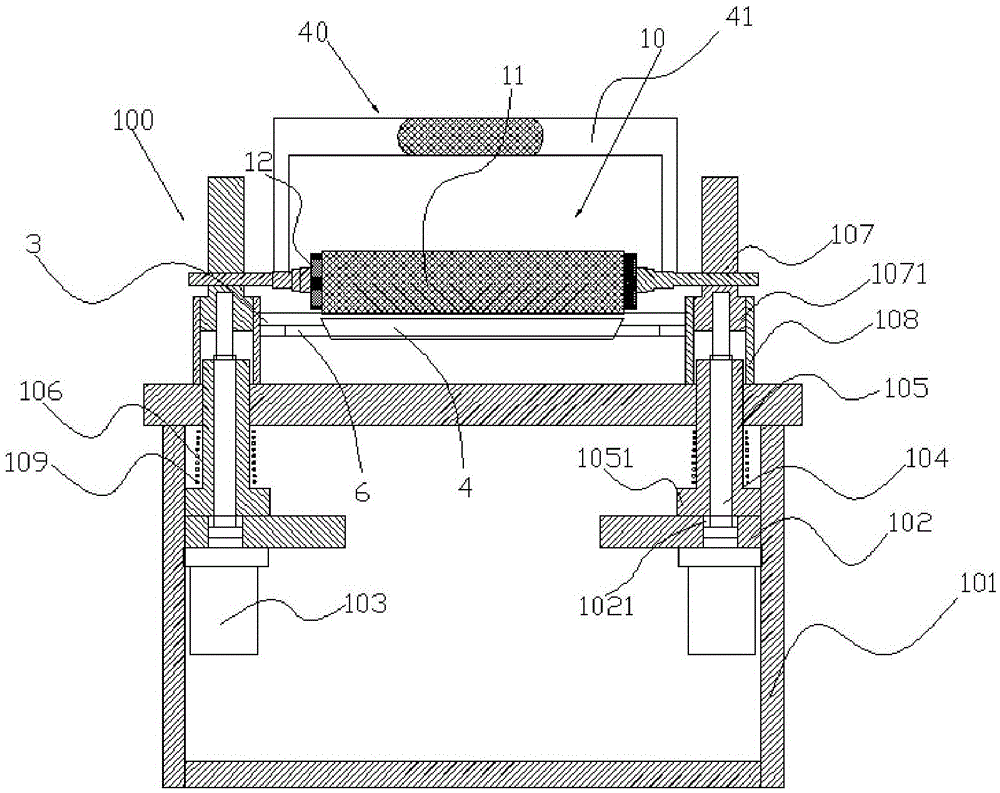

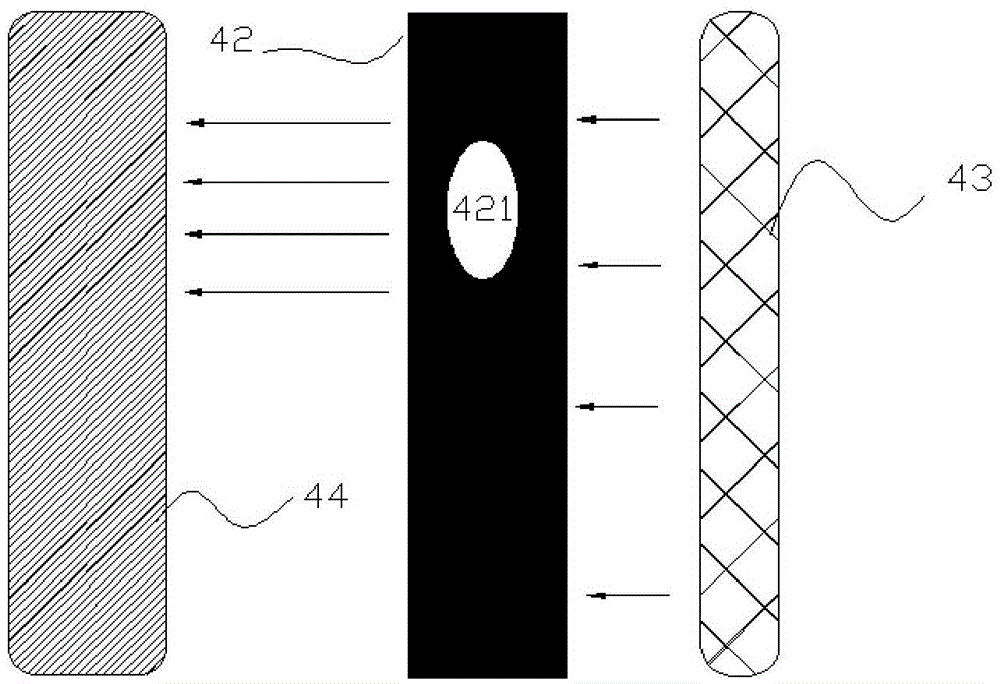

Tire rubber sheet electron radiation crosslinking pretreatment device and method

ActiveCN102092111AStrong penetrating powerIncrease the number of reflectionsTyresUltrasound attenuationPretreatment method

The invention discloses a tire rubber sheet electron radiation crosslinking pretreatment device and a tire rubber sheet electron radiation crosslinking pretreatment method. A conveyor belt used for realizing an arc-shaped conveying track is arranged in a shielding room; based on the ray absorption by the interior wall of the shielding room, the ratio of attenuation generated by multiple times of refraction is increased by increasing the reflection times of rays, and thus, the rays can be absorbed to a maximum degree and the ray leakage can be reduced so as not to pollute the environment and hurt the body the operators. The device mainly comprises a radiation room, the shielding room and the conveyor belt for conveying rubber sheets, wherein an electron accelerator is arranged in the radiation room and above the conveyor belt, and the conveyor belt runs through the radiation room and the shielding room. Ray absorbing plates are adhered on all of the inner walls of the radiation room and the shielding room. The conveyor belt comprises a horizontal conveying part arranged in the radiation room and below the electron accelerator and an oblique conveying part arranged in the shielding room. The oblique conveying part has at least one group of left and right symmetric and vertically bent continuous conveying section.

Owner:MESNAC

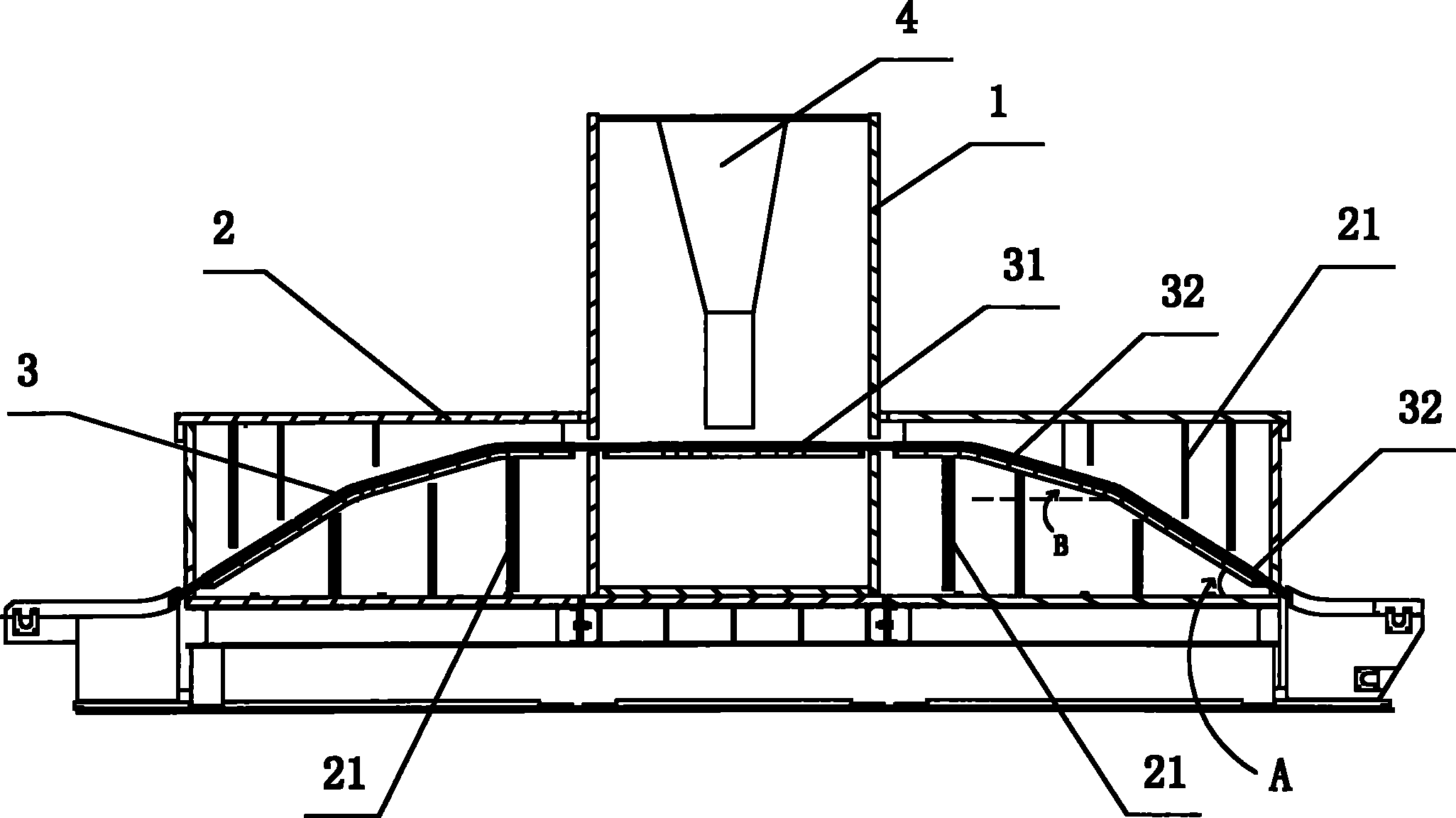

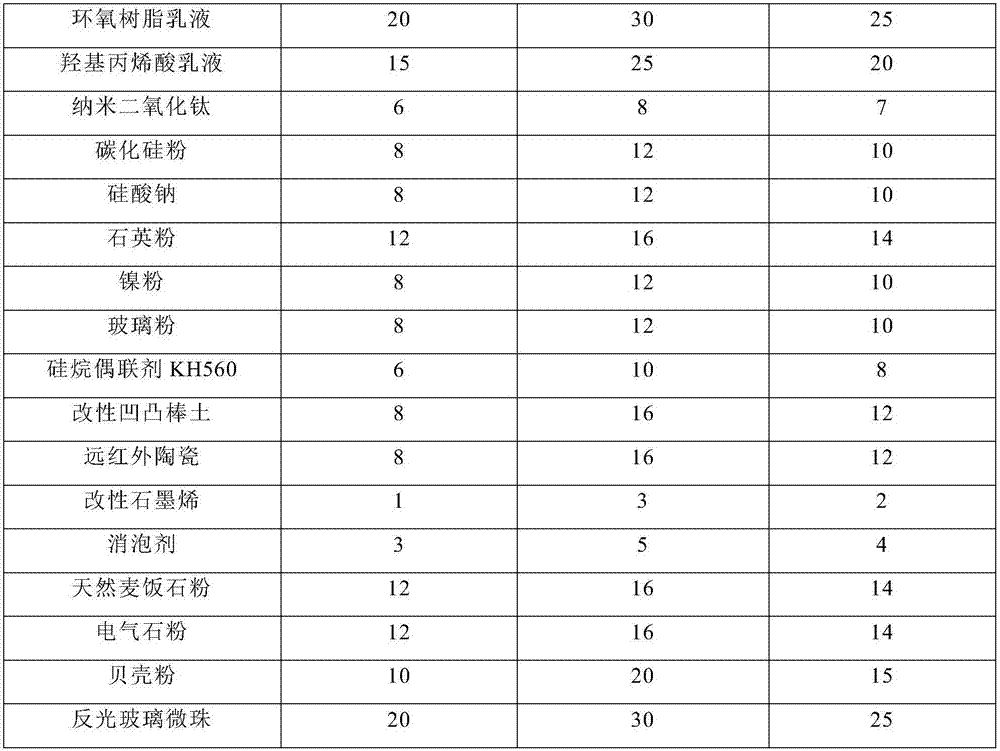

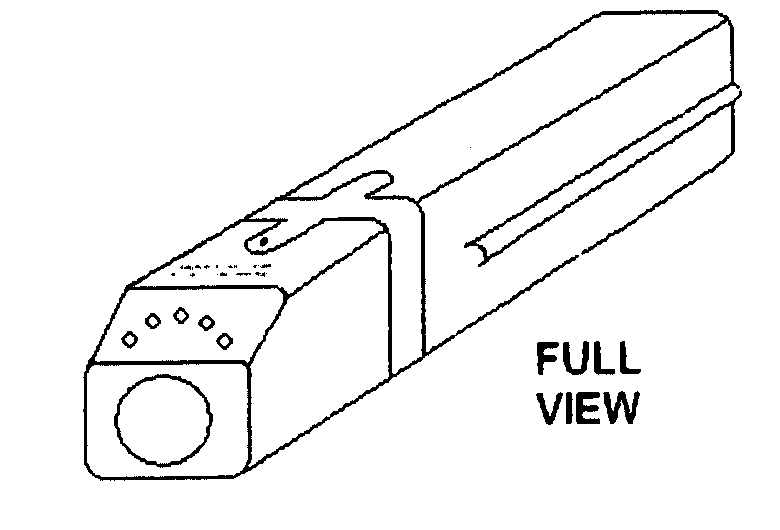

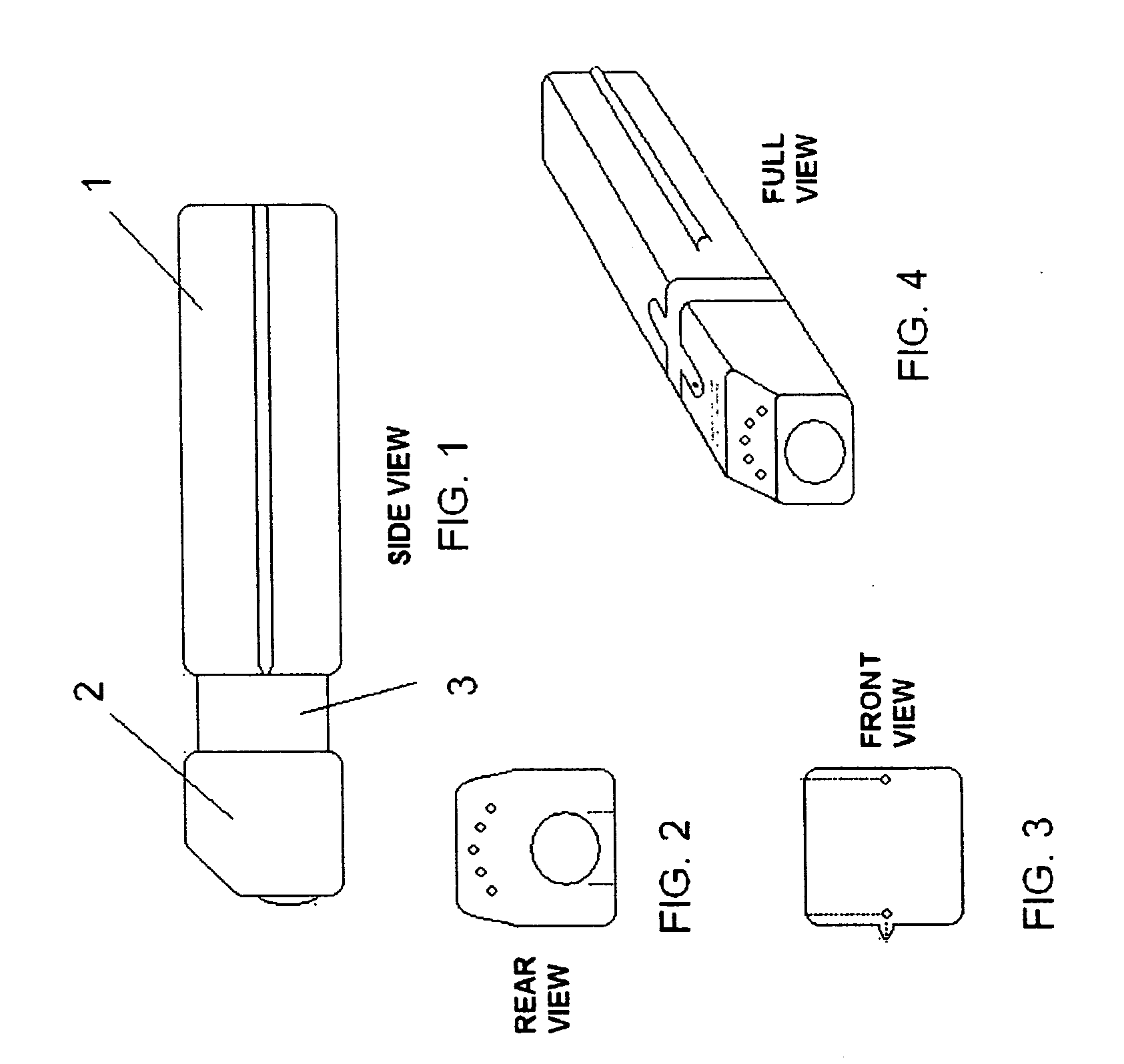

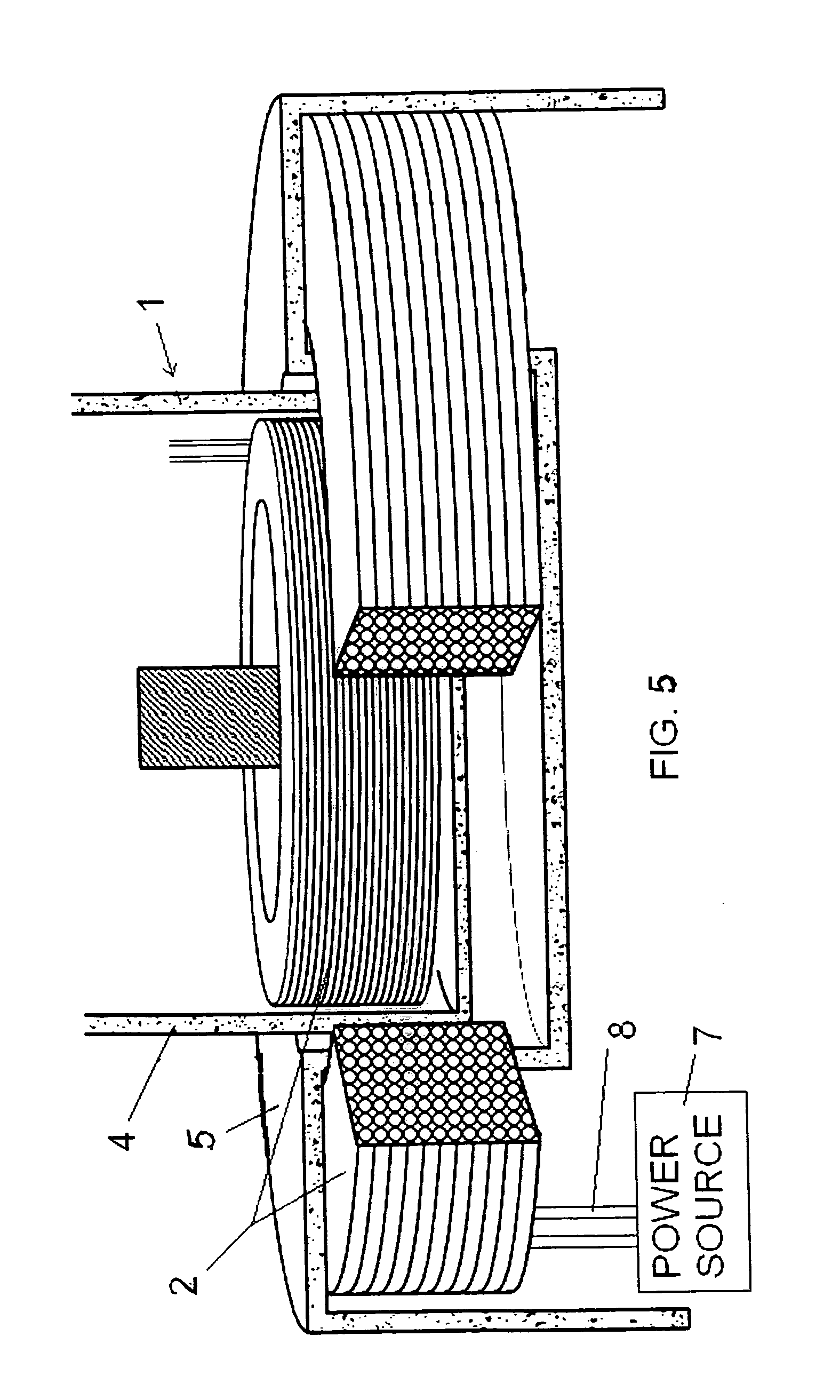

Bi-directional rechargeable/replaceable induction power pack and method

ActiveUS7654683B2Avoid corrosion damageAvoid water damageBattery isolationWith electric batteriesHigh humidityUnderwater

A bi-directional rechargeable / replaceable induction power pack and method employing sealed induction coils to power an electrical device underwater, in liquids, or in high humidity conditions.

Owner:VUTILITI INC

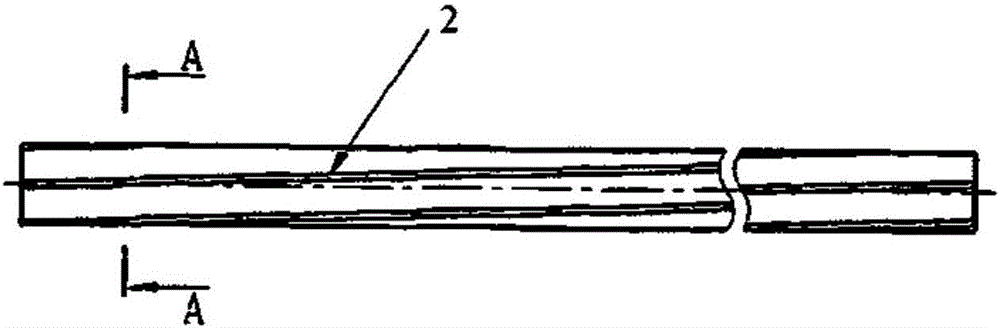

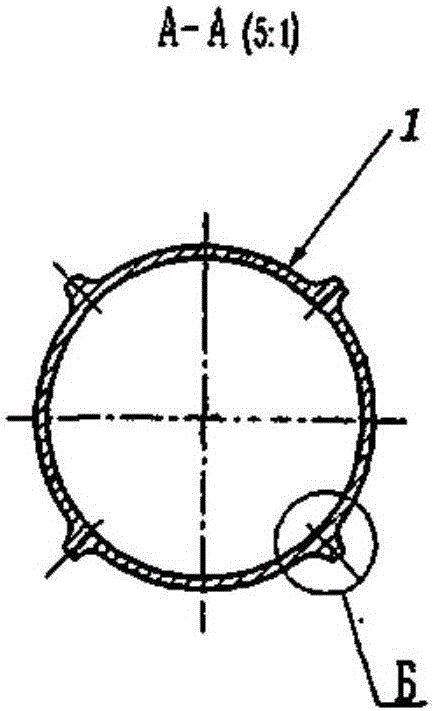

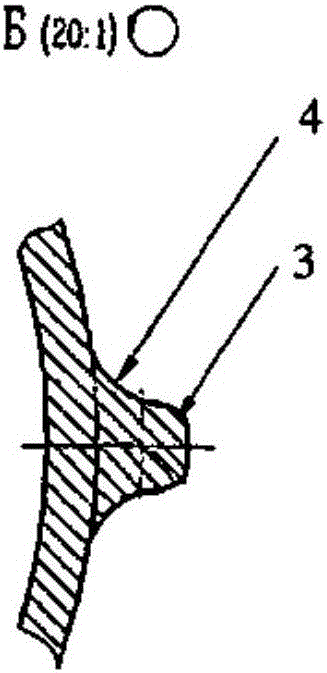

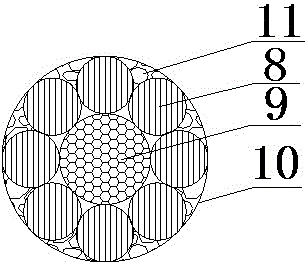

Fuel rod cladding, fuel rod and fuel assembly

ActiveCN105723465AImprove performanceAvoid corrosion damageFuel elementsNuclear energy generationNuclear engineeringLong term durability

The invention relates to the field of nuclear engineering and can be used in the manufacture of fuel rods and fuel assemblies for heavy liquid metal cooled reactors, and also in the manufacture of fuel rod simulators for use in irradiation devices designed to test the operability of real fuel assemblies. The present cladding of a fuel rod for a heavy liquid metal cooled reactor is in the form of a weldless tubular element with helically-coiled fins disposed on the outer surface of said element, which is made from a ferritic-martensitic chromium-silicon steel with a minimum ferrite grain size of 7 on the GOST 5639 scale, wherein each fin has an opening angle of from 22 to 40 DEG C (preferably from 30 to 40 DEG C) and the cross-section of the fin is in the shape of a trapezoid with rounded corners at the top of the trapezoid and smooth corners at the base of the trapezoid. Also disclosed are a fuel rod comprising the above cladding, and a fuel assembly. The technical result of the invention is an improvement in the performance characteristics of fuel rods and assemblies as a result of the long-term resistance of the cladding in the environment of a heavy liquid metal coolant such as lead or a eutectic of lead and bismuth.

Owner:JOINT CO AKME ENG

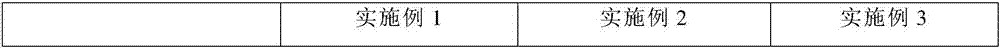

Wear-resistant and corrosion-resistant waterproof coating for environmental protection equipment

InactiveCN107573811AImprove compactnessHigh strengthAnti-corrosive paintsEpoxy resin coatingsWear resistantFar infrared

The invention relates to a wear-resistant and corrosion-resistant waterproof coating for environmental protection equipment. The wear-resistant and corrosion-resistant waterproof coating has the advantages of having good acid and alkali corrosion resistance, oil and water resistance, scratch resistance and wear resistance, effectively avoiding the corrosion damage on the outer surface of the equipment, reducing the frictional damage, and prolonging the service life of the equipment; modified graphene has the advantages of having better dispersibility, increasing the density and strength of thecoating, and effectively improving the waterproof performance of the coating and the permeability of a solvent; modified attapulgite has the advantages of having better viscosity, dispersibility andcompatibility, improving the adhesion between various components, and increasing the adhesion and anti-stripping performance of a paint; tourmaline powder, medical stone, far-infrared ceramics and other functional accessories are added to enhance the functionality of the coating, and benefit the human health; reflective glass beads are used to enhance the recognition capability of operators; a preparation method is simple in process, and low in energy consumption and cost.

Owner:SUZHOU TIANJIANHENG ELECTRONICS INFORMATION TECH CO LTD

Deplating method for carbon-based thin film on surface of metal workpiece

The invention discloses a deplating method for a carbon-based thin film on the surface of a metal workpiece. Oily pollutants on the surface of the steel-substrate workpiece are removed firstly; then the pretreated workpiece is fixed to a workpiece rack in a vacuum chamber of a vacuum coating system containing a hollow cathode ion source, a gas inlet pipeline for guiding in working gas is mounted, and oxygen plasma is obtained when oxygen is led in; and the surface of the sample is bombarded by the oxygen plasma generated by the ion source, and then the workpiece separated from the carbon-based coating is soaked in a faintly-acid soak solution and then cleanly rinsed. The carbon-based coating can be completely stripped off in the oxygen plasma bombarding process, and the stripping speed can reach 0.5-1.0 micron / h; due to oxidation protection in the carbon-based surface layer stripping process, the positions where the coating is abraded or stripped are protected, and excessive etching of the positions cannot be caused by the proper oxygen ion density and energy.

Owner:广州今泰科技股份有限公司 +1

Bi-directional rechargeable/replaceable induction power pack and method

ActiveUS20080112158A1Avoid corrosion damageAvoid water damageBatteries circuit arrangementsBattery isolationHigh humidityUnderwater

A bidirectional rechargeable / replaceable induction power pack and method employing sealed induction coils to power an electrical device underwater, in liquids, or in high humidity conditions.

Owner:VUTILITI INC

Novel ceramic ink-jet ink and production process thereof

The invention relates to a novel ceramic ink-jet ink and a production process thereof. The novel ceramic ink-jet ink is prepared from the following components by percentage by weight: 38%-42% of water-soluble metal salt, 7%-9% of a complexing agent, 14%-25% of a surfactant, 29%-34% of a water-soluble organic solvent, 1%-4% of an auxiliary material and 0.05%-0.1% of a pH value regulator. The novel ceramic ink-jet ink has strong stability, the influences caused by other substances such as solvents are small, the solubility range is relatively wide, the liquidity and the color development property are stable, and the pH value is neutral, so that the corrosion damage caused to a spray head is avoided; the novel ceramic ink-jet ink can directly infiltrate by 5mm-10mm into a tile blank, infiltration color development is formed, and the infiltration effect is good; the color development effect of metal salt is rich and stable, and after novel ceramic ink-jet ink infiltrates into the surface of a tile, the color is relatively fine and bright; the novel ceramic ink-jet ink can be subjected to 1260 DEG C high-temperature sintering with the tile blank, can meet the high-temperature sintering requirements of the tile blank and can reach Moh's hardness 6-7, and the hardness is obviously improved; lots of water grinding fineness processes are not required, the machining process is relatively environmentally friendly, and the energy consumption is relatively low.

Owner:佛山市理想家科技有限公司

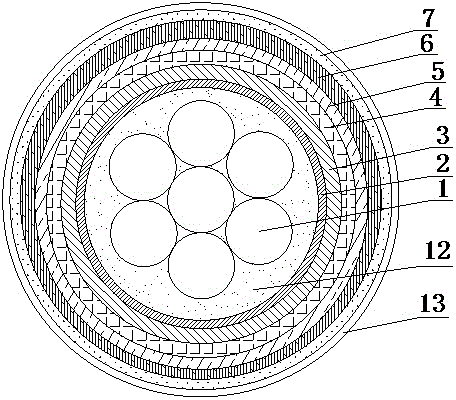

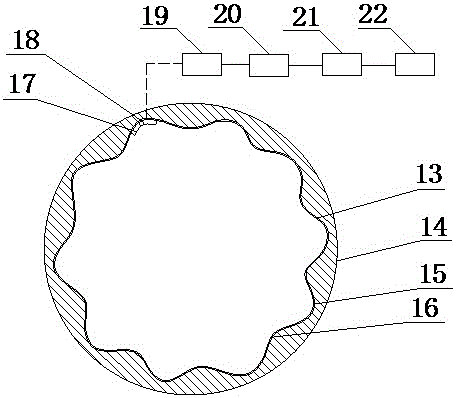

Moistureproof underground cable protection device

ActiveCN106057327AAvoid corrosion damageImprove water resistanceInsulated cablesAnti-corrosive paintsFiberCarbon fibers

The invention provides a moistureproof underground cable protection device, and belongs to the technical field of a cable. The device comprises a moistureproof underground cable and a protection sleeve. The moistureproof underground cable comprises a cable body. The cable body comprises conduction cores, an insulation layer I, a lining layer, a first waterproof layer, a metal sheath, a second waterproof layer and a jacket layer, from the inside to the outside. There are multiple conduction cores. An insulation layer II is wrapped out of the conduction cores. Cross-linking polyolefin is filled among the conduction cores. Carbon fibers are doped in the cross-linking polyolefin. The protection sleeve is sleeved out of the moistureproof underground cable. The protection sleeve comprises a protection sleeve body. The shape of the protection sleeve body matches the shape of the moistureproof underground cable. The inner surface of the protection sleeve body is a structure that concave surfaces and convex surfaces are alternated. An anticorrosive material is coated on the inner surface. According to the device, the structure of an existing underground cable protection device is improved and optimized; the comprehensive performance of the cable is improved; in particular, the corrosion resistance is remarkably improved; and the waterproof performance is excellent; and the stability is high.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

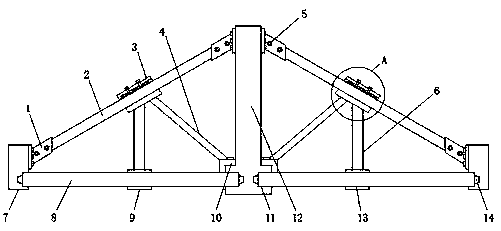

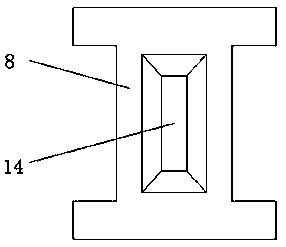

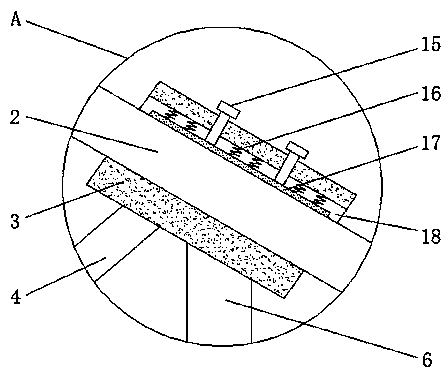

Steel structure roof frame with pressure resistance function

PendingCN109322434AImprove structural rigidityIncrease bearing pressureBuilding roofsShock proofingEngineeringSteel structures

The invention discloses a steel structure roof frame with pressure resistance function. The steel structure roof frame comprises pressure-bearing rods, cross rods and a main frame body, wherein the cross rods are arranged at the two ends of the bottom of the main frame body, one ends of the cross rods extend to the bottom of the main frame body and clamped and fixed with the main frame body, and fixing seats are fixedly arranged at the other ends of the cross rods; fixing plates are installed on the two sides of the main frame body, and first connecting rods are installed at the tops of the fixing plates; clamping connecting seats are fixedly arranged at one ends of the first connecting rods and second connecting rods, and fixing cavities are formed in the center of the clamping connectingseat; the pressure-bearing rods penetrate through the center of the fixing cavities; and connecting seats are fixedly arranged at the two ends of the pressure-bearing rods, and the fixing seats and the main frame body are correspondingly fixed to one ends of the connecting seats. According to the steel structure roof frame with the pressure resistance function, the connecting seats, the pressure-bearing rods, the fixing seats, the cross rods and the main frame body are installed, so that a triangular structure is formed through the fixing seats, the cross rods and the main frame body conveniently, the structure rigidity of the device is increased conveniently, and the bearing pressure of the device is increased conveniently.

Owner:辰信重工(江苏)有限公司

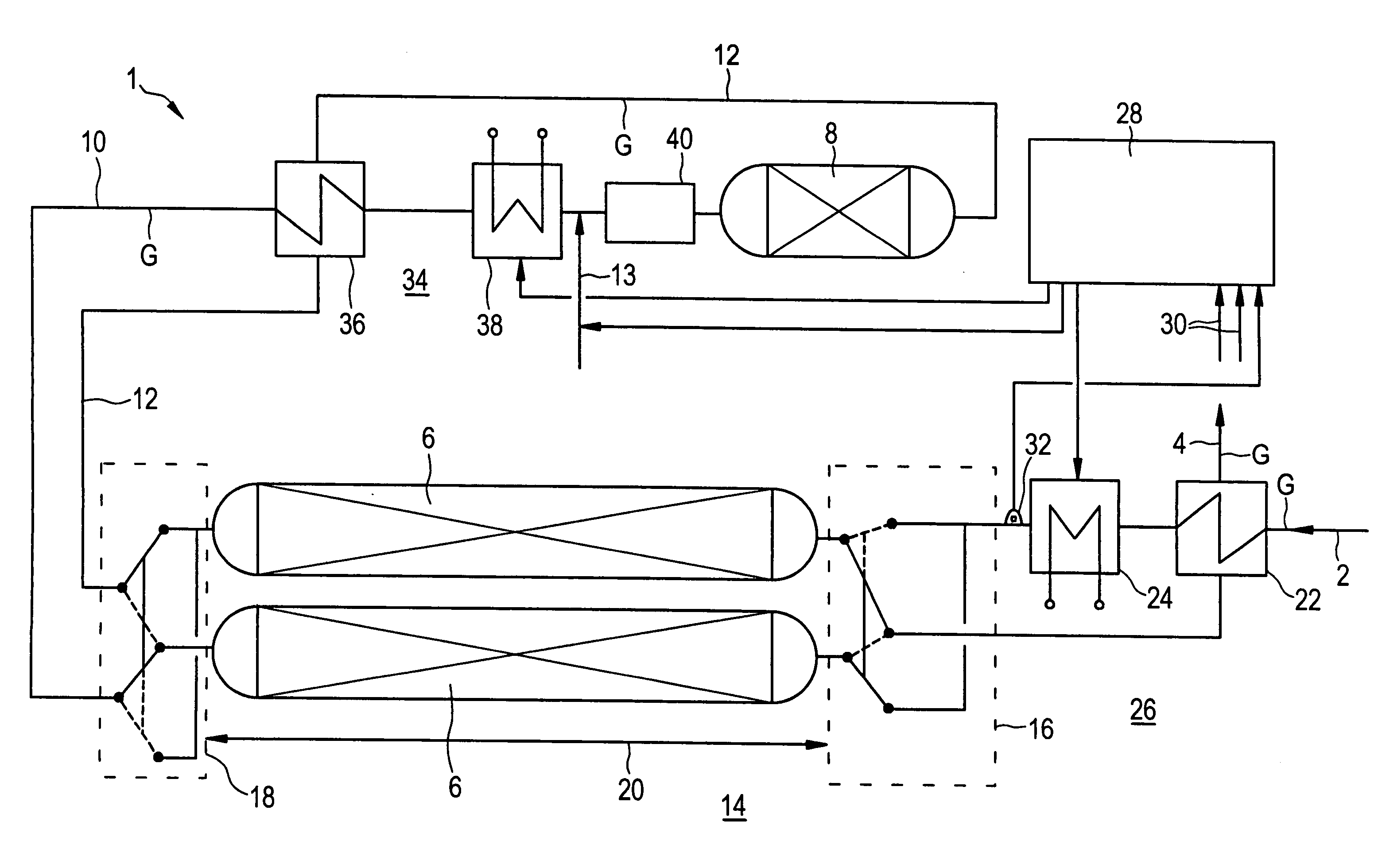

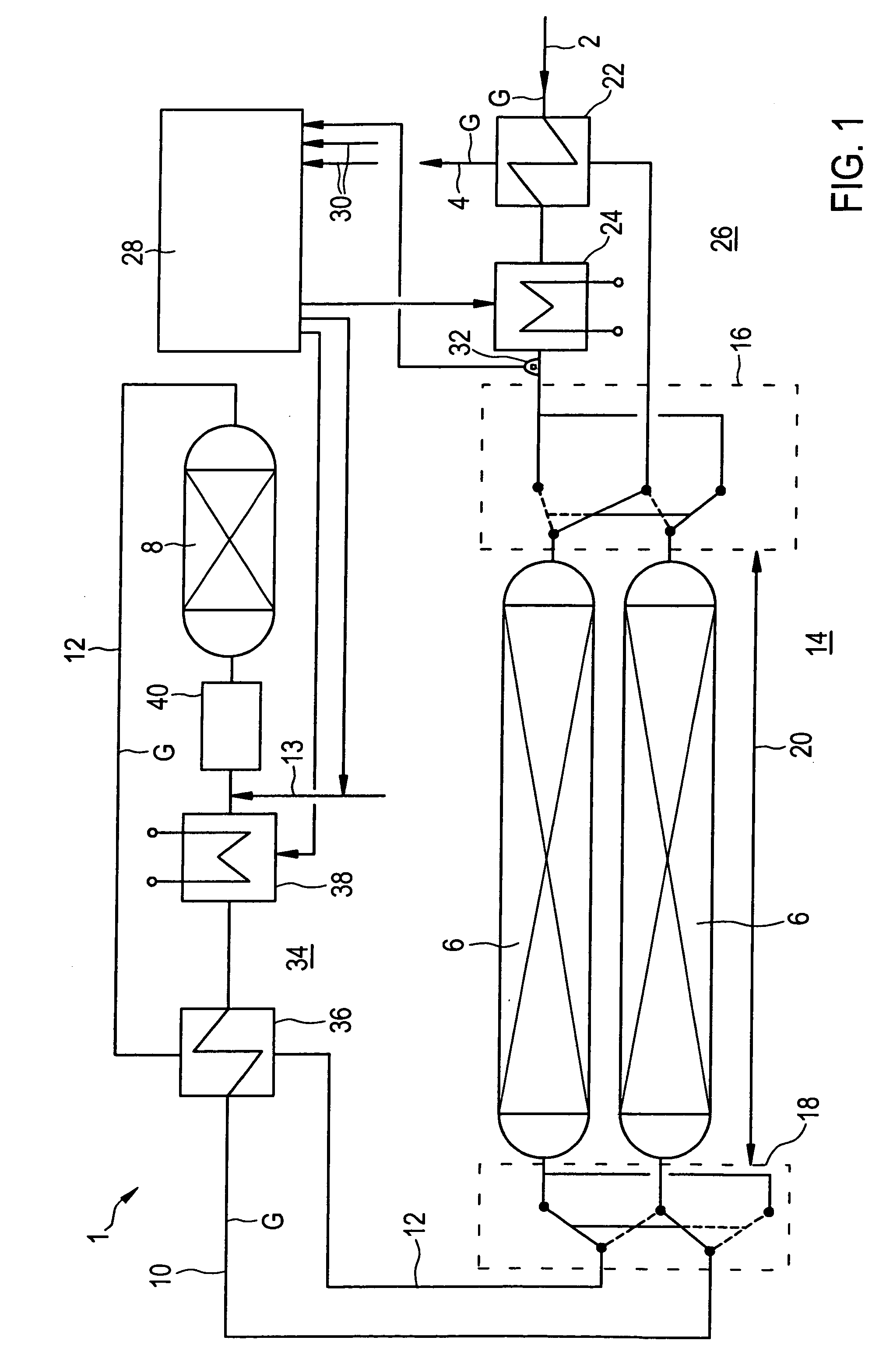

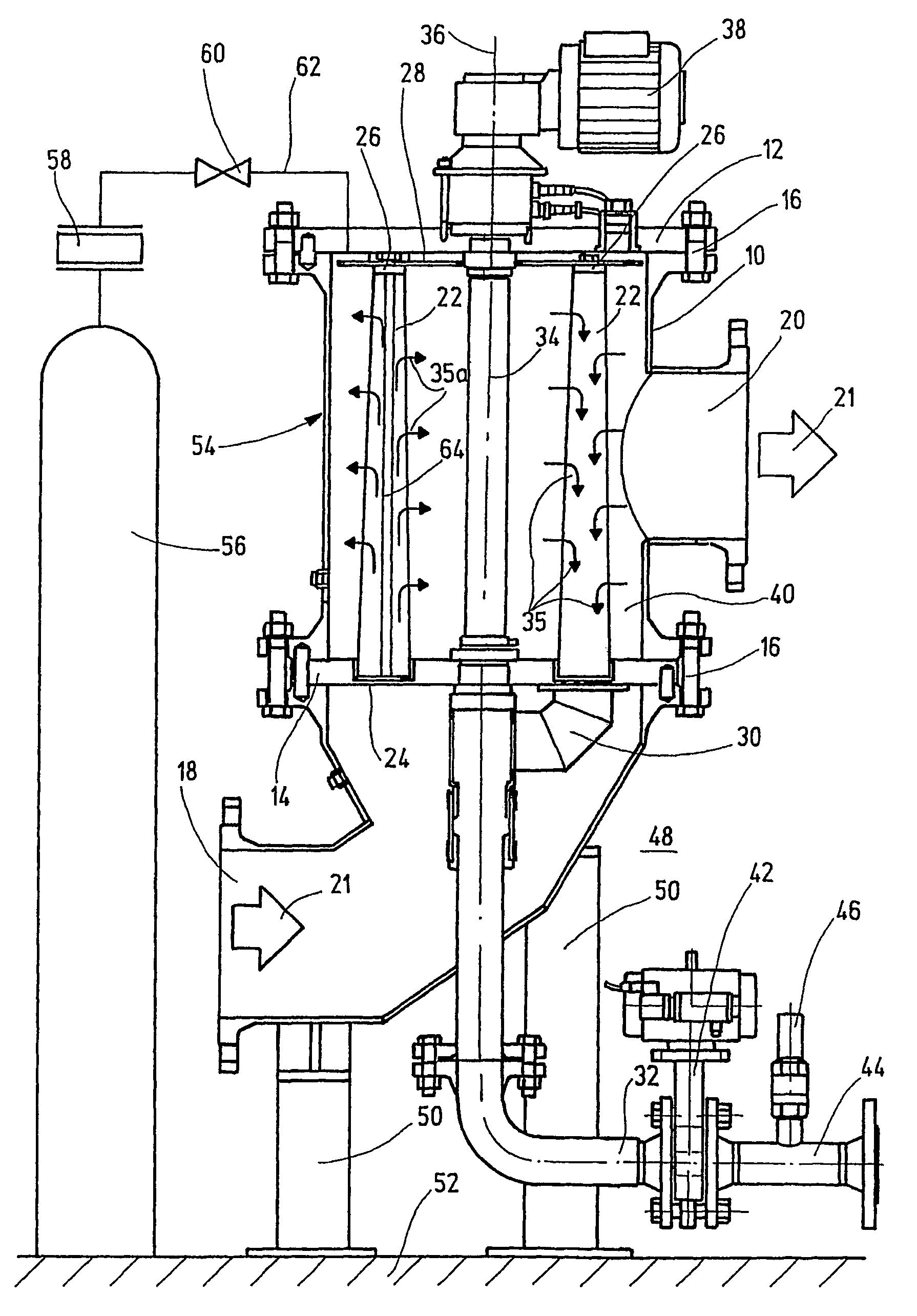

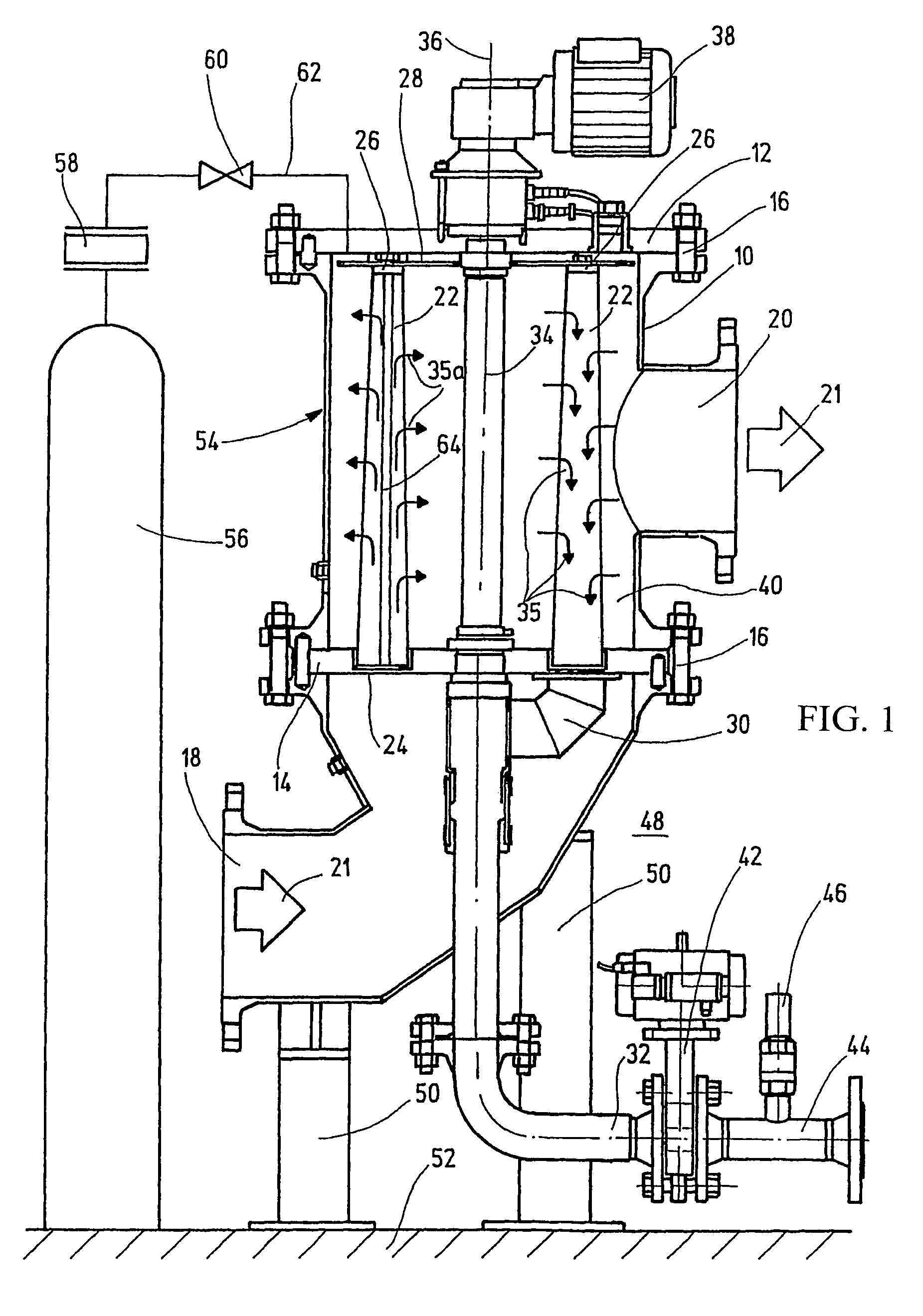

Method for treating a flow of gas and gas treatment system

InactiveUS20050220689A1Simple and rapid process operationAvoid corrosion damageCombination devicesOrganic chemistryAtomic oxygenTreatment system

A method treats a flow gas that is guided via a catalytic adsorber module to oxidize contaminants carried in the flow gas. The method reliably purifies the flow gas using equipment that is held to a comparatively low level of complexity. To this end, the flow gas is guided in a first purification step via a first catalytic adsorber module to oxidize contaminants carried along therewith, during which molecular or atomic oxygen is added to the flow gas, and the flow gas mixed with the added oxygen is guided in a second purification step via an oxidation catalyst. The flow gas flowing away from the oxidation catalyst is guided in a third purification step via a second catalytic adsorber module to reduce excessive oxygen.

Owner:AREVA GMBH

Rotary screen printing machine with liftable roller device

The invention discloses a rotary screen printing machine with a liftable roller device. The rotary screen printing machine comprises a long strip groove formed below a rotary screen and a printing belt, wherein the outer sides of the two ends, in the lengthwise direction, of the long strip groove are fixedly connected with a fixing frame; the fixing frame is fixed to side plates on the two sides; supporting plates are also fixed to the side plates on the two sides and fixed with drive motors respectively; an output shaft of each drive motor is inserted into and sleeves in a jack formed in the corresponding supporting plate and is fixed with a vertical regulation rod through a coupler; the lower end of each vertical regulation rod and the corresponding coupler are arranged in the corresponding jack; each vertical regulation rod is inserted into and sleeves in a regulation sleeve; each regulation sleeve is inserted into and sleeves in a through hole formed in a top plate of a bench; and the top end of each vertical regulation rod extends out of the corresponding regulation sleeve and is in threaded connection to a connecting block. The rotary screen printing machine can regulate a roller of a printing machine up and down, and thus the roller presses against cloth to carry out printing, and the printing effect is good.

Owner:SUZHOU HUACE TEXTILE SCI & TECH

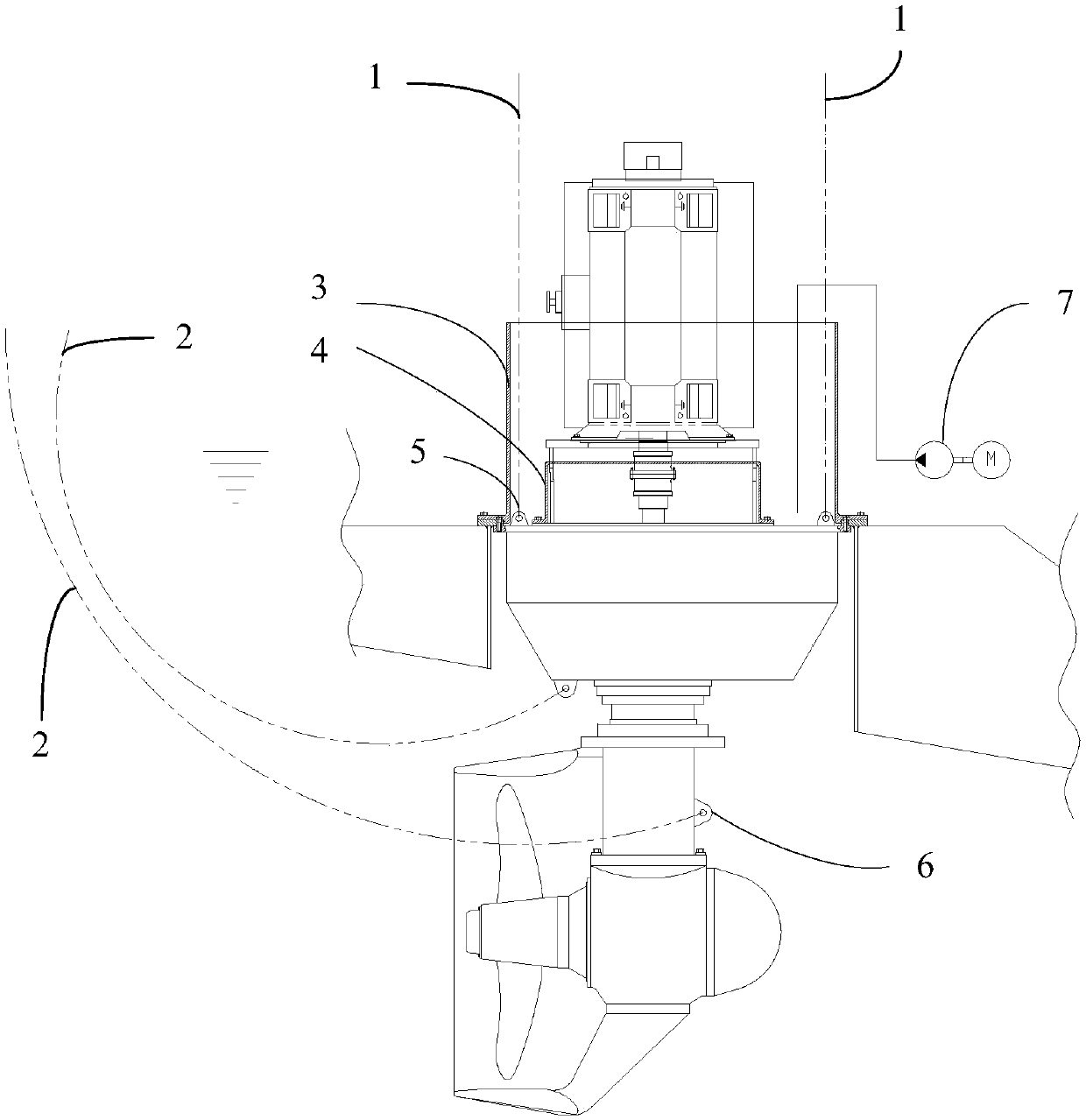

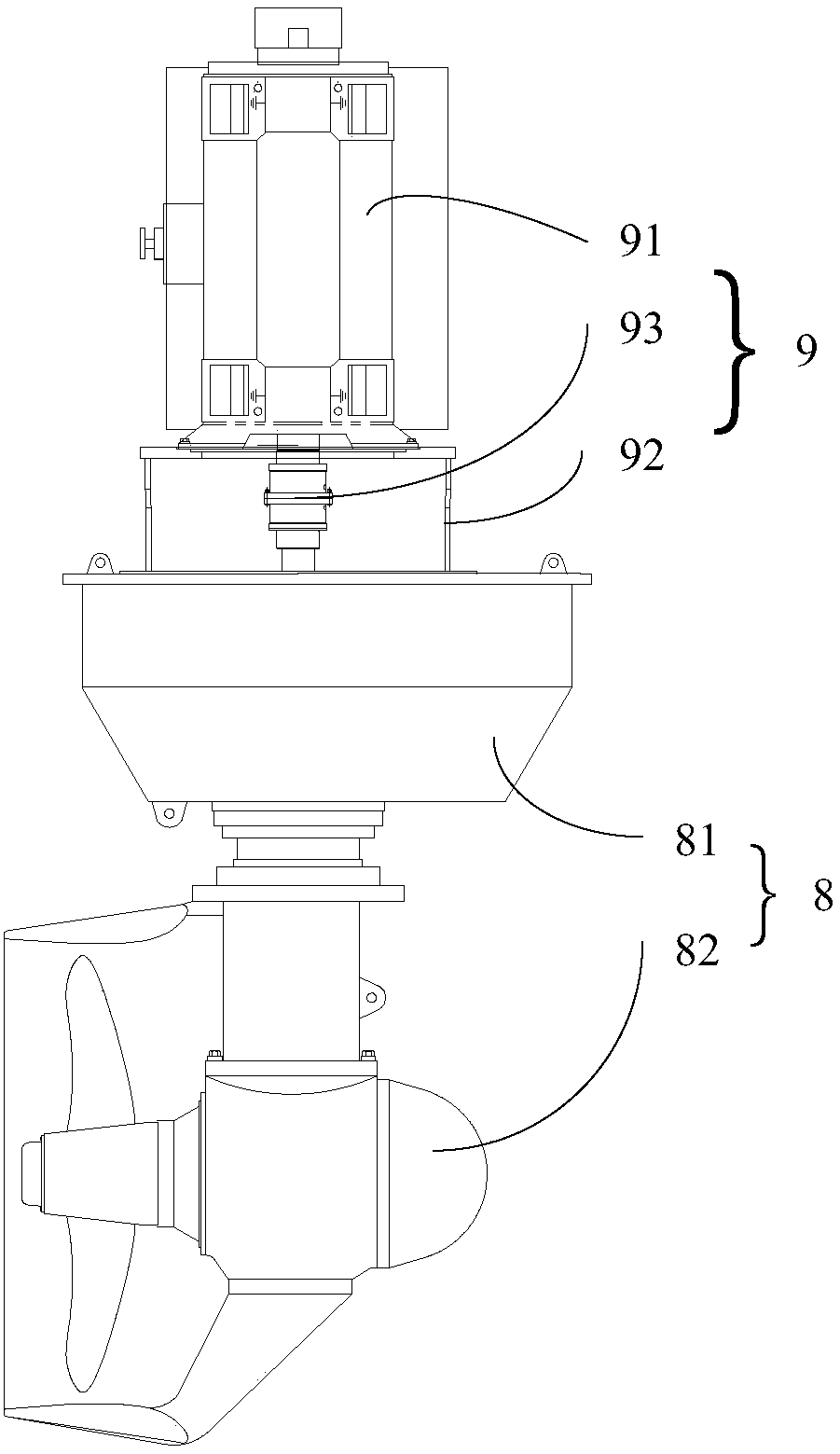

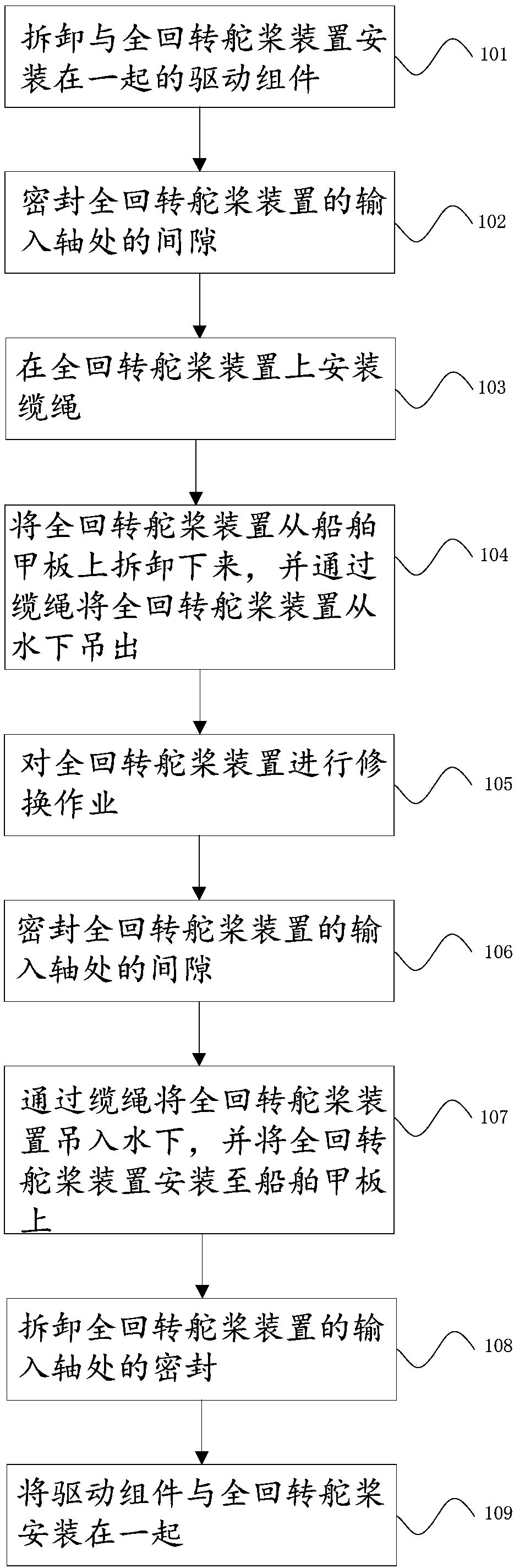

Repairing and changing method of full rotation steering oar device

ActiveCN108045496AAvoid Huge Economic LossAvoid corrosion damageVessel designingPropulsive elementsMaintainabilityEngineering

The invention discloses a repairing and changing method of a full rotation steering oar device. The repairing and changing method includes: demounting a drive assembly which and the full rotation steering oar device are arranged together; sealing a gap on an input shaft of the full rotation steering oar device; arranging cables on the full rotation steering oar device; demounting the full rotationsteering oar from a ship enclosure well, and hoisting the full rotation steering oar device out of water through the cables; performing repairing and changing on the full rotation steering oar device; sealing the gap on the input shaft of the full rotation steering oar device; hoisting the full rotation steering oar device into water through the cables, and mounting the full rotation ship steering oar device onto the ship closed well; demounting the seal on the input shaft of the full rotation steering oar device; and mounting the drive assembly and the full rotation steering oar together. The repairing and changing method can effectively prevent huge economic loss due to the damaged full rotation steering oar device during ship dockage, can shorten the maintenance period, can reduce themaintenance cost, and can improve the maintainability of the device.

Owner:WUHAN MARINE MACHINERY PLANT

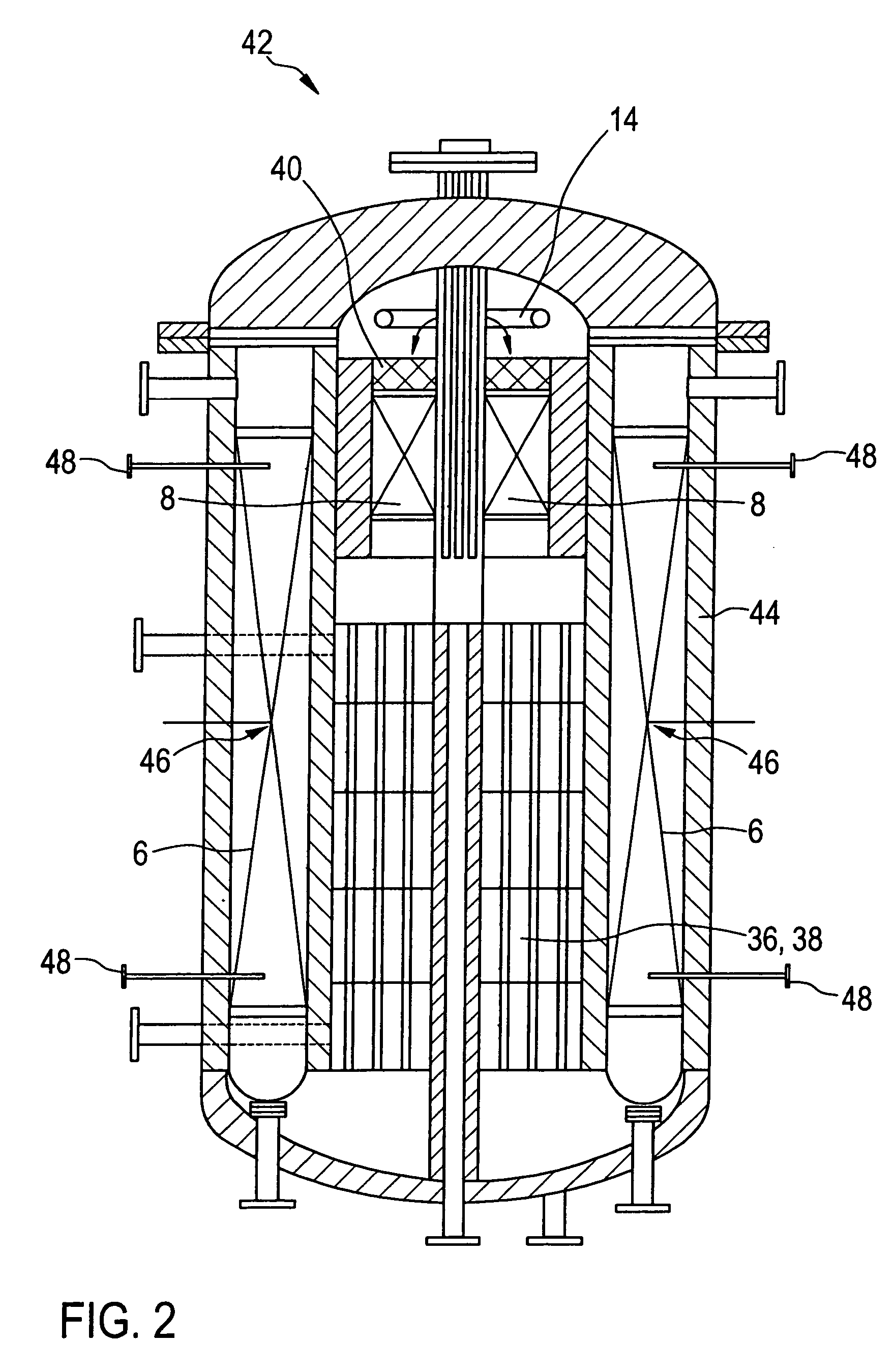

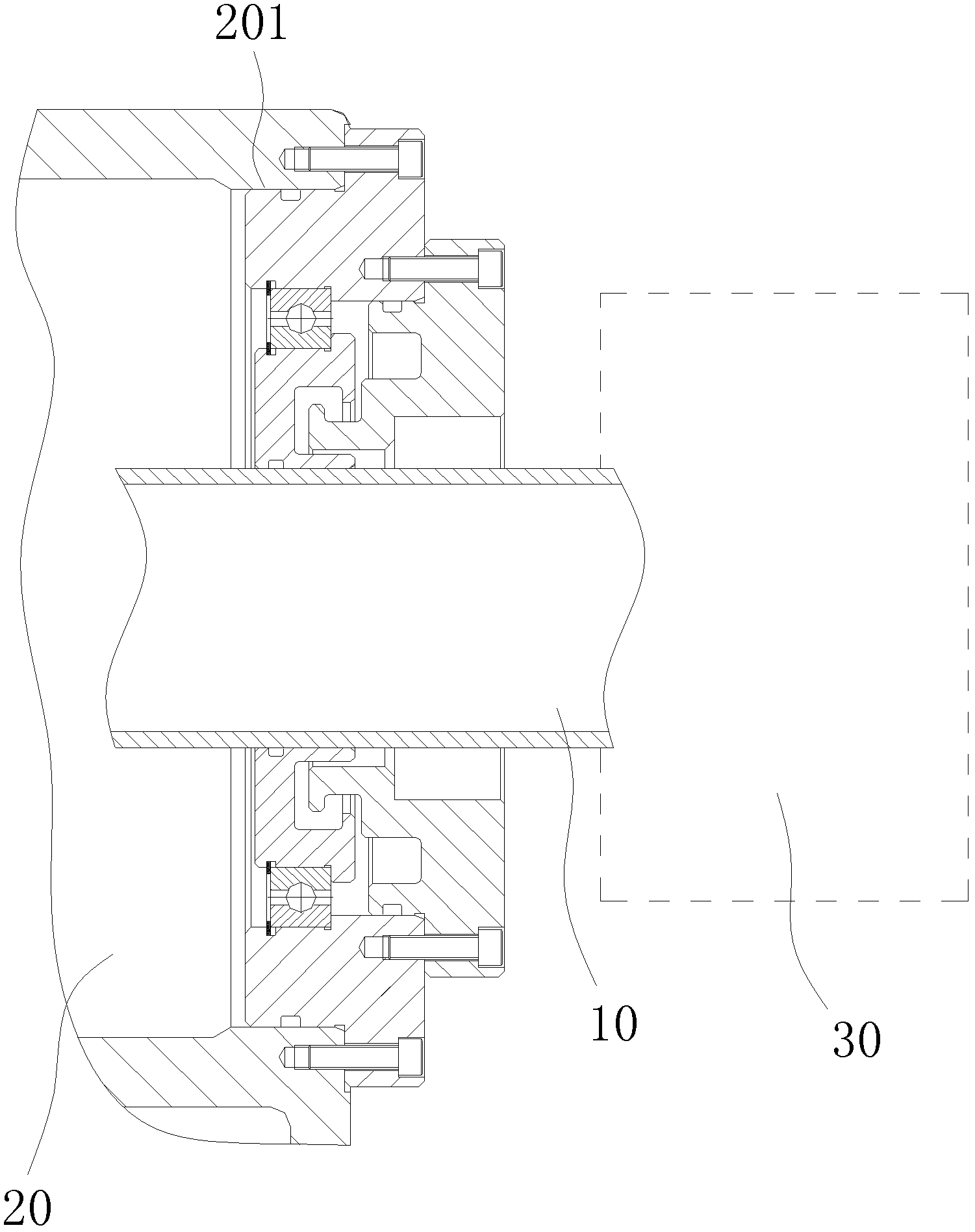

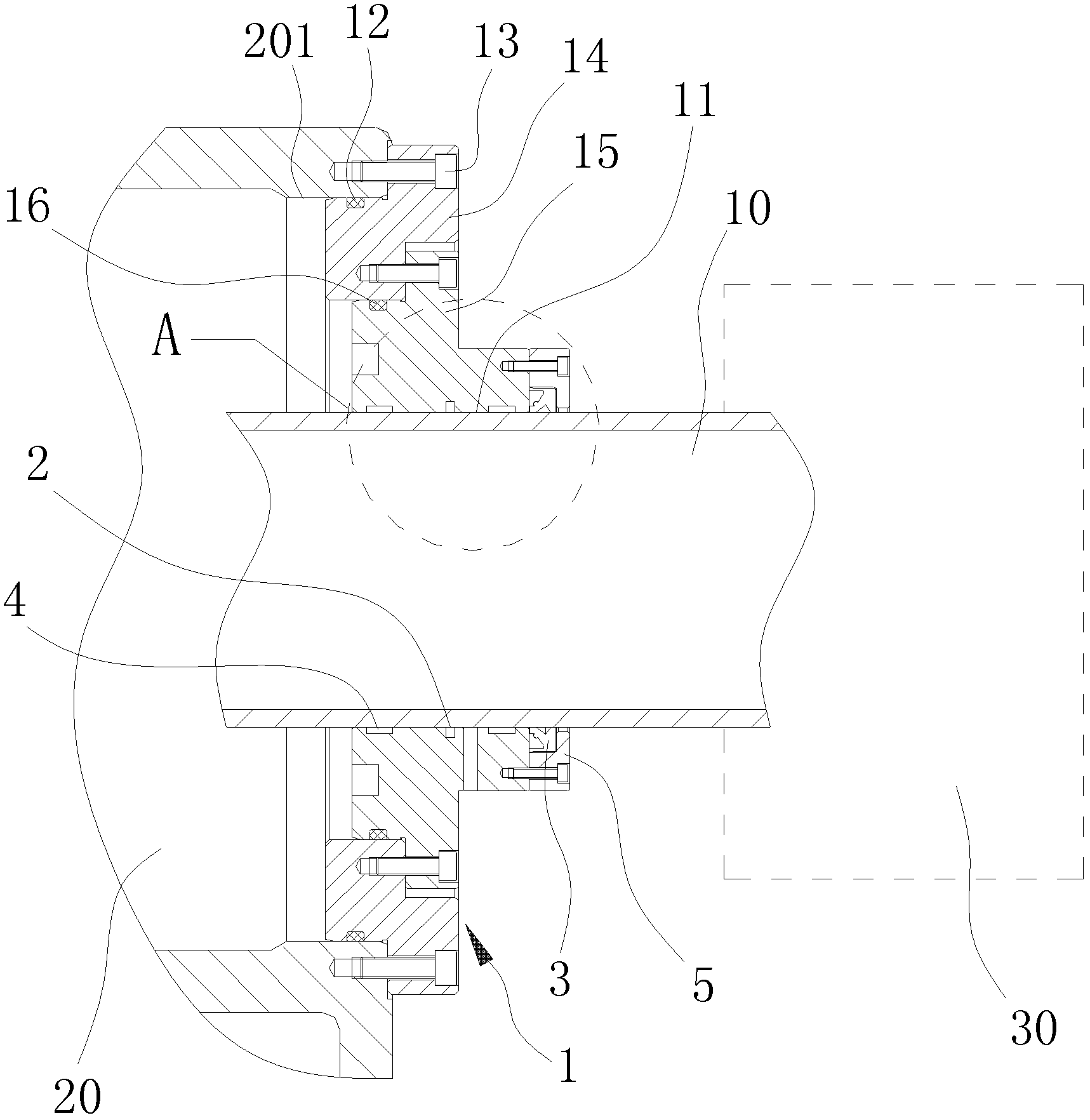

Filter installation and method for operating one such filter installation

InactiveUS7691274B2Highly effective decontaminationEffective and economical cleaningGeneral water supply conservationSeawater treatmentSubstance useBiological fluids

A filter installation and method, especially a seawater filter installation and method, includes at least one fluid line (18,20) for transporting a biological fluid, a filter device (54) mounted in the fluid line with at least one filter element (22) in a filter housing (10), and a device for biological decontamination. The device for biological decontamination contains active substances that can be introduced into the filter housing (10), such as inert gases or special metals, ensuring that toxic impurities cannot enter. The active substances used are ecofriendly unlike chemically produced fungicides and herbicides.

Owner:HYDAC PROCESS TECH

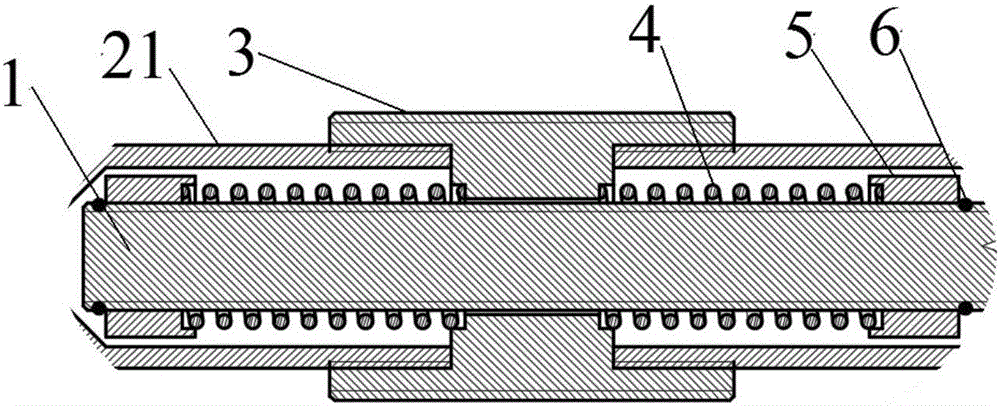

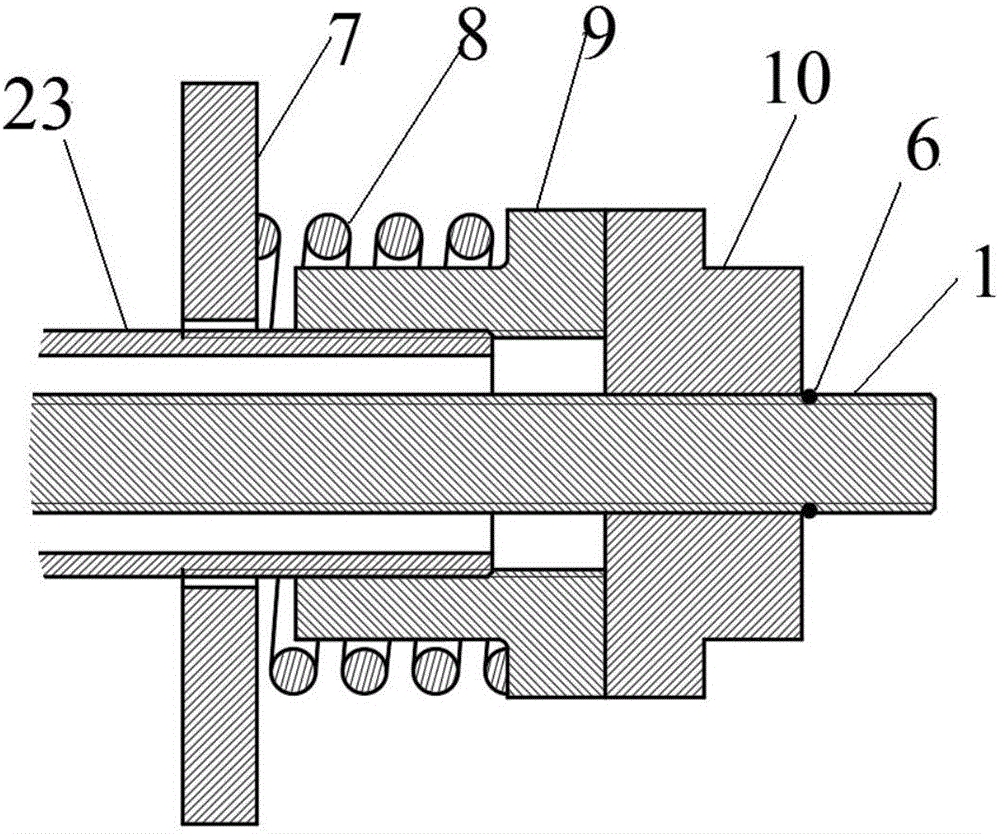

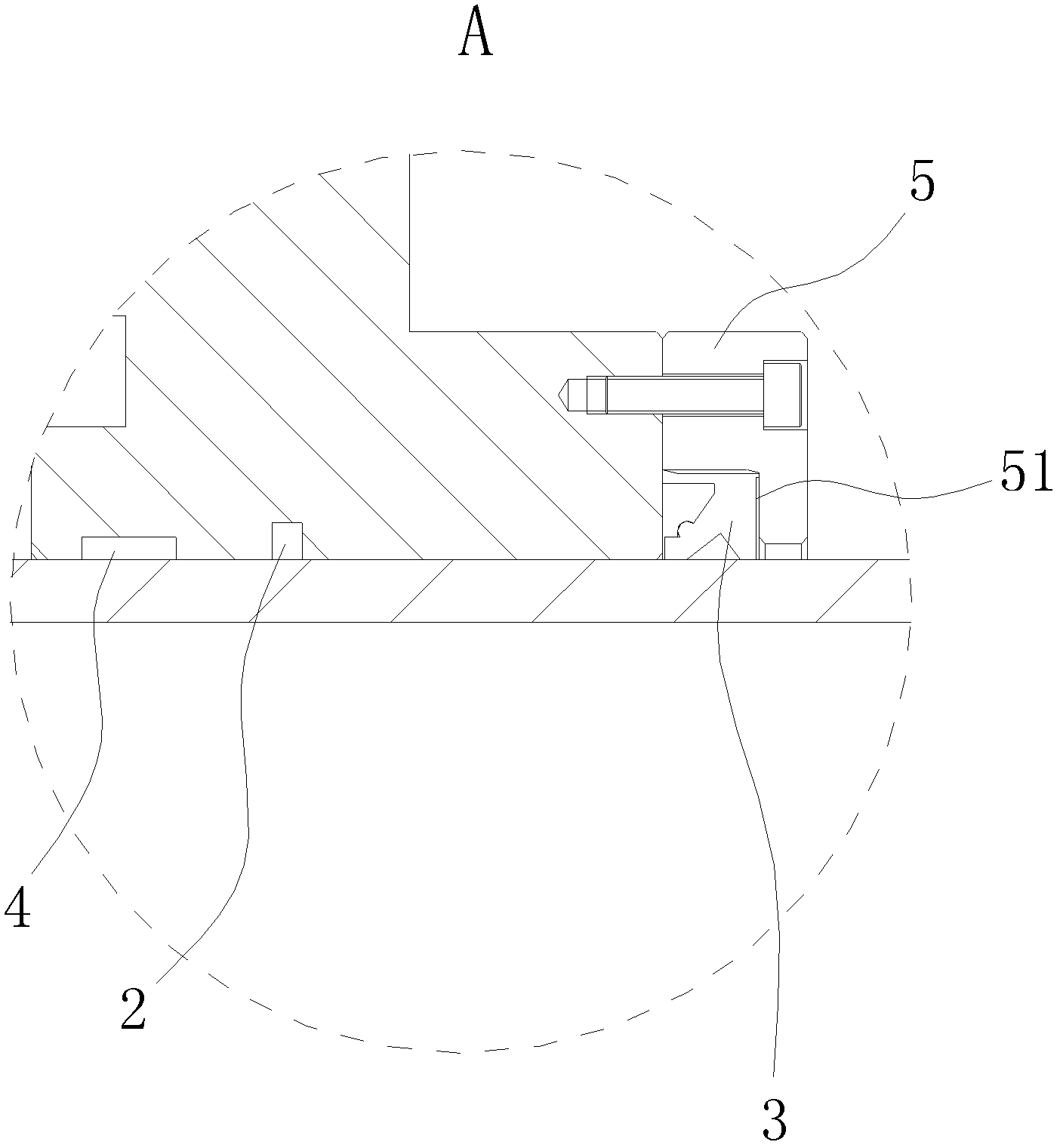

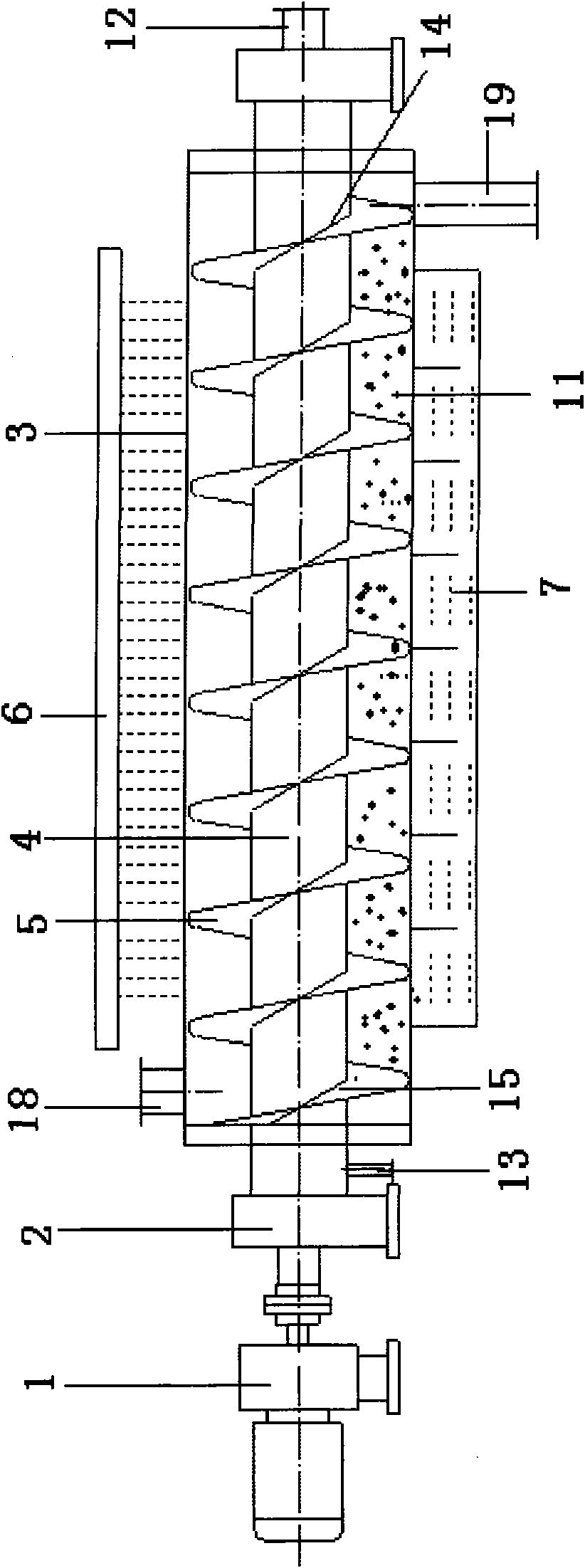

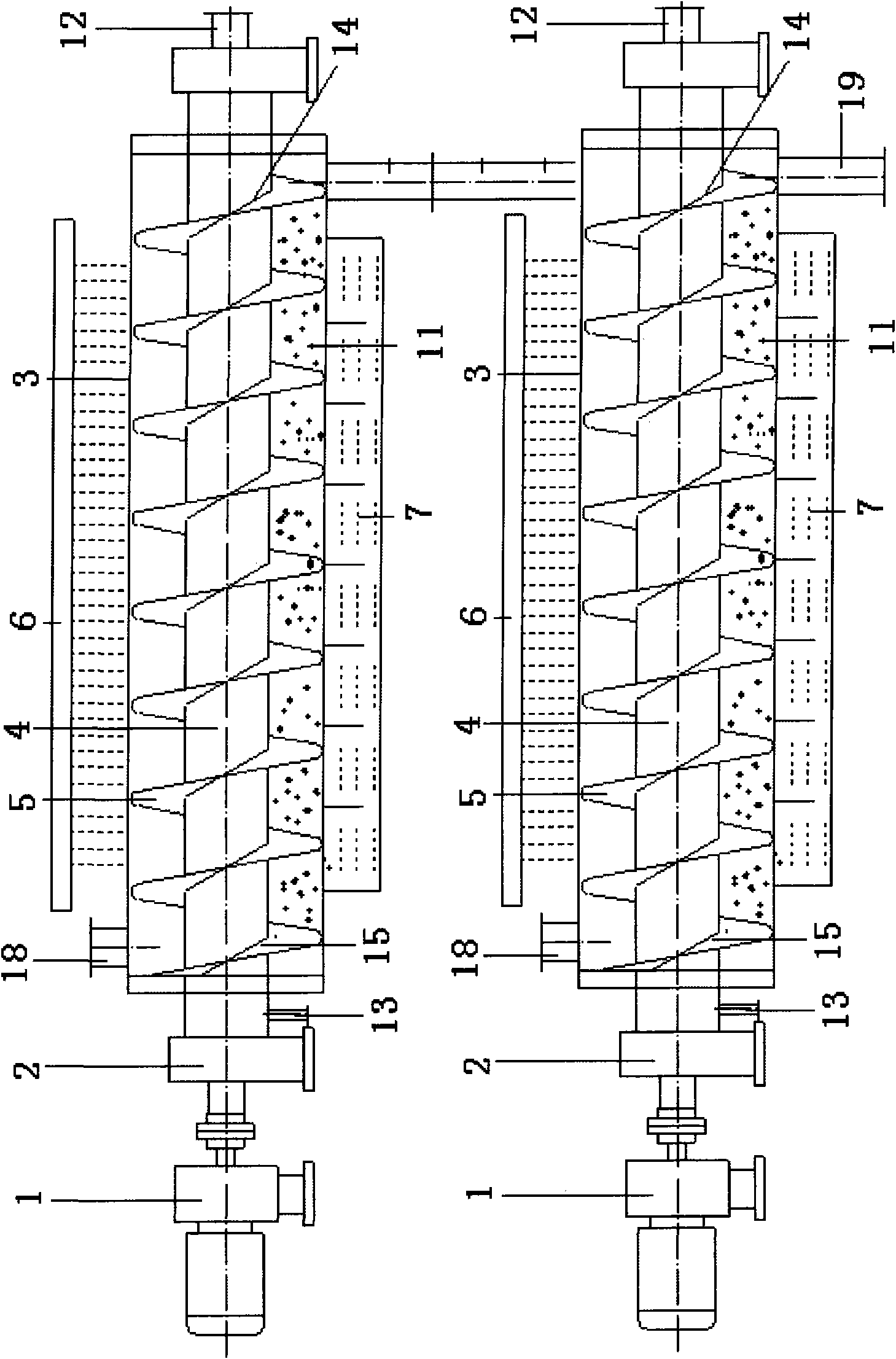

Scraping-rolling machine boring rod spiral sealing mechanism and scraping-rolling machine

InactiveCN102588596AGuaranteed uptimeImprove sealingEngine sealsBoring barsReciprocating motionEngineering

The invention discloses a scraping-rolling machine boring rod spiral sealing mechanism and a scraping-rolling machine, wherein the scraping-rolling machine boring rod spiral sealing mechanism comprises a flange plate, a reciprocating sealing piece and a rotary sealing piece; the outer edge of the flange plate is fixedly connected with a wall plate at an opening part of an oil receiver, so that the flange plate covers the opening part; an installation hole is arranged in the middle of the flange plate, and a boring rod is arranged in the installation hole in a penetrating way; the reciprocating sealing piece is arranged between the inner wall of the installation hole and the boring rod; and the rotary sealing piece is sheathed on the boring rod and is clung to the end surface of the flange plate, close to a boring rod box. The scraping-rolling machine boring rod spiral sealing mechanism and the scraping-rolling machine can realize the rotary sealing and the reciprocating sealing of the boring rod simultaneously, and are simple in structure and stable in performance.

Owner:SANY GRP

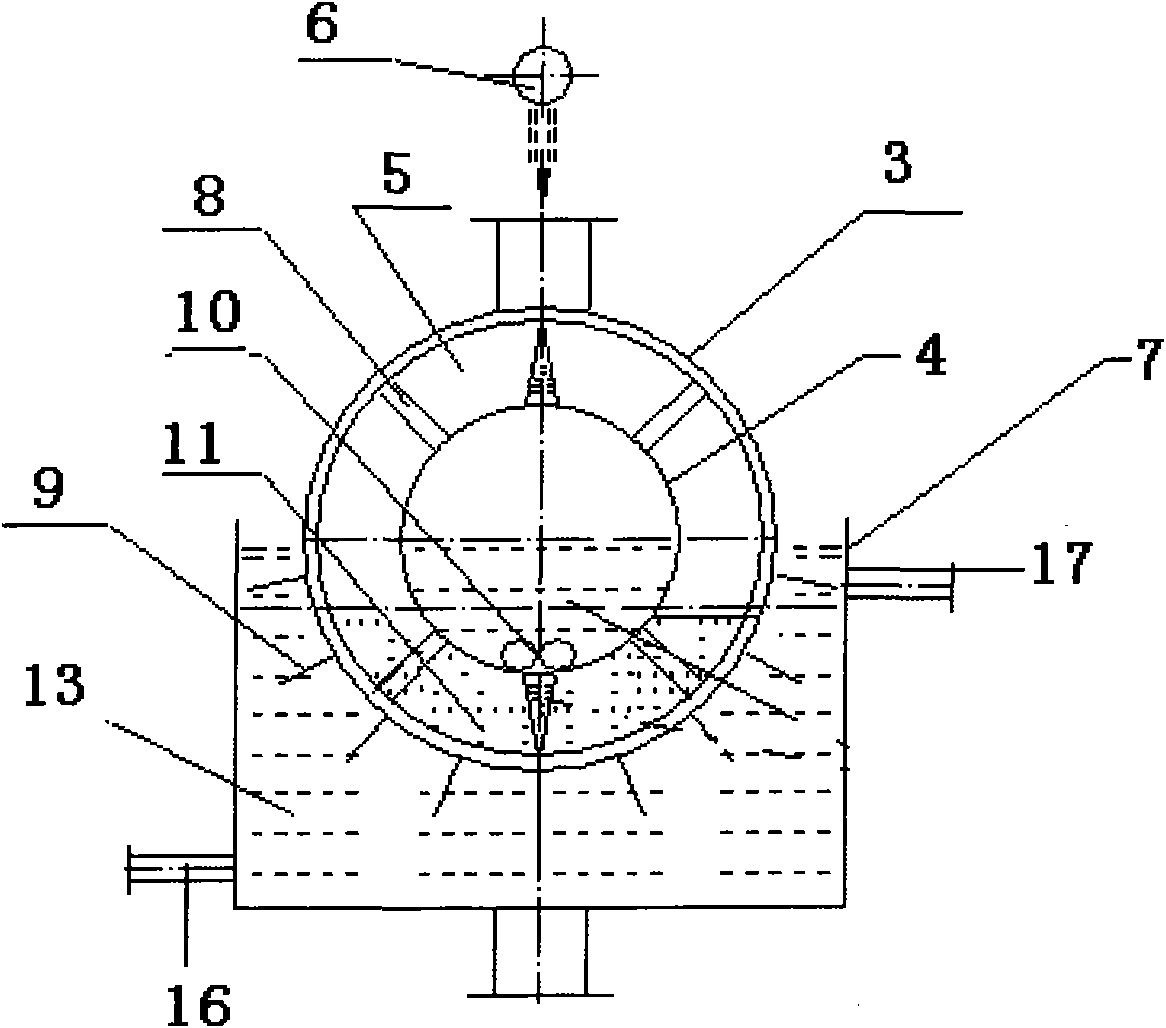

Horizontal spiral cement cooler

InactiveCN101891061AAvoid corrosion damageAccelerate heat dissipation and coolingPackagingConveyor partsPipingEngineering

The invention discloses a horizontal spiral cement cooler, which comprises a support. A horizontal barrel is arranged on the support; a hollow shaft is rotatably arranged in the barrel; a hollow spiral blade which is communicated with the hollow shaft is arranged on an outer circumferential surface of the hollow shaft; a plurality of spray pipes are arranged above the barrel; and a cooling water tank capable of soaking the barrel is arranged under the barrel. The horizontal spiral cement cooler has the advantages of simple structure, reliable operation, good cooling effect, simple and convenient maintenance and operation, low operation and manufacturing cost, and the like, and can be used for cooling powdery high-temperature materials in various industries.

Owner:HEFEI CEMENT RES DESIGN INST

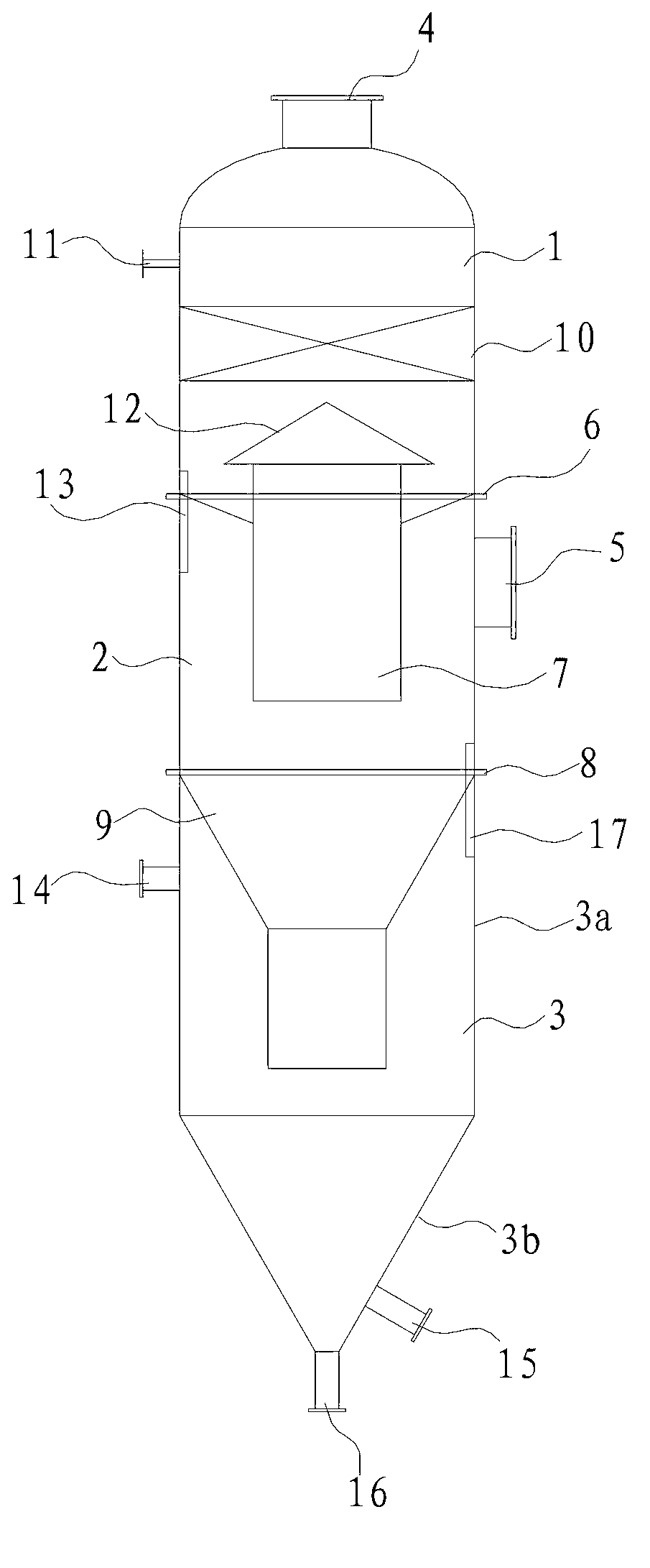

Anti-blocking evaporation sedimentation chamber producing clean secondary steam

ActiveCN103055525AAvoid corrosion damageAvoid cloggingEvaporator accessoriesSolution crystallizationEnvironmental engineeringSmall footprint

The invention discloses an anti-blocking evaporation sedimentation chamber producing clean secondary steam. The evaporation sedimentation chamber comprises a steam collection chamber, an evaporation chamber, and a sedimentation chamber, which are sequentially arranged from top to bottom and which communicate with each other. A steam discharge port is provided on the top of the steam collection chamber. A feeding port is provided on a side wall of the evaporation chamber. A crystallization liquid discharge port is provided on the bottom of the sedimentation chamber. A material liquid discharge port is provided on a side wall of the sedimentation chamber. A de-foaming device is arranged on the steam collection chamber. A circulation liquid feeding port is arranged on the bottom of the sedimentation chamber. The position of the circulation liquid feeding port is lower than that of the crystallization liquid discharge port. According to the invention, the evaporation device and the sedimentation device are realized in a same device, such that land occupation is low, and equipment investment is saved. When adopted material liquid is discharged from the material liquid discharge port, one part of the material liquid is pumped from the circulation liquid feeding port back to the sedimentation chamber by using a liquid pump, such that solid-liquid mixture in the sedimentation chamber form circulation flow, and crystallization liquid discharge port is effectively prevented from being blocked by solid precipitate. Therefore, device normal operation is ensured.

Owner:CHONGQING GREEN FINE TECH CO LTD

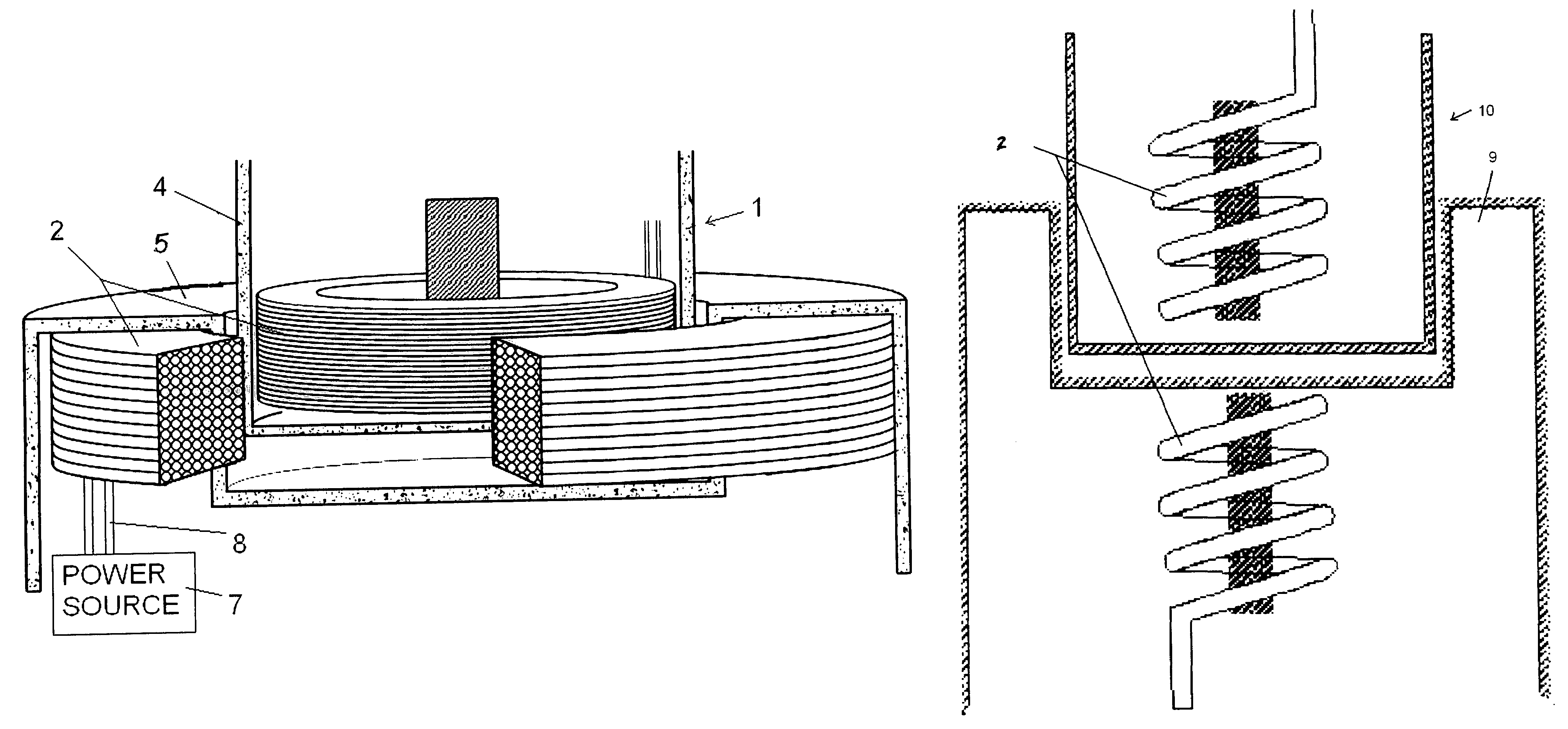

Waterstop protection device and immersed tube tunnel structure comprising device

ActiveCN104652491AAvoid corrosion damageImprove connection tightnessArtificial islandsUnderwater structuresDevice formImmersed tube

The invention relates to the technical field of sea bottom immersed tube tunnels, and provides a waterstop protection device. The waterstop protection device is arranged between joints of two sections of an immersed tube, and comprises a steel plate protection cover, wherein the steel plate protection cover is positioned at the outer side of the waterstop and is formed through splicing welding, the joint parts of adjacent steel plates of the steel plate protection cover adopt a seamless welding mode, and in addition, additional welding processing is carried out; sponge rubber is arranged in inner positions, near the two ends, of the steel plate protection cover. A seamless welding mode is adopted between the adjacent steel plates, and in addition, the additional welding processing is carried out, so that the connecting sealing performance between the steel plates and concrete immersed tube sections is improved, the whole waterstop protection device forms a more sealed space, the goal of isolating air, dust, water and the like is achieved, the problem of waterstop corrosion damage due to contact of the waterstop with the air and the water is effectively solved, and the service life of the immersed tube is ensured.

Owner:CCCC SECOND HARBOR ENG +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com