Anti-blocking evaporation sedimentation chamber producing clean secondary steam

A secondary steam and settling chamber technology, applied in the field of evaporative settling chambers, can solve problems such as easy blockage of equipment, and achieve the effects of ensuring normal operation, improving service life, and high defoaming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

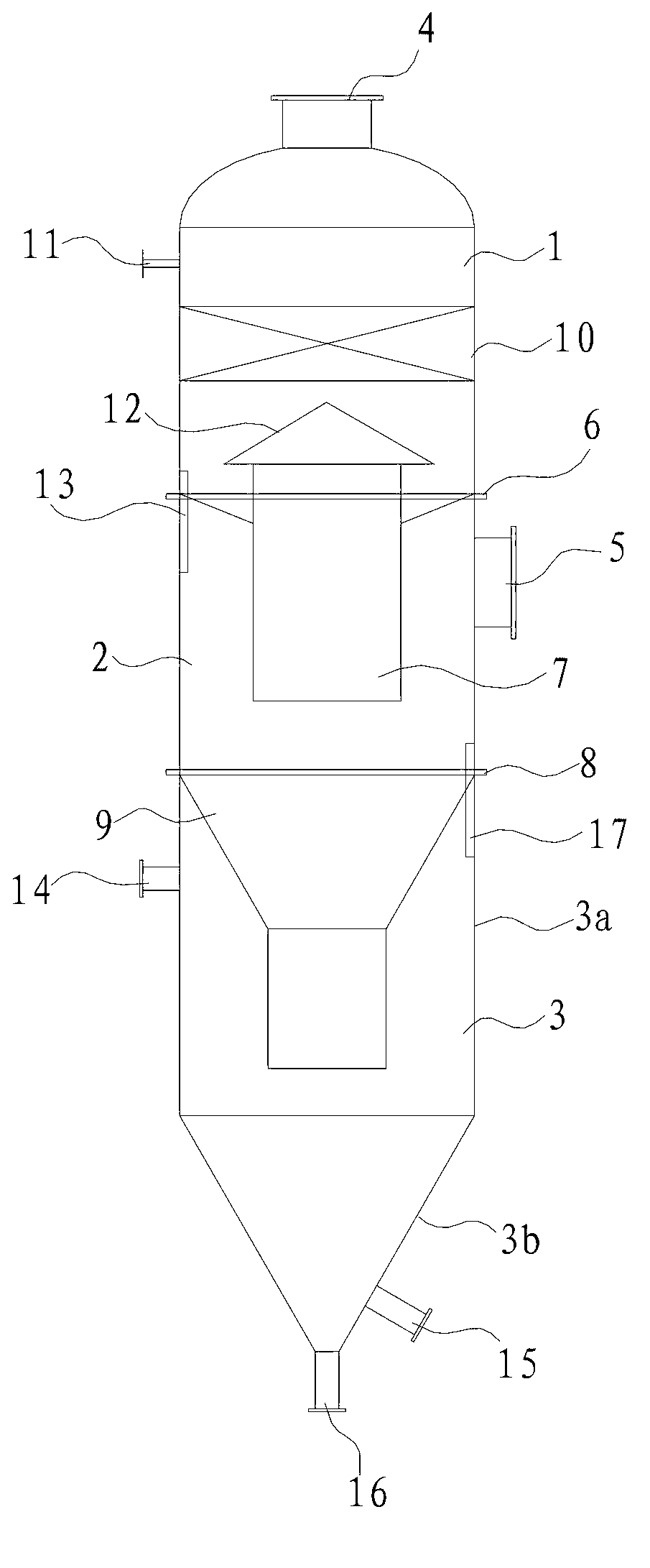

[0029] Such as figure 1 As shown, an evaporative settling chamber that prevents clogging and produces clean secondary steam is different from Example 1 in that the demister 10 between the steam collecting chamber 1 and the evaporating chamber 2 is a packing layer to remove the The liquid foam entrained in the steam that the riser pipe 7 leads into the steam collection chamber 1; the top of the steam outlet 4 is provided with a wire mesh demister; the liquid return channel 13 is one or more hole structures arranged on the fixed plate 6 , so that the liquid in the vapor collection chamber 3 flows back to the evaporation chamber 2;

[0030] Among them, the raw material to be treated is a mixture of supersaturated sodium chloride solution and water vapor, the feed rate is 12t / h, the solid content is 40%, the material output after crystallization is 5t / h, and the steam output is 7t / h, the circulation amount is 80t / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com